Patents

Literature

296 results about "Compressible fluid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

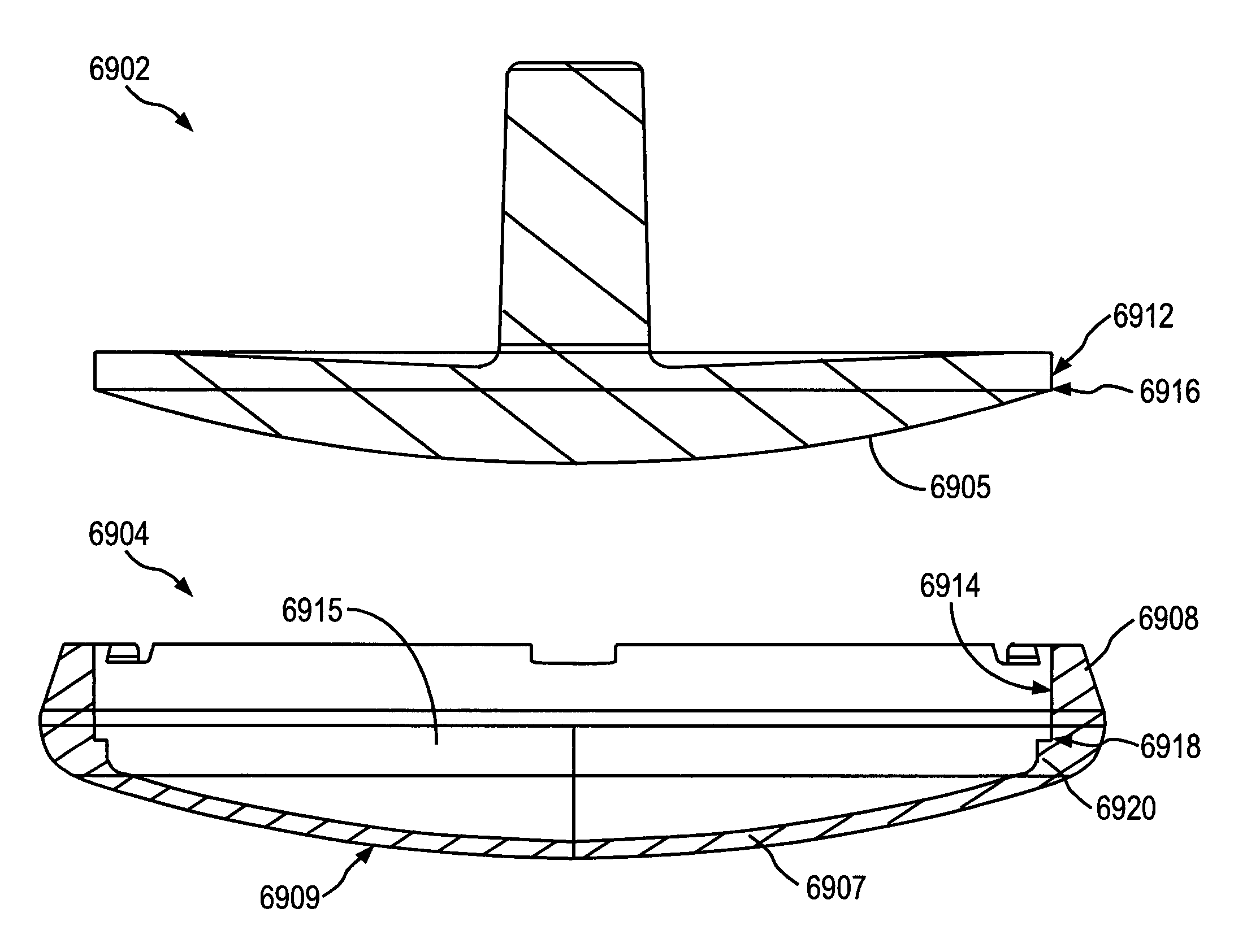

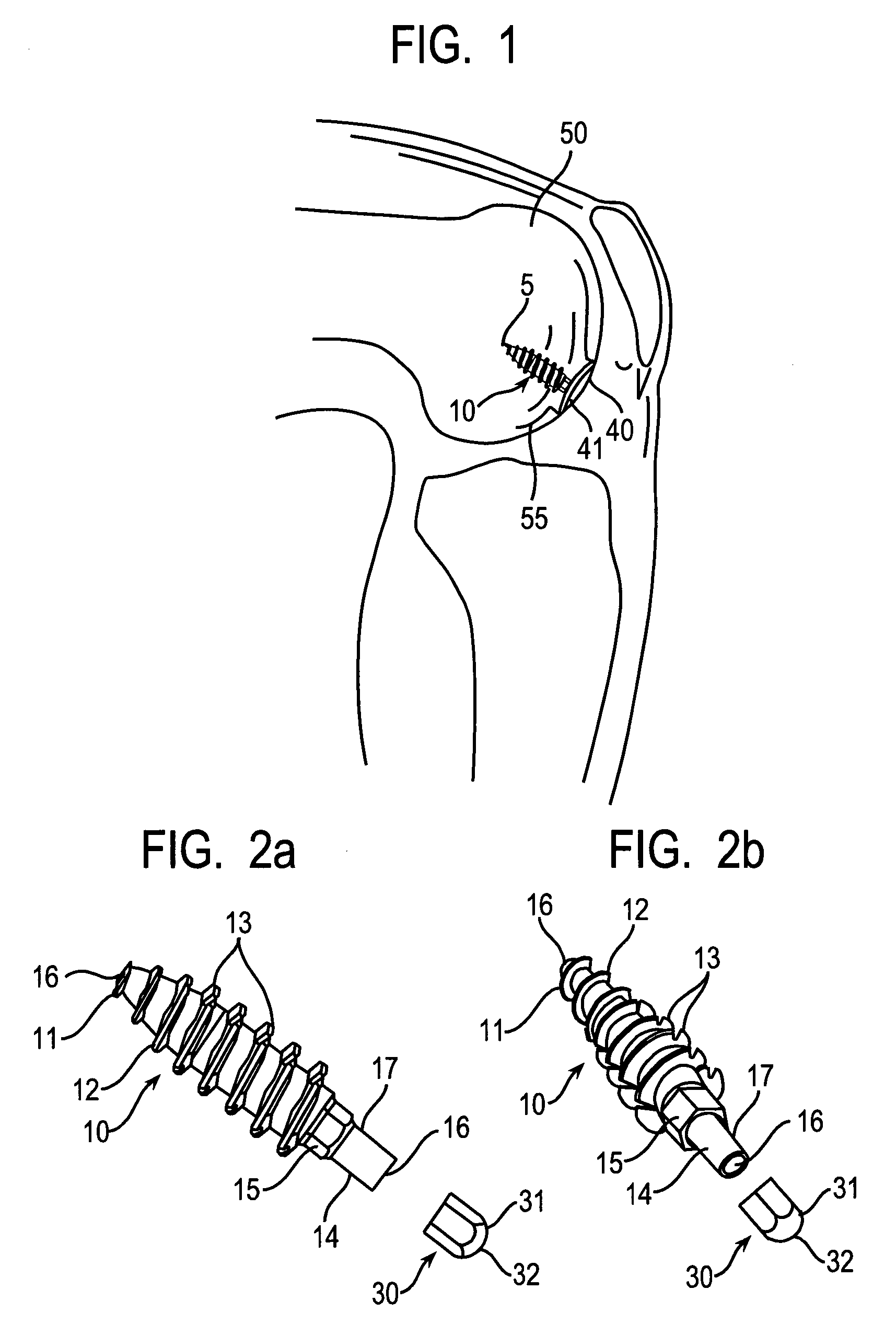

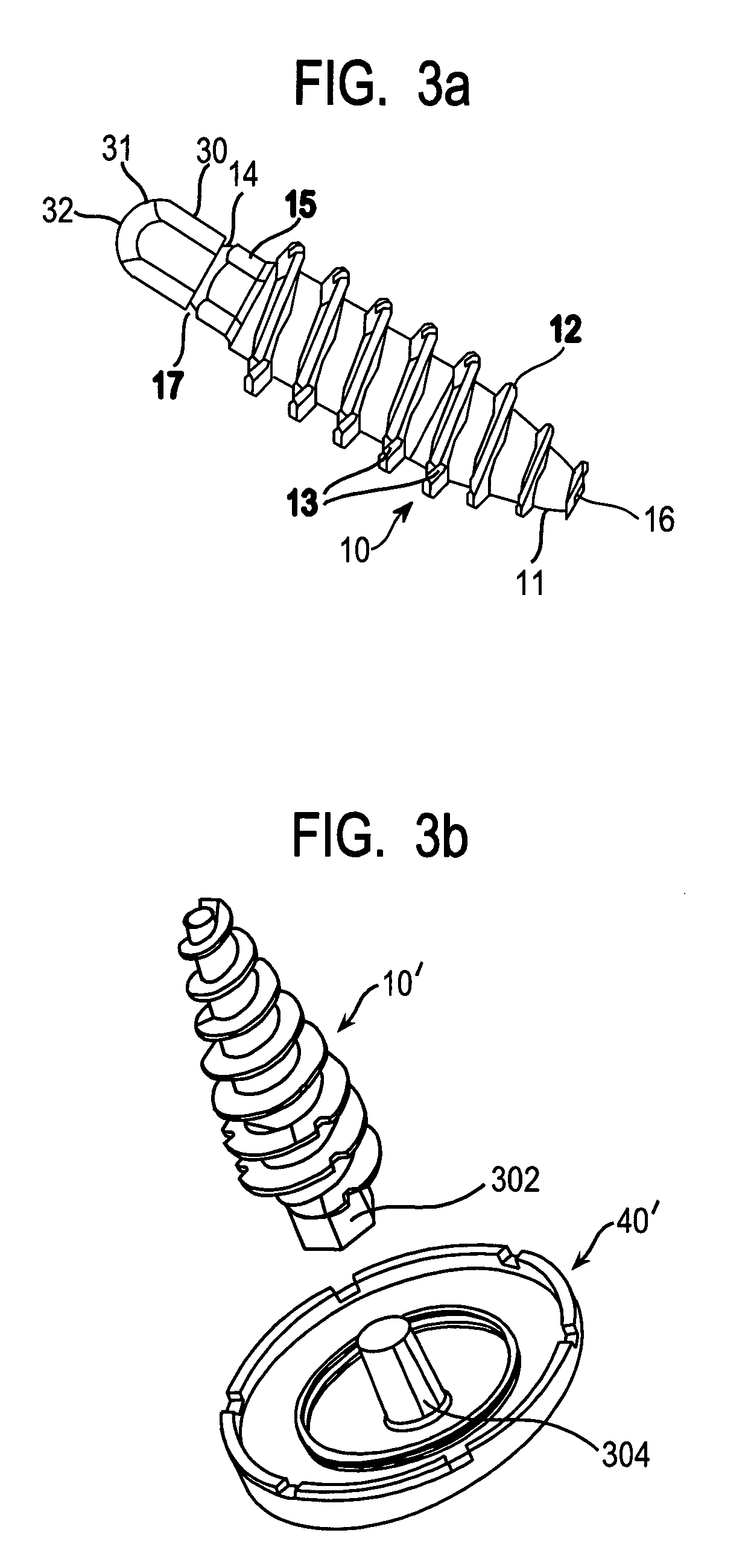

System and method for joint resurface repair

An implant for installation into a portion of an articular surface includes an implant shell component having a proximal load bearing wall with an outer proximal load bearing surface. A peripheral rim extending distally relative to the load bearing wall may provide a bone-facing distal pocket on the shell component. An inner implant component may be received in the bone-facing distal pocket of the implant such that a proximal surface of the inner component is spaced apart from a distal surface of the load bearing wall. The contour of the load bearing surface may be based on an original surface contour of an articular surface, and the load bearing wall of the shell component may be a deflectable wall, so that the load bearing surface can deflect under an applied load. The space between the load bearing wall and the inner implant may include a compressible fluid such as elastomeric gels.

Owner:ARTHROSURFACE

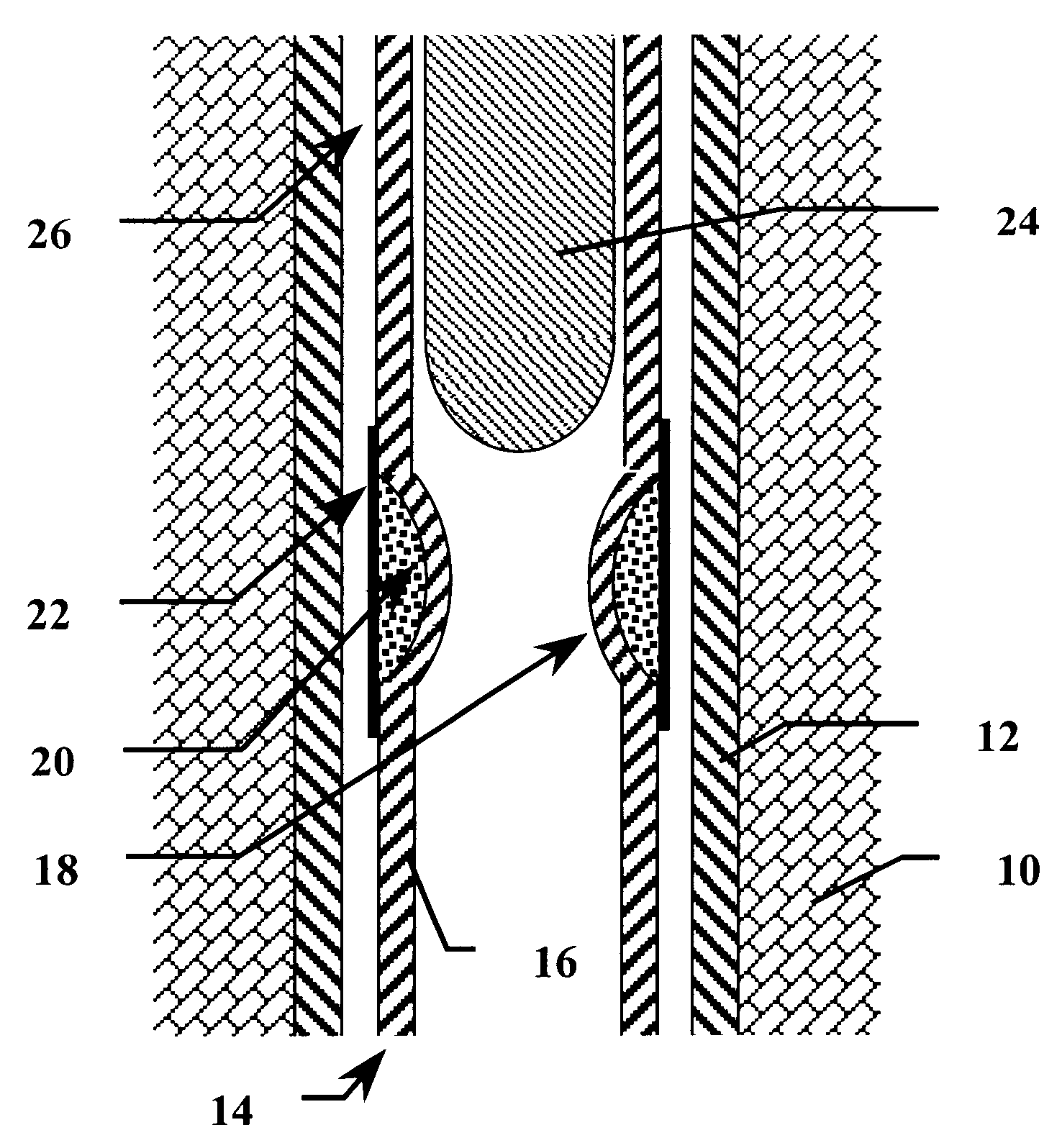

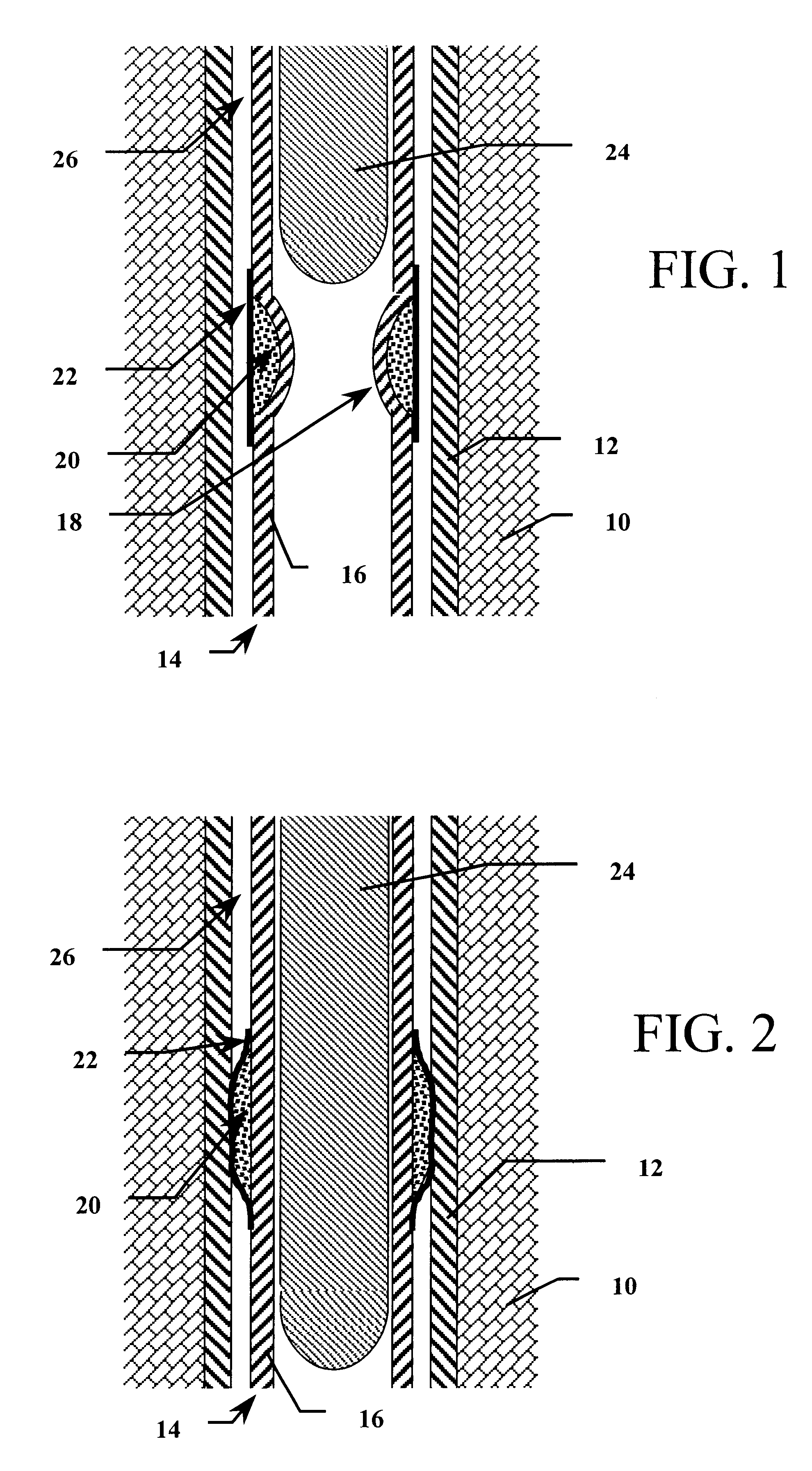

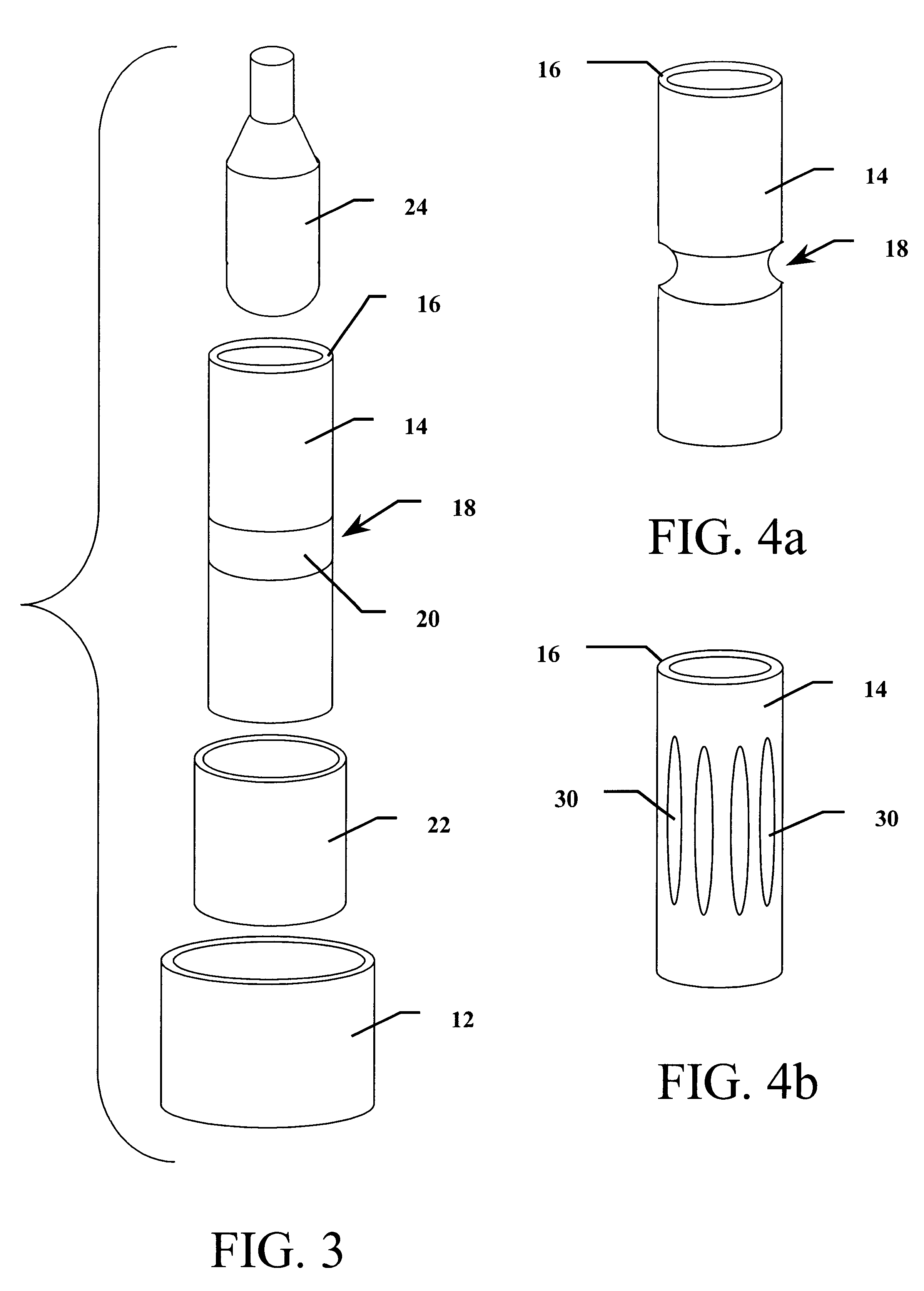

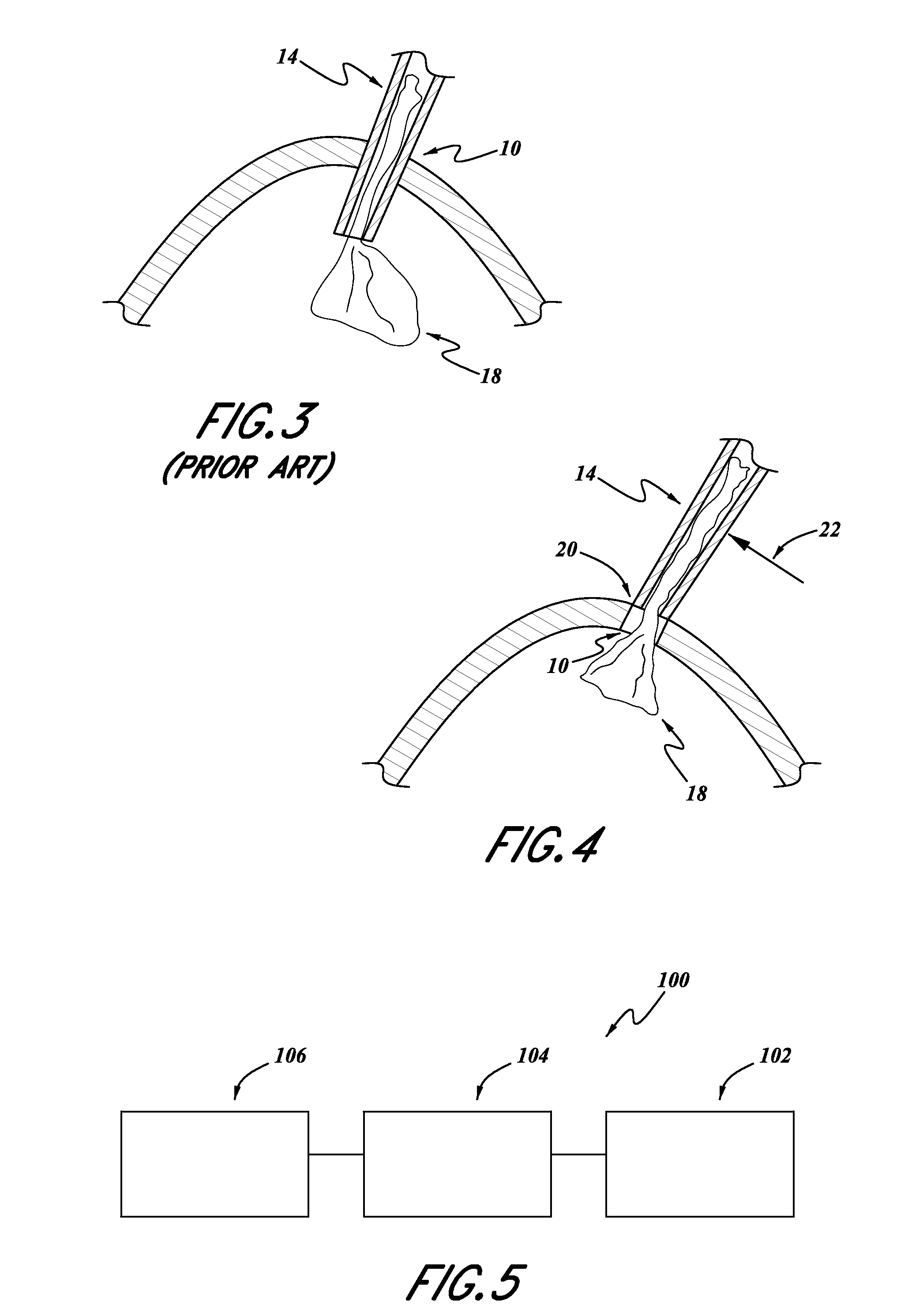

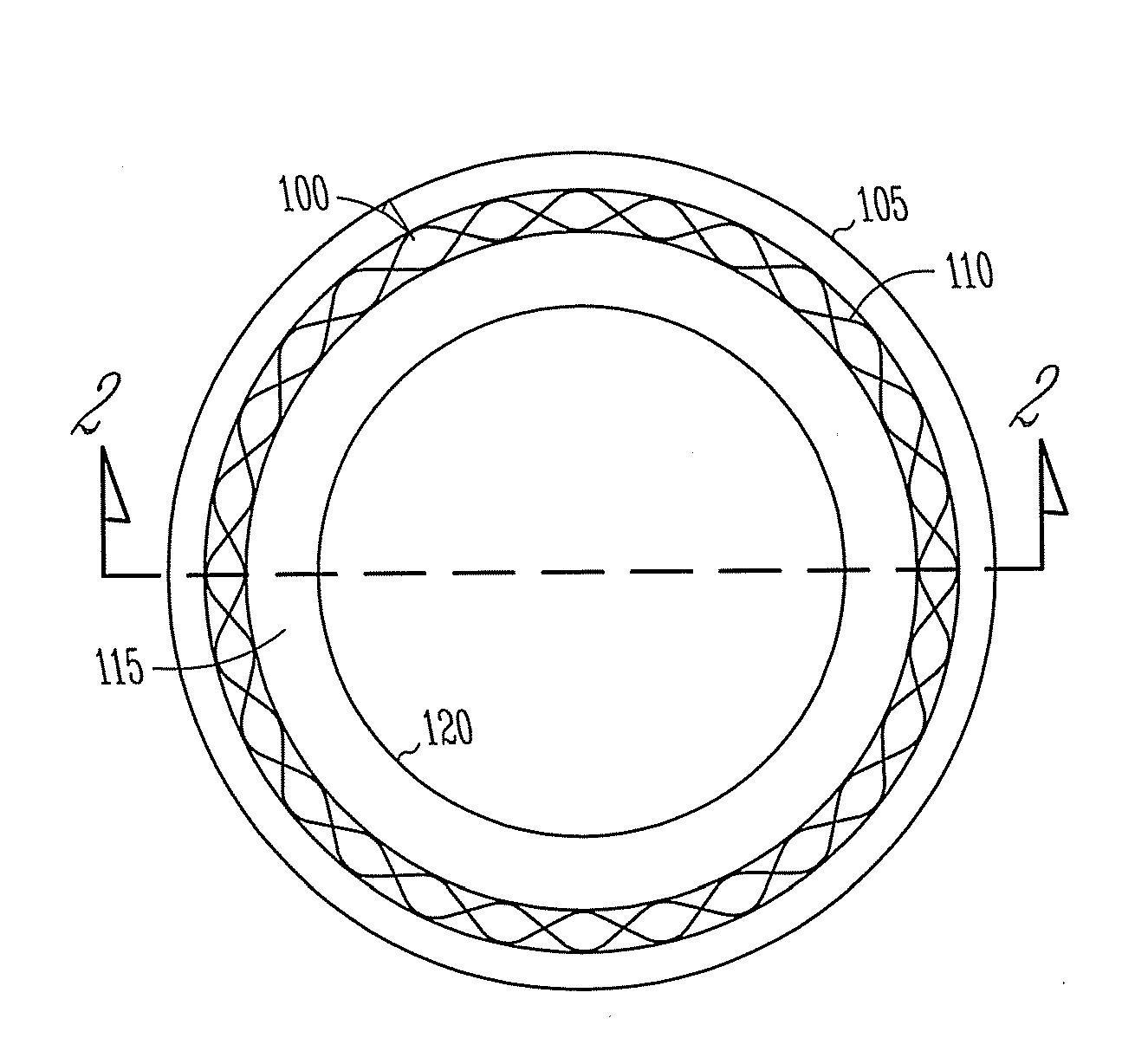

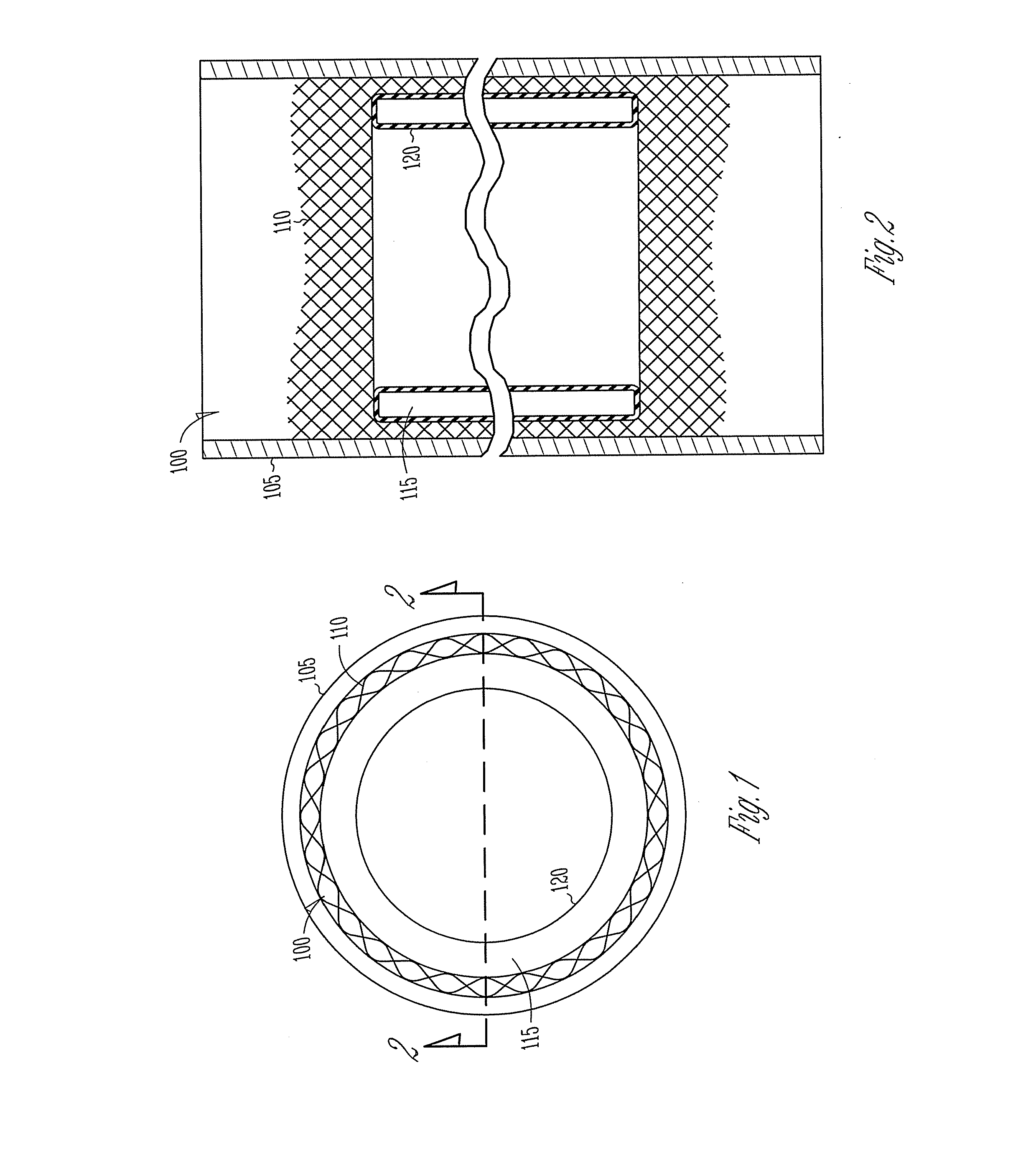

Method and apparatus for expansion sealing concentric tubular structures

InactiveUS6530574B1Resistance to degradationReduce the possibilitySleeve/socket jointsEngine sealsEngineeringSealant

A device and method for sealing a first cylinder in a fixed position inside a second concentric cylinder. The inner cylinder has an annular depression in its wall at the point of sealant placement, which causes the wall of the inner cylinder to intrude inwardly. The depression is filled with a partially compressible fluid and is covered over by a malleable / ductile sleeve. The inner cylinder is placed within the outer cylinder with the covered annular depression positioned at the desired sealing point. A cylindrical displacement device is directed through the inside of the inner cylinder where it encounters the intrusion of the annular depression. The displacement device is forced past the annular intrusion and pushes the wall outward. The partially compressible fluid is forced to expand outward under the malleable / ductile cover in a manner that intrudes into the annular space between the inner cylinder and the outer cylinder and into contact with the outer cylinder. The partially compressible fluid has a residual energy sufficient to maintain the sealing element in contact with the outer cylinder.

Owner:BAILEY GARY L +1

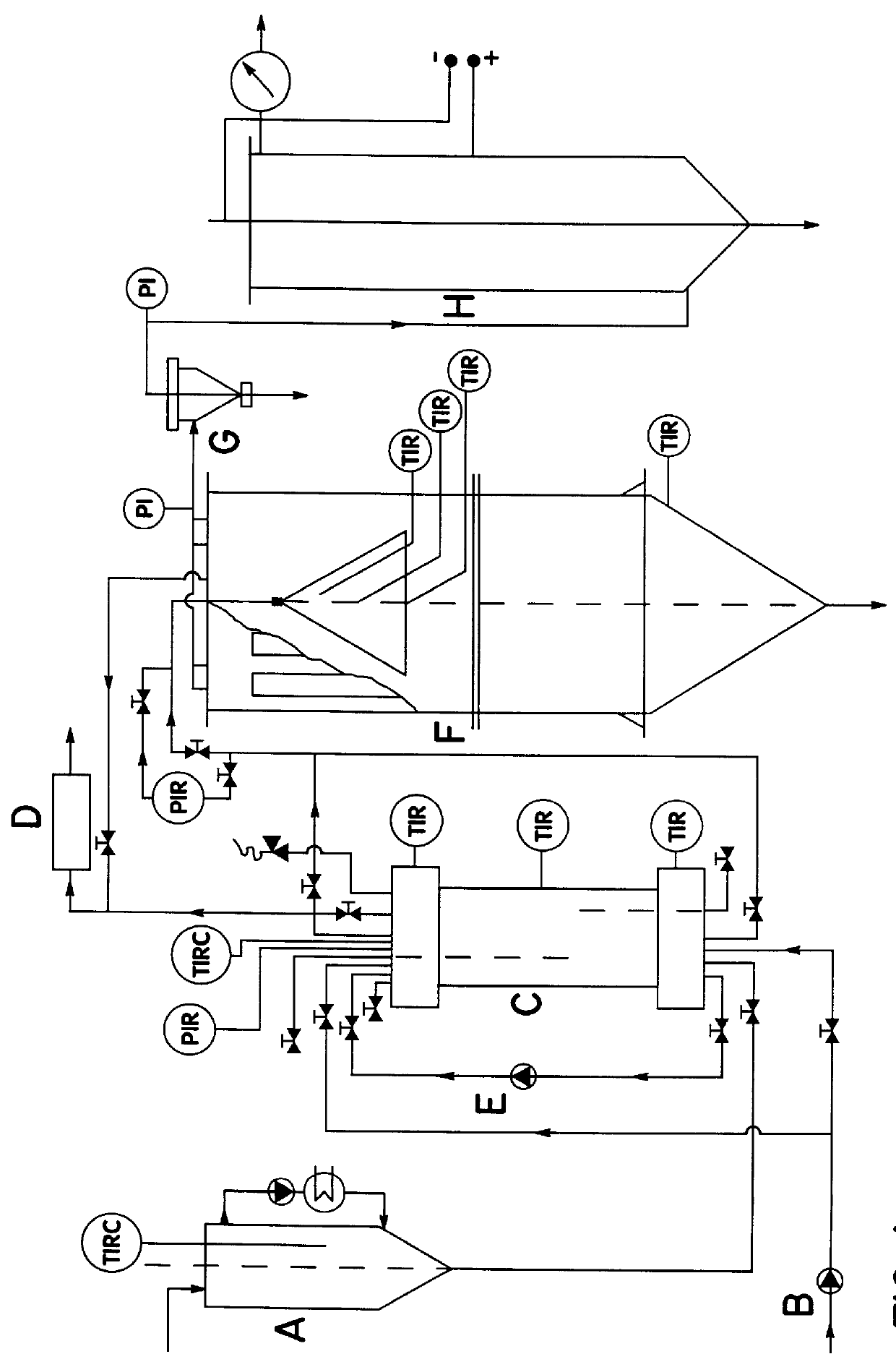

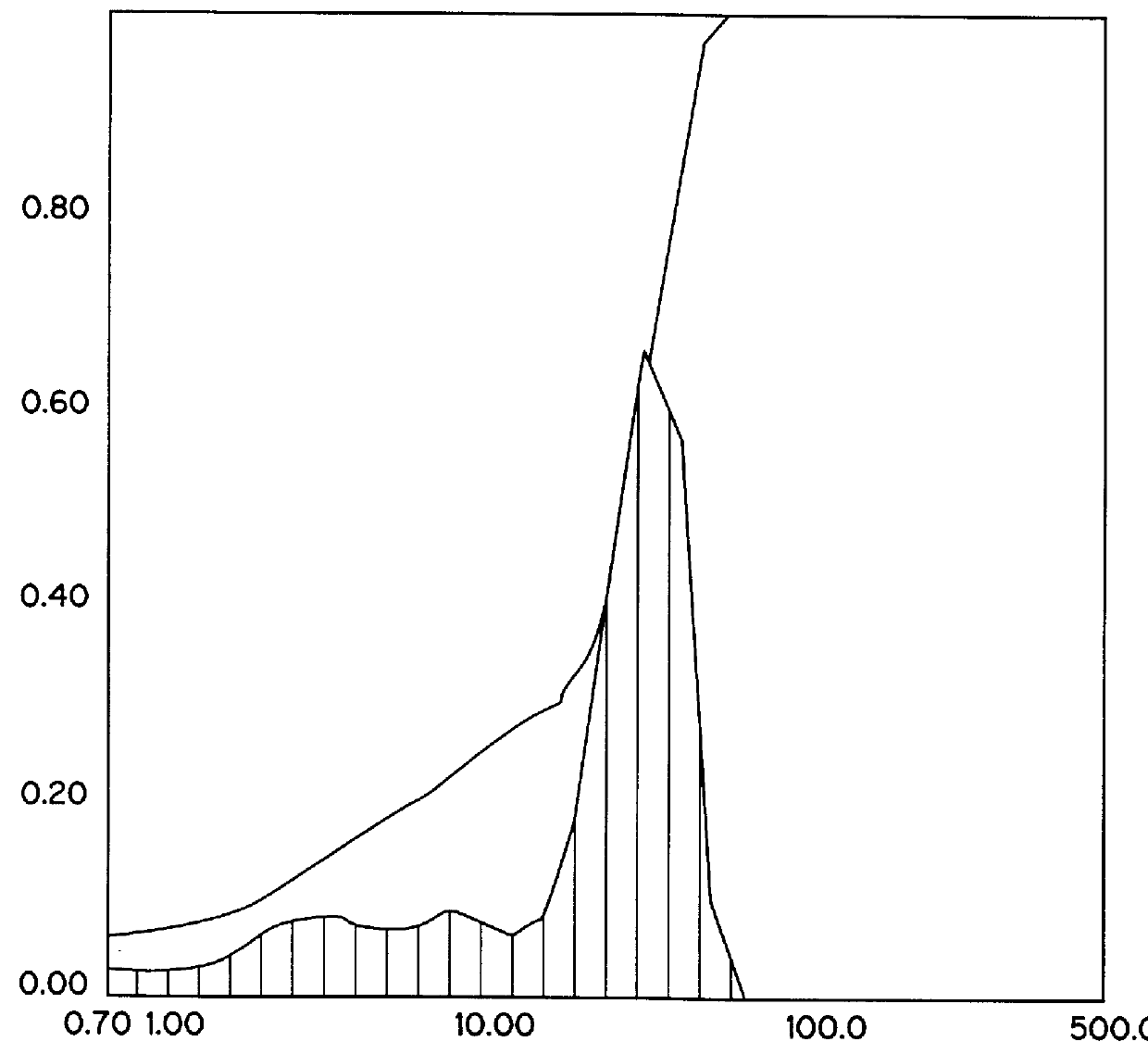

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

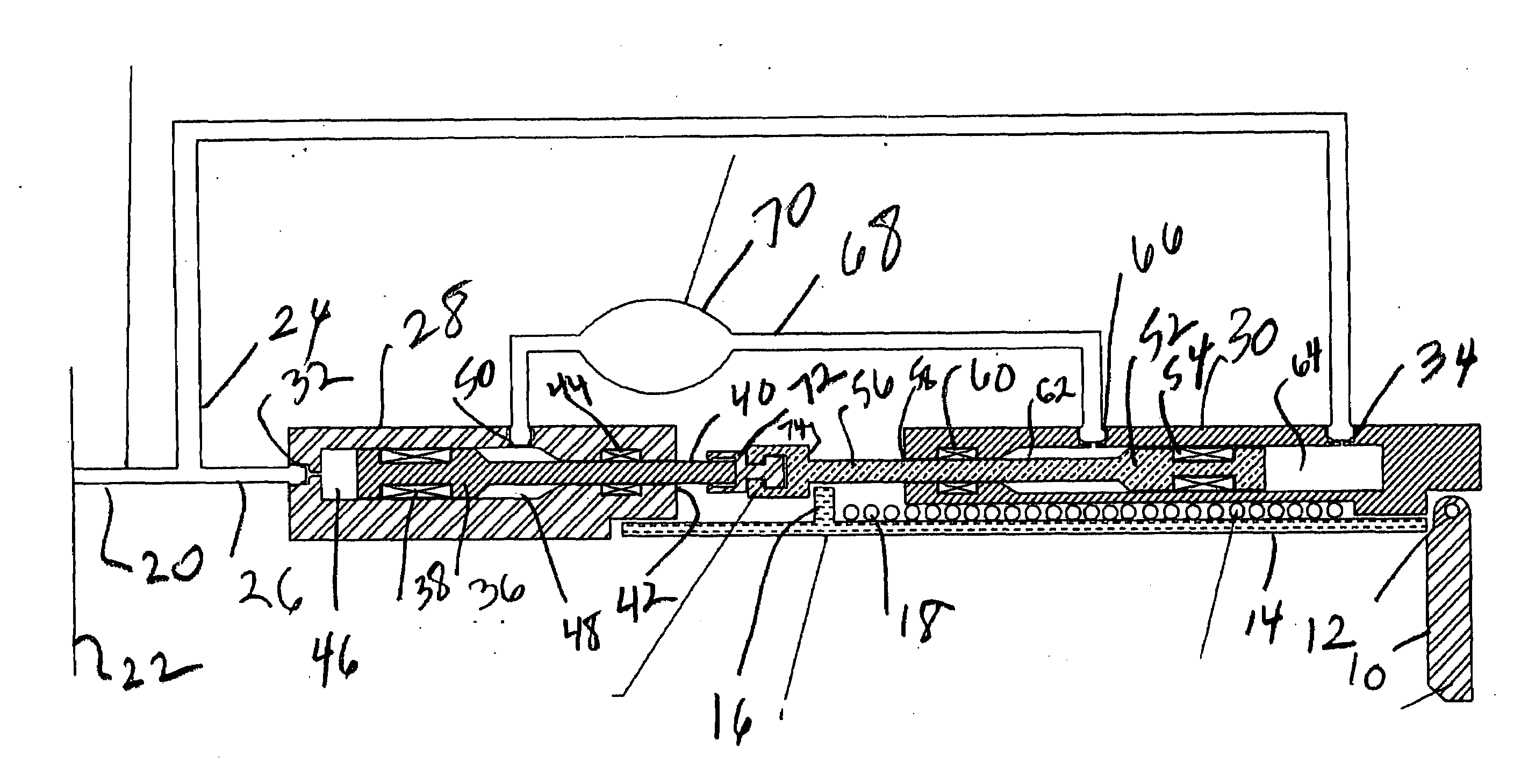

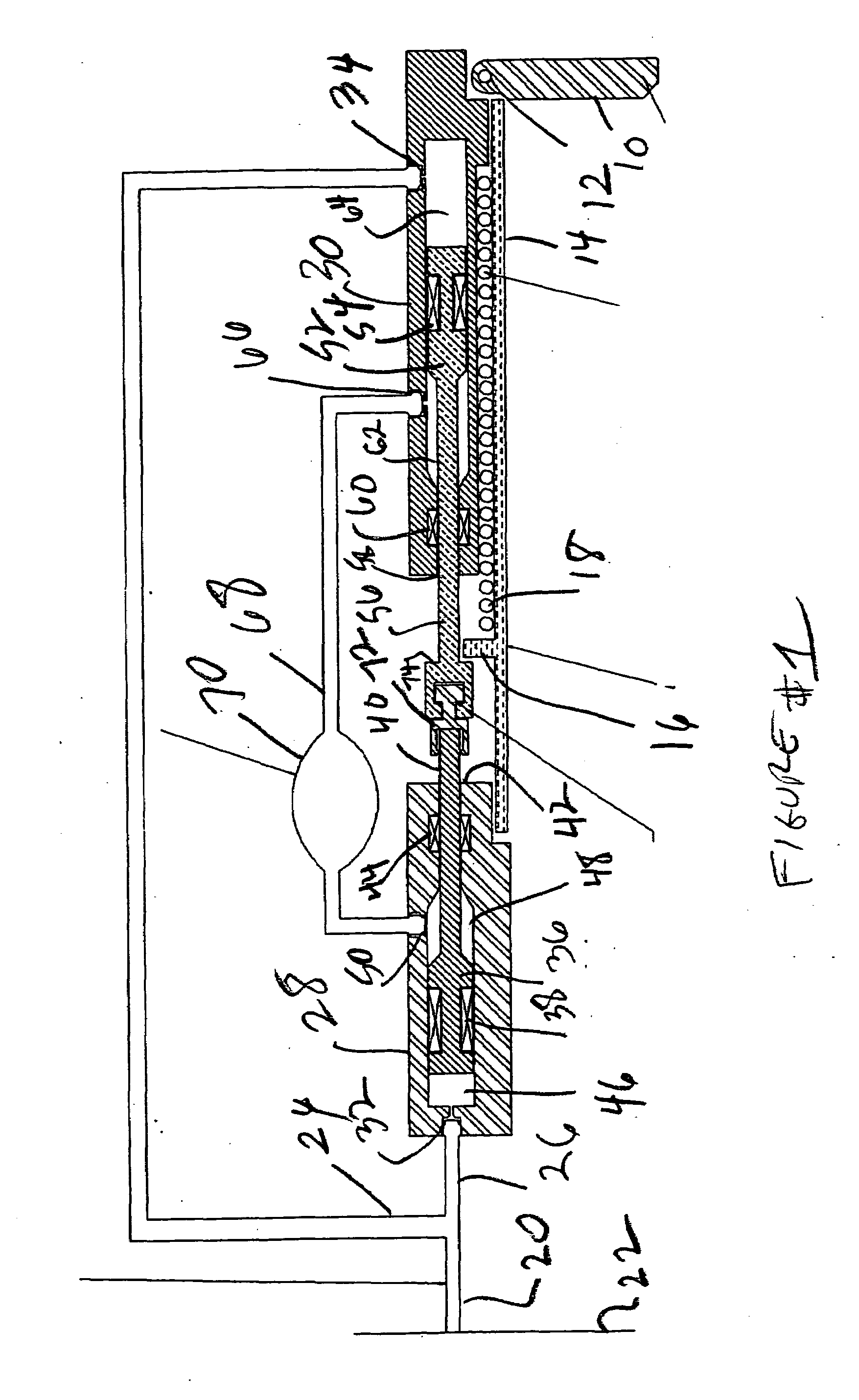

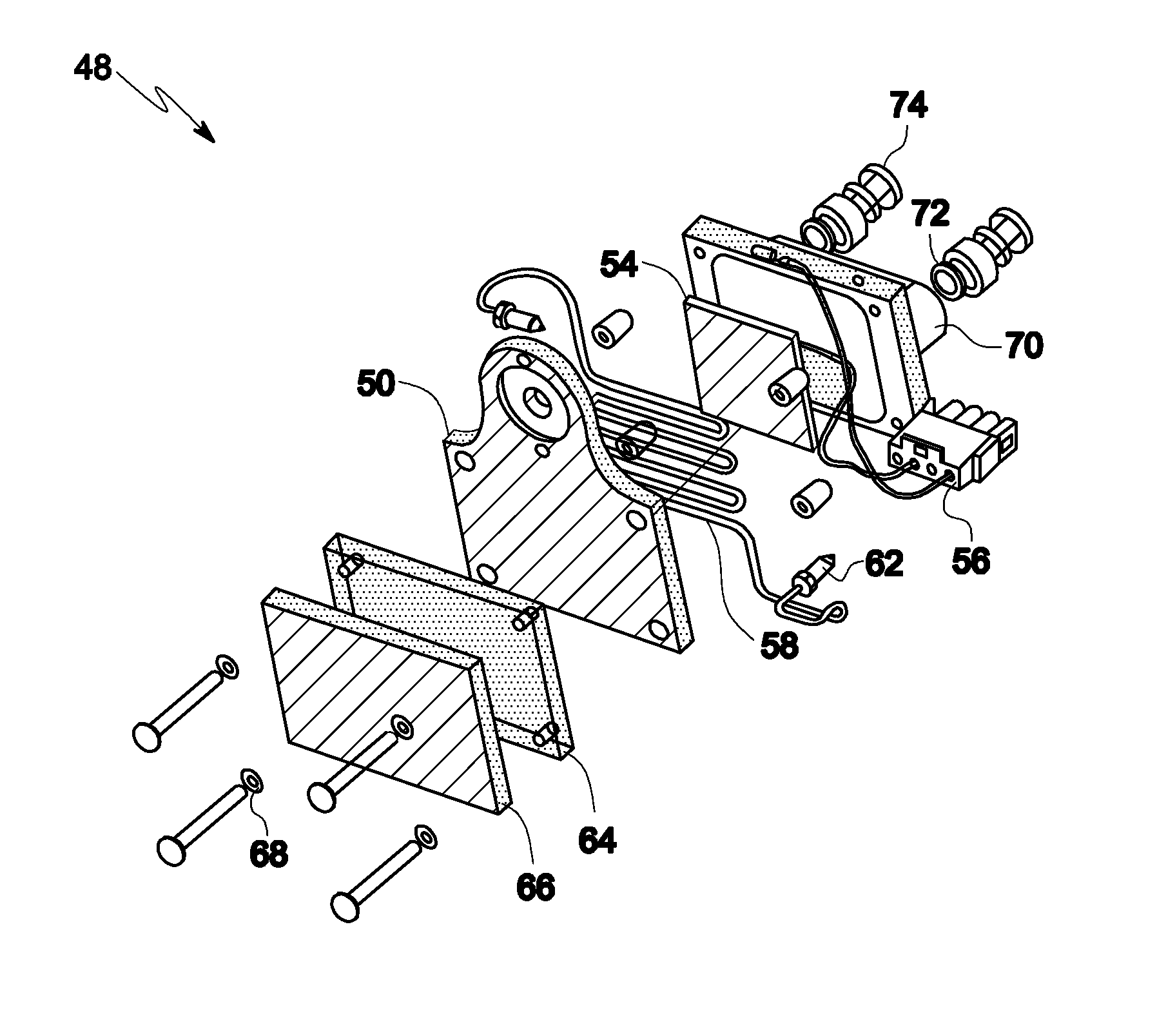

Infusion pump and method for use

InactiveUS7008403B1Small and lightLess componentsContracting/expanding measuring chambersVolume variation compensation/correction apparatusSolenoid valveContact method

A fluid dispensing system provides a non-contact method of monitoring the change in the fluid volume over time. This approach avoids the use of probes or sensors that come into direct contact with the fluid to be dispensed. The system comprises an apparatus comprising three chambers. The first chamber has a fixed volume and contains a pressurized gas. A solenoid valve is used to control the flow of gas from the first chamber into the second. The second chamber is sealed so that the combined mass of air in the first and second chambers remains fixed. The third chamber is adjacent to the second and contains medication in the form of incompressible fluid that is to be administered to a human or animal subject via a suitable delivery port. A piston is disposed between the second and third chambers and is movable responsive to the flow of gas into the second chamber to dispense fluid from the third chamber as desired. By sensing the pressure in the first and second chambers at any point in time, a processor is programmed to calculate the flow rate or dispensed volume of the fluid being delivered using principles derived from the Ideal Gas Law.

Owner:TANDEM DIABETES CARE INC

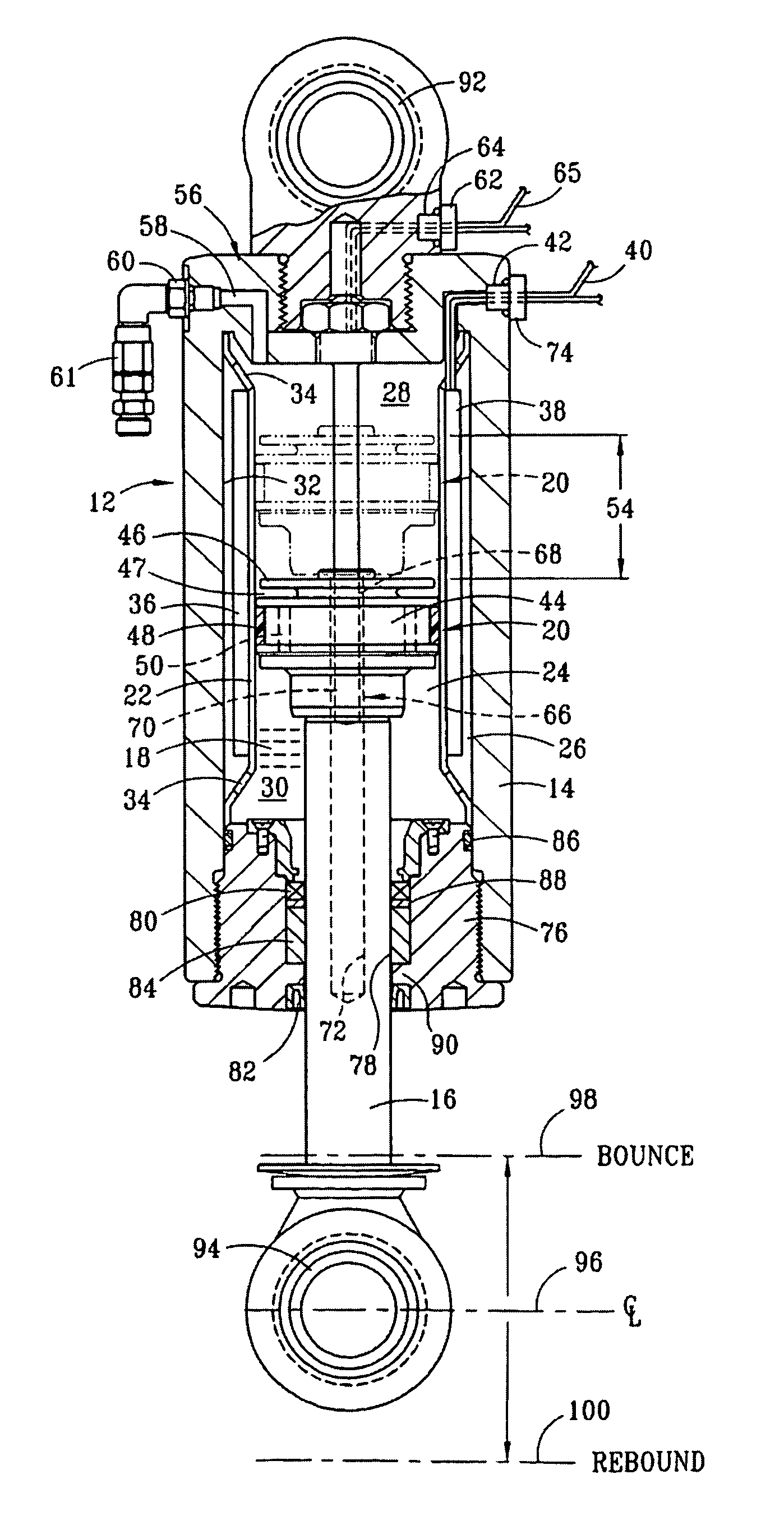

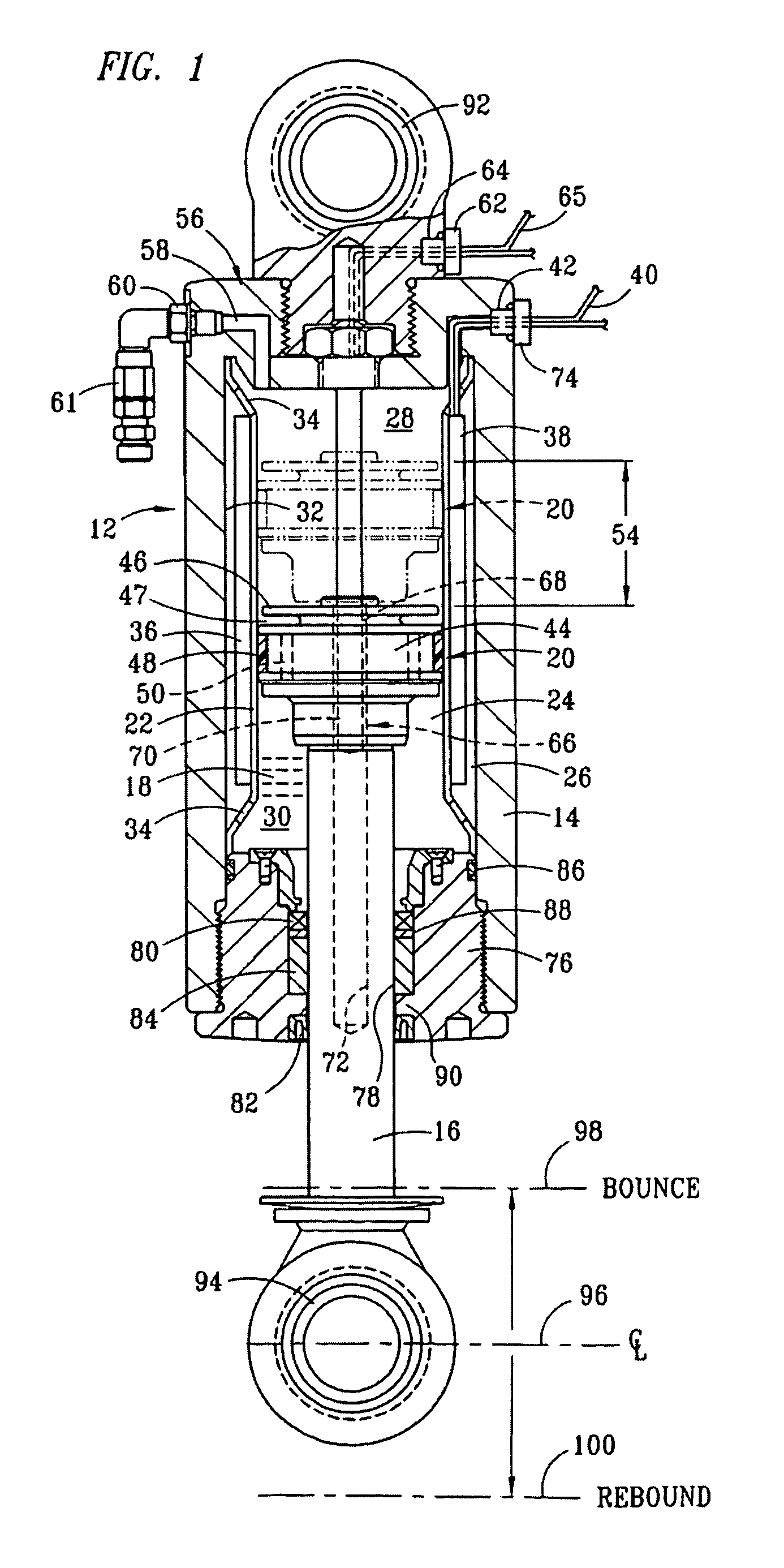

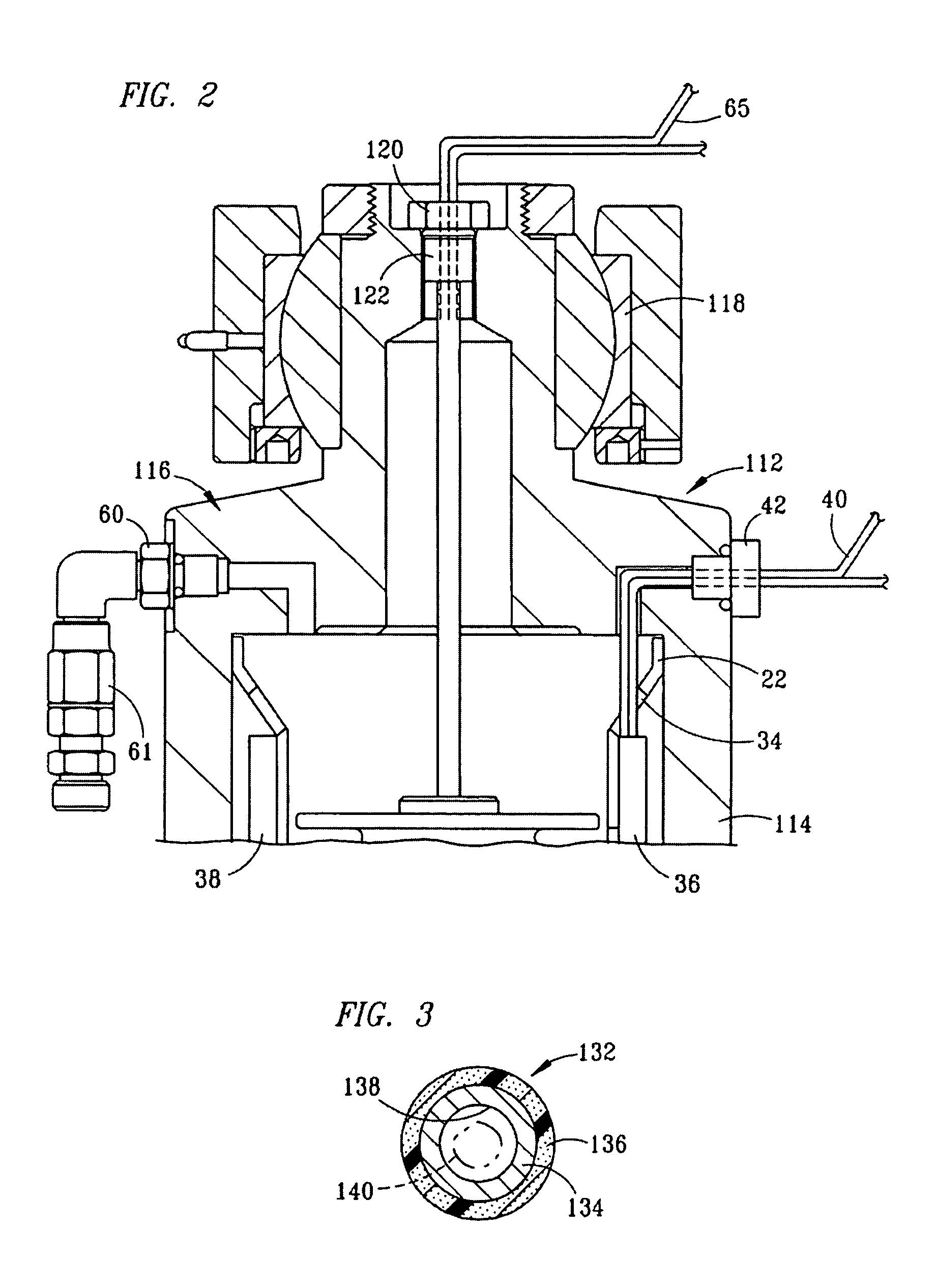

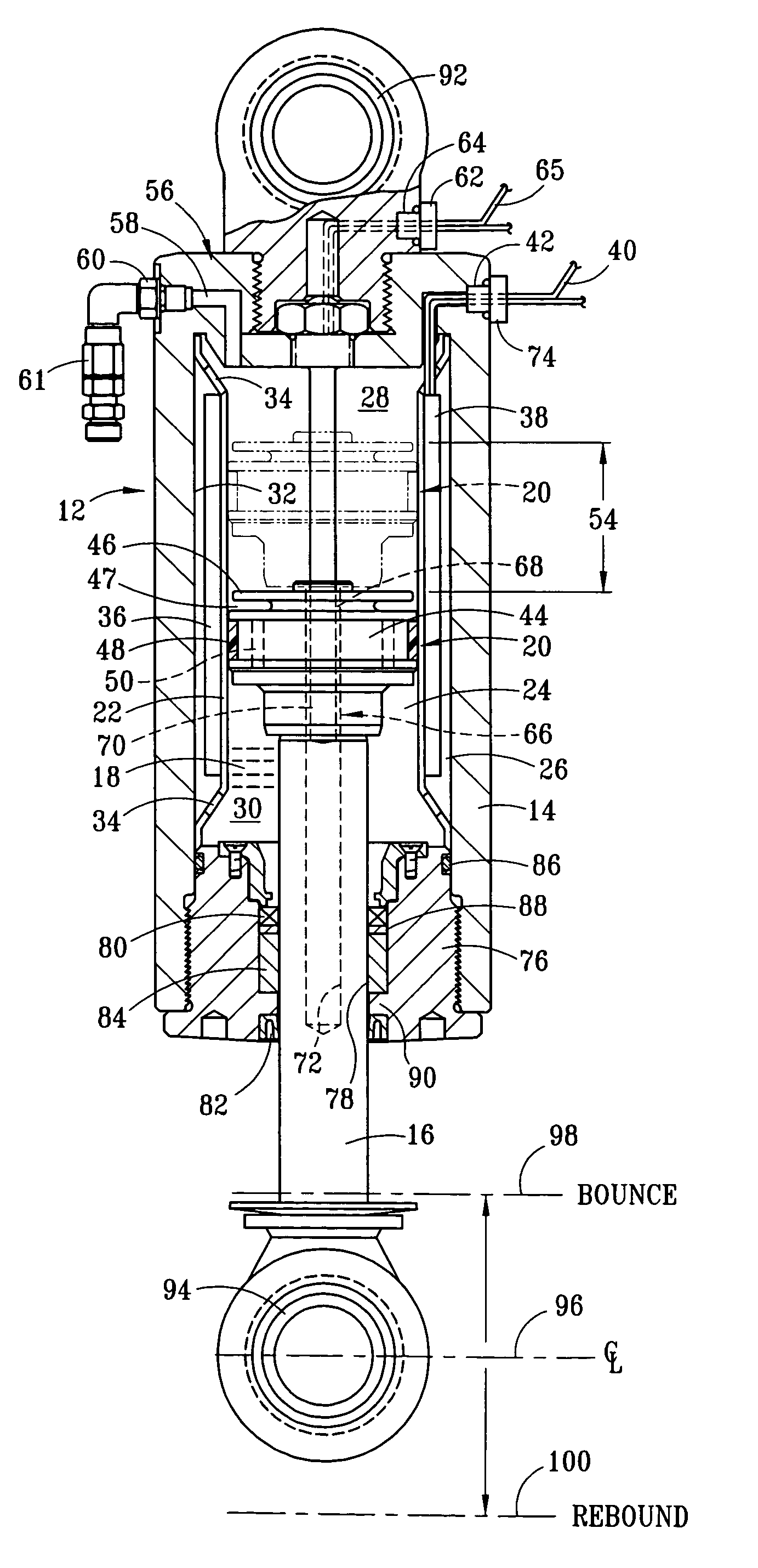

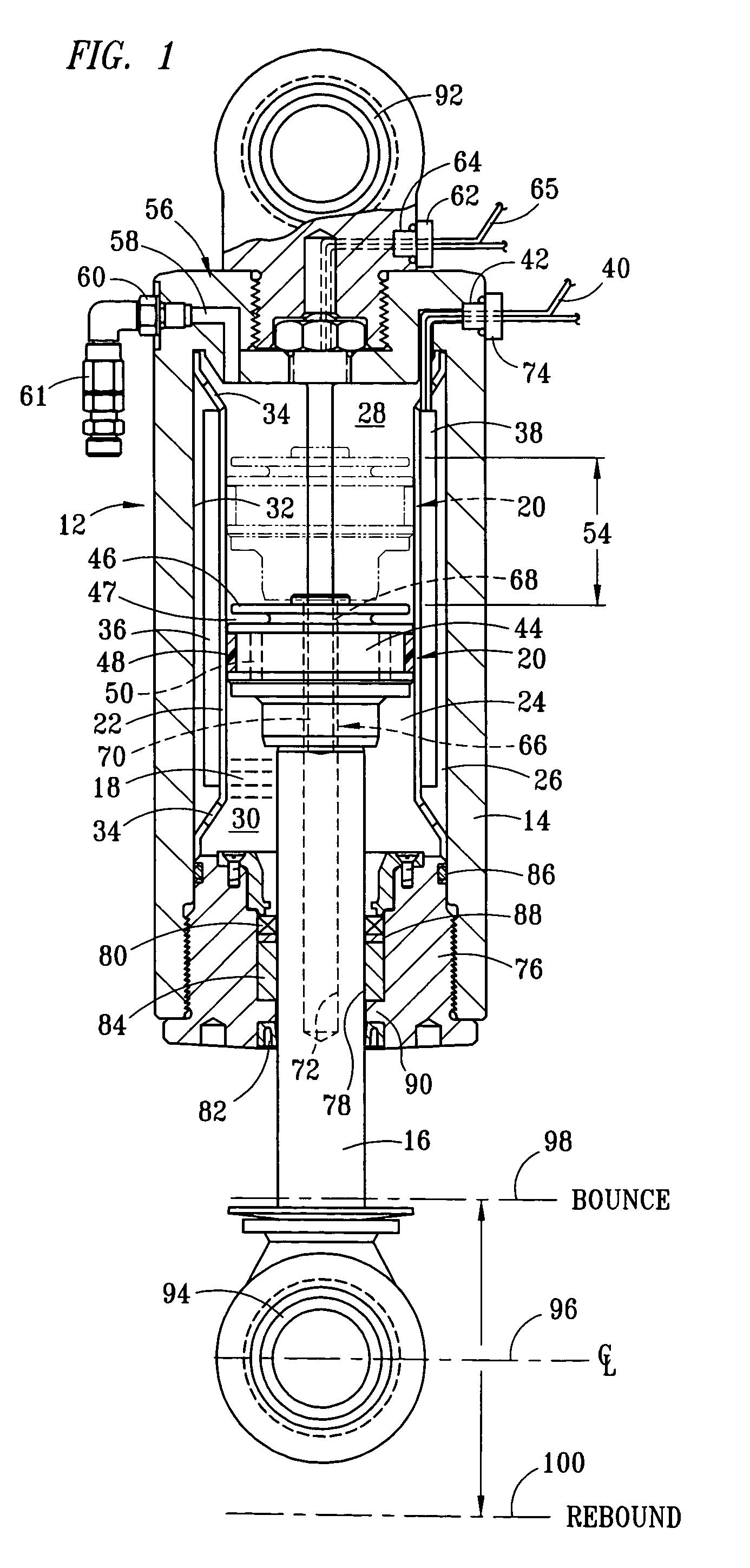

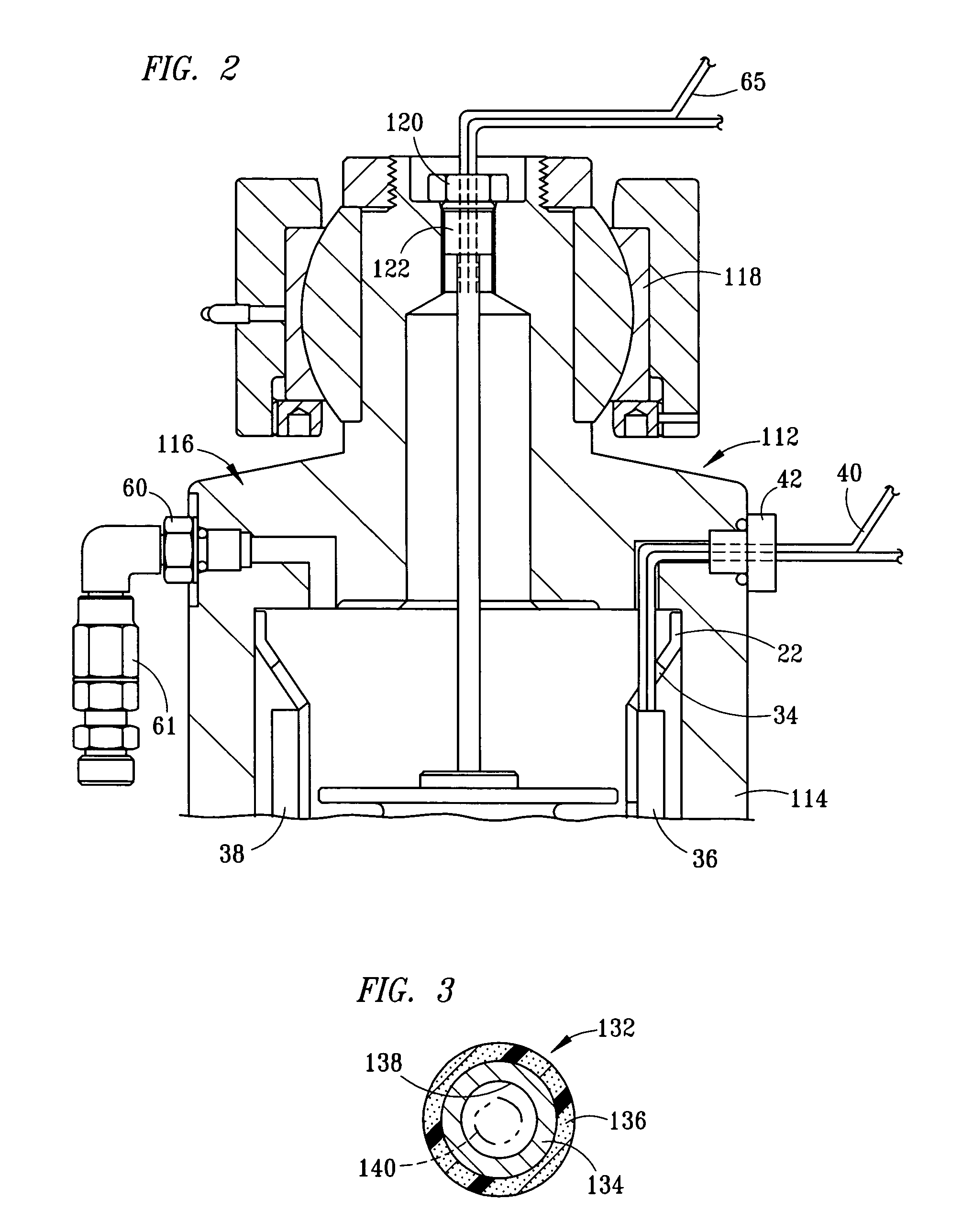

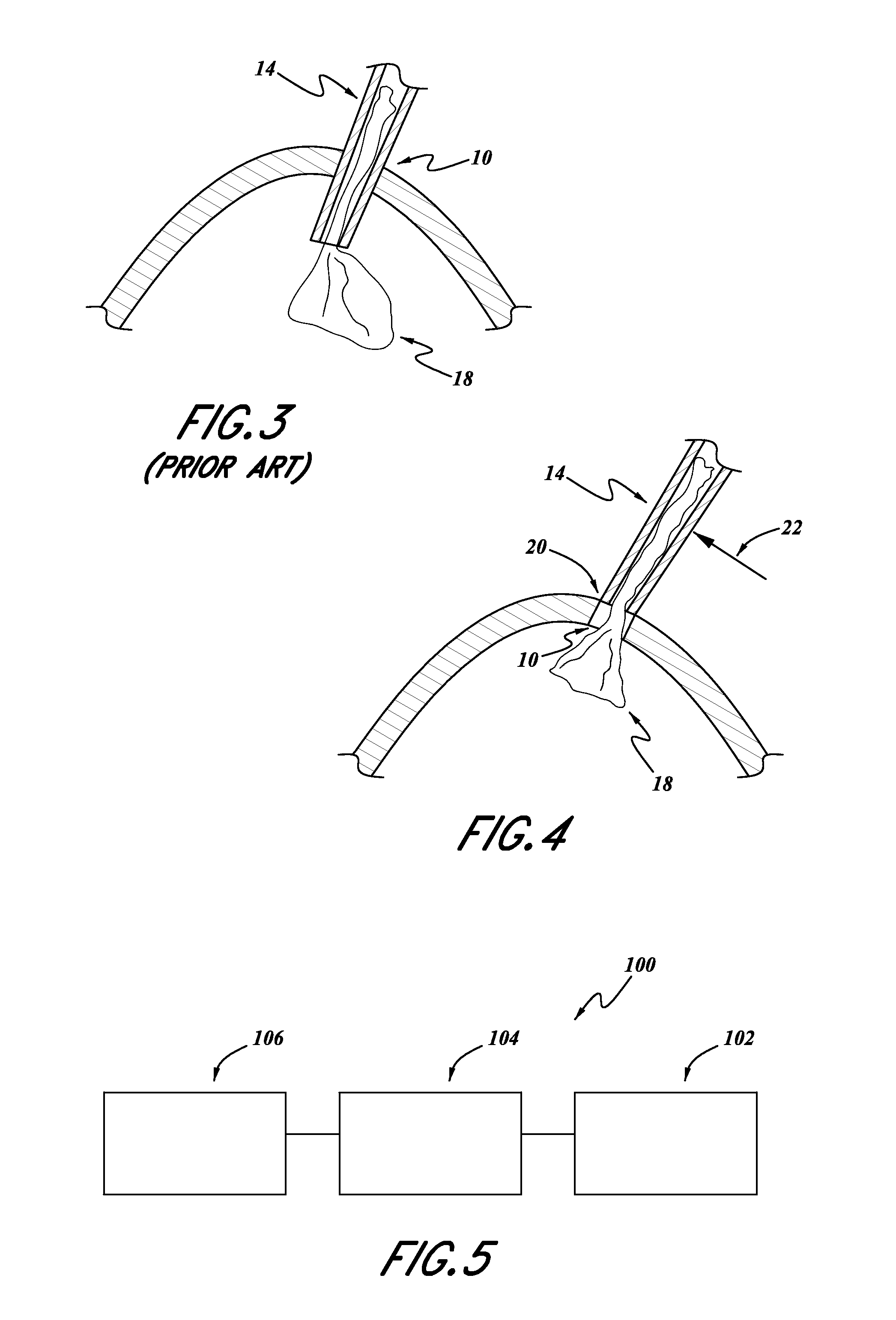

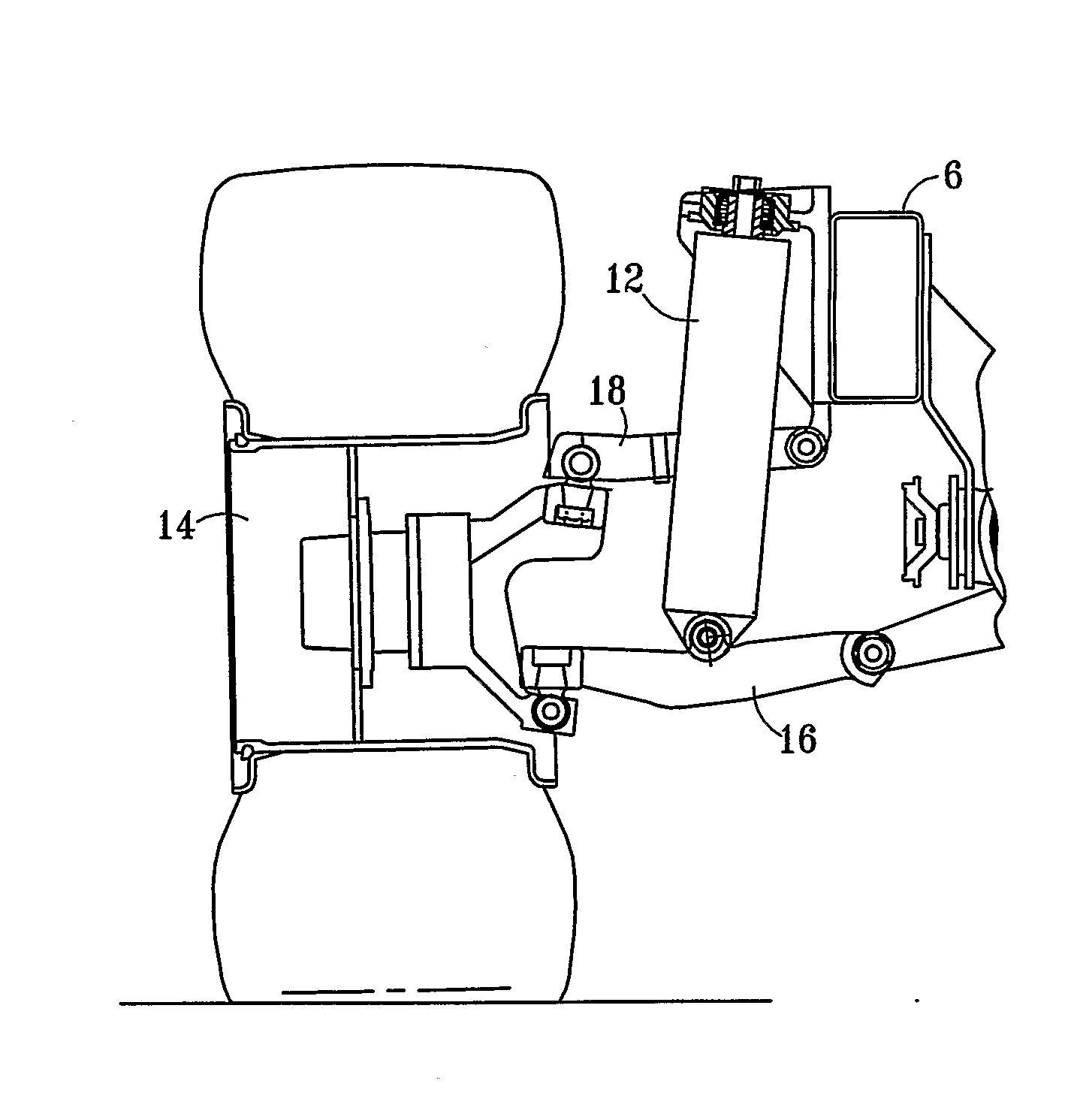

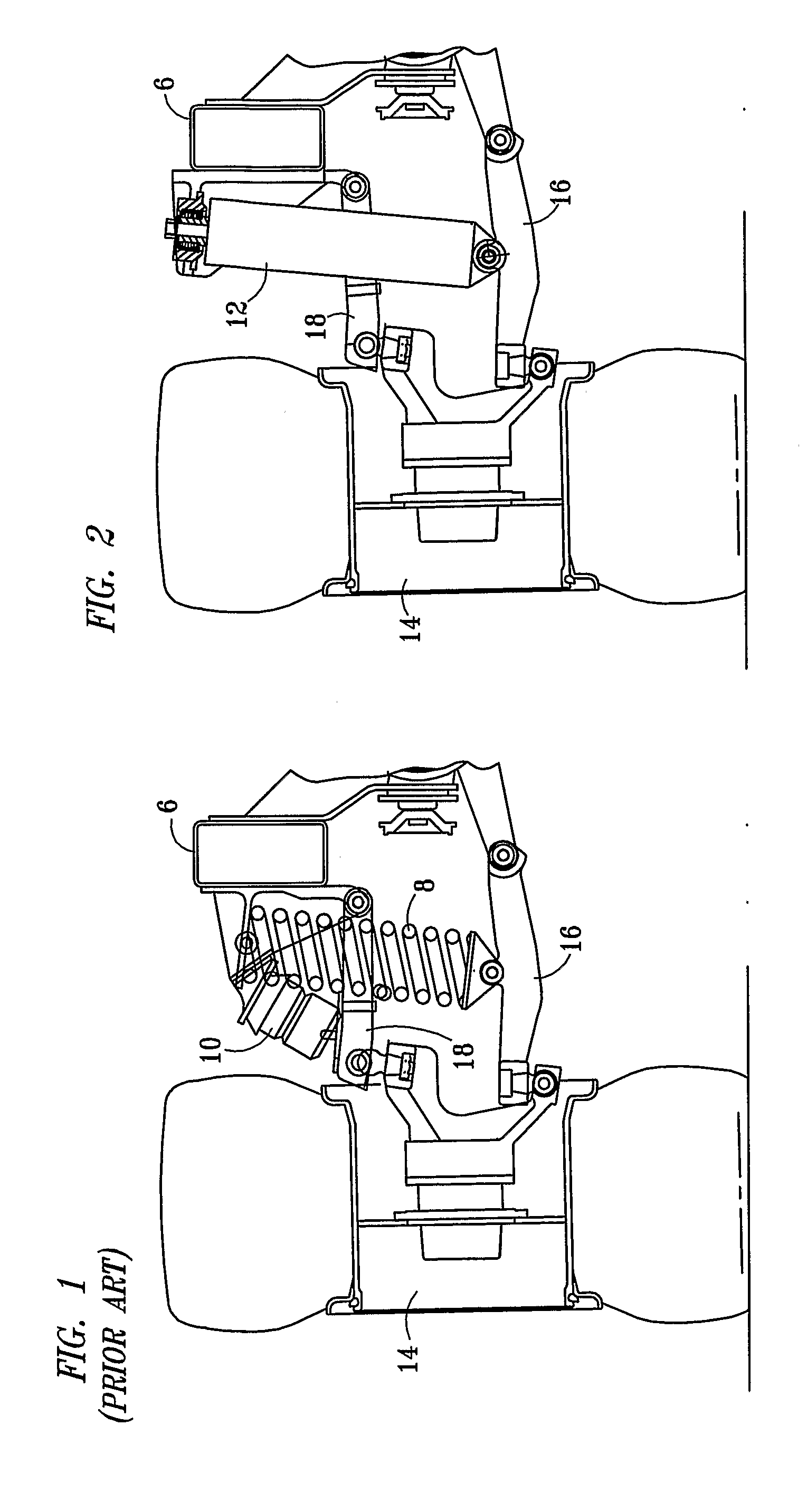

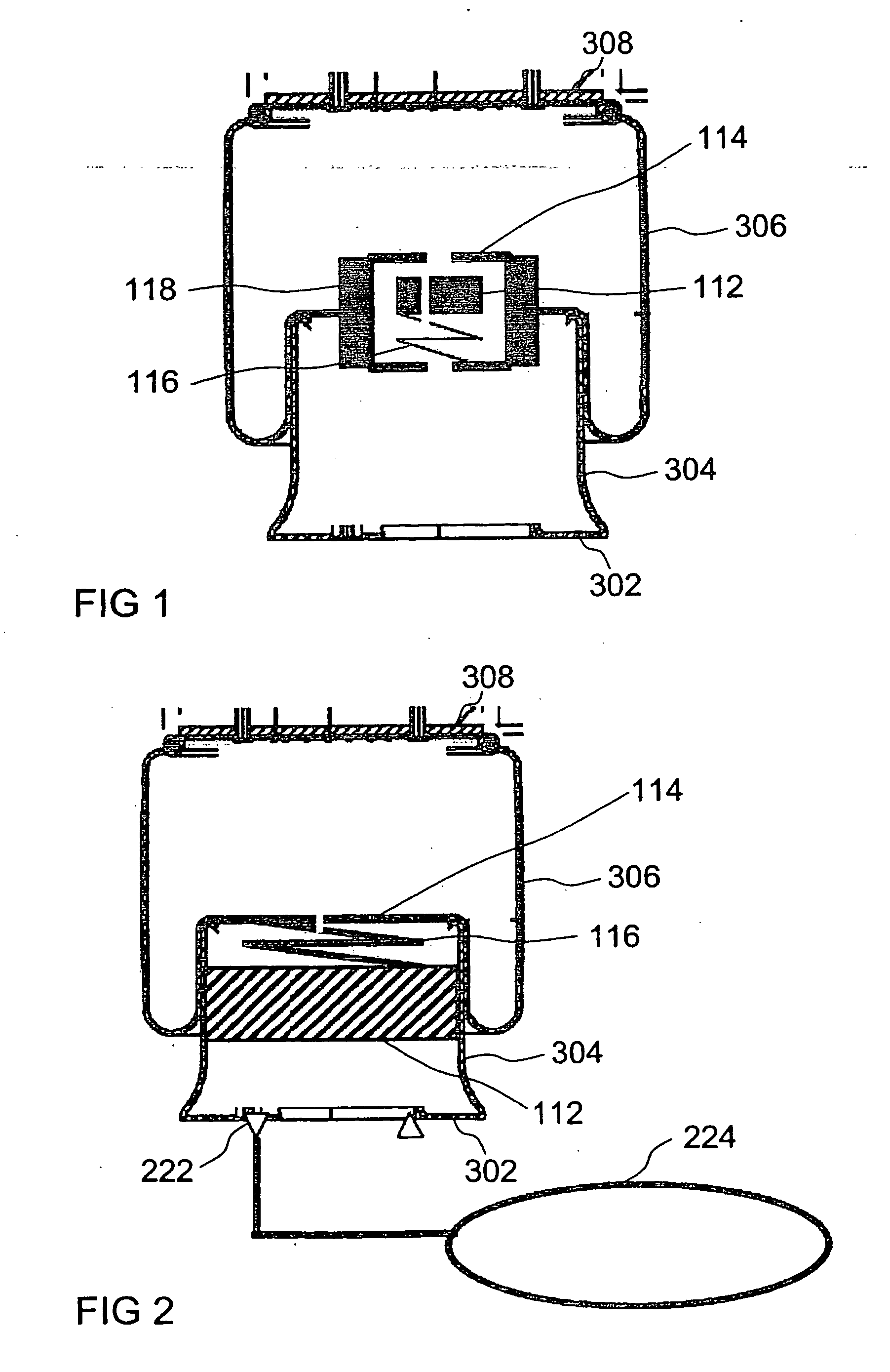

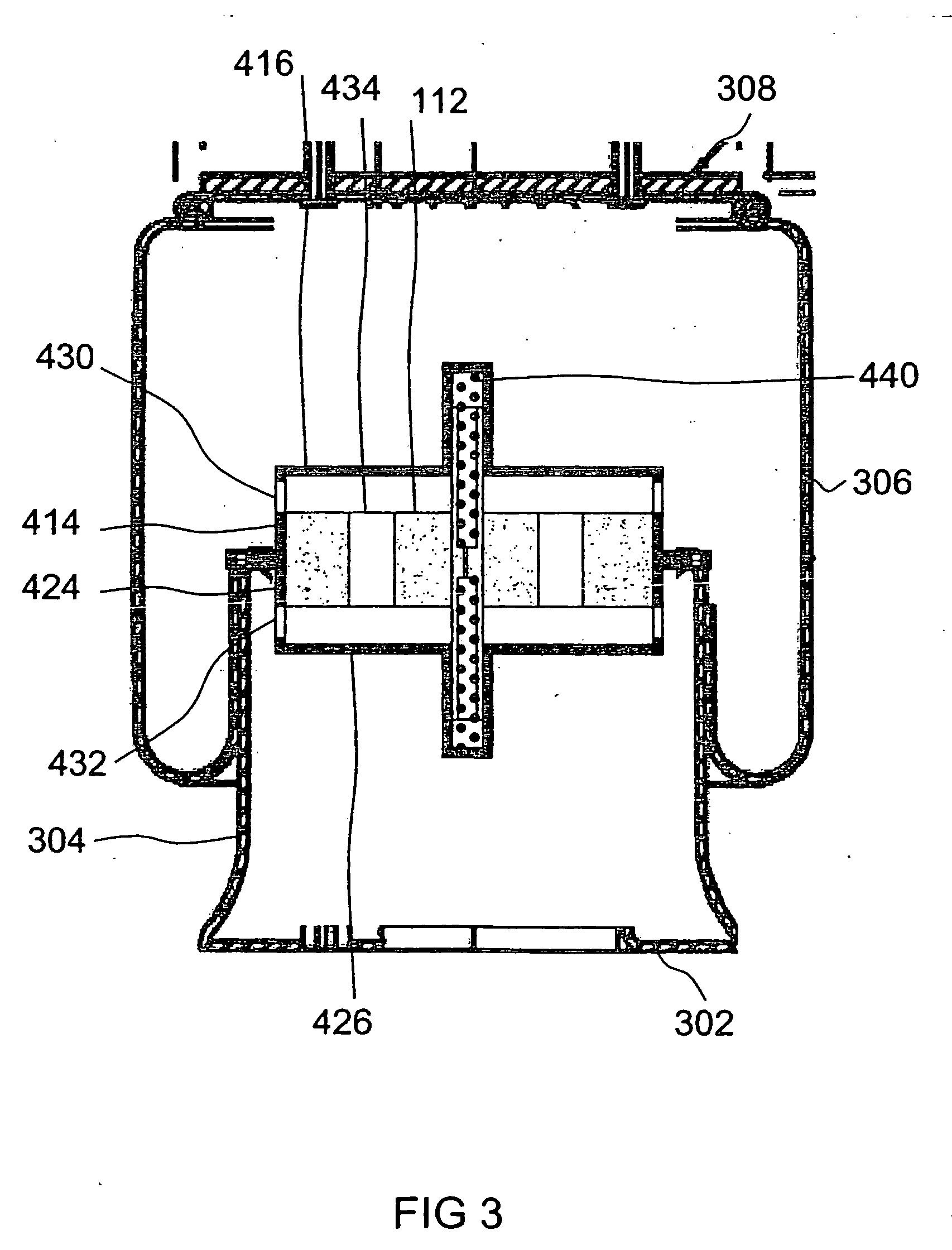

Suspension strut for use with a compressible magnetorheological fluid

ActiveUS7770701B1Prevent precipitationStay flexibleSpringsNon-rotating vibration suppressionMagnetorheological fluidVolumetric Mass Density

A strut (12) is configured for an active suspension system (142) which provides electronic control for both the force applied by the strut (12) and the dampening characteristics of the strut (12). A compressible fluid (18) is used within the strut (12), and preferably includes a compressible base fluid and electromagnetic field responsive particles (132) which are suspended in the compressible base fluid. The electromagnetic field responsive particles (132) are preferably closely matched in density and modulas of elasticity to that of the compressible base fluid to prevent sedimentation of the particles (132) and to maintain the elasticity of the compressible fluid (18). The amount compressible fluid (18) within the strut (12) is electronically controlled to determine the force applied by the strut (12) and a field strength applied to the compressible fluid in a fluid flow passage is electronically controlled to determine the dampening characteristics of the strut (12).

Owner:HORSTMAN

Compressible fluid magnetorheological suspension strut

ActiveUS7413063B1Prevent precipitationStay flexibleSpringsNon-rotating vibration suppressionEngineeringVolumetric Mass Density

A strut (12) is configured for an active suspension system (142) which provides electronic control for both the force applied by the strut (12) and the dampening characteristics of the strut (12). A compressible fluid (18) is used within the strut (12), and preferably includes a compressible base fluid and electromagnetic field responsive particles (132) which are suspended in the compressible base fluid. The electromagnetic field responsive particles (132) are preferably closely matched in density and modulas of elasticity to that of the compressible base fluid to prevent sedimentation of the particles (132) and to maintain the elasticity of the compressible fluid (18). The amount compressible fluid (18) within the strut (12) is electronically controlled to determine the force applied by the strut (12) and a field strength applied to the compressible fluid in a fluid flow passage is electronically controlled to determine the dampening characteristics of the strut (12).

Owner:HORSTMAN

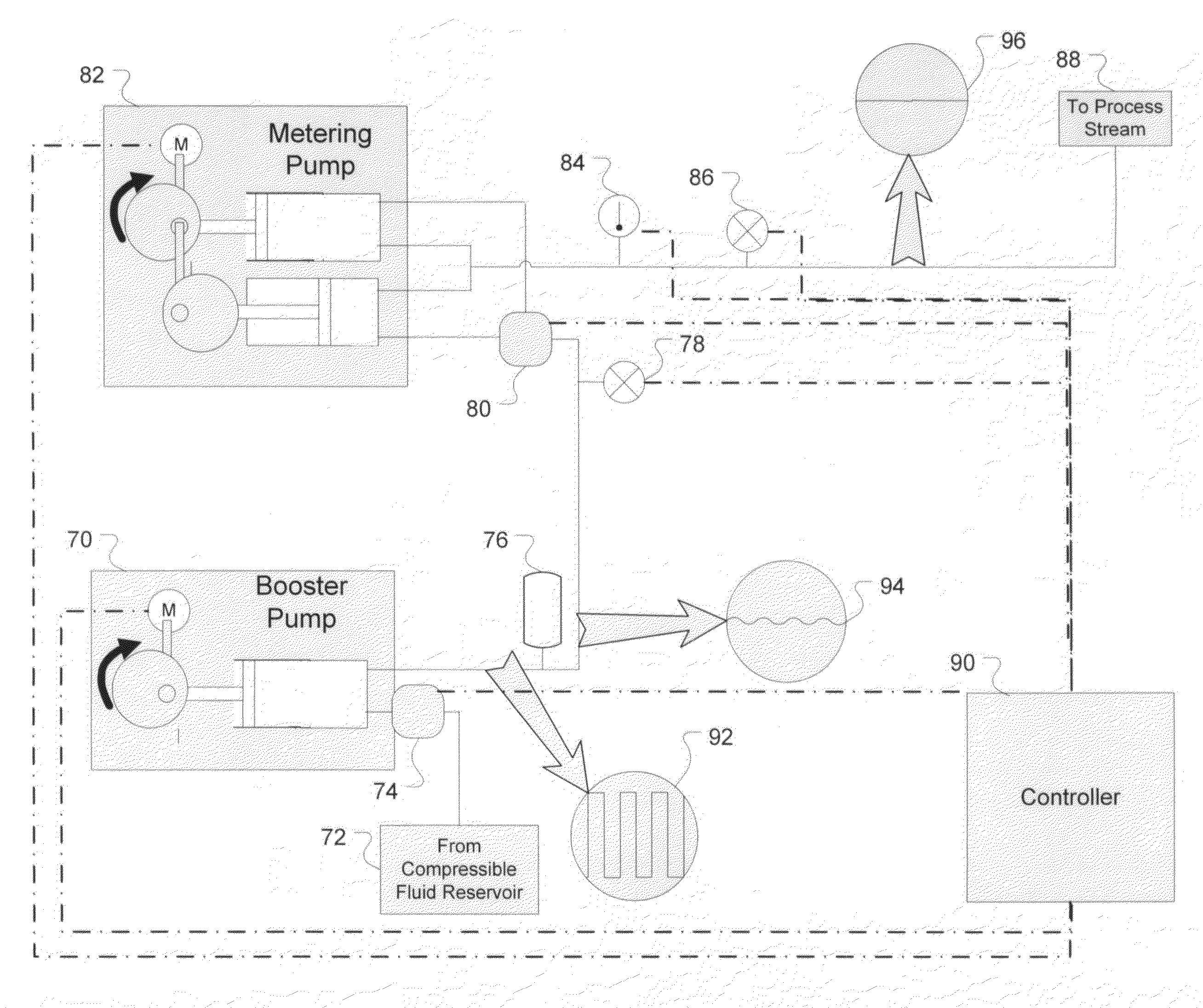

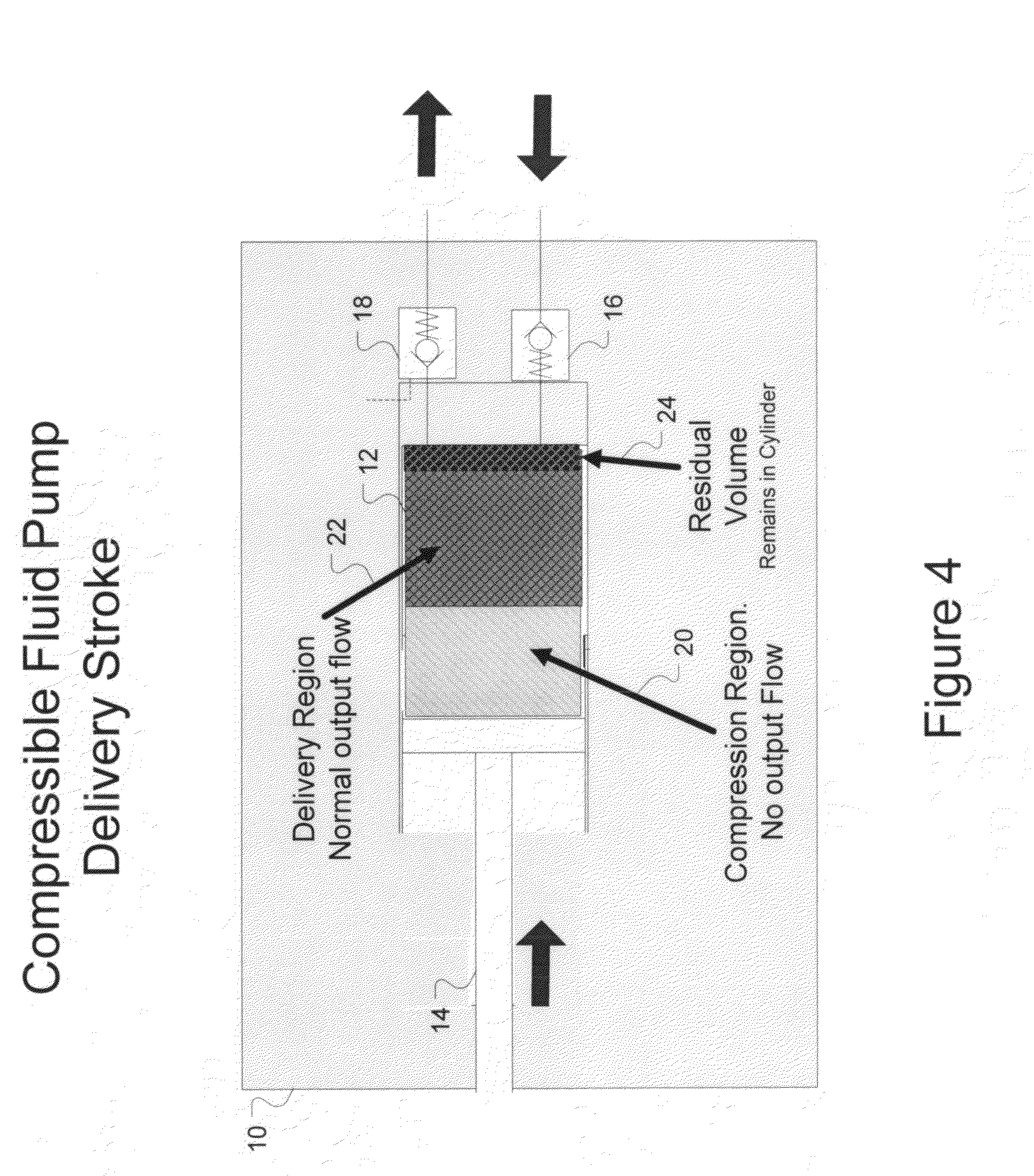

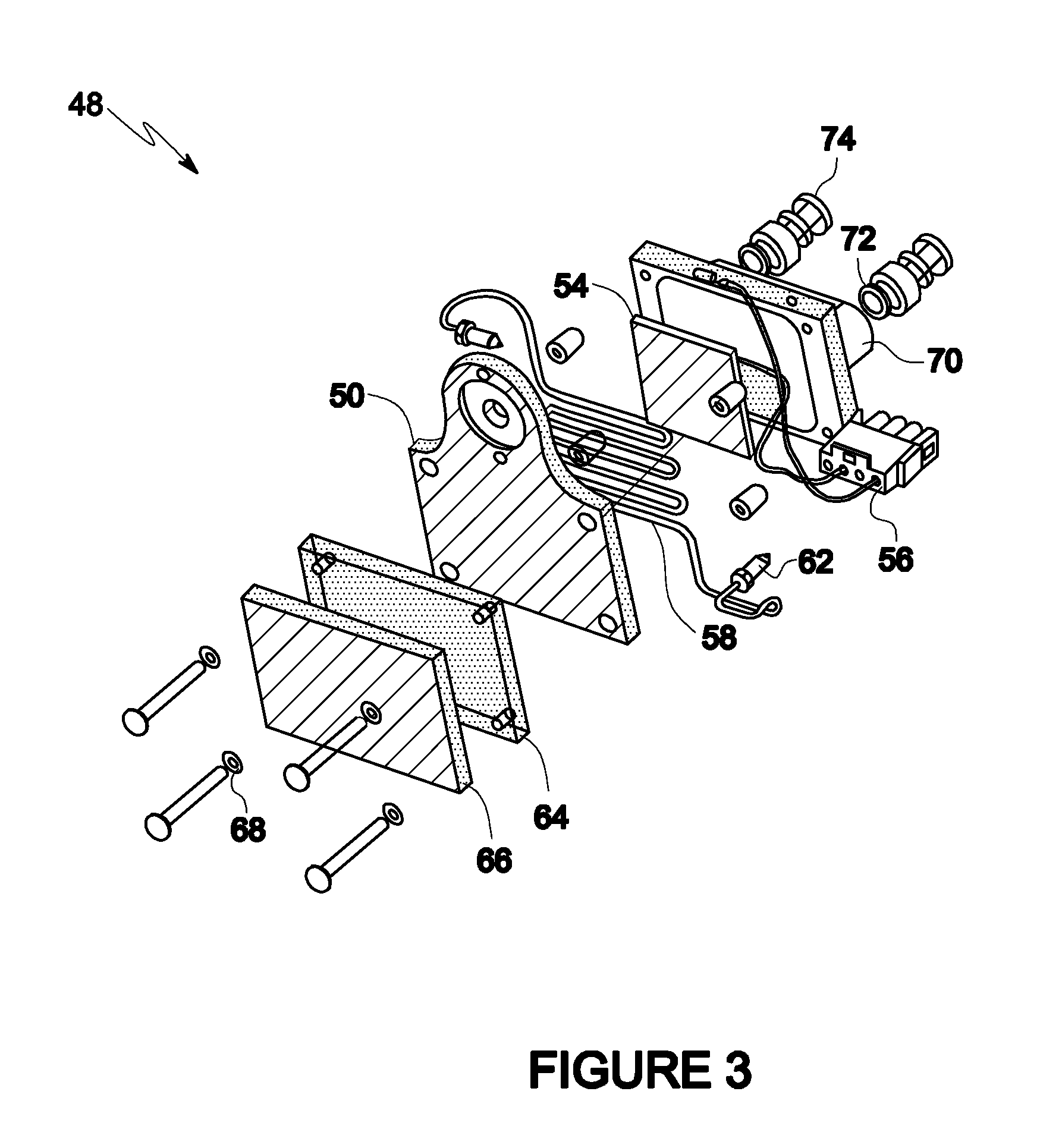

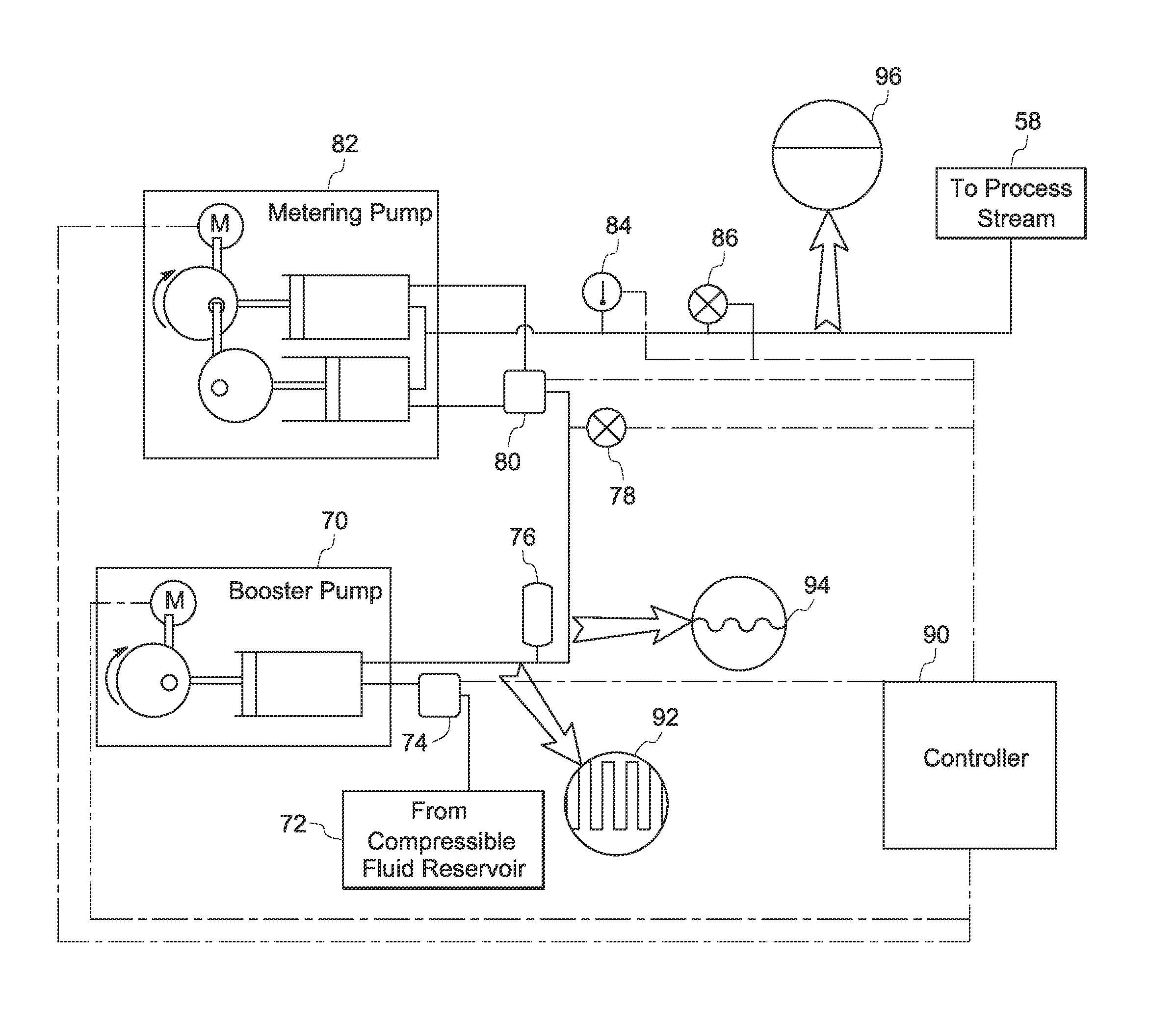

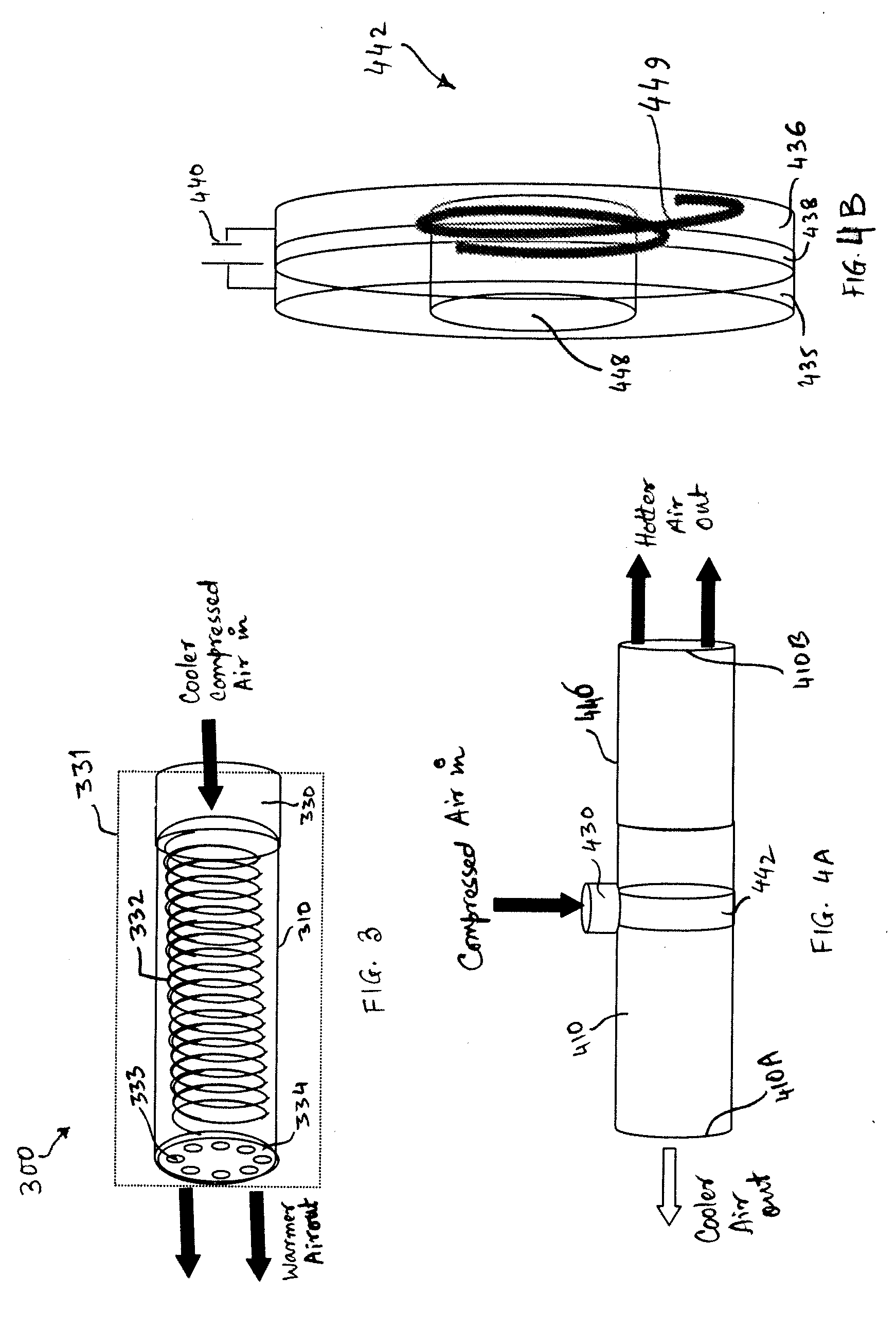

Compressible fluid pumping system

ActiveUS20100040483A1Low compressibilityPrecise functionComponent separationFlexible member pumpsEngineeringHigh pressure

An invention is claimed that enables the pumping of compressible fluids at high pressures when an accurate flow is desired. Two pressure sources, for example pumps plumbed in series, separate thermodynamic work, such as pressurization, at the first pressure source from a volumetric or matter metering function in the second pressure source. One example is a flowstream delivery for a chemical instrumentation system that is manufactured from relatively unsophisticated pumps yet delivers precise flows with low pulsation (<1 %) over pressures greater than 100 bar. An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

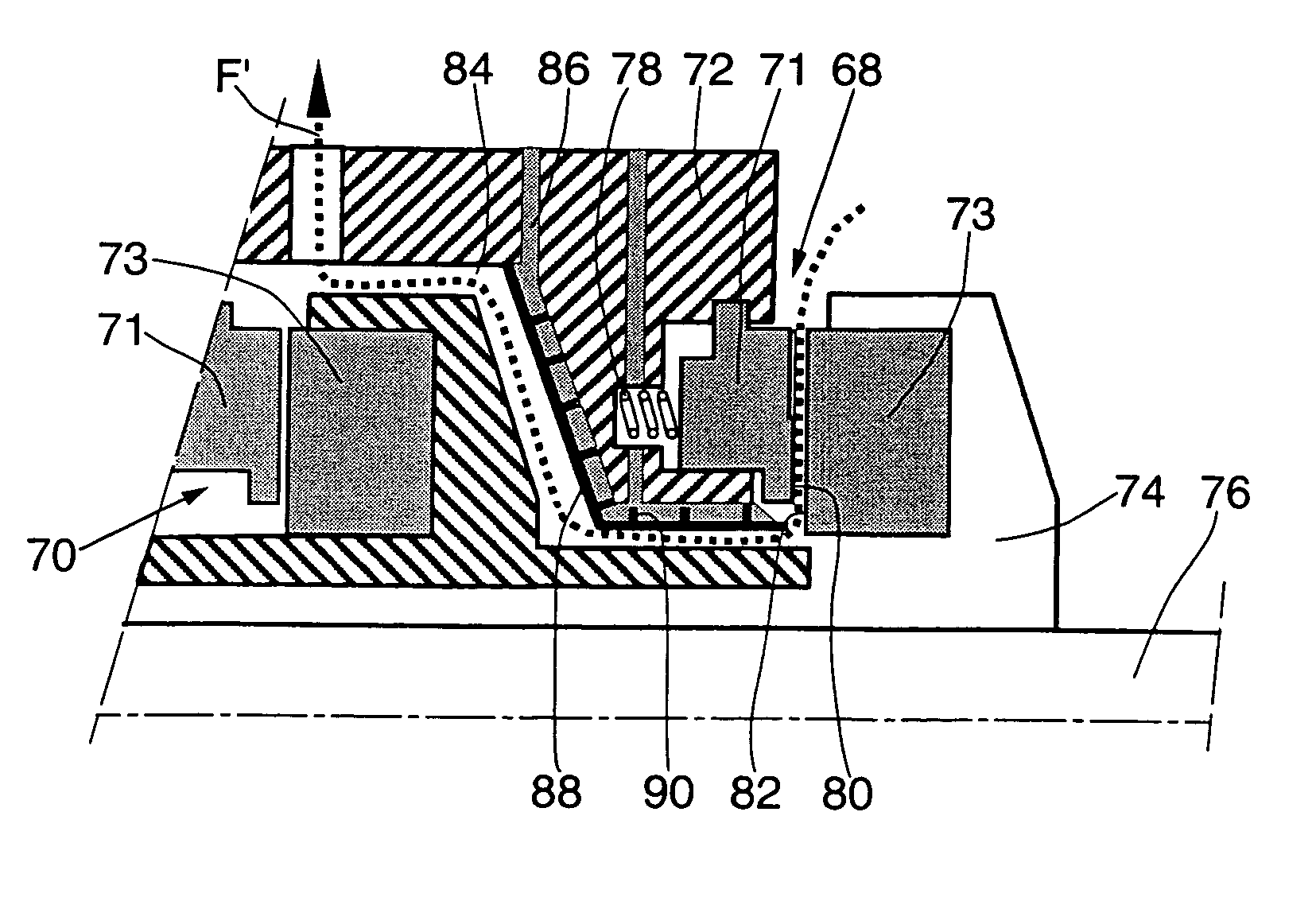

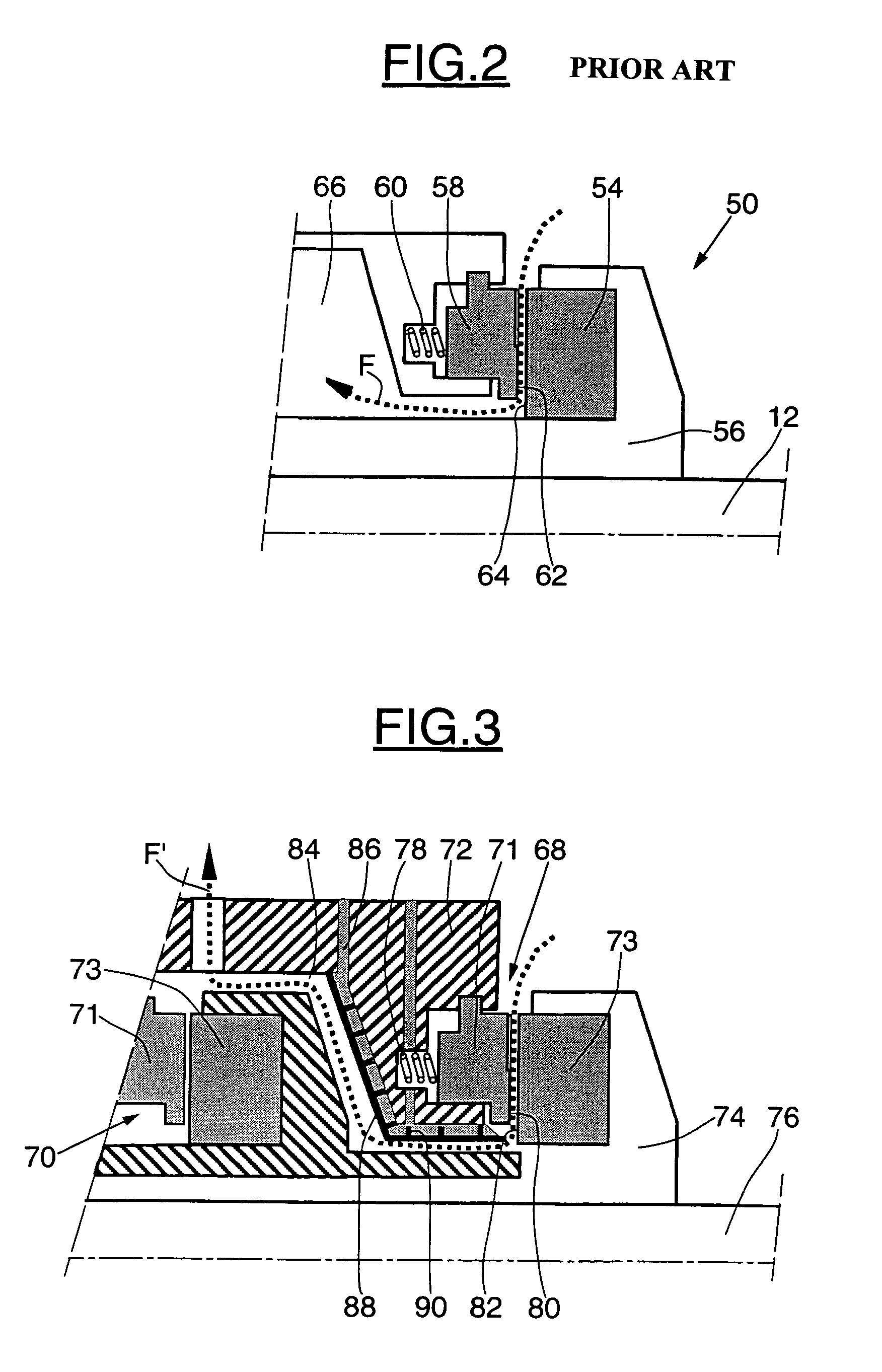

Seal for a compressor and centrifugal compressor equipped with such a seal

A seal for a rotary compressor comprises a casing, at least one assembly having a rotating seal face ring which rotates as one with a sleeve intended to be mounted on a shaft of the compressor and of a stationary seal face ring mounted on the casing, the seal face rings being urged to press against one another via their rubbing face. The seal design further incorporates fluid circulation for heating leaks of compressible fluid conveyed by the compressor that occur between the seal face rings, this fluid circulation being formed in the casing and extending at least partially downstream of the seal face rings with respect to the direction of flow of the fluid stream.

Owner:THERMODYN

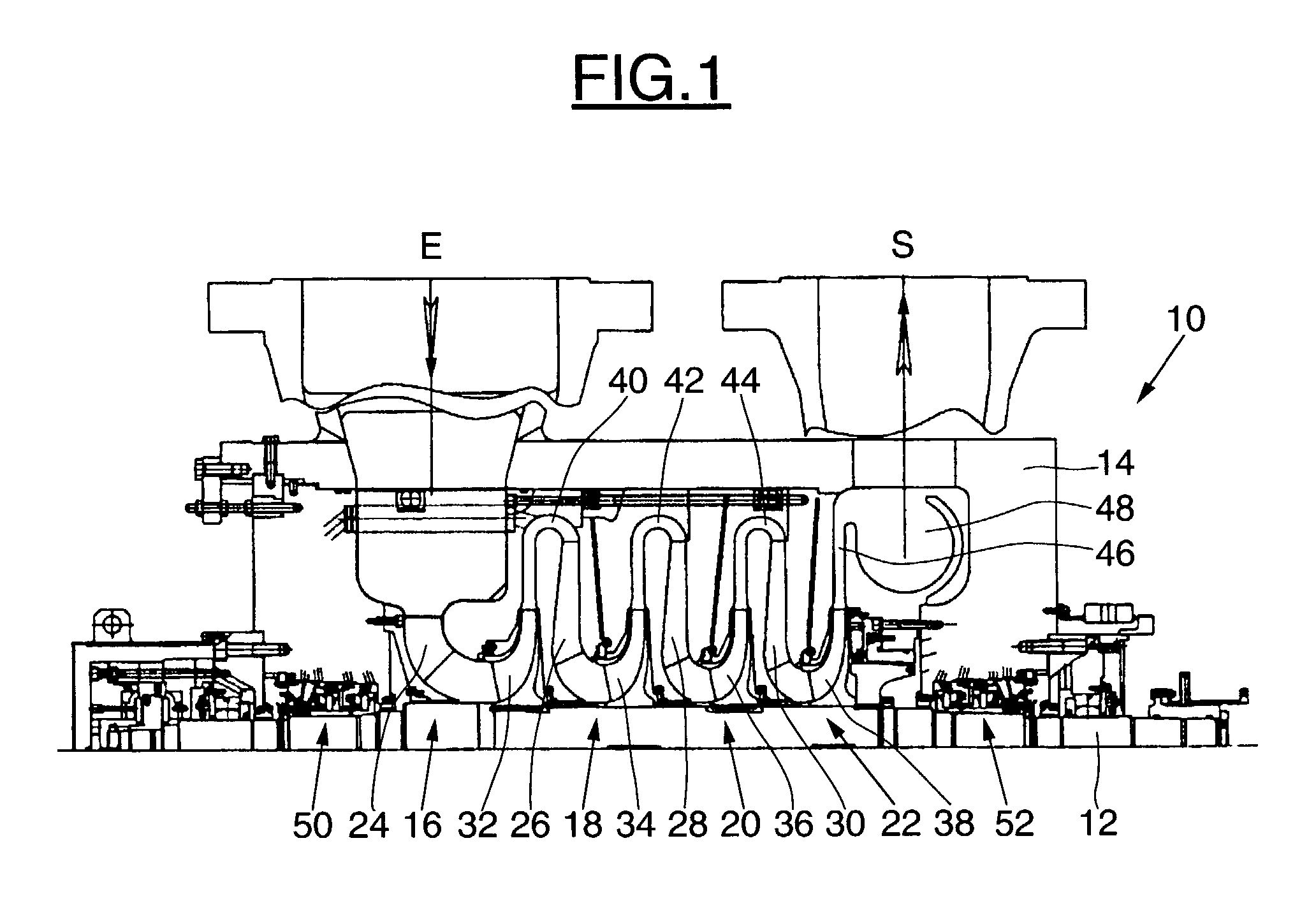

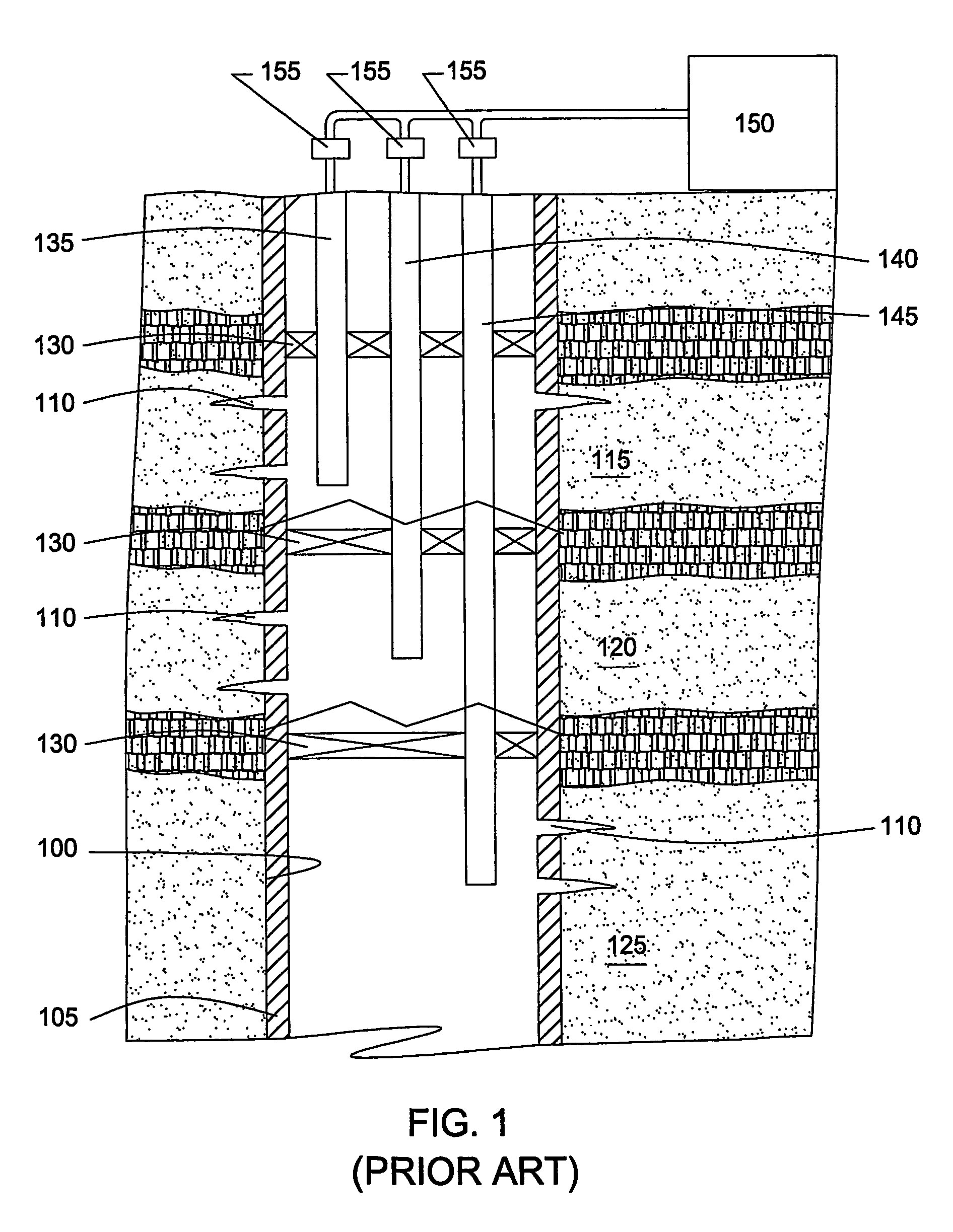

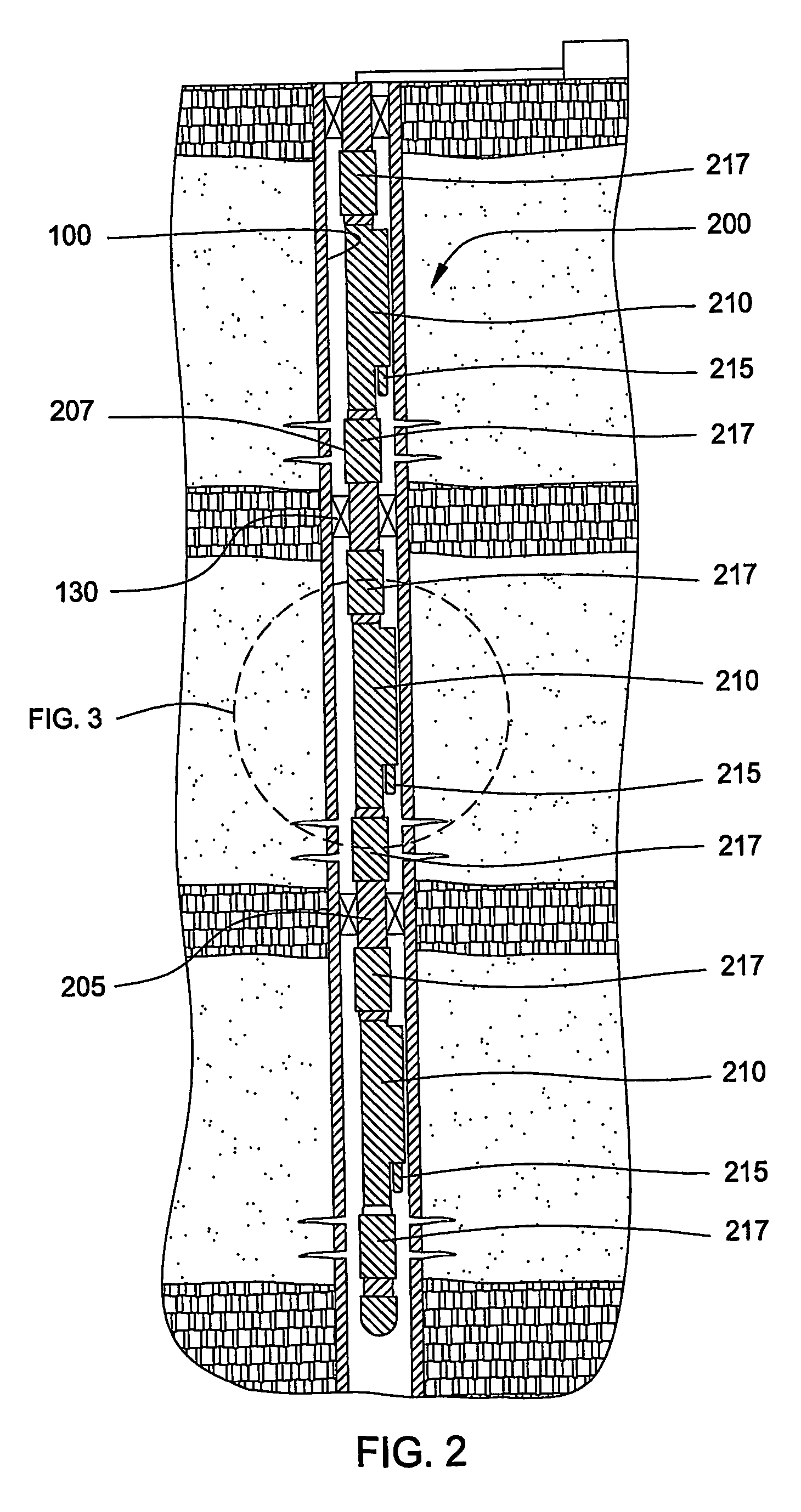

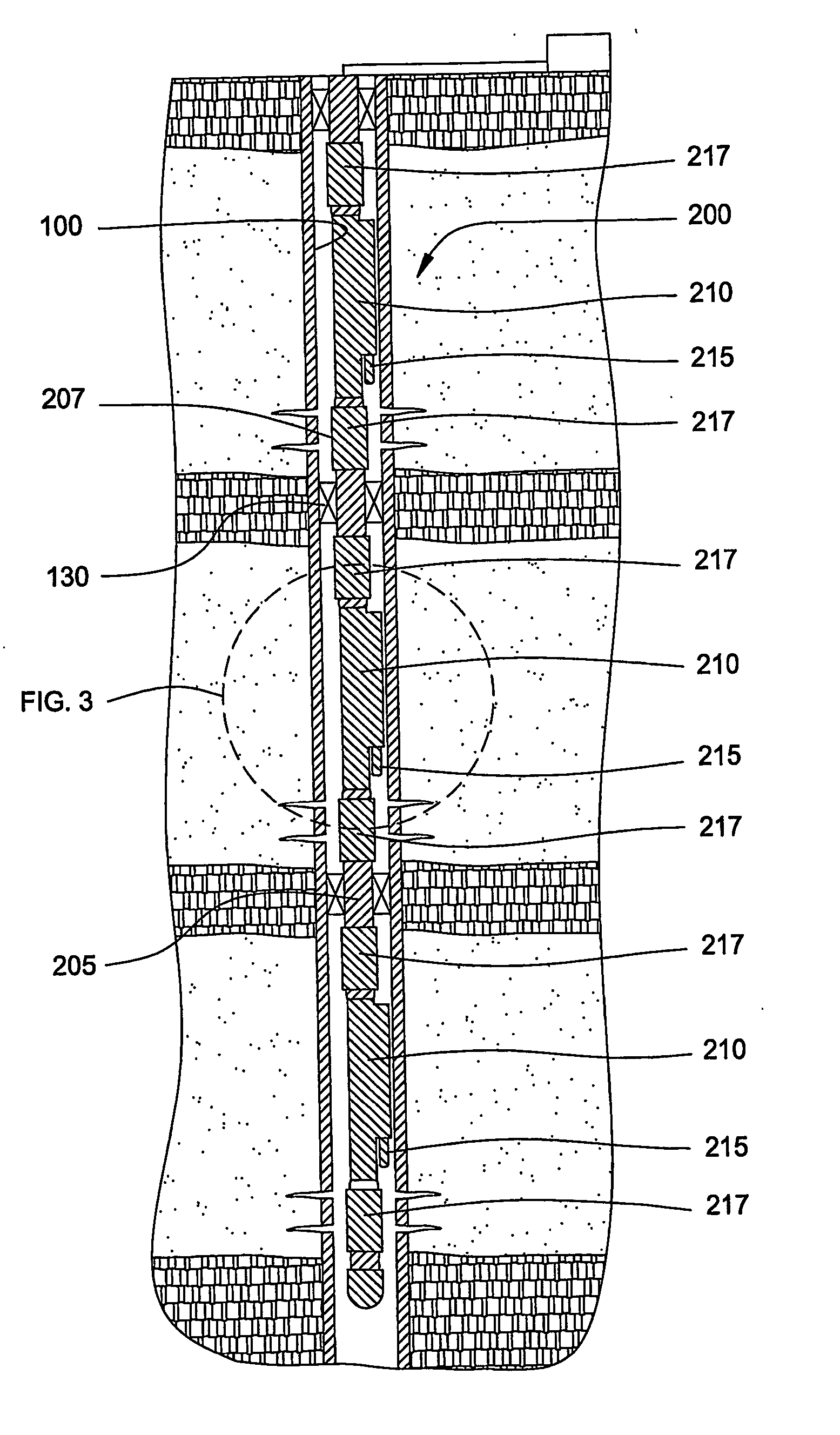

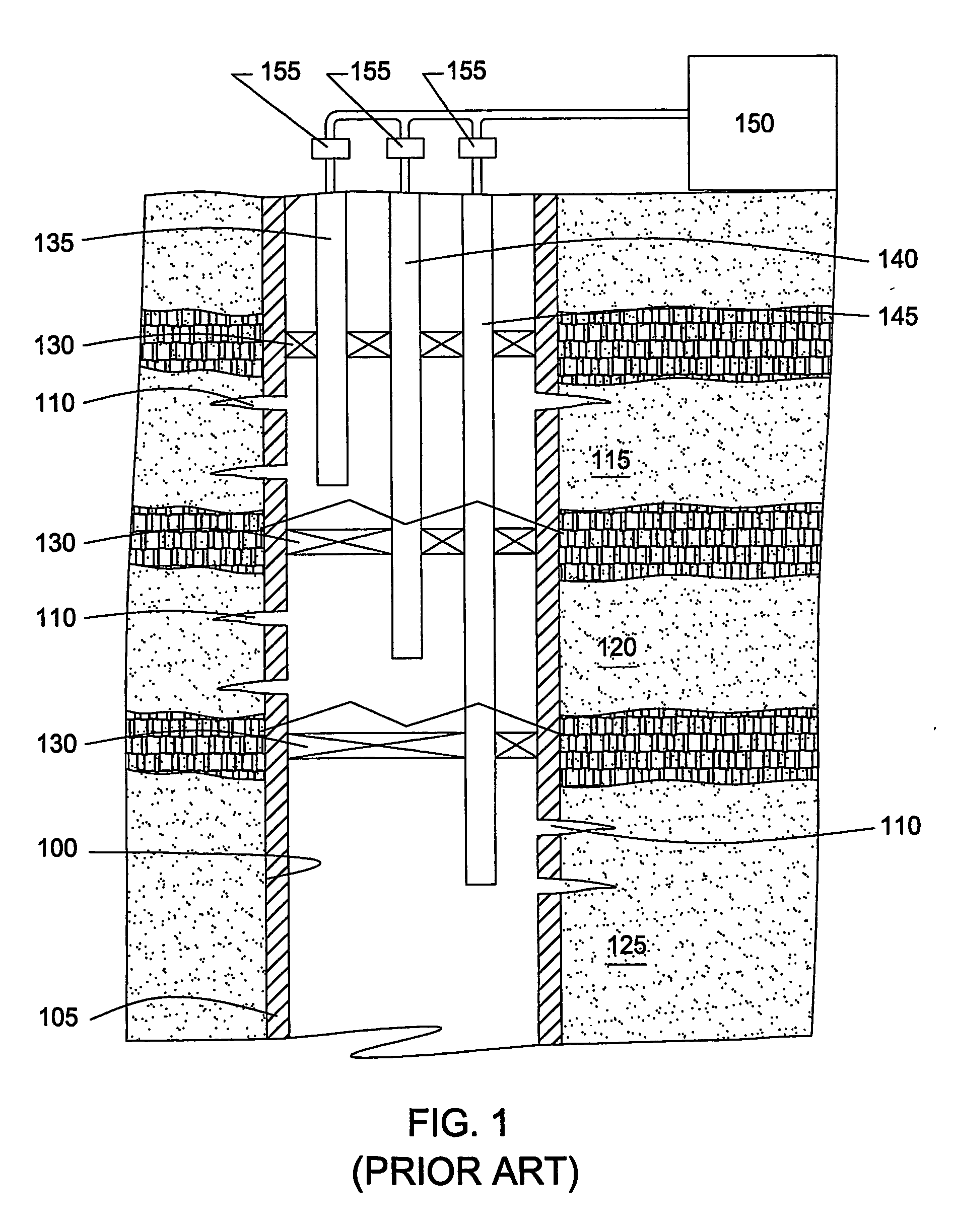

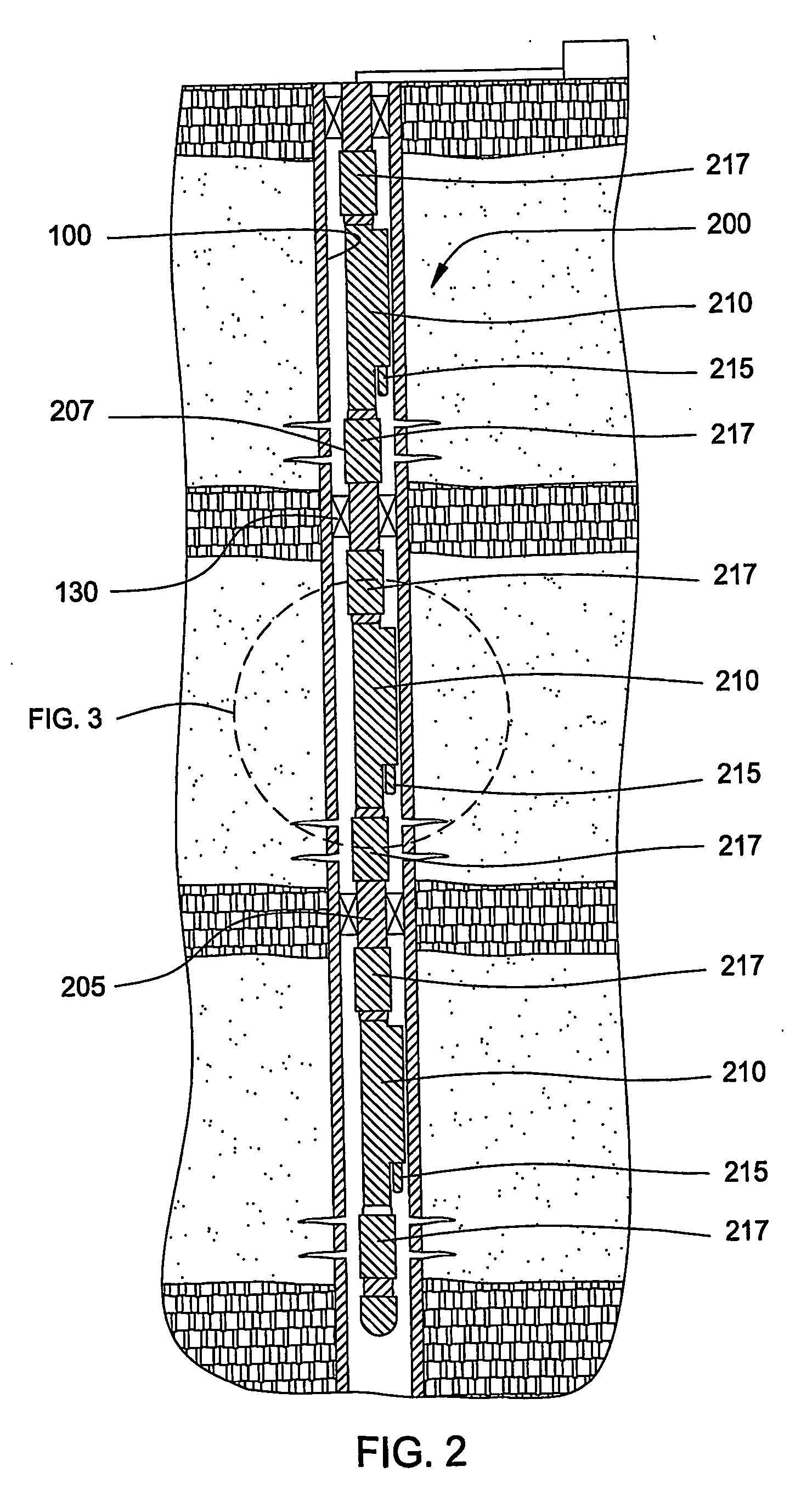

Method and apparatus for injecting steam into a geological formation

The present invention generally provides a method and apparatus for injecting a compressible fluid at a controlled flow rate into a geological formation at multiple zones of interest. In one aspect, the invention provides a tubing string with a pocket and a nozzle at each isolated zone. The nozzle permits a predetermined, controlled flow rate to be maintained at higher annulus to tubing pressure ratios. In another aspect, the present invention assures that the fluid is supplied uniformly to a long horizontal wellbore by providing controlled injection at multiple locations that are distributed throughout the length of the wellbore. In another aspect, the invention ensures that saturated steam is injected into a formation in a predetermined proportion of water and vapor by providing a plurality of apertures between a tubing wall and a pocket.

Owner:WEATHERFORD TECH HLDG LLC

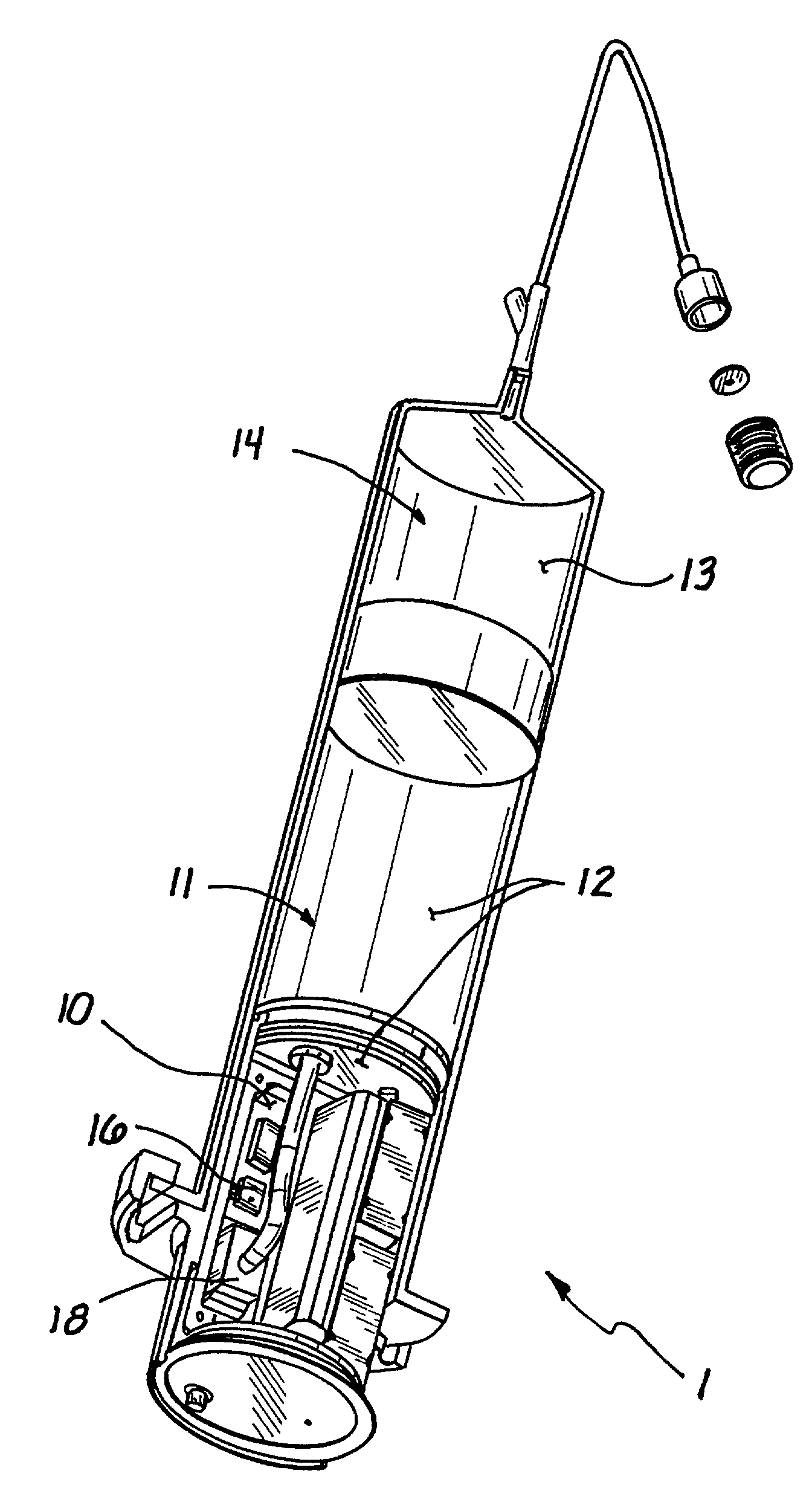

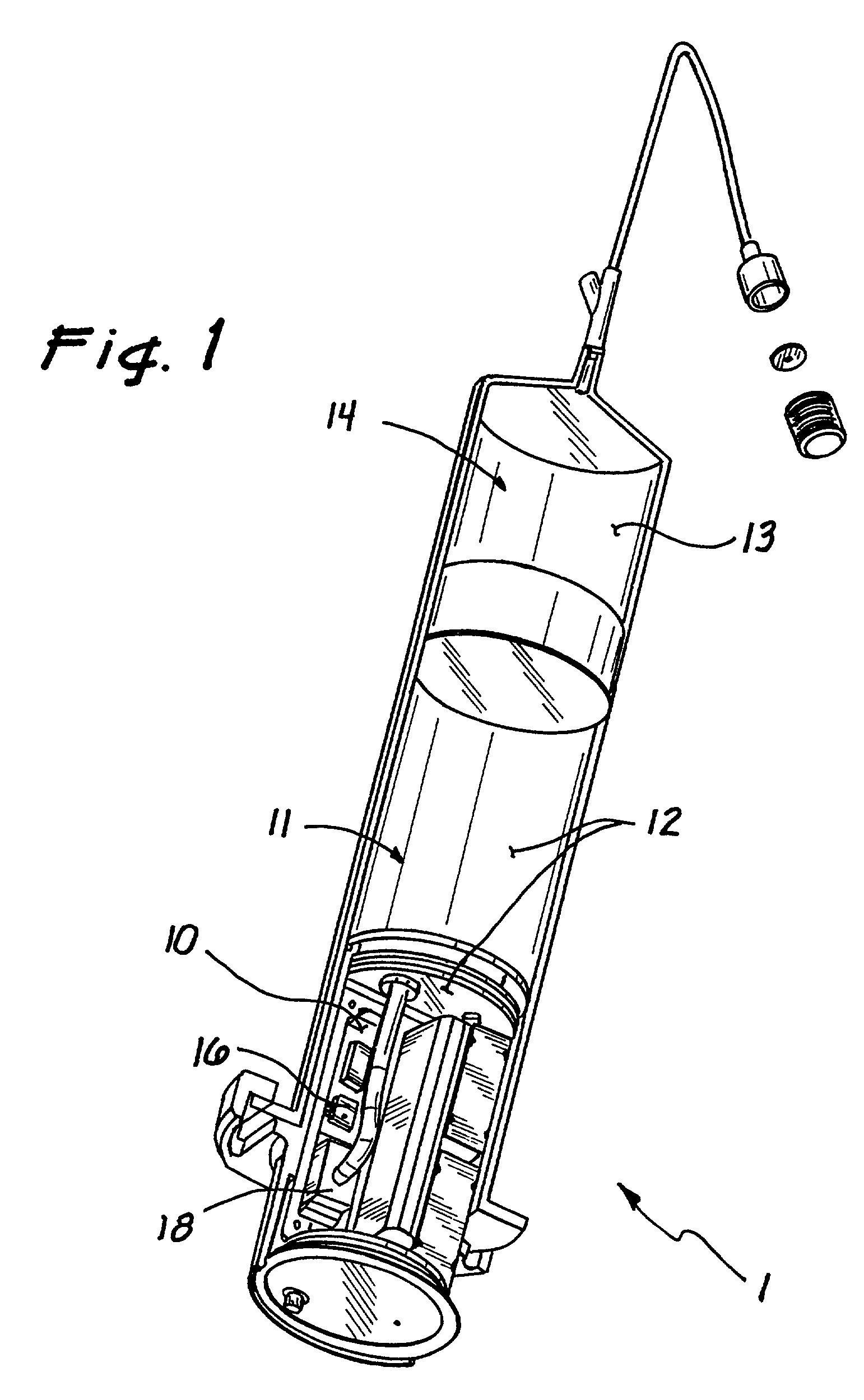

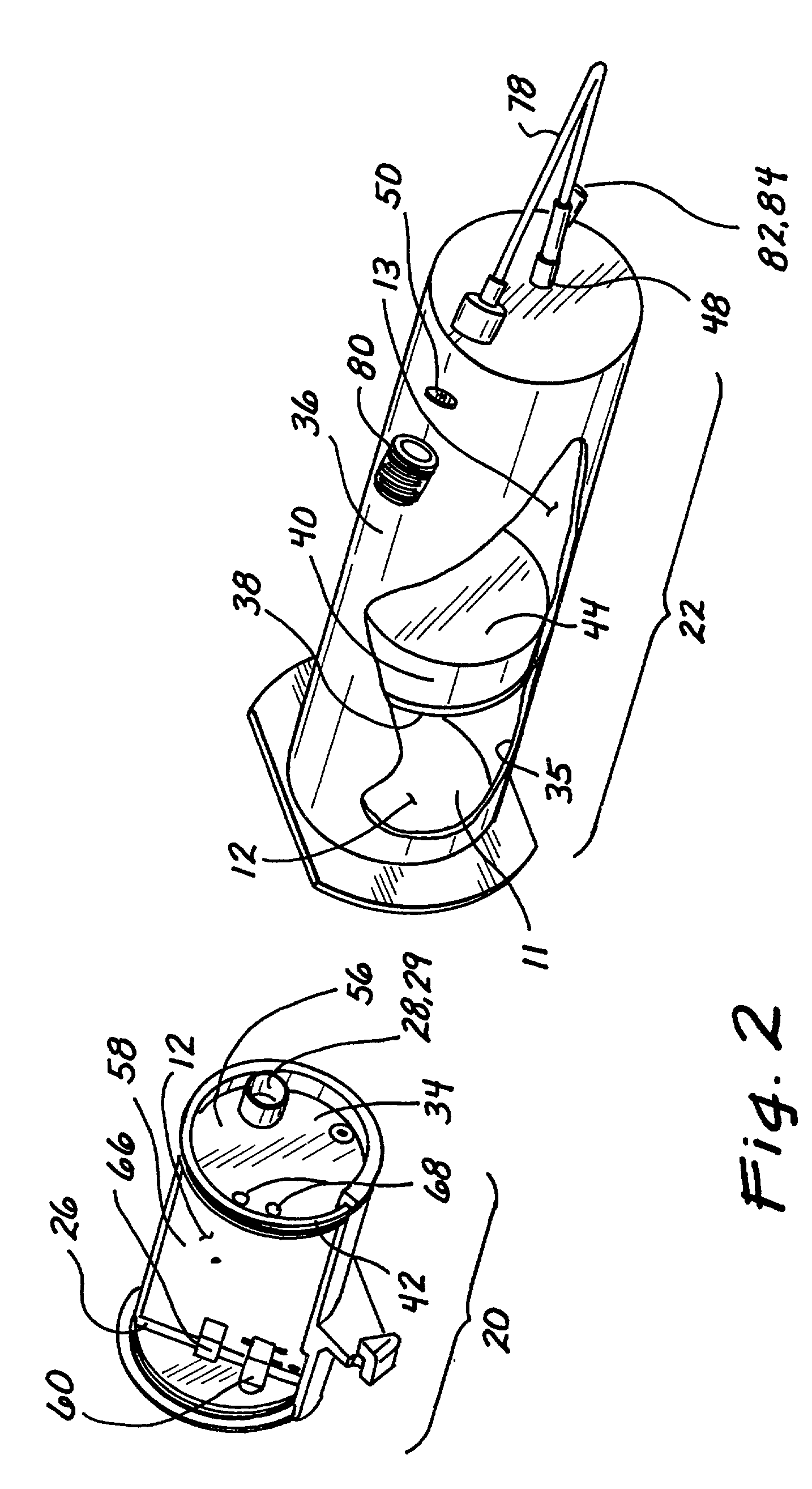

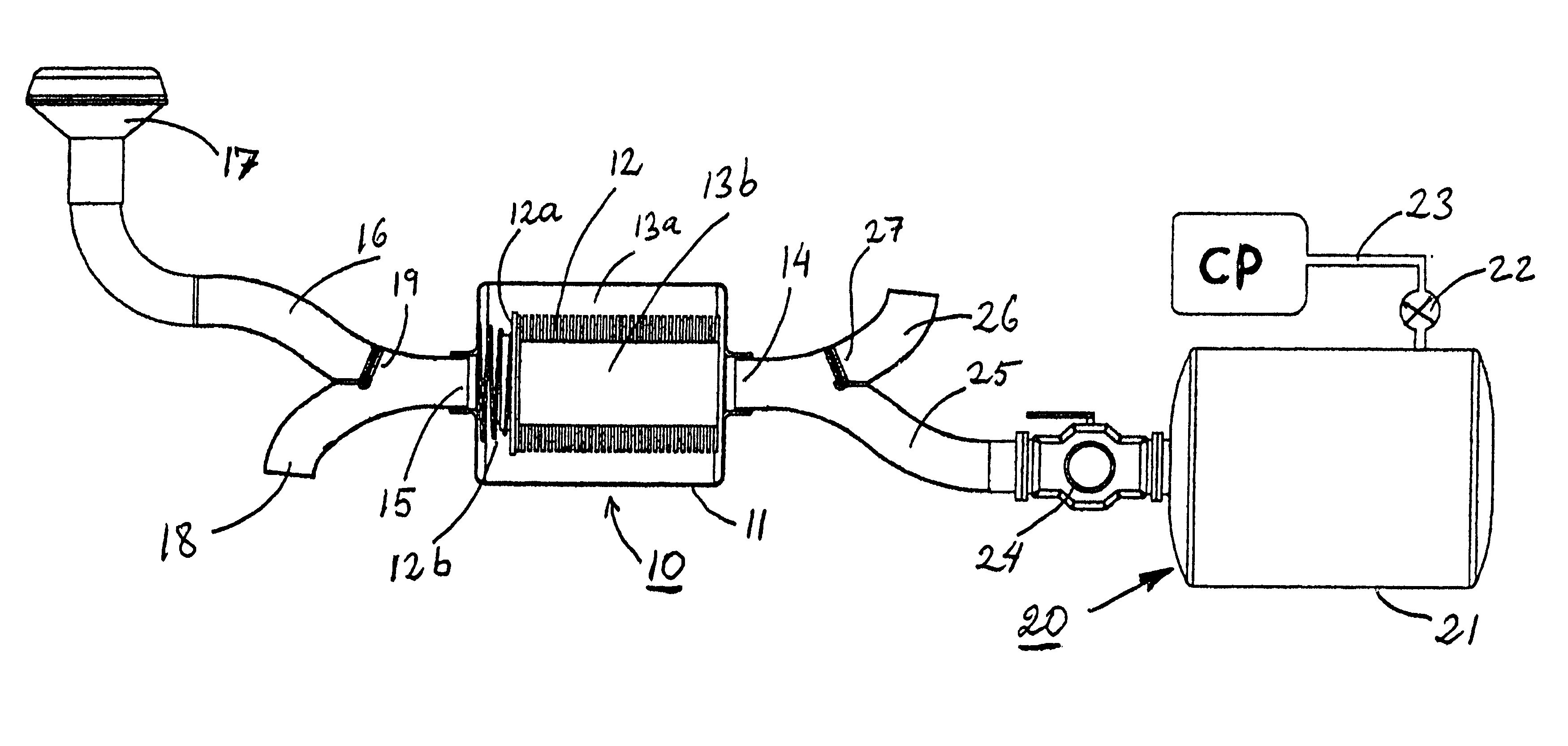

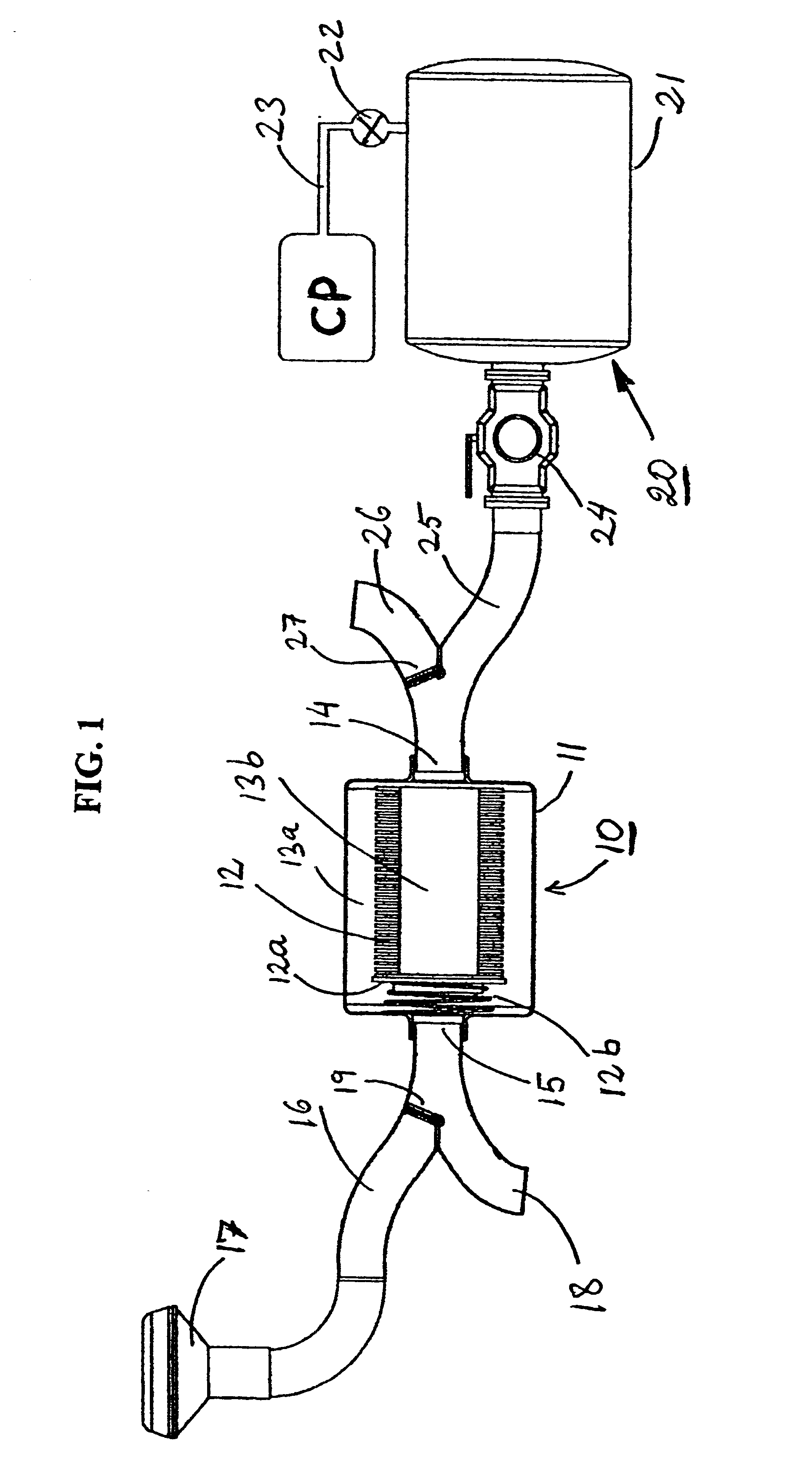

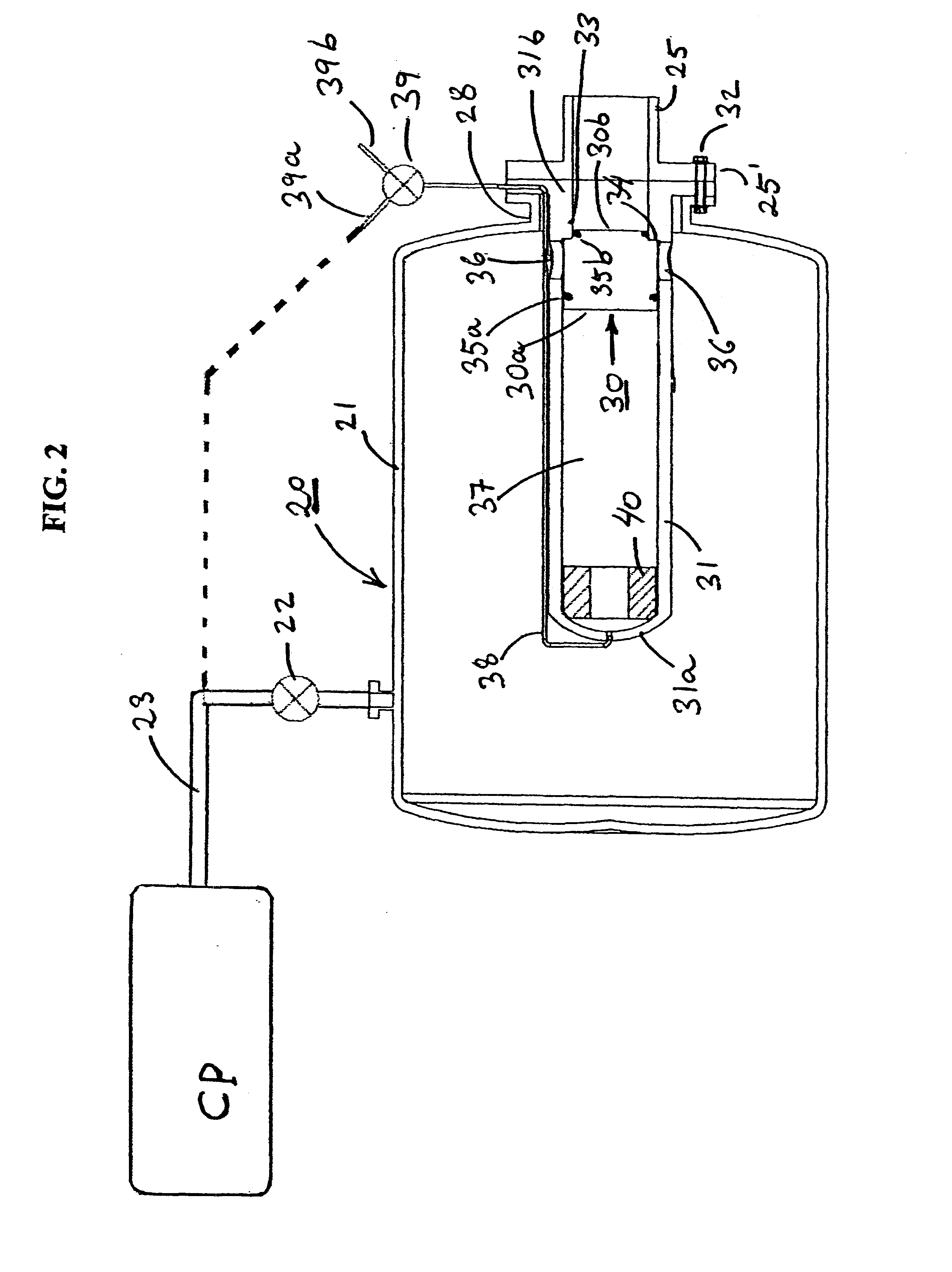

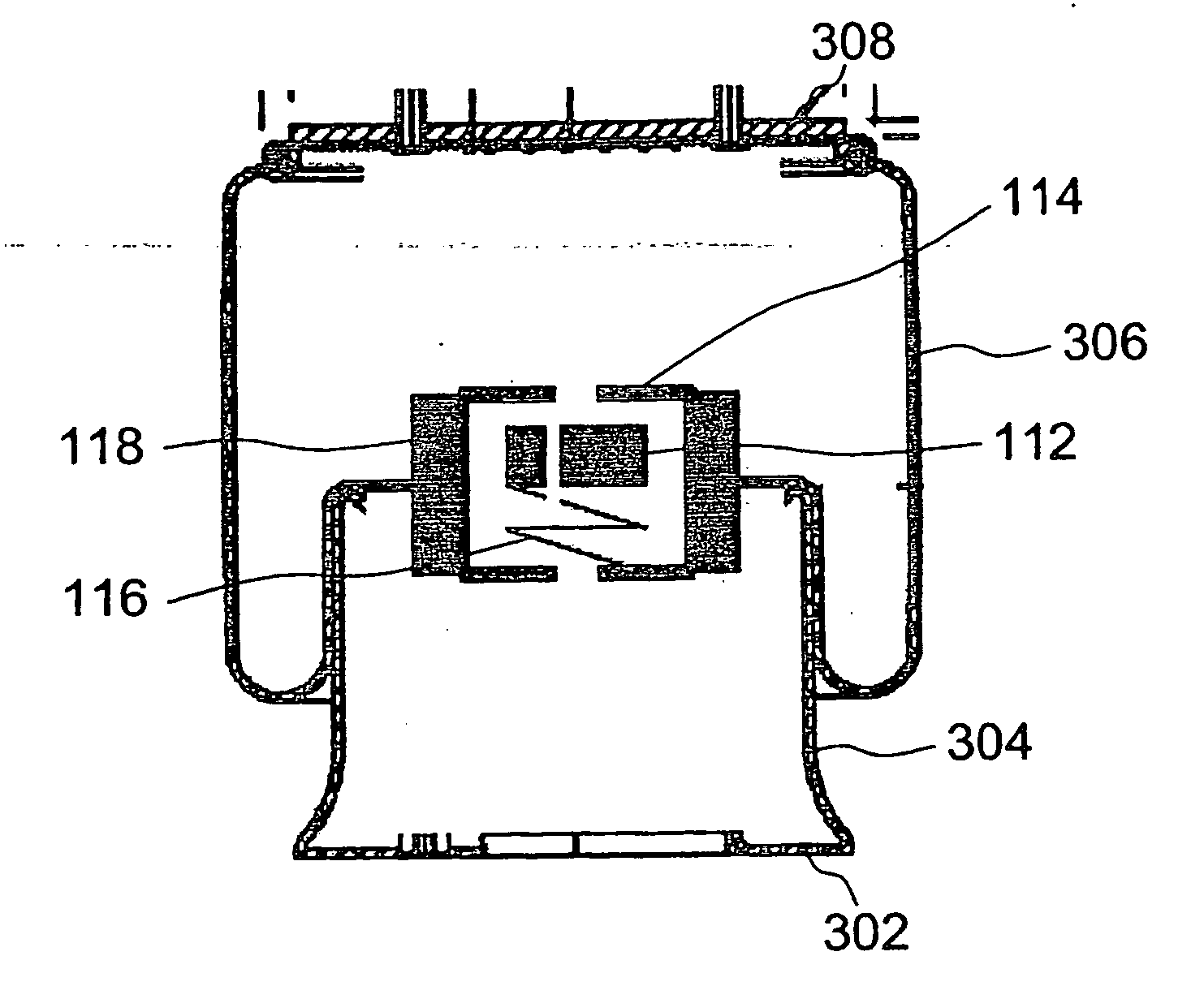

Filter-cleaning device and method, and fluid pulse generator particularly useful therein

InactiveUS6641646B2Thoroughly and efficiently cleaningUse cleanCombination devicesAuxillary pretreatmentFuel tankHigh pressure

A filter-cleaning device and method for cleaning a filter (10) utilizing a compressible fluid pulse generator (20) including a pressure tank (21), a tank inlet (23) for inletting pressurized air or other compressible fluid, and a valve member (24) normally in a closed position closing the tank outlet (28), but being openable in a quick-action manner to produce a high-pressure high-flow impulse of fluid applied via the tank outlet to the filter outlet to back-flush the filter.

Owner:GIDEON ROSENBERG D B A ITEC +1

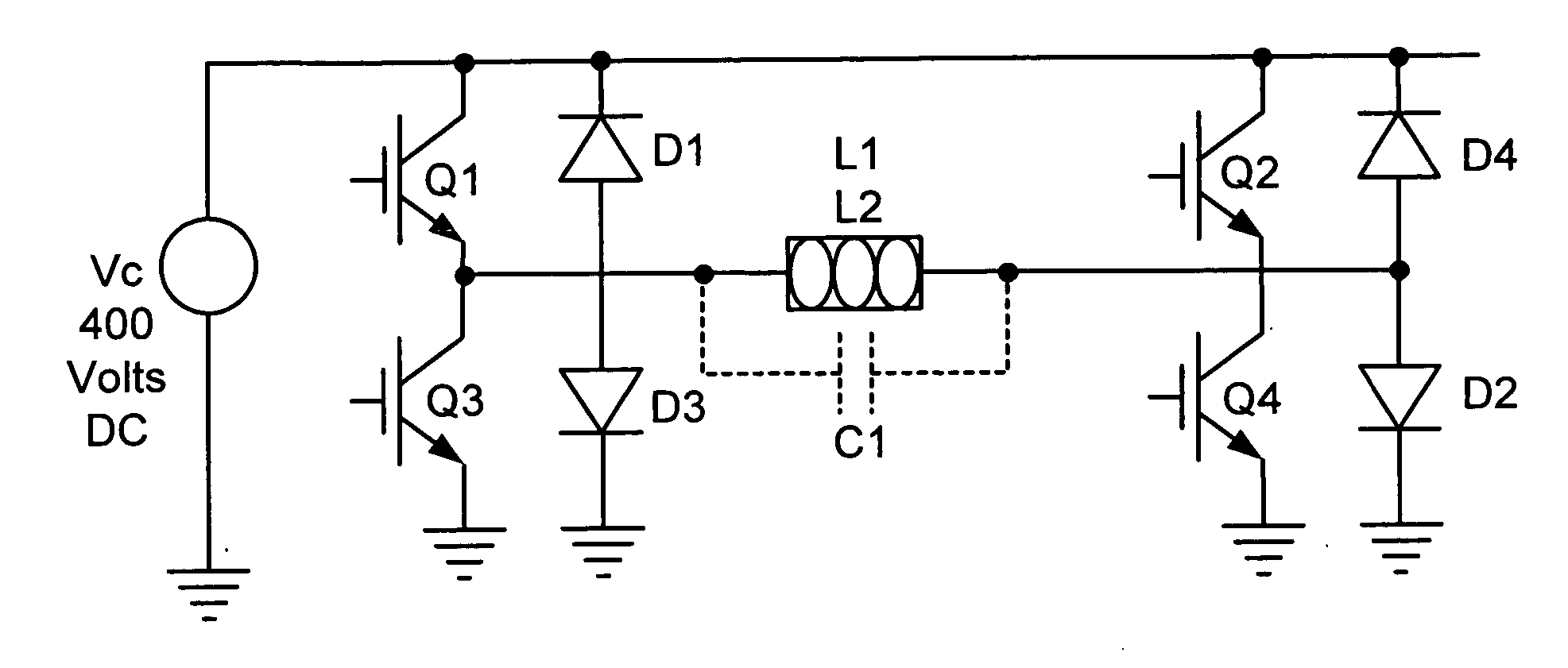

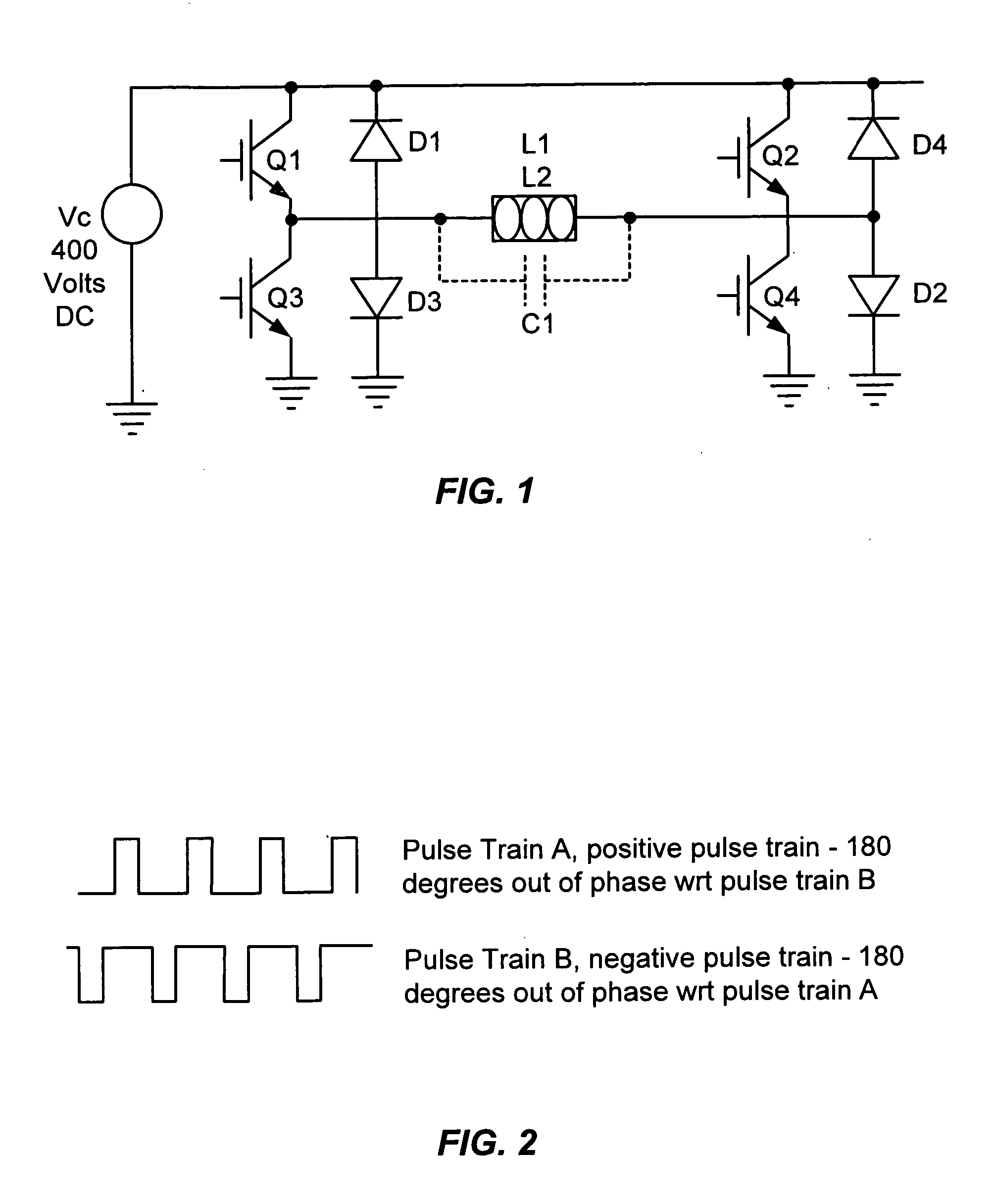

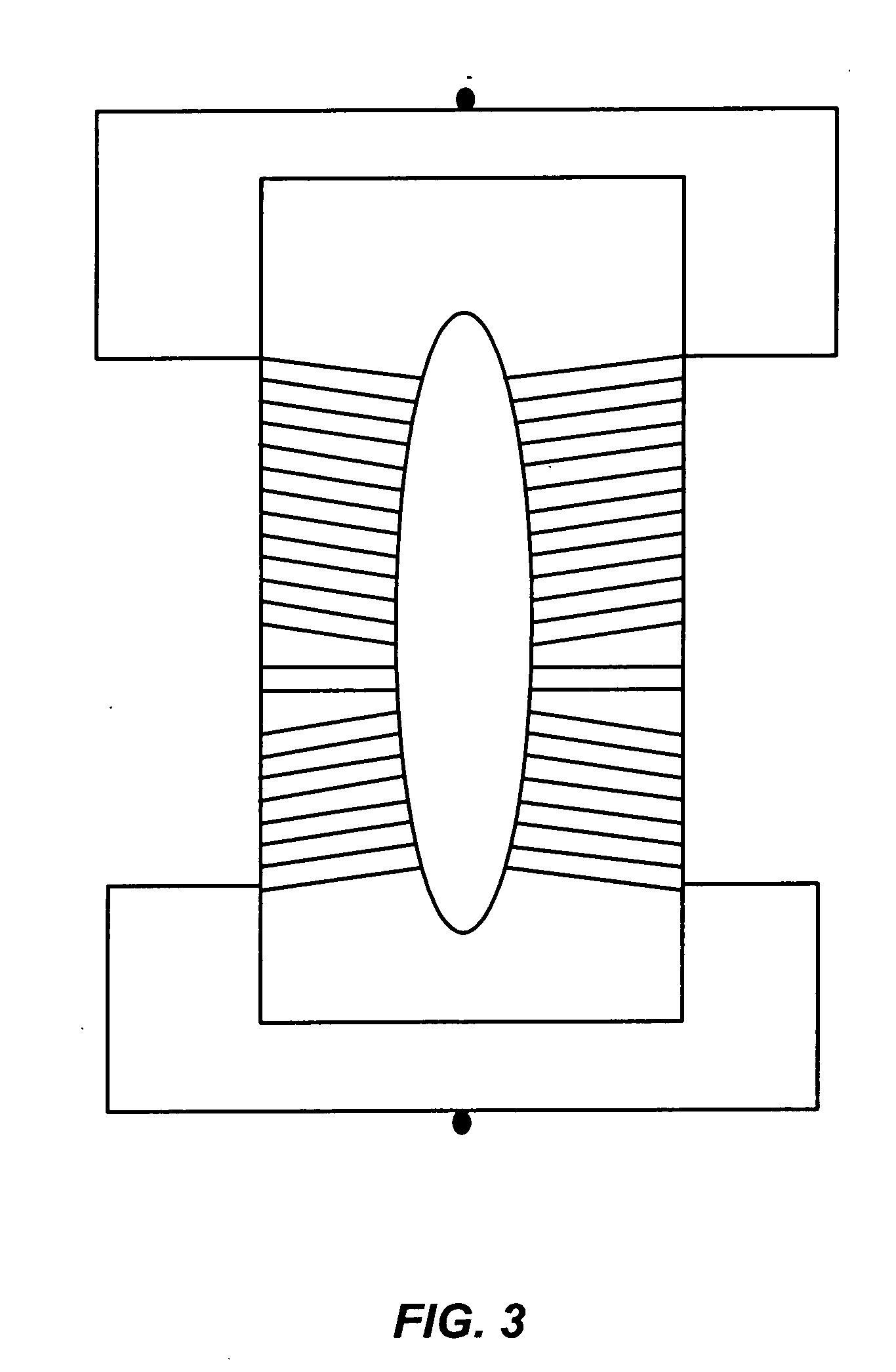

Power driving circuit for controlling a variable load ultrasonic transducer

InactiveUS20060238068A1Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesSilicon-controlled rectifierEngineering

The present invention is directed to a high-powered (e.g., >500 W) ultrasonic generator for use especially for delivering high-power ultrasonic energy to a varying load including compressible fluids. The generator includes a variable frequency triangular waveform generator coupled with pulse width modulators. The output from the pulse width modulator is coupled with the gates of an Isolated Gate Bipolar Transistor (IGBT), which amplifies the signal and delivers it to a coil that is used to drive a magnetostrictive transducer. In one embodiment, high voltage of 0-600 VDC is delivered across the collector and emitter of the IGBT after the signal is delivered. The output of the IGBT is a square waveform with a voltage of ±600V. This voltage is sent to a coil wound around the ultrasonic transducer. The voltage creates a magnetic field on the transducer and the magnetorestrictive properties of the transducer cause the transducer to vibrate as a result of the magnetic field. The use of the IGBT as the amplifying device obviates the need for a Silicon Controlled Rectifier (SCR) circuit, which is typically used in low powered ultrasonic transducers, and which would get overheated and fail in such a high-powered and load-varying application.

Owner:SULPHCO

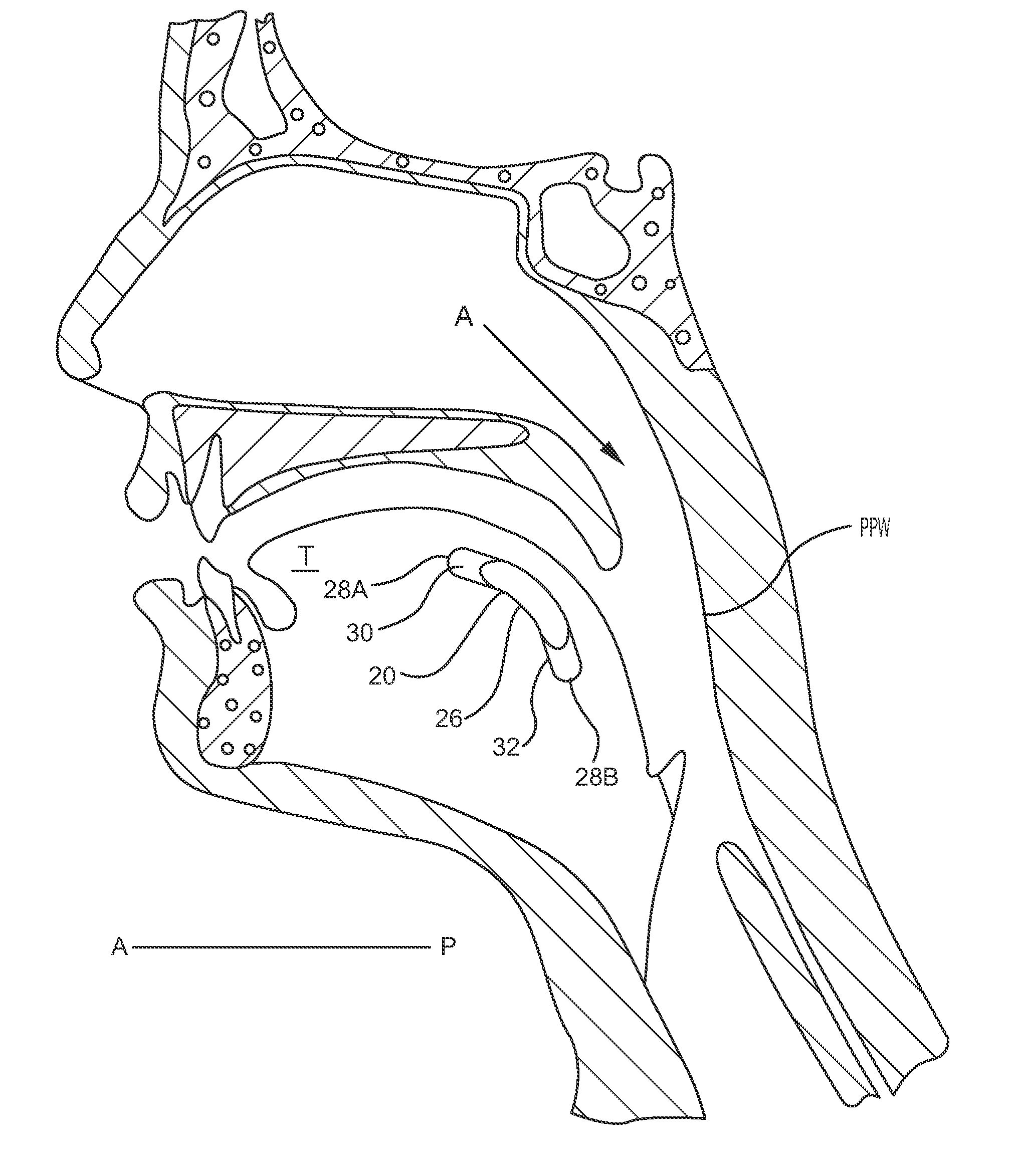

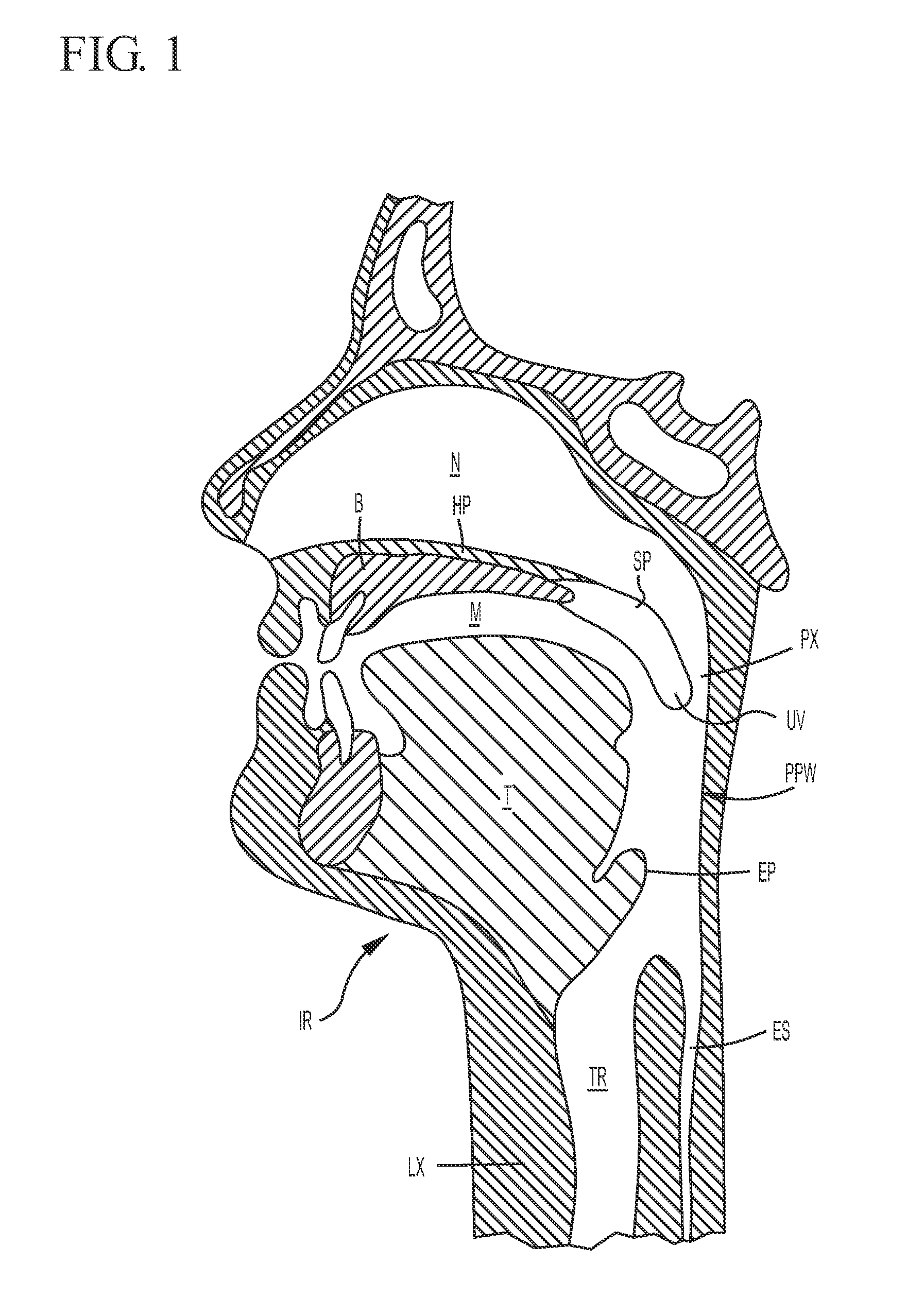

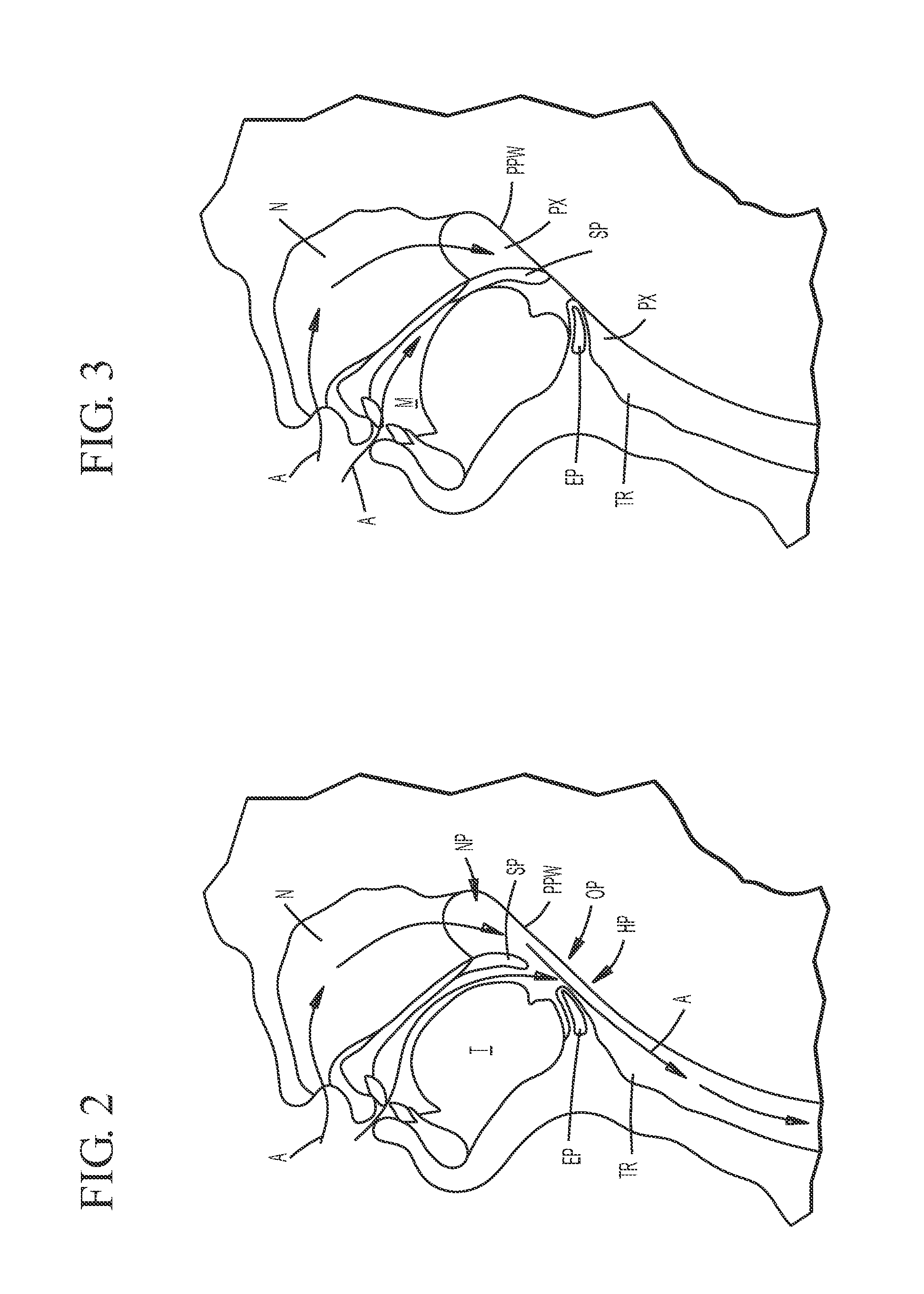

Flexible implants having internal volume shifting capabilities for treating obstructive sleep apnea

InactiveUS20110100378A1Lower the volumeLower resistanceSnoring preventionNon-surgical orthopedic devicesSleep apneaBiomedical engineering

An implant for treating obstructive sleep apnea includes a first chamber containing an incompressible fluid, a second chamber containing a compressible fluid, and a flexible diaphragm separating the first and second chambers. The incompressible fluid is in communication with the compressible fluid via the flexible diaphragm. The first chamber has a first volume that remains constant in response to an external force applied upon the implant and the second chamber has a second volume that is changeable when the external force is applied upon the implant. The flexible diaphragm is extendible into the second chamber for reducing the second volume of the second chamber and compressing the compressible fluid within the second chamber. The compressible fluid within the second chamber provides less resistance to flexing during initial flexing of the implant and more resistance to flexing during further flexing of the implant.

Owner:ETHICON INC

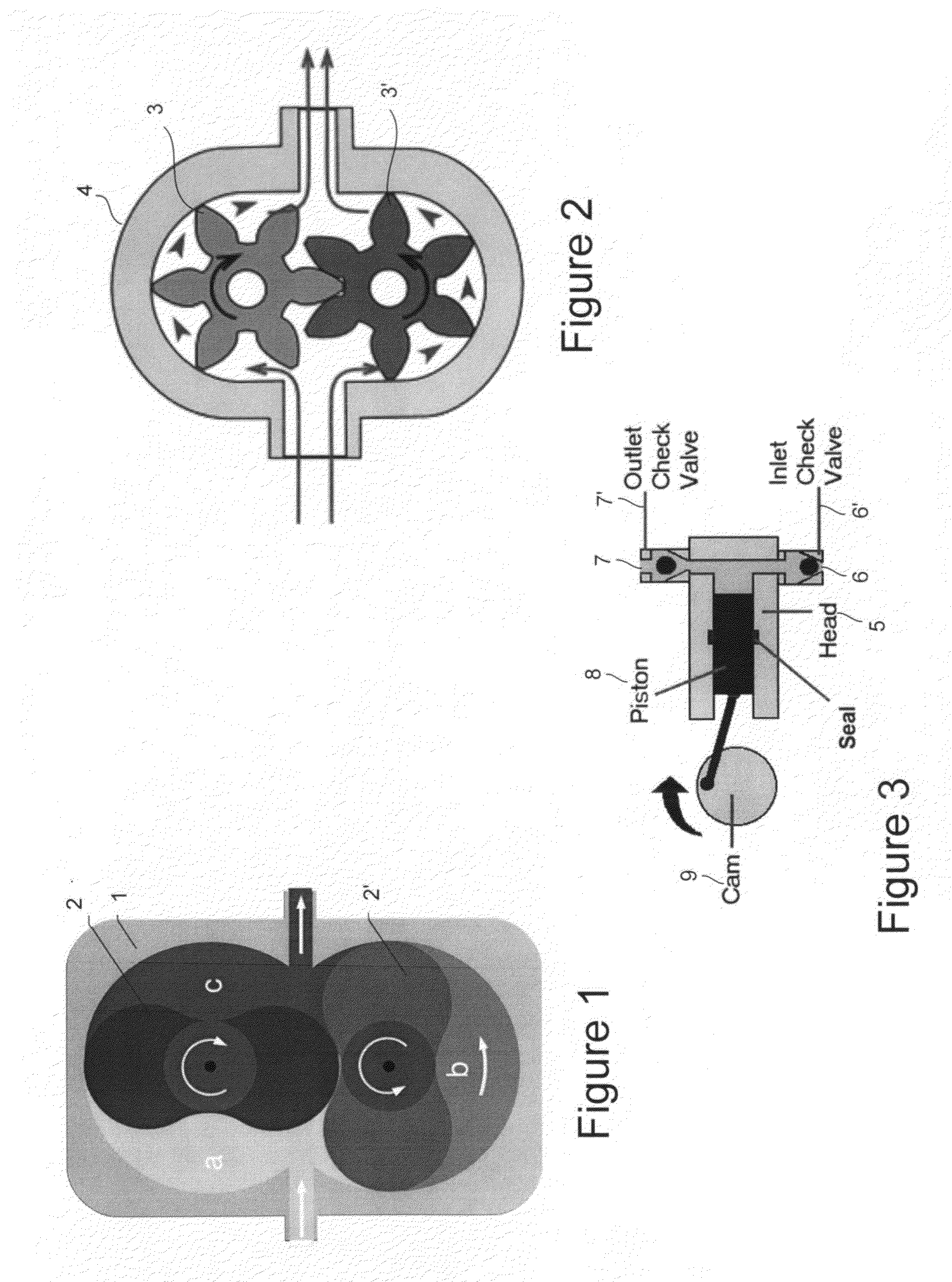

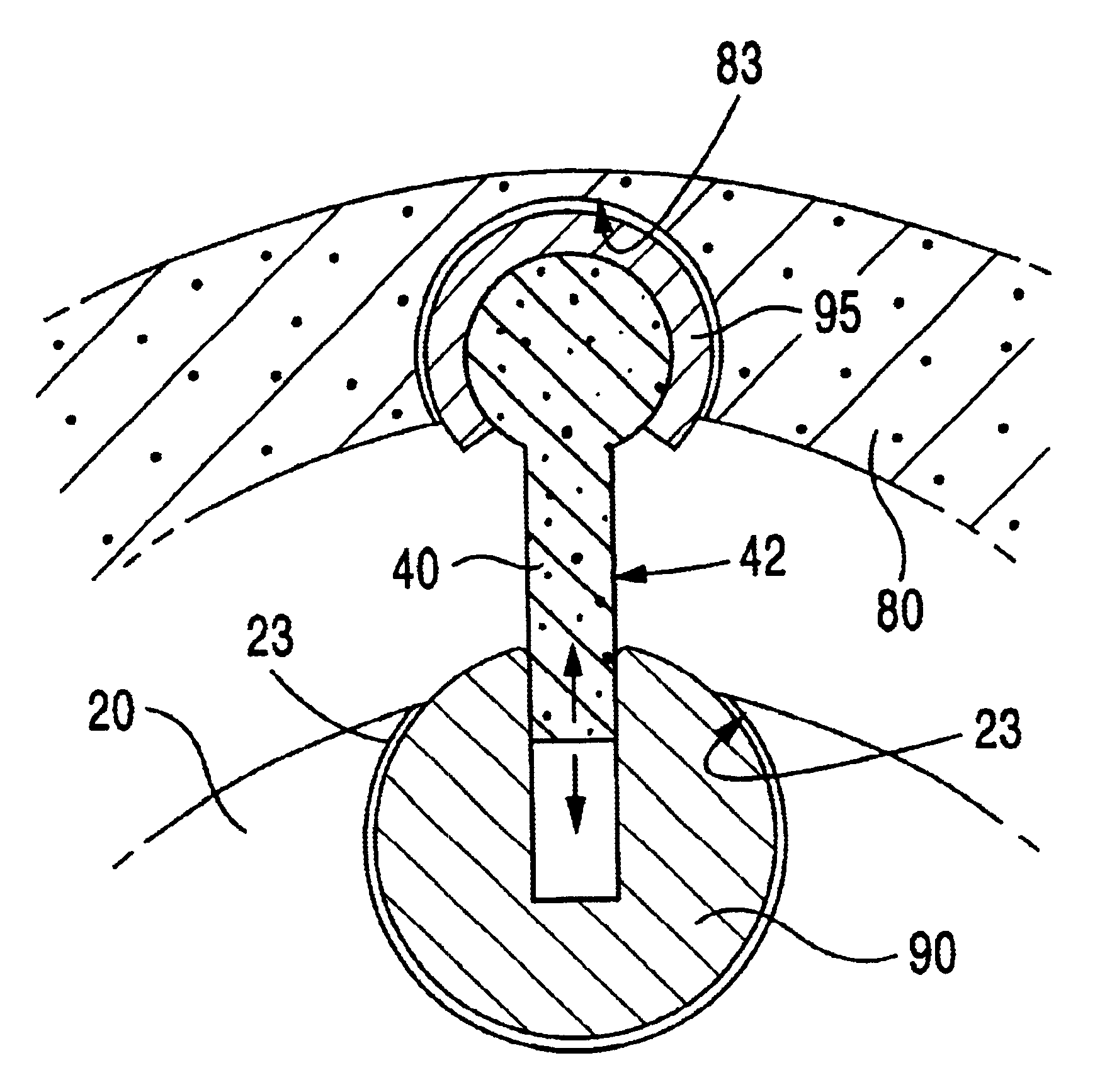

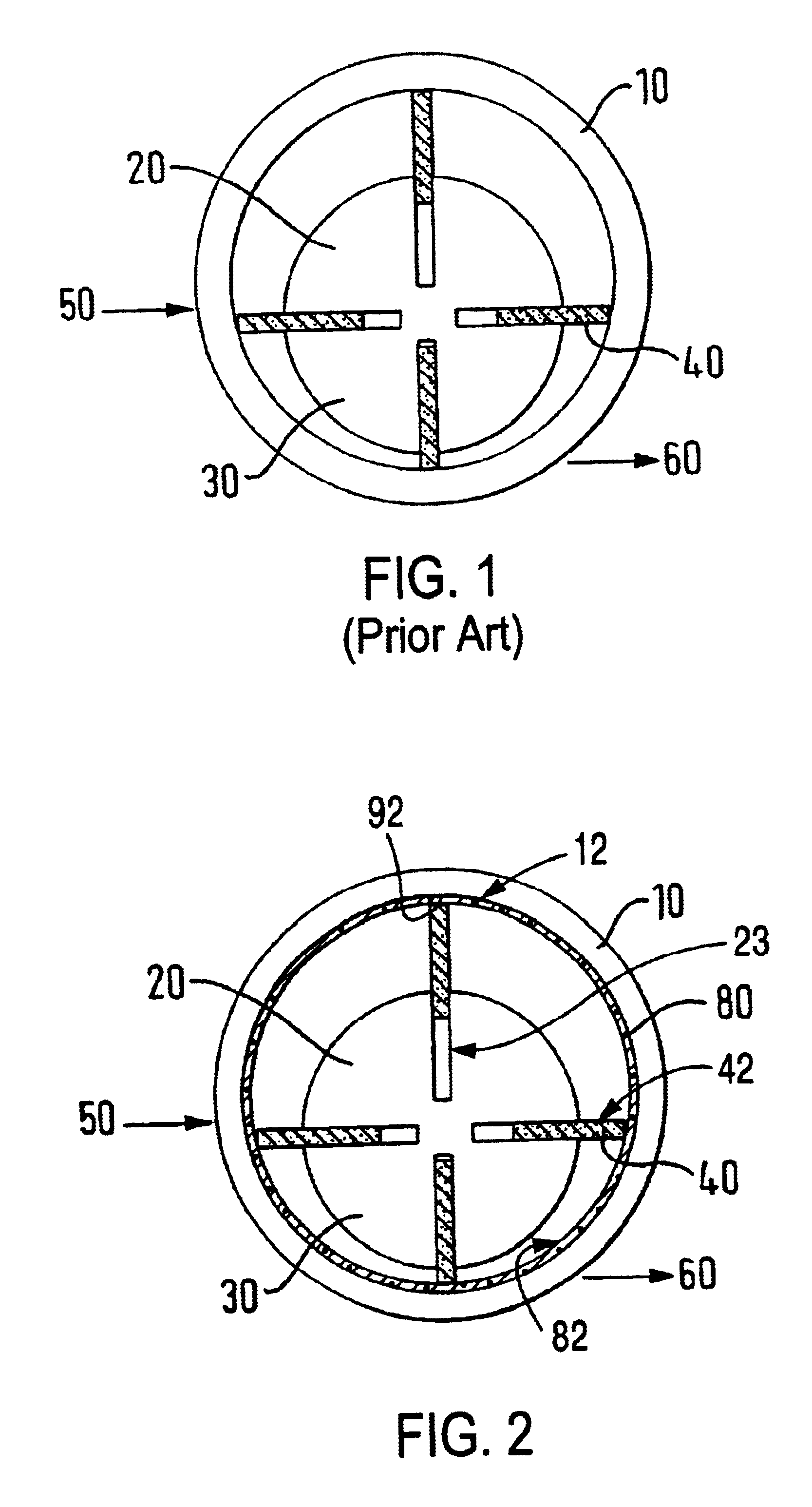

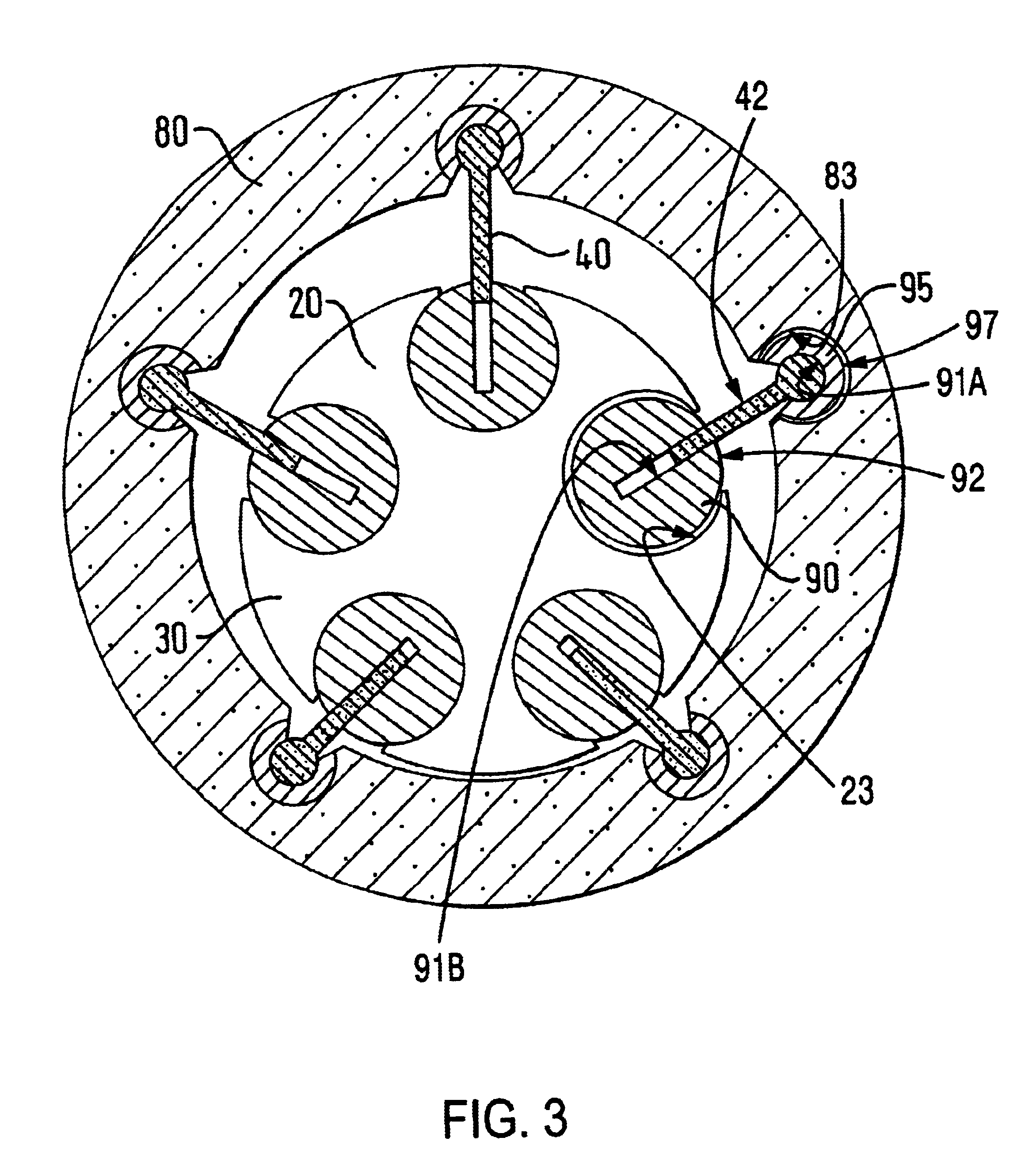

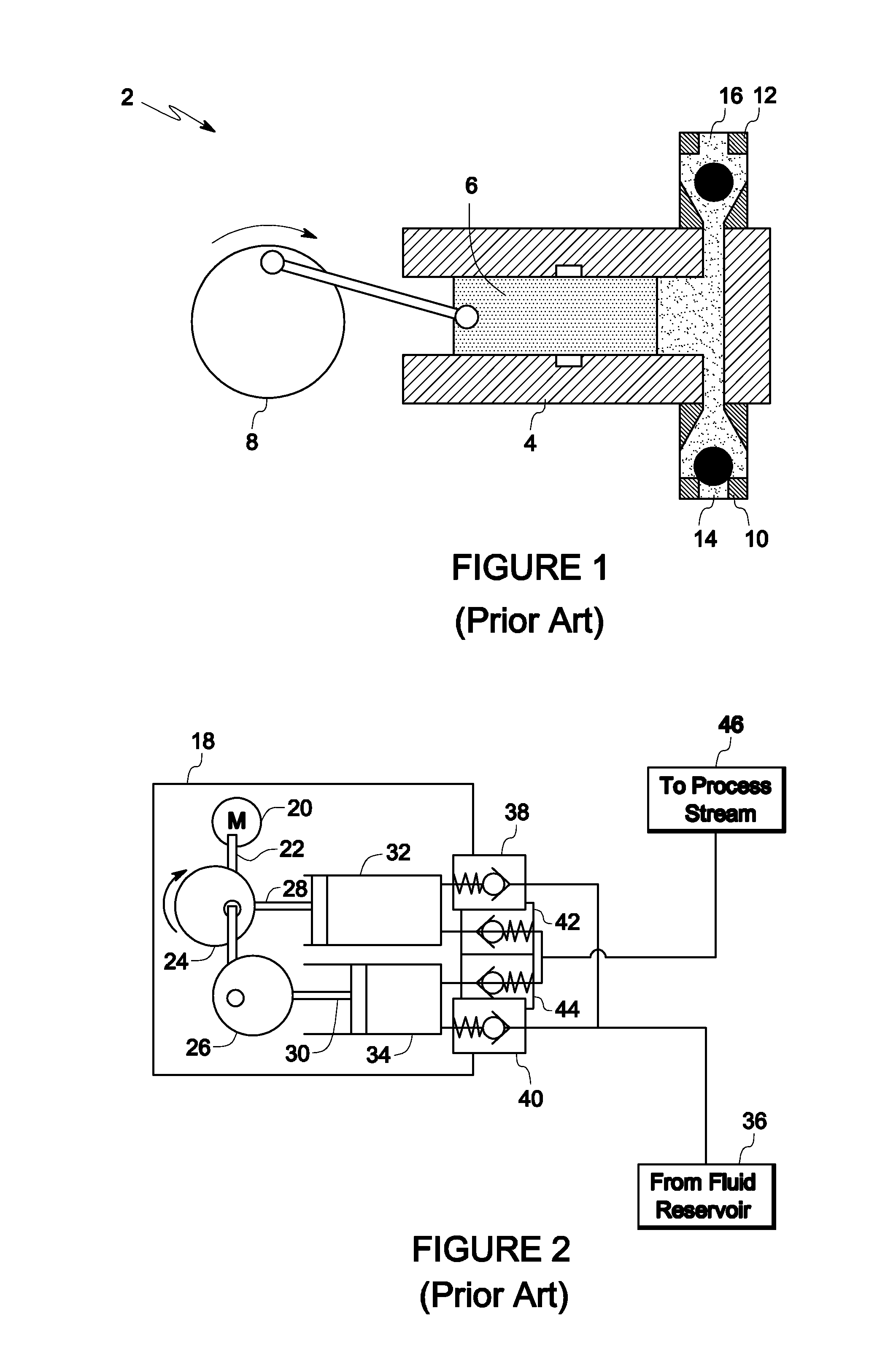

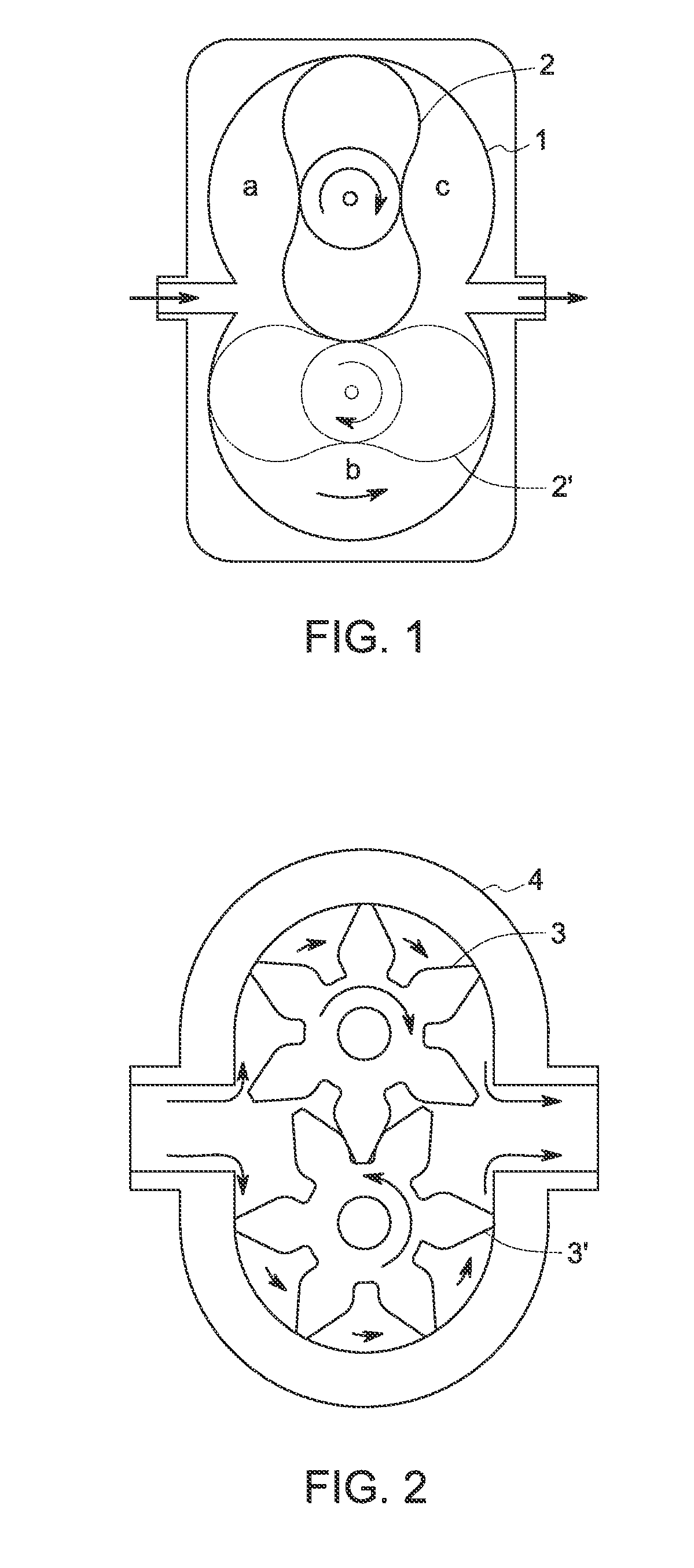

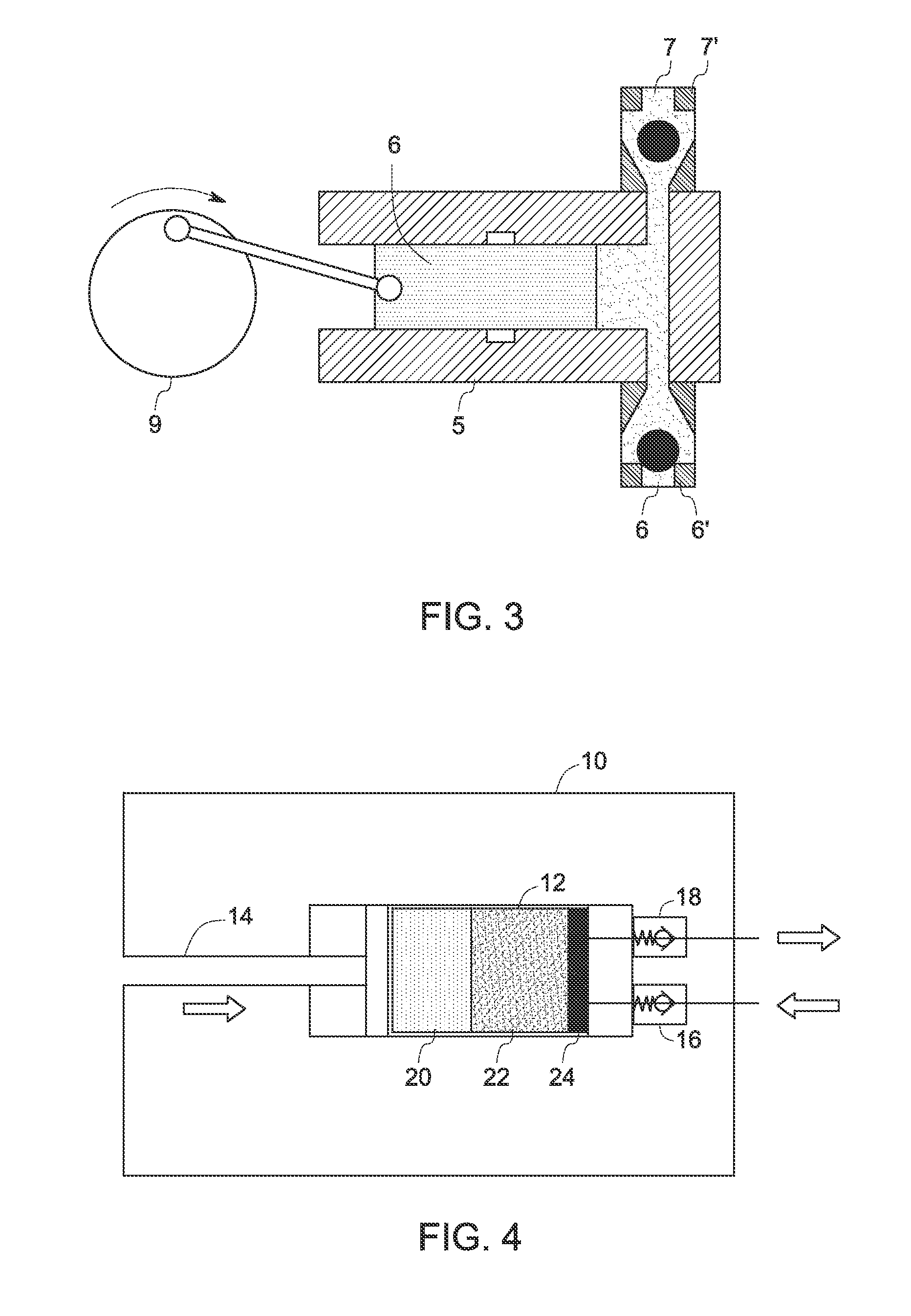

Rotary pump

InactiveUS6666671B1Shorten speedReduce wear rateOscillating piston enginesSealing arrangement for pumpsRotary pumpFree rotation

A rotary pump for pumping compressible fluid comprising an eccentrically mounted rotor 20 and a stator 10. The stator 10 comprises a stator inner liner 80 that is free to rotate, driven directly or in response to rotation of the rotor 20 such that the relative velocity between the outer surface of the rotor 20 and the inner surface of the stator 10 is reduced. The vanes 40 are held at each end by sockets 90, 95 in the rotor 20 and stator 10. The vane 40 and socket 90, 95 coupling provides fluid sealing without liquid lubricant. Opposing solid lubricant and hard surfaces are used on contact surfaces between the elements.

Owner:IC INNOVATIONS

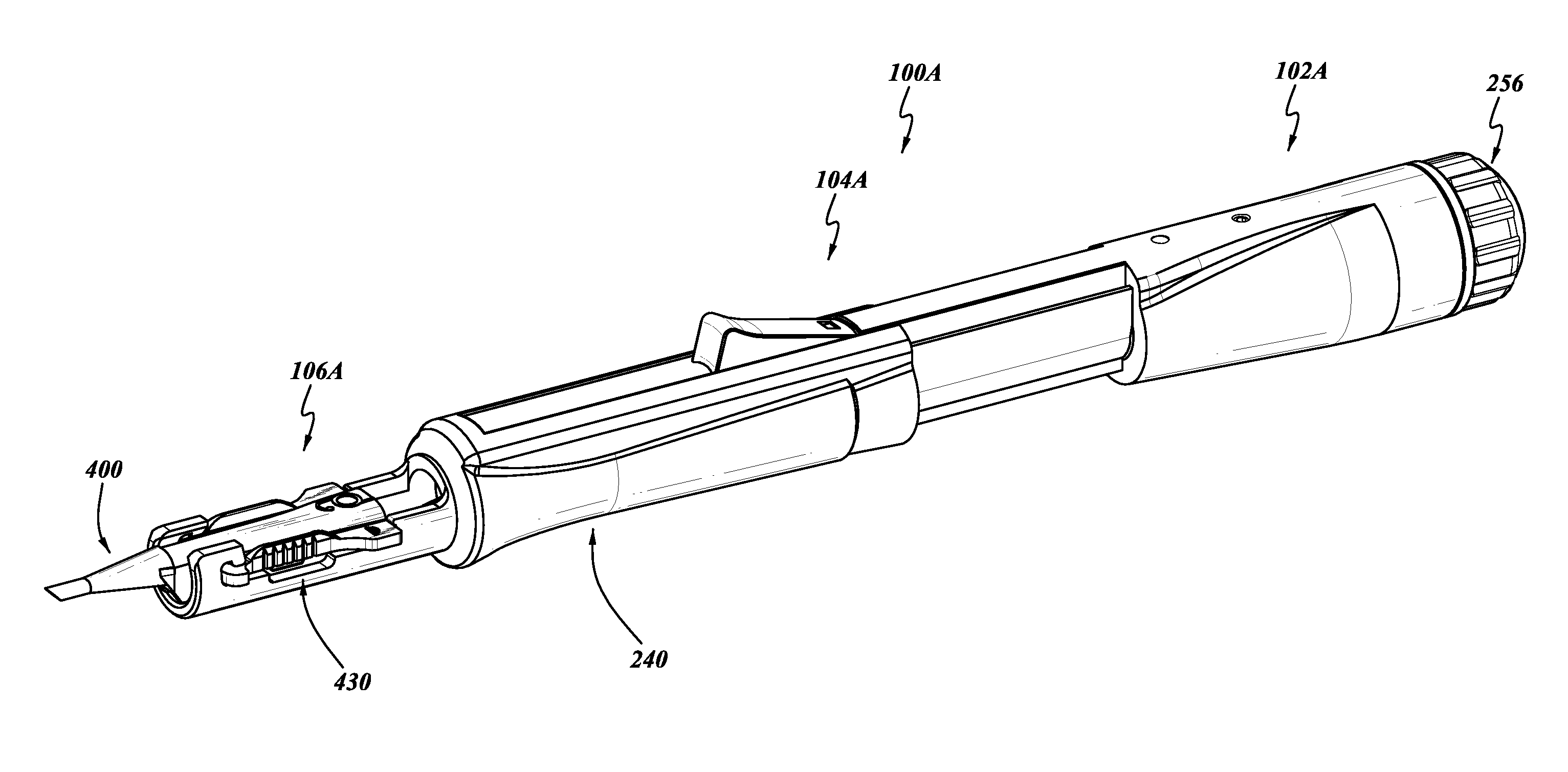

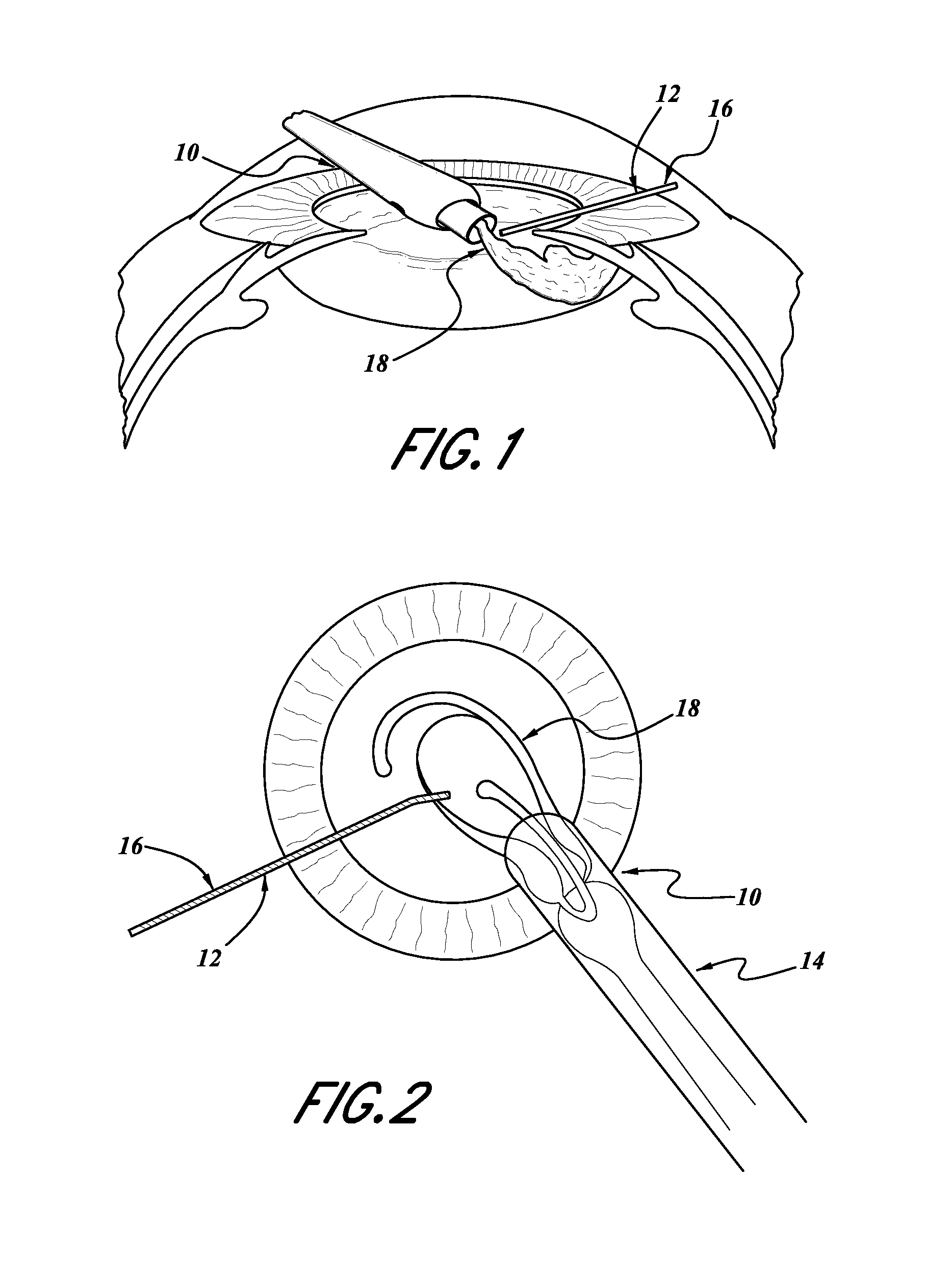

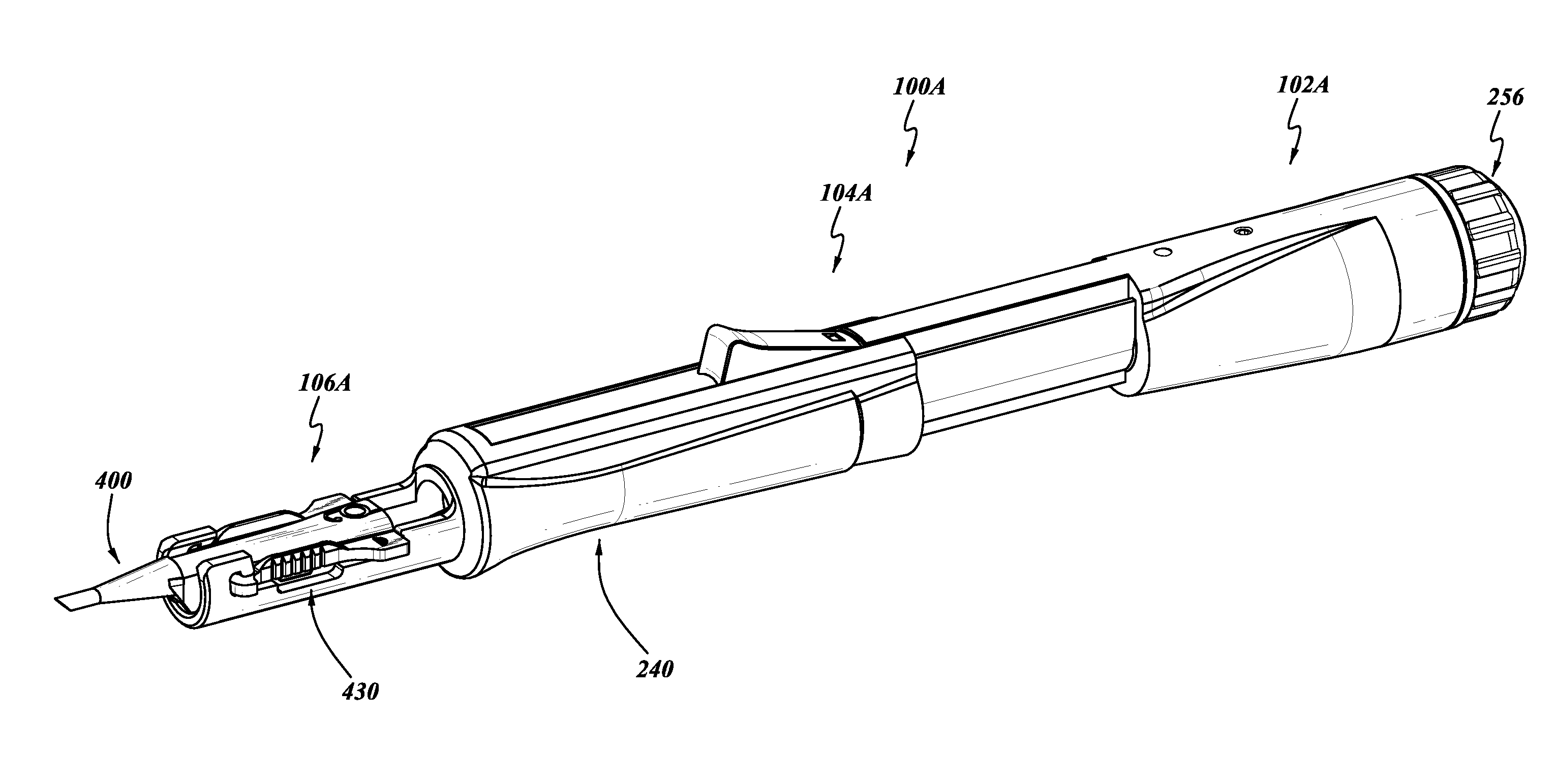

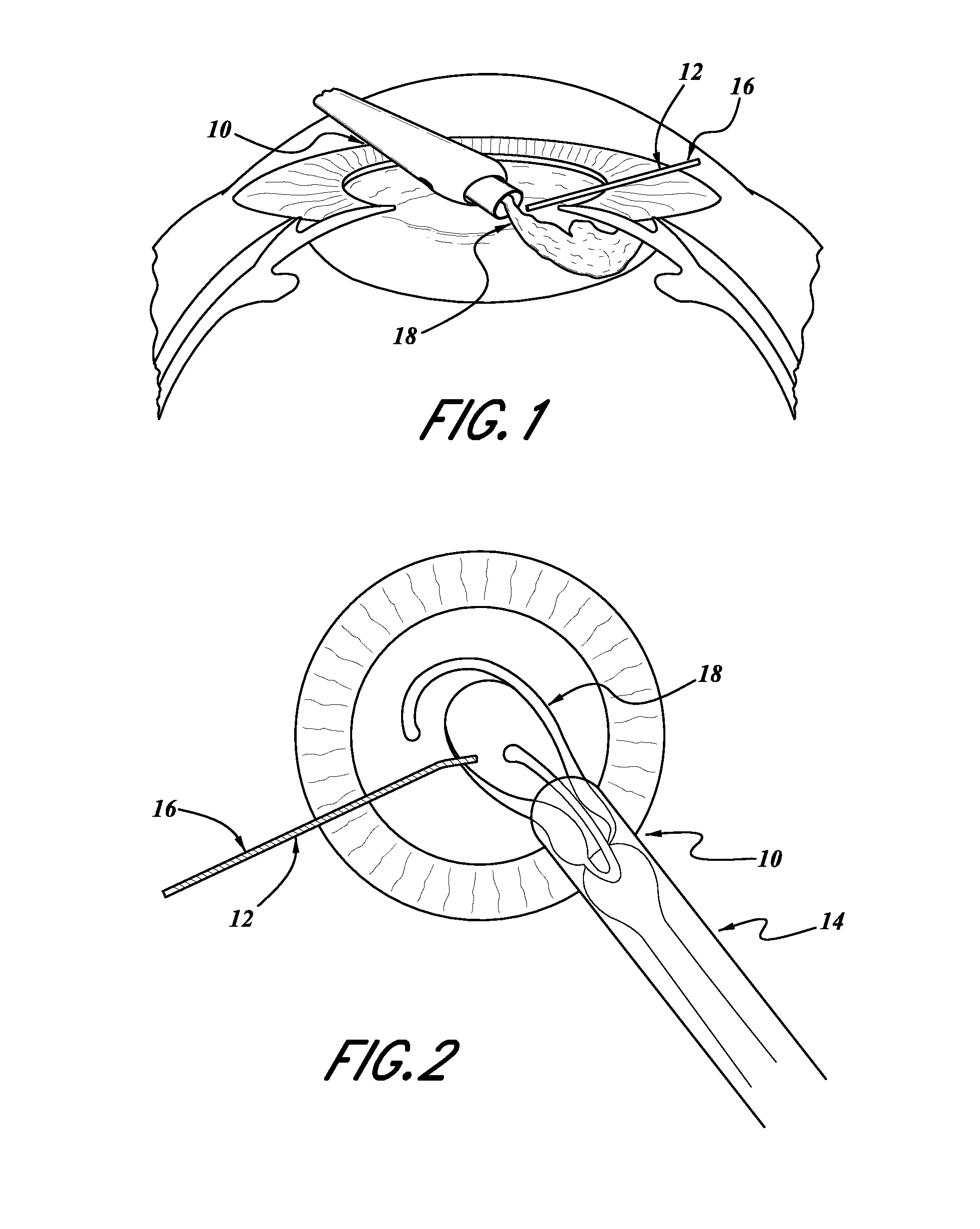

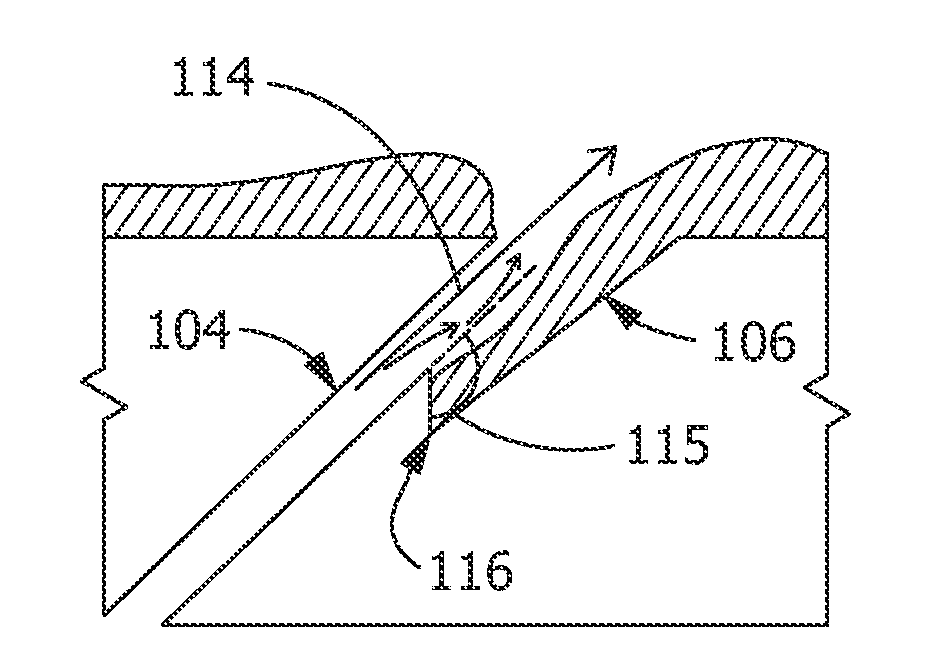

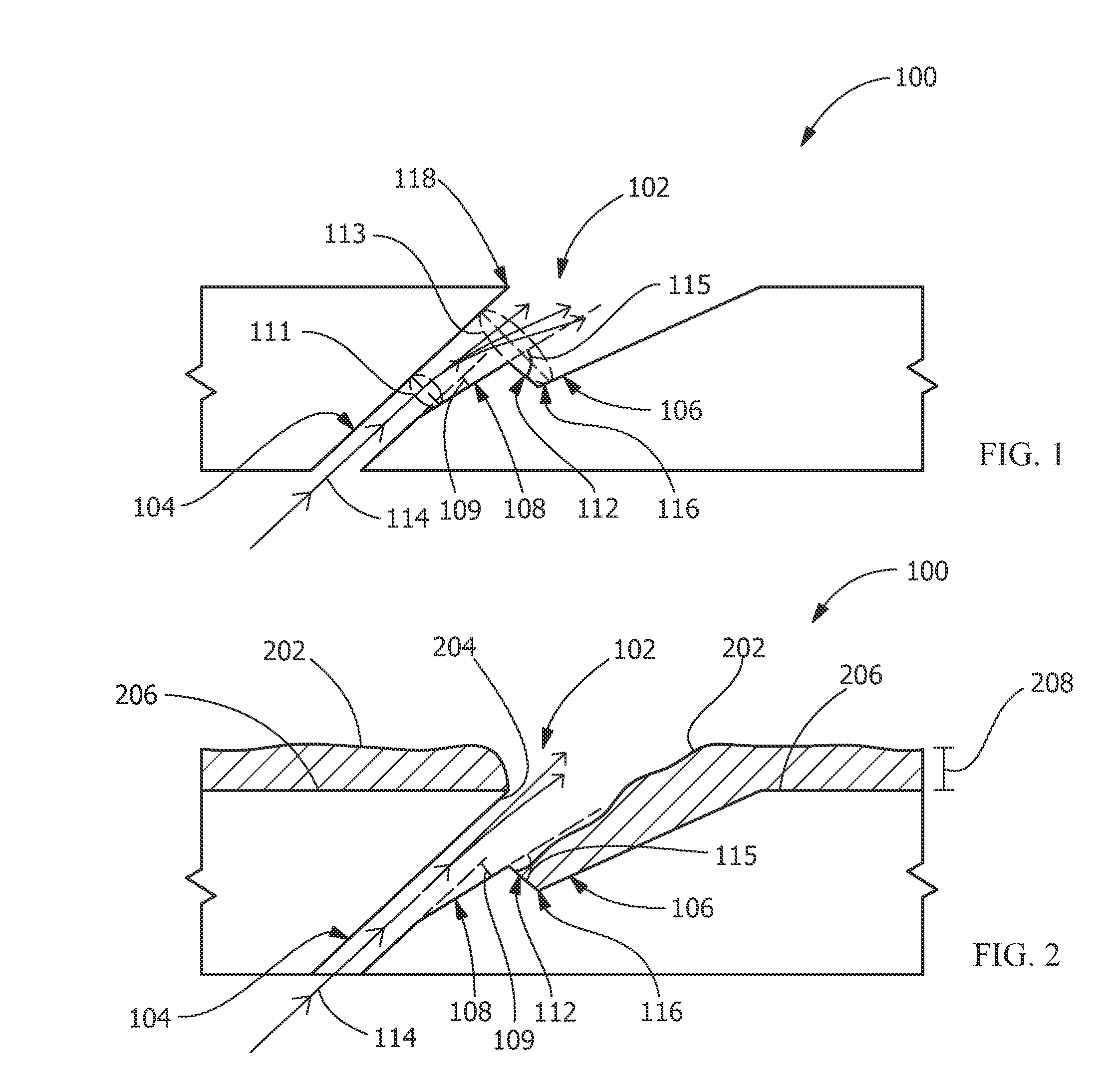

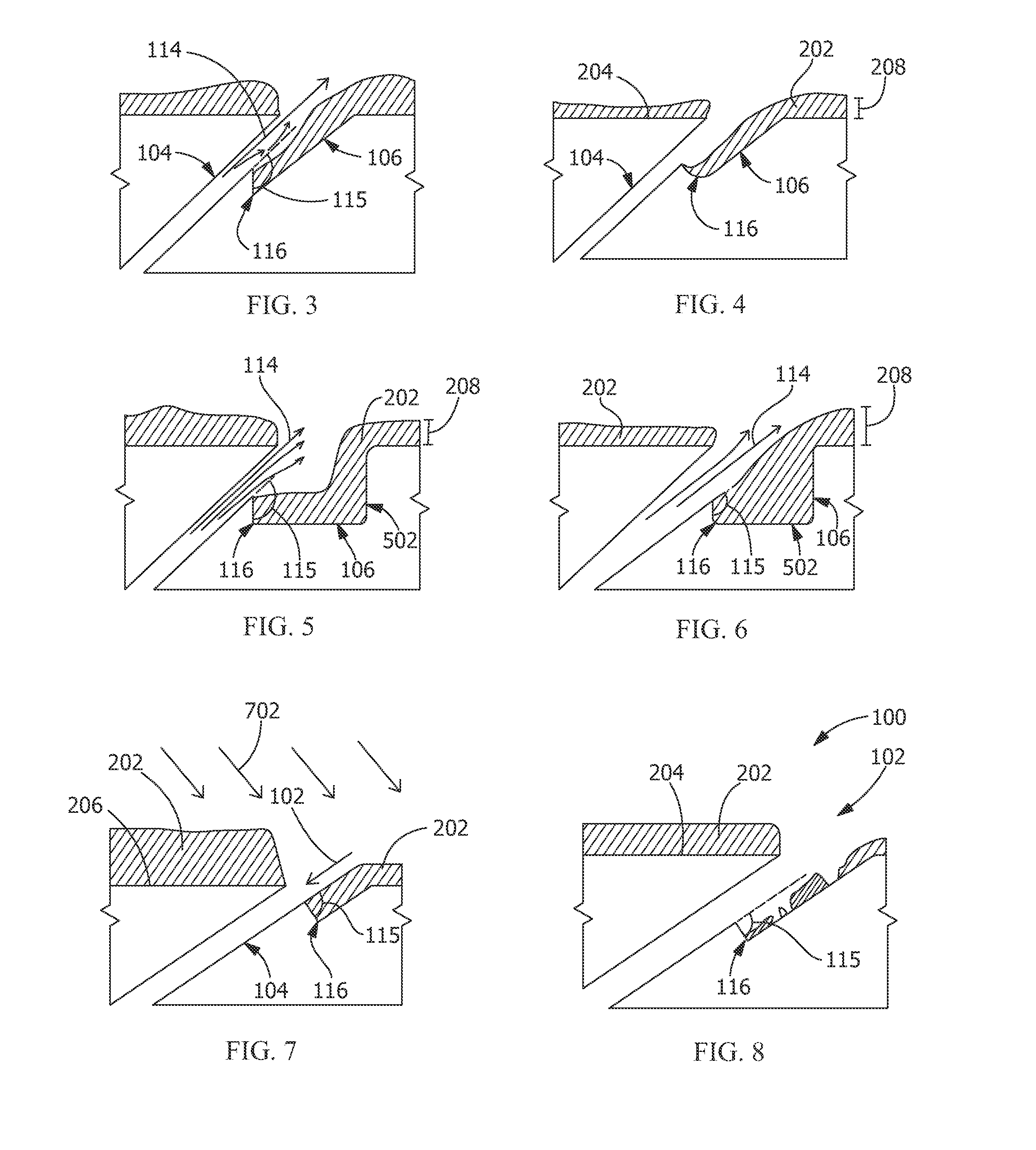

Intraocular lens inserters

ActiveUS20140276901A1Reduce manual forceReduce forceEye surgeryIntraocular lensIntraocular lens insertionEngineering

An intraocular lens inserter can include an energy storage portion, an actuator portion, and a lens support portion. The energy storage portion can include a compressible energy storage device, such as a compressible fluid, springs, and other devices. The inserter can include an actuator portion operating with a substantially incompressible fluid, such as liquids or other noncompressible fluids. The actuator can be configured to provide an operator with control over the release of energy from the energy storage portion so as to move a plunger for the discharge of a lens from an intraocular lens cartridge.

Owner:ALCON INC

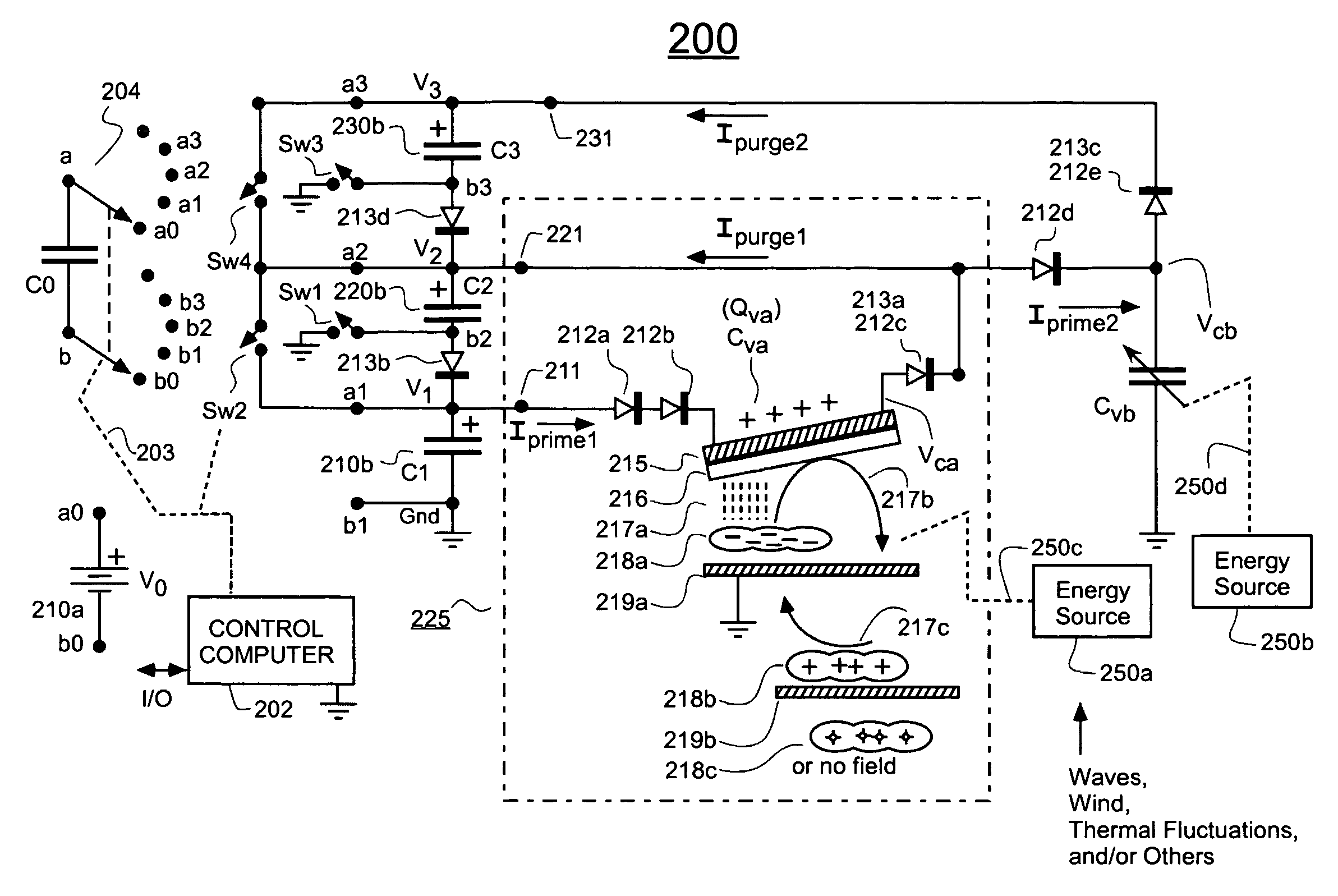

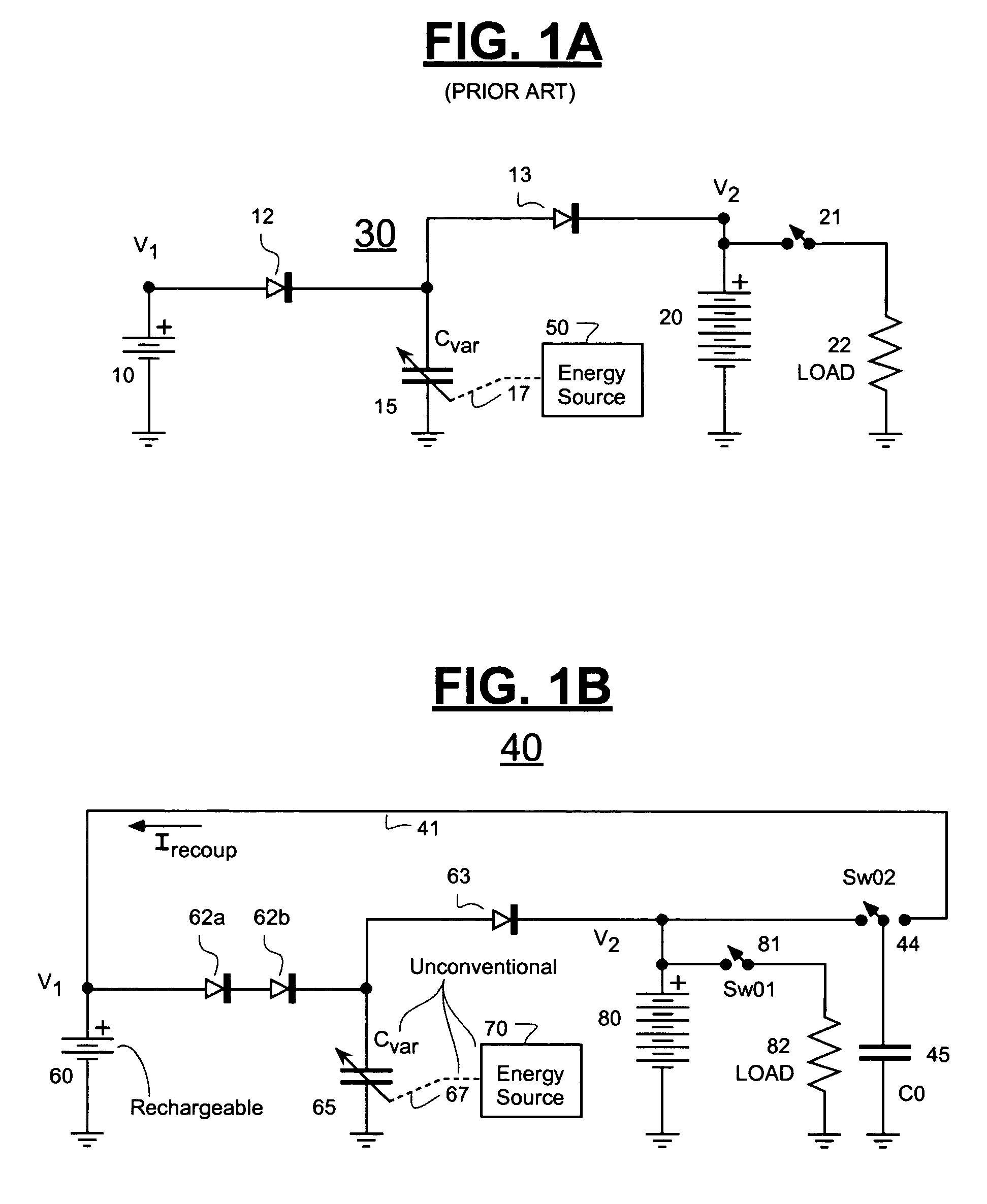

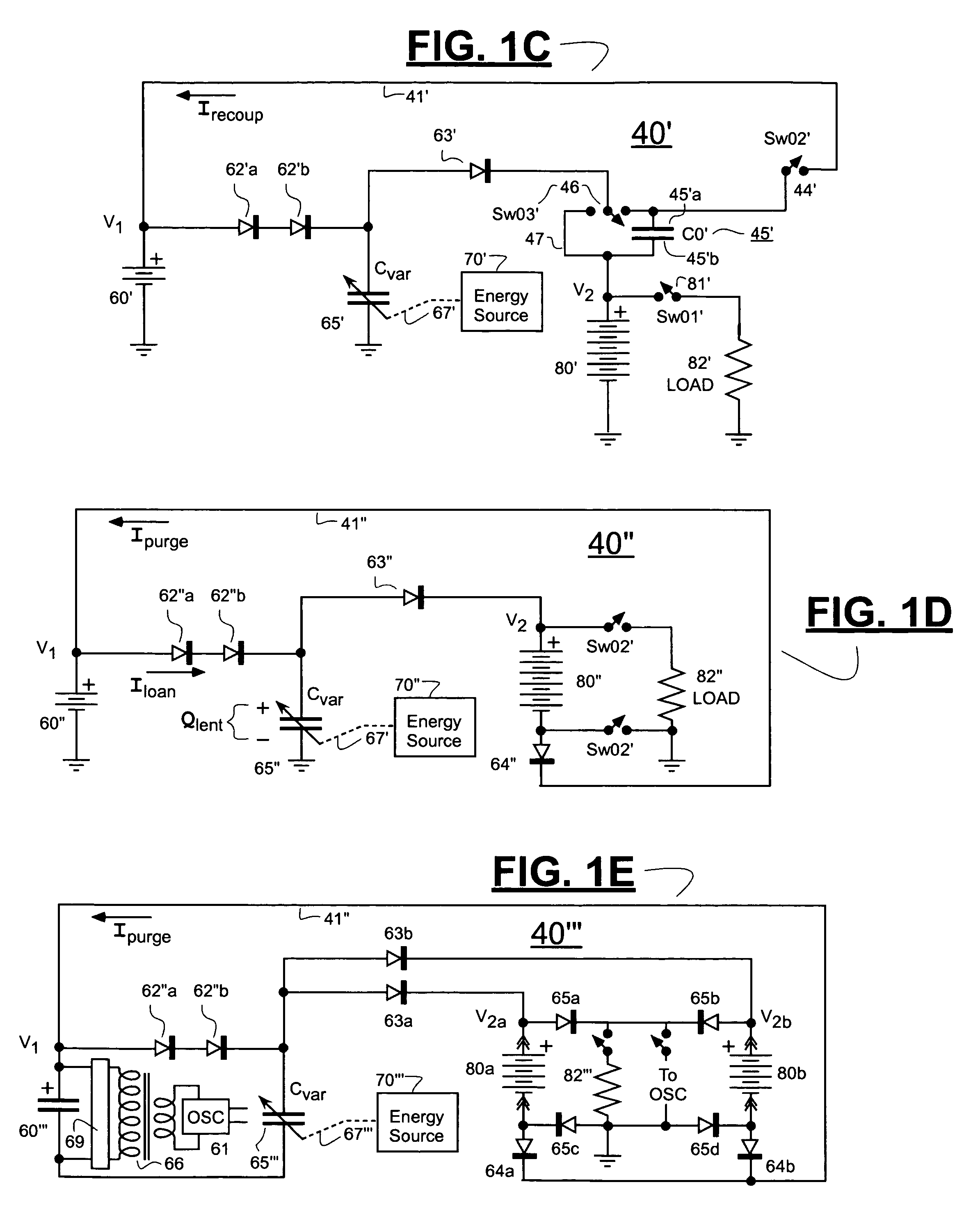

Energy invest and profit recovery systems

InactiveUS7615970B1Weaken energyLow densityBatteries circuit arrangementsSecondary cellsThermal energyDielectric

A variable density actualizing means is provided for supporting one or both of temporarily condensed electric charge and intensified magnetic flux flow and for thereby generating electrical energy. More specifically, such an actualizing means comprises: (a) condensing means for condensing one or more of an amount of electrical charge supplied from a charge donating source and flux flow induced by a magnetic field generated by a magnetic field source; (b) decondensing means, integrated with the condensing means and couplable to one or more energy sources, for reducing the density of (decondensing) the charge and / or flux flow condensed by the condensing means, the decondensing being powered by input energy received from one or more of the energy sources; wherein the decondensing means is powered by at least one of (b.1) heat energy received from one or more of the energy sources; (b.2) pressure energy received from one or more of the energy sources; (b.3) displacement energy received from one or more of the energy sources; (b.4) electrolytic ion removal energy received from one or more of the energy sources; (b.5) dielectric constant reducing energy received from one or more of the energy sources; and (b.6) magnetic permitivity reducing energy received from one or more of the energy sources. The variable density actualizing means of one embodiment is provided as an integral part of a compressor of compressible fluids (i.e., refrigerants). The variable density actualizing means of one embodiment is provided as an integral part of a fluid condenser and / or heat radiator.

Owner:GIMLAN GIDEON

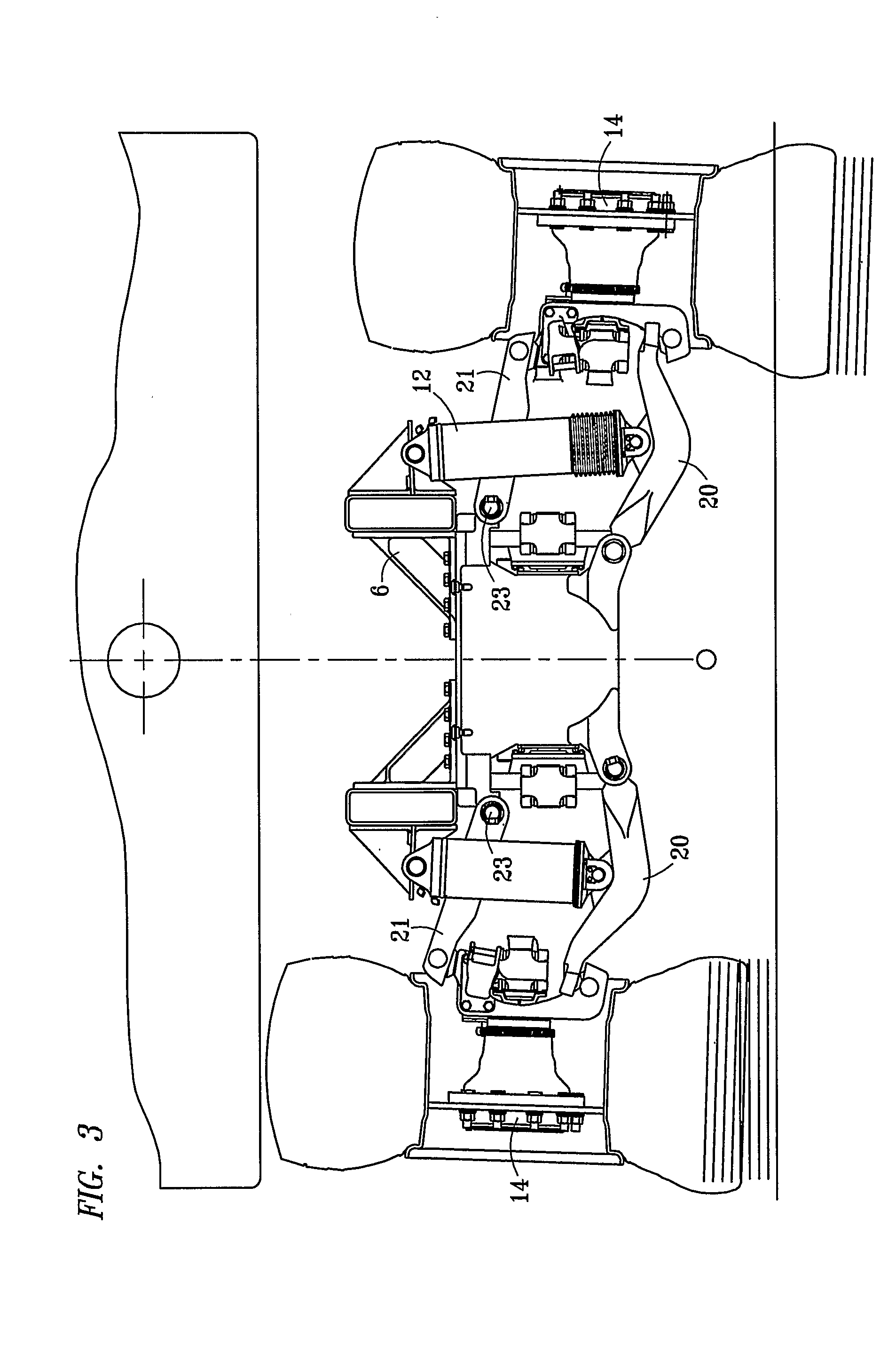

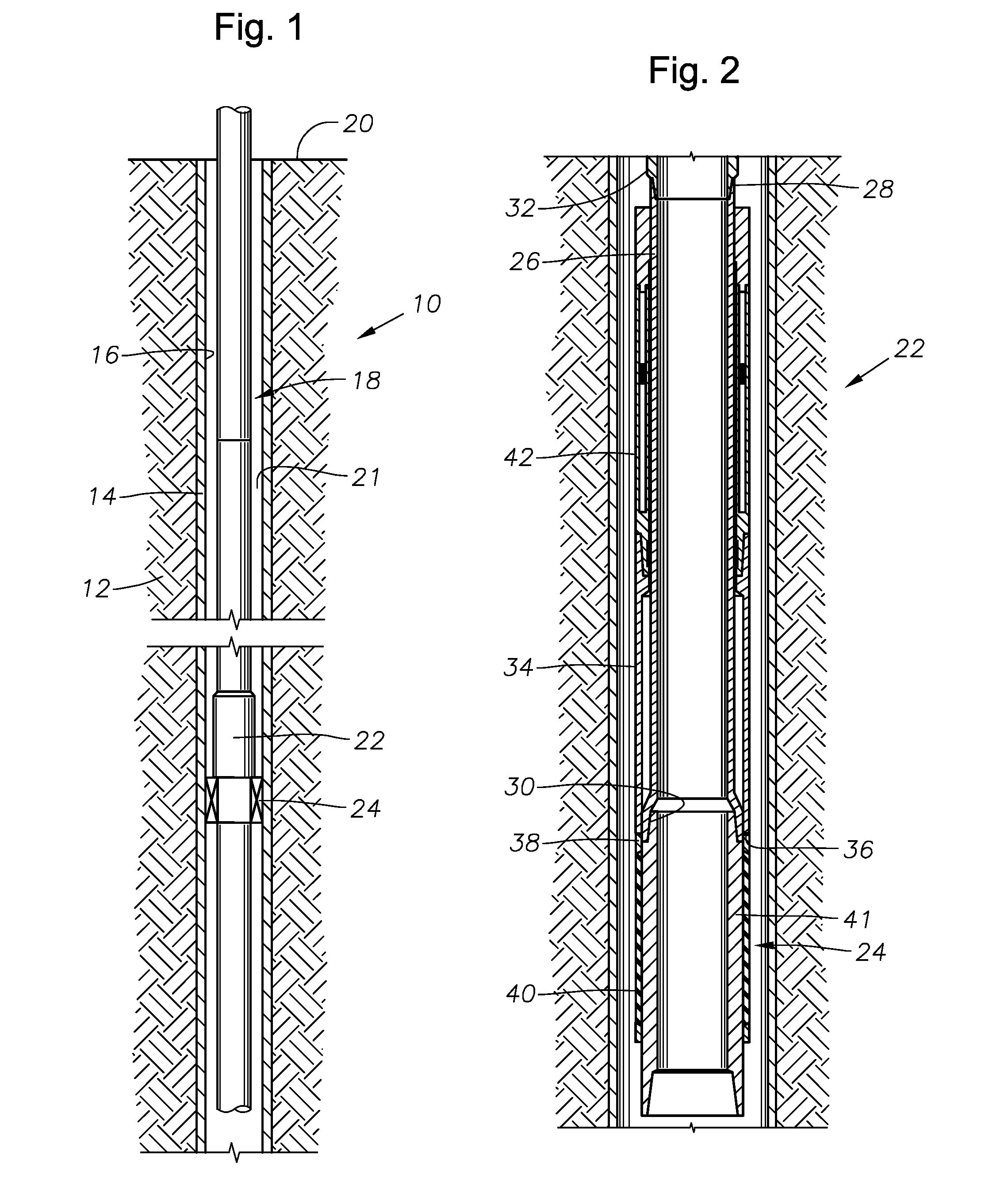

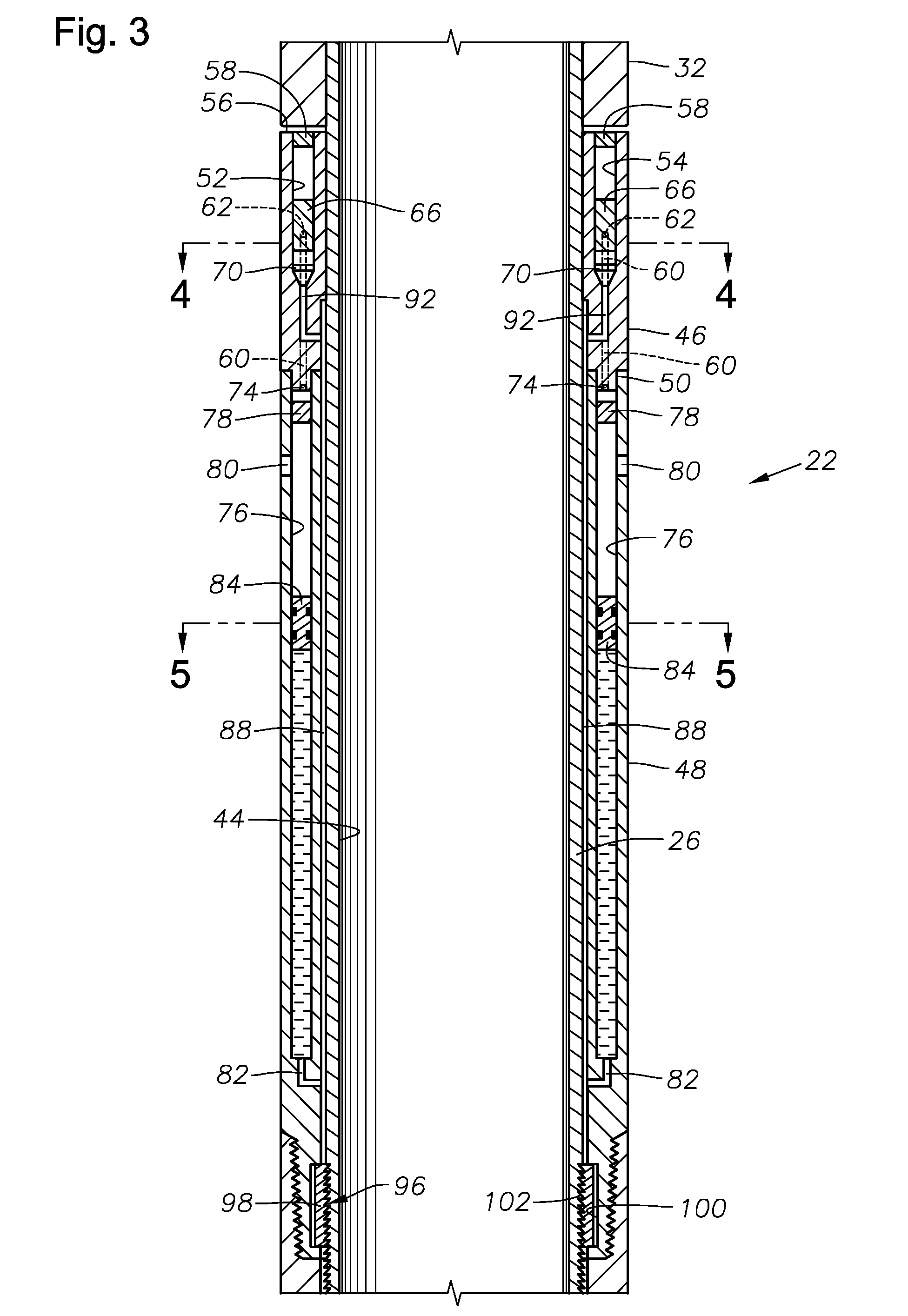

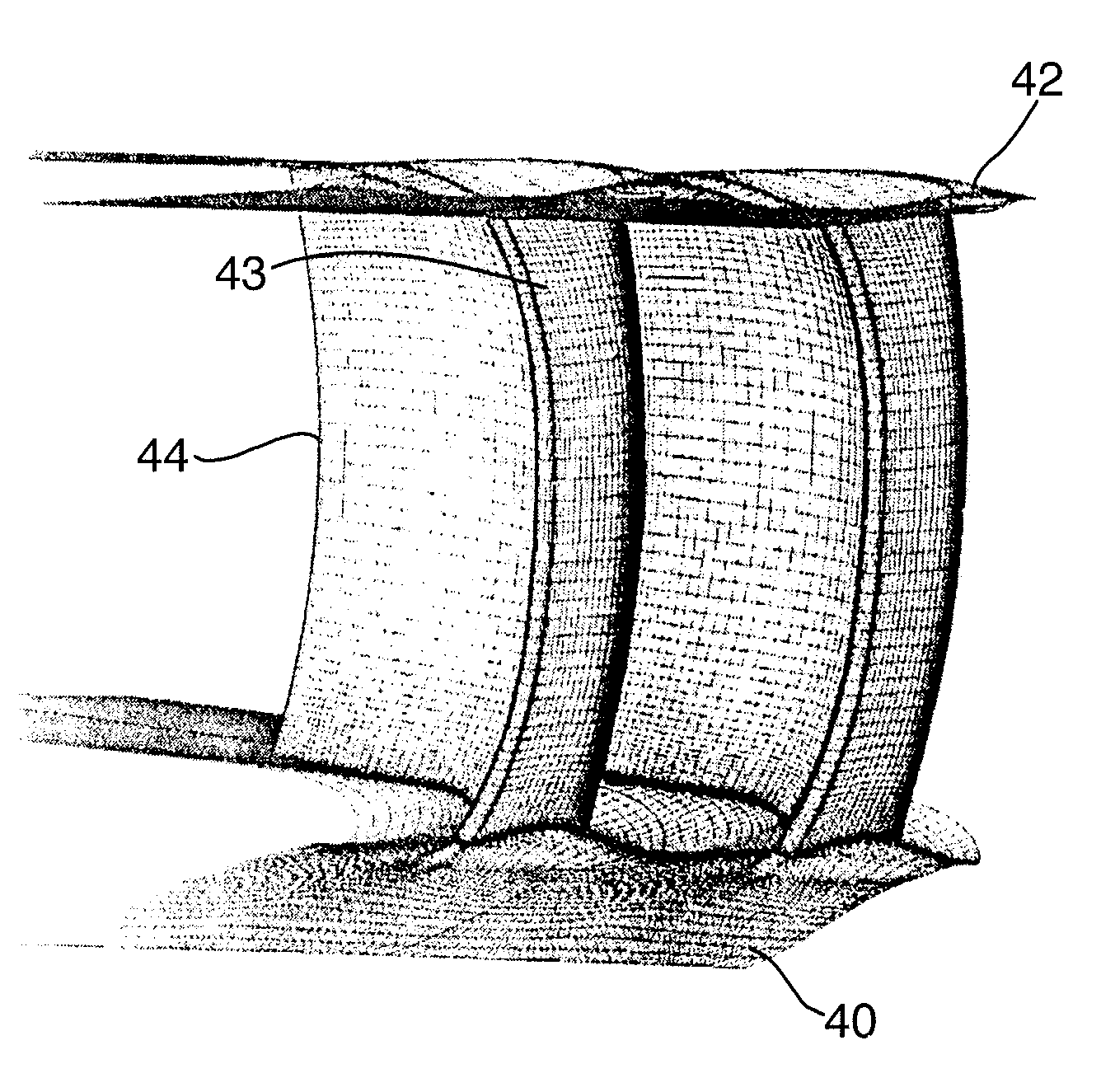

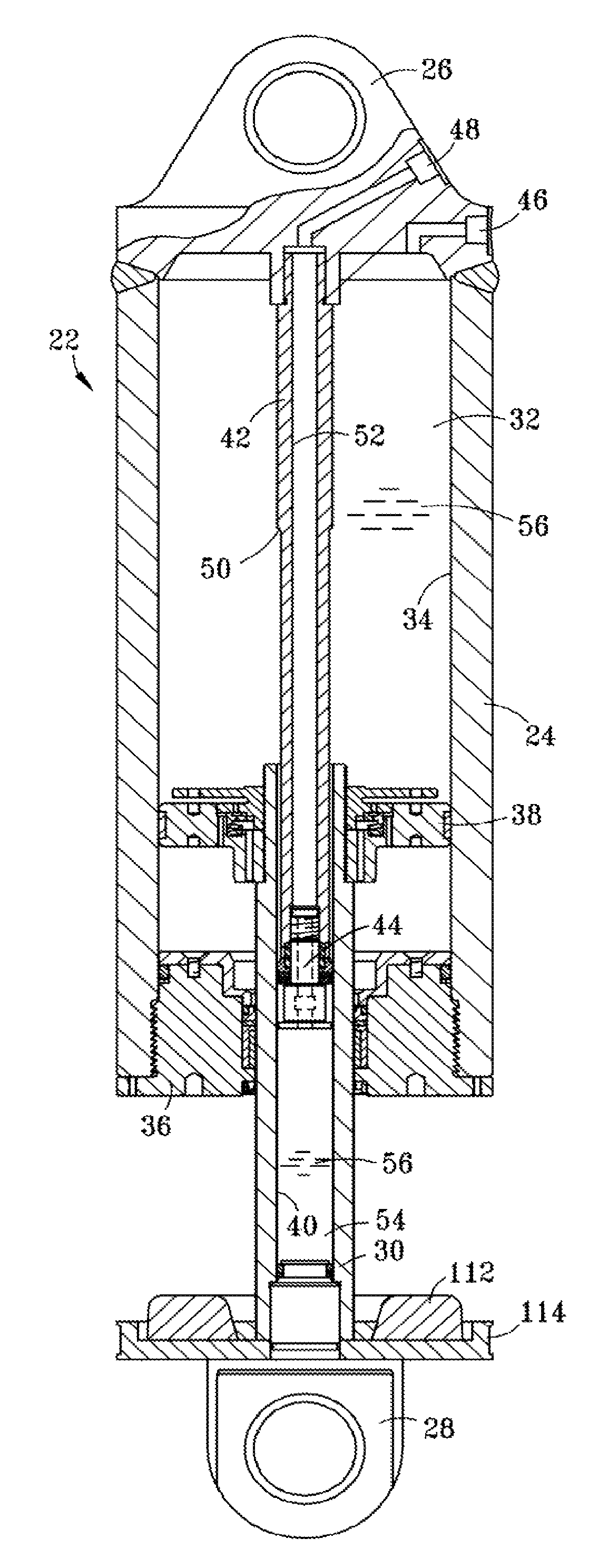

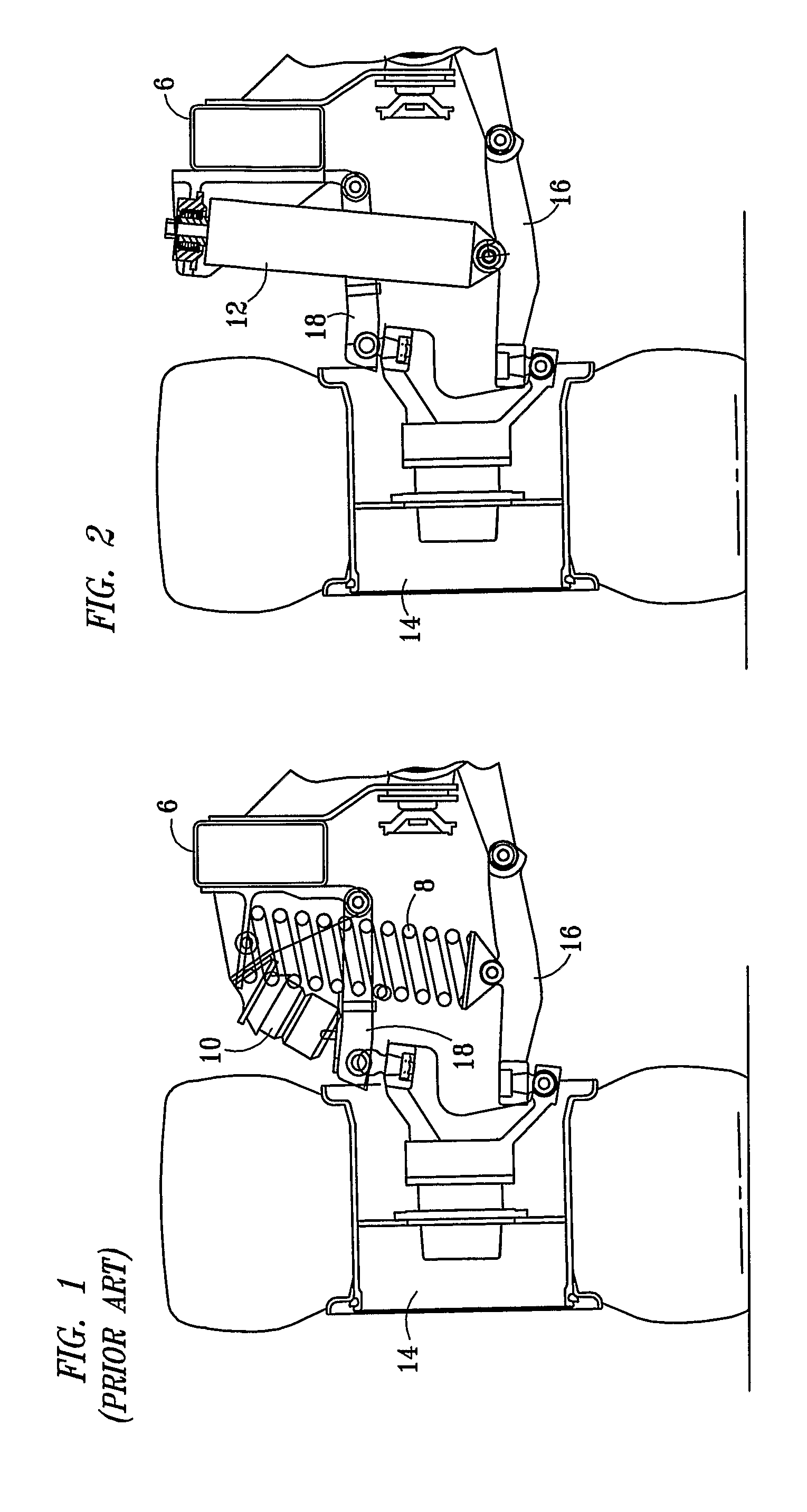

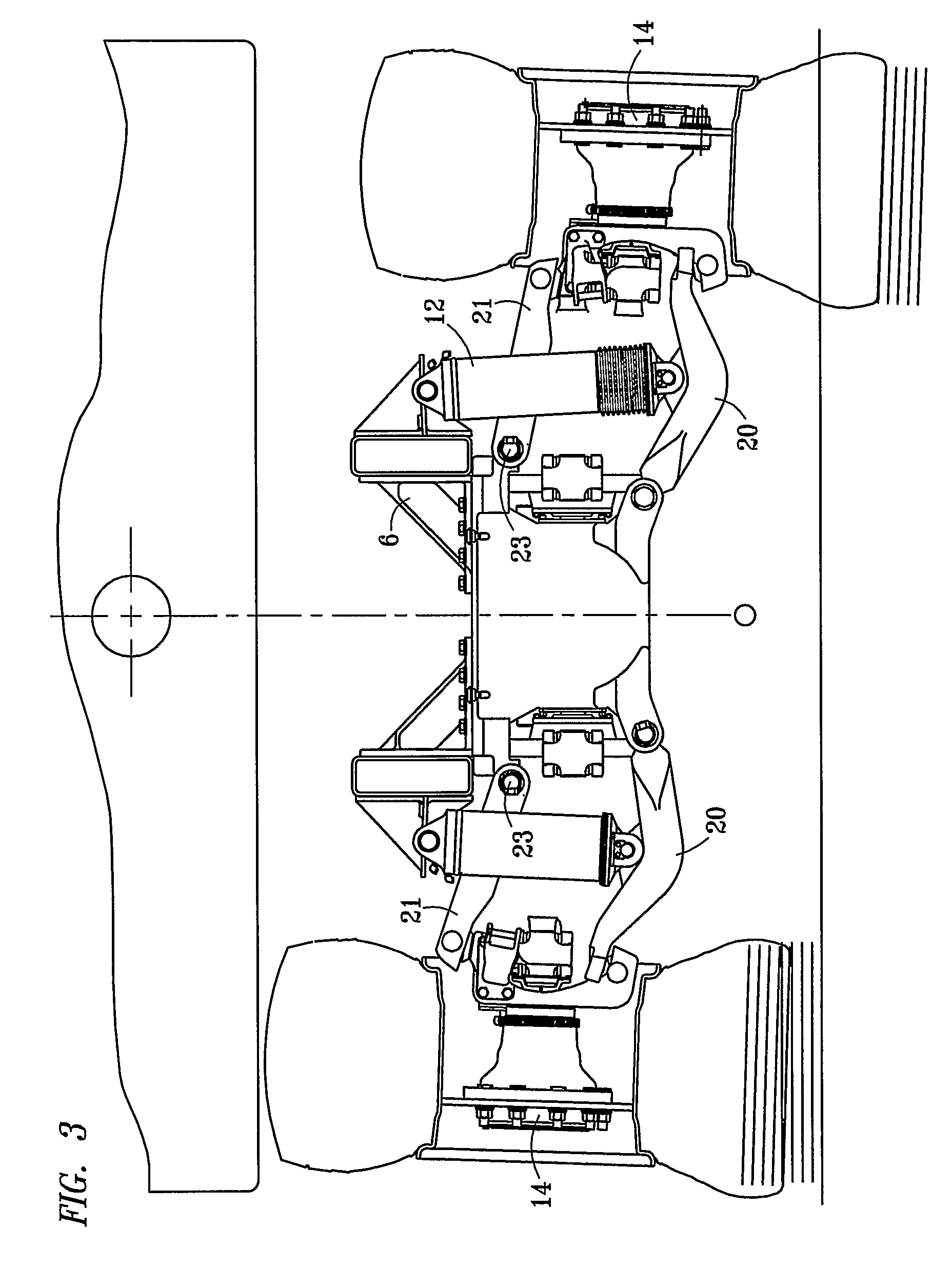

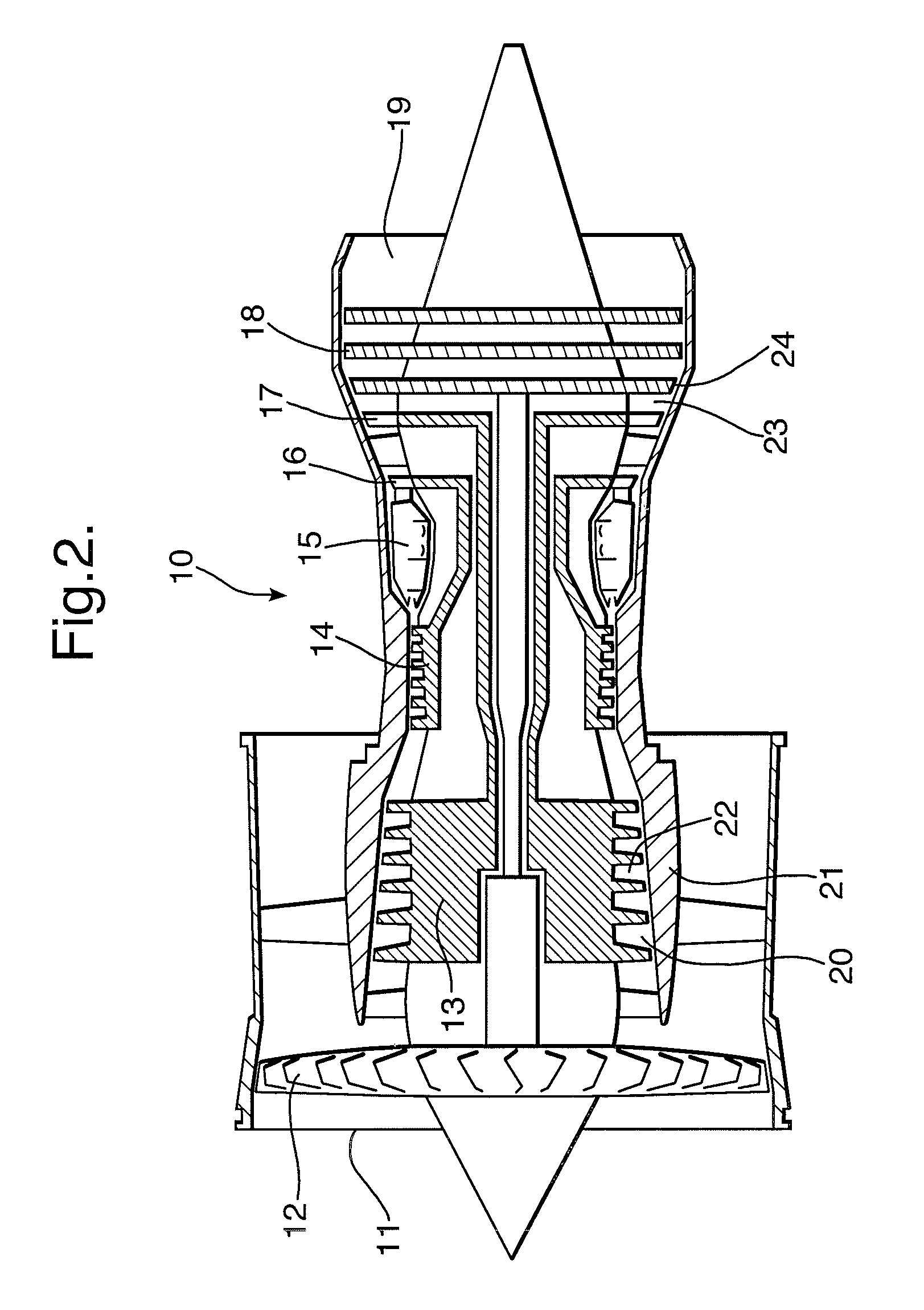

Compressible Fluid Independent Active Suspension

An active, independent suspension system has dual piston, compressible fluid struts (22). Each of the dual piston struts (22) has an outer cylinder (24) and an outer piston rod (30), which each respectively define exterior peripheries for an outer pressure chamber (32) and an inner pressure chamber (54). Pressures applied to a compressible fluid (56) in respective ones of the outer and inner pressure chambers (32, 54) urge the outer piston to extend from within the outer cylinder (24). A control system (240) is provided for actively controlling an amount of compressible fluid (56) disposed within each of the outer and inner chambers (32, 54).

Owner:HORSTMAN

Intraocular lens inserter

ActiveUS20150088149A1Reduce forceLow costEye surgeryIntraocular lensIntraocular lens insertionEngineering

An intraocular lens inserter can include an energy storage portion, an actuator portion, and a lens support portion. The energy storage portion can include a compressible energy storage device, such as a compressible fluid, springs, and other devices. The inserter can include an actuator portion operating with a substantially incompressible fluid, such as liquids or other noncompressible fluids. The actuator can be configured to provide an operator with control over the release of energy from the energy storage portion so as to move a plunger for the discharge of a lens from an intraocular lens cartridge.

Owner:ALCON INC

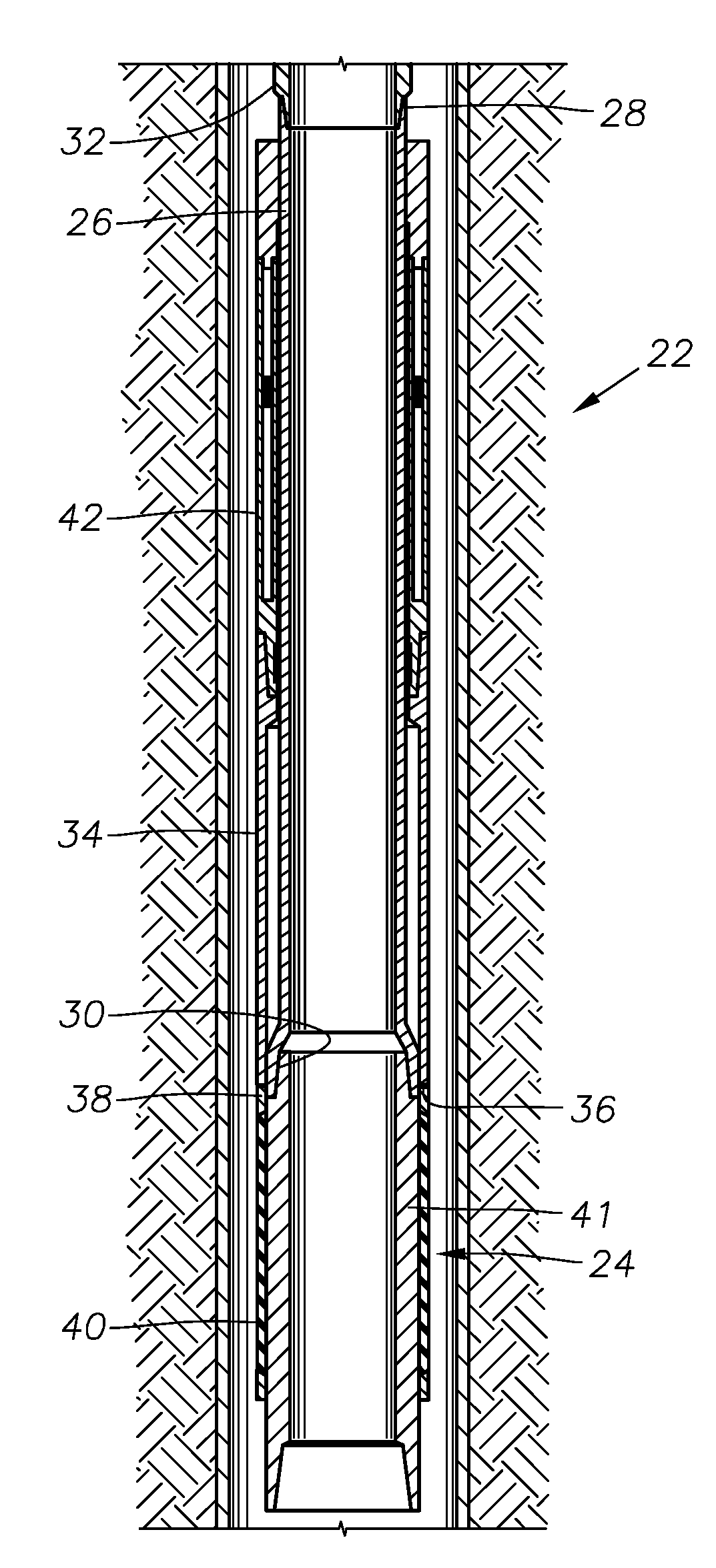

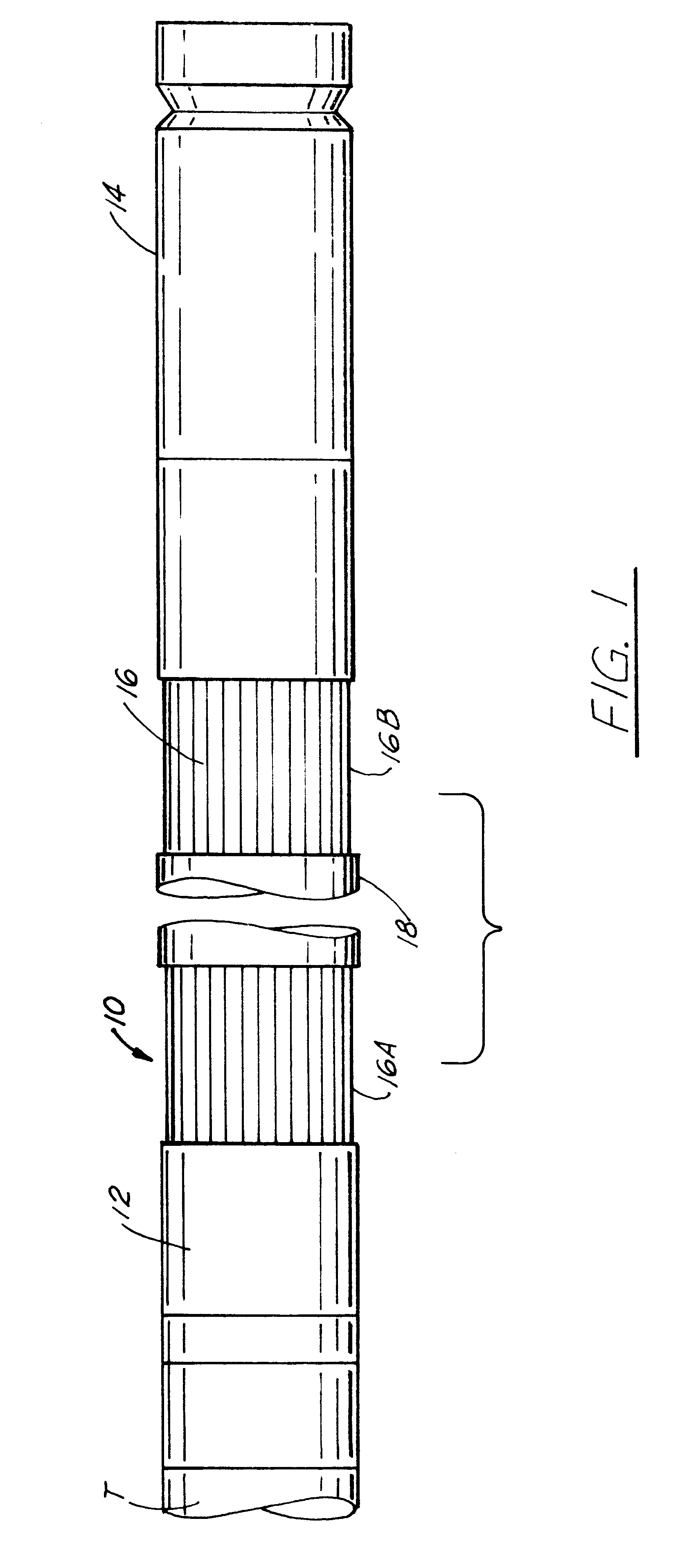

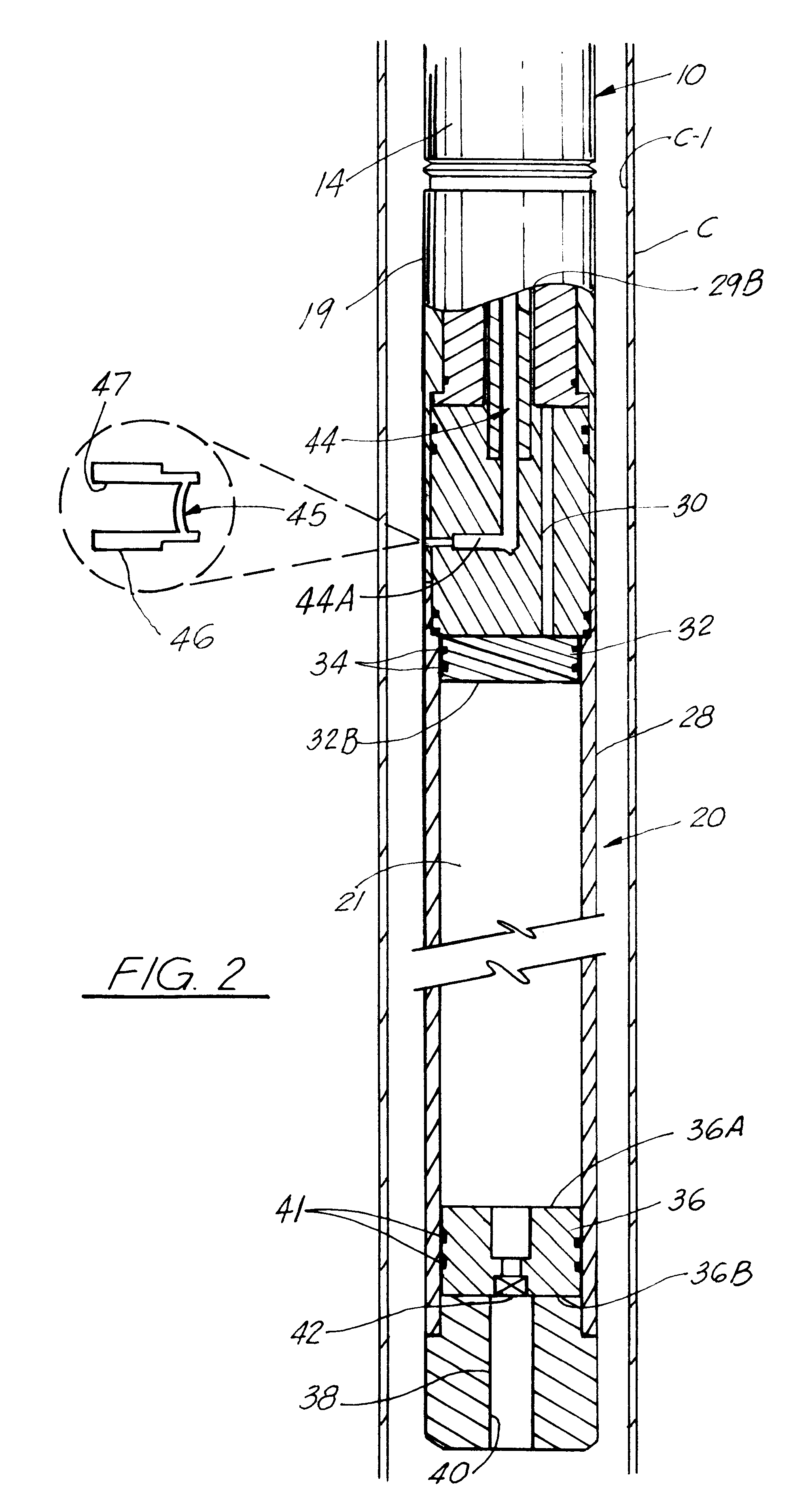

Packer setting device for high-hydrostatic applications

A packer setting device provides a buffered setting mechanism as a substantially incompressible fluid is selectively flowed into a compressible fluid chamber to compress a compressible fluid. This fluid transfer causes movement of a setting sleeve so that an associated packer device is set within a wellbore.

Owner:BAKER HUGHES INC

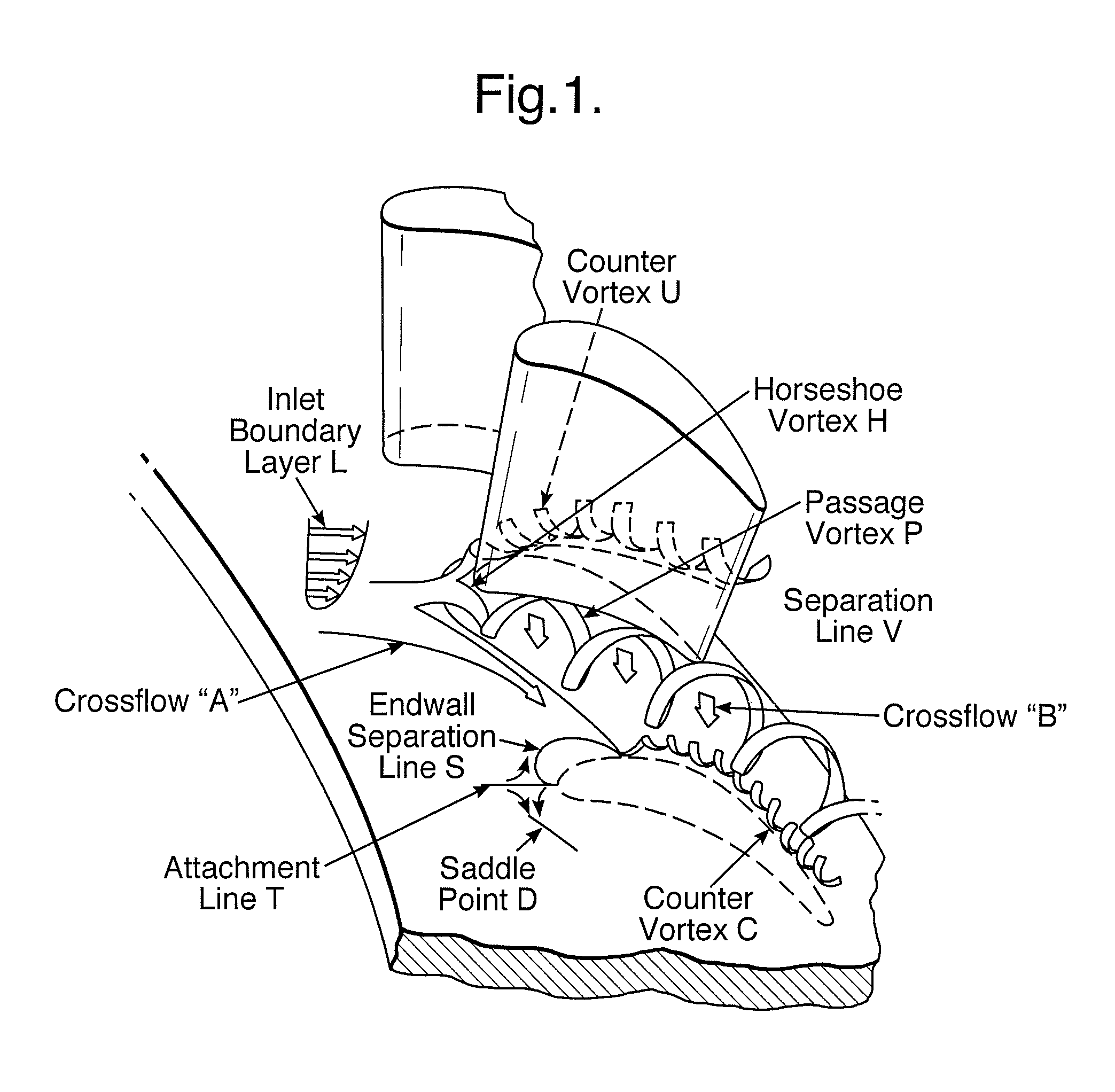

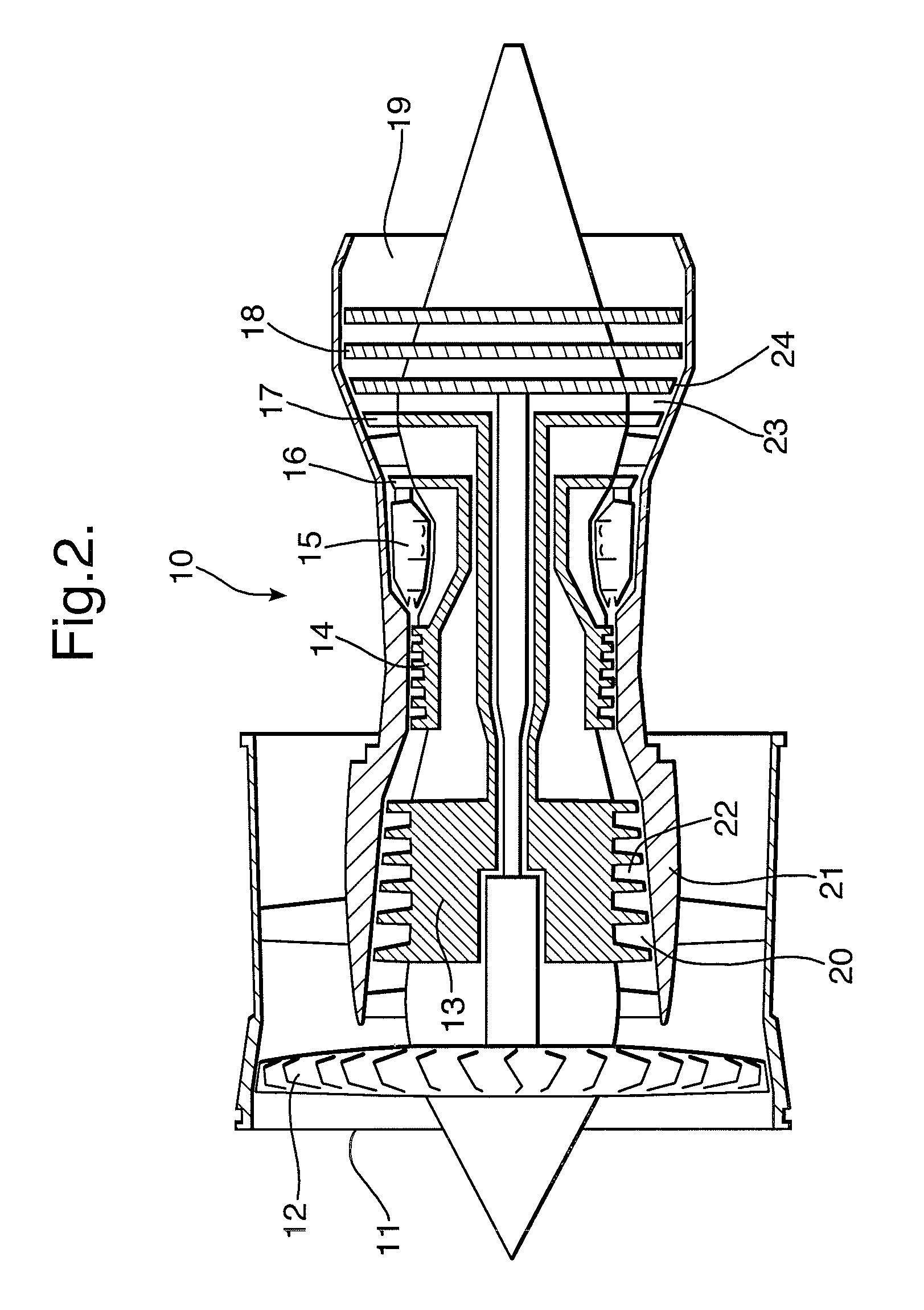

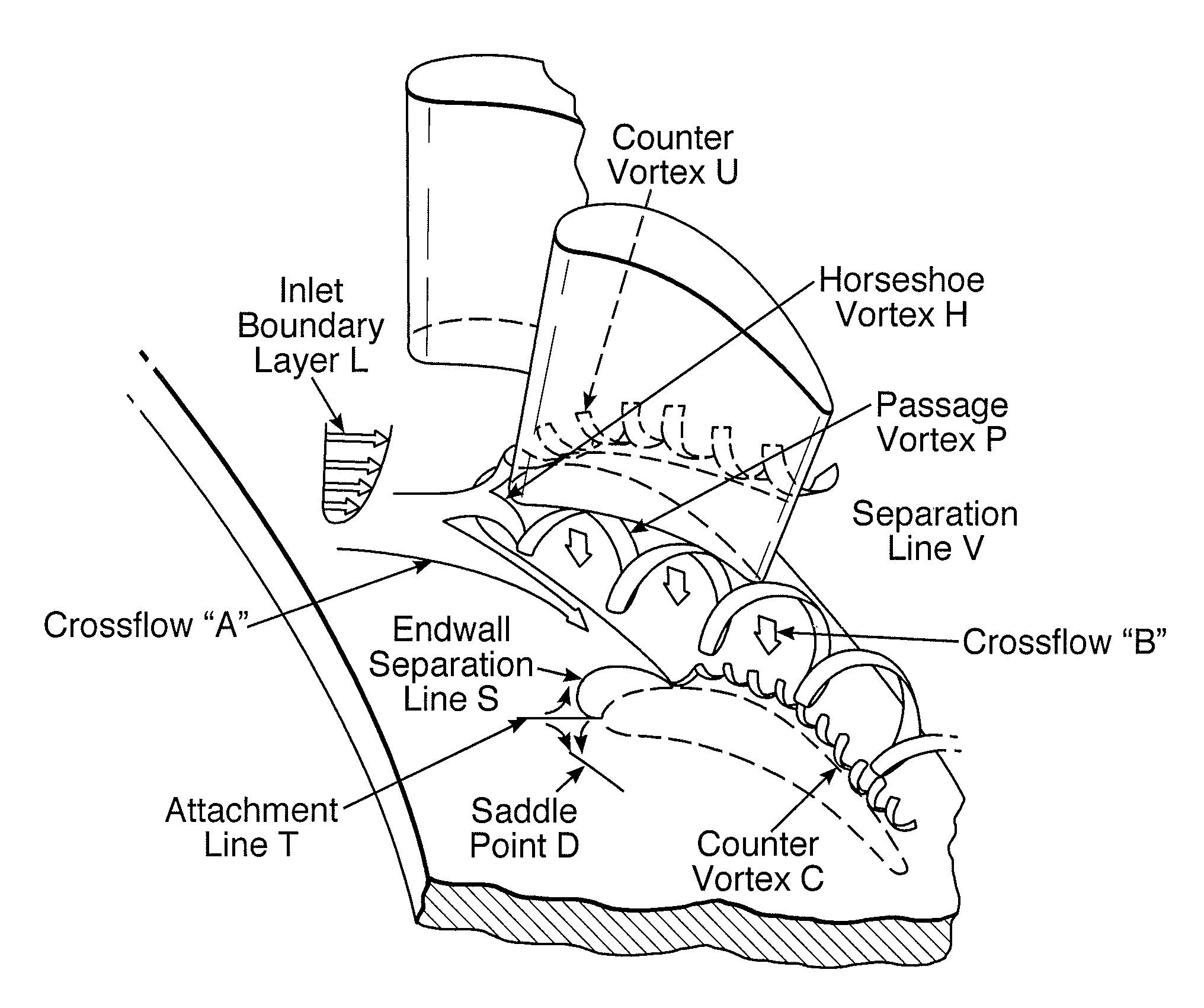

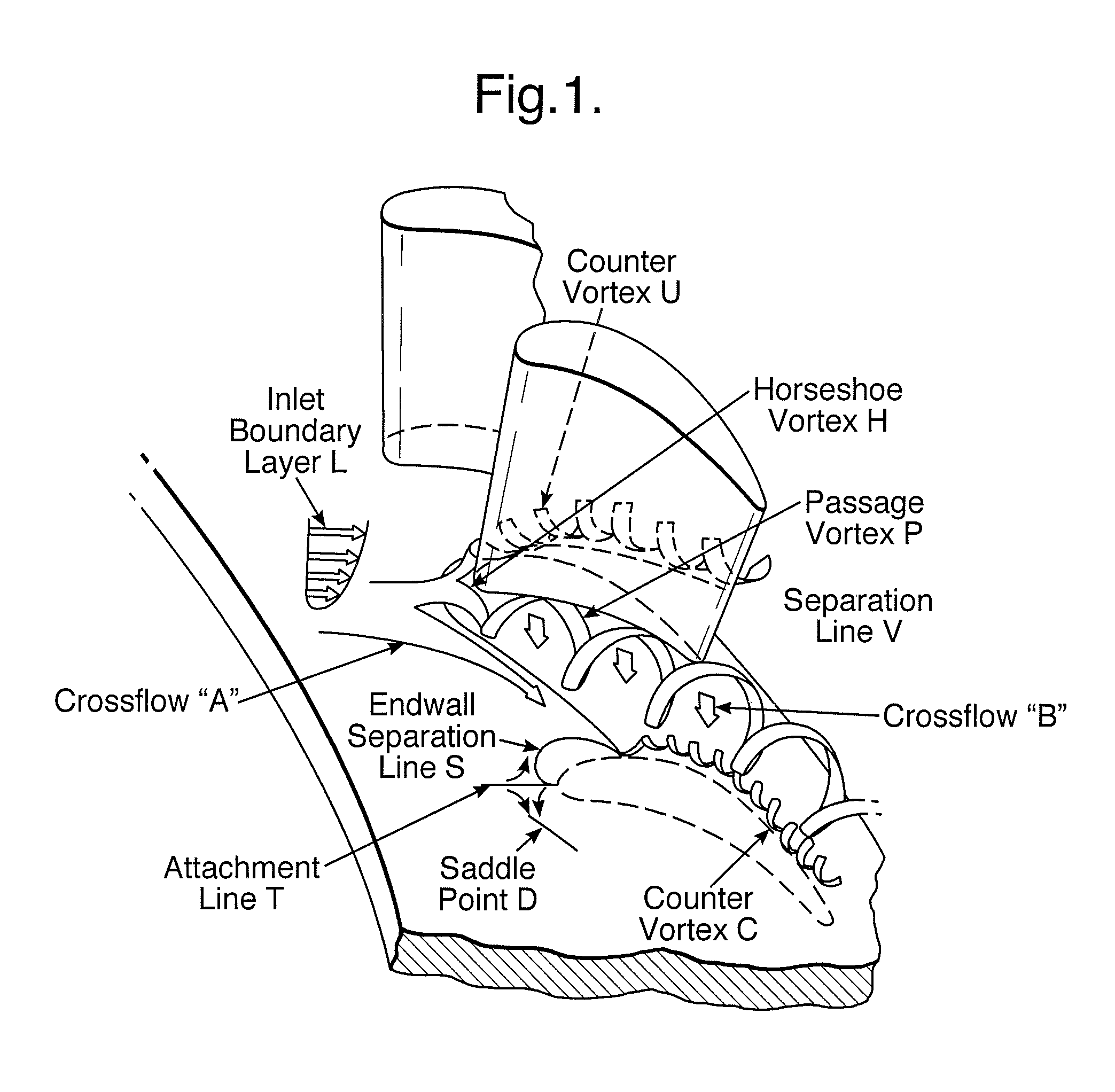

Aerofoil members for a turbomachine

A circumferential row of aerofoil members span an annular duct for carrying a flow of compressible fluid. The duct is centered on the axis of a turbomachine. Pressure and suction surfaces of neighboring aerofoil members bound respective sectoral passages which receive the flow of compressible fluid. The row of aerofoil members includes at least one radial endwall to which the tangent to the trailing edge of each aerofoil member at midspan is substantially orthogonal. Each aerofoil member has reverse compound lean. Each aerofoil member further has a leading edge which has a position at the endwall which is upstream of its position at midspan. The endwall at each sectoral passage has a non-axisymmetrical cross-section formed by a region that, in meridional section, is convexly profiled immediately adjacent the pressure surface and a region that, in meridional section, is concavely profiled immediately adjacent the suction surface.

Owner:ROLLS ROYCE PLC

Compressible fluid independent active suspension

Owner:HORSTMAN

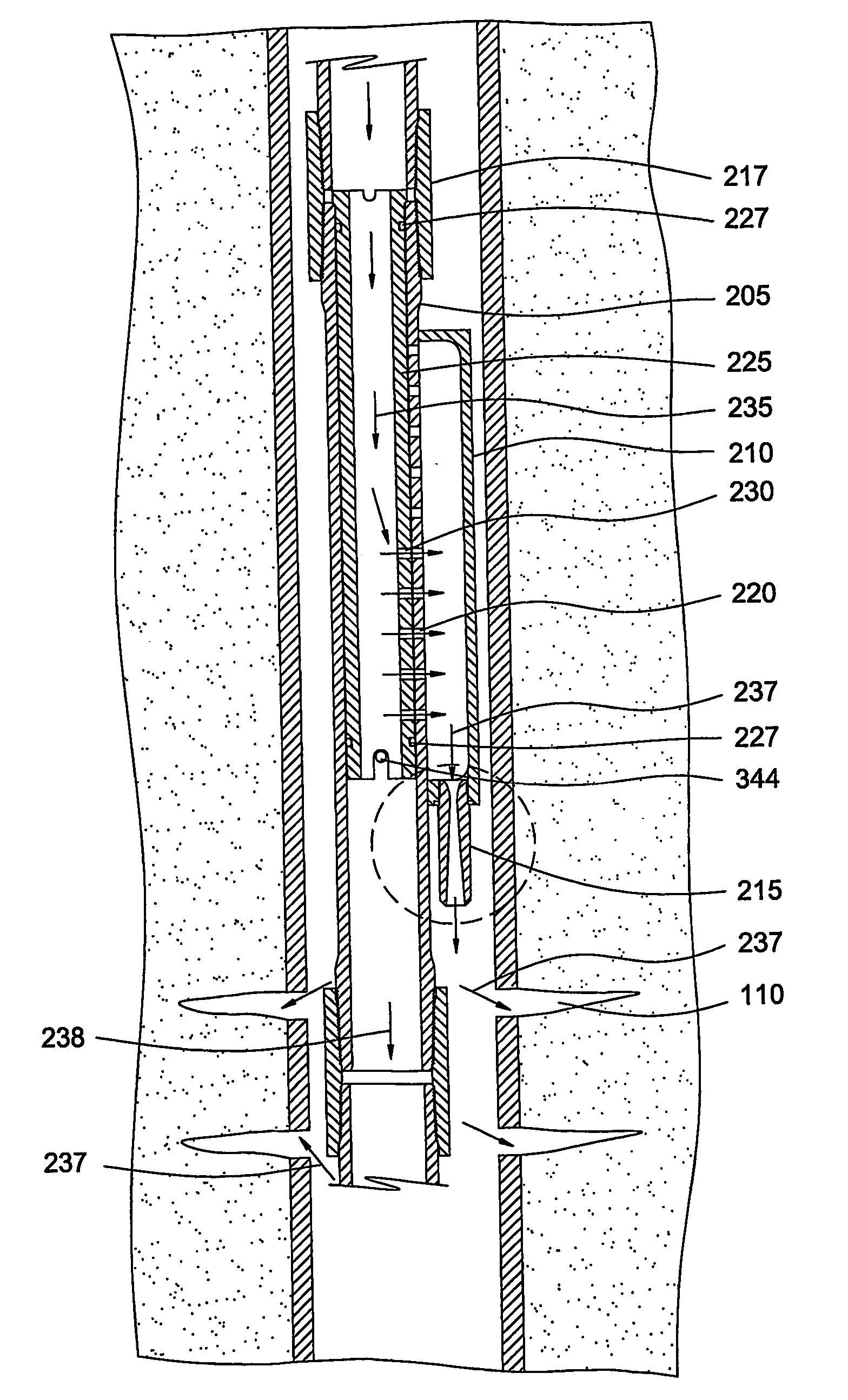

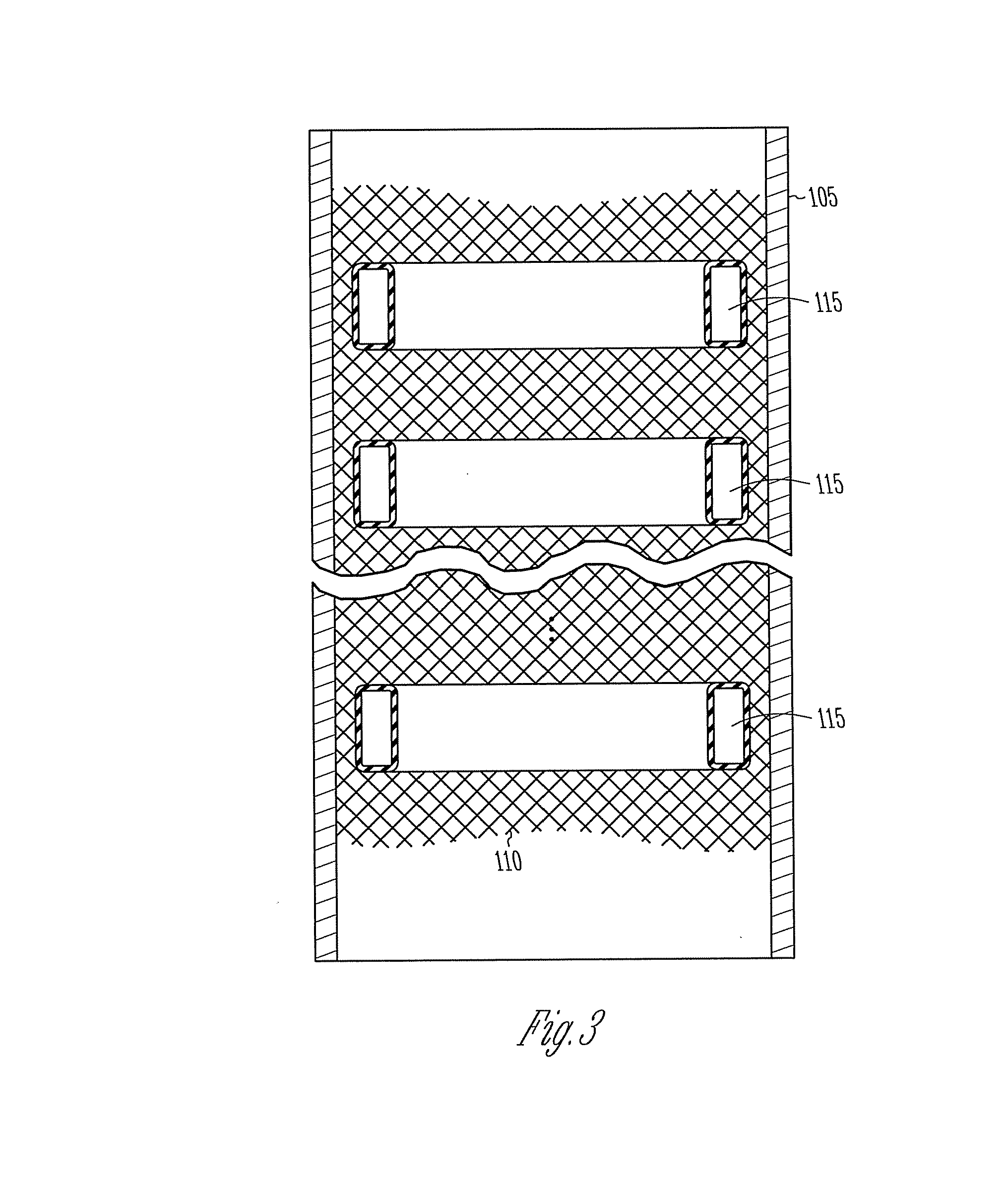

Method and apparatus for injecting steam into a geological formation

The present invention generally provides a method and apparatus for injecting a compressible fluid at a controlled flow rate into a geological formation at multiple zones of interest. In one aspect, the invention provides a tubing string with a pocket and a nozzle at each isolated zone. The nozzle permits a predetermined, controlled flow rate to be maintained at higher annulus to tubing pressure ratios. The nozzle includes a diffuser portion to recover lost steam pressure associated with critical flow as the steam exits the nozzle and enters a formation via perforations in wellbore casing. In another aspect, the present invention assures that the fluid is supplied uniformly to a long horizontal wellbore by providing controlled injection at multiple locations that are distributed throughout the length of the wellbore. In another aspect, the invention ensures that saturated steam is injected into a formation in a predetermined proportion of water and vapor by providing a plurality of apertures between a tubing wall and a pocket. The apertures provide distribution of steam that maintains a relative mixture of water and vapor. In another aspect of the invention, a single source of steam is provided to multiple, separate wellbores using the nozzle of the invention to provide a controlled flow of steam to each wellbore.

Owner:WEATHERFORD TECH HLDG LLC

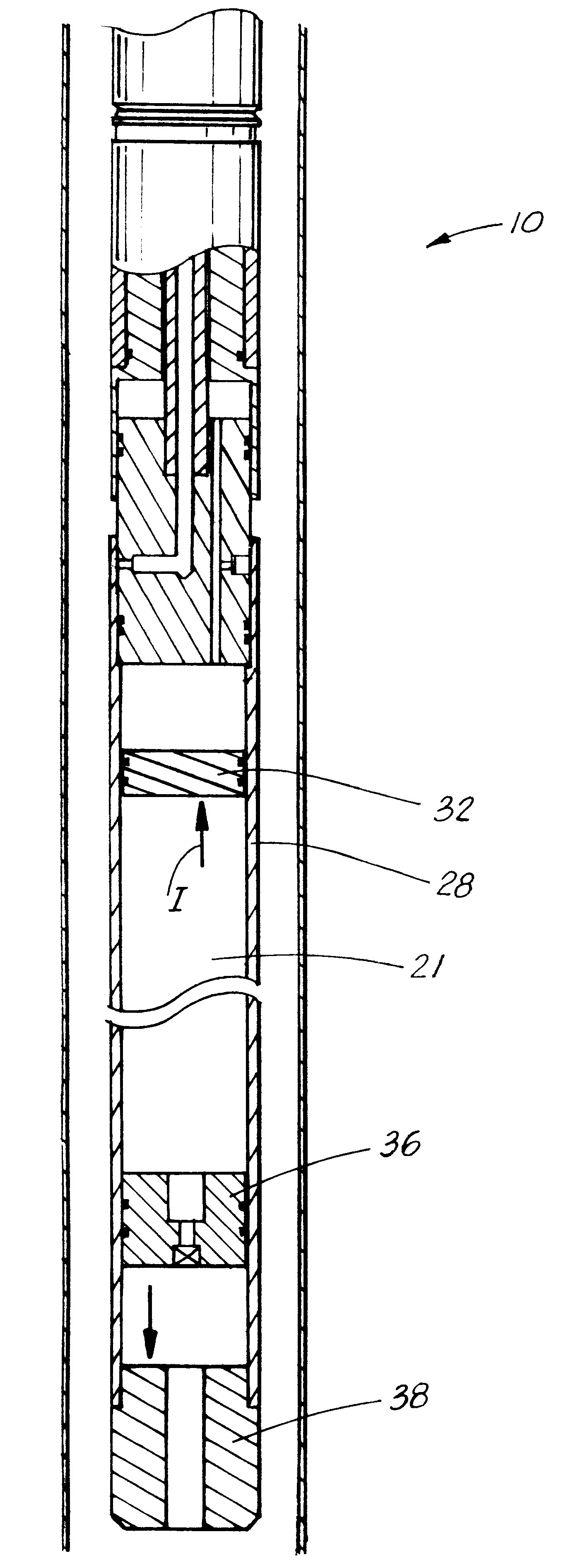

Downhole hydraulic control system with failsafe features

ActiveUS20080066921A1Fail safeOperating means/releasing devices for valvesFluid removalControl systemControl line

A control system for a subsurface safety valve addresses normal open and closed operation and a failsafe operation if key system components fail. It features a single control line from the surface that splits at the subsurface safety valve and goes to one end of two discrete piston chambers that are aligned and isolated from tubing pressure. The piston in one chamber is larger than in the other and the pistons are connected for tandem movement. Each side of the unbalanced system's piston has a seal mounted to it and another for the rod attached to it that exits the chamber. A jumper line connects the chambers at a point between the seals in each chamber and features a large reservoir. The jumper line is filled with a compressible fluid. Fail safe closure of the valve occurs if any of the four seals fail.

Owner:BAKER HUGHES INC

Aerofoil members for a turbomachine

A circumferential row of aerofoil members span an annular duct for carrying a flow of compressible fluid. The duct is centred on the axis of a turbomachine. Pressure and suction surfaces of neighbouring aerofoil members bound respective sectoral passages which receive the flow of compressible fluid. The row comprises at least one radial endwall to which the tangent to the trailing edge of each aerofoil member at midspan is substantially orthogonal. Each aerofoil member has reverse compound lean. Each aerofoil member further has a leading edge which has a position at the endwall which is upstream of its position at midspan.

Owner:ROLLS ROYCE PLC

Efficient chiller for a supercritical fluid chromatography pump

ActiveUS20140190183A1Reduce flow noiseReduce the temperaturePositive displacement pump componentsComponent separationCompressible fluid flowChiller

Owner:AGILENT TECH INC

Shock absorber having compressible fluid

A shock absorber for a vehicle, having a bellows piston, bellows, and a fluid as the damping medium. The shock absorber has a first partition wall, which is situated on the bellows piston, and is implemented to separate a volume area of the bellows piston from a volume area of the bellows. The first partition wall has a first opening, which is implemented to limit a fluid flow between the volume area of the bellows piston and the volume area of the bellows. The shock absorber further has a sprung mass, which is situated inside the shock absorber to influence the fluid flow inside the shock absorber.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Turbo-machine component and method

InactiveUS20140161585A1Shorten speedPump componentsReaction enginesEngineeringMechanical engineering

A component, a component manufacturing process, and a component operation process are disclosed. The component has a diffuser permitting compressible fluid to flow throughout a first region and a second region of the diffuser at a decreasing velocity. The diffuser includes a coating collection feature. The component manufacturing process includes positioning the component and applying the coating to at least a surface of the component outside of the diffuser and to at least a portion of the second region, not to the first region, to the coating collection feature, or a combination thereof. The component operation process includes positioning the component and transporting the compressible fluid through the diffuser.

Owner:GENERAL ELECTRIC CO

Vascular elastance

ActiveUS20130079871A1Reduce pulsatile stiffness componentImprove systemic arterial elastanceStentsOcculdersBlood vesselElastance

Owner:RGT UNIV OF MINNESOTA

Gas operated apparatus and method for maintaining relatively uniformed fluid pressure within an expandable well tool subjected to thermal variants

A thermal compensating apparatus method for maintaining a substantially constant fluid pressure within a subterranean well tool of the type that includes a bladder that is selectively expandable upon the introduction of pressurized actuation fluid for actuating said tool at a location in a well. A body includes first and second fluid chambers. The first fluid chamber houses a substantially incompressible fluid and communicates with the actuating fluid used for activating said tool in the well. The second fluid chamber is charged with a compressible fluid. Both chambers define first volumetric sizes within the body upon actuation of said tool in the well. The fluid chambers are operatively connected to each other without transmitting fluid there between so that changes in the volumetric size of the first chamber caused by temperature variations in the actuation fluid will change the volumetric size of the second fluid chamber for maintaining the actuating fluid at a substantially constant pressure.

Owner:WEATHERFORD TECH HLDG LLC

Compressible fluid pumping system for dynamically compensating compressible fluids over large pressure ranges

ActiveUS8215922B2Low compressibilityPrecise functionComponent separationFlexible member pumpsState of artEngineering

An invention is claimed that enables the pumping of compressible fluids at high pressures when an accurate flow is desired. Two pressure sources, for example pumps plumbed in series, separate thermodynamic work, such as pressurization, at the first pressure source from a volumetric or matter metering function in the second pressure source. One example is a flowstream delivery for a chemical instrumentation system that is manufactured from relatively unsophisticated pumps yet delivers precise flows with low pulsation (<1%) over pressures greater than 100 bar. An advantage of one embodiment allows the economical conversion of typical HPLC systems to state of-the-art supercritical fluid chromatography (SFC) systems with minimal modification to system components.

Owner:AGILENT TECH INC

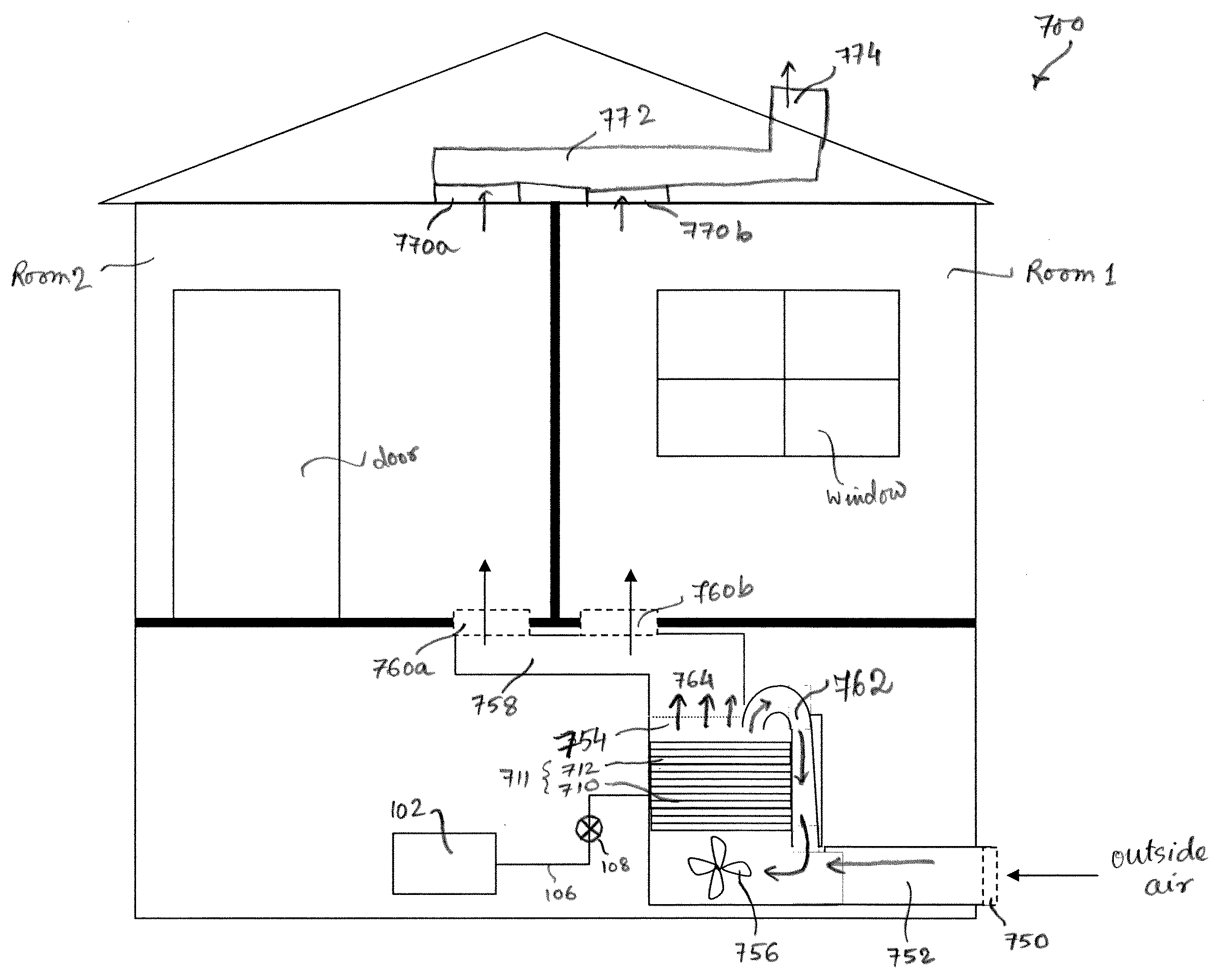

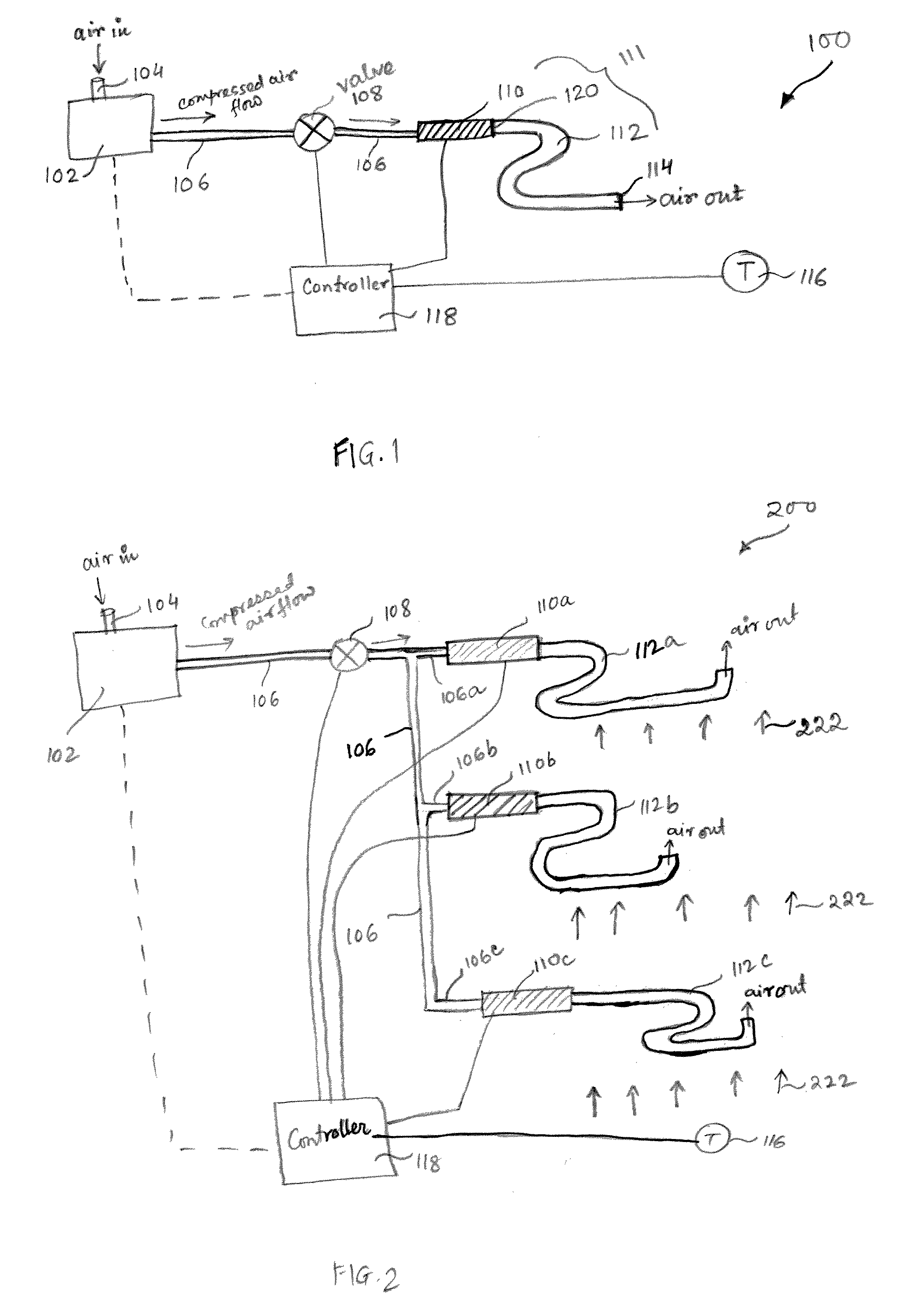

Heating and cooling system using compressed fluid

InactiveUS20100070090A1Sampled-variable control systemsComputer controlThermal energyCompressed fluid

Use of compressed air for indoor ambient temperature conditioning is disclosed. Thermal energy is imparted to or extracted from a quantity of compressed air, and the compressed air is then directed to be released inside a structure enclosing a space, whose ambient temperature needs to be controlled. Thus, the compressed air may be used as a direct heat conduction / extraction medium. A flow of external air is created over a heat exchanger mass (a “heating mass” or a “cooling mass”), so that thermal energy of the compressed air flowing inside the heat exchanger mass is transferred to the external flow of air flowing outside the heat exchanger mass. Thus, in addition to being a direct heat conduction / extraction medium, the compressed air is being used as a heat transfer medium, that ultimately gets mixed with the flow of external air. A fresh supply of external air may be used rather than using re-circulated air, in order to maintain a high quality of breathable air. A local feedback loop may be used to route back a portion of temperature-conditioned air produced by a system according to the present invention, to regulate a flow of external air over a heat exchanger mass. Other types of environmentally benign compressible fluids may be used as a heat transport / transfer fluid instead of compressed air.

Owner:AIR ENERGY SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com