Full-automatic intelligent punching production system based on remote control

A technology of remote control and intelligent production, applied in manufacturing tools, other manufacturing equipment/tools, feeding devices, etc., can solve problems such as low production capacity, inability to realize automatic production, backward production technology, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

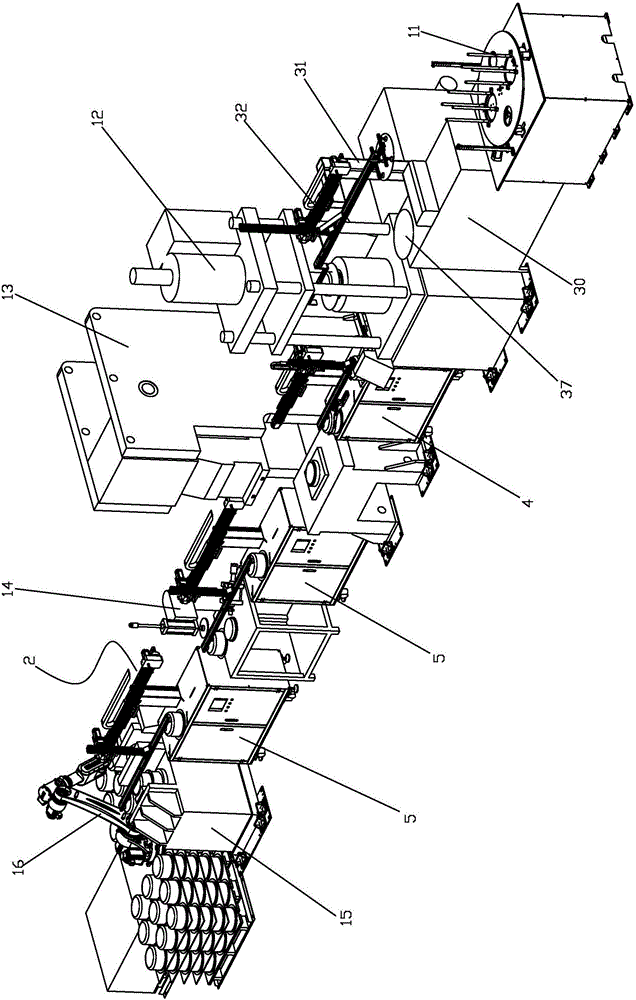

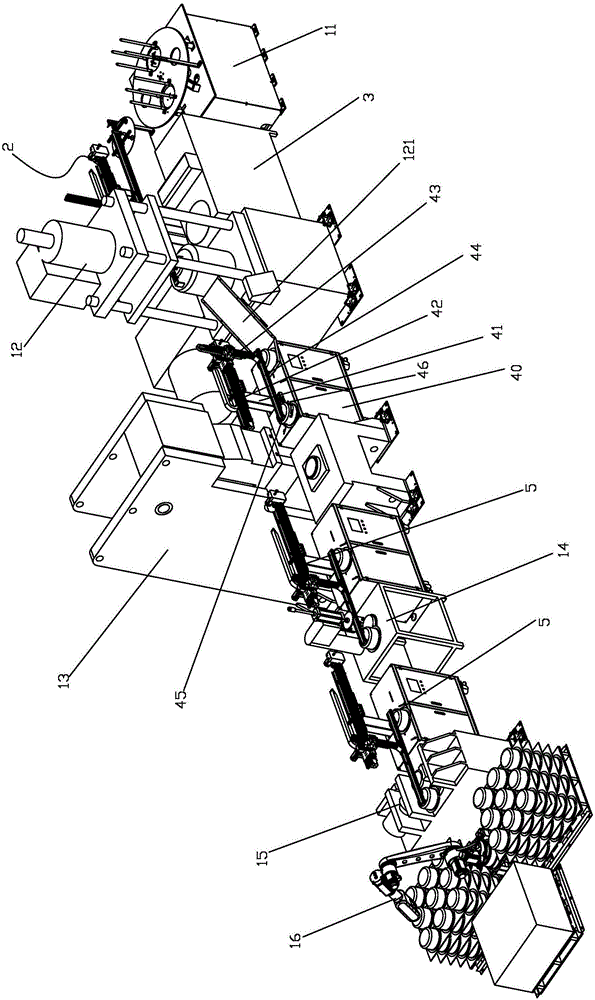

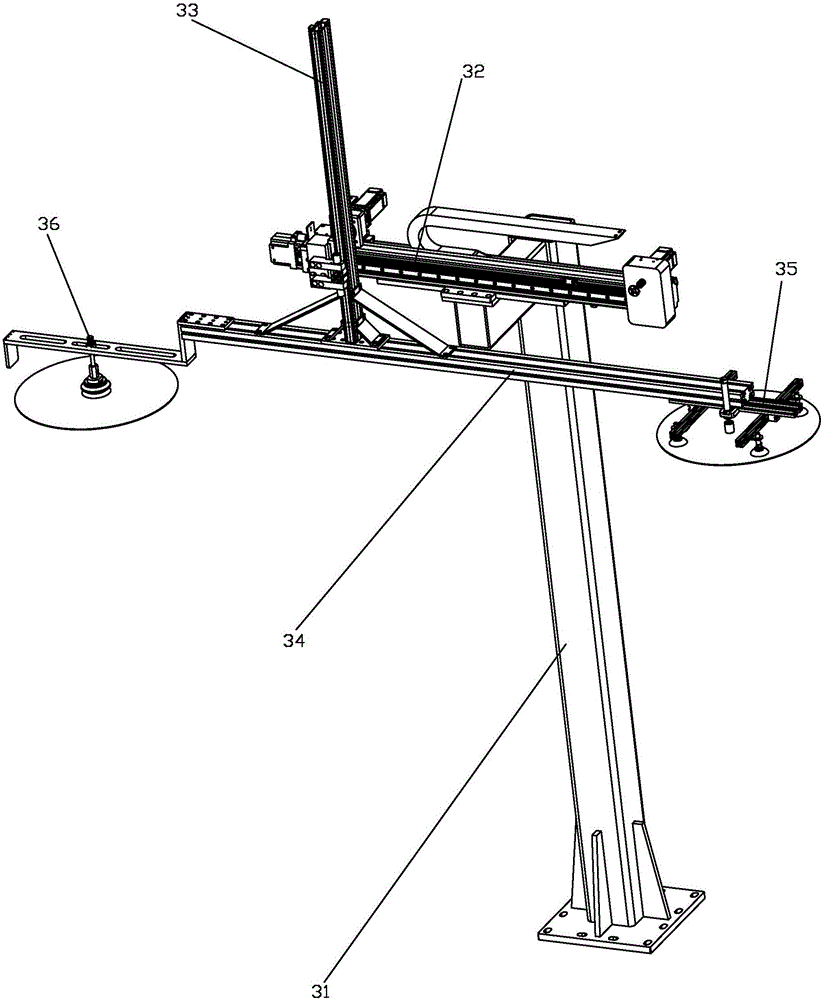

[0031] according to Figure 1-11 The described stamping full-automatic intelligent production system based on remote control includes an automatic feeding device 11, an automatic stretch forming device 12, an automatic trimming device 13, an automatic crimping device 14, an automatic labeling device 15 and an automatic The stacking device 16 also includes an automatic control system 2 for remotely controlling the operation of the production line. The first pushing robot 3 of the semi-finished product, the second pushing robot 4 arranged between the automatic stretch forming device 12 and the automatic trimming device 13, the automatic trimming device 13 and the automatic curling device 14, and The third push robot 5 between the automatic crimping device 14 and the automatic labeling device 15 . The stamping automatic intelligent production system based on remote control includes automatic feeding device, automatic stretch forming device, automatic edge trimming device, automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com