A membrane-making method for improving the surface smoothness of lining microfiltration membrane

A technology with smooth surface and microfiltration membrane, which is applied in the field of water treatment, can solve the problems of unsmooth membrane surface, enlarged support surface gap, material seepage, etc., achieve low cost of atomization treatment, maintain smoothness, and reduce cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

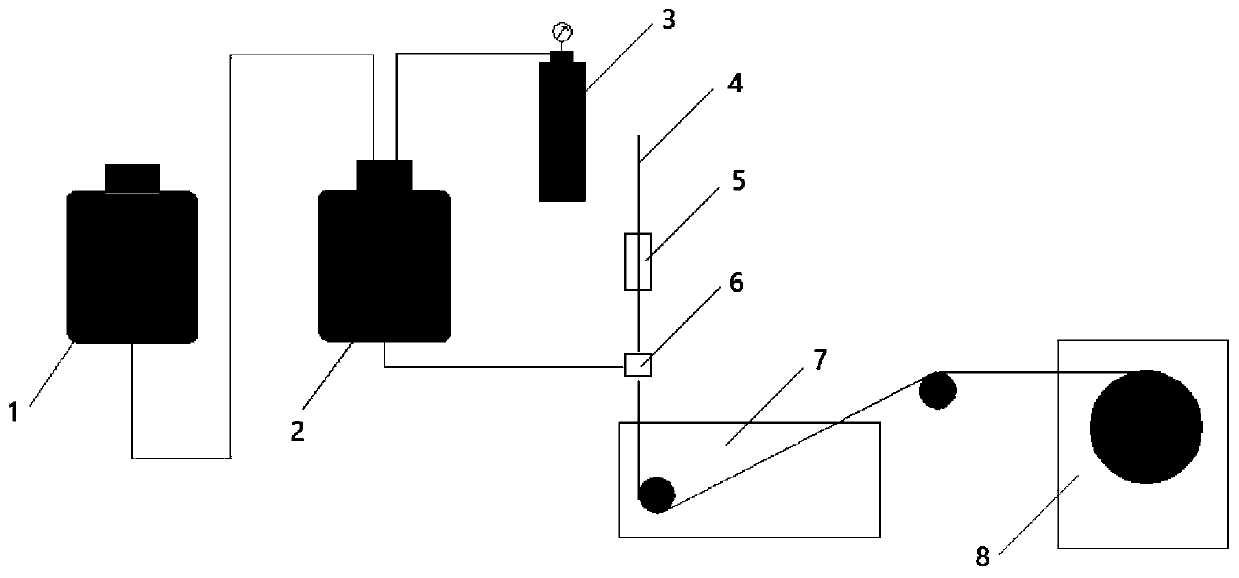

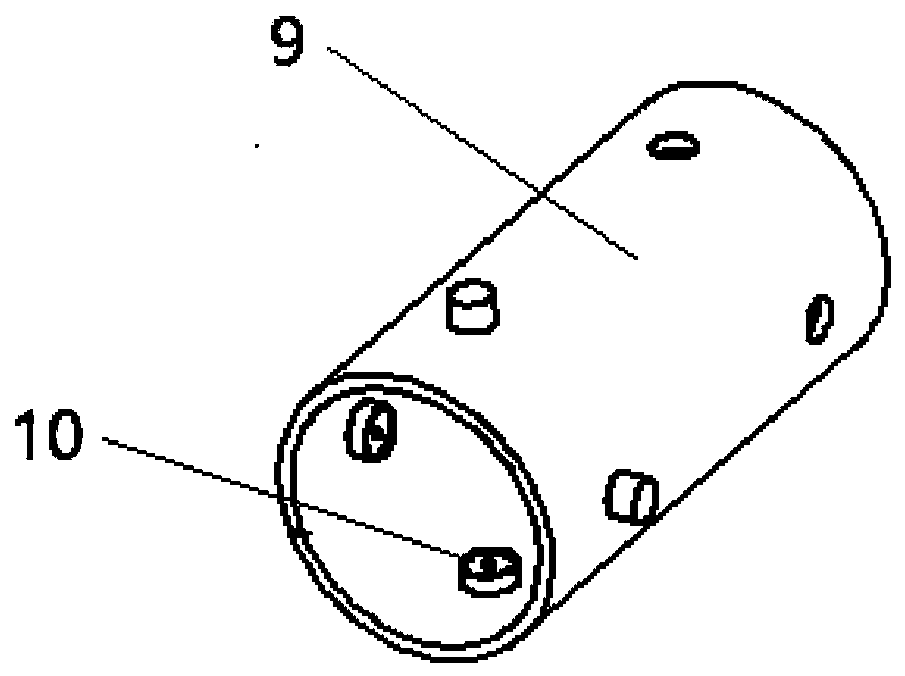

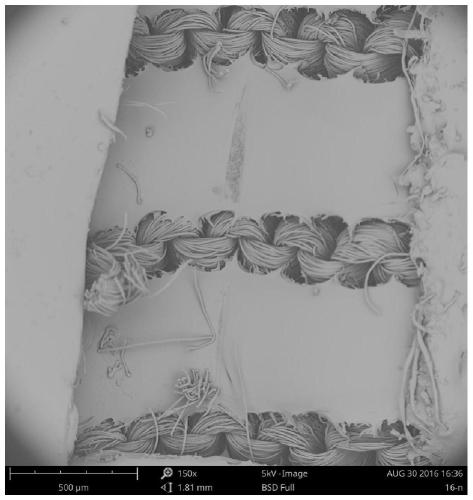

[0021] refer to figure 1 , according to an embodiment of the present invention, a method for making a membrane that improves the surface smoothness of the lining microfiltration membrane is specifically to put resin, solvent, and additives in a stirring tank 1 in a certain proportion and stir and dissolve to form a casting solution; The formed casting solution enters the spinneret 6 through the spinning kettle 2 and the filter after degassing. Optionally, the spinning kettle 2 is connected to the nitrogen tank 3, and nitrogen gas is fed into the spinning kettle 2 to promote spinning of the casting solution. The advantage of nitrogen is that it is stable, and the casting solution is not easily oxidized. The support body 4 enters the spinneret 6 after being atomized by the atomization device 5 and is combined with the casting solution at the exit of the spinneret 6 so that the casting solution is evenly coated on the surface of the support body 4 to form a film filament; After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com