Patents

Literature

55results about How to "Reduced component wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

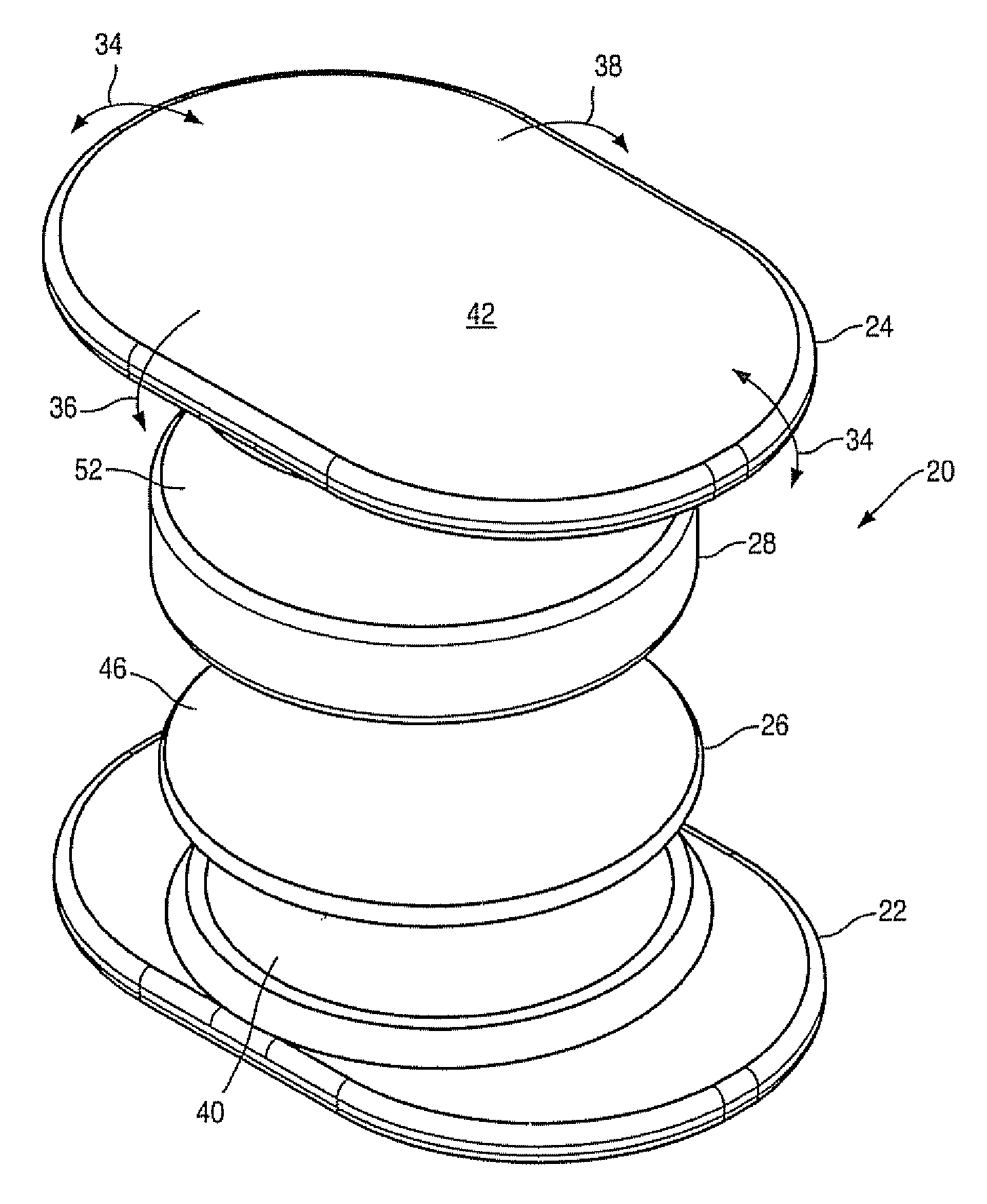

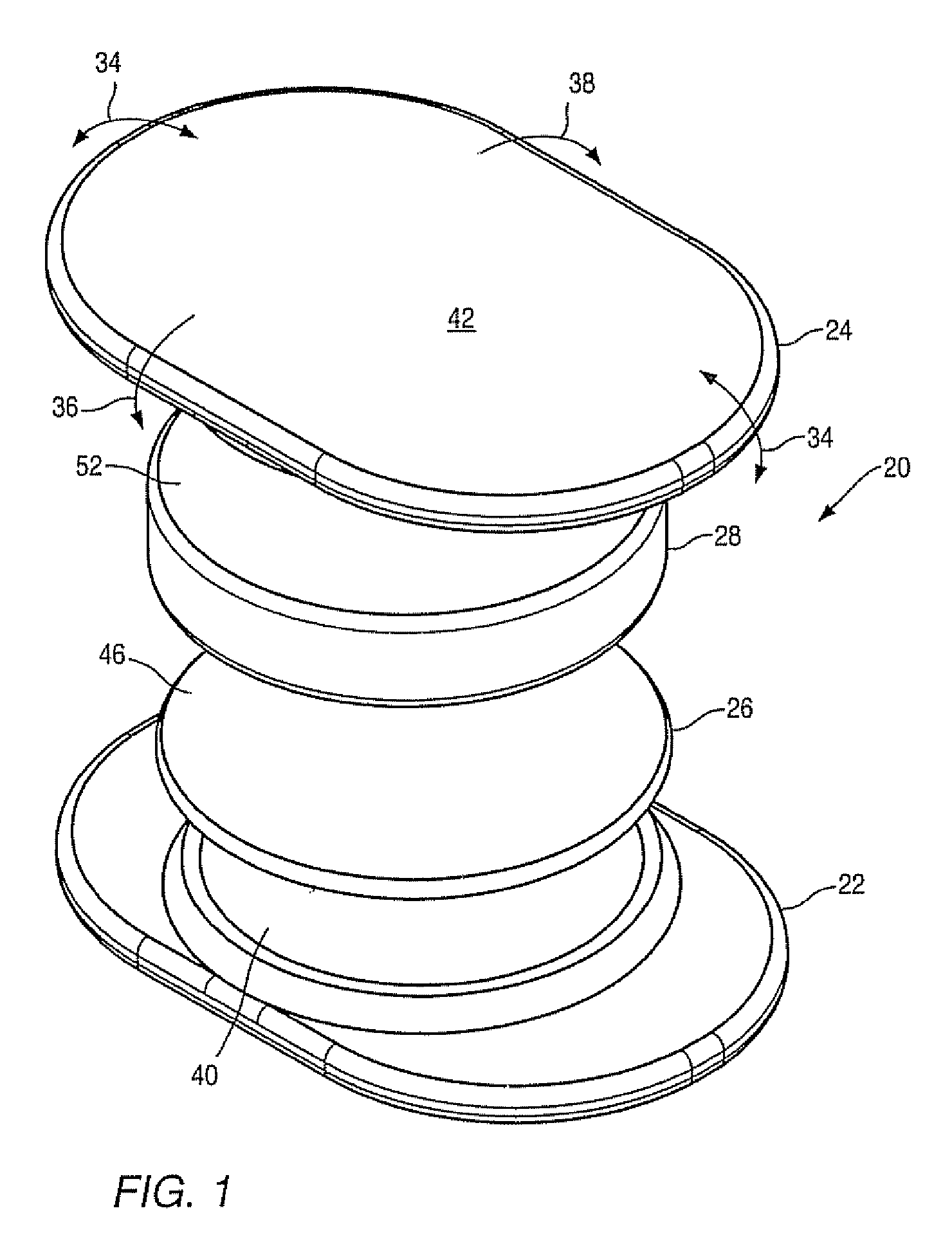

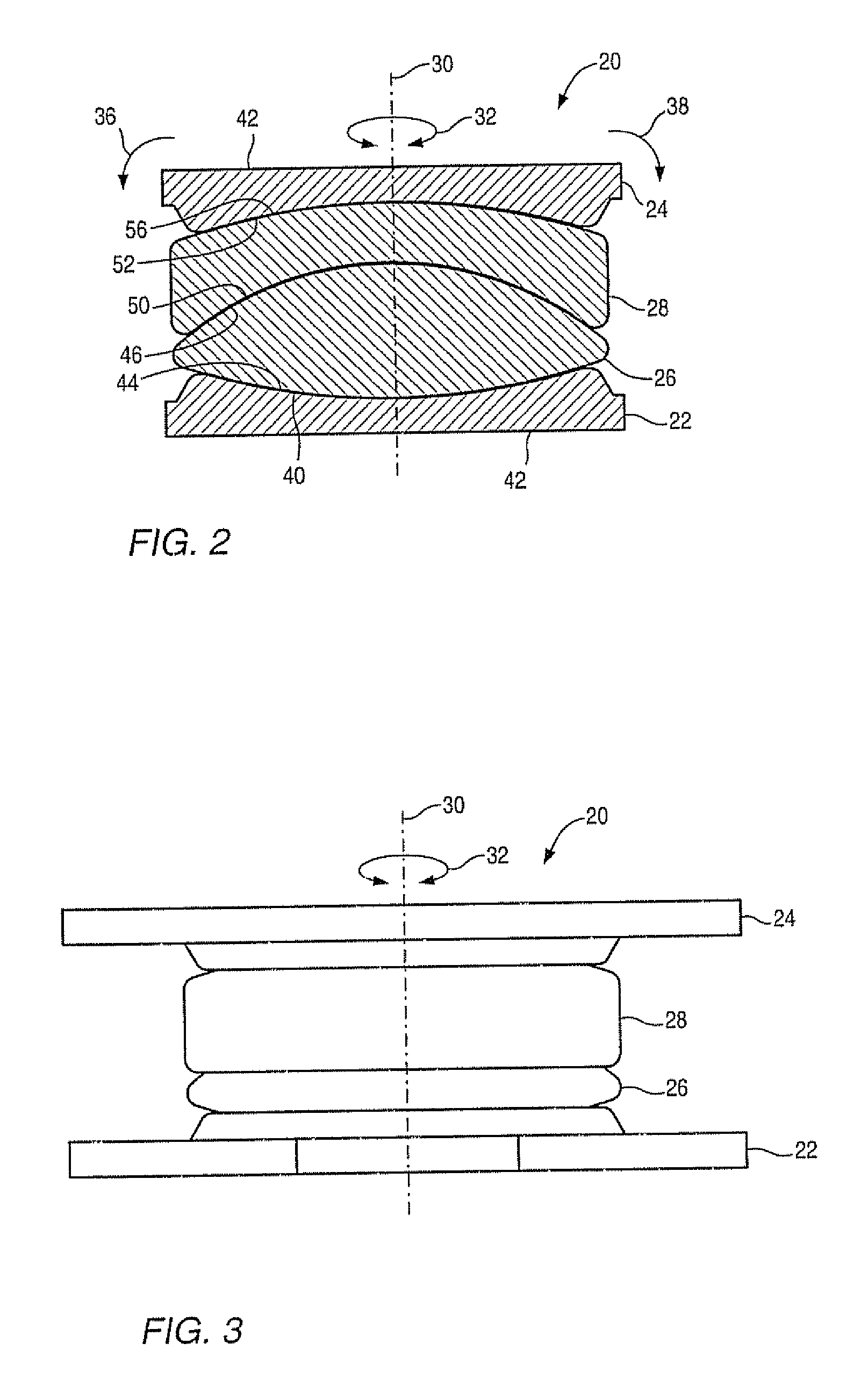

Spinal disc implant

InactiveUS20080015698A1Reduced component wearEasy to keepInternal osteosythesisBone implantBiomedical engineeringAxial rotation

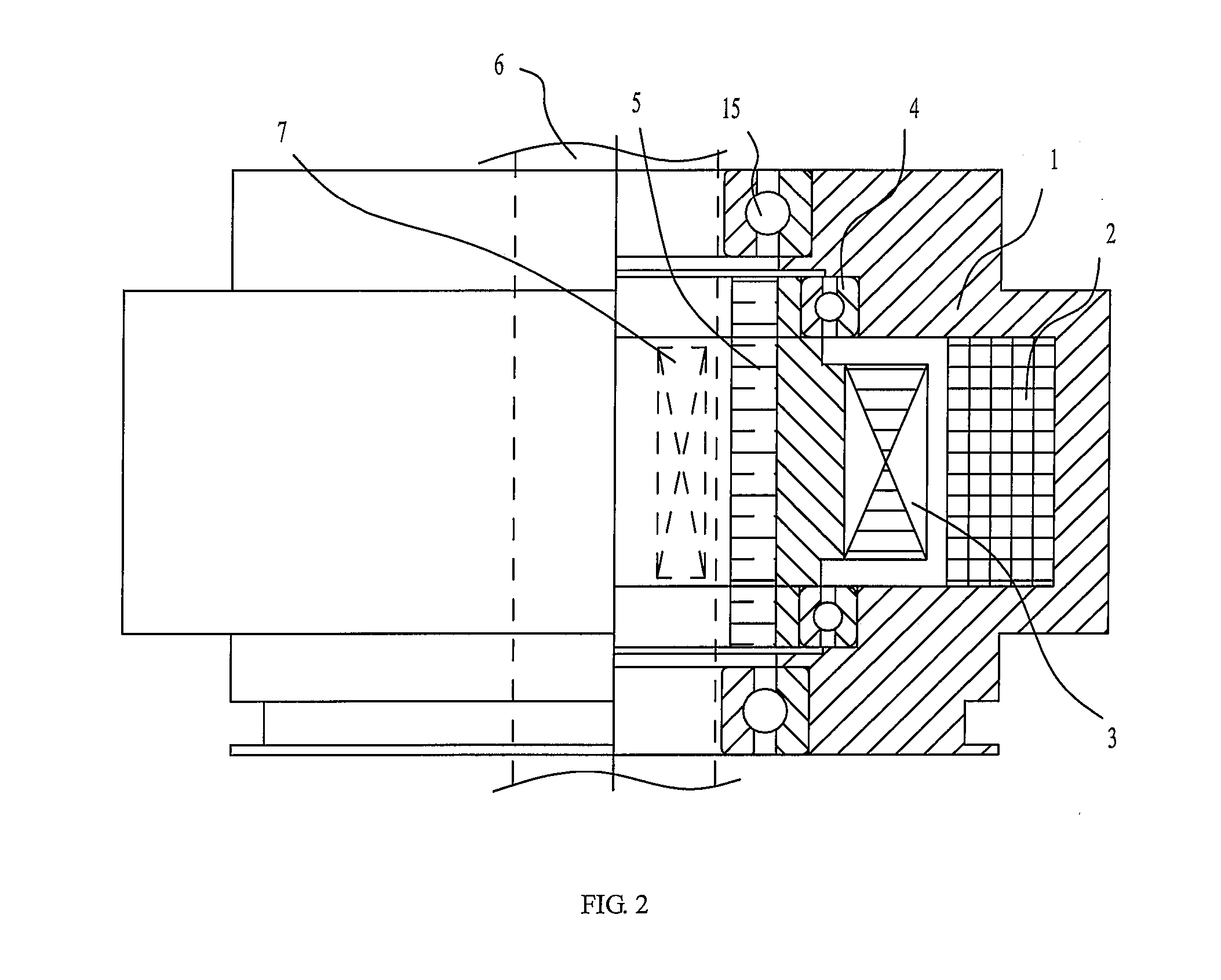

A disc implant is provided which maintains intervertebral spacing and stability of the spine. In an embodiment, a disc implant may include four or more components. Components of the disc implant may include engaging plates and two or more members positioned between the engaging plates. In certain embodiments, a disc implant may include a retainer positioned between one of the engaging plates and one of the members. Complementary portions of the implant components may allow for lateral movement, anteroposterior movement, and / or axial rotation of the engaging members relative to each other during use. In some embodiments, at least one of the members may include a stop to inhibit movement of adjacent vertebrae outside of normal physiological ranges.

Owner:MARINO JAMES F +2

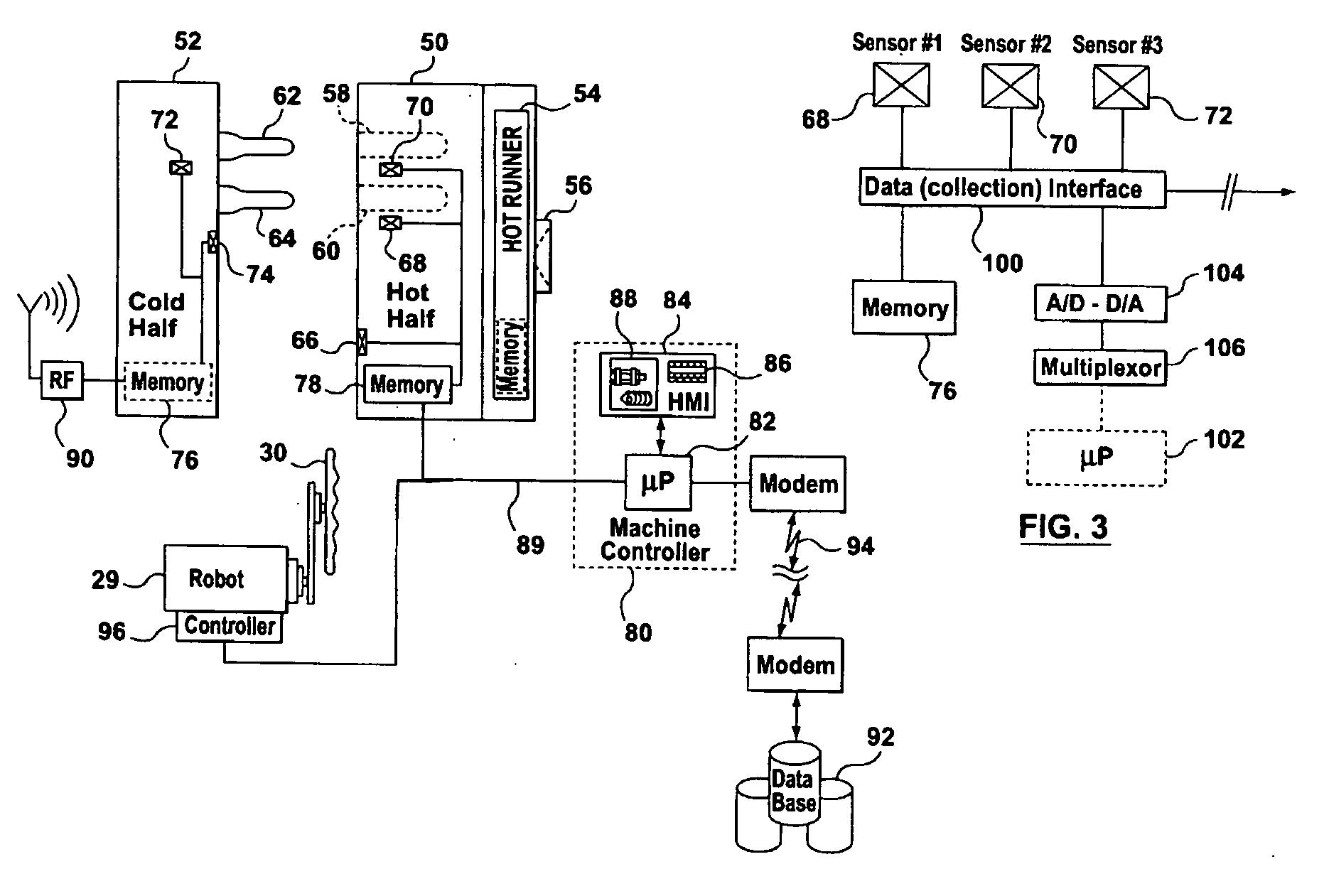

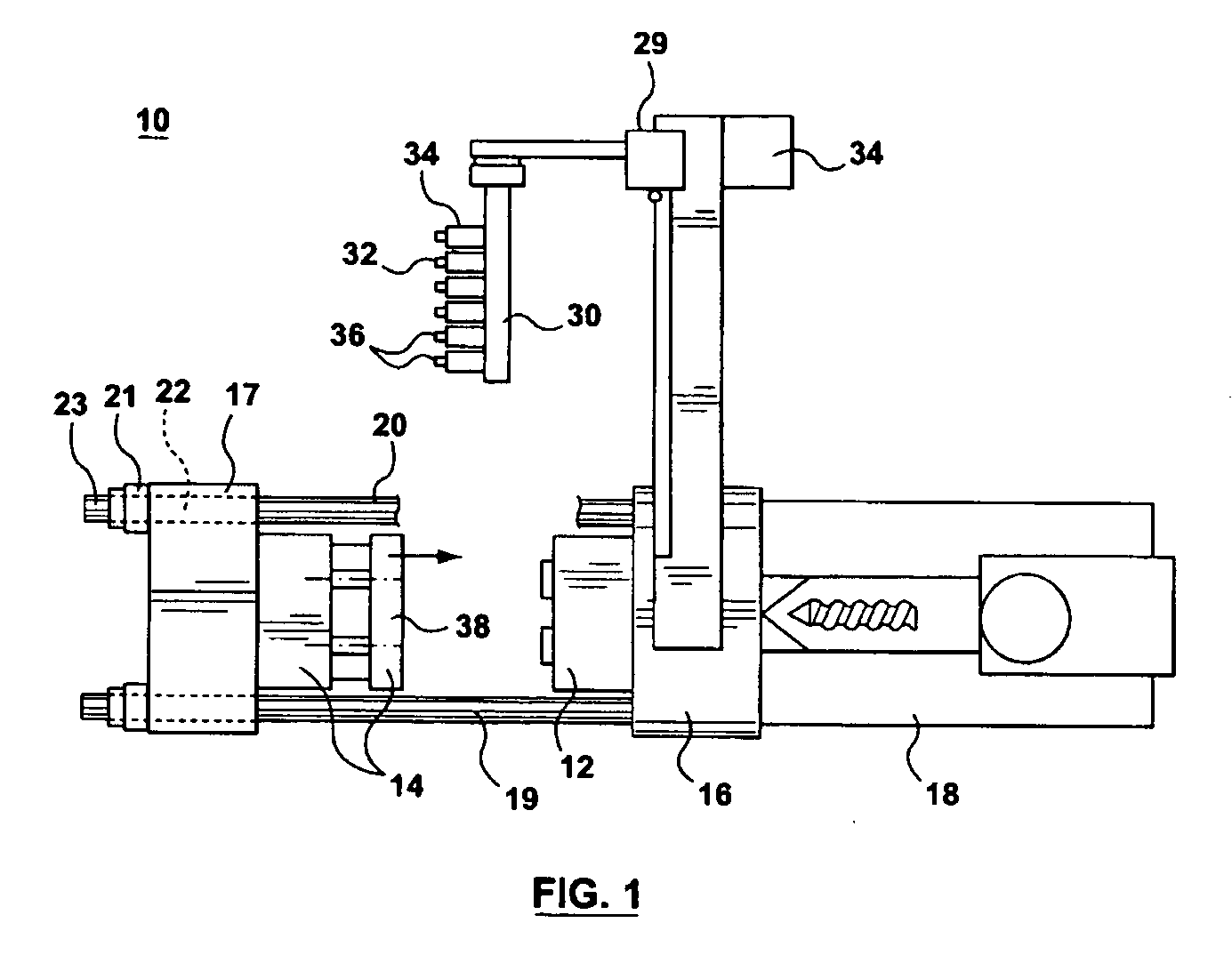

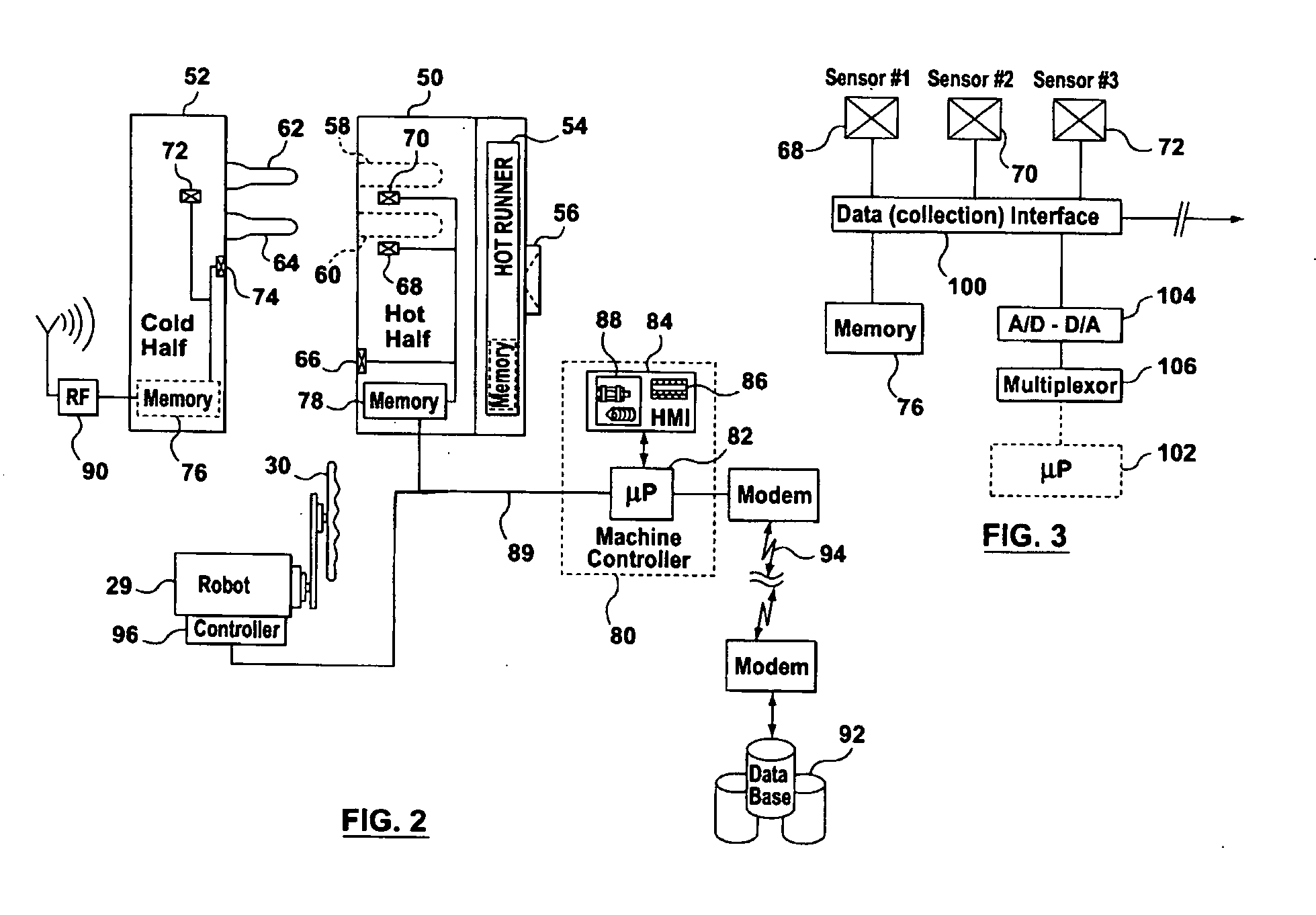

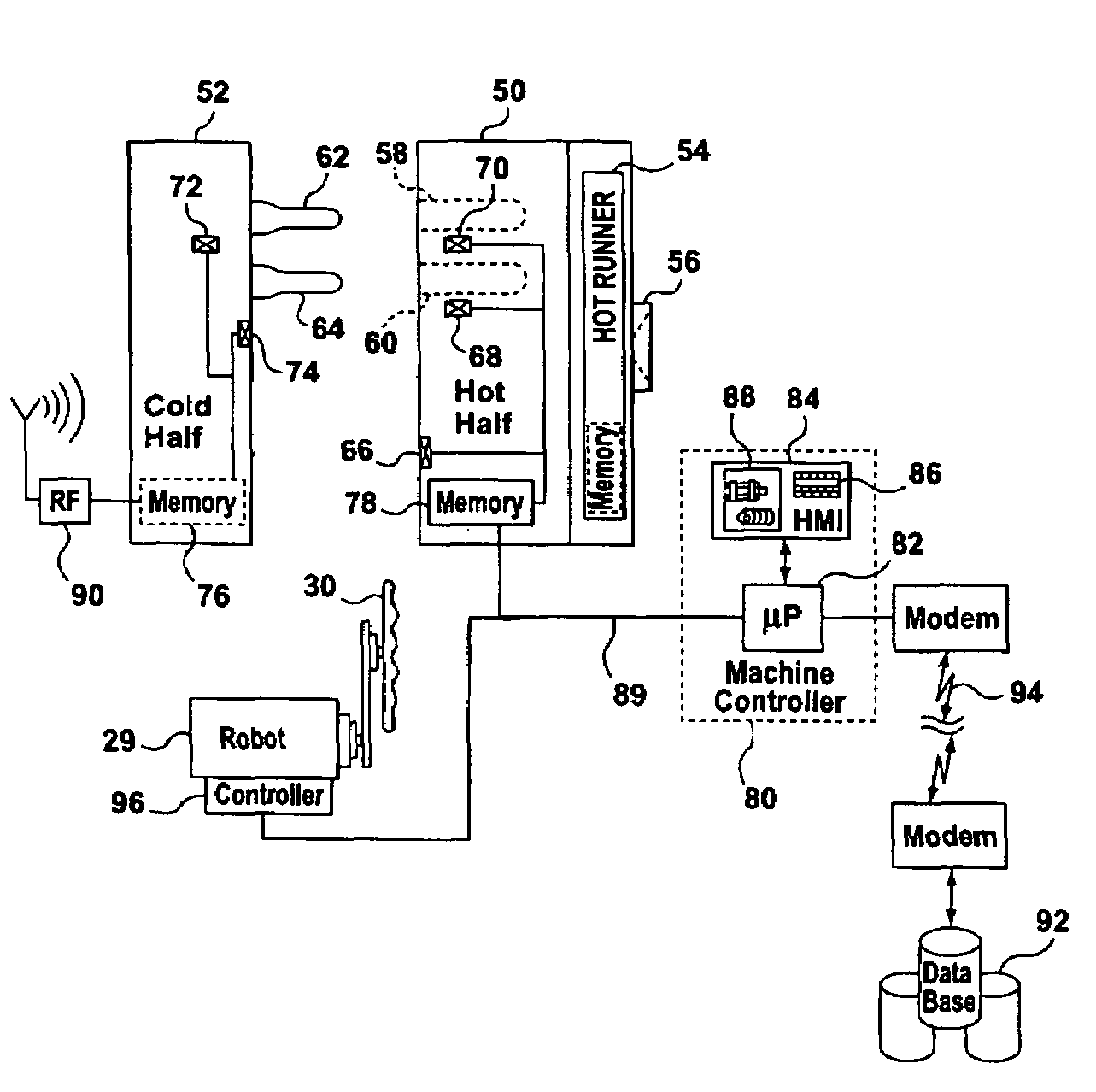

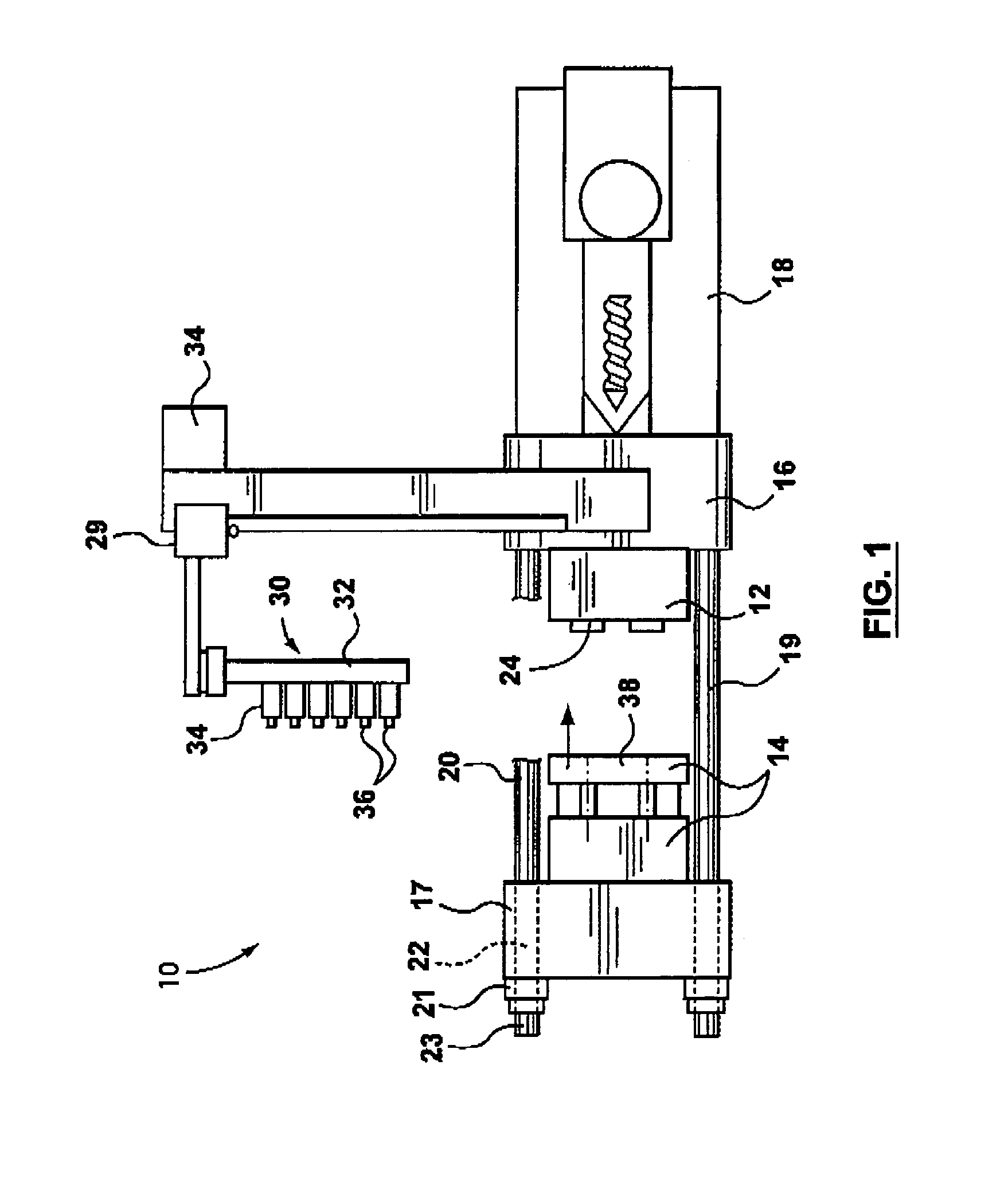

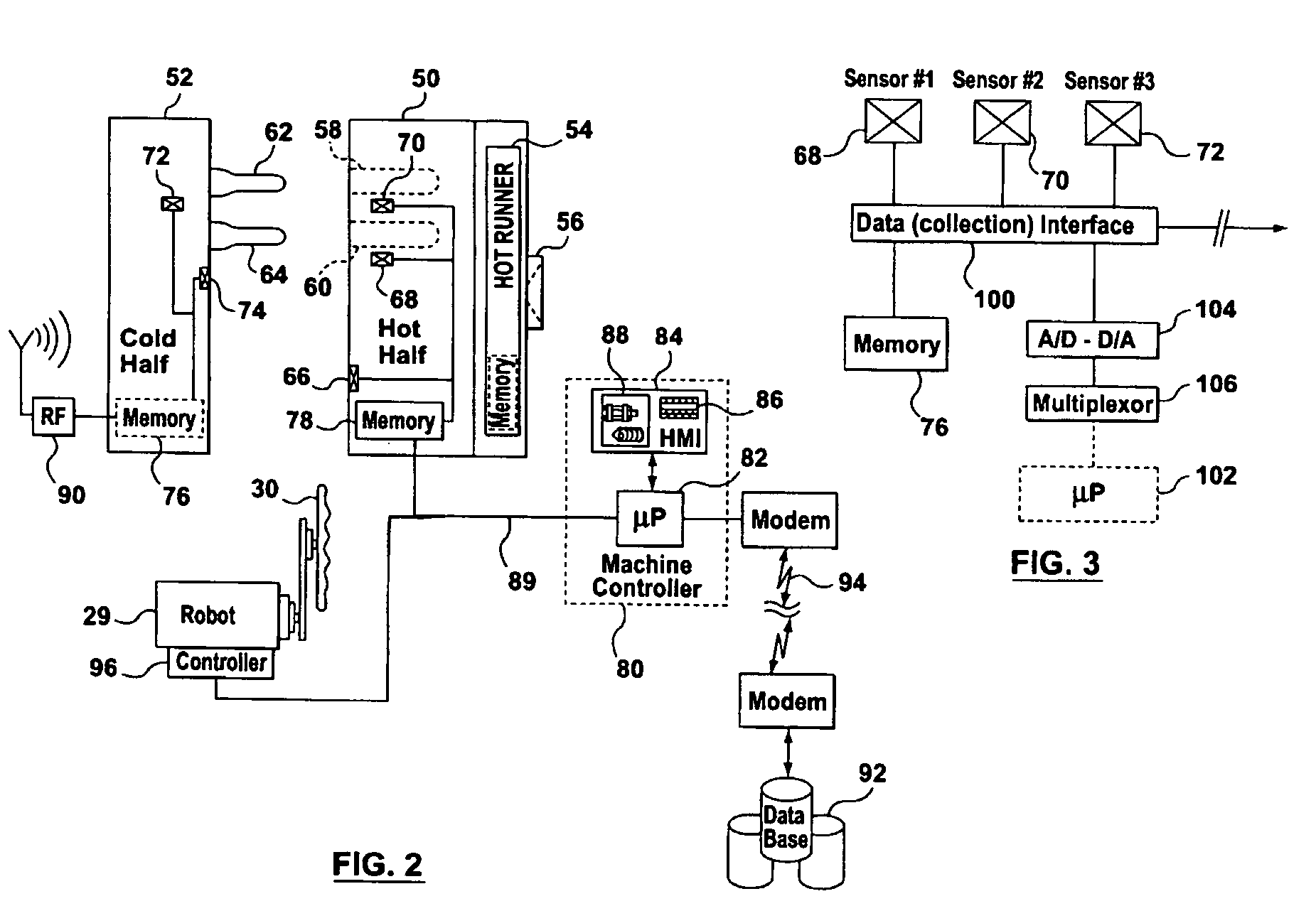

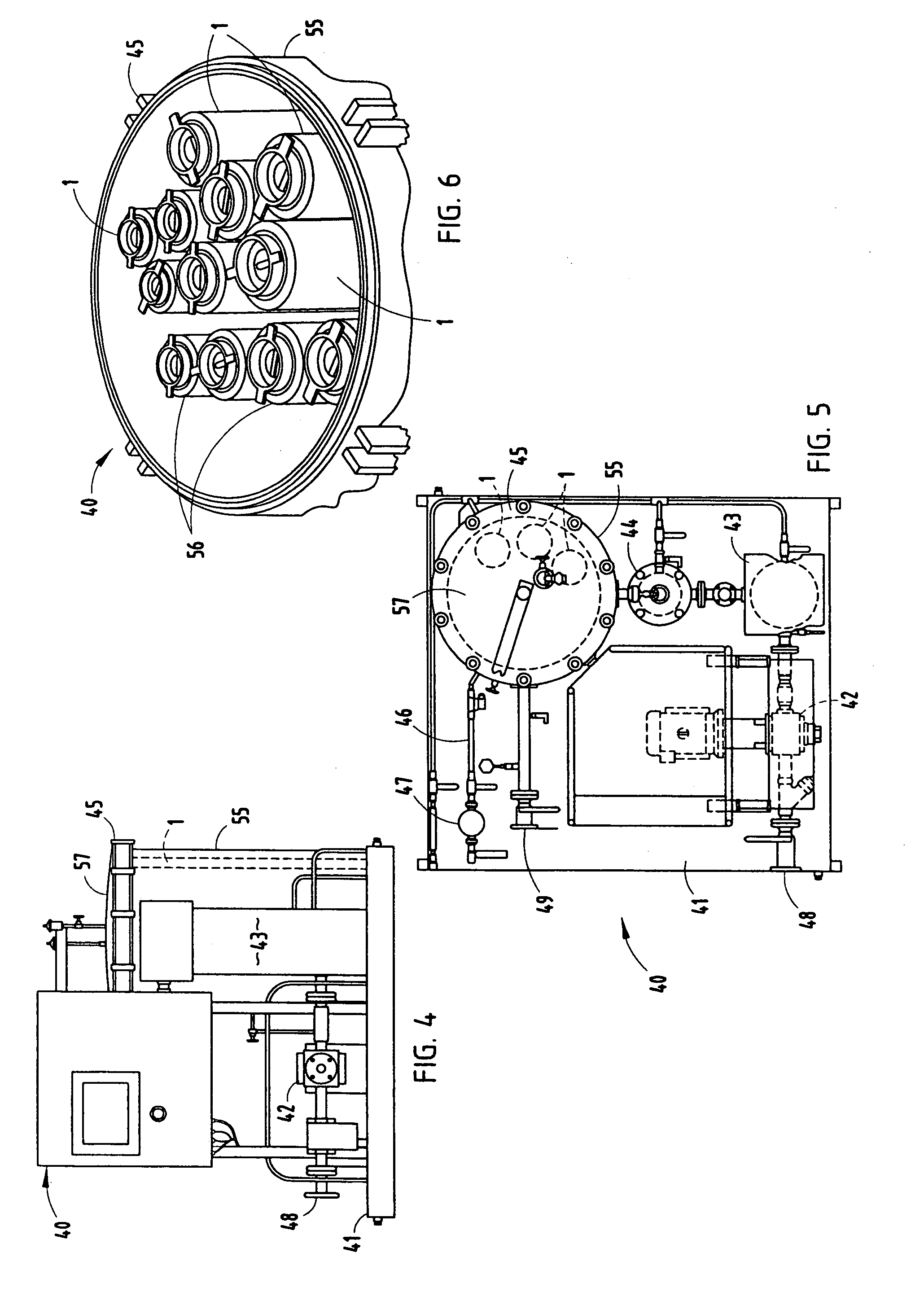

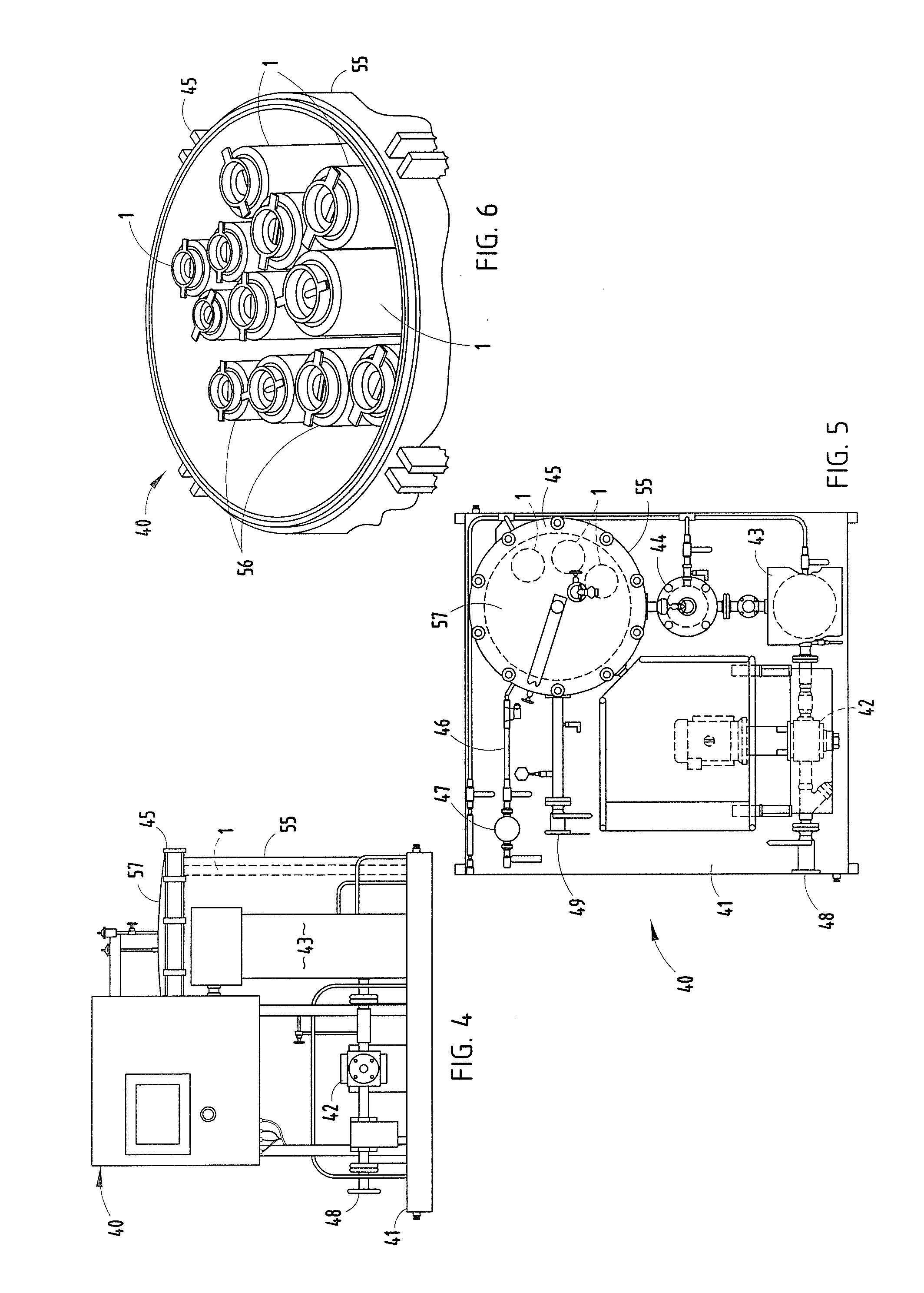

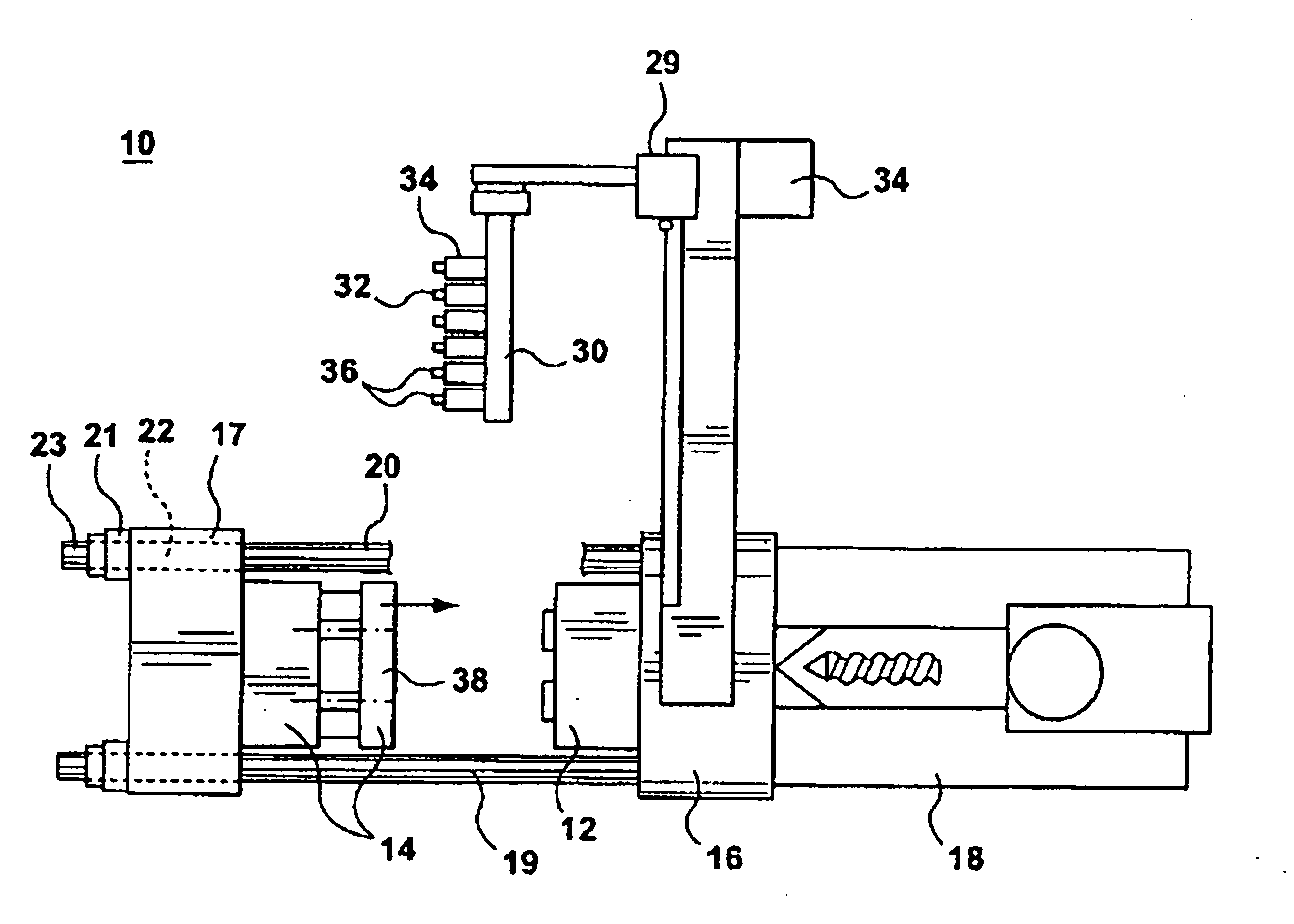

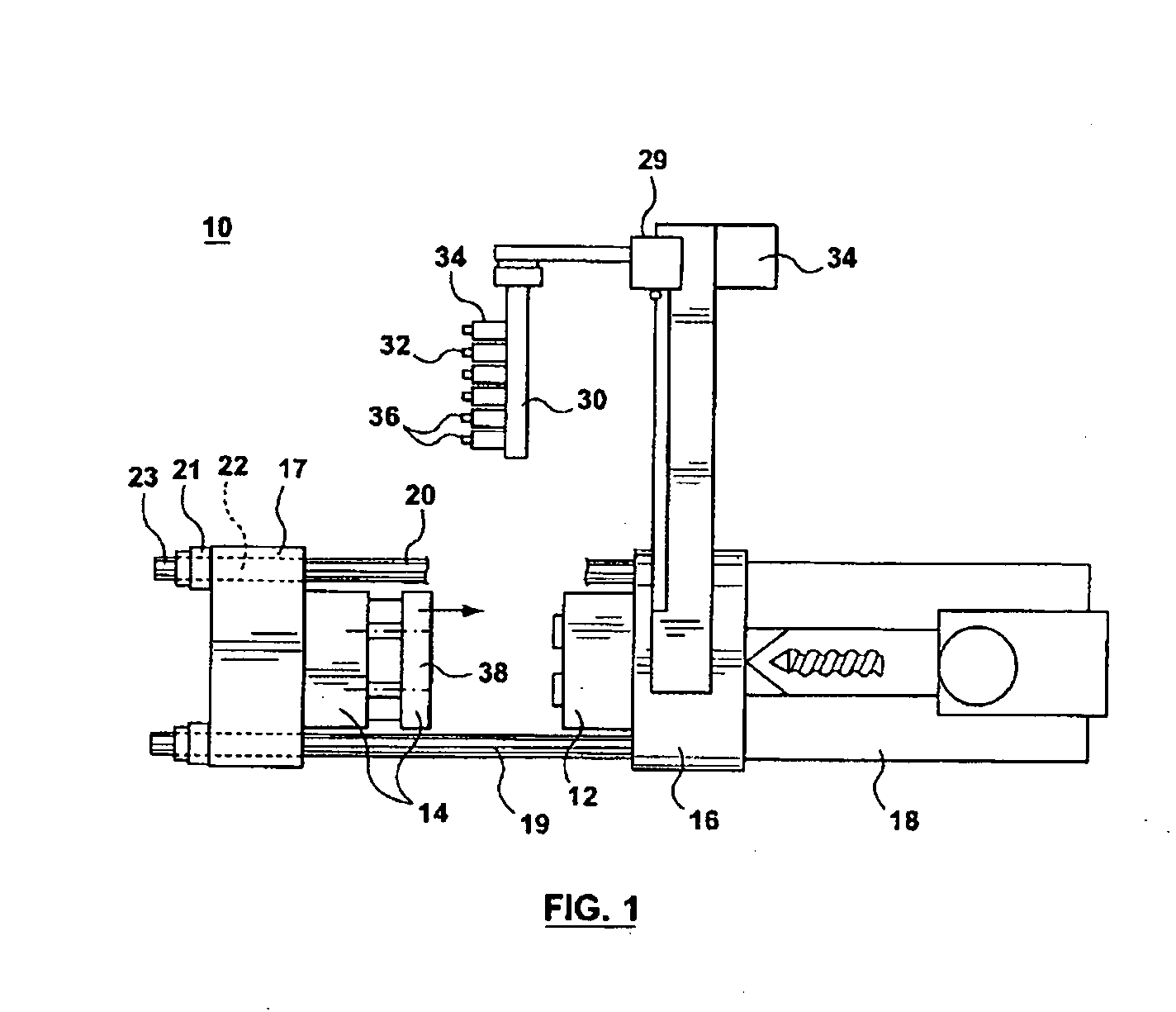

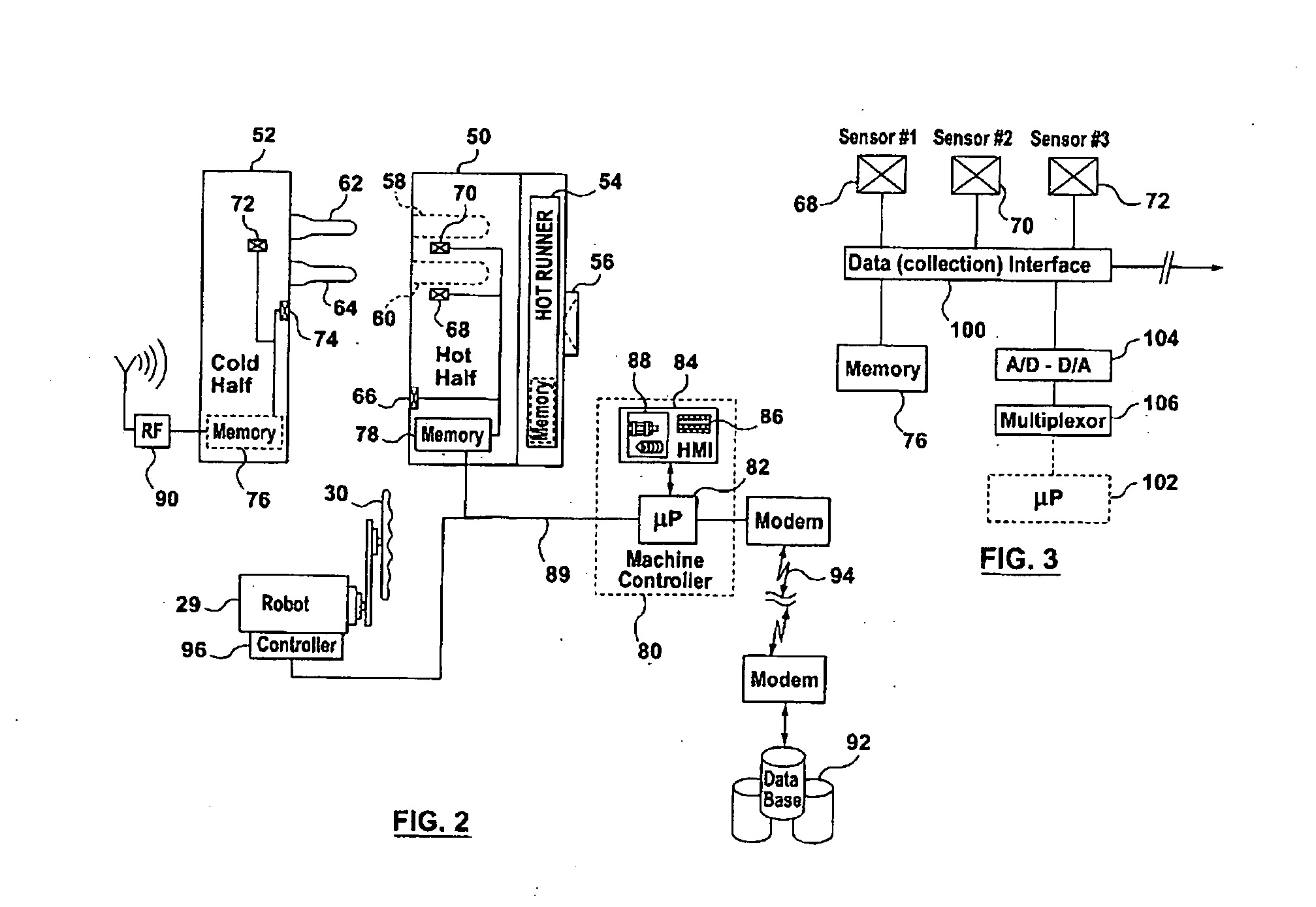

Intelligent molding environment and method of configuring a molding system

ActiveUS20060082009A1Easy to operate and controlReduce complexityAuxillary shaping apparatusMolding machineEngineering

An intelligent molding system (FIG. 2) is provided that makes use of data directly associated with a molding environment or particular mold (50, 52). Accessible data, typically stored locally in an in-mold memory device (76, 78) or input via an HMI (86), identifies parameters germane to mold set-up and machine operation. Upon receiving such data, a machine controller (80) operates to configure a molding machine (10) to an initial set-up defined by the data considered close to an optimal operating condition for the mold. Mold set-up data can include information relating to a fill profile for a molded article that is partitioned into different zones having different thicknesses and geometries. Weighting factors for the various zones compensate for differing cooling and flow characteristics. The memory (76, 78) can also be used to store historical data pertaining to mold operation, settings and alarms.

Owner:HUSKY INJECTION MOLDING SYST LTD

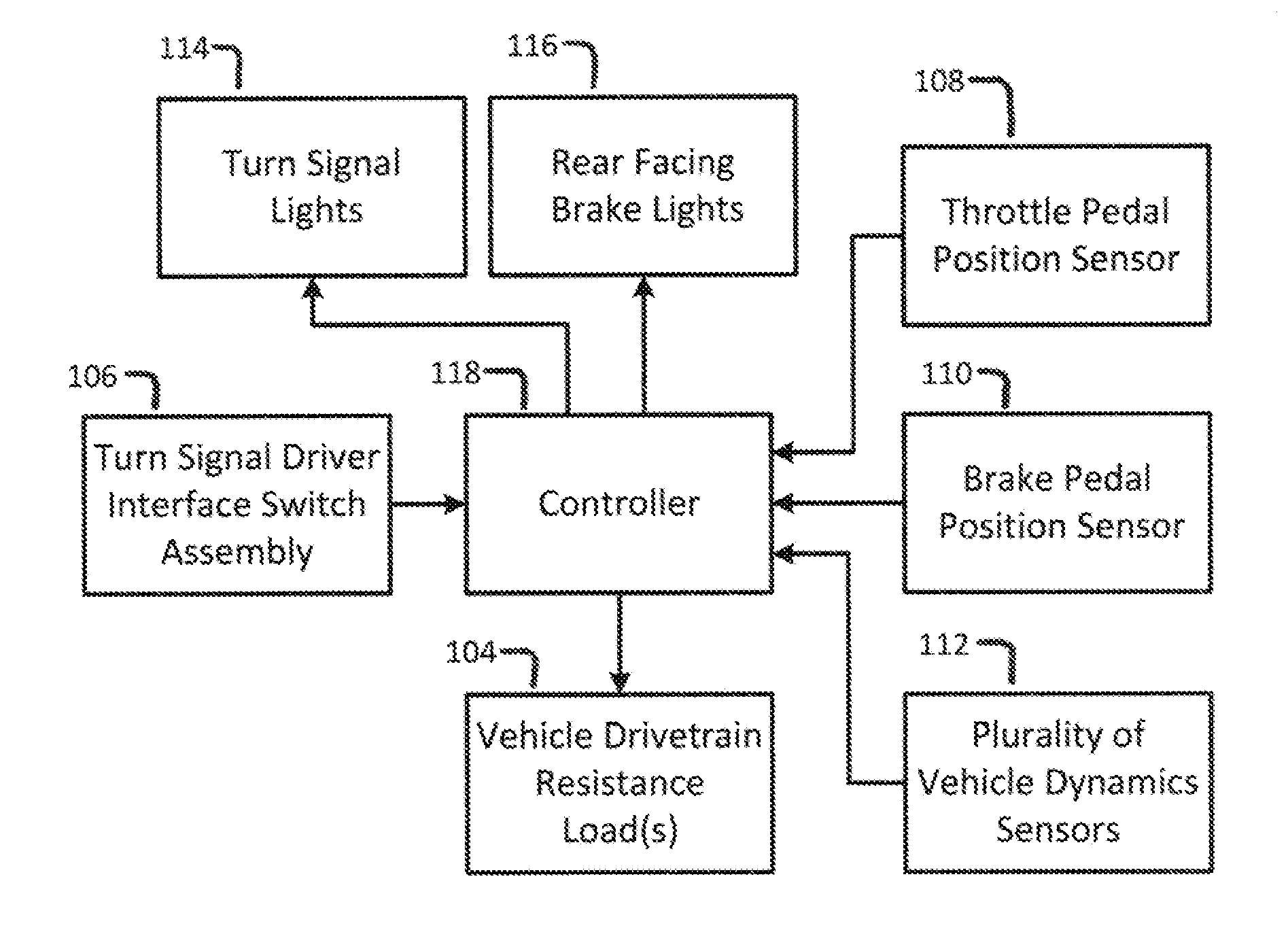

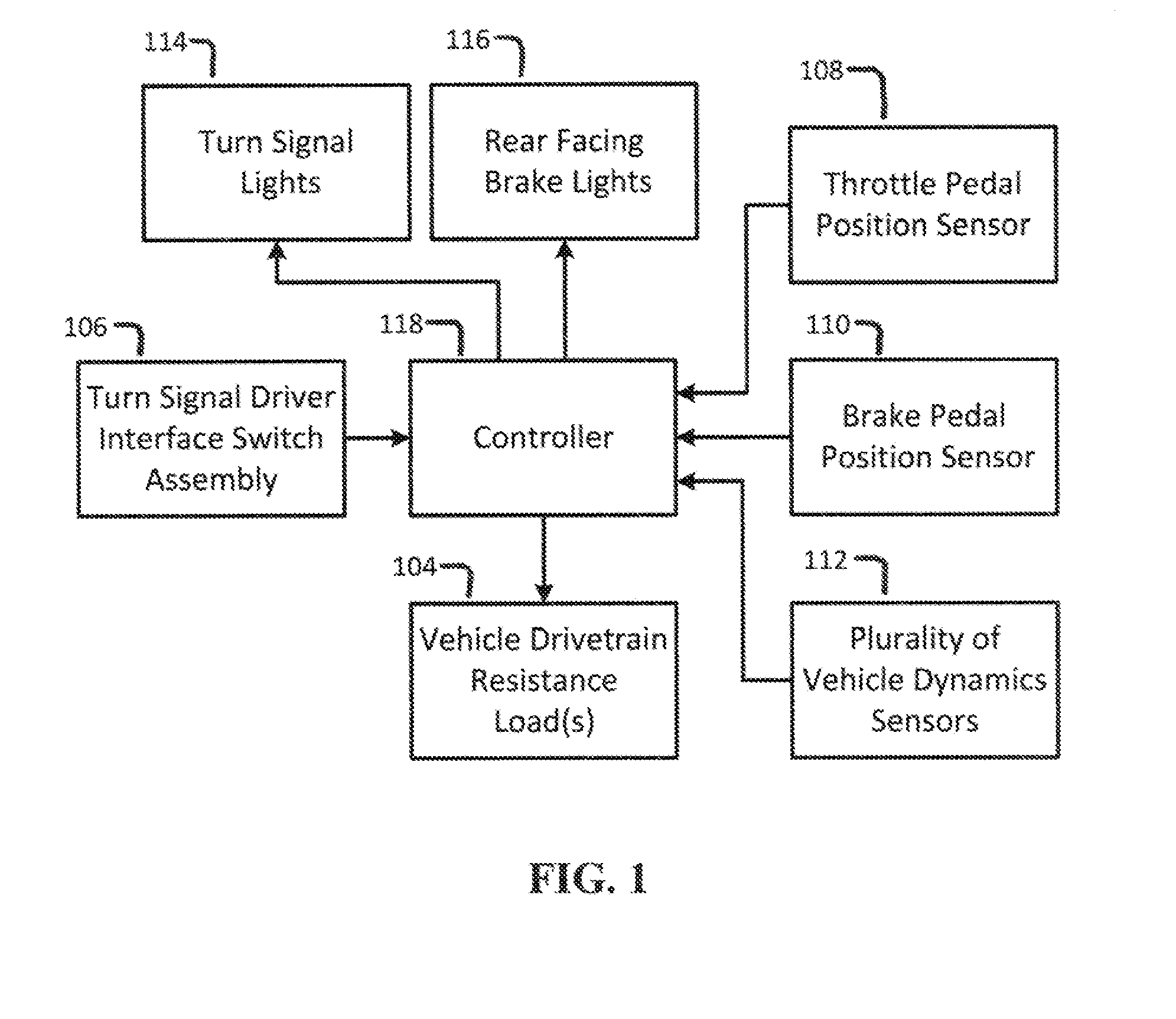

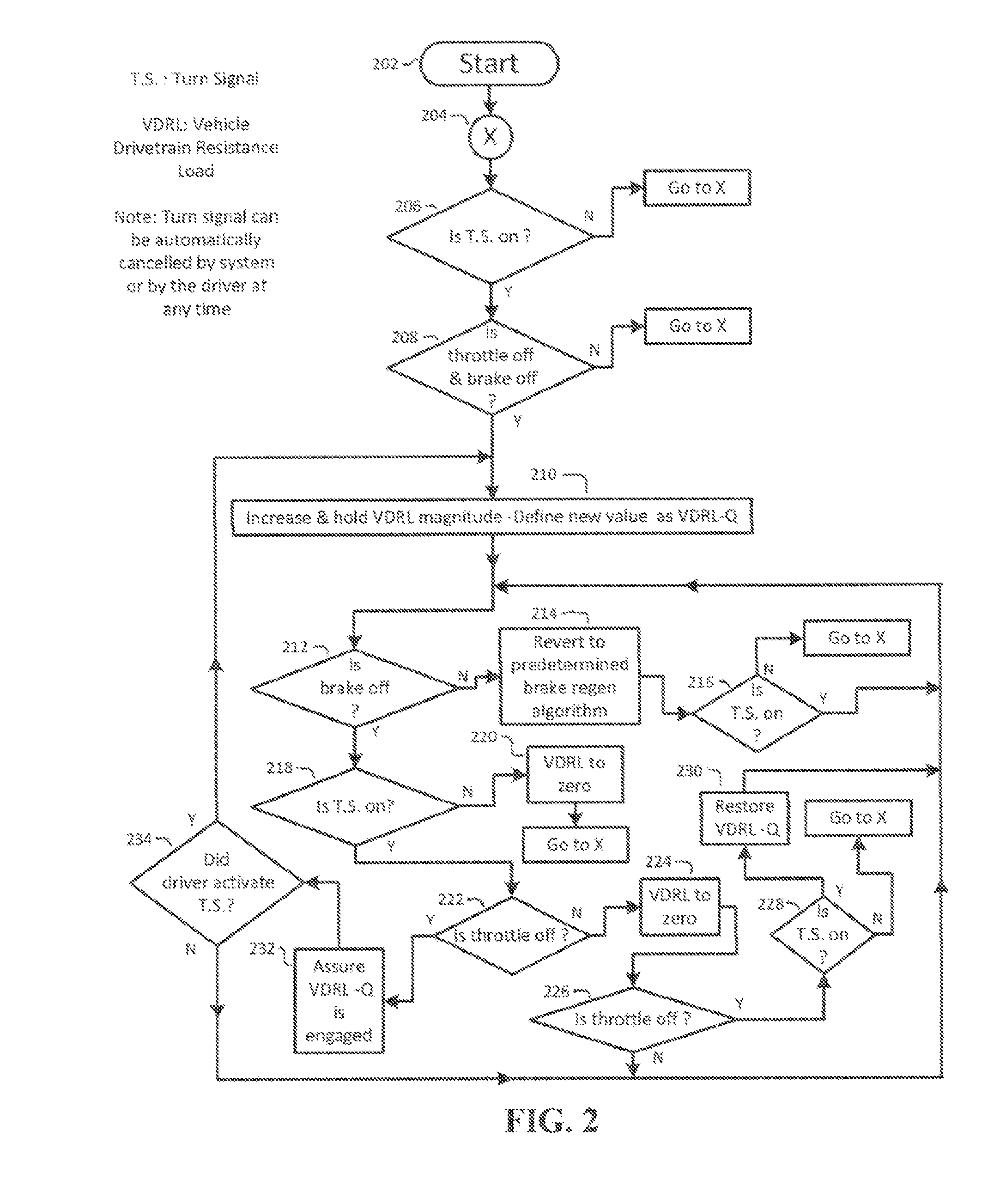

Turn Signal Controlled Regenerative Braking And Decelerative Loading

ActiveUS20130268162A1Increase propulsionReduce usageDigital data processing detailsOptical signallingDriver/operatorRegenerative brake

A vehicle executing a turn will most likely be slowed down before the turn and when a driver activates a turn signal to indicate the turn, a vehicle internal controller uses this information to engage regenerative braking for energy recapture while slowing down the vehicle for the pending turn. Since the turn signal is usually activated very early in the turn event, and turns are an ongoing, frequent part of driving, a greater overall vehicle efficiency can be realized without special effort from the driver. Implementation is relatively simple for the manufacturer and adds no cost since the controllers and sensors are already installed on nearly all roadworthy vehicles. Fuel mileage and vehicle driving ranges are improved on a large scale and brake system wear is reduced.

Owner:PONZIANI RICHARD LOUIS

Intelligent molding environment and method of configuring a molding system

ActiveUS7580771B2Easy to operate and controlReduce complexityAuxillary shaping apparatusSpecial data processing applicationsHuman–machine interfaceMachine control

An injection molding machine, including: a human machine interface being configured to provide graphical representation of a status of the injection molding machine; a machine controller being configured to: (i) provide operational control of the injection molding machine, (ii) operationally couple with the human machine interface, the machine controller having; (i) a machine-controller processor; and (ii) machine-controller memory being coupled with the machine-controller processor; an injection unit being configured to plasticizing and inject a molding material; a tie-bar clamping mechanism being associated with the injection unit; and a mold assembly being supported by the tie-bar clamping mechanism, the mold assembly being coupled with the injection unit, the mold assembly being adapted to receive the molding material from the injection unit so that a molded article may be molded, and the mold assembly including: a mold assembly body; and a mold memory device being coupled with the mold assembly body, and being operatively coupled with the machine controller so that data being stored in the mold memory device may be accessed by the machine controller, the mold memory device including; mold set-up data being related with the molded article to be molded in the mold assembly.

Owner:HUSKY INJECTION MOLDING SYST LTD

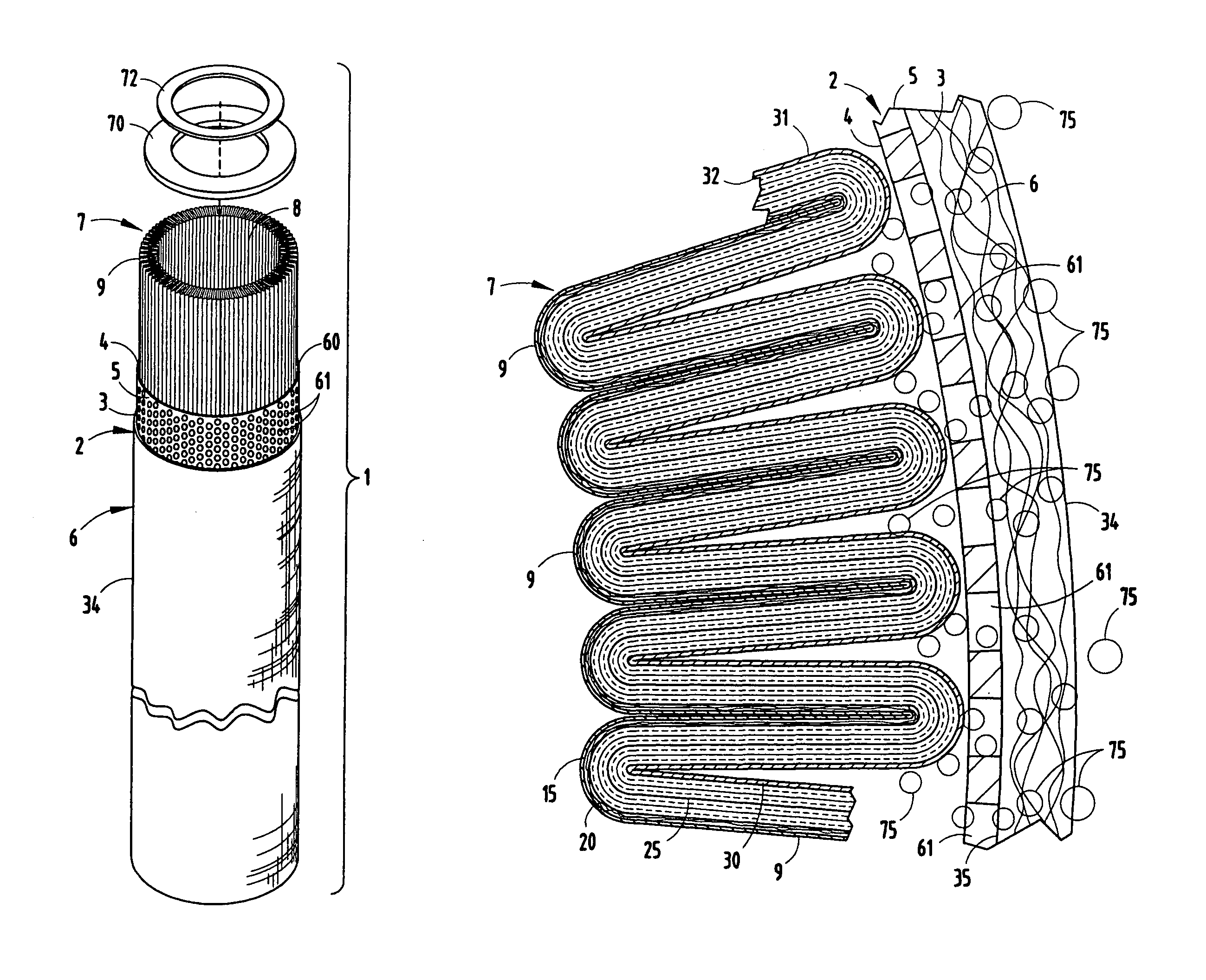

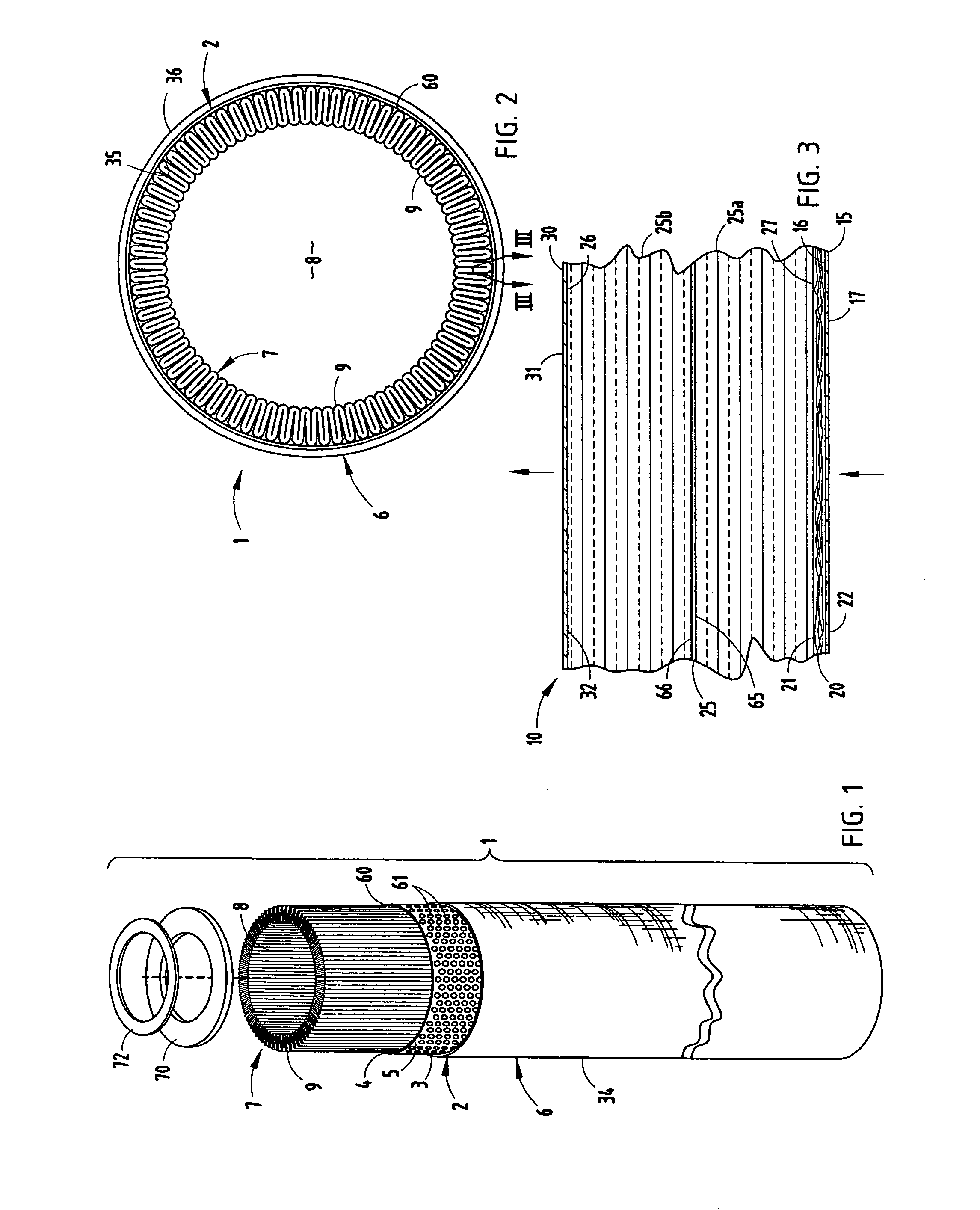

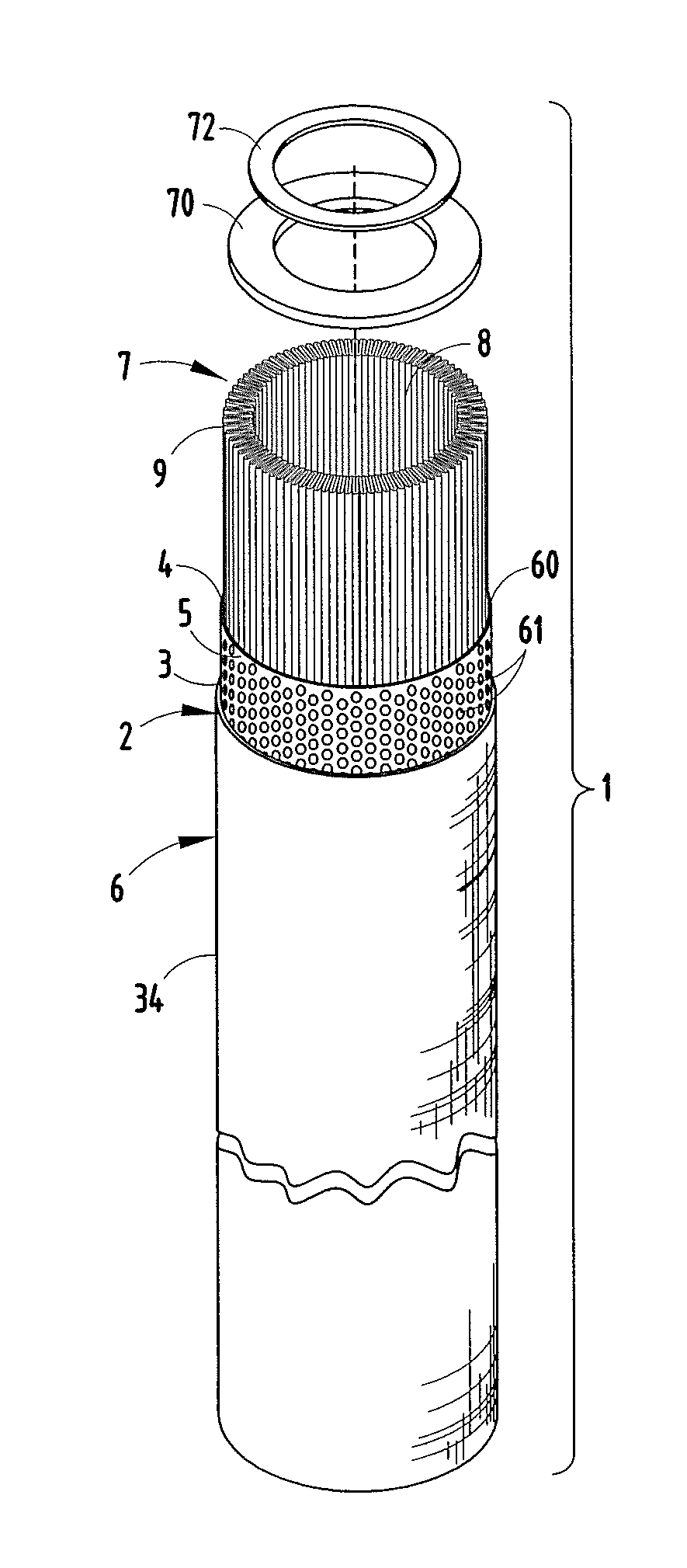

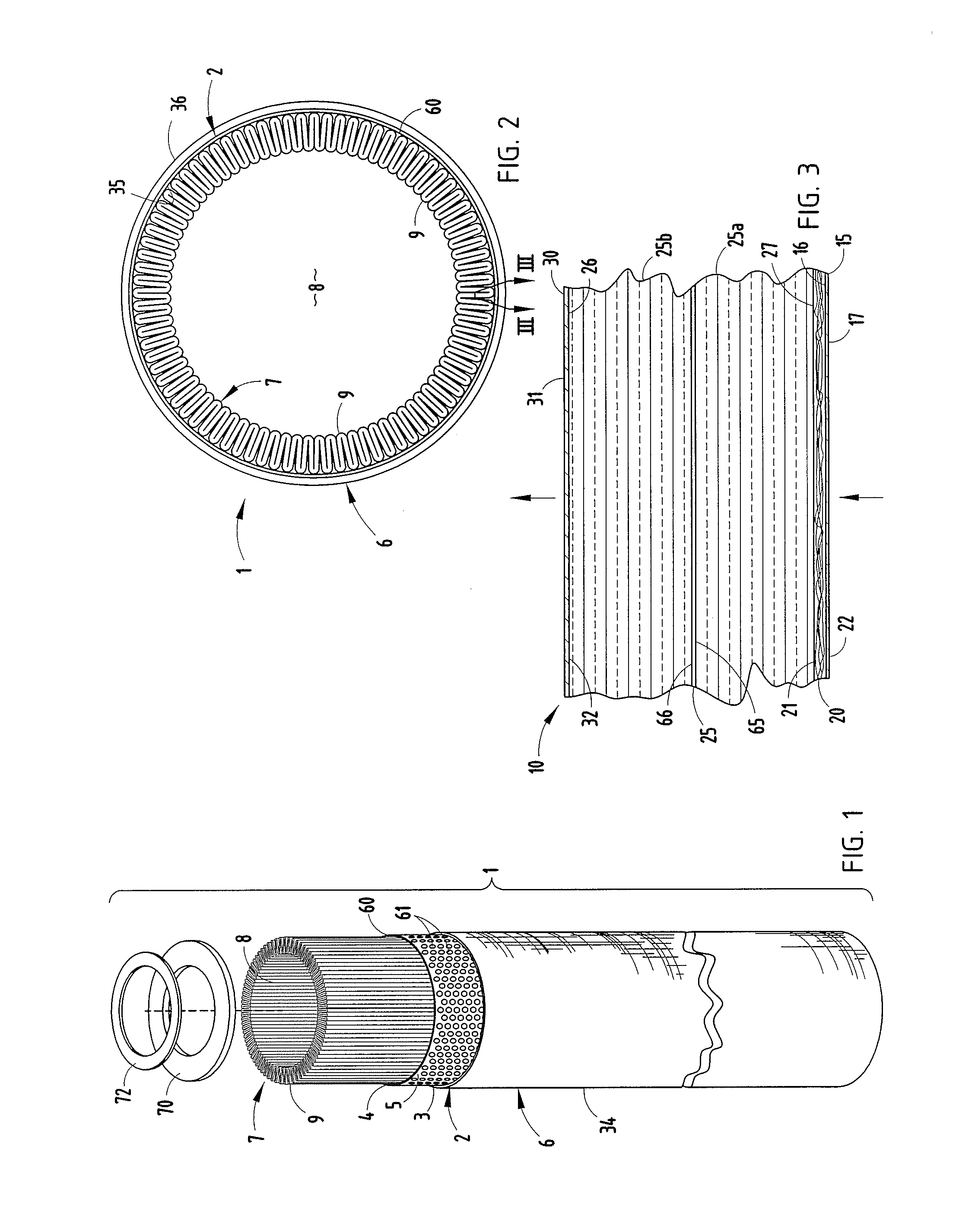

Pleated single phase filter coalescer element and method

ActiveUS8017011B2Improve efficiencyLow flow resistanceMechanical working/deformationSeparation devicesEngineeringSolid particle

A filter coalescer element for oil based industrial fuels includes a rigid, porous support tube, and a hydrophobic drainage layer covering the outer surface of the same. A single phase, dual function combination water coalescer and particle filter pleat block is positioned in the support tube, and is formed from a multilayer material having a first porous support layer, a synthetic microfiber layer, a synthetic fiber media layer and a second porous support layer. As the fluid passes through the pleat block, solid particles are physically filtered therefrom, and water is coalesced into droplets which pass from the pleats directly through the support tube and directly into the drainage layer, where the droplets grow into a size sufficient that they fall under gravity to the bottom of the element for collection.

Owner:KAYDON CUSTOM FILTRATION CORP

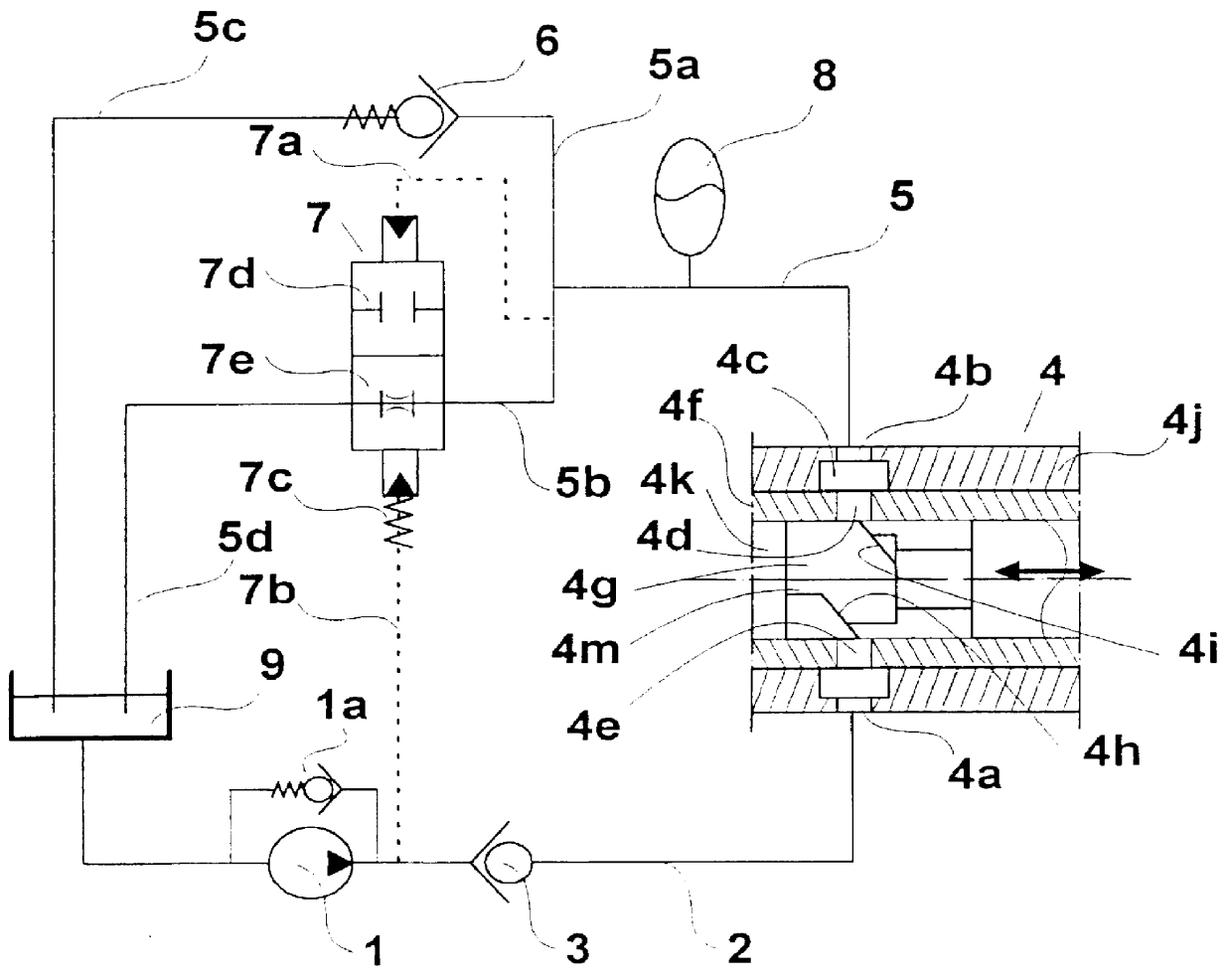

Device for avoiding cavitation in injection pumps

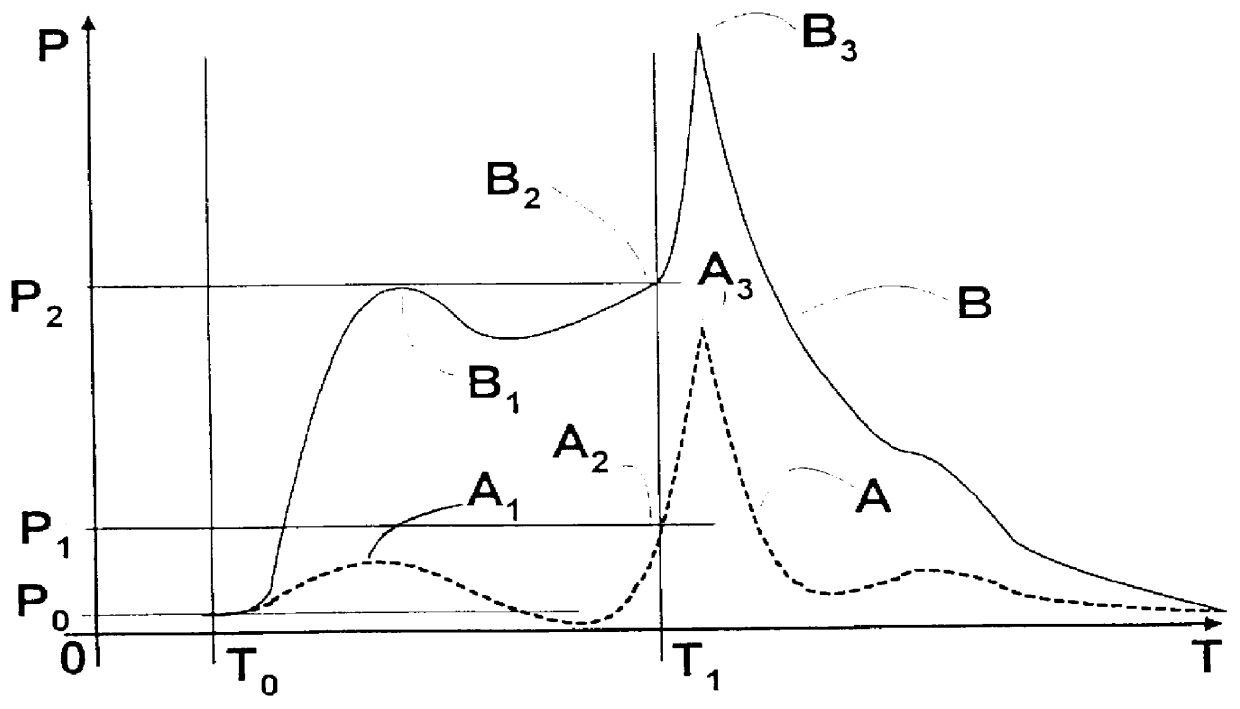

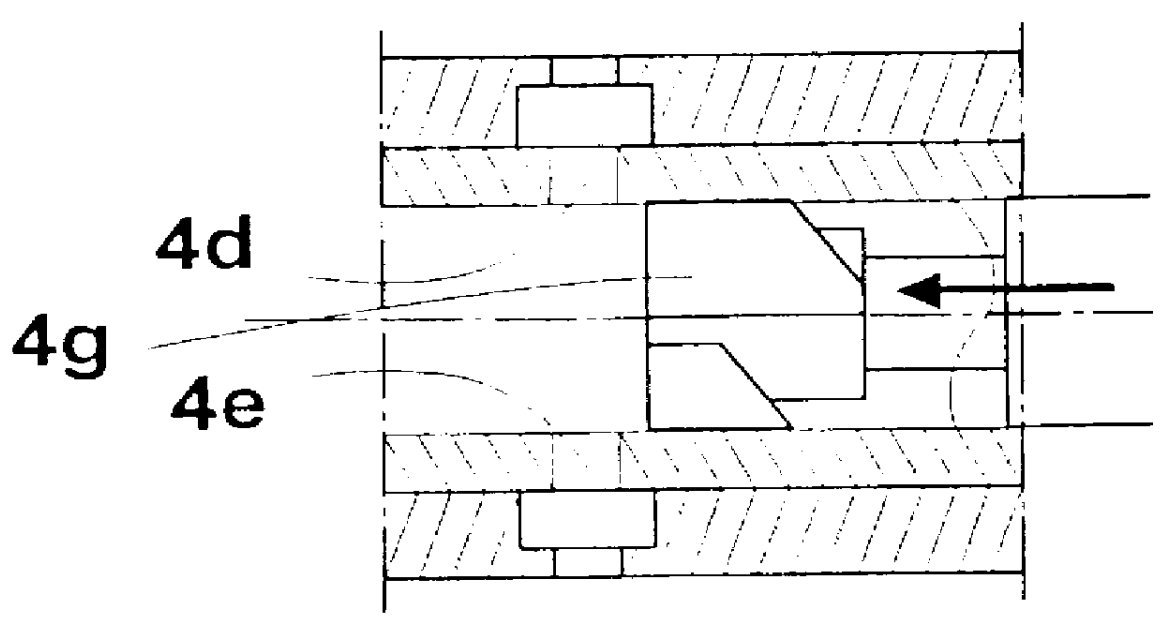

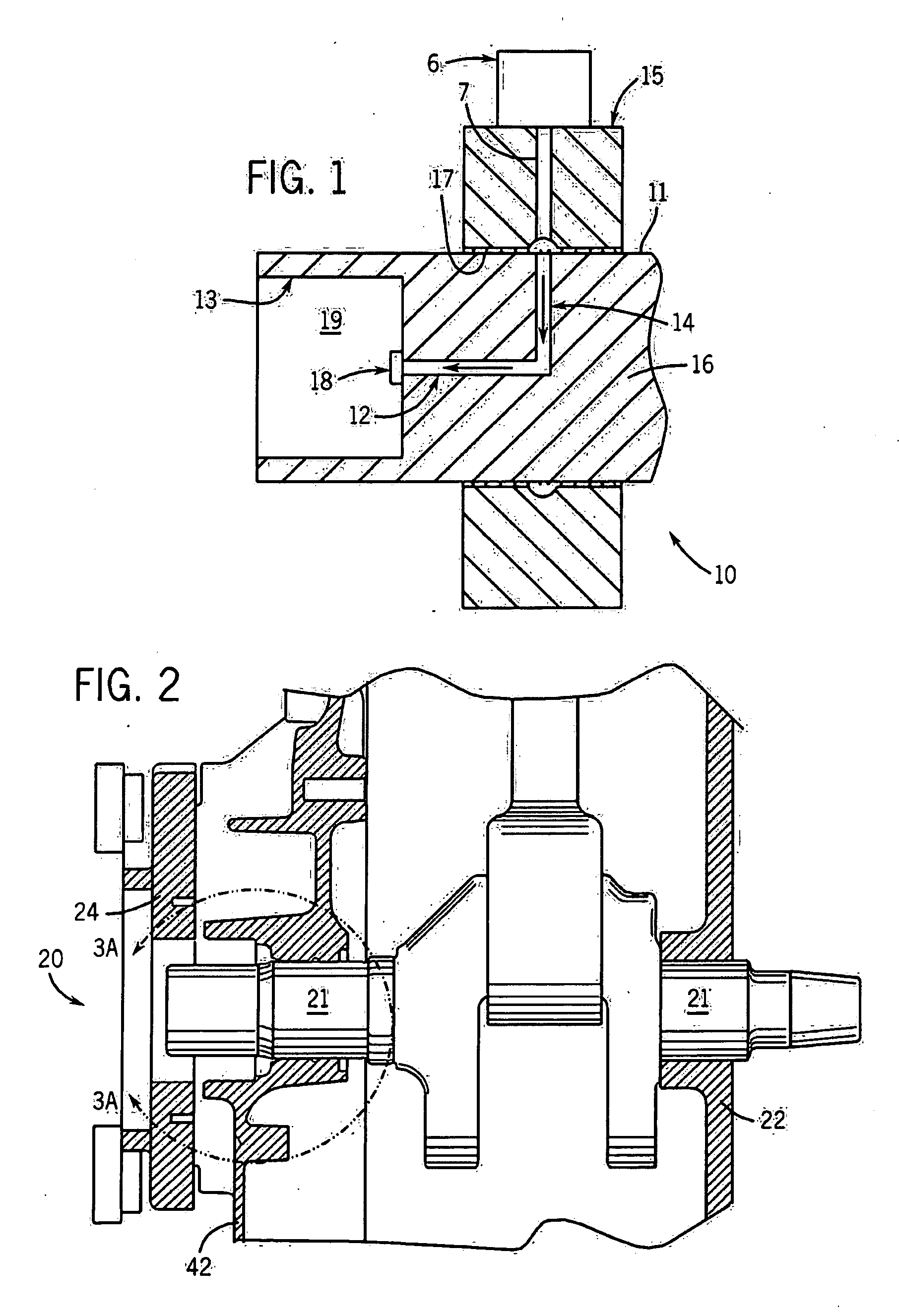

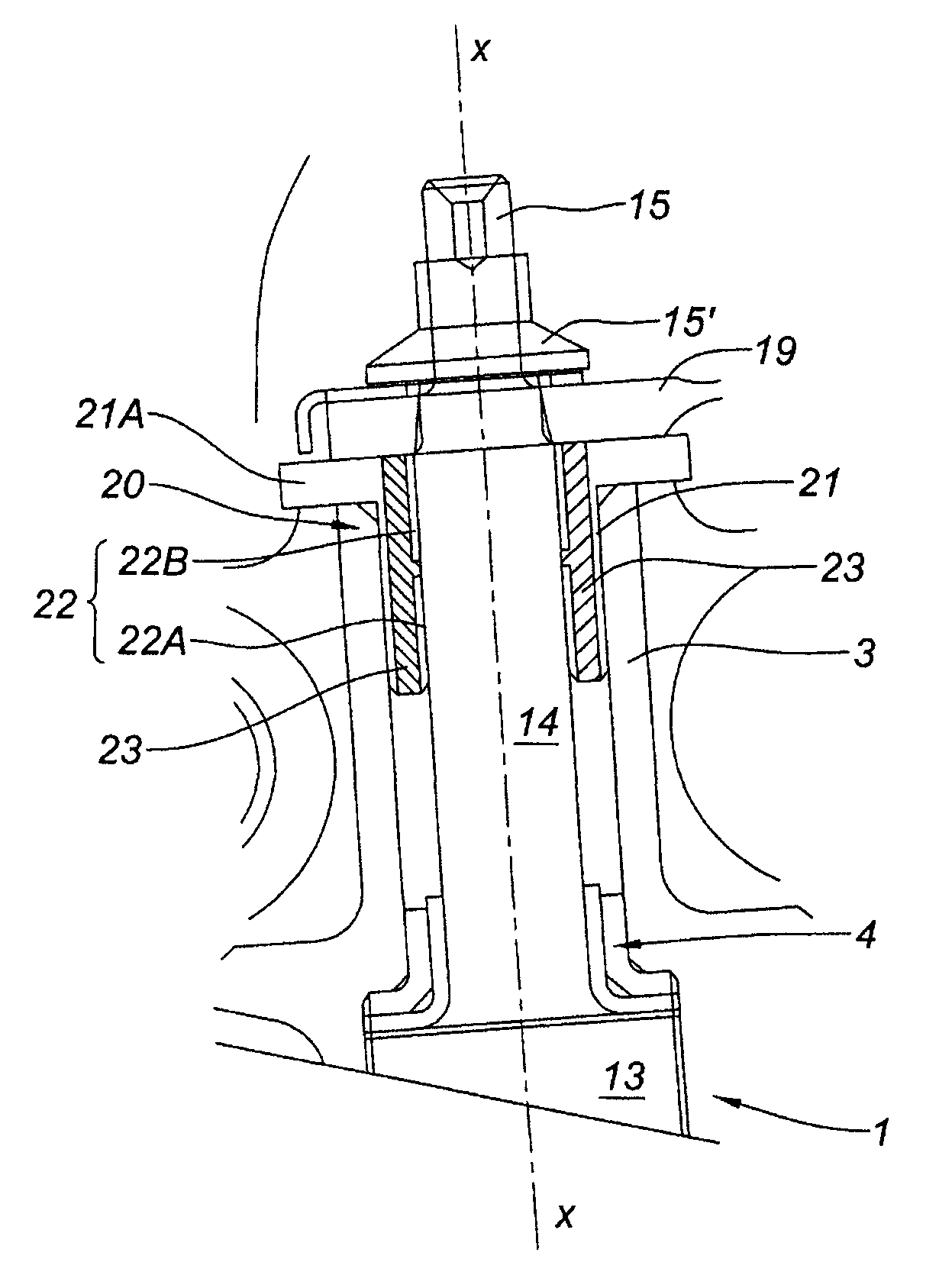

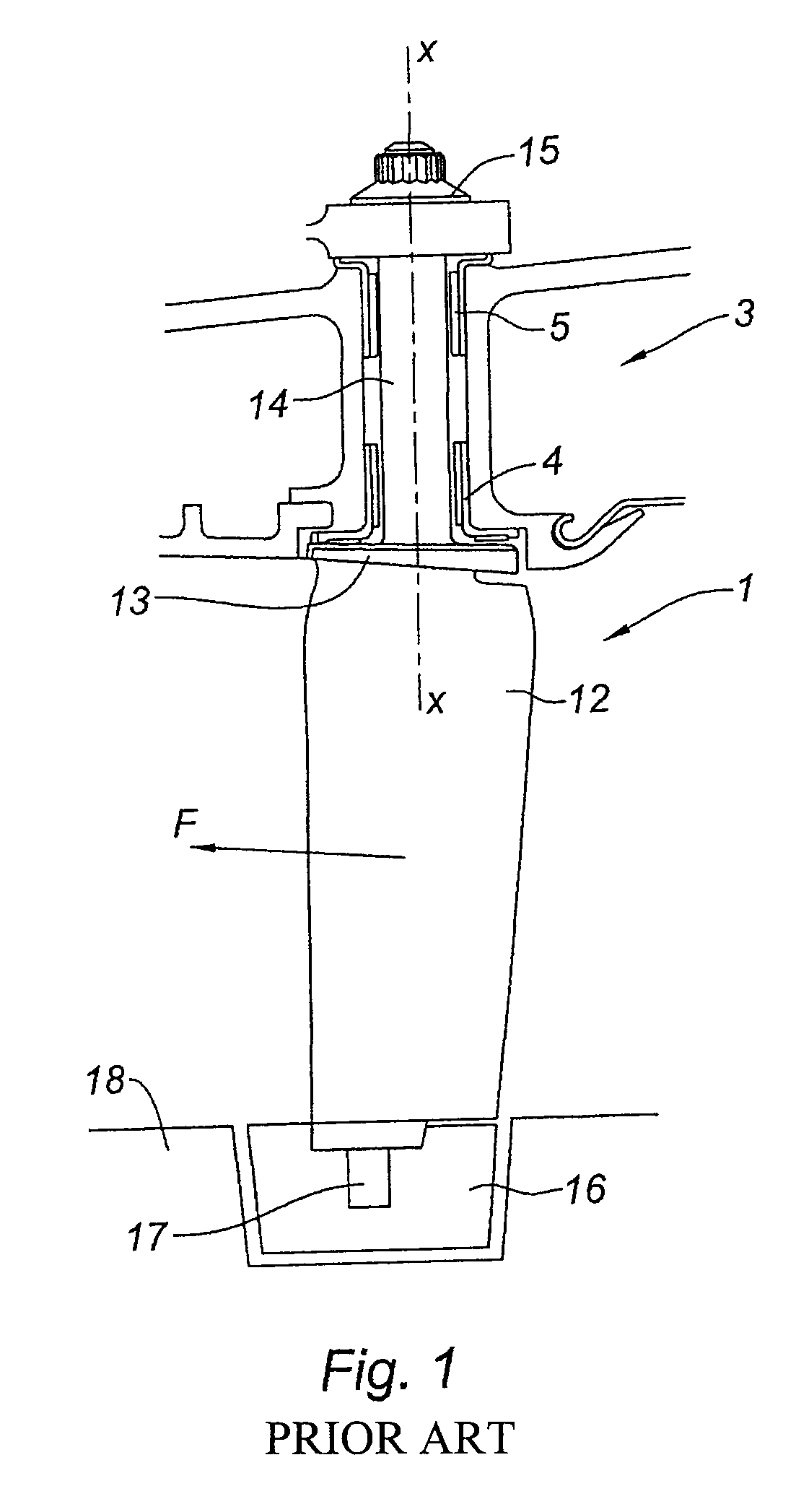

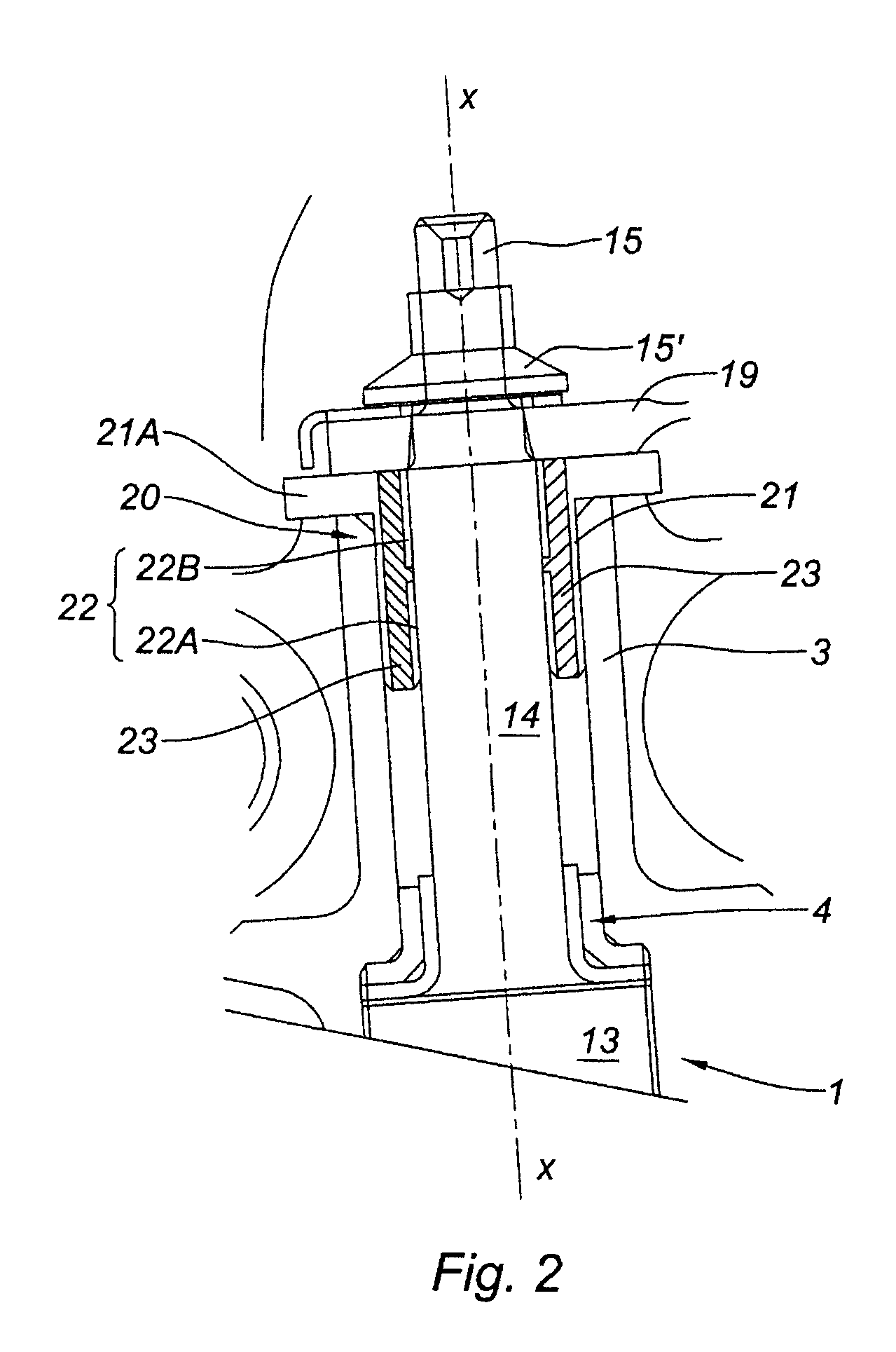

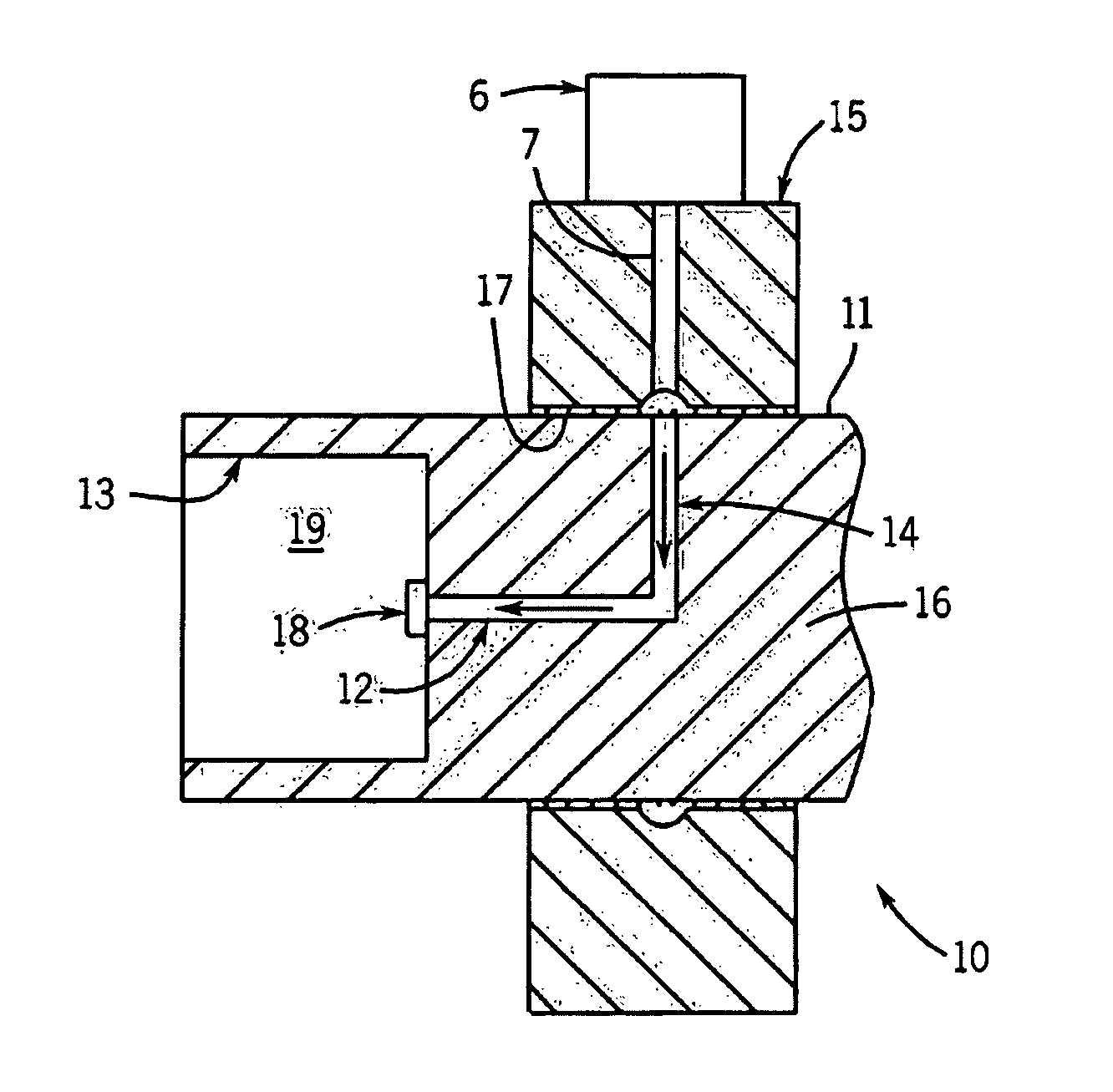

InactiveUS6065453AReduced component wearMinimize dispersionMachines/enginesFuel injecting pumpsCavitationInternal combustion engine

The invention provides a device for eliminating cavitation in the excess fuel return orifice(s) in the compression chamber of a fuel injection pump of an internal combustion engine after the end of the injection stage, said injection pump being connected firstly to a feed duct including a first check valve having low headloss enabling fuel to reach the compression chamber, and secondly to an excess fuel return duct, wherein the return duct comprises in parallel and close to the return orifice of the injection pump, a second check valve that is rated to cause the pressure in said return orifice of the injection pump to rise, and a two-port valve that is normally open and that is caused to close by the appearance of pressure in the return orifice greater than the pressure which obtains in the feed duct upstream from said first check valve.

Owner:SEMT PIELSTICK

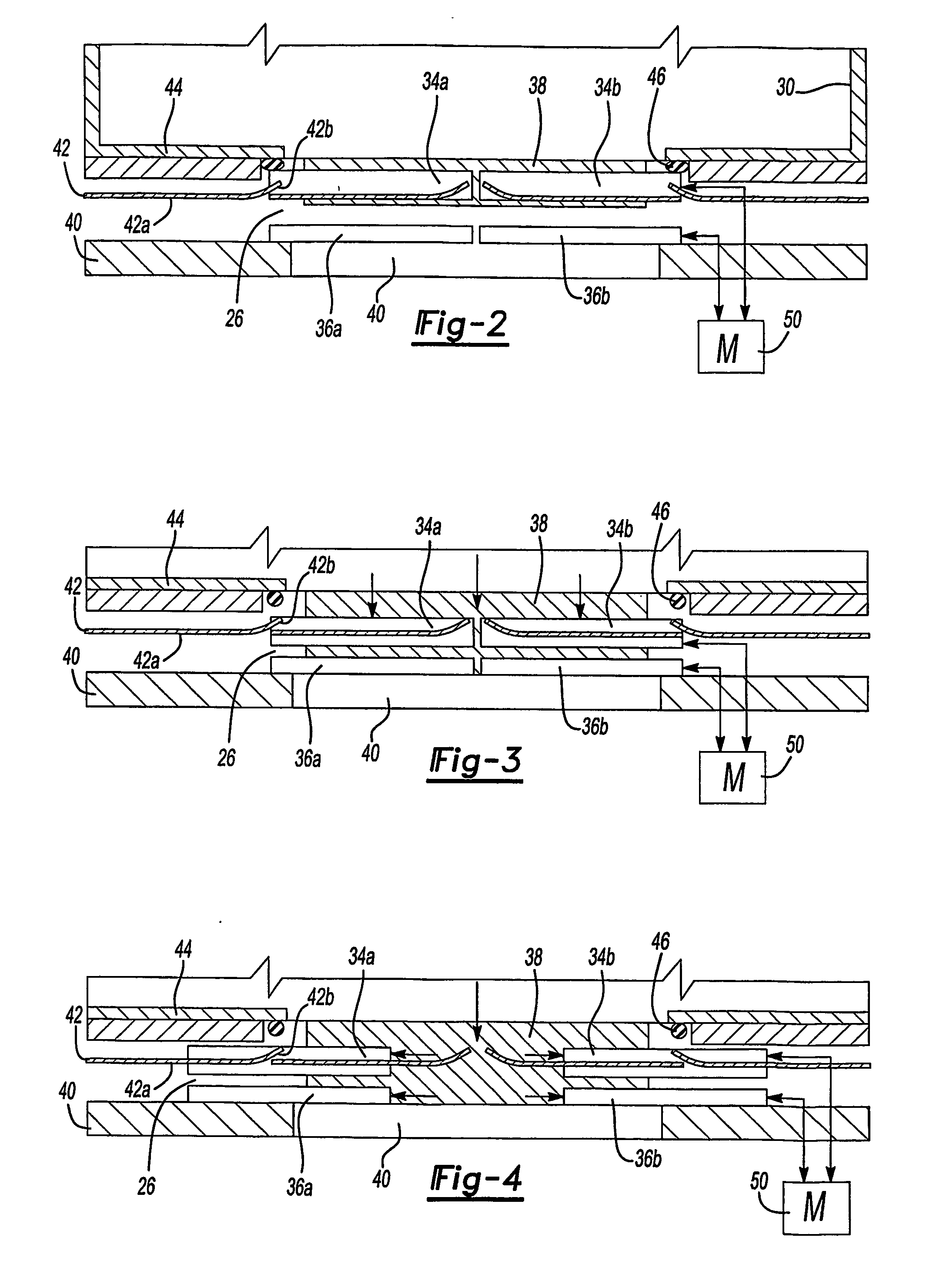

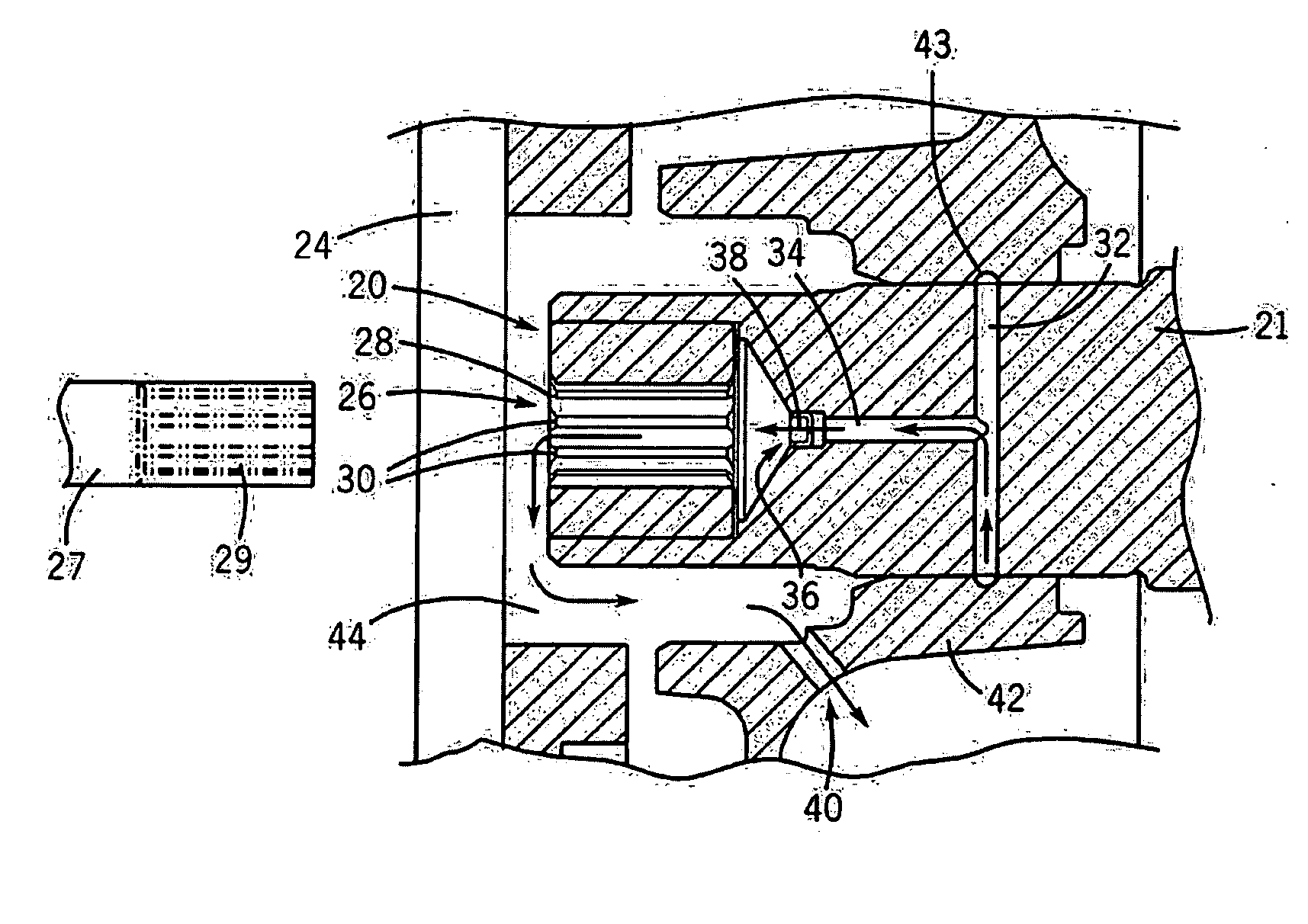

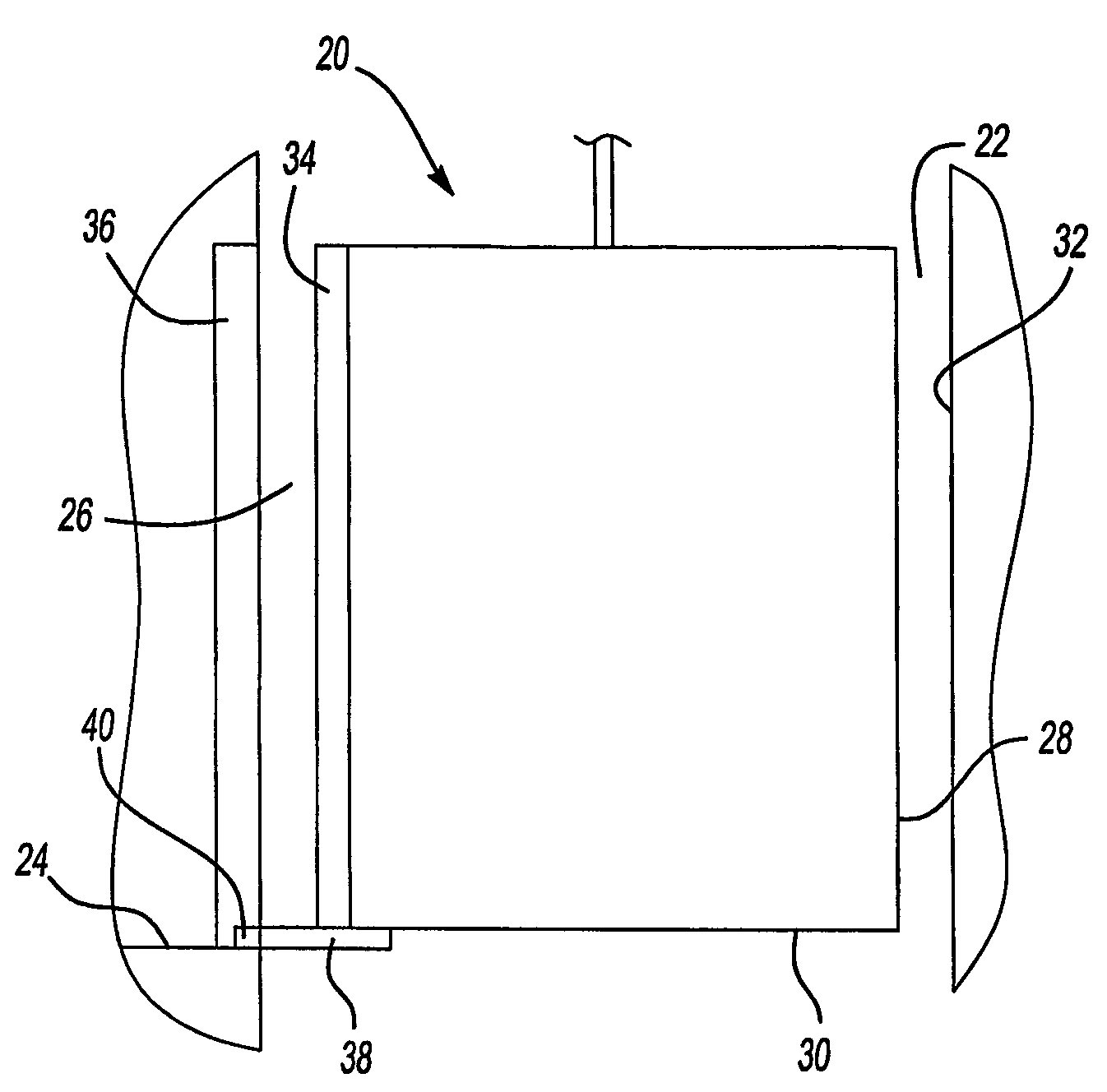

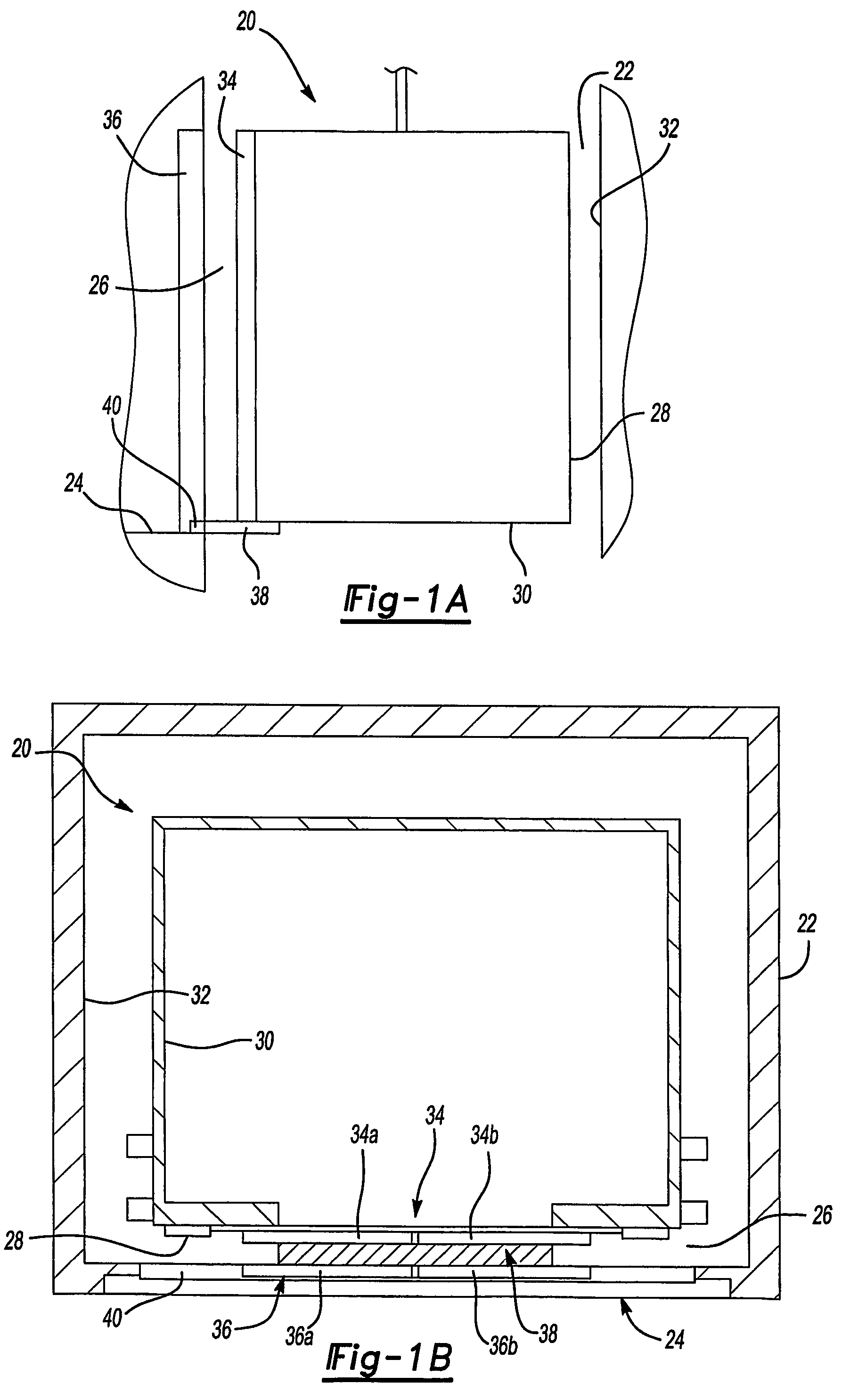

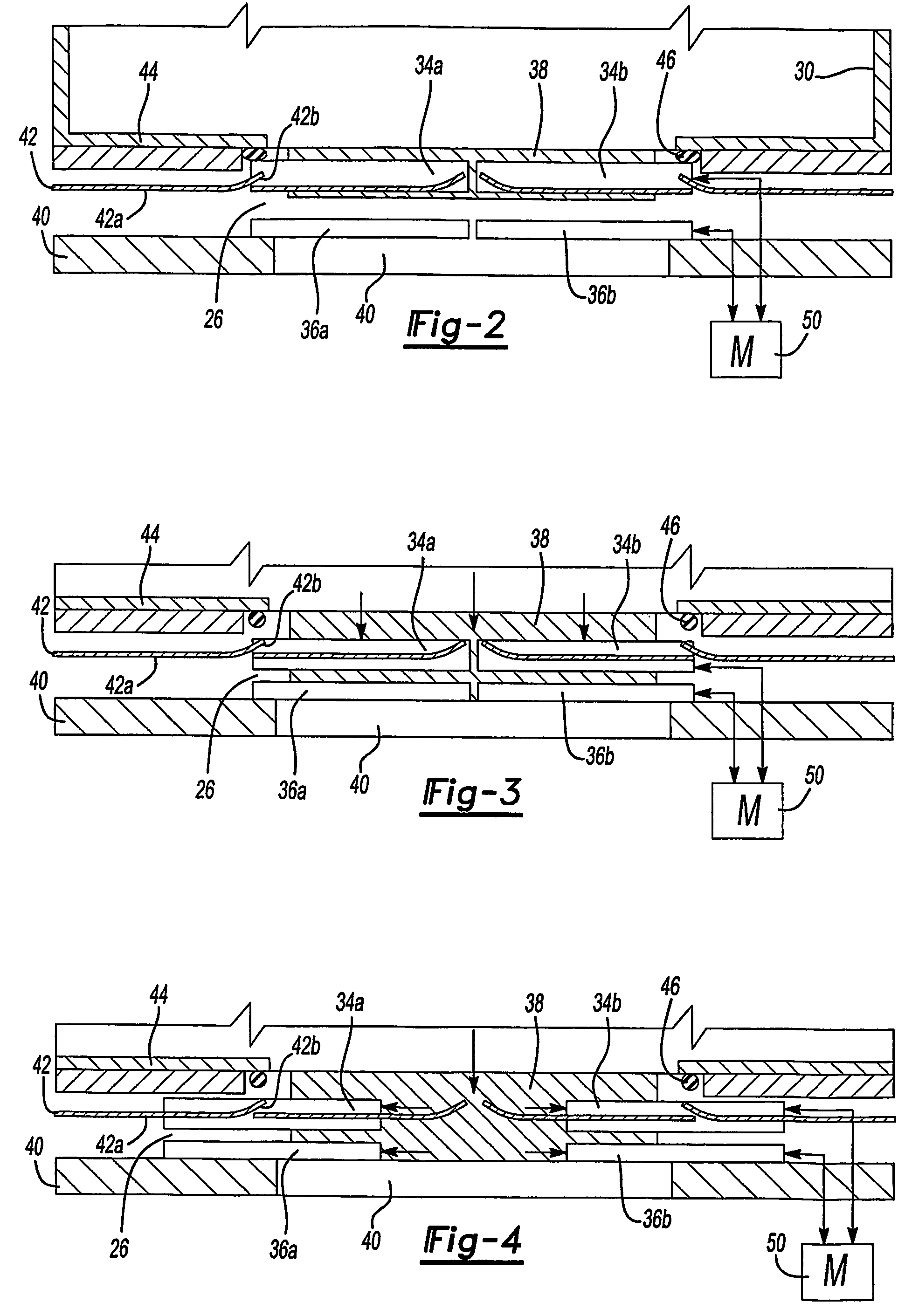

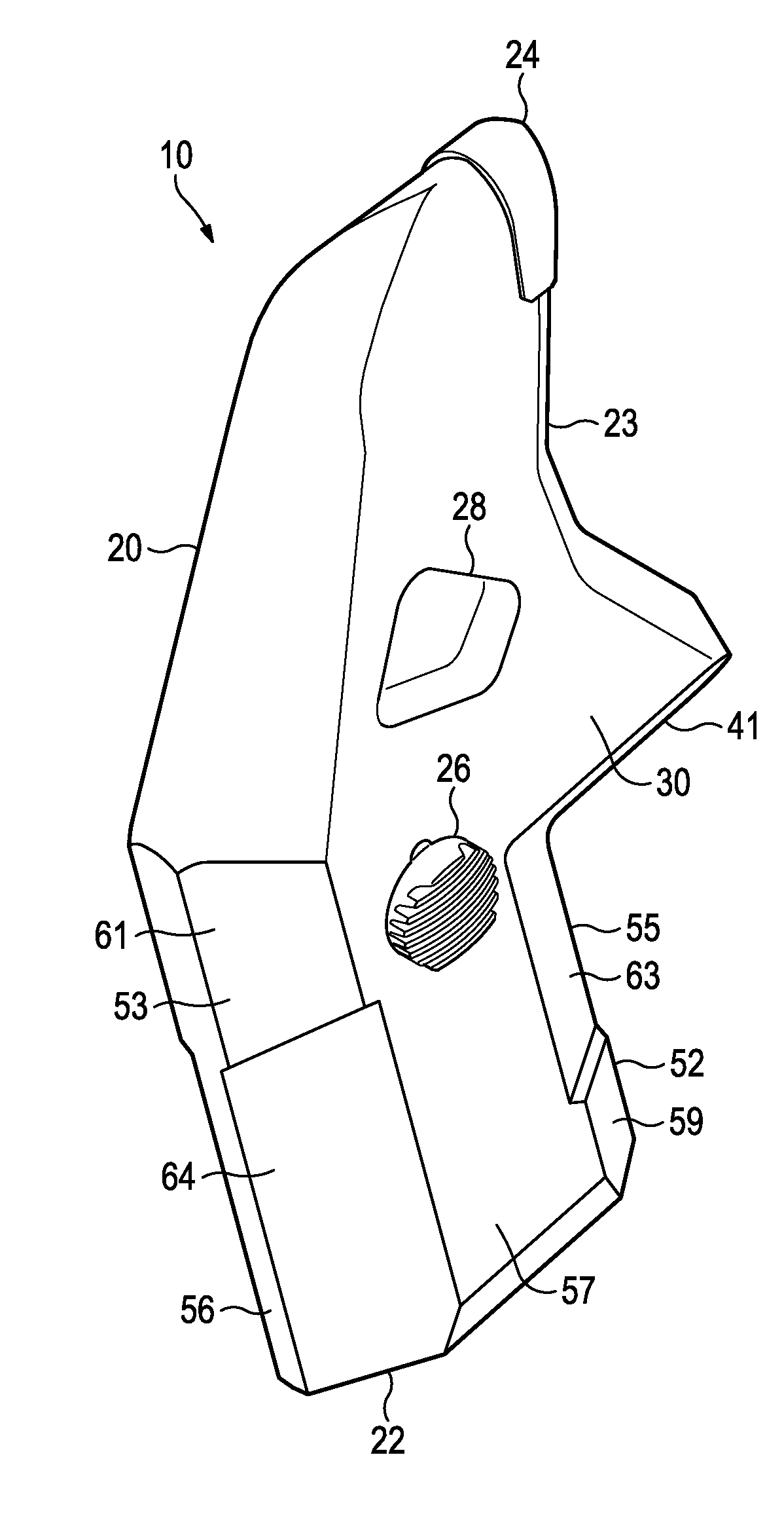

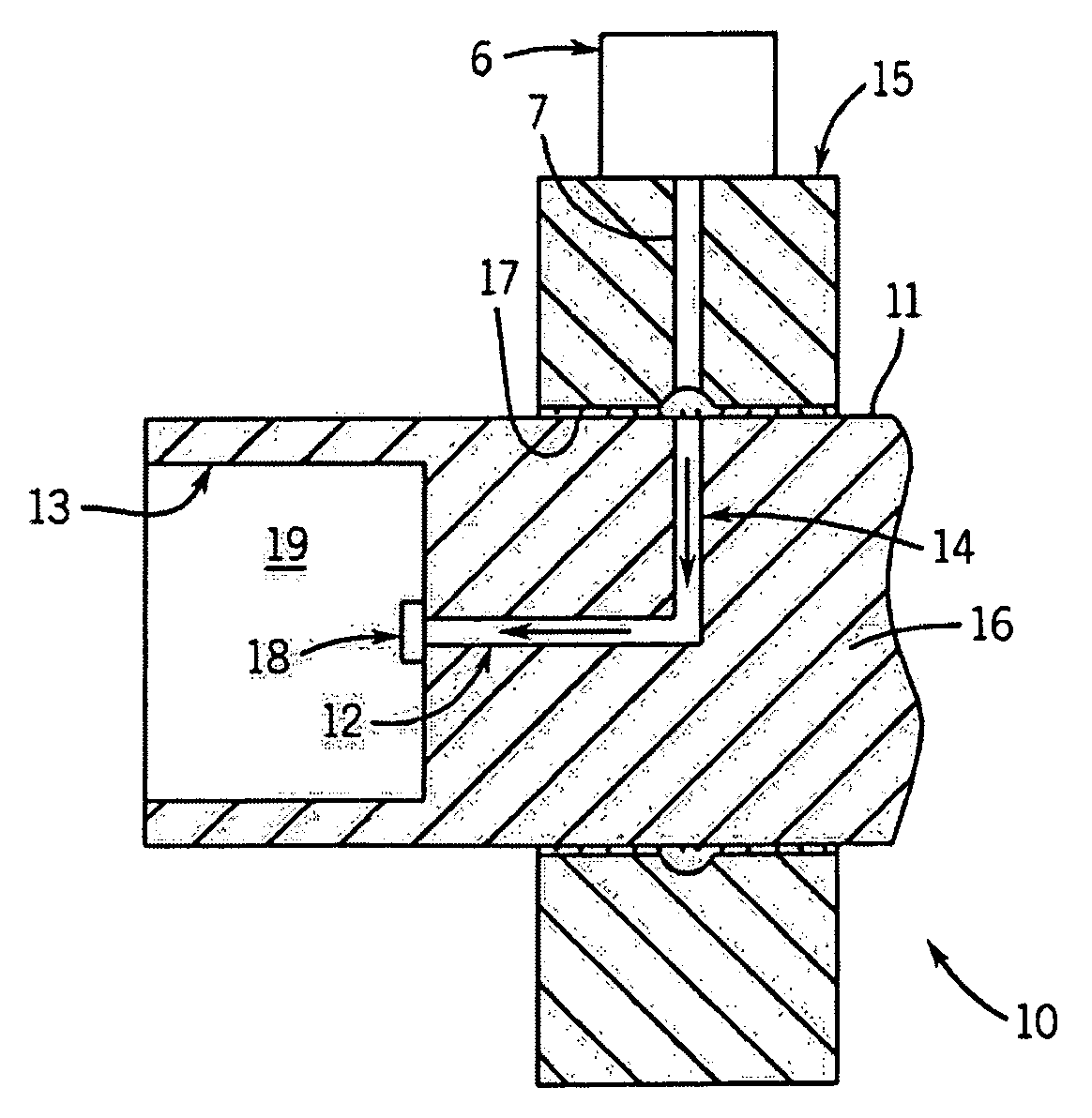

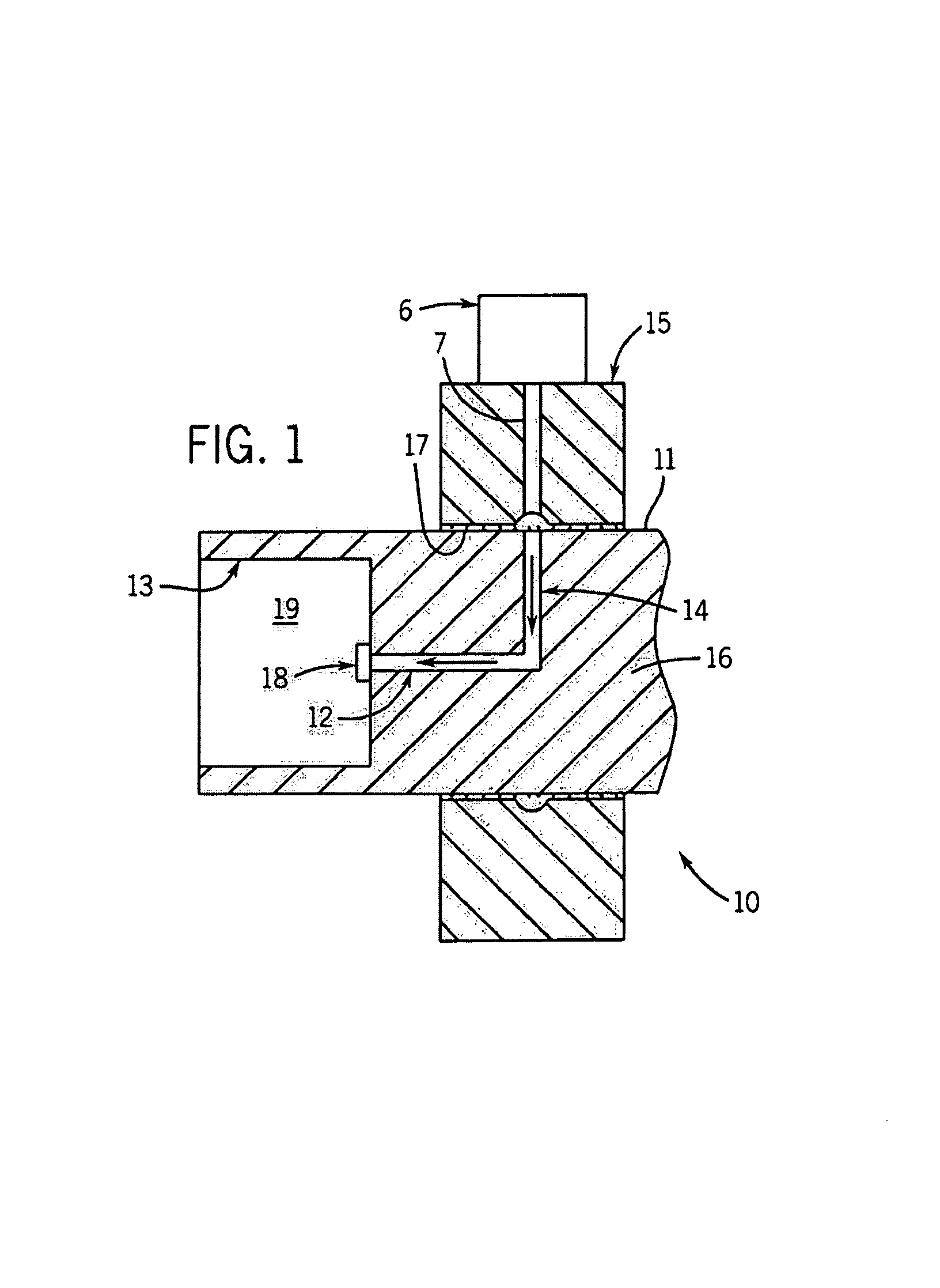

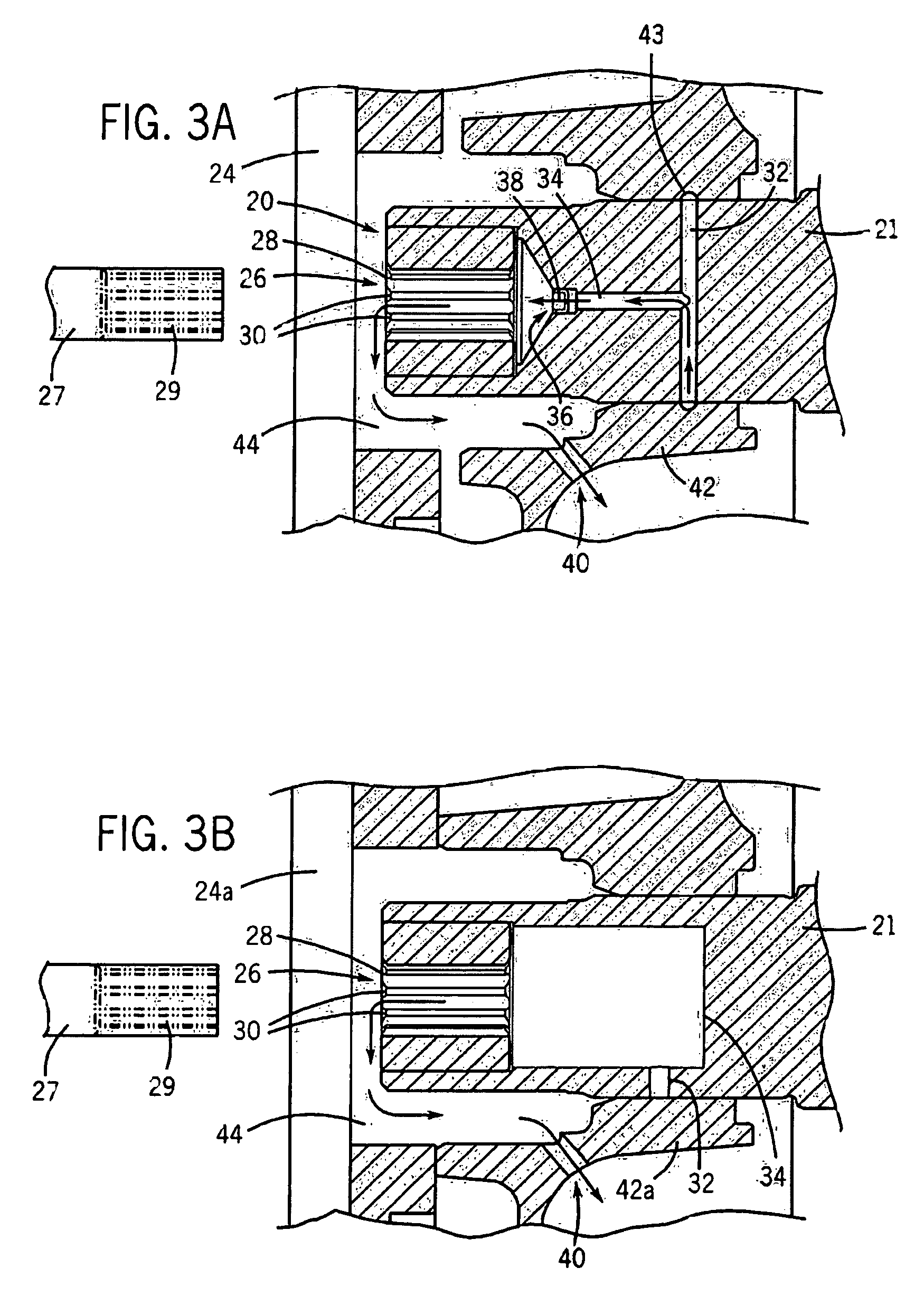

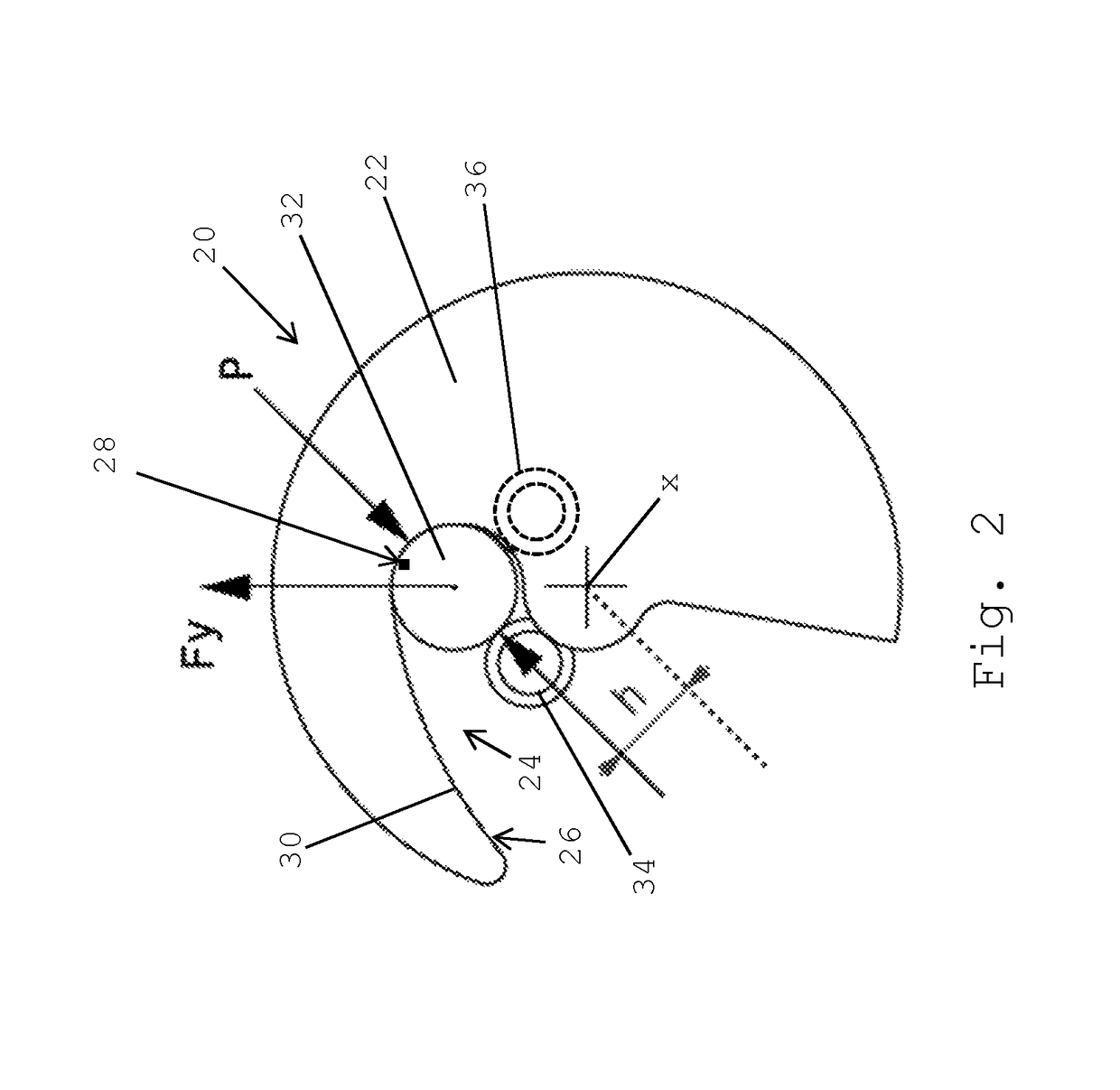

Elevator assembly with extendable sill

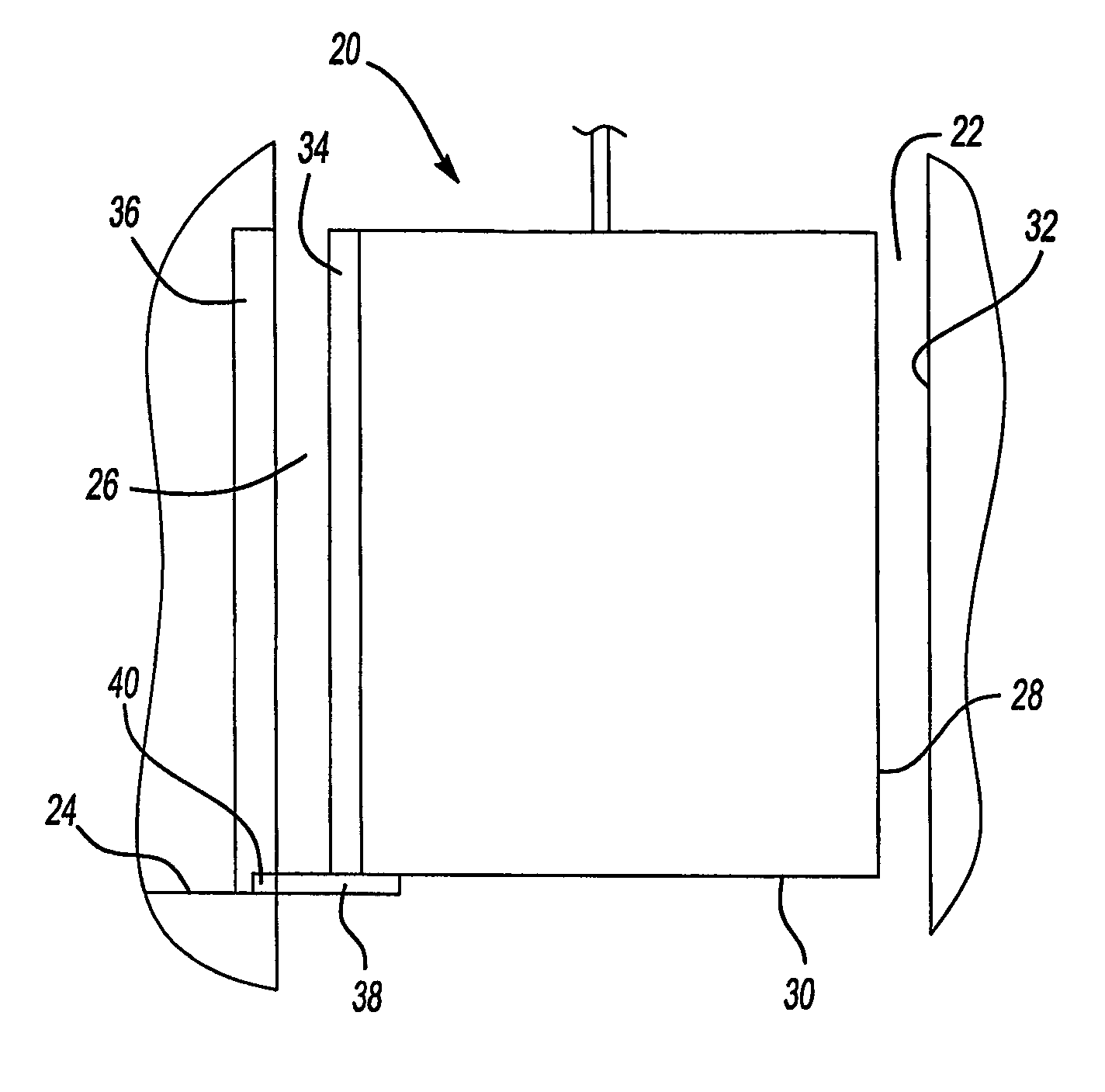

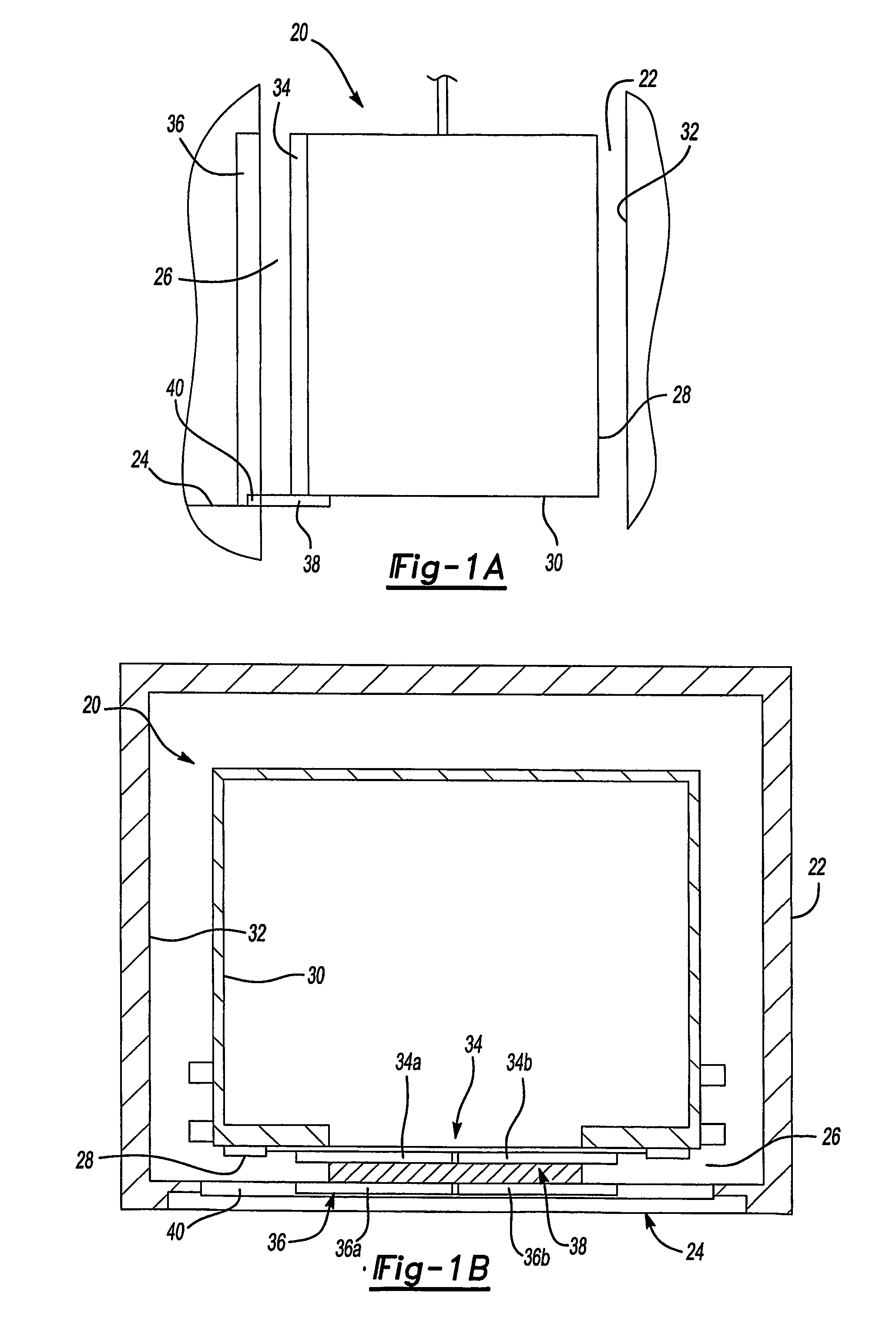

InactiveUS20060243534A1Quick installationMore running clearanceBuilding liftsMine liftsLocking mechanismAerospace engineering

An elevator (20) includes a sill (38) that extends out from underneath an elevator car (30) to bridge an operating gap (26) between the car (30) and a landing (24). When an elevator door (34) is aligned with a landing door (36), the sill (38) extends outwardly from the car (30) until the sill (38) makes contact with a landing structure (40). A locking mechanism (52) securely locks the sill (38) to the landing structure (40). In one example, once proper sill alignment and locking engagement occurs, a door moving mechanism (50) is released and the elevator (34) and landing (36) doors open.

Owner:OTIS ELEVATOR CO

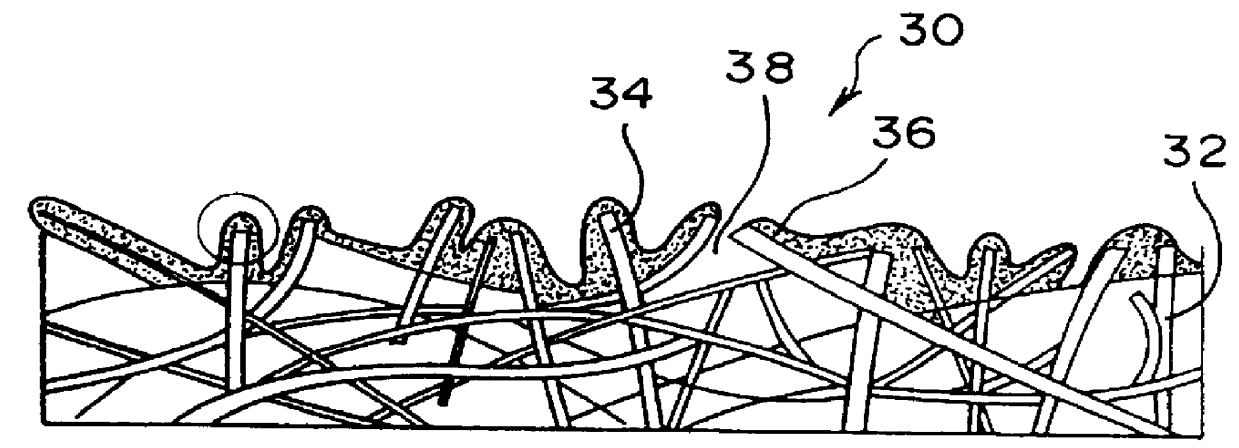

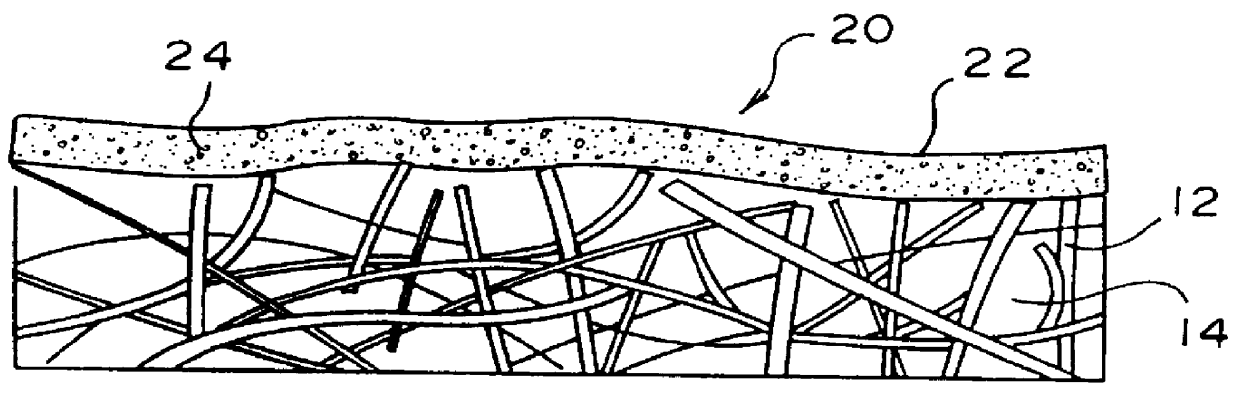

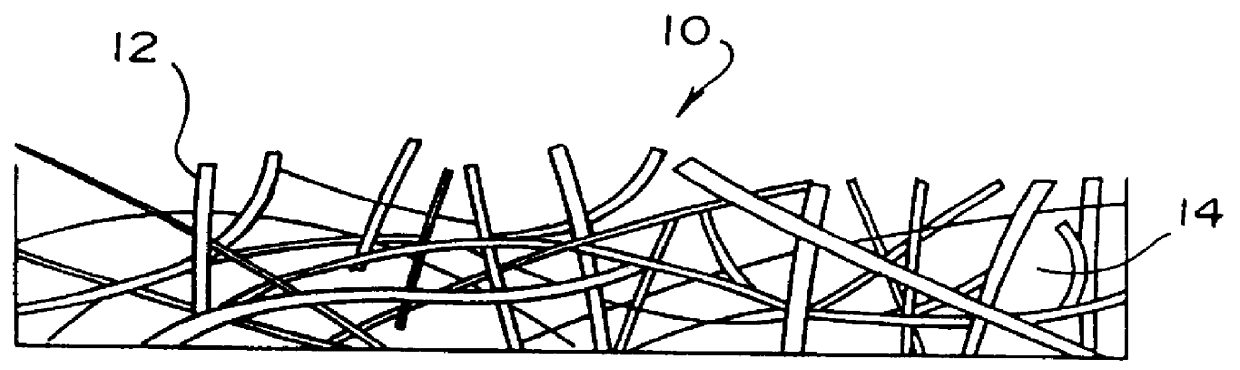

Fluorocarbon particle coated textiles for use in electrostatic printing machines

InactiveUS6054399AEasy to cleanDecreased fiber sheddingSynthetic resin layered productsTraffic signalsFiberFluorocarbon

A textile material whose fibers have been coated, at least in part, with fluorocarbon particles is usable in an electrophotographic printing machine to clean toner particles off a fuser roll, and to supply a toner release agent to the fuser roll. The textile material can include woven goods, as well as non-woven felts and the like. The resultant product has reduced friction and decreased fiber shedding.

Owner:BMP AMERICA

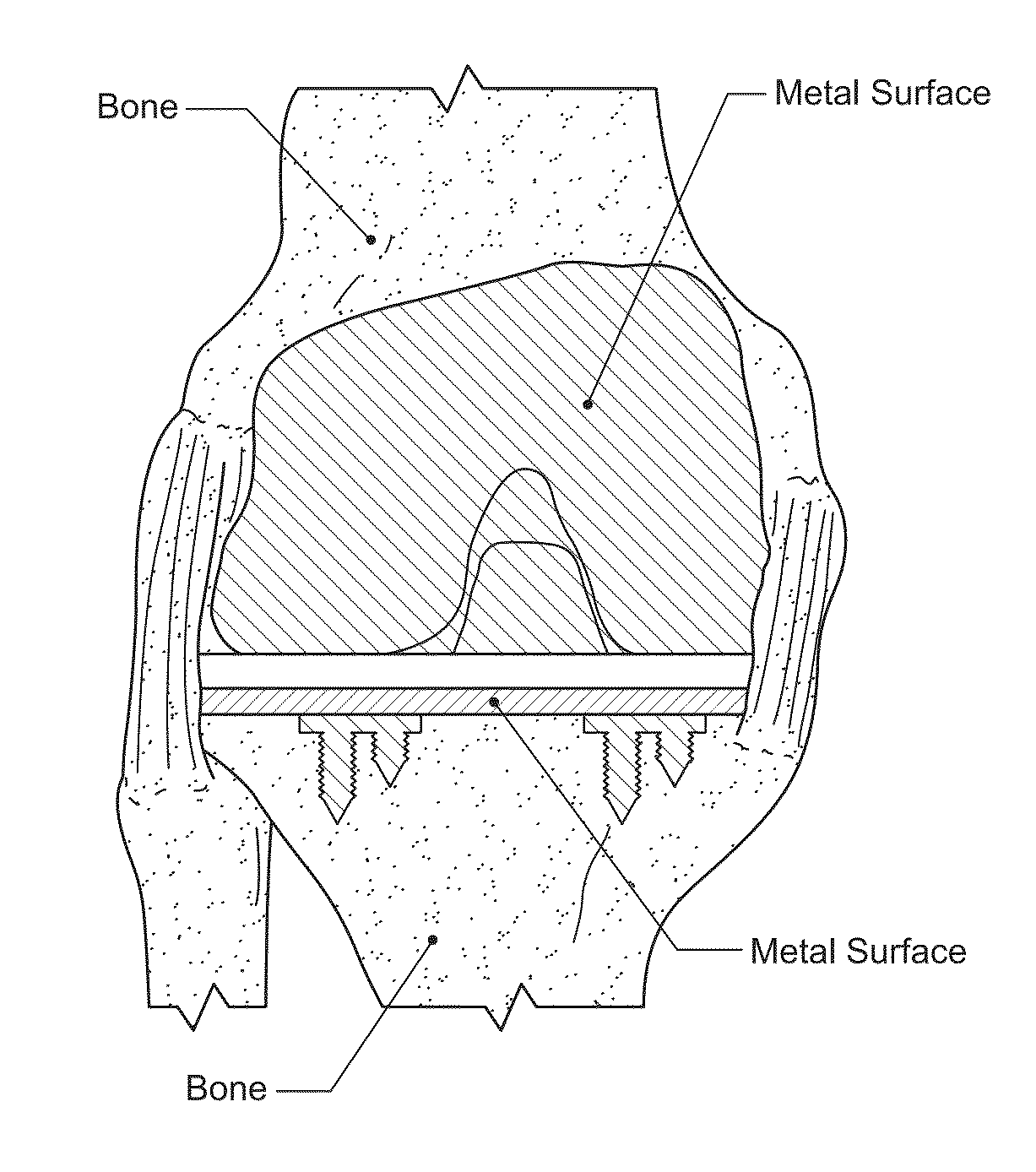

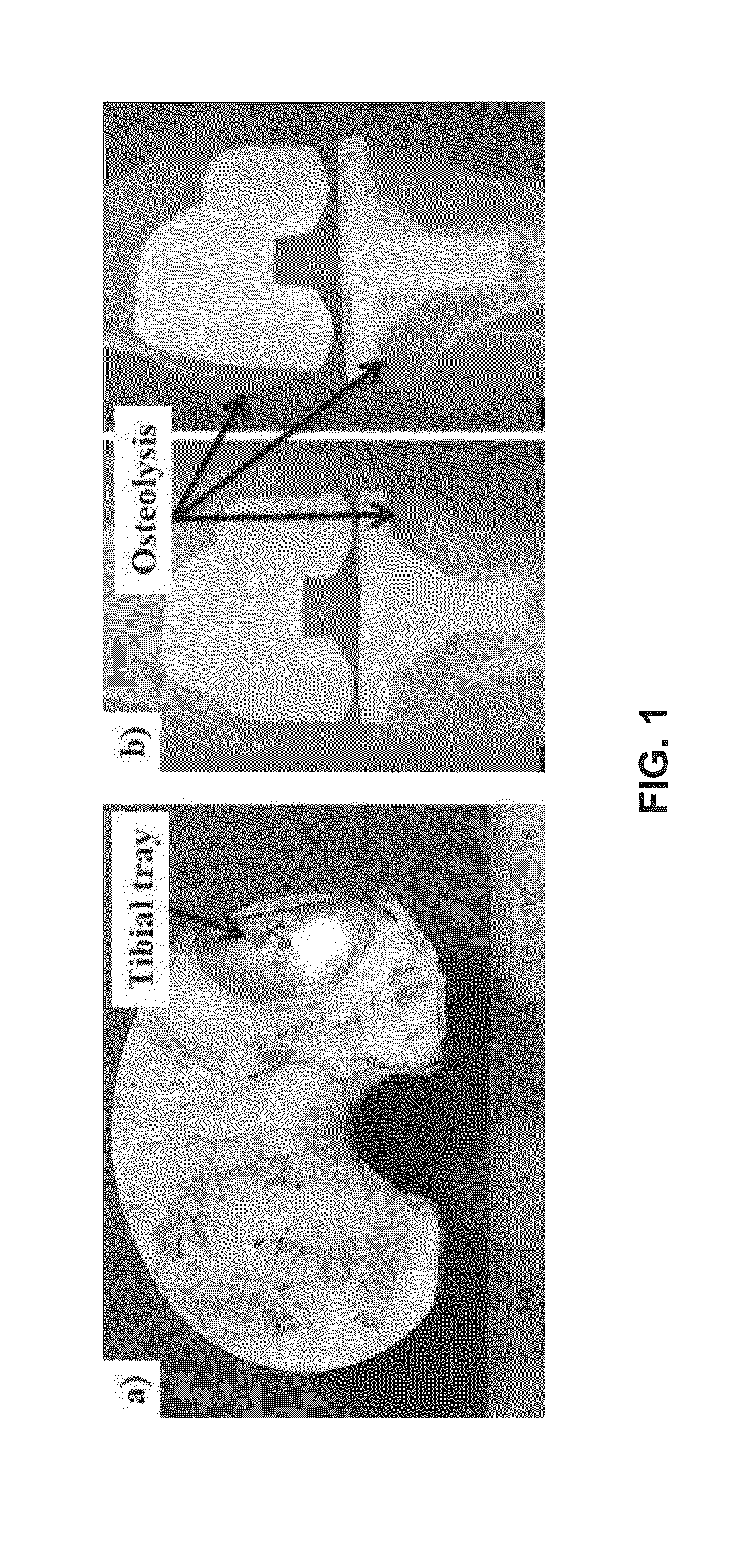

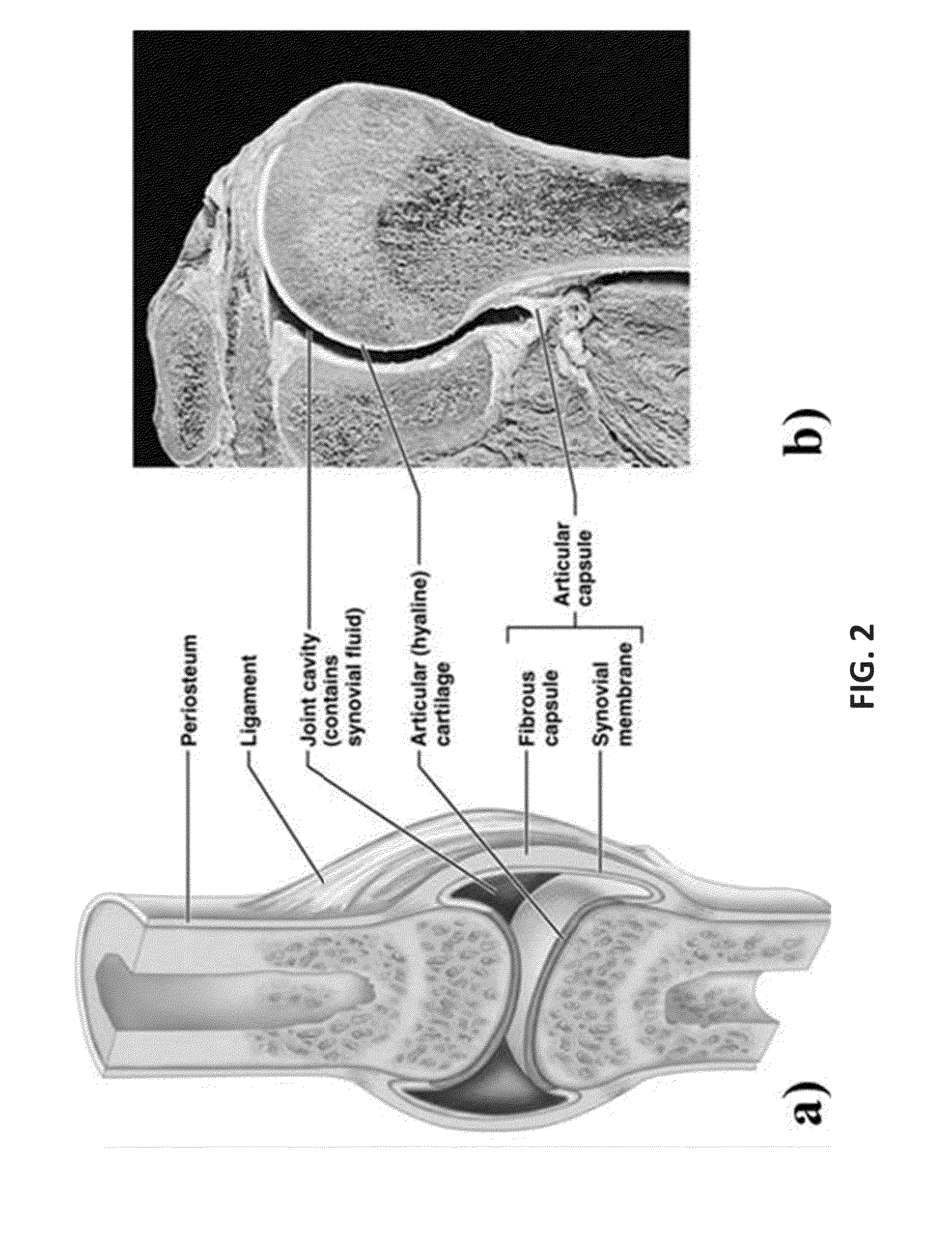

Orthopaedic Joints Providing Enhanced Lubricity

ActiveUS20150066152A1Increase surface lubricityWear minimizationJoint implantsProsthesisProsthetic joint component

The present disclosure provides, among other things, prosthetic joint components having textured surface(s) for improving lubrication and increasing the useful life of the prosthetic joint components. The textured surface includes solid features configured to stably contain a biological fluid or a synthetic biological fluid therebetween or therewithin for a non-zero residence time.

Owner:MASSACHUSETTS INST OF TECH

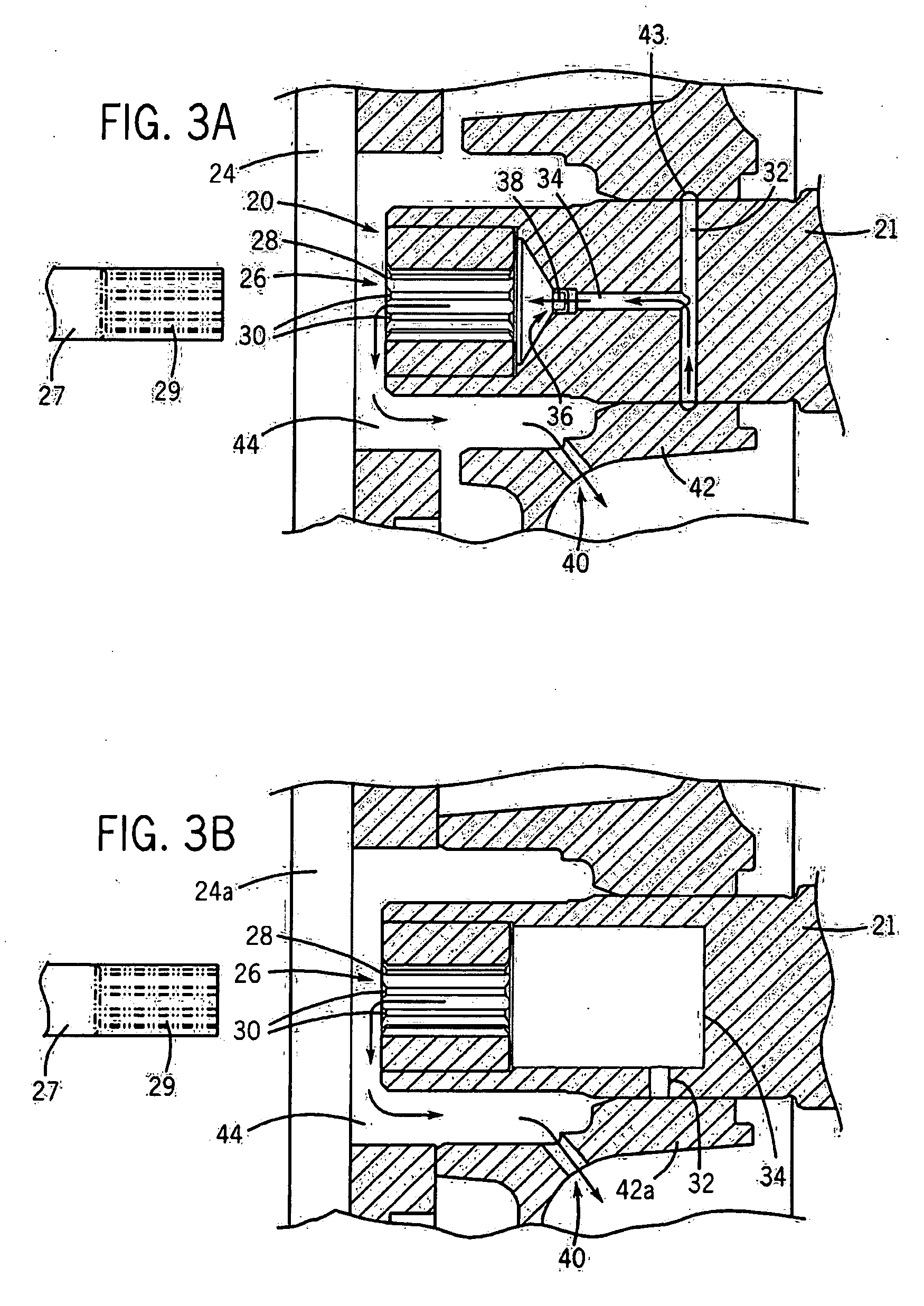

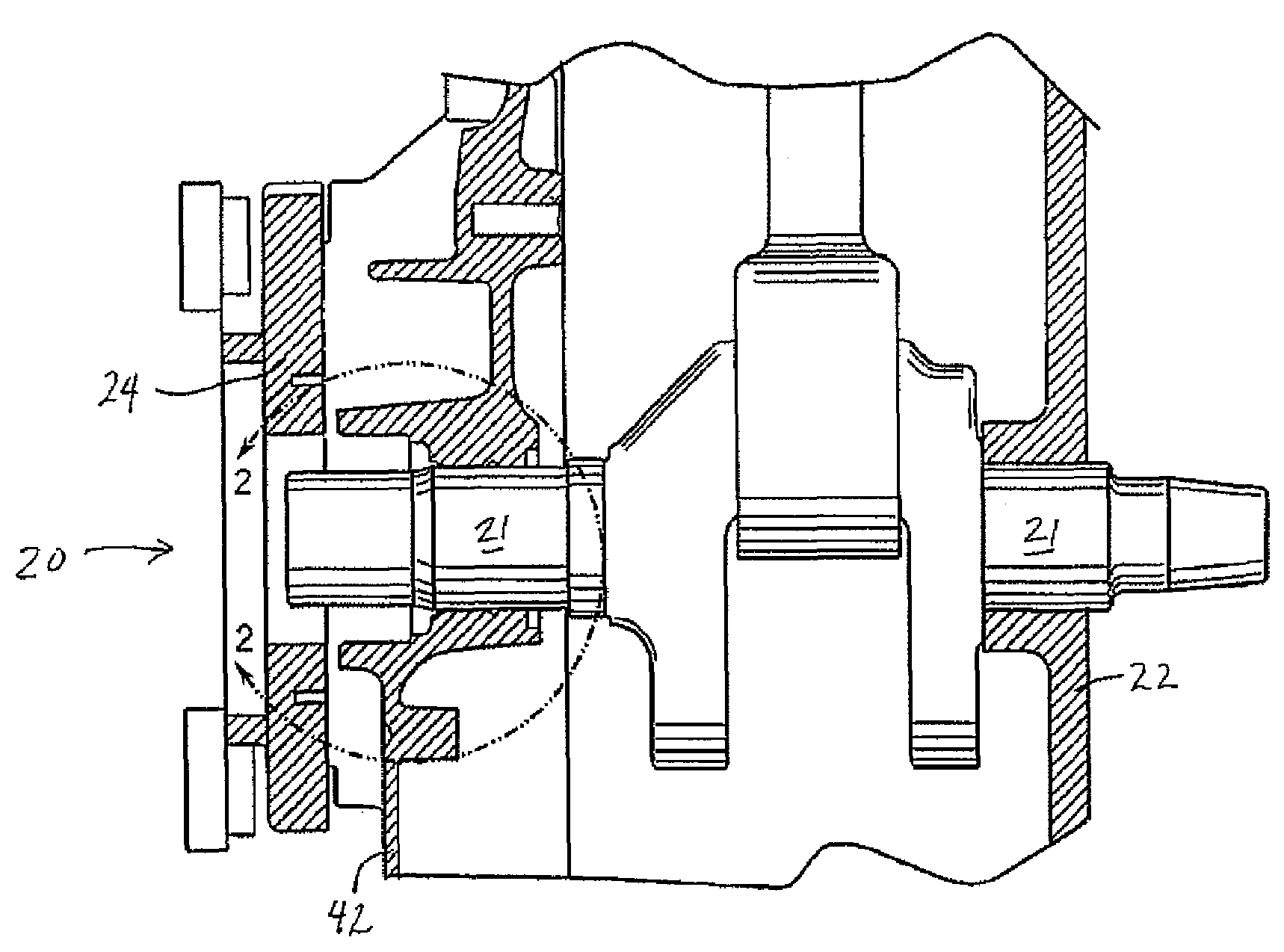

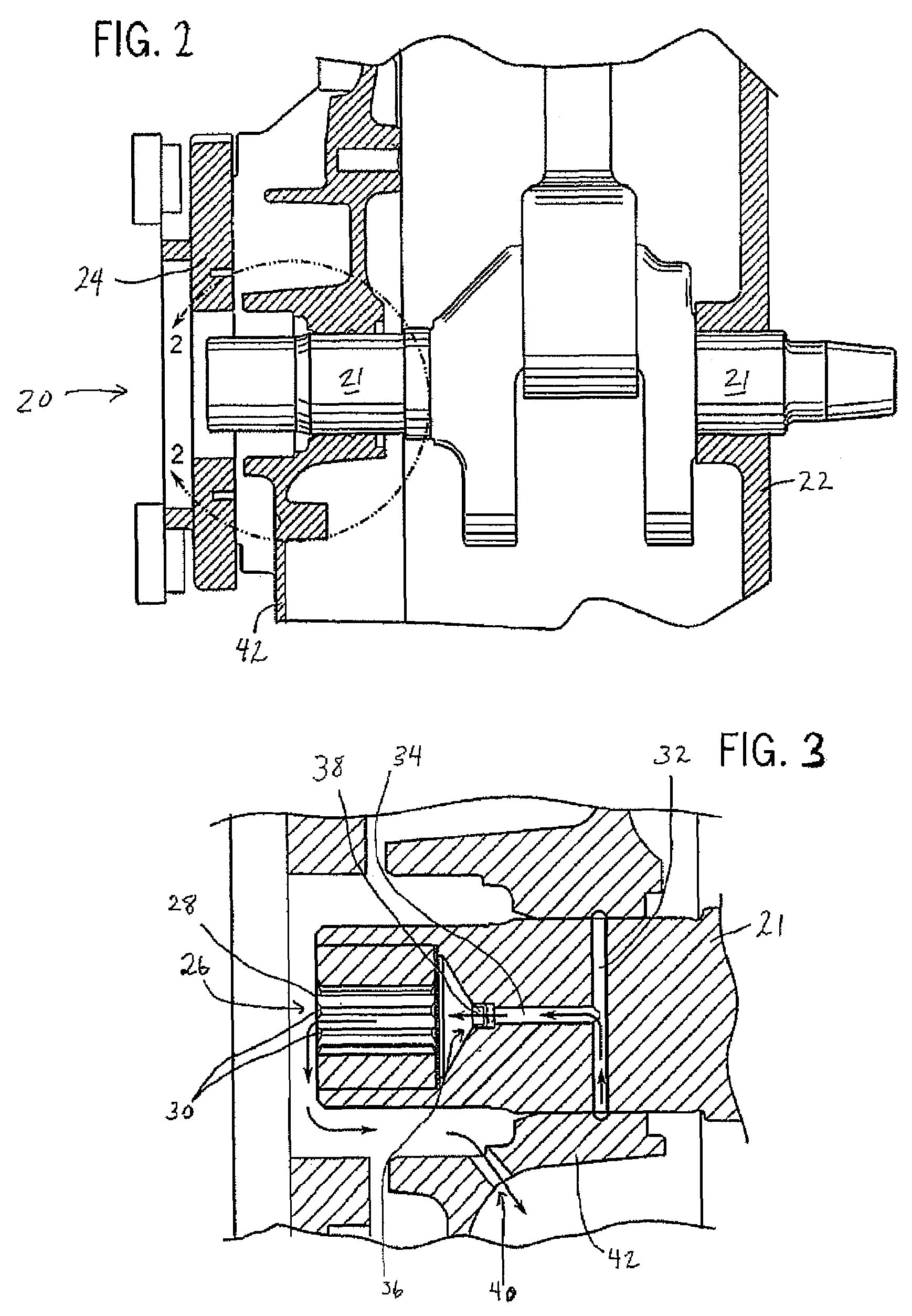

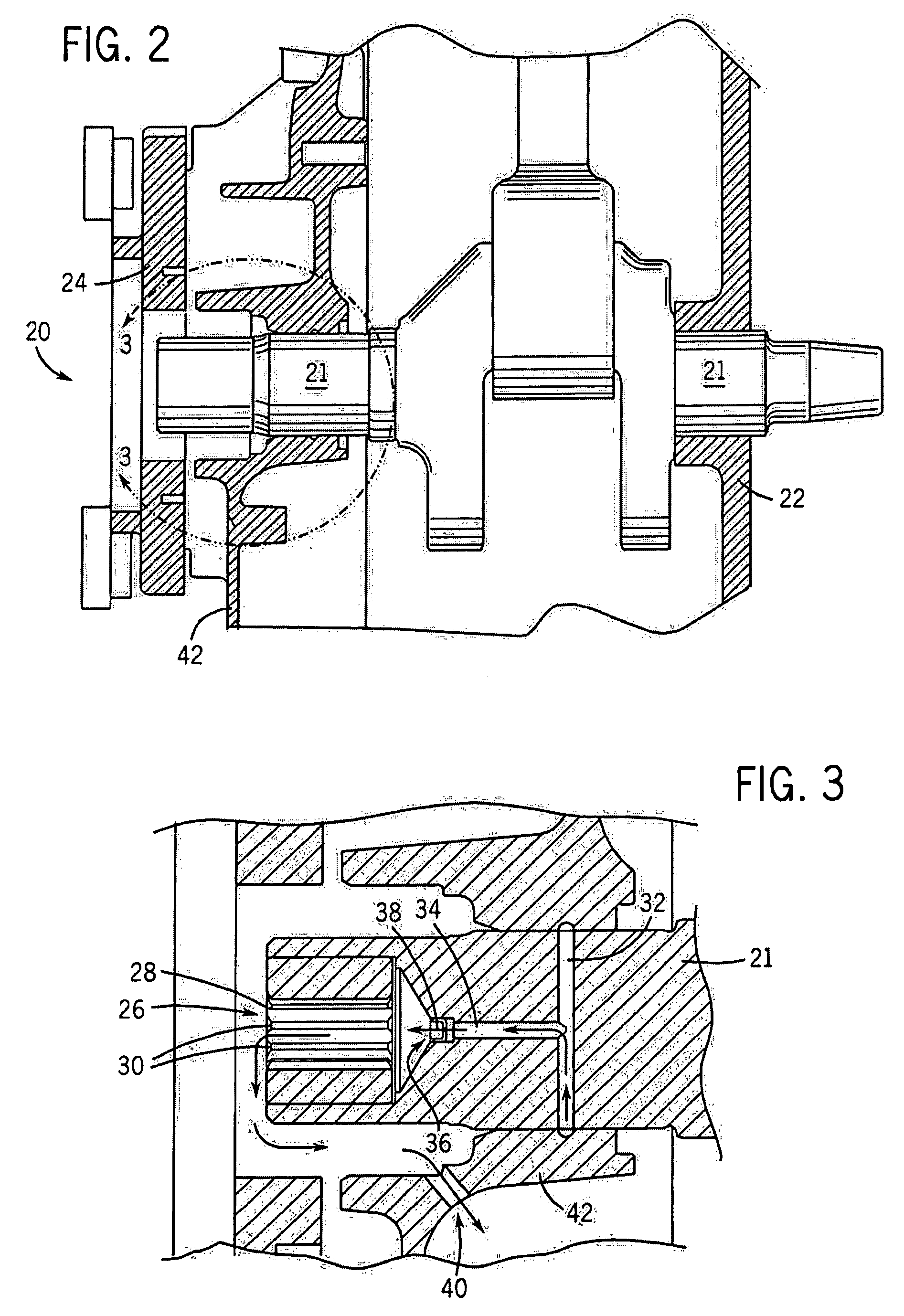

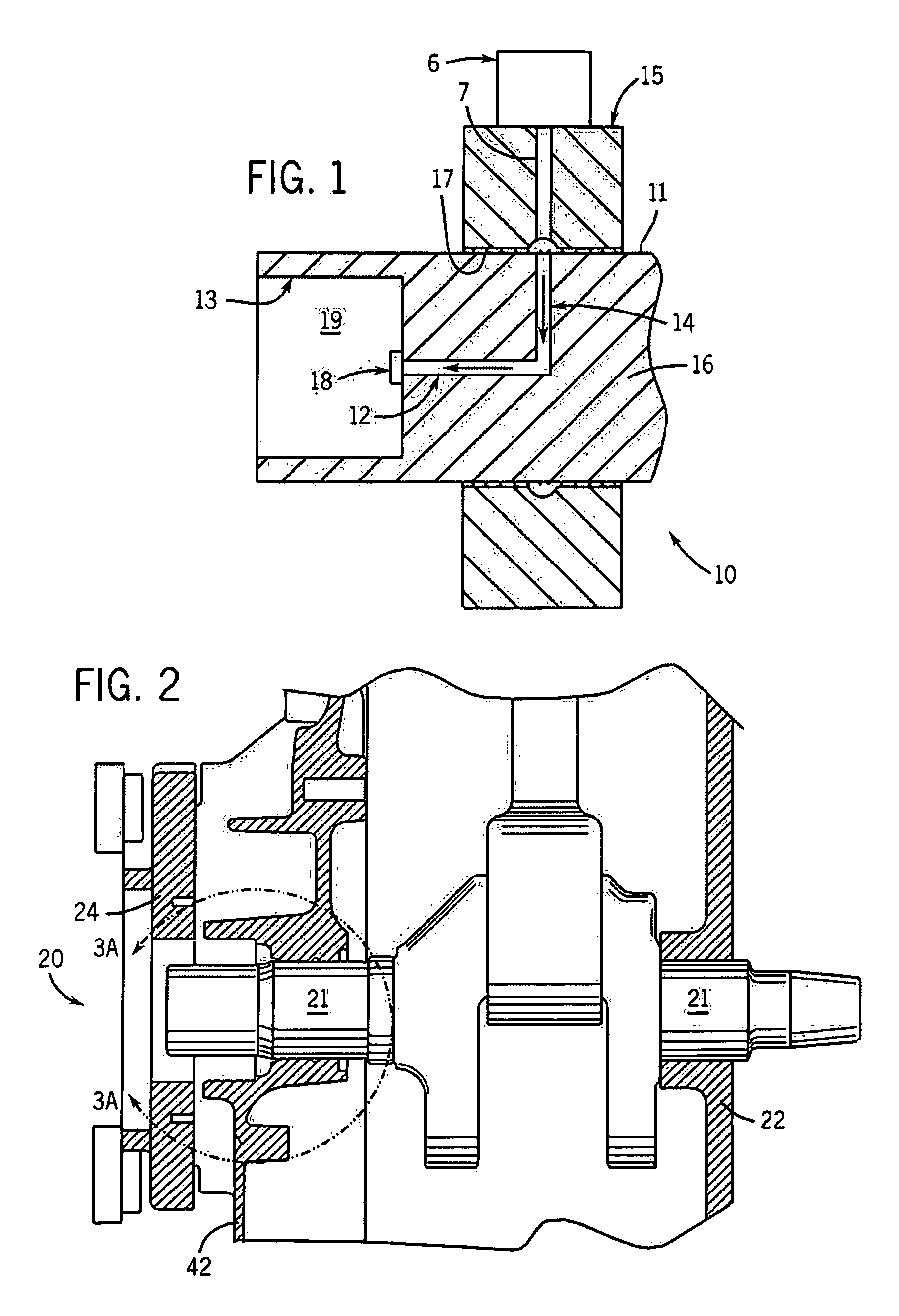

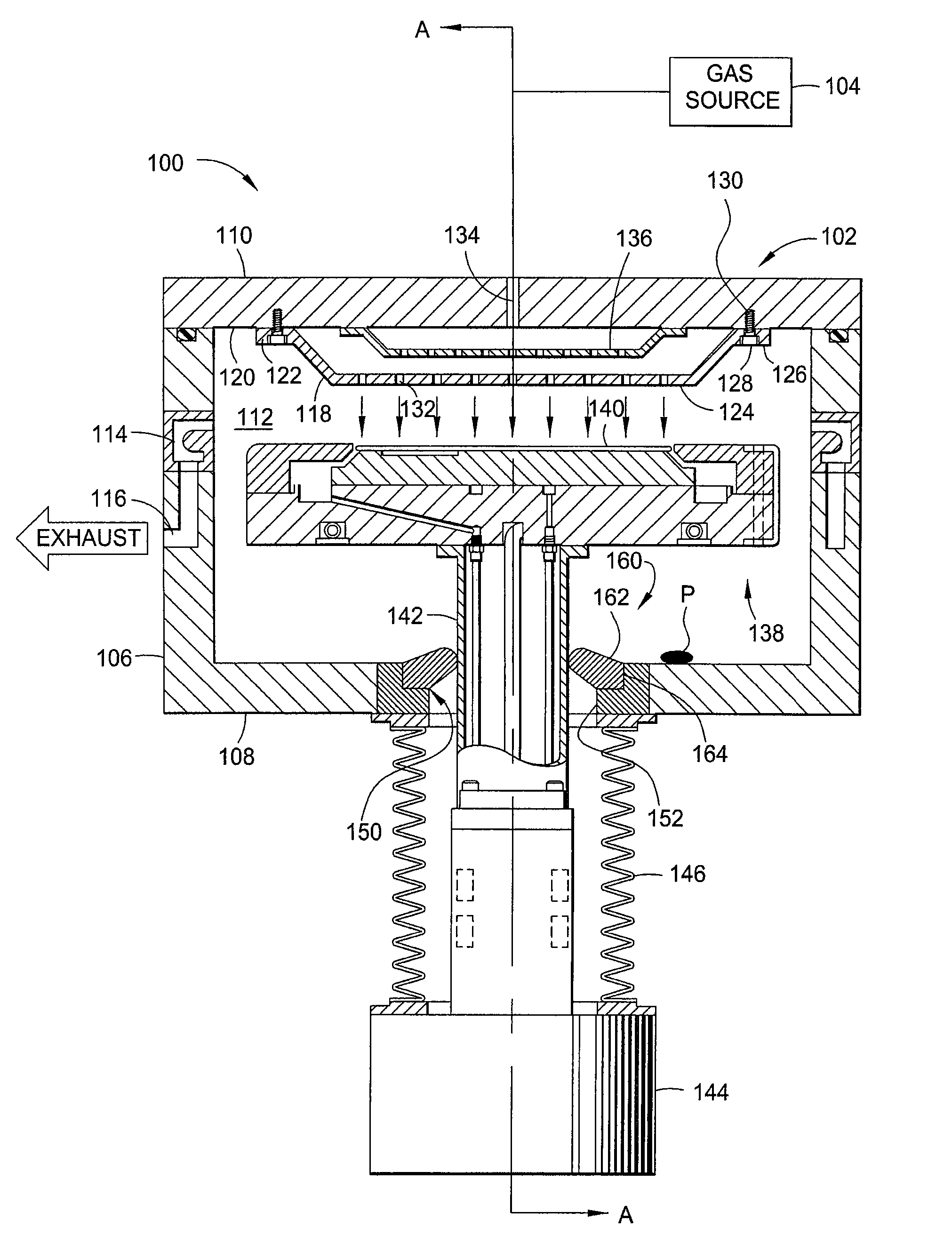

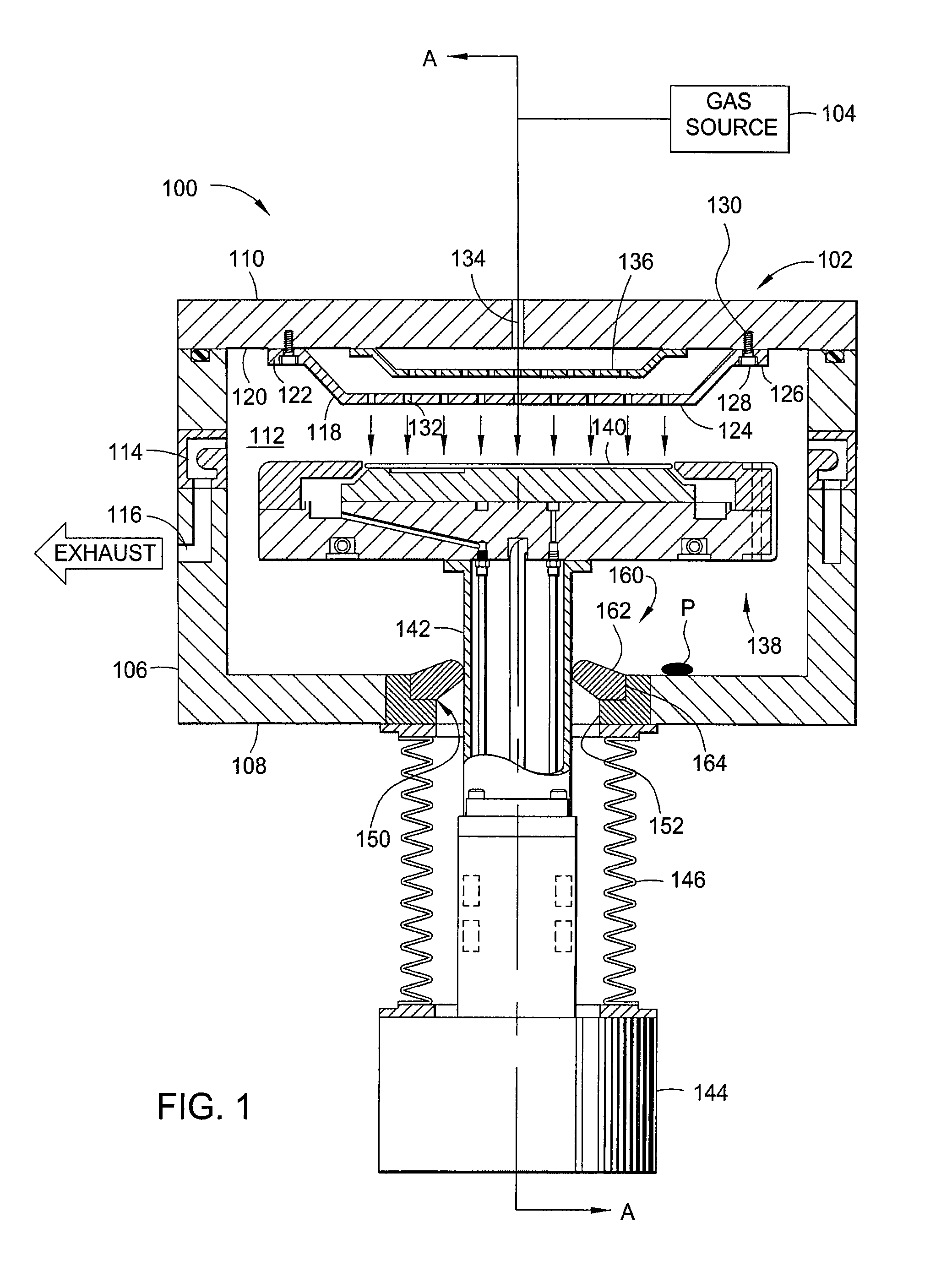

System and Method for Lubricating Power Transmitting Elements

InactiveUS20090000871A1Reduced component wearExtended service lifeDrip or splash lubricationGear lubrication/coolingTransmitted powerEngineering

A lubrication system and method are disclosed. The system includes a main engine bearing and a crankshaft in operational association with the bearing. The crankshaft includes an end having a cavity with a power transmitting element (e.g., splines). The cavity can receive and engage a mating mechanism to transmit power thereto. The crankshaft further includes a first oil passage that is disposed within the end and a second oil passage that extends from the main engine bearing into the crankshaft. The first oil passage intersects the second oil passage. The system can also include a pump mechanism for circulating lubricating oil from the main engine bearing to the crankshaft through the second oil passage and the first oil passage, and to the cavity to lubricate the power transmitting element. During engine operation, a constant supply of lubricating oil can be provided to the power transmitting element to reduce component wear.

Owner:KOHLER CO

Elevator assembly with extendable sill

InactiveUS7621379B2Quick installationMore running clearanceBuilding liftsMine liftsLocking mechanismEngineering

Owner:OTIS ELEVATOR CO

Bearing for variable pitch stator vane

ActiveUS8038387B2Increase the effective areaReduced component wearWind motor controlPump componentsEngineeringMechanical engineering

A bearing for a turbomachine variable pitch stator vane pivot mounted in a bore of the turbomachine casing is disclosed. The bearing includes an inner bushing secured to the pivot and an outer bushing secured to the bore. An elastomeric material is inserted between the inner bushing and the outer bushing to allow the vane to pivot about its axis and absorb at least some of the flexing of the pivot at right angles to the axis. The design makes it possible to reduce bearing bushing wear.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

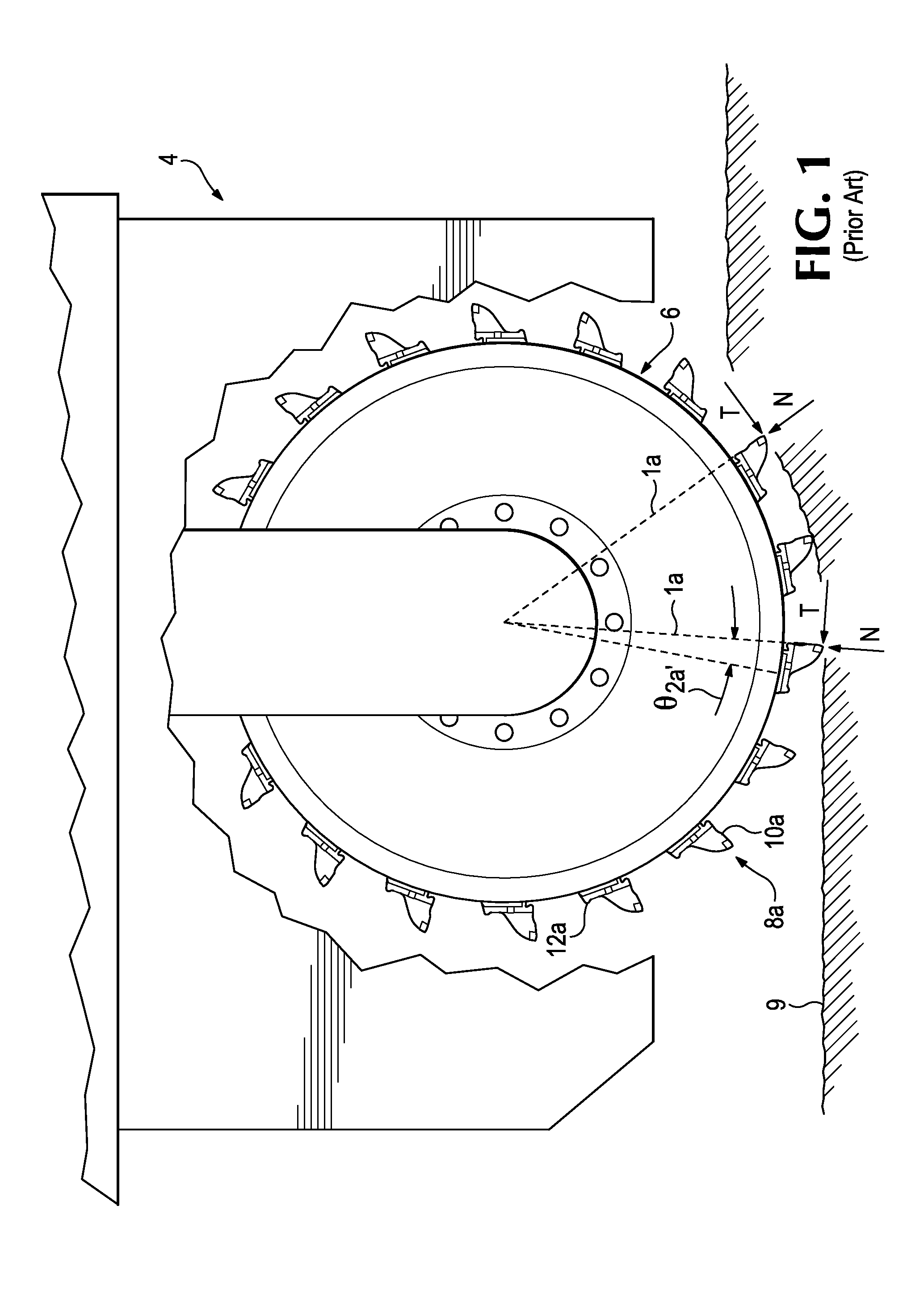

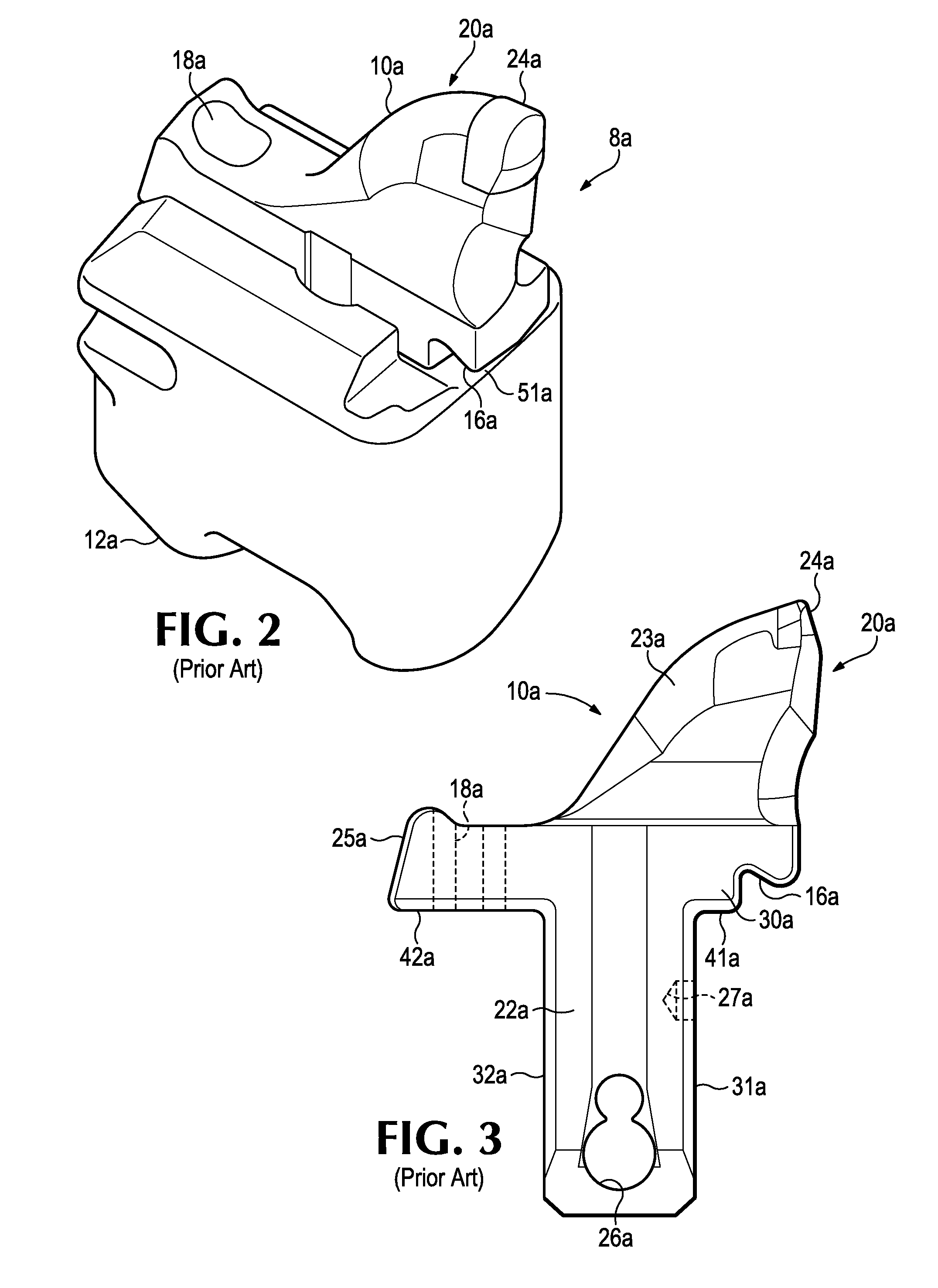

Mineral Winning Pick, Pick Holder, And Combination

ActiveUS20140368022A1Less downtime encounteredIncrease production capacitySlitting machinesCutting machinesEngineeringBearing surface

An improved pick and pick holder assembly for use in mineral winning and the like. The improved pick and pick holder increases the effective life of a tool and pick holder by minimizing the shifting of the pick within the pick holder. The movement of the pick is minimized by front and rear bearing surfaces that remain positively engaged with front and rear bearing surfaces of the pick holder for loads applied to the pick that are predominantly inward and predominantly rearward.

Owner:ESCO GRP LLC

System and Method for Lubricating Power Transmitting Elements

InactiveUS20080149423A1Reduce wearExtend service lifeLubrication of auxillariesLubricant conduit arrangementsLubricationEngineering

Disclosed herein is a lubrication system and method. The system includes a main engine bearing and a crankshaft in operational association with the bearing. The crankshaft includes an end having a cavity with a power transmitting element (e.g., splines). The cavity can receive and engage an additional mechanism to transmit power thereto. The crankshaft further includes a first oil passage that is disposed within the end and a second oil passage that extends from the main engine bearing into the crankshaft. The first oil passage intersects the second oil passage. The system also includes a pump mechanism for circulating lubricating oil from the main engine bearing to the crankshaft through the second oil passage and the first oil passage, and to the cavity to lubricate the power transmitting element. During engine operation, a constant supply of lubricating oil can be provided to the power transmitting element to reduce component wear.

Owner:KOHLER CO

System and method for lubricating power transmitting elements

InactiveUS7431006B2Reduced component wearExtended service lifeLubrication of auxillariesLubricant conduit arrangementsTransmitted powerEngineering

Owner:KOHLER CO

Pleated single phase filter coalescer element and method

ActiveUS20110277301A1Improve efficiencyImprove filtration efficiencyMechanical working/deformationSeparation devicesSolid particleEngineering

A filter coalescer element for oil based industrial fuels includes a rigid, porous support tube, and a hydrophobic drainage layer covering the outer surface of the same. A single phase, dual function combination water coalescer and particle filter pleat block is positioned in the support tube, and is formed from a multilayer material having a first porous support layer, a synthetic microfiber layer, a synthetic fiber media layer and a second porous support layer. As the fluid passes through the pleat block, solid particles are physically filtered therefrom, and water is coalesced into droplets which pass from the pleats directly through the support tube and directly into the drainage layer, where the droplets grow into a size sufficient that they fall under gravity to the bottom of the element for collection.

Owner:KAYDON CUSTOM FILTRATION CORP

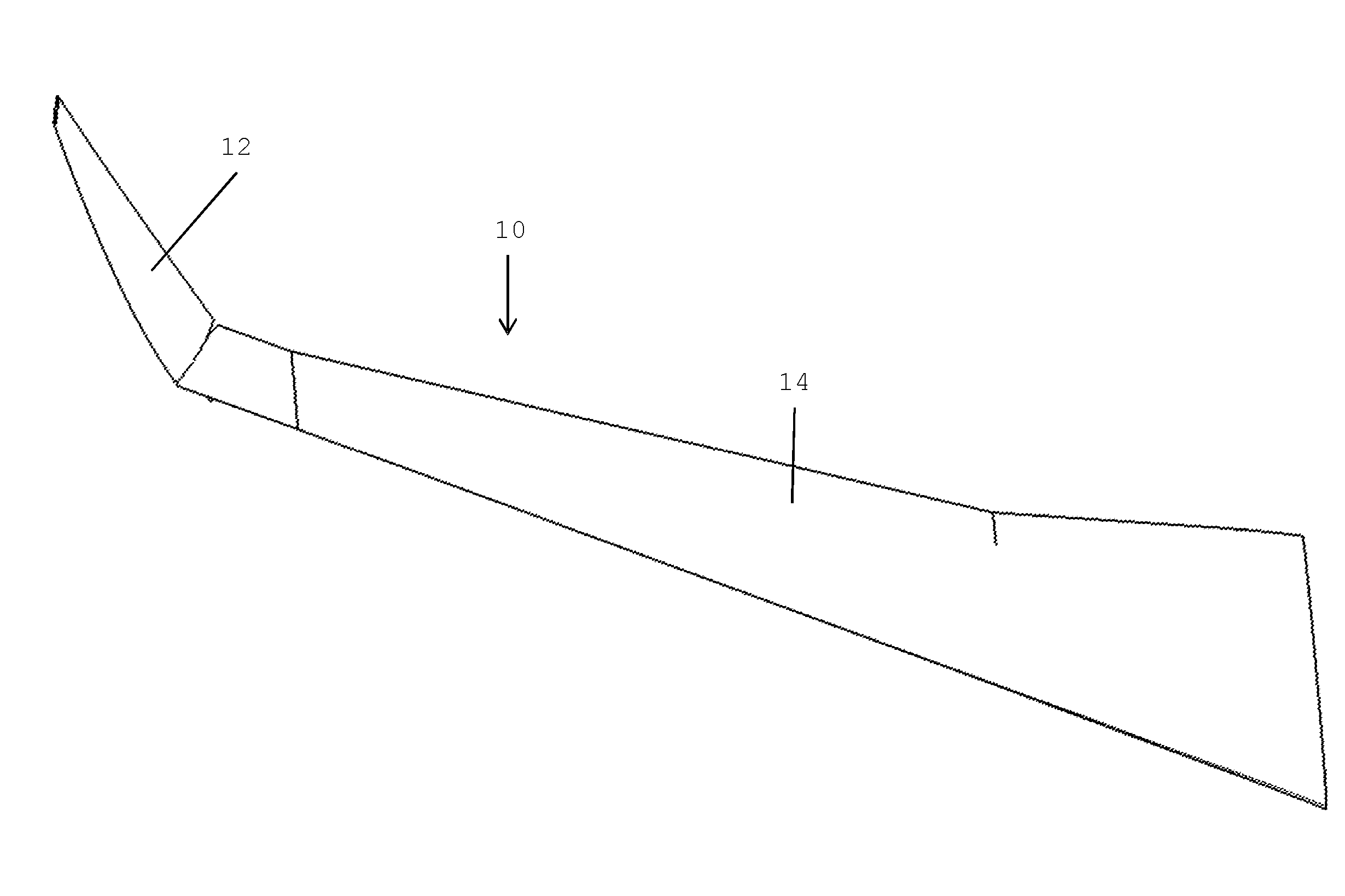

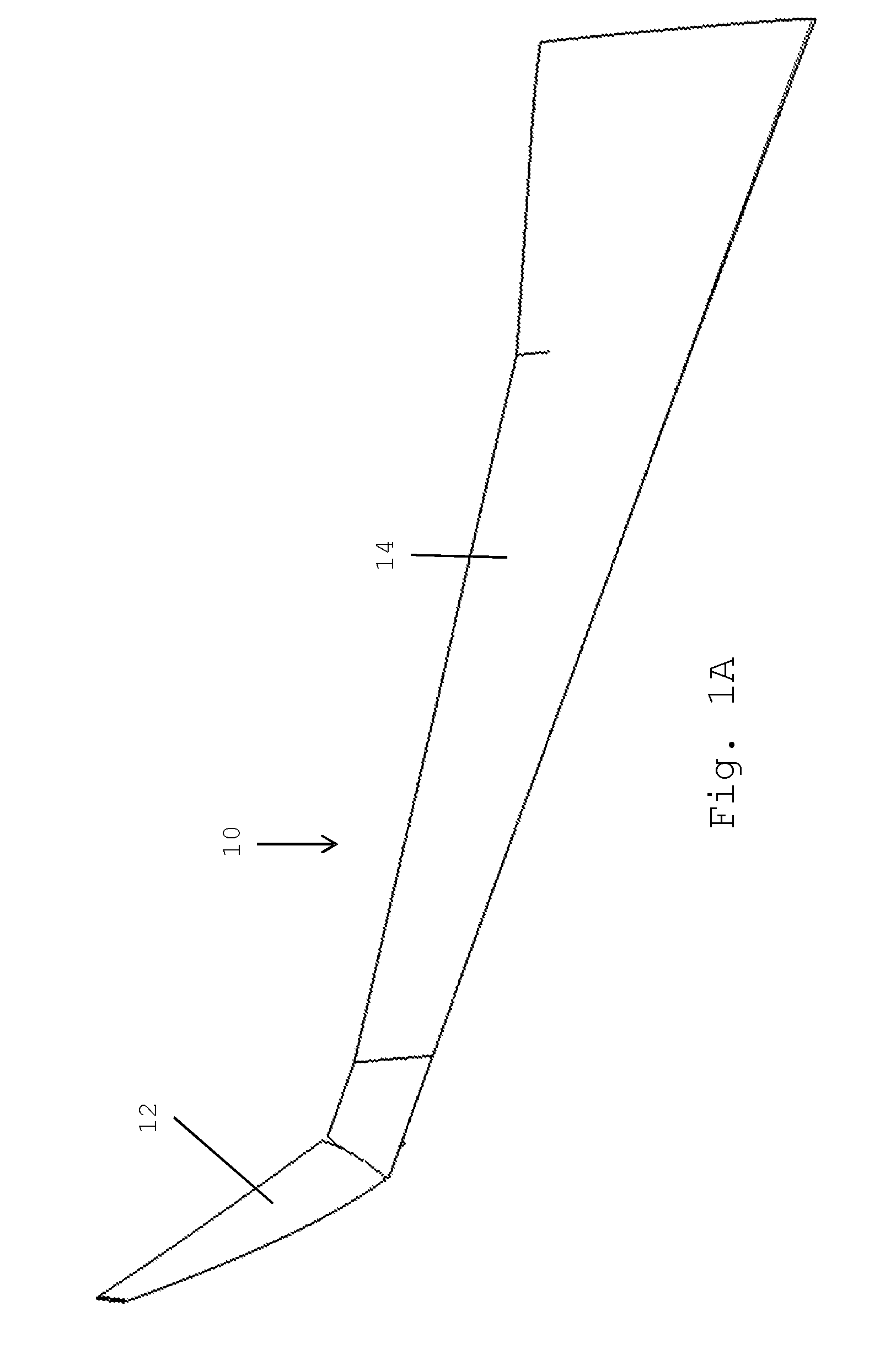

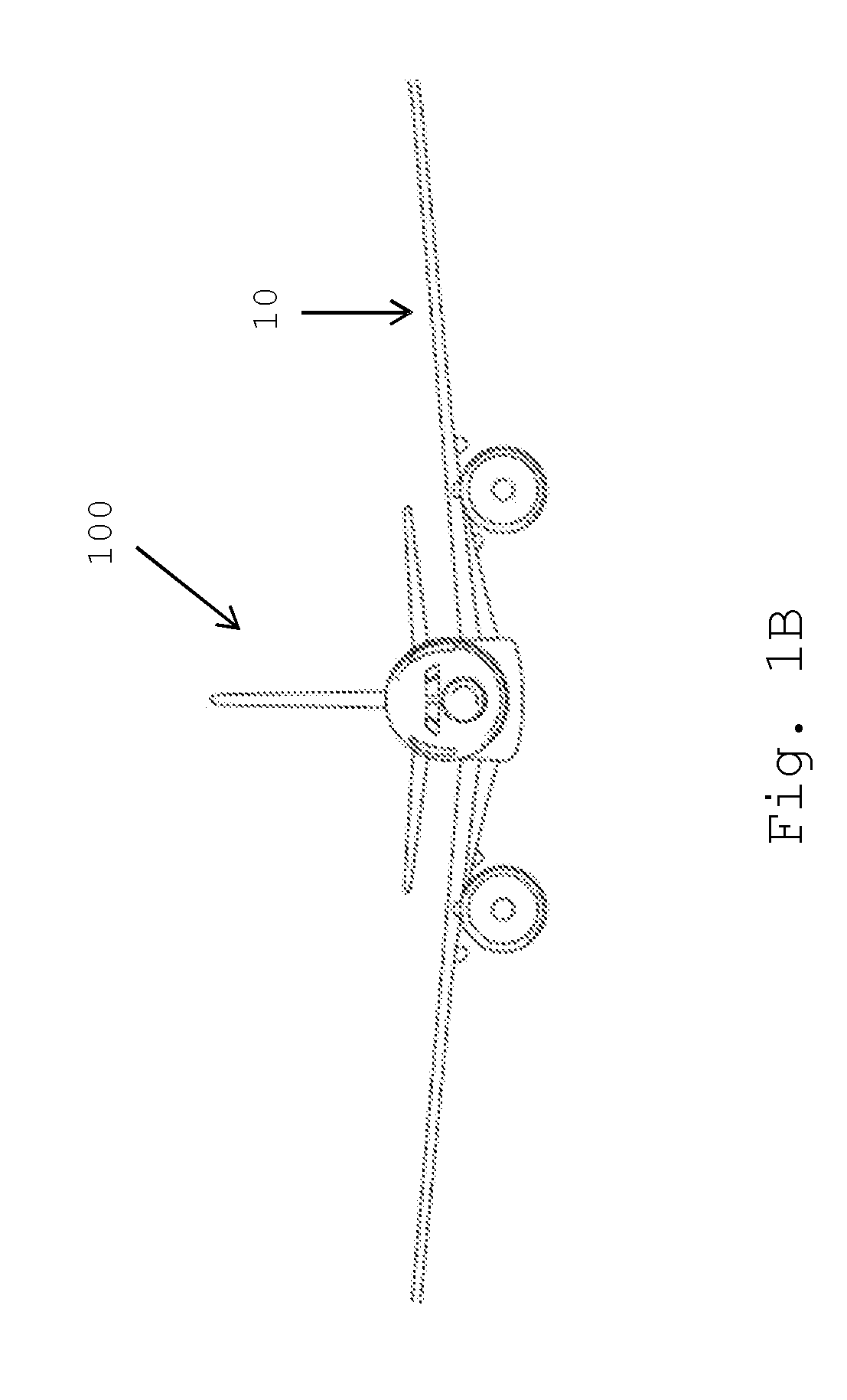

Folding wing tip and rotating locking device

ActiveUS20160332723A1Reduce chanceImproves strength and stabilityWithout power ampliicationWing adjustmentsLocking mechanismWing configuration

The invention provides an aircraft wing, comprising a fixed wing and a wing tip device at the tip. The wing tip device is configurable between: (i) a locked flight configuration for use during flight and (ii) a ground configuration for use during ground-based operations. The wing further comprises a locking mechanism for locking the folding wing tip device in the locked flight configuration. A rotatable locking member is associated with one of the folding wing tip device and the fixed wing, and a locking pin associated with the other. The rotatable locking member comprises a guide surface to guide the locking pin to a locked configuration, in which the guide surface is shaped such that the locking pin is urged toward the rotation axis of the rotatable locking member by a camming action of the guide surface on the locking pin, thereby preloading the locking mechanism.

Owner:AIRBUS OPERATIONS LTD

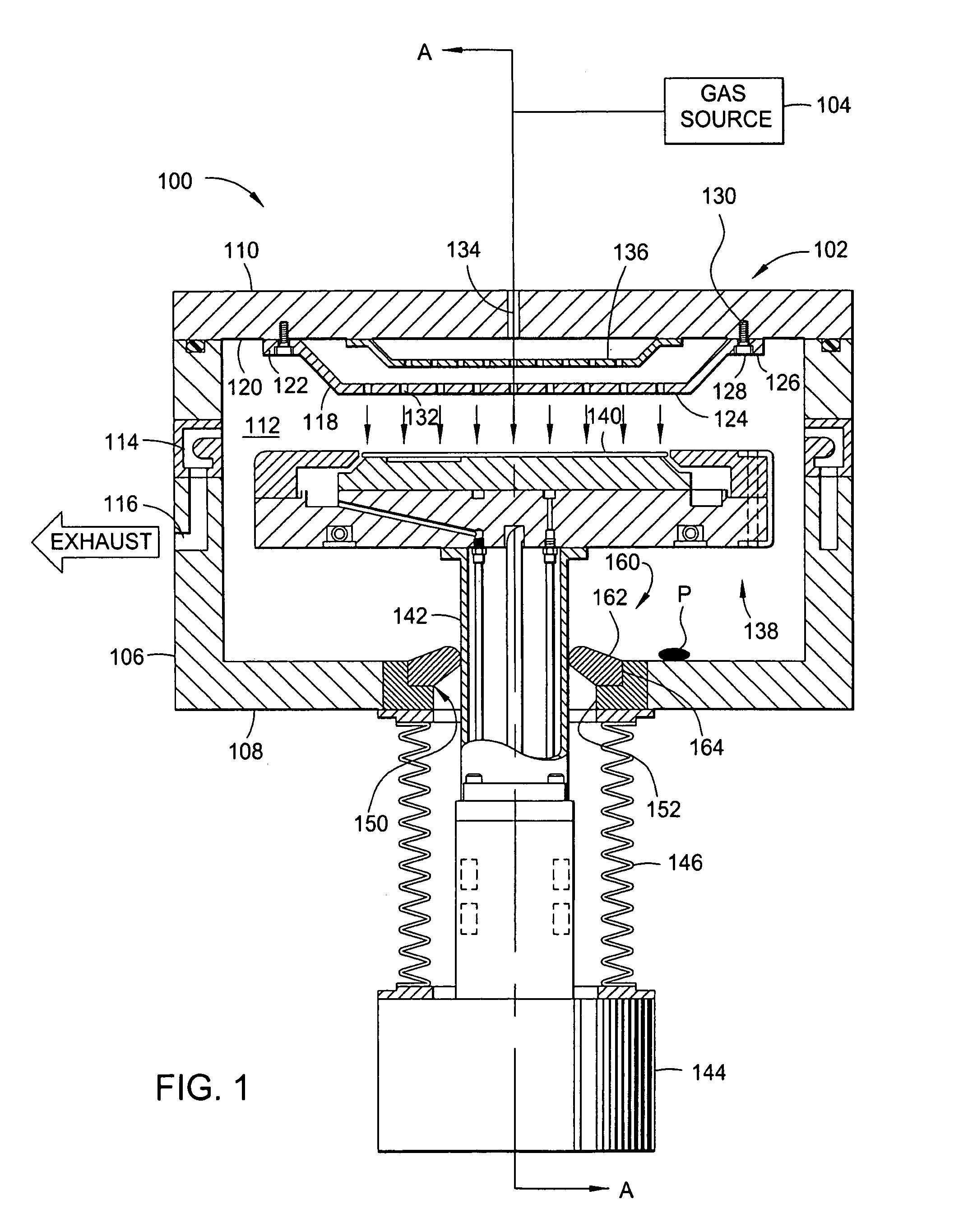

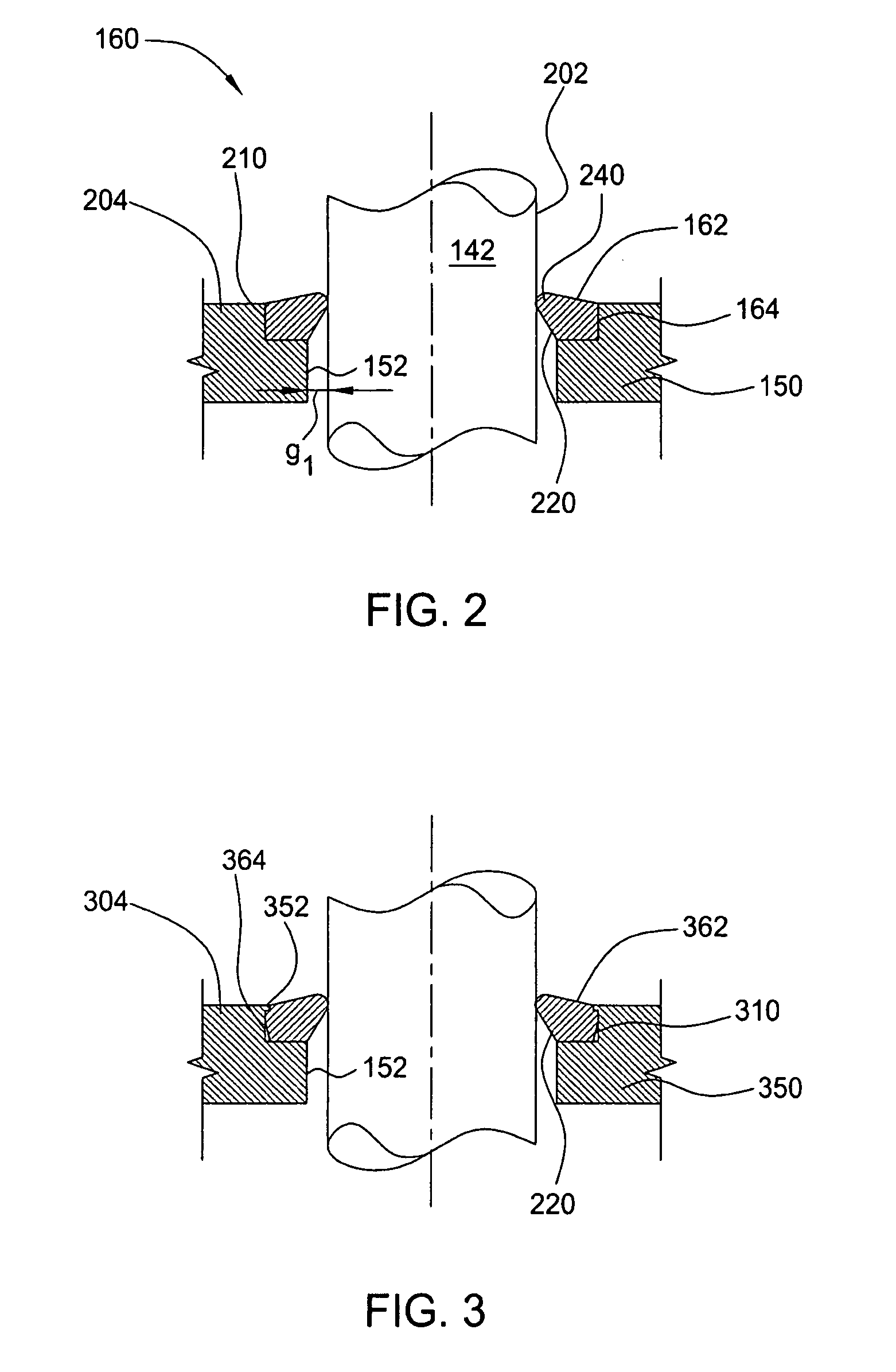

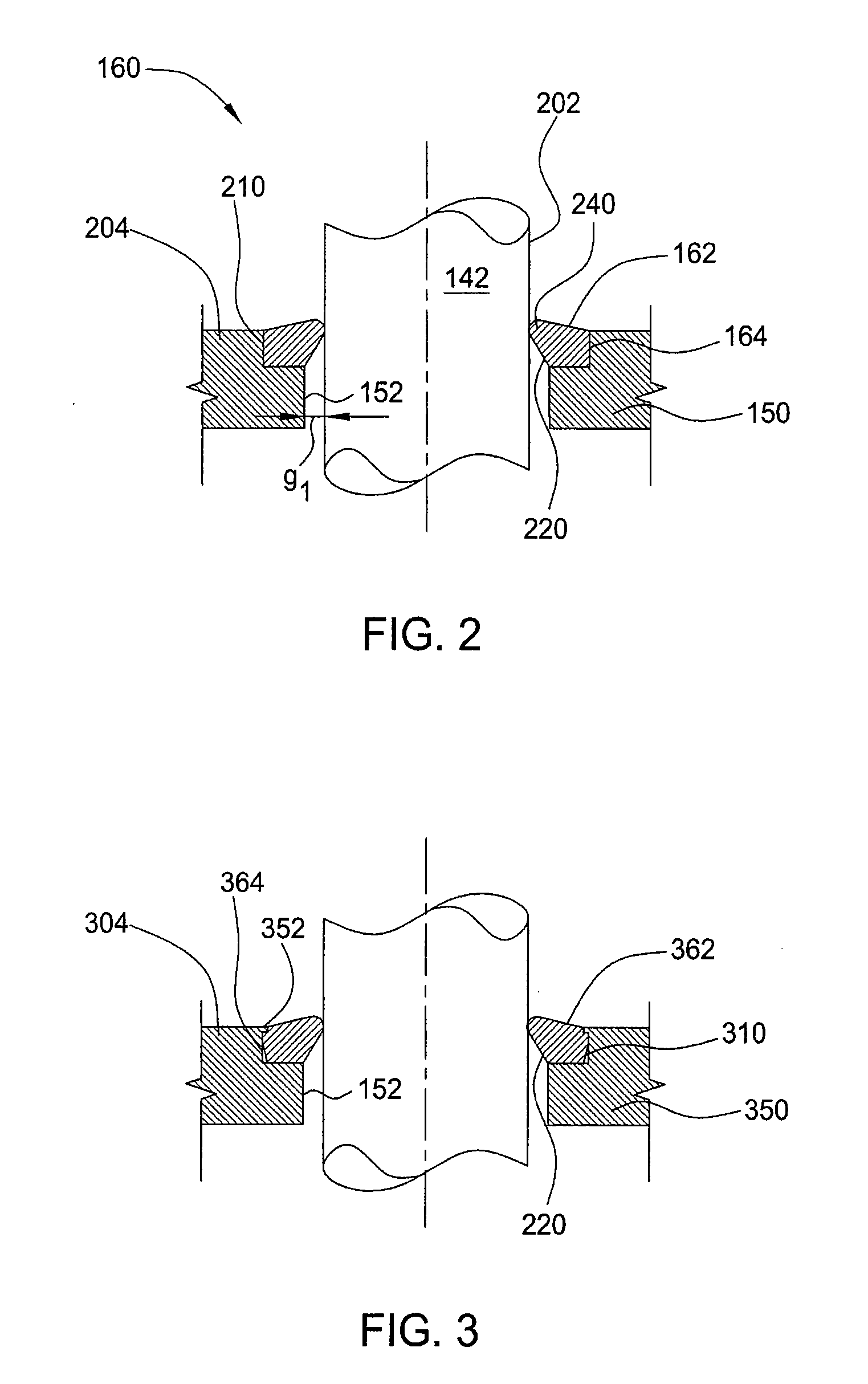

Apparatus for reducing entrapment of foreign matter along a moveable shaft of a substrate support

InactiveUS7279049B2Reduced component wearReduce entrapmentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForeign matterEngineering

In one embodiment, the invention is a guard ring for reducing particle entrapment along a moveable shaft of a substrate support. In one embodiment, the guard ring comprises a substantially annular guard ring positioned within a step formed in a sleeve that circumscribes the shaft. The guard ring is positioned to substantially seal a gap separating the shaft from the sleeve, so that the amount of particles and foreign matter that travel within or become trapped in the gap is substantially reduced. In another embodiment, a guard ring comprises a base portion having an inner perimeter and an outer perimeter, a first flange coupled to the inner perimeter, a second flange coupled to the outer perimeter, and a continuous channel separating the first flange from the second flange. The first flange is adapted to function as a spring that accommodates displacement of the shaft.

Owner:APPLIED MATERIALS INC

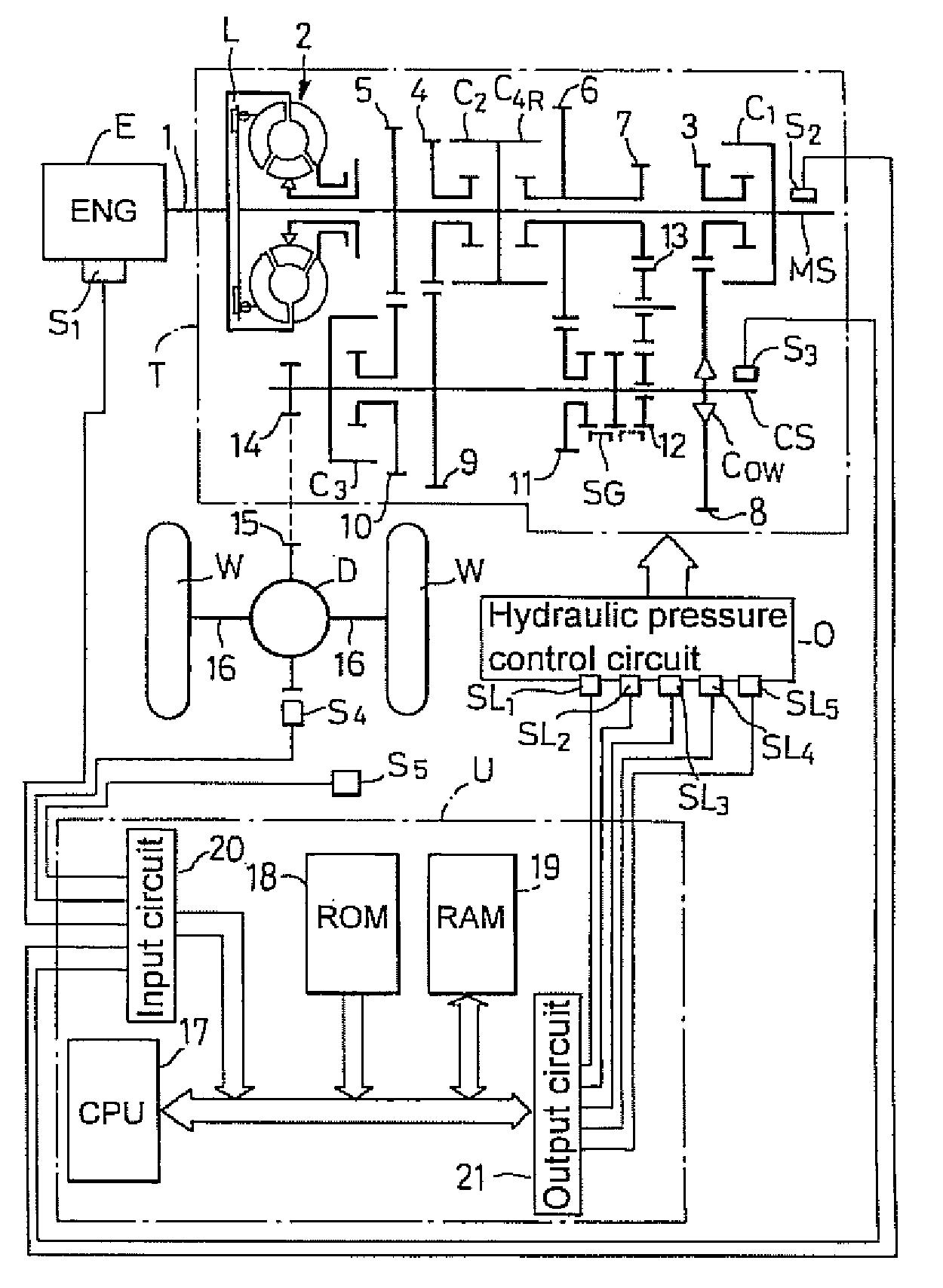

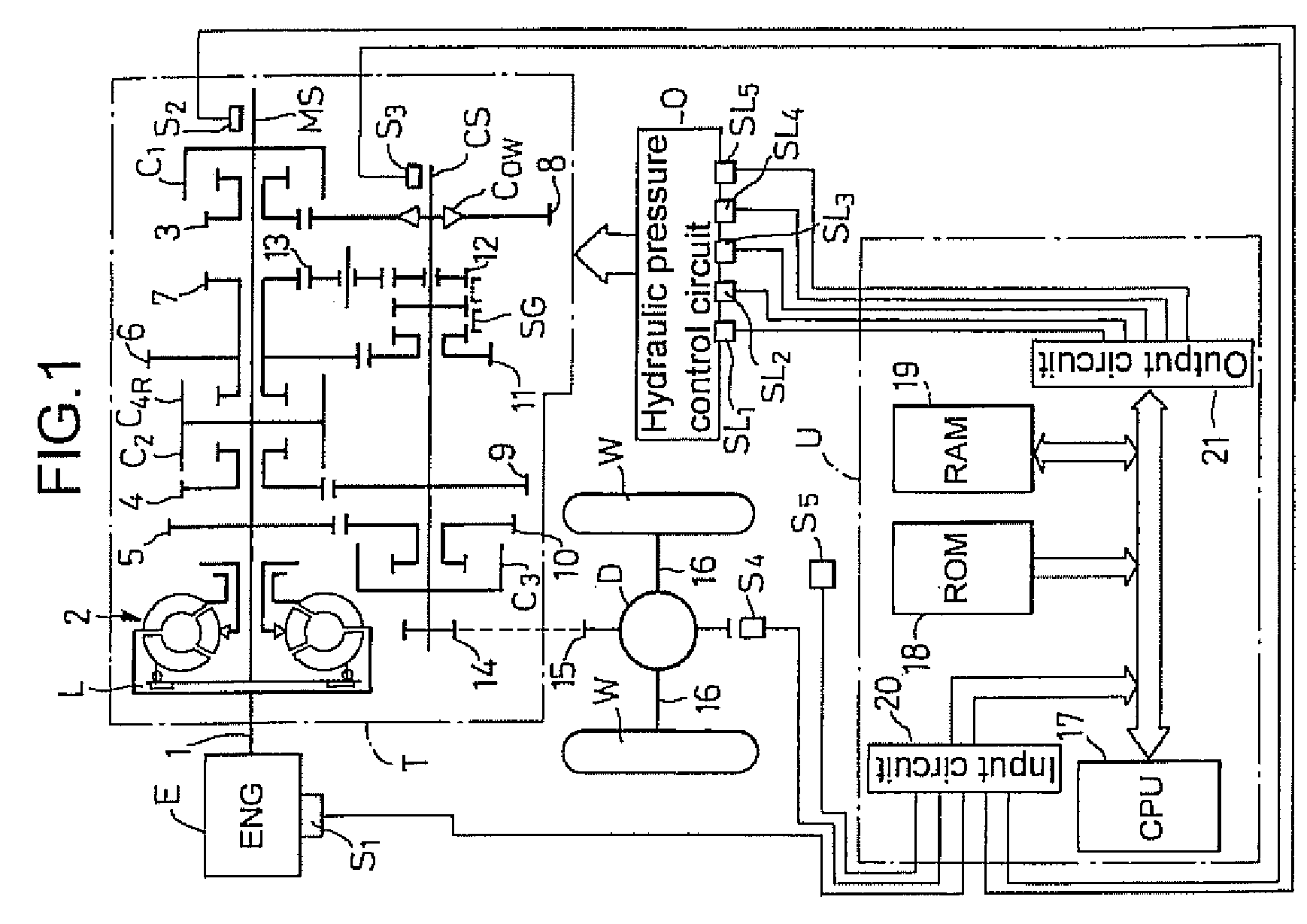

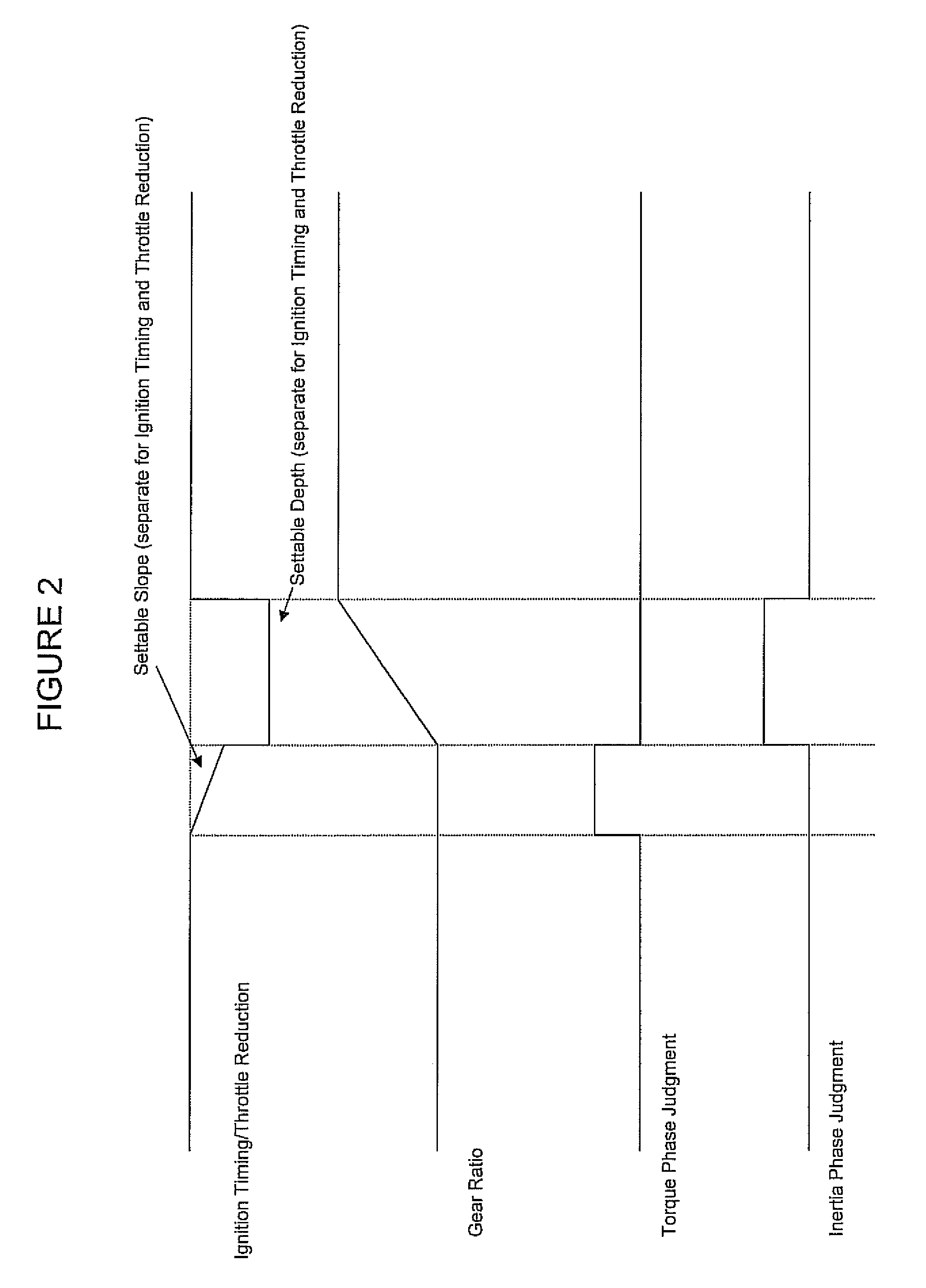

Engine power reduction during automatic transmission shifting

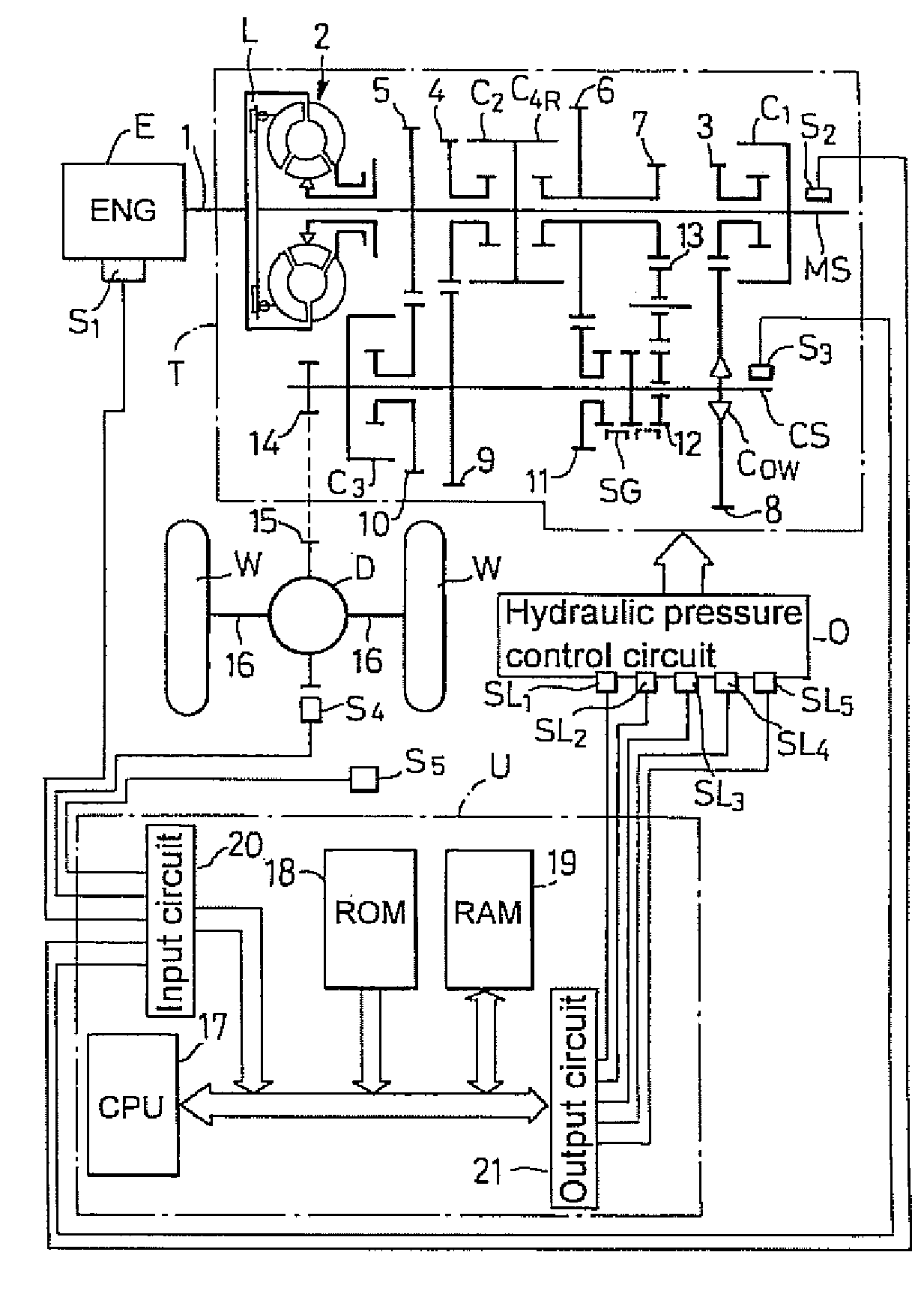

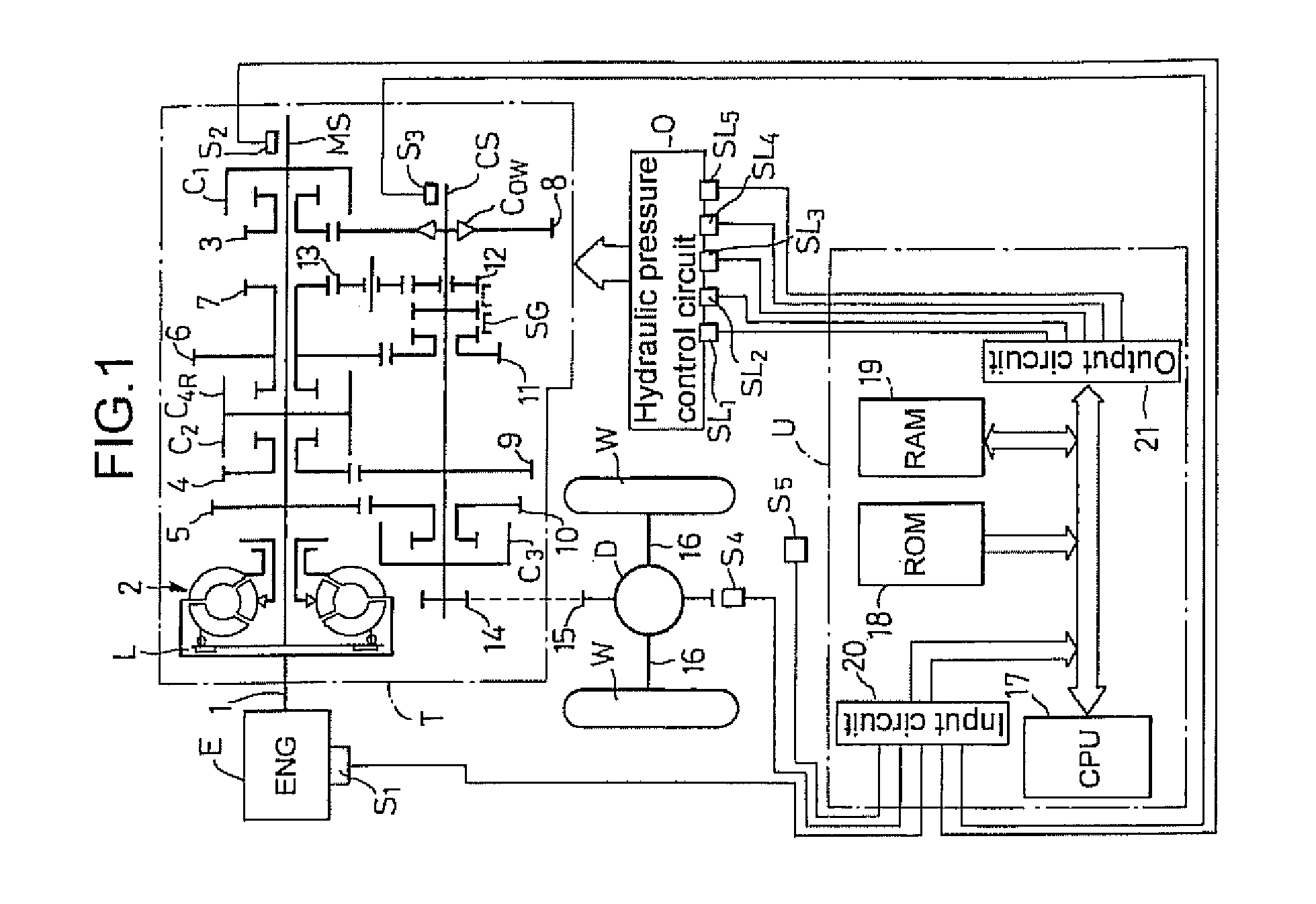

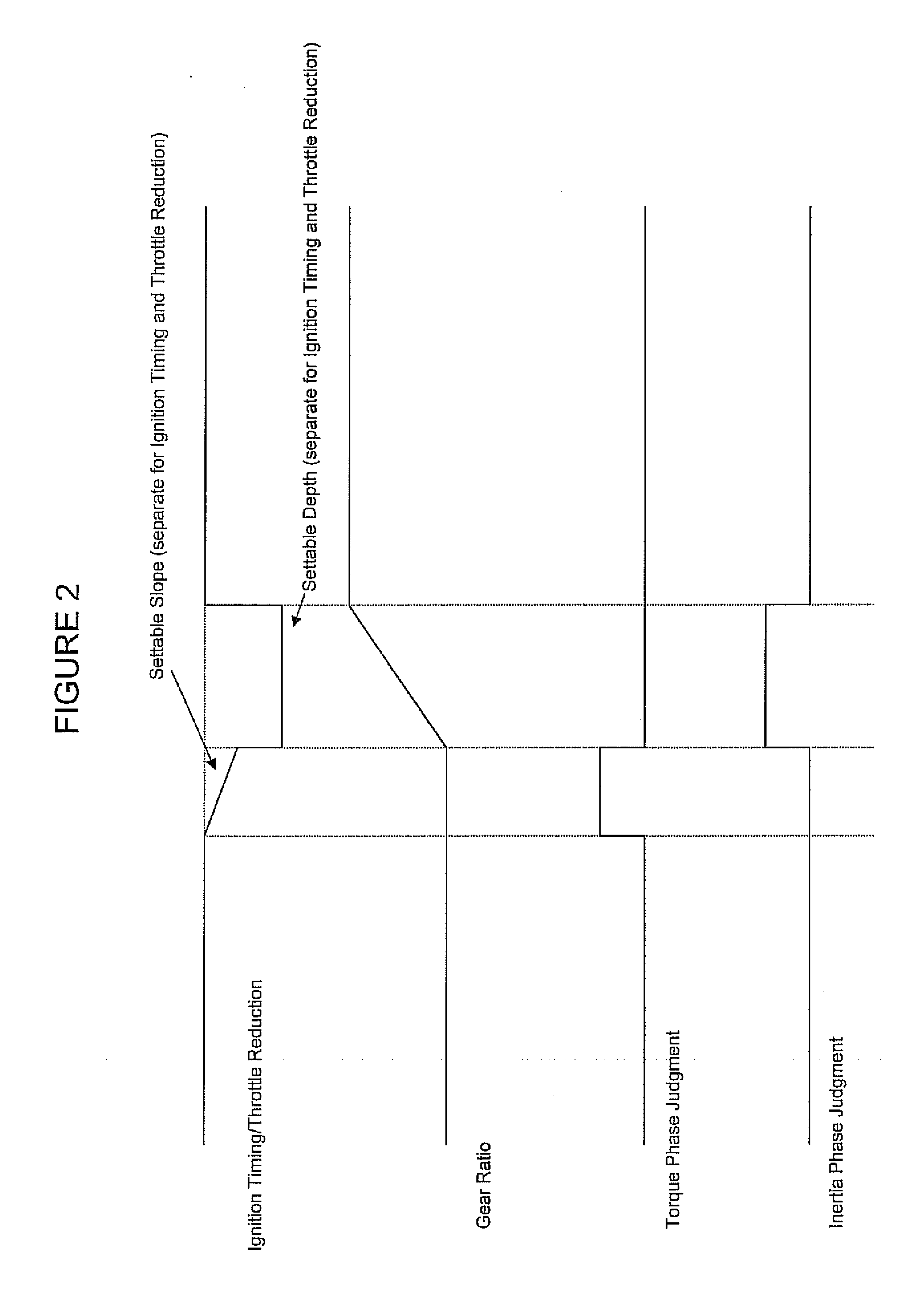

InactiveUS7762925B2Reduce the required powerIncrease powerHybrid vehiclesDigital data processing detailsAutomatic transmissionEngineering

An engine's power may be gradually reduced during a torque phase of a clutch-to-clutch up-shift within an automatic transmission and then reduced fully during a subsequent inertia phase.

Owner:HONDA MOTOR CO LTD

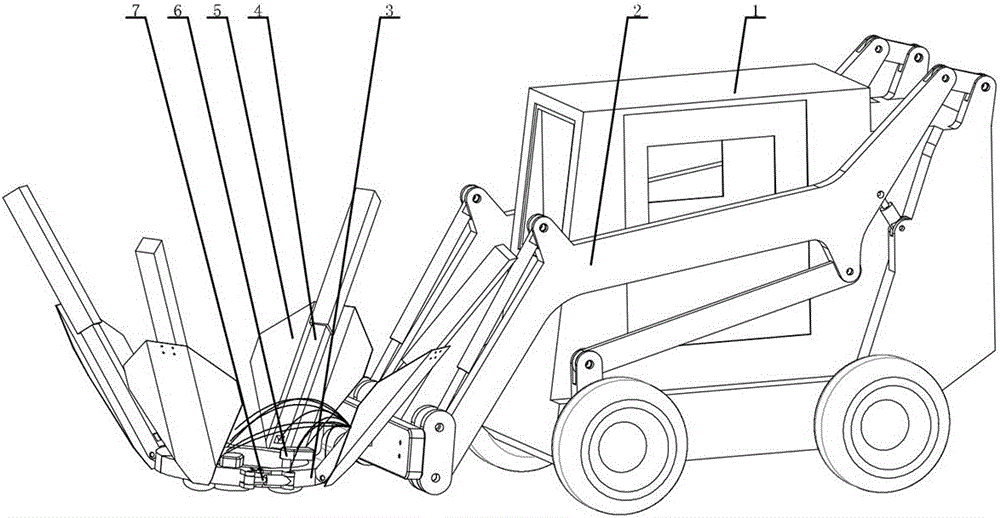

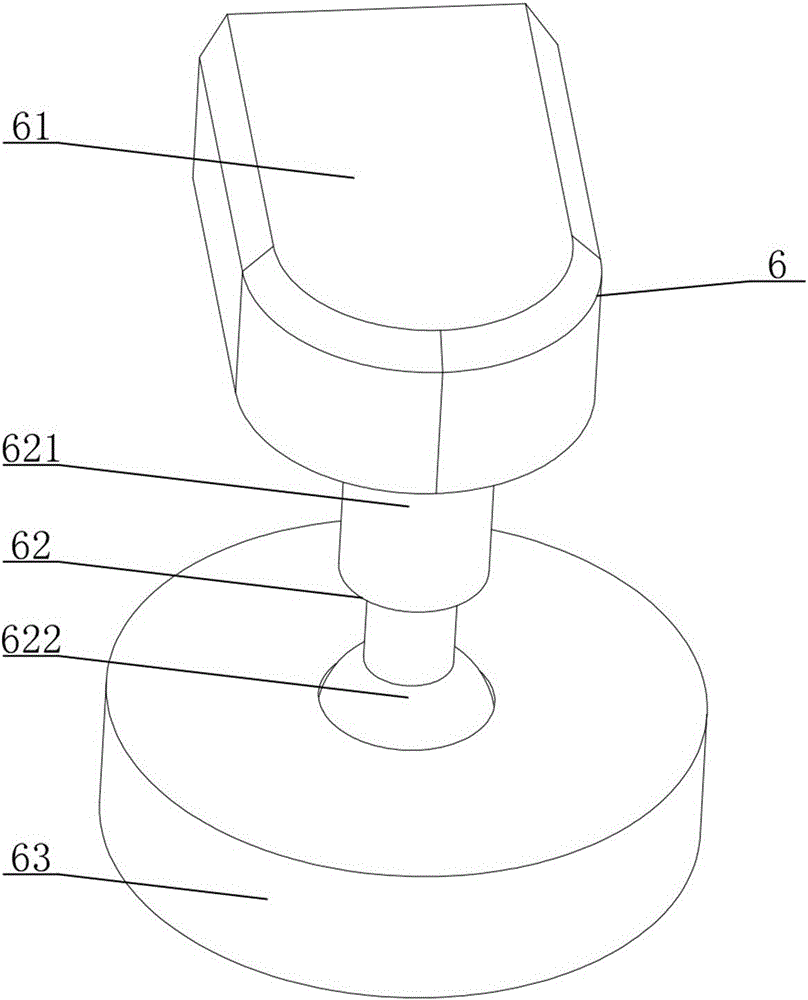

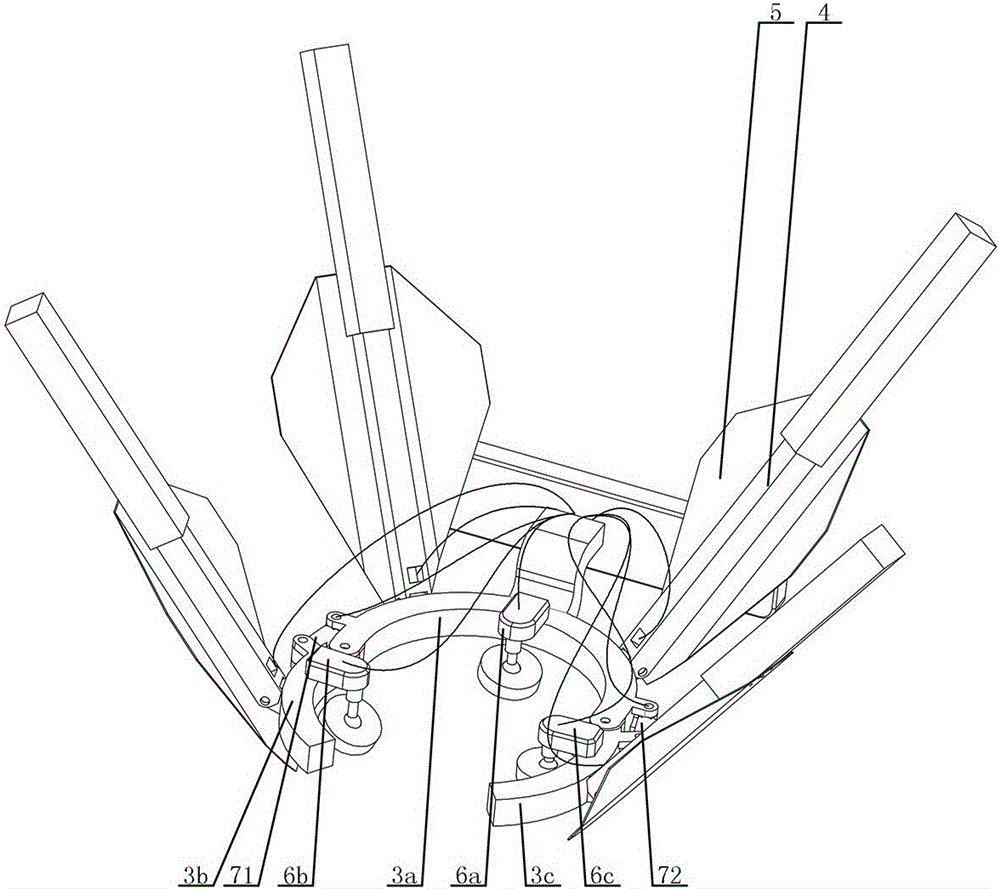

Adjustable shovel guide rail bracket of tree moving machine

The invention provides an adjustable shovel guide rail bracket of a tree moving machine. The adjustable shovel guide rail bracket comprises a shovel guide rail bracket body, wherein the shovel guide rail bracket body comprises a fixed front frame, a first rotary rear frame and a second rotary rear frame; the first rotary rear frame and the second rotary rear frame are hinged to the fixed front frame respectively; the adjustable shovel guide rail bracket further comprises at least three groups of leveling mechanisms; each leveling mechanism comprises a leveling hydraulic cylinder fixed block, a leveling hydraulic cylinder and a leveling cushion; the leveling hydraulic cylinder fixed blocks are arranged on the shovel guide rail bracket body; cylinder barrel ends of the leveling hydraulic cylinders are arranged on the leveling hydraulic cylinder fixed blocks; piston rod ends of the leveling hydraulic cylinders are hinged to the leveling cushions; and the leveling cushions do up-down movement through the leveling hydraulic cylinders. According to the adjustable shovel guide rail bracket of the tree moving machine, provided by the invention, at least three groups of the leveling mechanisms are coordinated, so that the shovel guide rail bracket body can still keep horizontal under the leveling effect of the leveling mechanisms; and the problems that the machine is inclined and a soil ball swings and the like when the machine works on an inclined ground are solved.

Owner:ZHEJIANG SAFUN IND +1

Intelligent Molding Environment and Method of Controlling Applied Clamp Tonnage

InactiveUS20080279974A1Easy to operate and controlReduced component wearAuxillary shaping apparatusInjection pressureClosed loop

Owner:HUSKY INJECTION MOLDING SYST LTD

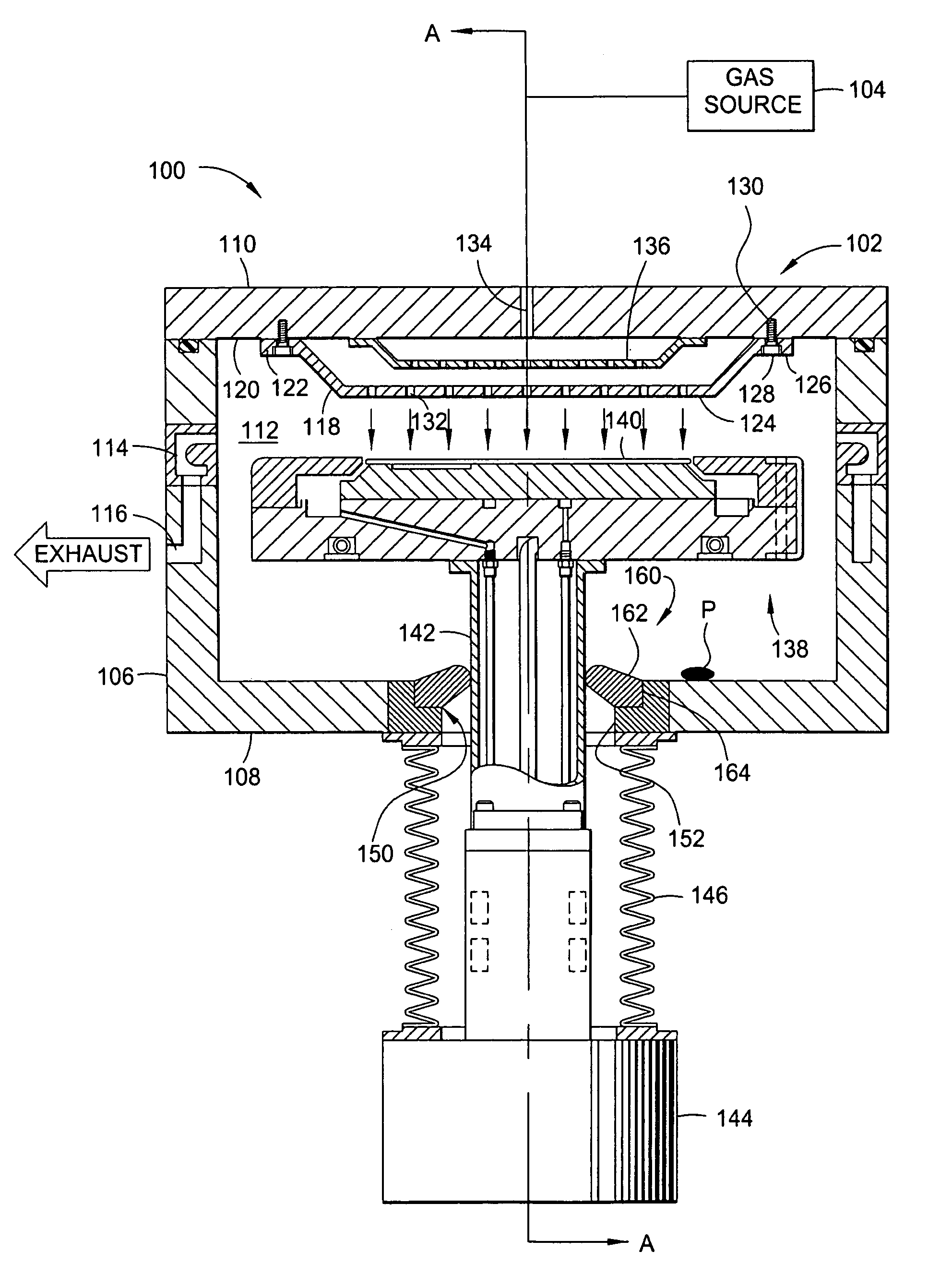

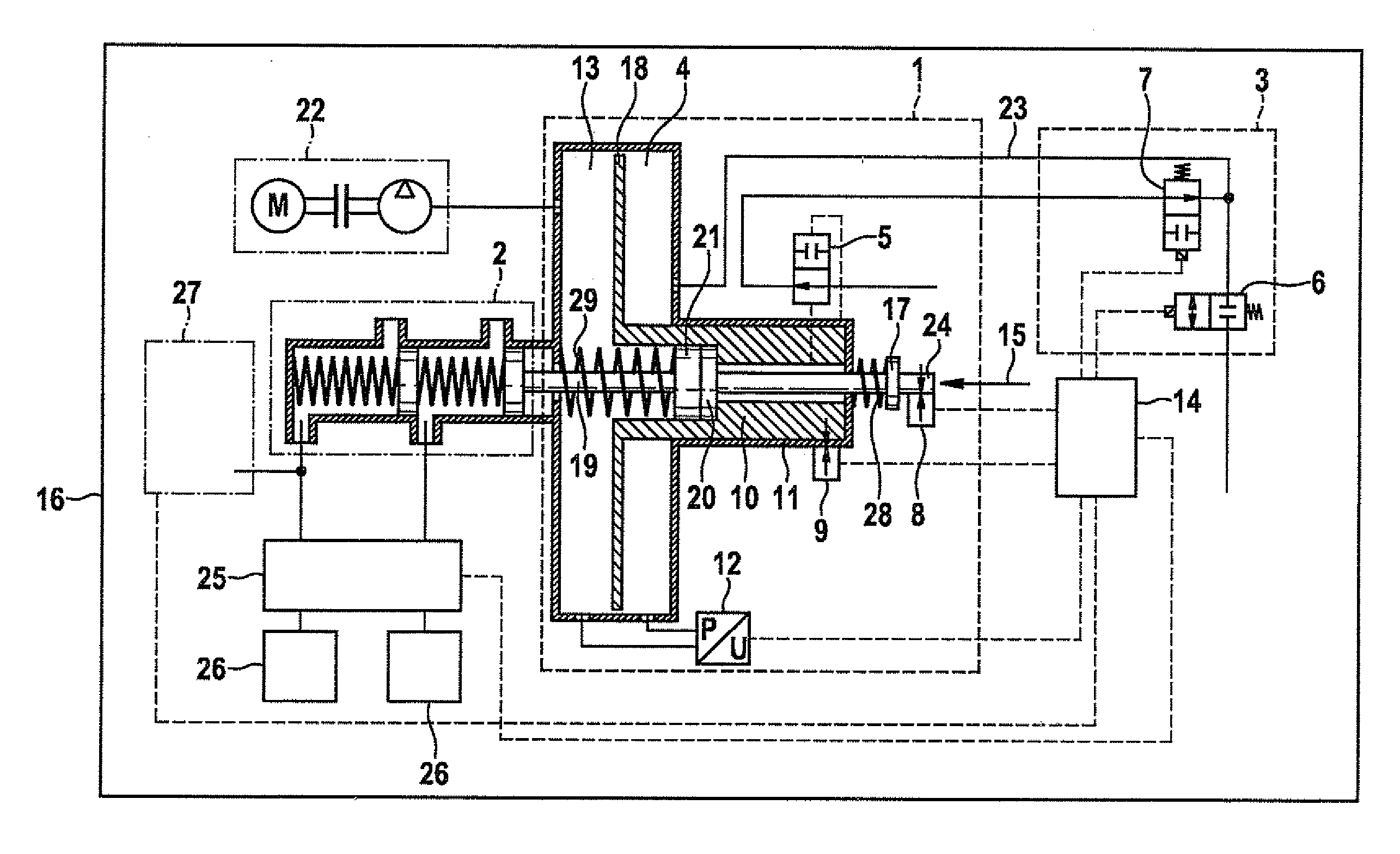

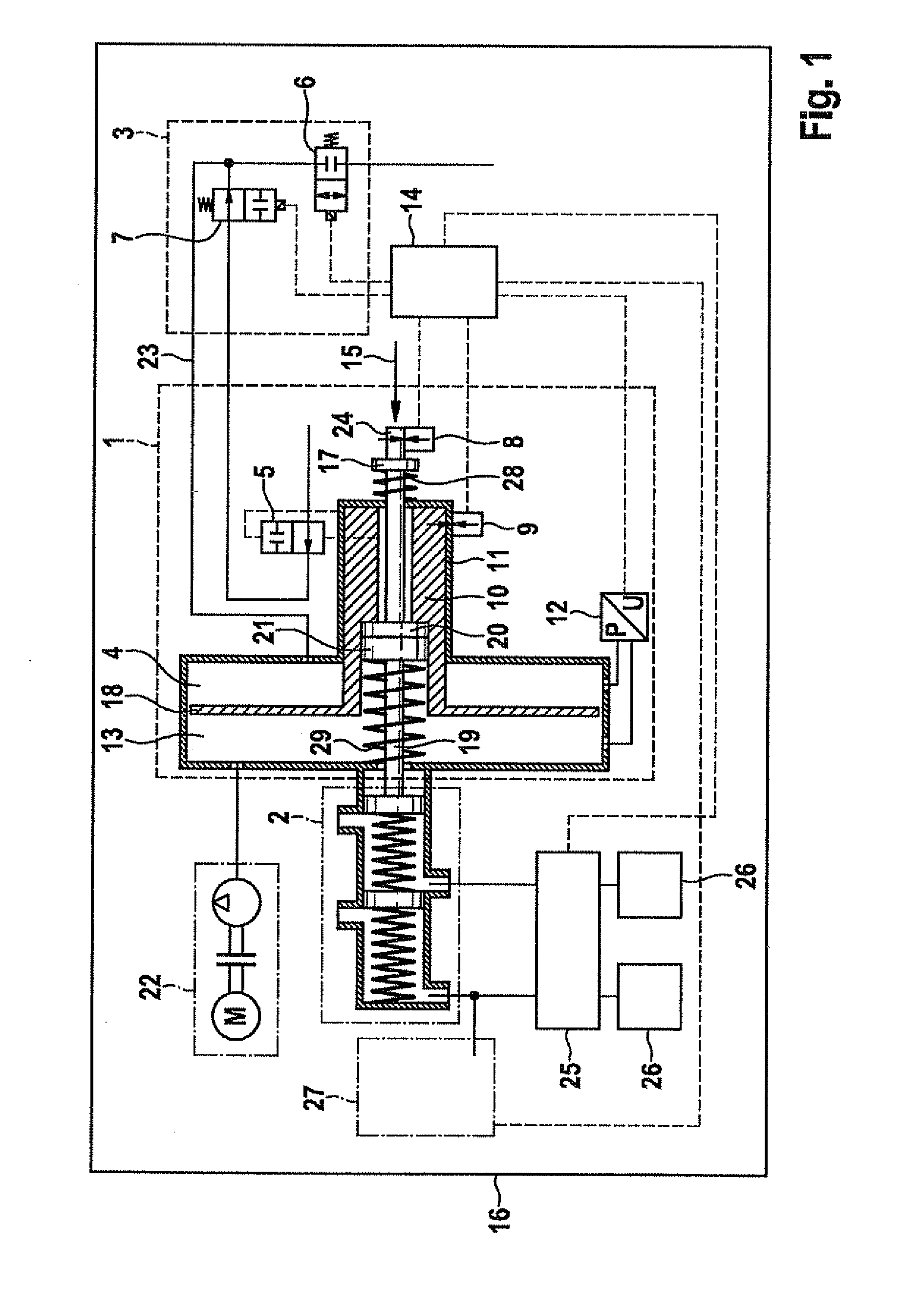

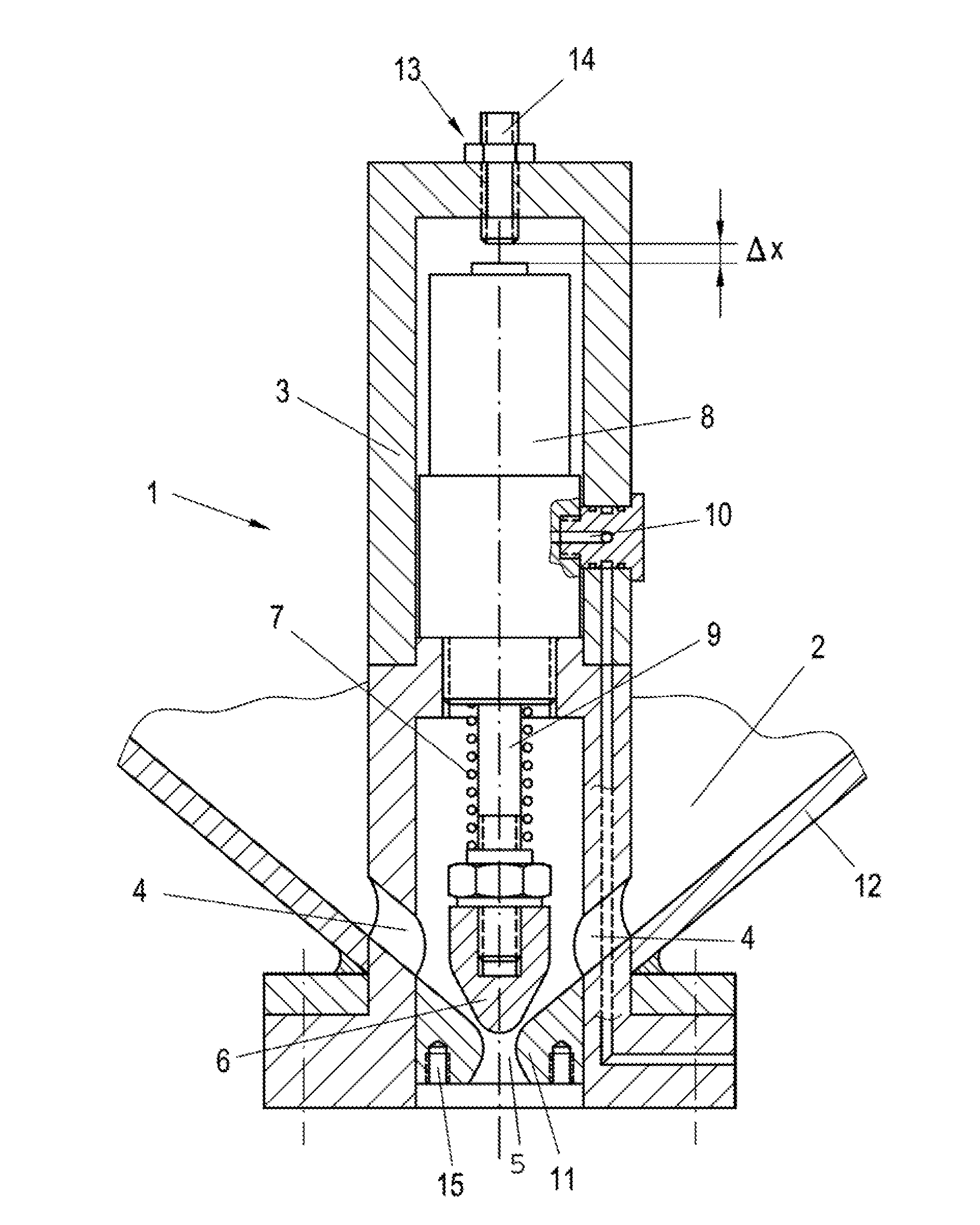

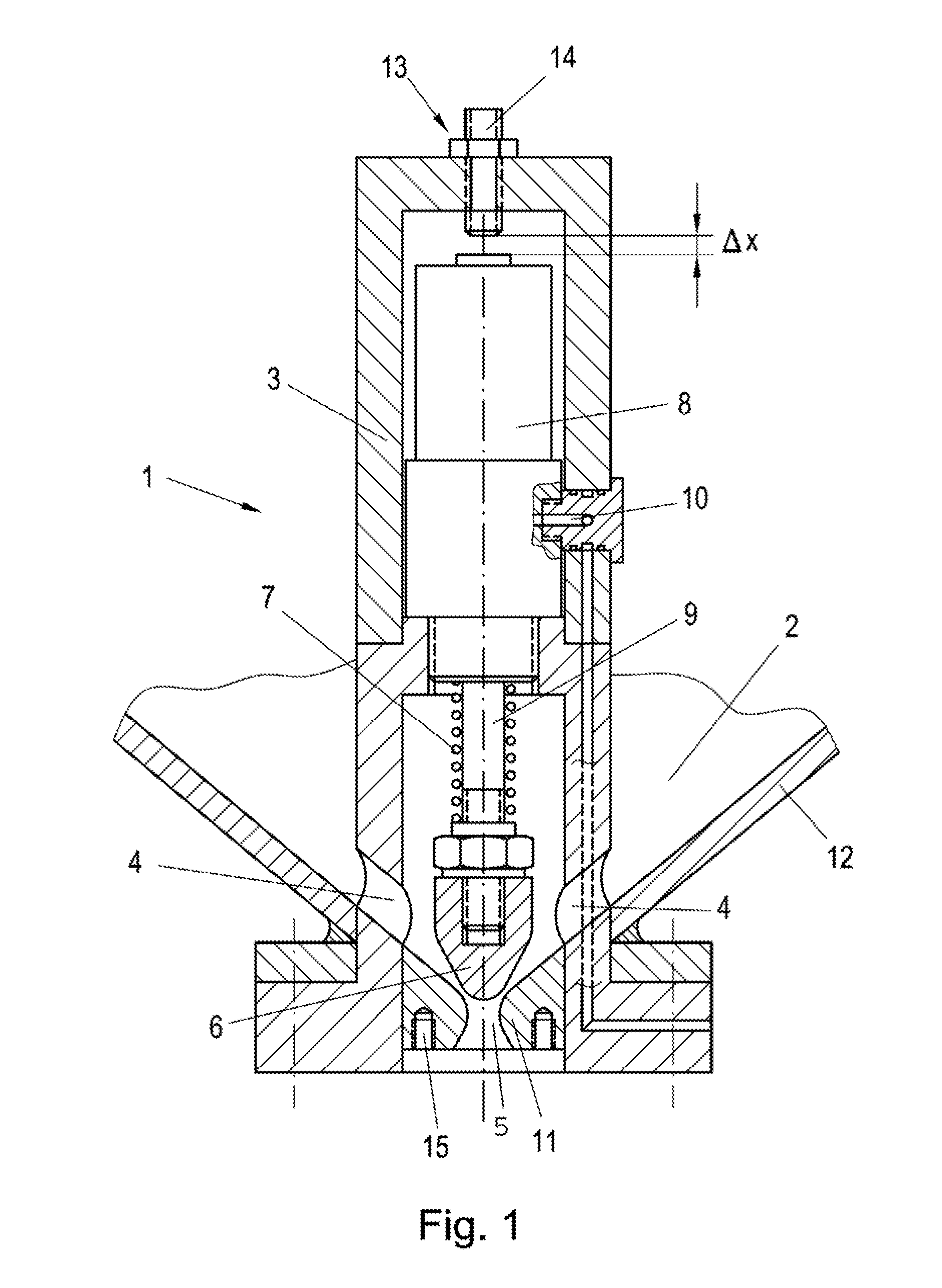

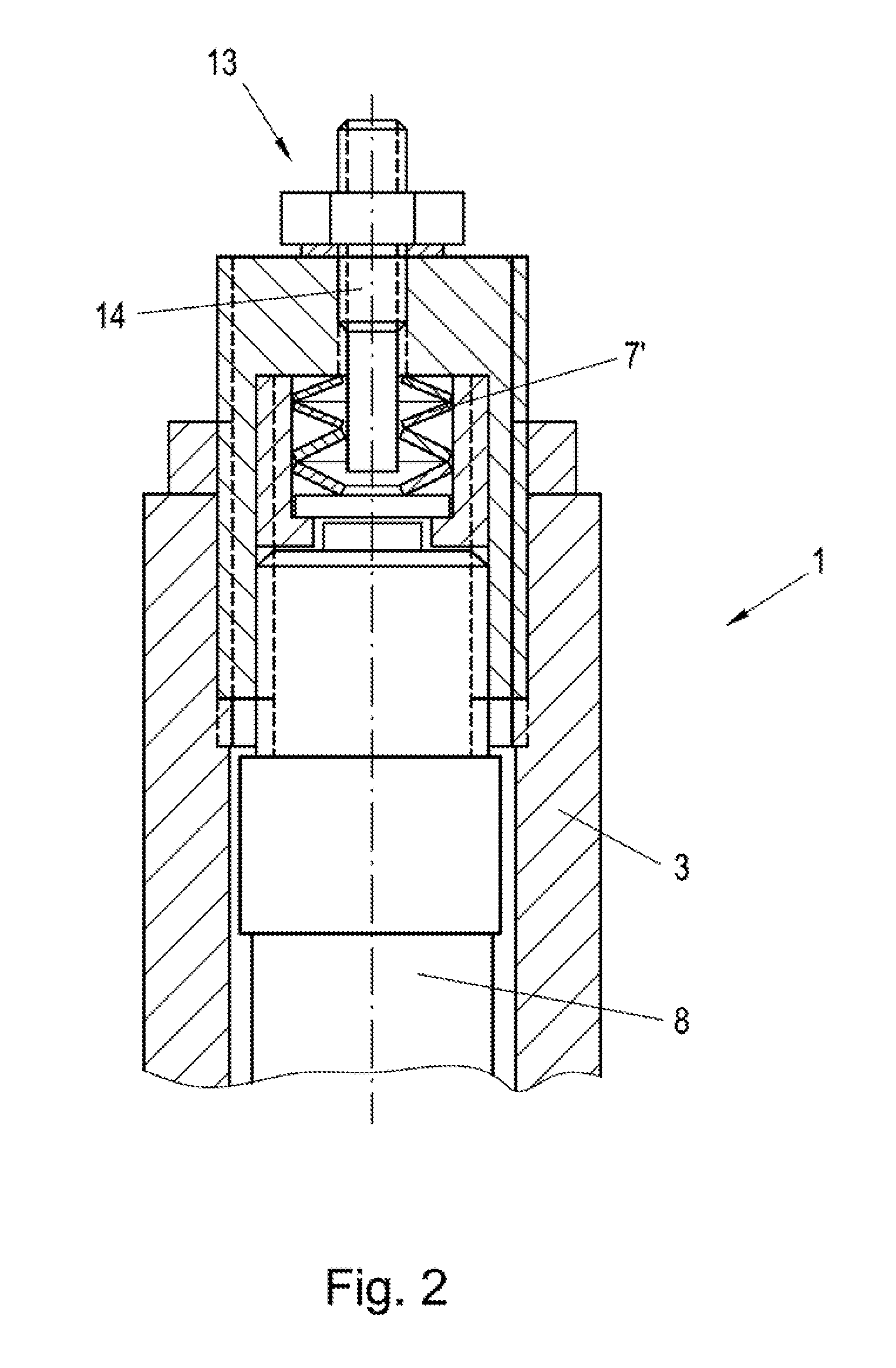

Controllable pneumatic brake booster and method for operating it

InactiveUS20120222745A1Reduced component wearReduce wearServomotor componentsServomotorsAutomotive engineeringMaster cylinder

Owner:ROBERT BOSCH GMBH

Measuring device for measuring consistency of cement slurry for a consistometer

InactiveUS20120024046A1High indexImprove performanceFlow propertiesMaterial testing goodsEngineeringCement slurry

This present invention relates to a measuring device for measuring consistency of cement slurry for a consistometer. The measuring device comprises a high-pressure vessel, a slurry cup and a magnetic driver, wherein the slurry cup is rotatably mounted inside the high-pressure vessel by the magnetic driver, stir blades are hanged in the slurry cup, and the magnetic driver is driven by a driving motor which is located outside the high-pressure vessel and is further provided with a tension sensor. The invention cancels the conventional mode for measuring consistency by a potentiometer, uses the tension sensor to measure the torque transferred from the driving motor to the magnetic driver, i.e. the cutting torque created by the stir blades on cement slurries within the slurry cup, thereby measuring the consistency of cement slurry.

Owner:CHINA OILFIELD SERVICES +1

Engine power reduction during automatic transmission shifting

InactiveUS20080156552A1Reduce the required powerIncrease powerHybrid vehiclesDigital data processing detailsAutomatic transmissionEngine power

An engine's power may be gradually reduced during a torque phase of a clutch-to-clutch up-shift within an automatic transmission and then reduced fully during a subsequent inertia phase.

Owner:HONDA MOTOR CO LTD

System and method for lubricating power transmitting elements

InactiveUS8312858B2Reduced component wearExtended service lifeLubrication of auxillariesDrip or splash lubricationTransmitted powerEngineering

A lubrication system and method are disclosed. The system includes a main engine bearing and a crankshaft in operational association with the bearing. The crankshaft includes an end having a cavity with a power transmitting element (e.g., splines). The cavity can receive and engage a mating mechanism to transmit power thereto. The crankshaft further includes a first oil passage that is disposed within the end and a second oil passage that extends from the main engine bearing into the crankshaft. The first oil passage intersects the second oil passage. The system can also include a pump mechanism for circulating lubricating oil from the main engine bearing to the crankshaft through the second oil passage and the first oil passage, and to the cavity to lubricate the power transmitting element. During engine operation, a constant supply of lubricating oil can be provided to the power transmitting element to reduce component wear.

Owner:KOHLER CO

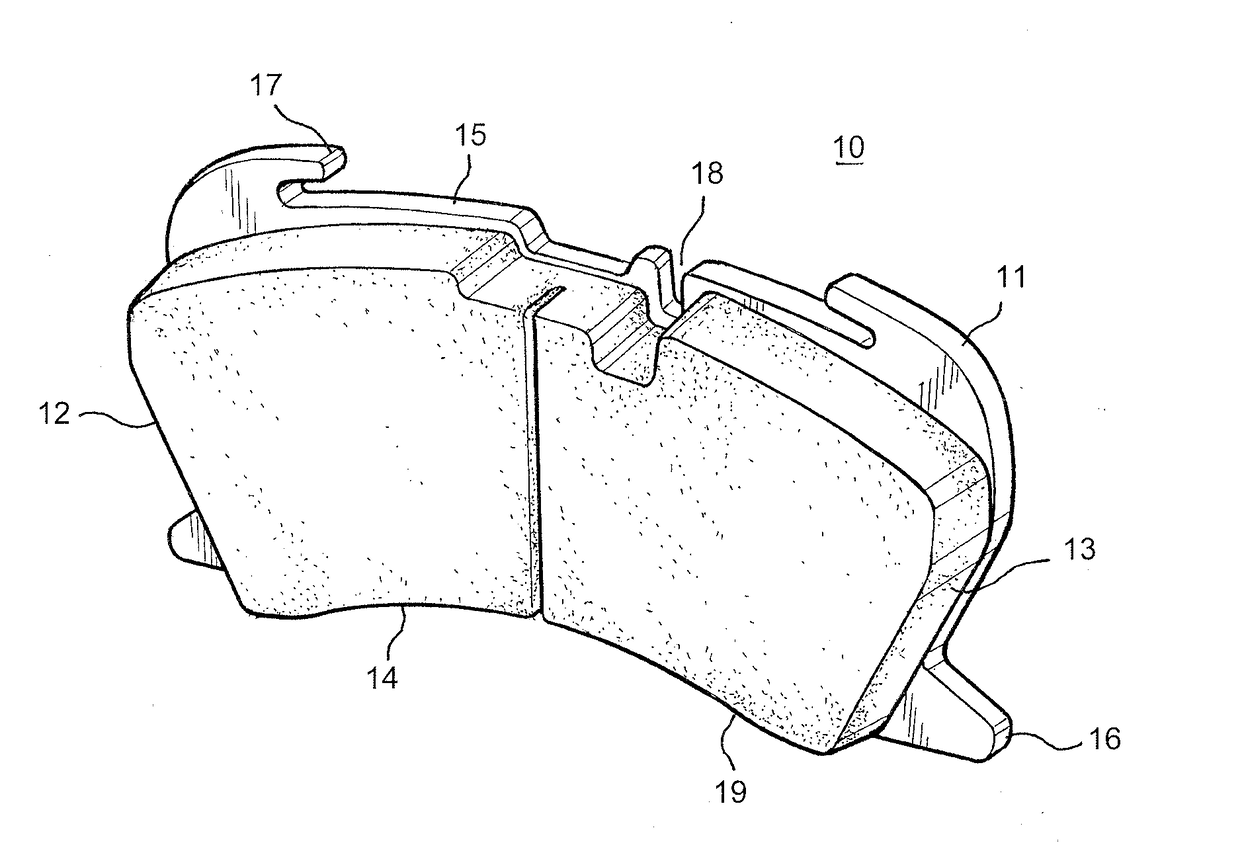

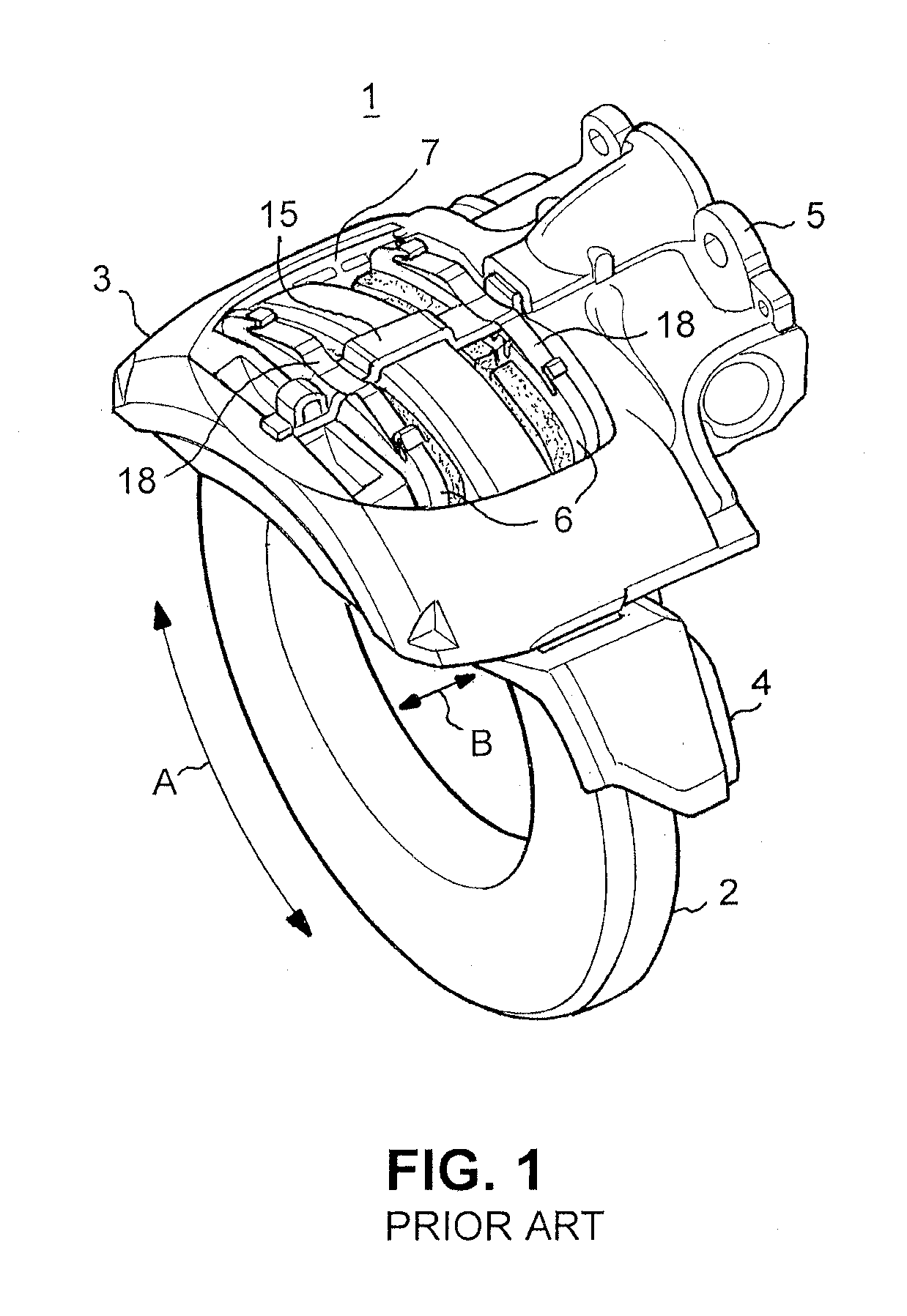

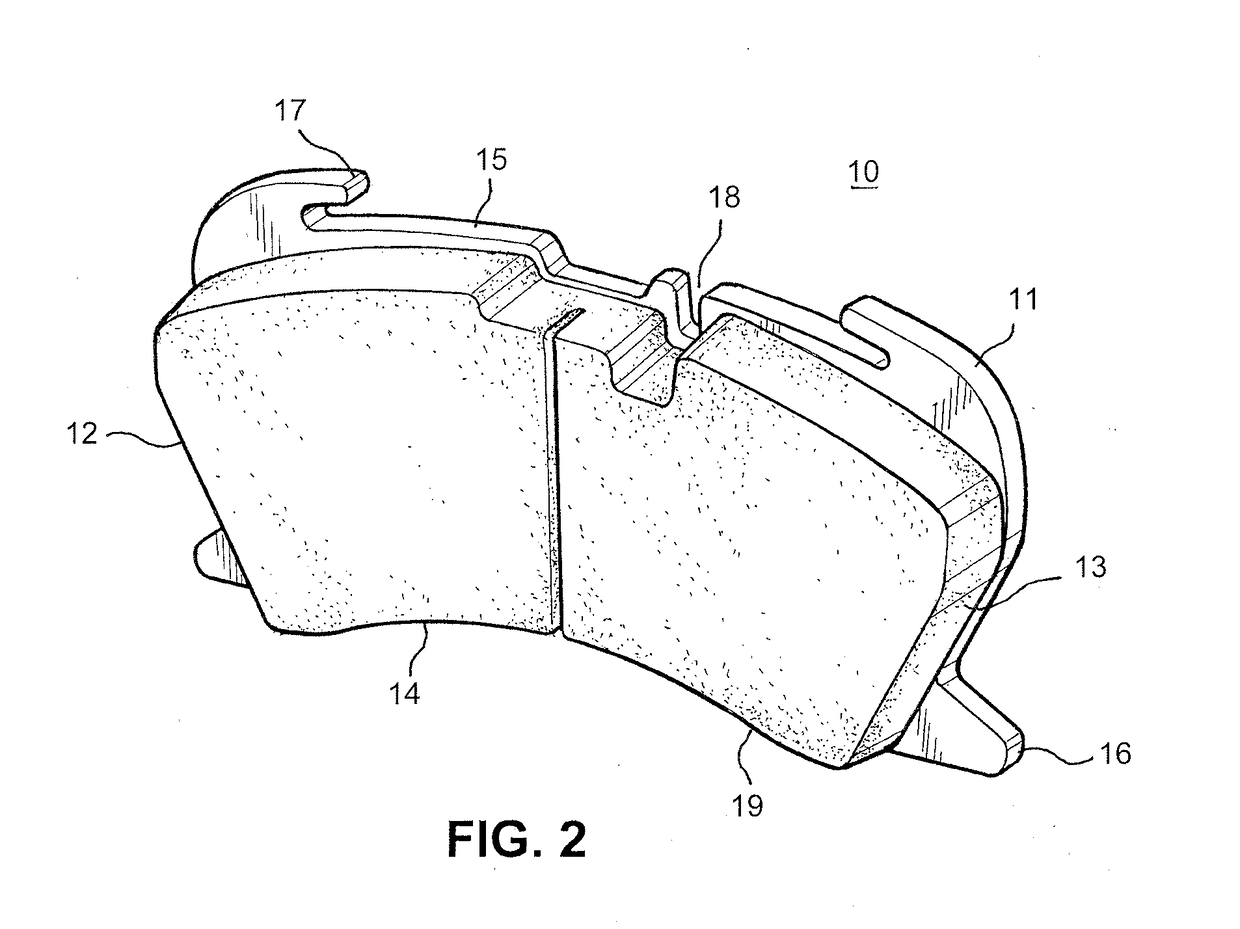

Wear Optimized Pad Design

ActiveUS20170067520A1Reduce wearReduce widthBraking element arrangementsAxially engaging brakesDisc brakeEngineering

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

Folding wing tip and rotating locking device

ActiveUS10227128B2Reduce chanceImproves strength and stabilityInfluencers by generating vorticesWing adjustmentsLocking mechanismEngineering

The invention provides an aircraft wing, comprising a fixed wing and a wing tip device at the tip. The wing tip device is configurable between: (i) a locked flight configuration for use during flight and (ii) a ground configuration for use during ground-based operations. The wing further comprises a locking mechanism for locking the folding wing tip device in the locked flight configuration. A rotatable locking member is associated with one of the folding wing tip device and the fixed wing, and a locking pin associated with the other. The rotatable locking member comprises a guide surface to guide the locking pin to a locked configuration, in which the guide surface is shaped such that the locking pin is urged toward the rotation axis of the rotatable locking member by a camming action of the guide surface on the locking pin, thereby preloading the locking mechanism.

Owner:AIRBUS OPERATIONS LTD

Apparatus for reducing entrapment of foreign matter along a moveable shaft of a substrate support

InactiveUS20080017115A1Reduced component wearReduce entrapmentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingForeign matterEntrapment

In one embodiment, the invention is a guard ring for reducing particle entrapment along a moveable shaft of a substrate support. In one embodiment, the guard ring comprises a substantially annular guard ring positioned within a step formed in a sleeve that circumscribes the shaft. The guard ring is positioned to substantially seal a gap separating the shaft from the sleeve, so that the amount of particles and foreign matter that travel within or become trapped in the gap is substantially reduced. In another embodiment, a guard ring comprises a base portion having an inner perimeter and an outer perimeter, a first flange coupled to the inner perimeter, a second flange coupled to the outer perimeter, and a continuous channel separating the first flange from the second flange. The first flange is adapted to function as a spring that accommodates displacement of the shaft.

Owner:APPLIED MATERIALS INC

Metering device for granular material

ActiveUS20160332639A1The way is simple and fastImprove braking effectLiquid surface applicatorsOperating means/releasing devices for valvesEngineeringPiston

A metering device for granular material, includes a housing that can be arranged inside a container for the granular material. The housing has at least one inlet for the granular material and an outlet, which outlet can be closed by a sealing element. The sealing element is arranged on a metering piston, which is preloaded by a spring and can be moved axially in a compressed-air cylinder, wherein a compressed-air connection is provided on the compressed-air cylinder such that the metering piston can be moved against the spring by compressed air and the outlet can be opened, and the spring has an at least two-stage design such that the stroke of the metering piston can be changed at least in two stages by varying the compressed air.

Owner:NOWE

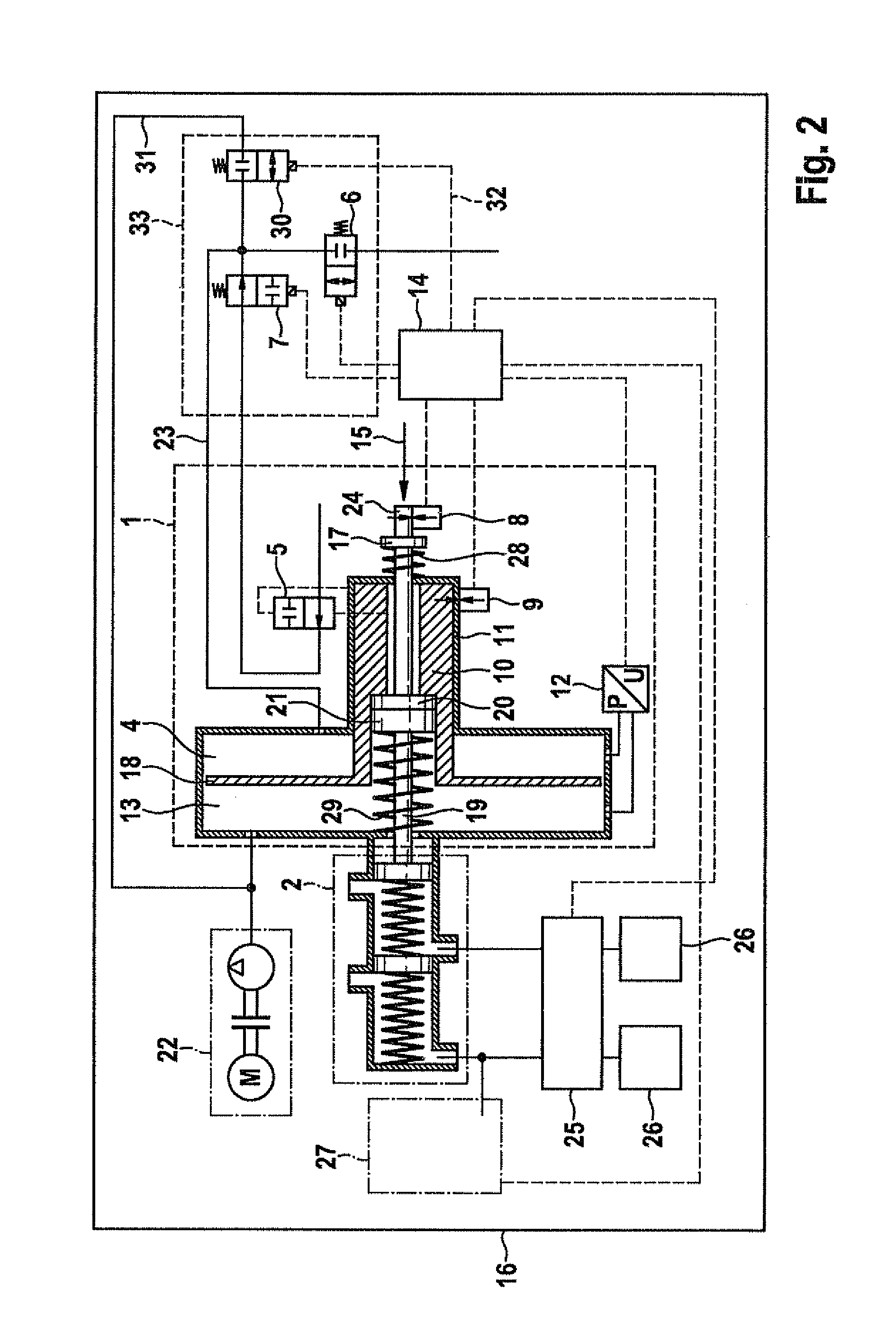

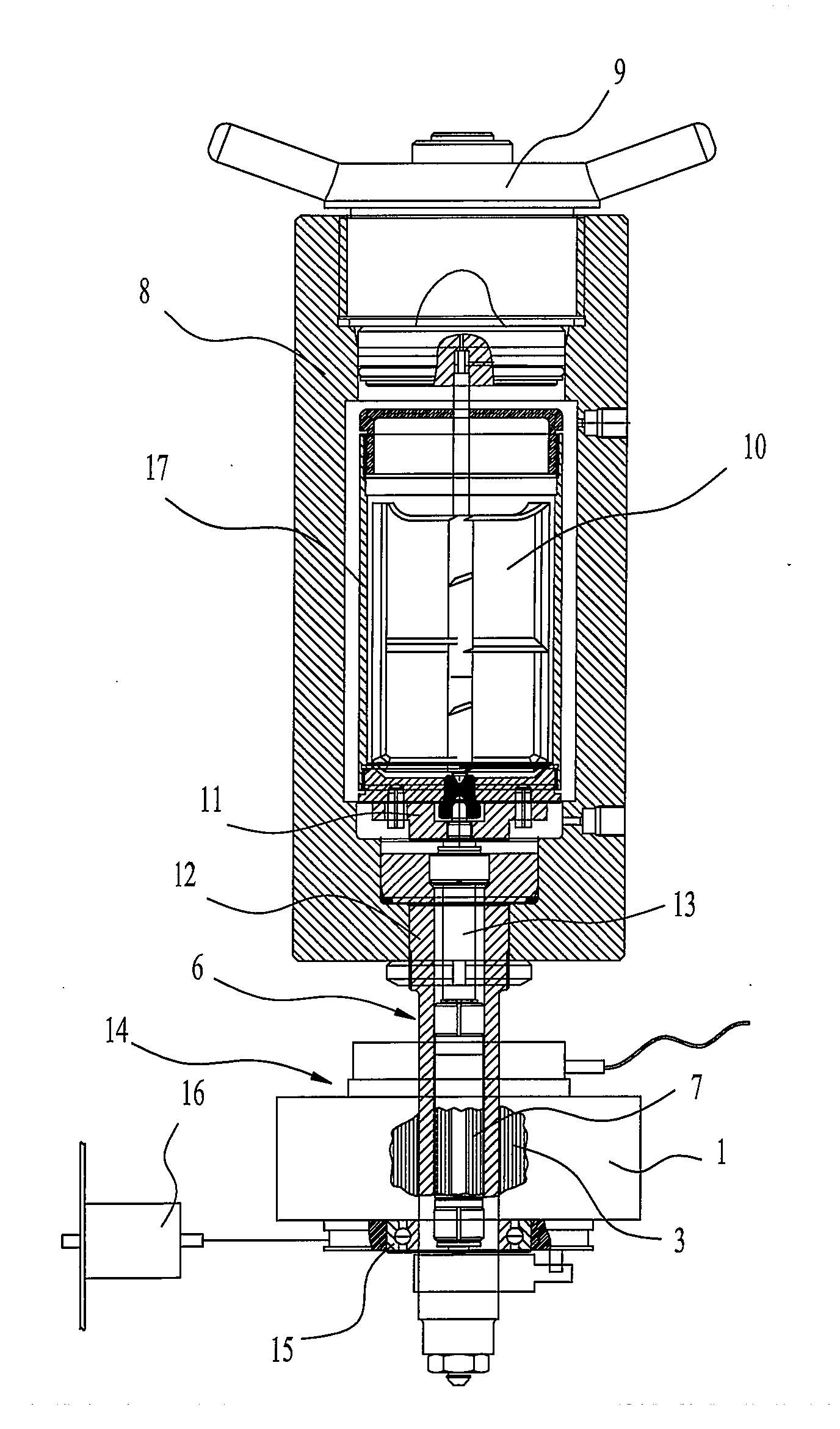

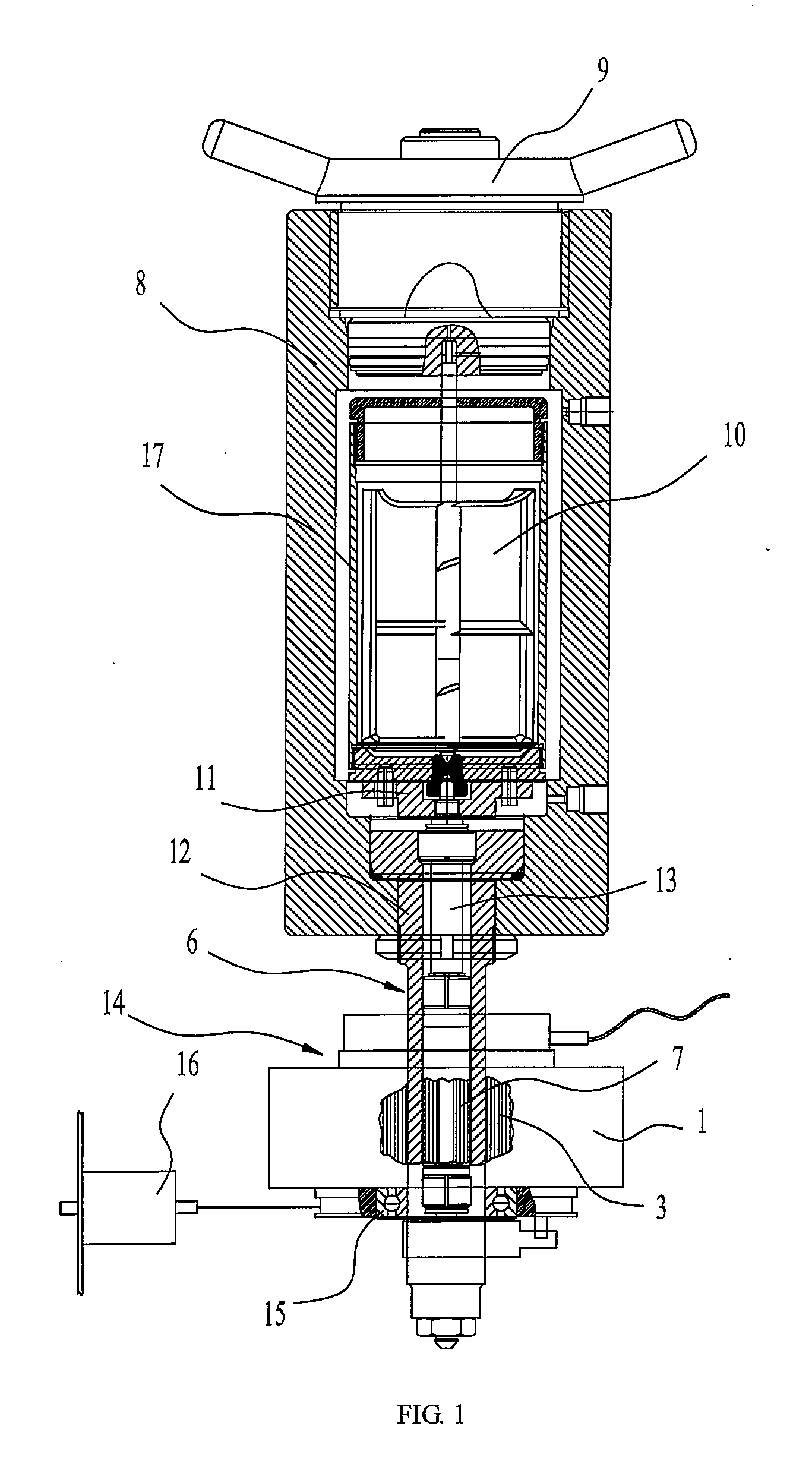

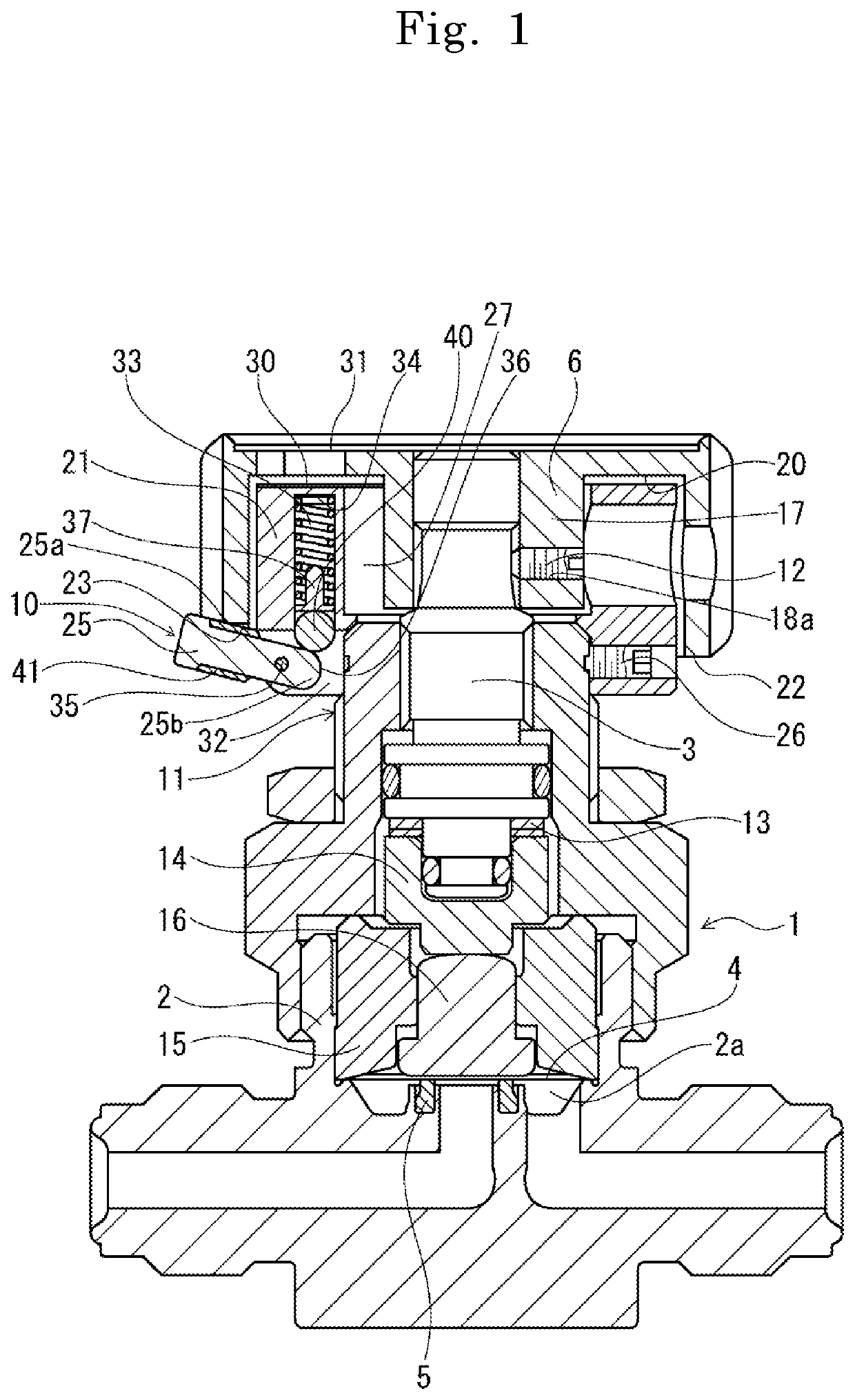

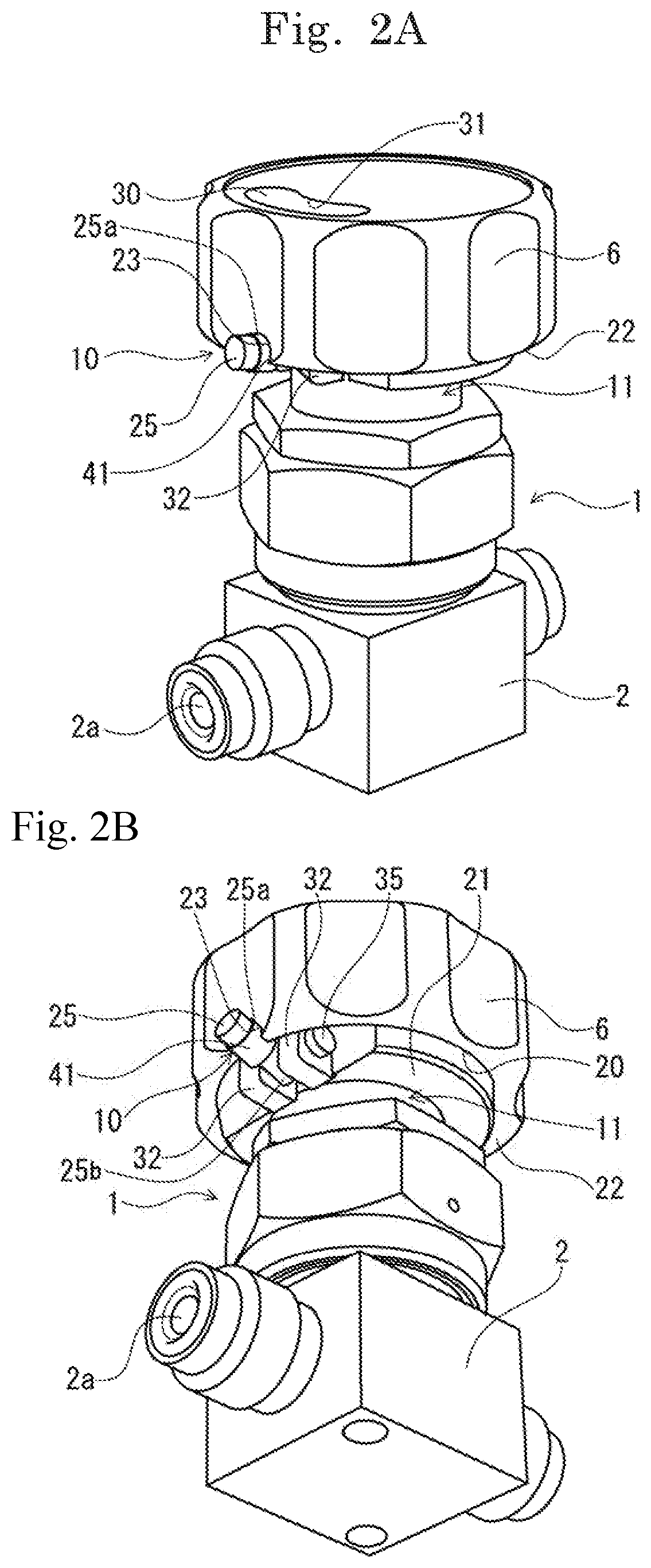

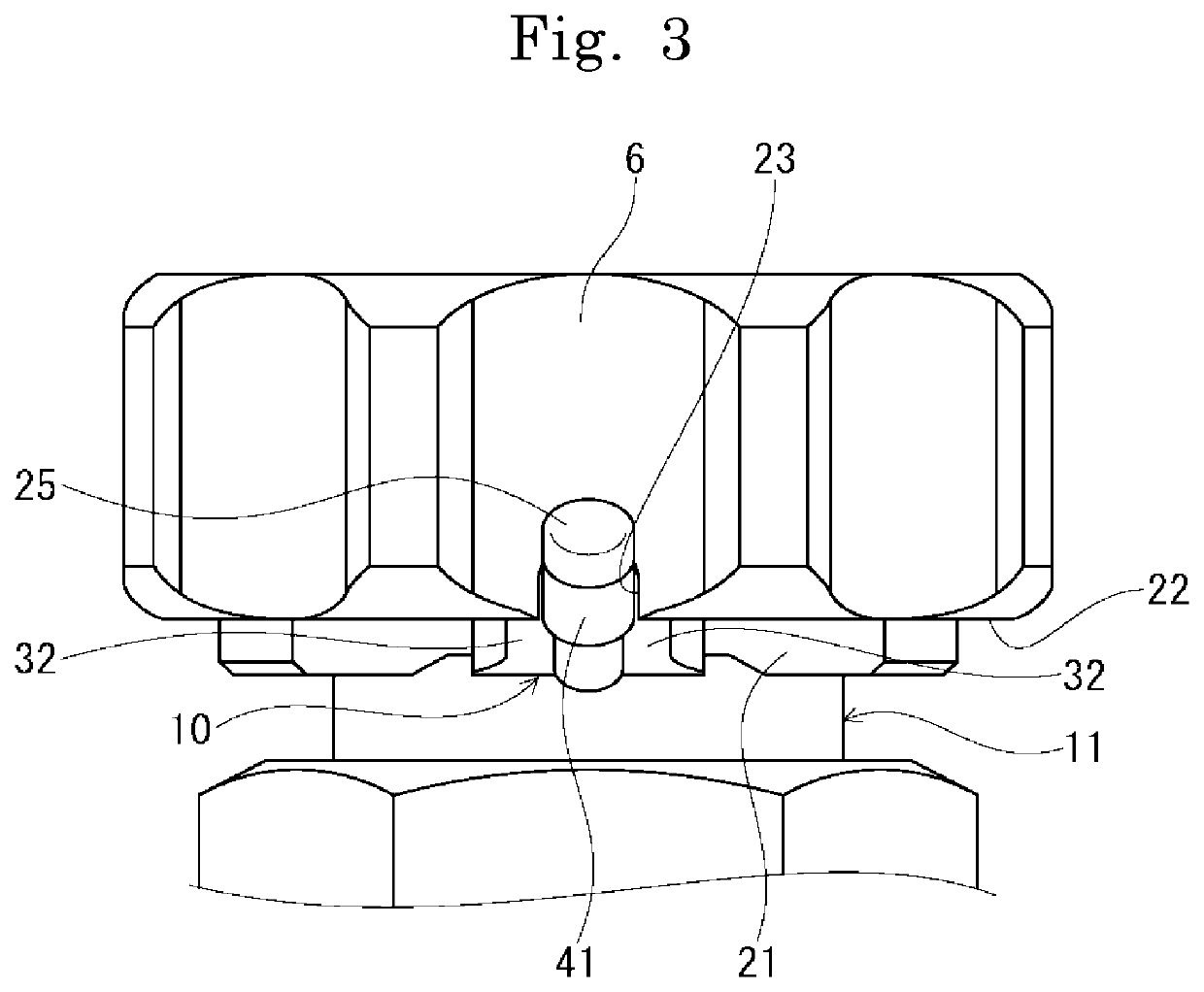

One-touch lock valve and raw material container

ActiveUS20200173577A1Avoid wear and tearEasy to operateOperating means/releasing devices for valvesLift valveEngineeringVALVE PORT

A one-touch valve including a valve main body (1) having a valve body incorporated therein, a stem (3) mounted on the valve main body, a rotating handle (6) fixedly attached to an upper part of the stem, a holder (21) accommodated in the rotating handle, and a lock mechanism (10) arranged in the holder and the rotating handle. The lock mechanism is formed of a spring inserted into the holder, a spherical body provided on a lower spring-back side of the spring, a lock member having a midway on a rear end side axially attached to the holder, having a rear end part pressed by spring-back via the spherical body, and having a tip part side abutting on a lower edge part of the rotating handle in a spring-back state, and an engagement groove where the tip end part side of the lock member is locked by the rotating handle.

Owner:KITZ SCT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com