Multivariant linear arc-shaped motor

An arc-shaped motor and degree of freedom technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of complex mechanical structure, large rotational inertia, large bearing wear, etc., and achieve small rotational inertia, reduce wear, and bearing wear. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

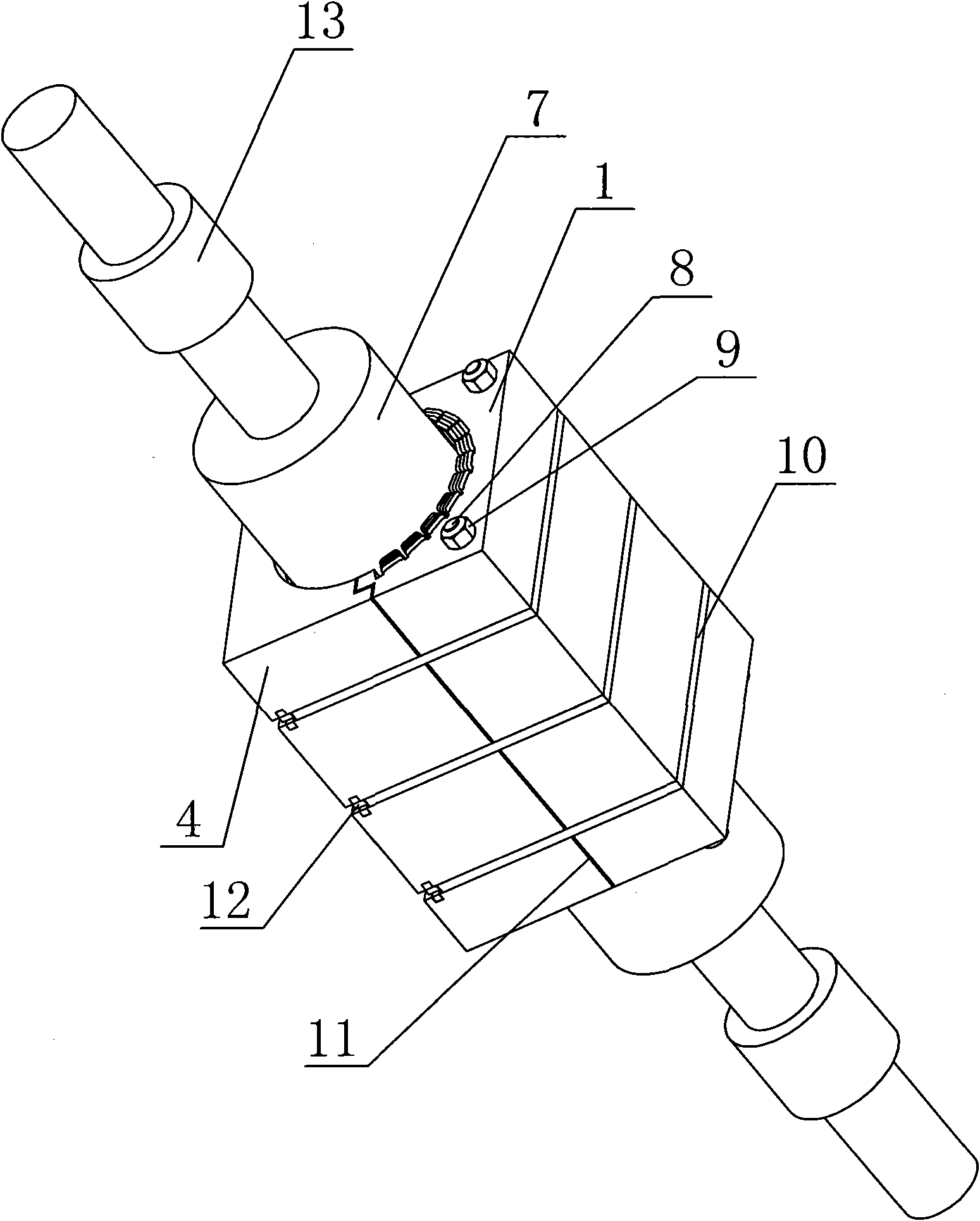

[0028] Such as figure 1 Shown is a three-dimensional schematic diagram of the overall structure of the present invention. The multi-degree-of-freedom linear arc motor is composed of a rotary motion linear arc motor stator 1, a linear motion linear arc motor 4, and a motion shaft 7.

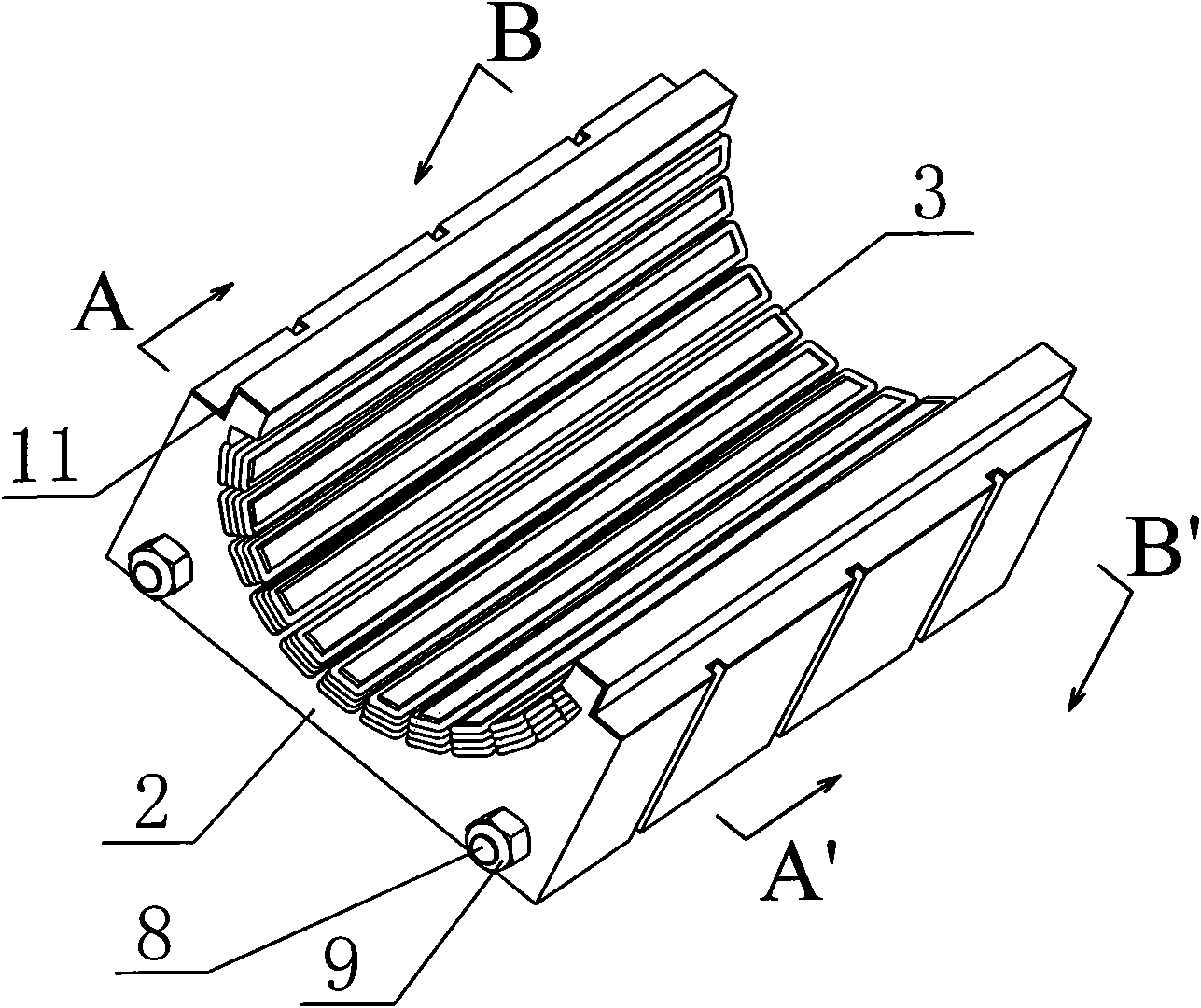

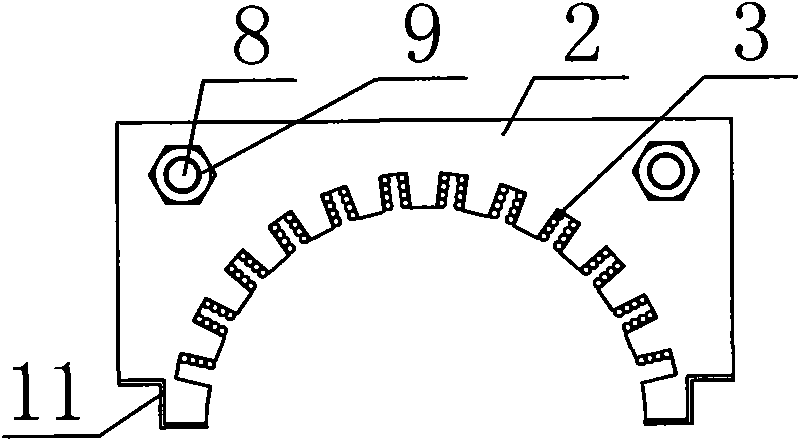

[0029] The three-dimensional schematic diagram of the stator 1 of the linear arc motor with rotary motion is as follows: figure 2 As shown, it is in the shape of a "bridge bow" and is composed of a stator core 2 of a rotary motion linear arc motor and a stator winding 3 of a rotary motion linear arc motor. The stator core 2 of the linear arc-shaped rotary motor is made of silicon steel sheets of uniform shape and slotted in the axial direction, and is connected with the bolt 8 and the nut 9 in the axial direction. The stator winding 3 of the rotary motion linear arc motor is filled and pressed in the slot of the stator core 2 of the rotary motion linear arc motor. When an alternating current is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com