Patents

Literature

106 results about "Thermowell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

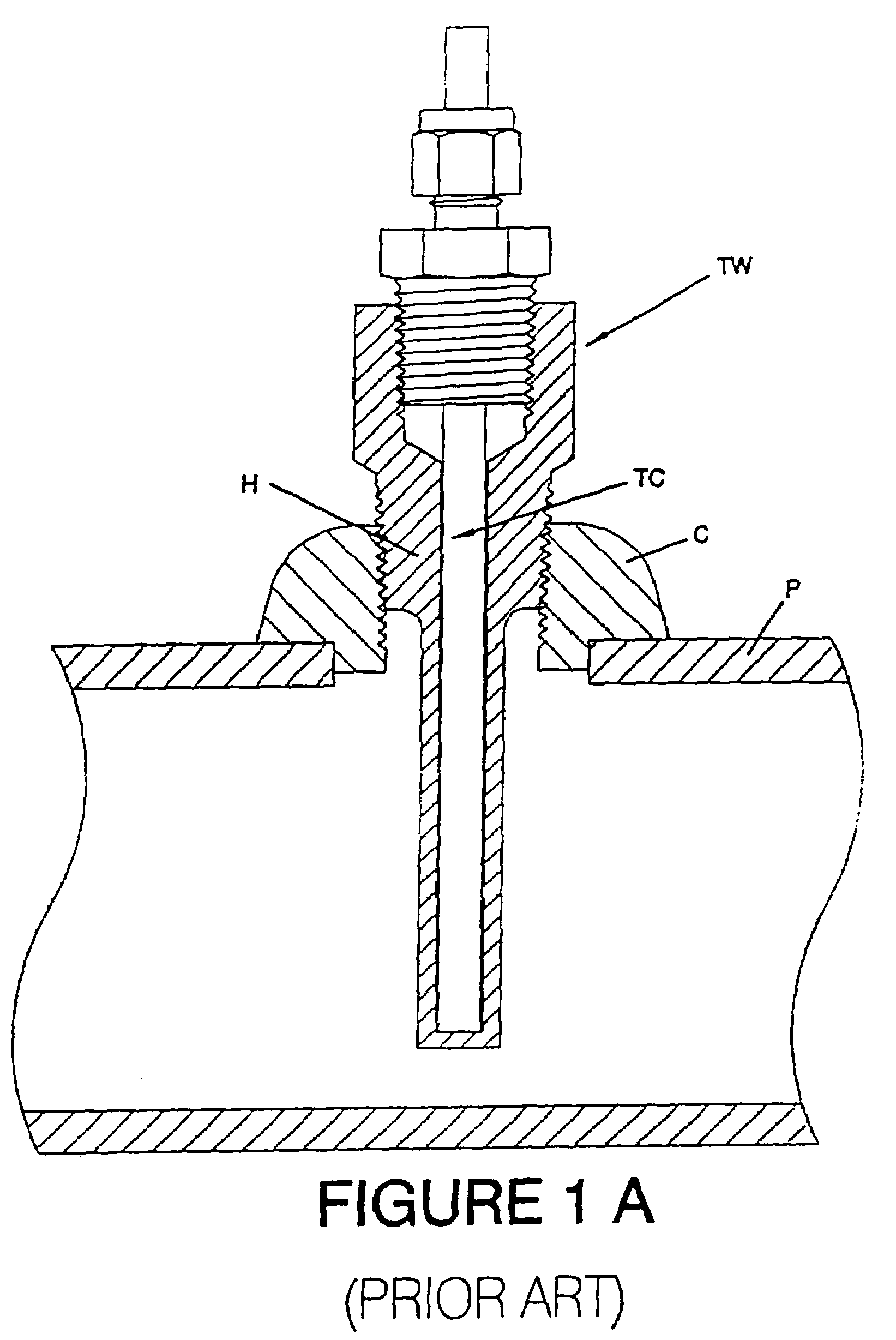

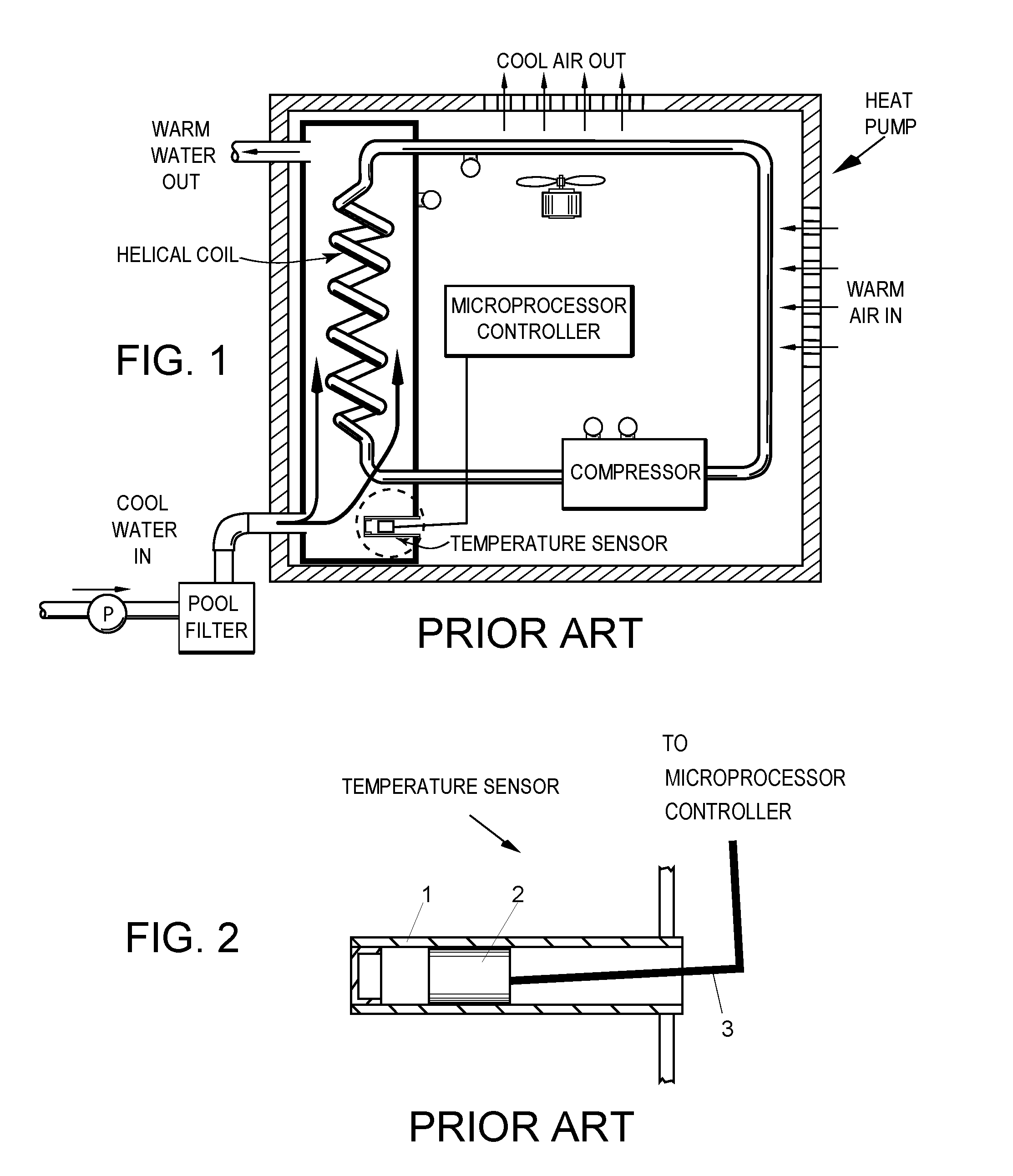

Thermowells are cylindrical fittings used to protect temperature sensors installed in industrial processes. A thermowell consists of a tube closed at one end and mounted in the process stream. A temperature sensor such as a thermometer, thermocouple or resistance temperature detector is inserted in the open end of the tube, which is usually in the open air outside the process piping or vessel and any thermal insulation. Thermodynamically, the process fluid transfers heat to the thermowell wall, which in turn transfers heat to the sensor. Since more mass is present with a sensor-well assembly than with a probe directly immersed into the process, the sensor's response to process temperature changes is slowed by the addition of the well. If the sensor fails, it can be easily replaced without draining the vessel or piping. Since the mass of the thermowell must be heated to the process temperature, and since the walls of the thermowell conduct heat out of the process, sensor accuracy and responsiveness is reduced by the addition of a thermowell.

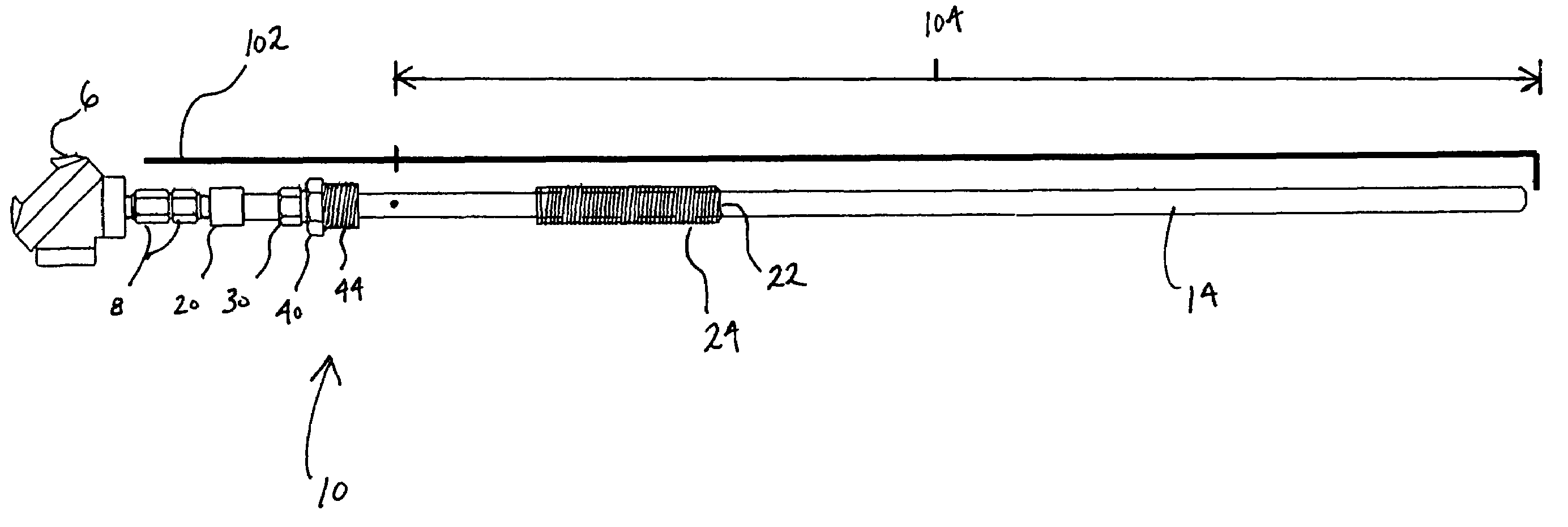

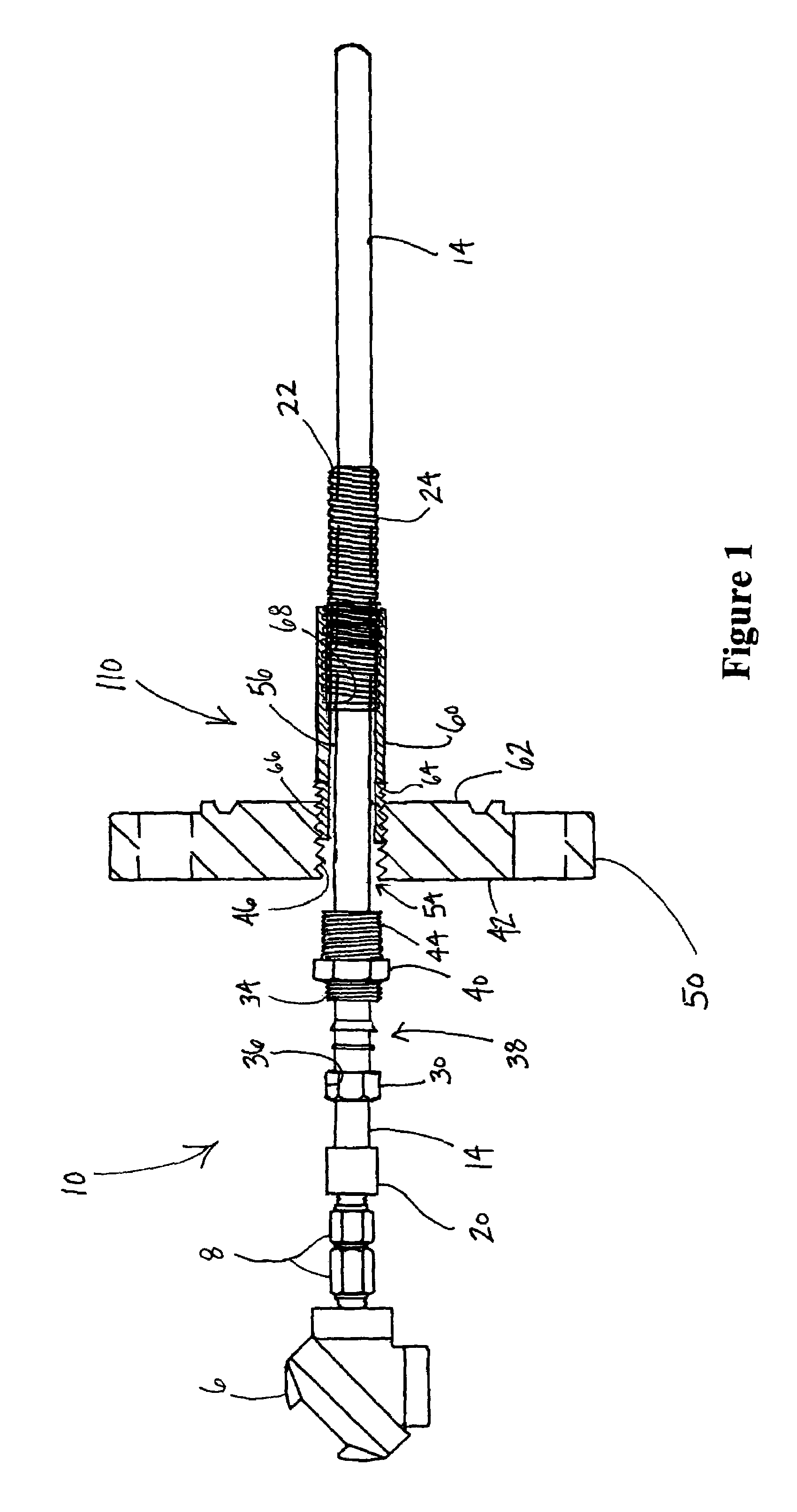

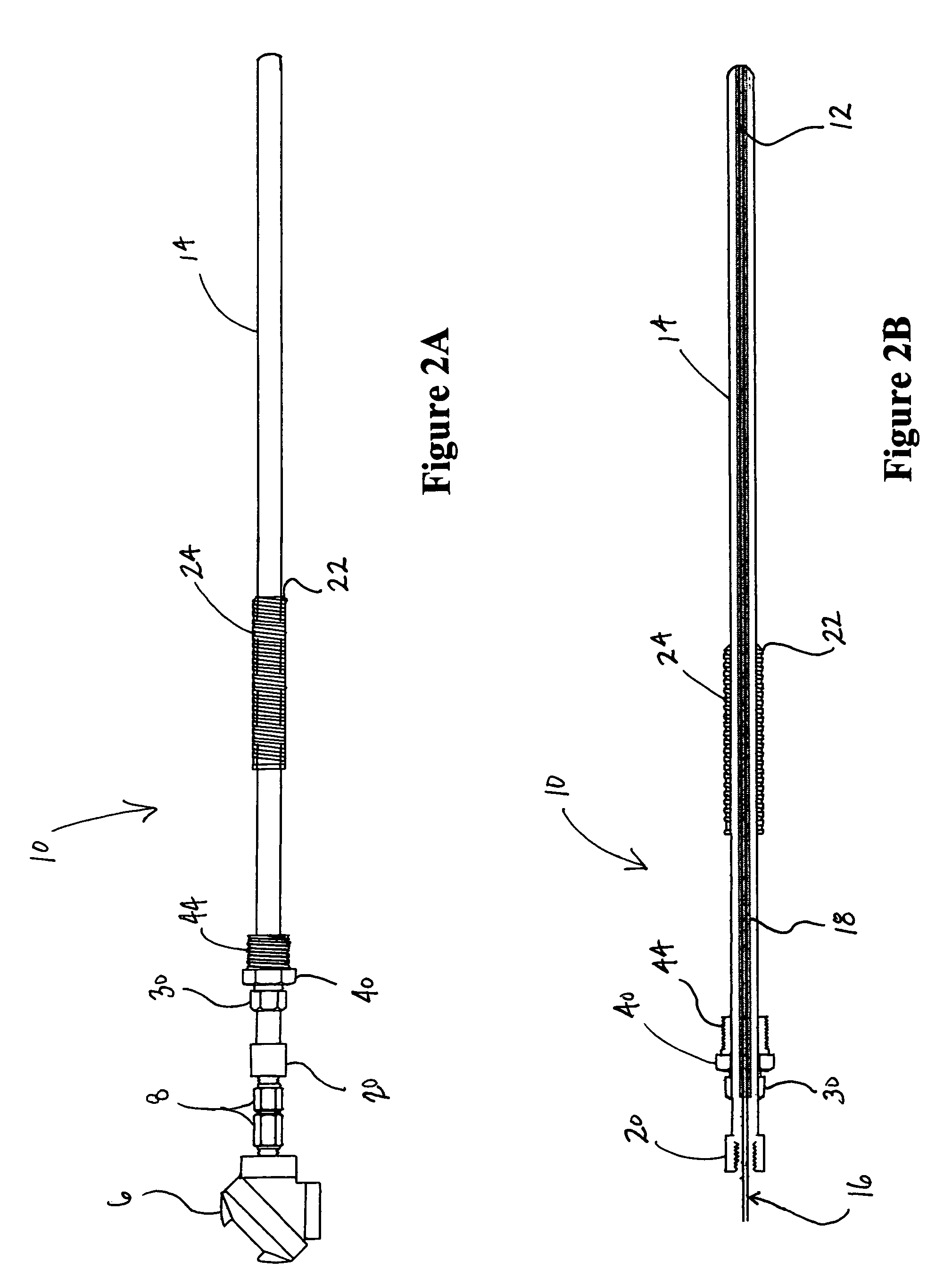

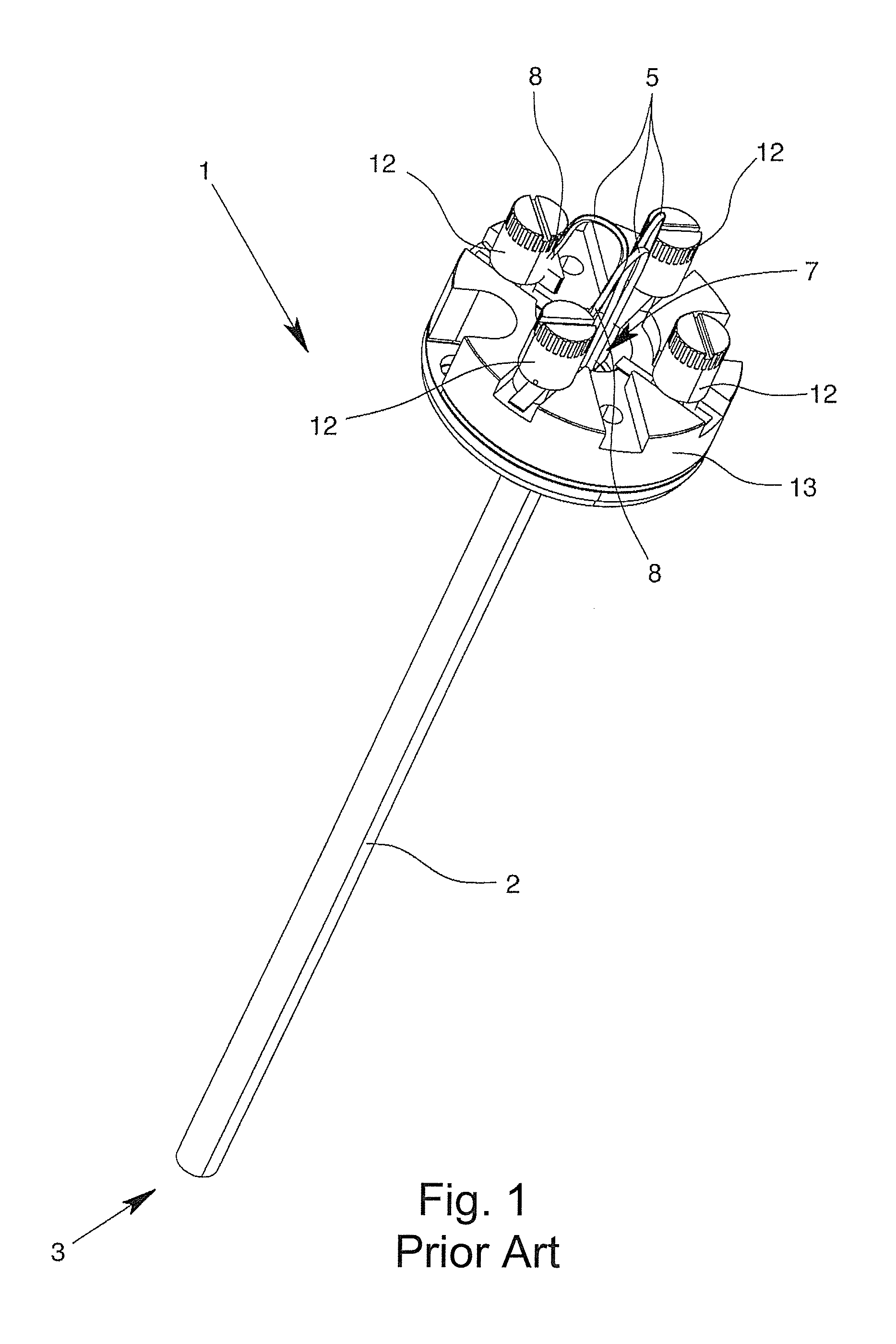

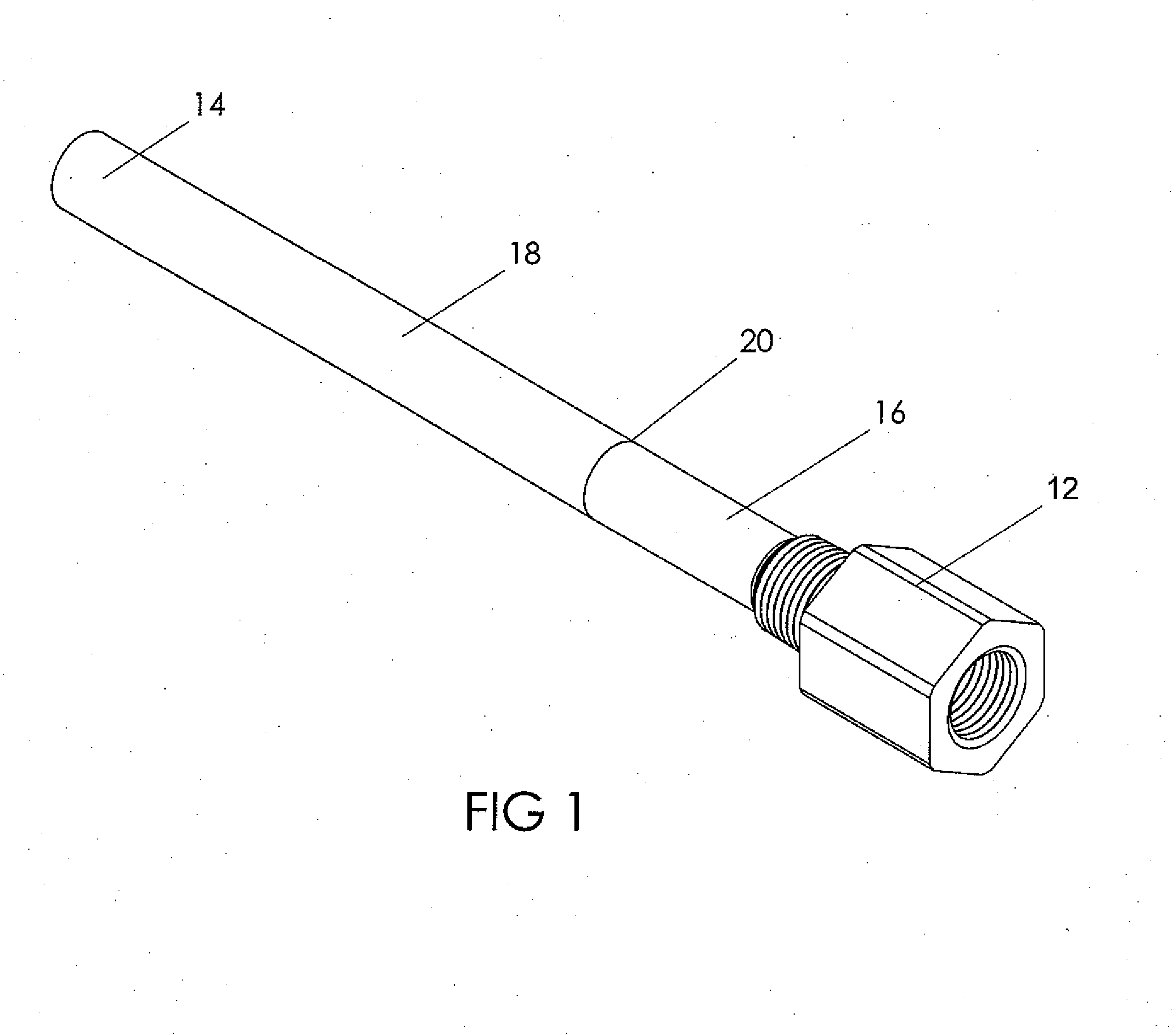

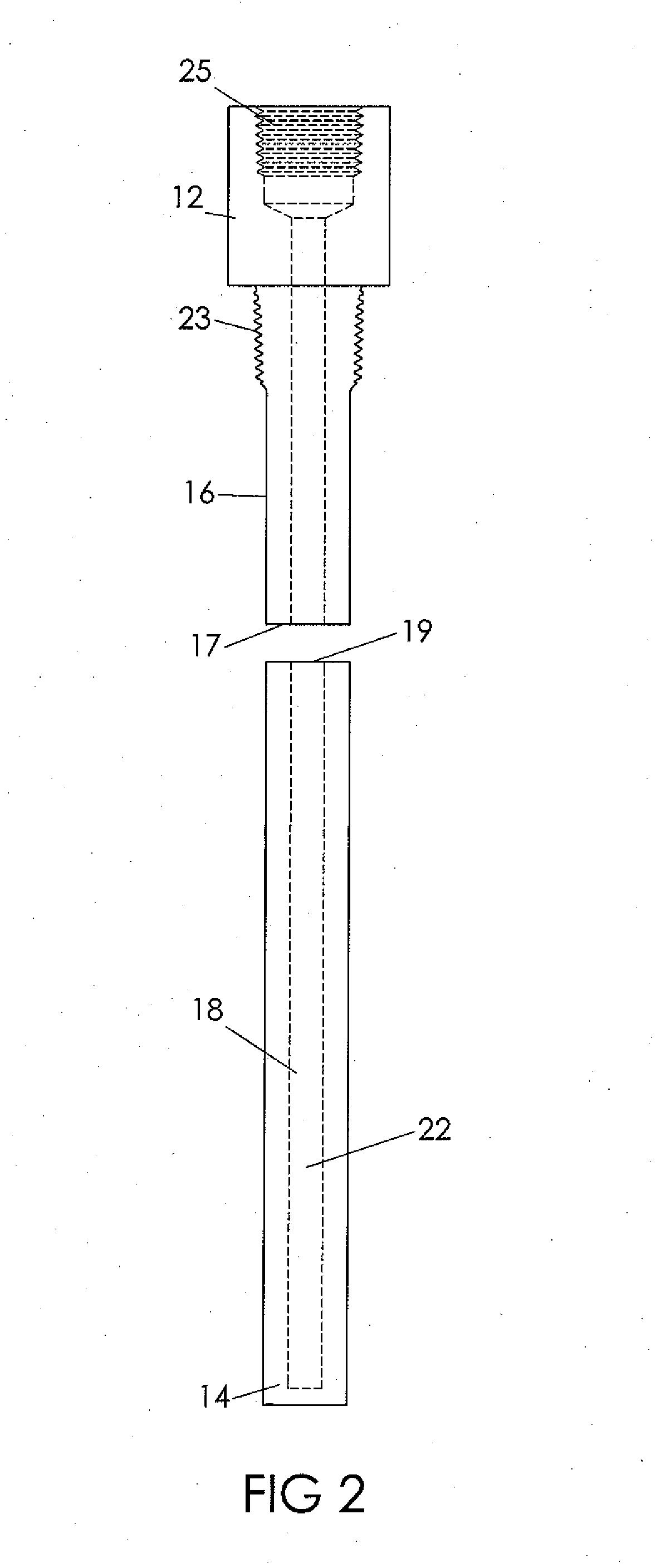

Adjustable length thermowell

ActiveUS7465086B1Easy to adjustThermometer detailsThermometers using electric/magnetic elementsEngineeringThermowell

Owner:FOREMAN INSTR & CONTROLS

Temperature sensing device for metering fluids

InactiveUS20050038172A1Improve thermal conductivityImproves rate of temperature transferThermometer detailsThermometers using electric/magnetic elementsThermowellAnnular fin

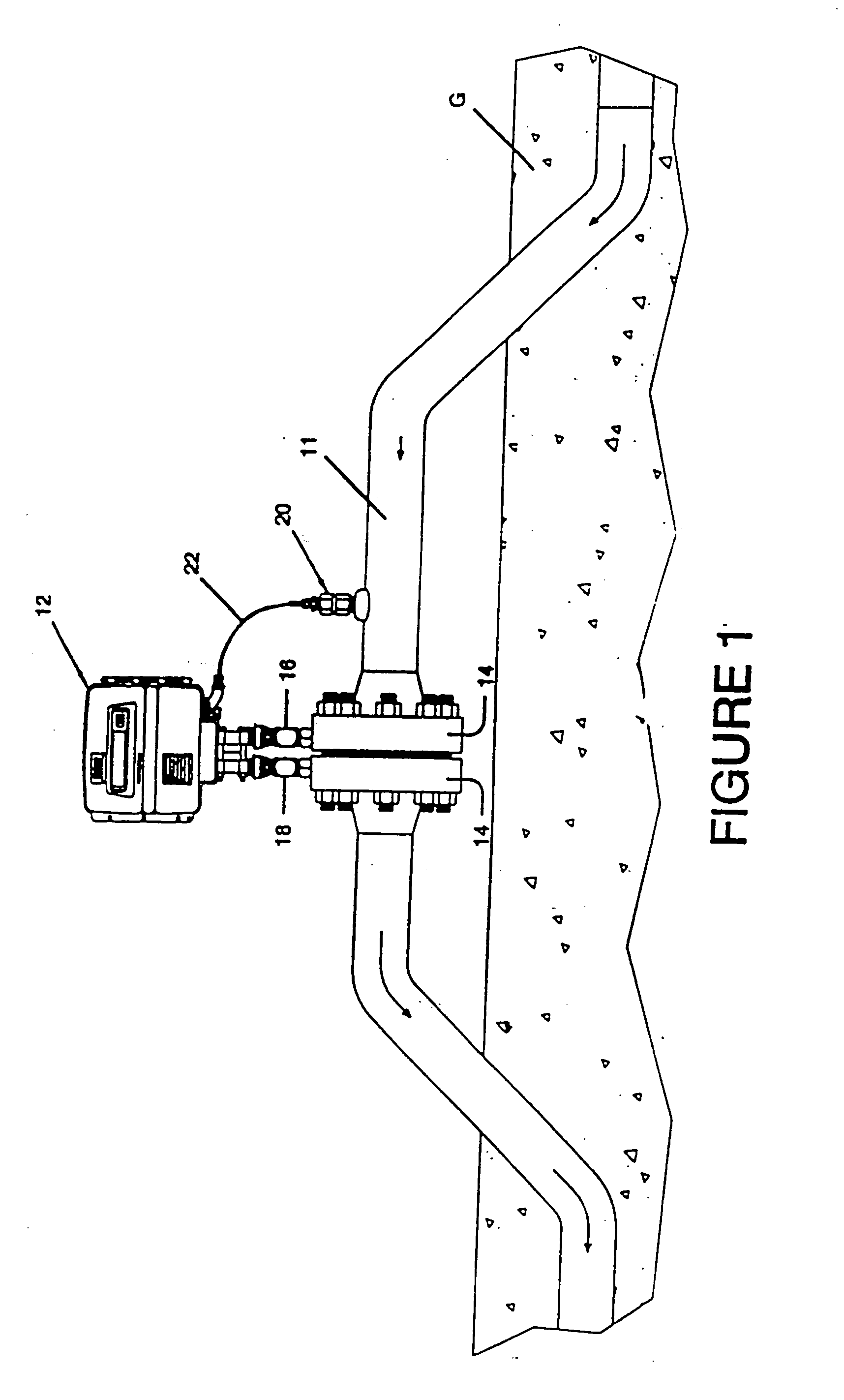

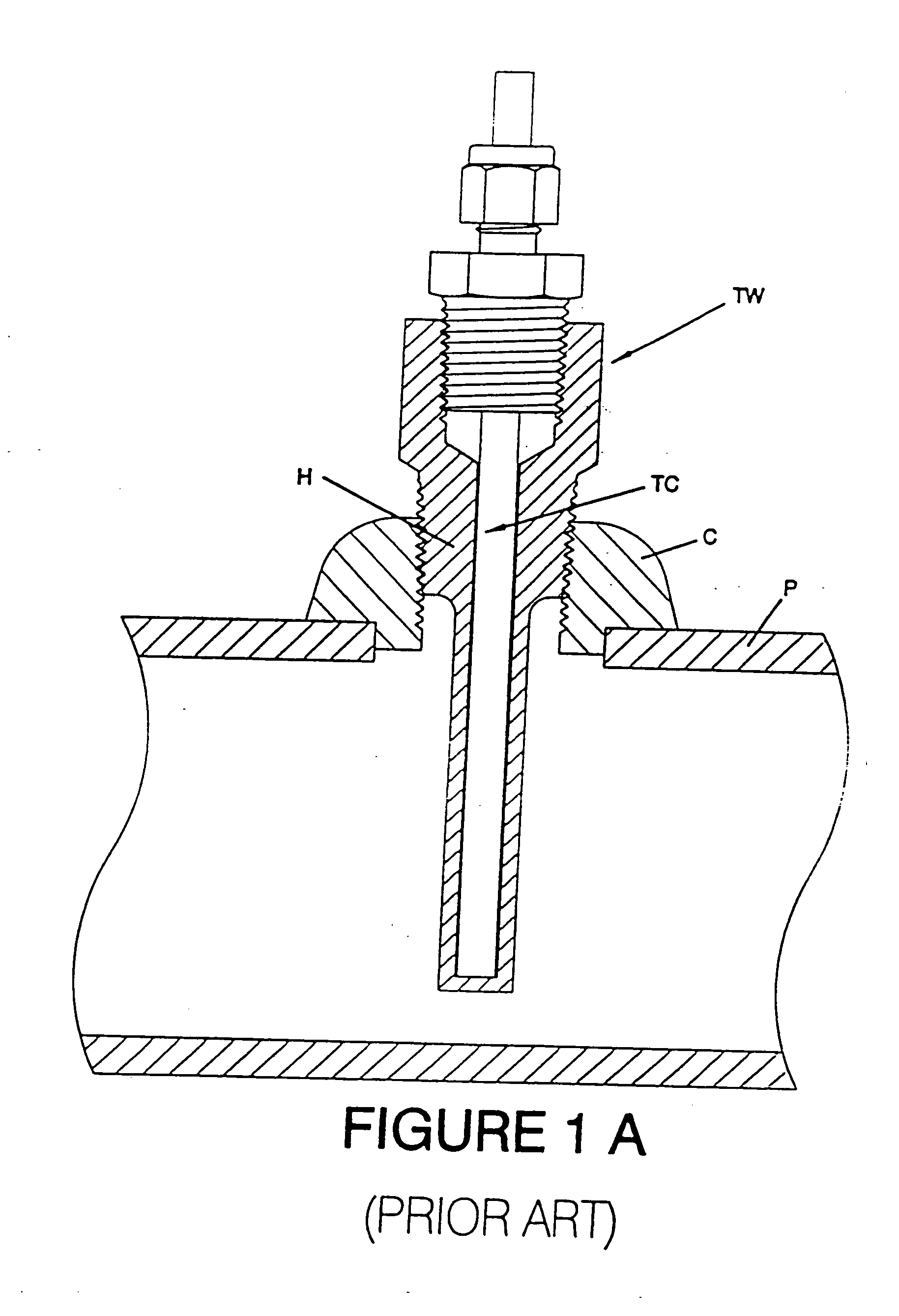

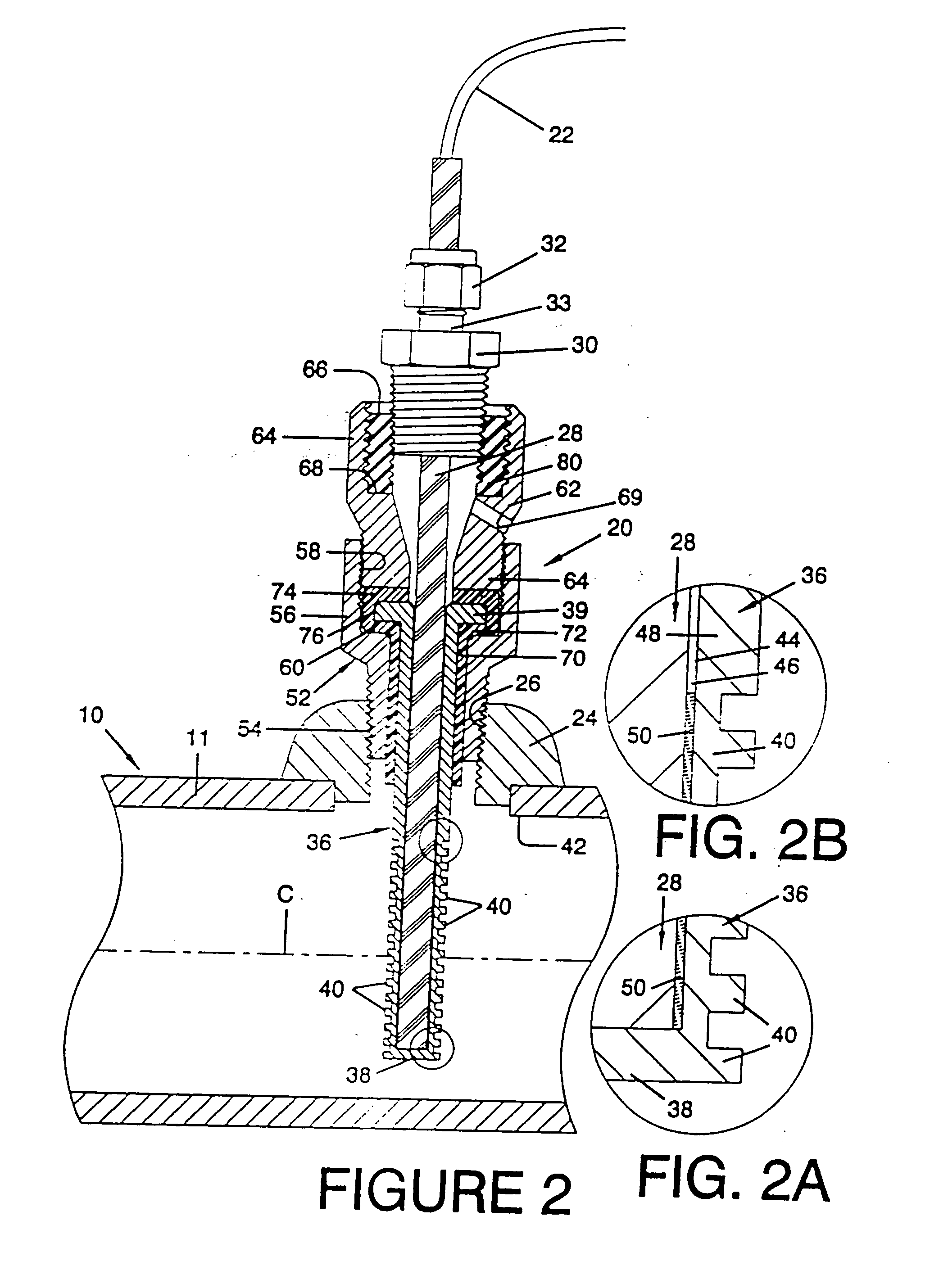

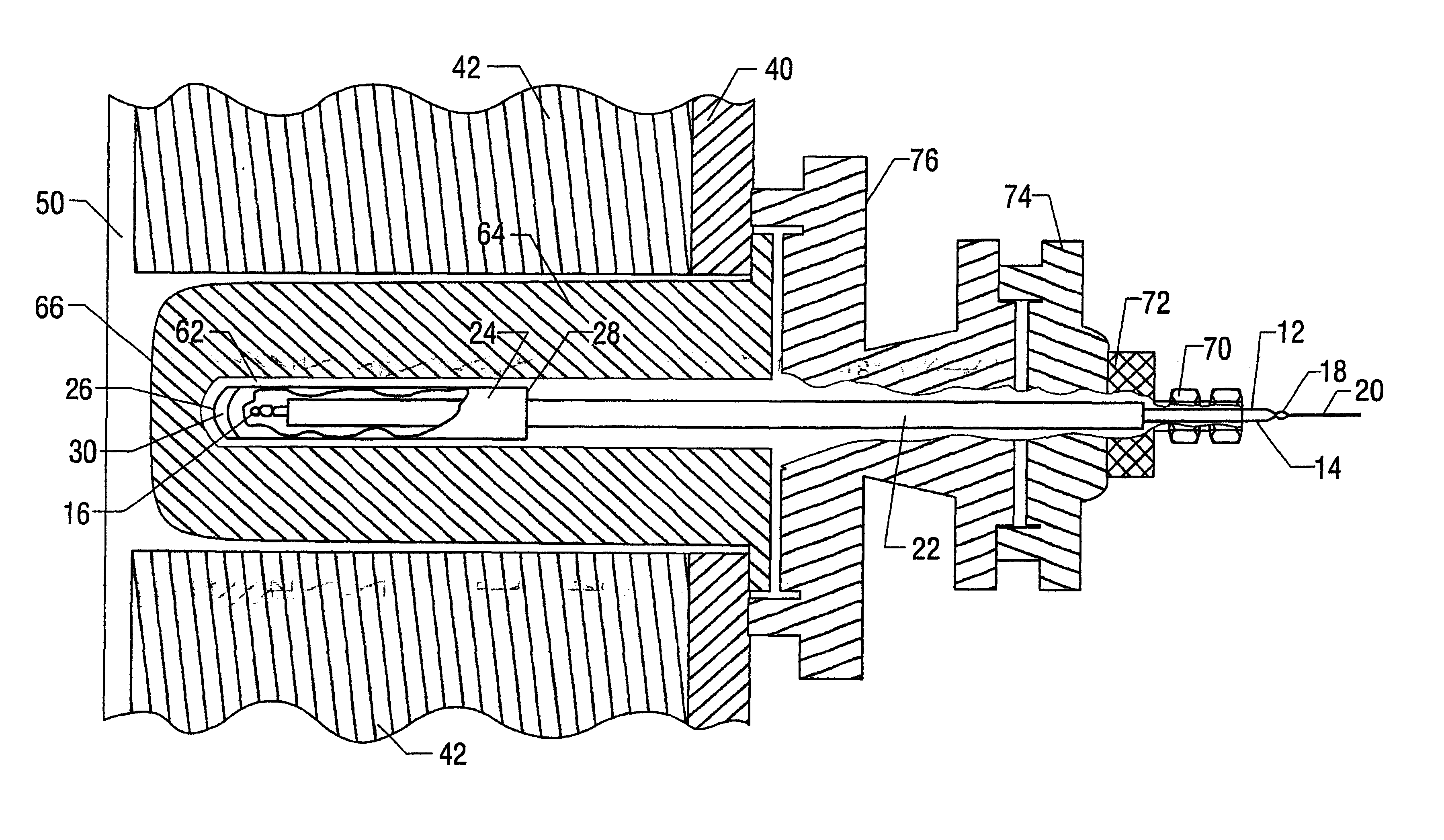

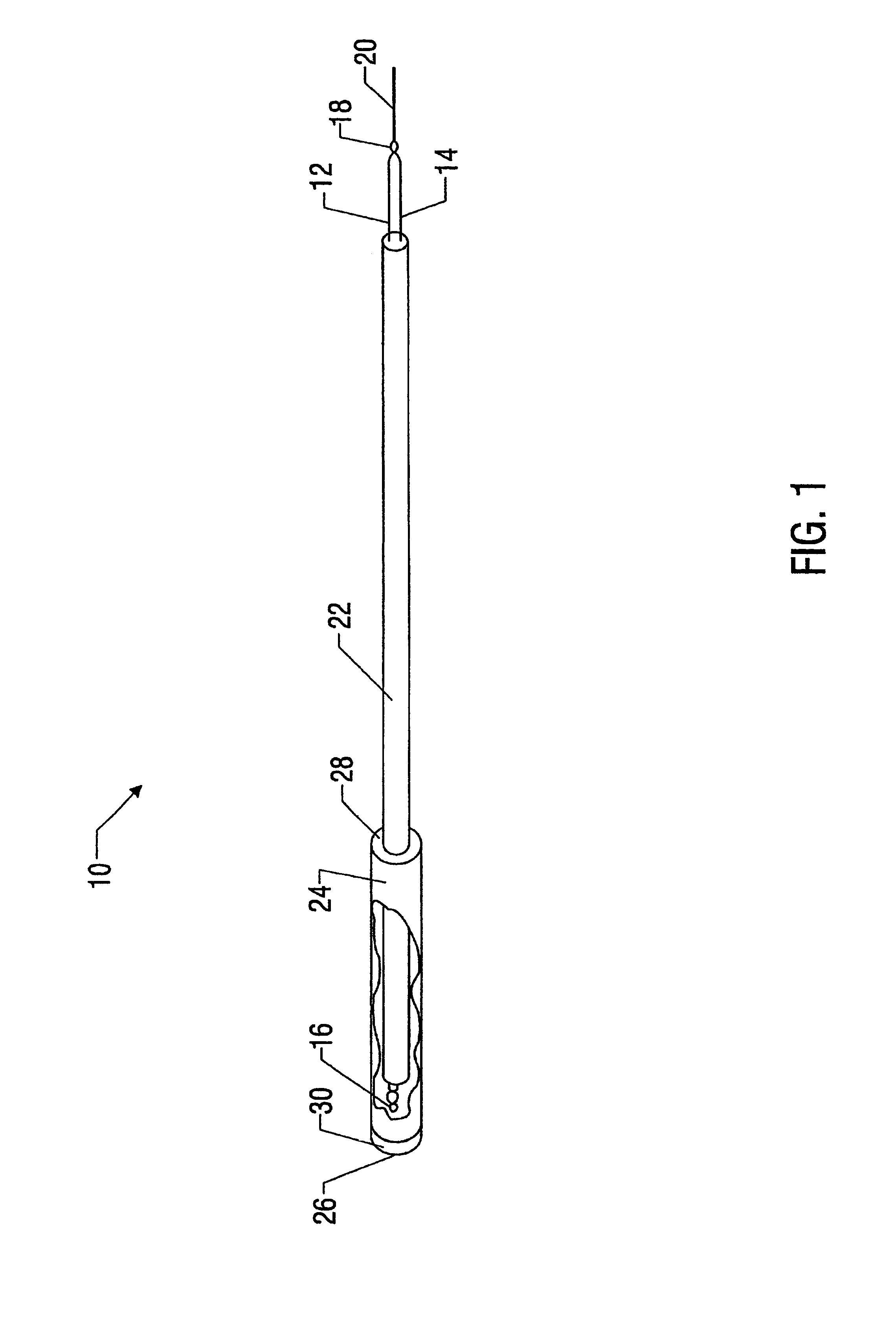

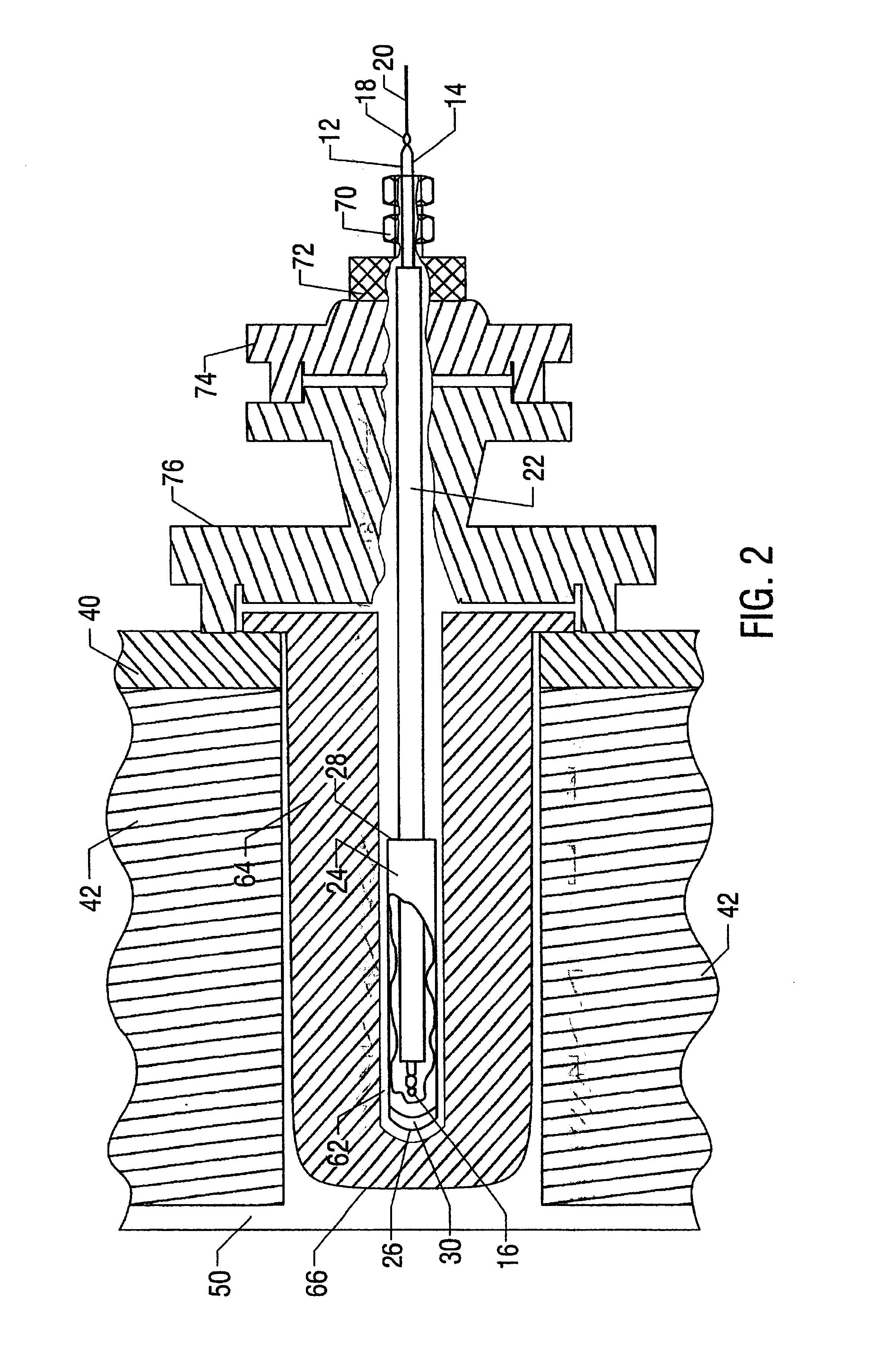

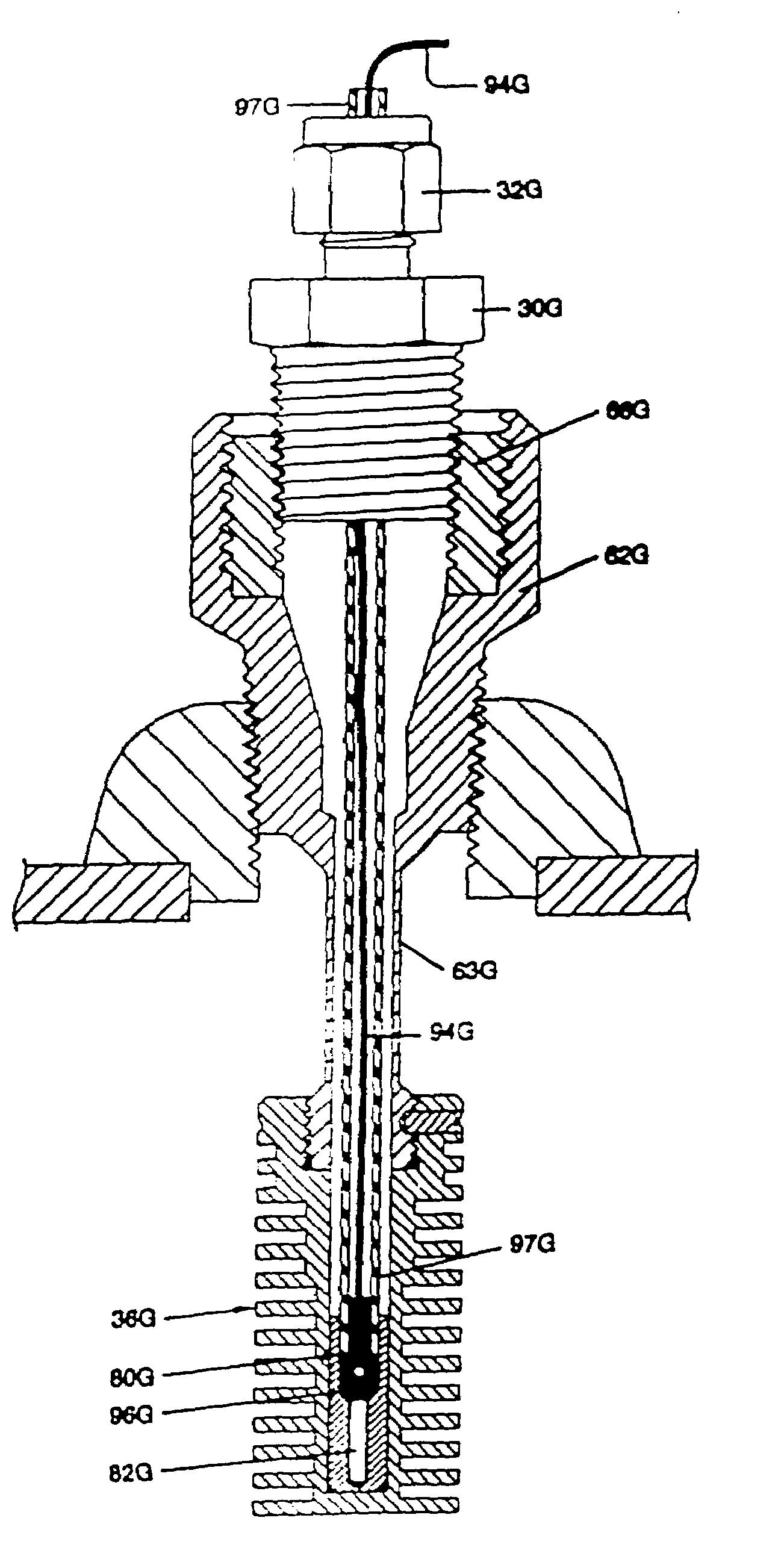

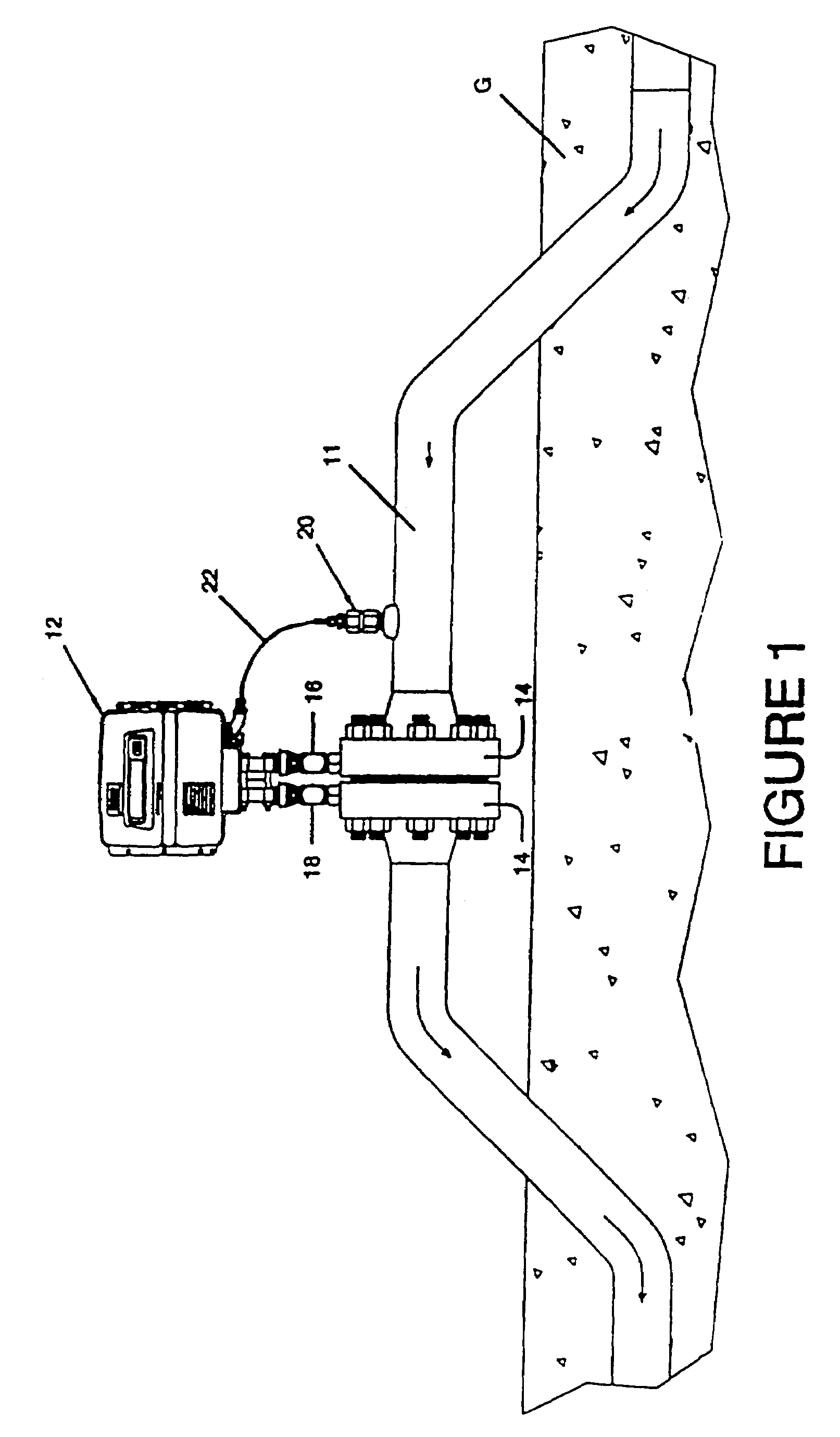

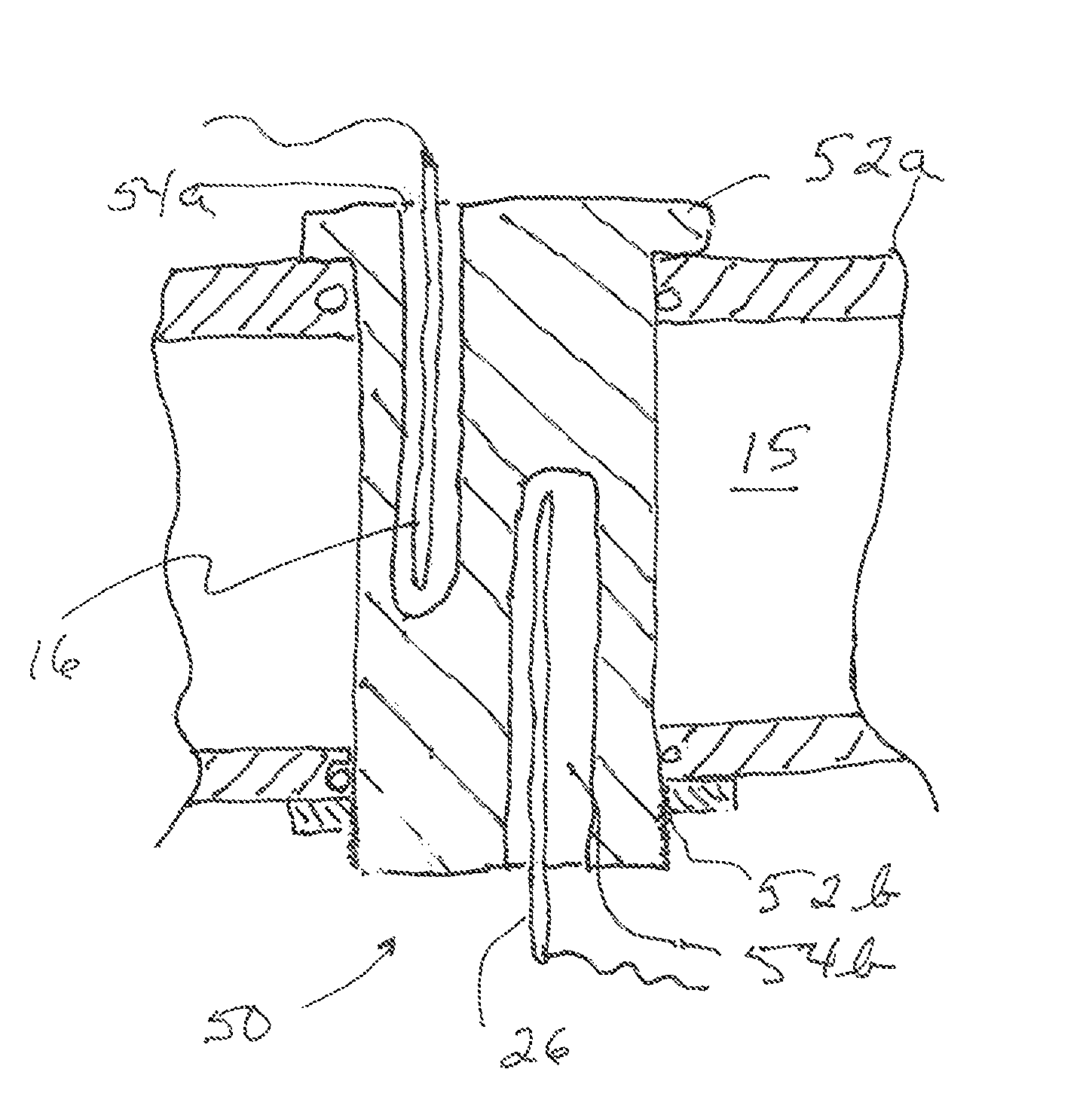

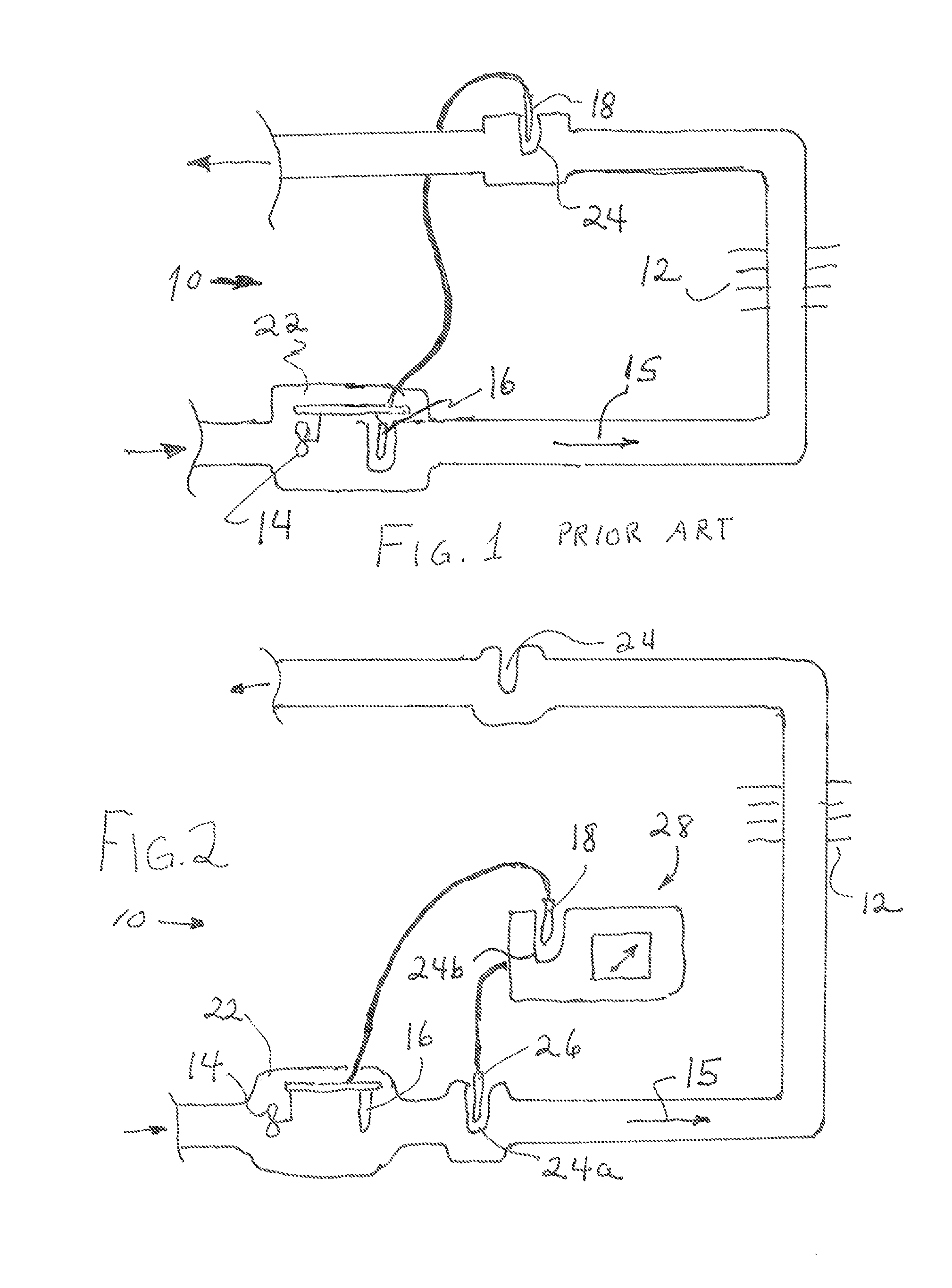

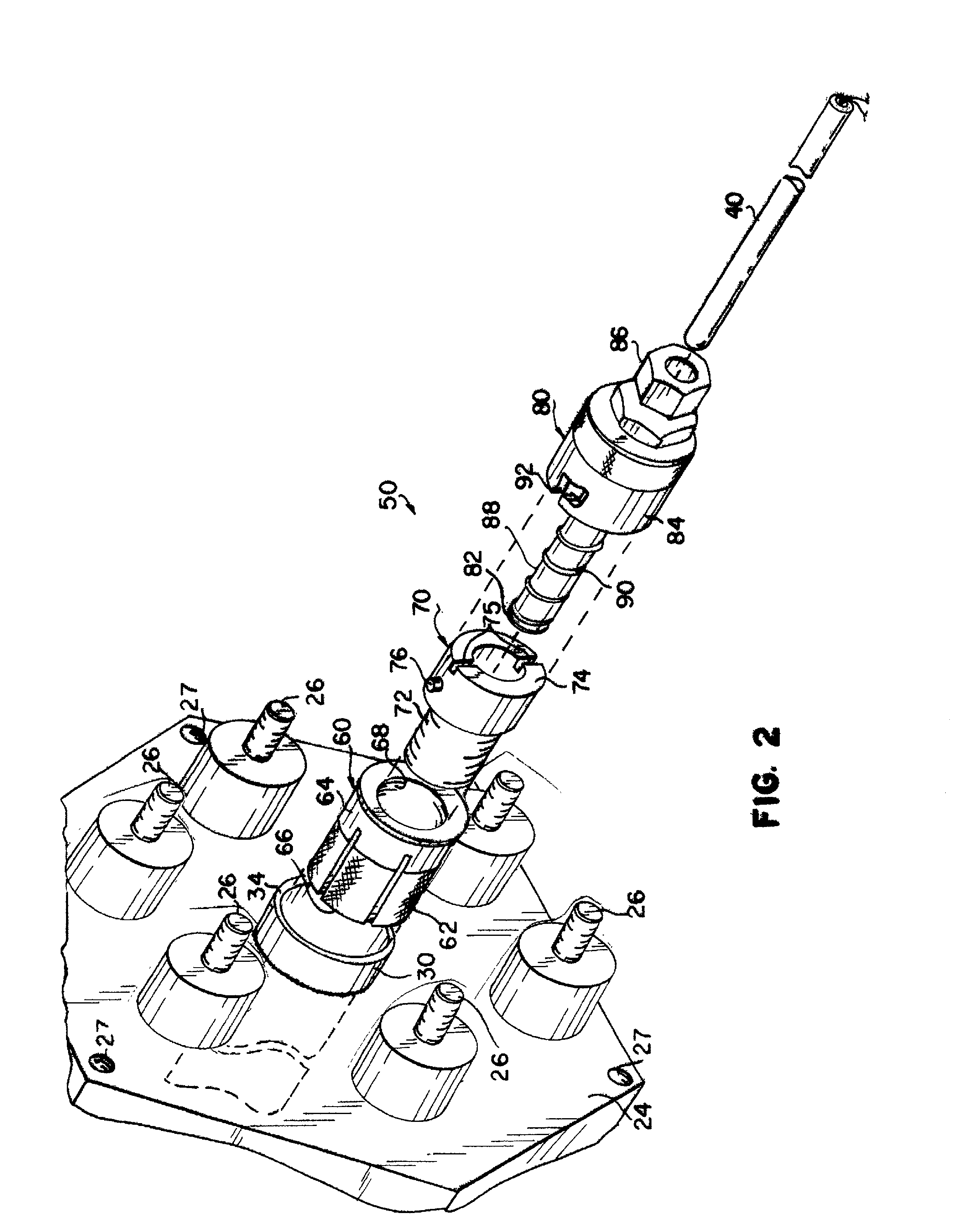

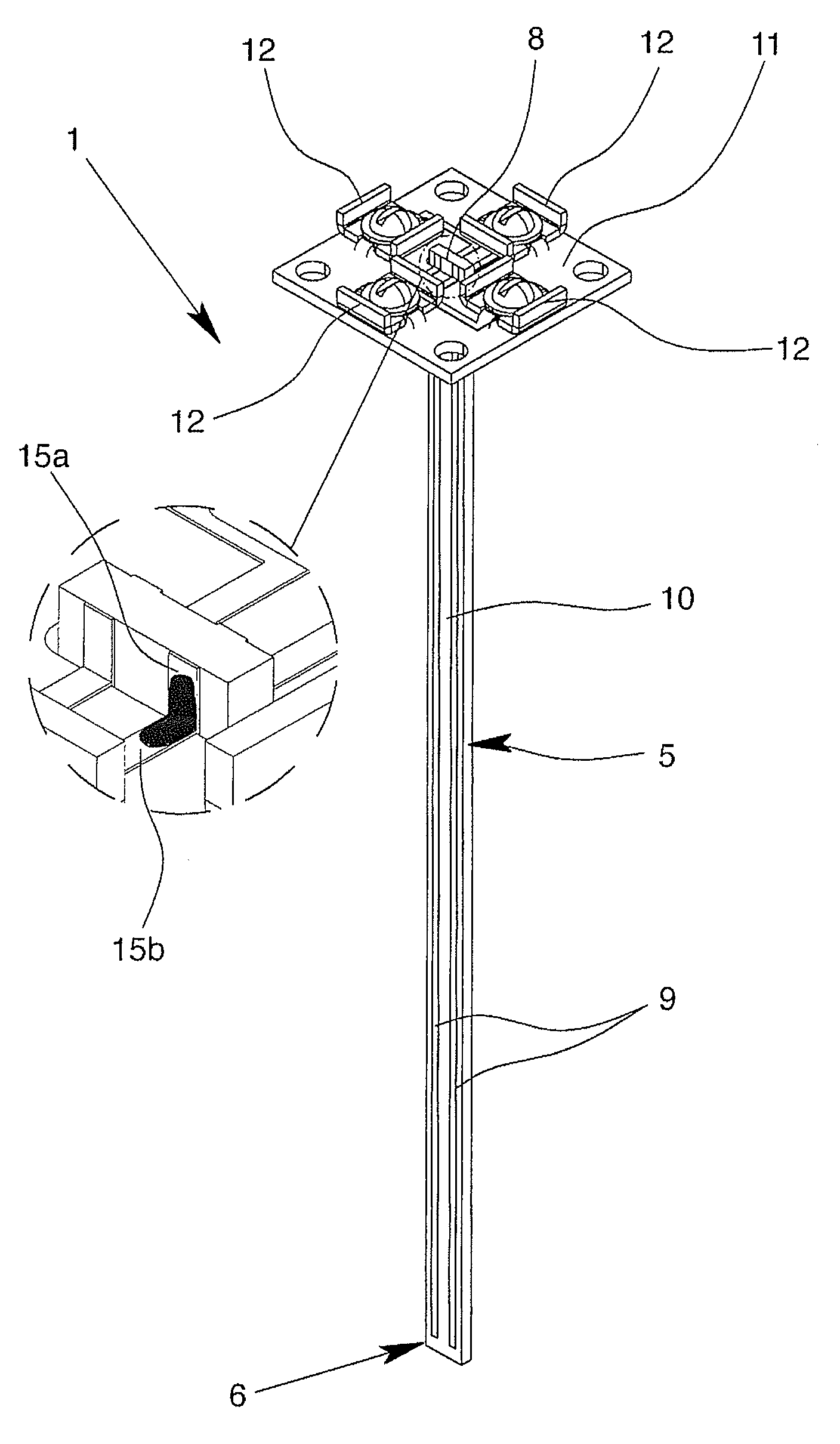

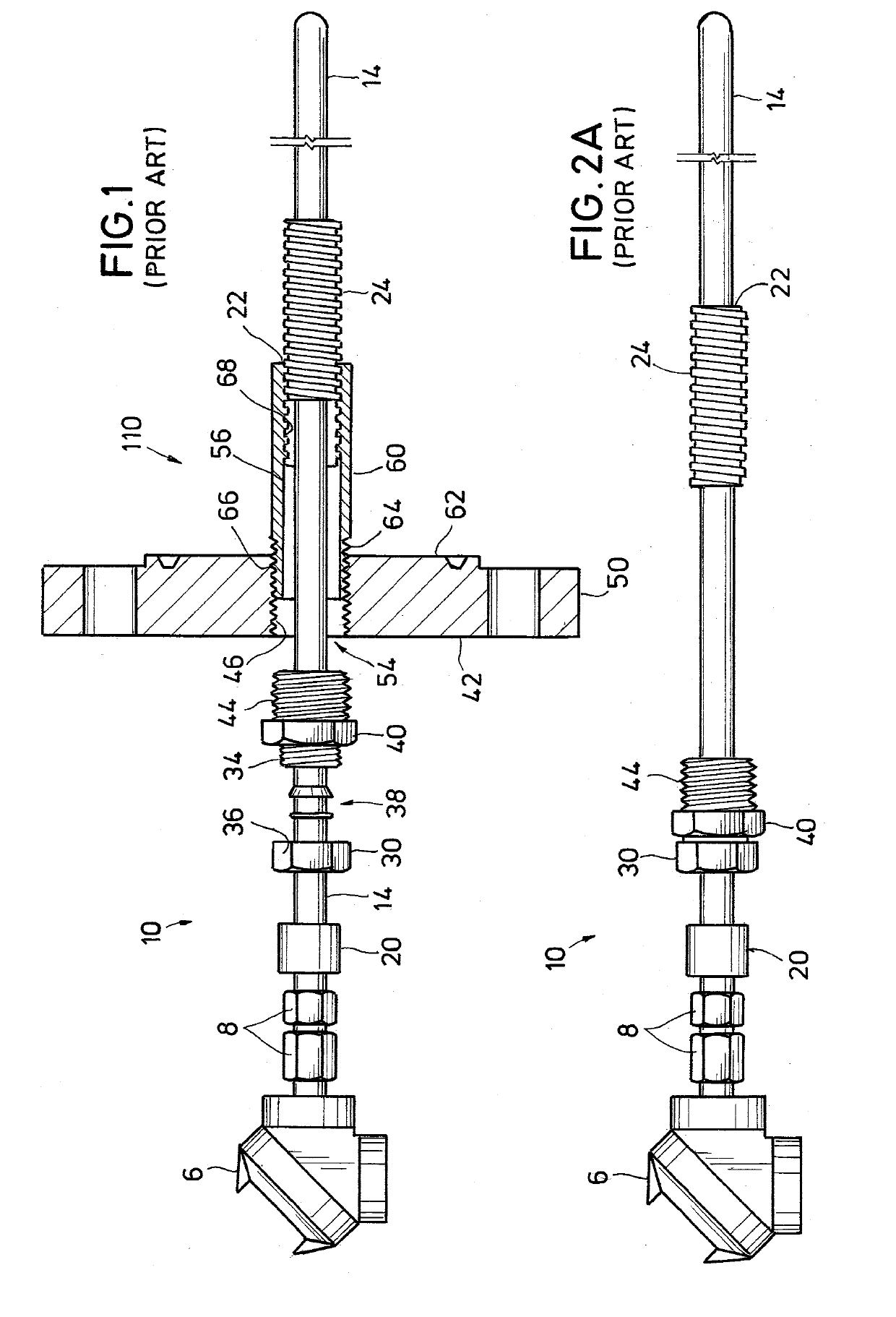

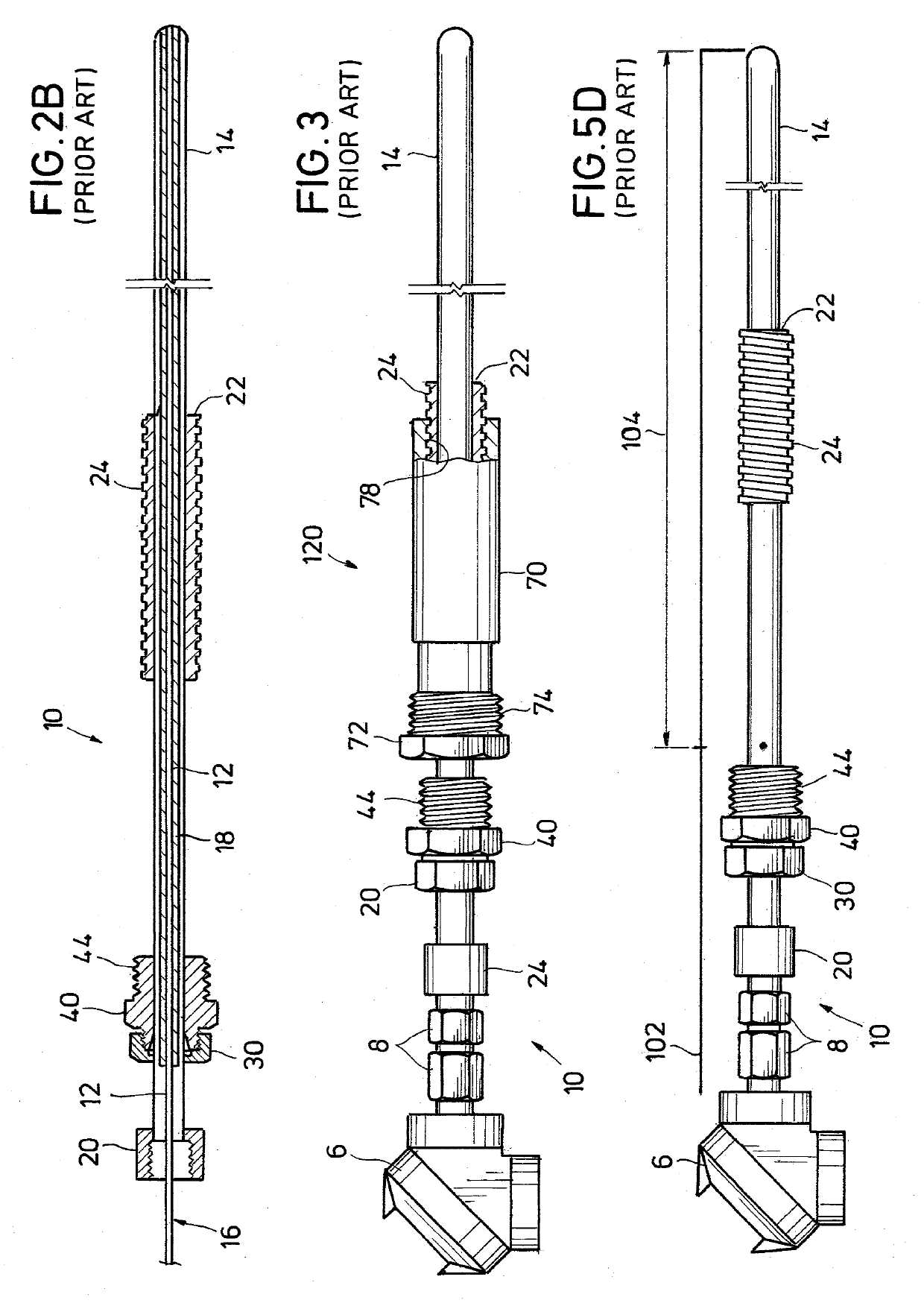

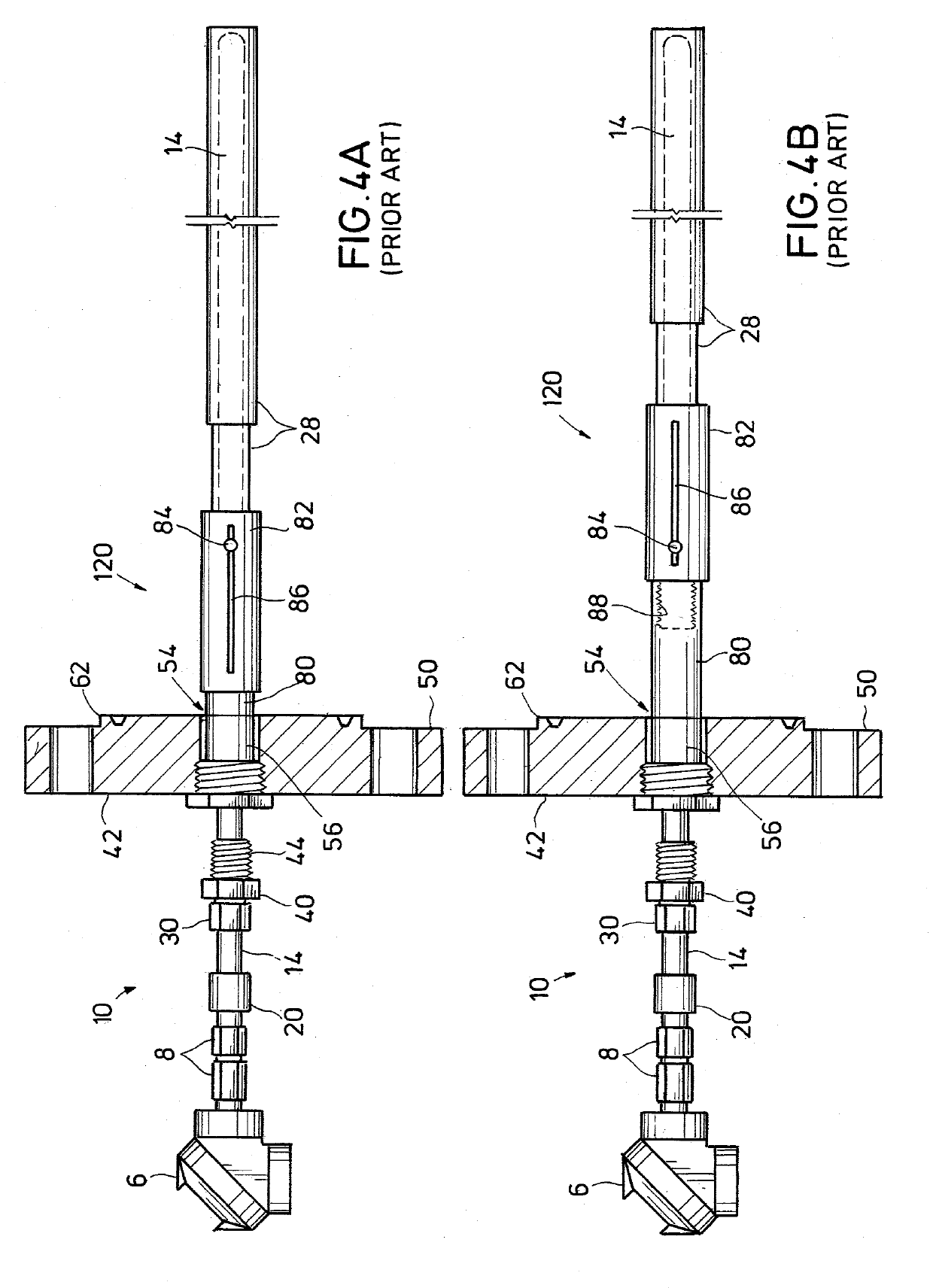

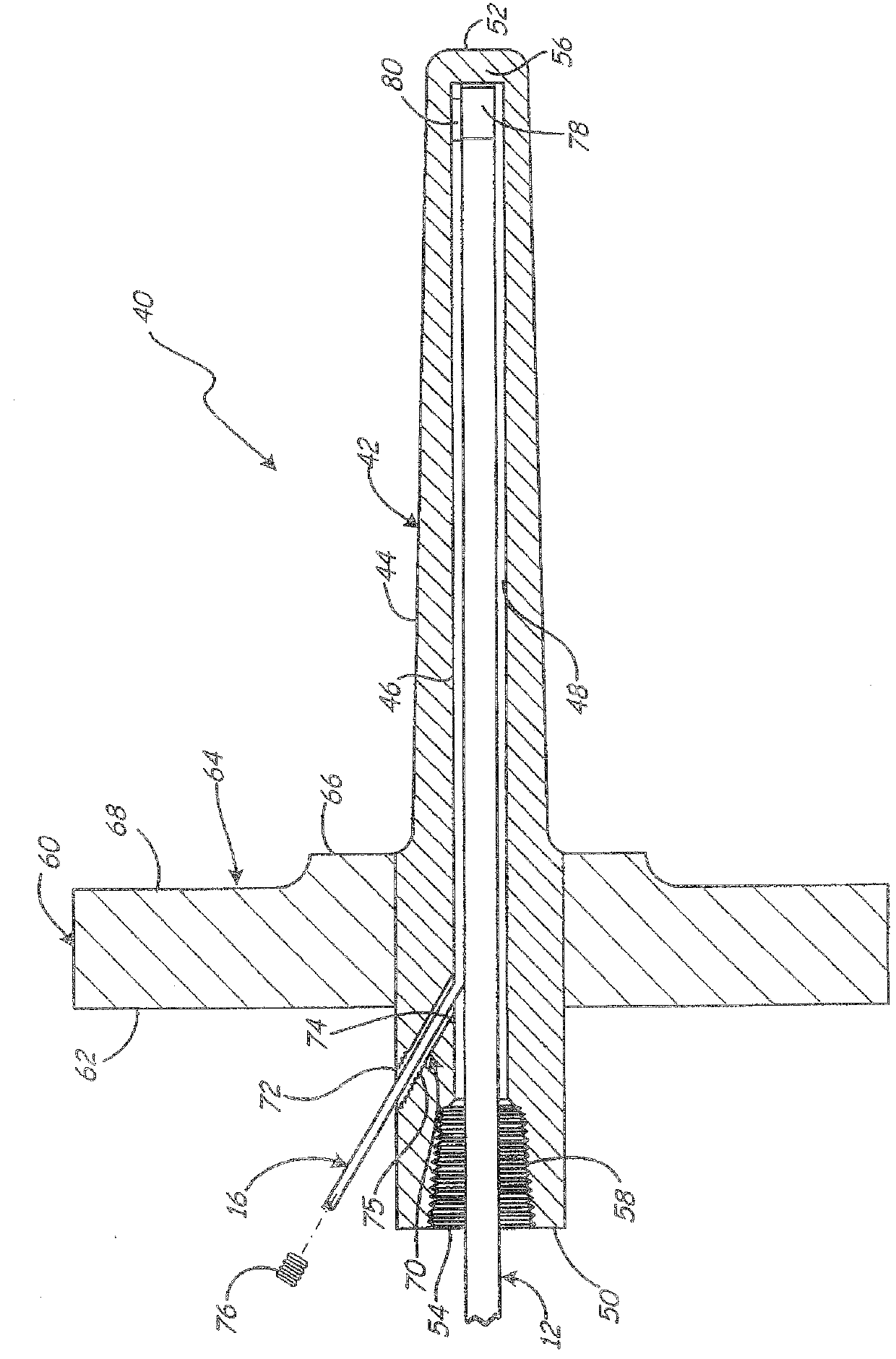

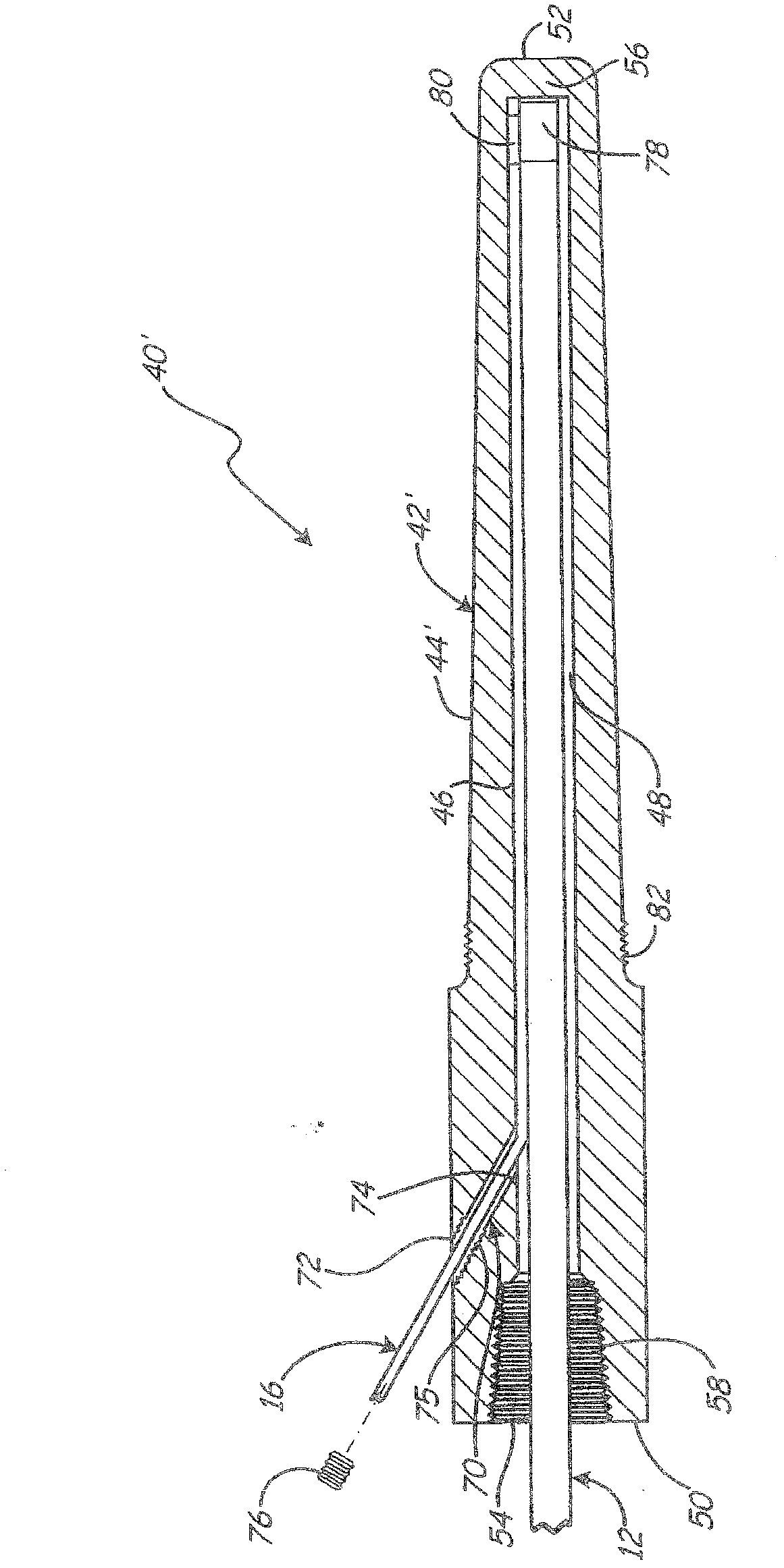

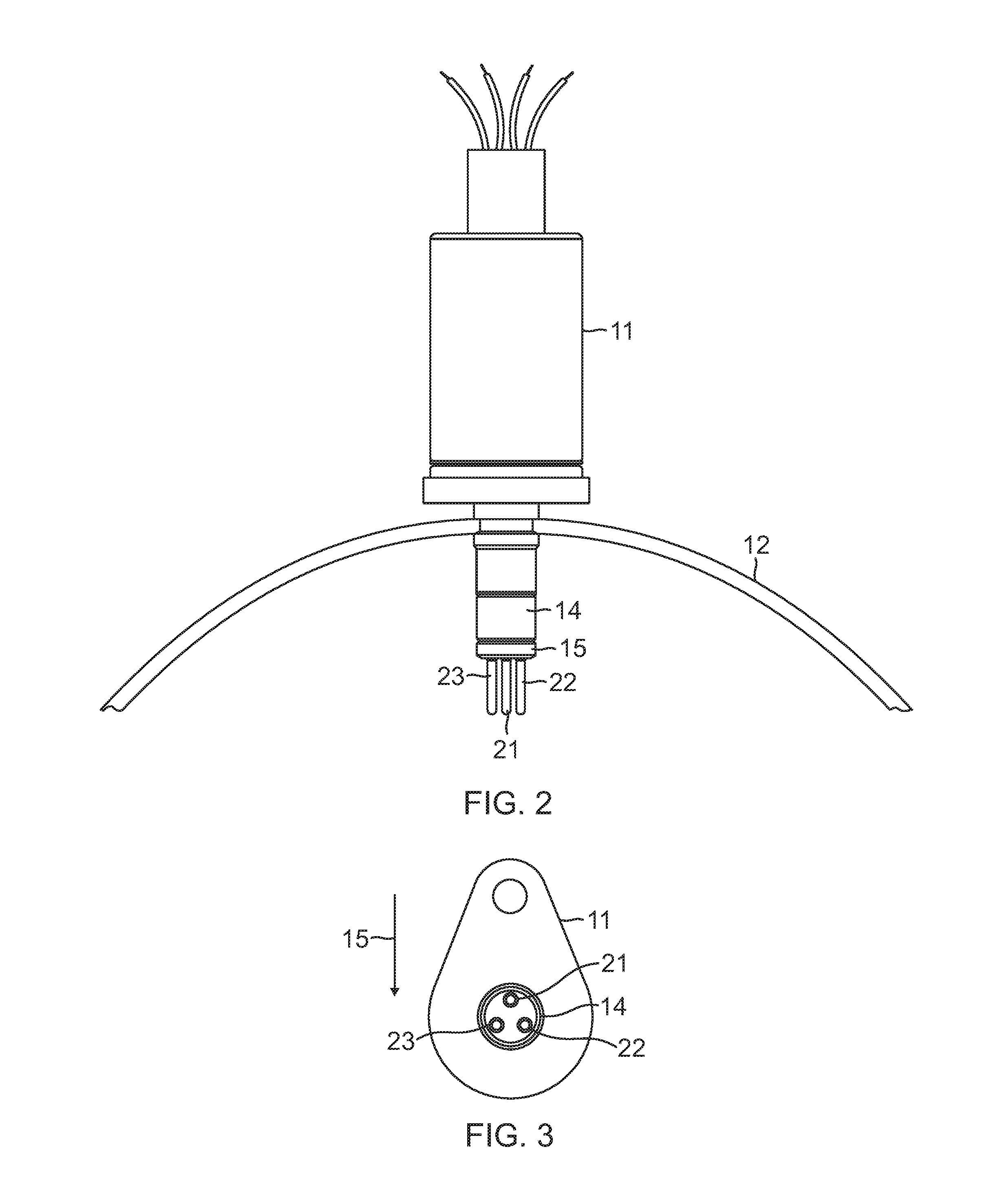

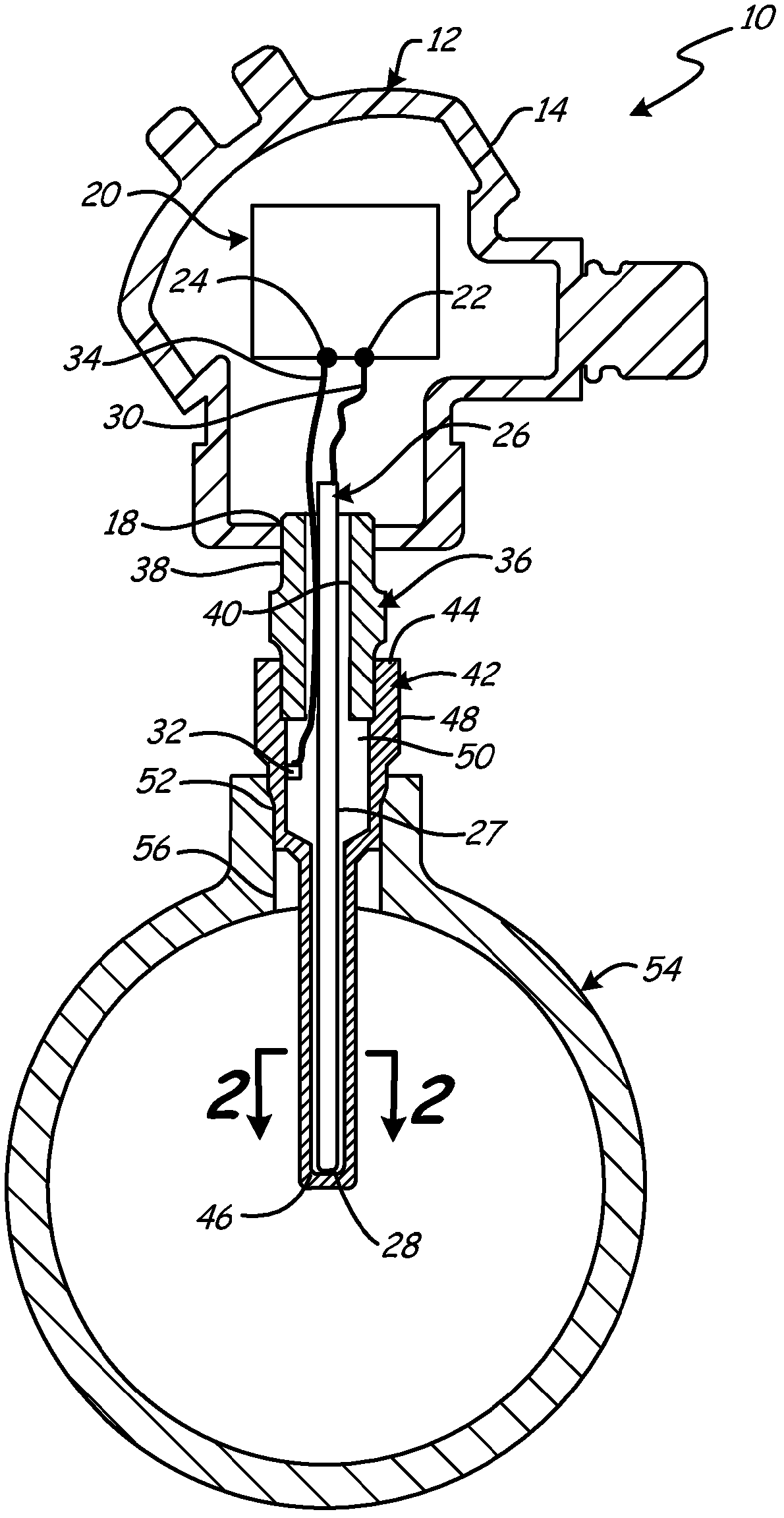

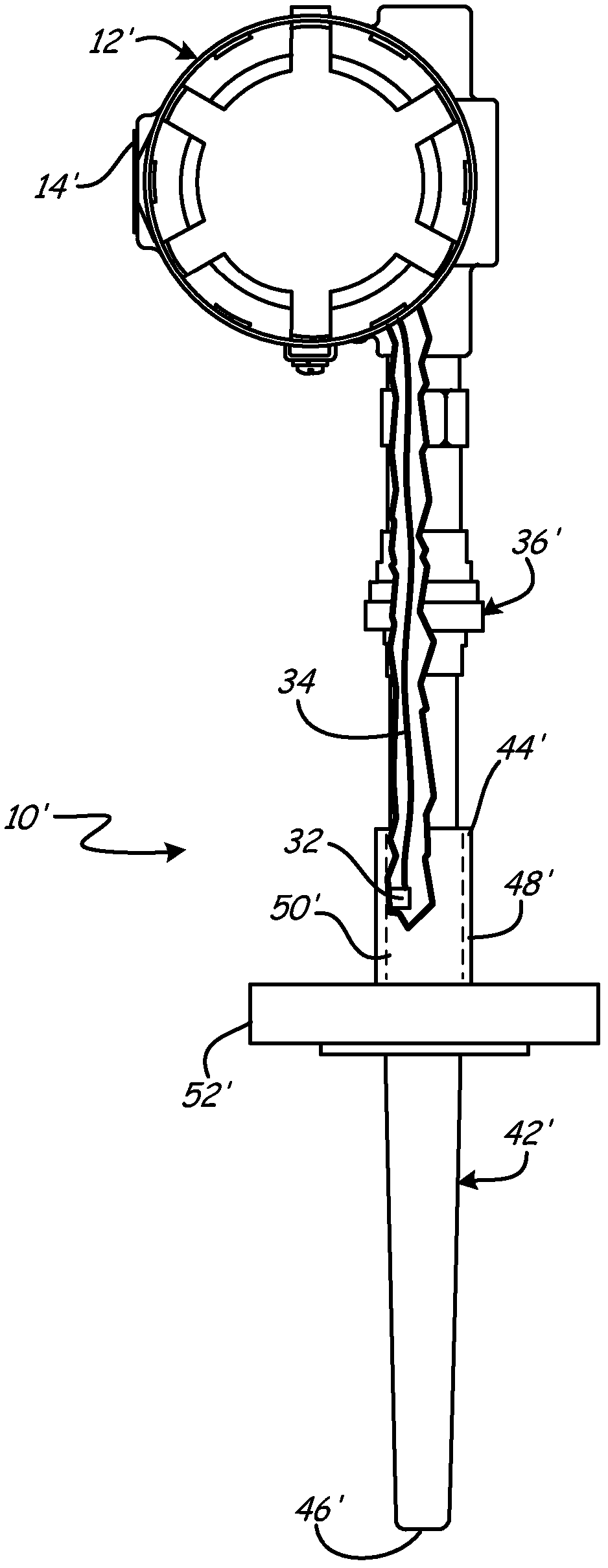

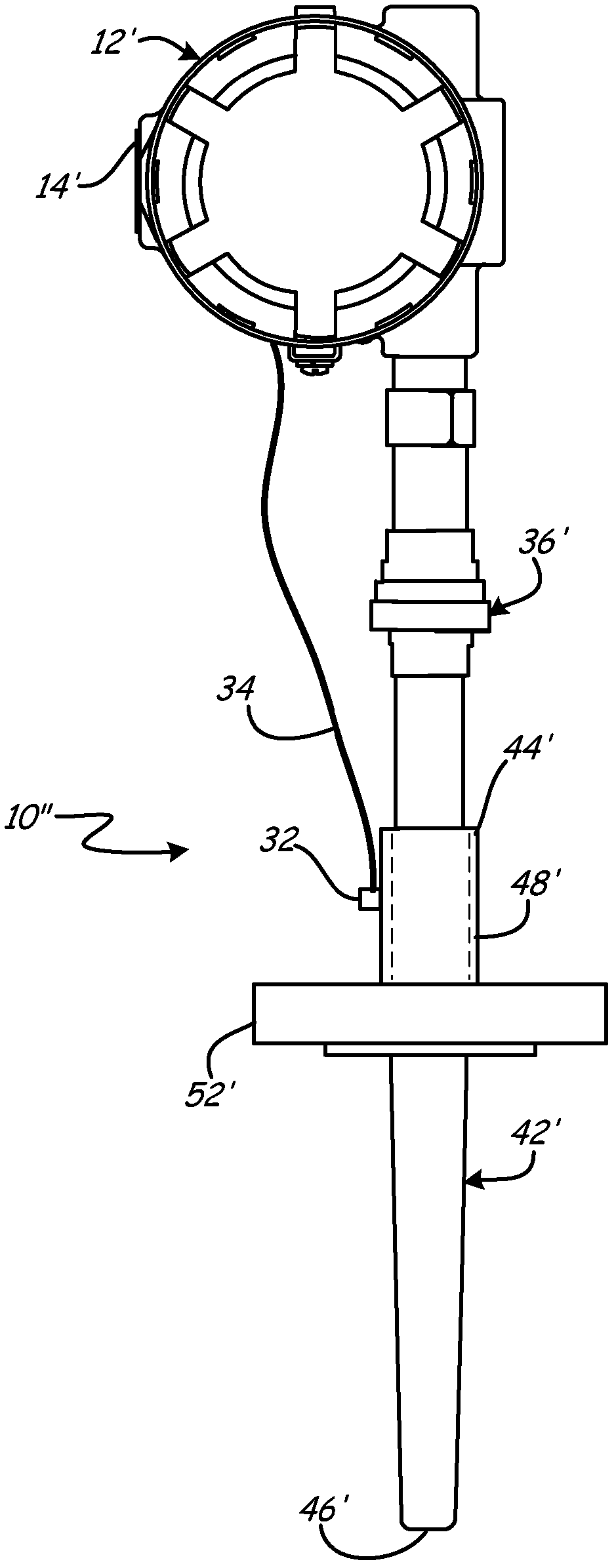

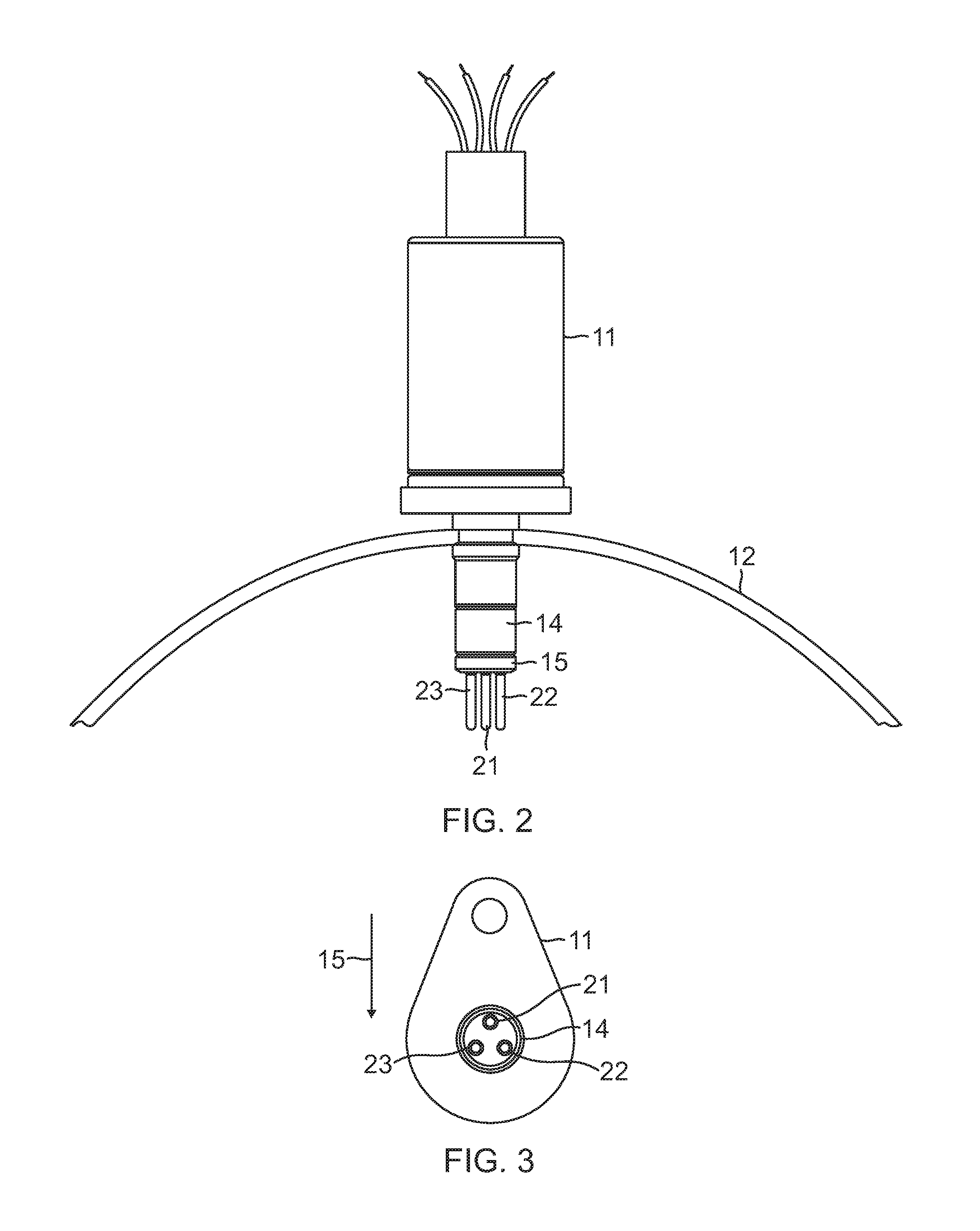

A thermowell assembly (20) shown in FIG. 2 is positioned in a pipeline (10) for sensing the temperature of the fluid medium in the pipeline (10) for transmitting the sensed temperature to a meter (12). A temperature sensing probe is received within a temperature conducting tube (36) forming a thermowell and having a plurality of annular fins (40) extending thereabout. In the embodiments of FIGS. 1-7, a liquid (50) is provided in an annular space between the thermocouple (28) and the temperature conducting tube (36). Non-metallic members (70, 74, 80) are positioned between the pipeline (10) and the temperature transmitting tube (36) to isolate thermocouple (28) from ambient changes in the temperature of metal pipeline (10) which may result in an error in the temperature of the flow medium sensed by the thermowell assembly (20). High temperature embodiments shown in FIGS. 4 and 5 do not contain any non-metal components and provide a minimal metal to metal contact between the metallic temperature conducting tube (36B) of the thermowell (20B) and the adjacent metal mounting structure (52B, 62B). The embodiments shown in FIGS. 8-12 illustrate a temperature sensing probe comprising a temperature sensing assembly (80F, 80G) mounted within the internal bore (37F, 37G) of the finned tube (36F, 36G). The temperature sensing assembly (80F, 80G) includes a carrier (82F, 81G) with epoxy (96F, 96G) mounting a temperature sensing element (93F, 93G) within the carrier (82F, 81G).

Owner:PARKER INTANGIBLES LLC

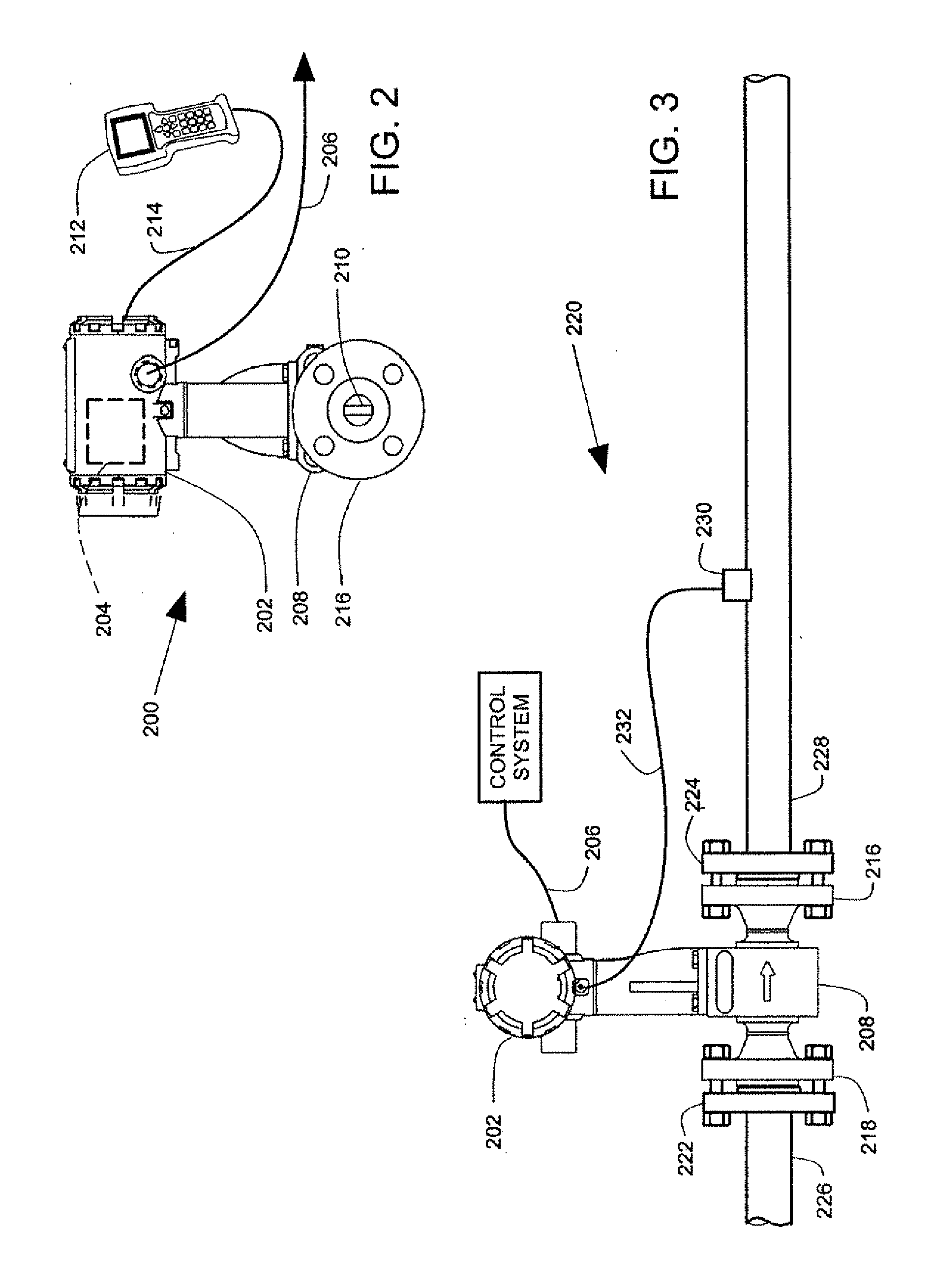

Vortex flowmeter with temperature compensation

ActiveUS20080141769A1Thermometer detailsVolume/mass flow by thermal effectsEddy-current sensorThermowell

A vortex flowmeter has a vortex sensor and terminals that receive a thermal junction output from a thermowell assembly that is remote from the vortex flowmeter. The vortex flowmeter has a data input that receives data representing a thermal property of the thermowell assembly. The vortex flowmeter has a circuit that receives the first thermal junction output and the vortex sensor output, and that provides a flowmeter output that is compensated for temperature and for the thermal property.

Owner:MICRO MOTION INC

Thermocouple for use in gasification process

InactiveUS7036983B2Extend your lifeThermometer detailsThermometers using electric/magnetic elementsThermowellBiomedical engineering

An improved apparatus comprising a thermocouple for measuring the temperature in a gasification process is provided. The improvement comprises a sapphire envelope for enclosing at least a portion of the thermocouple. The sapphire envelope may be in the form of a sapphire sheath fitted over the thermocouple. The apparatus may also comprise a thermowell, with the sapphire envelope being provided by the thermowell.

Owner:GENERAL ELECTRIC CO

Temperature sensing device for metering fluids

InactiveUS7165883B2Improve thermal conductivityImproves rate of temperature transferThermometer detailsThermometers using electric/magnetic elementsEpoxyEngineering

A thermowell assembly (20) shown in FIG. 2 is positioned in a pipeline (10) for sensing the temperature of the fluid medium in the pipeline (10) for transmitting the sensed temperature to a meter (12). A temperature sensing probe is received within a temperature conducting tube (36) forming a thermowell and having a plurality of annular fins (40) extending thereabout. In the embodiments of FIGS. 1–7, a liquid (50) is provided in an annular space between the thermocouple (28) and the temperature conducting tube (36). Non-metallic members (70, 74, 80) are positioned between the pipeline (10) and the temperature transmitting tube (36) to isolate thermocouple (28) from ambient changes in the temperature of metal pipeline (10) which may result in an error in the temperature of the flow medium sensed by the thermowell assembly (20). High temperature embodiments shown in FIGS. 4 and 5 do not contain any non-metal components and provide a minimal metal to metal contact between the metallic temperature conducting tube (36B) of the thermowell (20B) and the adjacent metal mounting structure (52B, 62B). The embodiments shown in FIGS. 8–12 illustrate a temperature sensing probe comprising a temperature sensing assembly (80F, 80G) mounted within the internal bore (37F, 37G) of the finned tube (36F, 36G). The temperature sensing assembly (80F, 80G) includes a carrier (82F, 81G) with epoxy (96F, 96G) mounting a temperature sensing element (93F, 82G) within the carrier (82F, 81G).

Owner:PARKER INTANGIBLES LLC

Device and method for measuring temperature in a tubular fixed-bed reactor

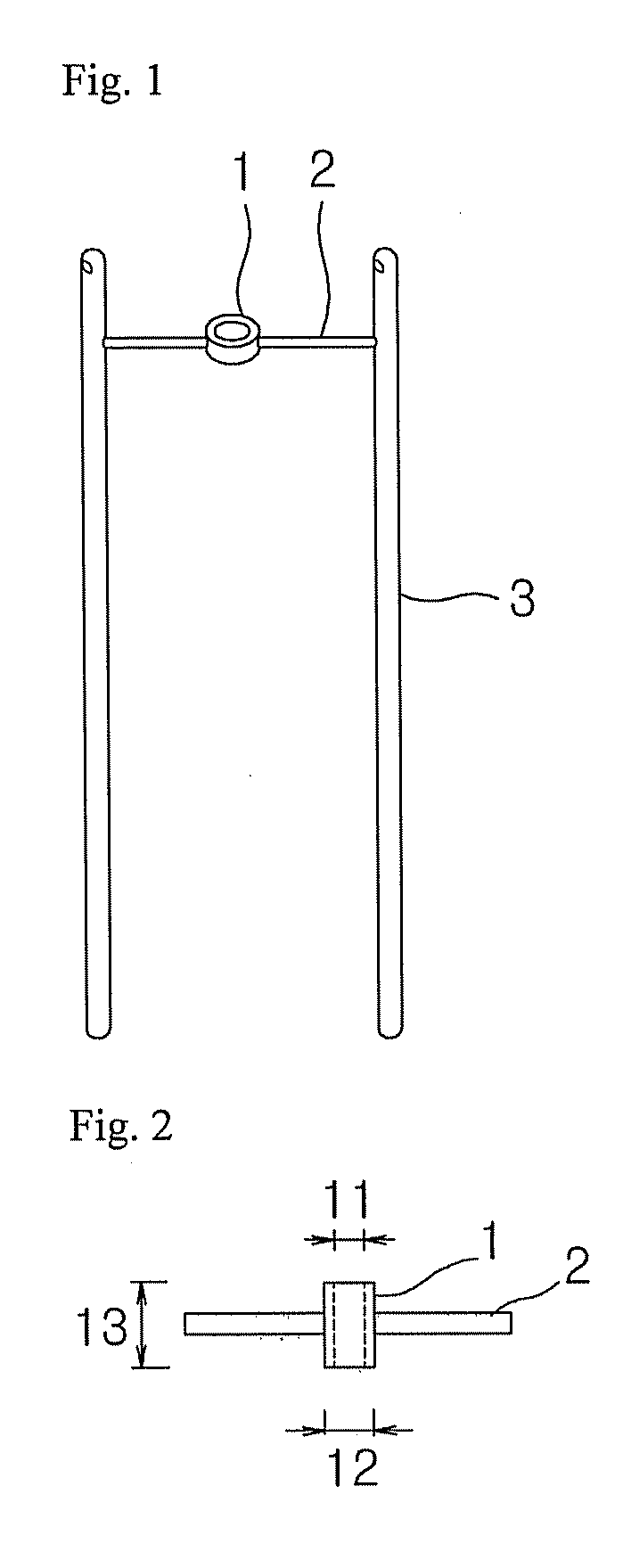

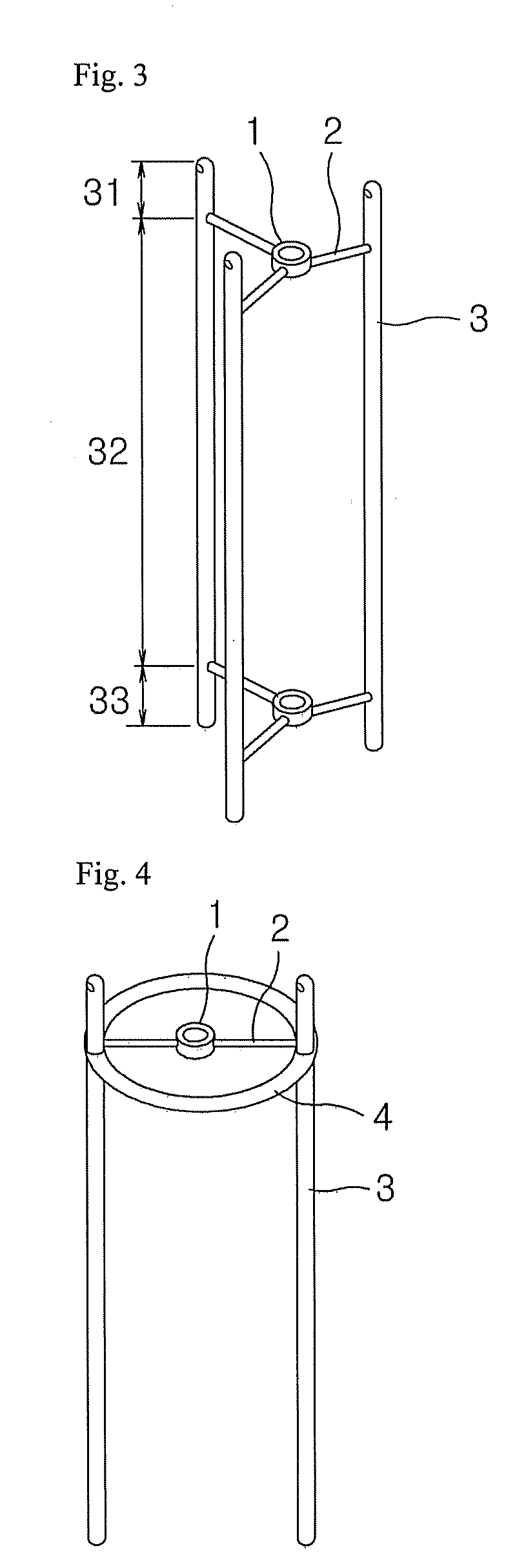

ActiveUS20070116090A1Efficient measurementThermometer detailsThermometer applicationsFixed bedEngineering

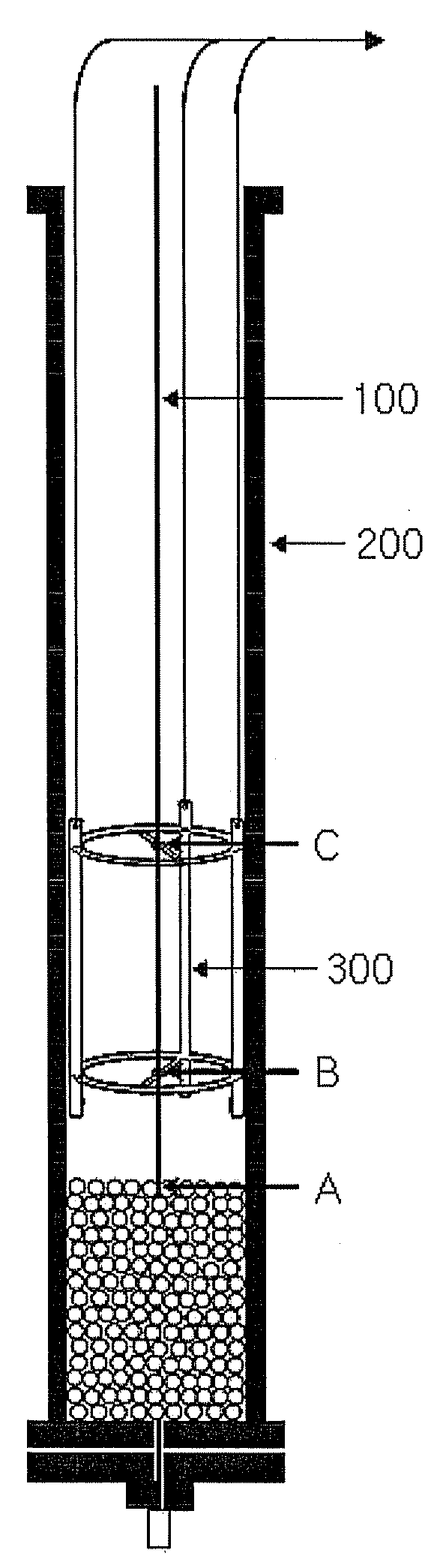

Disclosed is a structure for guiding the installation of a thermowell for temperature sensor, which is used to measure the axial temperature inside a fixed-bed catalyst reaction tube when it is filled with a catalyst, at a predetermined location in the reaction tube. In addition, a method for installing a thermowell for temperature sensor is provided. The method includes the steps of installing a structure for guiding the installation of a thermowell for temperature sensor in a reaction tube and fixing the thermowell for temperature sensor while filling the reaction tube with a catalyst.

Owner:LG CHEM LTD

Calibration apparatus and method for heat transfer measurement

A calibrator for calibrating a compatible heat transfer meter comprises a temperature controlled reference thermowell and a reference temperature sensor. The reference thermowell is similar in dimensions to thermowells usable for measuring inlet and outlet temperatures of a heat exchanger so that the reference temperature sensor is selectively insertable into any of the thermowells. The calibrator also comprises temperature measurement circuitry operable to generate a temperature reading from an output of the reference temperature sensor; and control circuitry operable to control the temperature of the reference thermowell.

Owner:ONICON INC

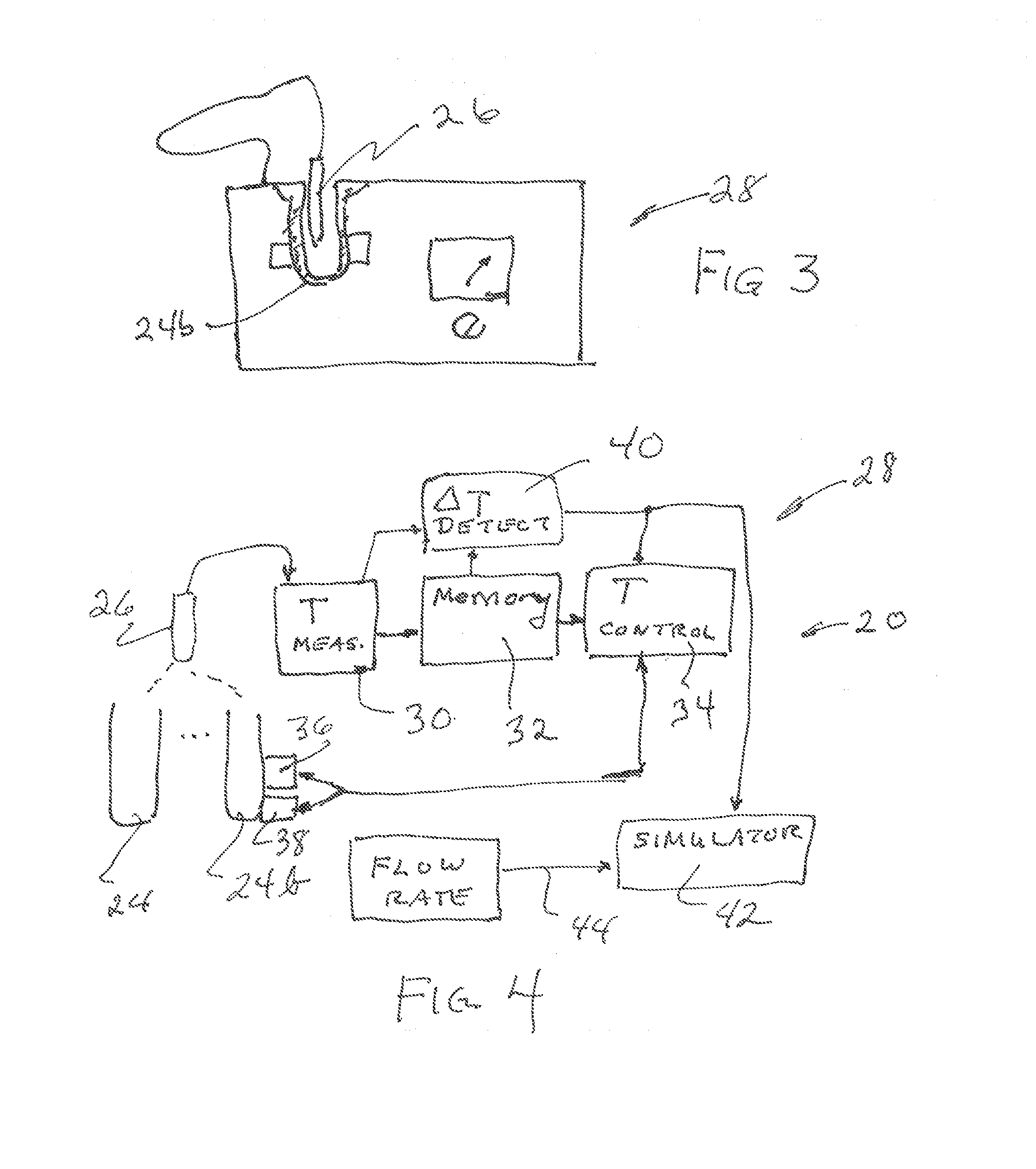

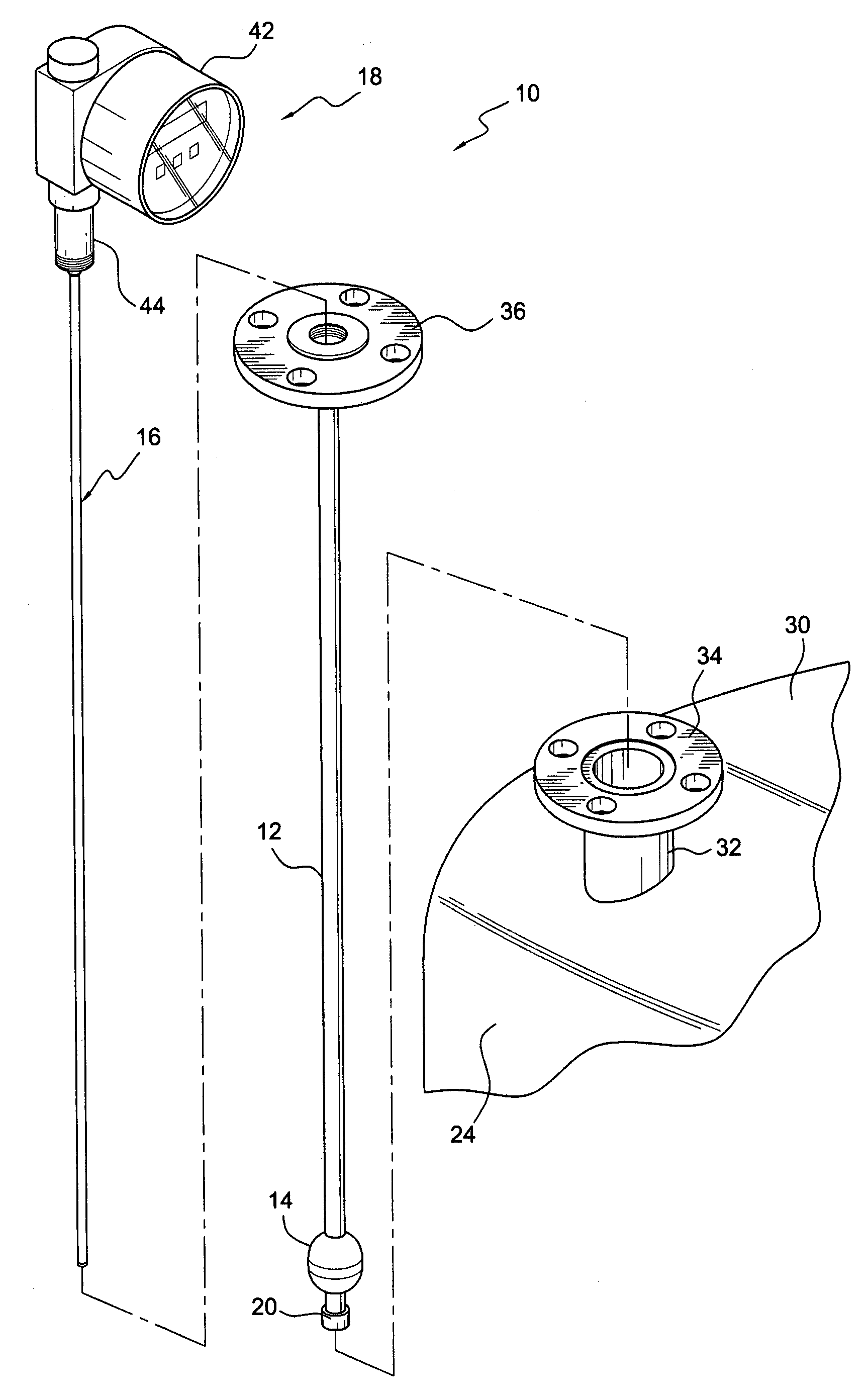

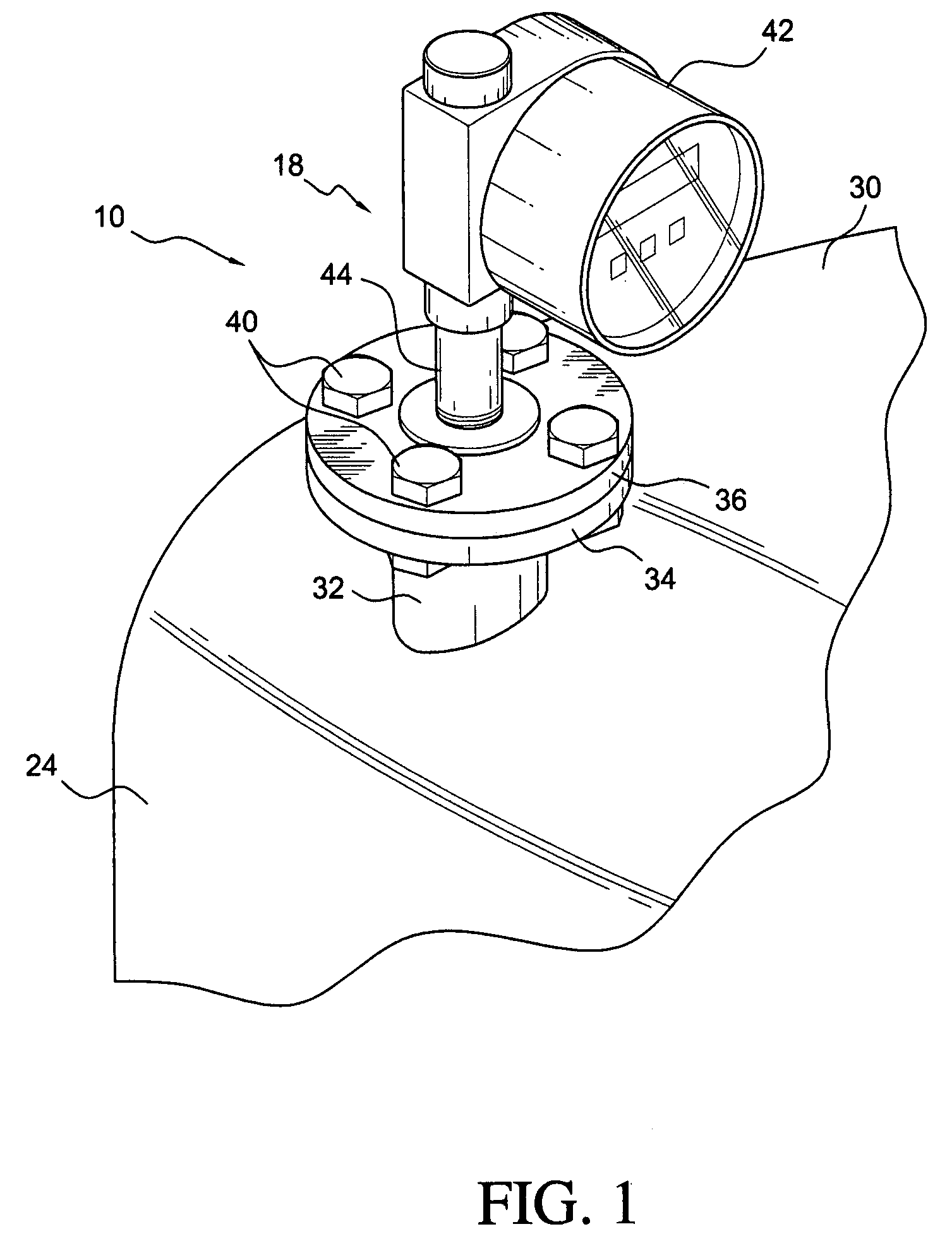

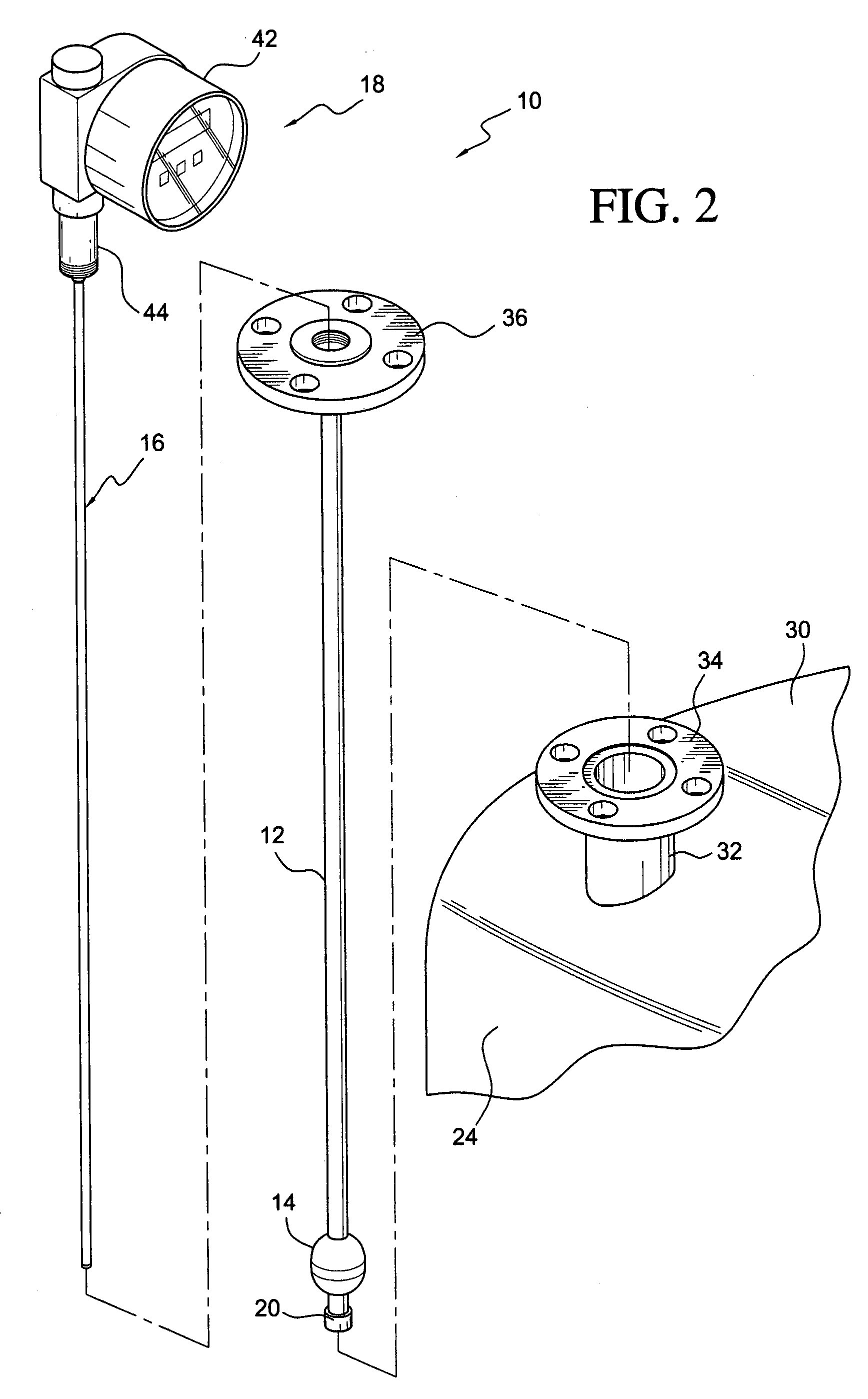

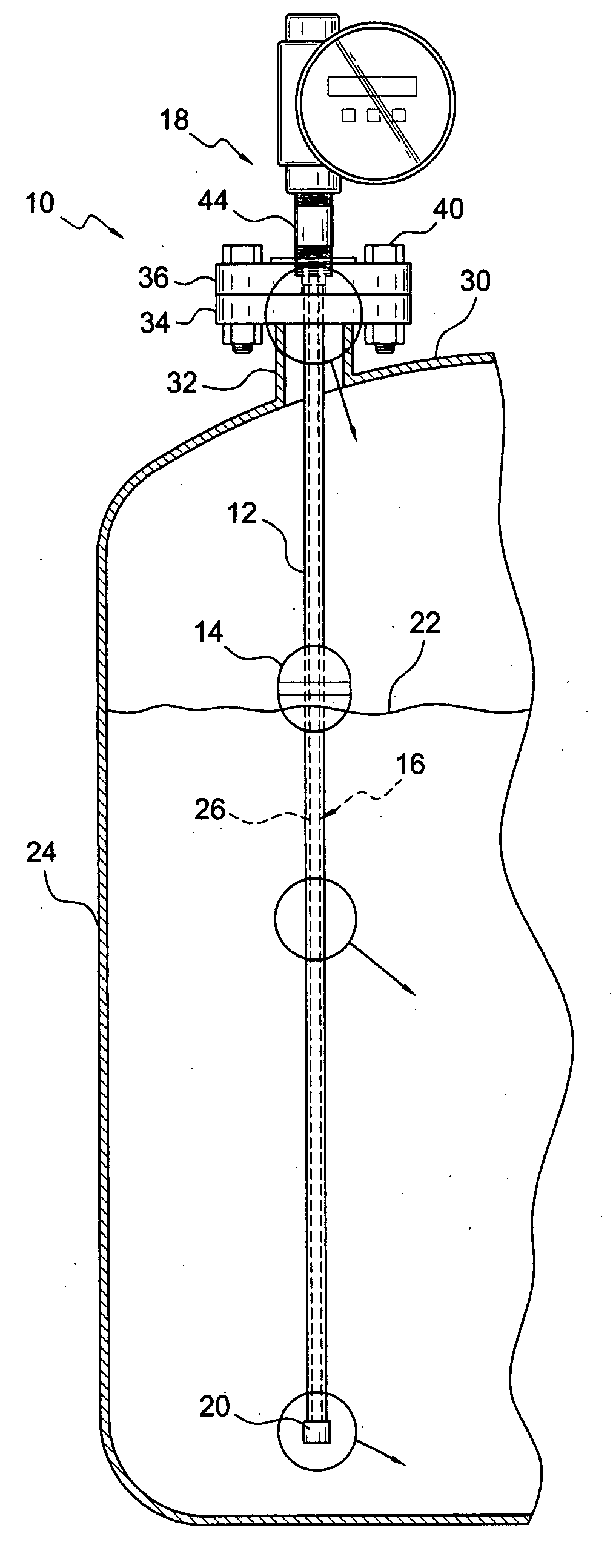

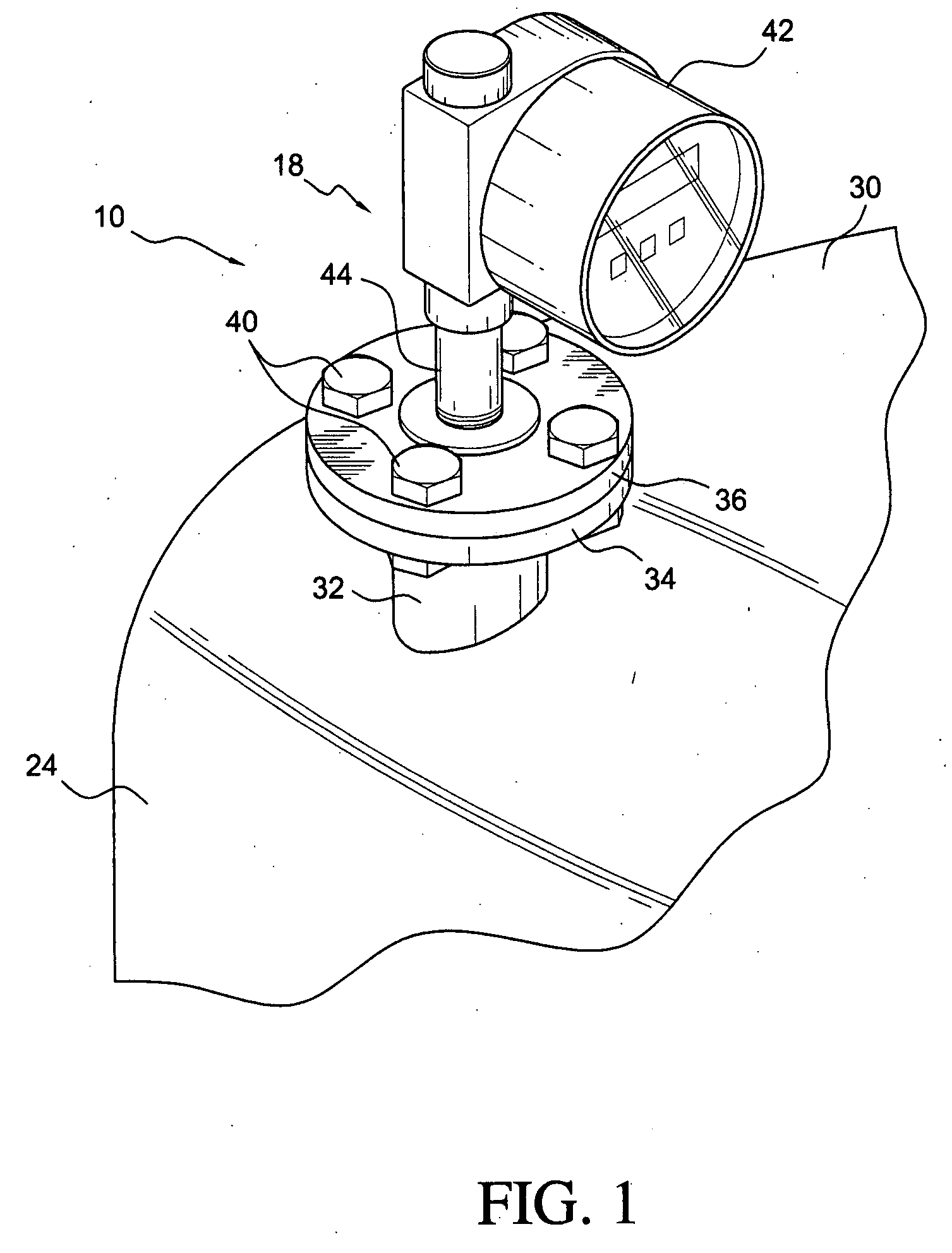

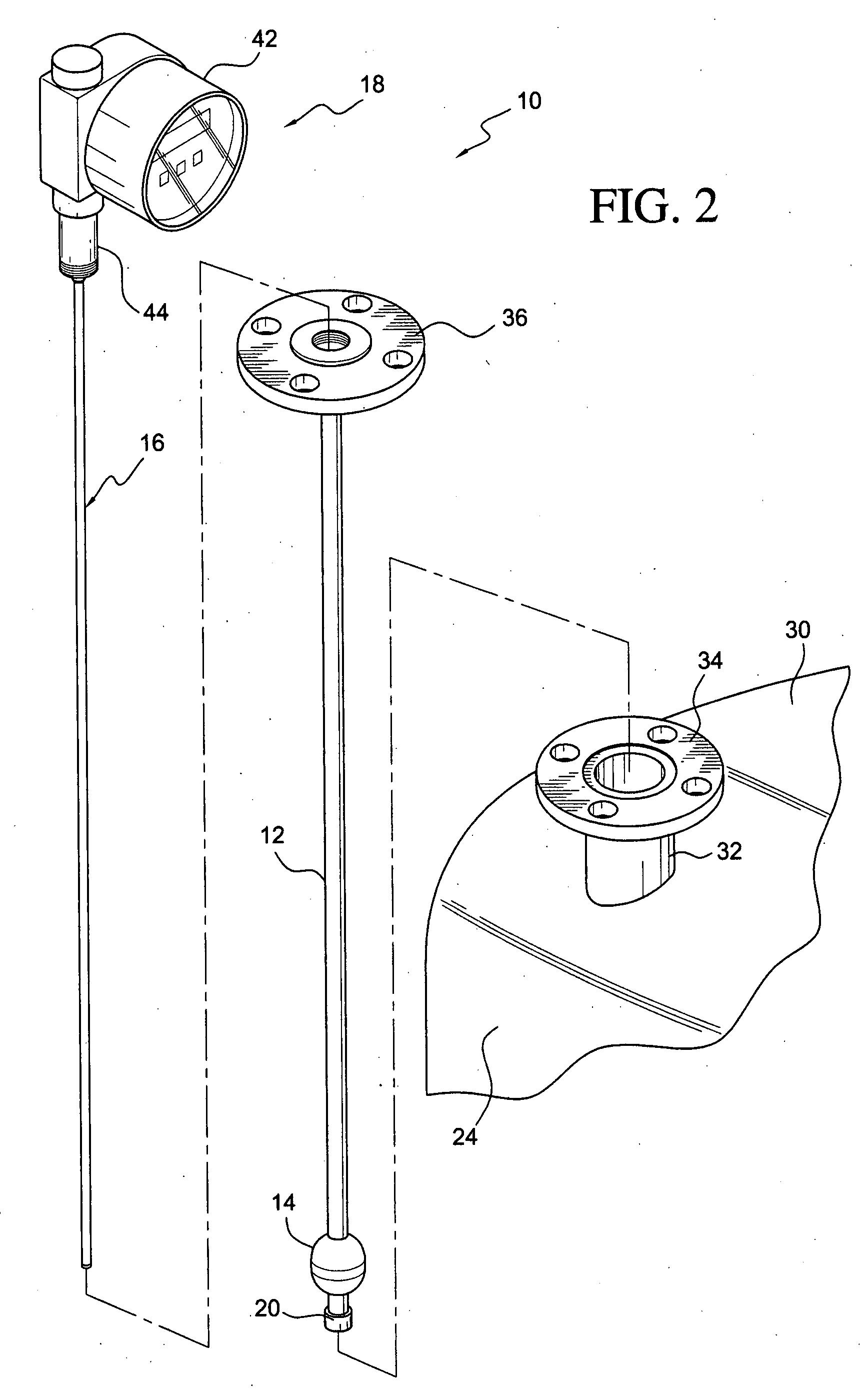

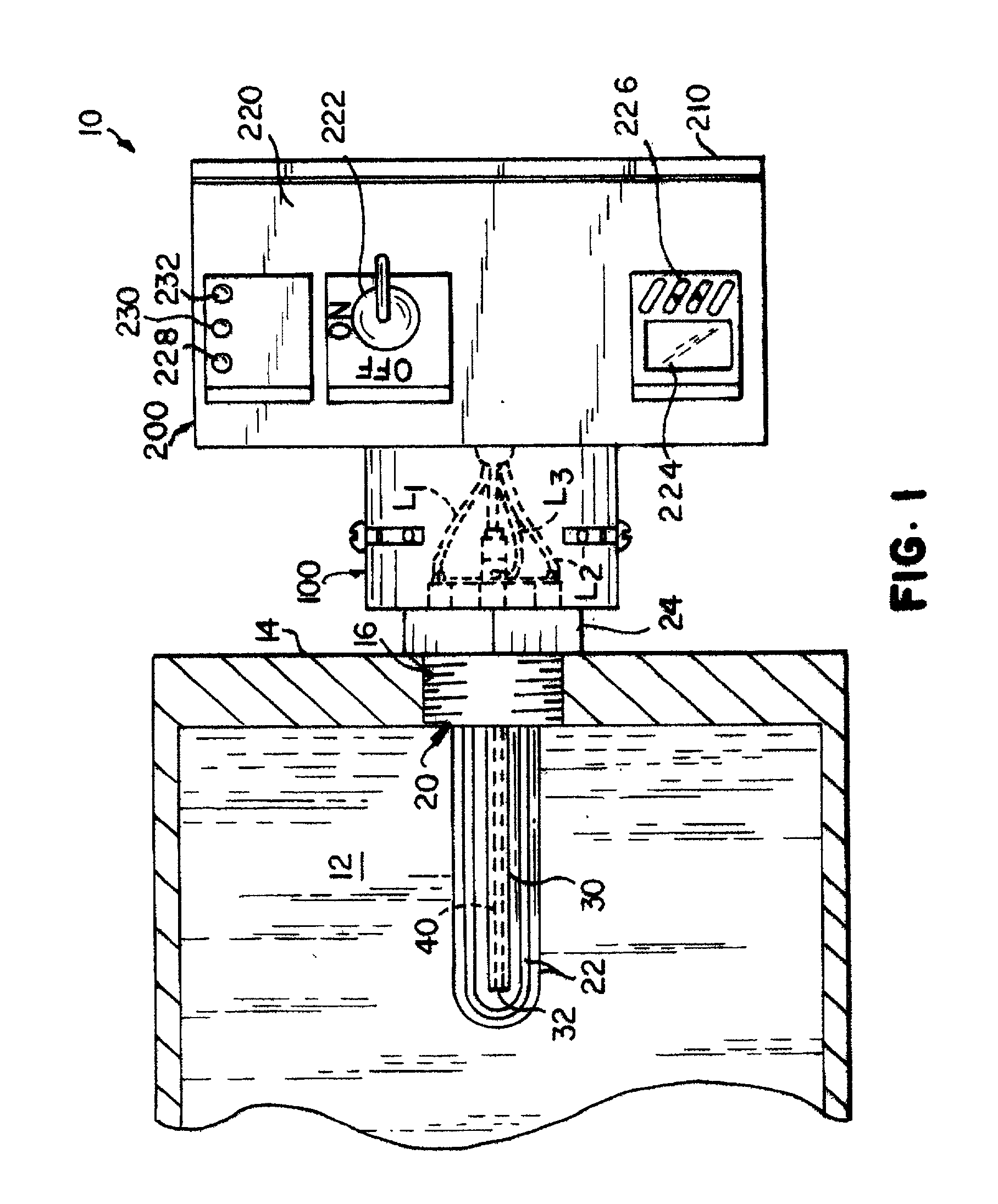

Electronic level gage assembly

A thermowell extends downwardly into tank liquids from the roof of the tank. A magnetostrictive wave guide probe is positioned on the inside of the thermowell and a magnetic float is slidably positioned on the outside of the thermowell. The probe is connected to a head unit containing the necessary electronics for operability which is positioned outside of the tank. The position of the float, and thus the liquid level, is remotely sensed by the probe, and the probe can be removed from the thermowell if necessary without breaking the seal of the tank.

Owner:JOGLER

Electronic level gage assembly

A thermowell extends downwardly into tank liquids from the roof of the tank. A magnetostrictive wave guide probe is positioned on the inside of the thermowell and a magnetic float is slidably positioned on the outside of the thermowell. The probe is connected to a head unit containing the necessary electronics for operability which is positioned outside of the tank. The position of the float, and thus the liquid level, is remotely sensed by the probe, and the probe can be removed from the thermowell if necessary without breaking the seal of the tank.

Owner:JOGLER

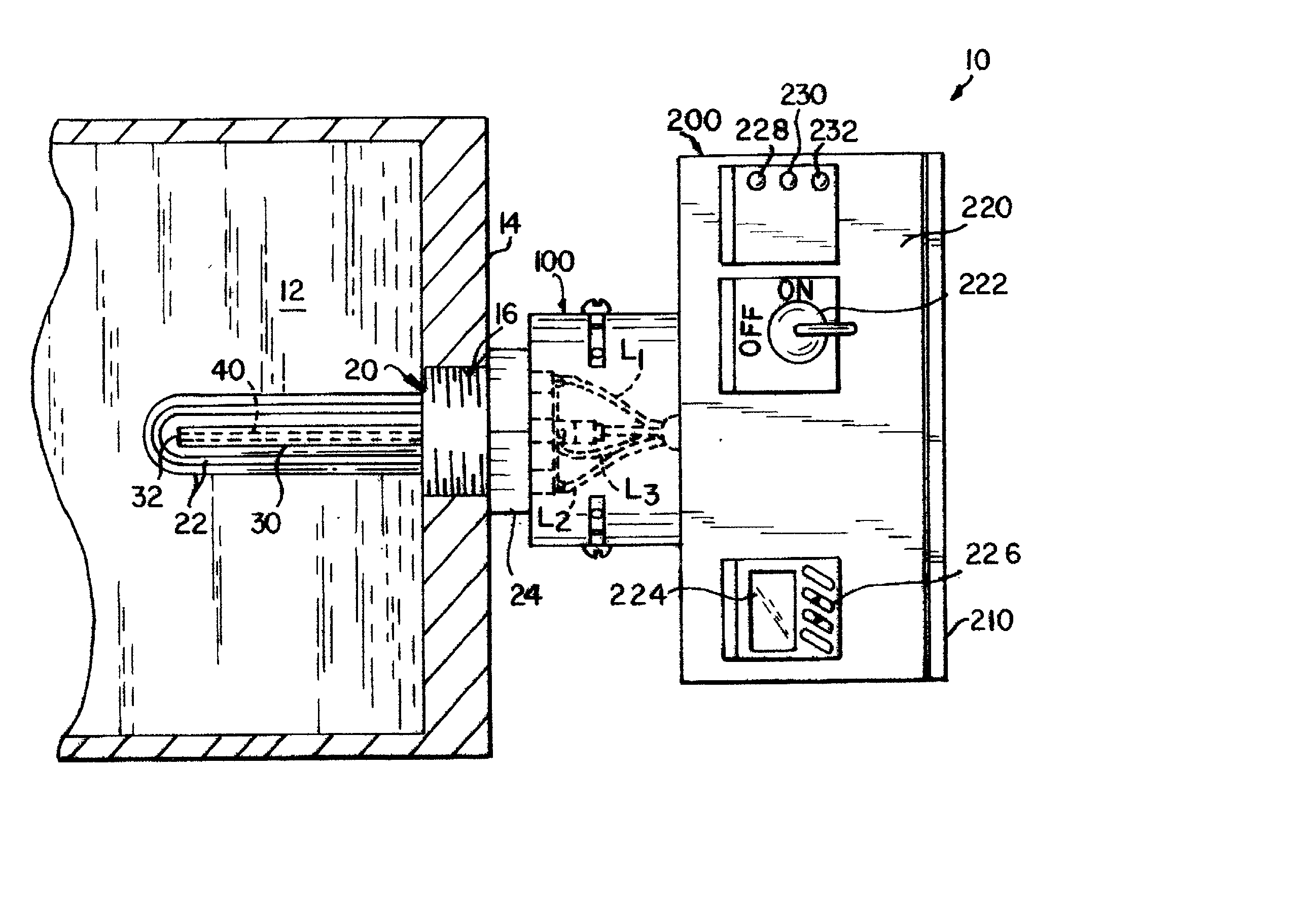

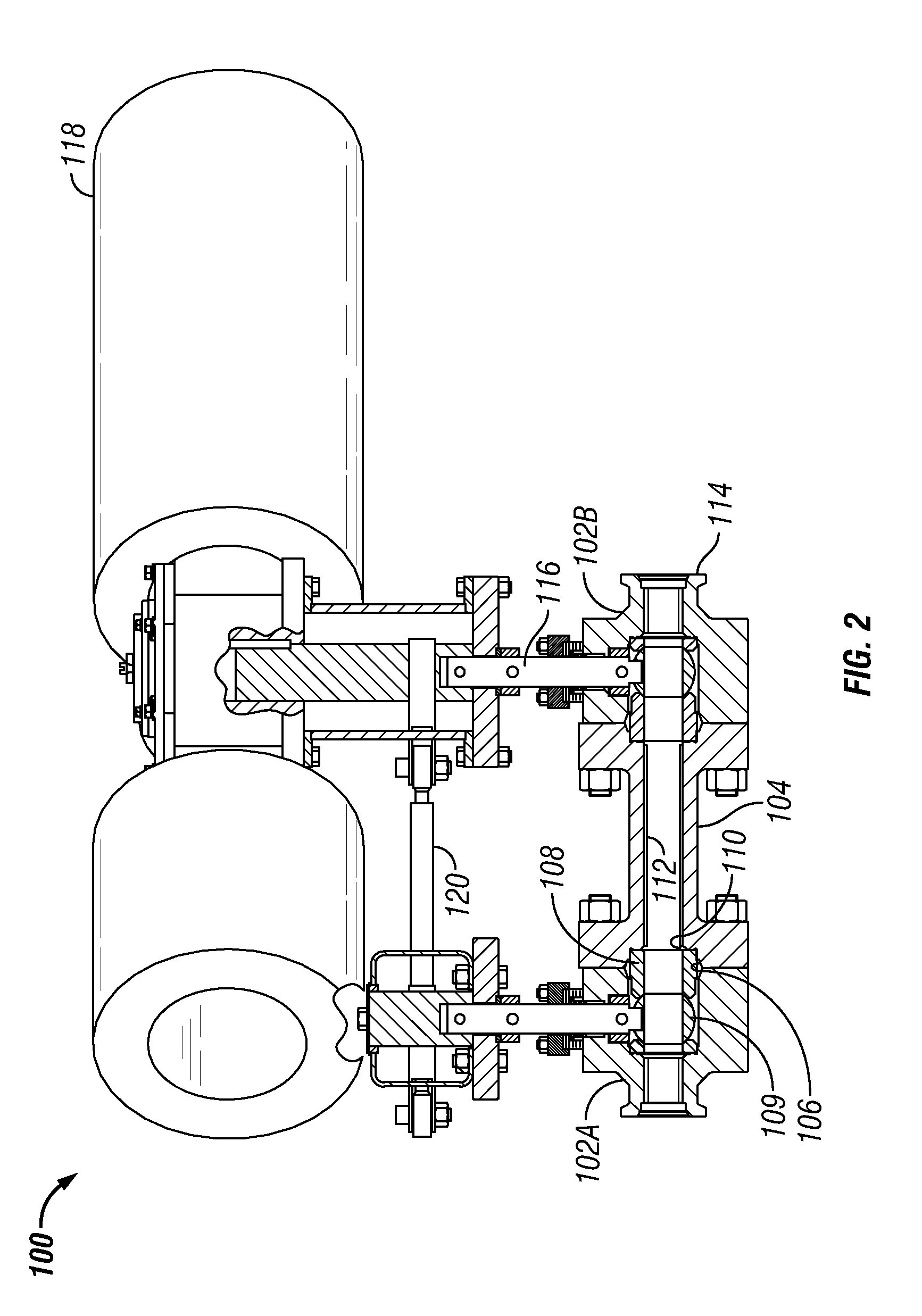

Integrated heater and controller assembly

An integrated heater and controller assembly for monitoring and controlling the heating of a process in a reservoir is disclosed. The assembly includes a heater, a coupling adapter, a control unit, and a temperature sensor. The heater attaches to the reservoir and has a heating element extending into the process. The coupling adapter includes a first tubular portion and a second tubular portion. The first tubular portion attaches to the heater. The second tubular portion attaches to the control unit. The first tubular portion is rotatably attached to the second tubular portion. Wires from the control unit communicate through a pathway in the first and second tubular portions and connect to the heater. The control unit has control circuitry to control the power supplied through the wires to the heater. The heater may also have a thermowell that extends into the process. A thermowell adapter may be used to mount the temperature sensor inside the thermowell to measure and report the temperature of the process to the control unit.

Owner:CHROMALOX INC

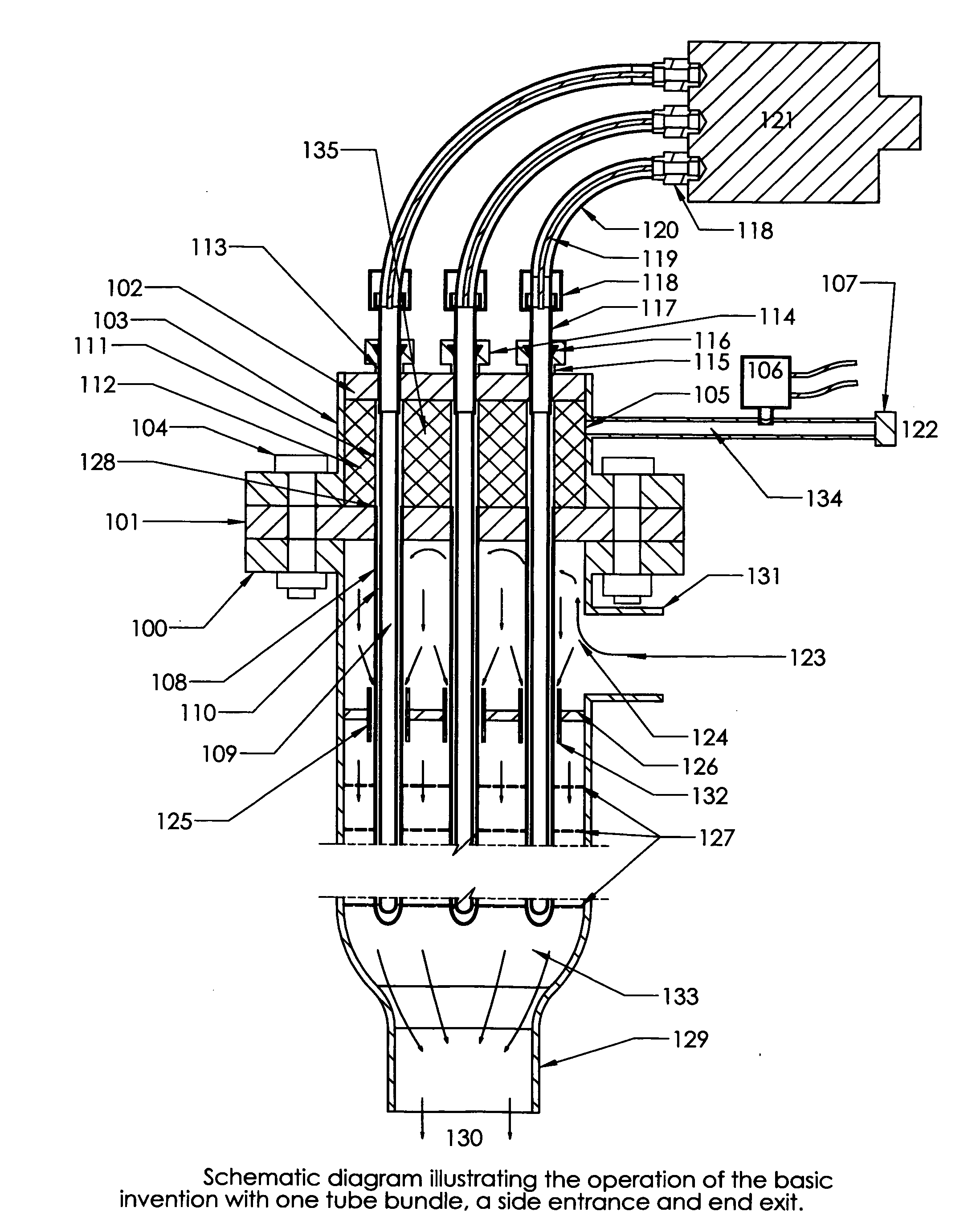

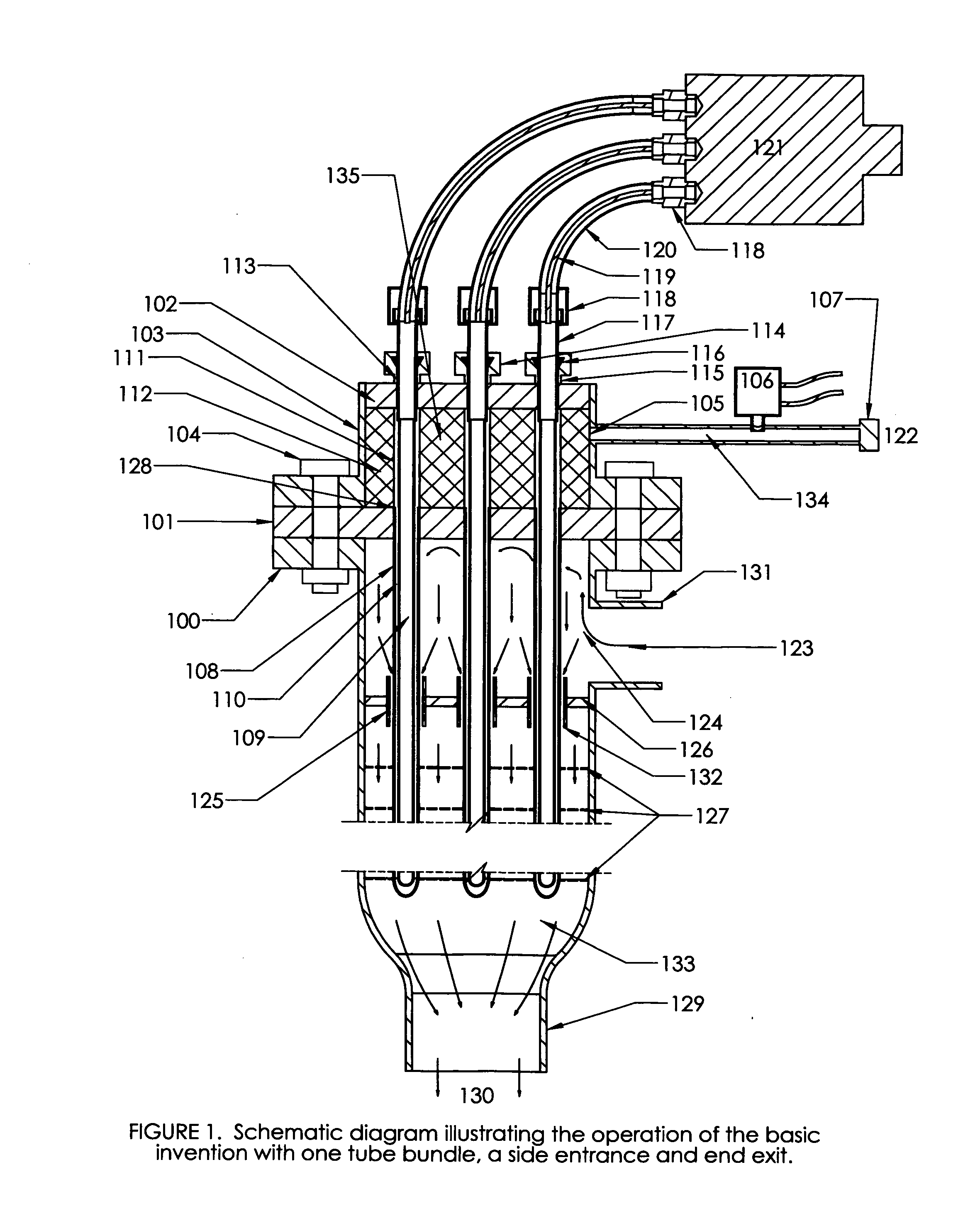

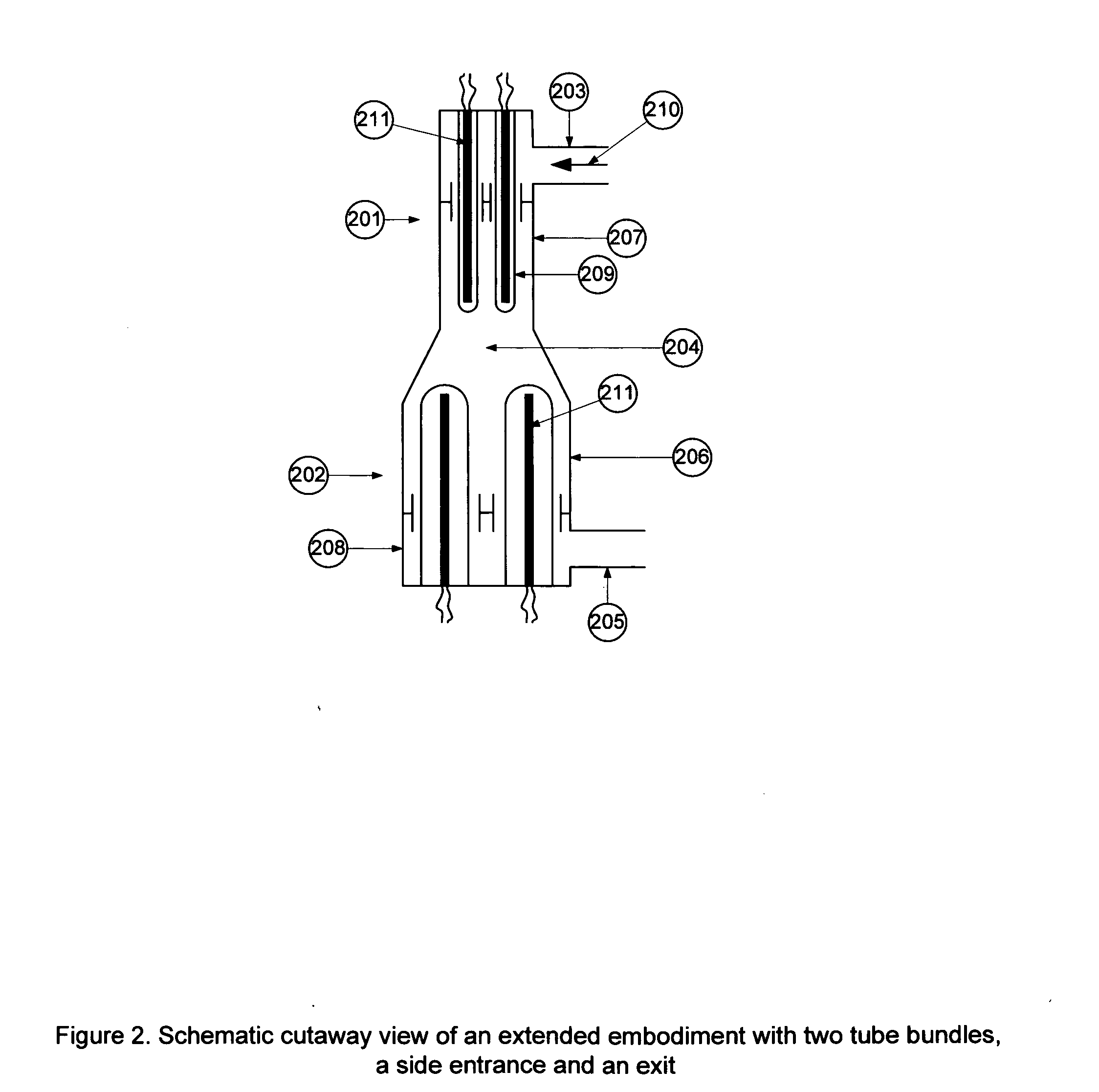

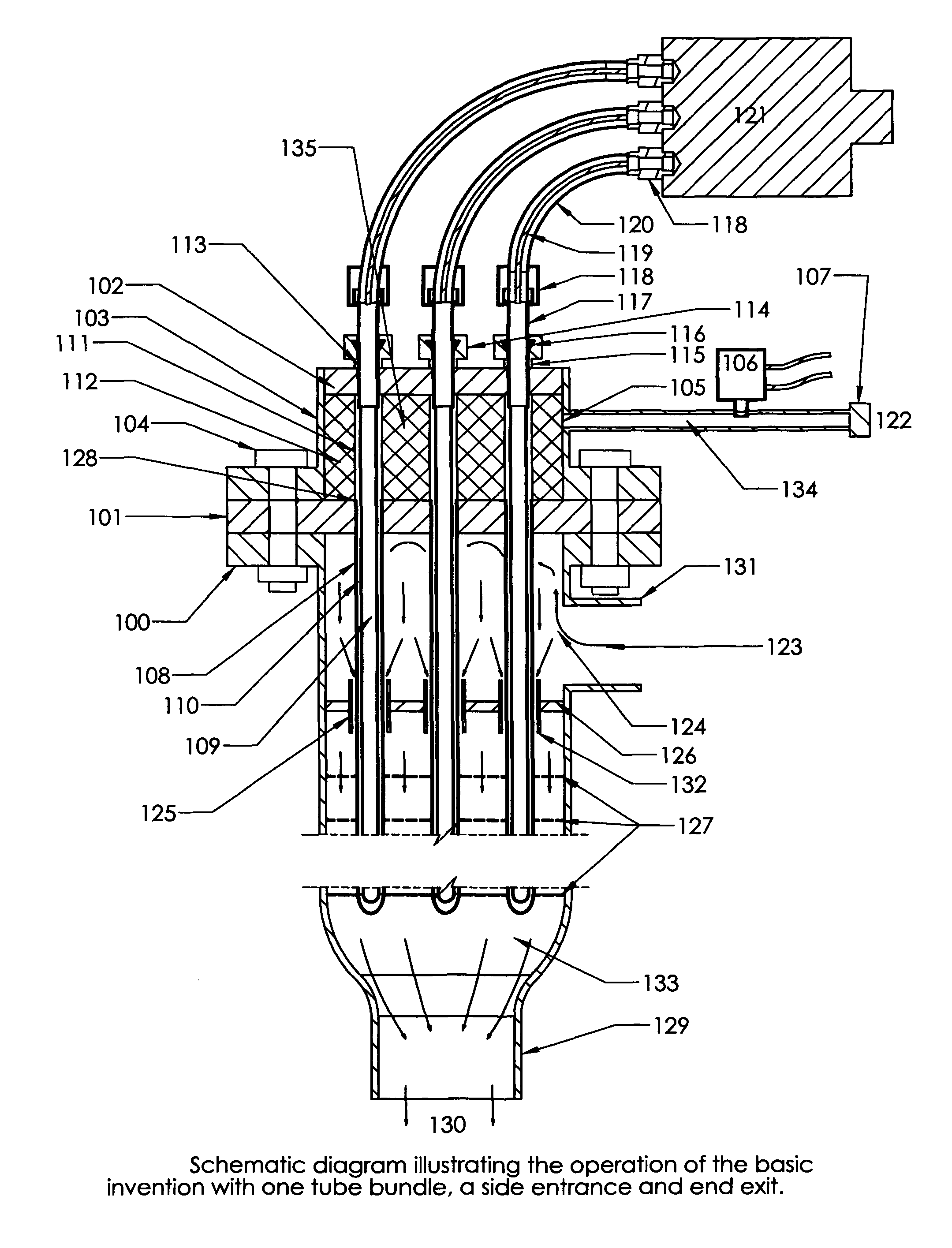

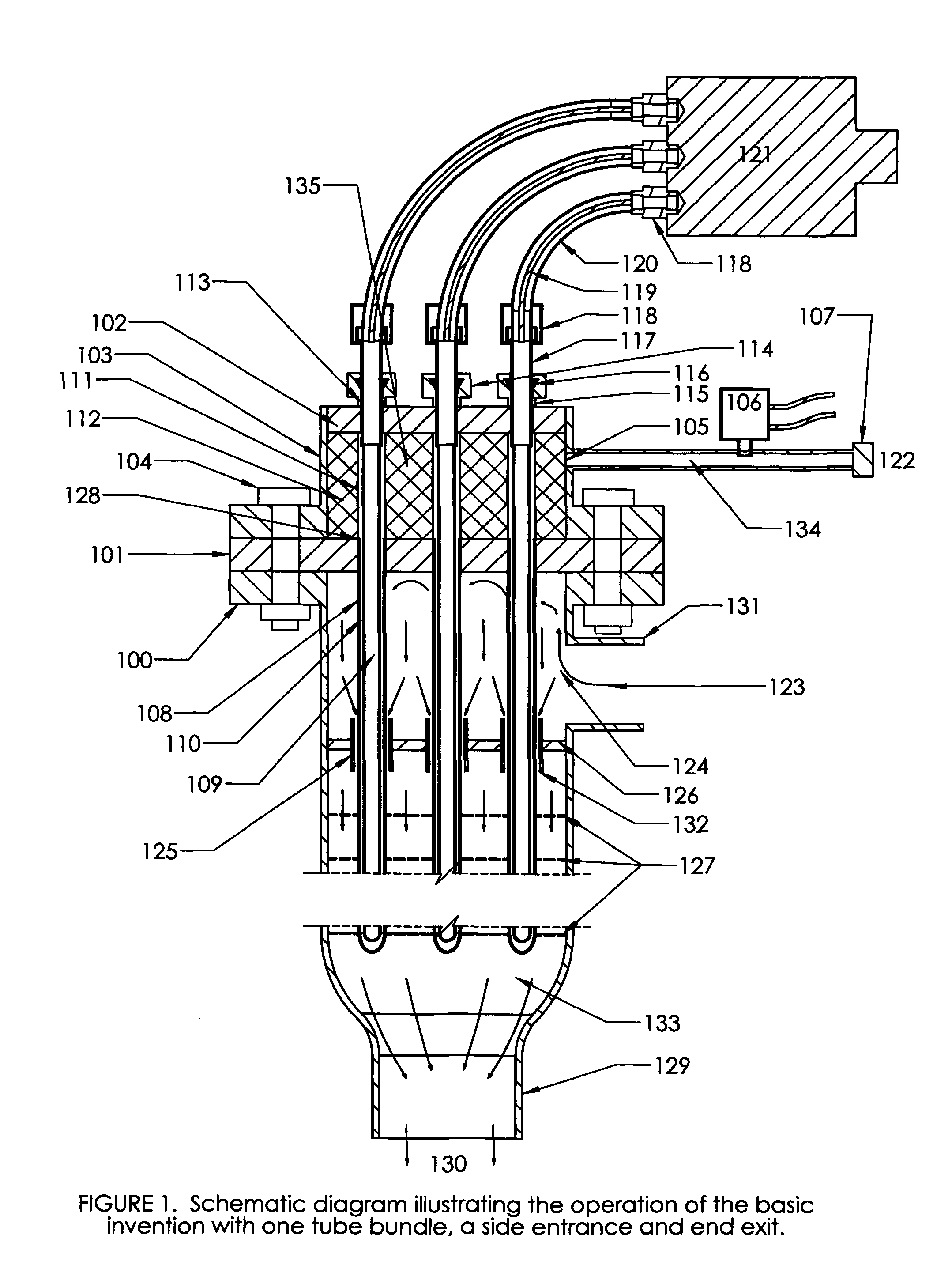

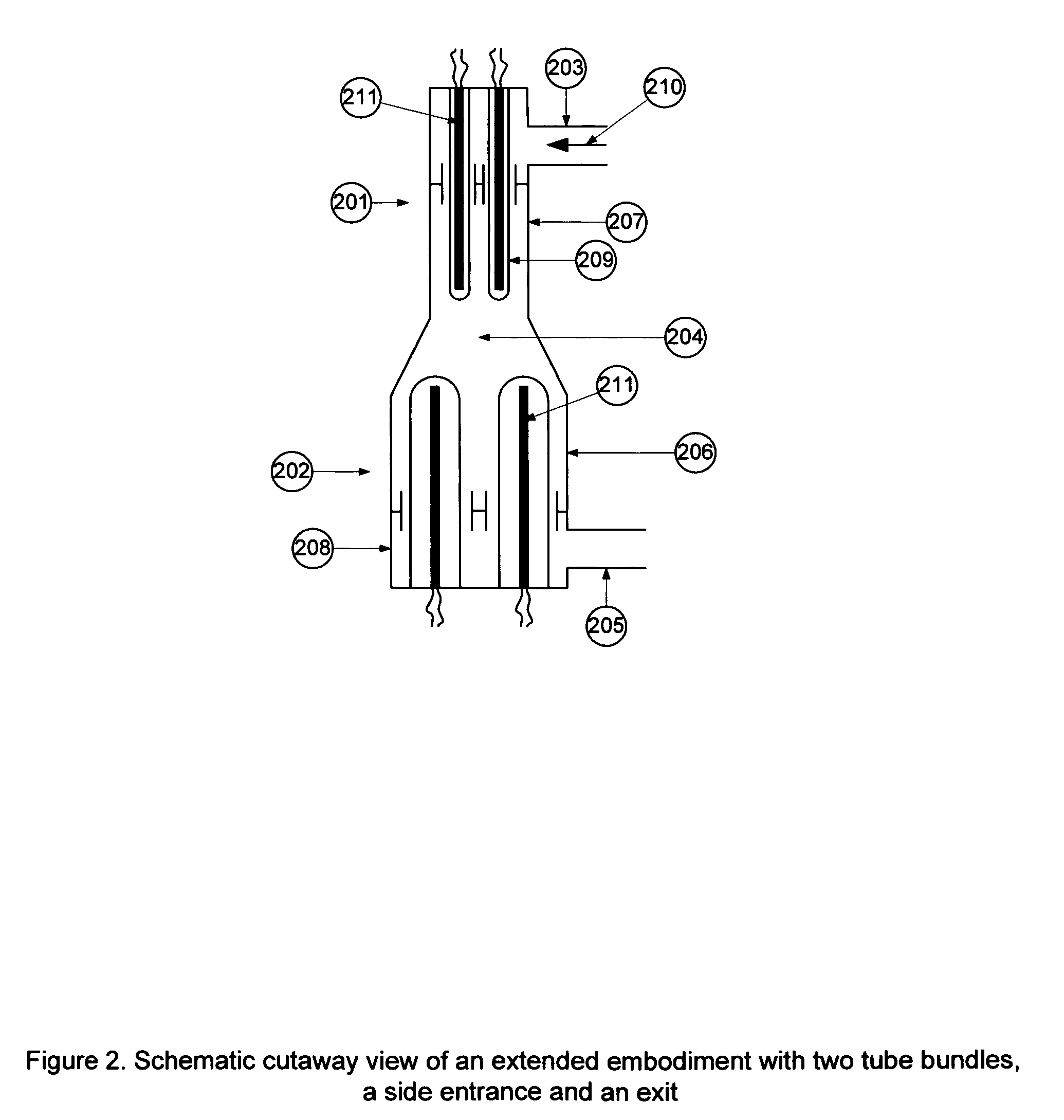

Dual wall axial flow electric heater for leak sensitive applications

A dual wall axial flow electric heater for leak sensitive applications provides an improved corrosion and leak resistant assembly and includes protective tubes over electrical heater rods, double tubesheets spaced apart by a plenum and leak detectors positioned to sensor leaks through the walls of the protective tubes. The design includes the option of two or more tube bundles with each inserted into opposite ends of a shell surrounding the tube sheets and heaters. The design provides ease of maintenance since each heater rod can be replaced independently while the unit is in service. Variable heat flux is provided from standard single flux heater rods by providing protective tubes of varying diameters. A built-in thermowell is provided to allow the rod temperatures to be monitored directly. Hot spots are avoided by the use of turning baffles and vibration is avoided by use of spider baffles to support the tubes.

Owner:LORD LTD LP

Experiment segment based on fusion and fission mixed pile water cooling cladding layer and experiment method of experiment segment

InactiveCN103280143AMeet operational requirementsGuaranteed spacingEducational modelsElectricityNuclear reactor

The invention relates to an experiment segment based on a fusion and fission mixed pile water cooling cladding layer and an experiment method of the experiment segment. The experiment segment comprises a high-temperature resistance stainless steel pipe, an electric heating rod with a thermocouple at the inside, an electric heating rod without a thermocouple, cover plates, separation plates, pressure taking pipes and an inlet and outlet branch pipe, wherein the electric heating rods are respectively assembled in the high-temperature resistance stainless steel pipe, the cover plates are welded at the two ends of the electric heating rods, two stainless steel separation plates are welded in the high-temperature resistance stainless steel pipe, three armored thermowells are simultaneously welded outside the high-temperature resistance stainless steel pipe, the pressure taking pipes are respectively welded on the outer wall surface of the high-temperature resistance stainless steel pipe, three heating rods are placed at the left end of the experiment segment, four heating rods are placed at the right end, and the heating rods at the left end and the heating rods at the right ends are in crossed placement. By aiming at the experiment segment of the fusion and fission mixed pile water cooling cladding layer model manufacture, the flowing heat exchange condition under the structure is simulated, the experiment segment can be used at high temperature and high pressure, the sealing insulation performance is good, the results can be easily measured, the structure is compact, and the experiment segment is suitable for being assembled onto a nuclear reactor thermal hydraulic high-temperature and high-pressure experiment loop.

Owner:XI AN JIAOTONG UNIV

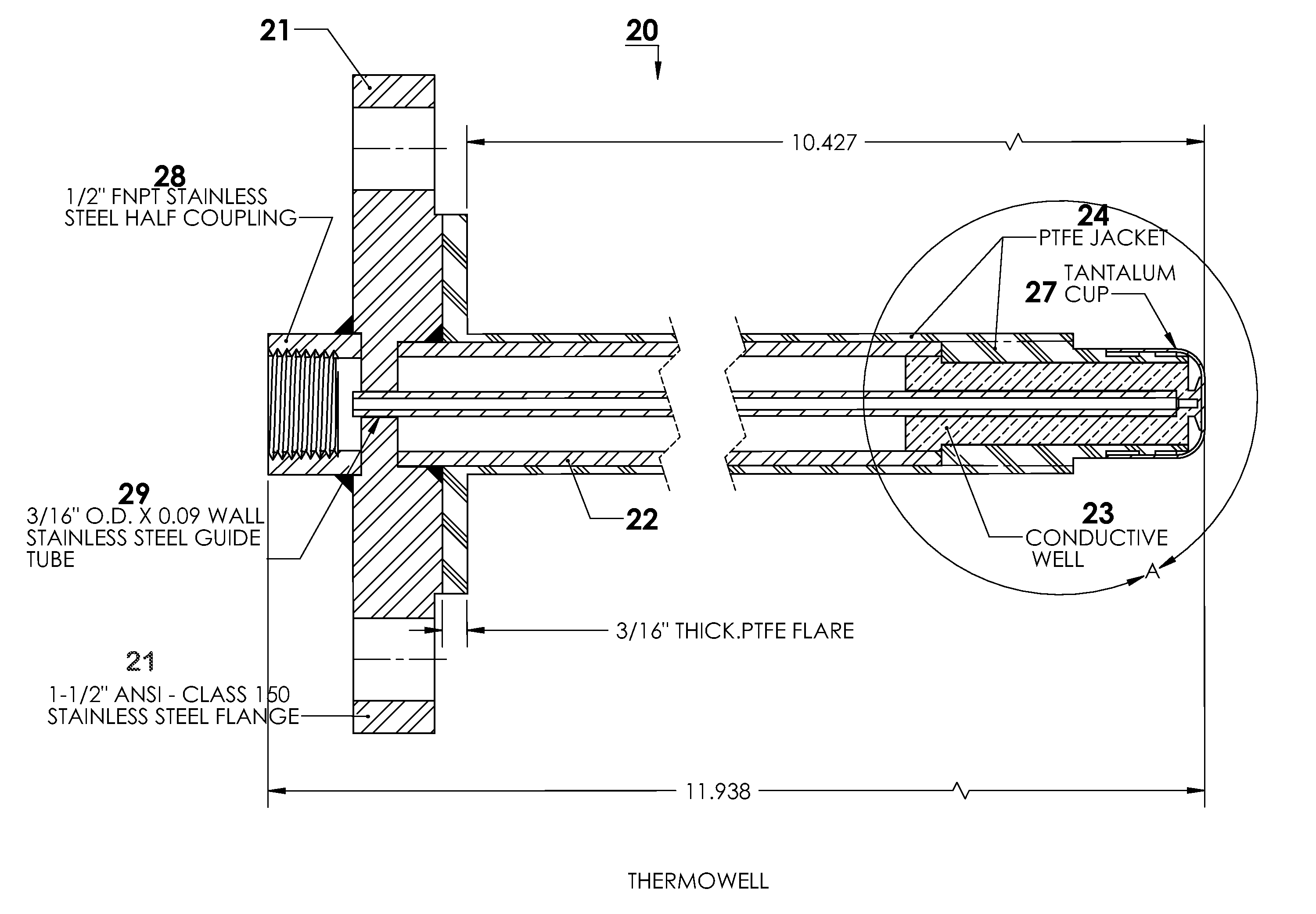

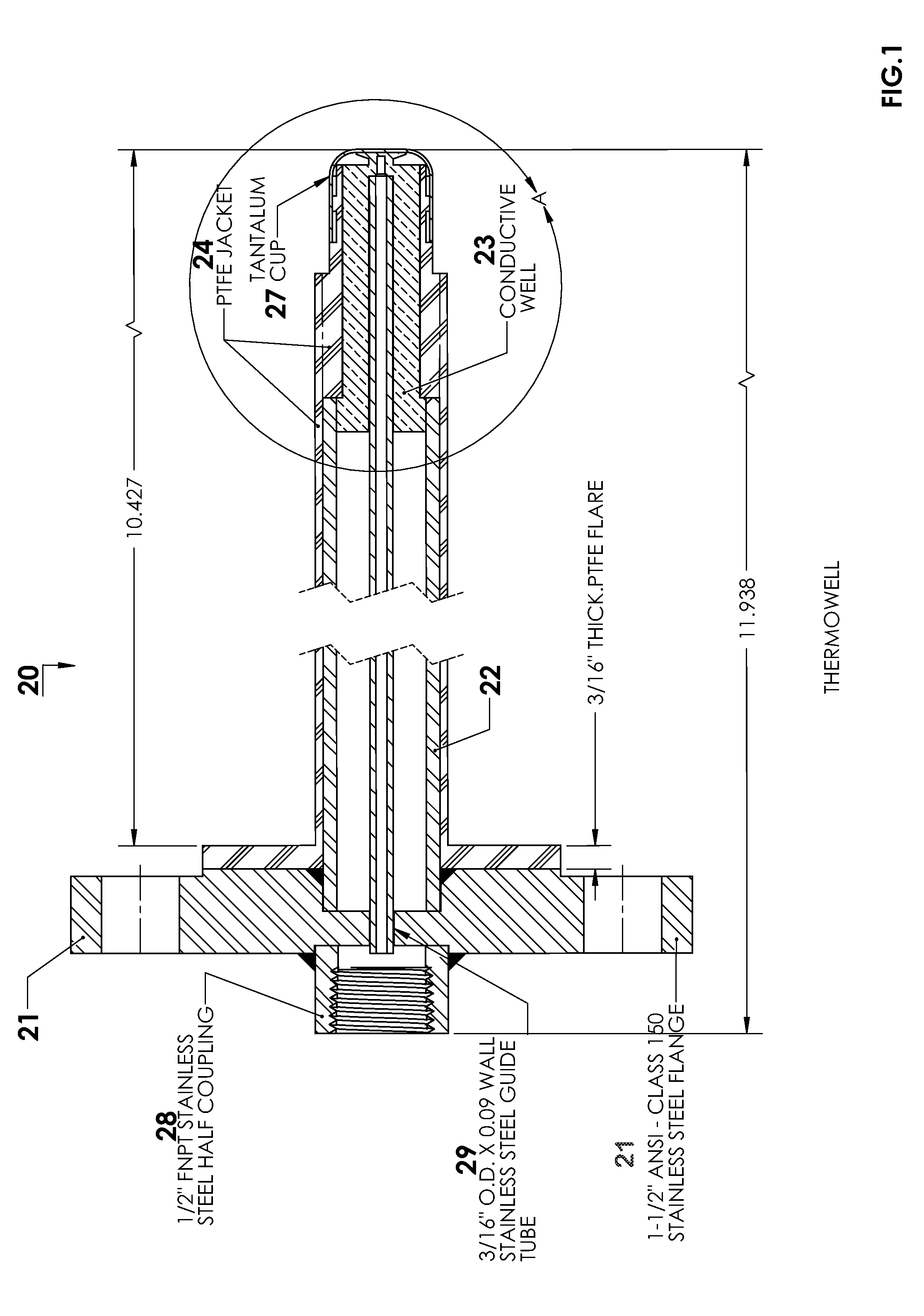

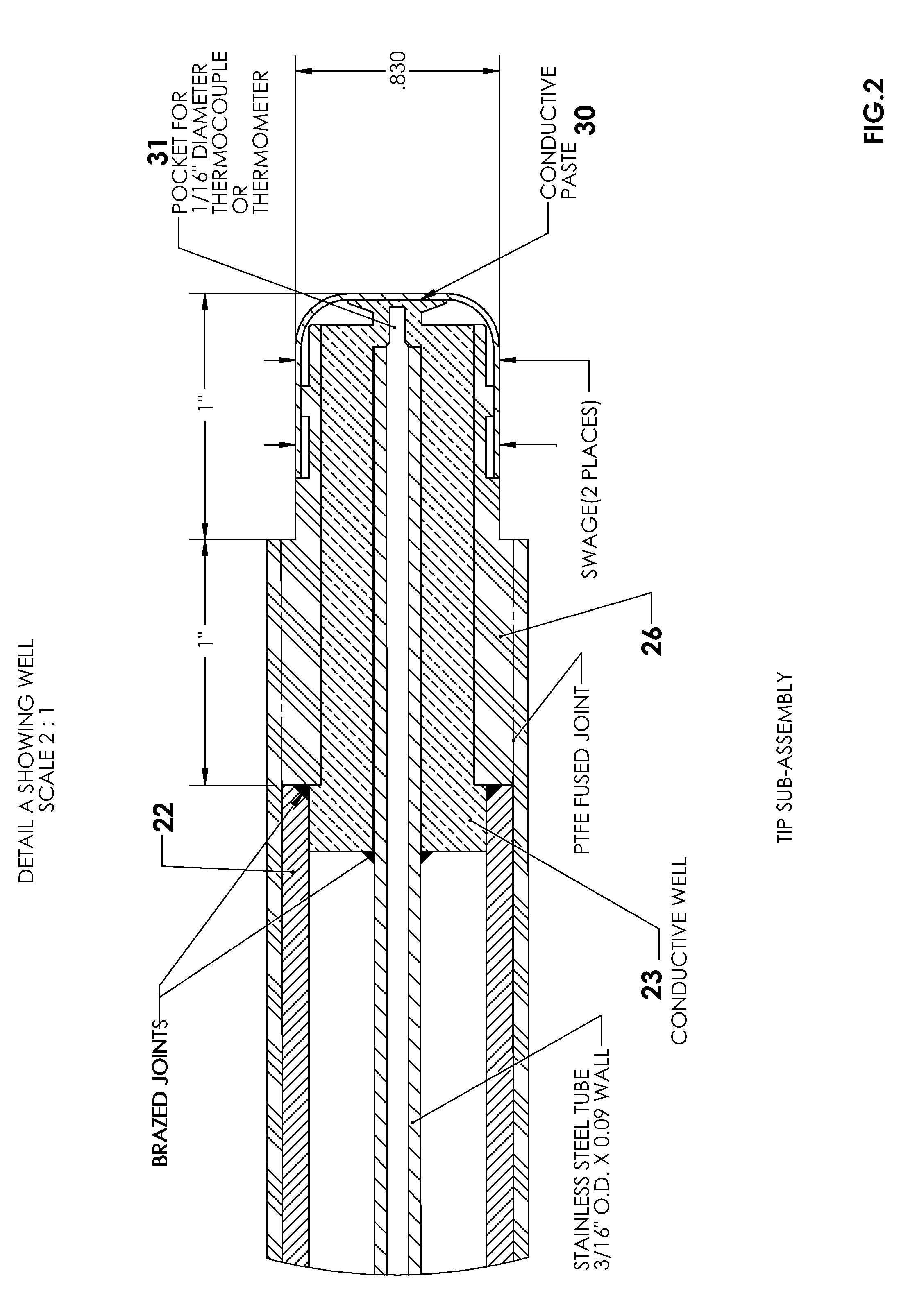

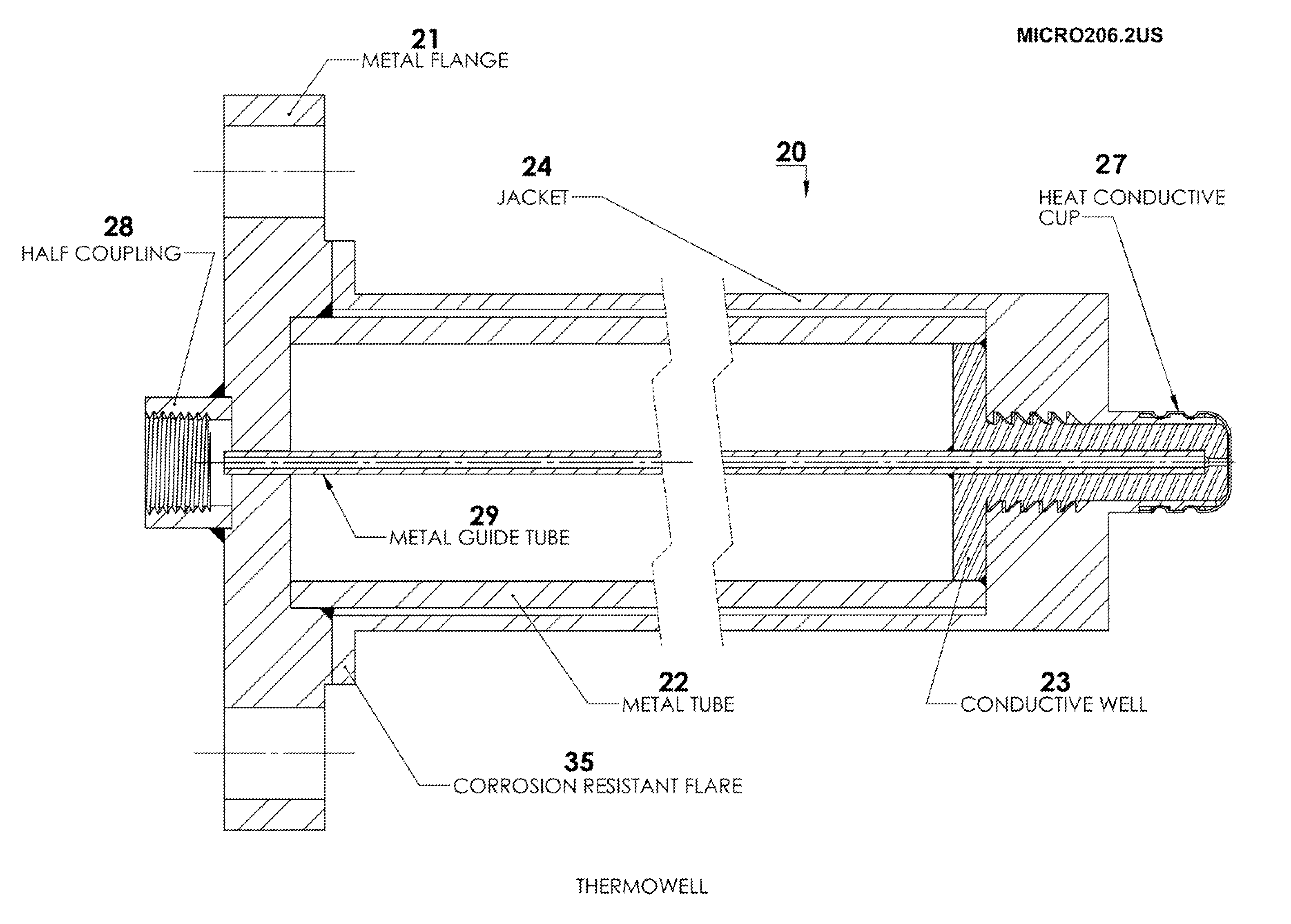

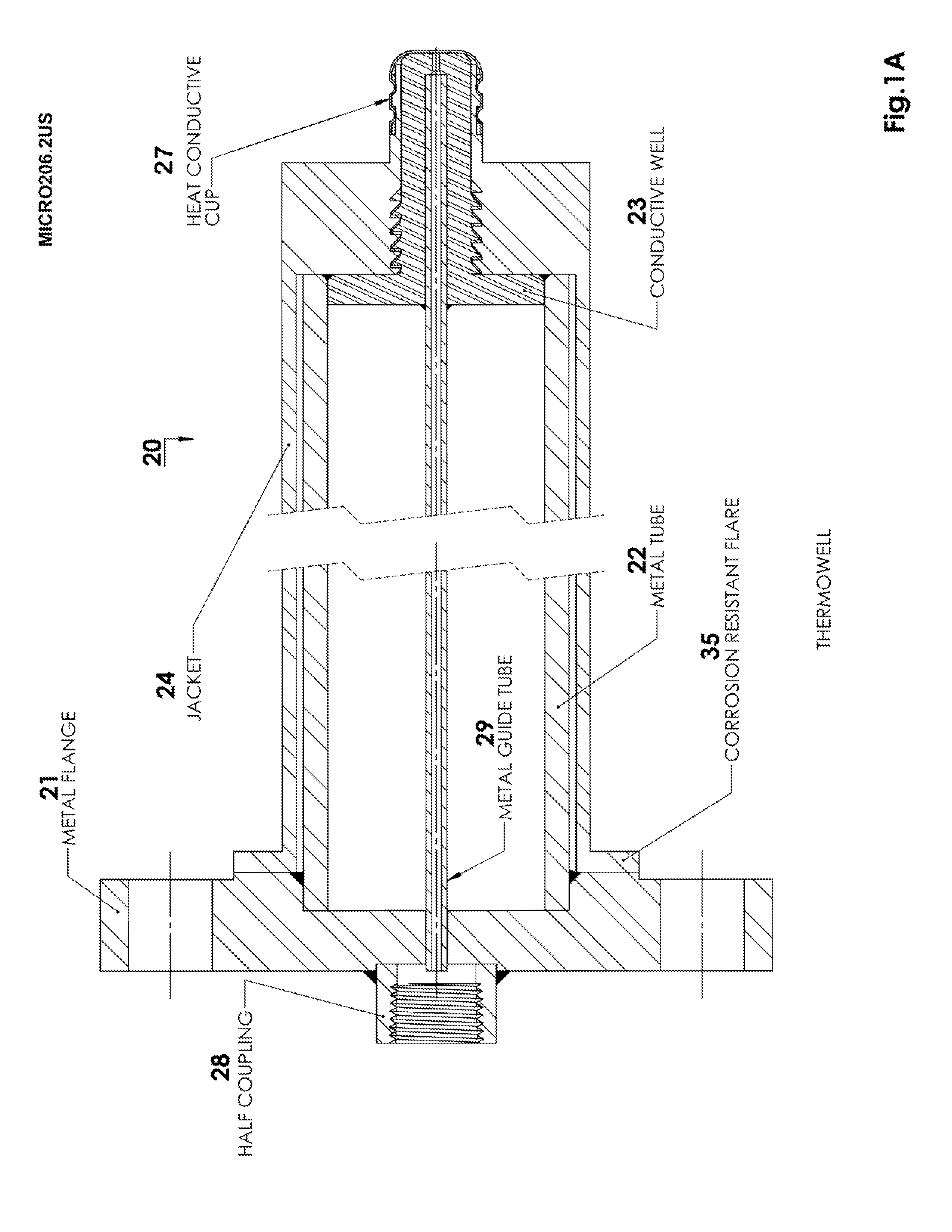

PTFE jacketed tantalum tipped thermowell

ActiveUS20130107908A1Ensures quick responseHigh sensitivityThermometer detailsProcess engineeringThermowell

A PTFE jacketed tantalum tipped thermowell that can be used in unusually difficult industrial applications such as pharmaceutical and chemical process plants and semiconductor manufacturing facilities. These facilities have process environments that may include at least one of the following: highly corrosive fluids, difficult mechanical conditions such as rapid or turbulent fluid flows, and / or reasonably high process temperatures and / or pressures.

Owner:MICROMOLD PRODS

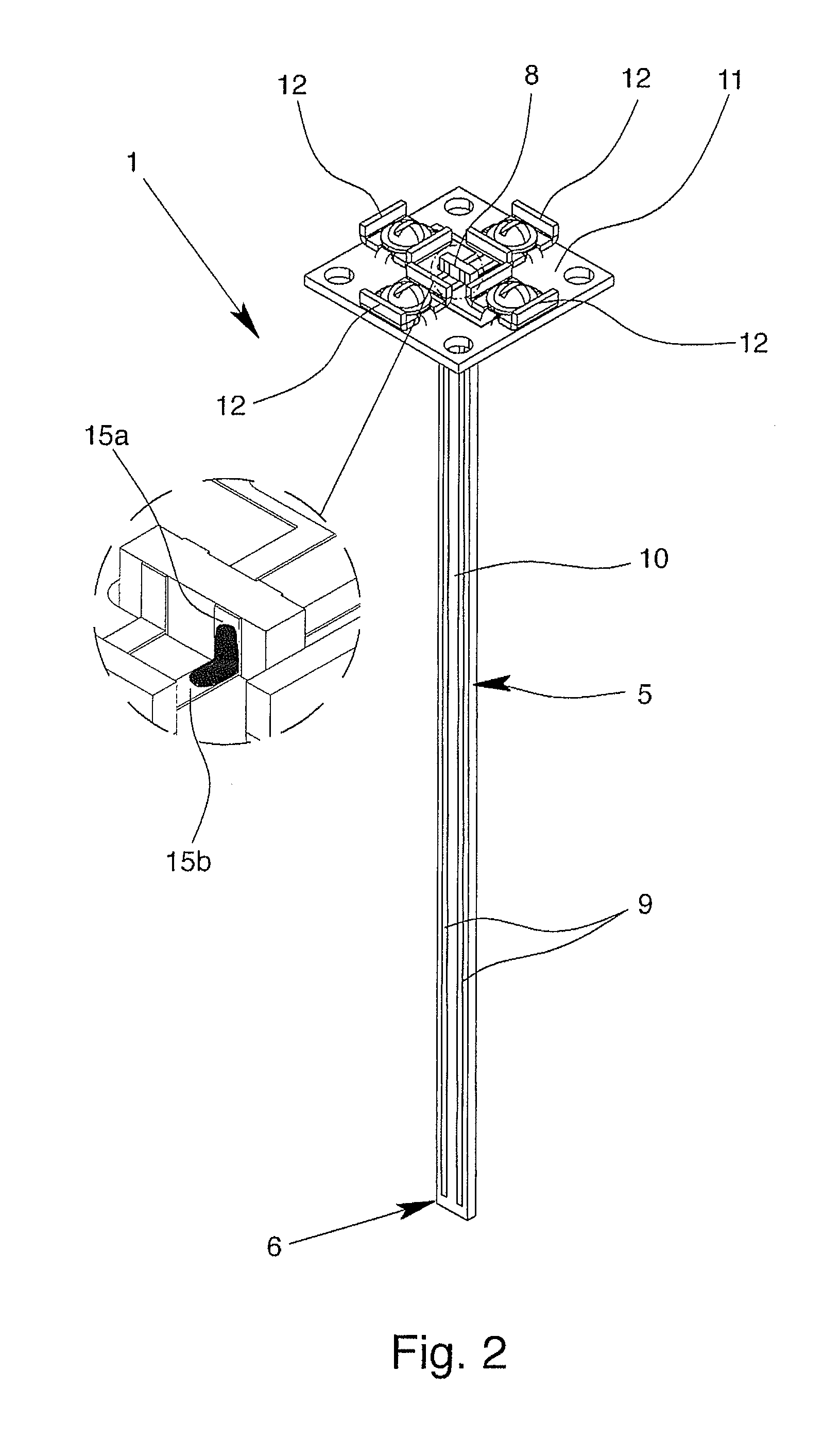

Temperature detector for a contact thermometer

ActiveUS8911148B2Simple and economical structureEasy to installThermometer detailsResistor terminals/electrodesElectricityEngineering

A temperature detector for a contact thermometer of process measurement technology having a thermowell, at least one thermal sensor element arranged in a process-side end of the thermowell, and at least one electrical connecting means connected to the thermal sensor element with a first connection side and extending in the thermowell at least up to an evaluation-side end of the thermowell, so that the thermal sensor element can be electrically contacted via a second connection side of the electrical connecting means, and in which the electrical connecting means is formed by a connection printed circuit board with conducting paths.

Owner:INOR PROCESS

Thermowell With Expansion Joint

ActiveUS20190101453A1Thermometer detailsThermometers using electric/magnetic elementsBrickRefractory

A thermowell-thermocouple assembly for installation in a refractory-lined process vessel has an expansion joint for compensating for expansion, contraction and movement of the refractory. Examples of expansion joints include unsupported bellows, bellows that have a support sleeve around the bellows, a sliding, hexagonal coupling with crimping to hold the sliding tubes together, a pin-and-slot coupling and a spring-loaded, pin-and-slot sliding connection. The thermocouple-thermowell assembly can include a metal, a ceramic material, a refractory brick and / or a conical-shaped tip at a distal end, which can be or which can become fixed to the refractory.

Owner:FOREMAN INSTR & CONTROLS

Online calibration of a temperature measurement point

ActiveCN102803912AThermometer detailsThermometers using electric/magnetic elementsMeasurement pointEngineering

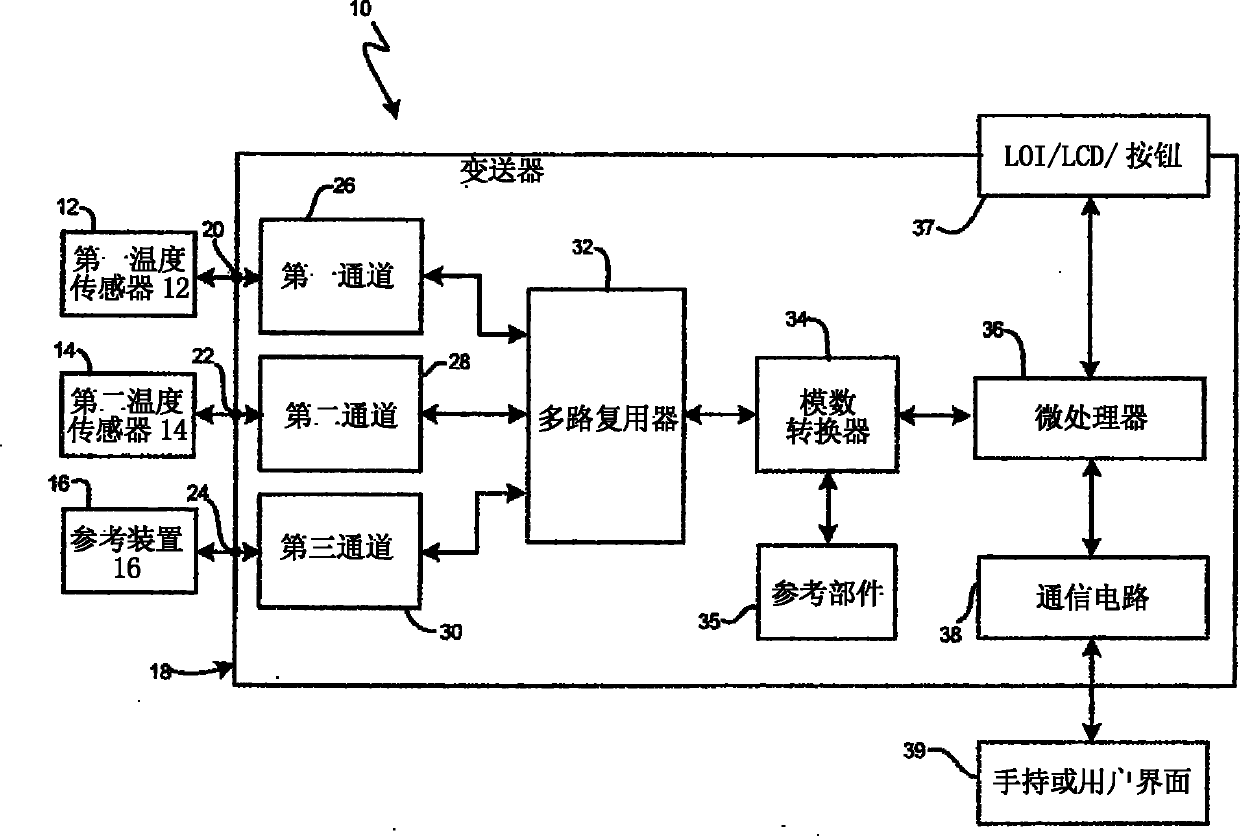

A system for measuring temperature includes a thermowell, a primary temperature sensor, a reference sensor, and a transmitter. The thermowell has a measurement instrument connection and a side port. The primary temperature sensor extends into the thermowell through the measurement instrument connection, and the reference sensor extends into the thermowell through the side port. The transmitter is connected to each of the primary temperature sensor and the reference sensor. The transmitter has circuitry for measuring temperature based upon signals received from the primary temperature sensor and for concurrently calibrating based upon signals received from the reference sensor.

Owner:ROSEMOUNT INC

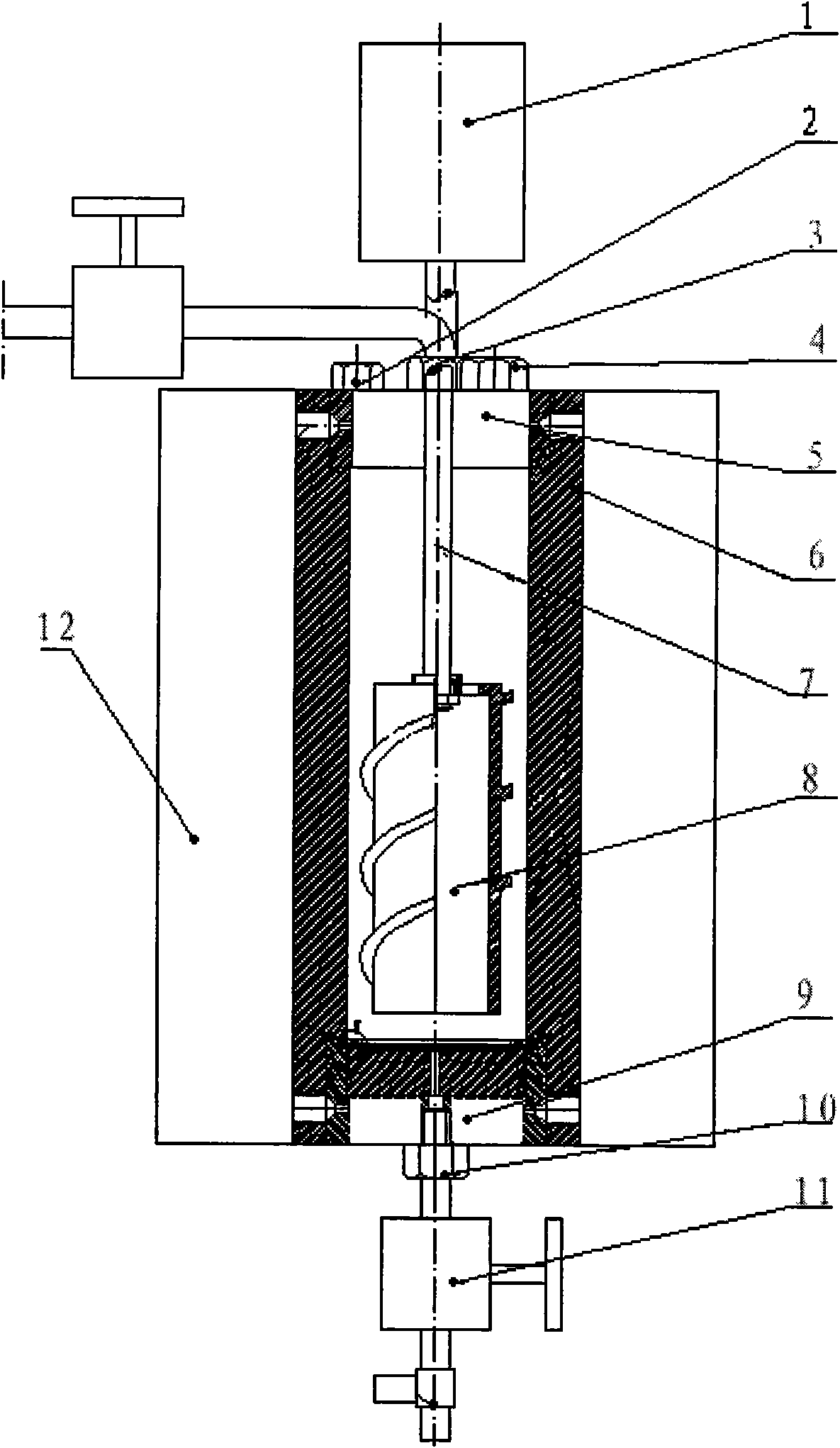

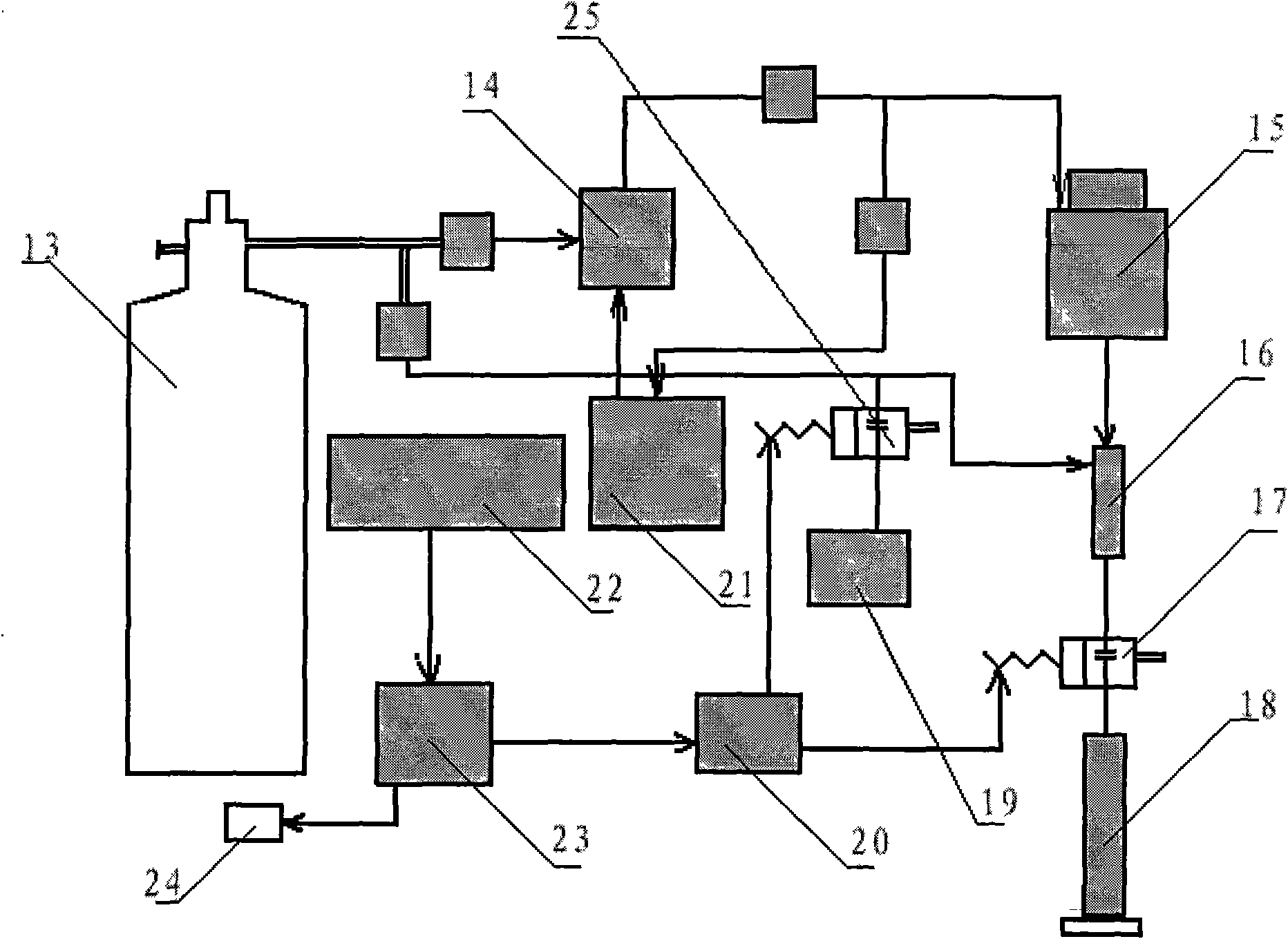

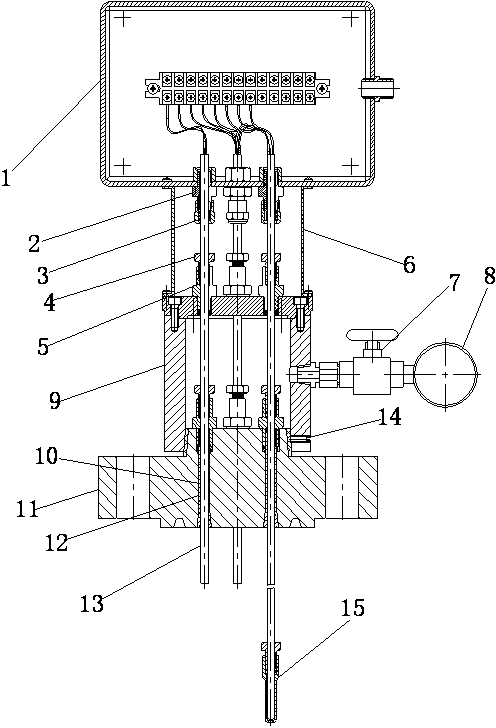

Intelligent type high-temperature high-pressure multifunctional dynamic evaluation experimental apparatus of drilling fluid

InactiveCN101672725AShear rate is continuously adjustableErosionHydrodynamic testingFluid-tightness measurement using fluid/vacuumSlurryEngineering

The invention provides a high-temperature high-pressure multifunctional dynamic evaluation experimental apparatus of drilling fluid, mainly comprising a boosting pump, an experimental tank, a condenser, an electromagnetic valve, a material storage tank, a filter liquor measuring cylinder, a pulp receiving tank, a sensor, a computer and a time controller, wherein the experimental tank mainly comprises a tank body, a magnetic transmission system, a thermowell, a boosting hole joint, a liquid adding hole joint, a slurry cup, a stirring shaft and a stirring cylinder. The invention has the advantages of simple, convenient and easy operation, enhanced work efficiency, real simulation of an actual underground working condition, higher safety, more stable apparatus and longer service life and alsoforms a high-temperature high-pressure multifunctional dynamic evaluation experimental technique.

Owner:SHANDONG LUHAI DRILLING & PRODN TECH

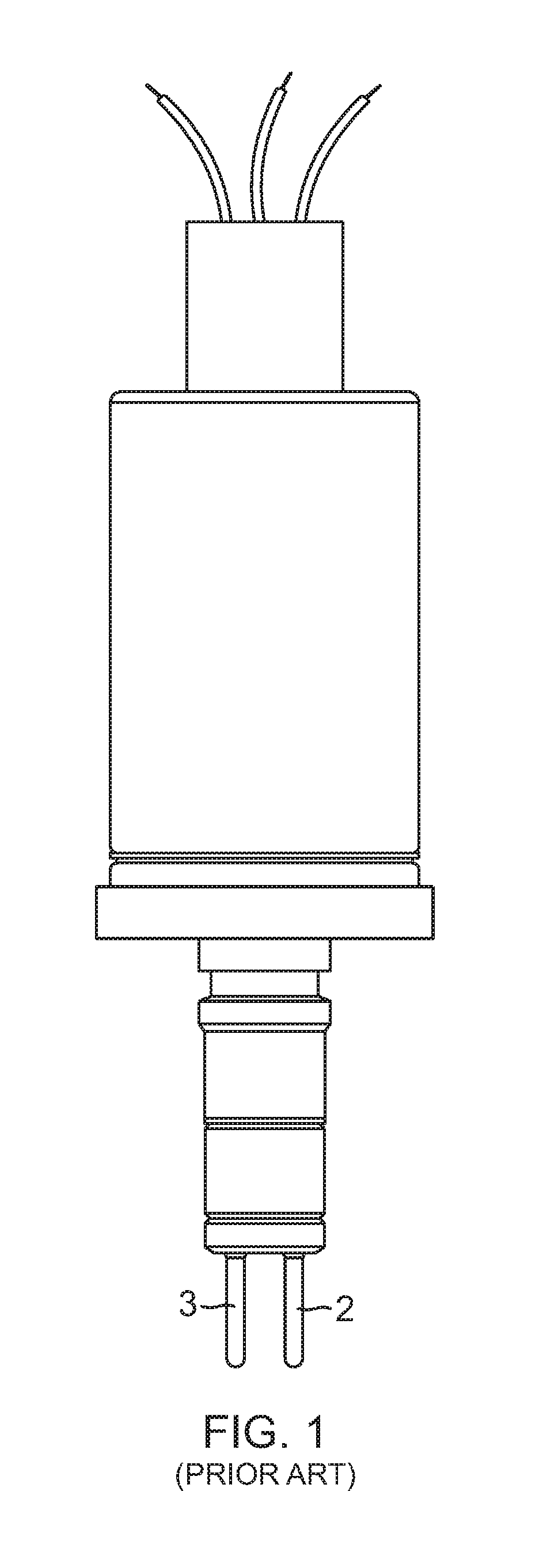

Dual sensor head configuration in a fluid flow or liquid level switch

ActiveUS20160187174A1Improve reliabilityReduce weightTesting/calibration apparatusVolume/mass flow by thermal effectsReference sensorThermowell

A fluid flow or liquid level switch providing a high level of reliability. Dual reference sensors in a single thermowell operates with two active, independent sensors, which operate with independent electronics having dual signal outputs, to provide constant and continuous redundancy in operation.

Owner:FLUID COMPONENTS INTERNATIONAL

Straight tube for chemical adsorption instrument and sample loader thereof

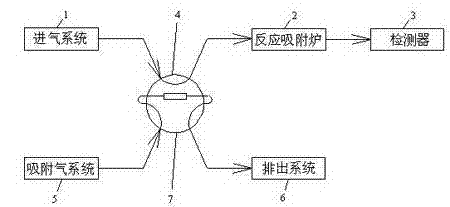

InactiveCN102590438AFill evenlyAvoid drivingPreparing sample for investigationChemical methods analysisTemperature controlStraight tube

The invention relates to a straight tube for a chemical adsorption instrument and a sample loader thereof. The straight tube for the chemical adsorption instrument comprises an adsorption tube, a duty ratio tube and a thermowell, wherein the duty ratio tube is arranged at the inner part of the adsorption tube, and two ends of the duty ratio tube are open; and one end of the thermowell is airtight. The sample loader is composed of a sample loading funnel and a tamper. As the straight tube for the chemical adsorption instrument and the corresponding sample loader are used, samples can be uniformly filled, the impulsive force of airflow is avoided to drive silica wool and the samples, and meanwhile the silica wool and the samples are prevented from being tight to jam a gas path. The whole structure is good in airtight property and the straight tube can be applied to atmospheric or high pressure adsorption instruments. The structure is very simple and the straight tube is easily dismantled, the wall of the adsorption tube is easily cleaned, and the samples are easily loaded and replaced. A thermocouple is inserted into a reacting sample, so that the true temperature of the samples can be well responded, and temperature control is more accurate. Thus, the straight tube for the chemical adsorption instrument, provided by the invention, can be perfectly applied to the adsorption instrument through combing with the corresponding sample loader.

Owner:TIANJIN XIANNQUAN IND & TRADE DEV

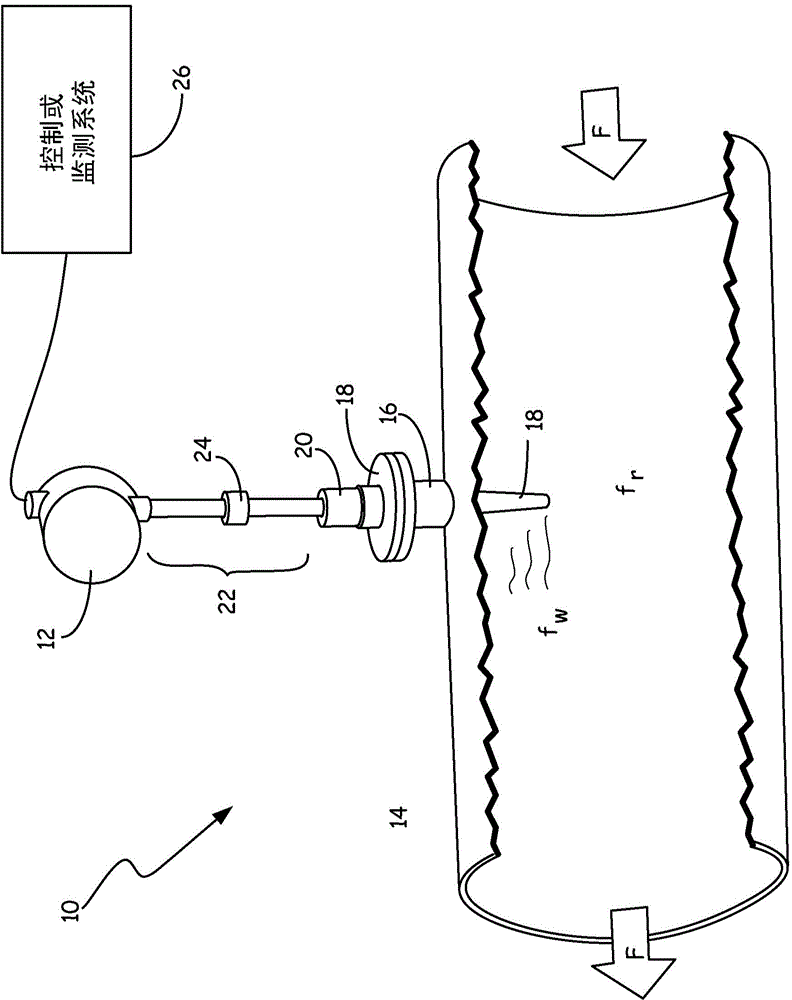

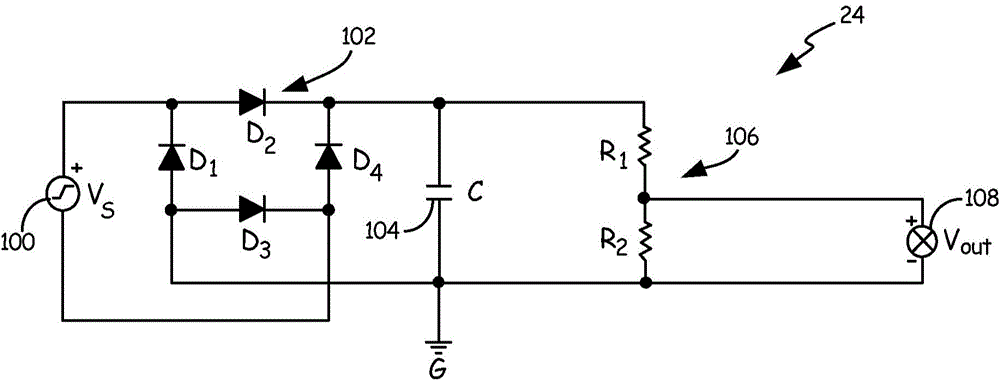

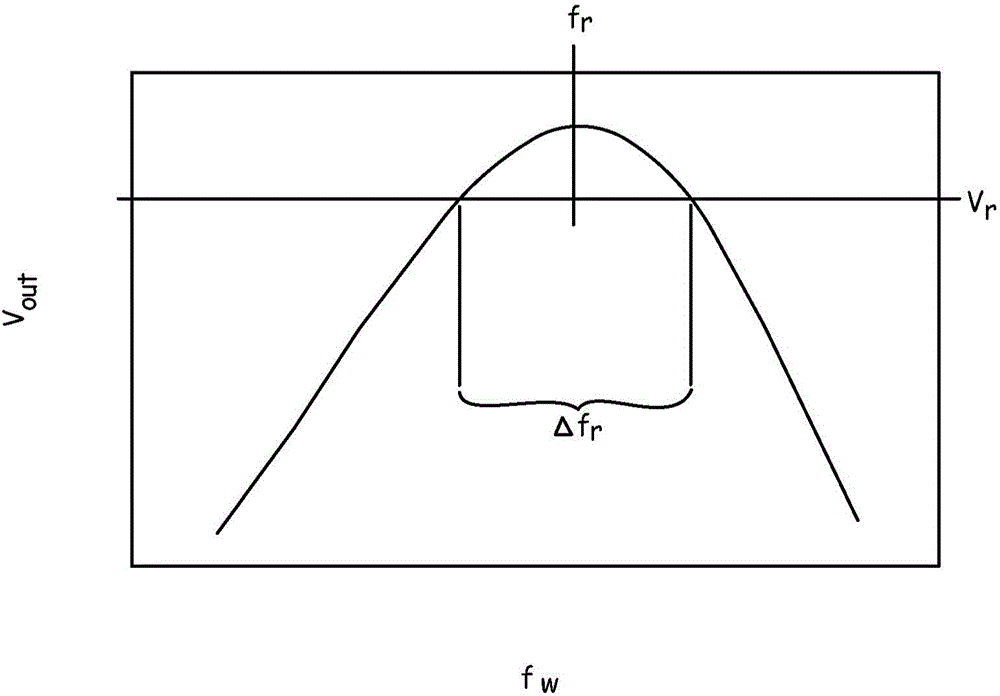

Vibration detection in thermowells

A sensor system comprises a process transducer, an unpowered vibration sensor, and a process transmitter. The process transducer is disposed within a thermowell and configured to produce a first sensor signal. The unpowered vibration sensor is configured to produce a second sensor signal reflecting vibration of the thermowell. The process transmitter is configured to receive, process, and transmit the first and second sensor signals.

Owner:ROSEMOUNT INC

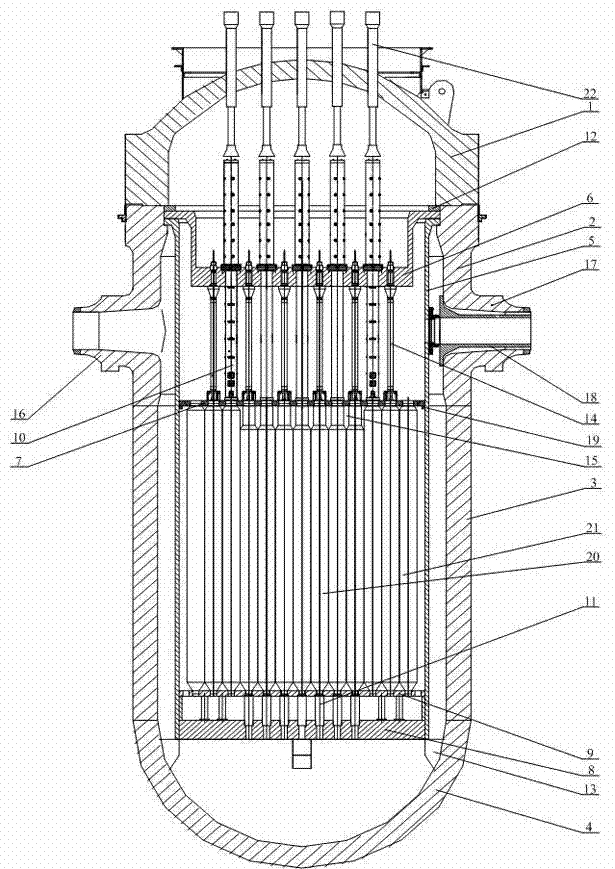

Tube-plate double-process supercritical water cooled reactor

ActiveCN103117097AAchieve isolationClear Process ChannelNuclear energy generationShieldingNuclear engineeringThermowell

The invention discloses a tube-plate double-process supercritical water cooled reactor. The reactor comprises a pressure container, a basket barrel, an inlet connecting tube and an outlet connecting tube, wherein an upper bearing subassembly, an upper reactor core plate and a lower tube plate are installed in the basket barrel, a lower reactor core plate is installed above the lower tube plate and parallel to the lower tube plate, a plurality of control rod guide subassemblies are installed on the upper bearing subassembly, a plurality of first-process fuel subassemblies and second-process fuel subassemblies are installed between the lower reactor core plate and the upper reactor core plate, the first-process fuel subassemblies are communicated with a bottom cavity of the pressure container through communication tubes, and an airtight cavity formed between the lower reactor core plate and the lower tube plate is communicated with the second-process fuel subassemblies. Supercritical outlet water is isolated from the inner wall of the reactor pressure container through an outlet thermal sleeve structure, so that the pressure container can be designed based on a conventional material; and double-process coolant circulation is realized in the supercritical water cooled reactor through designing reactor internals, and clear process channels and reasonable flow field distribution are provided.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

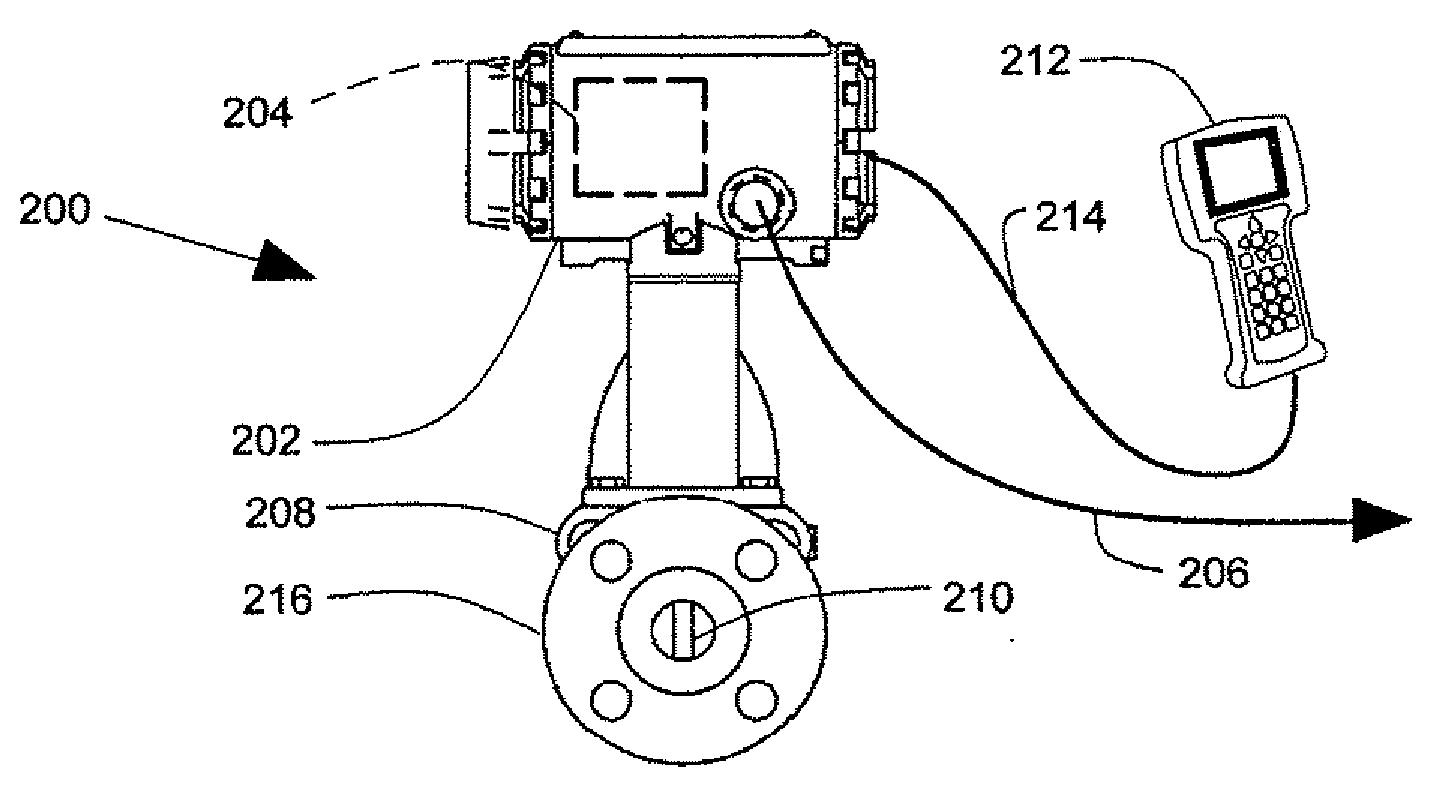

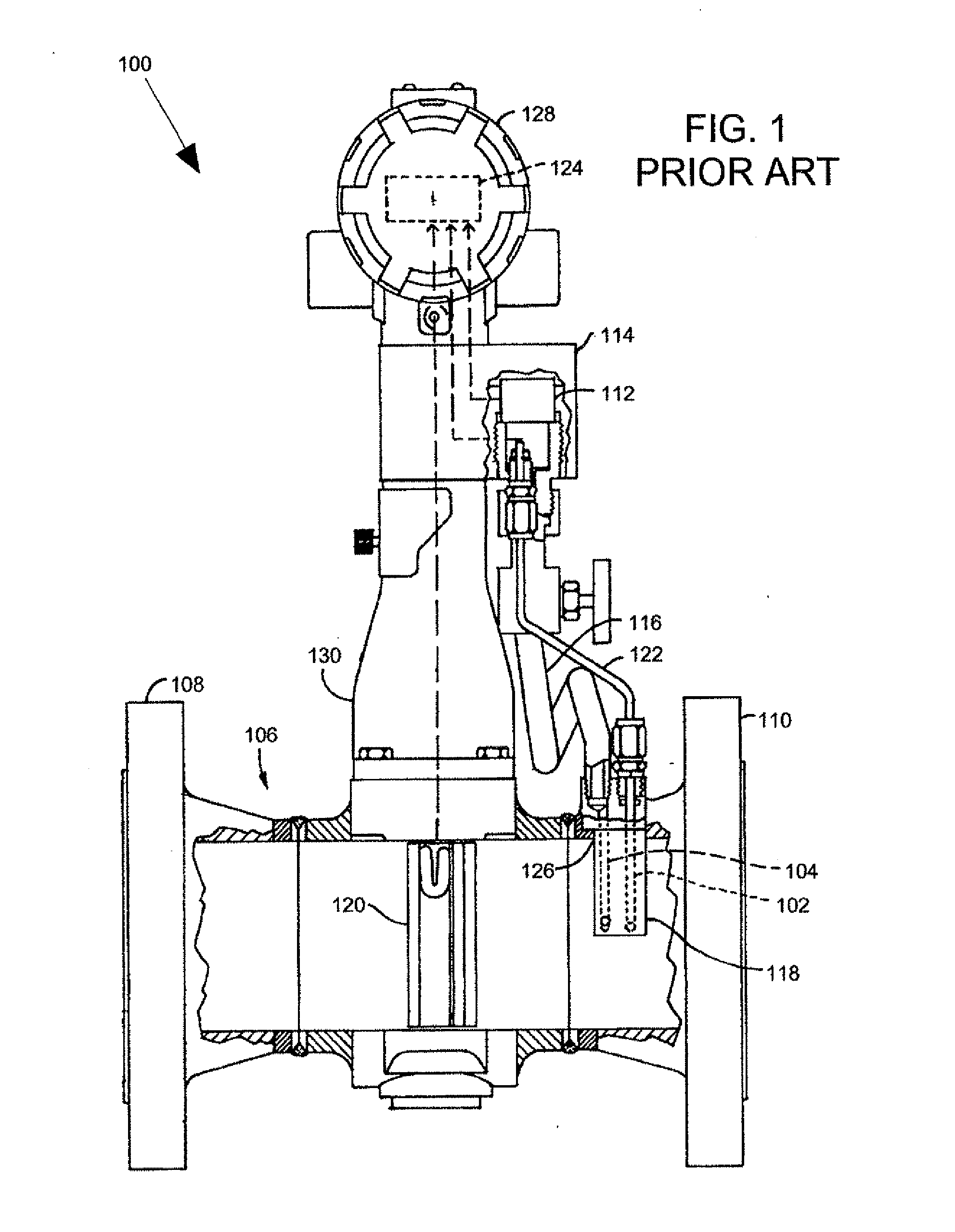

Thermowell vibration frequency diagnostic

An apparatus and a method monitor condition of a temperature measurement point in an industrial process system by sensing vibration frequency of a thermowell positioned in a process fluid flow passage and providing a diagnostic output based upon the vibration frequency sensed. The apparatus includes a temperature measurement point having a thermowell, a vibration sensor, a temperature sensor, and a transmitter. The vibration sensor is fixedly attached to the thermowell, and the temperature sensor is positioned inside a bore cavity of the thermowell. The transmitter is electrically connected to both the temperature sensor and the vibration sensor.

Owner:ROSEMOUNT INC

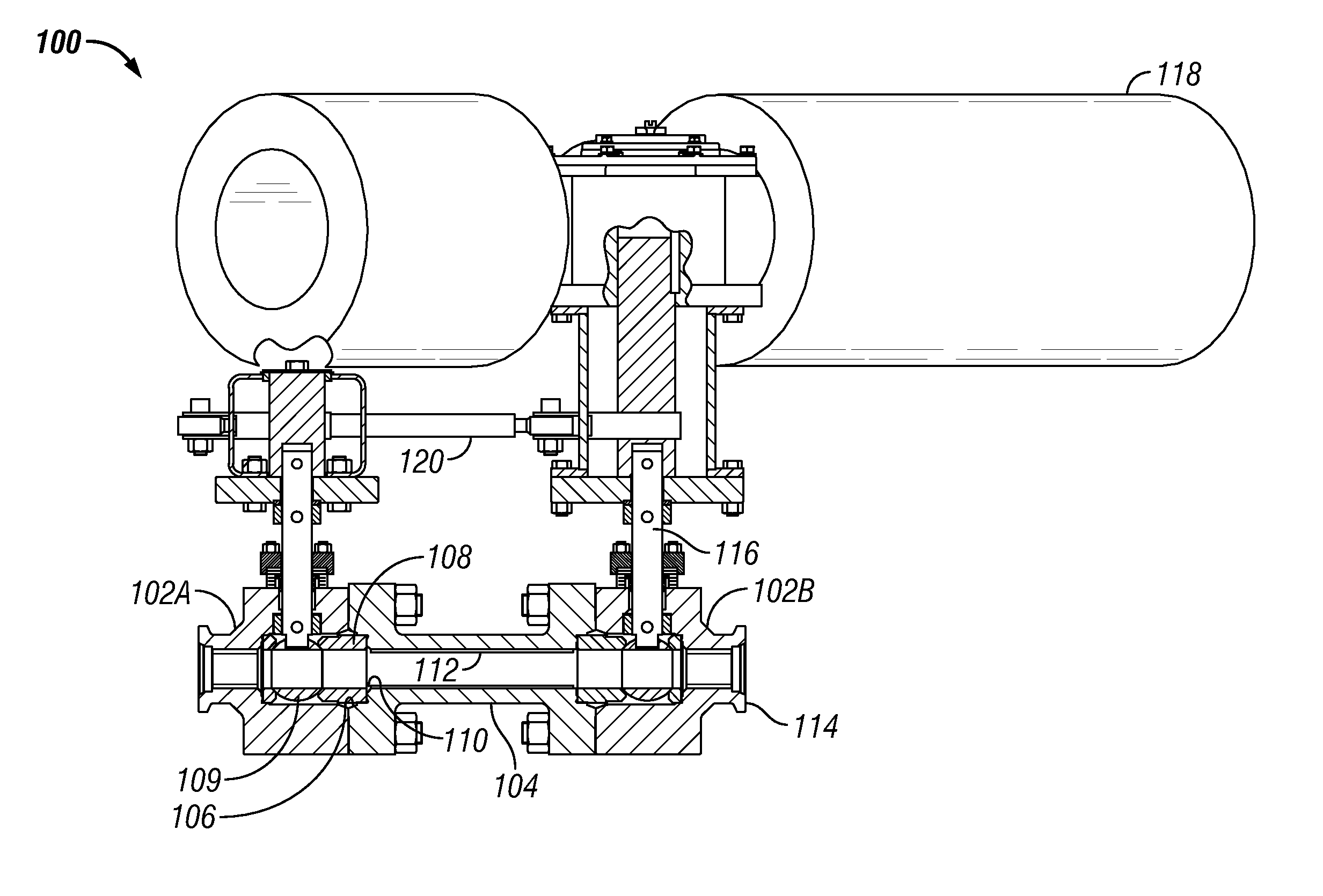

Dual wall axial flow electric heater for leak sensitive applications

ActiveUS8260126B2Reduce riskReduction and elimination of overheatingHeating fuelAir heatersHeat fluxHeater Rod

A dual wall axial flow electric heater for leak sensitive applications provides an improved corrosion and leak resistant assembly and includes protective tubes over electrical heater rods, double tubesheets spaced apart by a plenum and leak detectors positioned to sensor leaks through the walls of the protective tubes. The design includes the option of two or more tube bundles with each inserted into opposite ends of a shell surrounding the tube sheets and heaters. The design provides ease of maintenance since each heater rod can be replaced independently while the unit is in service. Variable heat flux is provided from standard single flux heater rods by providing protective tubes of varying diameters. A built-in thermowell is provided to allow the rod temperatures to be monitored directly. Hot spots are avoided by the use of turning baffles and vibration is avoided by use of spider baffles to support the tubes.

Owner:LORD LTD LP

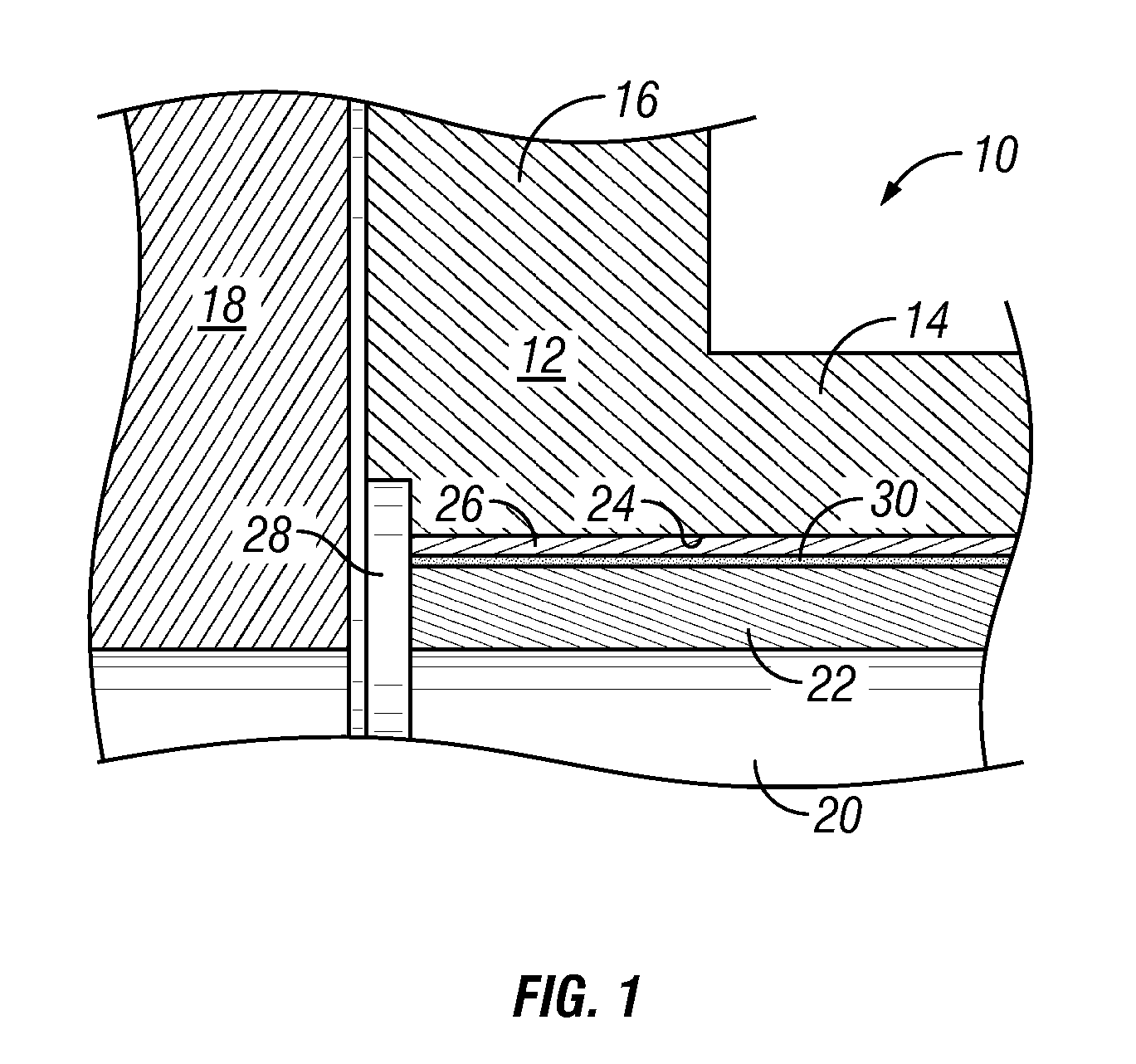

Tubular member with thermal sleeve liner

ActiveUS8783279B2Inhibit thermal fatigue stress crackingCycle fastPipeline systemsFluid pressure control without auxillary powerHigh pressureThermal barrier coating

A tubular fluid flow device of varying outside dimensions adapted for use in a high pressure, rapidly cycling temperature environment, an isolation ball valve, a ball valve isolation method and a catalyst transfer method. The flow device 10 can have a tubular member 12 having at least one locus 14, 16 of non-uniform outside dimension and an axial flow passage 20 with a uniform inside diameter between opposite end connection elements. A thermal sleeve liner 22 can be disposed about the axial flow passage in a bore 24 formed in the tubular member, wherein the sleeve comprises an outer surface having a thermal barrier coating 26. A pressure-relief passage 28 is provided in fluid communication between the axial flow passage and an interface between an exterior surface of the thermal sleeve liner and an inner surface of the bore.

Owner:MOGAS IND

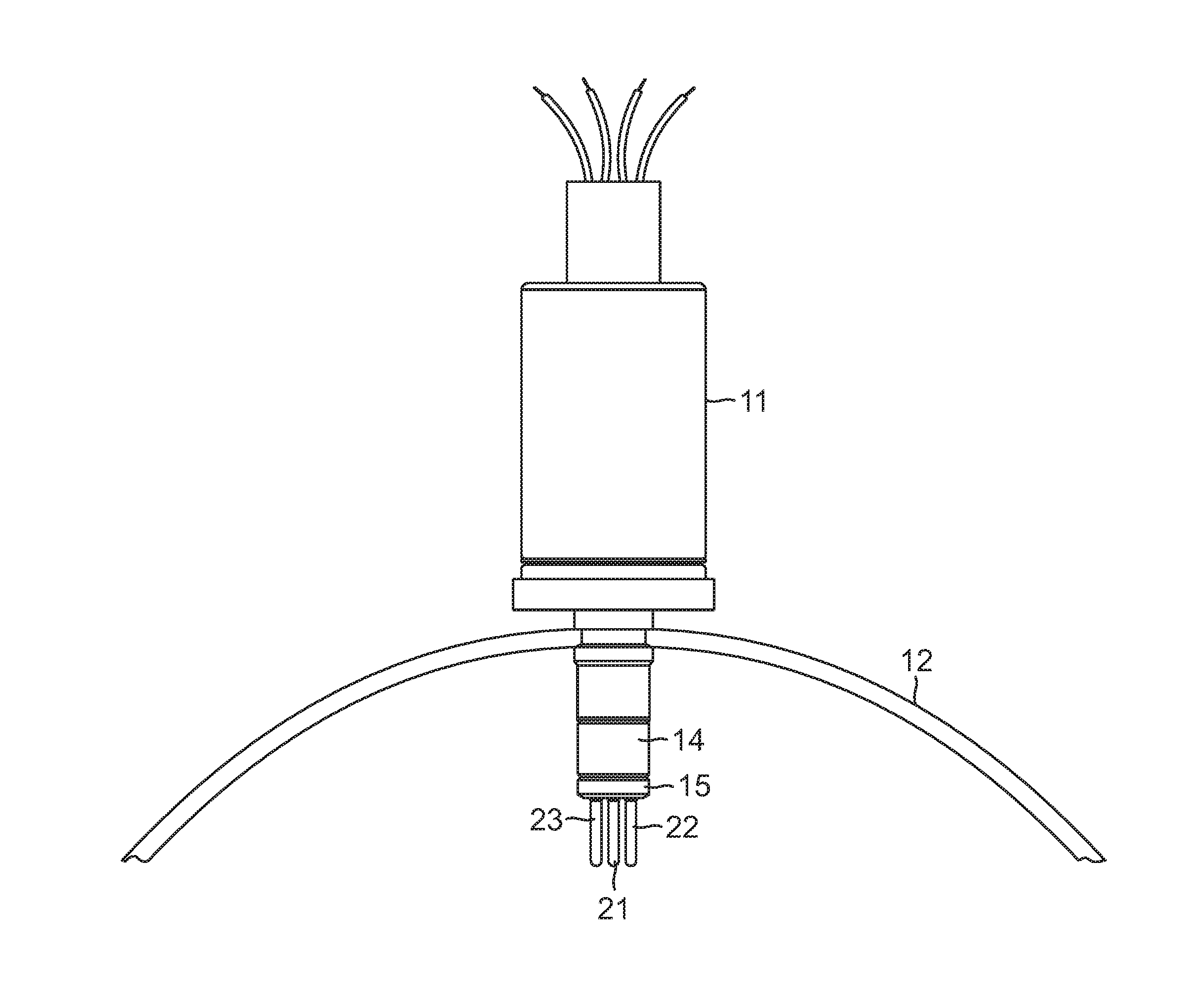

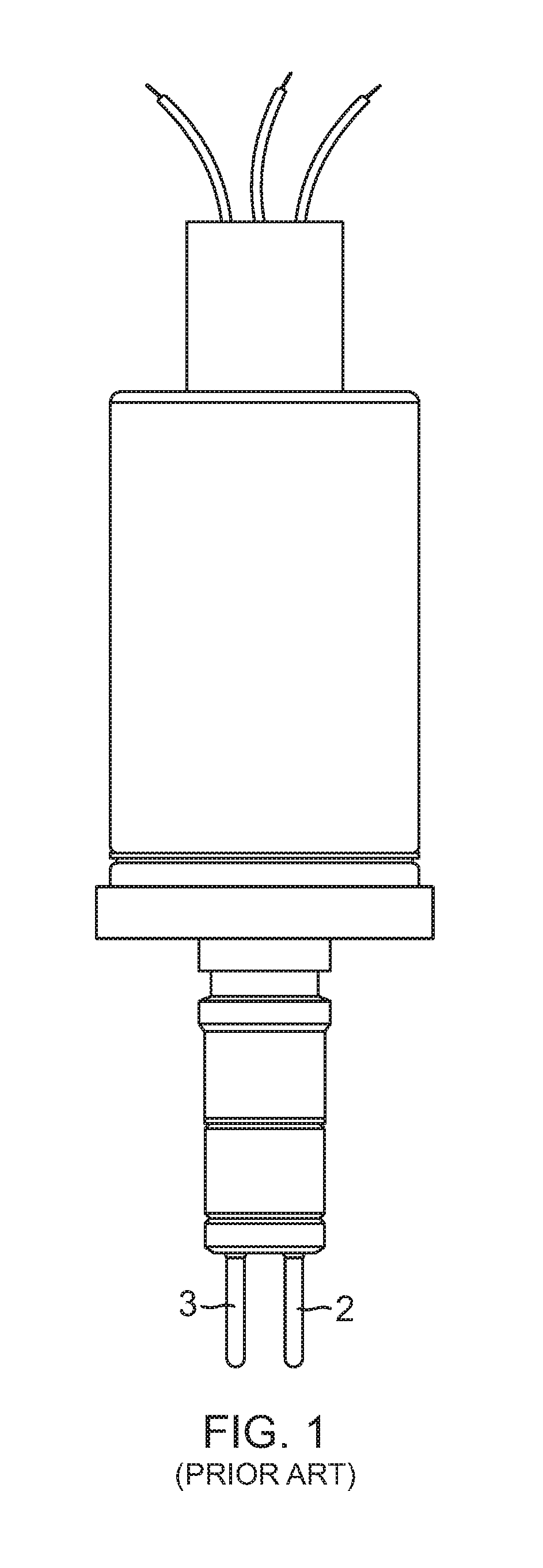

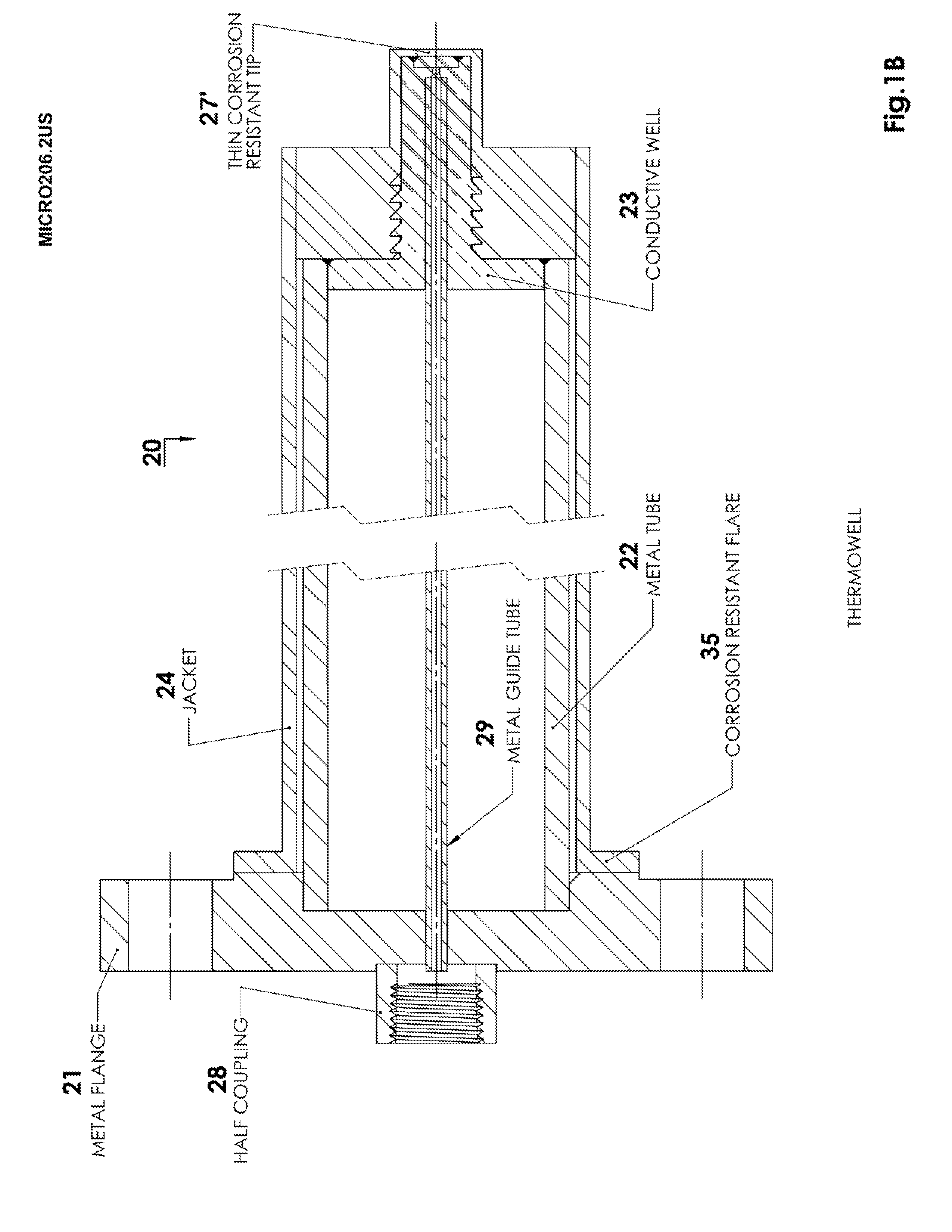

Corrosion resistant thermowells with thin wall tips

ActiveUS20150330840A1Rapid responseImprove corrosion resistanceThermometer detailsThermowellSemiconductor

A corrosion resistant thermowells with thin wall tips for use in unusually difficult industrial applications such as pharmaceutical and chemical process plants and semiconductor manufacturing facilities. These facilities have process environments that may include at least one of the following: highly corrosive fluids, difficult mechanical conditions such as rapid or turbulent fluid flows, and / or reasonably high process temperatures and / or pressures. The corrosion resistant thermowells provide isolation between a temperature sensor and a fluid to be measured.

Owner:MICROMOLD PRODS

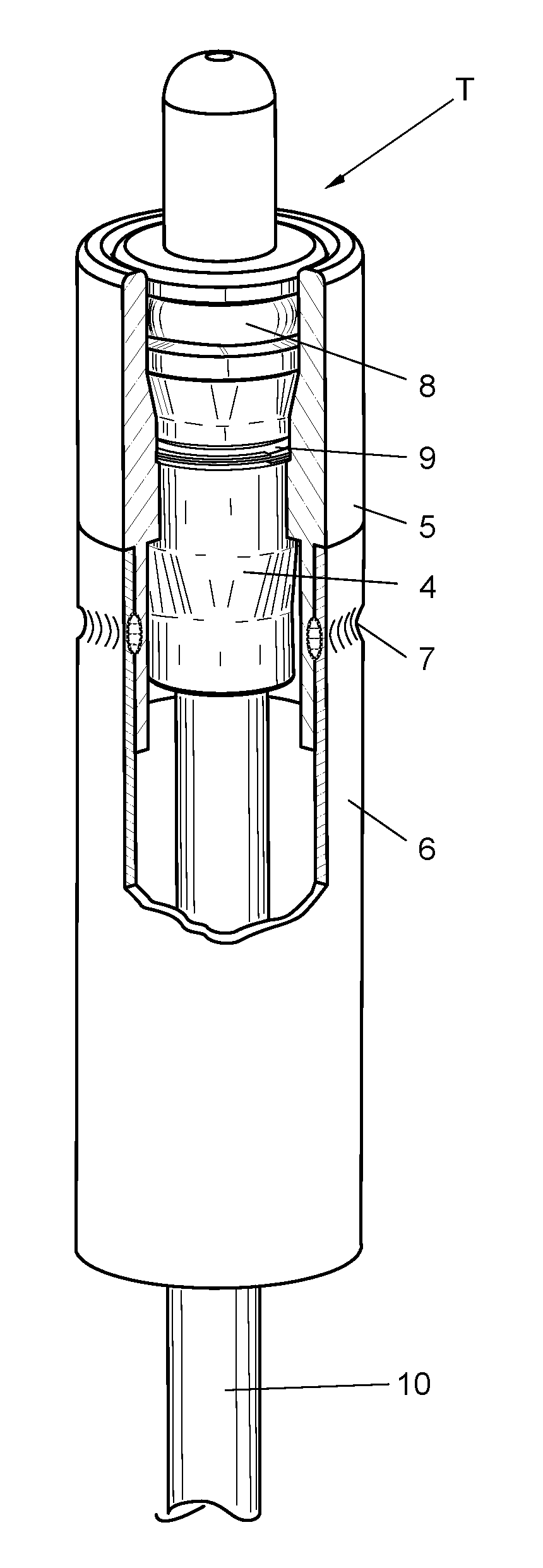

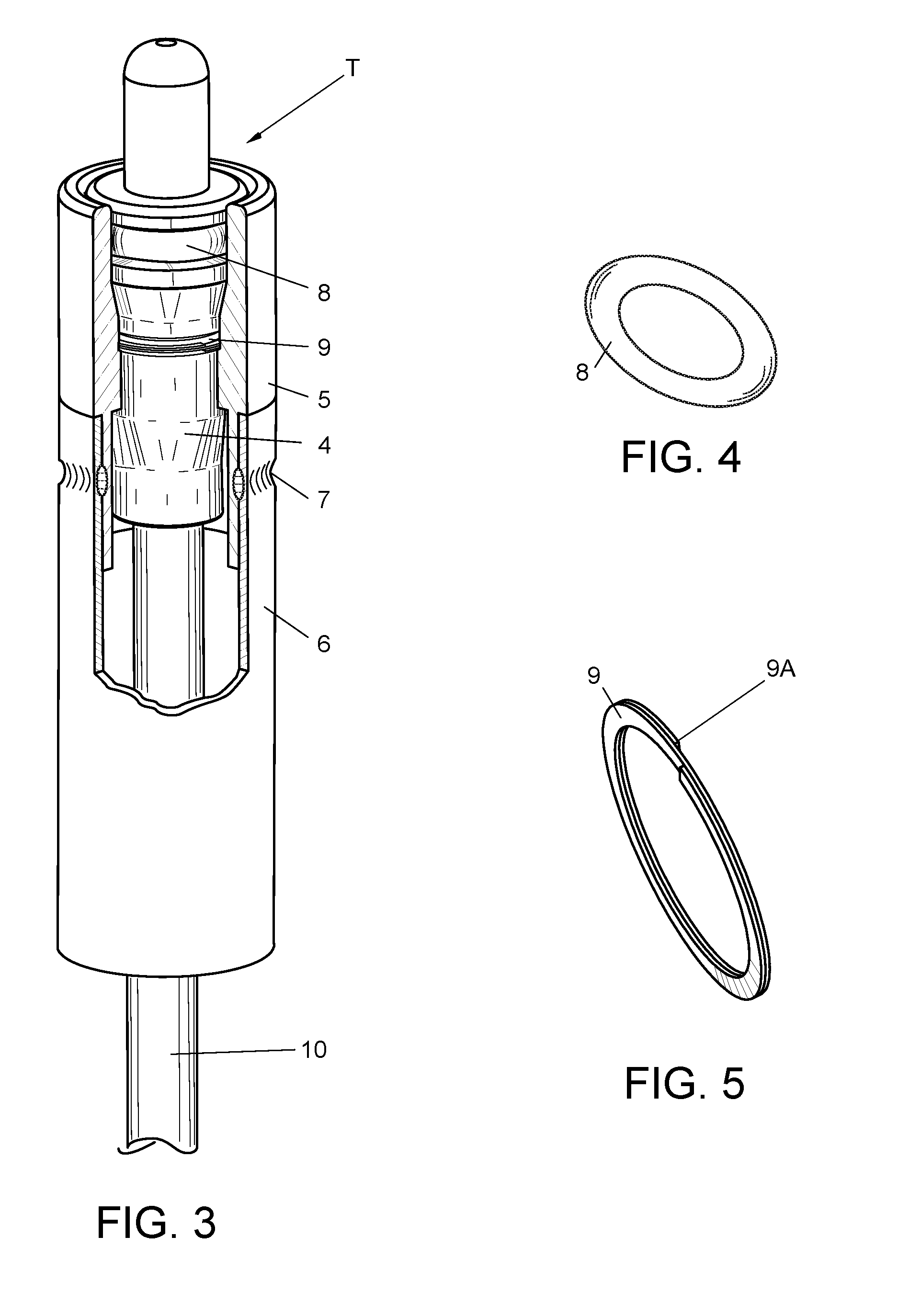

Temperature probe thermowell assembly

InactiveUS20160320242A1Reduced thermal mass and conductivityFunction increaseThermometer detailsThermometers using electric/magnetic elementsThermowellBiomedical engineering

A temperature probe assembly includes an internal fitting having an exterior and a hollow interior; a temperature sensor disposed within the hollow interior of the internal fitting, the temperature sensor being configured to be placed in communication with an external controller; an external fitting disposed on the exterior of the internal fitting; and a tube connected to the external fitting. The temperature probe assembly is configured to be inserted into a thermowell. The tube and external fitting are configured to house and support the internal fitting in the thermowell.

Owner:US THERMOAMP

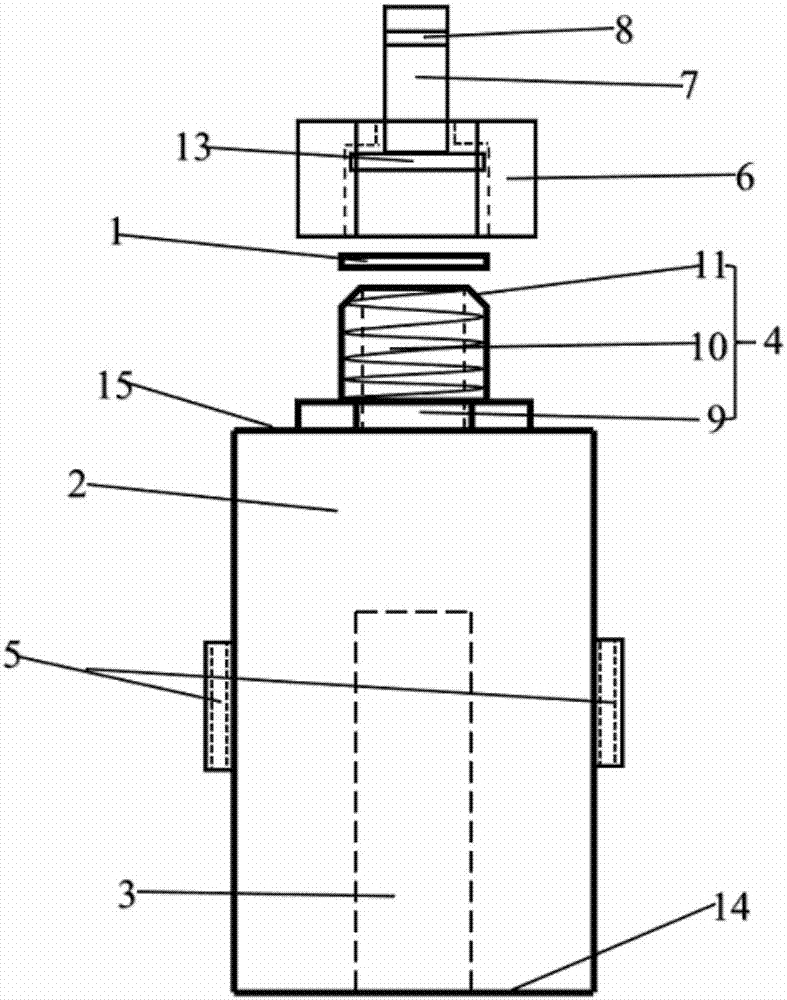

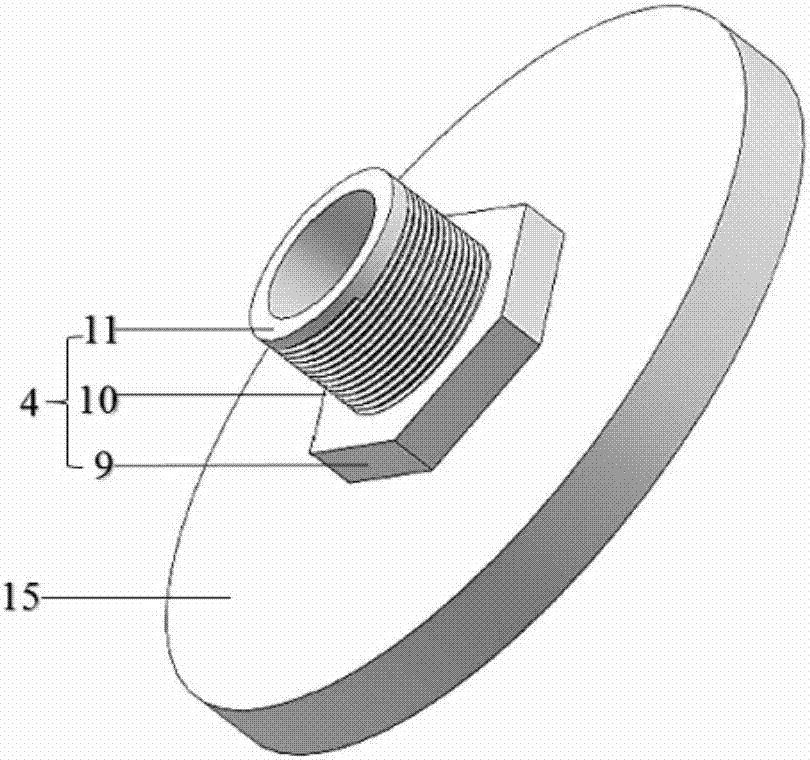

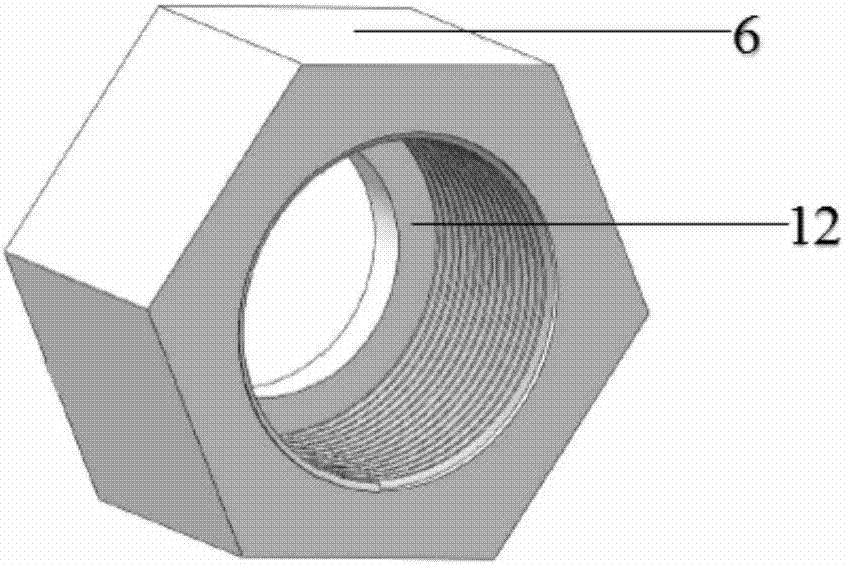

Heat meter sample cell with sample change convenience, high sample change speed and good sealing performance

ActiveCN107884437ACompact structureSimple designMaterial heat developmentWorking temperatureEngineering

The invention discloses a heat meter sample cell with sample change convenience, high sample change speed and good sealing performance. The heat meter sample cell has the highest work temperature of 600K, and can be conveniently and reliably fixed in a heat meter. The sample cell concretely comprises a metal gasket, a sample cell main body, thermocouple sheaths, a hollow hexagonal nut and a solidcylinder, wherein the metal gasket has the set dimension and hardness (mechanical strength); the sample cell main body is a cylindrical barrel body; a cylindrical trap extending into the barrel body is arranged in the center position of the bottom for placing a thermometer-heating unit; the upper part of the barrel body is provided with a sealing bearing module; the thermocouple sheaths are symmetrically welded at the side surface of the sample cell; an upper hole is provided with an inward annular clamp groove; the upper part of the solid cylinder is provided with a hanging hole so as to hangthe sample cell; the lower part of the solid cylinder is provided with an annular epitaxy buckled with the annular clamp groove; the sealing bearing module is a hollow cylinder, wherein the lower part is in a hexagon rectangle shape, the main body is screw threads, and a knife edge is formed in the top. The heat meter sample cell has the advantages that the structure is compact; the design is novel; the sealing is tight; the sample change is convenient; the use is flexible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

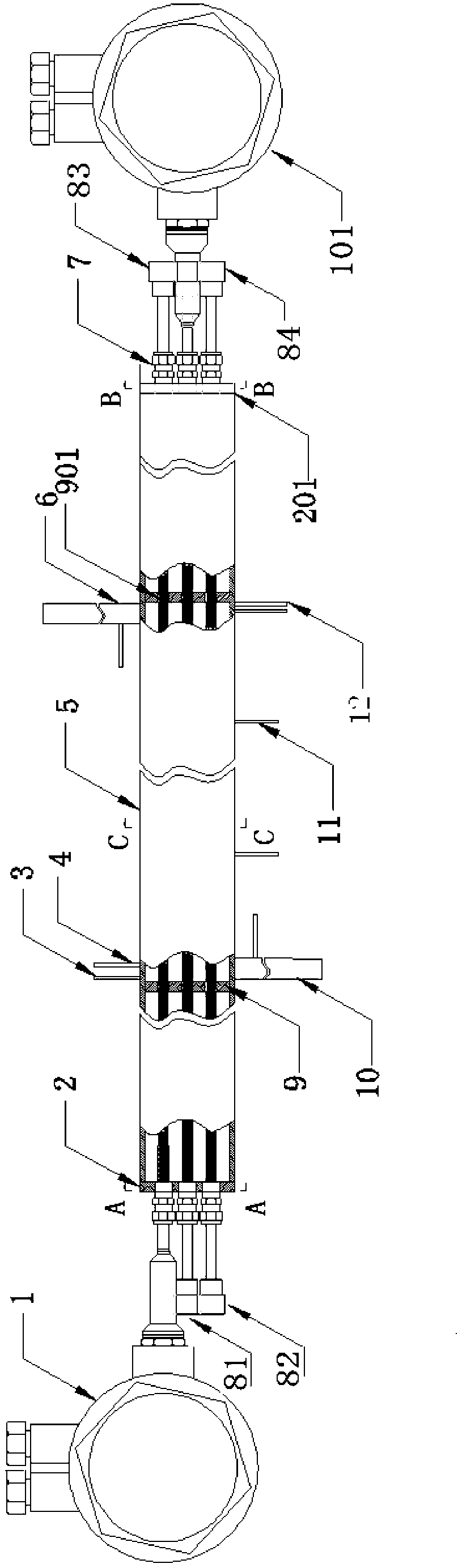

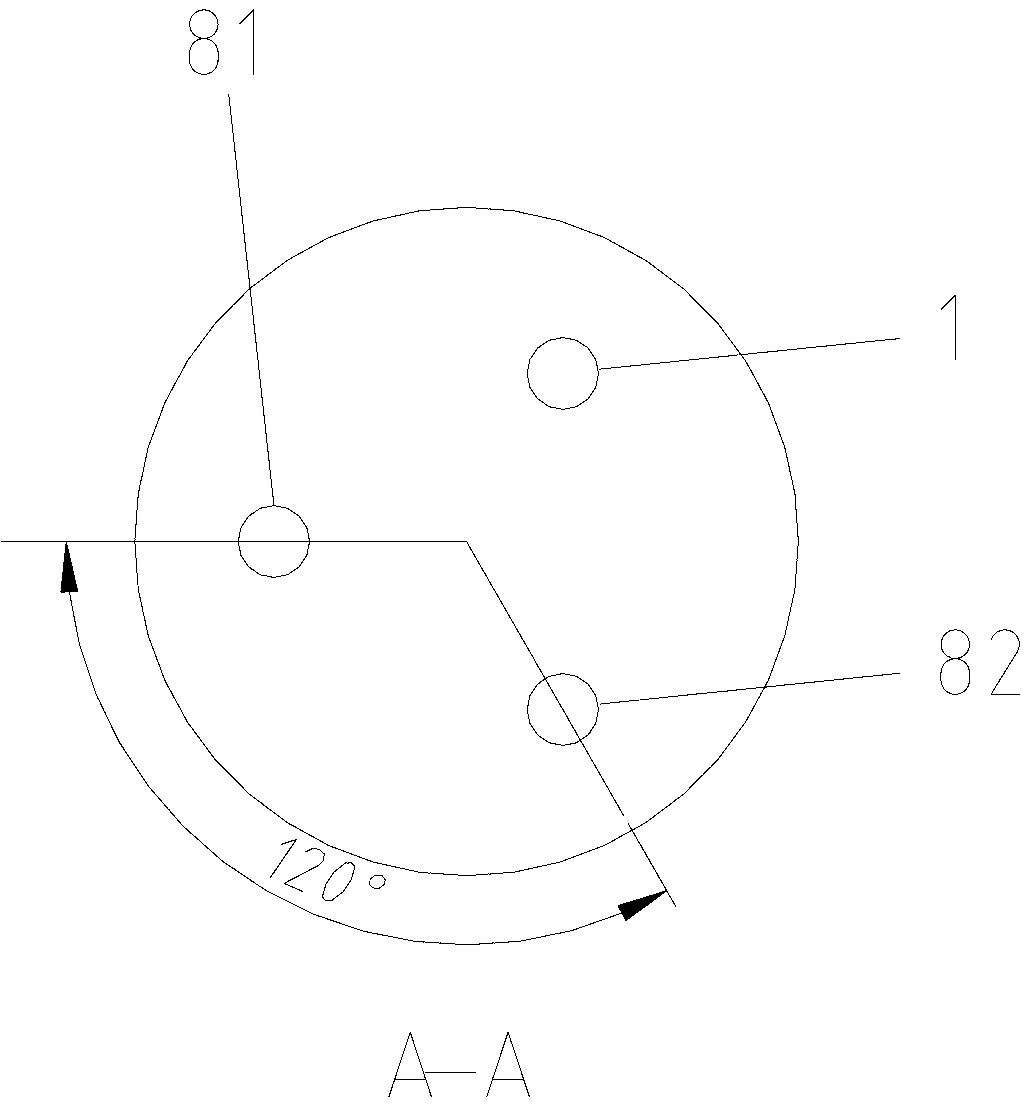

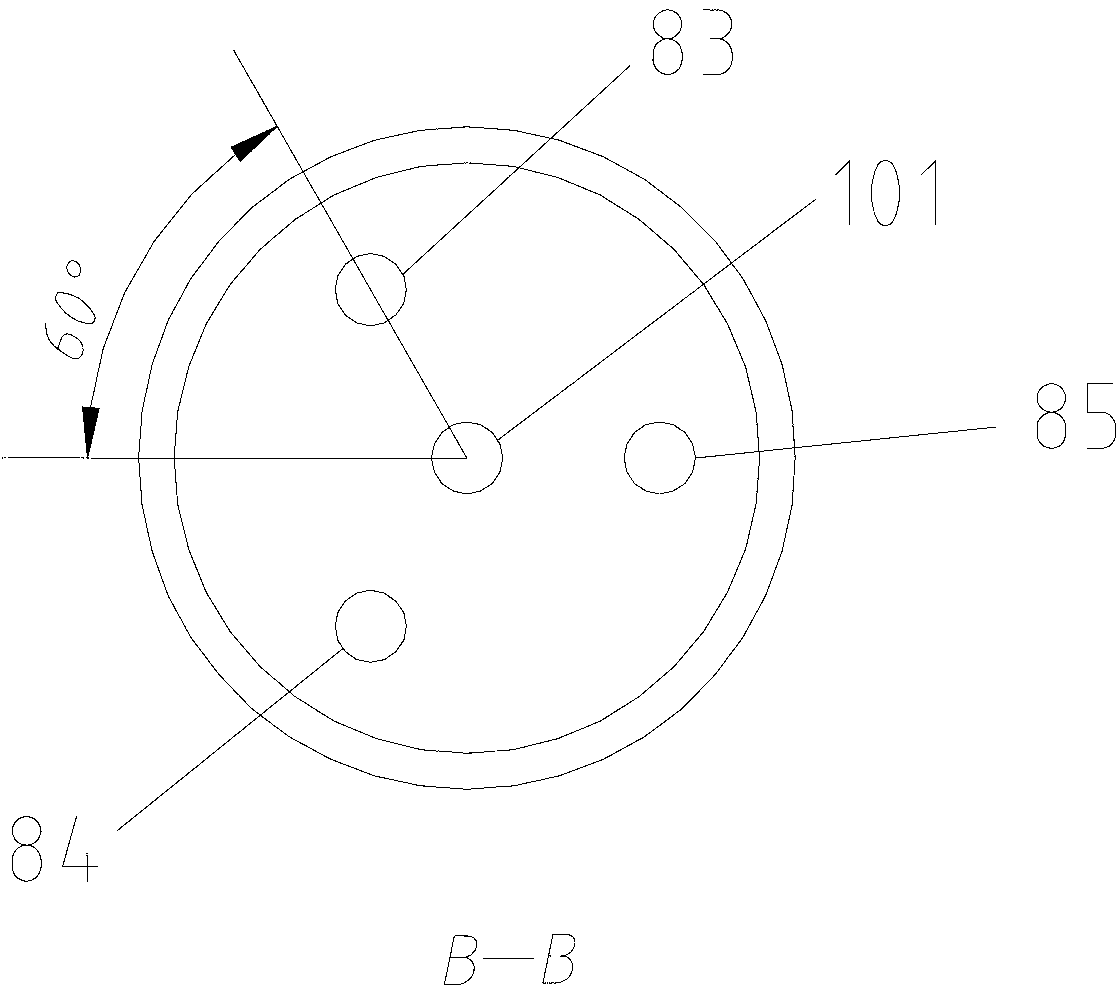

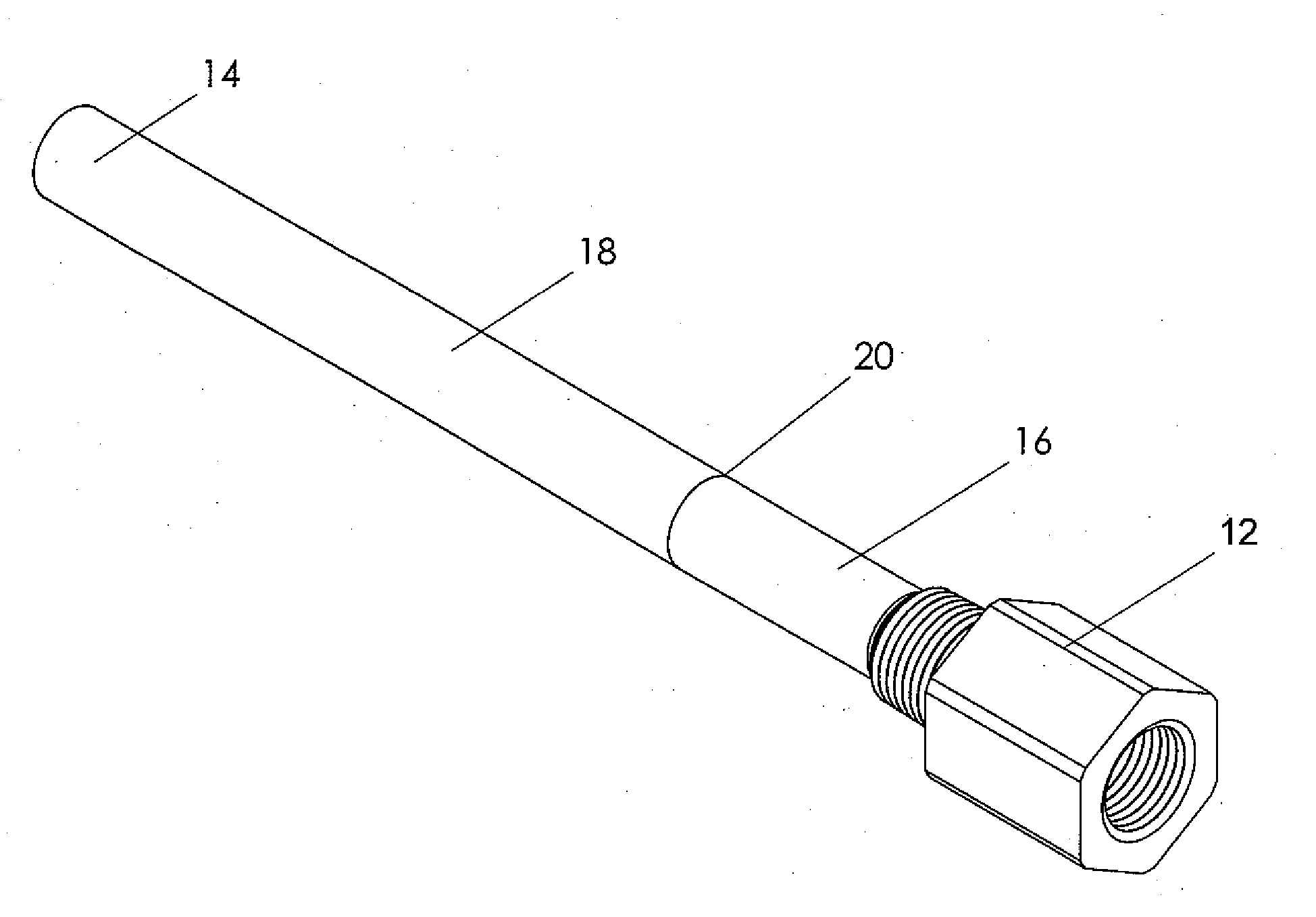

Detachable high pressure resistant multipoint flexible thermocouple

ActiveCN103528705ASolving High Pressure Sealing ProblemsGuaranteed stiffnessThermometer detailsThermometers using electric/magnetic elementsThermodynamicsProcess engineering

The invention relates to a high pressure resistant split multipoint flexible sheathed thermocouple, in particular to a split, weldless and detachable high pressure resistant multipoint flexible thermocouple suitable for a high-pressure hydrocracking reactor. A flange and a multipoint flexible thermocouple well are different in material, so that the problem that hydrogen embrittlement fracture can be easily caused to the flexible thermocouple due to the welding reason of a hydro interface of the flange is solved. Meanwhile, the flexible thermocouple is convenient to disassemble and replace when overhauling is performed, so that the use cost is reduced, and the problems that the cost is high and the complete set needs to be replaced when maintenance and replacement are performed under the requirement that the flange and the multipoint flexible thermocouple well have to be consistent in material by adopting a welding process of the multipoint flexible sheathed thermocouple because the same material is easy for welding are solved.

Owner:杭州亿泰自控设备有限公司

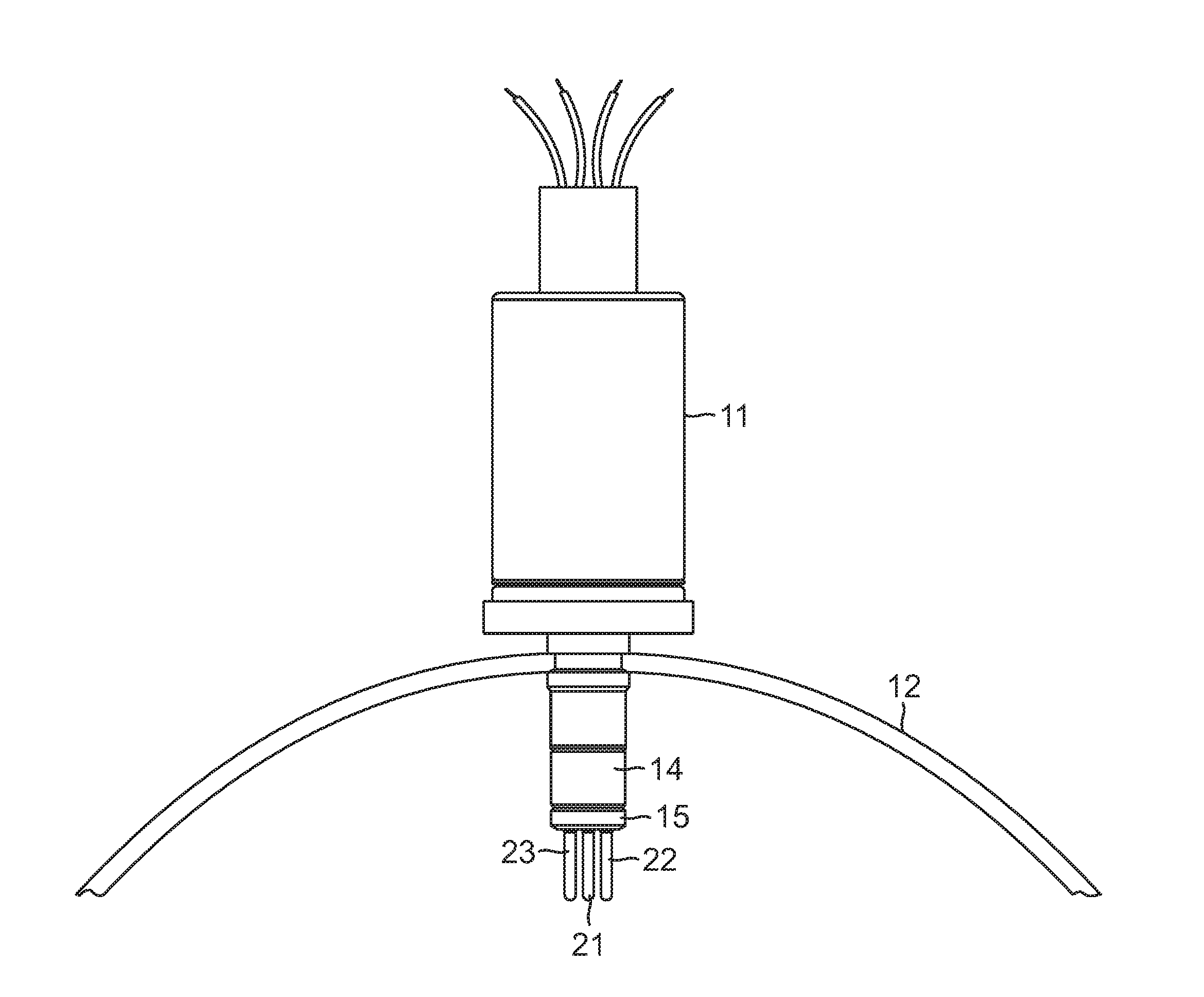

Modular Thermowell and Method

ActiveUS20140036960A1Maintain integrityMaintain strengthThermometer detailsMetal working apparatusFriction weldingThermowell

A thermowell is provided for positioning on a pipeline or tank to measure the temperature. The thermowell comprises a head for receiving a probe, and the well has a closed end. An elongated hollow tubular connects the head and the well. The tubular includes one or more tubular parts, each of a selected axial length, joined by a friction welding to one of the more of the head, the well or another of the tubular parts.

Owner:PARKER HANNIFIN CORP

Dual sensor head configuration in a fluid flow or liquid level switch

ActiveUS9528868B2Low weight and size and power consumptionImprove reliabilityTesting/calibration apparatusVolume/mass flow measurementEngineeringThermowell

A fluid flow or liquid level switch providing a high level of reliability. Dual reference sensors in a single thermowell operates with two active, independent sensors, which operate with independent electronics having dual signal outputs, to provide constant and continuous redundancy in operation.

Owner:FLUID COMPONENTS INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com