Vibration detection in thermowells

A thermowell, vibration signal technology, applied in the direction of vibration measurement in solids, measuring vibration, thermometers with directly sensitive electrical/magnetic components, etc., can solve problems such as increasing the possibility of resonance conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

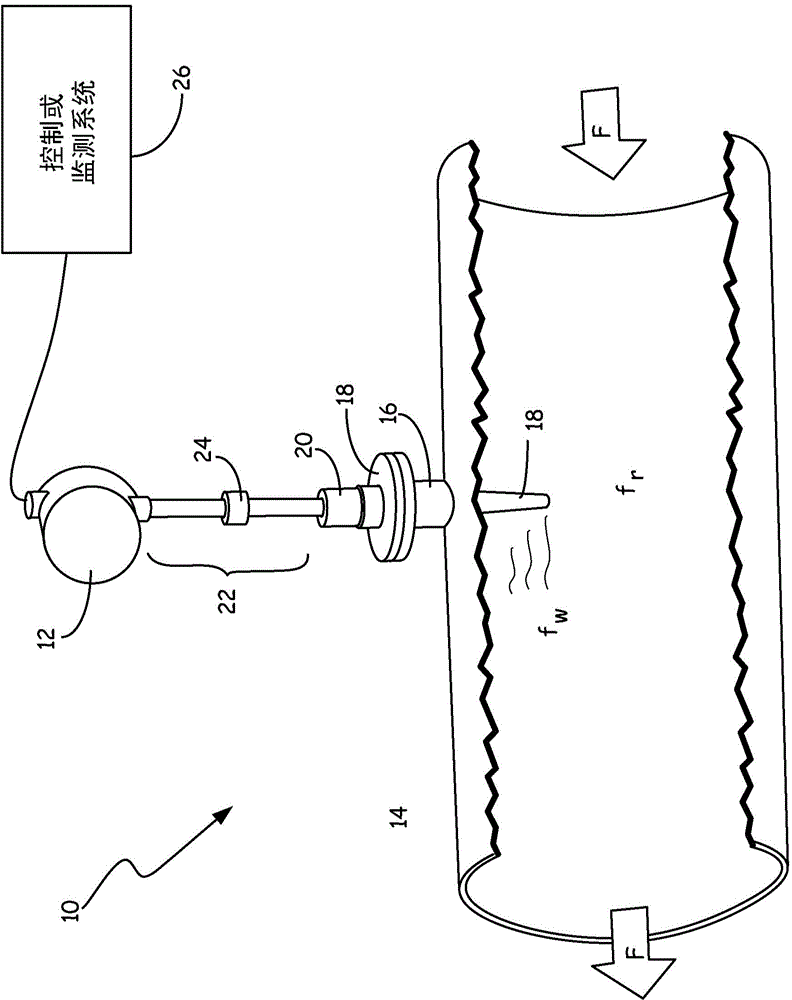

[0009] figure 1 is a simplified cross-sectional view of one embodiment of a process system 10 (a system for monitoring and / or stimulating an industrial fluid process). In the depicted embodiment, process system 10 includes process transmitter 12, process piping 14 (with flanged connection 16), thermowell 18, process transducer 20, extension 22, vibration sensor 24, and control Or monitoring system 26 .

[0010] Process line 14 carries process stream F for an industrial process. Process lines 14 may be, for example, tubes or ducts configured to carry fluids, such as oil slurries, viscous manufacturing materials, gases, or liquids. Process line 14 includes at least one flange connection 16 to facilitate connection of flange-mounted equipment to measure at least one characteristic of process flow F, such as temperature, flow rate, pressure, or pH. In the illustrated embodiment, flange connection 16 provides an attachment point for thermocouple well 18 and process transducer 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com