Patents

Literature

112results about How to "Reduce assembly clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

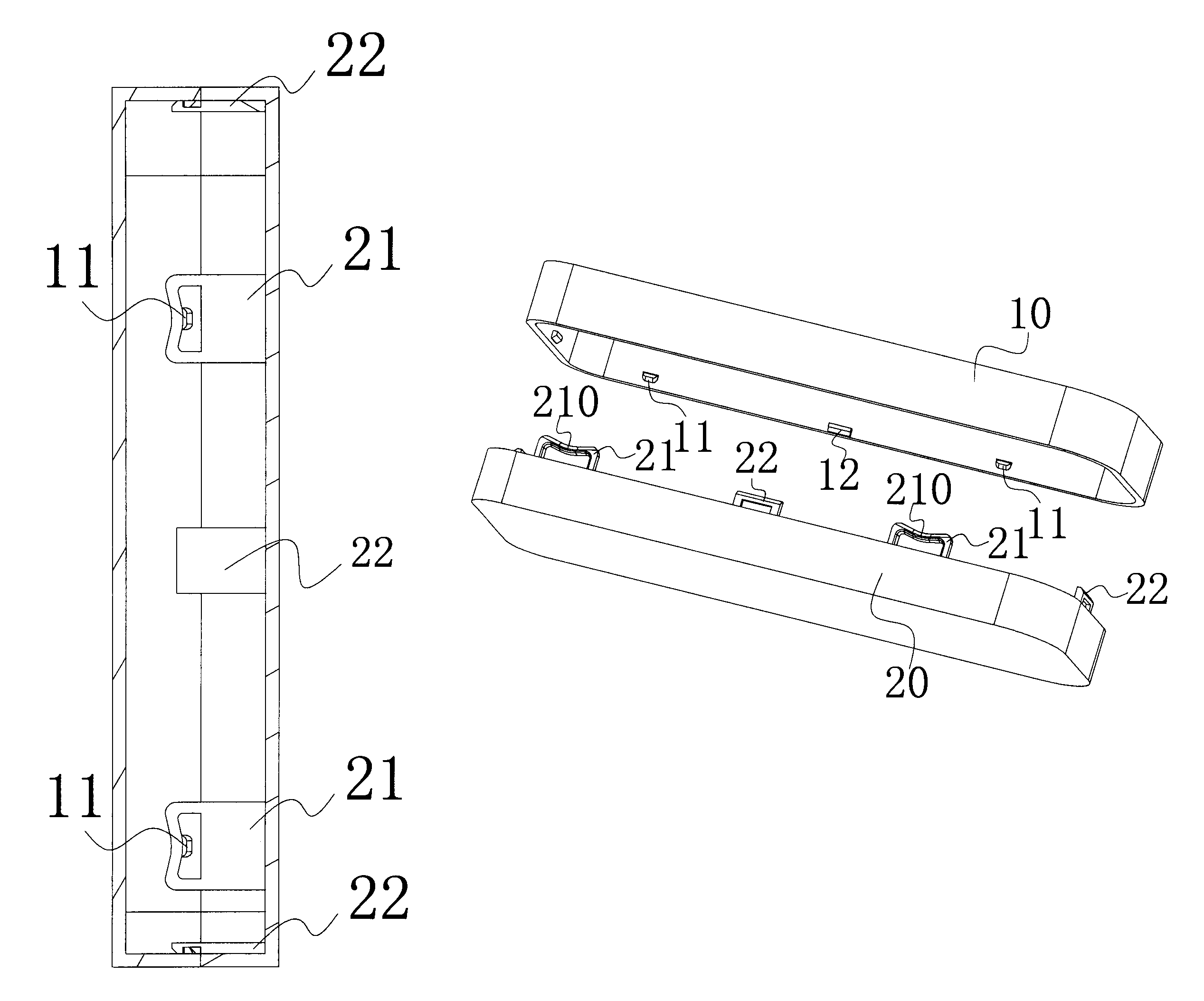

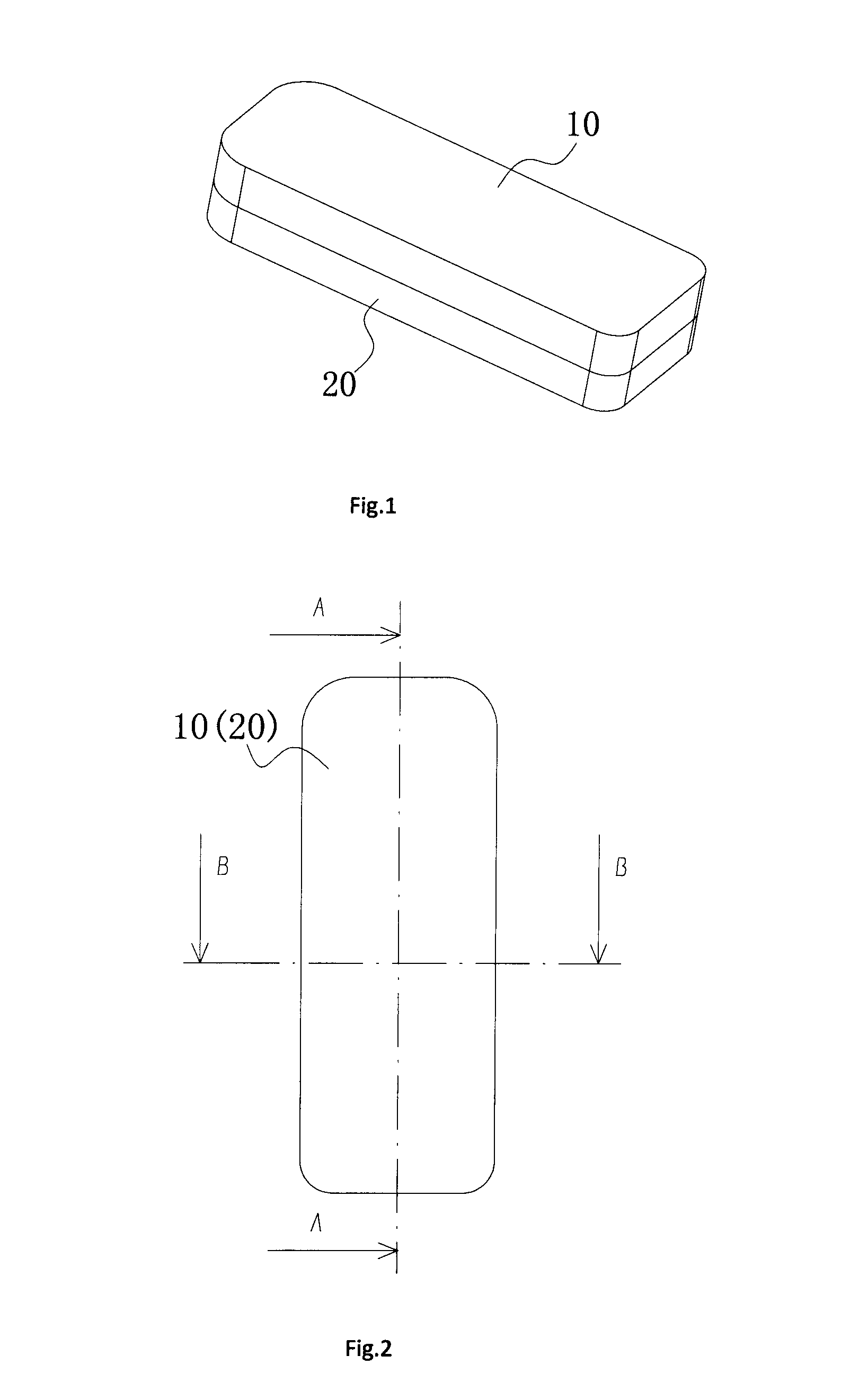

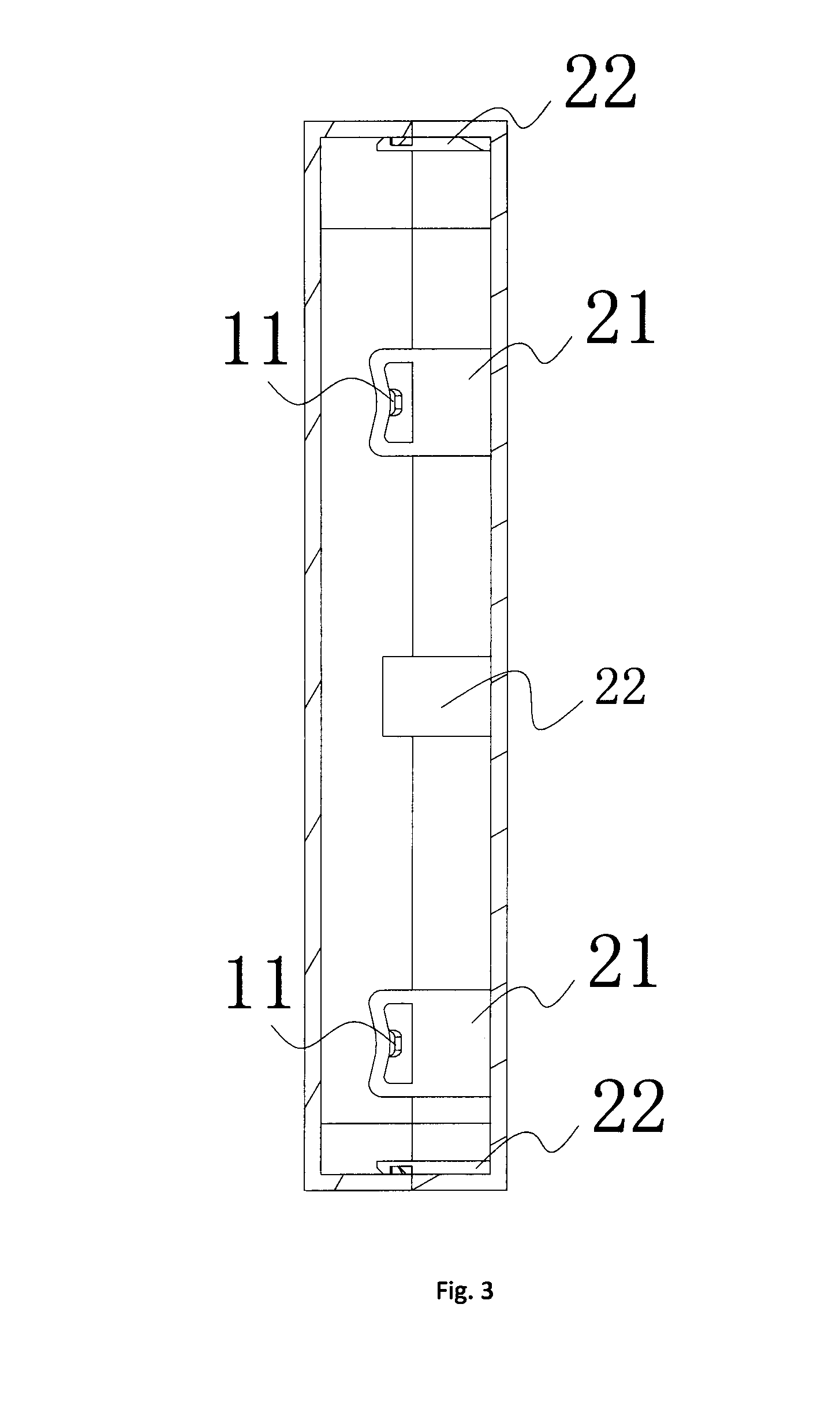

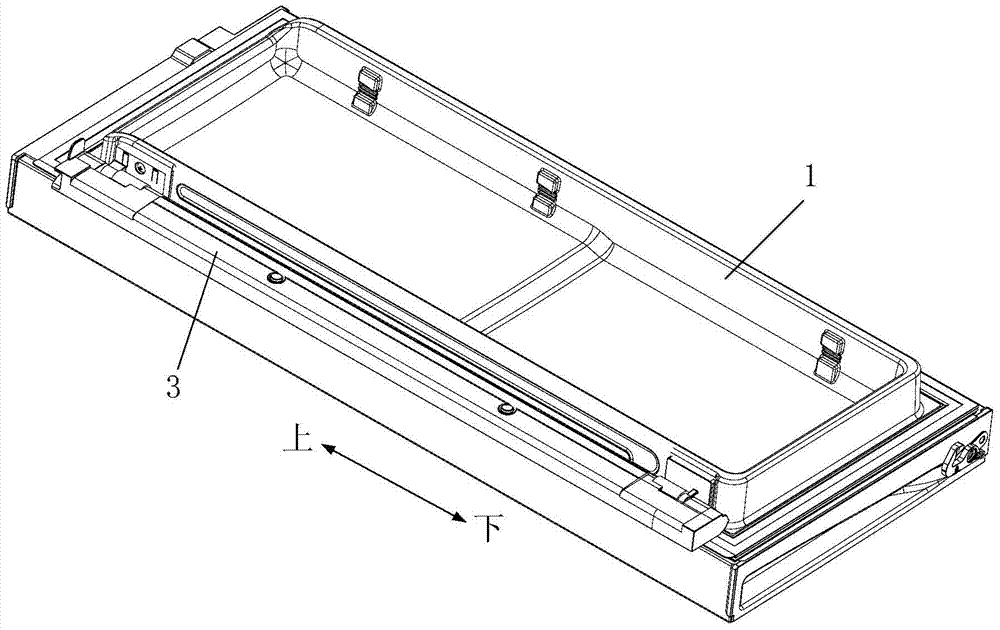

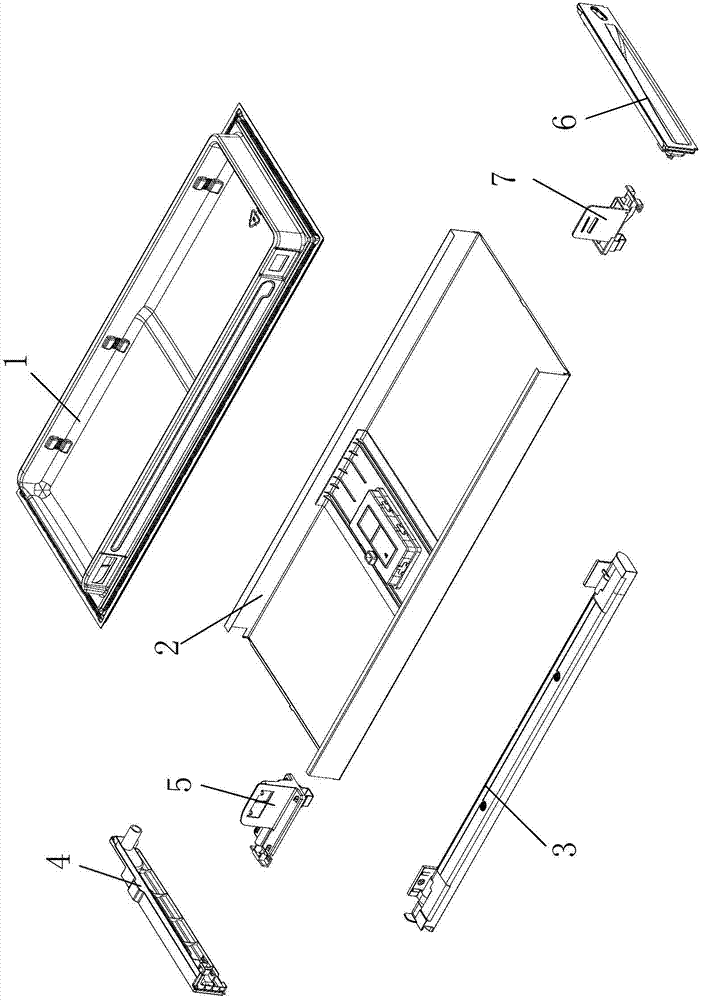

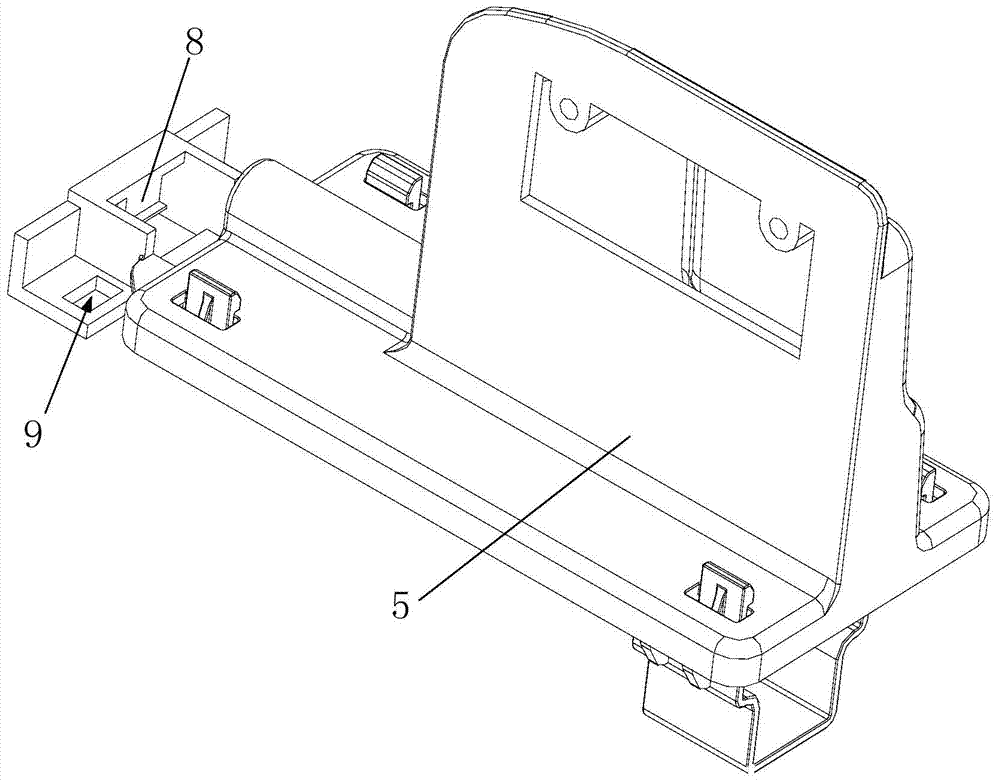

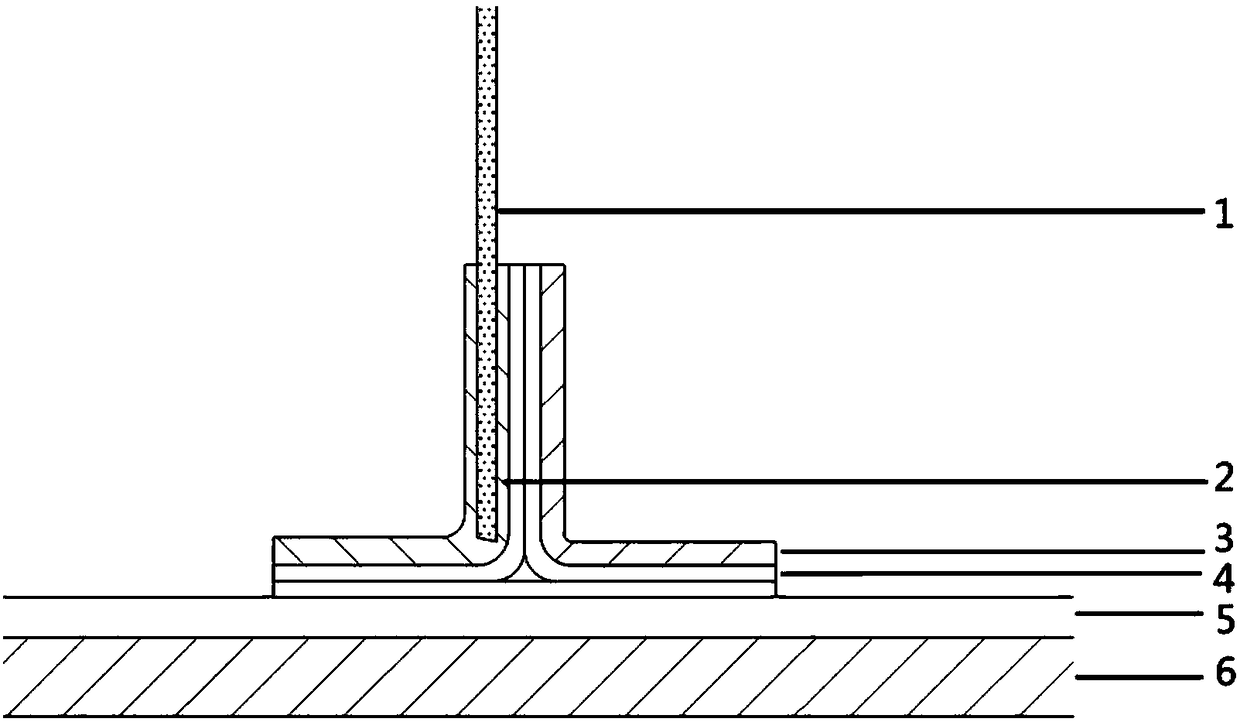

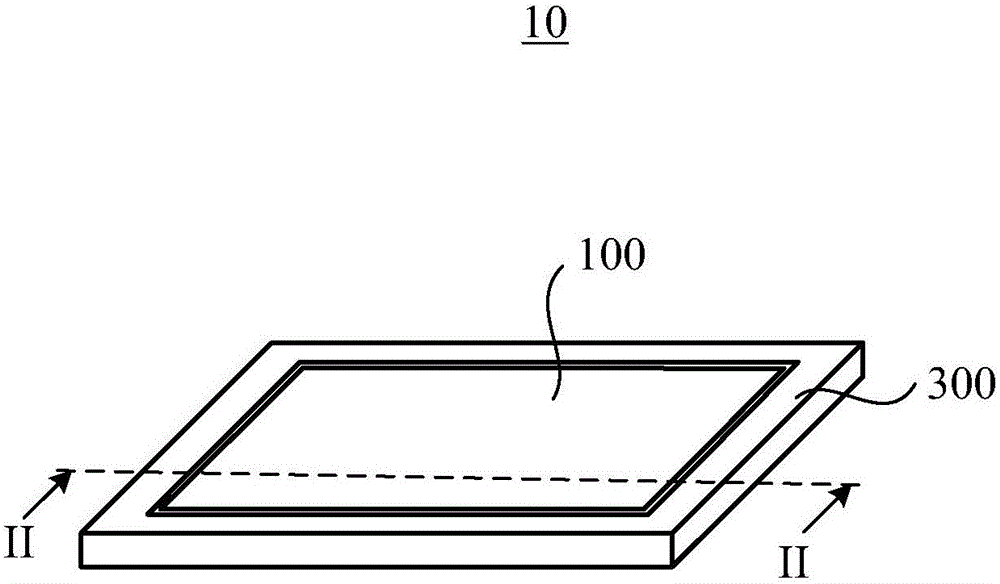

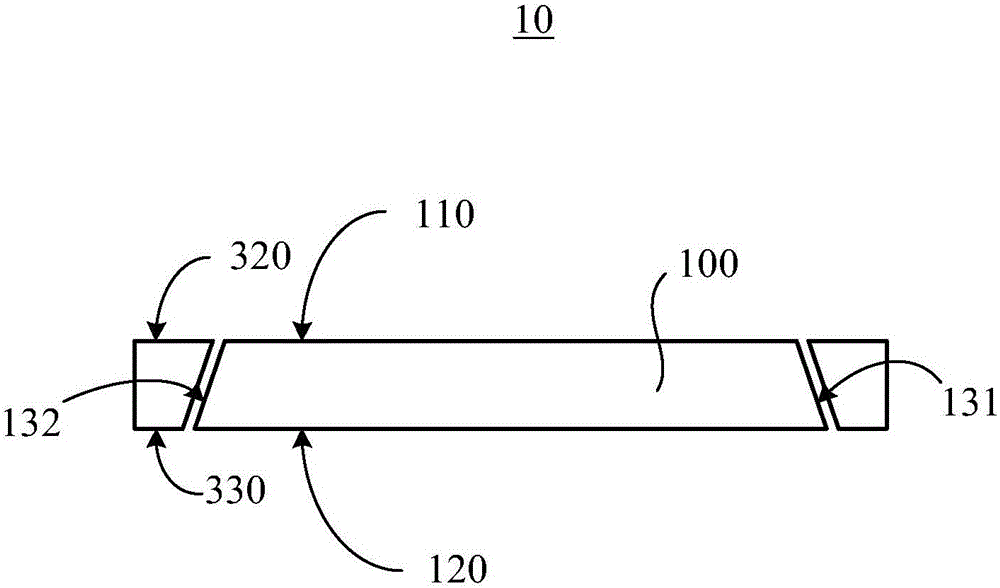

Shell assembling device and shell having the same

ActiveUS8480186B2Disadvantageous effect of tolerance can be eliminatedAssembly clearanceClosed casingsRopes and cables for vehicles/pulleyBiomedical engineering

Owner:BYD CO LTD

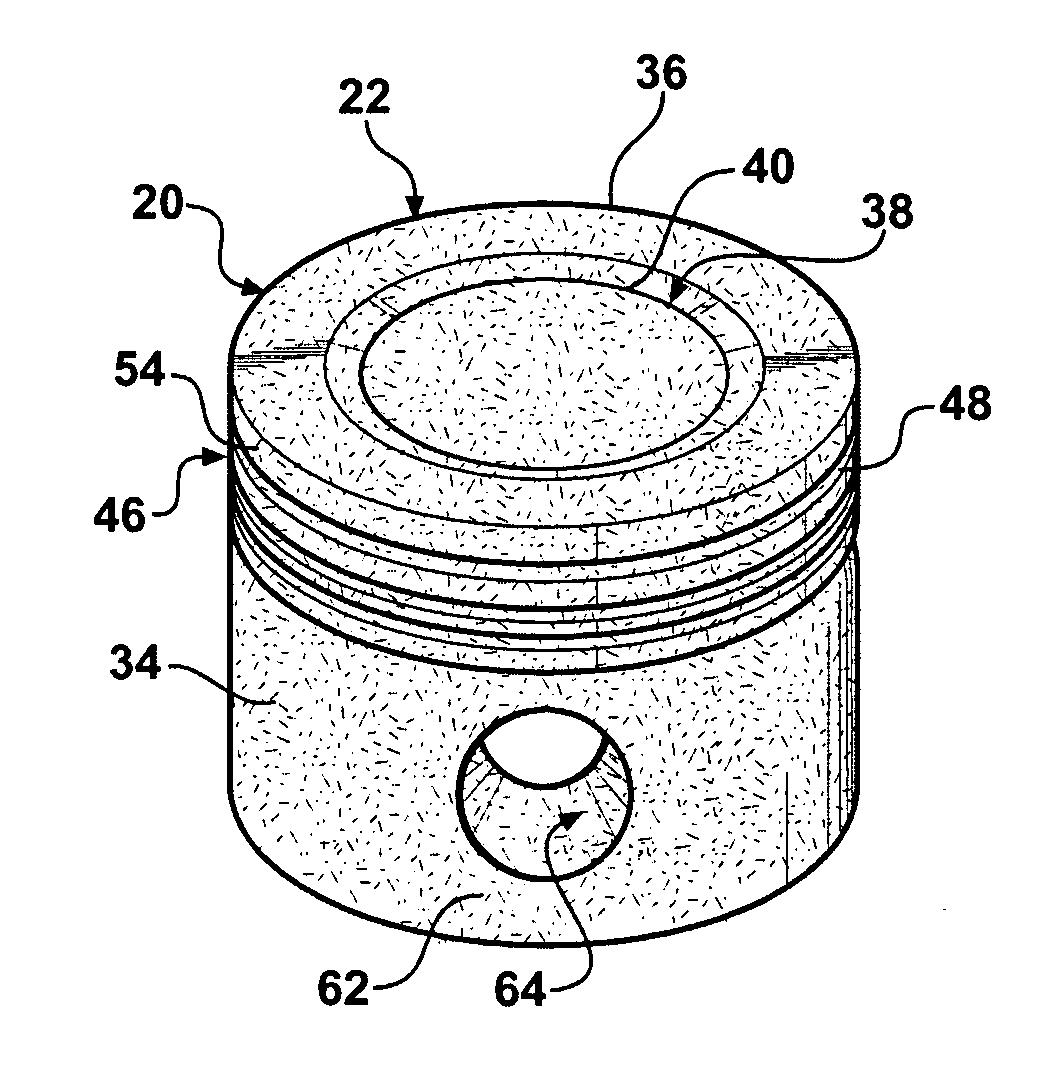

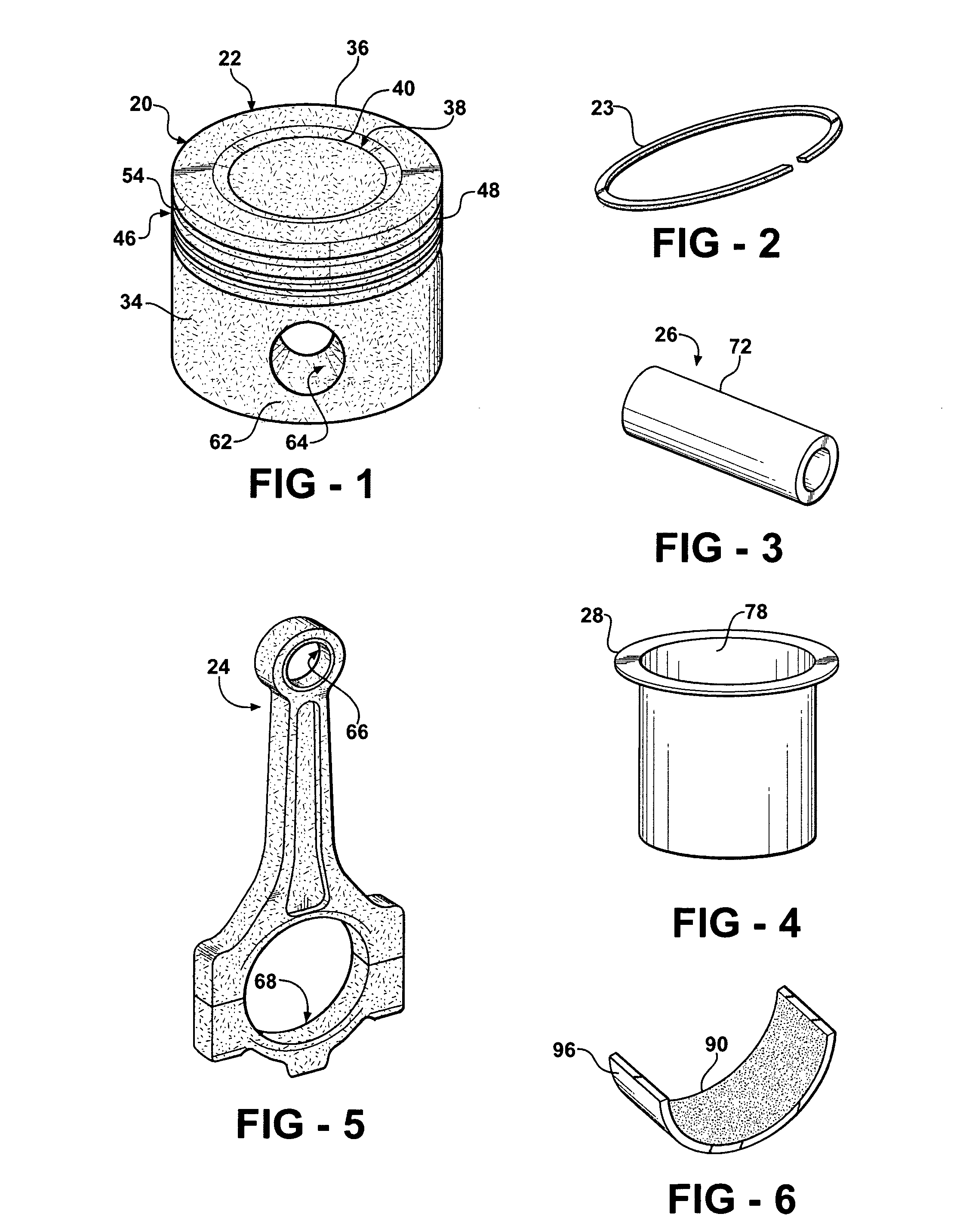

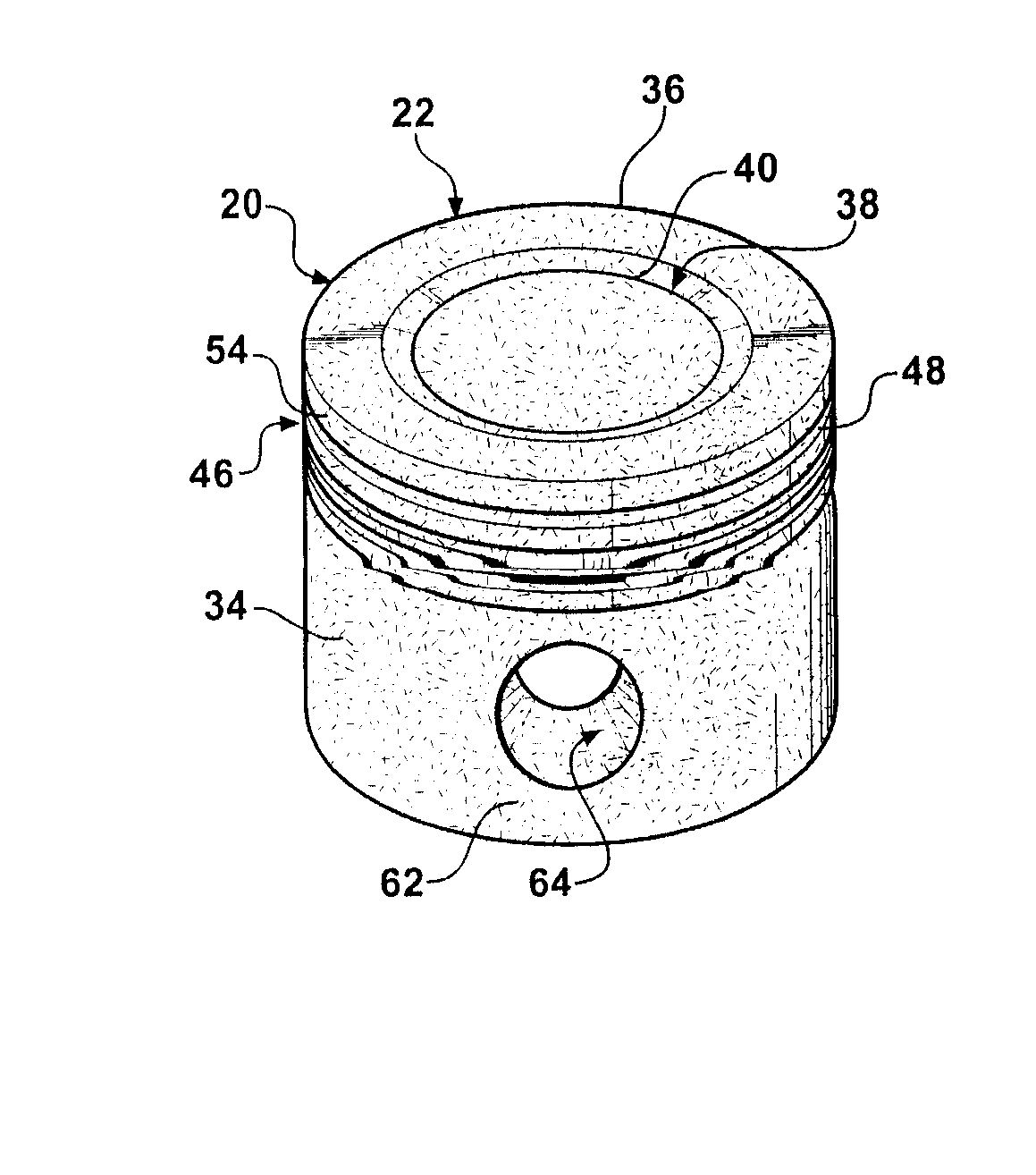

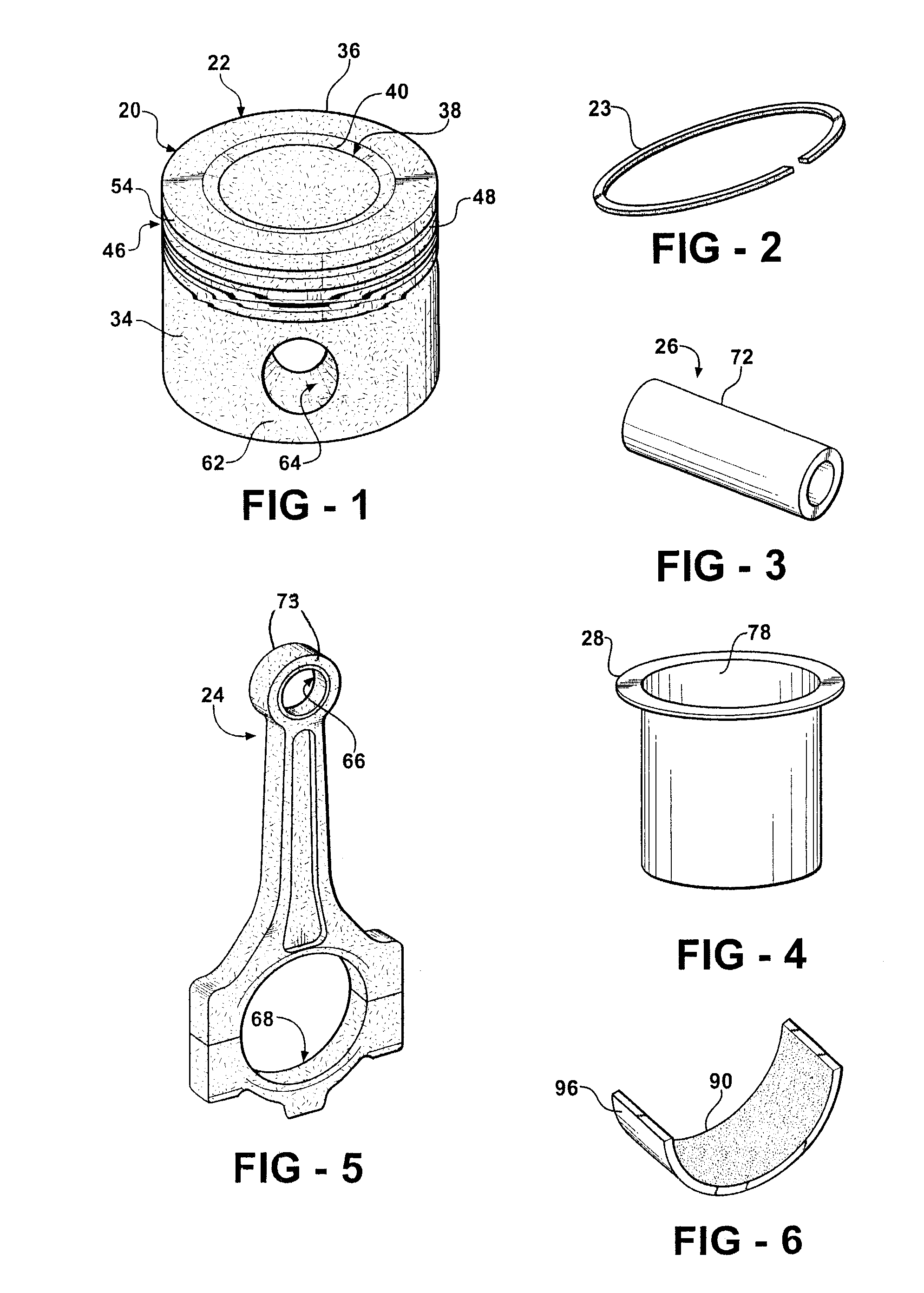

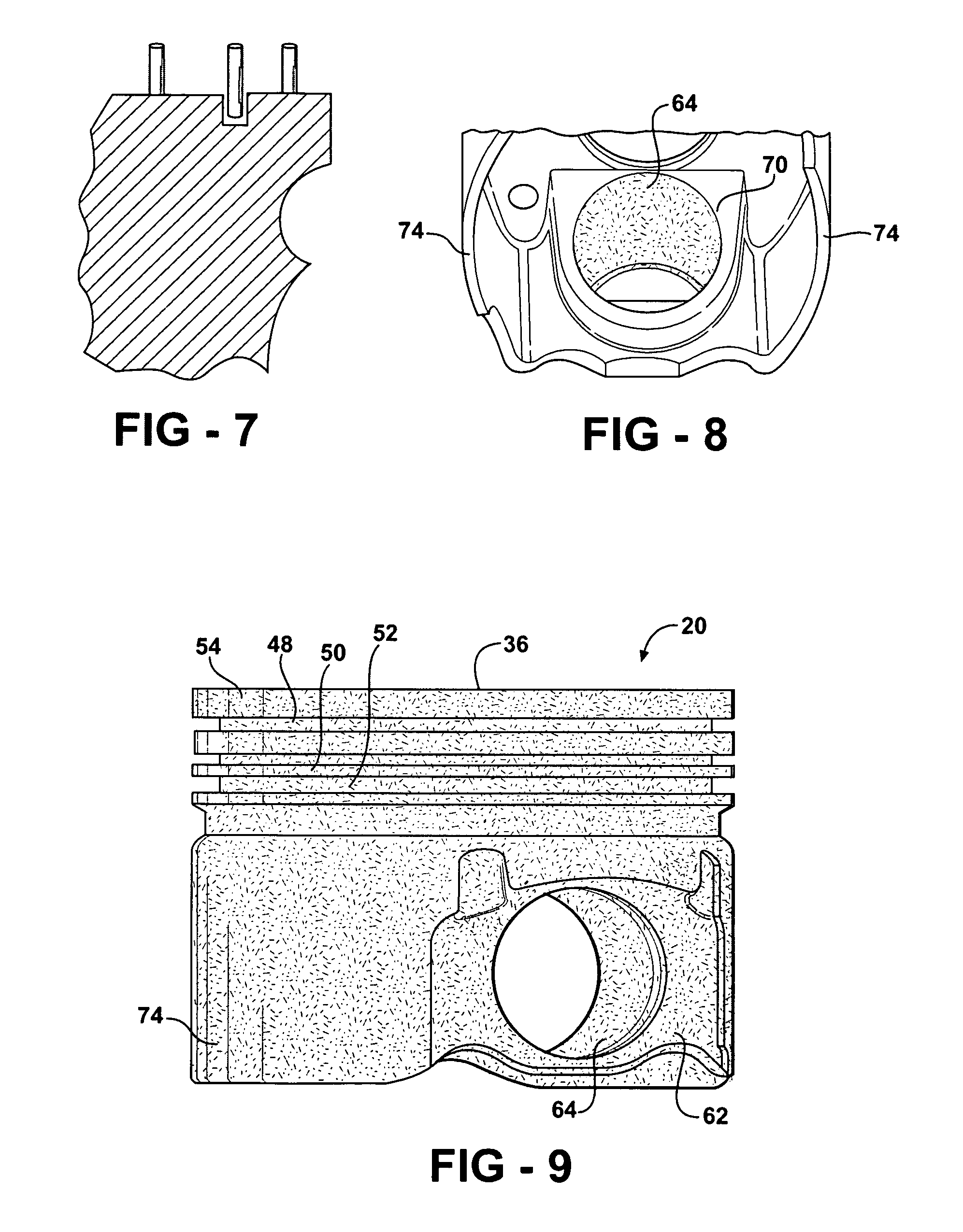

Coated power cylinder components for diesel engines

A diesel engine piston assembly comprises a piston body having a top wall with a combustion bowl formed in the top wall and having a combustion bowl edge, an outer ring belt formed with a plurality of ring grooves including a top ring groove with an upper wall of the top ring groove and a top land portion of the ring belt disposed between the top ring groove and the top wall, a pair of pin bosses with aligned pin bores and a skirt; and a diamond dispersed chromium composite coating applied to at least the top wall, the combustion bowl edge, the top land portion and the upper wall of the top ring groove.

Owner:FEDERAL MOGUL WORLD WIDE LLC

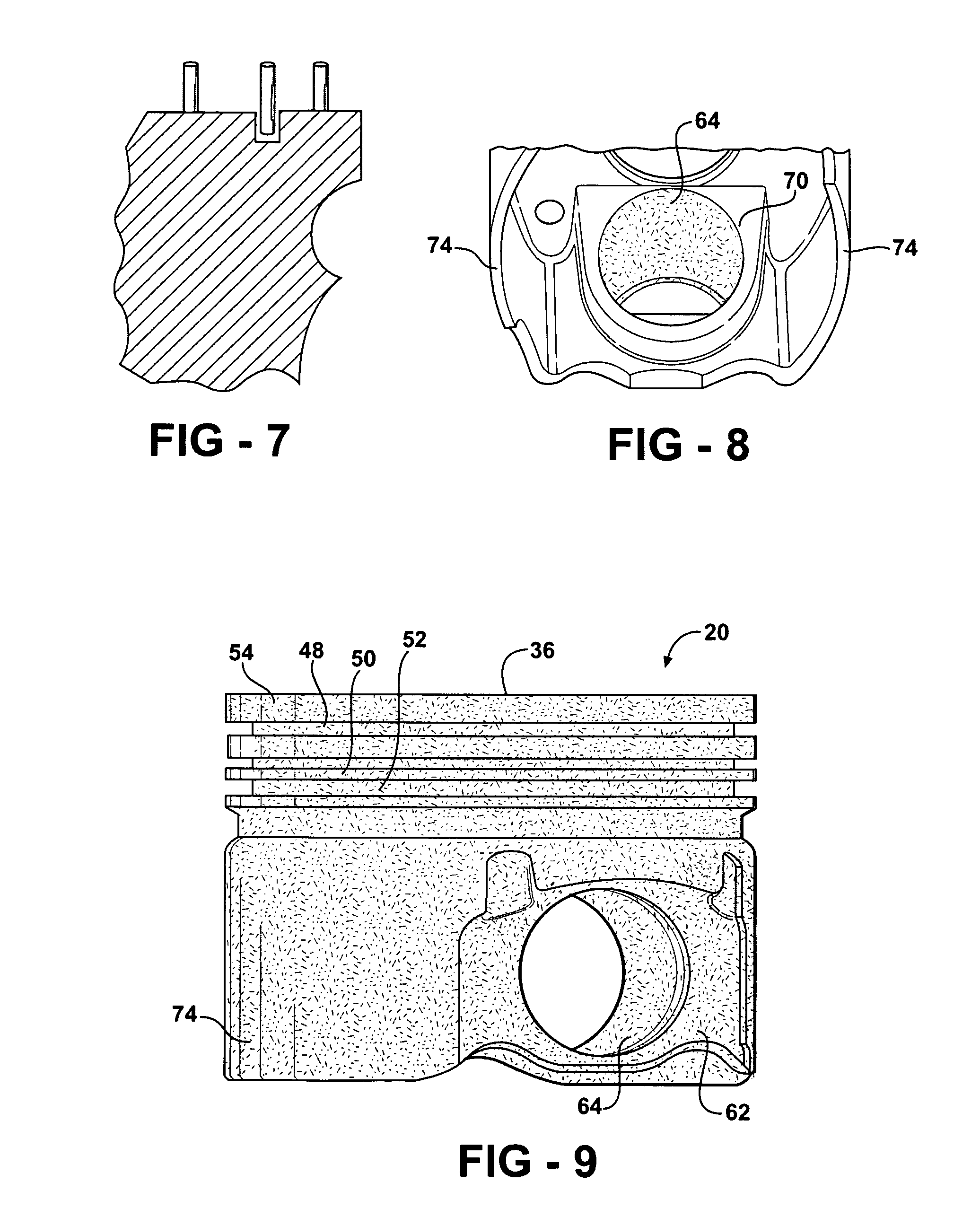

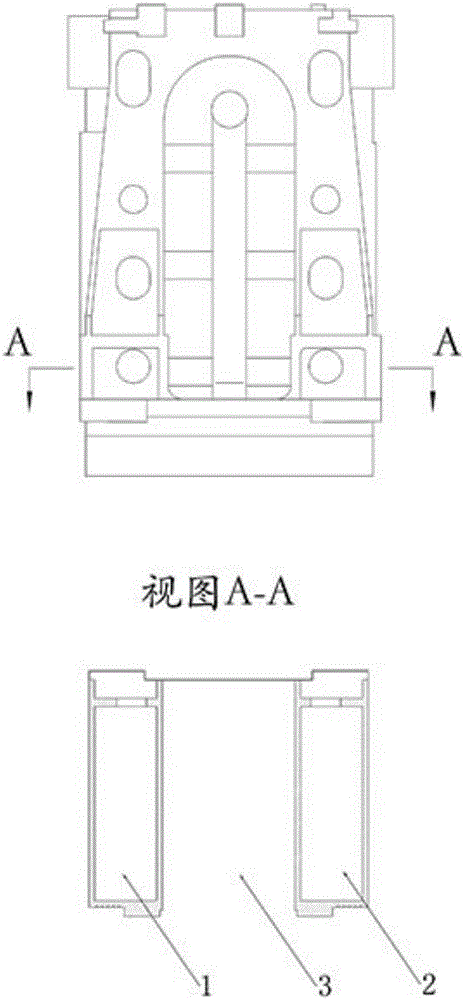

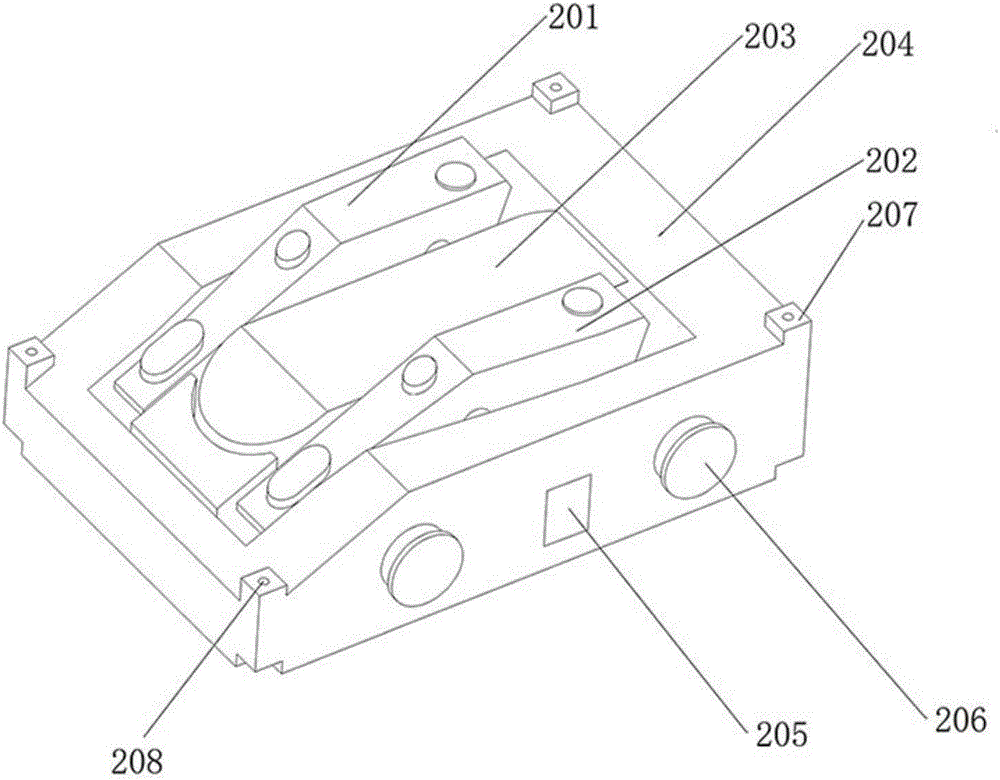

Sand mould used for casting machine tool double-arm vertical column casting and manufacturing method of sand mould

ActiveCN106670383AReduce in quantityAvoid increased technical deficienciesAdditive manufacturing apparatusFoundry mouldsMachine toolCasting

The invention provides a sand mould used for casting a machine tool double-arm vertical column casting. The sand mould comprises a first casting mould unit, a second casting mould unit and a third casting mould unit, wherein the first casting mould unit is used for forming the bottom outer outline shape of the machine tool double-arm vertical column casting; the second casting mould unit is used for forming an inner cavity structure, a side wall outer outline and a vertical face outer outline of the machine tool double-arm vertical column casting; the third casting mould unit is used for forming side wall, inclined face and top face outer outline shapes of the machine tool double-arm vertical column casting; the second casting mould unit comprises a left arm moulding part used for moulding a left arm inner cavity structure of the machine tool double-arm vertical column casting, a right arm moulding part used for moulding a right arm inner cavity structure of the machine tool double-arm vertical column casting, a double-arm in-leg moulding part used for moulding a double-arm in-leg inner cavity structure of the machine tool double-arm vertical column casting, and an outer moulding part used for moulding an outer outline structure of the machine tool double-arm vertical column casting. Besides, the invention provides a manufacturing method of the sand mould and an assembling method of the sand mould.

Owner:NINGXIA KOCEL MOLD

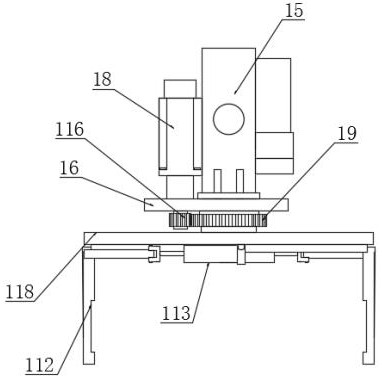

Housing case flanger and use method thereof

ActiveCN104985041AImprove aerodynamic performanceImprove efficiencyMetal-working feeding devicesPositioning devicesImpellerEngineering

The invention discloses a housing case flanger, which comprises an axial feed mechanism, a main shaft box, a clamp device and a rotary pressing device, wherein the clamp device is fixed to the axial feed mechanism; and the rotary pressing device is in transmission connection with the main shaft box. The use method of the housing case flanger comprises the steps of fixing a housing case, rotary pressing a horn mouth, rotary pressing a right-angle side and the like. The housing case flanger and the use method thereof are adopted; through the autorotation of main rotating wheels and auxiliary rotating wheels and the rotation of a turnplate, a horn side and a right-angle side flange of the housing case are subjected to rotary pressing; since the clamp device which internally expands and externally holds is used for fixing the housing case, and the clamp device has an automatic centring rounding function, a necking-down phenomenon cannot happen to an opening of the housing case in the rotary pressing process, an assembling clearance between the impeller outer diameter of a draught fan which is finally assembled and the inner wall of the housing case can be reduced, and the aerodynamic performance and the efficiency of the draught fan are improved.

Owner:ZHEJIANG SHANGFENG SPECIAL BLOWER IND CO LTD

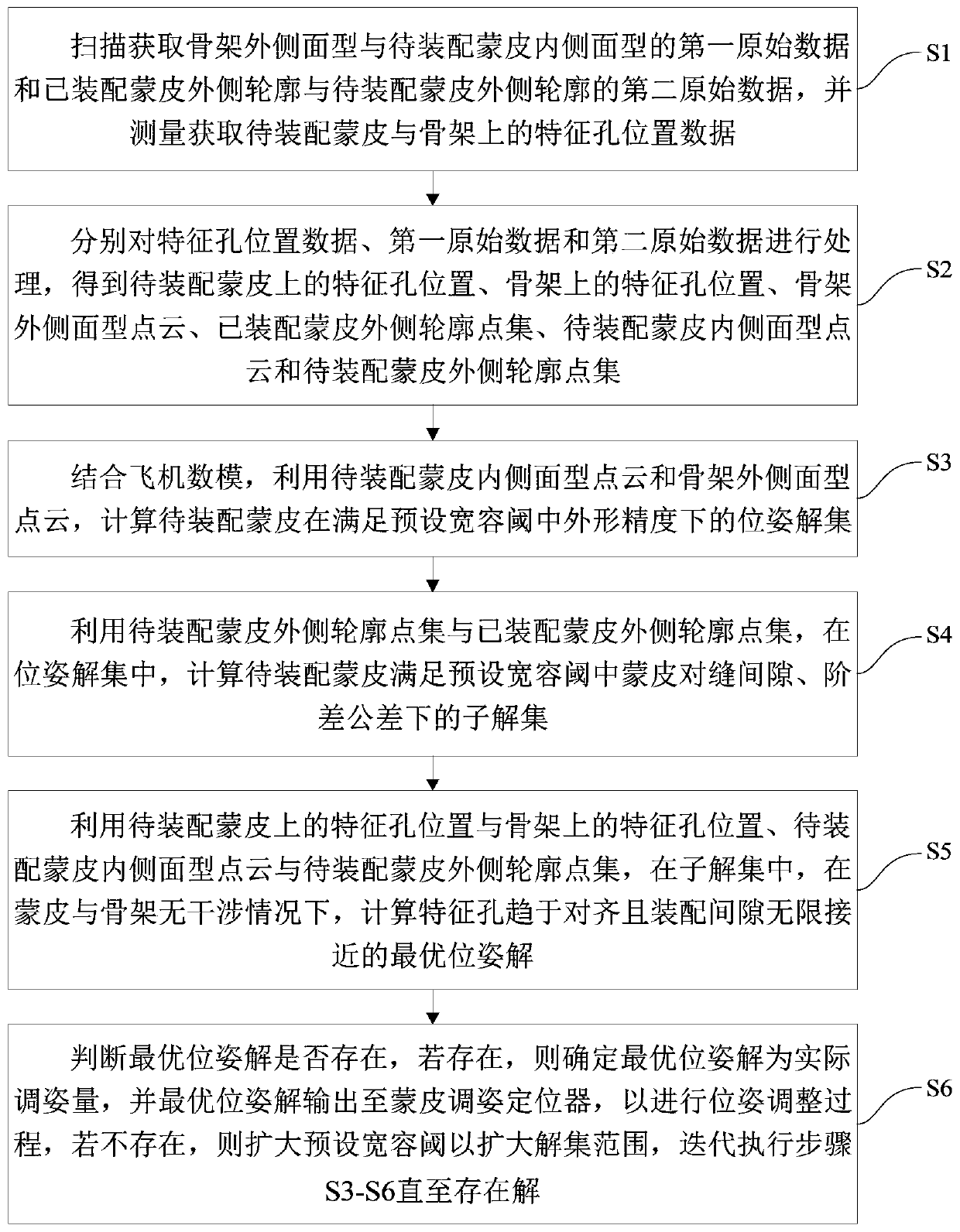

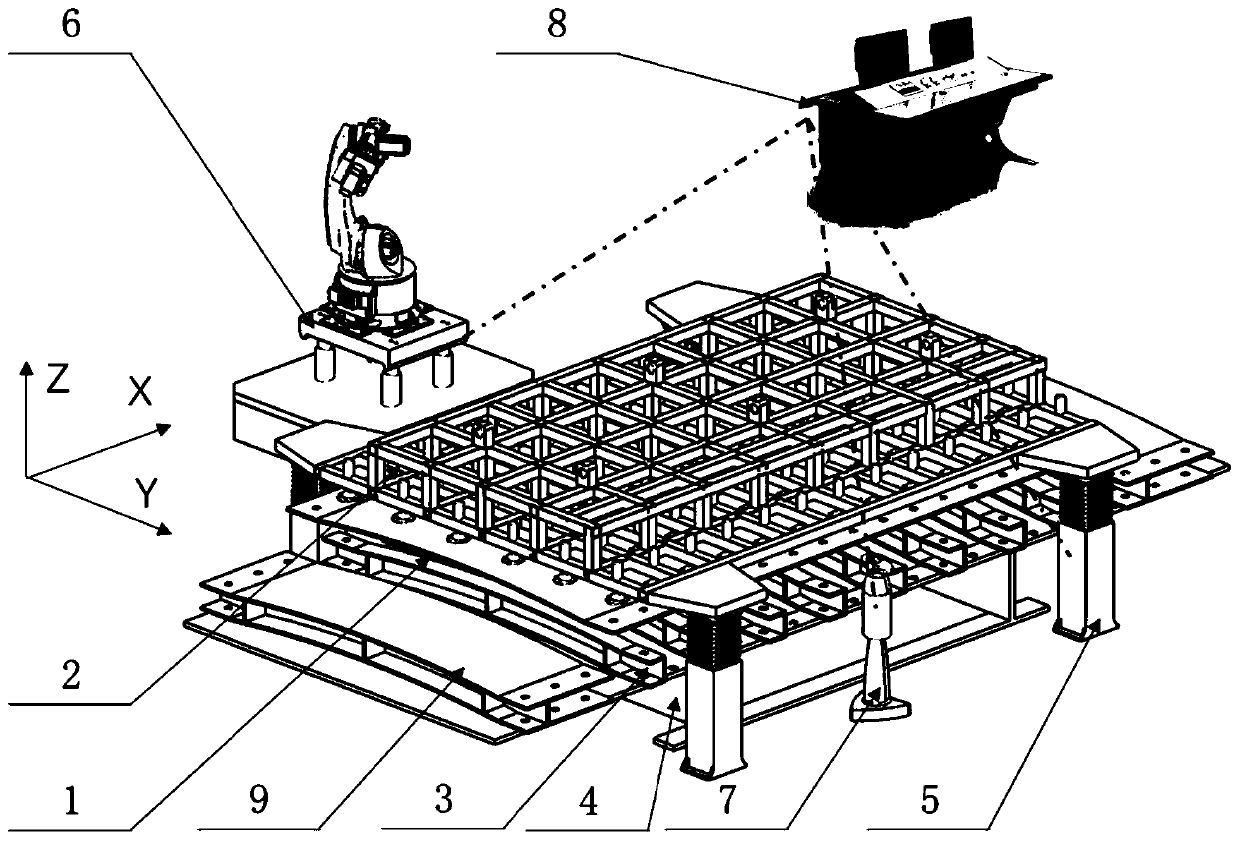

Multi-constraint-condition aircraft skin attitude adjustment method and system

ActiveCN111137468AGuaranteed shape accuracyReduce assembly clearanceAircraft assemblyEngineeringComputer vision

The invention discloses a multi-constraint-condition aircraft skin attitude adjustment method and system. The method comprises the steps: acquiring related position data of a skeleton and inner and outer sides of an assembled skin / a to-be-assembled skin; processing the data to obtain a feature hole position on the to-be-assembled skin, a feature hole position on the skeleton, an outer side surfacetype of the skeleton, an inner side surface type point cloud of the to-be-assembled skin and an outer side contour point set of the to-be-assembled skin; calculating a pose solution set of the to-be-assembled skin under the condition of meeting a tolerance threshold by using the point cloud; enabling the point set to be in the pose solution set, and calculating a sub-solution set, under the condition of meeting a tolerance threshold, of the to-be-assembled skin; calculating an optimal pose solution with an infinitely small assembly gap in the sub-solution set by utilizing the positions of thefeature holes, the inner side point cloud and the point sets of the outer side contour of the to-be-assembled skin; and judging whether the optimal pose solution exists or not, if so, carrying out apose adjustment process according to the solution, otherwise, expanding a tolerance threshold, and iterating the process until the solution exists. With the method, the docking task requirement can bemet on the premise of multi-tolerance constraint.

Owner:TSINGHUA UNIV

Coated power cylinder components for diesel engines

A diesel engine piston assembly comprises a piston body having a top wall with a combustion bowl formed in the top wall and having a combustion bowl edge, an outer ring belt formed with a plurality of ring grooves including a top ring groove with an upper wall of the top ring groove and a top land portion of the ring belt disposed between the top ring groove and the top wall, a pair of pin bosses with aligned pin bores and a skirt; and a diamond dispersed chromium composite coating applied to at least the top wall, the combustion bowl edge, the top land portion and the upper wall of the top ring groove.

Owner:FEDERAL MOGUL WORLD WIDE LLC

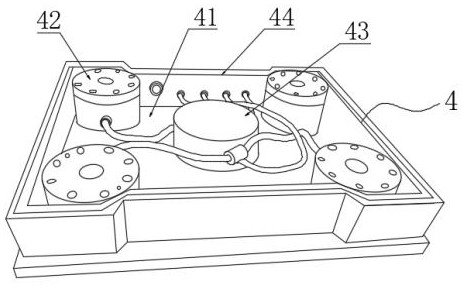

Intelligent production line for part manufacturing and working method thereof

ActiveCN112108929AFully automatedLarge locking forceMeasurement/indication equipmentsMetal working apparatusProduction lineRobot hand

The invention discloses an intelligent production line for part manufacturing and a working method thereof. The intelligent production line comprises a loading and unloading mechanism, a conveying mechanism, a production mechanism and a tray mechanism, wherein the conveying mechanism comprises a fixing frame and a truss rail which is fixed to the upper side of the fixing frame; the surface of thetruss rail is slidably connected with a mechanical arm assembly; and an inner cavity of the mechanical arm assembly is slidably connected with a lifting mechanical arm. The invention relates to the technical field of part machining. According to the intelligent production line for part manufacturing and the working method thereof, it is achieved that different parts are machined on a same device on the premise that a clamping way and cutting tools are not changed; by using a zero-point positioning module, the machined workpiece is fixed to a clamping tray; a truss robot grabs the clamping trayto place the clamping tray on a clamping base well fixed on a CNC machine; it is achieved that loading and unloading of the CNC machine are automatic; an operator clamps the workpiece on a loading table without occupying a machine tool; and it is achieved that one truss robot can be responsible for loading and unloading of multiple CNC machines.

Owner:AVIC POWER SCI & TECH ENG

Shell assembling device and shell having the same

ActiveUS20120043867A1Disadvantageous effect of tolerance can be eliminatedAssembly clearanceClosed casingsRopes and cables for vehicles/pulleyEngineering

Owner:BYD CO LTD

Refrigerator door body

ActiveCN104236226AImprove insulation effectSmall sizeDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

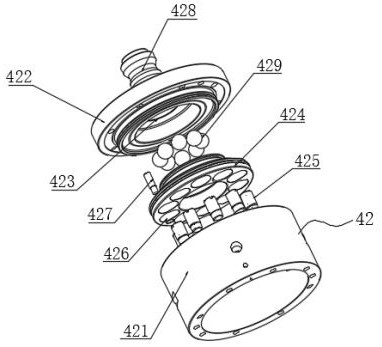

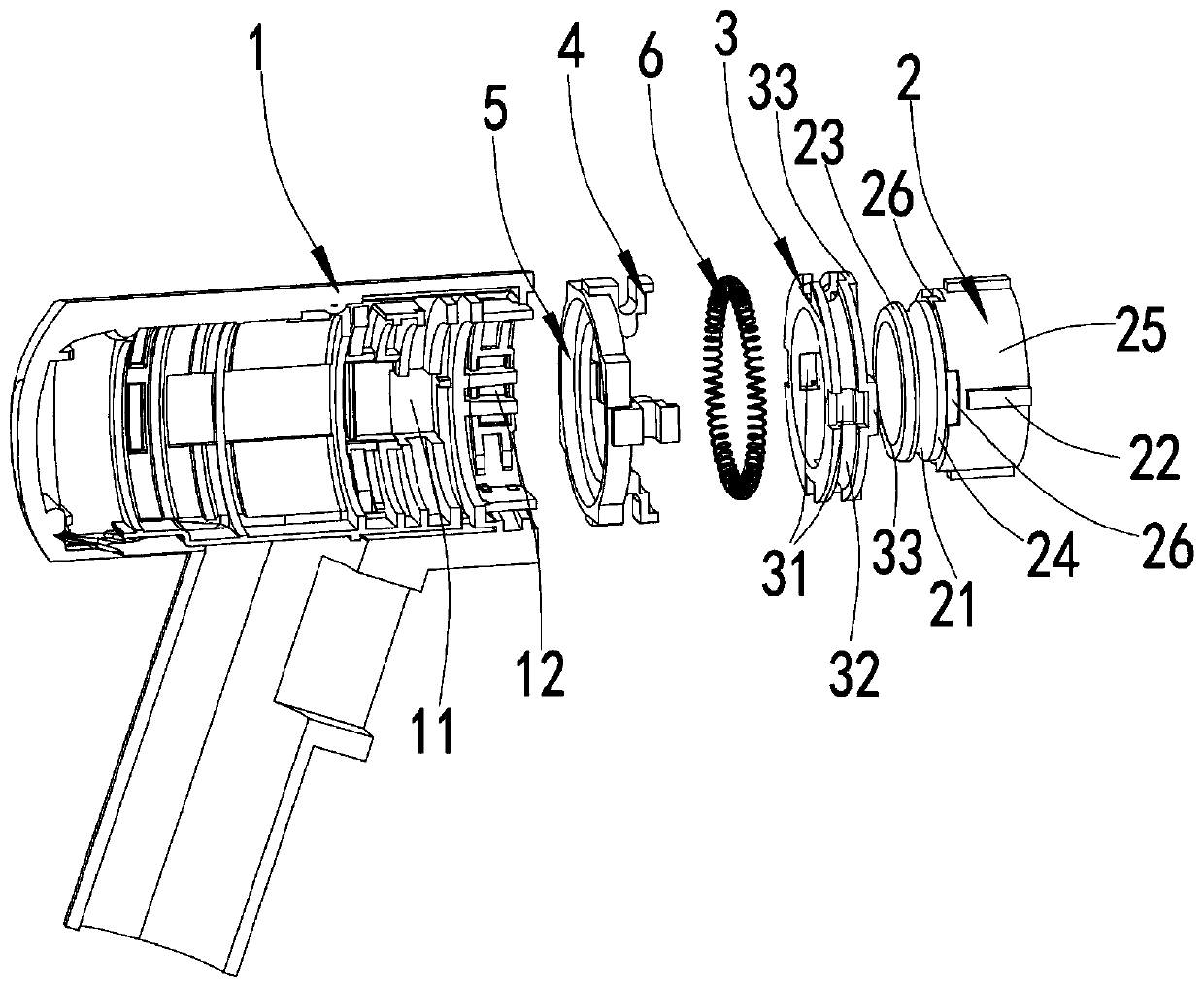

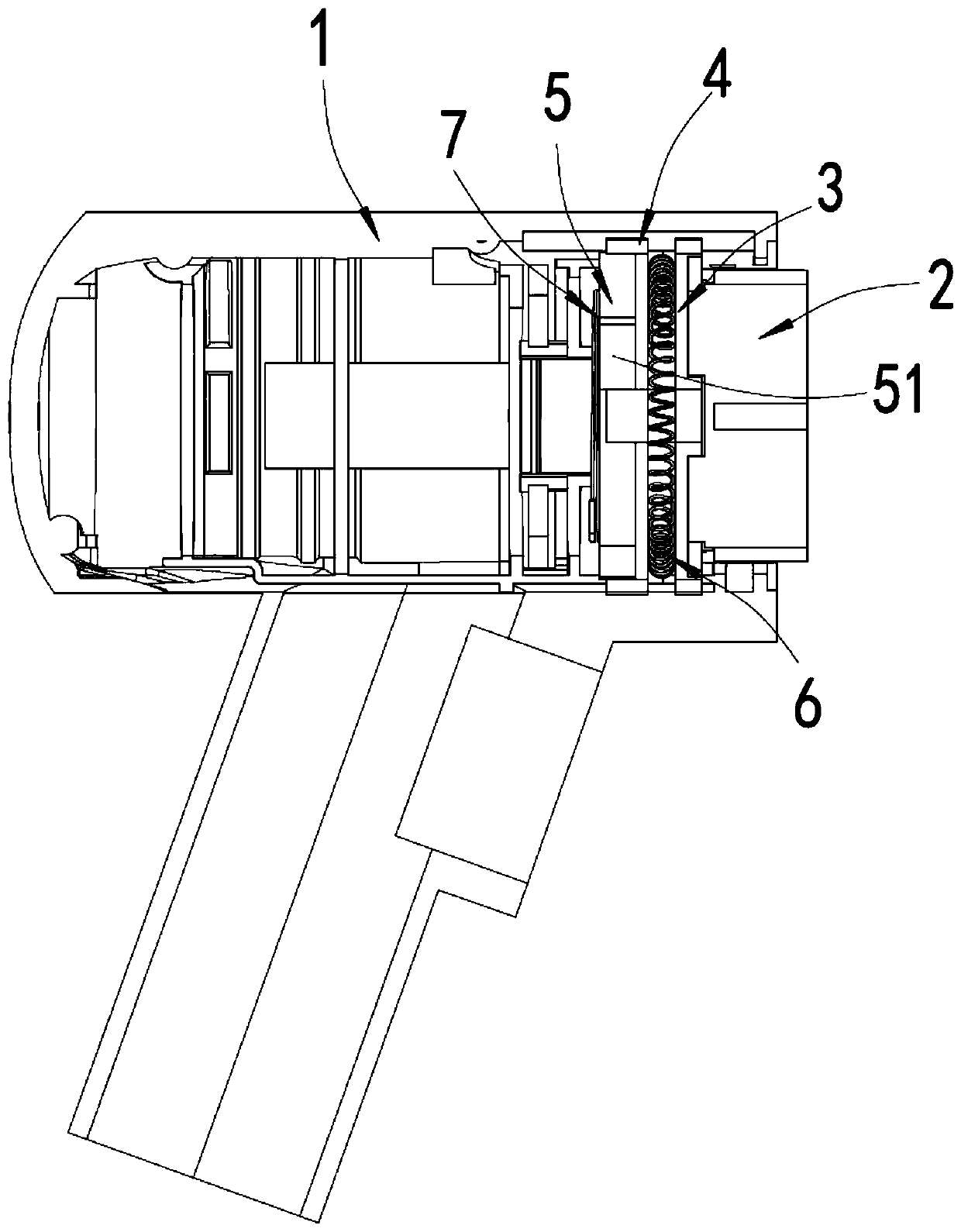

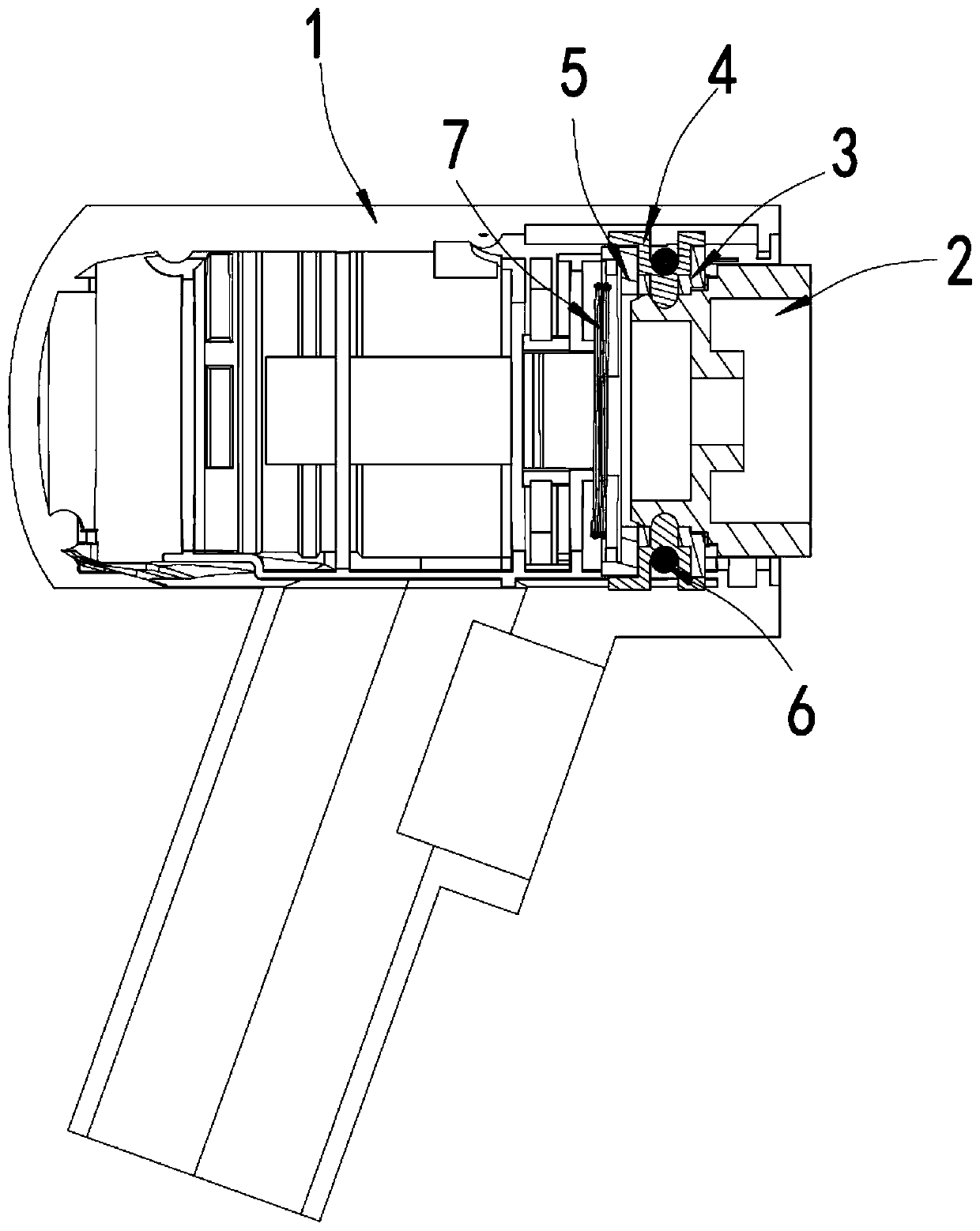

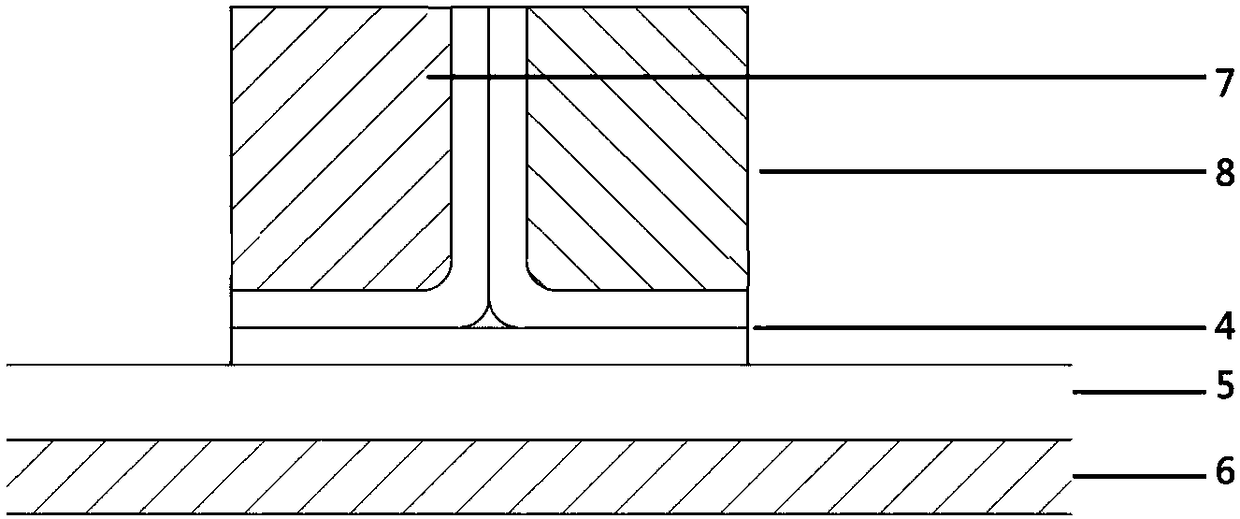

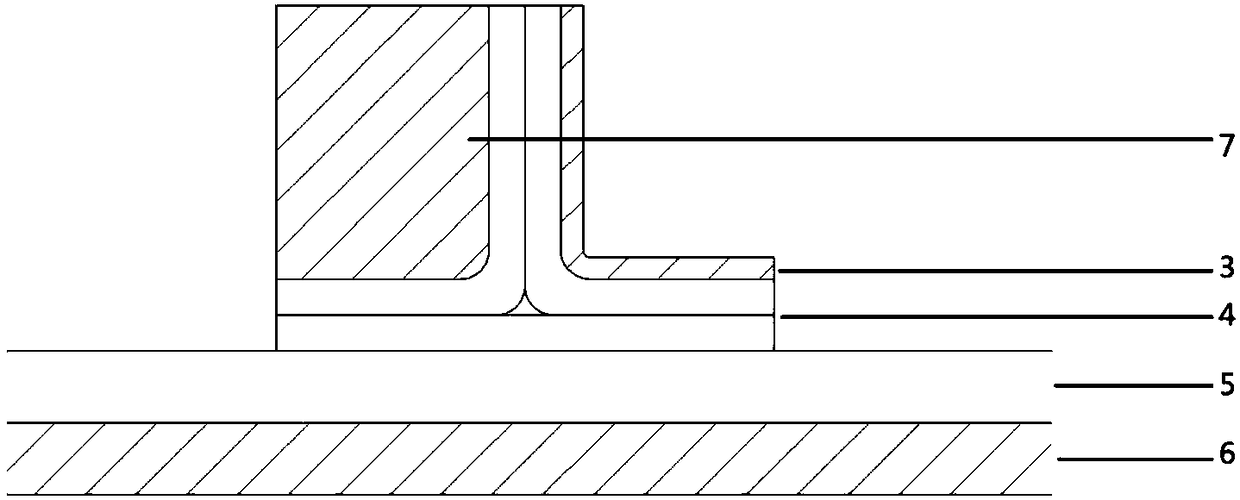

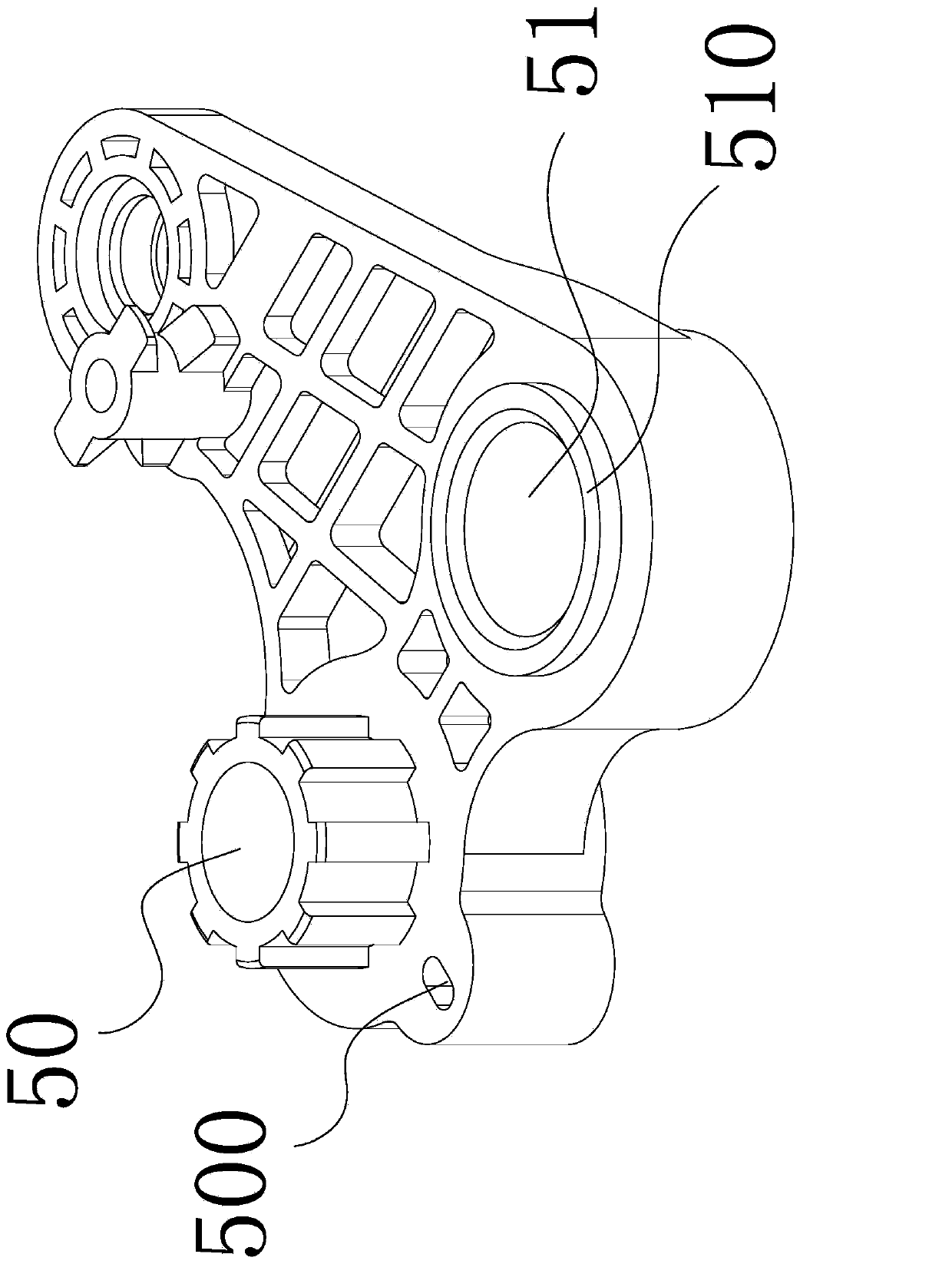

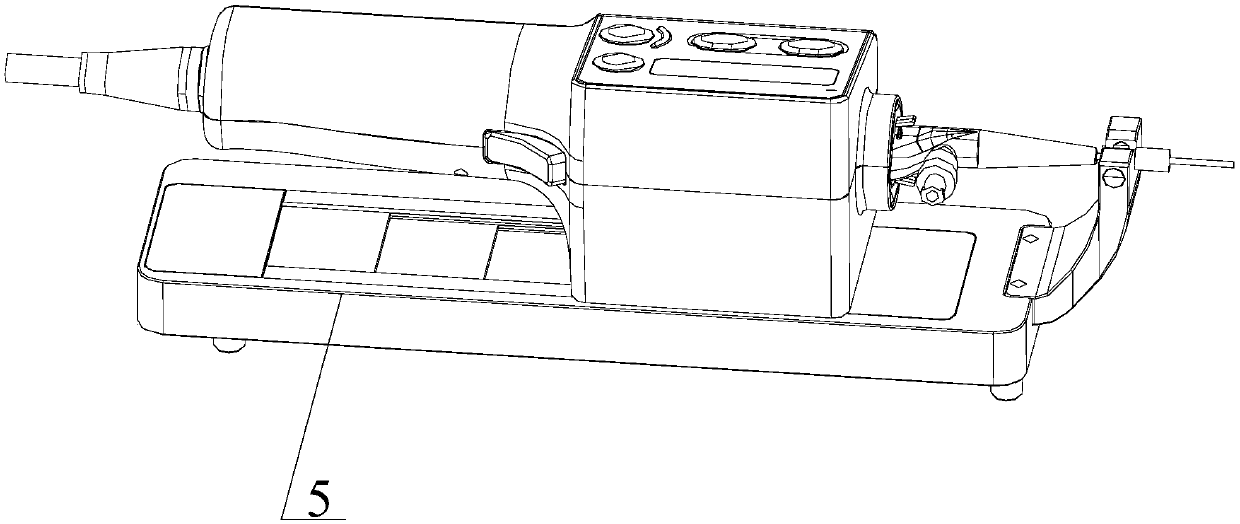

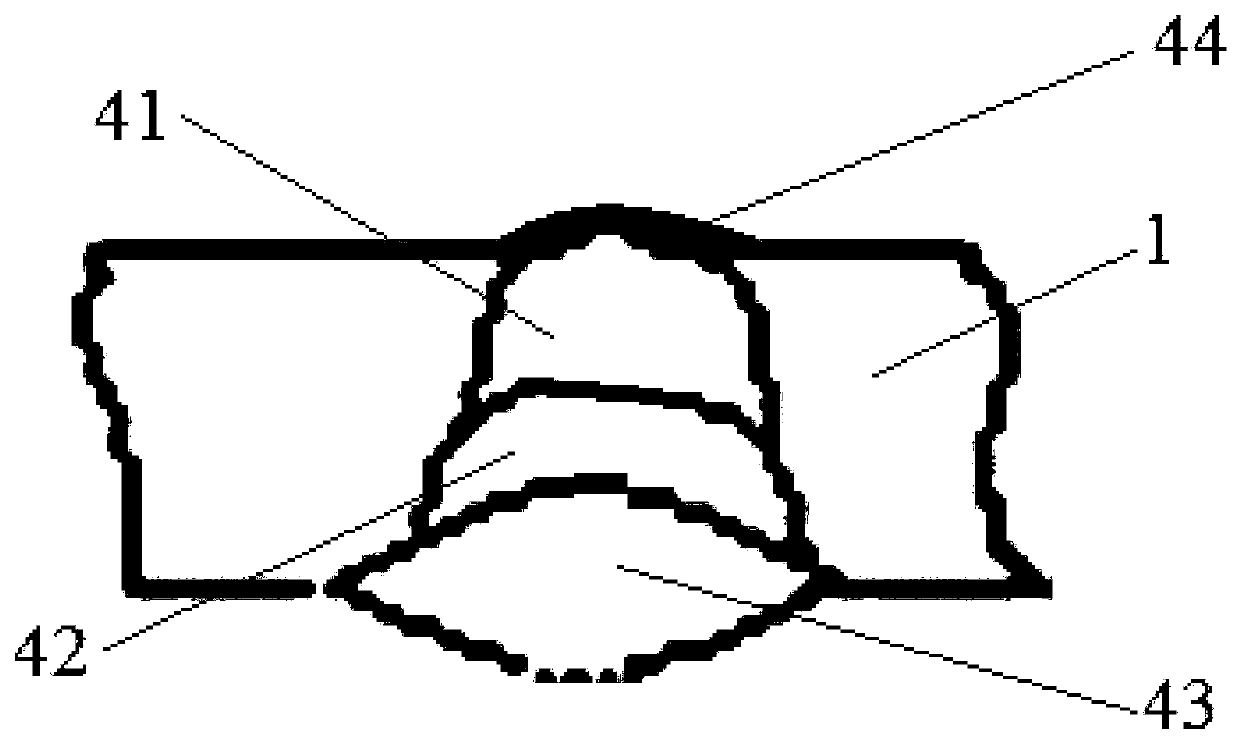

Assembling and disassembling structure for main machine and cutter rest and handheld tool

PendingCN111360767AAvoid reaction forceApply little forcePortable power-driven toolsEngineeringMachine

The invention discloses an assembling and disassembling structure for a main machine and a cutter rest and a handheld tool. The assembling and disassembling structure for the main machine and the cutter rest comprises a main shell and an auxiliary shell detachably connected with the main shell. The auxiliary shell achieves rapid locking and unlocking with the main shell through matching between alocking ring, multiple lock buckles and a drive ring in the main shell and a locking groove on the auxiliary shell. By manually rotating the drive ring, the multiple lock buckles can be driven to switch between a third position and a fourth position; when the lock buckles are located at the third position, the lock buckles are embedded into the locking groove of the auxiliary shell to achieve locking; and when the lock buckles are located at the fourth position, the lock buckles retreat from the locking groove, and then locking of the auxiliary shell can be eliminated, and disassembly can be conducted. The assembling and disassembling structure adopts a rotary knob type unlocking structure, during unlocking, the situation that pressing is conducted hard to enable an elastic hoop to expandis not needed, and operation is easy; by the adoption of the assembling and disassembling structure for the main machine and the cutter rest, during installation, it is just needed to insert the auxiliary shell, pressing a button is not needed, the requirement for a user is low, and operation is convenient; and the locking stability of the assembling and disassembling structure for the main machine and the cutter rest is good.

Owner:ZHEJIANG DESHI ELECTRICAL APPLIANCE CO LTD

Forming method suitable for T-shaped and L-shaped composite material wall plates

The invention belongs to the technical field of forming of composite materials, and relates to a forming method suitable for T-shaped and L-shaped composite material wall plates. A forming mode combining a soft film positioning plate and a soft film is adopted, a fit clearance does not exist, pressure transmission is uniform, and the internal quality of formed wall plates is good. There are only afew molds in a vacuum bag, heat transferring is uniform, and the uniformity of a temperature field is good. The number of molds entering a tank is small, a soft film forming mold is low in precisionand does not need to enter the tank, and the overall mold cost is low. The assembling clearance is small, the forming quality is good, and the forming method is suitable for wall plates with large skin thickness change or large skin shape change. By means of the forming method suitable for T-shaped and L-shaped composite material wall plates, the internal quality of composite material wall platesformed through the method is high, studs are high in position precision, and the forming method is particularly suitable for forming wall plates with complex surfaces and many variable-thickness areas, and lays a certain technical foundation for development of composite materials.

Owner:AVIC COMPOSITES

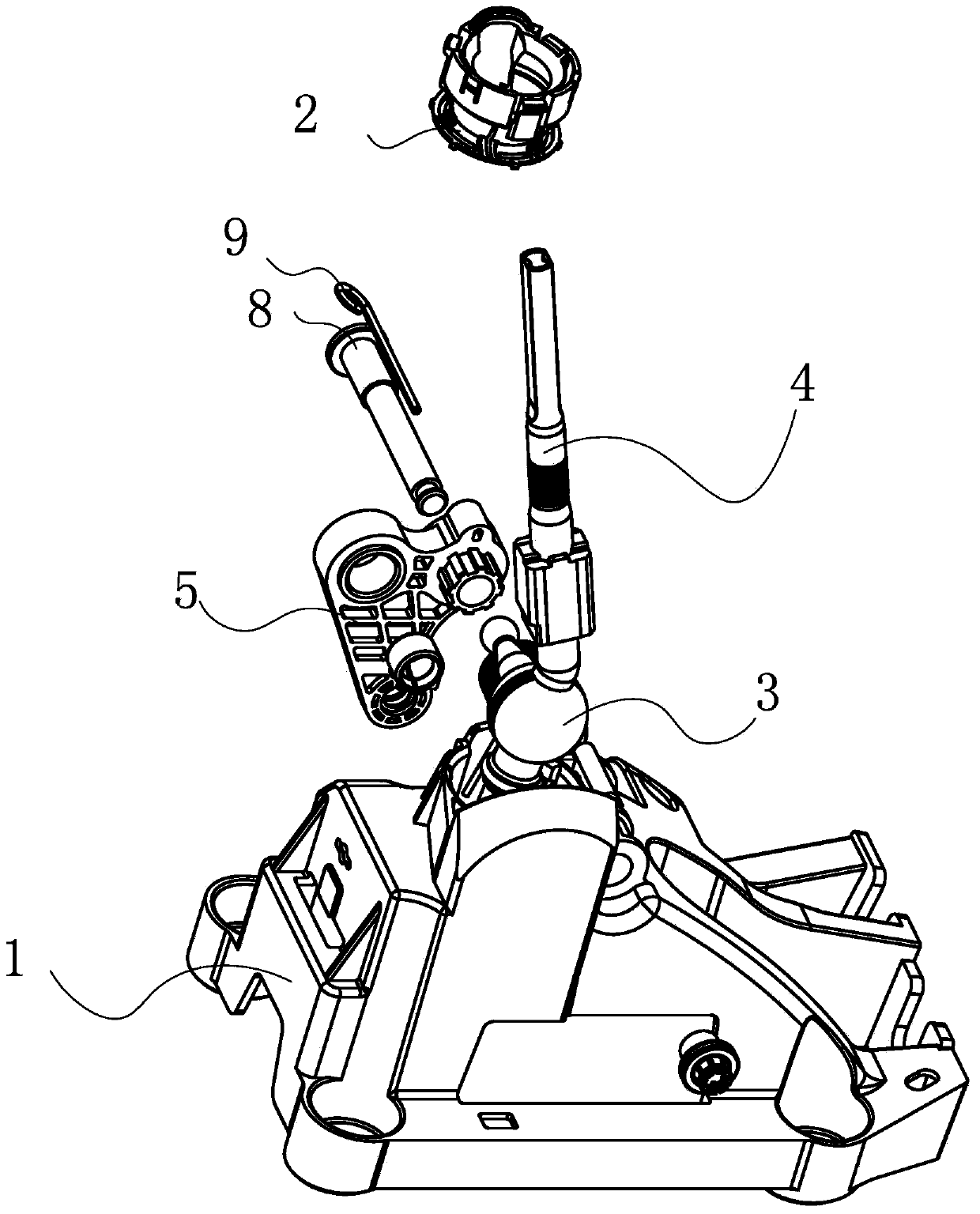

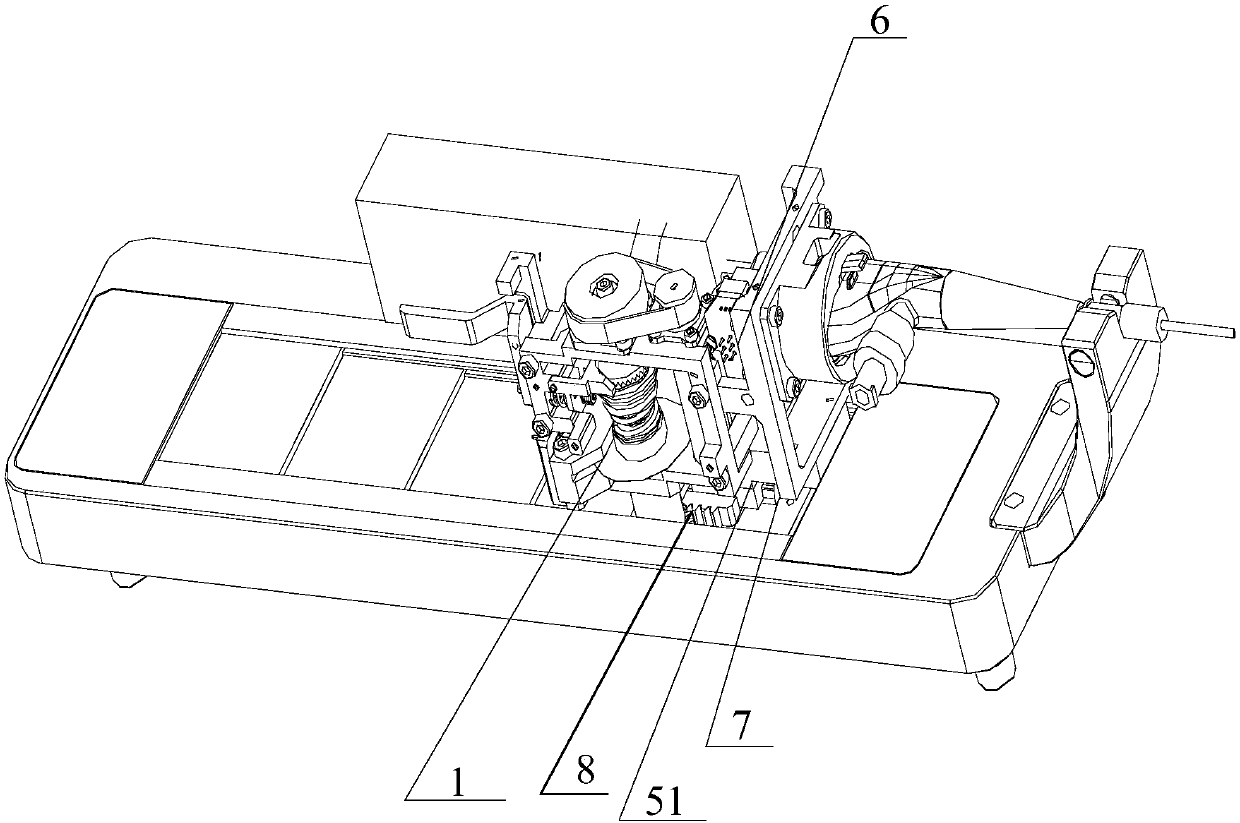

Automobile gearshift

ActiveCN103994207AReduce assembly clearanceAvoid manipulative lockGearing controlEngineeringMechanical engineering

The invention provides an automobile gearshift, and belongs to the technical field of automobiles. The automobile gearshift comprises a base, a cover circle, a rotating central ball, an operating rod and a gear selection arm. The base is provided with a first shaft hole and a ball seat hole, the gear selection arm is provided with a second gear shaft hole and a spherical shaft hole, the rotating central ball is fixedly provided with a first spherical pin, the cover circle is embedded in the ball seat hole, the rotating central ball is arranged in the cover circle in a rotatable mode, the gear selection arm is fixedly connected with the rotating central ball through the spherical shaft hole and the first spherical pin, the gear selection arm is linked with the base through a shaft, the operating rod is fixedly and longitudinally connected to the rotating central ball, the rotating central ball is a ball body formed by a first semi-ball and a second semi-ball, the spherical surface of the first semi-ball and the spherical surface of the second semi-ball are provided with scrap edge portions respectively, the scrap edge portions are arranged at the equipment joints of the first semi-ball and the second semi-ball, and each scrap edge portion is a circular ring with the outer diameter equal to the outer diameter of the corresponding semi-ball and the inner diameter slightly smaller than the outer diameter of the corresponding semi-ball. The automobile gearshift has the advantages of being high in safety performance and low in noise.

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

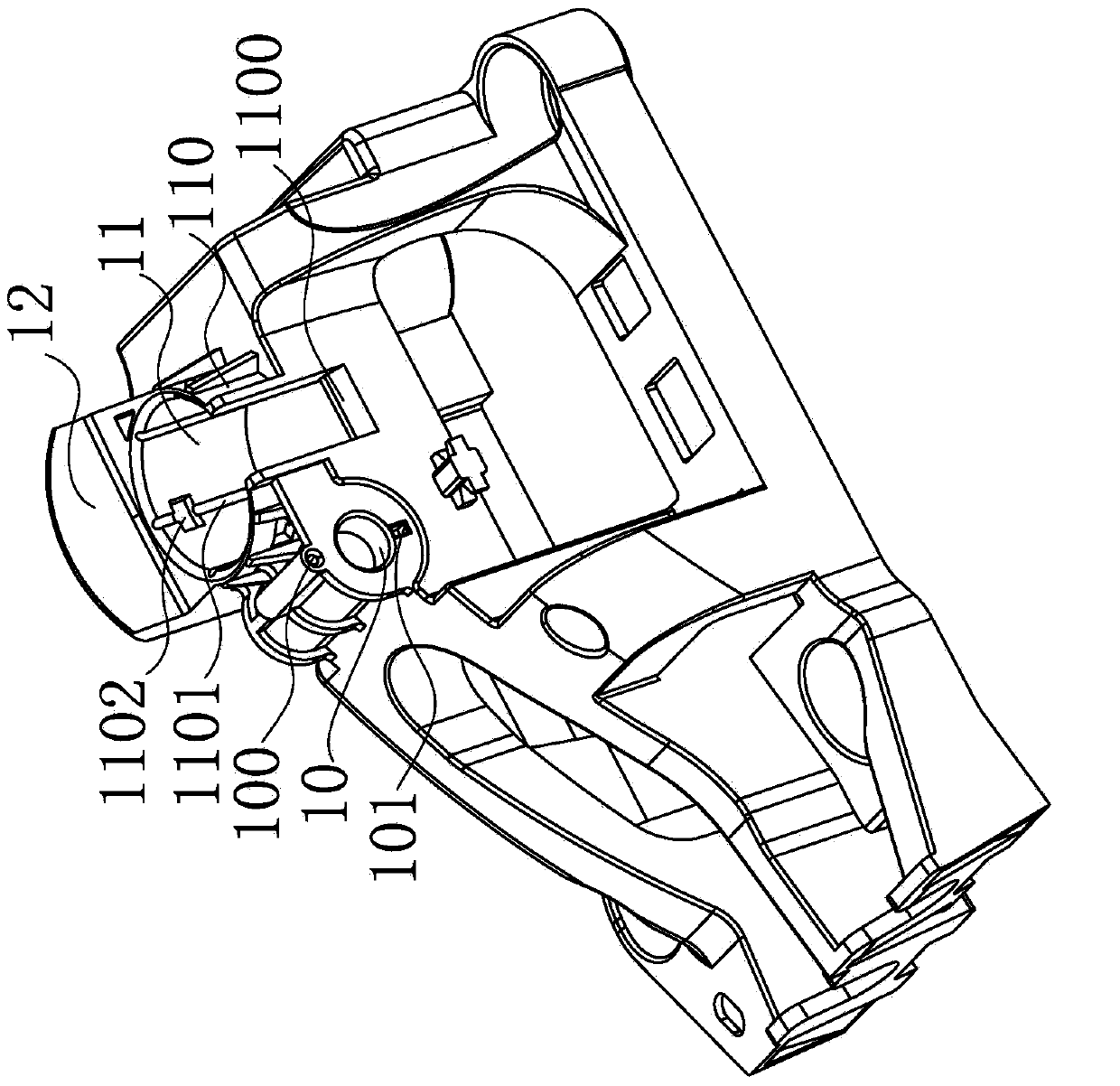

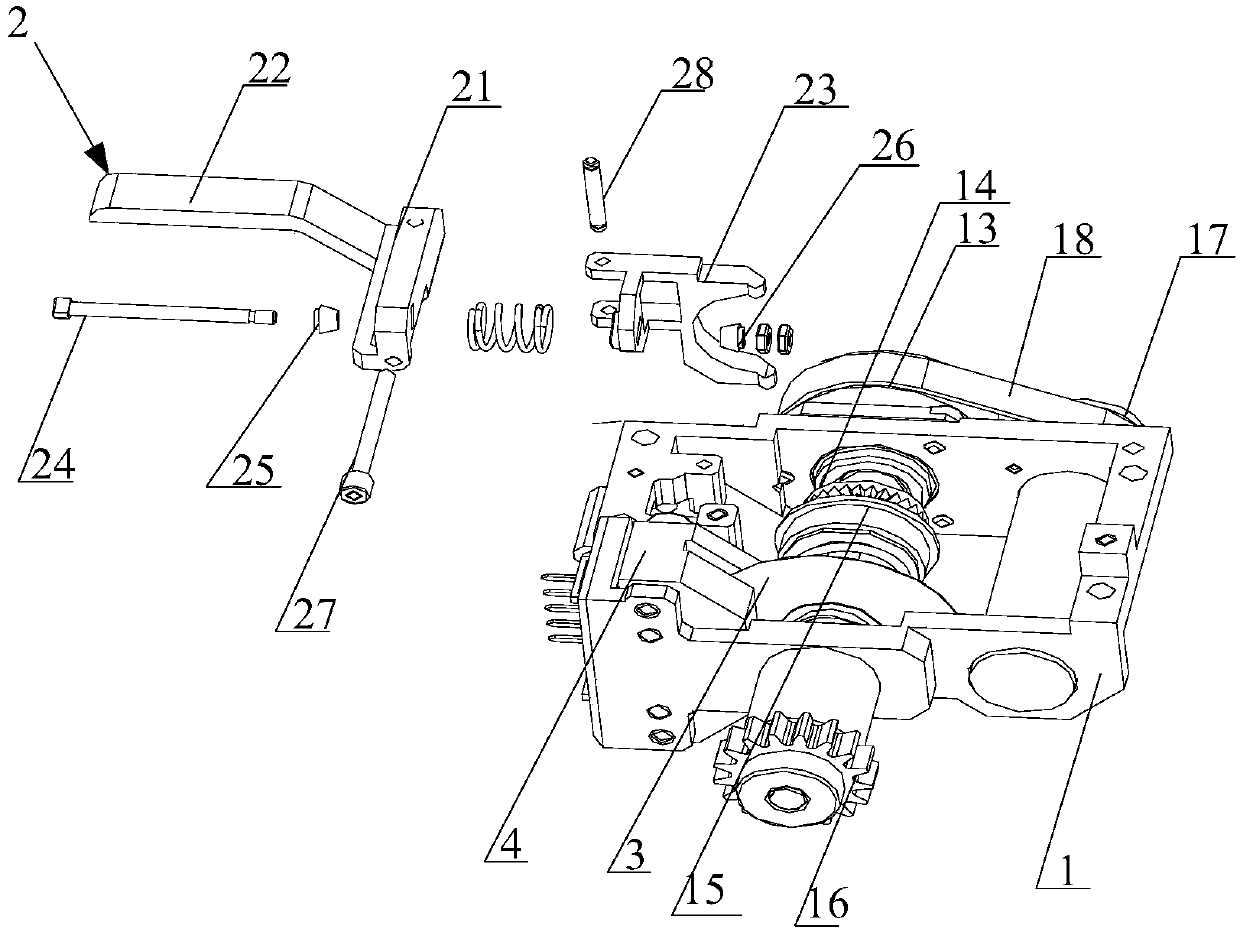

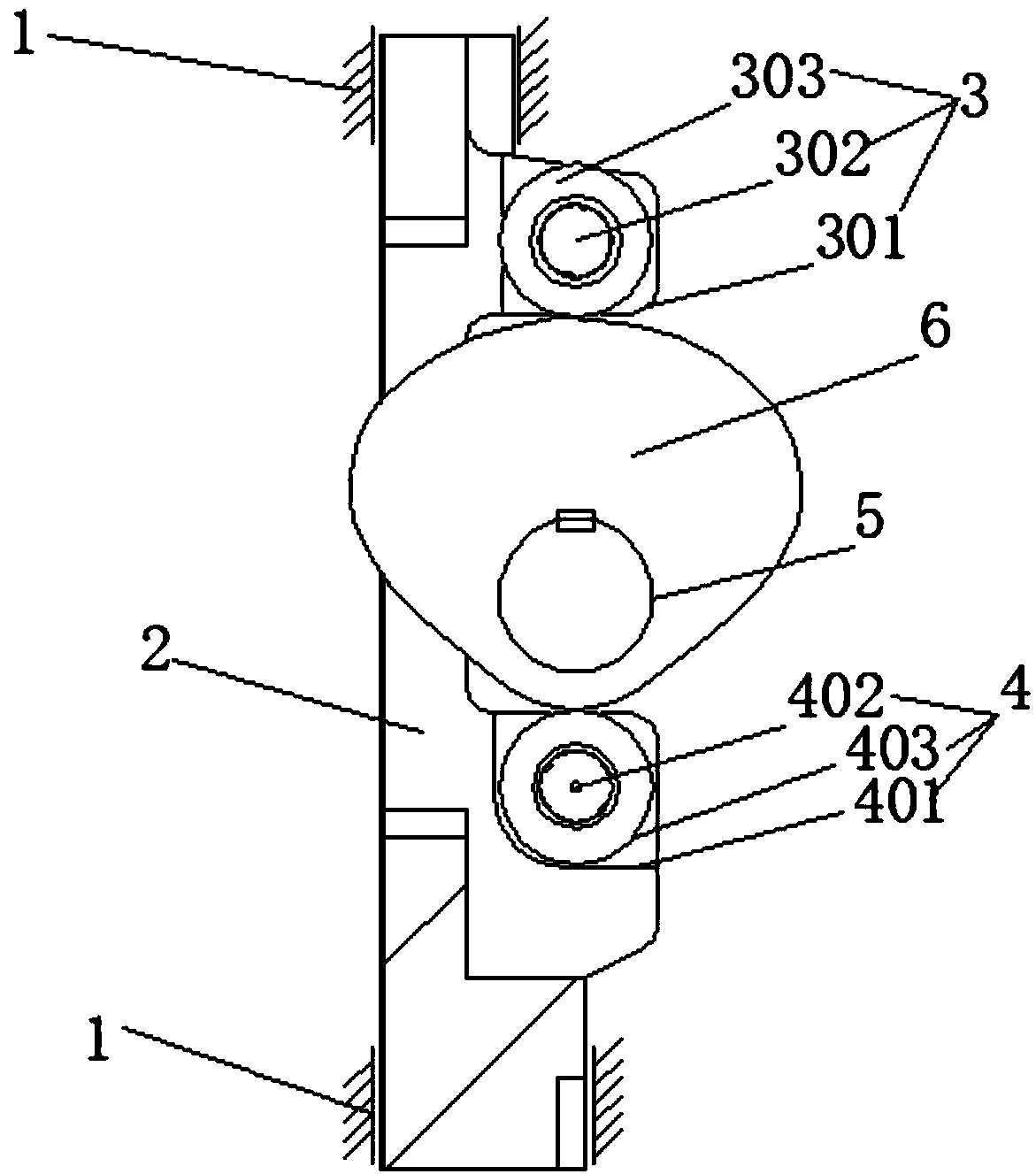

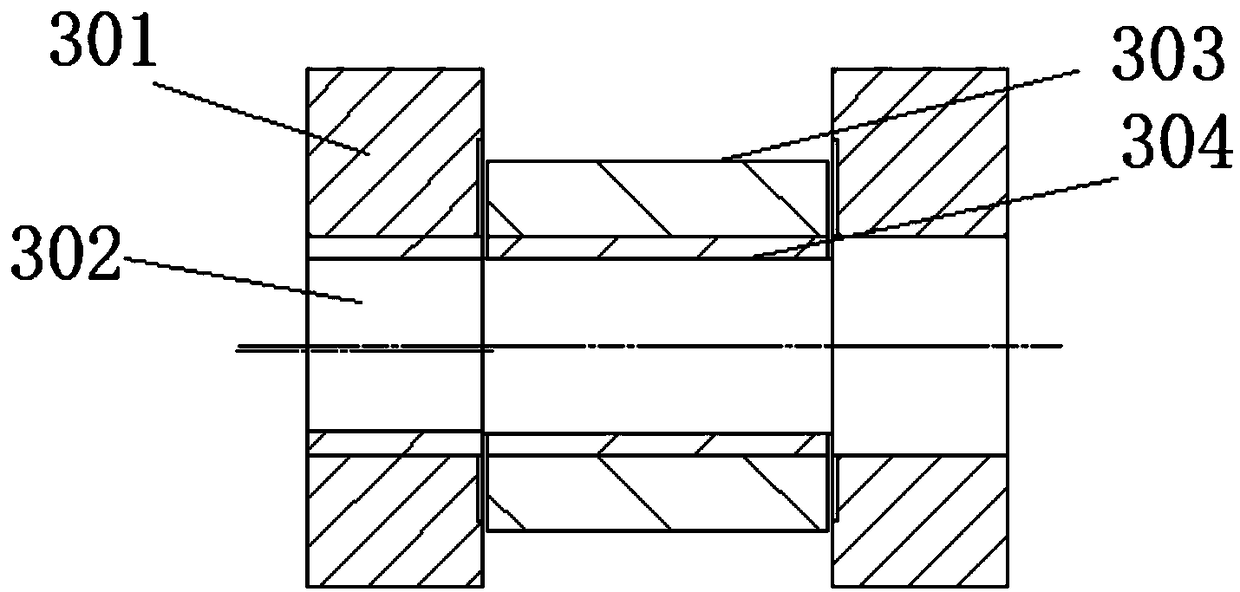

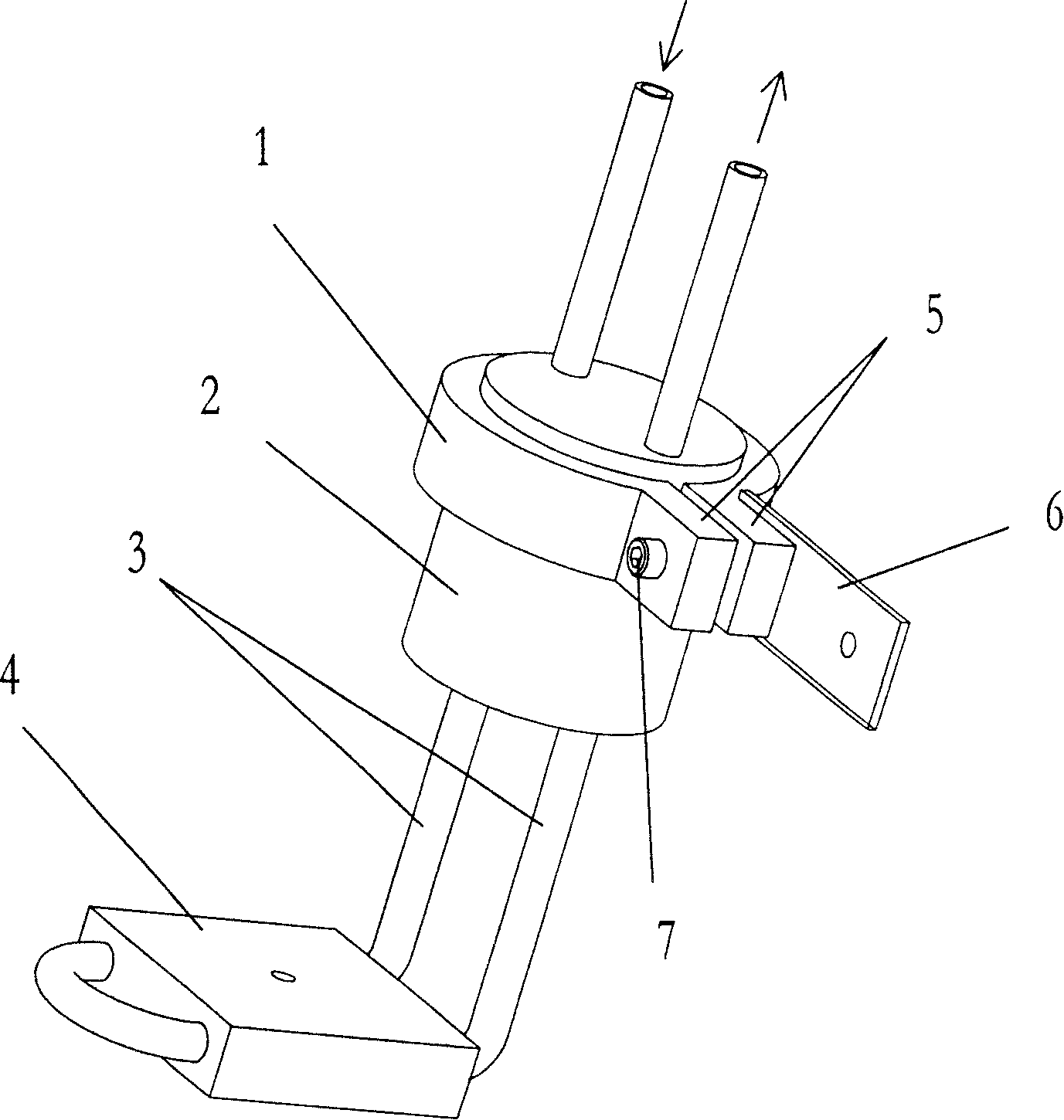

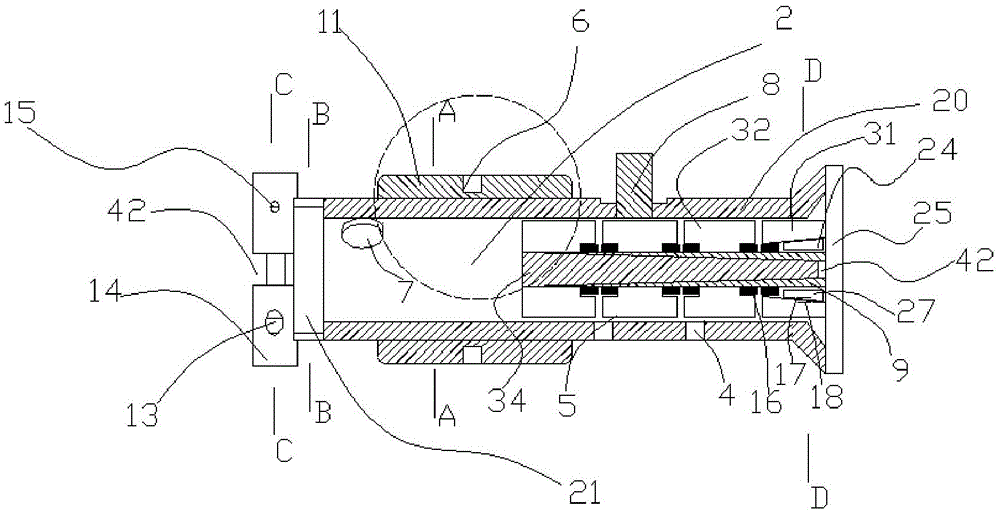

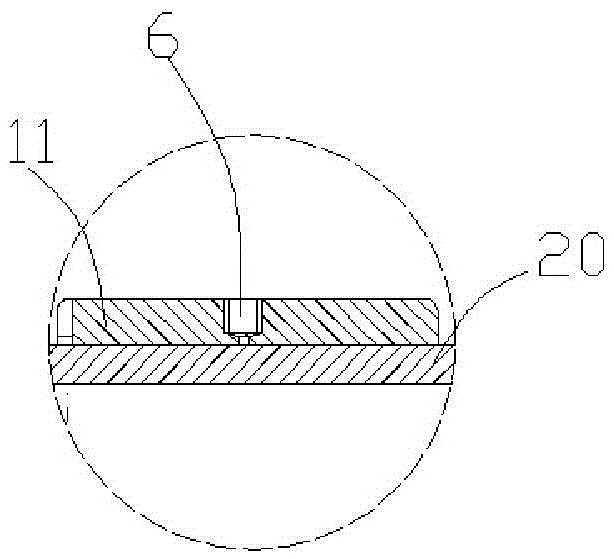

Intravascular ultrasound retractable mechanism

InactiveCN110432932AReduce assembly clearanceRetracement realizedOrgan movement/changes detectionSurgeryTransmitted powerUltrasound angiography

The invention discloses an intravascular ultrasound retractable mechanism. The retractable mechanism includes a retractable support, and a clutch shaft and a retractable shaft which are rotatably connected to the retractable support; one end of the clutch shaft is connected to a driving system, and the other end of the clutch shaft is provided with a first semi-clutch; one end of the retractable shaft is provided with a second semi-clutch used for matching the first semi-clutch, and the other end of the retractable shaft is provided with a movable device capable of moving; and the driving system is arranged on the retractable support. When the automatic retracement of an intravascular ultrasound catheter is performed, the first semi-clutch and the second semi-clutch are in a combined state, the driving system can be started and transmits power to the clutch shaft, the clutch shaft can transmit the power to the retractable shaft, the retractable shaft can rotate, so that the movable device can be driven to move, and therefore, the automatic retracement of the intravascular ultrasound catheter can be realized; the retractable mechanism adopts a synchronous belt to perform power transmission, so that the assembling gap between parts can be reduced; and the retractable mechanism is simple in structure and can realize stable operation.

Owner:SONOSCAPE MEDICAL CORP

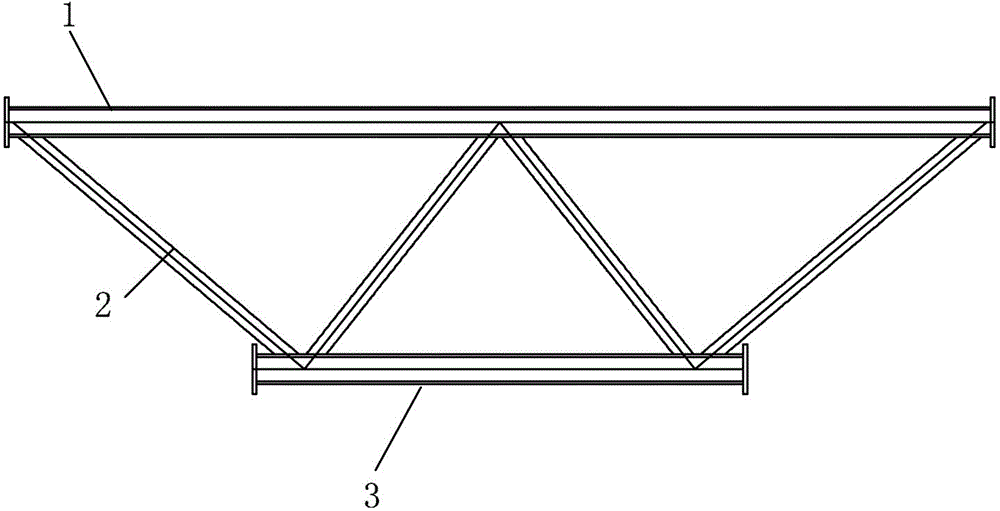

Assembly type truss formwork support

ActiveCN104453222AGuaranteed stiffnessReduce the effect of eccentricityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksVertical deflectionEngineering

The invention provides an assembly type truss formwork support, belongs to the technical field of construction, and particularly relates to a truss and a support which are used for construction. The truss is obtained by assembling one-meter single-rod units, I type truss units (one meter), II type truss units (two meters) and end rods through shaping truss units with end plates by means of bolt connection joints instead of assembling existing single rods. Upper chords, lower chords and inclined supports of all the truss units are connected through welding, the end plates with bolt holes are adopted for the ends of the truss units, the truss units are connected through bolts, different spans of trusses can be formed after assembly, the end rods are additionally arranged at the ends of the assembly truss, vertical supports are additionally arranged on the end rods, and the assembly type truss formwork support is formed. The assembly type truss formwork support is obtained by connecting and assembling the end plate shaping truss units with the bolt holes through the bolts, the number of splicing times is reduced, and therefore the rigidity of the trusses is ensured, web member eccentric influences and assembly gaps are reduced, the vertical deflection is reduced, and the bearing capacity is improved. All the truss units are assembled through the connection plate joints with the bolt holes, and different spans of trusses can be obtained after assembly.

Owner:山东高速德建集团有限公司

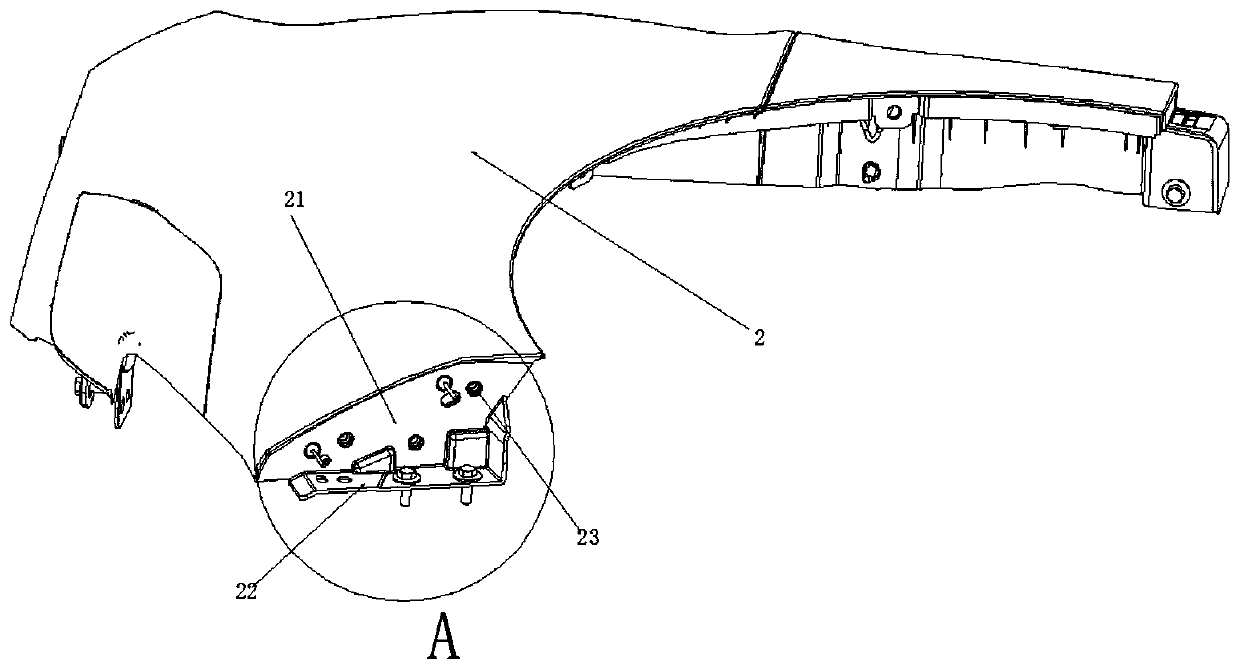

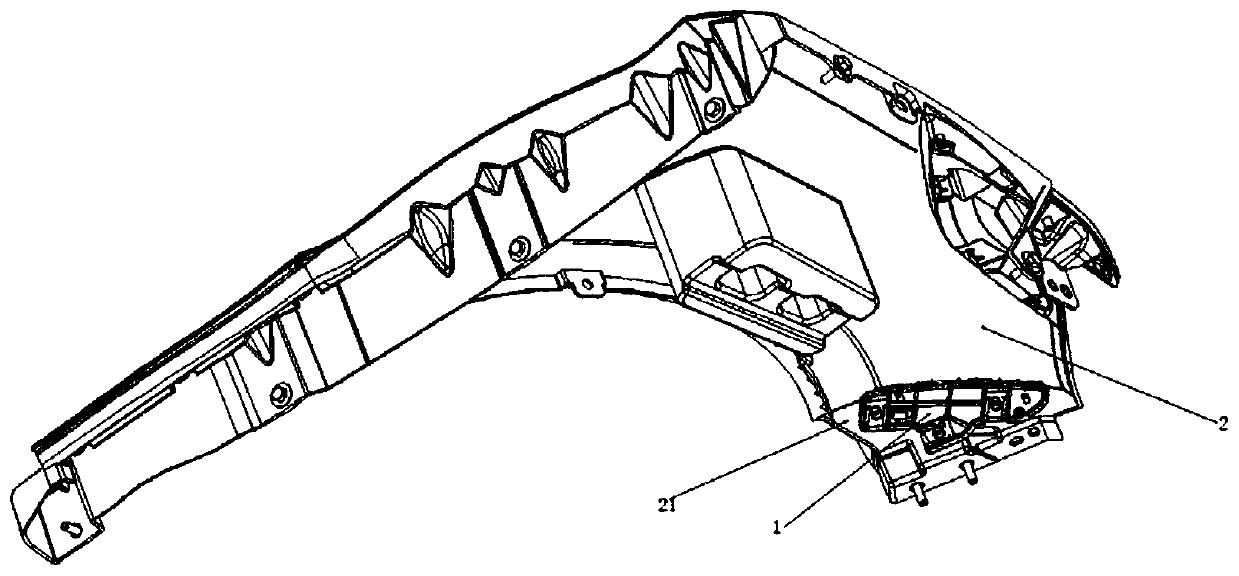

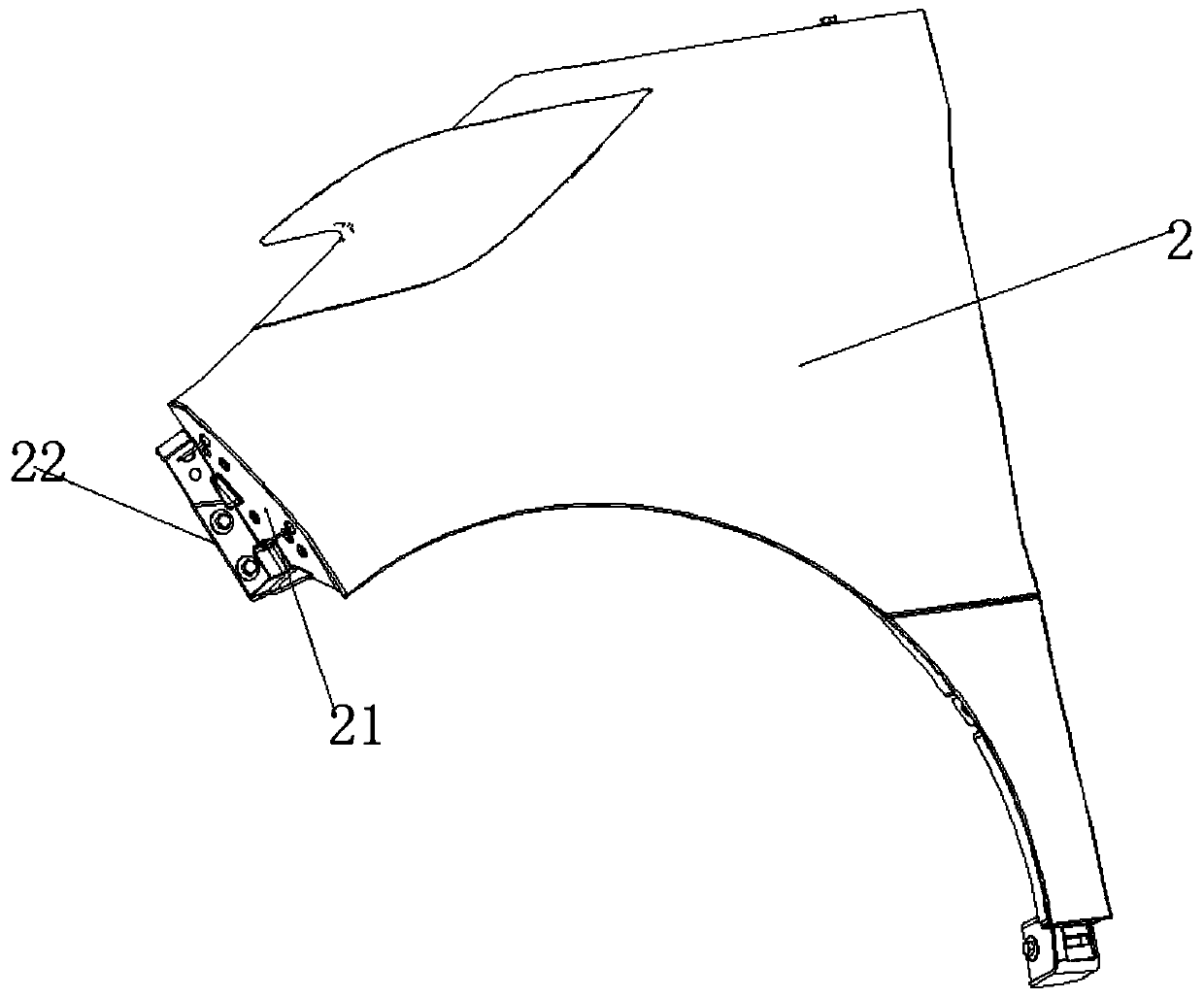

Plug-in type fender structure

ActiveCN110606128AImprove assembly accuracyImprove connection strengthSuperstructure subunitsEngineeringUltimate tensile strength

The invention relates to the field of fenders, in particular to a plug-in type fender structure. The plug-in type fender structure comprises a fender body; the fender body comprises a connecting partconnected with a front bumper; the connecting part comprises a connecting end plate arranged on the side surface of the connecting end of the fender body and the front bumper; and the connecting end plate is connected with the end part of the front bumper through a plug pin. The invention discloses the plug-in type fender structure; through the arranging of the plug pin, the clamping type connecting mode adopted between a traditional fender and the front bumper is changed; through cooperation of the plug pin and a bolt, the fender and the front bumper can be fixed after being positioned to bebeneficial for improving the assembling precision of the fender and the front bumper, reducing the assembling clearance between the fender and the front bumper and preferably satisfying actual production demands; and meanwhile, by arranging a reinforcing mechanism, the connecting strength between the fender and the front bumper is enhanced so that the connecting stability of the fender and the front bumper is preferably guaranteed.

Owner:WUHU GUOFENG PLASTIC TECH

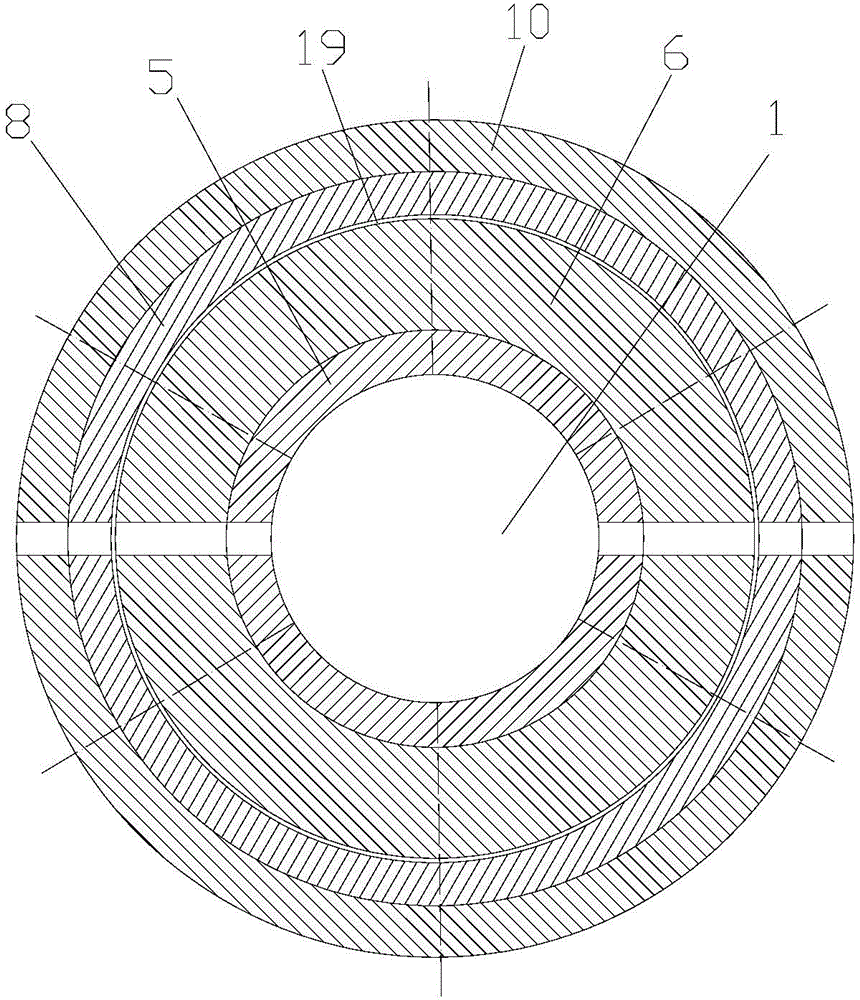

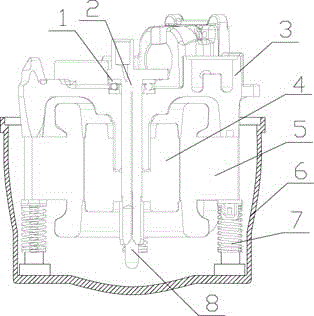

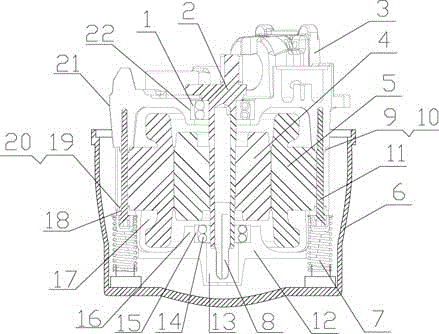

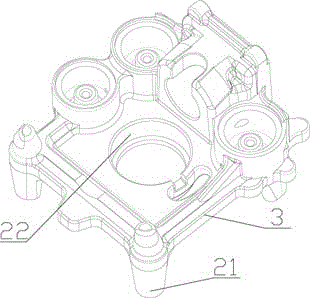

Reinforced inner support structure for refrigeration compressor

InactiveCN106351841AIncrease stiffnessImprove stabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorEngineering

The invention relates to an improvement technology of a refrigeration compressor, in particular to a reinforced inner support structure for the refrigeration compressor. The reinforced inner support structure for the refrigeration compressor comprises a stator, a rotor, a cylinder base mounted above the stator and a crankshaft inserted between the cylinder base and the rotor; a counter bore is formed in the middle part of the cylinder base; a bearing A is mounted to form rotational bearing for the upper end of the crankshaft. The reinforced inner support structure for the refrigeration compressor is characterized in that a bracket is additionally arranged below the stator; left and right bolt holes are formed in the bracket, and the bracket is in threaded connection with the cylinder base by enabling bolts to pass through the bolt holes in the bracket and bolt holes in the stator; a boss is formed at the middle part of the bracket; a bearing hole is formed in the upper part of the boss for mounting a bearing B; an oil suction pipe assembly vortex cavity is formed in the lower part of the boss; the bearing B and the lower end of the crankshaft are assembled to form a rotational bearing. The reinforced inner support structure for the refrigeration compressor, which is disclosed by the invention, solves the problems of low working efficiency of an existing compressor and the like, which are caused by the case that a crankshaft and rotor assembly is supported and positioned by a stator inner hole and a single-point cantilever, the compressor works unstably, a gap between a stator and a rotor is large and an operation electrical air gap is unstable, and is mainly applicable to refrigeration equipment such as a refrigerator, a freezer and the like.

Owner:黄石艾博科技发展有限公司

Driving device

PendingCN112065180AImprove installation efficiencySmall footprintConstruction fastening devicesWing handlesEngineeringRack and pinion

The invention discloses a driving device. The driving device comprises a transmission mechanism, a lever handle and a locking mechanism. The transmission mechanism comprises an installation shell anda movable piece, a sliding groove is formed in the installation shell, and limiting edges are arranged at the tops of the two side walls of the sliding groove respectively. The movable piece is arranged in the sliding groove in a penetrating manner, and a transmission rack is arranged on the bottom wall of the movable piece. The lever handle comprises a handle body, a fixing base, a connecting shaft and a second fastener, a second mounting groove is formed in one end of the handle body, and an inner tooth part is arranged in the second mounting groove; the fixing base is arranged in the secondmounting groove and can be connected with a profile part; the connecting shaft is rotationally arranged in the fixing base and comprises a first outer tooth part and a second outer tooth part, the first outer tooth part is meshed with the inner tooth part, and the second outer tooth part can be meshed with the transmission rack; one end of the second fastener is connected with the bottom wall ofthe second mounting groove; and the locking mechanism can be arranged in the mounting shell and the mounting wall in a penetrating manner and is connected with the fixing base. The driving device hasa small installation space.

Owner:SHENZHEN HOPO WINDOW CONTROL TECH CO LTD

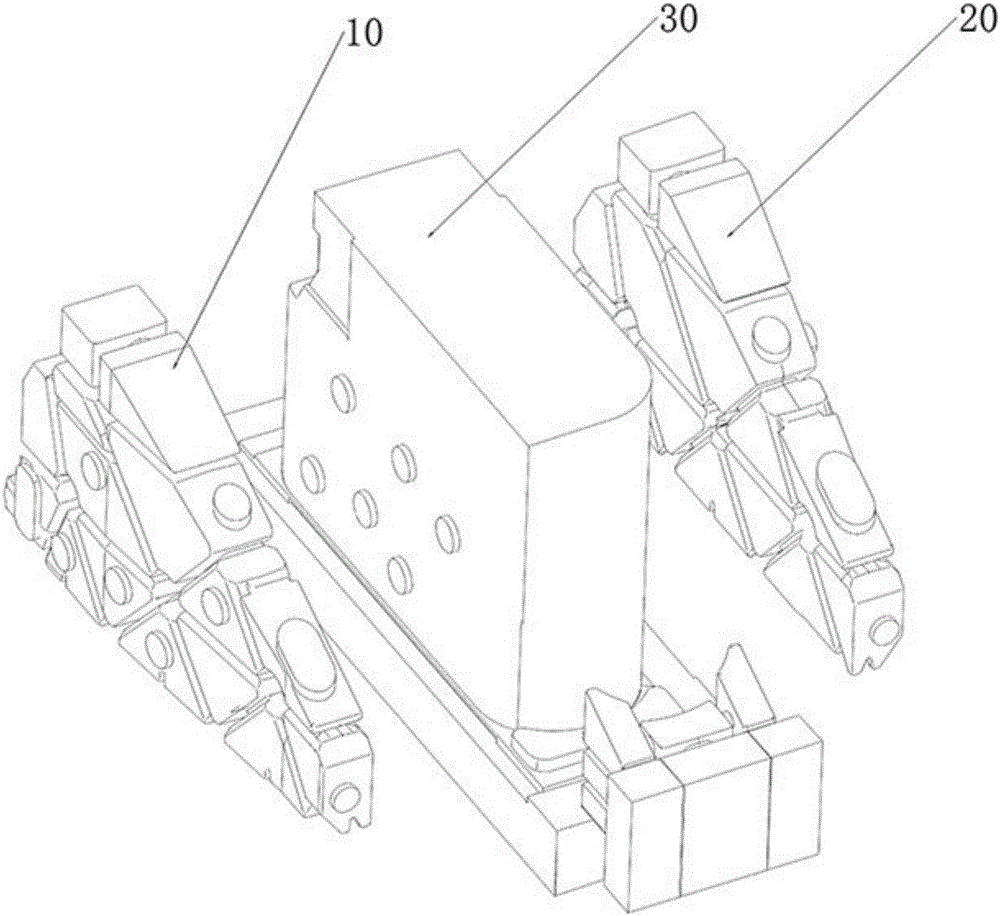

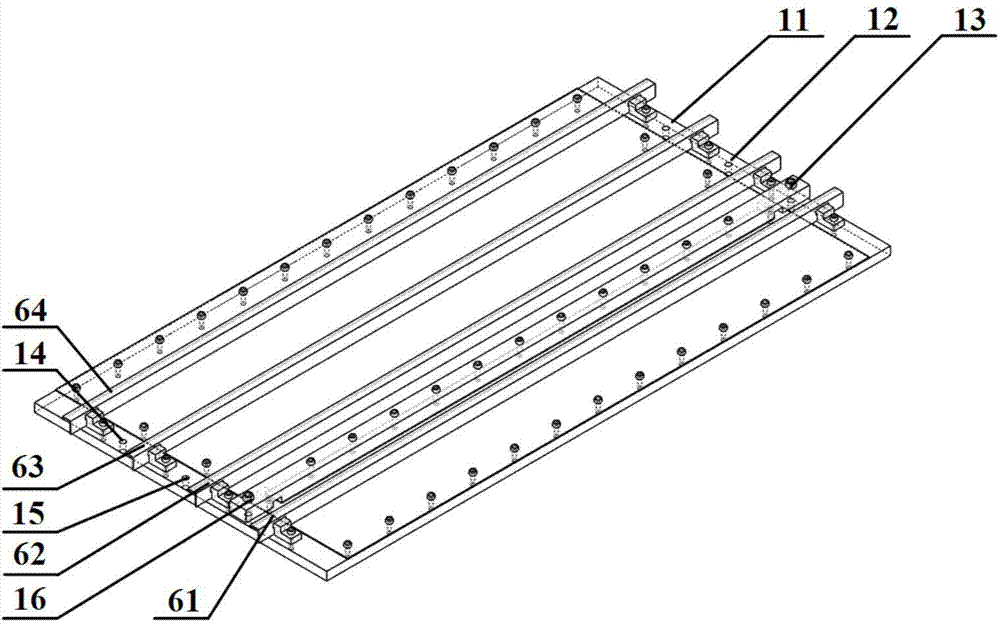

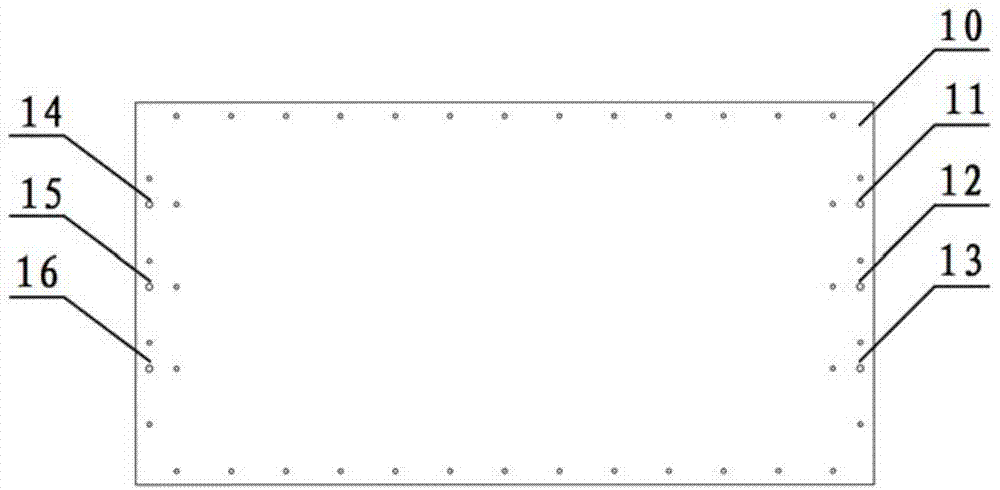

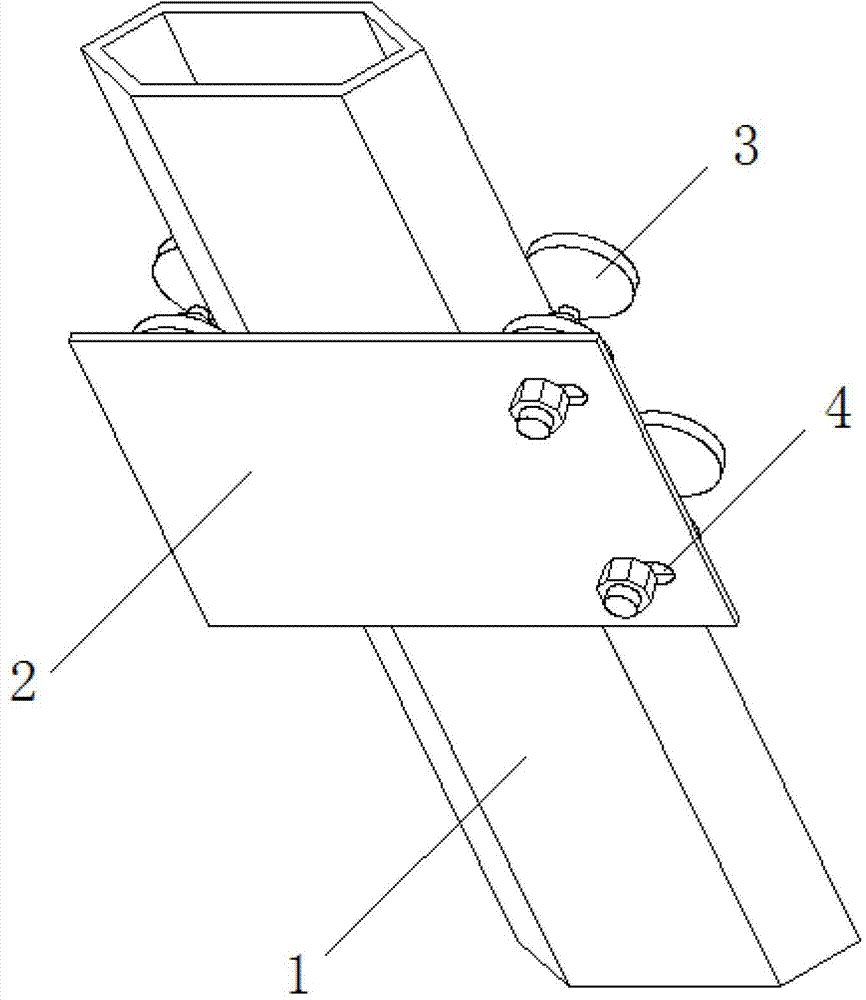

Laser welding clamp for T-shaped structural component

ActiveCN104259661AControl deflectionInhibition of crystallization cracksWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a laser welding clamp for a T-shaped structural component, and the T-shaped structural component comprises an envelope and a stringer, the laser welding clamp comprises a bottom plate for supporting the envelope; a pressing bar which is used to press the envelope such that the envelope is tightly close to the bottom plate; a corner-bending pressing block which is respectively arranged on both ends of each stringer, one end of the corner-bending pressing block is connected with the stringer while the other end thereof is connected with the bottom plate. The laser welding clamp can effectively control deflection deformation of the stringer and restrain generation and extension of solidification cracks at laser welding end points.

Owner:SHANGHAI AIRCRAFT MFG +1

One-side welding and one-side forming welding method for MAG faced-up butt joint

ActiveCN110640274AFast welding speedReduce weld thicknessElectrode supporting devicesWelding accessoriesWeld seamEngineering

Owner:CRRC ZHUZHOU ROLLING CO LTD

Cam-driven-type multi-station press transmission system

The invention discloses a cam-driven-type multi-station press transmission system. The system comprises a rack, a slide block and a main shaft; the slide block is slidably installed on the rack, and an upper idle wheel mechanism and a lower idler wheel mechanism are spaced on the slide block; the main shaft is installed on the rack, a main cam is installed on the main shaft, the main shaft is located between the upper idler wheel mechanism and the lower idler wheel mechanism, and the main cam is tangent to the upper idler wheel mechanism and the lower idler wheel mechanism separately. By meansof the system, the technical problem in the prior art that the processing precision of workpieces is poor when large assembly gaps exist in a station press is solved.

Owner:扬州精善达伺服成形装备有限公司

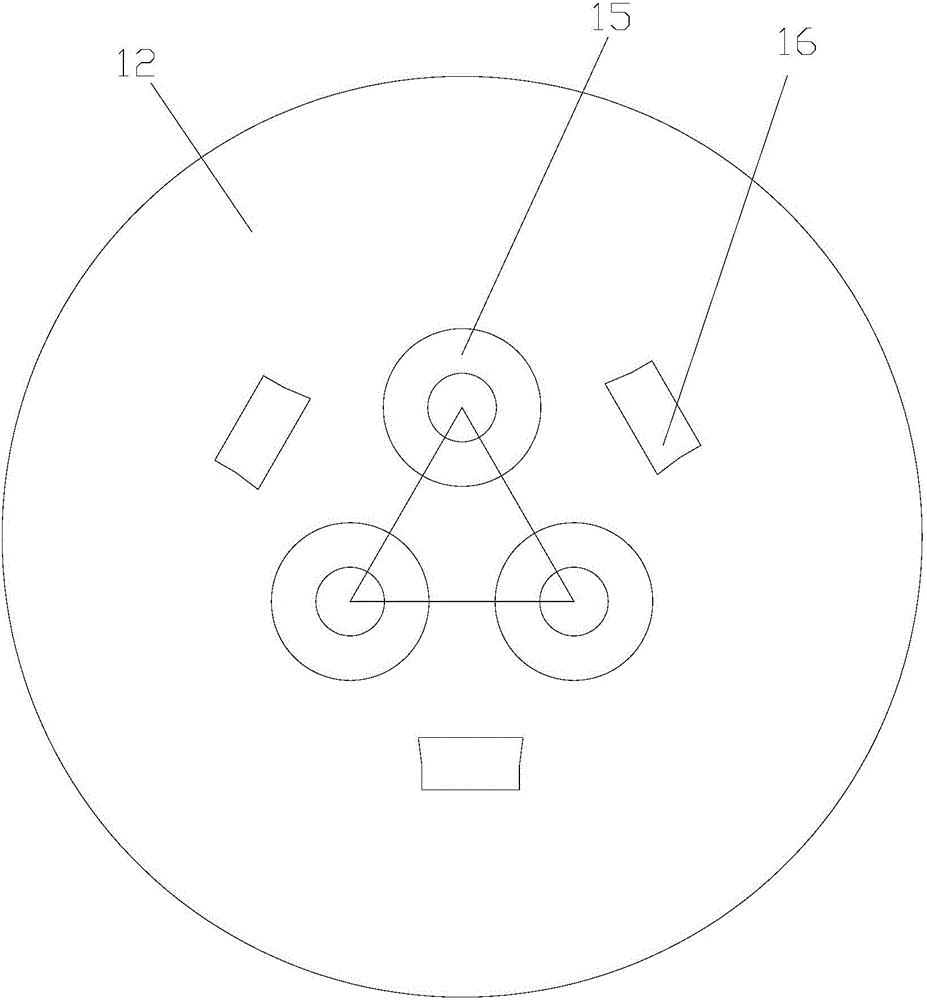

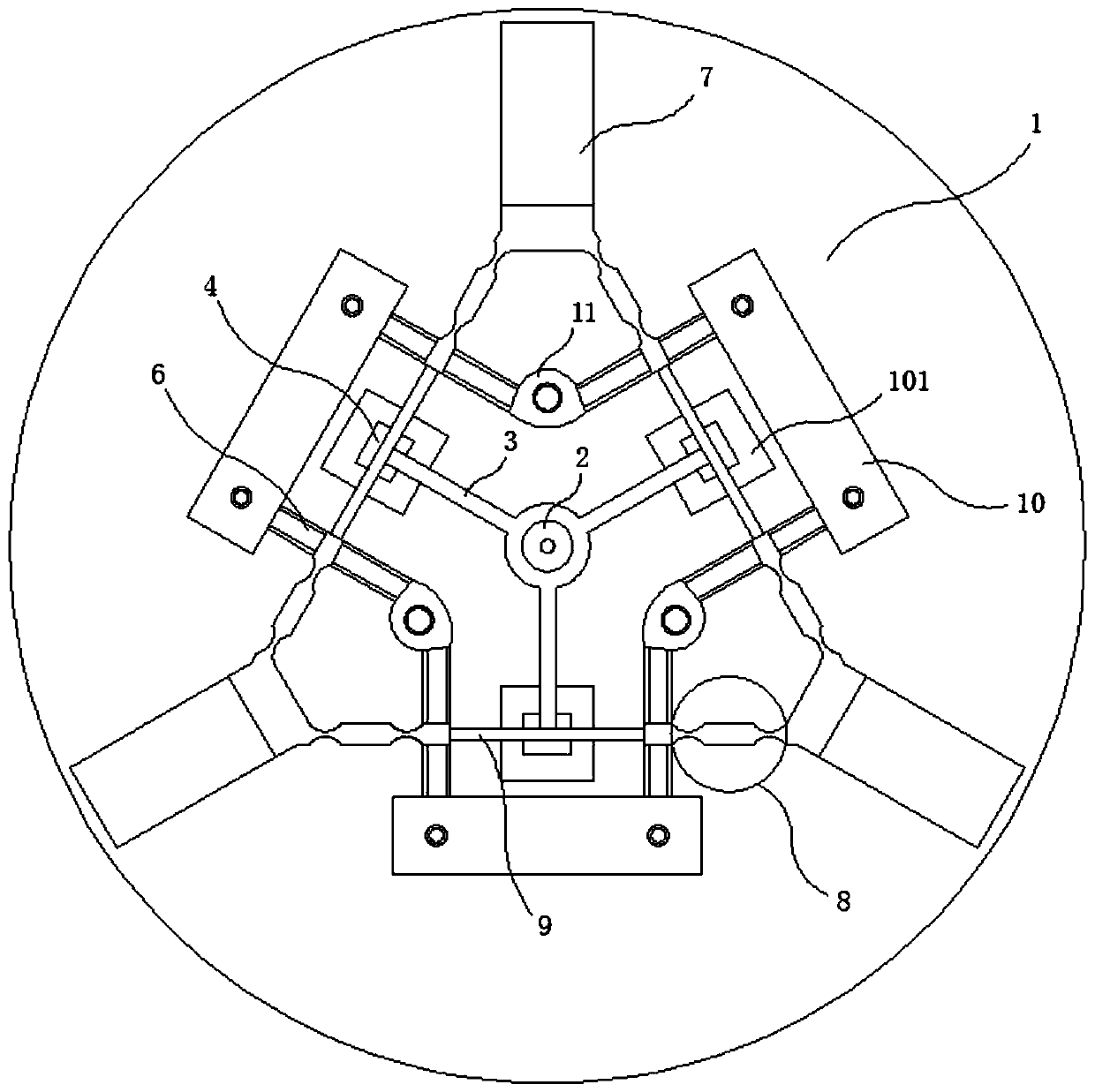

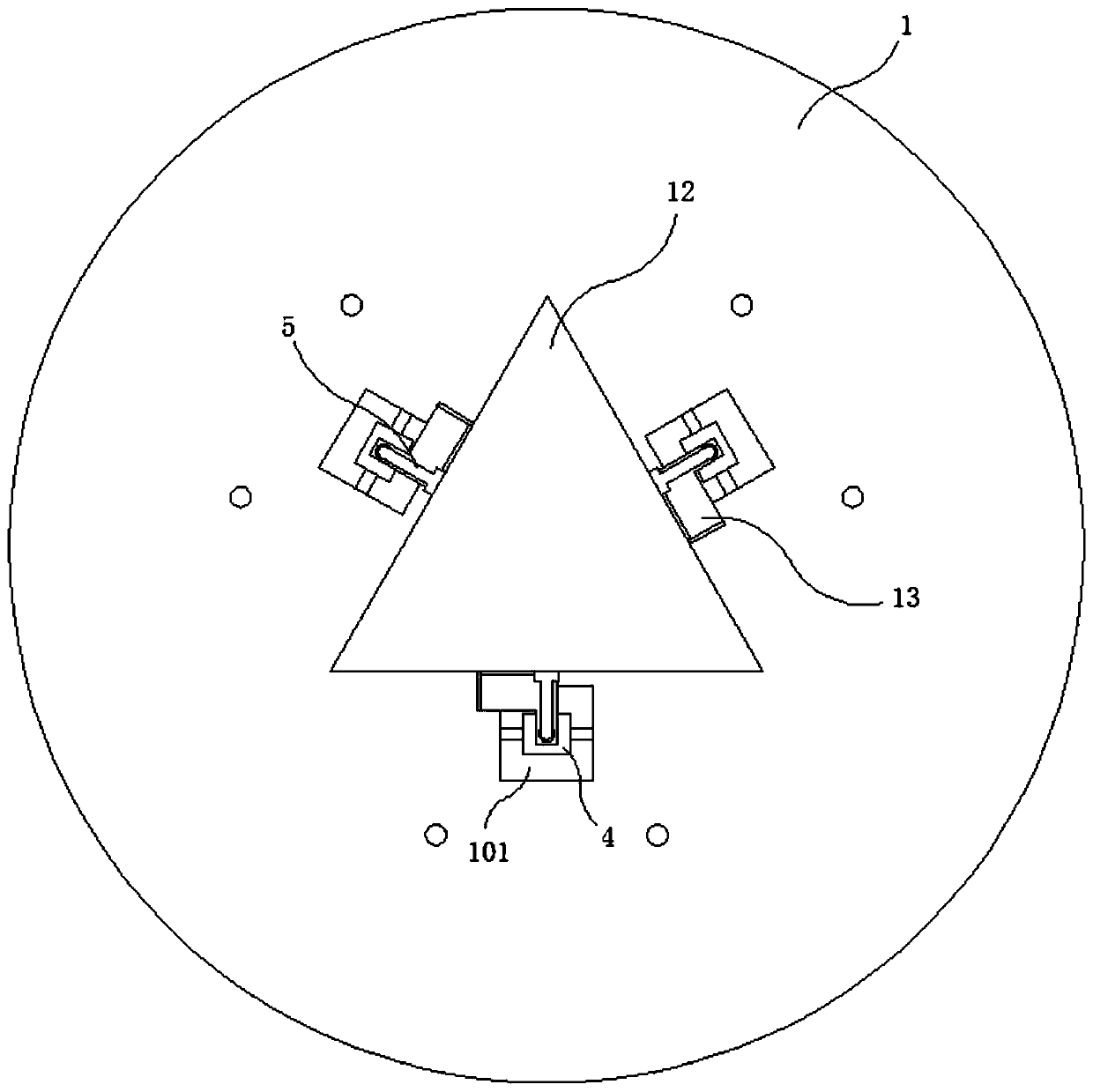

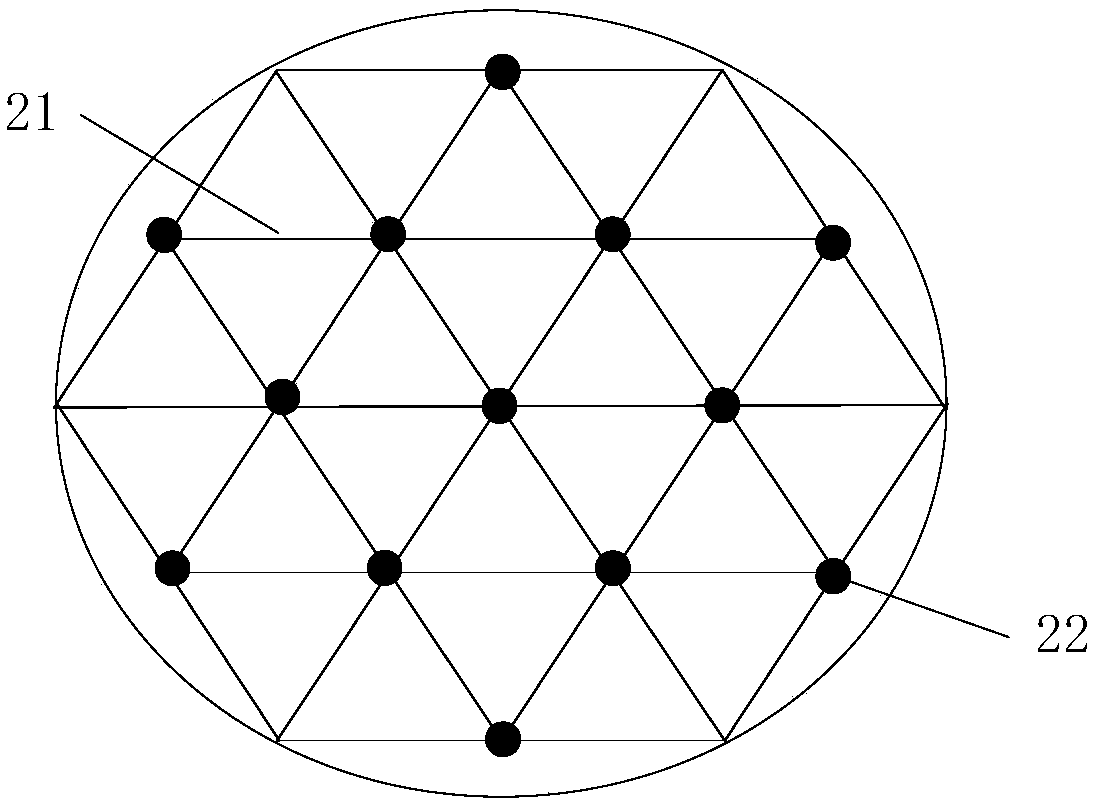

Triangular beam flexible constraint variable stiffness micro-nano measuring head

ActiveCN110095050ASolve the problem of prone to driftSolve the problem of translationPoint coordinate measurementsMicro nanoEngineering

The invention discloses a triangular beam flexible constraint variable stiffness micro-nano measuring head, which comprises a moving platform, wherein the moving platform is in the shape of a truncated cone, one side of the moving platform is provided with a measuring component, the measuring component is connected with the moving platform by means of a measuring and supporting structure, the center of the measuring and supporting structure is coaxial with a circle center of the measuring component, a plurality of reflecting sheets are fixedly mounted on the measuring and supporting structure,the other side of the moving platform is provided with a plurality of interferometers corresponding to the reflecting sheets, and penetrating holes are formed in the moving platform at positions corresponding to the reflecting sheets; one end of the measuring and supporting structure is connected with the measuring component, the other end is connected with a piezoelectric stacker by means of flexible adjusting members, and the flexible adjusting members are distributed in a triangle under the moving platform; and a gap is formed between the top part of the measuring component and the bottomsurface of the moving platform. The triangular beam flexible constraint variable stiffness micro-nano measuring head can change the stiffness of the measuring component by adjusting different operating states of the piezoelectric stacker, and can satisfy requirements for different stiffness of the measuring component due to different measuring processes and measuring objects.

Owner:ANHUI UNIV OF SCI & TECH

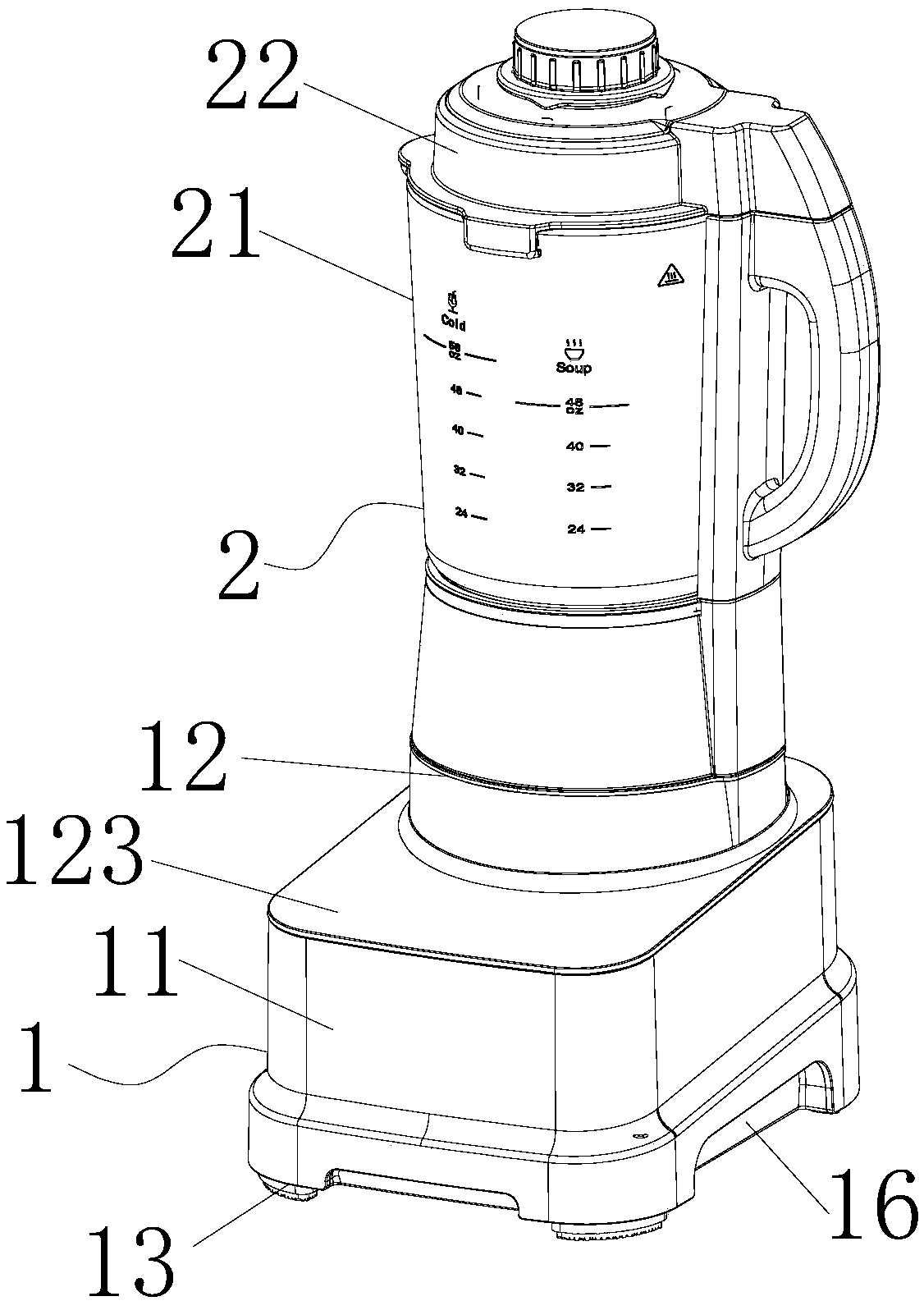

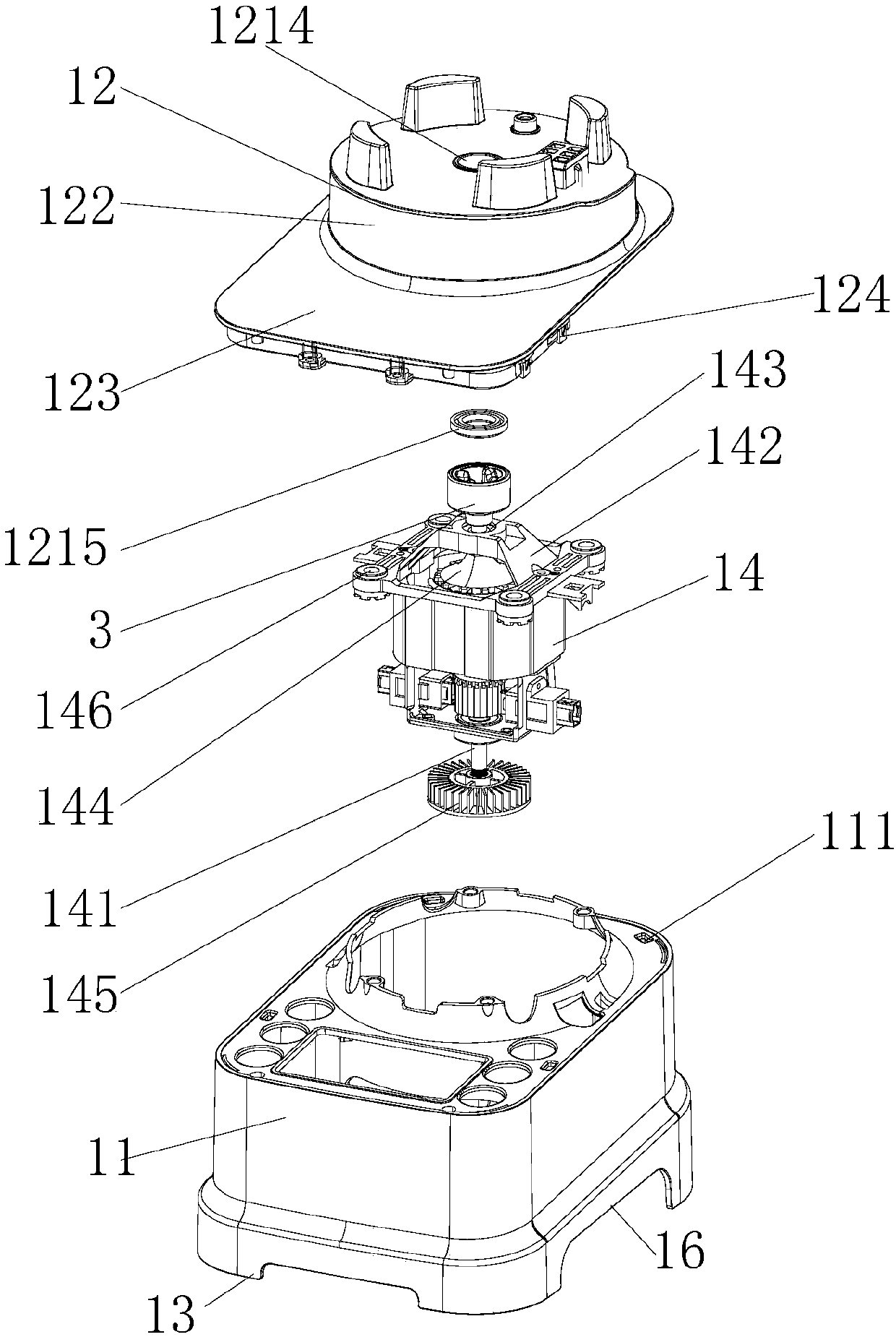

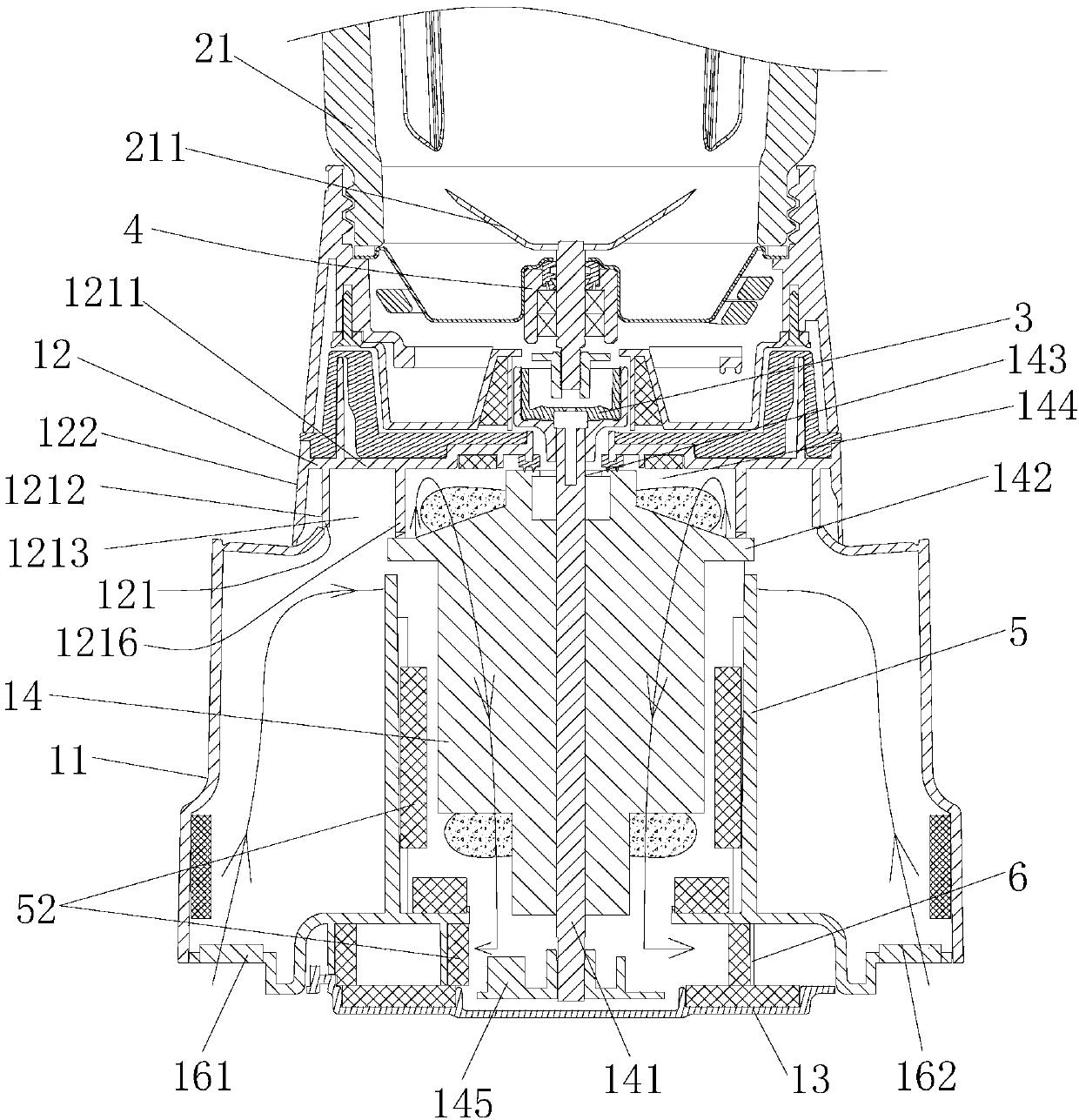

Low-noise food processor

ActiveCN110876571AEffective coolingPlay a guiding roleKitchen equipmentElectric machineryControl theory

The invention discloses a low-noise food processor. The low-noise food processor comprises a machine base with a motor, a stirring cup connected with the machine base and a pulverizing cutter arrangedin the stirring cup. A fan is arranged at the lower end of a motor shaft of the motor; the machine base is provided with an air inlet and an air outlet. The air outlet is positioned on one side belowthe machine base; the machine base comprises a machine shell, a top cover and a bottom cover. A motor cylinder used for containing a motor is arranged in the machine shell. A motor support is arranged at the upper end of the motor, the motor support is mounted at the top of the motor barrel; a shaft hole through which the upper end of the motor shaft penetrates is formed in the center of the motor support; the motor support is provided with a communication port communicated with the interior of the machine shell. The top cover is provided with a wind scooper; the wind scooper stretches into the machine shell and covers the upper portion of the motor support. When the motor works, the fan is driven to rotate, so that external air enters the machine shell from the air inlet and flows into the motor barrel through the communicating opening after being guided by the a wind scooper, and the wind scooper can play a role in guiding airflow and can prevent noise generated in the working process of the motor from being exhausted outwards.

Owner:JOYOUNG CO LTD

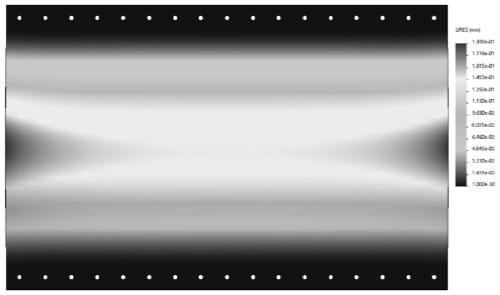

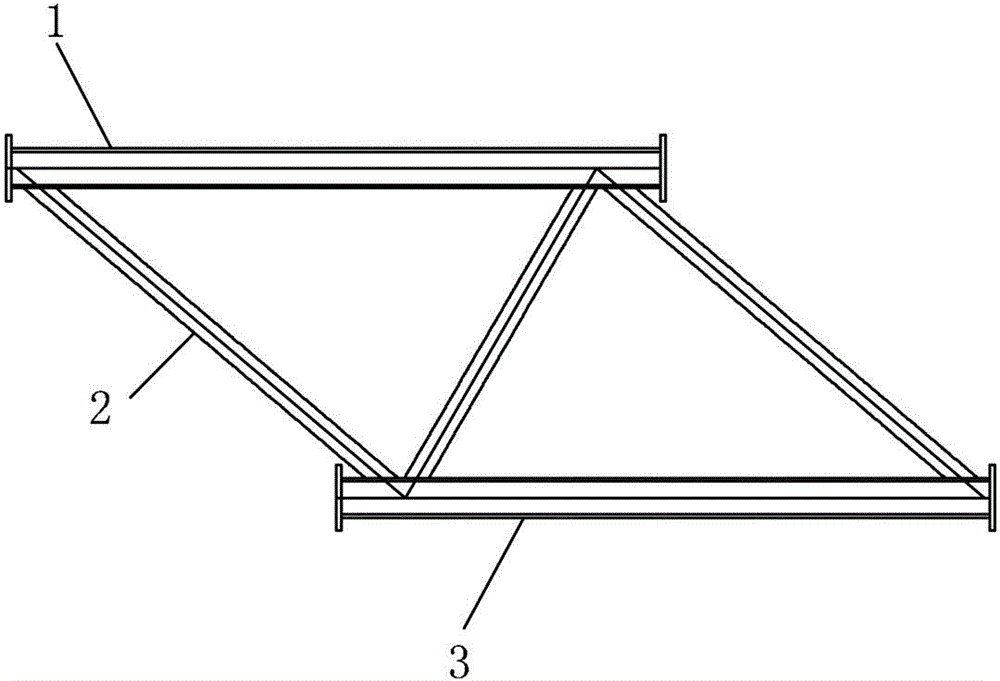

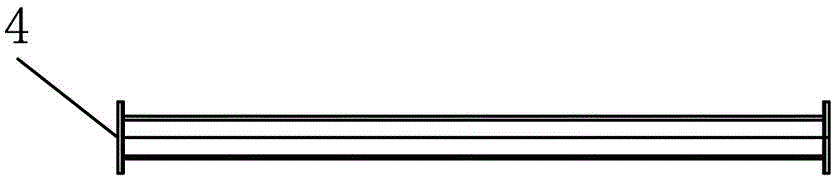

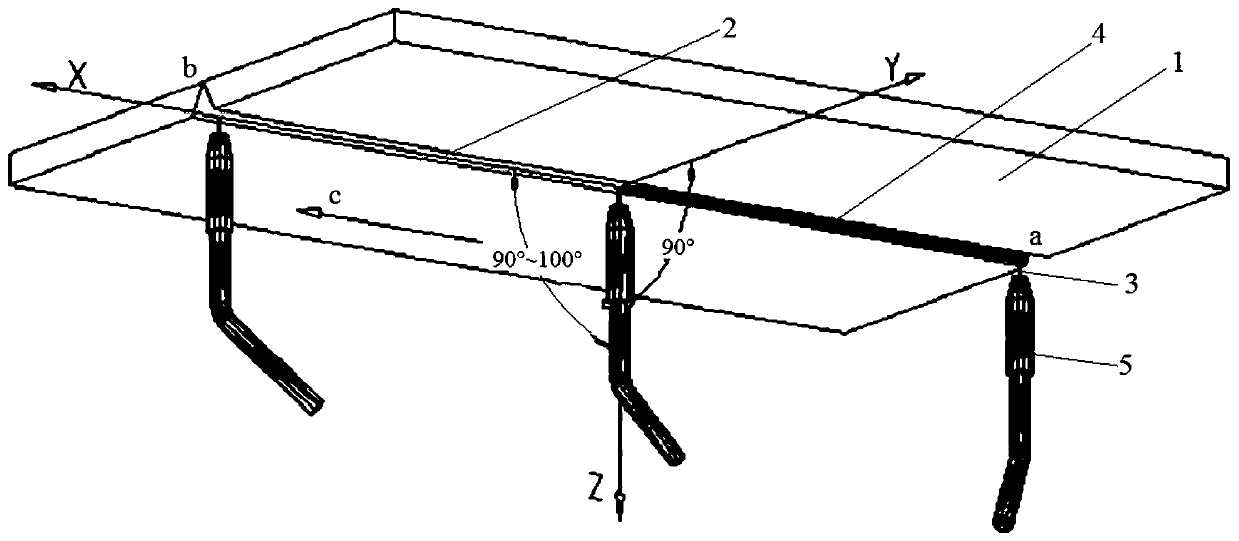

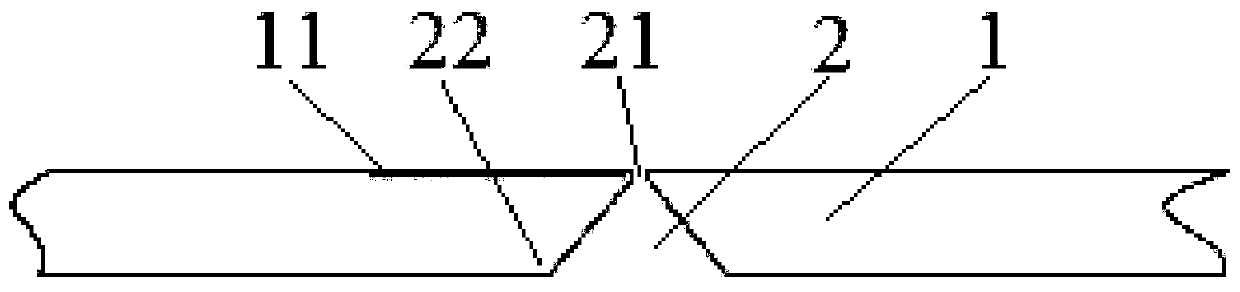

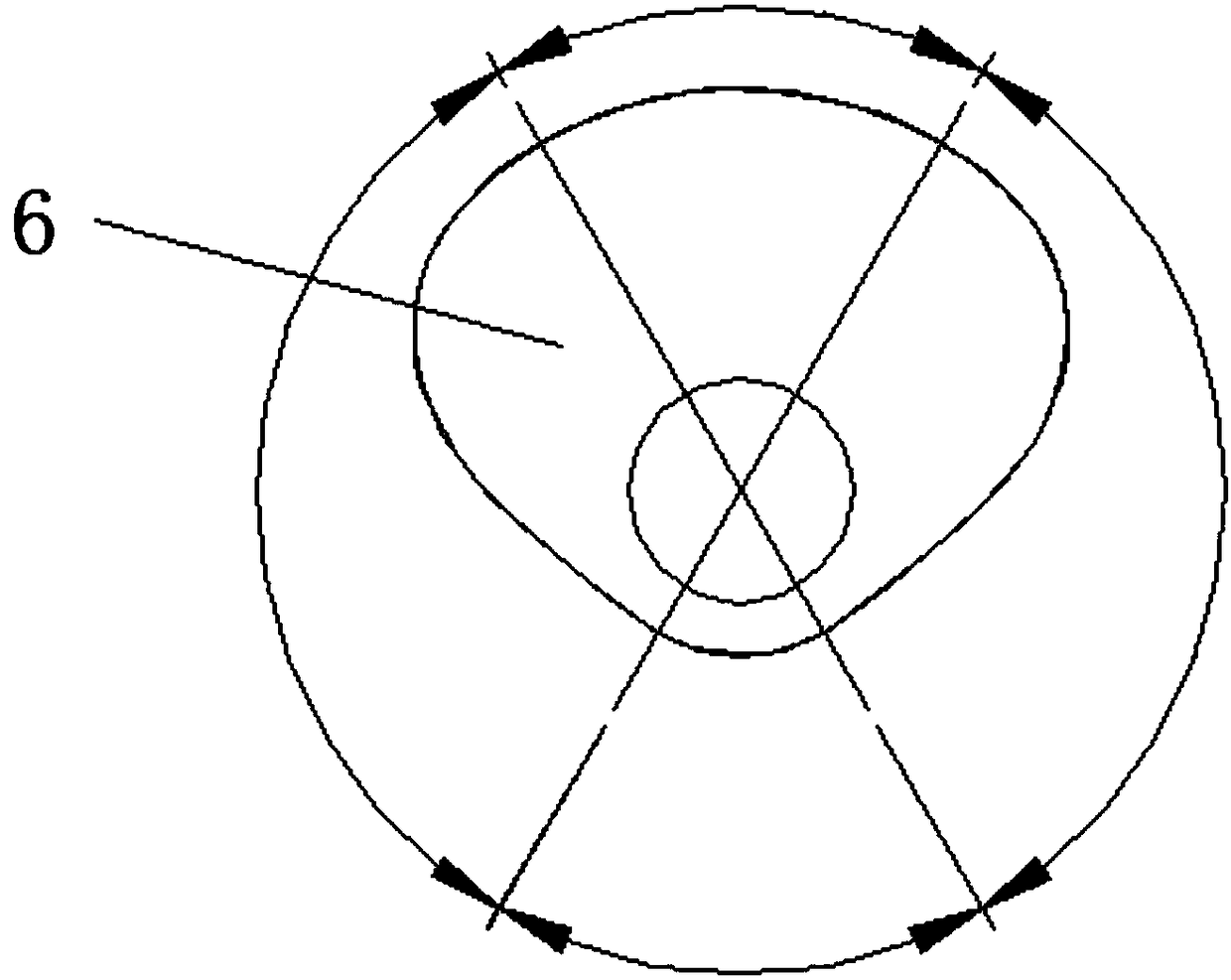

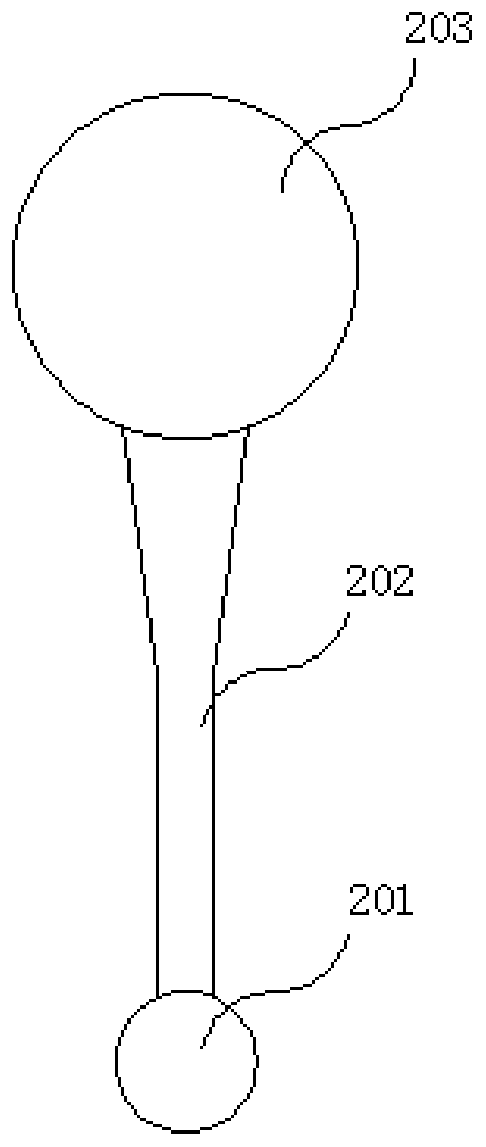

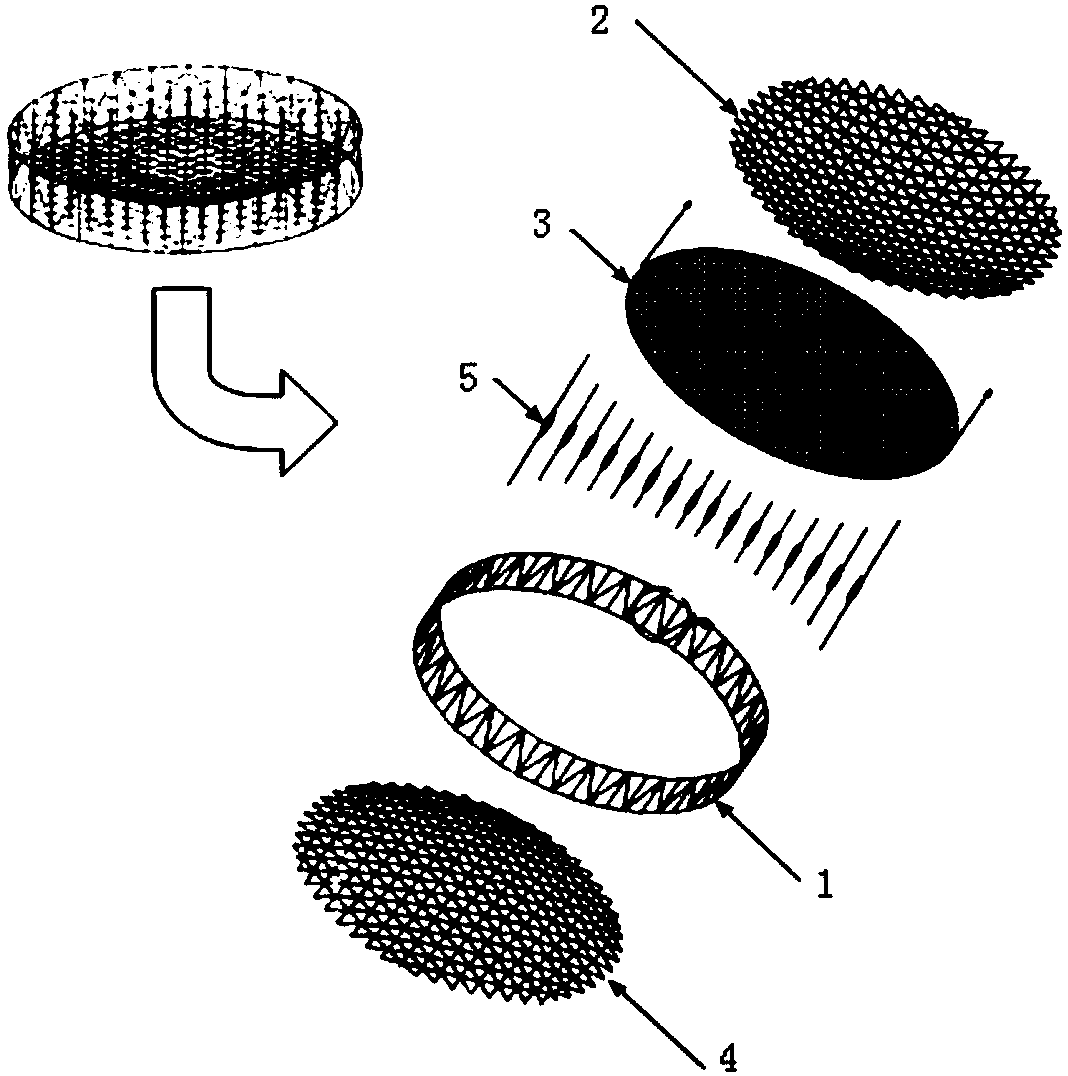

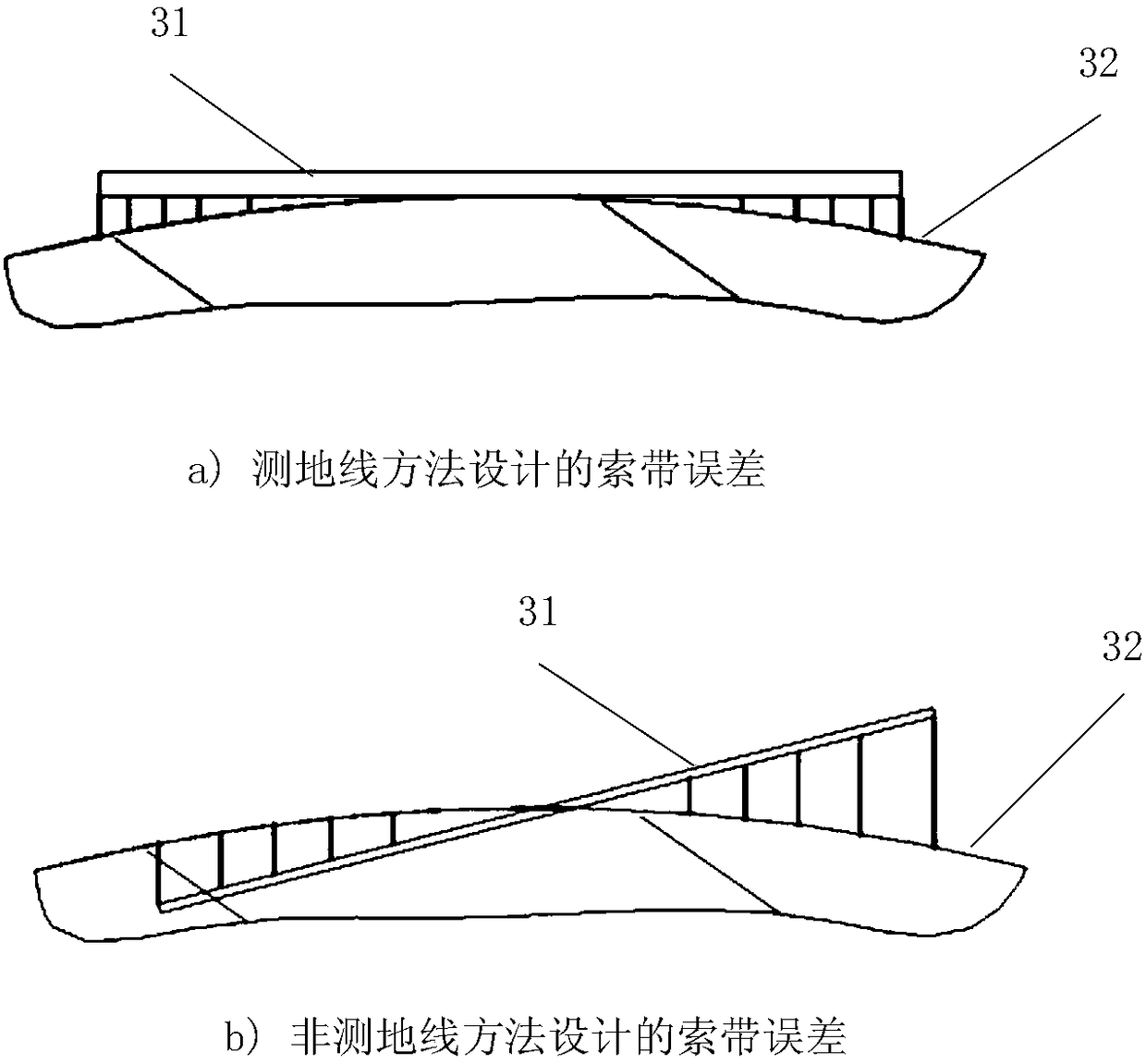

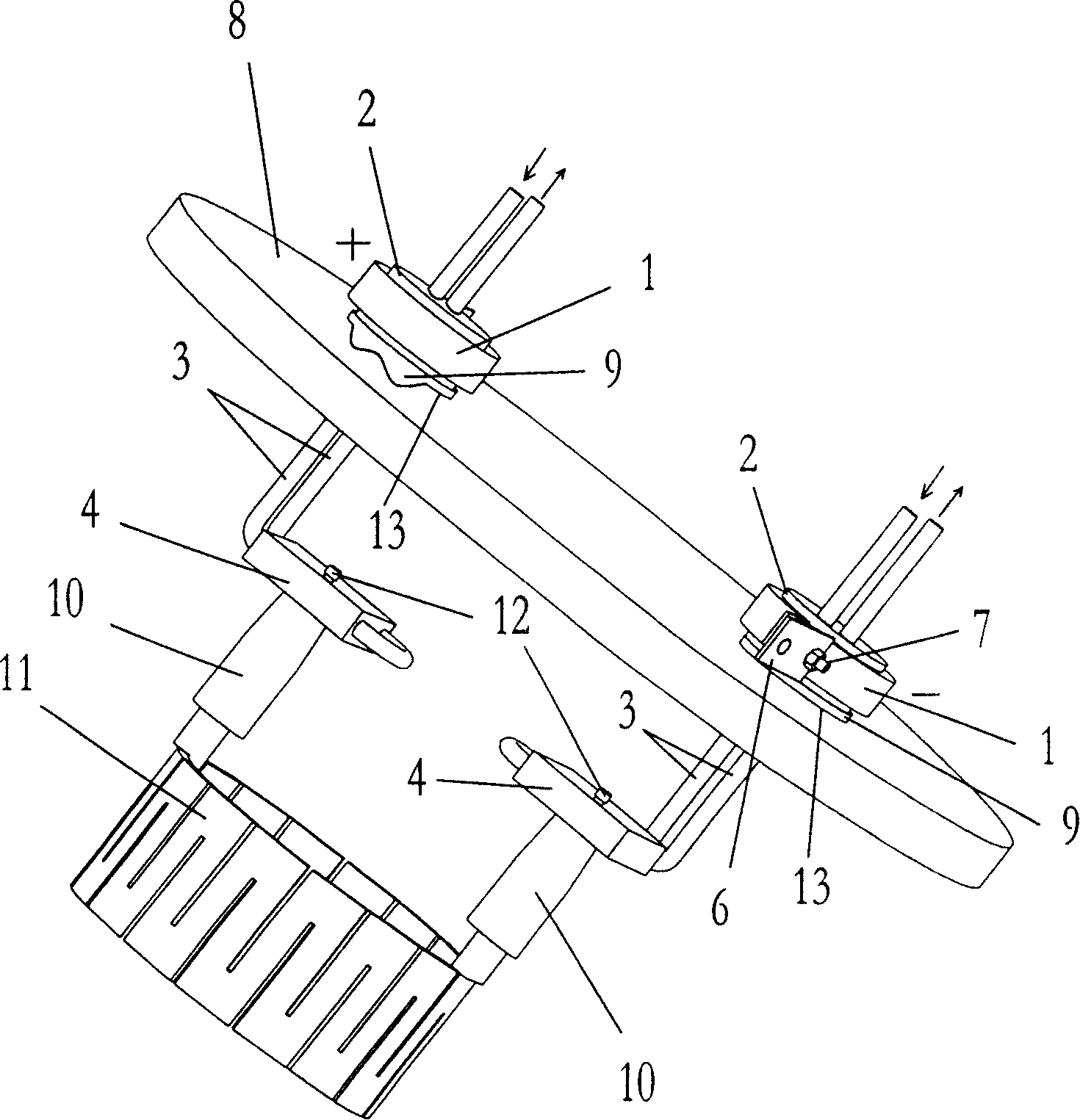

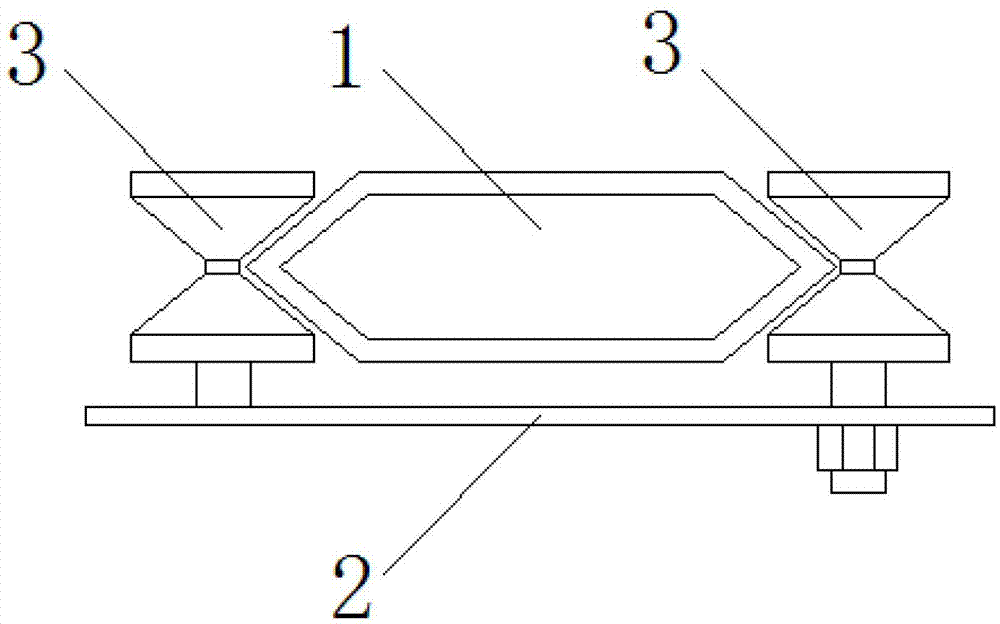

Mesh surface of spaceborne mesh antenna

ActiveCN108539365AReduce assembly clearanceUnable to meet the needs of web designAntenna supports/mountingsRadiating elements structural formsCircular sectionLarge aperture

The invention discloses a mesh surface of a spaceborne mesh antenna, and the mesh surface employs a rectangular-section rope belt for replacing a circular-section rope, and is used for the mesh surface design of a large-scale high-precision mesh antenna. In order to reduce the errors, caused by the processing and assembly, of a segmented rope, the whole rope belt is used for replacing the segmented rope, and a screw assembly mode is employed for splicing the rope belts to form the whole mesh surface. According to a proposed mesh surface design method, the method can achieve the mesh surface ofa spaceborne high-precision mesh antenna, so as to meet the domestic demands for the large-aperture high-precision mesh antennas.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

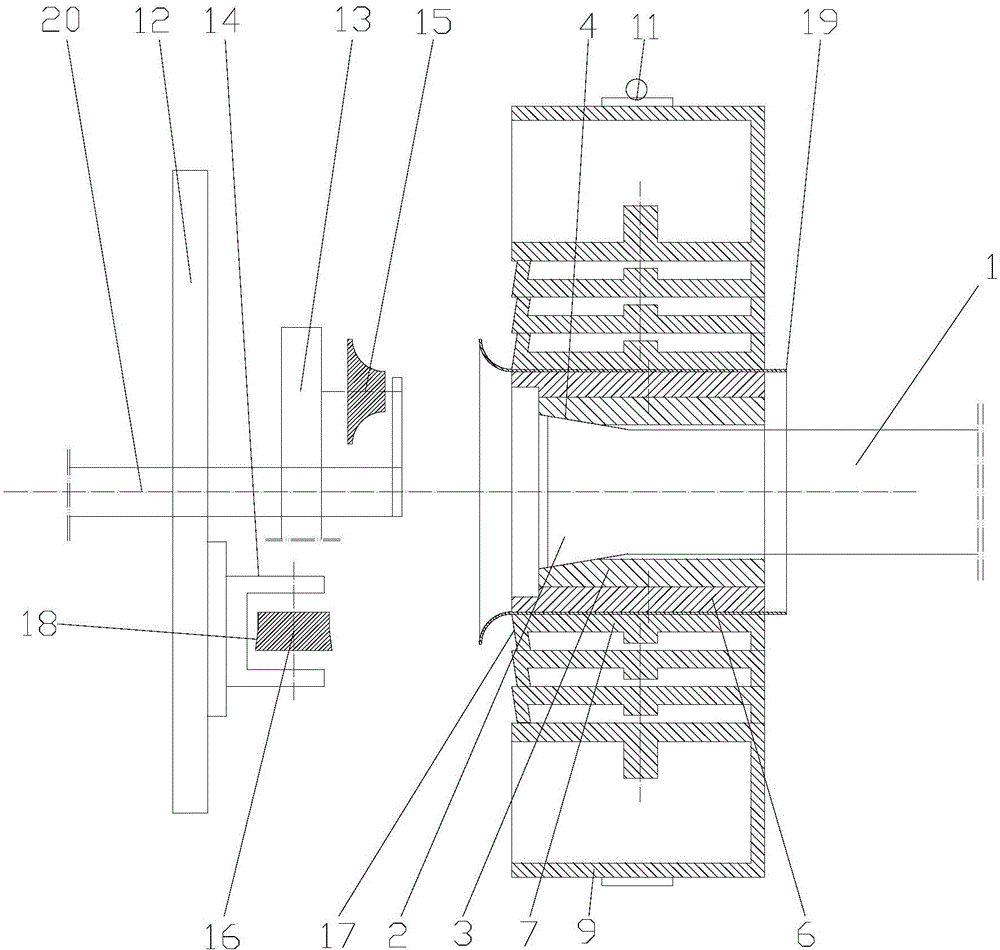

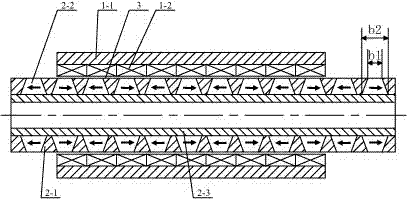

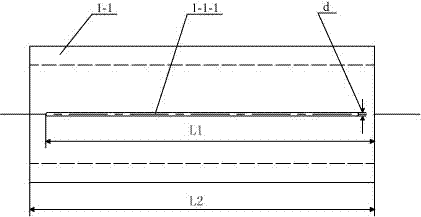

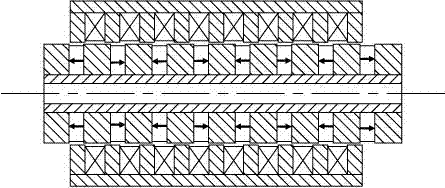

Cylindrical permanent magnet linear motor with high thrust density

ActiveCN101795048BReduce processing difficultyReduce assembly clearancePropulsion systemsIsosceles trapezoidPermanent magnet linear motor

Owner:HARBIN INST OF TECH

Flexible water-cooling metal electrode for monocrystalline furnace

InactiveCN101205630AGood thermal fieldReduce assembly clearances and errorsAfter-treatment apparatusOhmic-resistance electrodesGraphite electrodeStainless steel electrode

The invention relates to a flexible water-cooling metal electrode used for a mono-crystal furnace, comprising a water-cooling copper pipe electrode, a stainless steel terminal clamp and a copper gland cover, wherein, the lower part of the water-cooling copper pipe electrode is welded with the stainless steel terminal clamp, and a water-cooling cycle is formed; the upper part of the water-cooling copper pipe electrode passes through the copper gland cover and is hermetically welded with the copper gland cover; the water-cooling copper pipe electrode is a complete water-cooling copper pipe which passes through the stainless steel terminal clamp and then returns back to the stainless steel terminal clamp to form a water-cooling cycle. Because the water-cooling copper pipe has an ability of plastic deformation and can be properly deformed under an exogenic action, thereby a position of the stainless steel terminal clamp can be conveniently moved within a certain range, and then a position of a connecting point between a stainless steel electrode and a graphite electrode and a heater. The invention is favorable for removing errors caused by factors like processing, assembly, time-dependent deformation and so on, and for accurately fixing the heater, thereby a good thermal field is obtained.

Owner:GRINM ELECTRO OPTIC MATERIALS

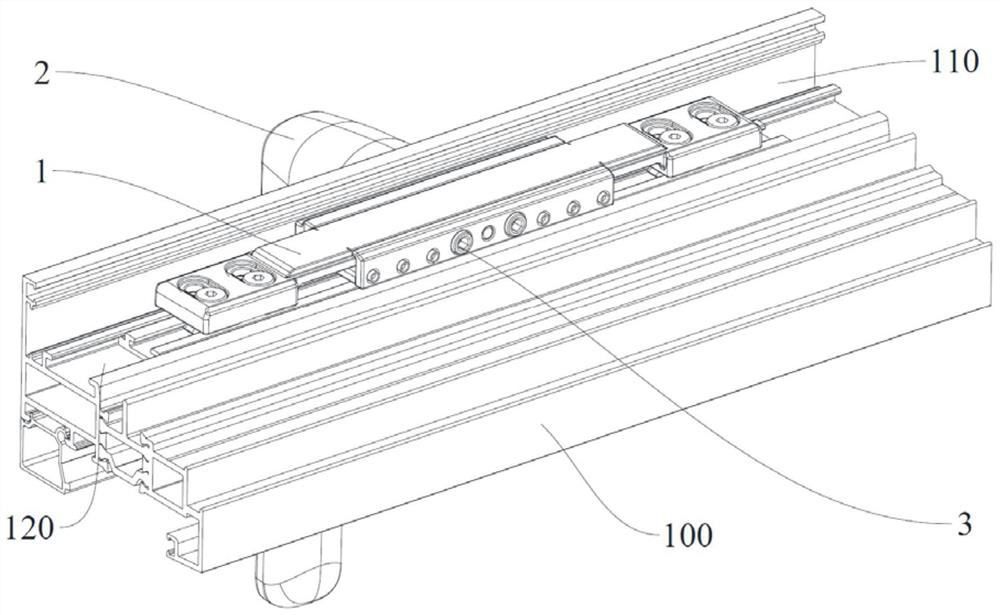

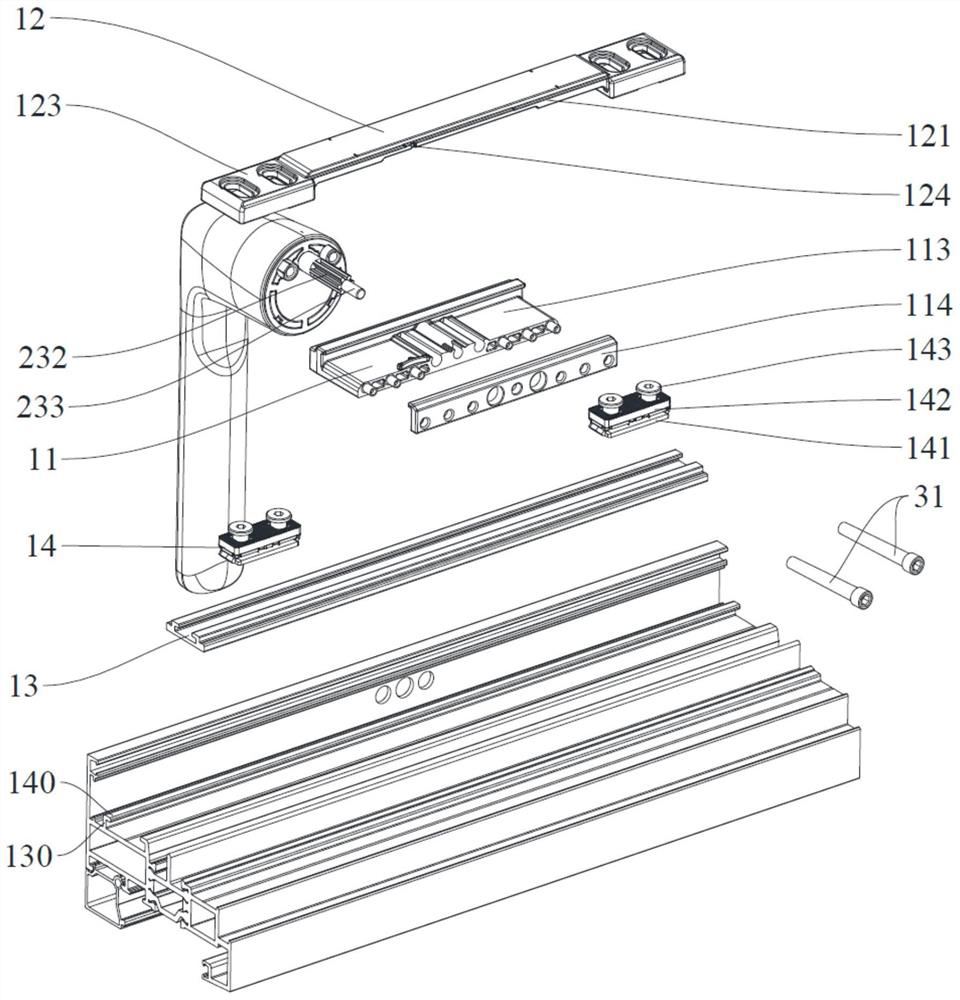

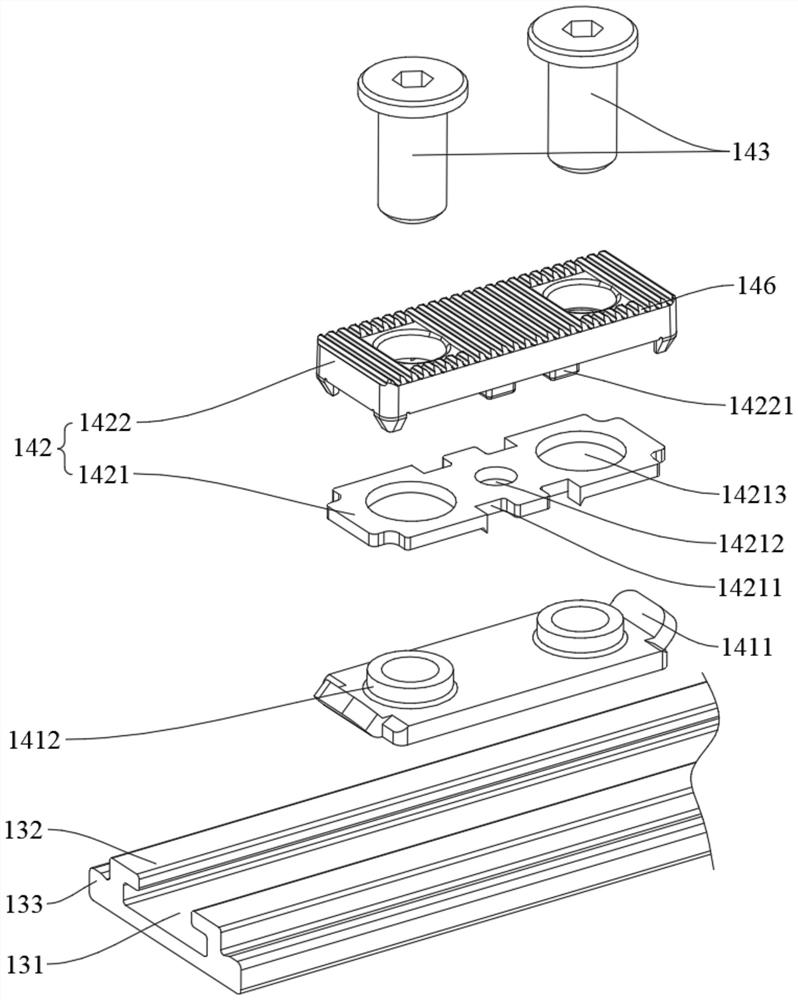

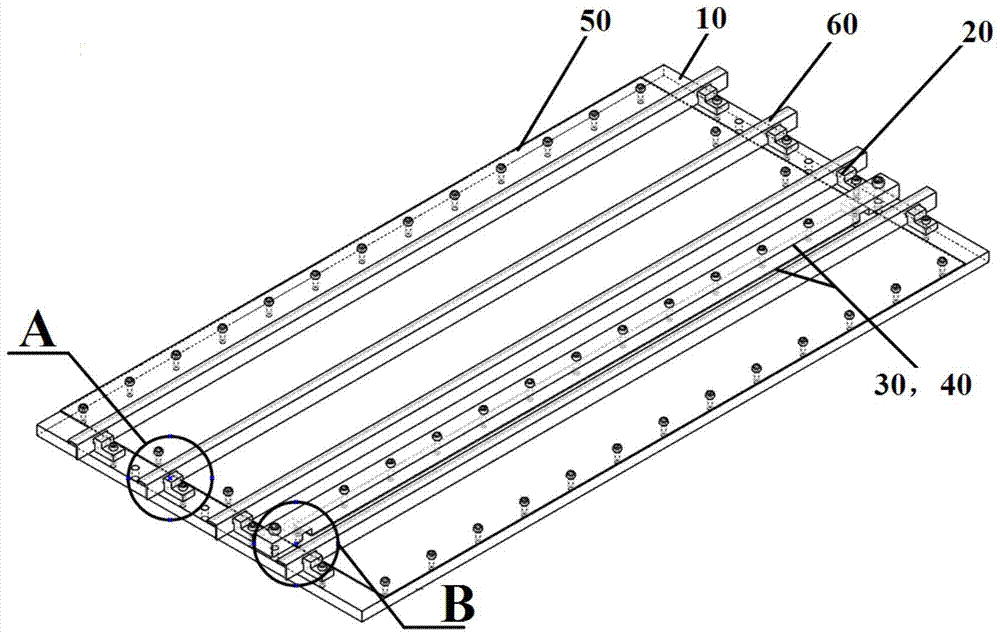

Lifting track

The invention discloses a lifting track which comprises a track and a lifting device. A plurality of pulleys are arranged on the lifting device and are respectively arranged on the left side and the right side of the track, a pulley face of each pulley is a conical surface, and both the left end and the right end of the track are tangent with the pulley faces of the pulleys. The lifting track has the advantages that the lifting track ascends and descends by the aid of the pulleys, the pulley faces of the pulleys are the conical surfaces, and the track is tangent with the pulley faces of the pulleys, so that the assembly clearance between the lifting device and the track is small, and the lifting device cannot be jammed on the track.

Owner:SUZHOU SENTEC CLEANING EQUIP

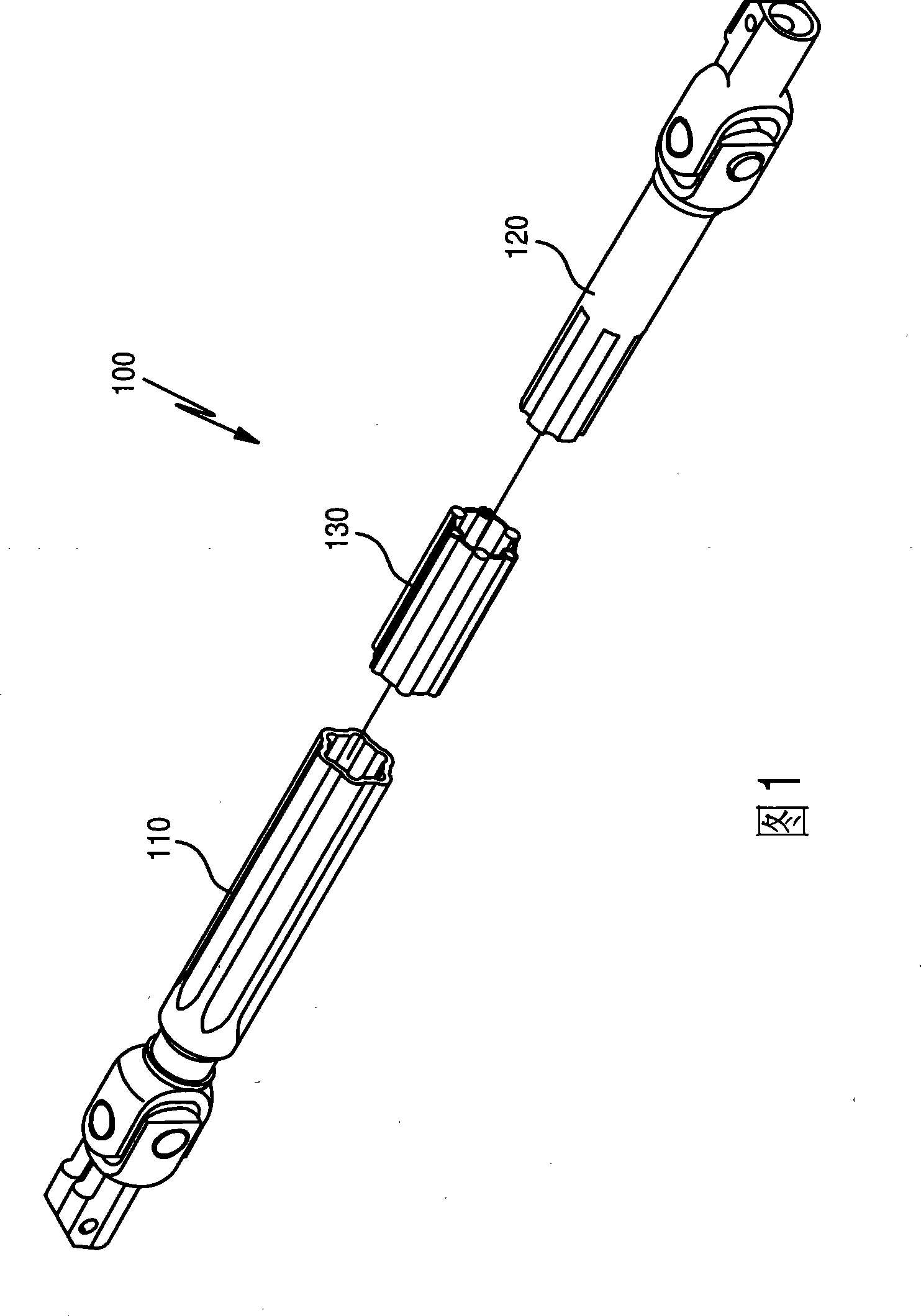

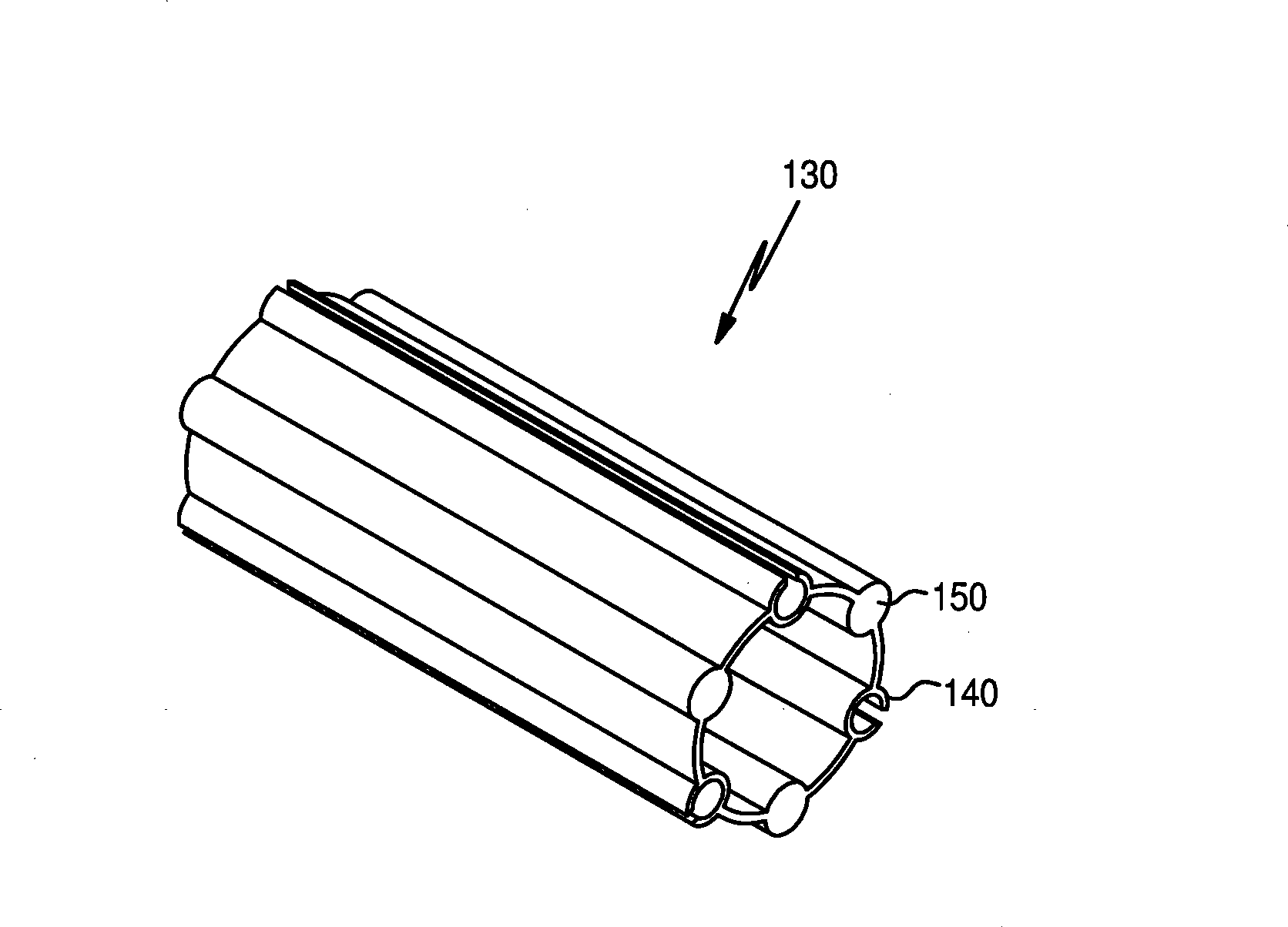

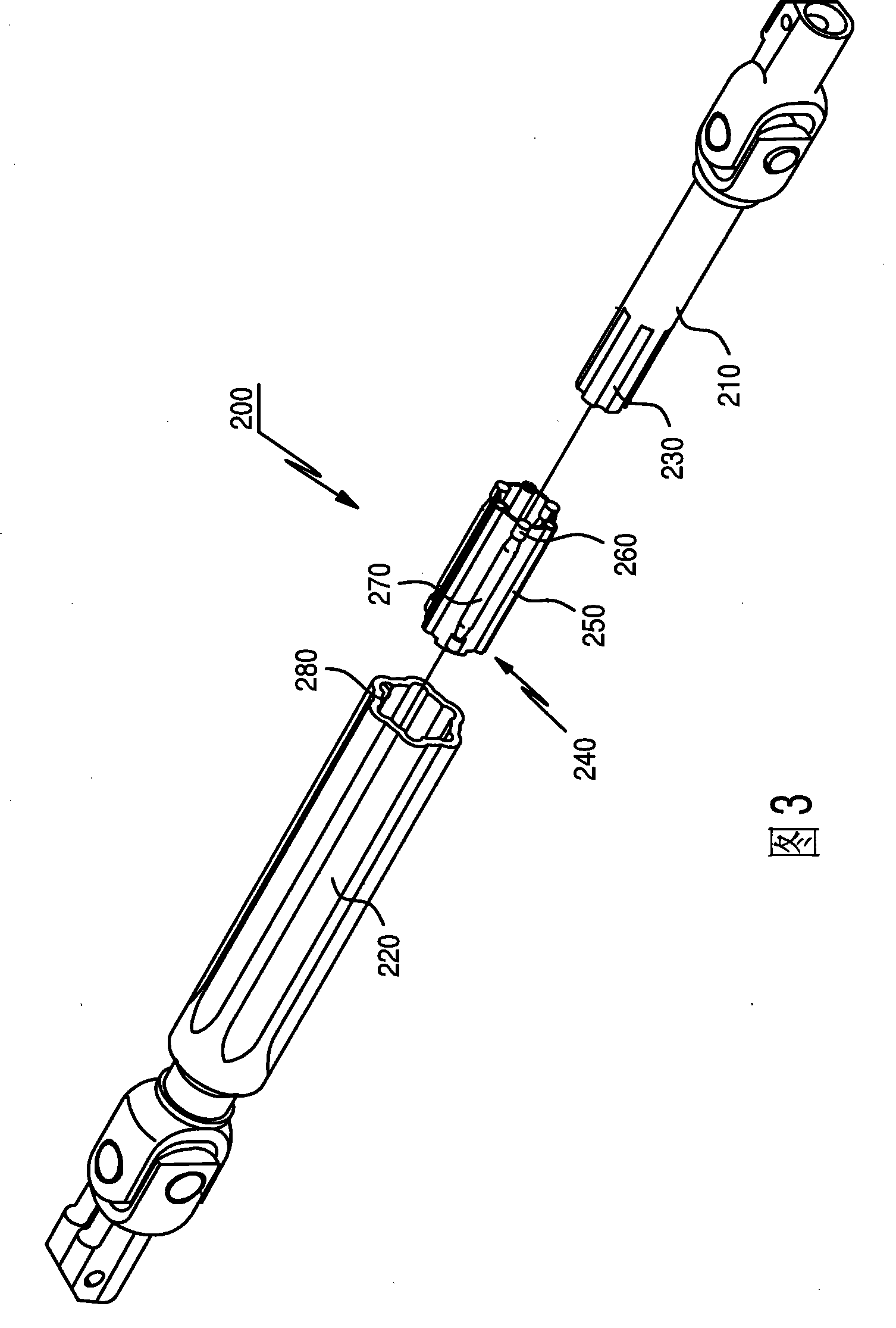

Universal joint

ActiveCN101434260AHigh strengthImprove rigidityYielding couplingSteering linkagesUniversal jointUltimate tensile strength

A universal joint includes a tube having a hollow shape; a slip bush inserted into the tube; and a shaft assembled with the tube through the slip bush, wherein the slip bush includes power transmission parts, which are arranged along an circumferential surface of the slip bush in an axial direction and have pins positioned at centers of the power transmission parts and supports supporting both ends of each pin, and elastic parts, which are arranged along the circumferential surface of the slip bush while being spaced from the power transmission parts and have a section with a C-shape, which is formed in such a manner that a side portion is cut out in the axial direction. Therefore, strength and rigidity are improved, even when twist is generated in the universal joint, so that clearance and noise due to abrasion, pressing, etc. can be minimized.

Owner:HL MANDO CORP +1

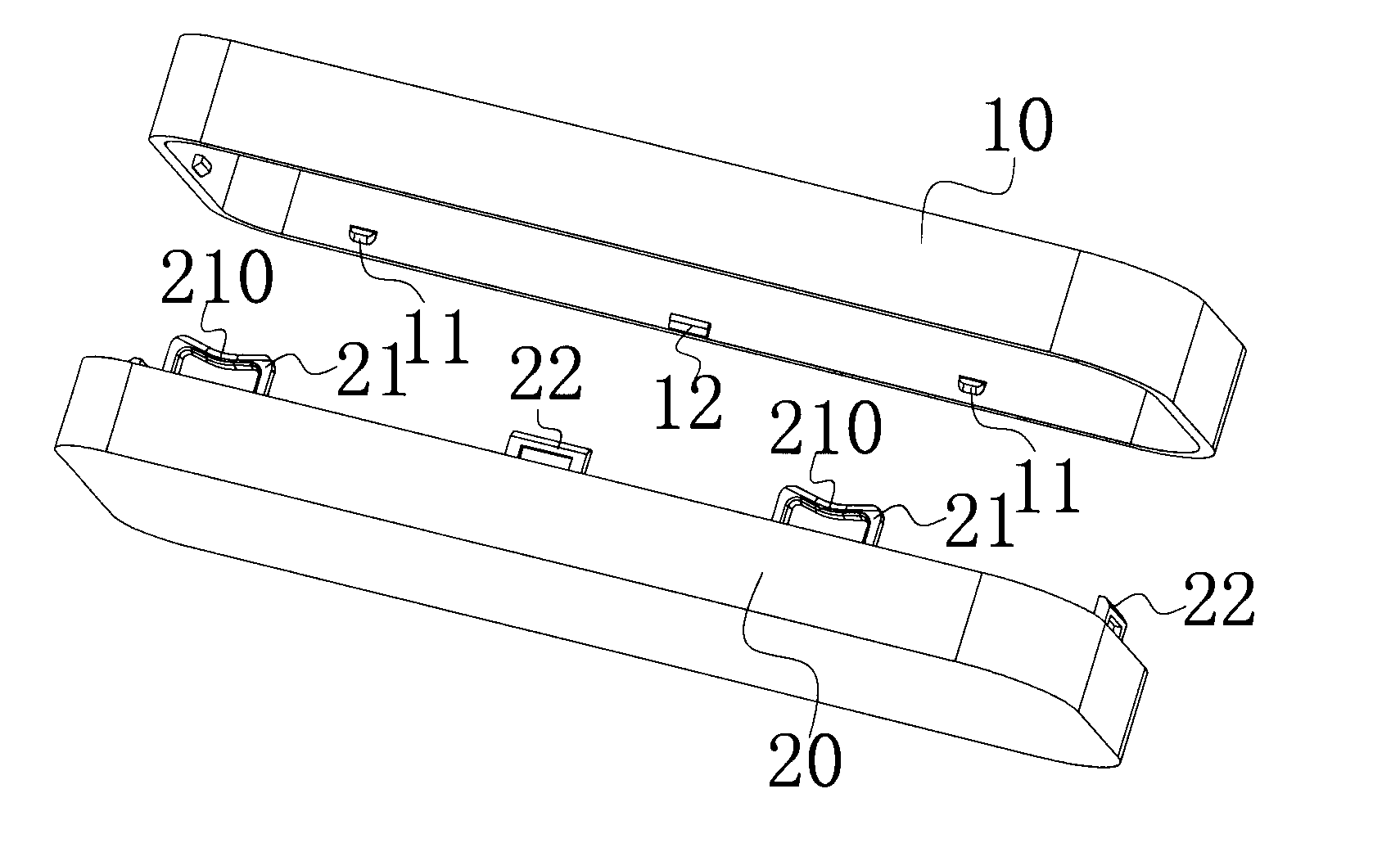

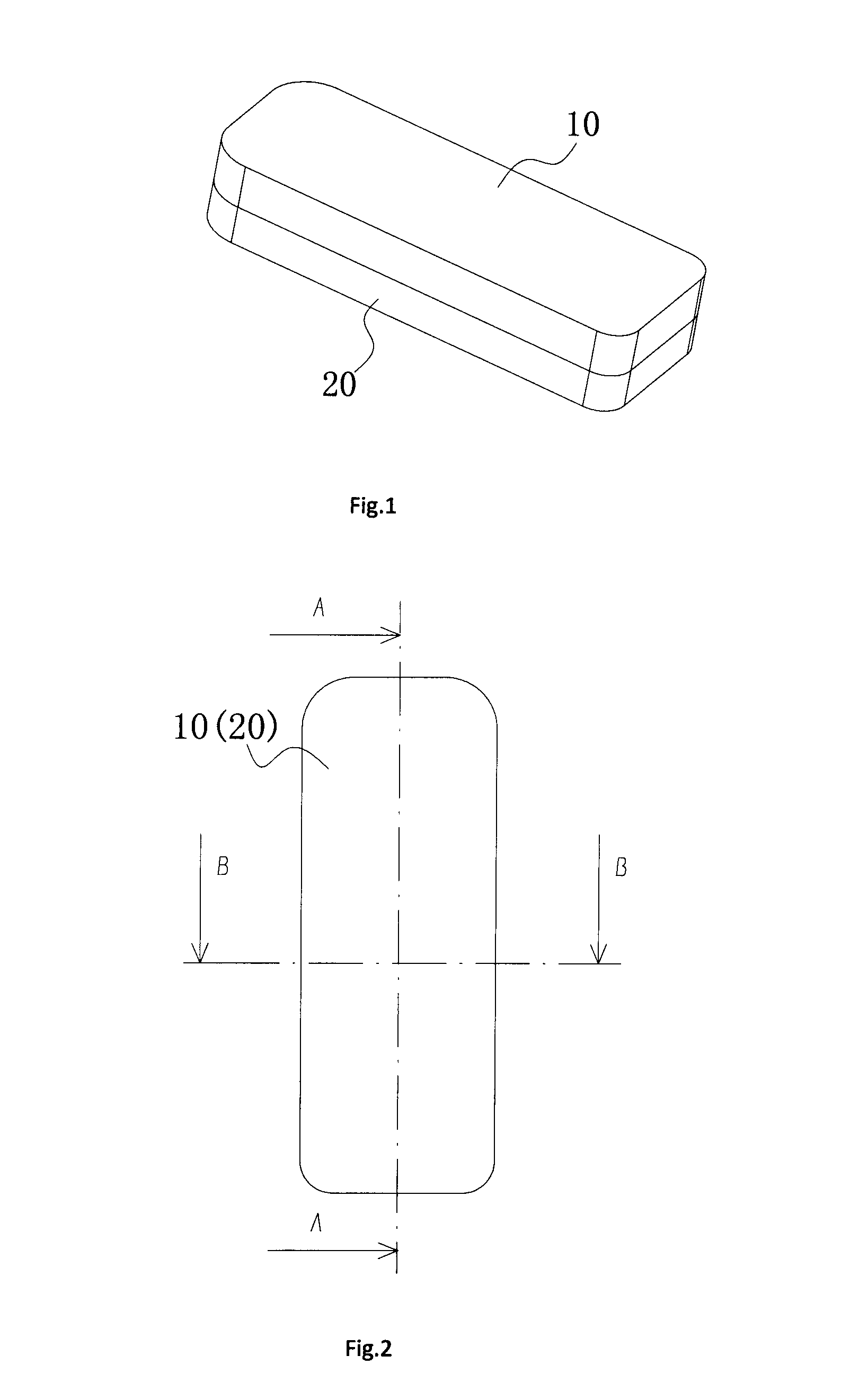

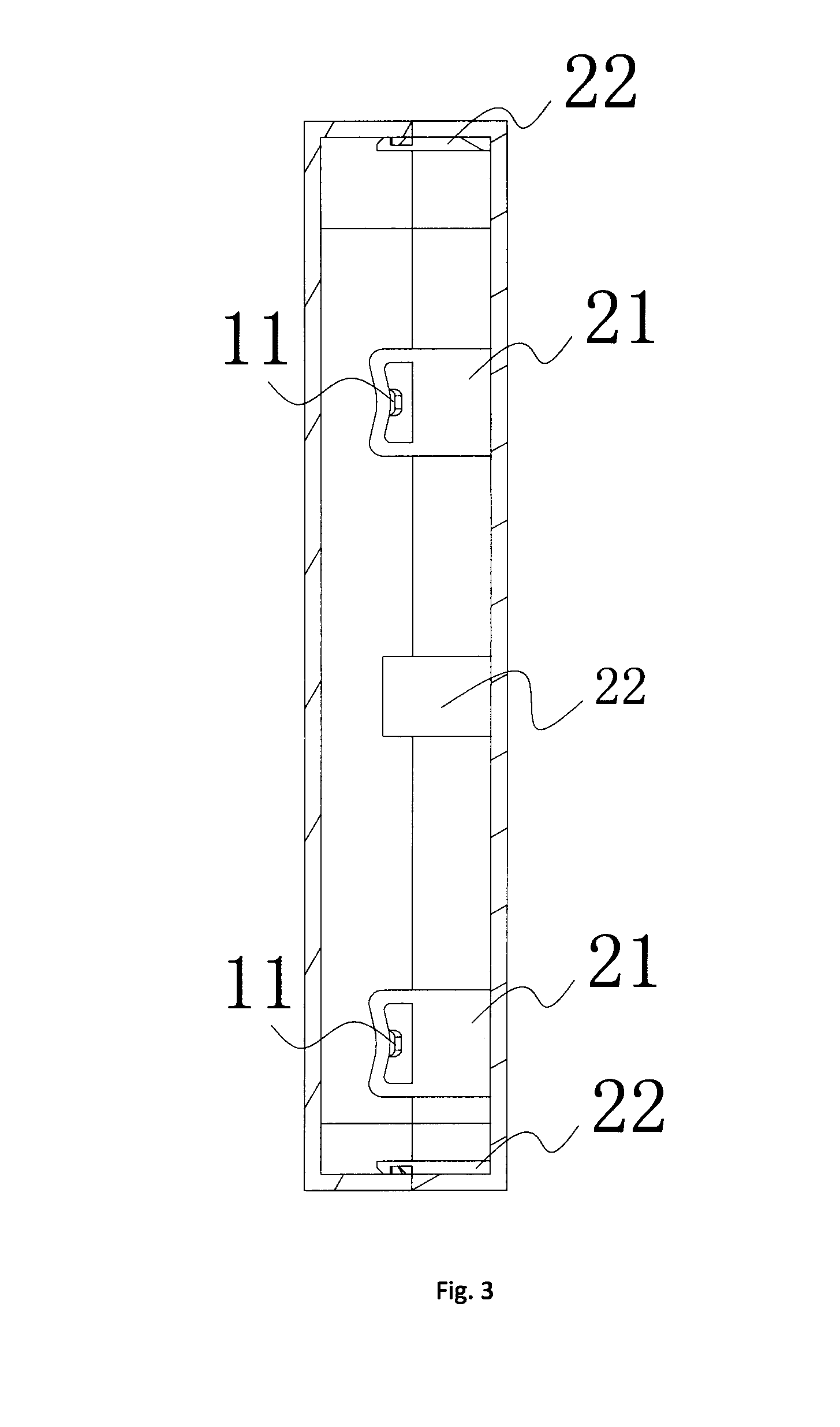

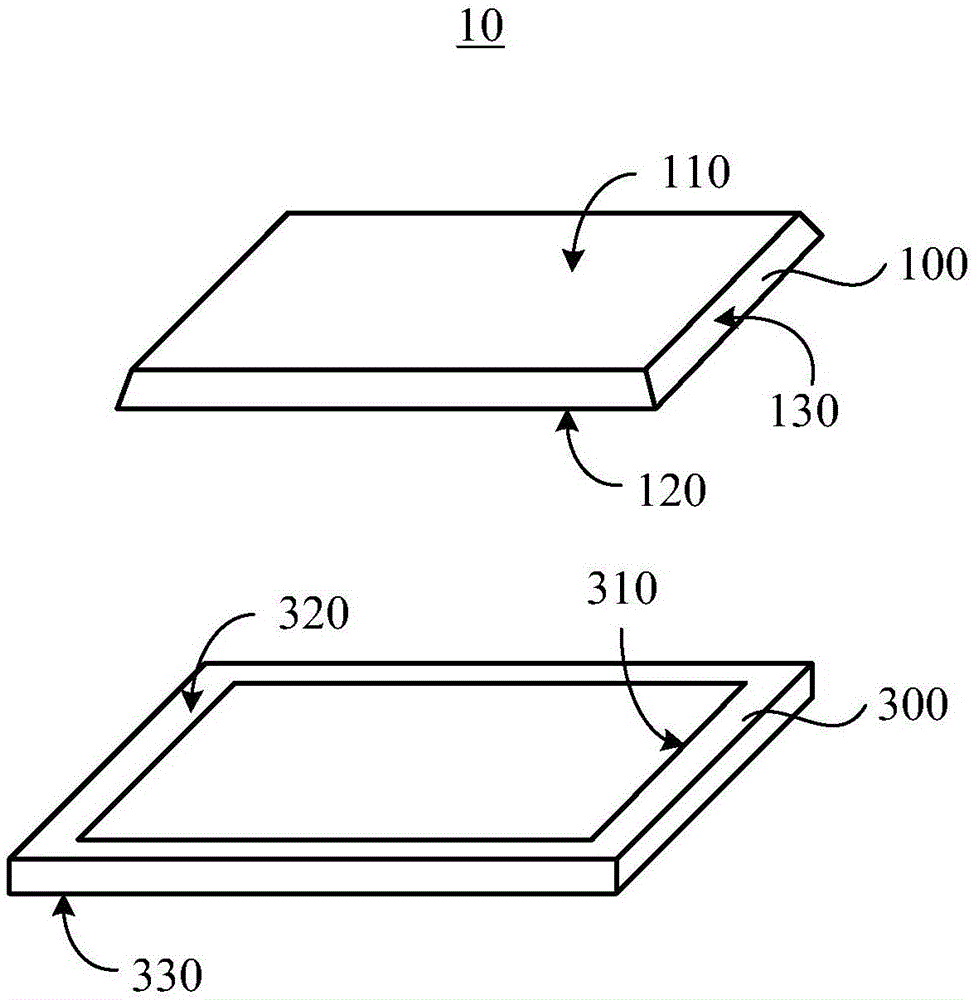

Fingerprint module and electronic device

InactiveCN105867547AReduce gapReduce assembly clearanceDigital data processing detailsCharacter and pattern recognitionComputer scienceFingerprint

The invention provides a fingerprint module and an electronic device. The fingerprint module comprises a fingerprint chip and a hollow frame, wherein the fingerprint chip comprises a first surface, a second surface and side surfaces, wherein the first surface and the second surface are arranged oppositely, and the side surfaces intersect with the first surface and the second surface respectively and incline relative to a perpendicular line perpendicular to the first surface; the frame is used for accommodating the fingerprint chip and comprises an inner surface, and the inner surface of the frame is close to the side surfaces of the fingerprint chip and inclines relative to the perpendicular line perpendicular to the first surface; an included angle between the inner surface of the frame and each side surface of the fingerprint chip is smaller than or equal to a preset threshold.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

Improved cleaning doctor locking sleeve structure of rotary screen printing machine

InactiveCN105584201AReduce the impactEasy to lock and deformScreen printersScreen printingThin metal

The invention discloses an improved cleaning doctor locking sleeve structure of a rotary screen printing machine. The locking sleeve structure comprises a locking sleeve side wall, a locking sleeve head blank holder, an open groove and a blank holder groove opening, and further comprises a cylindrical cleaning doctor positioning sleeve which is mounted on a cleaning doctor of the rotary screen printing machine in a sleeving manner, wherein the cleaning doctor positioning sleeve is a hollow body; the interior of the hollow body takes the shape of a stepped structure; the cleaning doctor corresponding to the hollow body is also of the stepped structure; the locking sleeve side wall which is made of a thin metal plate through chipless forming; the locking sleeve head blank holder is designed at one end of the locking sleeve side wall; the open groove is designed on the side near the locking sleeve side wall and the locking sleeve head blank holder; and the blank holder groove opening is also formed in the locking sleeve head blank holder. By virtue of a reinforcing part which is separately machined with the cleaning doctor positioning sleeve, namely the hollow body, the locking sleeve structure is reinforced. The reinforcing part is a thin slat which is partially leant on the locking sleeve side wall.

Owner:SUZHOU HUACE TEXTILE SCI & TECH

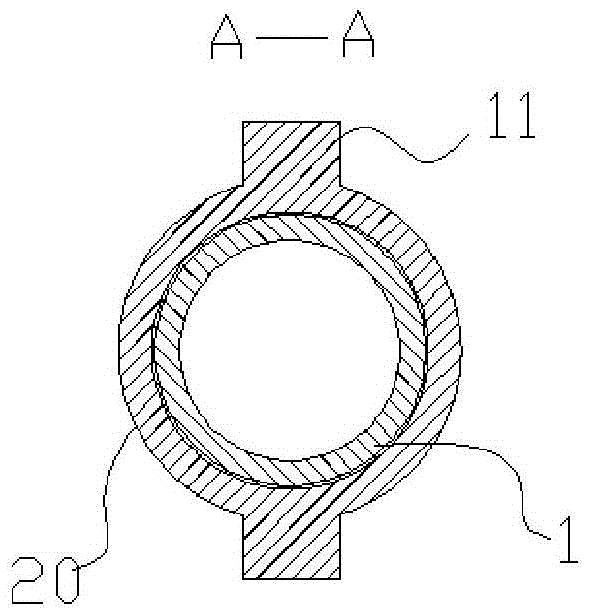

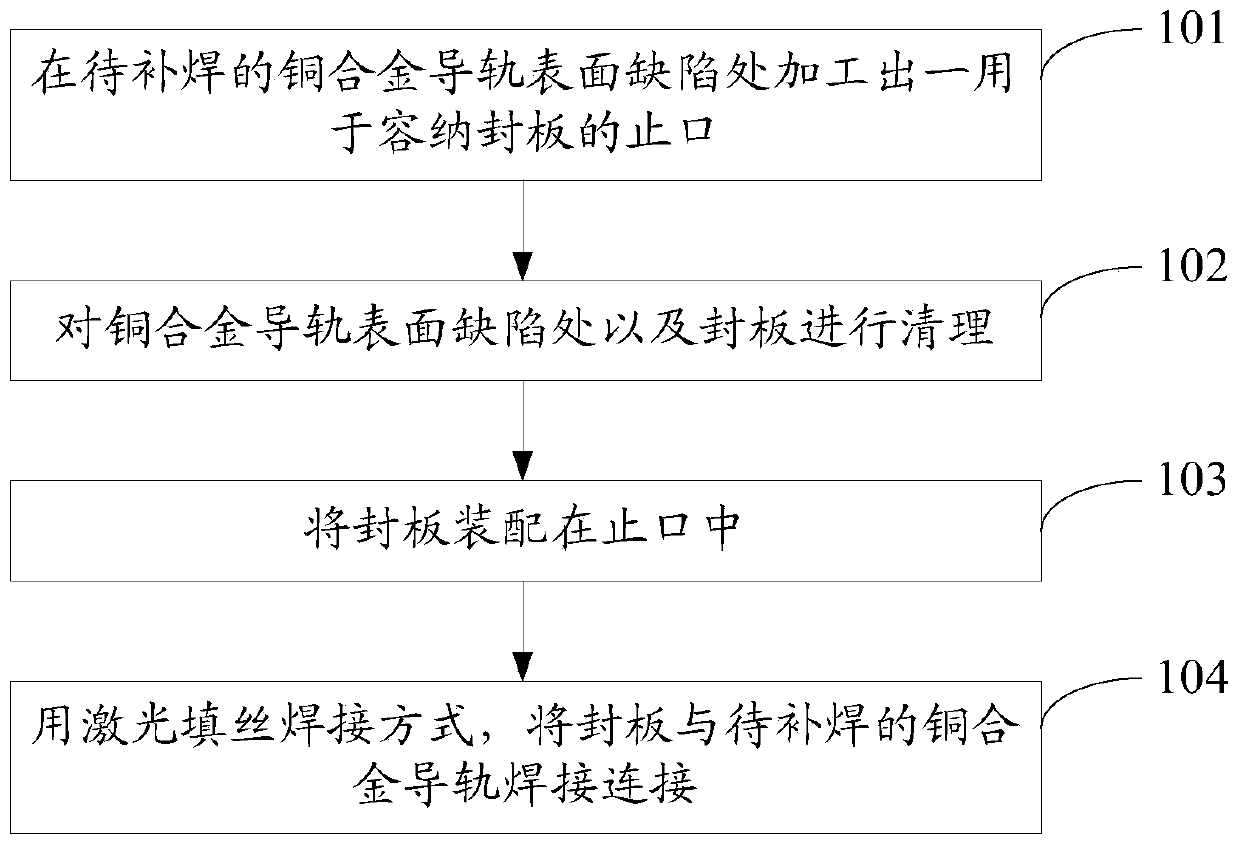

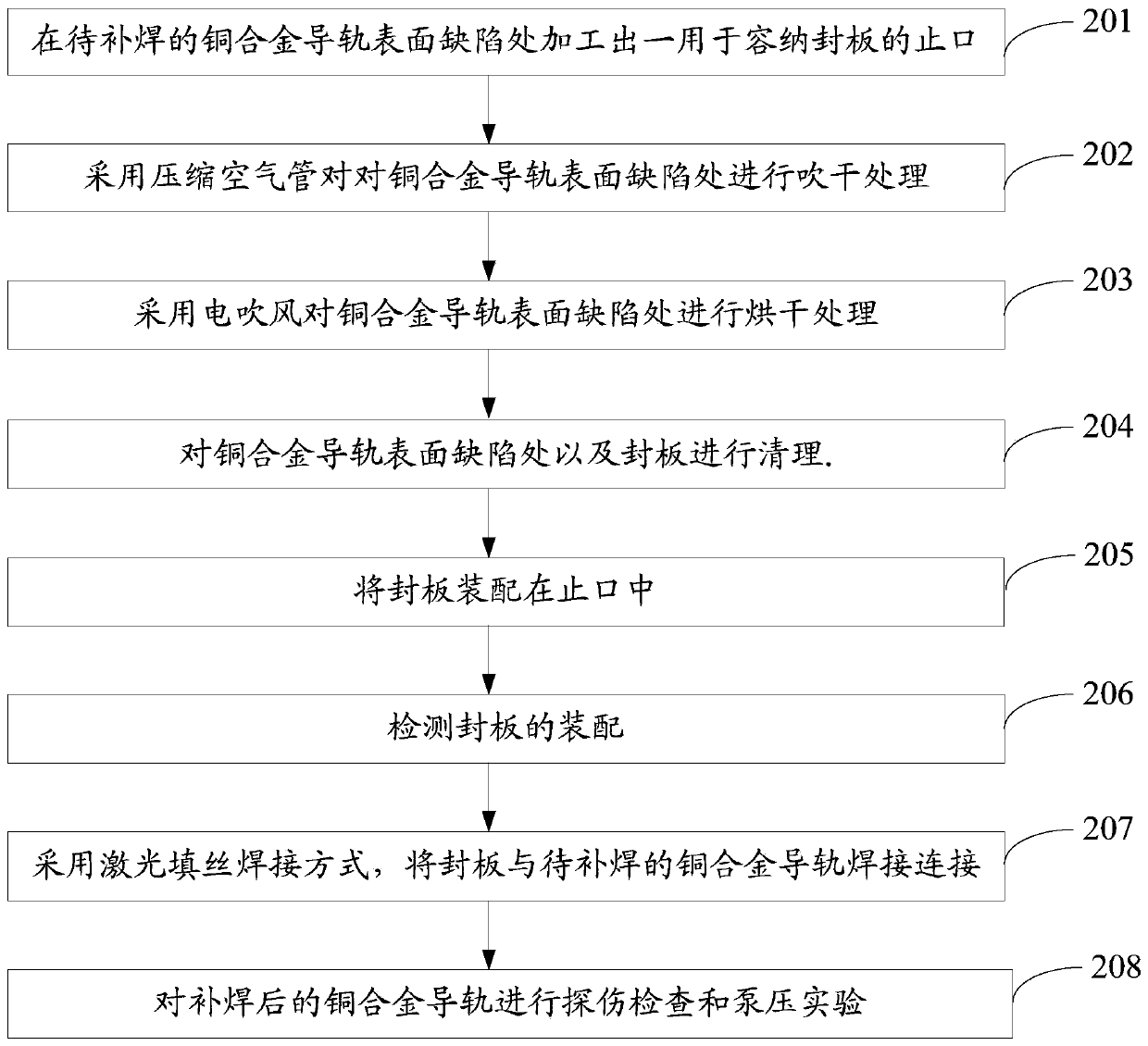

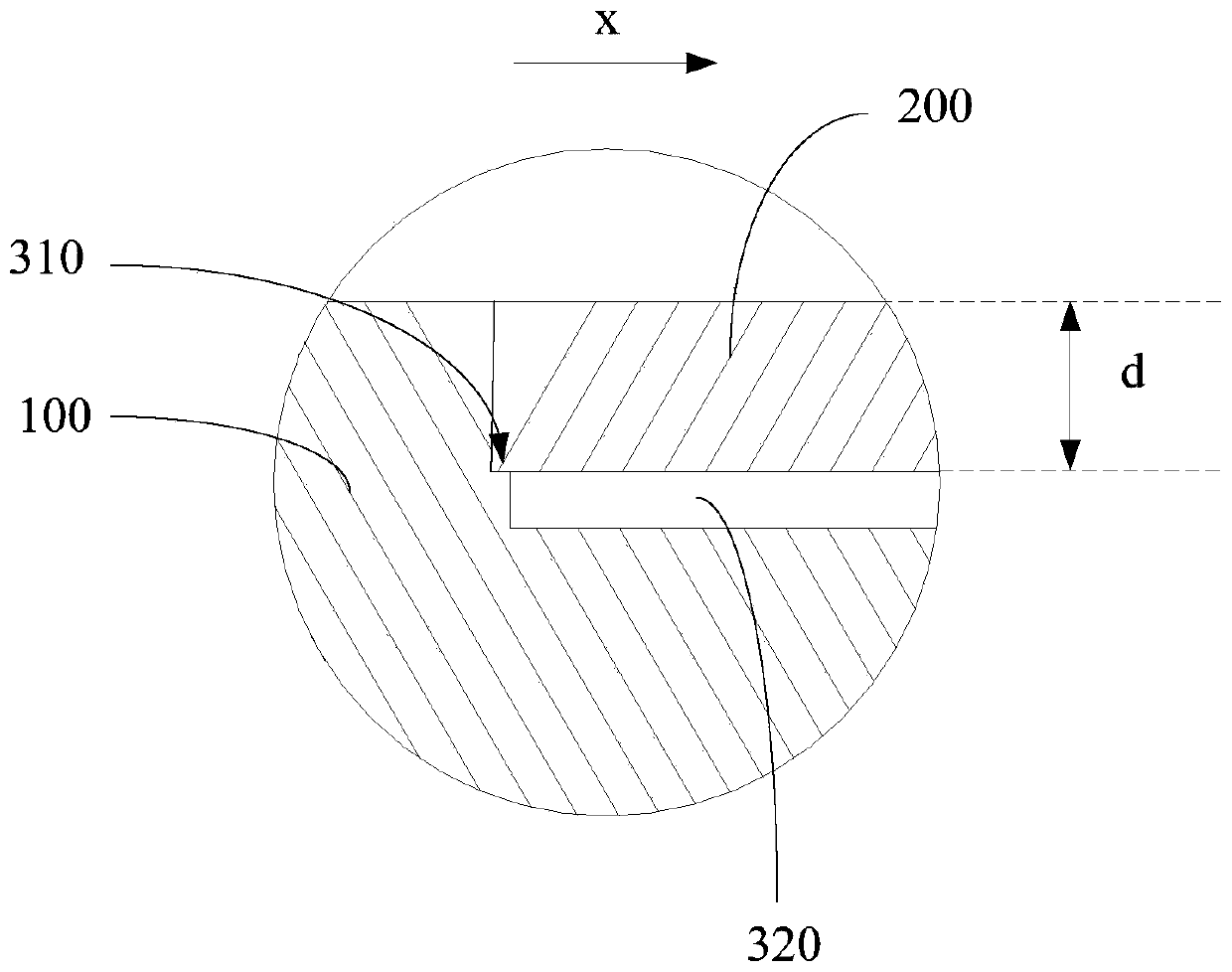

Repair welding method of copper alloy guide rail

InactiveCN110434468AMeet the pump pressure test requirementsReduce assembly clearanceRailsWelding/soldering/cutting articlesHydrogenPressure experiment

The invention discloses a repair welding method of a copper alloy guide rail, and belongs to the technical field of welding. The repair welding method comprises the following steps of machining a spigot for containing a sealing plate at the surface defect of a copper alloy guide rail to be repaired; cleaning the surface defect and the sealing plate of the copper alloy guide rail; assembling the sealing plate in the spigot; and welding the sealing plate with the copper alloy guide rail to be welded by adopting a laser filler wire welding mode. The sealing plate and the copper alloy guide rail are welded by adopting a laser filler wire welding mode, the laser welding speed is high, the welding depth is deeper, and the deformation amount generated by welding is small. Meanwhile, in the welding process, the solubility of hydrogen in the copper alloy increases sharply along with the increase of the temperature of a molten pool, bubbles exist at the root of a weld joint, the spigot is machined at the defect, so that the bubbles can be discharged from a gap between the spigot and the bottom surface of the defect position, so that the quality of the weld joint can be improved, and the pumping pressure experiment requirements of the copper alloy guide rail after repair welding are met.

Owner:WUHAN MARINE MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com