Multifunctional floor coating plate manufacturing platform

A floor coating and platform-making technology, which is applied to flat products, household appliances, and other household appliances, can solve problems that affect production efficiency, consume a lot of manpower and material resources, and occupy a large space, so as to improve processing efficiency and avoid long Long-distance transportation and the effect of reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

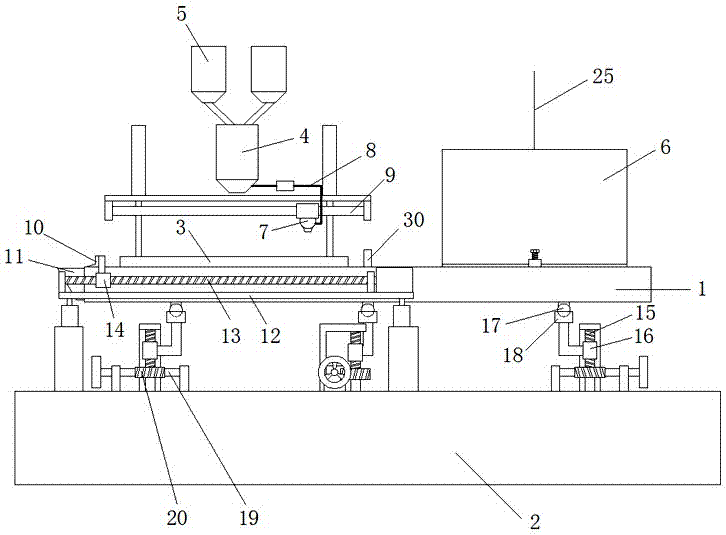

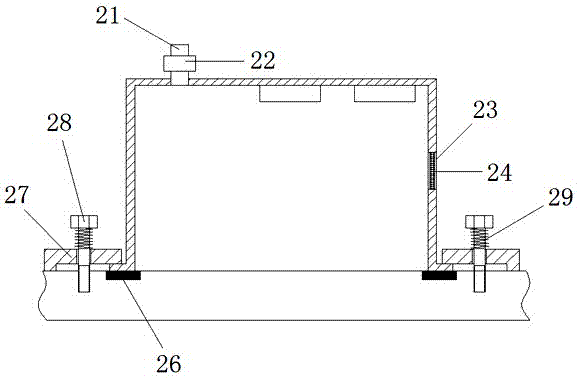

[0016] Such as Figure 1~2 As shown, a multifunctional floor coating board production platform includes a base 2 and a platform 1 located above the base and separated into a production area and a maintenance area by a partition 30. The production area of the platform 1 is provided with a The liftable bottom plate 3 of the paint board, the bottom plate 5 is driven up and down by the hanging cylinder, the upper part of the bottom plate 3 is provided with a mixing hopper 4, and at least two weighing hoppers 5 are arranged above the mixing hopper; the maintenance area of the platform 1 is provided with a dust-free constant temperature Cover 6; various ingredients are stored in each weighing hopper 5, and the specified amount of each ingredient is transported to the middle of the mixing hopper 4 for mixing, and the resin obtained by mixing is used to make the floor coating board, and the mixing hopper 4 is used after blanking The trowel is used for paving, and the floor coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com