Patents

Literature

45results about How to "Production is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic bentonite composition modified emulsified asphalt and its preparing method

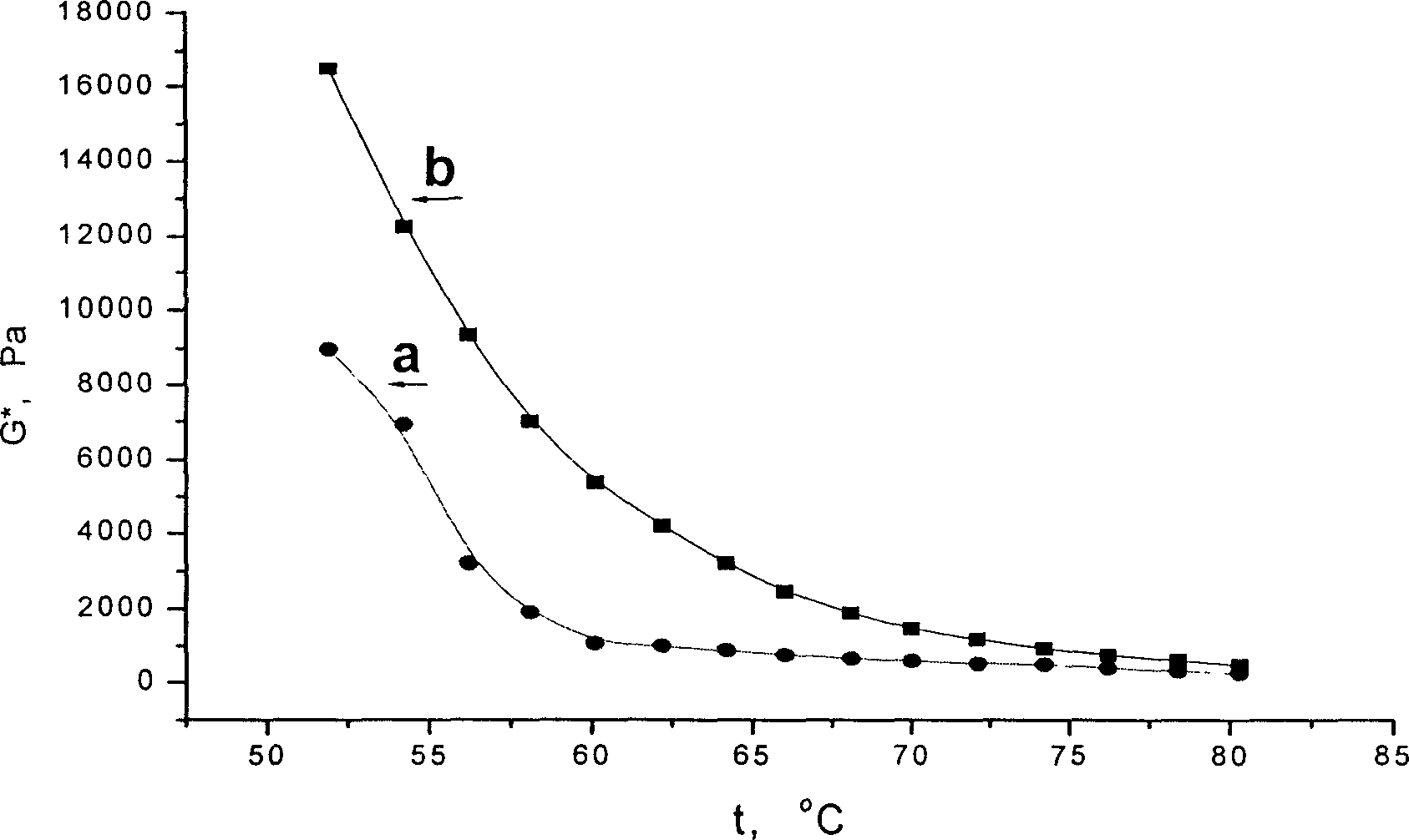

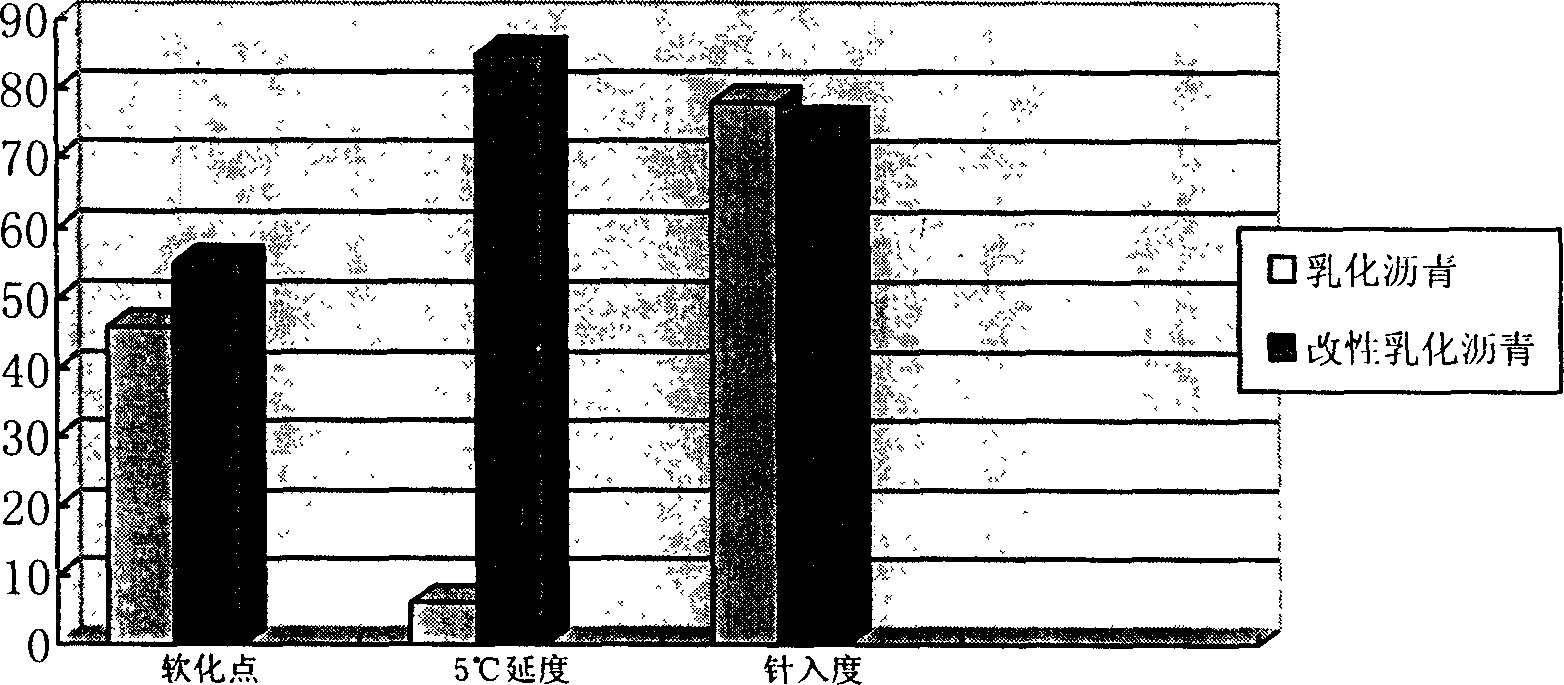

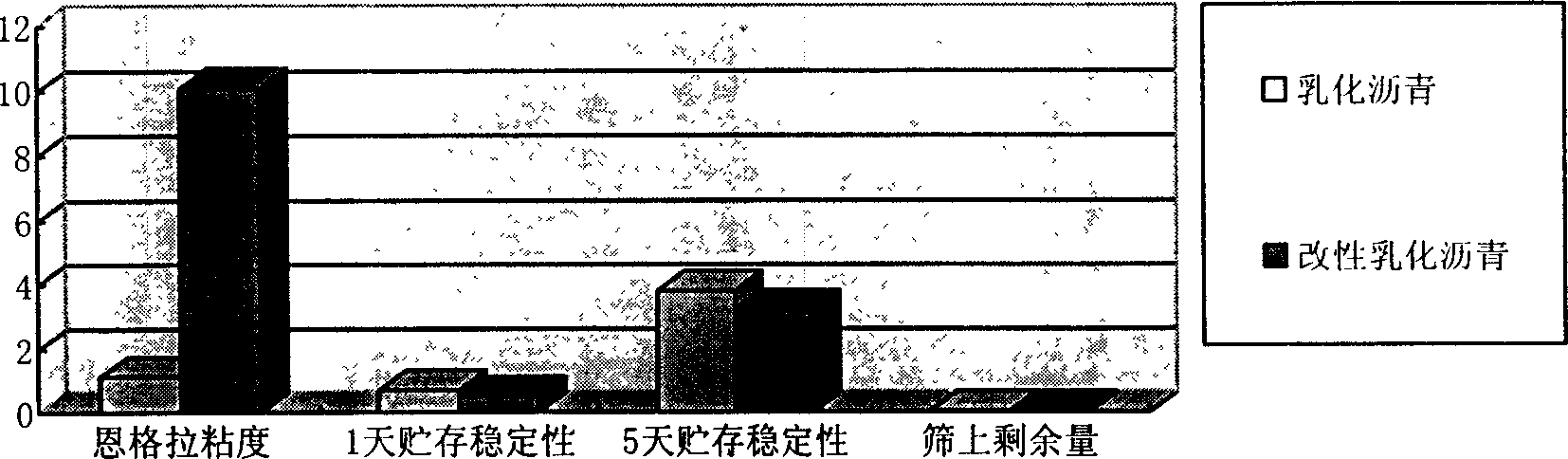

The invention relates to an organobentonite composition modified emulsified bitumen and its preparing method. The bitimen is composed of 60-62 protions base bitumen,34-36.4 protions water,0.5-0.8 protions cationic emulsifier,1-3 protions organobentonite,2-4 protions butadiene styrene latex,0.1-0.2 protions thickening agent.Its prparing method comprises: mixing emulsifier solution uniformly, then mixing and emulsifying with base bitumen by emulsifying machine, then adding organobentonite and thickening agent to emulsified bitumen, mechanically stirring, mixing uniformly and deforming to obtain modified emulsifier bitumen. The invention has advantages of fine capability, high production efficiency, easy control, convenient operation and low cost.

Owner:NORTHWEST NORMAL UNIVERSITY

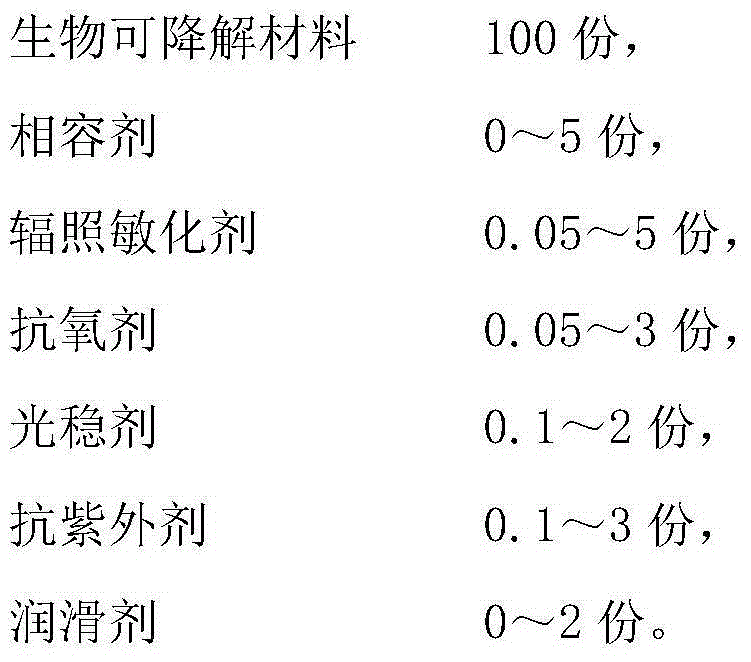

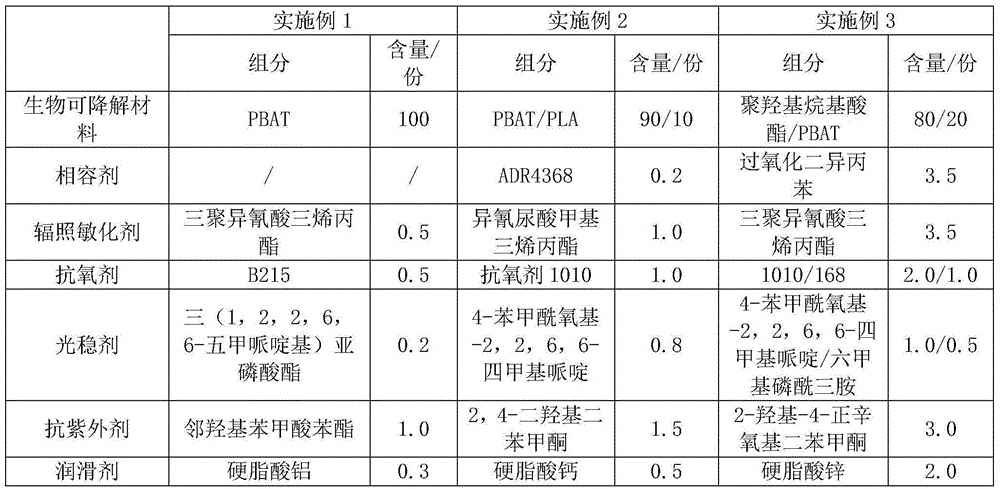

Biodegradable film based on irradiation modification and preparing method thereof

The invention discloses a biodegradable film based on irradiation modification and a preparing method thereof. The degradable film is composed of, by weight, 100 parts of biodegradable materials, 0-5 parts of compatilizer, 0.05-5 parts of irradiation sensitizing agents, 0.05-3 parts of antioxidants, 0.1-2 parts of light stabilizer, 0.1-3 parts of anti-ultraviolet agents and 0-2 parts of lubricating agents in a mixed mode. Compared with the prior art, the biodegradable film has the following advantages of having excellent mechanical strength, barrier performance, ageing resistance and the like, and being innovative, and application of the biodegradable film is expanded; the composite film keeps complete biodegradable performance, and has high application potentiality in medical science and environmental science, the composite film can replace petroleum-base general films to be used greatly, and environmental pressure is relieved. The preparing method is simple and easy to implement, the addition quantity of all the auxiliaries is small, cost is low, and the production process is controllable.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

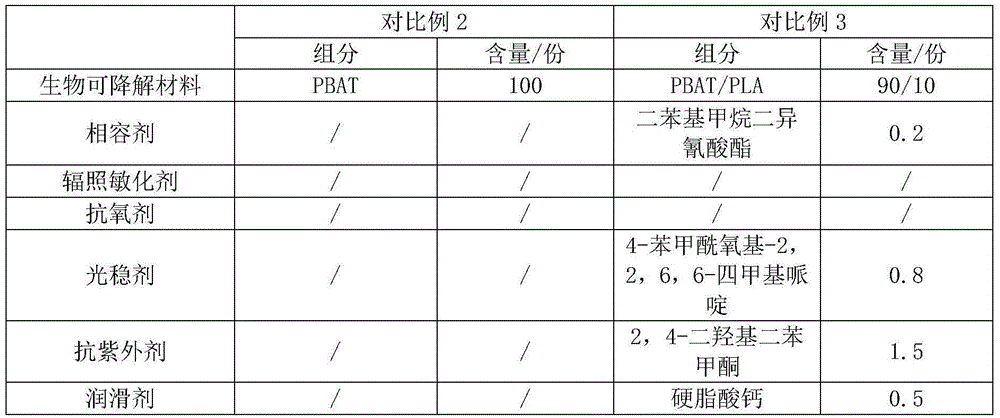

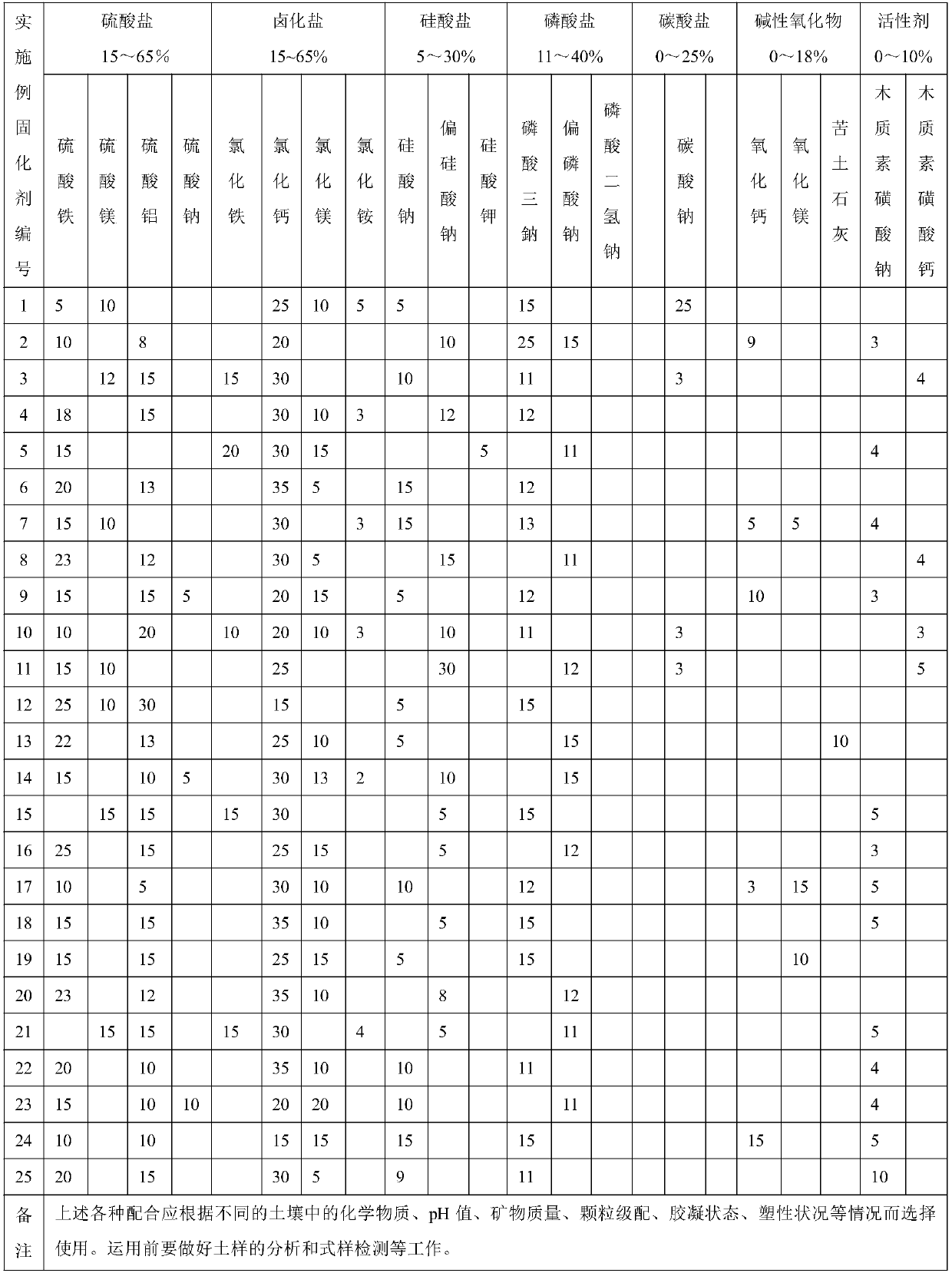

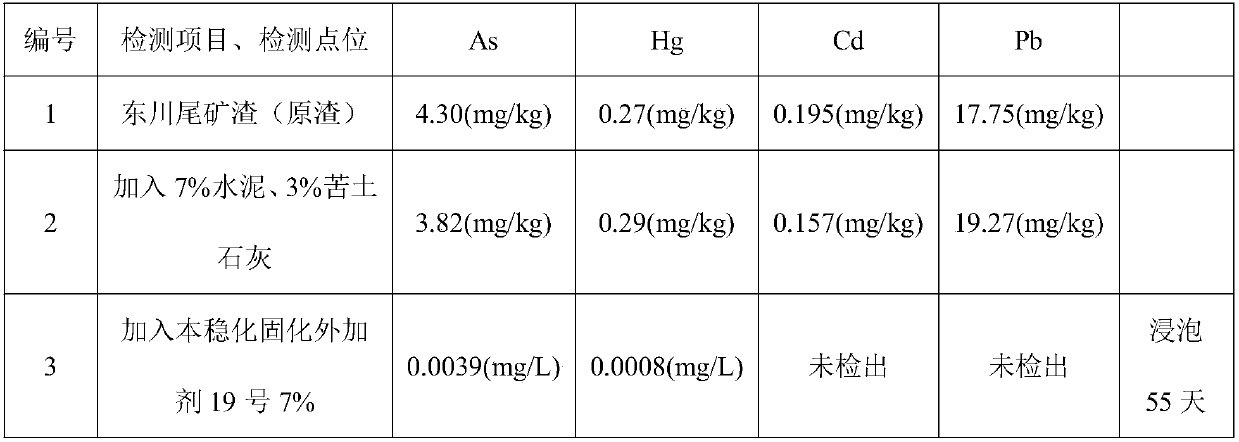

Environment-friendly inorganic soil solidification additive

InactiveCN105950157AImprove compatibilityFull effectOther chemical processesBuilding constructionsSoil propertiesHazardous substance

The invention provides an environment-friendly inorganic soil solidification additive which comprises, by mass, 15-65% of sulfate, 15-65% of halide salt, 11-40% of phosphate, 5-30% of silicate, 0-25% of carbonate, 0-18% of basic oxide and 0-10% of lignosulfonate. The environment-friendly inorganic soil solidification additive is characterized in that all components in soil directly or indirectly undergo soil particle surface chemical modification and modification of substances among soil particles, and generation of colloidal gel materials and generation of various materials of crystal structures are promoted. As time goes, hardened skeletons such as ettringite needle-shaped crystals and apatite crystals appear gradually in solidified soil, soil solidification compressive strength, hydrophobicity, water permeability, stability of heavy metal and other harmful materials and other physical and chemical solidification effects are good, and the environment-friendly inorganic soil solidification additive can adapt to various climates, geographies and soil properties and is high in compatibility and obvious in stabilization and solidification effect on heavy metal and other harmful materials.

Owner:松田勤

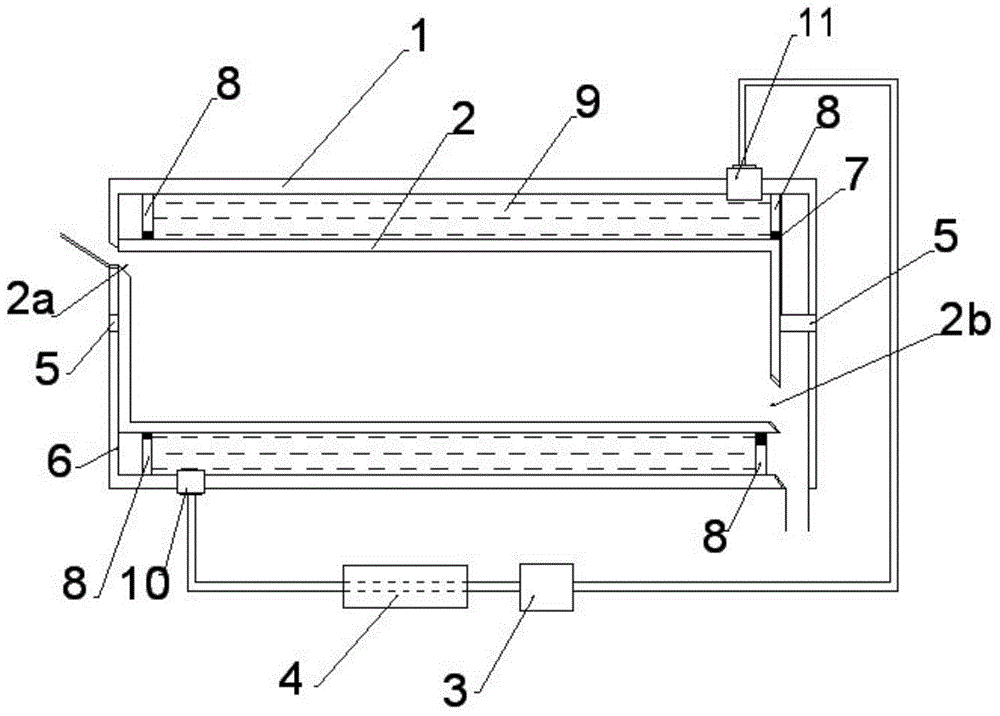

Method and system for automatically controlling textile dyeing

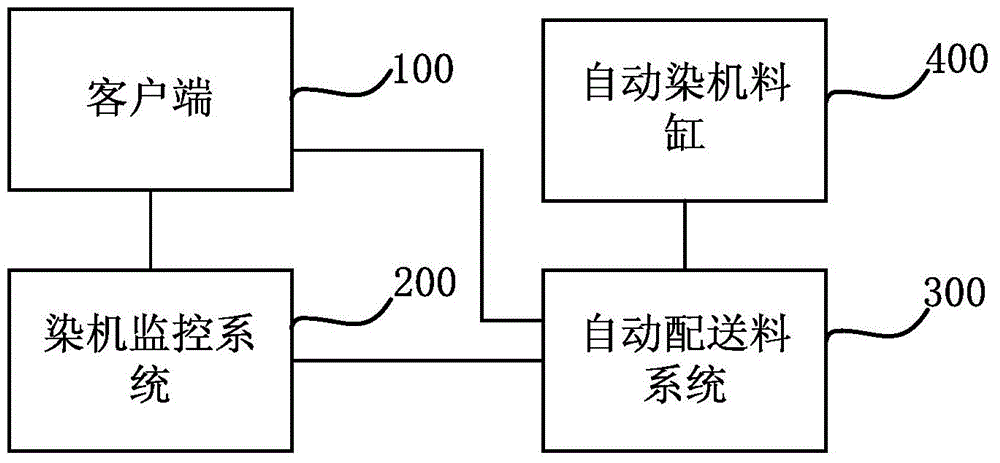

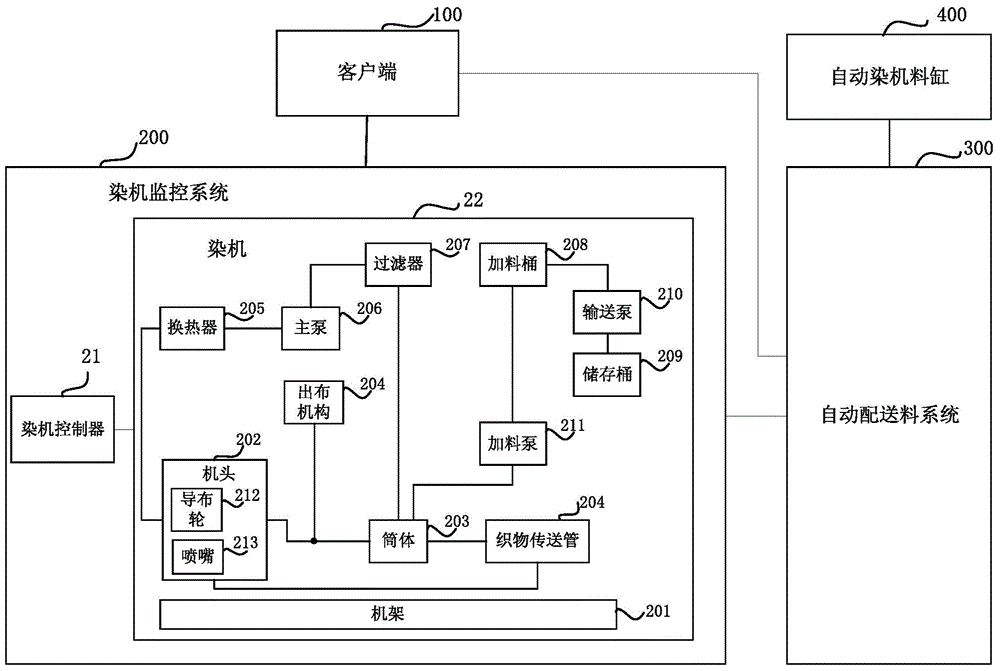

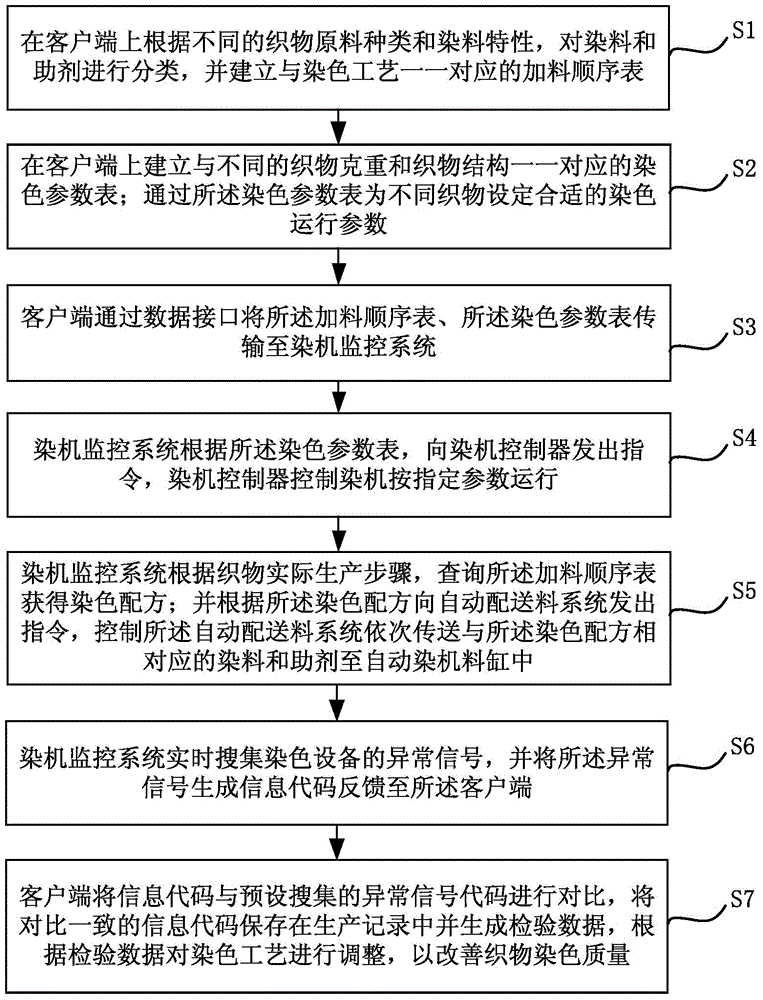

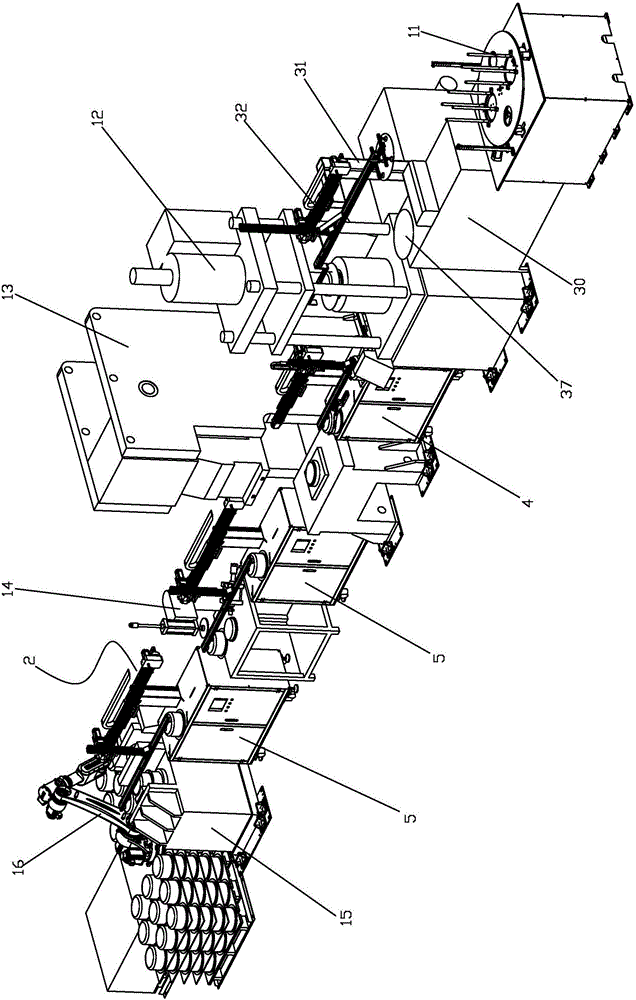

ActiveCN104593977ARealize automatic controlImplement automatic transferTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentControl systemMonitoring system

The invention discloses a system for automatically controlling the textile dyeing. The system comprises a client side, a dyeing machine monitoring system, an automatic material distributing and feeding system and an automatic dyeing machine material cylinder; wherein the client side is provided with a feeding sequence list which is in one-to-one correspondence with a dyeing technology and a dyeing parameter list of various textiles which are operated on a dyeing machine; the client side is used for transmitting the feeding sequence list to the dyeing machine monitoring system and sending an order to write parameters corresponding to the dyeing technology in the dyeing parameter list of the dyeing machine monitoring system; the dyeing machine monitoring system is used for writing the dyeing parameter list in a dyeing machine controller; the dyeing machine controller is operated according to the dyeing parameters and is used for querying the feeding sequence list according to actual production steps of textiles to obtain a dyeing recipe and controlling the automatic material distributing and feeding system to sequentially transmit dyestuff and auxiliaries into the automatic dyeing machine material cylinder. The invention also provides a method for automatically controlling the textile dyeing. The method and the system, provided by the invention, have the advantages of high stability and wide applicability.

Owner:TIANHAI LACE CO LTD

Health-care toothpaste containing Chinese prickly ash extracts

InactiveCN102727407AImprove the bactericidal effectGood antibacterial effectCosmetic preparationsToilet preparationsOral healthSide effect

The invention, relating to the field of chemicals for daily use, especially relates to an application of Chinese prickly ash extracts in toothpaste. The invention further discloses health-care toothpaste and a health-care toothpaste additive. The health-care toothpaste comprises 0.1-3.5 wt% of Chinese prickly ash extracts containing no less than 30 wt% of extracts of volatile oil from Chinese prickly ash. The toothpaste additive comprises 0.1-3.5 weight parts of Chinese prickly ash extracts, and 0.1-2.5 weight parts of eugenol. According to the invention, the health-care toothpaste containing Chinese prickly ash extracts of the invention adopts Chinese prickly ash extracts and eugenol which have antibacterial action and analgesia action, thus the toothpaste has no toxicity and no side effect to human's bodies, and the safety of the toothpaste is greatly better than synthetic antibacterial agents; the synergistic effect of Chinese prickly ash extracts and eugenol can enhance the antimicrobial antibacterial functions, and the purposes of diminishing inflammation, easing pain, removing halitosis, improving gingivitis and oral ulcer, cleaning oral cavity and carrying out oral health are achieved.

Owner:CHONGQING HEXIN AGRI DEV +1

Measurement method of soft asphalt quinoline insoluble substance

InactiveCN102621029ASolve the problem of inaccurate measured valuesImprove qualityWeighing by removing componentFiltrationDistilled water

The invention provides a measurement method of a soft asphalt quinoline insoluble substance. The method comprises the following steps of: putting a soft asphalt sample into quinoline for completely dissolving the soft asphalt sample into quinoline, and performing suction filtration with filter paper to leave the quinoline insoluble substance on the filter paper; washing the insoluble substance for 4-6 times by using quinoline, repeatedly washing the insoluble substance with toluene till a washing solution is not yellow, and dissolving the insoluble substance on the filter paper into quinoline and toluene; performing suction filtration on the washed filter paper, drying at the temperature of 115-120 DEG C, and cooling; washing the filter paper for 8-12 times with distilled water, dissolving diethylene glycol on the filter paper into water, and filtering; and soaking the filter paper with toluene, performing suction filtration, drying the filter paper at the temperature of 115-120 DEG C, weighing, and calculating to obtain the content of the quinoline insoluble substance. According to the method, accurate content of the quinoline insoluble substance in soft asphalt can be obtained, the enhancement on the quality of soft asphalt is facilitated, production of an acicular coke product is easy to control, and the quality of the acicular coke product is further guaranteed.

Owner:云南昆钢煤焦化有限公司

Ceramic wine-bottle and preparation method thereof

ActiveCN101671175AProduction is easy to controlAccurate bottle sizeCeramic shaping apparatusCeramic containersParaffin waxHot press

The invention improves preparation method of ceramic wine-bottle and is characterized in that at least molding of the bottleneck is steel mold hot-press paraffin wax casting molding, after sintering the molded bottleneck, and cementing with a sintered or unsintered bottle body. The invention breaks through the technical problems that the precision of bottleneck of ceramic wine-bottle is low and the difficulty in solving bottleneck shaping limit; the requirement that ceramic wine-bottles have precise bottleneck dimension and diverse shaping variation like glass wine-bottles is realized; the uniformity of outer caliber dimension of the bottlenecks is high; the common difference of inner diameter and outer diameter can be less than or equal to 0.1mm; the yield, compared with the prior art, can be enhanced by at least 3%; the mold loss can be greatly reduced; the economic benefit is very obvious; the high requirements of wine market on sealing, opening, anti-counterfeiting of the wine-bottles can be completely satisfied; and matched use range of novel anti-counterfeiting bottle caps is widened, and irregular bottle caps such as full screw, fine screw and the like can be obtained, thusbeing applicable to ceramic wine-bottles, and initiating steel mold hot-press paraffin wax casting molding technique and sintering technique for at least the bottlenecks of ceramic wine-bottles.

Owner:宜兴市昊源陶瓷厂(普通合伙)

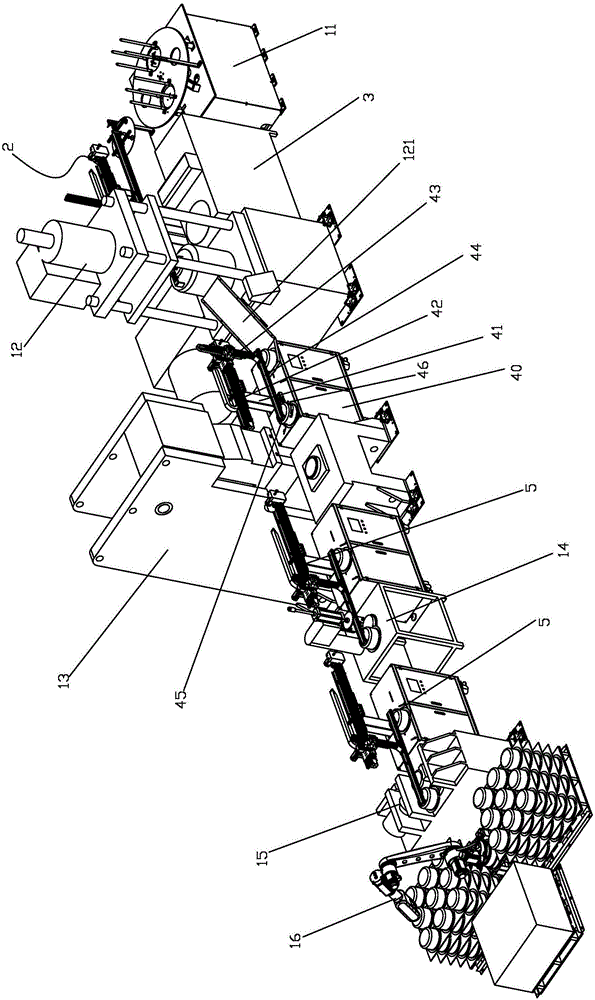

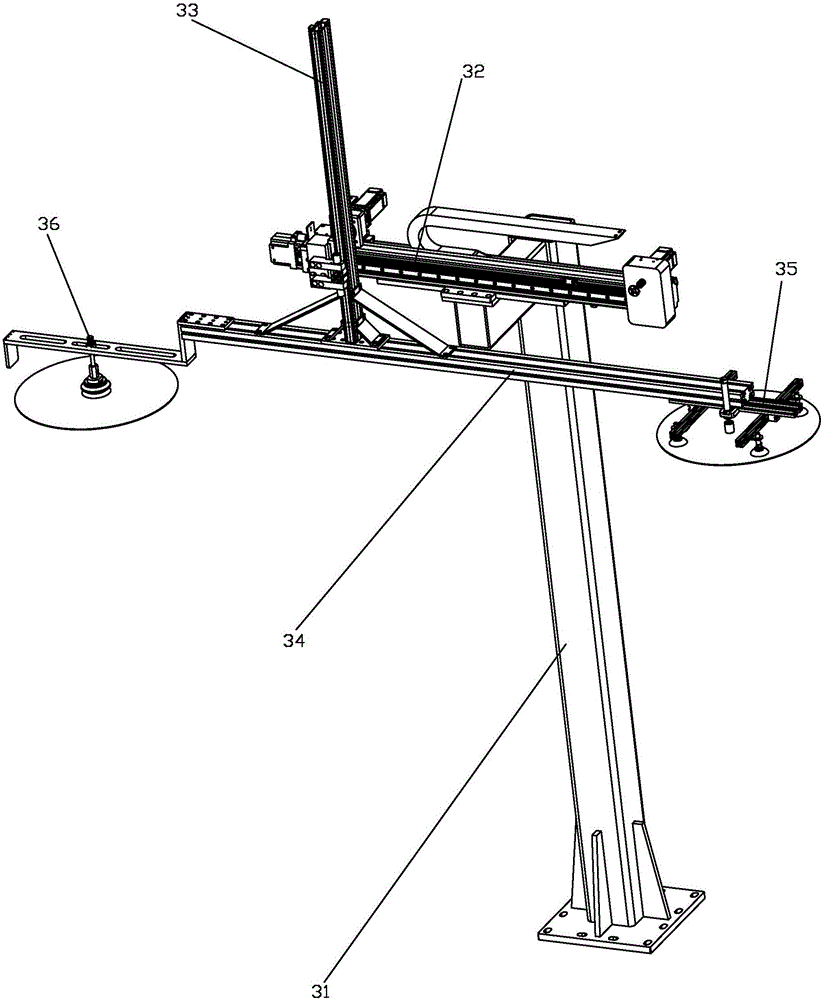

Full-automatic intelligent punching production system based on remote control

InactiveCN105834291AControllable production speedReduce the quantity in processMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineAutomatic train control

The invention discloses a full-automatic intelligent punching production system based on remote control. According to the technical scheme, the full-automatic intelligent punching production system is characterized by comprising an automatic feeding device, an automatic drawing molding device, an automatic edge trimming device, an automatic edge curling device, an automatic labeling device and an automatic stacking device which are arranged in sequence, and further comprising an automatic control system used for controlling the production line to operate in a remote mode. The automatic control system comprises a first pushing robot, a second pushing robot and third pushing robots, wherein the first pushing robot is arranged between the automatic feeding device and the automatic drawing molding device and used for automatically transferring and pushing semi-finished products; the second pushing robot is arranged between the automatic drawing molding device and the automatic edge trimming device; and the third pushing robots are arranged between the automatic edge trimming device and the automatic edge curling device and between the automatic edge curling device and the automatic labeling device. According to the full-automatic intelligent punching production system based on remote control, unmanned automated operation can be realized in all manufacture procedures, the semi-finished products can be transferred automatically between the manufacture procedures, and therefore automatic production is achieved in a real sense.

Owner:GUANGDONG CLAW ROBOT CO LTD

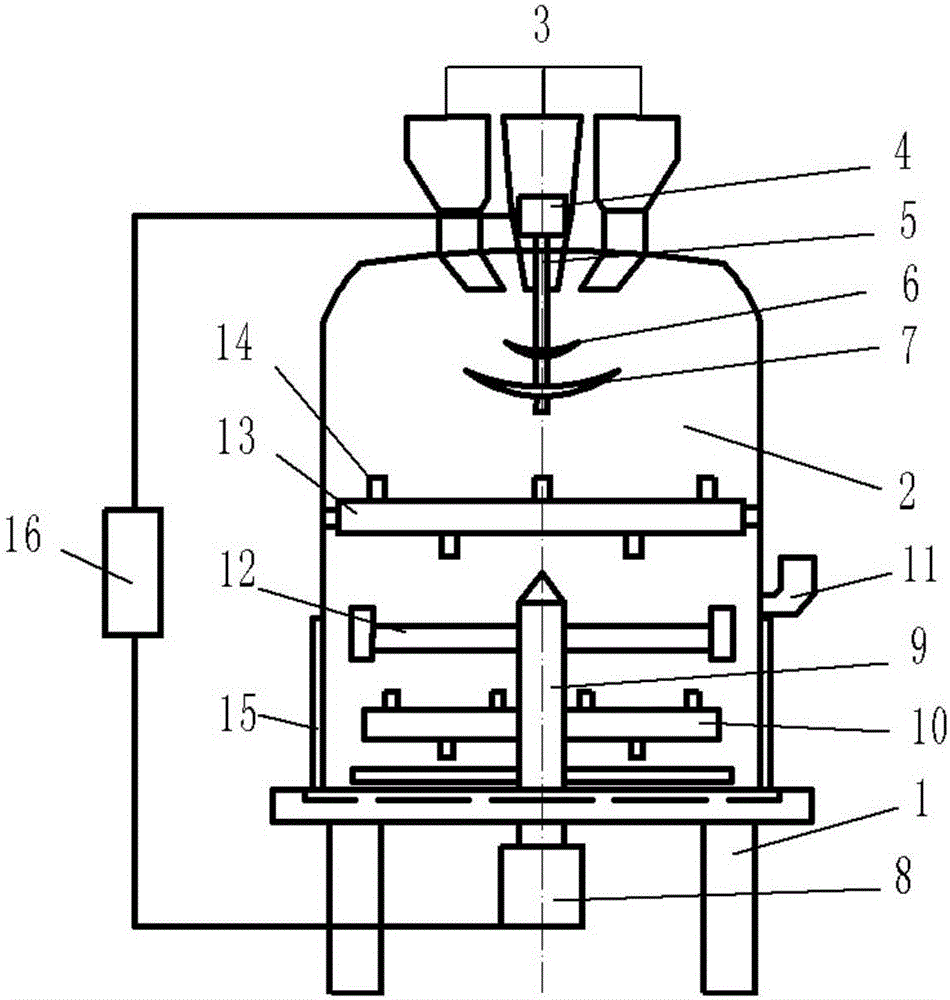

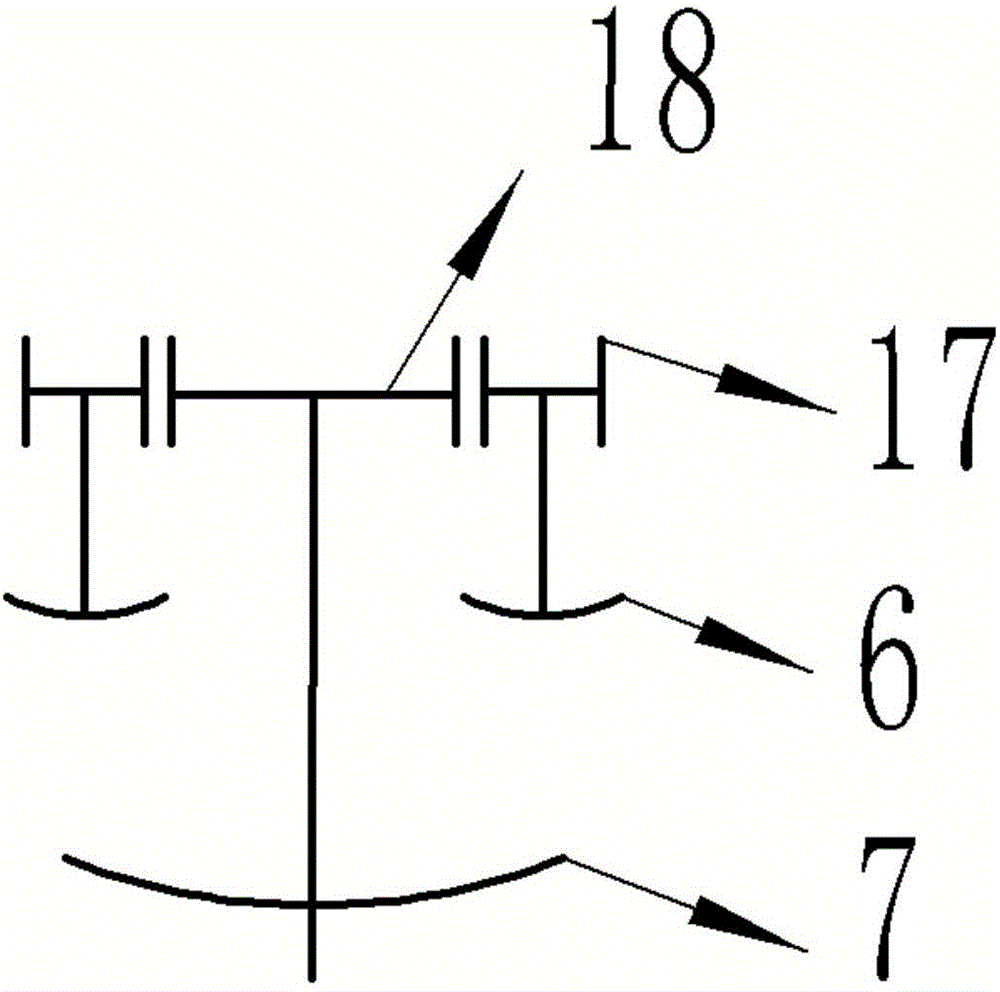

Sand mixer with enhanced preliminary mixing function

ActiveCN106799459AImprove the mixing effectImprove efficiencyMould handling/dressing devicesTemperature controlWork period

The invention relates to a sand mixer with an enhanced preliminary mixing function. The sand mixer is provided with an intelligent composite material inlet, wherein a multi-stage preliminary mixing disk for preliminarily mixing supplied materials is mounted on a main mixing bin; by the adoption of an optimized curved surface material throwing structure with a rotating speed and a rotating direction which are different from the rotating speed and the rotating direction of a main mixing mechanism, a load can be scientifically distributed according to an actual requirement; by the independent design of the mechanical loads and power of a preliminary mixing mechanism and the main mixing mechanism, the mechanical effect is effectively enhanced; a special material conveying opening for supplying an adhesive and / or a curing agent is formed in the middle part or the lower part of the main mixing bin of the sand mixer, so that the workload and the working time of the main mixing mechanism can be reduced to an extremely large extent, and the workload of the preliminary mixing mechanism is also reduced; furthermore, the sand mixer realizes controllability of production from quantitative material feeding and precise temperature control, and equipment works safely and reliably.

Owner:青岛科润机电设备有限公司

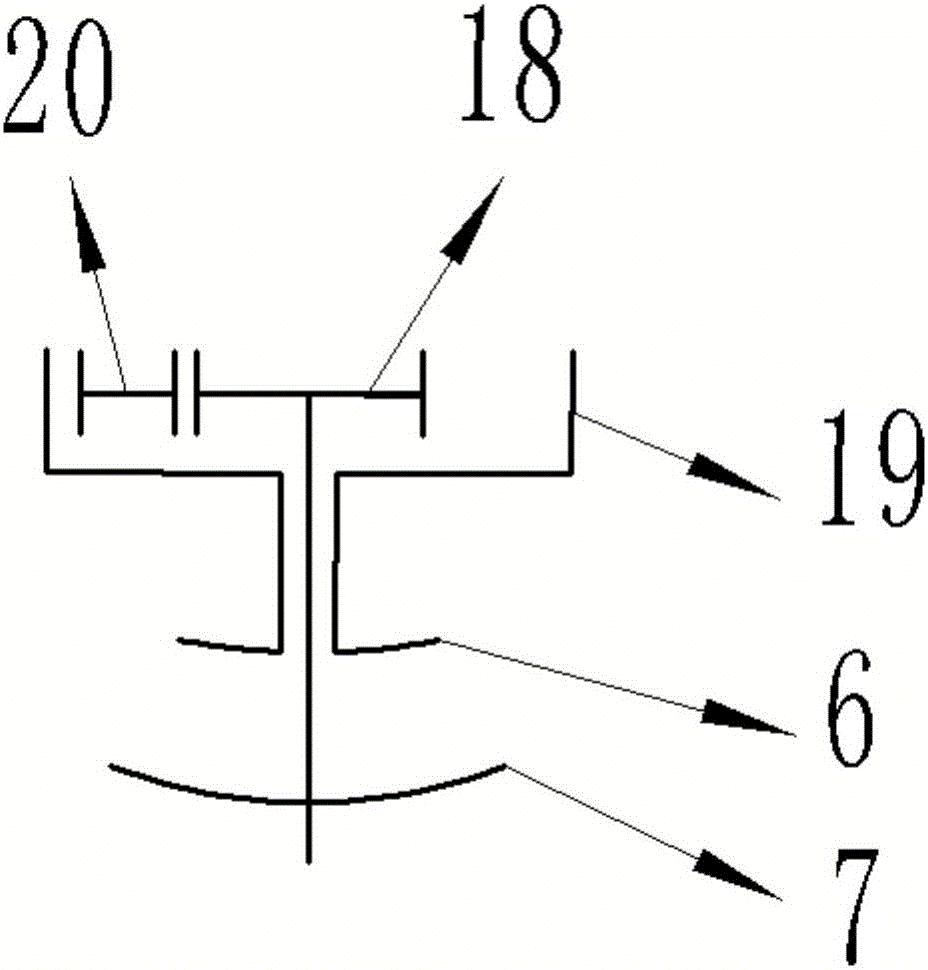

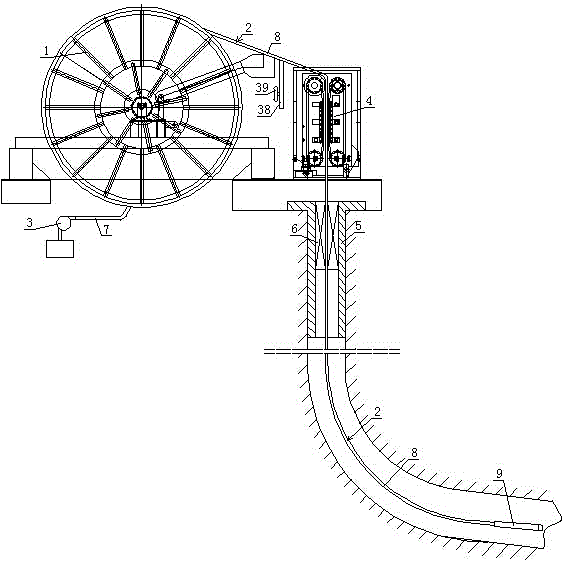

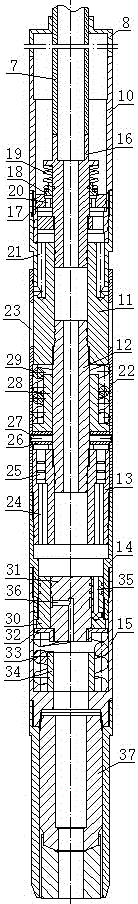

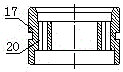

Double-layer coiled tube sand pumping device and double-layer coiled tube sand pumping technology

The invention discloses a double-layer coiled tube sand pumping device. The double-layer coiled tube sand pumping device comprises a coiled tube roller, a driving device, a coiled tube, a water pump, an injection head, a pit shaft arranged in a wellhead and a blowout preventer; the double-layer coiled tube sand pumping device is characterized in that the coiled tube comprises an inner tube and an outer tube, an annular space is formed between the inner tube and the outer tube, and the rear end of the annular space is sealed; a de-plugging spray head is arranged on the front end of the coiled tube; the outer tube which is higher than the wellhead is connected with a sand discharging tube which is communicated with the annular space, and the sand discharging tube is provided with a valve. The invention also discloses a double-layer coiled tube sand pumping technology. According to the double-layer coiled tube sand pumping device and the double-layer coiled tube sand pumping technology, disclosed by the invention, sand liquid is enabled to enter the annular space by pumping high-pressure water into the inner tube and opening a sand inlet in the de-plugging spray head during a sand blasting, and discharging the sand liquid by utilizing a high-pressure gas in a well; the double-layer coiled tube sand pumping device and the double-layer coiled tube sand pumping technology have the advantages that the damage to the stratum is small, the follow-up production is facilitated, the sand discharging efficiency is high, and the energy consumption is low.

Owner:LUZHOU CHANGJIANG GASOLINEEUM ENG MACHINERYCO

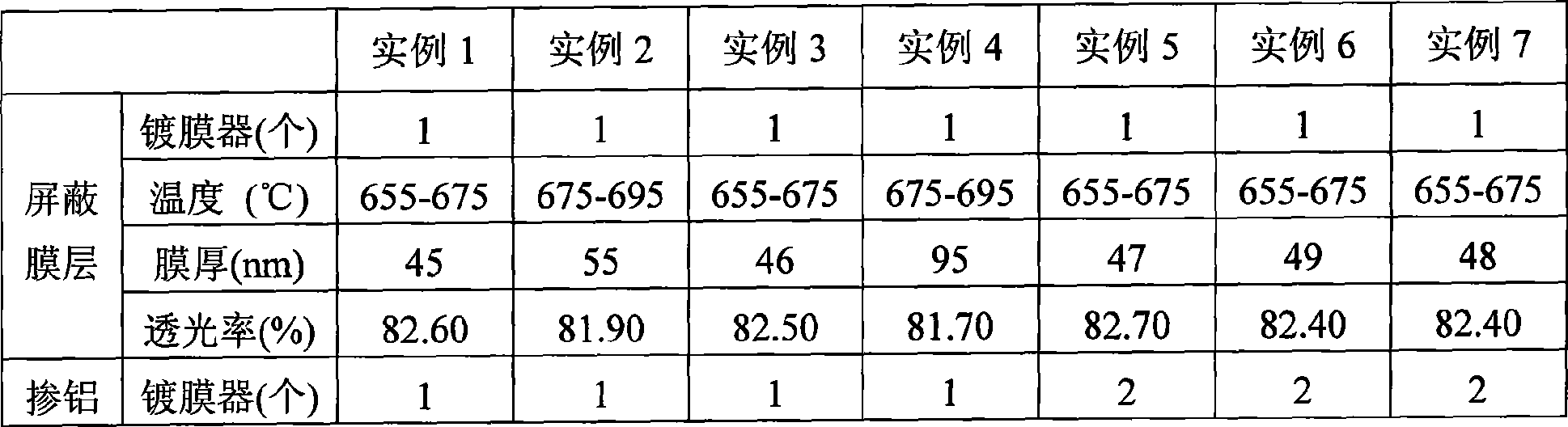

Method for online production of TCO film glass by float process

The invention discloses a float online method for producing TCO film glass. The method comprises that: a chemical vapor deposition method is adopted in a tin groove of a float glass production line; a proplastid gas mixture containing silane, ethene, phosphine, an oxygenous source and a phosphorus source dopant uses inert gas as a carrier; a shielding film layer with thickness of between 45 and 95 nm and refractive index of between 1.65 and 1.85 is formed on the surface of a glass substrate at a temperature of between 635 and 695 DEG C; and within the temperature range of between 550 and 630 DEG C, the proplastid gas mixture containing a zinc source, an aluminum source, a stabilizing agent and a catalyst prefabricated to be gasified uses nitrogen gas or air as the carrier and is introduced to the movable glass surface deposited with the shielding film layer to form a TCO film with thickness of between 250 and 450 nm and low resistivity. The TCO glass has even film layer, high surface resistivity, high conductivity, good wearing resistance, strong alkali resistance and high conductivity and visible light transmittance.

Owner:WUJIANG CSG GLASS CO LTD

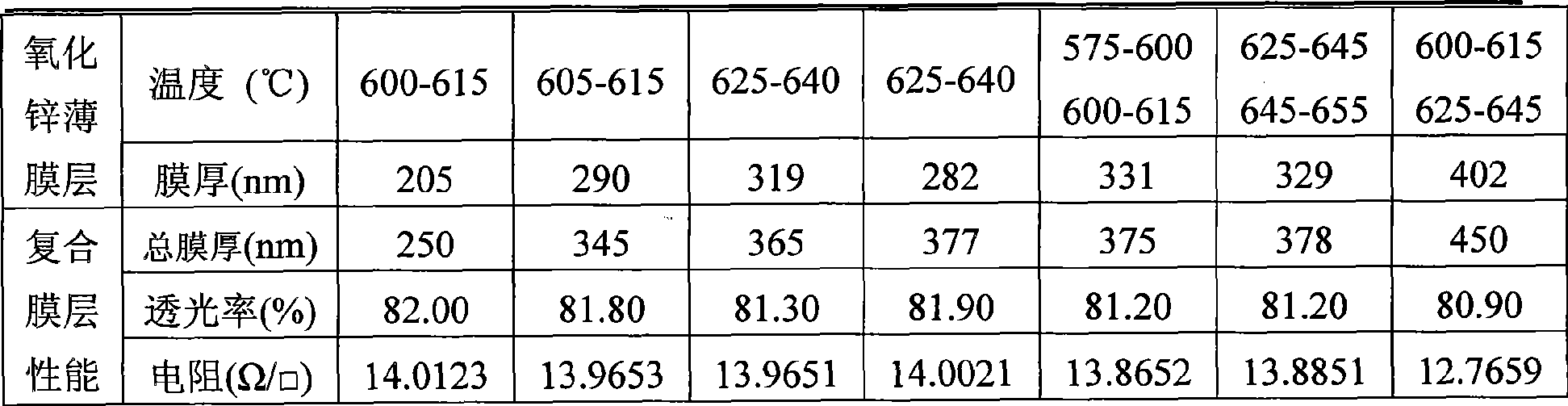

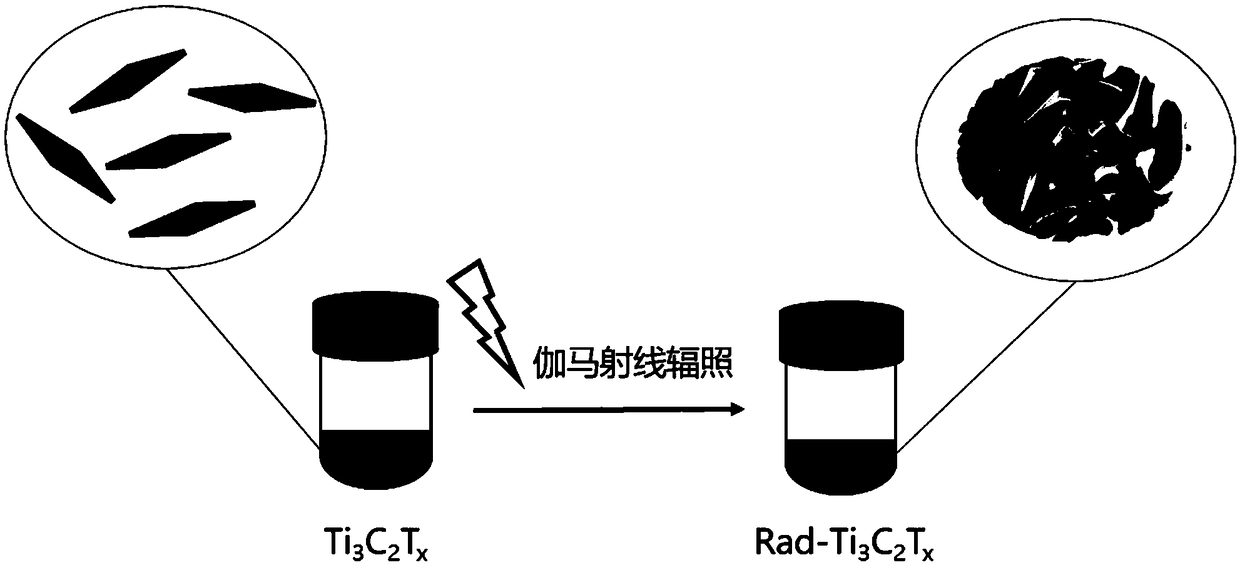

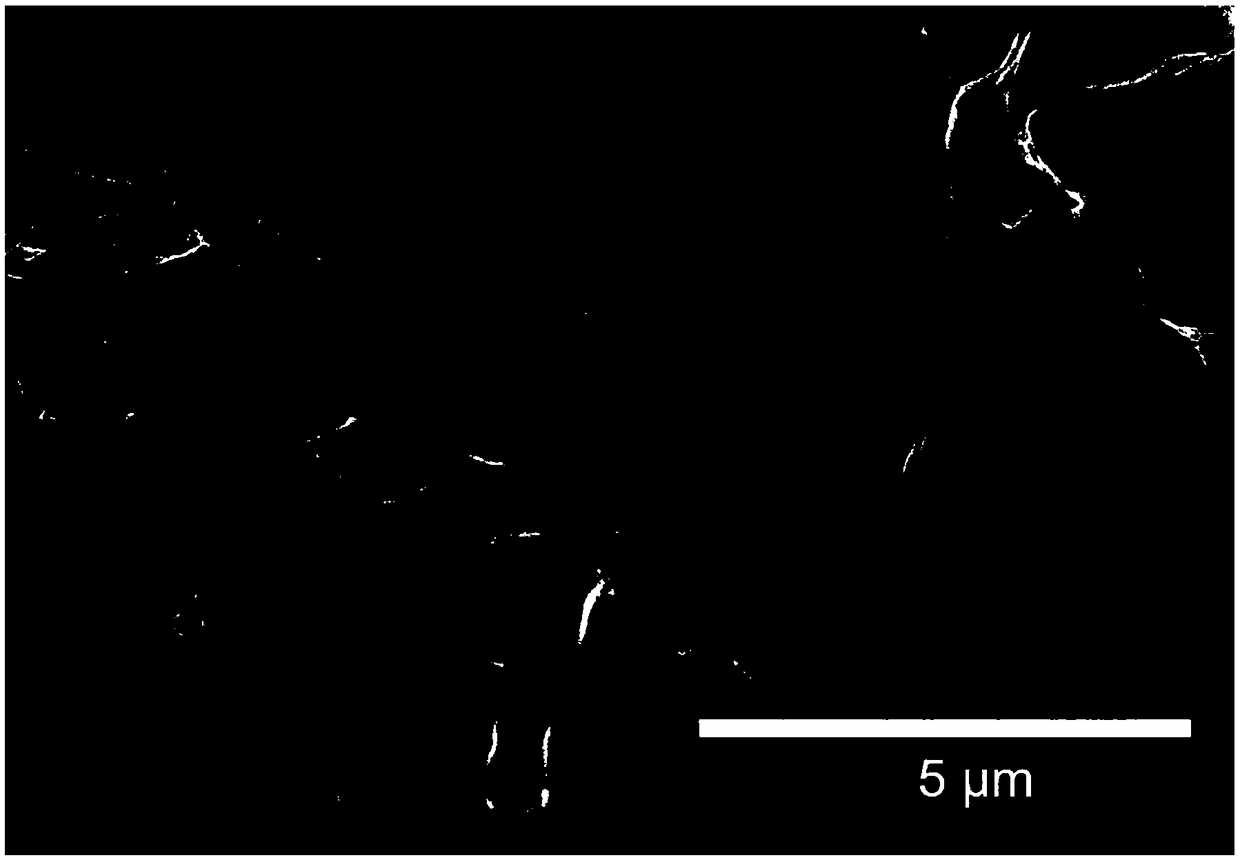

Modified Ti3C2Tx material and preparation application thereof

ActiveCN109449002AImprove conductivityRealize industrial productionHybrid capacitor electrodesHybrid/EDL manufactureSupercapacitorSolvent free

The invention discloses a modified Ti3C2Tx material and preparation application thereof. The Ti3C2Tx material has a pleated structure and amorphous-form carbon, and is prepared through irradiating inTi3C2Tx aqueous dispersion by adoption of gamma rays or electron beams. Solvent free radicals generated in the irradiation process interact with Ti3C2Tx, thereby not only generating the amorphous-formcarbon on the surface of the Ti3C2Tx so as to improve the conductivity of the Ti3C2Tx material, but also inducing Ti3C2Tx fragments to be assembled into a chip layer with the pleated structure so asto increase the active specific area of the Ti3C2Tx material and facilitate the sufficient contact between the Ti3C2Tx material and electrolyte. The material serves as a supercapacitor electrode material, expresses favorable reversibility and stability in electrochemical performance test, and has a potential application value in the field of energy storage.

Owner:PEKING UNIV

Fluorescent glaze for artistic porcelain

The invention discloses florescent glaze for artistic porcelain. The florescent glaze for the artistic porcelain is prepared from the following components in part by weight: 20 to 30 parts of potash feldspar, 5 to 10 parts of soda feldspar, 6 to 10 parts of red lead, 5 to 10 parts of boric acid, 3 to 8 parts of spodumene, 20 to 30 parts of quartz, 2 to 6 parts of calcite, 3 to 8 parts of barium carbonate, 2 to 5 parts of talc, 2 to 5 parts of zinc oxide, 2 to 5 parts of bone ash, 0.5 to 1.0 part of zirconium silicate, 0.5 to 1.0 part of vanadium pentoxide, 1.0 to 2.0 parts of copper oxide, 1.0 to 2.0 parts of ferric oxide, and 3 to 8 parts of manganese oxide. The florescent glaze for the artistic porcelain is simple in formula, and reasonable in proportioning; the florescent glaze which is prepared according to the formula has the characteristics of long luminescence duration, and fine and smooth glaze; and meanwhile, the phenomenon that luminescent powder is not oxidized at high temperature during firing of the glaze is avoided in a production process, and production is easy to control.

Owner:陈新基

Polyester/cotton fabric printing technology

InactiveCN104562800AHigh color fixing rateImprove stabilityDyeing processDisperse dyePulp and paper industry

The invention discloses a polyester / cotton fabric printing technology. The polyester / cotton fabric printing technology adopts the technical process as follows: preforming, printing, baking, performing alkali rolling and rapidly steaming, soaping, performing hot water washing, and drying. Through adoption of two-phase printing, the color fixing rate of disperse / reactive dye is greatly improved; through optimization of the disperse dye, the problem of background contamination easily caused by a disperse / reactive complete printing method is effectively solved; a color paste does not contain an alkaline agent, so that the color paste is high in stability and can be stored for more than two days; the polyester / cotton fabric printing technology is easy in production control and simple in pulping operation; a large amount of urea is saved, so that environment protection is benefited.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

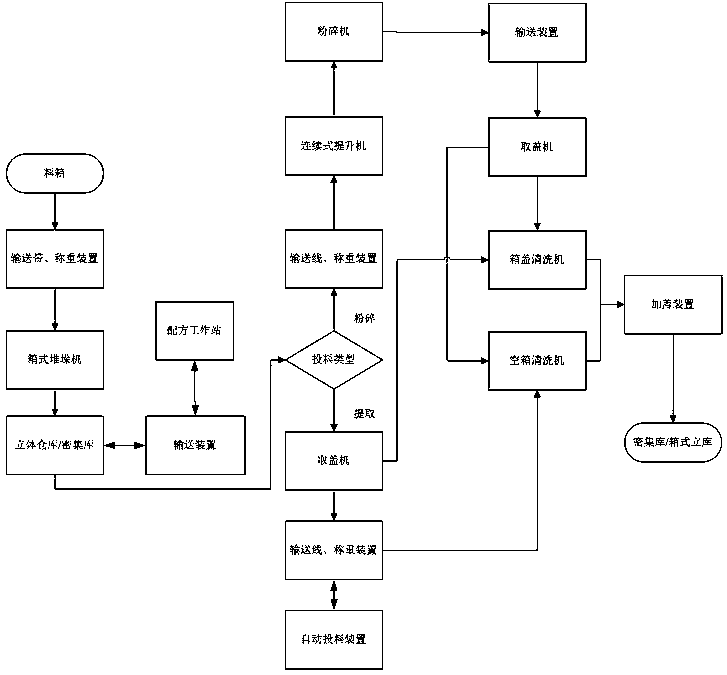

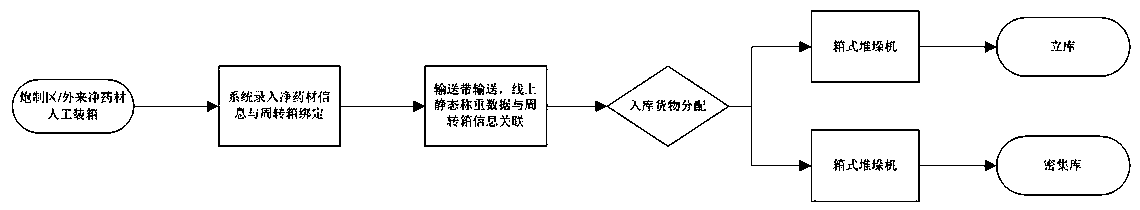

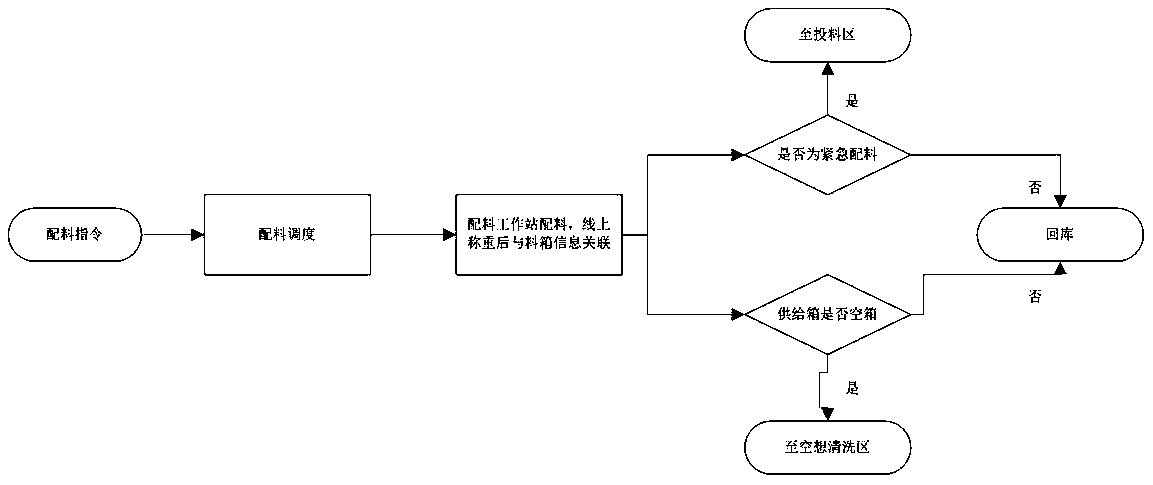

Material transferring and automatic batching system and process for traditional Chinese medicine pretreatment

ActiveCN110422635ATimely storageNeatly stackedConveyorsStorage devicesCollection systemControl system

The invention relates to a material transferring and automatic batching system and process for traditional Chinese medicine pretreatment, and belongs to the technical field of pretreatment in the traditional Chinese medicine industry. The system comprises a dense warehouse feeding system, an automatic batching system, a material ex-warehouse discharging system, a empty material box collecting system, an information tracing system and an automatic controlling system, wherein the dense warehouse feeding system, the automatic batching system, the material ex-warehouse discharging system and the empty material box collecting system are sequentially connected by a conveying line device and are electrically connected with the automatic controlling system. According to the material transferring and automatic batching system and process for traditional Chinese medicine pretreatment, the labor intensity of operators, the requirements for professional skills of the operators, the production costand the risk of misoperation of the operators are reduced; the reliability of the system and the utilization rate of a production operation area are improved; the digitized, standardized and normalized management of a production workshop are realized; and implementing is simple, the production performance is stable and the operability is high.

Owner:KUNMING CHINESE MEDICINE FACTORY

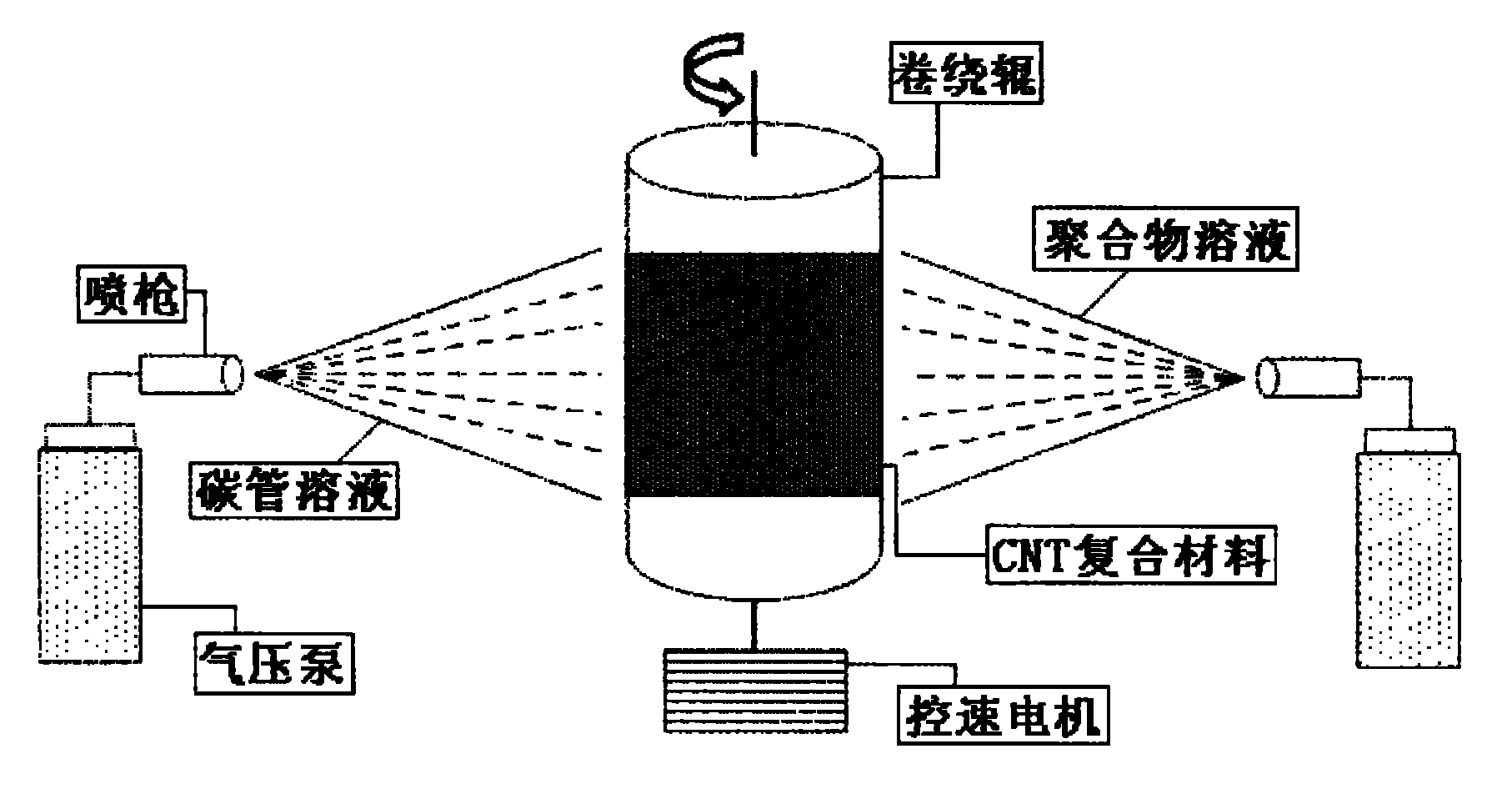

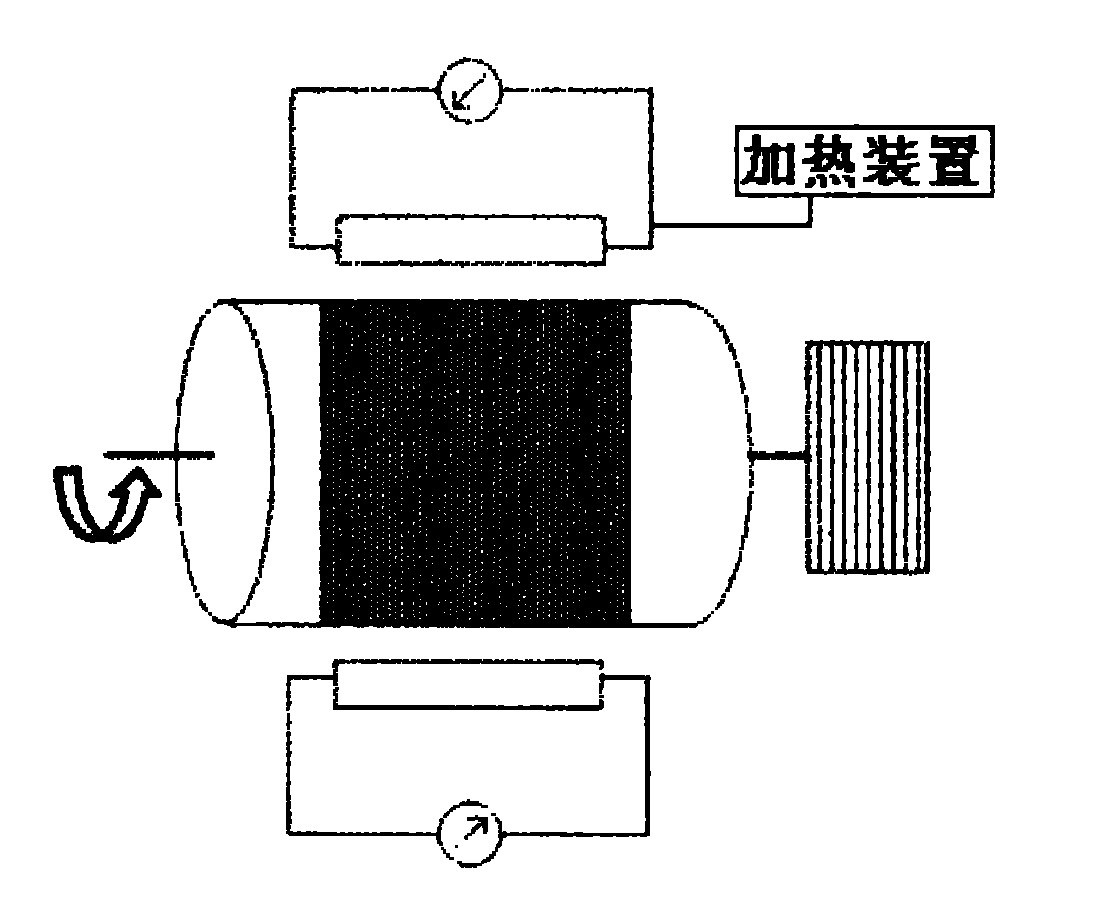

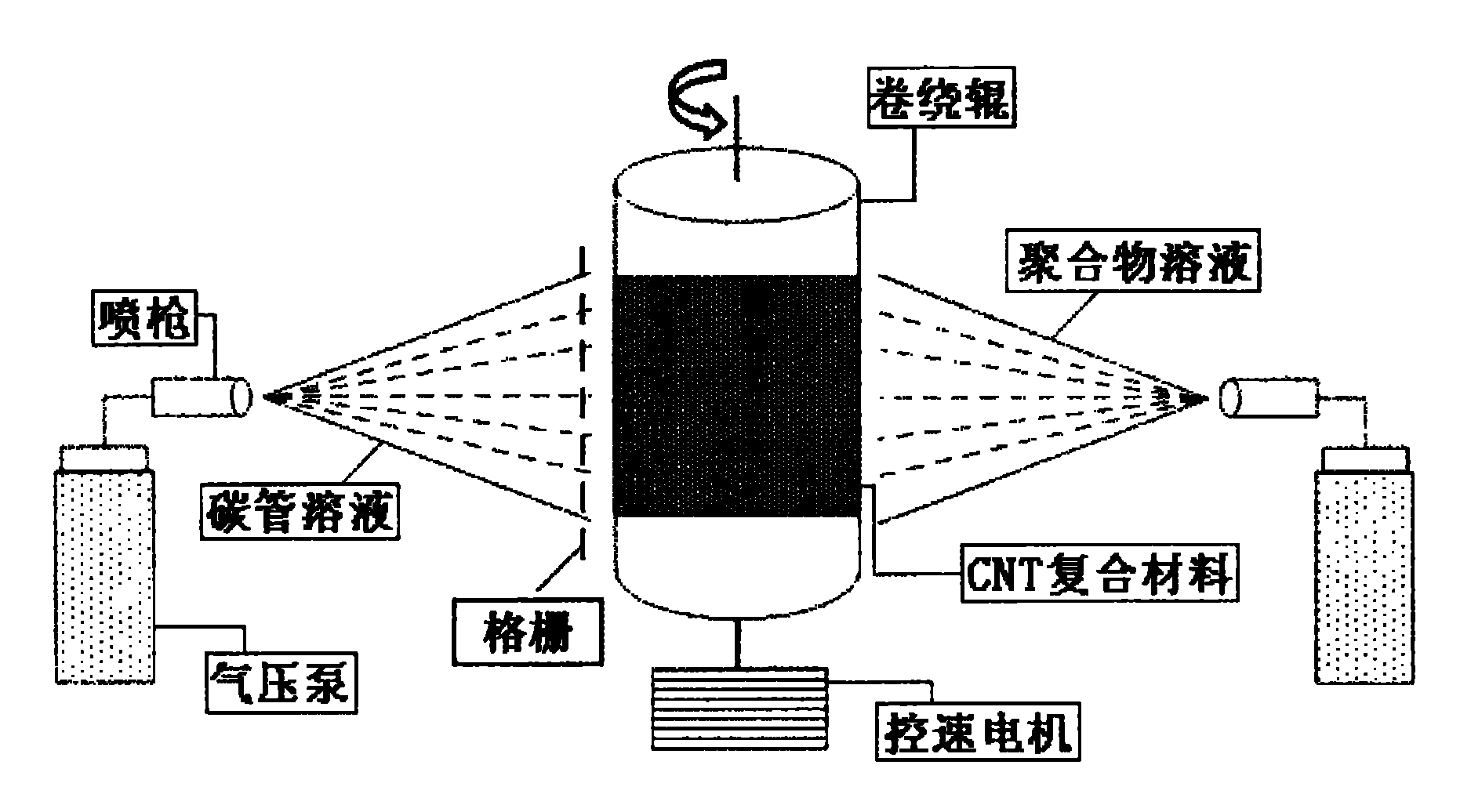

Preparation method of carbon nano tube composite material with high-content uniformly dispersed carbon nano tubes

The invention relates to a preparation method of a carbon nano tube composite material. The preparation method is characterized by comprising specific steps as follows: adding carbon nano tubes in a first volatile solvent; adding a dispersing agent; uniformly dispersing the carbon nano tubes in a volatile solvent to obtain a dispersed carbon nano tube solution; dissolving a polymer in a second volatile solvent to obtain a polymer solution; connecting a wind-up roll with a speed control motor; spraying the dispersed carbon nano tube solution on the rotating wind-up roll at one side of the wind-up roll by using a spray gun; spraying the polymer solution on the wind-up roll at the other side of the wind-up roll by using the spray gun; turning on a heating device which is close to the wind-uproll so that the first volatile solvent and the second volatile solvent are volatilized; and continuously spraying, winding and volatilizing, so that the carbon nano tube composite material consisting of carbon nano tubes and the polymer is formed on the wind-up roll. The preparation method provided by the invention is simple and easy to operate, and is convenient to control.

Owner:DONGHUA UNIV

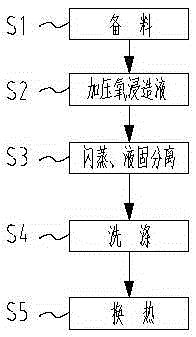

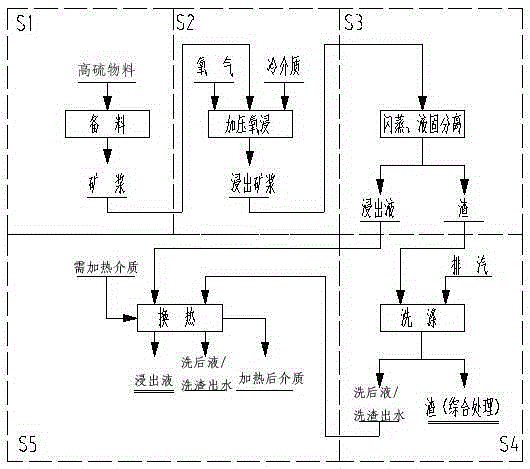

Method for treating high-sulfur materials through continuous pressure oxygen leaching

InactiveCN105349776ALow costNo consumptionProcess efficiency improvementAutomatic controlReaction temperature

The invention discloses a method for treating high-sulfur materials through continuous pressure oxygen leaching. The method comprises the steps of material preparation, liquid preparation through pressure oxygen leaching, flash evaporation, liquid-solid separation, washing, heat exchange and the like; the reaction temperature is kept through heat release in the oxidation process of low-valence sulfur in the materials, steam consumption and additive consumption are avoided, redundant heat in the reaction process is consumed by introducing cooling media, the reaction temperature rise is effectively controlled, and reaction heat energy is sufficiently and comprehensively utilized through heat exchange. According to the method, continuous pressure leaching is conducted in one stage, flash evaporation, continuous cooling and pressure reduction are conducted in another stage, leaching residues do not need to be treated to recycle sulfur, the whole production process is continuous, the automatic control degree is high, self-heating is achieved in the reaction process, the reaction temperature does not need to be kept by adding elemental sulfur or steam, the leaching time is short, the metal yield is high, the production energy consumption is low, and the continuity, the stability and the safety of production operation are higher.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

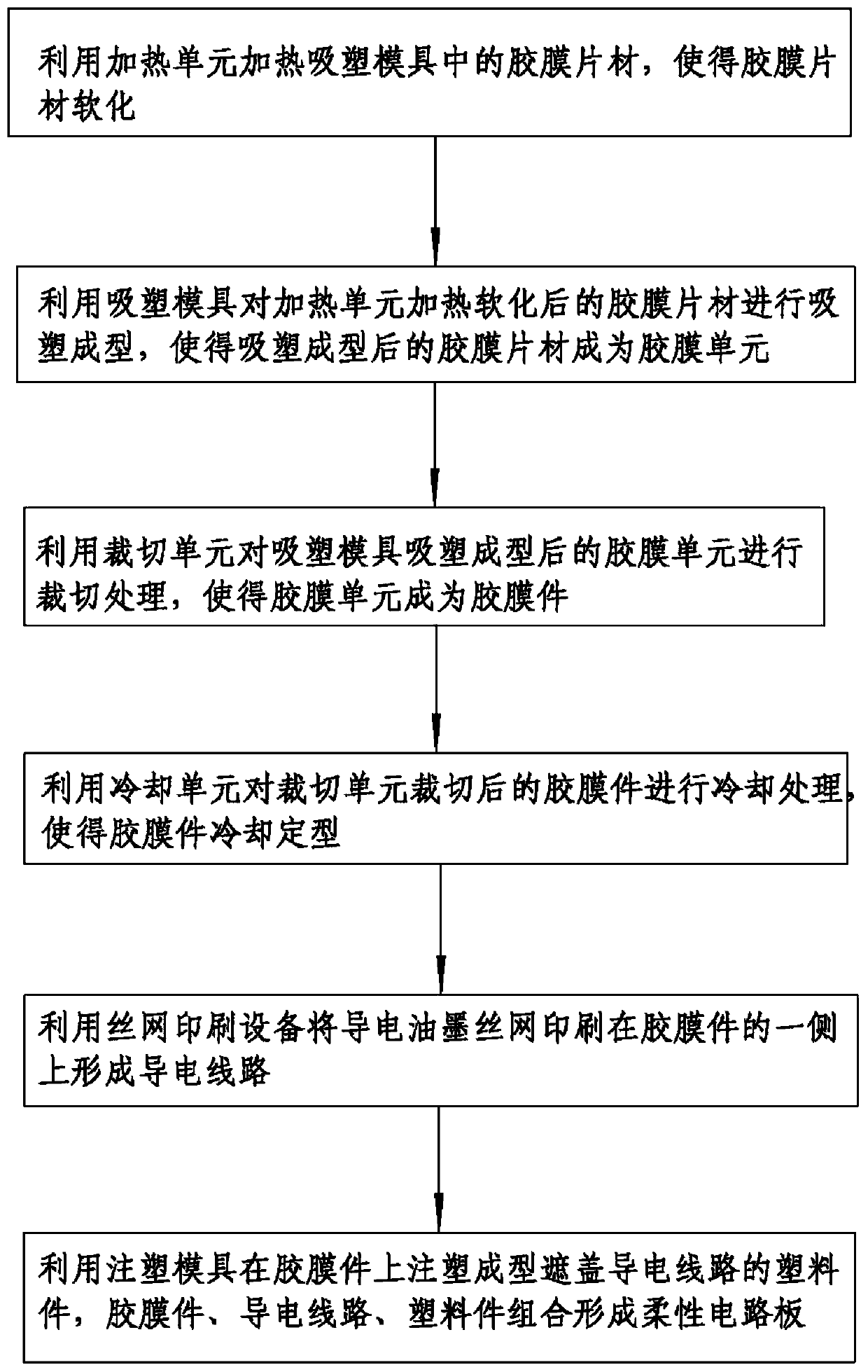

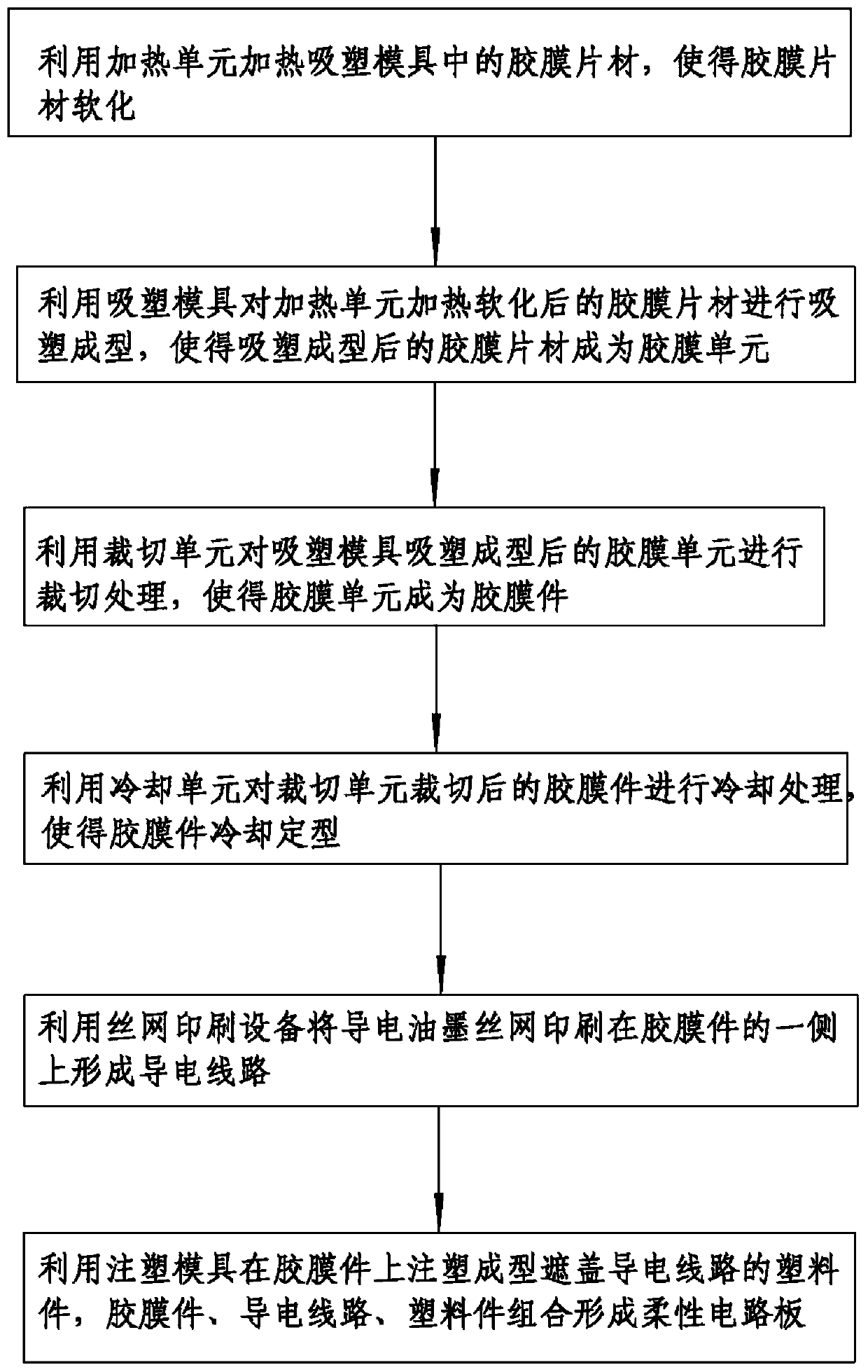

Manufacturing process of flexible circuit board

InactiveCN111113784ASimple production processProduction is easy to controlFlexible printed circuitsCircuit artworks manufactureScreen printingManufacturing technology

The invention relates to the technical field of flexible circuit board production, and particularly discloses a manufacturing process of a flexible circuit board. The process comprises the following steps that an adhesive film part is provided; conductive ink and silk-screen printing equipment are provided, wherein the conductive ink is printed on one side of the adhesive film part by using the silk-screen printing equipment to form a conductive circuit; and an injection mold is provided, wherein a plastic part is formed on the adhesive film part in an injection molding mode by using the injection mold, the conductive circuit formed by printing the conductive ink on the adhesive film part is clamped between the adhesive film part and the plastic part, and the adhesive film part, the conductive ink and the plastic part are combined to form the flexible circuit board. Processes of electroless plating copper, etching and the like of a flexible circuit board in the prior art are cancelled,so that a production process flow of the flexible circuit board is greatly simplified, the production of the flexible circuit board is simpler and more controllable, the production efficiency of theflexible circuit board is improved, and the manufacturing cost of the flexible circuit board is reduced.

Owner:DONGGUAN HIROCA AUTOMOTIVE TRIM TECH CO LTD

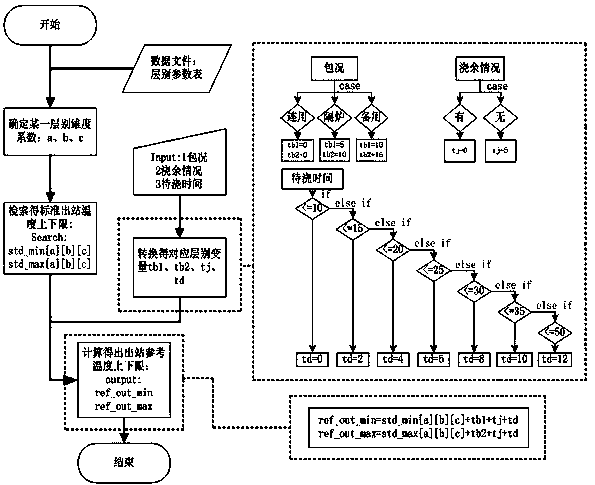

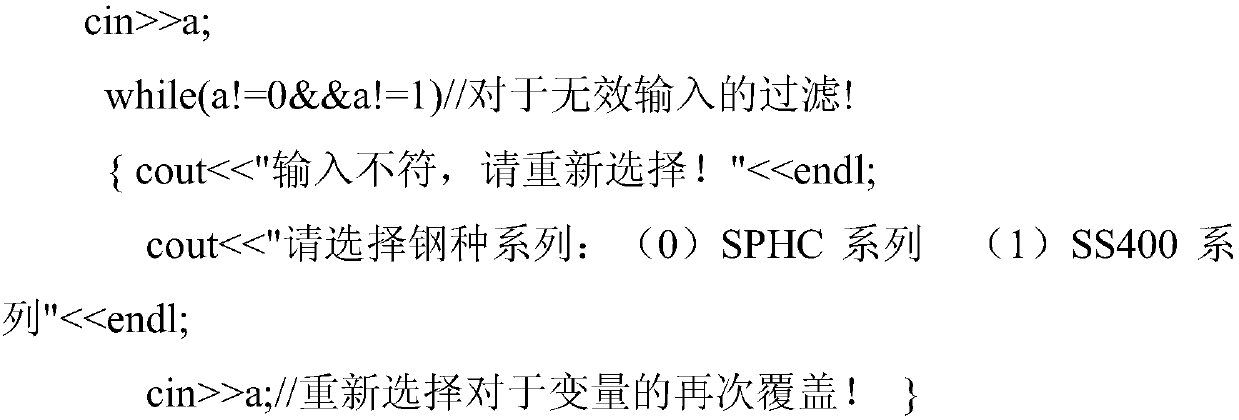

Method for improving precise control of refining worker over molten steel temperature

InactiveCN107557535AEasy to control temperatureStable temperature controlProcess efficiency improvementLower limitTemperature control

The invention relates to a method for improving precise control of a refining worker over the molten steel temperature and belongs to the technical field of steel melting control. According to the technical scheme, the method is characterized in that the out-station temperature of LF refined molten steel is automatically calculated through an automatic temperature calculation model; the model is built through the processes that according to the three-stage layers of the steel grade, a continuous casting machine and the continuous casting number, on the basis of an upper limit value and a lowerlimit value of the standard out-station temperature and by combining the process that three sets of parameters of the tundish condition, the residual casting molten steel recycling condition and theto-be-cast time of the molten steel are input by the refining worker according to the actual production condition and converted into variables of the corresponding layers, the upper limit value and the lower limit value of the out-station temperature of the LF refined molten steel are calculated finally; and the refining worker only needs to conduct control operation according to the temperature of the LF refined molten steel automatically calculated in the model. The method for improving precise control of the refining worker over the molten steel temperature has the beneficial effects that areasonable temperature scheme of the refining process is built, and the temperature control level of the refined molten steel is improved, so that the qualification rate of controlling the tundish temperature is increased, the constant casting speed in continuous casting is guaranteed, and the molten steel quality is improved.

Owner:TANGSHAN IRON & STEEL GROUP +1

Roller feed drying equipment

InactiveCN105716398AAdjustable sizeDry evenlyDrying chambers/containersDrying machines with non-progressive movementsEngineeringFodder

The invention discloses roller feed drying equipment. An inner barrel is sleeved with an outer barrel and can rotate. A sealed interface space is defined by the outer barrel and the inner barrel and filled with circulating fluid. A liquid inlet and a liquid outlet are formed in the outer wall of the outer barrel. A circulating pump and a heater are sequentially connected with the liquid outlet and the liquid inlet through pipelines. A feeding opening and a discharging opening are formed in the front wall and the rear wall of the inner barrel. A roller type drying device is adopted, and therefore the drying process can be even and free of dead corners. The feeding opening and the discharging opening are separated, so that continuous production is achieved. A heating system capable of achieving circulating and controllable in temperature is utilized, so that the drying process is controllable, and energy is saved. A power system is located in a case, so that safety is improved.

Owner:JIANGMEN YUEHAI FEED

Method for seeding portunus tritubereulatus by means of water retention

InactiveCN102124969APromote growthAvoid stimulationClimate change adaptationPisciculture and aquariaMicroecosystemDisease

The invention discloses a method for seeding the portunus tritubereulatus by means of water retention. The method comprises an earlier stage water treatment step, a spawning step and a cultivating step. The earlier stage water treatment step comprises the steps of: adding water at 15 DEG C to 17 DEG C into an impounding reservoir, adding quicklime, formaldehyde and penicillin sodium in the manner of aeration, adequately mixing, and sterilizing for 3-4 days. The spawning step comprises the steps of: adding concentrated photosynthetic bacteria and nitrifying bacteria into a spawning pool, rising the temperature of the water in the spawning pool to be 20 DEG C to 25 DEG C, aerating, disinfecting the portunus tritubereulatus by potassium permanganate, and suspending the disinfected portunus tritubereulatus above the spawning pool to spawn. The cultivating step comprises the steps of: disinfecting larva bait by the potassium permanganate, adding the disinfected larva bait into the spawning pool, adding the concentrated photosynthetic bacteria and bacillus into the spawning pool every 4-6 days, and cultivating for 20-30 days to obtain the seed of the portunus tritubereulatus. After the method is used, the balance of a water area micro ecological system can be maintained, the antibiotic drugs can not be abused during producing, the disease incident rate can be reduced, the production yield can be improved, and the method is low in cost, free of public hazard, and green.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

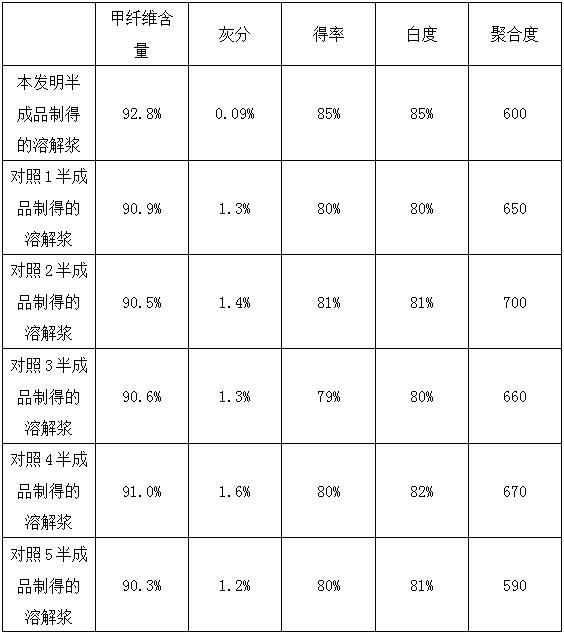

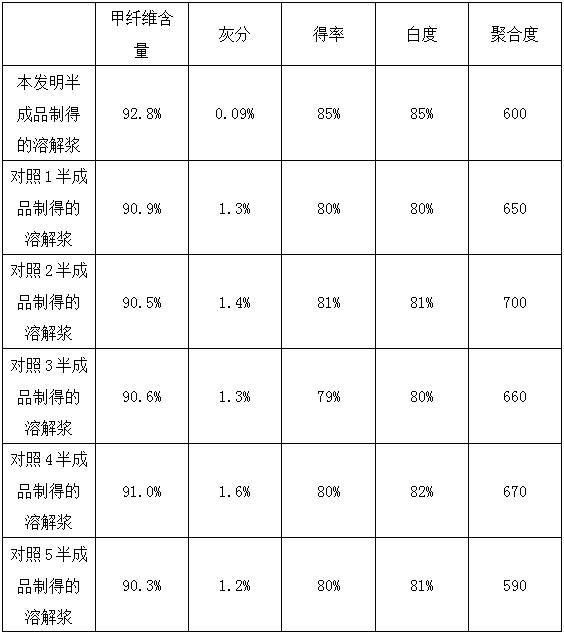

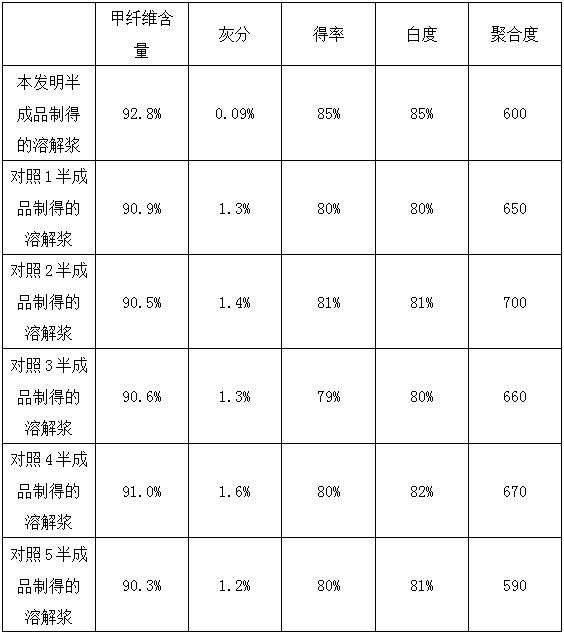

Material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in modified mode

InactiveCN102677500AMonotonous performanceUniform shapePretreatment with alkaline reacting compoundsRaw material divisionFiberMaterials preparation

The invention discloses a material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in a modified mode. The process comprises procedures of raw material preparation, dispersion, slicing, impregnation and the like. Specific to unbleached wood pulp raw materials, special process steps and process control parameters are utilized so that the purposes of improving quality of end products, energy saving and emission reduction can be achieved, armour fiber content, yield and whiteness of the end products can be improved, ash content of the end products is reduced, cost control of chemical liquid drug is facilitated, the curve of temperature rising in the follow-up cooking process is stable, poly reduction is even, prepared semi-finished products are suitable for various cooking modes, and the material preparation process has a wide application range.

Owner:YIBIN GRACE GROUP CO LTD

Method of preparing oxidation methyl tin

A method of preparing oxidation methyl tin belongs to the technical field of preparing method of chemical products. The method comprises the steps as follows: adding chloride methyl tin into a reactor, adding with water to stir until totally solving, heating up to 50 to 60 DEG. C; slowing and uniformly dropping alkali metal hydroxide solution or ammonia, the reaction temperature being 30 to 110 DEG. C, the reaction time being 2 to 5 hours, the reaction terminal being controlled at PH value 7 to 9, finally filtering the reaction solution, washing and purifying, the obtained solid being the oxidation methyl tin. The method of preparing oxidation methyl tin is simple and the production is easily controlled; the prepared products have excellent and stable quality and high yield. The prepared oxidation methyl tin is easily stored and transported, and is conveniently applied, and can be the raw materials of preparing thiol methyl tin and organic acid methyl tin such that the cost of preparing thiol methyl tin and organic acid methyl tin is obviously reduced; the production process has no pollution to the environment, and the production is easily controlled, the prepared products have excellent and stable quality.

Owner:衢州建华南杭药业有限公司

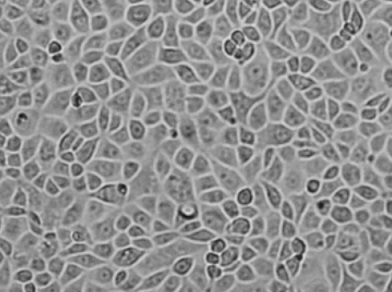

Domestication method of full suspension culture-type MDCK cell line

PendingCN111676185AHigh densityFully contactedSsRNA viruses negative-senseViral antigen ingredientsBiotechnologyEmbryo

The invention relates to the field of cell culture, in particular to a domestication method of a full suspension culture-type MDCK cell line. According to the domestication method, adherent MDCK cellsare domesticated into a low-serum full suspension culture-type MDCK cell line and a serum-free full suspension culture-type MDCK cell line, so that traditional production of an avian influenza virusthrough chicken embryos can be replaced, the subsequent separation and purification efficiency is improved, further upgrade of a process is promoted, a culture process is also simplified while the cost is reduced, and the domestication method is easier to industrialize.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA

Preparation method of black foamed cement insulation board

InactiveCN111116140AImprove insulation effectFire and Flame Retardancy Class ACeramicwareFiberFoaming agent

The invention discloses a preparation method of a black foamed cement insulation board, and belongs to the field of building materials, and the preparation method comprises the following steps: uniformly mixing cement, fly ash, a fiber reinforced material and a foaming stabilizing dispersant, adding hot water at 40-60 DEG C, stirring the components to form slurry, adding a foaming agent, uniformlystirring the mixture, pouring the mixture into a mold, foaming the mixture, and curing and molding the foamed product in a greenhouse, and demolding the product; and maintaining the shaped product atnormal temperature for 24 hours, cutting the product into decorative plates, and naturally curing the decorative plates for 30 days. The decorative plate has excellent strength, heat preservation andcolor effect, and reaches the flame retardant property grade-A.

Owner:南通金信达建筑装饰工程有限公司

Material preparation process for preparing dissolving pulp by modifying bleached needle leave wood and broadleaf wood composite pulp

InactiveCN102677509AMonotonous performanceUniform shapePulp bleachingMultistage pulping processMaterials preparationPulp and paper industry

The invention discloses a material preparation process for preparing dissolving pulp by modifying bleached needle leave wood and broadleaf wood composite pulp. The process comprises the steps of preparing raw materials, dispersing, splicing, soaking and the like, specific process steps and process control parameters are adopted for composite pulp material of the bleached needle leave wood and the bleached broadleaf wood, so that the quality of a final product is improved, the energy is saved, the emission is reduced, the content, the yield and the whiteness of alpha cellulose in the finished product are improved, the ash content of the alpha cellulose is reduced, and a cost control of chemical liquid medicine is facilitated, a subsequent cooking heating curve is stable, degree of polymerization is uniformly decreased, the obtained semi-finished product is suitable for all kinds of cooking manners, and the application range is wide.

Owner:YIBIN GRACE GROUP CO LTD

Method for separating and refining isobomyl acetate

ActiveCN102329230AOvercome the shortcomings of high energy consumption and low product yield in batch separationHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcid waterPtru catalyst

The invention relates to a method for separating and refining isobomyl acetate. The method is characterized in that: an acetic acid solution containing water is produced on the top of a crude ester rectification tower; a mixture of camphene and acetic acid is mainly obtained through side take-off; a crude product of the isobomyl acetate is produced from the tower; and the crude product enters a refined ester evaporator, is whitened and then enters a refined ester vapor-liquid separation tank for separation so as to obtain high-purity isobomyl acetate. The disadvantages of high energy consumption of batch separation, low product yield and the like existing in the prior art are overcome; acid water is produced from the top of the crude ester rectification tower, crude ester is produced fromthe tower, the clear segmentation is realized by using a single tower, teichoic acid is produced from one side and only contains the acetic acid and the camphene, and when the teichoic acid is used for the circular reaction, the selectivity of the reaction is improved and the service life of a catalyst is prolonged, so the process is advanced and the energy consumption is low; and the method has the advantages of continuous production, compact flow, low energy consumption and the like, and the product is high in yield and has stable quality.

Owner:福建南平青松化工有限公司

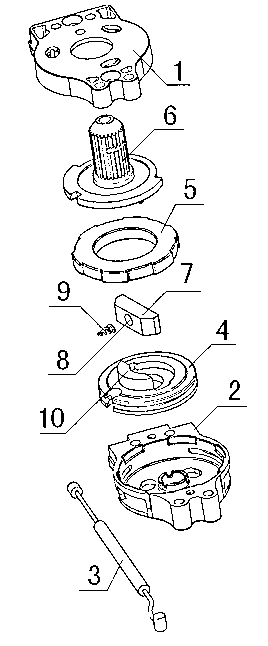

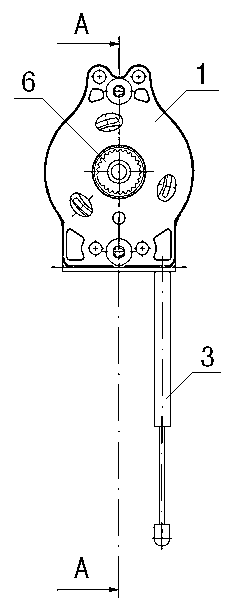

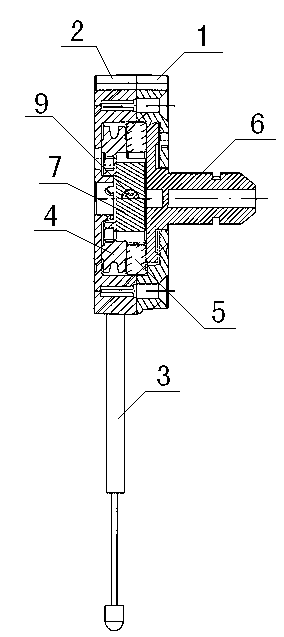

Clutch type manual waist support adjustor for automobile seat

ActiveCN102923029ALabor-saving operationFlexible and convenient adjustmentBack restsCar seatWire wheel

The invention relates to an automobile seat accessory, in particular to a clutch type manual waist support adjustor for an automobile seat. The adjustor comprises an upper shell, a lower shell, a stay wire, a wire wheel, a shaft sleeve and a shifting fork; the adjustor also comprises a clutch block arranged in the shaft sleeve and a pressure spring arranged in an inner hole of the clutch block, the shaft sleeve is sheathed on a braking terminal of the wire wheel; the clutch block with the pressure spring is arranged in the shaft sleeve; one end of the pressure spring in the clutch block pushes against the interior of the hole of the clutch block, and the other end of the pressure spring pushes against the inner wall of the braking terminal of the wire wheel; a pushing terminal is arranged below a shifting fork, one side of the pushing terminal is provided with two contact surfaces; and during installation, the pushing terminal is inserted in the shaft sleeve and corresponds to one end of the clutch block and the braking terminal of the wire wheel. Due to the adoption of the structure, the clutch type manual waist support adjustor has the advantages that the operation is labor-saving, the adjustment is convenient and flexible, the structure is simple and reasonable, the cost is low, the production is easily controlled, the product percent of pass is high.

Owner:江苏恩迪汽车系统股份有限公司

Material preparation technology applied in preparation of dissolving pulp by modifying bleached wood pulp

InactiveCN102691221AMonotonous performanceUniform shapeNatural cellulose pulp/paperPretreatment with alkaline reacting compoundsMaterials preparationPulp and paper industry

The invention discloses a material preparation technology applied in preparation of dissolving pulp by modifying bleached wood pulp. The technology comprises the procedures of raw material preparation, dispersion, slicing, dipping and the like. Specific process steps and process control parameters thereof are adopted for a bleached wood pulp raw material, so that the aims of improving the quality of the finished product, saving energy and reducing emission can be fulfilled, the alpha cellulose content, the yield and the whiteness of the finished product are improved, the ash content is reduced, cost control of chemical agents is facilitated, and the subsequent digestion temperature rise curve is stable and uniform in sharp drop; the prepared semi-finished product can be applied to various digestion modes; and the technology is wide in application range.

Owner:YIBIN GRACE GROUP CO LTD

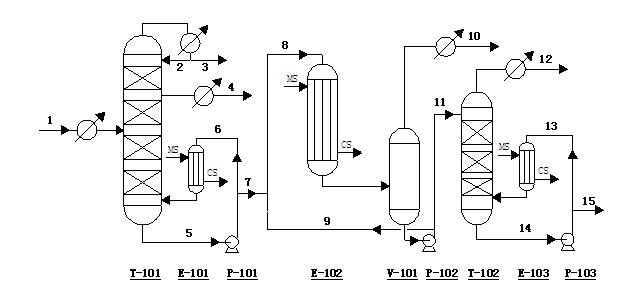

Photo-thermal shape memory functional material as well as preparation method and application thereof

ActiveCN111704691ALow viscosityThe polymerization reaction is fastLight protection screensEmulsionAqueous solution

The invention provides a preparation method of a photo-thermal shape memory functional material. The preparation method comprises the following steps: preparing a monomer aqueous solution; preparing aphoto-thermal material aqueous solution; adding the photo-thermal material aqueous solution into the monomer aqueous solution to form an emulsion, and shearing the emulsion by using a high-speed shearing machine; preparing an ammonium persulfate aqueous solution, adding a part of the ammonium persulfate aqueous solution and a part of the emulsion into a four-neck flask, and stirring the mixed liquid for prepolymerization; shearing the remaining emulsion by using a high-speed shearing machine, adding the remaining ammonium persulfate aqueous solution into the emulsion, dropwise adding the mixed solution into a four-neck flask at a constant speed, and stirring the mixed liquid for polymerization; and after the polymerization is finished, pouring the solution into a beaker, refrigerating thesolution at low temperature, pouring the solution into a mold, and drying the solution to obtain the photo-thermal shape memory functional material. The invention also provides a photo-thermal shapememory functional material and application thereof. The photo-thermal shape memory functional material has the characteristics of shape memory, photo-thermal response, intelligent cooling and the like, and is suitable for large-scale low-cost manufacturing.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com