Turbo-machine component and method

a technology of turbine machine and component, which is applied in the direction of machines/engines, manufacturing tools, liquid fuel engines, etc., can solve the problems of inability to meet the requirements of the operating environment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Provided is an exemplary component, a component manufacturing process, and a component operation process. Embodiments of the present disclosure permit airflow for cooling components, reduce or eliminate partial or complete blockages of diffusers, permit operation in more harsh environments (for example, environments having greater thermal gradients), permit additional control of fluid flow-paths and / or fluid velocity profiles within diffusers, facilitate a controlled decrease in velocity of compressible fluids within diffusers, increase operational efficiencies, or combinations thereof.

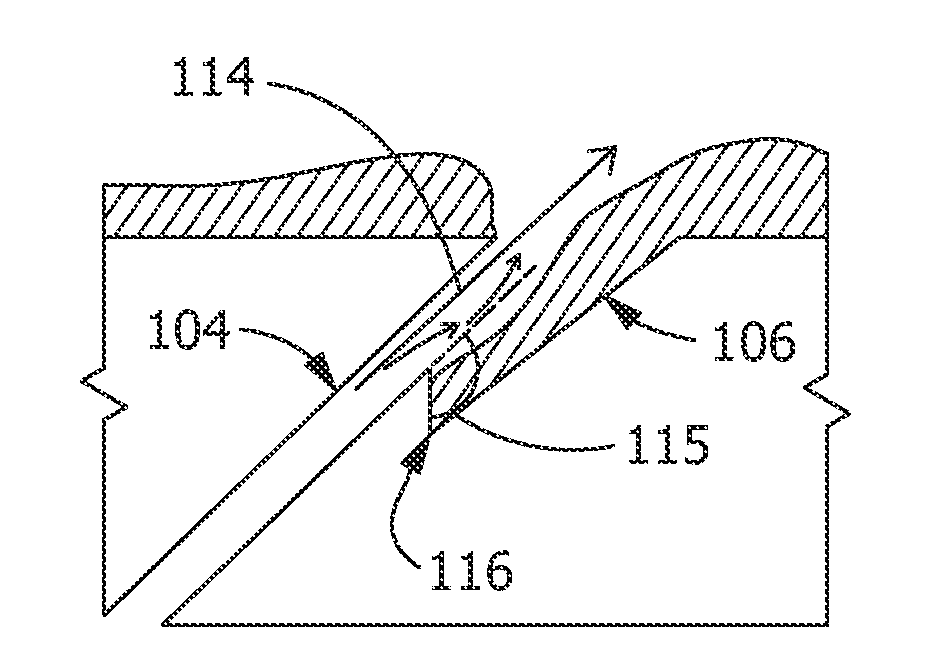

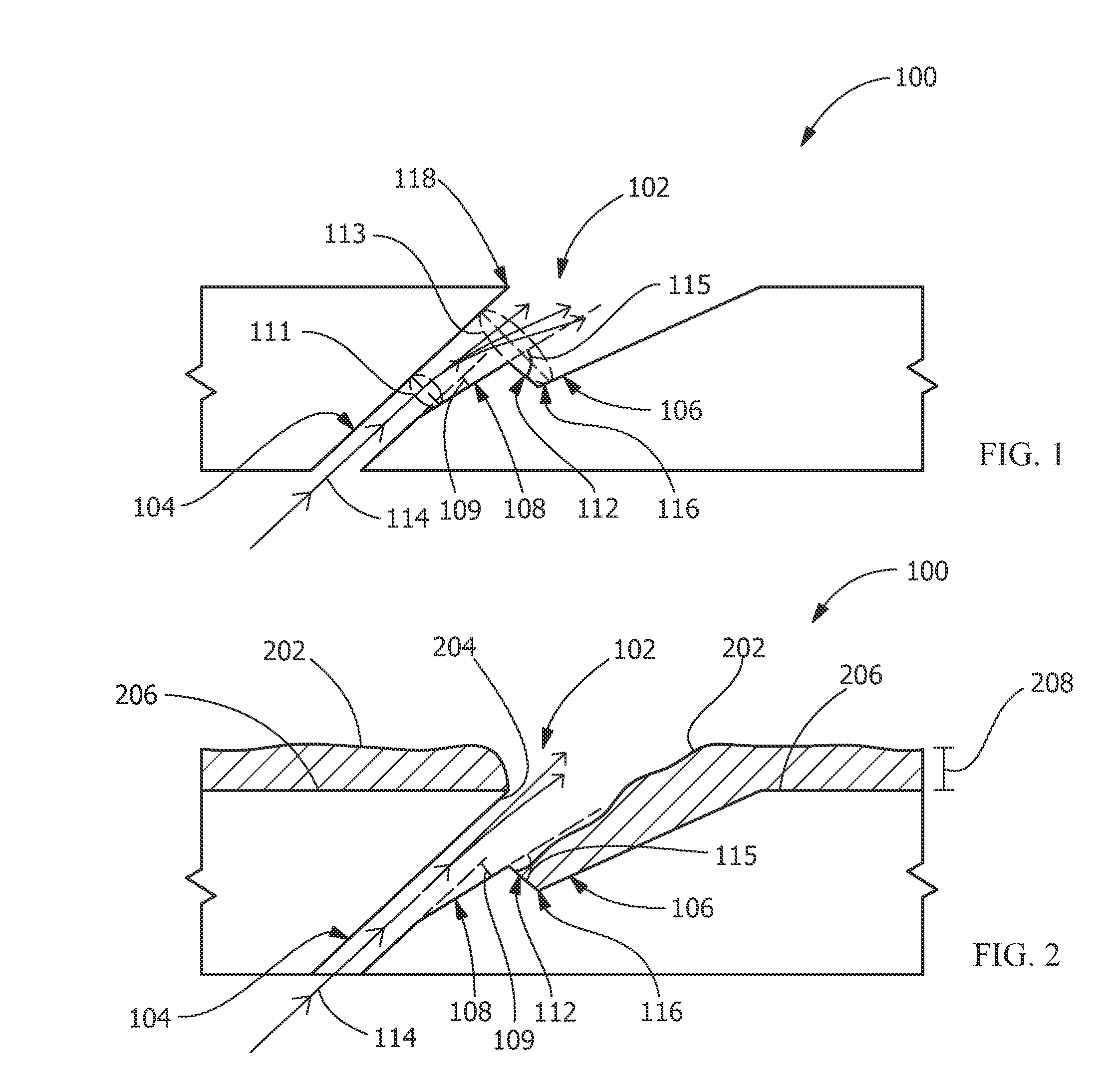

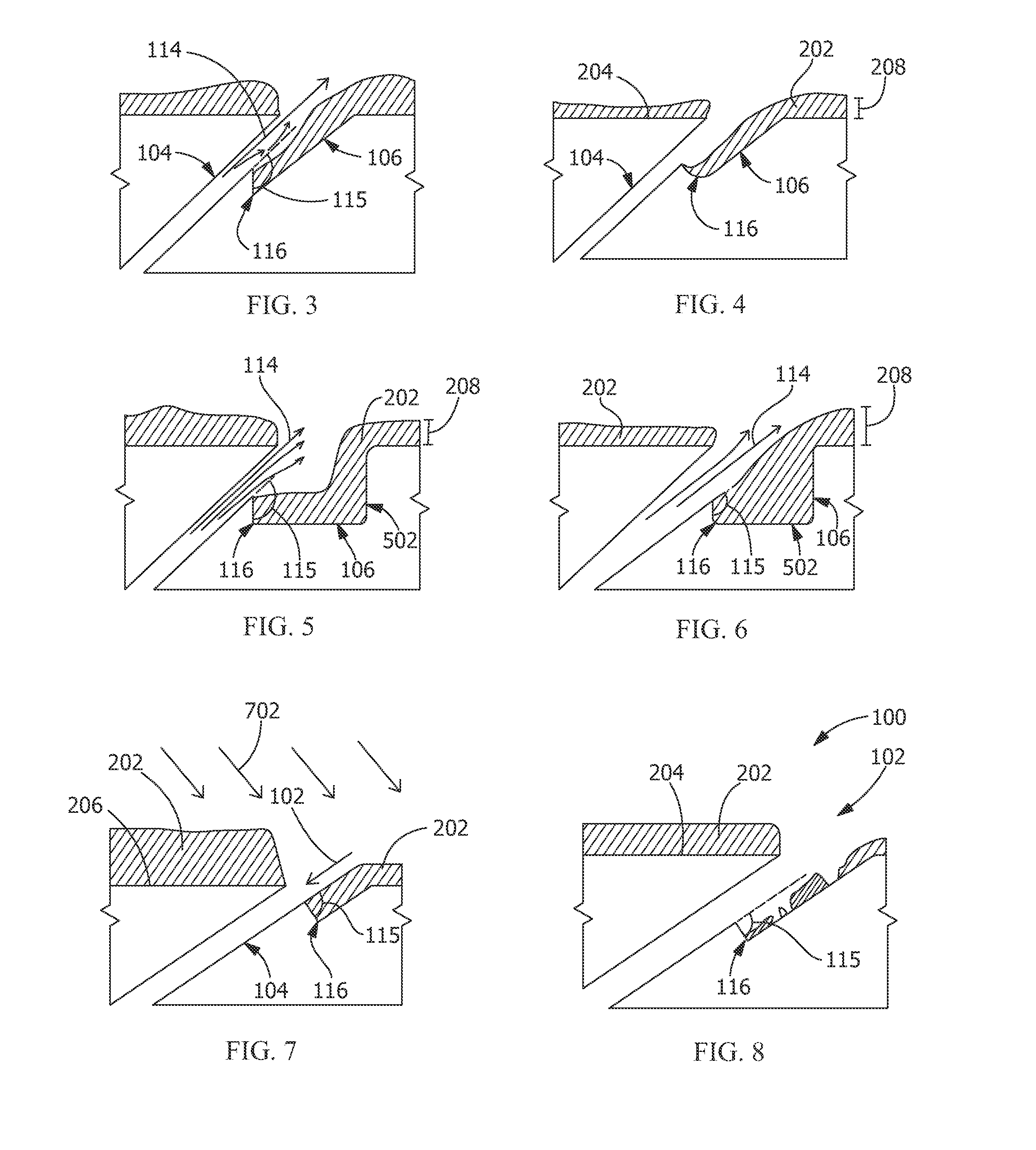

[0024]FIG. 1 shows a portion of a component 100 according to an embodiment of the disclosure. The component 100 is any suitable article for transport of a fluid. For example, in one embodiment, the component 100 is a turbine component, such as, a turbine blade 902 (see FIG. 9), a nozzle 910 (see FIG. 10), or any other article containing one or more diffusers 102 for transporting a fluid, such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com