Online calibration of a temperature measurement point

A technology for temperature measurement and measuring instruments, which is used in thermometer testing/calibration, temperature measurement of moving fluids, thermometer components, etc. It can solve problems such as hindering users from calibrating temperature measurement points and expensive calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

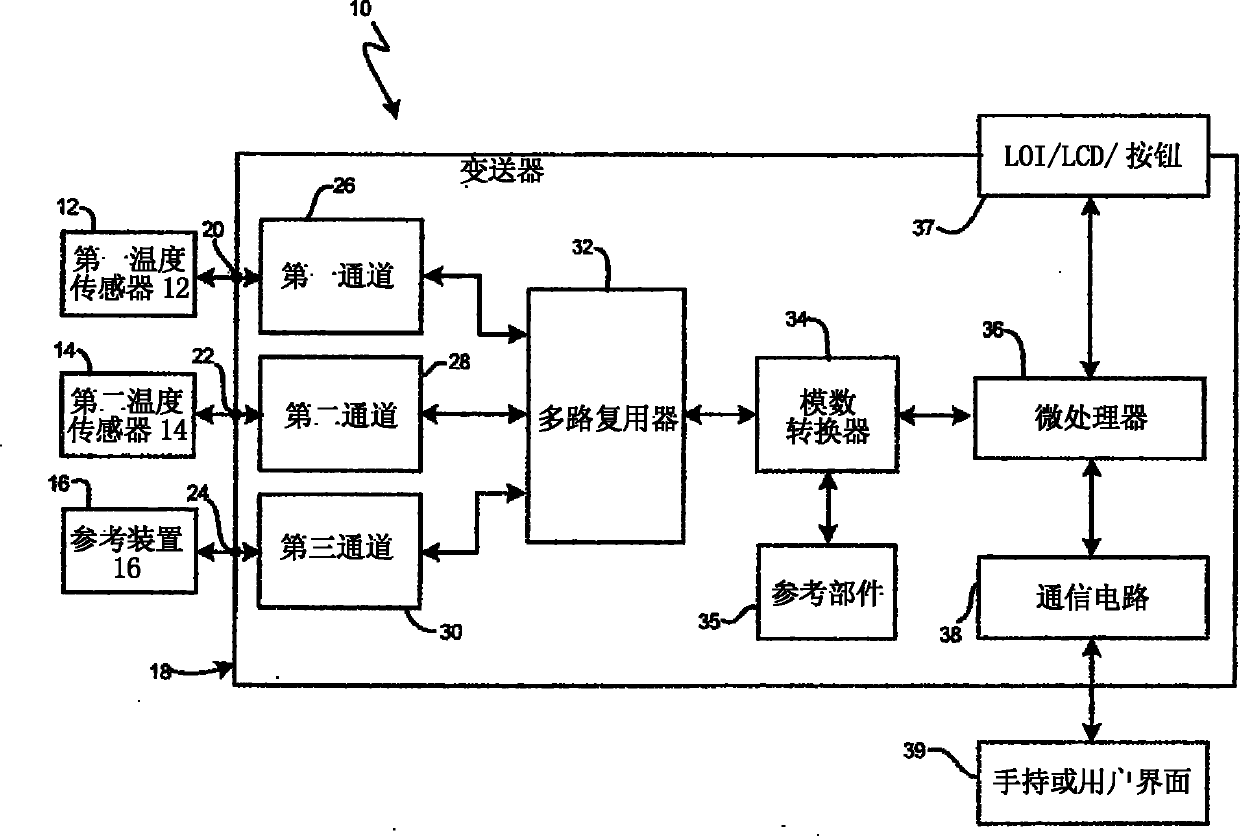

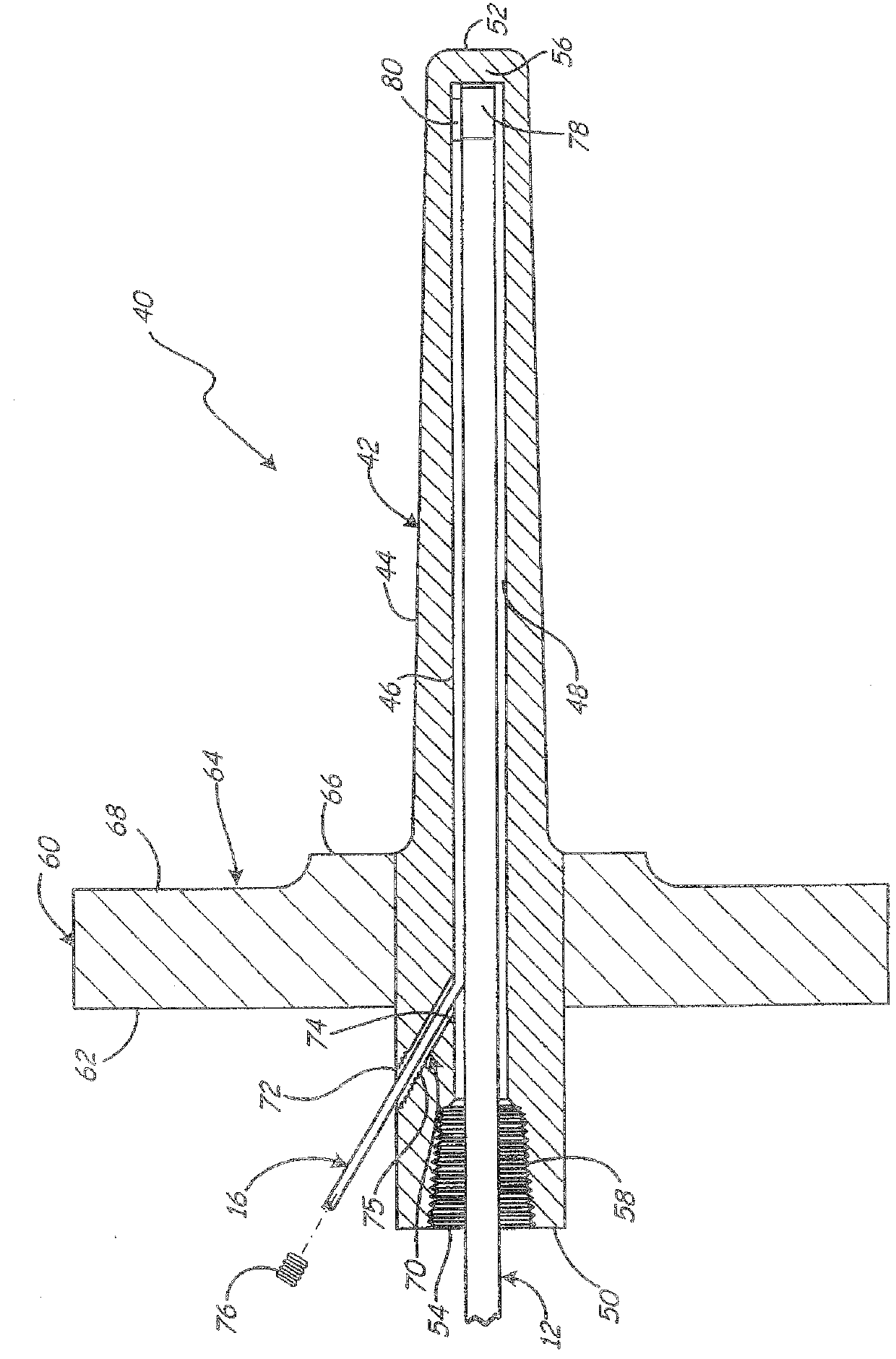

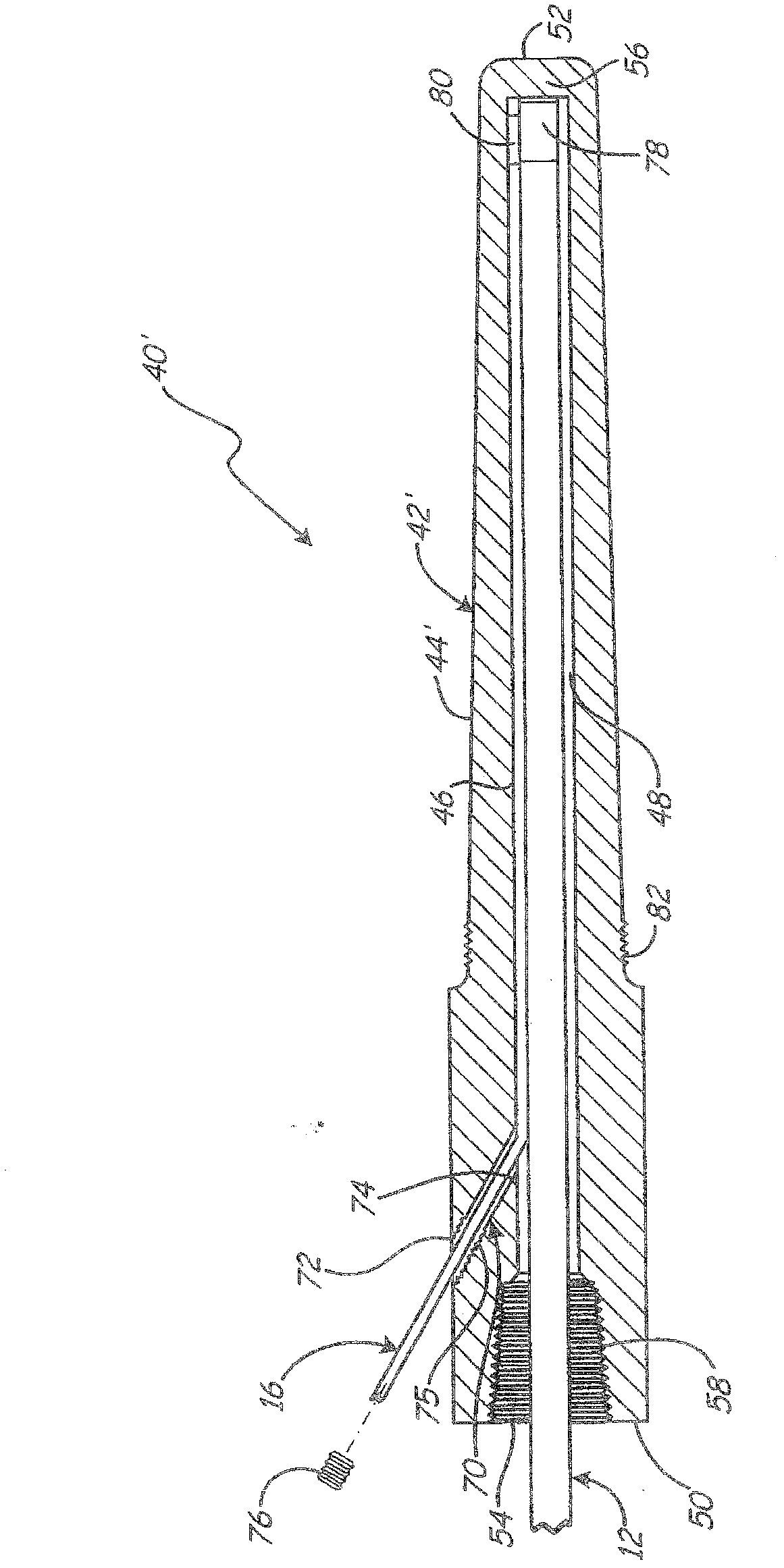

[0019] In general, the present invention provides apparatus and methods for calibrating temperature measurement points. The transmitter is configured to be able to calibrate against one channel while continuing to measure temperature using the other channel. The thermowell has a bore configured to allow insertion of a temperature sensor and a side channel configured to allow insertion of a reference device, wherein the reference device rests proximate to the temperature sensor for calibration. Various methods allow calibration of transmitters, temperature sensors, or both. In each method, the temperature sensor remains connected to the transmitter, the temperature sensor remains in the thermowell, or both.

[0020] figure 1 is a schematic diagram of the temperature measurement point 10. The temperature measurement point 10 comprises a first temperature sensor 12 , a second temperature sensor 14 , a reference device 16 and a transmitter 18 . The transmitter 18 includes a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com