Patents

Literature

111results about How to "With recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

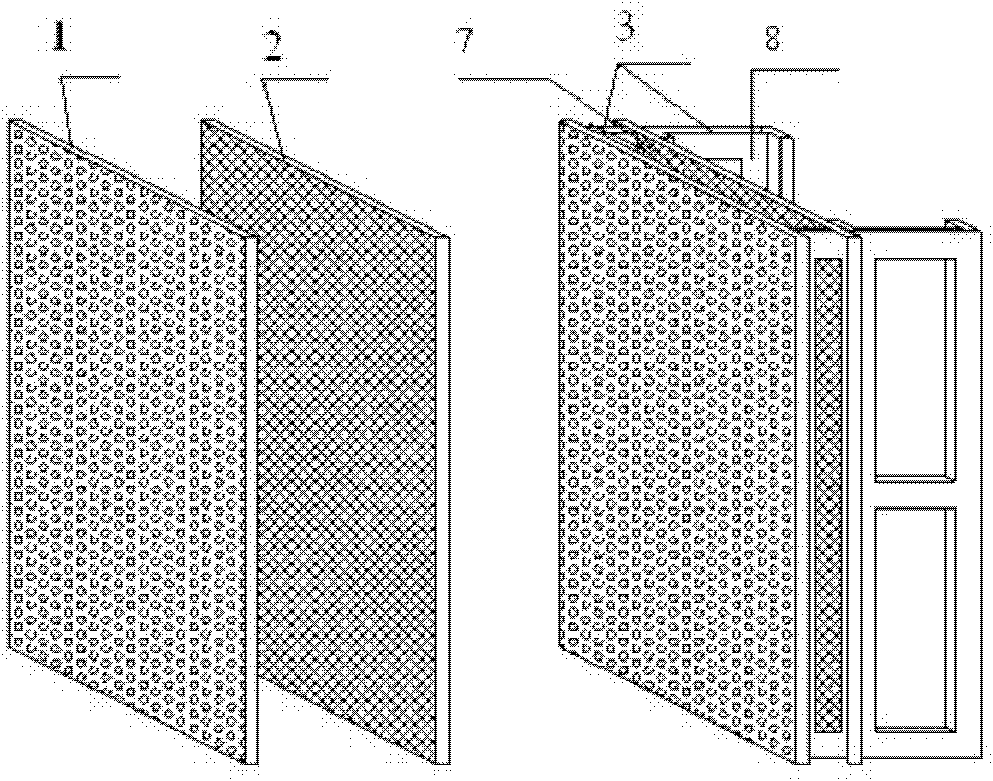

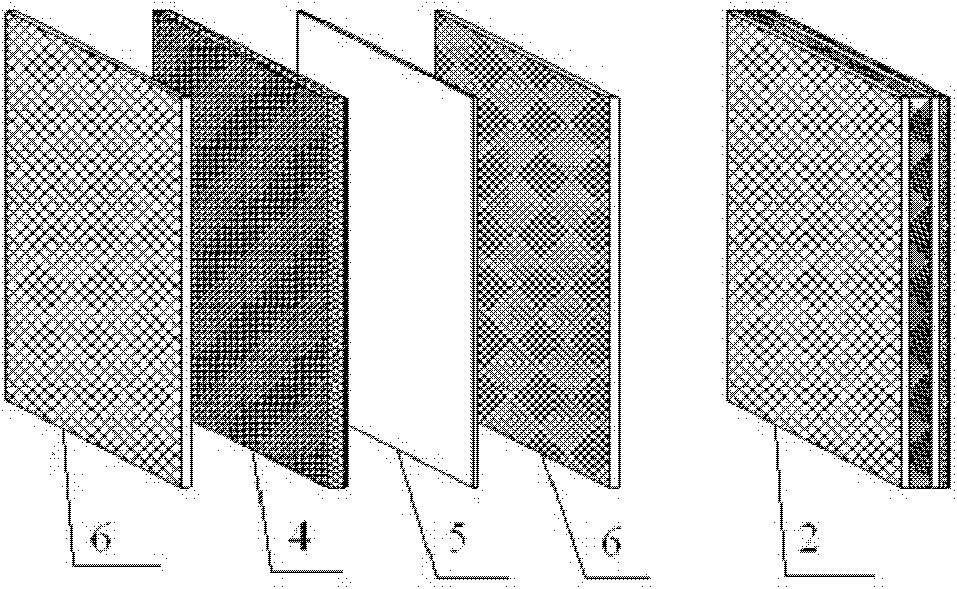

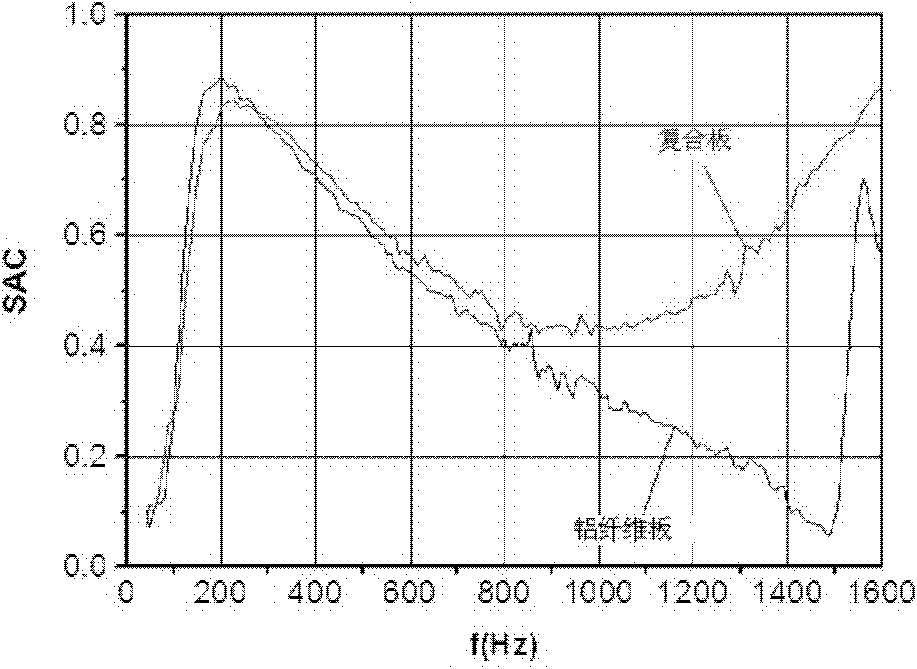

Microporous-fiber composite sound absorbing board

ActiveCN102842303AImprove low-frequency sound absorption coefficientSound absorption frequency bandwidthSound producing devicesCompound aFiber

The invention provides a microporous-fiber composite sound absorbing board, belonging to the field of instruments for absorbing noises through adopting the resonance principle. The sound absorbing board has a good low-frequency sound absorbing effect, and the sound absorbing coefficient of the sound absorbing board is larger than 0.5 at 125Hz. Compared with an aluminum fiber absorbing board, the sound absorbing board has a wider absorbing absorption band. The sound absorbing coefficient of the sound absorbing board is not smaller than 0.4 at 250-1600Hz. The composite sound absorbing board is formed by compounding a micro-perforated board with an aluminum fiber board and adopts a double-resonance coupling structure. The micro-perforated board is connected with the aluminum fiber board through a keel frame to form a first resonating cavity, and the aluminum fiber board is connected with a wall through the keel frame to form a second resonating cavity. The micro-perforated board and the aluminum fiber board are coupled through a resonance peak to achieve the purposes of increasing the low-frequency sound absorbing effect and expanding the absorbing absorption band. The composite sound absorbing board adopting an all aluminum structure has the characteristic of good recycling, and the problems of aging, dropping and the like do not exist. The sound absorbing board also has the characteristic of good heat conduction, and is convenient for equipment to dissipate heat.

Owner:CHINA ELECTRIC POWER RES INST +3

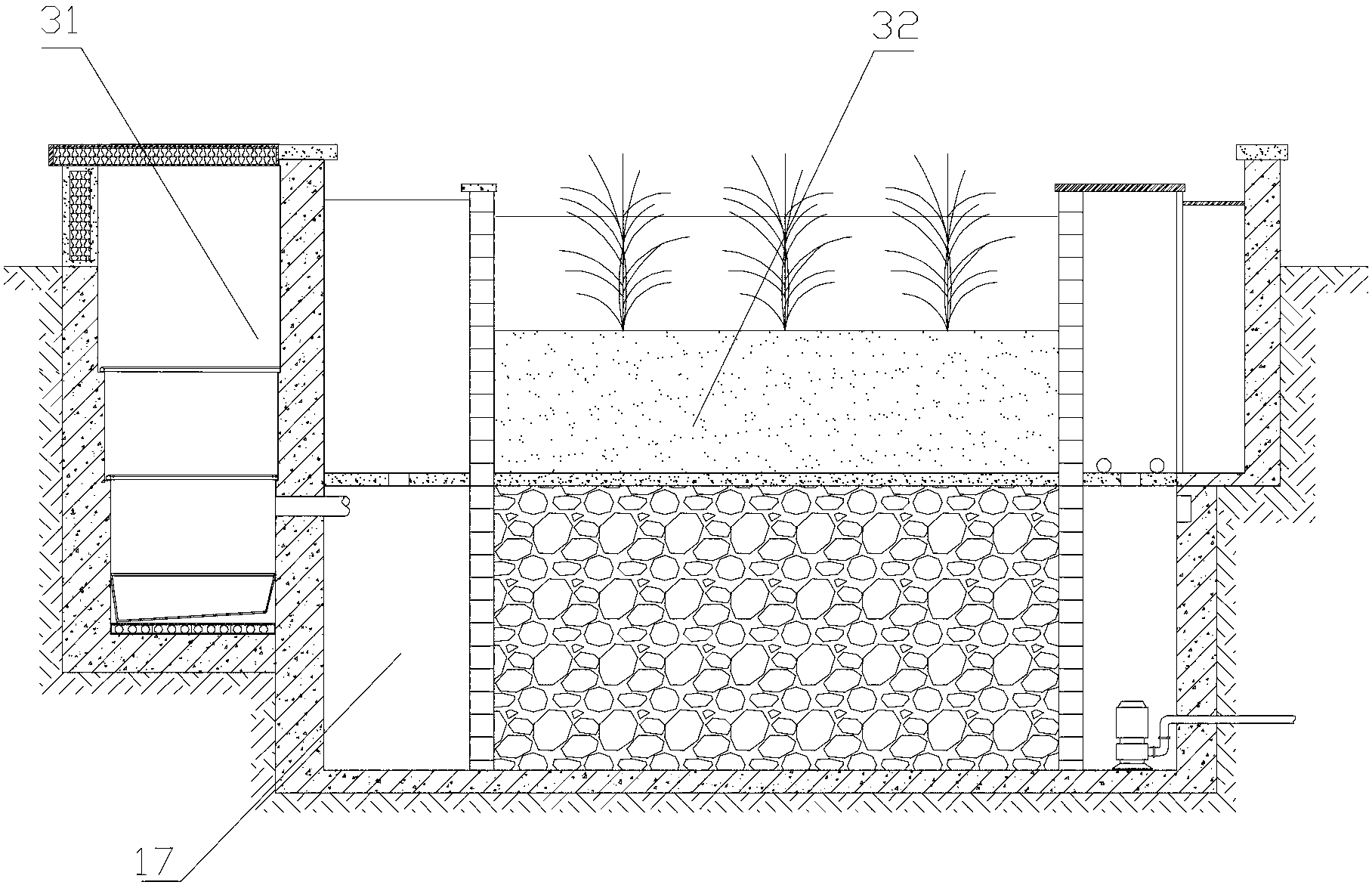

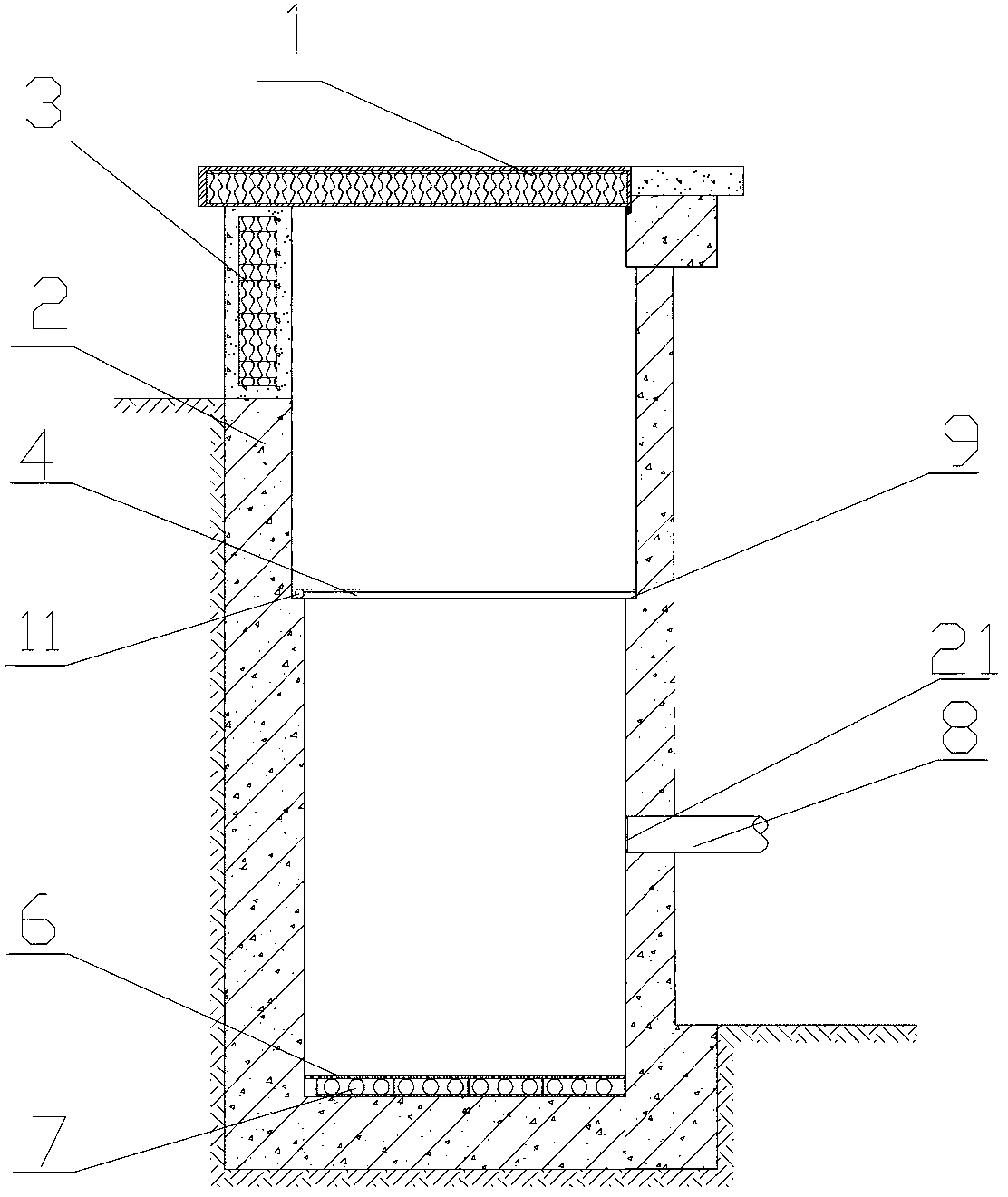

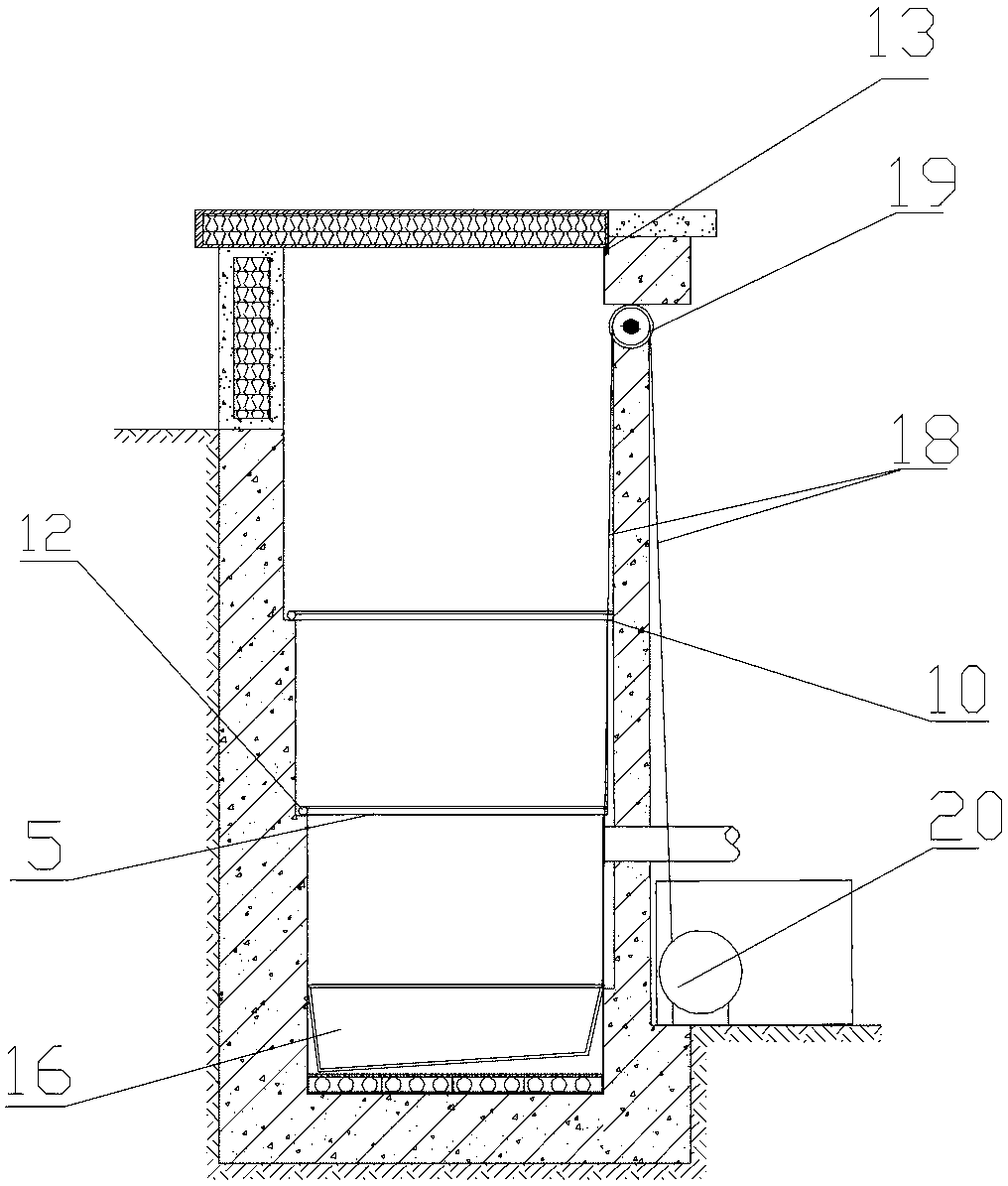

Hot-air circulating two-layered snow melting system and method for recycling accumulated snow

ActiveCN102704368AEasy on-site recyclingEasy to handlePaving detailsDrinking water installationConstructed wetlandSnowpack

The invention relates to a snow melting system and a method for recycling accumulated snow, particularly to a hot-air circulating two-layered snow melting system and the method for recycling accumulated snow, which solve the problems that the existing method for treating the accumulated snow wastes resource and pollutes the environment. The hot-air circulating two-layered snow melting system includes a two-layered subsurface-flow constructed wetland landscape pond and a snow melting well, wherein the snow melting well includes a thermal insulation cover, a well wall, a thermal insulation operation door, a heating grate A, a heating layer, a bottom heating pipe, a water drain pipe, a first step, a first rotating shaft, a heating vertical pipe, a groove and a filter grating. The method includes the following steps: collecting the accumulated snow, throwing the accumulated snow into the snow melting well through the thermal insulation operation door, and carrying the melted snow to the two-layered subsurface-flow pond through the deposited and overflowed clear water. The hot-air circulating two-layered snow melting system avoids the environmental pollution caused by snow melting agent, as well as the resource waste caused during accumulated snow transferring and toppling, is environment-friendly, facilitates the timely accumulated snow treatment, avoids the pollution caused by long-time exposure, and solves the road freezing problem caused by repeated freeze-thaw. The method is used for recycling the accumulated snow.

Owner:HARBIN INST OF TECH

High temperature resistant anti-salt solid-free environment protection drilling and completing fluids

ActiveCN101230259AReduce harmImprove heat and salt resistance stabilityDrilling compositionFiltrationPollution

The invention relates to a high temperature resistant salt-resistant no-solid-phase environment-friendly well completion drilling fluid, which can effectively overcome the shortcomings in the performance and the application of the prior well completion drilling fluid, in particular can avoid damage to stratum, and can meet the strict requirements for environment protection. The invention has the technical proposal that the well completion drilling fluid is made up from water, formate, viscosity increaser, filtration loss reducing agent, oil layer protective solute and polymeric-alcohol collapse preventing agent. The well completion drilling fluid is ensured to contain no solid-phase component, reduces the damage to the stratum greatly, has fine structural components, not only optimizes the overall performances of the system, but also improves the stability of heat resistance and salt resistance of the system. The constituents adopted by the invention are all water-soluble substances, the pollution on the environment caused by emissions is reduced, the system also can be recovered and recycled, and high-priced fluid preparing cost can be reduced greatly.

Owner:PETROSTAR OIL TECH

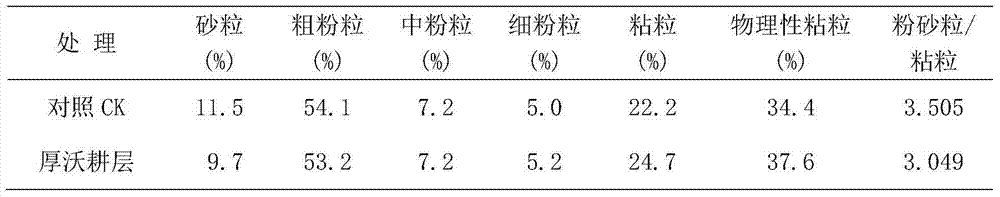

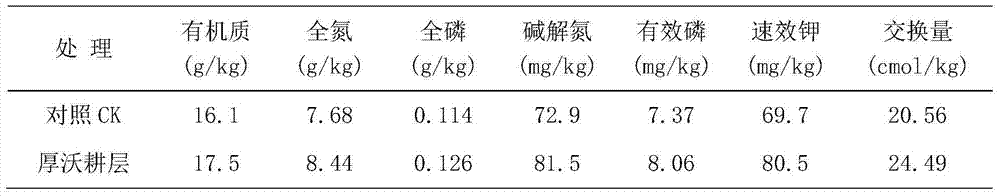

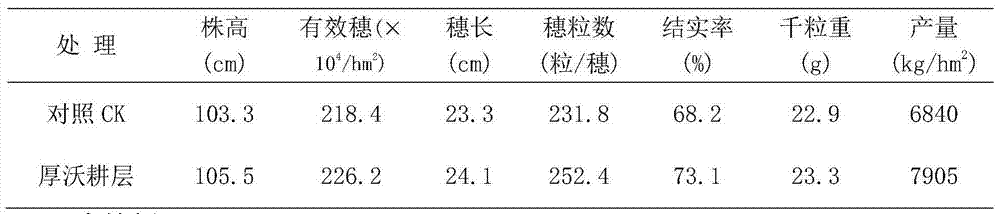

Method for deepening and fertilizing middle-low yield argil rice field plough layer

InactiveCN104718837AImprove fertilityDeepen the thicknessSoil-working methodsHazardous substancePhysics

The invention discloses a method for deepening and fertilizing a middle-low yield argil rice field plough layer in the hilly areas of south China. The technology for direct wheat straw field return for soil improvement, the technology for applying organic fertilizer, curing the plough layer and improving soil fertility, the technology for deeply ploughing soil to transform the bad soil structure of middle-low yield argil, the technology for applying a soil conditioner to neutralizing hazardous substances, the technology for rice optimization fertilizer application and nitrogenous fertilizer operation management for soil nutrient balance, the technology for improving the soil nutrient deficiency condition and recovering soil fertility through scientific crop rotation and the like are integrated.

Owner:INST OF SOIL & FERTILIZER ANHUI ACAD OF AGRI SCI

Double-layer plastic-wood composite material and preparation method thereof

InactiveCN101168262AAlleviate "white pollution"Reduce white pollutionDomestic articlesFlat articlesCouplingHost material

The invention discloses a two-level wood-plastic composite material and process for preparation. An inner core body of the composite material is compounded by coarse wood flour or agricultural straw powder and waste plastics. According to the percentage by weight, the coarse wood flour or the agricultural straw powder is 60-75%, and the waste plastic is 25-40%. When being combined, added coupling agent is additionally weighed and is 1-5% of the gross weight of main body materials, and lubricating agent is 0.5-5%. An outer layer is compounded by pure wood floor and novel plastic. According to the percentage by weight, the pure wood floor is 30-50%, and the novel plastic is 50-70%. When being combined, the added coupling agent is additionally weighed and is 1-5% of the gross weight of the main body materials, functional auxiliary agent is 1-5%, lubricating agent is 0.5-5%, and the thickness of the outer layer is equal or more than 3 millimeters. The process for preparing the composite material has the steps of raw material preparation, mixing granulation, extrusion molding, shaping, cooling, pulling, cutting and the like. The two-level wood-plastic composite material of the invention has the advantages of wood property and plastics property.

Owner:XIAN UNIV OF TECH

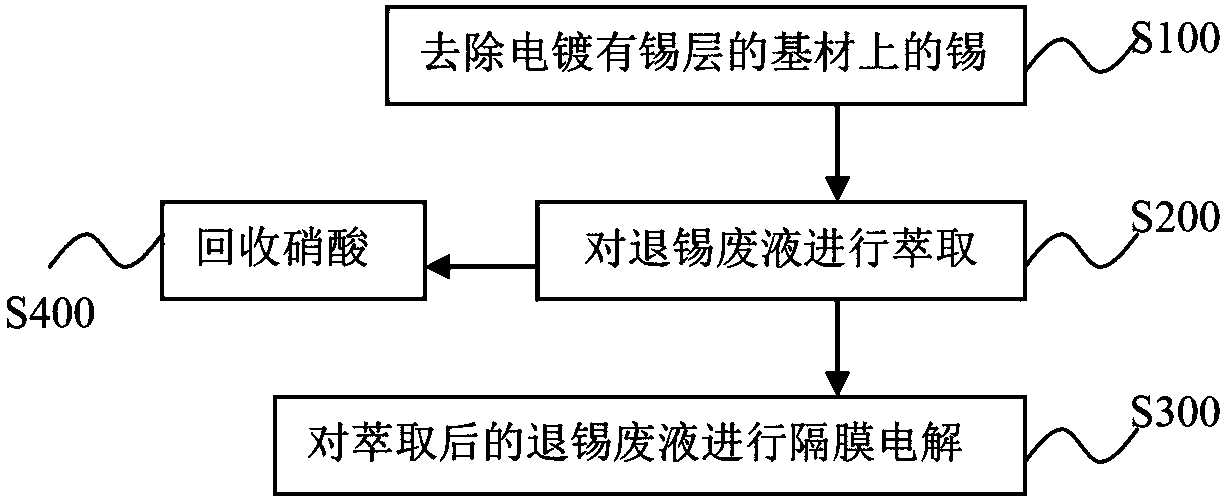

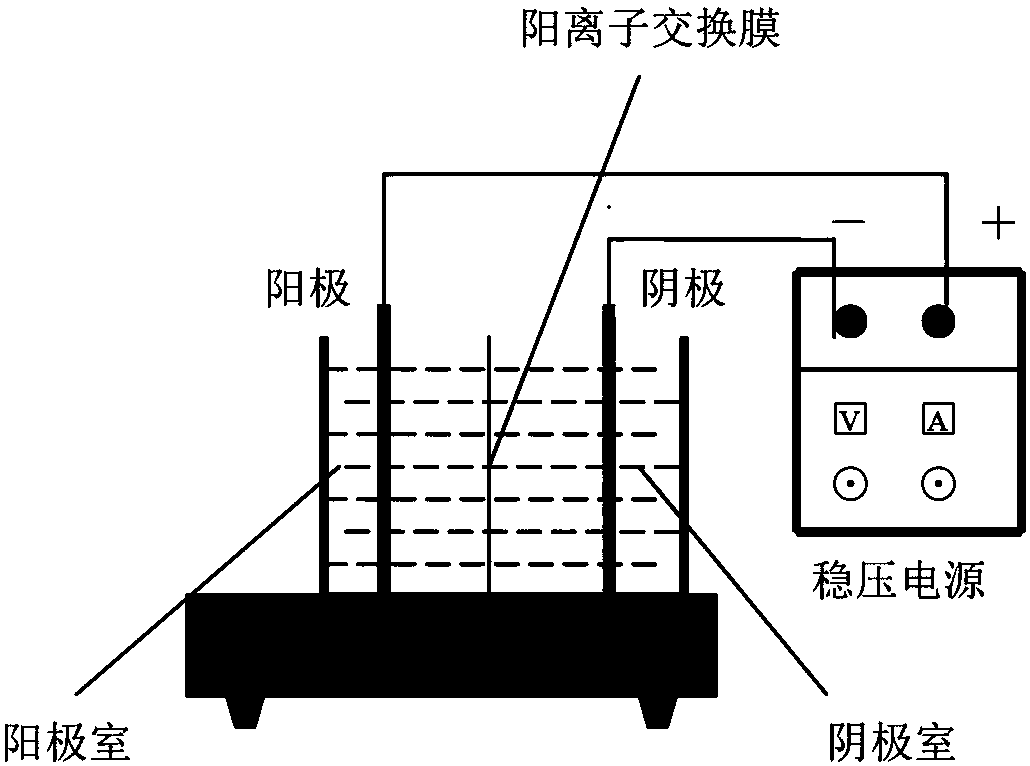

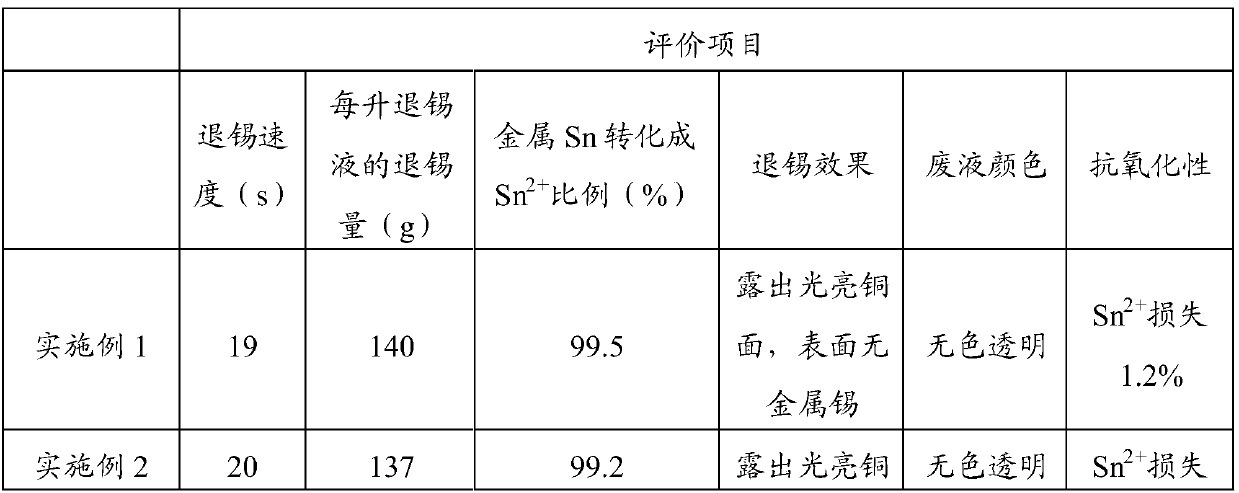

Tin stripping liquid, method for removing tin-containing layer on base material and method for recycling simple substance tin

ActiveCN107686893AWith regenerationHas zero emissionsPhotography auxillary processesProcess efficiency improvementLiquid wasteElectrolysis

The invention discloses a method for recycling simple substance tin. The method for recycling the simple substance tin comprises the steps that a tin-containing layer on a base material is removed byusing tin stripping liquid to obtain tin stripping waste liquid, wherein the tin stripping liquid comprises nitric acid with the concentration being 5 g / L-100 g / L, a complexing agent with the concentration being 70 g / L-640 g / L, a stabilizer with the concentration being 10 g / L-150 g / L and an antioxidant with the concentration being 0.5 g / L-25 g / L, wherein the stabilizer comprises at least one of carboxylic acid compounds, urea compounds and amino acids; an extractant and the tin stripping waste liquid are mixed to make the nitric acid in the tin stripping waste liquid enter the extractant, andseparation is conducted to obtain the extracted tin stripping waste liquid and extraction liquid containing the extractant and the nitric acid; and diaphragm electrolysis is conducted on the extractedtin stripping waste liquid to obtain the simple substance tin. The method for recycling the simple substance tin has the advantages of regenerating and recycling of the waste liquid and zero discharge of the waste liquid.

Owner:苏州金易得环保科技有限公司

Hyperelastic three-dimensional (3D) printing nano-crystalline cellulose composite material and preparation method thereof

ActiveCN111452352AHigh elasticity, excellent anti-fatigue compression performanceLow costAdditive manufacturing apparatusAdditive manufacturing with liquidsComposite materialPolymer chemistry

The invention relates to a hyperelastic three-dimensional (3D) printing nano-crystalline cellulose composite material and a preparation method thereof. The preparation method comprises the following steps of mixing a nano-crystalline cellulose water solution with the concentration ranging from 1.5 to 12 percent by weight and inorganic nano-particles, carrying out 3D printing forming after homogenization treatment, steeping printing hydrogel with hygroscopic salt, freeze drying for forming, and obtaining the hyperelastic 3D printing nano-crystalline cellulose composite material. The antifatiguehyperelastic 3D composite material provided by the invention has a broad application prospect in the aspects such as substance adsorption, water collection and bioengineering.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

Method for absorbing carbon dioxide by using mixed solution containing ionic liquid

InactiveCN102600715AWill not polluteImprove pollutionDispersed particle separationAir quality improvementSolubilityTetrafluoroborate

The invention relates to a method for absorbing carbon dioxide by using mixed solution containing ionic liquid, belonging to the technical field of carbon dioxide treatment. The mixed solution is mixed solution of ionic liquid A and ionic liquid B, or mixed solution of ionic liquid A or ionic liquid B and organic solvent C, wherein cations in the ionic liquid A are N, N-dialkyl imidazole cations and anions in the ionic liquid A are tetrafluoroborate radical anions, hexafluorophosphate radical anions or chloride ions; cations in the ionic liquid B are N, N-dialkyl imidazole cations and anions in the ionic liquid B are trifluoromethyl sulfamide anions; and the organic solvent C is methanol or acetone. The method comprises the steps of adding mixed solution containing the ionic liquid into a reaction kettle, vacuum pumping, feeding in CO2, keeping absorbing temperature to be 10-80 DEG C, agitating for absorption, and keeping CO2 balance pressure to be 0.01-10Mpa. The method for absorbing carbon dioxide by using mixed solution containing ionic liquid has the advantages that the solubility and the selectivity are higher and the defects of high volatility and high toxicity caused by a reason that pure organic solvent is used can be overcome at the same time.

Owner:BEIJING UNIV OF CHEM TECH

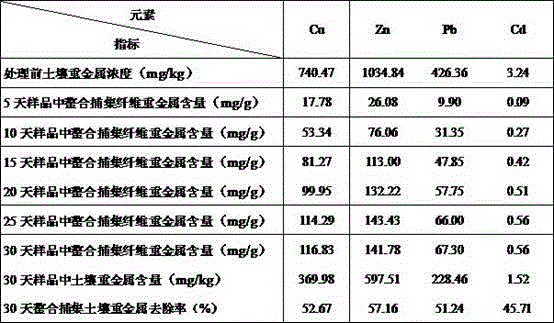

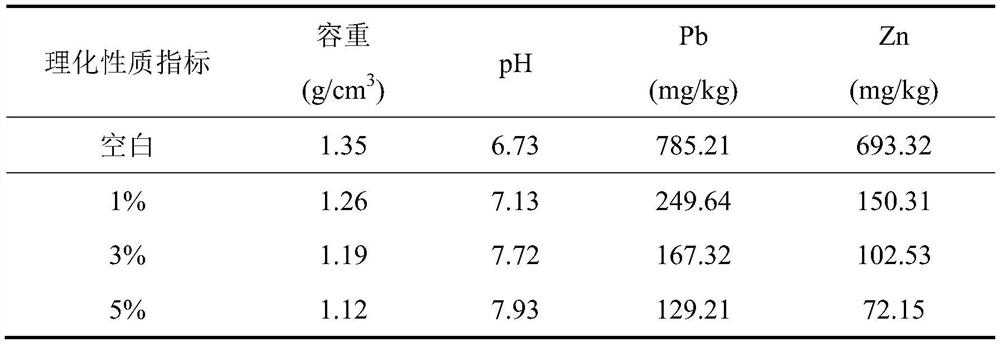

In-situ capturing treatment method for soil heavy metal pollution

ActiveCN105689371AImprove capture capacityProcessing speedContaminated soil reclamationHigh concentrationHeavy metal chelation

The invention discloses an in-situ capturing treatment method for soil heavy metal pollution. The method comprises the steps of 1 deep ploughing and cleaning-up of soil, 2 burying of chelating capturing materials, 3 dry and wet adjustment, 4 soil heavy metal activation, 5 removing of the chelating capturing materials, 6 activating and recycling of the chelating capturing materials, 7 soil microelement supplementing and the like. According to the method, the chelating capturing materials are used for effectively removing water-soluble heavy metal, exchangeable heavy metal and part of carbonate-exchangeable heavy metal in soil, and the main route of soil heavy metal environmental risk transfer is effectively interdicted. The heavy metal chelating capturing materials adopted in the method can effectively treat trace metal pollution, high-concentration heavy metal pollution and multi-metal combined pollution, and the chelating capturing materials obtained after treatment can be activated and recycled. In addition, the method has the beneficial effects of being easy to operate, capable of being used in combination with other restoring methods easily, good in treatment effect, low in cost, free of secondary environmental risks and the like.

Owner:SHENZHEN DUOYUAN TUOZHAN ENVIRONMENTAL PROTECTION TECH CO LTD

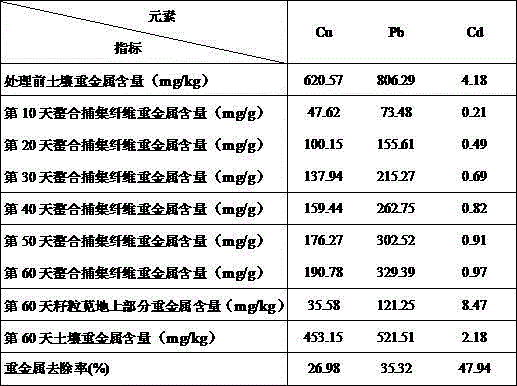

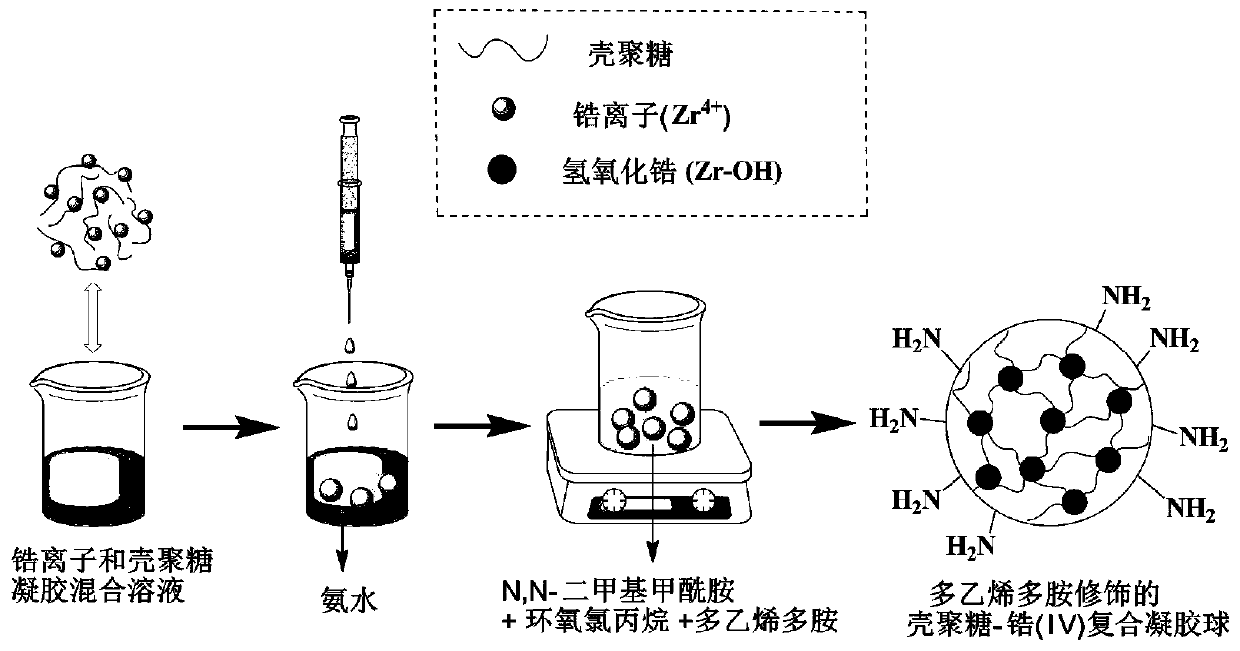

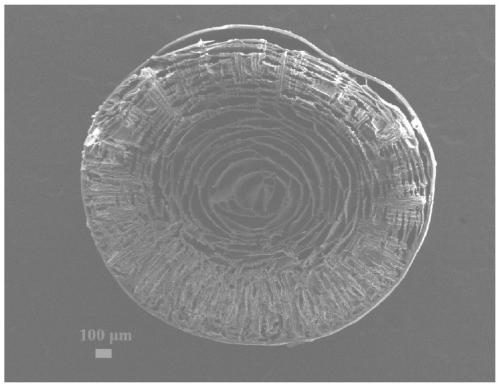

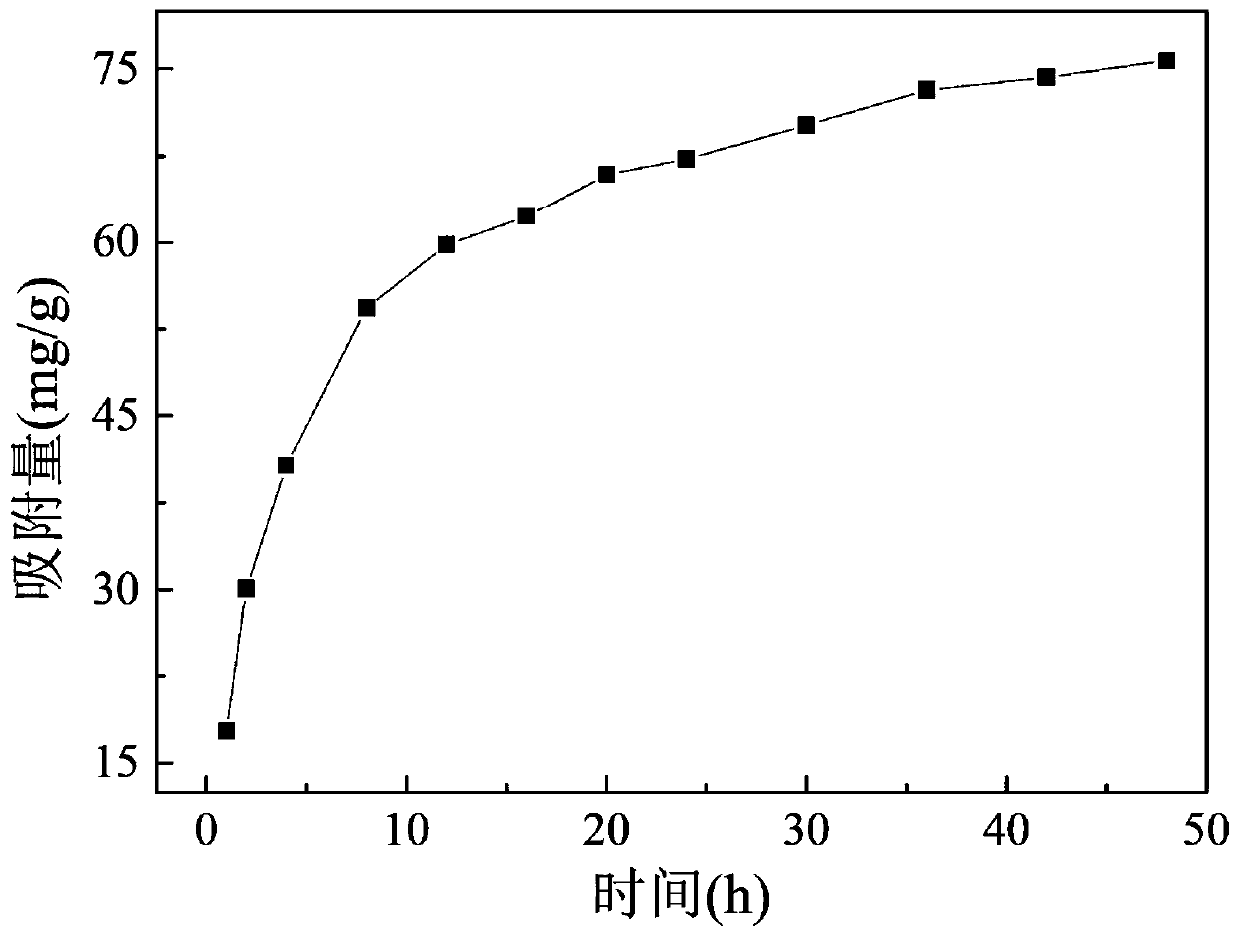

Amino-rich compound modified chitosan-zirconium composite gel ball as well as preparation and application thereof

InactiveCN111468076AWith recyclingHigh mechanical strengthOther chemical processesWater contaminantsPhysical chemistryChemistry

The invention relates to an amino-rich compound modified chitosan-zirconium composite gel ball as well as preparation and application thereof. An amino-rich compound is cross-linked and grafted on a chitosan-zirconium (IV) composite gel ball. The method comprises the following steps: adding an ammonia water solution into a precursor solution containing zirconium ions and chitosan gel to form chitosan-zirconium (IV) composite gel balls; preparing a mixed solution from the chitosan-zirconium (IV) composite gel balls, a cross-linking agent and the amino-rich compound, and heating for reaction toobtain the amino-rich compound modified chitosan-zirconium (IV) composite gel balls. Rich amino groups and zirconium (IV) with strong adsorption performance on phosphate radicals in water are introduced into the surface of the gel ball material; the prepared composite gel ball has good adsorption performance on phosphate radicals, the theoretical maximum adsorption capacity reaches up to 103.96 mg-P / g, the adsorption capacity is kept stable after the composite gel ball is repeatedly used for five times, and the composite gel ball has good column adsorption characteristics.

Owner:GUANGZHOU UNIVERSITY

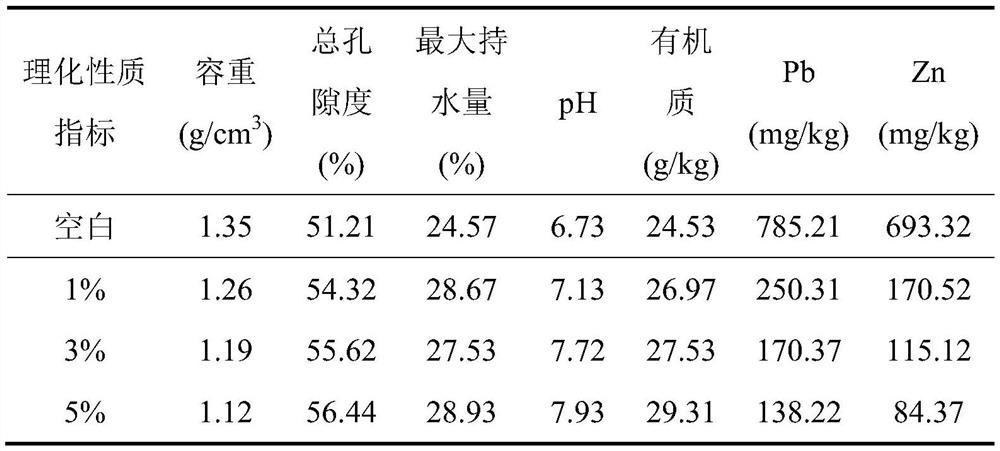

Carbon aerogel material, preparation method thereof, and application of carbon aerogel material as heavy metal contaminated soil remediation material

ActiveCN111876160AThe preparation method is simpleMild reaction conditionsOrganic fertilisersSoil conditioning compositionsFertilizerContaminated soils

The invention discloses a carbon aerogel material, a preparation method thereof, and an application of the carbon aerogel material as a heavy metal contaminated soil remediation material. The preparation method of the carbon aerogel material comprises the following steps: by taking linear phenolic resin as a raw material and metal chlorate as a template, forming gel by crosslinking the linear phenolic resin and forming an imprint by utilizing the metal chlorate; therefore, the carbon aerogel material which is developed in pore structure and large in specific surface area, contains polar groupsand has a similar molecular imprinting specific structure is obtained; the carbon aerogel material can achieve selective adsorption of heavy metal, has good water and fertilizer retention performance, can improve the volume weight of soil, and is particularly suitable for remediation of heavy metal contaminated soil.

Owner:WUHAN UNIV

Method for burning chlorine-containing waste liquid and chlorine-containing waste gas and treating tail gas

InactiveCN107559837AAdaptableEasy to operateIndirect carbon-dioxide mitigationIncinerator apparatusFlue gasNitrogen

The invention relates to a method for burning chlorine-containing waste liquid and chlorine-containing waste gas and treating tail gas. The method comprises the steps of furnace baking, burning of thewaste liquid and the waste gas, recycling of waste heat, removing of chlorine in a rapid cooling mode, nitrogen removing through hydrogen peroxide and alkaline cleaning for dust removing. Various forms of dangerous waste are treated through an incinerator, adaptability is high, operation is easy, safety and reliability are achieved, and operation is stable. The flue gas is subjected to removing of chlorine in a rapid cooling mode, removing of nitric oxide and alkaline cleaning for dust removing in sequence and then discharged into atmosphere, and the purpose of recycling a heat source is alsoachieved while environmental pollution is reduced.

Owner:西安山岳环保科技有限公司

Titanium dioxide/nanosilver/cocoon fiber magnetic porous composite material and preparation method thereof

The invention discloses a titanium dioxide / nanosilver / cocoon fiber magnetic porous composite material and a preparation method thereof. The preparation method comprises the following steps: modifying salix psammophila cellulose by using polydopamine; carrying out freeze-drying treatment by using liquid nitrogen to obtain the magnetic porous composite material; immersing the magnetic porous composite material into a mixed solution with a silver-ammonia solution and titanium dioxide nanotubes for reacting for 60-300 minutes, taking the magnetic porous composite material out of the mixed solution, then repeatedly washing the magnetic porous composite material with deionized water, and carrying out vacuum drying to obtain the magnetic porous composite material. According to the magnetic porous composite material, salix psammophila and cocoon fibers are used as base materials, so that raw materials are abundant and the cost is low; then magnetic nano ferroferric oxide, nanosilver and titanium dioxide nanotubes are effectively and synergistically self-assembled to obtain a porous nanocomposite material; the porous nanocomposite material has important application values in the fields such as adsorption materials, photocatalysis, biological materials and medical materials and the like.

Owner:钱景

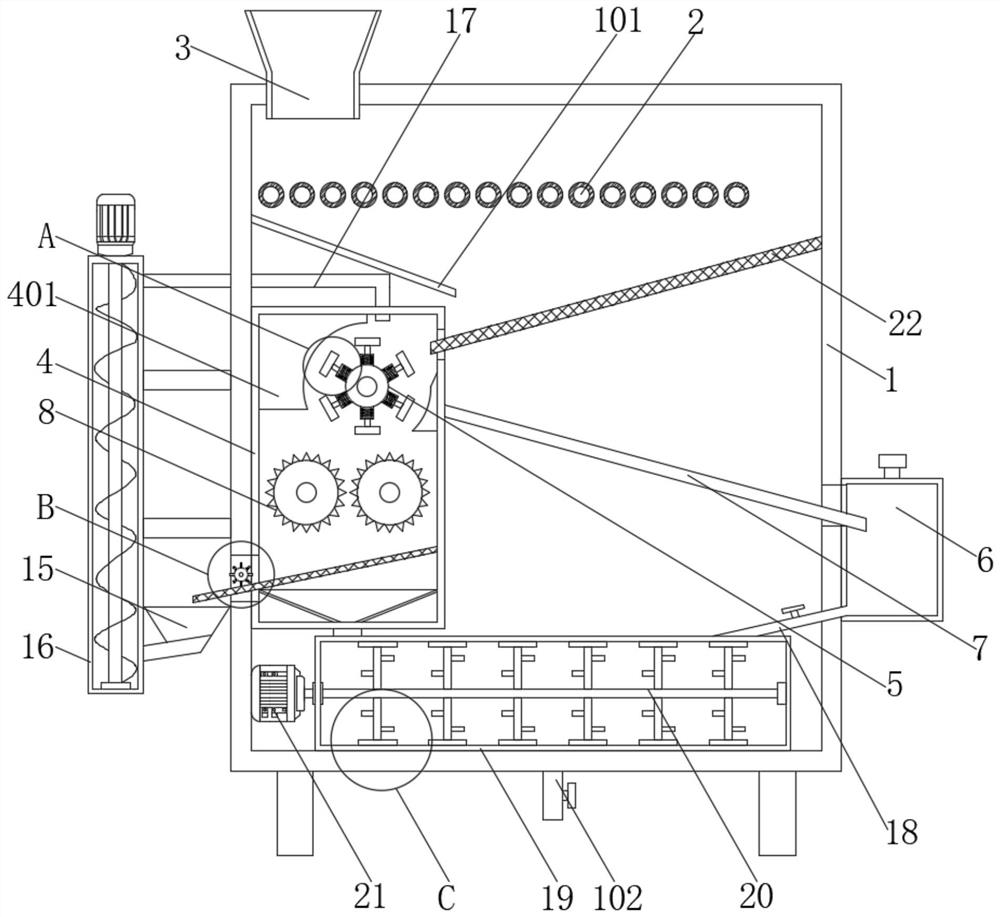

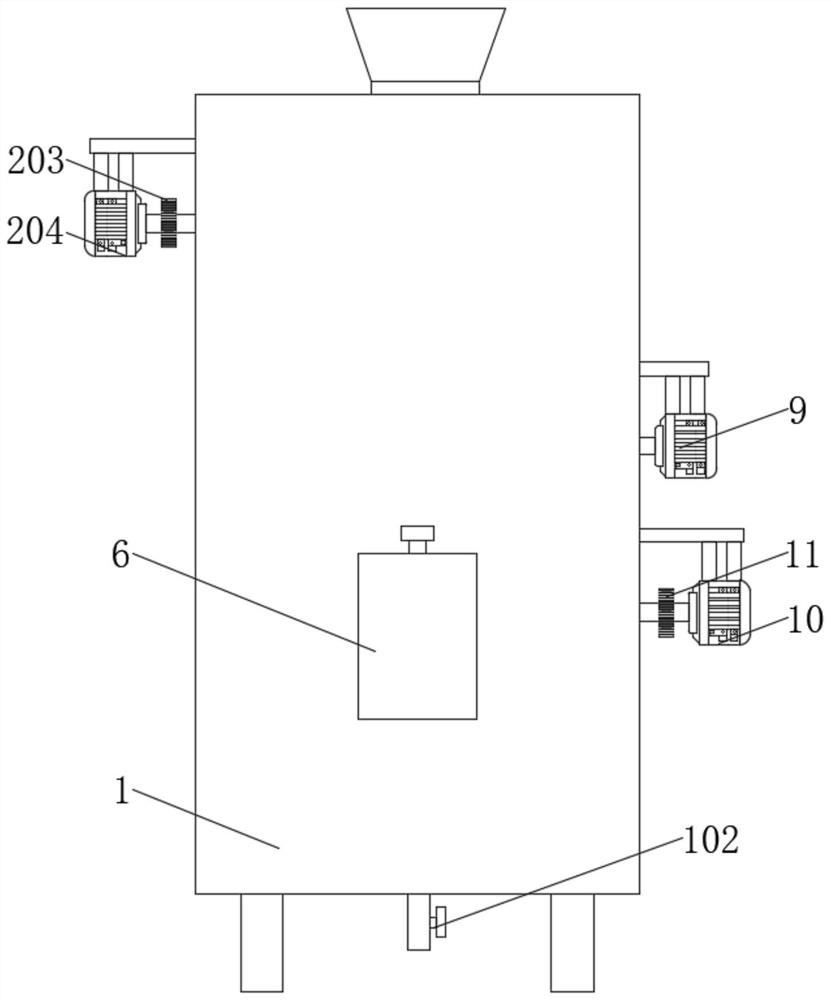

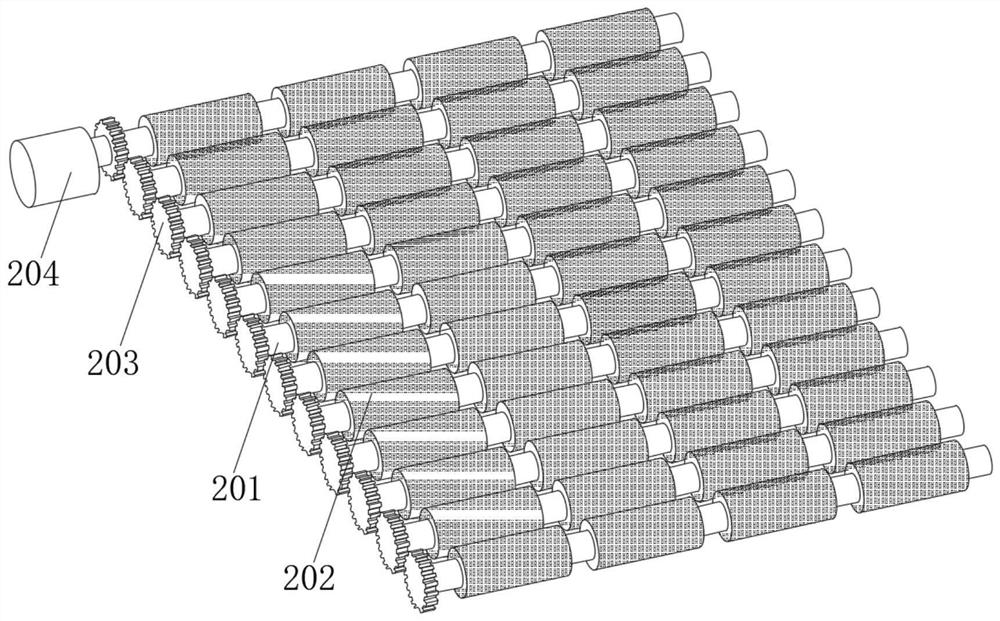

Equipment for cyclic regeneration of construction waste into garden soil and garden soil manufacturing process

ActiveCN112024047ARealize cyclic crushingEffective first filter collectionSievingGas current separationEnvironmental resource managementMechanical engineering

The invention discloses equipment for cyclic regeneration of construction waste into garden soil and a garden soil manufacturing process. The equipment comprises an equipment box, a crushing box is fixedly connected to the left side of the inner wall of the equipment box, a first filter plate is fixedly connected to the right side of the inner wall of the equipment box, a first material guide plate is fixedly connected to the right side of the crushing box, and the first material guide plate is arranged below the first filtering plate, sequentially penetrates through the equipment box and a collecting box and extends into the collecting box. The left side of the equipment box is fixedly connected with a spiral conveying piece, the right side of the spiral conveying piece communicates witha feeding hopper, the right side of the spiral conveying piece communicates with a conveying pipe, and the conveying pipe penetrates through the equipment box and communicates with the top of the crushing box. The first filtering plate and a second filtering plate are arranged for filtering in the two transportation processes correspondingly, construction waste meeting the size condition can be effectively filtered and collected in advance, and does not need to enter the crushing box for unnecessary crushing, energy is saved, and the efficiency is improved.

Owner:SHENZHEN LEIXIN LANDSCAPE & CONSTR CO LTD

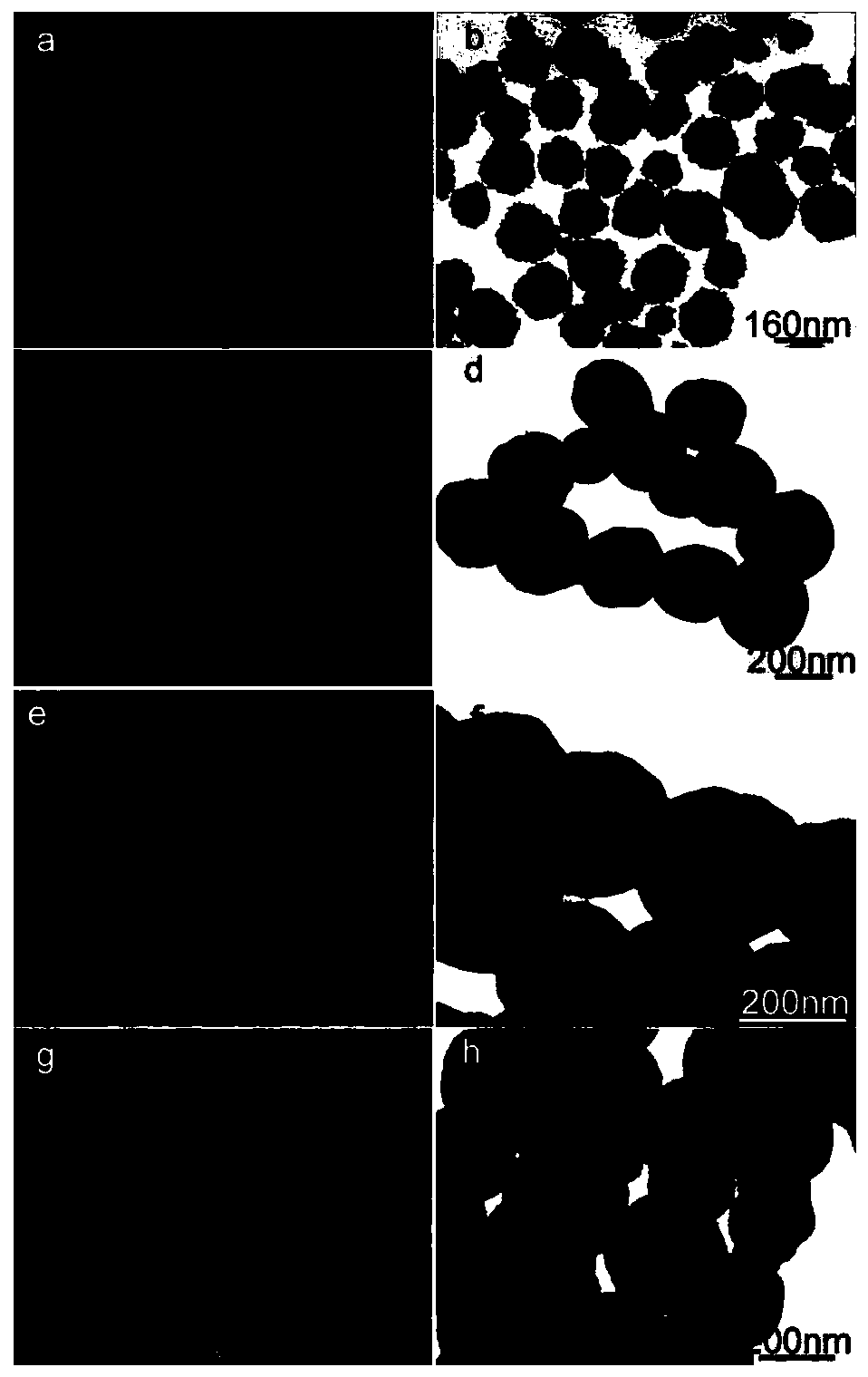

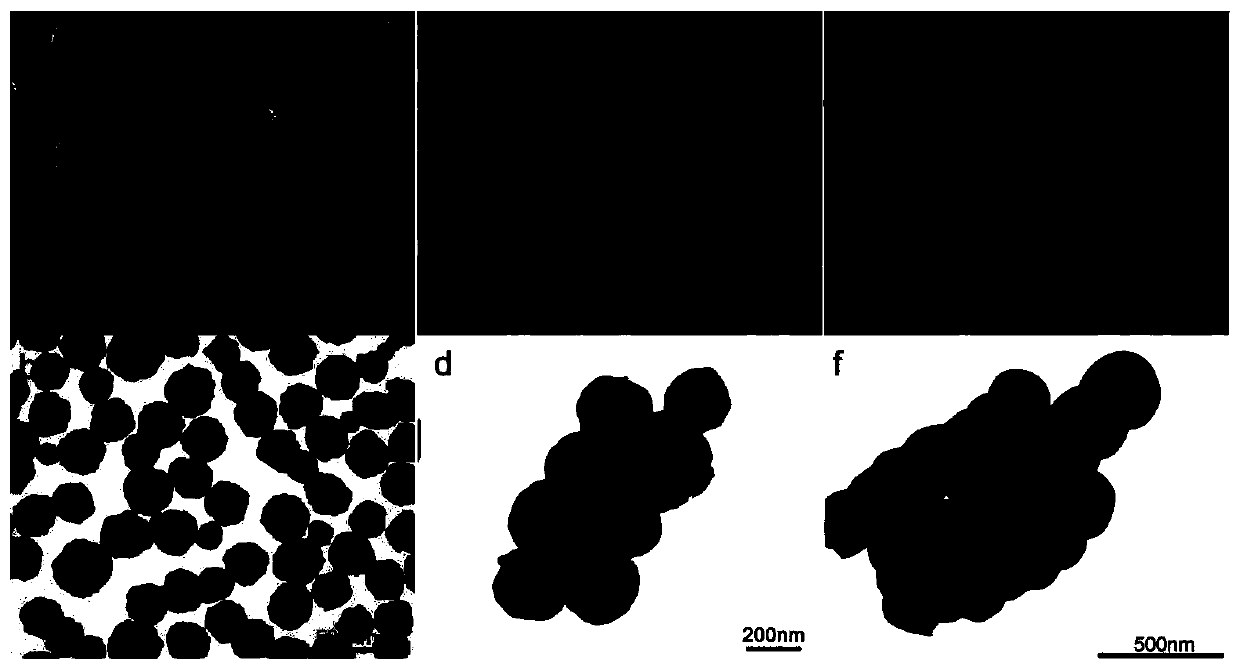

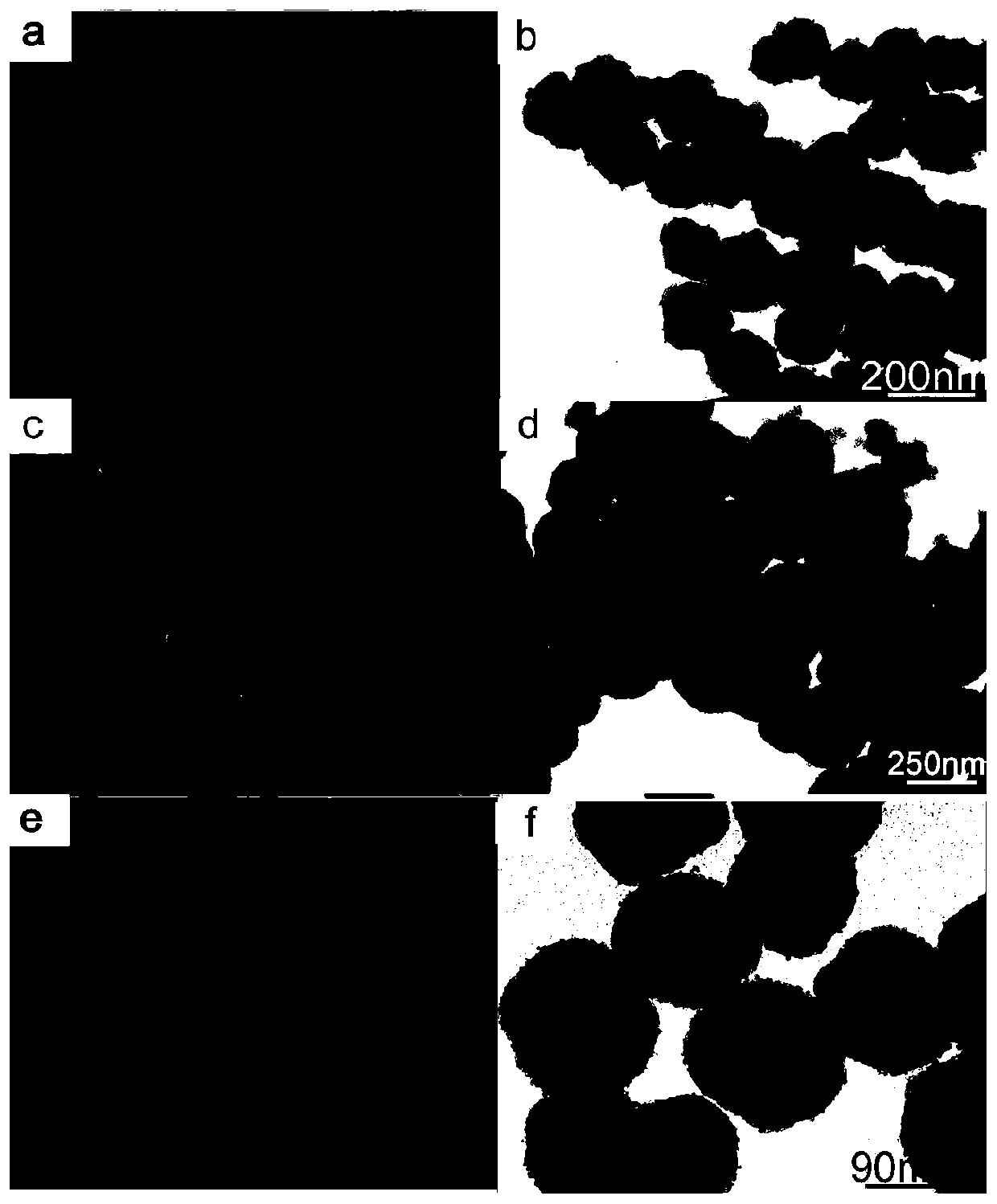

Preparation method and application of magnetic one-dimensional chain-shaped nano composite

ActiveCN109935430AEasy to operateSuitable for industrial mass productionMagnetic materialsMicrosphereParamagnetism

The invention discloses a preparation method of a magnetic one-dimensional chain-shaped nano composite. The method comprises preparation of Fe3O4 nano microspheres, preparation of Fe3O4@SiO2@PDA-Ni2+and preparation of Fe3O4@SiO2@C / Ni. The Fe3O4@SiO2@PDA-Ni<2+> is prepared by adding 80 to 120 mg of Fe3O4 nano microspheres into a mixed solvent composed of ethanol and water, adding ammonia water, placing the mixture in a magnetic field, stirring the mixture, adding ethyl orthosilicate, stirring the mixture to obtain a mixture A; mixing and dissolving 8 to 20 mg of dopamine and 30 to 40 mg of Nisalt in an aqueous solution of ethanol to obtain a mixture B, then adding the mixture B to the mixture A, stirring the mixture in the magnetic field, and performing washing and drying. The magnetic one-dimensional chain-shaped nano composite has a simple preparation process and is suitable for industrial mass production. The magnetic one-dimensional chain-shaped nano composite has paramagnetism, can be magnetically separated, can be recycled, can be used for catalytic degradation of an aromatic nitro group dyes, and can also be used for the enrichment, purification and separation of proteins.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Fully-degradable disposable vegetable fiber tableware

The invention relates to the field of disposable tableware, and aims to provide fully-degradable disposable vegetable fiber tableware which is capable of realizing full degradation. The fully-degradable disposable vegetable fiber tableware is prepared by mixing and pressing the following components in parts by weight: 65-80 parts of vegetable fibers, 6-8 parts of polyvinyl alcohol, 0.5-1.0 part of edible pigment, 1-2 parts of polyethylene wax, 1-2 parts of glycerol, 1-2 parts of sodium bicarbonate, 1-2 parts of edible gelatine, 1-2 parts of terpene resin and 1-2.5 parts of shellac.

Owner:王占其

Method for extracting jack fruit aromatherapy oil from ionic liquid

InactiveCN103725418AKeep aroma componentsAvoid volatile lossEssential-oils/perfumesAromatherapySlurry

The invention relates to a method for extracting jack fruit aromatherapy oil from ionic liquids, which belongs to the technical field of aromatherapy oil. The method comprises the following steps: weighing 50-100 parts of jack fruit pulp, pulping at -30 to -10 DEG C by a low-temperature liquid nitrogen pulping technique so as to obtain a jack fruit pulp liquid to ensure that the fragrance ingredients in the jack fruit are effectively prevented from volatilization loss, uniformly mixing the jack fruit pulp liquid with 20-40 parts of 1-ethyl-3-methylimidazole hexafluorophosphate ([Bmin]PF6), putting the mixture into an extraction liquid, extracting jack fruit volatile oil under the microwave power of 100-500 W and at 100-170 DEG C, condensing and recycling the volatile oil by an extractor for 30-50 minutes till that the volatile oil is completely extracted, collecting the volatile oil, drying by anhydrous sodium sulfate, and sealing, refrigerating and storing the volatile oil at 0-5 DEG C. The extraction method is high in extraction rate, the extracted medium ionic liquids can be recycled and circulated, and the method has environment-friendly and non-pollution effects and is applicable to industrial production.

Owner:MAOMING DEWEISHENG TECH

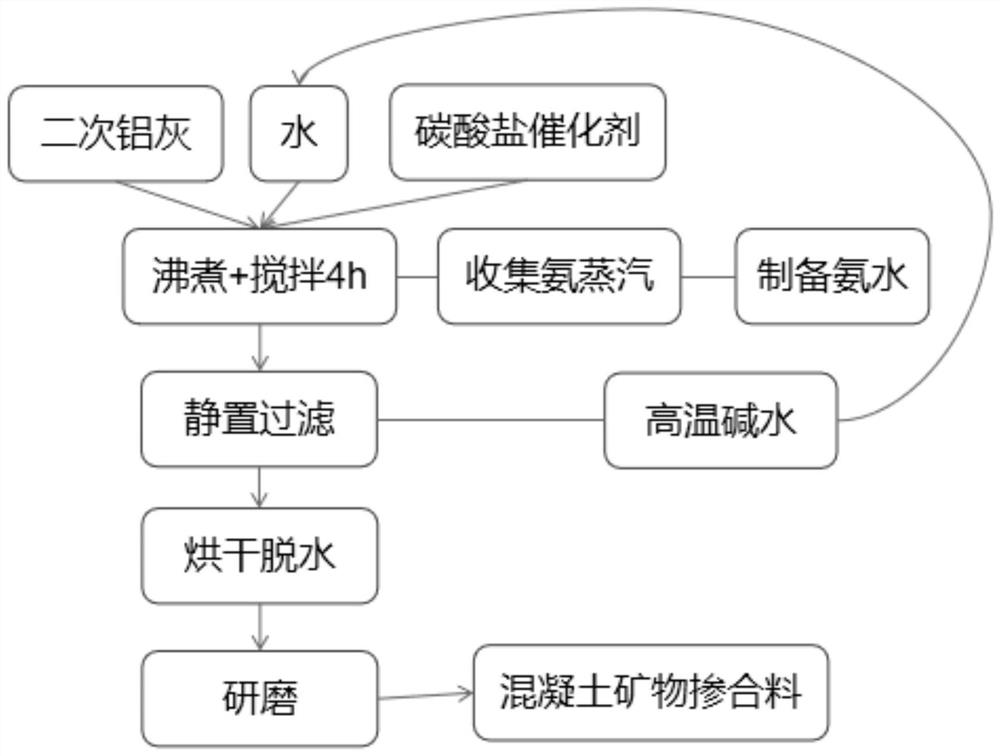

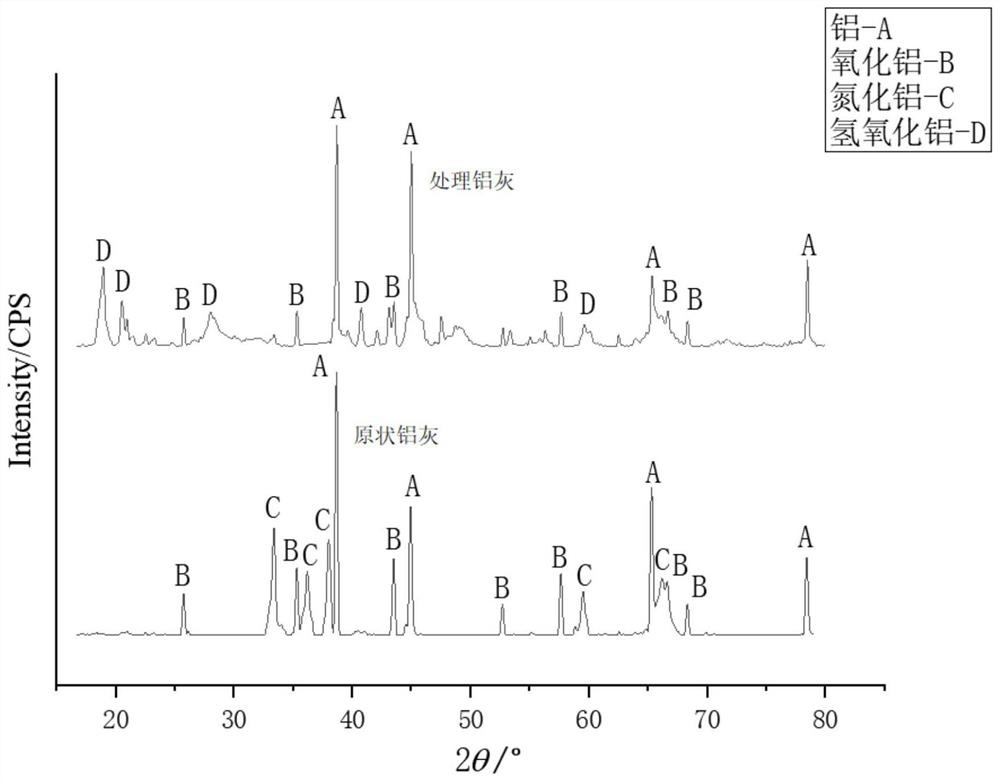

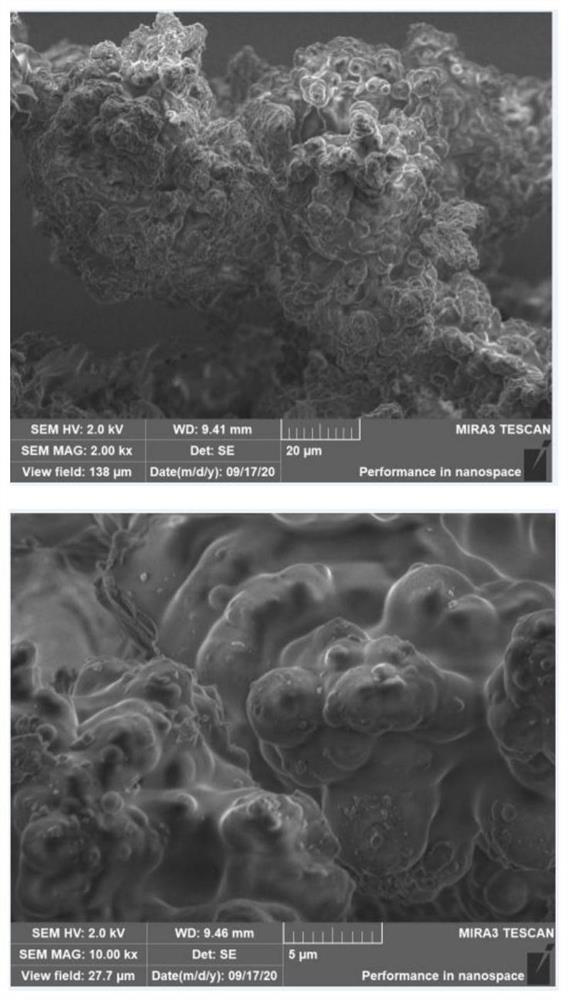

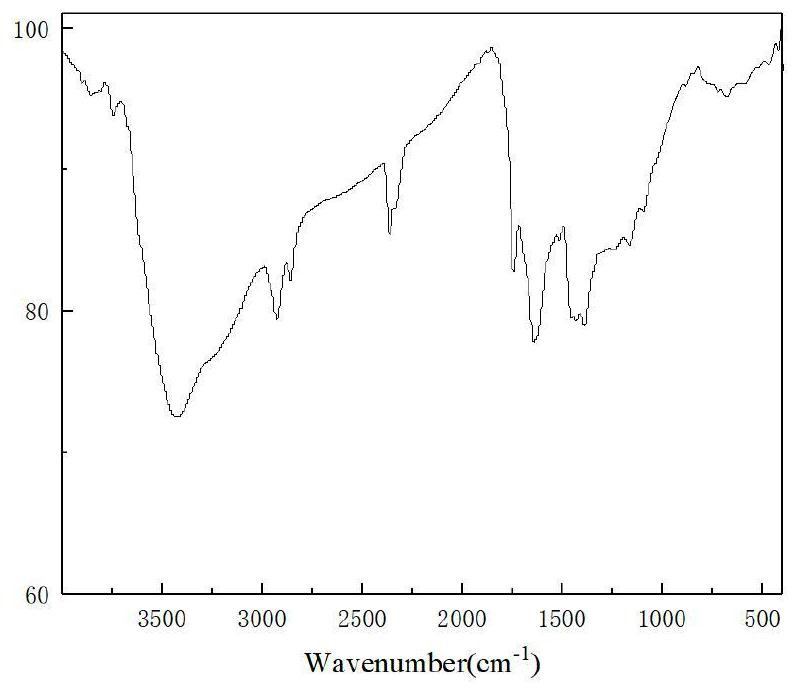

Method for innocent treatment of secondary aluminum ash by weakly alkaline water washing

PendingCN114671636AImprove solubilitySatisfy the needs of dissolutionSolid waste managementAmmonia preparation/separationChemical treatmentAlkaline water

The invention discloses a secondary aluminum ash alkalescent washing harmless treatment method, belongs to the technical field of aluminum ash treatment, and adopts a technical method for hydrolyzing aluminum nitride in a high-temperature water bath heating environment by doping an alkalescent catalyst. According to the method, the problems that in the harmless treatment process of the secondary aluminum ash, a traditional chemical treatment method is difficult to separate, high in manufacturing cost, prone to generating secondary hazardous waste, very difficult to apply to concrete mineral admixtures and the like are solved, aluminum nitride in the secondary aluminum ash can be remarkably removed, and the volatilization toxicity of the secondary aluminum ash is effectively reduced.

Owner:UNIV OF JINAN

Planting method for high-yield fruit corn

InactiveCN107567989AHigh activityPromote photosynthesisBiocideBio-organic fraction processingInsect pestPlant disease

The invention discloses a planting method for high-yield fruit corn. The method comprises the following steps of 1 seed treatment, wherein corn seeds are subjected to virus-free treatment, then soakedwith a sodium bicarbonate solution and then mixed with fermented bean flour to be stored; 2 germination acceleration, wherein the stored seeds are activated and soaked with a germination accelerationsolution to be treated; 3 soil preparation, wherein organic fertilizer is applied to land, a plant ash solution, an EM bacteria agent solution and functional charcoal dust are adopted for soil afterploughing is performed; 4 seedling growing, wherein loess, organic fertilizer and functional charcoal dust are mixed and put into a planting cup, the planting cup is sleeved with a plastic cup, germinating seeds are sown in the planting cup for seedling growing; 5 planting, wherein the plastic cup outside the planting cup is removed, the planting cup is placed into a planting pit and covered withsoil; 6 daily management, wherein when seedlings grow to 1-1.2 m and bloom, organic fertilizer is applied in a dressing mode, a plant ash solution and a limewater solution are sprayed periodically, and insecticide is applied according to the actual plant disease and insect pest condition.

Owner:界首市庆军家庭农场

Lignosulfonate-phenolic resin based carbon aerogel microsphere as well as preparation method and application thereof

ActiveCN112063387AThe preparation method is simpleMild reaction conditionsAgriculture tools and machinesCarbon preparation/purificationLignosulfonatesContaminated soils

The invention discloses a lignosulfonate phenolic resin based carbon aerogel microsphere as well as a preparation method and application thereof. The preparation method comprises the steps of dissolving lignosulfonate, a phenolic compound, an aldehyde compound and a polyamine compound in water to obtain a water phase; mixing the water phase with a non-water-soluble oil phase, carrying out polymerization reaction under a stirring condition, filtering and separating after the polymerization reaction is finished, and carrying out water seal aging and drying on the obtained solid product to obtaindry gel microspheres; carrying out carbonization treatment on the dry gel microspheres, and washing to obtain the lignosulfonate phenolic resin-based carbon aerogel microspheres which are small in macroscopic particle size, developed in microscopic pore structure and large in specific surface area and contain polar groups and a molecular imprinting-like specific structure. The carbon aerogel microsphere material can be used for selective and efficient adsorption of heavy metals, and is especially suitable for remediation of heavy metal contaminated soil. The preparation raw materials of the carbon aerogel microsphere are wide in source and low in cost, so that large-scale production and application are facilitated.

Owner:WUHAN UNIV

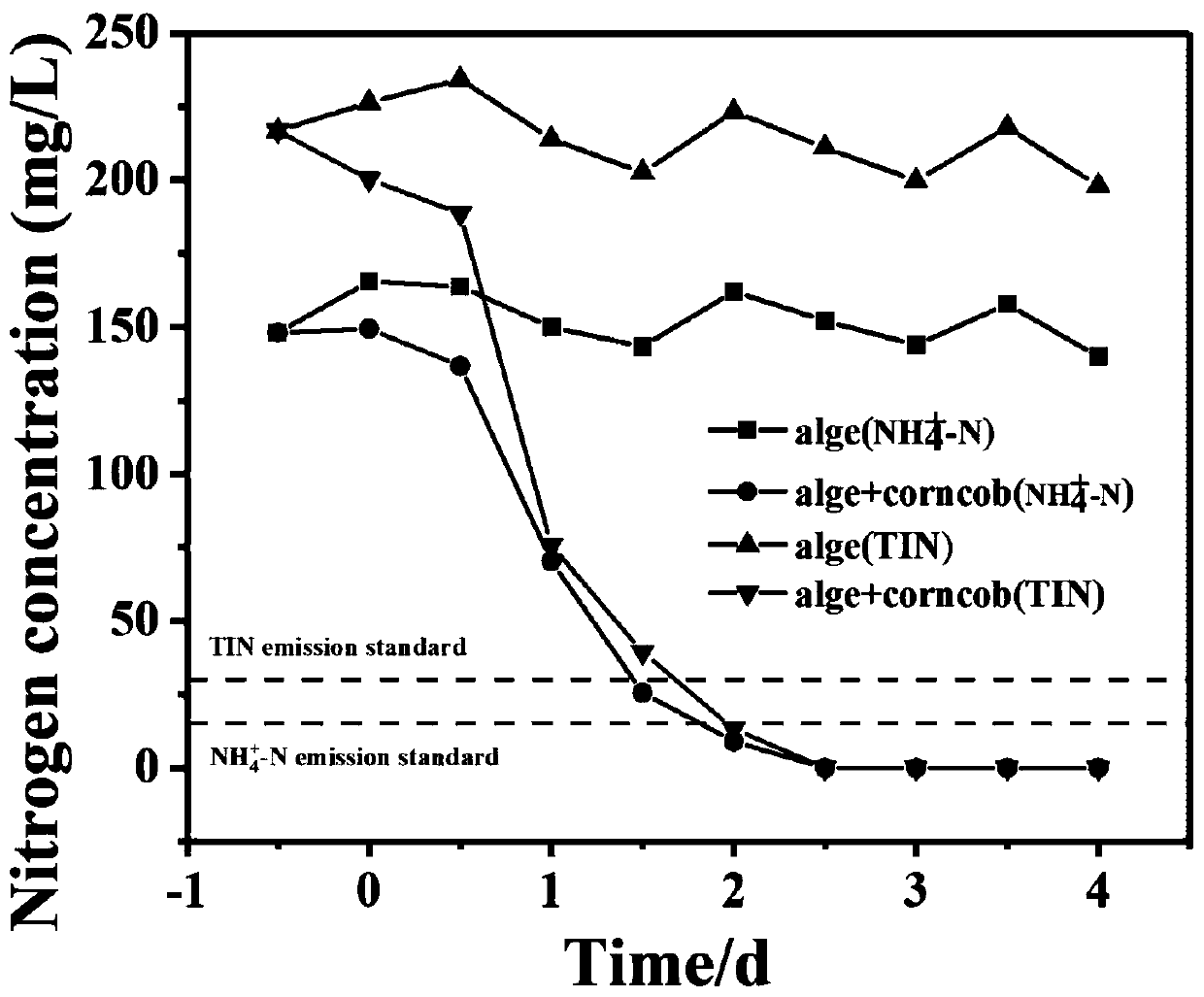

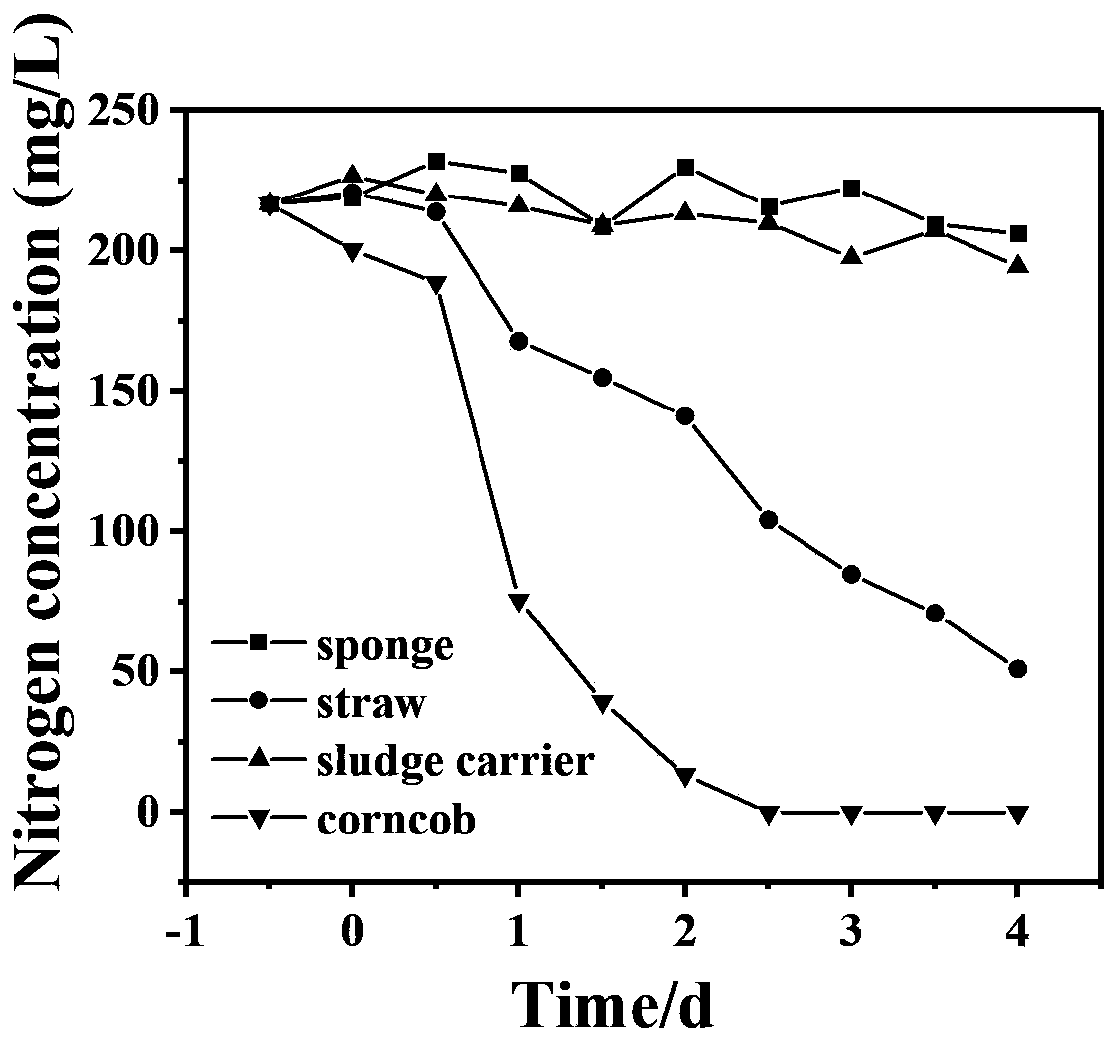

Method for denitrifying rare earth ore wastewater by using supported microalgae

PendingCN111470720AImprove nitrogen removal capacityEconomic treatmentWaste water treatment from quariesWater treatment compoundsRaw waterEnvironmental chemistry

The invention provides a method for denitrifying rare earth ore wastewater by using supported microalgae, and belongs to the technical field of wastewater treatment. The invention provides a method for denitrifying rare earth ore wastewater by using supported microalgae, which comprises the following steps: carrying out quicklime precipitation on rare earth ore wastewater raw water to obtain clarified water; and denitrifying the clarified water, wherein the denitrification is carried out under the condition that flocculation microalgae and corncobs exist at the same time. According to the method provided by the invention, rapid, effective and economic treatment of the high-ammonia-nitrogen rare earth ore wastewater is realized; the total nitrogen and ammonia nitrogen removal capacity is high, the average ammonia nitrogen removal capacity is 83.3 mg. L <-1 >. d <-1 >, the average total nitrogen removal capacity is 86.7 mg.L <-1 >. d <-1 >, and the method further has a series of advantages of being low in treatment cost, simple in process operation equipment, stable in effect, environmentally friendly, capable of achieving rare earth element recycling and algae colony recycling and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

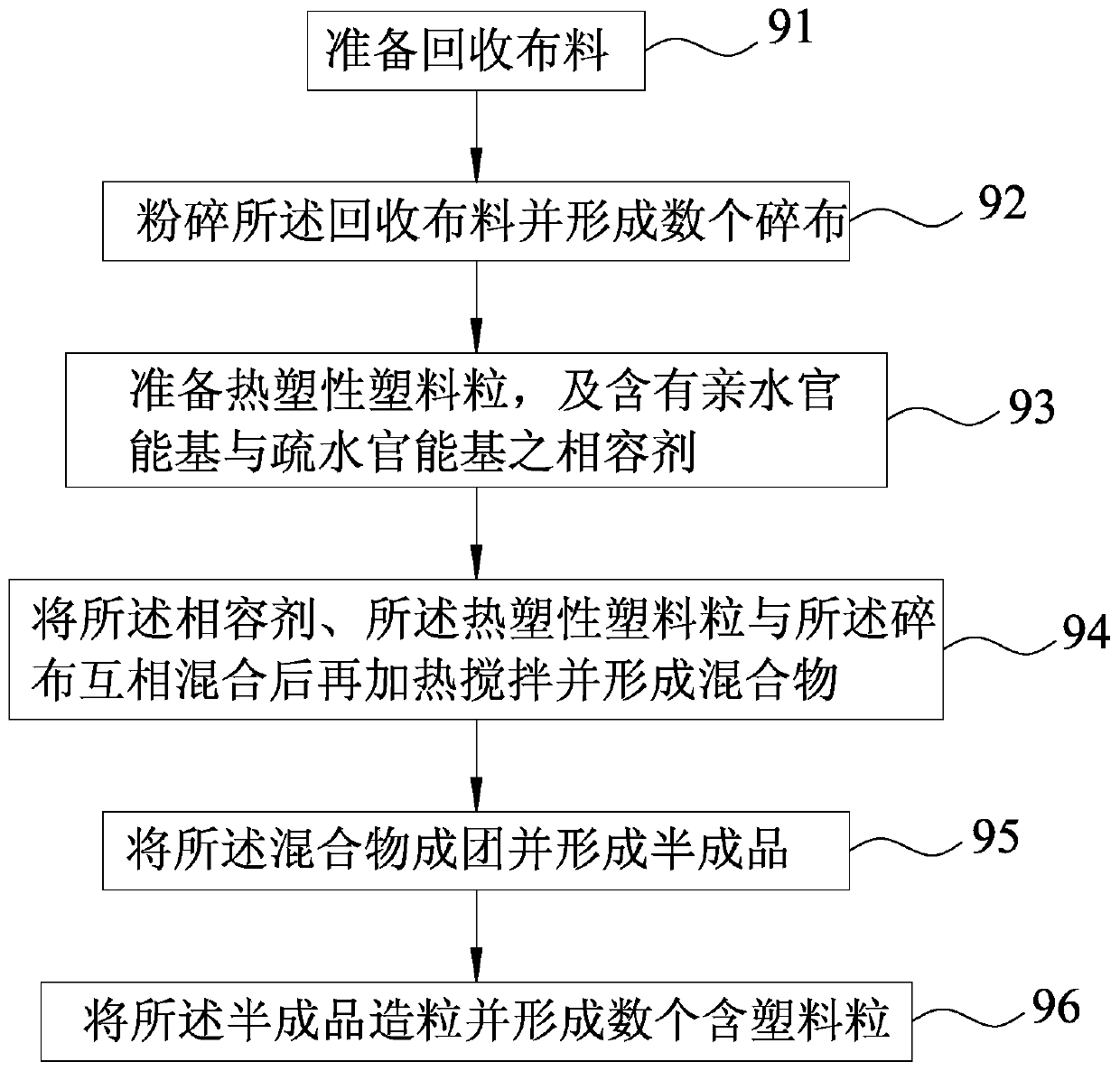

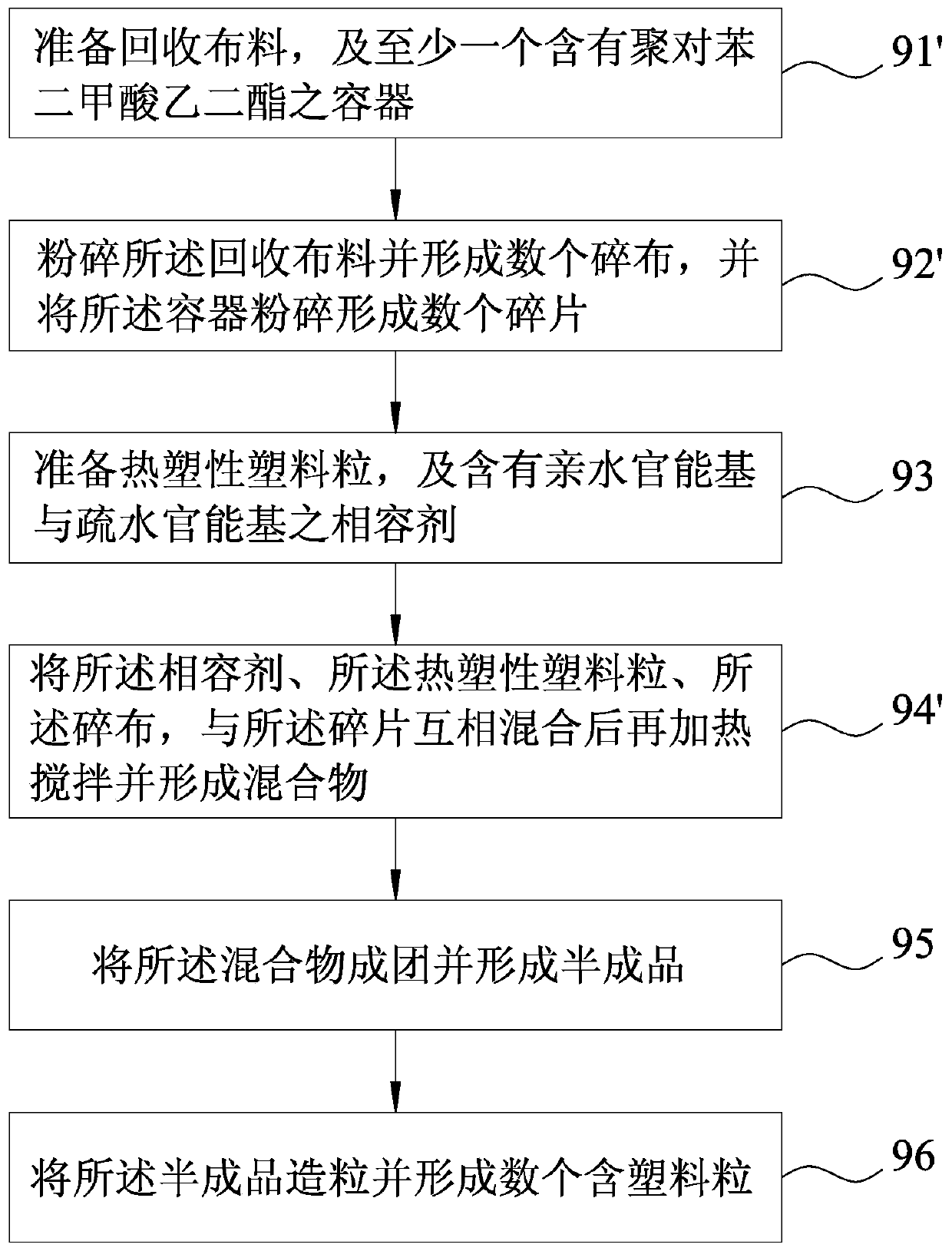

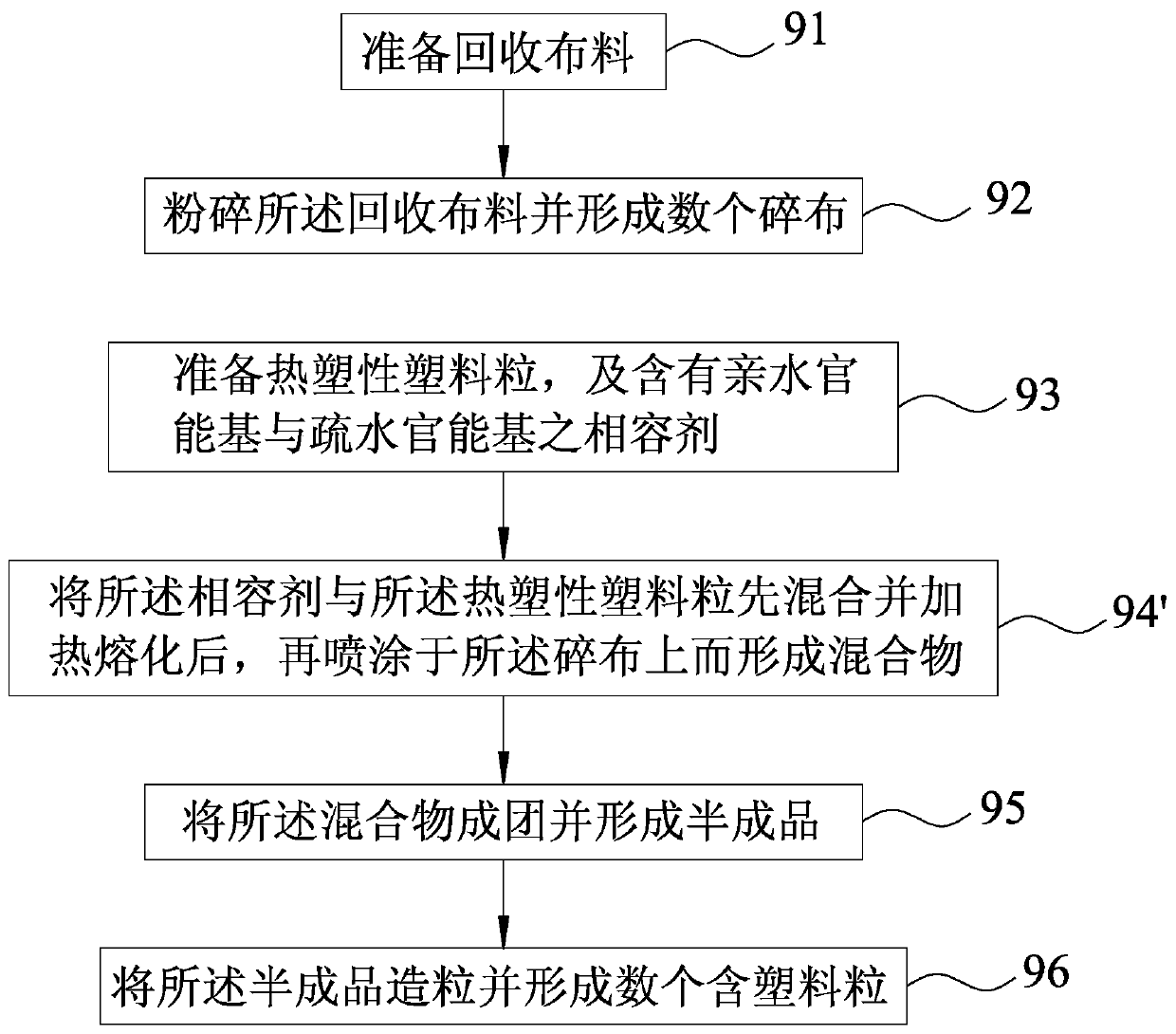

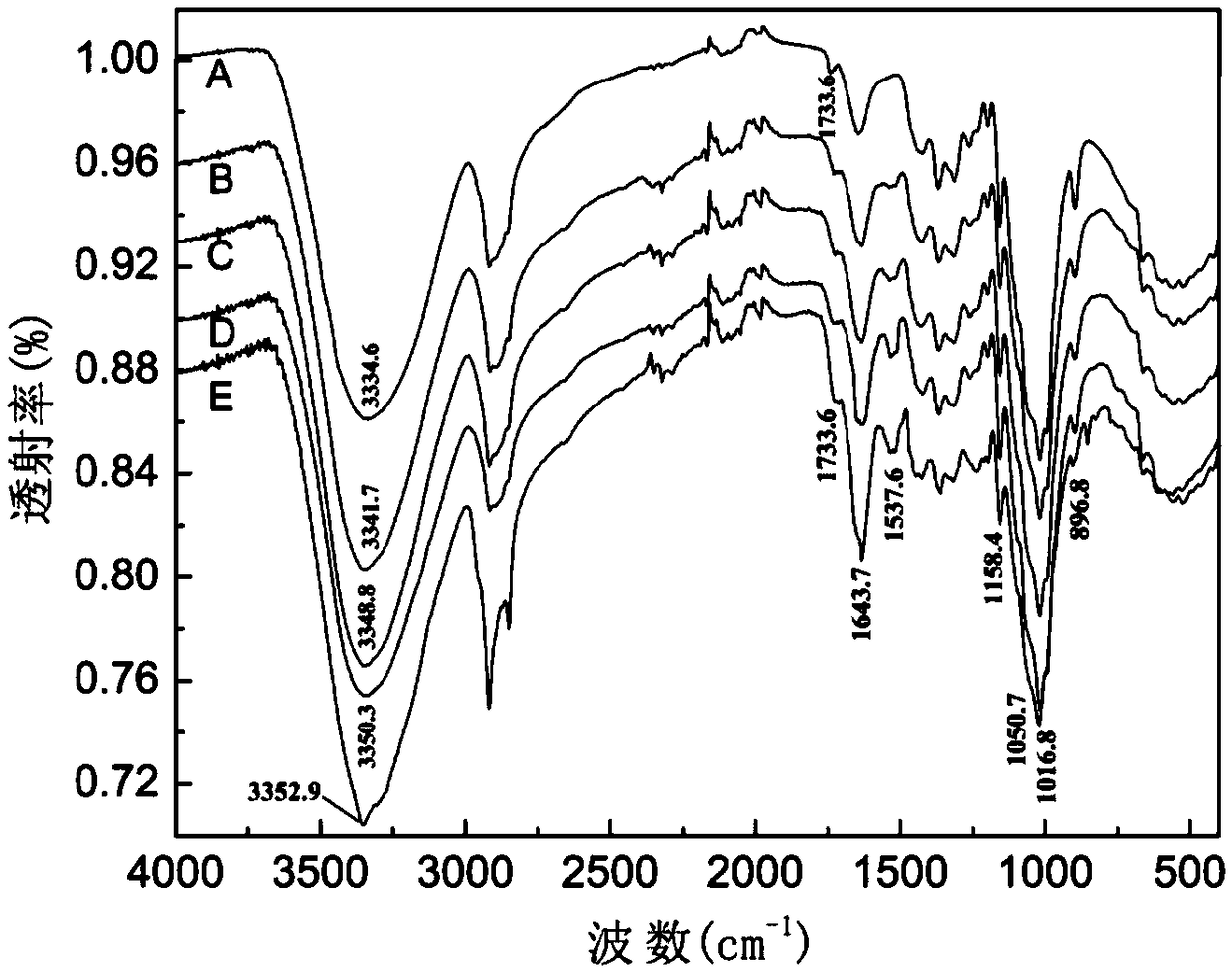

Manufacturing method for forming recycled fabric into plastic-containing pellets, and plastic-containing pellet

InactiveCN110256752AWith recyclingPlastic recyclingTextile disintegration and recoveryThermoplasticResource recovery

A manufacturing method for forming recycled fabric into plastic-containing pellets, and plastic-containing pellets. The manufacturing method for forming the recycled fabric into the plastic-containing pellets comprises the following steps: (1) preparing a recycled fabric, (2) pulverizing the recovered cloth, and forming a plurality of rags of 10 cm<2> or less, (3) preparing thermoplastic granules, and a compatibilizing agent containing a hydrophilic functional group and a hydrophobic functional group, the thermoplastic granules having a weight percentage of 30% to 70%, and the compatibilizing agent having a weight percentage of 5% to 20%, and combining the compatibilizer and the thermoplastic granules with the rag and heating them to form a mixture, (4) agglomerating the mixture and forming a semi-finished product, and (5) granulating the semi-finished product and forming into a plurality of plastic-containing granules. Thereby, textile waste can be reduced, and the resources can be recycled and reused.

Owner:AITECH

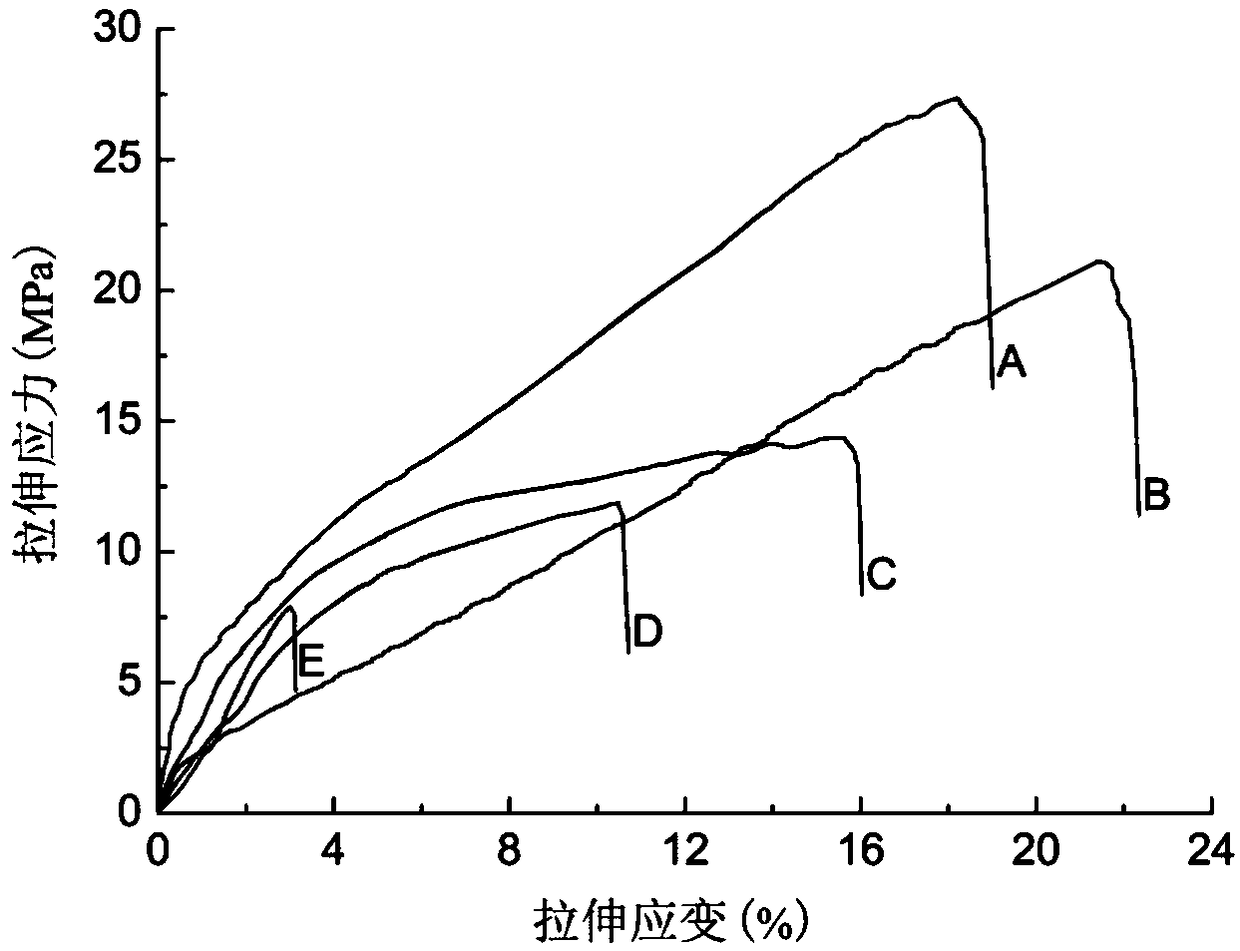

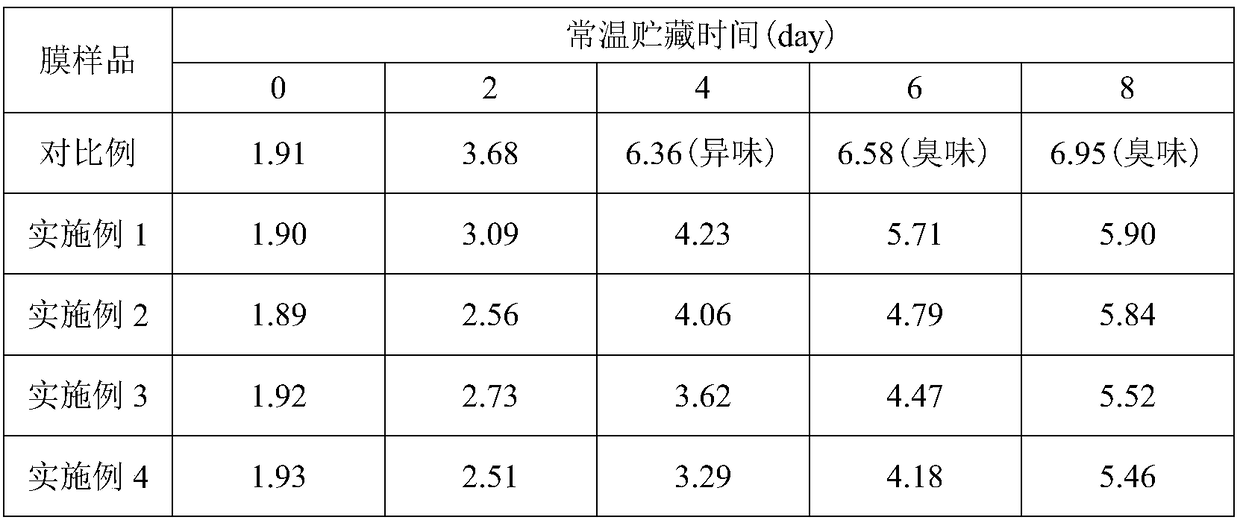

Tea leaf residue modified oxidized cellulose composite film, and preparation method and application thereof

ActiveCN109293959AWide variety of sourcesLow priceMeat/fish preservation using chemicalsChemical reactionComposite film

The invention discloses a tea leaf residue modified oxidized cellulose composite film, and a preparation method and an application thereof. The tea leaf residue modified oxidized cellulose composite film is obtained by an imine chemical reaction of an aldehyde group in a selectively oxidized cellulose molecule and an amino group in tea leaf residue. The tea leaf residue modified oxidized cellulosecomposite film prepared in the invention has good mechanical strength, biodegradability and anti-oxidation performance, is safe and sanitary, can be used for fresh-keeping of fresh pork at room temperature, and can prolong the shelf life of foods.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of N,N'-dicyclohexylurea

InactiveCN106008274ALarge absorption capacityFast absorption rateUrea derivatives preparationOrganic compound preparationChemical effectsDicyclohexylurea

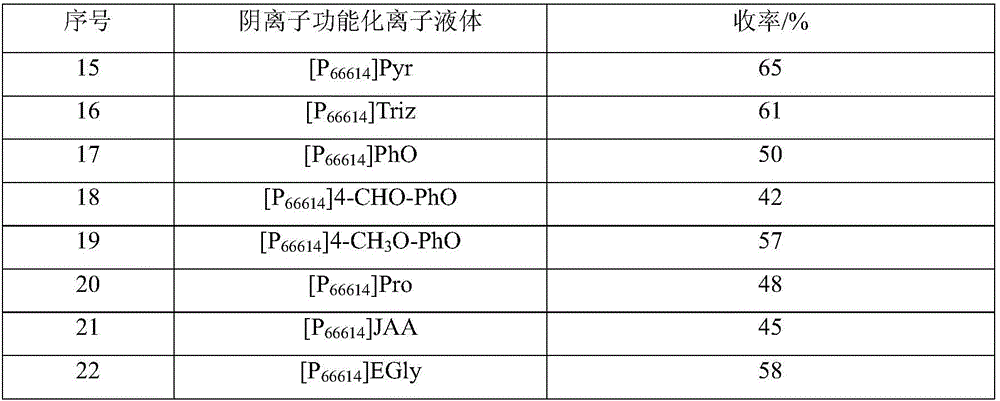

The invention discloses a preparation method of N,N'-dicyclohexyl urea, which is characterized in that: anionic functionalized ionic liquid absorbs CO through chemical action 2 In situ reaction of carbon source and cyclohexylamine, N,N'-dicyclohexylurea was prepared under mild conditions. with traditional CO 2 Compared with the method of preparing N,N'-dicyclohexyl urea directly with cyclohexylamine reaction, this method has the advantages of low reaction temperature and pressure, CO 2 The utilization rate is high, the anionic functionalized ionic liquid can be recycled, and no additional catalyst, dehydrating agent and solvent are needed. It is a preparation method of N,N'-dicyclohexyl urea with industrial application potential.

Owner:SHAOXING UNIVERSITY

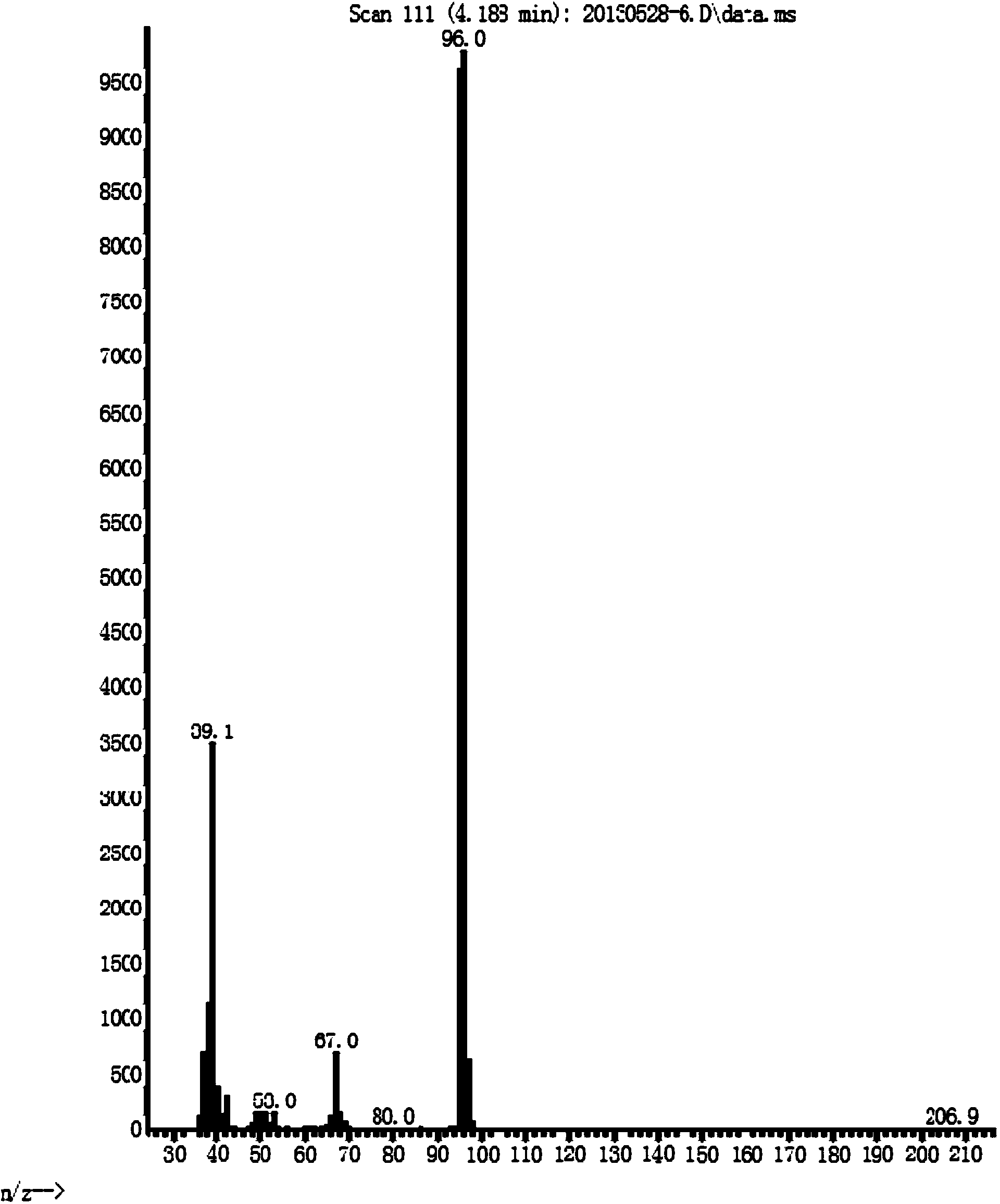

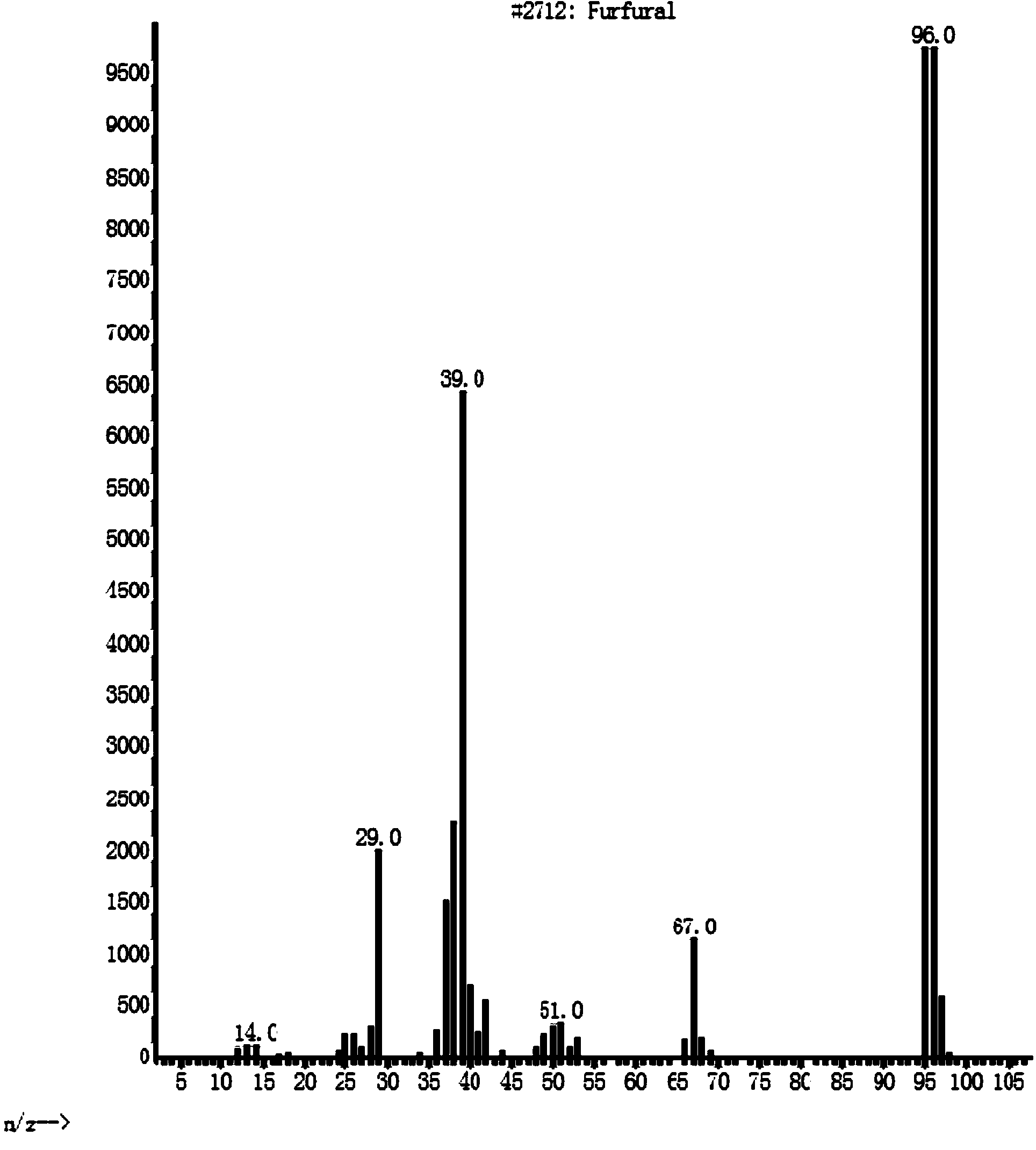

Method for preparing furfural by inorganic salt-adopted composite catalysis of xylose in homogeneous system

InactiveCN104086517AHigh catalytic efficiencySynergistic catalytic efficiency is highOrganic chemistryXyloseCorrosion

The invention discloses a method for preparing furfural by inorganic salt-adopted composite catalysis of xylose in a homogeneous system. The method comprises that xylose and a composite inorganic salt are added into a homogeneous reaction system and undergo a reaction at a temperature of 110-160 DEG C for 10-600min, wherein the composite inorganic salt comprises an inorganic salt A selected from SnCl4, AlCl3 and CrCl3 and an inorganic salt B selected from LiCl, KCl and NaCl, the homogeneous reaction system is a mixed solution of water and dimethyl sulfoxide and a volume ratio of water to dimethyl sulfoxide is 0.5-1.5: 1, the reaction solution is naturally cooled and then is subjected to organic solvent-based extraction, and the extract is washed and distilled so that furfural is obtained. The homogeneous catalysis system used by the method has the characteristics of high efficiency, environmental friendliness and cyclic utilization. The composite inorganic salt has the characteristics of good selectivity and high catalytic efficiency. The method has the characteristics of mild technical conditions, operation easiness, high efficiency and good selectivity, is free of inorganic acid used in the reaction process and prevents corrosion on equipment.

Owner:SOUTH CHINA UNIV OF TECH

An environmental friendly energy-saving recycled building template and a manufacturing method thereof

The invention relates to an environmental friendly energy-saving recycled building template and a manufacturing method thereof. The building template and the method are characterized in that the building template is prepared from following components: 80-90% of powder of waste PPR, PE and PVC with the particle fineness of the powder being 60-80 meshes, 10-20% of active calcium carbonate powder with the particle fineness being 1500-2000 meshes, and 5-8% of various-color foaming adjusting agents. Compared with the prior art, building wastes are fully utilized, and the produced building template has advantages of environment protection, energy conservation, cyclic regeneration, ageing resistance, waterproofness, moisture-proofness, no deformation, no cracking, no mildew, light and convenient conveying, capability of being economical, and the like.

Owner:威海和光新材料科技有限公司

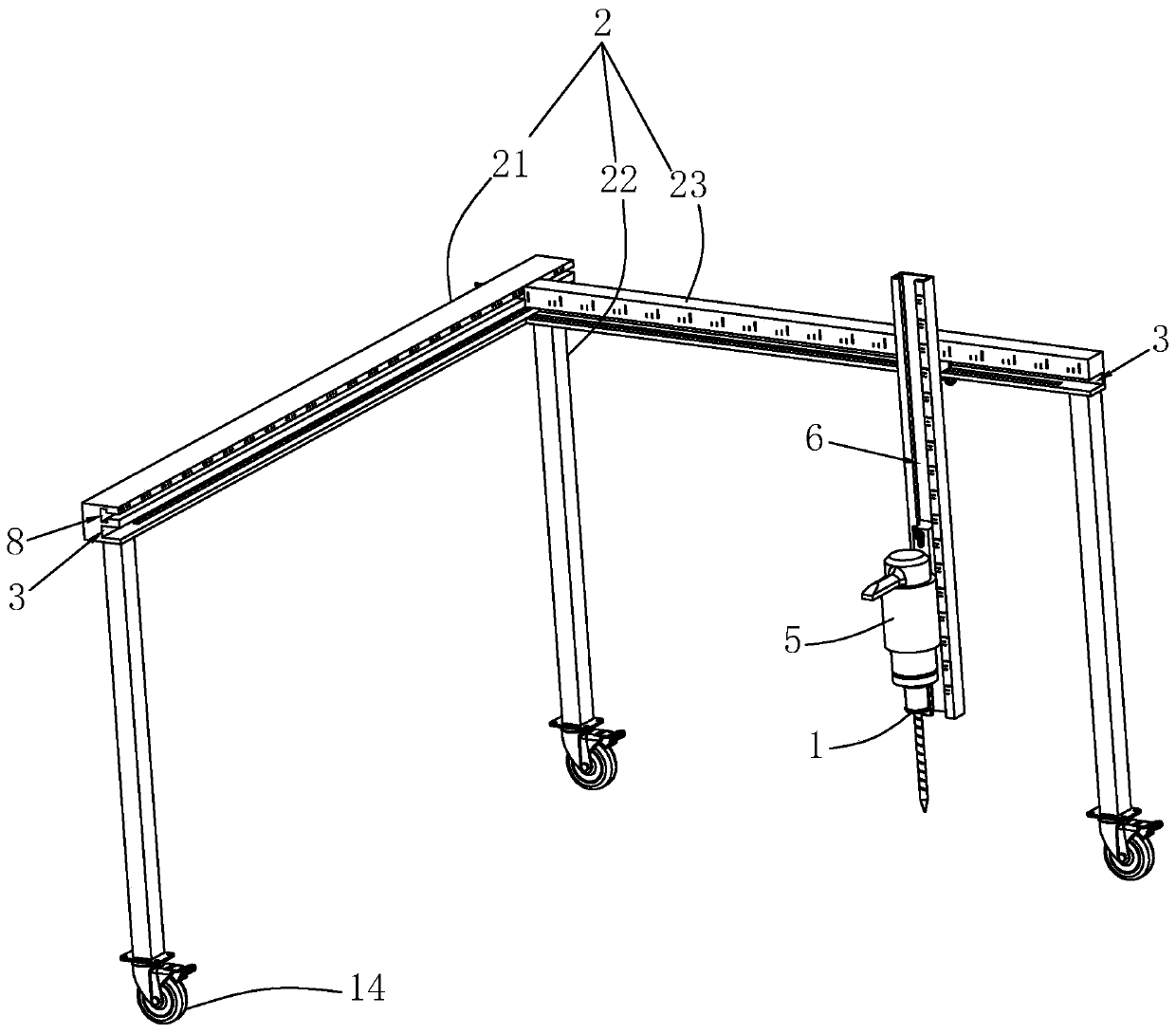

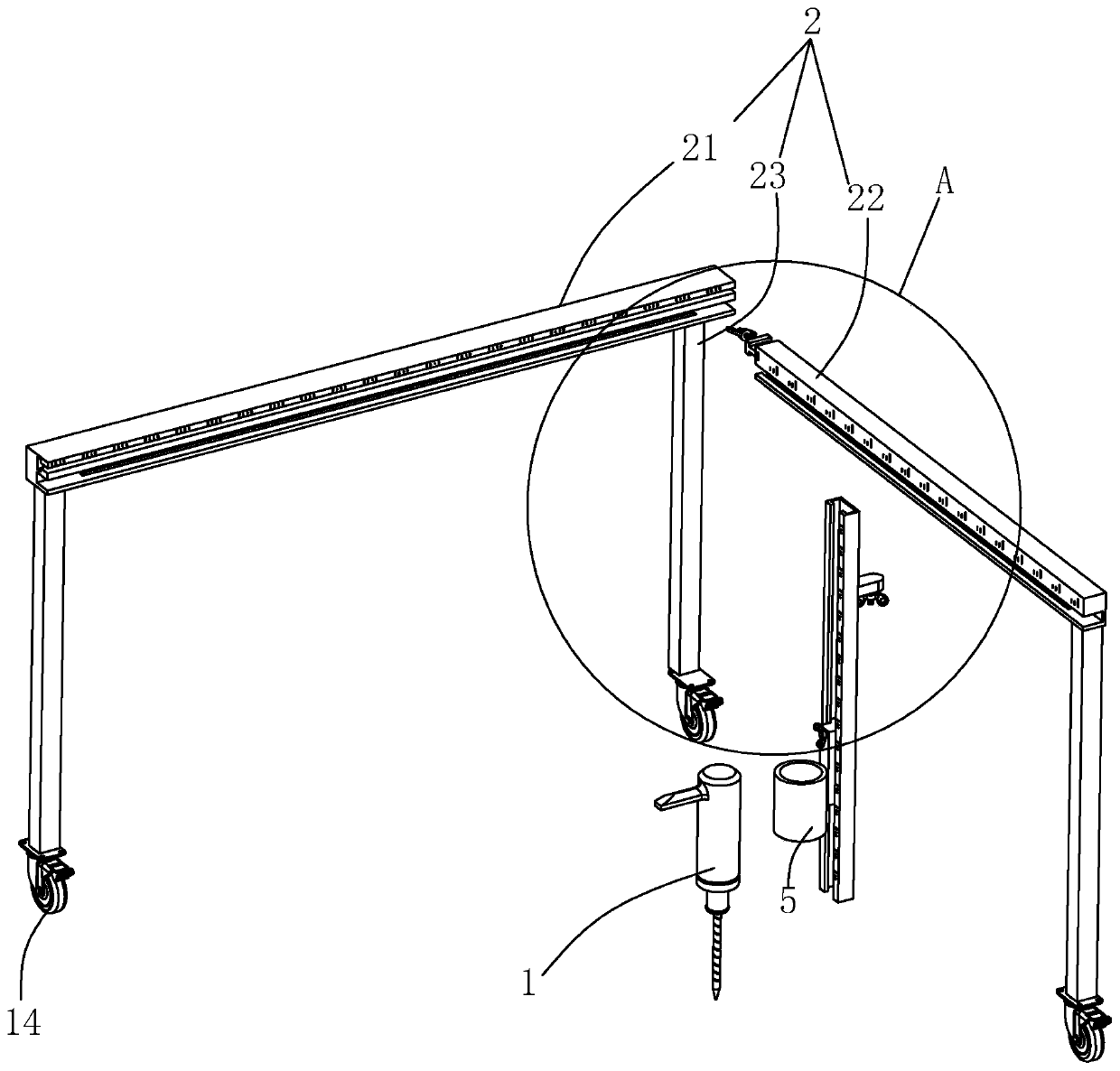

Construction tool and method for repairing highway asphalt pavement

InactiveCN110904801AEasy to determineSave materialIn situ pavingsRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to a construction tool for repairing a highway asphalt pavement. The tool comprises a drilling machine and a support, the support comprises a first transverse rod, a second transverse rod and a plurality of vertical rods. The first transverse rod is vertically connected with the second transverse rod; the vertical rods are respectively vertical to the first transverse rod andthe second transverse rod; first sliding grooves are formed in the first transverse rod in the length direction and the second transverse rod in the length direction. The first sliding groove of thefirst transverse rod is communicated with the first sliding groove of the second transverse rod; the first sliding groove is slidably connected with a sleeve used for sleeving a drilling machine through a first sliding block, the first sliding block penetrates out of the first sliding groove and is provided with a second sliding groove in the direction parallel to the vertical rod, and a second sliding block is slidably connected in the second sliding groove and penetrates out of the second sliding groove to be connected with the sleeve. The method has the effect of conveniently determining the range and depth of the milling groove.

Owner:四川路通建设(集团)有限公司

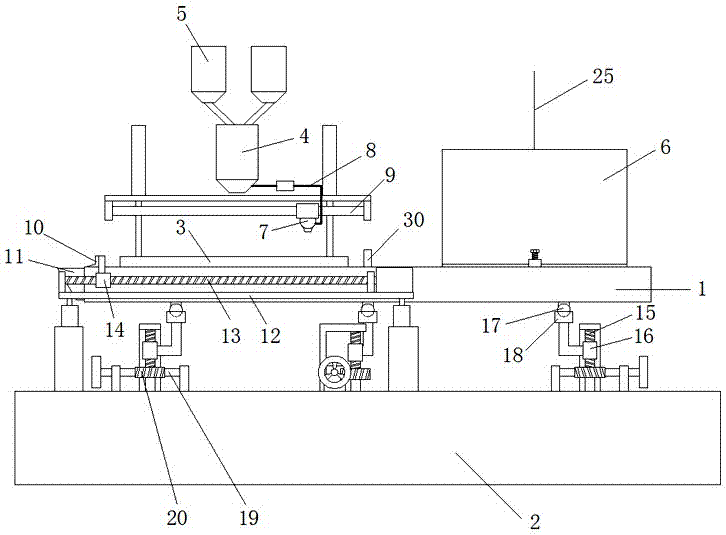

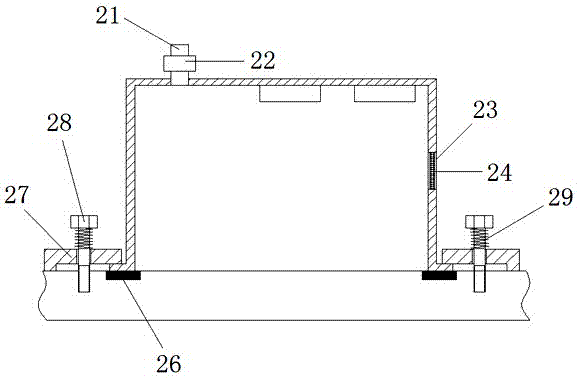

Multifunctional floor coating plate manufacturing platform

The invention relates to a multifunctional floor coating plate manufacturing platform. The multifunctional floor coating plate manufacturing platform comprises a base and a platform which is positioned above the base and is separated into a manufacturing area and a maintenance area by a baffle plate; the manufacturing area of the platform is provided with a lifting baseplate which is used for manufacturing floor coating plates; a blending hopper is arranged above the baseplate; at least two weighing hoppers are arranged above the blending hopper; and the maintenance area of the platform is provided with a dust-free constant temperature cover. The multifunctional floor coating plate manufacturing platform has the beneficial effects that the manufacturing area and the maintenance area of the floor coating plate are arranged on the same platform, thereby avoiding the long-distance conveying and reducing occupied space; meanwhile, the multifunctional floor coating plate manufacturing platform has the functions of weighing, recycling wastes and leveling on the platform and greatly improves the manufacturing efficiency.

Owner:FUZHOU ROYAL FLOOR

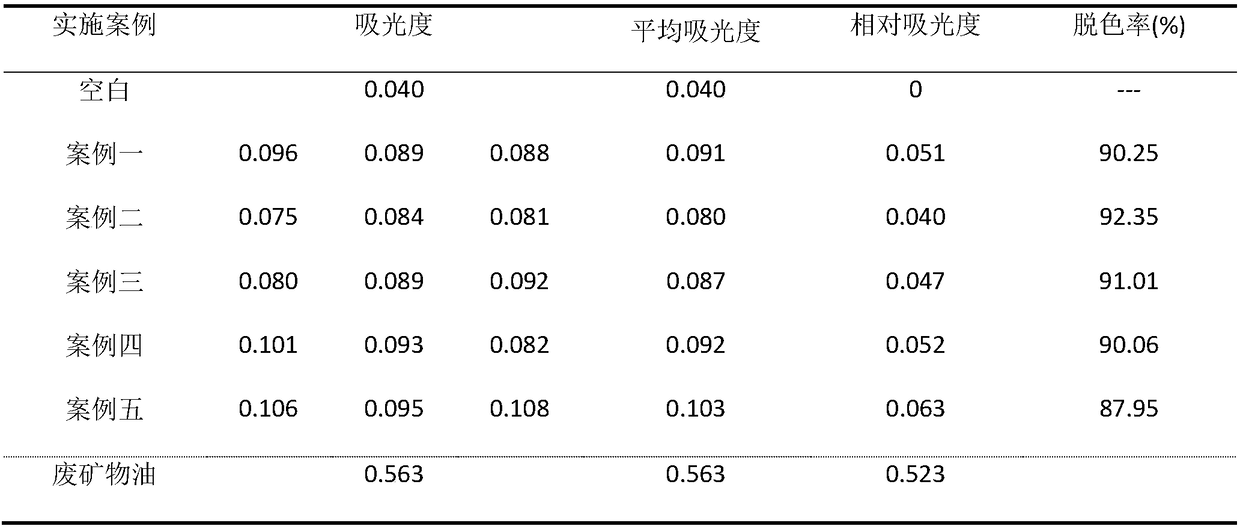

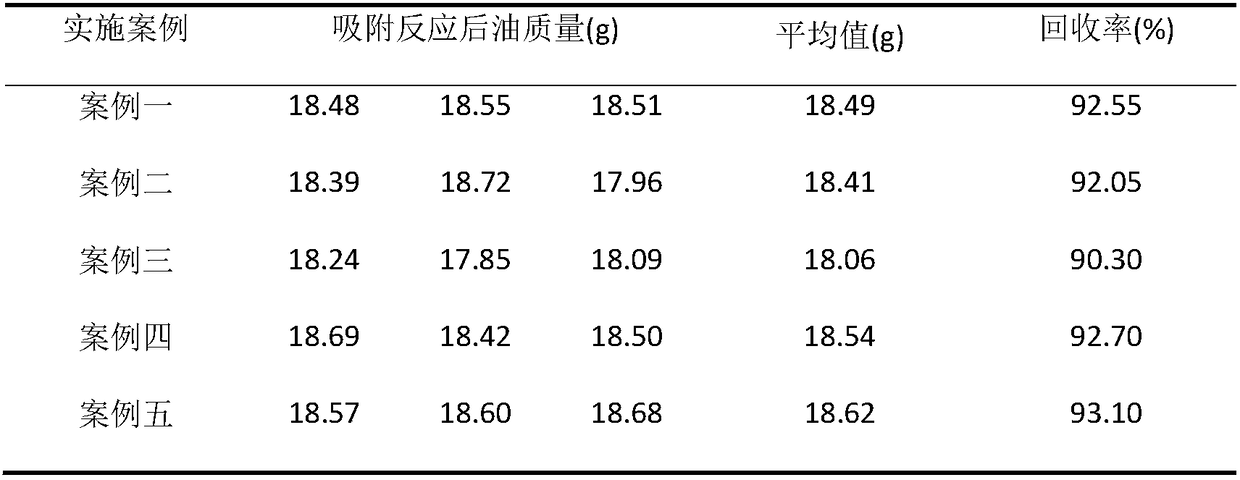

Method for regenerating waste lubricating oil by combining solvent extraction with composite metal oxide adsorbent

The invention discloses a method for regenerating waste lubricating oil by combining solvent extraction with a composite metal oxide adsorbent. The method comprises the steps: loading waste lubricating oil to be regenerated into a container, placing in a constant temperature drying box, depositing for at least 12 h, and removing primary upper clear oil; then adding an organic solvent to the primary upper clear oil, carrying out extraction and refining treatment, cooling the obtained oil-containing mixture to room temperature, then depositing the oil-containing mixture for at least 2 h, then removing secondary upper clear oil, next taking the secondary upper clear oil, mixing with the composite metal oxide adsorbent to form a reactant system, controlling the temperature of the reactant system to 60-90 DEG C, and decolorizing the secondary upper clear oil for 20-40 min; and finally, separating to remove a compound metal oxide decolorizer, and thus obtaining regenerated base oil. Qualityindexes of the waste oil treated by the method meet the requirement standards of the base oil, an acid-free and alkali-free process is adopted throughout the process, the yield of the regenerated oilis high, the repeated utilization rate of the adsorbent is high, and the requirements of green sustainable development are met.

Owner:SHANGHAI UNIV

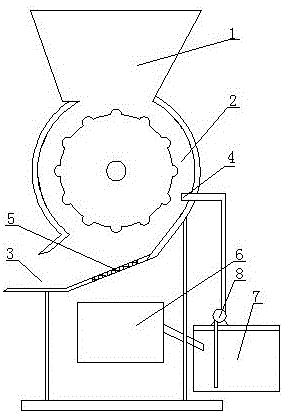

Walnut peeler with water washing device

The present invention relates to a walnut peeling machine, the name is a walnut peeling machine with a water flushing device, comprising a walnut peeling machine body, the walnut peeling machine body has an inlet, a crushing chamber and a discharge port; There is also a water inlet pipe below the crushing chamber, a screen is arranged below the discharge port, a pool is arranged below the screen, the pool is connected to the filter pool, and a water pump is connected to the filter pool, and the water pump is connected to the water inlet. Such a walnut peeling machine has the advantages of being able to separate the walnut skin and the walnut fruit and being easy to use; there is a pool below the screen, the pool is connected to the filter pool, and the water pump is connected to the filter pool, and the water pump is connected to the water pipe. The advantages of water recycling and water saving.

Owner:CHANGGE JIQING MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com