Work bench of laser cutting ceramic circuit substrate

A circuit substrate and laser cutting technology, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of surface tumor dissolution pollution, etc., and achieve the effect of simple material replacement operation, easy access to materials, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

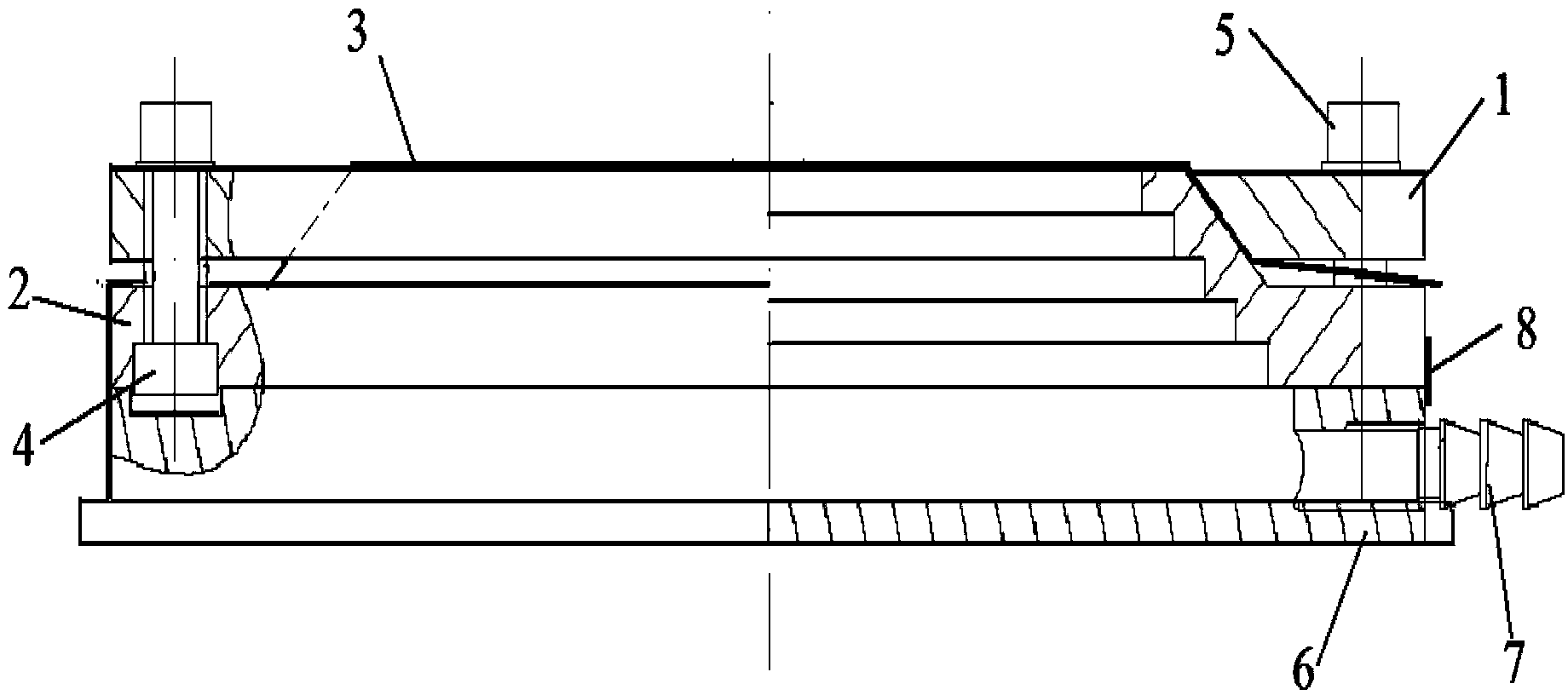

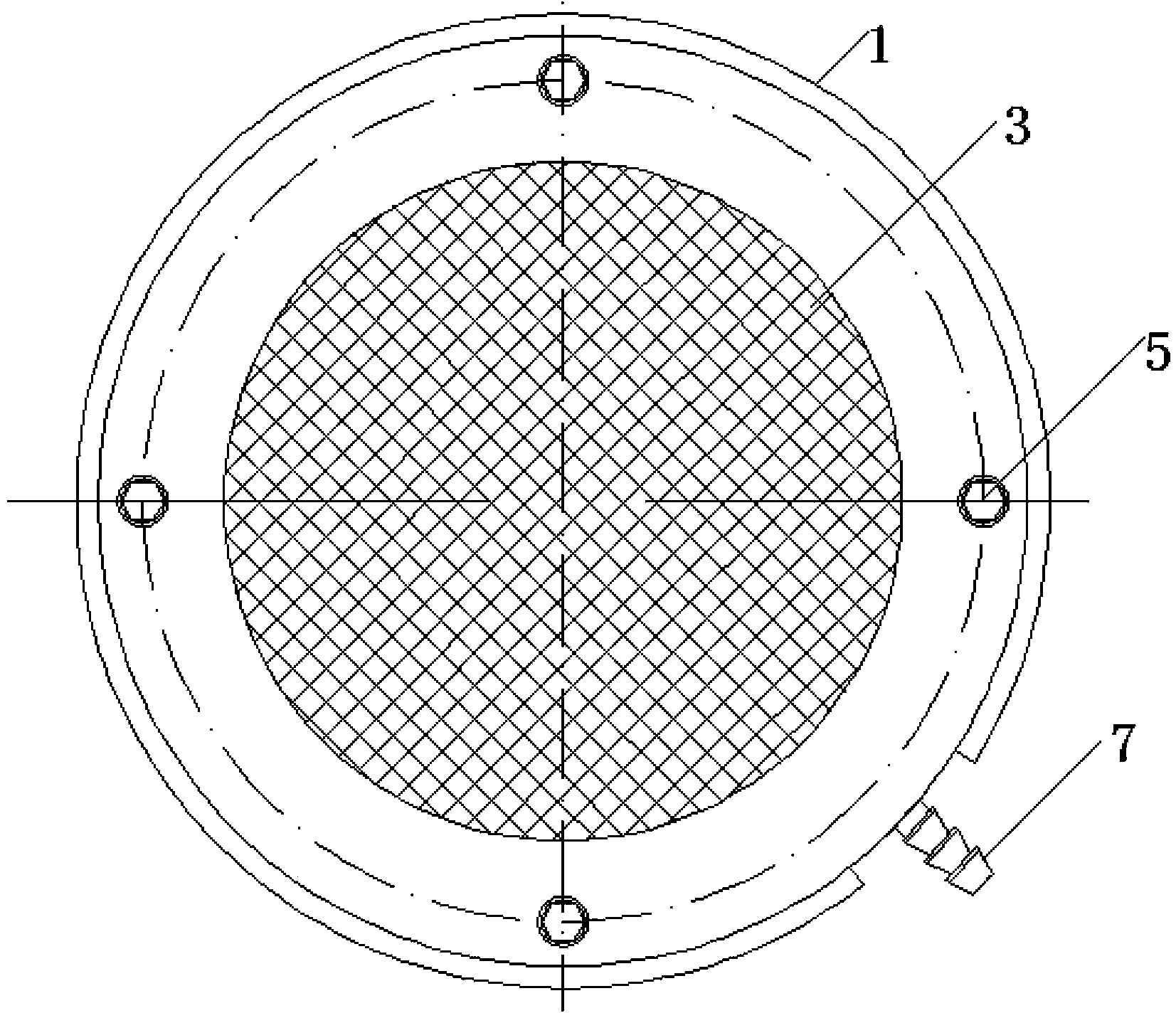

[0015] exist figure 1 , figure 2 In the shown embodiment, the workbench for laser cutting ceramic circuit substrates includes a moving stage that can be flexibly connected to the fixed seat 6 through circumferential sealing. The workbench is a combined structure of upper and lower parts, and the upper part is a movable joint mobile platform combination table, which is a supporting body for realizing the clamping, tensioning and quick sealing of the surrounding material wire mesh 3 . The lower part is a hollow fixed seat 6, which is the parent body for fixedly movably connecting the combined table of the mobile platform and fixing the workbench to the equipment table and installing the vacuum pipeline interface.

[0016] The movable connection mobile table is an annular disc with a radial outer edge, a locking ring seat 2 that forms a conical boss in the axial direction and a locking ring 1 that is coaxially fitted on the conical boss. A combination that is fastened together...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com