Patents

Literature

112 results about "Pressure experiment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure experiments are experiments performed at pressures lower or higher than atmospheric pressure, called low-pressure experiments and high-pressure experiments, respectively. Pressure experiment are necessary because substances behave differently at different pressures. For example, water boils at a lower temperature at lower pressures. The equipment used for pressure experiments depends on whether the pressure is to be increased or decreased and by how much. A vacuum pump is used to remove the air out of a vacuum vessel for low-pressure experiments. High-pressures can be created with a piston-cylinder apparatus, up to 5 GPa (50 000 bar) and ~2000 °C. The piston is shifted with hydraulics, decreasing the volume inside the confining cylinder and increasing the pressure. For higher pressures, up to 25 GPa, a multi-anvil cell is used and for even higher pressures the diamond anvil cell. The diamond anvil cell is used to create extremely high pressures, as much as a million atmospheres (101 GPa), though only over a small area. The current record is 560 GPa, but the sample size is confined to the order of tens of micrometres (10⁻⁵ m).

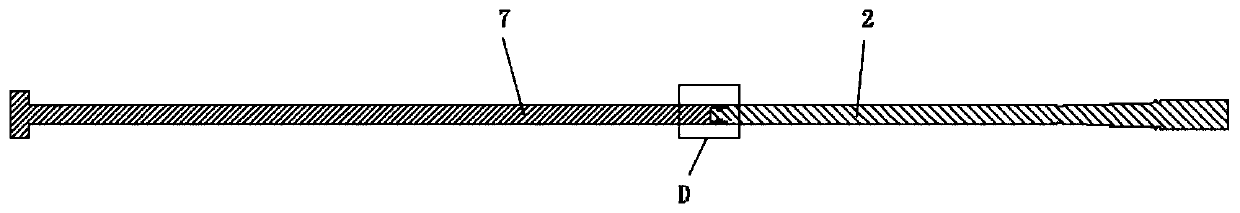

Method for determining relative permeability of dense rock oil phase

ActiveCN110346258AHigh measurement accuracyStrong ability to spontaneously absorb wet phase fluidsPermeability/surface area analysisPorosityDry weight

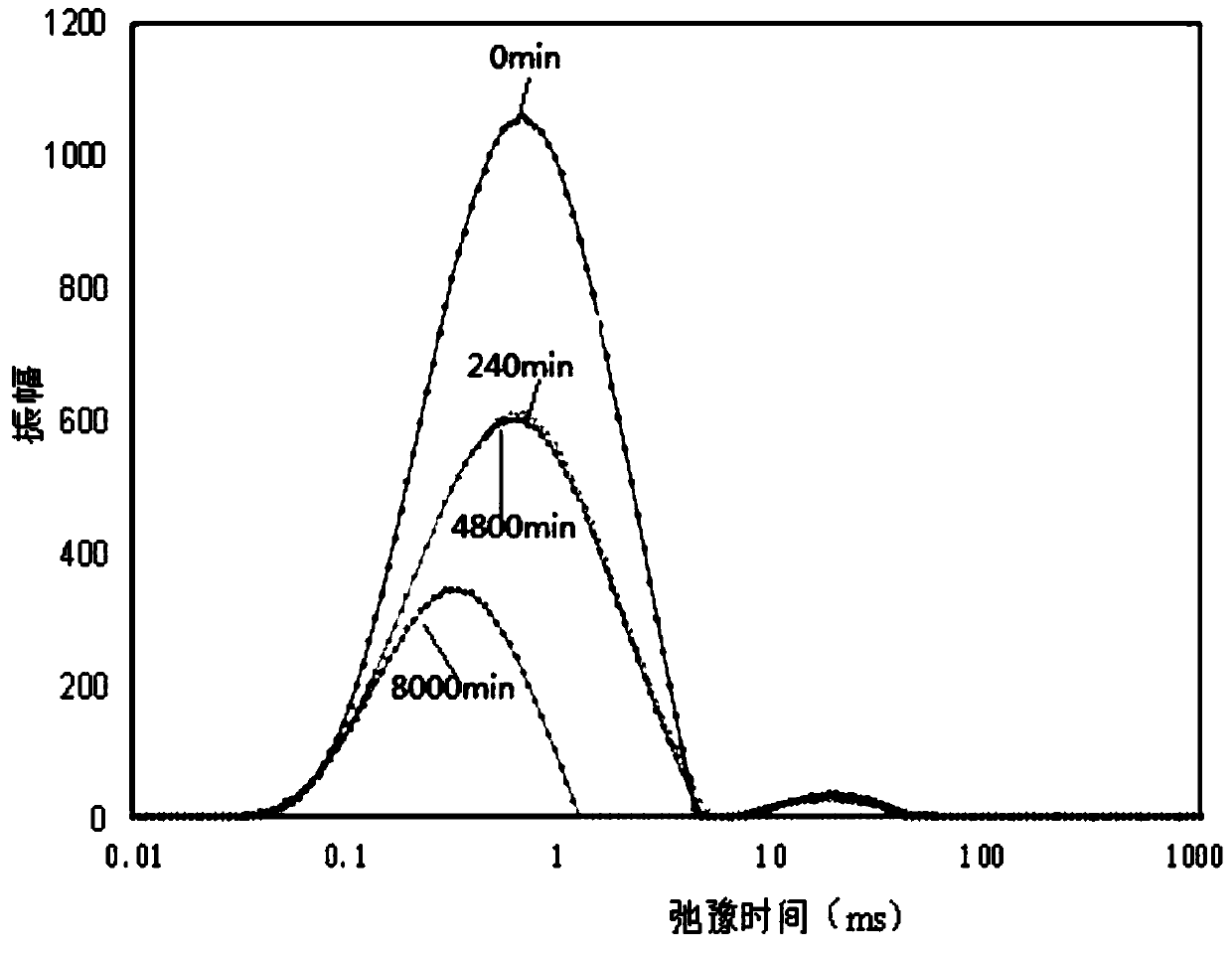

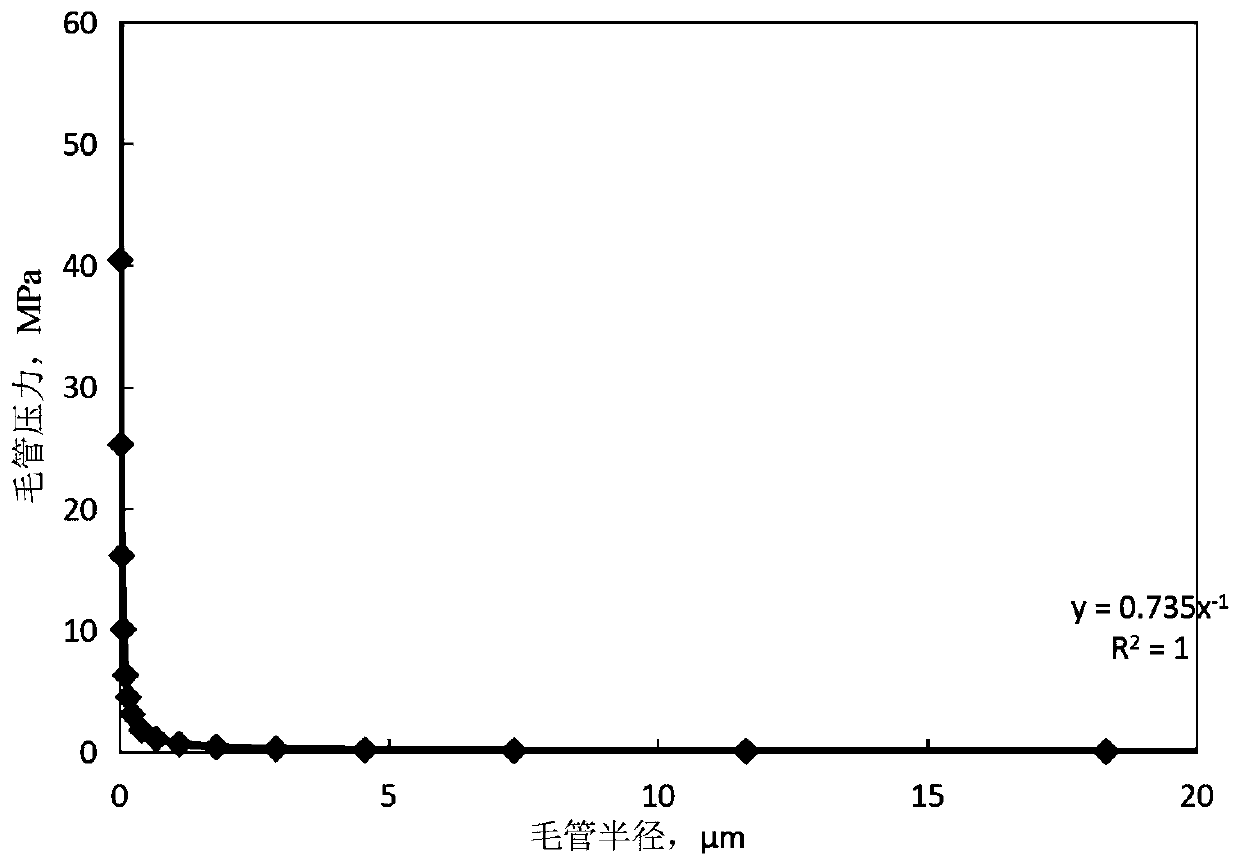

The invention discloses a method for determining relative permeability of a dense rock oil phase. The method for determining the relative permeability of the dense rock oil phase comprises the following steps: S1, taking a cylindrical rock sample of the dense rock; S2, cutting the rock sample into three sections; S3, performing an oil-water capillary pressure test on the first section of the rocksample; S4, performing a constant-rate mercury injection experiment on the second section of the rock sample; S5, measuring the porosity [phi]<He>, permeability k, length L, diameter D, dry weight m<0> and density [rho] of the third section of the rock sample; S6, vacuuming the third section of the rock sample and pressurizing a saturated MnCl<2> solution; S7, performing an oil flooding water experiment on the third section of the rock sample after the saturation is completed, and taking out the core for aging; and S8, wiping off the surface oil of the third section of the rock sample after aging, then weighing the third section of the rock sample and recording as m2, and meanwhile, obtaining a T2 spectrum curve and a nuclear magnetic porosity of the rock sample by using a nuclear magneticresonance spectrometer; then performing a self-water absorption and oil discharge test; and finally, processing the data. When using the method for determining the relative permeability of the denserock oil phase to test the experimental data, the measurement precision is high, and the operation is simple; the characteristics of the dense rock and the related seepage theory are fully utilized; and the applicability is better.

Owner:SOUTHWEST PETROLEUM UNIV

A reinforced composite material sleeper for rail transit and its production process

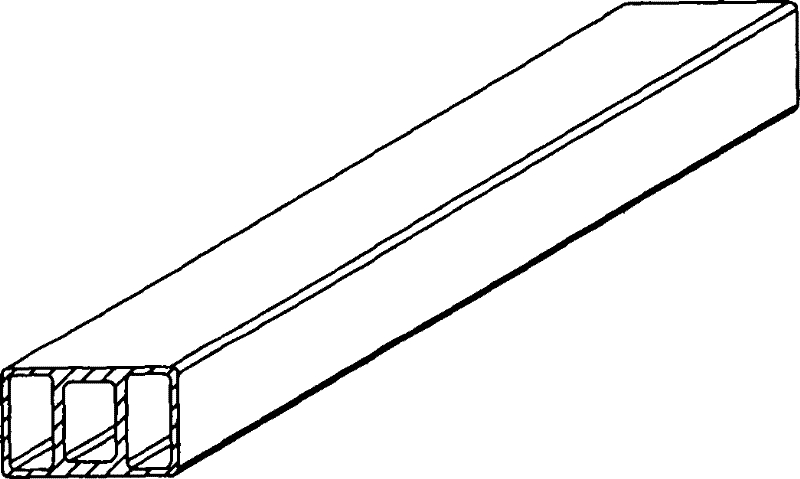

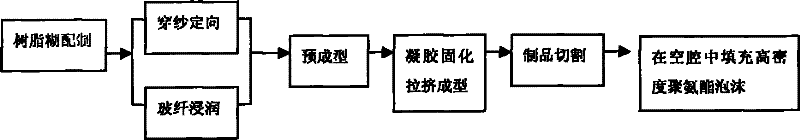

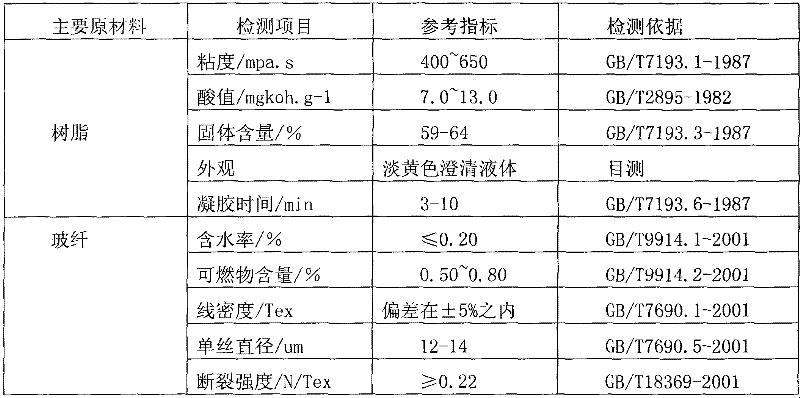

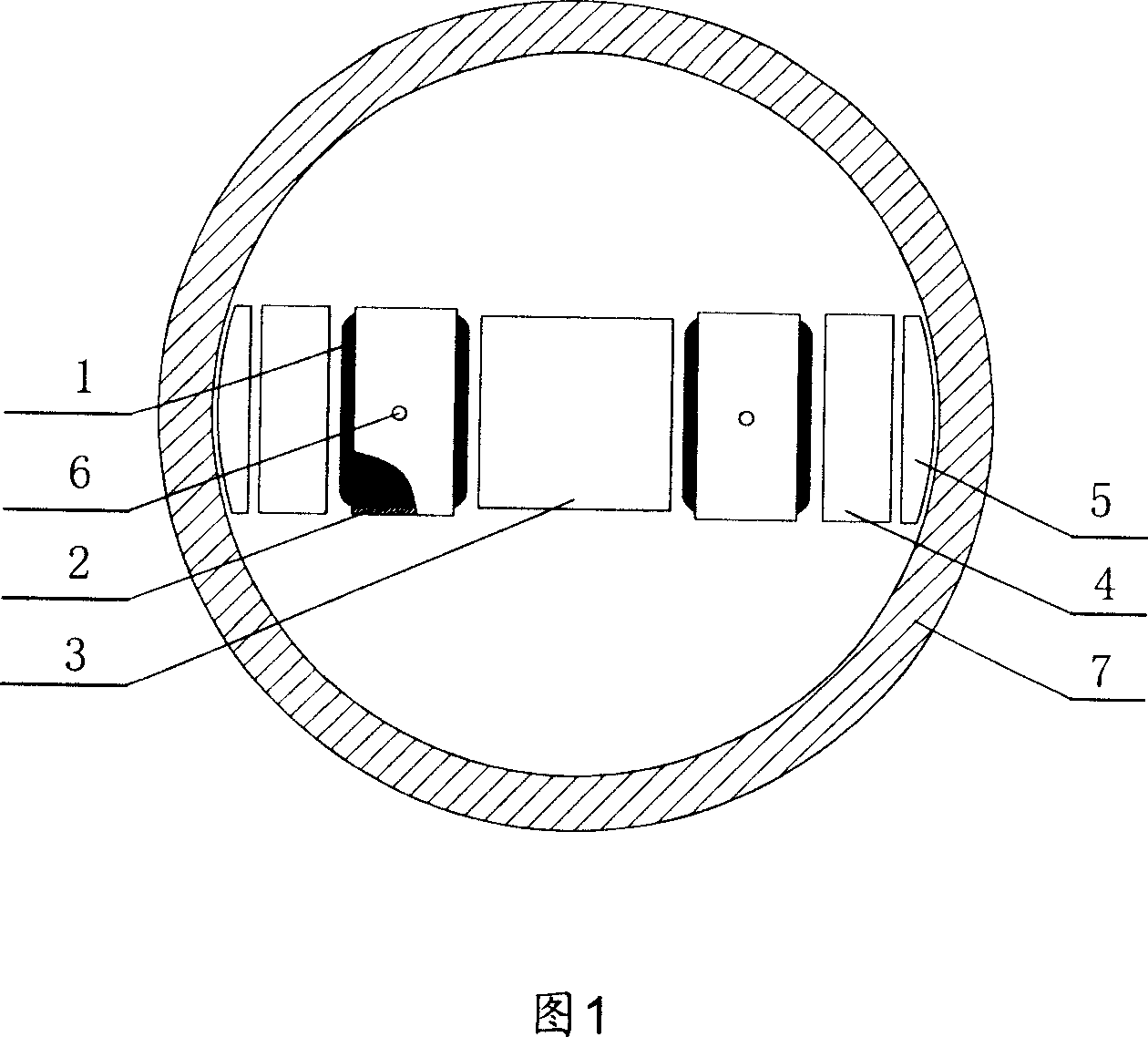

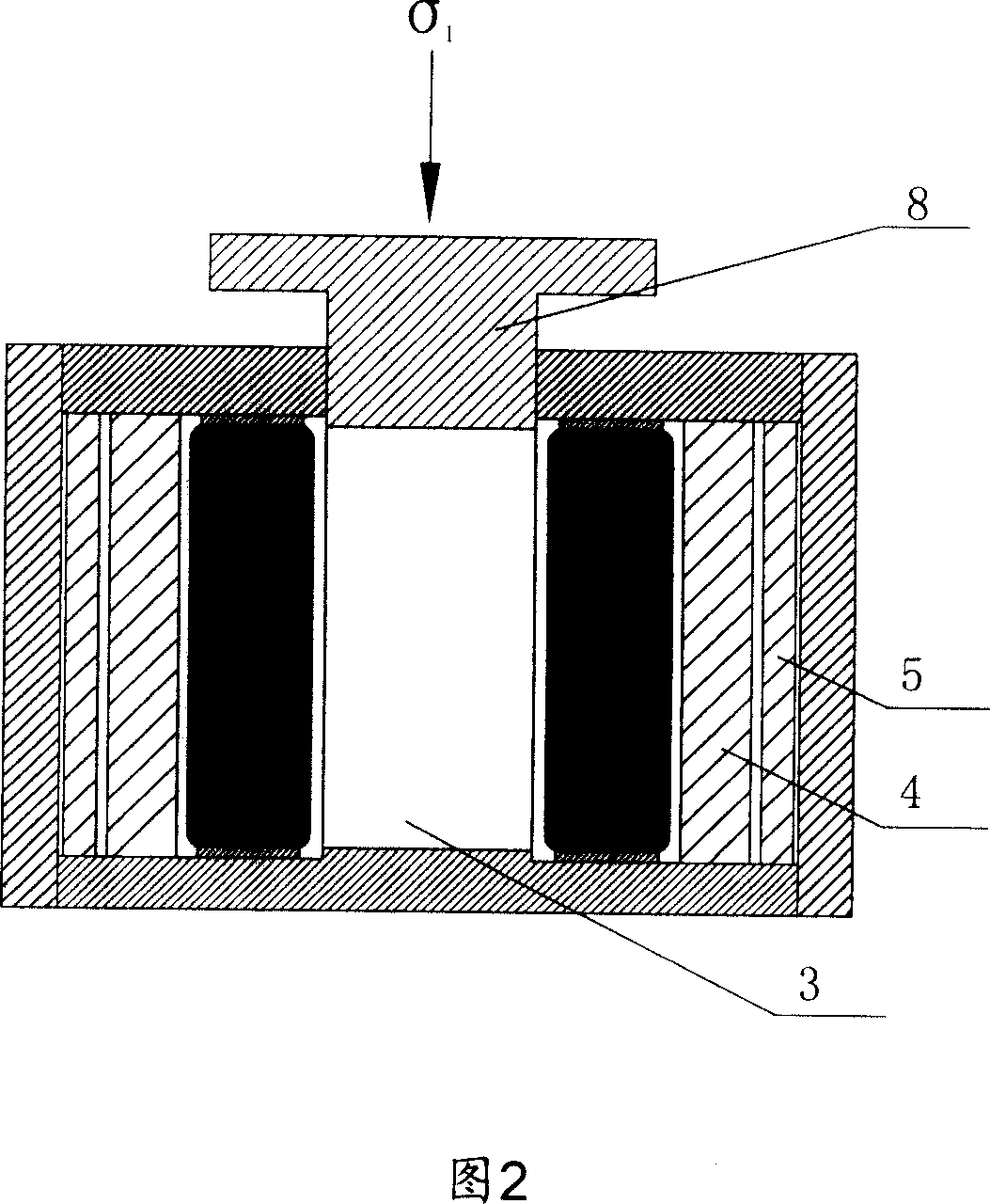

The invention discloses a reinforced composite material sleeper for rail transit. The sleeper comprises a sleeper body and high-density polyurethane foam filled in the sleeper body; the sleeper body is made of the following raw materials in parts by weight: unsaturated polyurethane 80-100 parts of ester resin, 1-2 parts of initiator, 1-2 parts of liquid release oil, 30-50 parts of filler, 1-2 parts of viscosity reducer, 1-3 parts of auxiliary agent, glass fiber, glass fiber mat 150-200 parts of mixture with glass fiber multi-axial cloth; the ratio of glass fiber, glass fiber felt and glass fiber multi-axial cloth in the mixture is 60:10:30. After the present invention is filled with high-density polyurethane foam, the modulus of elasticity of the overall sleeper is increased by about 20%, the bending strength is increased by 18%, the compressive recovery strength is increased by 20%, and the effect of shock absorption and noise reduction is slightly improved. And it effectively solves the problem that the overall performance of the sleeper is reduced by opening holes on the surface of the glass fiber composite sleeper. After the static load pressure test is performed on the composite sleeper introduced with high-density polyurethane foam, the overall compressive strength of the composite sleeper does not change much. At the same time, because polyurethane foam is a microporous material, its weight is relatively light.

Owner:QINGDAO HUACI MARINE EQUIP TECH CO LTD

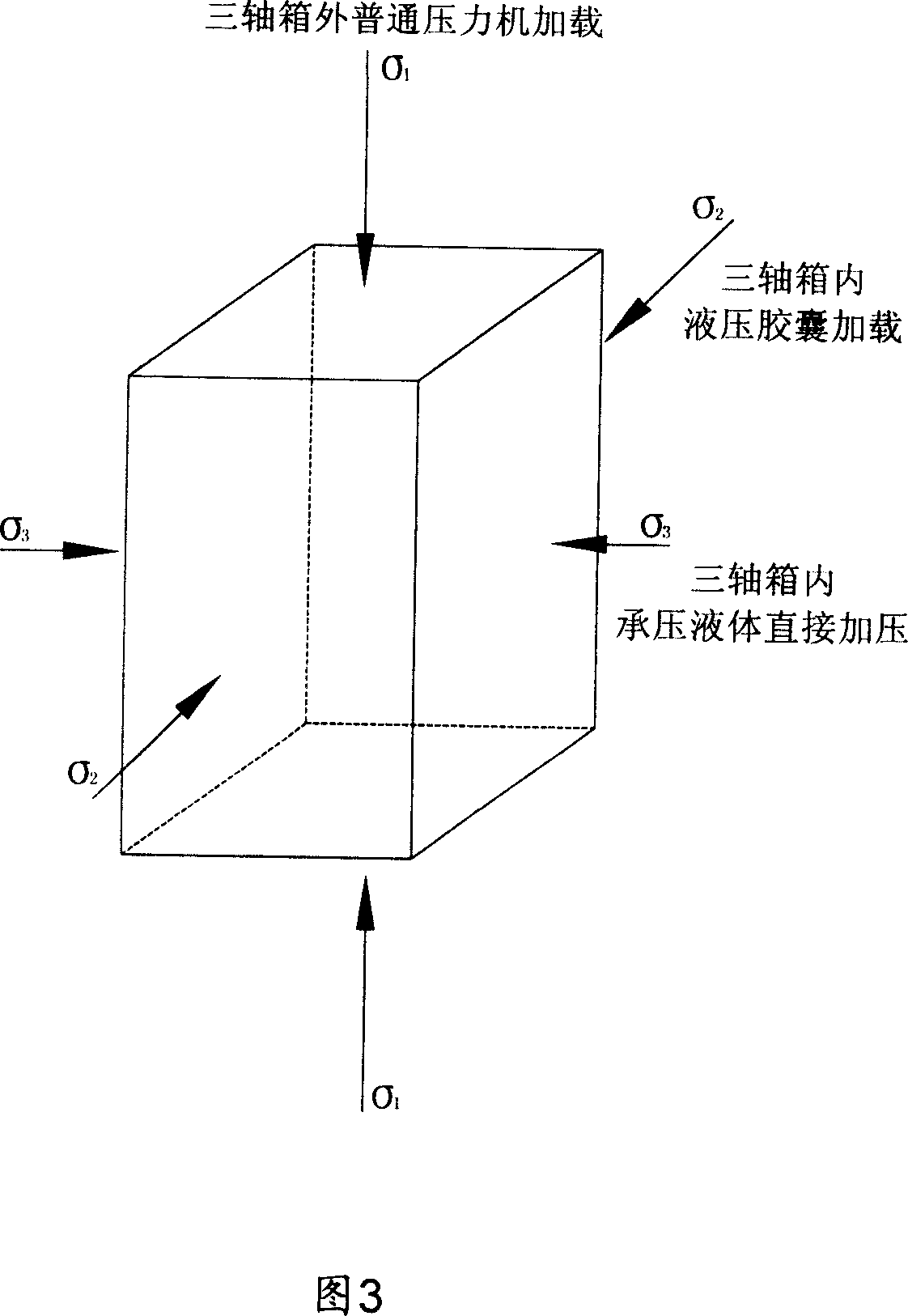

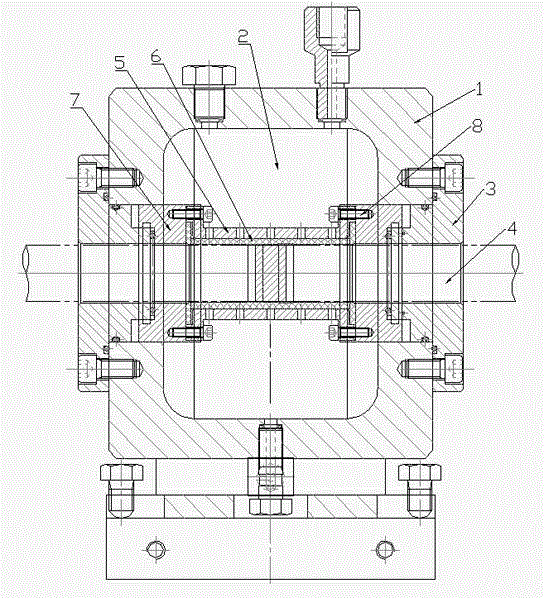

Real three shaft pressure box

InactiveCN1945268ASimple structureMeet the technical requirements of pressurizationMaterial strength using tensile/compressive forcesLiquid mediumPressure experiment

The true three axis pressure box for providing test piece with unequal triaxial pressure includes one sealed cylinder for the test piece to be set in; one external pressure device set on the cylinder, communicated to outside and capable of sliding relatively to the cylinder to apply maximum main stress to the test piece; one inside pressure device inside the cylinder to apply middle main stress to the test piece; and liquid medium filled inside the cylinder to apply minimum main stress to the test piece. The inside pressure device flexible bag with inner flexible steel network and outer rigid frame. The true three axis pressure box has simple structure, high adaptability and reliable pressurizing, and is suitable for use in different types of triaxial pressure test, especially on rock.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

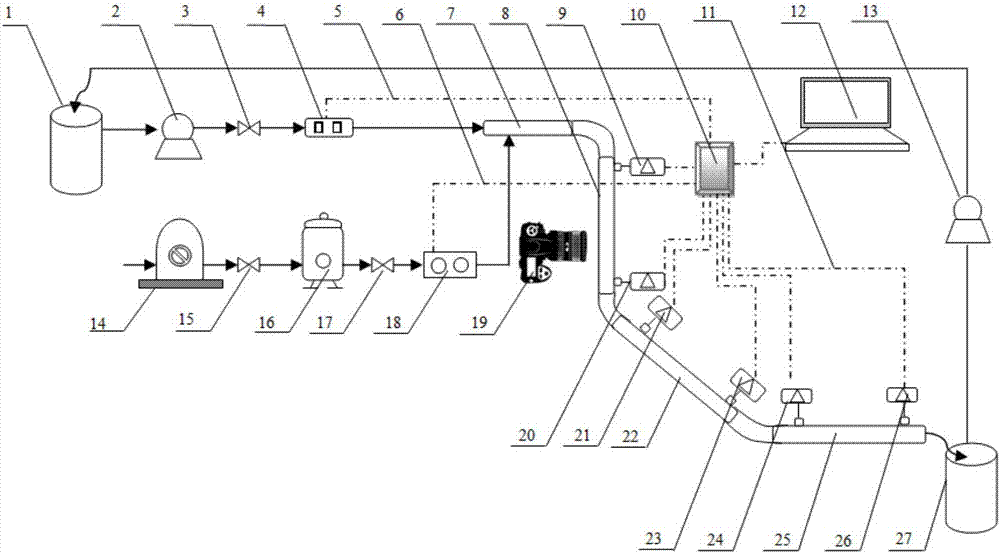

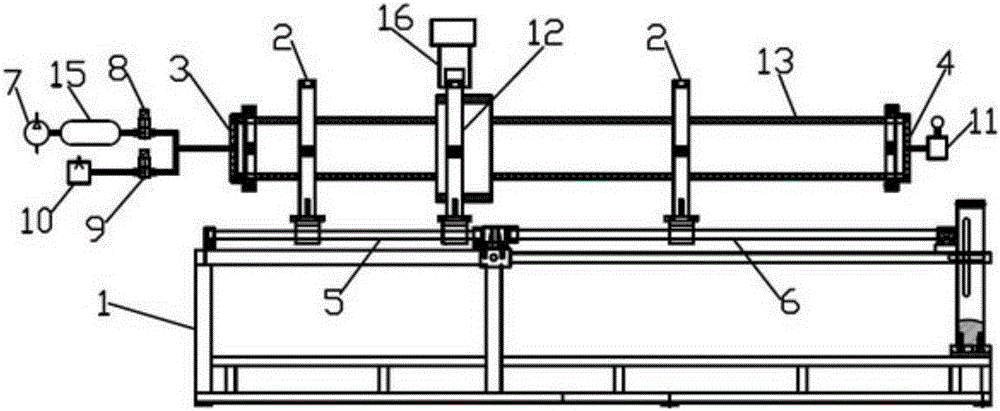

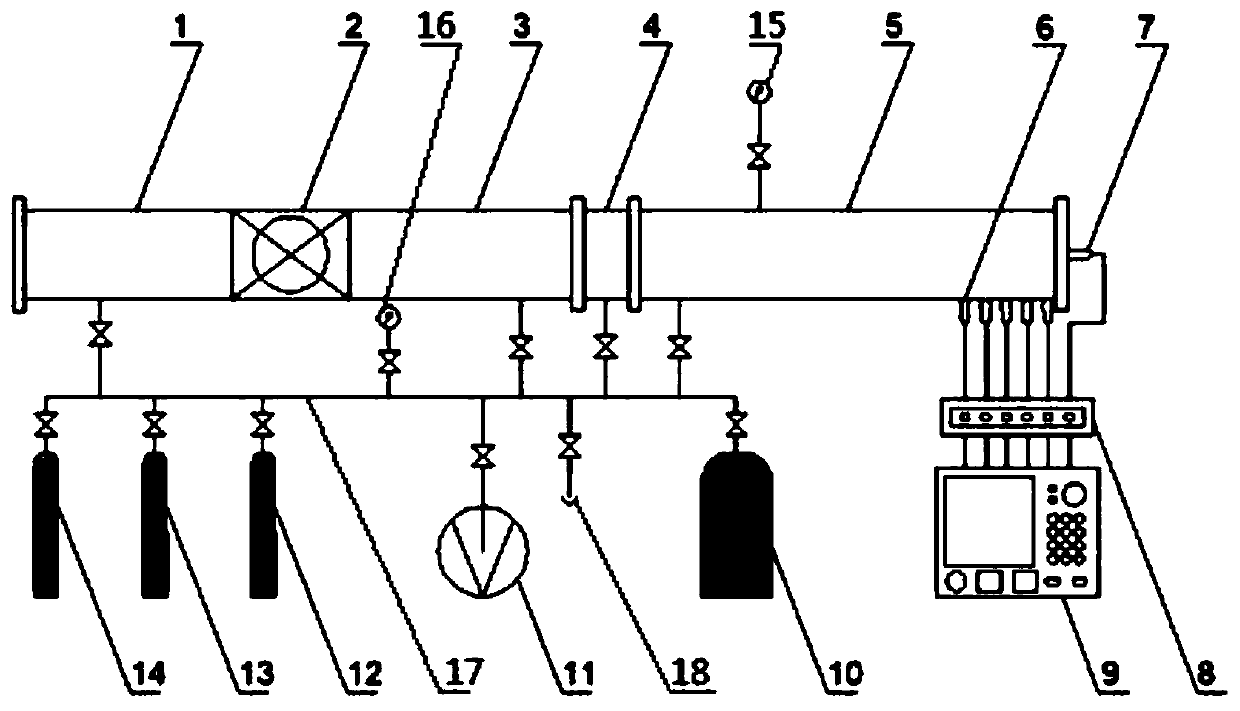

Flow pattern and pressure simulation experiment device and method for two-phase flow of wellbore of air and water mixed injection well

The invention provides a flow pattern and pressure simulation experiment device and method for two-phase flow of a wellbore of an air and water mixed injection well. The device mainly comprises an experiment loop, an supporting system and a measurement and control system, and can realize flow pattern and pressure experimental simulation for air-water two-phase down flow of vertical, tilting and horizontal sections of the air and water mixed injection well. Experimental mediums comprise air and water; the air is supplied by an air compressor, and the water is supplied by a centrifugal pump; the air and the water flow into the vertical pipe section, the tilting section and the horizontal section after passing through an air-liquid mixing section; all the pipe sections are transparent organic glass pipes, so that the flow pattern can be conveniently observed; pressures at two ends are respectively measured through pressure sensors; the angle of the tilting pipe section can be adjusted within 0 to 90 degrees, so that flow pattern and pressure experimental simulation for the air-liquid two-phase down flow of the tilting pipe section under any angle condition can be realized; the flow pattern of the air-liquid two-phase down flow of each pipe section can be shot through a high speed camera. The flow pattern and pressure simulation experiment device and method can realize the flow pattern and pressure experimental simulation for the air-water two-phase down flow of the vertical, tilting and horizontal sections of the air and water mixed injection well.

Owner:SOUTHWEST PETROLEUM UNIV

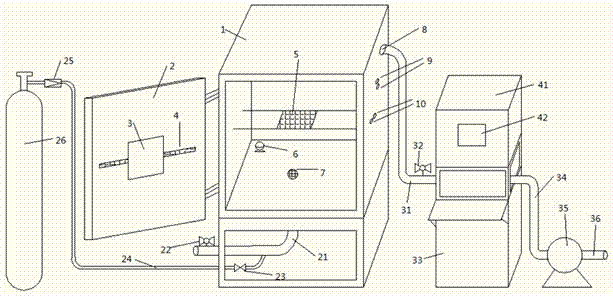

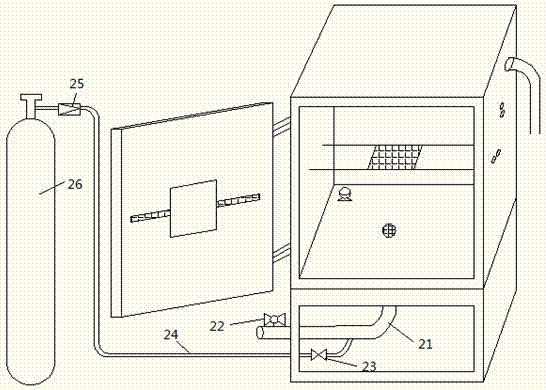

Material flameless pyrolysis and flame combustion experiment box capable of changing environment stress and atmosphere conditions

InactiveCN104749317AResearch on Realizing Fire Hazard CharacteristicsRealize researchChemical analysis using combustionThermodynamicsCombustion

The invention relates to a material flameless pyrolysis and flame combustion experiment box capable of changing environment stress and atmosphere conditions, which overcomes the defect of unavailability of experiment devices for material flameless pyrolysis and flame combustion characteristic researches compared with the prior art. The material flameless pyrolysis and flame combustion experiment box disclosed by the invention comprises a reaction box, wherein an experiment box door is movably installed in the side part of the reaction box; an observation window is formed in the experiment box door; an intake hole is formed in the bottom of the reaction box; an intake pipeline is connected to the intake hole and located outside the reaction box; an exhaust hole, a radiation source wiring terminal and an aviation plug are arranged on the reaction box; a pressure sensor is installed on the exhaust hole; the material flameless pyrolysis and flame combustion experiment box further comprises an intake assembly, an exhaust assembly and a radiation source assembly. The material flameless pyrolysis and flame combustion experiment box disclosed by the invention has the fire-fighting research experiment functions of a conventional low-pressure experiment box, and can also be used for flameless pyrolysis and flame combustion characteristic researches for solid combustibles.

Owner:UNIV OF SCI & TECH OF CHINA

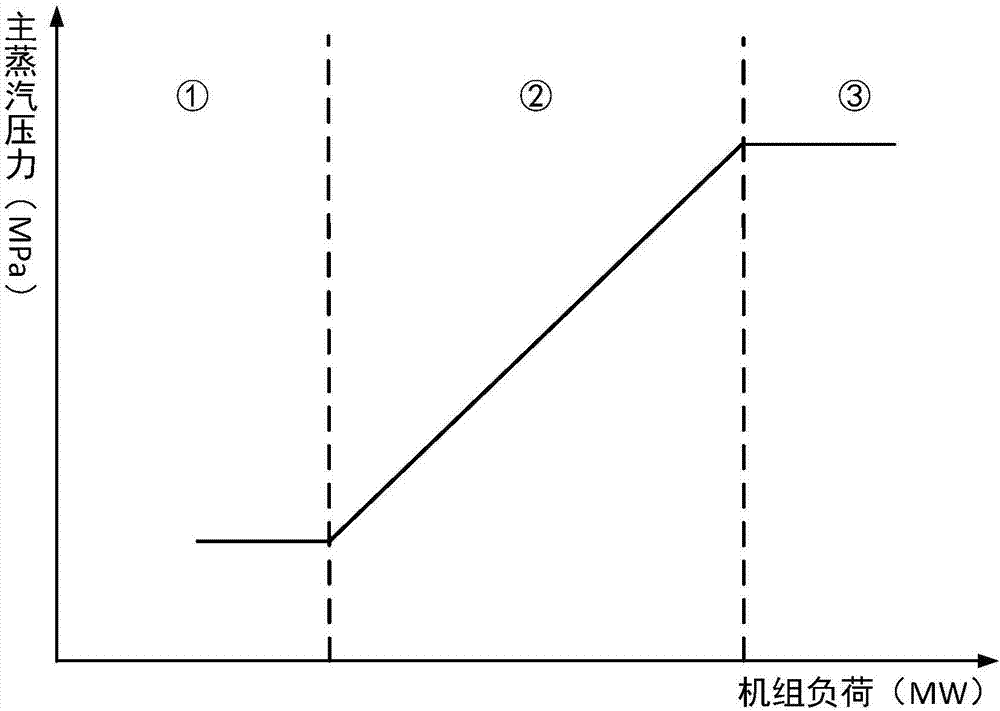

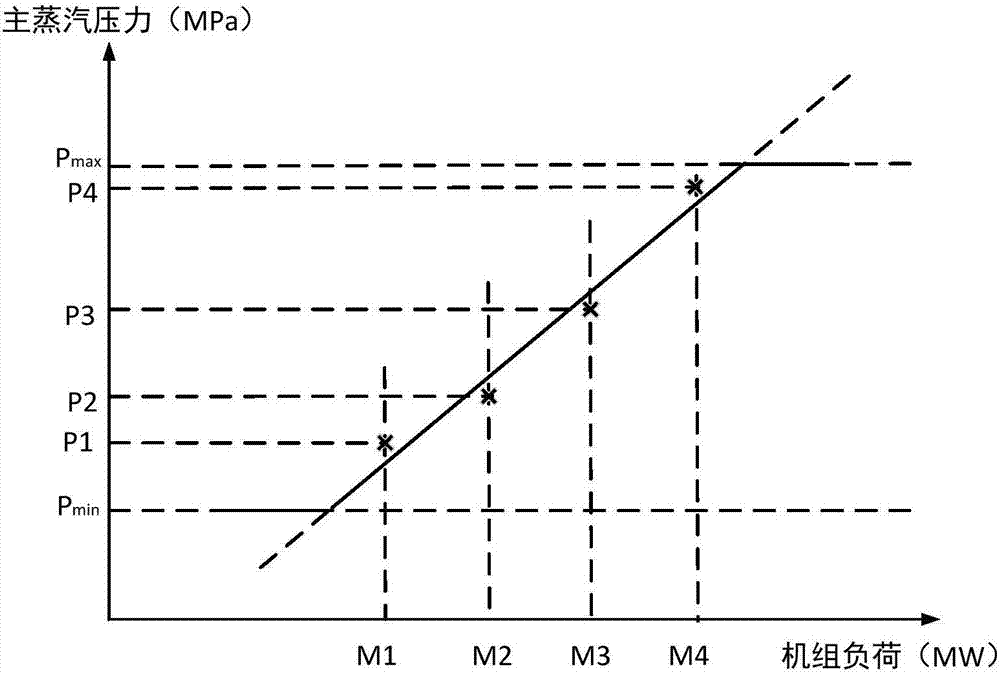

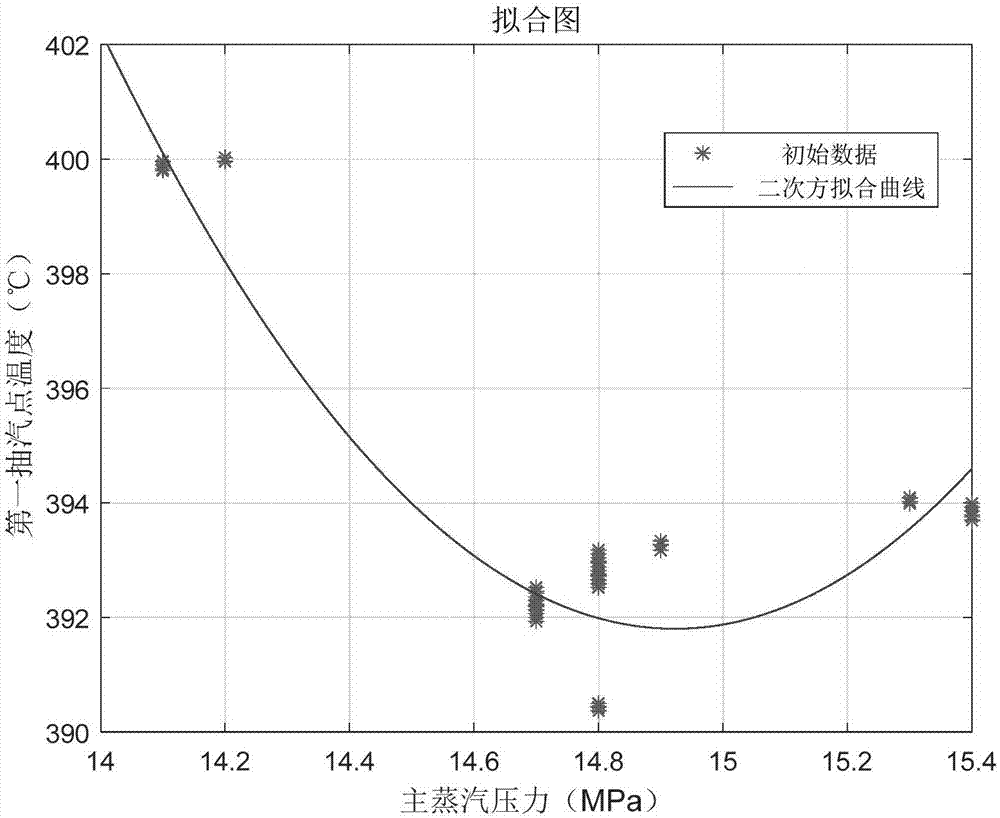

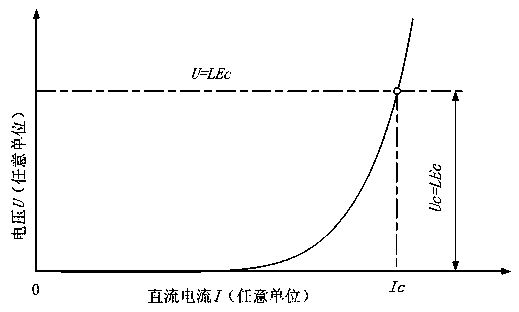

Thermal power unit pure-condensing working condition sliding pressure curve determination method with valve throttling loss being taken into consideration

The invention provides a thermal power unit pure-condensing working condition sliding pressure curve determination method with valve throttling loss being taken into consideration and relates to a thermal power unit pure-condensing working condition sliding pressure curve determination method, and is to solve the problems of complex sliding pressure experiment data obtaining process, inaccuracy of a sliding pressure curve obtained through a sliding pressure experiment and high thermal loss of a thermal power unit in an existing sliding pressure curve determination method. The method comprises the following steps: 1) collecting overall working condition historical data in a unit DCS system; 2) screening the data in the step 1), and carrying out grouping statistics on the data in a load interval to be collected; 3) carrying out data analysis on the data in each load interval to obtain optimal main steam pressure corresponding to corresponding load points; and 4) obtaining a sliding pressure curve by utilizing the optimal main steam pressure of each load point obtained in the step 3). The method is used in steam turbine operation.

Owner:HARBIN INST OF TECH +2

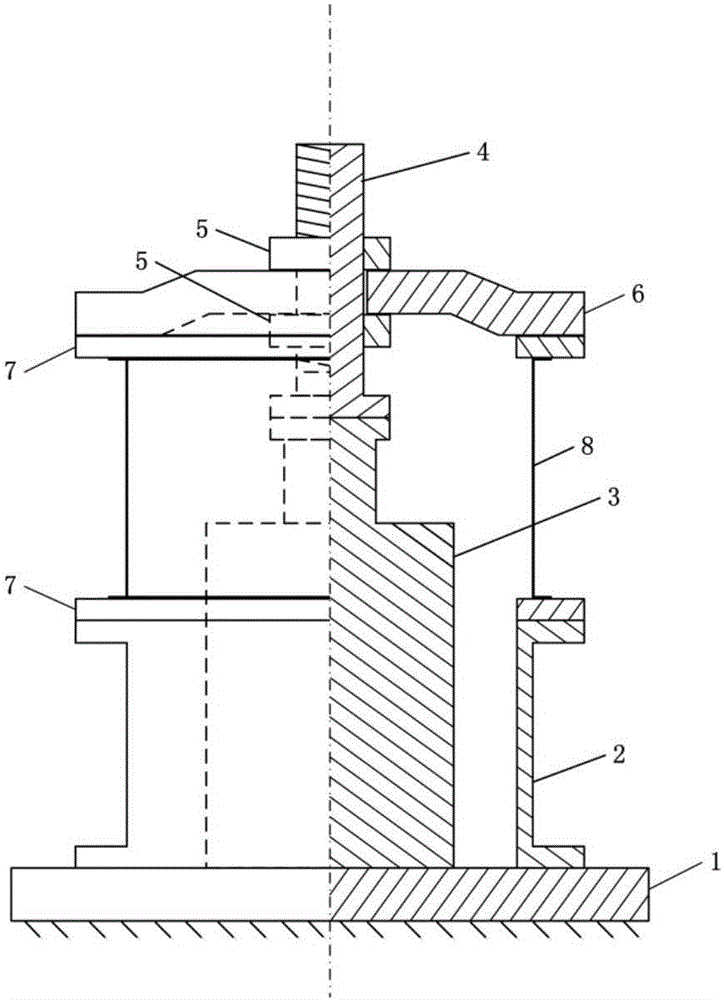

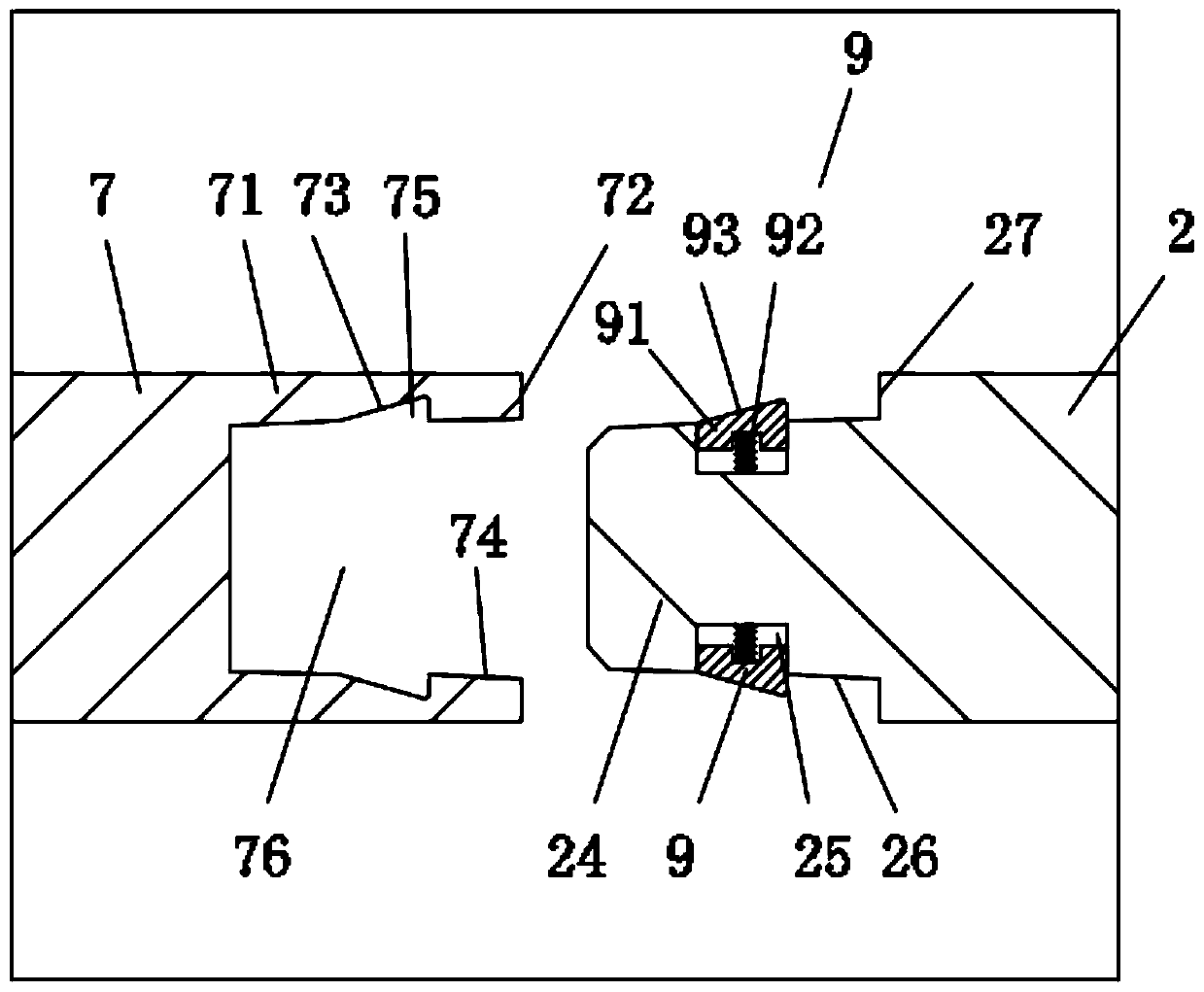

Confining pressure cylinder device for novel split Hopkinson pressure bar active confining pressure experiment

InactiveCN104677725APrevent outward movementSolve the problem of not pressing the test piece tightlyStrength propertiesPressure experimentHigh pressure

The invention relates to an impact loading experimental device for material dynamic mechanical property, and in particular relates to a confining pressure cylinder device for a novel split Hopkinson pressure bar active confining pressure experiment. The confining pressure cylinder device comprises a cylinder body, a pressure cavity in the cylinder body, cylinder covers, pressing blocks, a metal sleeve, a rubber sleeve and a shaft hole; the confining pressure cylinder device is characterized in that the cylinder covers are respectively arranged at two ends outside the cylinder body; corresponding to the cylinder covers, pressing blocks are respectively arranged at two ends of the pressure cavity, and one end of each pressing block extends into the cylinder body; the metal sleeve is arranged between the pressing blocks at two ends of the pressure cavity and is connected by virtue of a screw; the rubber sleeve is arranged on the inner side of the metal sleeve; and the rubber sleeve is arranged between the pressing blocks at two ends of the pressure cavity, so that the pressing blocks, the metal sleeve and the rubber sleeve are integrated. The device disclosed by the invention not only can prevent the rubber sleeve, in the case of deforming, from entering into a clearance formed between a sealing cover and a rod piece to drive the rod piece to move outwards, but also can solve a problem that a test piece cannot be tightly pressed by the rod piece since the rod piece is stressed to cause a trend of moving towards the outer side of the cavity body when the rod piece is closely held in the rubber sleeve under high pressure; and the confining pressure cylinder device is simple in structure.

Owner:LUOYANG LIWEI TECH

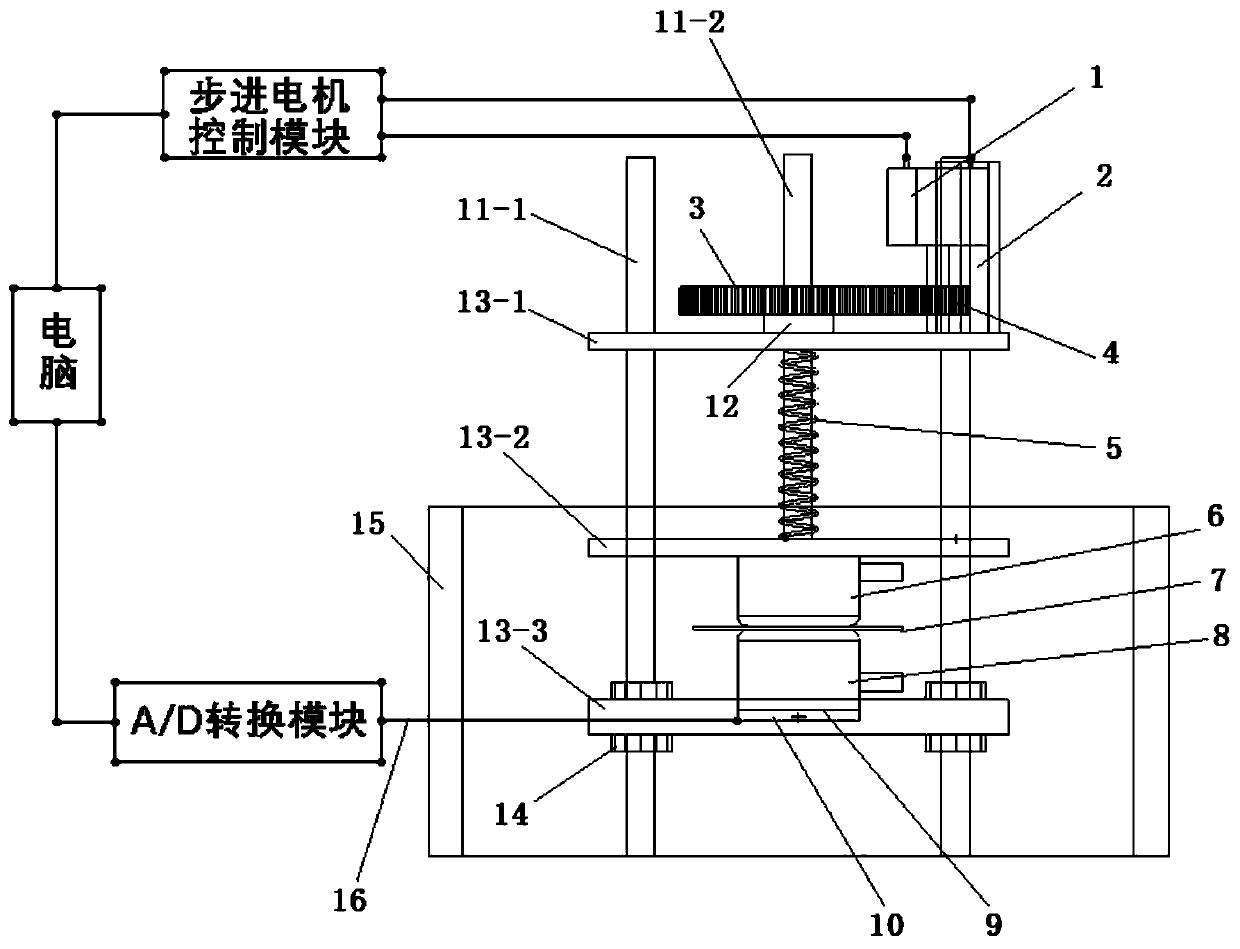

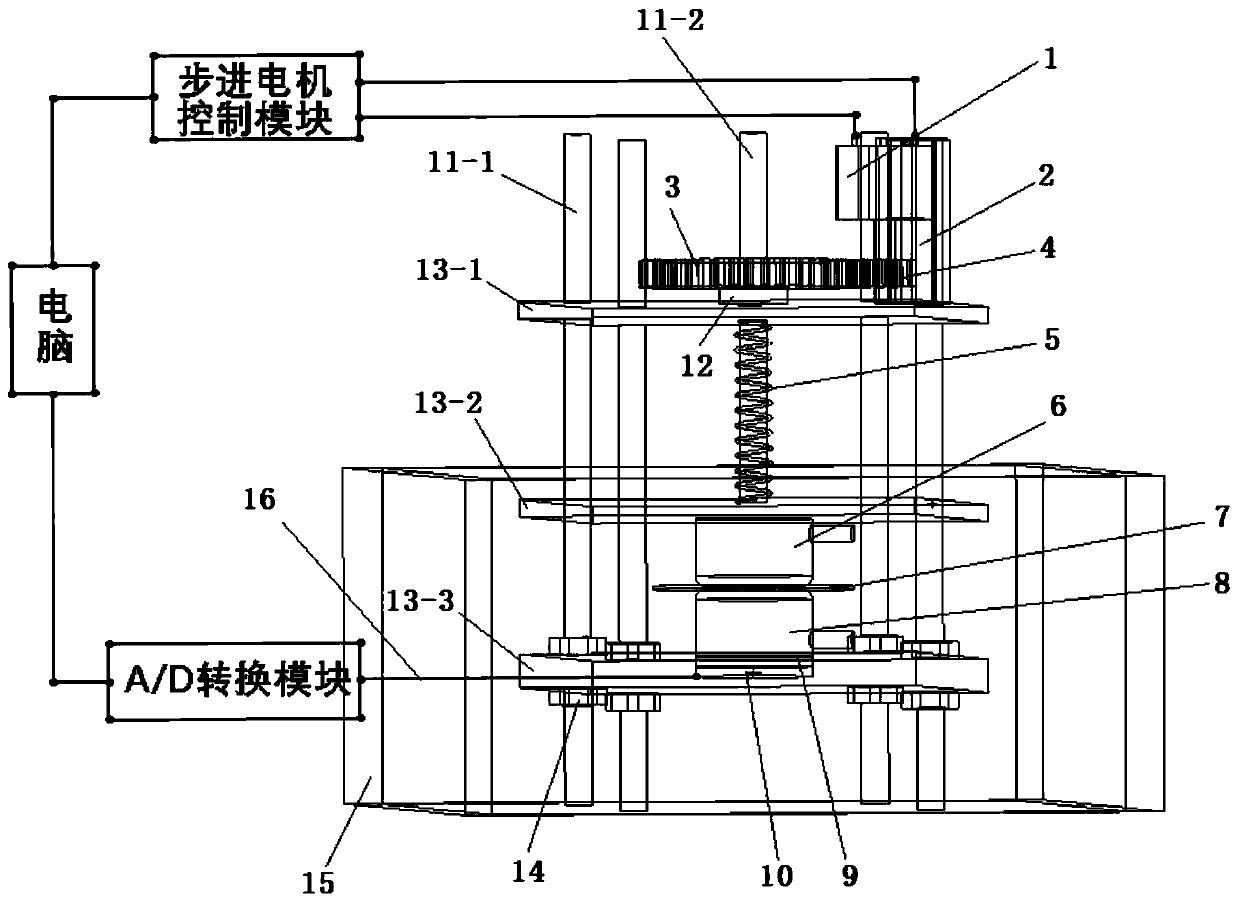

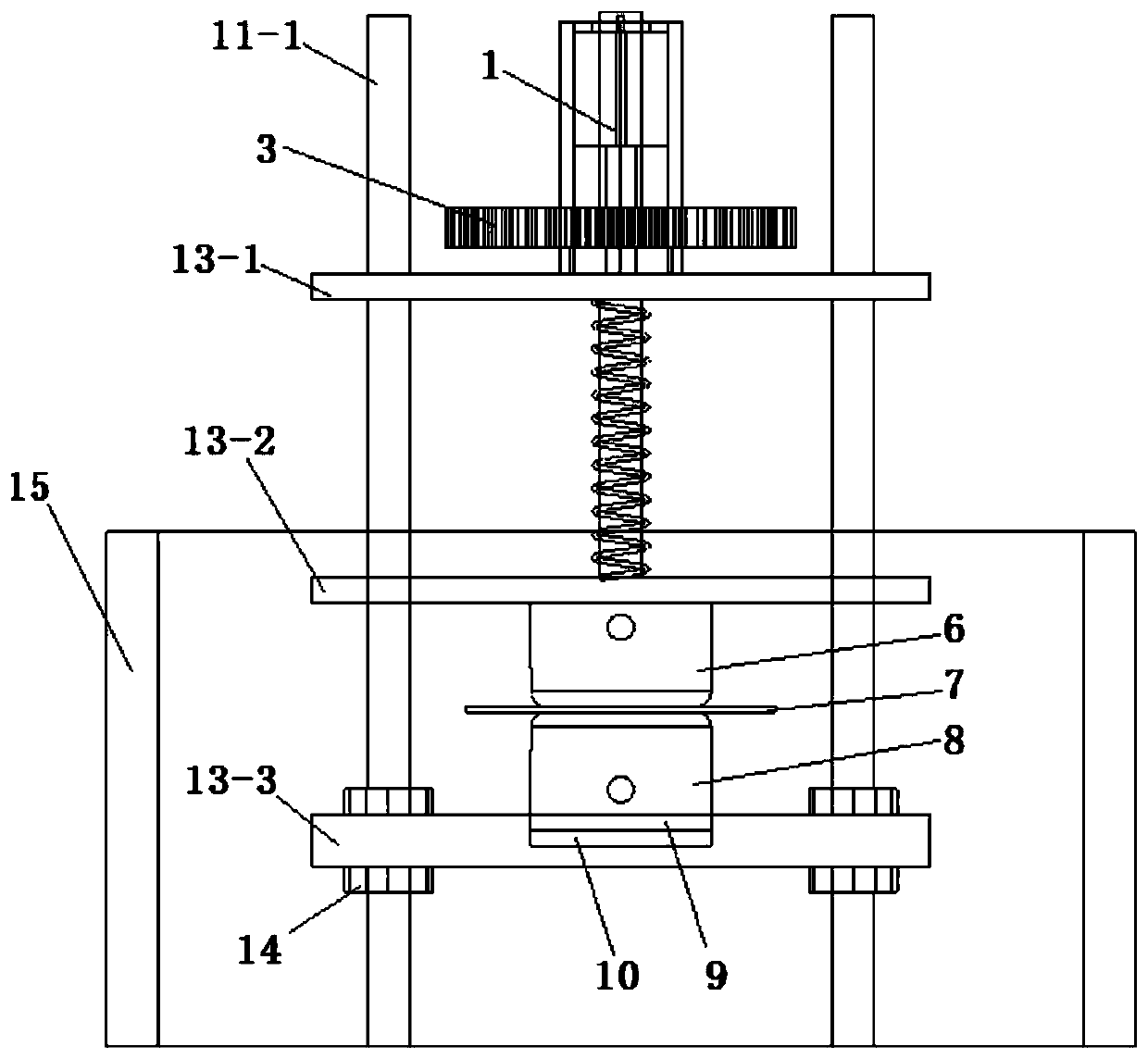

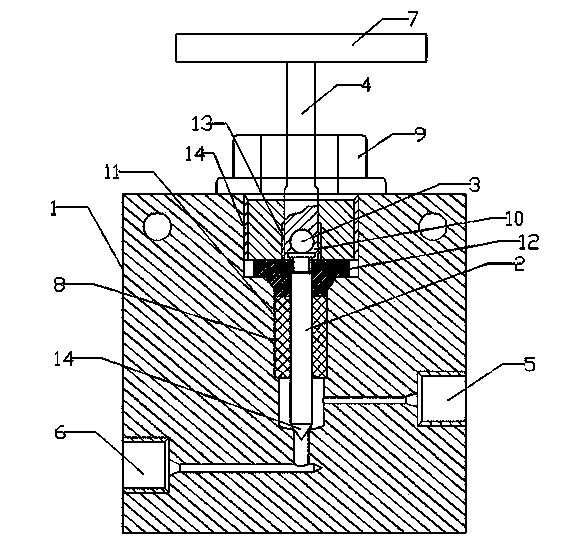

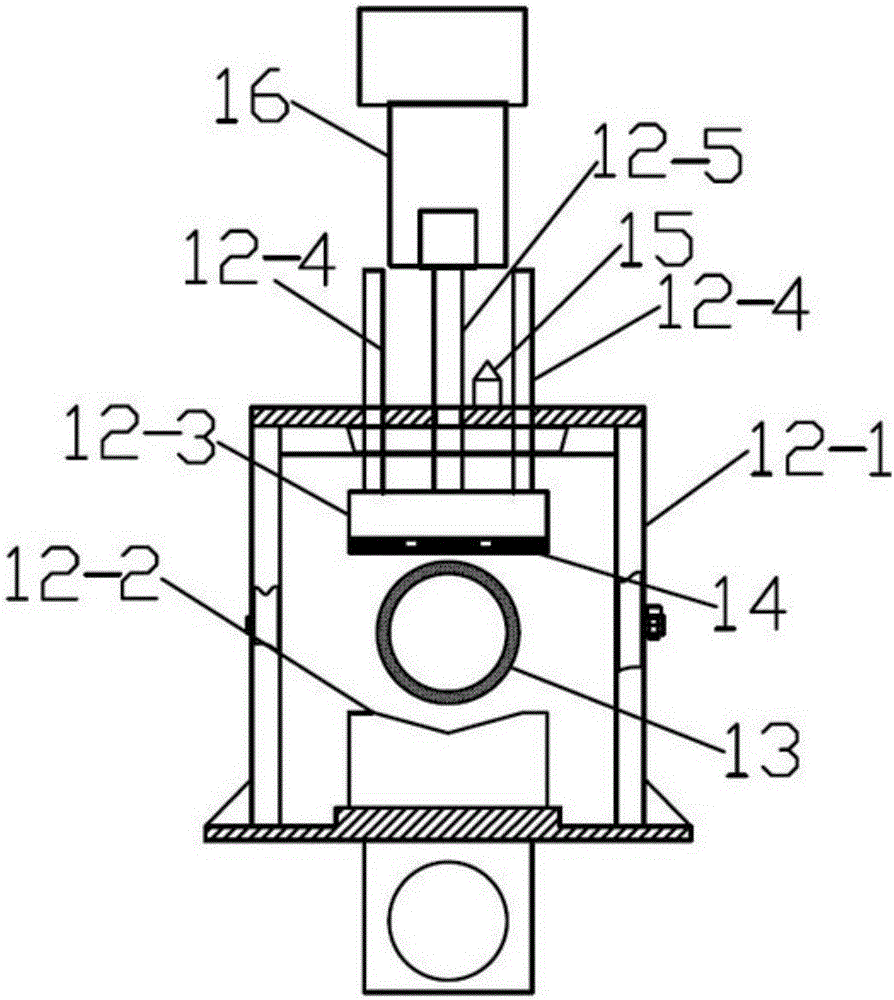

Insulating material electric resistance experiment plate electrode device for providing dynamic pressure and insulating material electric resistance experiment method

InactiveCN110850250AConstant test pressureStable structureTesting vessel constructionDielectricPressure experiment

The invention discloses an insulating material electric resistance experiment plate electrode device for providing dynamic pressure and an insulating material electric resistance experiment method, belongs to the technical field of electrical insulating material dielectric property testing, and fills the blank of a dynamic pressure experiment technology. The device comprises a stepping motor, a gear, an elastic element, a ground electrode, a high-voltage electrode, an insulating spacer, a piezoelectric sensor, a supporting guide rod, an epoxy plate, an oil tank, an A / D conversion module, a computer and a stepping motor control module. The computer control end controls the stepping motor to drive the gear to rotate through the stepping motor control module, the length of the spring is adjusted so as to provide constant pressure or continuously changed pressure set according to a program, the piezoelectric sensor below the ground electrode is transmitted to the A / D conversion module through the signal transmission line, and the A / D conversion module uploads a signal to the computer for displaying the pressure at the control end of the computer in real time and forming a complete feedback control loop. According to the invention, the electrical resistance test of the polymer insulating material under the condition of constant or dynamic pressure change is realized.

Owner:HARBIN UNIV OF SCI & TECH

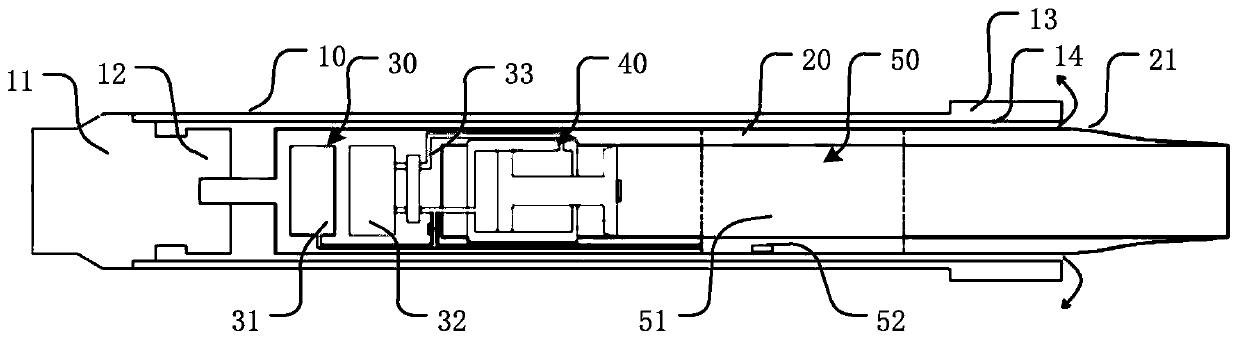

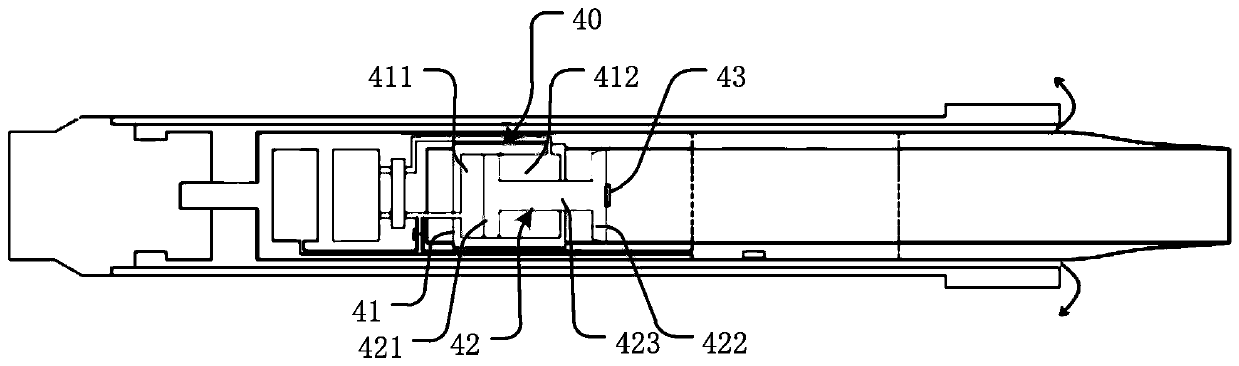

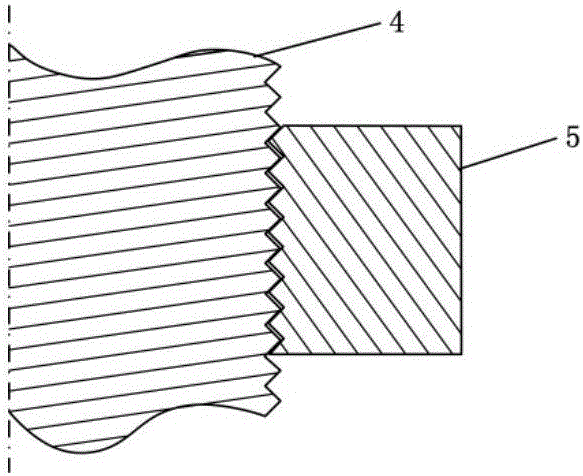

Ultrahigh pressure high-temperature needle valve

InactiveCN103939620AImprove pressure bearing capacityMeet the requirements of ultra-high pressure experimental conditionsSpindle sealingsLift valveUltra high pressurePressure experiment

The invention discloses an ultrahigh pressure high-temperature needle valve which mainly comprises a valve body, a valve needle rod, a roll ball, a threaded rod, a handle, a fluid inflow channel, a fluid outflow channel and a sealing ring. The handle (7) is connected with the threaded rod (4), an I-shaped groove (10) is machined in the lower end of the threaded rod, a vertical hole (11) is formed in the valve body (1), the valve needle rod (2) of a clamping and guiding type is arranged in the vertical rod and is clamped into the I-shaped groove (10) of the threaded rod, the roll ball (3) is embedded between the valve needle rod (2) and the I-shaped groove (10) of the threaded rod, the sealing ring (8) is arranged between the valve needle rod and the vertical hole, a trapezoid pad (12) is arranged on the upper portion of the sealing ring, a valve needle point (14) and the valve body (1) are in metal hard sealing, and the valve body (1) is provided with the fluid inflow channel (5) and the fluid outflow channel (6). The ultrahigh pressure high-temperature needle valve can be applied to ultrahigh pressure experiment conditions, a valve needle is flexible in opening and closing, no rotary friction exists in the sealing cone of the valve body, the valve needle rod and the threaded rod are independent of each other, machining difficulty is reduced, the valve needle rod is convenient to replace after being abraded, and materials are saved.

Owner:SOUTHWEST PETROLEUM UNIV

Pulse wave reinforced hydraulic fracturing evaluation experimental device and method

InactiveCN111058818AExpand the scope of the experimentEasy to operateSurveyFluid removalPressure experimentFracturing fluid

The invention discloses a pulse wave reinforced hydraulic fracturing evaluation experimental device and method, relates to the technical field of hydraulic fracturing, and solves the problems that thedamage degree of shock waves to shale and a fracturing crack causing mechanism are unknown, and the shock waves cannot be applied to the compact reservoir transformation. The pulse wave reinforced hydraulic fracturing evaluation experimental device and method are characterized in that a triaxial pressure experimental device comprises a sleeve, a shock wave generator and a power supply control cabinet; a rock sample is arranged in the sleeve; the shock wave generator is arranged in the rock sample; an upper base is arranged at the top end of the sleeve, and a lower base is arranged at the bottom end of the sleeve; a fluid conveying control device comprises a fracturing fluid tank, a first pipeline, a second pipeline, a third pipeline and a fourth pipeline; an experimental parameter monitoring device comprises a data collection system, a flowmeter and a pressure sensor; the flowmeter is arranged on the third pipeline; and the pressure sensor is arranged on the fourth pipeline. The effect of simultaneously completing experiments of rock fracturing by shock waves, rock fracturing in different shock wave reinforced hydraulic fracturing modes, permeability tests before and after fracturing and the like can be achieved.

Owner:YANGTZE UNIVERSITY

Bentonite swelling force experiment device and test method

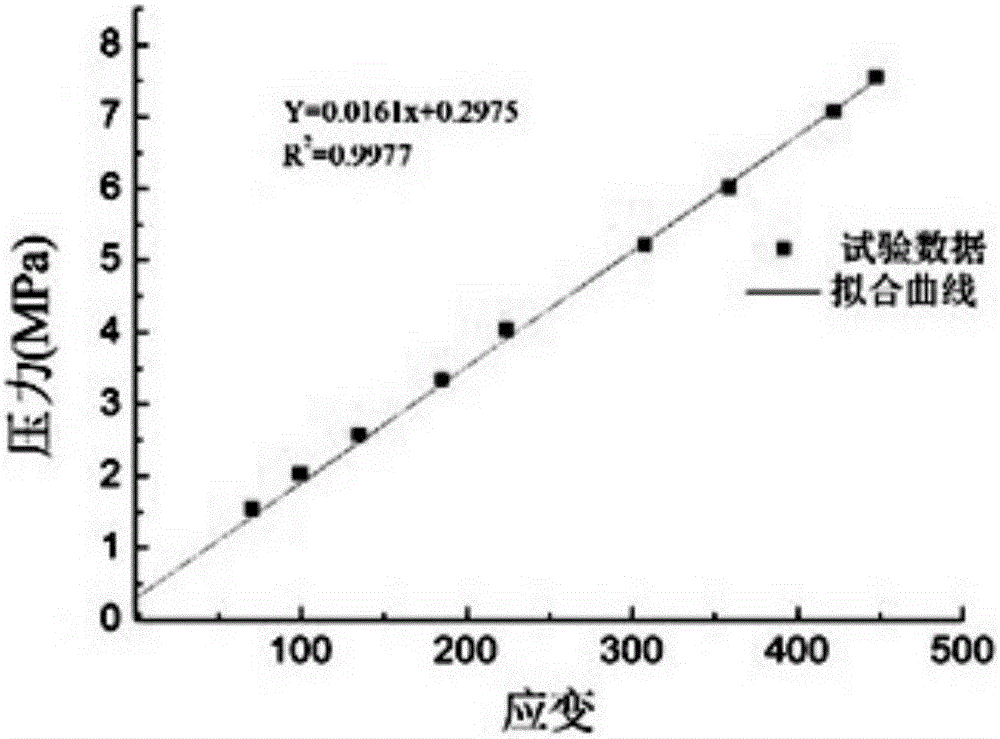

InactiveCN106769419AAccurate measurementHigh practical guidance valueMaterial strength using tensile/compressive forcesPressure experimentEngineering

The invention discloses a bentonite swelling force experiment device and test method. The device comprises a sealed pressure chamber; a closed sample container is arranged in the middle position in the pressure chamber; the side wall of the sample container is successively provided with a rigid sleeve and a rubber sheath from inside to outside; the sample container is fixed on the pressure chamber through the rubber sheath; a plurality of strain gages are distributed between the rigid sleeve and the rubber sheath; the strain gages are fixed on the outer wall of the rigid sleeve and on the middle height position of the outer wall; the strain gages are connected to a strainmeter; a gas pressure system and a hydraulic pressure system entering into the sample container are arranged on the top of the pressure chamber and below the pressure chamber respectively; an oil hydraulic system communicated to the inner part of the pressure chamber is also provided. The bentonite swelling force experiment device and test method are simple and feasible, accurate measurement for a swelling force in a triaxial pressure experiment process is realized, and meanwhile, the swelling force can be distinguished from other forces.

Owner:CHINA UNIV OF MINING & TECH

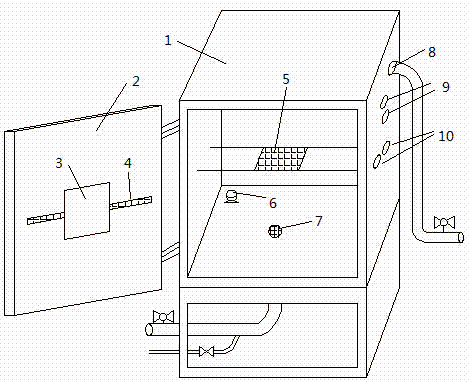

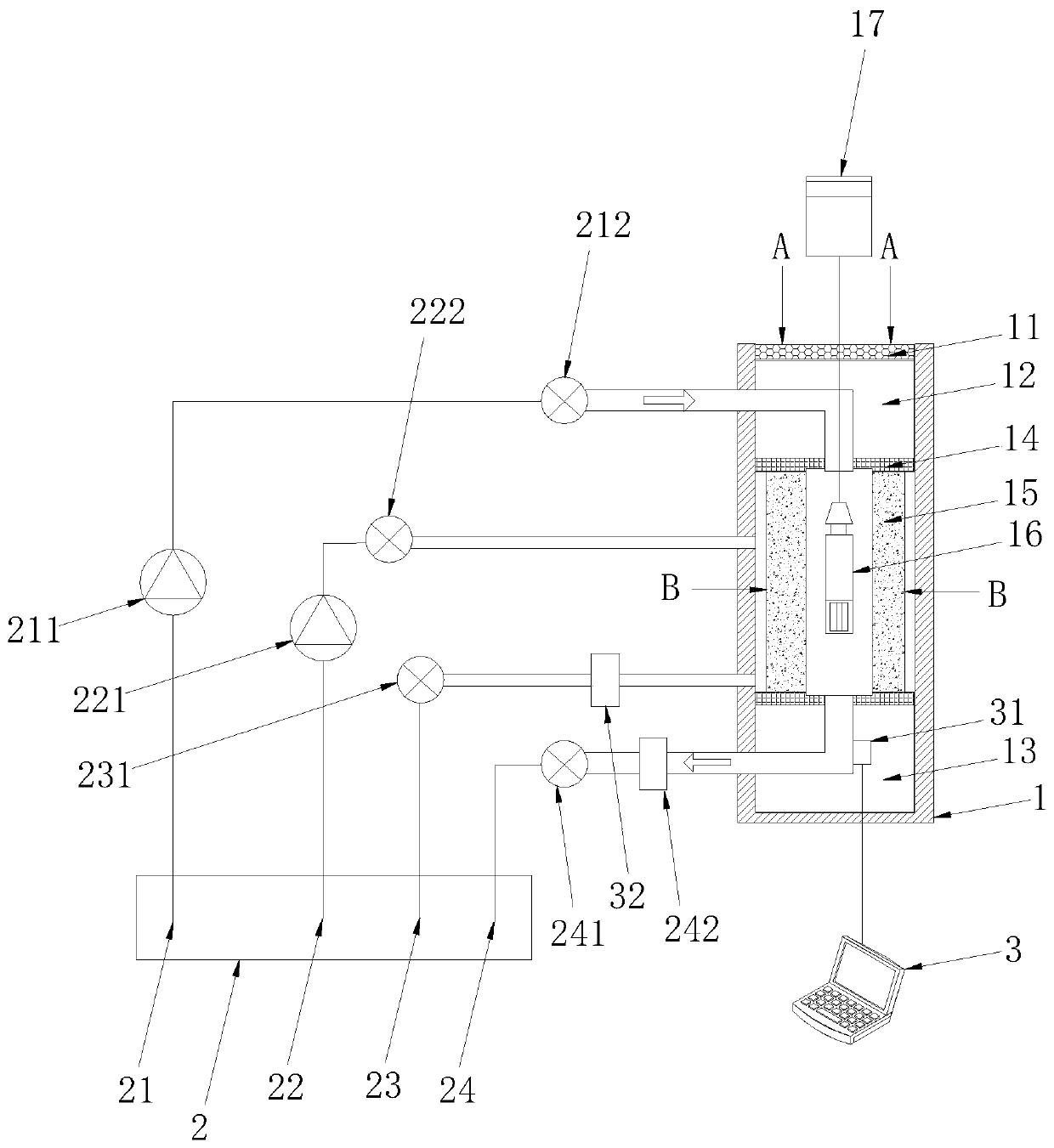

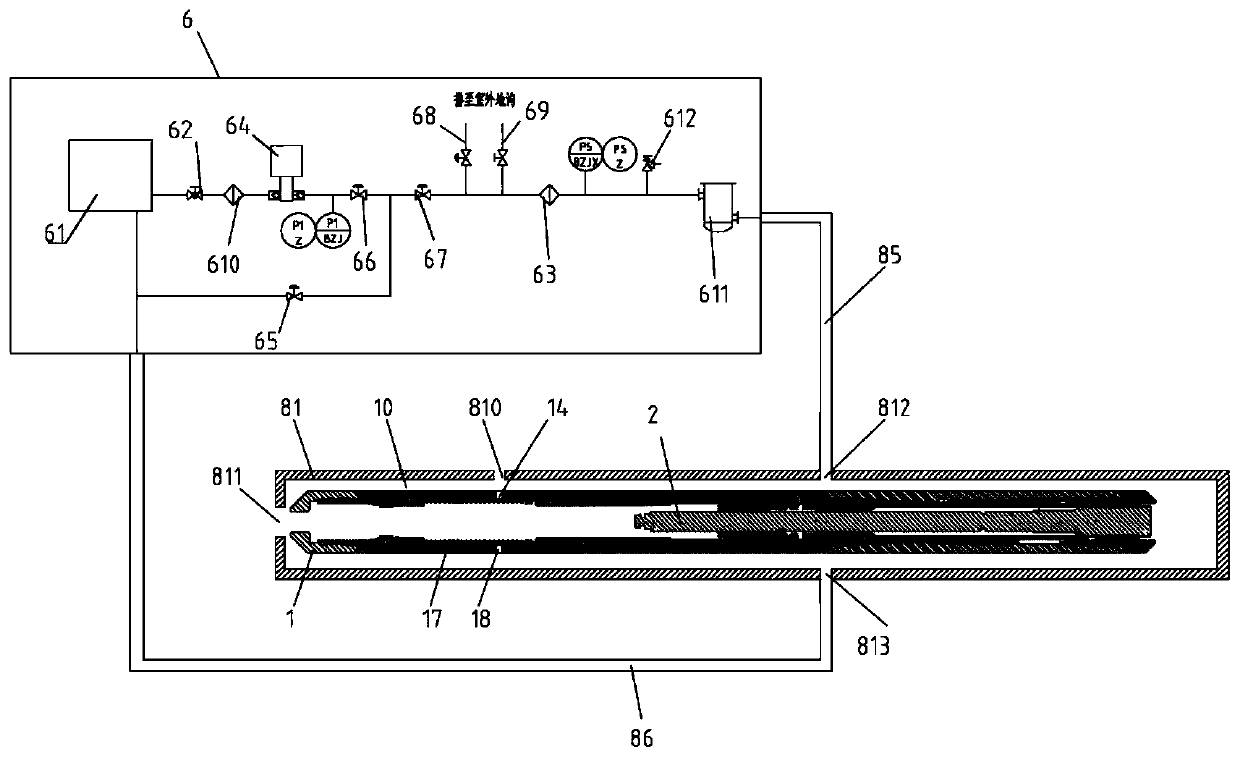

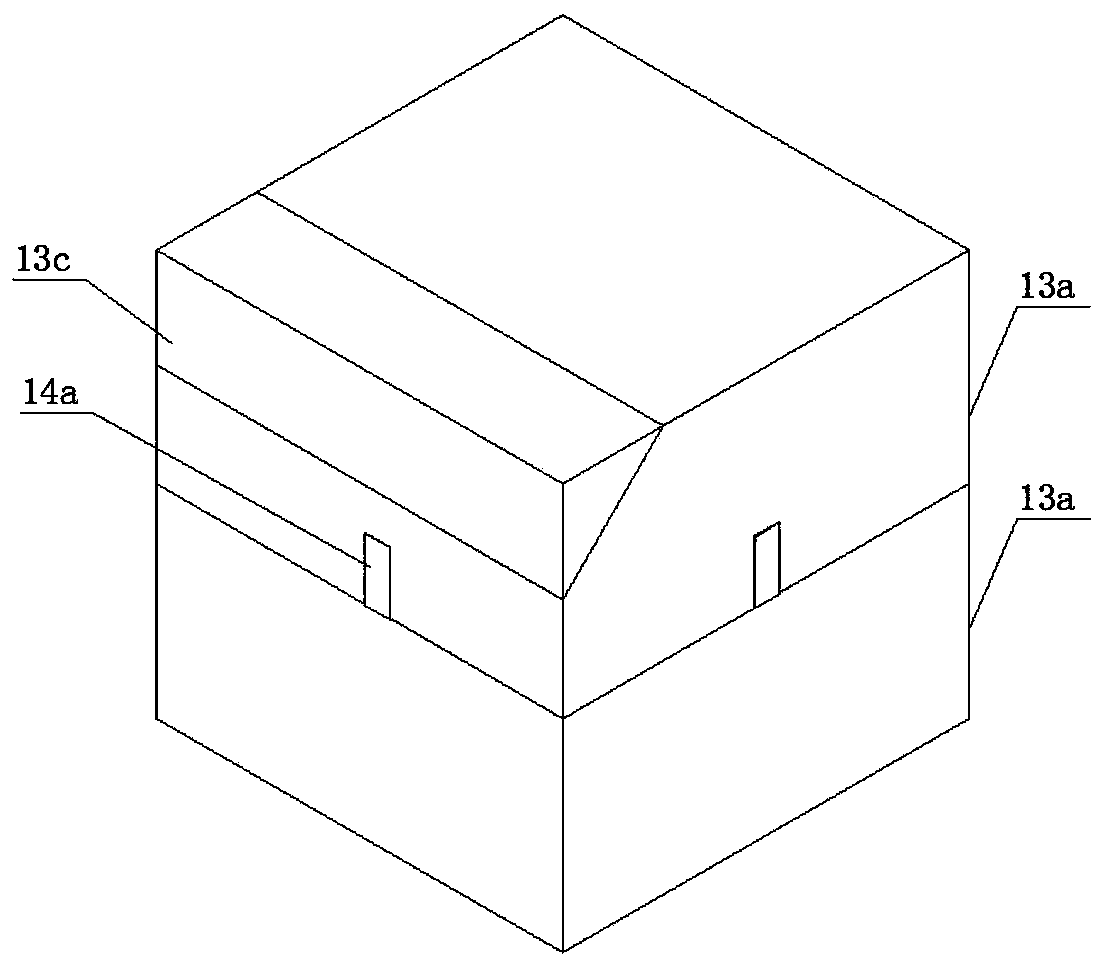

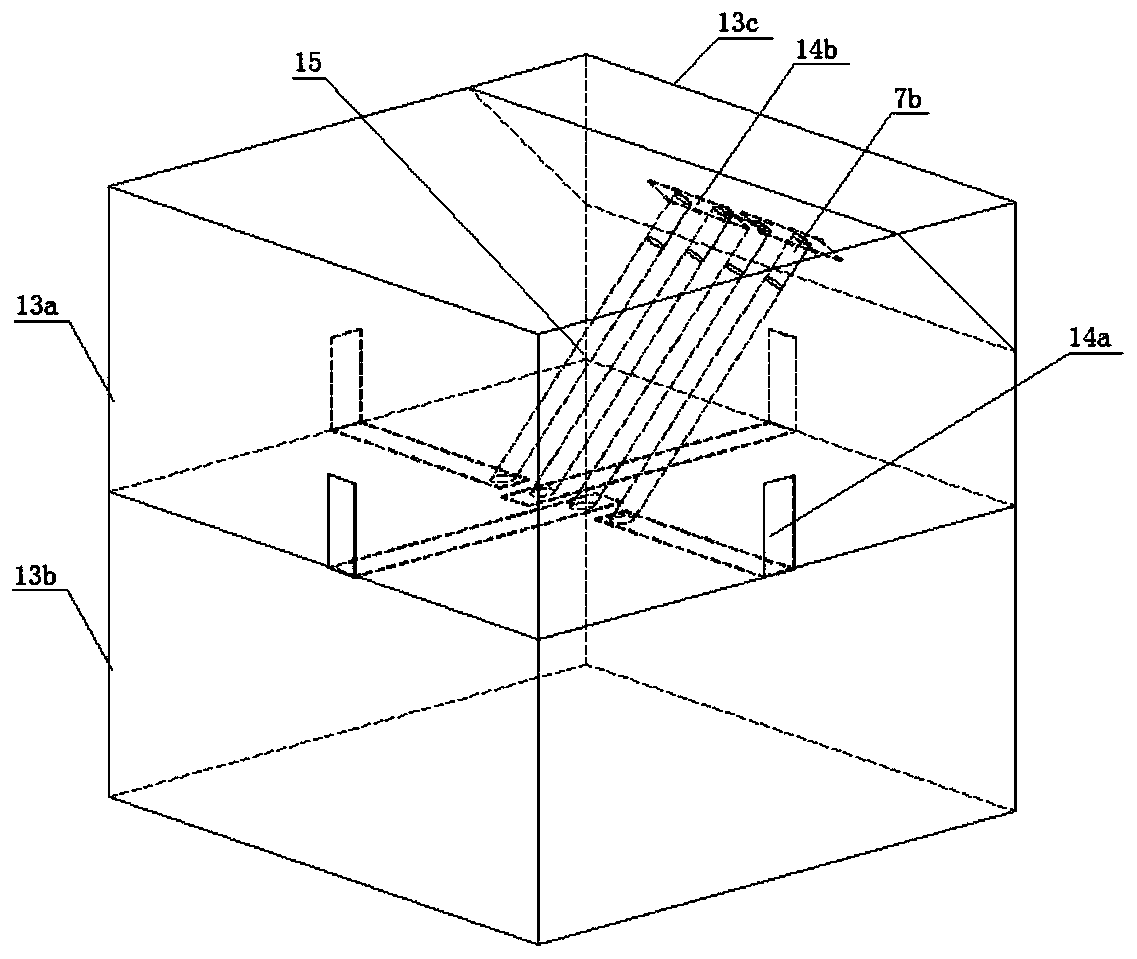

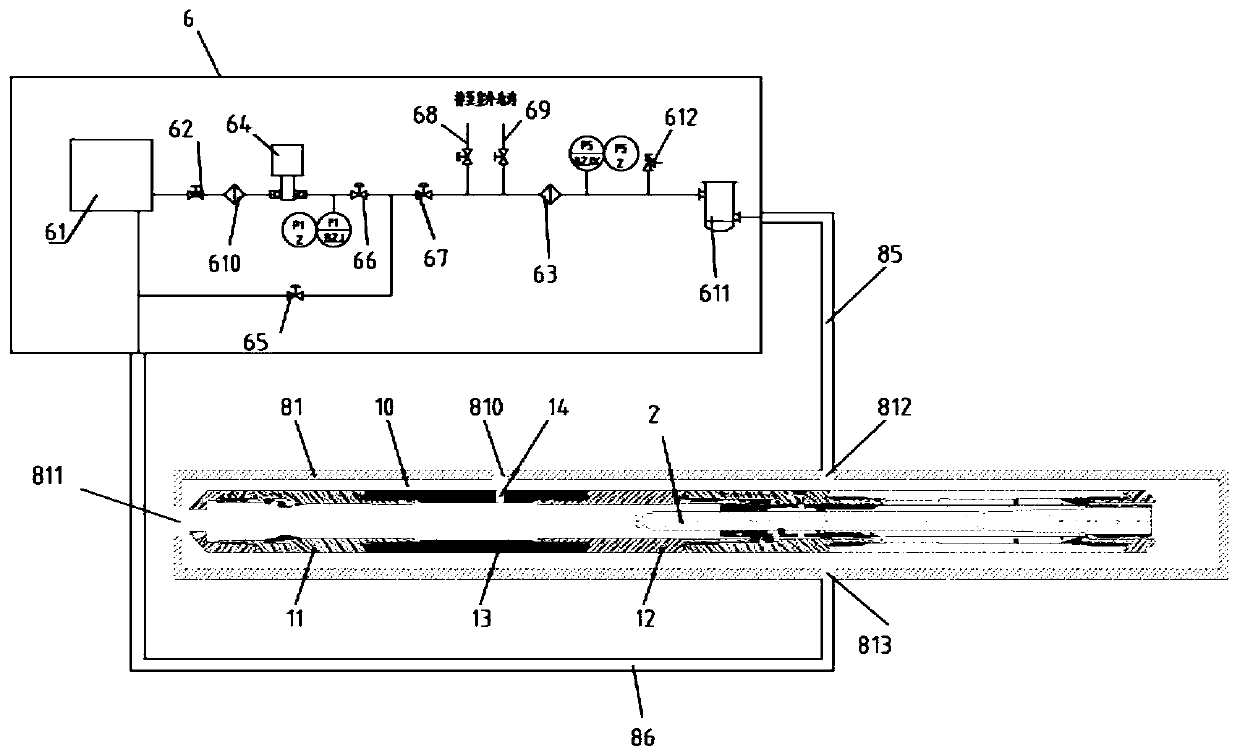

Oil bath type internal and external temperature control fidelity coring device experimental platform

PendingCN111550211APromote reductionComplete experimentSurveyInsulationTemperature controlPressure experiment

The invention relates to an oil bath type internal and external temperature control fidelity coring device experimental platform. The oil bath type internal and external temperature control fidelity coring device experimental platform comprises a box body, an external heating system and a pressure experimental cabin used for simulating a fidelity cabin of a fidelity coring device. The inner wall of the cabin body of the pressure experimental cabin is provided with an electric heating structure, and the cabin wall of the pressure experimental cabin is provided with a side hole. The pressure experimental cabin is arranged in the box body, the box body is provided with a liquid inlet and a liquid outlet, the external heating system comprises a liquid supply system and an electric heater, an outlet of the liquid supply system is connected with an inlet of an electric heater, and an outlet of the electric heater is connected with the liquid inlet through a liquid inlet pipeline. According to the experimental platform, a high-temperature environment can be simulated, the high-temperature environment can be provided for the pressure experimental cabin, a real in-situ environment can be achieved, an experiment is more complete and objective, and data is more reliable. Internal and external heating can be achieved simultaneously, the heating efficiency can be improved, the experiment time is easily shortened, and the experiment efficiency is improved. The internal electric heating structure is arranged on a pressurizing and heating intermediate piece, the structure of the pressure maintaining experimental cabin is not changed, and the experiment cost can be reduced.

Owner:SICHUAN UNIV

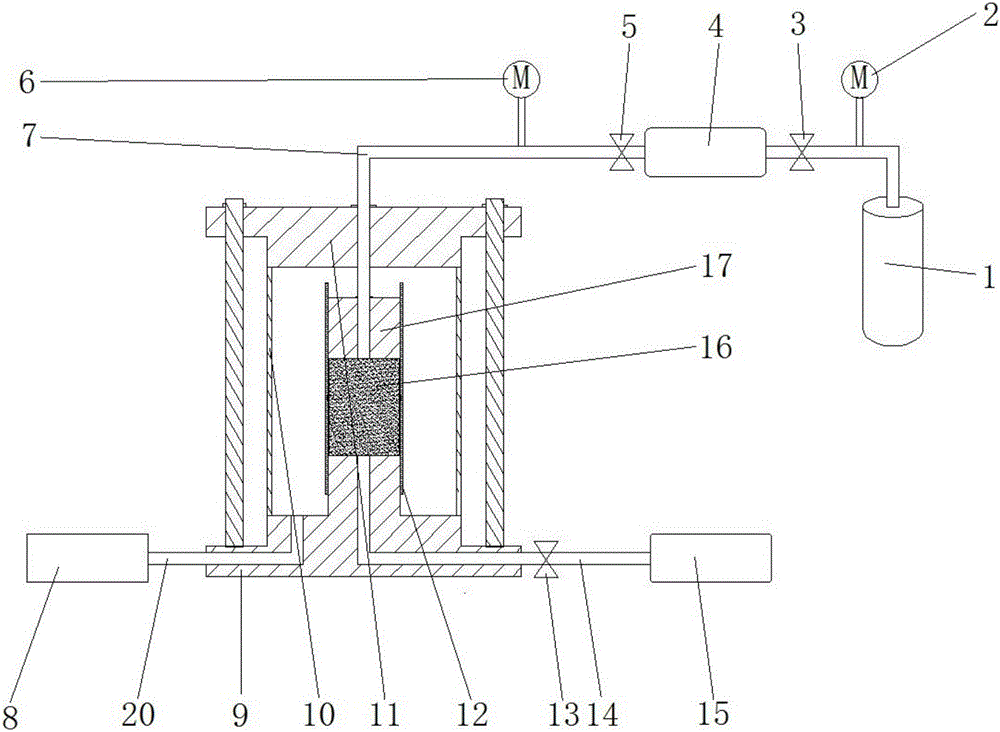

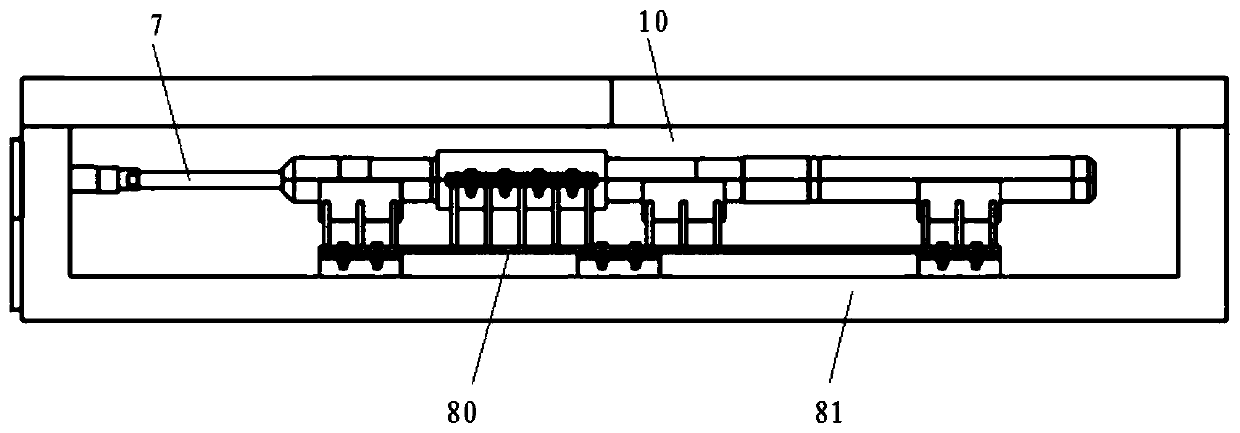

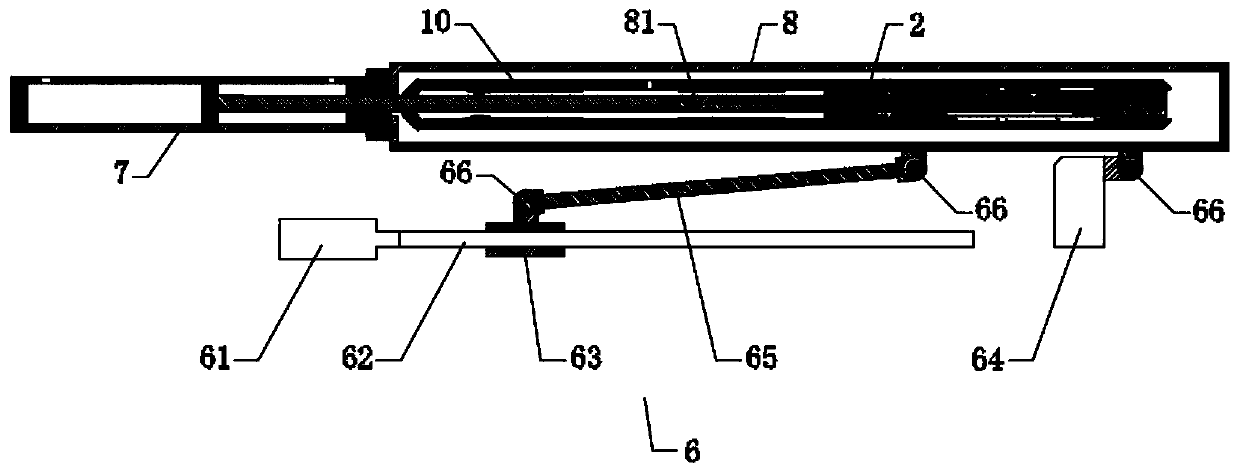

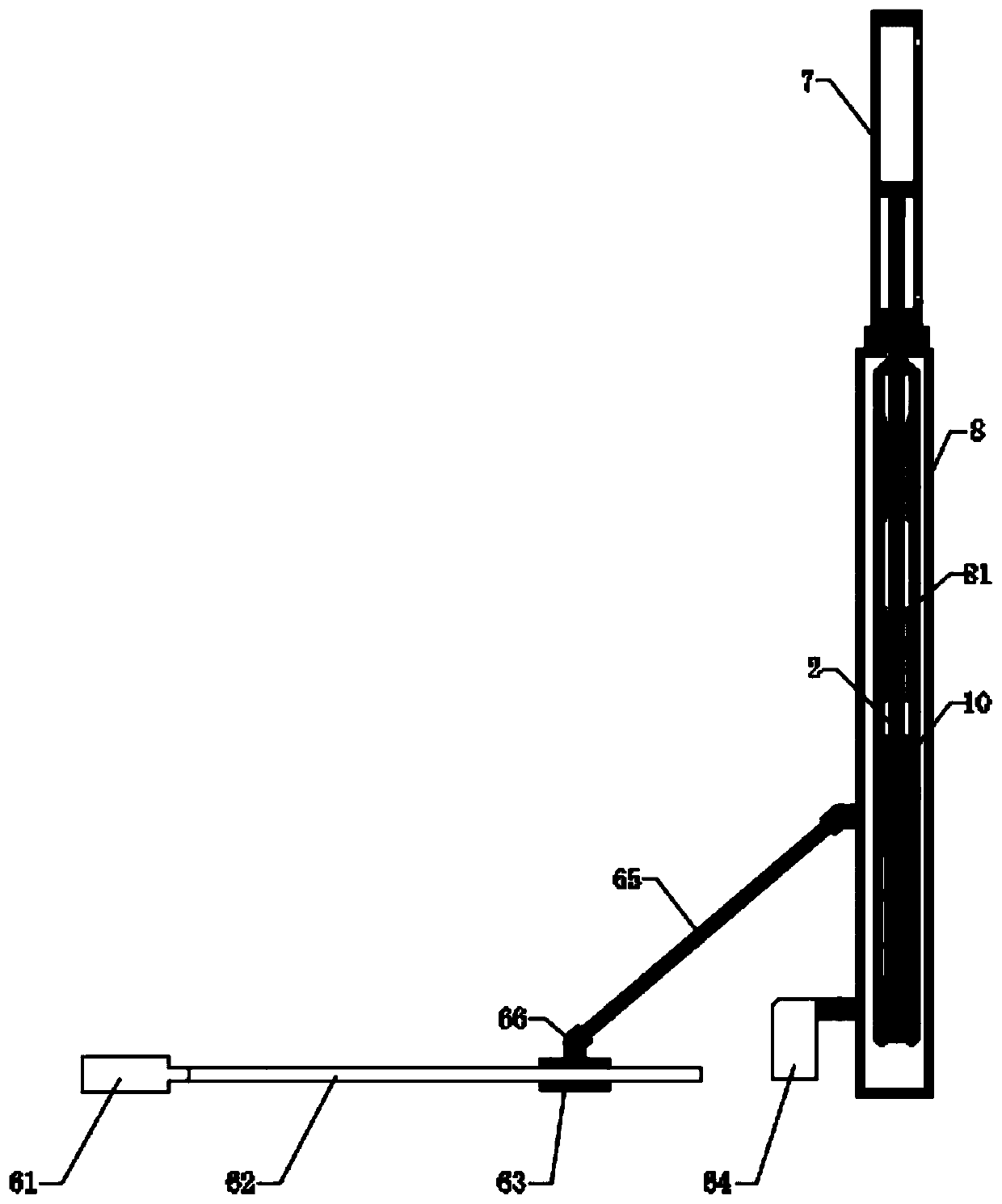

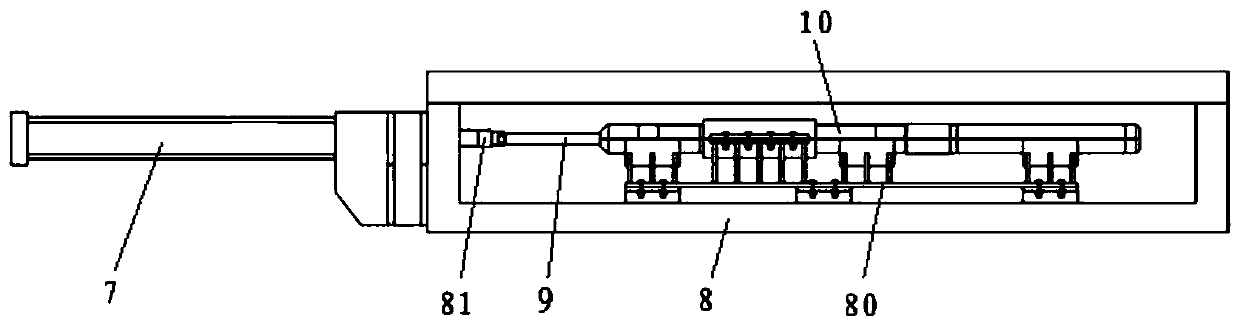

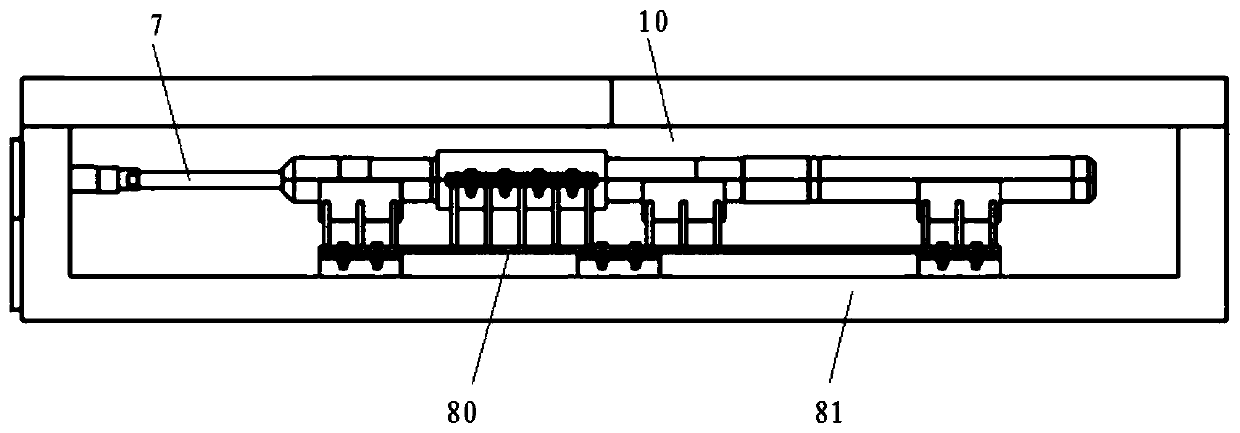

Rotary experiment platform for fidelity coring device

PendingCN111577184AEasy to switchEasy to verify feasibilitySurveyEducational modelsPressure experimentClassical mechanics

The invention relates to a rotary experiment platform for a fidelity coring device. The rotary experiment platform comprises a box body, a pressure experiment cabin used for simulating a fidelity cabin of the fidelity coring device and a rotary driving mechanism enabling the box body to change between the horizontal state and the vertical state, wherein the pressure experiment cabin comprises a cabin body fixedly installed in the box body, the rotary driving mechanism comprises a motor, a transmission mechanism, a movable block, a supporting arm and a support base, the bottom end of the box body is movably connected with the support base, the transmission mechanism converts rotary movement of the motor into linear movement of the movable block, and the two ends of the supporting arm are movably connected with the movable block and the box body respectively. According to the rotary experiment platform, convenience is brought for the pressure experiment cabin to switch among the horizontal state, the slant state and the vertical state, the pressure maintaining performance of a pressure-maintaining experiment cabin under conditions like vertical drilling, horizontal drilling and slantdrilling and reliability of motions of parts like a center rod, a flap valve and a core barrel can be verified, and the feasibility and scientificity of a design scheme are convenient to verify, andso that improvement in the fidelity cabin in terms of the structure and material is facilitated.

Owner:SICHUAN UNIV

Plastic pipe sealing performance experiment device

ActiveCN106404316AAvoid damageAvoid axial stressMeasurement of fluid loss/gain rateAxial displacementControl system

The invention discloses a plastic pipe sealing performance experiment device comprising a first pipe clamp fixing shaft and a second pipe clamp fixing shaft which have the same axial line. A buffer gap is arranged between the first pipe clamp fixing shaft and the second pipe clamp fixing shaft. The first pipe clamp fixing shaft or the second pipe clamp fixing shaft is provided with an axial displacement device. The plastic pipe sealing performance experiment device also comprises an air compressor. The air compressor is communicated with the plastic pipe pressure experiment communicating port of a first port sealing clamp through an air source electromagnetic valve. The plastic pipe pressure experiment communicating port of the first port sealing clamp is communicated with a vacuum pump through a vacuum electromagnetic valve. The plastic pipe pressure experiment communicating port of a second port sealing clamp is the pressure tap of the pressure transmitter of a pipe under test. The air compressor, the air source electromagnetic valve, the vacuum electromagnetic valve and the pressure transmitter of the pipe under test are communicated with an embedded control system. The plastic pipe sealing performance experiment device has the characteristics of being high in test parameter precision and high in degree of automation.

Owner:CHENGDE PRECISION TESTING MACHINE

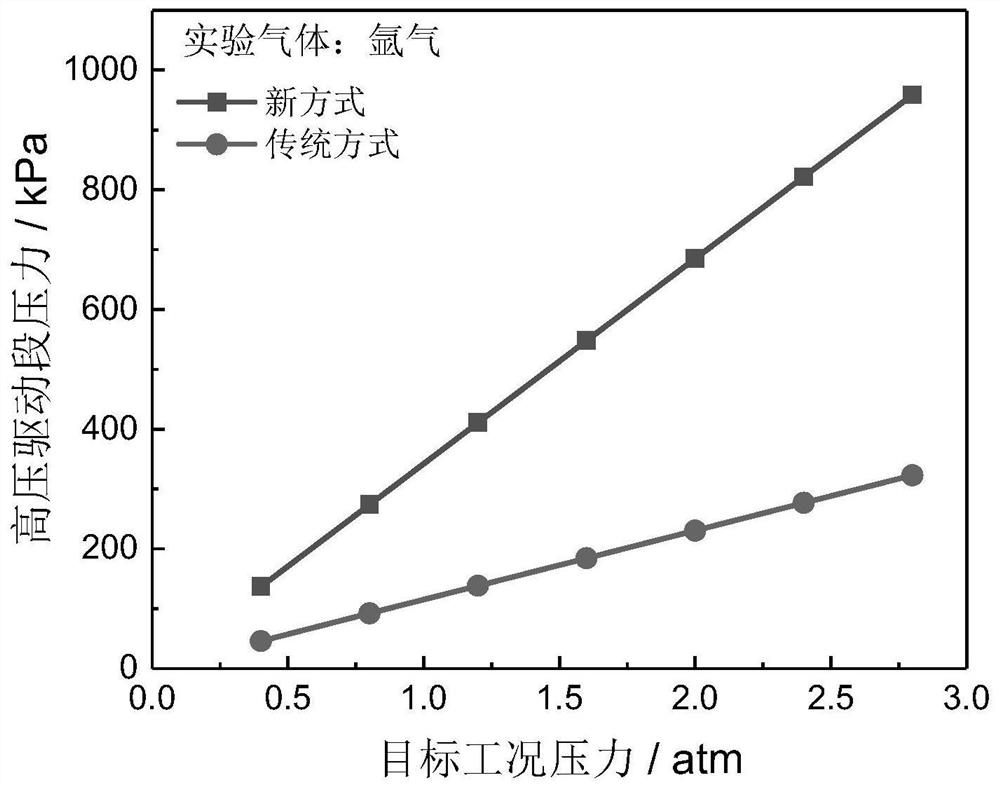

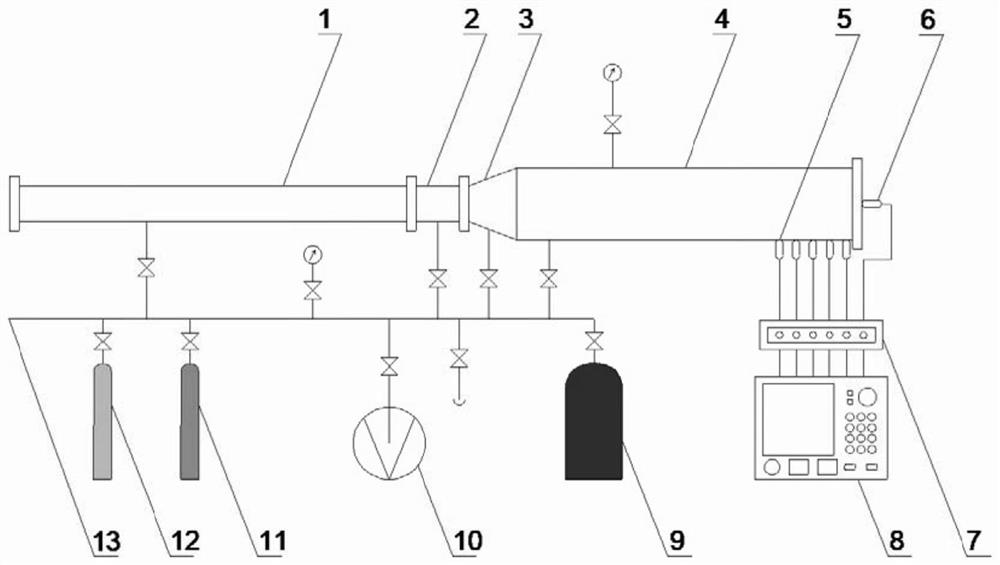

Staged air inlet device and method for inducing strong shock waves

PendingCN110686902AIncrease the lengthReduce usageEngine testingHydrodynamic testingConvertersPressure experiment

The invention discloses a staged air inlet device and method for inducing strong shock waves. The staged air inlet device comprises an expansion section, a driving section, a diaphragm clamping section and an experiment section which are sequentially connected and coaxially arranged, the expansion section communicates with the driving section through a valve, the diaphragm clamping section is arranged between the driving section and the experiment section, diaphragms for separating chambers are respectively arranged between the diaphragm clamping section and the driving section and between thediaphragm clamping section and the experiment section, the signal output end of the pressure sensor is connected to a data collector through a signal converter, the data collector is used for collecting voltage signals collected by the pressure sensor, the expansion section, the driving section, the diaphragm clamping section and the experiment section are connected to a gas conveying pipeline through valves, and an expansion gas tank used for inflating the expansion section is connected to the gas conveying pipeline. According to the invention, the use of rare resource helium can be greatlyreduced, the experiment cost is saved, and the physical boundary of shock tube high-pressure experiment measurement can be remarkably widened.

Owner:XI AN JIAOTONG UNIV

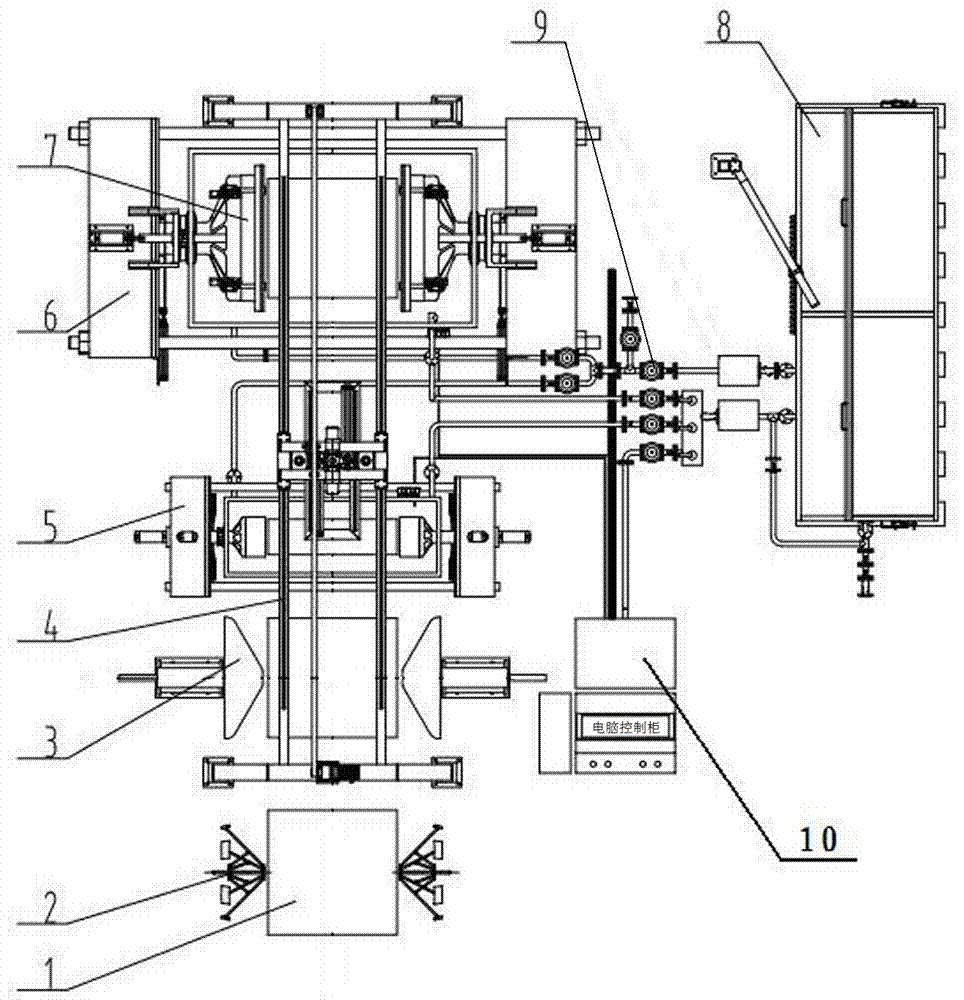

Automatic pipe pressure experiment device

InactiveCN106908321AReduce labor intensitySave moneyMaterial strength using tensile/compressive forcesTemperature controlPressure experiment

The invention discloses an automatic pipe pressure experiment device. The automatic pipe pressure experiment device comprises an inner wall supporting apparatus, a centering apparatus, a hoisting apparatus, a small-specification experiment box, a large-specification experiment box, a sealing apparatus, an insulating water storage box, a pipeline, and an electrical and a temperature control system. A supporting range of the inner wall supporting apparatus is adjusted by adopting a nut and screw structure; the centering apparatus drives a conical centering disc by virtue of an air cylinder to position a pipe; the hoisting apparatus moves along a rectilinear guide rail by virtue of a motor and a belt, and a claw sheet is pushed by the air cylinder to grip different specifications of pipes; the large and the small test boxes push a pushing rod by virtue of the air cylinder so as to install and seal a clamp; and the air cylinder pushes an ejector plate, after the pipe is filled with high-pressure experiment water, the pushing rod tightly presses the ejector plate, and the pressure of the experiment water applied to the pushing rod is transferred to a stress support and a drawing rod, so that the stress support and the drawing rod are deformed to provide a thrust. By adopting the automatic pipe pressure experiment device, the automatic installation of large-sized pipe pressure experiments is realized, no large-sized hoisting device is needed, the labor intensity is reduced, and the cost and a needed space are saved.

Owner:合海橡塑装备制造有限公司

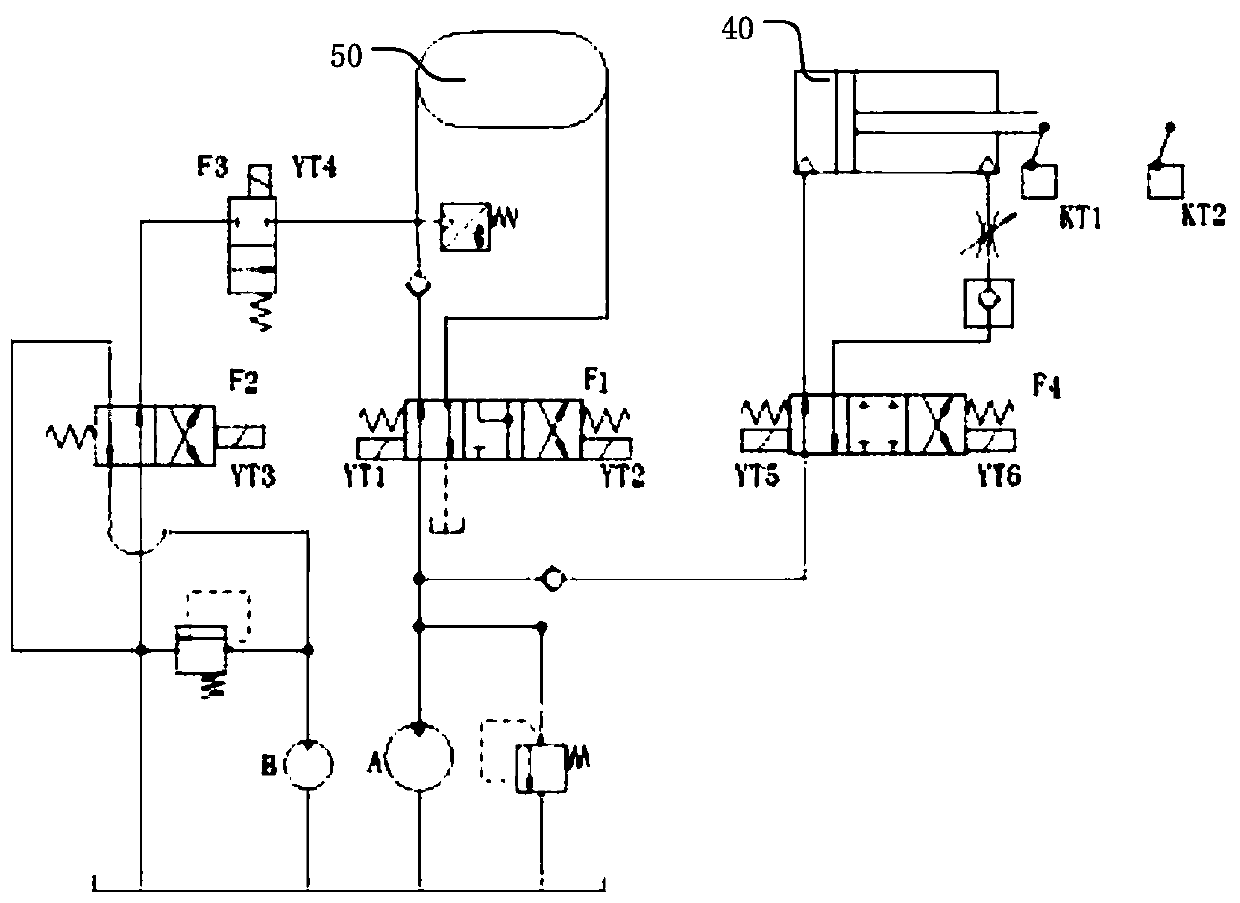

In-situ confining pressure experiment device for rock-soil body in rock-soil drilling

PendingCN109696324AImprove stabilityHigh precisionWithdrawing sample devicesMaterial strength using tensile/compressive forcesPressure experimentHydraulic circuit

The invention provides an in-situ confining pressure experiment device for a rock-soil body in rock-soil drilling. The device comprises a cylindrical hollow outer pipe; one end of the outer pipe is anexternal power connecting end and an experiment control end; the other end is a drill bit end; an inner pipe used for taking soil is movably mounted in the outer pipe; the end, located at the drill bit end, of the inner pipe is of a pipe shoe structure and extends out of the outer pipe, and a hydraulic part for providing hydraulic power, a vertical pressure part driven by the hydraulic part to apply vertical pressure to a collected soil sample and a confining pressure part for applying radial confining pressure to the collected soil sample are installed in the inner pipe. The sampling power principle of a soil sampler is utilized, and a ground power device is adopted to carry out micro-disturbance soil sampling; two sets of hydraulic circuits are adopted to apply vertical pressure and confining pressure, so that the stability of load can be ensured, and the accuracy of experimental data is ensured and improved to the maximum extent.

Owner:孟达

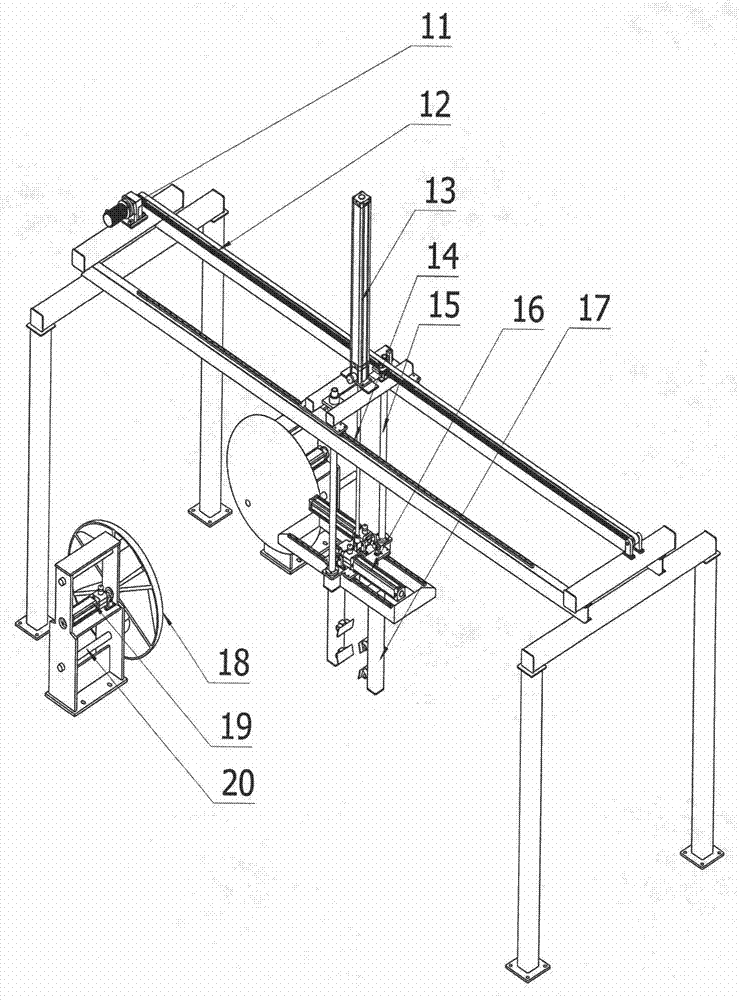

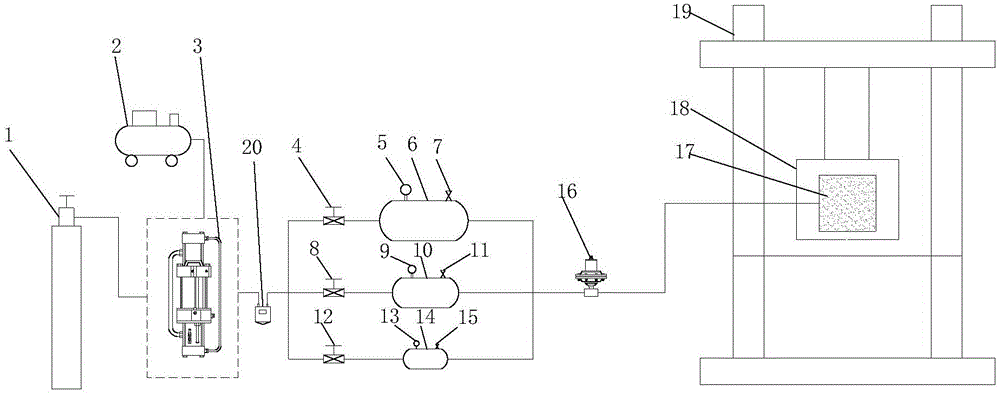

High-pressure nitrogen blast cracking permeability increase experimental device and method

The invention provides a high-pressure nitrogen blast cracking permeability increase experimental device and method and belongs to coal bed gas blast cracking permeability increase experimental devices and methods. The device comprises a nitrogen steel cylinder, an air compressor, a gas booster pump, a high-pressure gas bag and a three-axis pressure experimental machine. The gas booster pump is connected with the air compressor and the nitrogen steel cylinder through hoses. A pressure meter and a safety valve are arranged on the high-pressure gas bag. One end of the high-pressure gas bag is connected with the gas booster pump through a stainless steel gas guide tube, and the other end of the high-pressure gas bag is connected with a three-axis pressure chamber filled with a blasted medium through a gas guide hose. A gas control valve is arranged on the gas guide hose between the high-pressure gas bag and the three-axis pressure chamber. The method includes the steps that nitrogen is generated through the nitrogen steel cylinder and boosted to be stored in the high-pressure gas bag, when the pressure in the gas bag reaches the standard, the gas control valve is opened, the high-pressure nitrogen is instantaneously released, the loaded blasted medium is cracked, and blast cracking of nitrogen of different pressures and different volumes is achieved through high-pressure bags of different volumes. The device is easy and convenient to use, and the blast cracking effect of high-pressure nitrogen at different pressures and different volumes is achieved.

Owner:CHINA UNIV OF MINING & TECH

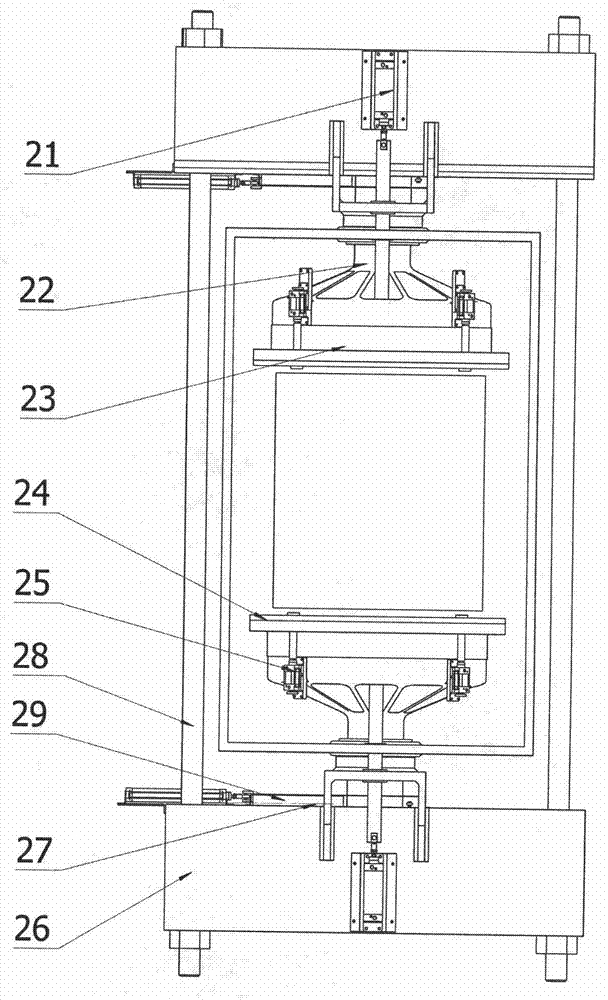

Loading tool system for axle pressure experiment of spaceflight cylindrical shell

ActiveCN106057059ACompact structureThe principle is simpleEducational modelsAviationPressure experiment

The invention provides a loading tool system for an axle pressure experiment of a spaceflight cylindrical shell, and belongs to the field of experiment tool design of a main bearing member of an aviation and spaceflight structure. The tool system mainly comprises a tool pedestal, a tool pedestal switching frame, a bidirectional actuator, an approximate rigid connection column, a force sensor, a limiting block, a loading cap and an experimental switching ring. The tool system is simple in principle, simple in loading control, compact in structure, and small in occupation space, a loading system is independent from a measuring system, and a measuring space is ensured to the largest extent. The installation sequence is changed to realize switching between an axle pressing condition and an axle pulling condition simply, and the tool system can fully ensure that load distribution is uniform and accurate.

Owner:DALIAN UNIV OF TECH

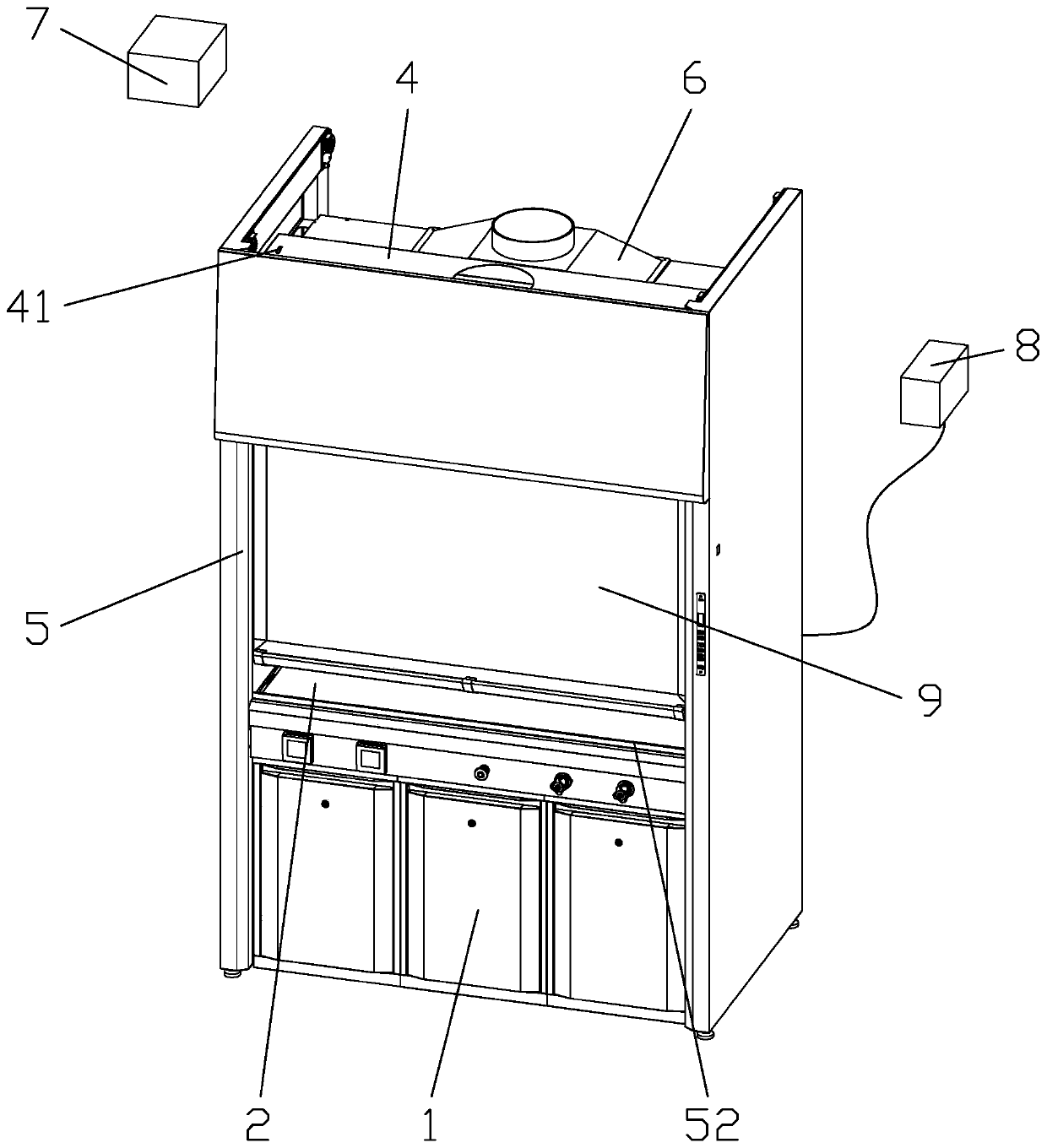

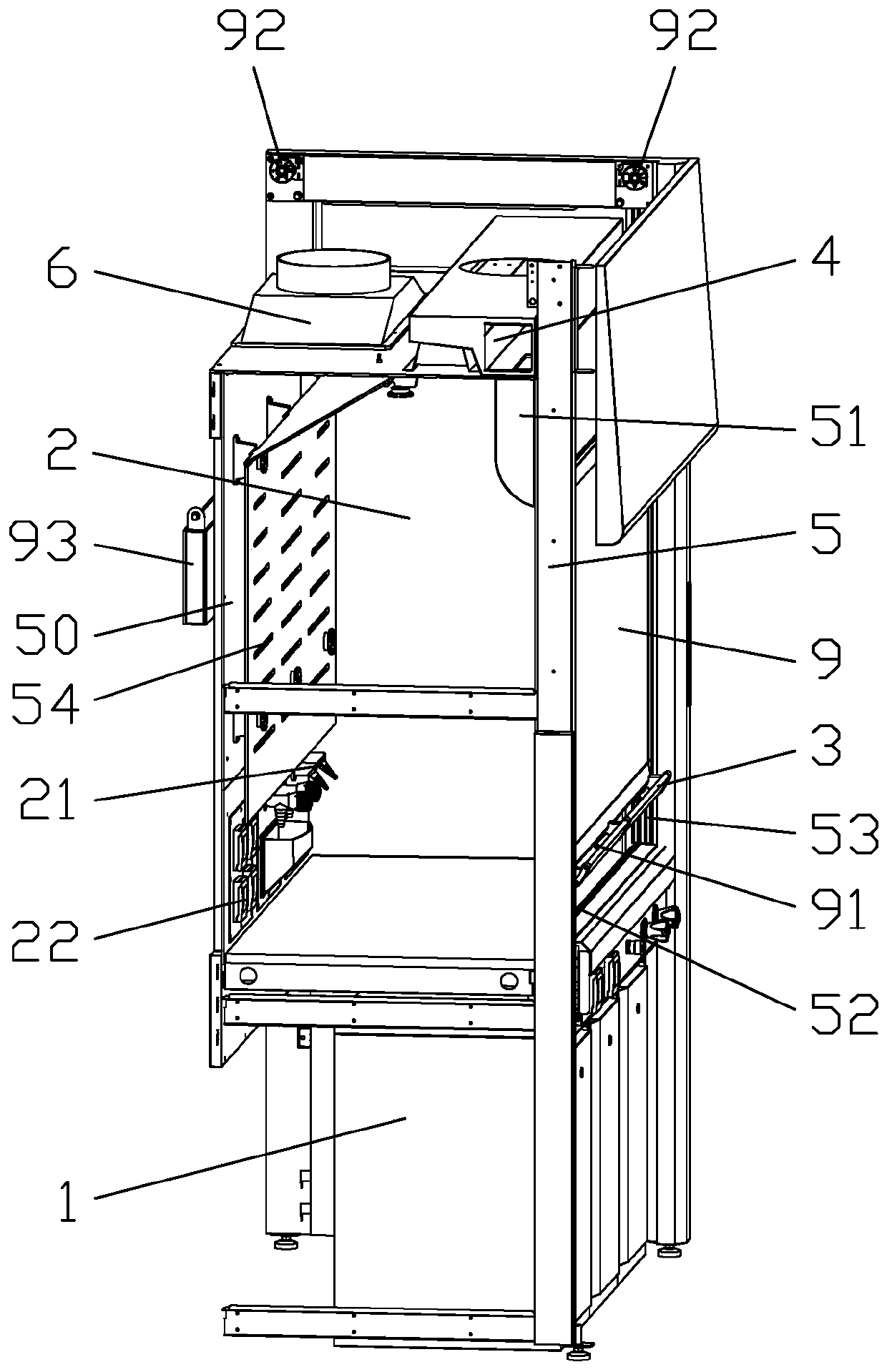

Laboratory integrated experiment ventilation cabinet

ActiveCN110560447AIntegrate ventilation connectionsImprove efficiencyDirt cleaningPressure experimentFume hood

The invention discloses a laboratory integrated experiment ventilation cabinet. The laboratory integrated experiment ventilation cabinet comprises a circulating air supplementing ventilation cabinet,a negative pressure experiment operation cavity is formed in the circulating air supplementing ventilation cabinet, and a water nozzle and a socket are arranged in the negative pressure experiment operation cavity. A flow guiding air way is arranged on the back side of the circulating air supplementing ventilation cabinet, air outlets are formed in the flow guiding air way, and an air outflow boxis arranged on the upper side of the circulating air supplementing ventilation cabinet to communicate with the flow guiding air way. The laboratory integrated experiment ventilation cabinet further comprises a ventilation integrated connector, and the ventilation integrated connector communicates with an air inflow box and the air outflow box through an air inflow pipe and an air outflow pipe. Thelaboratory integrated experiment ventilation cabinet further comprises an external integrated connector. Through the cooperation of optimization and improvement of the ventilation cabinet air way andthe design of the ventilation integrated connector, ventilation connection integration of the ventilation cabinet is achieved, water supply and power supply connection integration of the ventilationcabinet is achieved through the external integrated connector, once the ventilation cabinet needs to be moved and modified, it is not needed to be connected with an air pipe, a water pipe, an electricwire or else, and the safety is improved while the efficiency is improved.

Owner:GUANGDONG TIANCIWAN LAB EQUIP MFG CO LTD

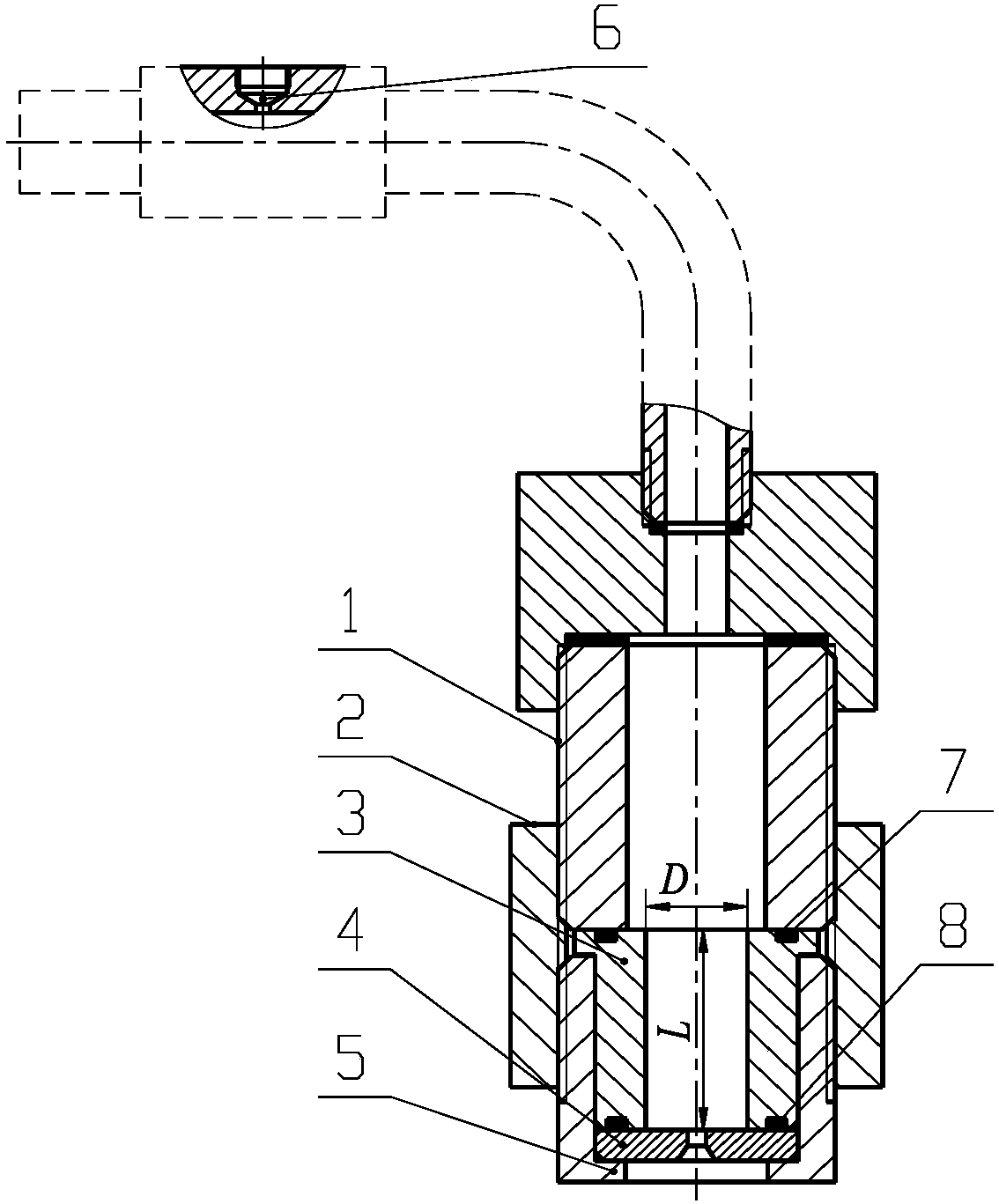

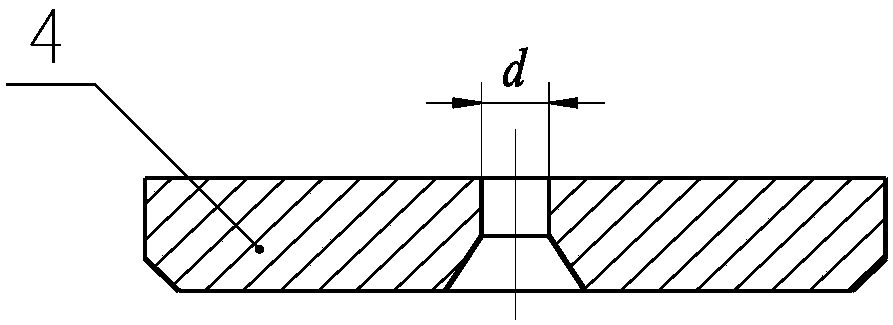

High-pressure water jet self-oscillation nozzle device with adjustable structure

PendingCN108031566AWork around volume limitationsExpand the adjustment range of structural parametersSpray nozzlesJet flowPressure experiment

The invention discloses a high-pressure water jet self-oscillation nozzle device with an adjustable structure, and belongs to the field of industrial cleaning. The device comprises an inlet shrinkagepipe, an oscillation cavity, a water outlet spray sheet and the like. The high-pressure water jet self-oscillation nozzle device is characterized in that a pressure sensor is arranged at a front end pipeline of the nozzle device, and the pressure sensor is always arranged outside a high-pressure container during confining pressure experiments so as to avoid the limit from confining pressure environment; in addition, the free combination of the inlet shrinkage pipe, the oscillation cavity and the water outlet spray sheet can be used for greatly changing the structure parameter ratio of a nozzle, and the self-excitation frequency adjusting range is enlarged; and the oscillation signal real-time detection function is combined with the structure parameter adjustment function so that the oscillation characteristic of the jet flow can be accurately obtained, and then the optimal resonance effect is obtained.

Owner:UNIV OF SCI & TECH BEIJING

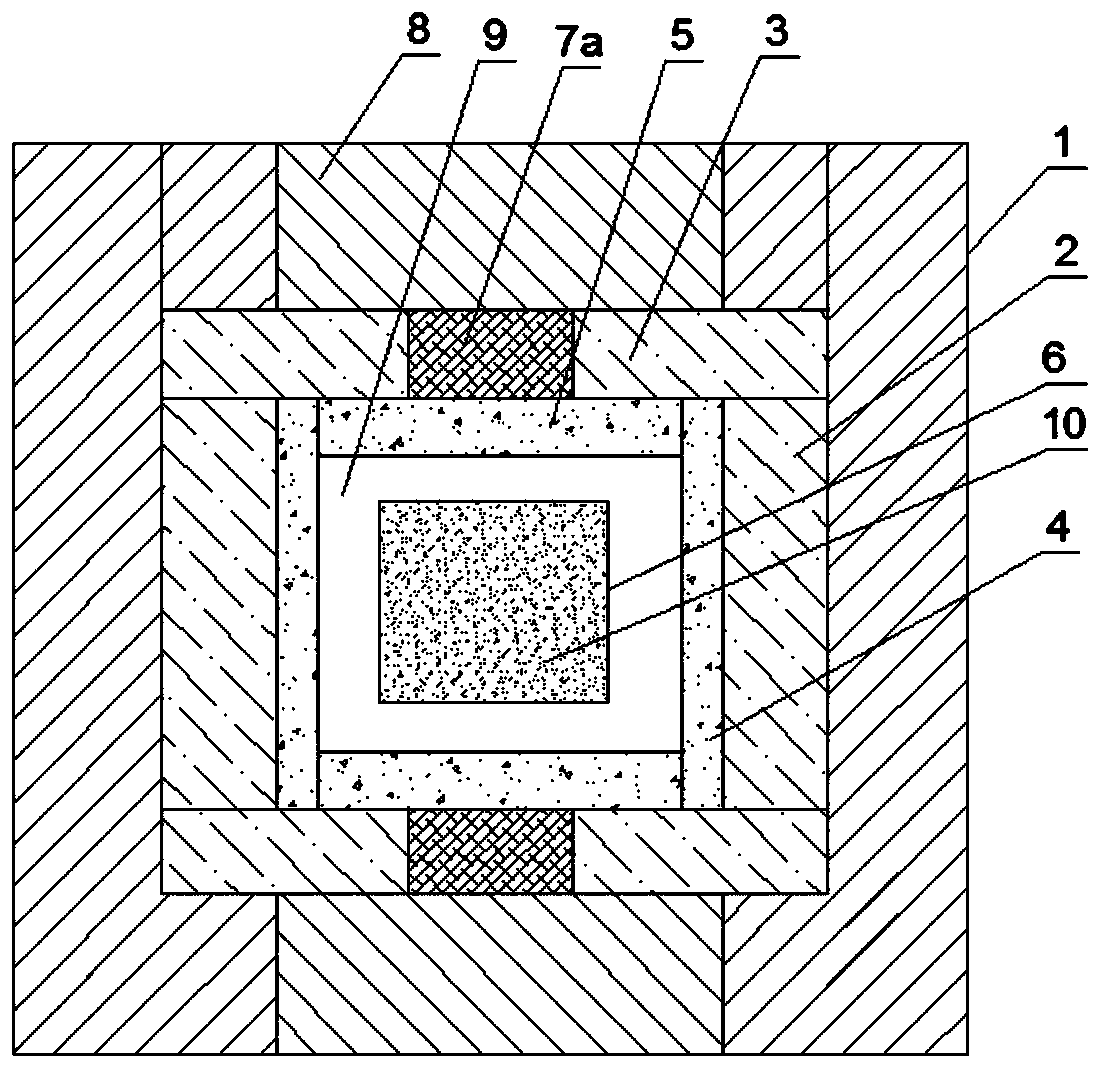

Conducting medium for high-stress and large-deformation environment, assembly part and application thereof

ActiveCN111025055ARealize in-situ measurementAchieve high-quality deliveryElectrical testingMaterial strength using tensile/compressive forcesElectrical conductorTest sample

The invention provides an assembly part for a stress and deformation environment. A to-be-tested sample and a conductive medium are arranged in the assembly part, one end of the conductive medium is connected with the sample, the other end of the conductive medium is conductively connected with the exterior of the assembly part, and the conductive medium and the assembly medium surrounding the conductive medium keep synchronous rheology in a stress and deformation environment. Conductor powder or a block which is formed by pre-pressing the conductor powder and can be rheological under high pressure is used as a conducting medium, the conducting medium is kept flowing and continuous in the high-temperature and high-pressure experiment process, and high-quality transmission of current and electric signals in the high-temperature and high-pressure experiment is realized by combining with dynamic high-pressure and static high-pressure experiment technologies.

Owner:SICHUAN UNIV

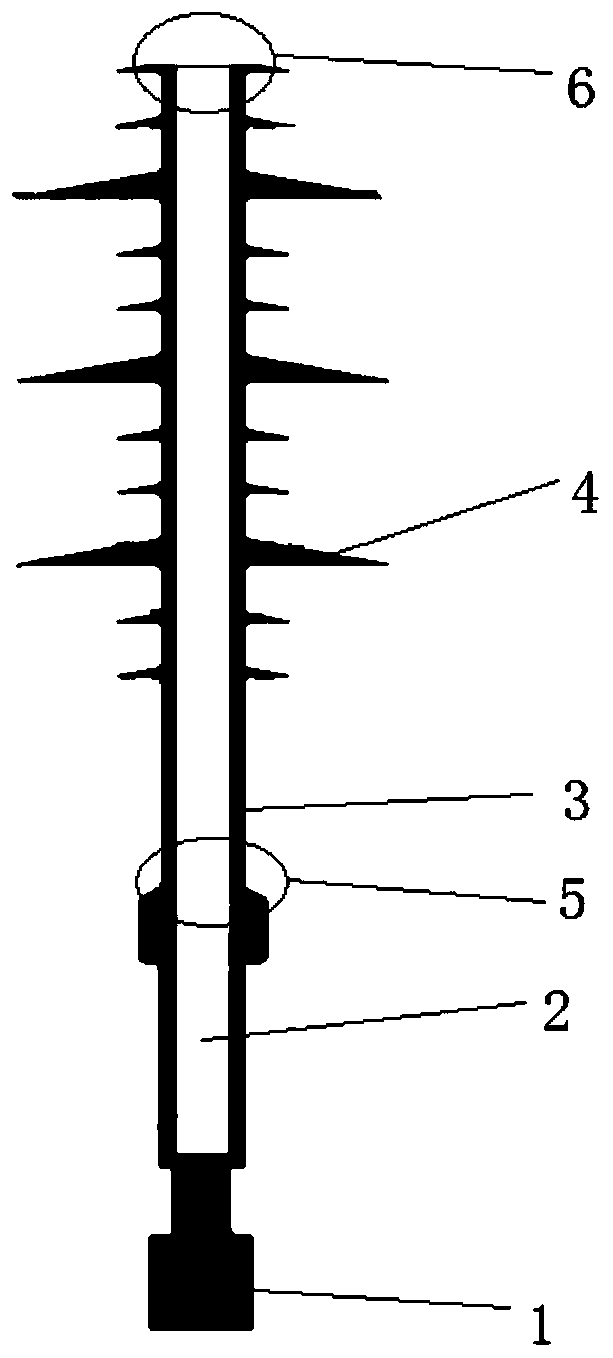

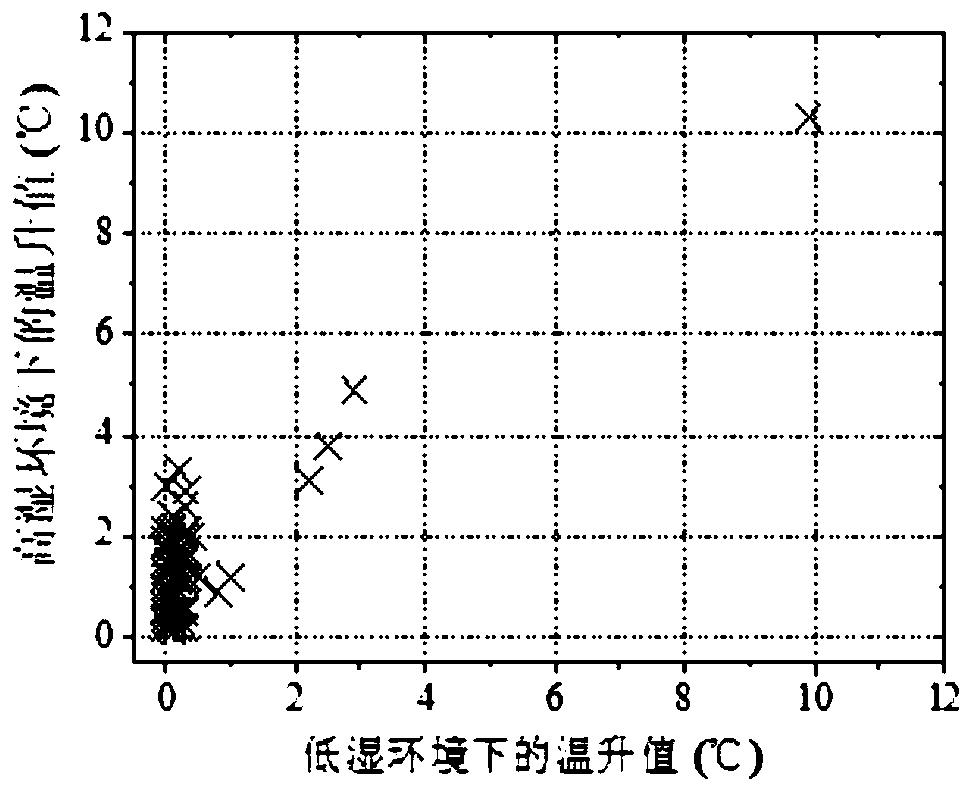

Temperature rising judgment method of composite insulator

ActiveCN110672956AGuaranteed uptimeRadiation pyrometryElectrical testingComposite insulatorsPressure experiment

The invention discloses a temperature rising judgment method of a composite insulator. By the temperature rising judgment method, identification forecast can be performed on a crisp broken accident ofthe composite insulator, reliable guidance is provided for running and maintenance of the composite insulator, high-pressure experiment is performed on the composite insulator under a high-humidity or low-humidity environment, an infrared thermal image of the composite insulator is acquired, a temperature rising part of the composite insulator is judged, meanwhile, temperature rising value data of the composite insulator is acquired, the temperature rising type is judged according to the temperature rising part and the temperature rising value data of the composite insulator, the temperaturerising is smaller than or equal to 1.0K if the composite insulator is in the low-humidity environment, the temperature rising part is concentrated in a region far away from a metal fitting of the composite insulator within 20 centimeters, and the temperature rising of the composite insulator is point temperature rising; and if the composite insulator is in the high-humidity environment or the low-humidity environment, the temperature rising is larger than 1.0K, the temperature rising part extends from a high-voltage end to a low-voltage end of the composite insulator, and the temperature rising of the composite insulator is segmented temperature rising.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

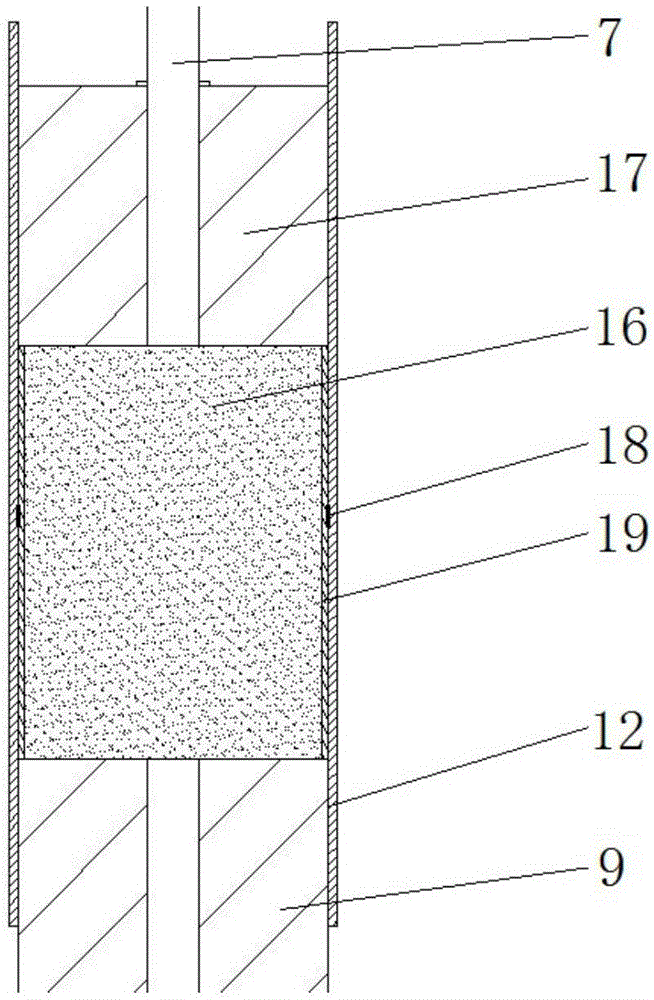

Oil bath type temperature control fidelity coring device experiment platform

PendingCN111504699AComplete experimentExperiment objectiveWithdrawing sample devicesTemperature controlControl system

The invention relates to an oil bath type temperature control fidelity coring device experiment platform, which comprises a box body, a temperature control system and a pressure experiment cabin. Thepressure experiment cabin is arranged in the box body, and the box body is provided with a liquid inlet, a liquid outlet and a first preformed hole. The temperature control system comprises a liquid supply system and an electric heater, an outlet of the liquid supply system is connected with an inlet of the electric heater, and an outlet of the electric heater is connected with a liquid inlet of the box. The pressure experiment cabin comprises a first test piece, a second test piece and a middle connecting piece. The first test piece is connected with the second test piece through the middle connecting piece, and a liquid injection hole is formed in the cylinder wall of the middle connecting piece. The high-temperature environment can be simulated, the pressure maintaining experiment cabincan be heated, the high-temperature environment can be provided for the pressure experiment cabin, an experiment is more complete and objective, and data is more reliable. The middle connecting pieceis used for connecting the test piece, so that drilling on the test piece can be avoided, the test piece is prevented from being damaged, and the experiment accuracy can be improved.

Owner:SHENZHEN UNIV

Simulation physical model capable of visualizing different fracture network forms and manufacturing method

PendingCN112927592AAchieve reuseMeet the requirements of high temperature and high pressure experimentsEducational modelsPressure experimentPhysical model

The invention provides a simulation physical model capable of visualizing different fracture network forms and a manufacturing method. The simulation physical model comprises an etched glass mother plate and a smooth glass accessory plate, the two plates are both square and are mutually bonded to form a cube, an injection port and an extraction port are formed in a plate body of the smooth glass accessory plate, the injection port and the extraction port are communicated with an embedded nano-scale pore network structure of the etched glass mother plate, and the pore network structure at least comprises different fracture network forms. According to the simulation physical model capable of visualizing different fracture network forms, the pore structure and different fracture forms of a tight oil reservoir core are truly simulated, the pore size and shape can be autonomously designed, simulation research of reservoir microcosmic parameters under the nano-micron size is simulated, the manufactured simulation physical model can bear microcosmic seepage research at 60 DEG C or below and 6 MPa or below, the requirement for high-temperature and high-pressure experiments is met, in addition, the smooth glass accessory plate in the simulation physical model can be separated from the etched glass mother plate, and therefore the accessory plate can be reused.

Owner:PETROCHINA CO LTD

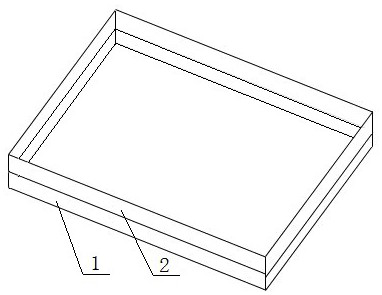

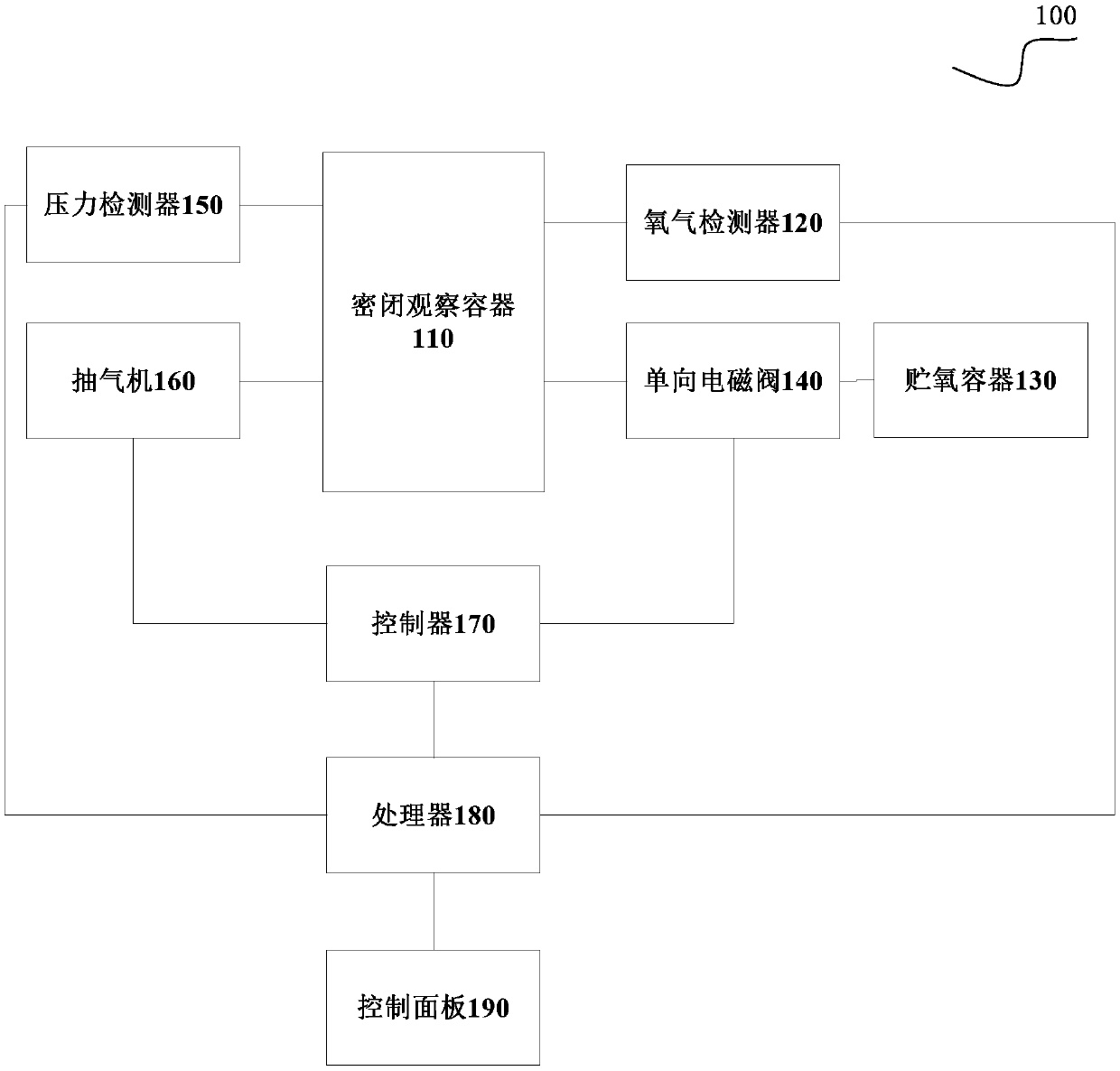

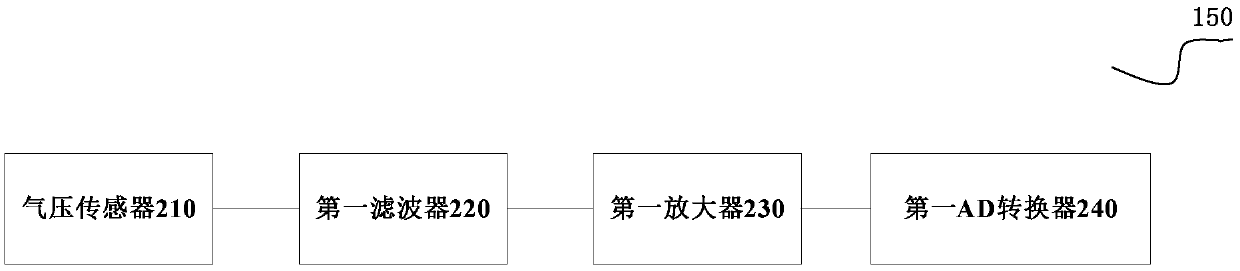

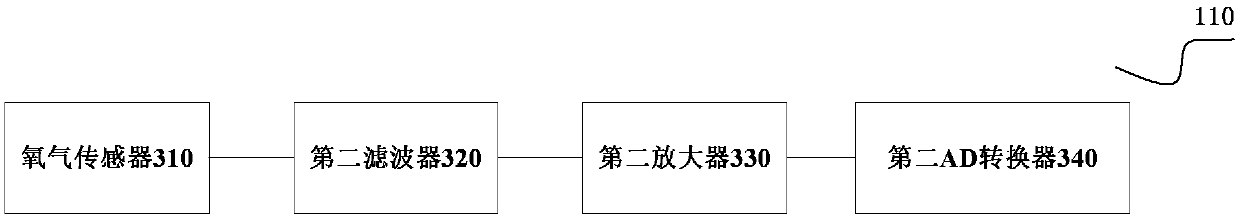

Low air pressure experiment device capable of setting and automatically controlling air pressure and oxygen content

ActiveCN109620597AEliminate the effects ofThe test result is accurateBreathing protectionTreatment roomsAutomatic controlPressure experiment

The invention discloses a low air pressure experiment device capable of setting and automatically controlling the air pressure and oxygen content. The device comprises a closed observation container,an oxygen detector, an oxygen storage container, a one-way electromagnetic valve, a pressure detector, an air pump, a controller, a processor and a control panel. The oxygen detector is connected withthe closed observation container; the one-way electromagnetic valve is connected with the closed observation container and the oxygen storage container separately; the pressure detector is connectedwith the closed observation container; the air pump is connected with the closed observation container; the controller is connected with the one-way electromagnetic valve and the air pump separately;the processor is connected with the controller, the oxygen detector and the pressure detector separately and used for calculating the operation time of the air pump and switch-on and switch-off time of the one-way electromagnetic valve according to the gas pressure value and the oxygen concentration value and sending a calculation result to the controller; the control panel is connected with the processor. According to the device, the low air pressure anaerobic state does not exist any more after air pumping, the low air pressure is maintained, the oxygen content also meets the experiment demand, and accordingly the testing result is more accurate.

Owner:济南昆仲信息科技有限公司 +1

Variable cross-section shock wave induced ultralow-pressure self-ignition experimental device and method

PendingCN113465931AImprove sealingIncrease drive gas pressureGas-turbine engine testingJet-propulsion engine testingPressure experimentFlight vehicle

The invention discloses a variable cross-section shock wave induced ultralow-pressure self-ignition experimental device and method. The variable cross-section shock wave induced ultralow-pressure self-ignition experimental device comprises a high-pressure driving section, a dual-mode membrane breaking mechanism, a conical transition section and a low-pressure experimental section which are coaxially connected in sequence, wherein the high-pressure driving section is coaxially connected with the dual-mode membrane breaking mechanism; the high-pressure driving section and the double-membrane breaking mechanism are separated by a membrane; the double-membrane breaking mechanism is coaxially connected with a small-diameter port of the conical transition section, and the double-membrane breaking mechanism and the conical transition section are blocked by a membrane; the large-diameter port of the conical transition section is coaxially connected with the low-pressure experiment section, high-strength shock waves generated by a traditional shock tube can be matched, the defect that the traditional shock tube cannot stably block the high-pressure driving section and the low-pressure experiment section can be overcome, and accurate measurement of ultralow-pressure self-ignition delay of the near-space aircraft is effectively obtained.

Owner:XI AN JIAOTONG UNIV

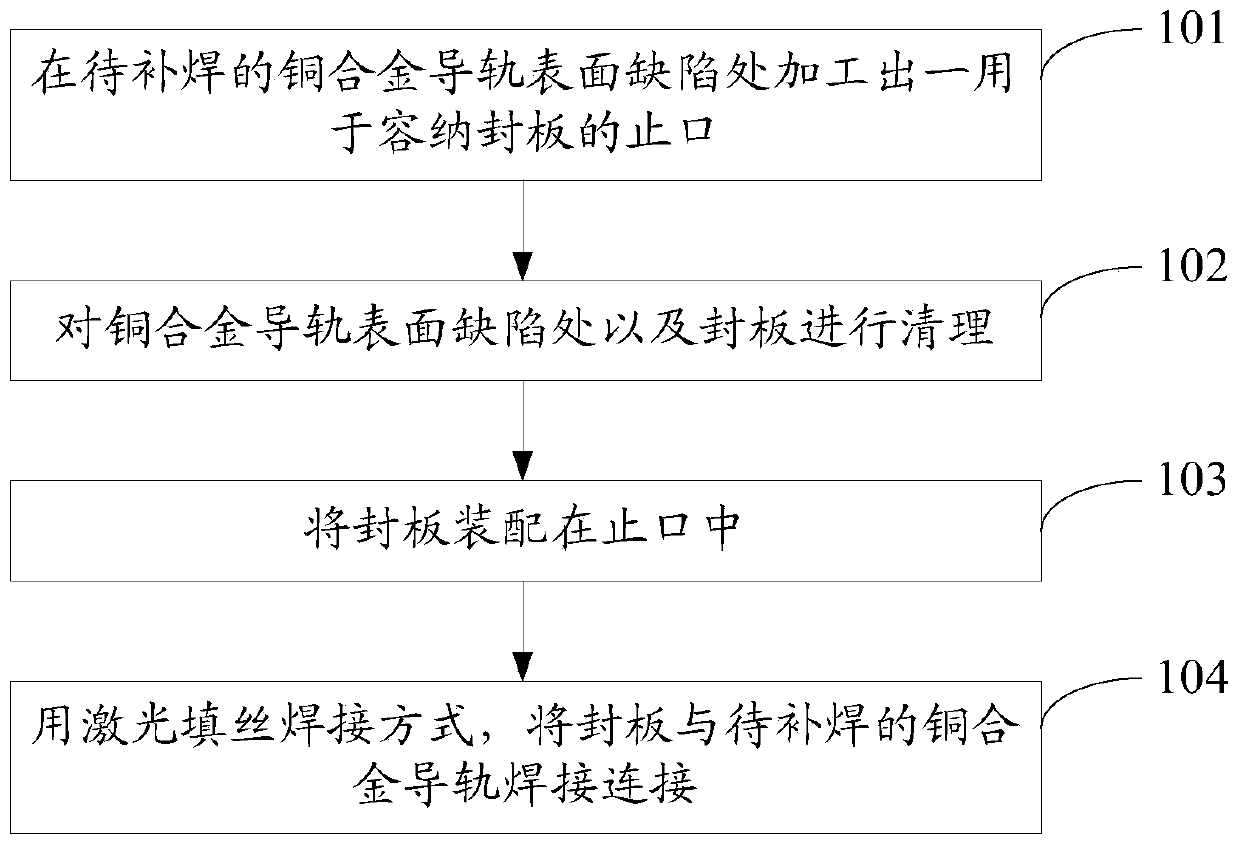

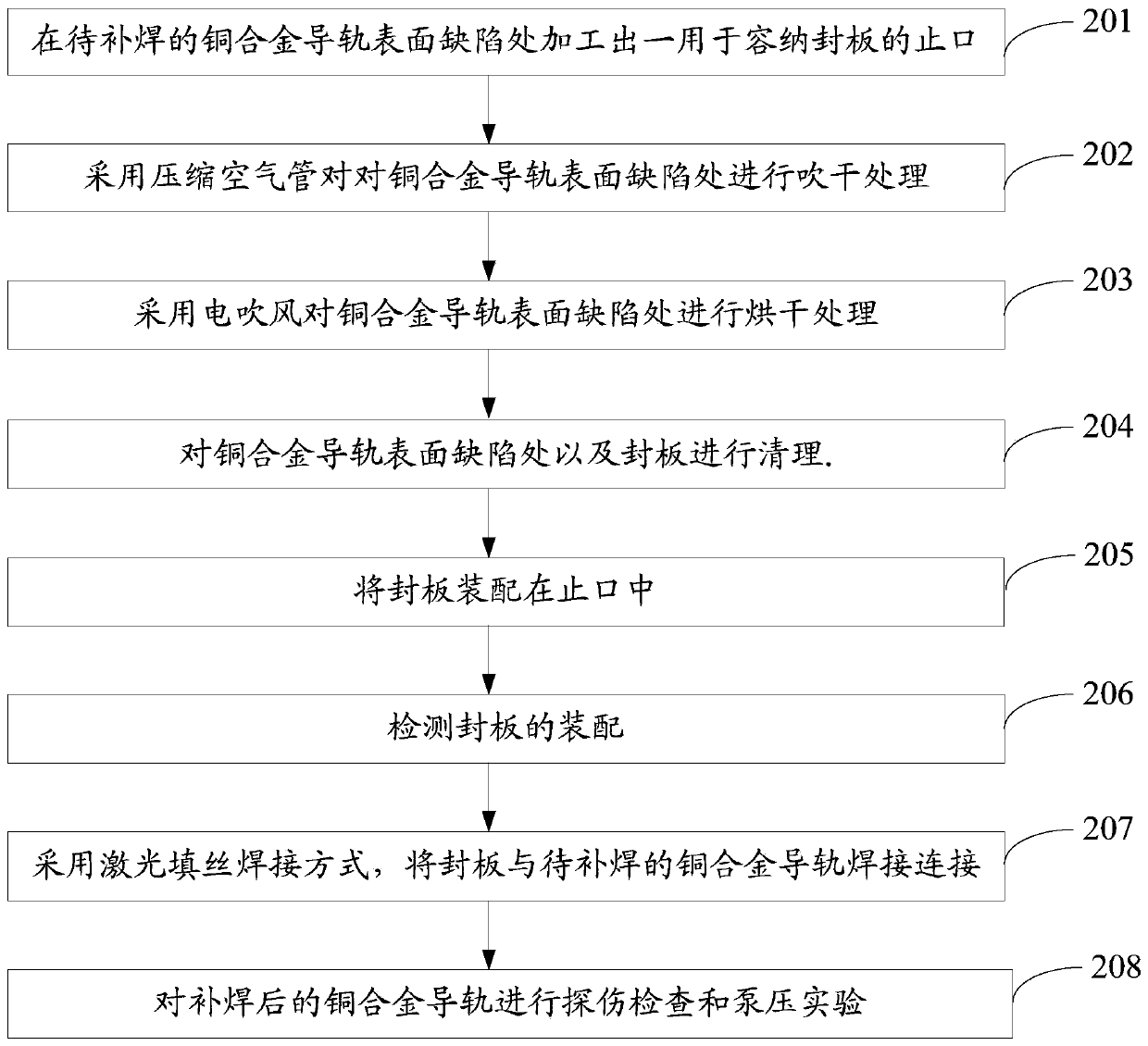

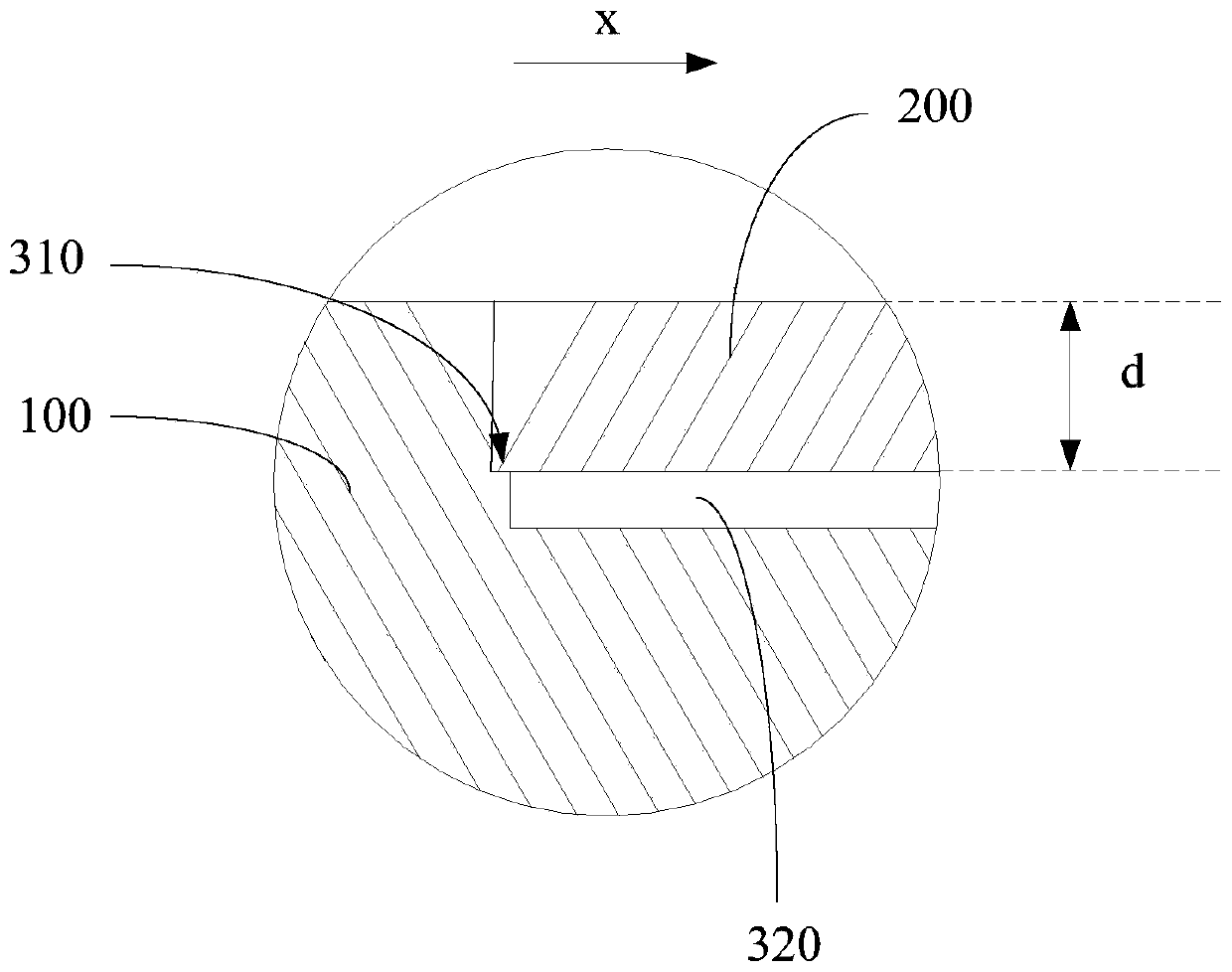

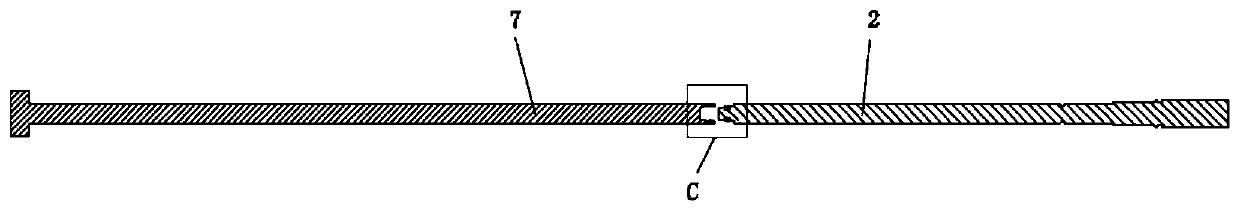

Repair welding method of copper alloy guide rail

InactiveCN110434468AMeet the pump pressure test requirementsReduce assembly clearanceRailsWelding/soldering/cutting articlesHydrogenPressure experiment

The invention discloses a repair welding method of a copper alloy guide rail, and belongs to the technical field of welding. The repair welding method comprises the following steps of machining a spigot for containing a sealing plate at the surface defect of a copper alloy guide rail to be repaired; cleaning the surface defect and the sealing plate of the copper alloy guide rail; assembling the sealing plate in the spigot; and welding the sealing plate with the copper alloy guide rail to be welded by adopting a laser filler wire welding mode. The sealing plate and the copper alloy guide rail are welded by adopting a laser filler wire welding mode, the laser welding speed is high, the welding depth is deeper, and the deformation amount generated by welding is small. Meanwhile, in the welding process, the solubility of hydrogen in the copper alloy increases sharply along with the increase of the temperature of a molten pool, bubbles exist at the root of a weld joint, the spigot is machined at the defect, so that the bubbles can be discharged from a gap between the spigot and the bottom surface of the defect position, so that the quality of the weld joint can be improved, and the pumping pressure experiment requirements of the copper alloy guide rail after repair welding are met.

Owner:WUHAN MARINE MACHINERY PLANT

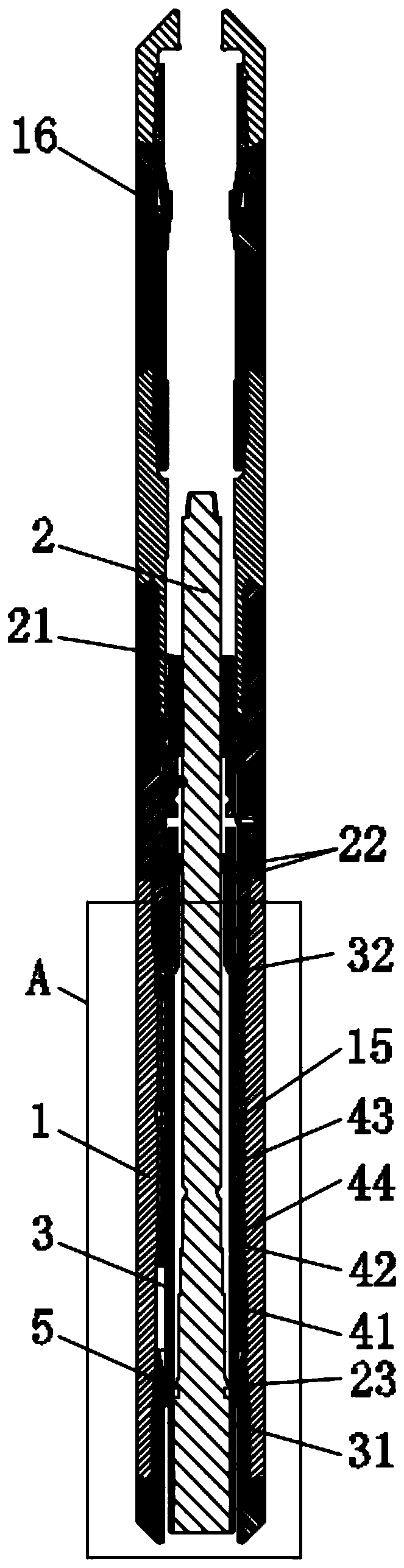

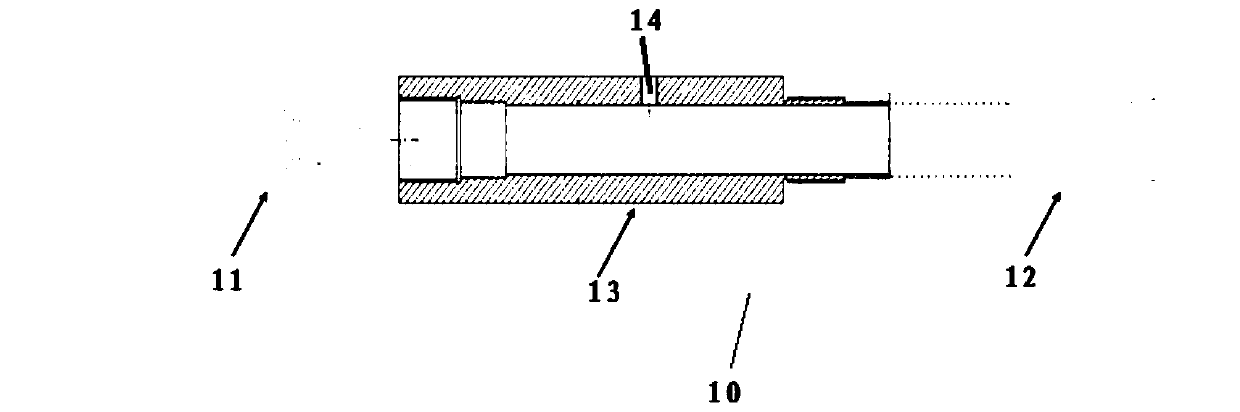

Quick-connection type center rod pulling structure and split type fidelity corer pressure experiment structure

PendingCN111577185AQuick dockingEasy to operateCore removalNuclear energy generationButt jointPressure experiment

The invention relates to a quick-connection type center rod pulling structure and a split type fidelity corer pressure experiment structure. The quick-connection type center rod pulling structure comprises a pull rod, a center rod and a quick inserting structure, wherein the quick inserting structure comprises a plug part, an inserting hole part and at least two spring buckles; the plug part and the inserting hole part are connected with one of the pull rod and the center rod respectively; and the plug part and the inserting hole part can be axially clamped and fixed through the spring buckles. Each spring buckle comprises a clamping block and a spring which is arranged in the radial direction; a groove for avoiding the clamping block is formed in an outer side wall of the plug part; an inclined plane is arranged at the outer side of the clamping block; when the plug part is inserted into the inserting hole part, the inserting hole part acts on the inclined plane and axial force can generate radial component force; and the clamping block is pushed to move in the radial direction until the clamping block is completely immersed into the groove. The quick-connection type center rod pulling structure is simple to operate and can realize rapid butt joint of the center rod and the pull rod, so that the working efficiency is conveniently improved; and a middle connection piece is usedfor connecting the upper end and the lower end of a pressure maintaining experiment cabin, so that a condition that holes are drilled in the pressure maintaining experiment cabin can be avoided and damages to the pressure maintaining experiment cabin are prevented.

Owner:SICHUAN UNIV

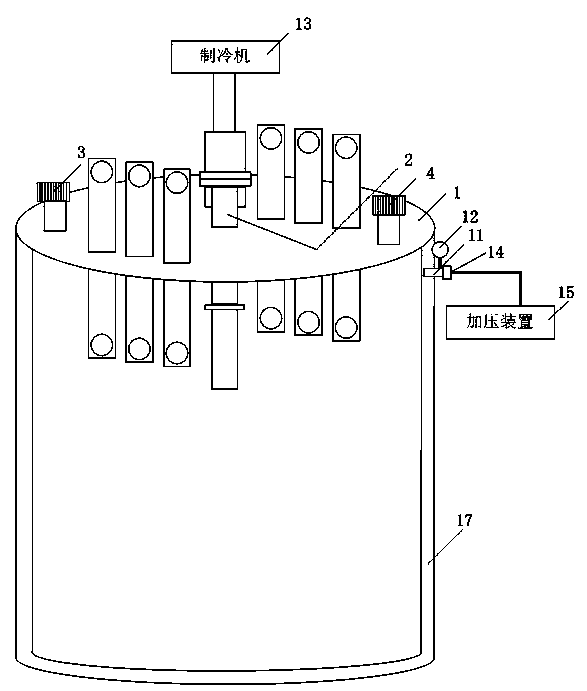

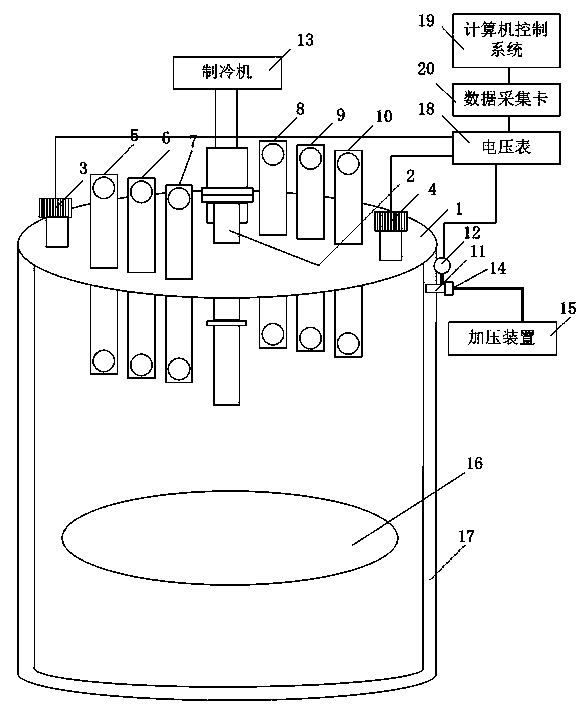

Low-temperature container capable of achieving temperature changing and pressure changing

ActiveCN103713220AEasy to testThe testing process is simpleElectrical testingPotential measurementTest efficiency

The invention provides a low-temperature container capable of achieving temperature changing and pressure changing. The low-temperature container comprises a low-temperature container body used for containing liquid nitrogen and providing a low-temperature environment needed by superconductive belt material tests, a flange used for sealing the low-temperature container body and allowing a measurement line to be led out from the inside of the low-temperature container body, a refrigerator arranged on the flange and used for carrying out low-temperature refrigeration on the low-temperature container body, a high-voltage wire leading-out end and a low-voltage wire leading-out end which are arranged on the flange and used for leading out a high potential measurement lead and a low potential measurement lead respectively, a pressurization device used for generating different pressure in the low-temperature container body, a pressurization port used for connecting the low-temperature container body with the pressurization device, and a pressure meter used for testing pressure in the low-temperature container body. According to the low-temperature container, temperature changing and pressure changing experiment conditions can be provided simultaneously, convenience is brought for the superconductive belt material tests, test accuracy is improved, the test process is easier and test efficiency is improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com