Patents

Literature

333 results about "Low copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Some of the most common symptoms and signs of a copper deficiency include (2): Fatigue. Arthritis. Osteoporosis. Paleness. Low body temperature, or always feeling cold. Anemia.

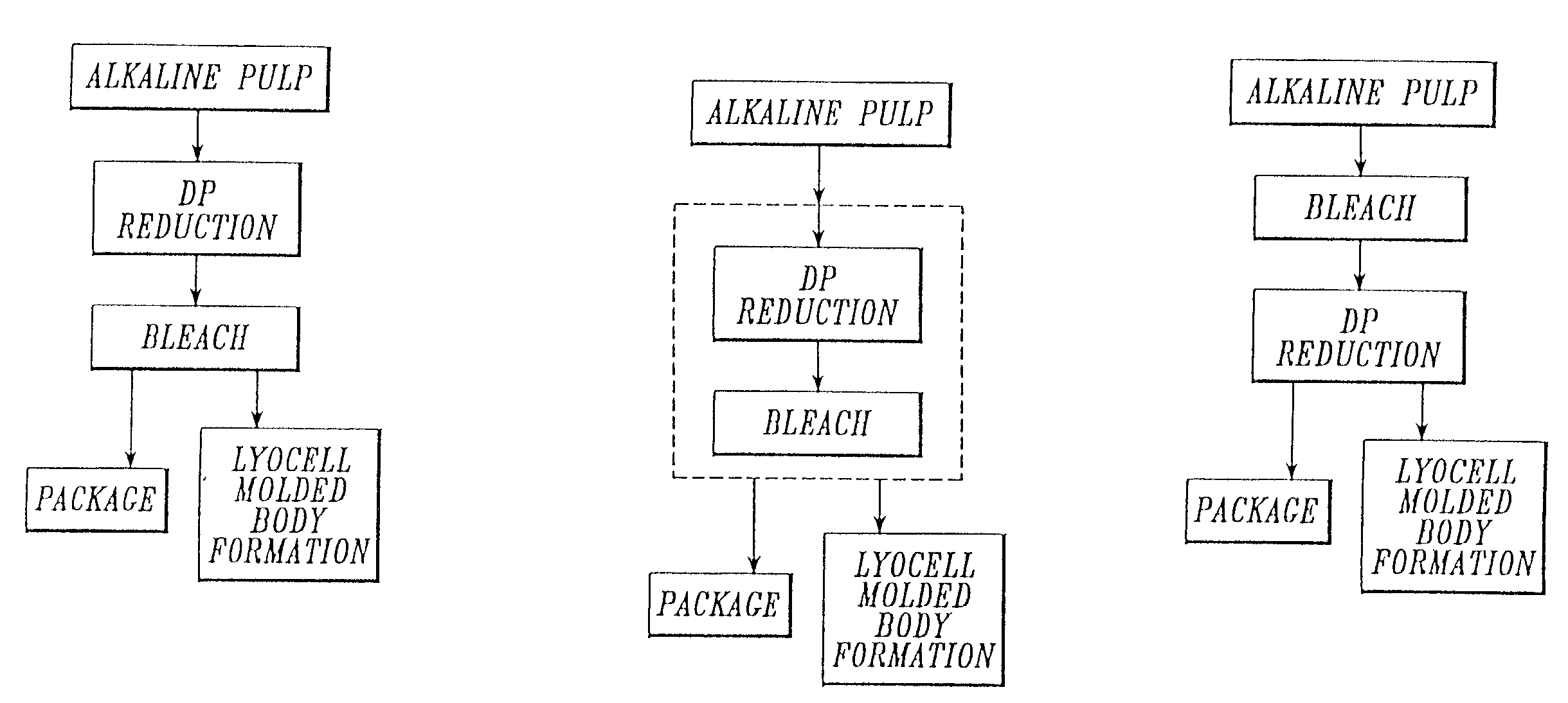

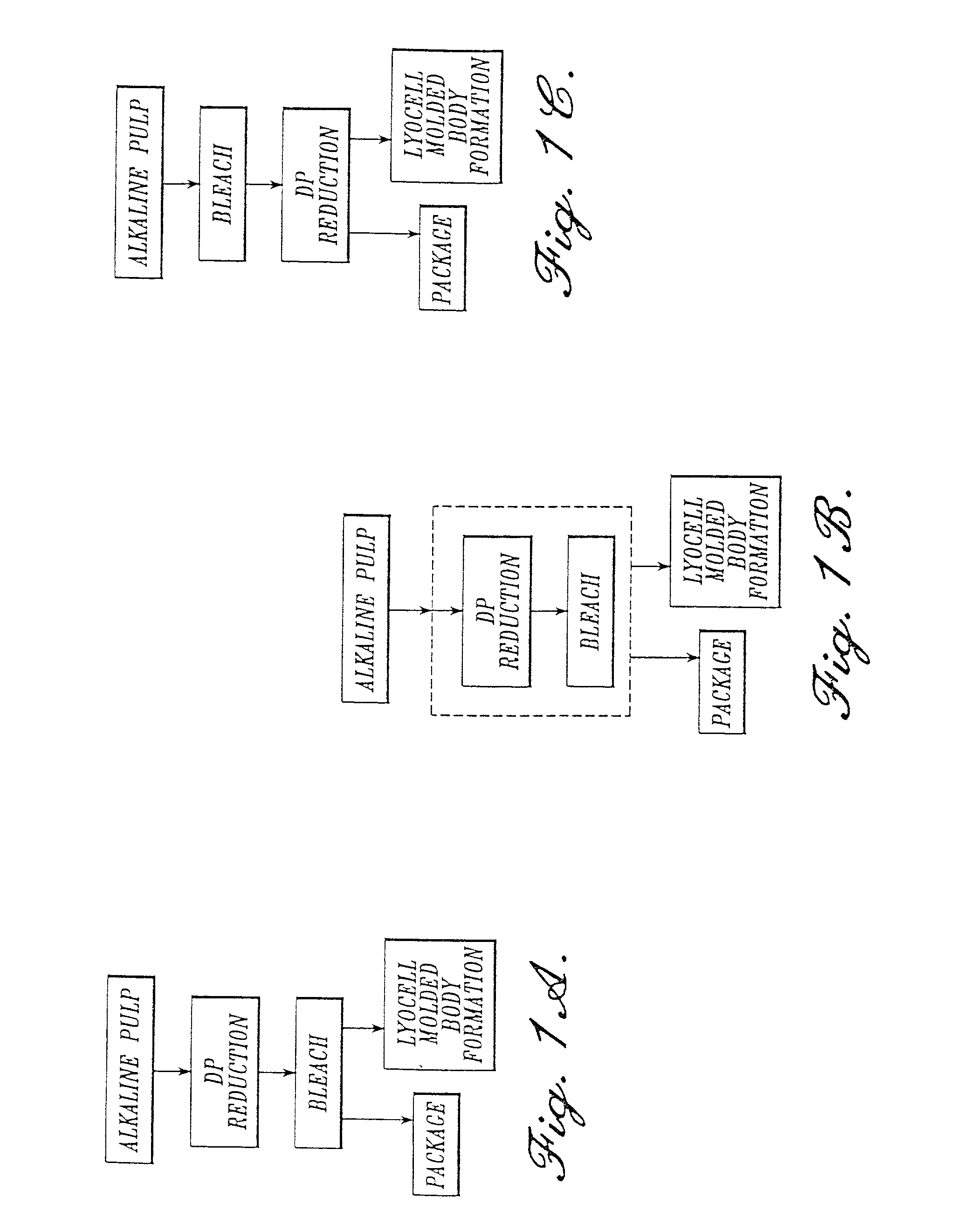

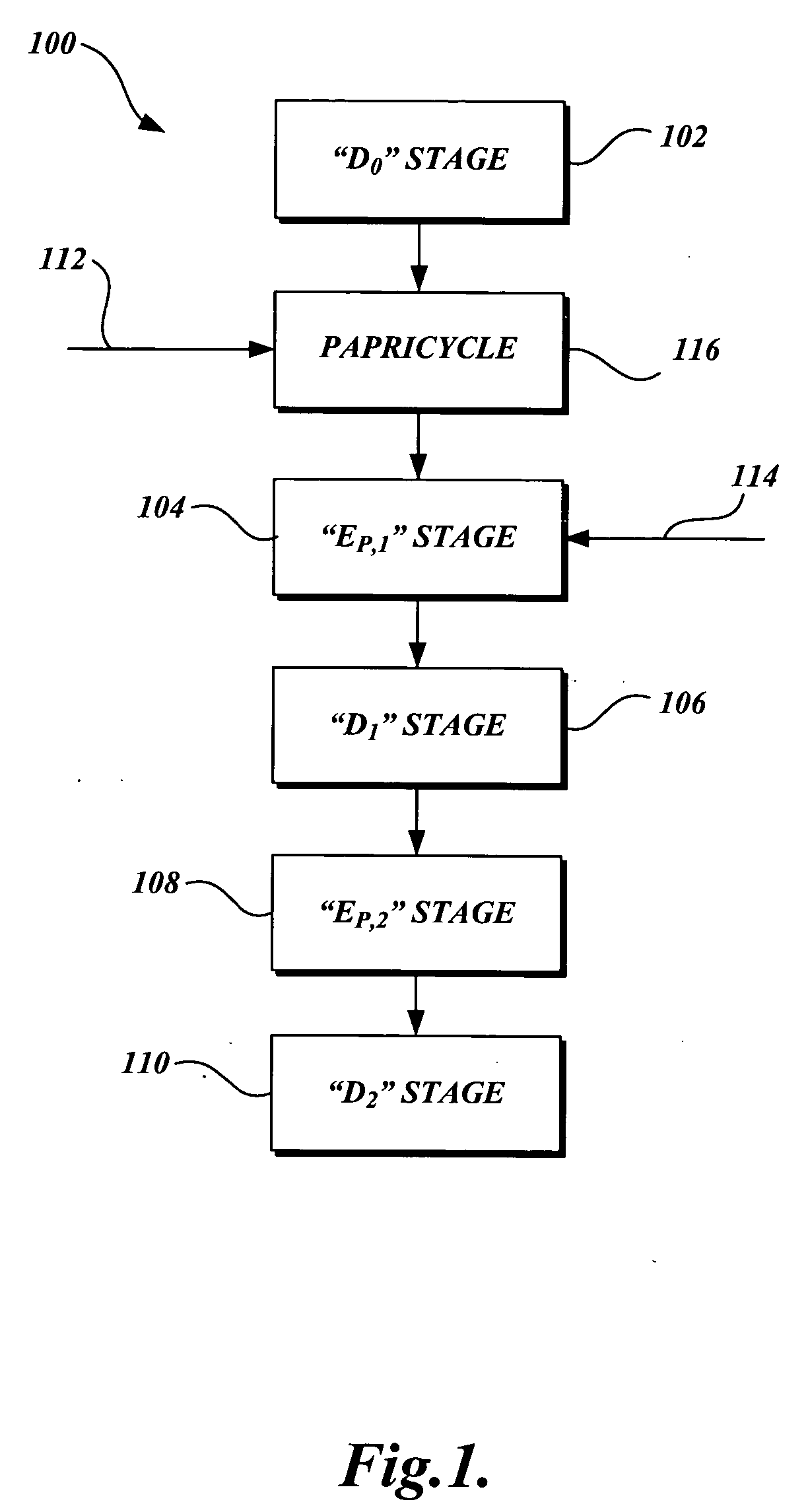

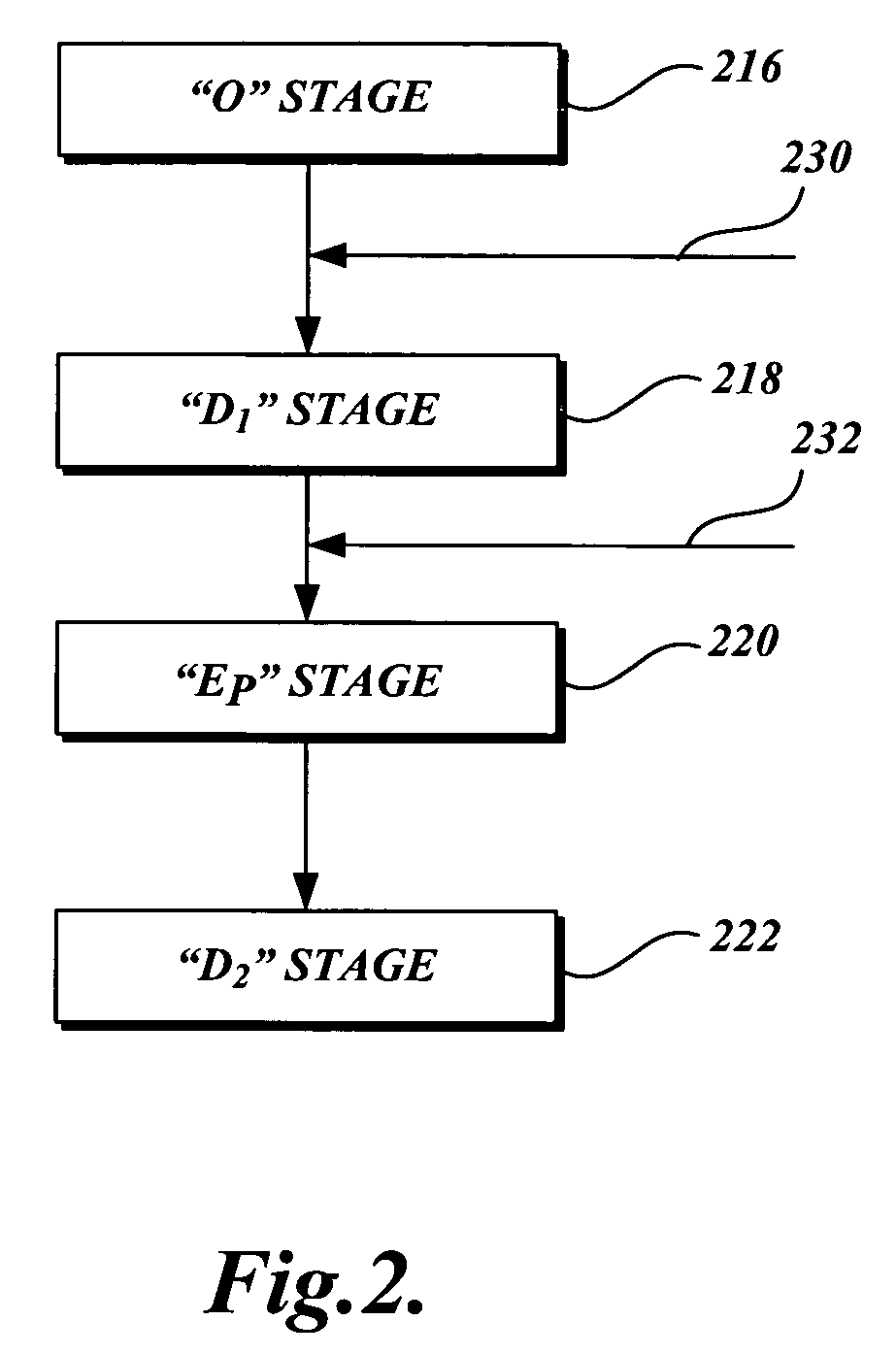

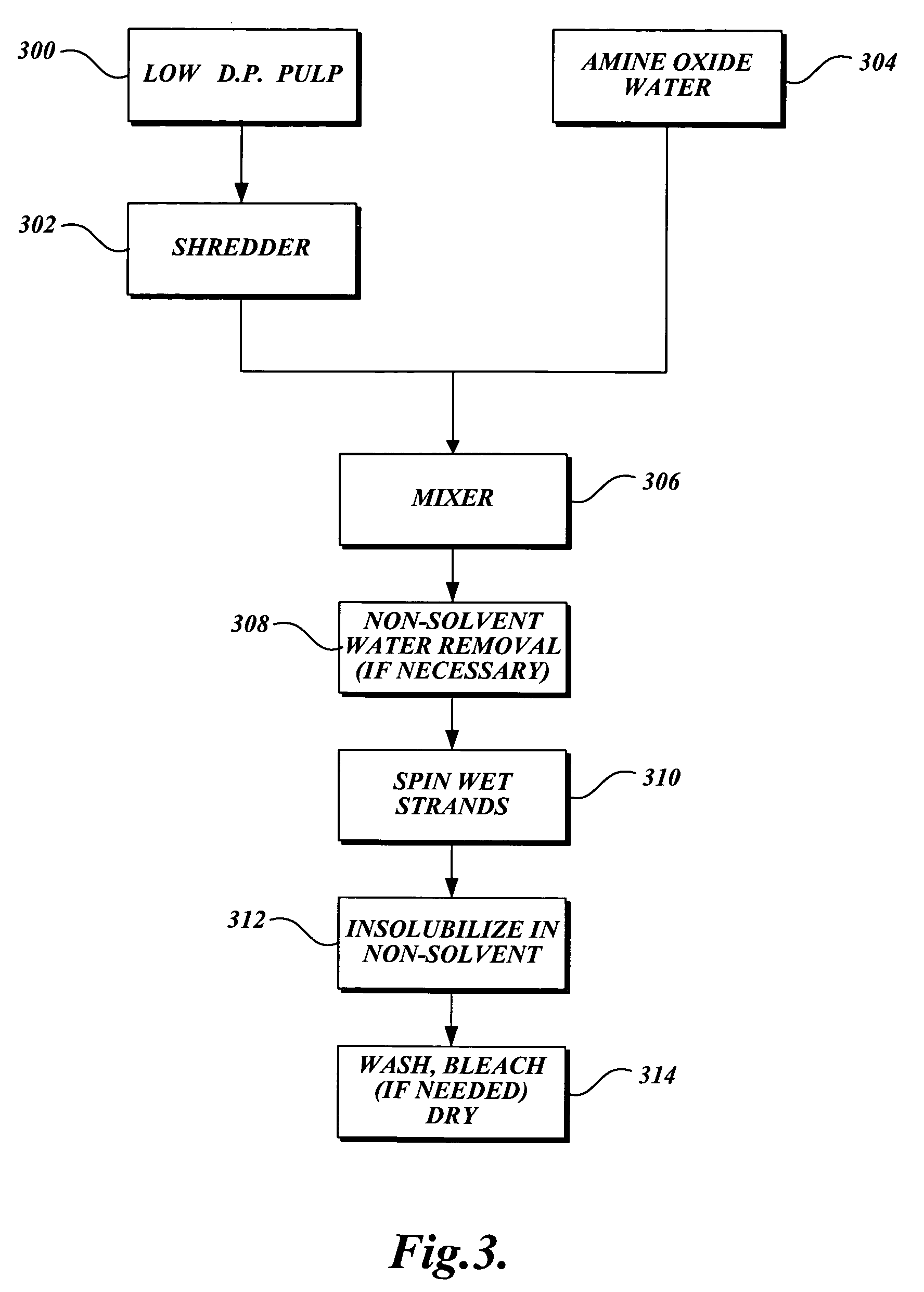

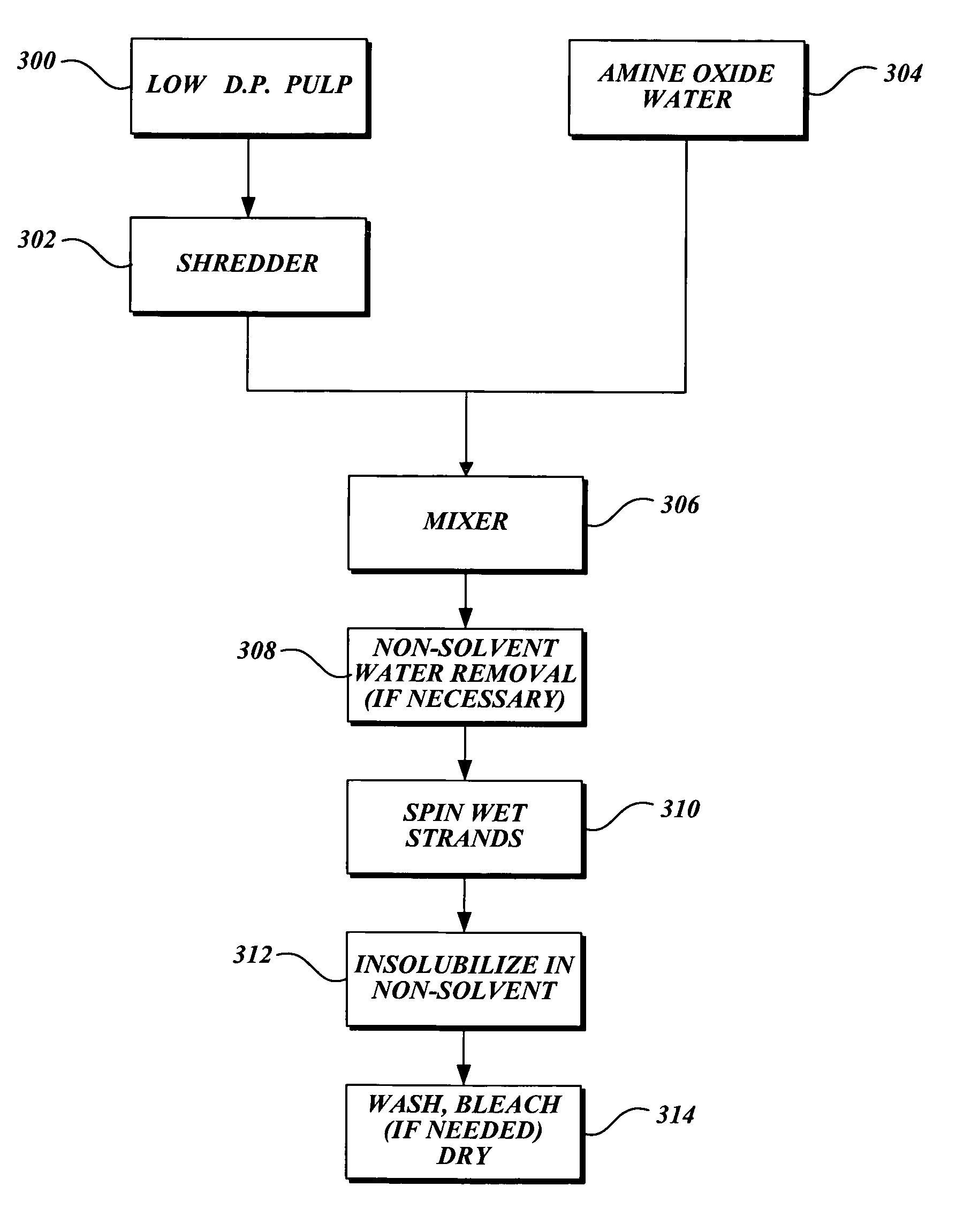

Process for making a composition for conversion to lyocell fiber from an alkaline pulp having low average degree of polymerization values

InactiveUS7083704B2Reducing hemicellulose contentIncreasing copper numberPulp properties modificationMonocomponent cellulose artificial filamentHemicelluloseLyocell

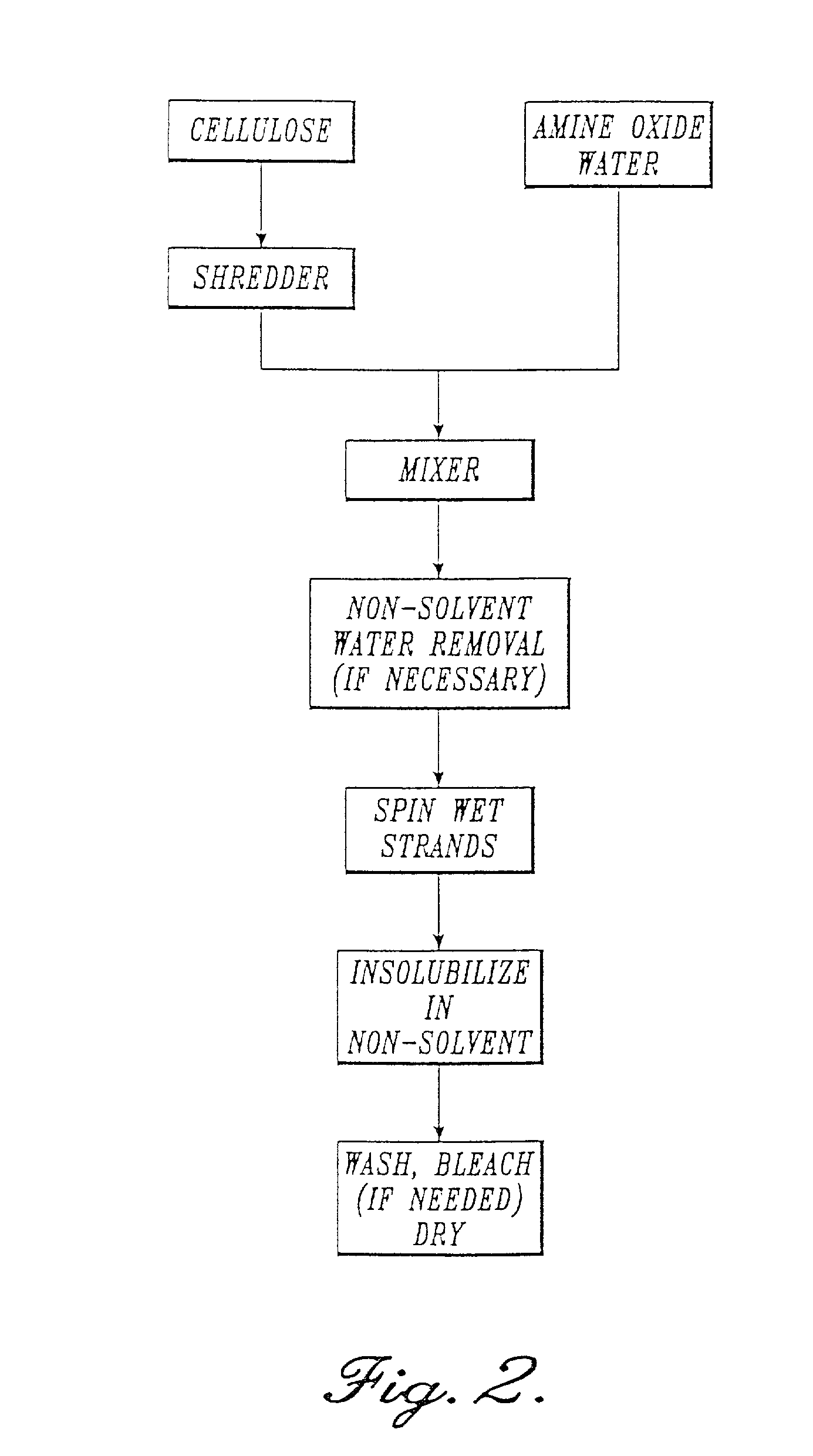

The present invention provides compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization (D.P.) and a narrow molecular weight distribution. Further, the present invention provides processes for making compositions, useful for making lyocell fibers, by contacting an alkaline pulp having a high hemicellulose content of at least about 7% with an oxidant sufficient to reduce the average degree of polymerization to about 200 to 1100 without substantially reducing the hemicellulose content or increasing the copper number of the pulp.

Owner:INT PAPER CO

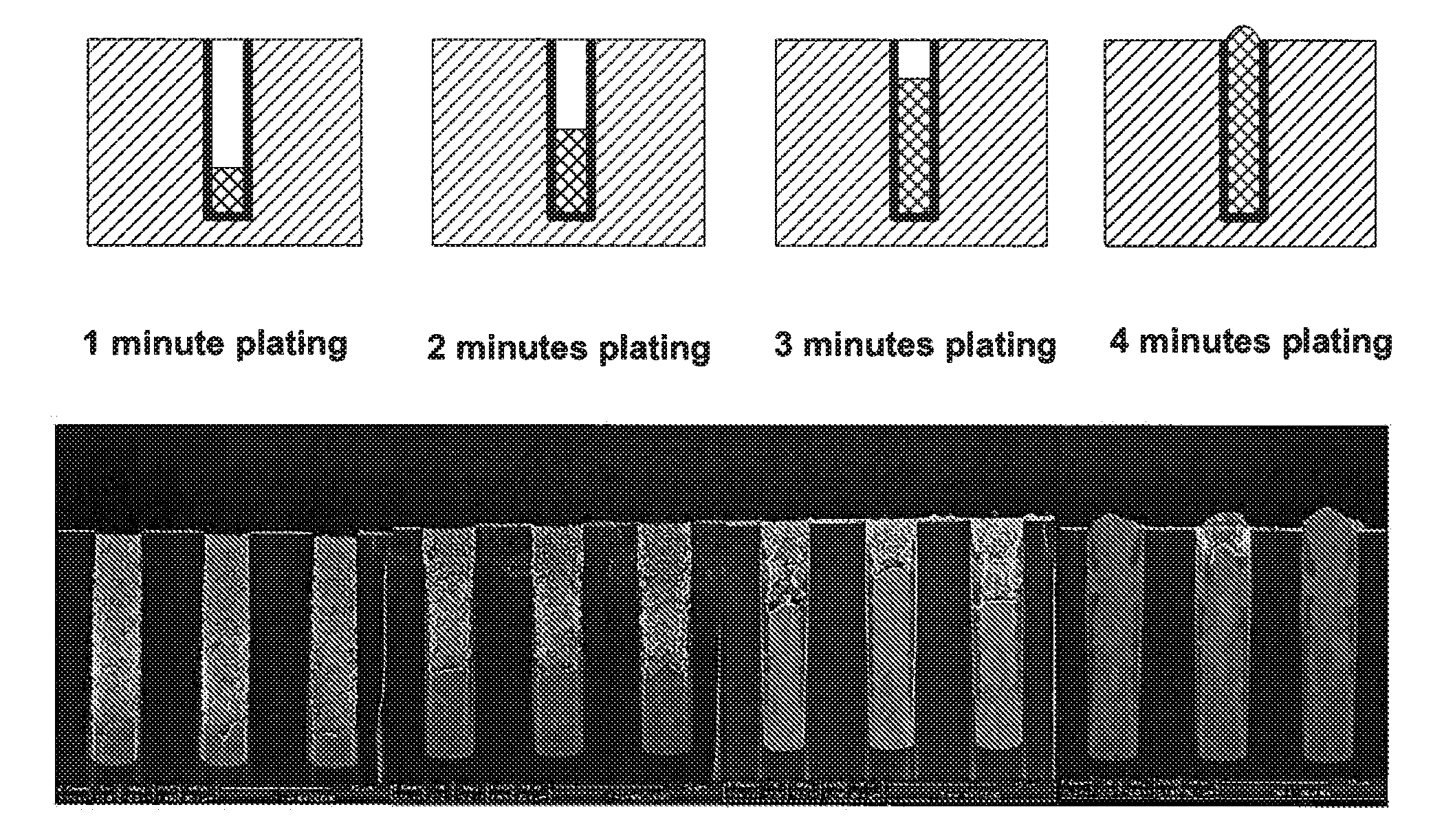

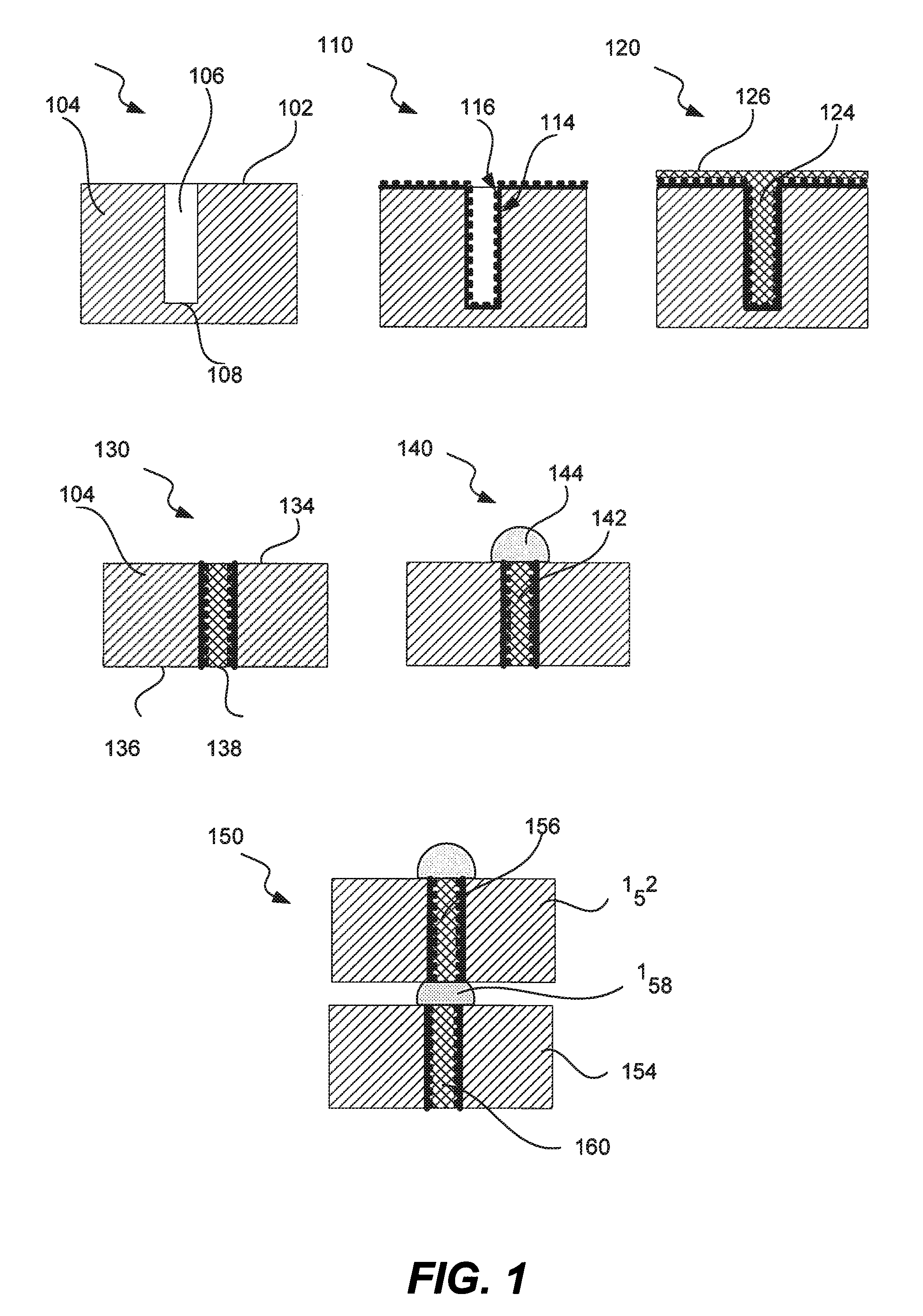

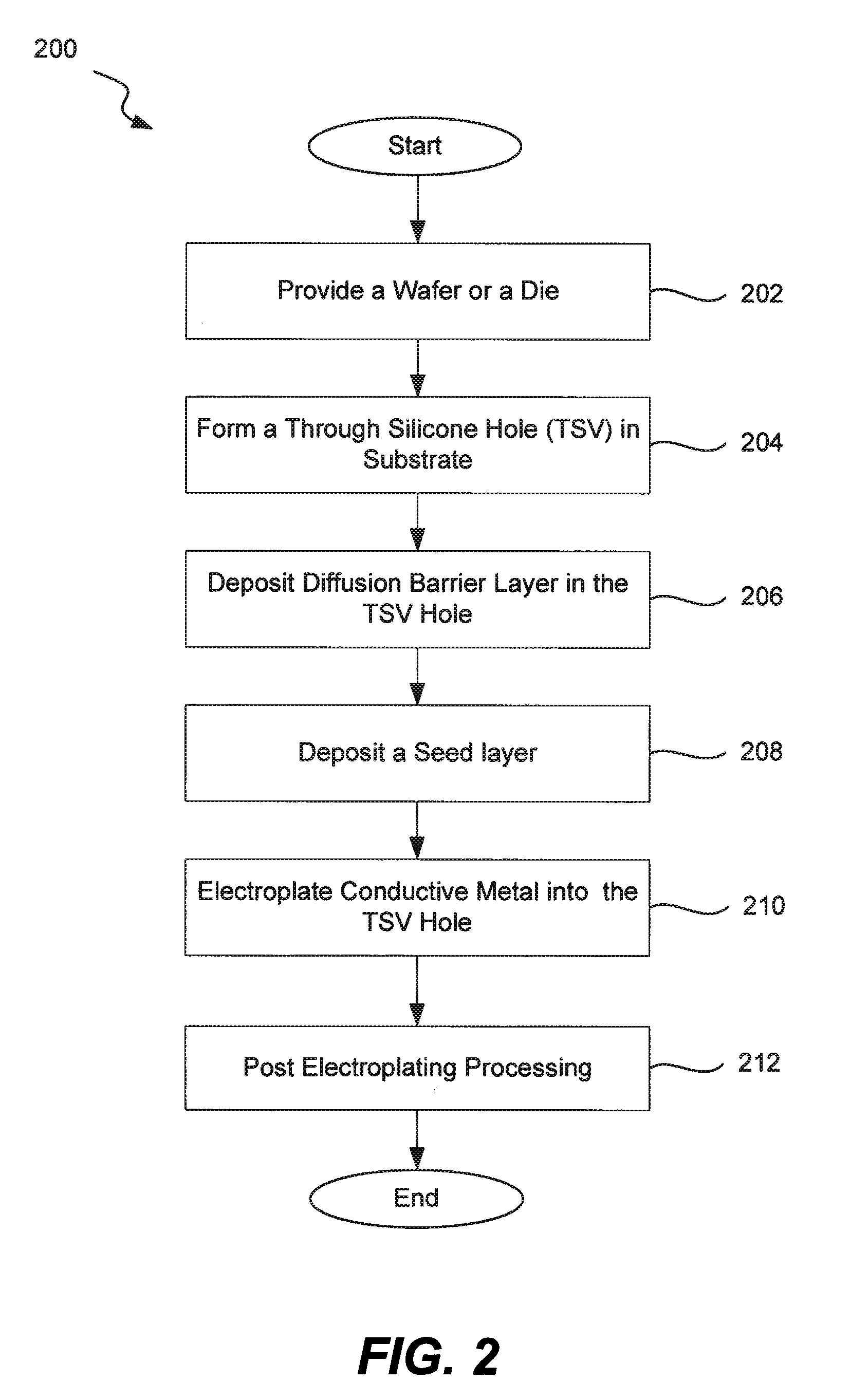

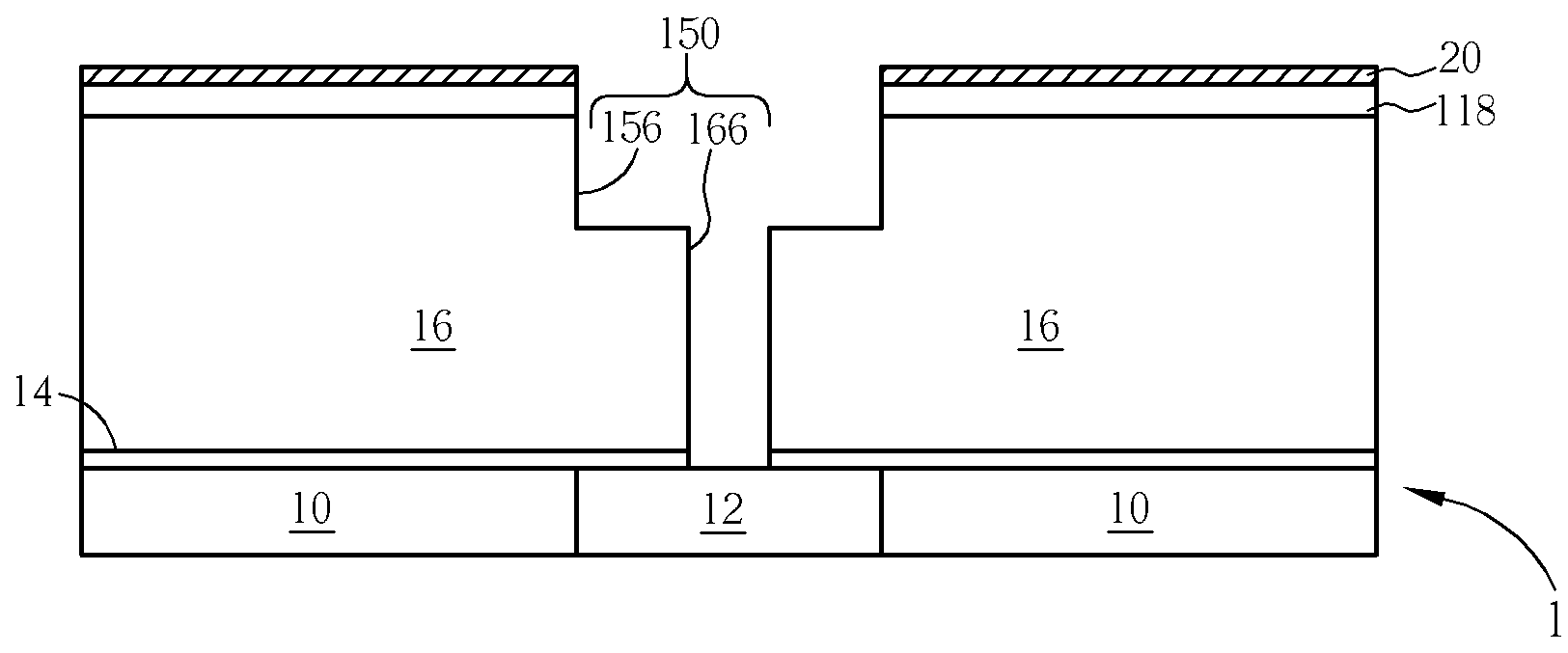

Process For Through Silicon Via Filing

A semiconductor electroplating process deposits copper into the through silicon via hole to completely fill the through silicon via in a substantially void free is disclosed. The through silicon via may be more than about 3 micrometers in diameter and more that about 20 micrometers deep. Low copper concentration and high acidity electroplating solution is used for deposition copper into the through silicon vias.

Owner:NOVELLUS SYSTEMS

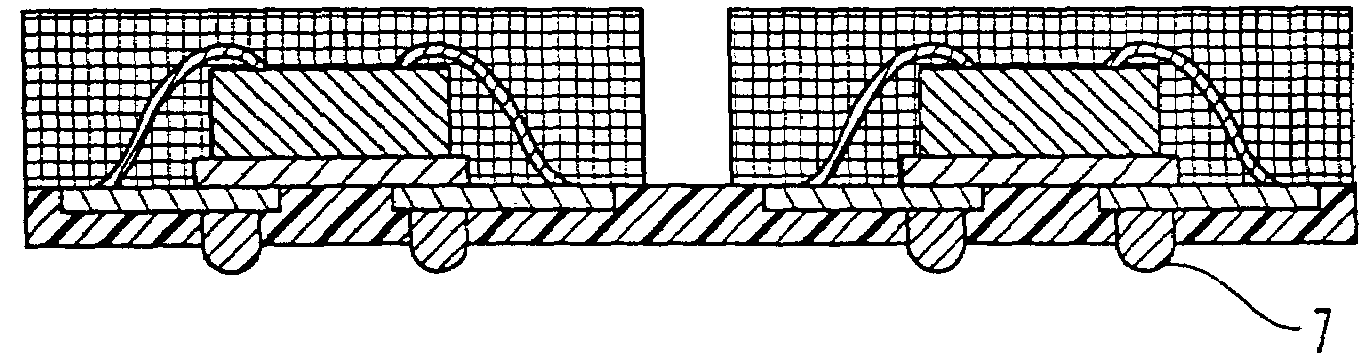

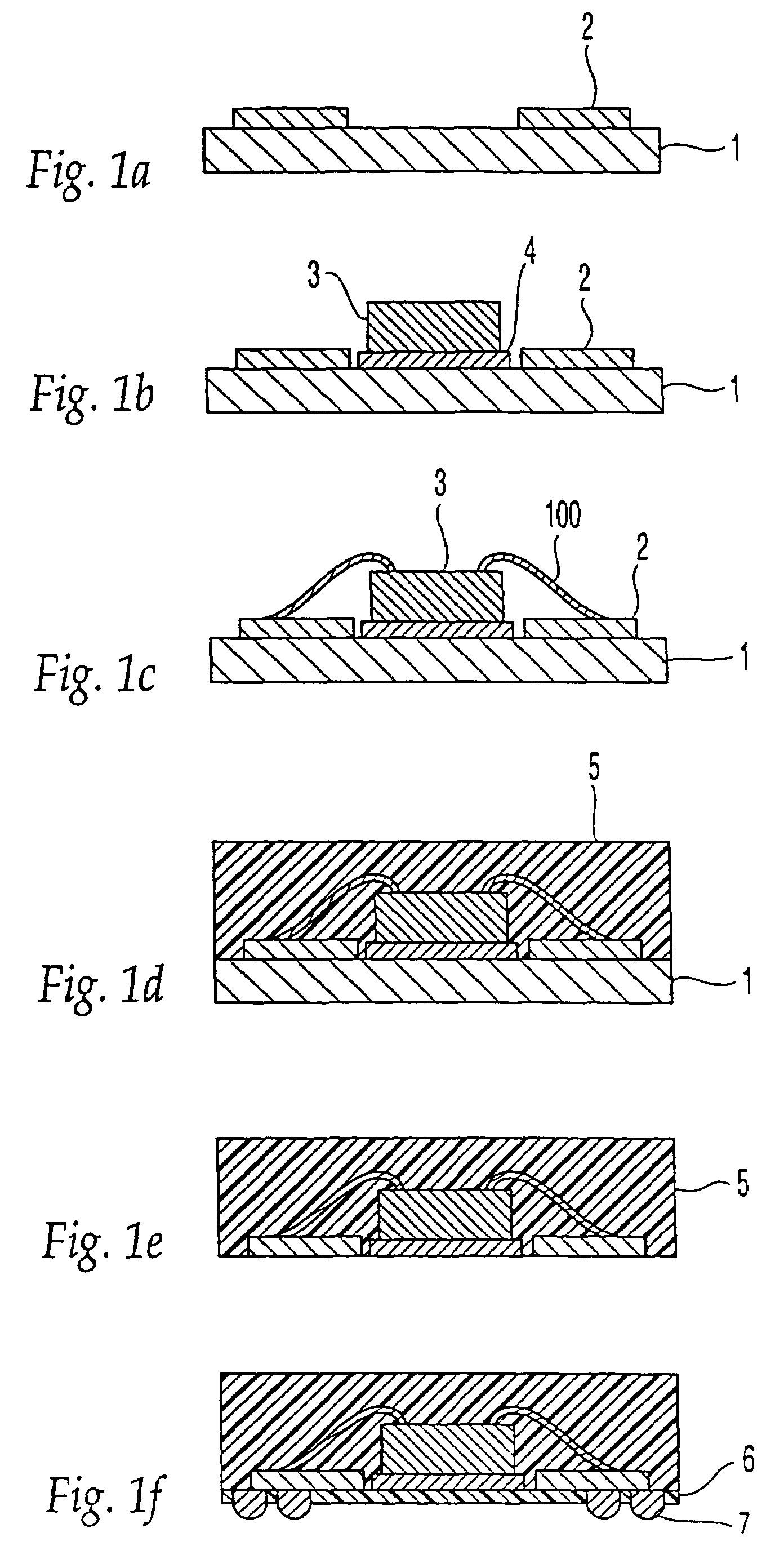

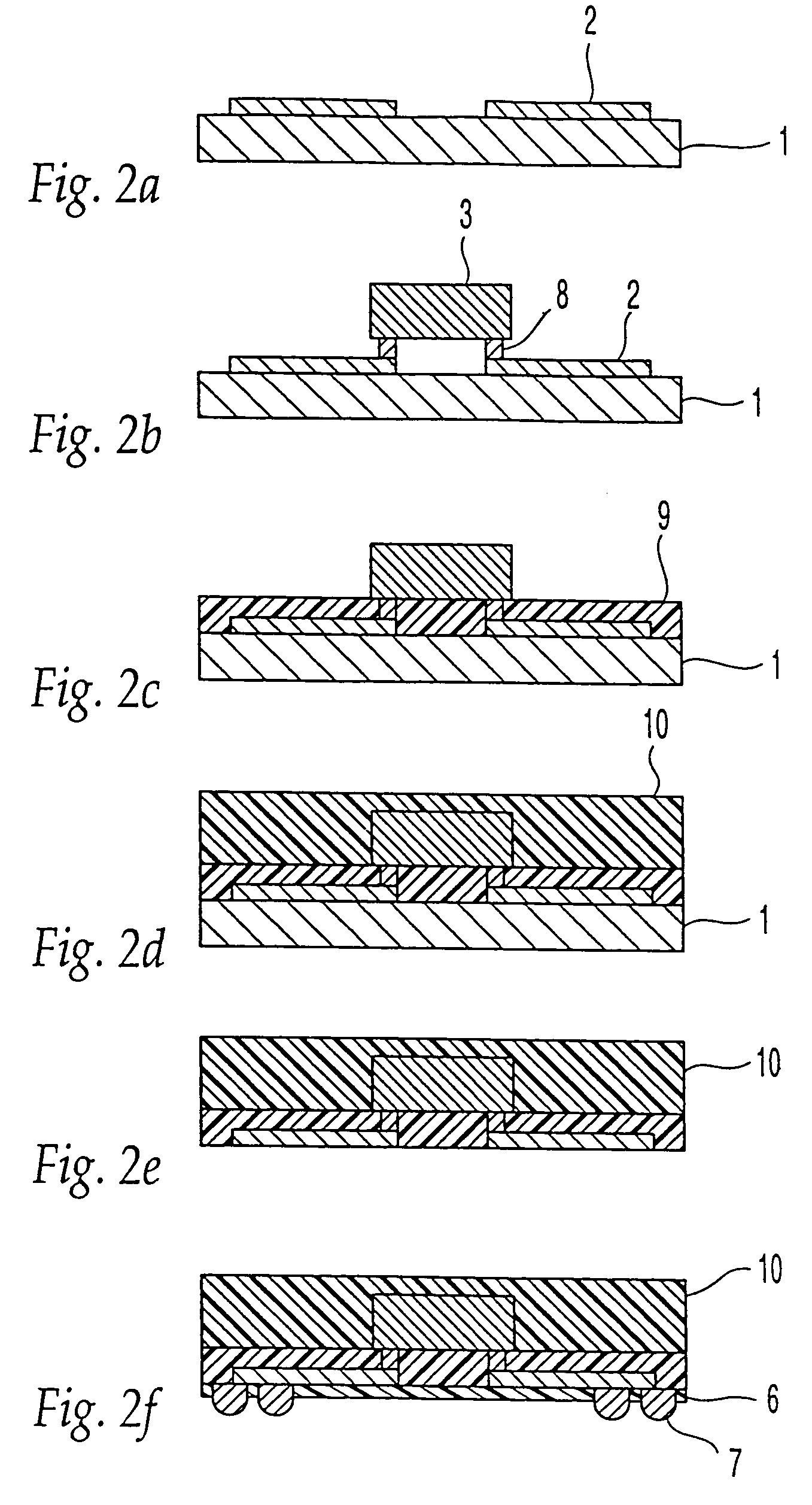

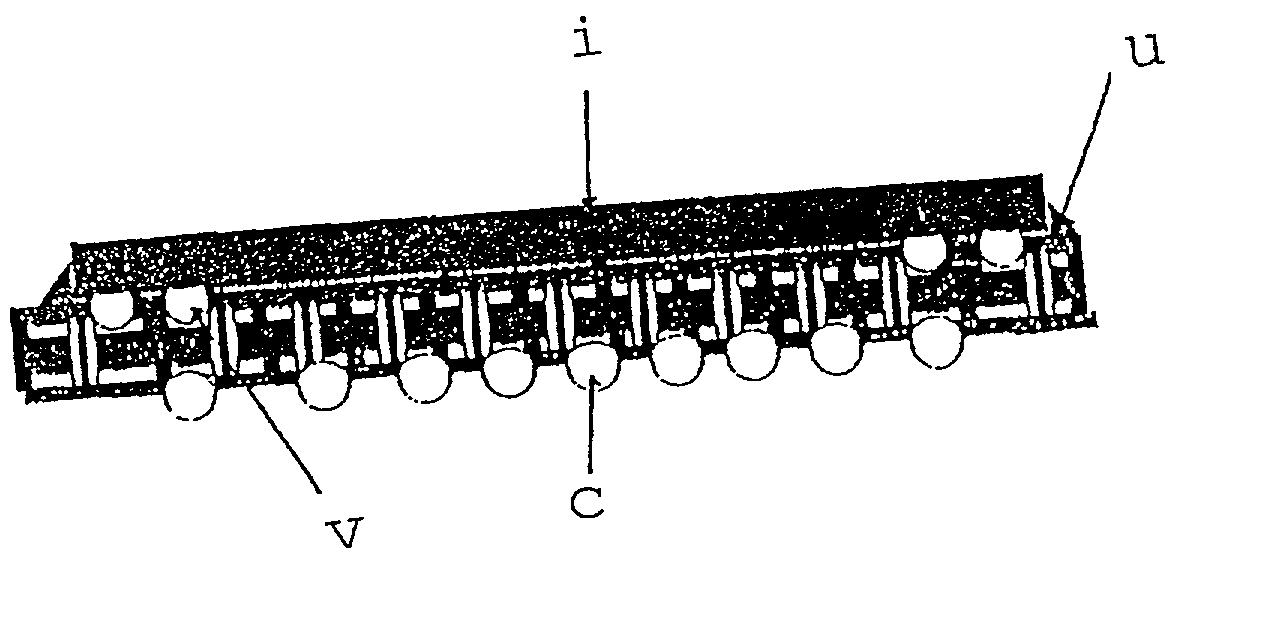

Fabrication process of semiconductor package and semiconductor package

InactiveUS7187072B2Removing residual strainReduce the impactPrinted circuit assemblingSemiconductor/solid-state device detailsResistEpoxy

A semiconductor package substrate is provided, which can meet the move toward high integration of semiconductors. A nickel layer is plated on an electroplated copper foil to form a wiring pattern. An LSI chip is mounted on the copper foil, and terminals of the LSI chip and the wiring pattern are connected by wire bonding, followed by sealing with a semiconductor-sealing epoxy resin. Only the copper foil is dissolved away with an alkali etchant to expose nickel. With a nickel stripper having low copper-dissolving power, the nickel layer is removed to expose the wiring pattern. A solder resist is coated, and a pattern is formed in such a way that connecting terminal portions are exposed. Solder balls are placed at the exposed portions of the wiring pattern and are then fused. The wiring pattern is connected to an external printed board via the solder balls.

Owner:HITACHI CHEM CO LTD

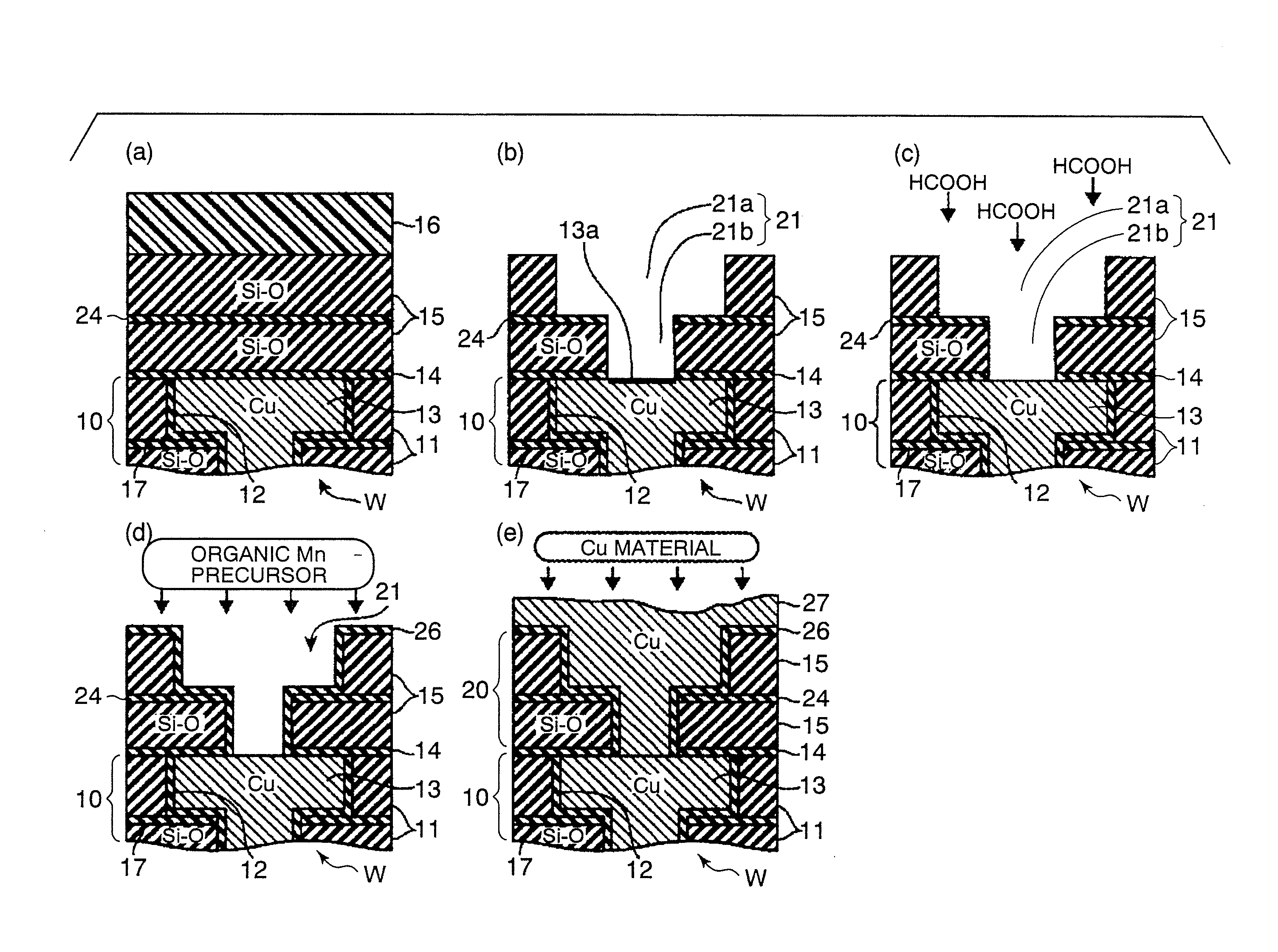

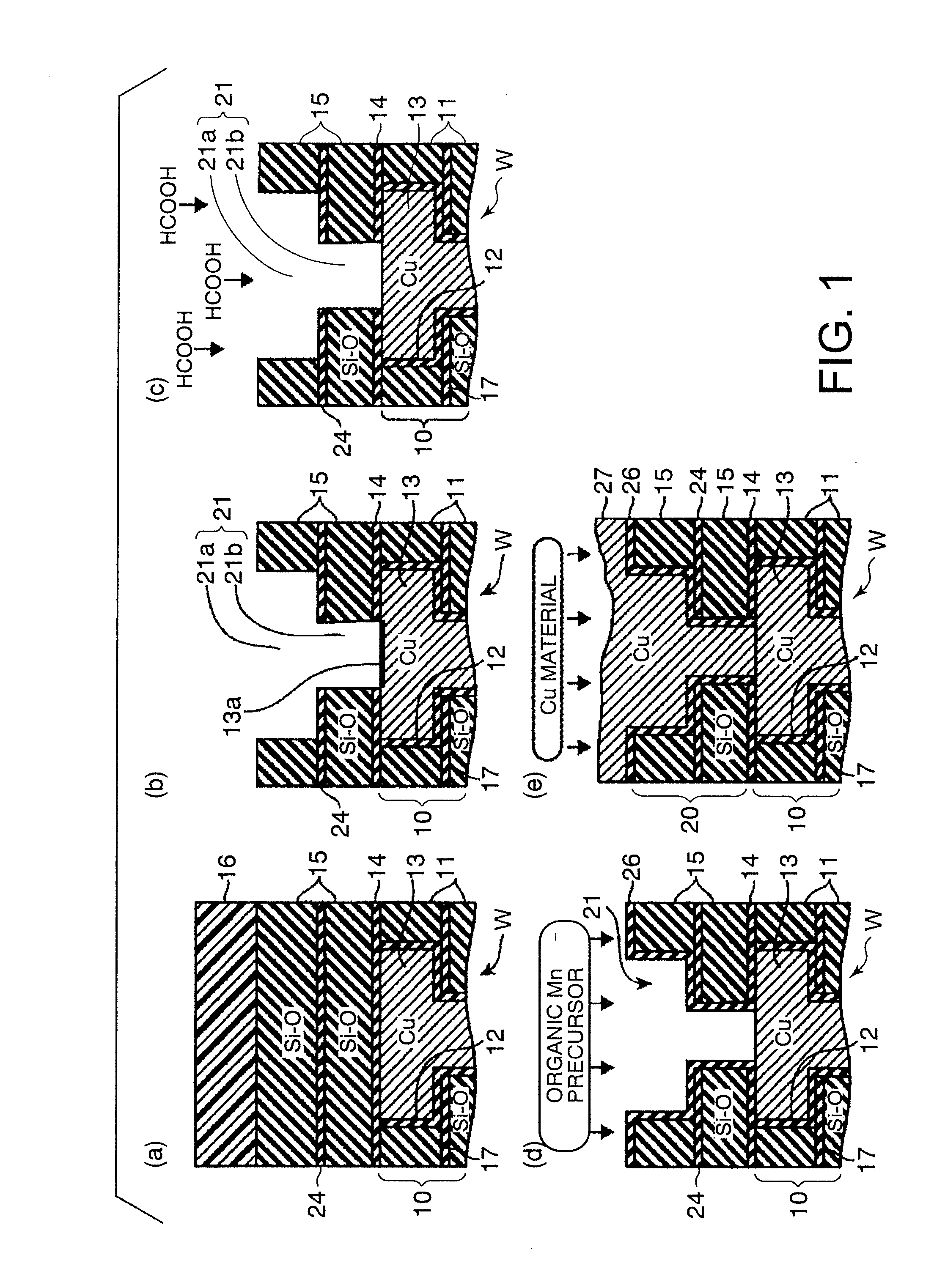

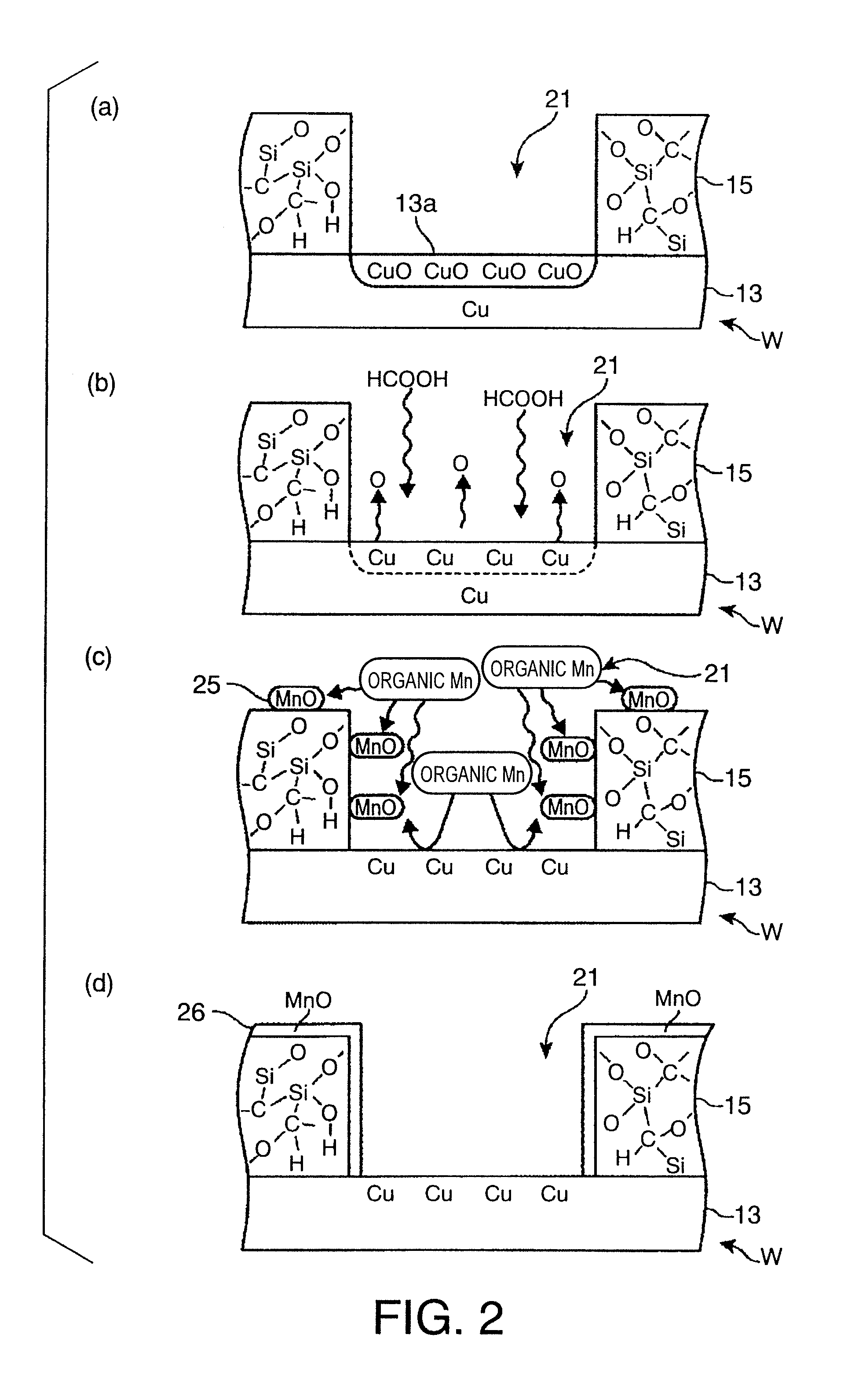

Method of manufacturing semiconductor device, semiconductor device, electronic instrument, semiconductor manufacturing apparatus, and storage medium

InactiveUS20110049718A1Low costGood step coverageLiquid surface applicatorsSemiconductor/solid-state device detailsDevice materialCopper-wiring

When a barrier film is formed on an exposed surface of an interlayer insulation film on a substrate, the interlayer insulation film having a recess formed therein, and a metal wiring to be electrically connected to a metal wiring in a lower layer is formed in the recess, a barrier film having an excellent step coverage can be formed and increase of a wiring resistance can be restrained. An oxide film on a surface of the lower copper wiring exposed to a bottom surface of the interlayer insulation film is reduced or edged so as to remove oxygen on the surface of the copper wiring. Then, by supplying an organic metal compound containing manganese and containing no oxygen, generation of manganese oxide as a self-forming barrier film is selectively allowed on an area containing oxygen, such as a sidewall of the recess and a surface of the interlayer insulation film, while generation of the manganese oxide is not allowed on the surface of the copper wiring. Thereafter, copper is embedded in the recess.

Owner:TOKYO ELECTRON LTD +1

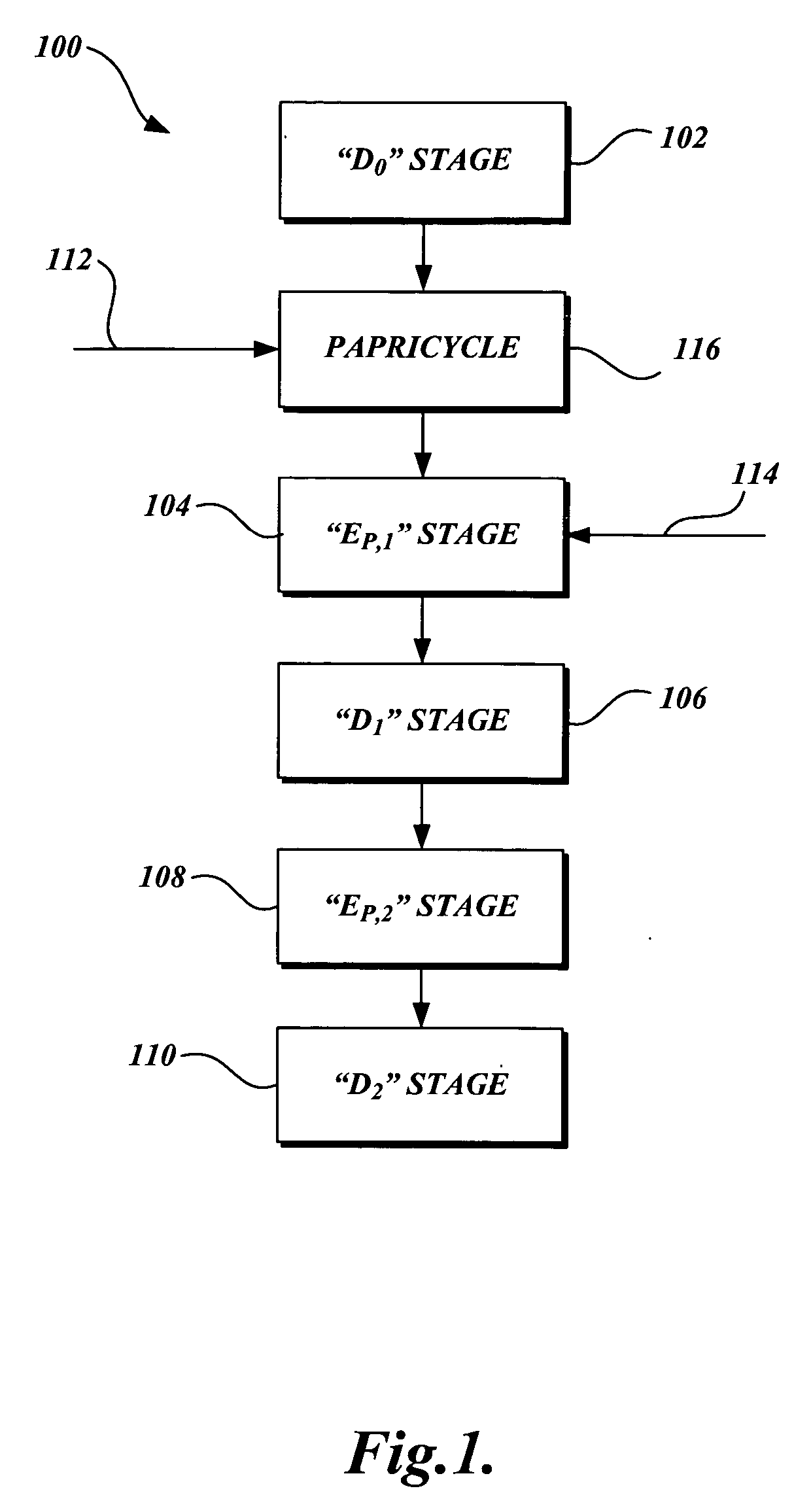

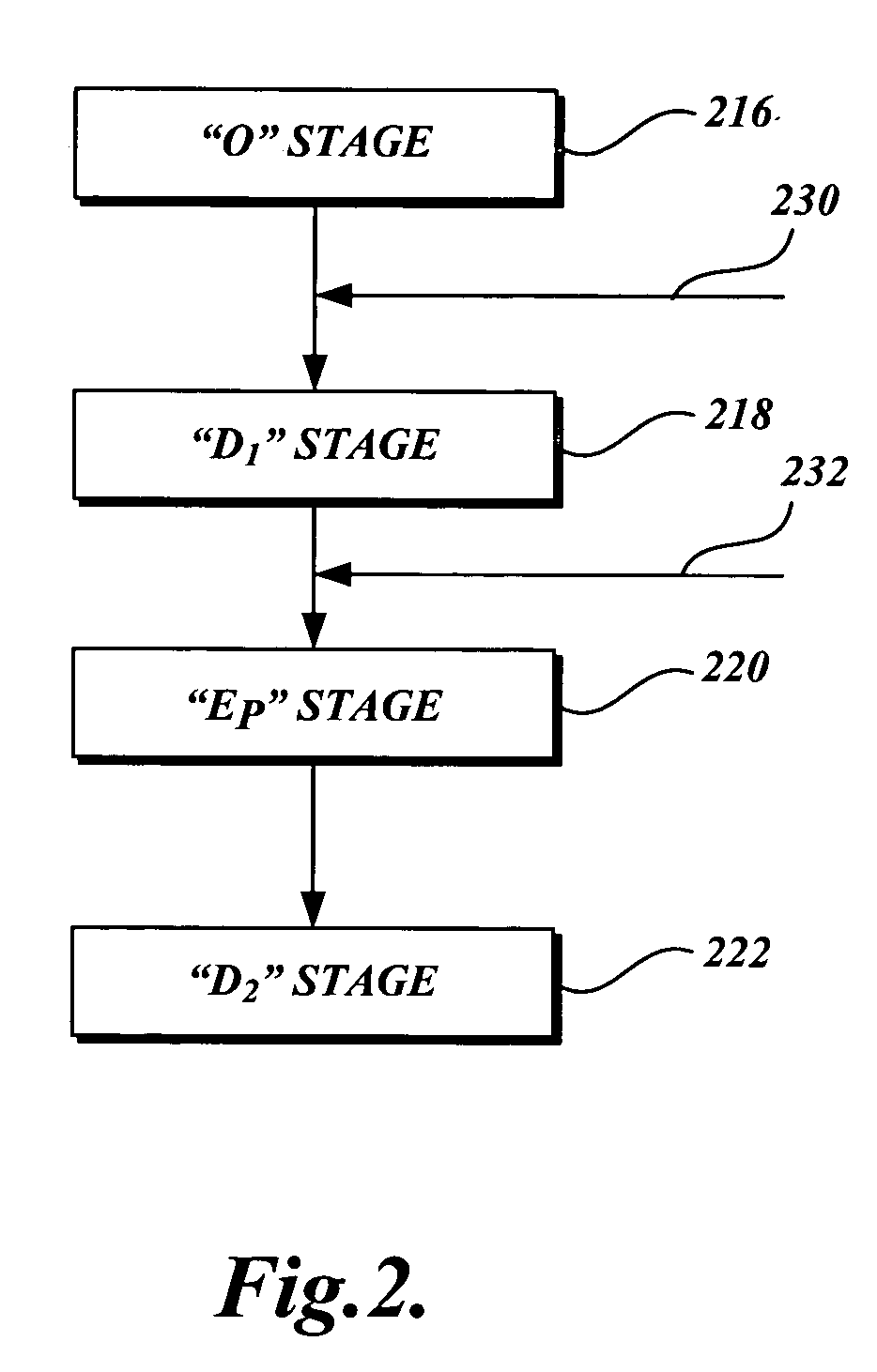

Low pH treatment of pulp in a bleach sequence to produce pulp having low D.P. and low copper number for use in lyocell manufacture

InactiveUS20060070711A1Reduce the degree of polymerizationIncreasing copper numberPulp properties modificationLayered productsBleachPulp mill

A high pH and a low pH process for reducing the degree of polymerization of a pulp having a hemicellulose content of at least 7%. The high pH is greater than 8, and the low pH process is 2 to 8. The high pH process reduces the degree of polymerization without substantially increasing the copper number. The low pH process requires a subsequent treatment with alkali to reduce the copper number of the pulp to less than 2. The process can be practiced in pulp mills with a bleaching sequence having one or more E or D stages. At the end of the bleach sequence, a pulp having a degree of polymerization of 200 to 1100, a copper number of less than 2, and a hemicellulose content of at least 7% is provided. The pulp can be used to make lyocell fibers.

Owner:WEYERHAEUSER NR CO

Lead-free solder with low copper dissolution

InactiveUS20070172381A1Minimize formation of oxideAdvantageously producedWelding/cutting media/materialsSoldering mediaDissolutionImpurity

Lead-free solder compositions suitable for joining electronic devices to printed wiring boards, which comprises by weight 0.2 to 0.9% copper, 0.006 to 0.07% nickel, 0.03 to 0.08% bismuth, less than 0.5% silver, less than 0.010% phosphorus, and a balance of tin and inevitable impurities. A solder composition embodying this invention finds particular application in automated wave-soldering machines where conventional lead-free solders dissolve excessive copper from printed wiring circuitry and component terminations.

Owner:KESTER

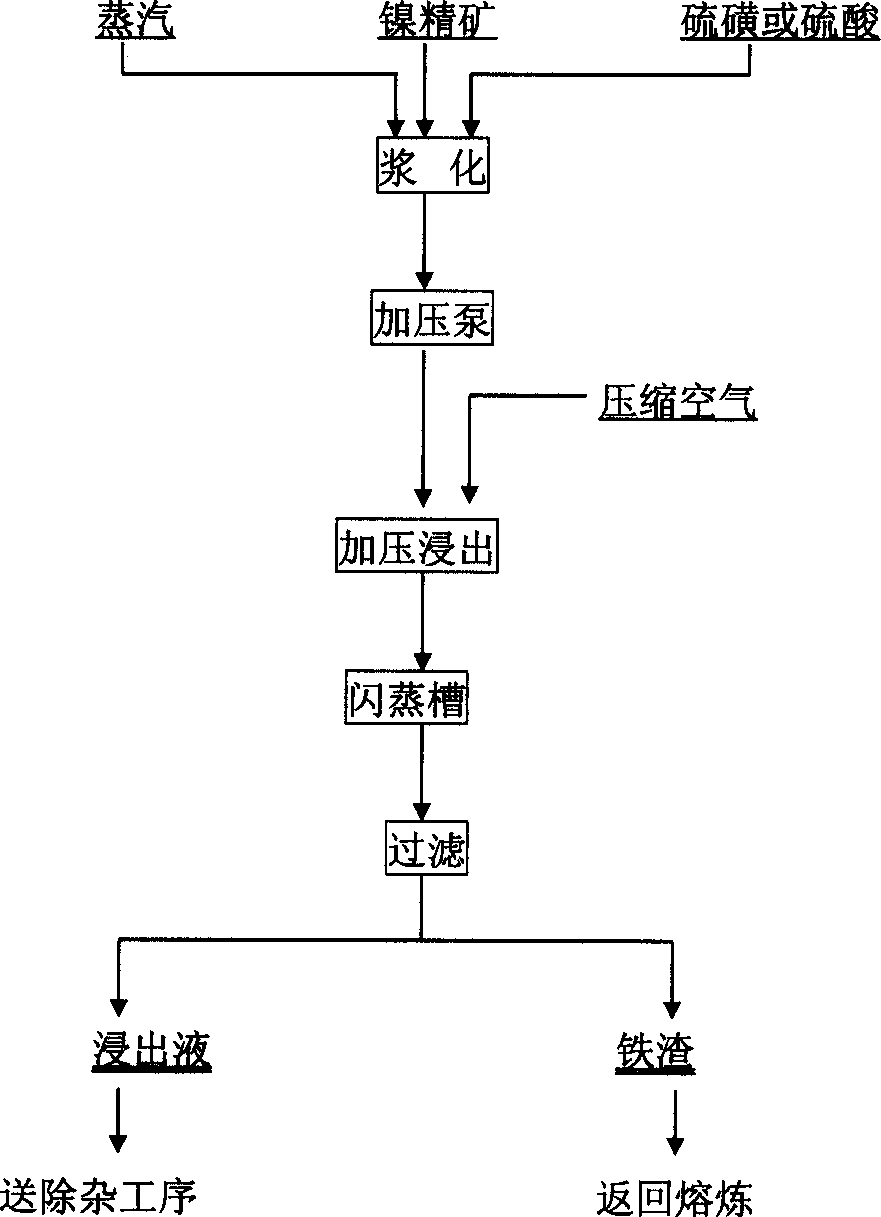

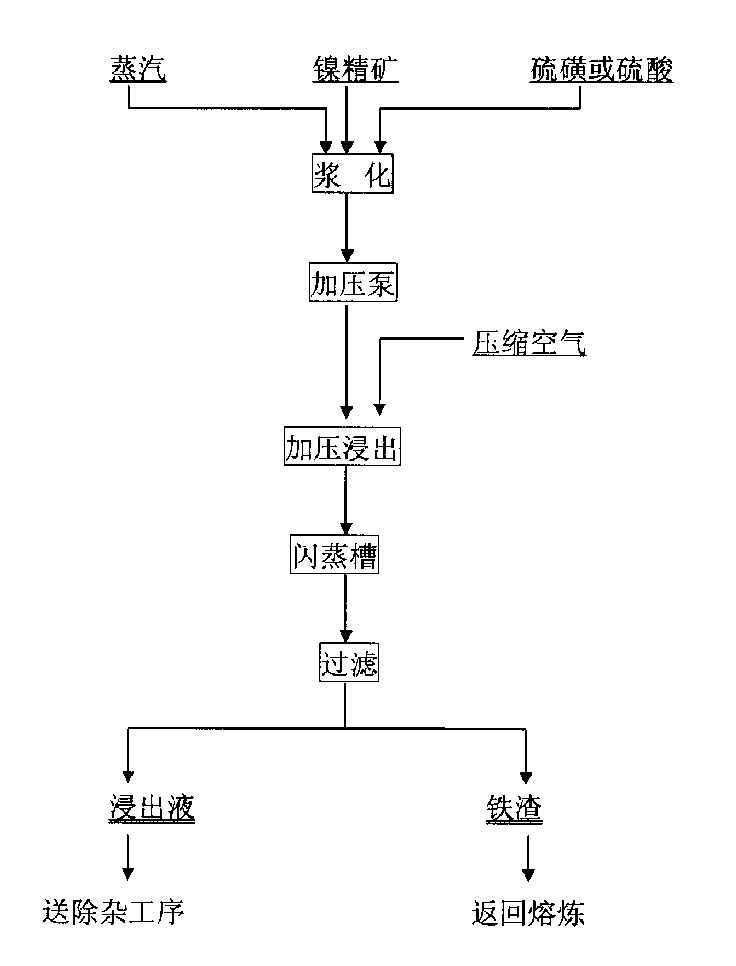

Process for extracting nickel from nickel sulfide material with low copper content

The nickel extracting process of the present invention relates to the one-stage pressurized leaching extraction of nickel from nickel concentrate with low copper content or high sulfur nickel concentrate separated through milling and floating procedure. The process features that under oxygenation and adding sulfur or sulfuric acid, and in 100-180 deg.c and oxygen pressure 50-300 KPa, nickel concentrate is one-step pressurized leached to complete the Ni, Co and Cu leaching process with Fe being fixed in slag. Nickel sulfate solution after liquid-solid separation may be used in production pure nickel sulfate or electrolyte while recovering Co, Cu and other valuable metals. The process is simple and high in production efficiency.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

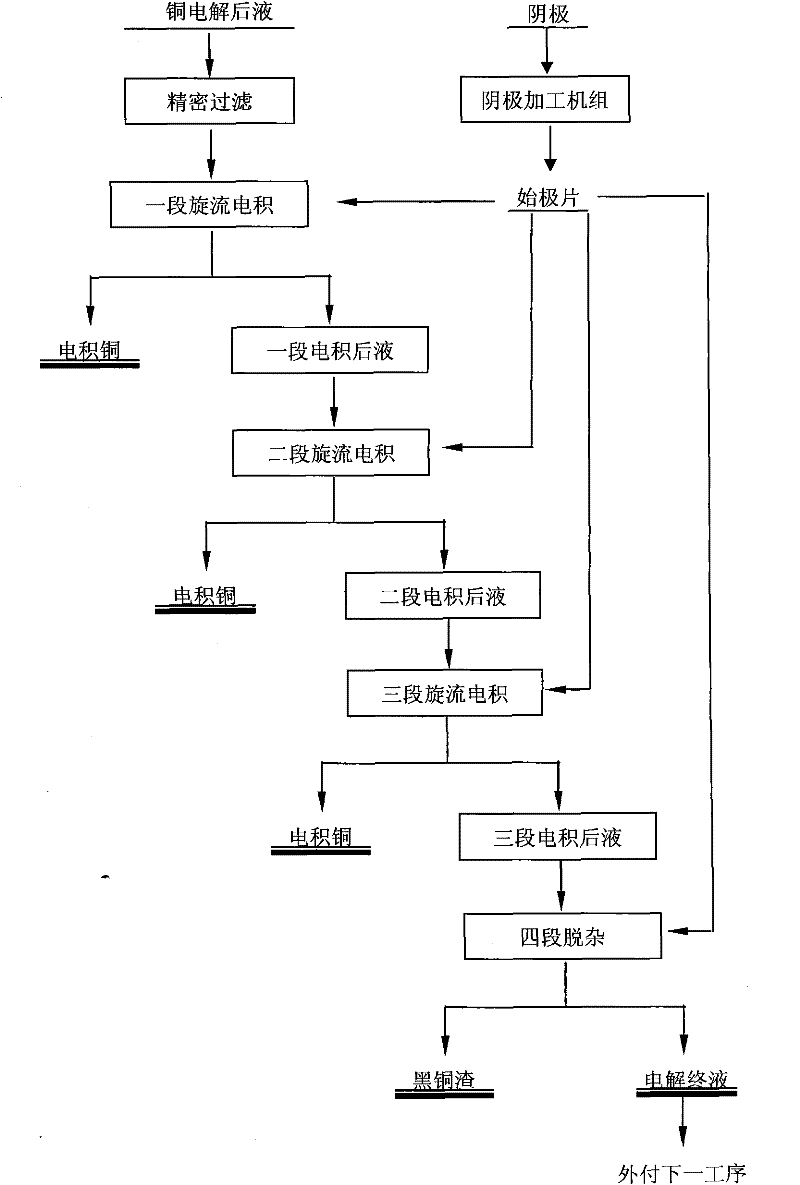

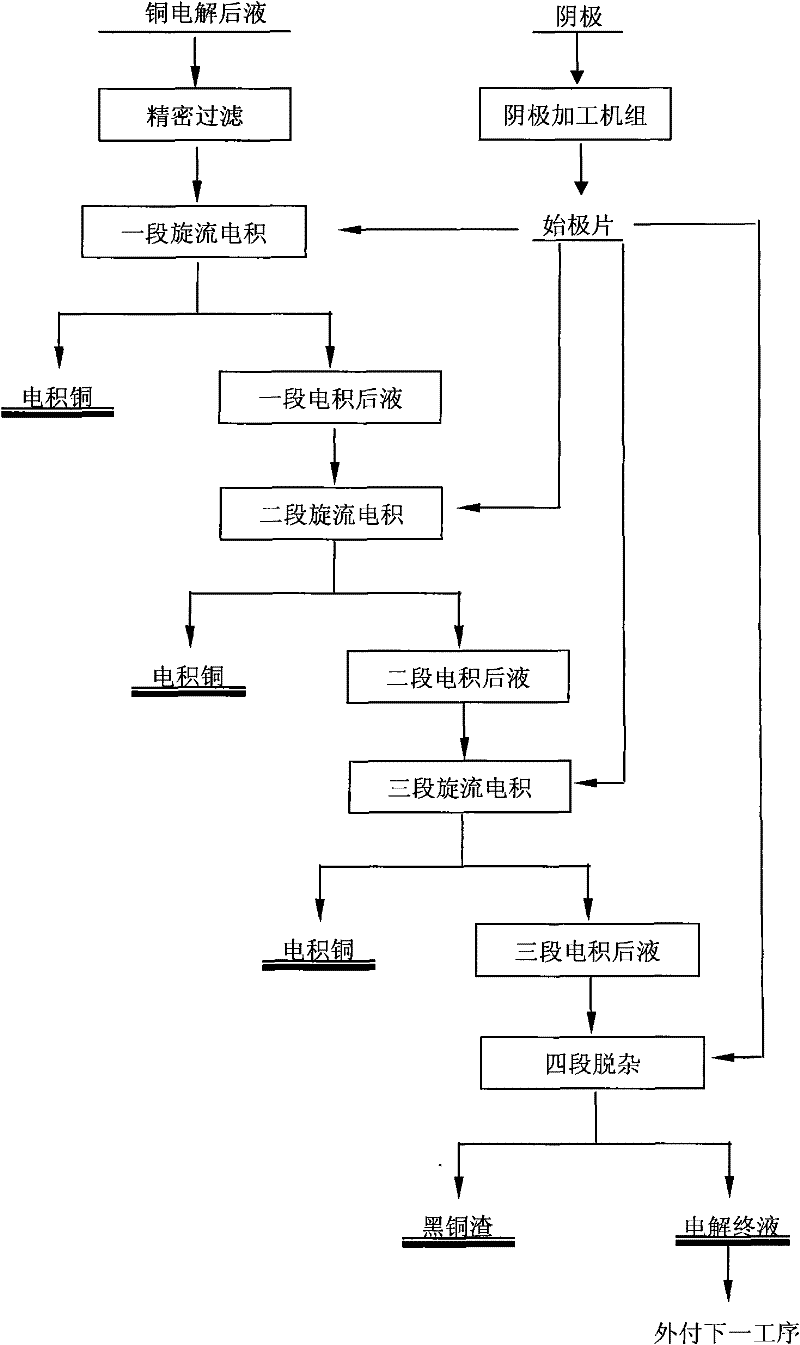

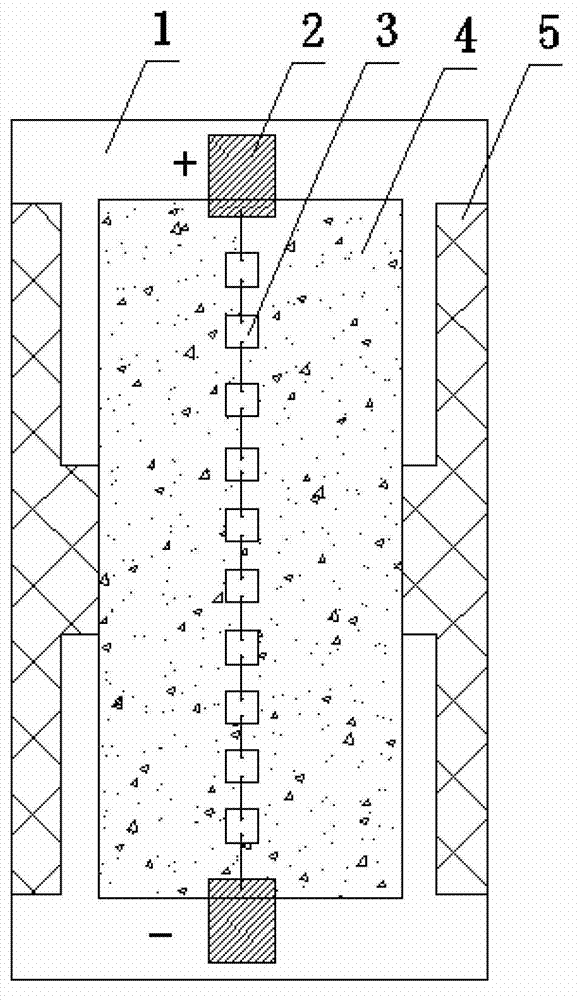

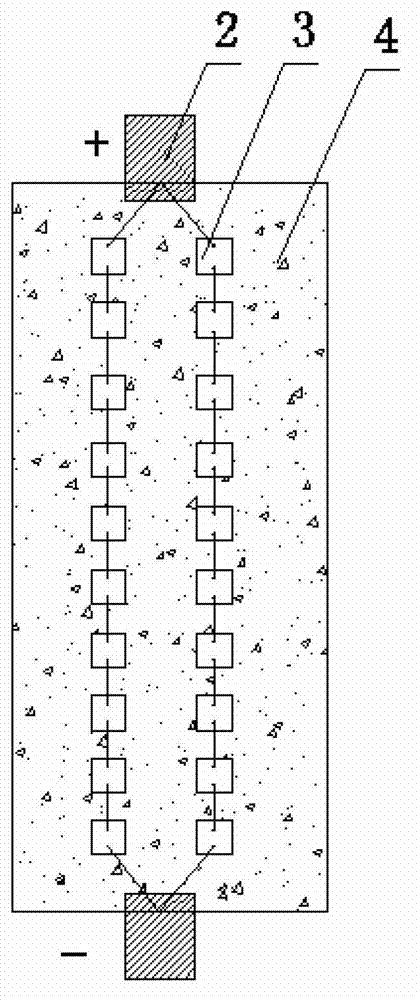

Technology for treating and purifying copper electrolyte by vortex electrolysis

InactiveCN102453931AIncrease current densityImprove current efficiencyPhotography auxillary processesElectrolysis componentsElectrolysisBismuth

A technology for treating and purifying copper electrolyte by vortex electrolysis relates to the technical field of copper electrolyte purification. The treatment process comprises the steps of: 1. carrying out secondary filter on copper electrolyte to be purified and treated; 2. sending into a vortex electrolysis system to produce standard cathode copper; 3. after three segments of vortex electrolysis, sending the solution with a copper content of 2-4g / L to a vortex electrolysis powder impurity removal stage; 4. removing impurities of arsenic, antimony and bismuth in a powder vortex electrolytic tank; and 5. forming a small amount of black copper ash with a low copper content in a filter cake after press filtration and sending a filtrate into a next operation. The technology of the invention can substitute a traditional induction copper and impurity removal method for purifying and treating copper electrolysis waste liquid, so as to provide an electrolysis technical scheme, which is efficient and reliable, and has simple process flow, simple operation and low cost, for purifying copper electrolysis waste liquid.

Owner:浙江科菲科技股份有限公司

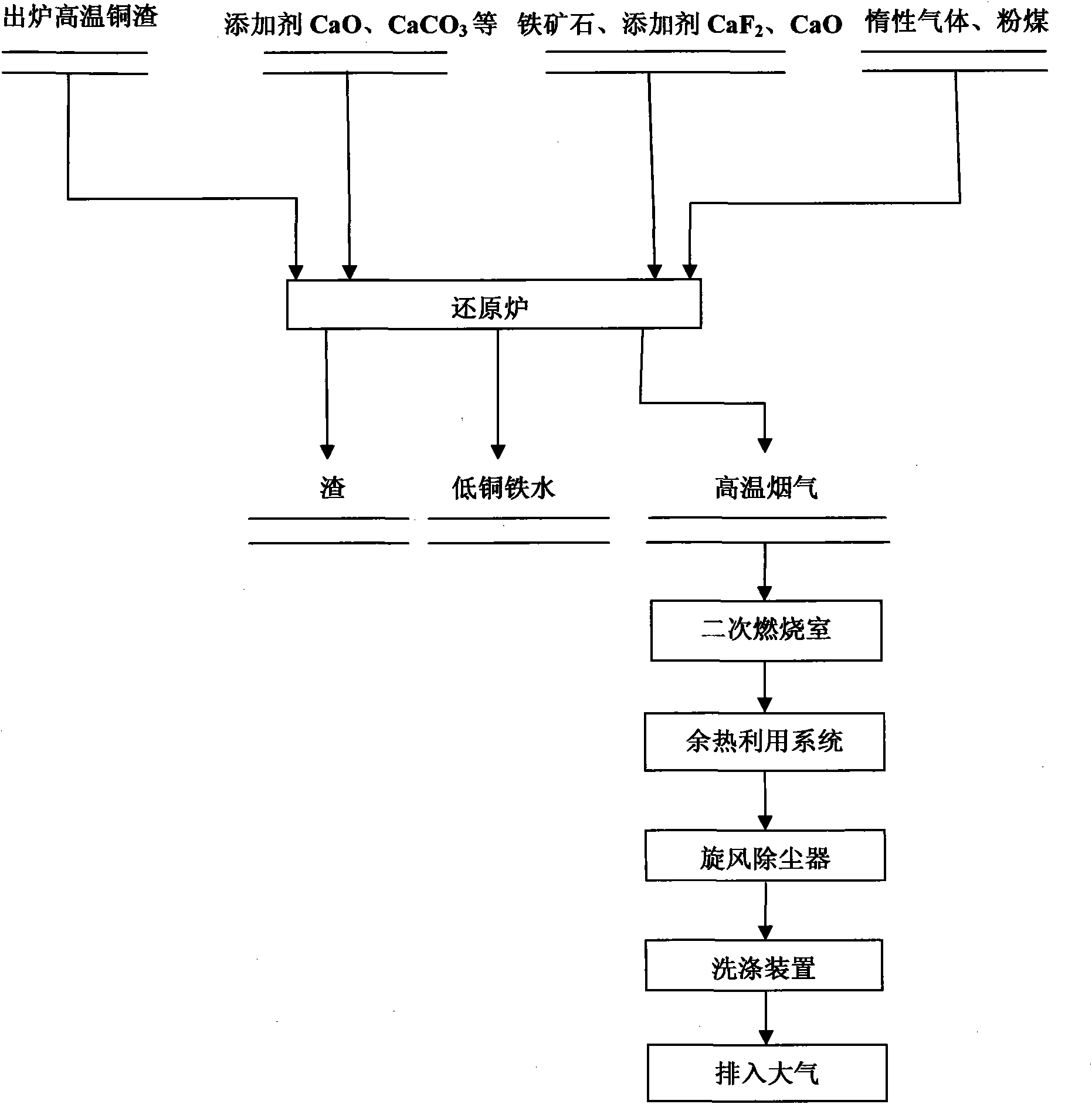

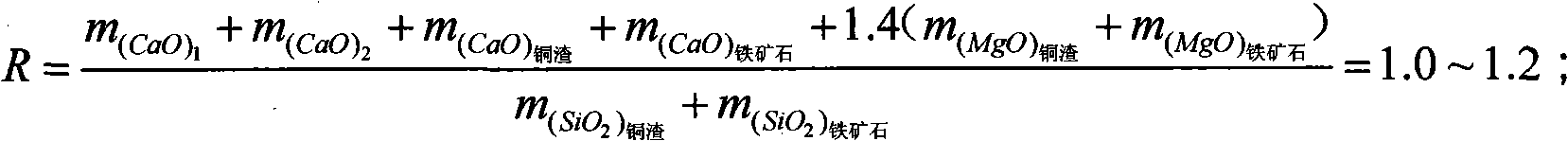

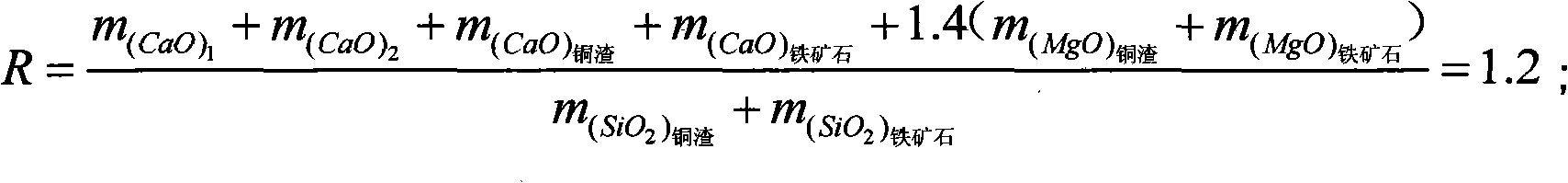

Method for preparing low-copper molten iron by mixed melting reduction of copper slag and iron ore

InactiveCN101886154AHigh copper concentrationOvercome the disadvantage of higher concentrationFluidised-bed furnacesGranularityCoal

The invention discloses a method for preparing low-copper molten iron by mixed melting reduction of copper slag and iron ore. The method comprises the following processes of: putting the high-temperature molten copper slag into a reduction furnace, grinding a certain amount of slag forming agent CaO, CaCO3 and the like into certain granularity, adding the ground slag forming agent into the reduction furnace, fully melting the mixture, and standing the molten pool for 10 minutes; grinding the iron ore, quantitative additive CaF2 and CaO into certain granularity respectively, then uniformly mixing the iron ore, the CaF2 and the CaO, adding the mixture into the reduction furnace, raising the temperature of the furnace to between 1,600 and 1,700 DEG C, fully melting the materials in the furnace, and then standing the molten pool for 20 minutes; and crushing a coal reducing agent to certain granularity, spraying the crushed coal reducing agent to the molten pool by using inert gas as carrier gas through a spray gun, and performing mixed melting reduction reaction of the copper slag and the iron ore. The method greatly reduces the defect of high copper in the molten iron obtained by single copper slag melting reduction by fully using the mutual coupling effect of the components among the copper slag, the iron ore and the additive and the diluting effect of the molten iron obtained by iron ore reduction on high copper content of the molten iron obtained by copper slag reduction, and has wide applicability.

Owner:KUNMING UNIV OF SCI & TECH

Copper extraction method of etching waste liquid or low copper containing waste liquid

InactiveCN1904142AReduce processing costsReduce etching costsPhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

This invention relates to a process of extracting copper from etching effluent or low copper waste water. The process includes follow steps: mix the etching effluent or low copper waste water with copper extractant to transfer the copper ion; poaching the extractant with 10%-50% sulphuric acid to gain copper sulfate solution; process electrolysis of copper sulfate solution in electrolytic tank to gain electrolytic tough pitch copper; add sulphuric acid, chlorizated ammonia or liquid ammonia to the used etching effluent for reapplication.

Owner:JIANGMEN CITY PENGJIANG DISTRICT DA YING MECHANICAL & ELECTRICAL EQUIP

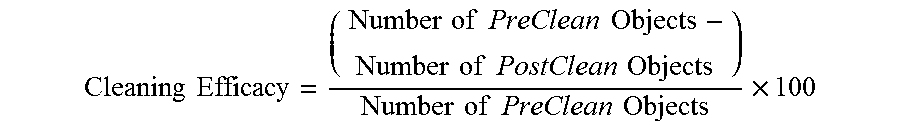

Aqueous clean solution with low copper etch rate for organic residue removal improvement

InactiveUS20150114429A1Minimize water mark defectsImprove compatibilityDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSolventLow copper

A cleaning composition and process for cleaning post-chemical mechanical polishing (CMP) residue and contaminants from a microelectronic device having said residue and contaminants thereon. The cleaning compositions include at least one quaternary base, at least one amine, at least one corrosion inhibitor, and at least one solvent. The composition achieves highly efficacious cleaning of the post-CMP residue and contaminant material from the surface of the microelectronic device while being compatible with barrier layers.

Owner:ENTEGRIS INC +1

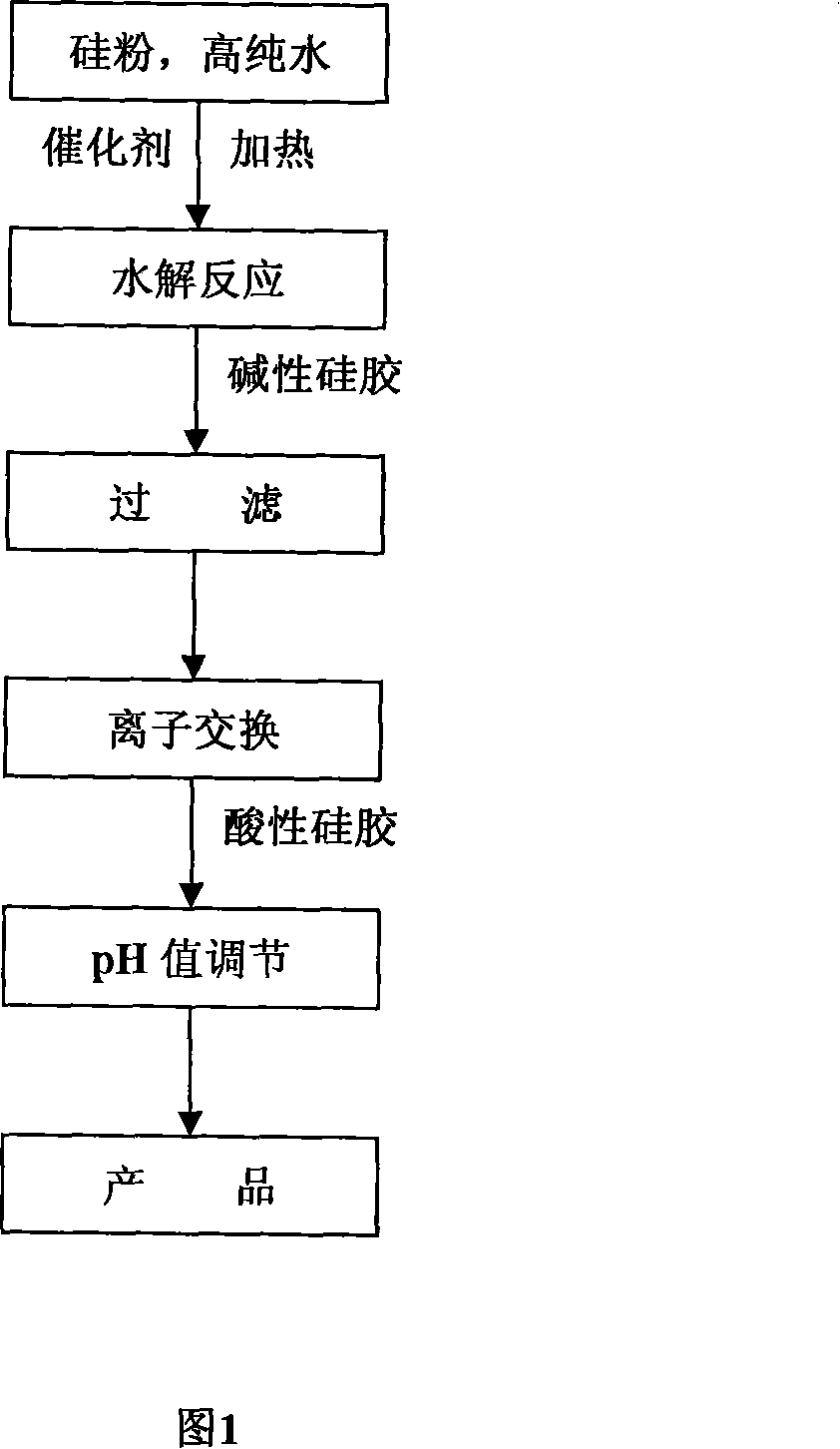

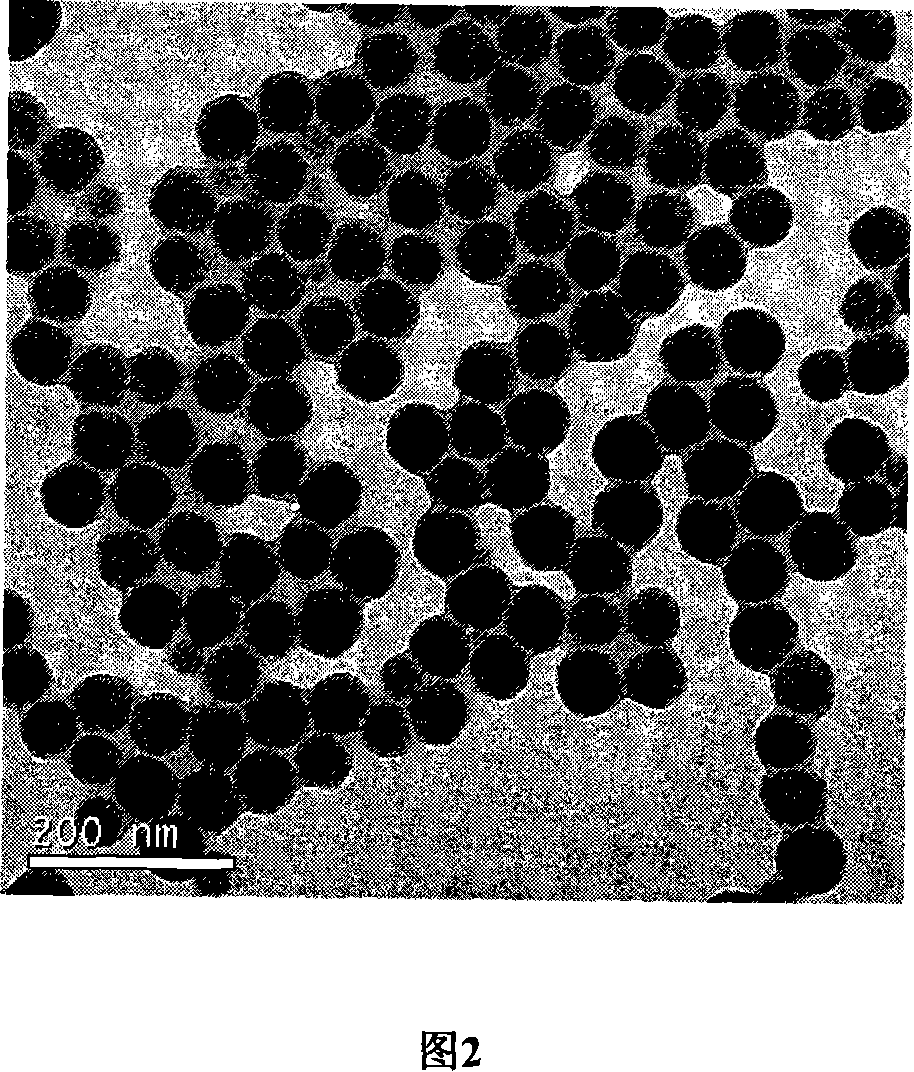

Acidic silicon dioxide sol and its preparation method and use

InactiveCN101121520AExtended shelf lifeReduce copper ion contentSilicon compoundsColloidal silicaIon content

The invention provides an acidic silica sol, which is characterized in that: it comprises water and silicon dioxide colloids with a nanometer or submicron particle size dispersed in water and made of silicon powder as a raw material, and the pH value of the sol is 1.5~3.5, copper ion content ≤50ppb. The sol has the characteristics of high stability and high purity, and can be applied to chemical mechanical polishing (CMP) in the electronics industry, semiconductors, hard disks, compound crystals, precision optical devices, etc., because of its low copper content, it has advantages in the field of semiconductor polishing. The present invention also provides the preparation method and application of the above-mentioned acidic silica sol.

Owner:BEIJING GRISH HITECH

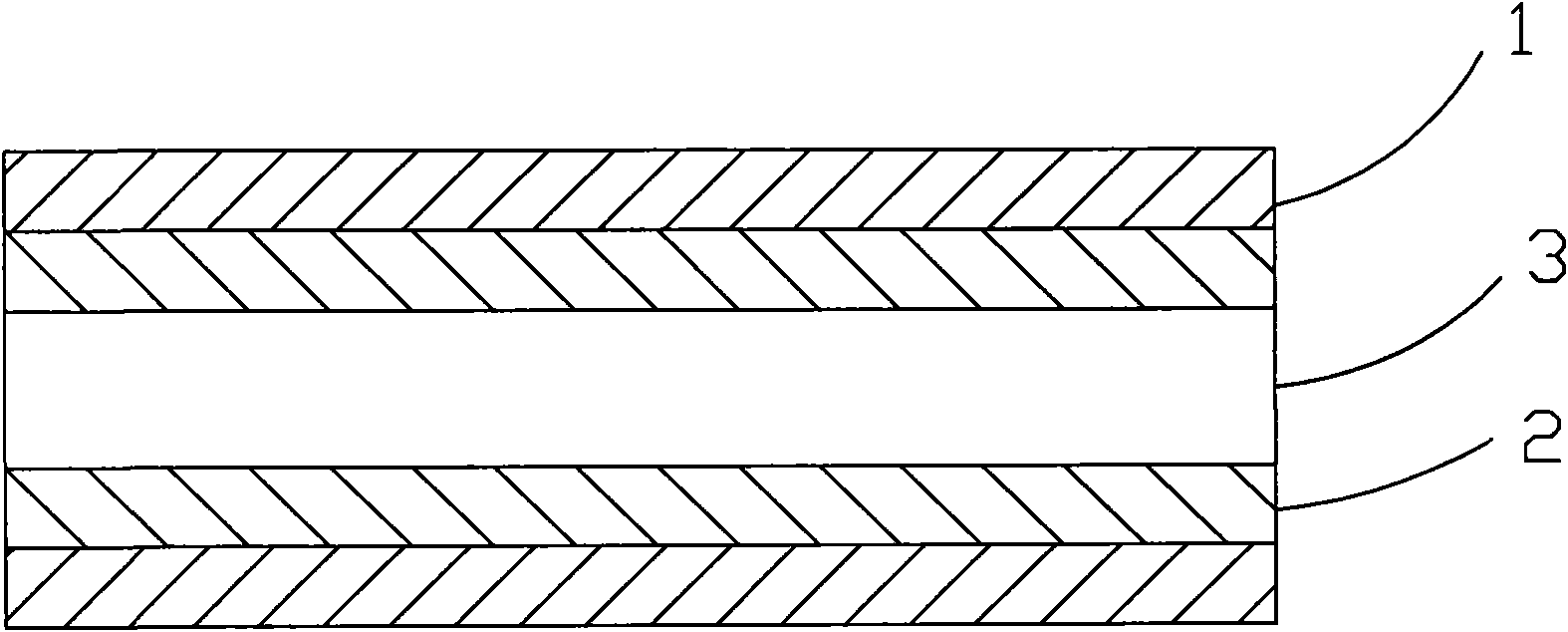

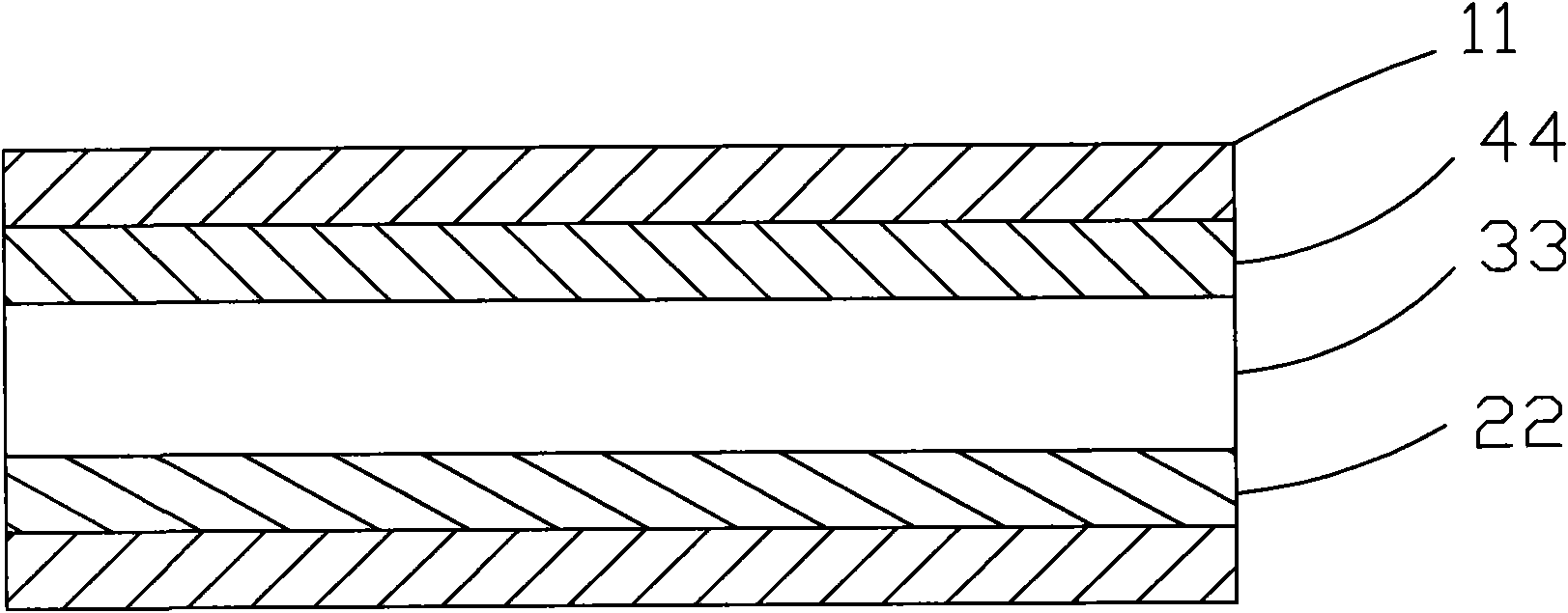

Two-layer-process double-sided flexible copper-clad laminate (CCL) and manufacture method thereof

ActiveCN101786354AImprove heat resistanceImprove moisture resistanceLaminationLamination apparatusHeat resistanceThermal expansion

The invention relates to a two-layer-process double-sided flexible copper-clad laminate (CCL) and a manufacture method thereof. The two-layer-process double-sided flexible CCL comprises an upper copper foil, a lower copper foil and three polyimide resin layers sequentially clamped between the two copper foils, i.e. a thermoplastic polyimide resin layer with a thermal expansion coefficient larger than 40 ppm / DEG C, a thermoset polyimide resin layer with a low thermal expansion coefficient of 0-20 ppm / DEG C and a thermoset polyimide resin layer with a high thermal expansion coefficient of 20-40 ppm / DEG C. The two-layer-process double-sided flexible provided by the invention has higher thermal stability and high moisture fastness and can still have excellent high thermal stability, favorable size stability and high stripping strength under the harsh environment of high temperature, high moisture, and the like, thereby having favorable industrial prosperities. The double-sided flexible CCL manufactured by the invention has practically improved size stability under the condition of heavy moisture. When being applied to the environment of high temperature, high moisture, and the like, the double-sided flexible CCL and printing circuits made by the same have excellent thermal stability, high temperature reliability and moisture fastness stability.

Owner:GUANGDONG SHENGYI SCI TECH

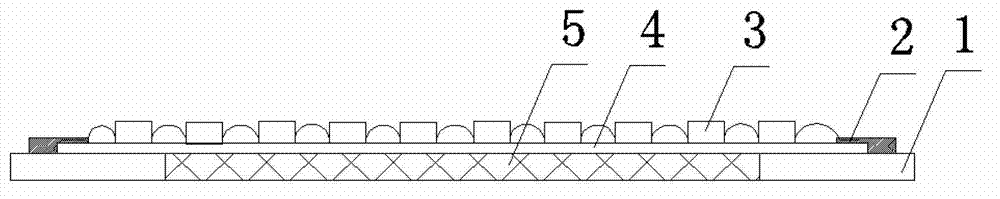

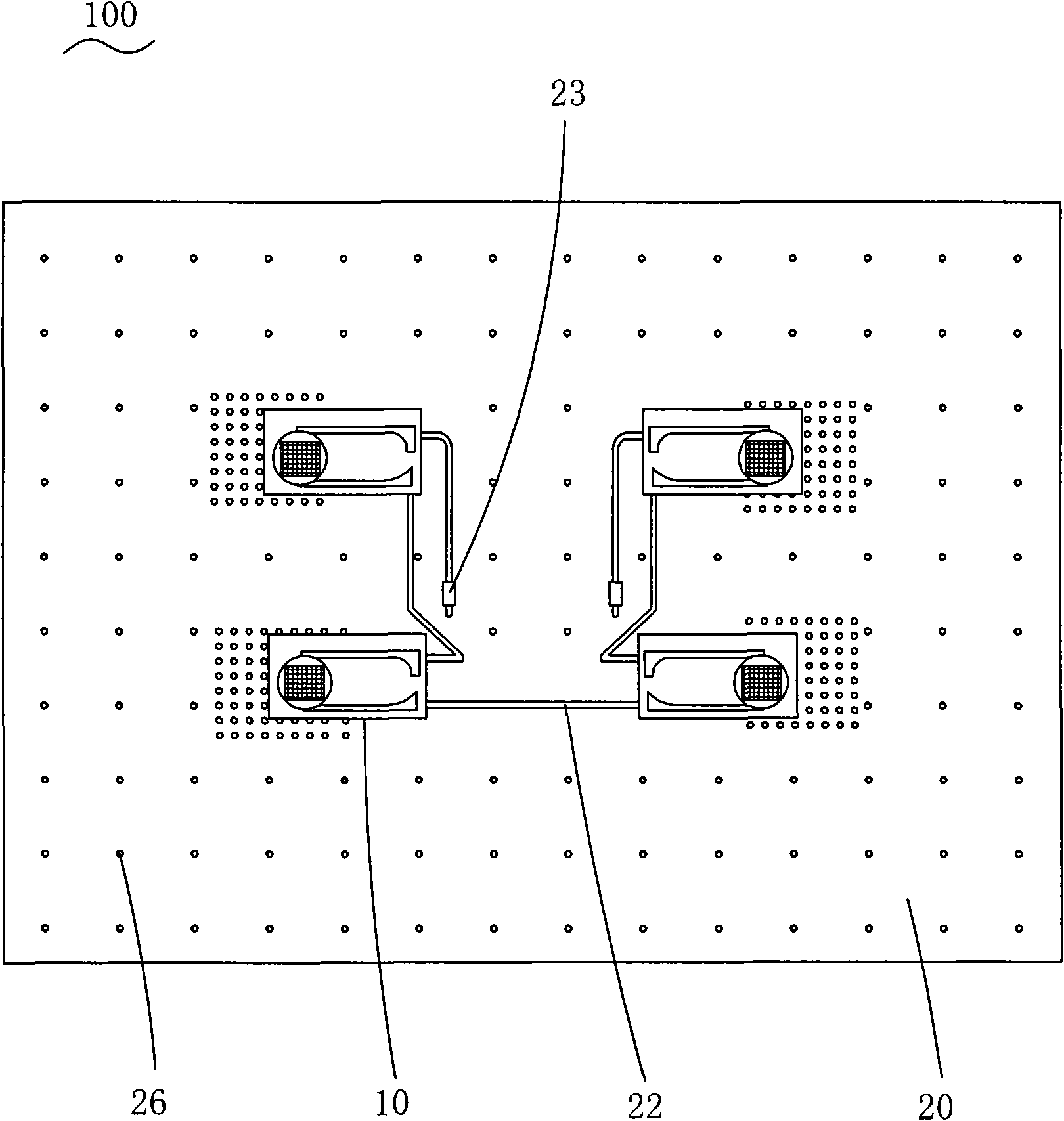

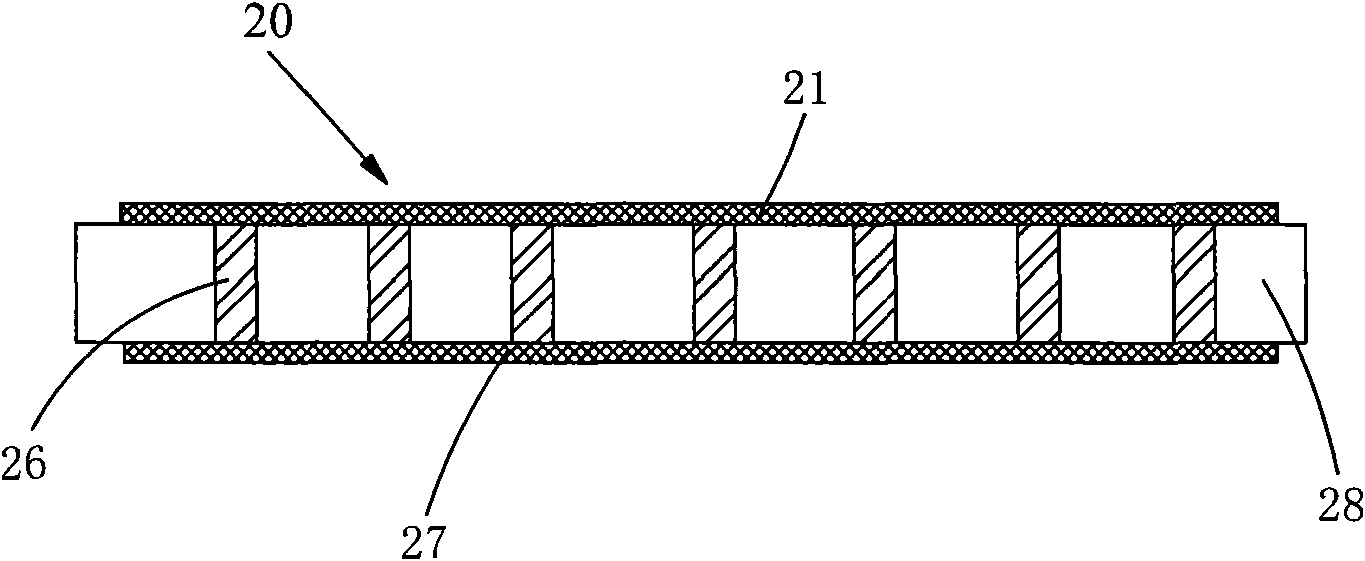

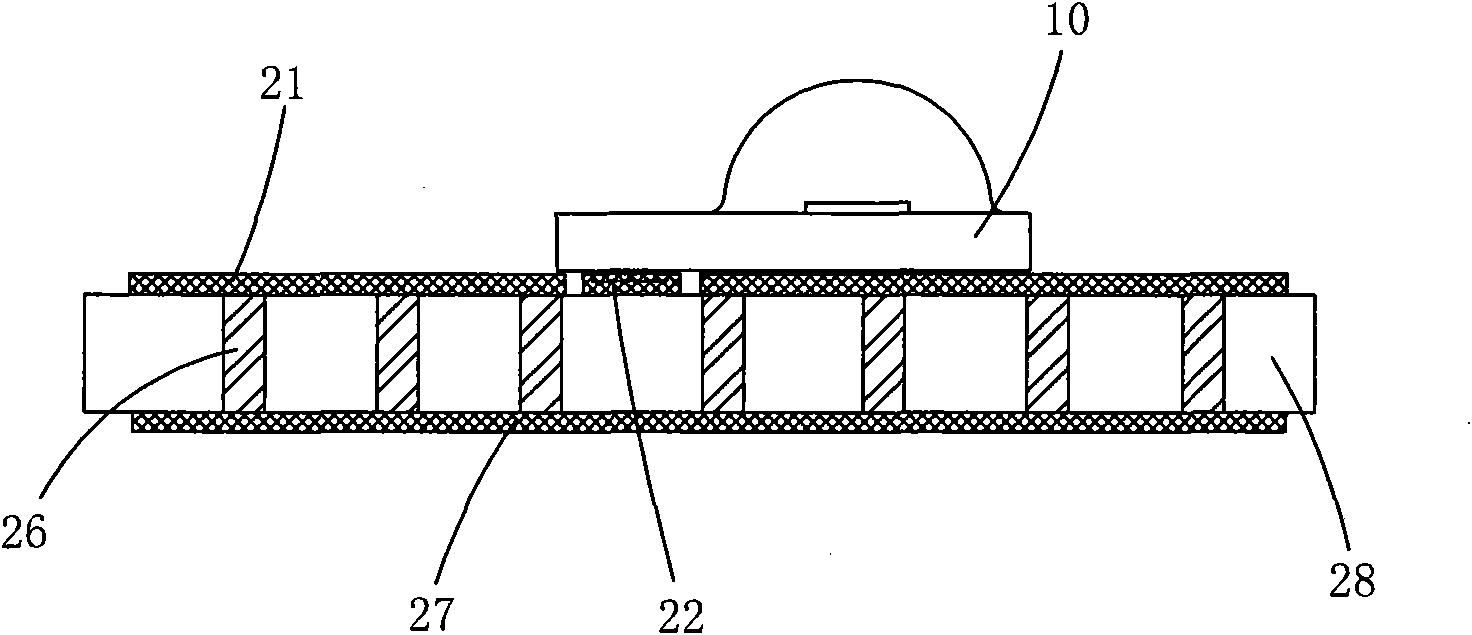

Flexible light-emitting diode (LED) lamp band and manufacturing method thereof

InactiveCN102788284AGood flexibilityImprove cooling effectPoint-like light sourceElectric circuit arrangementsOn boardEngineering

The invention discloses a flexible light-emitting diode (LED) lamp band and a manufacturing method thereof. The lamp band is formed by arranging a plurality of LED light source modules. The flexible LED lamp band is characterized in that each LED light source module comprises an upper copper sheet, a lower copper sheet and an insulation sheet, wherein the upper copper sheet and the lower copper sheet are isolated; the insulation sheet is connected between the upper copper sheet and the lower copper sheet; heat conduction layers are respectively coated on the upper surface of the copper sheet and the upper surface of the insulation sheet; at least one string of LED chips is mounted on each heat conduction layer; the corresponding upper copper sheet and the corresponding lower copper sheet are respectively provided with an electrode soldering point; and the LED chips are connected in series between each upper electrode soldering point and each lower electrode soldering point. The manufacturing method comprises the following six steps of cutting, etching, packing, coating, mounting and wiring. The invention has the obvious effects that the lamp band is good in connectivity; chip on board (COB)-packaged LED light source modules are high in stability and convenient in assembly. The single LED light source module can be mounted or multiple LED light source modules can be combined; and large-scale mass production manufacturing can be realized. The flexible LED lamp band not only can be applied to corn lamps but also can be used for manufacturing various traditional lamps and also can be well utilized on street lamp light source modules or tunnel lamp light source modules.

Owner:重庆楚商光电科技有限公司

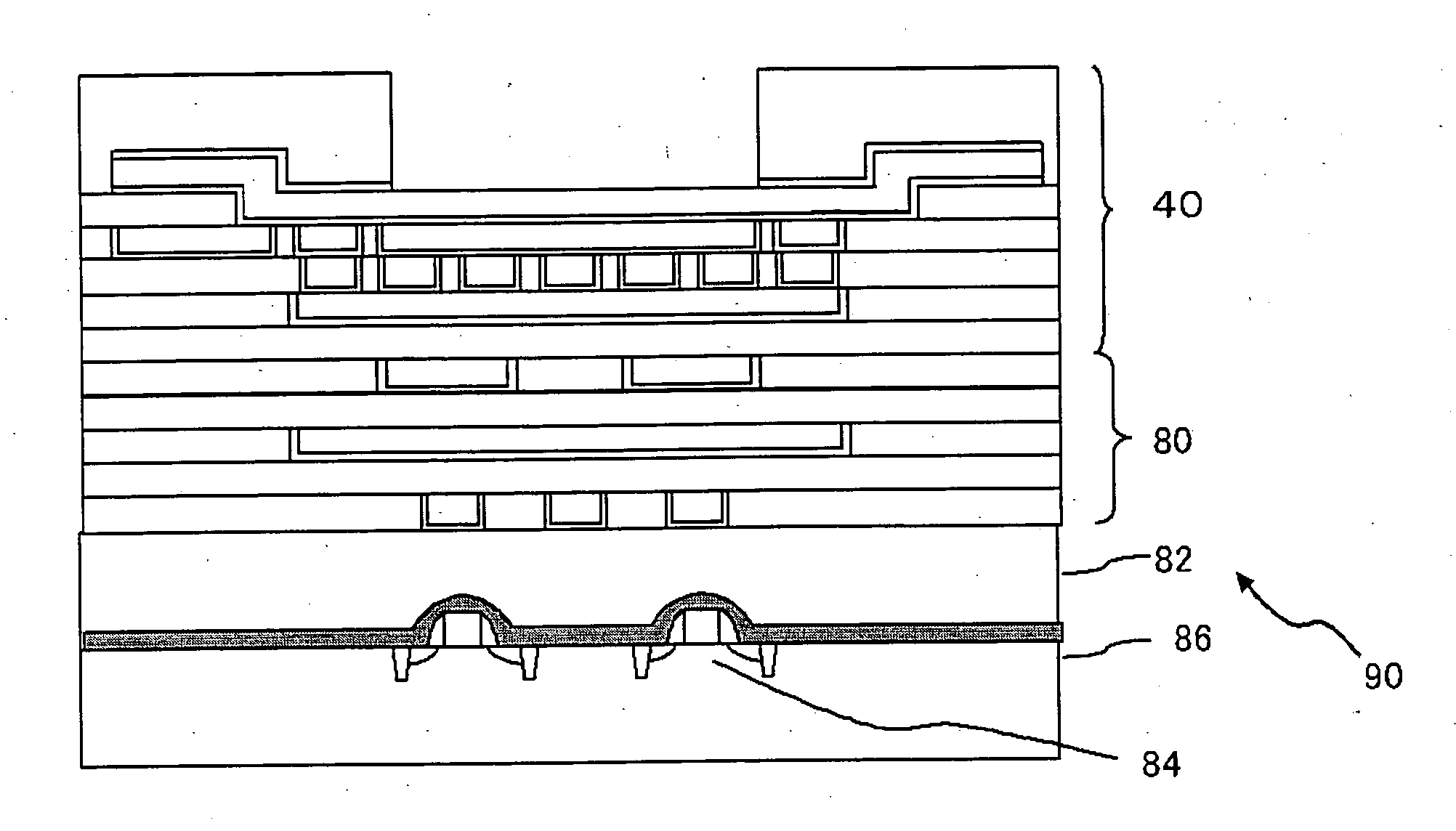

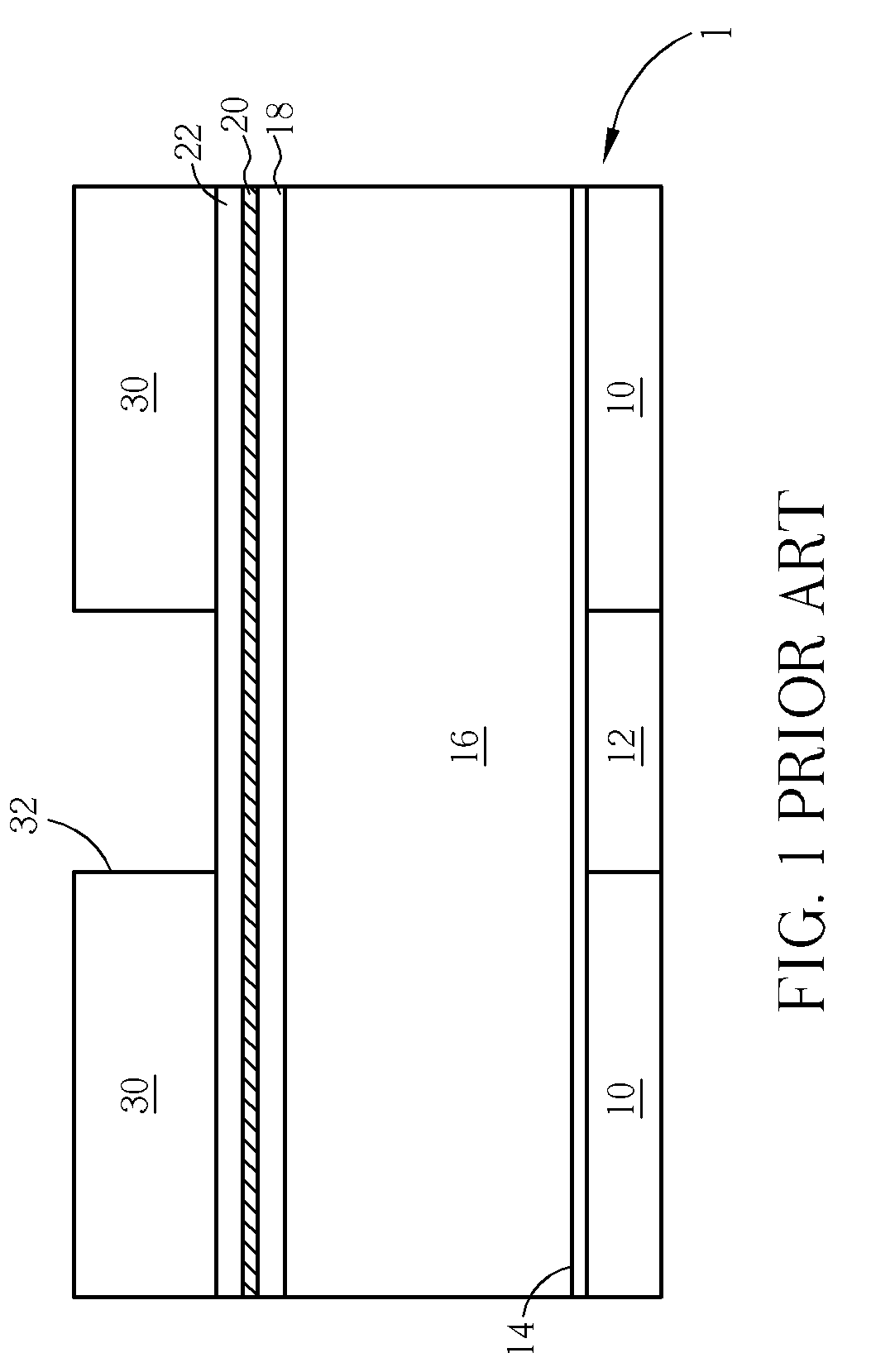

Semiconductor device

InactiveUS20050280149A1Reduce the impactRule out the possibilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A semiconductor device should have a structure that allows locating electronic components in a region under a bonding pad. The semiconductor device includes a bonding pad constituting the external connection terminal; a region under the bonding pad including at least two copper layers and a connection via plug, under said bonding pad, disposed so as to connect copper layers that form a pair out of the at least two copper layers; a seal ring constituted of an annular conductor, disposed so as to surround the region under the bonding pad, and to connect a lower one of the copper layers that form said pair to copper layer to form a pair with the lower copper layer; and an interconnect connected to the bonding pad outside the seal ring.

Owner:RENESAS ELECTRONICS CORP

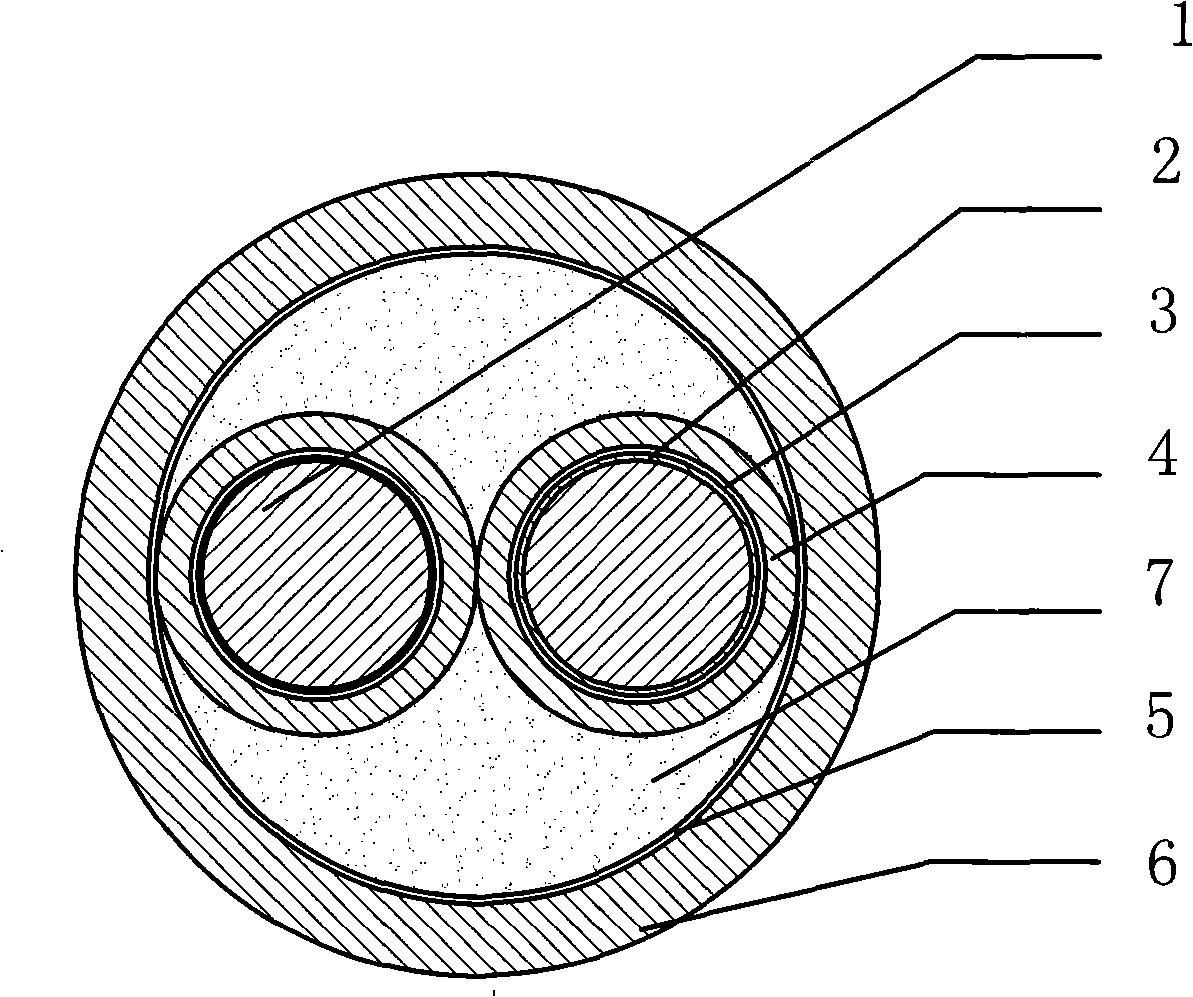

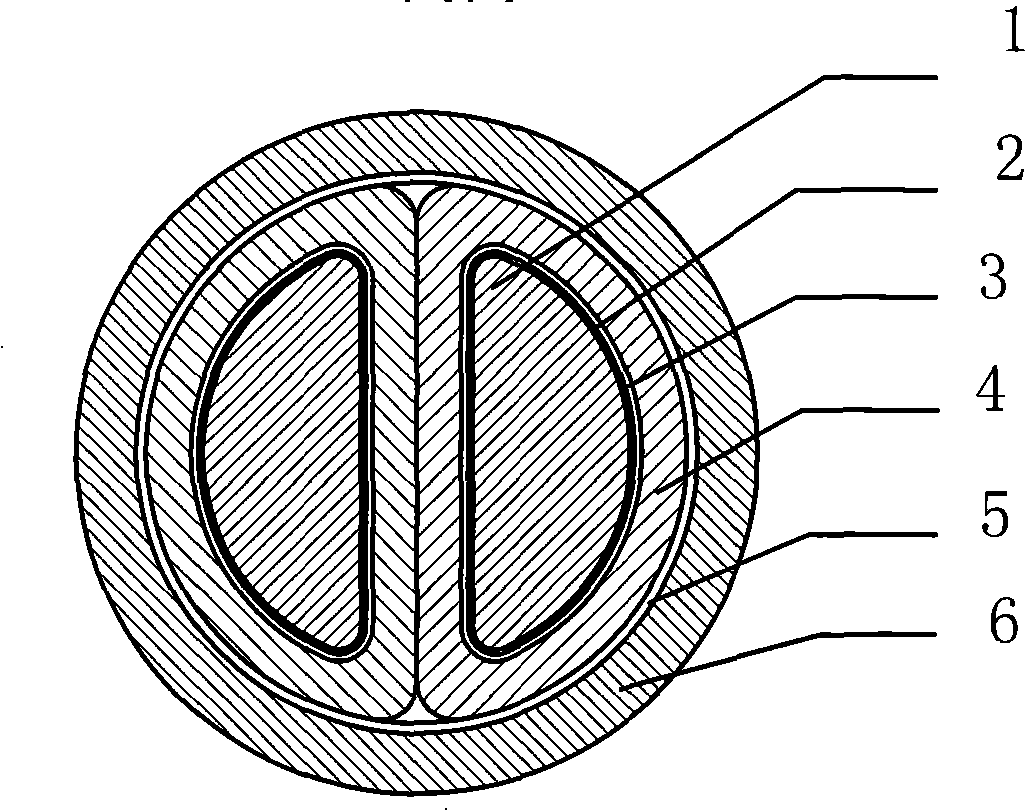

Copper coated aluminum dual-core flame-retardant refractory flexible electric cable and manufacturing method thereof

ActiveCN101335114AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum two-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a semi-round section; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with a semi-round section; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to two insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

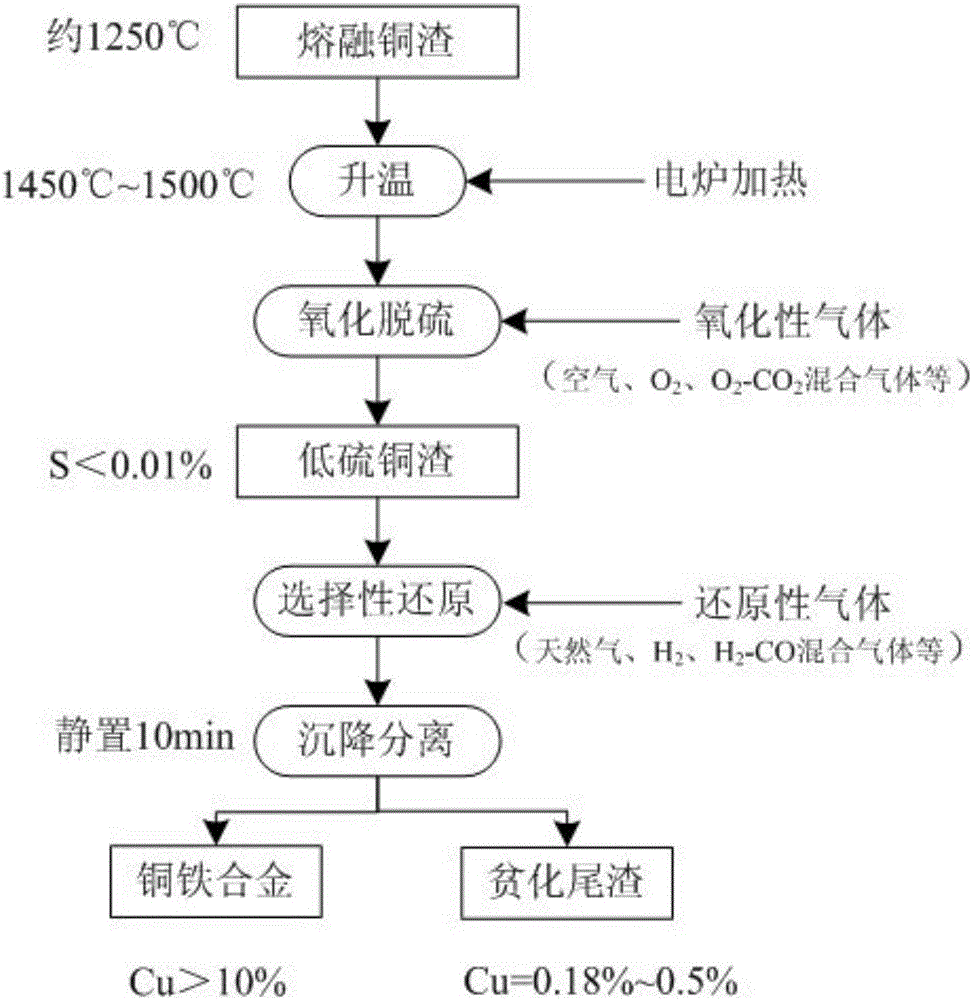

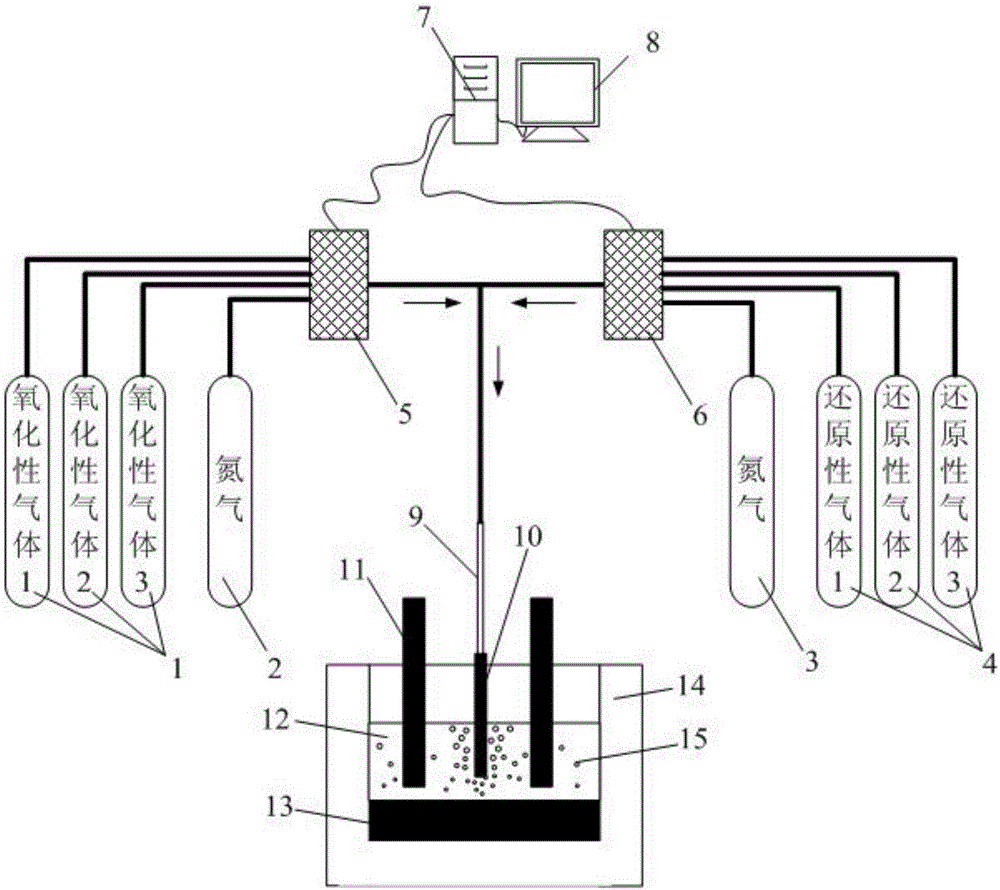

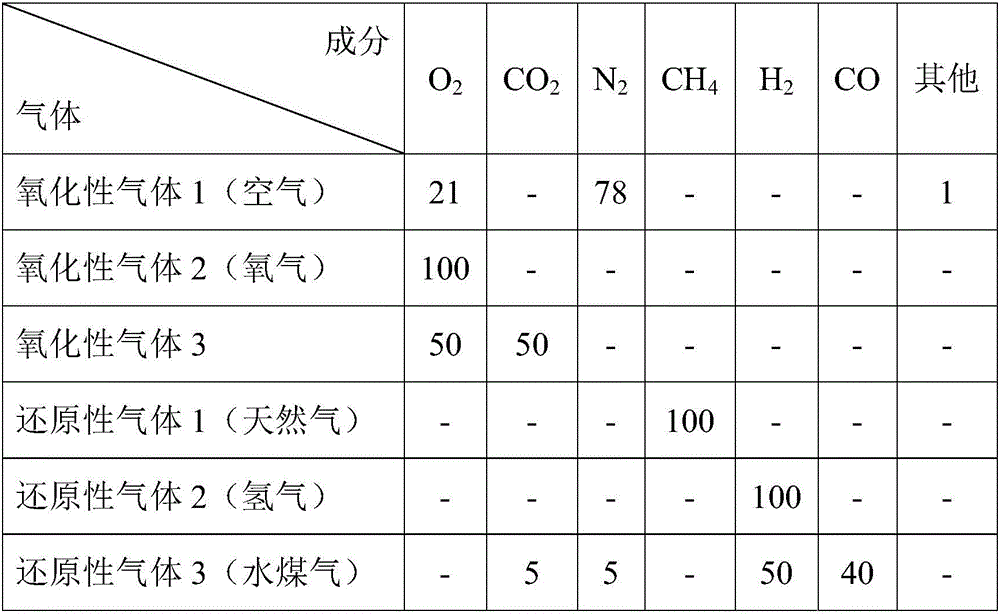

Method for realizing deep depletion on copper slag through multielement gas substep injection

ActiveCN106756062ARealize deep depletionComprehensive depletion results are excellentRotary drum furnacesCrucible furnacesLow copperMaterials science

The invention provides a method for realizing deep depletion on copper slag through multielement gas substep injection. The method fully utilizes waste heat of molten copper slag, copper matte is converted into oxide through gasification desulphurization, then selective reduction is carried out to obtain copper iron alloy with higher copper content, the problem of copper slag depletion in a smelting process is solved, and low-sulfur low-copper depletion slag is produced, so that conditions are created for a follow-up iron extracting process, and the deep depletion on the copper slag is realized; the traditional matte-producing depletion process is abandoned, but a gasification desulphurization process is firstly carried out for converting the copper matte into the oxide, then the oxide is subjected to selective reduction by virtue of a reducing agent, so that a copper-iron alloy phase is obtained. Operation is simple, adaptability is strong, the method can be realized by modifying the original electric furnace, nickel slag similar to the copper slag in properties can be treated, and metal elements such as Cu, Ni, Co and Fe can be comprehensively recycled.

Owner:UNIV OF SCI & TECH BEIJING

Manufacture of silver-copper-germanium alloy

InactiveCN101218361ANot commercially viableWelding/cutting media/materialsSoldering mediaImpuritySilver copper

Silver alloys containing copper and germanium e.g. about 1 wt % Ge and of very low copper content e.g. about 0.8 wt % Cu can be precipitation hardened to 65 HV or above, whereas alloys of similar copper content and not containing germanium remain soft. In an embodiment, a silver alloy comprises 92.5-97 wt % Ag, 1-4.5 wt % Cu, 0.4-4 wt % Zn, 0.8-1.5 wt % Ge, 0 to 0.2 wt % Si, In or Sn and 0-0.2 wt % Mn, the balance being boron as grain refiner, incidental ingredients and impurities. The said alloy preferably comprises boron as grain refiner added as a boron hydride, e.g. sodium borohydride. A further group of alloys comprises a ternary alloy of silver, copper and germanium containing from more than 93.5 wt % to 95.5 wt % Ag, from 0.5 to 3 wt % Ge and the remainder, apart from incidental ingredients (if any), impurities and grain refiner, copper, the grain refiner being sodium borohydride or another boron hydride. Silicon-containing casting grain that gives rise to bright as-cast products is also disclosed. In a further embodiment, a zinc-containing silver alloy resistant to tarnish under severe conditions e.g. exposure to human sweat or French dressing comprises 1-5 wt % Zn, 0.7-3 wt % Cu, 0.1-3 wt % Ge, 0-0.3 wt % Mn, 0-0.25 wt % Si, B in an amount effective for grain refinement, up to 0.5 wt % incidental ingredients, the balance being Ag in an amount of 92.5-96 wt %, and impurities. A preferred manufacturing method giving an alloy with favourable physical properties involves melting together the ingredients, and incorporating boron by dispersing into molten silver alloy to foirn the whole or a precursor pait of said alloy a compound selecting fiom alkyl boron compounds, boron hydrides, boron halides, boron-containing metal hydrides, boron-containing metal halides and mixtures thereof The alloy is particularly suitable for castings which may be hardened in an oven e.g. at about 300 DEG C. for 30-45 min.

Owner:ARGENTIUM INT

Metal alloy manufacturing

Silver alloys containing copper and germanium e.g. about 1 wt % Ge and of very low copper content e.g. about 0.8 wt % Cu can be precipitation hardened to 65 HV or above, whereas alloys of similar copper content and not containing germanium remain soft. In an embodiment, a silver alloy comprises 92.5-97 wt % Ag, 1-4.5 wt % Cu, 0.4-4 wt % Zn, 0.8-1.5 wt % Ge, 0 to 0.2 wt % Si, In or Sn and 0-0.2 wt % Mn, the balance being boron as grain refiner, incidental ingredients and impurities. The said alloy preferably comprises boron as grain refiner added as a boron hydride, e.g. sodium borohydride. A further group of alloys comprises a ternary alloy of silver, copper and germanium containing from more than 93.5 wt % to 95.5 wt % Ag, from 0.5 to 3 wt % Ge and the remainder, apart from incidental ingredients (if any), impurities and grain refiner, copper, the grain refiner being sodium borohydride or another boron hydride. Silicon-containing casting grain that gives rise to bright as-cast products is also disclosed. In a further embodiment, a zinc-containing silver alloy resistant to tarnish under severe conditions e.g. exposure to human sweat or French dressing comprises 1-5 wt % Zn, 0.7-3 wt % Cu, 0.1-3 wt % Ge, 0-0.3 wt % Mn, 0-0.25 wt % Si, B in an amount effective for grain refinement, up to 0.5 wt % incidental ingredients, the balance being Ag in an amount of 92.5-96 wt %, and impurities. A preferred manufacturing method giving an alloy with favourable physical properties involves melting together the ingredients, and incorporating boron by dispersing into molten silver alloy to foirn the whole or a precursor pait of said alloy a compound selecting fiom alkyl boron compounds, boron hydrides, boron halides, boron-containing metal hydrides, boron-containing metal halides and mixtures thereof The alloy is particularly suitable for castings which may be hardened in an oven e.g. at about 300° C. for 30-45 min.

Owner:ARGENTIUM INT

Dual damascence process utilizing teos-based silicon oxide cap layer having reduced carbon content

A dual damascene process starts with providing a substrate having thereon a base layer, a lower copper wiring inlaid into the base layer, and a lower cap layer covering the inlaid lower copper wiring. A dielectric layer is deposited on the lower cap layer. A TEOS-based oxide cap layer is deposited on the dielectric layer. The TEOS-based oxide cap layer has a carbon content lower than 1×1019 atoms / cm3. A metal hard mask is deposited on the TEOS-based oxide cap layer. A trench recess is etched into the metal hard mask and the TEOS-based oxide cap layer. A partial via feature is then etched into the TEOS-based oxide cap layer and the dielectric layer through the trench recess. The trench recess and partial via feature are etch transferred into the underlying dielectric layer, thereby forming a dual damascene opening, which exposes a portion of the lower copper wiring.

Owner:UNITED MICROELECTRONICS CORP

High PH treatment of pulp in a bleach sequence to produce pulp having low D.P. and low copper number for use in lyocell manufacture

InactiveUS20060065377A1Reduce the degree of polymerizationIncreasing copper numberNon-fibrous pulp additionNatural cellulose pulp/paperPulp millBleach

A high pH and a low pH process for reducing the degree of polymerization of a pulp having a hemicellulose content of at least 7%. The high pH is greater than 8, and the low pH process is 2 to 8. The high pH process reduces the degree of polymerization without substantially increasing the copper number. The low pH process requires a subsequent treatment with alkali to reduce the copper number of the pulp to less than 2. The process can be practiced in pulp mills with a bleaching sequence having one or more E or D stages. At the end of the bleach sequence, a pulp having a degree of polymerization of 200 to 1100, a copper number of less than 2, and a hemicellulose content of at least 7% is provided. The pulp can be used to make lyocell fibers.

Owner:WEYERHAEUSER CO

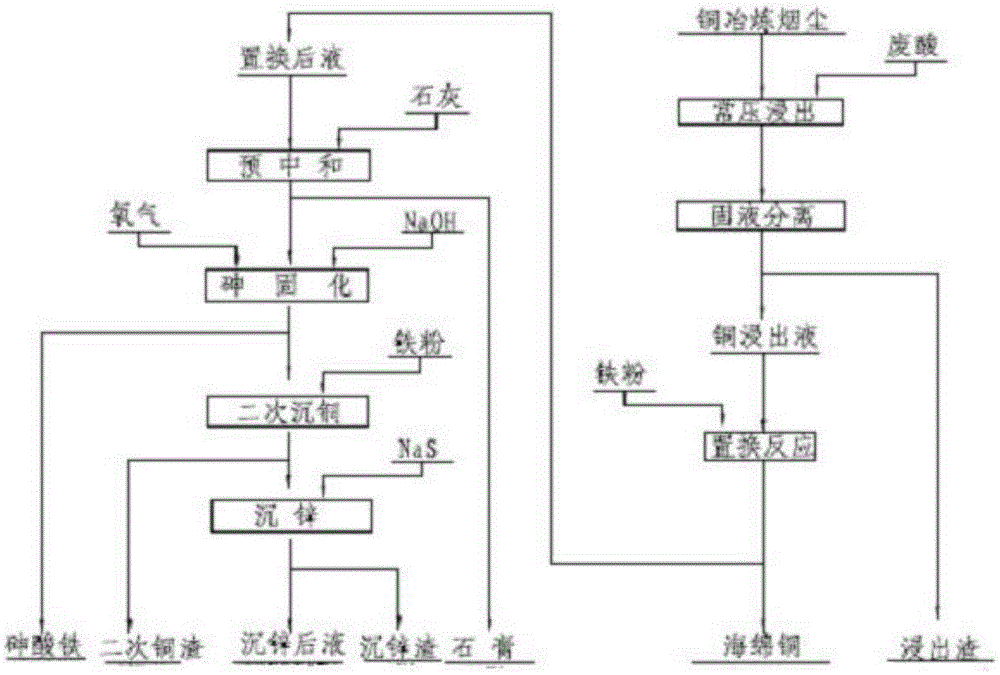

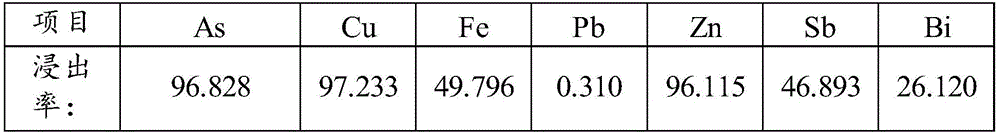

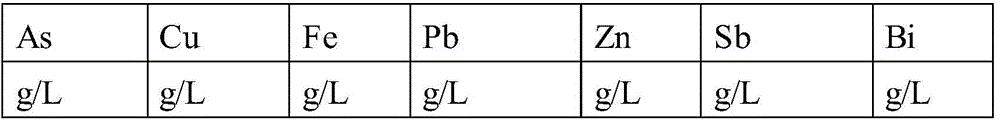

Treatment process for copper smelting smoke dust

ActiveCN105543489AImplement gradient recoveryRealize comprehensive utilizationProcess efficiency improvementArsenateVulcanization

The invention discloses a treatment process for copper smelting smoke dust. The treatment process comprises the following steps that 1, after the copper smelting smoke dust is subjected to acid leaching, acid leaching liquor and acid leaching residues are obtained; 2, after the acid leaching liquor obtained in the step 1 is subjected to copper depositing through metal replacement, filter liquor with copper being deposited is obtained; 3, after the filter liquor with the copper being deposited in the step 2 neutralizes and oxidizes with alkali, ferric arsenate and filter liquor with arsenic being deposited are obtained; 4, after the filter liquor with arsenic being deposited in the step 3 is subjected to the secondary copper depositing through metal replacement, filter liquor being subjected to the secondary copper depositing and copper residues are obtained; and 5, after the filter liquor being subjected to the secondary copper depositing in the step 4 is subjected to zinc depositing through vulcanization, filter liquor with zinc being deposited and zinc residues are obtained. According to the treatment process for the copper smelting smoke dust provided by the invention, particularly, a treatment process for high-arsenic low-copper smoke dust, the harmless treatment of arsenic in the high-arsenic low-copper smoke dust is achieved; meanwhile, valuable metal copper, zinc, lead, bismuth and the like in the high-arsenic low-copper smoke dust are recovered comprehensively, and gradient recycle and comprehensive utilization of the impurities of the smoke dust are achieved.

Owner:YANGGU XIANGGUANG COPPER

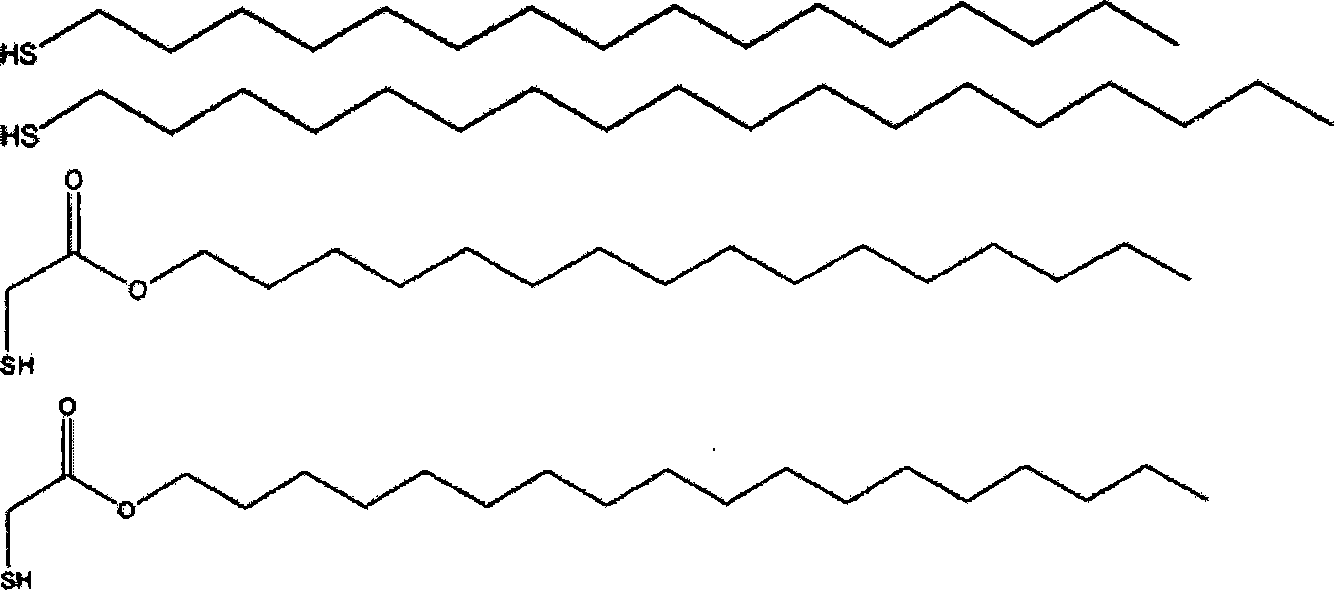

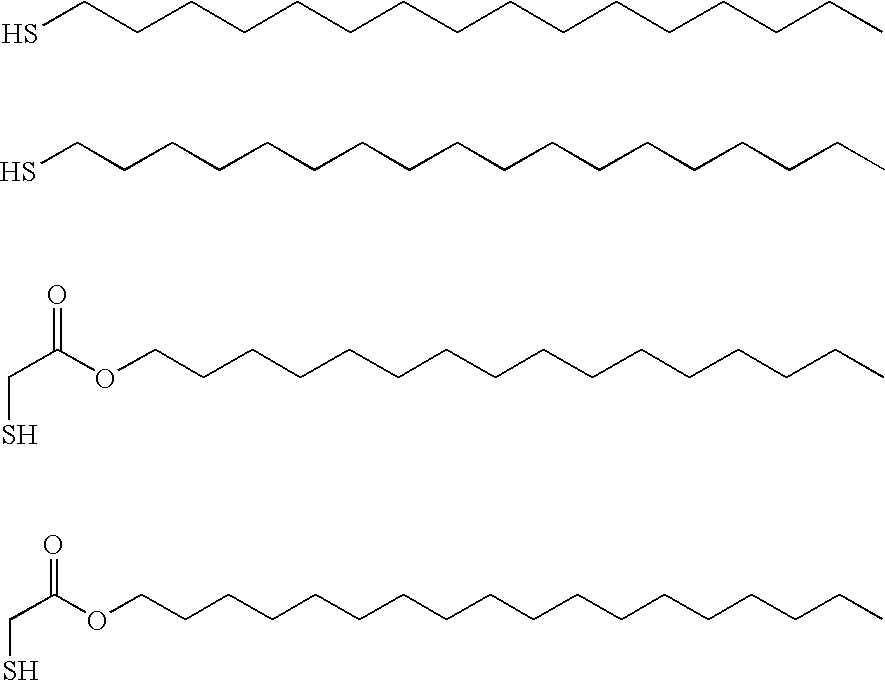

Copper gold silver ore flotation collecting agent and flotation method

InactiveCN107213992AStrong harvesting abilityGood harvesting effectFlotationMineral flotationLow copper

The invention discloses a copper gold silver ore flotation collecting agent and a flotation method, belongs to the technical field of ore flotation, and solves the prominent problems of low copper gold silver ore beneficiation efficiency, high cost and the like. The copper gold silver ore flotation collecting agent ester-205 is prepared from the following raw materials: 30 to 40 parts of N,N-diethyl dithiocarbamate, 20 to 25 parts of diisopropyl dithiophosphate, 10 to 15 parts of black powder acid, 20 to 30 parts of terpenic oil and 2 to 5 parts of ethyl alcohol. The flotation method comprises the following steps: preparation of flotation pulp, flotation preparation and copper gold silver ore flotation. According to the copper gold silver ore flotation collecting agent and the flotation method, multiple circulation times and metal loss of target metal ores in a flotation process are effectively avoided, so that the trunk flotation process is shortened, and the investment and operation cost is reduced; the collecting agent ester-205 is high in collecting capacity; the flotation speed is increased; the copper gold silver recycling rate is increased; the number of the scavenging times is reduced; and the types and the use amounts of flotation agents are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

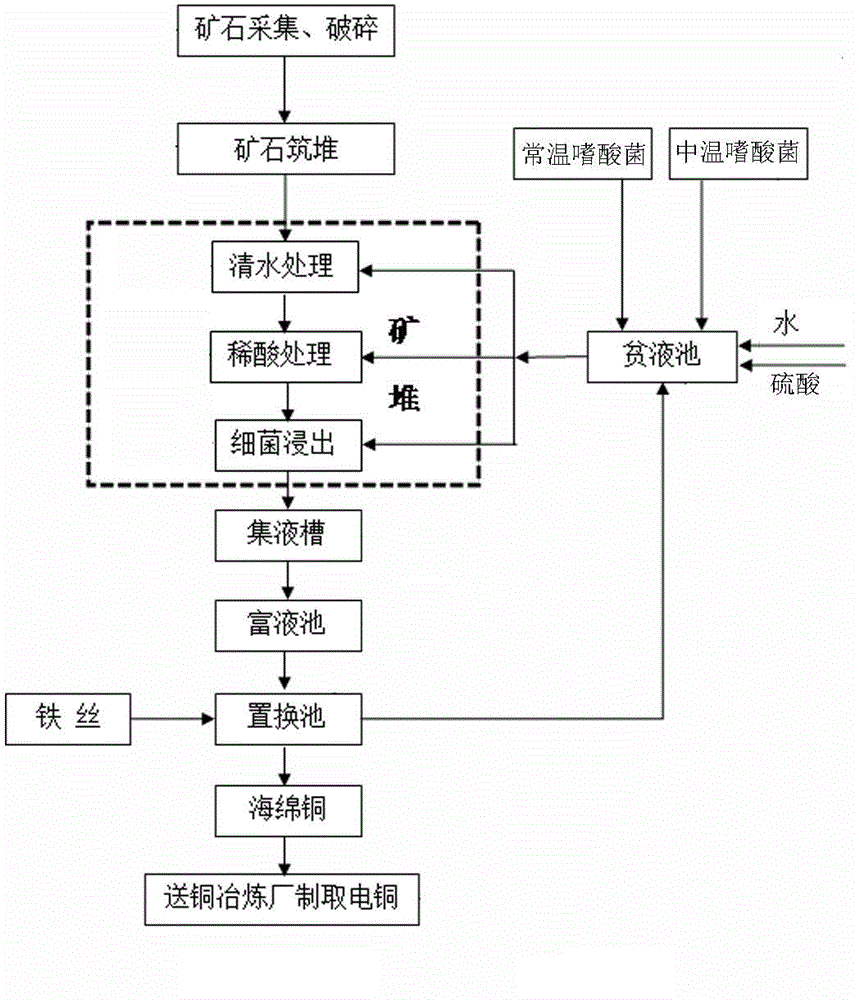

Biological heap leaching technology for stripmining copper sulfide mines

ActiveCN104152691ASimple processShort processProcess efficiency improvementPregnant leach solutionSulfidation

The invention provides a biological heap leaching technology for stripmining copper sulfide mines. The technology comprises the following steps: the copper sulfide mines with a low copper grade and high oxidizability are crushed, sieved and heaped, water and dilute sulphuric acids are dripped and sprinkled successively, a pH value is adjusted, then normal-temperature acidophile and middle-temperature acidophile are dripped and sprinkled successively according to temperature changes, and copper in leach liquor is displaced. The technology has the advantages that the technology is simple, the technological process is short, the pollution is small, the copper sulfide mines with a lower grade can be processed, and the like. Mineral leaching bacteria which are adopted are widely distributed, so that the mineral leaching bacteria are easy to obtain.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

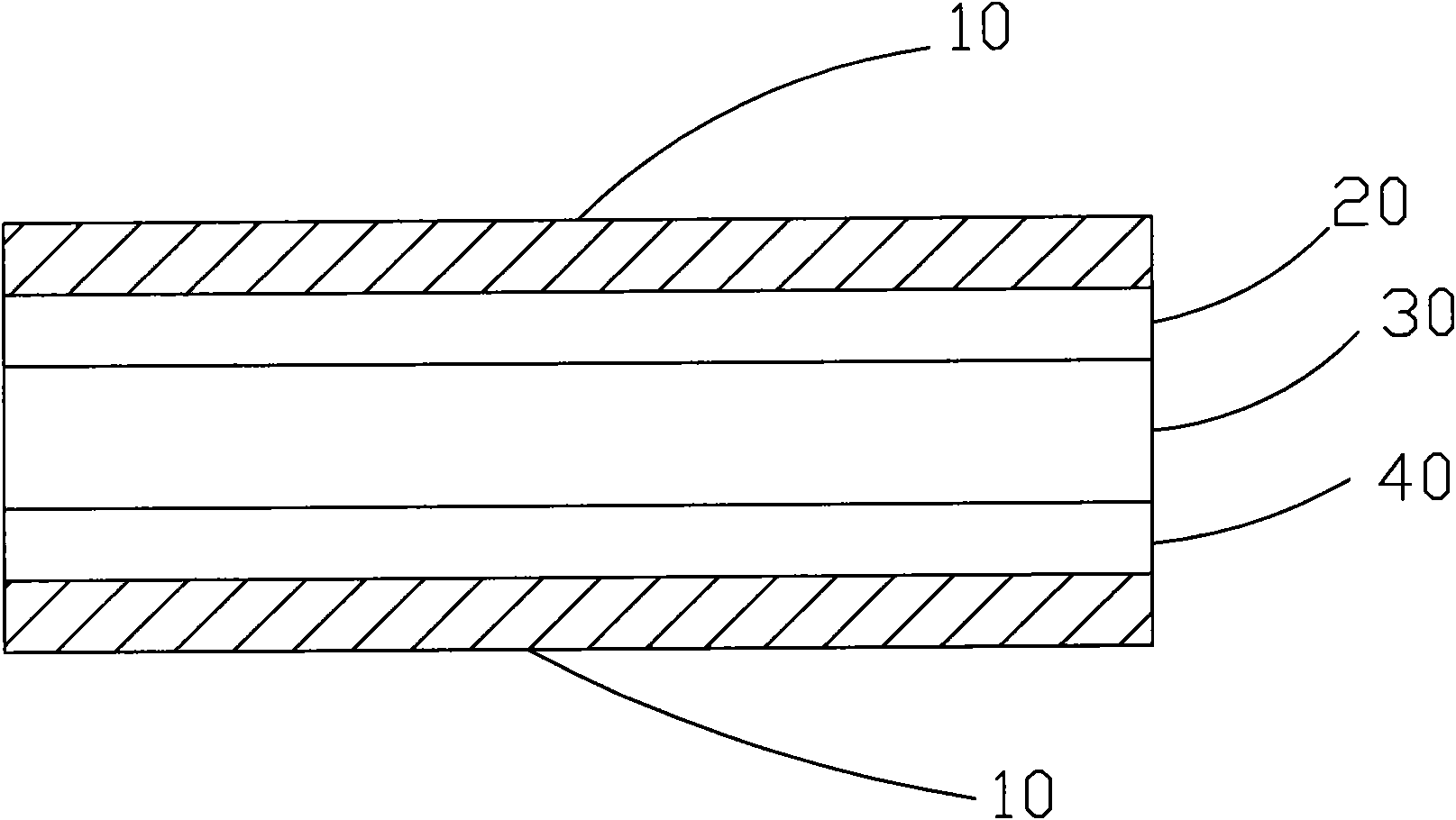

Light emitting diode (LED) lamp with heat dissipation circuit board

InactiveCN101994919ASimple designExtended service lifePoint-like light sourceElectric circuit arrangementsElectricityCopper foil

The invention discloses a light emitting diode (LED) lamp with a heat dissipation circuit board, which comprises a circuit board and an LED light emitting unit which is electrically connected on the circuit board, wherein the circuit board is a double-layer copper foil board; an insulating layer is integrally formed between the upper and lower copper foil layers; the circuit board is provided with a through hole; a heat conduction material is arranged in the through hole to form a heat conduction column; the upper and lower copper foil layers are communicated with each other by the heat conduction column; and heat, which is formed by the LED light emitting unit arranged on the upper copper foil layer, is evenly transferred to the upper and lower copper foil layers through the heat conduction column, thereby effectively radiating heat through the upper and lower copper foil layers. Therefore, the lamp has simple design structure, and the heat dissipation circuit board adopted in the invention can be freely provided with LED light emitting units with different powers according to the power of the lamp in actual demands, so that heat inside the LED lamp can be effectively radiated, thereby prolonging the service life of the lamp and effectively preventing light attenuation of the lamp.

Owner:林万炯

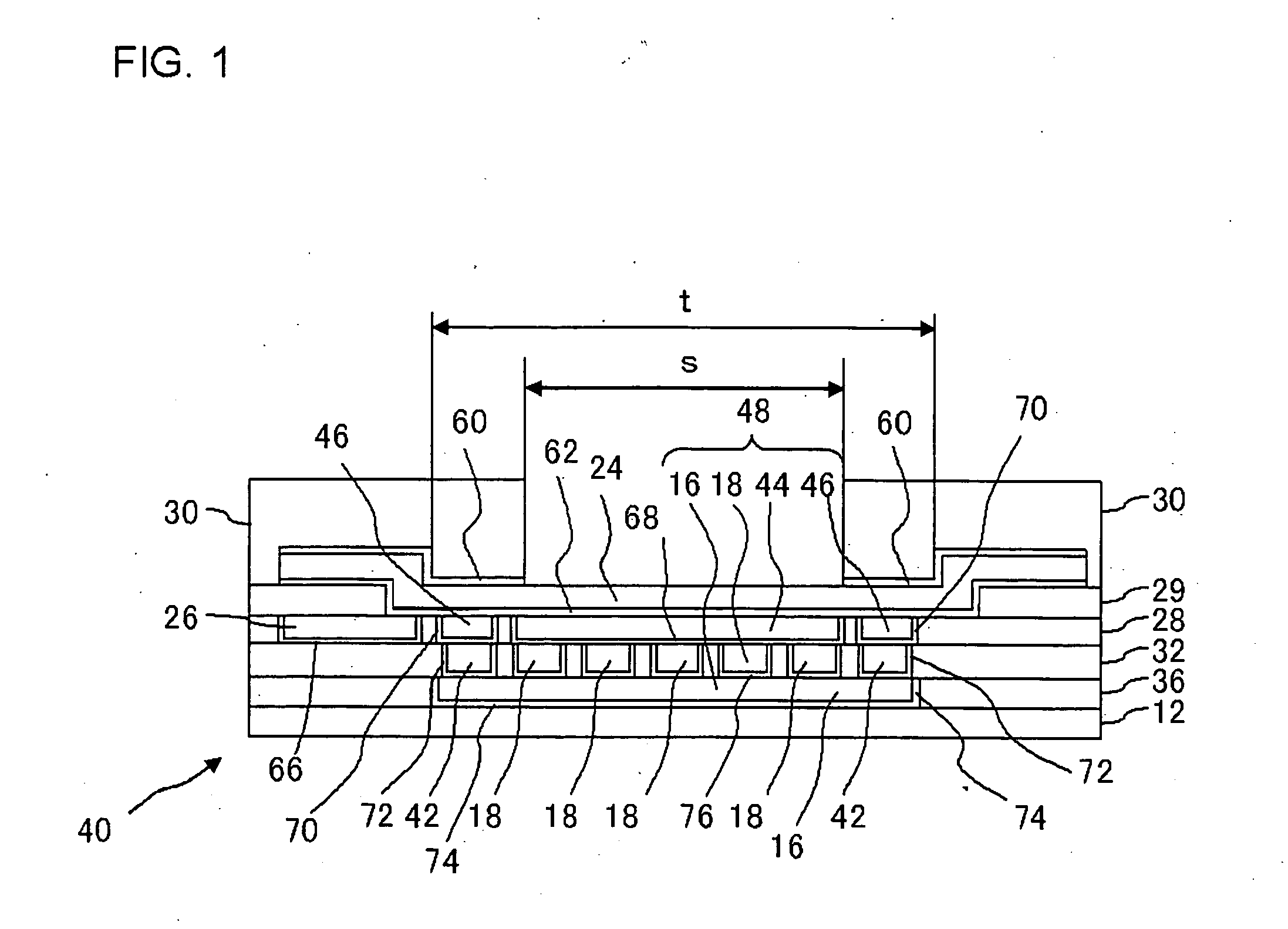

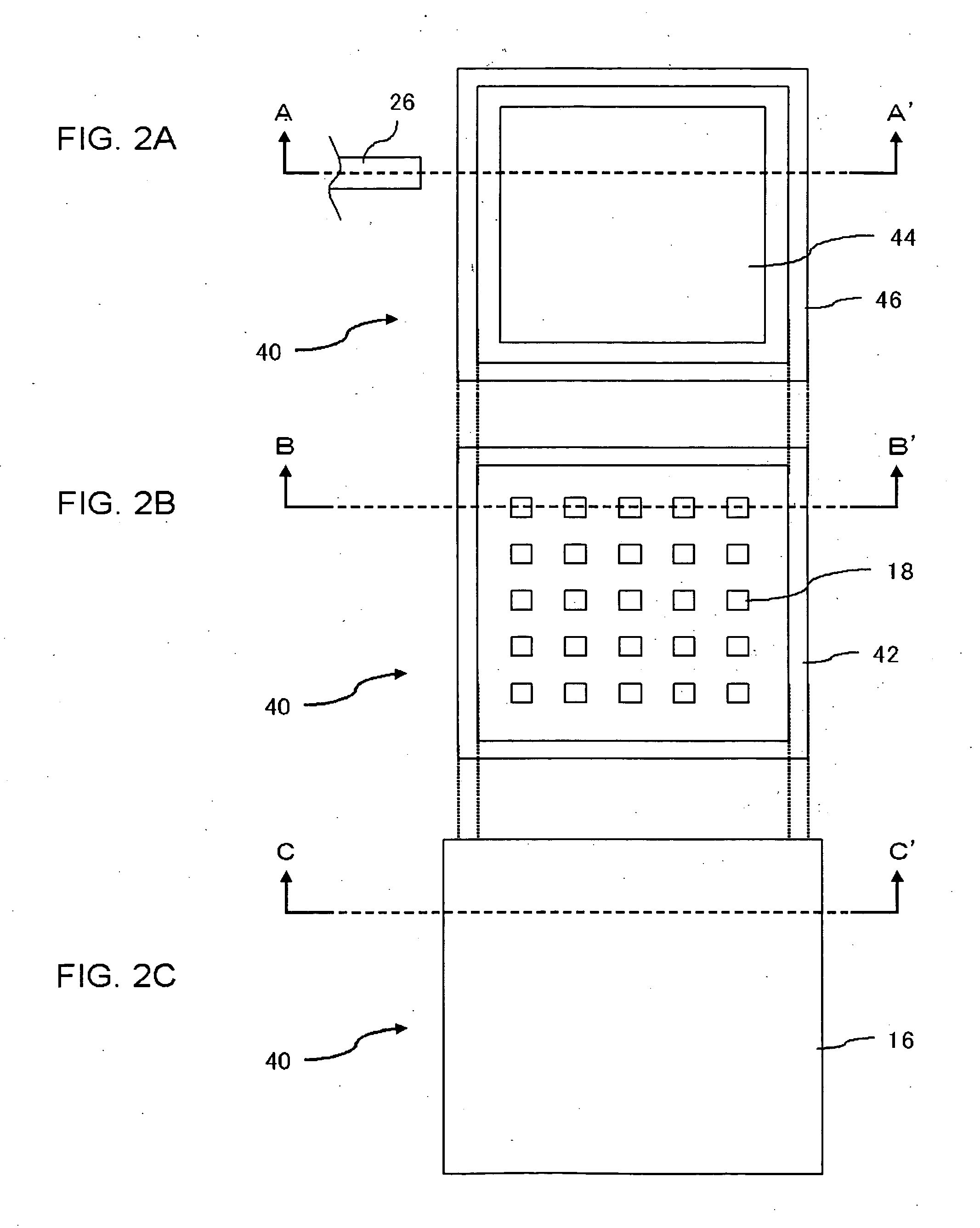

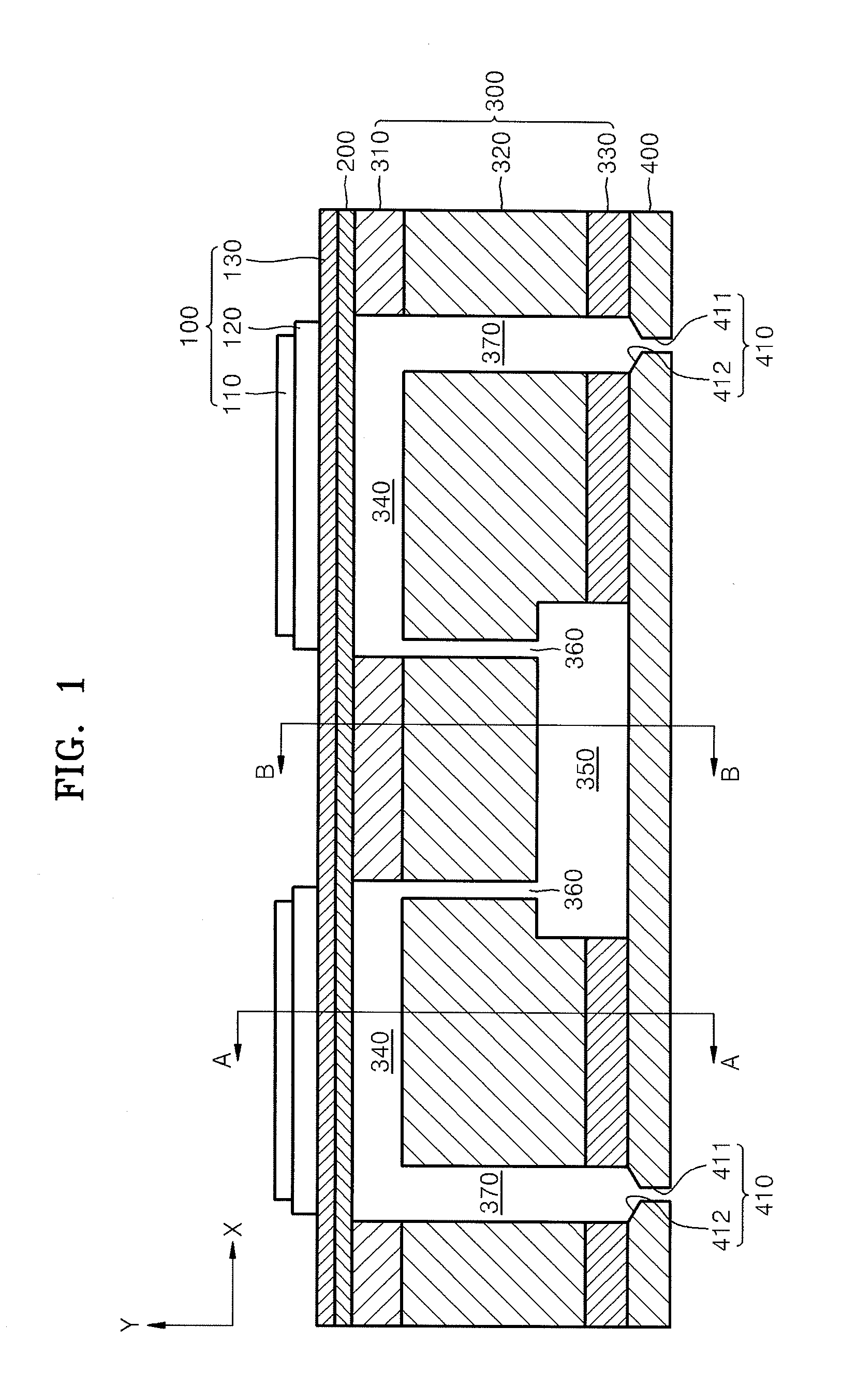

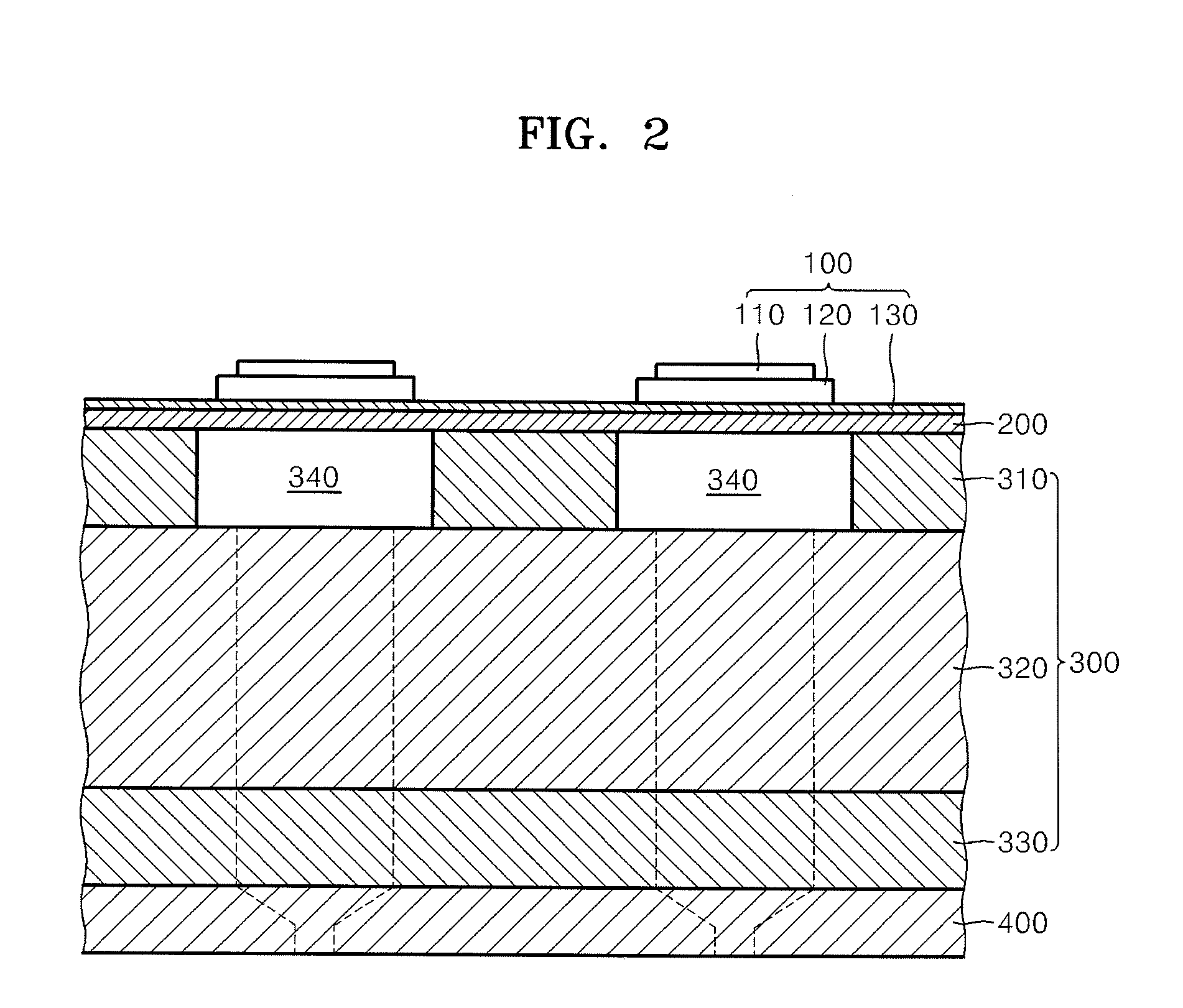

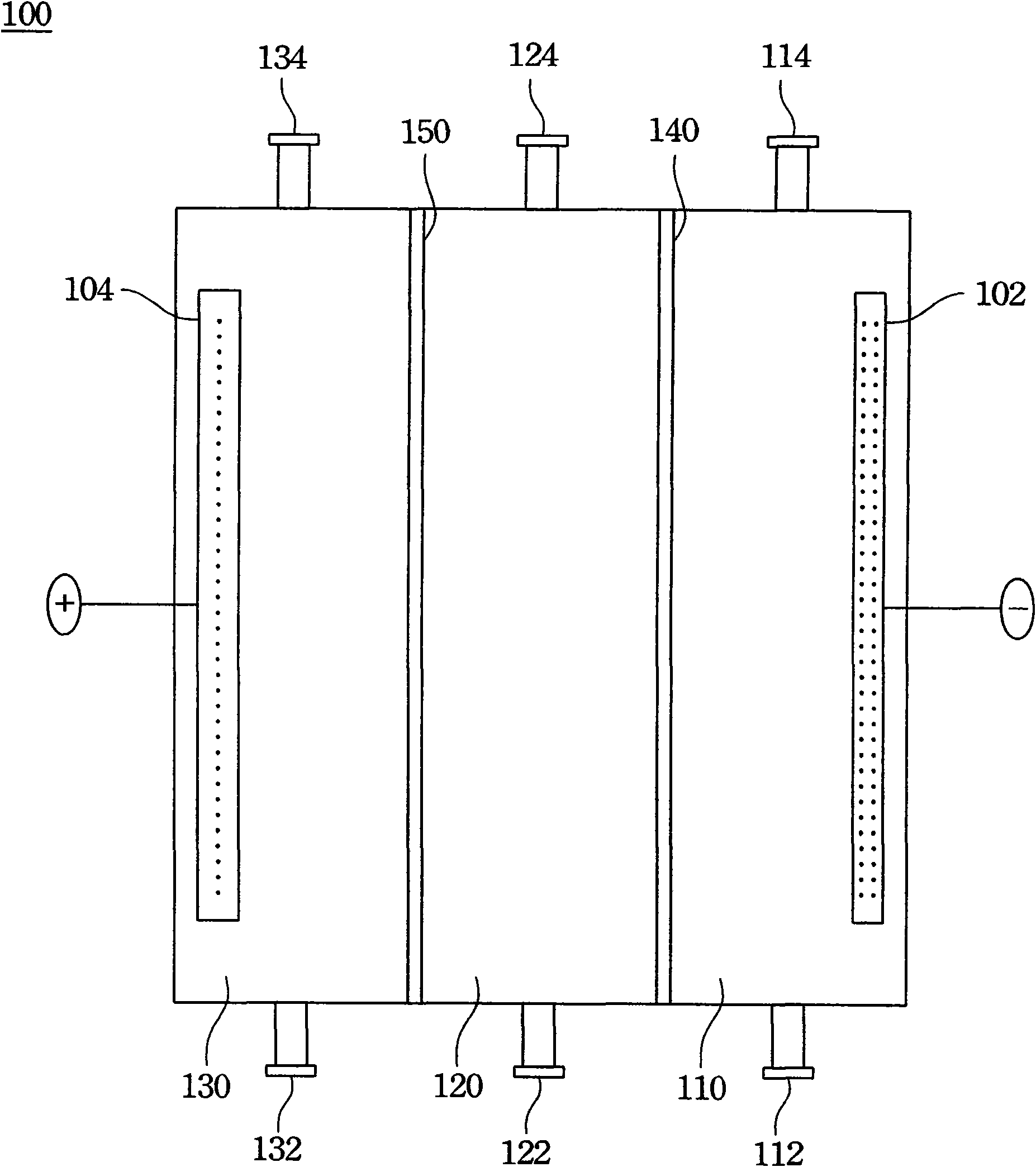

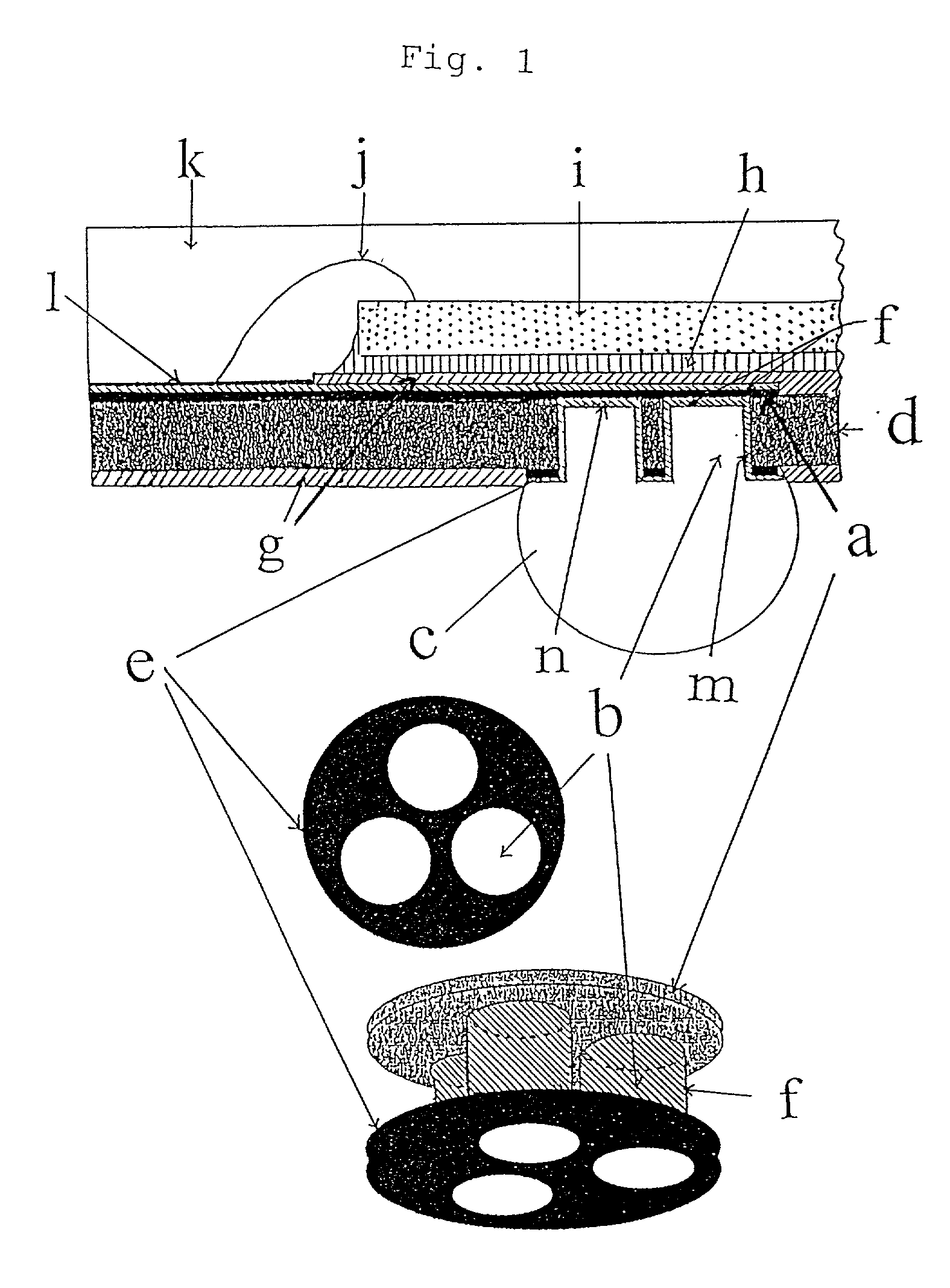

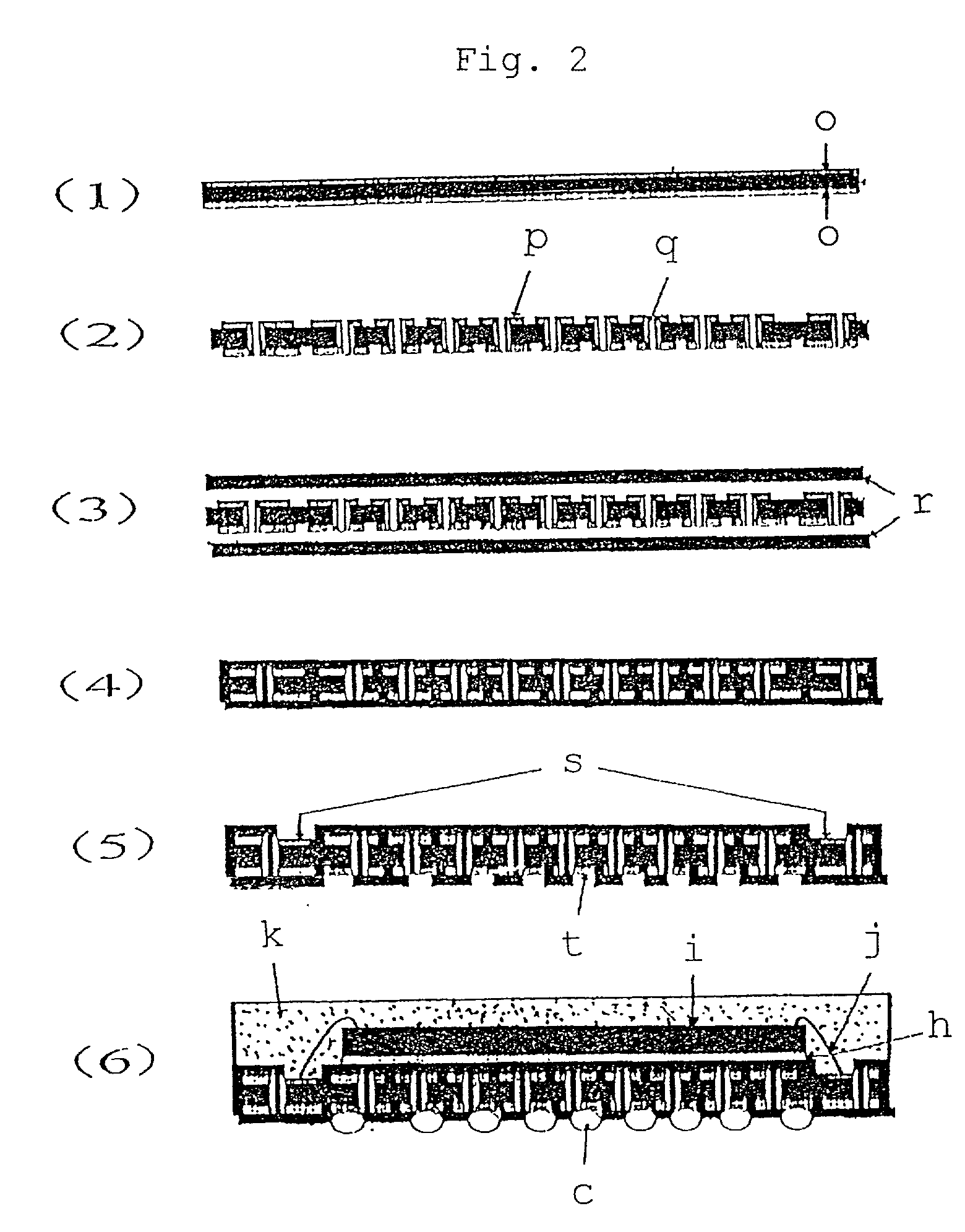

Piezo-electric type page width inkjet printhead and image forming apparatus having the same

InactiveUS20080136873A1Reduce manufacturing costInking apparatusOther printing apparatusPiezoelectric actuatorsPiezo electric

A piezo-electric type page width inkjet printhead includes an intermediate substrate that includes a pressure chamber to be filled with ink to be ejected, a manifold connected to an ink entrance hole to store ink that flows in through the ink entrance hole, a restrictor to connect the manifold to one end of the pressure chamber, and a damper formed through the intermediate substrate corresponding to the other end of the pressure chamber, a lower substrate including a nozzle formed through a portion of the lower substrate, which corresponds to the damper, to eject the ink, an upper substrate formed on the intermediate substrate to seal an upper side of the pressure chamber, and a piezoelectric actuator formed on the upper substrate to generate a driving power to the pressure chamber to eject the ink through the nozzle, wherein the intermediate substrate comprises a both-sided copper clad laminate plate comprising an upper copper film and a lower copper film that are respectively formed on top and bottom surfaces of the laminate plate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Copper-containing waste etching solution treatment method and etching solution regeneration method

InactiveCN102002729AEasy to handleWith recyclingPhotography auxillary processesProcess efficiency improvementSolution treatmentEtching

The invention provides a copper-containing waste etching solution treatment method. In the electrodialysis step, copper ions and ammonium ions contained in the copper-containing waste etching solution are removed for obtaining treatment solution with low copper content. The concentration of the copper ions in the treatment solution with the low copper content is not more than 1ppm. In the reduction step, the removed copper ions are reduced for producing copper, copper oxide and / or cuprous oxide, and the removed ammonium ions are reduced for producing ammonia gas. The invention further relates to an etching solution regeneration method.

Owner:KISMART

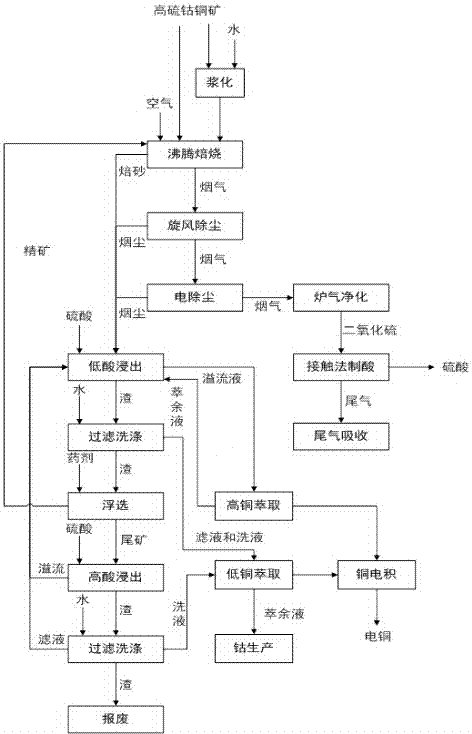

High-sulfur cobalt copper ore treatment process with low cost and high leaching rate

ActiveCN106916946ALow costWill not corrodePhotography auxillary processesFlotationExternal energySlag

The invention belongs to the technical field of metallurgy, and in particular, relates to a high-sulfur cobalt copper ore treatment process. The high-sulfur cobalt copper ore treatment process with low cost and high leaching rate mainly comprises such procedures as fluidized-bed roasting, low-acid leaching, flotation, high-acid leaching, high-copper extraction and low-copper extraction. The sulfation rates of cobalt and copper after fluidized-bed roasting of a high-sulfur cobalt copper ore are both higher than 85%; the leaching rates of cobalt and copper are both higher than 98%; the cobalt and copper grades of leaching slag are respectively lower than 0.15% and 0.30%; the roasting process is a self-heating process without replenishing external energy; the energy cost is low; steam generated by the ore fluidized-bed roasting can be used for heating wet leaching, fluidized-bed roasting of the high-sulfur cobalt copper ore, leaching and flotation; and other accessories are not needed besides of adding of few flotation reagents, so that the accessory cost is low, and such harmful elements as chlorine cannot be introduced to cause corrosion of equipment and degradation of a copper extracting agent.

Owner:ZHEJIANG HUAYOU COBALT

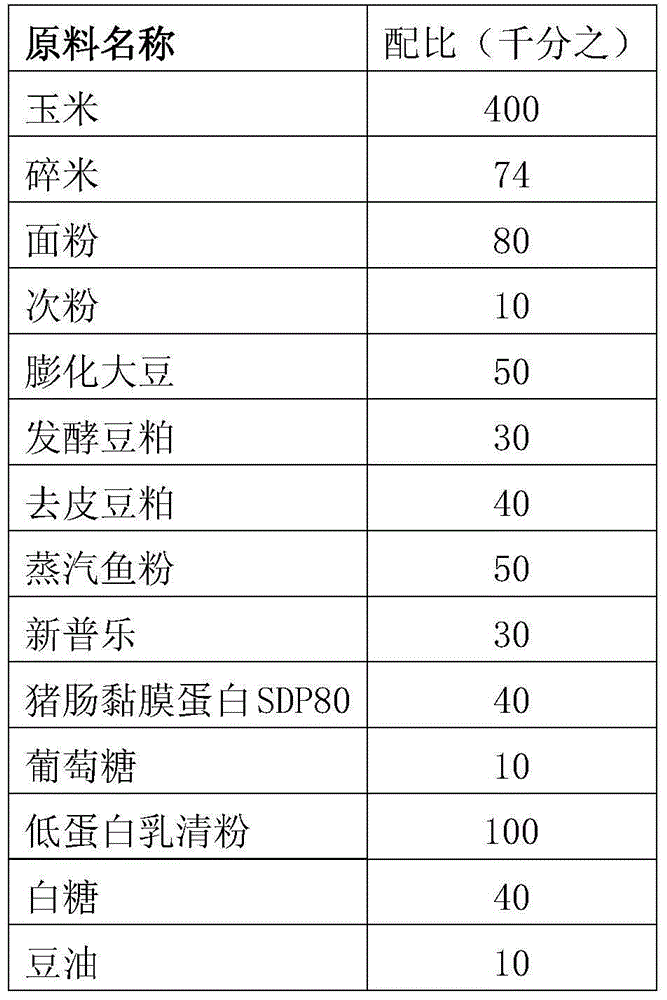

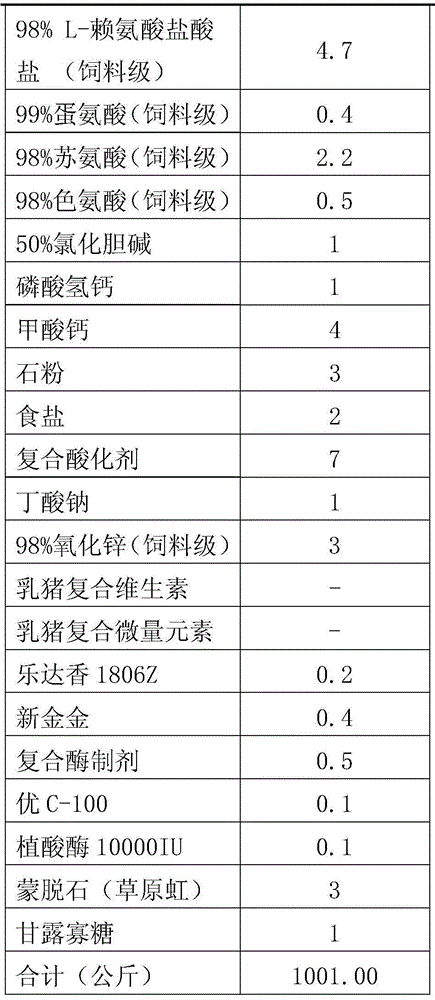

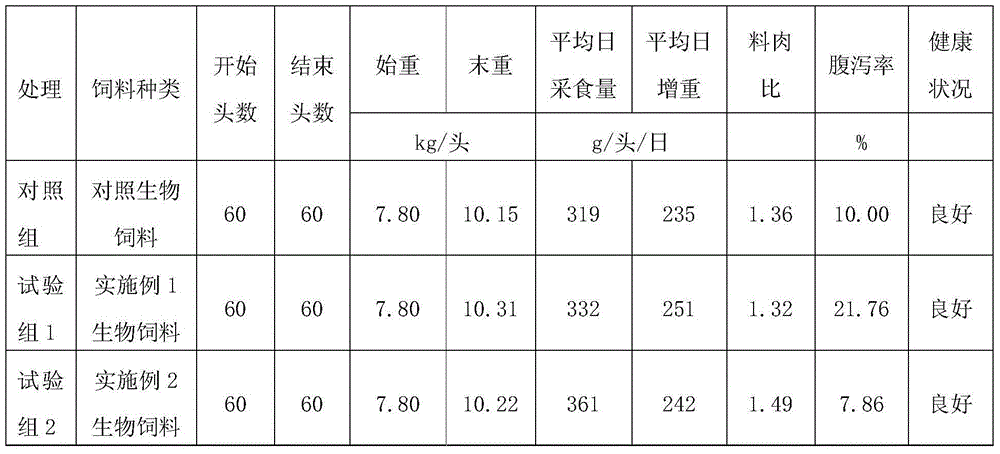

Safe low-copper biological compound feed free of antibiotics or plasma protein powder for suckling pigs

InactiveCN104543579AImprove immunityImprove palatabilityAnimal feeding stuffAnimal scienceFeed conversion ratio

The invention discloses a safe low-copper biological compound feed free of antibiotics or plasma protein powder for suckling pigs. The invention provides specific components and proportions of the biological feed, and application of the biological feed in improvement of daily gain, daily feed intake and / or feed conversion ratio. A biological composition free of the antibiotics or the plasma protein powder for the suckling pigs is developed from four aspects of improvement of the feed digestibility, improvement of the feed palatability, cultivation of intestinal flora and enhancement of the immunity of piglets according to the nutrient physiological characteristics of the suckling pigs; the selected raw materials are environmentally friendly and safe; a feeding experiment proves that the diarrhea rate is obviously reduced; the feed palatability is improved; the food intake and the daily gain are improved; and the biological compound feed disclosed by the invention is a safe, environment-friendly and efficient composition for the suckling pigs.

Owner:北京挑战牧业科技有限公司

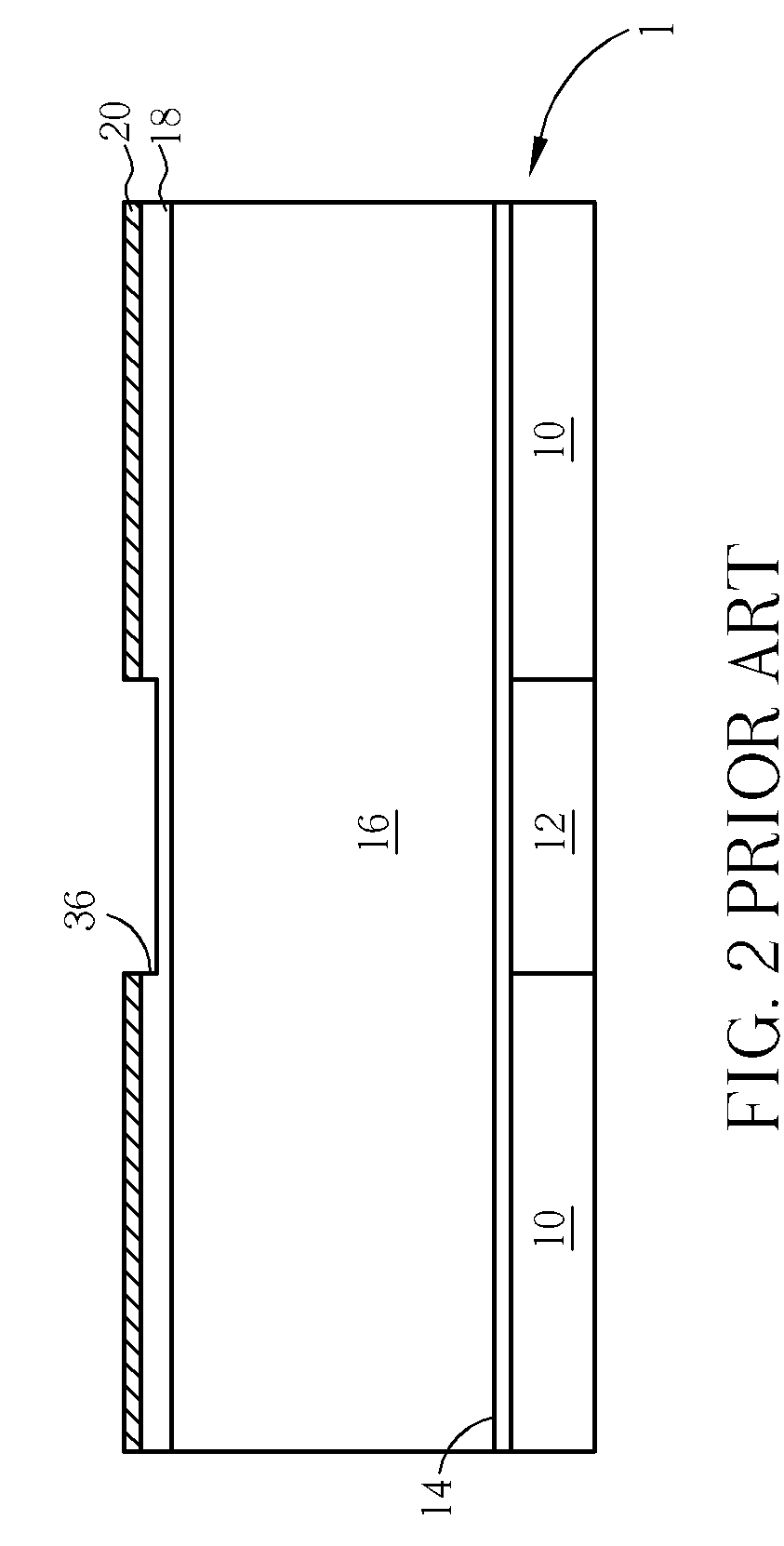

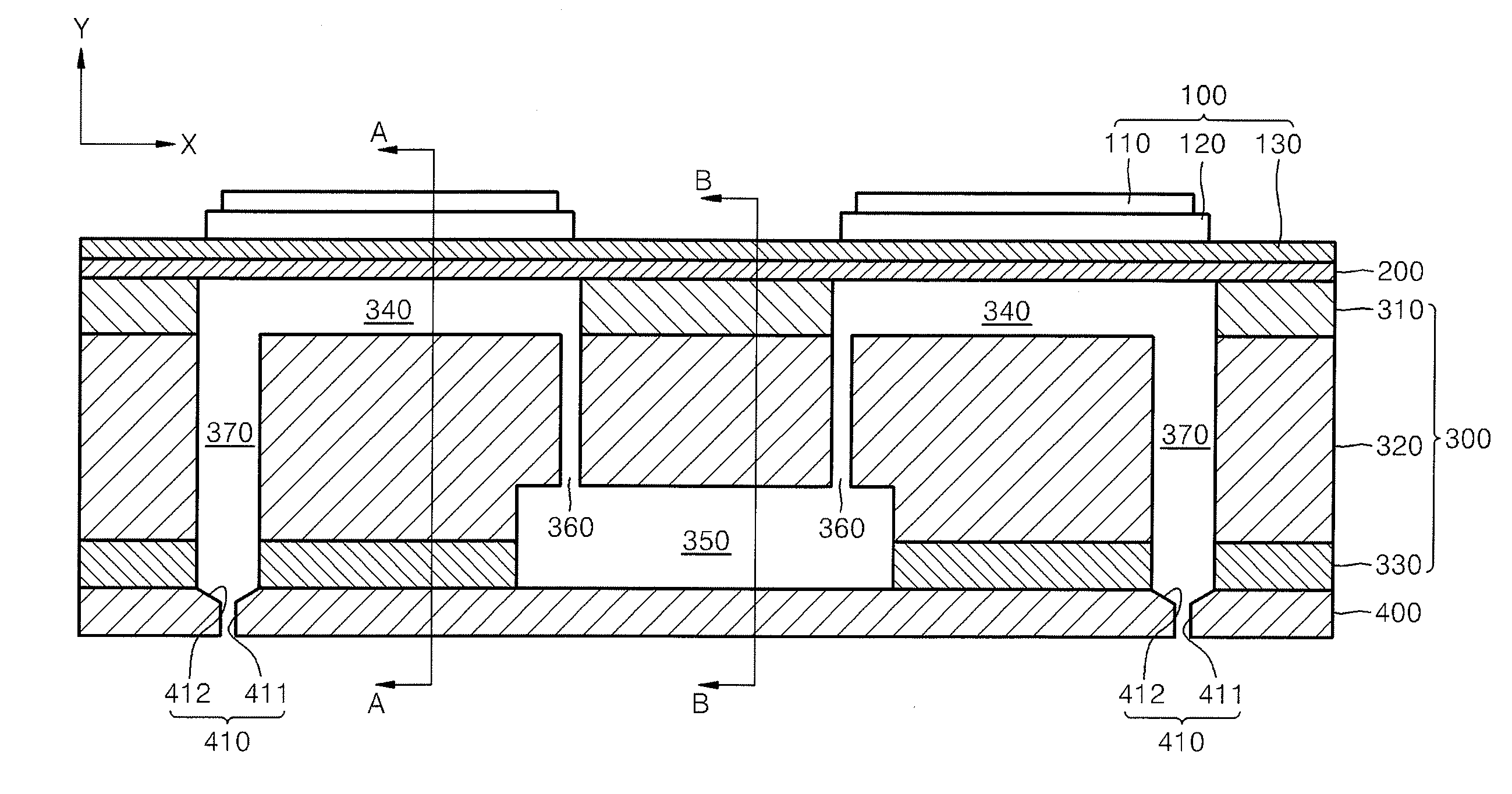

Printed wiring board for semiconductor plastic package

InactiveUS20020039644A1Reduce distortion problemsForm of distortionFinal product manufactureSemiconductor/solid-state device detailsInsulation layerLead bonding

Provided is a printed wiring board for a chip size scale package, which overcomes the poor adhesion of solder balls to a base material which poor adhesion is caused by a recent decrease in the size of the solder balls, and in the chip size scale package, the distortion of the printed wiring board is decreased and the distortion of a semiconductor plastic package formed by mounting a semiconductor chip on the printed wiring board by wire bonding or flip chip bonding is decreased. The printed wiring board has, as a substrate for a chip scale package, a double-side copper-clad laminate formed of an insulation layer and having copper foils on both surfaces, wherein the double-side copper-clad laminate has an upper copper foil surface and a lower copper foil surface, the upper copper foil surface has a wire bonding or flip chip bonding terminal and has a copper pad in a position where the copper pad can be electrically connected to said wire bonding or flip chip bonding terminal and can be connected to a blind via hole formed in the lower copper surface, the lower copper foil surface has a solder-balls-fixing pad in a position corresponding to said copper pad, the solder-balls-fixing pad has at least 2 blind via holes within itself, and the solder-balls-fixing pad connected to a reverse surface of the copper pad with a conductive material is electrically connected with solder balls which are melted and filled in blind via holes so as to be mounded.

Owner:MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com