Patents

Literature

63results about How to "Eliminate radial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

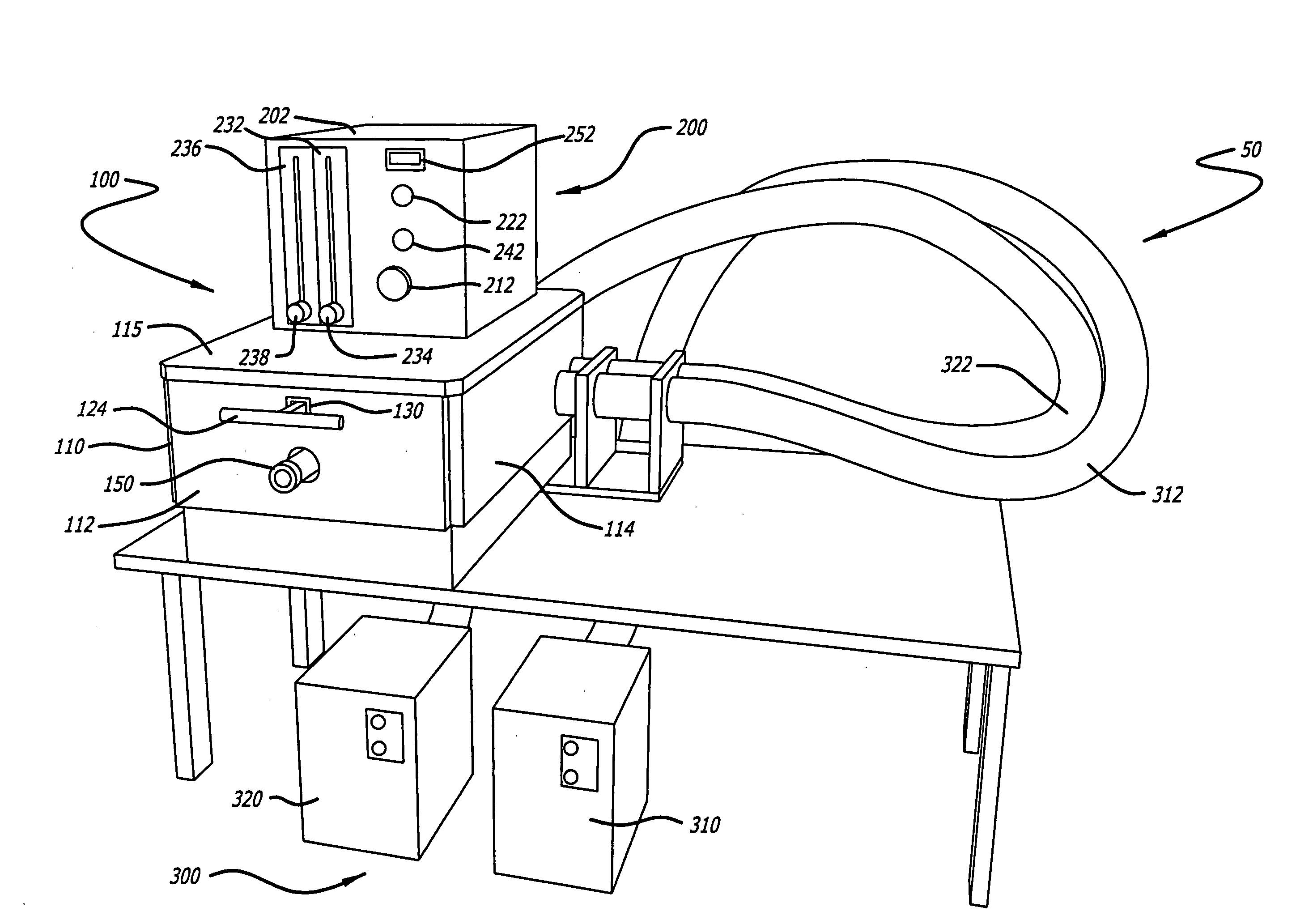

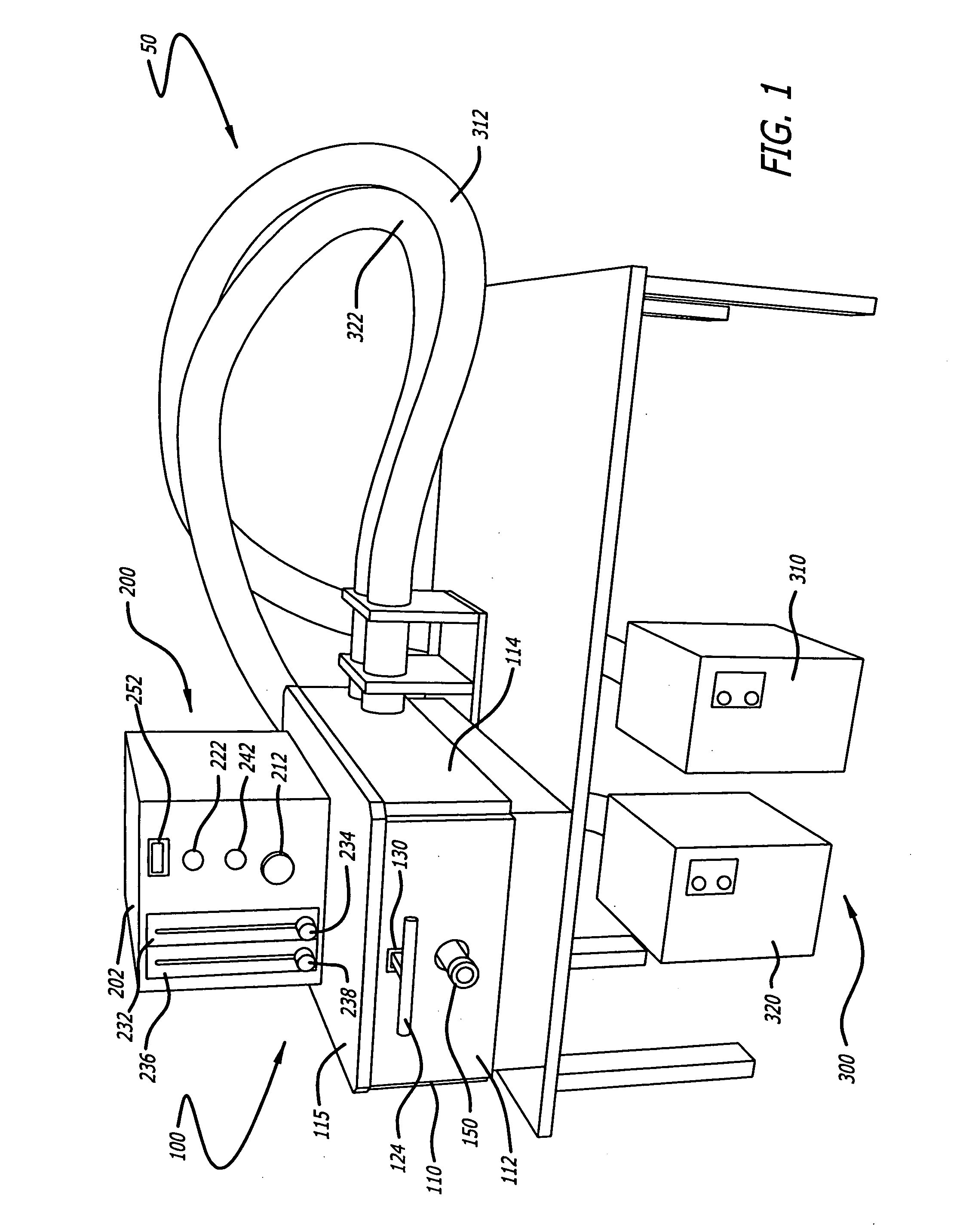

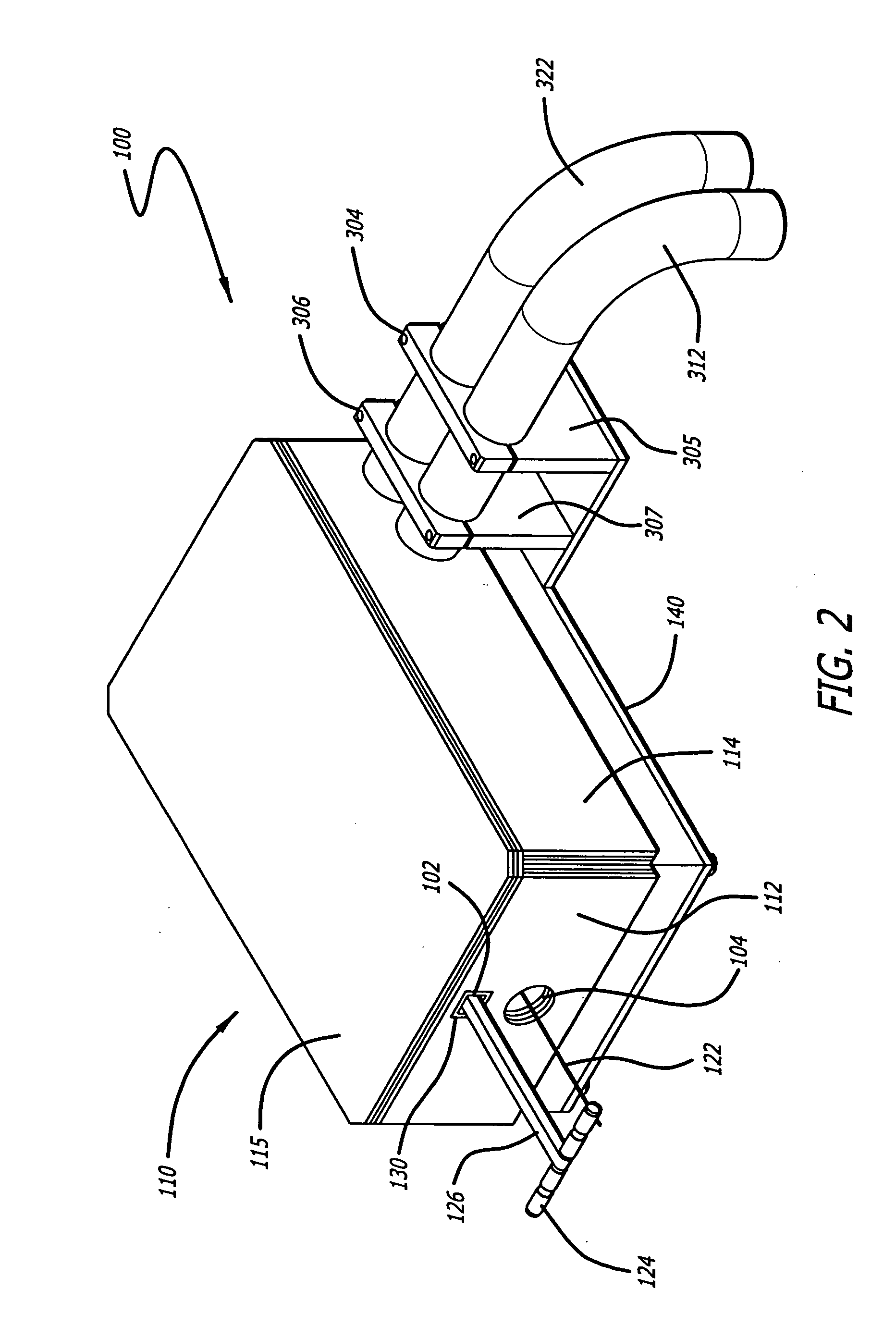

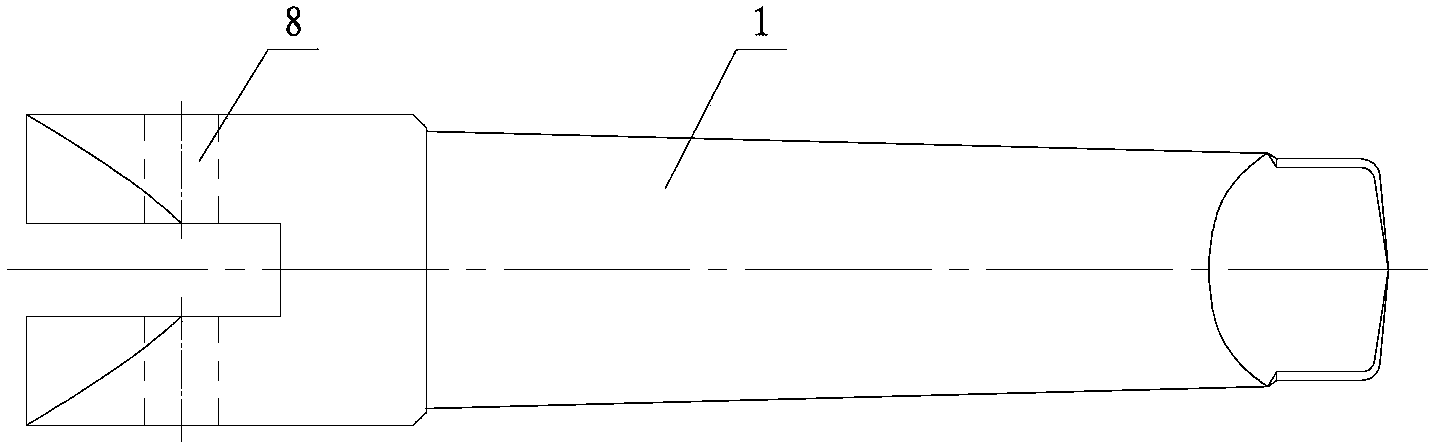

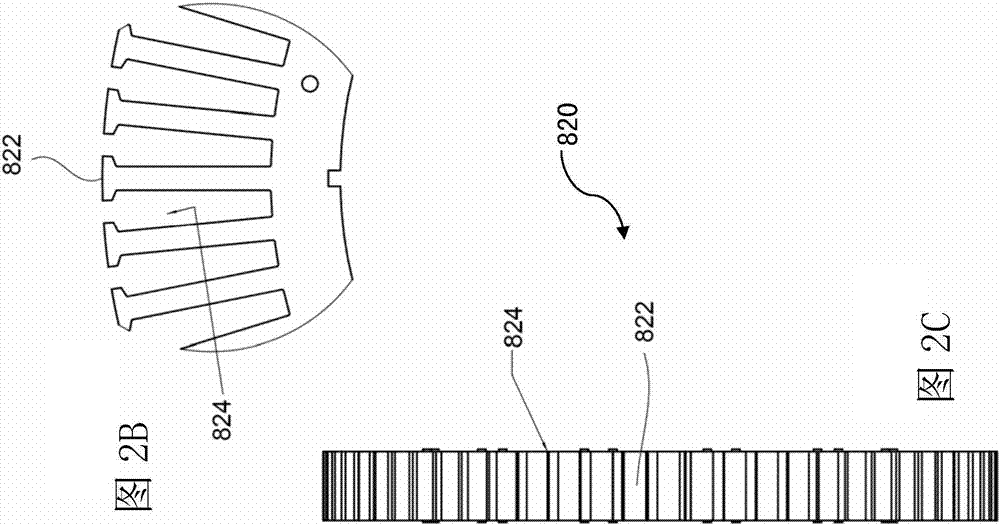

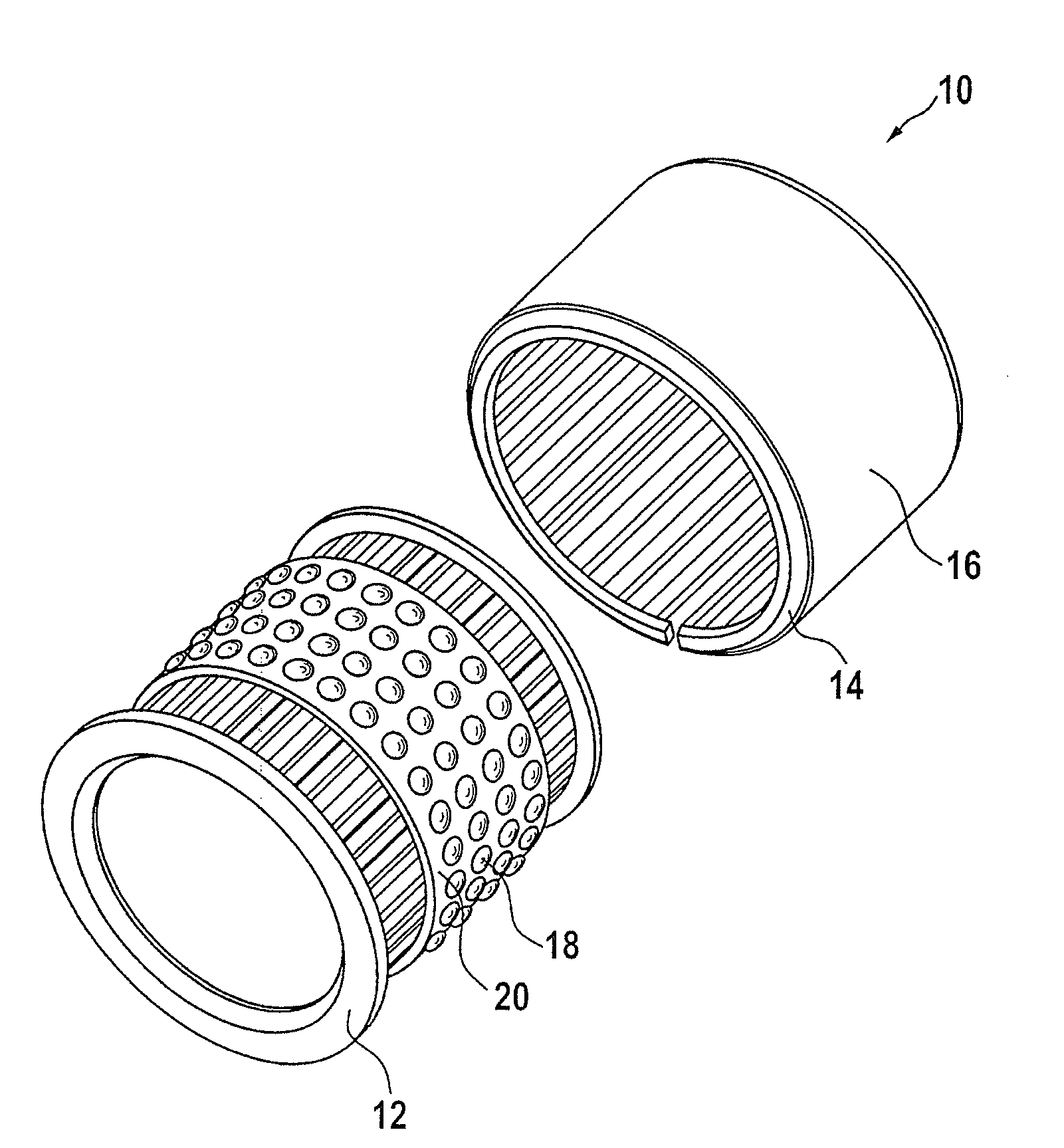

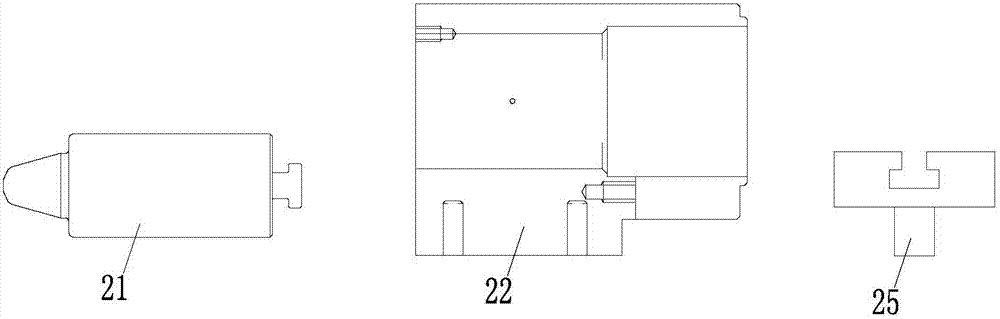

Cold collapse method and apparatus

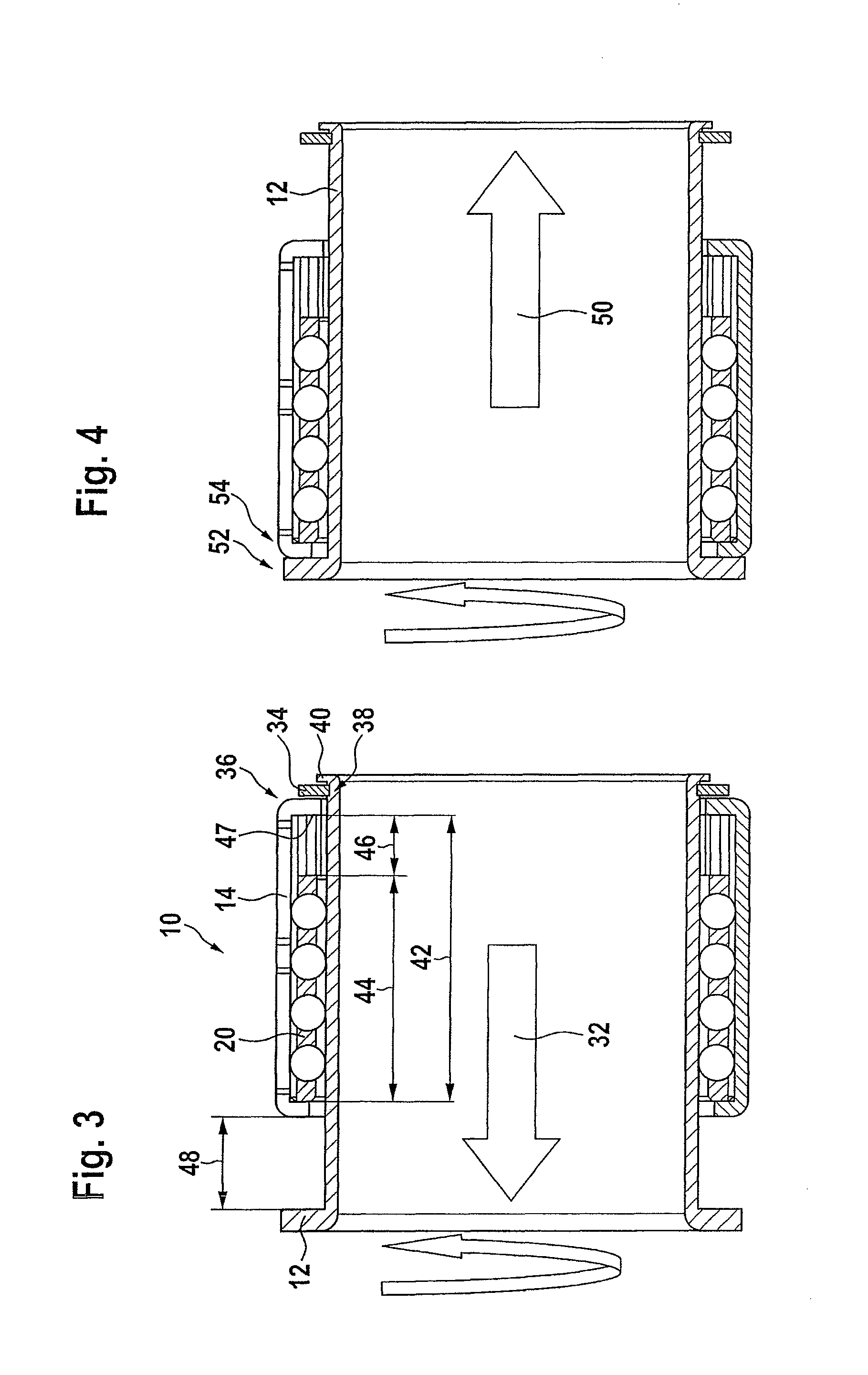

InactiveUS20080072653A1Eliminate radial forceReduces and eliminates radial forceStentsDomestic cooling apparatusDrug-eluting stentBiomedical engineering

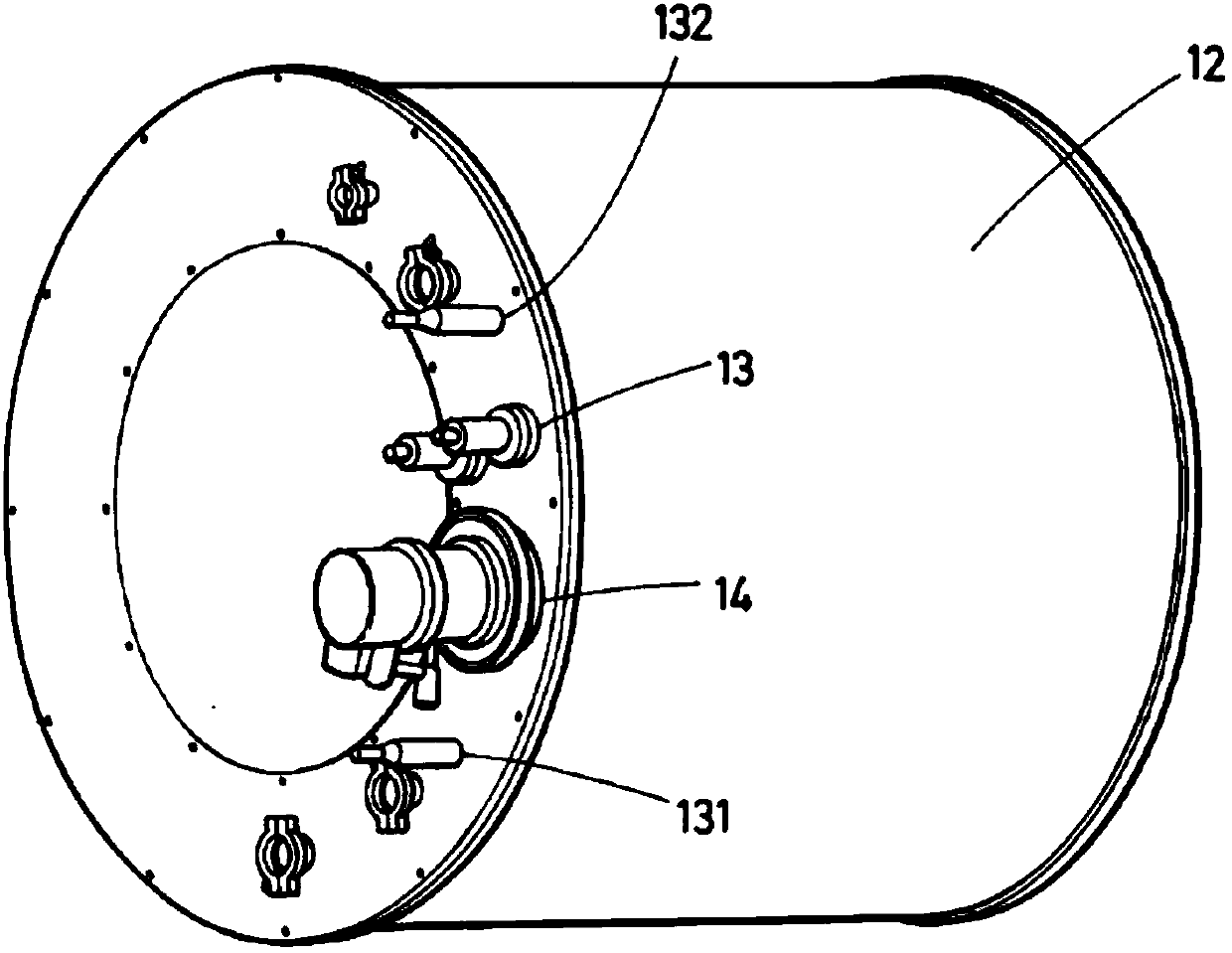

A system and method are disclosed for collapsing medical devices, such as self-expanding, drug-eluting stents for loading into delivery catheters. The collapsing apparatus may be used for crimping expandable stents and other devices onto a balloon catheter. The medical device is cooled below the austenitic phase transformation temperature of the material forming the device, such as stainless steel or nitinol, and may be cooled until the material has fully transformed to the martenstitic state. For coated medical devices, the device is warmed to a temperature just below the beginning of austenite phase transformation prior to collapsing. An apparatus having a plurality of offset blades, linear bearings, radial bearings and an actuator mechanism is provided for collapsing the medical device. The system is configured with a mandrel subassembly to push the medical device into a catheter sheath, and with a nozzle subassembly to direct cold gas to the medical device.

Owner:ABBOTT CARDIOVASCULAR

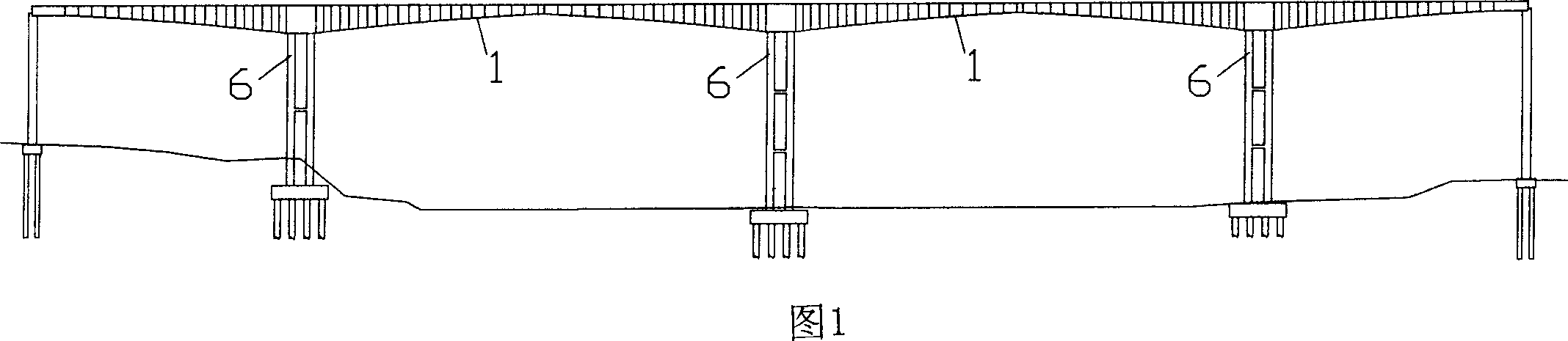

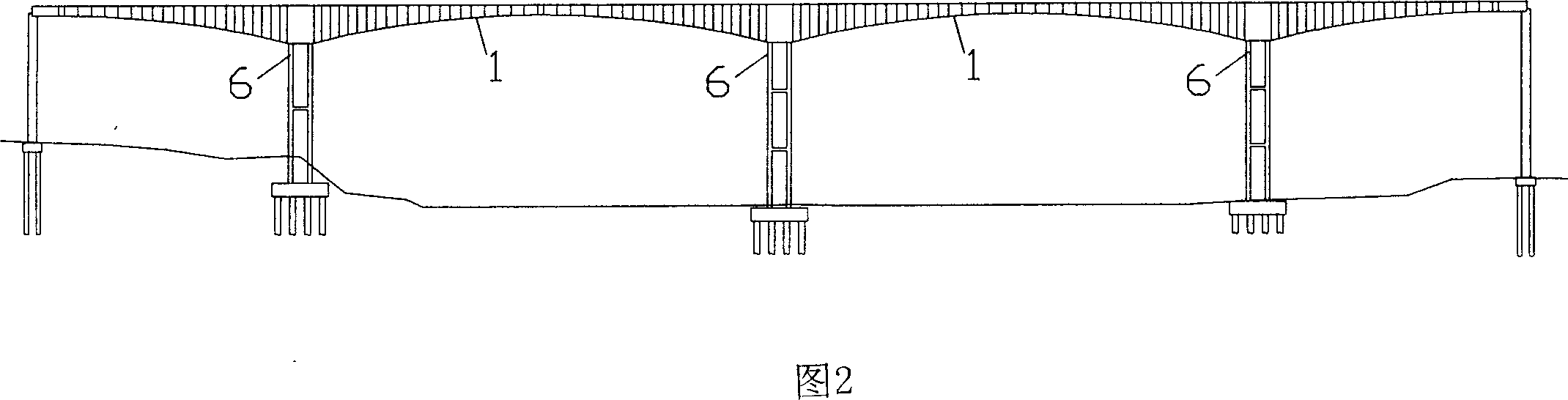

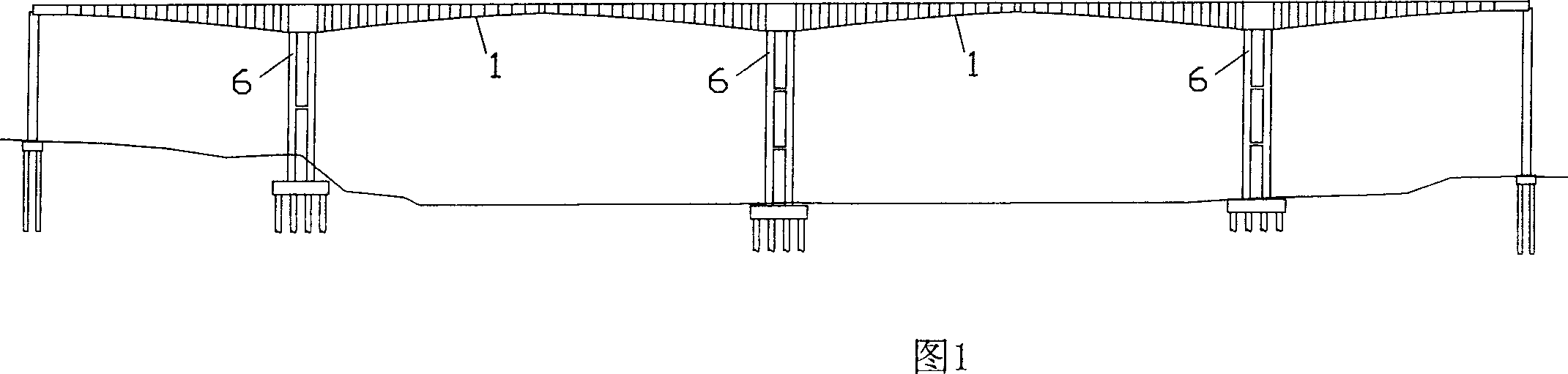

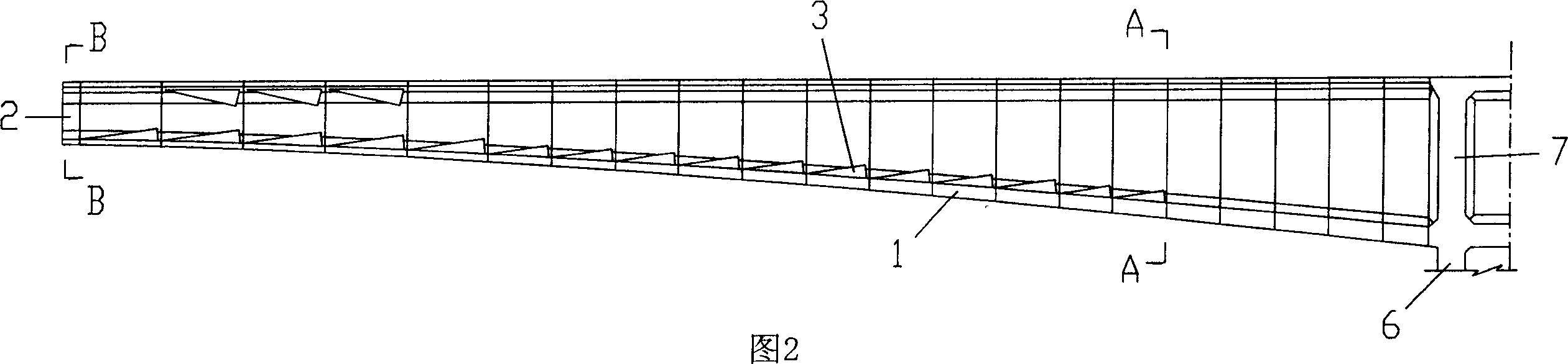

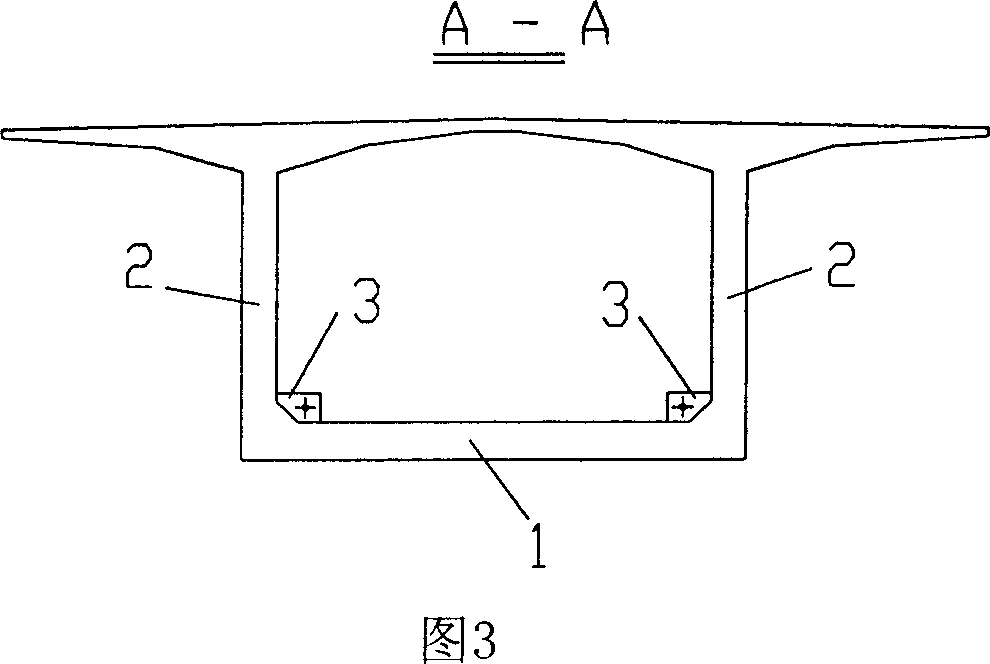

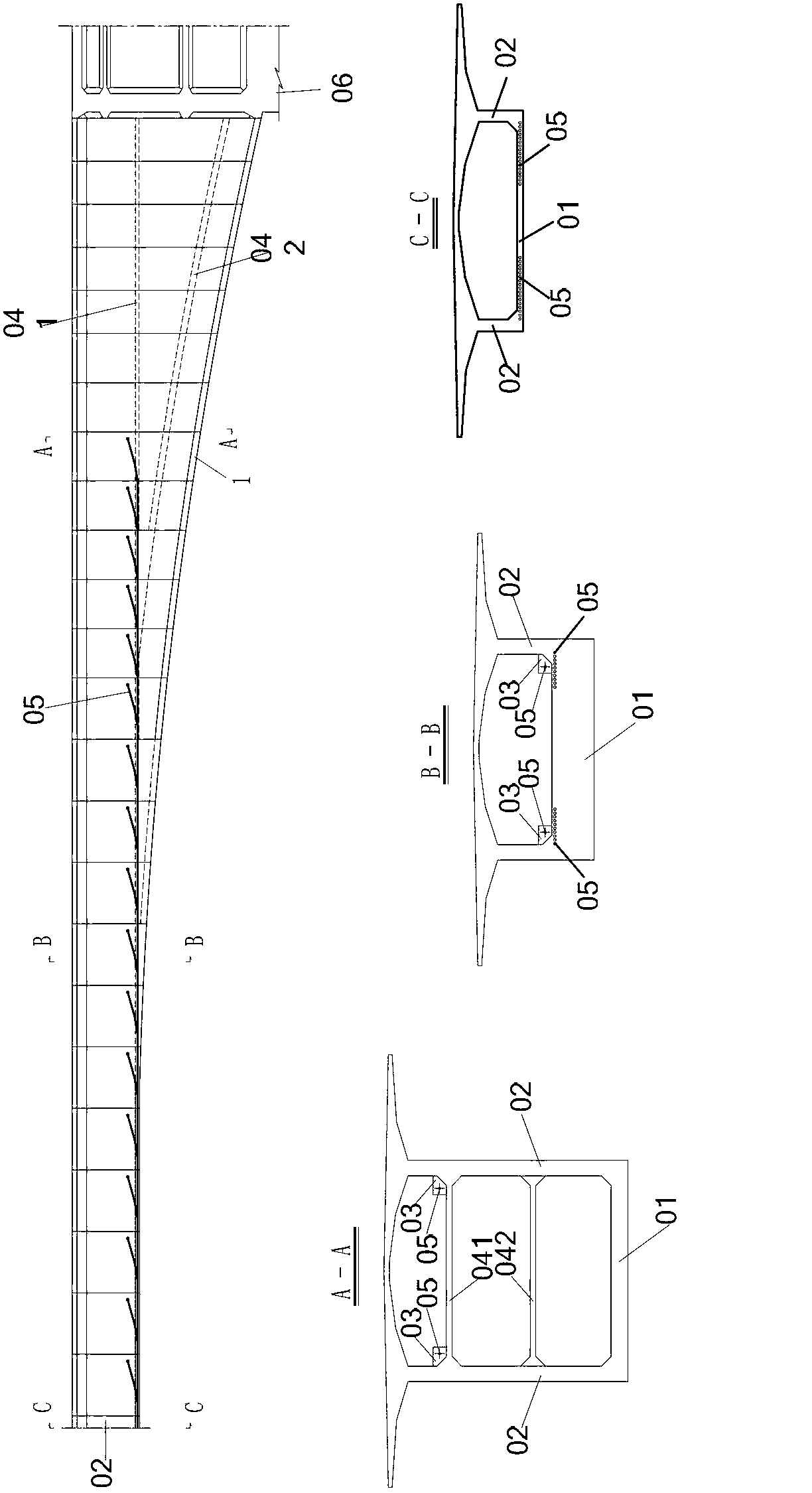

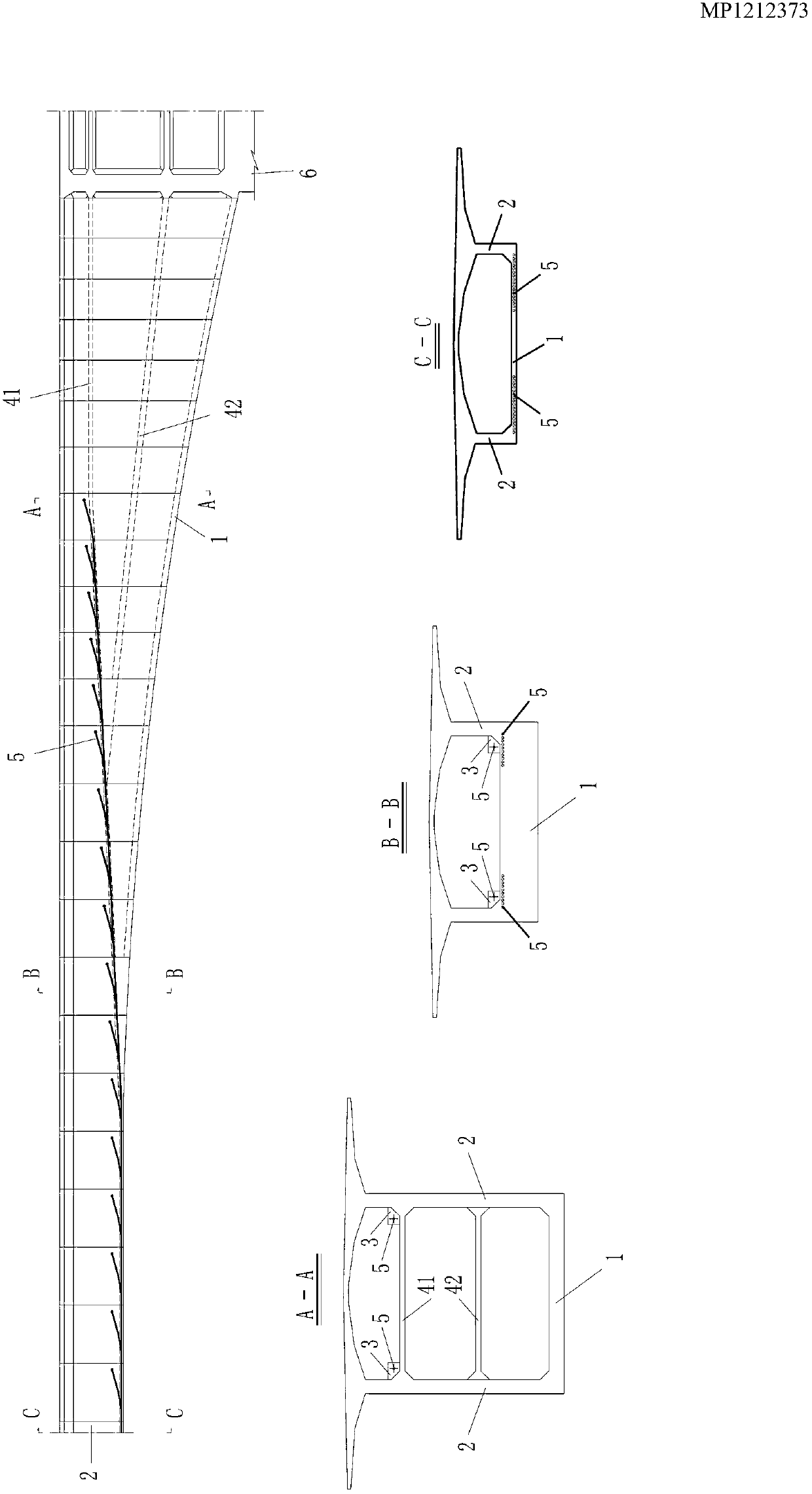

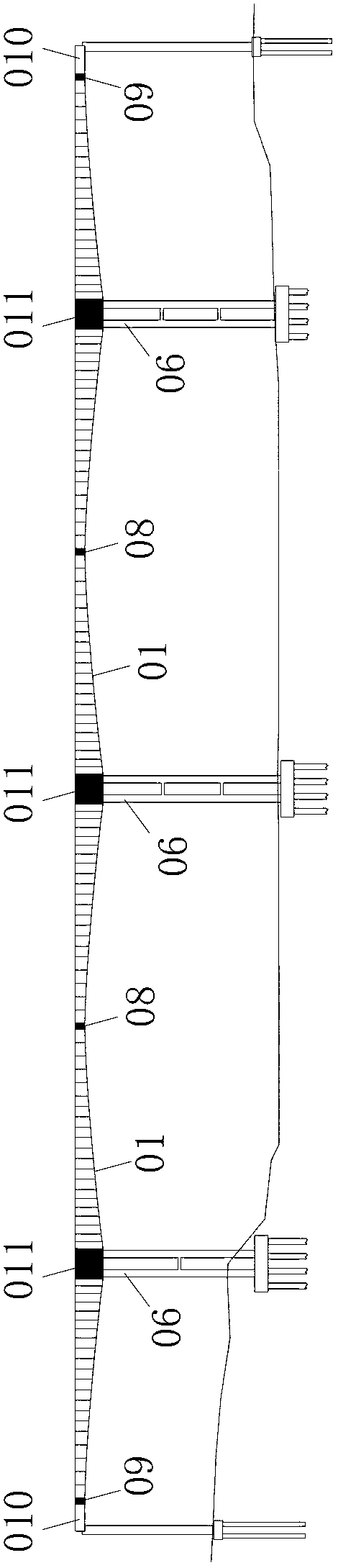

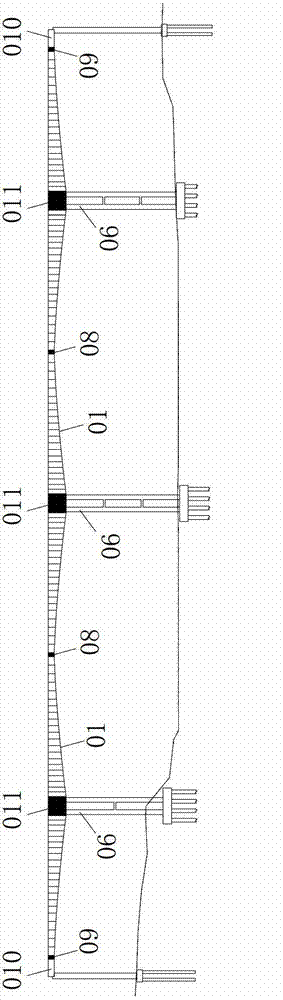

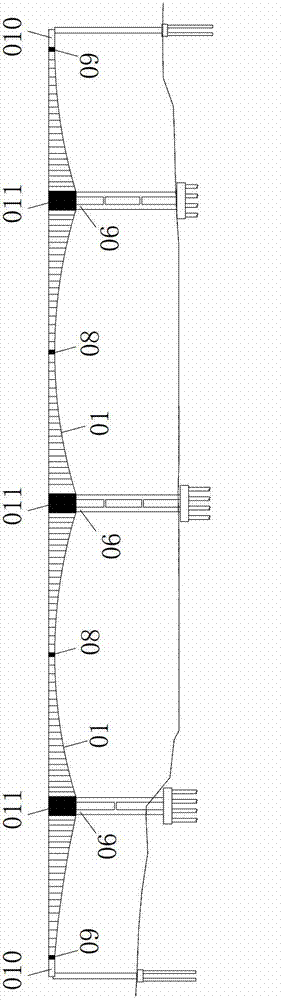

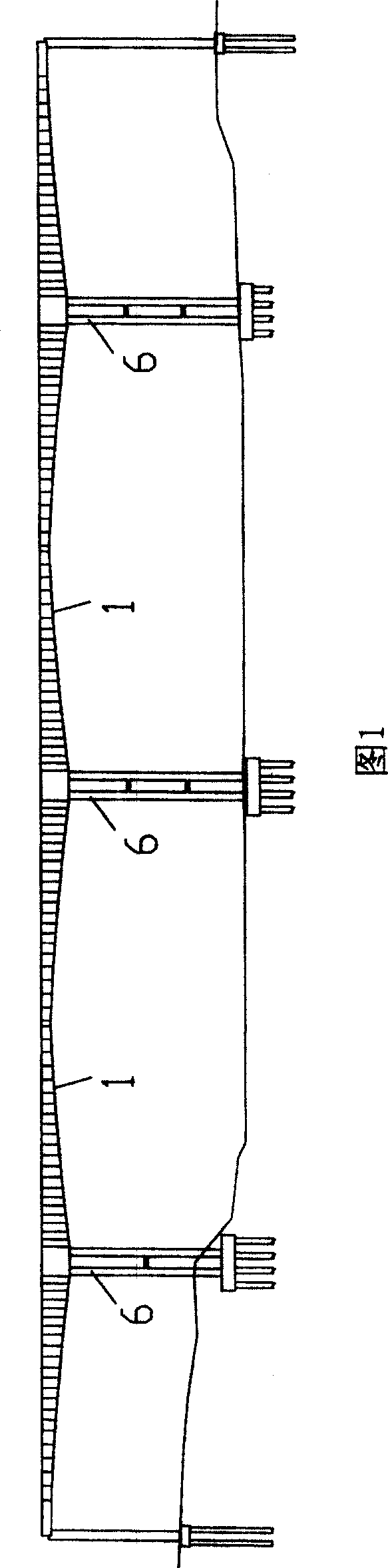

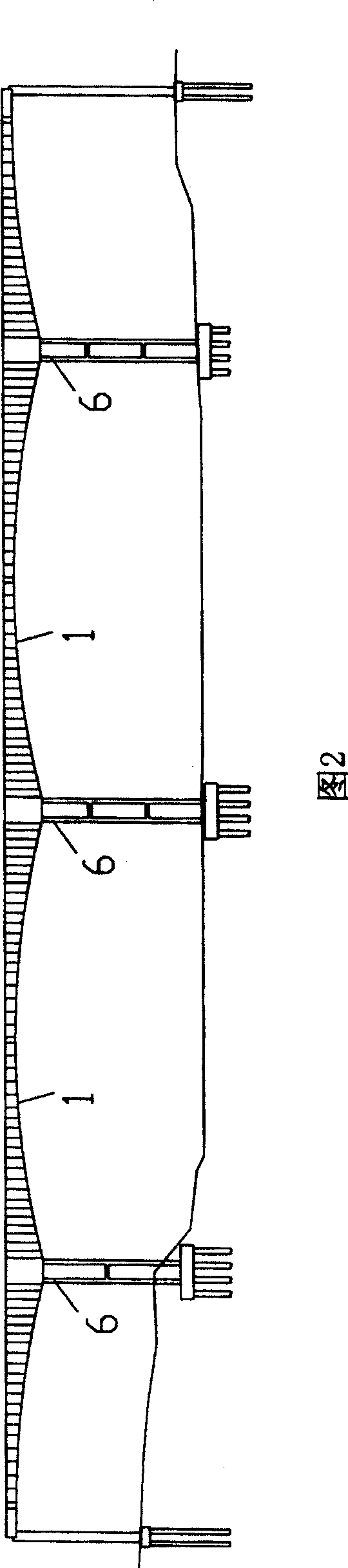

Built-in oblique leg rigid-frame prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN1974929ASolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsPre stressEngineering

The present invention belongs to the field of civil engineering bridge technology, and discloses a kind of built-in oblique leg rigid frame prestressed concrete non-uniform box beam bridge. It is characterized by that in its box beam interior an oblique leg rigid frame structure is set, said oblique leg rigid frame structure is formed from built-in longitudinal beam and built-in oblique leg. The built-in oblique leg and box beam baseplate are parallelly arranged and identical in thickness, and the built-in longitudinal beam and midspan baseplate are aligned and identical in thickness, the midspan baseplate, box beam baseplate and built-in longitudinal beam are combined into one body, so that said bridge structure has high integral rigidity, small deflection and strong resistance to shear, and the crossing capacity of said prestressed concrete non-uniform box beam bridge can be greatly raised.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

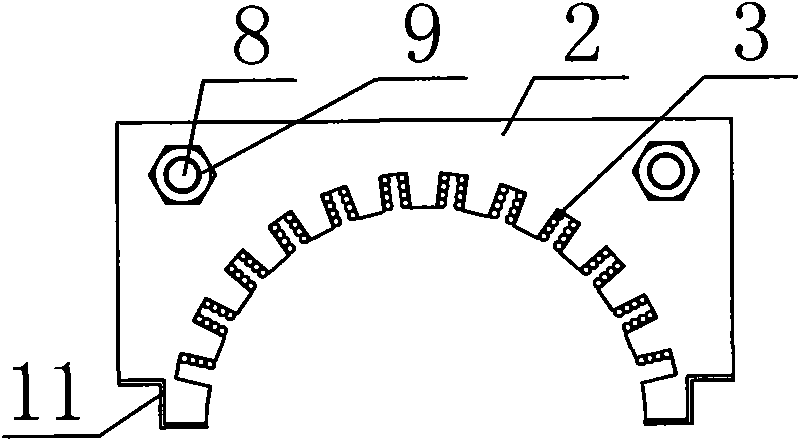

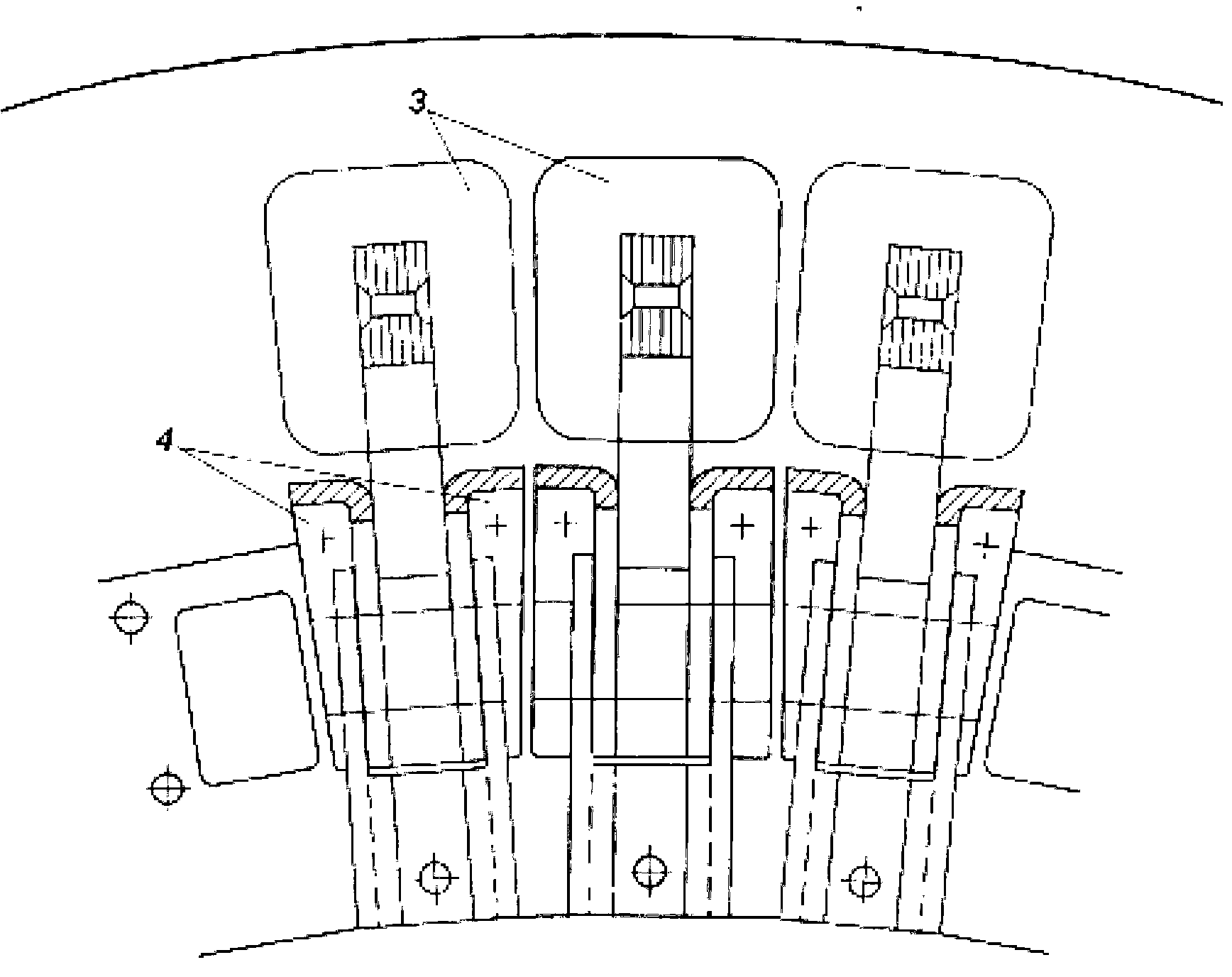

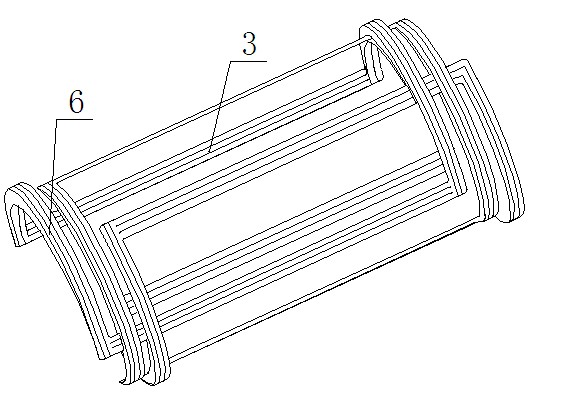

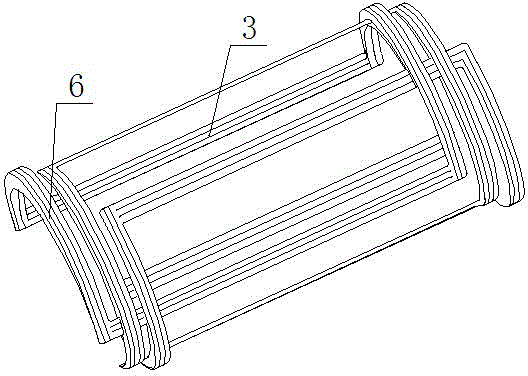

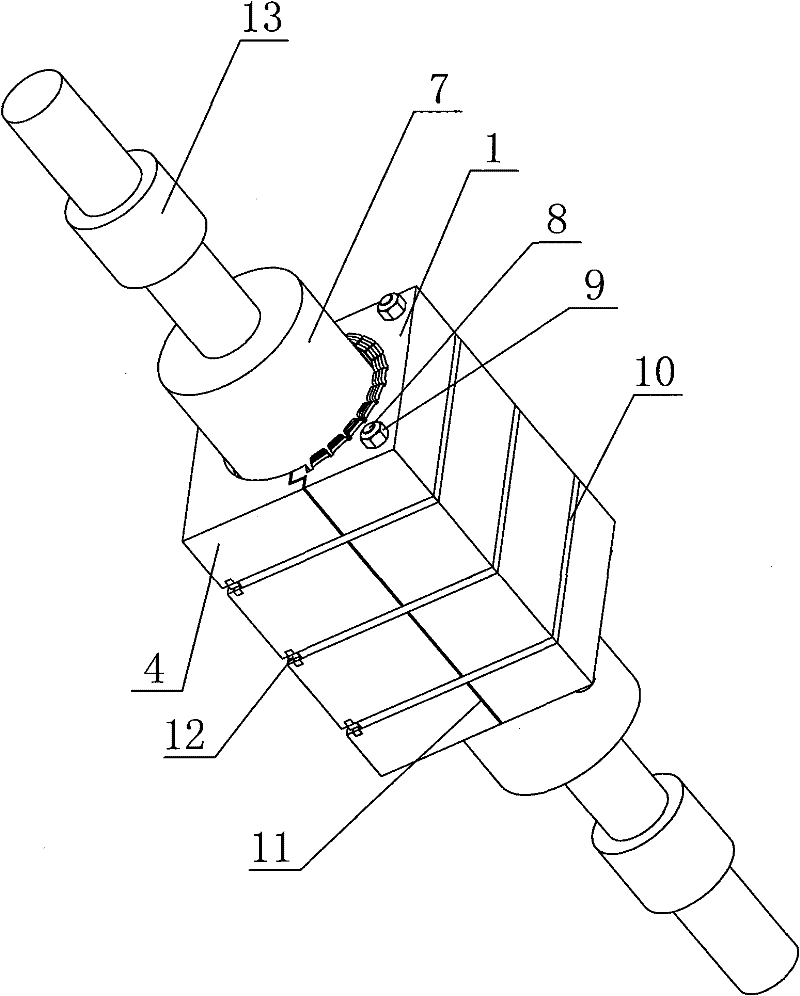

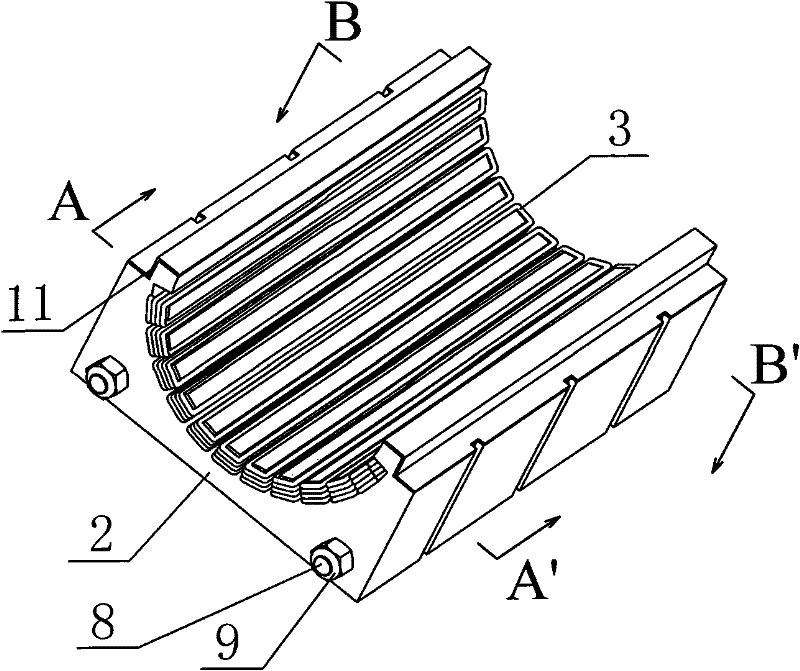

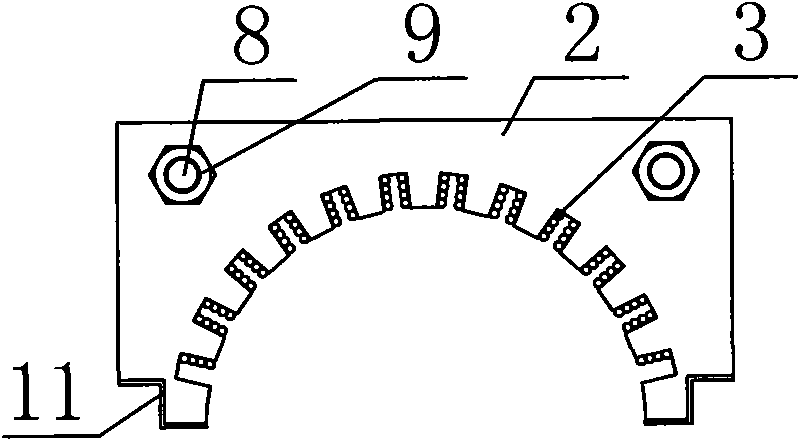

Multivariant linear arc-shaped motor

InactiveCN101789646AReduce wearEliminate radial forceMechanical energy handlingPerformance indexBearing wear

The invention discloses a multivariant linear arc-shaped motor, comprising a rotary motion linear arc-shaped motor, a rectilinear motion linear arc-shaped motor, a motion shaft and the like. Bridge arc-shaped stators of the rotary motion linear arc-shaped motor and the rectilinear motion linear arc-shaped motor are integrated into a whole by fasteners and step-shaped structures, stator core laminations are distributed in space in an orthogonal manner, stator windings are arranged in an orthogonal and zoning manner, a cylindrical rotor is shared by the two motors, and stator core zone areas and structural parameters thereof can be respectively selected for the two linear arc-shaped motors according to performance indexes. By adopting the scheme in the invention, a load can be directly driven to do linear, rotary or spiral motion, and the multivariant linear arc-shaped motor has the advantages of simple and compact structure, concise transmission mechanism, small bearing wear, easy control and the like.

Owner:HENAN POLYTECHNIC UNIV

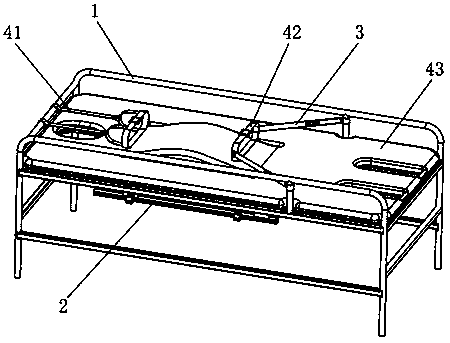

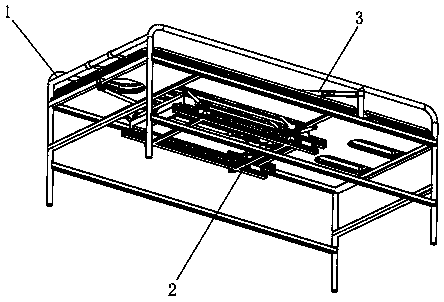

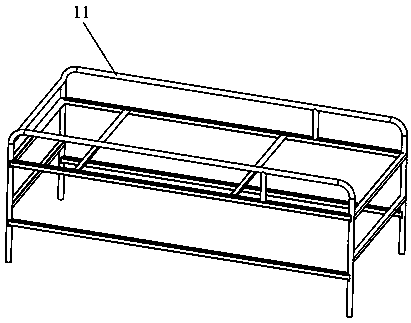

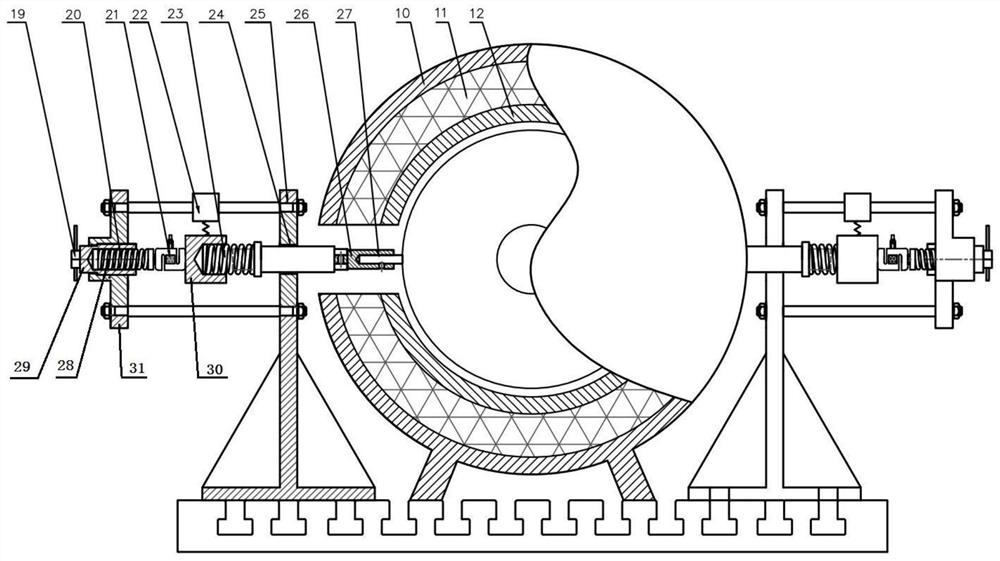

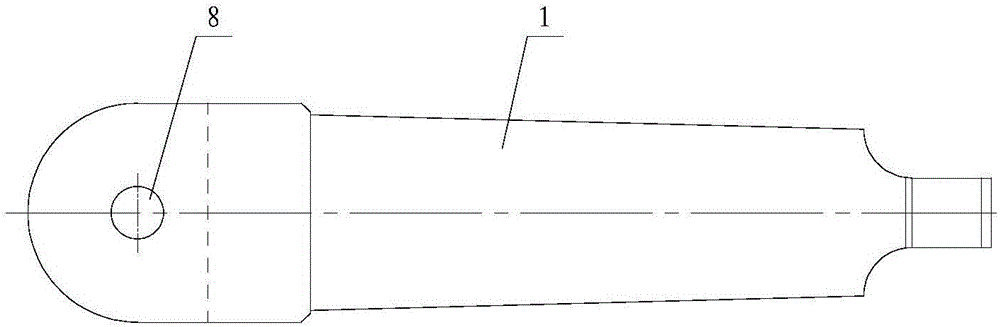

Lumbar traction bed

PendingCN107753167AEliminate radial forceAvoid Radial Traction ComponentsChiropractic devicesFractureBed boardsEngineering

The invention discloses a lumbar traction bed, which comprises a bed body, a traction device and a lumbar curve adjusting device. The bed body comprises a bed frame and a grid-shaped bed plate; the traction device comprises a stretching power element and an elastic element; the lumbar curve adjusting device is fixed under the bed frame, and comprises a lifting mechanism, a translation mechanism, atelescoping mechanism and a grid-shaped adjusting bow; grid gaps of the adjusting bow and grid gaps of the grid-shaped bed plate are arranged in a staggering way; grid bars of the adjusting bow can penetrate through the grid gaps of bed plate grids; one end of the adjusting bow is connected with the translation mechanism; the other end of the adjusting bow is connected with the telescoping mechanism. According to the lumbar traction bed, a radial force stressed on a sicken lumbar vertebra during a traction process can be effectively avoided, the defects of existing lumbar traction equipment are overcome, and a traction treatment effect is improved.

Owner:四川吉赛特科技有限公司

Baseboard cable horizontal arrangement prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN1974930ASolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsBaseboardPre stress

The present invention belongs to the field of civil engineering bridge technology, and relates to a baseplate ropes horizontally-arranged prestressed concrete non-uniform box beam bridge. It is characterized by that in the position of midspan baseplate which is correspondent to the beam height in the box beam interior a horizontal anchor plate is set longitudinally, said horizontal anchor plate and box beam baseplate are combined into one body, the thickness of said horizontal anchor plate is identical to that of midspan baseplate, the baseplate ropes are arranged in the horizontal anchor plate interior, and said horizontal anchor plate and box beam can be cast in-situ together. Said invention can raise durability of the bridge and can greatly raise crossing capacity of said bridge.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

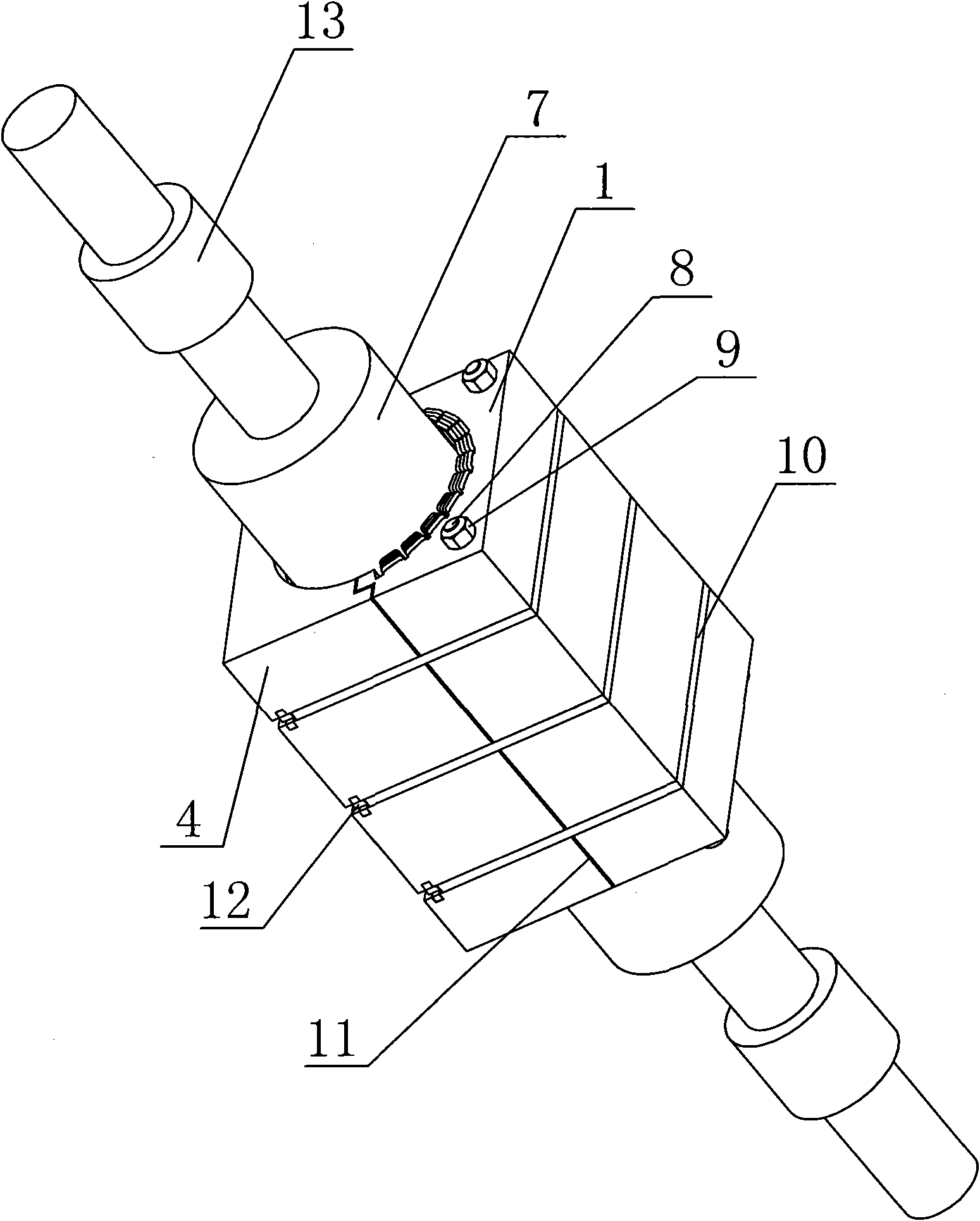

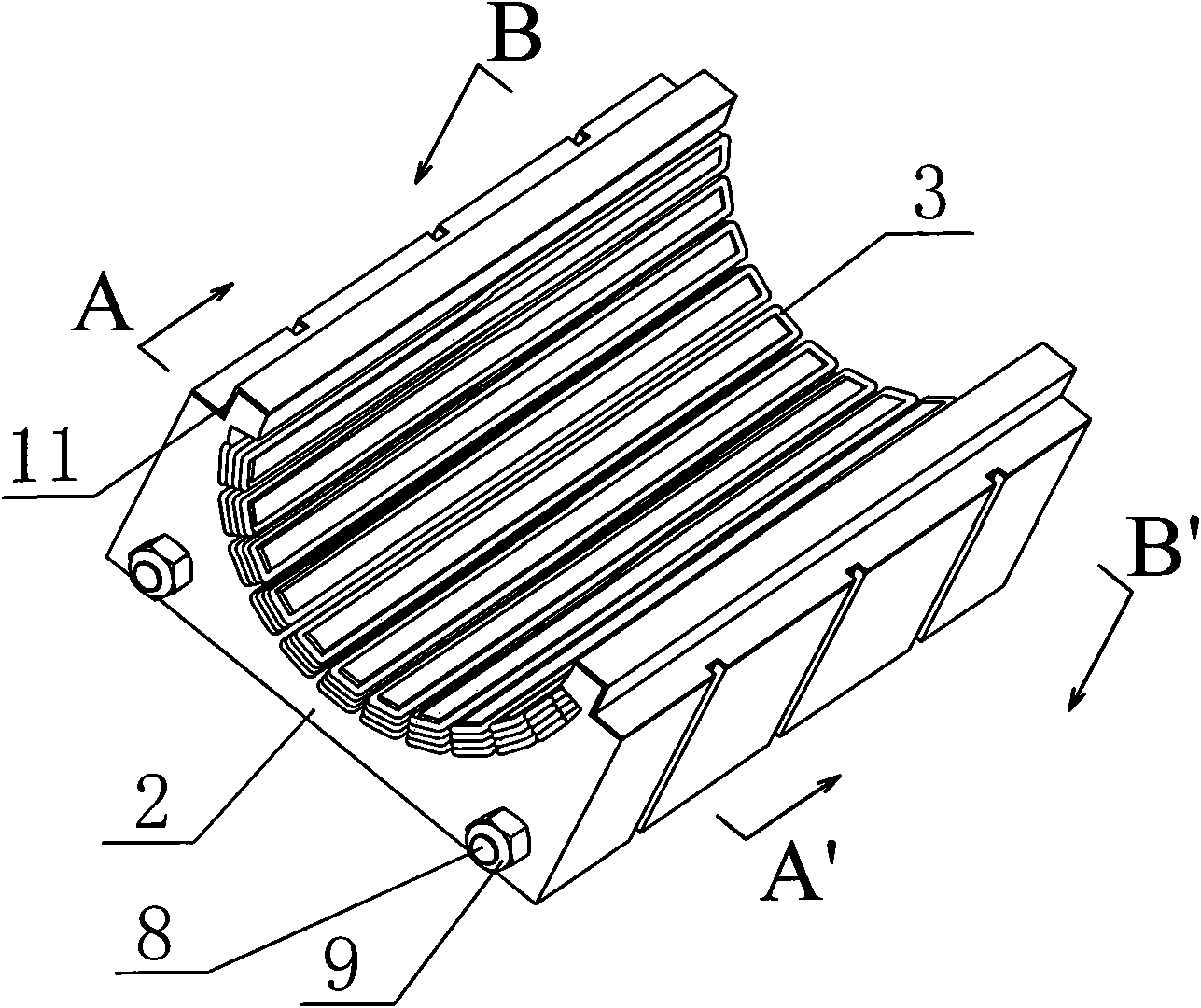

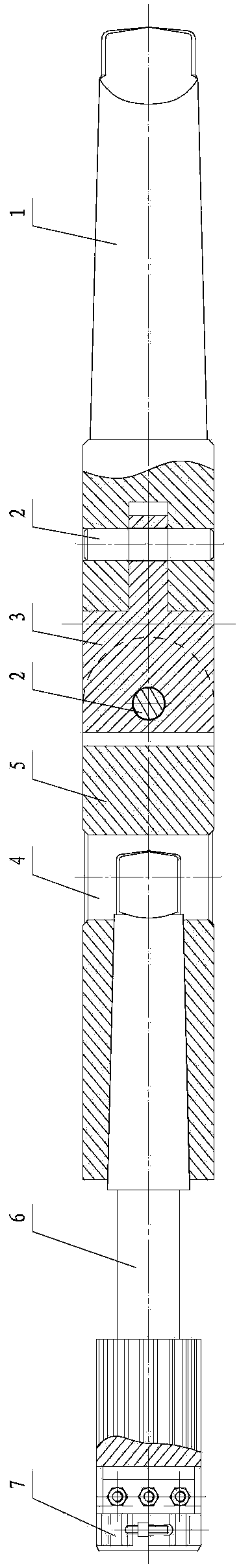

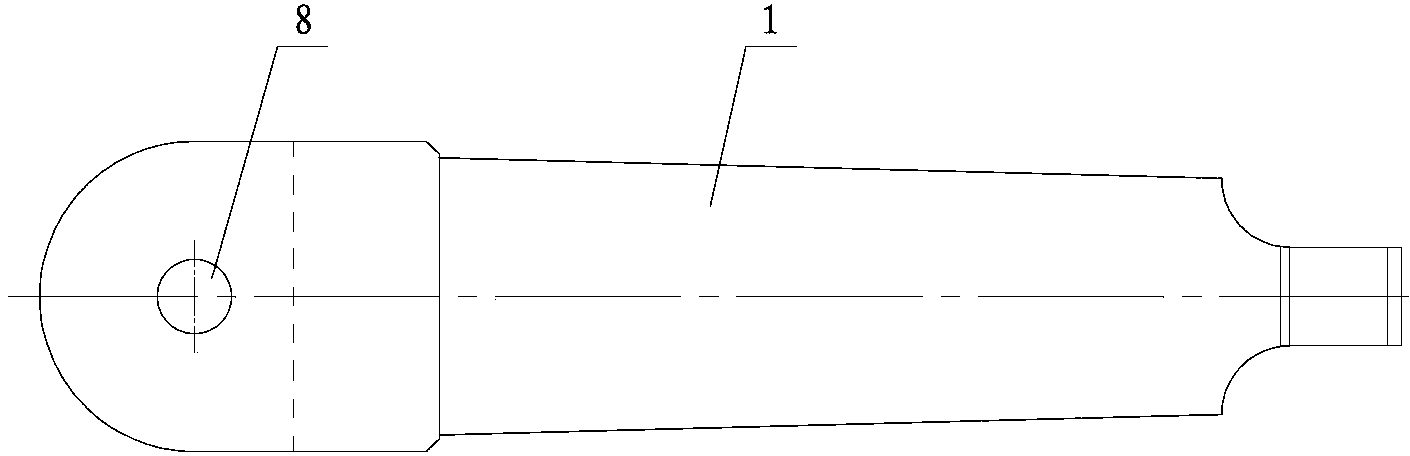

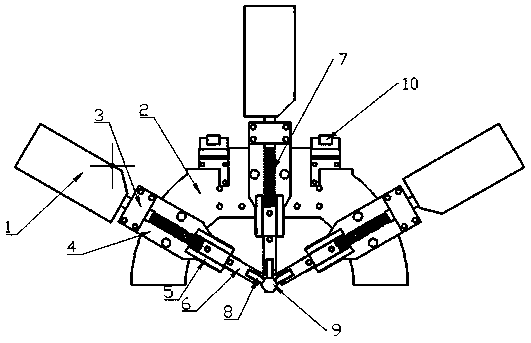

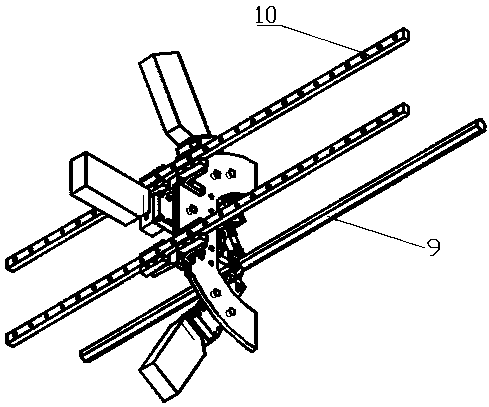

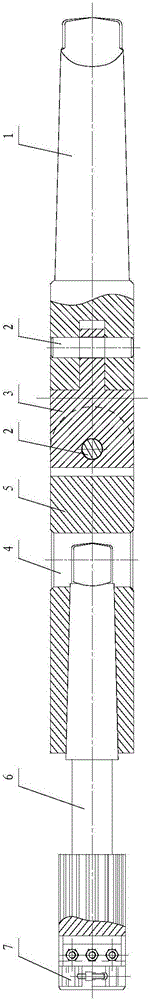

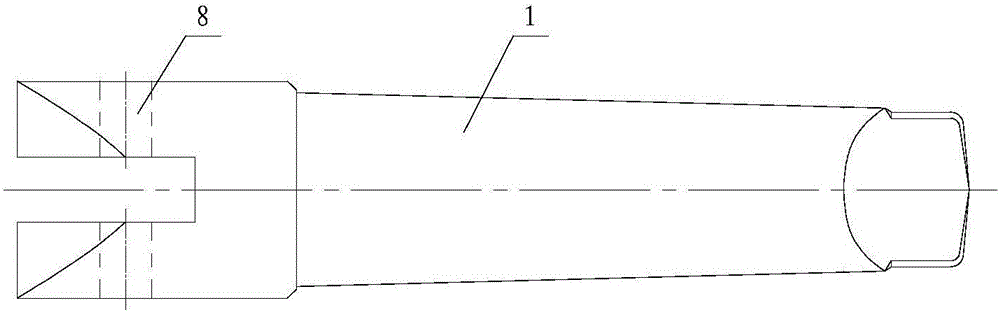

Adjustable floating reamer integrating universal adjusting, rough machining and finish machining

The invention relates to cutter and cutter bar tool equipment for machining a hole, in particular to an adjustable floating reamer integrating universal adjusting, rough machining and finish machining. The adjustable floating reamer comprises a universal adjusting cutter bar, a rough machining reamer and a floating reamer, wherein the universal adjusting cutter bar comprises a cutter bar handle, a universal joint and a cutter bar sleeve, and the cutter bar handle and the cutter bar sleeve are respectively in pin connection with two ends of the universal joint; one cutter bar end of the rough machining reamer is connected to the cutter bar sleeve in an inserting manner, one cutting edge end of the rough machining reamer is provided with a limiting groove; the floating reamer is contained in the limiting groove and can float in the limiting groove, and the rough machining reamer is used for limiting the floating reamer while being used for processing the hole through the cutting edge. According to the adjustable floating reamer disclosed by the invention, various error such as the cutter bar manufacturing error and the deformation error in a machine tool equipment system can be removed, the hole machining accuracy is increased, and thus the quality problems that due to the low equipment accuracy and special hole position, a machine tool main shaft cannot get close to the hole, the cutter bar stretches too long, and the reamed hole machining accuracy is low are completely solved; the rough machining and the finish machining are integrated, and the production efficiency of hole machining is greatly increased.

Owner:SHENYANG TURBO MASCH CORP

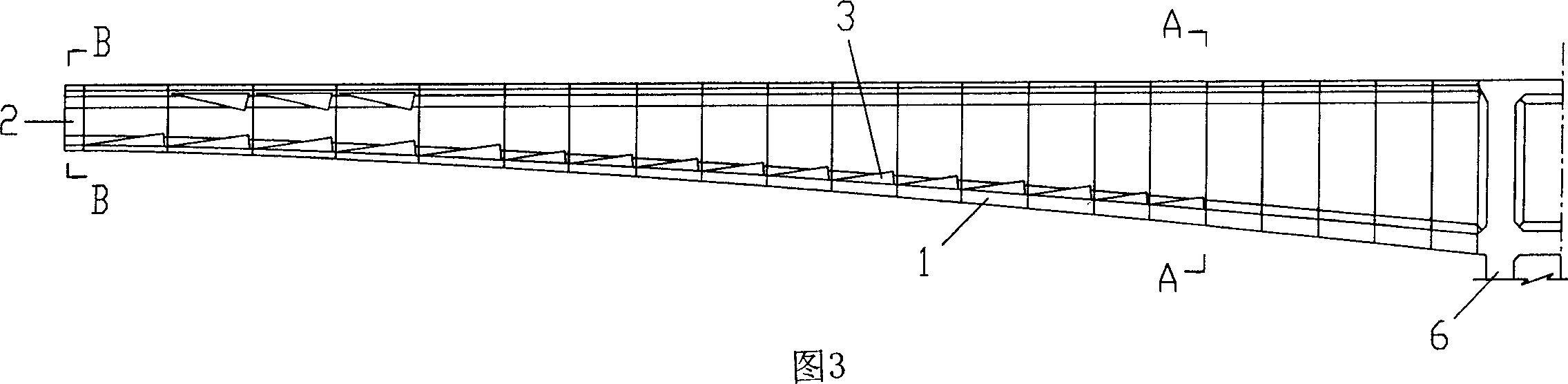

Prestressed concrete variable-cross-section box girder bridge with internal tilted-leg rigid frame and construction method of prestressed concrete variable-cross-section box girder bridge

InactiveCN103015304ASolve the crack along the bridgeEliminate radial forceBridge erection/assemblyBridge materialsRigid frameBending moment

The invention discloses a prestressed concrete variable-cross-section box girder bridge with an internal tilted-leg rigid frame. The prestressed concrete variable-cross-section box girder bridge with the internal tilted-leg rigid frame comprises a bottom plate and web plates which form a box girder, a tilted-leg rigid frame structure is arranged in a variable-cross-section box girder bridge box and comprises an internal longitudinal beam and an internal tilted leg, the internal longitudinal beam tilts upwards or is bent along the longitudinal direction of the box girder from the midspan to a pier direction, the internal longitudinal beam and the bottom plate are integrated in a segment from the midspan to the 3L / 8 section, the rest portions are separated from one another, a midspan positive-bending-moment bottom plate cable is bent along the internal longitudinal beam, jagged blocks are arranged at bottom plate cable tensioning and anchoring positions of the internal longitudinal beam, the bottom plate cable tensioning and anchoring ends are bent in the box from the jagged block positions, and the bottom plate cable is symmetrically tensioned and anchored on the jagged blocks by the two tensioning and anchoring ends. Down-warping deformation of a girder caused by second-phase dead load is eliminated or reduced by the aid of upward radial force of the bottom plate cable, and the box girder is reasonable in structural bearing. The invention further provides a construction method of the prestressed concrete variable-cross-section box girder bridge with the internal tilted-leg rigid frame.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

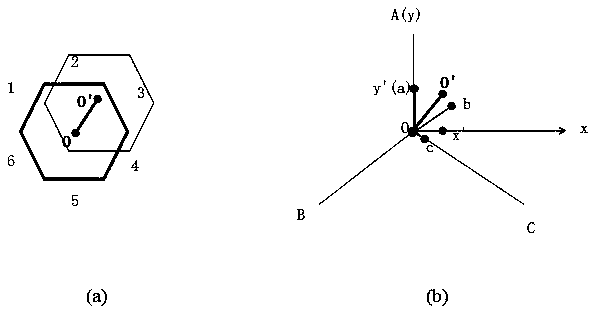

Straightness detection device for hexahedral shaft and data processing method

ActiveCN109373961AReduce frictionEliminate radial forceMeasurement devicesMeasurement deviceRectangular coordinates

The invention discloses a straightness detection device for a hexahedral shaft and a data processing method. Three sets of measuring devices of the same structure are mounted on a curved mounting plate with 60-degree angles formed between every two sets of measuring devices; three axial lines intersect at the ideal center of the hexahedral shaft; roller bearings are closely attached to three surfaces of the hexahedral shaft; the mounting plate slides on a guide rail through a slider, so that the measuring devices move from one end of the guide rail to the other end of the guide rail so as to measure relative error data; the hexahedral shaft is rotated by 180 degrees, so that relative error data are measured; the relative error data of every two opposite surfaces are subtracted from each other sequentially, obtained relative error data are divided by 2, and therefore, the deviation quantities of the axis of the hexahedral shaft in three directions are obtained; and the deviation quantities are displayed on a three-coordinate system having intervals of 120 degrees; and the obtained three-axis coordinate intuitive data are subjected to coordinate transformation so as to be transformedinto rectangular coordinate system coordinates, and therefore, the position coordinate of the deviated axis of the hexahedral shaft can be obtained. According to the straightness detection device forthe hexahedral shaft and the data processing method of the invention, sensors can be protected; the service life of the straightness detection device is prolonged; detection is fast; and the intuitive sectional deviation data can be obtained directly.

Owner:ZHEJIANG UNIV

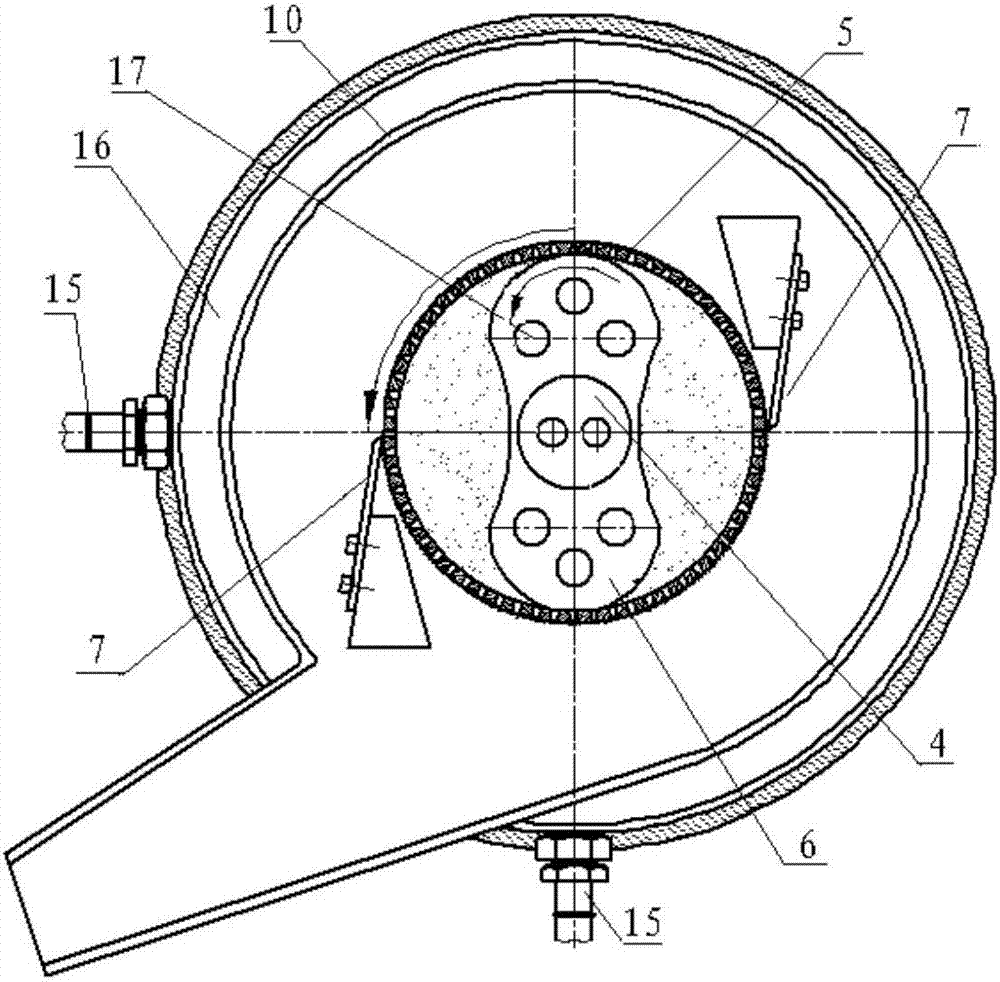

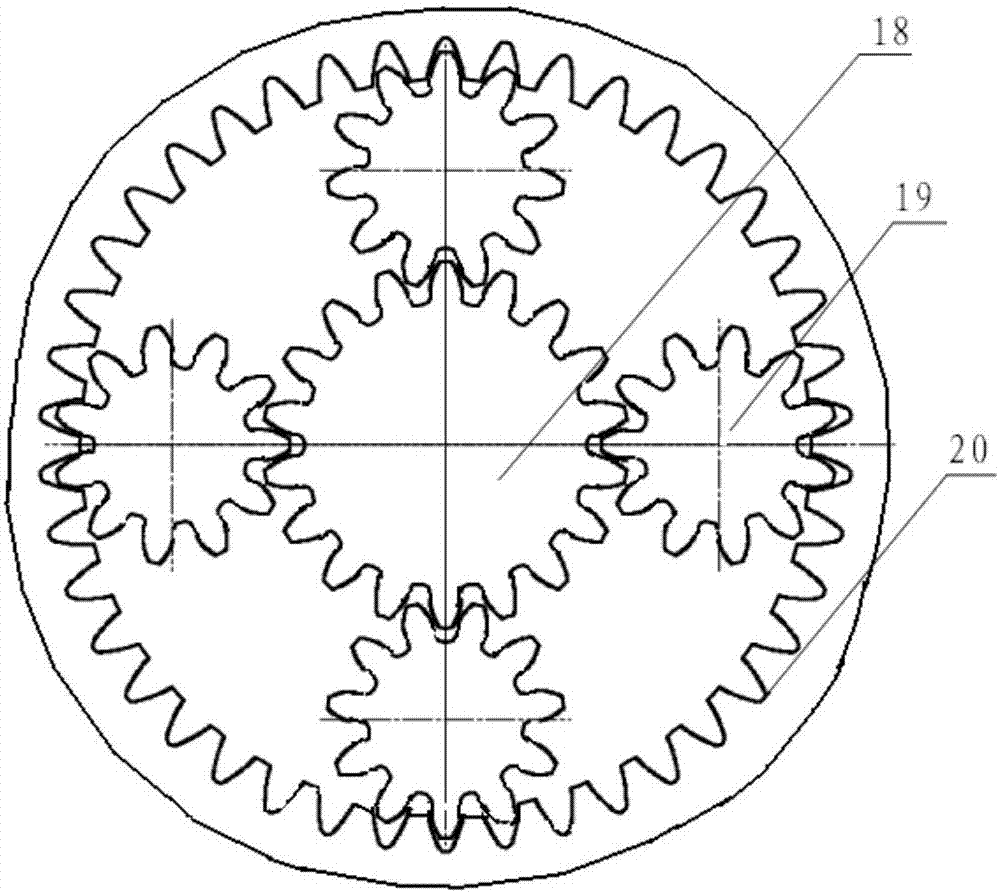

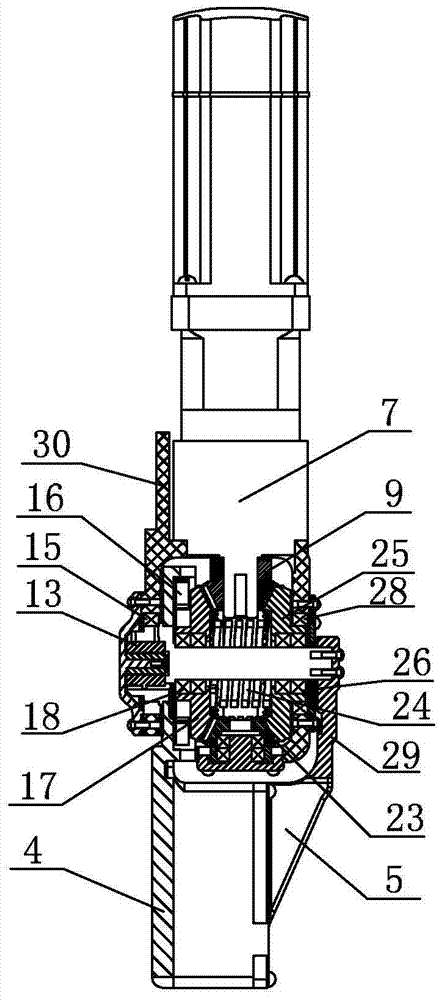

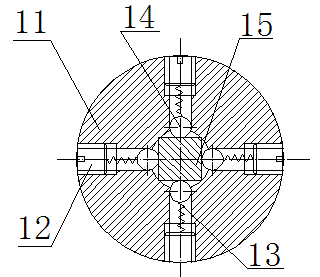

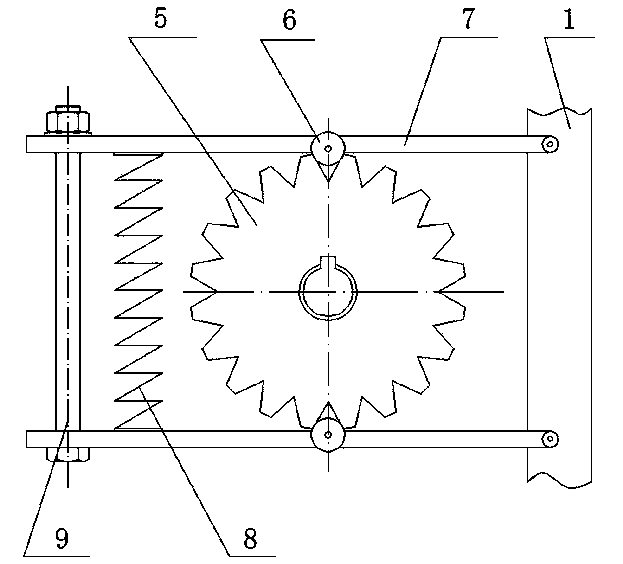

Shearing ring mold granulator

ActiveCN107413282AReduce traffic jamsSave construction spaceGranulation by material expressionGranulation by pressingEngineeringWater circulation

The invention discloses a shearing ring mold granulator which comprises a motor 13, a pulley 2, a gear box 3, a main shaft 4, a ring mold 5, a pressure roller 6, a cutter 7, a feed inlet 8, a discharge outlet 12, a screw feeder 9, a protective cover 10, a circulating water pipe 1, a base 11, a base pillar 14 and the like; both ends of the main shaft 4 are connected with the pulley 2 and the pressure roller 6 respectively, and the middle is embedded with a main shaft gear in a sleeving manner. The main shaft gear 18, a planetary gear 19 and a ring gear 20 are sequentially meshed with each other; the ring mold mounting plate 21 is arranged on the ring gear 20, and the ring mold 5 is connected with the ring mold mounting plate 21 by a clamp to facilitate disassembly and cleaning. The pressure roller 6 and the main shaft 4 are in involute spline connection, so that the granulator is convenient to load and unload; the pressure roller 6 is a double-cam structure, which facilitates the elimination of radial forces; water circulation channel is arranged to achieve the heating or insulation of materials and improve production efficiency. The speed ratio of the ring mold 5 to the pressure roller 6 is constant, the rotating speed is adjustable, and the ring mold 5 and the pressure roller 6 have a variety of combinations to adapt to a wide range of materials.

Owner:XIAN MODERN CHEM RES INST

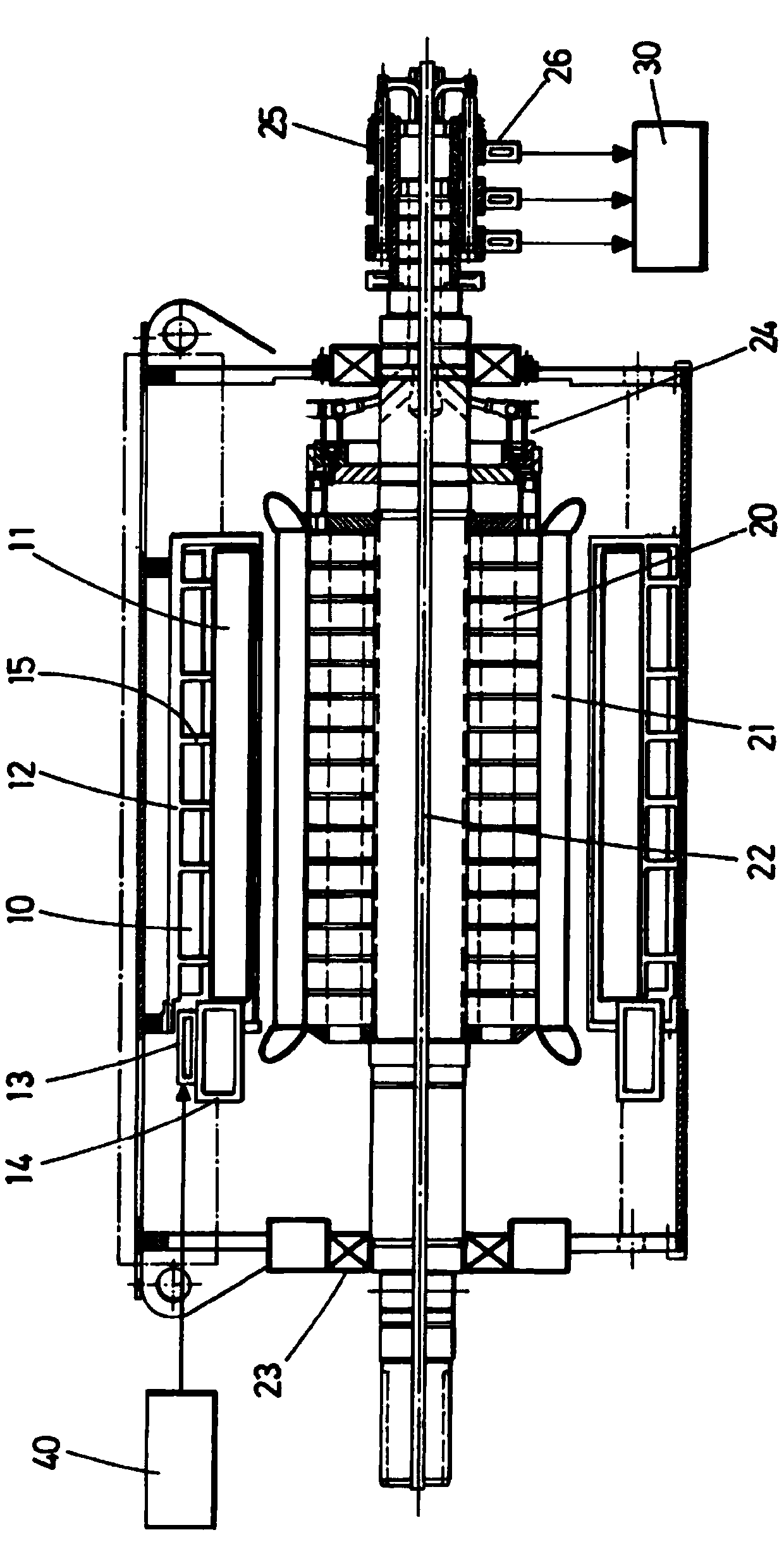

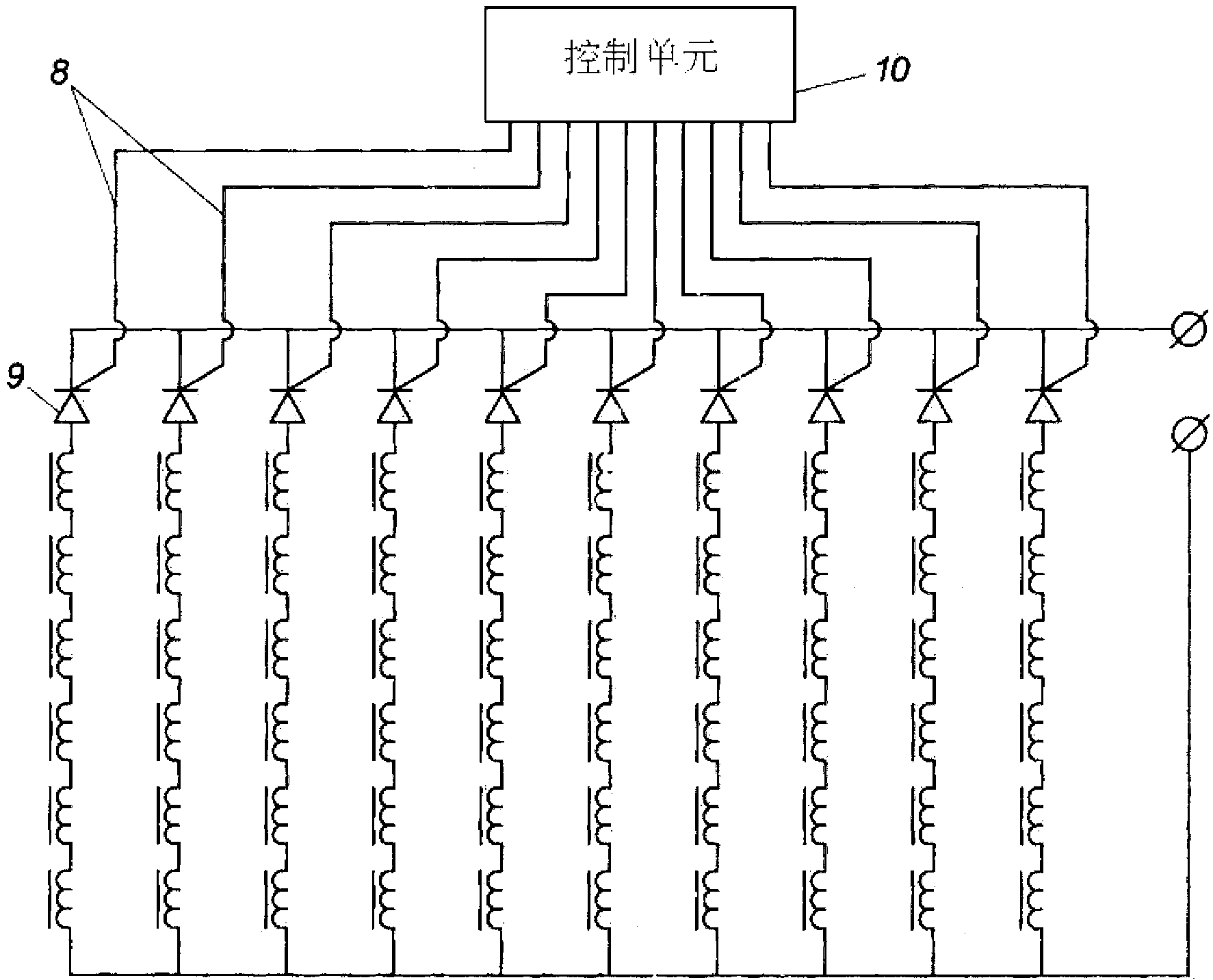

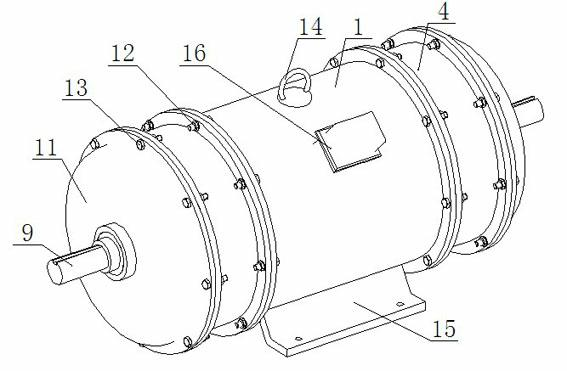

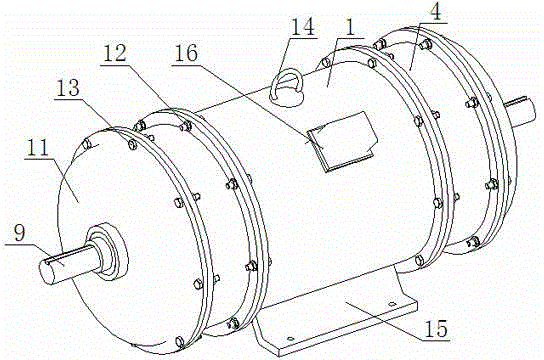

Synchronous generator for wind turbines

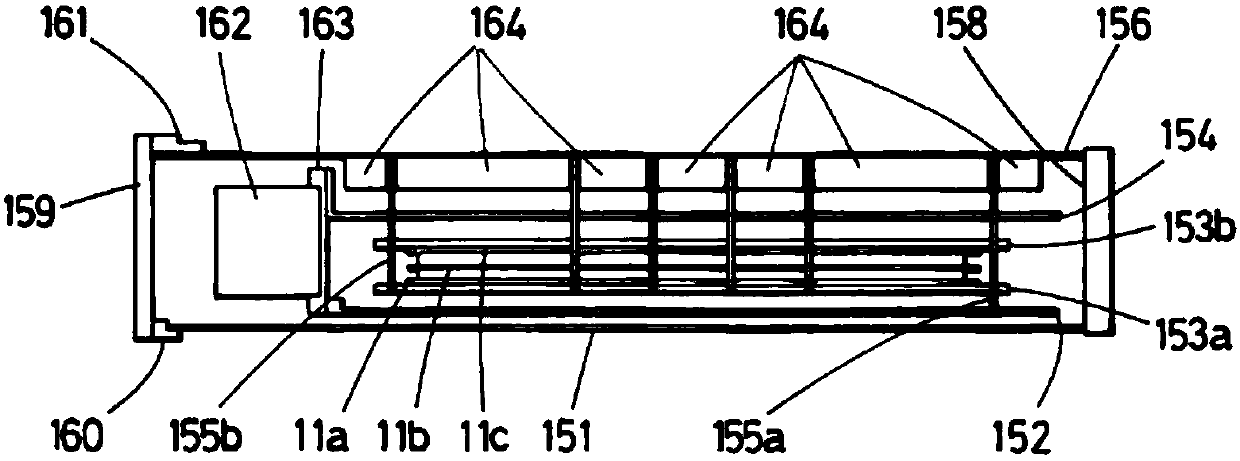

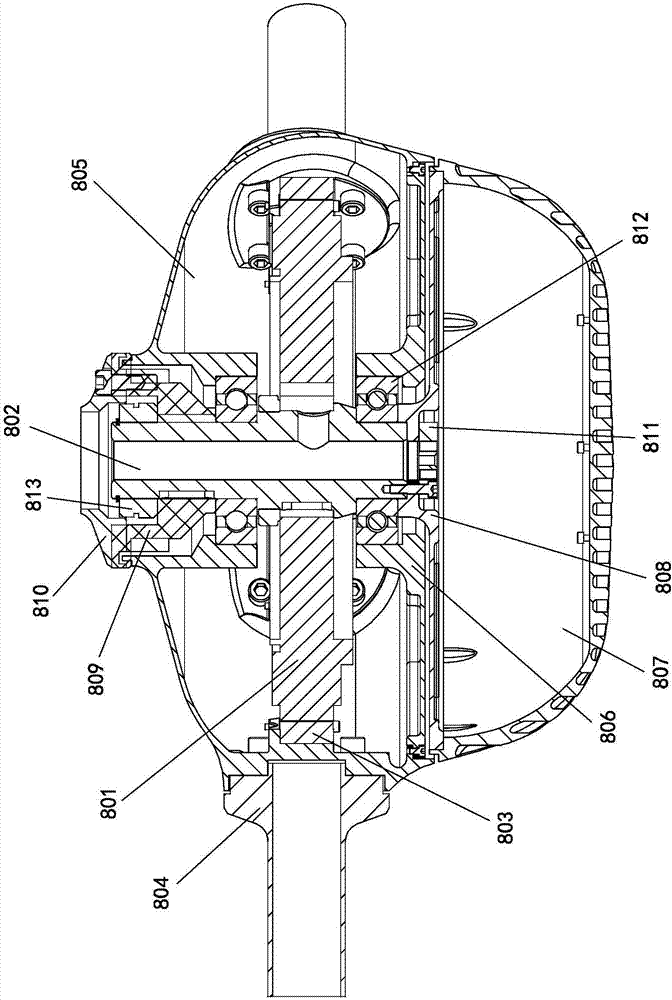

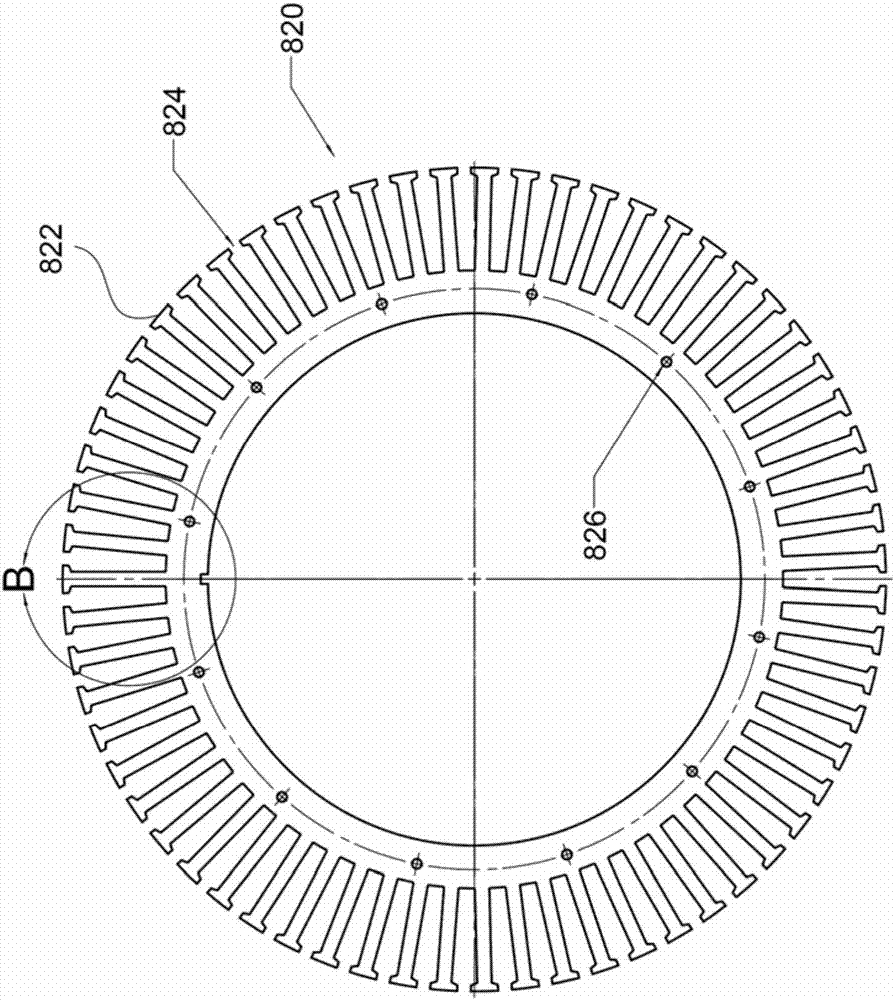

InactiveCN107800257AEasy to implementSimplified fastening systemSynchronous generatorsPrevention/reducing eddy-current losses in winding headsHigh temperature superconductingRefrigeration

This invention relates to a synchronous generator for wind turbines comprising a rotor (20) and a stator (10), wherein the stator (10) comprises a plurality of induction coils (11) of a high-temperature superconducting material arranged to generate a magnetic field. The use of the superconducting stator, instead of a superconducting rotor, allows simplifying the refrigeration system, thus eliminating, for example, the rotating joints for cryogenic gas and the rotating joints for high-purity helium gas.

Owner:GAMESA INNOVATION & TECH SA

Direct drive ceiling fan

InactiveCN106855059AReduce noiseIncrease capacityMagnetic circuit rotating partsPump componentsCeiling fanElectric machine

Owner:PHASE IND DESIGN NINGBO

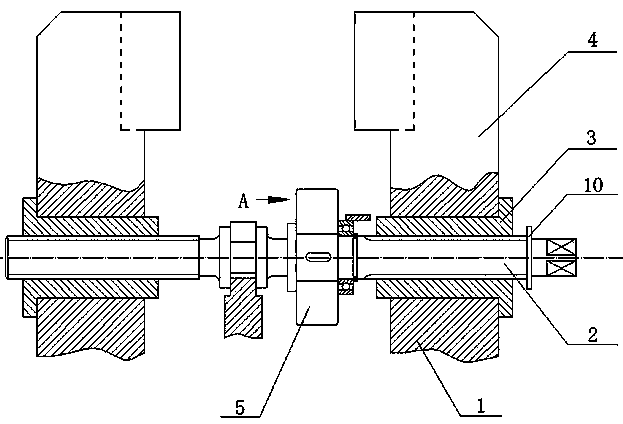

High-speed high-temperature friction and wear test bed adopting symmetrical loading

PendingCN112147068ASimple mechanical structureReduce noiseUsing mechanical meansMaterial analysisPhysicsEngineering

The invention provides a high-speed high-temperature friction and wear test bed adopting symmetrical loading, and belongs to the field of high-speed high-temperature friction and wear tests. The high-speed high-temperature friction and wear test bed comprises a base, a driving module, a test module, a heating module and a measurement monitoring module, wherein power and a high-temperature environment are provided for the test module through the driving module and the heating module respectively; a high-speed electric spindle of the driving module is fixed at one end of a bottom plate through aclamping mechanism, and an output shaft of the high-speed electric spindle is connected with the test module through a flexible coupling; the test module comprises a mechanical shaft, a bearing seatand loading devices; two ends of the mechanical shaft are supported and mounted at the other end of the bottom plate through the bearing and the bearing seat respectively; a test ring is coaxially mounted in the middle of the mechanical shaft through a modular test ring mounting seat and driven by the high-speed electric spindle to rotate synchronously; the two loading devices are symmetrical about the central axis of the mechanical shaft and fixed on the bottom plate; and the highest test rotating speed can reach 30,000 r / min, the highest linear speed of a contact point of the test ring and atest block can reach 400m / s, and the test is stable to complete the measurement function.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Slant leg rigid frame built-in prestressed concrete variable cross-section box girder bridge and construction method thereof

InactiveCN103031804AAvoid Cracking DiseaseReduce horizontal tensionBridge erection/assemblyPre stressPrestressed concrete

The invention discloses a slant leg rigid frame built-in prestressed concrete variable cross-section box girder bridge. The bridge comprises piers, and bottom plates and web plates forming a box girder; a slant leg rigid frame structure is arranged in a variable cross-section girder bridge box, and comprises internal longitudinal beams and internal aslant legs; upper bend anchoring plates upwards inclined along the longitudinal direction of the box girder from the midspan to the pier direction are arranged above the internal longitudinal beams; midspan sagging moment bottom plate ropes are arranged along the upper bend anchoring plates and upper bends of the internal longitudinal beams to form two layers of bottom plate ropes; sawtooth blocks are arranged at the tension anchoring positions of the bottom plate ropes on the internal longitudinal beams and the upper bend anchoring plates; and the tension anchoring ends of the bottom plate ropes are bent in the box at the sawtooth blocks. The bridge structure provides reasonable rope arrangement and anchoring positions to the sagging moment ropes so as to reduce the bottom plate section hollow rate and the bottom plate rope flat bending amplitude. The sagging moment bottom plate ropes generate the upward radial force to eliminate or reduce the influence of the second-phase dead load causing the girder down-warping deformation. The invention further discloses a construction method for the slant leg rigid frame built-in prestressed concrete variable cross-section box girder bridge.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Bi-directional coupling with axial disengagement

Owner:SCHAEFFLER TECH AG & CO KG

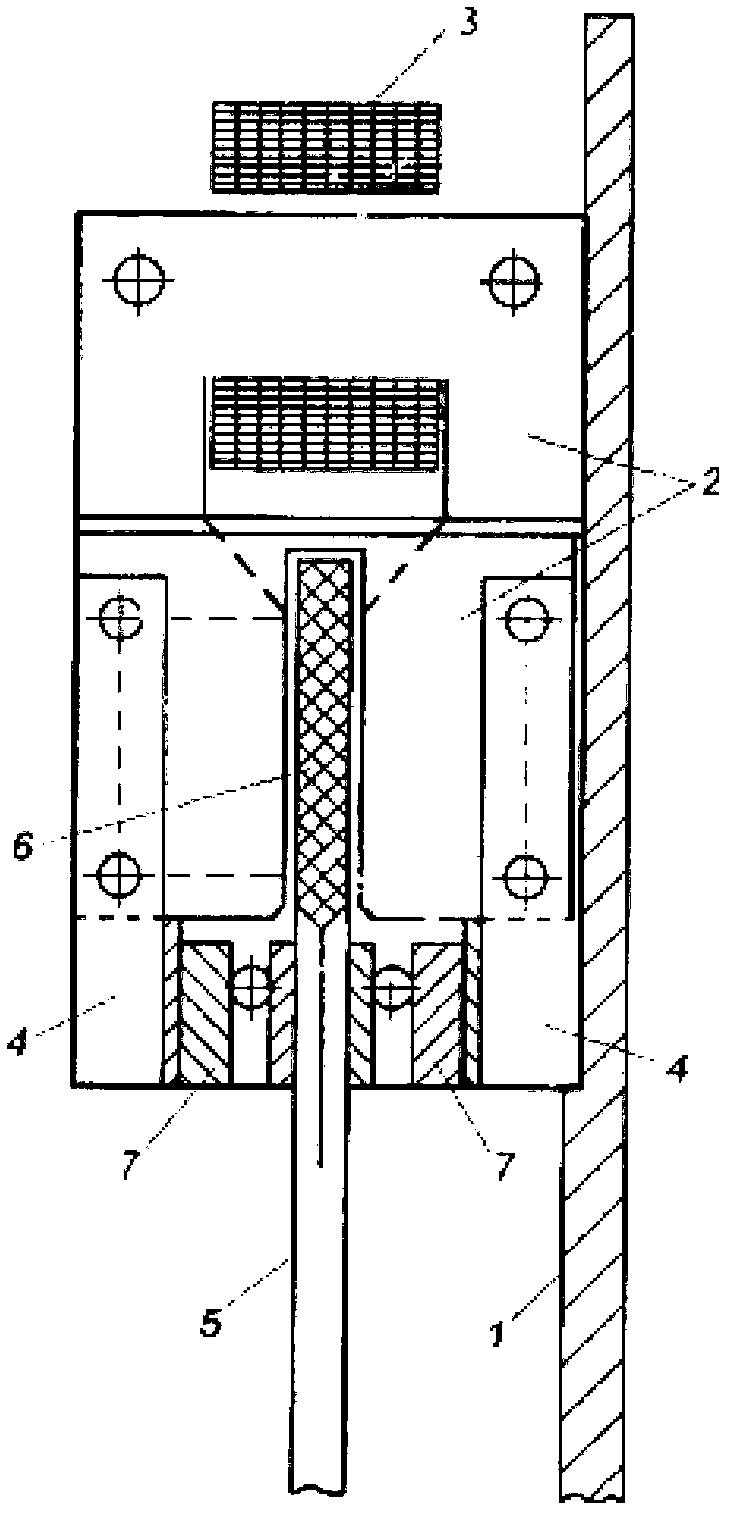

Low-speed multipole synchronous generator

InactiveCN103229399AReduce quality problemsSmall sizeMagnetic circuit rotating partsMechanical energy handlingLow speedStator coil

The invention relates to a low-speed multipole synchronous generator comprising a stator in the form of n-shaped segments with a winding formed from stator coils provided with one coil per pole and combined into different coil groups, as well as a rotor with permanent magnets arranged on the rim along the rotor. The rotor is in the form of a disk with inserts consisting of permanent magnets fixed alternately relative to the direction of magnetization, wherein the permanent magnets on the rotor are mounted with a circumferential shift relative to the yokes of the stator coils in such a way that every 10th magnet or yoke of the stator coil is arranged opposite one another depending on which poles there are more of.; The proposed synchronous generator has a significantly lower mass in comparison with the prior-art technical solution.

Owner:维克多·芬多诺维奇·切乎诺夫 +1

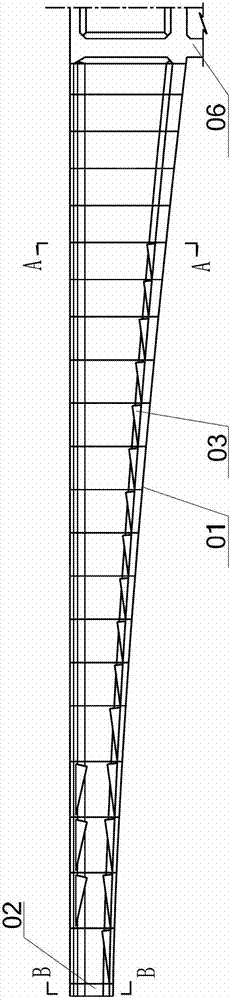

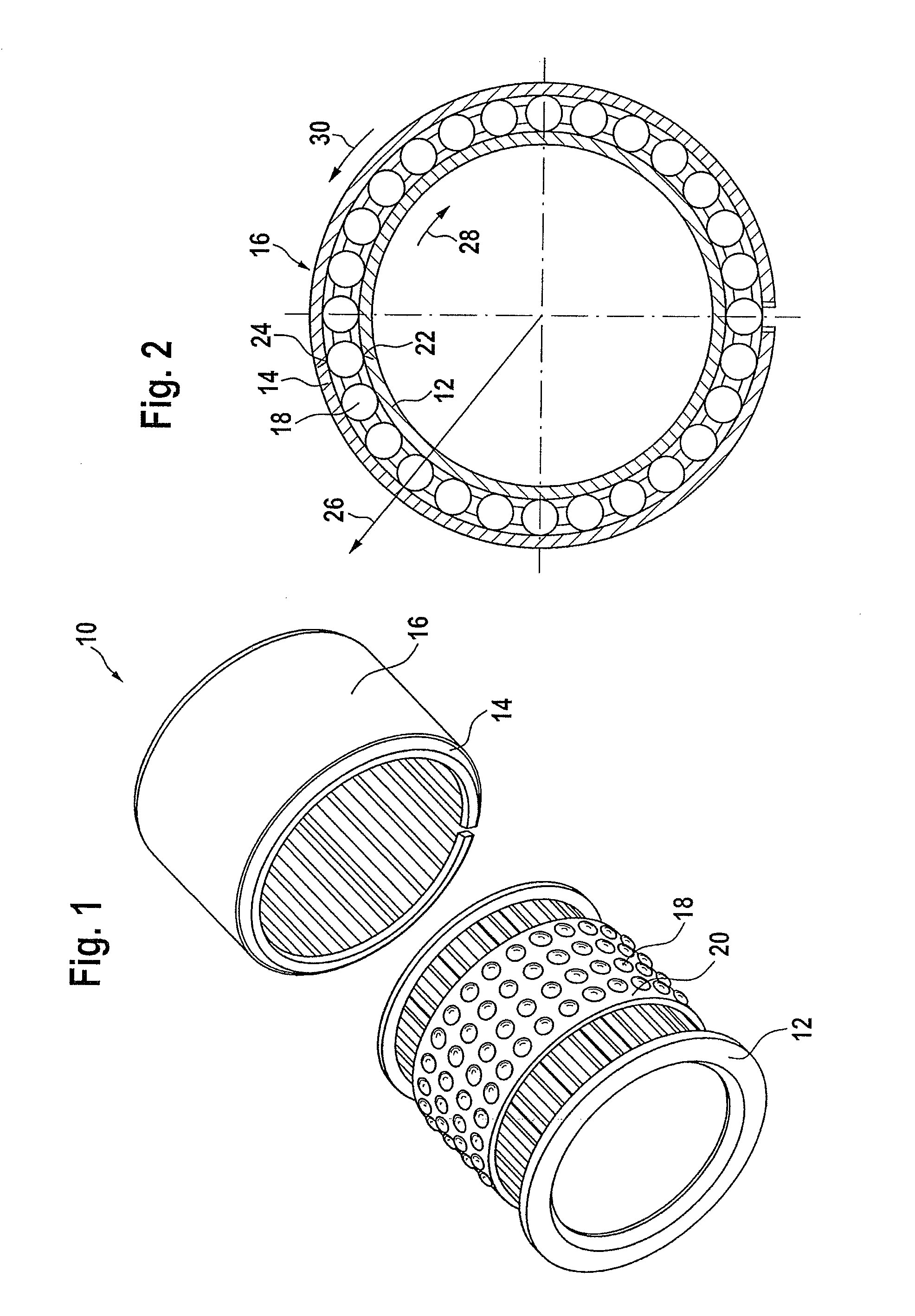

Bi-directional coupling with axial disengagement

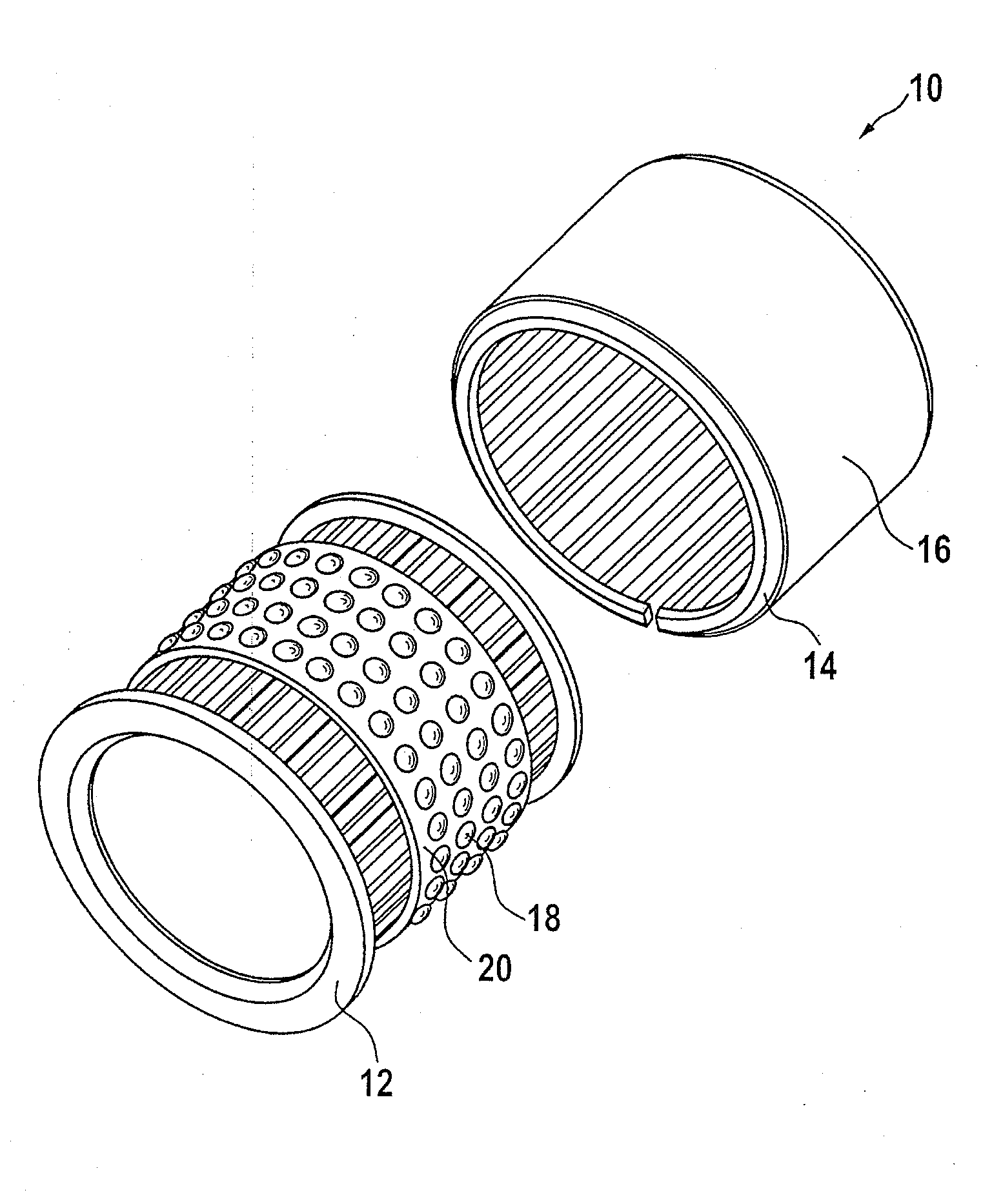

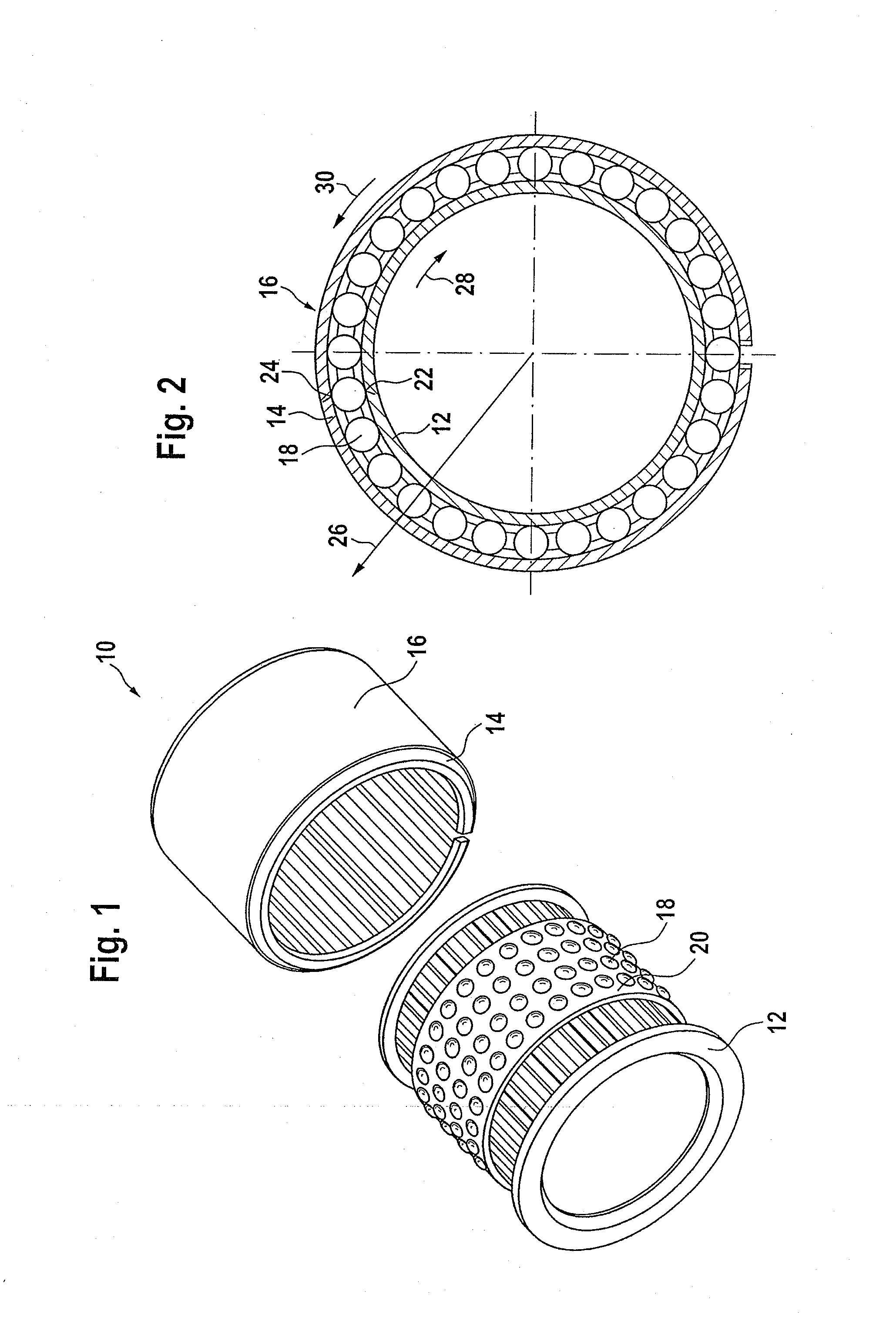

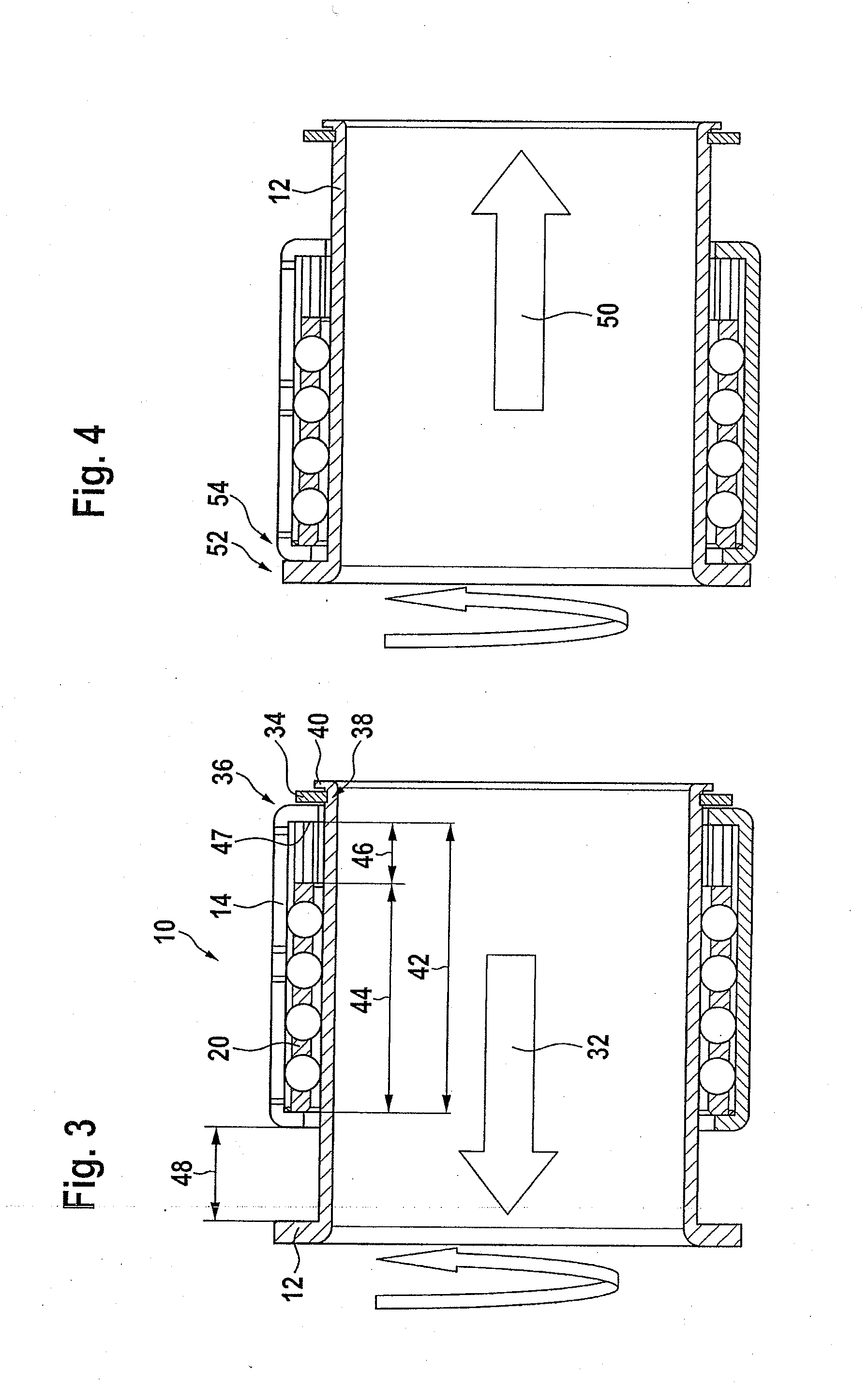

InactiveUS20100126818A1Eliminate radial forceYielding couplingFriction clutchesConcentric ringEngineering

Example aspects of the present invention comprise two concentric rings, the rings movable relative to each other and defining a clearance between them for receiving at least one ball. The first ring is a coupling member, the second ring is a tubular slipper with a friction surface on the far side of the clearance, and the ball contacts the coupling member to the tubular slipper. At least one ring has a first recess with side walls for receiving the least one ball, and the friction surface is configured to displace in a radial direction when the at least one ball is axially aligned with the first recess and forced to run up the side walls by rotating the rings relative to one another. In an example embodiment of the invention, the first recess is a calotte.

Owner:SCHAEFFLER TECH AG & CO KG

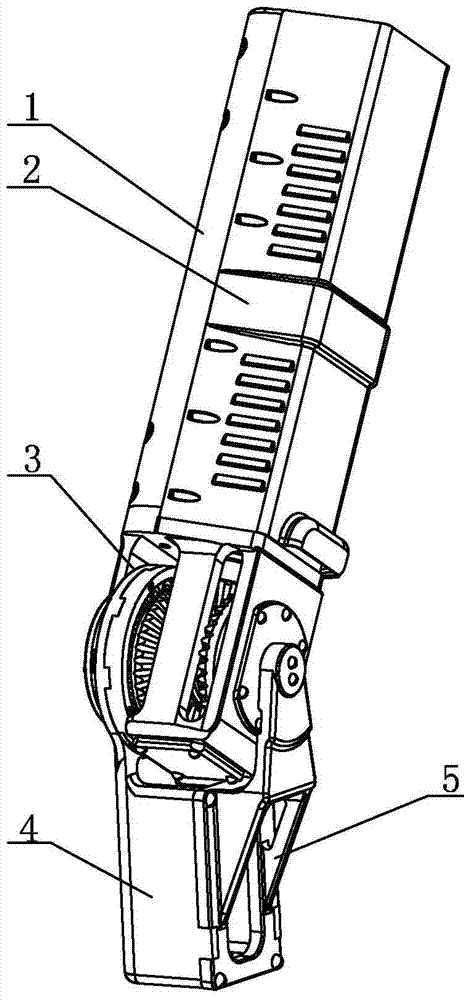

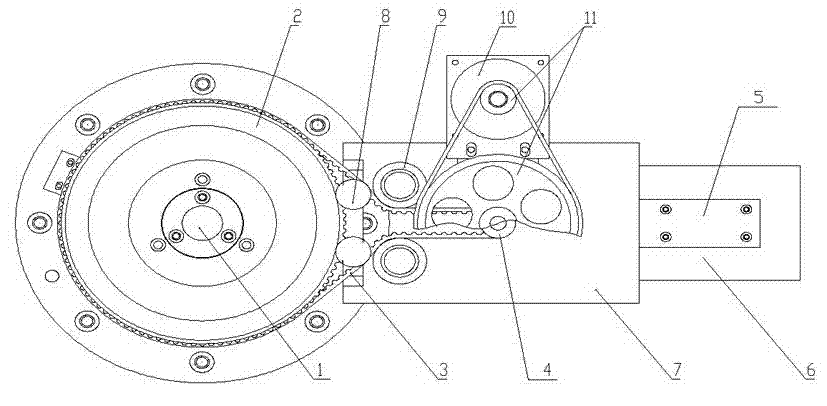

Large-output-force robot flexible energy-storing joint based on gravity energy storing

The invention discloses a large-output-force robot flexible energy-storing joint based on gravity energy storing and relates to a flexible driving device used for a robot. The large-output-force robot flexible energy-storing joint based on gravity energy storing aims to solve the problems that due to the linear type force output of an existing series elastic actuator of a robot joint, the structure is not compact, occupied space is large, power required by a motor is large, and accurate force output control and accurate position control of the joint are not facilitated. The large-output-force robot flexible energy-storing joint based on gravity energy storing comprises an upper limb connecting plate, an upper limb motor shell, a joint gearbox, a lower limb connecting plate, a lower limb support, a speed reducer, a rotary transformer, a motor provided with an encoder, an series elastic body and a torsion spring, wherein the joint gearbox comprises a shell body, a third bevel gear, a fourth bevel gear, a first bevel gear, a second bevel gear and a joint shaft, the series elastic body comprises an inner ring body, an outer ring body and at least four groups of wavy clips, the inner ring body and the outer ring body are concentric, and the at least four groups of wavy clips which are integrated are connected between the inner circle and the outer circle of the inner ring body in the circumferential direction and between the inner circle and the outer circle of the outer ring body in the circumferential direction. The large-output-force robot flexible energy-storing joint based on gravity energy storing is applied to the field of robots.

Owner:HARBIN INST OF TECH

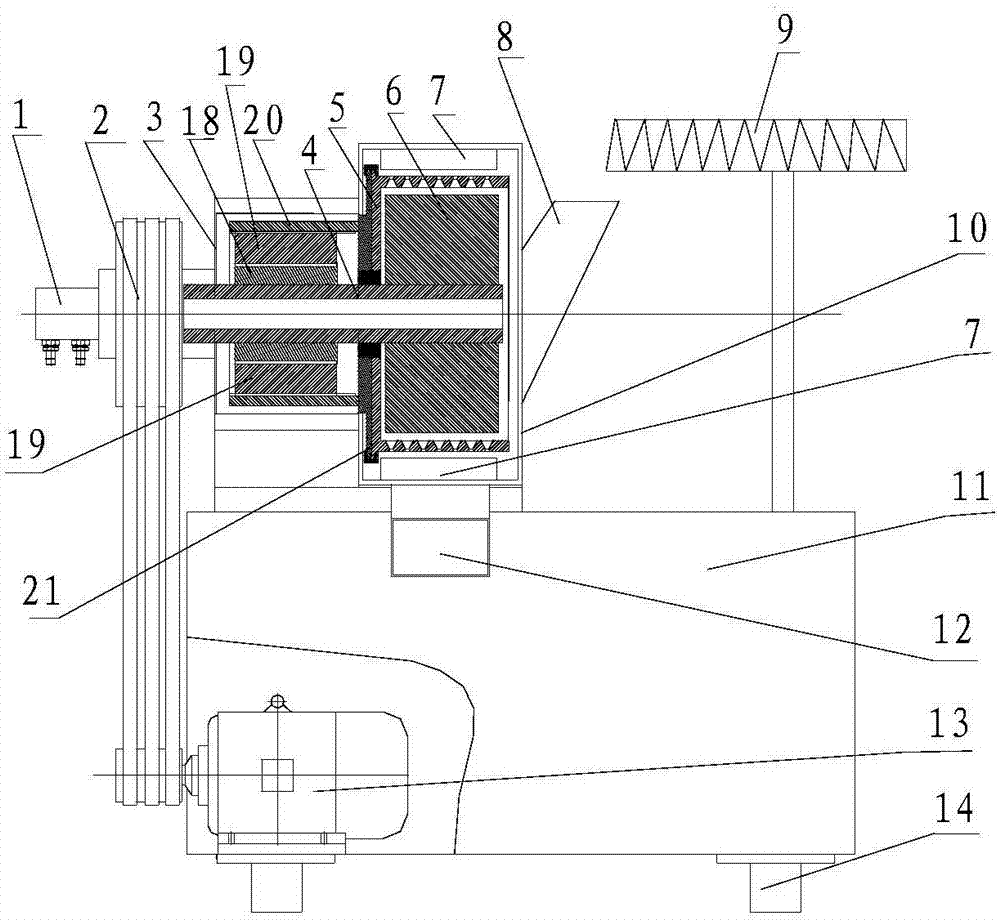

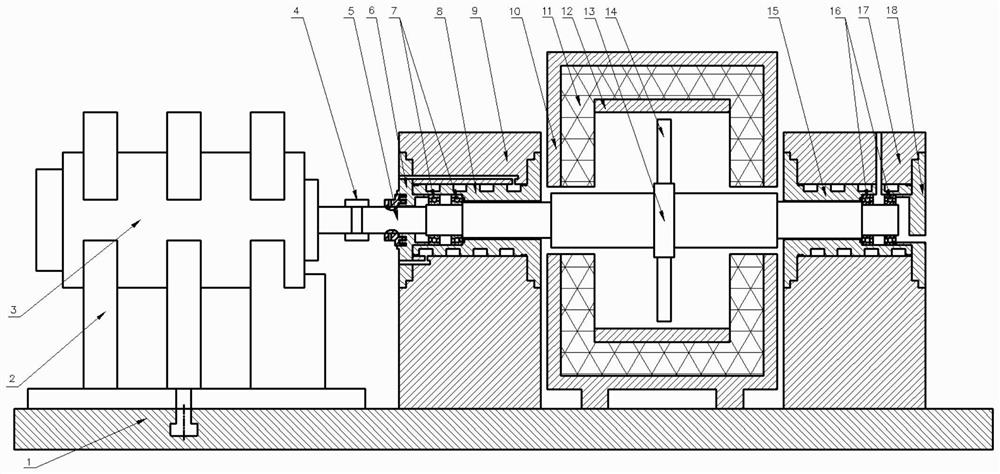

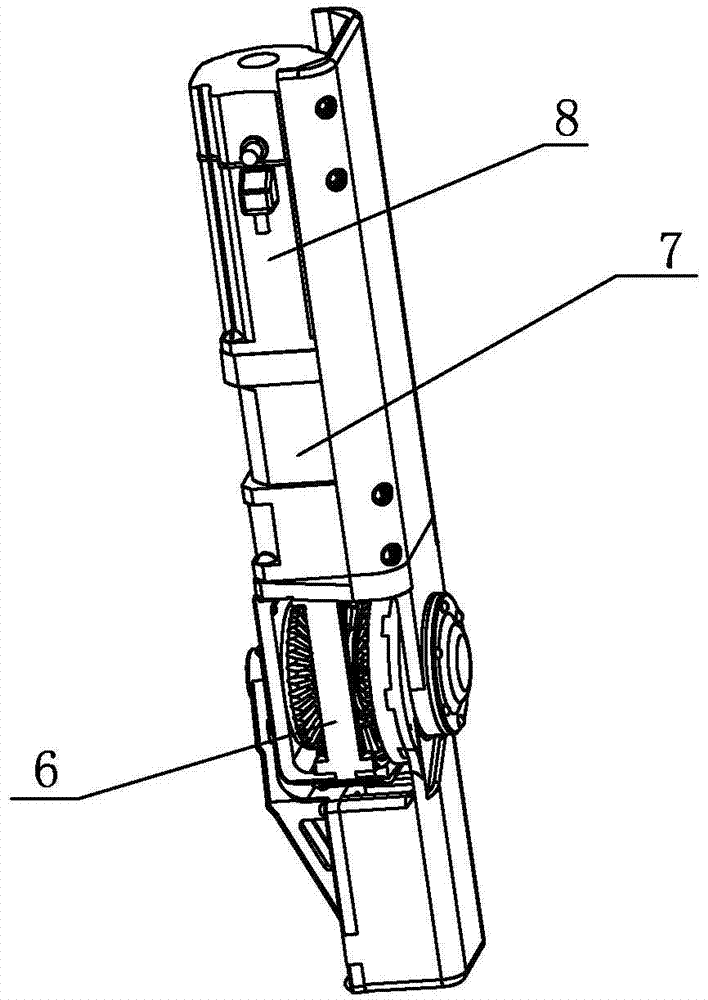

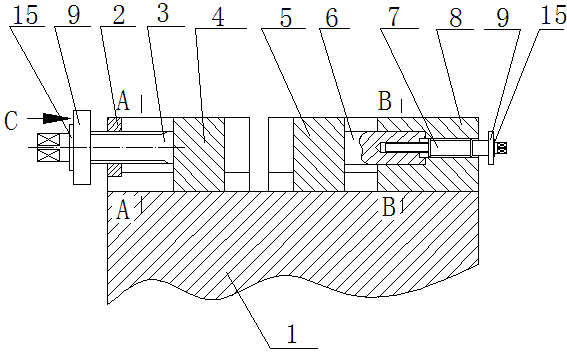

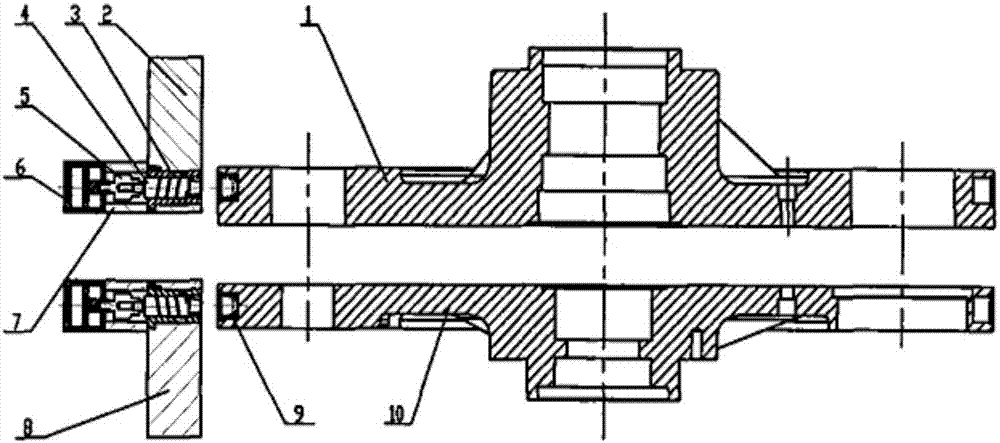

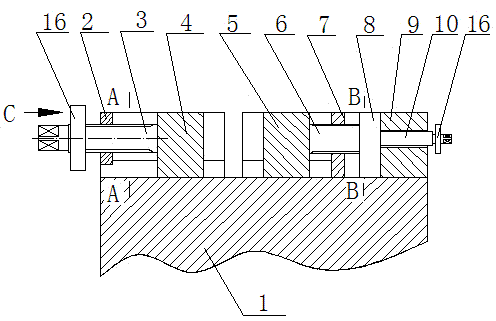

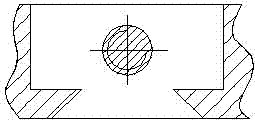

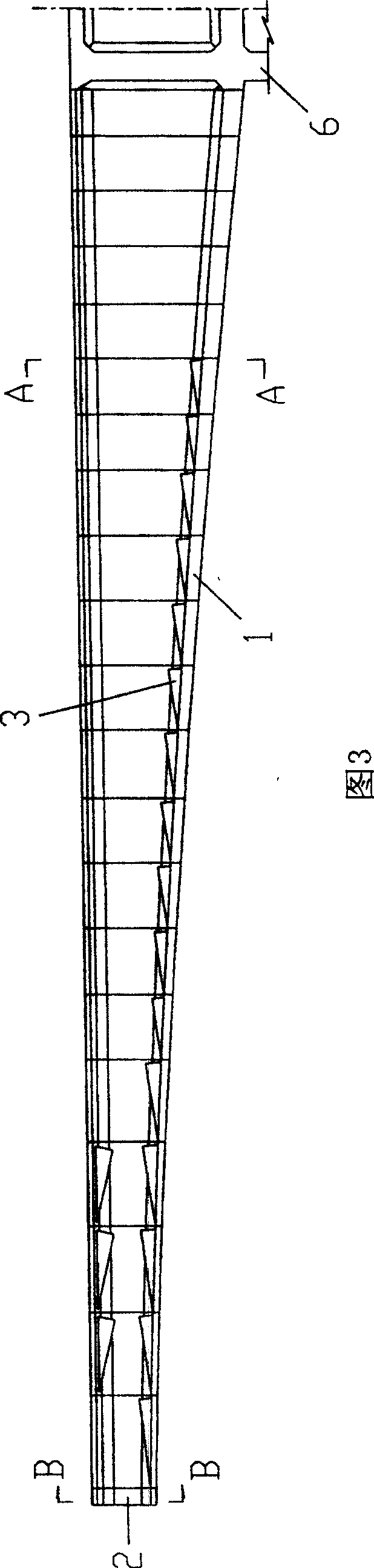

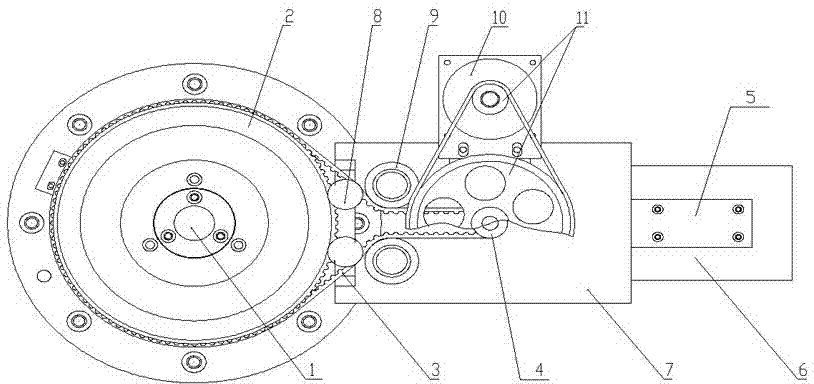

Main shaft transmission used for gear measurement center

ActiveCN103091101ALow costEliminate radial forceMachine gearing/transmission testingGearingTransmission beltSlide plate

The invention belongs to the technical field of measuring, and particularly relates to a man shaft transmission used for a gear measurement center. The problems that cost is high, manufacturing is difficult, and commissioning and maintenance are completed exist in the prior art. In order to solve the problems, the provided technical scheme is that the main shaft transmission used for the gear measurement center comprises a measurement center main shaft, a face plate, a transmission belt, a transmission wheel and a driving device, a base, a sliding plate and a pinch roller. The base is arranged on one side of the radial direction of the measurement center main shaft, the sliding plate is arranged on the base, the sliding plate is connected with the base through a linear guide rail arranged on the base, the driving device and the pinch roller are both arranged on the sliding plate, the pinch roller, the face plate and the transmission wheel are all arranged in a same plane, the pinch roller is arranged on the inner side of the transmission belt and between the face plate and the transmission wheel, and the pinch roller and the face plate are arranged in an external common tangent mode. Due to the fact that a common motor is adopted for transmission, the cost of a whole shafting is reduced.

Owner:XIAN HIGH TECH AEH INDAL METROLOGY

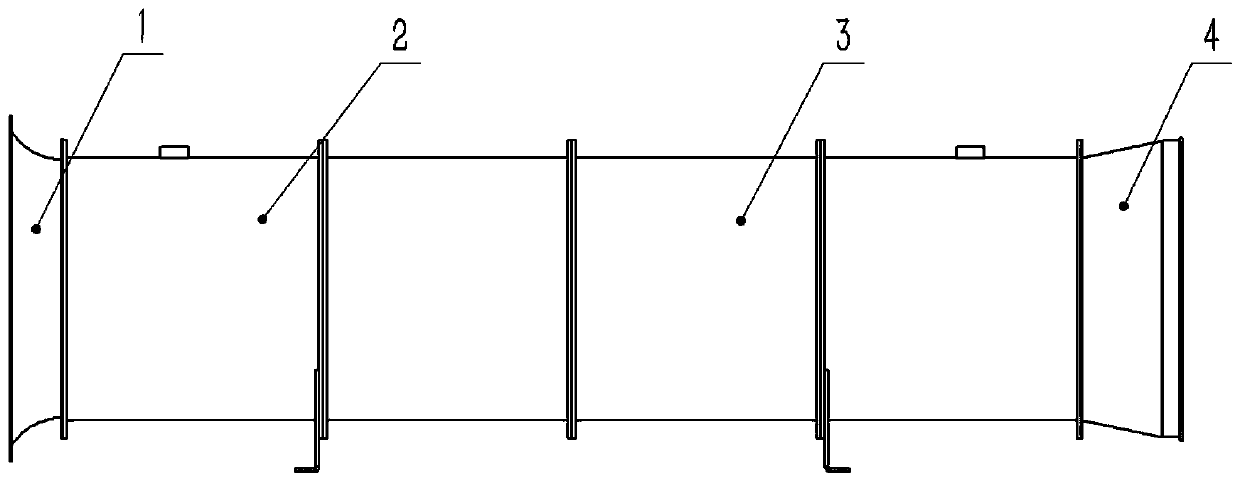

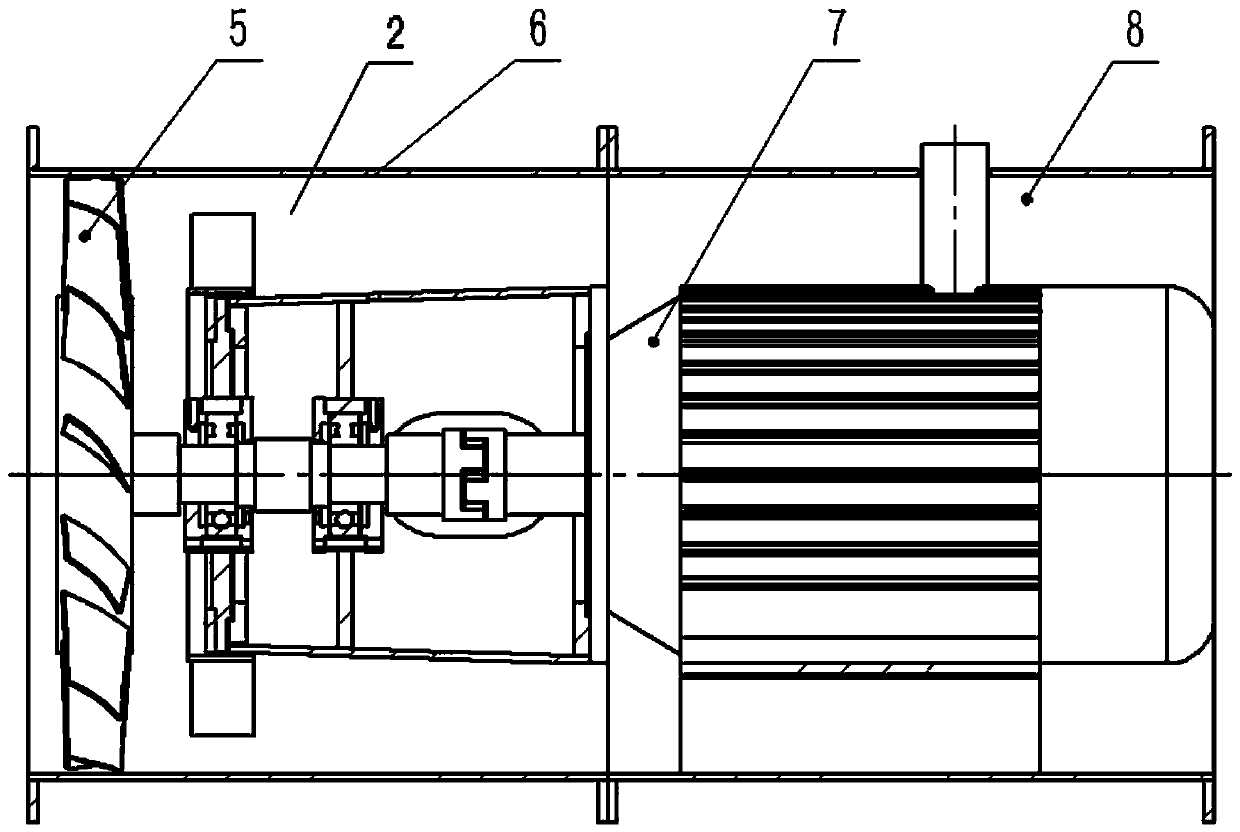

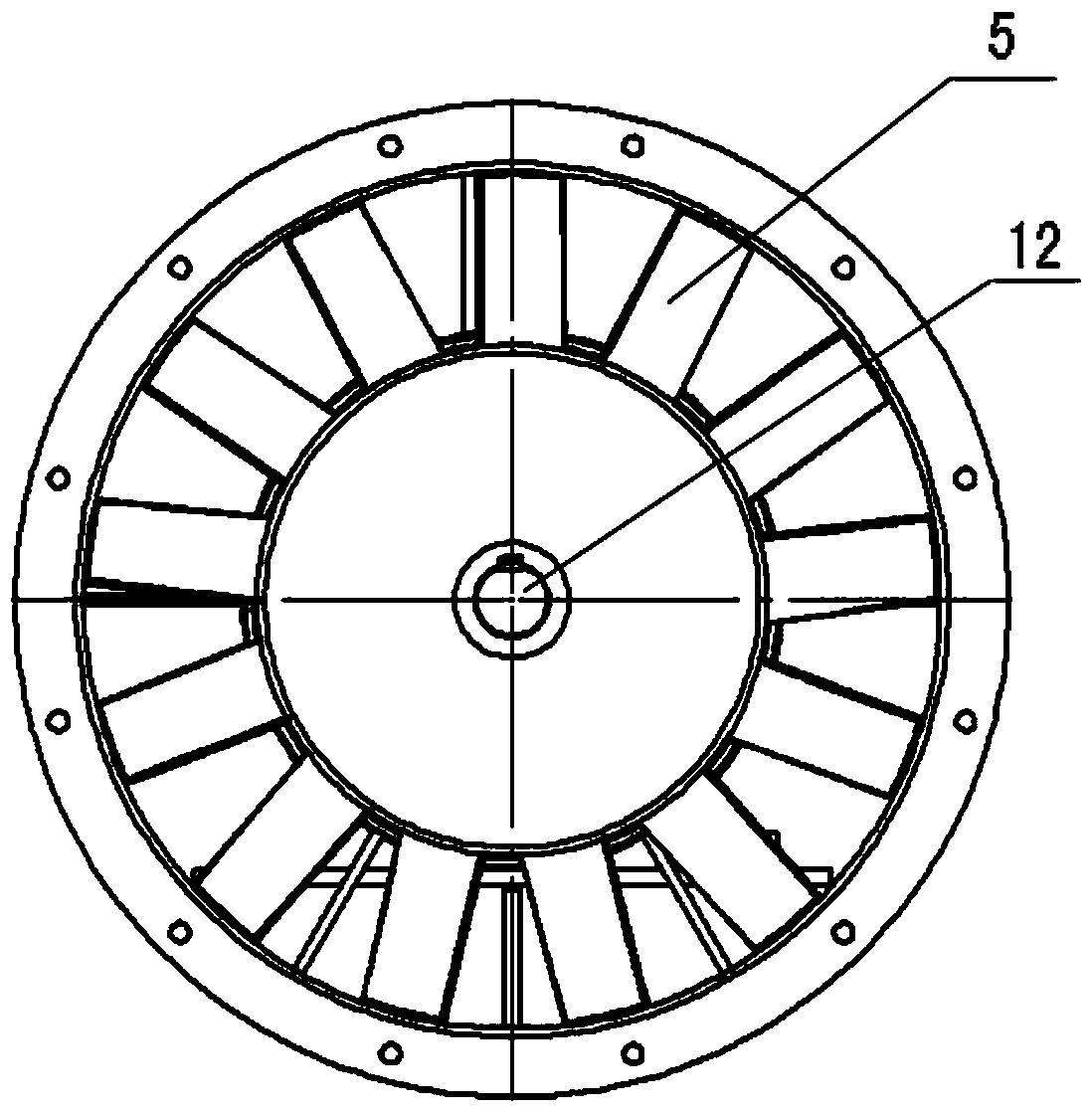

Local ventilator for coal mine application and provided with transmission cases

PendingCN107781195ABurn out preventionAvoid falling out etc.Pump componentsPump installationsImpellerCoupling

A local fan for coal mines with a transmission box, which is composed of a current collector, a primary main body, a secondary main body and an outlet joint, and bolts are used to connect each part, and it is characterized in that: the primary main body, The secondary main body is composed of an impeller, a main engine casing, a transmission group, and a motor casing. The transmission group is composed of a transmission box, a coupling, and a motor. The motor shaft and the main shaft of the transmission box are connected by a coupling; the transmission box It consists of a main shaft, an outer small cover, an outer bearing, an end cover, an inner small cover of an outer bearing, an outer small cover of an inner bearing, an inner bearing, a support plate, an inner small cover of an inner bearing, and a box; the beneficial effect is that the lubricating performance is significantly improved, The added coupling eliminates the axial force, radial force and unbalanced force when the impeller rotates, avoiding the occurrence of bearing burnout and bearing cage loosening; compared with ordinary direct-coupled fans, its service life The extension is doubled, which effectively guarantees the need for continuous ventilation underground.

Owner:SHANXI JULONG FAN & BLOWERS

Pressure controllable type limiting anti-loose fine adjusting clamp

InactiveCN104015073AHigh positioning accuracyEliminate radial forceWork clamping meansMeasurement/indication equipmentsIndustrial engineeringScrew thread

Owner:WUHU TIANXIONG NEW MATERIAL TECH

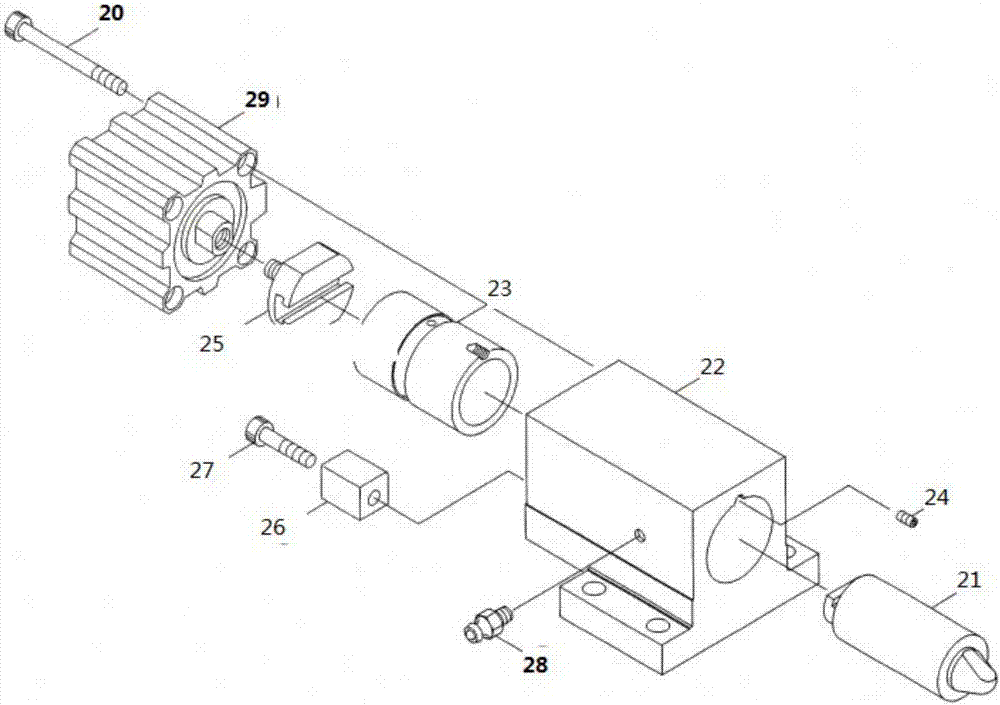

Turret positioning device of numerical control turret

InactiveCN107486491AEasy to installImprove assembly efficiencyShaping toolsStripping-off devicesNumerical controlEngineering

This invention discloses a turret positioning device of a numerical control turret. The turret positioning device comprises a mounting block, an air cylinder and a positioning pin, wherein the mounting block is provided with a cavity body with two ends communicated, the positioning pin is arranged in the cavity body, and the air cylinder is mounted at one end of the cavity body of the mounting block; the air cylinder is connected with the positioning pin and can drive the positioning pin to move in the extension direction of the cavity body; a connecting joint is mounted between the air cylinder and the positioning pin, and one end of the connecting joint is fixed to the air cylinder through threads, and a T-shaped notch is formed in the other end of the connecting joint; a T-shaped connecting joint is arranged at the tail end of the positioning pin in a matched mode; a guiding key parallel to the connecting joint is mounted below the connecting joint to eliminate the radial force of a air cylinder shaft; an oil nozzle is mounted on the mounting block, and an annular notch and an oil passing hole are processed in a turning mode in the corresponding positions of the inner wall and the outer wall of a pin sleeve, and lubricating oil can be periodically added between the pin sleeve and the positioning pin, component damaging caused by friction is reduced, meanwhile the fact that the positioning pin is out of action caused by locking due to heat expansion of the positioning pin and the pin sleeve due to overheating friction is prevented.

Owner:张家港市丰乐汽车设备有限公司

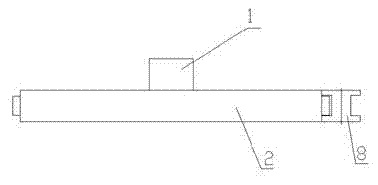

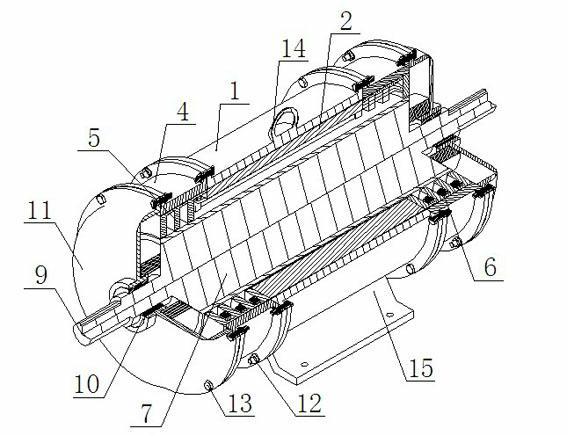

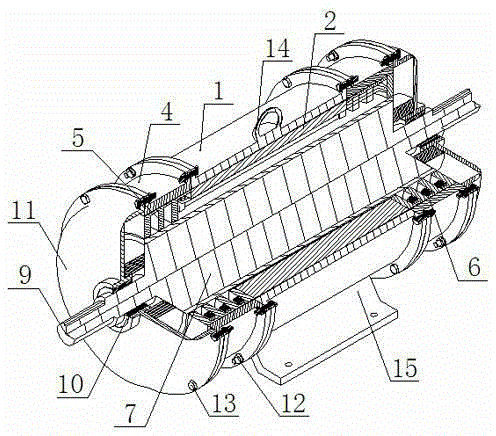

Winding-free end-part spiral-motion induction motor

The invention discloses a winding-free end-part spiral-motion induction motor which comprises a shell. The shell is internally provided with stator winding straight-line part stator iron cores and stator winding end part stator iron cores; the stator winding straight-line part stator iron cores and the stator winding end part stator iron cores are provided with stator windings; a rotating shaft is provided with a rotor of the motor; the surface of the rotor of the motor is provided with a conducting layer of the rotor; and the rotating shaft is movably connected with the shell through a sliding bearing. The winding-free end-part spiral-motion induction motor adopts a set of stator windings, the straight line parts of the stator windings can generate a rotating-motion magnetic field, two end parts of the stator windings can generate a linear-motion magnetic field, and the two magnetic fields jointly act on the rotor of the motor to directly drive a load to do spiral motion. The invention omits the end parts of the traditional motor, two end parts of the stator winding, which can generate linear motion magnetic field, are completely symmetric to stator iron cores on two ends of the motor in space, the radial force can be eliminated, and the wear of the bearing can be reduced. The invention is simple in structure, low in manufacturing cost and small in volume, is easy to implement and is convenient to use.

Owner:HENAN POLYTECHNIC UNIV

Limiting and looseness-preventing type overload protective clamp

InactiveCN103769883AAvoid overclampingGuaranteed to be reliableWork clamping meansPositioning apparatusSteel ballSpring steel

The invention discloses a limiting and looseness-preventing type overload protective clamp, and belongs to the field of clamps. The limiting and looseness-preventing type overload protective clamp comprises a clamp base, a left fixing block, a left threaded rod, a left clamping block, a right clamping block, a right threaded rod and a right fixing block, wherein a dovetail groove is formed in the clamp base, and the left fixing block and the right fixing block are arranged at the two ends of the dovetail groove respectively. The limiting and looseness-preventing type overload protective clamp further comprises a safety clutch mechanism, a fixed base, an adjusting rod, an outer ring, screws, springs, steel balls, a square handle and limiting and looseness-preventing devices, wherein the limiting and looseness-preventing devices are arranged on the adjusting rod and the left threaded rod respectively, the adjusting rod is assembled in a threaded hole of the fixed base, the square handle is connected with the adjusting rod, the screws are assembled in threaded holes of the outer ring, the steel balls are pressed on the surface of the square handle, and each spring is arranged between the corresponding screw and the corresponding steel ball. The limiting and looseness-preventing type overload protective clamp solves the problems that according to an existing clamp, clamping force cannot be easily controlled, and looseness can be easily caused, and has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Box type baseboard prestress concrete variable cross-section box girder bridge and construction method thereof

InactiveCN100491639CSolve the problem that the radial force increases continuously with the spanEliminate radial forceBridge erection/assemblyBridge materialsPre stressWhole body

The present invention belongs to the field of civil engineering bridge technology, and discloses a box-type baseplate prestressed concrete non-uniform box beam bridge. It is characterized by that the rectangular solid baseplate of box beam bridge is remade into the form of box. Said invention also provides its concrete structure characteristics. Its structure includes baseplate box top plate, horizontal anchor plate and box beam, they can be in-situ case together, and formed into one whole body. Said bridge has high structure whole body rigidity, small deflection and strong resistance to shear, and its crossing capacity also can be greatly raised.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Pressure-controlling limiting type anti-loosing fixture

InactiveCN103737344AAnti-loosePrevent looseningWork clamping meansMeasurement/indication equipmentsRatchetControl engineering

The invention discloses a pressure-controlling limiting type anti-loosing fixture, and belongs to the field of fixtures. The pressure-controlling limiting type anti-loosing fixture comprises a fixture base, a screw rod, a moving block, a clamping block, wherein the screw rod is meshed with the moving block, a ratchet, a roller, levers, a spring, bolts and a dial. The ratchet is assembled on the screw rod through a key, both ends of the spring are connected with the levers on both sides of the ratchet, the bolt penetrates through a reserved unthreaded hole of each levers, the dial is fixed to the screw rod. The pressure-controlling limiting type anti-loosing fixture solves the problems that in an existing fixture, the fixture is not reliably clamped, clamping force is not easy to control, looseness is prone to occurring are solved, and has the advantages of being simple in structure, reasonable in design and easy to manufacture.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Winding-free end-part spiral-motion induction motor

The invention discloses a winding-free end-part spiral-motion induction motor which comprises a shell. The shell is internally provided with stator winding straight-line part stator iron cores and stator winding end part stator iron cores; the stator winding straight-line part stator iron cores and the stator winding end part stator iron cores are provided with stator windings; a rotating shaft is provided with a rotor of the motor; the surface of the rotor of the motor is provided with a conducting layer of the rotor; and the rotating shaft is movably connected with the shell through a sliding bearing. The winding-free end-part spiral-motion induction motor adopts a set of stator windings, the straight line parts of the stator windings can generate a rotating-motion magnetic field, two end parts of the stator windings can generate a linear-motion magnetic field, and the two magnetic fields jointly act on the rotor of the motor to directly drive a load to do spiral motion. The invention omits the end parts of the traditional motor, two end parts of the stator winding, which can generate linear motion magnetic field, are completely symmetric to stator iron cores on two ends of the motor in space, the radial force can be eliminated, and the wear of the bearing can be reduced. The invention is simple in structure, low in manufacturing cost and small in volume, is easy to implement and is convenient to use.

Owner:HENAN POLYTECHNIC UNIV

Adjustable floating reamer integrated with universal adjustment for roughing and finishing

ActiveCN104096914BEliminate distortion errorsEliminate errorsReaming toolsUniversal jointEngineering

The present invention relates to tool bar tooling equipment for processing holes, in particular to a universally adjustable floating reamer for rough and fine machining, including universally adjustable tool bar, roughing reamer and floating reamer, and universally adjustable The tool bar includes a tool bar handle, a universal joint and a tool bar cover. The tool bar handle and the tool bar cover are respectively pinned to the two ends of the universal joint; One end has a limit slot; the floating reamer is accommodated in the limit slot and can float in the limit slot, and the rough machining reamer limits the position of the floating reamer while processing holes through the cutting edge. The invention eliminates various errors in the machine tool equipment system, the manufacturing error of the cutter bar and the deformation error, improves the machining accuracy of the hole, and thus completely solves the problem that the machine tool spindle cannot approach the hole due to low equipment precision and special hole position, and the tool bar protrudes too long. Hole processing accuracy quality problem; the present invention integrates rough and fine reaming processing holes, greatly improving the production efficiency of hole processing.

Owner:SHENYANG TURBO MASCH CORP

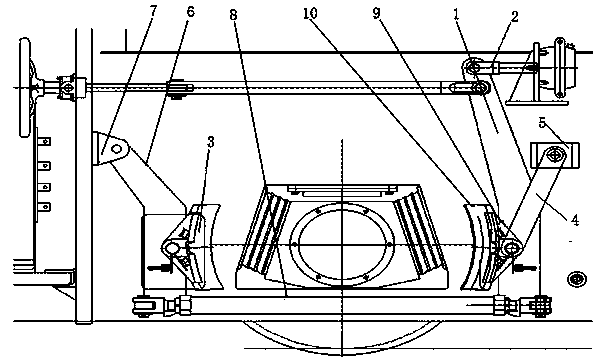

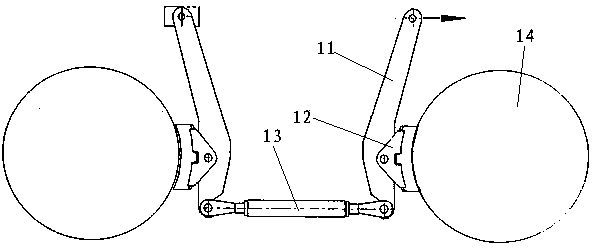

Metal mine underground electric locomotive braking device

InactiveCN104071178ASolve the problem of no brakingImprove braking effectRailway hydrostatic brakesRailway hydrodynamic brakesElectricityEngineering

The invention discloses a metal mine underground electric locomotive braking device. The metal mine underground electric locomotive braking device comprises a lever, an air cylinder, a brake shoe, a first group of special shape levers, a first group of hinge joints, a second group of special shape levers, a second group of hinge joints and couplers, wherein the air cylinder is fixedly installed at the upper end of the lever, the brake shoe is installed on the lower portion of the lever, one end of each special shape lever in the first group of the special shape levers is connected with the brake shoe, the other end of each special shape lever in the first group of the special shape levers is fixedly installed on each hinge joint in the first group of the hinge joints, one end of each special shape lever in the second group of the special shape levers is fixedly installed on each hinge joint in the second group of the hinge joints, the other end of each special shape lever in the second group of the special shape levers is connected with the brake shoe, the bottom of the lever is connected with the bottoms of the second group of the special shape levers through the couplers, the brake shoe comprises a brake shoe block and a brake shoe support, and the brake shoe block is connected with the brake shoe support. The metal mine underground electric locomotive braking device solves the problem that the braking distance of an electric locomotive is long, and eliminates negative effects caused by unidirectional acting force on a wheel and a shaft, generated by the brake shoe during the braking process.

Owner:NANJING MEISHAN METALLURGY DEV +1

Multivariant linear arc-shaped motor

InactiveCN101789646BReduce wearEliminate radial forceMechanical energy handlingClassical mechanicsElectric machinery

The invention discloses a multivariant linear arc-shaped motor, comprising a rotary motion linear arc-shaped motor, a rectilinear motion linear arc-shaped motor, a motion shaft and the like. Bridge arc-shaped stators of the rotary motion linear arc-shaped motor and the rectilinear motion linear arc-shaped motor are integrated into a whole by fasteners and step-shaped structures, stator core laminations are distributed in space in an orthogonal manner, stator windings are arranged in an orthogonal and zoning manner, a cylindrical rotor is shared by the two motors, and stator core zone areas and structural parameters thereof can be respectively selected for the two linear arc-shaped motors according to performance indexes. By adopting the scheme in the invention, a load can be directly driven to do linear, rotary or spiral motion, and the multivariant linear arc-shaped motor has the advantages of simple and compact structure, concise transmission mechanism, small bearing wear, easy control and the like.

Owner:HENAN POLYTECHNIC UNIV

Main shaft transmission used for gear measurement center

ActiveCN103091101BLow costEliminate radial forceMachine gearing/transmission testingGearingTransmission beltSlide plate

The invention belongs to the technical field of measuring, and particularly relates to a man shaft transmission used for a gear measurement center. The problems that cost is high, manufacturing is difficult, and commissioning and maintenance are completed exist in the prior art. In order to solve the problems, the provided technical scheme is that the main shaft transmission used for the gear measurement center comprises a measurement center main shaft, a face plate, a transmission belt, a transmission wheel and a driving device, a base, a sliding plate and a pinch roller. The base is arranged on one side of the radial direction of the measurement center main shaft, the sliding plate is arranged on the base, the sliding plate is connected with the base through a linear guide rail arranged on the base, the driving device and the pinch roller are both arranged on the sliding plate, the pinch roller, the face plate and the transmission wheel are all arranged in a same plane, the pinch roller is arranged on the inner side of the transmission belt and between the face plate and the transmission wheel, and the pinch roller and the face plate are arranged in an external common tangent mode. Due to the fact that a common motor is adopted for transmission, the cost of a whole shafting is reduced.

Owner:XIAN HIGH TECH AEH INDAL METROLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com