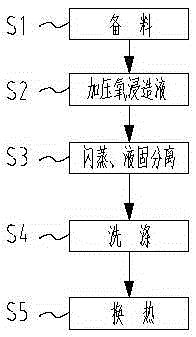

Method for treating high-sulfur materials through continuous pressure oxygen leaching

A pressurized oxygen leaching and high-sulfur technology, applied in the direction of improving process efficiency, can solve problems such as unsuitable process parameters, difficult follow-up treatment, long leaching time, etc., and achieve good production environment, high production efficiency, and small equipment scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

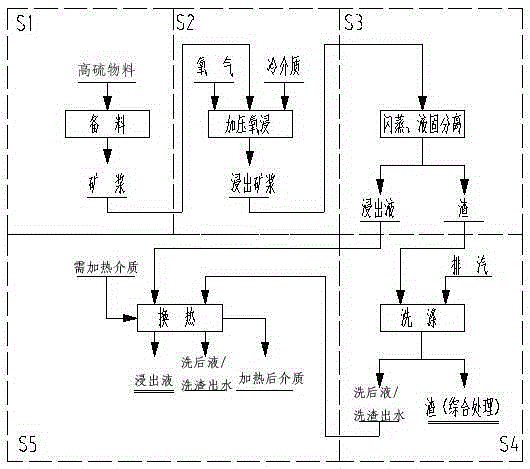

Method used

Image

Examples

Embodiment 1

[0040] A high-sulfur concentrate A: Co5.78%, Cu12.51%, Fe3.96%, S4.96%; a high-sulfur concentrate B: Co8.38%, Cu14.58%, Fe13.14%, S23.15%, mix the high-sulfur concentrates A and B uniformly according to the mass ratio of 1:1, and then send them to the crusher, classify, and pulp, and use the mixture of leachate and washed liquid returned after heat exchange to pre-acidify and dilute Ore pulp, the main parameters of the diluted pulp: solid particles -300 mesh ≥ 90%, the solid low-valence sulfur content of the pulp is 12.5%, the total solid content of the pulp is 26%, the initial pH of the pulp is 3.5, the temperature of the pulp is 35 ° C, the pulp stand-by.

[0041] The prepared pulp is continuously and stably transported to the pressure vessel device through an additional pump, and at the same time, industrial pure oxygen is continuously introduced. The mixture of effluent and washing liquid is used as a cold medium to adjust the reaction temperature, and the reaction condit...

Embodiment 2

[0046] A high-sulfur concentrate A: Ni12.93%, Co0.66%, Cu0.56%, Fe31.39%, S29.76%, a high-sulfur concentrate B: Co5.78%, Cu12.51%, Fe3.96%, S4.96%, mix the high-sulfur concentrate A and B according to the mass ratio of 1:2, send it to the crusher, classify, and pulp, and use the mixture of the leaching liquid returned after heat exchange and the washing liquid Liquid pre-acidification and dilution of pulp, main parameters of diluted pulp: solid particles -300 mesh ≥ 90%, solid low-valence sulfur content of pulp is 13.8%, total solid content of pulp is 25%, initial pH of pulp is 4, pulp temperature The temperature is 35°C, and the pulp is ready for use.

[0047] The prepared pulp is continuously and stably transported to the pressure vessel device through an additional pump, and at the same time, industrial pure oxygen is continuously introduced. The mixture of effluent and washed liquid is used as a cold medium to adjust the reaction temperature, and the reaction conditions i...

Embodiment 3

[0052] A high-sulfur precipitate A: Co9.83%, Ni14.69%, Cu5.54%, Fe0.88%, S24.49%; a high-sulfur precipitate B: Co1.03%, Ni34.83%, Cu0 .04%, Fe0.14%, S21.02%, the high-sulfur precipitates A and B are mixed uniformly at a mass ratio of 1:1 and sent to slurry, and the slurry is diluted with the washed liquid returned after heat exchange. The main parameters of the pulp: no coarse particles, the solid low-valence sulfur content of the pulp is 22.76%, the total solid content of the pulp is 15%, the initial pH of the pulp is 4-5, the temperature of the pulp is 35°C, and the pulp is ready for use.

[0053] The prepared pulp is continuously and stably transported to the pressure vessel device through an additional pump, and at the same time, industrial pure oxygen is continuously introduced. The mixture of effluent and washing liquid is used as a cold medium to adjust the reaction temperature, and the reaction conditions in the pressure vessel are controlled as follows: temperature 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com