Friction-type stud shearing-force connection part and construction method thereof

A connector and stud technology, applied in the field of shear connectors and their construction, can solve the problems of shear failure of connectors, increased construction difficulty, and increased engineering costs, so as to achieve controlled shear bearing capacity and improved transmission. force mode for precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] Figure 1a and Figure 1b Schematic diagram of a stud shear connection for a prior art beam or slab setup. It can be seen from the figure that the shear connector needs to be welded on the beam or plate, which is labor-intensive and wastes materials.

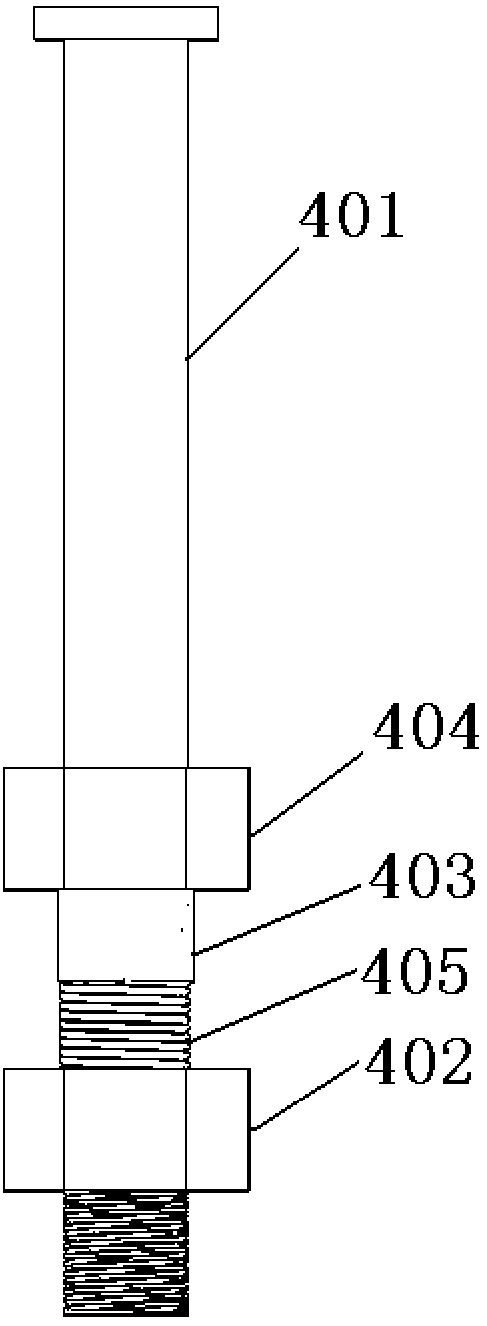

[0055] Such as Figure 2-Figure 4 As shown, it is a friction-type stud shear connector, which includes a stud shear connector body 401, a mounting nut 402, a sleeve 403, a fixing nut 404, and a semiconductor spring 405, wherein the stud shear connector body consists of From bottom to top, it includes threaded section 4001 , unthreaded extruded section 4002 and uplift-resistant piers 4003 . The upper end surface of the fixing nut is at the top of the threaded section and is welded together with the main body of the stud shear connector. The upper end of the sleeve is welded together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com