Patents

Literature

125results about How to "Change the cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coriolis mass flowmeter

InactiveUS6895826B1Improve pressure resistancePrevent inertial momentDirect mass flowmetersEngineeringVibration sensor

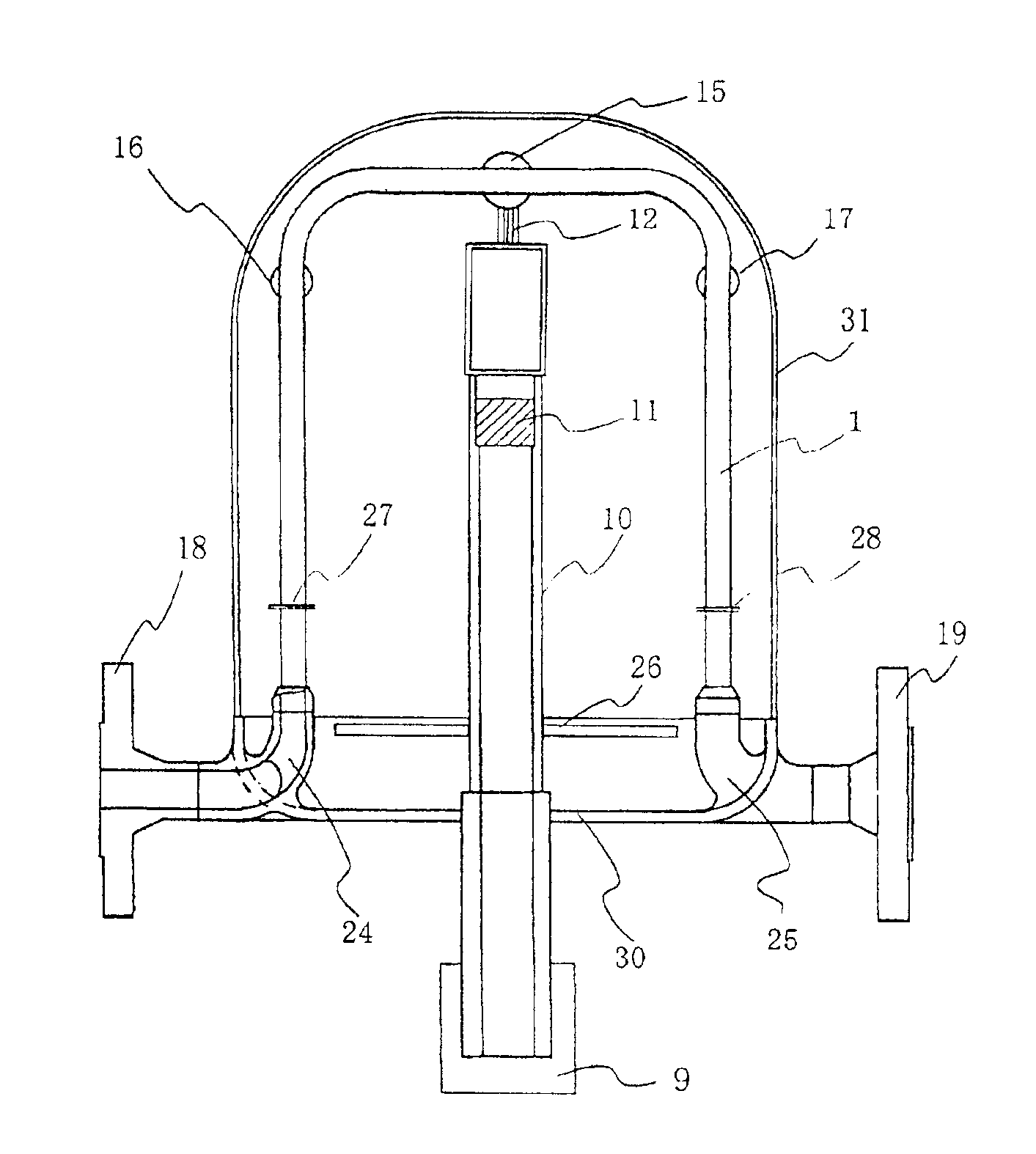

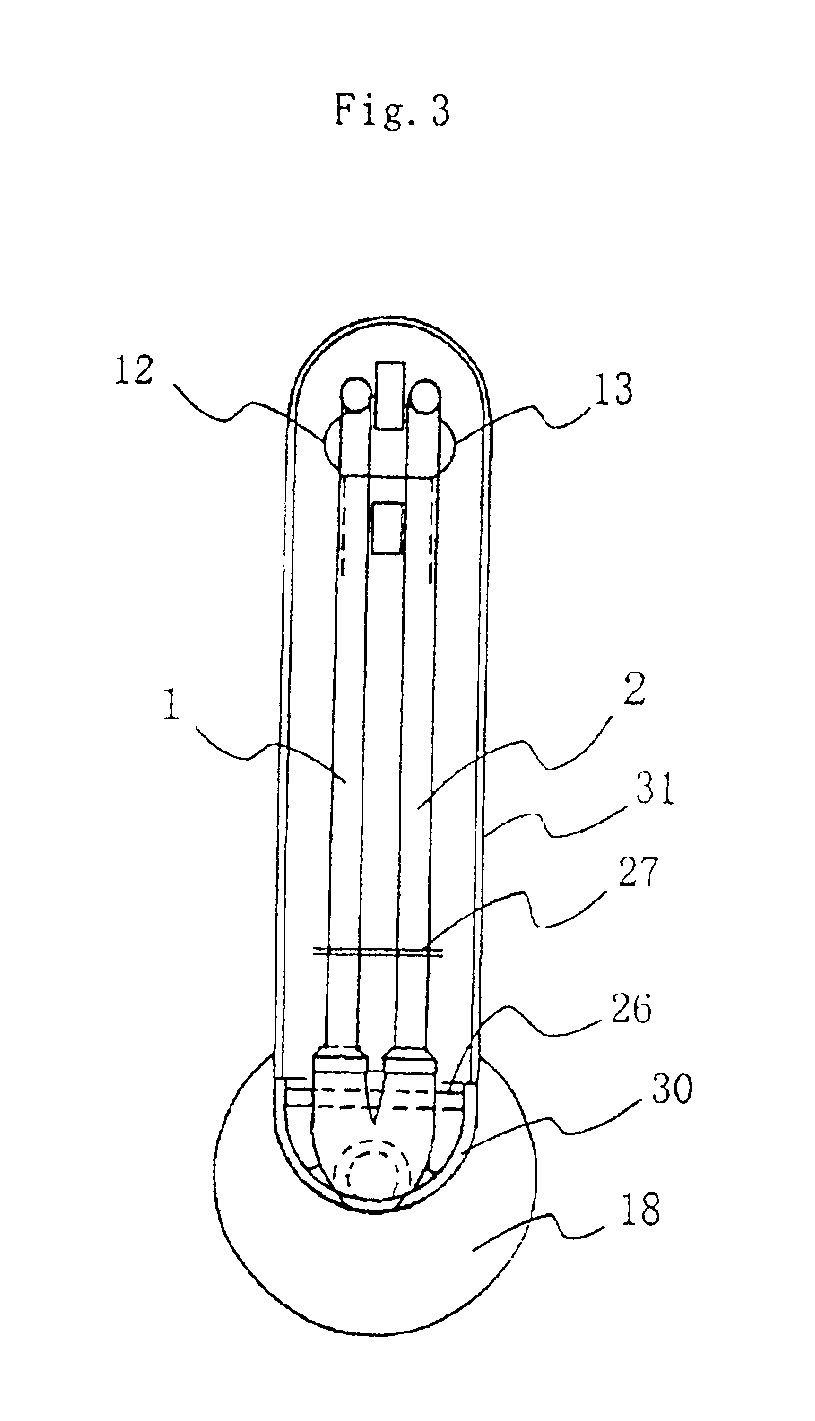

The Coriolis mass flow meter of this invention comprises two parallel curved flow tubes 1 and 2, a drive unit 15, and a pair of vibration sensors 16 and 17. An inlet-side manifold 24 dividing the flow of a fluid being measured into the two flow tubes 1 and 2 from the inlet thereof, and an outlet-side manifold 25 joining the fluid flows flowing in the two flow tubes 1 and 2 to discharge from the fluid outlet thereof are mechanically connected to a meter body 30 only at the inlet side of the inlet-side manifold 24 and at the outlet side of the outlet-side manifold 25, respectively. With this arrangement, the effects of vibration transmitted from the meter body 30 and all structures connected thereto can be reduced at the joint parts between the inlet-side and outlet-side manifolds 24 and 25 that serve as vibration fulcrums.

Owner:OVAL CORP

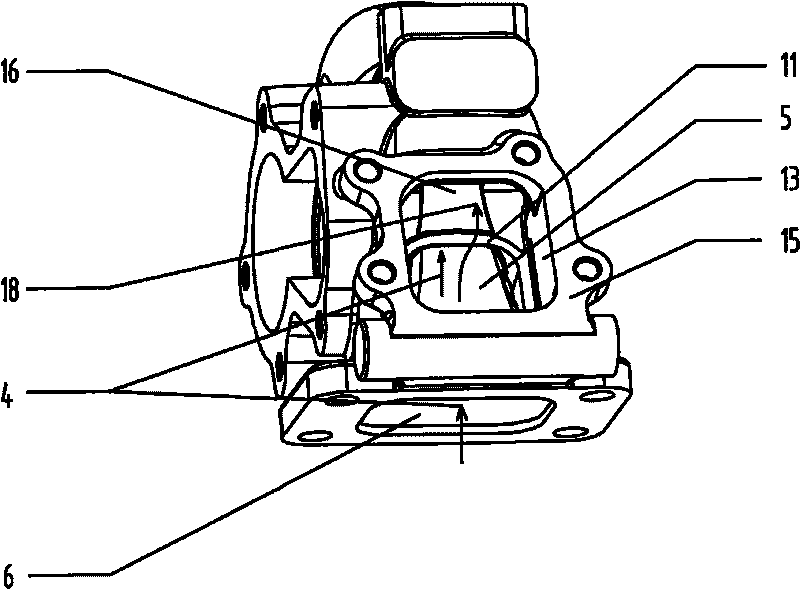

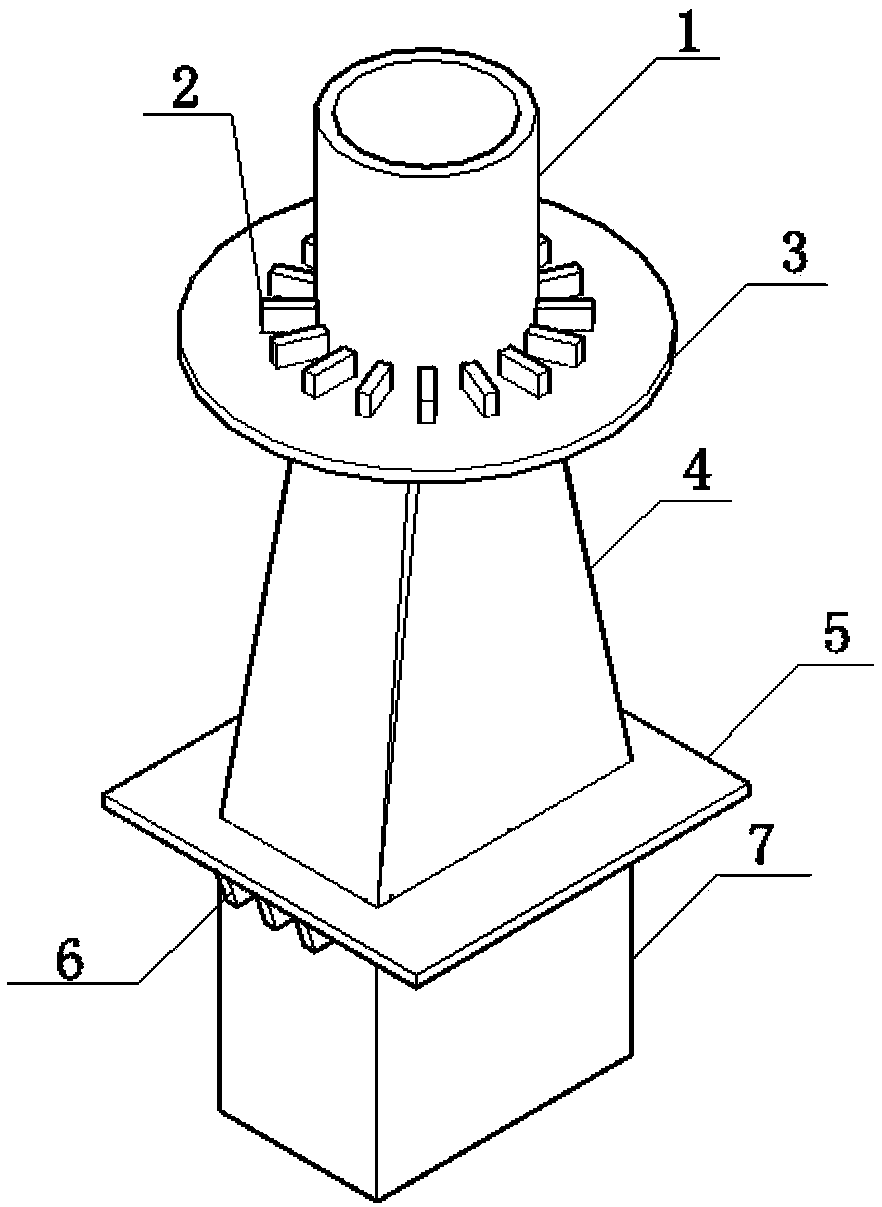

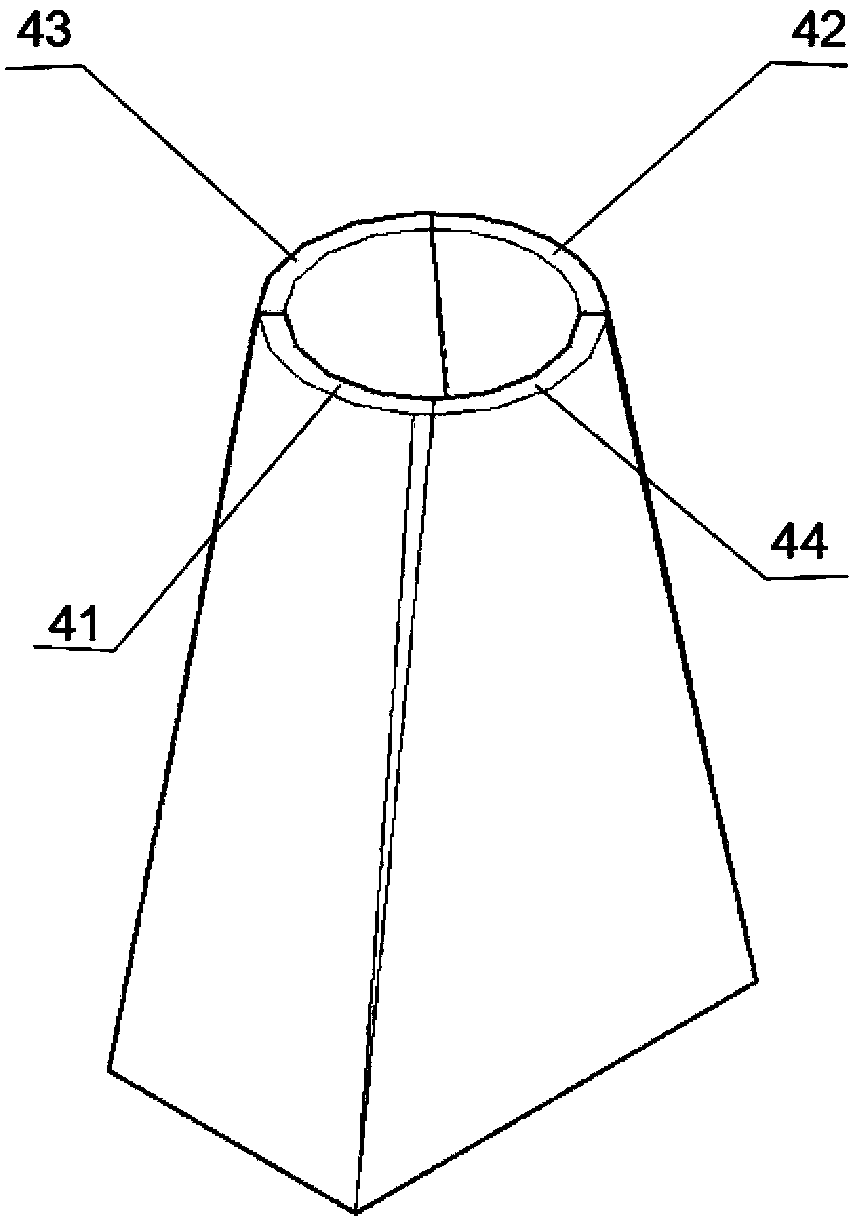

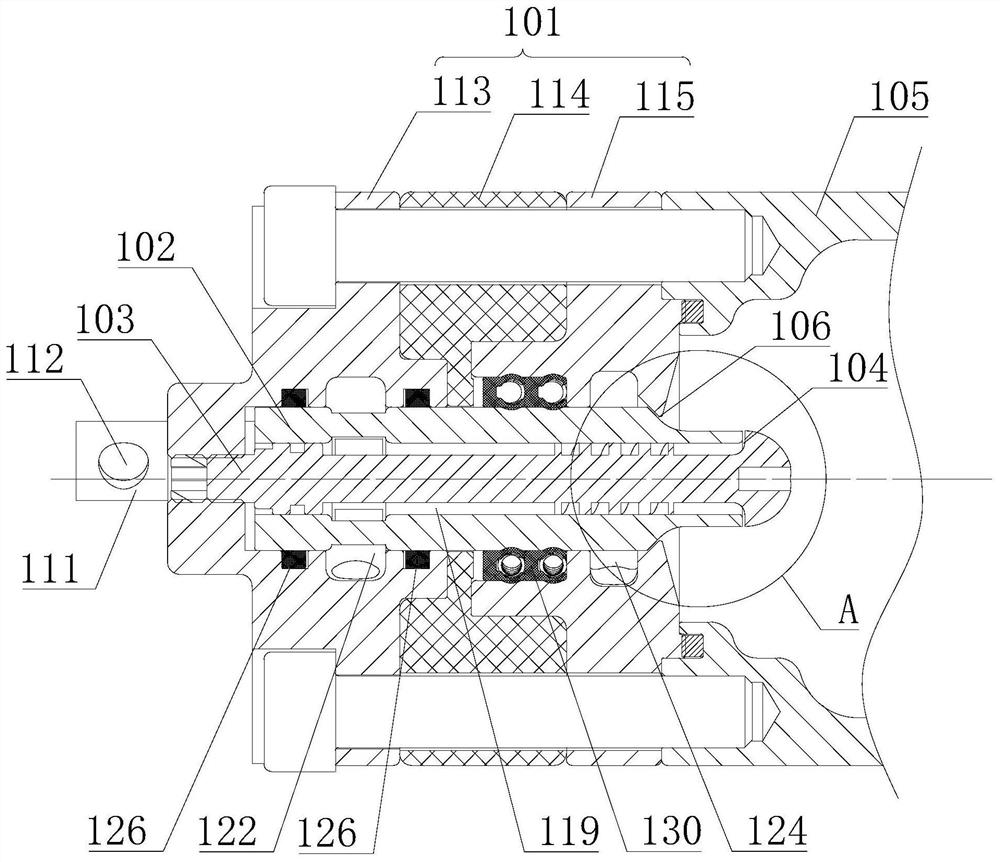

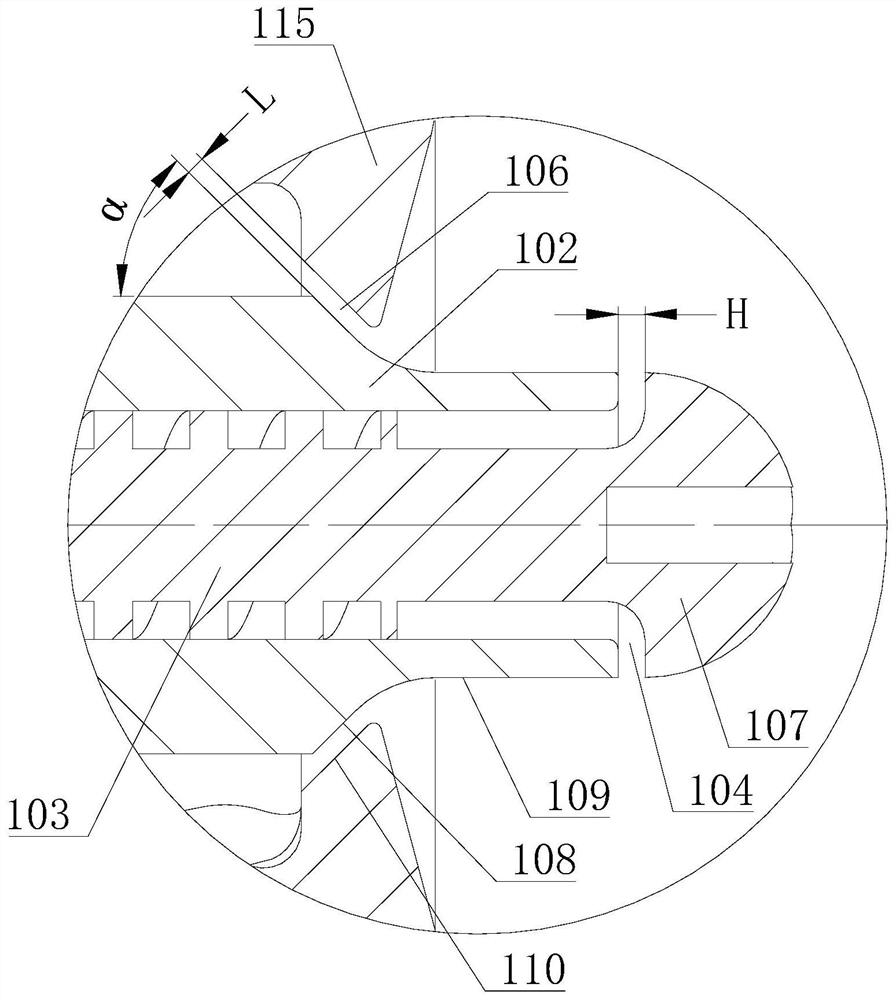

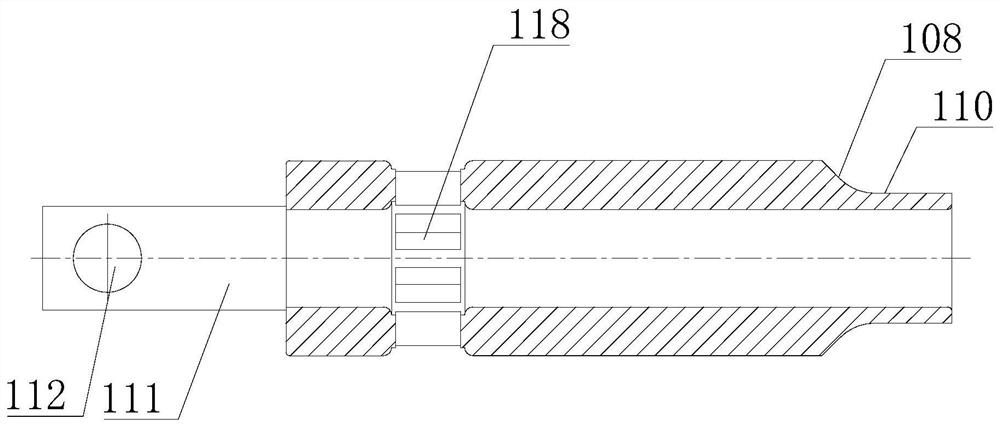

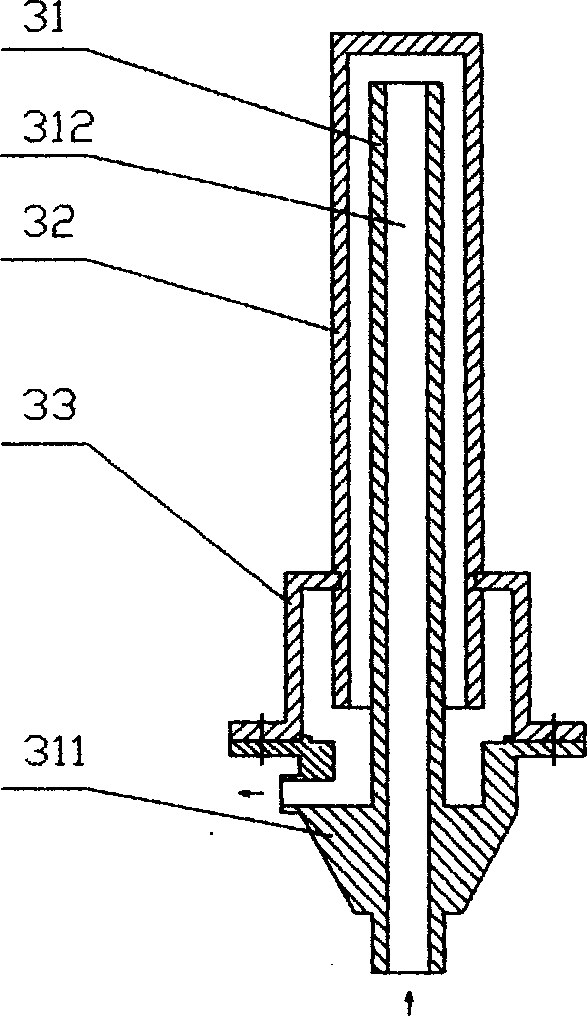

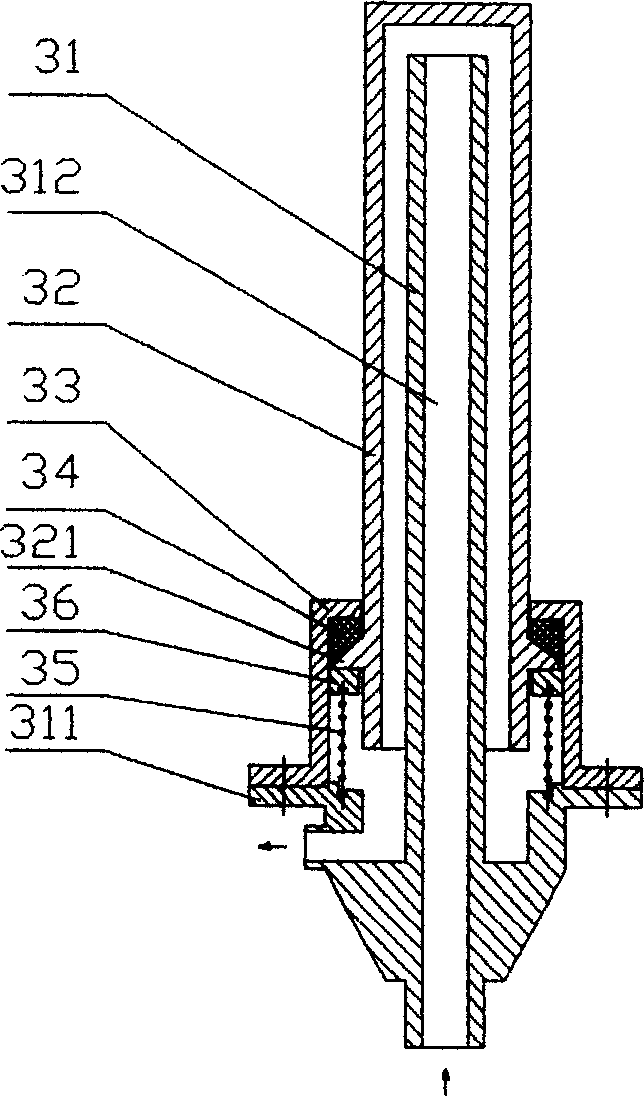

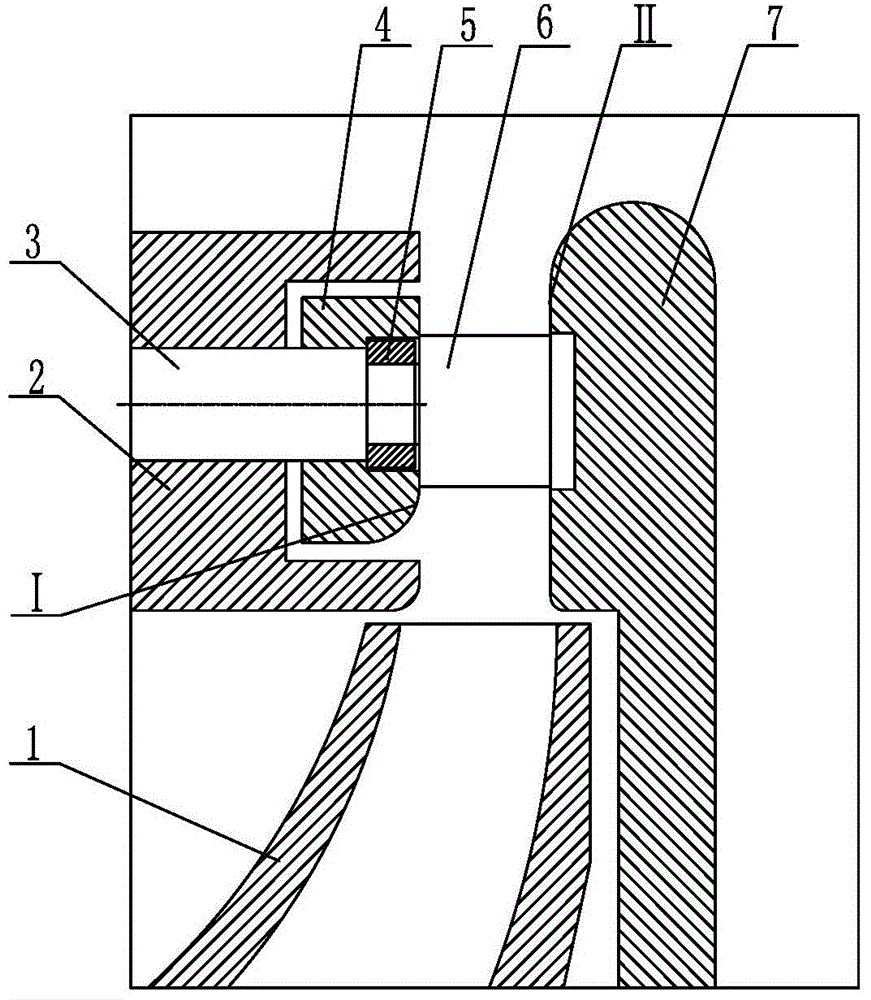

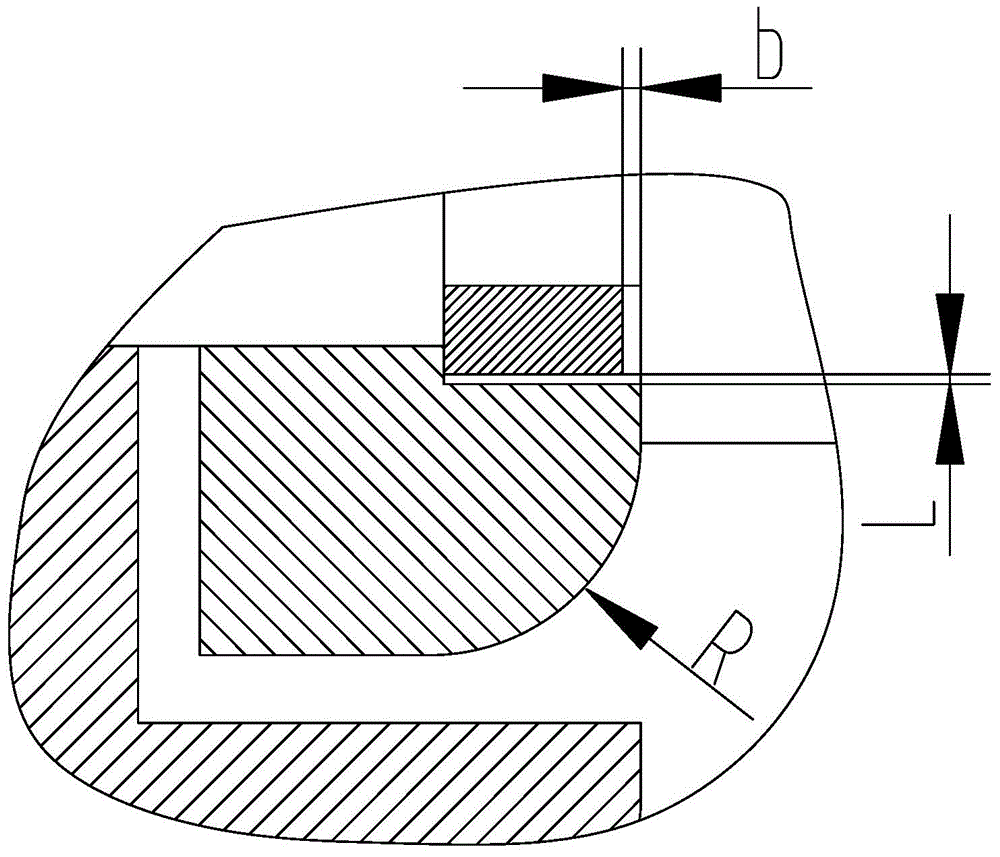

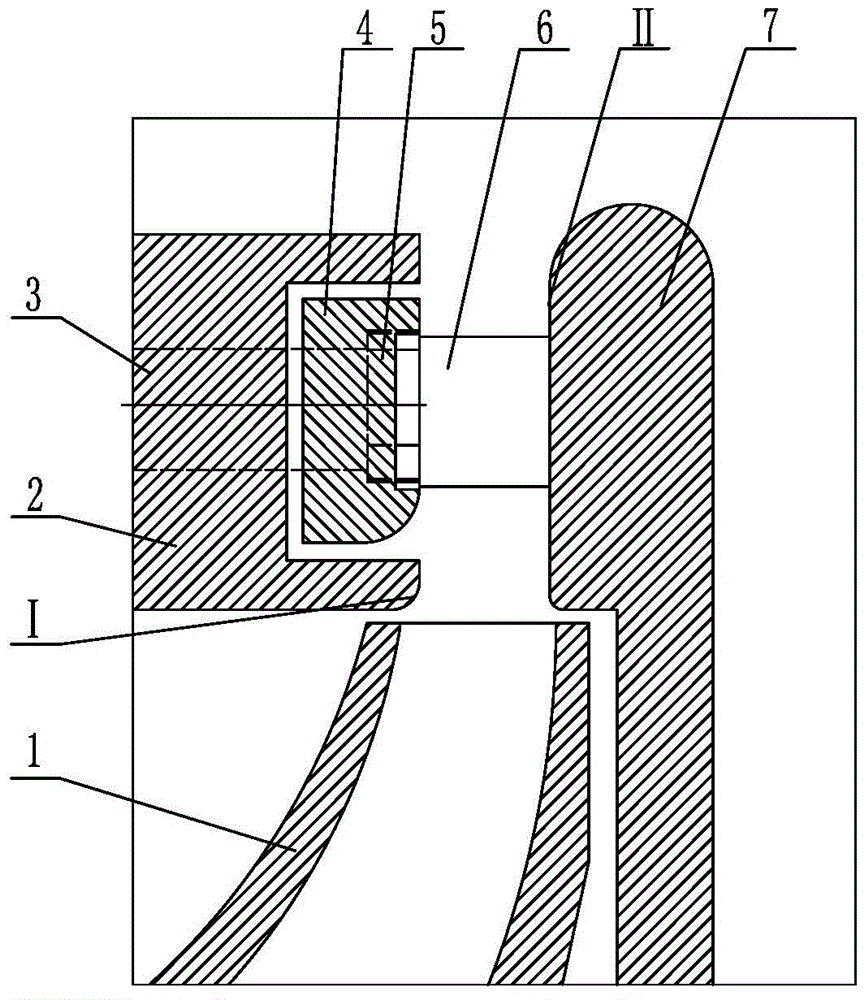

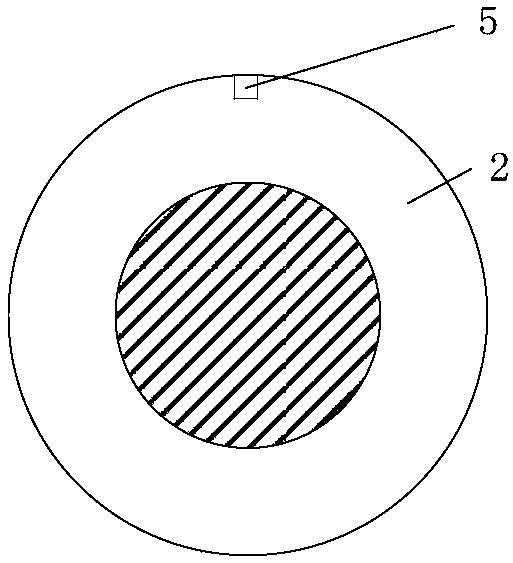

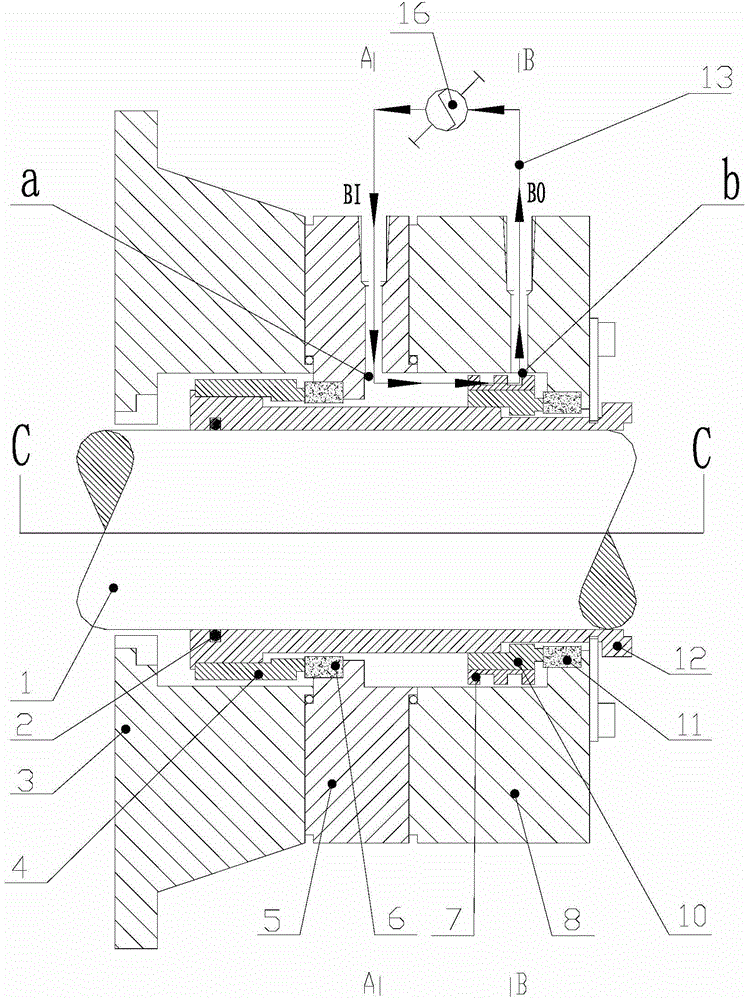

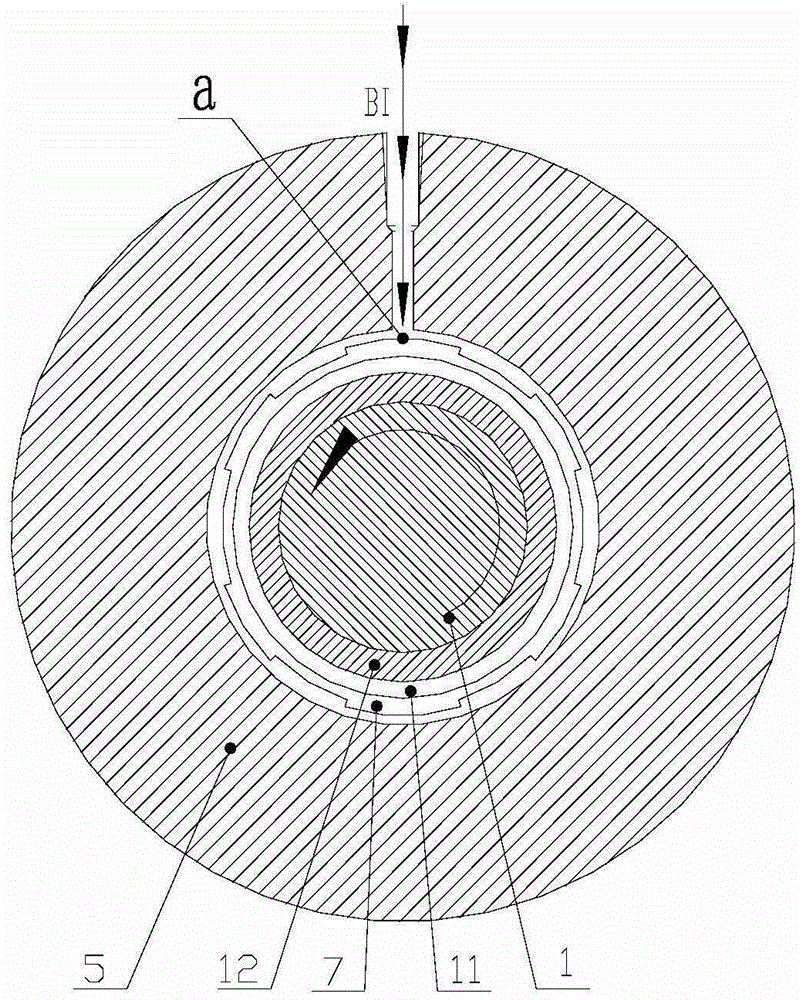

Double-layer channel variable-section turbine control device

ActiveCN101694166AChange the cross-sectional areaAddress reliabilityInternal combustion piston enginesGas turbine plantsInternal combustion engineTurbine

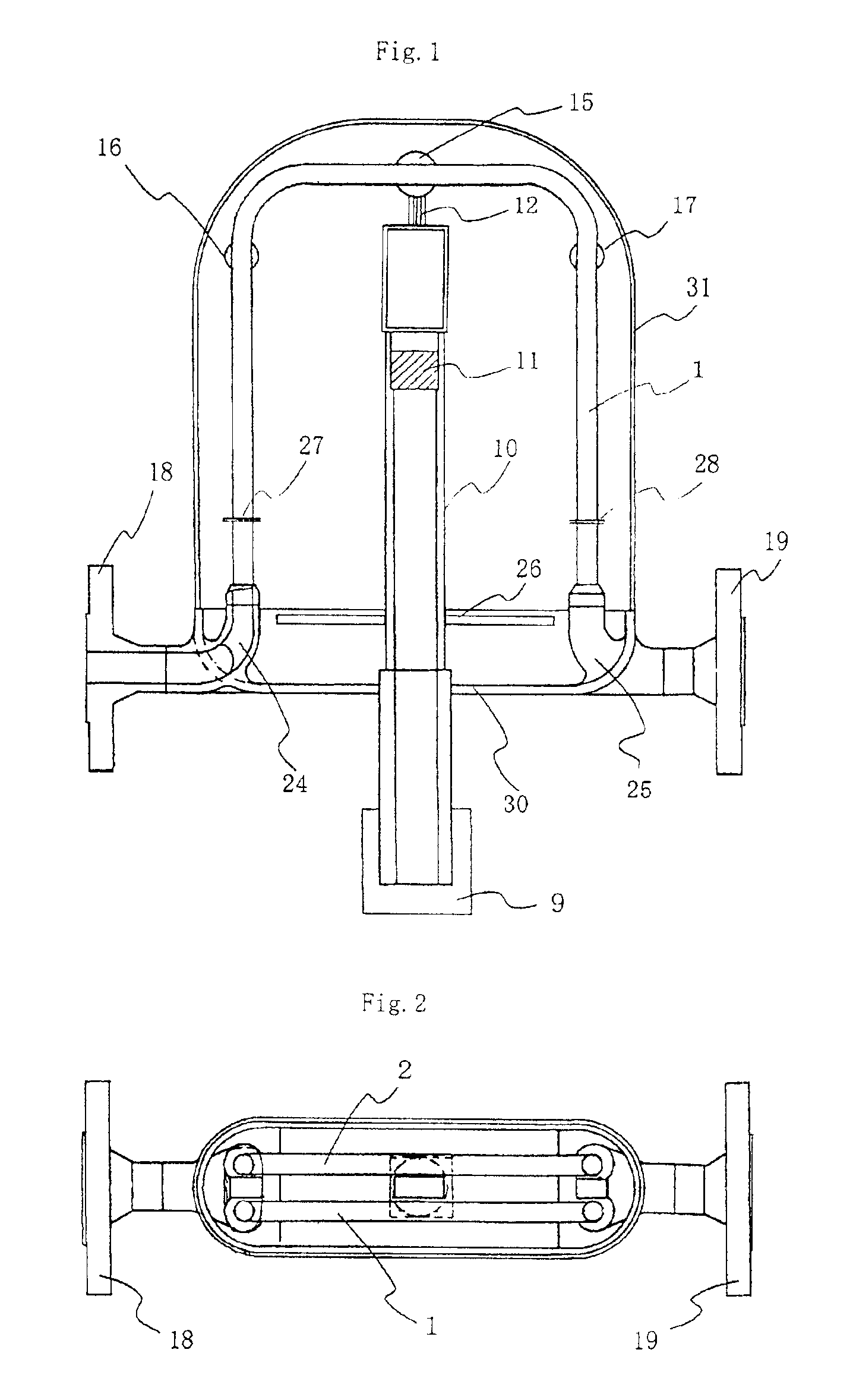

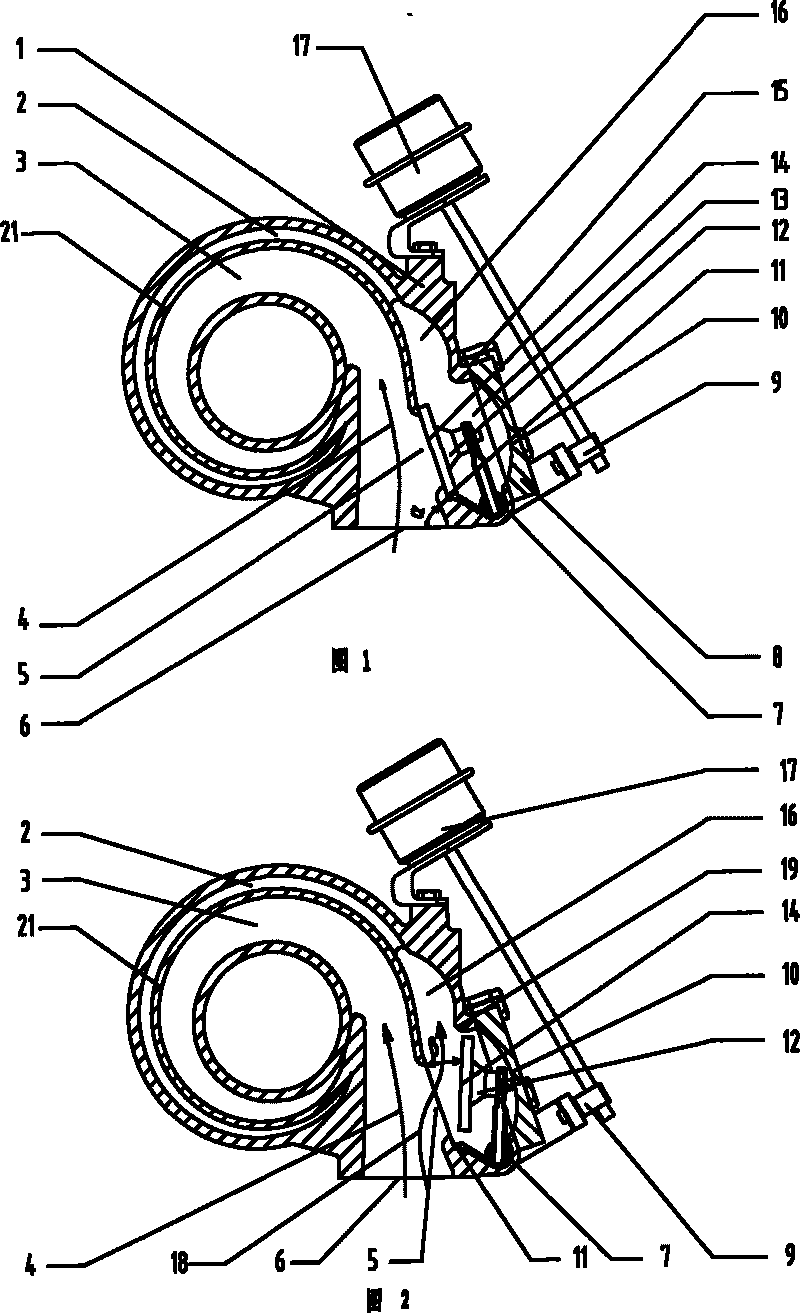

The invention discloses a double-layer channel variable-section turbine control device, belonging to the field of an internal combustion engine. The double-layer channel variable-section turbine control device comprises a turbine housing, wherein the turbine housing is internally provided with a gas inlet inner channel and a gas inlet outer channel; the gas inlet outer channel is positioned at the outer side of the circumferential direction of the gas inlet inner channel; and a partition wall is arranged between the gas inlet outer channel and the gas inlet inner channel. The double-layer channel variable-section turbine control device is characterized in that the gas inlet inner channel is provided with a gas inlet; the position on the partition wall, close to the gas inlet, is provided with an outer channel gas inlet which is provided with a gas inlet control device; the double-layer channel variable-section turbine control device can effectively guarantee that the double-layer channel variable-section turbine meets the supercharging needs of the all condition range of the engine, simultaneously has no existence of potential unreliability of rotary vane type and axial movement type variable-section turbine supercharger and has simple and reliable products.

Owner:康跃科技(山东)有限公司

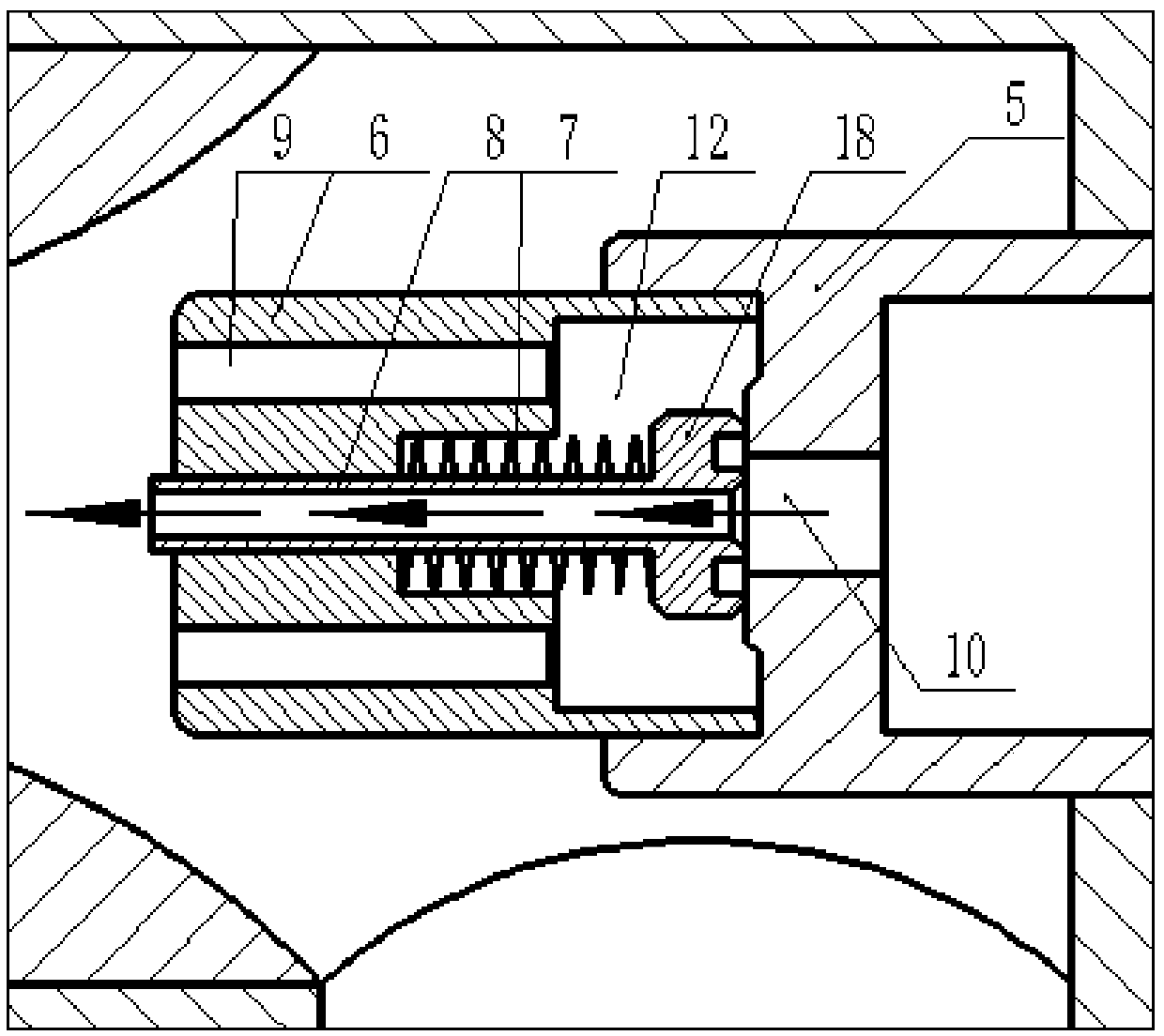

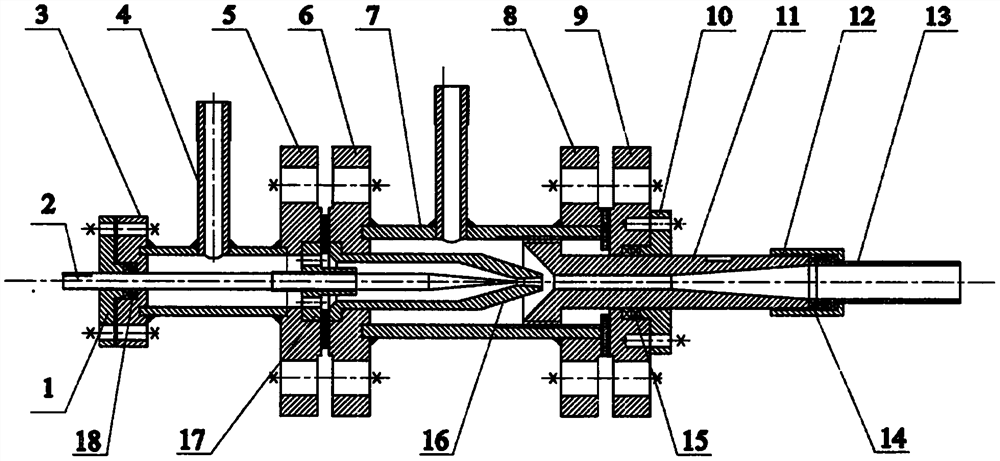

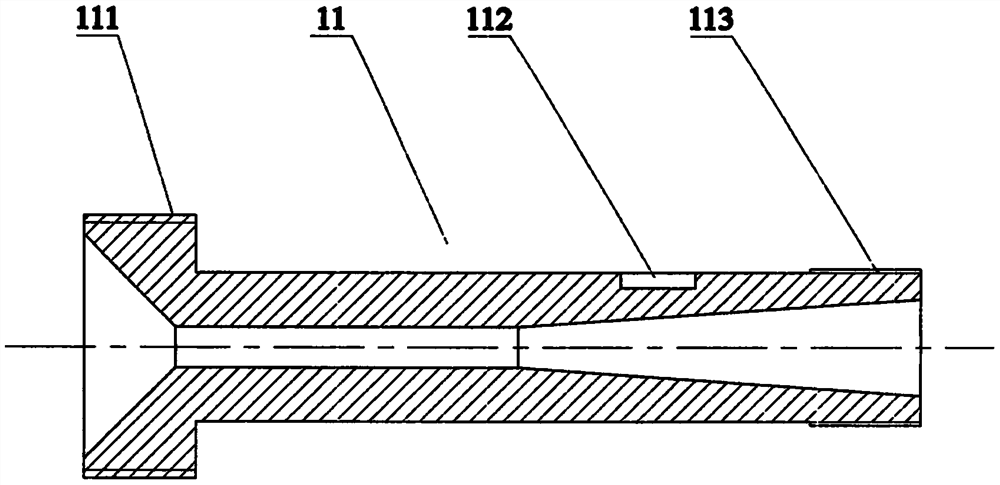

Nozzle, ejector based on nozzle and having adjustable flow characteristic, and application of ejector

InactiveCN109630479AImprove performanceReduce outlet pressureJet pumpsMachines/enginesAutomatic controlHydrogen

The invention discloses a nozzle, an ejector based on the nozzle and having an adjustable flow characteristic, and application of the ejector. The nozzle comprises a nozzle body, a small nozzle, a large nozzle and an elastic part; a thin and long hollow pipe with a valve is adopted as the small nozzle, and the elastic part is arranged between the set of large nozzle and the set of small nozzle; one end of the elastic part jacks the valve part of the small nozzle, and the other end of the elastic part jacks the large nozzle; and the elastic part can change the position of the valve of the smallnozzle under the effect of to-be-ejected gas, and then a flowing path of the to-be-ejected gas is controlled. The supply quantities of hydrogen and recycled hydrogen are automatically controlled by the nozzle according to system loads; when the low load exists, the small nozzle acts, the pressure of a nozzle outlet is small, the recovery rate of the recycled hydrogen is high, and the hydrogen utilization rate is increased; when the medium-high loads exist, the two sets of nozzles act simultaneously, and the large nozzle is used for enlarging the circulating area to provide the larger fuel flow; and the small nozzle is used for increasing the ejecting speed to improve properties of the ejector.

Owner:SHANDONG UNIV

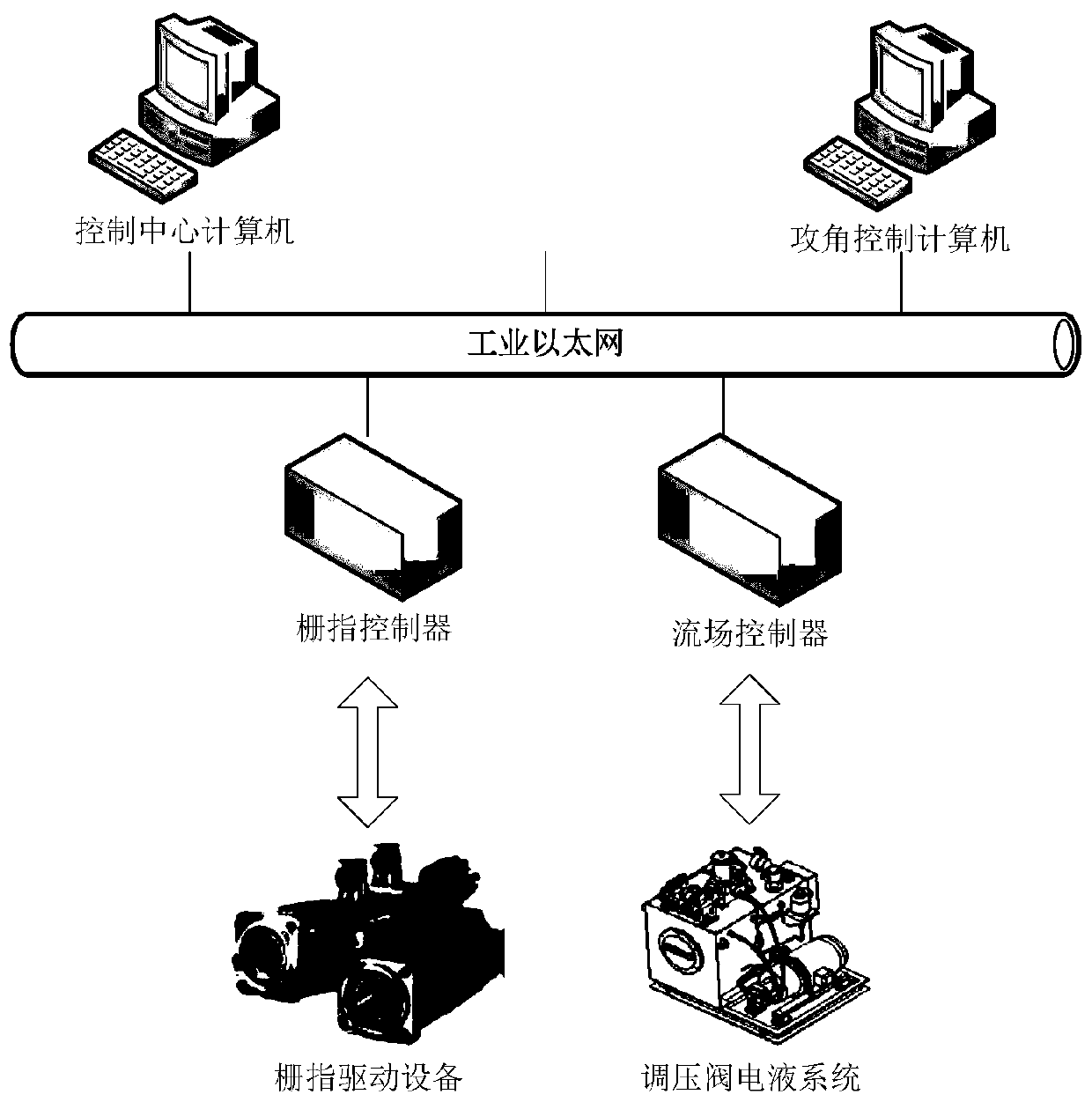

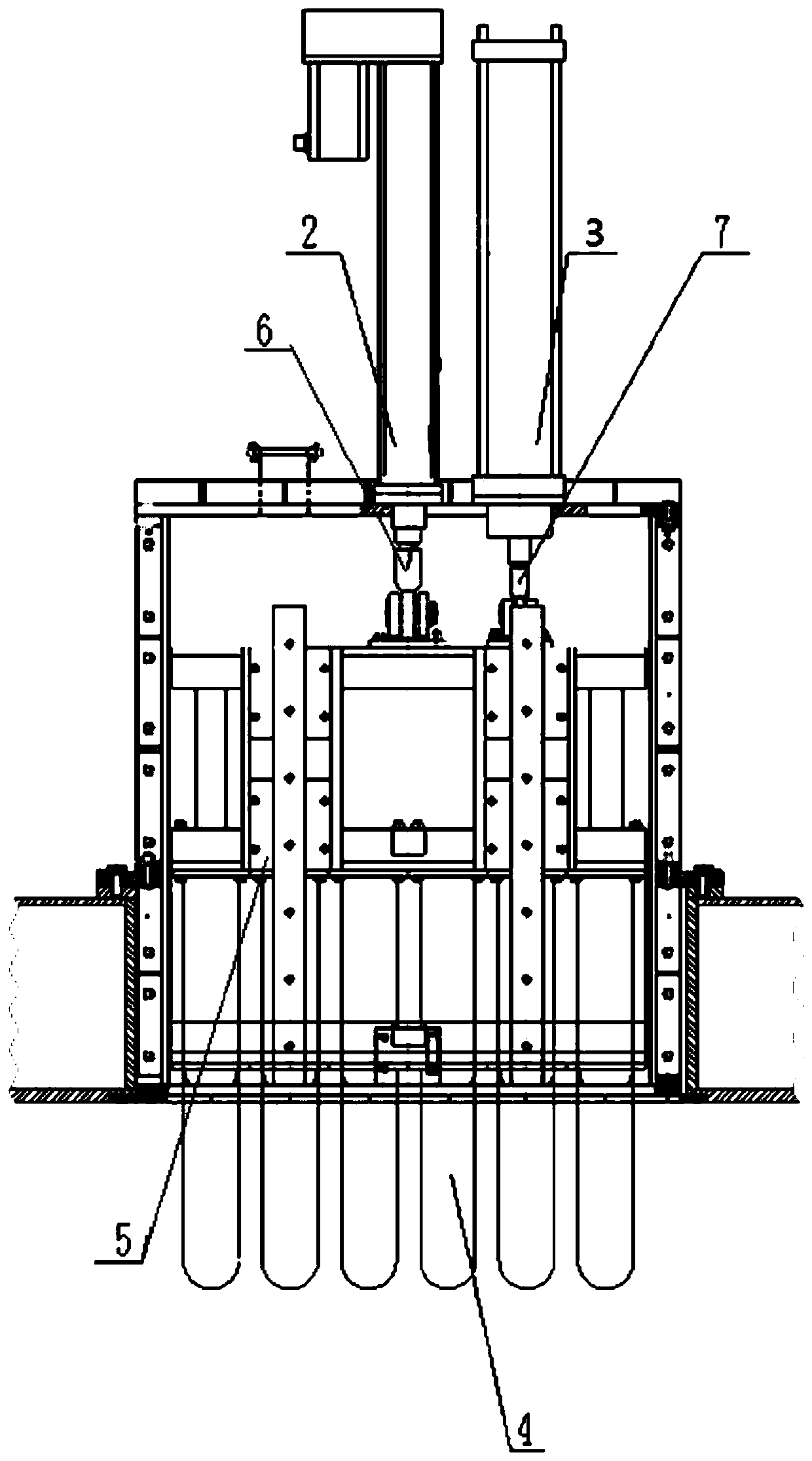

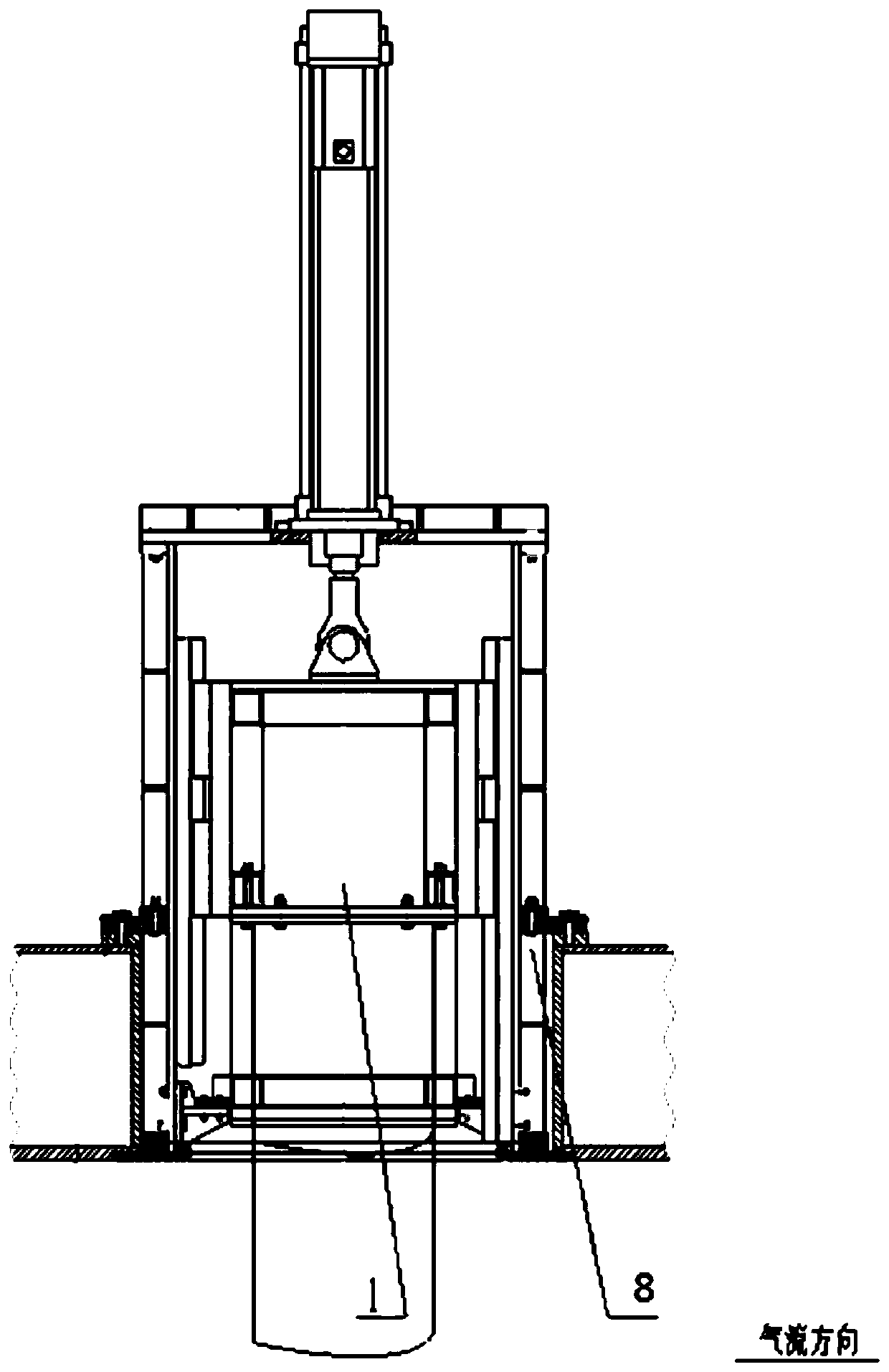

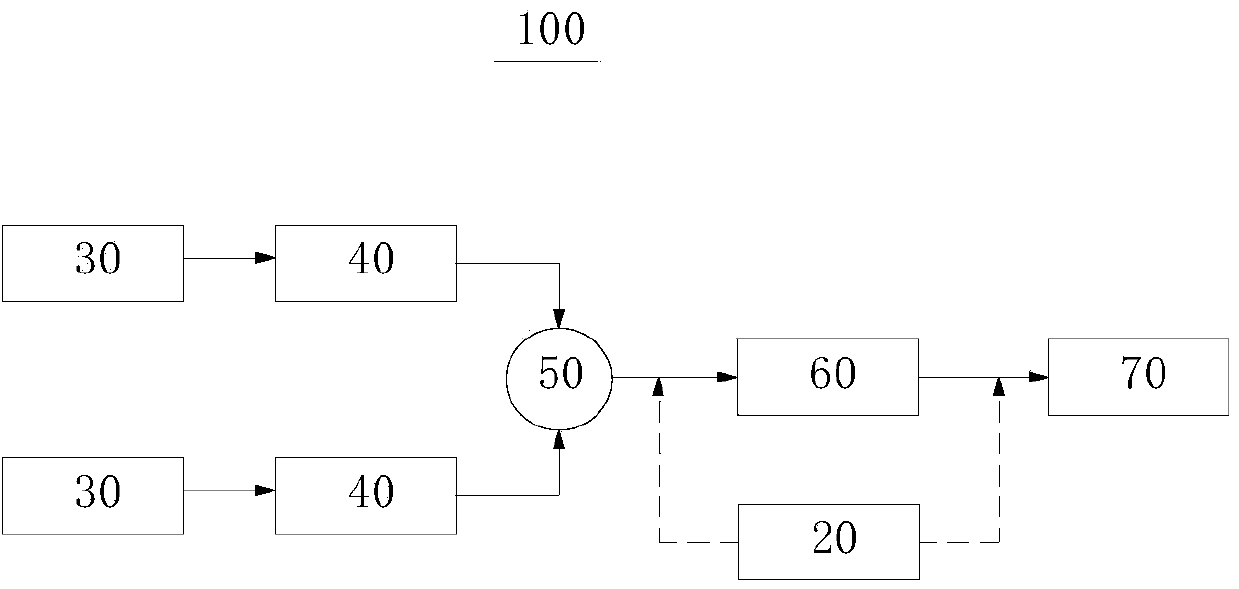

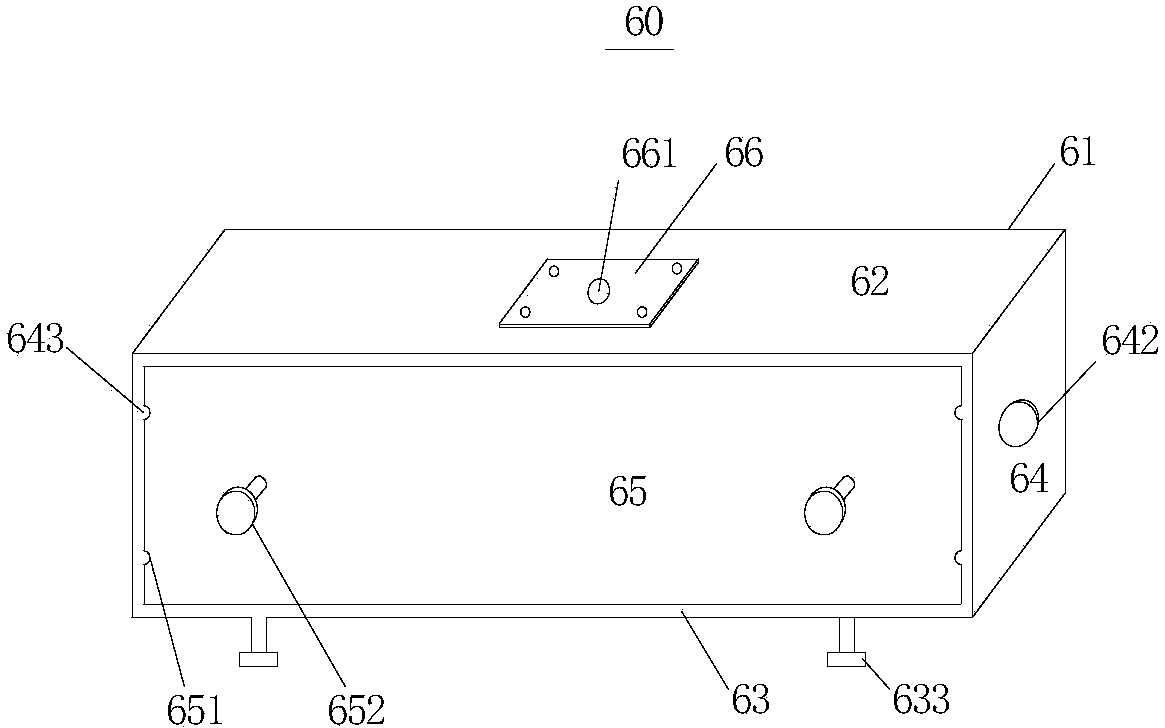

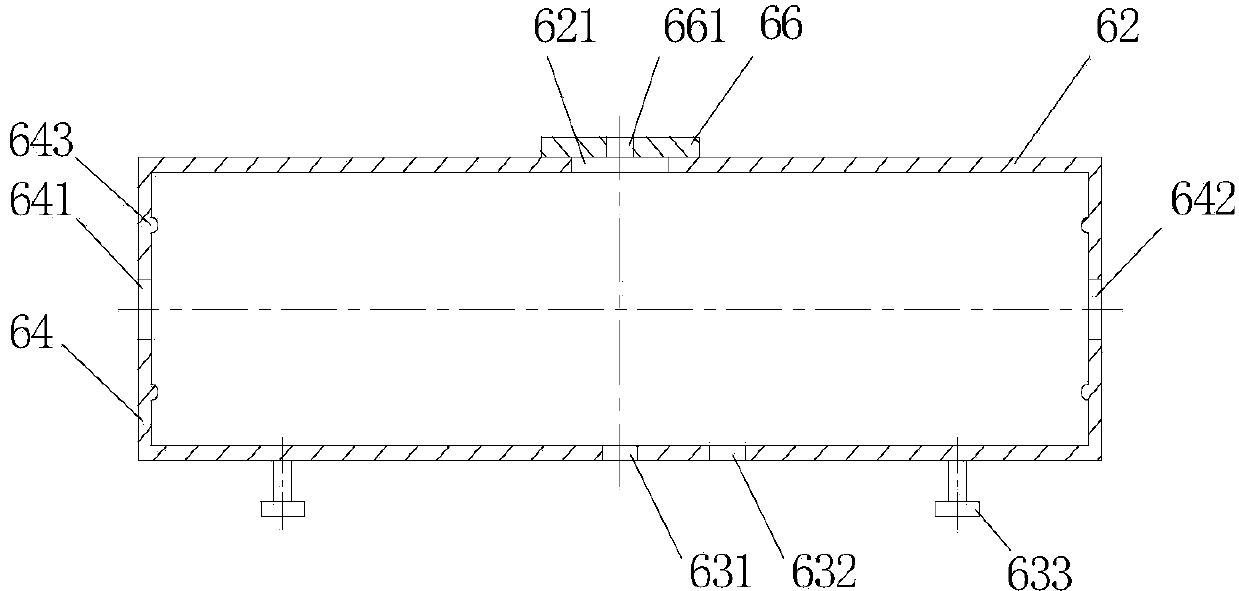

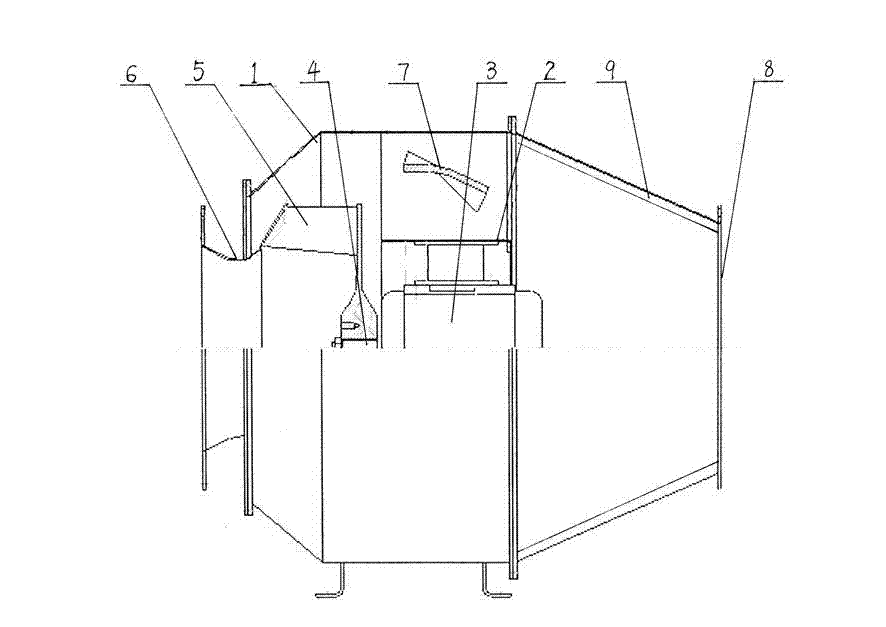

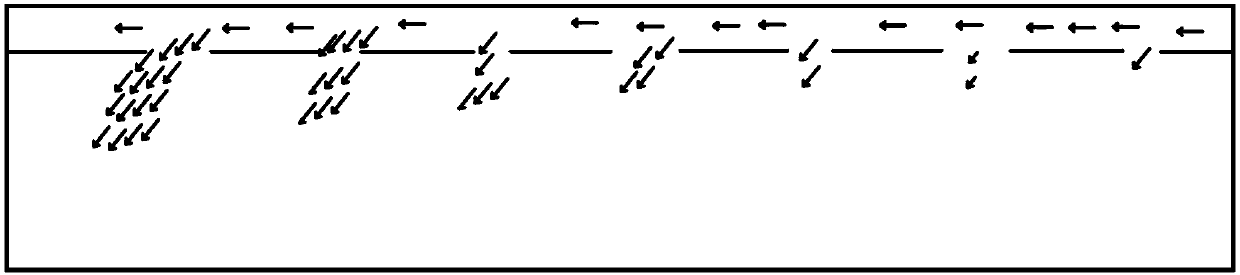

Flow field precise control system for DC transient impact type transonic wind tunnel and control method

PendingCN110702361ASolve the problem of control accuracySolve the problem that the accuracy does not meet the needs of new aircraft developmentAerodynamic testingControl systemControl manner

The invention discloses a flow field precise control system for a DC transient impact type transonic wind tunnel and a control method, which belong to the technical field of wind tunnel tests, and aimat the problem that existing equipment fails and cannot be braked in time. The flow field precise control system comprises a control center computer, an attack angle control computer, a gate finger controller, a flow field controller, gate finger driving equipment and a pressure regulating valve electro-hydraulic system, wherein the gate finger driving equipment comprises a gate finger device, the grid finger device comprises two groups of gate finger sections arranged at upper and lower wall plates of a second throat of a wind tunnel super-expansion section, each group of gate finger sections comprises six wing-shaped gate finger pieces, each group of gate finger sections are respectively fixed on upper and lower gate finger trolleys, each gate finger trolley is provided with four columns of linear guide rails, and a servo electric cylinder is provided with a linear displacement sensor. Therefore, the purpose of precisely controlling a Mach number of the flow field of the DC transient impact type transonic wind tunnel is achieved; and the control method solves the problem of Mach number control precision within a range that M is greater than or equal to 1.0 and less than or equalto 1.2 by adopting a control mode integrating PID control and feedforward control for the gate fingers and performing optimized control over the flow field.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

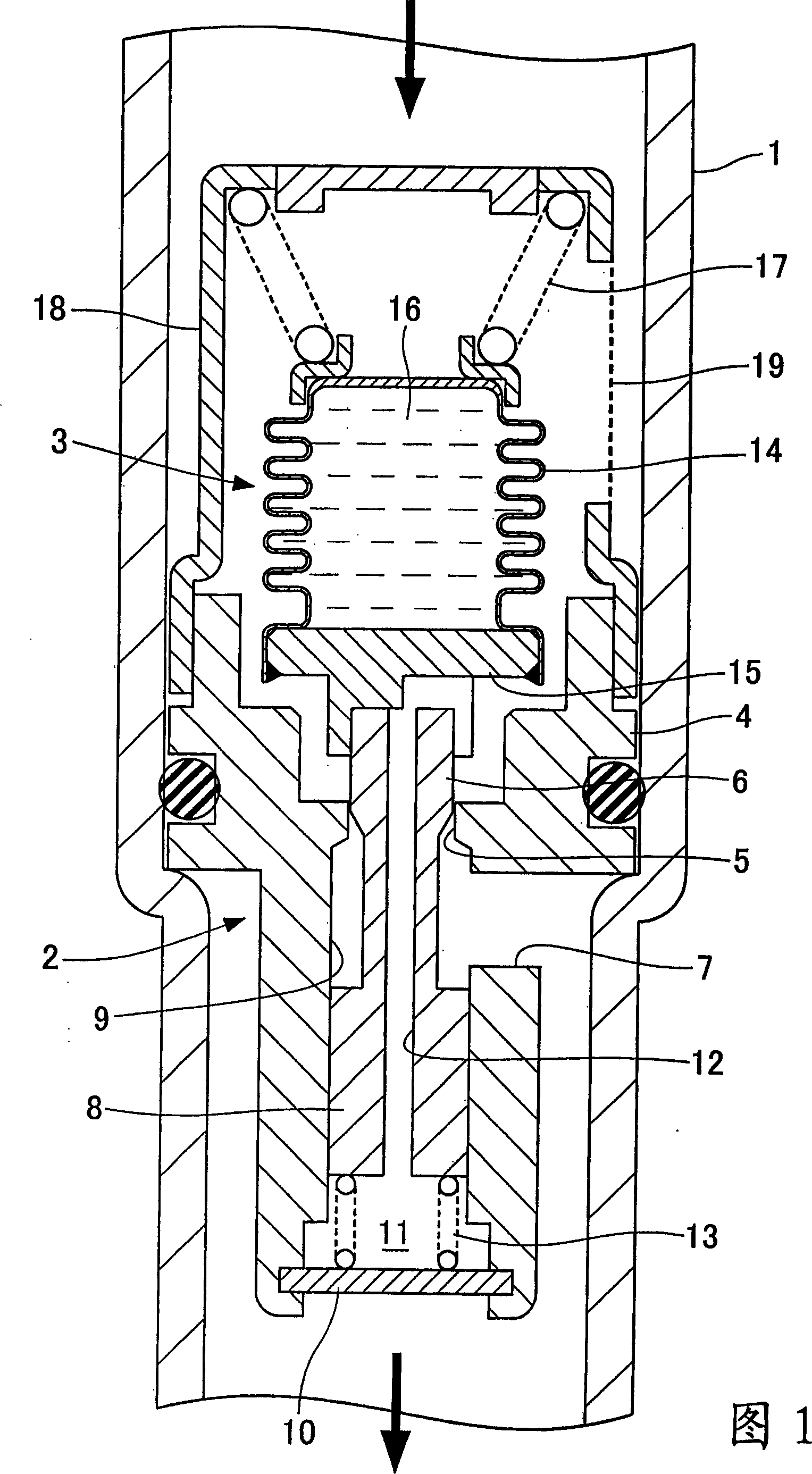

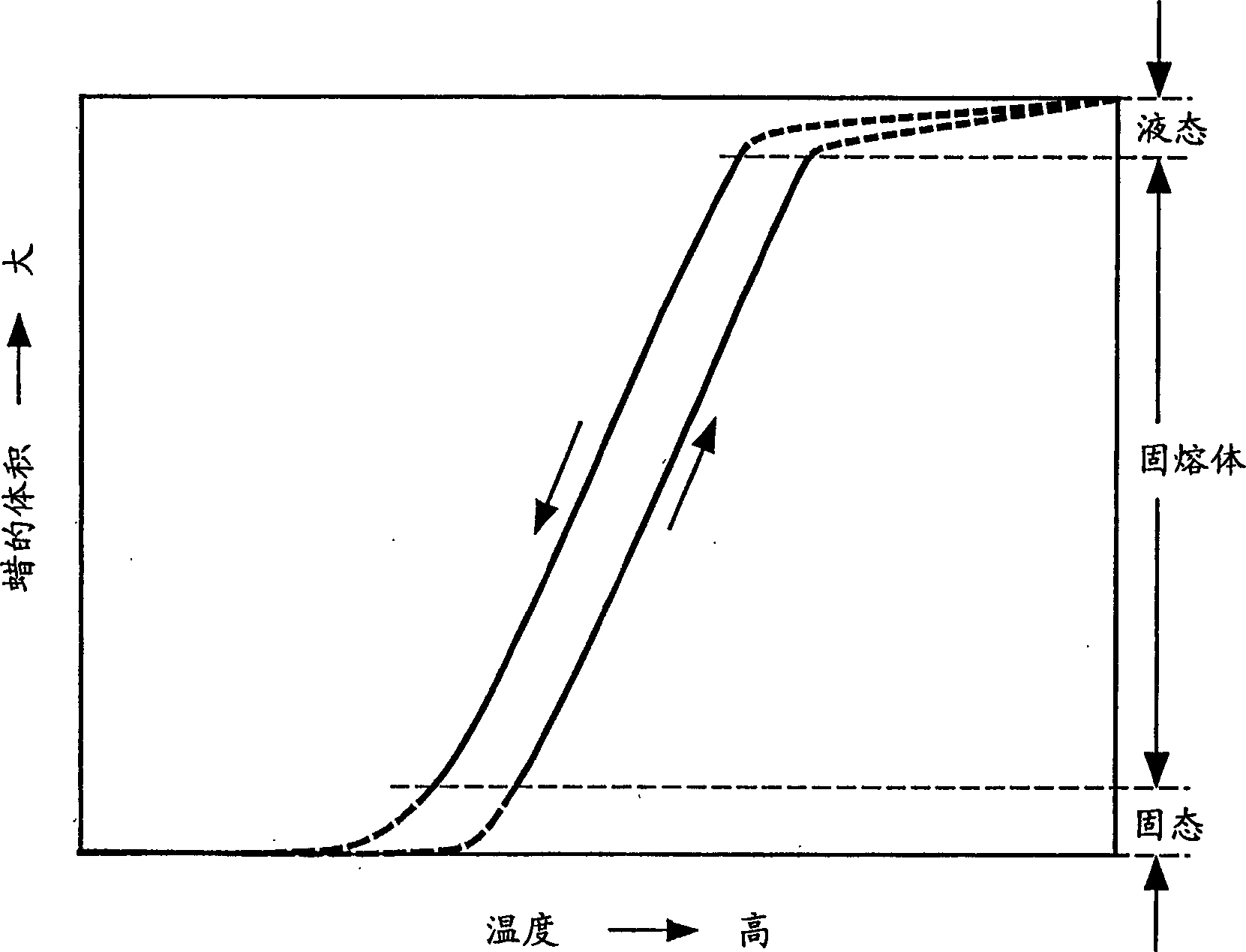

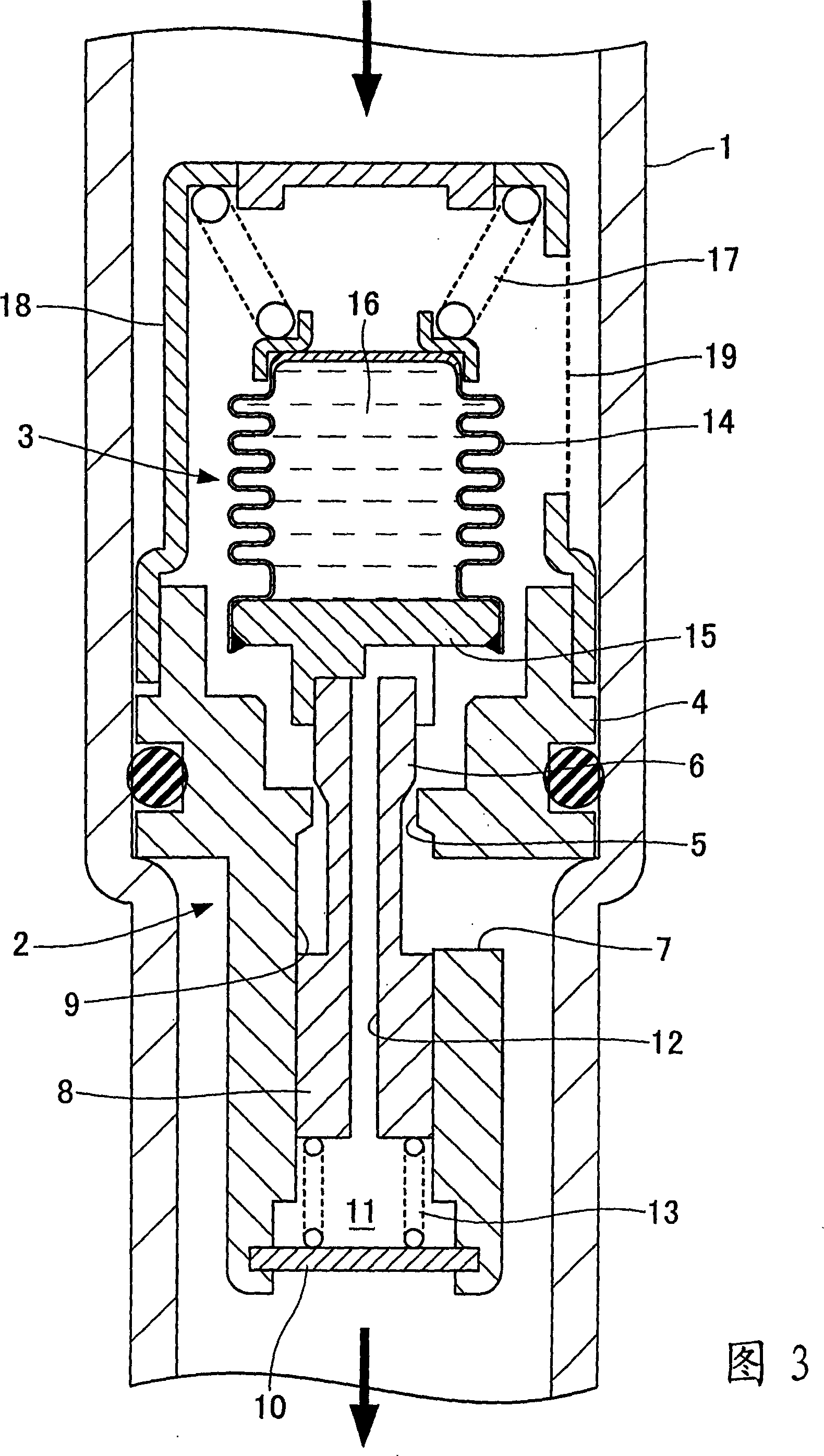

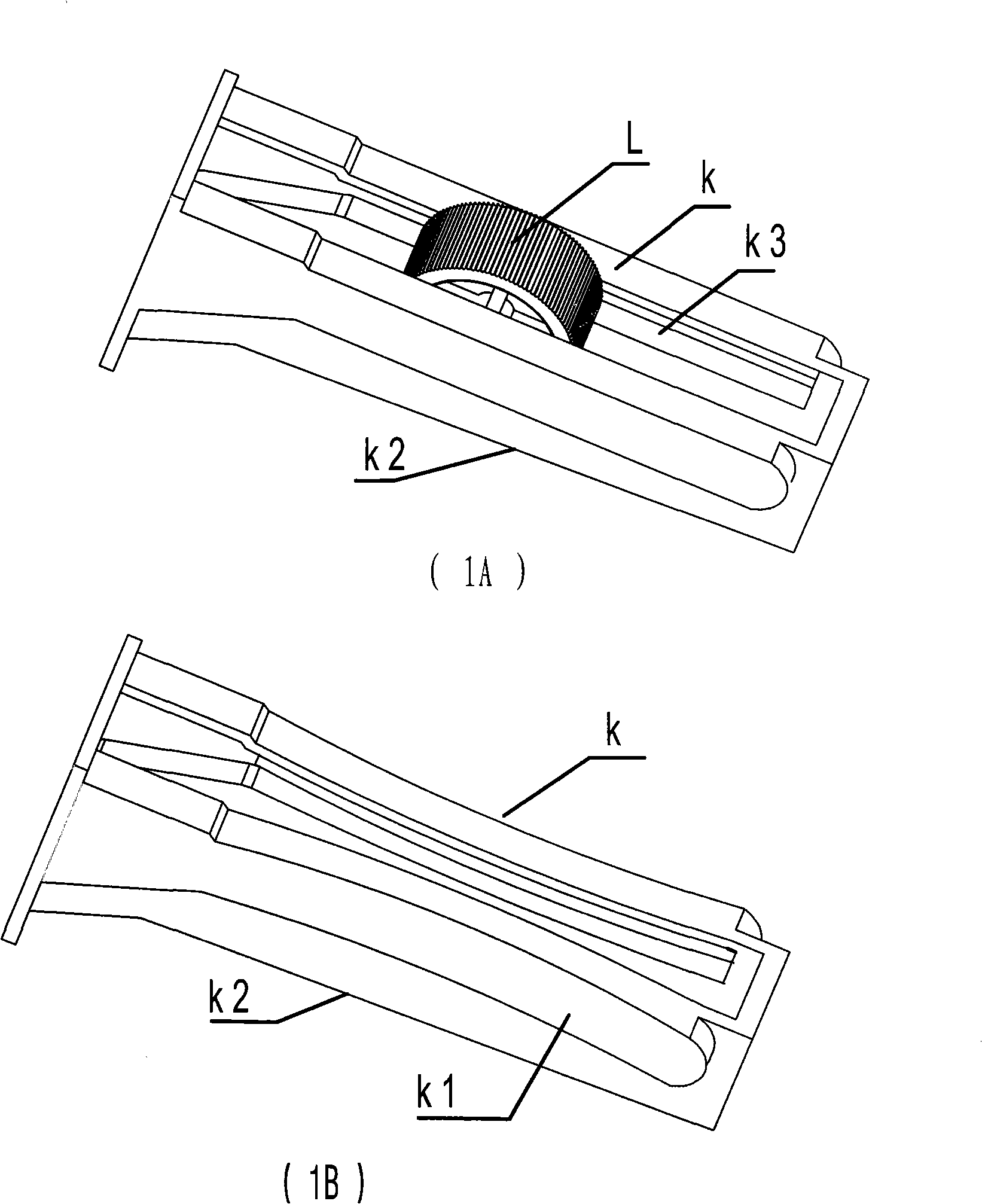

Expansion device

InactiveCN1776329AChange the cross-sectional areaEliminate high pressure confined spaceFluid circulation arrangementInlet pressureEngineering

Provided is a low-cost expansion device capable of changing the passage cross-sectional area of the throttling passage according to the pressure and temperature of the introduced refrigerant without providing a high-pressure closed space. The expansion device includes: a differential pressure valve for having its valve lift controlled according to a pressure difference across the expansion device; and a temperature sensing portion for further controlling the pressure difference according to refrigerant temperature The valve lift of the valve. The differential pressure valve includes a piston having a larger outer diameter than the valve element and integrally formed with the valve element. The piston forms a pressure regulating chamber into which the inlet pressure of the refrigerant is introduced through the pressure channel, so that when the inlet pressure of the refrigerant becomes higher, the differential pressure valve is operated in the valve opening direction. The temperature sensing part is formed by filling wax having a large bulk expansion coefficient into a bellows that can expand and contract axially, thereby operating the differential pressure valve in a valve-closing direction when the refrigerant inlet temperature becomes high.

Owner:TGK

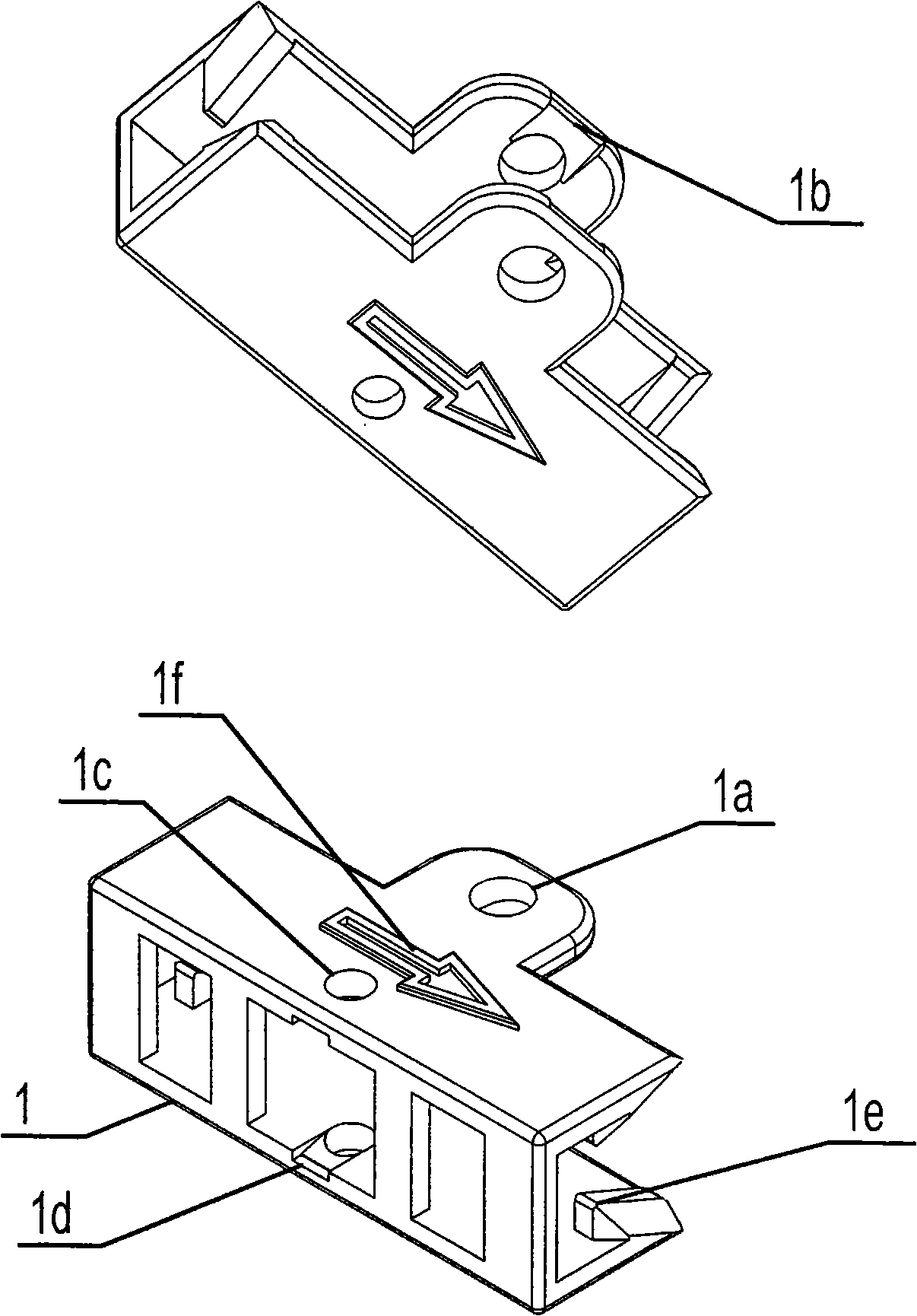

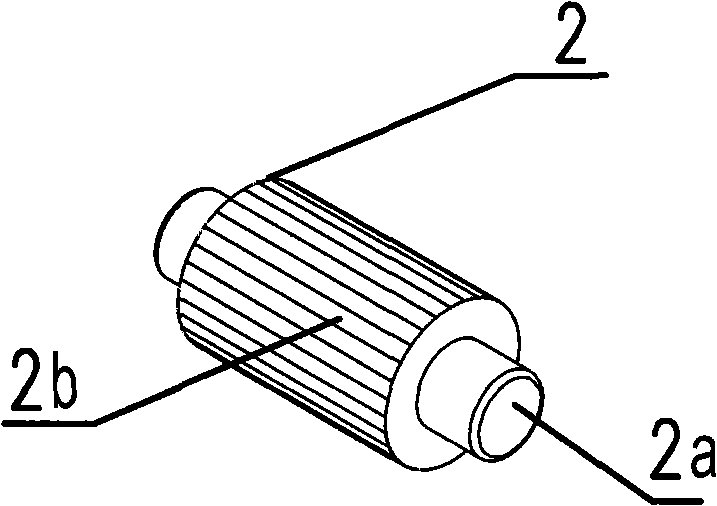

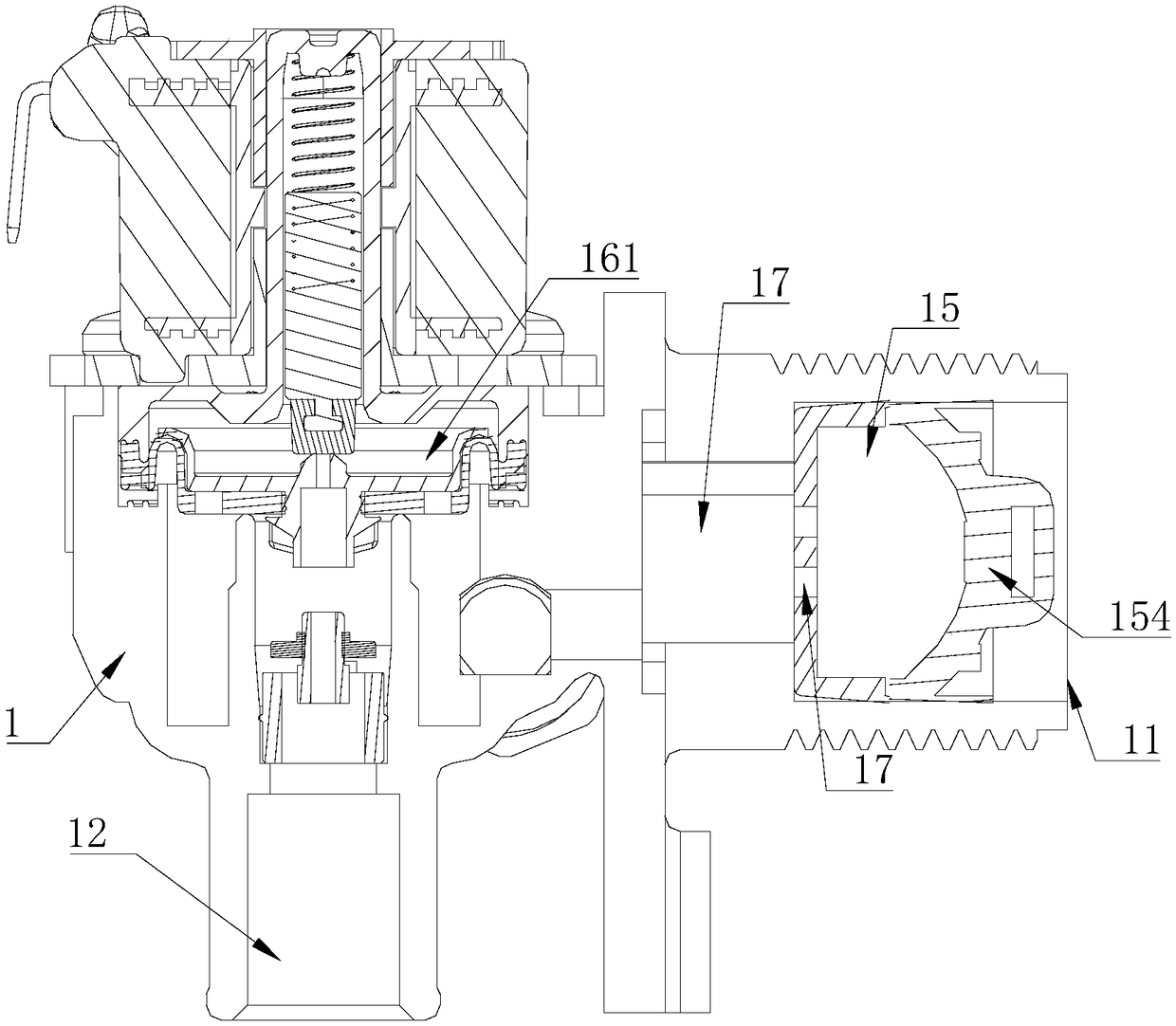

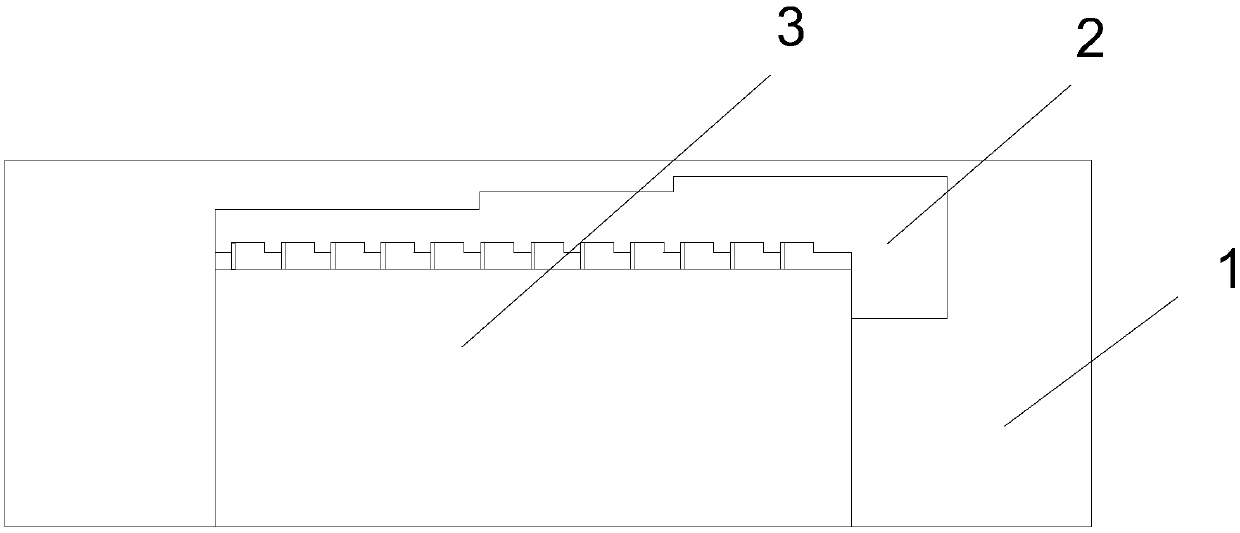

Cam type infusion regulator

InactiveCN101569769AChange the cross-sectional areaInfusion speed regulation and controlIntravenous devicesCamGuide tube

A cam type infusion regulator consists of a shell 1, a supporting wheel 2 and a regulating wheel 3. The shell has a structure of a U-shaped groove, two pairs of axle holes (1a, 1c) are correspondingly drilled on the upper side and the lower side, and axial lines of the two pairs of the axle holes (1a, 1c) are parallel with each other and perpendicular with each other; the supporting wheel 2 is arranged in the axle hole 1c on the lower part of the shell; the regulating wheel 3 is arranged in the axle hole 1a on the upper part of the shell; the surface 3c of the regulating wheel has a cam shape, the distance between the surface 3c of the regulating wheel and an axle center changes in an involute mode, and the curvature change of the surface 3c of the regulating wheel meets the regulating and control requirements on the infusion speed; an infusion conduit is arranged between the regulating wheel 3 and the shell 1 and the supporting wheel 2; and during use, fingers twist the regulating wheel 3, the change of the distance between a curved surface 3c of the regulating wheel and a supporting wheel 3 on the bottom of the shell extrudes or releases the conduit, and changes the sectional area of the conduit to achieve the aim of regulating and controlling the infusion speed. Compared with the prior infusion regulator, the cam type infusion regulator has the characteristics of small size, material conservation, capability of self-assembly, improvement on the efficiency, convenient use, reliable regulation and stable speed.

Owner:张亚平

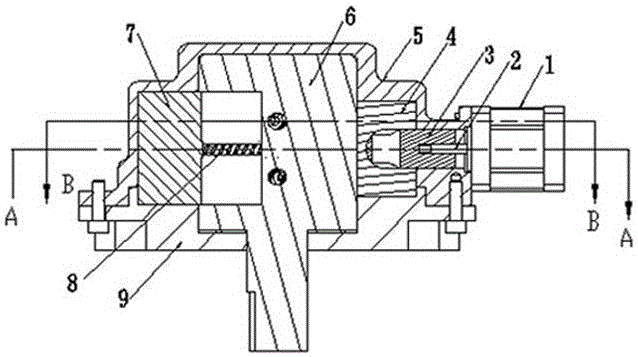

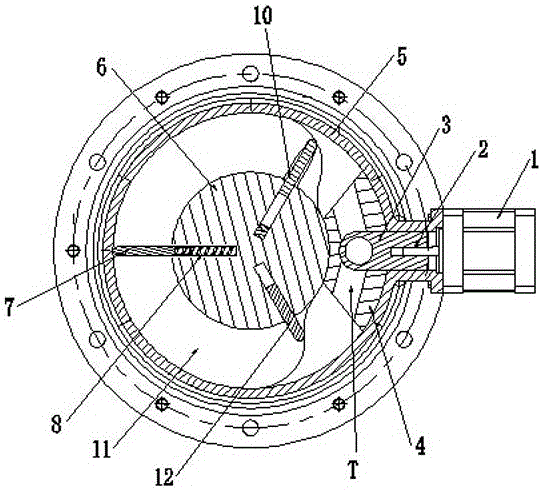

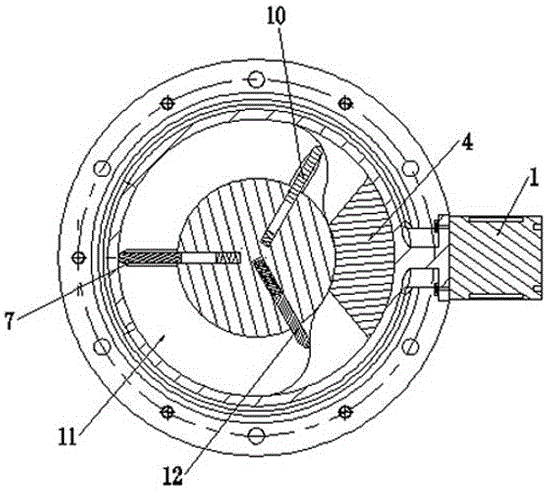

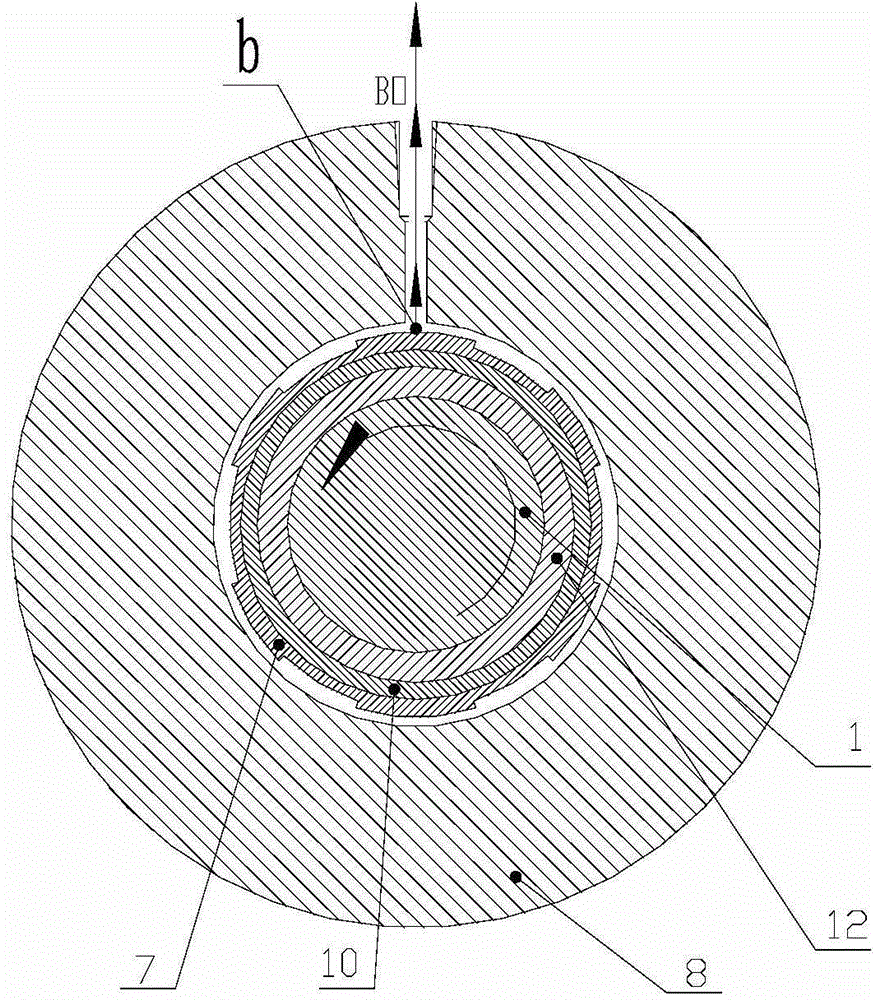

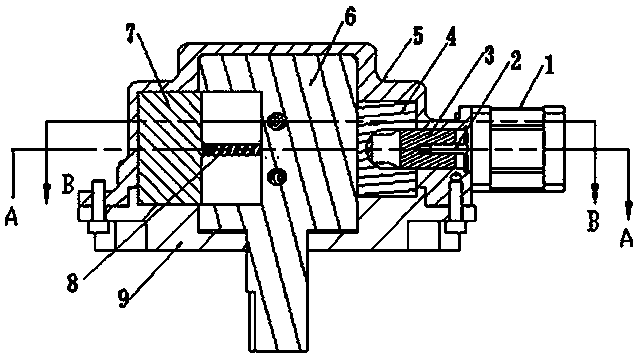

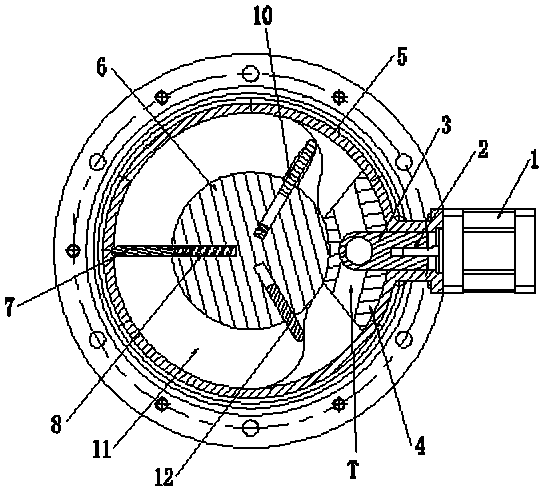

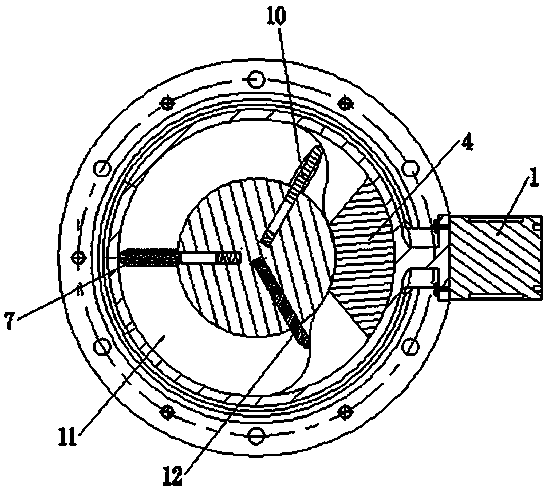

Electronic control variable-damping rotation hydraulic damper

InactiveCN106438815AChange the cross-sectional areaRealize controllableSpringsSprings/dampers design characteristicsEngineeringControl variable

The invention relates to an electronic control variable-damping rotation hydraulic damper which comprises a motor, an outer shell, a blade, a valve element, a valve body, a shaft, a spring, a cover plate and the like. Due to the fact that a guide groove is formed in the middle shaft of the variable-damping rotation hydraulic damper, a guide rail is arranged on the shell, the blade automatically moves transversely in the radial direction along with the guide rail during rotation, the volume of driven liquid is changed, the liquid flows in a circulated manner through the valve element, and the function that the rotation angle of the damper is unlimited is achieved; and the valve element is driven by a step motor to rotate, so that the size of the drift diameter of a runner composed of the valve element and the valve body is variable, and the function of being adjustable in rotation damping is achieved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

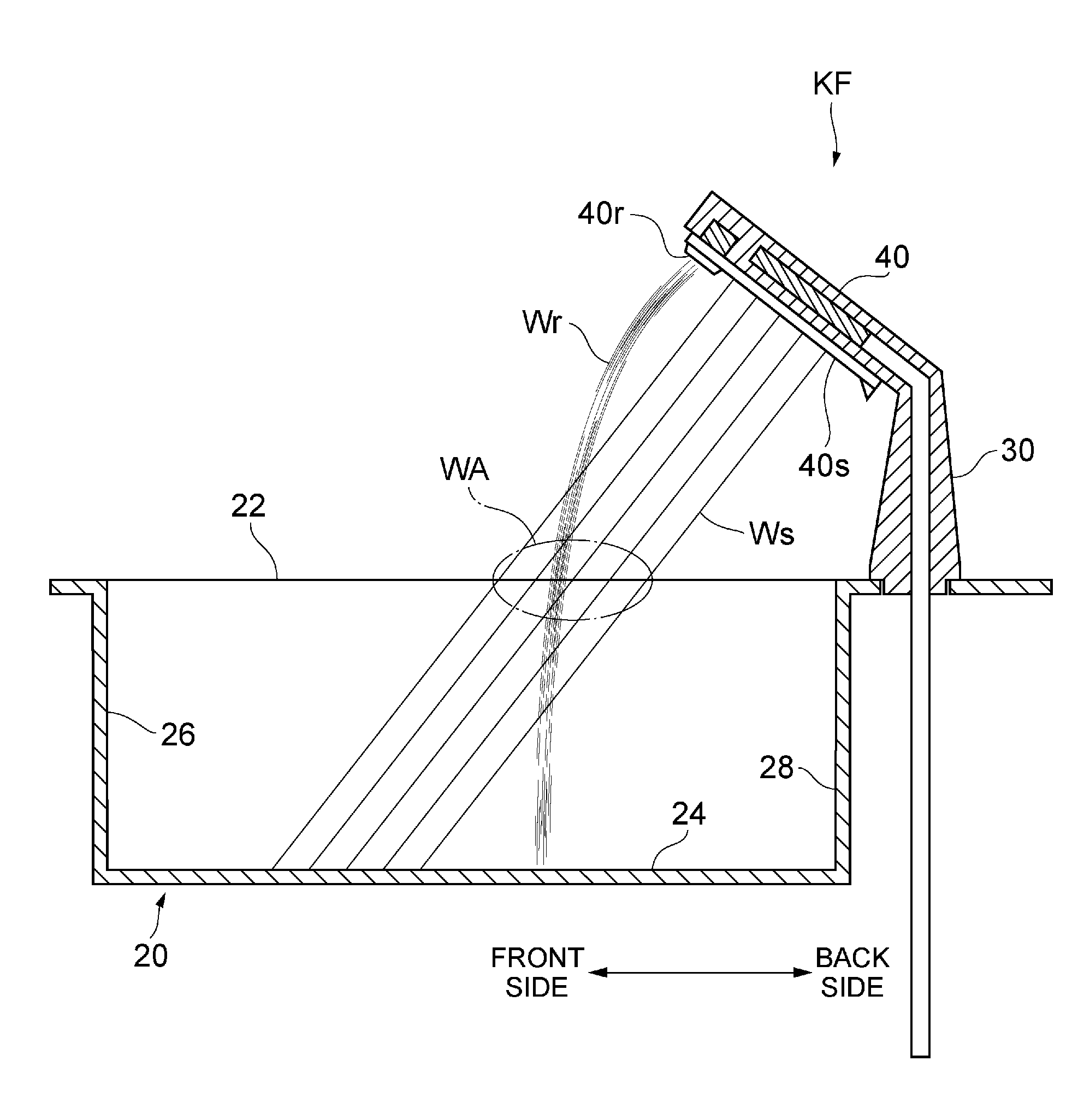

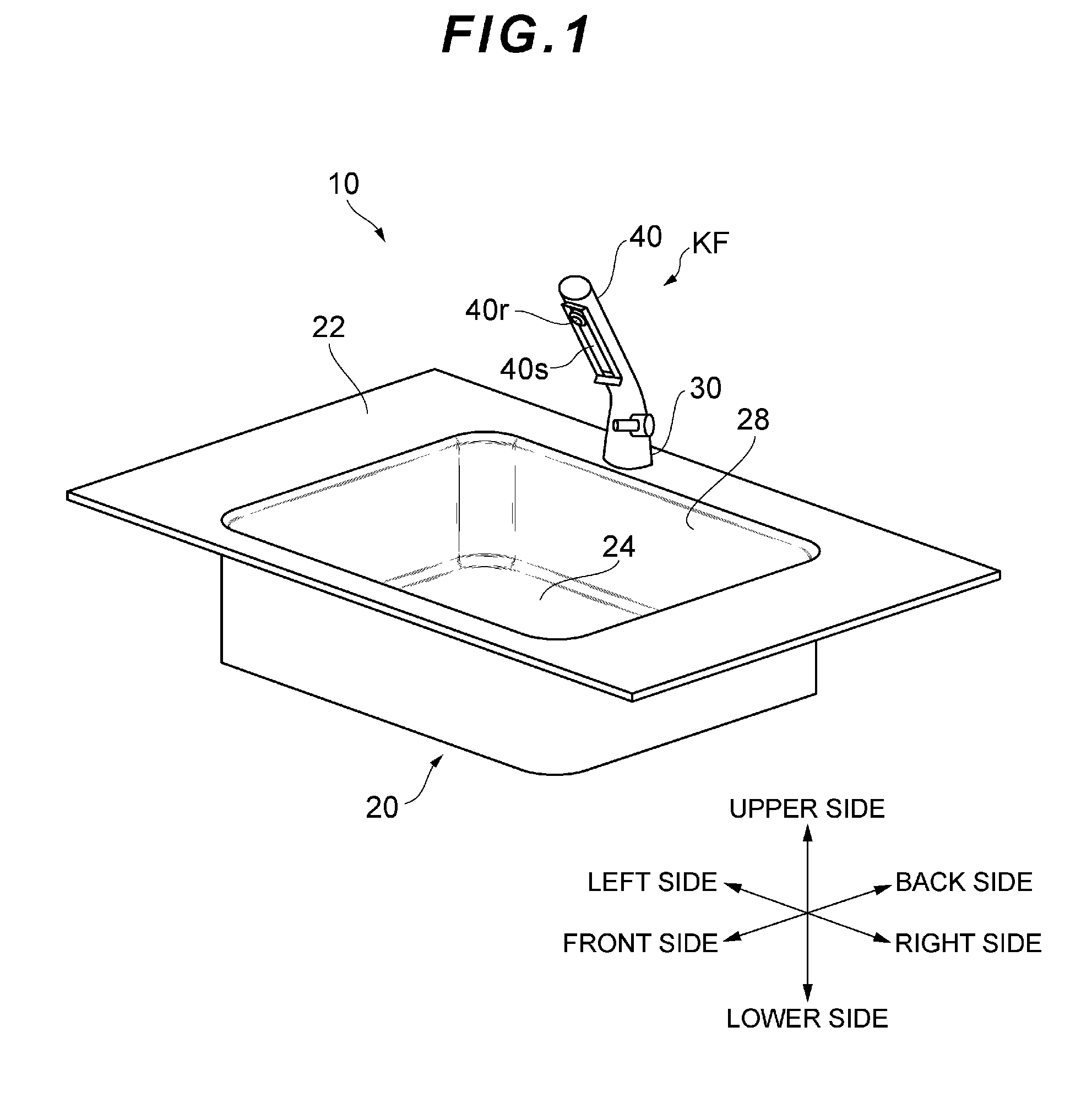

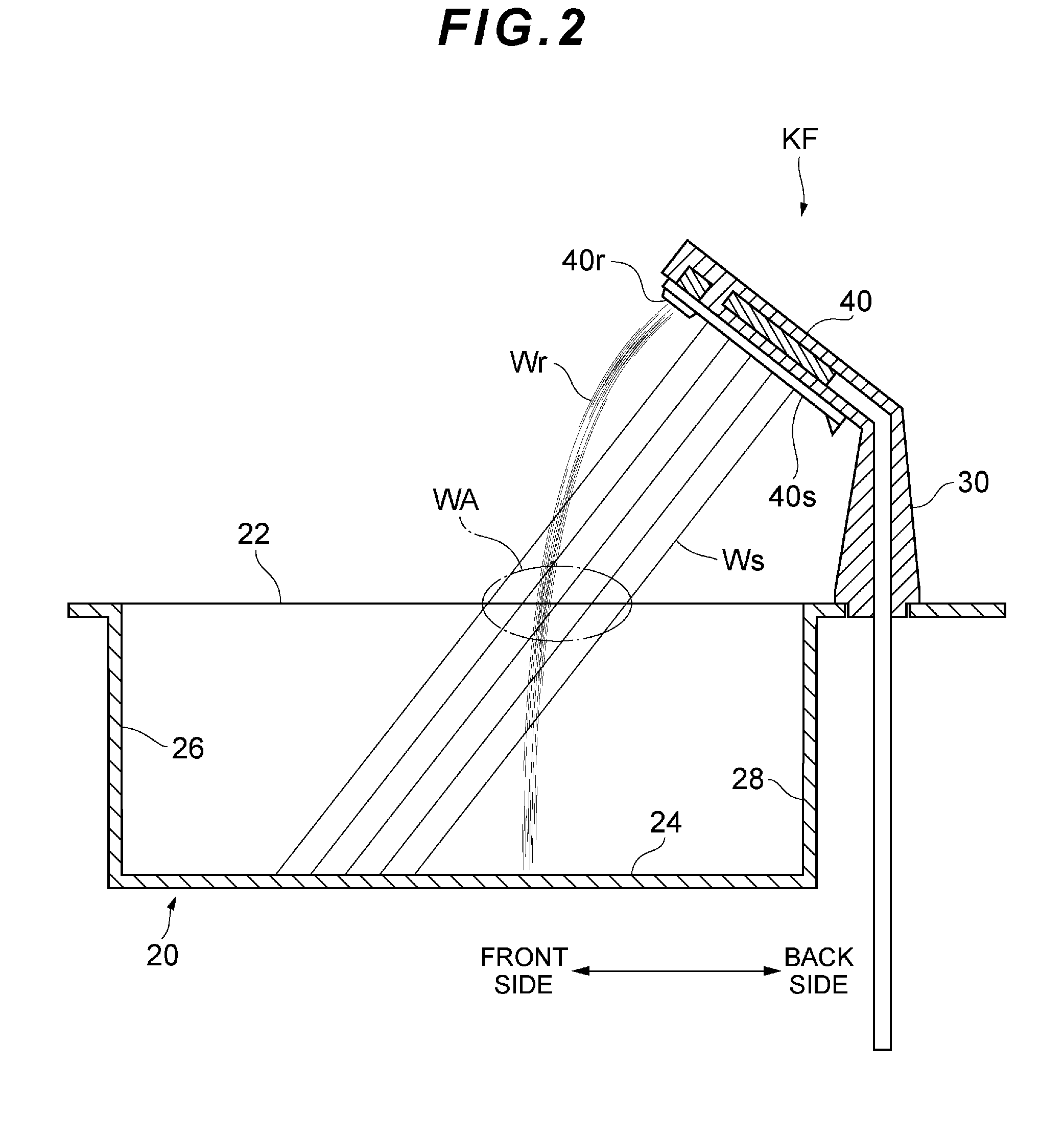

Water faucet

ActiveUS20150014447A1Reliably changed with timeReduce the cross-sectional areaDomestic plumbingSpray nozzlesWater flowEngineering

The present invention aims to provide a water faucet which allows a large space to be secured above the washing area and yet can deliver a high washing performance by landing streams or waterdrops having a large cross-sectional area evenly on a piece to wash. This water faucet includes a flow velocity changing part which changes the flow velocity of the stream discharged from each of multiple water spray holes such that the cross-sectional area of the stream changes with time. The multiple water spray holes are disposed at intervals such that, when the cross-sectional area of one stream discharged from one water spray hole exceeds a predetermined size, the one stream is merged with one of the other streams discharged from the multiple other water spray holes adjacent to the one water spray hole, and such that the one of the other streams with which the one stream merges changes with time.

Owner:TOTO LTD

Microwave irradiation chamber, microwave irradiation system and microwave irradiation and real-time observation method

ActiveCN103776682AReal-time biological indicator observationReduce microwave leakageMaterial analysis using microwave meansPreparing sample for investigationEngineeringIrradiation

The invention provides a microwave irradiation chamber, a microwave irradiation system and a microwave irradiation and real-time observation method. The microwave irradiation chamber comprises a shell and a shielding component, wherein a cuboid-shaped cavity is formed in the shell, a microwave receiving interface and a microwave absorption interface are arranged in the central positions of the two end walls of the shell, respectively, a first opening is formed in the central position of the top wall of the shell, and a second opening is formed in the central position of the bottom wall; the shielding component covers the first opening of the shell, and the center of the shielding component is provided with a through hole. According to the technical scheme of the invention, the microwave irradiation chamber can be directly connected into a real-time observation and analysis instrument to carry out biological index observation in real time, so that the microwave leakage is slight, and the cross-sectional area of the microwave irradiation chamber is adjustable, and therefore, the compound irradiation of microwaves with different frequencies can be realized.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

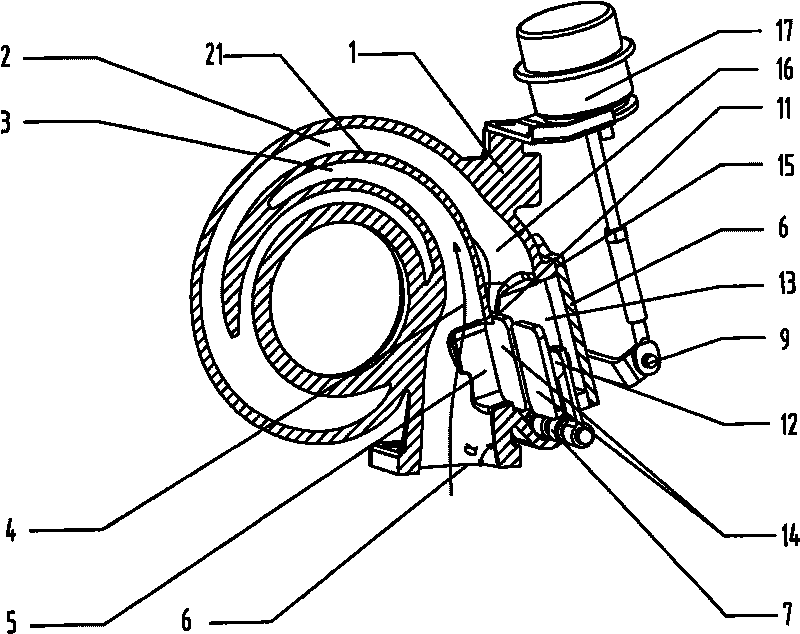

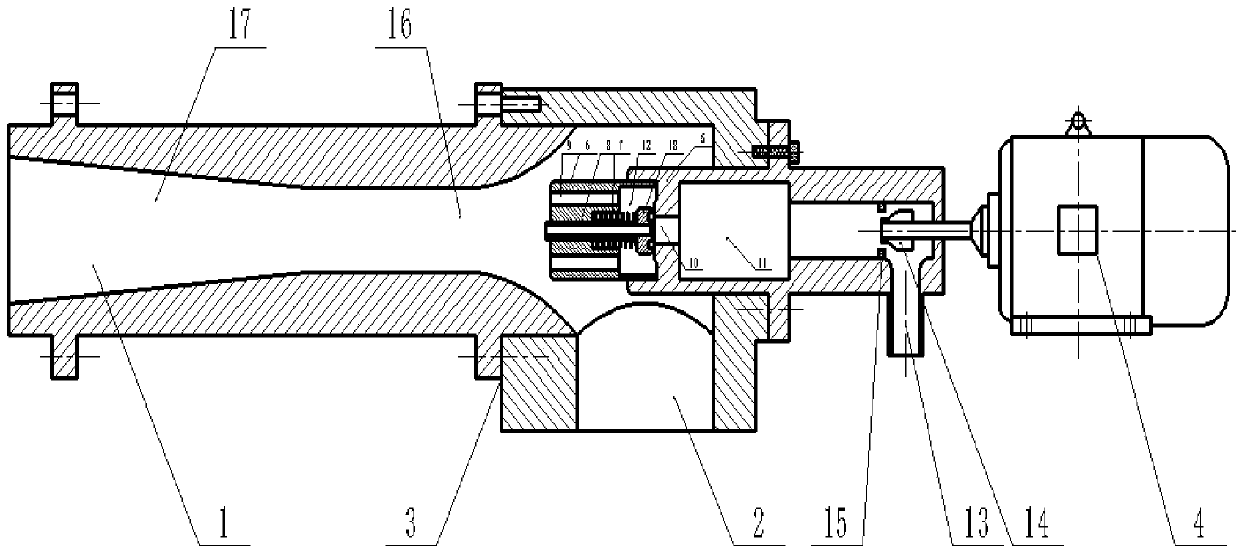

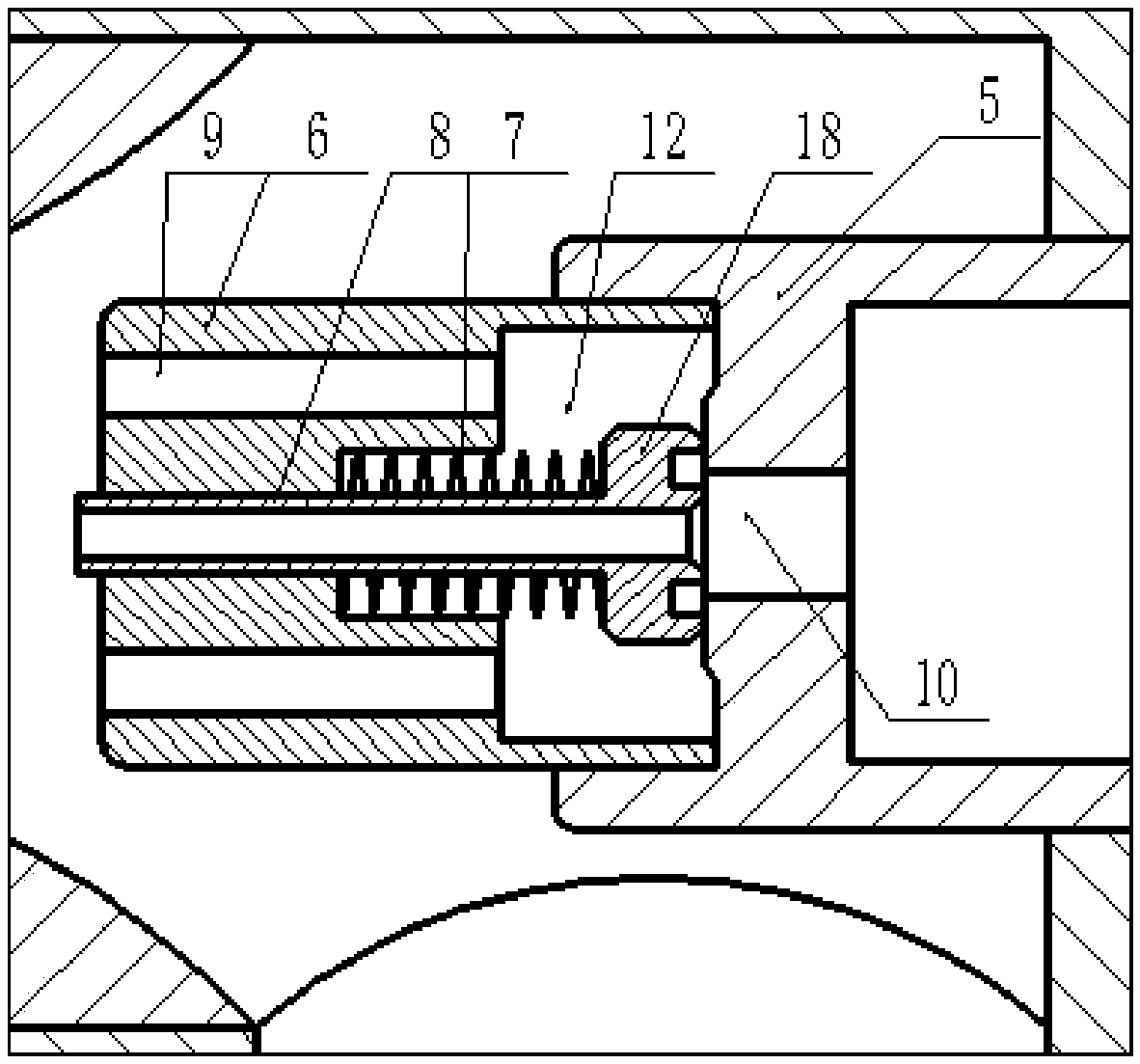

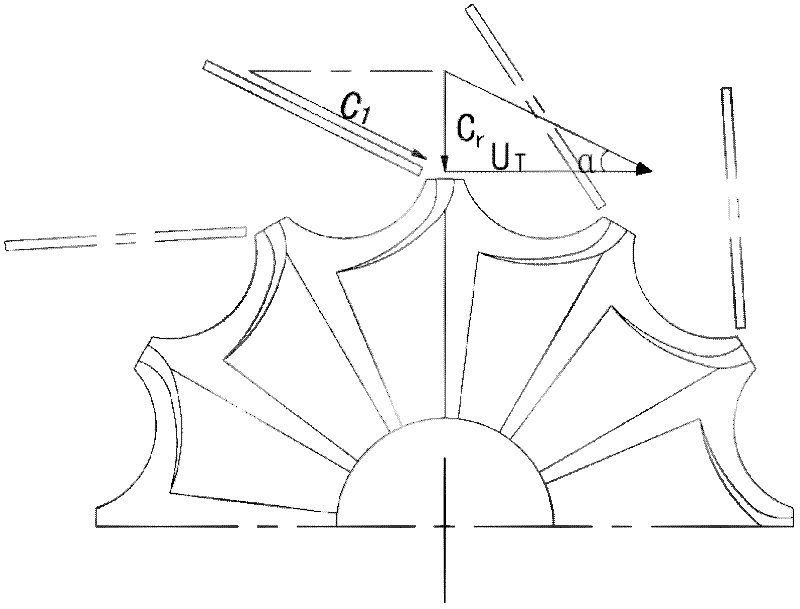

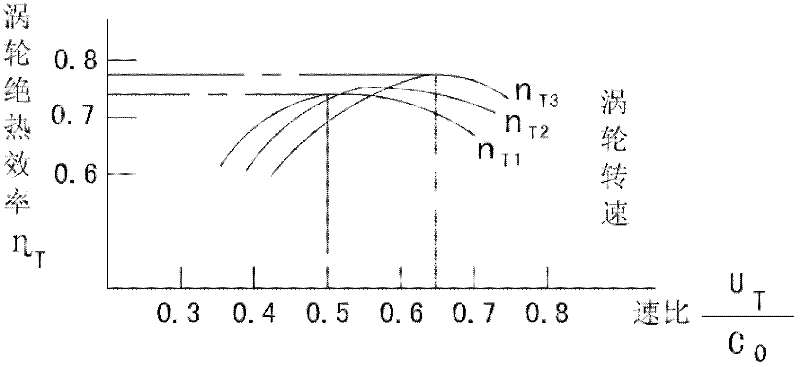

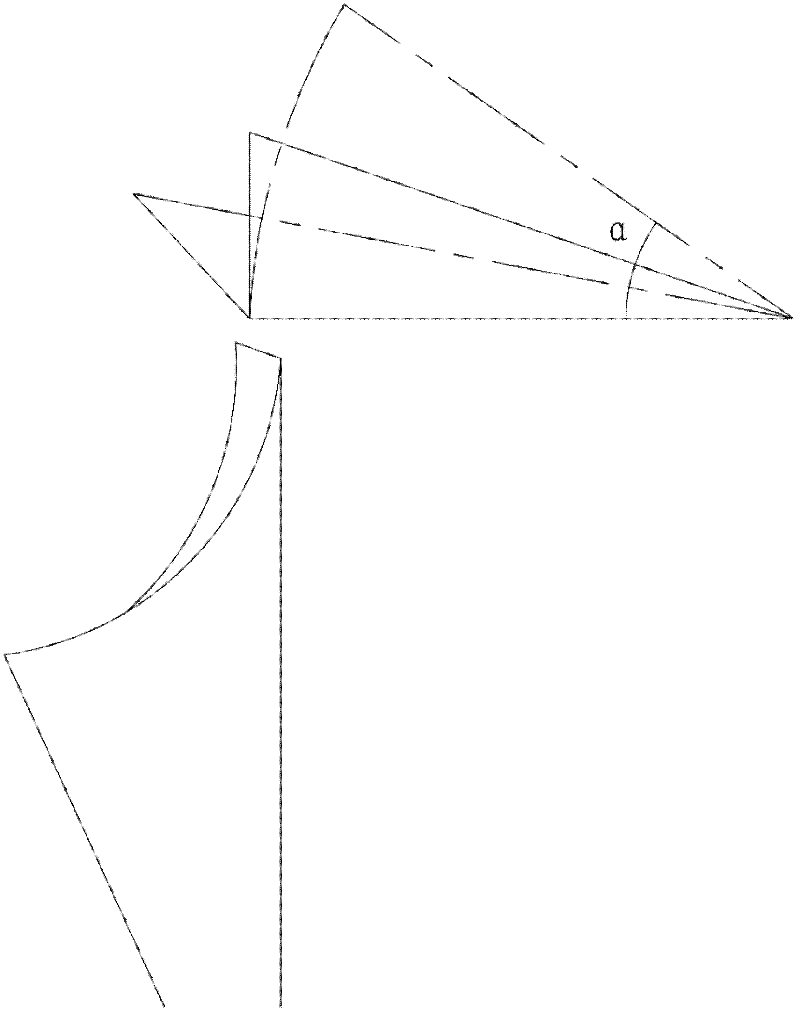

Turbocharger and working method thereof

InactiveCN102383871AImprove efficiencyChanging the cross-sectional area of the nozzleMachines/enginesEngine componentsImpellerTurbine wheel

The invention relates to a turbocharger and a working method thereof. The turbocharger comprises a volute arranged in a turbine casing body and a jet nozzle ring assembly which is fixed in the volute and sleeve on the periphery of an impeller of a turbine; the jet nozzle ring assembly comprises a jet nozzle ring, a plurality of long jet-nozzle blades distributed on the outer side face of the jet nozzle ring, a chute arranged between every two adjacent long jet-nozzle blades, short movable blades arranged in the chutes, linked rings concentrically arranged at the inner side surface of the jet nozzle ring, chute holes which are distributed on the linked rings and correspond to the corresponding chutes, a plurality of arc-shaped guide grooves which are distributed on the linked rings and are arranged concentrically to the linked rings, and a straight bolt arranged on the inner side surface of the jet nozzle ring; and a crank in transmission connection with a driving mechanism is arranged on an intermediate shell of the turbine and is connected with a pin hole in the linked rings through a crank shifting fork so as to drive the linked rings to rotate along a center and make the short movable blades displace in a linear reciprocating manner along a jet-nozzle airflow direction, and thus, the cross section of a jet nozzle is further controlled.

Owner:CHANGZHOU XINRUI AUTO PARTS MFG

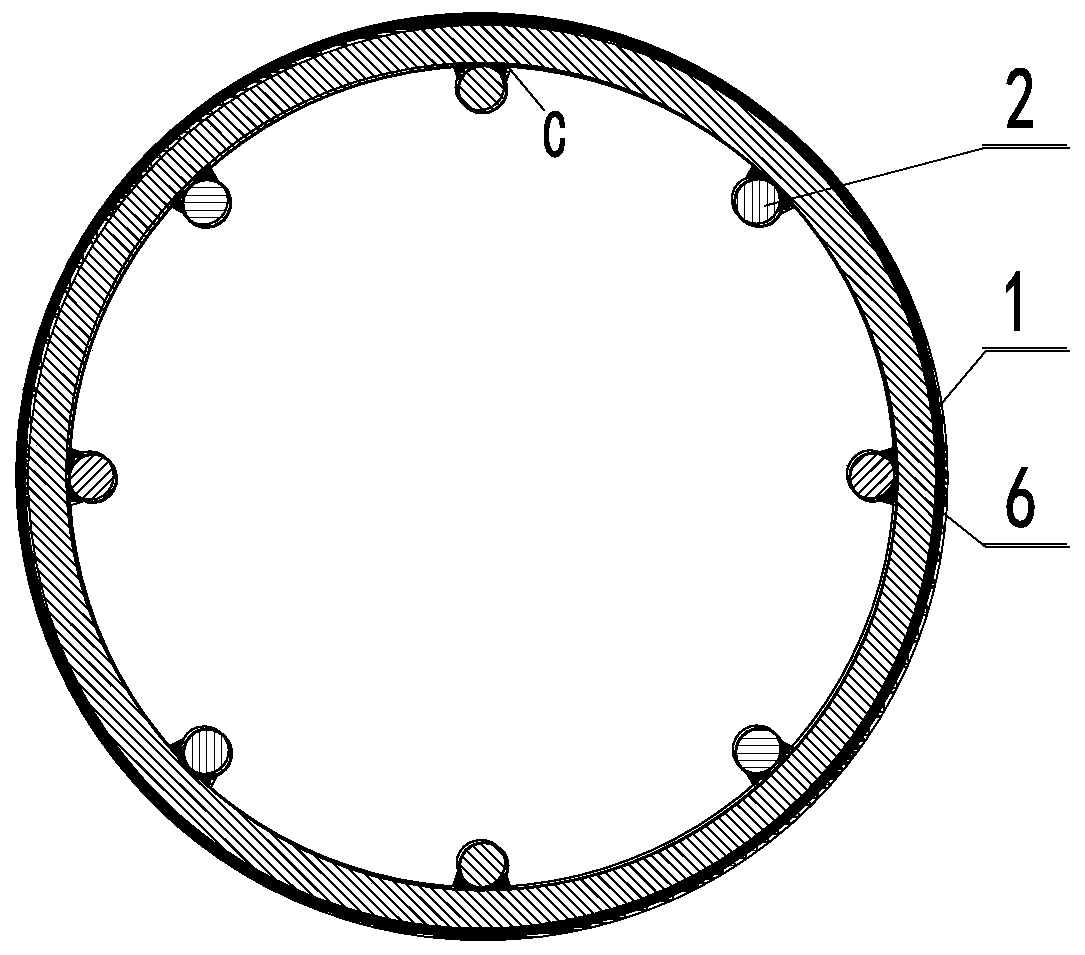

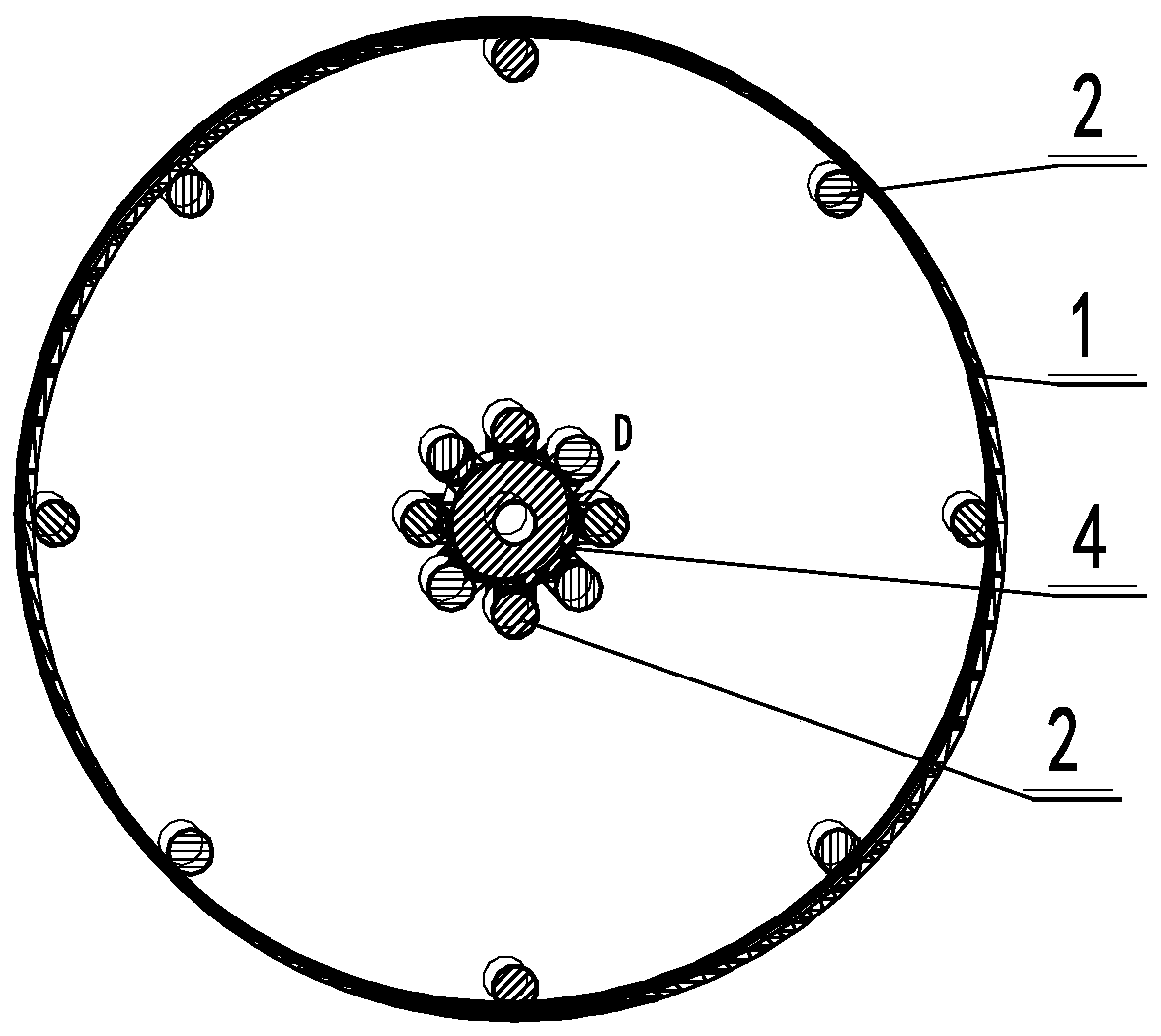

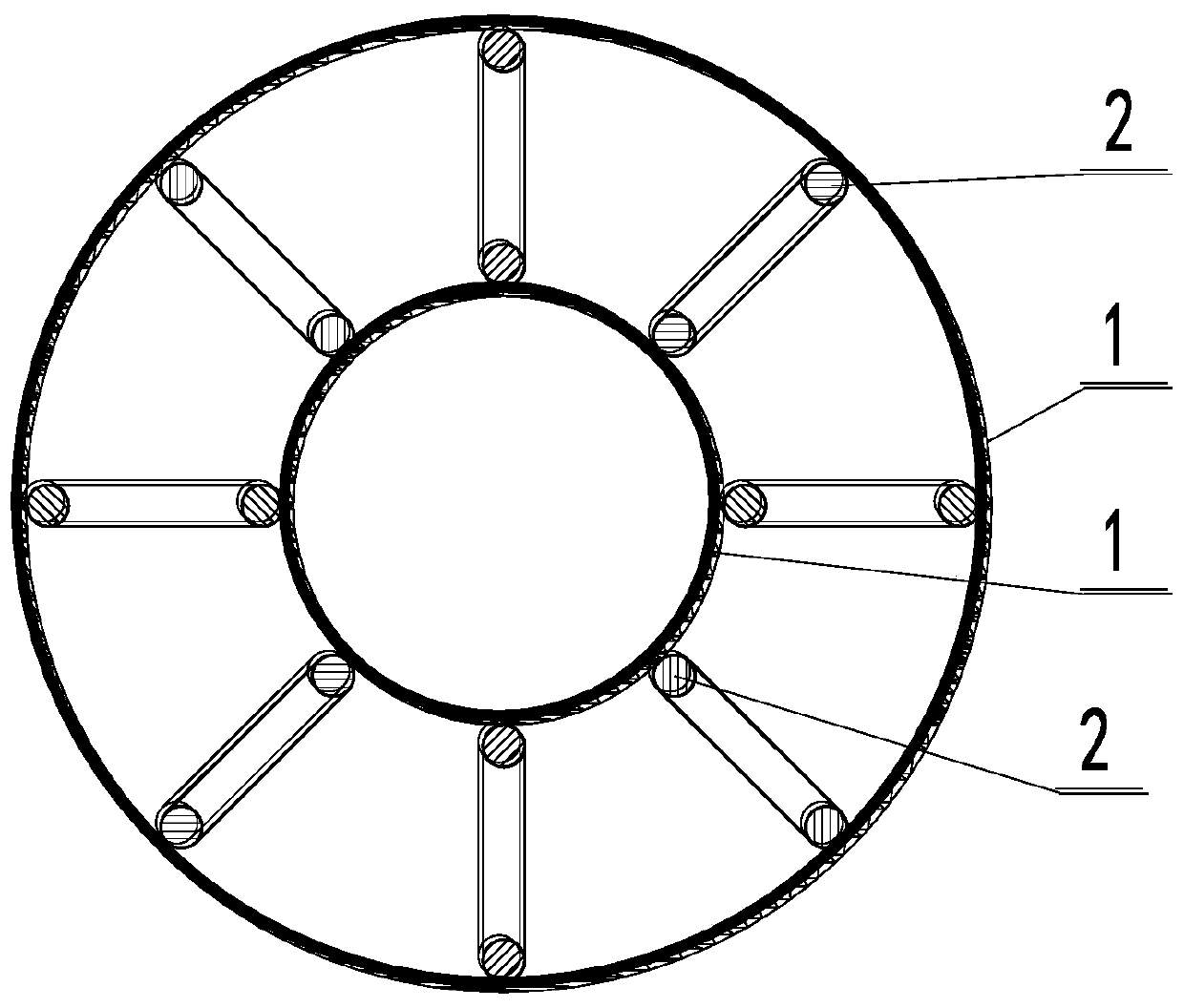

Discontinuous cross-section column transferring joint and construction method thereof

ActiveCN108661174AChange the cross-sectional areaReduce gravityBuilding constructionsPhotovoltaic energy generationSquare cross sectionStress concentration

The invention discloses a discontinuous cross-section column transferring joint and a construction method thereof. The discontinuous cross-section column transferring joint comprises a joint body which is of a column structure with hollow inside, a cross steel column connected into a column structure of the joint body, an upper end circular cross-section column transition plate connected to the upper end of the joint body, an upper end circular cross-section column connected to the upper part of the upper end circular cross-section column transition plate, a stiffening rib plate I connected between the upper end circular cross-section column and the upper end circular cross-section column transition plate, a lower end square cross-section column transition plate connected to the lower endof the joint body, a lower end square cross-section column connected to the lower part of lower end square cross-section column transition plate, and a stiffening rib plate II connected between the lower end square cross-section column and the lower end square cross-section column transition plate, wherein the outer edge of the cross steel column is connected with the inner wall of the column structure. The discontinuous cross-section column transferring joint has good cross section transition, and the occurrence of stress concentration phenomenon and the generation of anti-seismic weak partscaused by the transition of discontinuous joint steel columns only by single-layer steel plates are avoided.

Owner:CHINA RAILWAY CONSTR GROUP

Stepless speed-governing gas spring

ActiveCN102777530AChange the cross-sectional areaAdjust the cross-sectional areaSpringsGas based dampersGas springEngineering

The invention relates to a stepless speed-governing gas spring. A rear plug is installed at the outer end of an inner cylinder sleeve in a sealed mode, the inner cylinder sleeve is connected with a connecting seat, a piston is arranged in the inner cylinder sleeve and divides the inner cylinder sleeve into a front cavity and a rear cavity, a seal ring is installed in a radial chute of the piston, a piston air-returning hole axially arranged on the piston is communicated with the radial chute and the front cavity, a piston rod connected with the piston penetrates from a guiding sealing assembly, and the inner cylinder sleeve is provided with an air hole communicated with the front cavity and an outer cavity and located on the front side of the front cavity. An outer air-returning hole and an inner air-returning hole which are positioned on the rear plug are communicated with the rear cavity, a speed-governing screw is installed in a screwed hole of the rear plug, a valve rod positioned on the upper portion of the speed-governing screw penetrates through a gasket and the seal ring which are installed in a valve rod guiding hole, the end face of the valve rod and an orifice of the outer air-returning hole form a damping flow channel, and a cavity positioned on the upper portion of the valve rod guiding hole is communicated with the outer air-returning hole and the inner air-returning hole. The stepless speed-governing gas spring is reasonable in structure and is installed on a device, and the running speed of the gas spring can be adjusted conveniently.

Owner:CHANGZHOU GAS SPRING

Liquid oxygen kerosene pintle injector

ActiveCN112855382AChange the openingChange the cross-sectional areaRocket engine plantsCombustion chamberEngineering

The invention relates to the technical field of space propulsion, in particular to a liquid oxygen kerosene pintle injector. The liquid oxygen kerosene pintle injector comprises a shell, an adjusting cylinder and a center rod. The center rod sleeves outside the adjusting cylinder, a first liquid spraying outlet is formed between the adjusting cylinder and the center rod, and kerosene flows through the first liquid spraying outlet to enter a combustion chamber; the shell sleeves outside the adjusting cylinder, a second liquid spraying outlet is formed between the shell and the adjusting cylinder, and liquid oxygen flows through the second liquid spraying outlet to enter the combustion chamber; and the center rod is connected with the shell, and the adjusting cylinder can move in the axial direction relative to the center rod and the shell so that the sectional area of the first liquid spraying outlet and the sectional area of the second liquid spraying outlet can be synchronously changed. According to the liquid oxygen kerosene pintle injector, when the adjusting cylinder moves, the sectional area of the first liquid spraying outlet and the sectional area of the second liquid spraying outlet are synchronously changed, and the momentum of sprayed kerosene and the momentum of sprayed liquid oxygen can be synchronously changed, so that the momentum ratio can be always kept in the optimal state in the thrust changing period, and the injection performance is improved.

Owner:BEIHANG UNIV

Blast protection mixed flow blower for ship

InactiveCN102900685AImprove air intake efficiencyReduce airflow lossPump componentsPump installationsImpellerMotor shaft

The invention relates to a blast protection mixed flow blower for a ship. The blower comprises an air inlet, an axial flow motor, a centrifugal impeller, an inner barrel, an outer barrel, a back-positioned guide vane and an air outlet, wherein the centrifugal impeller is mounted to a motor shaft of the axial flow motor; the axial flow motor is mounted into the inner barrel; the inner barrel and the outer barrel are coupled via the back-positioned guide vane; the air inlet and the centrifugal impeller are cooperatively mounted to one end of the outer barrel; and the air outlet is mounted to the other end of the outer barrel. Through combining the air supply structures of traditional axial flow blower and centrifugal blower, the blast protection mixed flow blower for the ship meets the air quantity and air pressure requirements of the centrifugal blower, and possesses the advantage of installation flexibility of the axial flow blower, and is suitable to be used in ship equipment with high requirement.

Owner:JIANGSU JOSUN AIR CONDITIONER

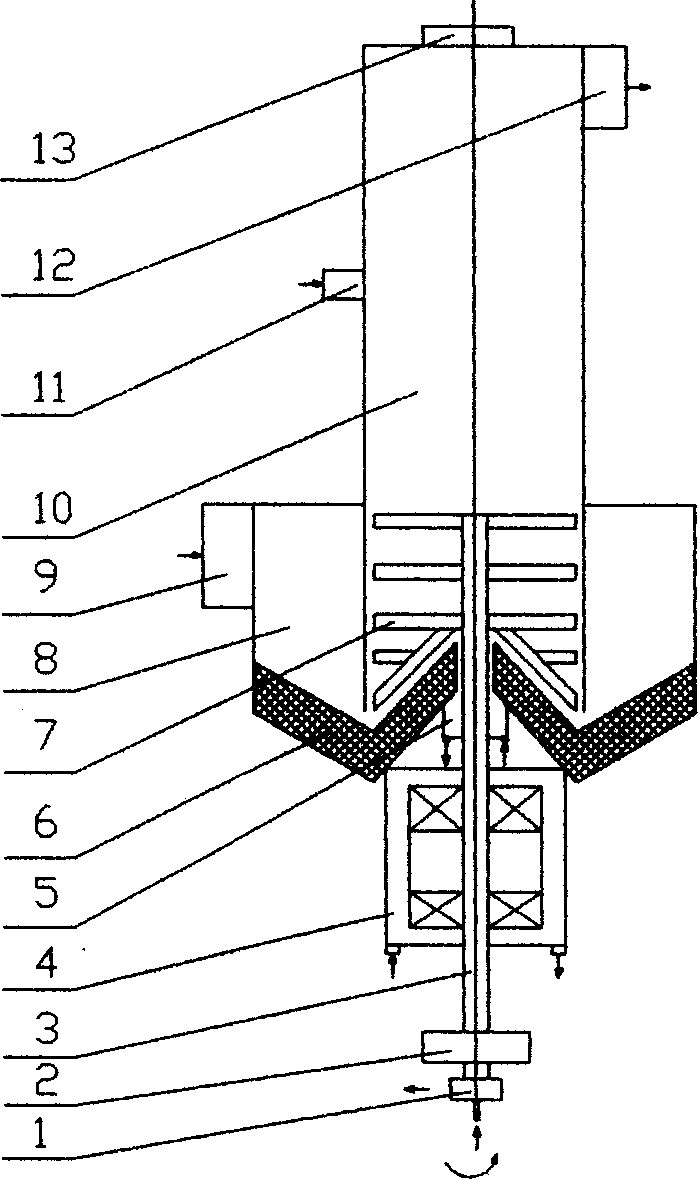

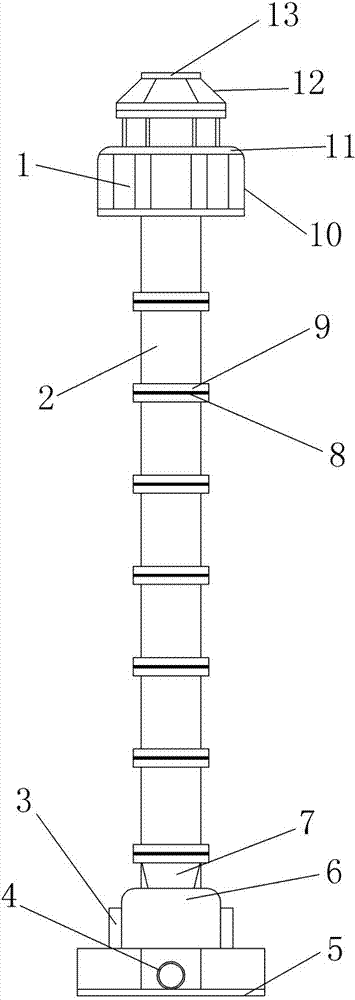

Swirl spouting device for drying sludge

InactiveCN1654377AReduces the possibility of deflagrationImprove airtightnessSludge treatment by de-watering/drying/thickeningDrive shaftSludge

The sludge drying cyclonic spouting apparatus includes main tower body, air chamber, driving shaft and drying and stirring paddle. The air chamber is set in the lower part of the main tower body, drying and stirring paddle is set onto the driving shaft, the air chamber has tangent air inlet port and bottom with W-shaped axial section, and the main tower body over the W-shaped bottom of the air chamber with its lower part extending into the air chamber, and has material feeding port and air outlet port in the upper part as well as tangent air exhaust port and air inlet port rotating in the same direction. The present invention has the high tightness, high drying efficiency, low power consumption, sterilization effect, no jamming and simple apparatus.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD +1

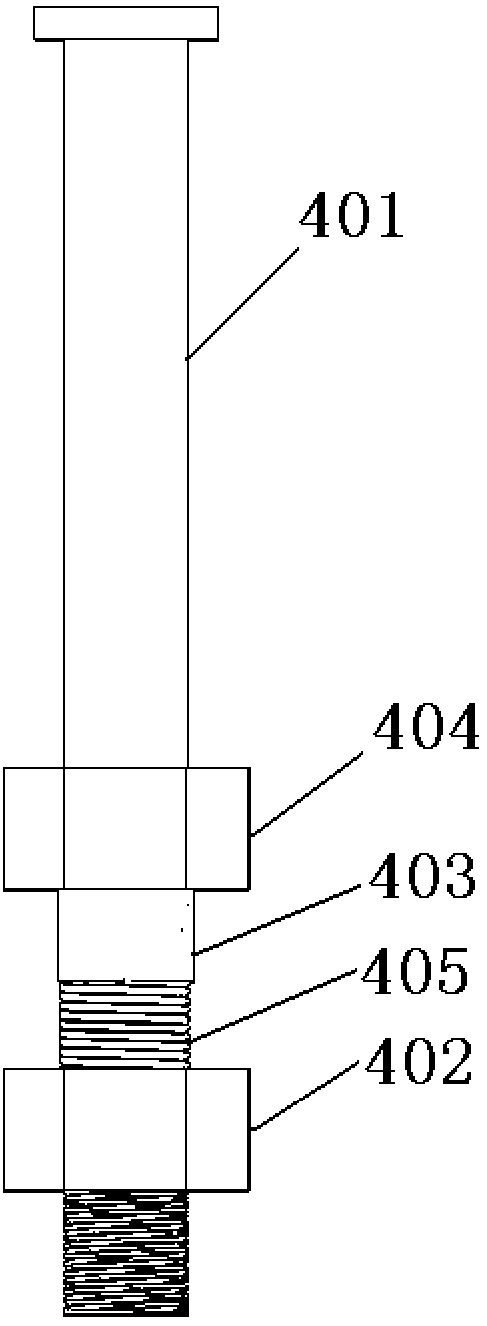

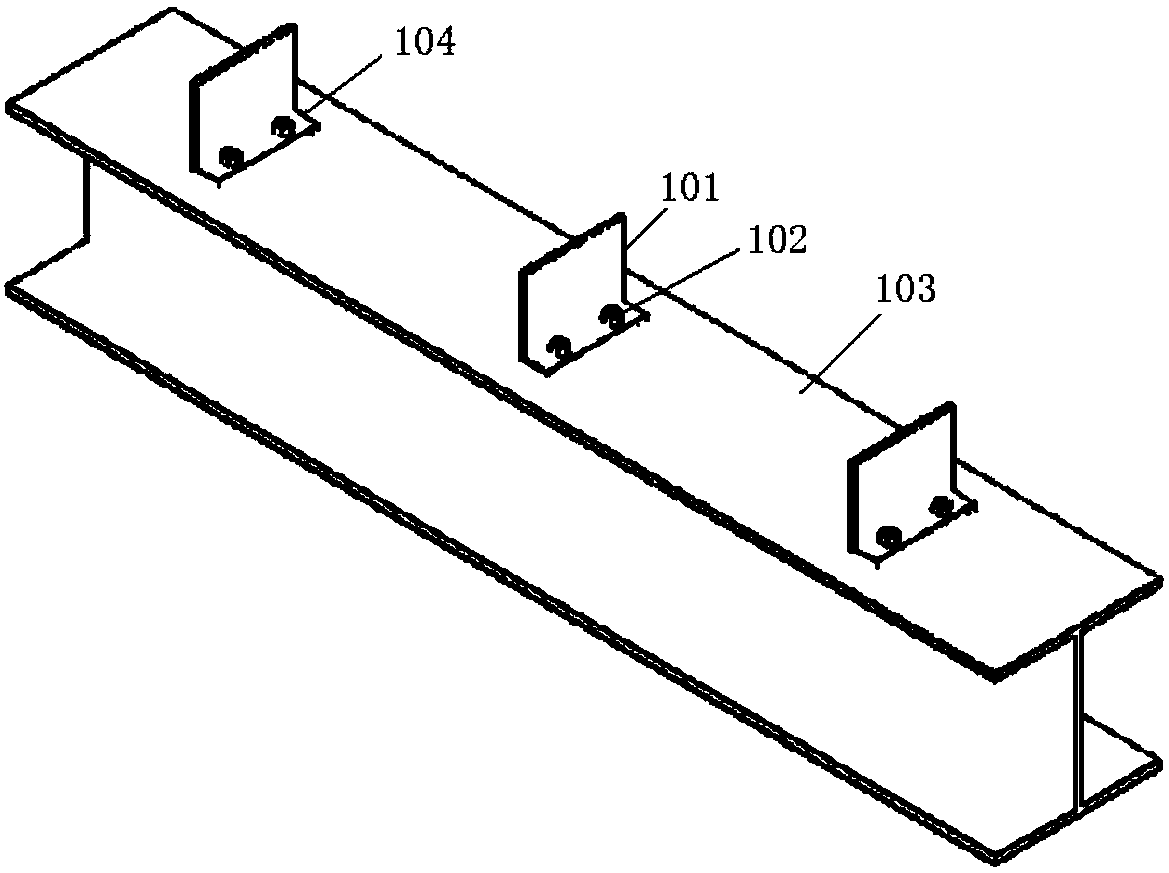

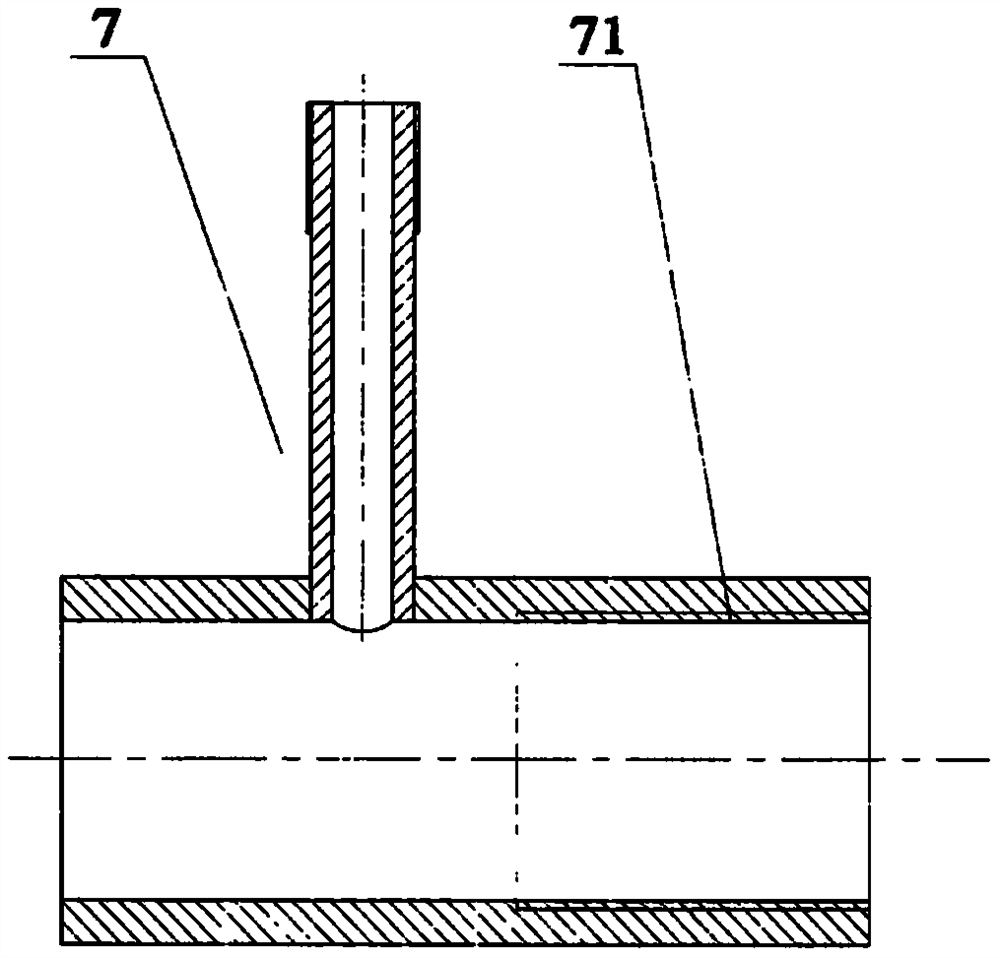

Friction-type stud shearing-force connection part and construction method thereof

InactiveCN107642031AHigh degree of prefabricationReduce labor costsBridge structural detailsBridge erection/assemblyTransfer modeSemiconductor

The invention discloses a friction-type stud shearing-force connection part and a construction method thereof. The friction-type stud shearing-force connection part includes a stud shearing-force connection part main body, a mounting nut, a sleeve, a fixing nut and a semiconductor spring; the stud shearing-force connection part main body comprises a thread section, a thread-free extrusion sectionand a pulling-resistant pier in sequence from bottom to top; during factory prefabrication, the stud shearing-force connection part main body is sleeved with the fixing nut, the sleeve and the semiconductor spring from the thread section in sequence, the upper end face of the fixing nut is located at the top of the thread section and is fixed, the upper end of the sleeve is fixed to the lower endface of the fixing nut, the upper end of the semiconductor spring and the lower end of the sleeve are connected into one, and the shearing-force connection parts are mounted on a maim beam at intervals according to needed shearing resistant requirements. By the adoption of the friction-type stud shearing-force connection part and the construction method thereof, force transferring modes of traditional shearing force connection parts are improved, interface friction is reasonably utilized, the pretension force of the friction-type stud shearing-force connection part can be monitored and controlled, and the design philosophy of combining resistance and releasement can be achieved. The factory prefabrication degree is high, bolt splicing is conducted on the spot, and the labor cost is saved.

Owner:HOHAI UNIV

Water inlet valve and washing machine

ActiveCN108866962AChange the cross-sectional areaReduce water consumptionOther washing machinesTextiles and paperLaundry washing machineInlet valve

The invention discloses a water inlet valve which comprises a valve. A water inlet and a water outlet are formed in the valve, a throttle channel is arranged in the valve, the water inlet and the water outlet can be communicated with each other via the throttle channel, and elastic elements for correspondingly adjusting the opening of the throttle channel along with pressure change of water flow at the water inlet are arranged at the throttle channel. The invention further discloses a washing machine with the water inlet valve. The water inlet valve and the washing machine have the advantagesthat the quantity of inlet water in water accommodating buckets of the washing machine can be controlled and regulated; the magnitude of the opening of the throttle channel can be adjusted by the aidof pressure difference of the water flow at the water inlet and water flow at the water outlet, accordingly, the water inlet valve and the washing machine have constant quantity of outlet water in a unit under total water pressures, water consumption of the washing machine can be reduced, and the washing efficiency can be enhanced.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

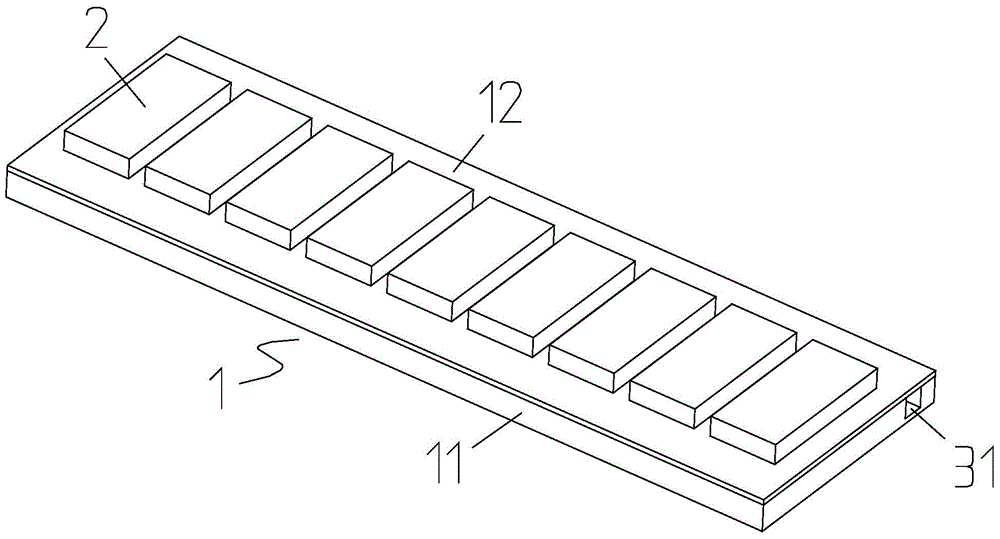

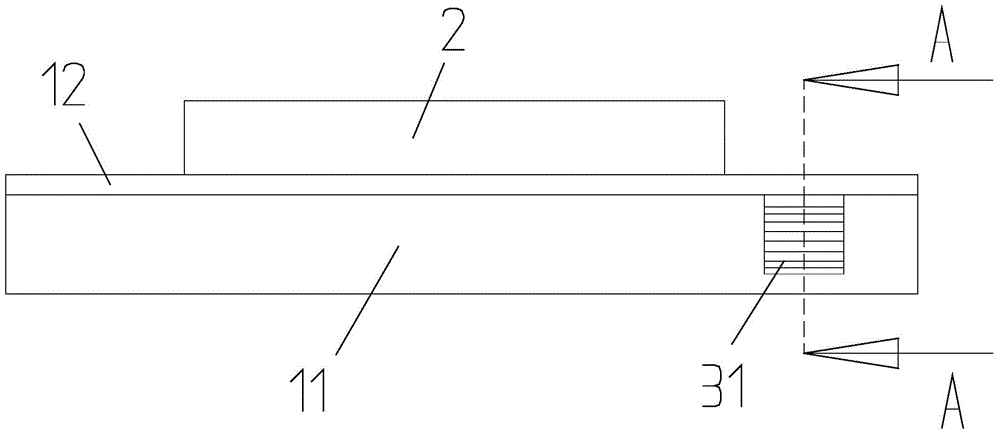

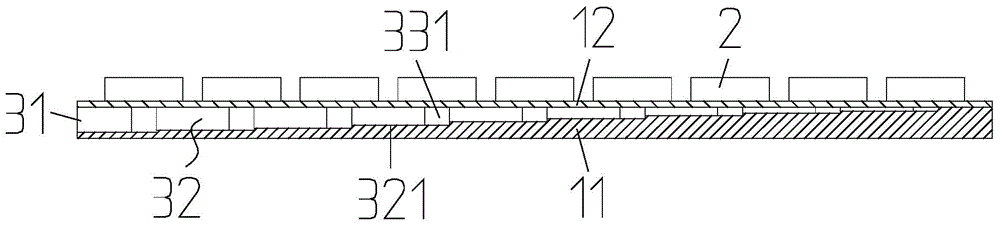

Power device parallel cooling structure and motor controller applying same

ActiveCN105992503AStable flow rateImprove performanceElectric motor controlCooling/ventilation/heating modificationsInlet channelNew energy

The invention discloses a power device parallel cooling structure and a motor controller applying the same. The power device parallel cooling structure comprises a heat dissipation base and a plurality of power devices, wherein the plurality of power devices are installed on the heat dissipation base at intervals, and a heat dissipation water channel is arranged in the heat dissipation base. The power device parallel cooling structure is characterized in that the heat dissipation water channel comprises a water inlet, a water inlet channel, a plurality of branch water channels, a water outlet channel and a water outlet, wherein the water inlet is communicated with the water inlet channel, the water outlet is communicated with the water outlet channel, the plurality of branch water channels are arranged side by side between the water inlet channel and the water outlet channel, the water inlet channel is connected with the water outlet channel in parallel by means of the plurality of branch water channels, and the cross sectional area of the water inlet channel is decreased gradually from the water inlet, thereby enabling temperature difference of different high-power devices to be minimum, giving full play to the performance of the high-power devices and a cooling system, and meeting requirements of integration and miniaturization of new-energy products.

Owner:上海汽车电驱动有限公司 +1

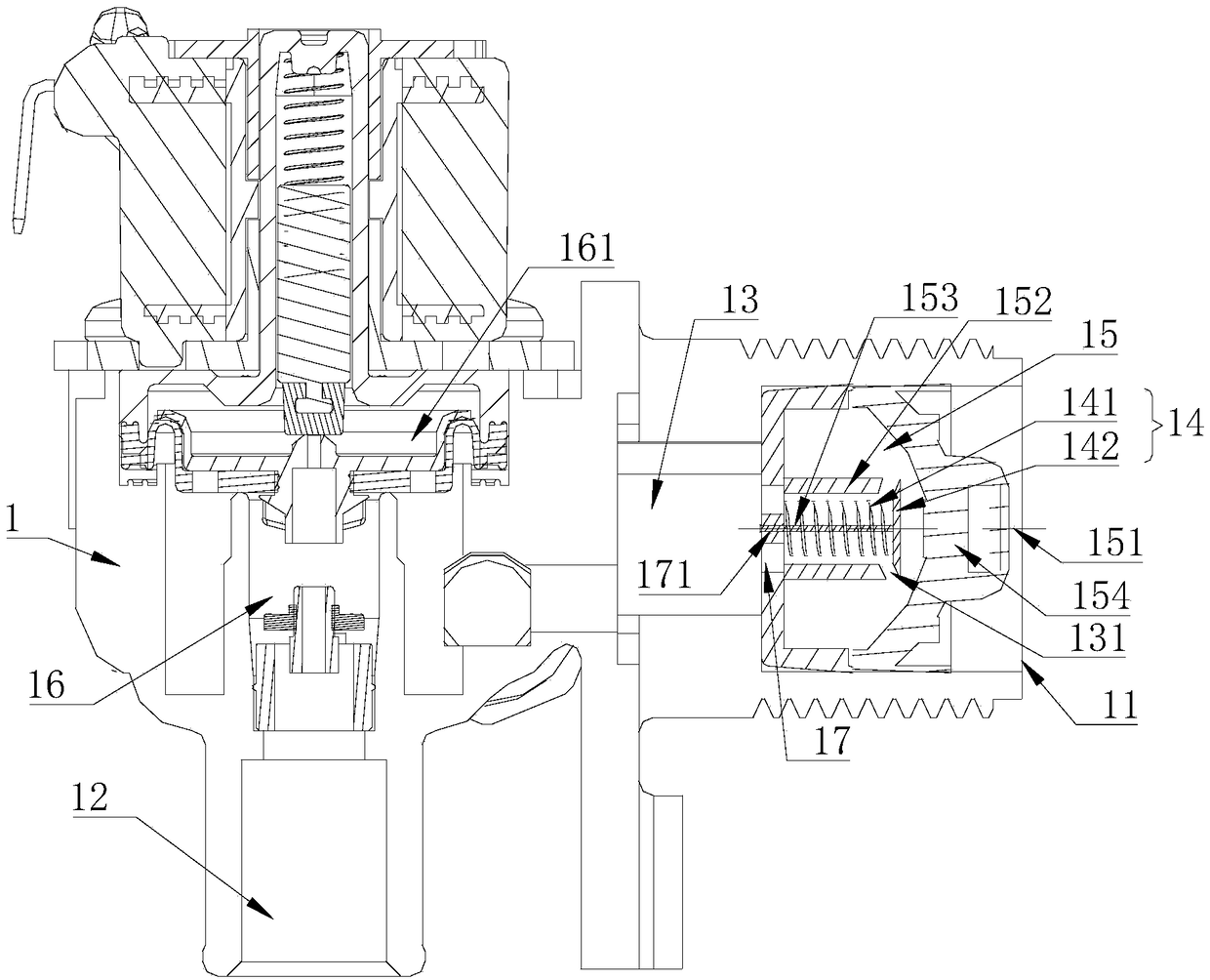

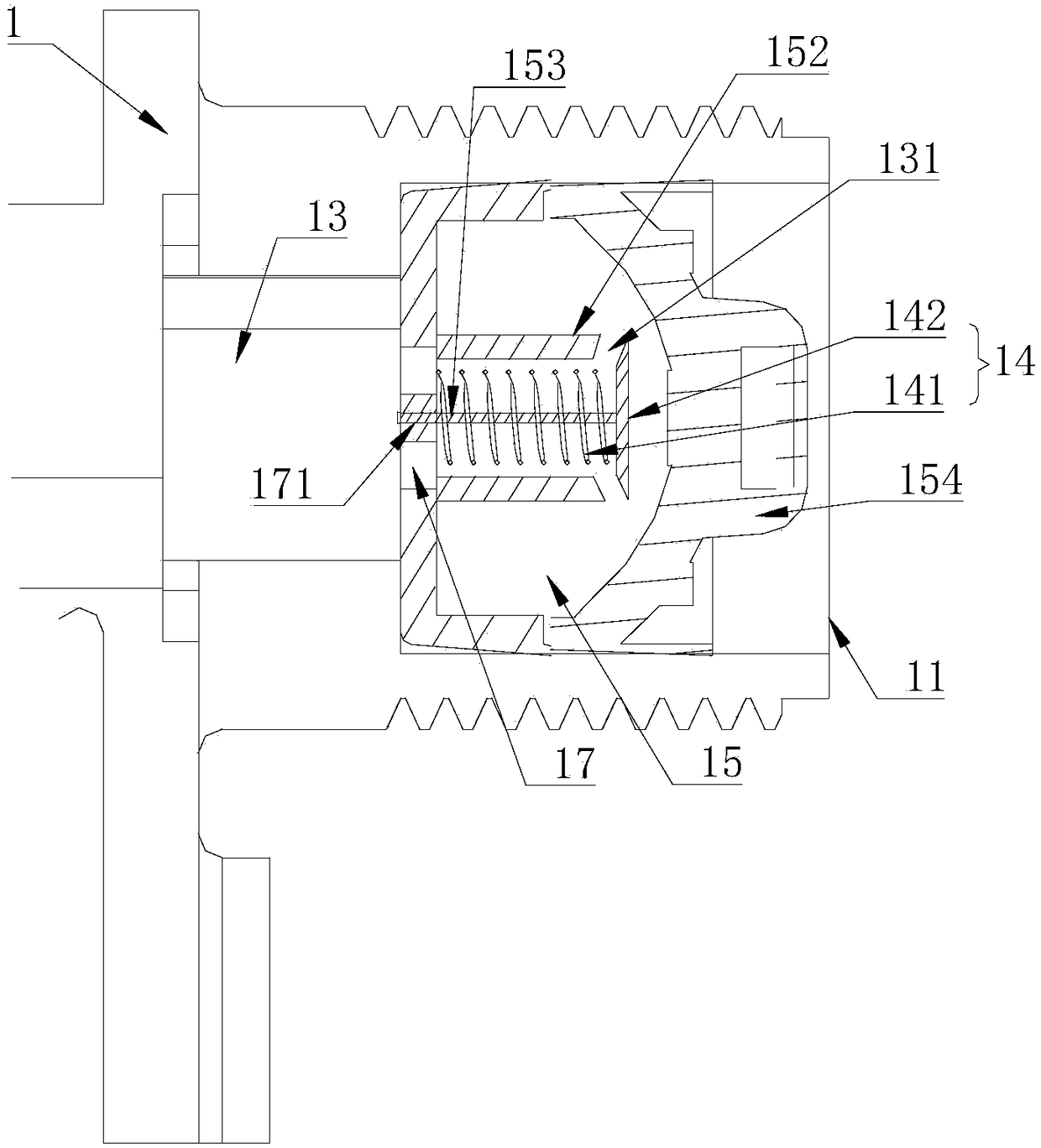

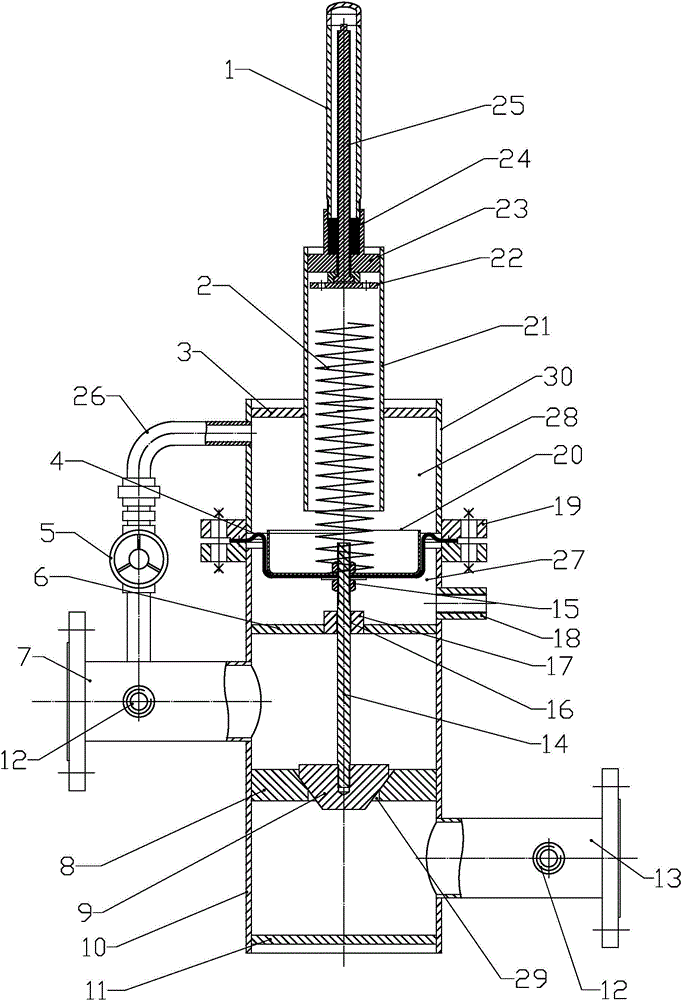

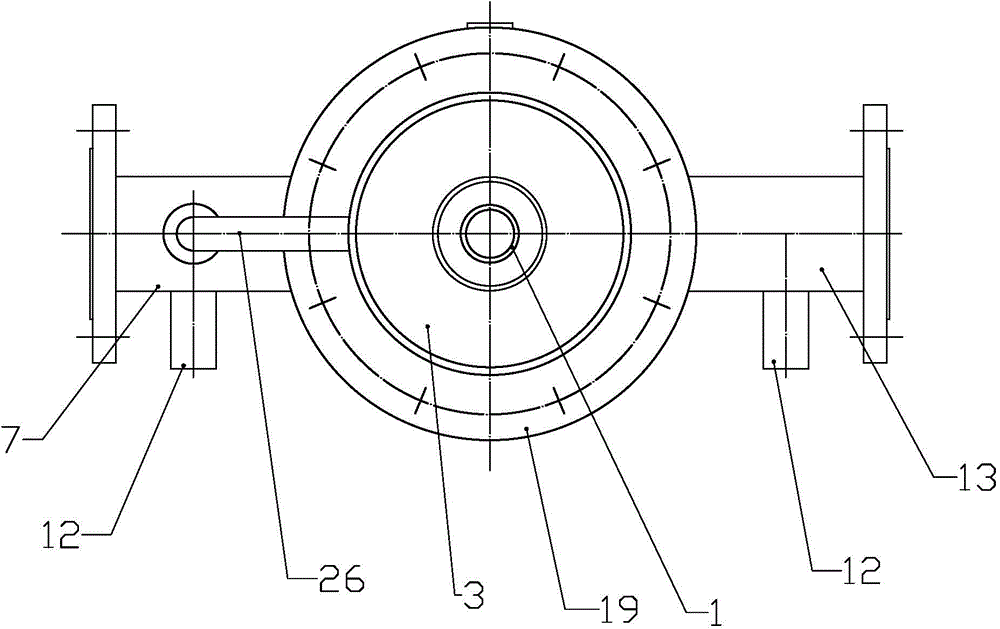

Pressure regulator

InactiveCN104132166AChange the cross-sectional areaChange the flow cross-sectional areaEqualizing valvesSafety valvesWater dischargeHigh pressure water

The invention discloses a pressure regulator, and belongs to pressure reduction devices. The pressure regulator structurally comprises an upper shell body, a lower shell body, a rubber diaphragm, a support, a partition plate, a guide groove, a push rod, a conical body, an inner core, a lower plugging plate, an upper plugging plate and a pressure-regulating device. The rubber diaphragm is arranged between the upper shell body and the lower shell body, the support is arranged on the upper portion of the rubber diaphragm, and the pressure-regulating device is arranged on the upper portion of the support. The partition plate and the inner core are arranged on the lower portion of the rubber diaphragm, the conical body is arranged on the inner core, the push rod is arranged on the upper portion of the conical body, and the push rod is fixedly connected with the rubber diaphragm and the support. An inlet pipe is arranged on the lower shell body arranged on the lower portion of the inner core, and a water discharging pipe is arranged on the lower shell body arranged on the upper portion of the inner core. An inner cavity between the lower shell body and the upper shell body and between the partition plate and the upper plugging plate is divided into a high pressure cavity and a low pressure cavity through the rubber diaphragm. A high pressure water inlet is formed in the lower shell body at the position of the high pressure cavity. A low pressure communicating pipe is arranged between the water discharging pipe and the upper shell body. The pressure regulator has the advantages of being capable of automatically adjusting return water pressure, automatically shutting down after a water pump stops and the like.

Owner:SHANDONG GUOSHUN PRESSURE VESSEL

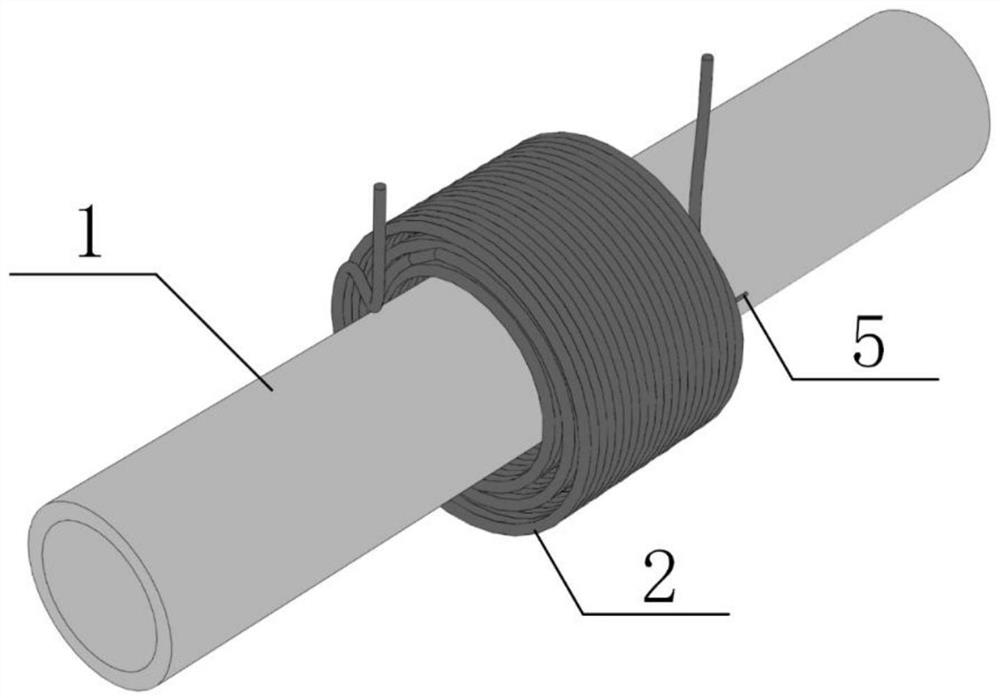

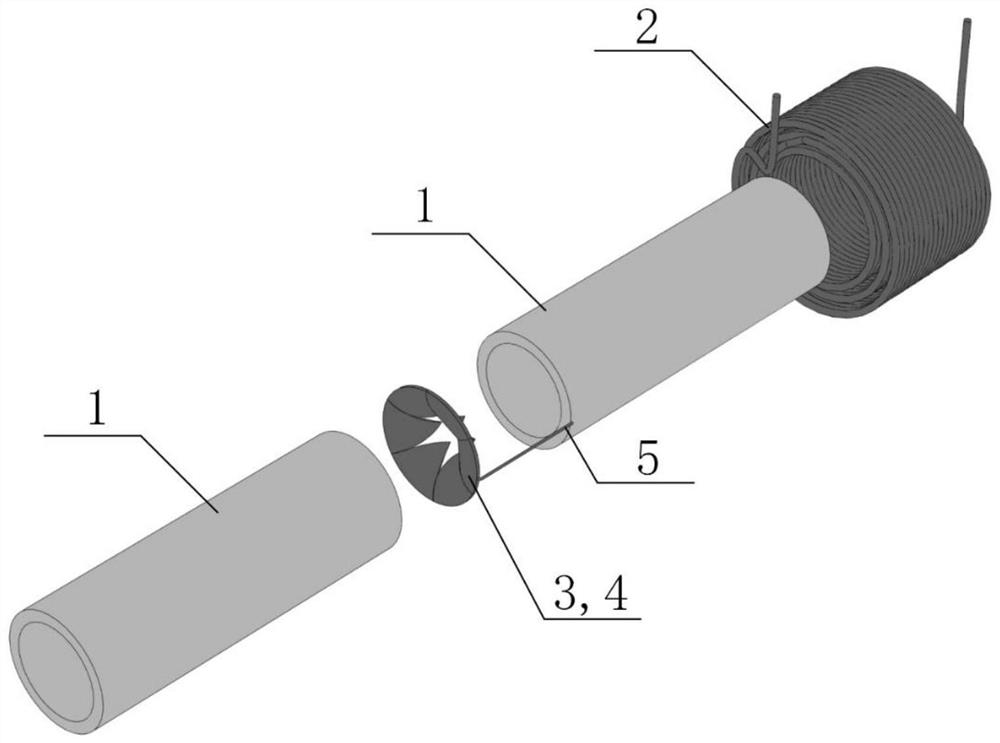

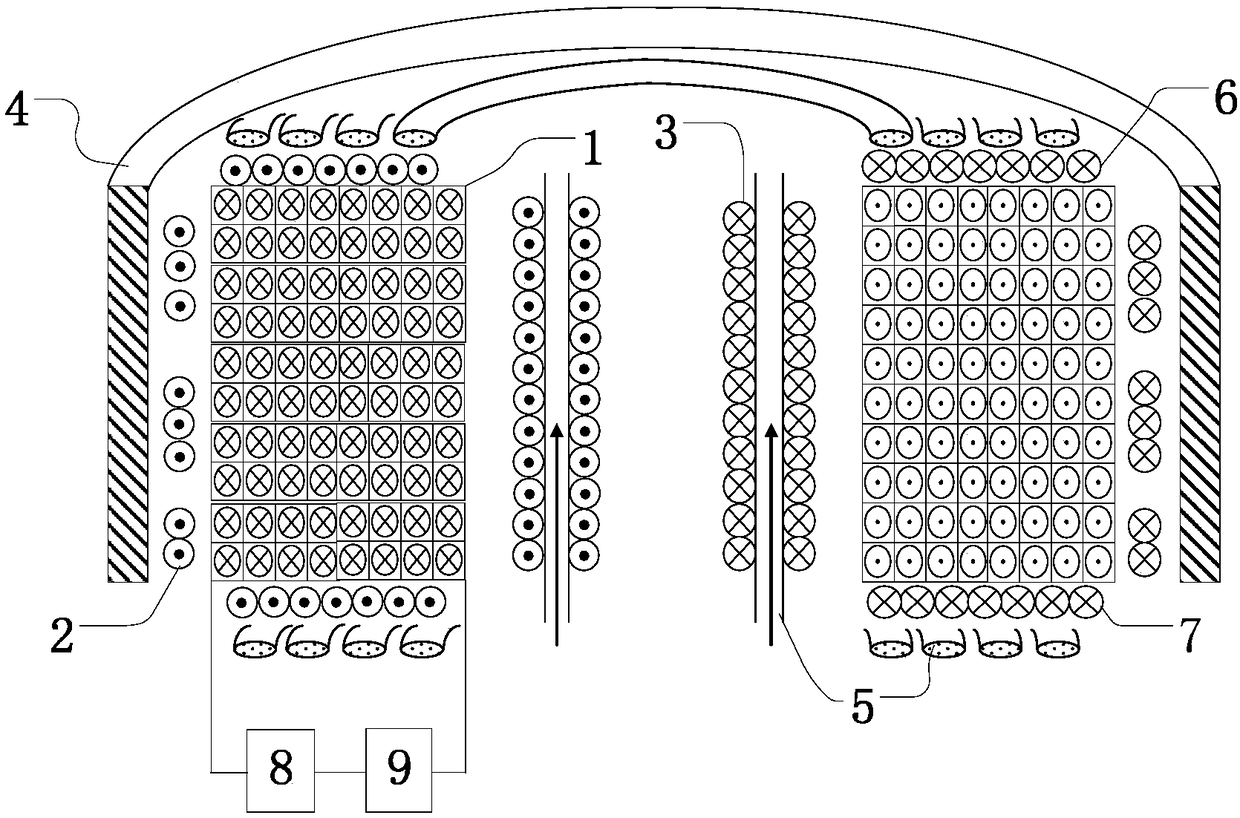

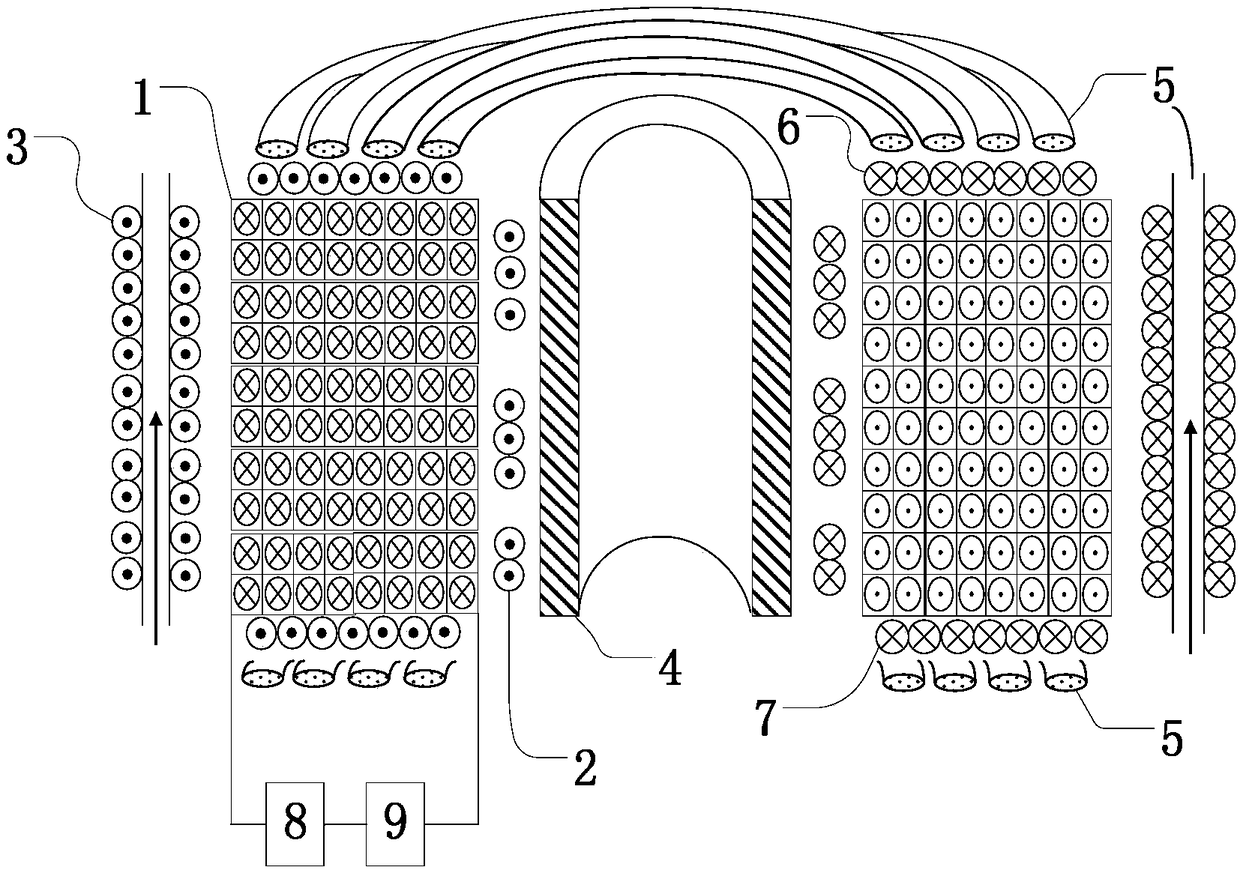

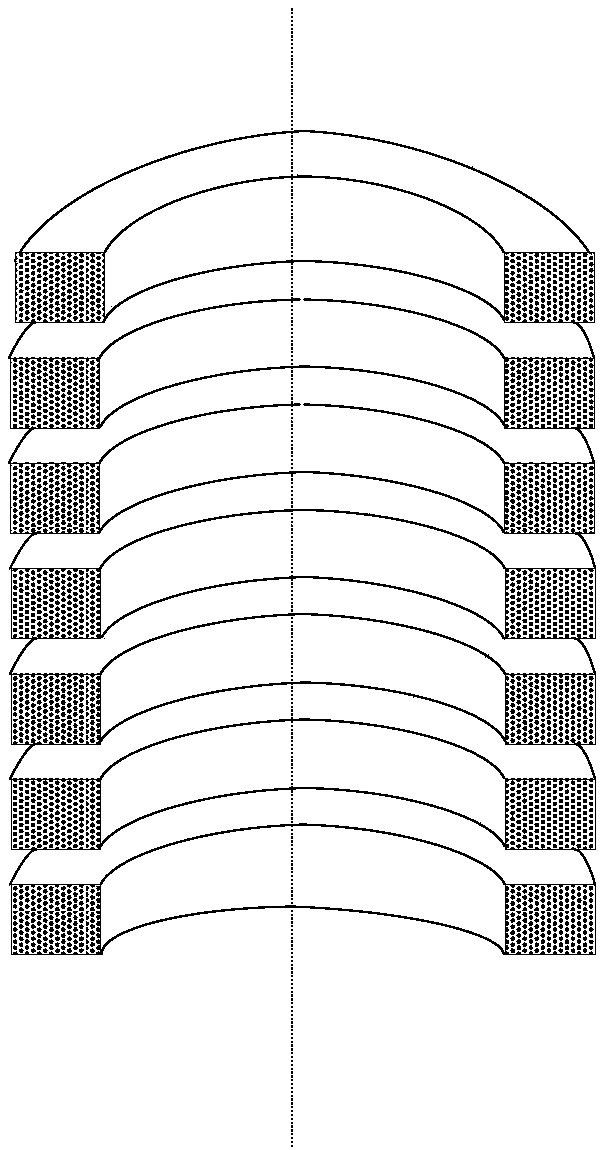

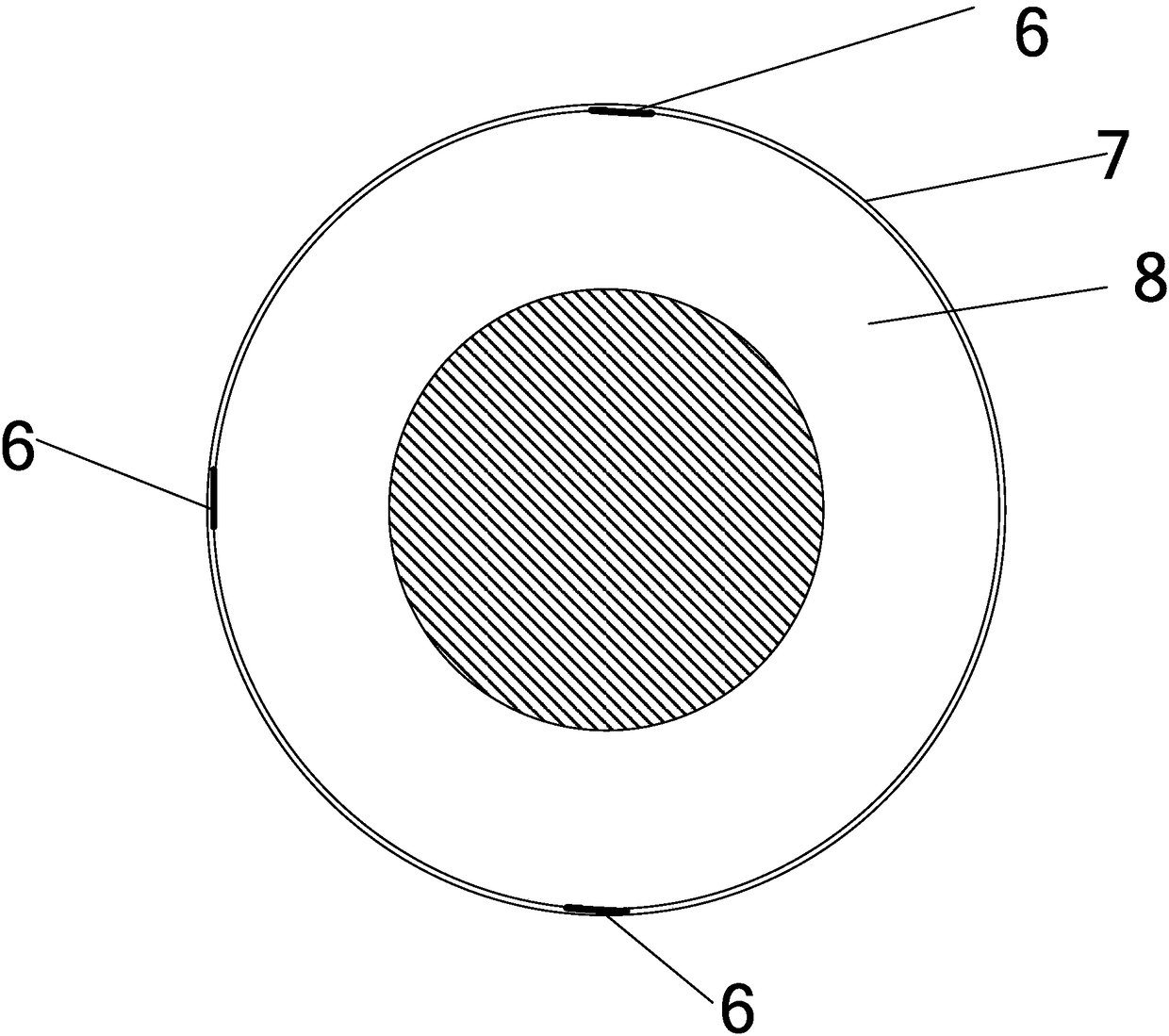

Shape-adaptive magnetic control self-sensing flexible pipeline and preparation method thereof

PendingCN112594415AEasy to adjust the sizeStrong shape adaptabilityDiaphragm valvesOperating means/releasing devices for valvesElastomerStructural engineering

The invention discloses a shape-adaptive magnetic control self-sensing flexible pipeline and a preparation method thereof. The shape-adaptive magnetic control self-sensing flexible pipeline comprisesa hollow cylindrical flow field pipeline, a plurality of turns of coils, a plurality of anisotropic magnetic sensitive elastomers and a piezoelectric film sensor, the plurality of anisotropic magneticsensitive elastomers are arranged on the cross section of the flow field pipeline in a central symmetry manner, the plurality of turns of coils are arranged on the outer surface of the correspondingposition of the flow field pipeline, and the piezoelectric film sensor attached to the anisotropic magnetic sensitive elastomers senses the deformation of the magnetic sensitive elastomers to achieveself-sensing of the flexible pipeline. The pipeline is simple in structure, low in material cost and diverse in function. The sizes of the anisotropic magnetic sensitive elastomers and the piezoelectric film sensor are easy to control, so that the flow field pipeline has excellent shape adaptability. The off-surface deformation of the anisotropic magnetic sensitive elastomers is changed by adjusting a magnetic field generated in the pipeline after the plurality of turns of coils are electrified, so that the cross sectional area of the pipeline is changed. The deformation degree of the anisotropic magnetic sensitive elastomers is obtained through the piezoelectric film sensor, and self-sensing is achieved.

Owner:UNIV OF SCI & TECH OF CHINA

Coupling-cooling-type pipe fitting flexible electromagnetic forming method and device

PendingCN108405700AIncrease electromagnetic forceElectromagnetic forming effect is goodPipe fittingCooling coil

Disclosed are a coupling-cooling-type pipe fitting flexible electromagnetic forming method and device. The coupling-cooling-type pipe fitting flexible electromagnetic forming device comprises multiturn and multiplayer main coils used for generating a pulsed high magnetic field, flexible electromagnetic force coils used for assisting the multiturn and multiplayer main coils to strengthen the coupling effect, coupling cooling coils taking heat of the multiturn and multiplayer main coils away for cooling the multiturn and multiplayer main coils, compressed air condensing pipes used for accelerating dissipating of heat of the coupling cooling coils, a pulse power source used for supplying power to the multiturn and multiplayer main coils and a control switch. Electromagnetic force is strengthened through the flexible electromagnetic force coils, and meanwhile the electromagnetic force can be controlled flexibly through the structure of the flexible electromagnetic force coils; and an induced eddy current is generated through mutual coupling of the coupling cooling coils and the main coils, a part of the heat in the main coils is taken away, thus temperature rise of the main coils is reduced, and the purpose of prolonging the life of the main coils is achieved.

Owner:CHINA THREE GORGES UNIV

Adjustable diffuser

ActiveCN104533838AChange the cross-sectional areaImprove surge phenomenonPump componentsPumpsImpellerLow load

The invention relates to a diffuser structure, and discloses an adjustable diffuser. The adjustable diffuser comprises a static diffuser, a dynamic diffuser and a dynamic diffuser fixing device. A guide rod sequentially penetrates a mounting hole arranged on the dynamic diffuser fixing device and a through hole arranged on the dynamic diffuser. A locking device is matched with the guide rod to fix the dynamic diffuser and the dynamic diffuser fixing device together. The guide rod can move along the depth direction of the mounting hole and the through hole, so that the distance between the dynamic diffuser and the static diffuser is adjusted. Air exhausted by an impeller is sent in the position between the static diffuser and the dynamic diffuser. According to the adjustable diffuser, the guide rod drives the dynamic diffuser to move so that the distance between the dynamic diffuser and the static diffuser can be adjusted, the sectional area between the dynamic diffuser and the static diffuser can be changed, the surge phenomenon caused by the backflow of fluid in a flow channel under the low-load condition can be effectively improved, the operation range of a compressor can be widened, and the working energy efficiency of the compressor can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

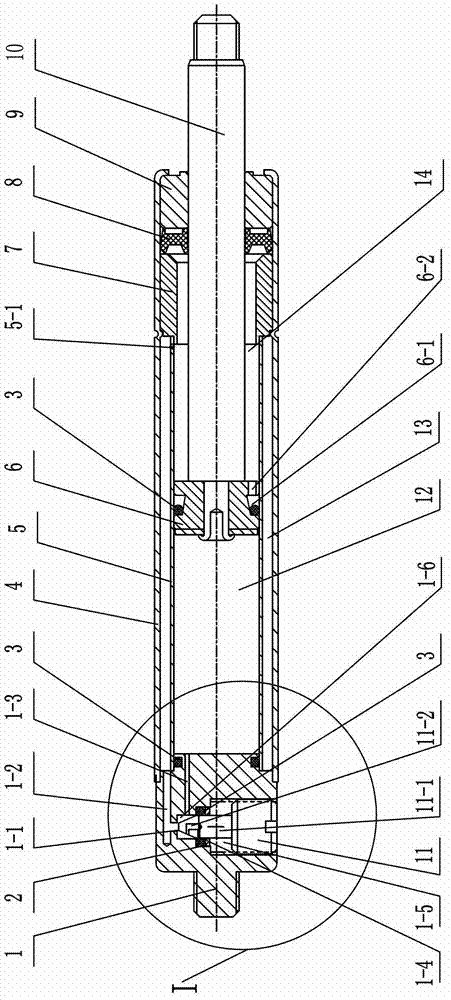

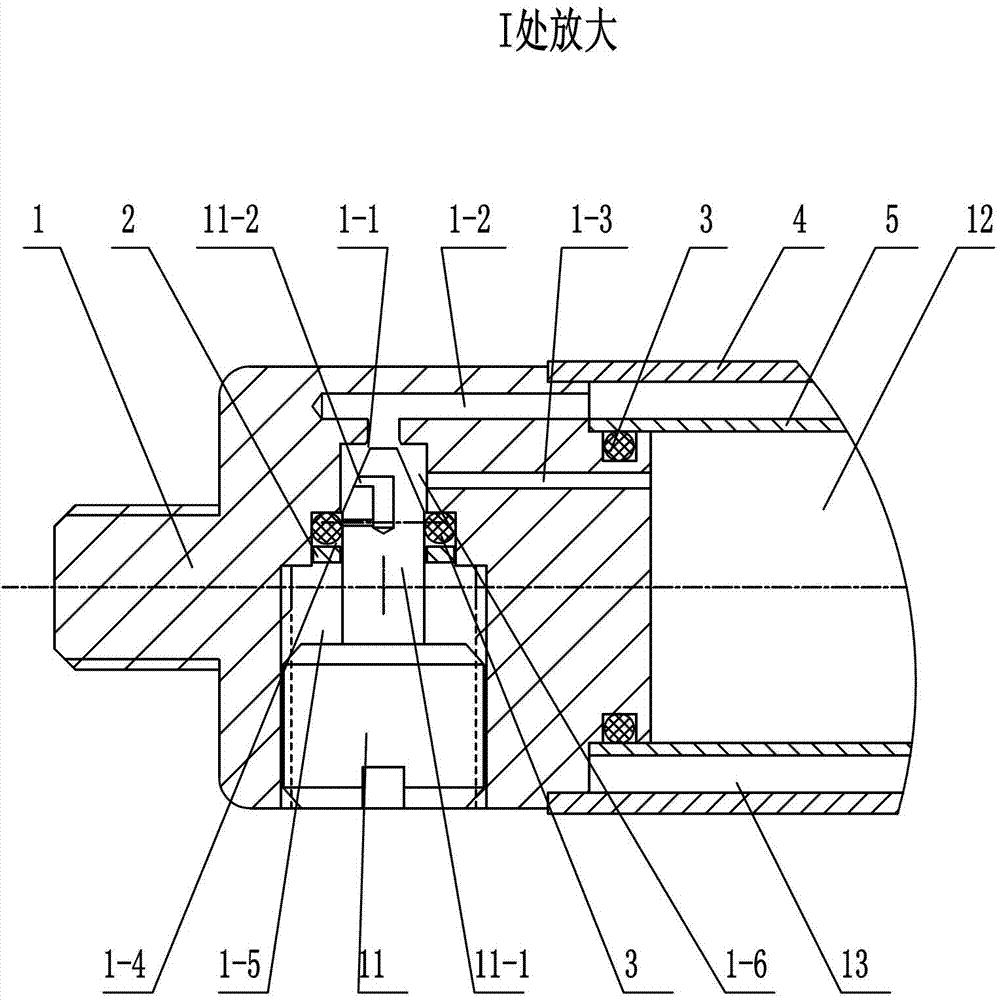

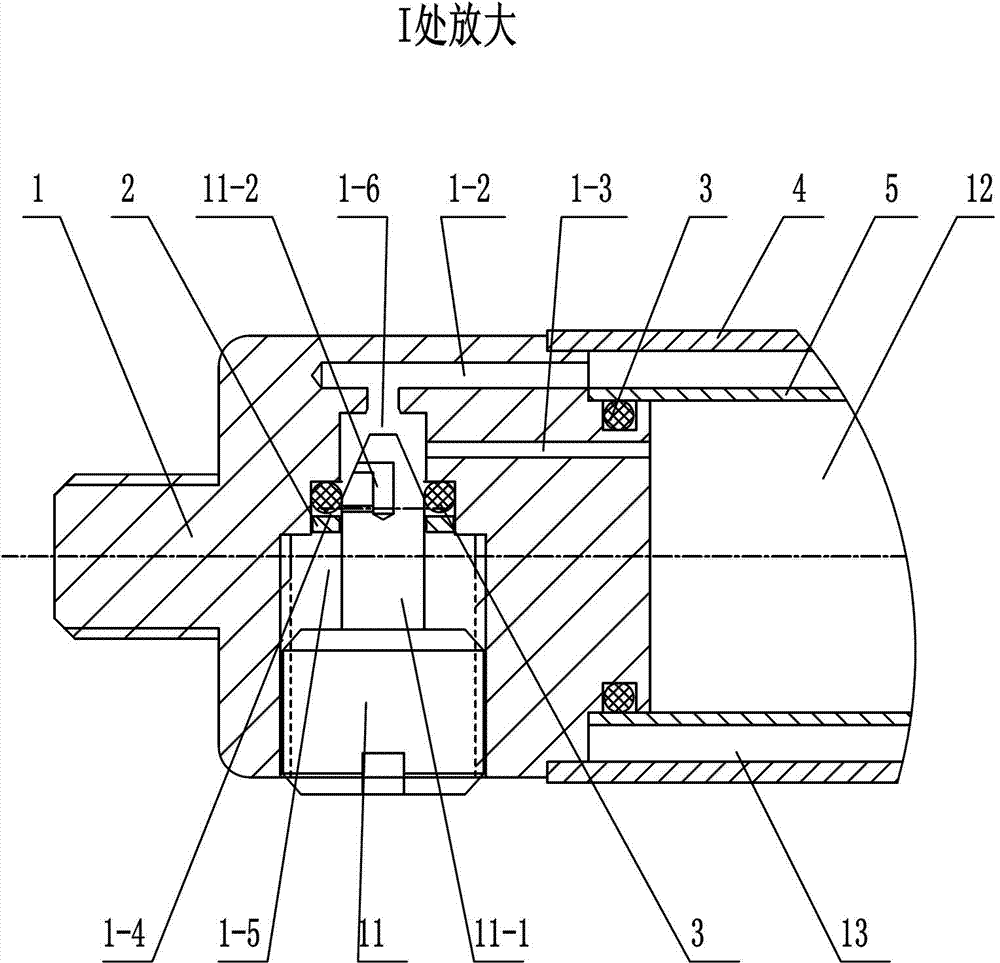

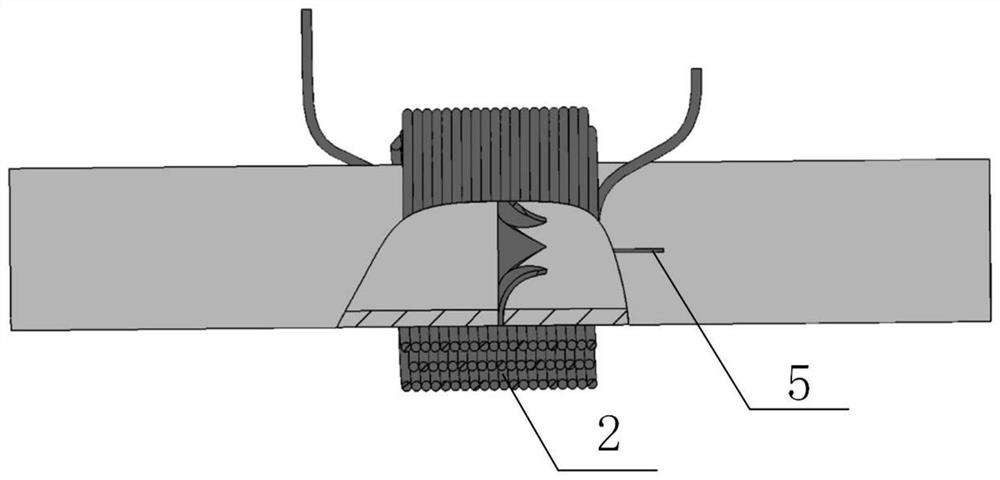

Method for measuring pressure of installation interface of cable central connector based on piezoresistive film

InactiveCN108534925AIncrease credibilityAccurate measurementForce measurement using piezo-resistive materialsForce sensorsSignal amplifierThin film sensor

The invention discloses a method for measuring the pressure of an installation interface of a cable central connector based on a piezoresistive film, and the method comprises the steps: (1), selectinga plurality of sections from a cable central connector structure, and selecting a placement point for a piezoresistive film sensor on each section; (2), determining the position of a lead wire, wherein the direction of the lead wire is a cable direction, and is parallel to the axial direction of a sensor, and marking the sensor placement point and the lead wire; (3), grinding of the section of the sensor placement point; (4), digging a trench along a drawn line; (5), enabling the sensor to be connected with the lead wire, pasting the sensor, and coating the sensor with a silicone grease layerafter pasting; (6), placing the lead wire along the trench, and connecting the lead wire to a signal amplifier; (7), carrying out the filling of a part, which is not filled, of the trench; (8), wiping the insulating surface of a cable, and starting the measurement after wiping. The method can be used for the actual measurement of the pressure of the installation interface of the cable central connector on the basis of an actual cable structure.

Owner:SOUTH CHINA UNIV OF TECH

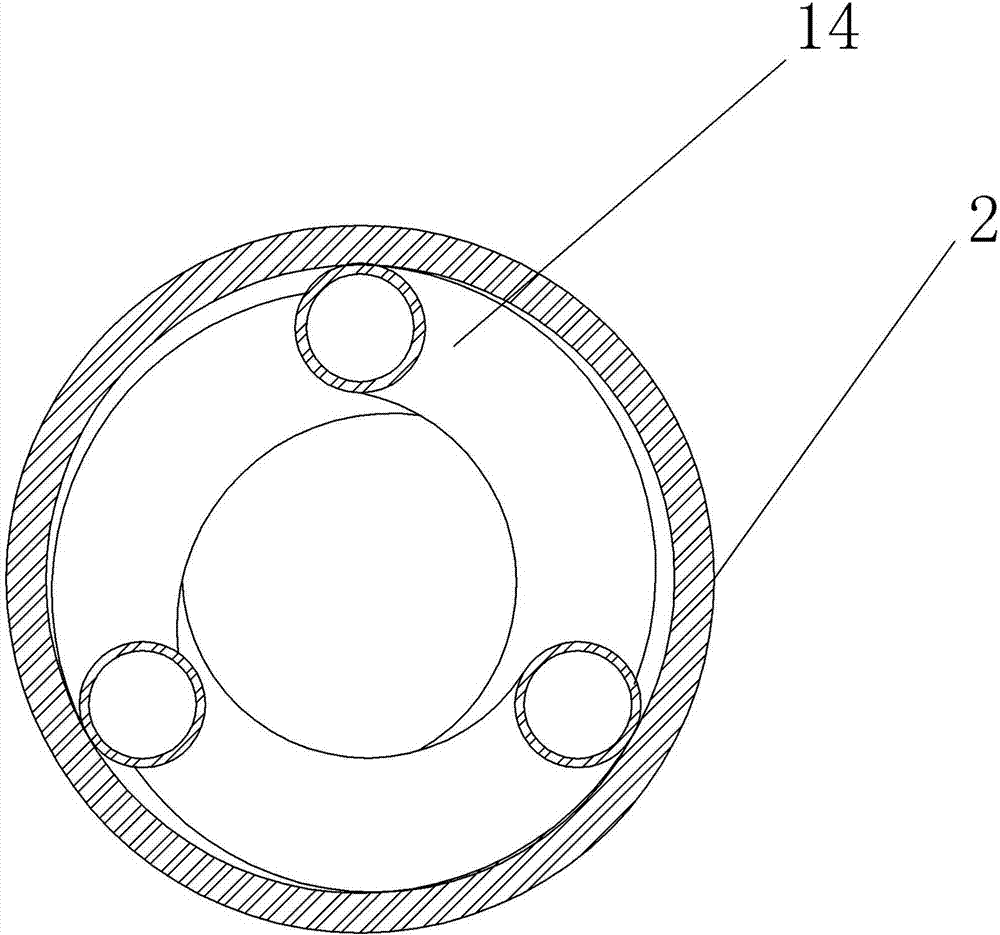

Closed mechanical-seal pump ring and shaft-seal flushing system with same

ActiveCN104696269AStable accelerationIncrease distancePump componentsPumpsEngineeringMechanical engineering

Disclosed are a closed mechanical-seal pump ring and a shaft-seal flushing system with the same. The pump ring is provided with an annular left pump ring side plate and an annular right pump ring side plate which are parallel to each other, inner circumferences of the left pump ring side plate and the right pump ring side plate sleeve the outer circumferential surface of a shaft sleeve of a centrifugal pump, the outer circumferential edges of the left pump ring side plate and the right pump ring side plate are connected with a sealing gland of the centrifugal pump at an interval, a plurality of blades in rotatable and radial arrangement are arranged between the left pump ring side plate and the right pump ring side plate and are perpendicular to the left pump ring side plate and the right pump ring side plate, an end opening formed by closing ends of the radial blades corresponds to a liquid outlet of the shaft sleeve, and an end opening formed by edges of radial ends of the radial blades corresponds to a liquid inlet of a liquid outlet passage formed on the sealing gland. The closed mechanical-seal pump ring has the advantages that liquid accelerating distance is increased, and idle work is reduced; most liquid in a seal cavity can be enabled to flow, and a fluid flowing path can be lengthened to widen the flow area.

Owner:天津长瑞大通流体控制系统有限公司

Shearing-resistant and not-pull-resistant friction-type shearing force connection part and construction method thereof

ActiveCN107642170AHigh degree of prefabricationReduce labor costsBuilding constructionsTransfer modeHigh intensity

The invention discloses a shearing-resistant and not-pull-resistant friction-type shearing force connection part and a construction method thereof. The shearing force connection part includes a shearing force connection part main body and a high-strength bolt assembly; the shearing force connection part main body is angle steel, a plurality of bolt holes matched with the high-strength bolt assembly are formed in one flange edge, and the shearing force connection part main body is connected with a main beam through the high-strength bolt assembly. According to the shearing-resistant and not-pull-resistant shearing force connection part, force transferring modes of traditional shearing force connection parts are improved, interface friction between the shearing force connection part main body and a plate is reasonably utilized, bolts are reasonably designed, shearing force of the bolts can be monitored and controlled in real time, the factory prefabrication degree is high, bolt splicingis conducted on the spot, and therefore the labor cost is saved. The shearing-resistant and not-pull-resistant friction-type shearing force connection part is not provided with a fixed end and has theeffects of being resistant to shearing and not resistant to pulling.

Owner:HOHAI UNIV

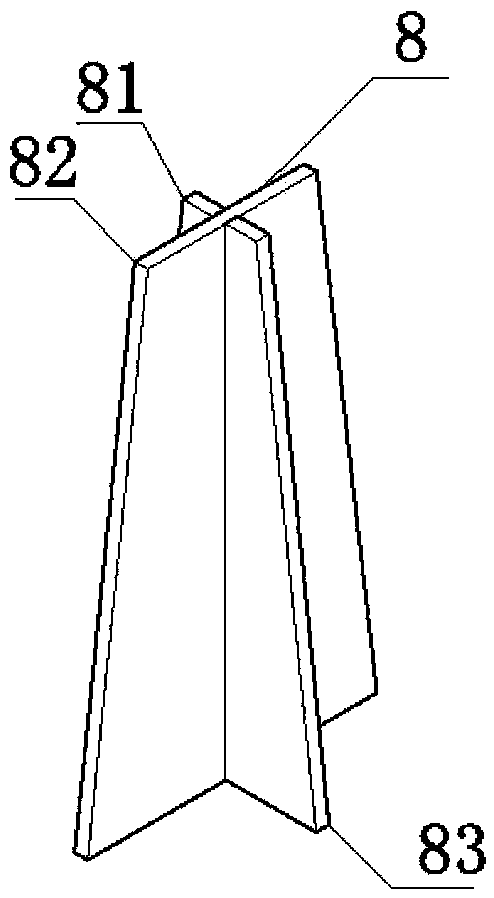

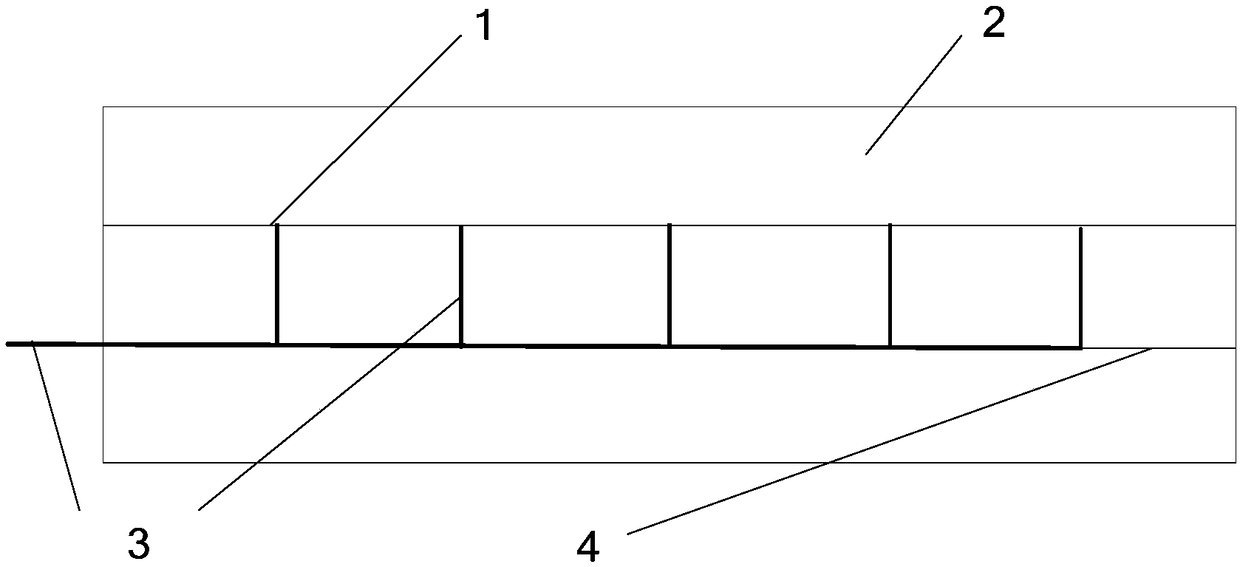

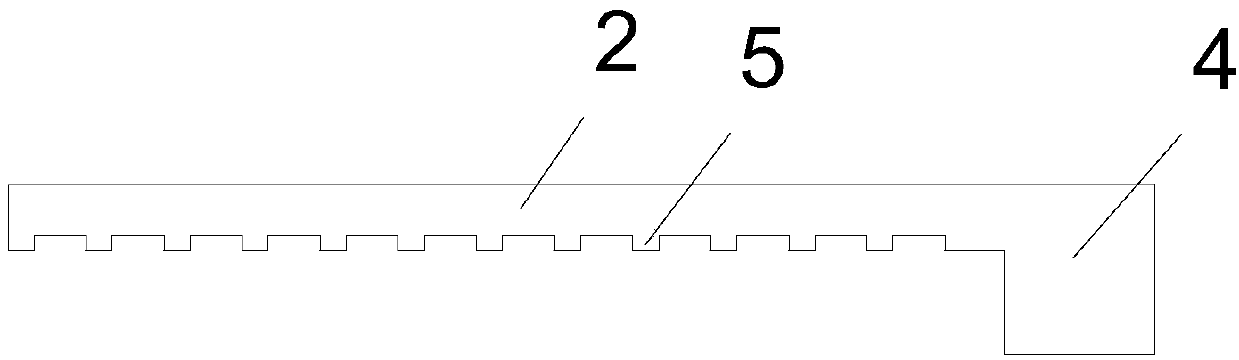

Bottom-reinforced filter bag ash removal method with variable inner channel and filter device

ActiveCN111544973AImprove airflow impact strength and impact speedReduce the cross-sectional areaGas treatmentDispersed particle filtrationStructural engineeringMechanical engineering

The invention discloses a bottom-reinforced filter bag ash removal method with a variable inner channel and a filter device, which are used for enhancing filter bag ash removal. The method comprises the following steps: introducing deashing airflow into the filter bag of which the cross section area of the inner channel is reduced along the direction from the filter bag opening to the bottom of the filter bag to flow into the bottom of the filter bag, and continuously reducing the cross section area of the inner channel of the filter bag to ensure that the filter bag continuously compresses the deashing airflow and improve the impact pressure and impact speed of the deashing airflow. The device comprises a cage framework and a framework pressing sleeve, wherein a cloth bag is arranged outside the cage framework in a sleeving manner and is attached to the cage framework; the cage framework comprises cohesion connecting pieces and at least three V-shaped steel rings, wherein one end of each V-shaped steel ring is fixed on the cohesion connecting piece to form a conical inward concave cavity; and a cloth bag tensioning sliding block is arranged in the conical inwards-concave cavity, wherein one end of the cloth bag is arranged on the framework pressing sleeve in a sleeving mode, the other end of the cloth bag is folded in the cloth bag tensioning sliding block; the cloth bag is embedded into the conical inwards-concave cavity along with the cloth bag tensioning sliding block and fastened by one end of the V-shaped steel rings.

Owner:SOUTHEAST UNIV

An electronically controlled variable damping rotary hydraulic damper

InactiveCN106438815BChange the cross-sectional areaRealize controllableSpringsSprings/dampers design characteristicsHydraulic pumpEngineering

The invention relates to an electronic control variable-damping rotation hydraulic damper which comprises a motor, an outer shell, a blade, a valve element, a valve body, a shaft, a spring, a cover plate and the like. Due to the fact that a guide groove is formed in the middle shaft of the variable-damping rotation hydraulic damper, a guide rail is arranged on the shell, the blade automatically moves transversely in the radial direction along with the guide rail during rotation, the volume of driven liquid is changed, the liquid flows in a circulated manner through the valve element, and the function that the rotation angle of the damper is unlimited is achieved; and the valve element is driven by a step motor to rotate, so that the size of the drift diameter of a runner composed of the valve element and the valve body is variable, and the function of being adjustable in rotation damping is achieved.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Adjustable ejector

PendingCN111822167AChange the cross-sectional areaChange section ratioLiquid spraying apparatusAxial displacementPipe fitting

The invention discloses an adjustable ejector, and belongs to the field of ejectors. The adjustable ejector is characterized in that a mixed diffuser is connected with internal threads at the front end of a low-pressure three-way pipe fitting through external threads at the rear end of the mixed diffuser, the front end of the mixed diffuser is connected with a metal braided hose through a movablejoint, and axial displacement of the mixed diffuser relative to the low-pressure three-way pipe fitting can be achieved by rotating the mixed diffuser, so that the axial distance (i.e. nozzle distance) of the outlet cross section of a nozzle to the inlet cross section of the mixed diffuser is changed; and meanwhile, a nozzle adjusting cone is arranged in the nozzle, and the circulation cross-sectional area of a nozzle throat can be changed by changing the axial position of the nozzle adjusting cone, so that the cross section ratio is adjusted. According to the adjustable ejector, on the premise of effectively avoiding mutual influence of double adjustment variables, independent adjustment of the nozzle distance and the cross section ratio of the ejector is achieved.

Owner:GUILIN UNIV OF AEROSPACE TECH

Attraction type spout hydraulic generator

ActiveCN104329203ALow costReduce energy consumptionHydro energy generationReaction enginesImpellerWater turbine

The invention relates to the technical field of a hydroelectric generator, in particular to an attraction type spout hydraulic generator. The attraction type spout hydraulic generator comprises a water turbine arranged at the bottom of the boat body, wherein the water turbine also comprises a water turbine water inlet cabin, the water turbine also comprises a middle shaft, an impeller and a bearing, the bearing is connected with the middle shaft, one end of the water turbine is also connected with a flow guide pipe in vertical arrangement, three coil pipes are wound on the inner wall of the flow guide pipe in a downwards circulating way, a water outlet pipe is connected with the other end of the flow guide pipe, a water pump is arranged at a connecting part of the water outlet pipe and the flow guide pipe, and is connected with a submersible motor, the water pump and the submersible motor are respectively arranged on one machine seat, and a cone tube-shaped water inlet hopper with a downward small opening is arranged above the water pump. The attraction type spout hydraulic generator adopting the technical scheme has the advantages that greater water flow energy is obtained, and the cost is low.

Owner:冉井福

Air-conditioning and ventilation device for energy storage container

PendingCN109516011AIncrease wind resistanceMaintain consistencyLarge containersTank wagonsEnergy storageBattery pack

The invention relates to an air conditioning and ventilation device for an energy storage container. The air conditioning and ventilation device comprises a ventilation air duct which is fixed to theinner side wall of a container shell and is located above a battery pack, wherein the ventilation air duct comprises an air inlet and an air hose connected to the air inlet; the cross-sectional area of the air hose is gradually decreased from the position of the air inlet to the position far away from the air inlet; air outlets are formed in the bottom of the air hose; and downward guide plates are arranged on the air outlet. The cross-sectional area of ventilation is changed, and the cross-sectional areas of parts away from the air inlet are sequentially reduced, so that the air resistance isincreased, the flow direction of air is forcibly changed, and the quantity of air passing through each air outlet is kept uniform to the greatest extent.

Owner:常州车之翼动力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com