Patents

Literature

844results about "Volume variation compensation/correction apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

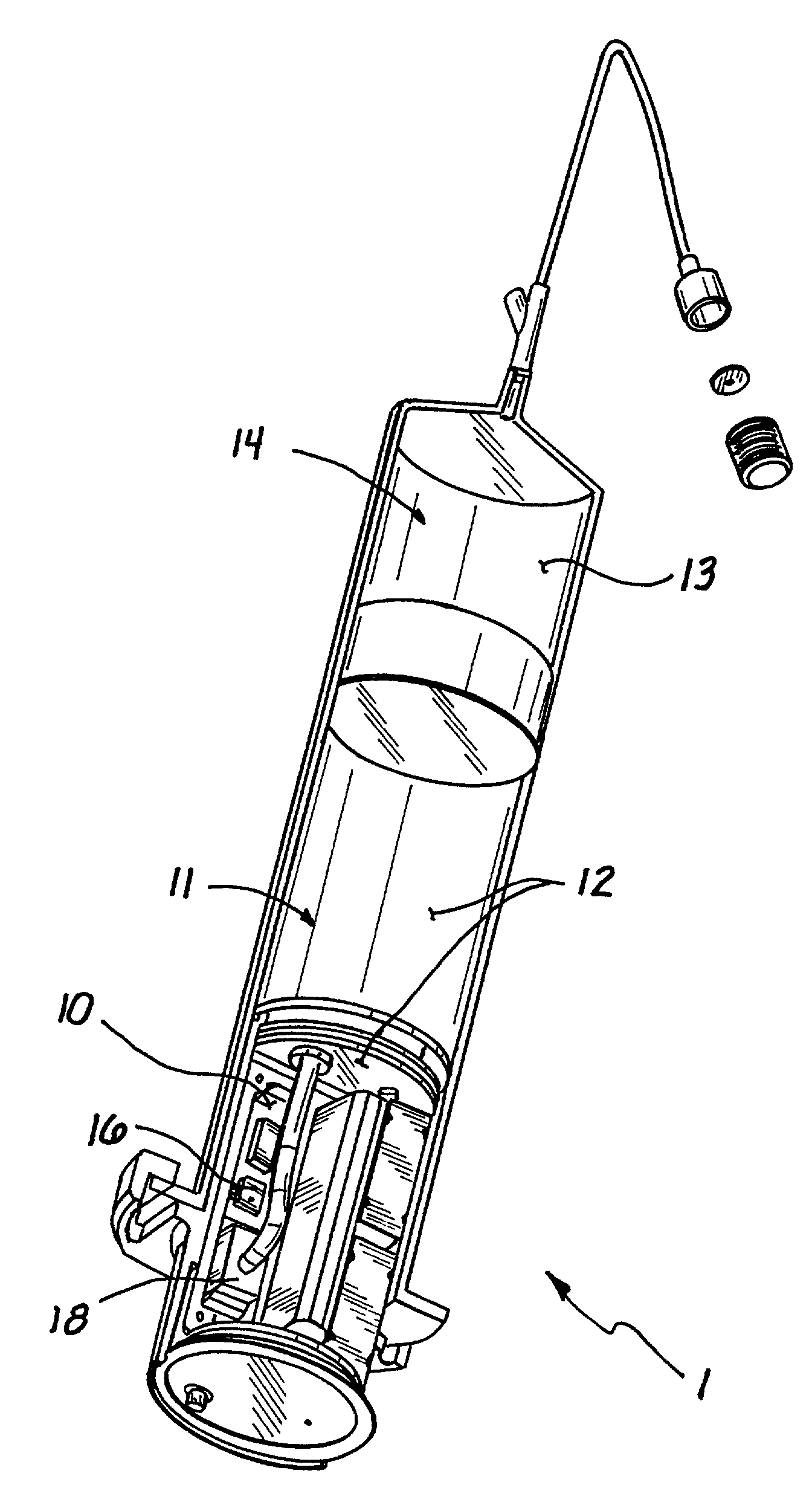

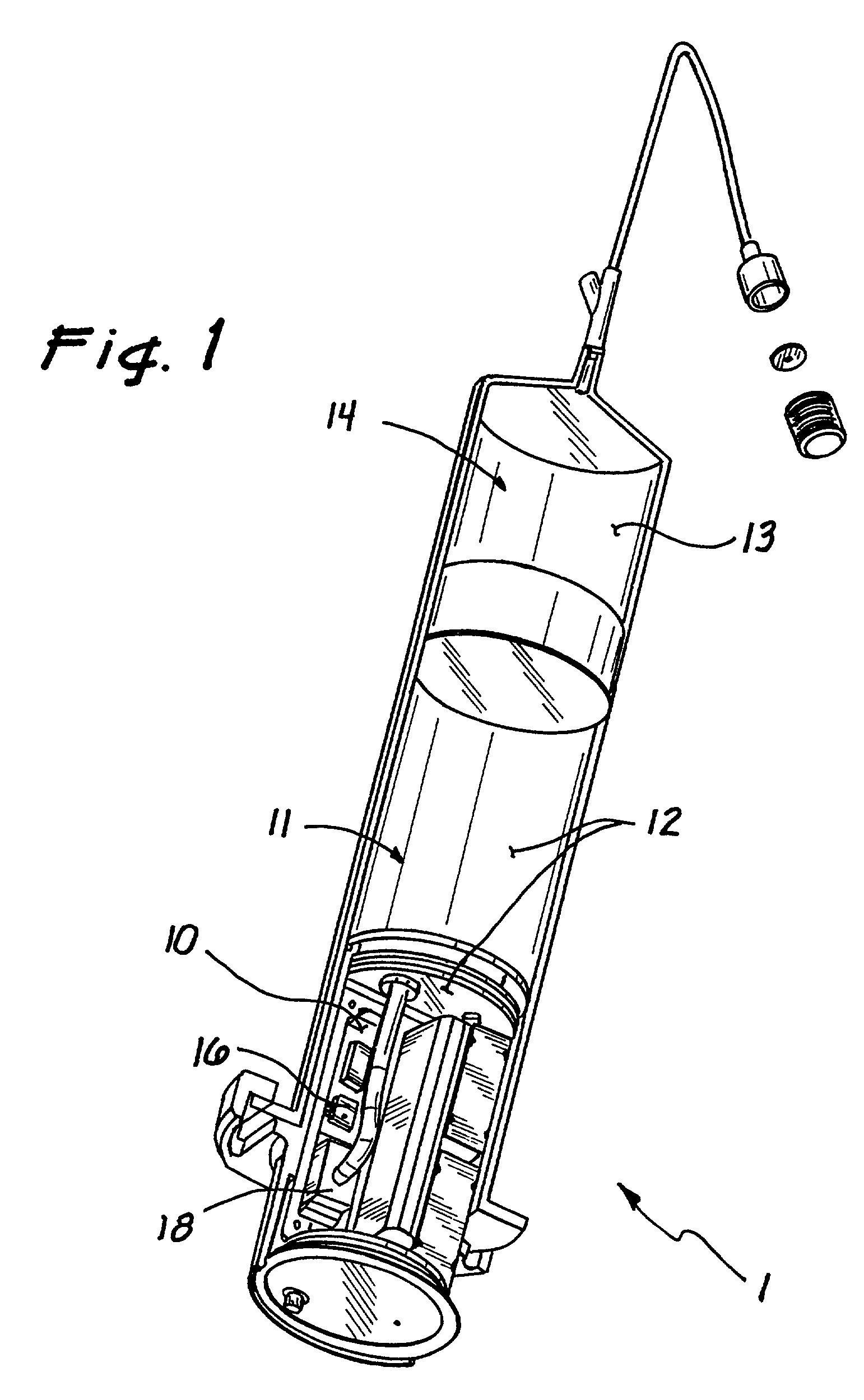

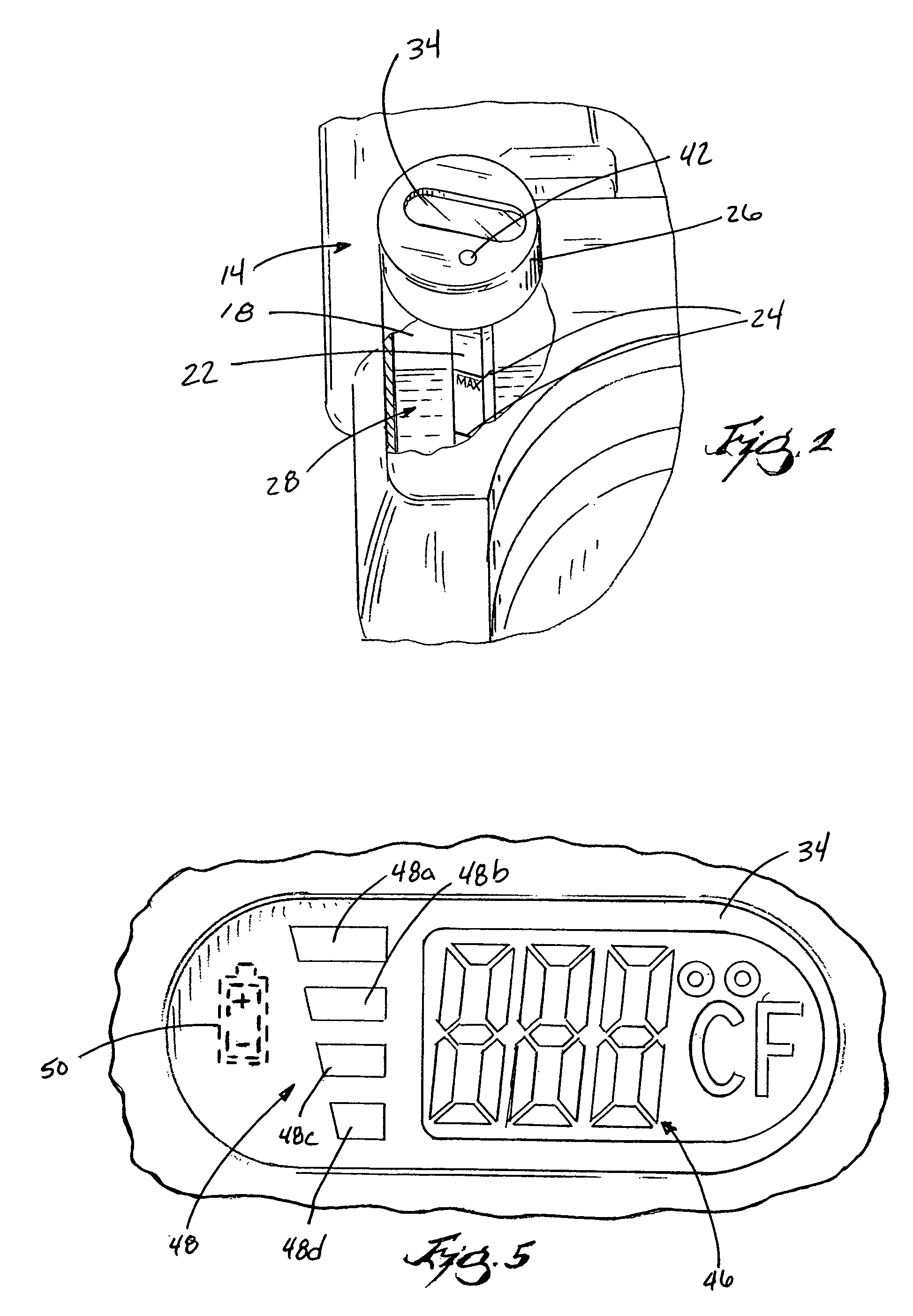

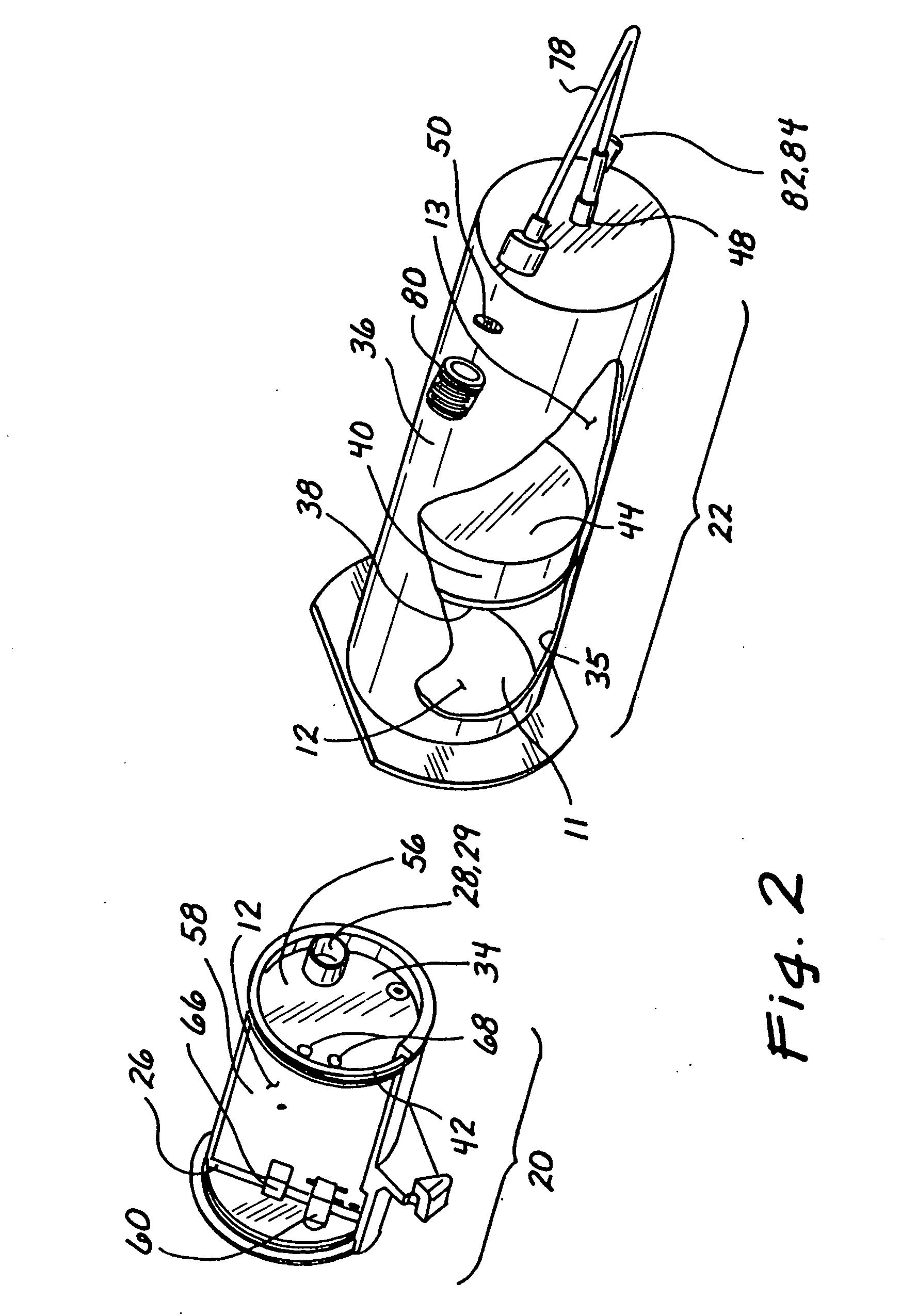

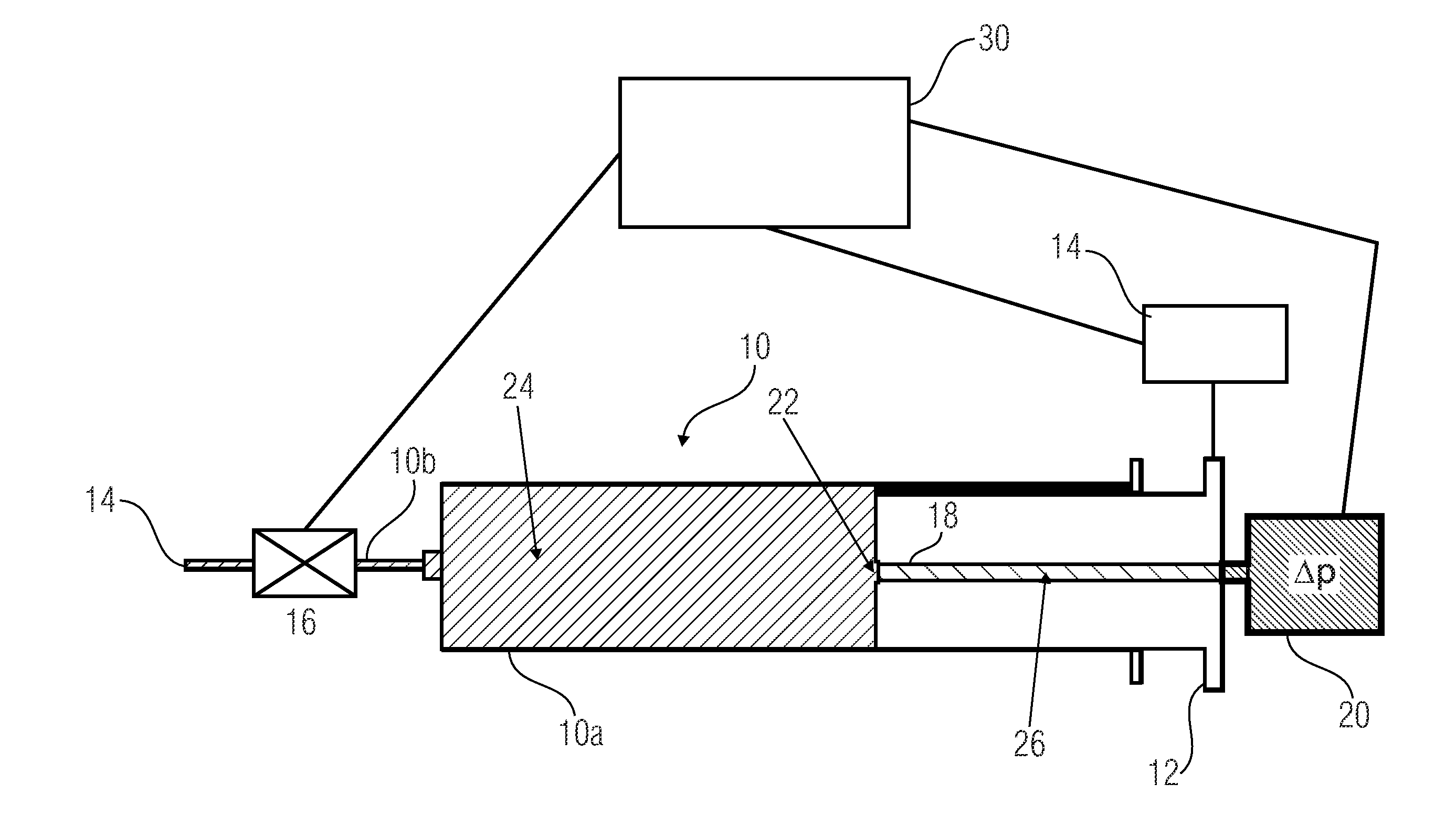

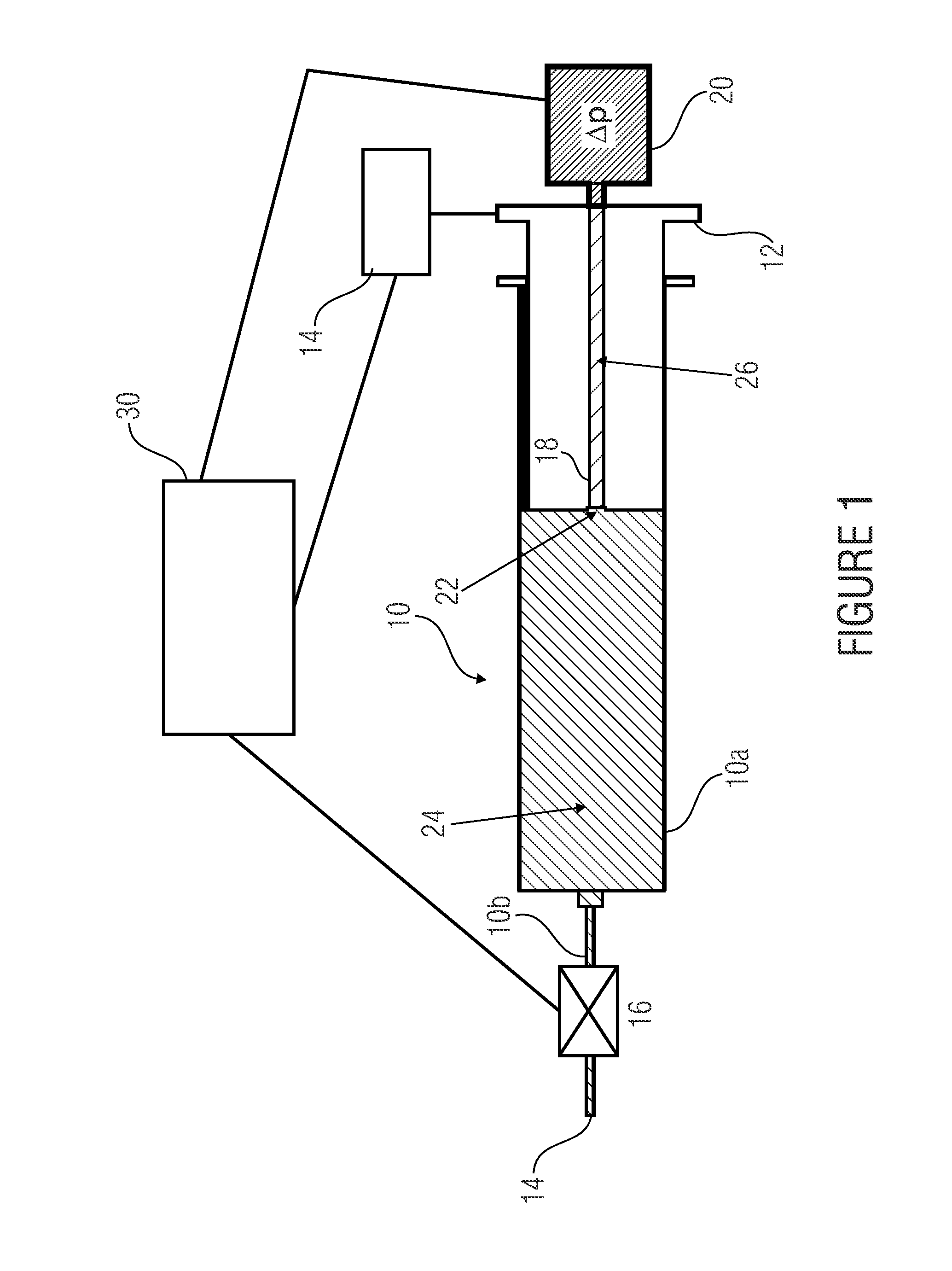

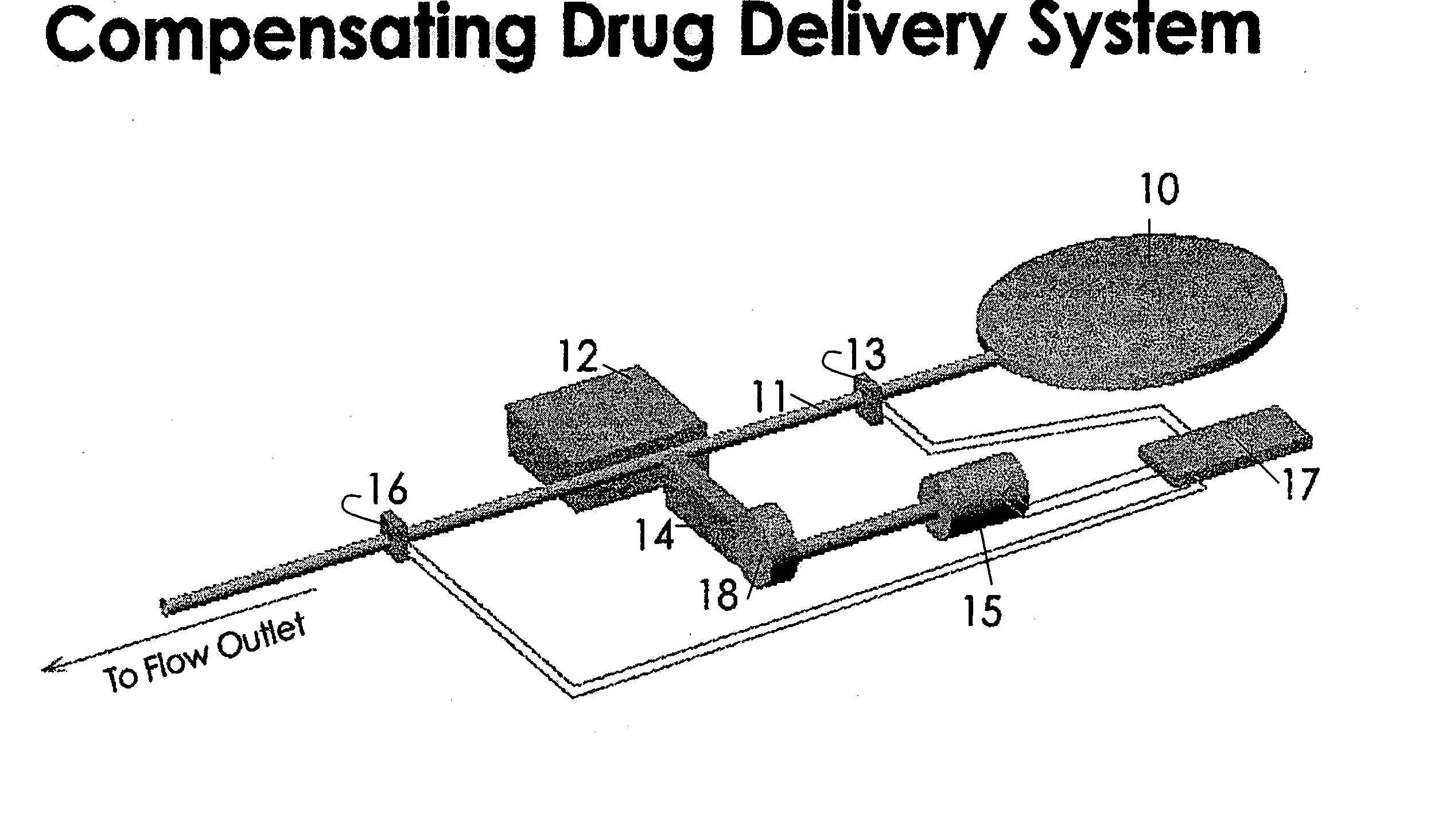

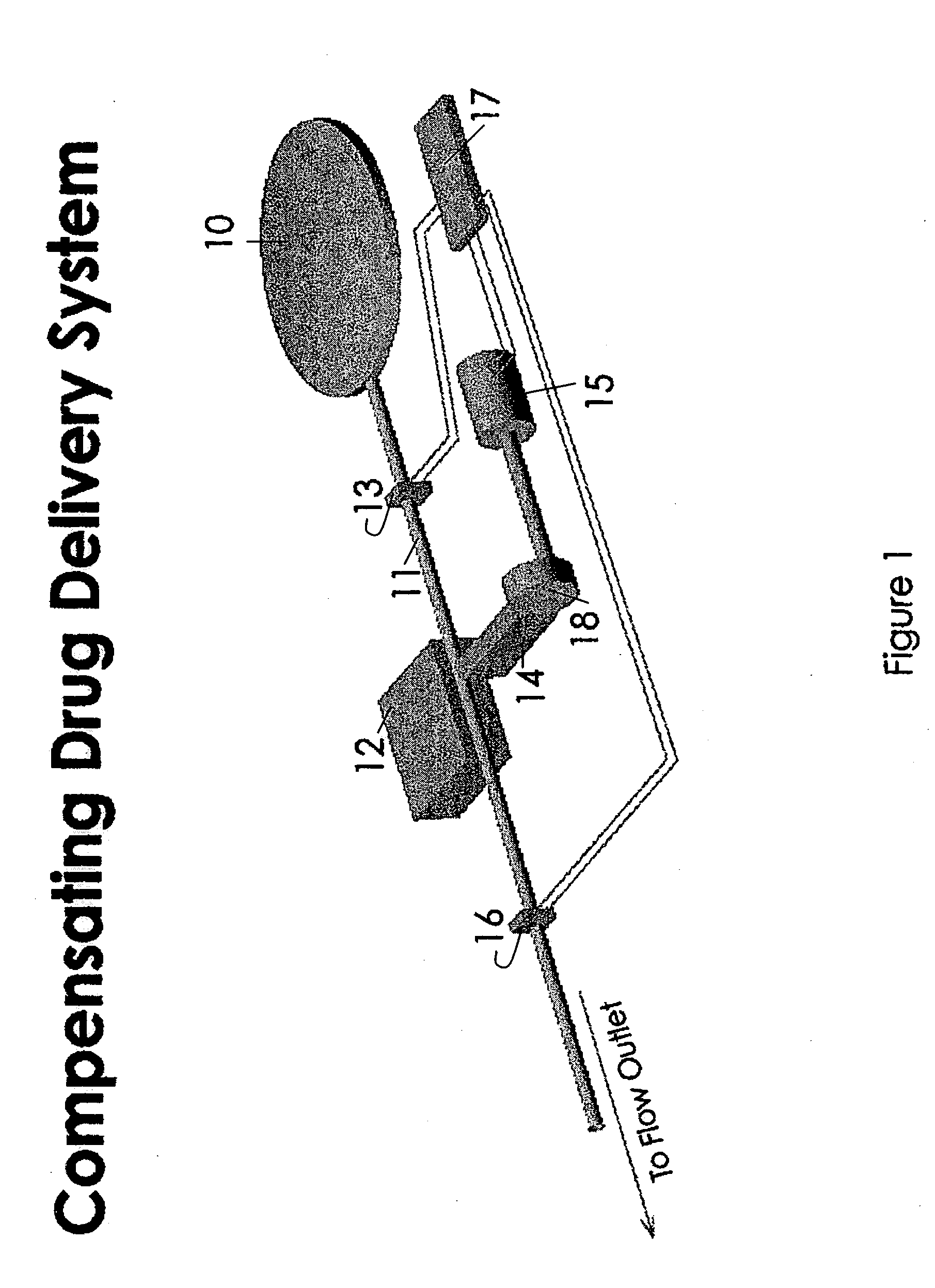

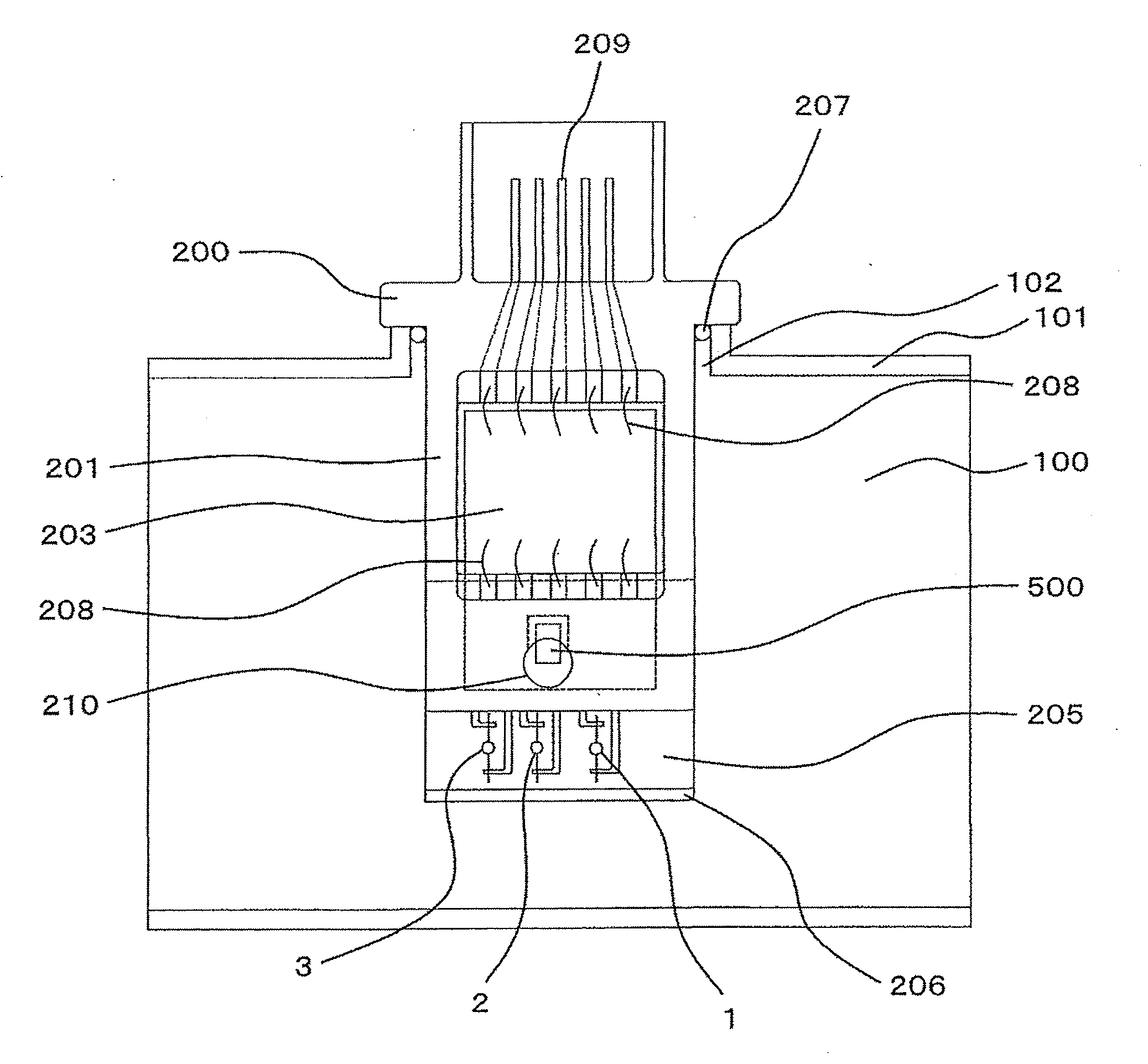

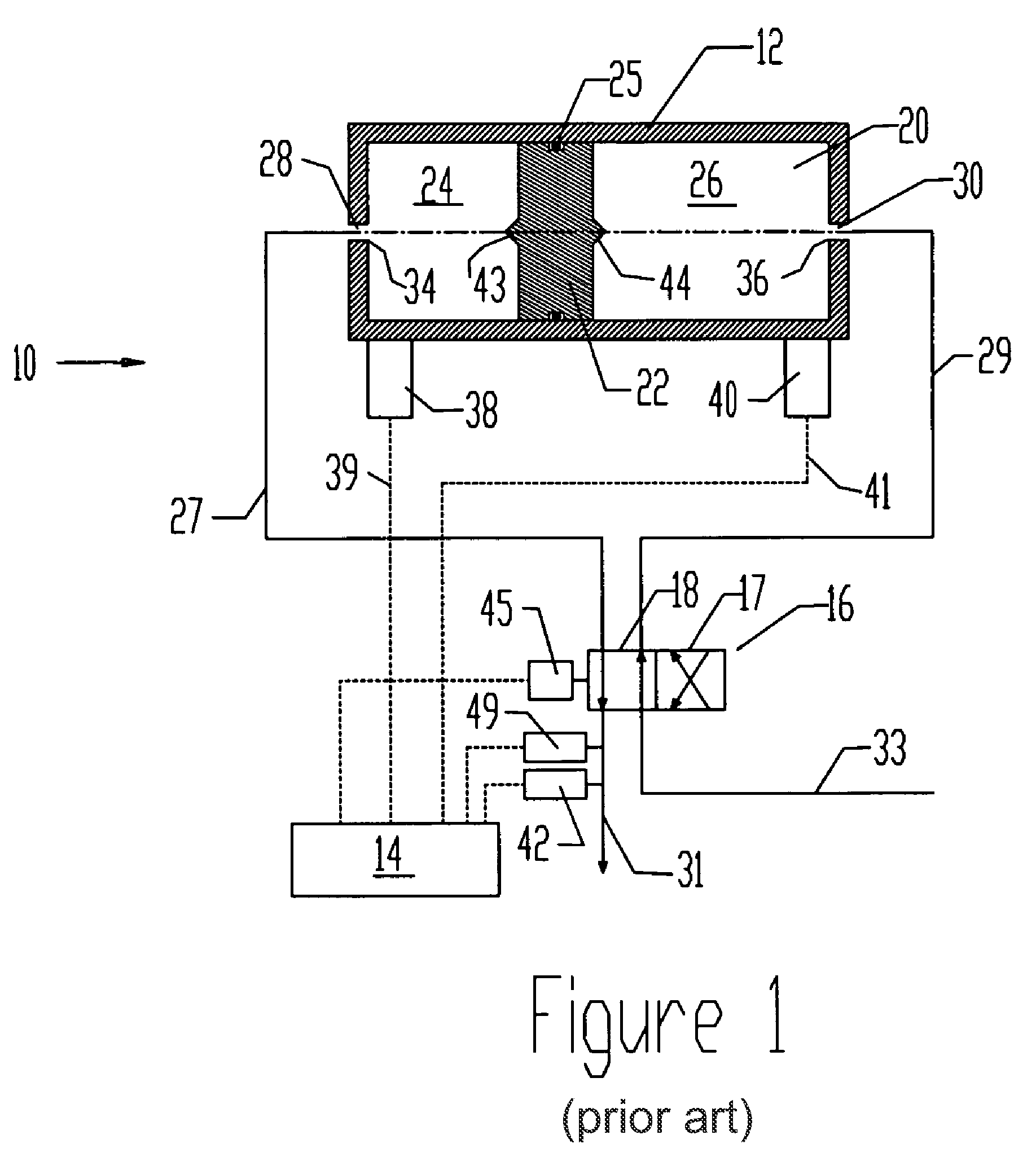

Infusion pump and method for use

InactiveUS7008403B1Small and lightLess componentsContracting/expanding measuring chambersVolume variation compensation/correction apparatusSolenoid valveContact method

A fluid dispensing system provides a non-contact method of monitoring the change in the fluid volume over time. This approach avoids the use of probes or sensors that come into direct contact with the fluid to be dispensed. The system comprises an apparatus comprising three chambers. The first chamber has a fixed volume and contains a pressurized gas. A solenoid valve is used to control the flow of gas from the first chamber into the second. The second chamber is sealed so that the combined mass of air in the first and second chambers remains fixed. The third chamber is adjacent to the second and contains medication in the form of incompressible fluid that is to be administered to a human or animal subject via a suitable delivery port. A piston is disposed between the second and third chambers and is movable responsive to the flow of gas into the second chamber to dispense fluid from the third chamber as desired. By sensing the pressure in the first and second chambers at any point in time, a processor is programmed to calculate the flow rate or dispensed volume of the fluid being delivered using principles derived from the Ideal Gas Law.

Owner:TANDEM DIABETES CARE INC

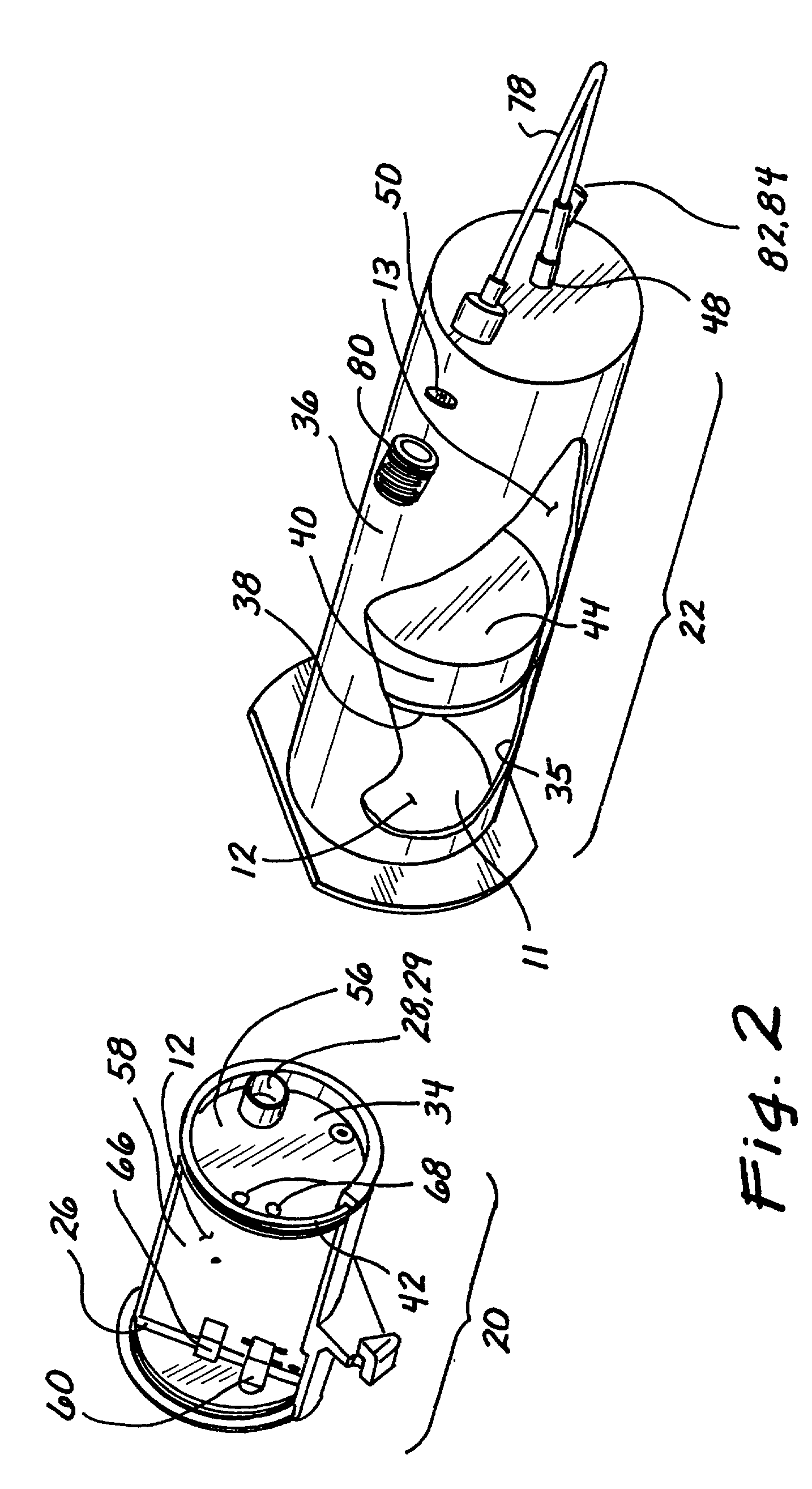

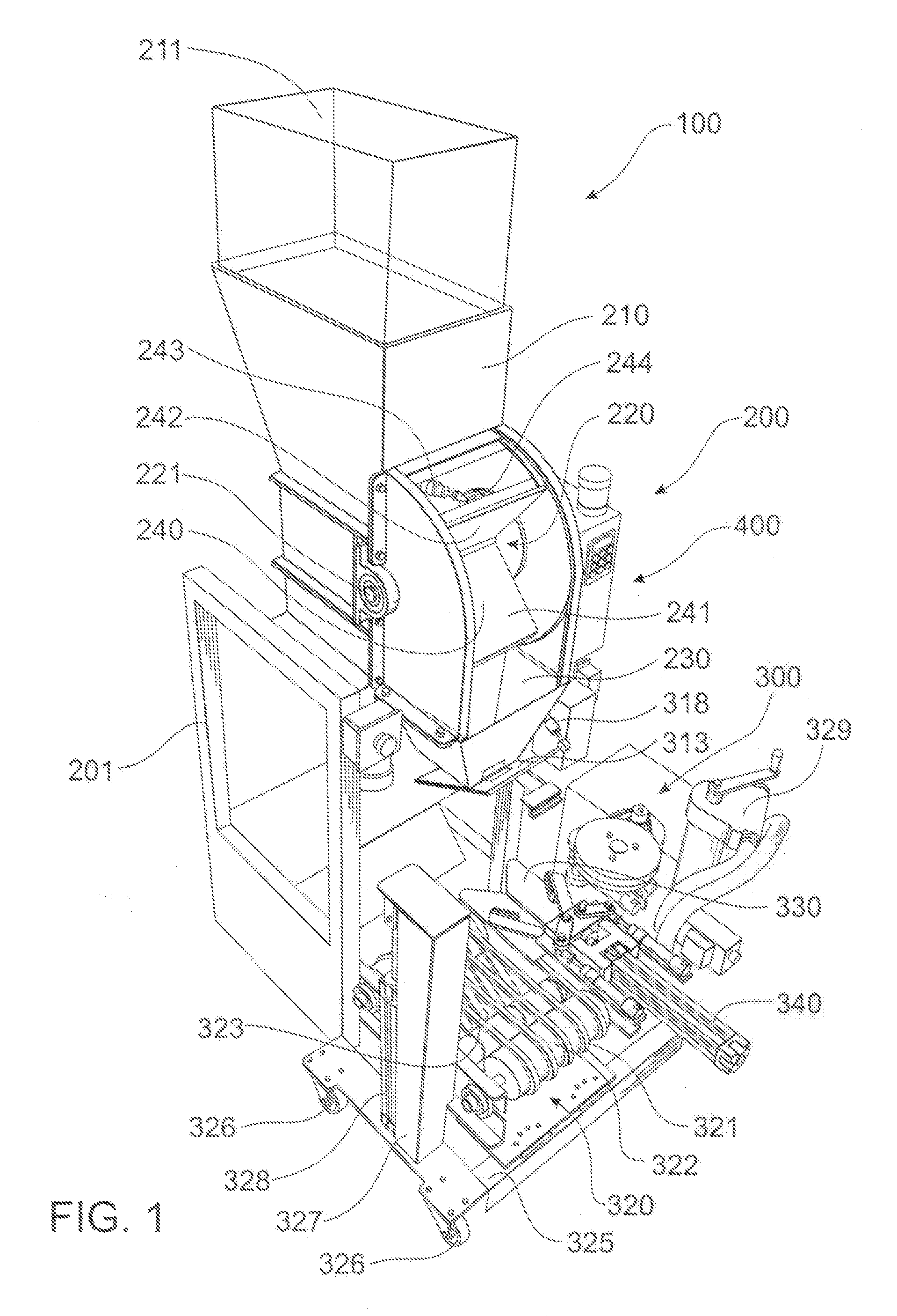

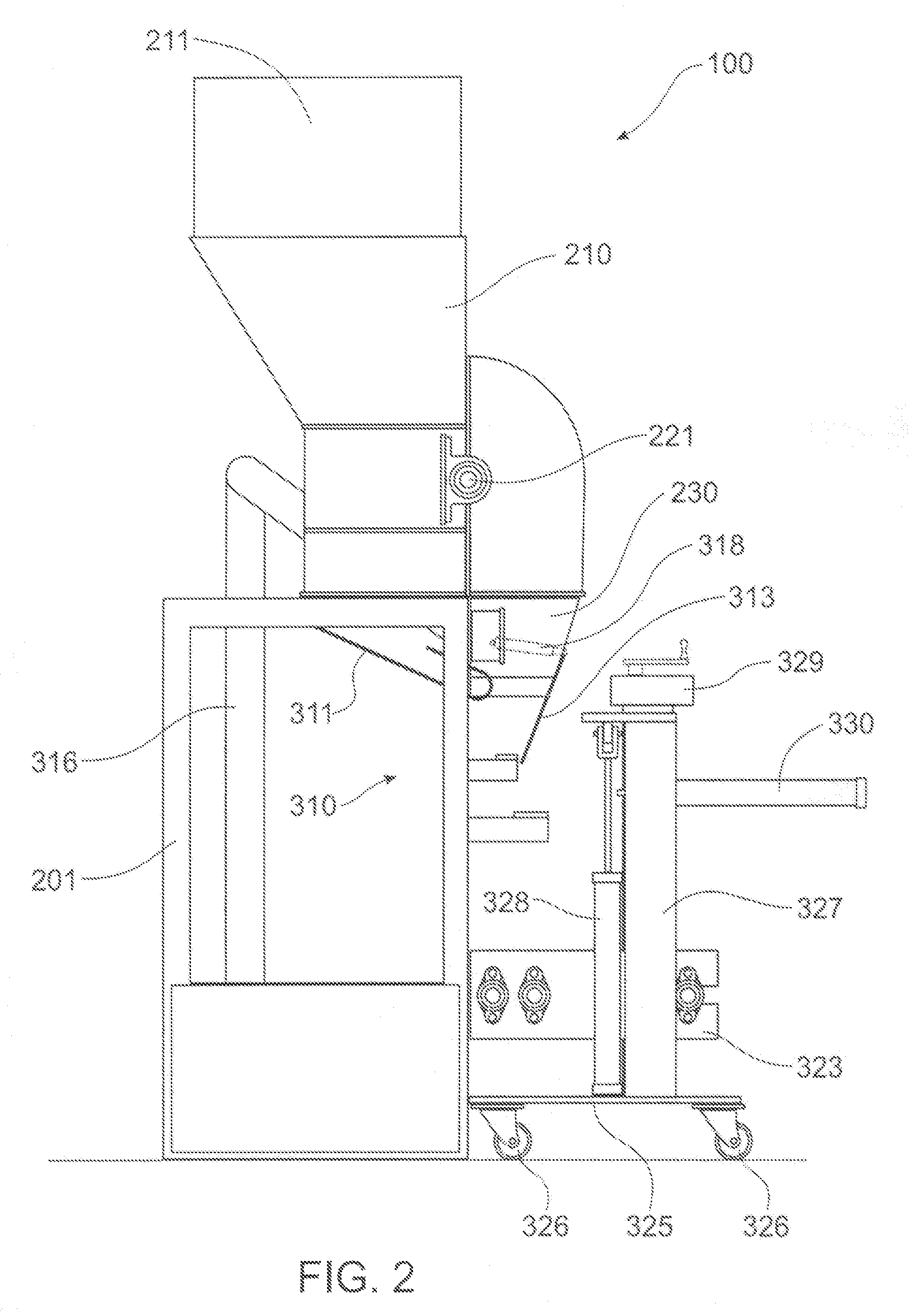

Ice measuring and dispensing apparatus

ActiveUS7421834B1Contracting/expanding measuring chambersLighting and heating apparatusHorizontal axisEngineering

An ice measuring and dispensing apparatus includes a rotating drum rotatable about a horizontal axis. The rotating drum has a plurality of chambers, and an ice supply hopper has a delivery opening for delivering ice into the plurality of chambers. A discharge tube to dispense ice from the plurality of chambers is also provided. The delivery opening of the supply hopper is larger than an opening of each of the chambers.

Owner:HAMER FISCHBEIN LLC

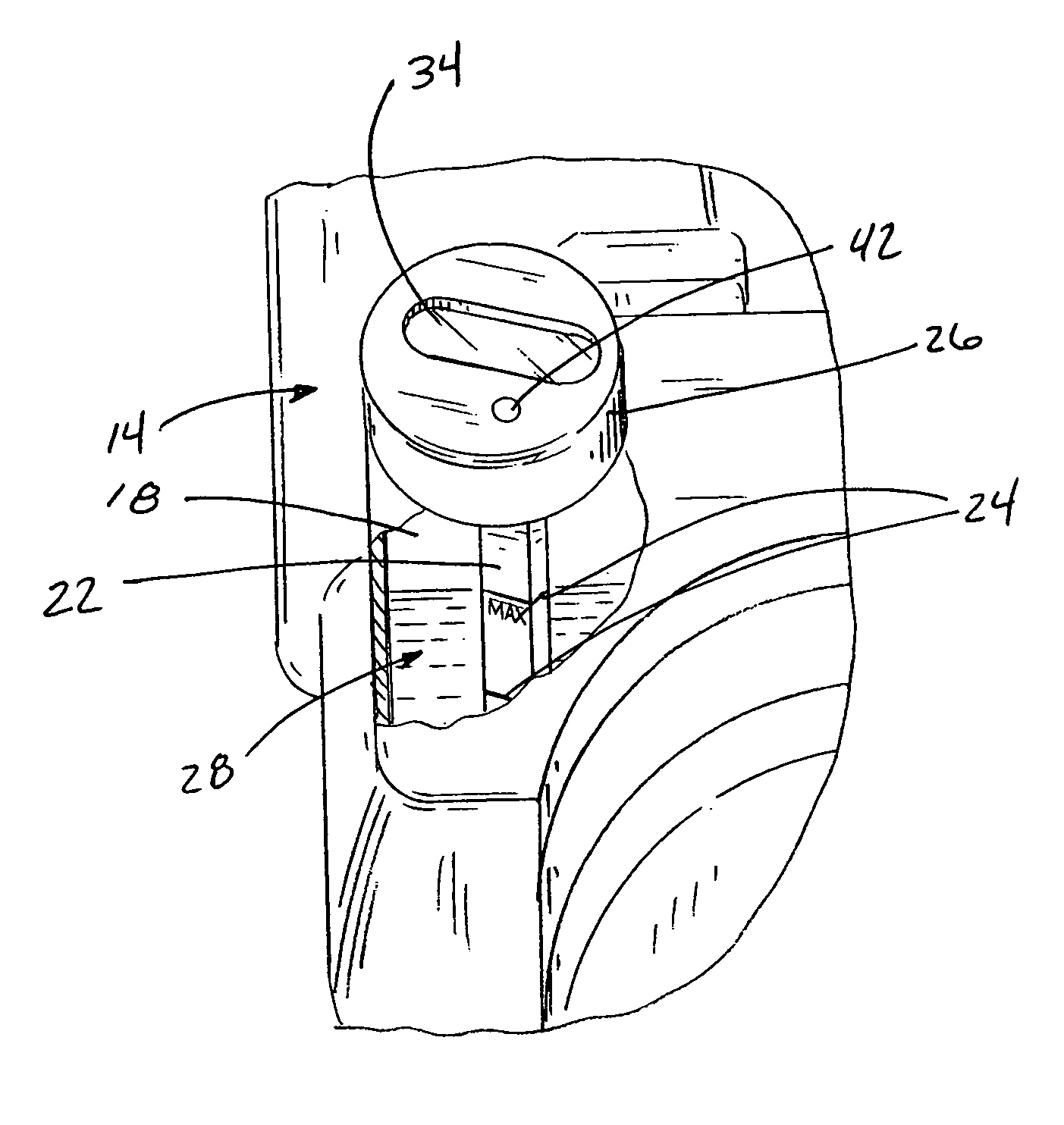

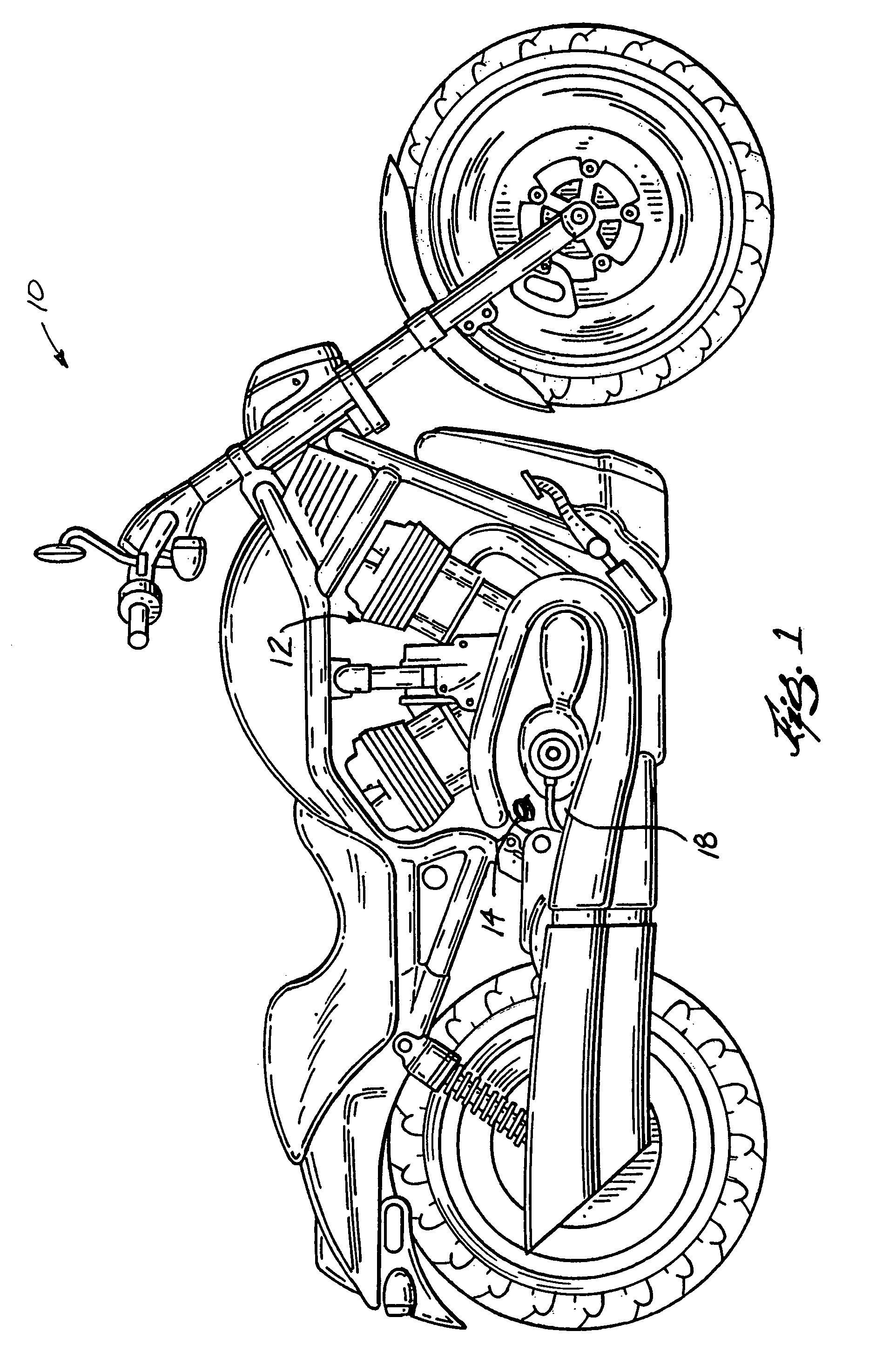

Apparatus for indicating oil temperature and oil level within an oil reservoir

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC

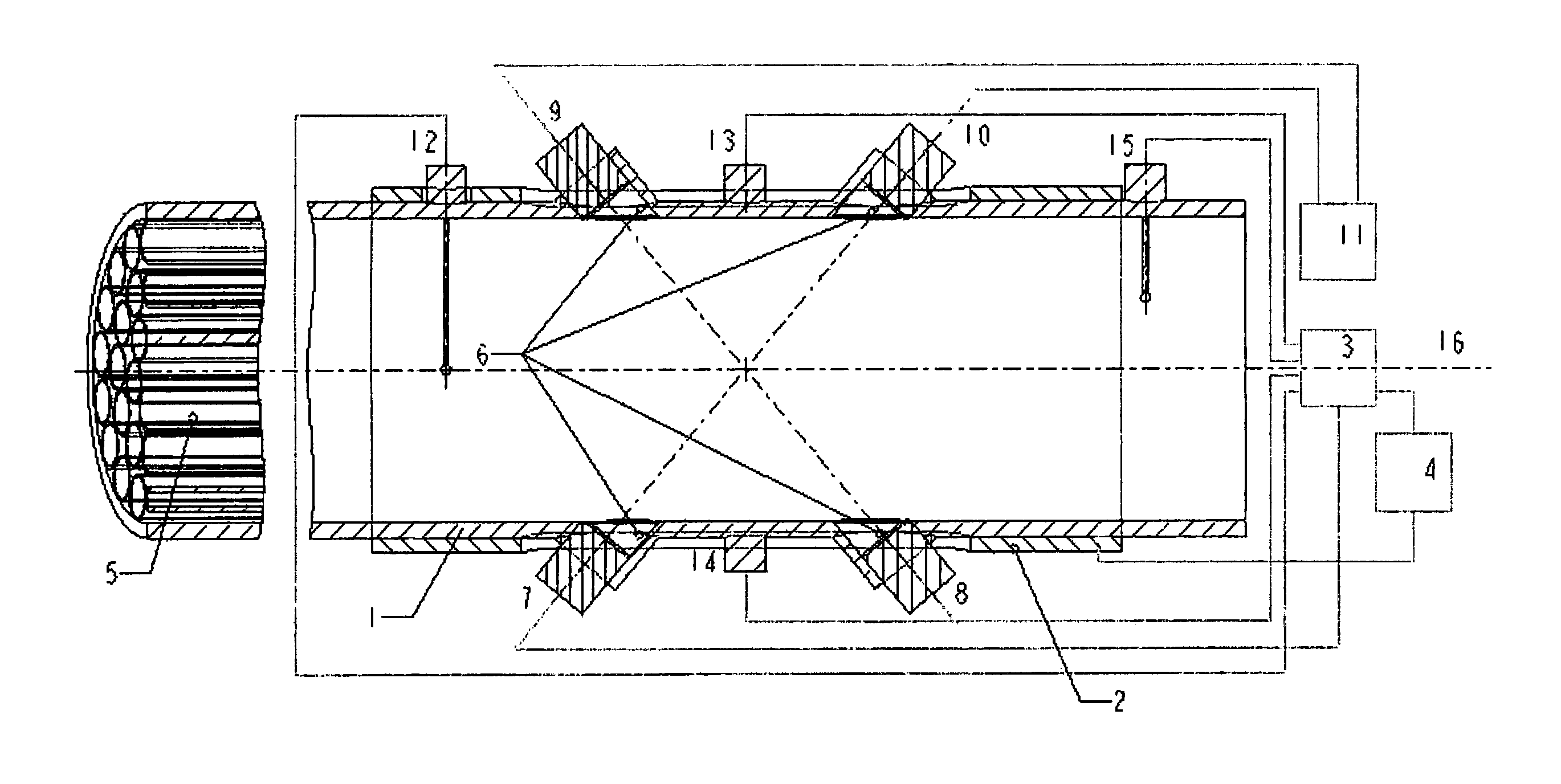

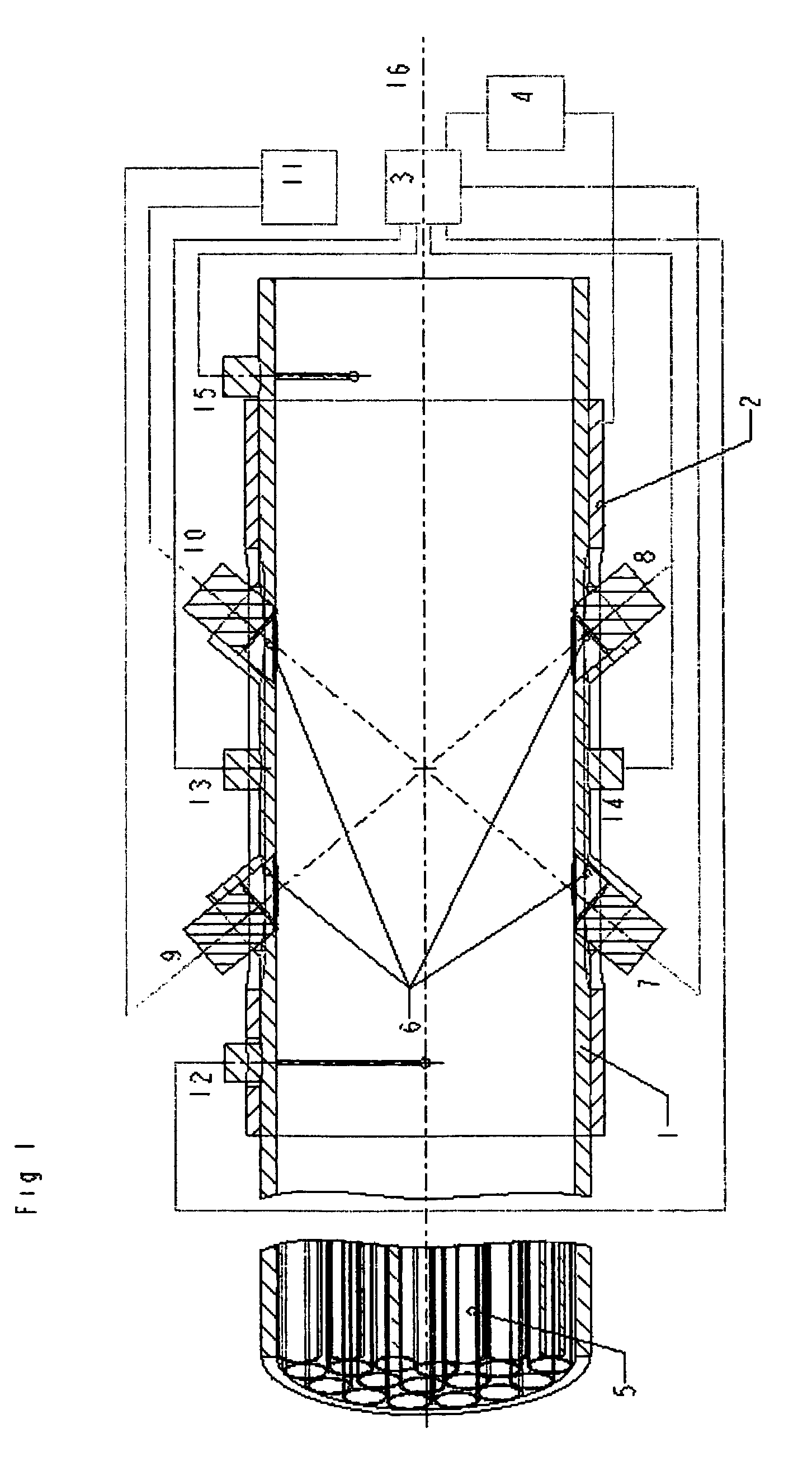

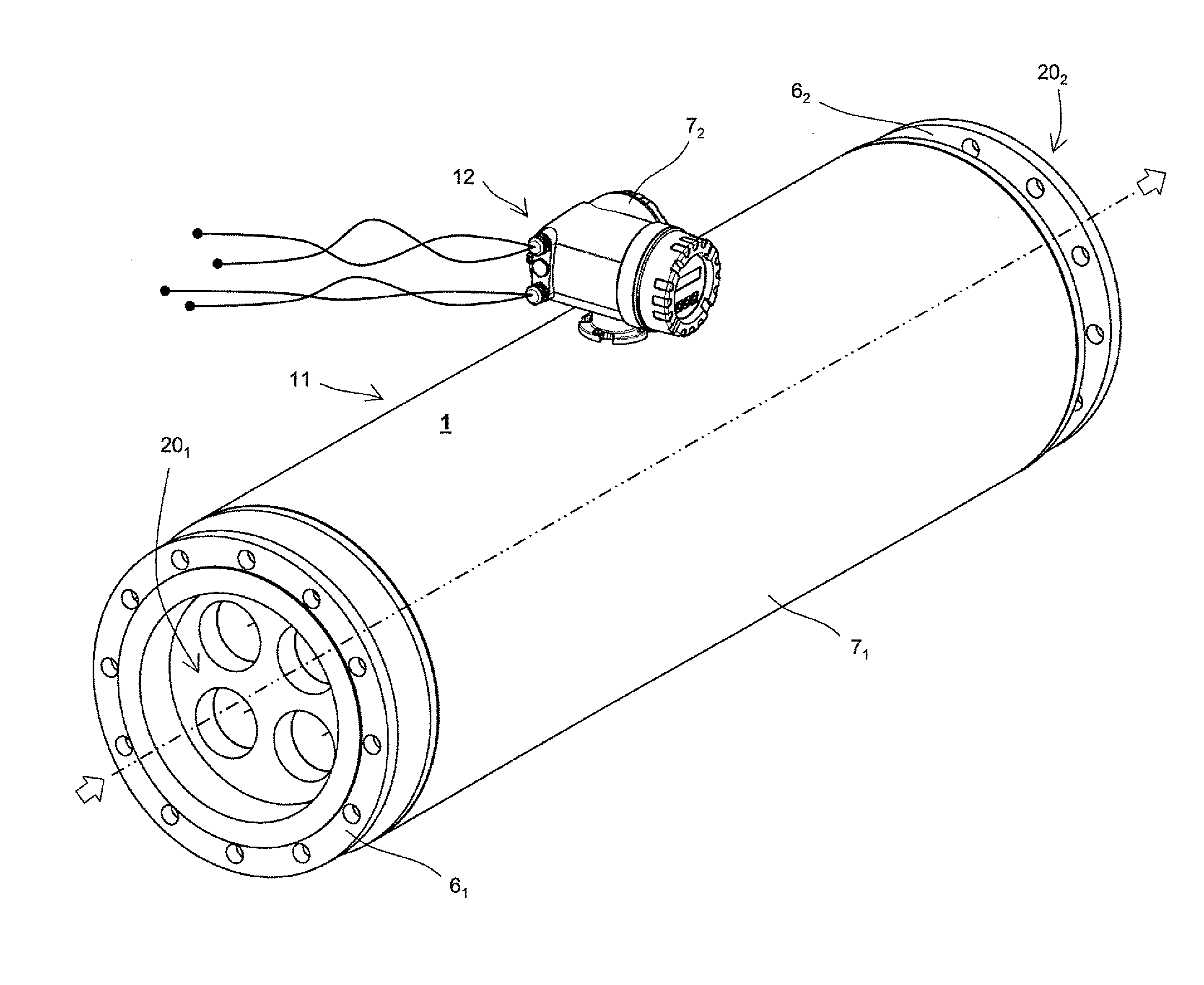

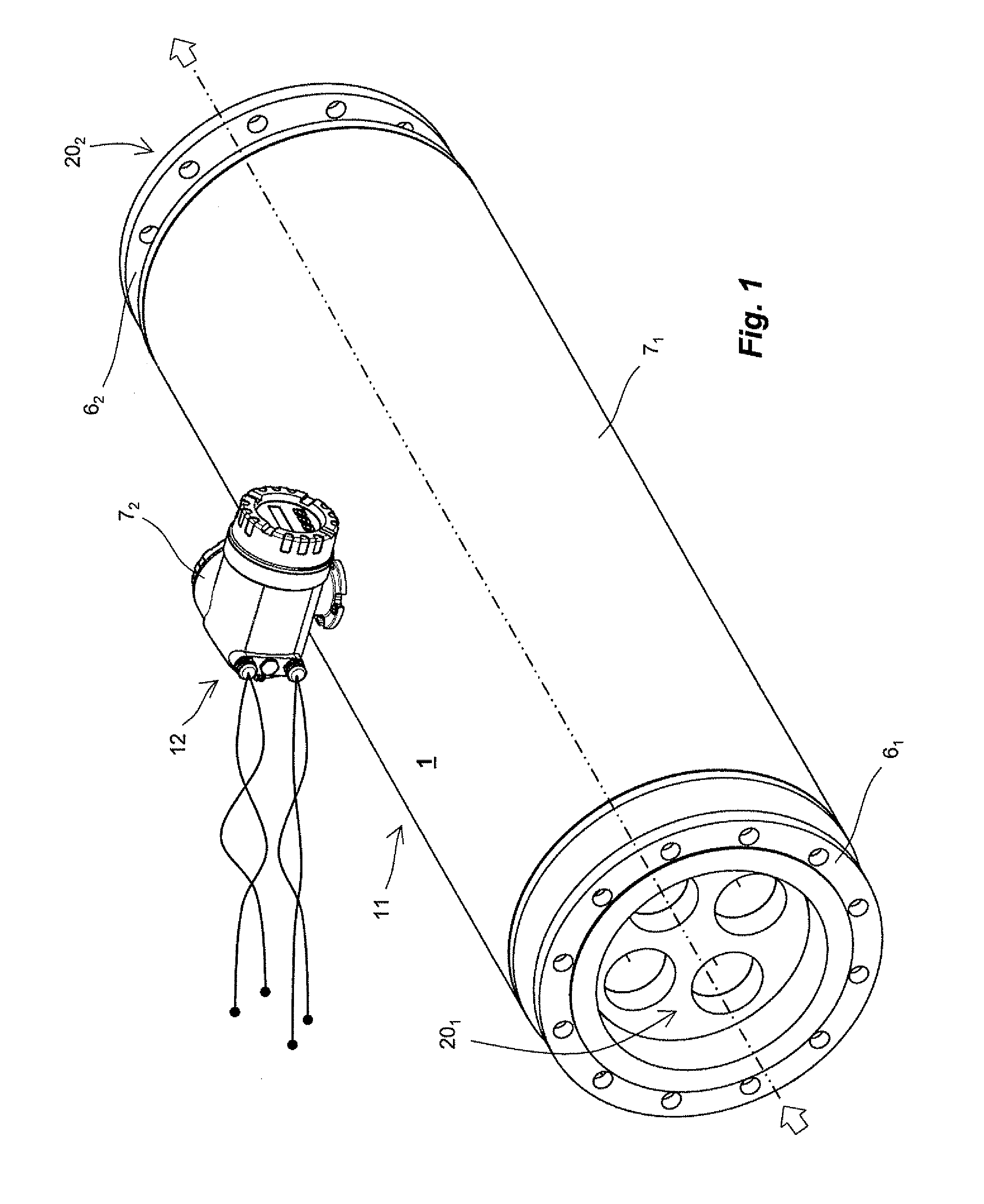

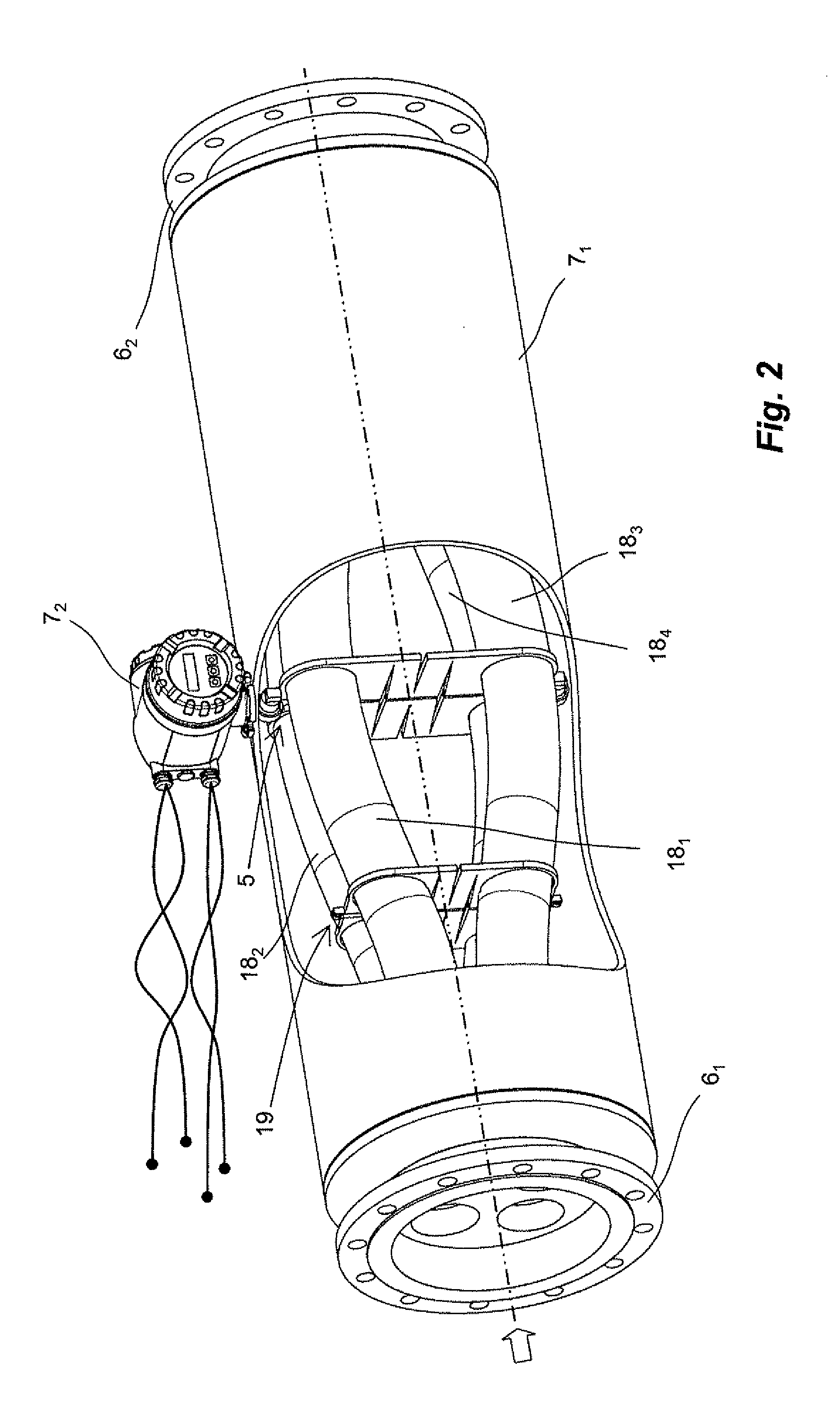

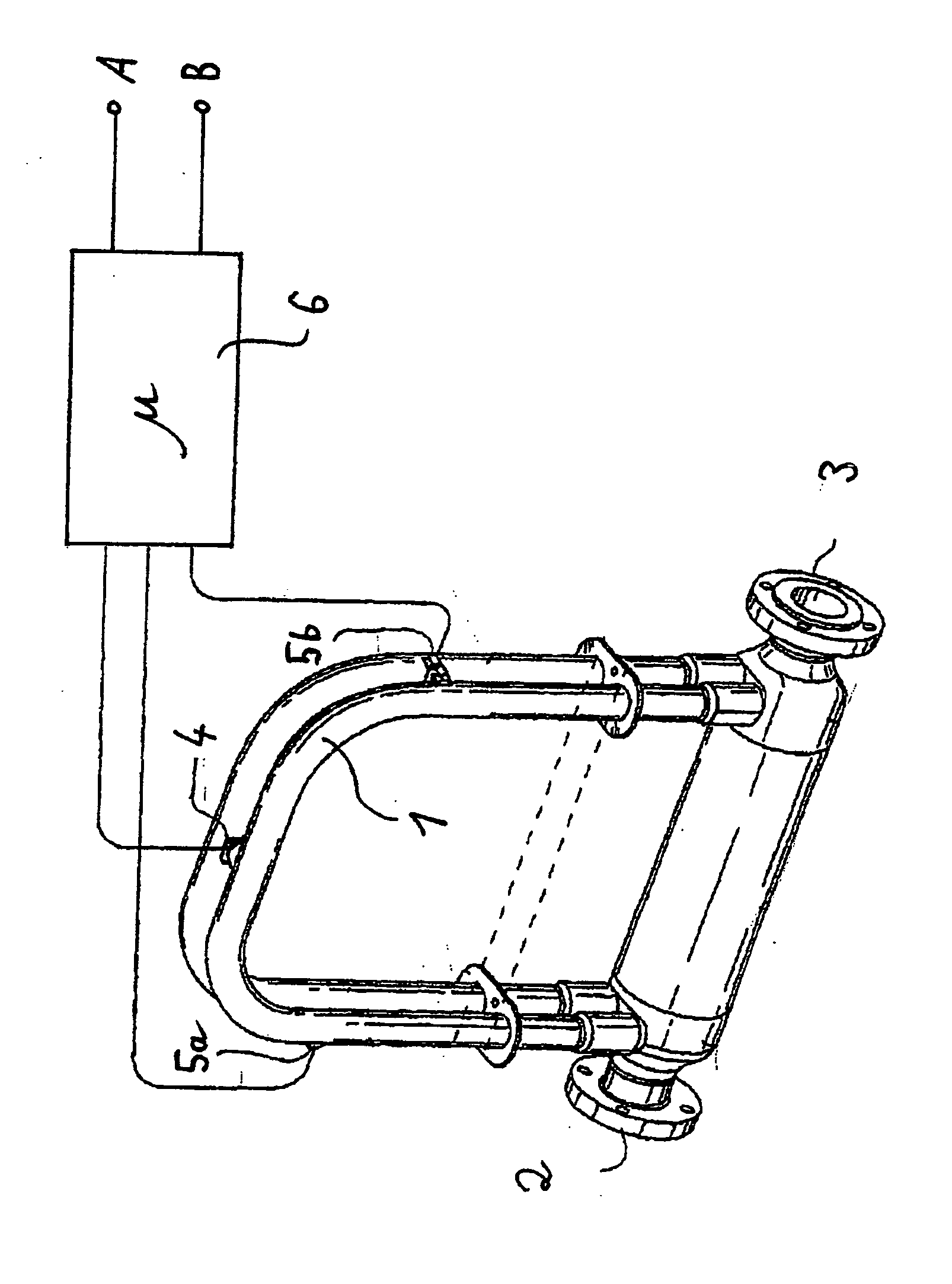

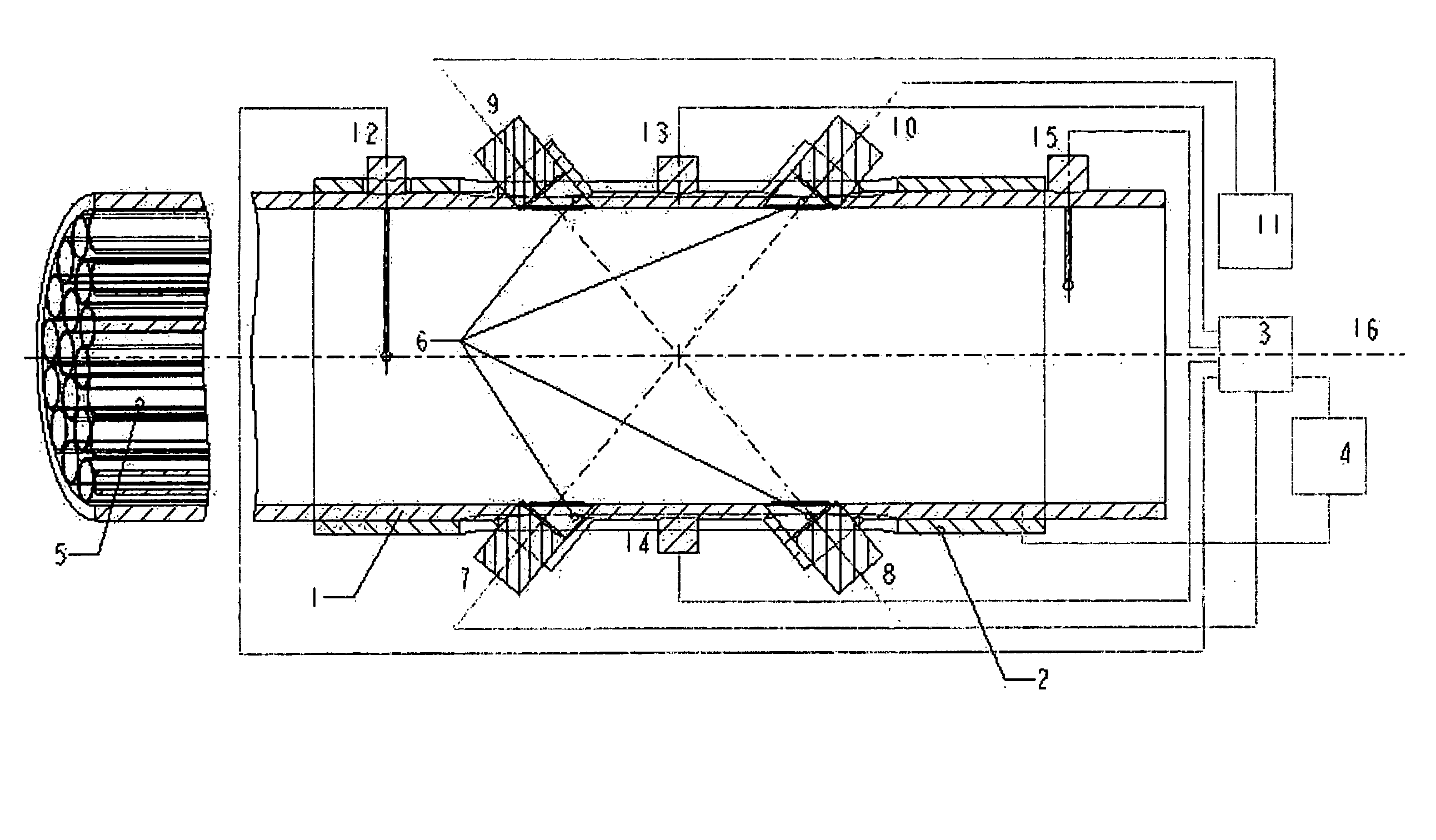

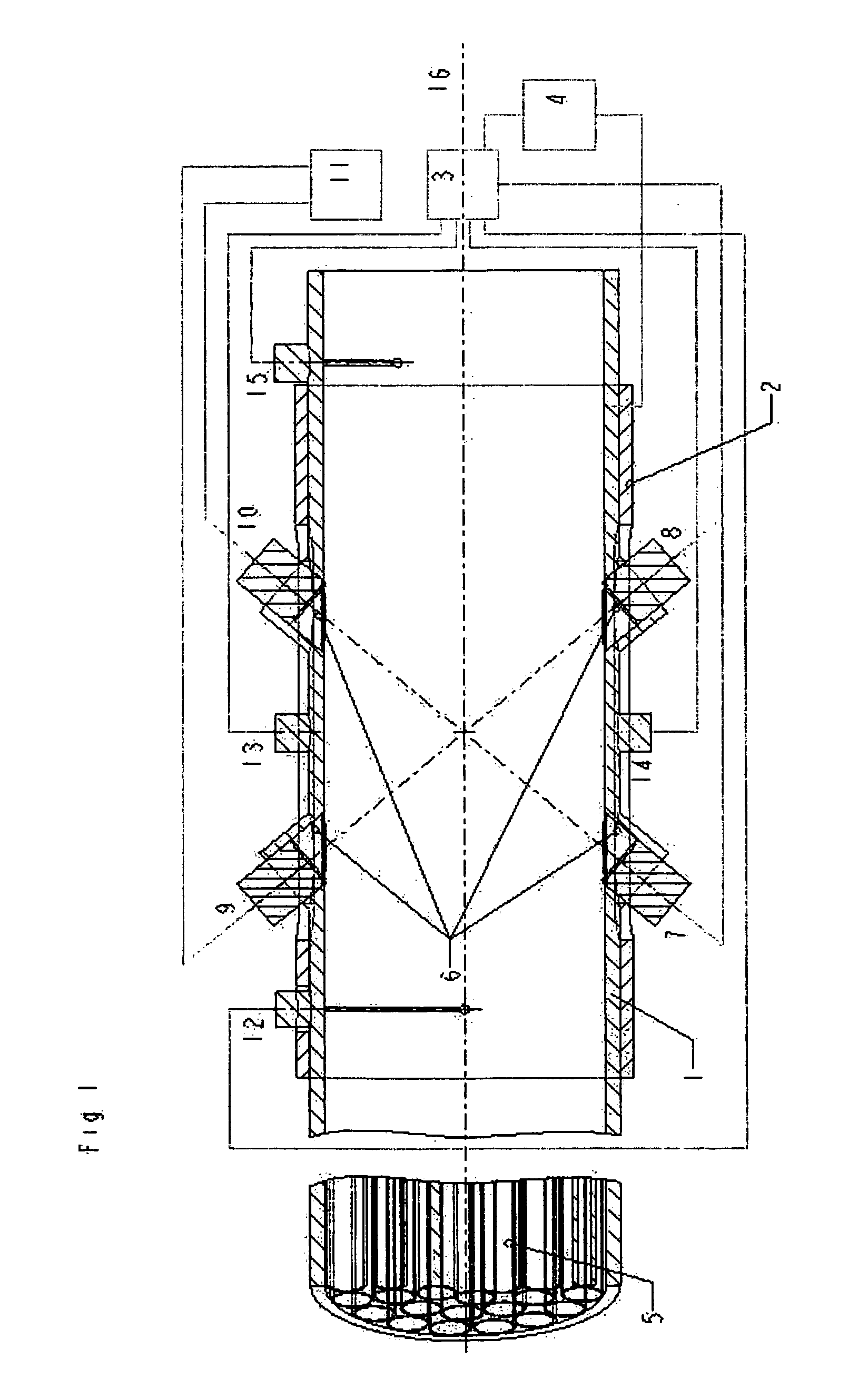

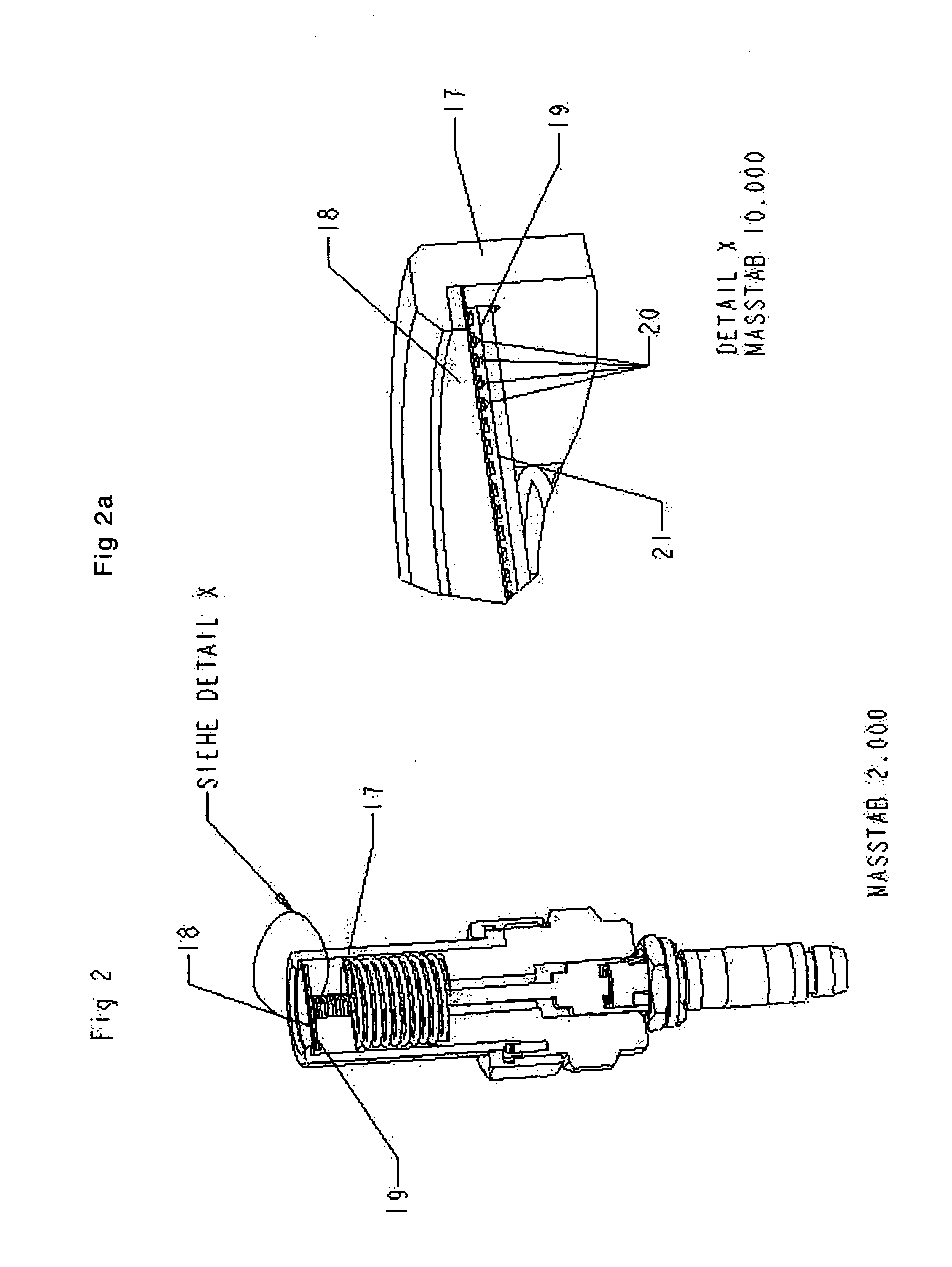

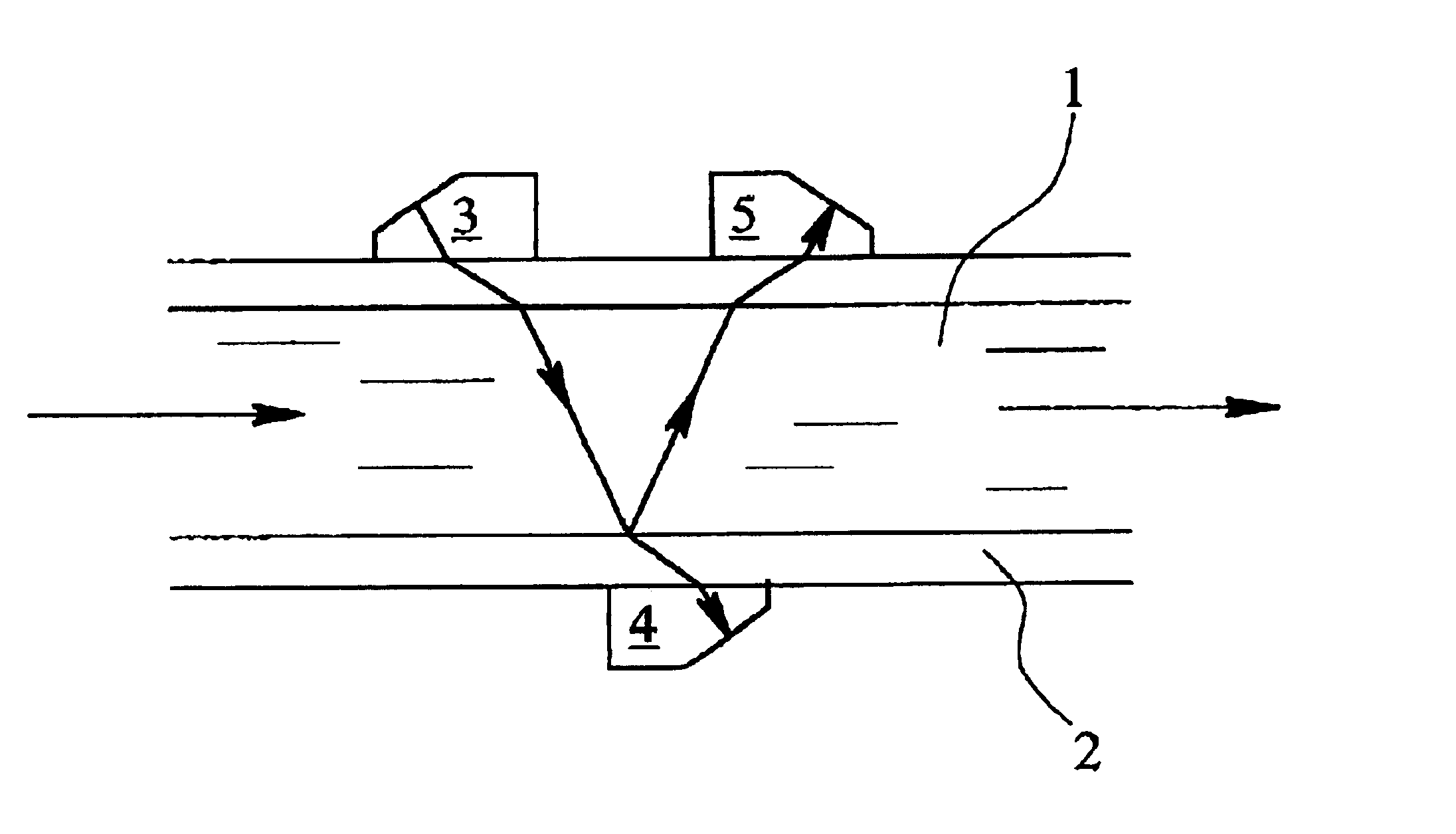

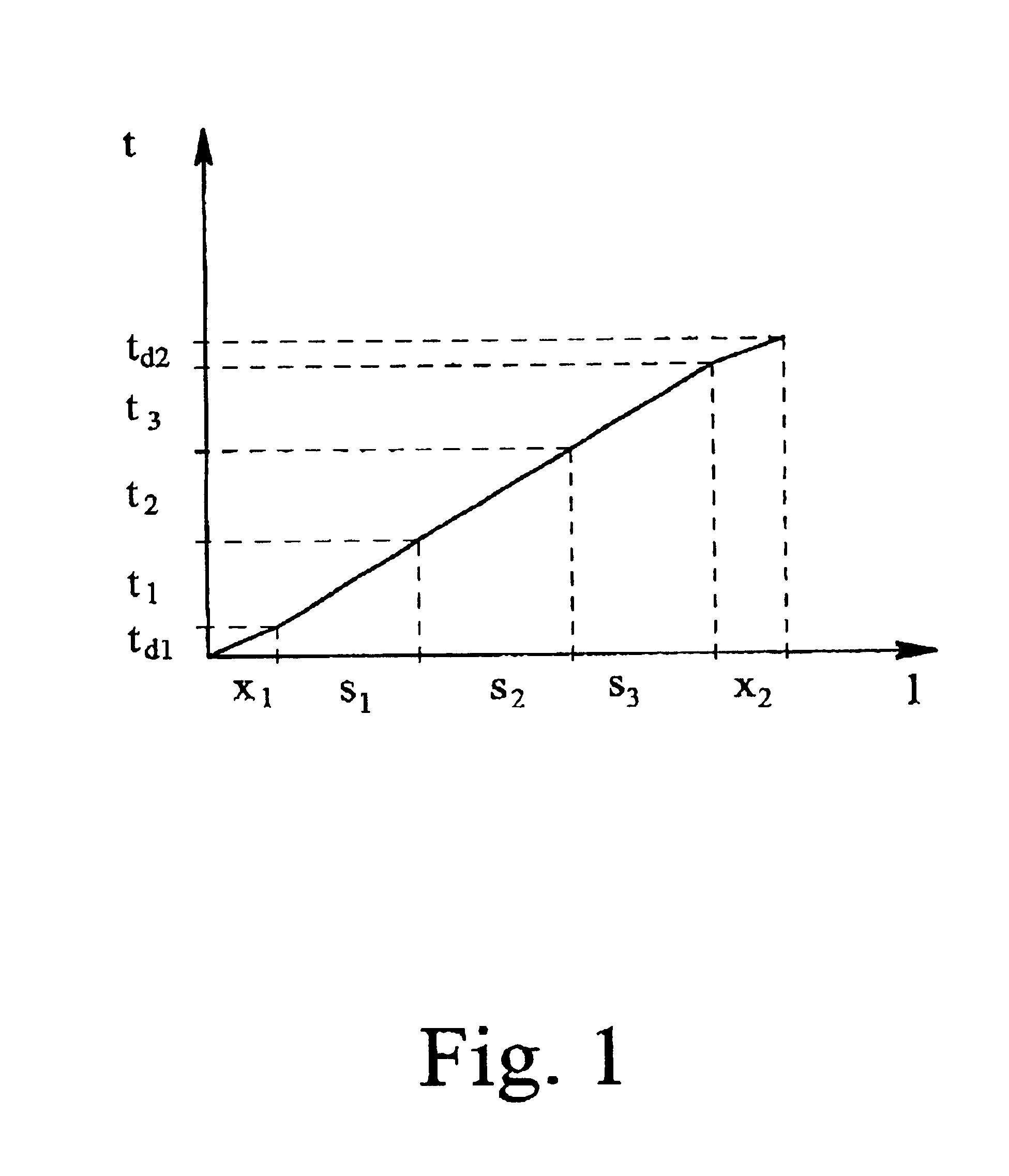

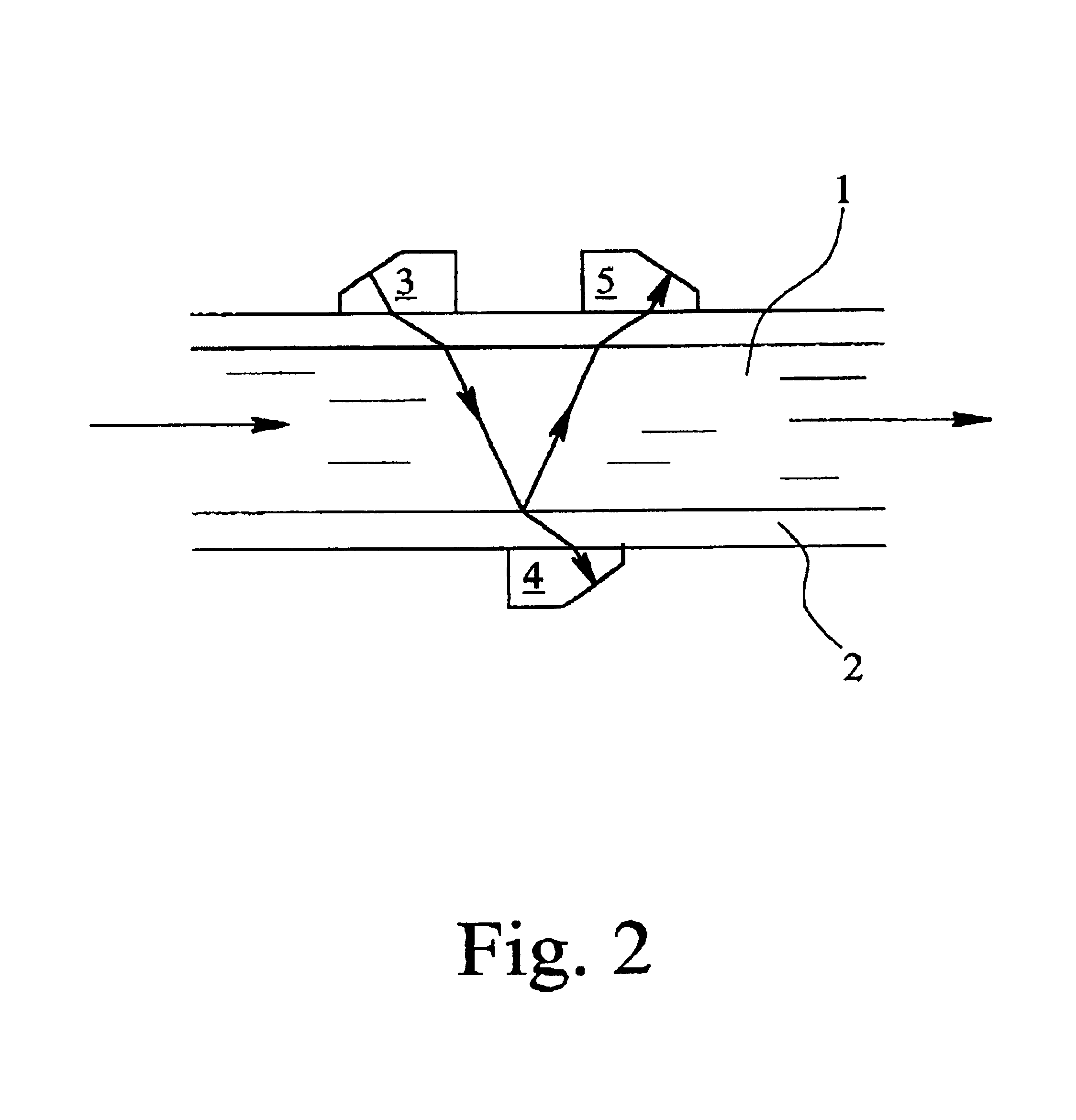

Ultrasonic gas flowmeter as well as device to measure exhaust flows of internal combustion engines and method to determine flow of gases

ActiveUS7093502B2Level gas temperature profileMinimize impactVolume/mass flow measurementVolume variation compensation/correction apparatusUltrasonic sensorDischarge measurements

An ultrasonic gas flowmeter includes a measuring pipe with flowing gas, transmitting and receiving sound transducers, transmission and reception electronics, and evaluation electronics. The sound transducers (7, 8, 9, 10) are designed as capacitive electro-acoustic ultrasonic transducers to construct a flowmeter with improved capacity, especially in view of temperature stability and the reduction and consideration of a temperature profile. Devices (5, 6) are provided to level the gas temperature profile and to minimize the influence of the temperature profile on the flow measurement. A more accurate and dependable detection of the volume flow or the mass flow of gases is to be achieved, especially in highly dynamic flows, for the method of determining the flow of gases whereby the mean flow velocity is determined and the flowing gas quantity is determined with highly synchronized resolution from the two transit times of two acoustic signals. In addition, an assessed value is computed (35) for the flow after the determination of the transit times and the assessed value is corrected at least by means of a characteristic temperature of the gas and the temperature of the wall of the measuring pipe (36).

Owner:AVL LIST GMBH

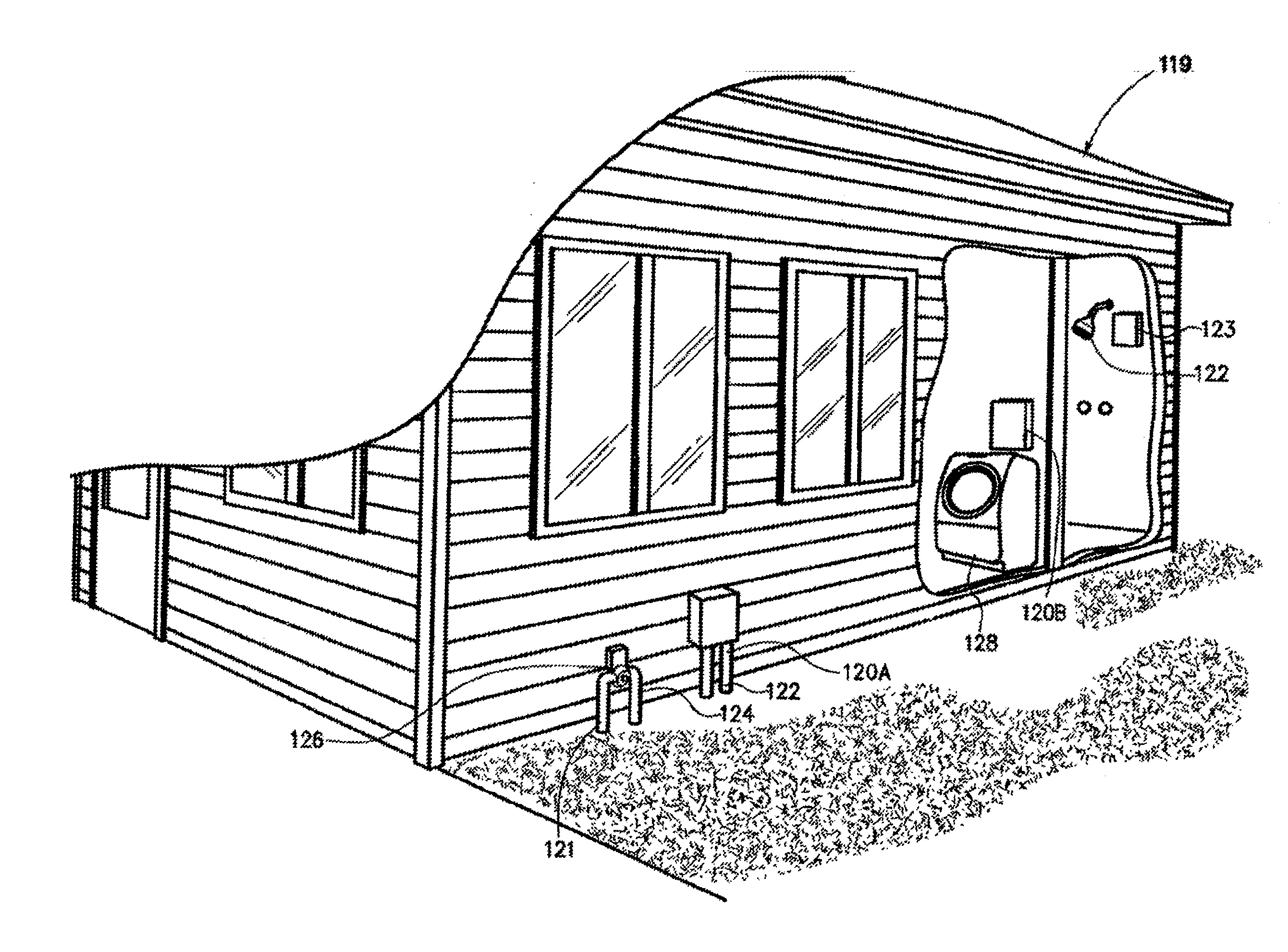

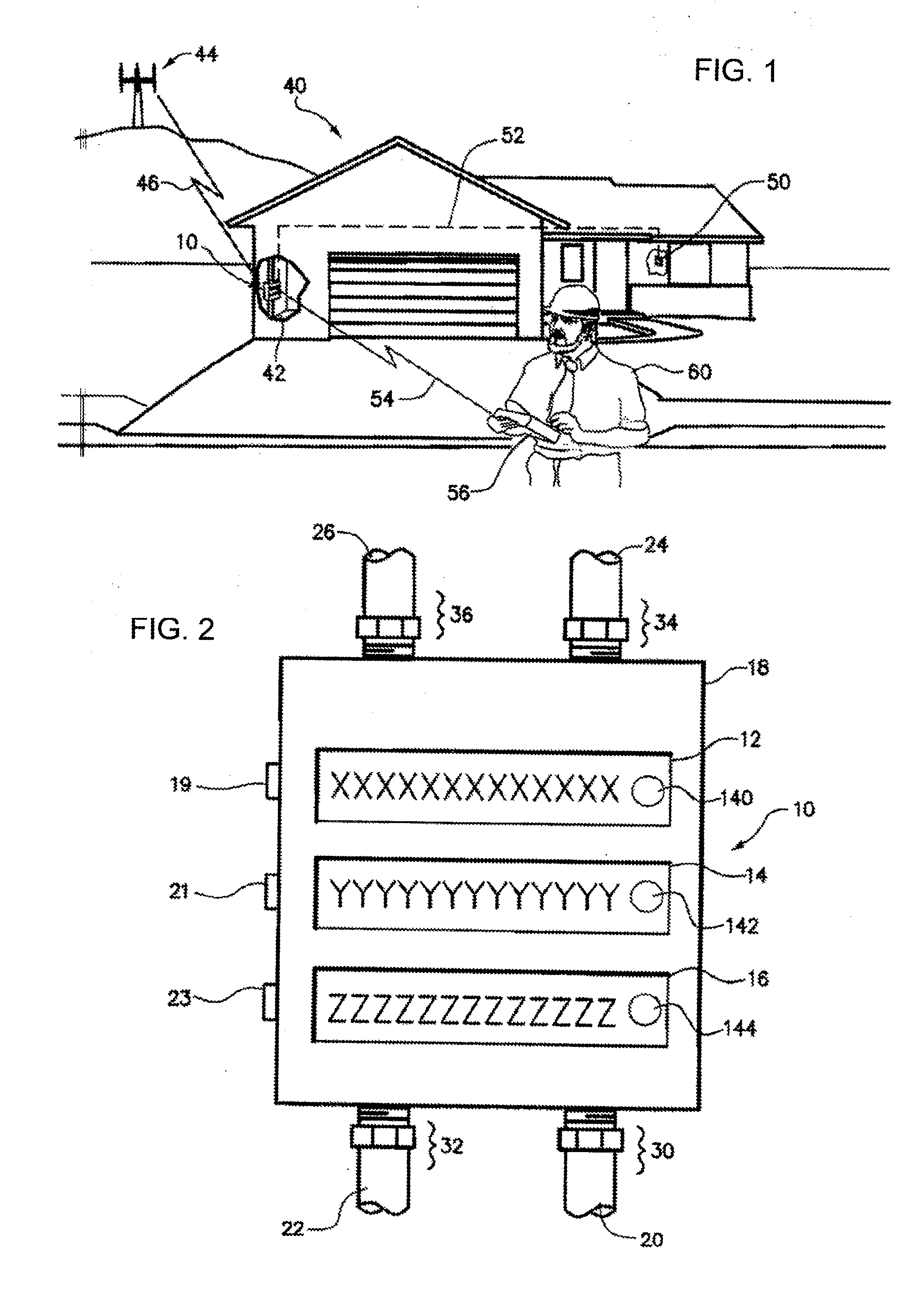

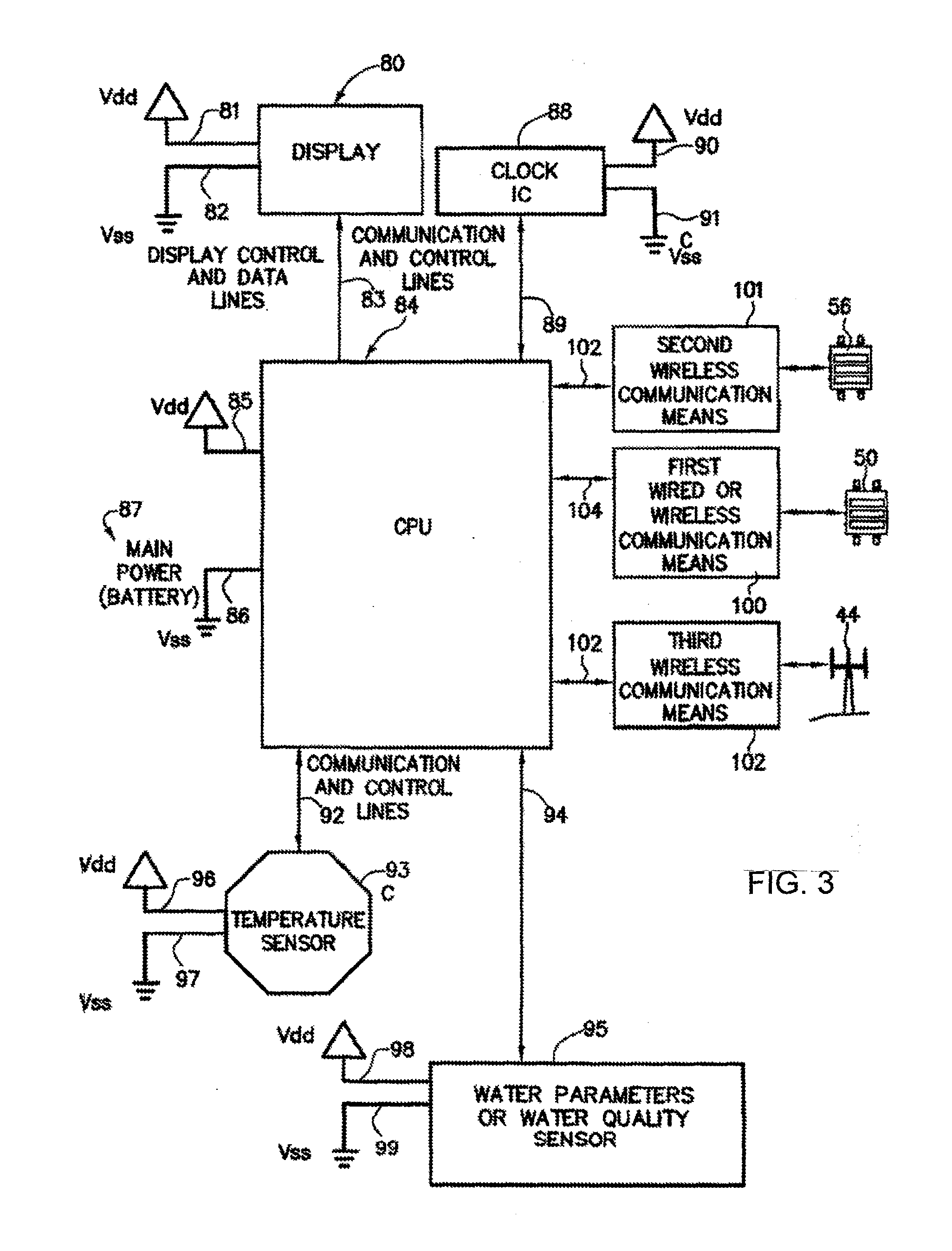

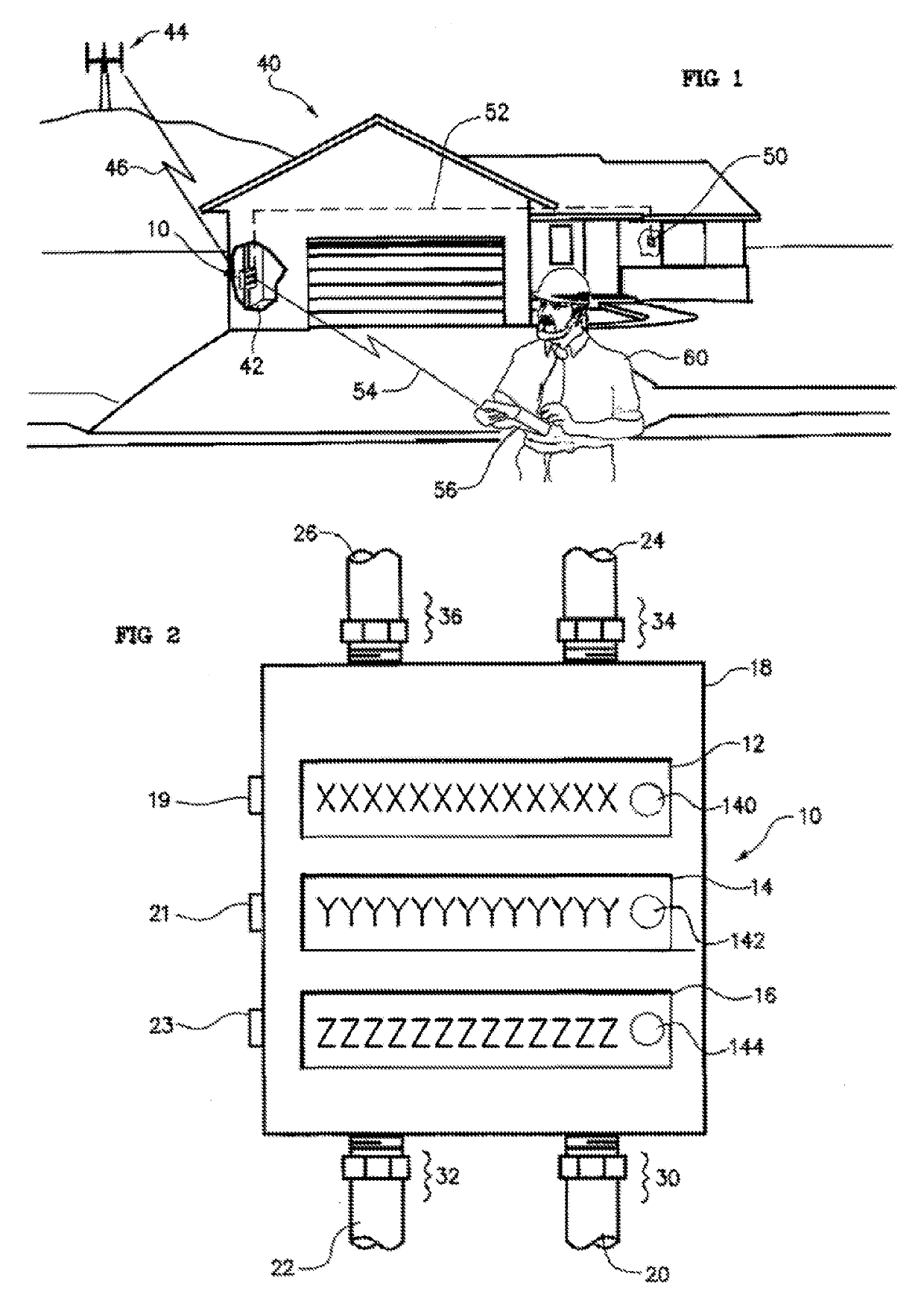

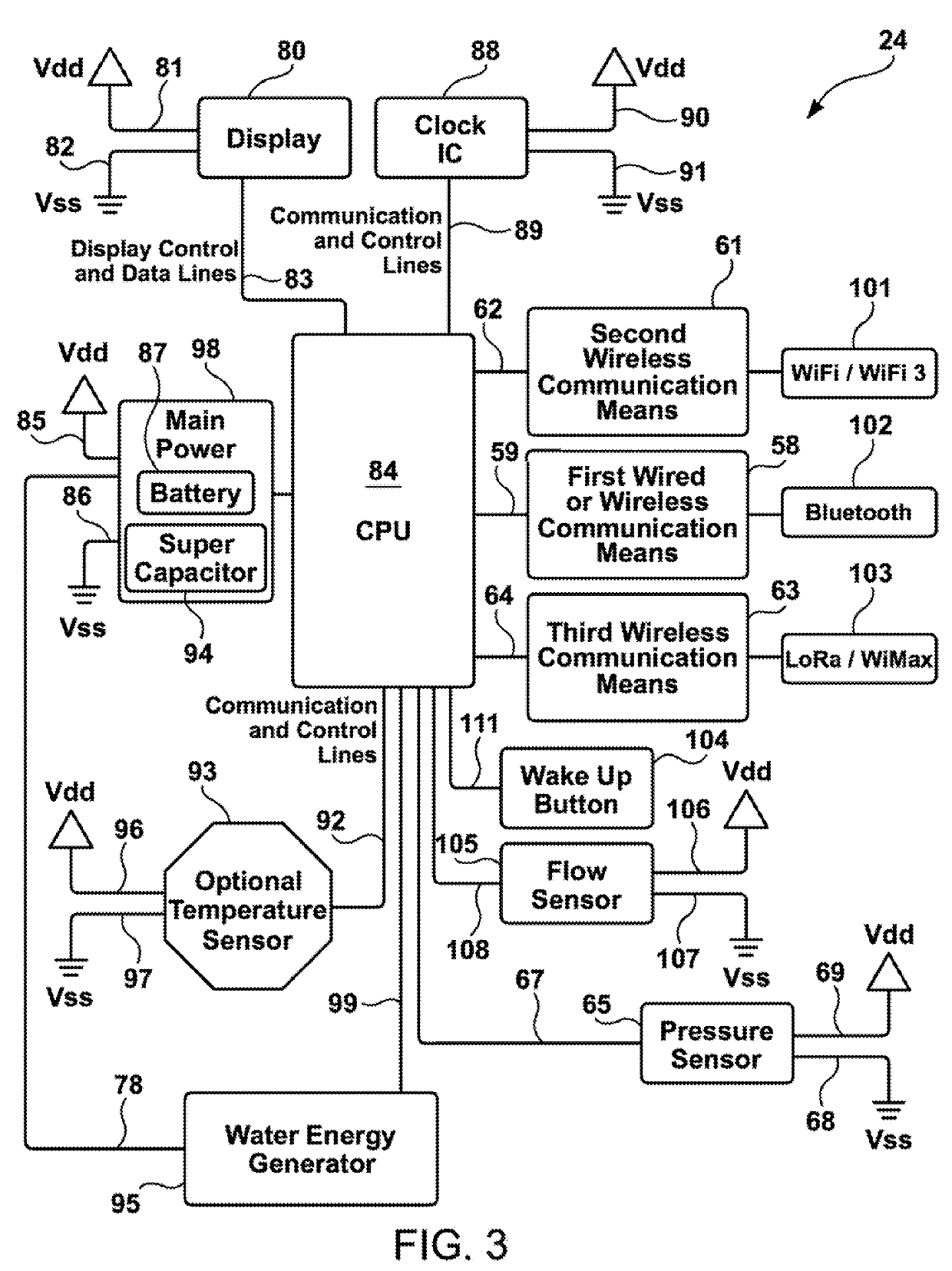

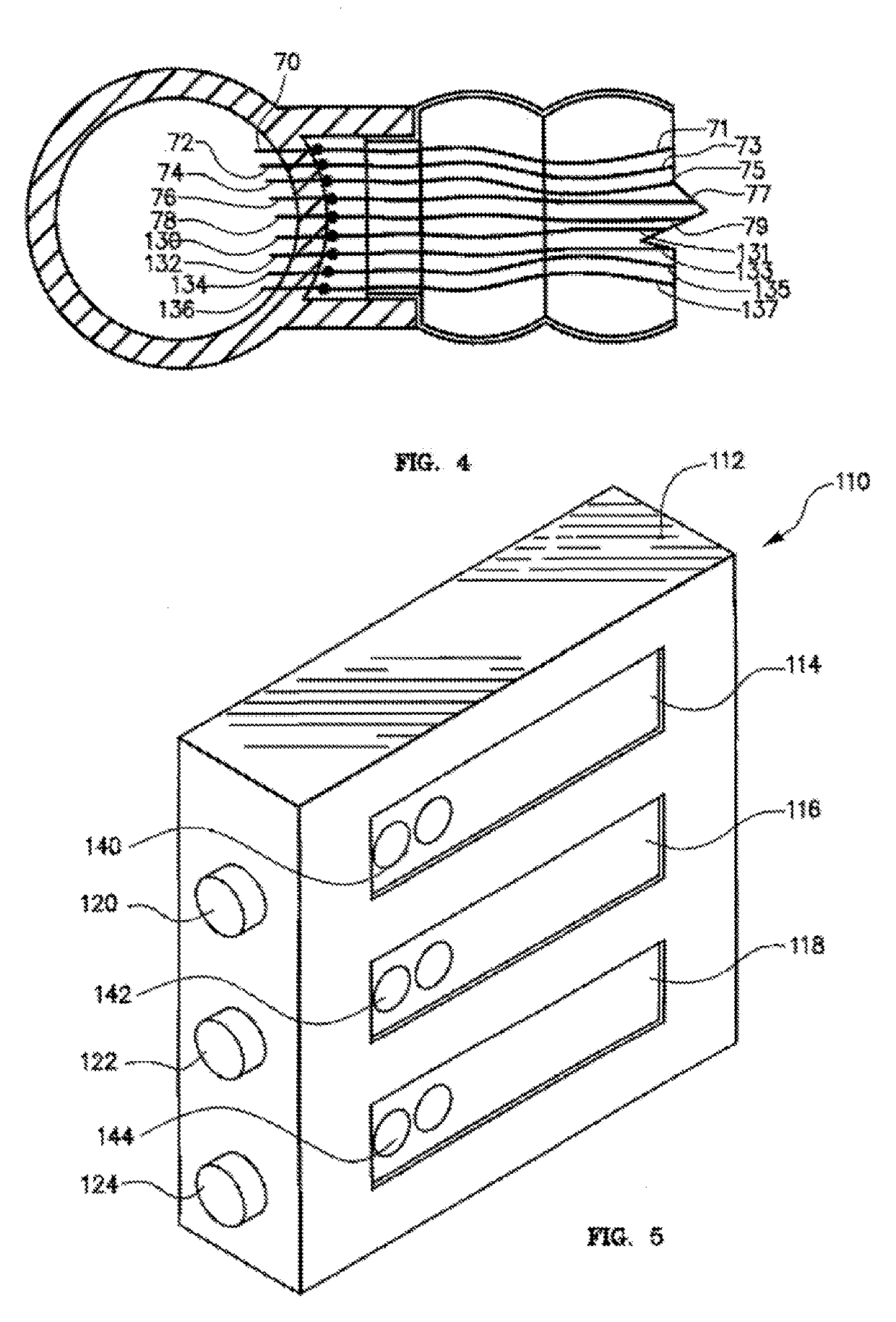

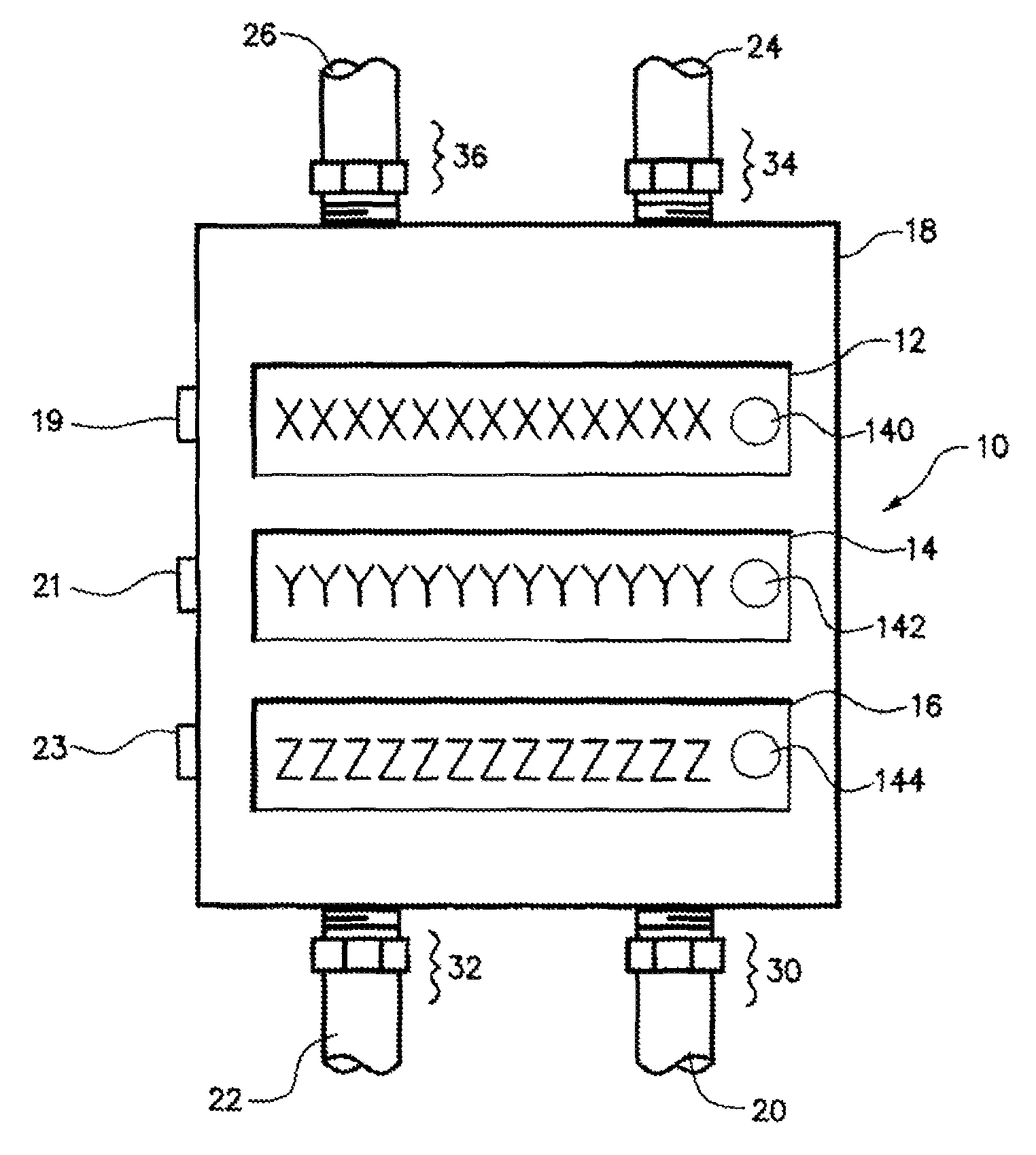

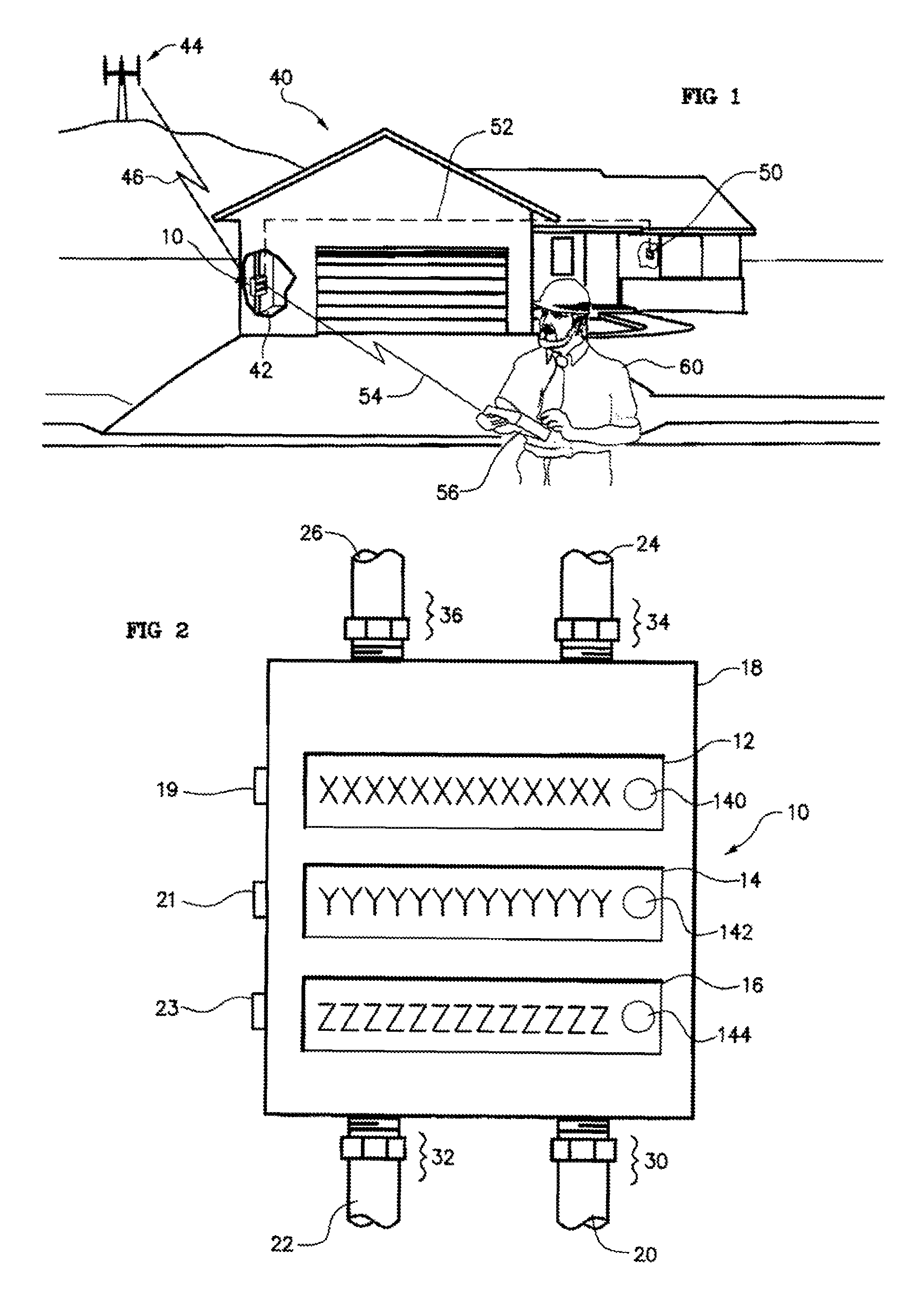

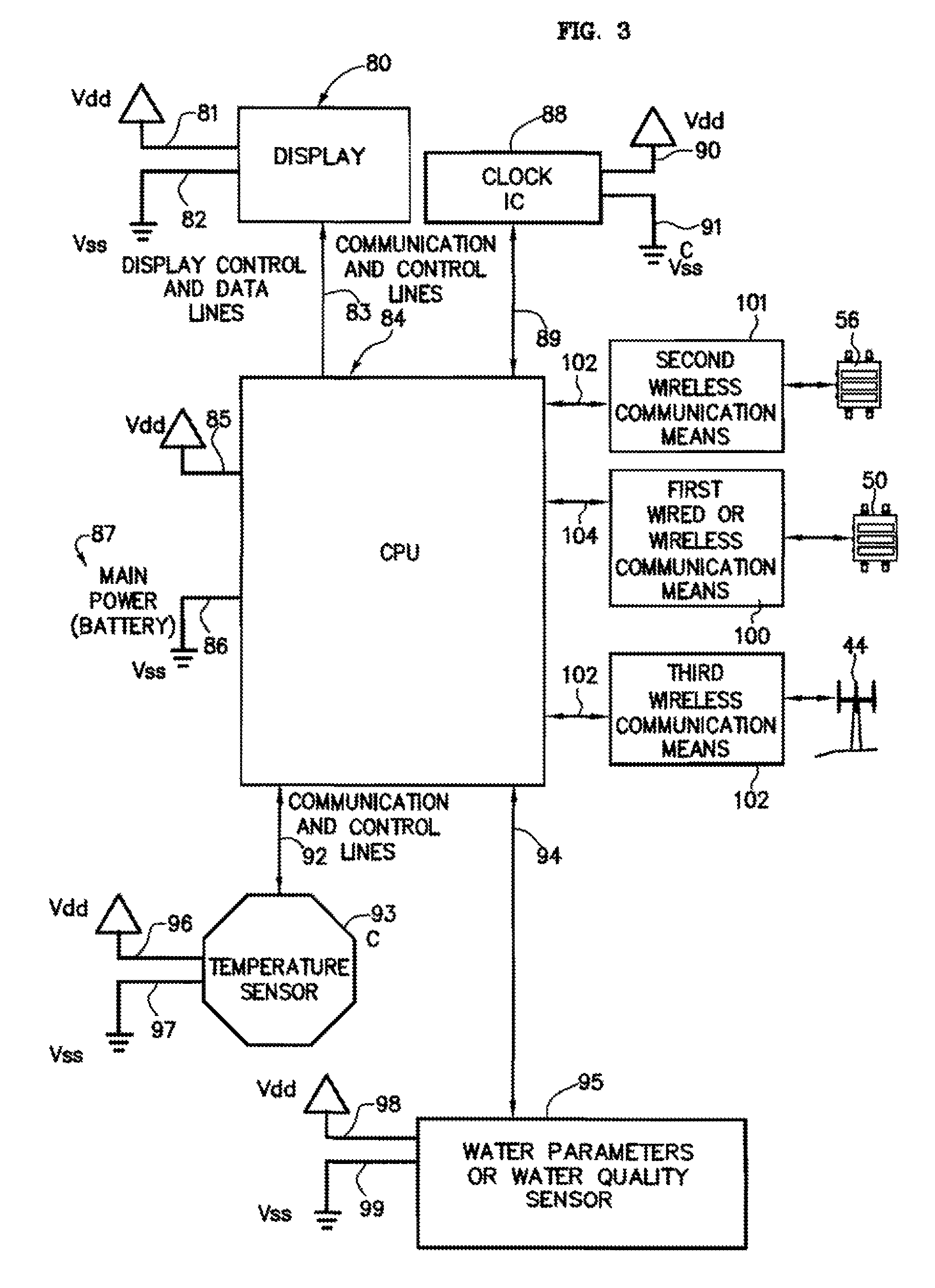

Water Use Monitoring Apparatus

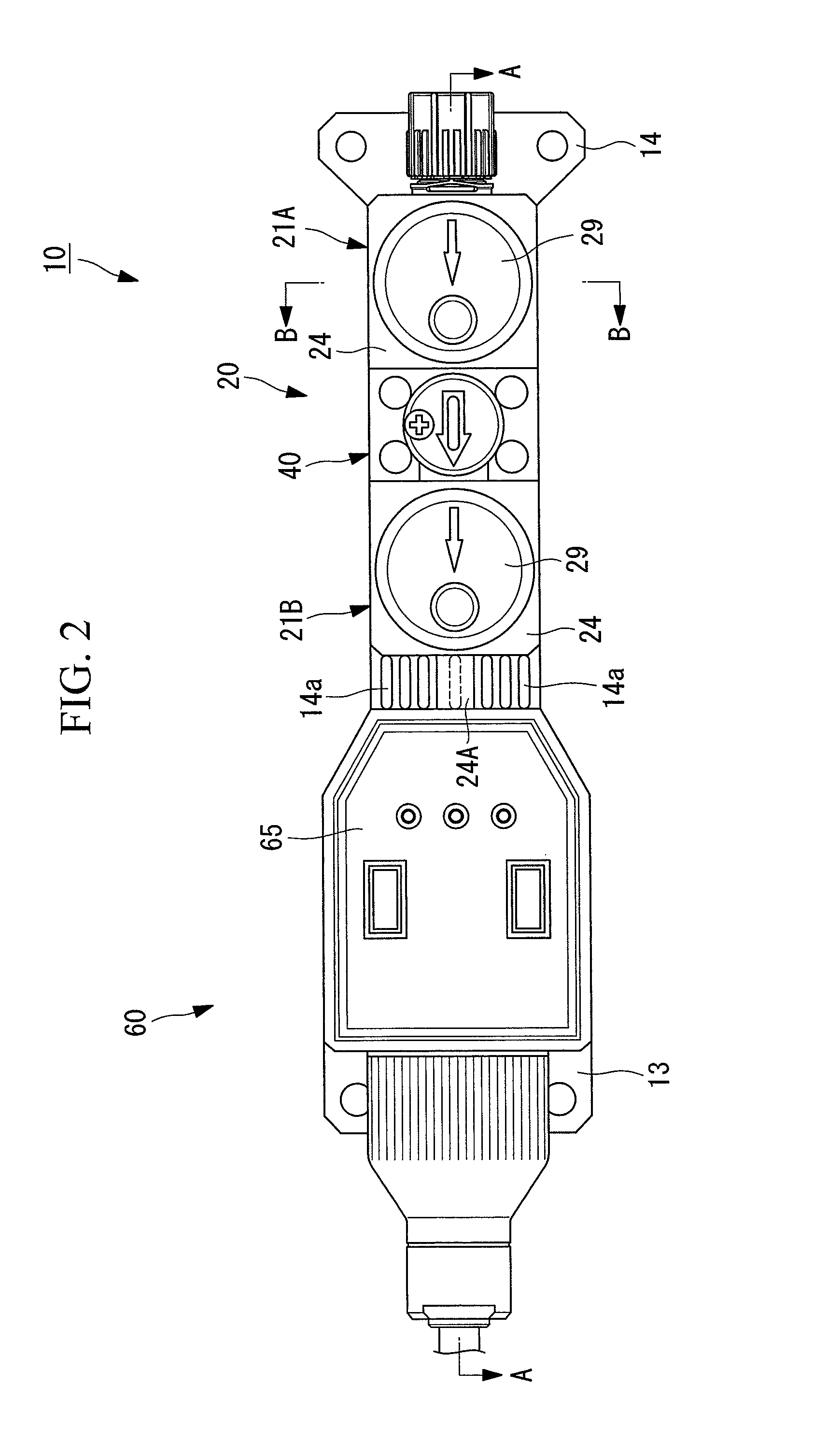

ActiveUS20160076909A1Easy to observeGeneral water supply conservationVolume/mass flow by thermal effectsWater useTechnology communication

The present invention is a water use and / or a water energy use monitoring apparatus that is affixed to the hot and cold water supply piping for continuously (or on demand) monitoring displaying the water and water energy (hot vs. ambient) use within a residential or commercial building. A first wire or wireless means is incorporated to communicate with a remote display for viewing by the owner of a commercial building or occupier / resident of a home. A second optional wire or wireless means can be incorporated that can be monitored by civil, commercial, governmental or municipal operators or agencies, using a remote display and / or recorder means or by a secure wire or wireless communication network (e.g. cell phone, smart phone or other similar technology communication means). A third wireless means communicates water parameter data utilizing typical cell tower technology and / or mesh network technology. The water use monitor apparatus includes a power generation, a microprocessor, temperature and water flow sensors, optional water quality sensors, timing circuits, wireless circuitry, and a display means. A wired or wireless means is designed to electronically communicate water use, water energy use and / or water quality information to a remotely located display apparatus or typical cell phone, smart phones, or similar apparatus for convenient observation by a commercial, operator or occupier, resident, municipal or government agency.

Owner:REIN TECH INC

Bi-directional differential pressure flow sensor

InactiveUS6725731B2Volume variation compensation/correction apparatusFluid-pressure actuatorsDifferential pressureEngineering

Disclosed is a bi-directional differential pressure flow sensor that is configured to establish a direction and flow rate of a fluid flow. The flow sensor includes a flow restriction member, a differential pressure sensor, and processing electronics. The flow restriction member is configured to produce a pressure drop when placed inline with the fluid flow. The differential pressure sensor is embedded or integral with the flow restriction member and produces a differential pressure signal that is indicative of the pressure drop. The processing electronics produces a flow rate signal that is indicative of the direction and flow rate of the fluid flow as a function of the differential pressure signal.

Owner:ROSEMOUNT INC

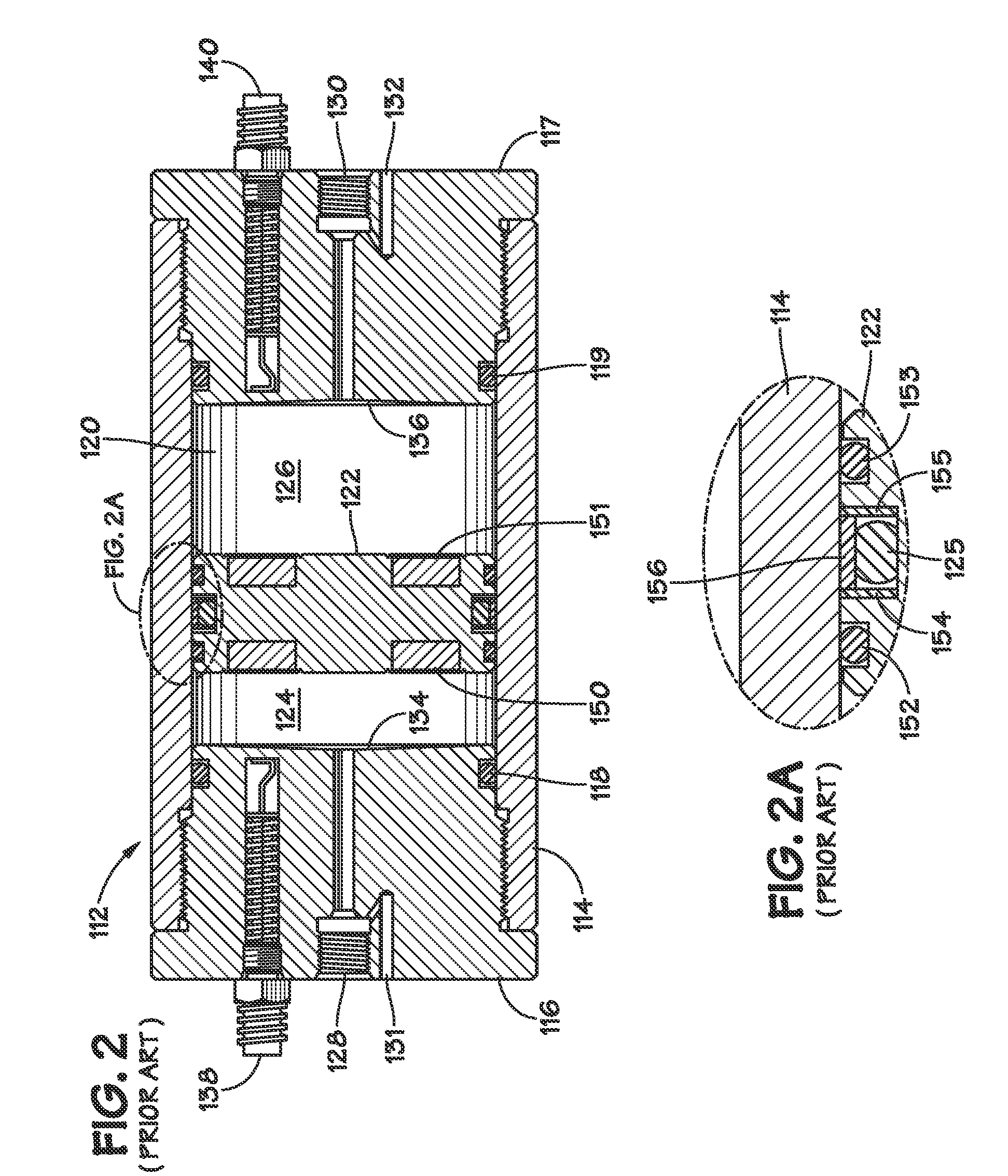

Infusion pump and method for use

InactiveUS20060150747A1Increased riskMeasurement is limitedContracting/expanding measuring chambersVolume variation compensation/correction apparatusSolenoid valveContact method

A fluid dispensing system provides a non-contact method of monitoring the change in the fluid volume over time. This approach avoids the use of probes or sensors that come into direct contact with the fluid to be dispensed. The system comprises an apparatus comprising three chambers. The first chamber has a fixed volume and contains a pressurized gas. A solenoid valve is used to control the flow of gas from the first chamber into the second. The second chamber is sealed so that the combined mass of air in the first and second chambers remains fixed. The third chamber is adjacent to the second and contains medication in the form of incompressible fluid that is to be administered to a human or animal subject via a suitable delivery port. A piston is disposed between the second and third chambers and is movable responsive to the flow of gas into the second chamber to dispense fluid from the third chamber as desired. By sensing the pressure in the first and second chambers at any point in time, a processor is programmed to calculate the flow rate or dispensed volume of the fluid being delivered using principles derived from the Ideal Gas Law.

Owner:TANDEM DIABETES CARE INC

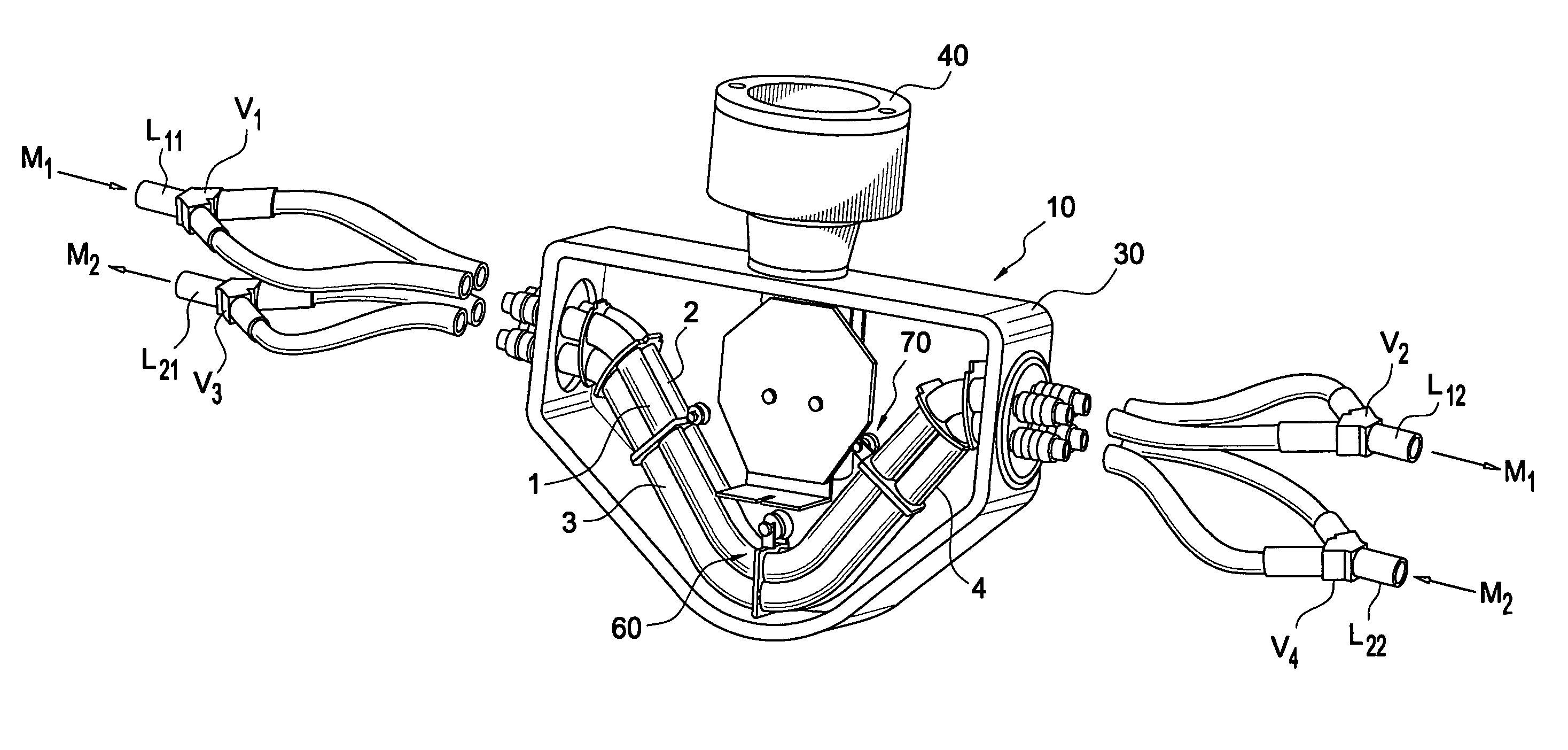

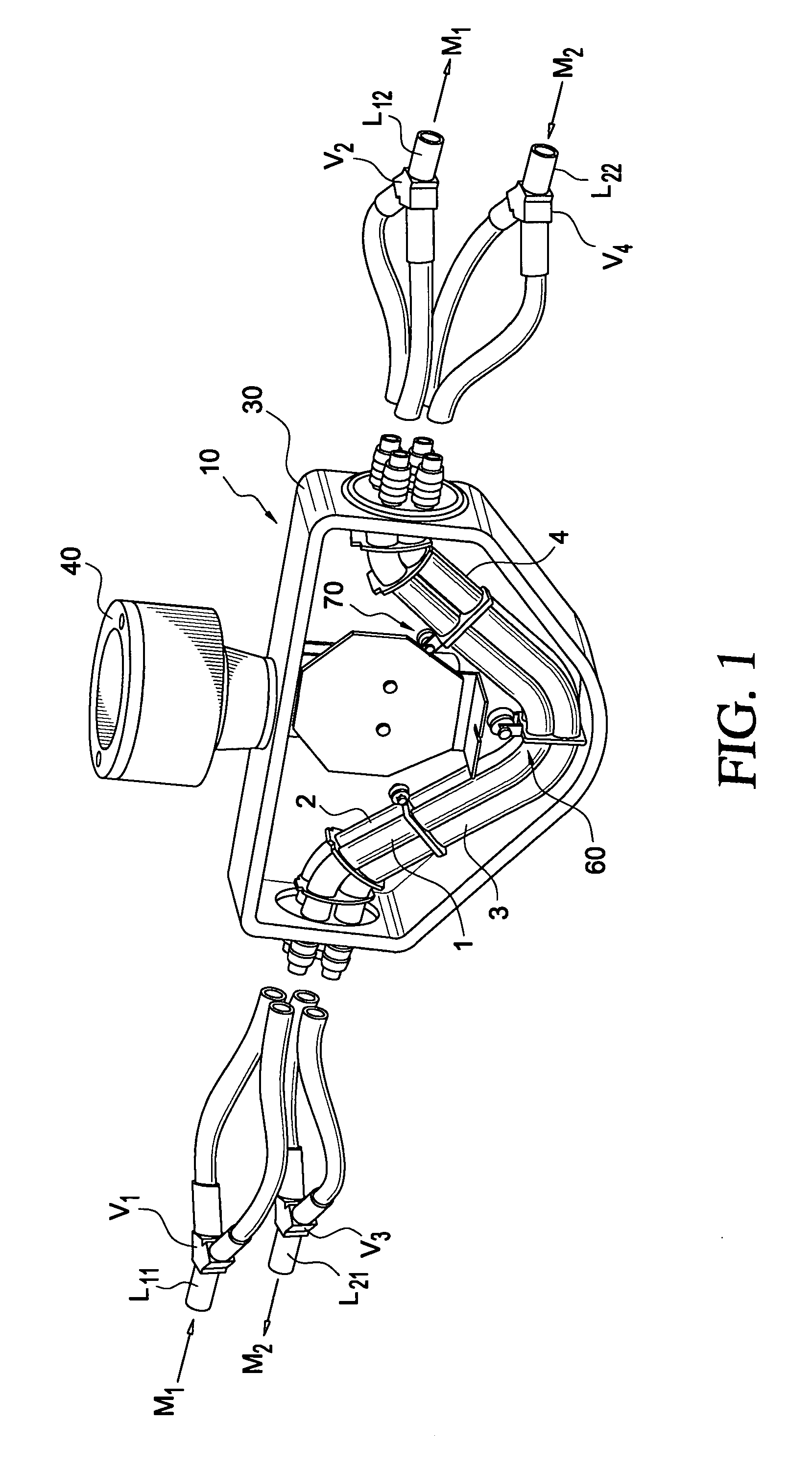

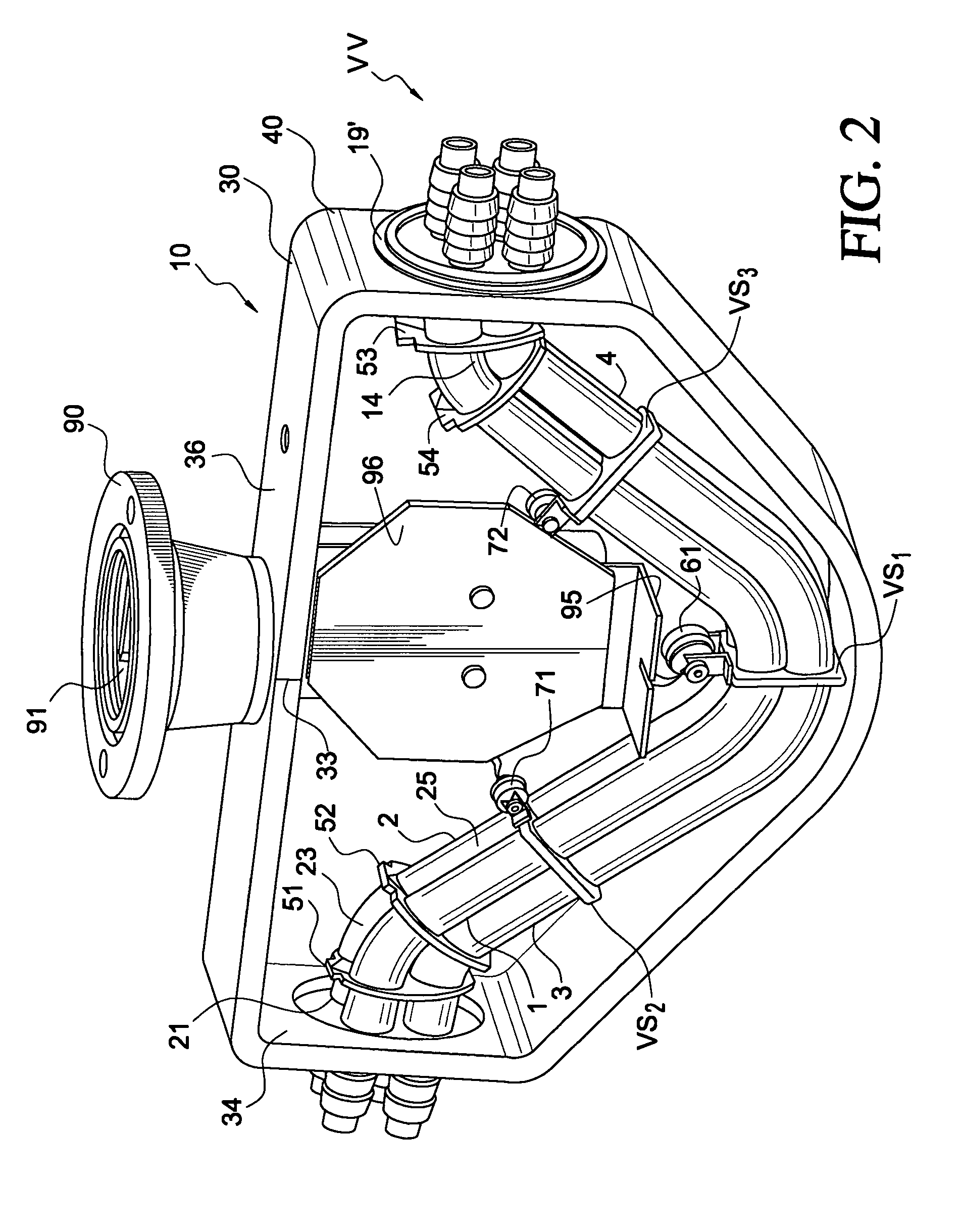

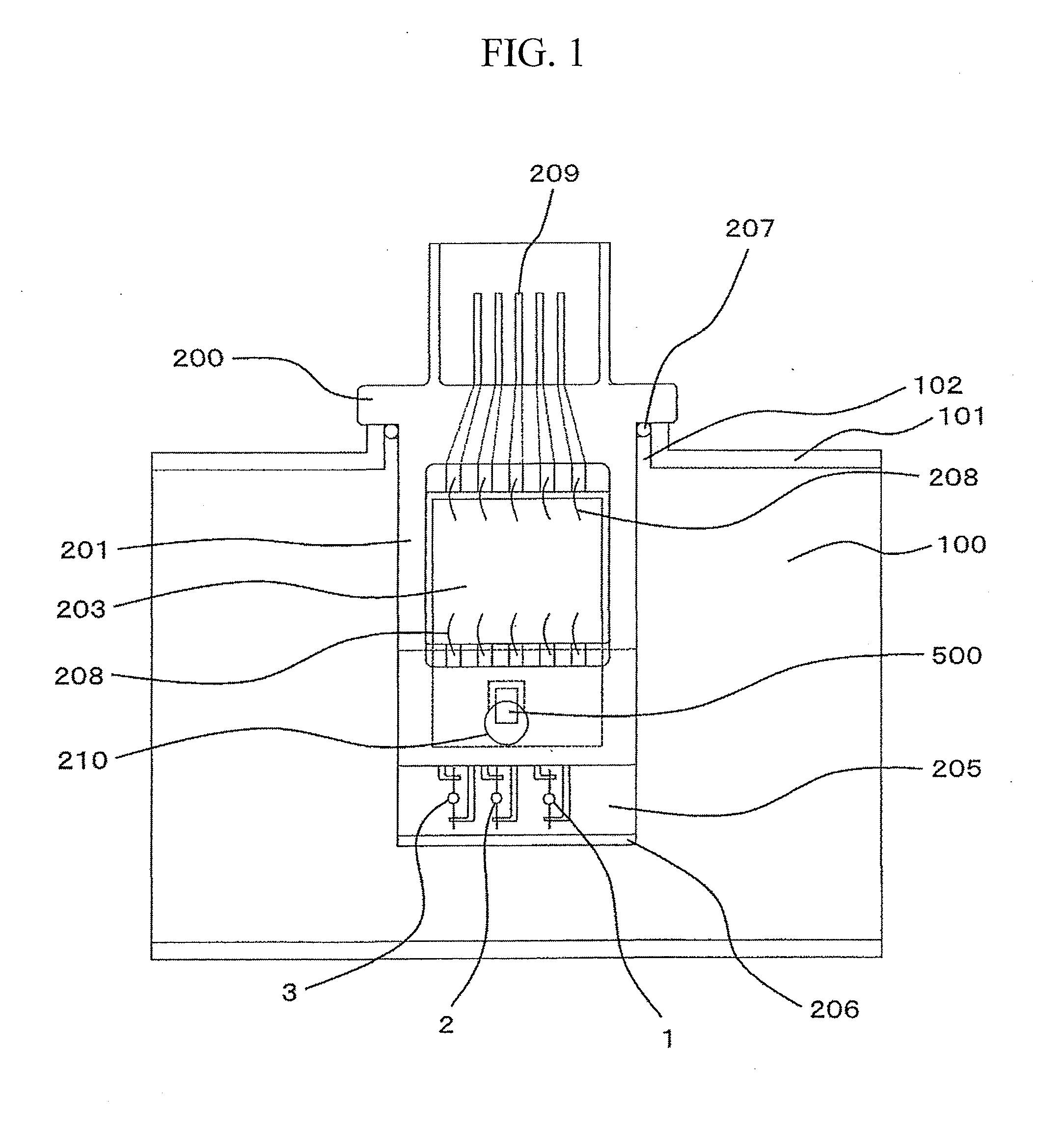

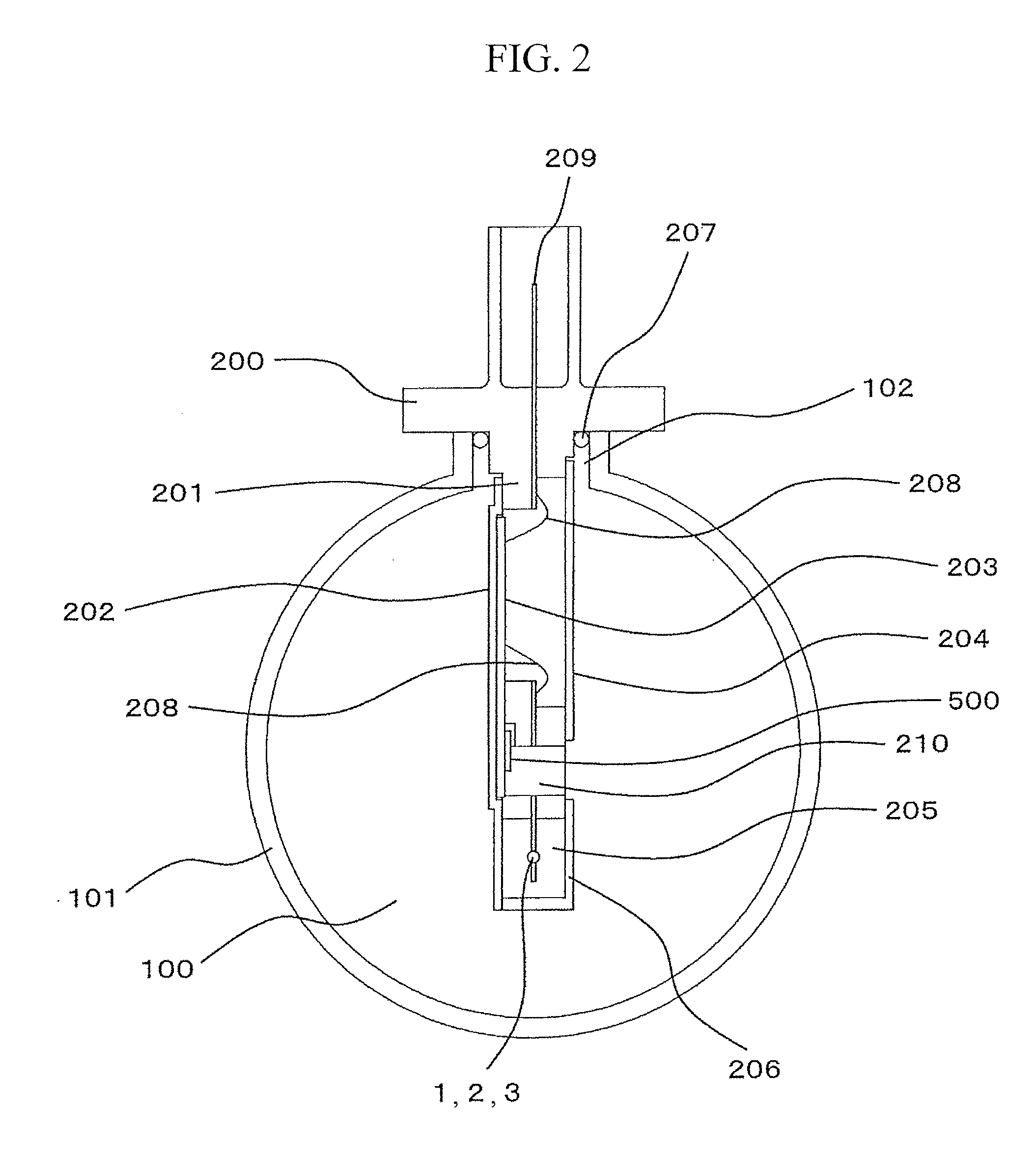

Measuring transducer of vibration-type

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

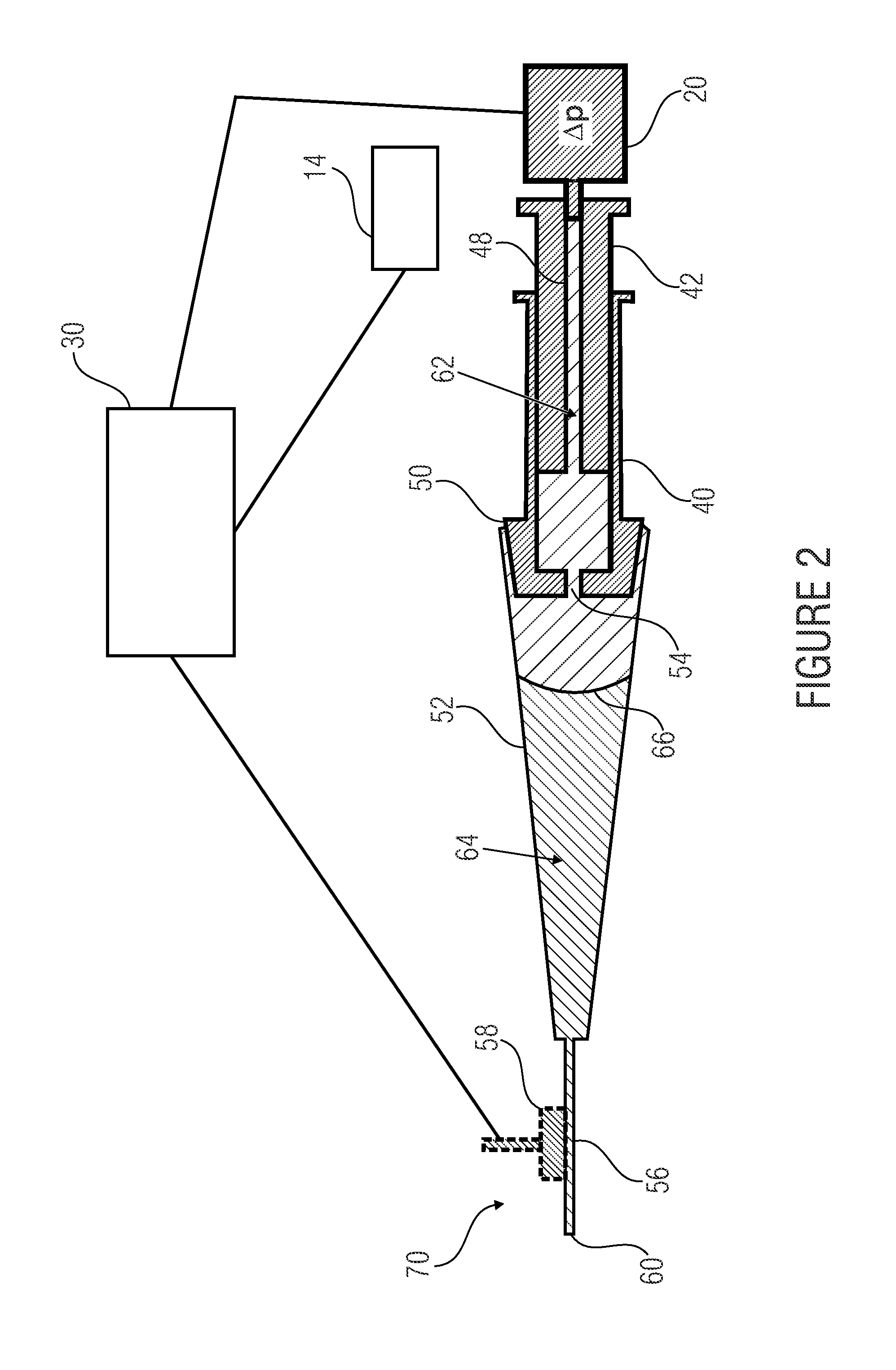

Device and method for dispensing or receiving a liquid volume

ActiveUS20130327787A1Precision and of dosing volumeEasy to set upVolume variation compensation/correction apparatusLiquid transferring devicesPressure generationBiomedical engineering

A device for dispensing or receiving a liquid volume comprises a liquid reservoir having an outlet, a pressure generation means which is implemented to provide a compressible enclosed gas volume of a constant amount of substance with a pressure, wherein the gas volume is in direct or indirect fluidic contact with the liquid in the liquid reservoir, a dosing means coupled to the outlet of the liquid reservoir and operable in order to enable the liquid to pass the outlet, a pressure sensor for measuring a current pressure in the gas volume and for outputting an output signal indicating the current pressure in the gas volume and a controller coupled to the pressure generation means, the dosing means and the pressure sensor. The controller is implemented to control the pressure generation means in order to change the pressure in the gas volume until the output signal of the pressure sensor indicates a first pressure, while the dosing means is not operated so that it prevents liquid from passing the outlet in order to operate the dosing means, depending on the output signal of the pressure sensor, to dispense or receive liquid through the outlet and, during dispensing or receiving liquid through the outlet, to monitor the output signal of the pressure sensor and, depending on the monitored output signal of the pressure sensor, terminate or repeat the operation of the dosing means.

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV +1

Method for operating a vibratory measuring instrument, and corresponding instrument

InactiveUS20100011882A1Made preciselyAccurate signalVolume variation compensation/correction apparatusTesting/calibration for volume flowMeasuring instrumentClassical mechanics

A method for operation of a vibratory measurement instrument comprises flowing a fluid through at least one measurement tube; causing the measuring tube to oscillate mechanically using an oscillation production unit; detecting an oscillation behavior of the tube using at least one oscillation sensor; determining at least one of a mass flow, a viscosity, and a density in a narrowband frequency range based on the oscillation behavior; evaluating at least one of the mass flow, the viscosity, and the density using signal processing of an electronics unit; and evaluating the oscillation behavior at least at times in a broadband frequency range using the electronics unit.

Owner:ABB PATENT GMBH

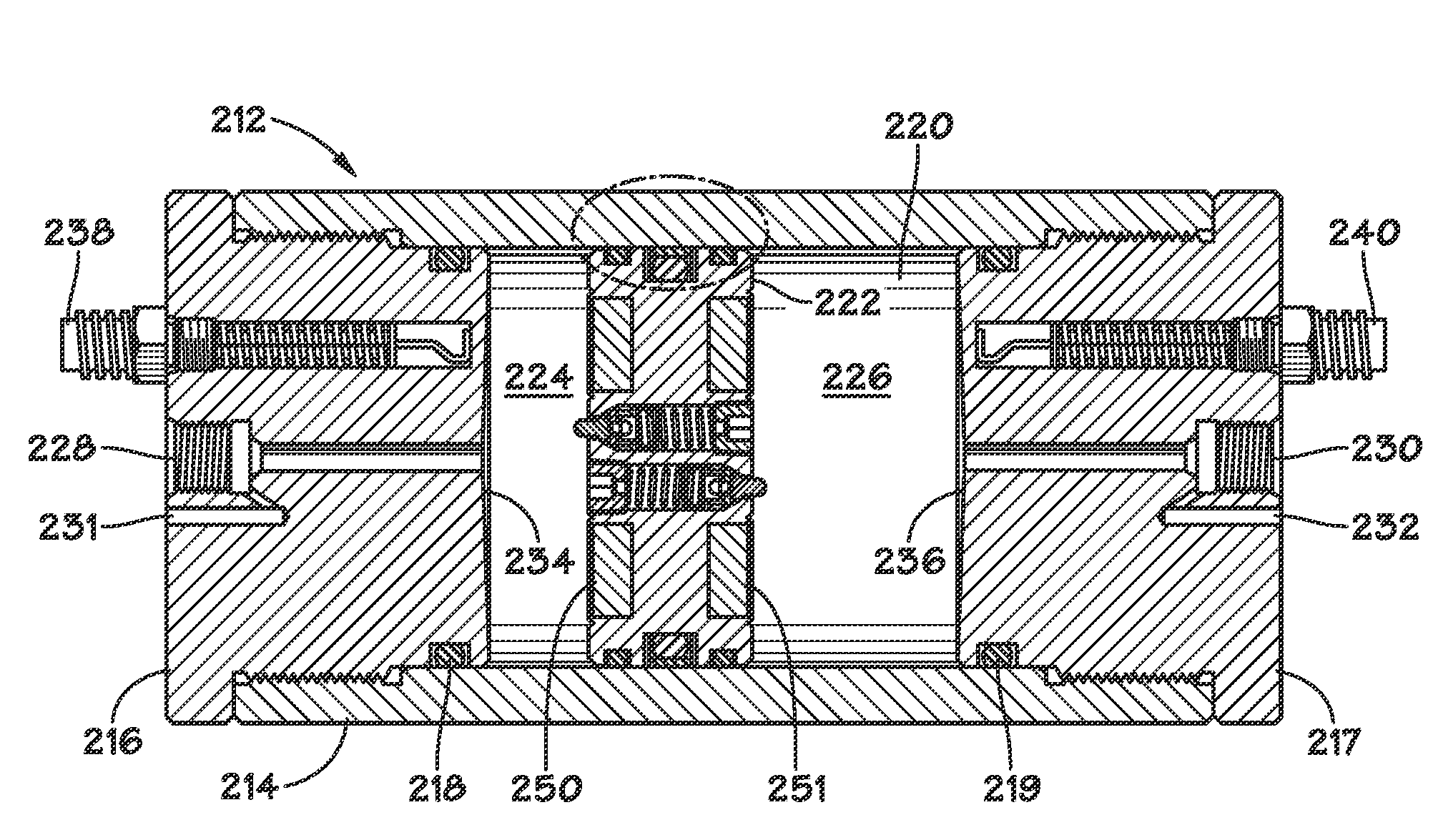

Vibration-type measurement pickup for measuring media flowing in two medium-lines, and inline measuring device having such a pickup

ActiveUS7127952B2Improved zero stabilityManufactured comparatively cost-favorablyVolume variation compensation/correction apparatusDirect mass flowmetersLine tubingMeasurement device

A measurement pickup includes at least four measuring tubes for conveying media to be measured. Each measuring tube has a first in- / outlet end and a second in- / outlet end. During operation, the measuring tubes vibrate, at least at times, especially simultaneously. The measurement pickup further includes an electromechanical exciter mechanism causing the measuring tube to vibrate, as well as a sensor arrangement reacting at least to local vibrations of the measuring tubes for producing at least one measurement signal influenced by vibrations of the measuring tubes. Of the at least four measuring tubes, two measuring tubes are, at least at times, inserted into the course of a first medium-line such that each of these two measuring tubes simultaneously conveys, in each case, a partial volume of a medium flowing through the first medium line, and two other measuring tubes of the at least four measuring tubes are, at least at times, inserted into the course of a second medium line such that each of these two measuring tubes simultaneous conveys, in each case, a partial volume of a second medium flowing through the second medium line. The measurement pickup can thus, on the one hand, have two media flowing through it, which differ measurably from one another in at least one physical property, for example mass flow rate, medium density and / or medium temperature, while having, on the other hand, despite the different media, a good zero-point stability.

Owner:ENDRESS HAUSER FLOWTEC AG

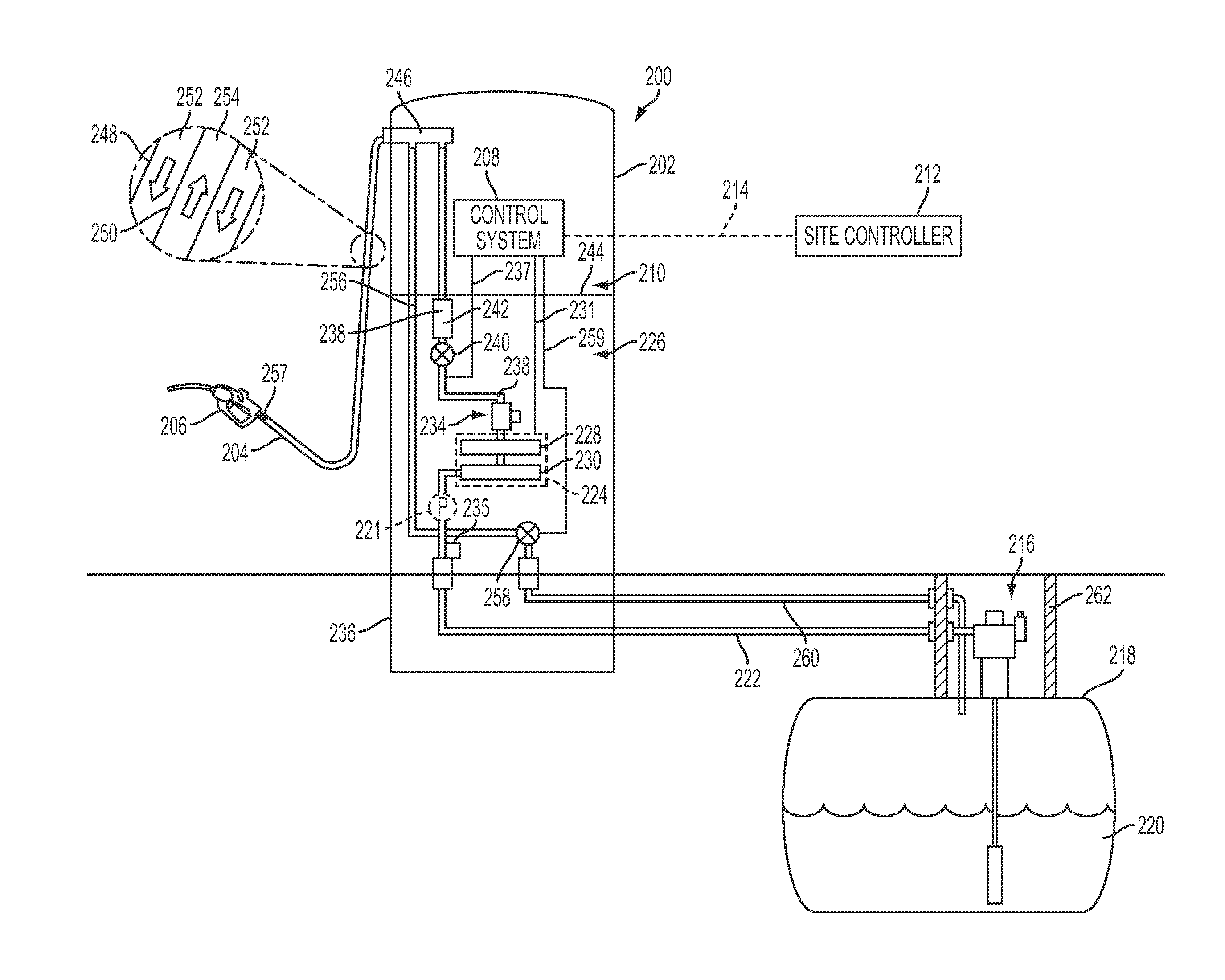

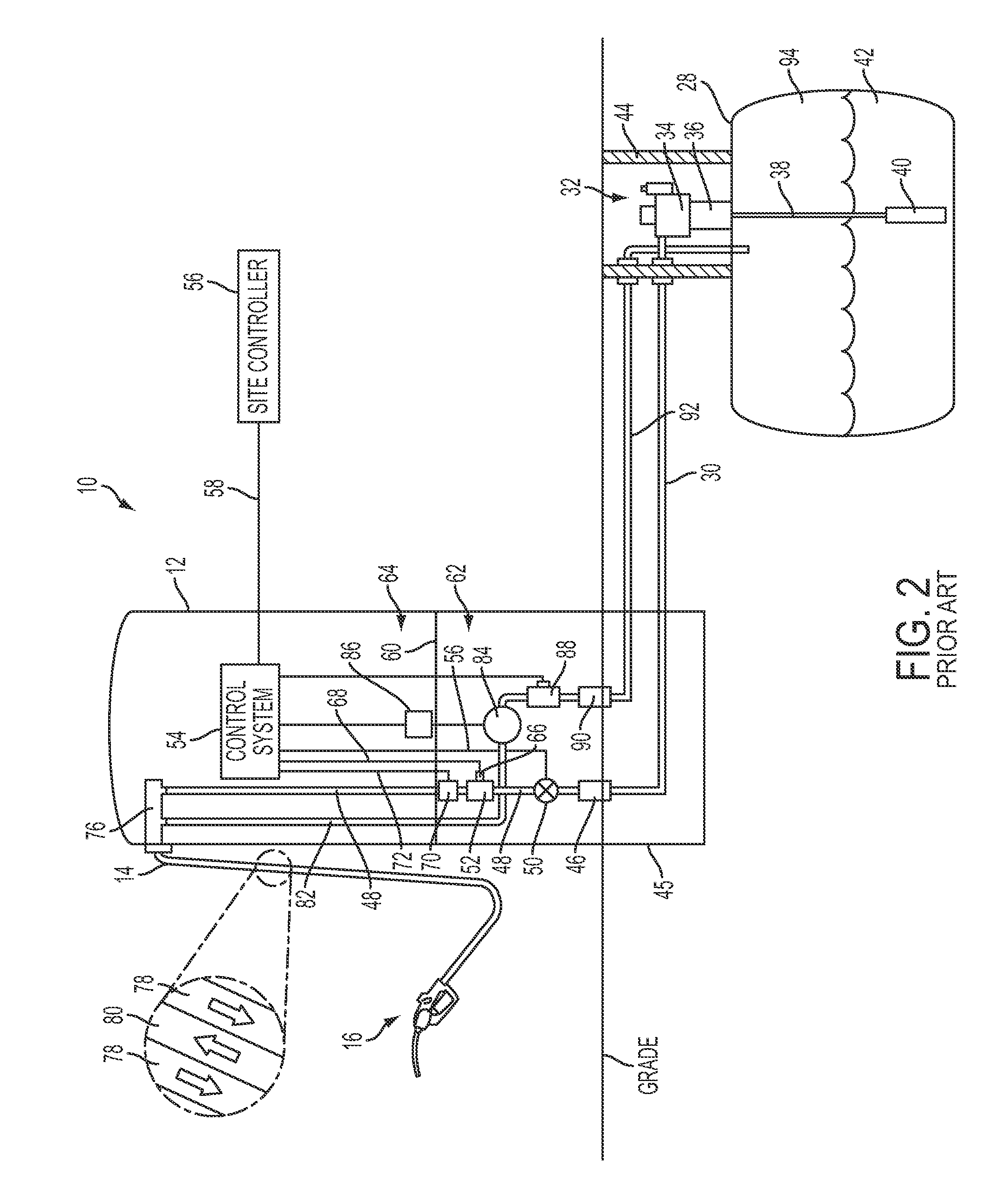

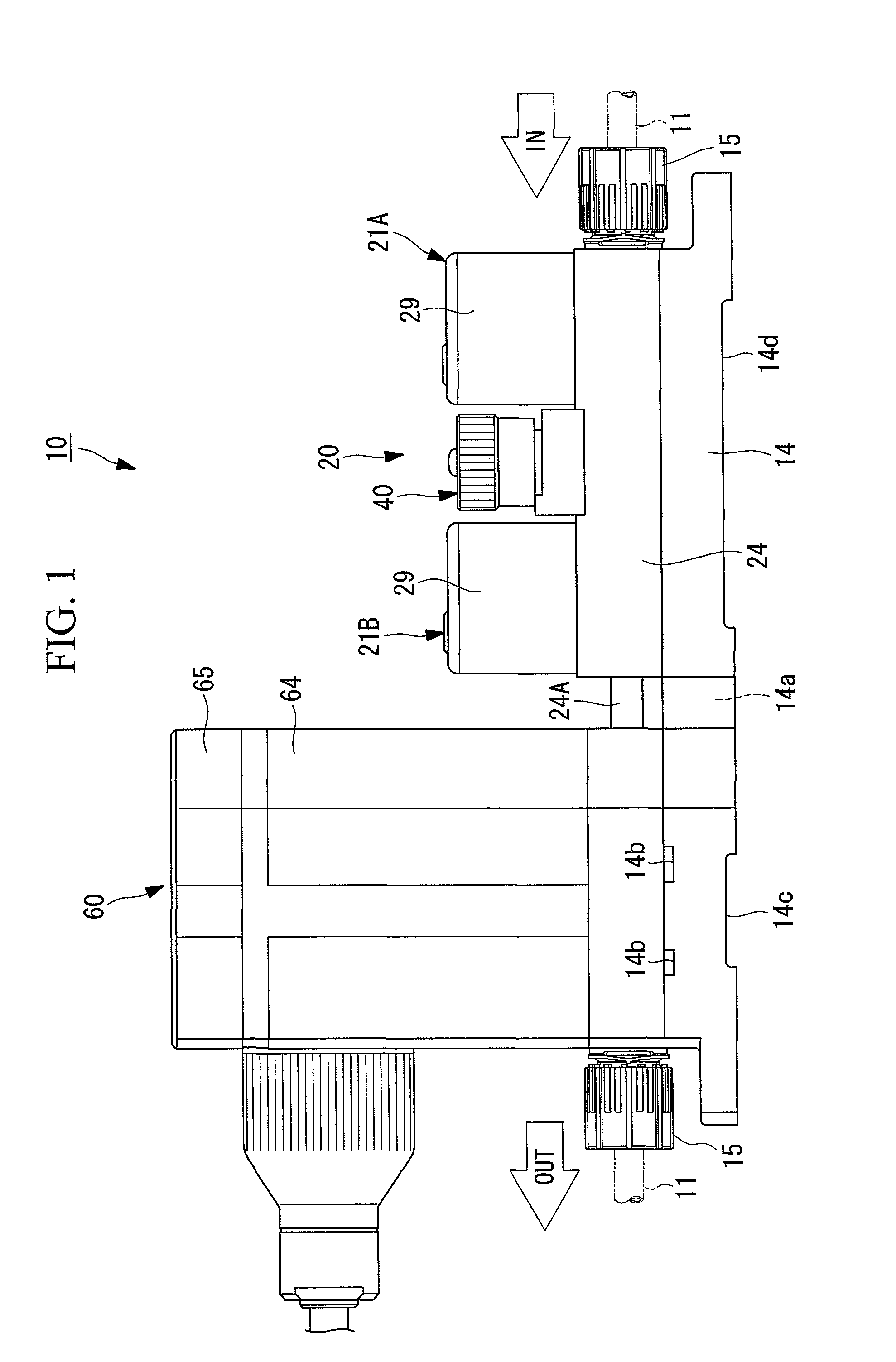

Fuel or def dispenser having fluid temperature conditioning and control system

ActiveUS20120024892A1Operating means/releasing devices for valvesUsing liquid separation agentControl systemEngineering

A fluid dispenser comprising a housing in which fluid flow control components are located and a fluid conduit completing a fluid flow path between a fluid storage tank and a nozzle coupled to the housing. The fluid dispenser further comprises a control system, at least one controllable valve in and a fluid flow meter located along the fluid flow path. The fluid dispenser further comprises a fluid temperature conditioning subsystem located along the fluid flow path upstream of the flow meter. The control system is selectively operates the fluid temperature conditioning subsystem upon detection of a predetermined temperature. At least one controllable recirculation valve may also be provided, and the control system may selectively actuate the controllable recirculation valve such that the fluid flows back to the fluid storage tank. A method of measuring the flow rate of a fluid in the fluid dispenser is also disclosed.

Owner:GILBARCO

Ultrasonic gas flowmeter as well as device to measure exhaust flows of internal combustion engines and method to determine flow of gases

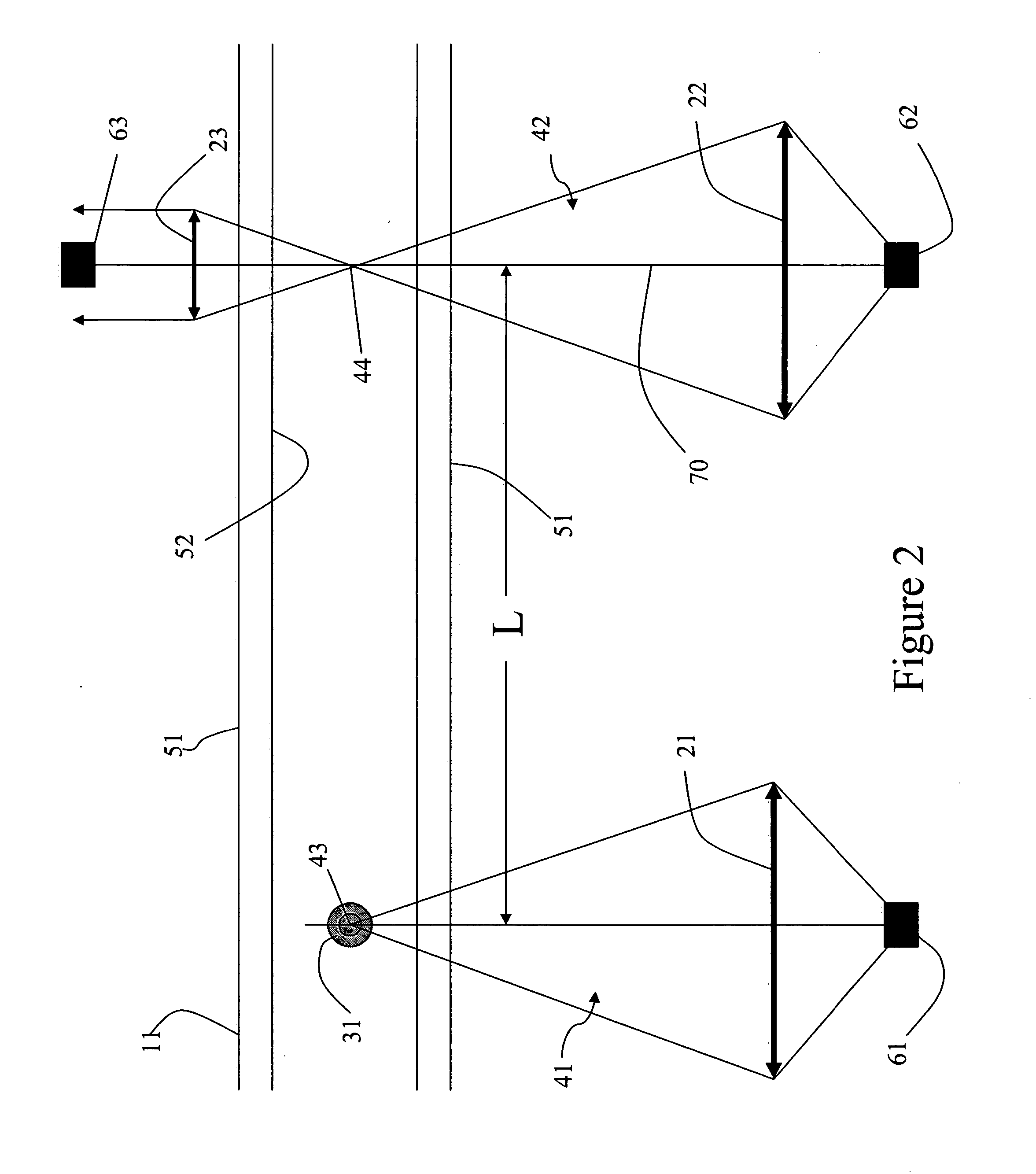

ActiveUS20050066744A1Minimize impactHigh precisionVolume variation compensation/correction apparatusIndirect mass flowmetersCombustionUltrasonic sensor

An ultrasonic gas flowmeter includes a measuring pipe with flowing gas, transmitting and receiving sound transducers, transmission and reception electronics, and evaluation electronics. The sound transducers (7, 8, 9, 10) are designed as capacitive electro-acoustic ultrasonic transducers to construct a flowmeter with improved capacity, especially in view of temperature stability and the reduction and consideration of a temperature profile. Devices (5, 6) are provided to level the gas temperature profile and to minimize the influence of the temperature profile on the flow measurement. A more accurate and dependable detection of the volume flow or the mass flow of gases is to be achieved, especially in highly dynamic flows, for the method of determining the flow of gases whereby the mean flow velocity is determined and the flowing gas quantity is determined with highly synchronized resolution from the two transit times of two acoustic signals. In addition, an assessed value is computed (35) for the flow after the determination of the transit times and the assessed value is corrected at least by means of a characteristic temperature of the gas and the temperature of the wall of the measuring pipe (36).

Owner:AVL LIST GMBH

Liquid metering system

InactiveUS20050005710A1Volume variation compensation/correction apparatusIndirect mass flowmetersThermal energyEngineering

Systems and methods for measuring the flow of a fluid along a passageway are disclosed. A heat source applies thermal energy to a portion of the fluid thereby elevating its temperature and decreasing its density. An optical sensing means measures a change in a property of illumination directed through the passageway caused by the change in the density of the heated portion of fluid. The time required for the heated portion of the liquid to move from the point of application of thermal energy to the point of optical sensing is measured. This measured time, and the distance of separation of the source of heat and the optical sensor permits calculation of the fluid velocity in the passageway.

Owner:THERAFUSE

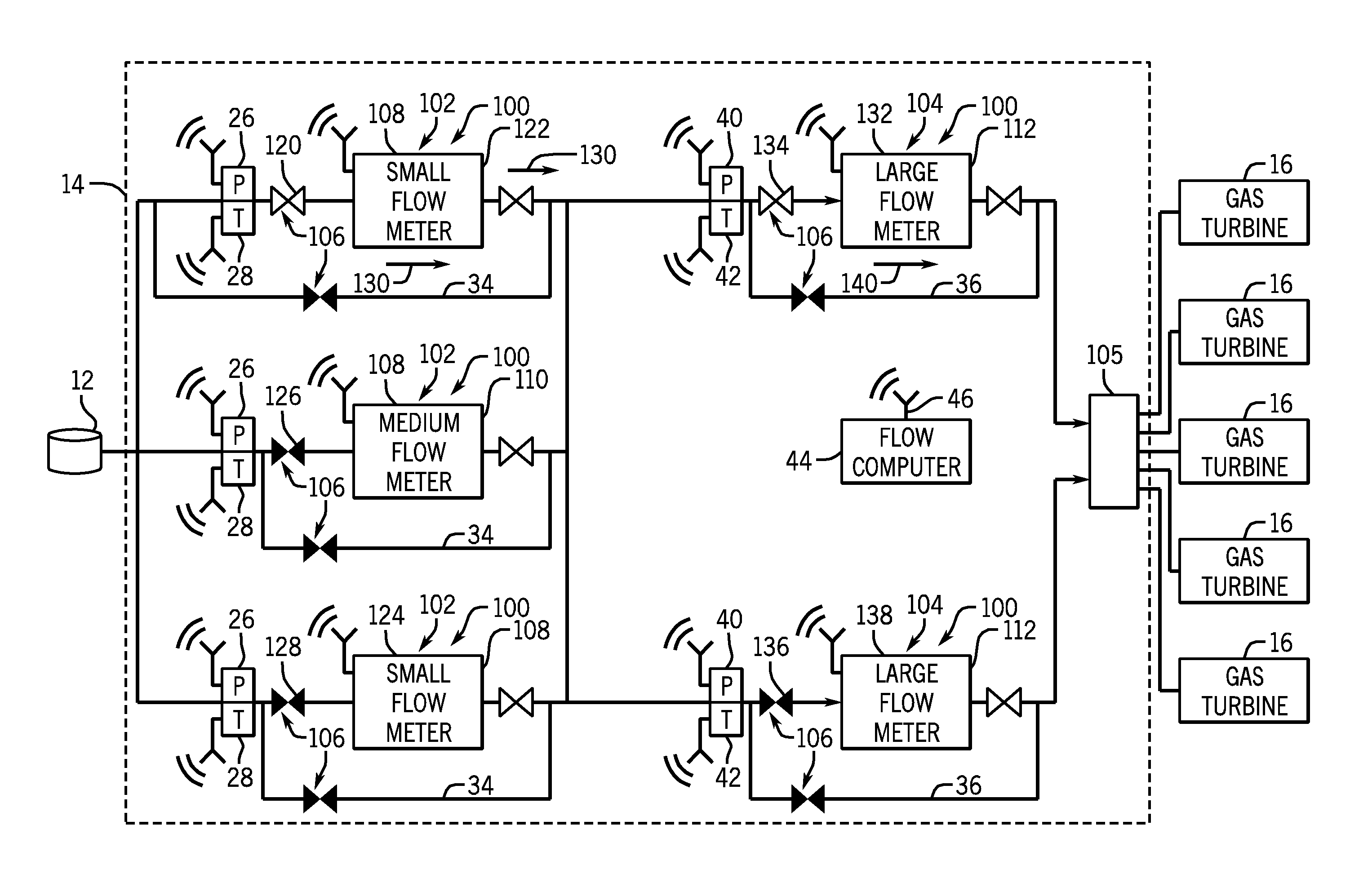

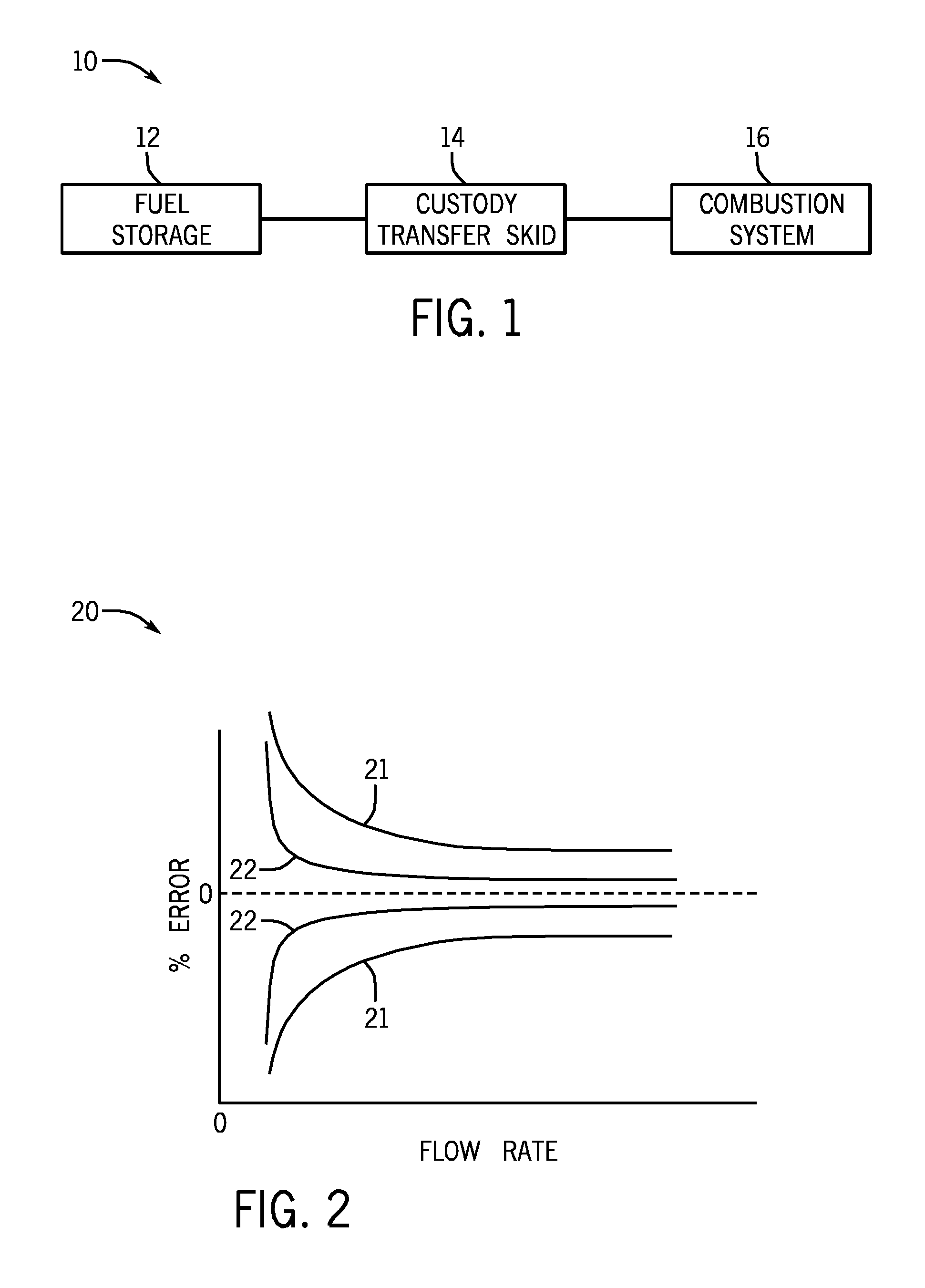

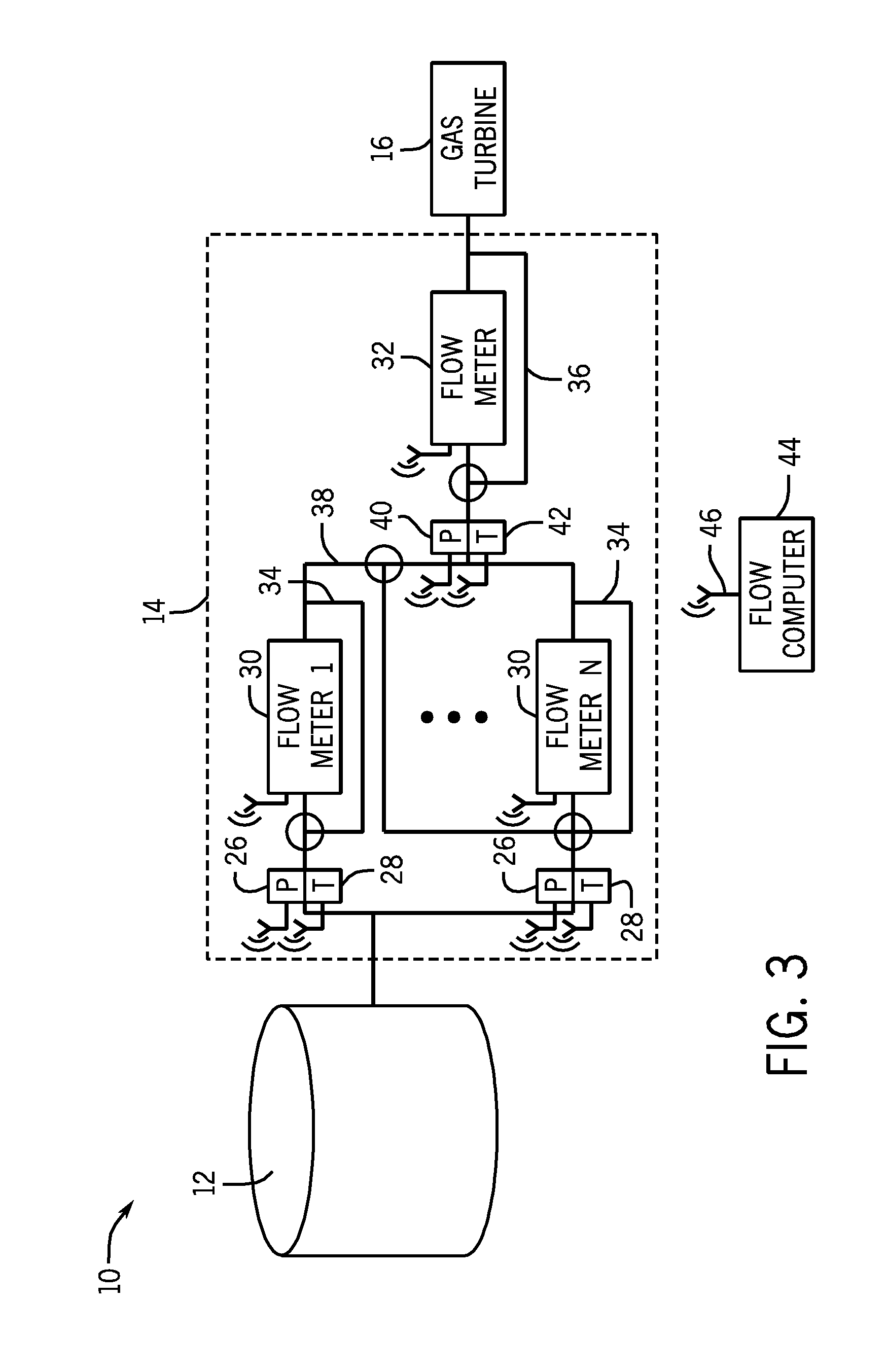

Custody transfer system and method for gas fuel

InactiveUS9175810B2Volume variation compensation/correction apparatusVolume flow proportion measurementTransfer systemProcess engineering

A system includes a custody transfer system configured to transfer a gas fuel from a gas supply to a plurality of gas turbines. The custody transfer system includes a first plurality of flow meters arranged in parallel with each other, wherein each of the first plurality of flow meters is configured to obtain a first measurement of a portion of a flow rate of the gas fuel flowing through the custody transfer system, and a second plurality of flow meters in series with the first plurality of flow meters, wherein each of the second plurality of flow meters is configured to obtain a second measurement of the flow rate of the gas fuel flowing through the custody transfer system, and wherein each of the first and second plurality of flow meters is configured to be blocked or unblocked from receiving the gas fuel based on a number of the plurality of gas turbines in operation.

Owner:GENERAL ELECTRIC CO

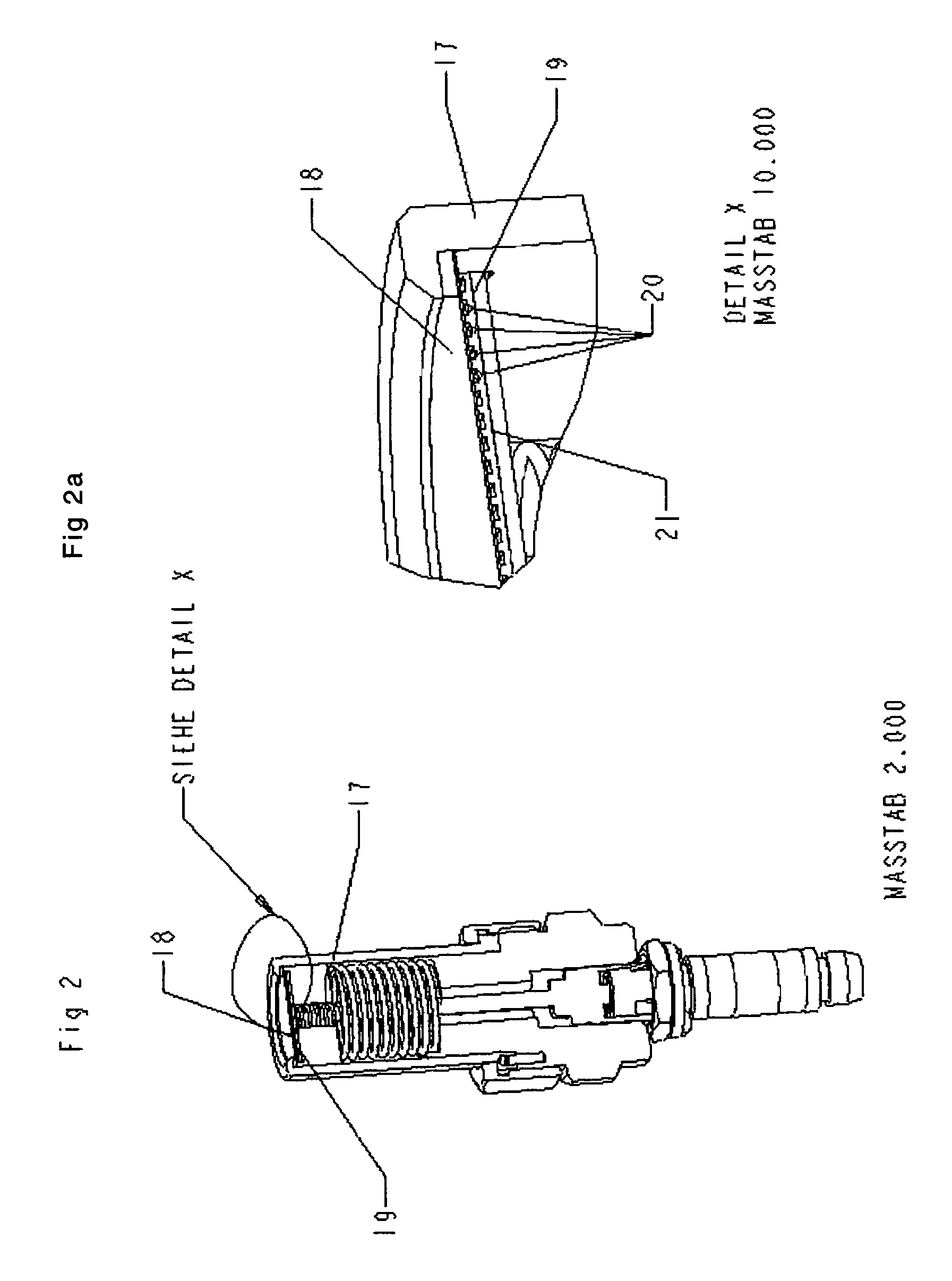

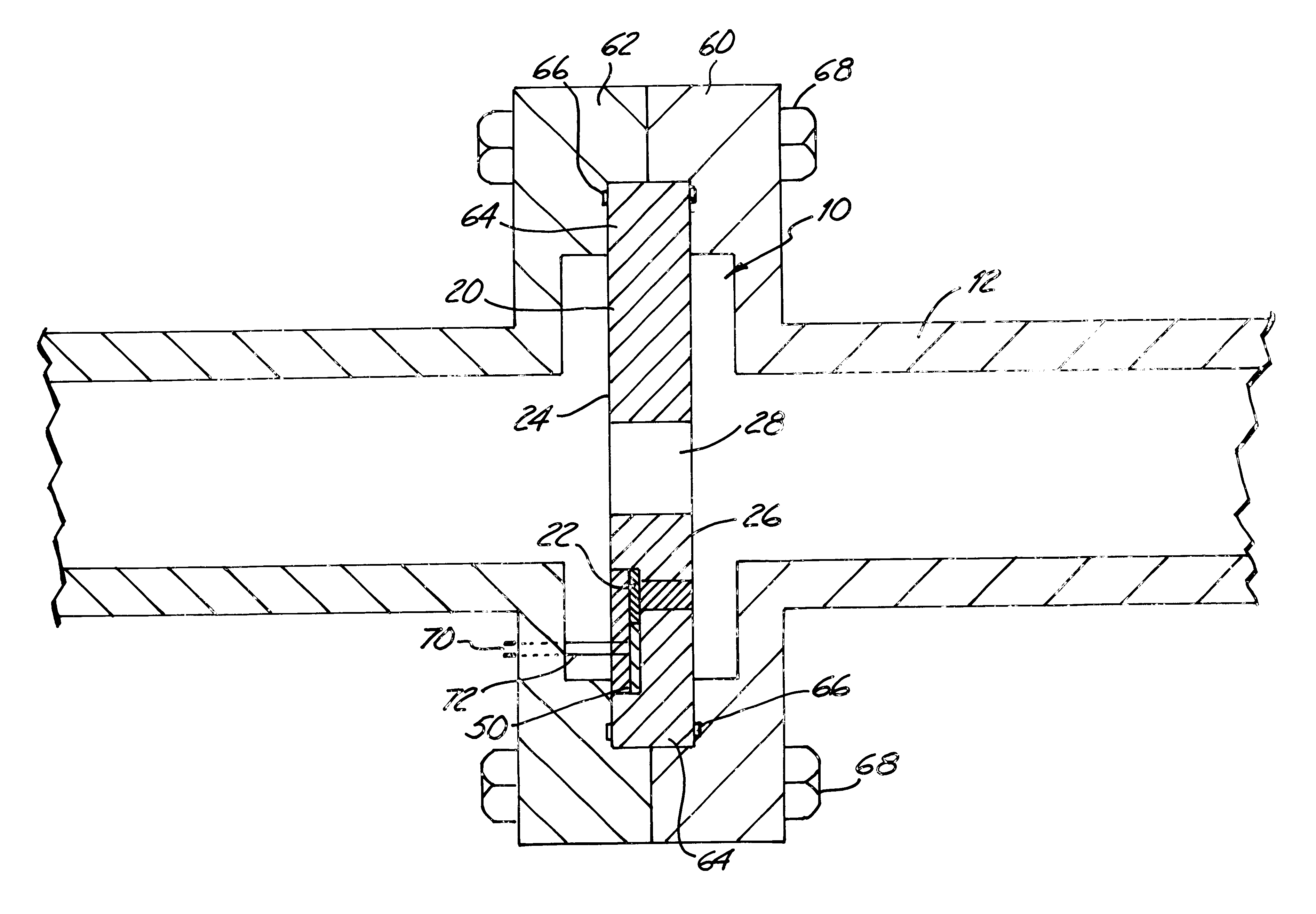

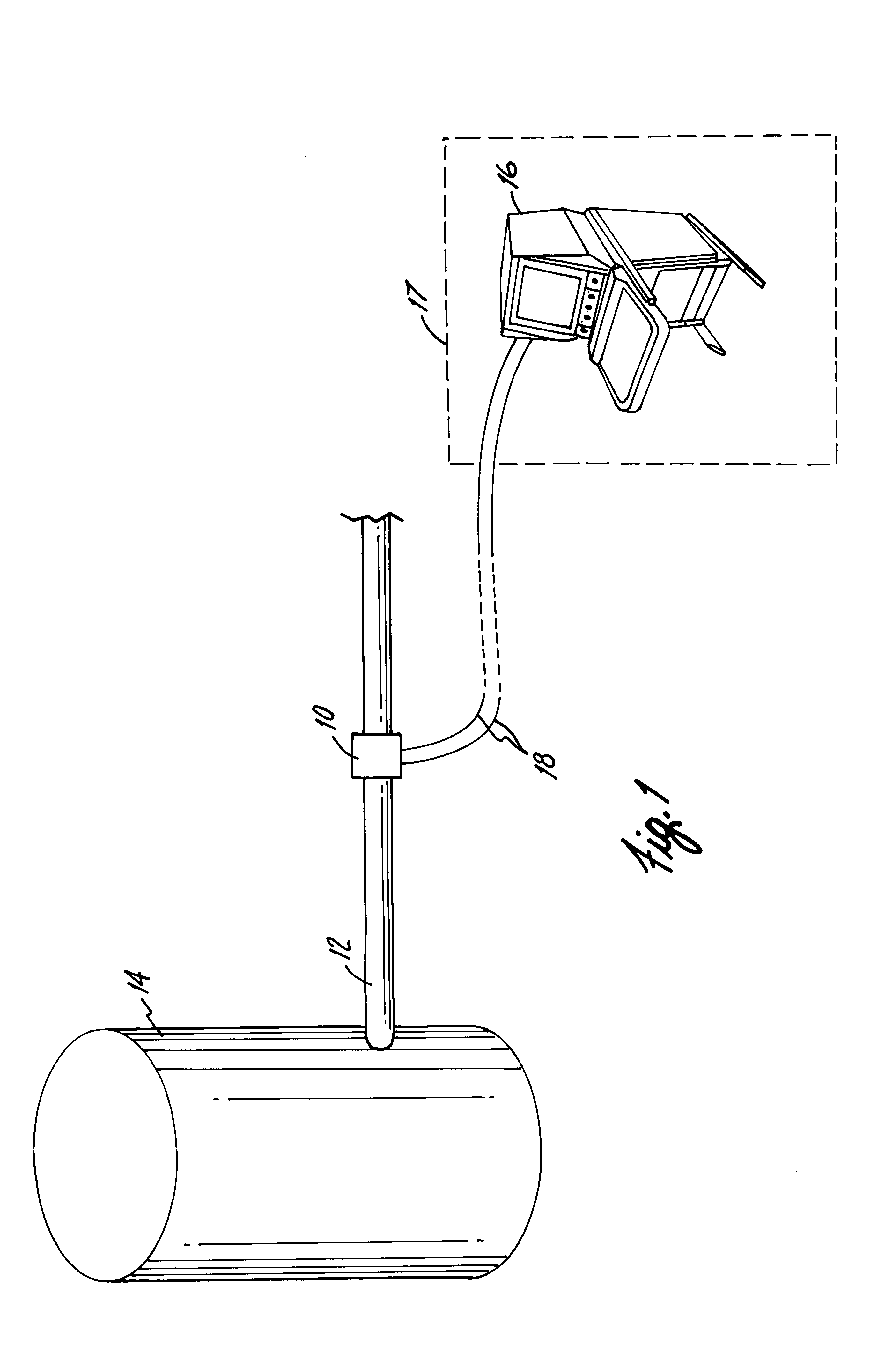

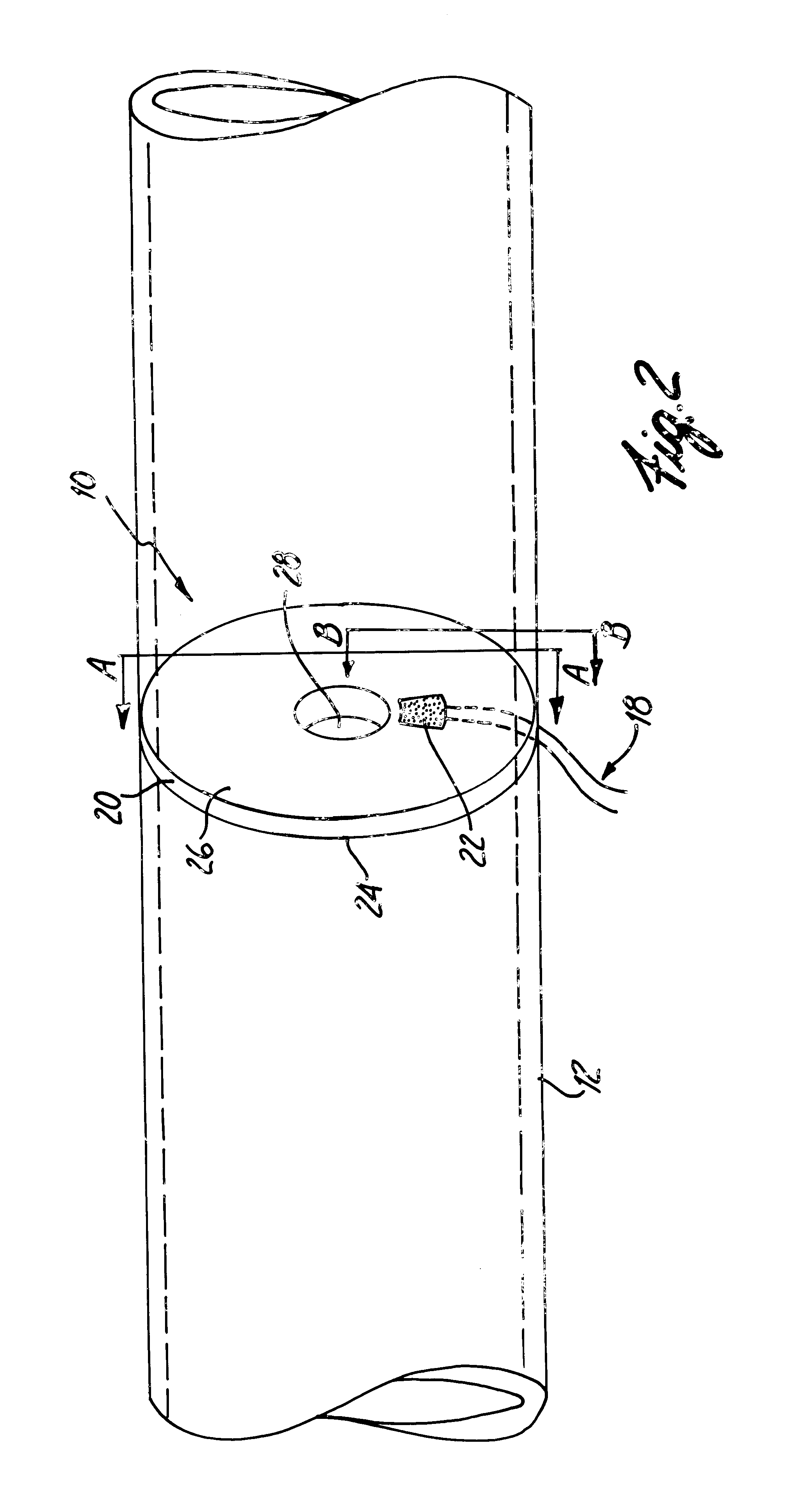

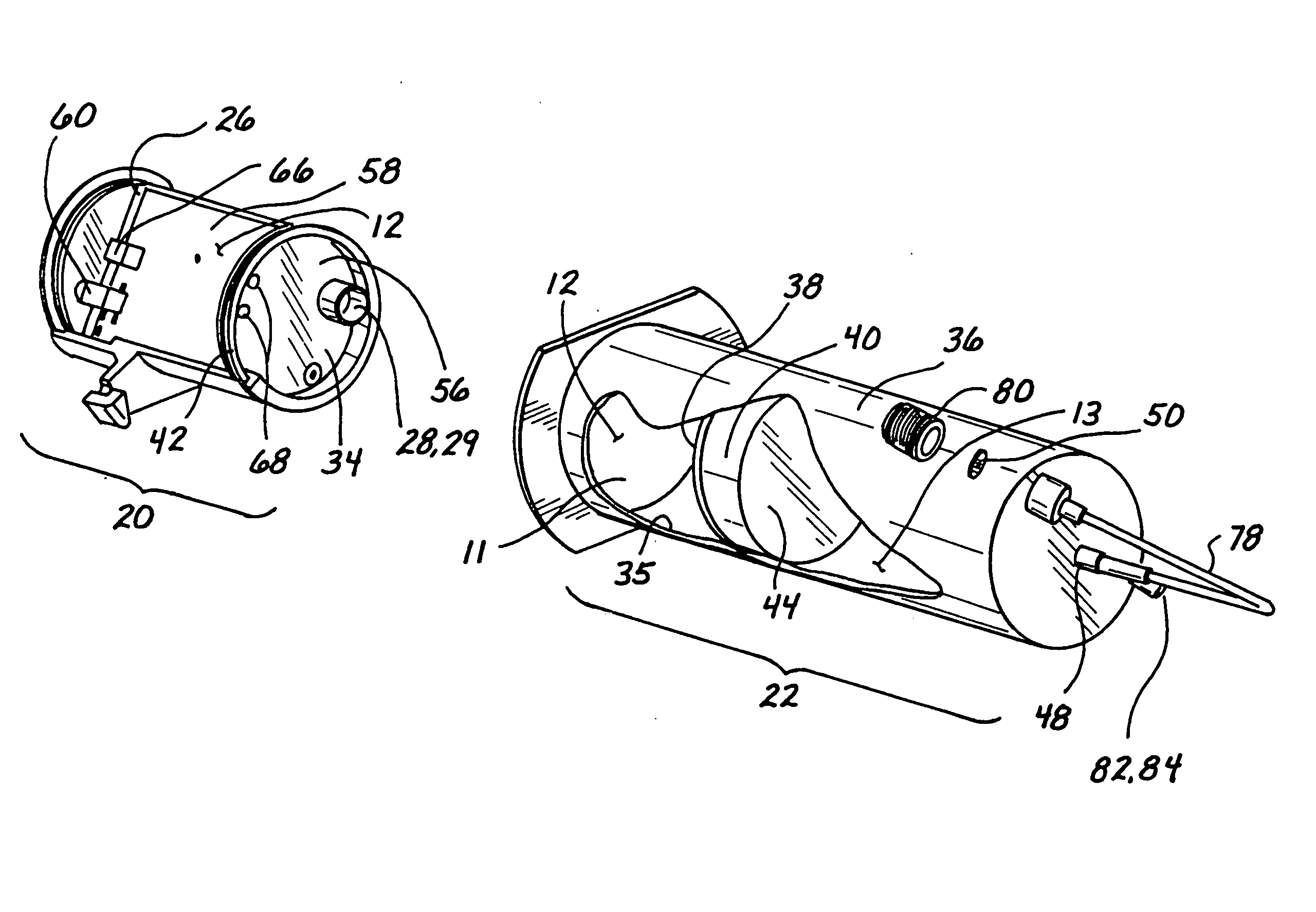

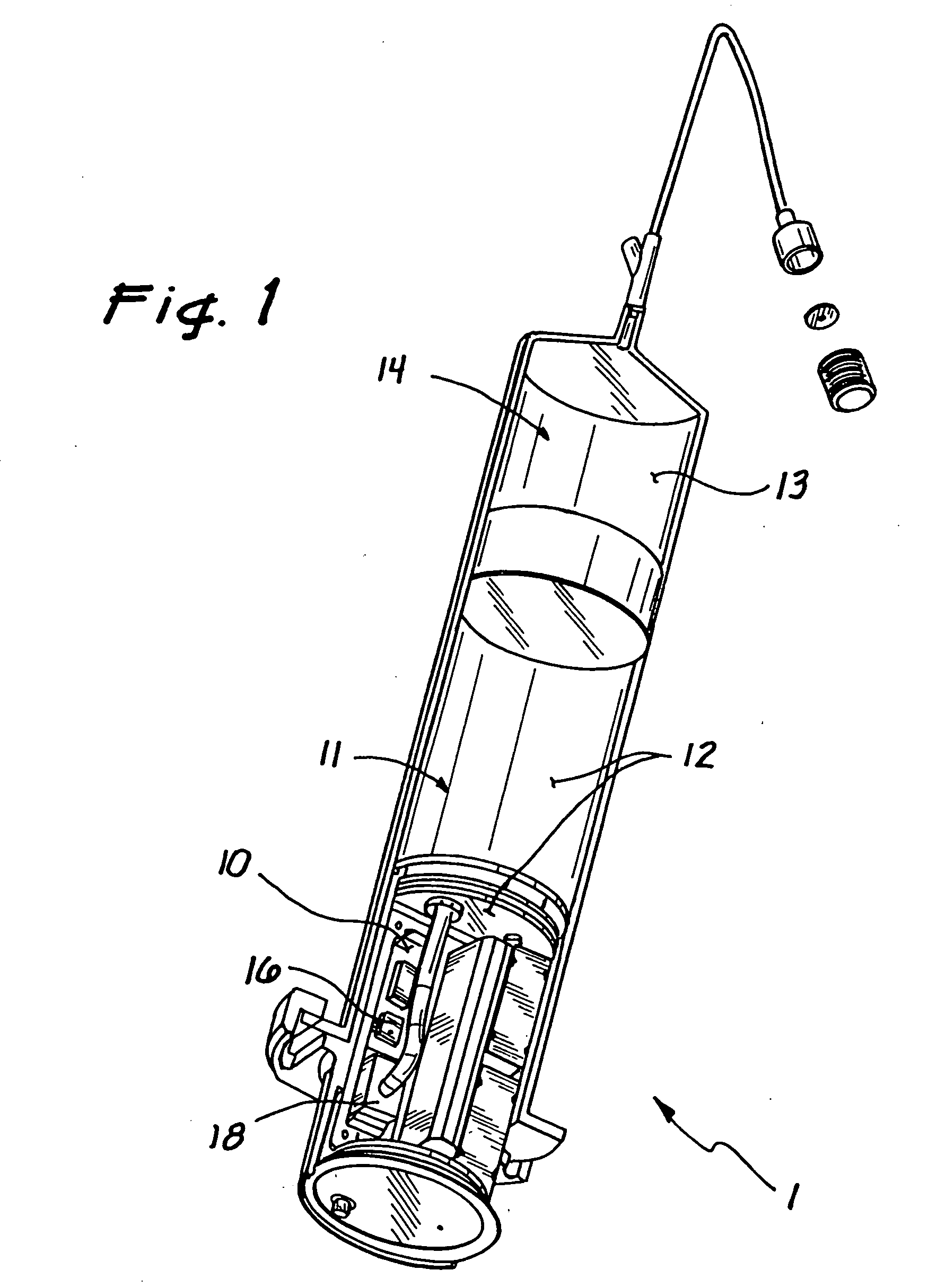

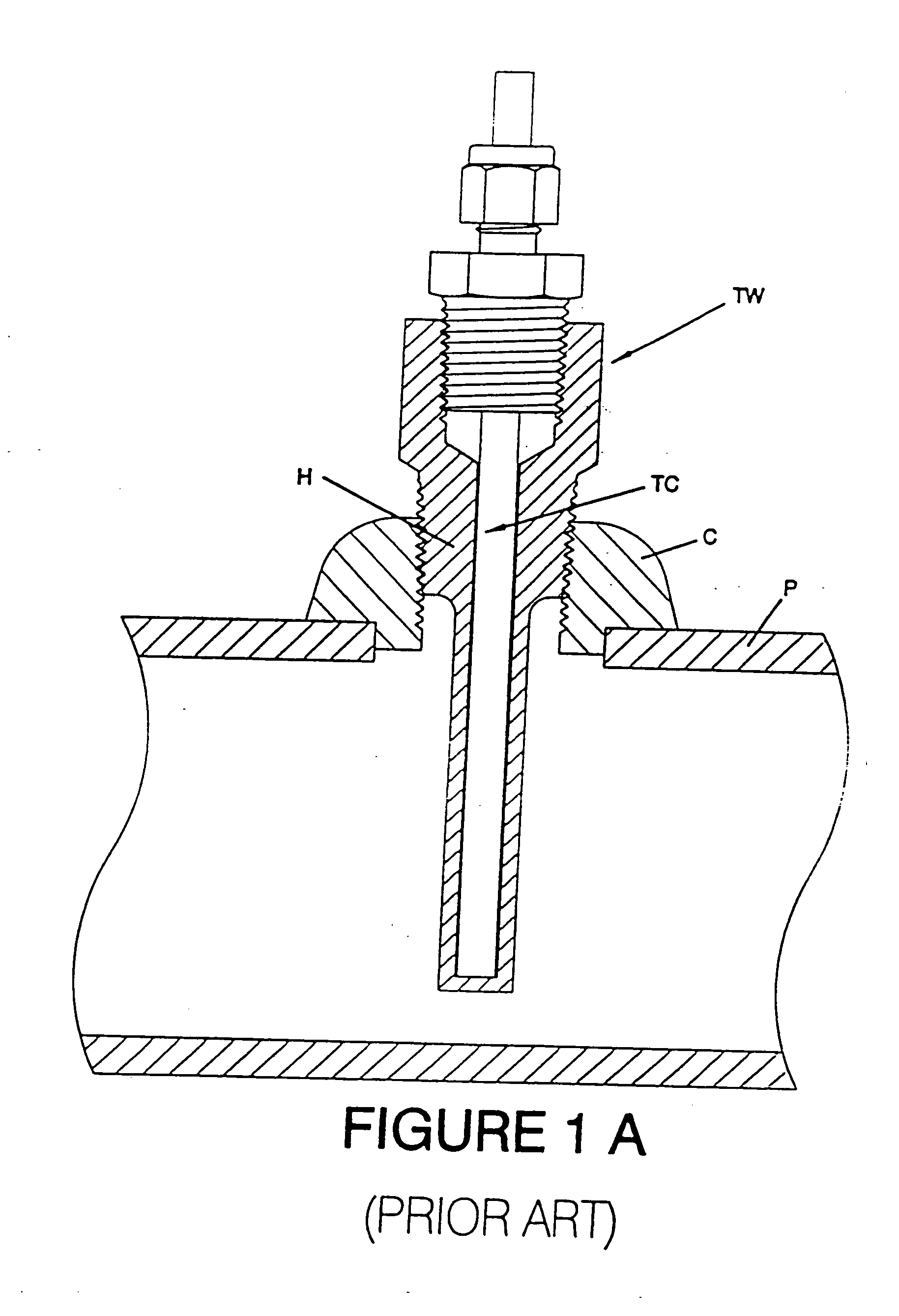

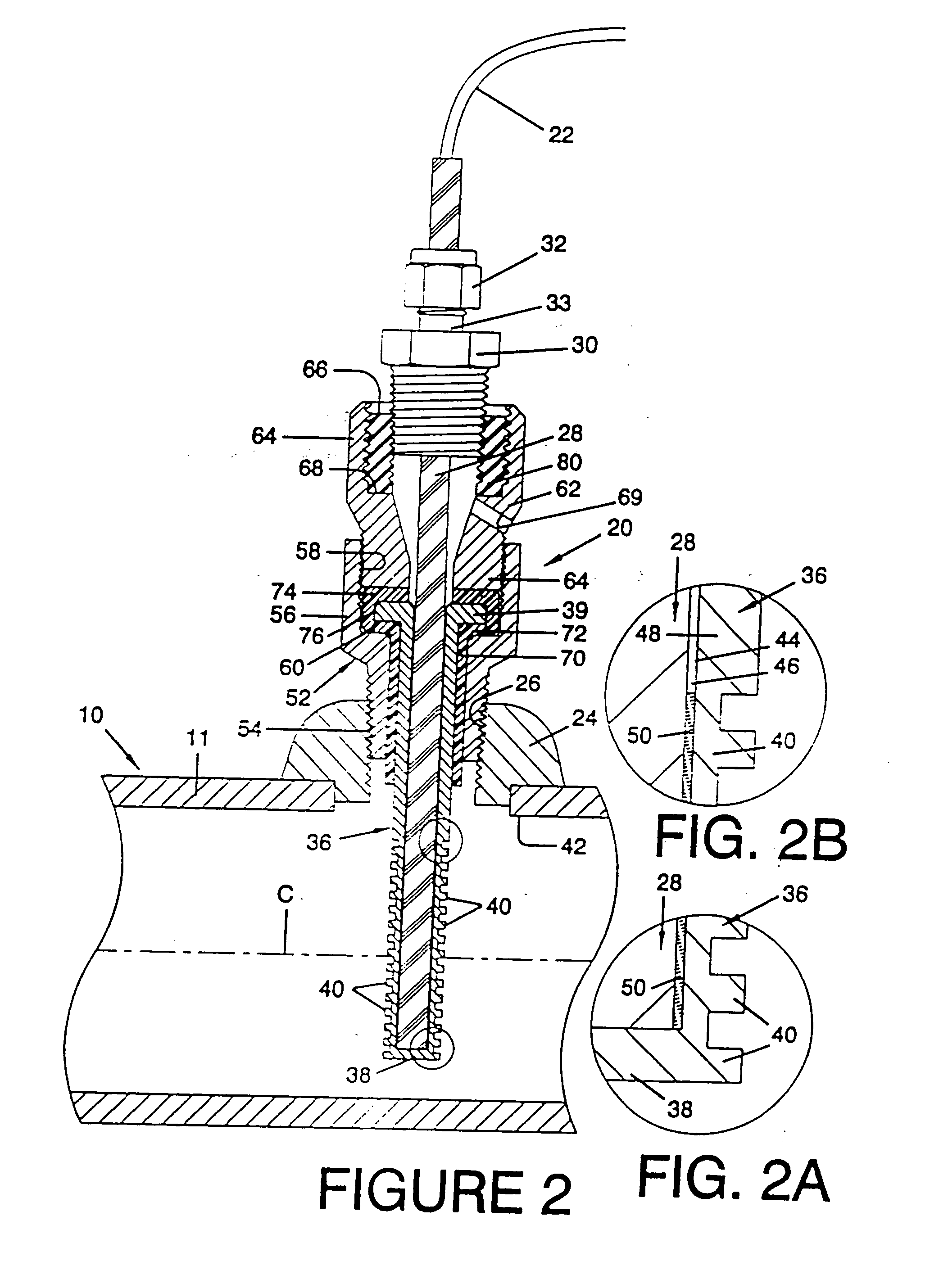

Temperature sensing device for metering fluids

InactiveUS20050038172A1Improve thermal conductivityImproves rate of temperature transferThermometer detailsThermometers using electric/magnetic elementsThermowellAnnular fin

A thermowell assembly (20) shown in FIG. 2 is positioned in a pipeline (10) for sensing the temperature of the fluid medium in the pipeline (10) for transmitting the sensed temperature to a meter (12). A temperature sensing probe is received within a temperature conducting tube (36) forming a thermowell and having a plurality of annular fins (40) extending thereabout. In the embodiments of FIGS. 1-7, a liquid (50) is provided in an annular space between the thermocouple (28) and the temperature conducting tube (36). Non-metallic members (70, 74, 80) are positioned between the pipeline (10) and the temperature transmitting tube (36) to isolate thermocouple (28) from ambient changes in the temperature of metal pipeline (10) which may result in an error in the temperature of the flow medium sensed by the thermowell assembly (20). High temperature embodiments shown in FIGS. 4 and 5 do not contain any non-metal components and provide a minimal metal to metal contact between the metallic temperature conducting tube (36B) of the thermowell (20B) and the adjacent metal mounting structure (52B, 62B). The embodiments shown in FIGS. 8-12 illustrate a temperature sensing probe comprising a temperature sensing assembly (80F, 80G) mounted within the internal bore (37F, 37G) of the finned tube (36F, 36G). The temperature sensing assembly (80F, 80G) includes a carrier (82F, 81G) with epoxy (96F, 96G) mounting a temperature sensing element (93F, 93G) within the carrier (82F, 81G).

Owner:PARKER INTANGIBLES LLC

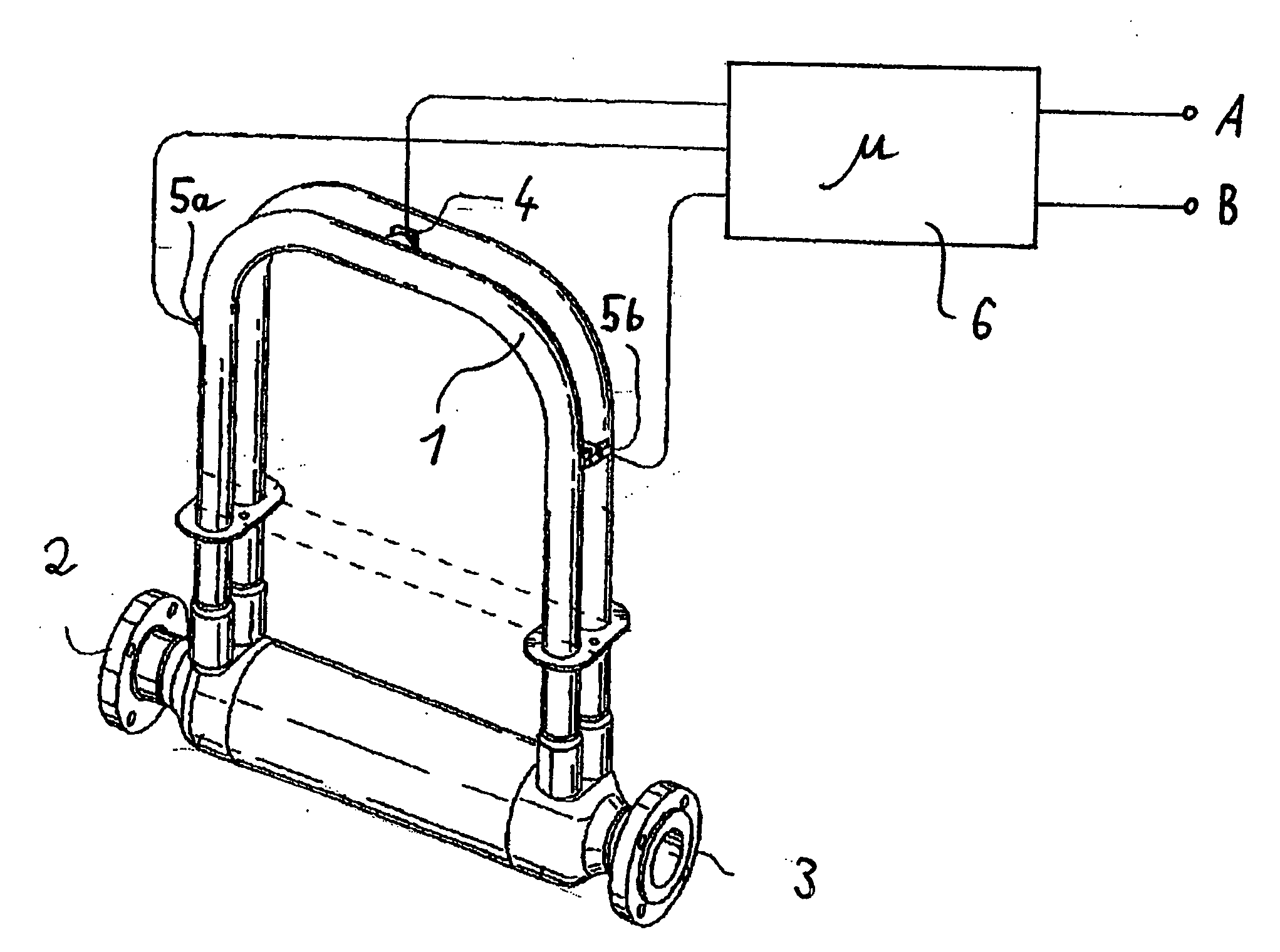

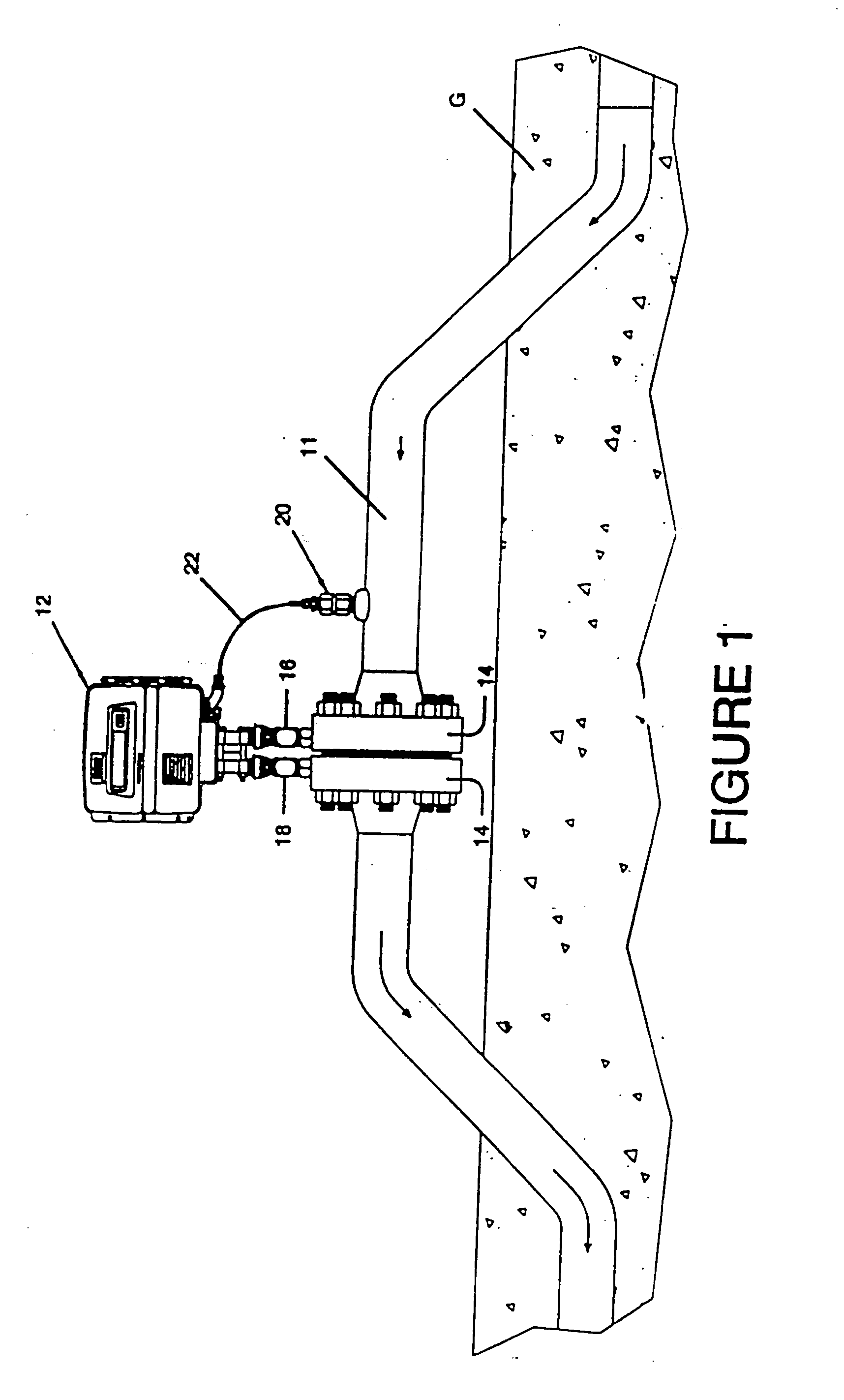

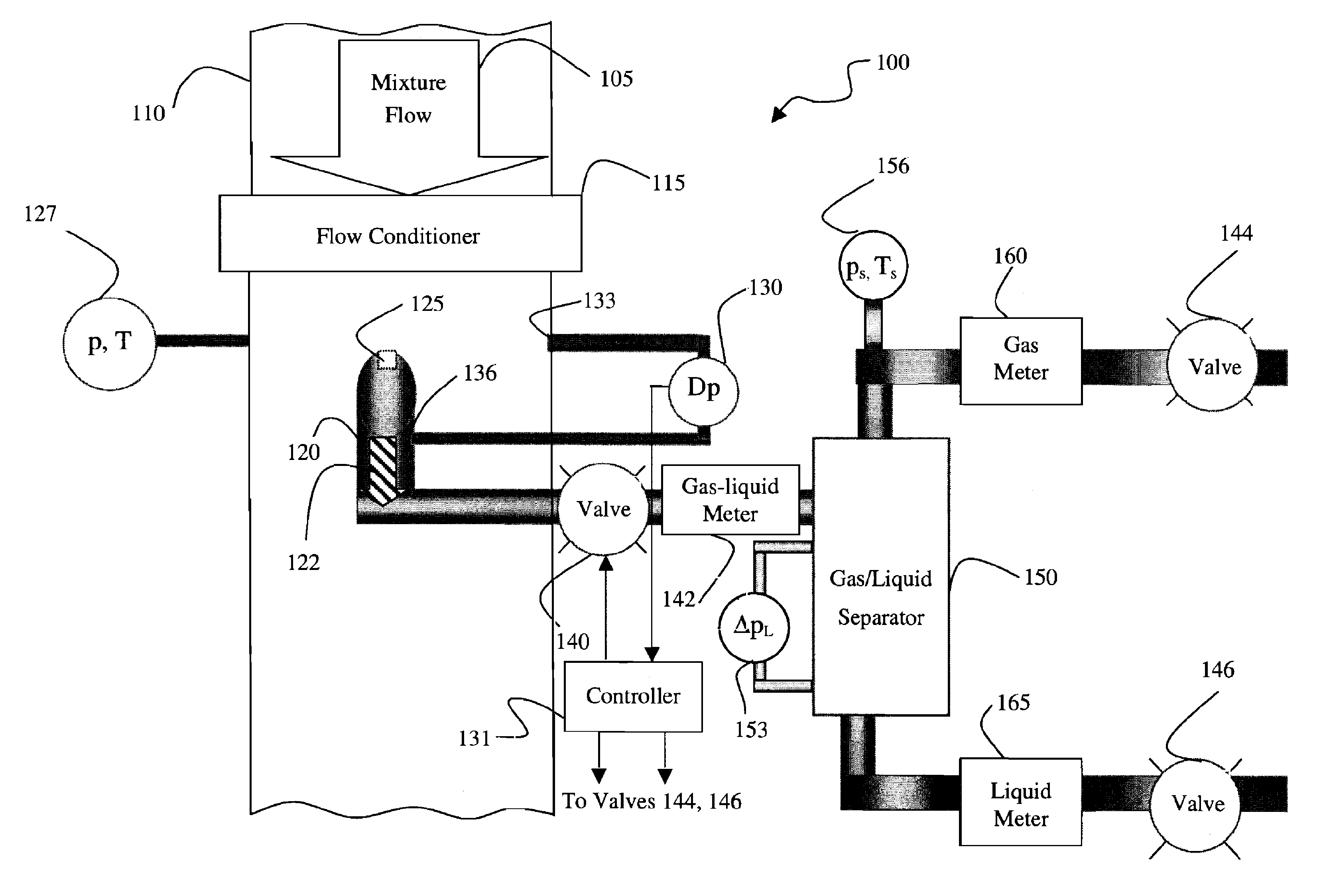

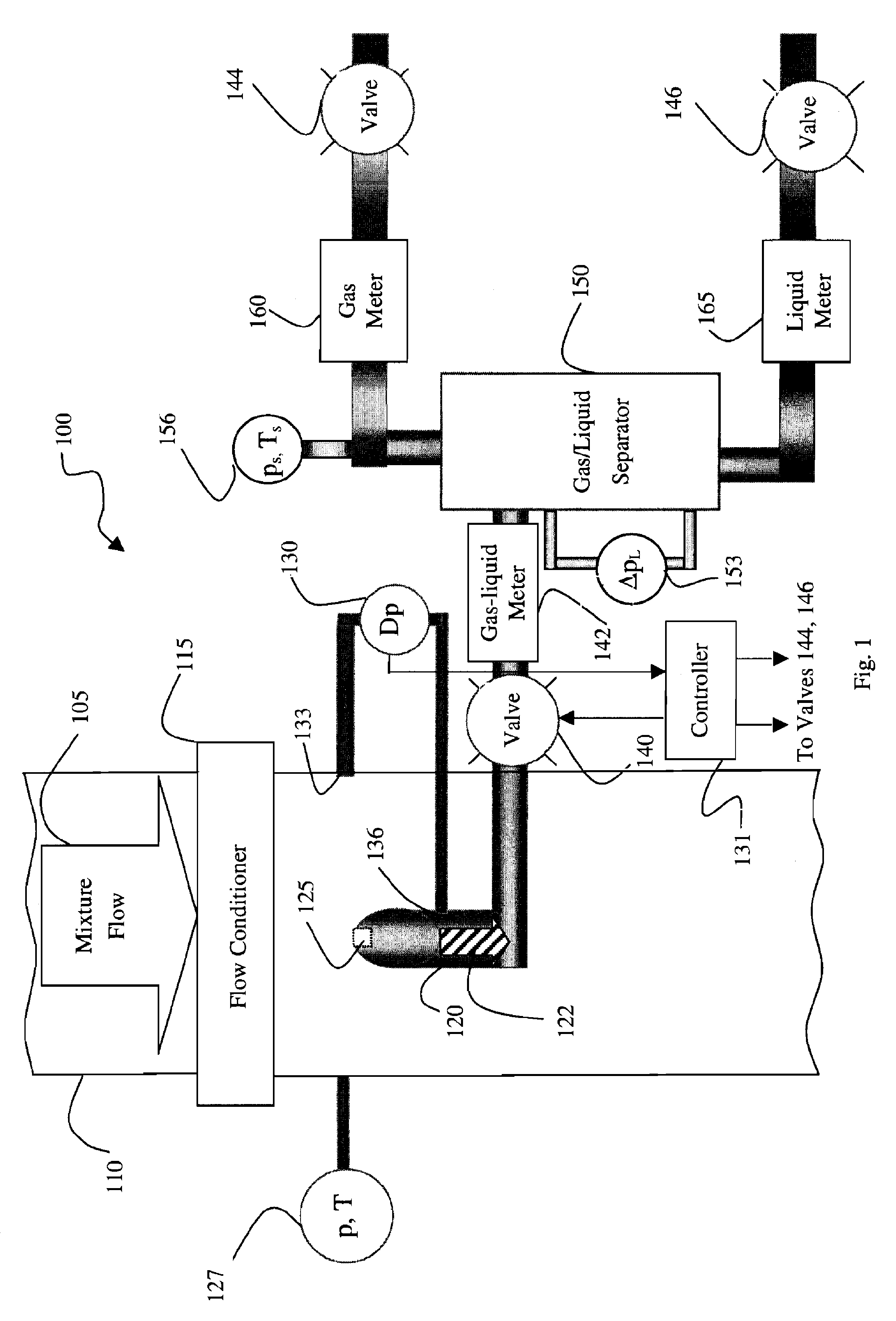

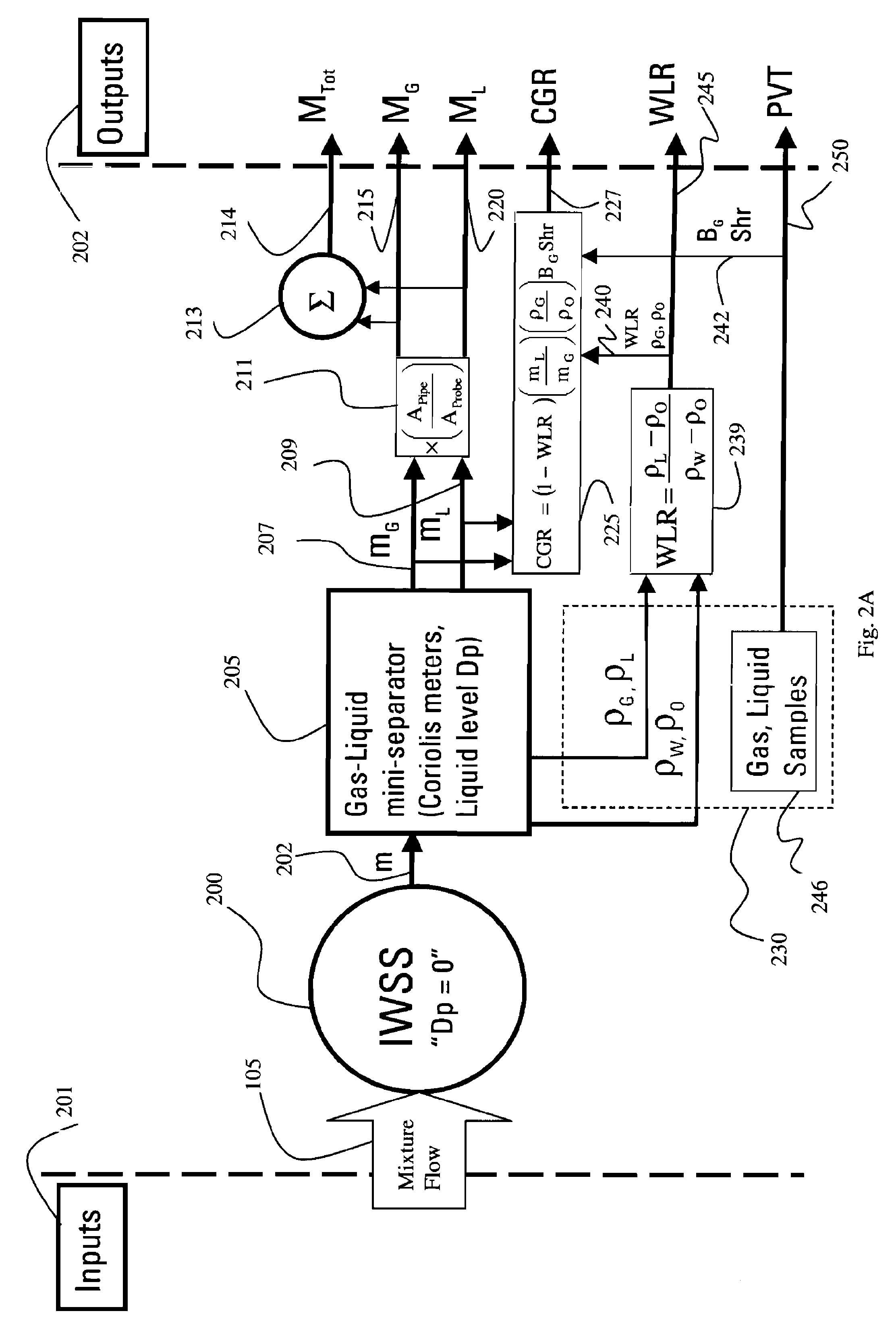

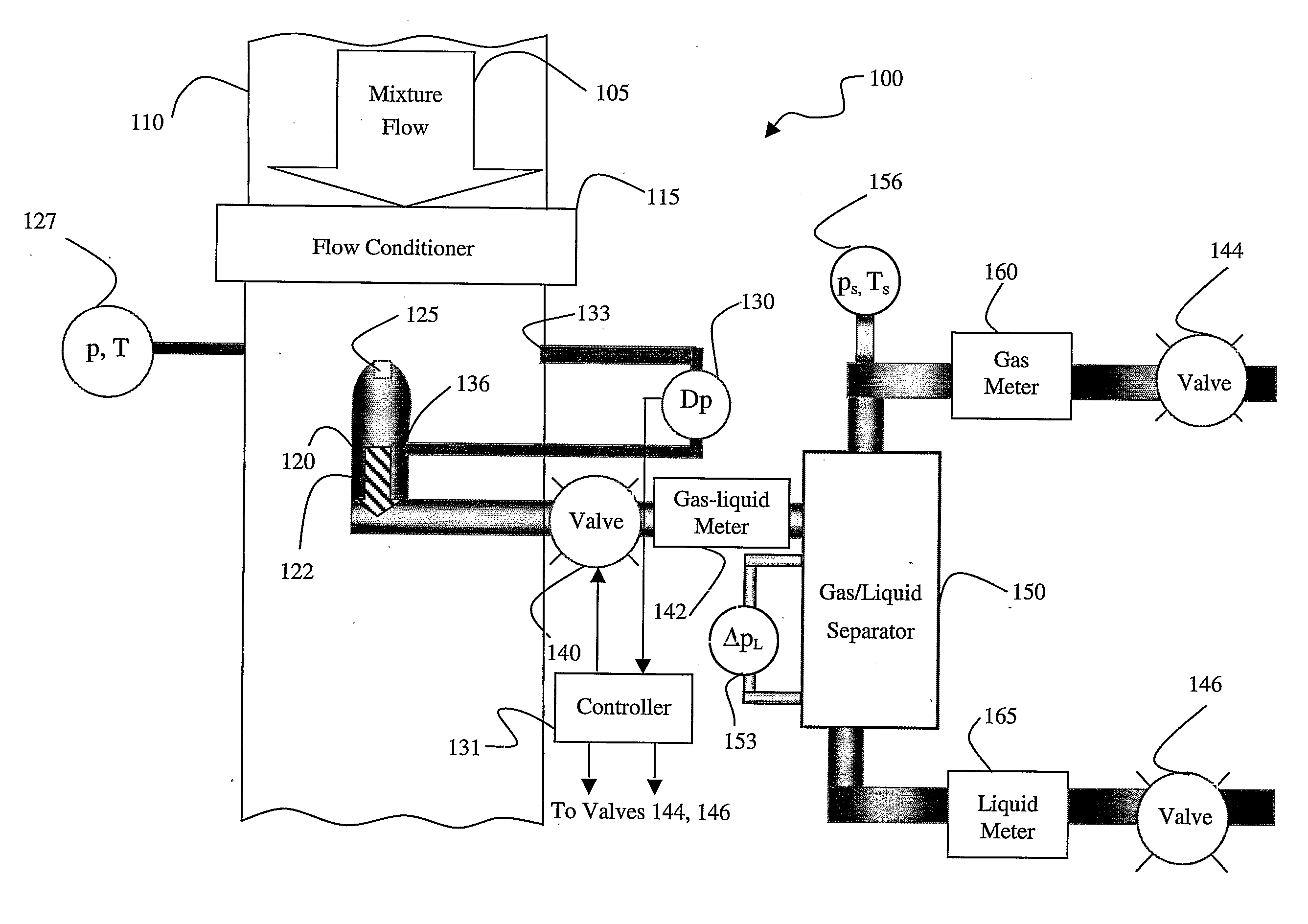

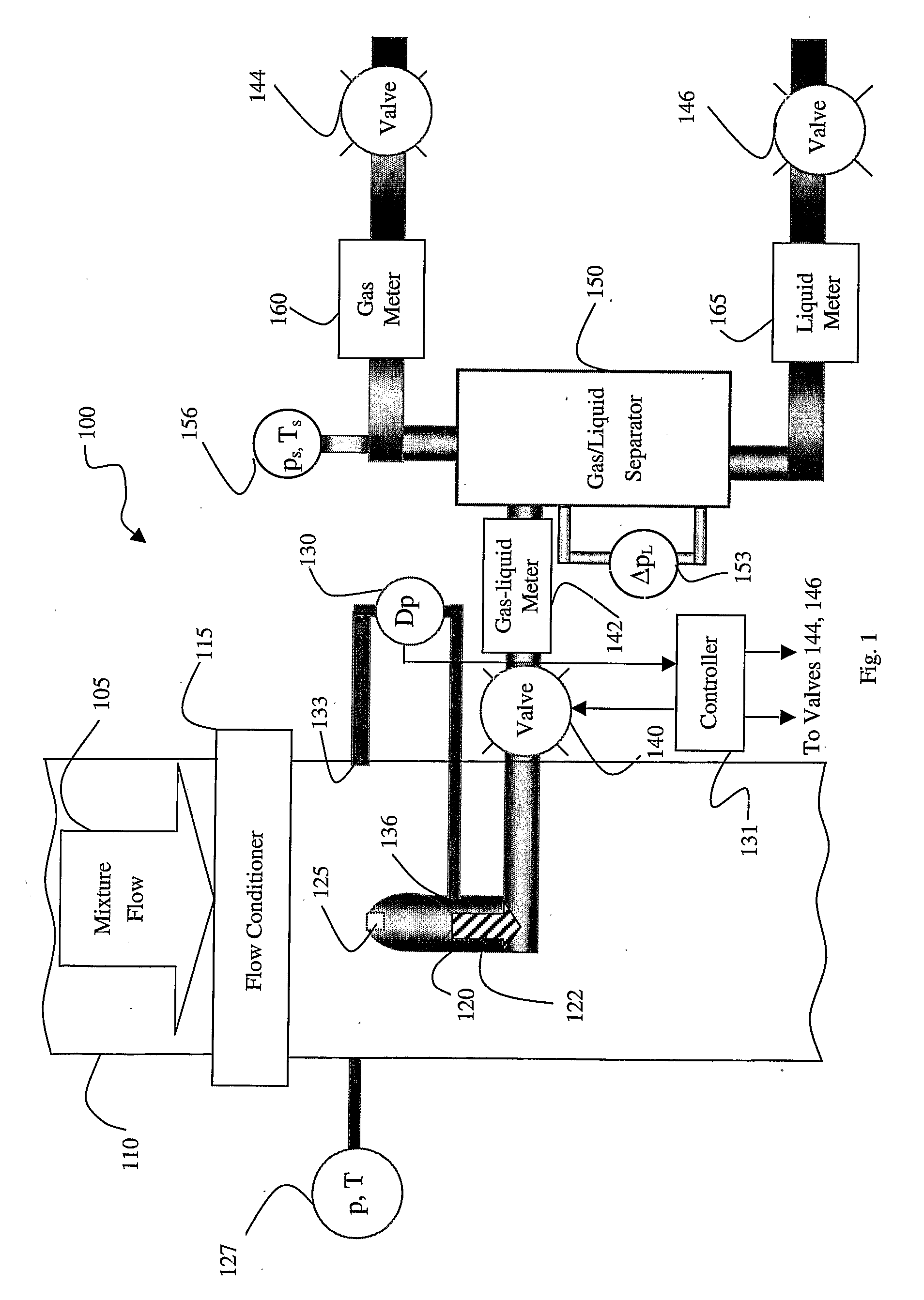

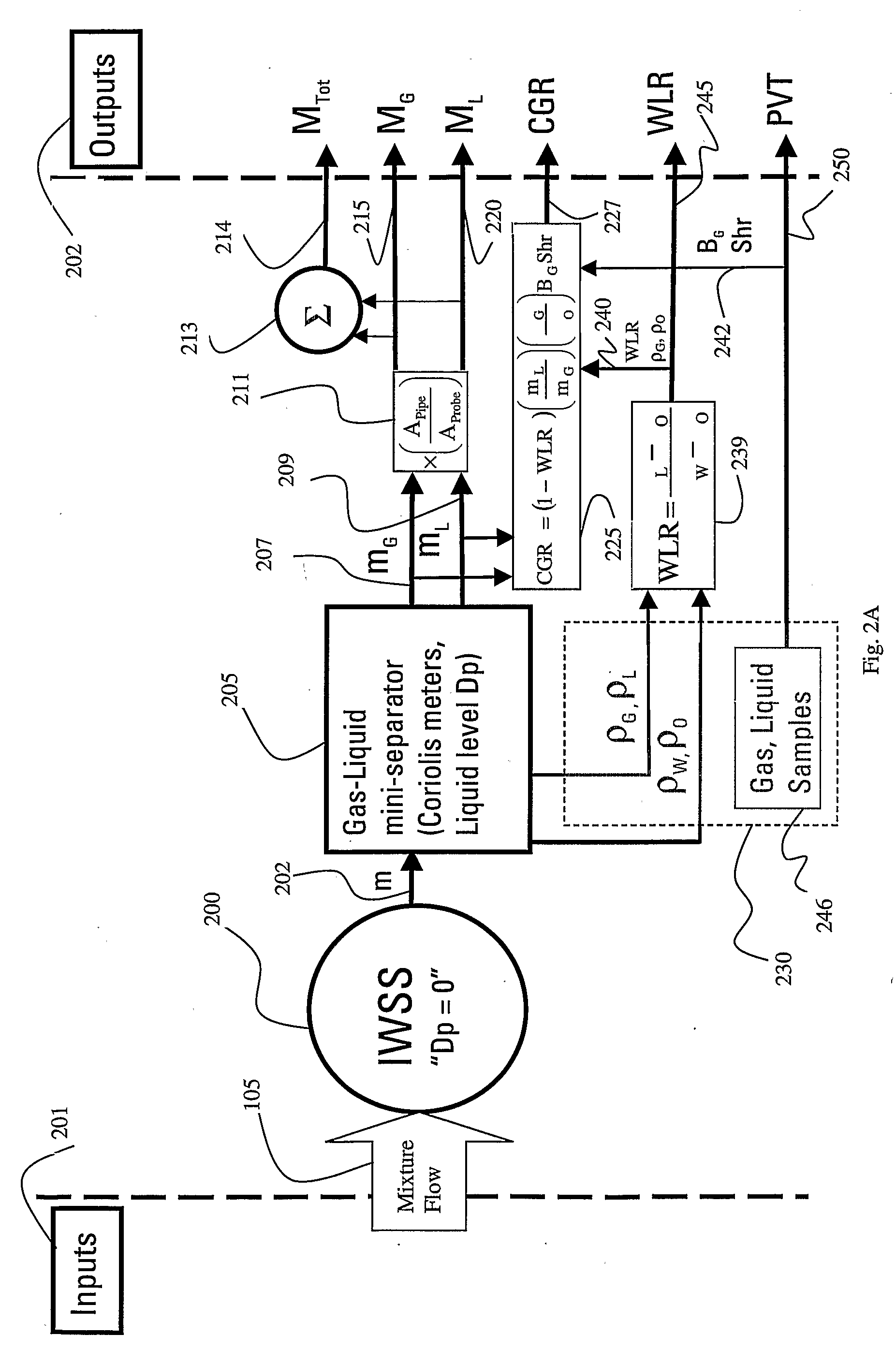

Isokinetic sampling method and system for multiphase flow from subterranean wells

InactiveUS7942065B2Withdrawing sample devicesVolume/mass flow measurementNuclear radiationControl flow

The invention relates in a one aspect to a method or apparatus for measuring flow properties of a multiphase fluid stream flowing in a pipeline comprising means for sampling, with a sampling probe, a portion of the fluid stream; for measuring a differential pressure between a first pressure of the fluid stream in the pipeline and a second pressure of the portion of the fluid stream in the sampling probe; for controlling flow rate of the sampled portion, wherein the flow rate of the sampled portion is controlled to provide for nullification of the differential pressure in order to obtain substantially isokinetic sampling of the fluid stream; for measuring properties of the portion of the fluid stream; and for processing the measured properties to determine the flow properties of the multiphase fluid stream flowing in the pipeline, wherein the above elements do not require- or are performed without the determination of the density of fluid in the fluid stream through nuclear radiation methods.

Owner:SCHLUMBERGER TECH CORP

Isokinetic sampling method and system for multiphase flow from subterranean wells

InactiveUS20090139345A1Volume/mass flow measurementVolume variation compensation/correction apparatusNuclear radiationControl flow

The invention relates in a one aspect to a method or apparatus for measuring flow properties of a multiphase fluid stream flowing in a pipeline comprising means for sampling, with a sampling probe, a portion of the fluid stream; for measuring a differential pressure between a first pressure of the fluid stream in the pipeline and a second pressure of the portion of the fluid stream in the sampling probe; for controlling flow rate of the sampled portion, wherein the flow rate of the sampled portion is controlled to provide for nullification of the differential pressure in order to obtain substantially isokinetic sampling of the fluid stream; for measuring properties of the portion of the fluid stream; and for processing the measured properties to determine the flow properties of the multiphase fluid stream flowing in the pipeline, wherein the above elements do not require- or are performed without the determination of the density of fluid in the fluid stream through nuclear radiation methods.

Owner:SCHLUMBERGER TECH CORP

Water Meter and Leak Detection System

ActiveUS20190234786A1Long wireless range capabilityMeasurement of fluid loss/gain rateData processing applicationsWi-FiTTEthernet

The present invention is a water meter and leak detection system that has a private or public property(ies) facility water supply interruption system. The system is comprised of a water meter collection node system with shut-off / on mechanism that has wireless Bluetooth, Bluetooth low energy, Zigbee, Z-wave LoRa, Wi-Fi, radio frequency and cellular technology with a private or corporate network, or internet connection that transfer water parameter data to a remote computer or server. Or the system can consist of a water meter collection node that communicates by Bluetooth, Bluetooth low energy, Zigbee, Z-wave LoRa, Wi-Fi, radio frequency and cellular technology with a data communication hub whereby the communication hub is in wired or wireless communication with an internet router that communicates with an internet connection, or with a private or commercial network system, to a remote computer / server or a cloud-computing commercial service.

Owner:REIN TECH INC

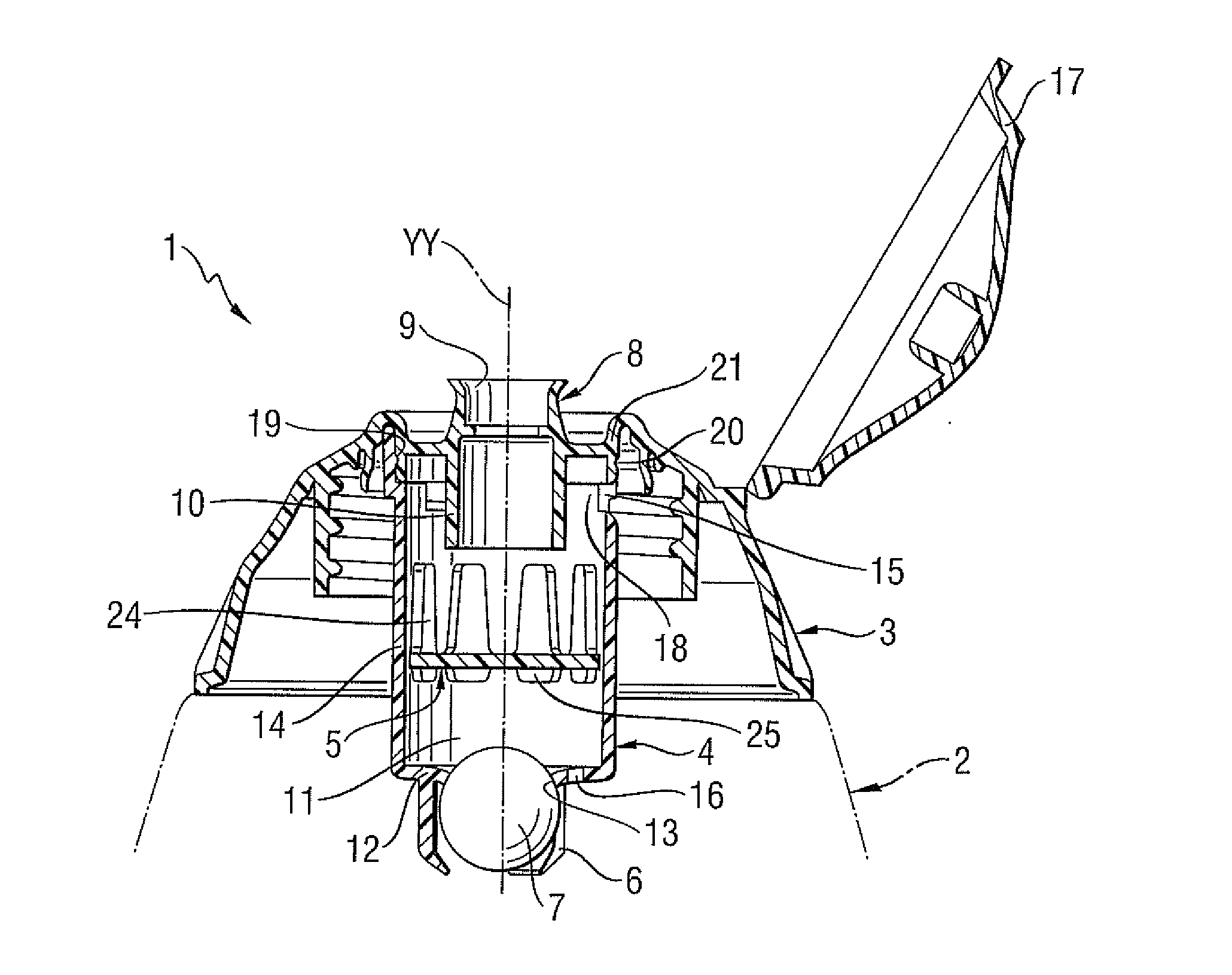

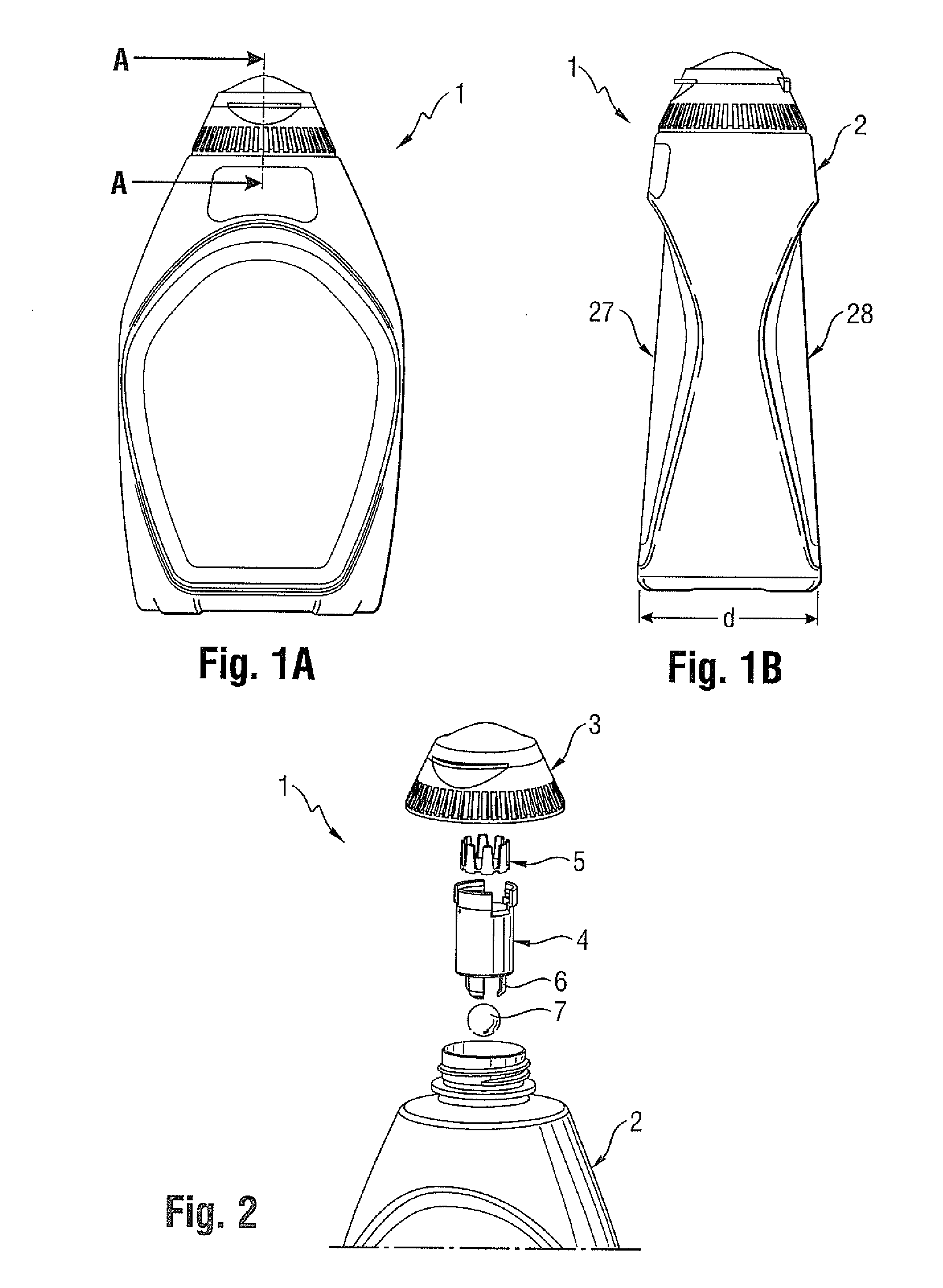

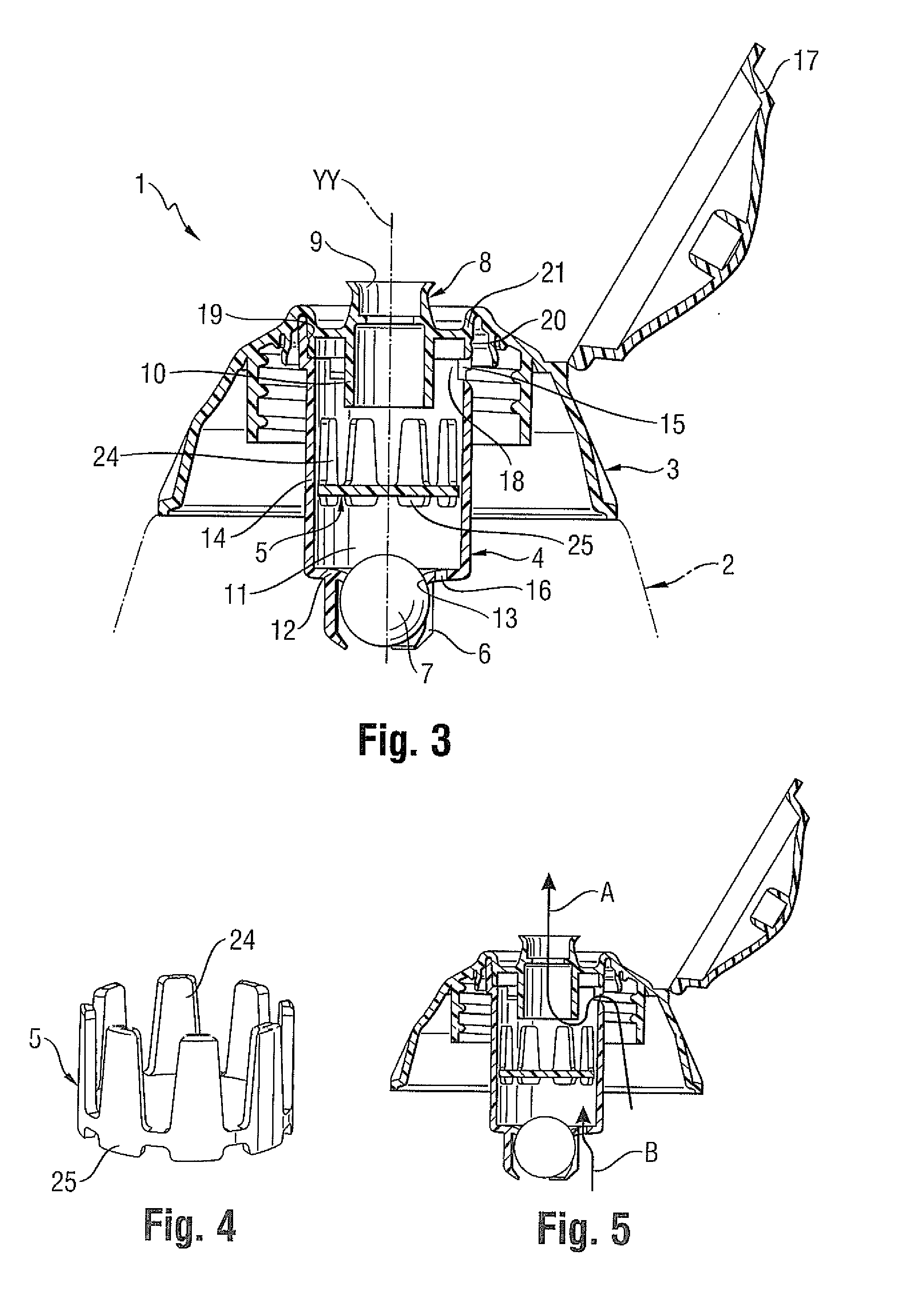

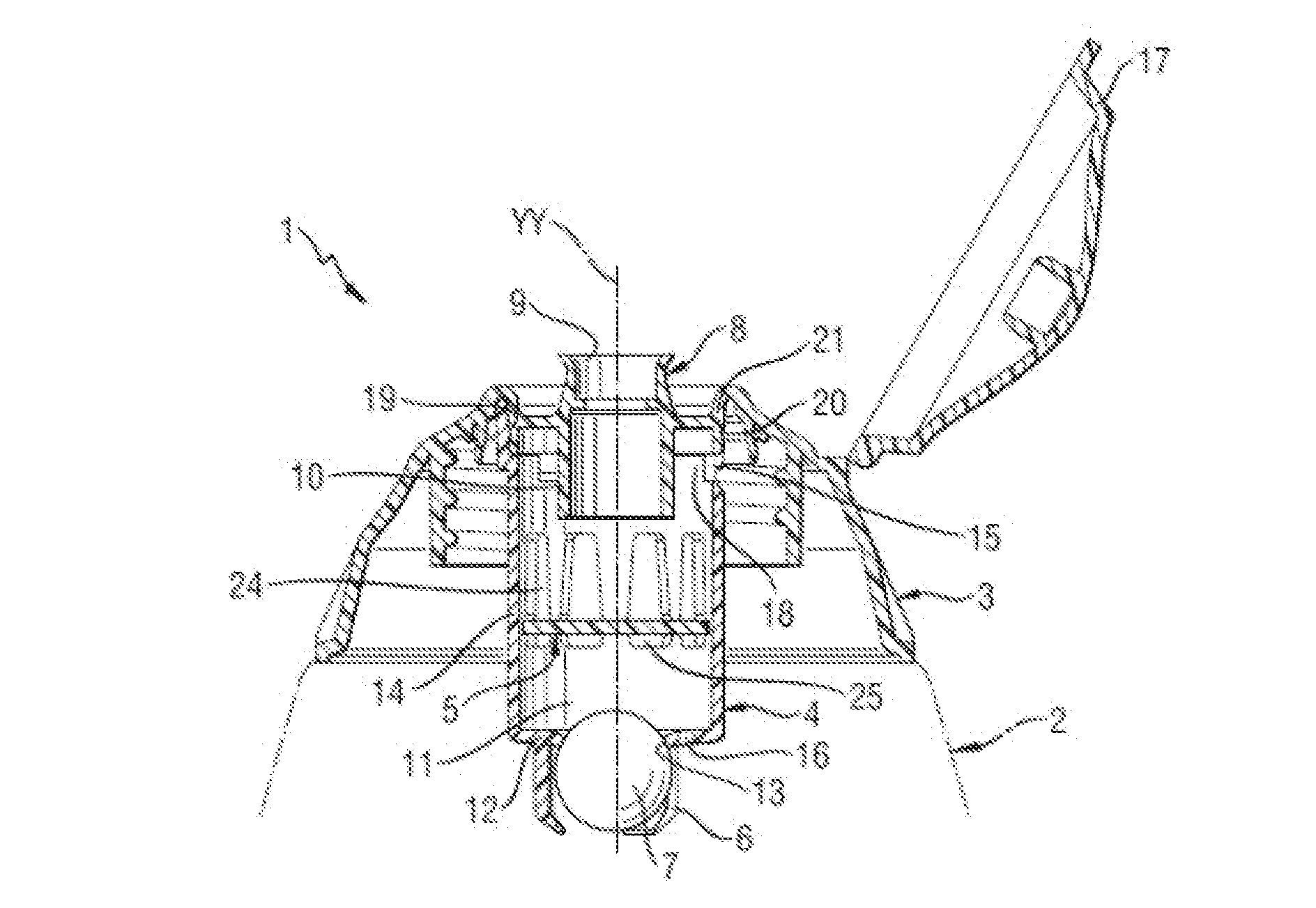

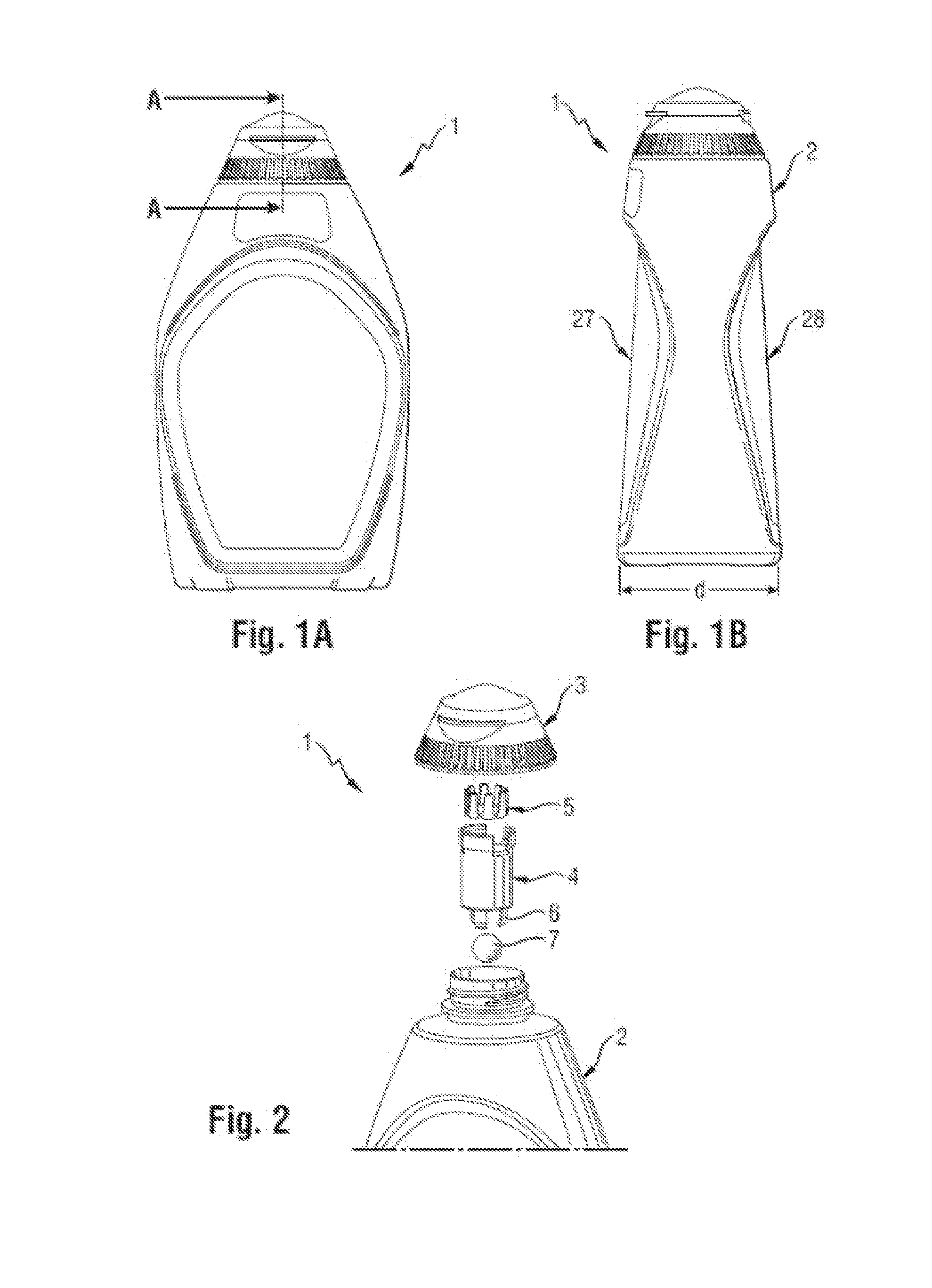

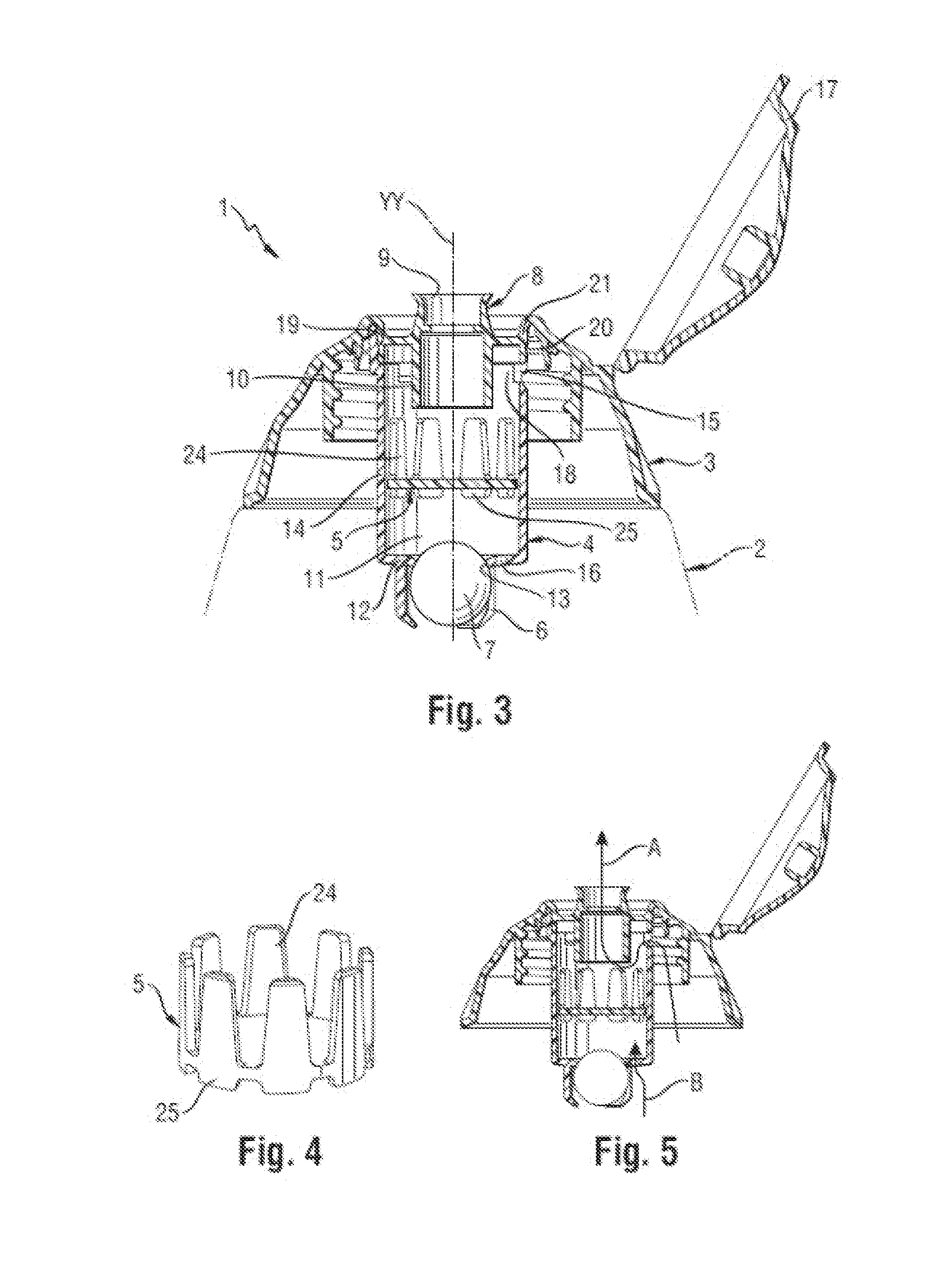

Liquid dosing apparatus

ActiveUS20120097714A1Constant dosageContracting/expanding measuring chambersClosuresBiomedical engineering

Owner:THE PROCTER & GAMBLE COMPANY

Sensor Structure

ActiveUS20110072894A1Accurate inductionReduce power consumptionInternal-combustion engine testingElectrical controlElectrical resistance and conductanceThermal radiation

The present invention utilizes self-heating of electronic components to improve a humidity sensing part with low environment resistance, such as a condensation problem and the like, and also to enhance the heat radiation efficiency of electronic components. The humidity sensing part is used in an intake tube of an automobile by integrating, for example, with a heating resister type mass air flow measurement device. A humidity sensing element is mounted on an electronic circuit board in a mass air flow measurement device with the temperature thereof starting to increase immediately after a sensor has been actuated. This urges the temperature of the humidity sensing element to start increasing (being heated) immediately after the sensor has been actuated. To urge the humidity sensing element to be further heated, a base plate is composed of two types of materials, resin and metal. A part of the base plate holding an area of the electronic circuit board generating a large quantity of heat is composed of the metal. A part of the base plate corresponding to the periphery of the humidity sensing part which is to be heated is composed of the resin.

Owner:HITACHI ASTEMO LTD

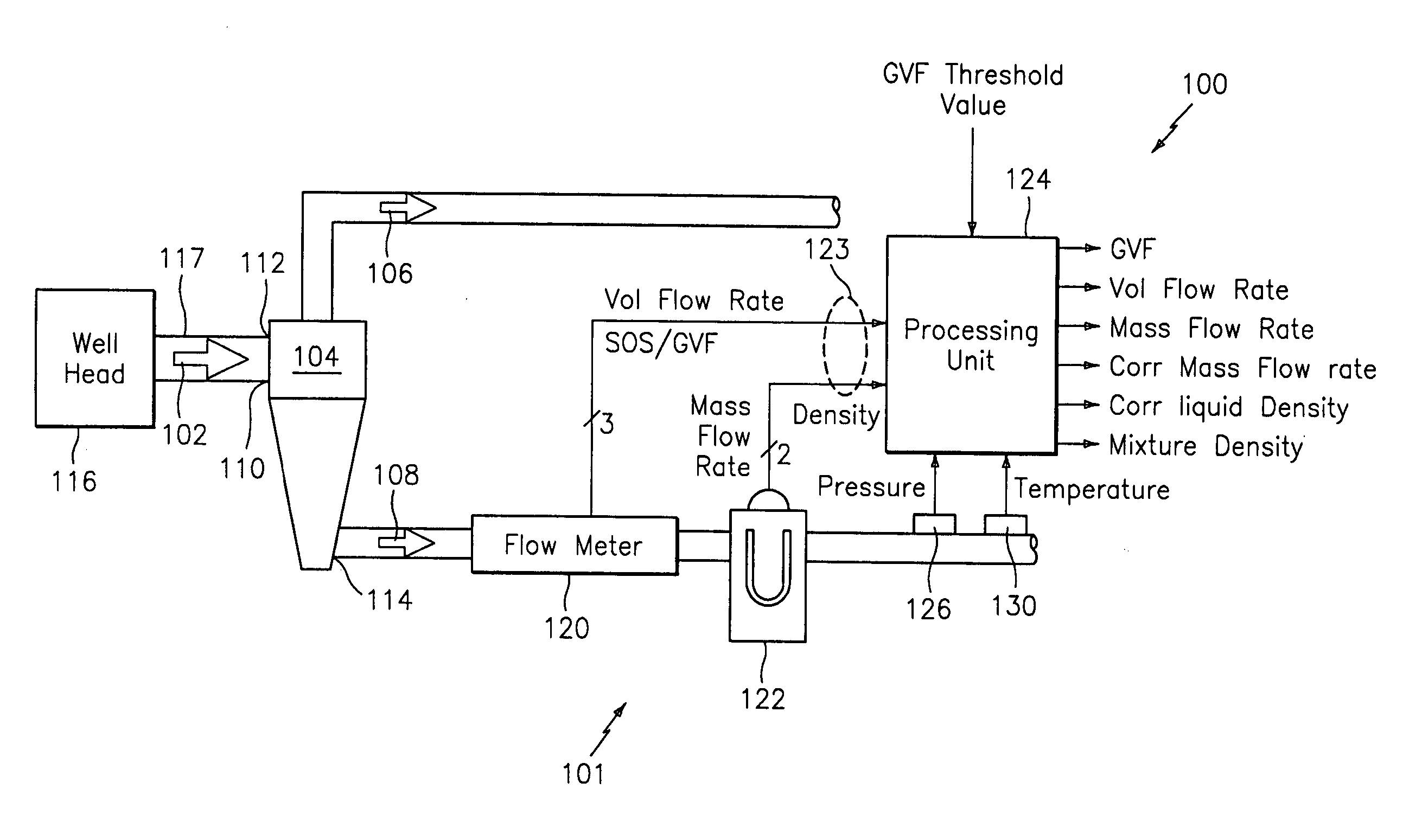

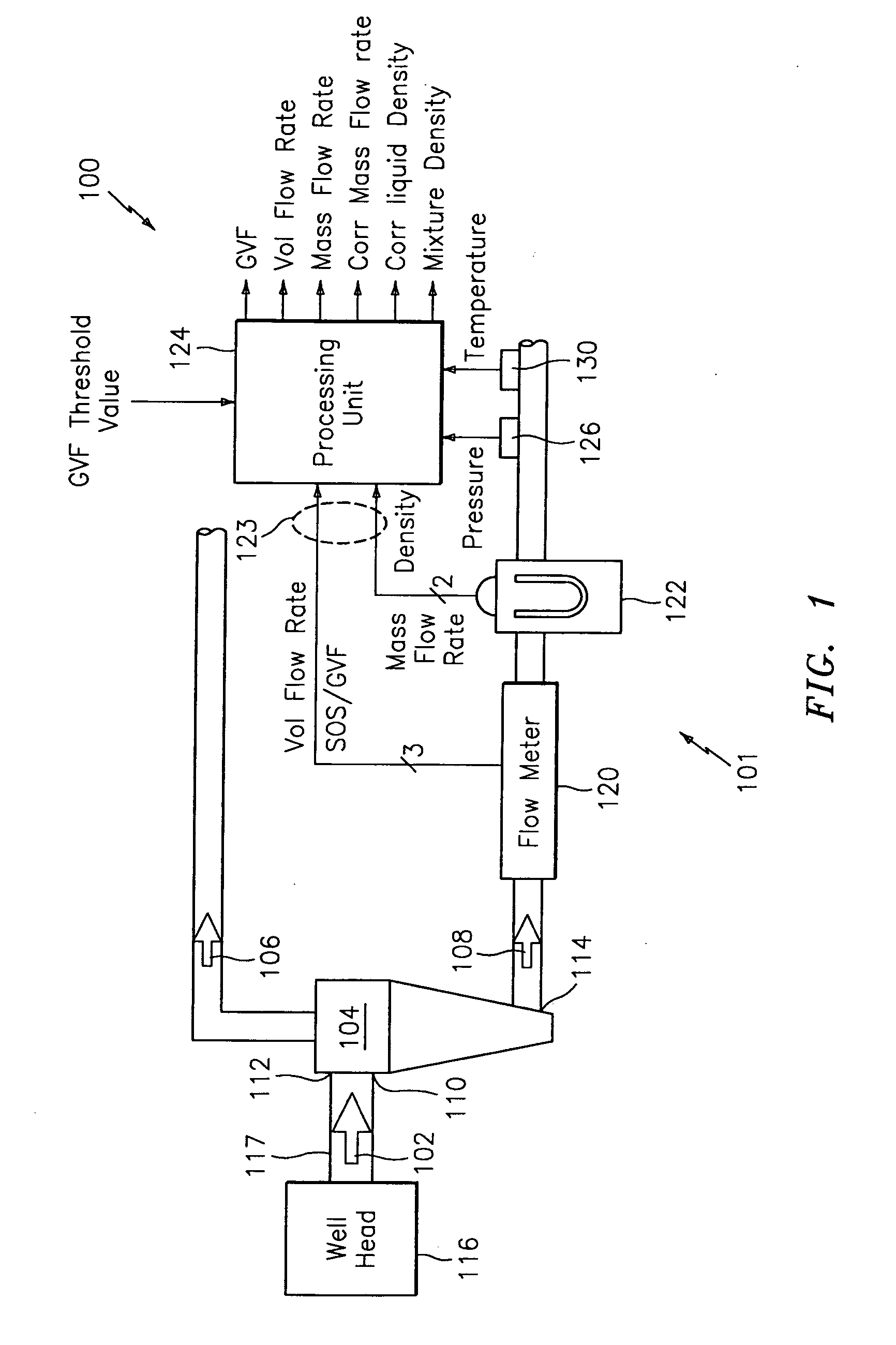

System for measuring a parameter of an aerated multi-phase mixture flowing in a pipe

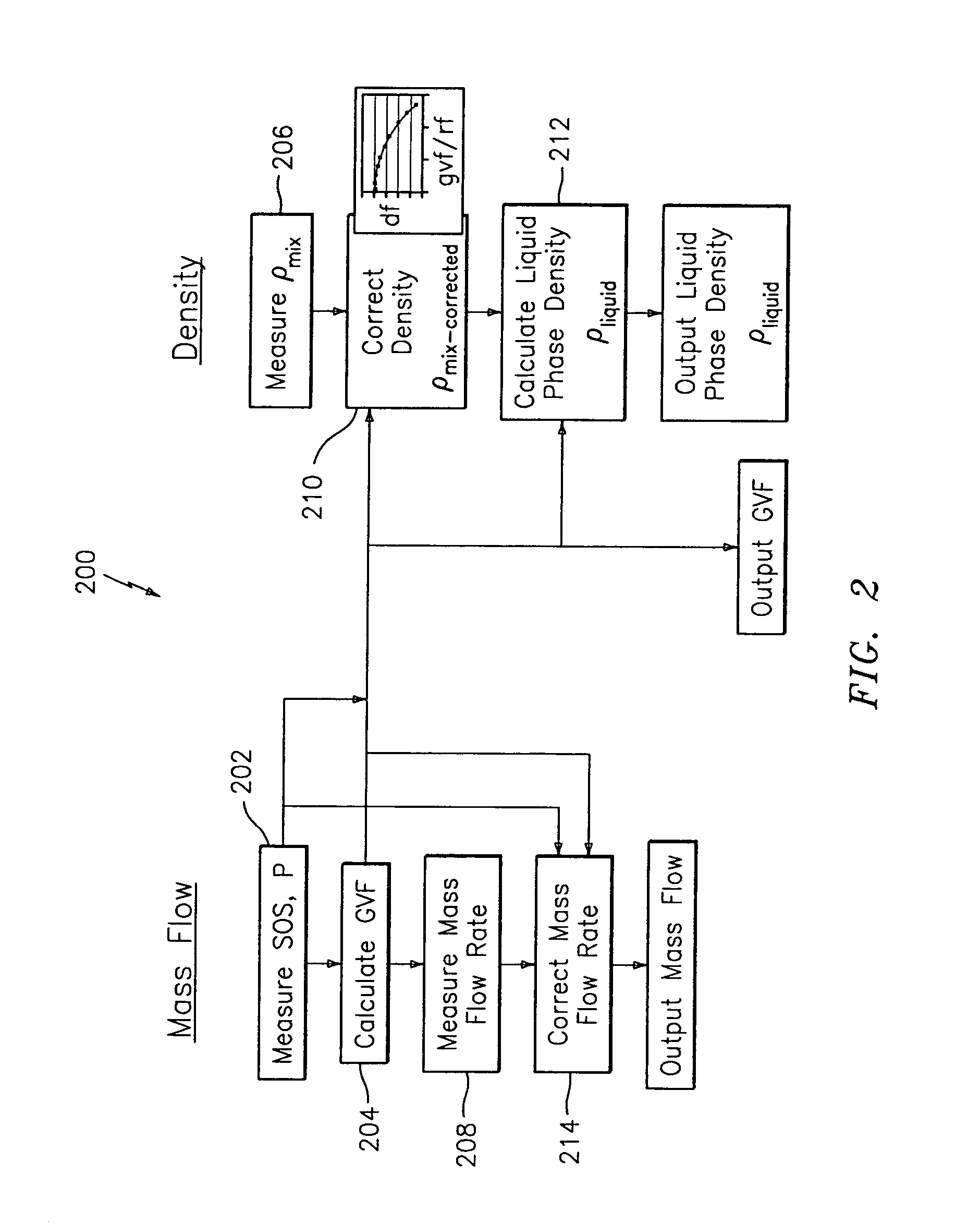

ActiveUS20060096388A1Volume variation compensation/correction apparatusIndirect mass flowmetersVolumetric Mass DensityMulti phase

A method and apparatus for measuring at least one characteristic of an aerated fluid flowing within a pipe is provided, wherein the method includes generating a measured sound speed, a measured density, a pressure and a gas volume fraction for the aerated fluid. The method also includes correcting the measured density responsive to the measured sound speed, the pressure and the gas volume fraction to generate a corrected density. The method further includes calculating a liquid phase density, determining whether the gas volume fraction is above a predetermined threshold value and generating a mass flow rate responsive to whether the gas volume fraction is above the predetermined threshold value.

Owner:EXPRO METERS

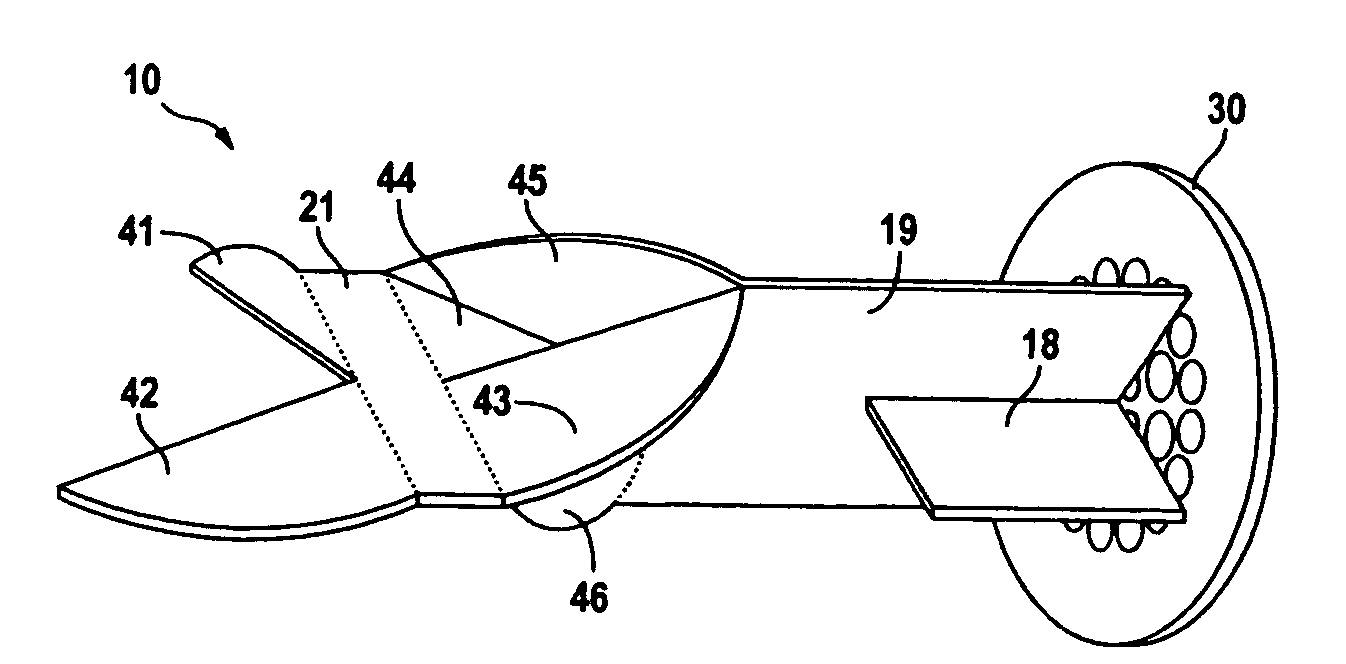

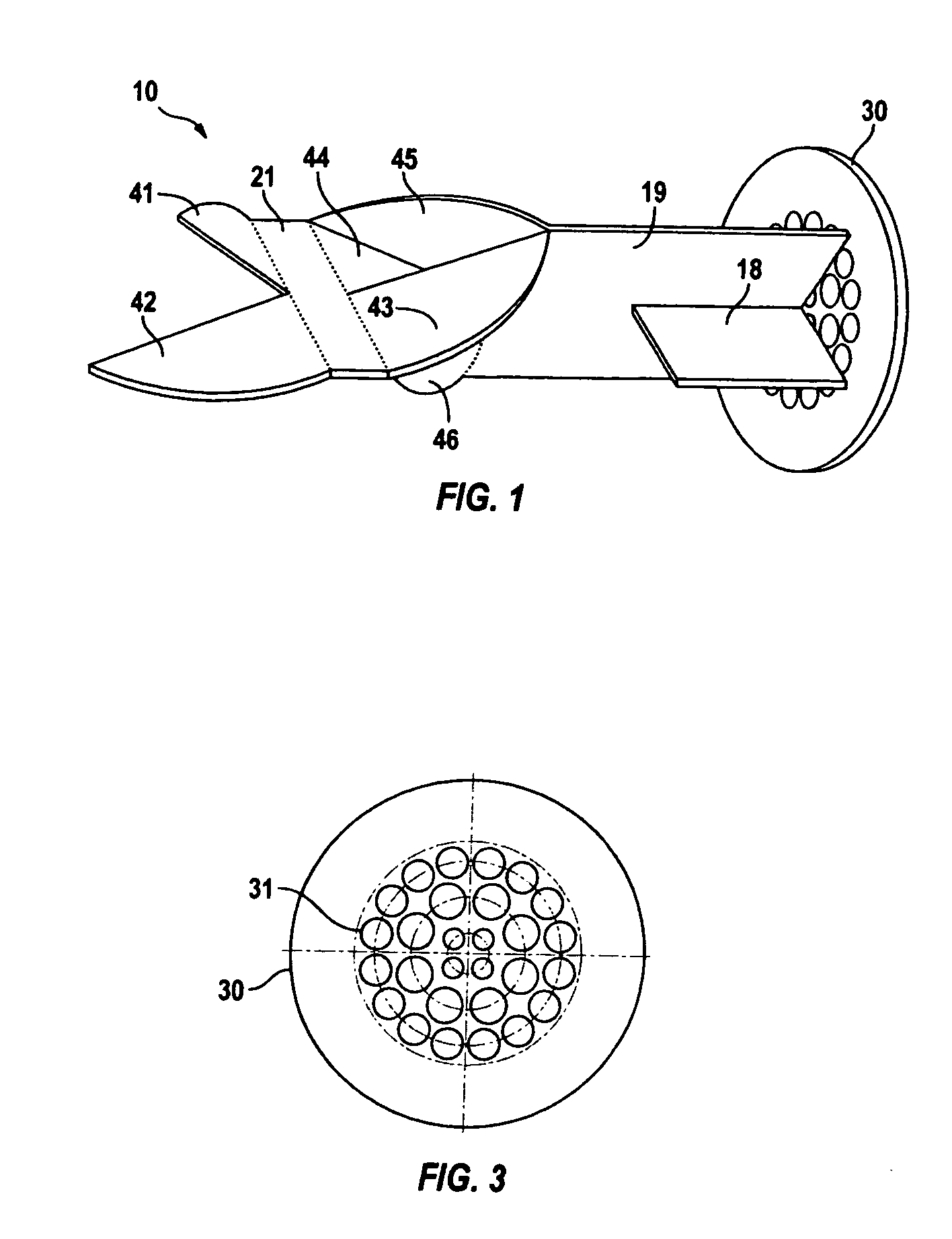

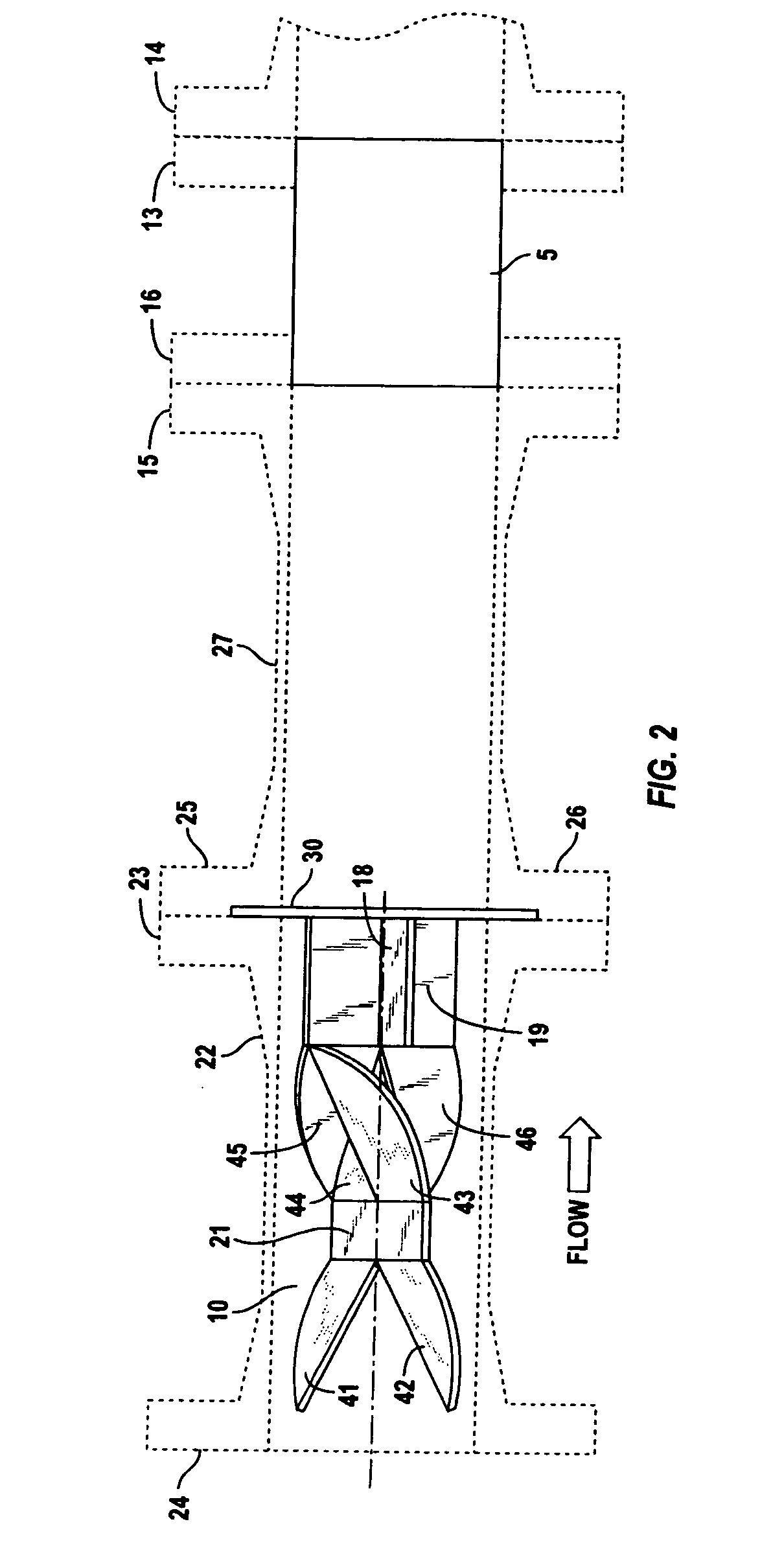

Meter flow conditioner

ActiveUS20080037366A1Easy accessFlow mixersVolume variation compensation/correction apparatusEngineeringStatic mixer

A fluid conditioner for a fluid traveling through a conduit, the conduit having a longitudinal axis and substantially circular cross-section. The fluid conditioner includes a static mixing element and a straightener plate. The preferred static mixer is one having a flat generally rectangular central portion having first and second sets of ears affixed on opposite sides of the central portion. The sets of ears include first and second ears bent respectively in upward and downward directions relative to the plane of the central portion wherein each pair of ears located diagonally opposite one another across the central portion are bent in the same direction relative to the plane of the central portion. A third set of ears extend from the central portion and terminate at a substantially rectangular member whose plane of orientation is substantially perpendicular to the central portion and a plate affixed to the substantially rectangular member and oriented substantially perpendicularly to the longitudinal axis of the conduit, the plate substantially covering the cross-section of the conduit having a plurality of openings to facilitate the passage of the fluid within the conduit.

Owner:KOMAX SYST

Water use monitoring apparatus

The present invention is a water use and / or a water energy use monitoring apparatus that is affixed to the hot and cold water supply piping for continuously (or on demand) monitoring displaying the water and water energy (hot vs. ambient) use within a residential or commercial building. A first wire or wireless means is incorporated to communicate with a remote display for viewing by the owner of a commercial building or occupier / resident of a home. A second optional wire or wireless means can be incorporated that can be monitored by civil, commercial, governmental or municipal operators or agencies, using a remote display and / or recorder means or by a secure wire or wireless communication network (e.g. cell phone technology communication means). A third wireless means communicates water parameter data utilizing typical cell tower technology and / or mesh network technology. The water use monitor apparatus includes a power generation, a microprocessor, temperature and water flow sensors, optional water quality sensors, timing circuits, wireless circuitry, and a display means. A first wired or wireless means is designed to electronically communicate water use and water energy use information to a remotely located display for convenient observation by a commercial operator or occupier, or resident. An optional second wireless means is designed to electronically communicate water and / or water energy use information to governmental or municipal operators or agencies.

Owner:KLICPERA MICHAEL

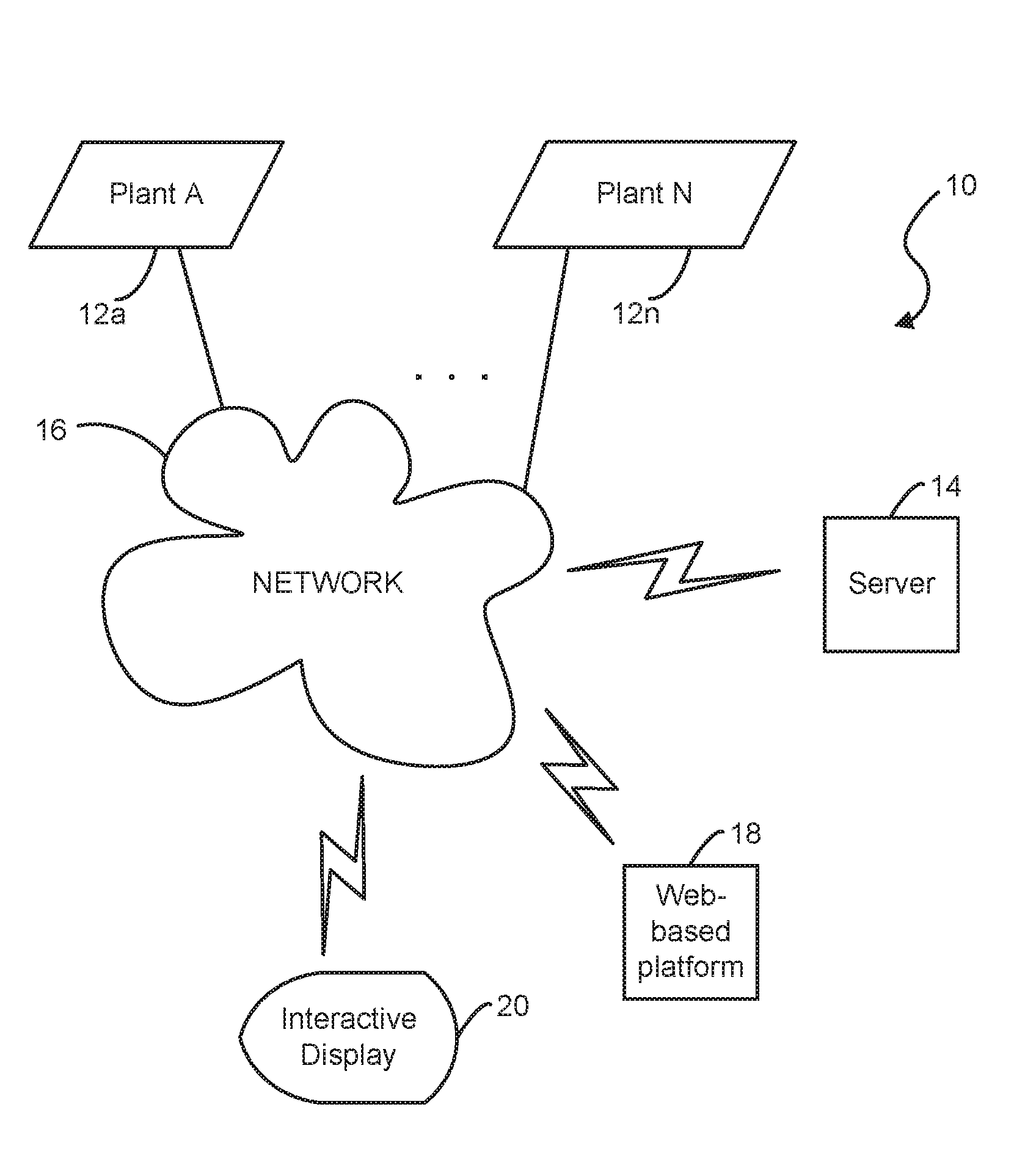

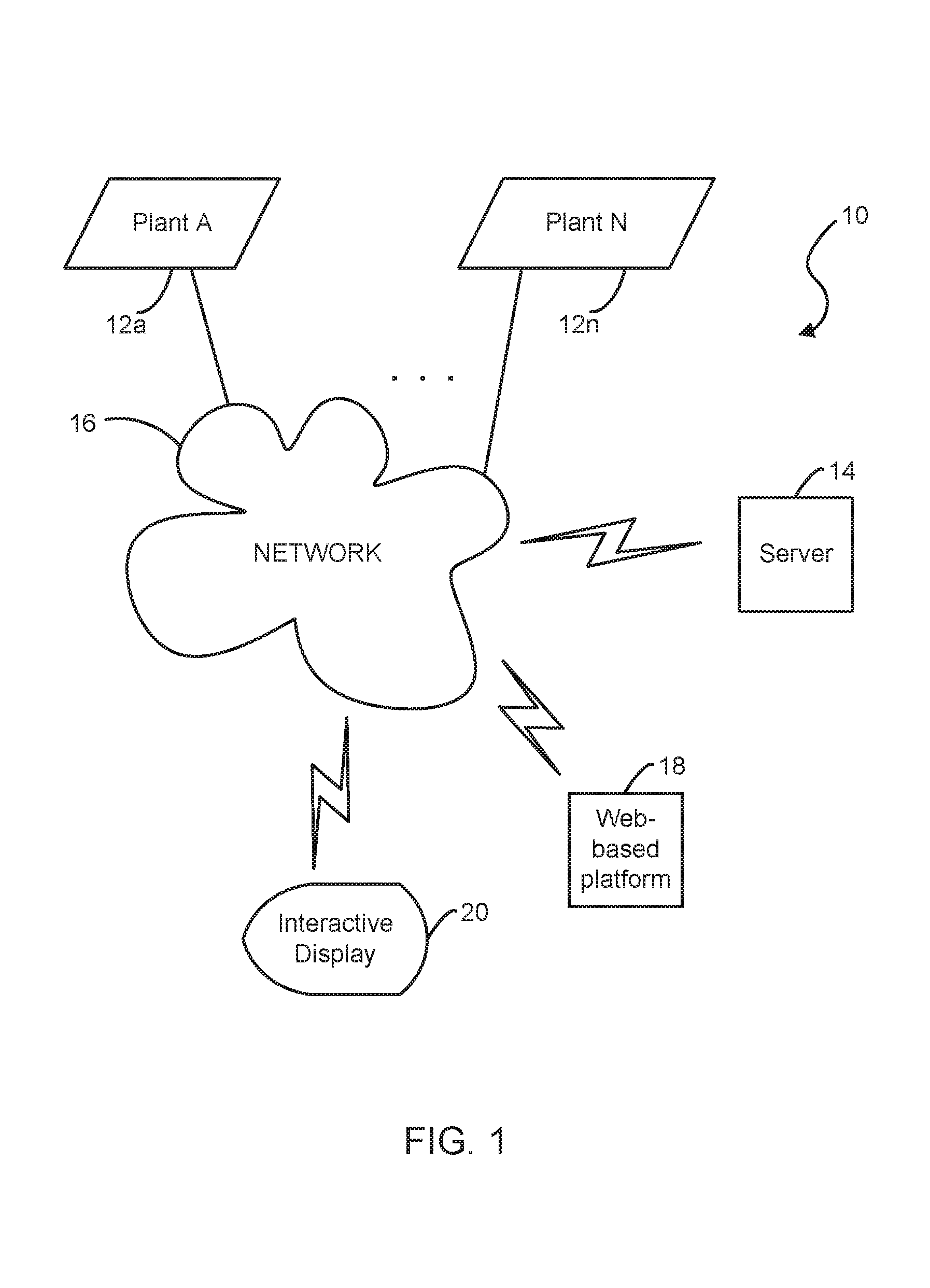

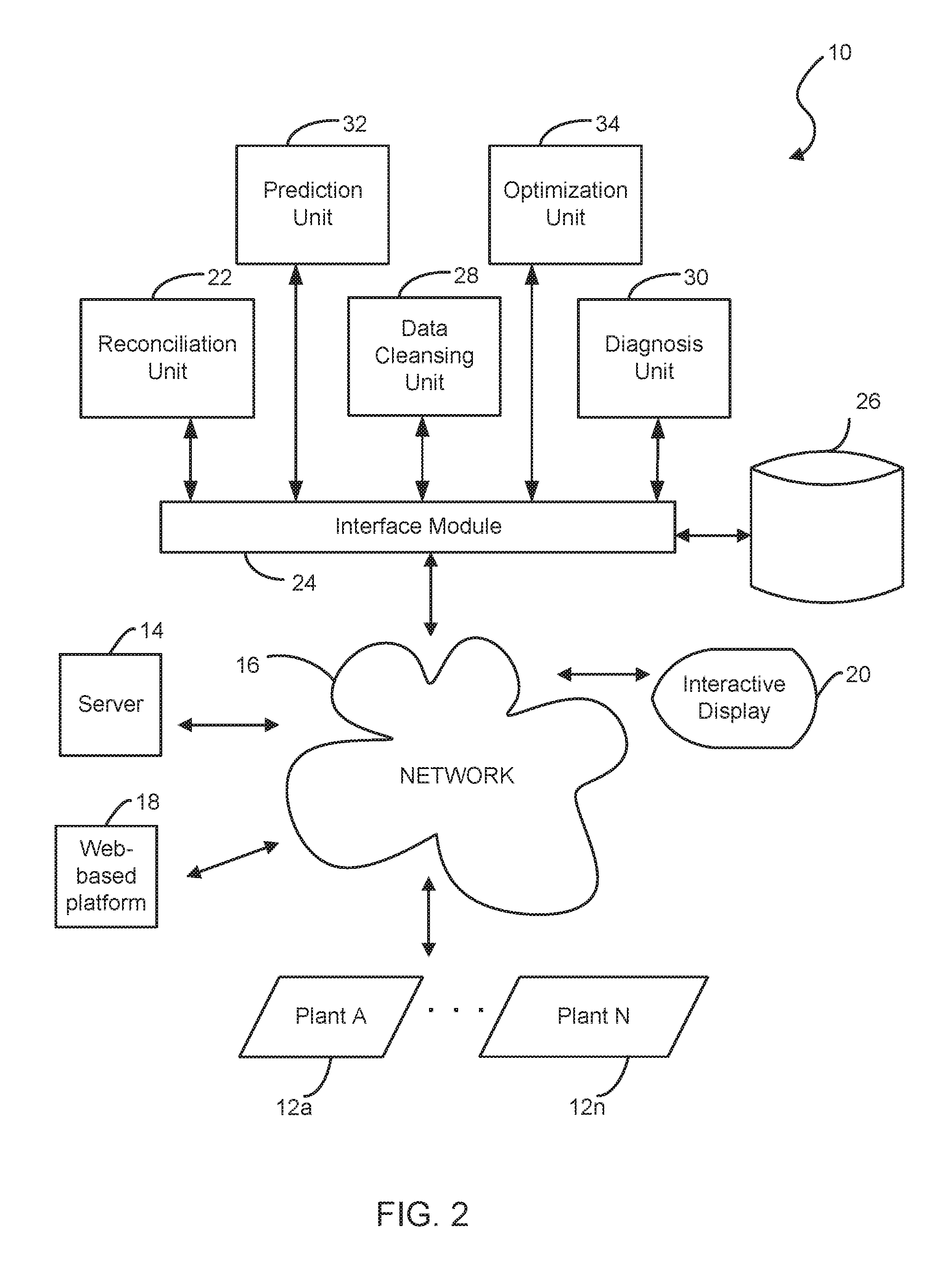

Advanced data cleansing system and method

InactiveUS20160292325A1Improving measurement error estimationEasy to detectTesting/monitoring control systemsVolume variation compensation/correction apparatusObservational errorComputerized system

A cleansing system for improving operation of a plant. A server is coupled to the cleansing system for communicating with the plant via a communication network. A computer system has a web-based platform for receiving and sending plant data related to the operation of the plant over the network. A display device interactively displays the plant data. A data cleansing unit is configured for performing an enhanced data cleansing process for allowing an early detection and diagnosis of the operation of the plant based on at least one environmental factor. The data cleansing unit calculates and evaluates an offset amount representing a difference between a measurement and a simulation for detecting an error of measurement during the operation of the plant based on the plant data.

Owner:UOP LLC

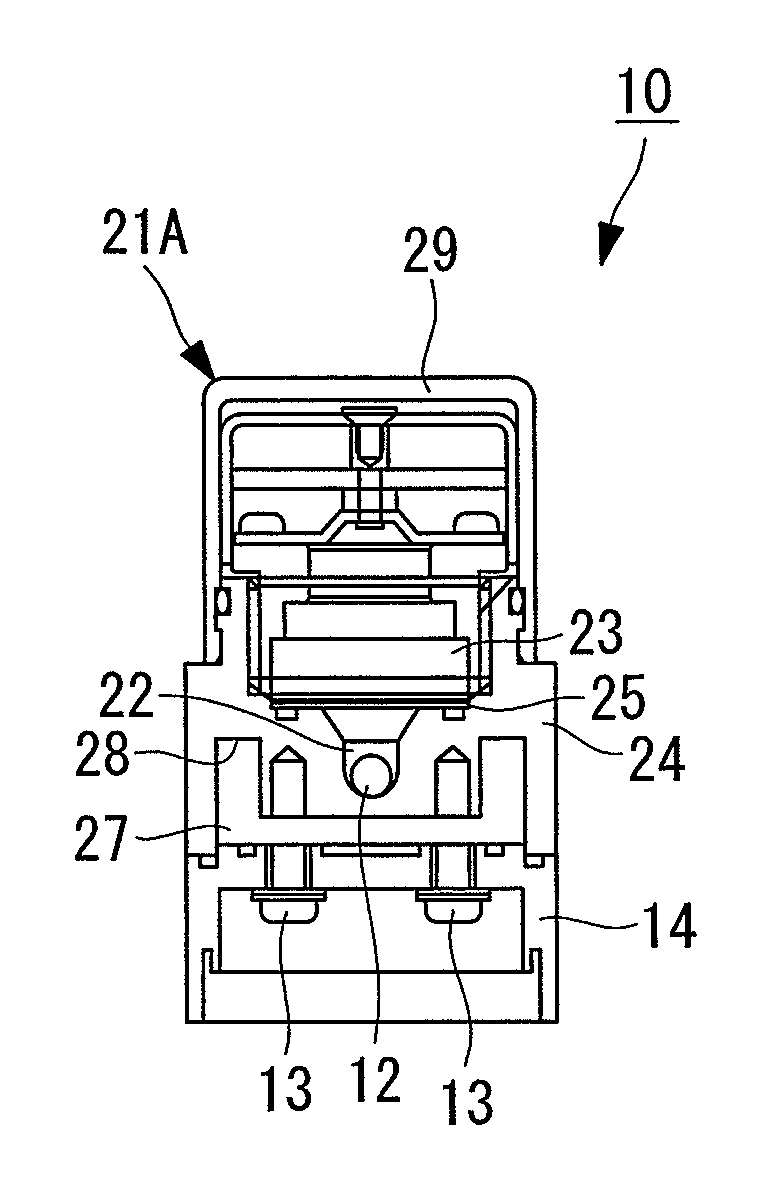

Differential-pressure flowmeter and flow-rate controller

ActiveUS8225814B2Reduce the differenceAccurate and stable pressureOperating means/releasing devices for valvesValve members for heating/coolingDifferential pressureEngineering

A differential-pressure flowmeter that can reduce (eliminate) a difference between the ambient temperature of one pressure sensor and the ambient temperature of another pressure sensor so as to allow for accurate and stable pressure measurement is provided, and a flow-rate controller equipped with such a differential-pressure flowmeter is provided. Provided are a body having a main fluid channel through which a fluid, whose pressure is to be measured, flows, and two pressure sensors held by the body and arranged in series relative to the main fluid channel, and a temperature balancer composed of a material with high thermal conductivity is accommodated in a recess that is formed in the body located below the two pressure sensors.

Owner:SURPASS IND

Ultrasonic flow-measuring method

InactiveUS6907361B2Accurate measurementEfficient configurationVolume variation compensation/correction apparatusVolume/mass flow by dynamic fluid flow effectSonificationDead time

Owner:KRONE GMBH

Liquid dosing apparatus

An apparatus and means of repeatedly dispensing controlled doses of liquid comprising a resiliently squeezable container for containing a liquid detergent composition; a cap operably connected to said container, the cap comprising a nozzle for expelling the liquid out of the container; a dosing chamber operably connected to the cap, wherein the dosing chamber comprises a base having a discharge opening therein, sidewalls extending upwardly along the perimeter of said base and at least one inlet opening located proximal the sidewalls; at least one timer aperture located proximal to the discharge opening; a plunger, provided in the dosing chamber and moveable relative to the chamber so as to advance upon squeezing of the container, up to a blocking position; a valve retaining means located below the base; a valve provided in the valve retaining mean wherein the valve is movable from an open position, allowing liquid flow through the discharge opening, and a closed position, where the valve blocks the discharge opening; wherein the liquid is a shear thinning liquid and the shear thinning liquid has a viscosity of greater than 150 mPa·s measured at 10 s−1 at 20° C.

Owner:THE PROCTER & GAMBLE COMPANY

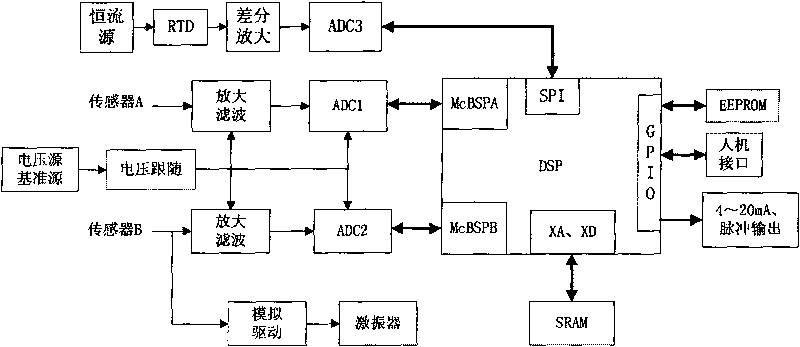

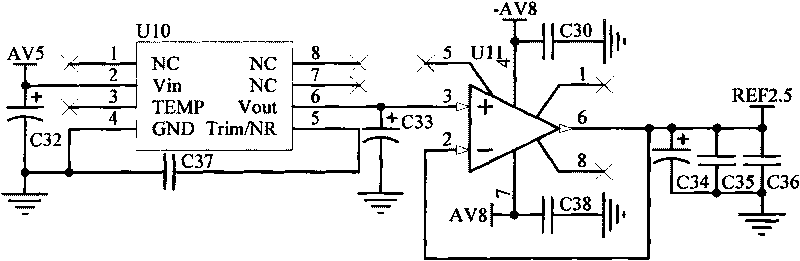

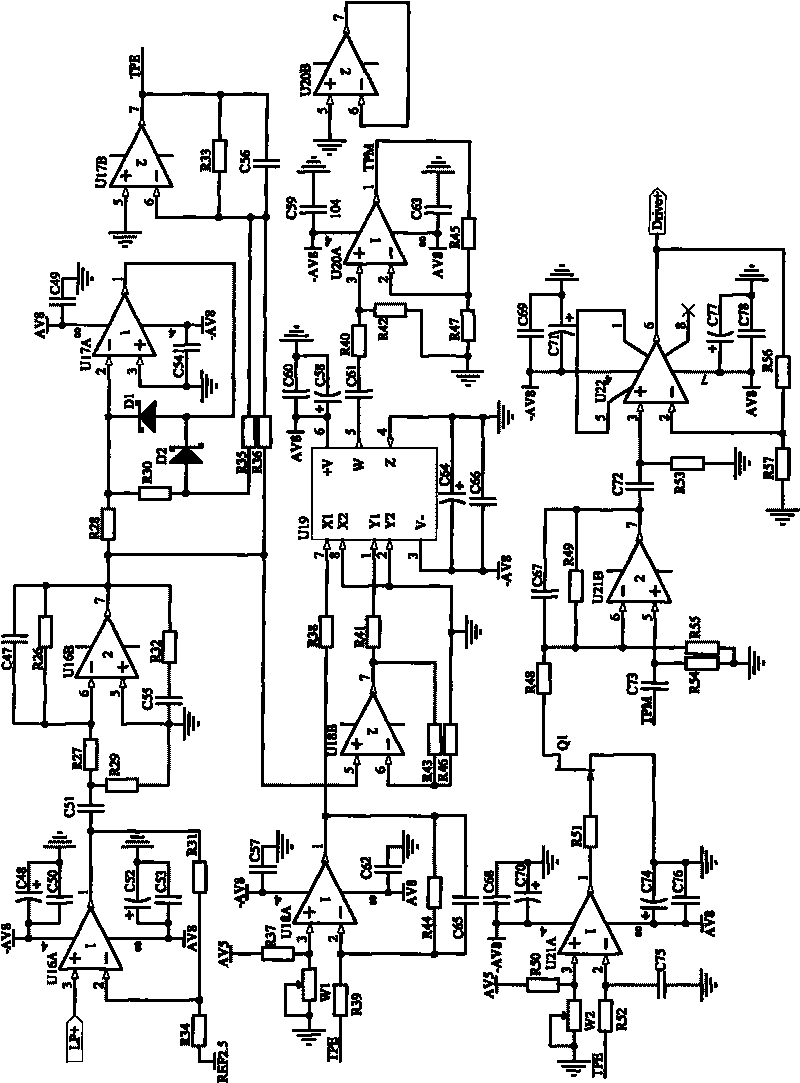

Coriolis mass flow transmitter based on DSP

ActiveCN101706299AImprove calculation accuracyShorten convergence timeVolume variation compensation/correction apparatusDirect mass flowmetersDigital signal processingPhase difference

The invention relates to the field of flow detection, and provides a Coriolis mass flow transmitter based on DSP, which comprises an amplifying filter circuit, an analog-to-digital converter 1, an analog-to-digital converter 2, a voltage reference source, a voltage follower, a current source, a difference amplifier, an analog-to-digital converter 3, a simulation driver module, a digital signal processor DSP minimum system, an expanding SRAM, an expanding EEPROM, a man-machine interface, 4-20mA current output and pulse output, a power module and a software. The simulation driver module stimulates a vibration exciter in the Coriolis mass flow transmitter so as to lead a flow tube to vibrate with natural frequency. Two magnetoelectric sensors positioned at two sides of the flow tube output two ways of sine-wave signals which are amplified and filtered by two ways of conditioning circuits with same parameter, then respectively and simultaneously sampled by two analog-to-digital converters with same model, and converted in digital value, and delivered to DSP by two multichannel buffered serial ports of the DSP. DSP adopts digital filter to eliminate the noise of the signals, is self-adaptive to a lattice notch filter to calculate the frequency, and then adopts the DTFT algorithm taking negative frequency into account to calculate to phase difference, thus obtaining the mass flow finally.

Owner:GOLDCARD HIGH TECH

Fault-tolerant chemical injection system for oil and gas wells

ActiveUS20100126600A1Operating means/releasing devices for valvesContracting/expanding measuring chambersCylinder headEngineering

A metering body for a chemical injection system comprises a free piston having a pair of mechanically-actuated poppet valves which may individually open to permit fluid to pass from one side of the free piston to the other. The free piston slides within a cylinder having cylinder heads at opposing ends. Input / output ports are provided in the cylinder heads. In a preferred embodiment, the poppet valves have actuators that extend beyond the opposing faces of the free piston. If one face of the piston moves to within a predetermined distance of a cylinder head, the actuator contacts the cylinder head and further movement of the piston causes the corresponding poppet valve to open, permitting fluid to flow through the piston. In this way, a fault-tolerant system may be implemented. If a power interruption or other failure of the controller occurs, the system will continue to supply fluid at the most recently selected flow rate. When power is restored (or the fault is corrected), the controller causes a valve to reverse the flow of fluid through the metering body and the spring-loaded poppet valve will close as the free piston moves away from the cylinder head.

Owner:NAT COUPLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com