Detachable high pressure resistant multipoint flexible thermocouple

A thermocouple and armored thermocouple technology, applied in the direction of measuring heat, using electrical devices, using electromagnetic means, etc., can solve the problems of uneven grains, waste, inconsistent welding melting point, etc., to improve the resistance to high temperature hydrogen embrittlement strength, The effect of reducing manufacturing cost and increasing temperature resistance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

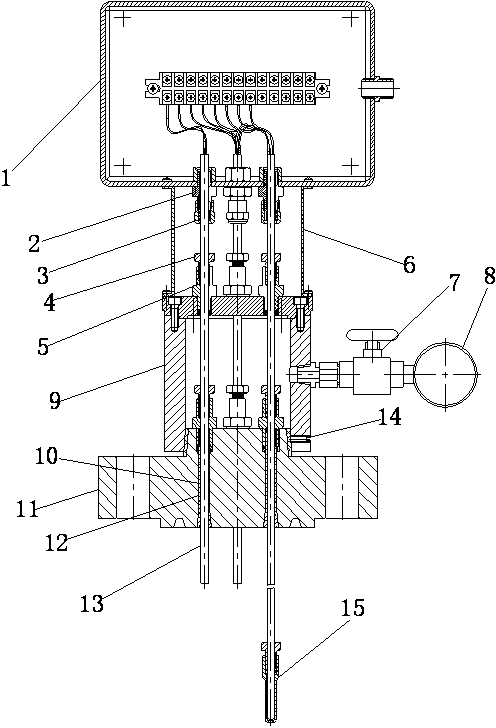

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1As shown, the detachable high-voltage multi-point flexible thermocouple of the present invention includes a flange 11, a high-pressure sealing chamber 9 is arranged on the upper part of the flange 11, a pressure plate is arranged on the top of the high-pressure sealing chamber 9, and the upper part of the pressure plate is connected to the explosion-proof The junction box 1 is connected, and several flexible armored thermocouples 13 pass through the flange 11, the high-pressure sealing chamber 9, the pressure plate and the bottom of the explosion-proof junction box 1 to connect with the multi-point terminal block inside the explosion-proof junction box 1, and the flexible armored thermocouples 13 It is fixedly connected with the flange 11, the pressure plate and the bottom of the explosion-proof junction box 1 through double ferrule joints resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com