Patents

Literature

592 results about "Girder bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridge are plate and box. [citation needed]The term "girder" is often used interchangeably with "beam" in reference to bridge design.

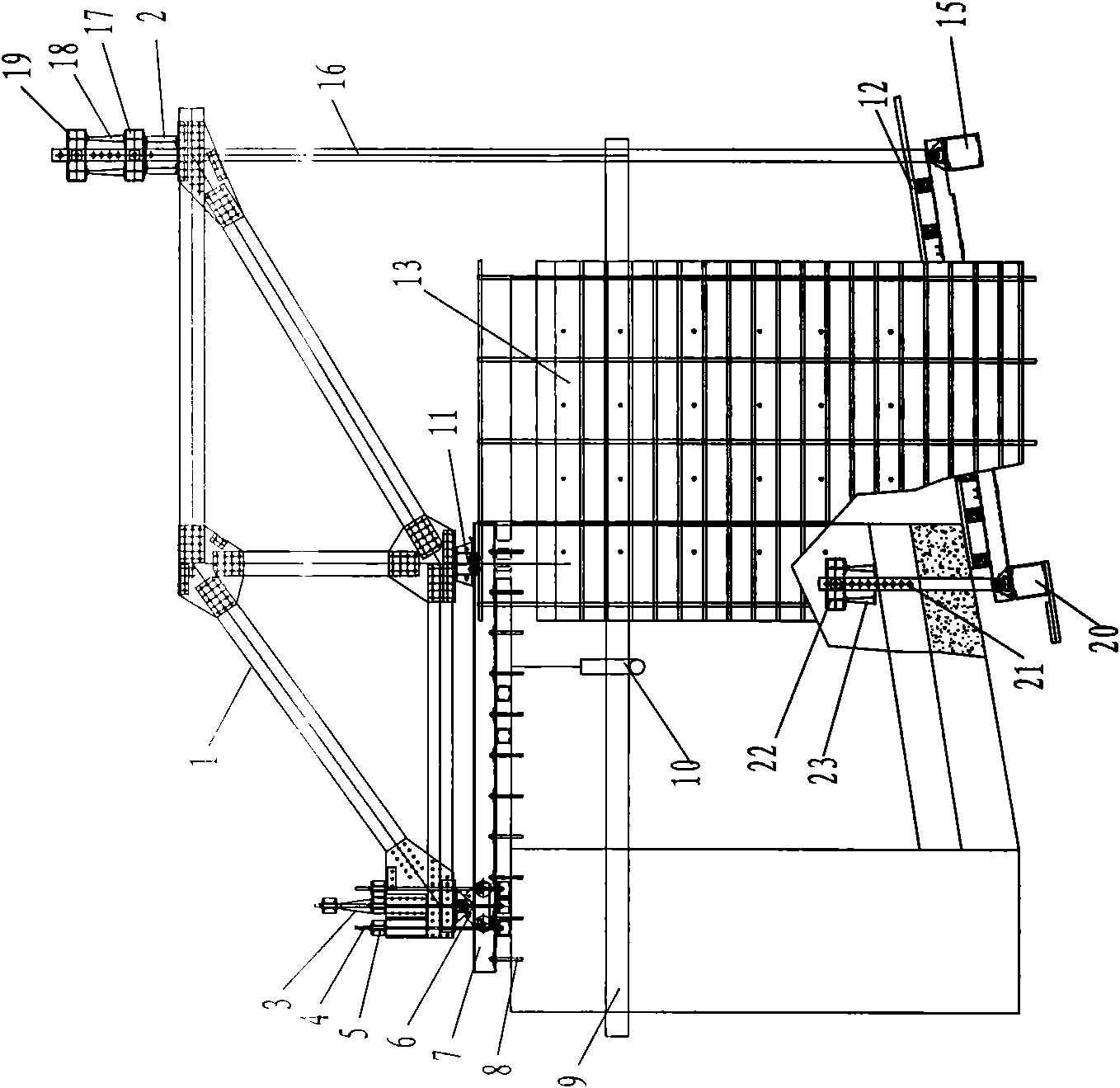

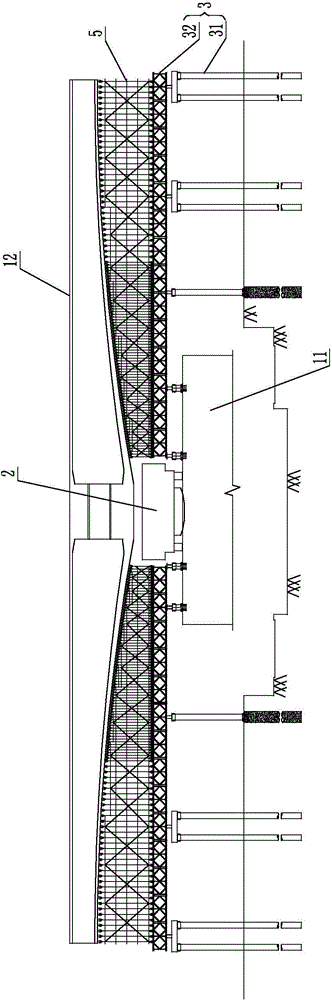

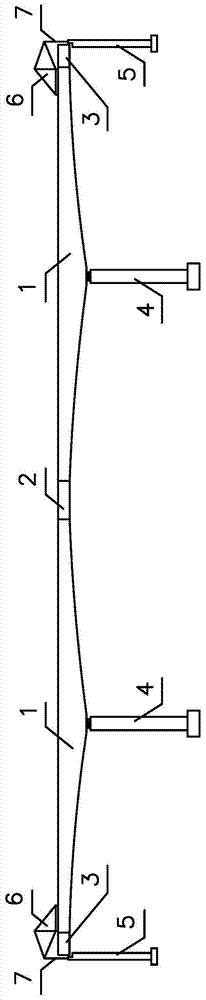

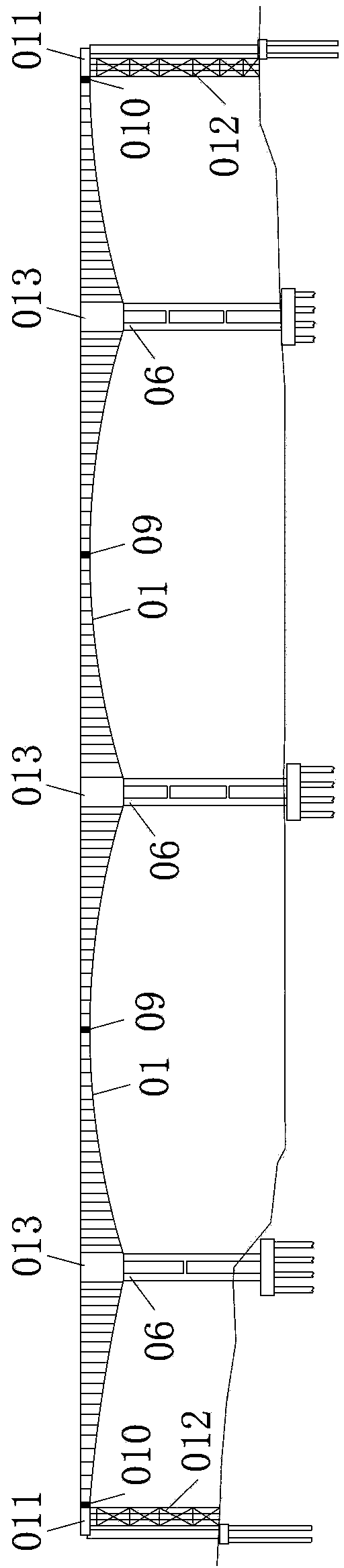

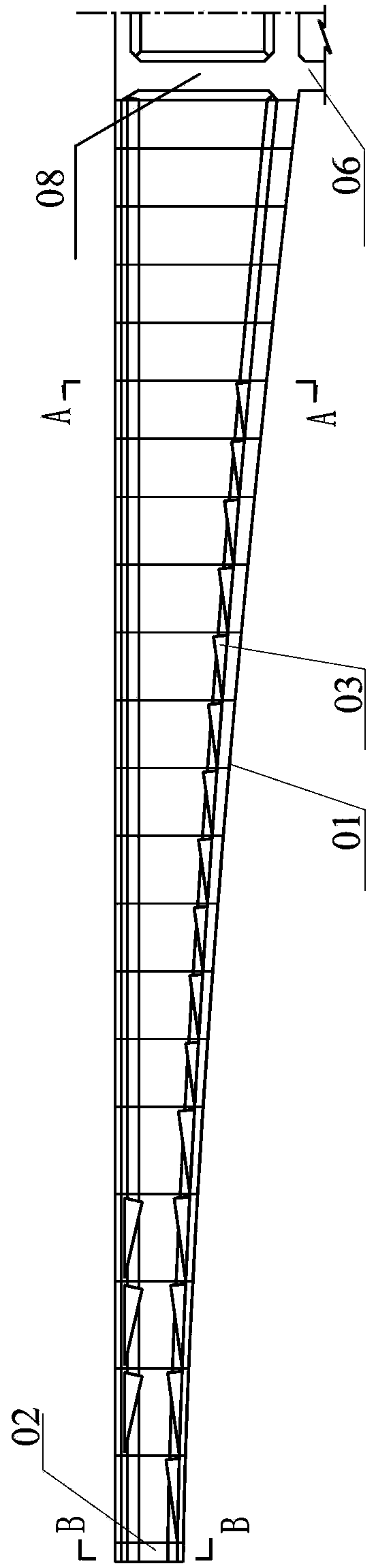

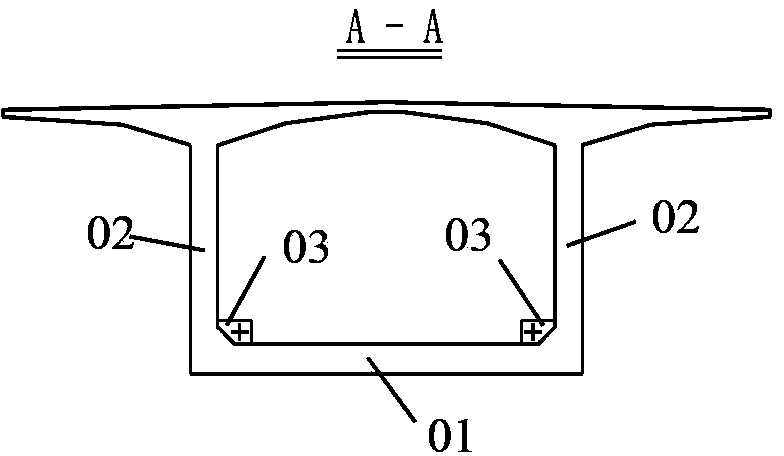

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

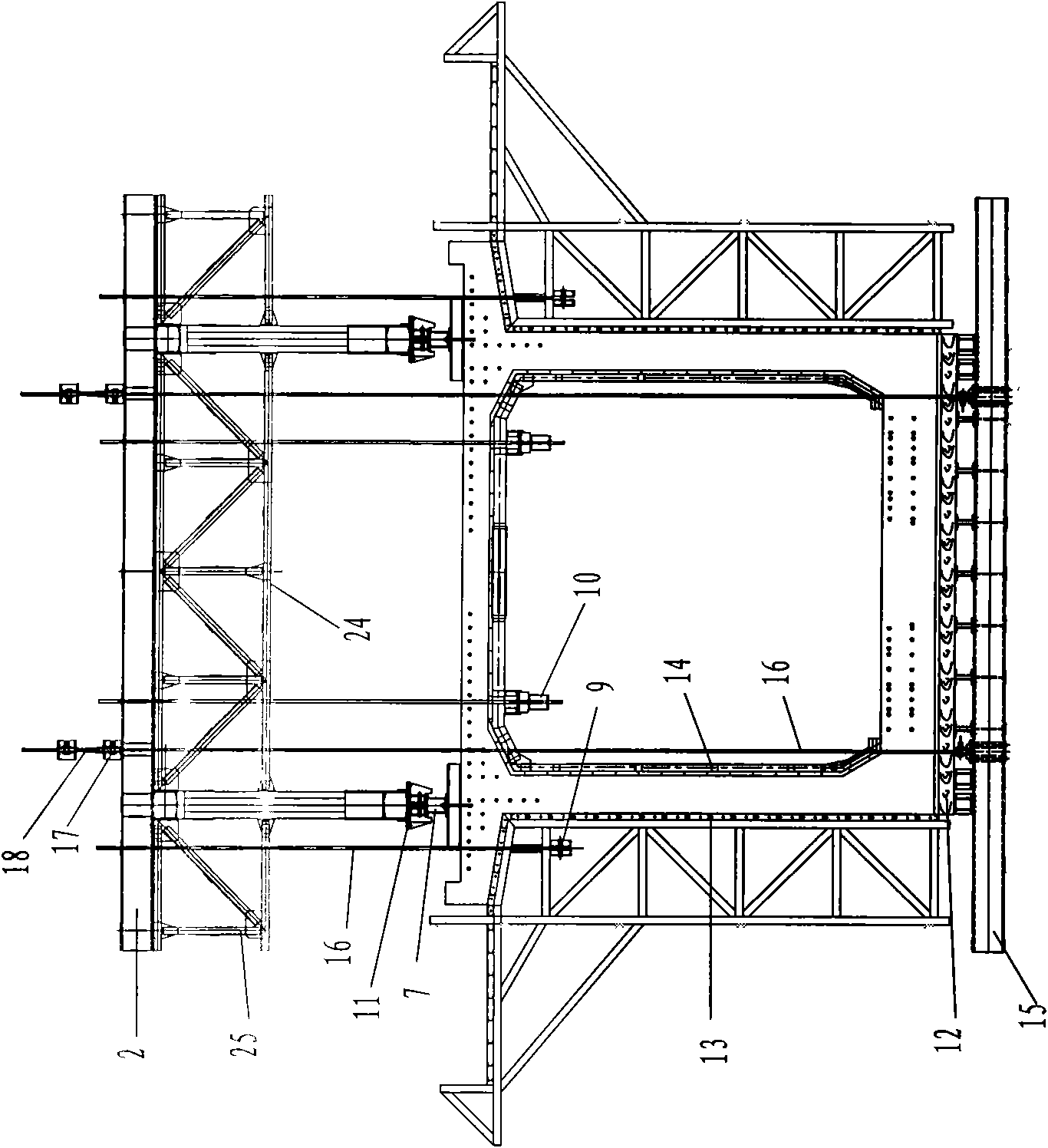

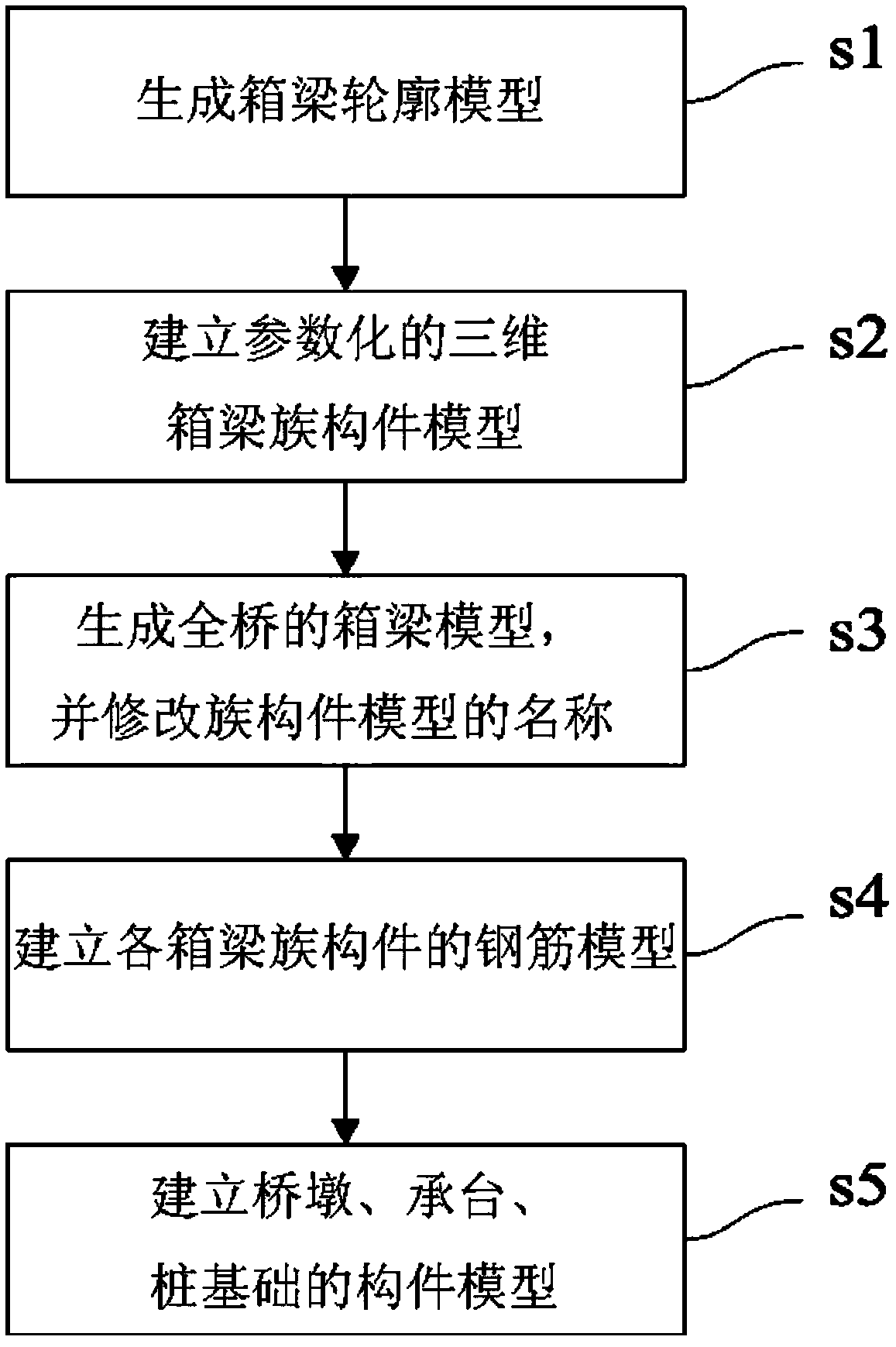

Revit platform based continuous-girder-bridge parametric modeling method

ActiveCN107609321AGood foundation of data platformImage data processingSpecial data processing applicationsData platformRebar

The invention relates to a Revit platform based continuous-girder-bridge parametric modeling method. The method includes: 1), leading in numerical values of coordinate points of box-girder sections ofa continuous girder bridge to generate a box-girder contour model; 2), adding datum lines, size markers and parameter constraints of the box-girder sections and establishing parametric three-dimensional box-girder component models; 3), according to instance data of a box girder, generating box-girder instance models of the entire bridge according to the parametric three-dimensional box-girder component models established in the step 2), and modifying names of the instance models of box-girder components according to actual needs; 4), establishing rebar models of the box-girder components; 5),establishing component models of bridge piers, bearing platforms and pile foundations. Automatic generation of statistic of work amount and drawings is achieved, and a good data platform foundation is provided for operation and maintenance of later bridge BIM (building information modeling); problems that two-dimensional drawings are repeated in data input, non-universal in data, dispersing in spatial relation, non-parametric, informative linkage forbidden in parameter design and the like are solved.

Owner:RAILWAY NO 10 ENG GRP CO LTD

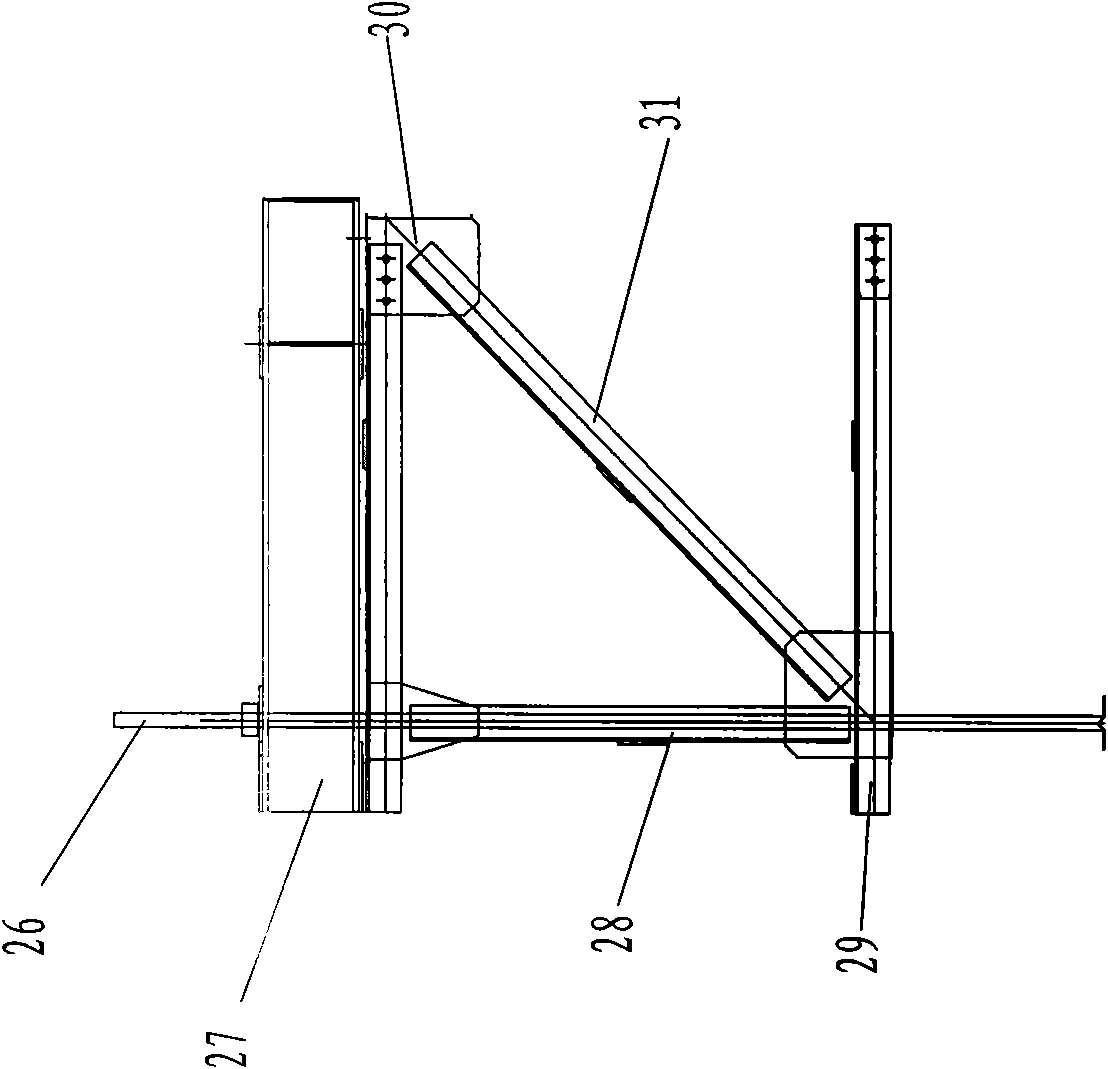

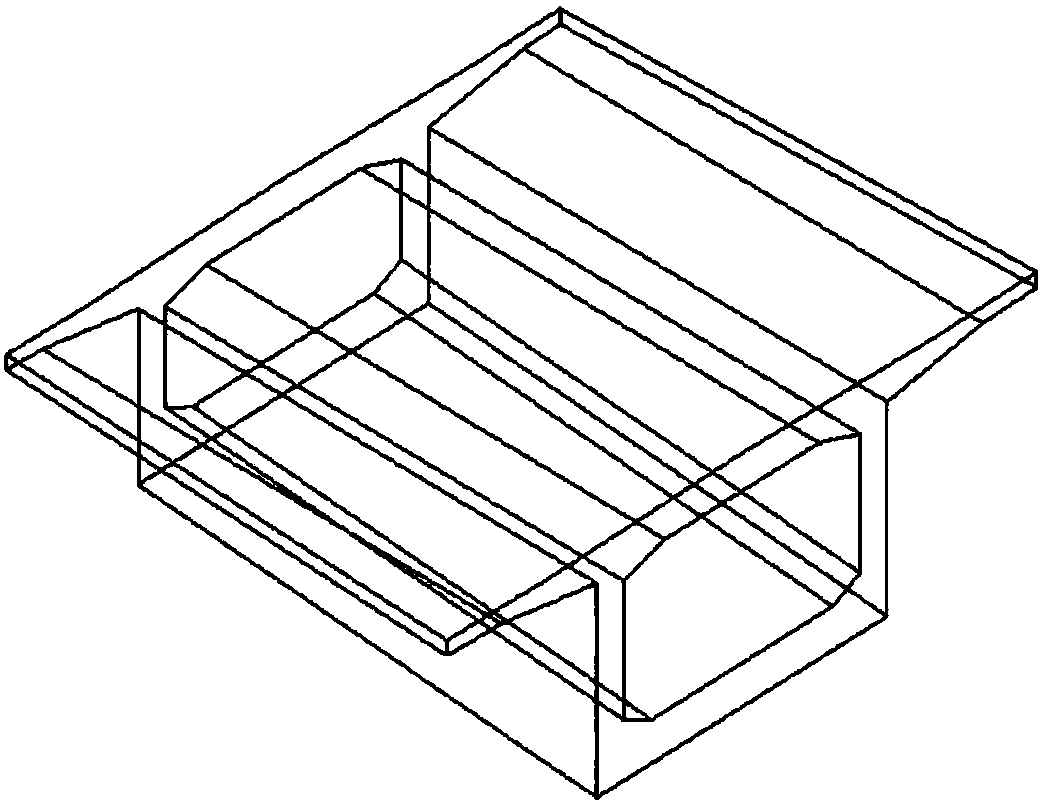

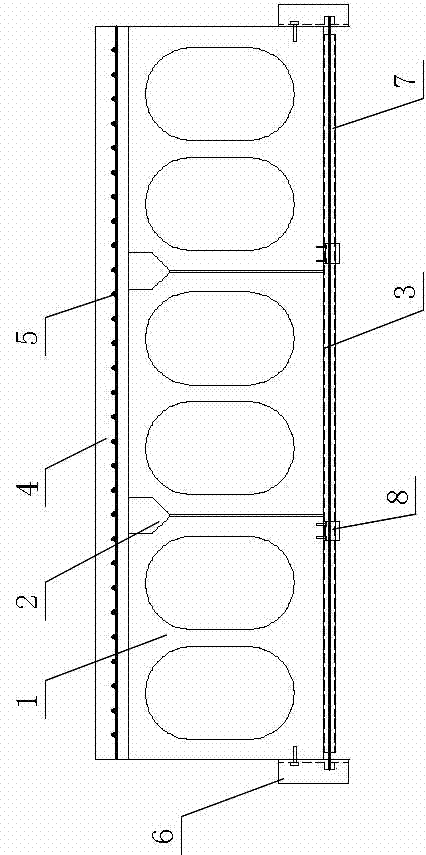

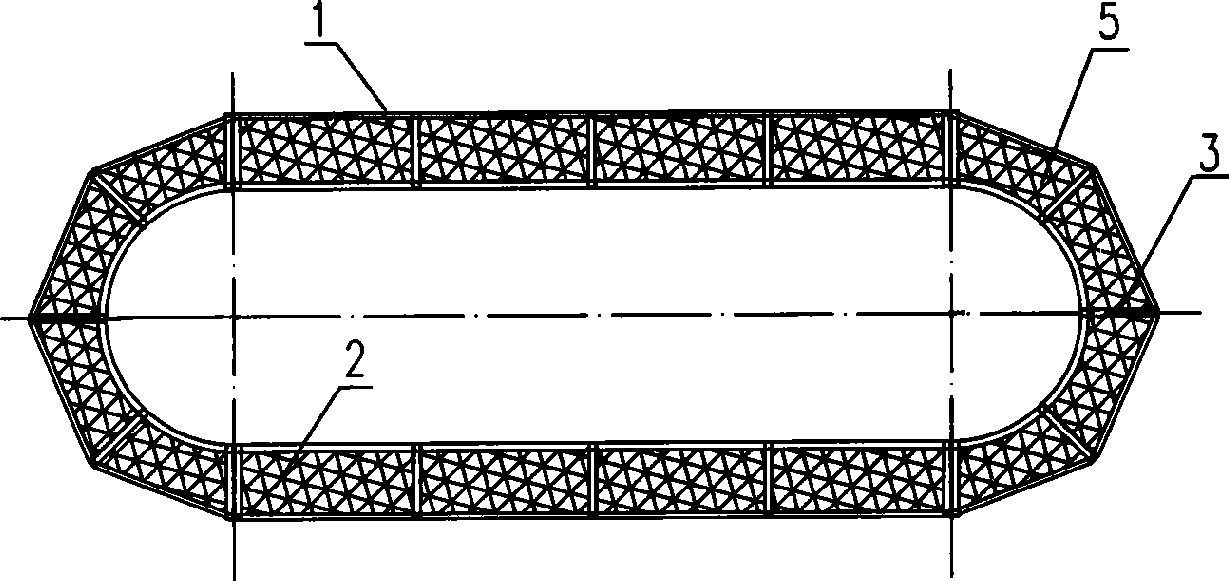

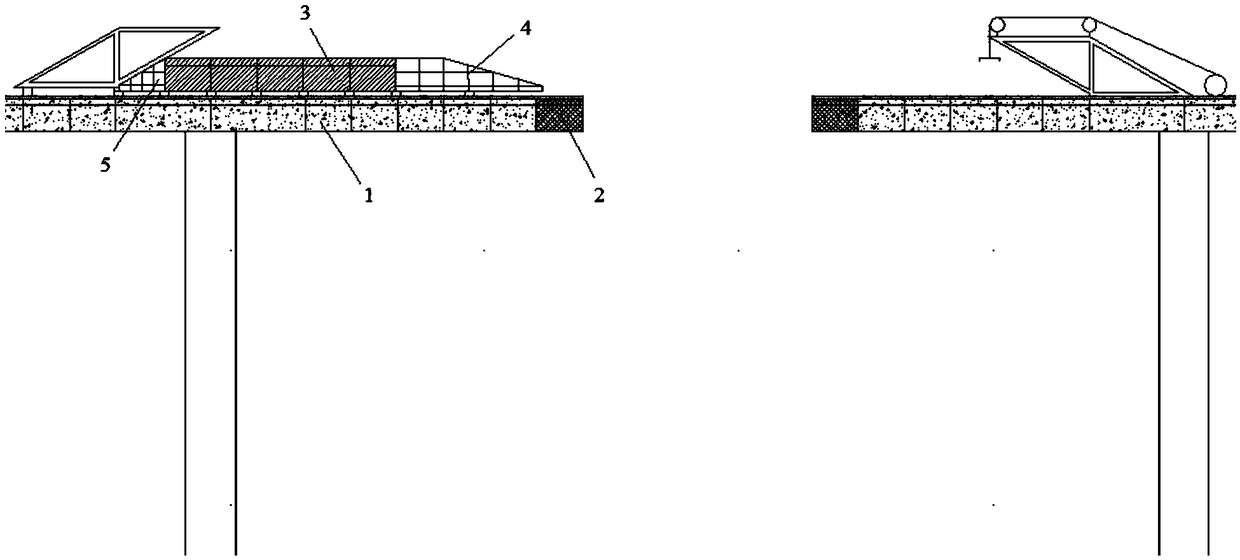

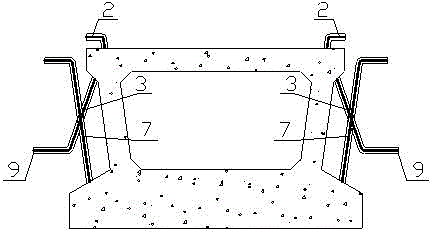

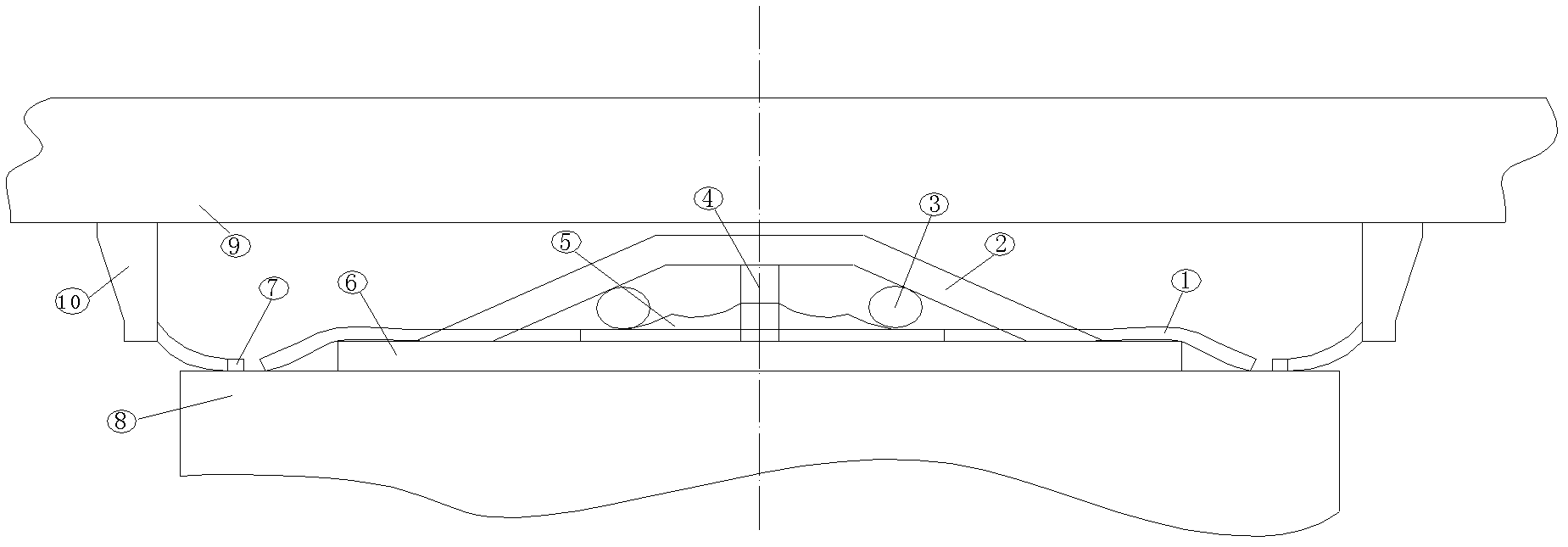

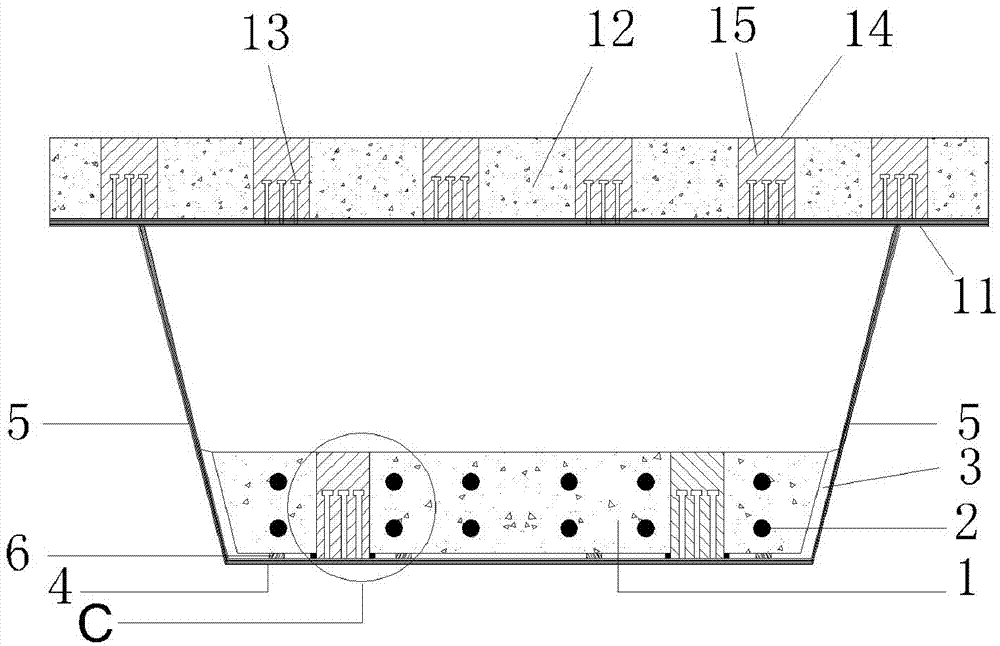

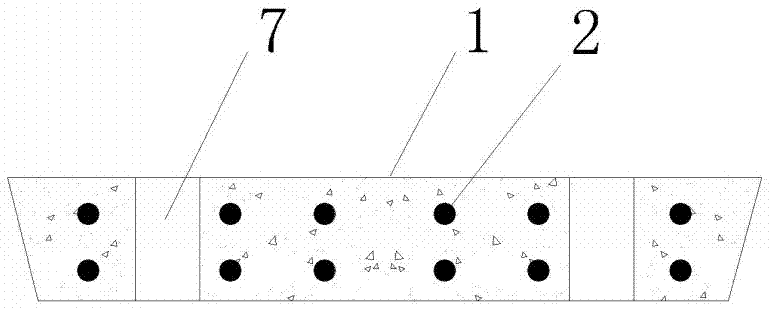

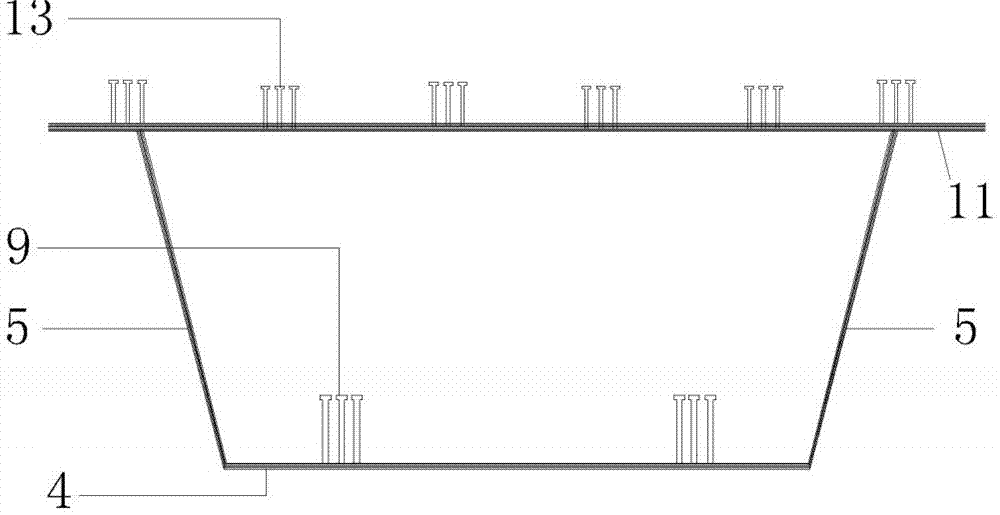

Stub matching prefabricated form system used for corrugated steel web composite structure girder bridge

ActiveCN105848839ASolving Die-in DifficultiesEasy to moldMould separation apparatusMouldsGirder bridgePush pull

The invention discloses a stub matching prefabricated form system used for corrugated steel web composite structure girder bridge. The system includes a fixed end mould, a fixed end mould holder, an outer mould, an outer mould holder, an inner mould, an inner mould holder, a bottom mould, a bottom mould holder, a bottom mould trolley, a hydraulic system and the like. The fixed end mould includes an upper part and an under part, and a push-pull moving block which is convenient to enter mould for the corrugated steel web is disposed on the upper part opposite of the corrugated steel web. A three-way position adjustment device is disposed on a girder of the outer mould which accurately positions the space attitude of the corrugated steel web. A sealing device on steel-concrete composite is disposed on the steel-concrete composite area, and the device has the locate function of the corrugated steel web. The parts of the mould are assembled and accurately positioned by the hydraulic system according to the structure size of the girder sections. The system overcomes the problems that the installation accuracy requirement of the corrugated steel web is high and the reinforcement cage integral installation is difficult, and the prefabrication construction of the composite girder sections has high-quality and high-efficient.

Owner:CCCC SECOND HARBOR ENG +2

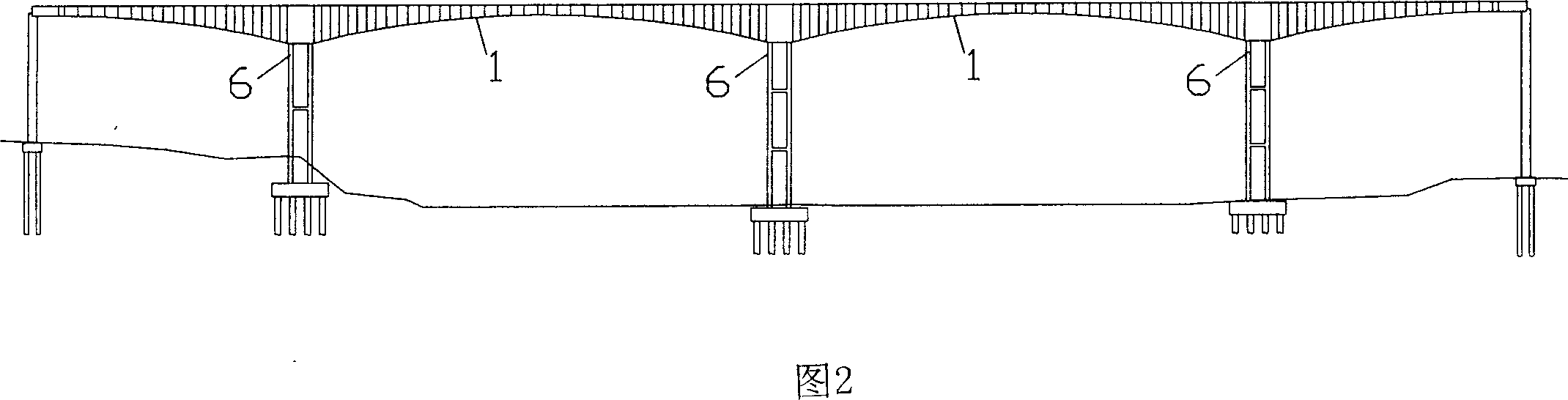

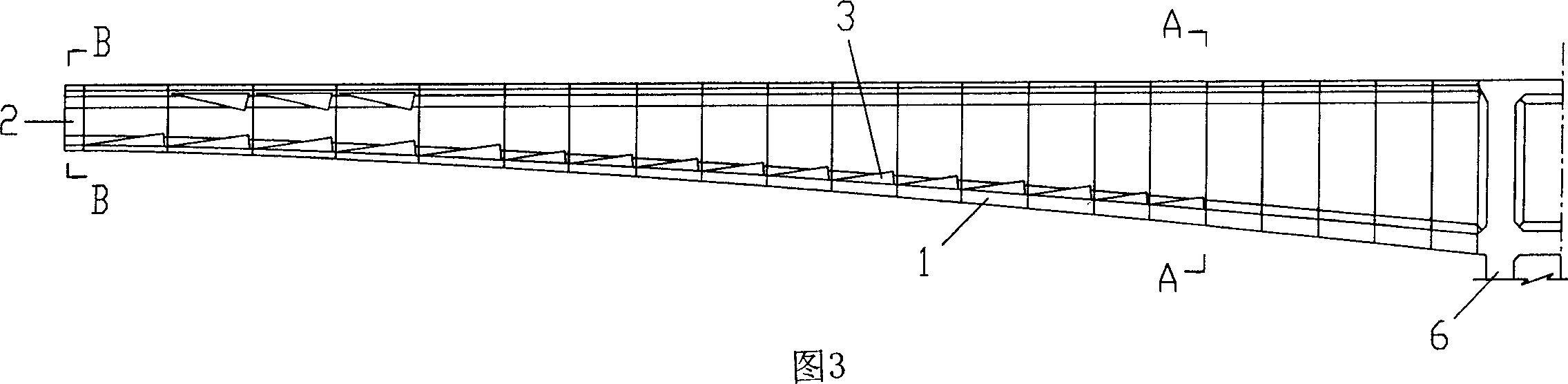

Double-deck bridge floor combined trussed girder bridge

InactiveCN101158143AIncrease capacityOpen sightTruss-type bridgeBridge structural detailsLow noiseBridge deck

A combined truss bridge of double bridge decks relates to a novel bridge structure and the combined truss bridge of double bridge decks consists of an upper concrete bridge deck, a steel structure web member and a lower concrete bridge deck. The upper and lower bridge decks are used for bearing the load of vehicles and are used as an upper chord part and a lower chord part to share the global stress with the global structure. The steel structure web member consists of a slant web member and a vertical web member, and combines the upper and the lower concrete bridge decks as a whole to be used for resisting the shearing force of the truss bridge. The upper concrete bridge deck and the lower concrete bridge deck in tensile areas are provided with vertically stressed steel bars or section steel. The invention, compared with traditional single bridge deck combined girder bridges, enjoys greater traffic capacity and higher traffic comfort; compared with steel truss bridges, the invention remarkably reduces steel consumption by using concrete bridge decks as compression chords, and has the advantages of low noise, easy maintenance, good durability and so on.

Owner:TSINGHUA UNIV

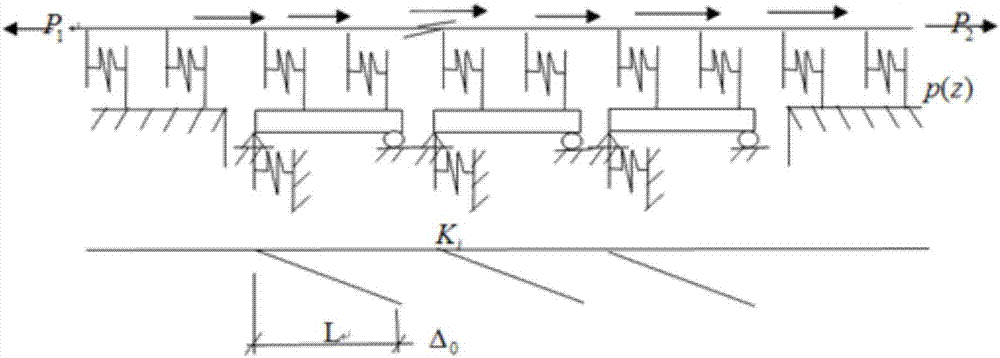

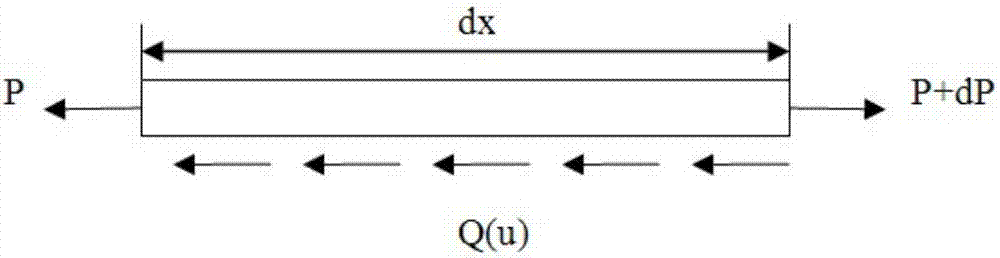

Design internal stress analyzing method for hinged hollow plank girder bridge with reinforced transverse prestress

InactiveCN102953347AAvoid analysisSimulation is accurateBridge erection/assemblyBridge strengtheningPlankPre stress

The invention discloses a design internal stress analyzing method for a hinged hollow plank girder bridge with reinforced transverse prestress. Transverse prestress is applied to reinforce a hollow plank girder bridge with a hinged joint, and the reinforcing mode is one of effective measures for solving the single-plate force applying and the crack along the hinged joint of the hinged hollow plank girder bridge. The patent aims at the characteristics that the plank girder reinforced by the reinforcing method can bear bending bidirectional stress in the longitudinal and transverse directions, and simulates the reinforced hollow plank girder bridge to an orthotropic anisotropic plate and adopts a corresponding longitudinal-transverse rigidity hypothesis to propose an internal stress analyzing method for designing the bridges with the reinforced transverse prestress, so that the problem that no practical design calculation methods are available for the internal stress analysis of the hinged hollow plank girder bridge is solved, and meanwhile, the complexity and time consumption of the modeling calculation in the finite element software calculation are avoided.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

Anti-cracking steel-concrete combined continuous girder bridge of negative moment region

ActiveCN102505624AOptimize layoutHigh tensile strengthBridge structural detailsBridge materialsFiberCrack resistance

The invention relates to an anti-cracking steel-concrete combined continuous girder bridge of a negative moment region. A main girder of the bridge girder is of a steel structure; a bridge deck is of a concrete structure; and the main girder and the bridge deck are connected through shear nails, wherein the main steel girder structure and the shear nails are made of a steel product with a standard model; the bridge deck is made of two concrete materials; a base material of the negative moment region of the bridge deck is made of high-strength organic polymer fiber concrete of which the dry apparent density is not less than 2400 kg / m<3>; the base material of the other region of the bridge deck is made of high-strength common concrete of which the dry apparent density is not less than 2400 kg / m<3>, and prestressed reinforcements are arranged in the negative moment region of the bridge deck. The cracking resistance of the negative moment region of the bridge is improved and the technical problem of low anti-cracking ability of the bridge deck in the negative moment region of the steel-concrete combined continuous girder bridge can be solved by using material characteristics, such as high tensile strength and shearing strength (over 20% greater than those of common high-strength concrete) of the high-strength organic polymer fibre concrete and optimizing the arrangement mode of prestressing tendons.

Owner:WUHAN UNIV OF TECH

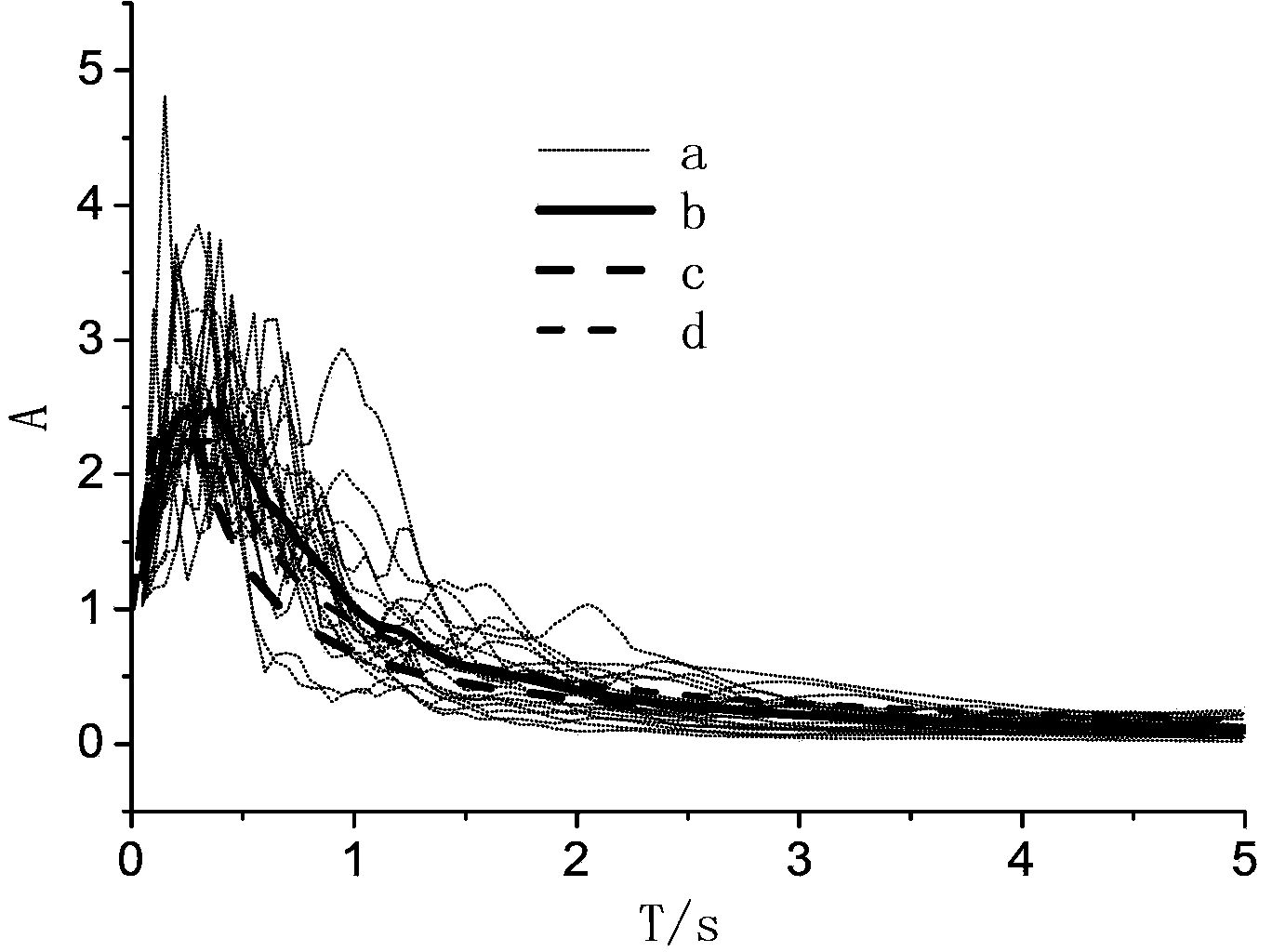

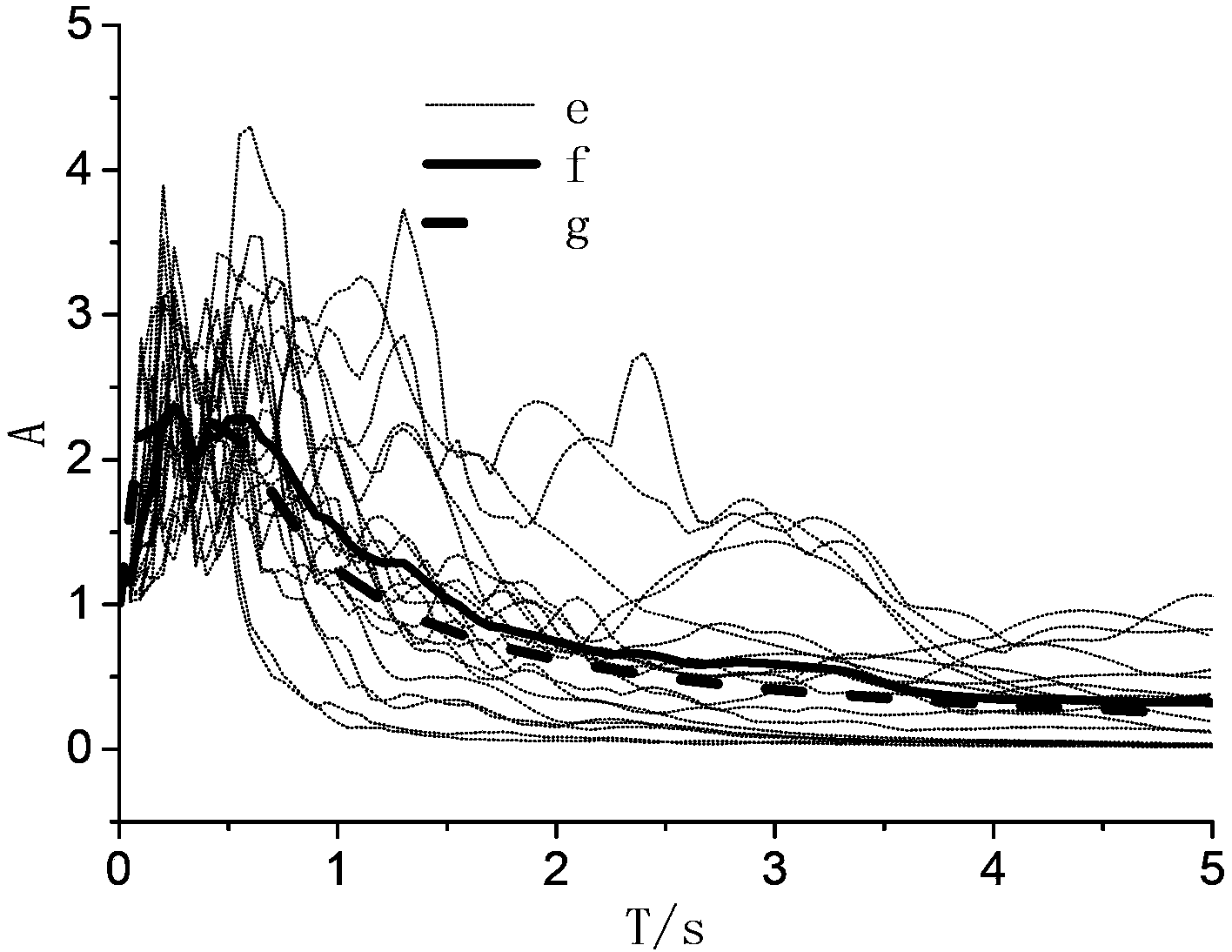

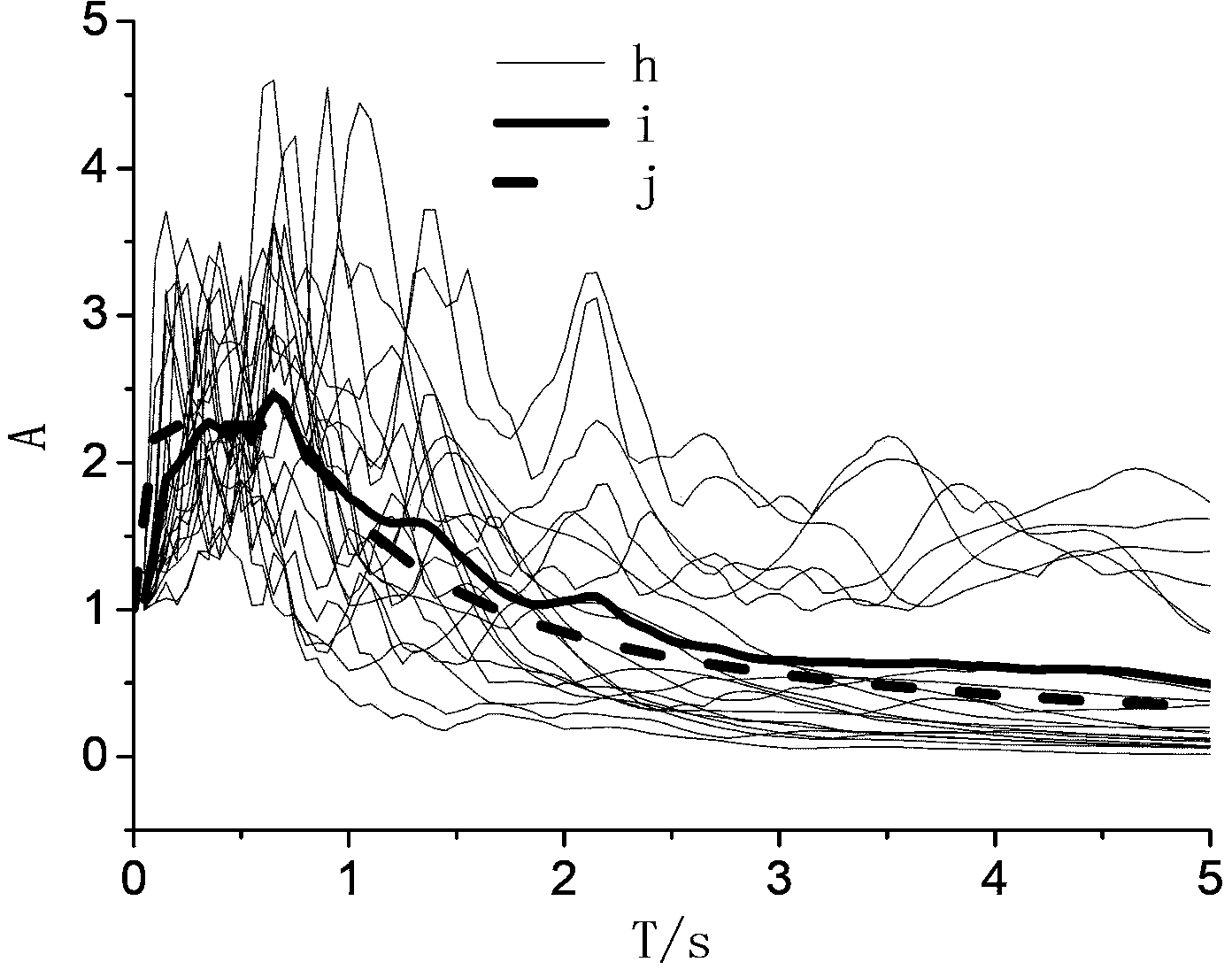

Selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures

The invention discloses a selection method for inputting earthquake waves in time-procedure analysis for earthquake resistance of complex structures to meet the earthquake-resistant requirements of the complex structures such as a high-pier long-span girder bridge, a cable-stayed bridge, a suspension bridge and a super high-rise building. The method comprises the steps that firstly, alternative earthquake waves which meet different site conditions such as earthquake magnitude, distance, an acceleration peak value and long cycle characteristics are selected in an American PEER strong earthquake record database, and a primary-selection database is formed; secondly, the minimum relative weighted average error of spectrum values of alternative earthquake wave response spectrums and design response spectrums in the primary-selection database near previous orders of periodic points of platforms stages and the complex structures is used as a double-control index according to site conditions, and the specific input earthquake waves are determined to meet the requirement that a time-procedure analysis result is in accordance with response spectrum analysis analytic statistics. According to the selection method, engineering realization is easy to achieve, and the method is compared with multiple mode decomposition reaction spectrum methods. In addition, due to the fact that the earthquake waves are selected in the appointed primary-selection database, similar classification of the site conditions is ensured, and the quality of input earthquake waves is ensured.

Owner:DALIAN MARITIME UNIVERSITY

Method for longitudinal stiffness control over high-pier large-span concrete continuous girder bridge and bridge

ActiveCN107201716AMeet vertical and horizontal control standardsProcess stabilityBridge structural detailsEngineeringFixed Bridges

The invention relates to the technical field of high-pier large-span concrete bridges, in particular to a method for longitudinal stiffness control over a high-pier large-span concrete continuous girder bridge and a bridge. The method for longitudinal stiffness control comprises a step a) of establishing a linear bridge pier integrated calculation model; a step b) of applying an analog load; a step c) of analyzing beam track acting force and jointless track stress deformation laws; and a step d) of determining longitudinal rigidity limits of a fixed bridge pier and track treatment measures. Therefore, beam shape arrangement and fixed pier rigidity are determined, a problem that in the prior art, it is difficult to control longitudinal stiffness of the high-pier large-span continuous girder bridge is solved, and the blank of the high-pier large-span girder bridge in the field of longitudinal stiffness control is filled. Meanwhile, normative standards of longitudinal linear stiffness limits of the high-pier large-span concrete continuous girder bridge are established, a reference and a basis are provided for bridge design and construction, so the design cost is reduced, and the actually built bridge meets specific usage environments.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

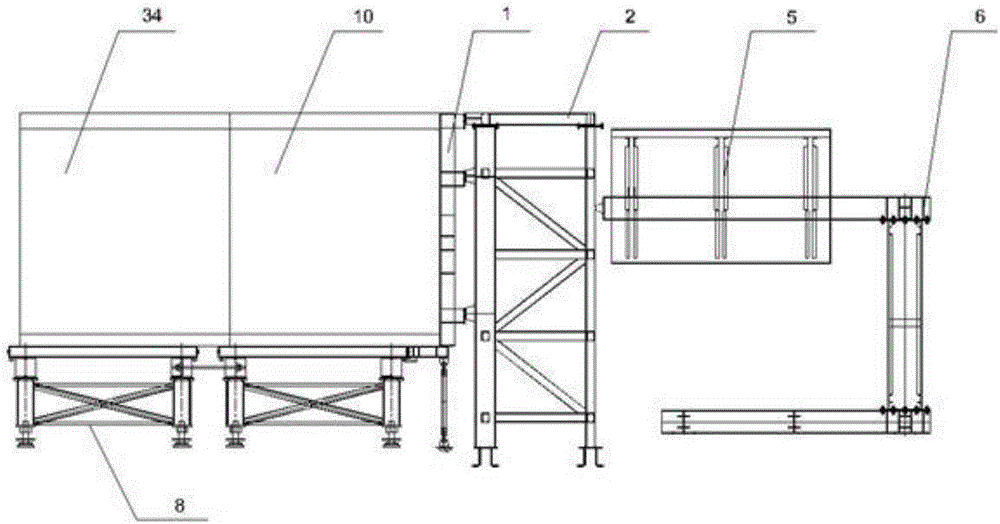

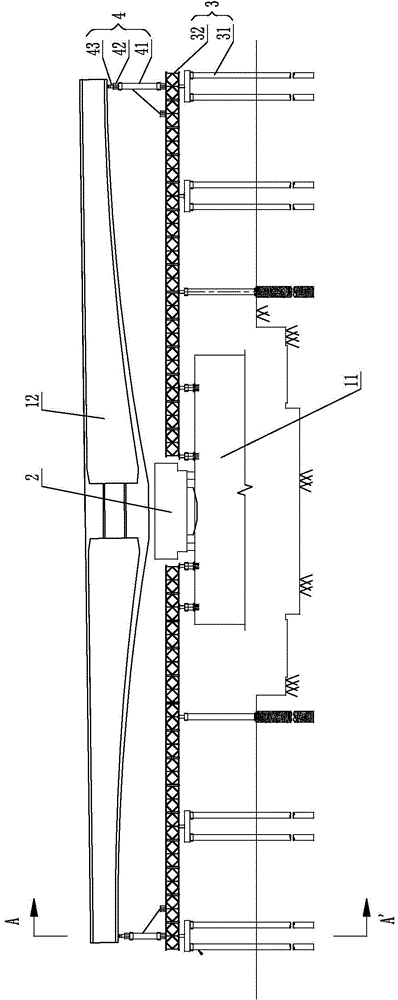

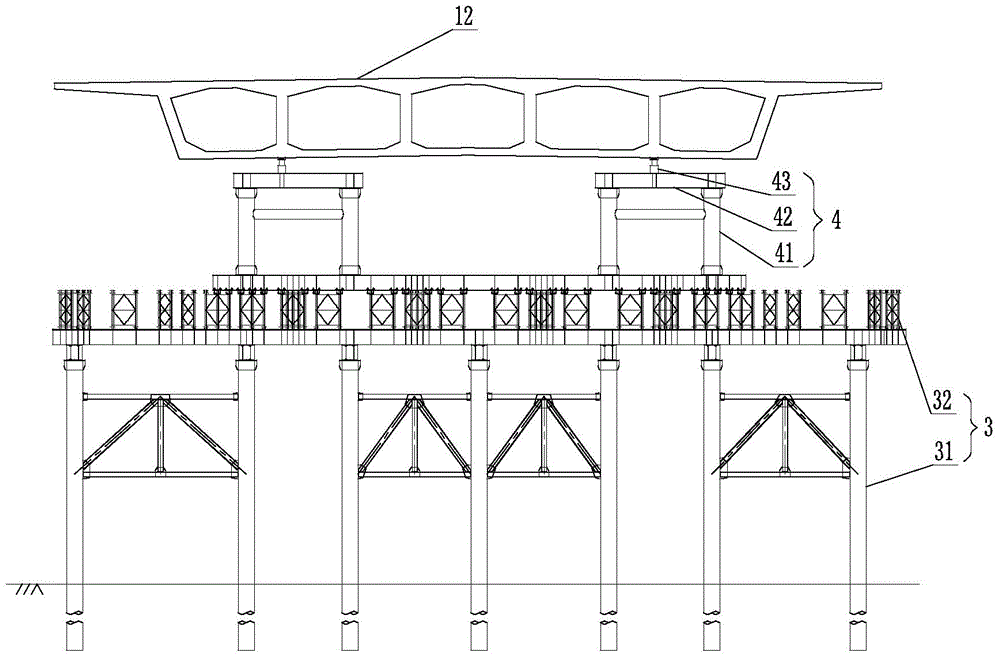

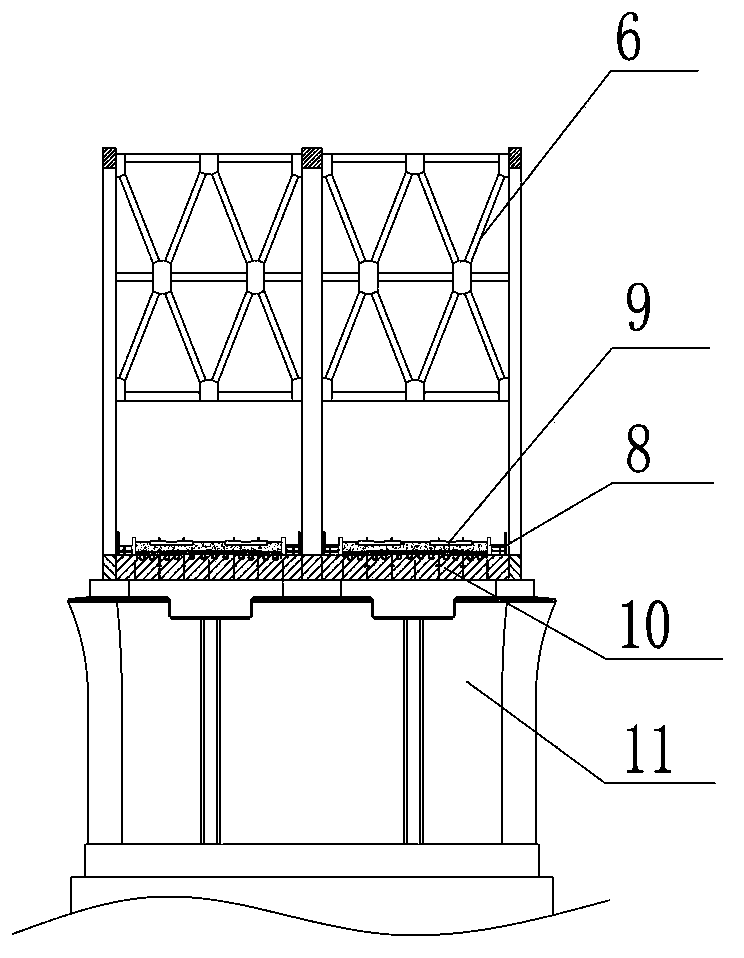

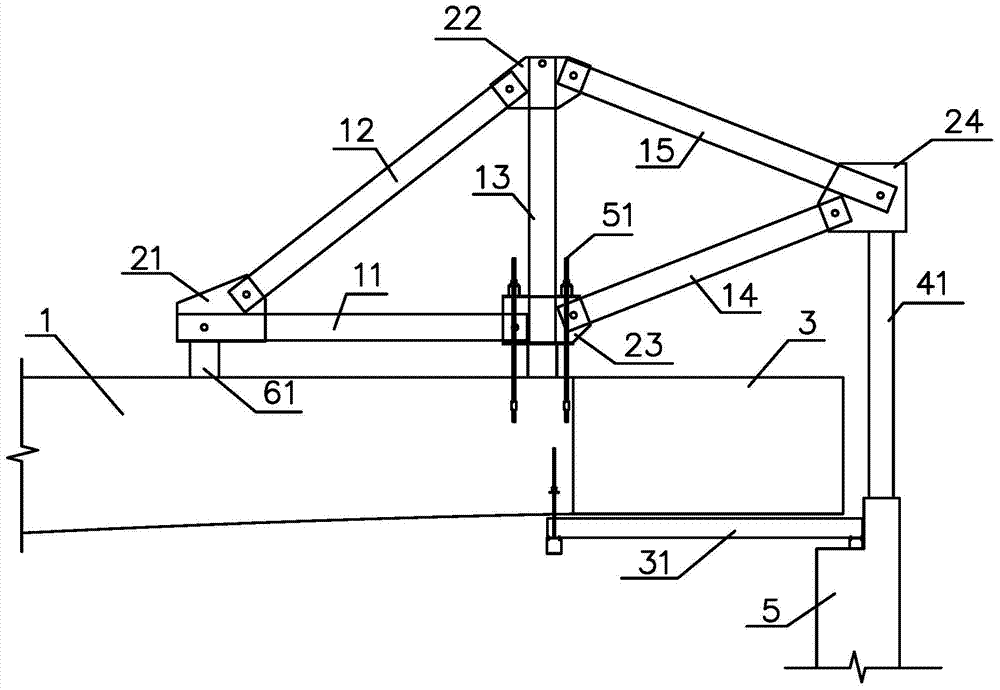

Method for mounting high pier, tower over-form construction reinforced bar and movable support thereof

InactiveCN101481944AEnsure safetyLow costForms/shuttering/falseworksBuilding reinforcementsRolloverReinforced concrete

The invention relates to a method for installing reinforcing steel for the rollover construction of a high pier and a tower and a moveable bracket thereof. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower has the construction steps as follows: (1) according to the characteristics of the sections of the pier and the tower, a moveable bracket (2) matched with a pier body and a tower body is designed and processed, a movable bracket (3) and reinforcing steel (4) are installed, the moveable brackets are dismounted, a pier body moulding board or a tower body moulding board is installed, concrete (5)for the section of a pier body or the section of a tower body on which the reinforcing steel is bound is cast, hoisting equipment is used for installing the moveable brackets, and finally, the installation and the construction of the next section of reinforcing steel are carried out. The method for installing the reinforcing steel for the rollover construction of the high pier and the tower and the moveable bracket thereof greatly reduce the construction cost and the security risk, and have obvious efficiency of accelerating the engineering speed. The invention provides the method for installing the reinforcing steel and the moveable bracket, which are safe, reliable, economic and convenient, for the construction of the high pier and the tower with the constant section and variable section reinforced concrete used for a suspension bridge, a cable stayed bridge, a continuous rigid frame bridge, a continuous girder bridge and bridges of other types.

Owner:SICHUAN ROAD & BRIDGE GRP

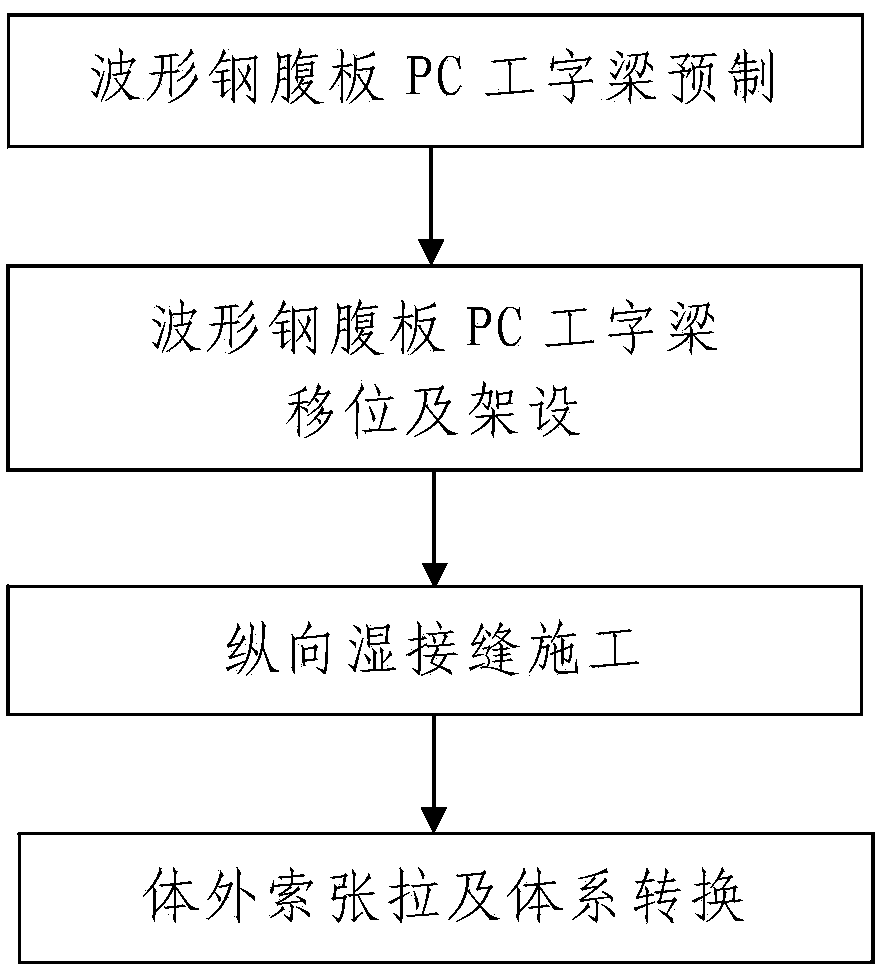

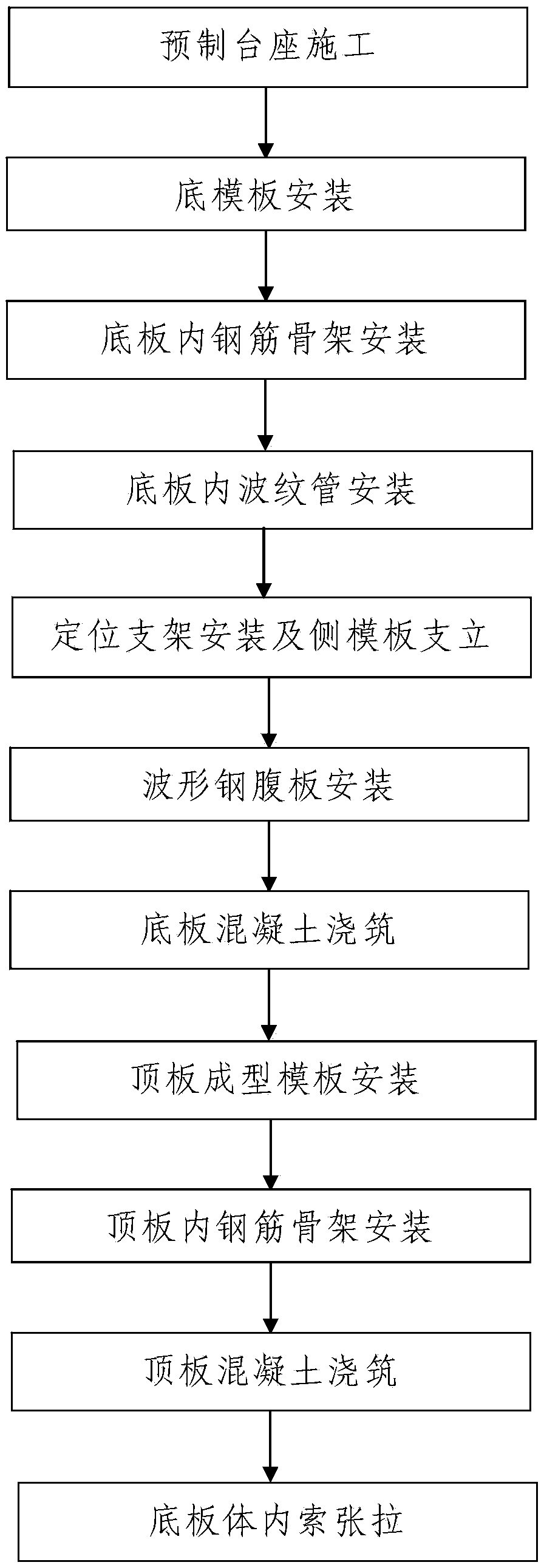

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

Linear adjustment method of track girder bridges of straddle-type monorail transportation simple-support-first rigid-framework-second system

InactiveCN104032681AAdapt to the requirements of linear adjustmentBridge erection/assemblyStructural engineeringGirder bridge

The invention discloses a linear adjustment method of track girder bridges of a straddle-type monorail transportation simple-support-first rigid-framework-second system. By means of the method, when a prefabricated track girder bridge is subjected to linear adjustment, fire working operation on site is omitted, weight deflection, generated in the simple support stage, of the prefabricated track girder bridge is reduced, accidents of track girder falling are prevented, and safety in the construction process is improved.

Owner:BEIJING JIAOTONG UNIV

Reinforced concrete superposed mixed girder bridge construction method

ActiveCN108547223ALight weight structureAvoid investmentBridge erection/assemblyConcrete beamsBridge deck

The invention discloses a reinforced concrete superposed mixed girder bridge construction method. The method includes the following steps that S1, concrete beam sections are constructed on adjacent piers at the same time, opposite front cantilever sections and opposite rear cantilever sections of the beam sections are formed, start number zero blocks are poured in place through a support, and other number blocks of the concrete beam sections are poured in a suspended mode through a hanging basket; S2, steel beams of reinforced concrete combination sections are hung and connected to the front cantilever sections of the beam sections and the rear cantilever sections of the beam sections; S3, the multiple small-section steel beams are hung section by section to the surfaces of the constructedconcrete beam sections and assembled into a large-section steel beam; S4, a front guide beam and a rear guide beam are installed at the two ends of the large-section steel beam to form a combined steel beam; S5, the large-section steel beam of the combined steel beam is hung; and S6, a bridge floor is paved. The method has the beneficial effects that the method is suitable for the construction conditions with the poor water transport environment and large stormy waves, construction is safe, construction efficiency is high, and the method can be widely applied to the technical field of bridgeconstruction methods.

Owner:CCCC SECOND HARBOR ENG +2

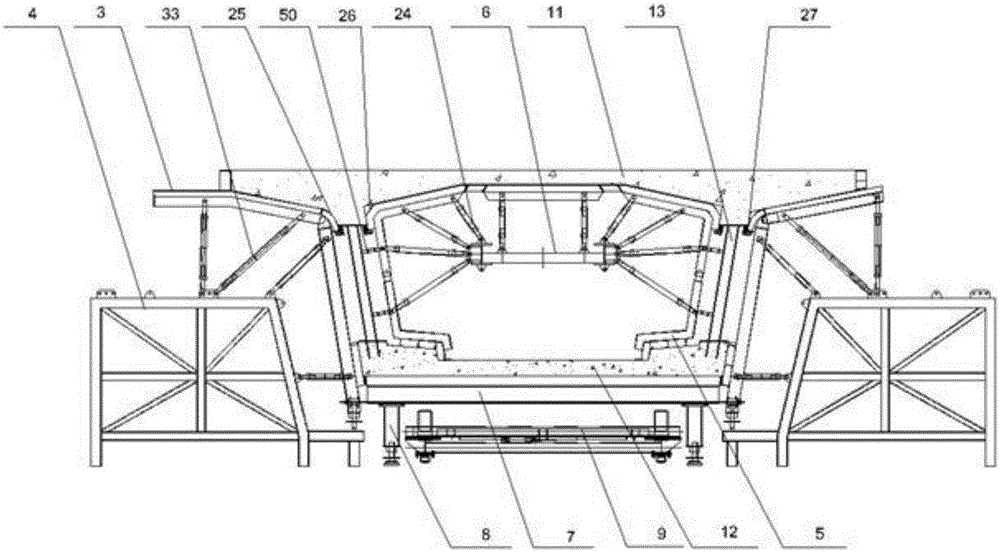

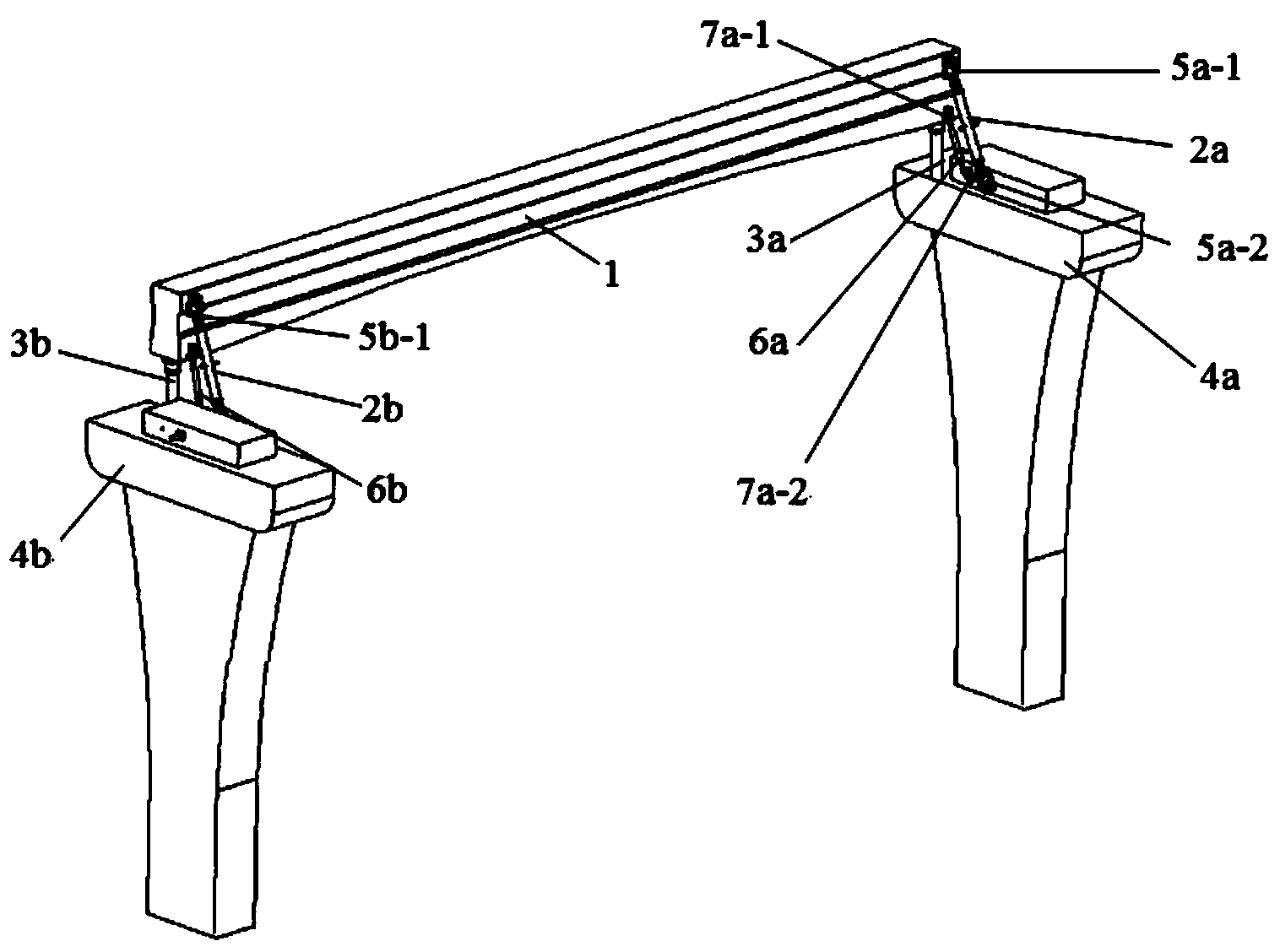

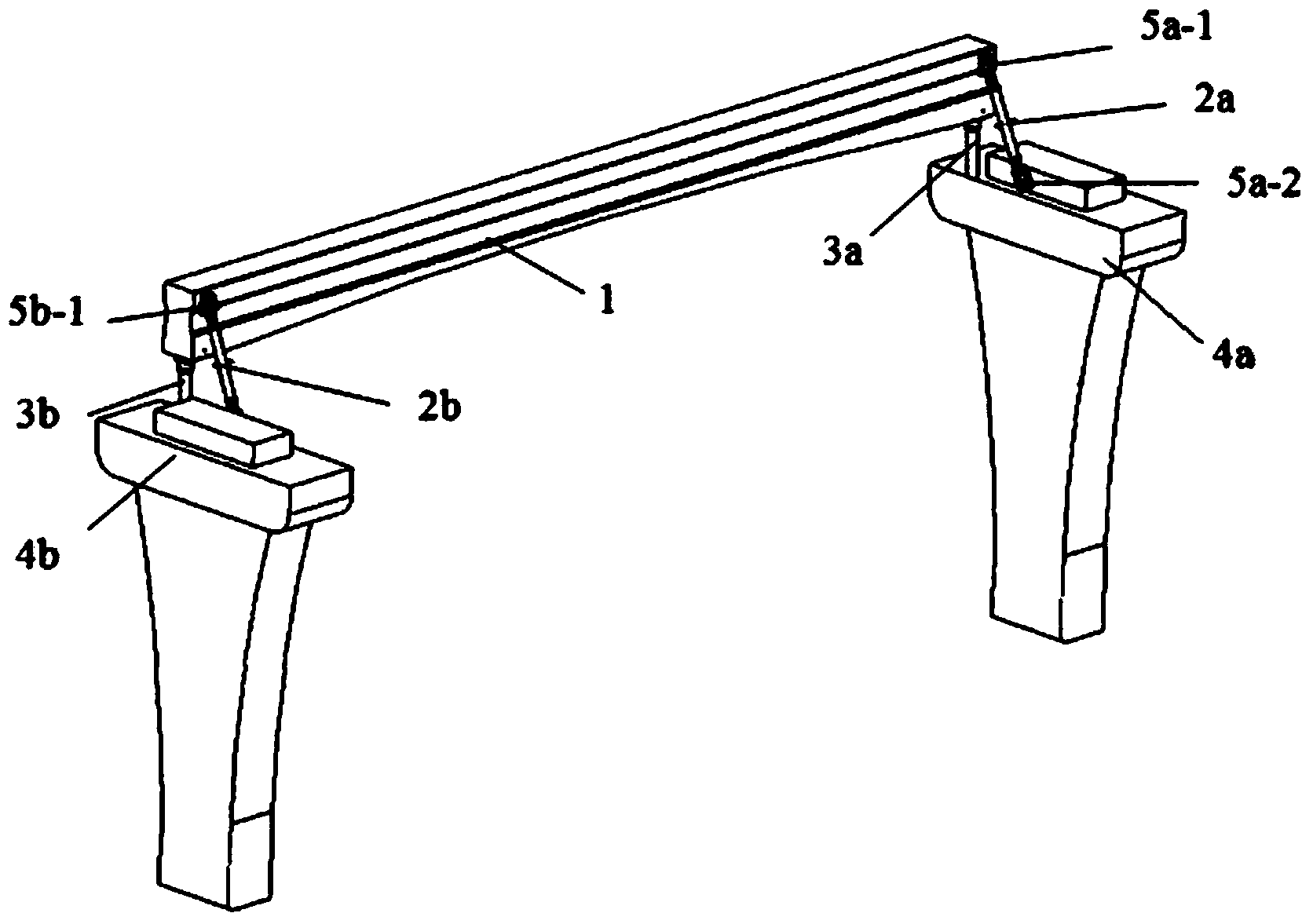

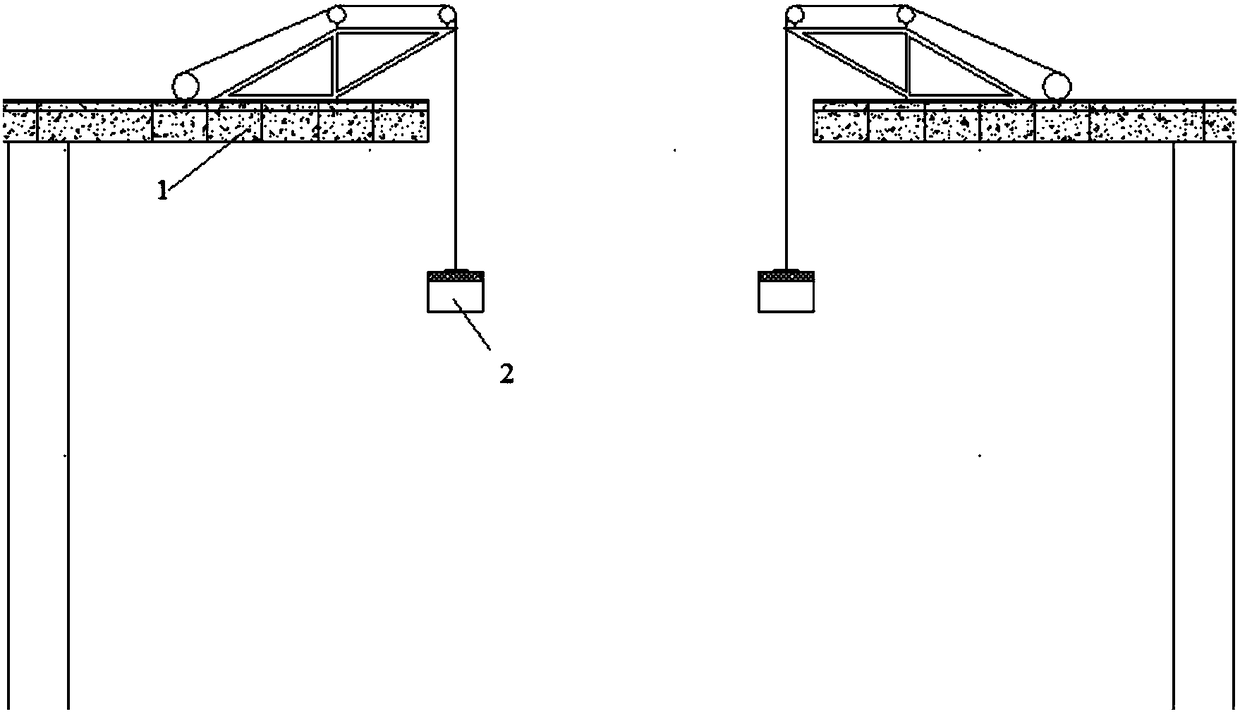

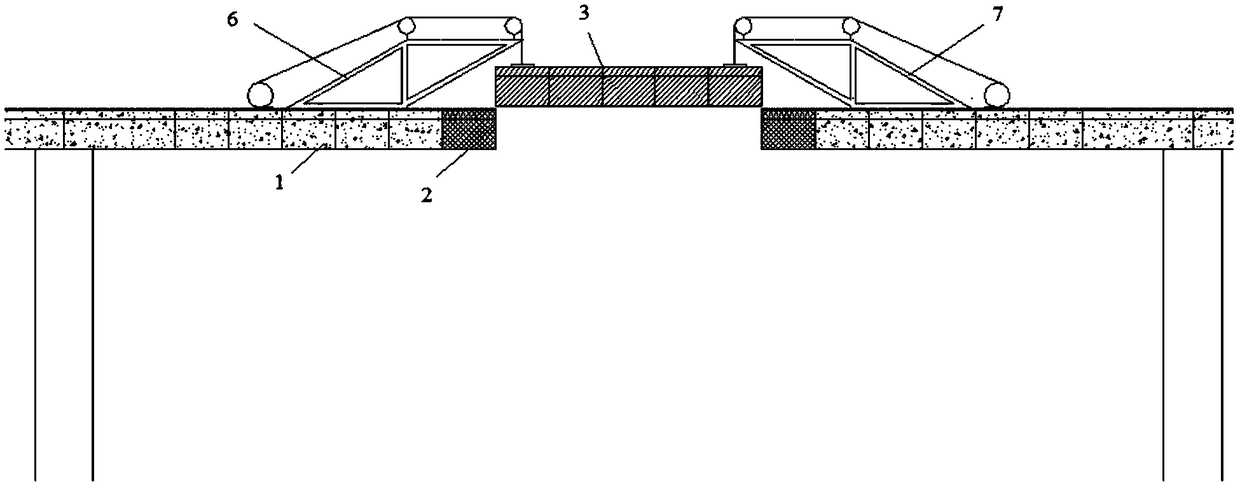

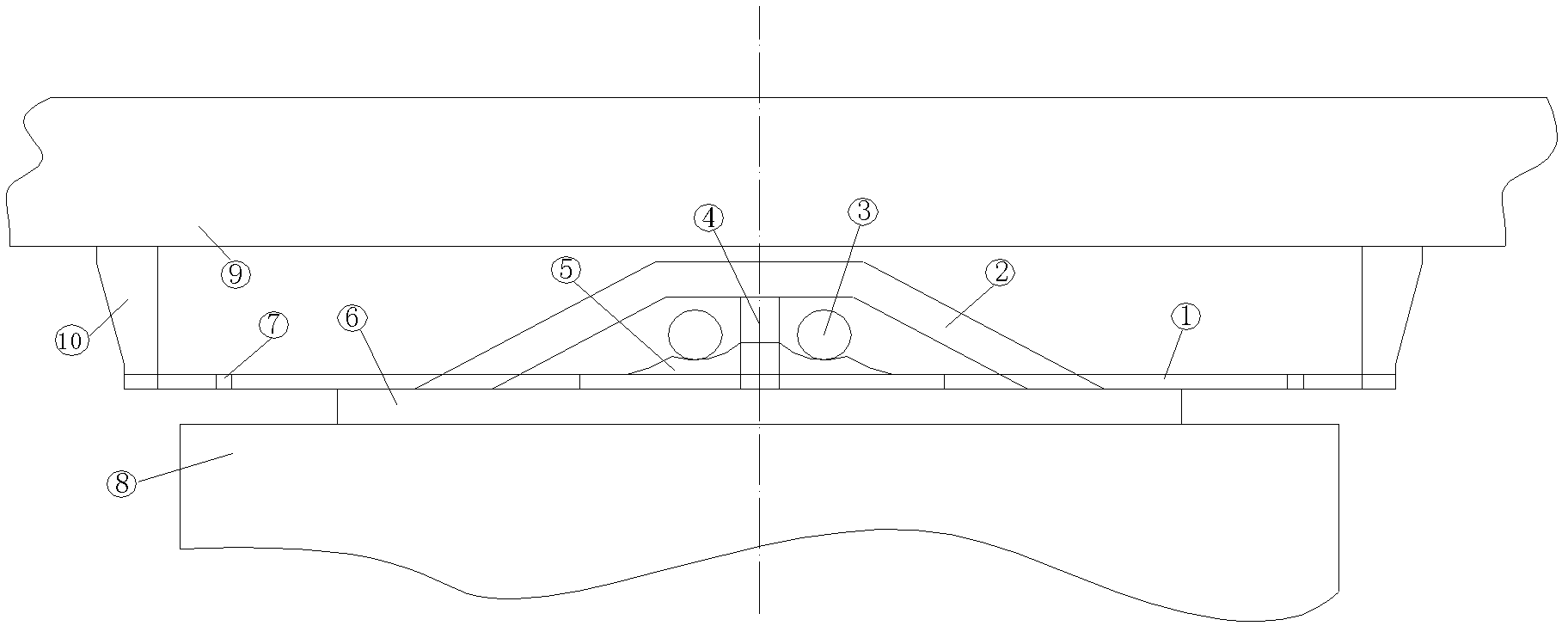

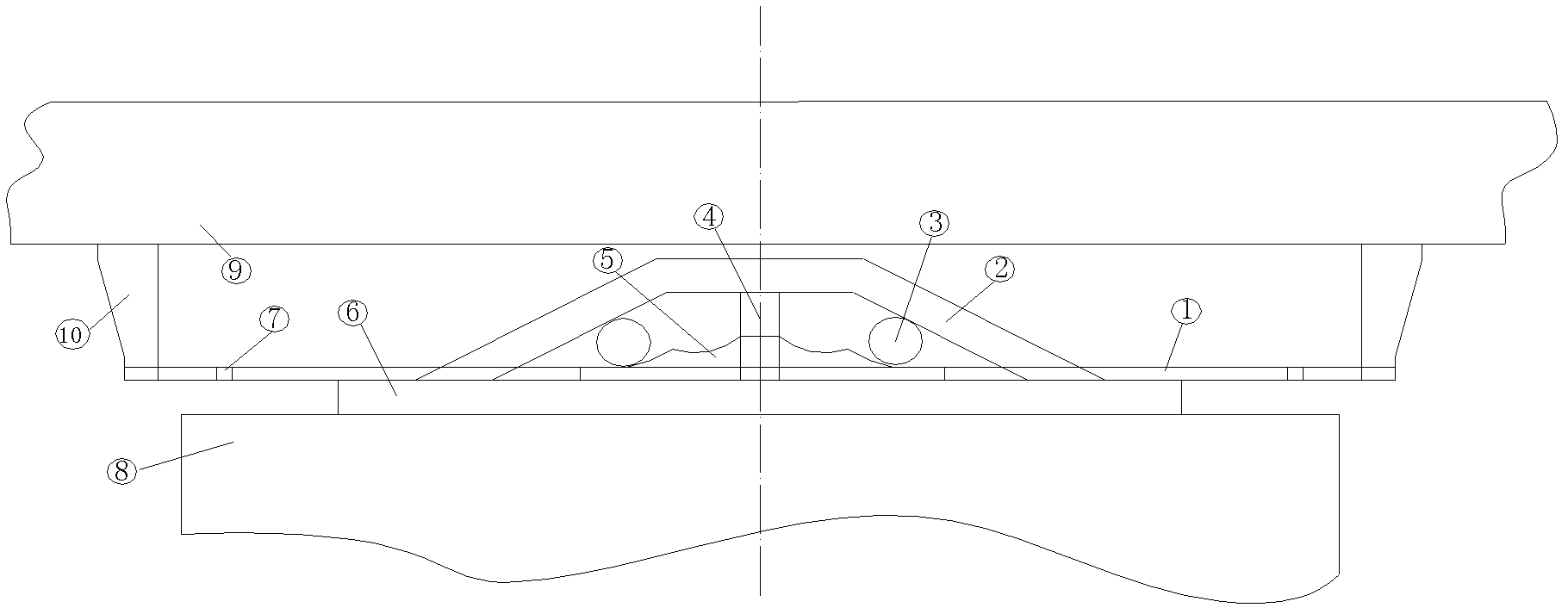

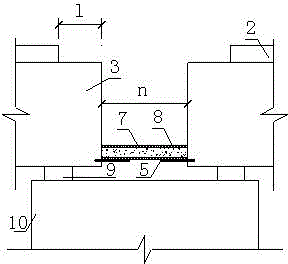

Balance weighing structure and balance weighing method for horizontal rotating construction of box girder bridge

ActiveCN104452603ASmall running resistanceAvoid damageBridge erection/assemblyBox girderBalance test

The invention relates to the technical field of bridge construction, in particular to a balance weighing structure and a balance weighing method for horizontal rotating construction of a box girder bridge. A rotation plate is arranged on the top of a pier and in the center of the bottom of a girder, each truss is arranged below the girder along the length direction of the girder, one end of each truss is fixed onto the top of the pier, and the other end of each truss is erected on the ground through a vertical column; each group of auxiliary weighing systems is positioned between the end, in the length direction, of the girder and the truss at the same end. The method includes: arranging a lower support and an upper support on two sides of the pier, and casting the girder in situ on the rotation plate and the two groups of upper supports; demounting part of the upper supports, and arranging the auxiliary weighing systems between the end of the girder and the lower supports at the same end; performing balance test, and balancing to enable a center of gravity of the girder to be coincided with the center of the rotation plate; rotating the rotation plate to complete construction. The balance weighing structure and the balance weighing method for horizontal rotating construction of the box girder bridge have the advantages that a T structure is adjusted to a balanced state, directly jacking on the rotation plate is avoided, and the bridge is protected from damages owing to low jacking force.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

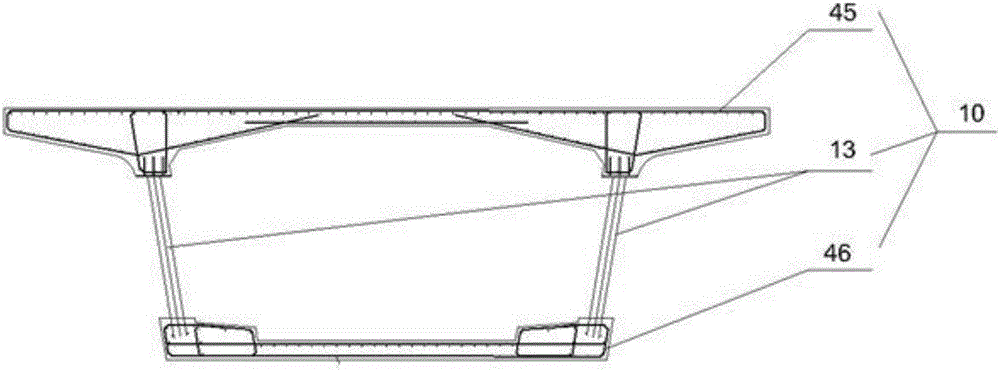

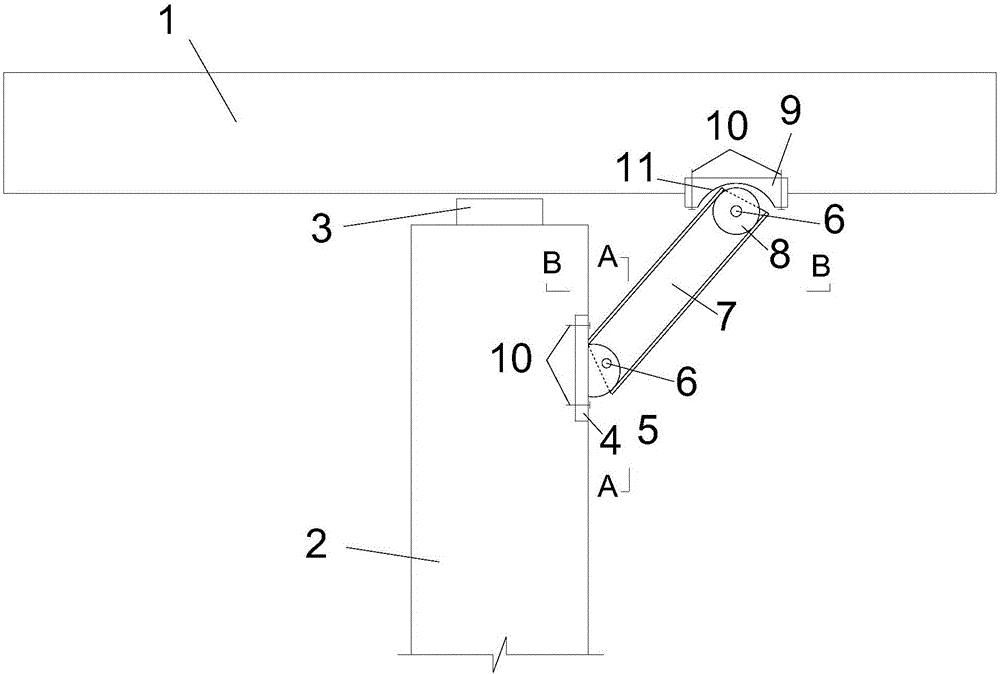

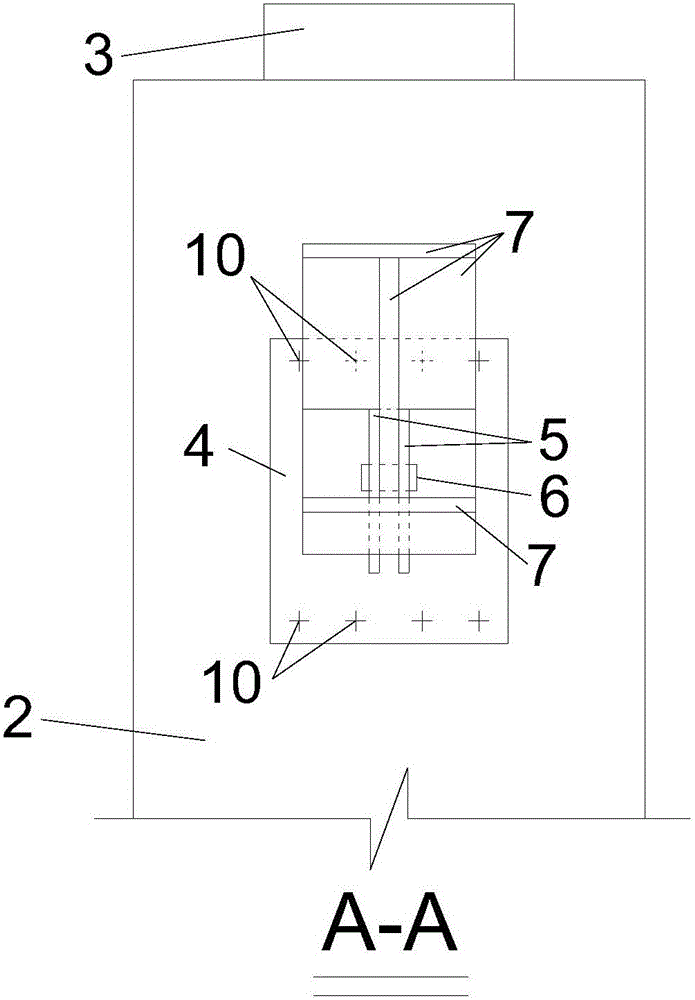

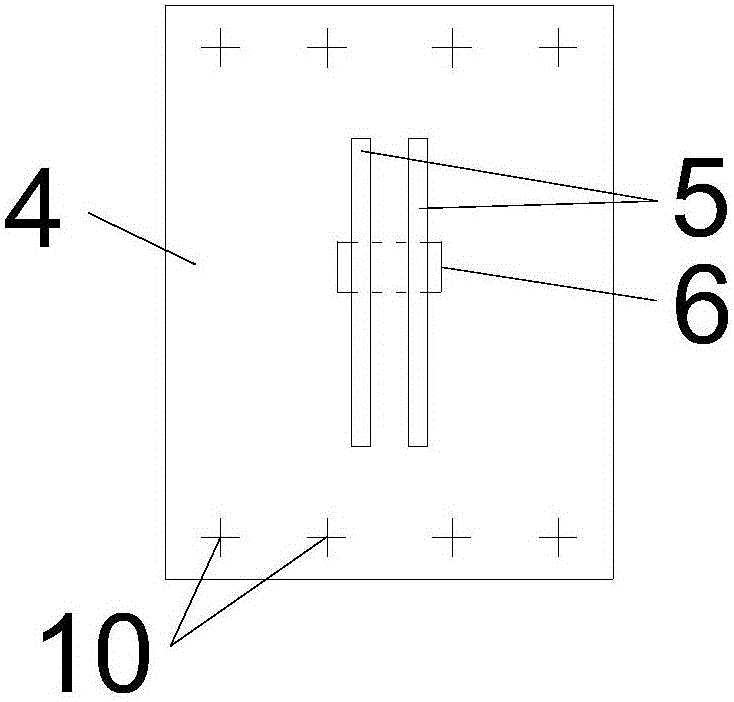

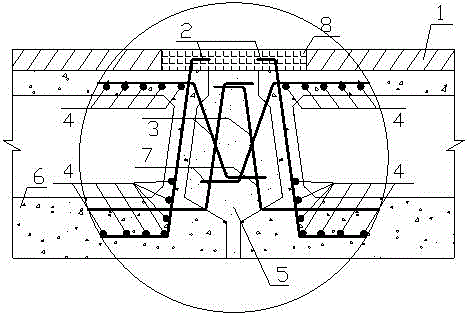

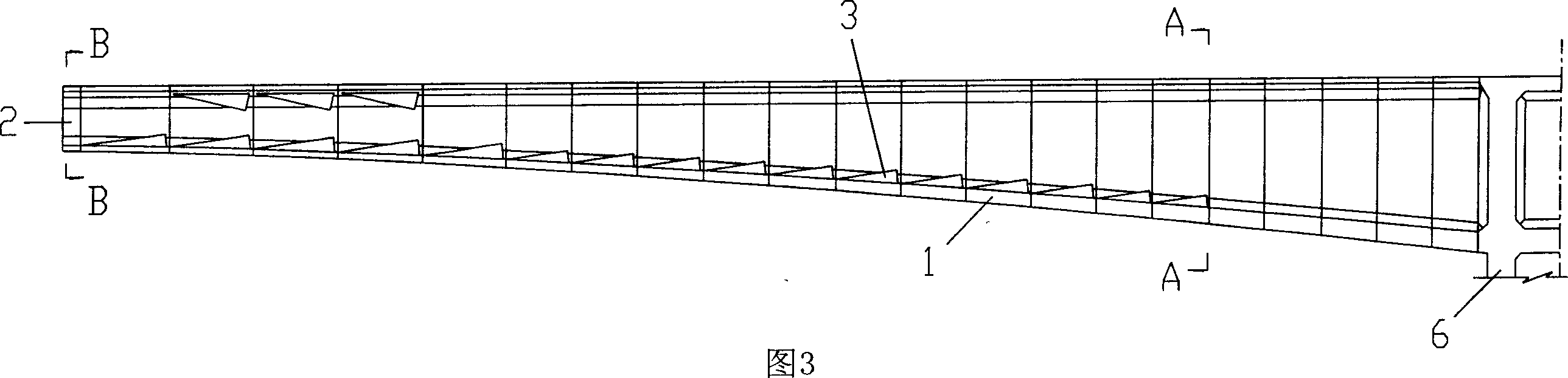

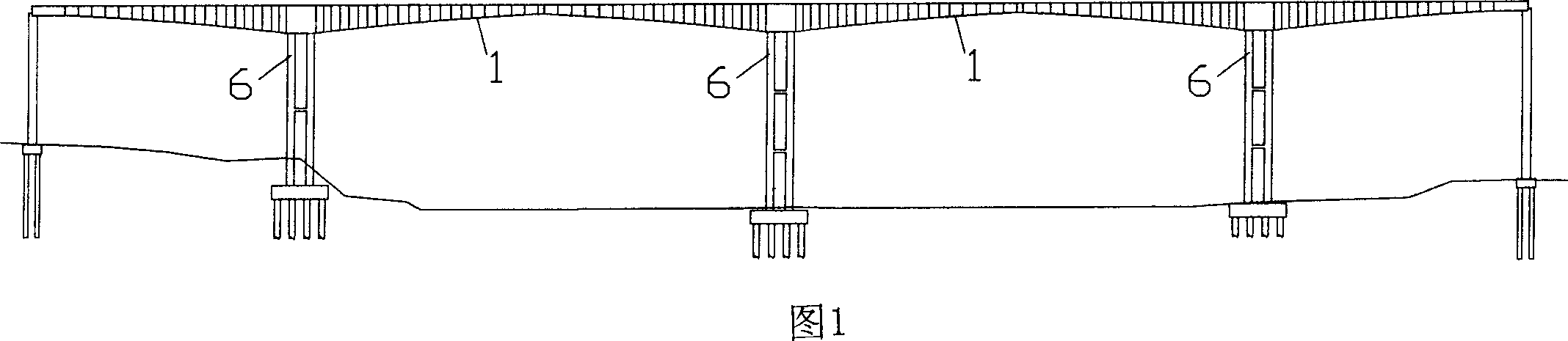

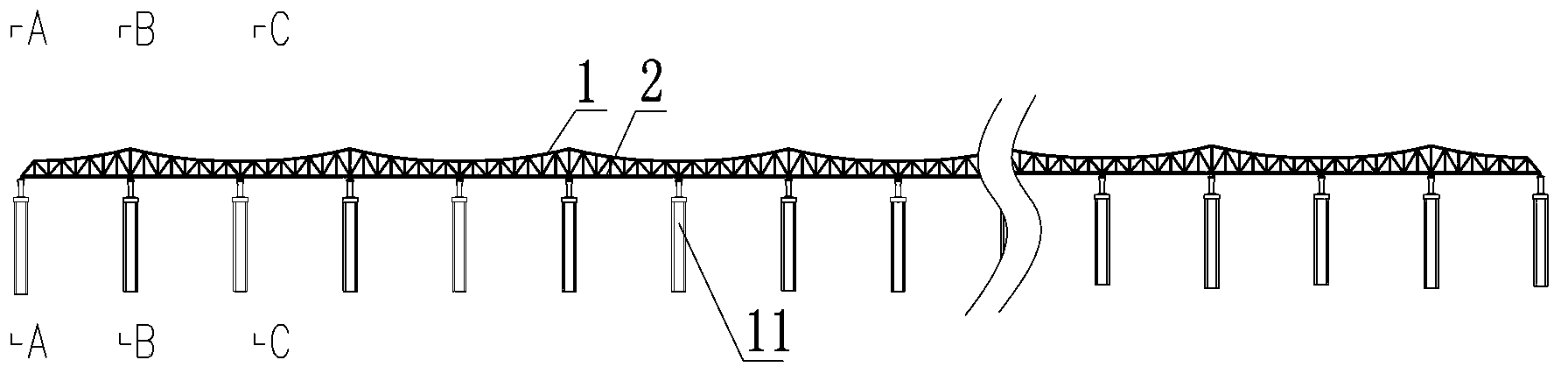

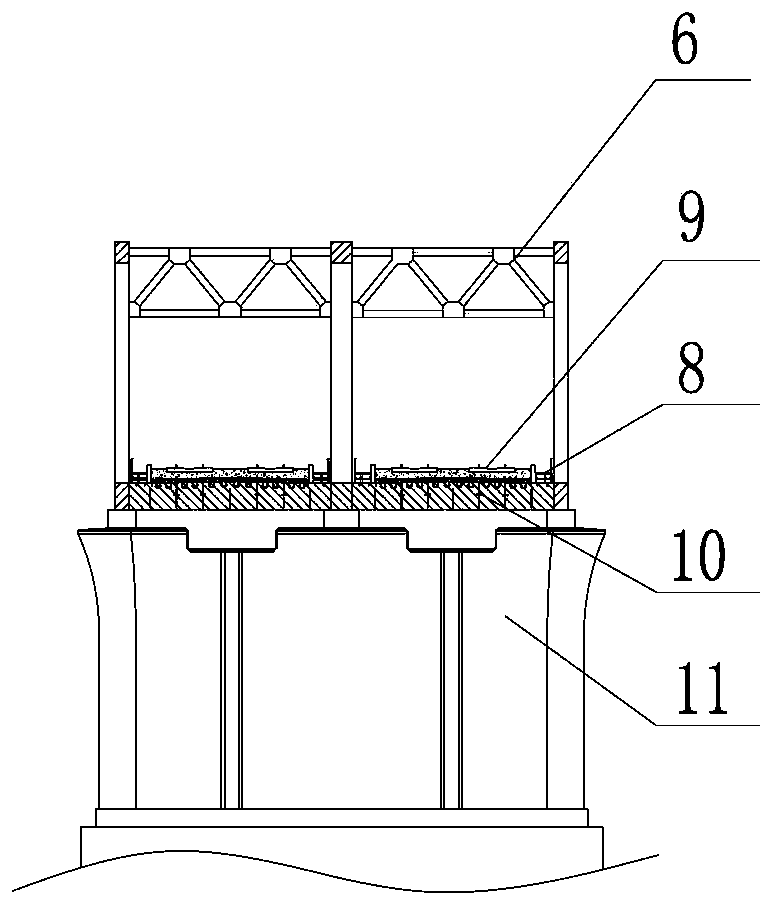

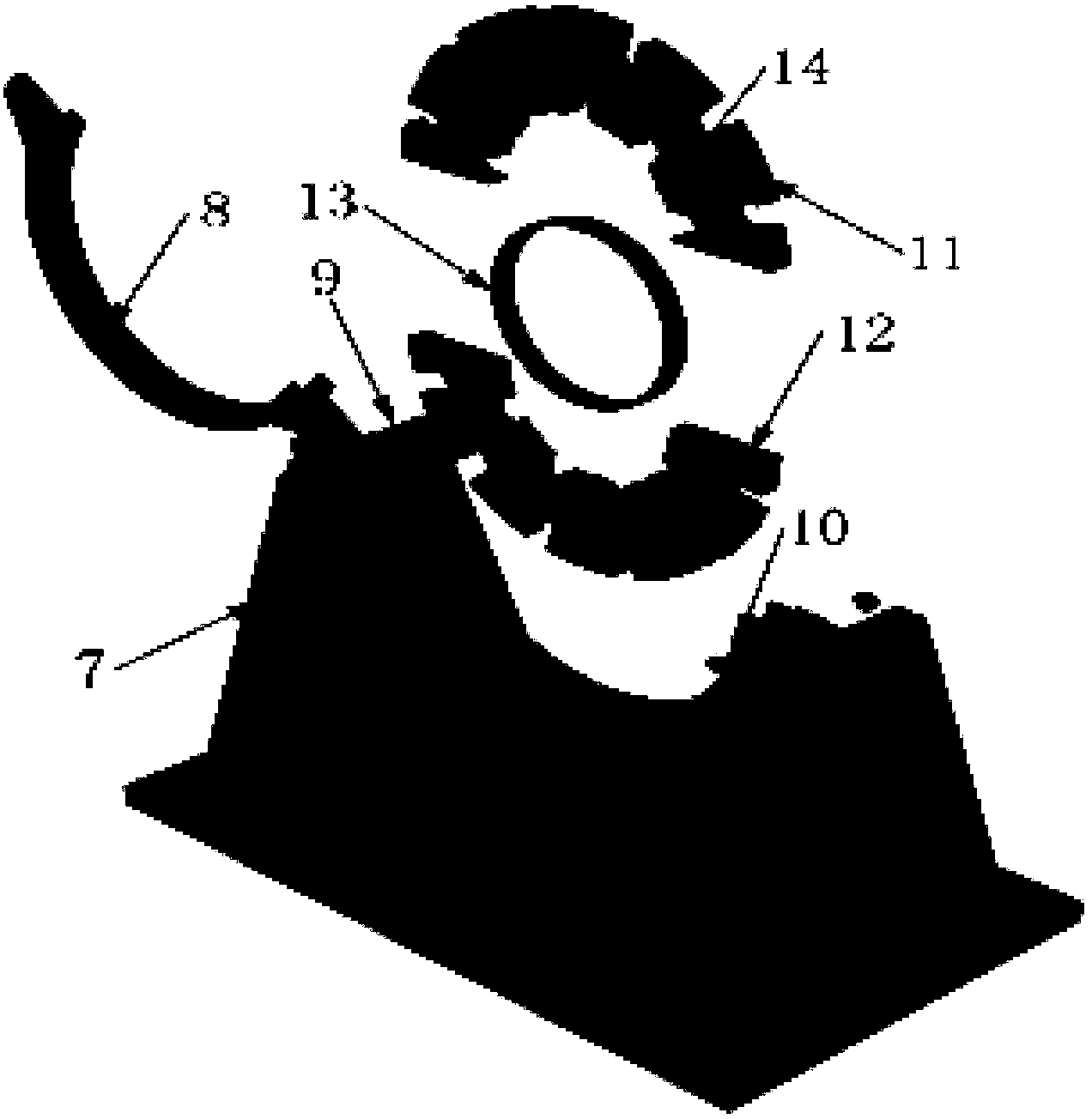

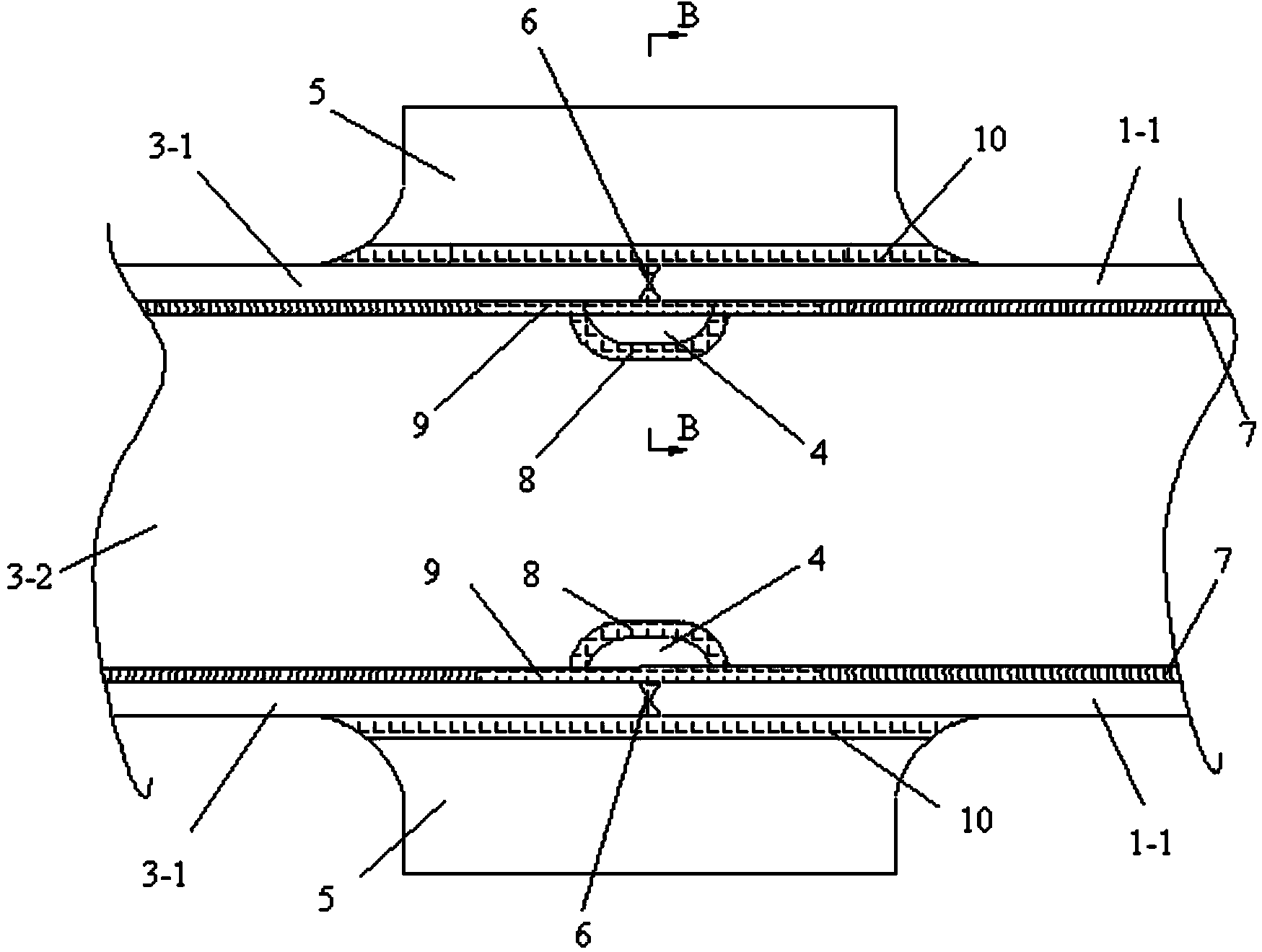

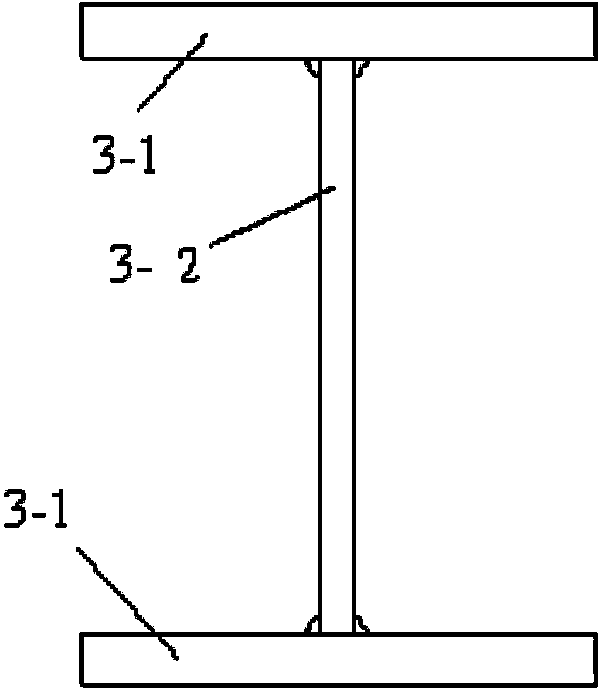

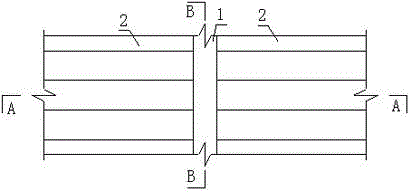

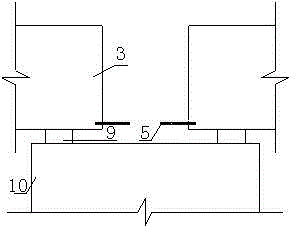

Anti-overturning reinforcing and supporting device of single-column pier girder bridge

InactiveCN106012874AImprove overturning stabilityAchieve mechanical effectBridge erection/assemblyBridge strengtheningSupporting systemEngineering

The invention discloses an anti-overturning reinforcing and supporting device of a single-column pier girder bridge. According to the anti-overturning reinforcing and supporting device of the single-column pier girder bridge, one side of a pier (2) is provided with a pier bearing steel plate (4) in the transverse direction of the bridge, the bottom of a girder (1) on the same side is provided with a girder arc bearing steel plate (9), an H-shaped steel supporting structure (7) is hinged to the pier bearing steel plate (4) through a hinge steel plate (5), hinge balls (8) are hinged to the H-shaped steel supporting structure (7) and embedded into the girder arc bearing steel plate (9), the hinge balls (8) and the girder arc bearing steel plate (9) are in sliding / rolling contact, and thus a steel structure supporting system for connecting one side of the pier (2) in the transverse direction of the bridge with a bottom plate of the girder (1) on the same side is formed; the same reinforcing and supporting structure is established on the other side symmetrical to the pier (2), finally a single-point supporting system of the single-column pier girder bridge is reinforced and supplemented, a three-fulcrum multi-point supporting system including an original supporting seat is formed, and the purpose of anti-overturning reinforcing of the single-column pier girder bridge is achieved.

Owner:SOUTHEAST UNIV +1

Novel articulated prefabricated hollow slab girder bridge hinge joint connector and construction method thereof

InactiveCN103981798AWith bending abilityReduce stressClimate change adaptationBridge erection/assemblyBridge deckRebar

The invention relates to a novel articulated prefabricated hollow slab girder bridge hinge joint connector and a construction method thereof. The hinge joint connector comprises a plurality of prefabricated hollow slab girders; a hinge joint is formed between every two adjacent hollow slab girders; cement paste fills in the hinge joints; a bridge deck pavement layer is poured above the hollow slab girders and the hinge joints; upper transverse reinforcements are embedded in the upper parts of the hollow slab girders; lower transverse reinforcements and reinforcing reinforcements which are located at the upper sides of the lower transverse reinforcements are embedded in the lower parts of the hollow slab girders; the outer ends of the upper transverse reinforcements stretch out of the side faces of the hollow slab girders and are downwards bent to stretch into the hinge joints; the outer ends of the reinforcing reinforcements stretch out of the side faces of the hollow slab girders and are upwards bent to stretch into the hinge joints; the stretching sections of the upper transverse reinforcements and the stretching sections of the reinforcing reinforcements intersect in the hinge joints; the outer ends of the lower transverse reinforcements are upwards bent to stretch out of the top surfaces of the hollow slab girders and stretch into the bridge deck pavement layer above the hinge joints. The novel articulated prefabricated hollow slab girder bridge hinge joint connector and the construction method thereof have the advantage that the shear resisting performance, the anti-cracking performance and the resistance to bending of the hinge joints are improved.

Owner:FUZHOU UNIV

Shock-absorbing device for bridge security belt connection system

ActiveCN102619165ALow costIncreased durabilityBridge structural detailsShock proofingBelt safetyAcceleration Unit

The invention provides a shock-absorbing device for a bridge security belt connection system, belonging to the field of bridge building. The cross section of an upper sealing board is arc-shaped; the bottom parts at the both sides of the upper sealing board and a lower bottom board are fixed through a designed inclined angle, so as to form a vertical face closing device; a static roller bearing platform is fixedly arranged inside the vertical face closing device of the lower bottom board; the upper part and the lower part of a separation board are respectively connected with the upper sealing board and the static roller bearing platform; locking rollers are symmetrically arranged on the static roller bearing platform; the static roller bearing platform is separated to the both sides by the separation board; one ends of two safety belts symmetrical to the separation board are connected with a beam body; the other ends of the two safety belts are free ends and are located on the lower bottom board, pass through a hole reserved on the upper sealing board to stretch, and are symmetrically arranged at the both sides of the separation board; each safety belt is provided with a yield control unit with a reconcilable tonnage; and axes of the locking rollers are vertical with the safety belts. The invention provides the novel security belt connection device for a large-tonnage continuous girder bridge, which is activated by earthquake motion acceleration and has the advantages of low manufacturing cost, good durability, and convenience for examination and maintenance.

Owner:BEIJING UNIV OF TECH

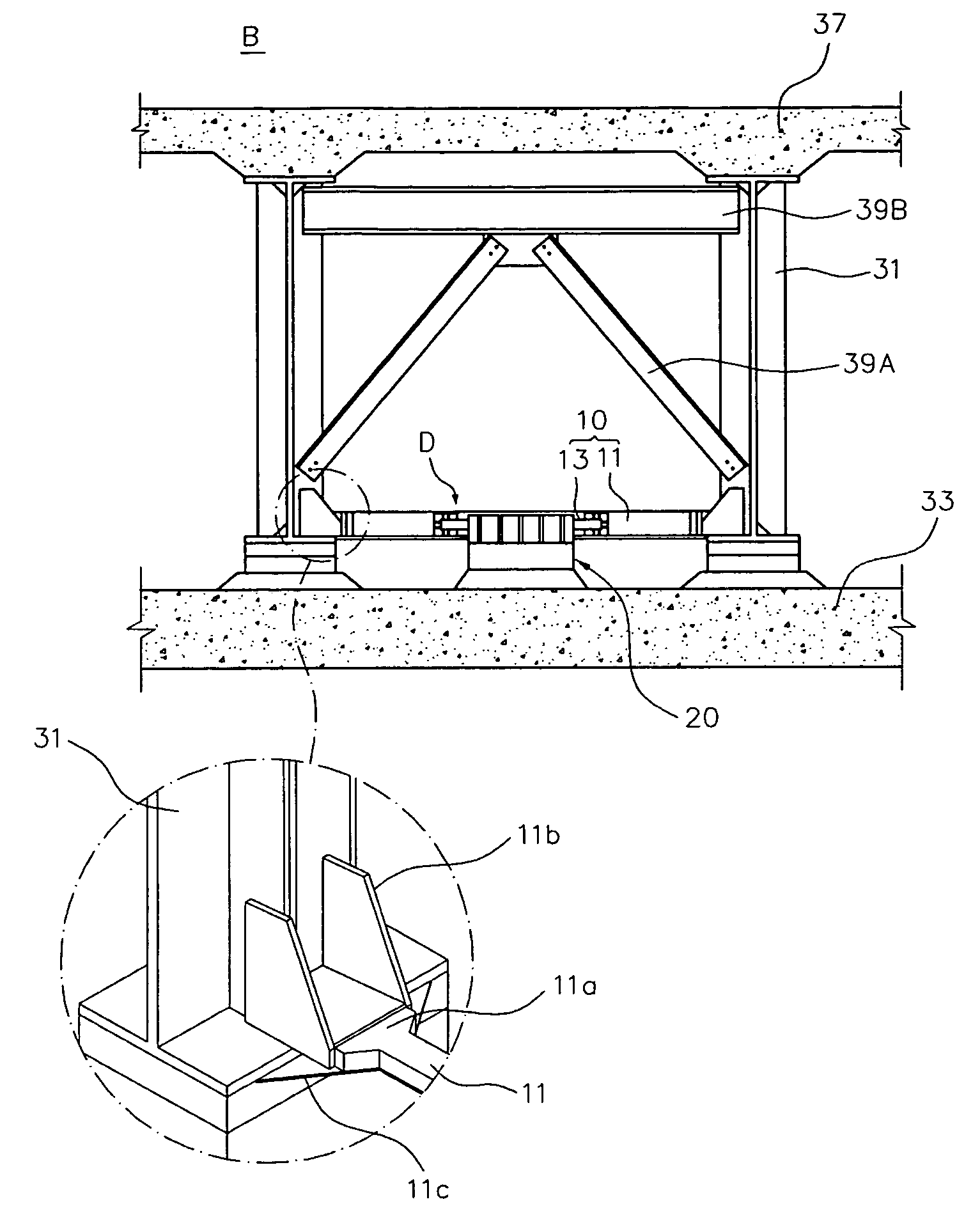

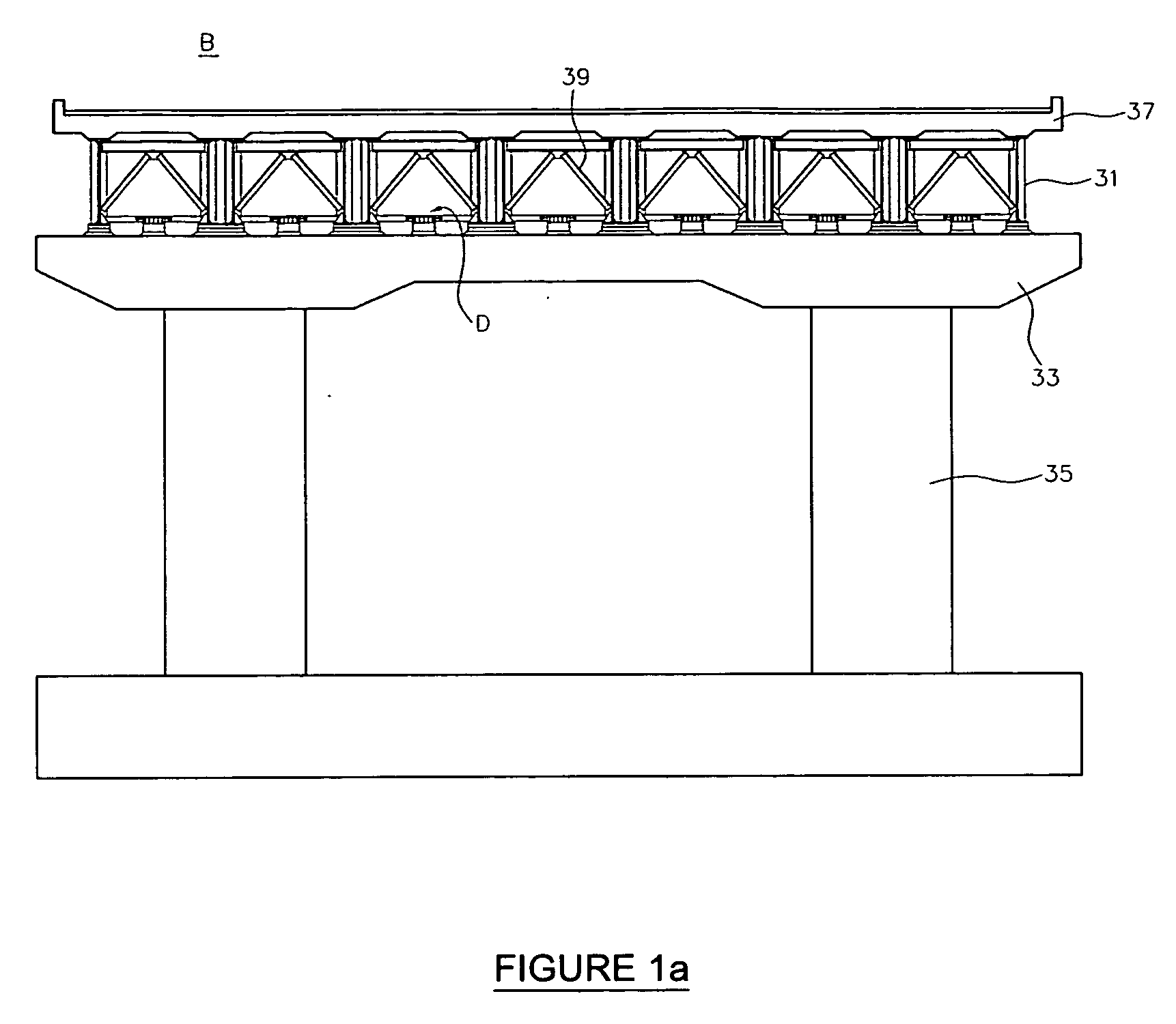

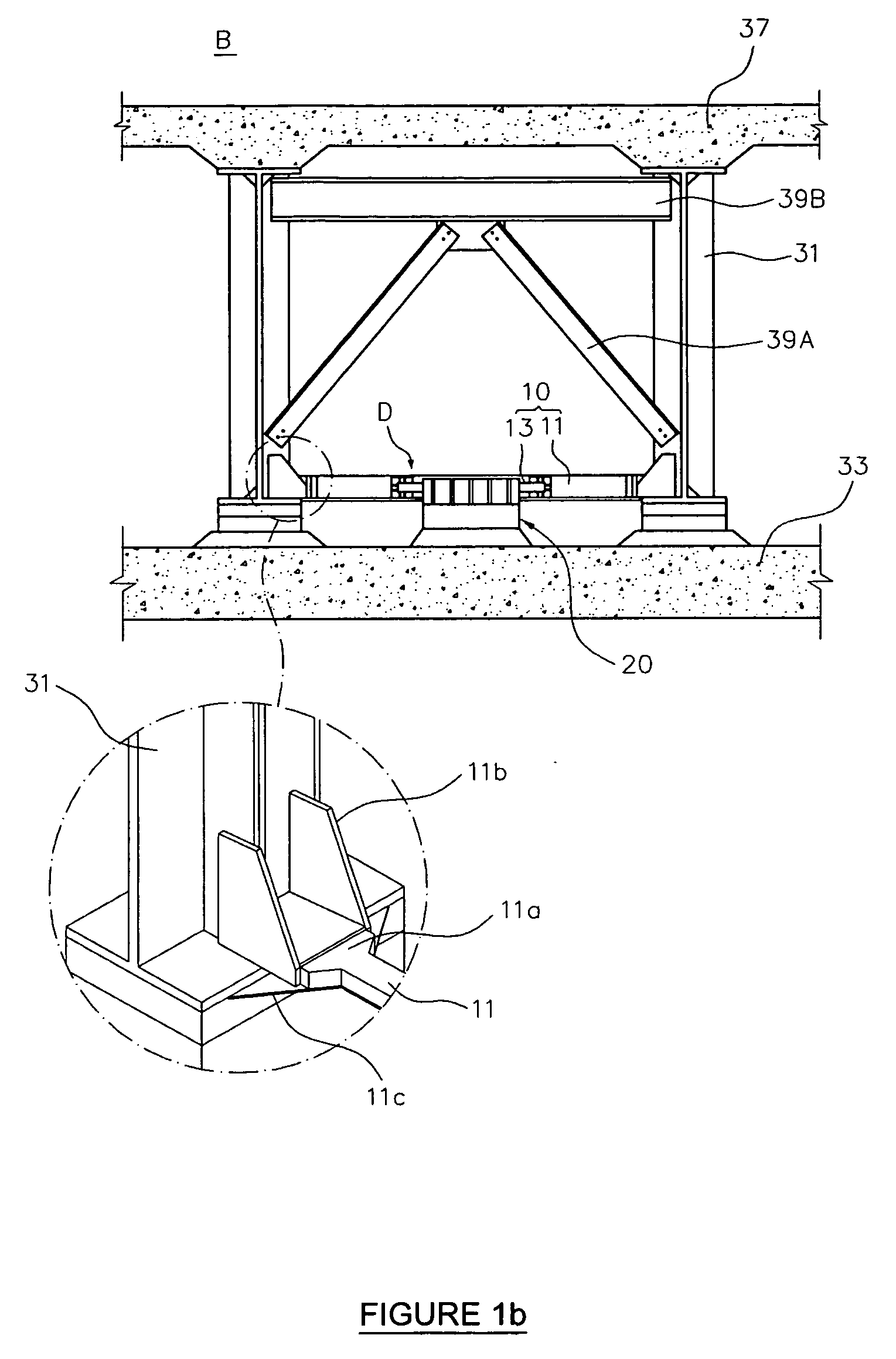

Girder bridge protection device usin sacrifice means

InactiveUS20070000078A1Improving structural behaviorEfficiently dissipatedBridge structural detailsProtective buildings/sheltersEngineeringAbutment

An girder bridge protection device comprises sacrifice means including girders which are installed on an upper surface of a bridge seat of an abutment or pier to support a bridge floor, a symmetrical main support member which connects two girders and has a pipe-shaped configuration, and an auxiliary support member which projects from one surface of a center portion of the main support member in a direction perpendicular to an axial direction of the main support member; and restraining means secured to the bridge seat of the abutment or pier and including an accommodating section which accommodates the auxiliary support member such that the auxiliary support member is separated from the accommodating section in a forward and rearward direction and in a leftward and rightward direction, thereby controlling the behavior of the auxiliary support member.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

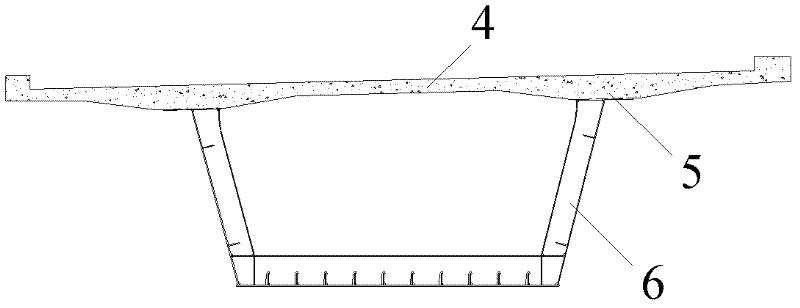

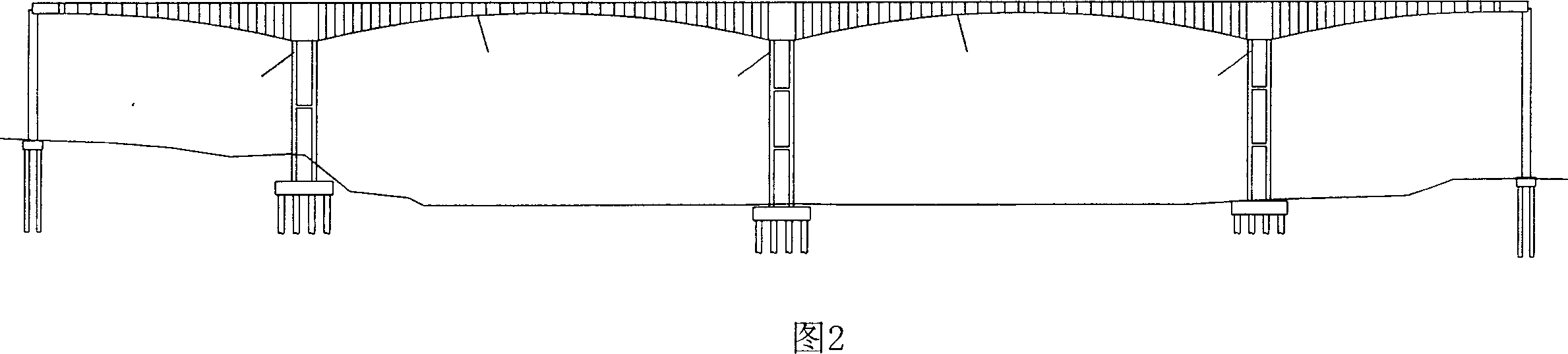

Box type baseboard prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN1974931ASolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsPre stressWhole body

The present invention belongs to the field of civil engineering bridge technology, and discloses a box-type baseplate prestressed concrete non-uniform box beam bridge. It is characterized by that the rectangular solid baseplate of box beam bridge is remade into the form of box. Said invention also provides its concrete structure characteristics. Its structure includes baseplate box top plate, horizontal anchor plate and box beam, they can be in-situ case together, and formed into one whole body. Said bridge has high structure whole body rigidity, small deflection and strong resistance to shear, and its crossing capacity also can be greatly raised.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

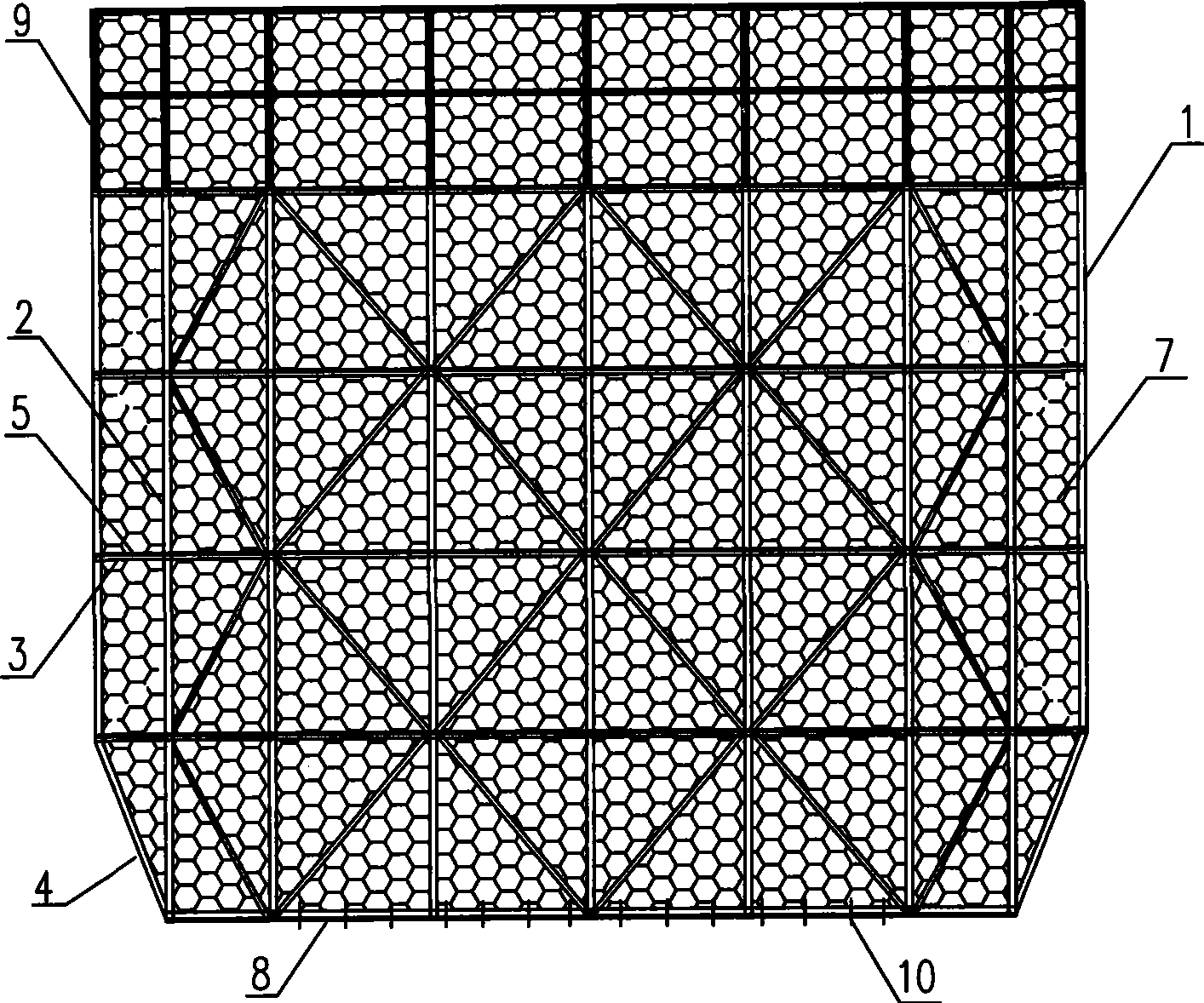

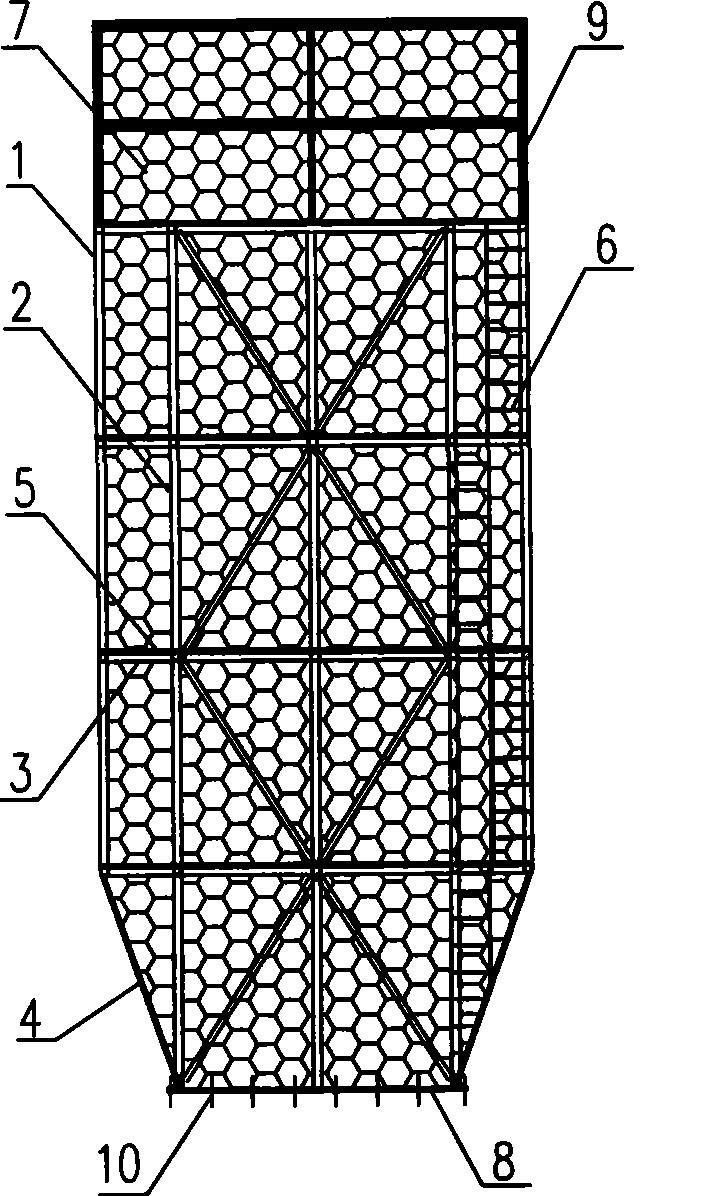

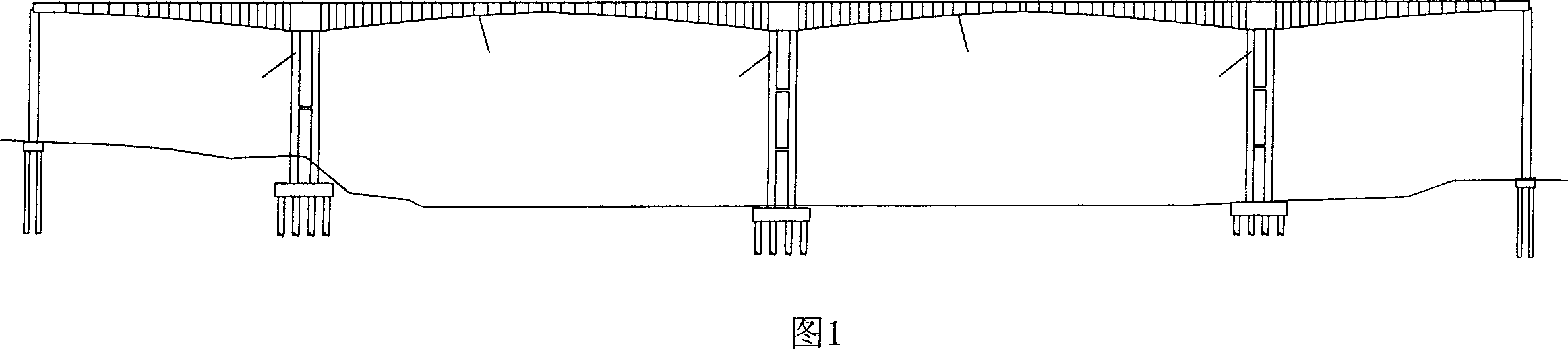

Built-in oblique leg rigid-frame prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN1974929ASolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsPre stressEngineering

The present invention belongs to the field of civil engineering bridge technology, and discloses a kind of built-in oblique leg rigid frame prestressed concrete non-uniform box beam bridge. It is characterized by that in its box beam interior an oblique leg rigid frame structure is set, said oblique leg rigid frame structure is formed from built-in longitudinal beam and built-in oblique leg. The built-in oblique leg and box beam baseplate are parallelly arranged and identical in thickness, and the built-in longitudinal beam and midspan baseplate are aligned and identical in thickness, the midspan baseplate, box beam baseplate and built-in longitudinal beam are combined into one body, so that said bridge structure has high integral rigidity, small deflection and strong resistance to shear, and the crossing capacity of said prestressed concrete non-uniform box beam bridge can be greatly raised.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

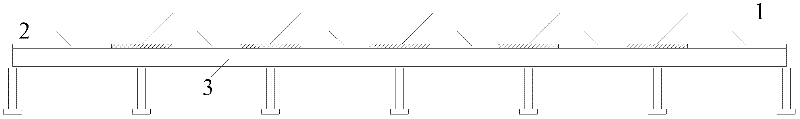

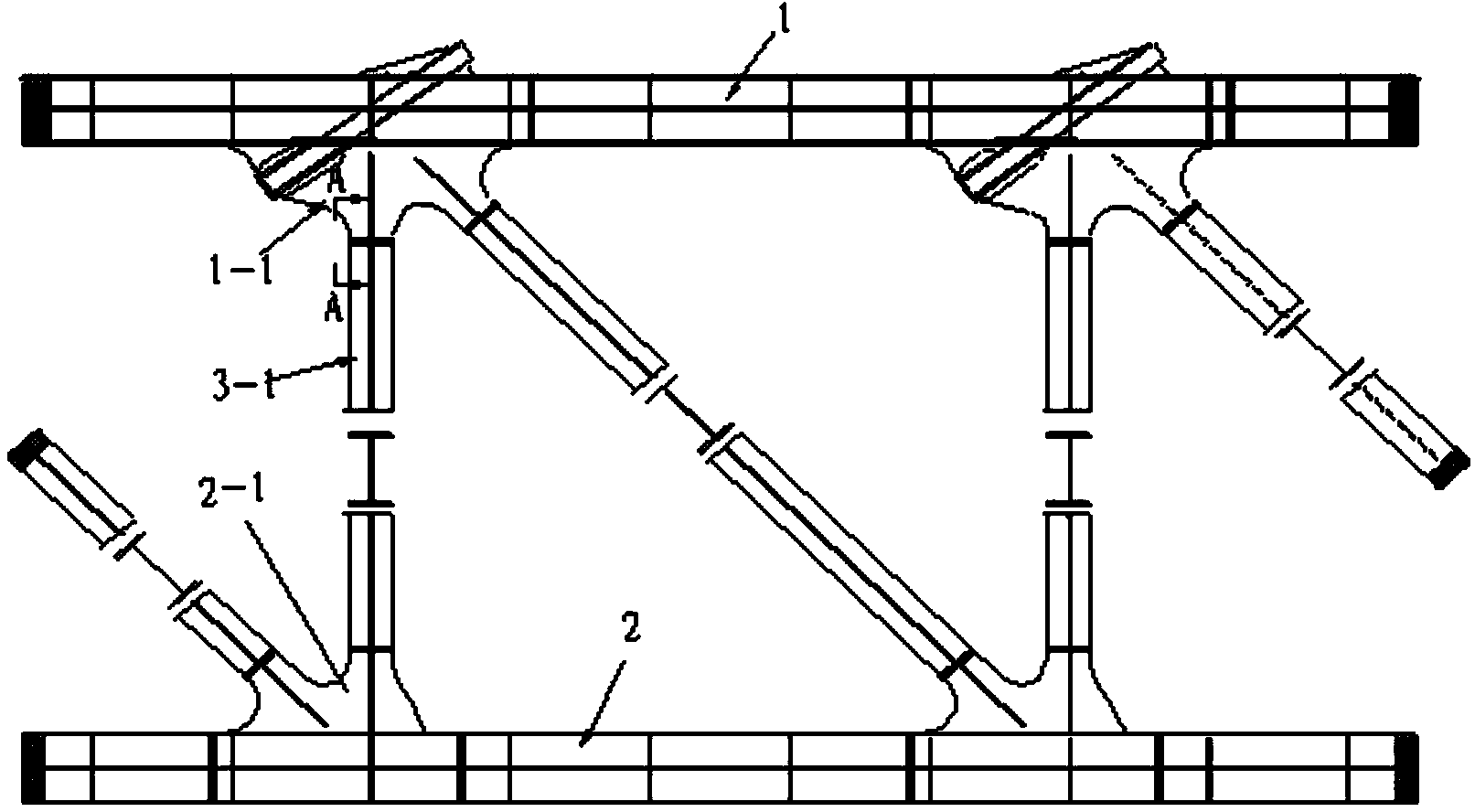

Multi-connection and multi-span continuous steel truss girder bridge and construction method thereof

InactiveCN104328734AEasy Connection HandlingSolve the problem of tight construction scheduleTruss-type bridgeBridge erection/assemblyEngineeringStructural engineering

The invention relates to a multi-connection and multi-span continuous steel truss girder bridge and a construction method thereof. The multi-connection and multi-span continuous steel truss girder bridge comprises a plurality of height-variable trusses, wherein the tail parts and head parts of the height-variable trusses are connected into a row, the upper part and lower part of each height-variable truss are respectively connected with an upper horizontal and longitudinal connection and a bridge surface, and the lower end of the bridge surface is fixedly connected with a plurality of bridge piers. The construction method comprises the following steps of preliminary work, building of the bridge piers, building of a top pushing splicing platform, jacking and pushing of the height-variable trusses, suspension and splicing of the height-variable trusses, paving of a worker walkway, cleaning of site, and completion. The multi-connection and multi-span continuous steel truss girder bridge and the construction method have the beneficial effects that the structure stress of the height-variable trusses is reasonable, and the steel consumption amount is reduced; by adopting the integral and splicing type node mixing structure, the splicing is simple; by adopting multiple main trusses, the transverse stress is reasonable; by arranging the worker walkway and a refuge platform in a gap between the main truss components, the truss width is effectively reduced, and the steel consumption amount is reduced; by adopting the multi-connection synchronous jacking, pushing, suspension and splicing combined construction method, the influence on the spliced jacking and pushing process of original connection caused by the new connection of splicing is avoided, the jacking and pushing quality is improved, the difficulty in synchronizing is decreased, the efficiency is improved, and the cost is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

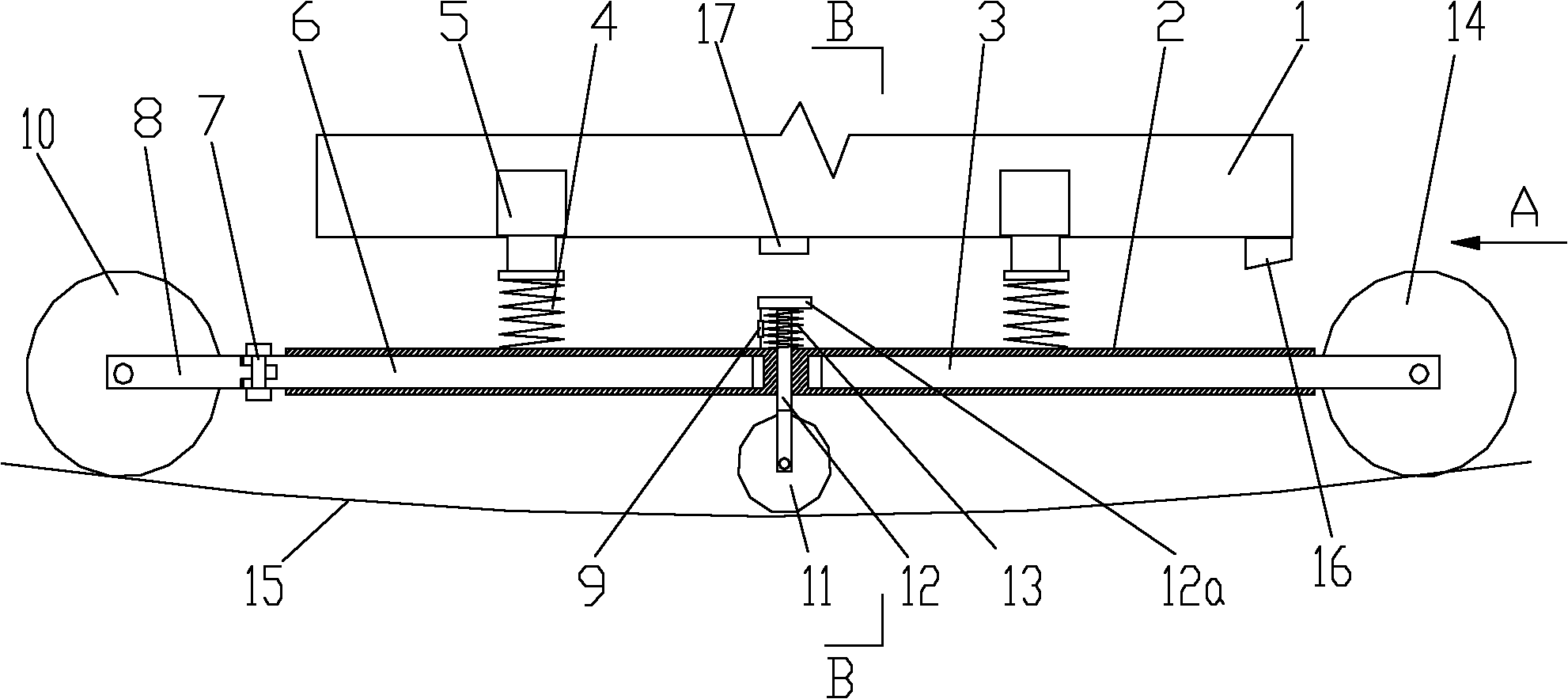

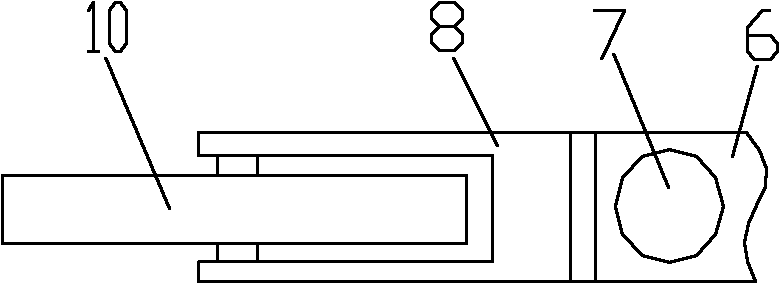

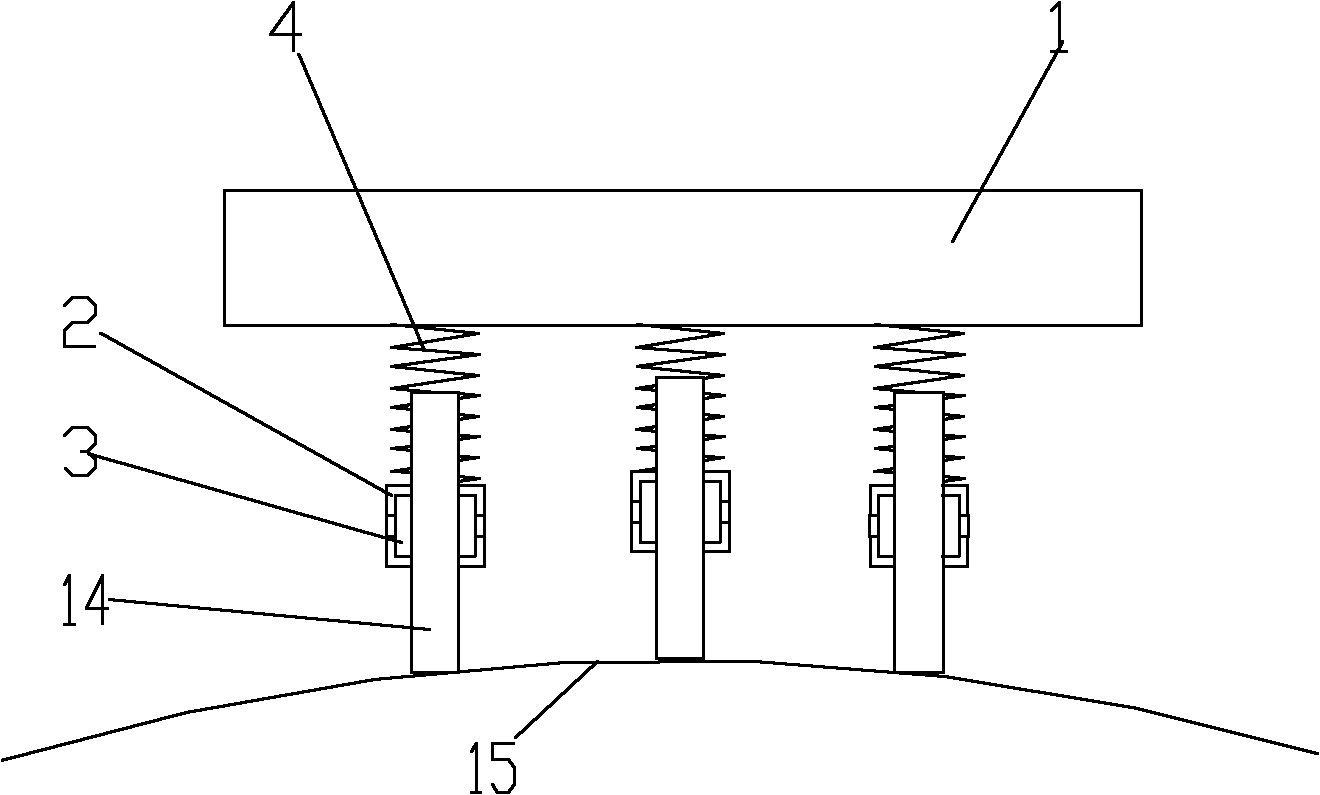

Bridge safety-appearance sensing monitoring car and safety assessment method utilizing same

ActiveCN102433834AImprove accuracyImprove efficiencyMeasurement devicesBridge structural detailsBridge deckTest fixture

The invention discloses a bridge safety-appearance sensing monitoring car and a bridge safety assessment method. The monitoring car comprises a walking car and a detection device, wherein the detection device comprises suspension components and three groups of detection assemblies; the detection assemblies comprise girders, front trolley wheels, rear trolley wheels and detection wheel components; and the detection assemblies are arranged on a walking car chassis in parallel along the transverse direction. The monitoring car and the method have the following beneficial effects that: the safety of the bridge structure can be predicted by only monitoring the bridge deck appearance and curvature changes; according to the law that changes of the bridge deck appearance and bridge deck structure curvature are inevitably caused when the conventional girder bridges and arch bridges have the defects endangering the structure safety, the digitalized curvature surfaces of the bridge deck structure in the test area can be obtained by arranging a bridge deck curvature testing device on the walking car; and the safety of the current bridge structure is distinguished by analyzing and comparing the monitored bridge appearance (bridge deck appearance and bridge deck curvature) changes obtained through previous detections.

Owner:CHONGQING JIAOTONG UNIVERSITY

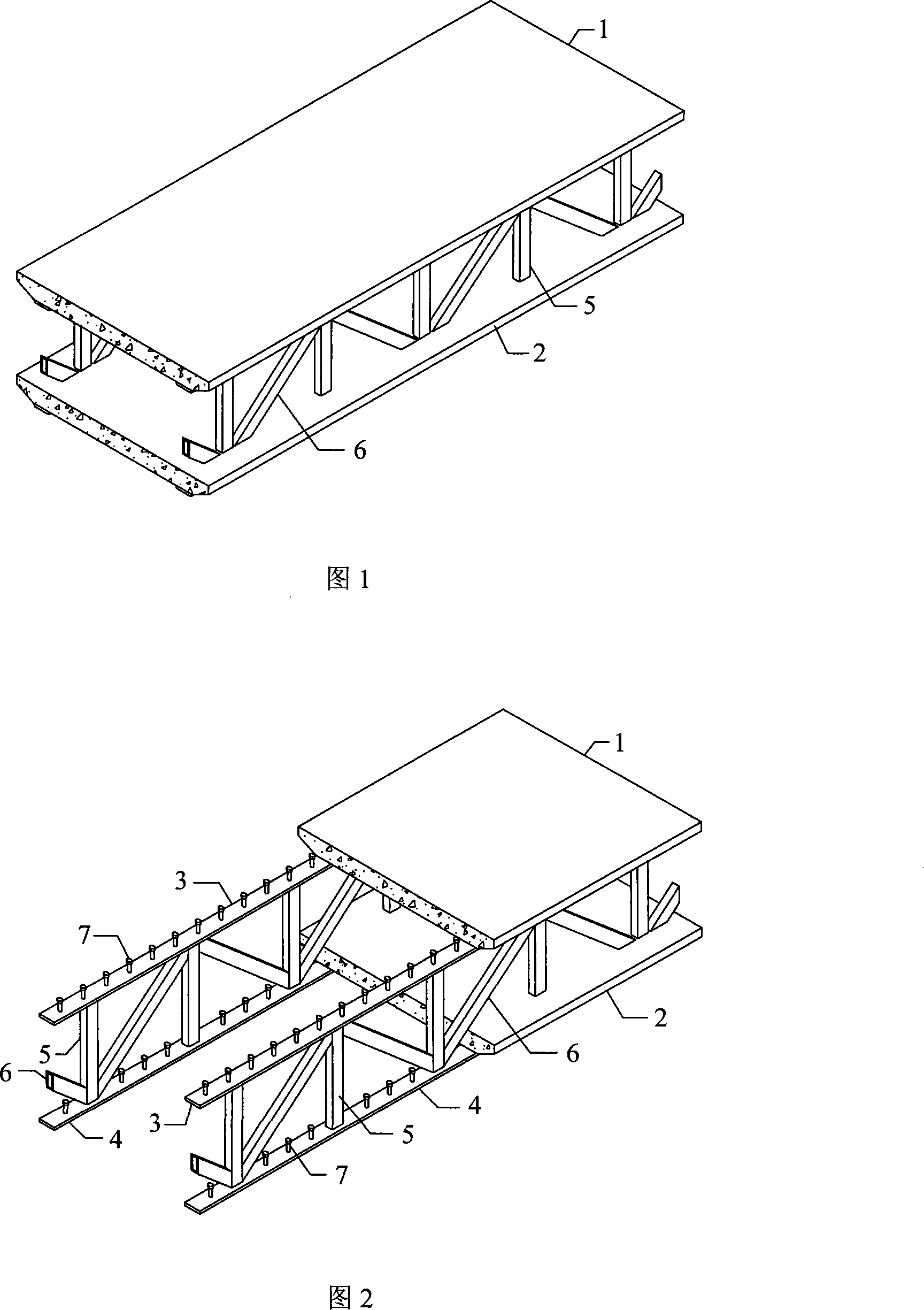

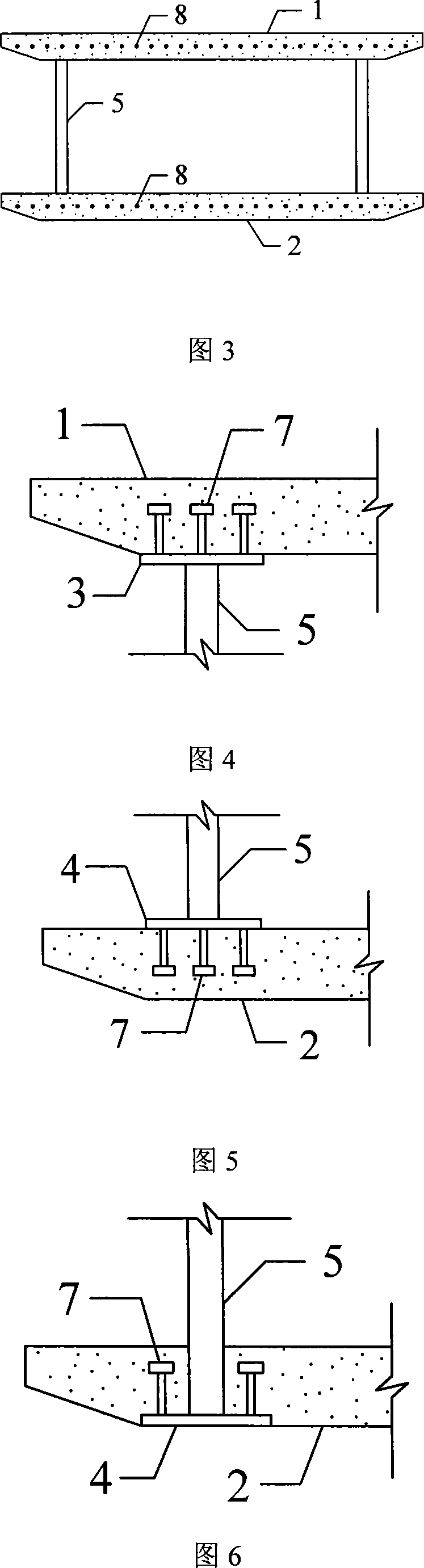

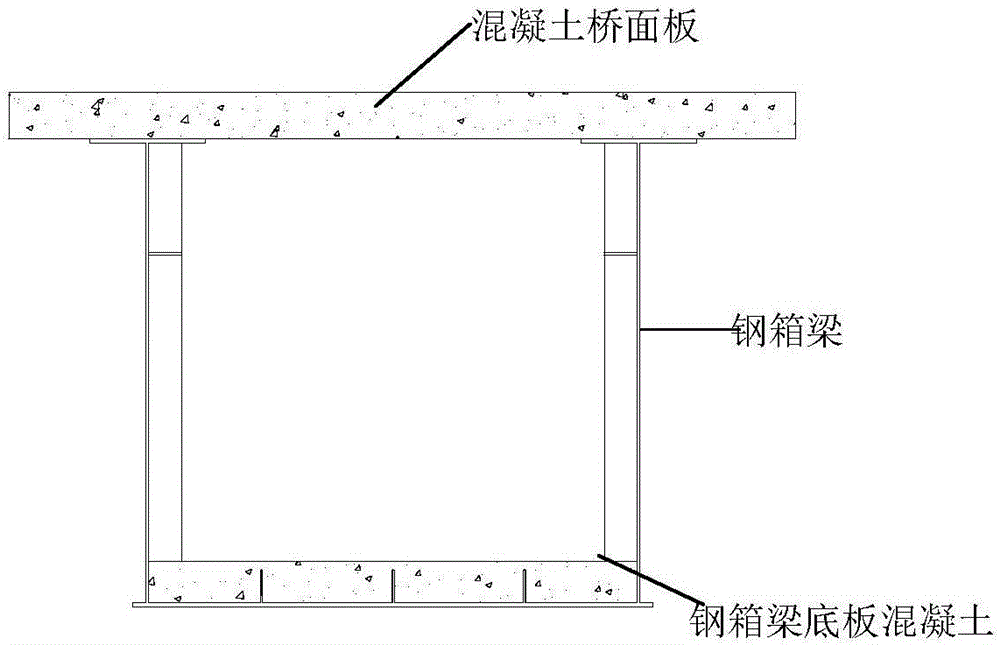

Combined steel box girder for high-speed railways and construction method thereof

ActiveCN107100065AEasy to liftLarge spanBridge structural detailsBridge erection/assemblyPre stressPrestressed concrete

The invention discloses a combined steel box girder for high-speed railways and a construction method thereof, belonging to the field of high speed railway bridges. A top flange plate of the steel box of the combined steel box girder is provided with a shearing resistance connecting member which connects the above concrete slabs with the top flange plate. At the same time, a steel base plate and a prefabricated prestressed concrete plate are combined to collectively act as the base plate of the combined steel box girder for jointly bearing stress. Concrete slabs on the top flange plate can be cast in situ or prefabricated. since the girder which is made of the steel box, the concrete top plate and the prestressed concrete plate inside the steel box can be assembled in site, which is convenient for transmission and hoisting and it is possible to build longer span simply supported girder bridges on land. Compared with present whole simple girders of the same span, the provided combined steel box girder has increased cross section rigidity of the steel box girder, the weight of girders is reduced and the span of girders is increased. The combined steel box girder of the invention has reasonable construction stress and is convenient to construct; technical support is provided for building longer span simply supported girder bridges on land.

Owner:ZHENGZHOU UNIV

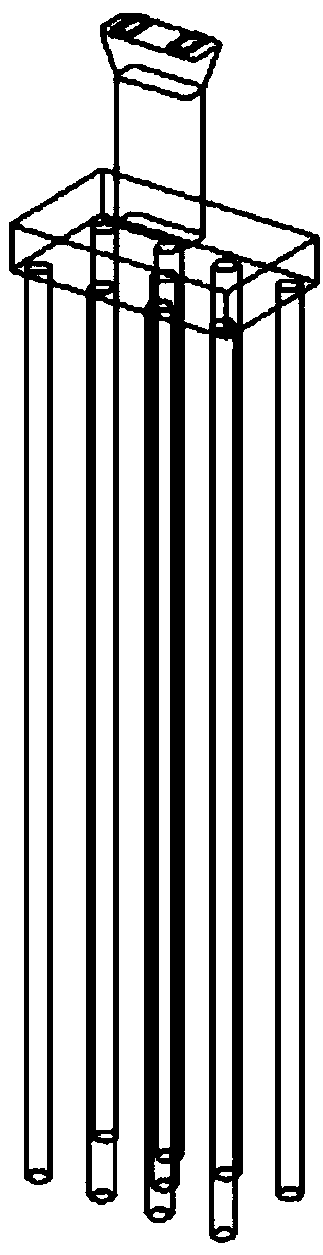

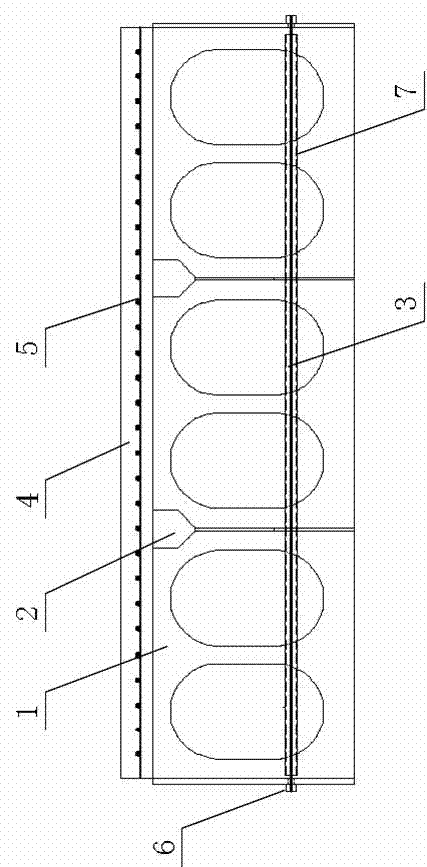

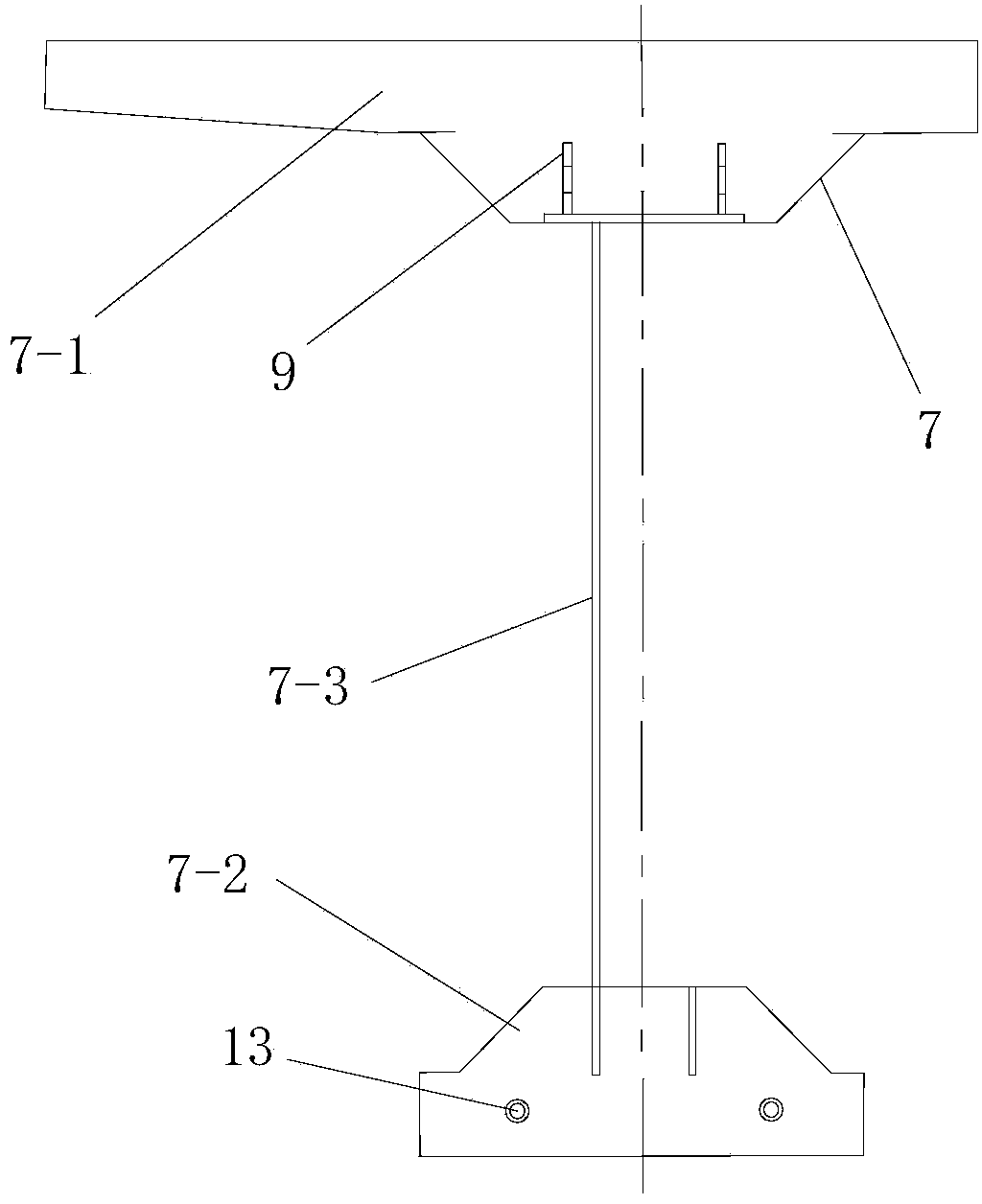

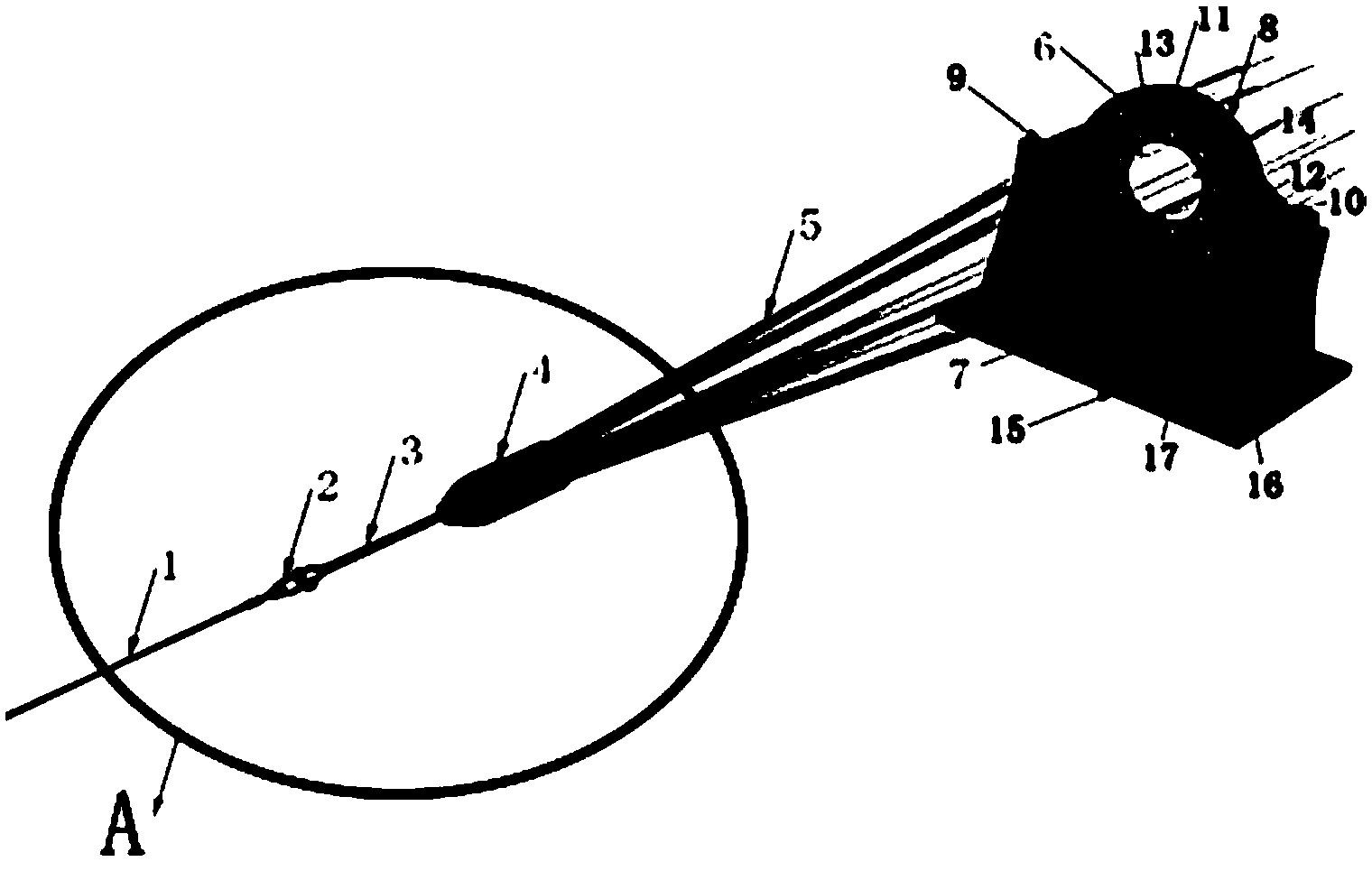

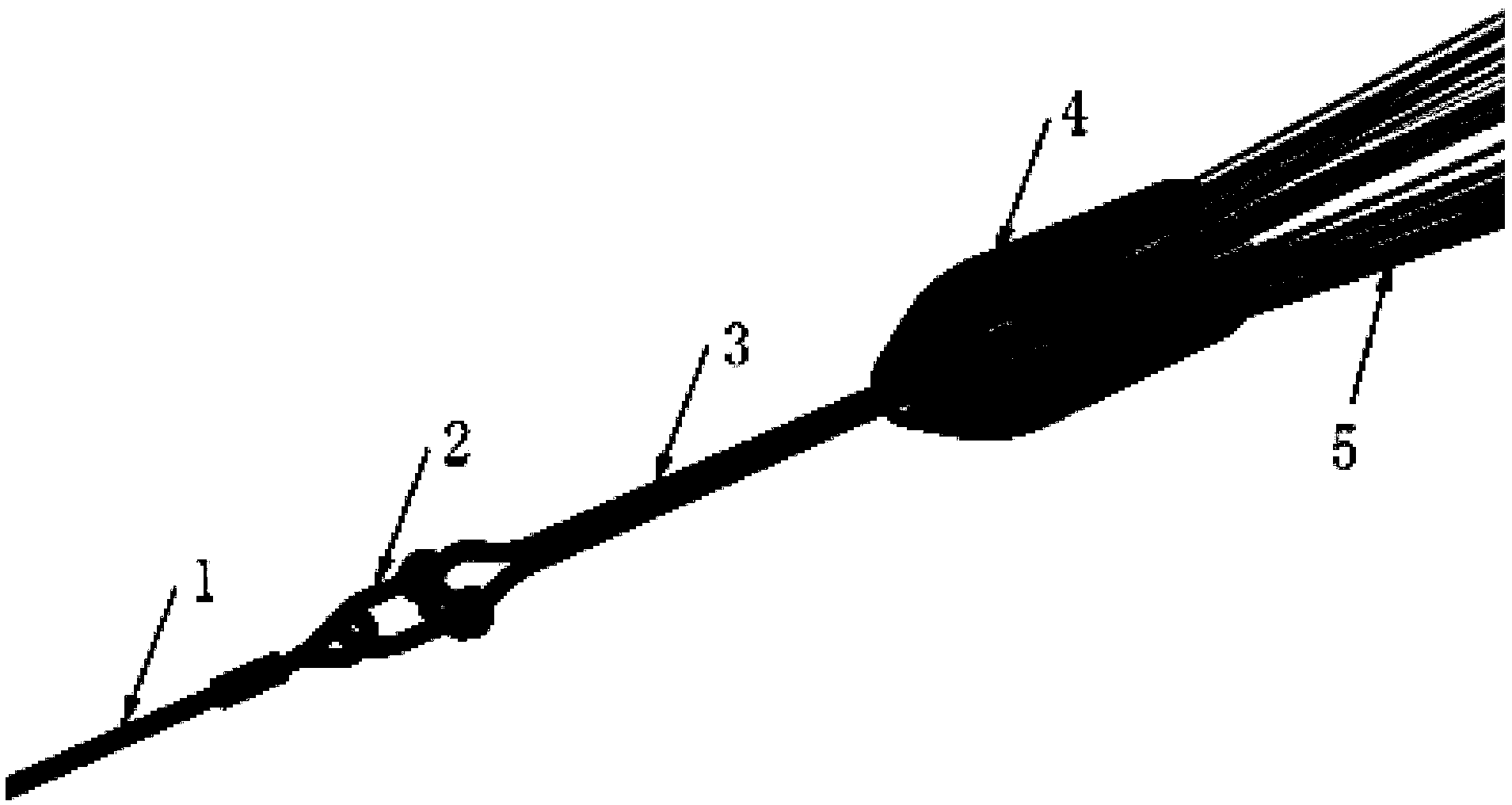

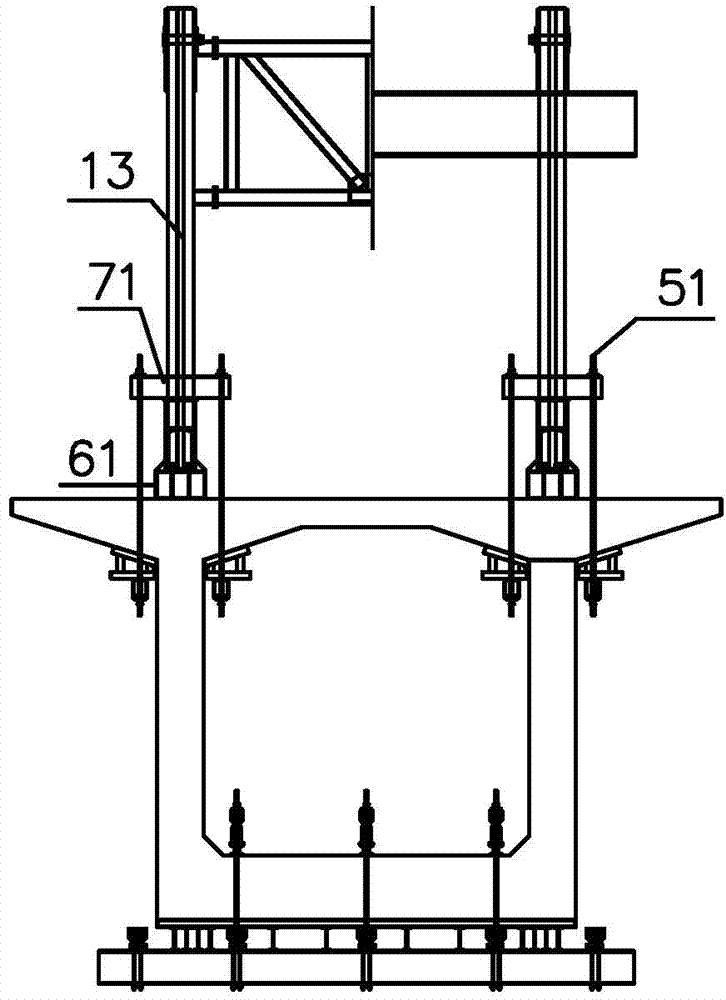

Superlong prestress strand combing, binding and strand pulling integrated device

InactiveCN103669214APlay a protective effectGuaranteed integrityBridge erection/assemblyCable stayedPre stress

The invention discloses a superlong prestress strand combing, binding and pulling integrated device, relates to the field of tools for combing, binding and pulling of steel strands in highway bridges, and aims to provide a superlong prestress strand combing, binding and pulling integrated device which is easy and convenient to operate, saves cost and can greatly improve strand pulling efficiency and quality. The superlong prestress strand combing, binding and pulling integrated device comprises a winch load cable (1), a traction bar (3), a clamping ring (2), a strand pulling sleeve (4), a strand combing plate, a base, a fixing hoop (8) and a sealing plate (13), wherein the load cable and the traction bar are connected through the clamping ring (2), one end of the traction bar is sleeved with the strand pulling sleeve (4), the base (7) is located at the bottom of the strand combing plate, the fixing hoop (8) is fixed to the outer side of the top end of the strand combing plate, and the sealing plate (13) is located in the middle of the strand combing plate. The superlong prestress strand combing, binding and pulling integrated device can be widely applied to all prestress strand pulling construction through a post-tensioning method, and particularly superlong prestress strand combing, binding and pulling of suspension casting segmental box girders of prestressed concrete large-span cable-stayed bridges, suspension bridges and continuous girder bridges. Strand pulling, combing and binding are integrated, so that the strand pulling efficiency and quality can be greatly improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

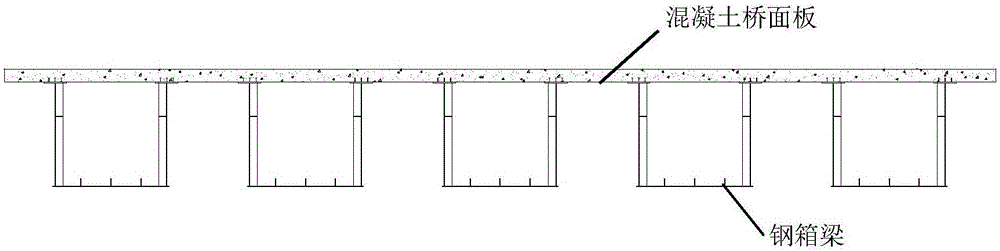

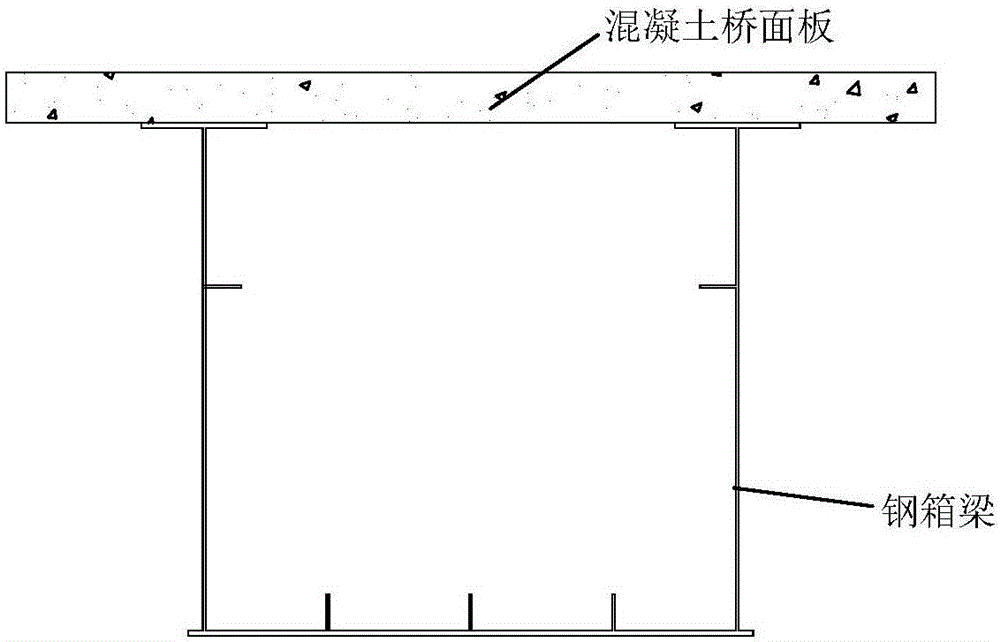

Method for improving stress performance of negative bending moment zone of steel-concrete combined multi-box continuous beam bridge

ActiveCN106758743AImprove compressive stiffnessImprove unfavorable stress situationsBridgesSpecial data processing applicationsStress conditionsContinuous beam

The invention discloses a method for improving stress performance of a negative bending moment zone ofa steel-concrete combined multi-box continuous beam bridge. The continuous girder bridge built by using the method comprises multiple horizontally connected separate small box beams. The upper portion of each small box beam is a concrete bridge surface plate. The lower portion is a steel box beam. The concrete bridge surface plate and the steel box beam are connected into an integral body by the shear force of the top flange of the steel box beam. Normal stress steel bars and constructional steel bars are arranged in the concrete bridge surface plates of the whole bridge. Normal horizontal and longitudinal stiffening ribs are arranged in the steel box beams. The longitudinal stress steel bars in the concrete bridge surface plates of the negative bending moment zone are intensified in density. After the steel box beams is erected, the surface plates are grouted and the preformed holes are prepared, concrete is grouted in the steel beam base plates of the negative bending moment zone through the holes, the concrete grade is identical to the concrete grade of the bridge surface plates. The method can increase the compression strength of the steel box beam base plate, improve the unfavorable stress condition that the steel box beam base plates in the negative bending moment zone is bent by pressure.

Owner:ZHEJIANG UNIV

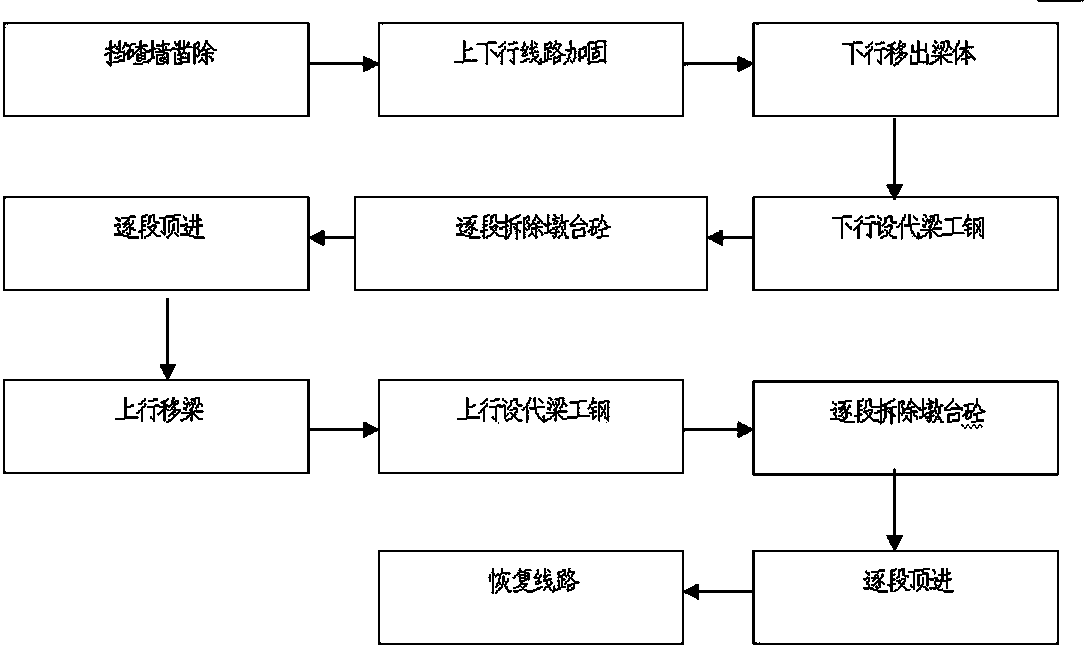

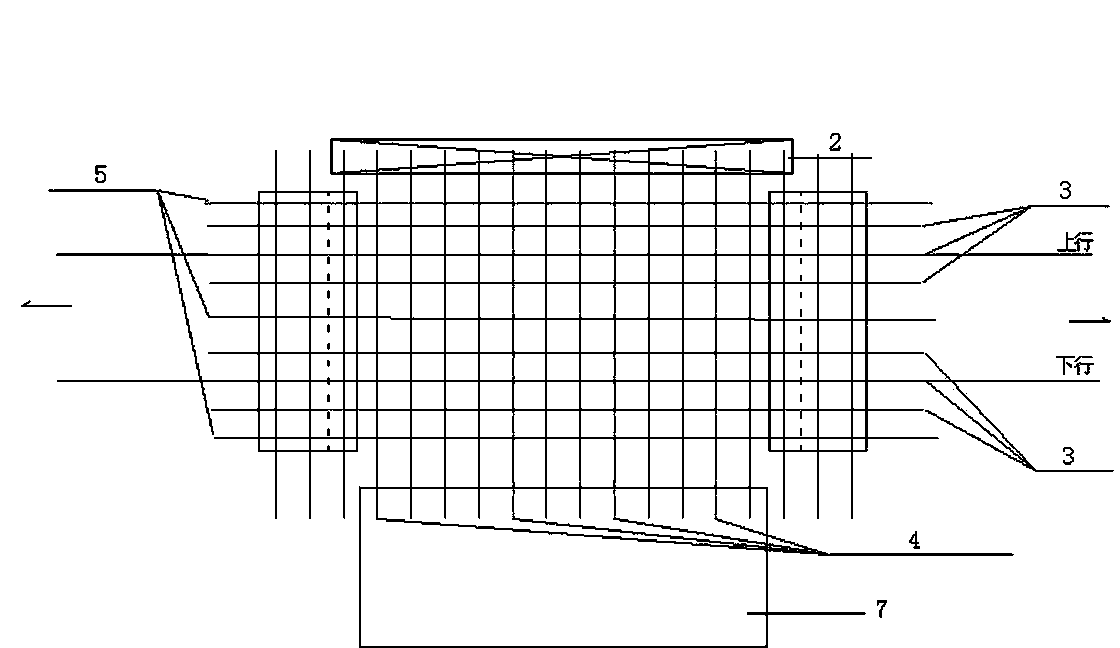

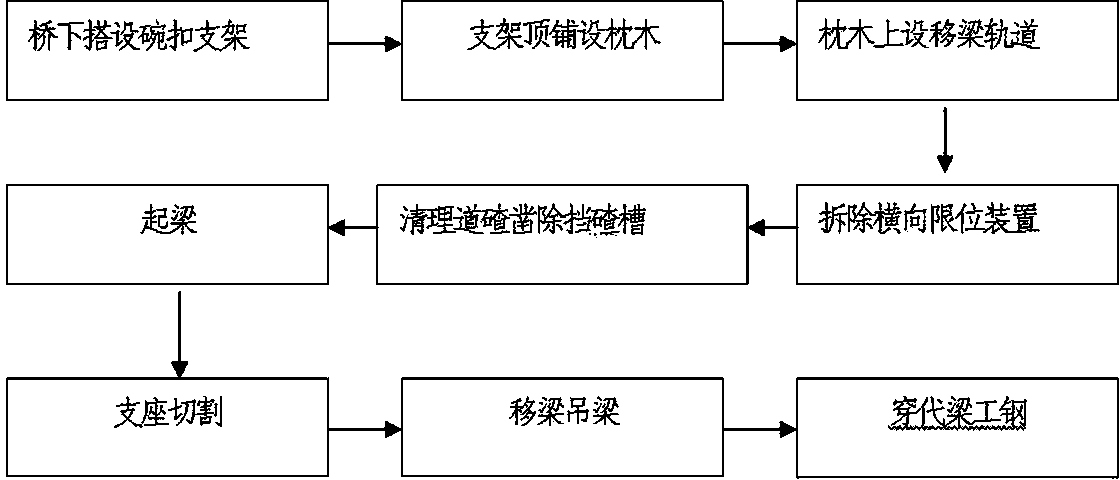

Railway construction method of dismantling existing girder bridge and pushing frame structure in situ

InactiveCN103726451AOperational impact is smallSolve the problem that the small spacing cannot be appliedBridge erection/assemblyBridge strengtheningSunroofRailway line

The invention relates to a railway construction method of dismantling an existing girder bridge and pushing a frame structure in situ. The method of conducting pushing after removing beams is adopted for construction, the position for a beam containing platform is reserved when the frame structure is prefabricated, the upper line and the lower line of a railway line are simultaneously reinforced, beam moving is conducted on the upper line and the lower line independently in the beam moving process, substitute I-beams are used for supporting the railway line after beam bodies are removed, the substitute I-beams are dismantled one by one while pushing is conducted, beam removing is conducted through night skylight closing points, the beams on the lower line are removed at a time from the lower line side, the beams on the upper line are removed at a time from the upper line side, the skylight closing points are occupied once when the beams on the upper line are removed and once when the beams on the lower line are removed, and the skylight closing points are closed for three hours each time. When the construction method is used, the railway operation of each railway line only needs to be interrupted for a short period of time, the operation is convenient, the construction cost is low, and it can be ensured that the influences on the railway operation are reduced to the maximum degree.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Large-span concrete continuous girder bridge side span folding device and method

InactiveCN103572708ASolve complexityResolution cycleBridge erection/assemblyHanging basketSupport point

The invention relates to a large-span concrete continuous girder bridge side span folding device so as to solve the problems that the existing side span bracket folding construction process is complex, long in period, high in cost and difficult to adjust and operate. The device comprises a double-frame hanging basket, wherein the frames are connected through a hanging basket gantry; a folding supporting rod is fixed on a side block and supports the front supporting point of the hanging bracket. A side span folding method comprises the following steps: a, moving the hanging basket forwards to the front end of a cantilever; b, anchoring the hanging basket at the cantilever end of the bridge by using an anchoring rod at the middle supporting point of the hanging basket. The invention has the benefits that compared with the existing commonly-used folding section for constructing side span by adopting a full space bracket method, the concrete continuous girder bridge side span folding process and the concrete continuous girder bridge side span folding device utilize the front hanging point of the hanging bracket which is used for supporting the bridge surface and on the side block to form a vertical restraint system with stable continuous girder side span so as to successfully solve the problems that the existing side span bracket folding construction process is complex, long in period, high in cost and difficult to adjust and operate.

Owner:SOUTHWEST JIAOTONG UNIV

Large-span steel truss girder bridge whole joist full-welding joint welding method

The invention relates to a large-span steel truss girder bridge whole joist full-welding joint welding method. The method comprises the following steps that A upper chords, lower chords, upper chord whole joint boards, lower chord whole joint boards, brace covering boards and brace webs are prefabricated; B the prefabricated chords are assembled in a welded mode to constitute whole joists; C over-welding hole blocking boards and outer reinforcing boards are welded; D ultrasonic hammering is conducted on weld joints. The method greatly reduces the usage quantity of high-strength bolts when the joists are assembled on a construction site, and not only reduces weight of the whole structure, but also reduces the work amount for screwing the bolts. According to the method, a welding sequence, welding materials, a welding standard and the like are provided, deformation produced during welding is reduced, the sizes of the chords are guaranteed, and it is guaranteed that the mechanical property of weld joint metal meets requirements. In order to guarantee fatigue strength of the whole joint welding structure, the invention further provides a technology for weld joint over-welding hole blocking and outer reinforcing board welding. By means of ultrasonic hammering, fatigue strength of the whole joist full-welding joint weld joints is enhanced.

Owner:中铁山桥(南通)有限公司

Simply supported girder bridge floor continuous new construction and construction method

InactiveCN104612050AImprove corrosion resistanceBridge structural detailsBridge erection/assemblySteel tubeCorrosion resistant

The invention relates to simply supported girder bridge floor continuous new construction. The construction comprises multiple girders of a simply supported girder bridge and bridge floor plates arranged on the girders, ultra-high performance concrete connecting plates are arranged and connected between the bridge floor plates on the adjacent girders, arc-shaped steel supporting pieces located at the same height are embedded in end faces of the adjacent girders, steel tube ultra-high performance concrete segments are arranged between the arc-shaped steel supporting pieces, two ends of each steel tube ultra-high performance concrete segment are connected with end faces of the girder at corresponding side respectively, and the invention further relates to two construction methods applied to new-built simply supported girder bridge and existing simply supported girder bridge. By utilizing the ultra-high performance concrete connecting plates arranged in the simply supported girder bridge floor continuous new construction, tensile deformation in longitudinal direction of a bridge at continuous construction on bridge floor caused by girder deformation of the adjacent girders is achieved, and corrosion resistant performance is improved; and by utilizing compression resistance performances of the ultra-high performance concrete connecting plates and the steel tube ultra-high performance concrete segments, compression deformation in longitudinal direction of the bridge at the continuous construction on the bridge floor caused by the girder deformation of the adjacent girders is achieved.

Owner:FUZHOU UNIV

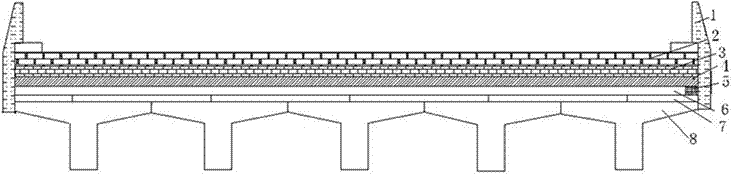

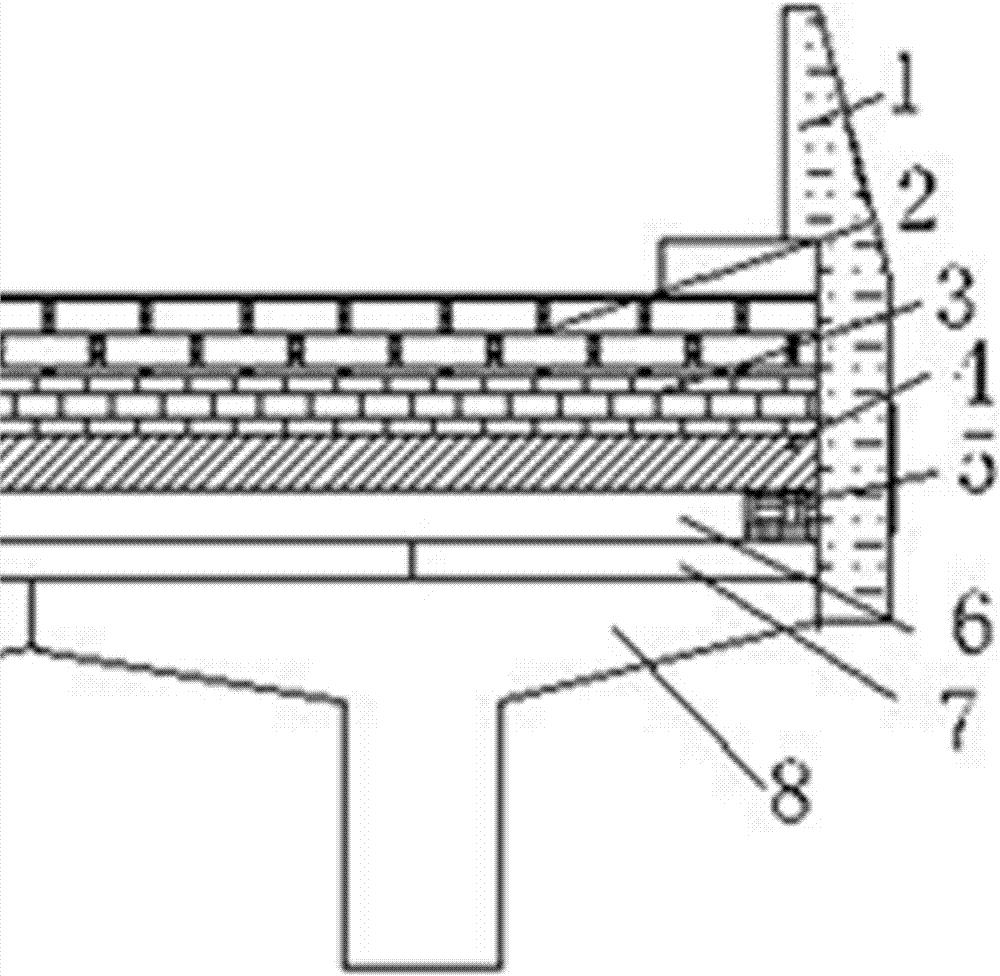

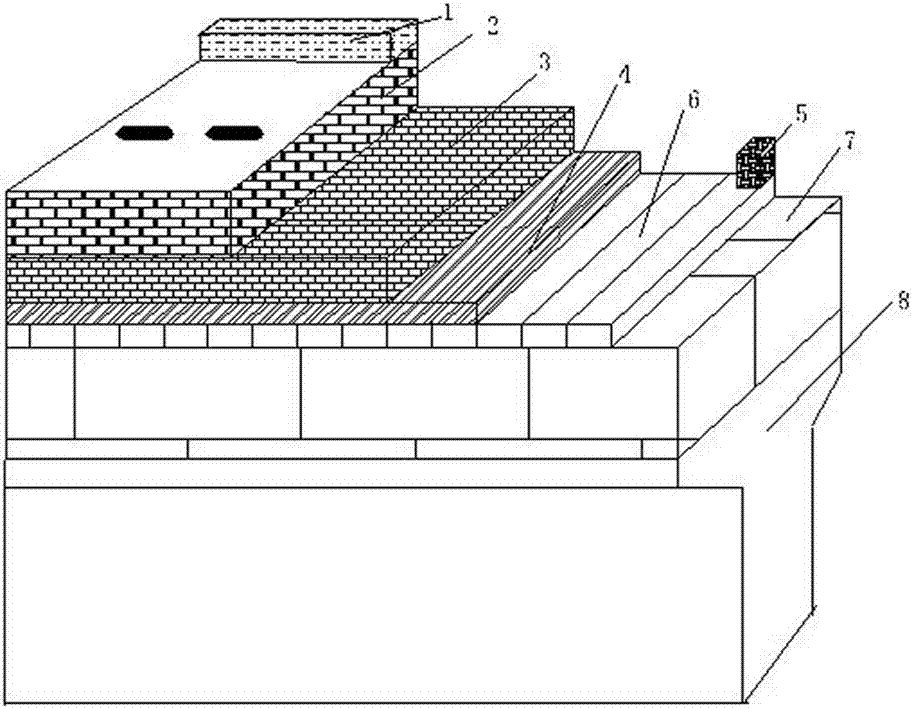

Construction method of T-shaped girder bridge pavement with graphene heating film

InactiveCN107100054AConvenient travelTravel safetyPaving detailsBridge structural detailsBridge engineeringForeign matter

The invention is related to a pavement construction technology in the direction of bridge engineering in the field of highway engineering, and discloses a construction method of a T-shaped girder bridge deck pavement by means of the heating principle of a graphene heating film. At present, thawing speed of snow on a bridge deck is increased by spreading a snow-melting agent usually, which occupies large amount of manpower and resources; and what is more, using the snow-melting agent for long time may cause corrosion on the bridge deck and bridge structure and further causes reduction of the service life of the bridge. The method includes the steps of: paving a reinforced concrete layer by 10 cm; 2) removing foreign matters from a bridge base layer; 3) paving the graphene heating film; 4) detecting heating performance of the graphene heating film; 5) paving a waterproof layer by 1 cm; 6) paving a cement concrete protective layer by 4 cm; 7) paving modified asphalt concrete by 5 cm; 8) testing ground surface temperature by an infrared temperature detector. The method solves problems of slow thawing speed of ice and water and corrosion on the bridge body due to the snow-melting agent after the T-shaped girder bridge pavement ices in winter. The method increases the service life of the T-shaped girder bridge pavement and reduces expenses of pavement maintenance and the snow-melting agent.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Prestressed concrete variable cross-section box girder bridge, movable suspended scaffolding and construction method of prestressed concrete variable cross-section box girder bridge

InactiveCN103352417AQuality improvementIncreased durabilityBridge erection/assemblyBridge materialsCrack resistancePre stress

The invention provides a prestressed concrete variable cross-section box girder bridge. The prestressed concrete variable cross-section box girder bridge comprises a top plate, a bottom plate and webs, wherein the top plate, the bottom plate and the webs form a box girder box chamber. The prestressed concrete variable cross-section box girder bridge further comprises FRP box board composite structures, wherein the FRP box board composite structures are arranged on the lower surface of the top plate, the outer surface and inner surface of each web and the lower surface of the bottom plate. Each FRP box board composite structure comprises FRP plates and FRP box type stiffening ribs, wherein the FRP box type stiffening ribs are arranged between the two layers of FRP plates, and the FRP box type stiffening ribs and the two layers of FRP plates are bonded and cured to form the FRP box board composite structure. The stress performance and the crack resistance of a box girder are greatly improved, the phenomenon that the box girder cracks is reduced or even avoided, the structural integrity is improved, and therefore the quality and durability of the prestressed concrete variable cross-section box girder bridge are improved. The invention further provides a movable suspended scaffolding structure for the construction of the prestressed concrete variable cross-section box girder bridge and a construction method of the prestressed concrete variable cross-section box girder bridge.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com