Thermowell vibration frequency diagnostic

A thermocouple well, vibration frequency technology, applied in the direction of measuring vibration, vibration measurement in fluids, thermometers with electric/magnetic elements directly sensitive to heat, etc., capable of solving environmental damage or other dangers, shutdowns, fires, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In general, the present invention includes methods and apparatus for measuring a thermowell vibration frequency in a process and comparing the frequency to a natural frequency of the thermowell. This can be performed by a transmitter electrically connected to an accelerometer fixedly connected to the thermowell. If a thermowell is found to vibrate near its natural frequency, an alarm can be sounded, signaling to the user that thermowell failure may be imminent.

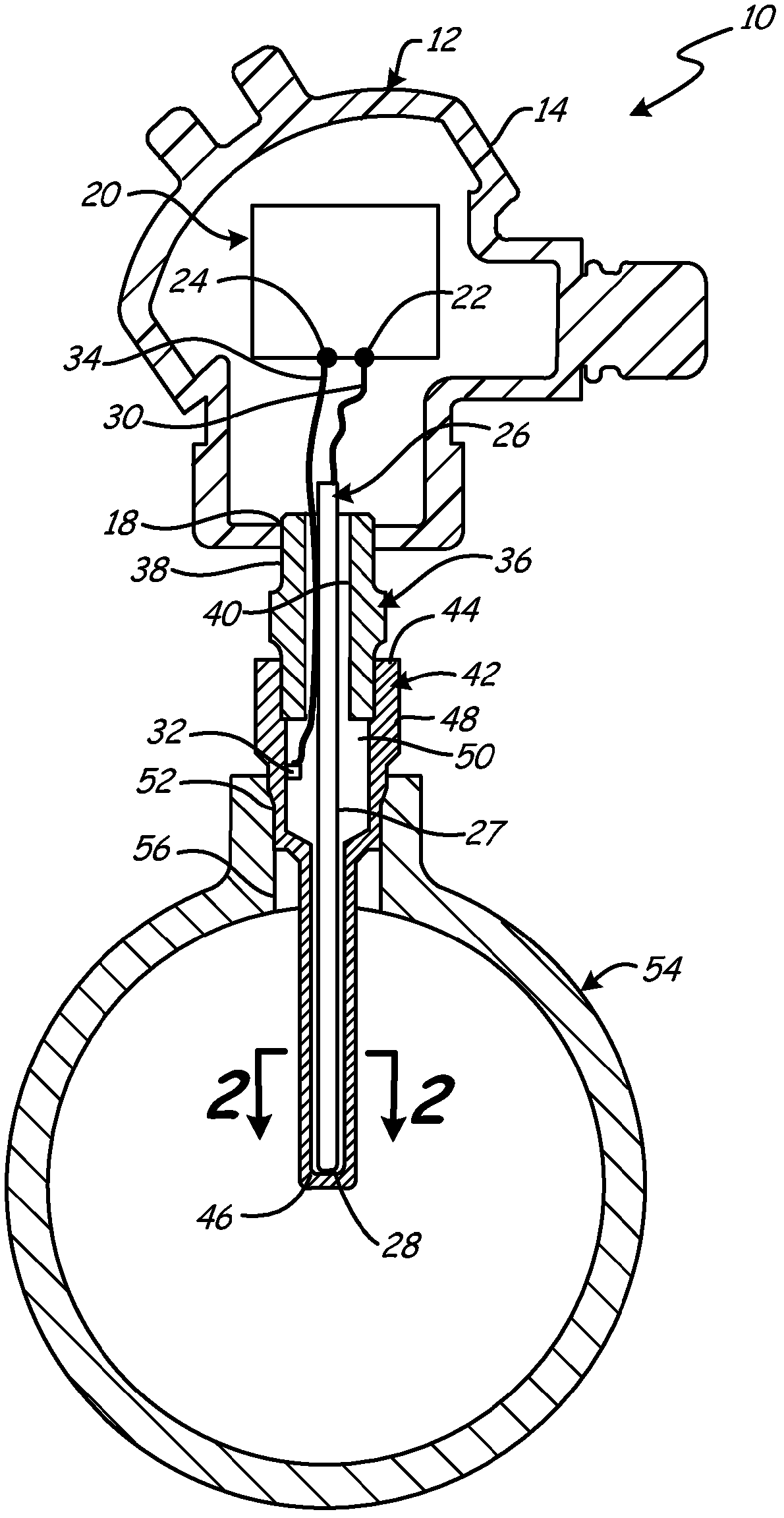

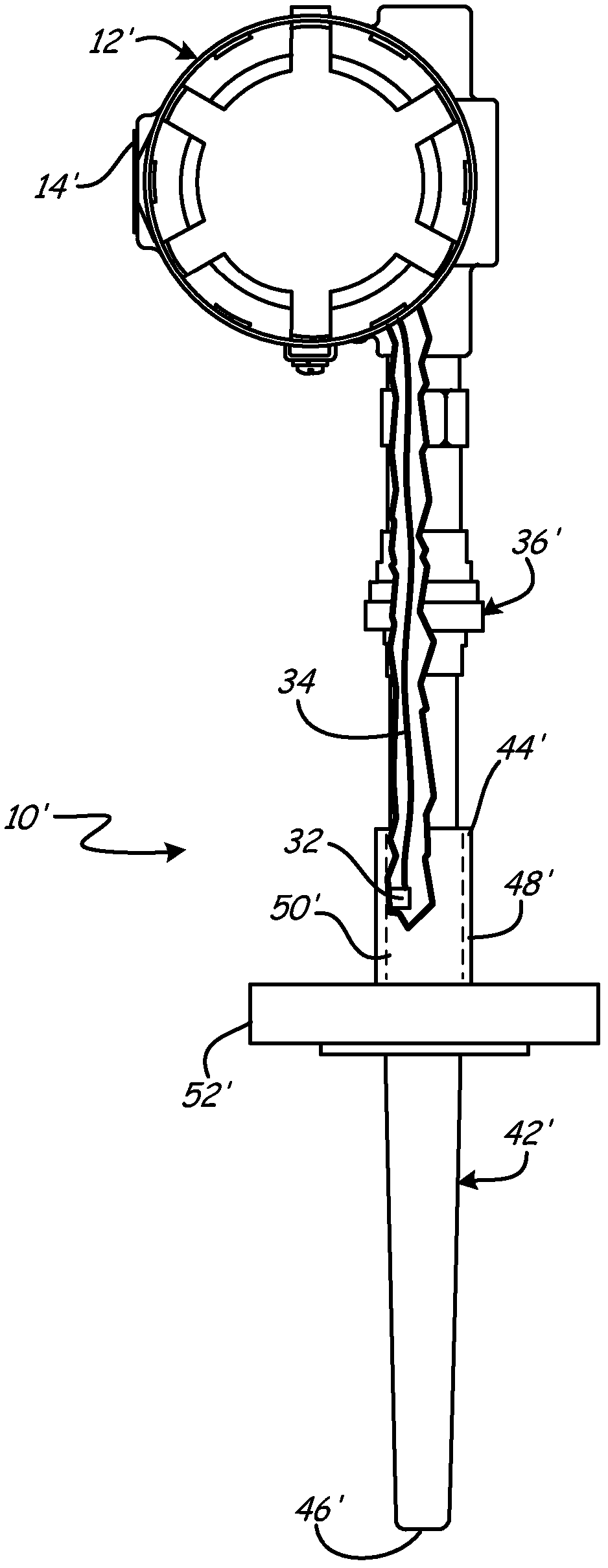

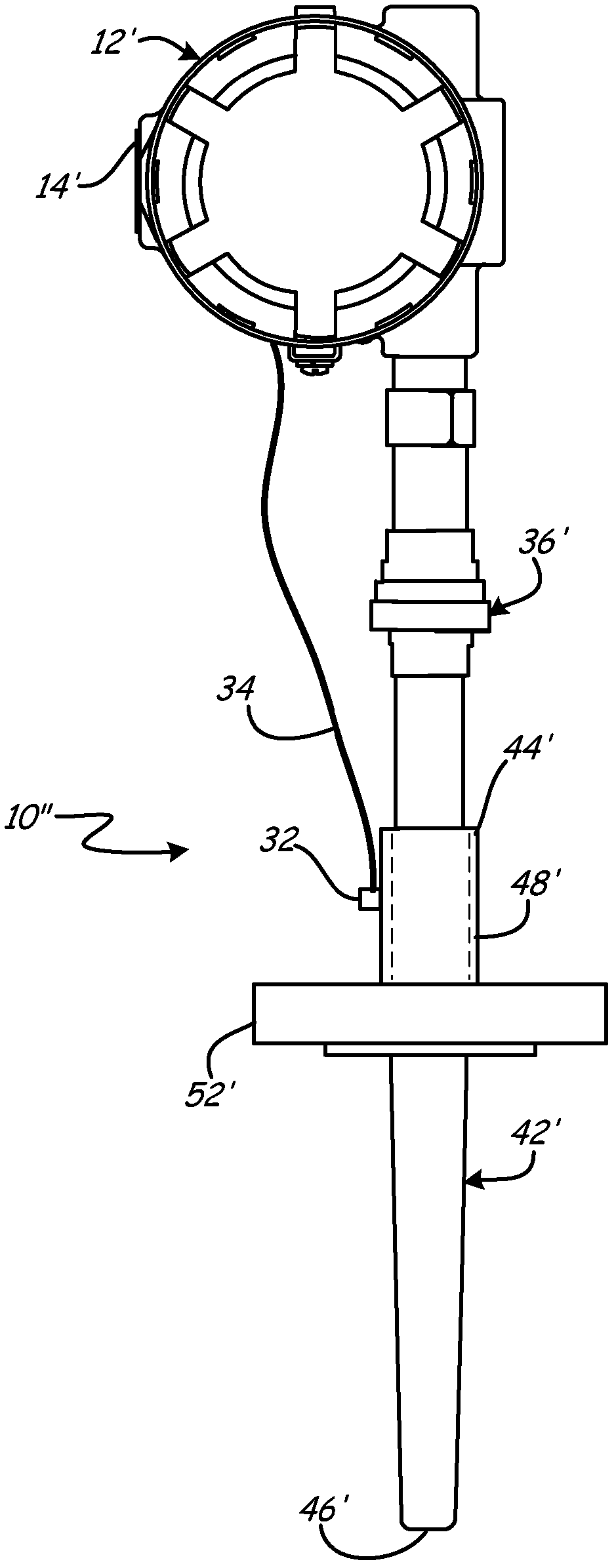

[0017] Figure 1A is a cross-sectional view of the temperature measurement point 10. According to one embodiment, the temperature measurement point 10 includes a transmitter 12 (which includes a housing 14, a housing bore 18, a transmitter circuit 20, a temperature sensor terminal 22 and a vibration sensor terminal 24), a temperature sensor 26 (which including protection tube 27, temperature sensor tip 28 and temperature sensor wire 30), vibration sensor 32 (which includes vibration sensor wire 34), thermowell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com