Patents

Literature

315results about How to "Won't get stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

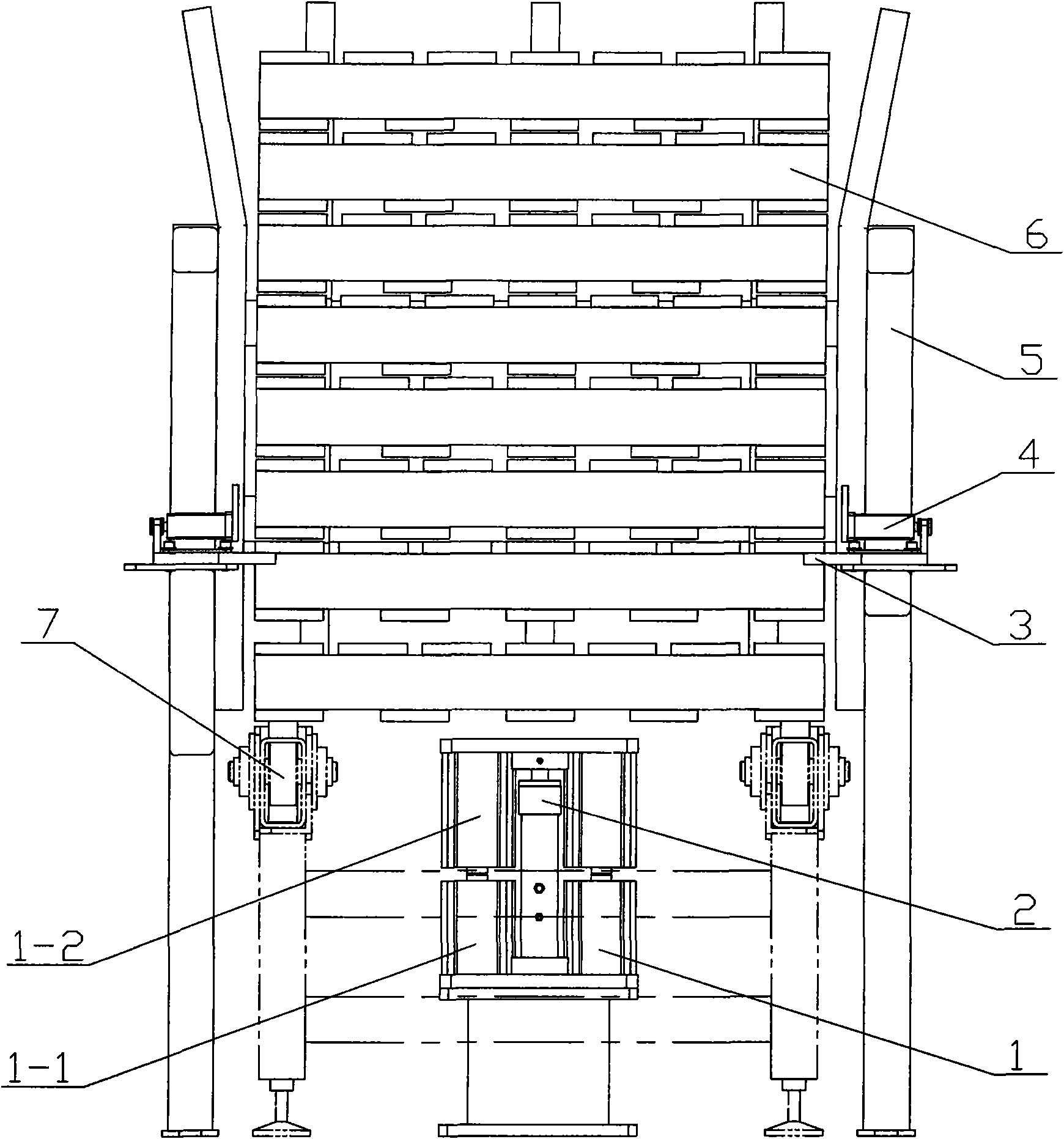

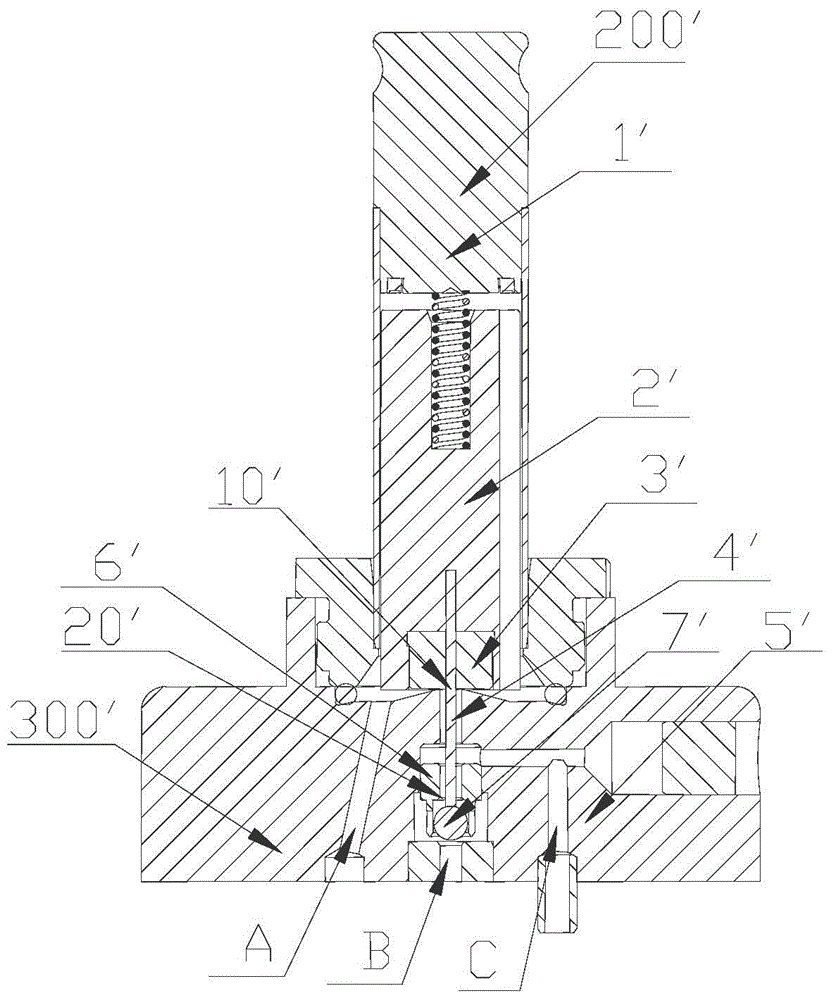

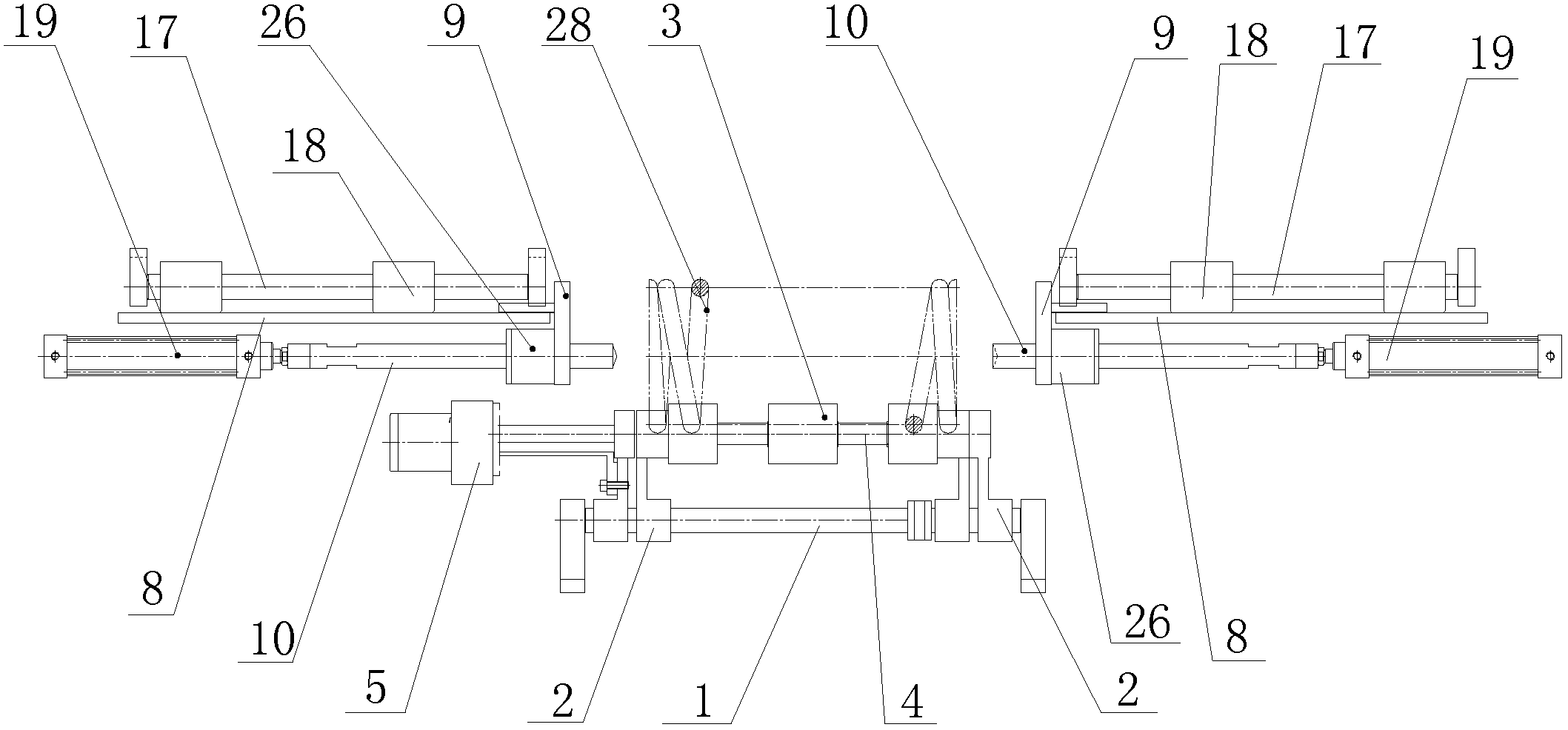

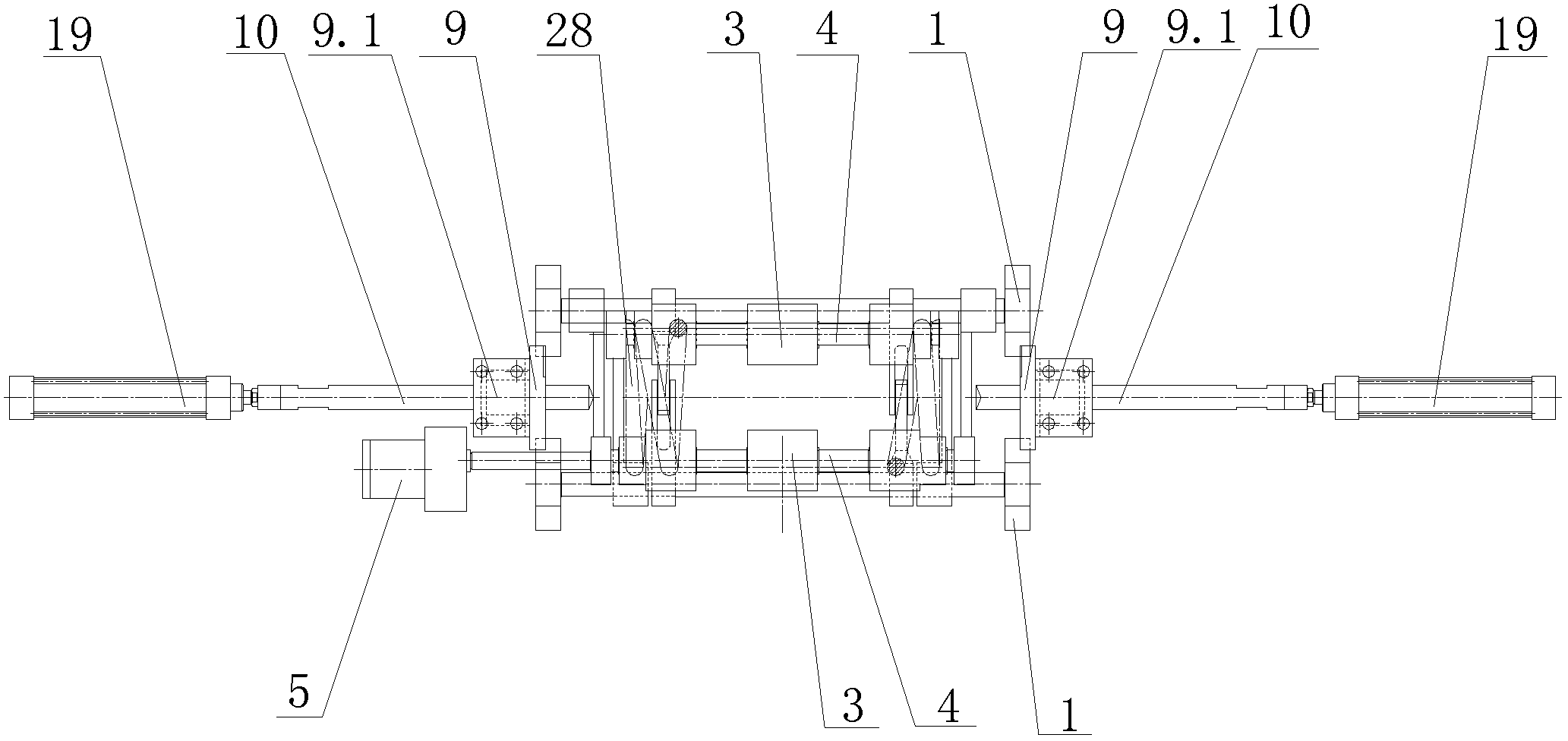

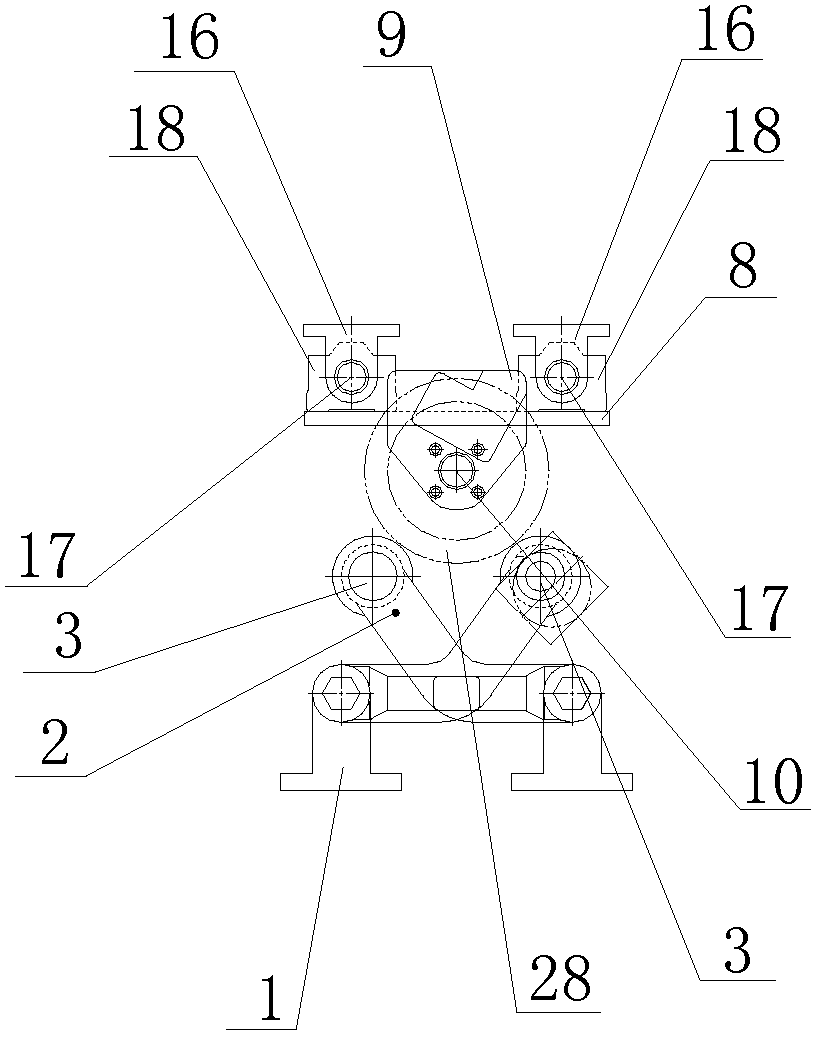

Automatic pallet delivering device for palletizing system

InactiveCN101554959AAvoid bending momentsSimple structureStacking articlesDe-stacking articlesLow noiseEngineering

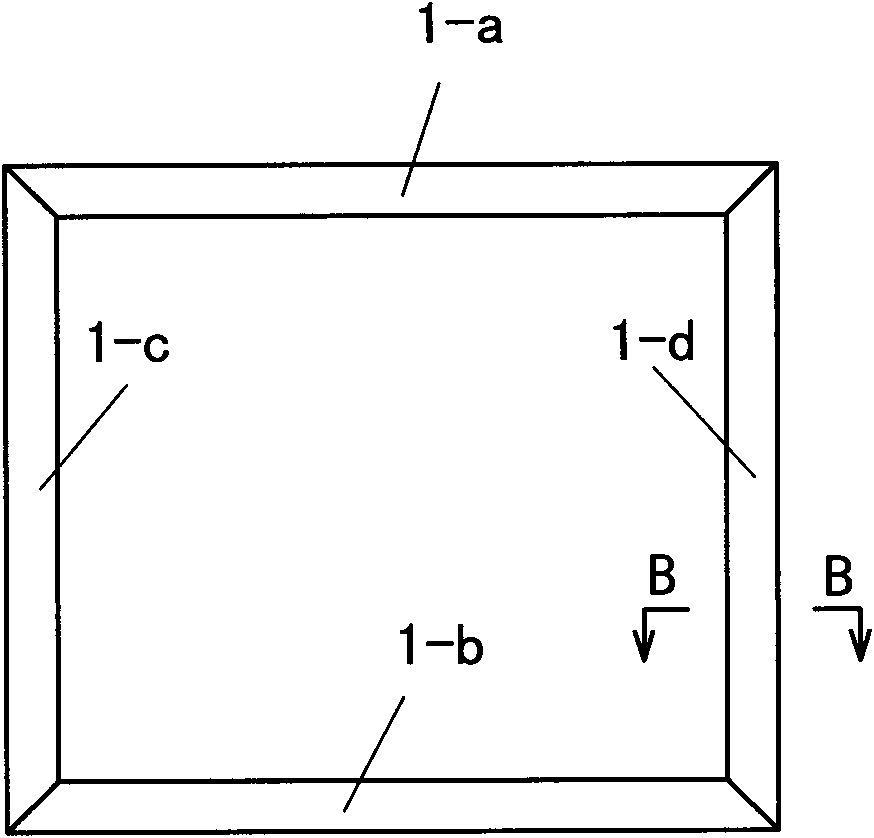

The invention discloses an automatic pallet delivering device for a palletizing system, which comprises a pallet stock, a lifting mechanism, a bolt locating mechanism and a control part, wherein, the lifting mechanism comprises 1 to 4 double-stroke cylinders arranged at the bottom of the pallet stock and a lifting guide mechanism; the bolt locating mechanism comprises a horizontal bolt and a driving cylinder arranged on the symmetrical lateral surfaces of the pallet stock; and the double-stroke cylinder can be a single cylinder with two strokes or a combined cylinder formed by connecting two one-stroke cylinders in series. The automatic pallet delivering device which is suitable for automatically delivering the pallets in the palletizing system of production lines, warehouses and docks has the advantages of simple structure, convenient maintenance, low noise, no pollution and low energy consumption; and compared with the existing hydraulic and electric pallet delivering devices, the automatic pallet delivering device is obviously improved.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

Fast stone breaking device for rare earth machining

The invention relates to a rare earth stone breaking device, in particular to a fast stone breaking device for rare earth machining. According to the technical purposes to be achieved, time and labor are saved in the breaking process, and the breaking device cannot be stuck when large-size or hard stone is broken. In order to achieve the above technical purposes, the fast stone breaking device for rare earth machining is provided and comprises a bottom plate, a collecting box, a first supporting plate, a second supporting plate, a first connecting block, a first hopper, a breaking box, a breaking block, a first rotating shaft, a movable plate and the like. The collecting box is arranged at the left side of the middle portion of the bottom plate, and the first supporting plate is installed on the left side of the bottom plate in a welding manner. By means of the fast stone breaking device for rare earth machining, the effects that time and labor are saved in the breaking process, and the breaking device cannot be stuck when large-size stone or hard stone is broken are achieved, and the manner for adopting the movable plate and a sharp plate for extruding stone on the breaking block is adopted.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

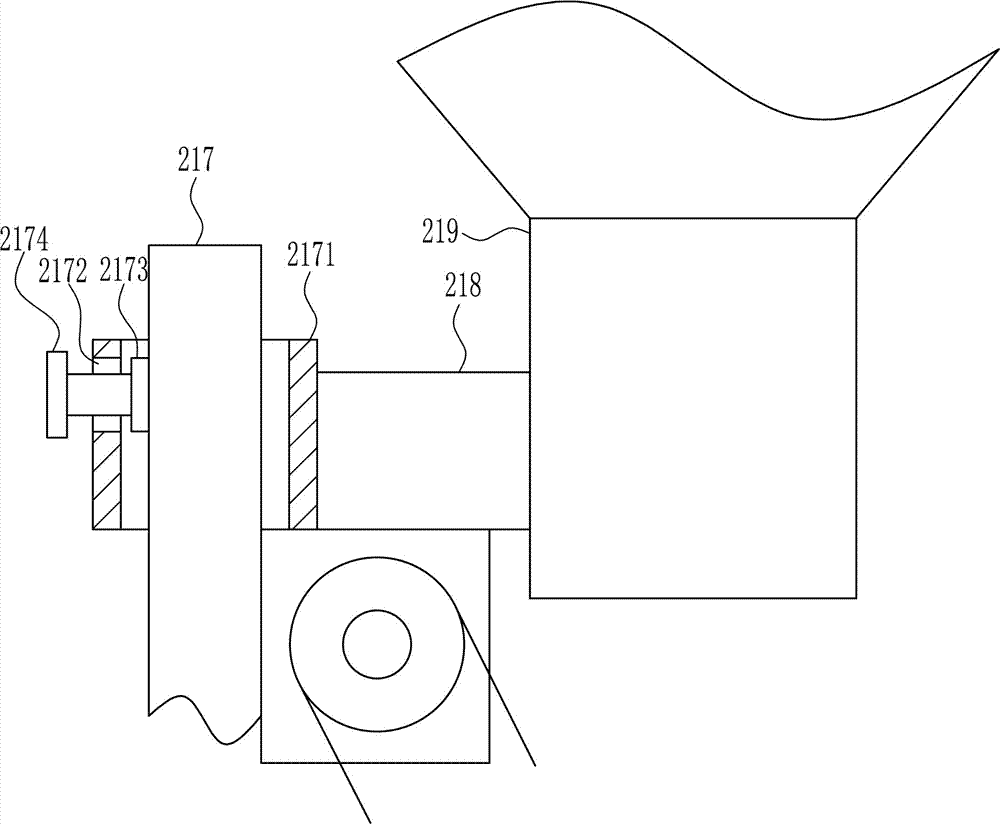

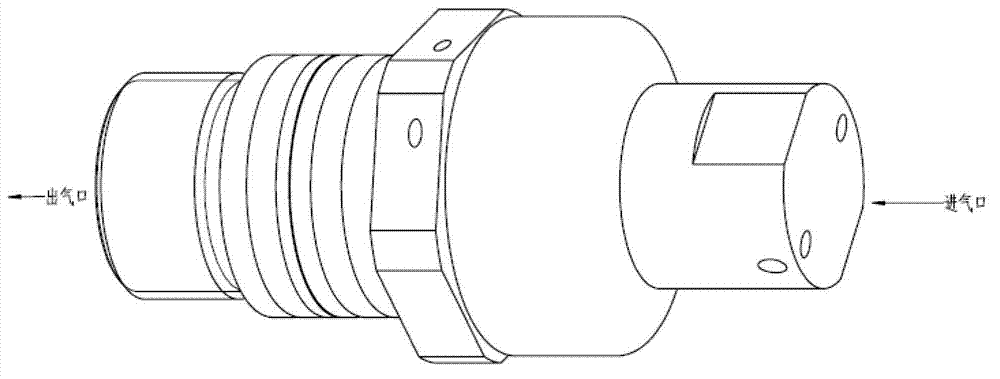

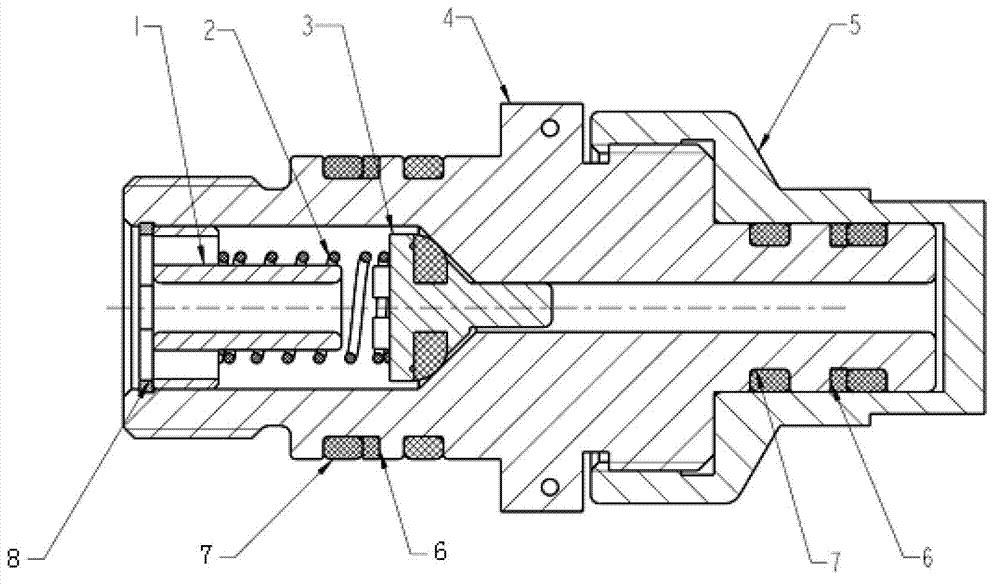

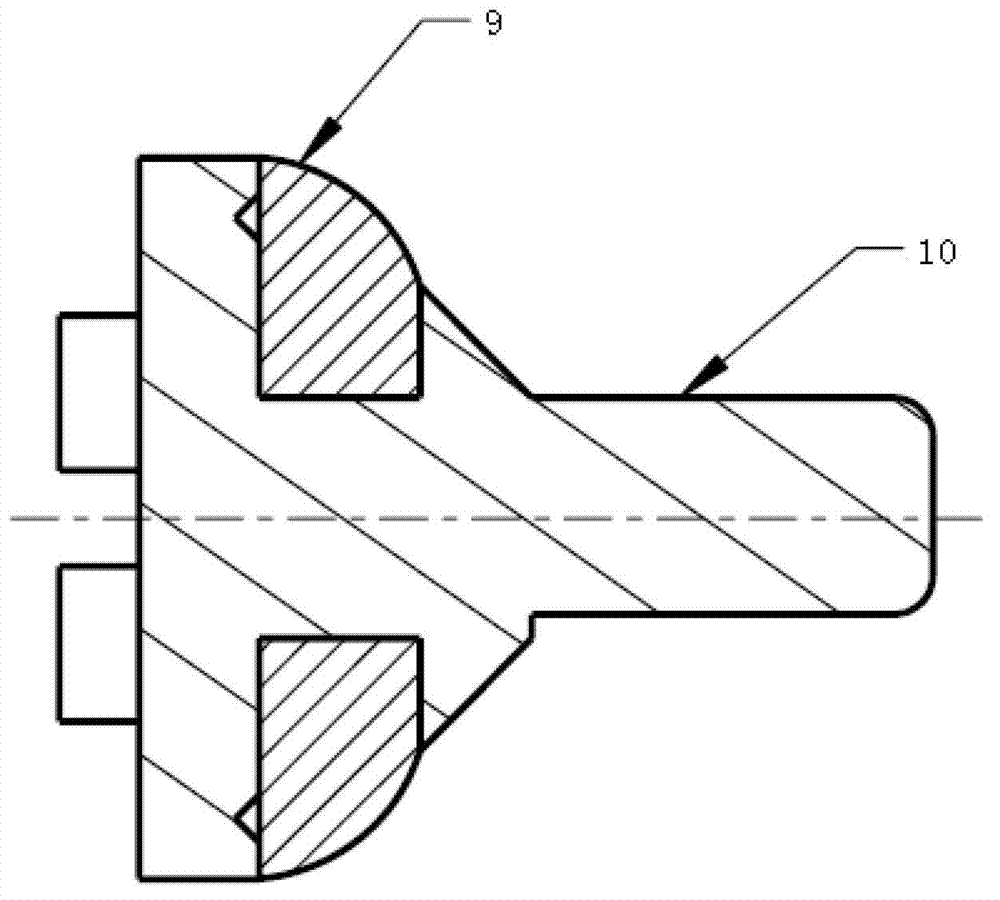

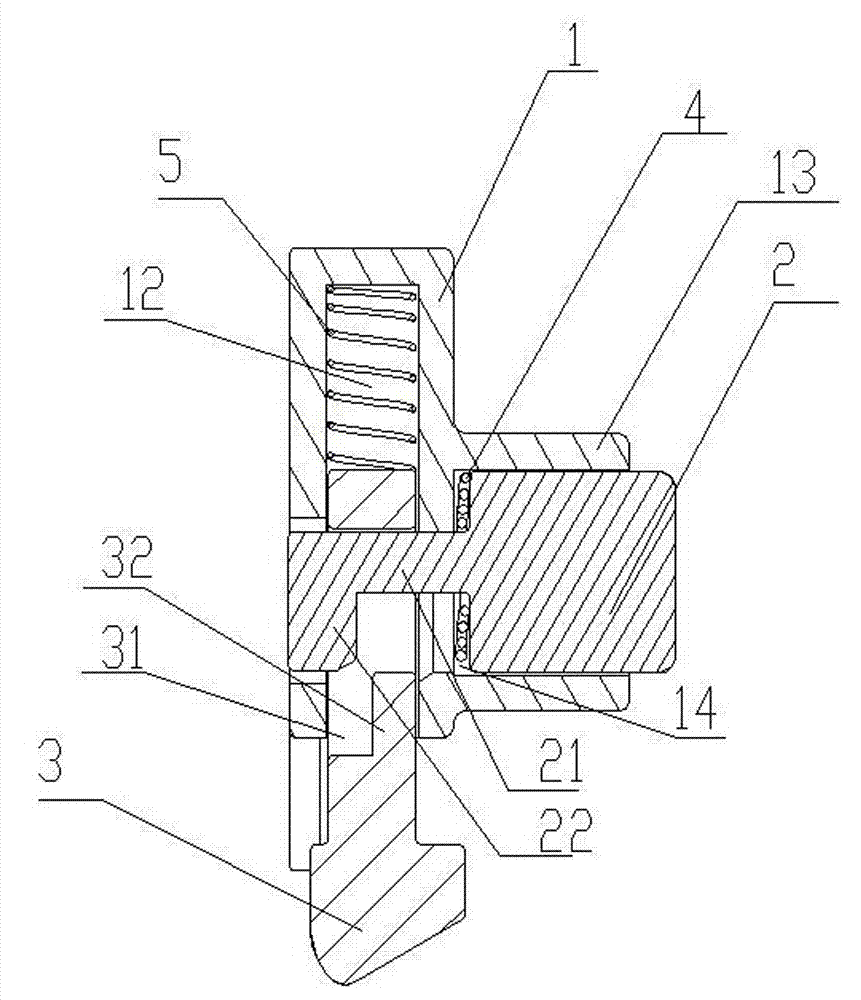

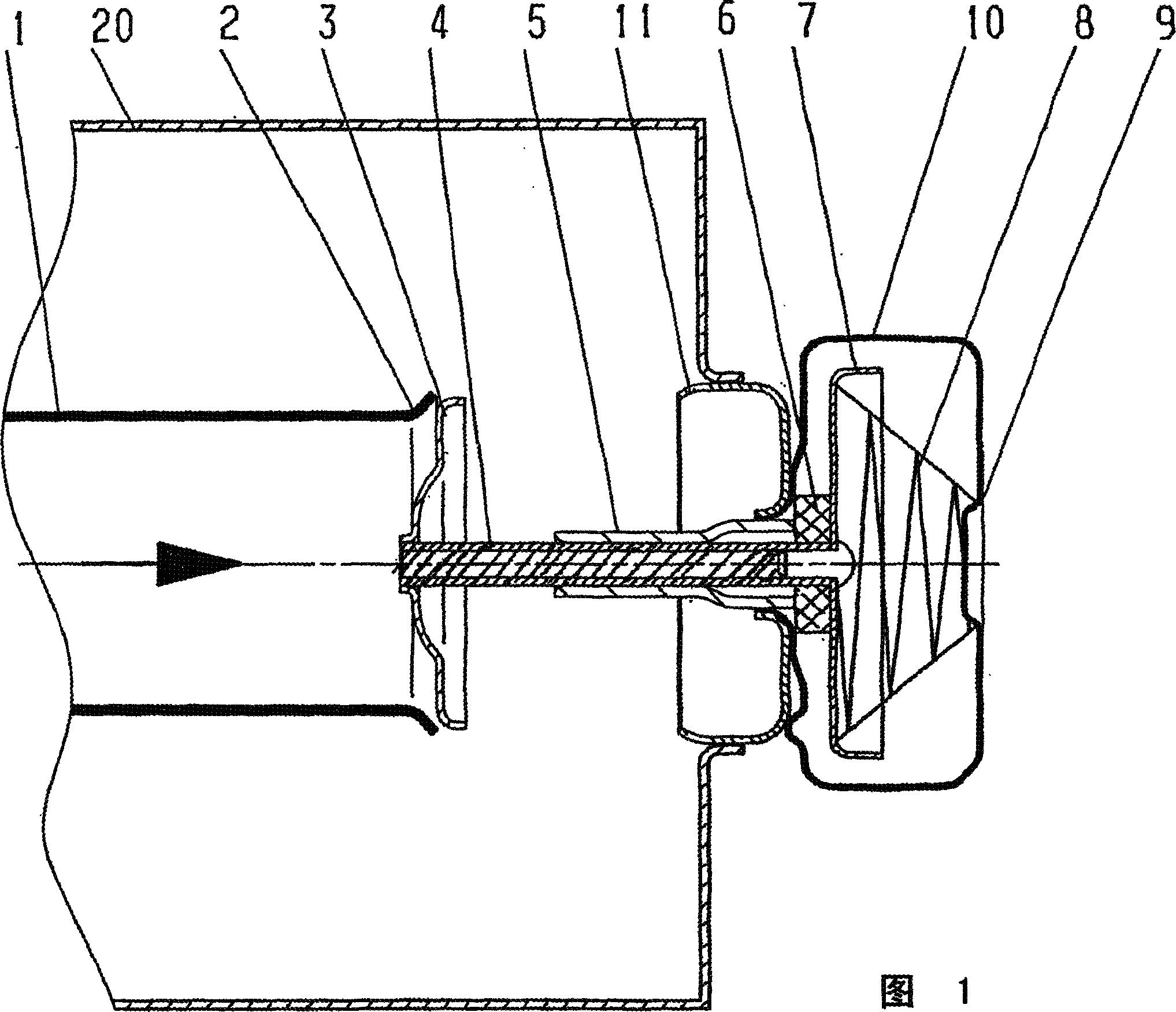

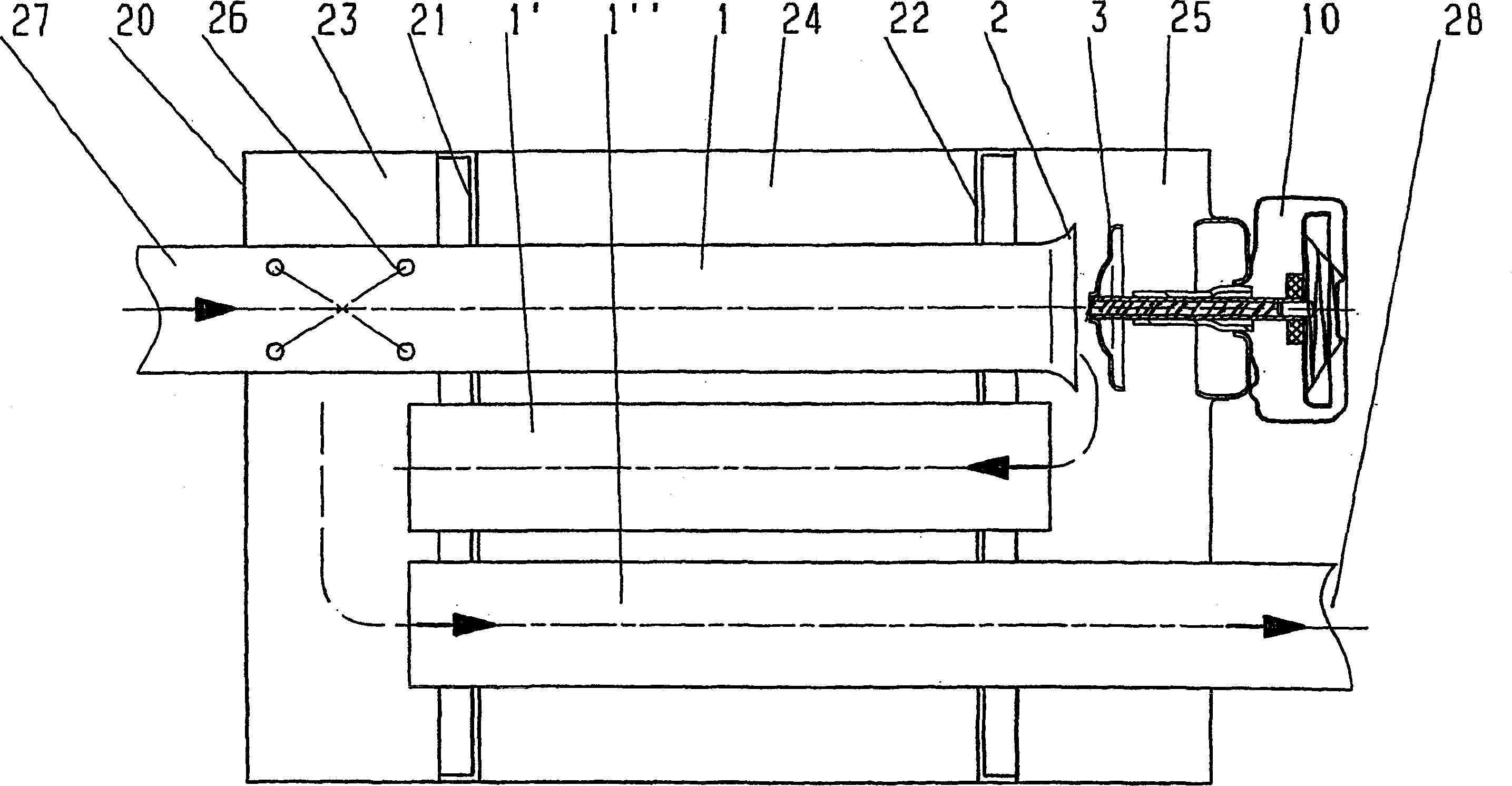

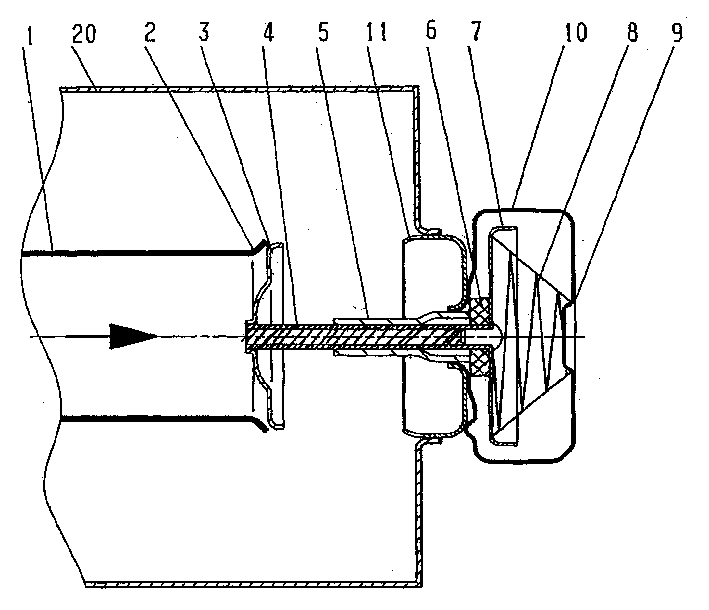

Novel high-pressure air charging nozzle

The invention belongs to an extrusion type servo system and in particular relates to a novel high-pressure air charging nozzle. The invention provides a novel high-pressure air charging nozzle which is specially designed for an extrusion type servo system and has good sealing performance at the reverse blocked state and can ensure that no air leaks at the nozzle after air is charged. The invention adopts the technical scheme that the novel high-pressure air charging nozzle comprises a one-way valve, a spring, a one-way valve core, a shell, a plugging cap, a protective retainer ring, an O-shaped seal ring and a circlip for a hole, wherein the shell is a hollow tubular body; the plugging cap is arranged at the right end of the shell; a one-way valve support, the spring and the one-way valve core are disposed inside the shell; and the one-way valve support is connected with the one-way valve core through the spring.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

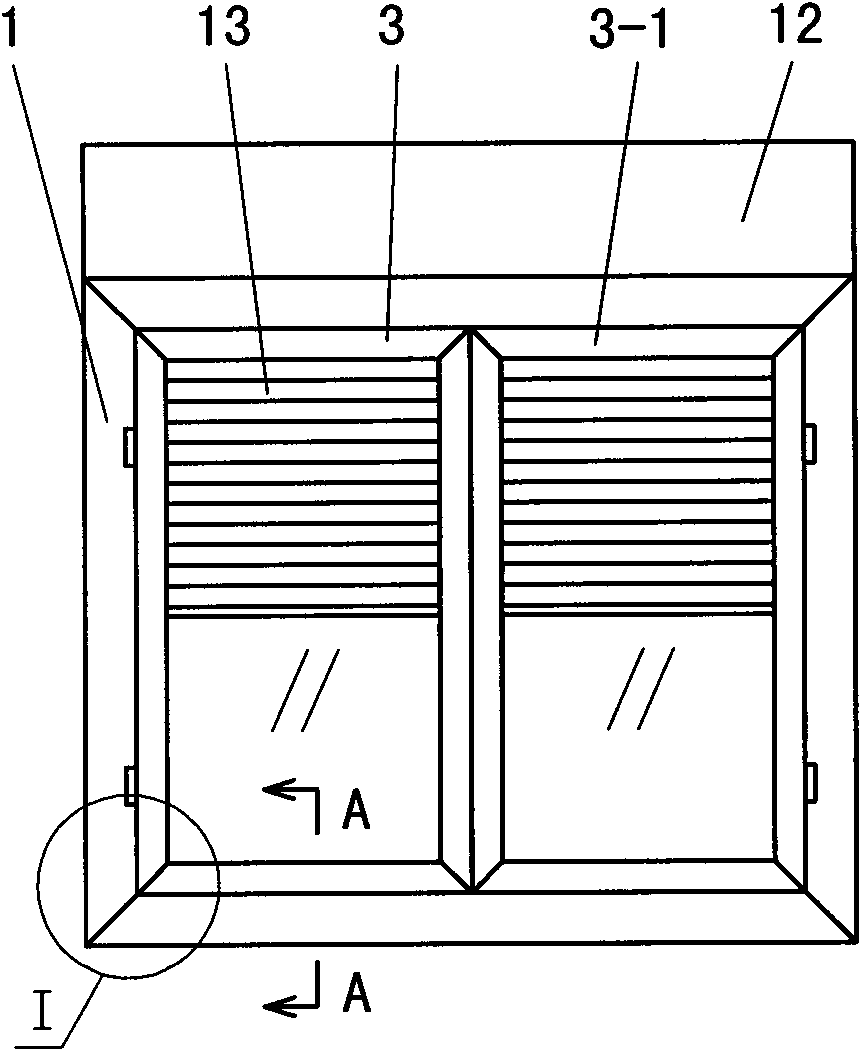

Energy-saving roller shutter

InactiveCN101929288AImprove thermal insulation performanceWith airtight sound insulationLight protection screensSealing arrangementsThermal insulationEngineering

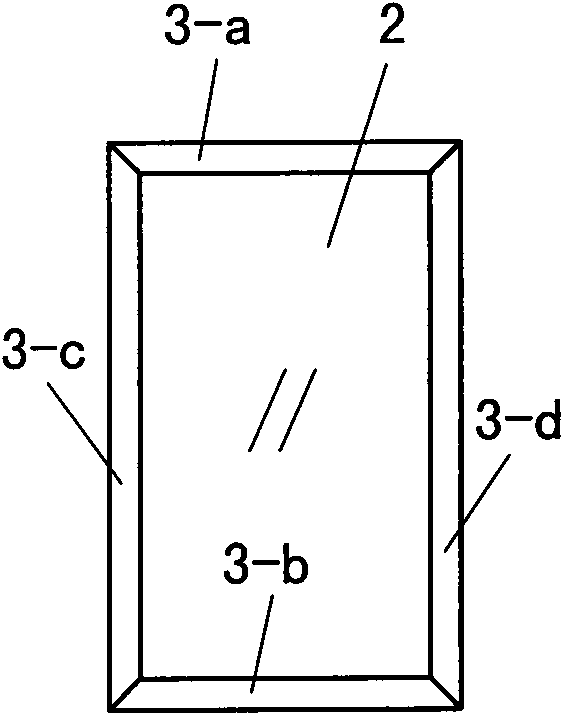

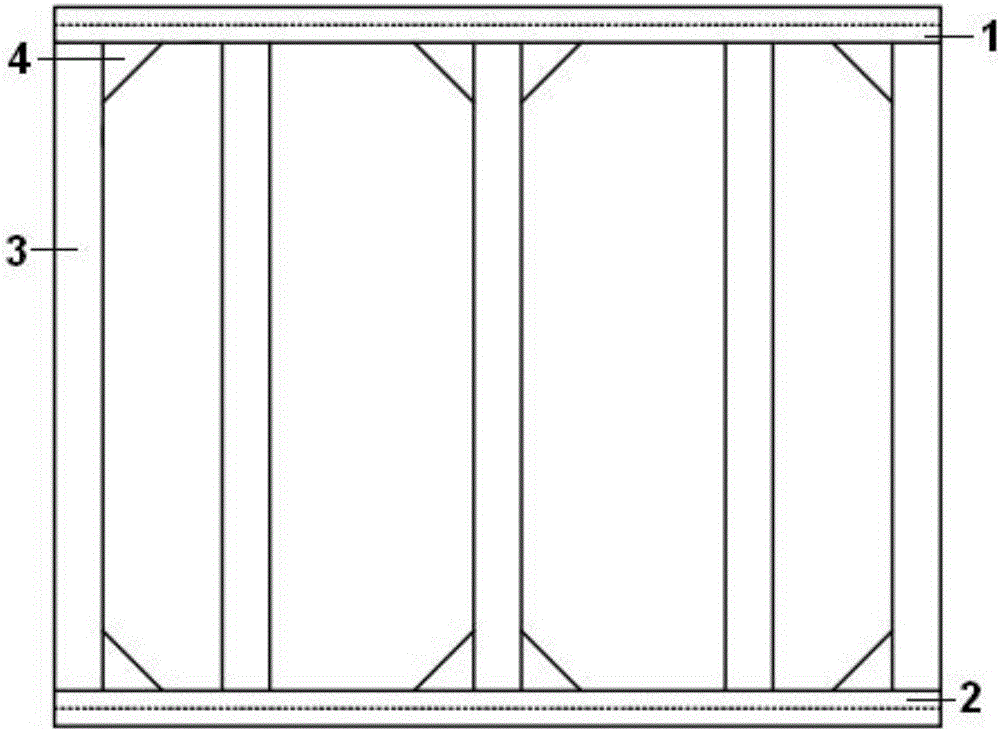

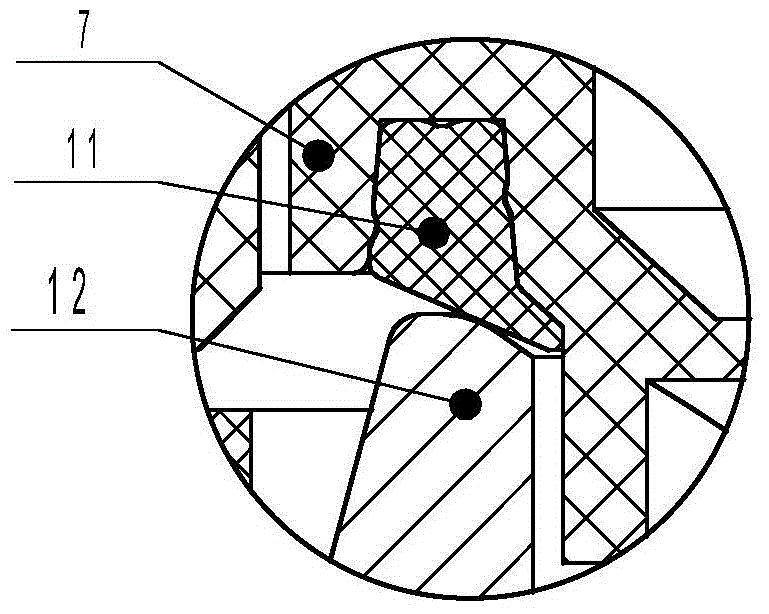

The invention relates to a technical field of building doors and windows and discloses an energy-saving roller shutter. For solving the problem of the low heat-preservation performance of windows in the prior art, the invention puts forward a technical scheme that: the energy-saving roller shutter comprises a broken bridge aluminum window and an outer-layer sunshading roller blind device, wherein the broken bridge aluminum window comprises a frame (1), window slashes (3) with hollow glass, sealing strips, pads (5) and the like and is characterized by comprising the reinforced sealing strips (16) which are elastic strip objects with the outsides connected with a frame outer layer (8) and the lower sides connected with a frame broken bridge (7); each reinforced sealing strip (16) has more than two protruding sealing long strips (16-1) which are sealed with and pressed against a window slash broken bridge (10); and both the frame broken bridge (7) and the window slash broken bridge (10) have a multi-cavity structure with more than three cavities. The energy-saving roller shutter has the advantages of improving the heat-preservation and thermal-insulation performance obviously, producing remarkable airtight and sound-insulation effects, and the like.

Owner:陈怡洁

Mechanical button lock

ActiveCN102877722AAchieve replacementEasy to openWing fastenersReciprocating motionAutomotive battery

The invention relates to a mechanical button lock. The mechanical button lock comprises a lock body and a spring bolt and a lock cylinder which are arranged in the lock body; the spring bolt does reciprocating motion relative to the lock body and has a locking position that the spring bolt is extended out of the lock body and an unlocking position that the spring bolt is retracted into the lock body; the movement direction of the lock cylinder is perpendicular to that of the spring bolt, and the lock cylinder has an avoiding position and a locking and stopping position; when the lock cylinder is positioned at the locking and stopping position, the spring bolt is locked at the locking position by combination of the lock cylinder and a locking and stopping structure which is correspondingly arranged on the spring bolt; when the lock cylinder is positioned at the avoiding positioning, the spring bolt moves freely by avoiding of the lock cylinder and the locking and stopping structure which is correspondingly arranged on the spring bolt; a spring bolt spring which is used for applying acting force to the spring bolt to ensure that the spring bolt moves toward the locking position, and a lock cylinder spring which is used for applying action force to the lock cylinder to ensure that the lock cylinder moves toward the locking and stopping position are arranged in the lock body; and one end of the spring bolt, which is extended out of the lock body when the spring bolt is positioned at the locking position, is provided with an inclined surface which is pushed by a corresponding object which moves in a direction perpendicular to the movement direction of the spring bolt into the lock body. According to the mechanical button lock, a battery box of an electric vehicle is automatically replaced by a pure mechanical mode.

Owner:XJ ELECTRIC +2

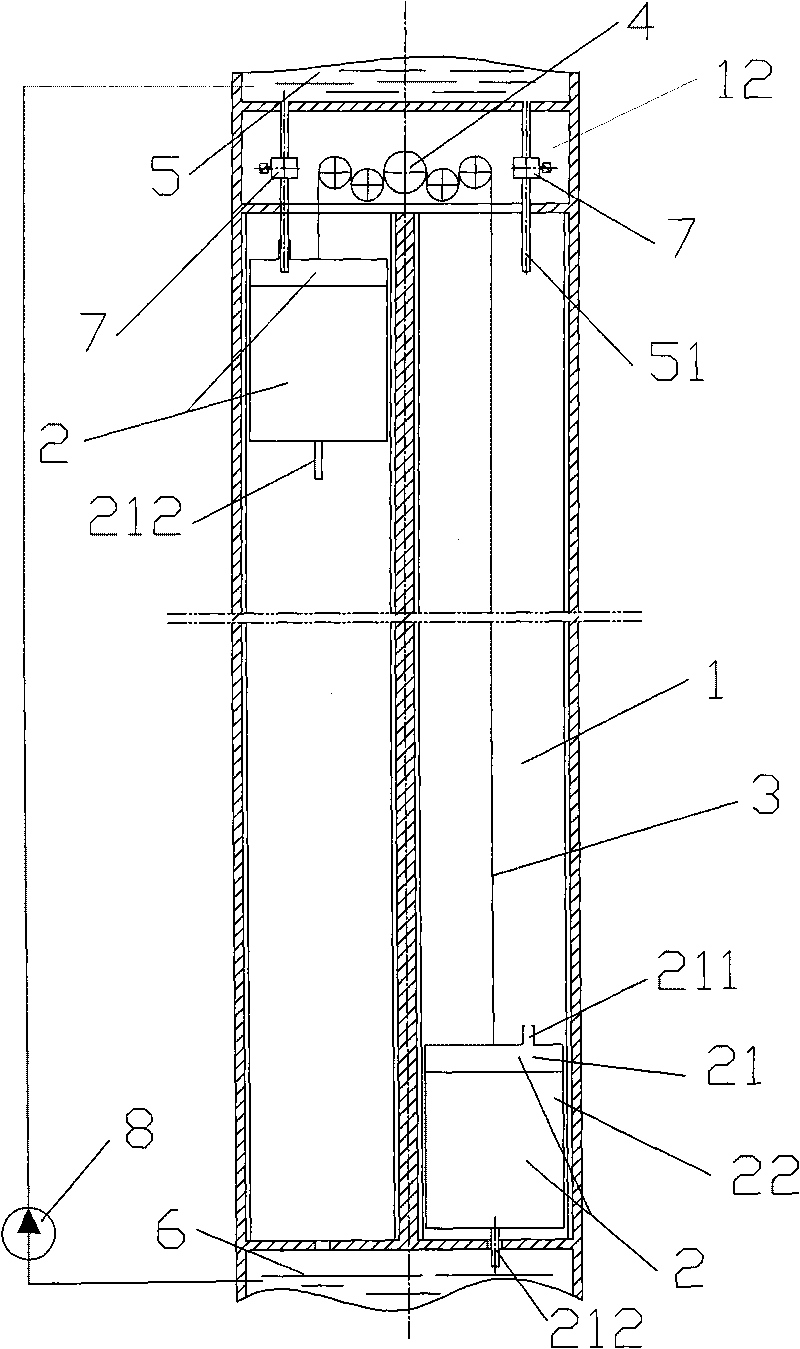

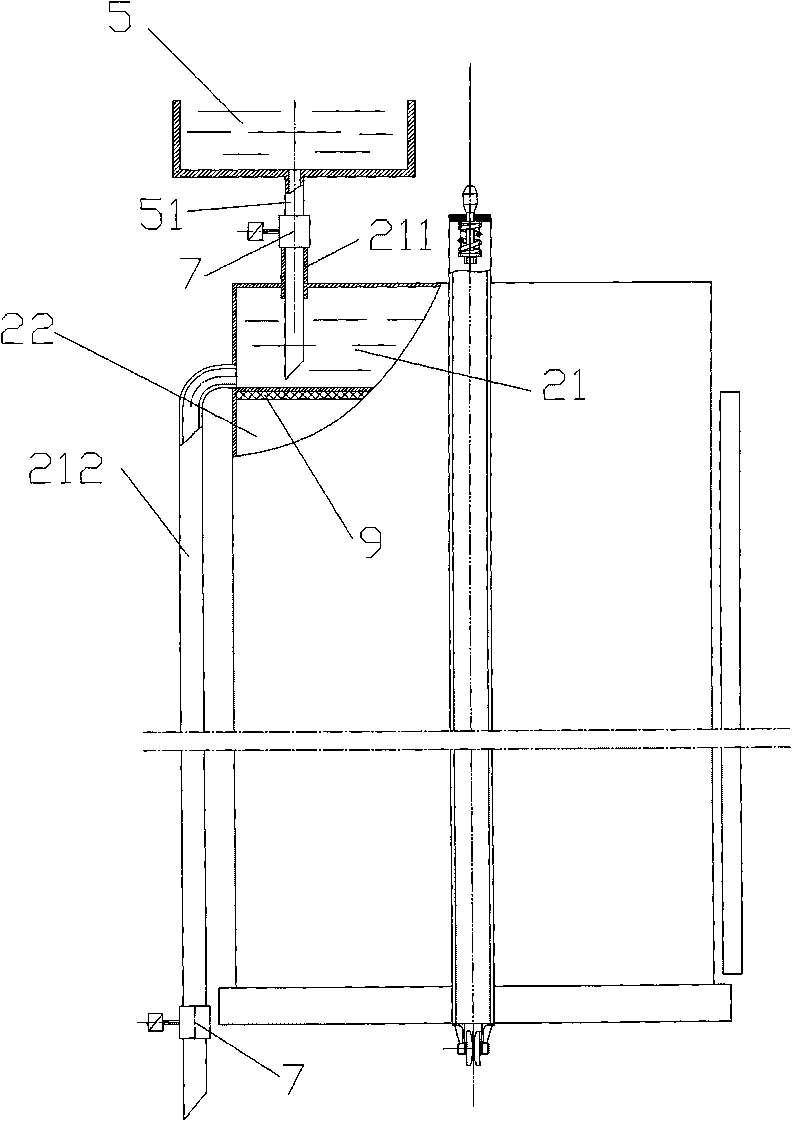

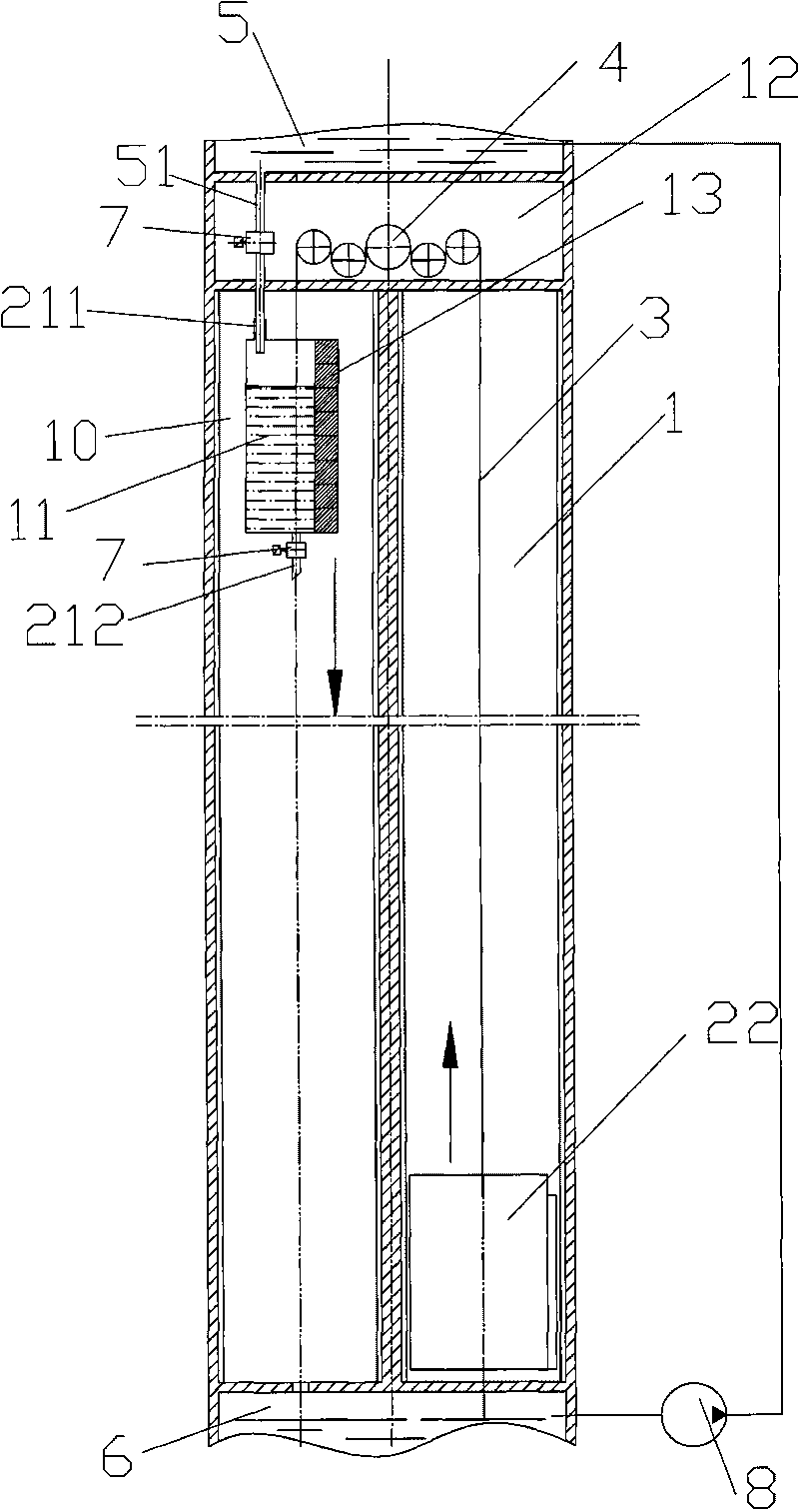

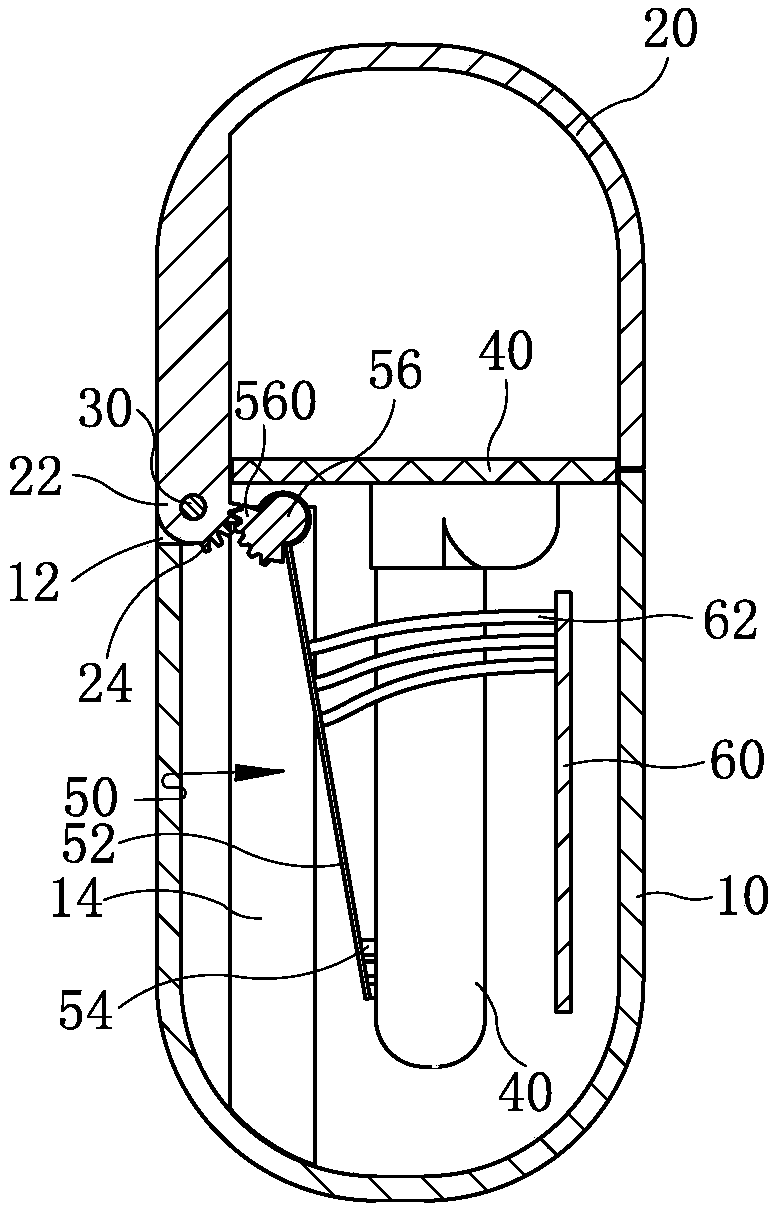

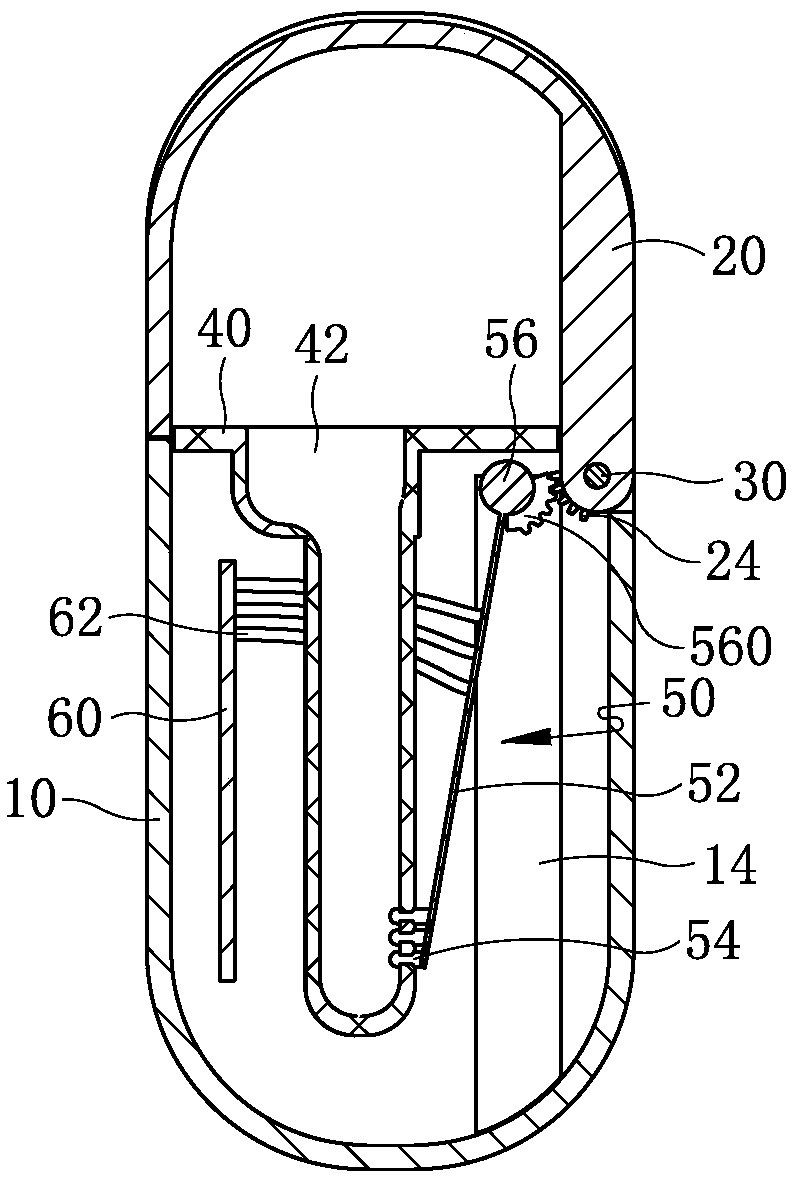

Energy storage type passenger and freight transportation vertical conveyer

InactiveCN101695981AWon't get stuckStable powerBuilding liftsEnergy efficiency in elevatorsTrappingEngineering

The invention discloses an energy storage type passenger and freight transportation vertical conveyer, comprising two driven wells and two ladder boxes. Each ladder box comprises a water box and a lift cage, the water box is arranged on the lift cage and is provided with a water intake pipe and a drainage pipe, the two ladder boxes are connected by steel wire ropes, the steel wire ropes are wound on a hub wheel set in a machine room, an impounding reservoir with a water injection pipe is arranged on the top of the machine room, and discharge bays are arranged in the bottoms of the driven wells. The invention also discloses an energy storage type passenger and freight transportation vertical conveyer, comprising a driven well, a balance weight well, a lift cage and a weight balance water box; a lift cage is arranged in the driven well, the balance weight water box is arranged in the balance weight well, wherein the balance weight water box is provided with a water intake pipe and a drainage pipe, the lift cage is connected with the balance weight water box through steel wire ropes, the steel wire ropes are wound on a hub wheel set in a machine room, an impounding reservoir with a water injection pipe is arranged on the top of the machine room, and a discharge bay is arranged at the bottom of the balance weight well. The invention has the advantages of completely avoiding trapping in the conveyer phenomenon caused by power failure, saving energy sources and reducing operating cost by utilizing the transformation of the potential energy of the water in the impounding reservoir into the kinetic energy used for driving the conveyer.

Owner:舒先达

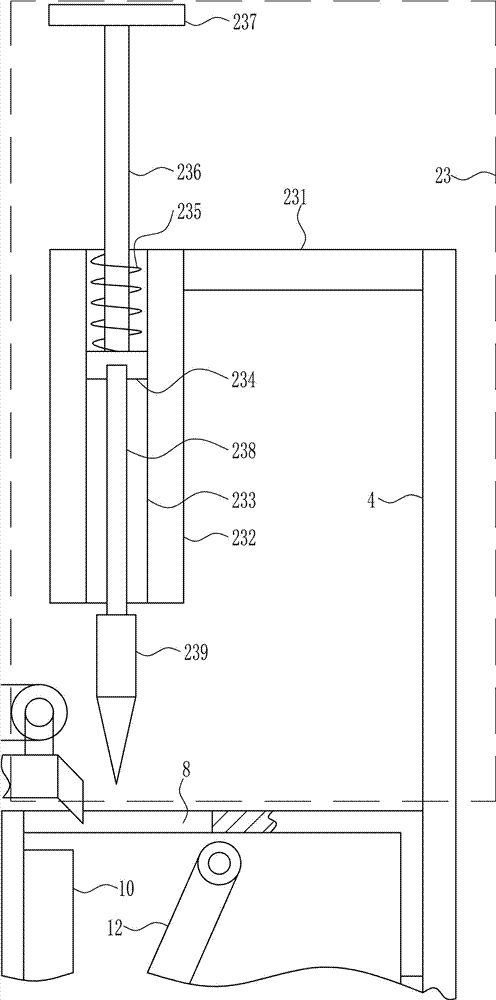

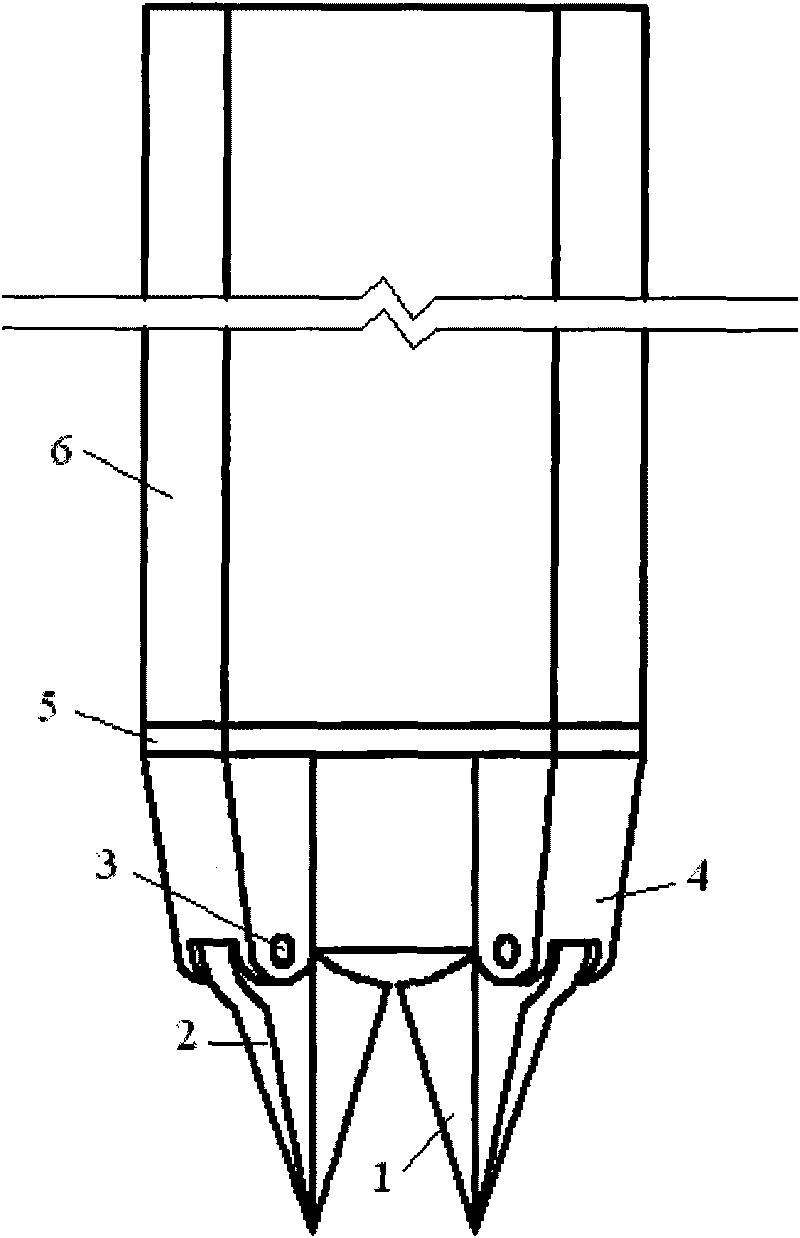

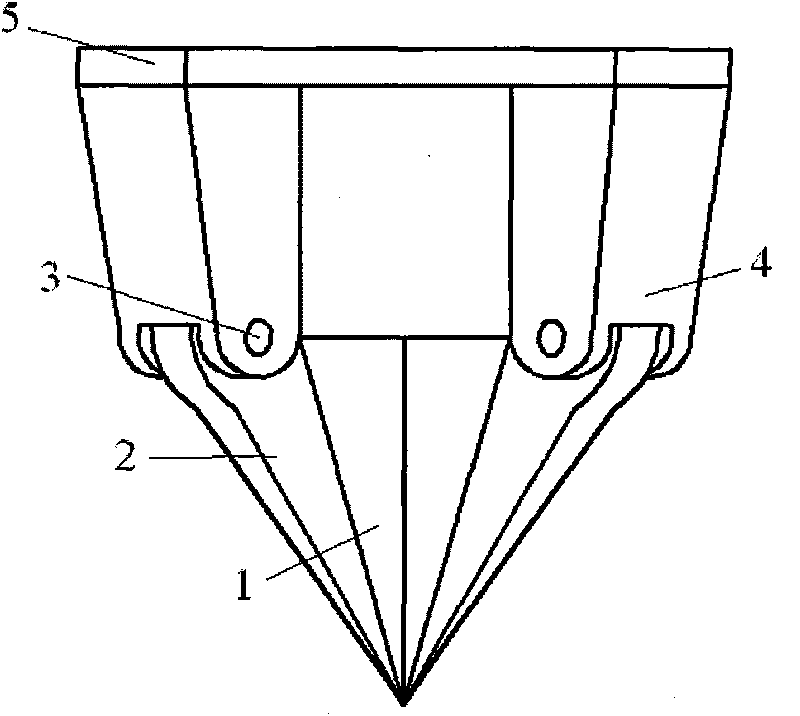

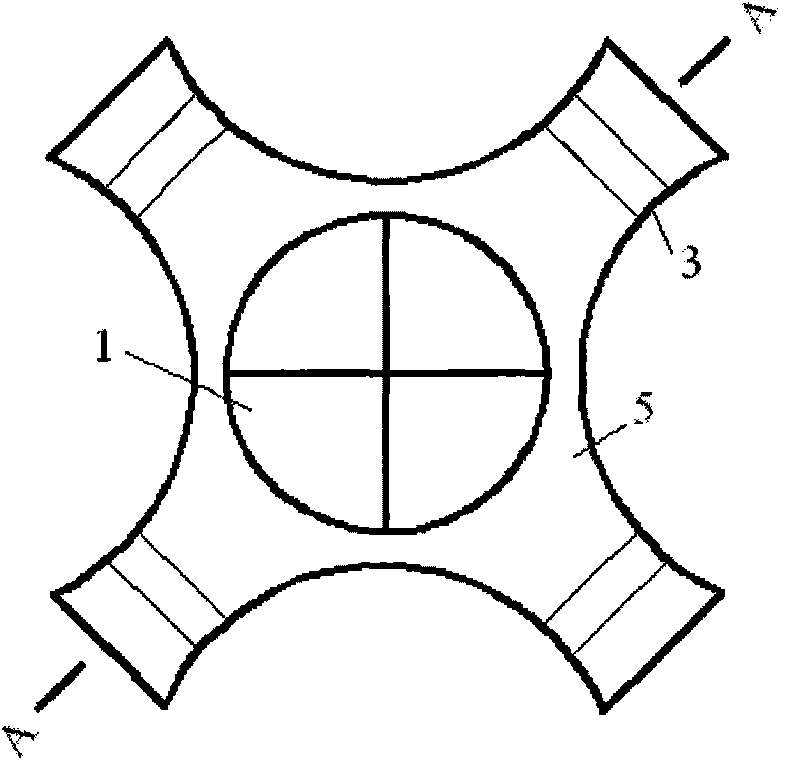

Valve pile tip structure device of cast-in-place X-shaped concrete pile and using method thereof

The invention relates to a valve pile tip structure device of a cast-in-place X-shaped concrete pile and a using method thereof. In the valve pile tip structure device, an X-shaped pile die is fixedly connected with a connecting section, the lower end of the connecting section is fixedly connected with a transition section, the lower part of the transition section is rotatablely connected with the upper part of a strengthening rib through a connecting hinge, and the strengthening rib is fixedly connected with a valve; and when the X-shaped pile die is dropped down, the valve pile tip is aligned with a pile position, and a curved surface triangular steel sheet is closed and inserted in a soil body, the X-shaped pile die is vibrated to reach a designed depth so that concrete enters an inner cavity of the valve, and the X-shaped pile die is pulled up to automatically open the curved surface triangular steel sheet so as to form the cast-in-place X-shaped concrete pile. The valve pile tip structure device overcomes the defects that a precast pile shoe is precast in a factory, has long consumed time, large volume and inconvenient transportation, moves and deflects downwards and even breaks away from the pile die, cannot be used repeatedly, has high manufacturing cost, and the like. The valve pile tip structure device avoids repeated physical work, does not need to be precast in the factory, shortens the construction period, and reduces the cost.

Owner:HOHAI UNIV +1

Blowing paper splicing device

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

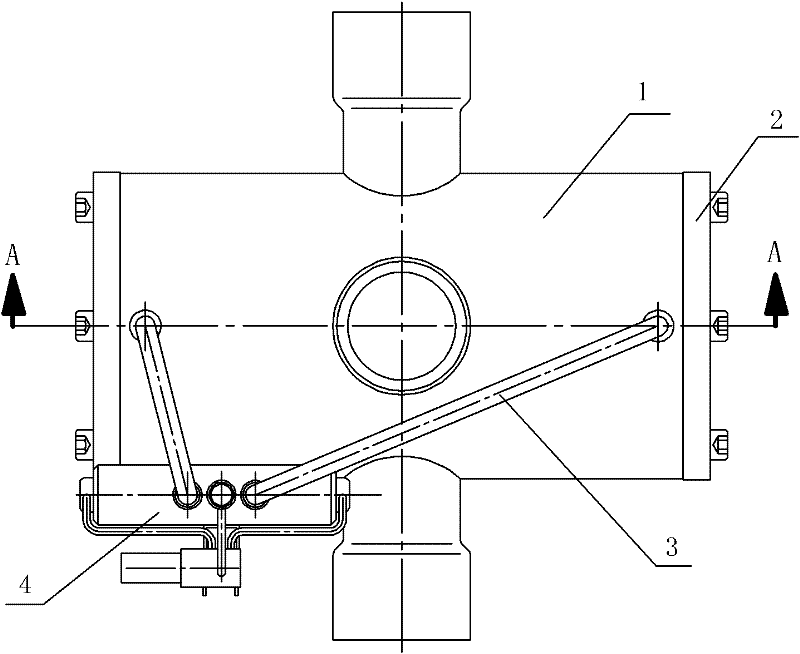

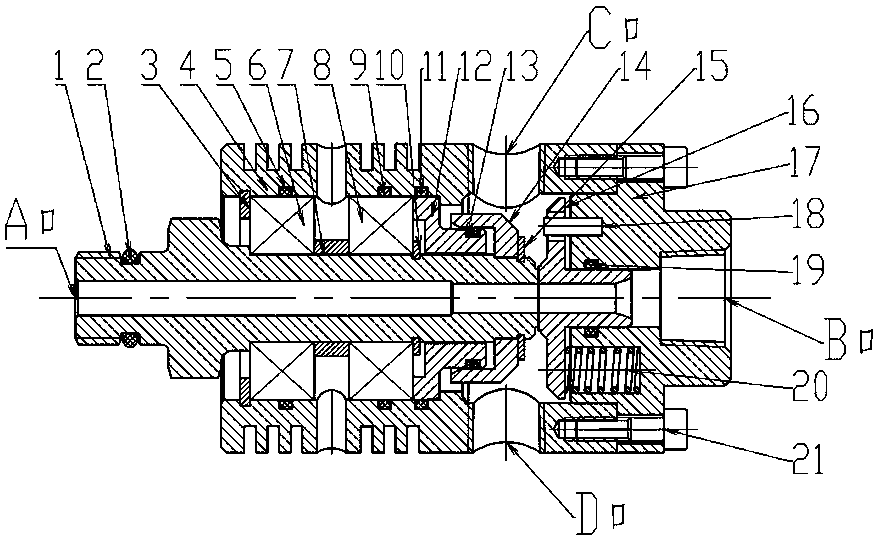

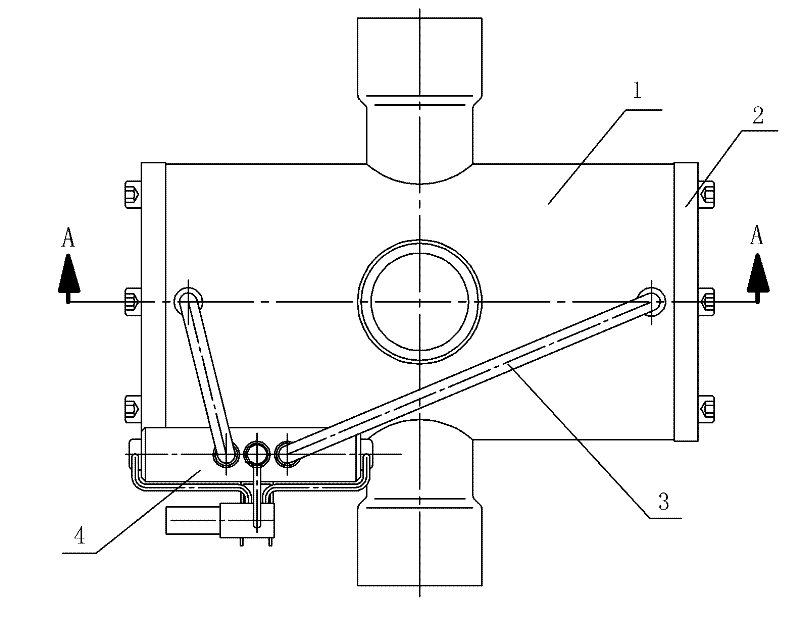

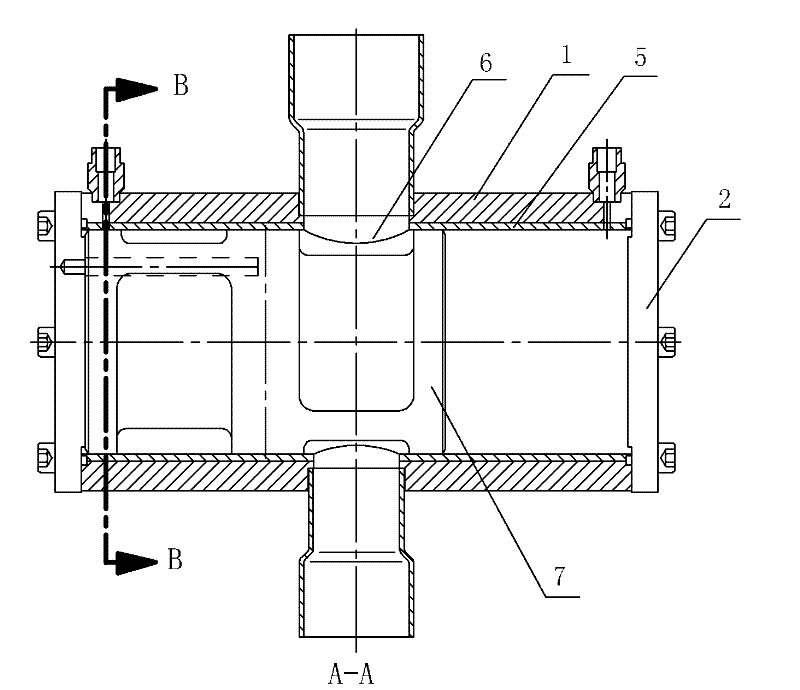

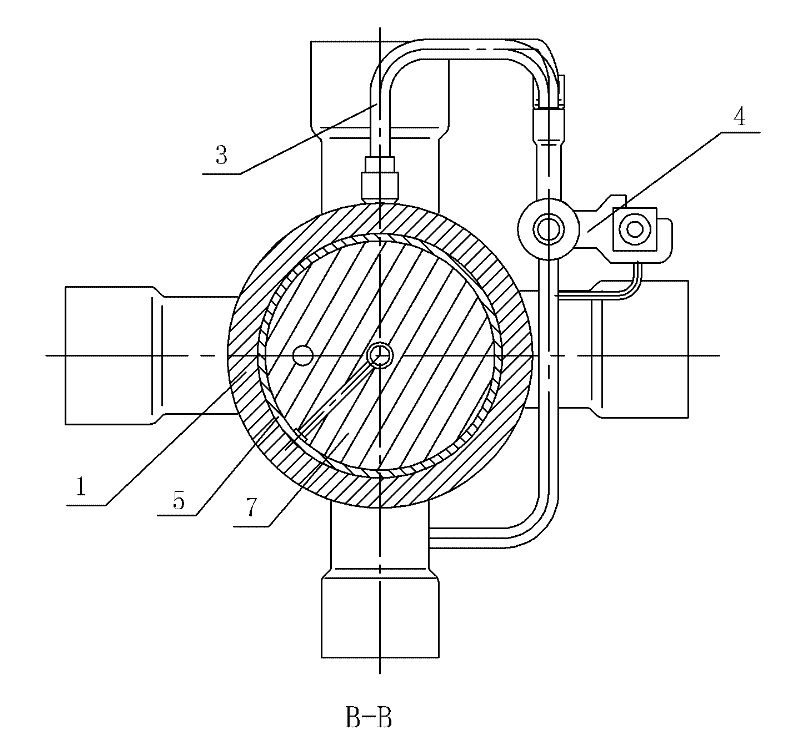

Piston type four-way reversing valve

InactiveCN102242814AWon't get stuckExtended service lifeOperating means/releasing devices for valvesMultiple way valvesPistonLubrication

The invention discloses a piston type four-way reversing valve and belongs to a valve for changing the flow direction of a refrigeration working substance, and the existing four-way reversing valve has a defect that after shutdown, an oil film can be easily cleaned by the refrigerating fluid so as to cause the lack of the lubricating oil and then cause that the piston is deadlocked. The piston type four-way reversing valve mainly consists of a main valve and a pilot valve, wherein the pilot valve is communicated with the cavity of the main valve through an air duct; the main valve comprises a valve body, a piston arranged in the valve body and two end covers arranged on the two ends of the valve body; four valve ports are arranged on the valve body, the piston is formed by connecting two components, which have I-shaped view patterns and are rotated to be vertical to each other, into a whole, a lubrication sleeve is arranged between the internal surface of the valve body and the piston, and the lubrication sleeve is fixedly connected with the valve body; through holes which correspond to valve ports and are communicated with the valve ports are arranged on the sleeve body of the lubrication sleeve, a plurality of oil holes are arranged on the internal surface of the sleeve body, and a solid lubricating material can be embedded in the oil holes; and the solid lubricating material without oil can lubricate the piston, the piston is ensure to move in the valve body flexibly and can not be deadlocked, and the service life is prolonged.

Owner:浙江新三荣制冷有限公司

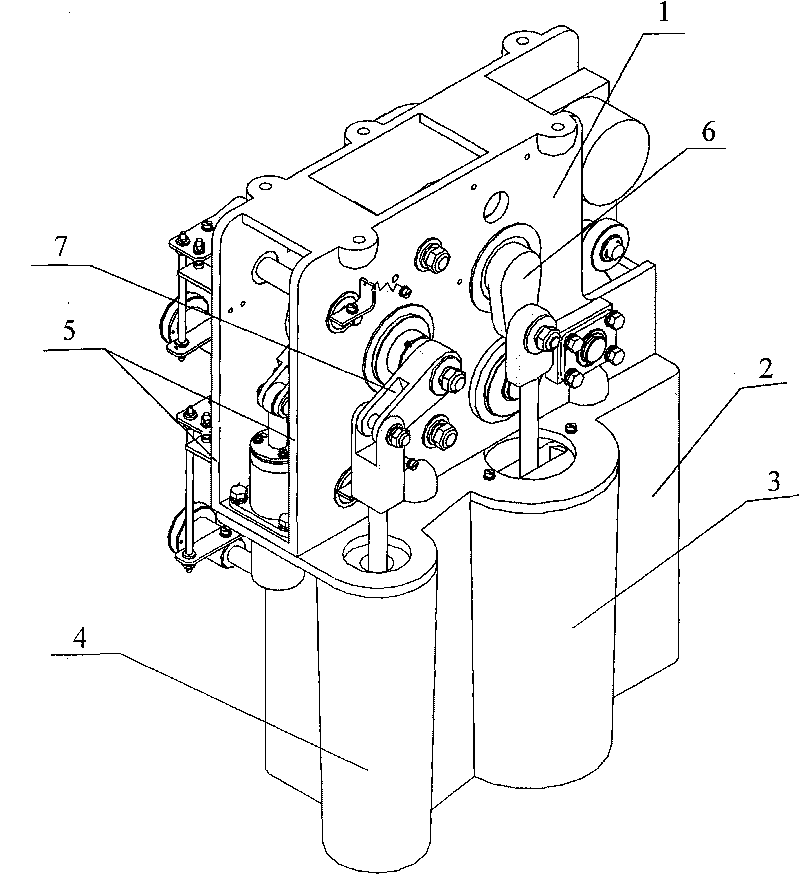

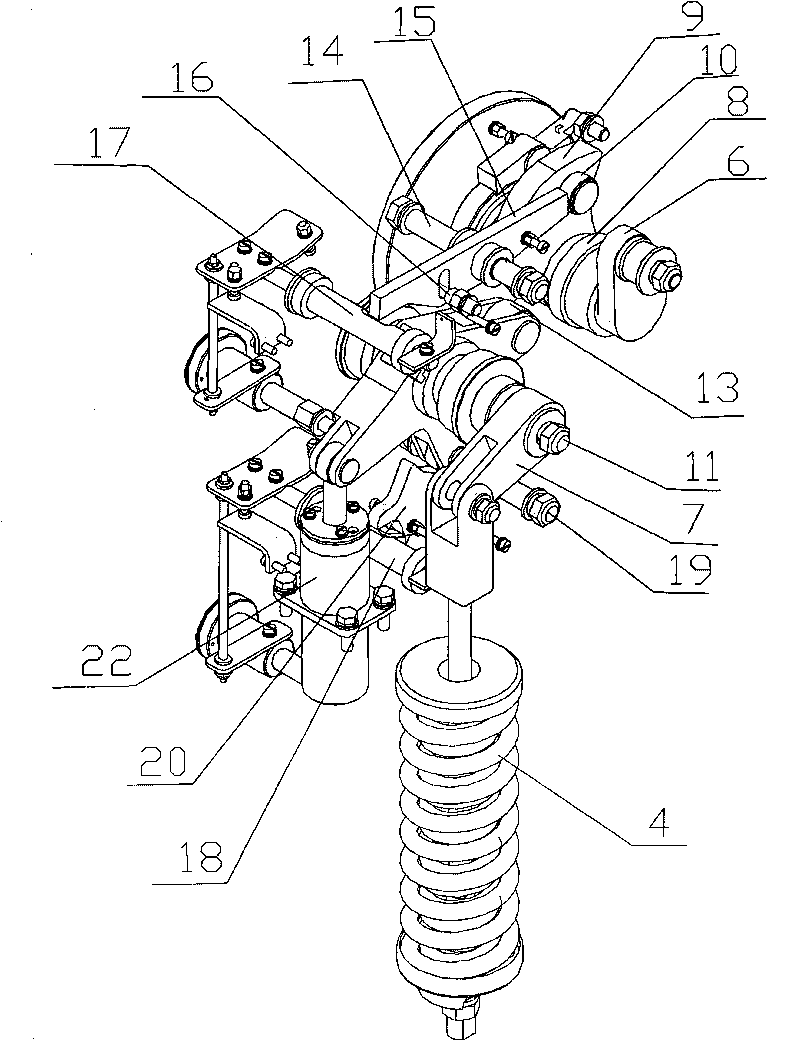

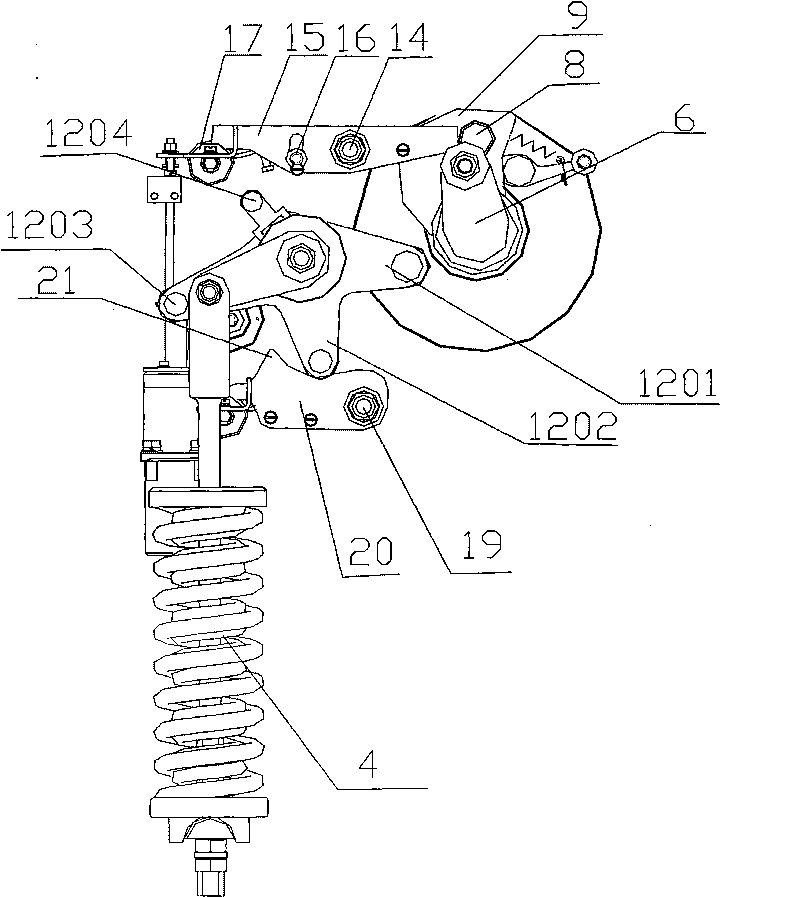

Spring operation mechanism used for high-voltage switch

ActiveCN101763960AOutstanding FeaturesHighlight significant progressSwitch power arrangementsDetentEngineering

The invention relates to the field of the operation mechanism of a power switch, which discloses a spring operation mechanism used for a high-voltage switch. The power transmission of an energy storage shaft and an output shaft is realized by utilizing the matching of a switching-on cam and a power arm, a switching-on half shaft and an energy storage retention detent are utilized to execute a switching-on command, a switching-off half shaft, a switching-on retention detent and a retention arm are utilized to execute a switching-off command, the retention, the switching off and the restoration of the switching-on retention detent are skillfully realized, the retention arm, a restoration arm and the power arm are also integrated into a transmission crankarm, and the restoration arm and a restoration wheel are matched to realize the restoration of the energy storage retention detent. The functions of energy storage, switching on and switching off of the invention are simple and convenient to realize, the used components are fewer, and the manufacturing cost is low.

Owner:CHINA XD ELECTRIC CO LTD

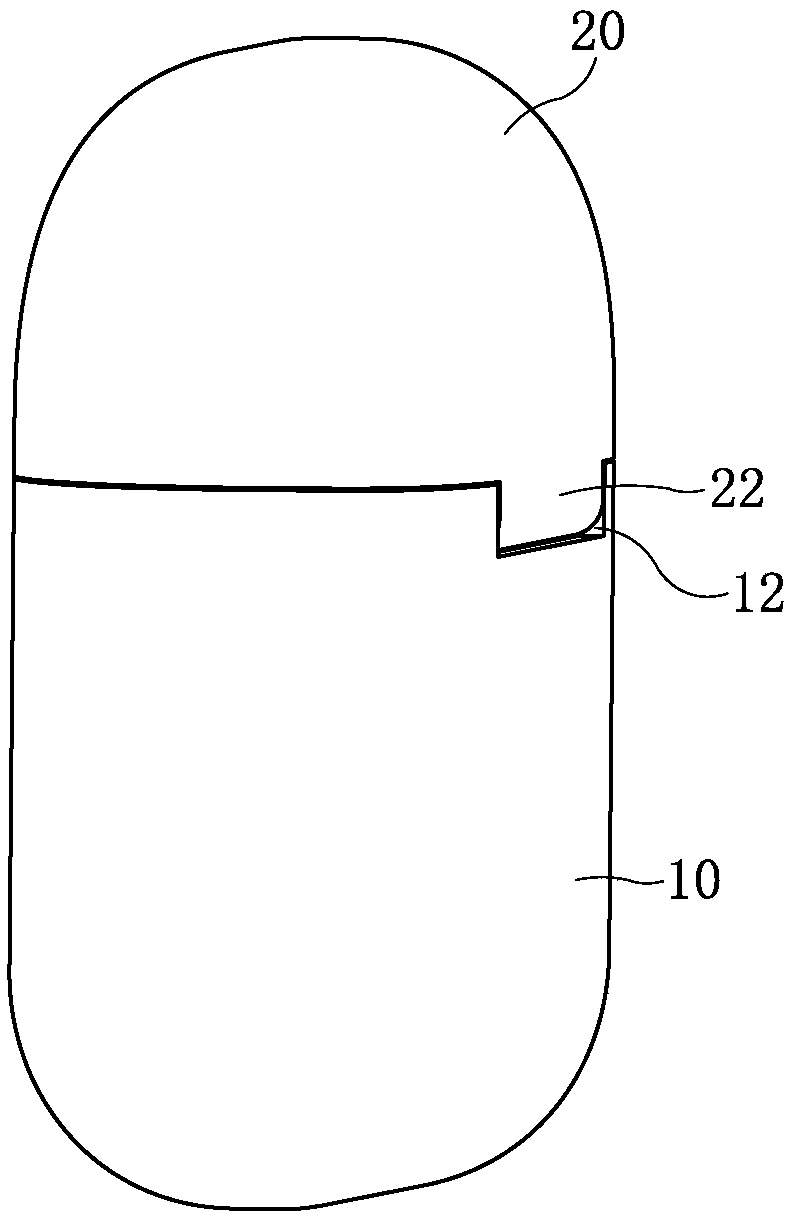

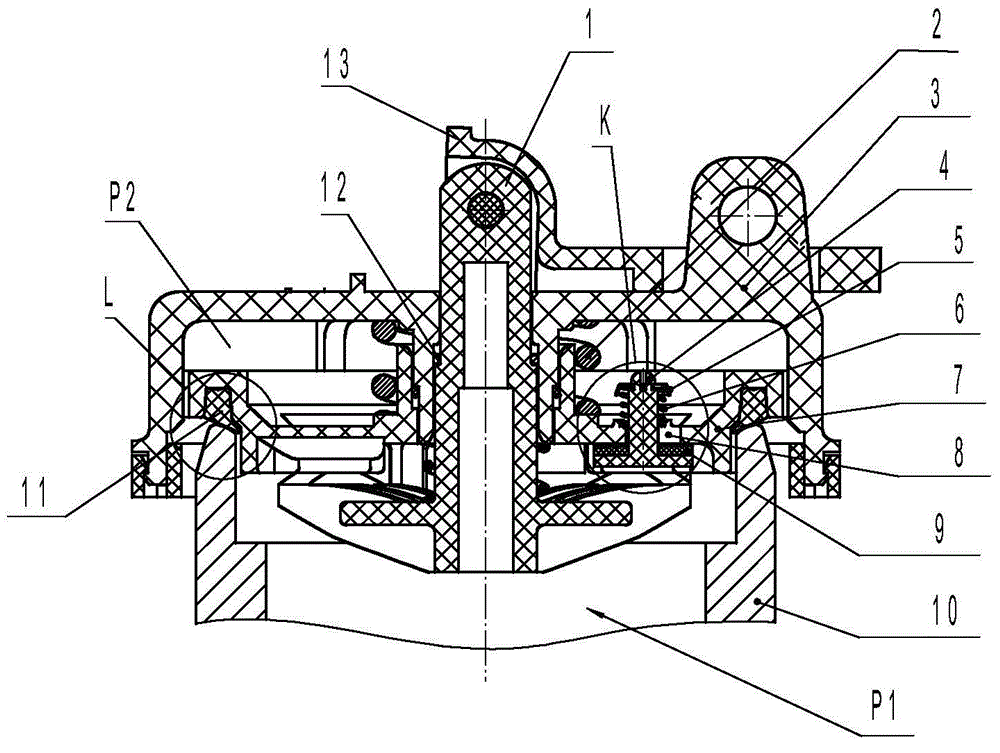

Silencer with variable damp characteristics

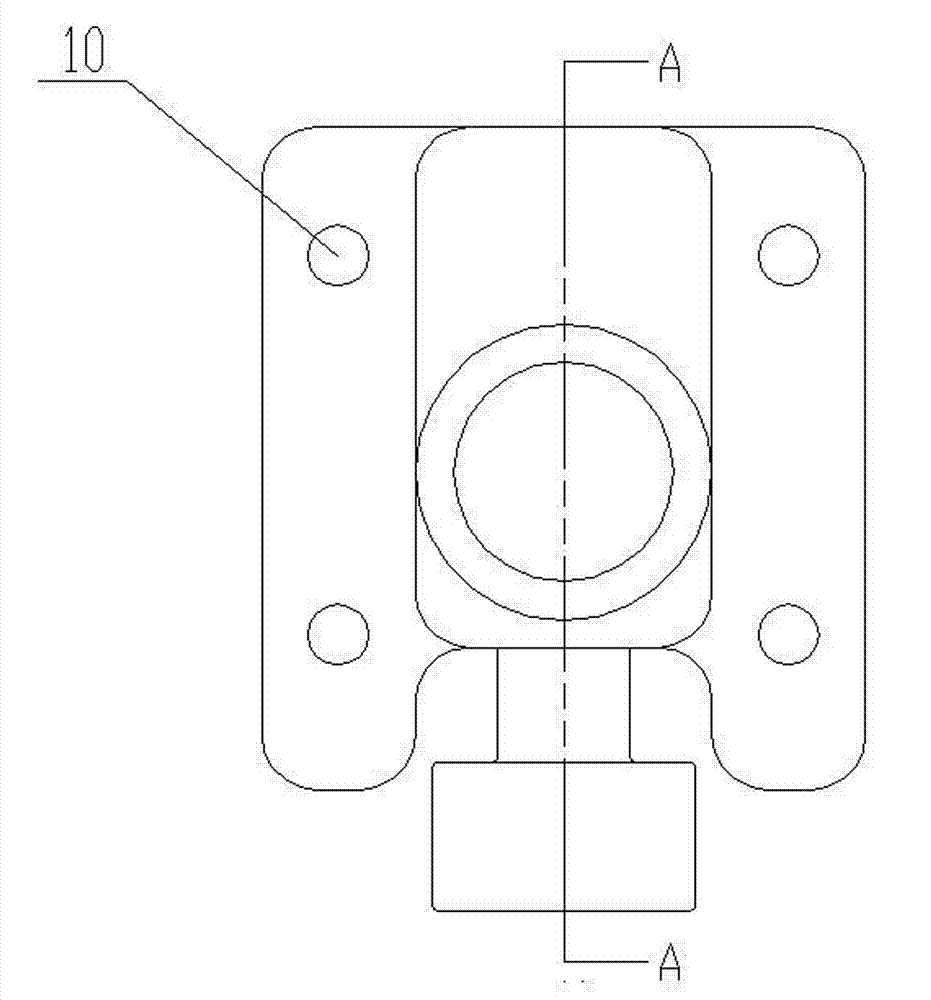

InactiveCN1530523ANo leaksWon't get stuckSilencing apparatusMachines/enginesMobile vehicleRest position

The Invention relates to mufflers with variable damping characteristic for motor vehicles with internal combustion engine, comprising a housing (20) with at least one gas pipe (1), terminating in the housing (20), and at least one valve whose closure element (3) closes the end (2) of the pipe (1) in rest position. The closure element (3) is a disk, seated on a guide rod (4). The guide rod (4) is guided in a guide sleeve (5) and performs a lifting mouvement. The spring (8) is positioned in a valve housing (10) which is gastight and connected in gastight manner to the muffler housing (20). As soon as the pressure in the gas pipe (1) is high enough, the valve disk (3) opens against the force of the spring (8).

Owner:HEINRICH GILLET GMBH & CO KG

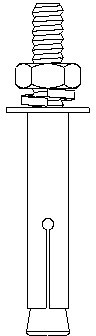

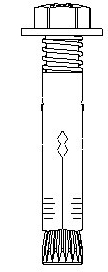

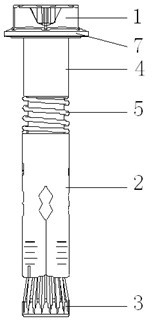

Invisible pressing expansion screw

The invention discloses an invisible pressing expansion screw which comprises a main body bolt (1), an upper sleeve (4), a pressing spring (5), an expansion pipe (2) and a round expansion head (3) which are sequentially sleeved on the main body bolt (1), wherein the round expansion head is spirally matched with external screw threads at the lower end part of the main body bolt; and the main body bolt (1), the upper sleeve (4), the pressing spring (5) and the expansion pipe (2) are removably connected together. The pressing spring is concealed in a mounting hole by the invisible pressing expansion screw provided by the invention, and working pieces can not be clamped; the screw is particularly suitable for the mounting construction for fastening thicker projects; and after the invisible pressing expansion screw provided by the invention is removed, the main body bolt can be recycled, the smoothness of the mounting field can be kept, and the screw is environmentally-friendly.

Owner:睢宁鑫非机械科技有限公司

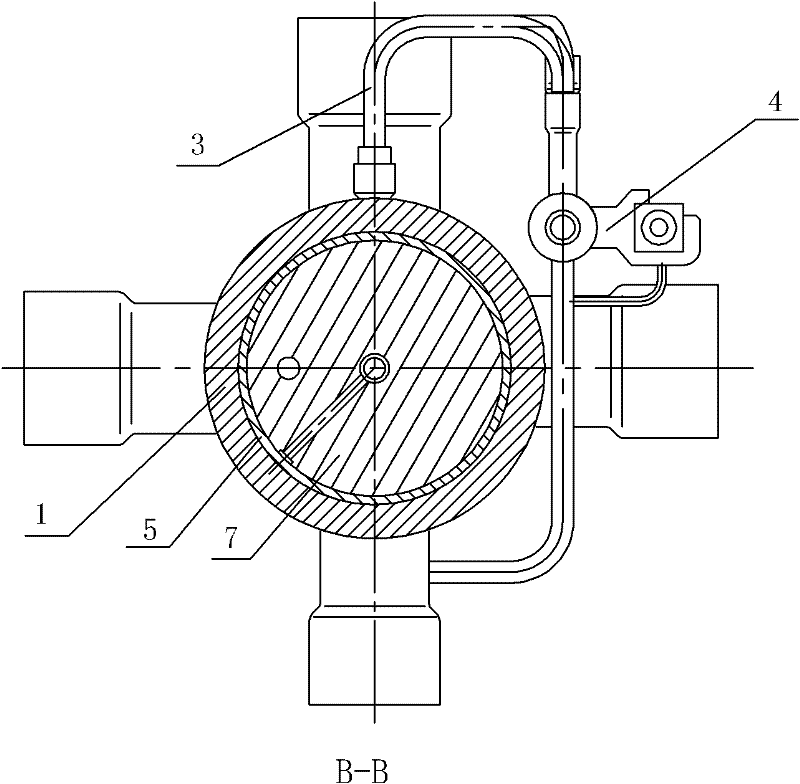

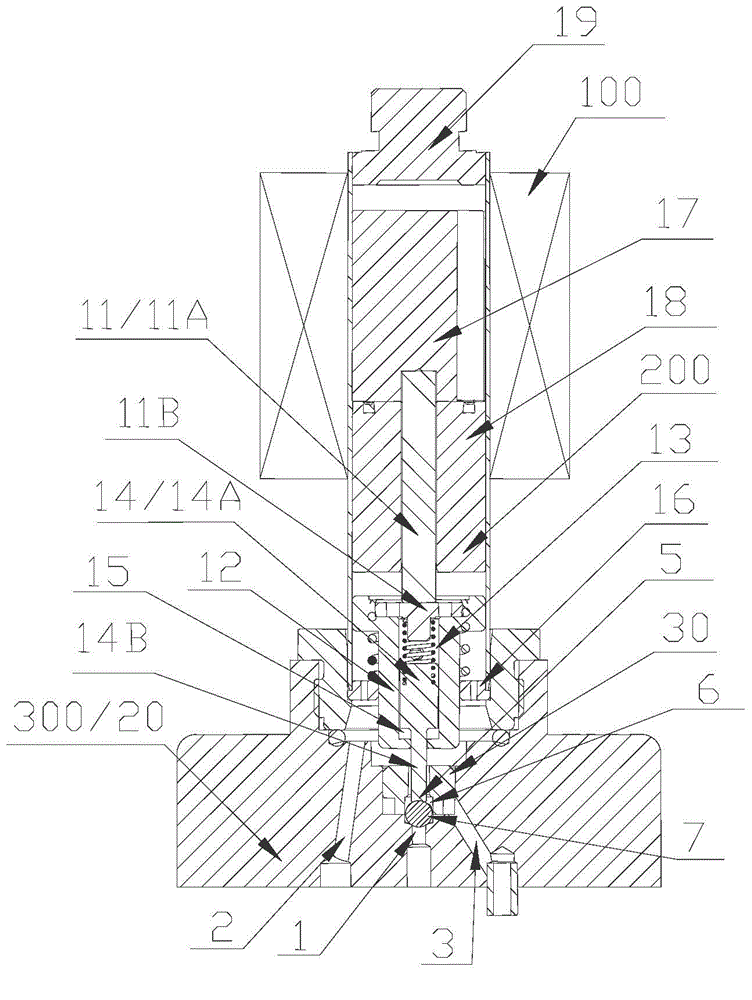

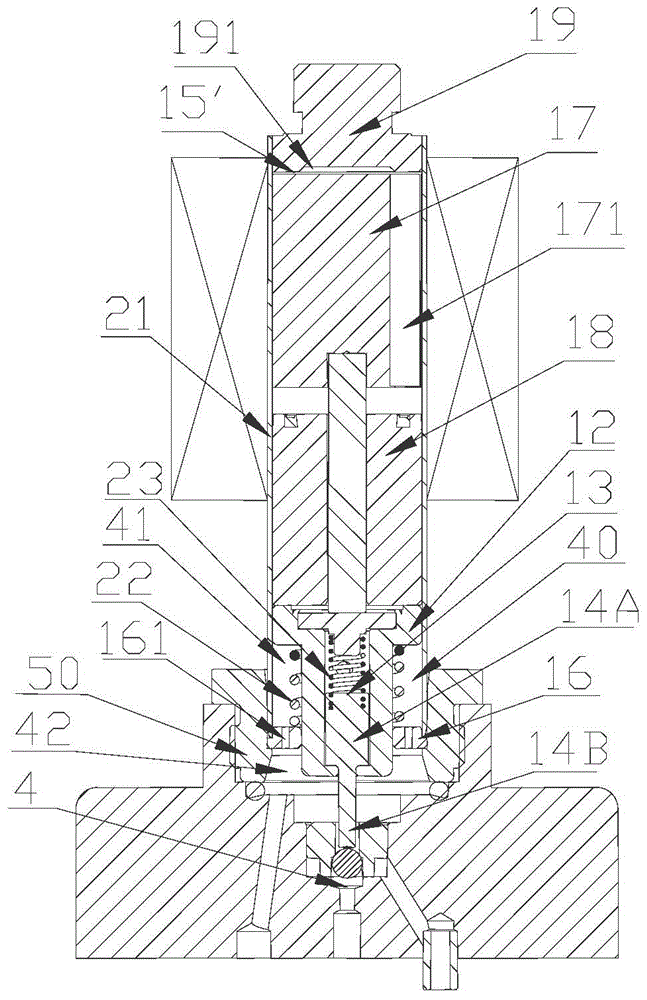

A solenoid valve for a compressor

ActiveCN106032853AWon't bendWon't get stuckOperating means/releasing devices for valvesMultiple way valvesWork performanceSolenoid valve

The invention provides a solenoid valve for compressor. The solenoid valve comprises a coil component, a valve body component and a valve seat component. The valve seat component comprises an inflow channel, an outflow channel, and a bypass channel. The valve seat component also comprises a main valve port and an auxiliary valve port, and a valve cavity is formed between the main valve port and the auxiliary valve port; a valve element is arranged in the valve cavity; when the coil component is electrified, the valve element closes the main valve port and opens the auxiliary valve port, so that the bypass channel communicates with the outflow channel; when the power for the coil component is cut, the valve element closes the auxiliary valve port and opens the main valve port, so that the bypass channel communicates with the inflow channel. When the power for the coil component is cut, the valve element closes the auxiliary valve port, so that the bypass channel communicates with the inflow channel. The solenoid valve meets the requirement of a loaded state in a power-cut state of a compressor, and is long in service life and stable and reliable in work performance.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

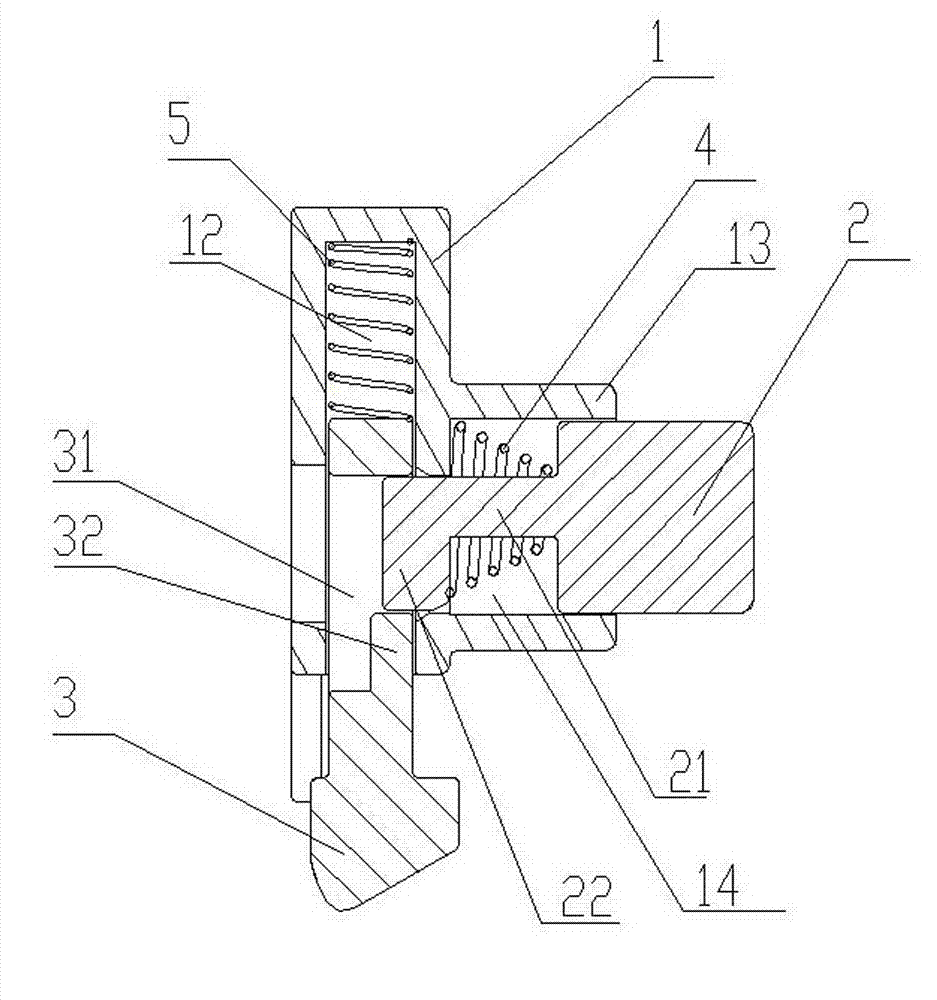

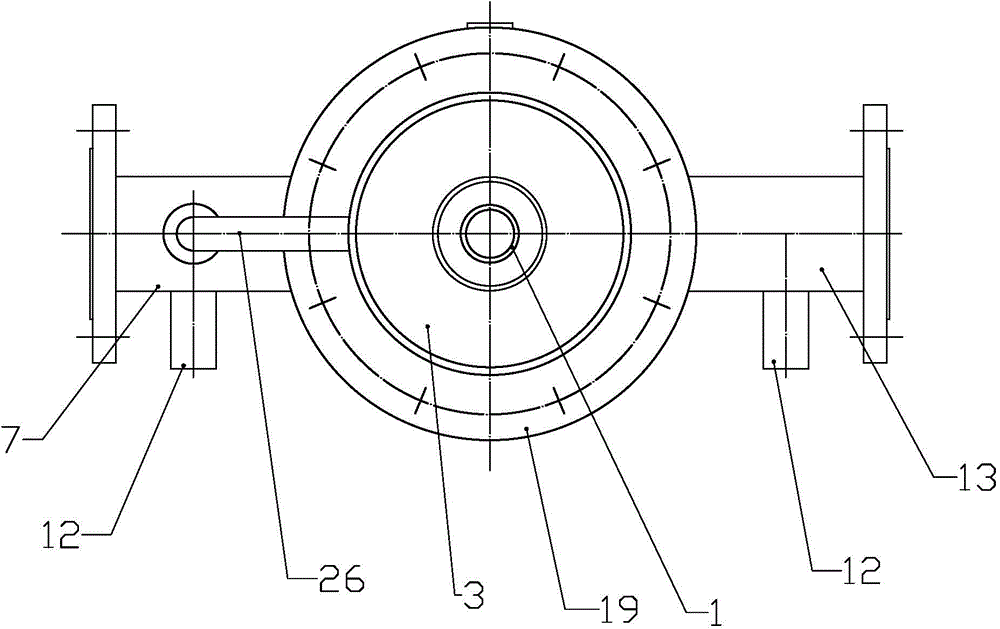

Medium-pressure high-speed rotating connector

The invention discloses a medium-pressure high-speed rotating connector. The medium-pressure high-speed rotating connector comprises a shell body; an end cover is fixedly connected to one end of the shell body, and a stationary sealing ring is connected to the inner side of the end cover in a clearance fit mode; a rotating shaft is connected in the shell body in a relative rotation mode, and a sealing spacer bush is connected to the inner wall of the shell body; the rotating shaft penetrates through the middle of the sealing spacer bush, and a boss is machined on the side, facing the stationary sealing ring, of the sealing spacer bush; the side surface of the boss is provided with an annular groove, piston rings are movably connected into the annular groove; a sealing sleeve is fixedly connected to the part, between the sealing spacer bush and the inner end surface of the rotating shaft, of the outside of the rotating shaft; a groove body is formed in the position, on the side surface of the sealing spacer bush, of the sealing sleeve; the sealing sleeve inner side wall where the groove is located makes fixed contact with the outer diameters of the piston rings in a sealed mode; the piston rings form a labyrinth seal between the sealing sleeve and the sealing spacer bush; the outer wall of the shell body is provided with two threaded connection openings which are located at the sealed contact surface of the inner end surface of the rotating shaft and the inner end surface of the stationary sealing ring.

Owner:TENGZHOU TIANXUAN ROTARY UNION

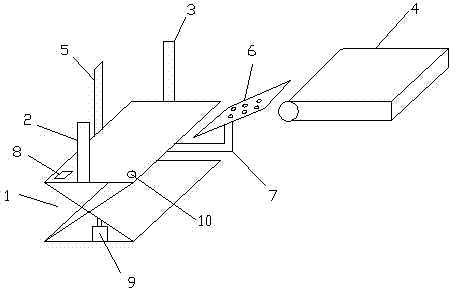

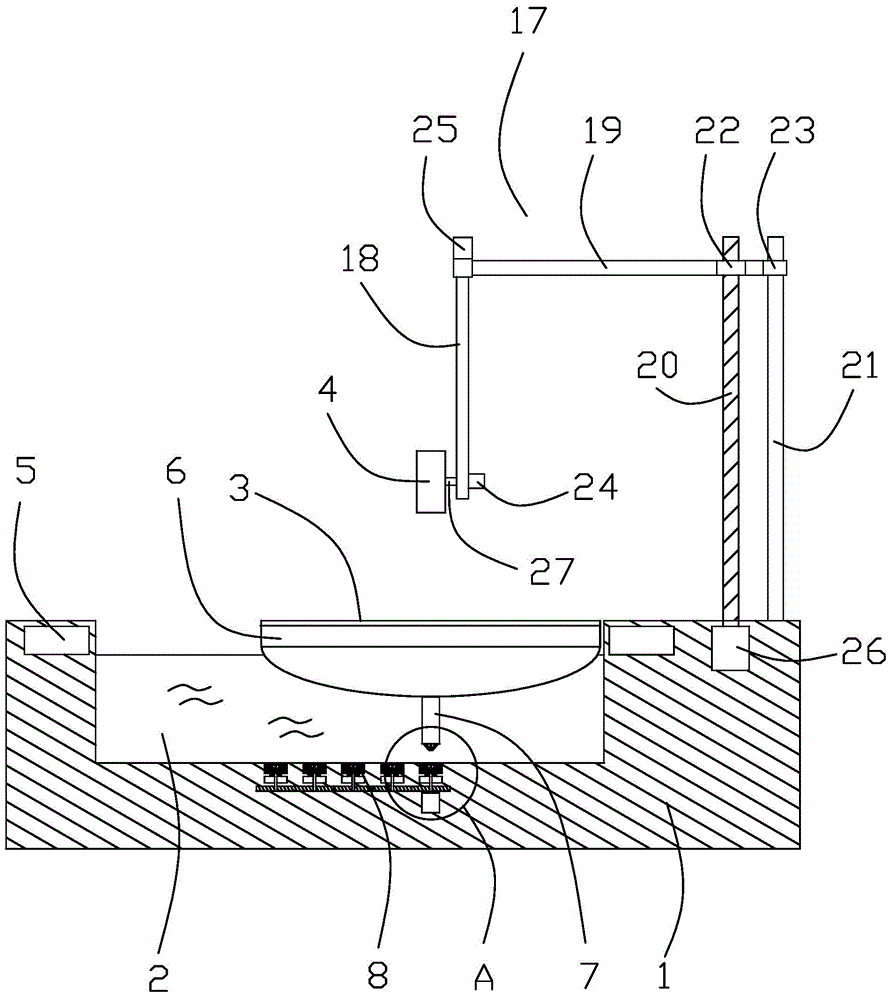

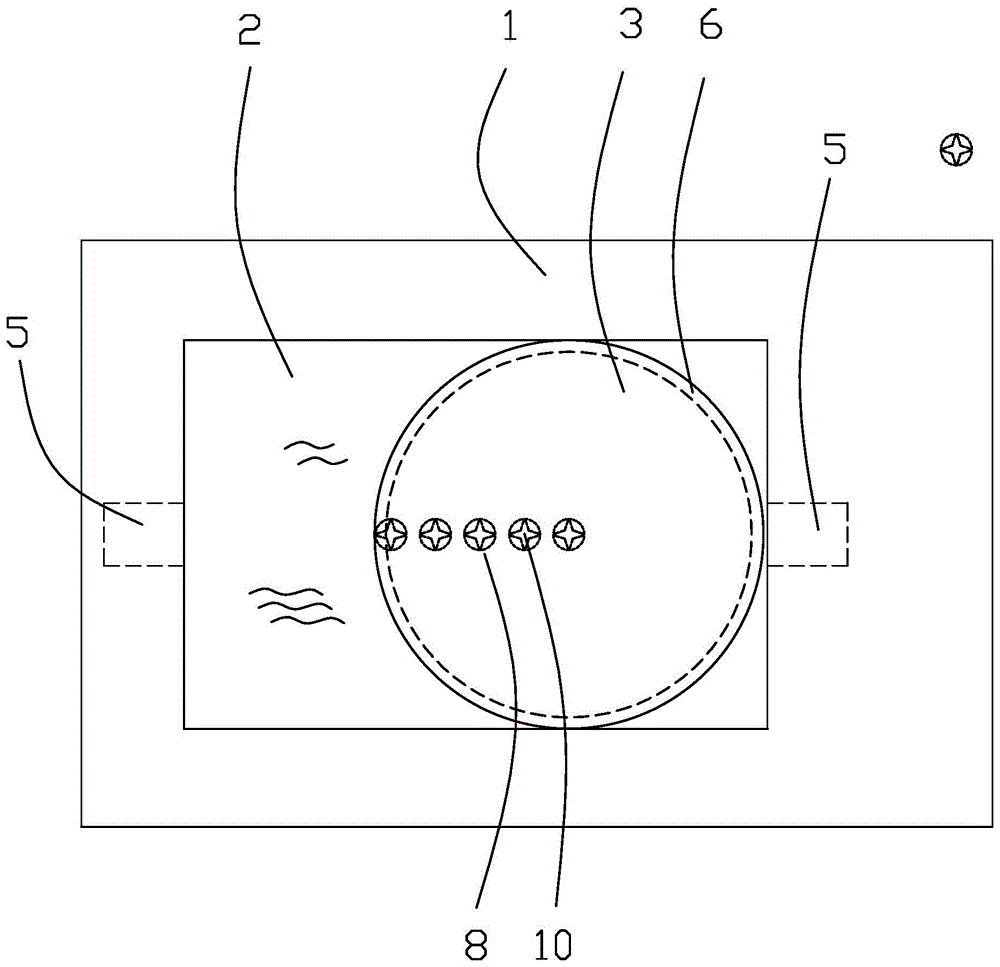

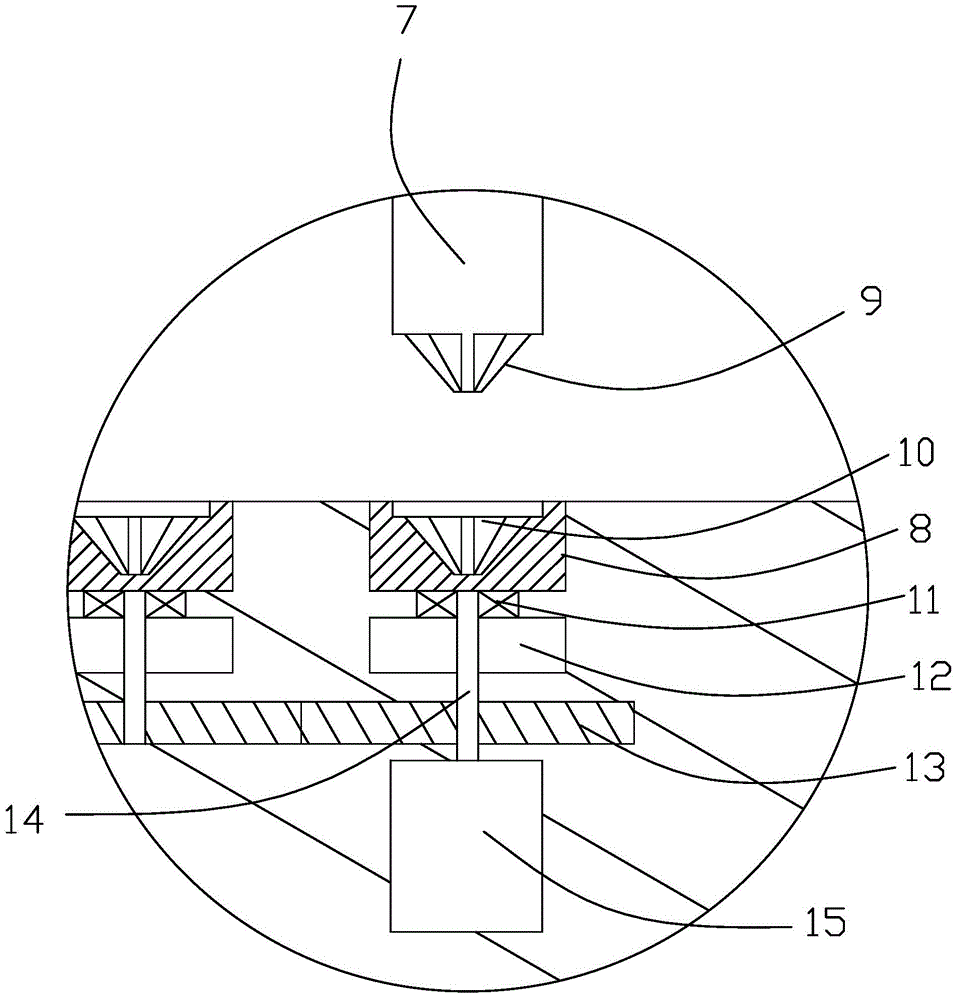

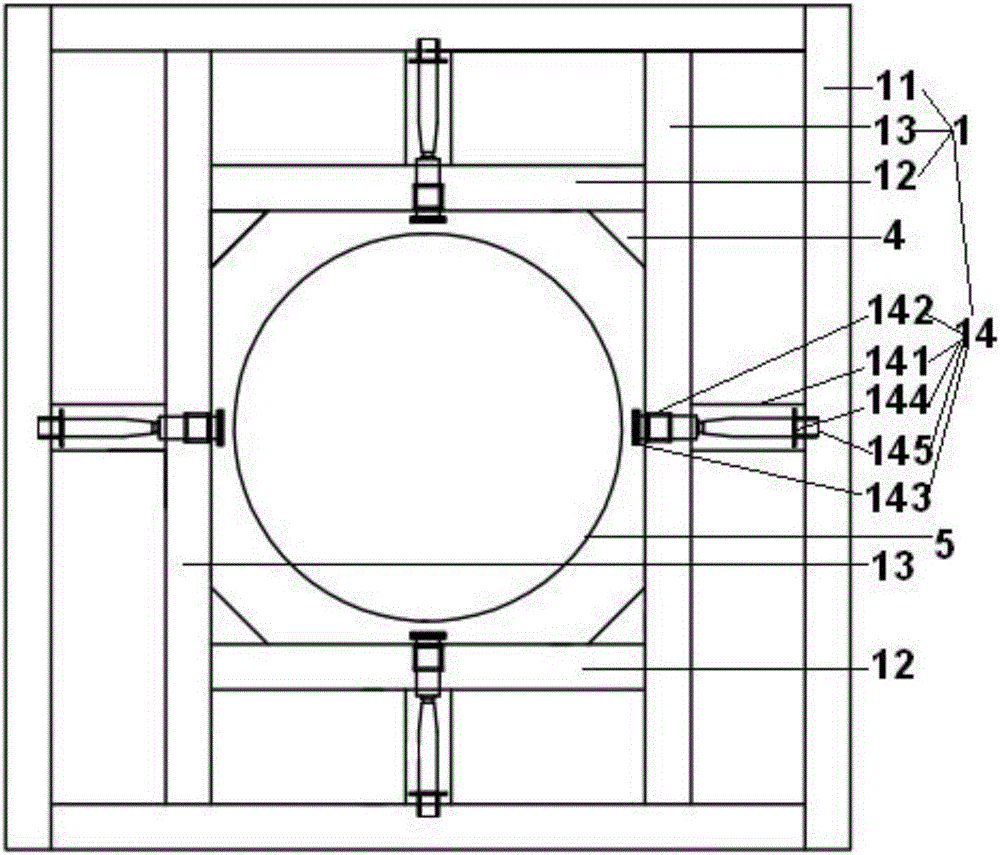

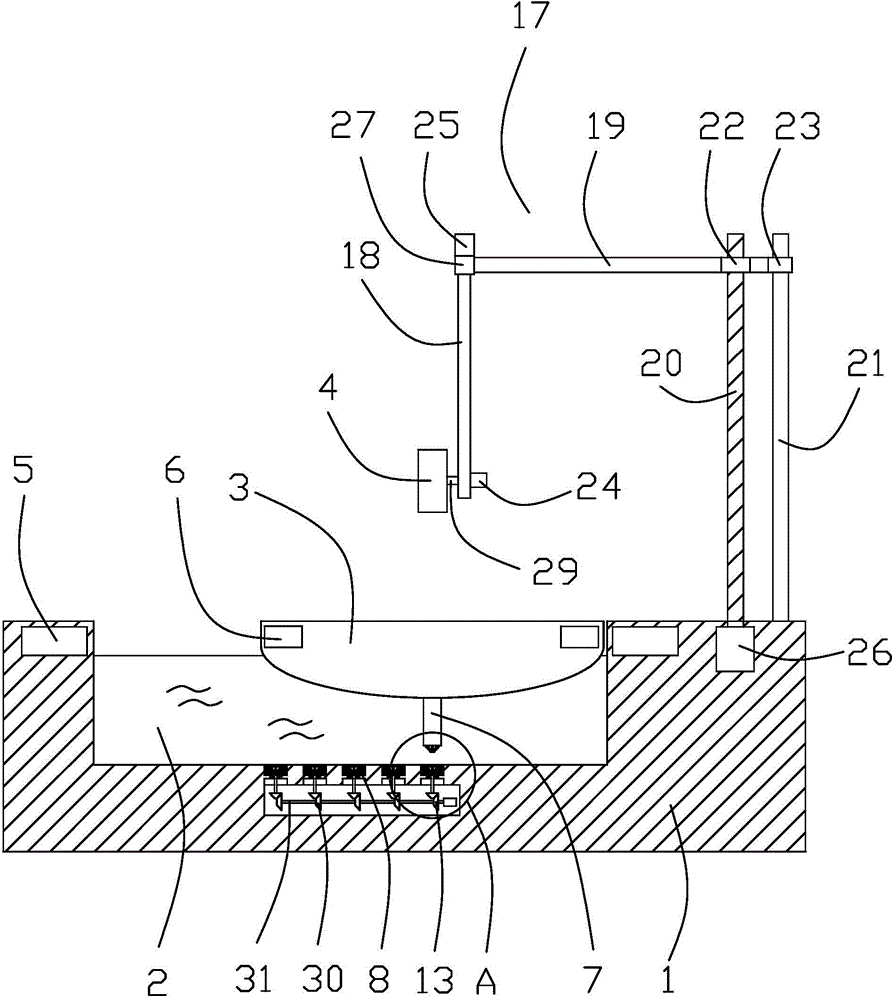

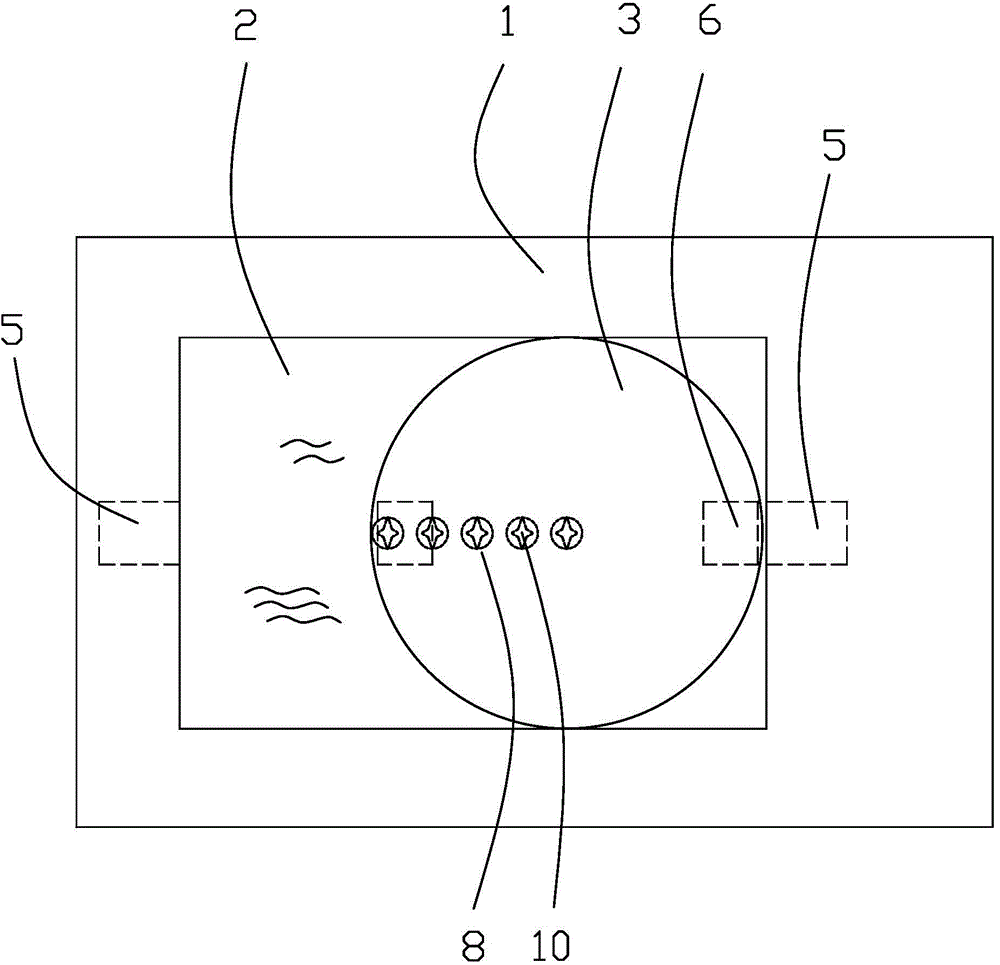

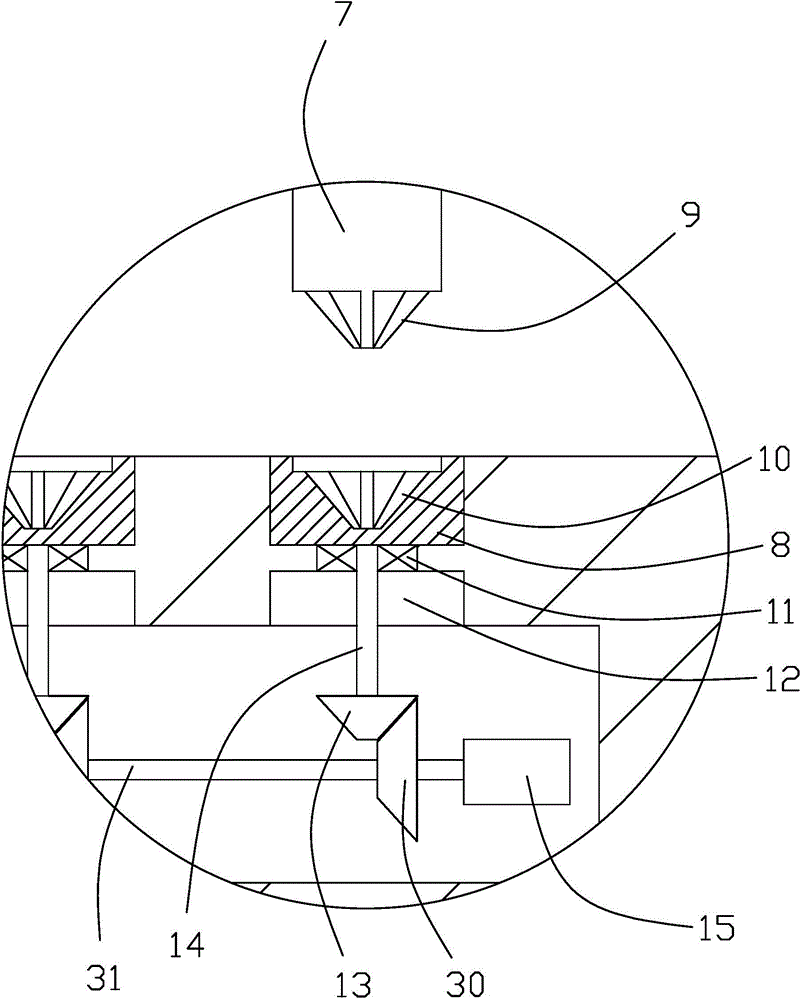

New beef freshness rapid nondestructive detection device and detection method

InactiveCN104374702APrecisely control the moving distanceMove preciselyColor/spectral properties measurementsEngineeringNondestructive testing

The invention relates to a new beef freshness rapid nondestructive detection device and detection method, and solves the problems, in the prior art, of subjective inaccuracy of beef freshness detection and complex detection equipment and detect process. The device comprises a seat body, the seat body is provided with a floating pool, a tray floats in the floating pool, the tray is controlled to move through magnetic force, an adjustment bracket is arranged above the seat body, the adjustment bracket is provided with a light source, and the seat body is also provided with a control unit. The control unit analyzes sample reflectance spectra data to judge the degree of beef freshness. The advantages of the new beef freshness rapid nondestructive detection device are that, by using a spectral detection mode, nondestructive testing of samples can be carried out; the new beef freshness rapid nondestructive detection device is reasonable in structure, the seat body moving resistance is small, and the new beef freshness rapid nondestructive detection device does not jam, and is convenient in operation and maintenance, and accurate in detection data.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Drilling pile casing guide device provided with calibration mechanisms and control method

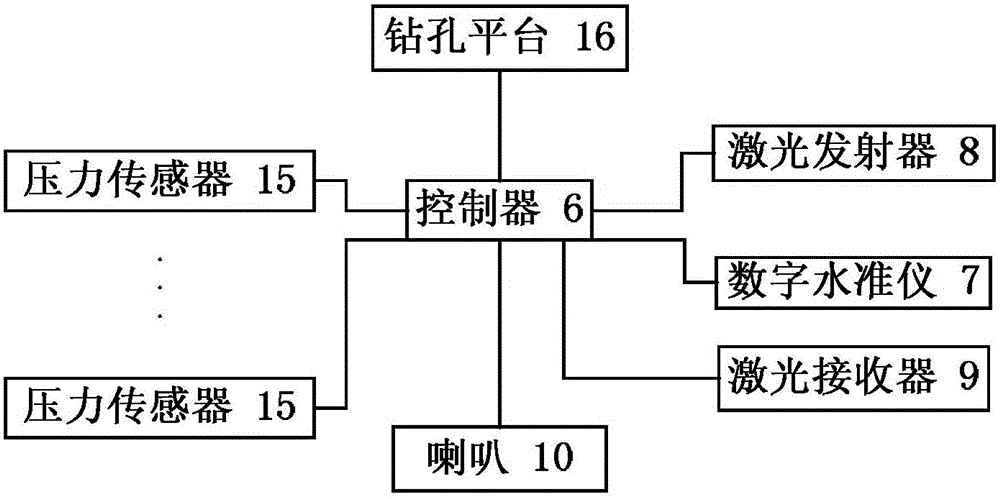

The invention discloses a drilling pile casing guide device provided with calibration mechanisms and a control method. The device comprises an upper support, a lower support, a plurality of supporting columns arranged between the upper support and the lower support, a controller, a digital level, a laser emitter, a laser receiver and a horn. The upper support comprises a rectangular frame, two transverse rods arranged in the rectangular frame, two longitudinal rods connected with the two ends of the two transverse rods correspondingly, the longitudinal calibration mechanisms and the transverse calibration mechanisms, wherein the longitudinal calibration mechanisms are arranged on the transverse rods and borders, corresponding to the transverse rods, of the rectangular frame, and the transverse calibration mechanisms are arranged on the longitudinal rods and borders, corresponding to the longitudinal rods, of the rectangular frame. The controller is electrically connected with the digital level, the laser emitter, the laser receiver and the horn. The lower support is identical with the upper support in structure. The device and the method have the characteristics of being capable of effectively controlling the perpendicularity of drilling pile casings and high in construction efficiency.

Owner:ZHEJIANG JINZHU TRANSPORTATION CONSTR

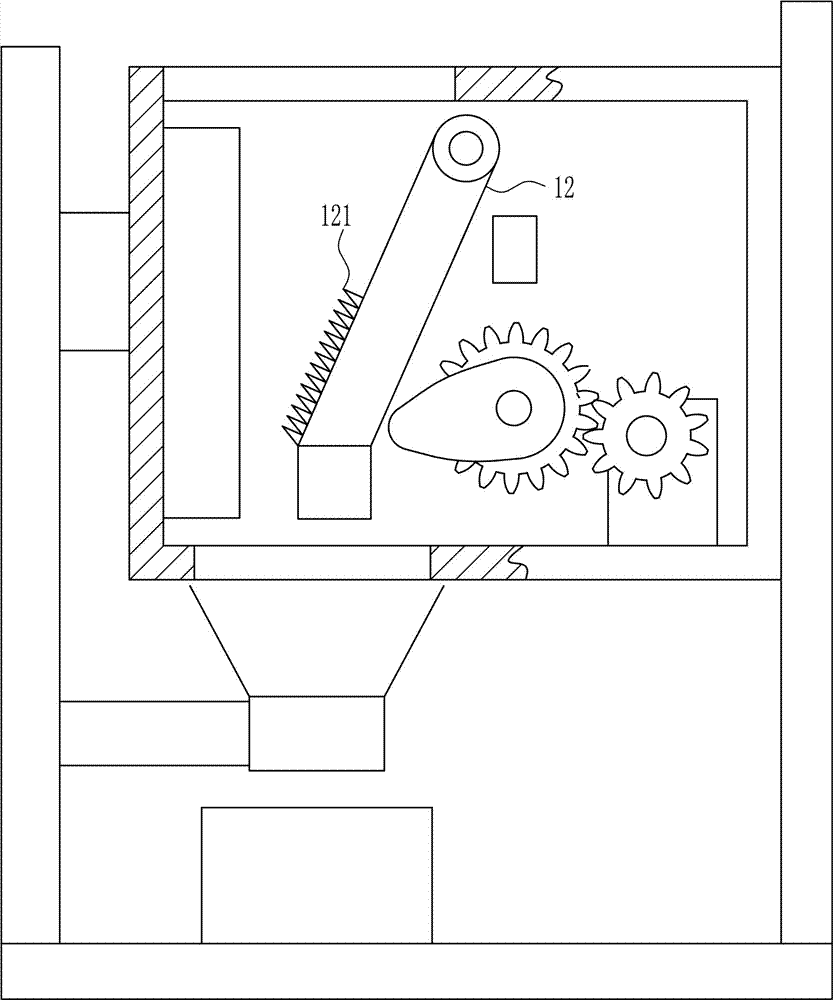

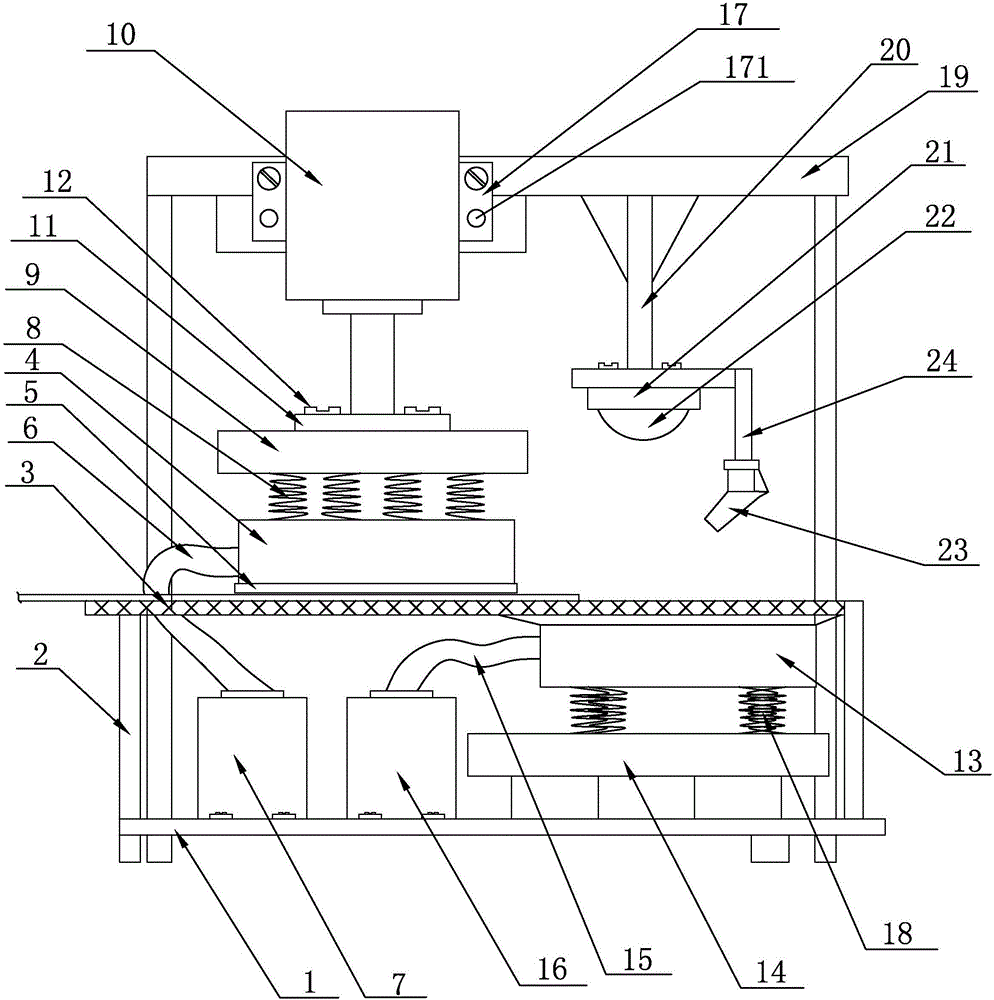

Winding type sheep manure collecting and bagging device

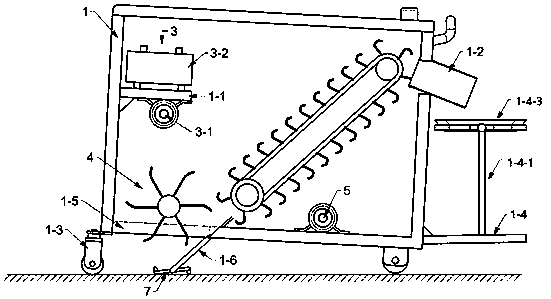

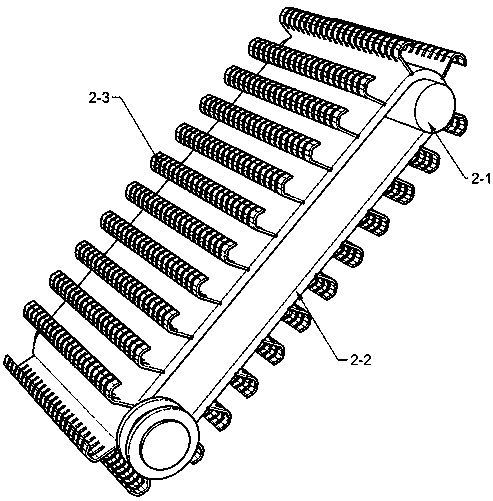

InactiveCN110255213AEasy to handle workReduce manufacturing costConveyorsAnimal housingEngineeringConveyor belt

The invention discloses a winding type sheep manure collecting and bagging device which comprises a case, a conveyor belt device, a power drive device and a collecting rolling wheel. The winding type sheep manure collecting and bagging device is characterized in that the conveyor belt device is inclinedly and upwards arranged in the case; the high end of the conveyor belt device is located at the middle upper section of the back side of the case; the low end of the conveyor belt device is located on the bottom part of the case; the collecting rolling wheel is arranged on the bottom part of the middle front section in the case and is partially located outside the bottom part of the case; an installation plate is arranged on the front side in the case; the power drive device is fixed onto the installation plate; the power drive device is arranged on the front side of the case and can play a role in balance weight at the same time, so that the occurrence of the phenomenon that after the back side of the case is fully bagged by a discharge hole, the case is turned over due to the pressing of bags is prevented; according to the device, through reducing the input of manpower, the collecting efficiency is improved, and a link for centrally collecting sheep manures from a sheep shed and a bagging link can be mechanized, so that the blanks of the two links can be thoroughly filled; and in addition, the winding type sheep manure collecting and bagging device is low in manufacturing cost, and suitable to be used by users in a sheep raising region.

Owner:XILINGOL VOCATIONAL COLLEGE

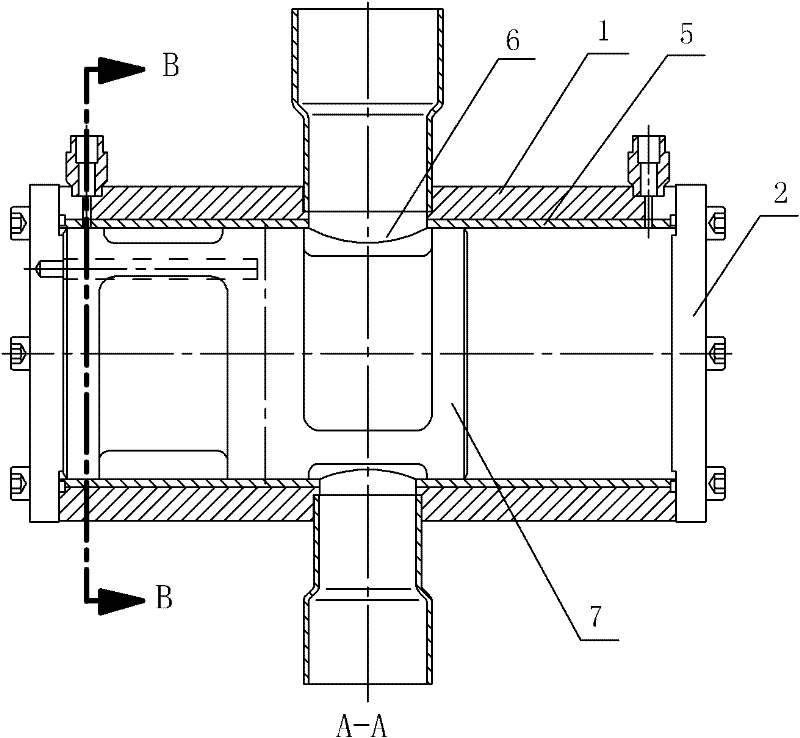

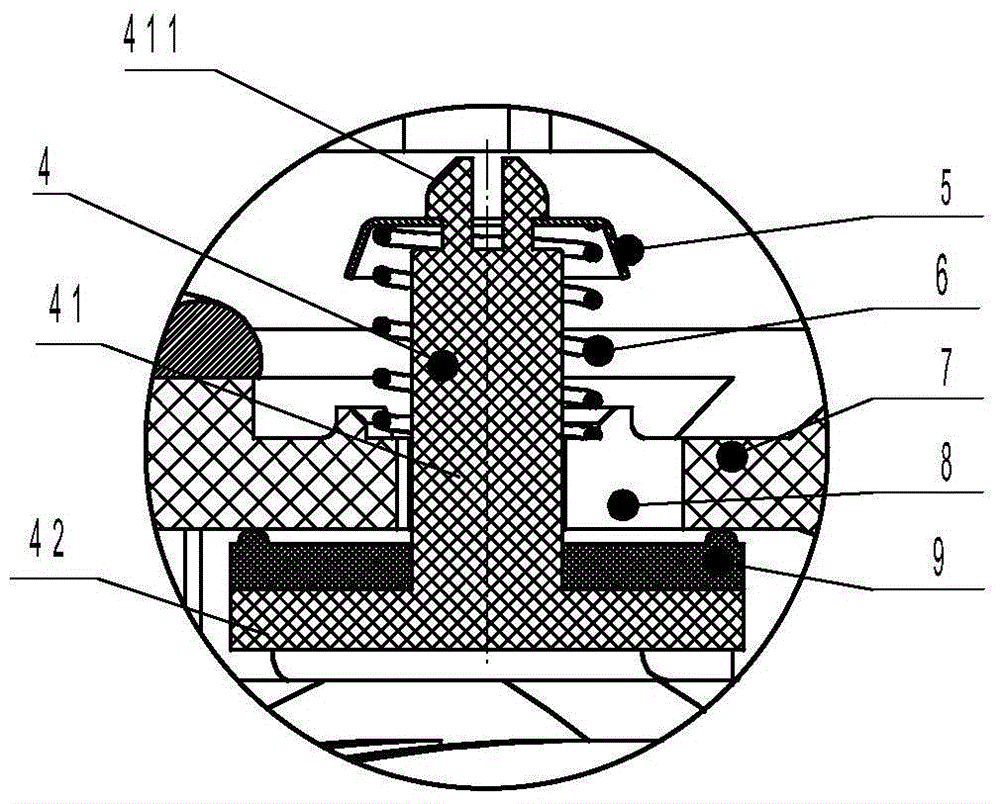

Piston four-way reversing valve for refrigerating system

InactiveCN102226482AAvoid dry rubbingWon't get stuckOperating means/releasing devices for valvesEngineeringAlloy

The invention discloses a piston four-way reversing valve for a refrigerating system and belongs to a valve which can be used for changing the flow direction of refrigerants. The existing four-way reversing valve in a stopped status has the defect that the piston is easily deadlocked due to lack of the lubricating oil when the oil film is easily washed and moved away by the refrigerating fluid. According to the invention, the piston four-way reversing valve is mainly composed of a main valve and a pilot valve, wherein the pilot valve is communicated with the cavity of the main valve through a gas-guide pipe; the main valve comprises a valve body, a piston which is arranged in the valve body and two end caps which are arranged on the two ends of the valve body; the valve body is provided with four valve ports, a lubricating sleeve is arranged between the inner surface of the valve body and the piston, the lubricating sleeve is fixedly connected with the valve body; a through hole which corresponds to and is communicated with the valve port is arranged on a lubricating sleeve body; the lubricating sleeve is divided into a steel substrate layer, a copper substrate alloy powder layer and a solid lubricating layer in the radial direction from outside to inside; and the first layer and the second layer are sintered into a whole, the third layer is rolled on the surface of the second layer, a solid lubricating material can play a role in lubricating the piston so as to ensure the piston to flexibly move in the valve body without being deadlocked, thus the service life can be prolonged.

Owner:ZHEJIANG XINSANRONG REFRIGERATION CO LTD

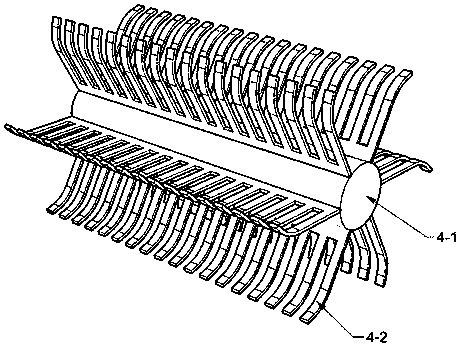

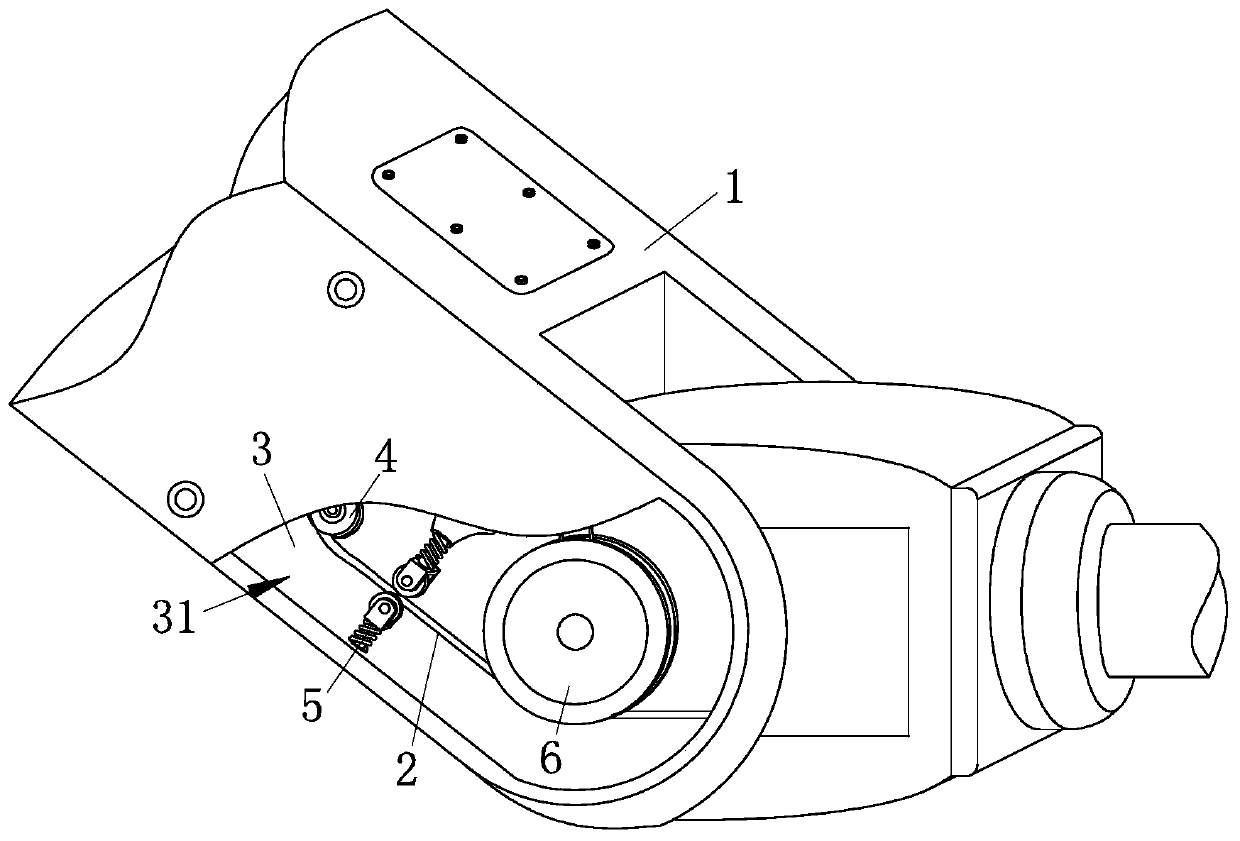

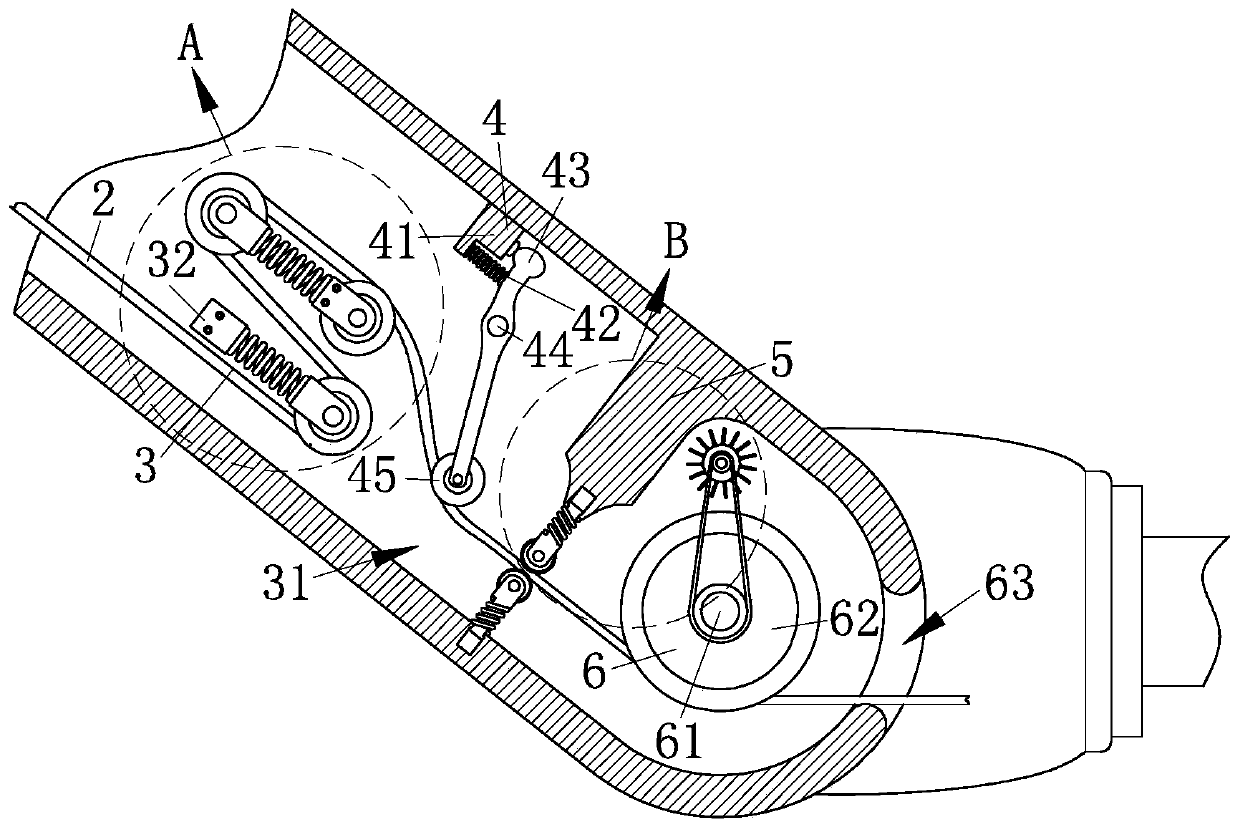

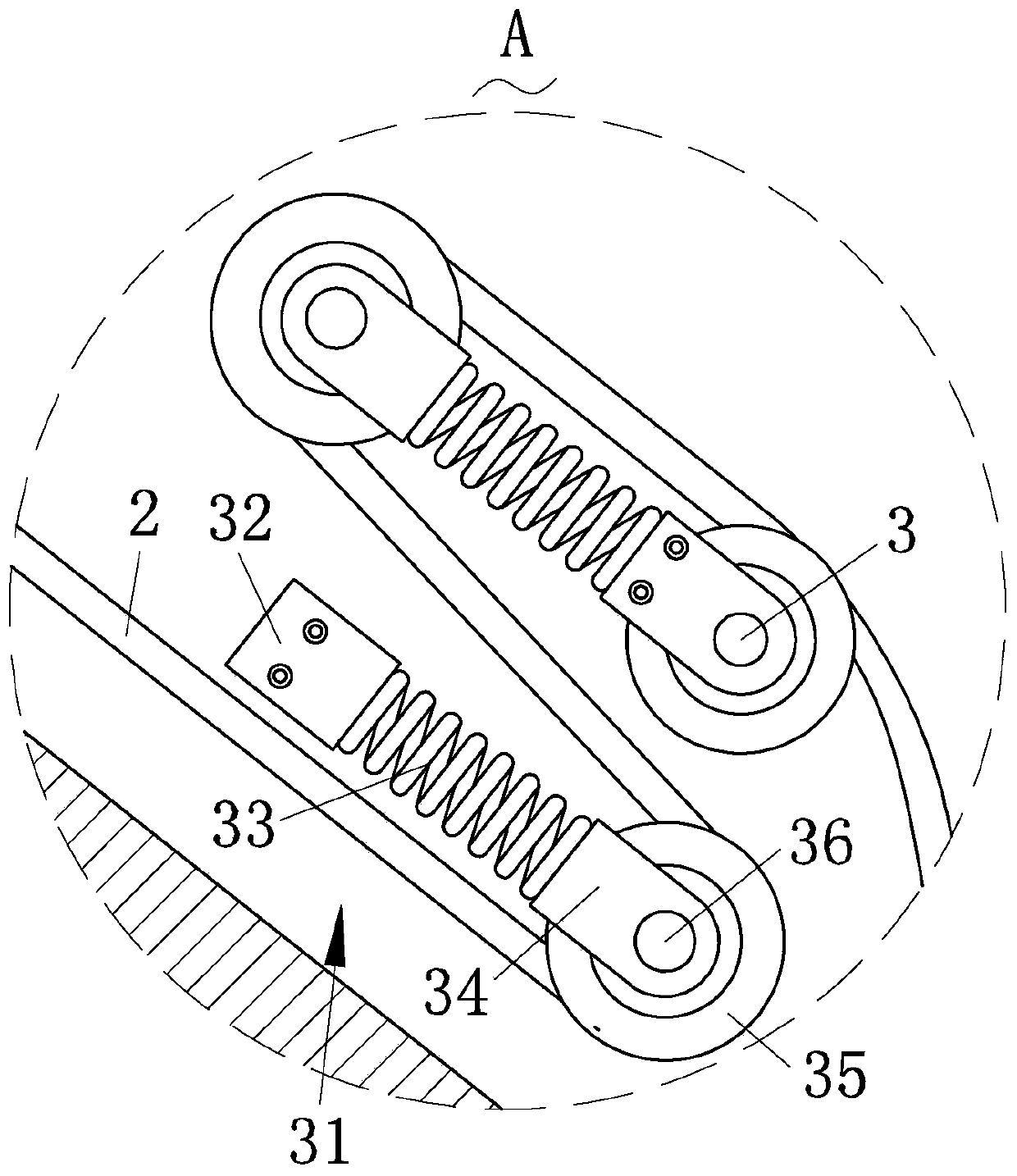

Cable winding device for robot using ultra-flexible wear-resistant cable

ActiveCN110683414AShrink freelyShrink freely, place the cable in the robot hand freelyFilament handlingManipulatorClassical mechanicsMachine

The invention relates to the field of a cable winding device for a robot using an ultra-flexible wear-resistant cable, in particular to a cable winding device for a robot using an ultra-flexible wear-resistant cable. The cable winding device comprises a machine hand body, a cable wire, a winding mechanism, a triggering mechanism, a damping mechanism and a heat dissipation mechanism. The cable wirecan be freely rolled under the movement of the machine hand body through the cooperation between the cable wire and the winding mechanism, the cable wire is prevented from blocking and pulling off, meanwhile, the cable wire can stop working after the machine hand body receives the instruction by touching the triggering mechanism when the cable wire is accidentally stuck, damage of the machine hand body is prevented, the cable wire can guide and slow the cable wire through the damping mechanism in the winding process, the cable wire cannot be pulled or blocked by pressure or elasticity duringmovement, damage to the machine hand body is caused, movement of the cable wire enables the heat dissipation mechanism to work, so that heat dissipation and blowing are conducted on other mechanisms in the machine hand body, and the service life of the machine hand body is prolonged.

Owner:广东坚宝电缆有限公司

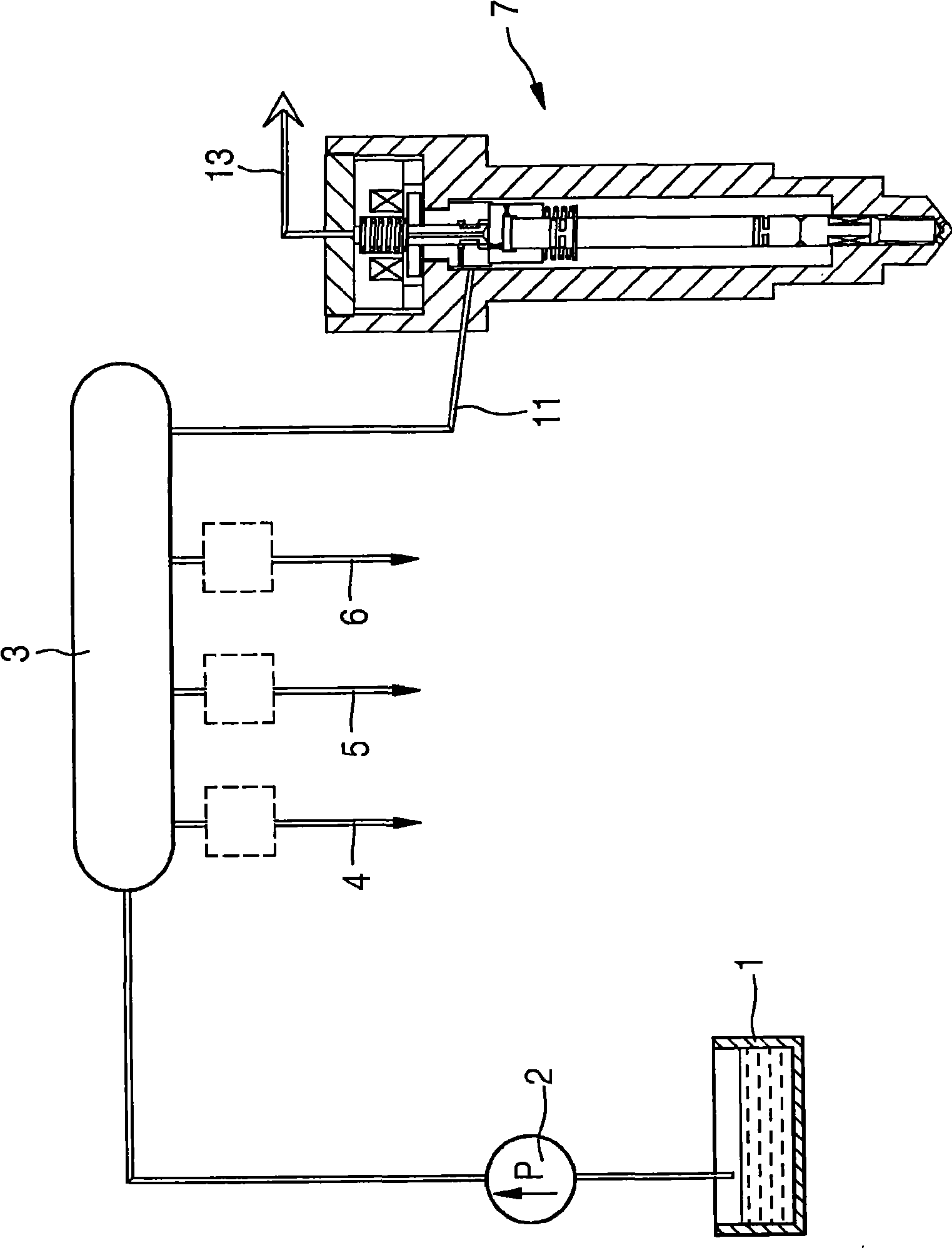

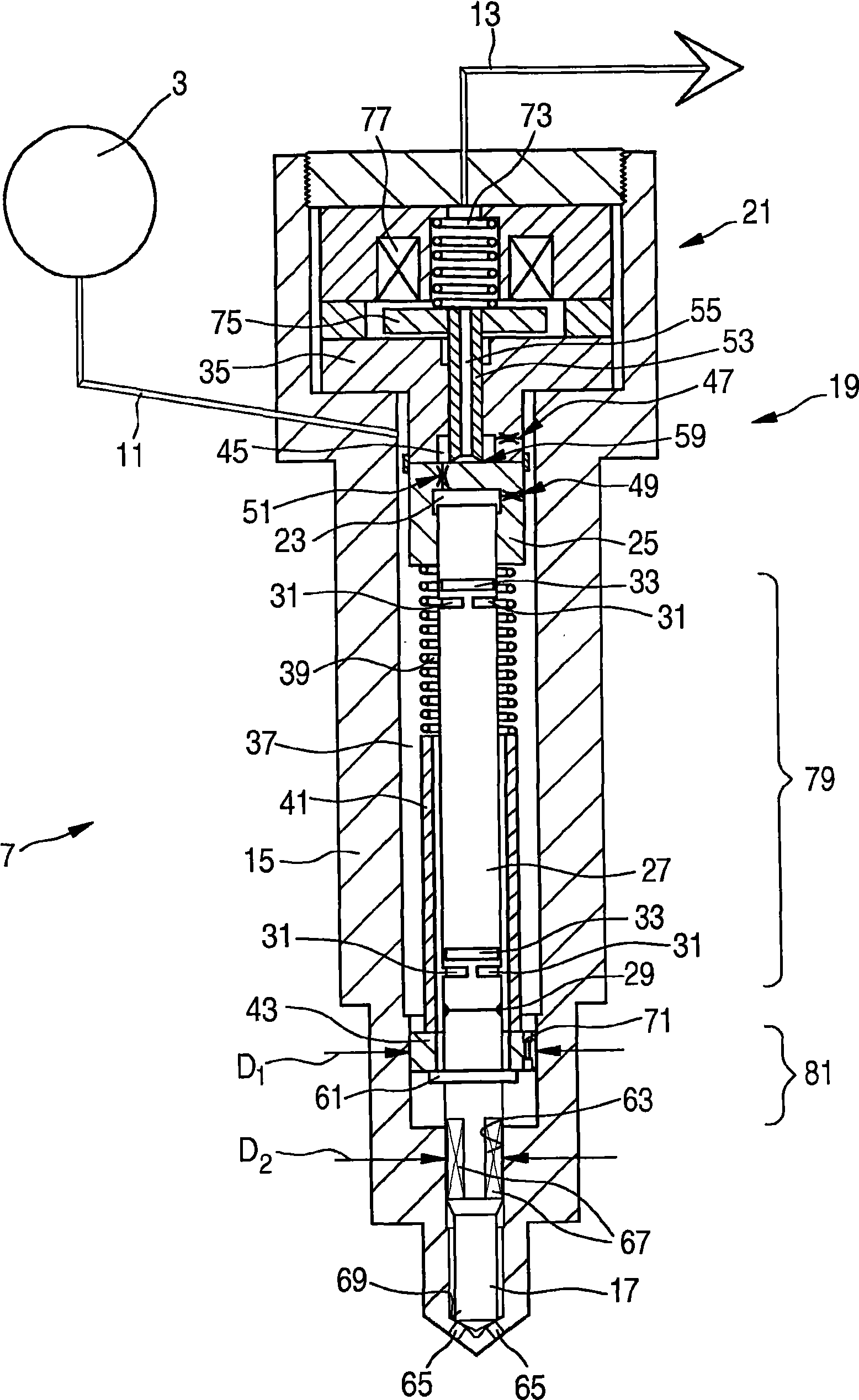

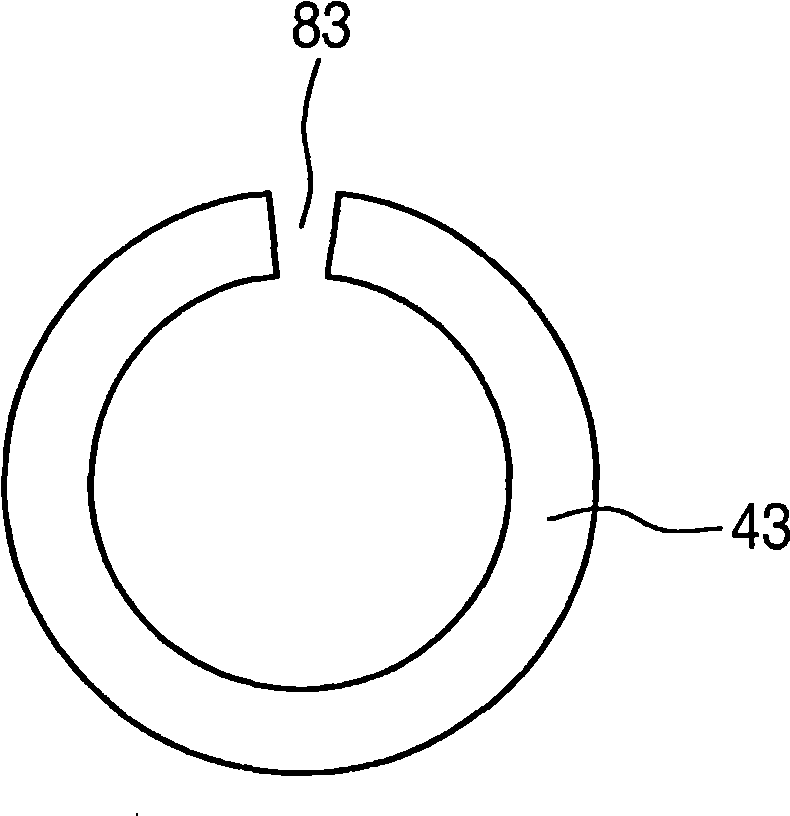

Injector for a fuel injection system

InactiveCN101501323AEnhanced closing forceIncreased pressure areaFluid pressure injection controlMachines/enginesEngineeringPiston

Owner:ROBERT BOSCH GMBH

Multifunctional fabric chip removing device of luggage production equipment

InactiveCN106801328AExtended service lifeElasticMechanical cleaningPressure cleaningEngineeringLED lamp

The invention discloses a multifunctional fabric chip removing device of luggage production equipment. The multifunctional fabric chip removing device comprises a pedestal. Four vertical supports are arranged on the pedestal. An object holding net is fixedly arranged over the four supports in a transverse manner. A first dust-absorbing apparatus is arranged right over the object holding net, and a second dust-absorbing apparatus is arranged under the object holding net. The second dust-absorbing apparatus is positioned right below the first dust-absorbing apparatus. A lighting apparatus and a monitoring apparatus are arranged above the second dust-absorbing apparatus. The lighting apparatus comprises a lamp stand, a lamp socket and an LED lamp, wherein the lamp socket is detachably connected with the lower end of the lamp stand, and the LED lamp is in threaded connection with the lamp socket. The monitoring apparatus comprises a camera and a camera support, wherein the upper end of the camera support and the lamp socket are welded fixedly, and the lower end of the camera support is detachably connected with the camera. According to the above scheme, the multifunctional fabric chip removing device is reasonable in structural design and simple in structure, is convenient to use, is provided with the lighting apparatus in a position where dust and fabric chips need to be removed, is convenient for management in terms of production, and exhibits good practicality.

Owner:平湖智铂自动化设备股份有限公司

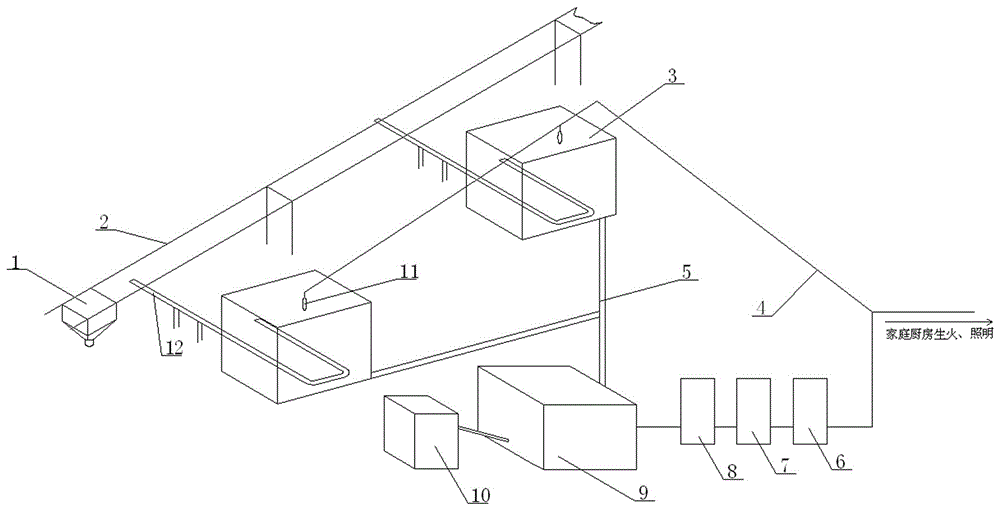

A goat house and goat breeding system

InactiveCN105941166AStay wildImprove meat qualityAnimal feeding devicesAnimal housingDiseaseEngineering

The invention provides a goat house and goat breeding system. The system comprises goat houses, a methane-generating pit and a feed delivery cable car. The feed delivery cable car delivers feed to each goat house via a track; goat excrement generated in the goat houses is conveyed to the methane-generating pit via pipelines; the methane-generating pit generates methane from the excrement through fermentation; the methane can be used for heating or lighting. According to the invention, large-scale culture of goats is realized; automatic feed delivery and feeding is realized, so that manpower and production costs are greatly saved; ecological breeding is realized, and goats are close to nature, so that the wild nature of the goats can be maintained; diseases and pests relating to goats can be prevented and controlled; the yield of goat meat is high; the meat is fresh and tender, and nutrients in the meat are of high value.

Owner:广西横县隆泉山羊养殖专业合作社

Flaw detection device of buffer spring

ActiveCN103018322AGuaranteed to work properlyFree from outside interferenceMaterial magnetic variablesEngineeringUltimate tensile strength

The invention discloses a flaw detection device of a buffer spring. The flaw detection device of the buffer spring comprises a fixing seat, a rotary support, a roller, a connecting shaft and a rotary motor, wherein support seats are arranged at two ends of the fixing seat; transversely arranged fixing plates are arranged on the support seats; a piston of a first cylinder on each fixing plate is connected with a movable plate; a clamping electrode plate is arranged at one end of the movable plate; circumferential magnetic threading bars inserted into the buffer spring are arranged near the movable plate; the circumferential magnetic threading bars are oppositely arranged and respectively insulated with the movable plate and the clamping electrode plate; the clamping electrode plate and the two circumferential magnetic threading bars are connected with two poles of an external power supply; a convex arc surface is arranged at the end part of one circumferential magnetic threading bar; and a concave arc surface is arranged at the end corresponding to the other circumferential magnetic threading bar, and the convex arc surface is matched with the concave arc surface. By adopting the flaw detection device, the magnetization intensity and the magnetic field distribution of the circumferential magnetic threading bars can be improved; a magnetization effect of the buffer spring for flaw detection is ensured; and interference in a magnetic circuit is avoided, and the flaw detection device can be widely applied to the fields of manufacturing and overhauling of railway vehicles.

Owner:CRRC YANGTZE CO LTD

Earphone charging box

ActiveCN108882088AImplement updateRealize chargingMicrophonesLoudspeakersElectrical connectionEngineering

The invention discloses an earphone charging box and relates to the technical field of an electroacoustic product. The earphone charging box comprises a shell and a cover body which are hinged together by a hinged shaft; earphone accommodation cavities are formed in the shell; contact through holes are formed at positions on the side walls of the earphone accommodation cavities, which correspond to contacts of an earphone; a first rotation part is arranged at a position where the cover body and the shell are hinged; a spring plate component is mounted in the shell; one end of the spring platecomponent is rotationally mounted in the shell by a rotating shaft; a second rotation part in transmission connection with the first rotation part is arranged on the rotating shaft; and electrical connection contacts which can be removed from and inserted into the contact through holes when the cover body is opened and closed are formed at the other end of the spring plate component. According tothe earphone charging box disclosed by the invention, when the earphone is put into or taken out, the surface of the earphone cannot be damaged, the earphone also cannot be clamped and the earphone issmooth to plug and pull.

Owner:GEER INTELLIGENT TECH CO LTD

Plastic fuel tank cover of engineering vehicle

InactiveCN104626974AGuaranteed to workGuaranteed pressure environmentFuel supplyEngineeringFuel tank

The invention relates to a plastic fuel tank cover of an engineering vehicle. The plastic fuel tank cover comprises a fuel tank oil filling port, a pressure-bearing plate, a pressure spring, an air inlet valve assembly, a plastic locking rod, a plastic housing and a handle pull rod. The plastic locking rod and the plastic housing are in interference fit with each other and sealed through an O-shaped rubber ring. The air inlet valve assembly comprises an air inlet valve, a cover-shaped gasket, a negative pressure spring and a rubber gasket. A valve rod of the air inlet valve penetrates through an air inlet valve installation hole of the pressure bearing plate. The cover-shaped gasket is arranged on the valve rod of the air inlet valve. The negative pressure spring is installed between the cover-shaped gasket and the pressure bearing plate. The rubber gasket is fixed to a bottom face circular plate of the air inlet valve. When the air pressure inside the oil tank and the external air pressure are balanced, the rubber gasket and the pressure bearing plate are attached and sealed, and the oil filling port of the fuel tank and the pressure bearing plate are attached and sealed. The plastic fuel tank cover solves the key common problems that due to the fact that in the work process of an existing engineering vehicle, rainwater enters the fuel tank, the fuel tank rusts and is corroded, vent holes of the air inlet valve are prone to blockage, an engine is blocked, and automatic flameout is caused or starting can not be achieved.

Owner:LIUZHOU RISUN FILTERS

Complex frame positioning assembling jig

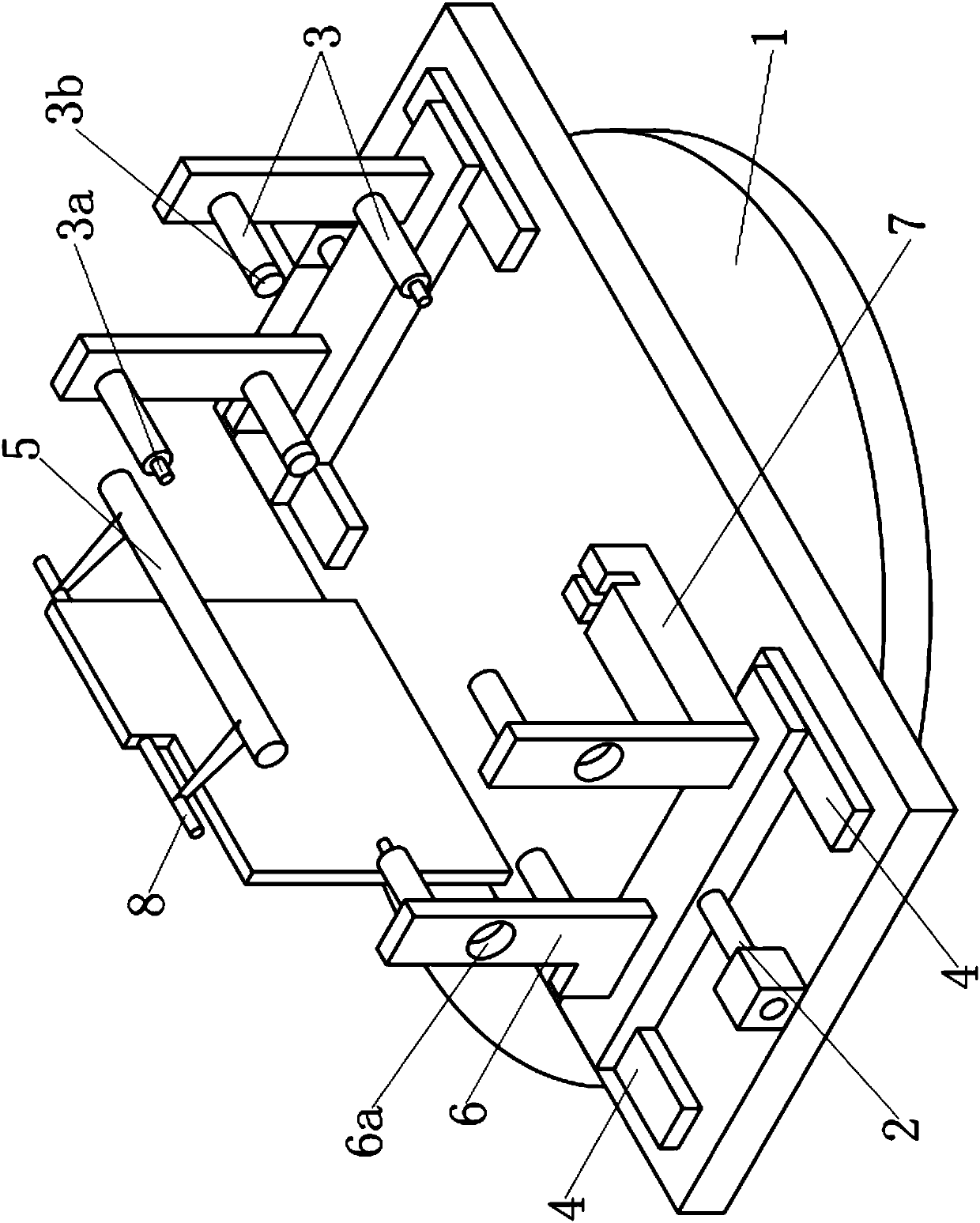

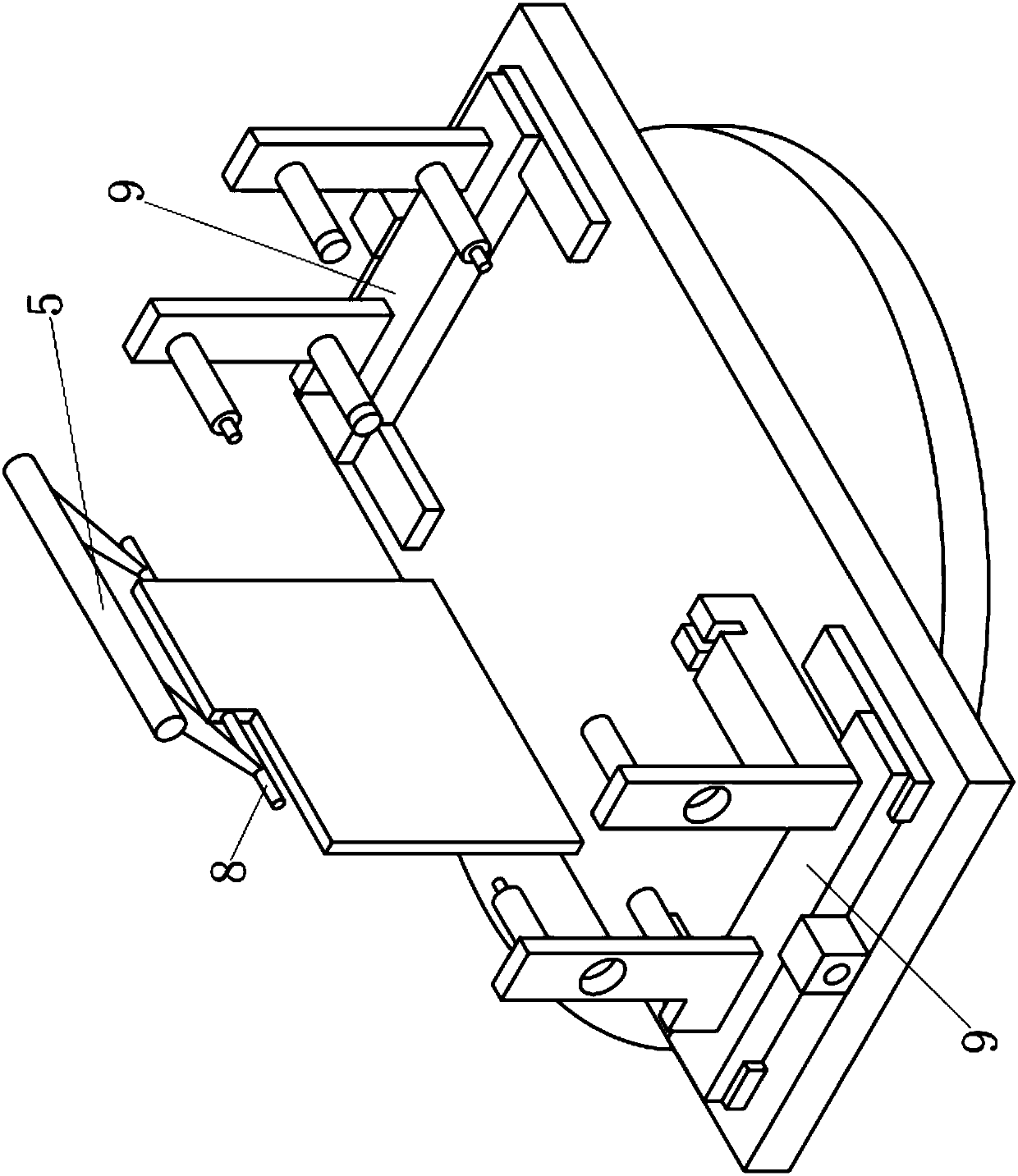

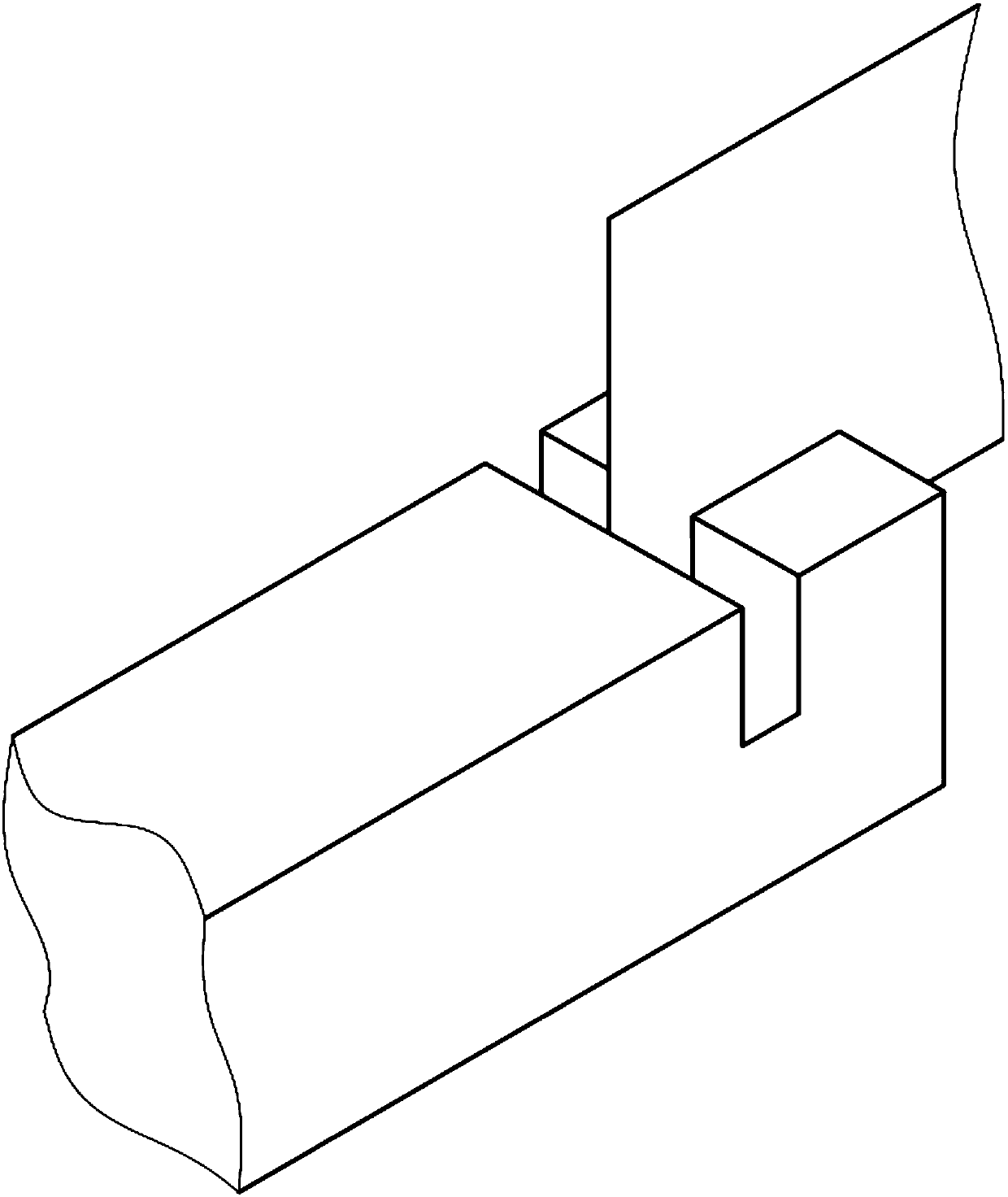

PendingCN107695924AEasy to locate and disassembleConvenient screw fixingWork holdersMagnetEngineering

The invention discloses a complex frame positioning assembling jig. The complex frame positioning assembling jig comprises positioning columns, sliding rails, a movable rod and a rotary plate, whereinthe multiple positioning columns are horizontally arranged; the positioning columns opposite approach to limit and fix a complex frame in the axial direction of the positioning columns; the sliding rails drive the positioning columns to oppositely approach or move away; the movable rod presses downwards to limit the complex frame from top to bottom; and the rotary plate is arranged at the bottomend of a complex frame positioning assembling jig body, so that the complex frame positioning assembling jig has the rotation degree of freedom in the horizontal plane; the bottoms of the positioningcolumns are fixed to a plurality of vertical stand columns; the stand columns on the same side are fixed to stand column bases arranged horizontally; the stand column bases are matched with the sliding rails; the sliding rails are matched with a bottom plate and the rotary plate from top to bottom; toggle clamps are connected between the stand column bases and the bottom plate; and magnets are arranged at the heads of the positioning columns. Through the complex frame positioning assembling jig, the complex frame of a printing machine is accurately butt-jointed and limited, convenience is provided for staff to achieve the screw fastening effect on the complex frame, and meanwhile, the fastening process efficiency is improved.

Owner:YIHE PRECISION IND SUZHOU

New beef freshness detection device and detection method

InactiveCN104374710APrecisely control the moving distanceMove preciselyColor/spectral properties measurementsTesting foodEngineeringNondestructive testing

The invention relates to a new beef freshness detection device and detection method, and solves the problems, in the prior art, of subjective inaccuracy of beef freshness detection and complex detection equipment and detect process. The device comprises a seat body, the seat body is provided with a floating pool, a tray floats in the floating pool, the tray is controlled to move through magnetic force, an adjustment bracket is arranged above the seat body, the adjustment bracket is provided with a light source, and the seat body is also provided with a control unit. The control unit analyzes sample reflectance spectra data to judge the degree of beef freshness. The advantages of the new beef freshness detection device are that, by using a spectral detection mode, nondestructive testing of samples can be carried out; the new beef freshness detection device is reasonable in structure, the seat body moving resistance is small, and the new beef freshness detection device does not jam, and is convenient in operation and maintenance, and accurate in detection data.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

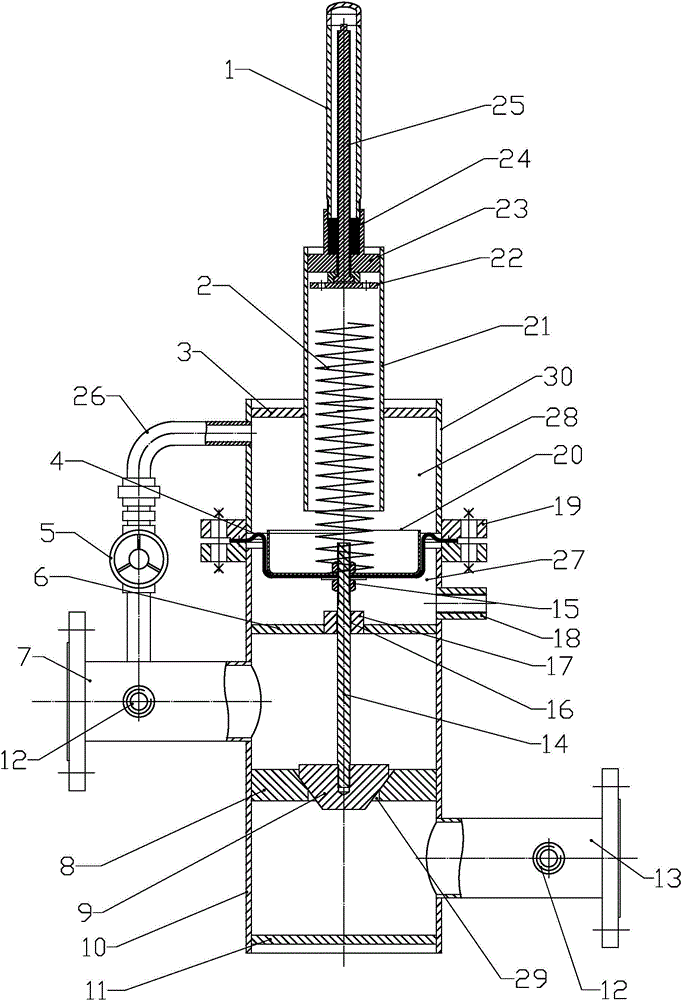

Pressure regulator

InactiveCN104132166AChange the cross-sectional areaChange the flow cross-sectional areaEqualizing valvesSafety valvesWater dischargeHigh pressure water

The invention discloses a pressure regulator, and belongs to pressure reduction devices. The pressure regulator structurally comprises an upper shell body, a lower shell body, a rubber diaphragm, a support, a partition plate, a guide groove, a push rod, a conical body, an inner core, a lower plugging plate, an upper plugging plate and a pressure-regulating device. The rubber diaphragm is arranged between the upper shell body and the lower shell body, the support is arranged on the upper portion of the rubber diaphragm, and the pressure-regulating device is arranged on the upper portion of the support. The partition plate and the inner core are arranged on the lower portion of the rubber diaphragm, the conical body is arranged on the inner core, the push rod is arranged on the upper portion of the conical body, and the push rod is fixedly connected with the rubber diaphragm and the support. An inlet pipe is arranged on the lower shell body arranged on the lower portion of the inner core, and a water discharging pipe is arranged on the lower shell body arranged on the upper portion of the inner core. An inner cavity between the lower shell body and the upper shell body and between the partition plate and the upper plugging plate is divided into a high pressure cavity and a low pressure cavity through the rubber diaphragm. A high pressure water inlet is formed in the lower shell body at the position of the high pressure cavity. A low pressure communicating pipe is arranged between the water discharging pipe and the upper shell body. The pressure regulator has the advantages of being capable of automatically adjusting return water pressure, automatically shutting down after a water pump stops and the like.

Owner:SHANDONG GUOSHUN PRESSURE VESSEL

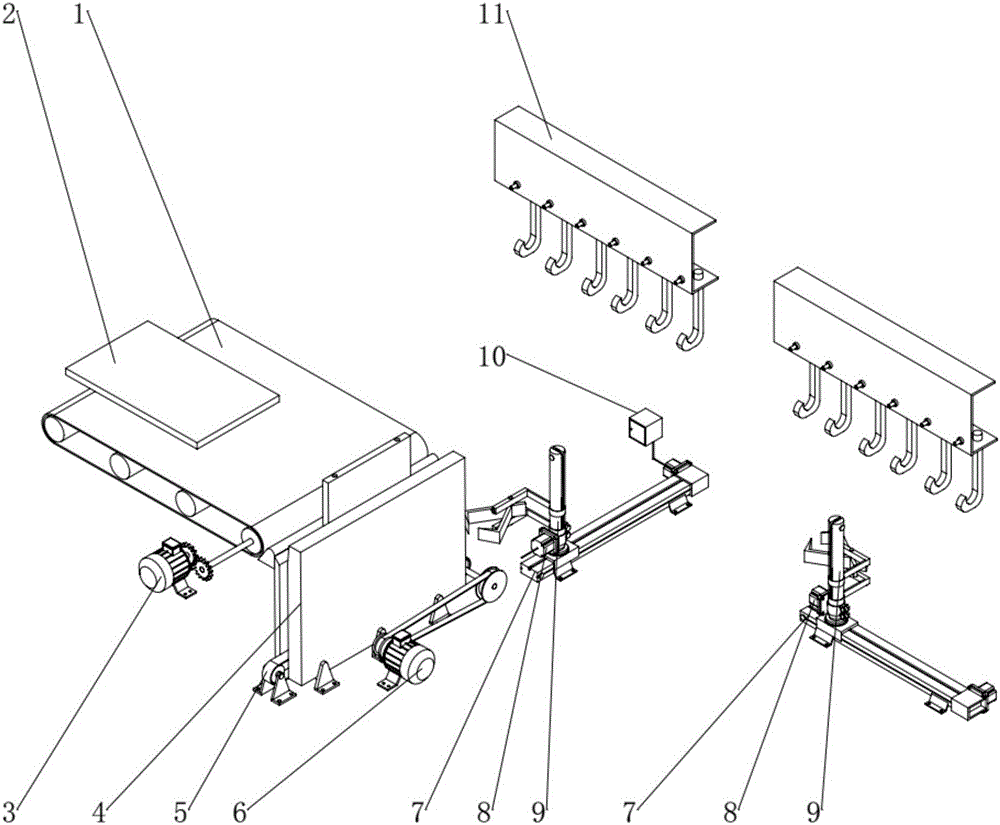

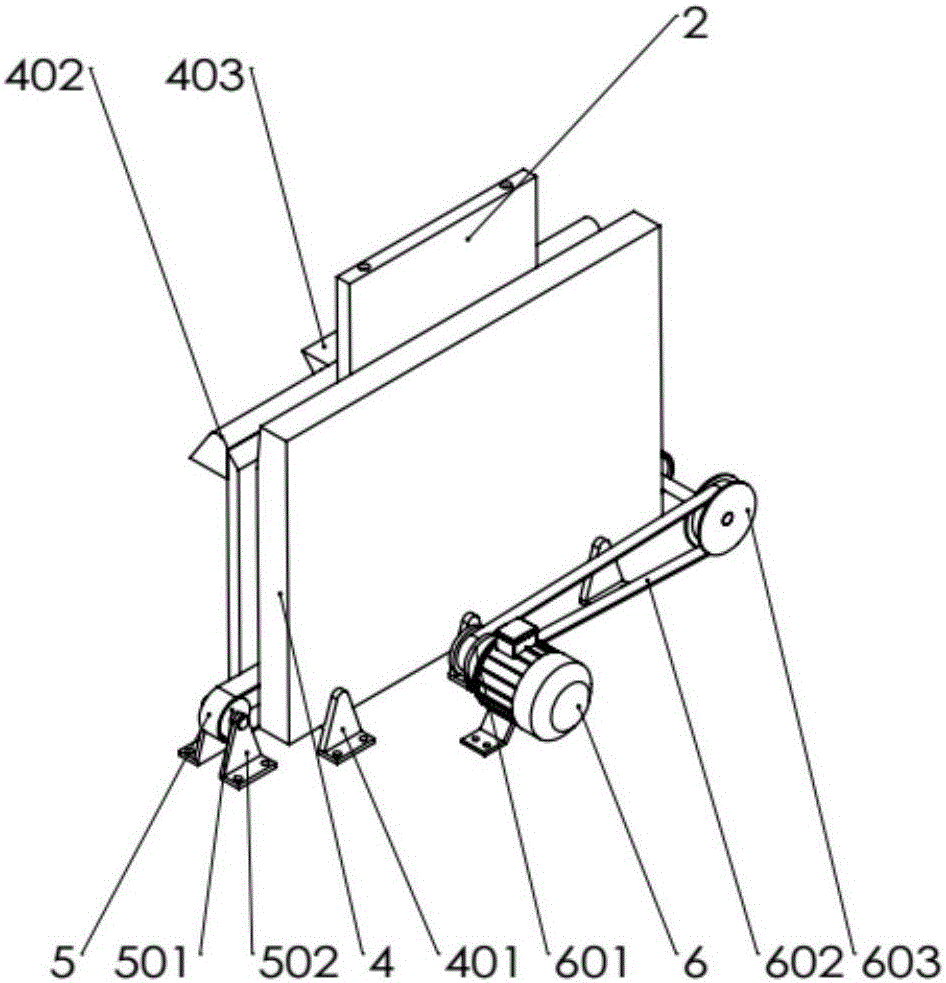

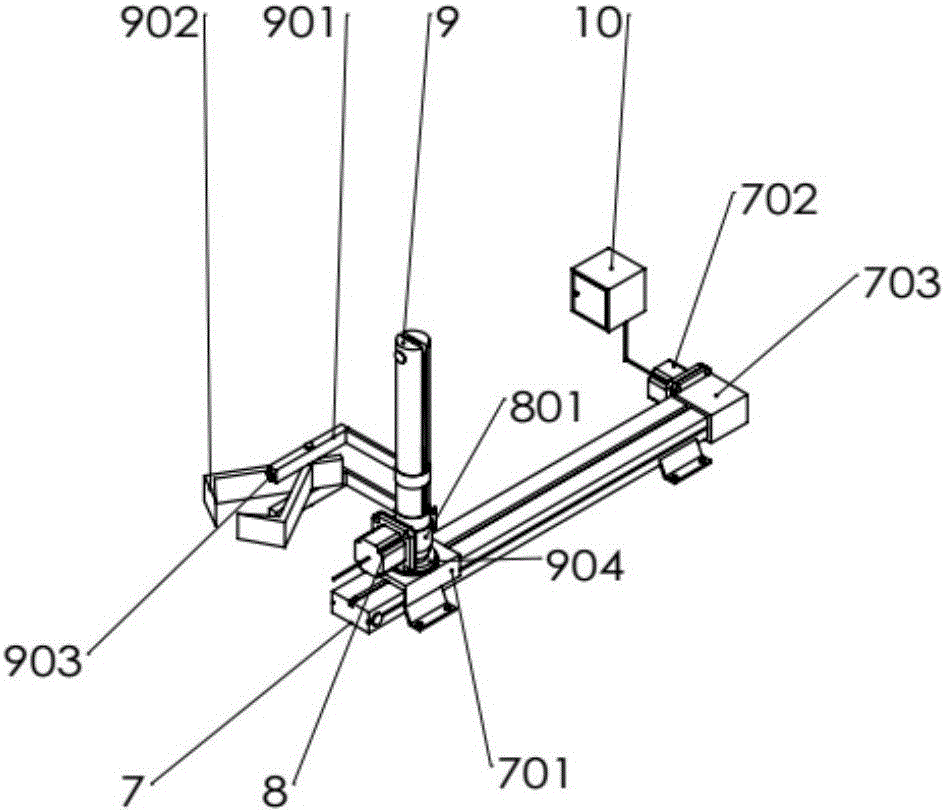

Elevator door plate spraying automatic loading and blanking device

The invention relates to an elevator door plate spraying automatic loading and blanking device, belonging to the field of elevator machinery. The elevator door plate spraying automatic loading and blanking device includes a door plate conveyor belt, a conveyor belt roller, an elevator door plate, a conveyor belt motor, a conveyor belt motor gear, high and low standing baffle plates, high and low standing baffle plate supports, an arc lower slide block, an arc lower slide block carriage, a door plate standing conveyor belt, a door plate standing conveyor belt roller, a door plate standing conveying device support, a door plate standing conveyor belt motor, a door plate standing conveying small belt wheel, a V-shaped belt, a door plate standing conveying large belt wheel, a clamping device slide rail, a displacement column seat, a clamping device slide rail motor, a slide rail motor seat, a displacement synchronous belt motor, a displacement synchronous belt motor slide bearing, a displacement column, a hand clamping device support, a hand clamping device, a hand clamping self-control button, a translocation disc, an appliance control cabinet, a suspension hook rack, an induction suspension hook, and a photoelectric sensor. The hand clamping is controlled by the hand clamping self-control button, so that the motion automation is realized.

Owner:JIANGSU XIWEI ELEVATOR

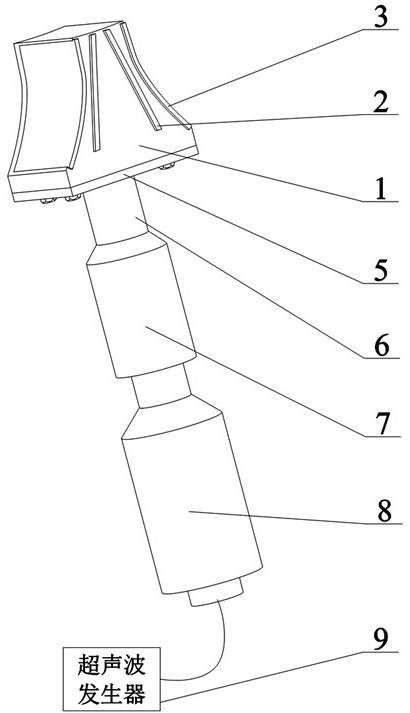

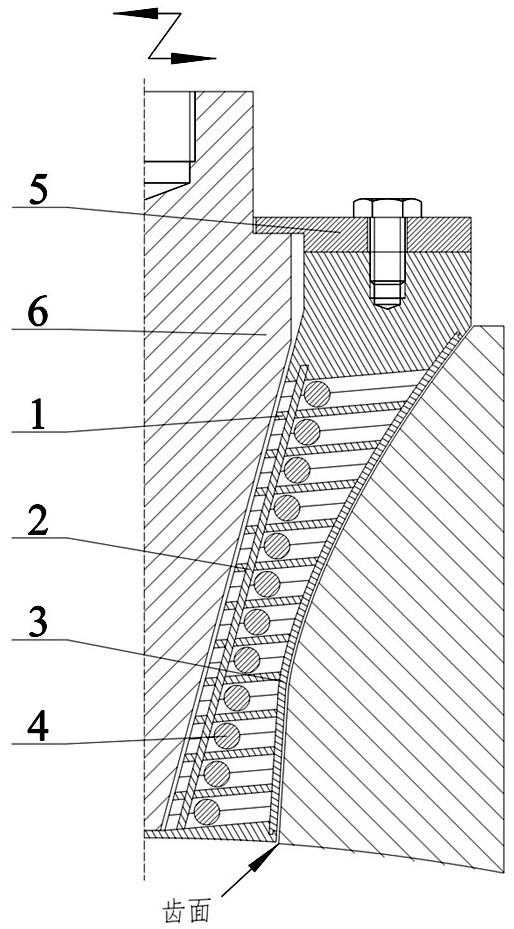

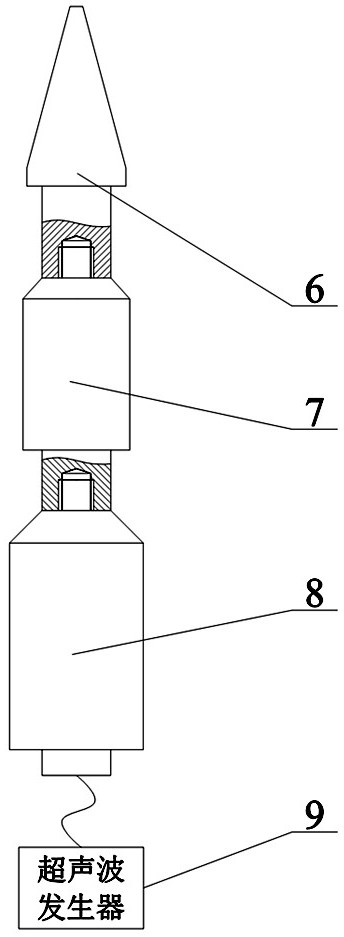

Shot type gear ultrasonic shot peening strengthening device

A shot type gear ultrasonic shot peening strengthening device comprises an ultrasonic vibration device and a shot impact mechanism, the ultrasonic vibration device is composed of an ultrasonic generator, a transducer, an amplitude-change pole and a vibration head, the section of the working end of the vibration head is trapezoidal, and the vibration mode is radial vibration. The shot impact mechanism is composed of a shell, an upper cover plate, inner baffles, outer baffles and shots, a cavity in the same shape as the vibration head is formed in the shell, the contour shapes of the two sides, matched with a machined gear, of the shell are involutes, honeycomb-shaped orthohexagonal shot paths are arranged at the two sides of the shell, and inner baffle grooves are formed in the ends, close to the vibration head, of the shot paths; and outer baffle grooves are formed in the end, close to the machined gear, and a shot is installed in each shot path. According to the shot type gear ultrasonic shot peening strengthening device, the radial vibration generated by the vibration head is used for driving the shots to move in the shot paths and impact the surface of the gear, so that ultrasonic shot blasting is achieved, and the problem that because the distance between an ultrasonic tool head and the tooth surface of the machined gear is large, an ideal processing effect is difficult to achieve is solved.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com