Patents

Literature

87results about How to "Extend service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

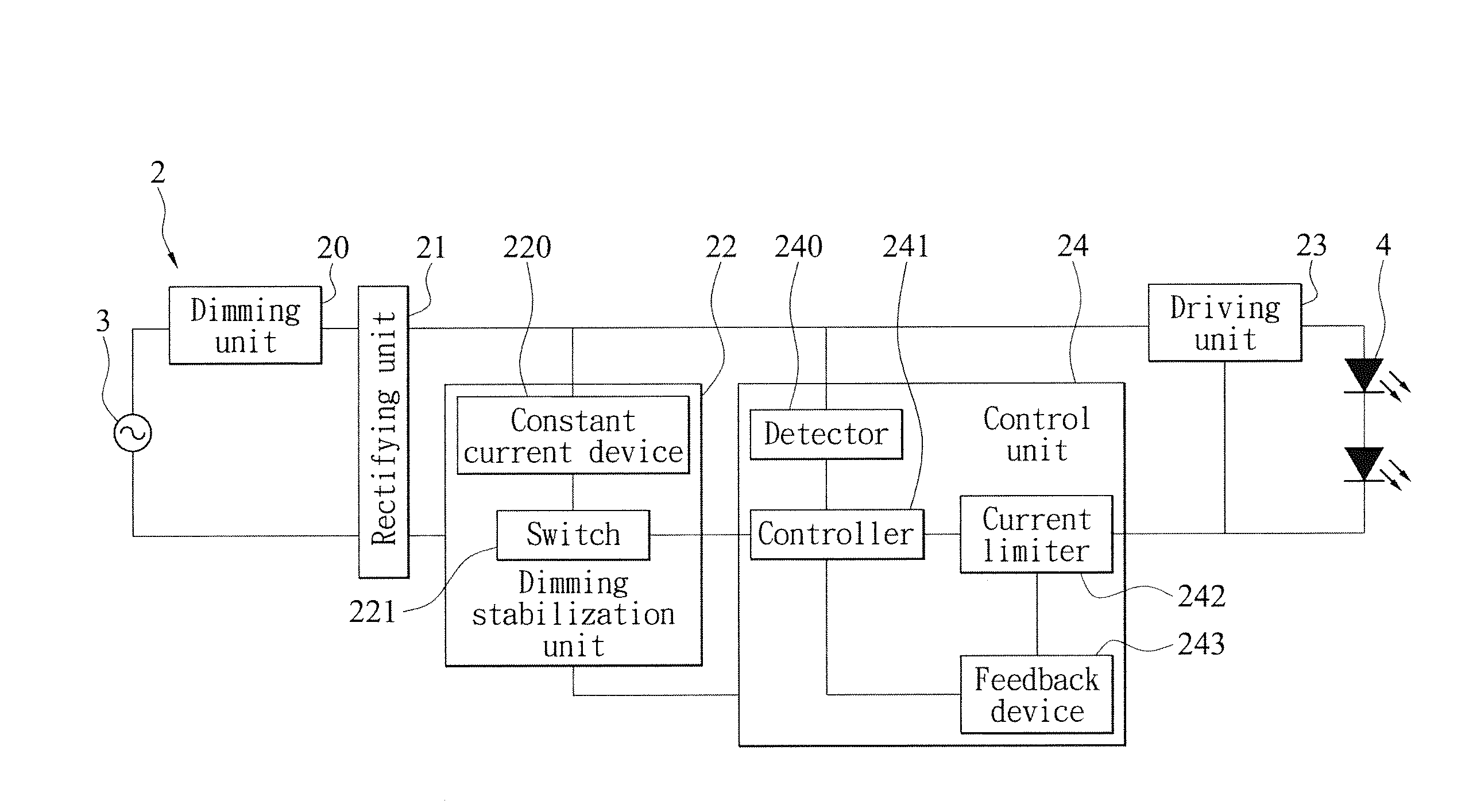

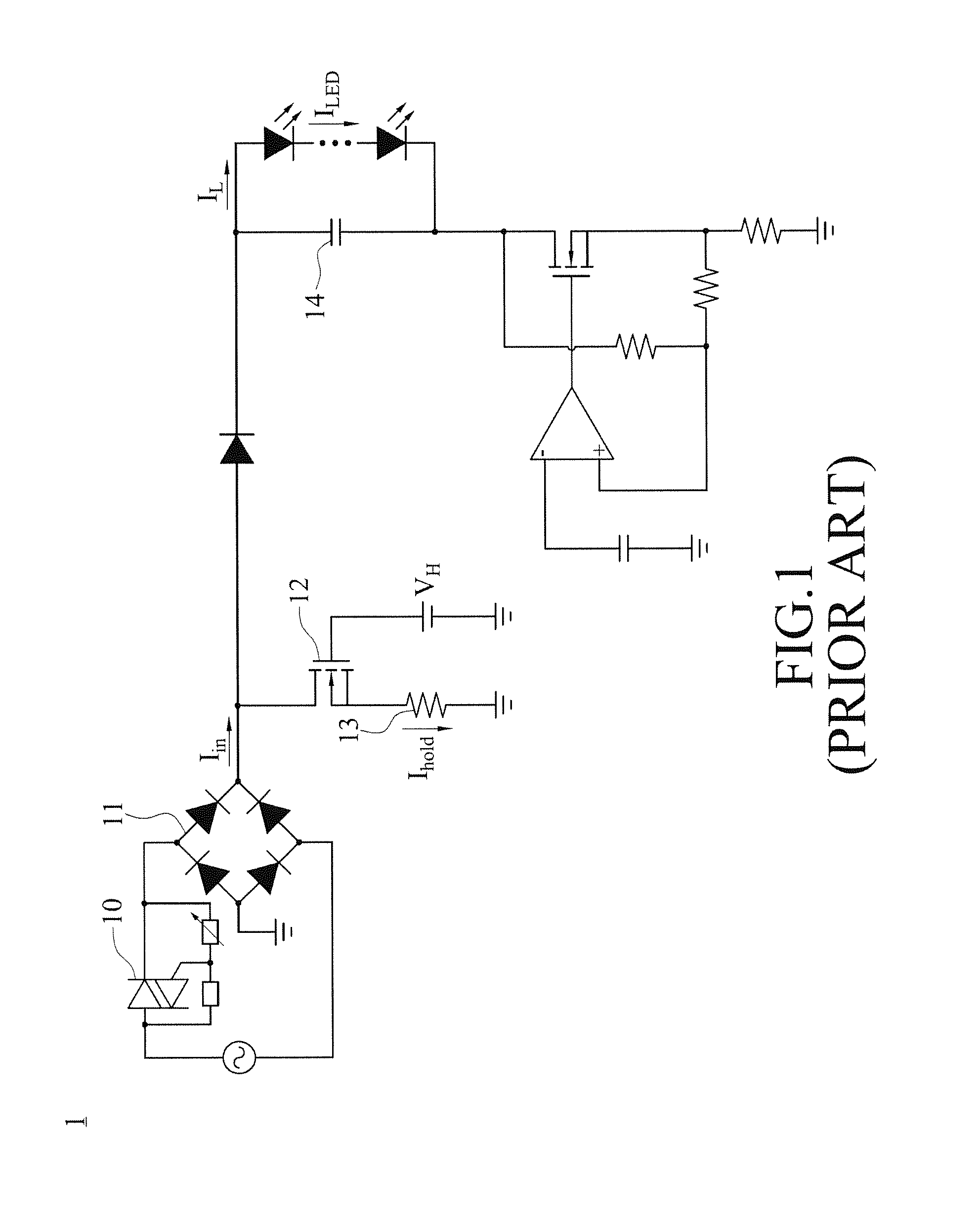

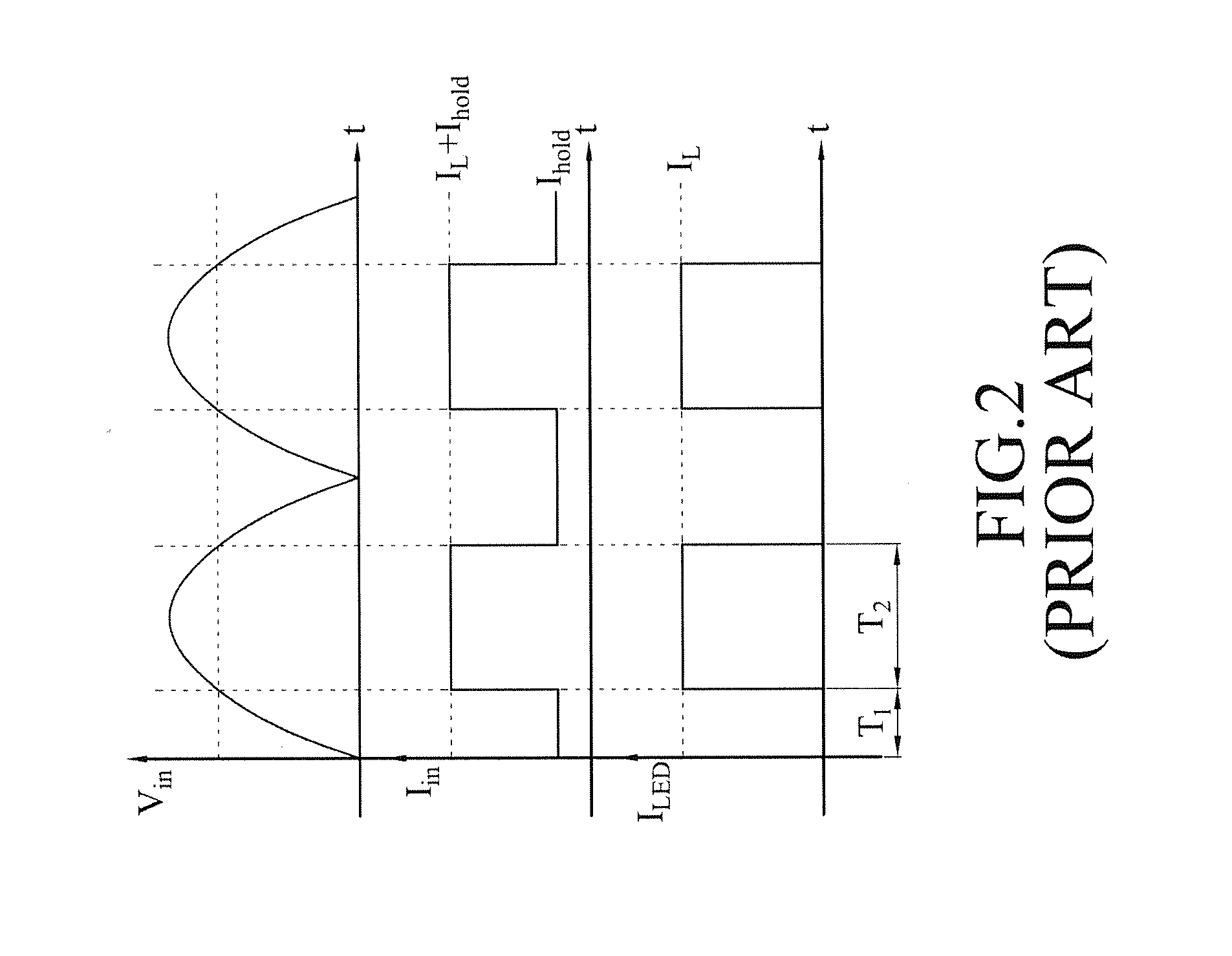

Variable power dimming control circuit

ActiveUS20140320031A1Extend service lifeOperation efficiency be enhanceElectrical apparatusElectroluminescent light sourcesEngineeringControl circuit

Disclosed is a variable power dimming control circuit for driving and linearly adjusting the illumination brightness of a plurality of light emitting diodes (LEDs), and the circuit includes a dimming stabilization unit and a control unit. The control unit is provided for detecting an input current of a circuit, and the dimming stabilization unit is driven for outputting a holding current when the input power is smaller than a standard, and stopping the output the holding current when the input power is greater than the standard. When the LEDs are dimmed to low luminance, a chip controls the operation of the dimming stabilization unit to assure the stability of the dimming operation of a TRIAC. When the LEDs are adjusted to high or full brightness, the chip stops the output of the holding current to reduce unnecessary power consumption and enhance the overall circuit performance effectively.

Owner:EPISTAR CORP

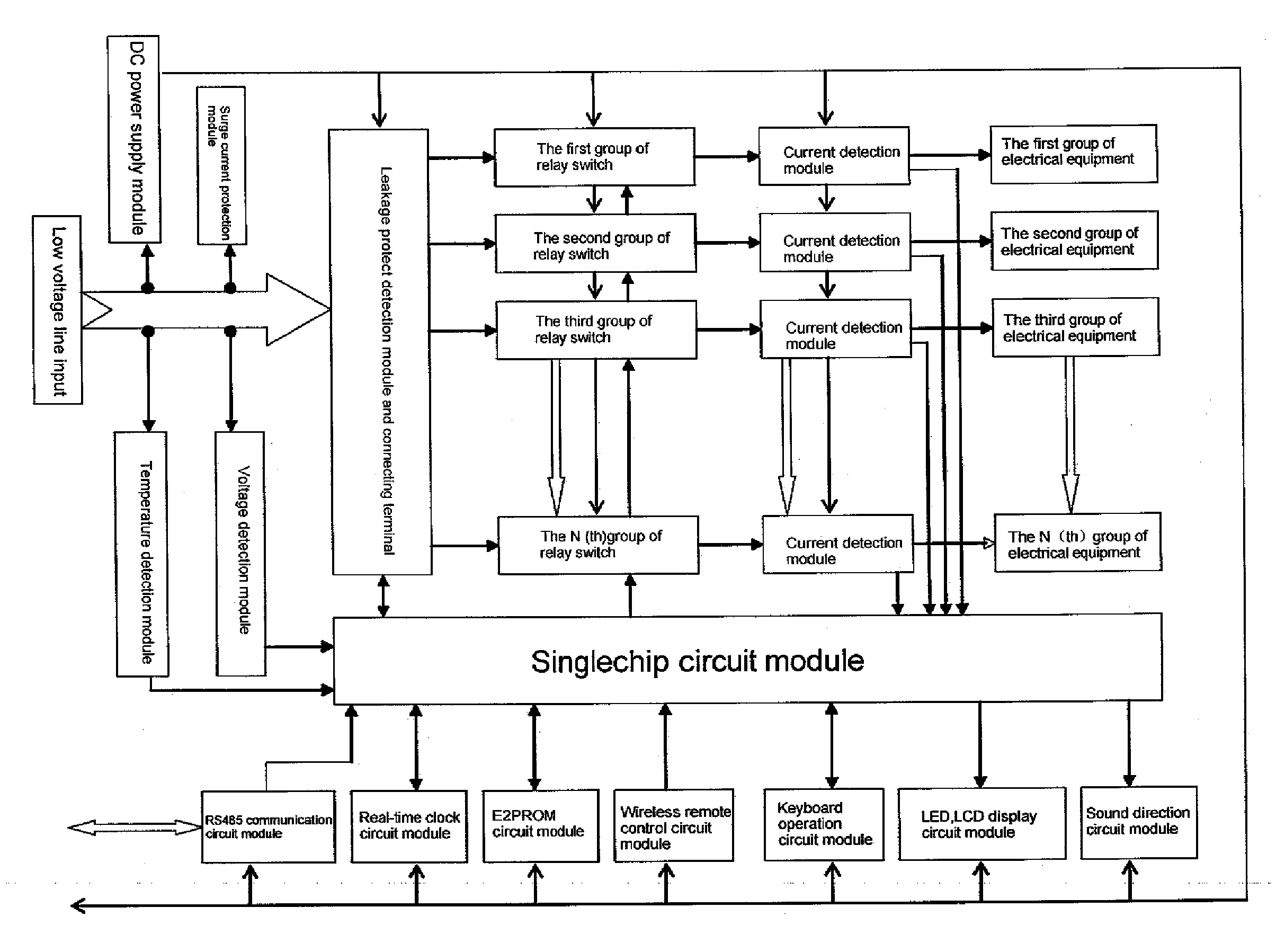

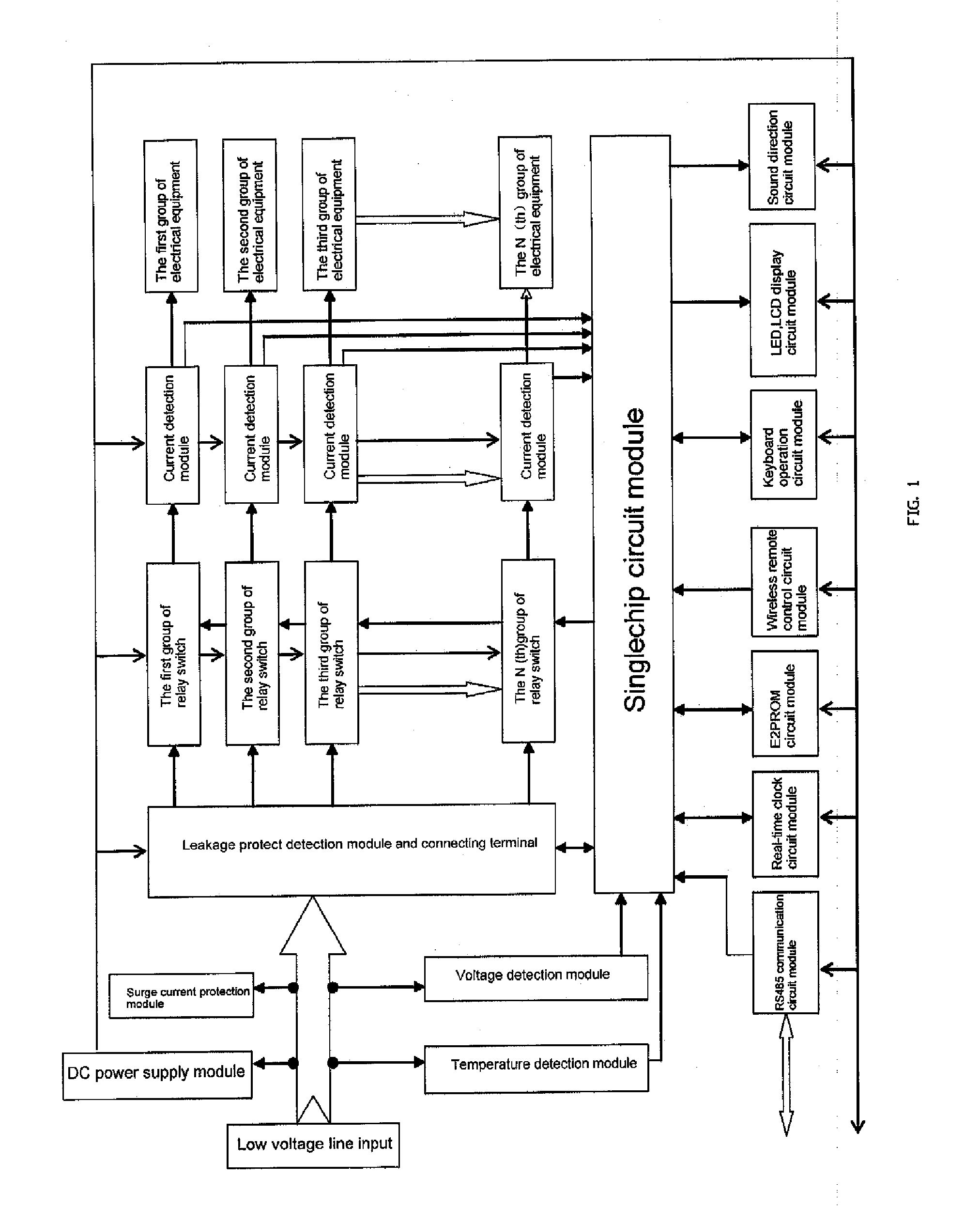

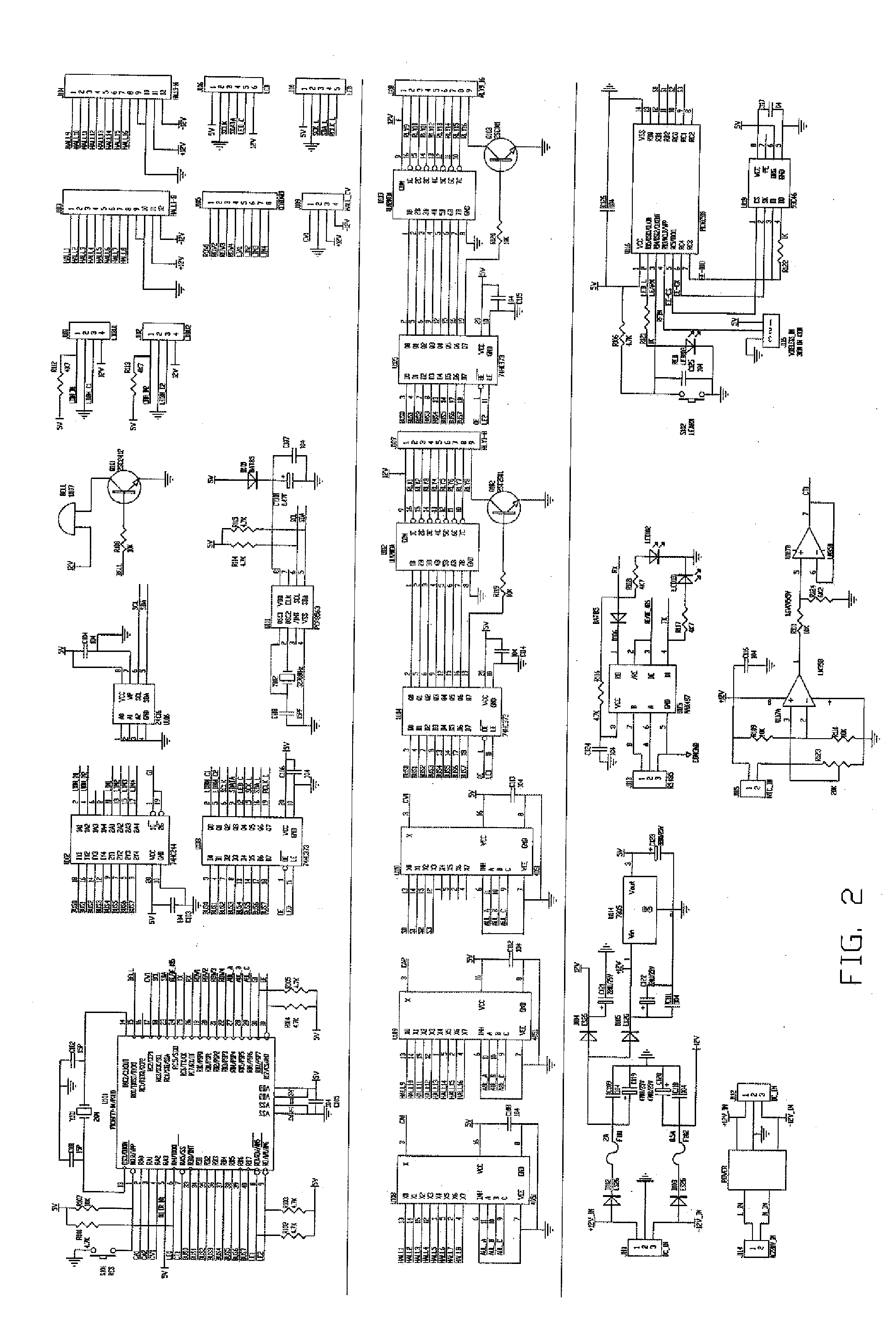

Intelligent electrical energy management system device

InactiveUS20110029145A1Extend service lifeSave powerMechanical power/torque controlLevel controlElectric energyControl switch

The present invention involves an intelligent electrical energy management system device. The device includes a power supply module (2), a control module, a memory module, an input module, a clock module (12) for providing a real-time clock, a current detection module (8) for detecting the current flowing in electrical equipments (91, 92, 93, 9n), and an electronic controlled switch. The memory module, the input module, the clock module (12), the output terminals of the current detection module (8), and the control terminal of the electronic controlled switch are connected to the data terminals of the control module respectively. An external power supply supplies power to the electrical equipments (91, 92, 93, 9n) via the electronic controlled switch and the current detection module (8). The power supply module (2) is connected to the external power supply and provides power to each module.

Owner:SHENZHEN WEILAI INTELLIGENT ELECTRIC +1

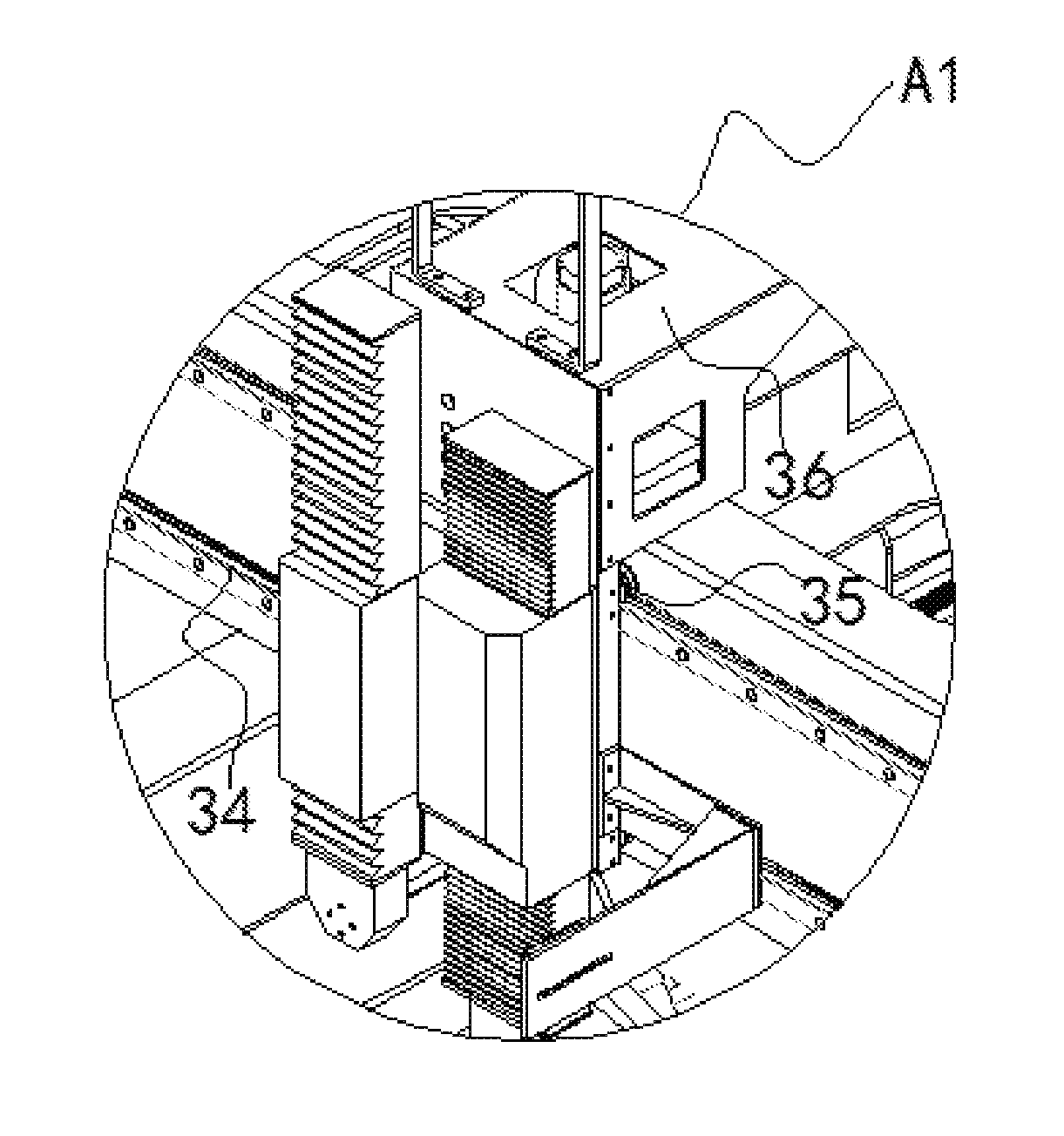

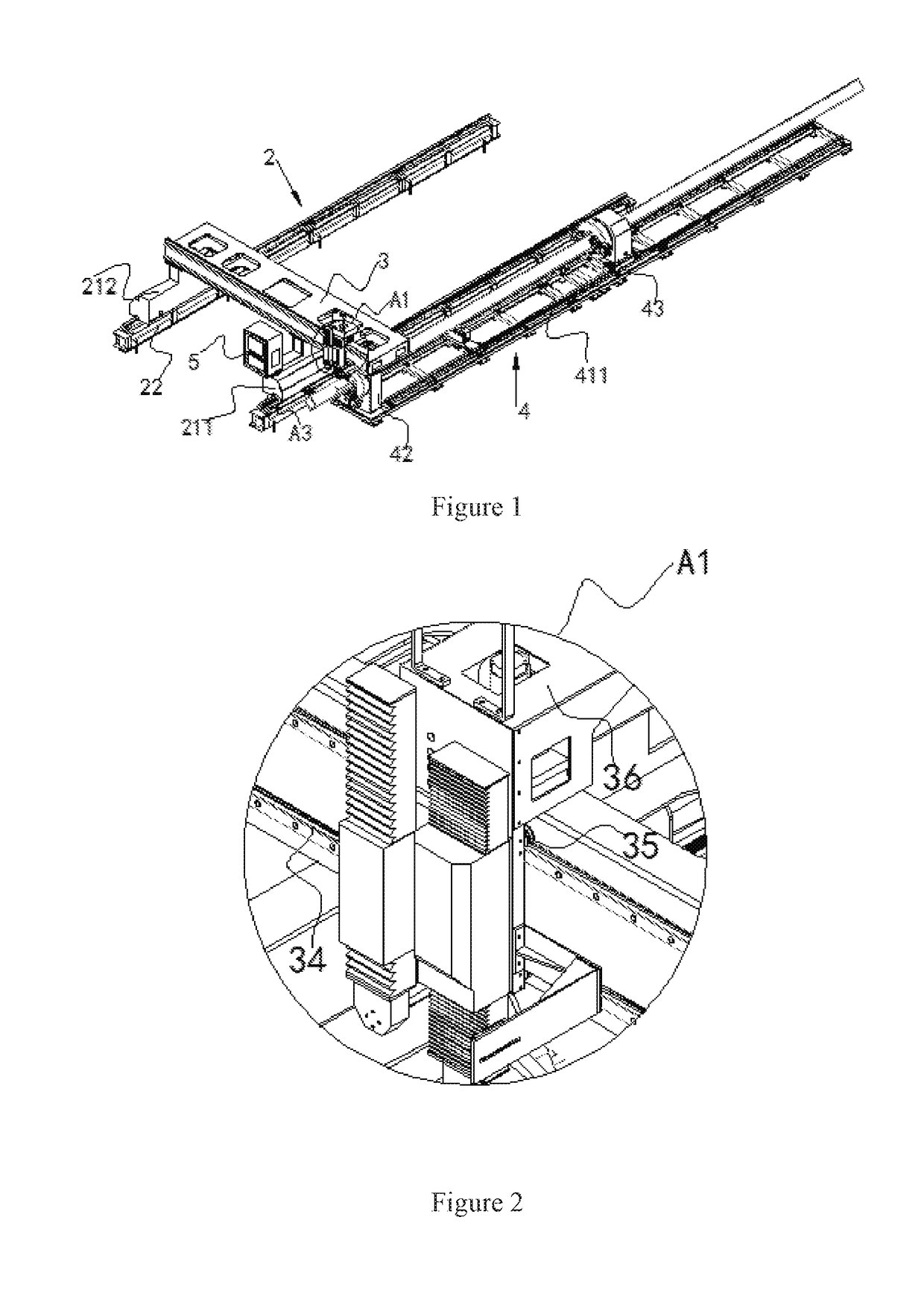

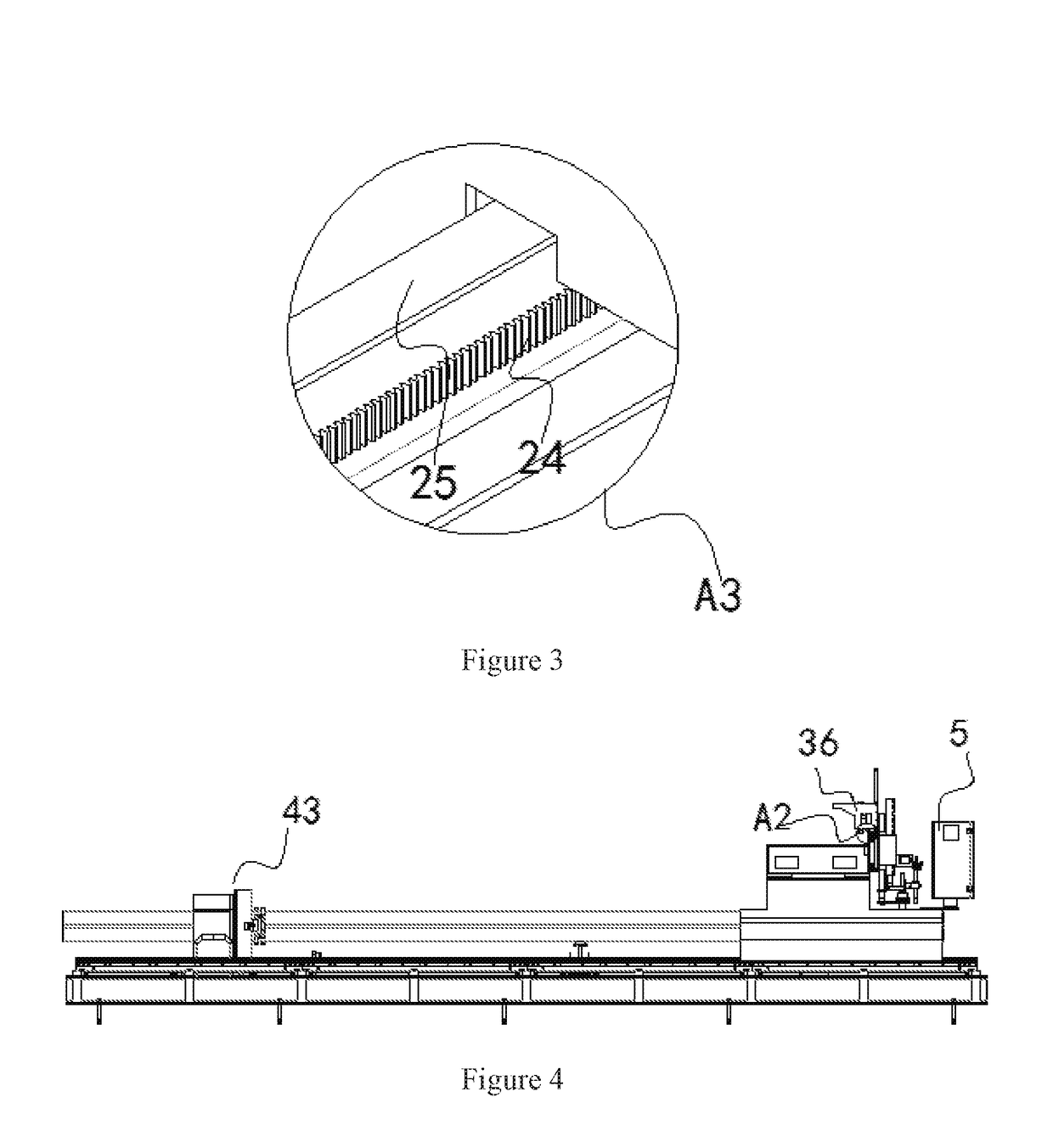

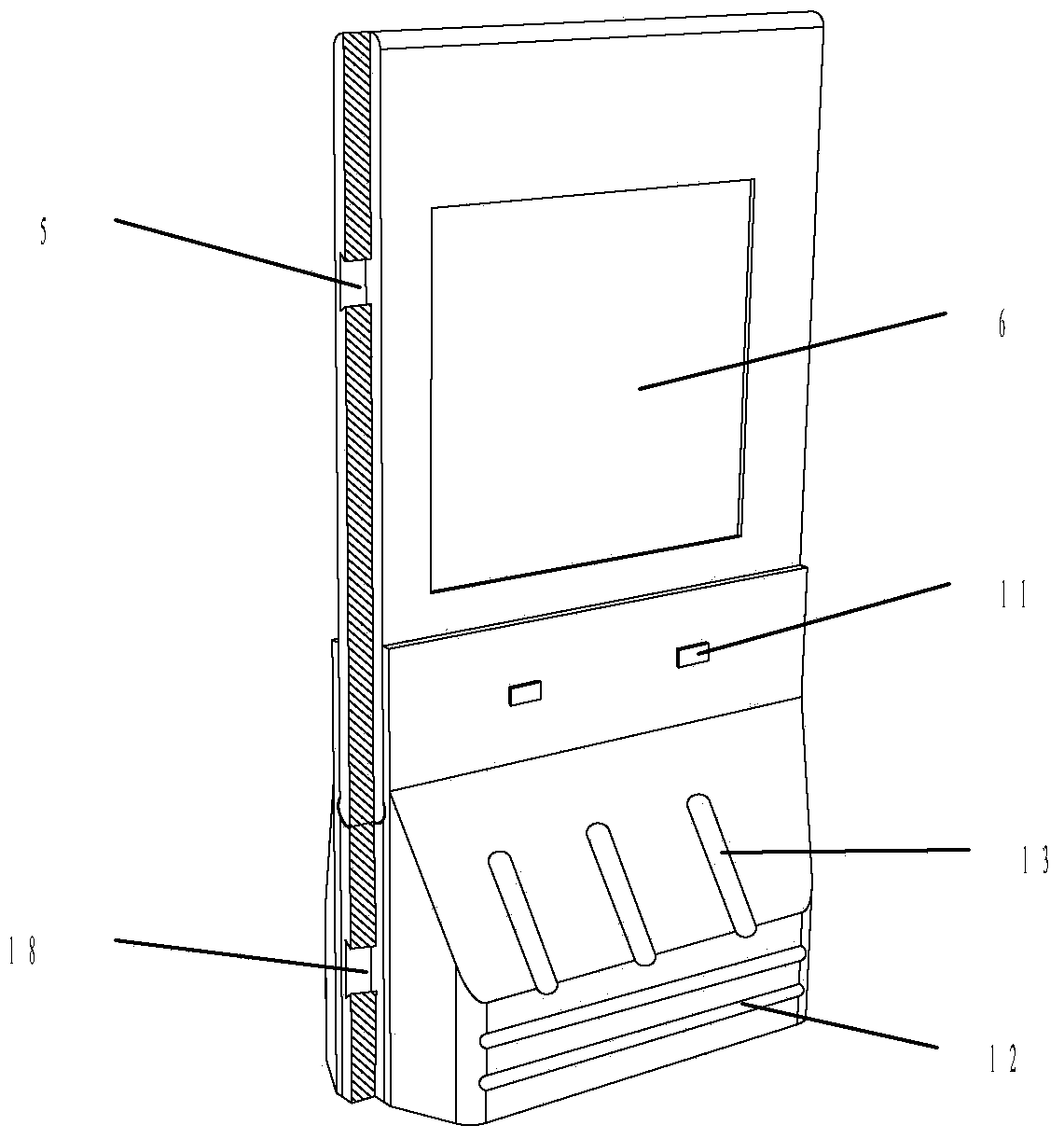

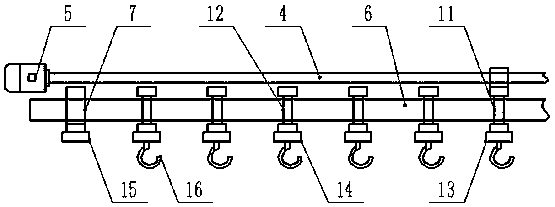

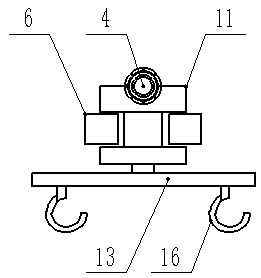

Gantry cutting machine for pipe and flat plate

ActiveUS20180200822A1Extend service lifeGood appearanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The present invention discloses a gantry cutting machine for pipe and flat plate, including a cutting assembly, a plate cutting mechanism, a pipe cutting mechanism and a crossbeam. The crossbeam is provided with a transverse driving unit. The cutting assembly is connected to the crossbeam. A cutting assembly mounting base is provided with a lifting-driving unit. The transverse driving unit includes a first gear, a first rack, a first motor and a first rail. The present invention provides a gantry cutting machine for pipe and flat plate to meet the demands in the field of numerically controlled cutting and machining of pipe products, which has a simple operation and is easy to use, and the clamping is flexible, so that the processing cost of pipe products can be reduced, and cutting and machining range of the numerically controlled cutting machine can be broadened.

Owner:JIANGSU ZHENGHE HEAVY IND CO LTD

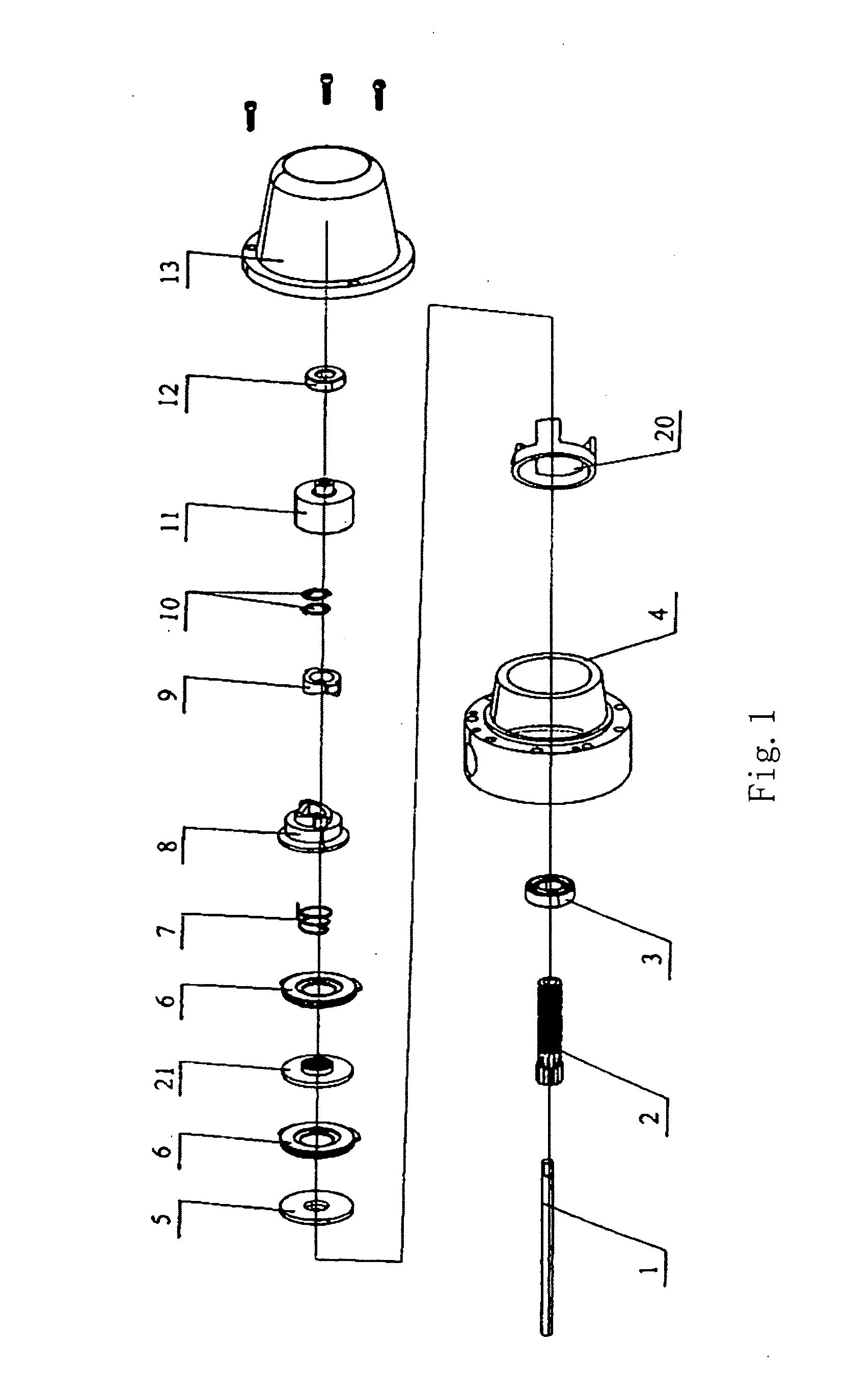

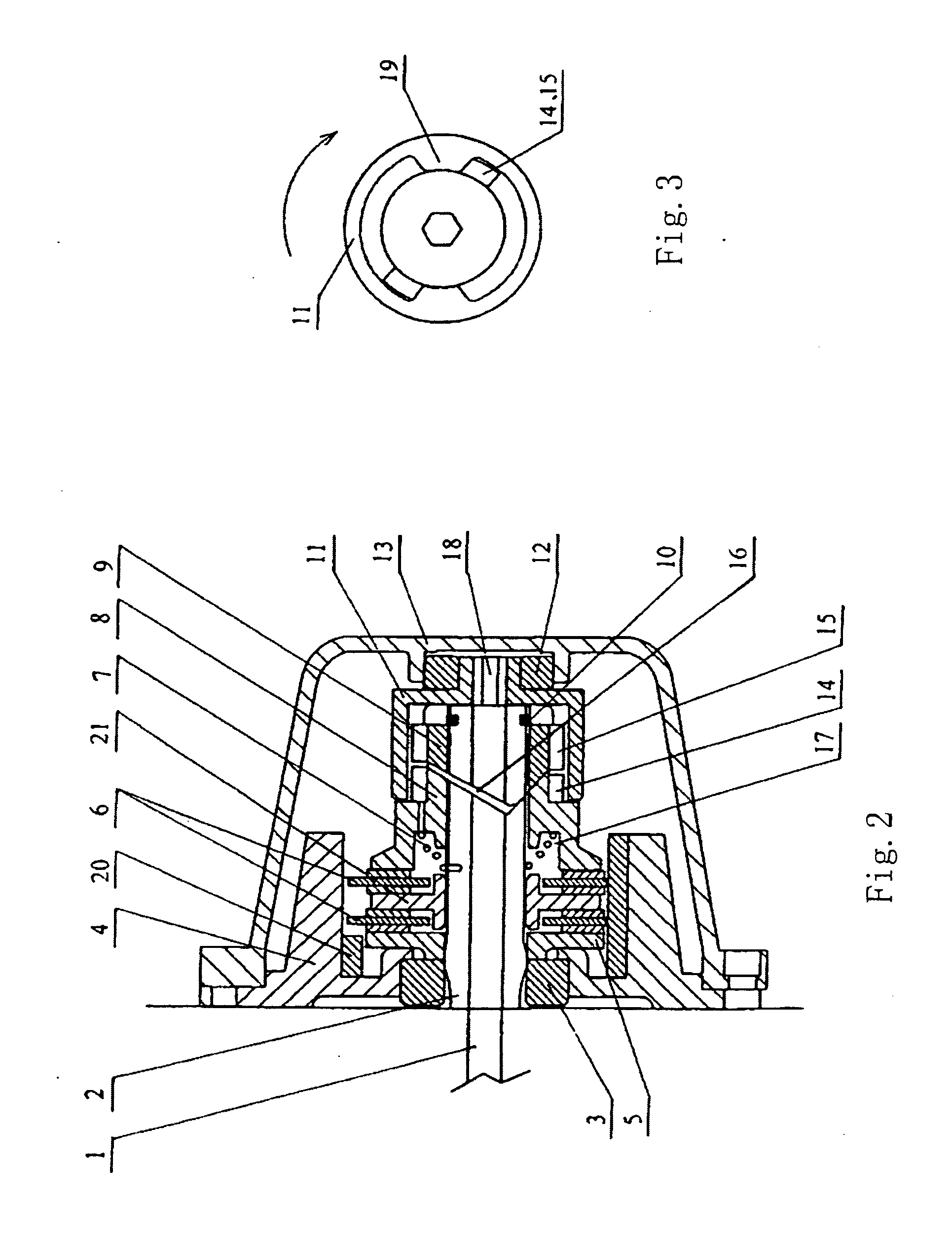

Plane braking device for electric winches and electric winch

The present invention discloses a plane braking device for electric winches and electric winch which disposes a section of hollow gear shaft, a section of core shaft, a fixing ring, a wedge shape support, a stopping piece, a braking plate, an elastic element, a wedge shape piece B, a wedge shape piece A, a braking clutch base and so on in a gear box of an electric winch. When a motor works, the section of core shaft of the motor drives the braking clutch base and the wedge shape pieces A, B to rotate, until a gap is formed between the adjacent braking plate and stopping piece between the braking clutch base and the wedge shape piece B, so that the braking effect disappears. When the motor stops suddenly, a heavy load lifted by a tight wire drum provides a reverse pulling force so that the wedge shape piece B produces a reverse thrust force to push the friction planes of the braking plate and the stopping piece, so the plane braking effect is achieved quickly. Based on the plane braking plate, the present invention can increase the braking area and the braking force and achieve safe braking. Furthermore, when there is wear of parts in long usage, so it only needs to replace the braking plate made of friction materials, which can simplify maintenance, reduce the parts costs and ensure service life of the gear box.

Owner:XIE YUZHI +1

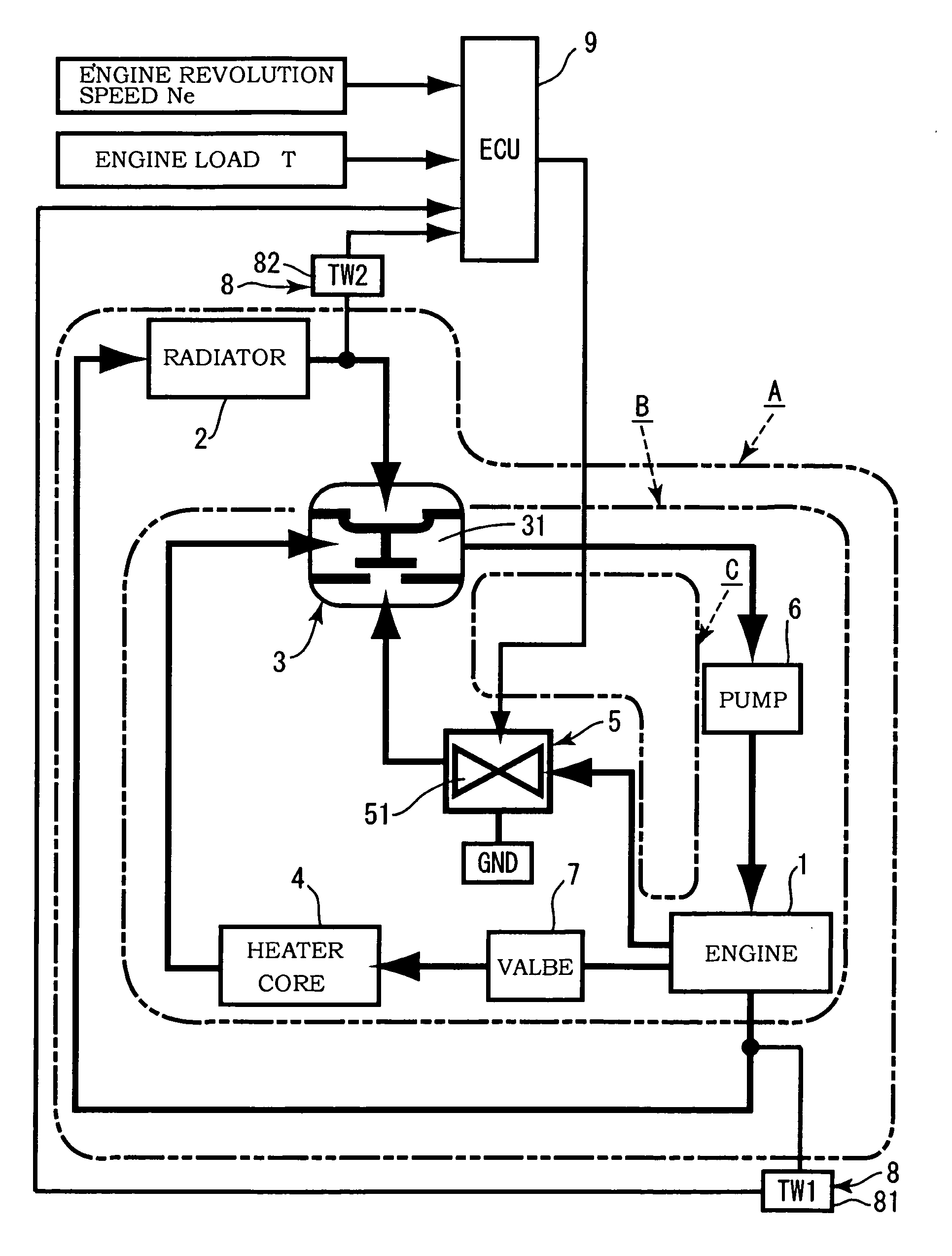

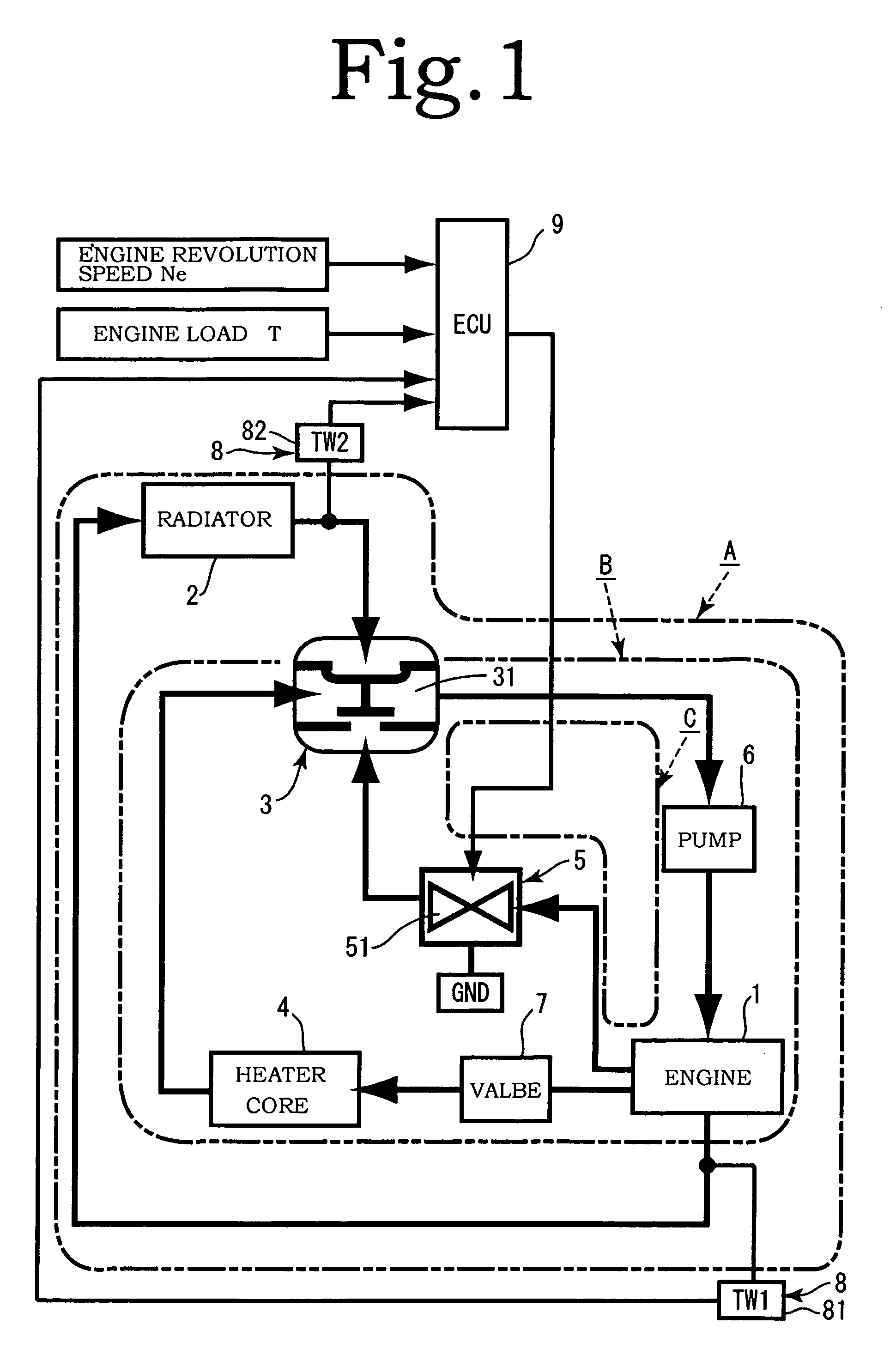

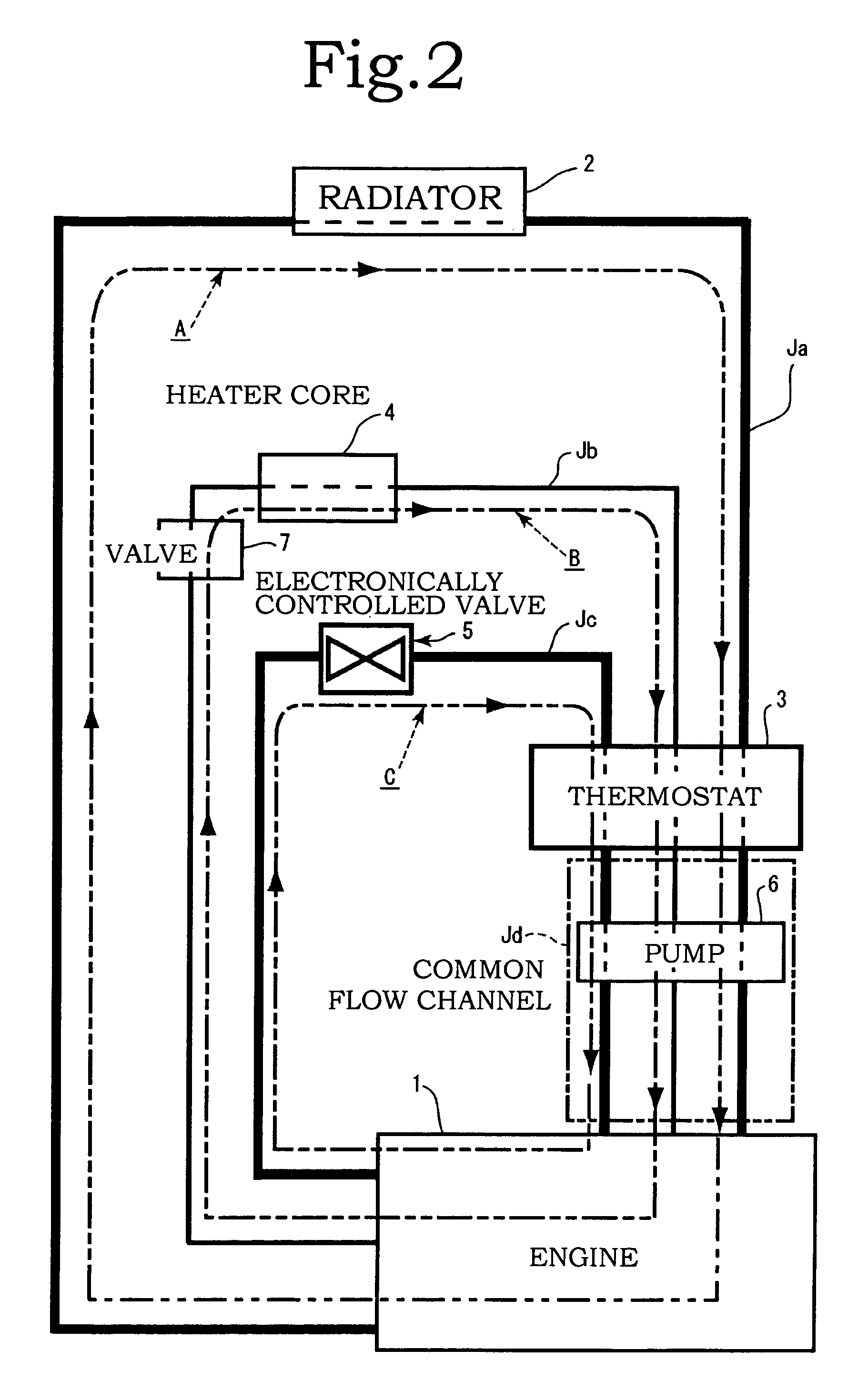

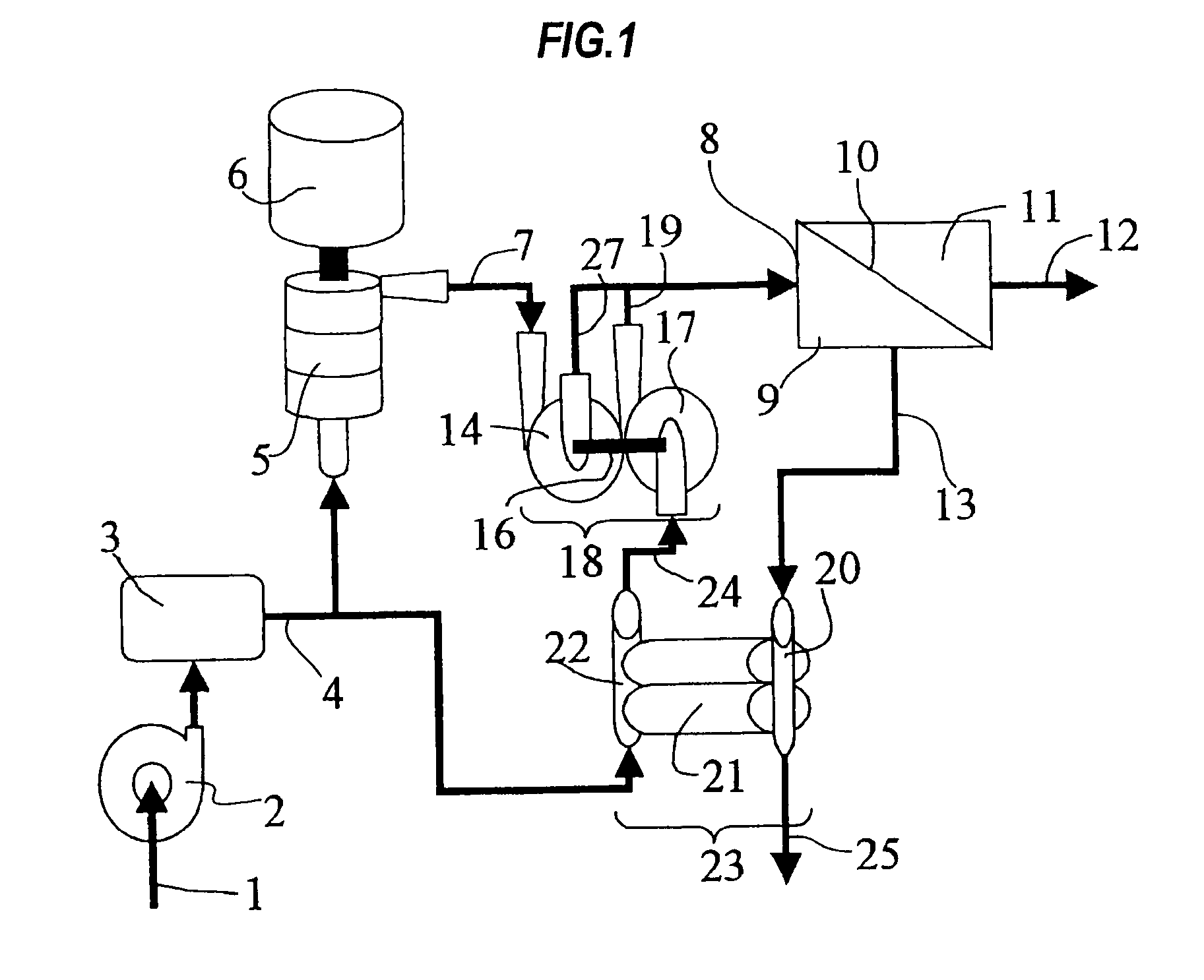

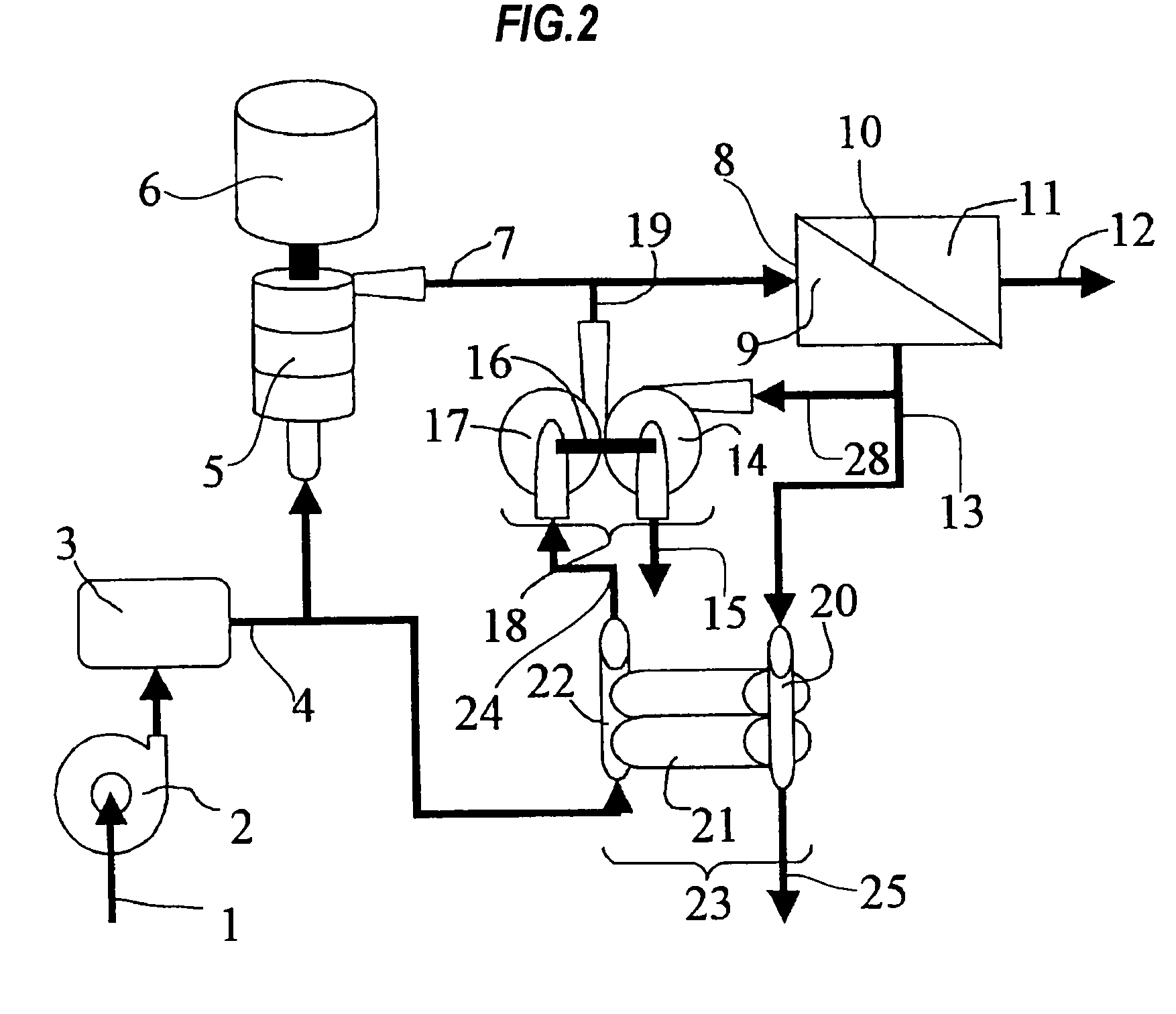

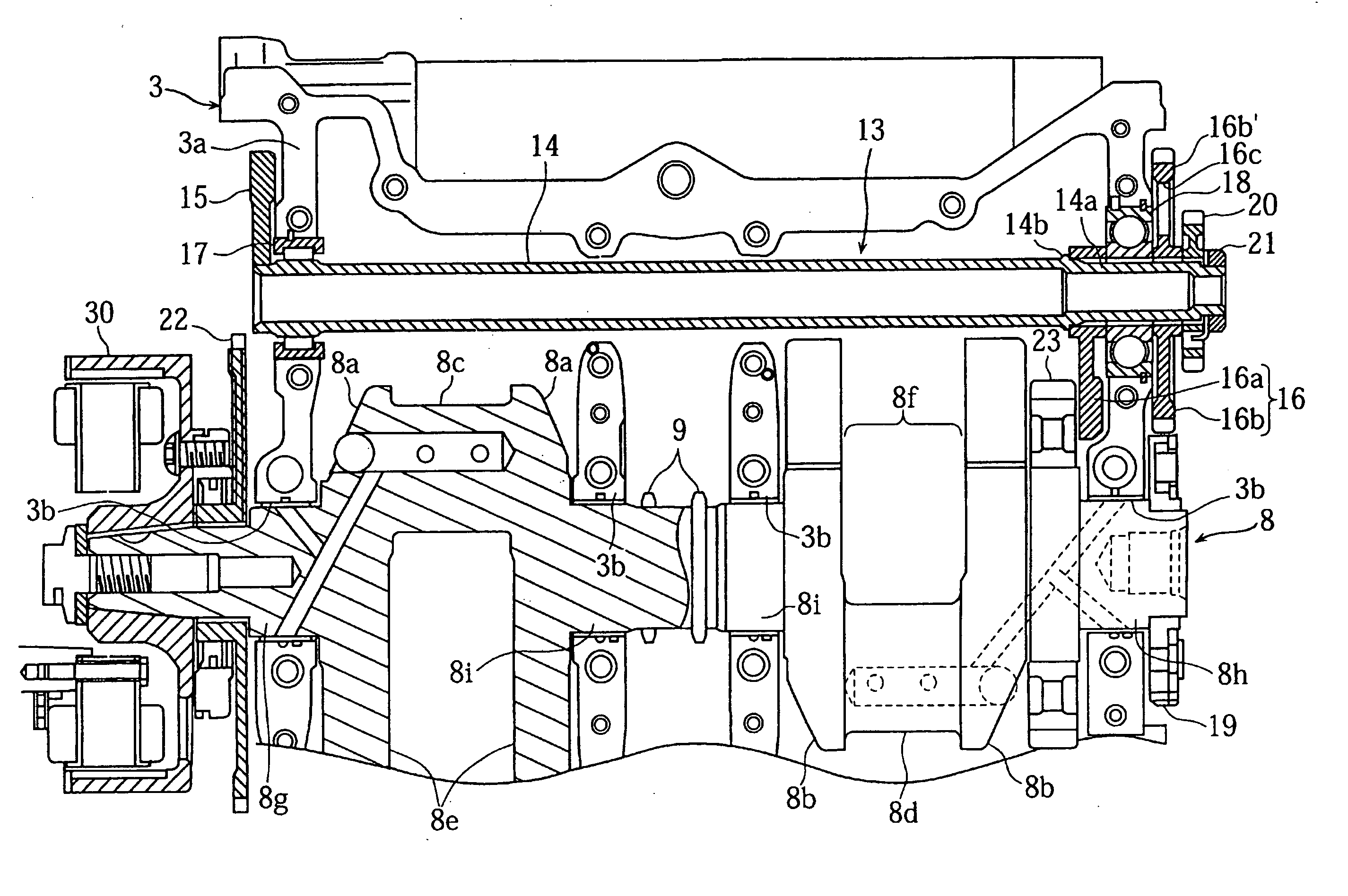

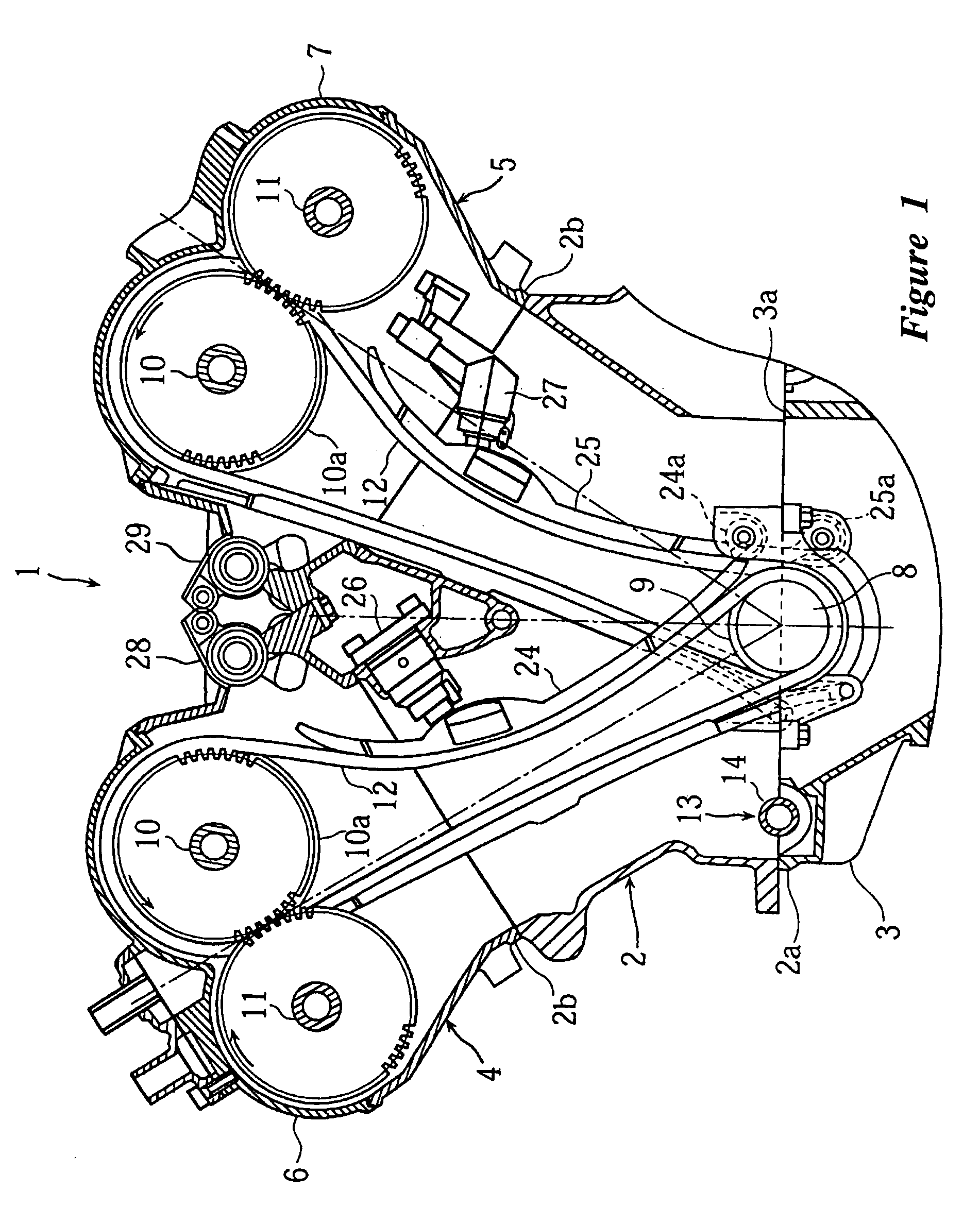

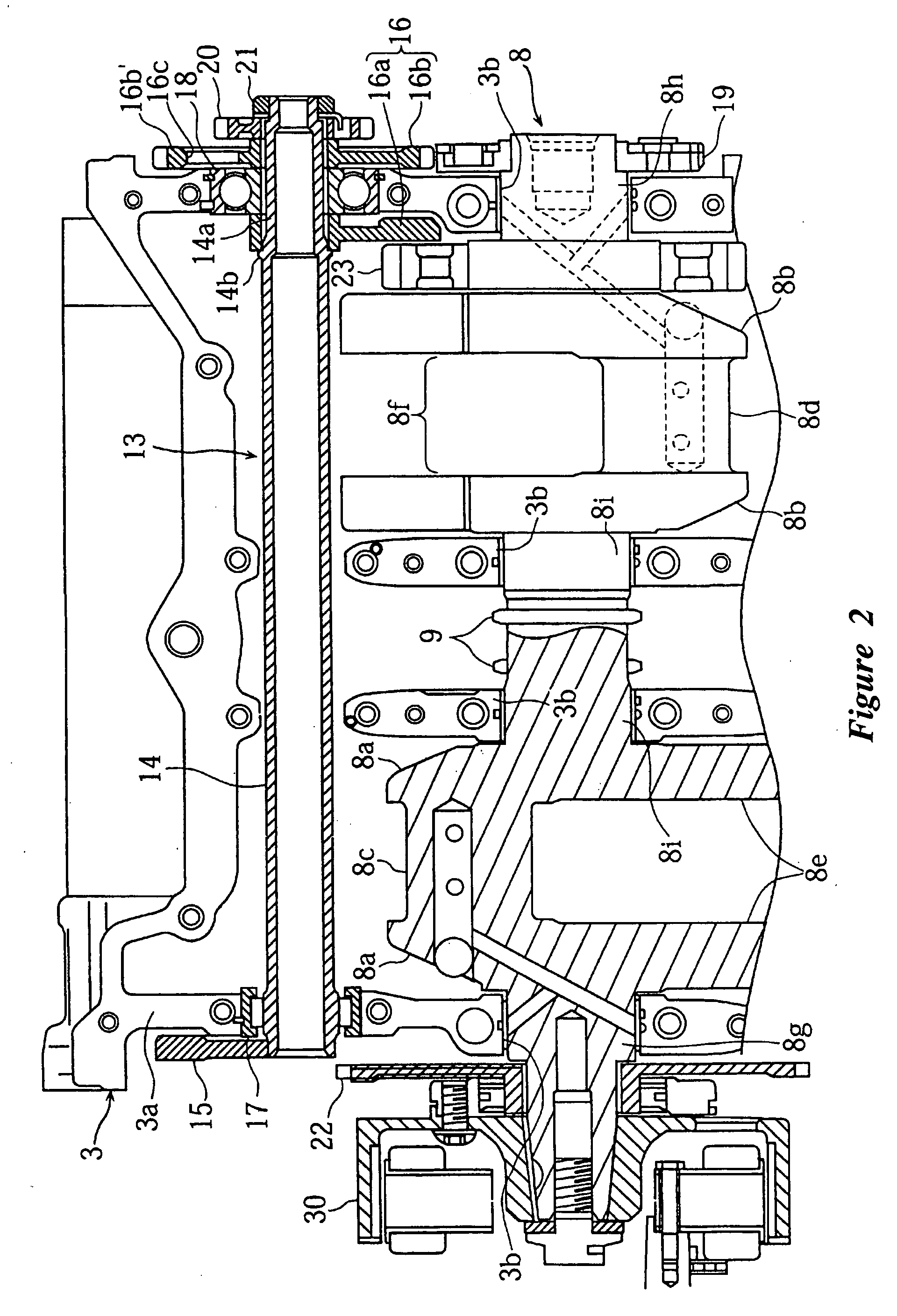

Cooling device for engine

InactiveUS20090255488A1Rapid temperature riseExtend service lifeCoolant flow controlCylinder headsWater circulationCooling water temperature

A cooling device for an engine that can raise the temperature of cooling water within a short period of time during the warm-up operation and allows a simple structure. The cooling device has a radiator circulation flow channel for circulation via an engine, a radiator, and a thermostat; a heater circulation flow channel for circulation via the engine, a heater core, and the thermostat; a bypass circulation flow channel for circulation via the engine and the thermostat; an electronically controlled valve; and a pump. The radiator circulation flow channel, heater circulation flow channel, and bypass circulation flow channel merge in the thermostat and form a common flow channel between the thermostat and the engine. The pump is provided in the common flow channel. At the start of the warm-up period and during the warm-up operation, the circulation in the radiator circulation flow channel is substantially stopped by the thermostat, cooling water circulation is actuated in the bypass circulation flow channel, and an opening degree of the electronically controlled valve is gradually increased from a minimum as the cooling water temperature rises. At the end of the warm-up period, circulation is actuated in the radiator circulation flow channel and substantially stopped in the bypass circulation flow channel.

Owner:YAMADA SEISAKUSHO KK

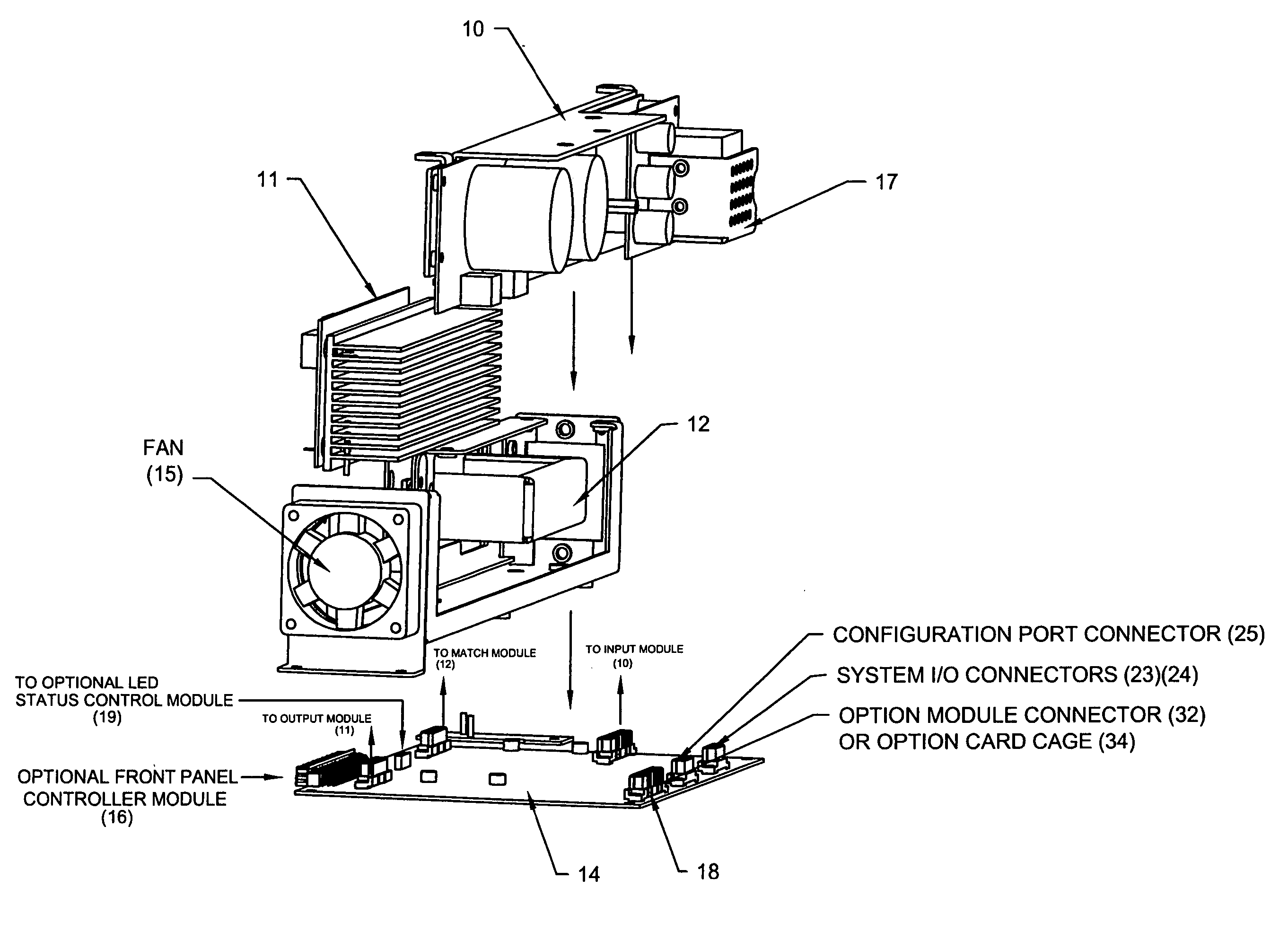

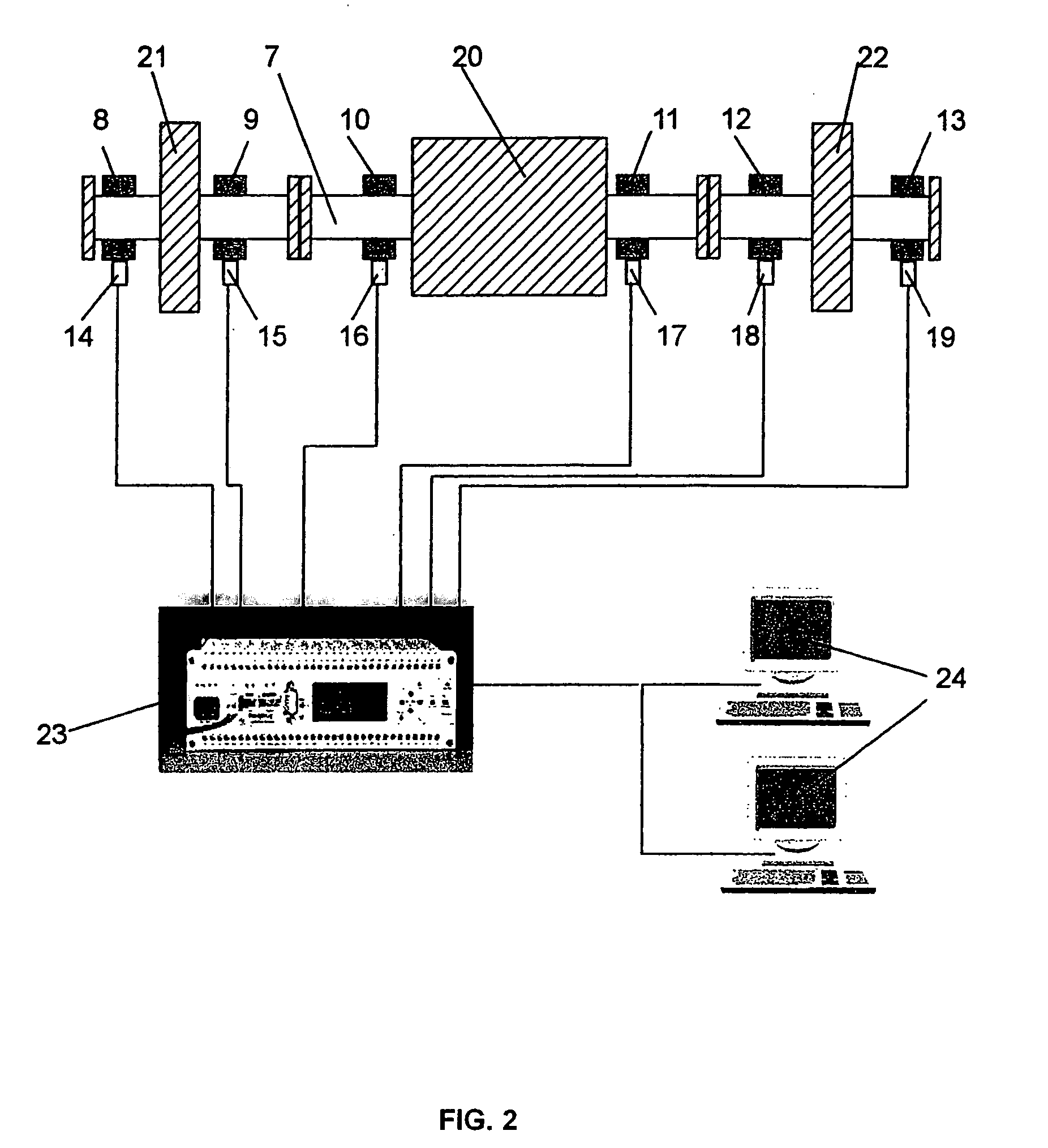

Systems for providing controlled power to ultrasonic welding probes

ActiveUS20070163349A1Output amplitude decreaseExtend service lifeVibration measurement in solidsWelding/cutting auxillary devicesUltrasonic generatorEngineering

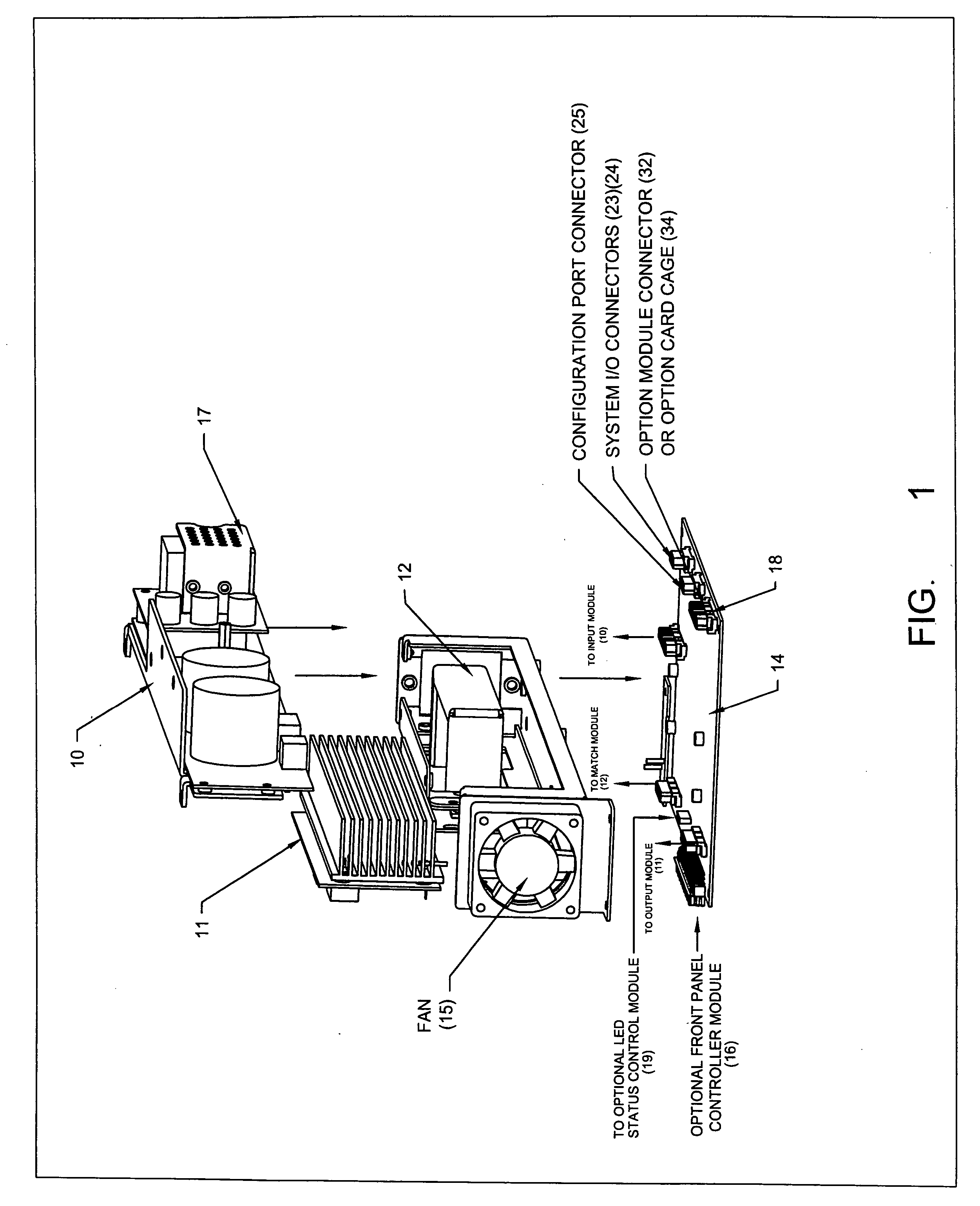

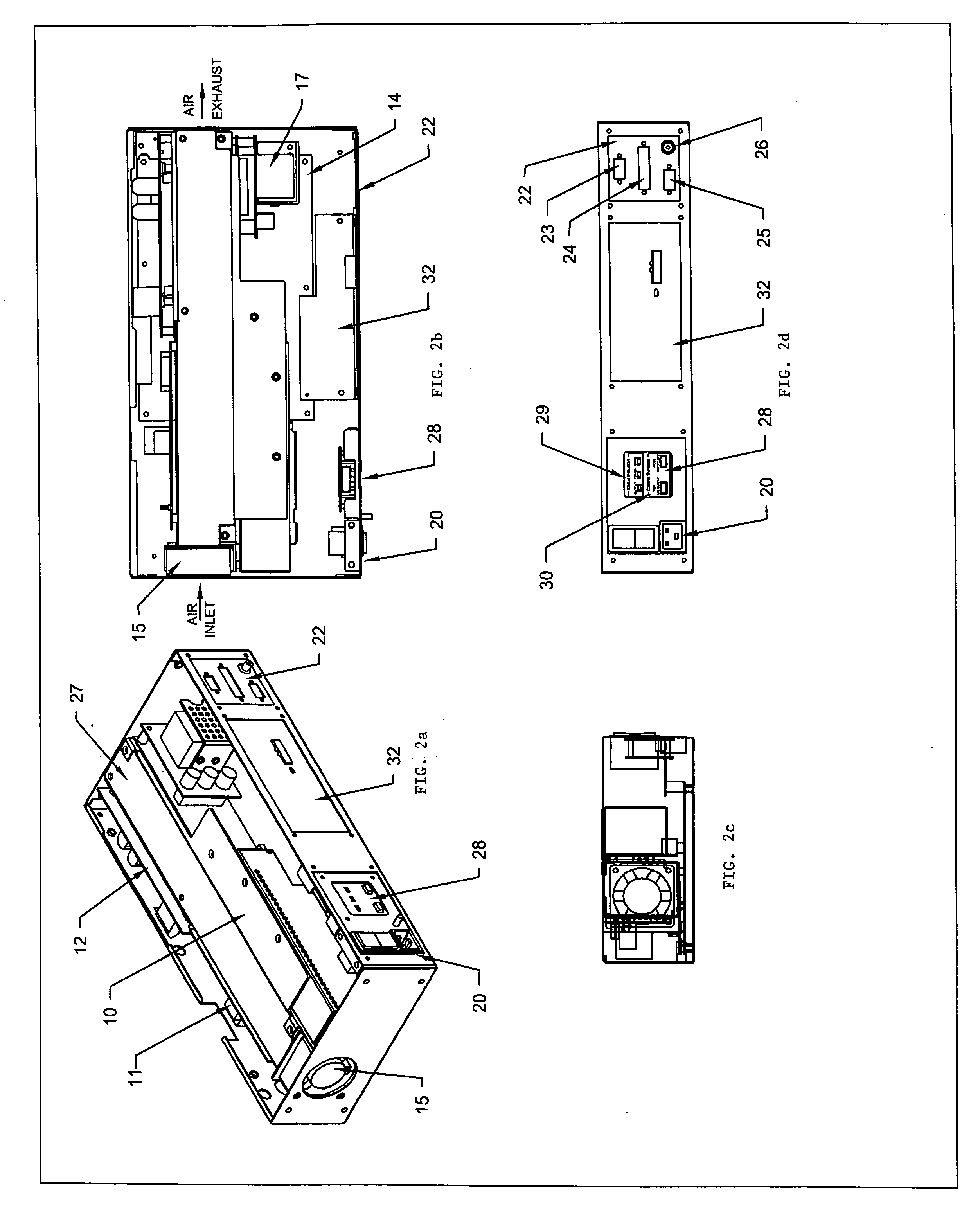

An ultrasonic generator comprising an input module for receiving a power signal. An output module for outputting an ultrasonic signal is also included in the generator. A motherboard is coupled to both the input module and the output module. The motherboard includes a digital controller adapted to control the input module and the output module.

Owner:DUKANE IAS LLC

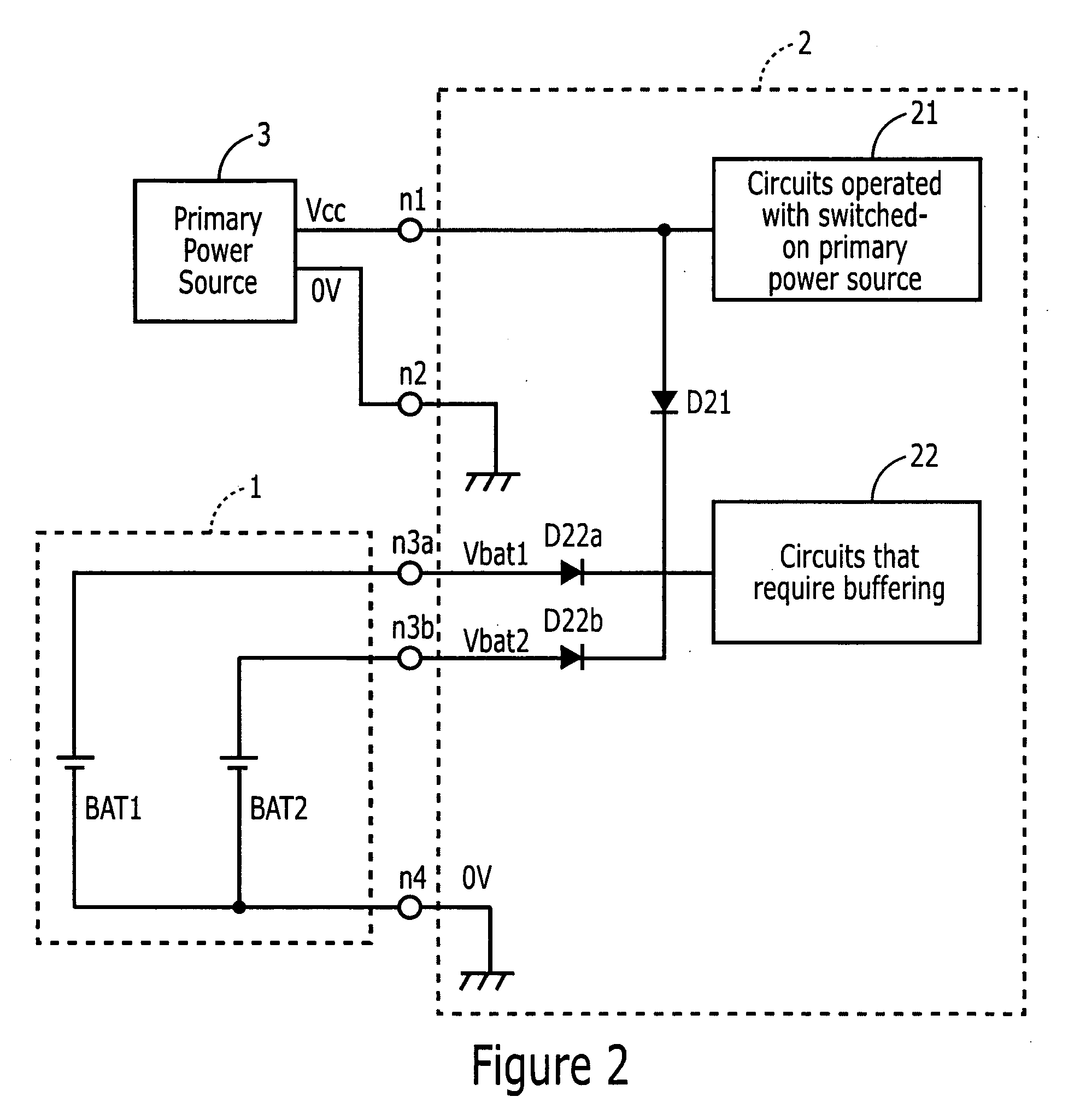

Position measuring device

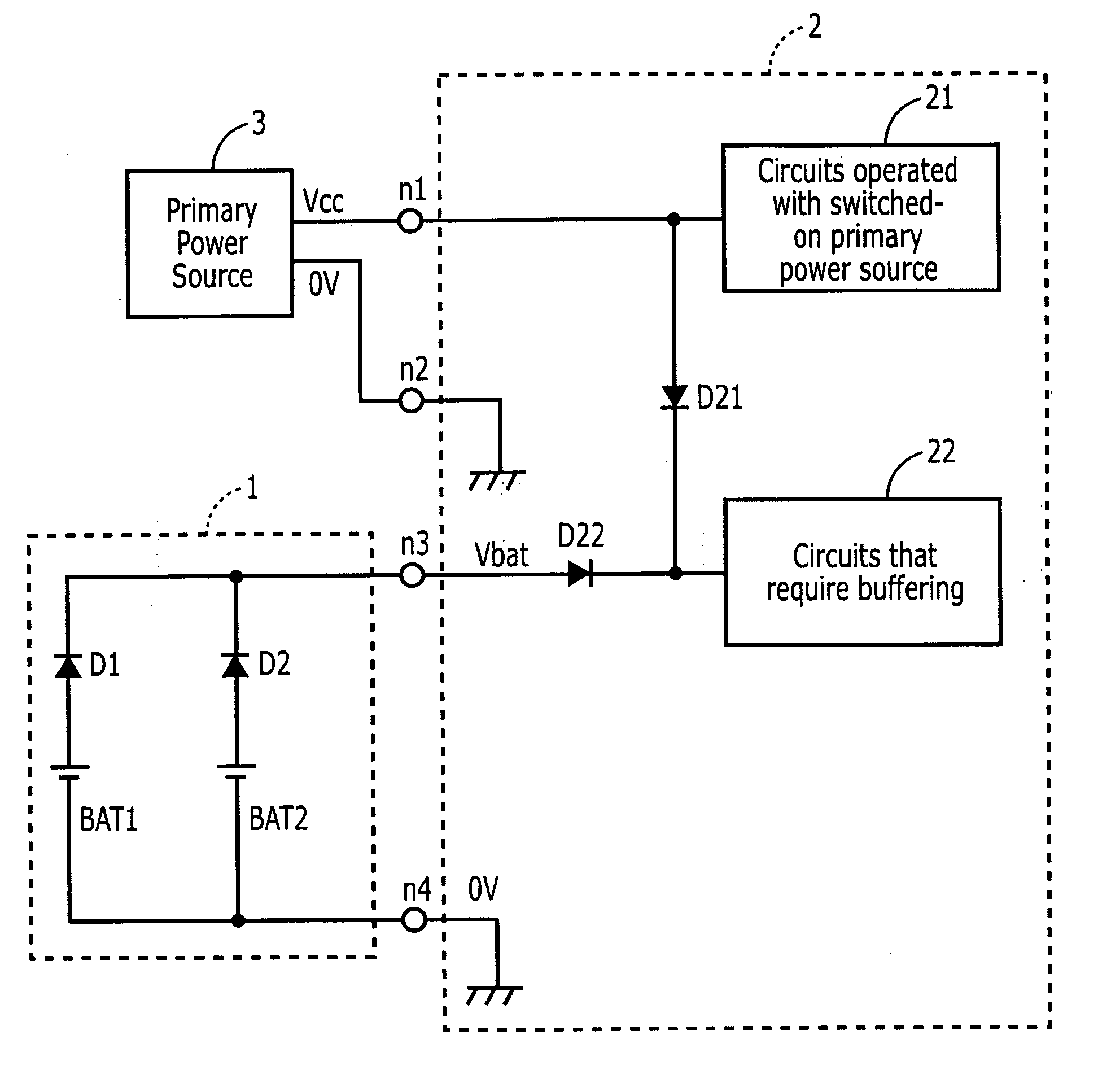

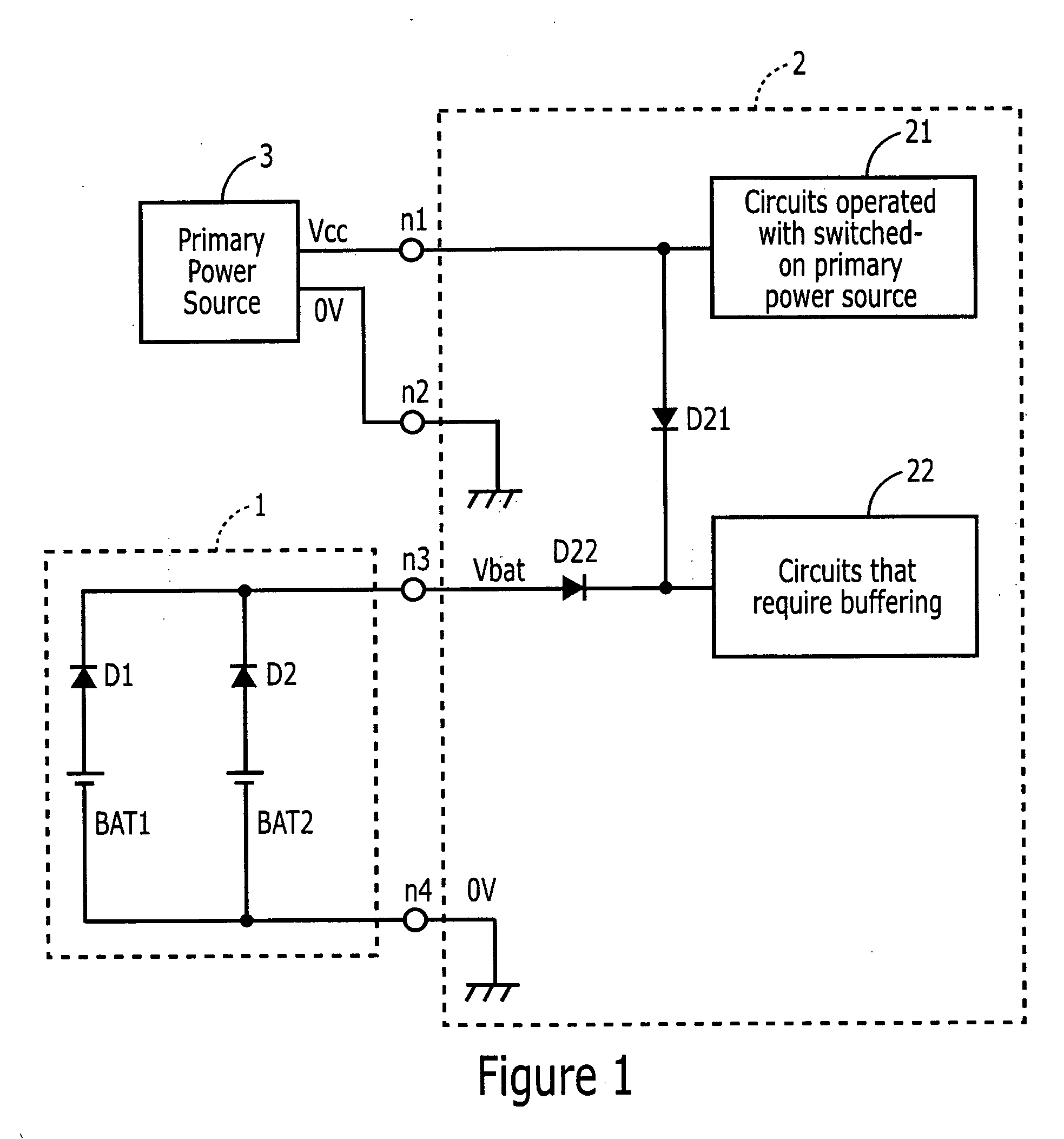

InactiveUS20050285446A1Reduce burdenExtend service lifeDc network circuit arrangementsBatteries circuit arrangementsElectrical batteryWorking capacity

In a position measuring device in which data, which requires buffering, may be held without accommodating a high-capacitance capacitor in the inside of the encoder, a backup current source may be exchanged while the circuits required for the operating capability state remain operable. In addition, current usage during the buffering time may be held low, and the service life of the backup current source may be extended, so that the demand for maintenance may be reduced. The position measuring device may include an encoder main part, arranged to measure the extent of the shift in position of an object to be measured, and a backup current source arranged to supply backup current when main current source, that supplies encoder main part with current, is interrupted. Outside of the encoder main part, an auxiliary current source is provided which, during the exchange of a main battery of the backup current source, undertakes supplying backup current in place of this main battery. The backup current source supplies backup current only to those circuits of the encoder main part which require buffering.

Owner:DR JOHANNES HEIDENHAIN GMBH

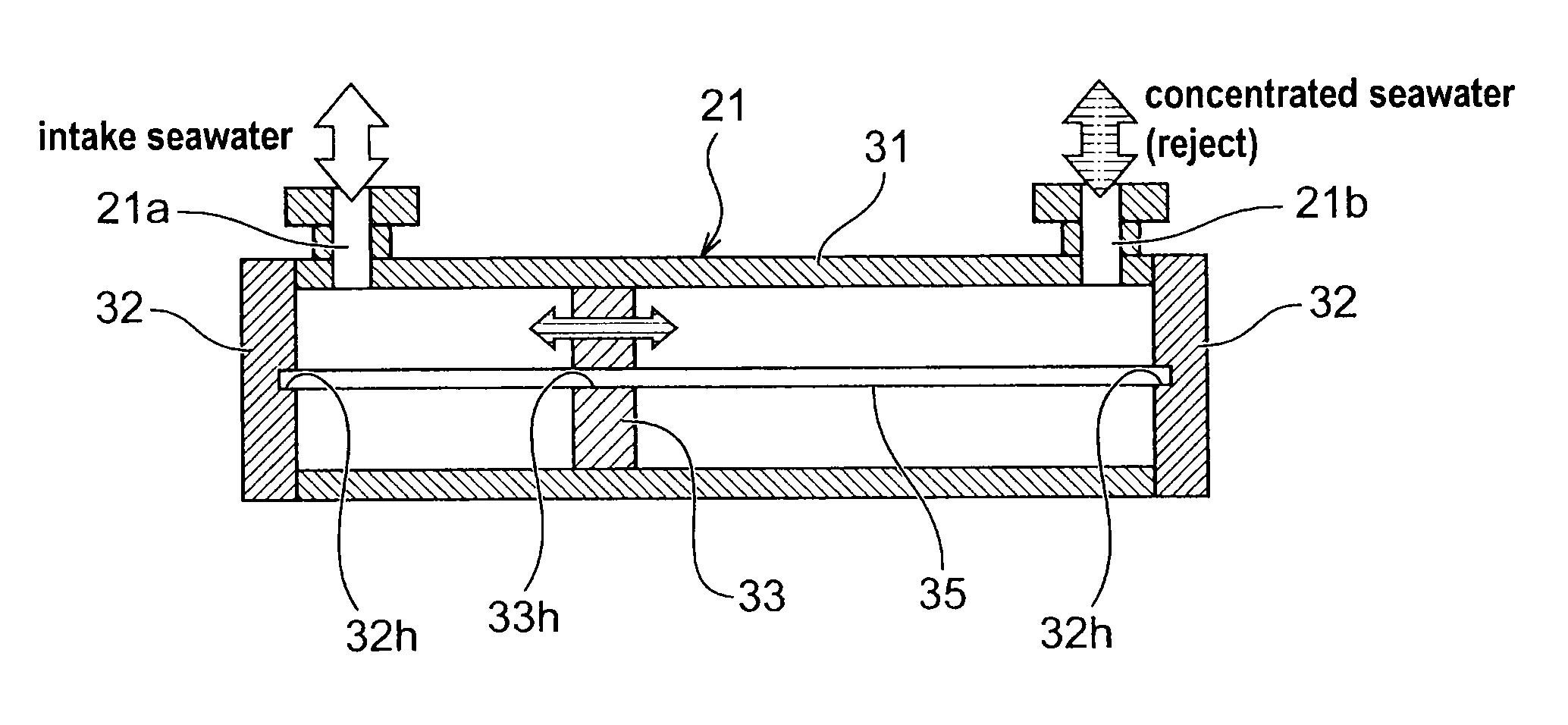

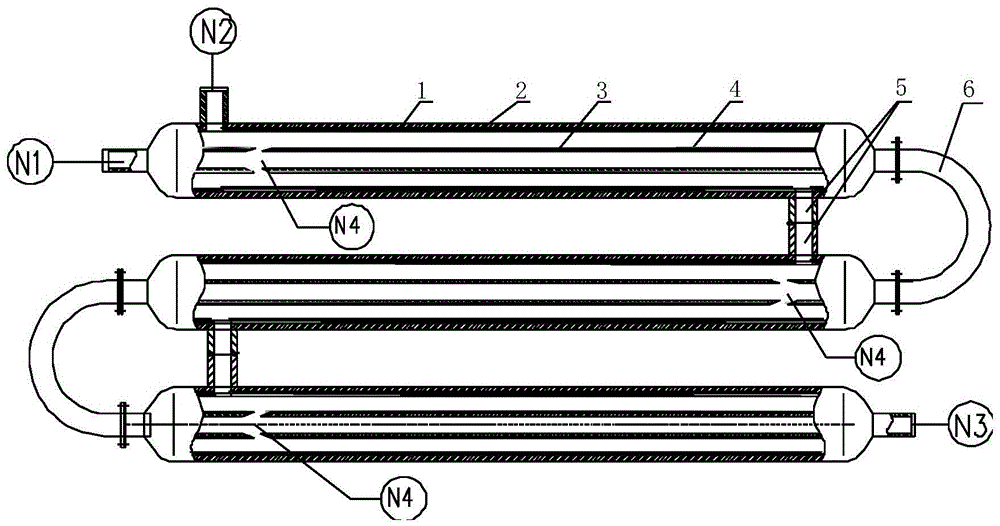

Power recovery chamber

ActiveUS20090242471A1Reduce generationExtend service lifeGeneral water supply conservationSeawater treatmentReciprocating motionPiston Guide

A power recovery chamber is used for a positive-displacement power recovery apparatus in the seawater desalination plant or system. The power recovery chamber includes a cylinder, a piston disposed in the cylinder and capable of being reciprocated in a longitudinal direction of the cylinder, and a piston guide disposed in the cylinder and extending in the longitudinal direction of the cylinder for guiding the piston when the piston is reciprocated in the longitudinal direction of the cylinder. At least a part of an outer circumferential surface of the piston is out of contact with an inner surface of the cylinder, and the piston is brought into contact with the piston guide at a part where the piston guide passes through the piston.

Owner:EBARA CORP

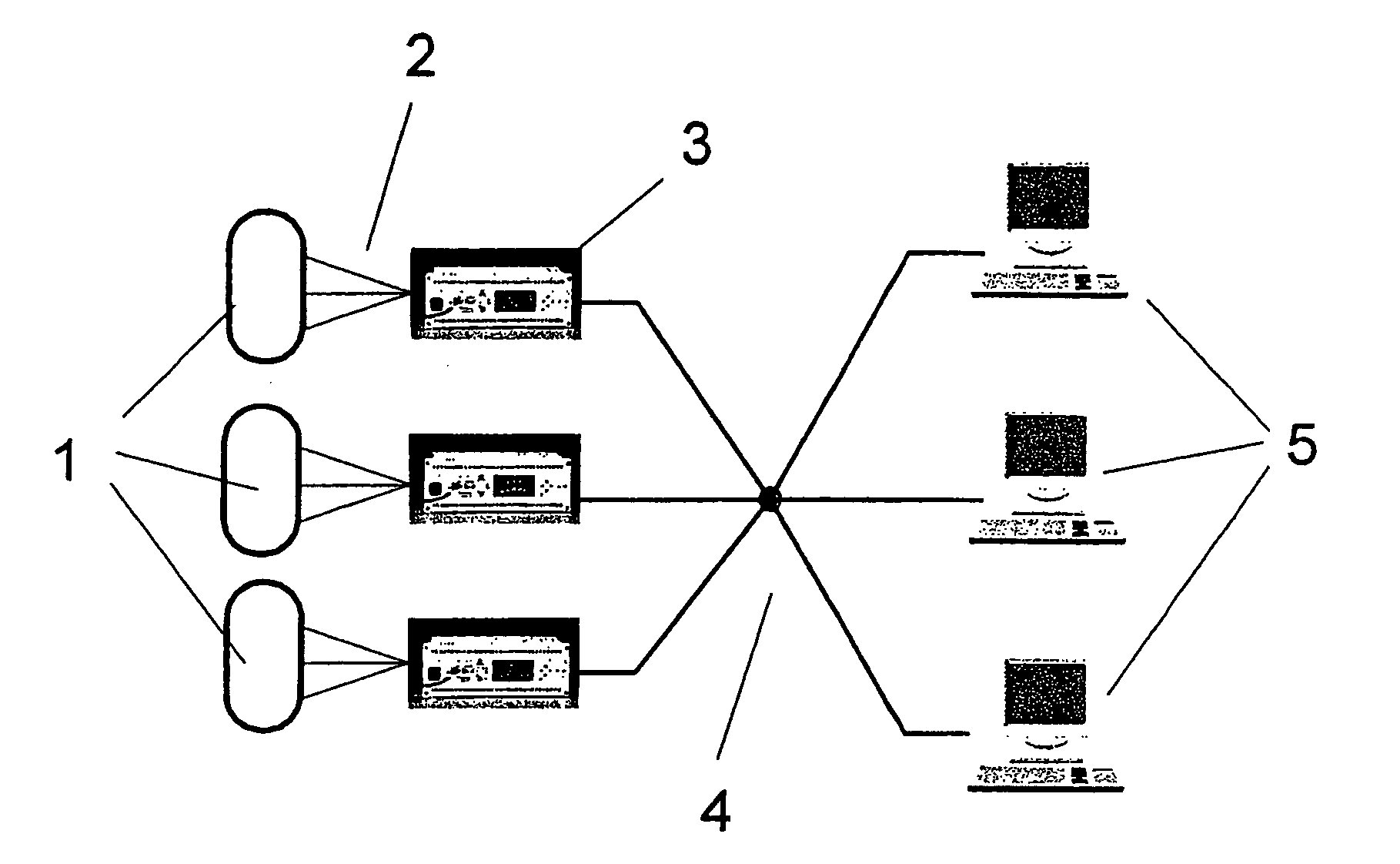

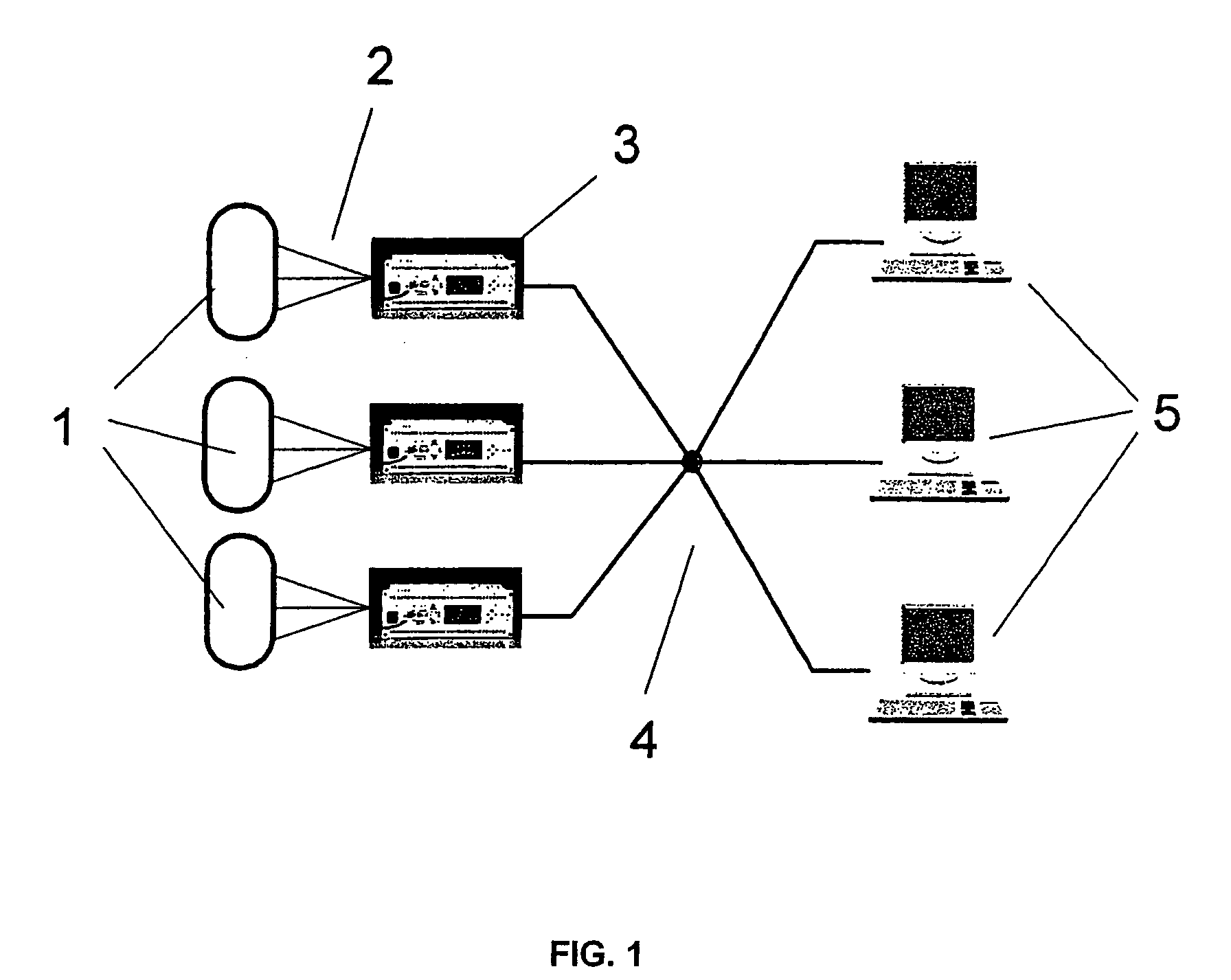

Condition monitoring in technical processes

ActiveUS20050171705A1Diminish energy consumptionExtend service lifeProgramme controlElectric testing/monitoringCondition monitoringNormal conditions

The invention makes a contribution in order that machines and installations are better utilized, their service life is extended, reliability is improved, the loss of valuable materials is avoided, test results are optimized, and energy consumption is diminished. It is an expert system that acquires and assesses the condition of installations, machines and apparatuses. The mechanism proceeds from a normal condition and permanently observes short-term, medium-term and long-term changes. If variations in the normal condition are detected promptly, major instances of damage can be avoided by promptly performing corrective actions before major instances of damage associated with prolonged downtimes occur.

Owner:RENNER PETER

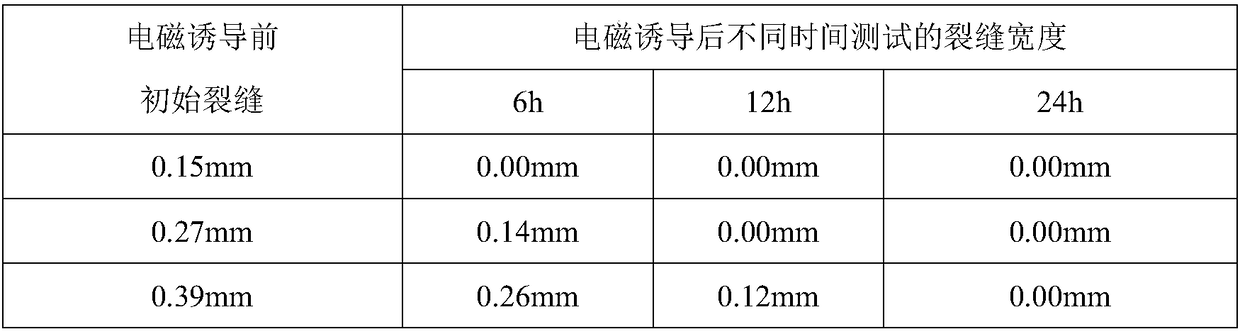

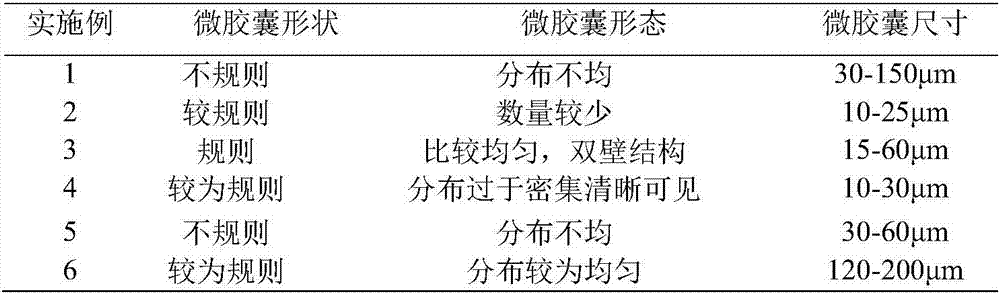

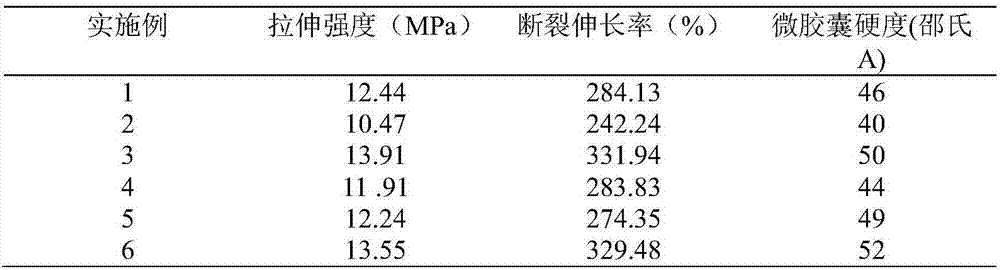

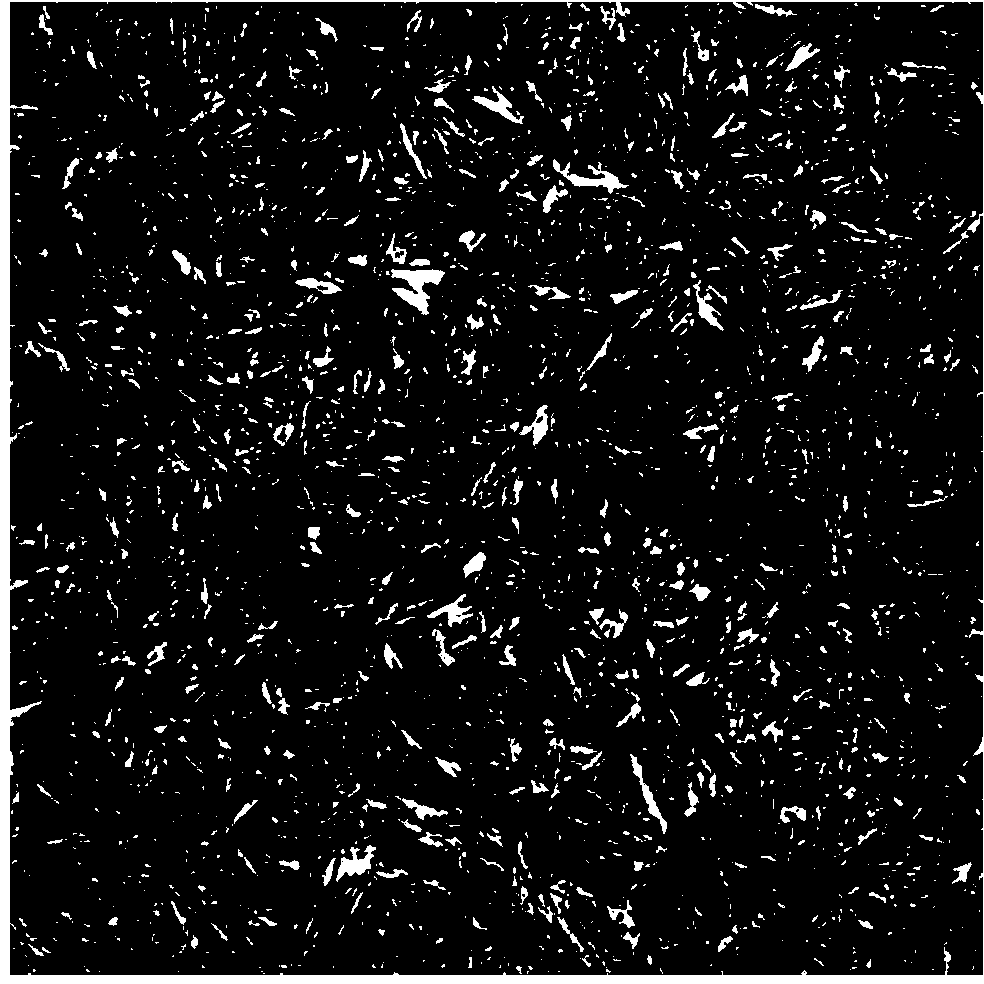

Electromagnetically-induced self-repairing epoxy resin type microcapsule for cement concrete cracks and preparation method thereof

ActiveCN108395137AStrong self-healing abilityExtend service lifeMicroballoon preparationMicrocapsule preparationPolyamidePOLYETHYLENE WAX

The invention belongs to the technical field of concrete, and particularly relates to an electromagnetically-induced self-repairing epoxy resin type microcapsule for cement concrete cracks and a preparation method thereof. The microcapsule consists of an epoxy resin microcapsule body and a curing agent microcapsule body. According to the microcapsule and the preparation method thereof, a paraffin / petroleum resin / polyethylene wax / iron powder mixture serves as a capsule wall, and epoxy resin and a low-molecular polyamide curing agent serve as a capsule core of the microcapsule; and when concretegenerates the cracks, the propagation tip stress of part of the cracks is large, so that the capsule wall of the microcapsule can be broken, the epoxy resin or the low-molecular polyamide curing agent inside the capsule flows out and is diffused to enter the cracks, curing reaction is generated to form a cross-linked product, so that the cracks can be repaired in time, cracks which are not repaired in time can enable the capsule wall of the microcapsule to be heated and melted under the action of an applied electromagnetic field, and the epoxy resin or the low-molecular polyamide curing agentis diffused to enter the cracks, so that the cracks can be repaired. The epoxy resin microcapsule has the advantages of being capable of endowing the concrete with stronger crack self-repairing capability and capable of prolong the service life of the concrete.

Owner:WUHAN UNIV OF TECH

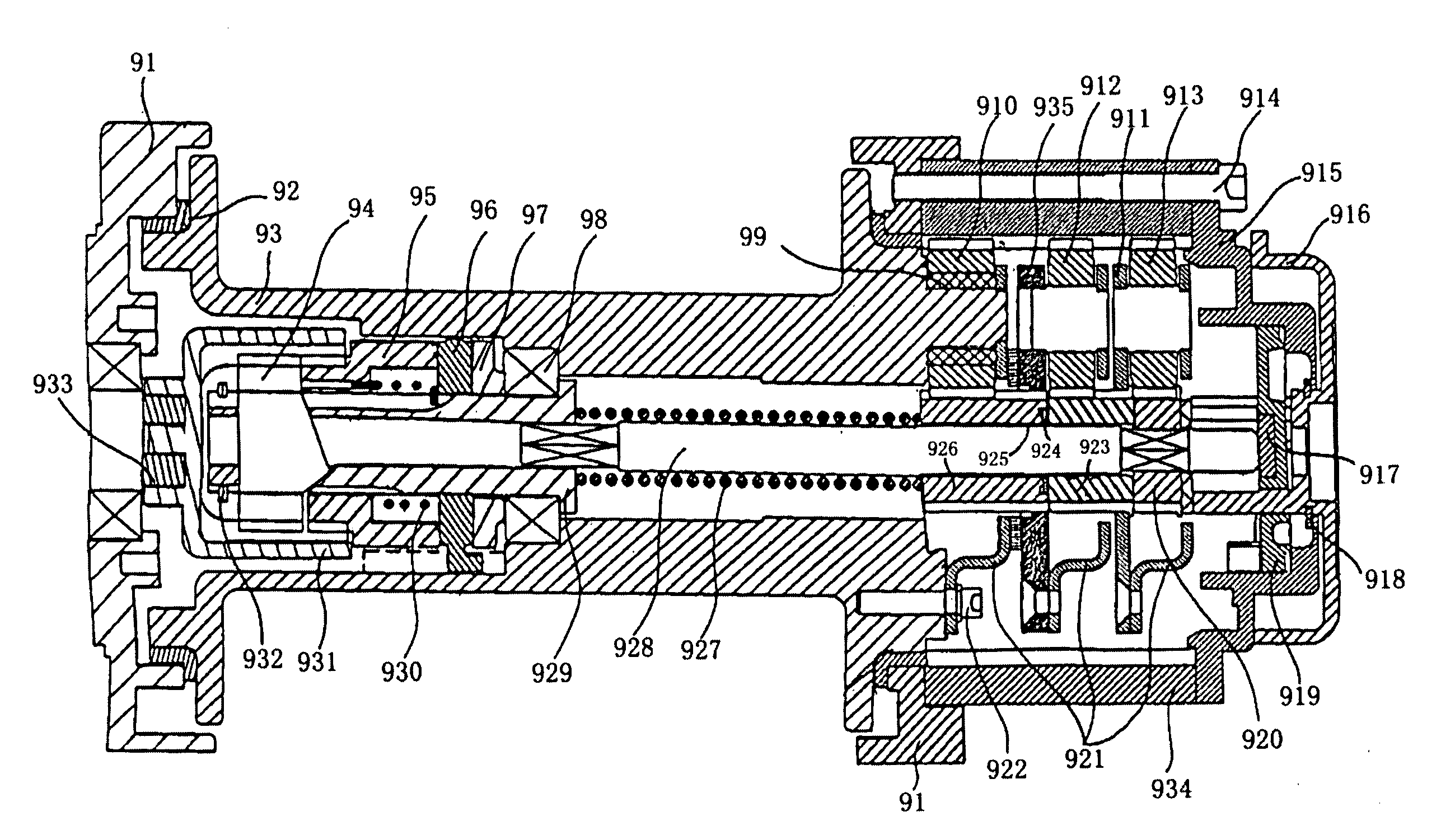

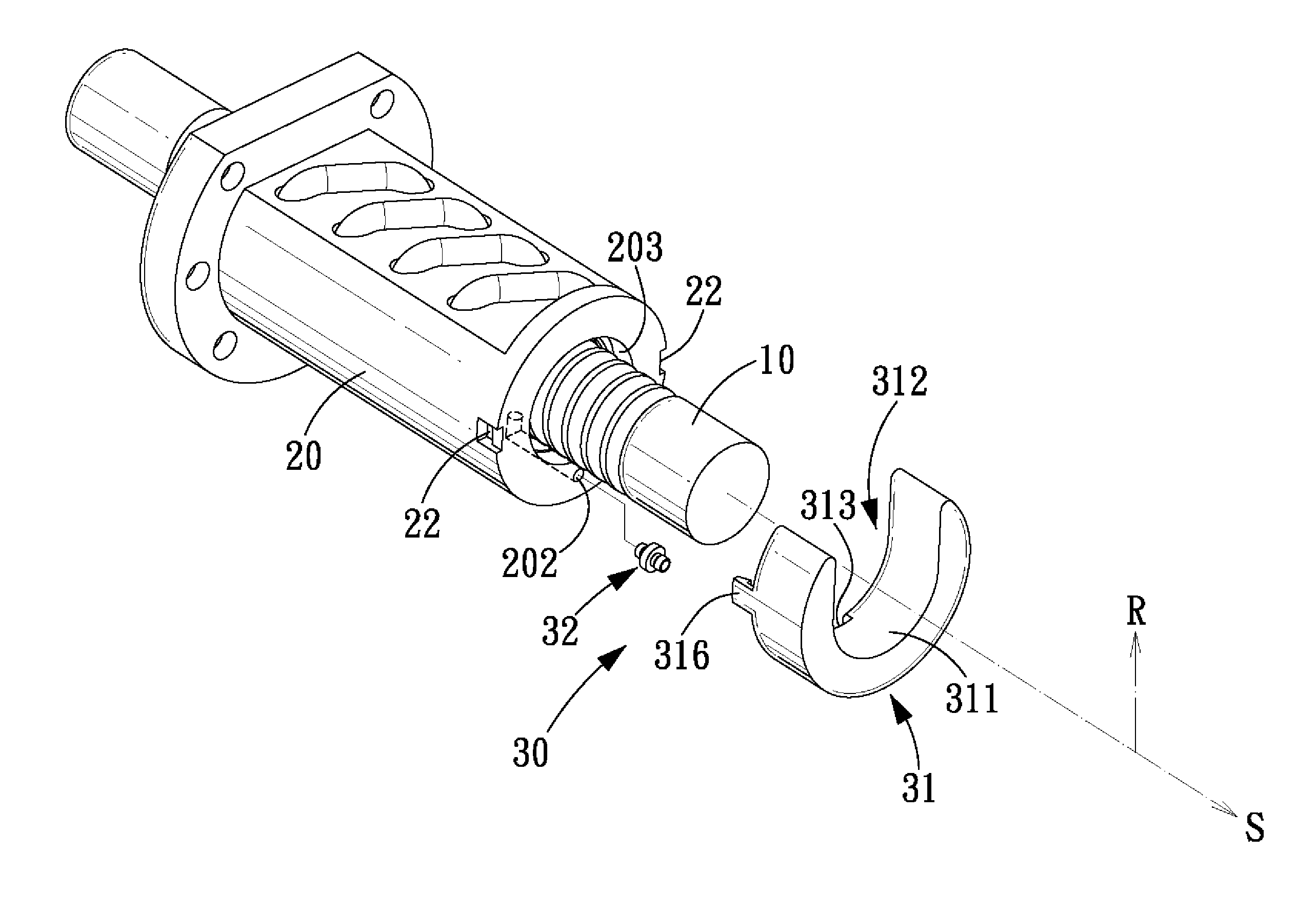

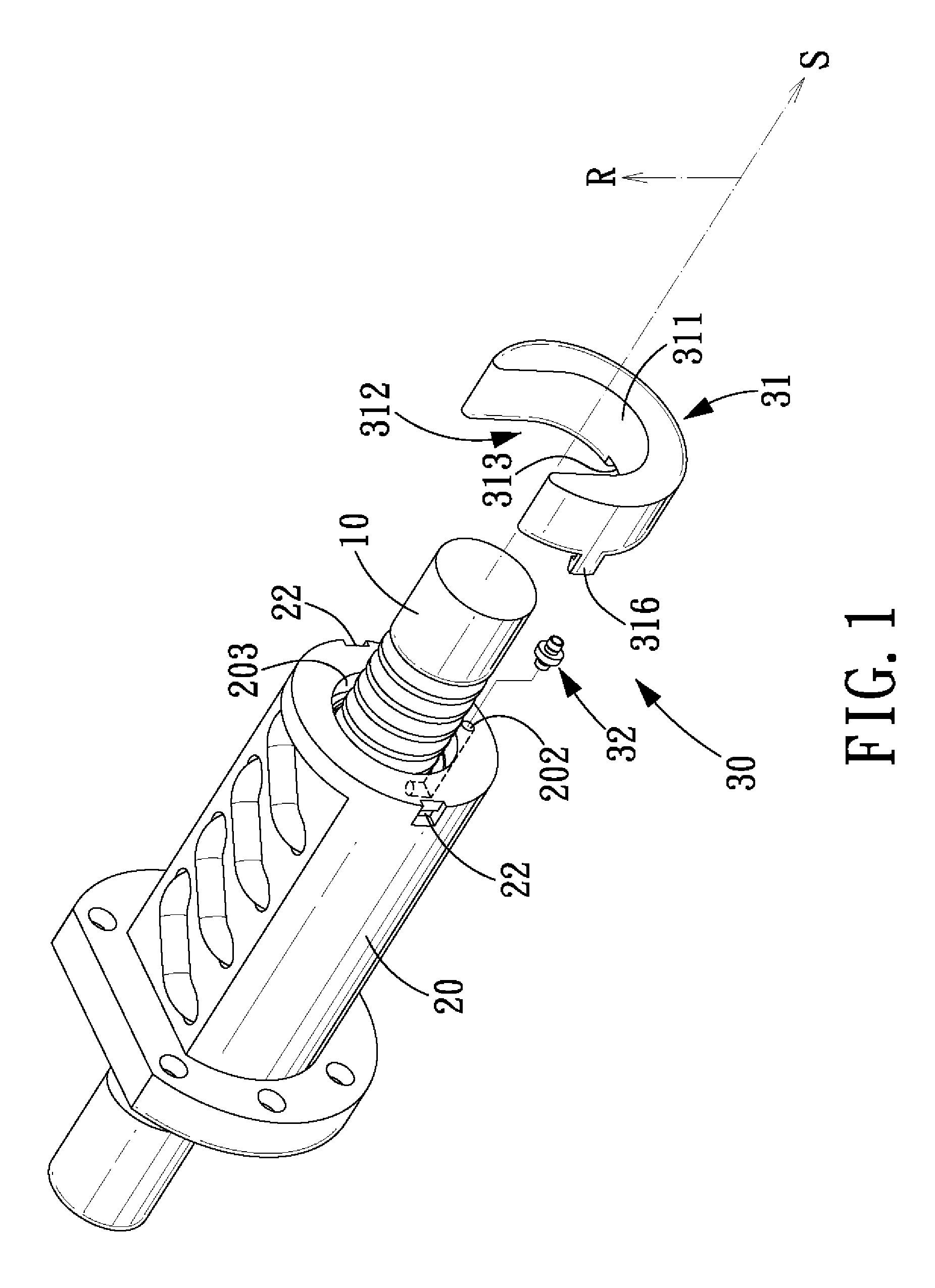

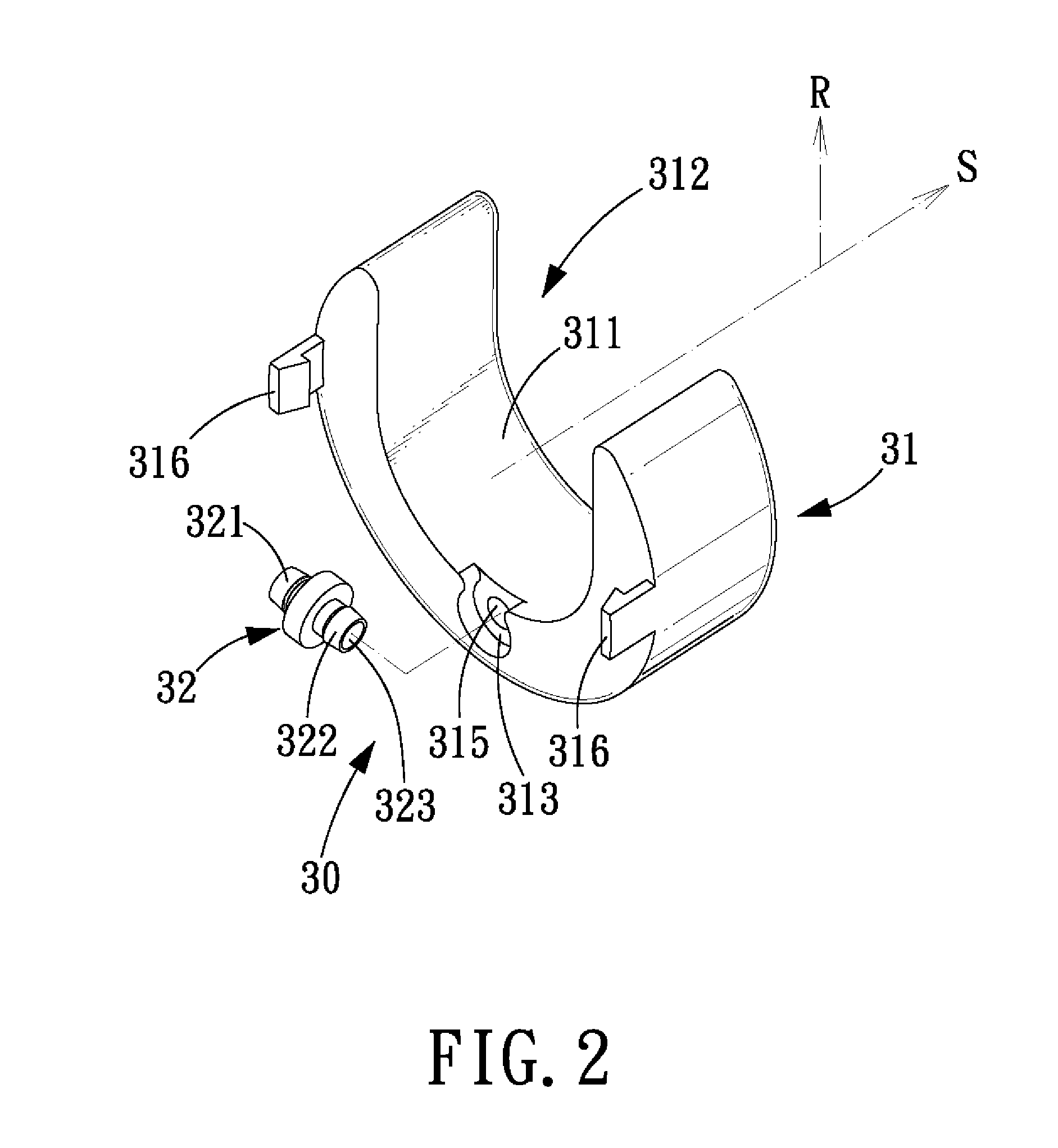

Ball screw with an oil-storage unit

ActiveUS20120266703A1Extend service lifeEasily assembleToothed gearingsGear lubrication/coolingConvex structureBall screw

A ball screw with an oil-storage unit, the oil-storage unit includes an oil tank and a connector. The connector has one end formed in the form of a convex or concave structure, and the connecting end of the oil tank is also in the form of a concave or convex structure for engaging with the connector, so as to achieve quick assembling of the connector onto the oil tank through the engagement of the convex and concave structures. Since the oil-storage unit can be quickly replaced after the oil is used up, which provides an automatic and continuous self-lubricating function to the ball screw, and consequently extending the service life of the ball screw.

Owner:HIWIN TECH

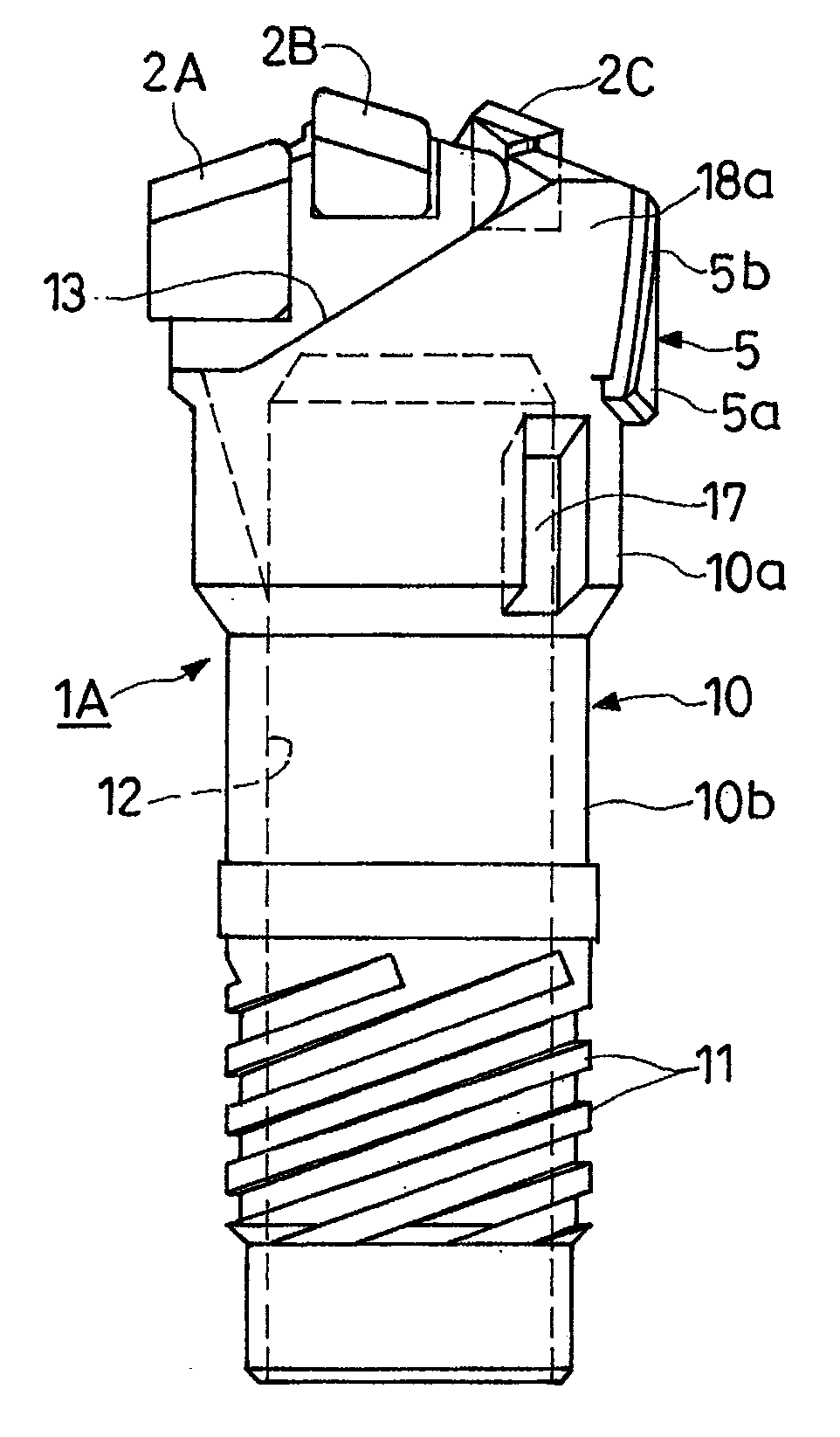

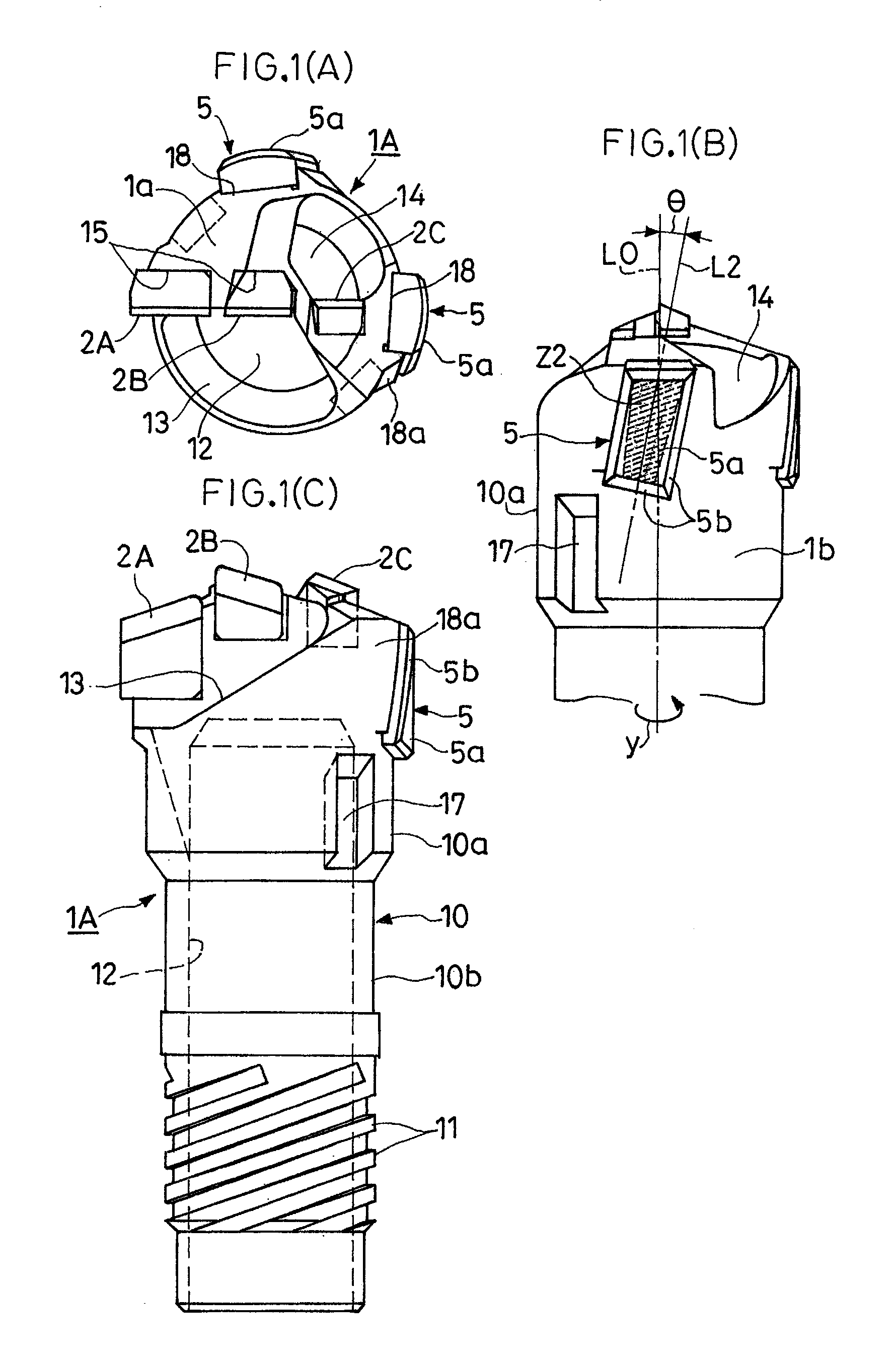

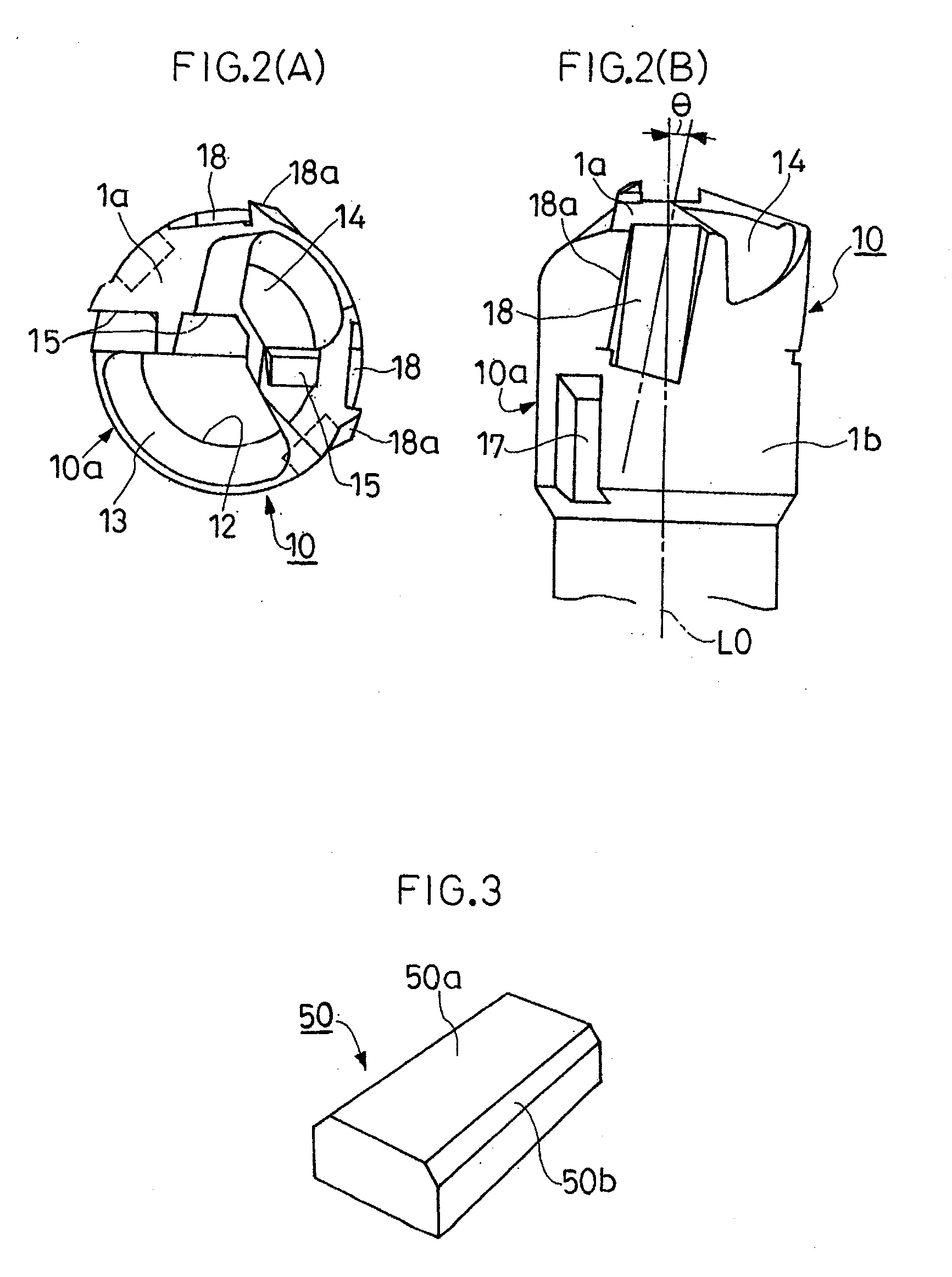

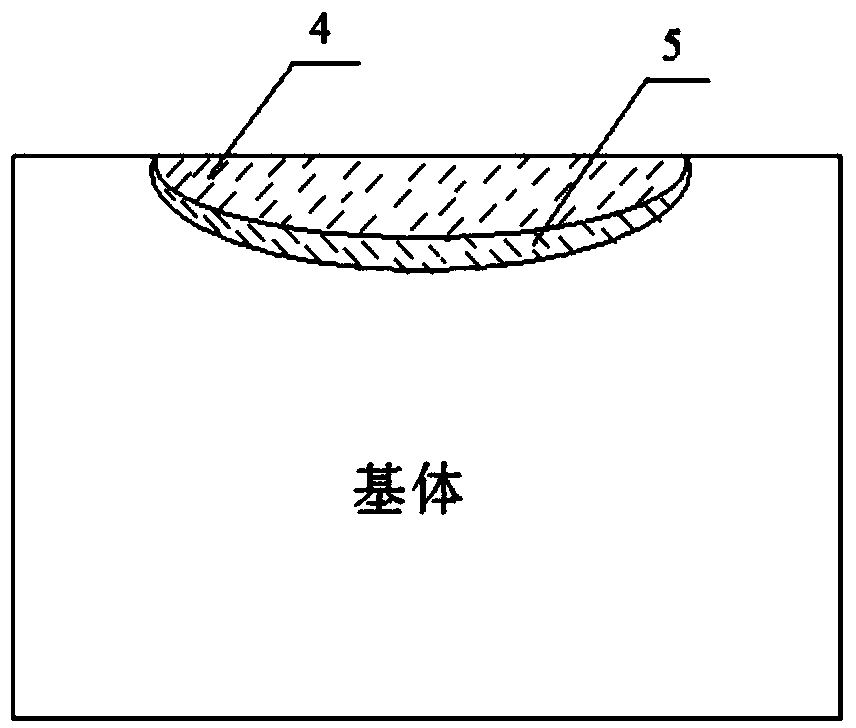

Deep Hole Cutting Apparatus

InactiveUS20100040425A1Improve workExtend service lifeDrilling/boring measurement devicesTool workpiece connectionEngineeringDeep hole

A deep hole cutting apparatus has a guide pad brazed to a cutting head section. With the deep hole cutting apparatus, high machining accuracy can be obtained in a stable cutting status and the service life of the guide pad is lengthened. A guide pad (5) brazed to a cutting head section (10a) is diagonally arranged so that the leading end side of the tool is closer to the front side in a tool rotating direction (y) compared with the rear end side of the tool.

Owner:YUNITAKKU

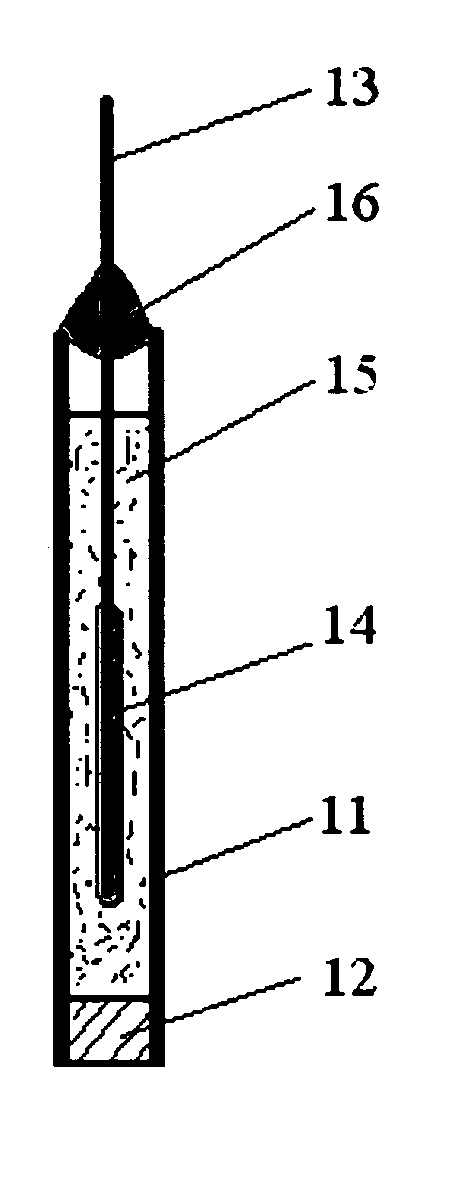

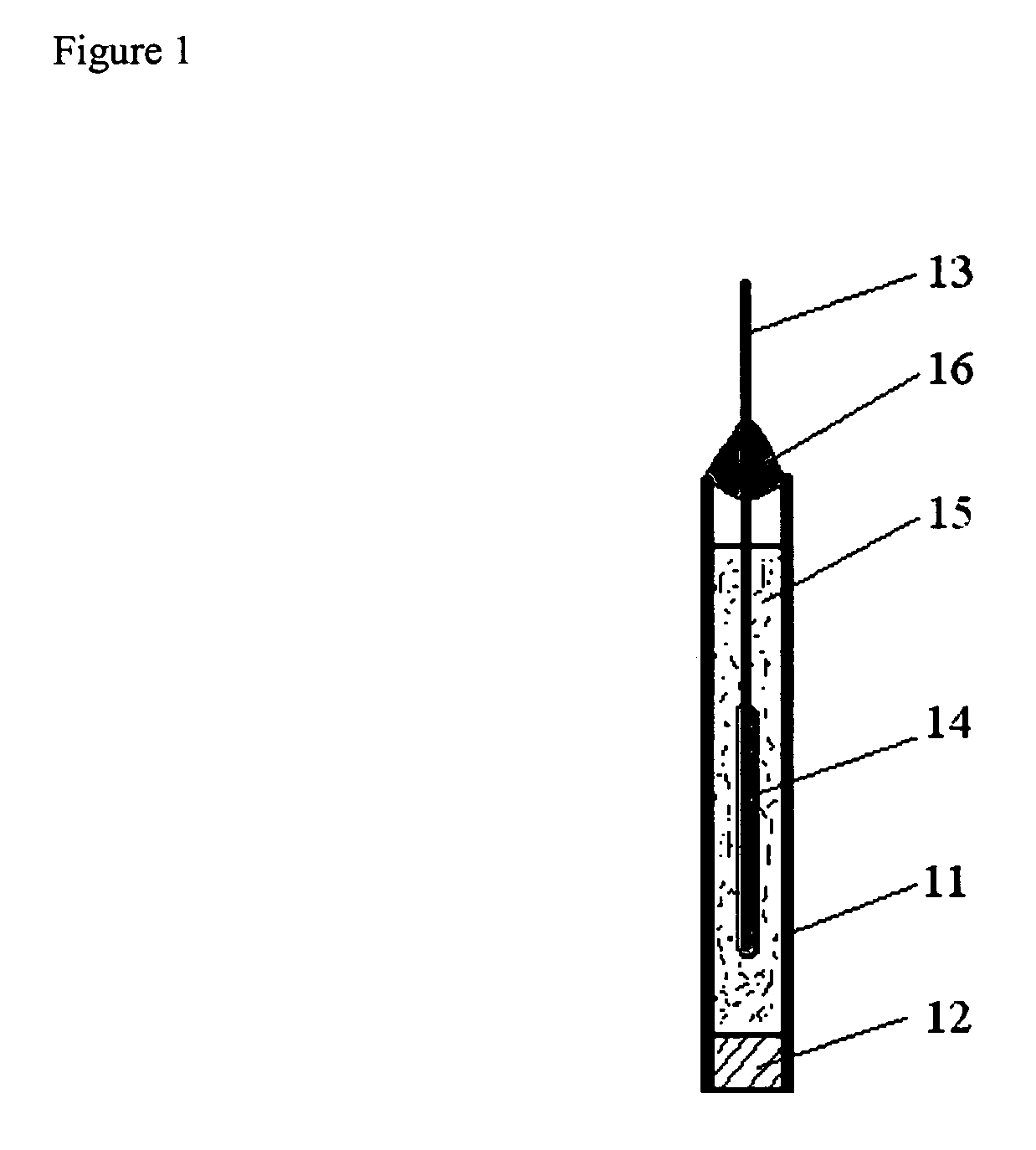

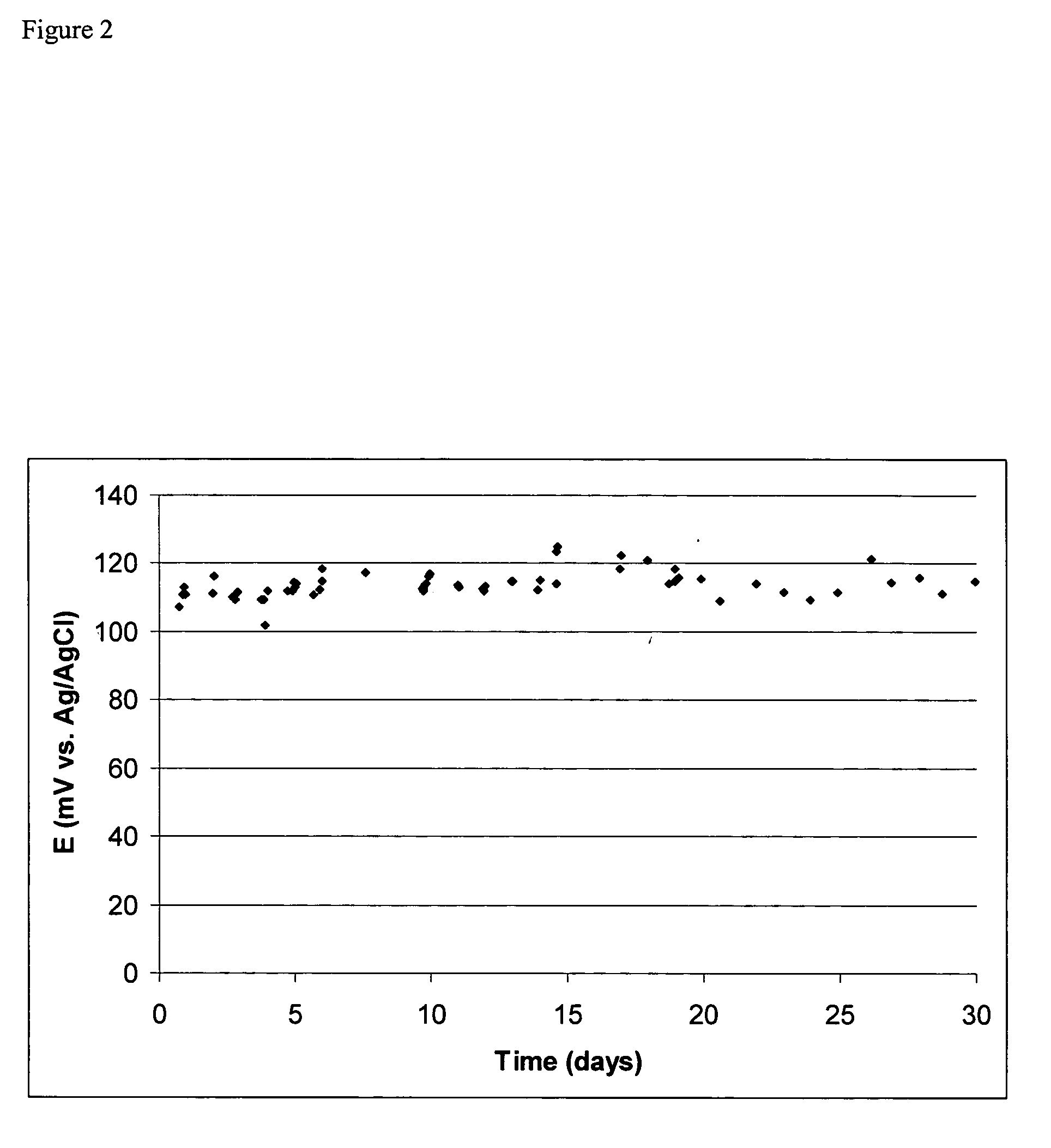

Reference electrode

InactiveUS20050258039A1Extend service lifeResistive failMaterial electrochemical variablesPolyelectrolyteAnalytical chemistry

A reference electrode consisting of a metal in contact in contact with an electrolyte containing an anion or cation whose concentration in part determines the redox potential of the electrode? This electrolyte contains a polyelectrolyte that partially and reversibly binds this chemical cation or anion thus lowering the free concentration of the cation or anion compared to the osmotic pressure of the same concentration of cation or anion if present as a simple salt. The polyelectrolyte can be anionic or cationic depending on the chemistry of the redox electrode and a thickener may also be added to the electrolyte.

Owner:MATCO ASSOCS

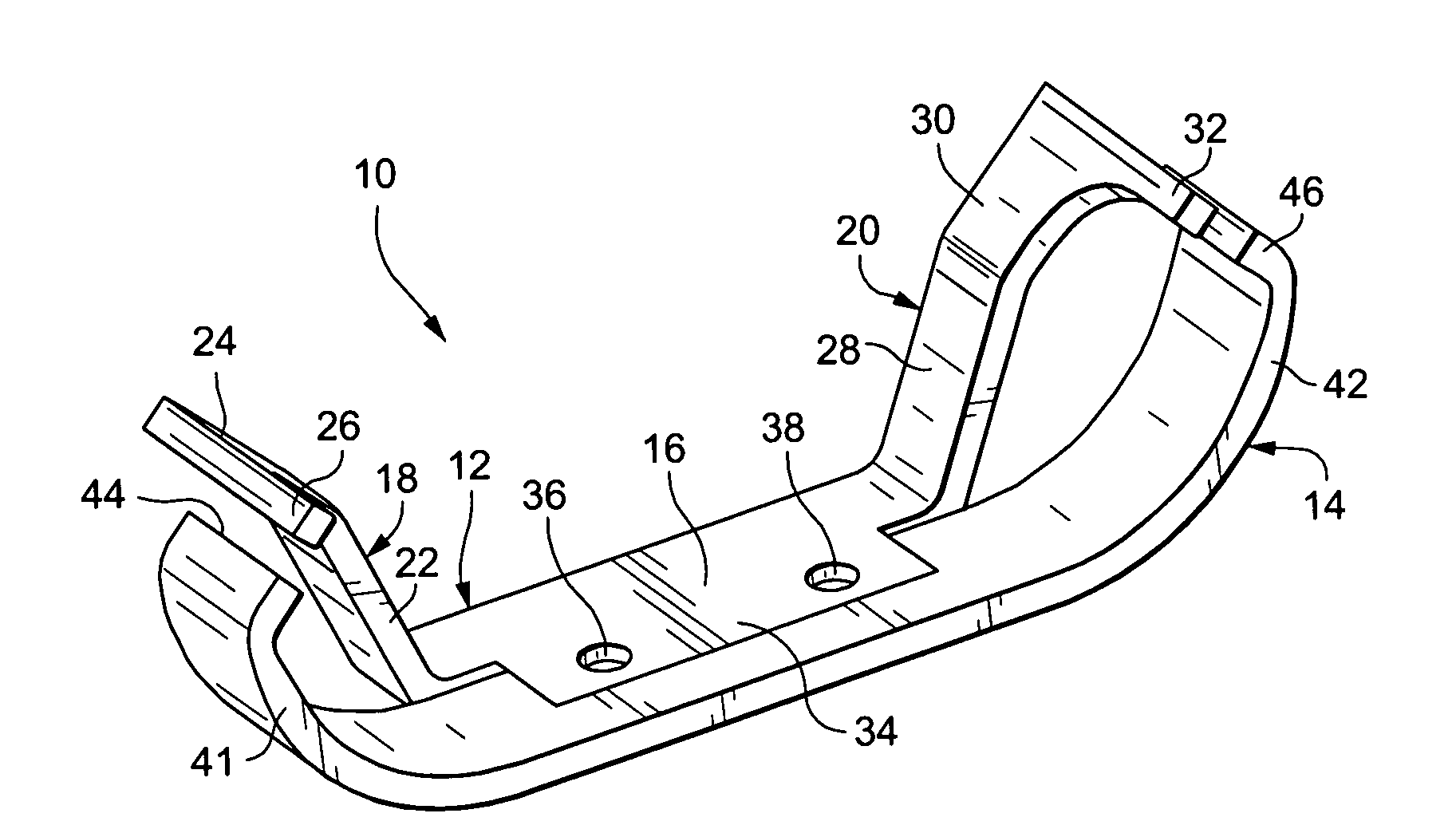

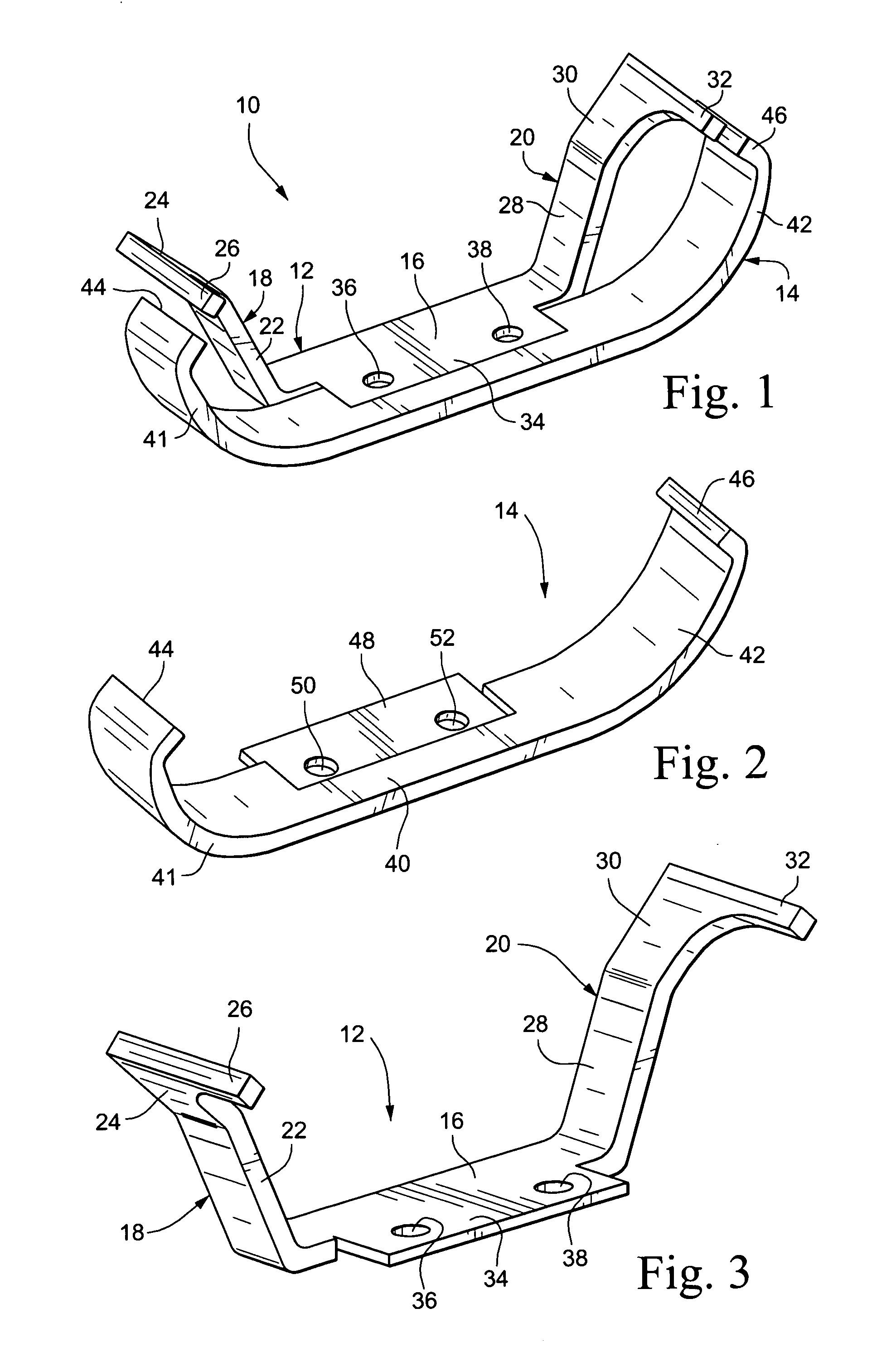

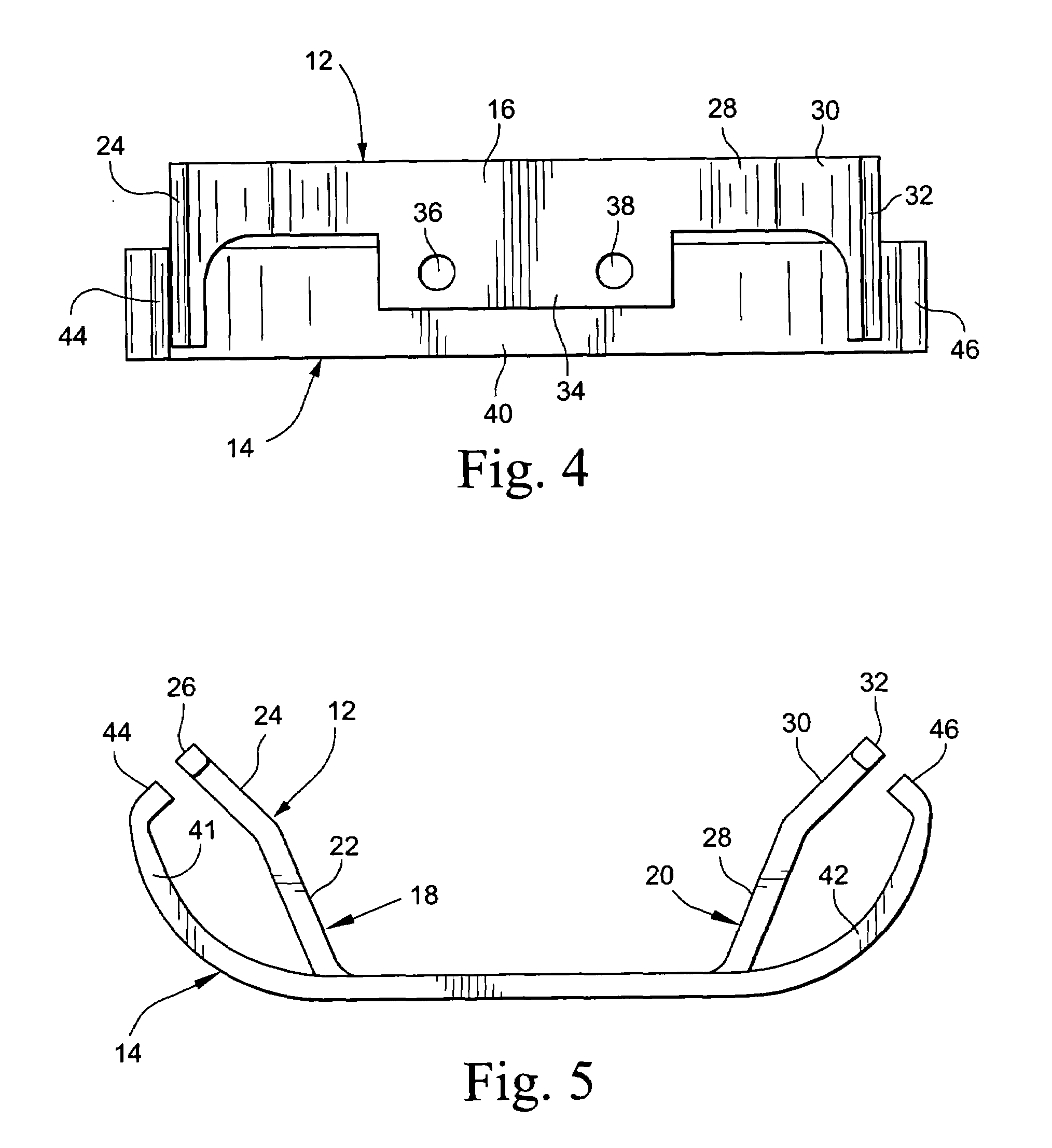

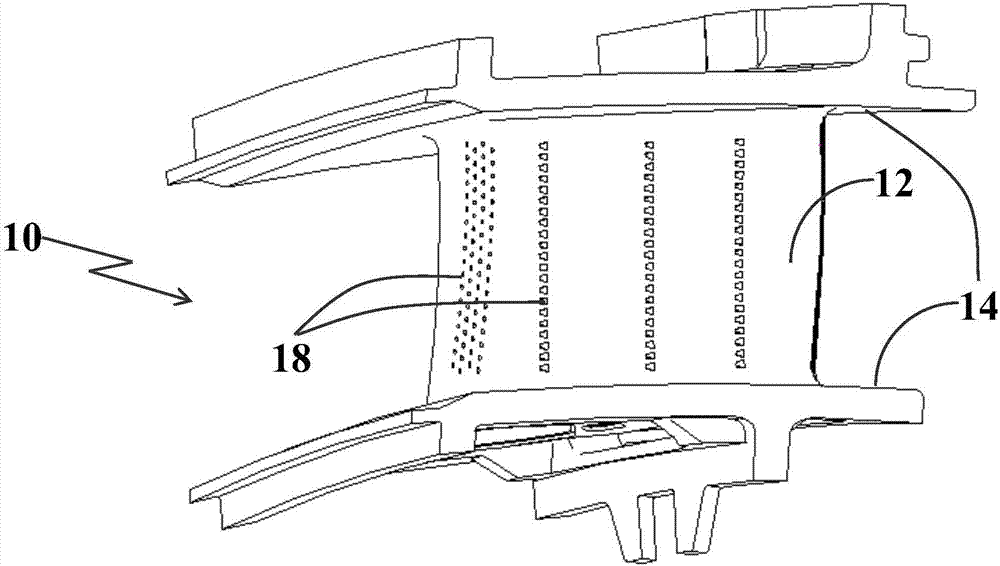

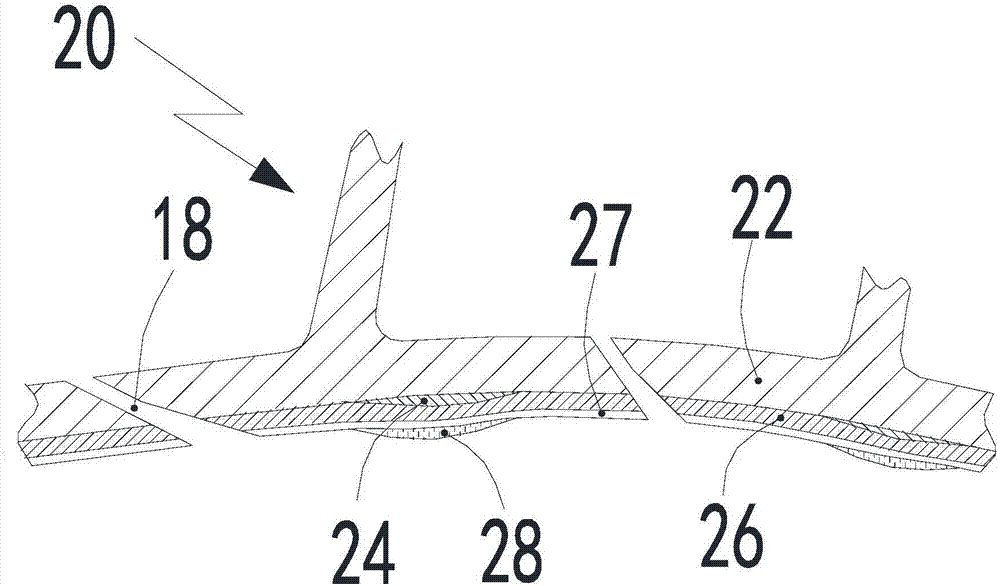

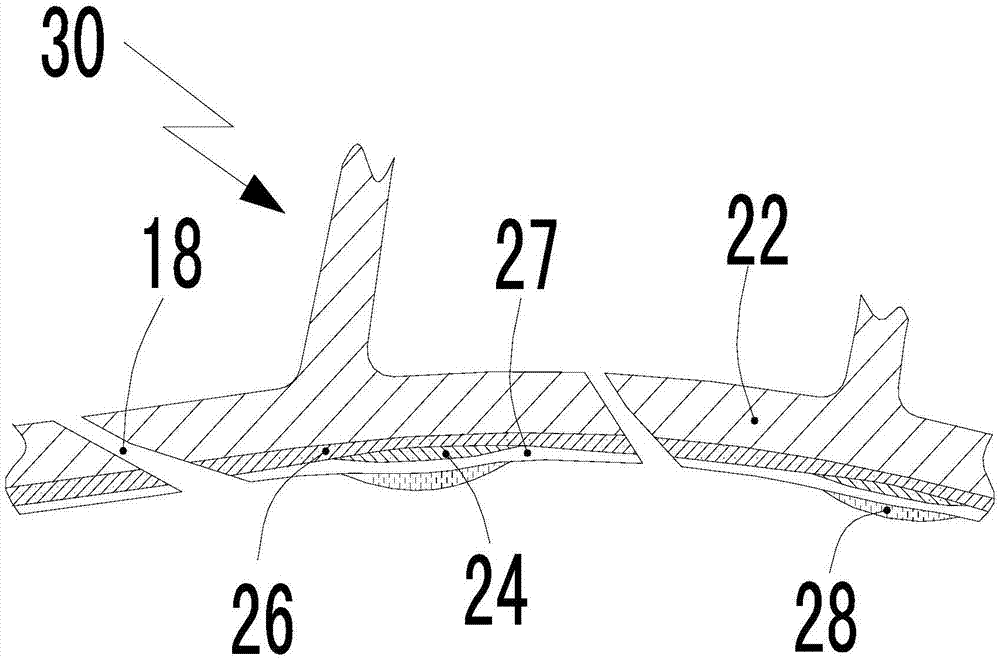

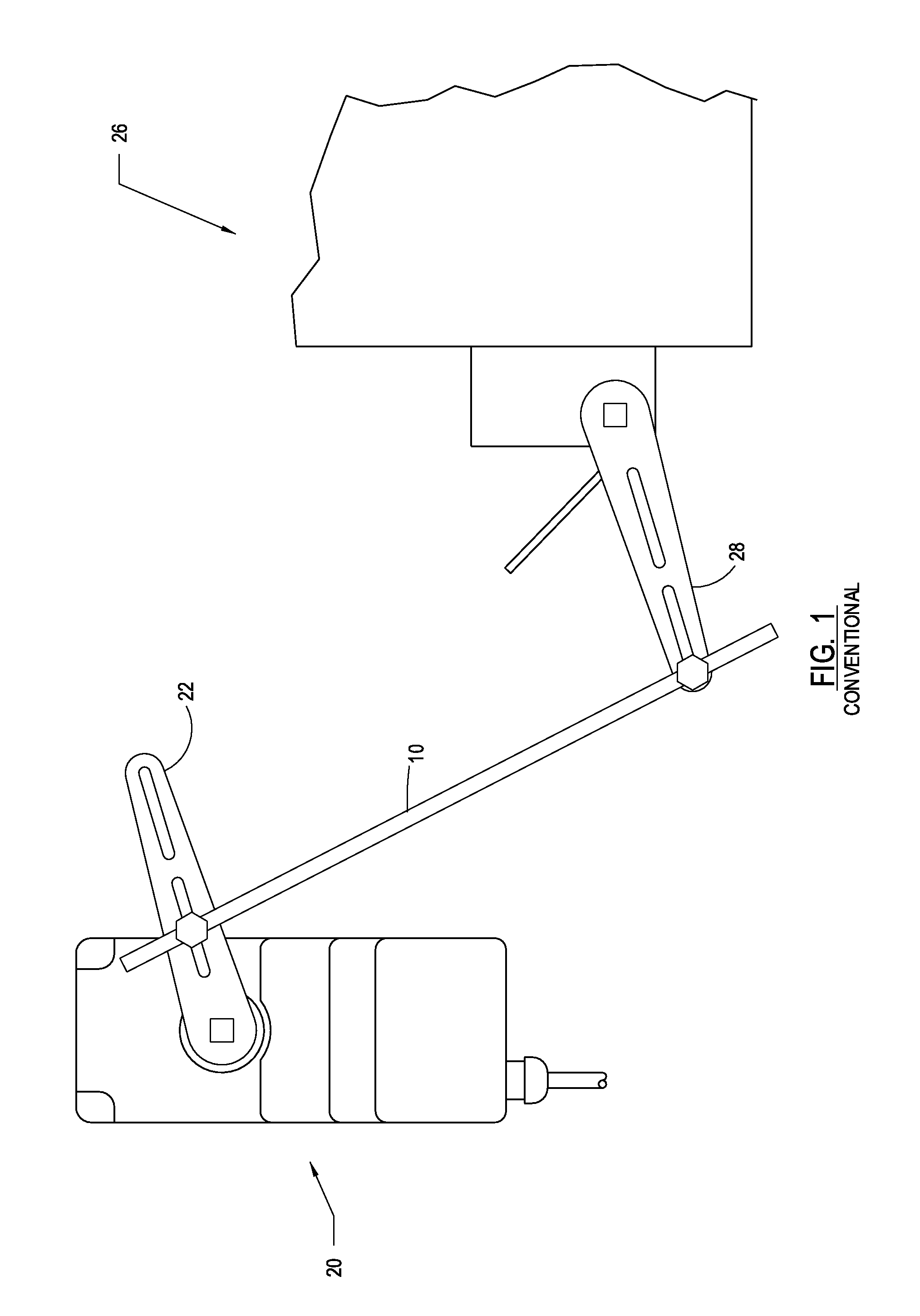

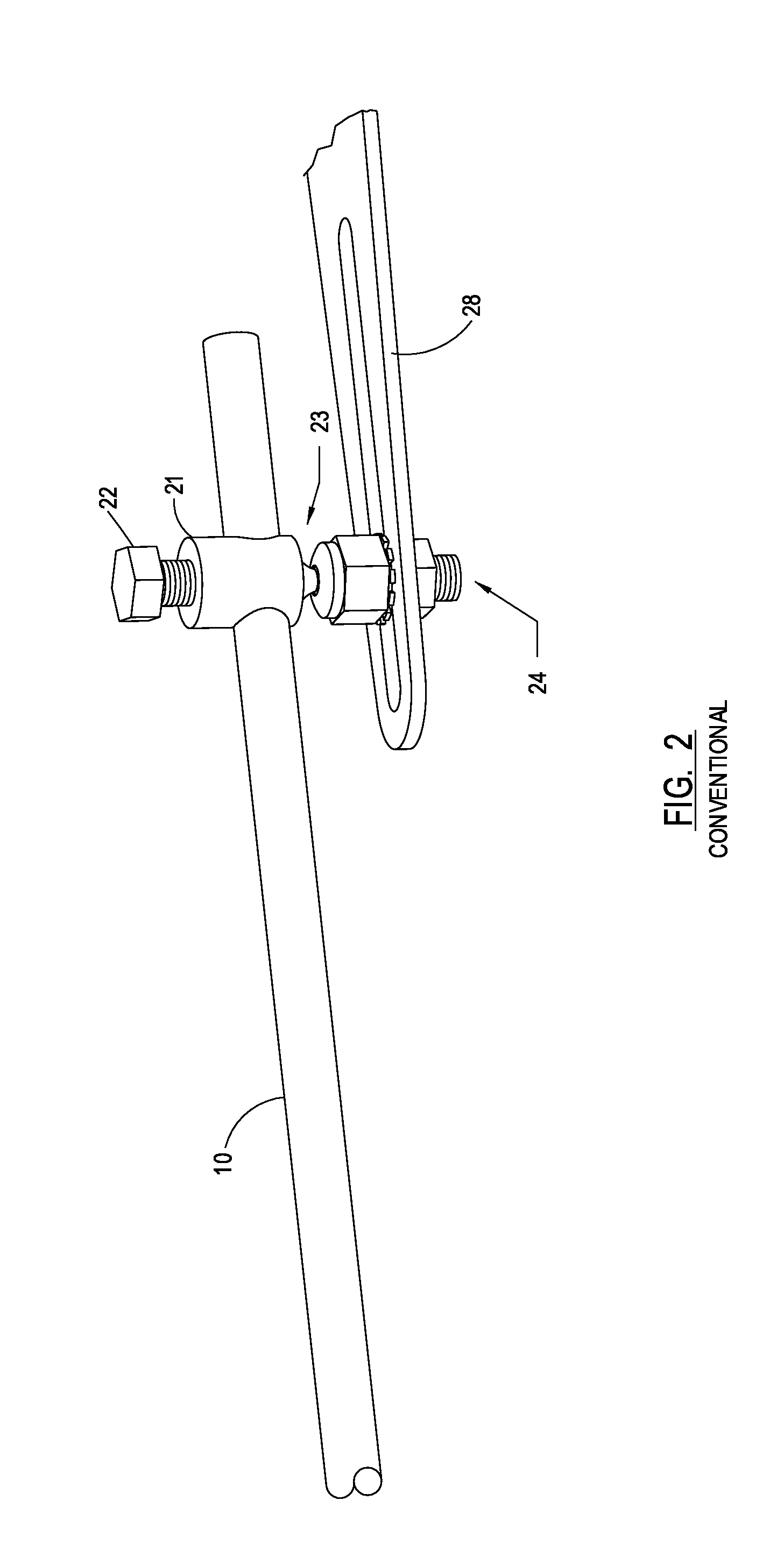

Transition piece mounting bracket and related method

ActiveUS20090321608A1Great specify service lifeExtend service lifePortable framesCandle holdersEngineeringCombustor

A mounting bracket assembly includes: a first bracket component having a first pair of laterally spaced securement tabs; a second bracket component having a second pair of laterally spaced securement tabs; wherein said first and second bracket components are engageable with each other such that respective ones of each of the first and second pairs of securement tabs are located adjacent each other and adapted to engage corresponding pairs of recesses in a machine component. A related method of securing a transition piece to a combustor casing without welding includes: providing a first mounting bracket component for attaching the transition piece to a turbine combustor casing, the first mounting bracket formed with a first set of securement tabs; providing a second mounting bracket component that is usable with the first bracket component, the second mounting bracket component formed with a second set of securement tabs; and slidably engaging the transition piece with the first and second mounting bracket components, such that the first and second pairs of securement tabs are received within corresponding axially-aligned recesses provided on the transition piece, thereby permitting the transition piece to grow thermally relative to the first and second mounting bracket components.

Owner:GENERAL ELECTRIC CO

Corrosion inhibition scale-removing agent used for CO2 flooding as well as preparation method and use method of corrosion inhibition scale-removing agent

ActiveCN109609110AExtend service lifeExtended service lifeOrganic chemistryDrilling compositionChemistryDiethylenetriaminepentaacetic acid

The invention provides a corrosion inhibition scale-removing agent used for CO2 flooding as well as a preparation method and use method of the corrosion inhibition scale-removing agent. The corrosioninhibition scale-removing agent is composed of the following substances, in percentages by weight: 17-21% of benzoic acid thioureido imidazoline, 1-3% of benzoic acid phosphate thioureido imidazoline,9-13% of isopropanol, 7-11% of acetic acid, 11-15% of sodium polyepoxysuccinate, 3-7% of OP-10, 12-16% of quinoline quaternary ammonium, 3-7% of poly(sodium-styrennesulfonate), 5-9% of ethylenediaminetetraacetic acid disodium salt, 11-15% of diethylenetriaminepentaacetic acid pentasodium salt, 2-6% of N-dodecyl methylene bis-sec-ammonium salt, and the balance of water. The corrosion inhibition scale-removing agent provided by the invention overcomes the problem that a current corrosion inhibitor usually has a single corrosion inhibiting effect and a current scale inhibitor usually has a single scale inhibiting effect, can effectively play a corrosion inhibition effect while efficiently preventing scaling of oilfield water, and especially has a better scale-removing effect on barium strontium scale formed by formation water with high barium and strontium ions.

Owner:PETROCHINA CO LTD

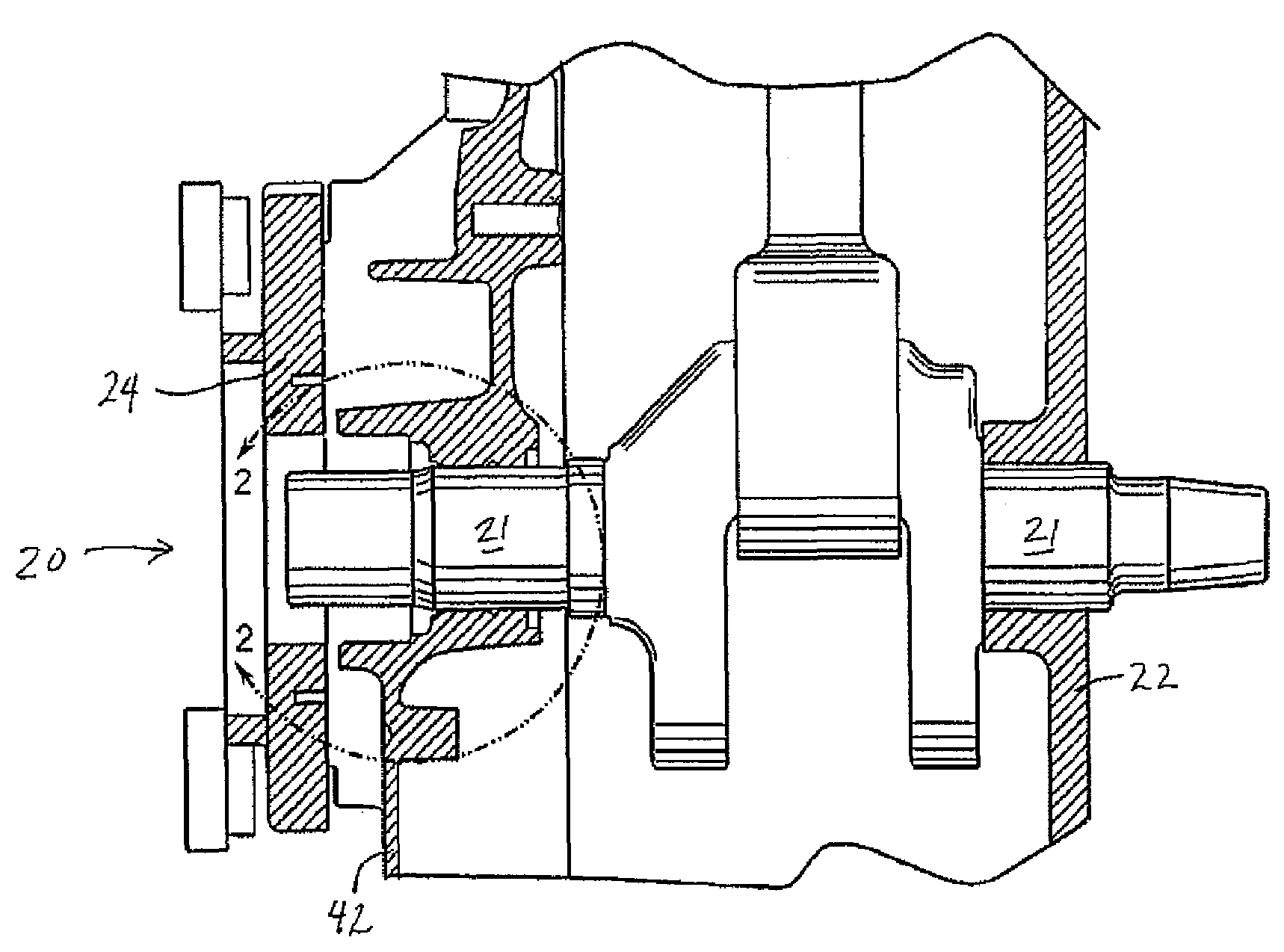

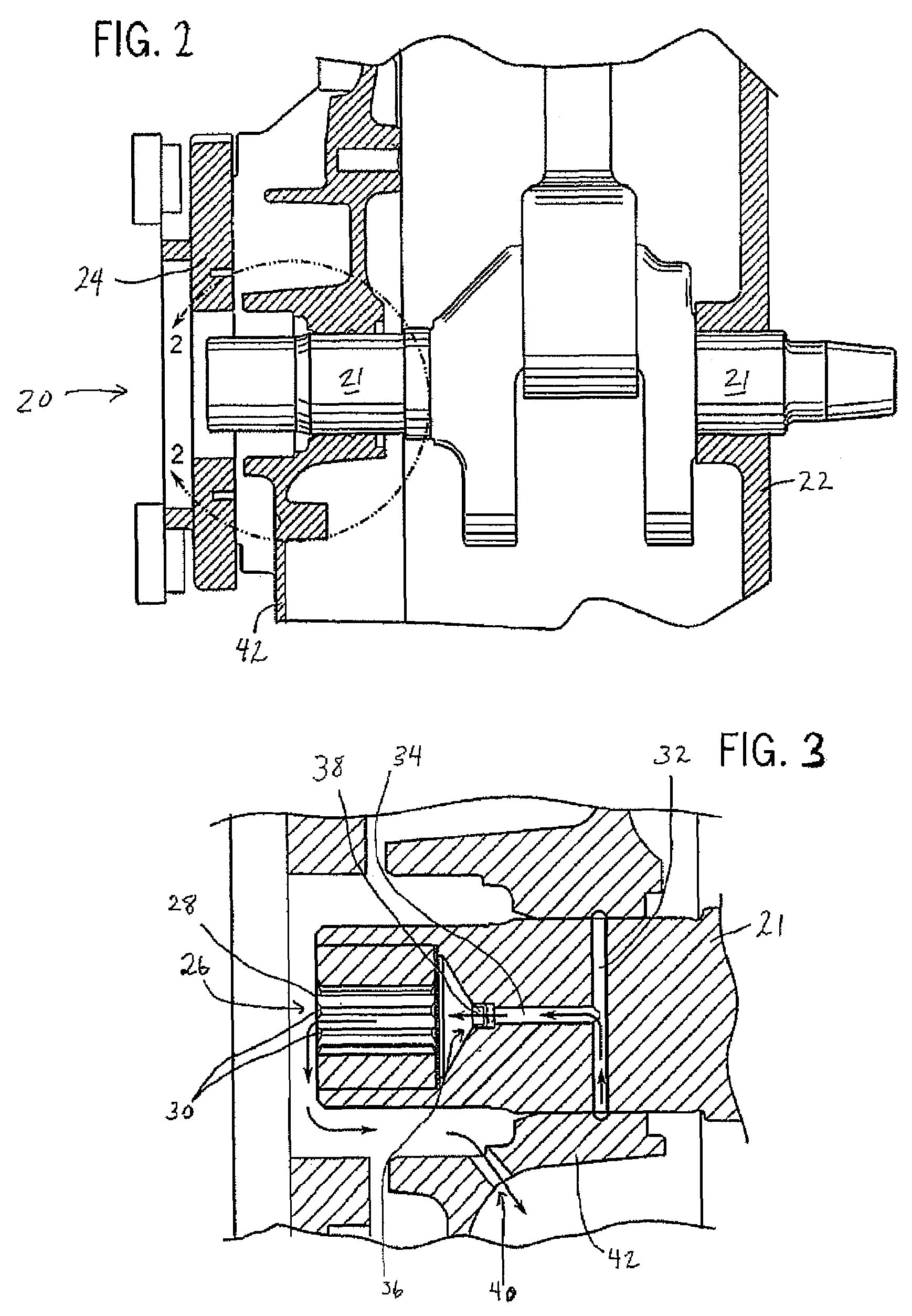

System and Method for Lubricating Power Transmitting Elements

InactiveUS20080149423A1Reduce wearExtend service lifeLubrication of auxillariesLubricant conduit arrangementsLubricationEngineering

Disclosed herein is a lubrication system and method. The system includes a main engine bearing and a crankshaft in operational association with the bearing. The crankshaft includes an end having a cavity with a power transmitting element (e.g., splines). The cavity can receive and engage an additional mechanism to transmit power thereto. The crankshaft further includes a first oil passage that is disposed within the end and a second oil passage that extends from the main engine bearing into the crankshaft. The first oil passage intersects the second oil passage. The system also includes a pump mechanism for circulating lubricating oil from the main engine bearing to the crankshaft through the second oil passage and the first oil passage, and to the cavity to lubricate the power transmitting element. During engine operation, a constant supply of lubricating oil can be provided to the power transmitting element to reduce component wear.

Owner:KOHLER CO

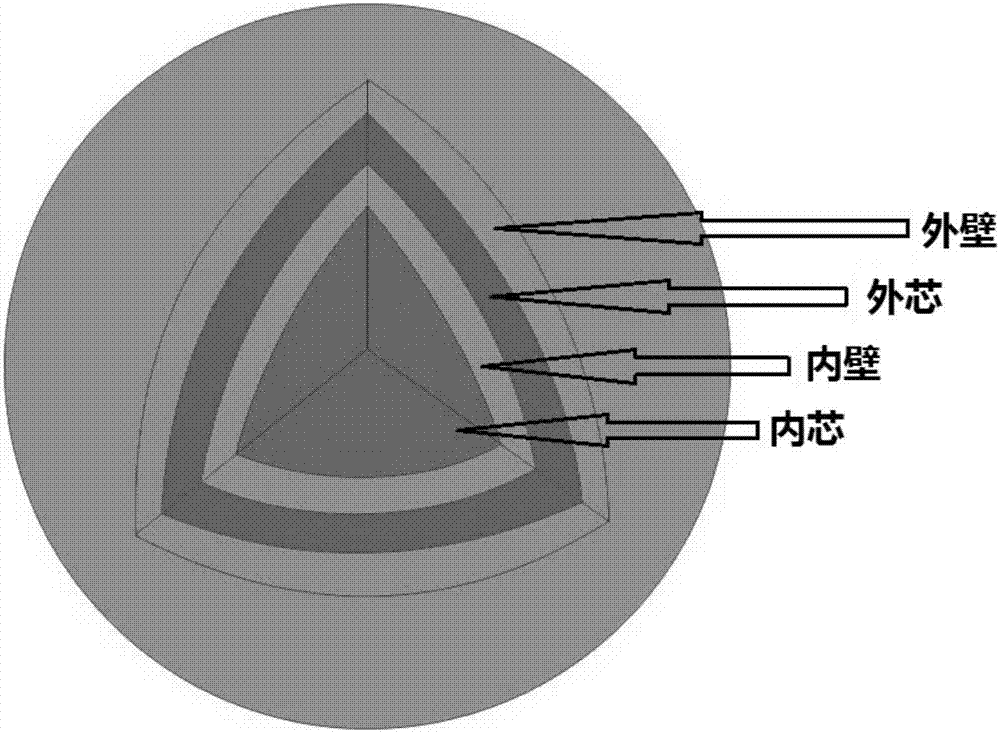

External repairing internal fixing type polyurea-based dual-wall self-repairing microcapsule and preparation method thereof

ActiveCN107970868AExcellent physical and chemical propertiesExtend service lifeCoatingsMicroballoon preparationPrepolymerEmulsion

The invention provides a dual-wall microcapsule system which takes aliphatic isocyanate-amine-terminated polyether polymer as a repair agent and takes an amine group chain extender as a curing agent.The external repairing internal fixing type polyurea-based dual-wall self-repairing microcapsule comprises an inner-layer capsule wall and an outer-layer capsule wall, wherein the inner-layer capsulewall coats the amine group chain extender emulsion, and the outer-layer capsule wall coats prepolymer emulsion; the inner-layer capsule wall and the outer-layer capsule wall are both polyurea preparedwith an interfacial polymerization method; the polyurea of the inner-layer capsule wall is obtained in a way that the amine group chain extender emulsion coated with the inner-layer capsule wall andthe prepolymer emulsion coated with the outer-layer capsule wall react; the polyurea of the outer-layer capsule wall is obtained in a way that the amine group chain extender emulsion and the prepolymer emulsion coated with the outer-layer capsule wall react; the repairing agent and the curing agent are respectively stored in an inner-layer capsule core and an outer-layer capsule core. Therefore, the problem that the contact rate of the repairing agent and the curing agent is low is solved, and in addition, the repairing agent and the curing agent quickly react so the quick repair of cracks isrealized and the external repairing internal fixing type polturea-based dual-wall self-repairing microcapsule also has a wide application prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Turbine blade assembly thermal barrier coating and preparation method thereof

ActiveCN107345299AImprove resistance to high temperature oxidationExtend service lifeEfficient propulsion technologiesSuperimposed coating processAluminideCorrosion

The invention provides a turbine blade assembly thermal barrier coating. The turbine blade assembly thermal barrier coating comprises a bonding layer, an aluminide layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged in an upward mode from a turbine blade assembly base material or comprises an aluminide layer, a bonding layer, an aluminum oxide layer and a ceramic layer which are sequentially arranged. The bonding layer is a MCrAlY layer, and M represents one or two or three sorts of nickel, cobalt and iron. According to the thermal barrier coating system provided by the invention, the high-temperature oxidation resistance, thermal corrosion resistance and endurance property of the thermal barrier coating are improved on the premise that the thermal barrier effect of the thermal barrier coating is guaranteed, and thus the service life of a turbine blade assembly is prolonged. By means of the thermal barrier coating system prepared through the method, the weight of the blade assembly can be lowered obviously, and therefore the creep degree of the assembly by tension of the turbine blade assembly in the high-speed rotating process is decreased and the service life of the turbine blade assembly is prolonged.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

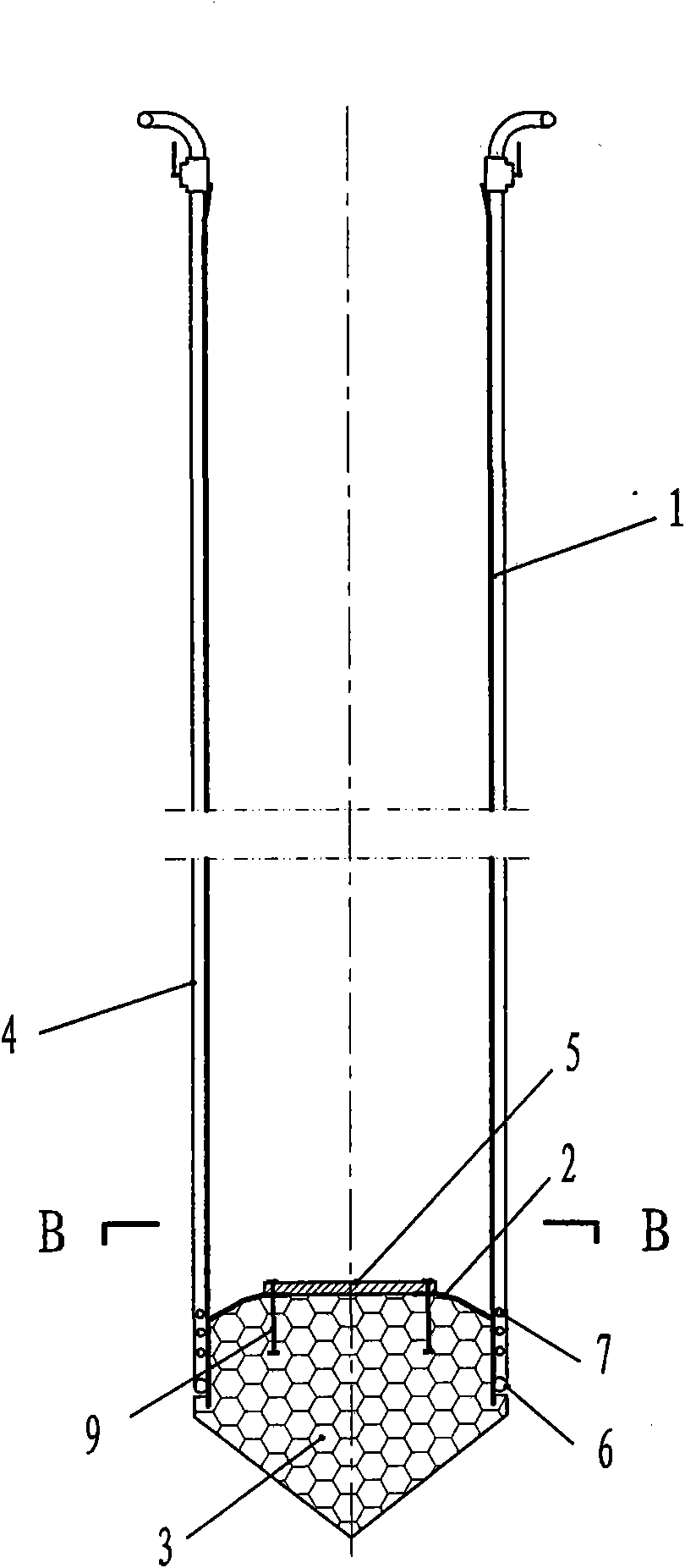

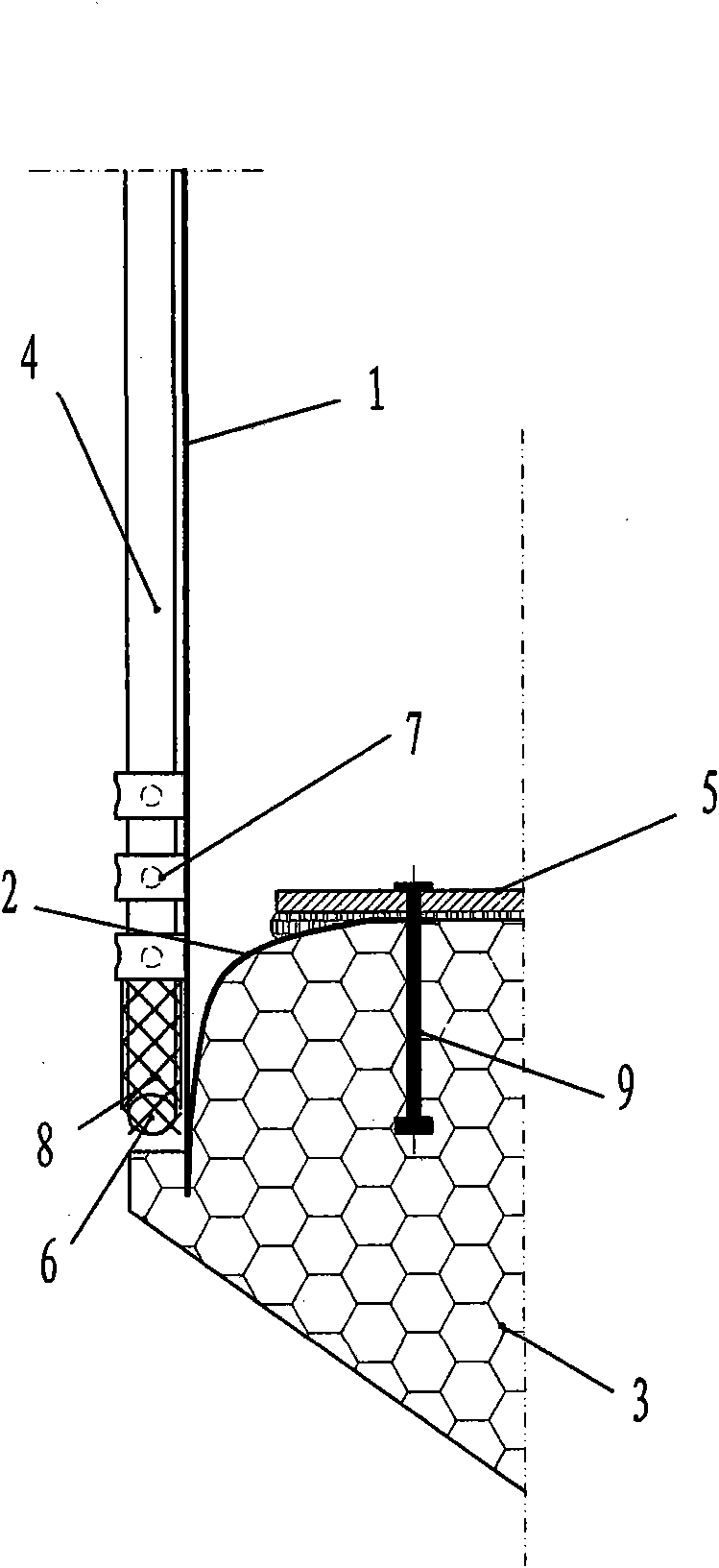

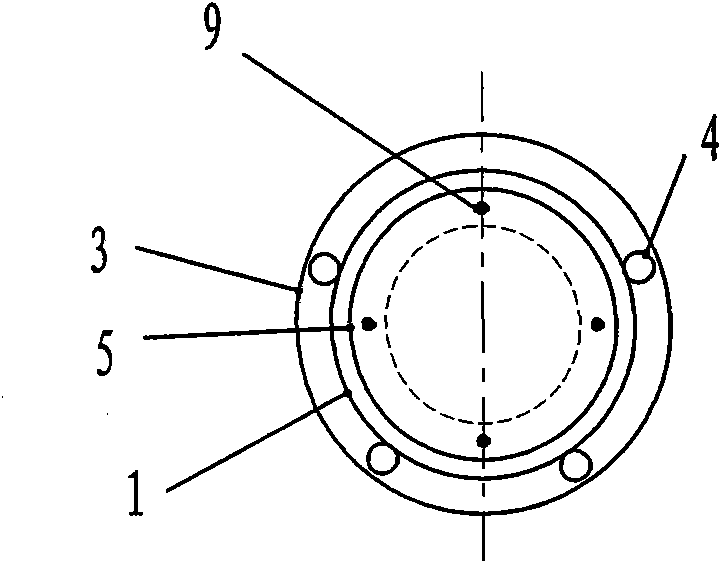

Capsule type anti-corrosion device with pile shoe and anti-corrosion and construction method using device

ActiveCN102002945AExtend service lifeImproved materials and anti-corrosion technologyBulkheads/pilesBiomedical engineeringHigh pressure

The invention relates to a capsule type anti-corrosion device with a pile shoe and an anti-corrosion and construction method using the device, the capsule type anti-corrosion device comprises a cylindrical coating capsule body made of anti-corrosion material, the inner surface and the outer surface of the coating capsule body are uneven surfaces, a supporting bottom is arranged at the lower part in the coating capsule body, the periphery of the supporting bottom is connected with the side wall of the coating capsule body, the hard anti-corrosion pile shoe is arranged in the coating capsule body, which is positioned at the lower end of the supporting bottom, at least one grouting pipe is arranged near to the outer side of the coating capsule body along the axial line direction the coating capsule body, the bottom end of each grouting pipe extends to the place which is near to the bottom end of the coating capsule body, and a low-pressure grouting hole and a plurality of high-pressure grouting holes are respectively arranged at the lower part of each grouting pipe, which is near to the supporting bottom. The invention aims at providing the capsule type anti-corrosion device with the pile shoe, which has reliable long-term anti-corrosion performance in a pile foundation and a composite foundation in a highly corrosive brine formation, and can reduce the expensive maintenance cost of the foundations of buildings and structures in the corrosive formation, and the anti-corrosion and construction method using the device.

Owner:CHINA JINGYE ENG +1

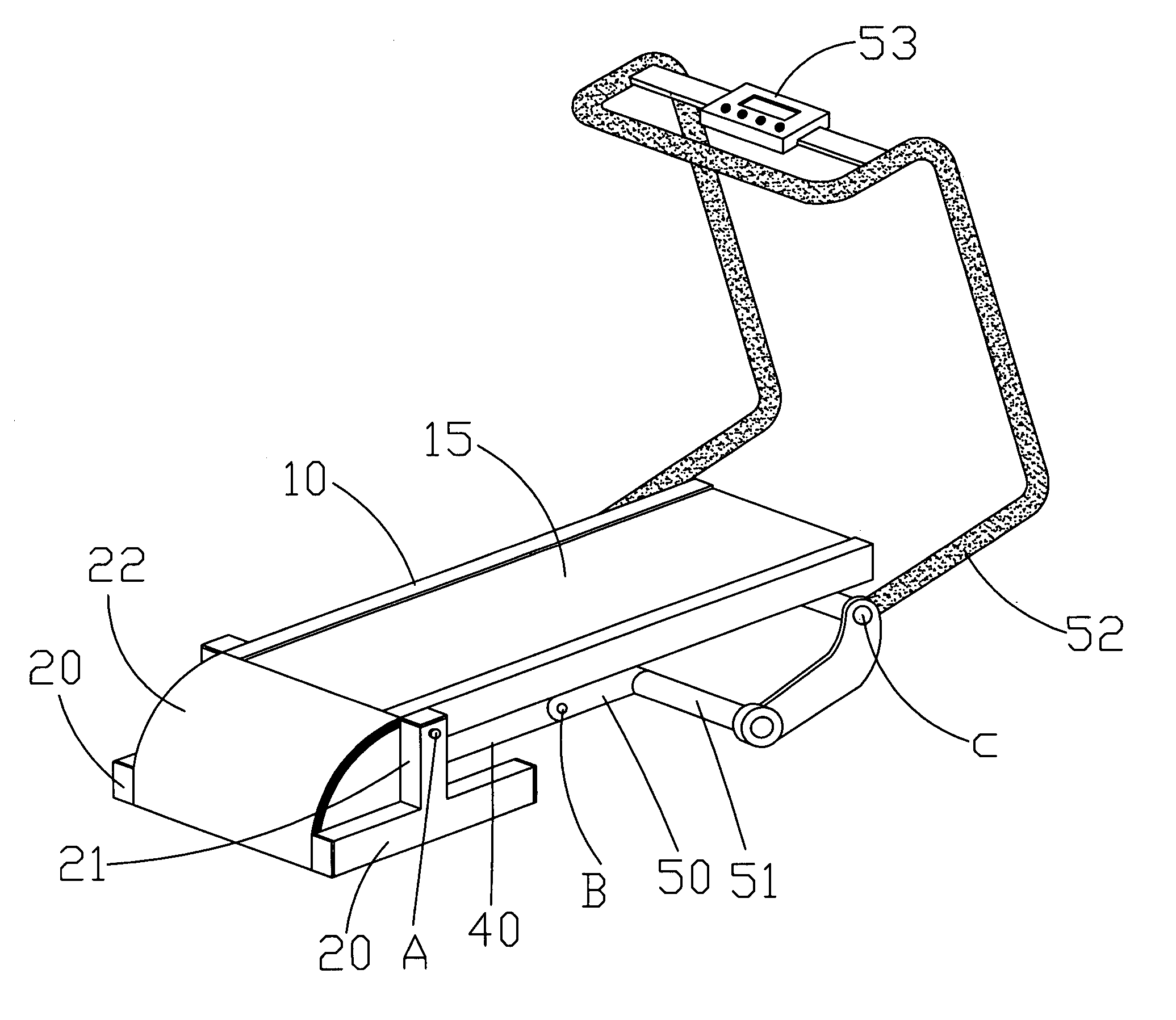

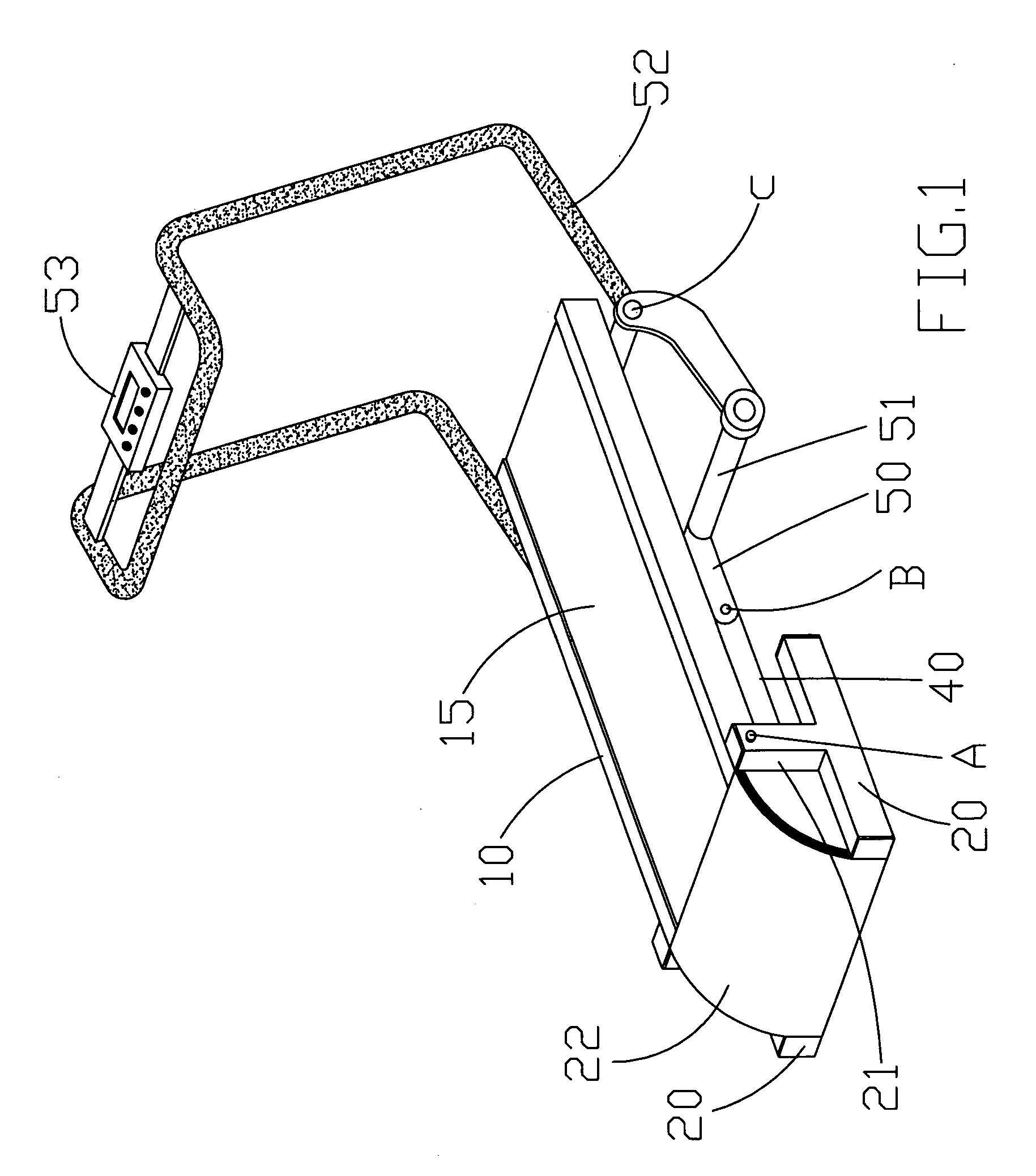

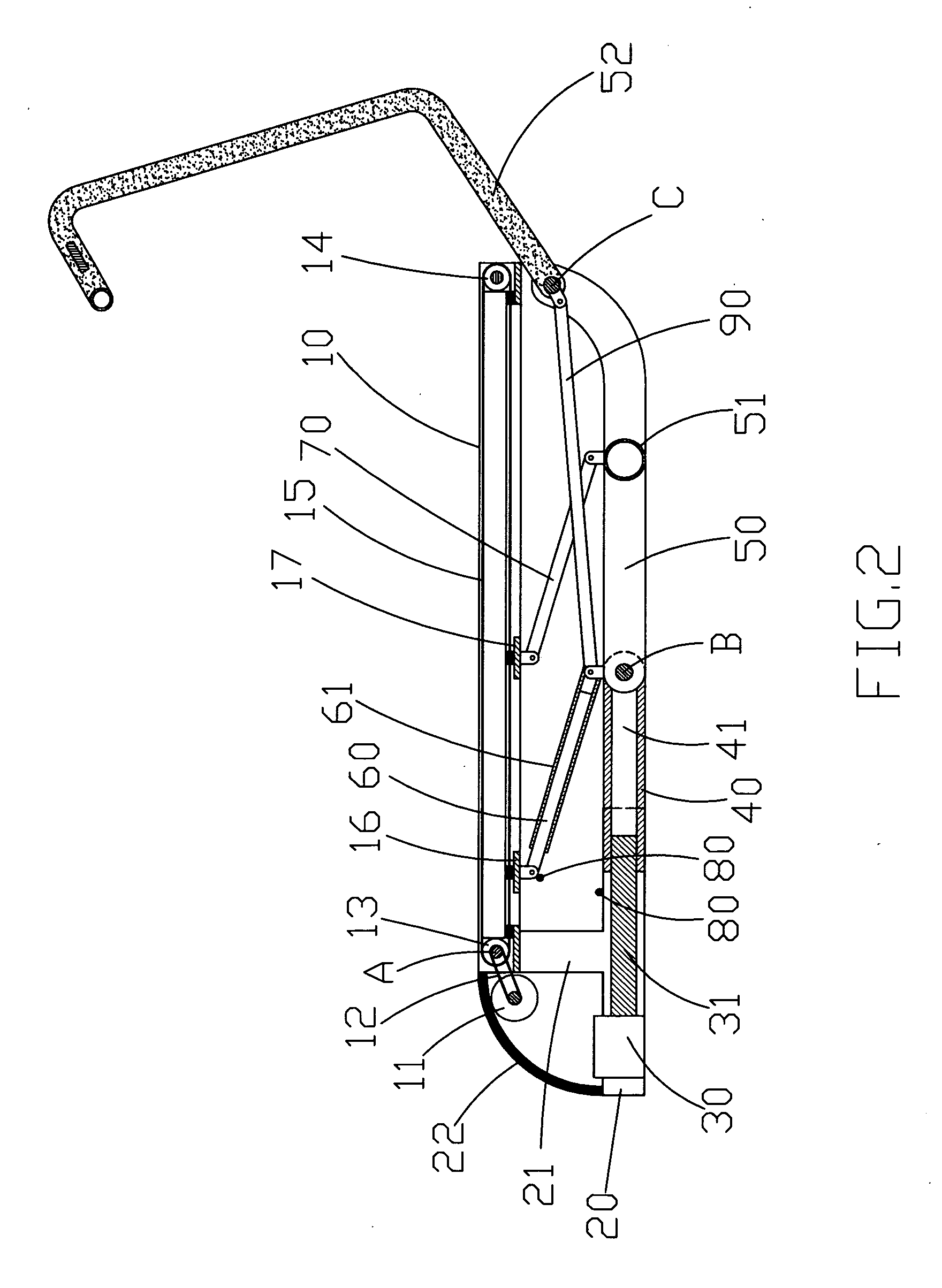

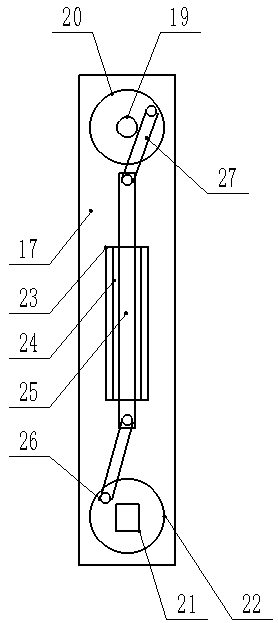

Folding-up mechanism for an electric treadmill

InactiveUS20060252605A1Less torque outputExtend service lifeRod connectionsSpace saving gamesHandrailTreadmill

A folding-up mechanism for an electric treadmill having a single lifting motor for adjusting a platform frame to an inclined and upright position with a handrail frame moved to a storage position. The lifting motor and a drive screw are interposed between two base frames. The drive screw is screwed in a slip pipe with female thread. An intermediate tube is pivotally coupled to a rear end of the slip pipe with a front crossbar and a handrail frame coupled to the opposing end of the intermediate tube. One end of the platform frame is pivotally attached to an upright bar of the base frames while a bottom side of the platform frame is pivotally coupled to a telescopic tube, a pull rod, and a push rod that are in turn coupled to the slip pipe, the intermediate tube, and the handrail frame so that the slip pipe is movable to and fro when the lifting motor is activated to impart an in-place rotation to the drive screw, thereby achieving the expected effects.

Owner:WANG LEAO

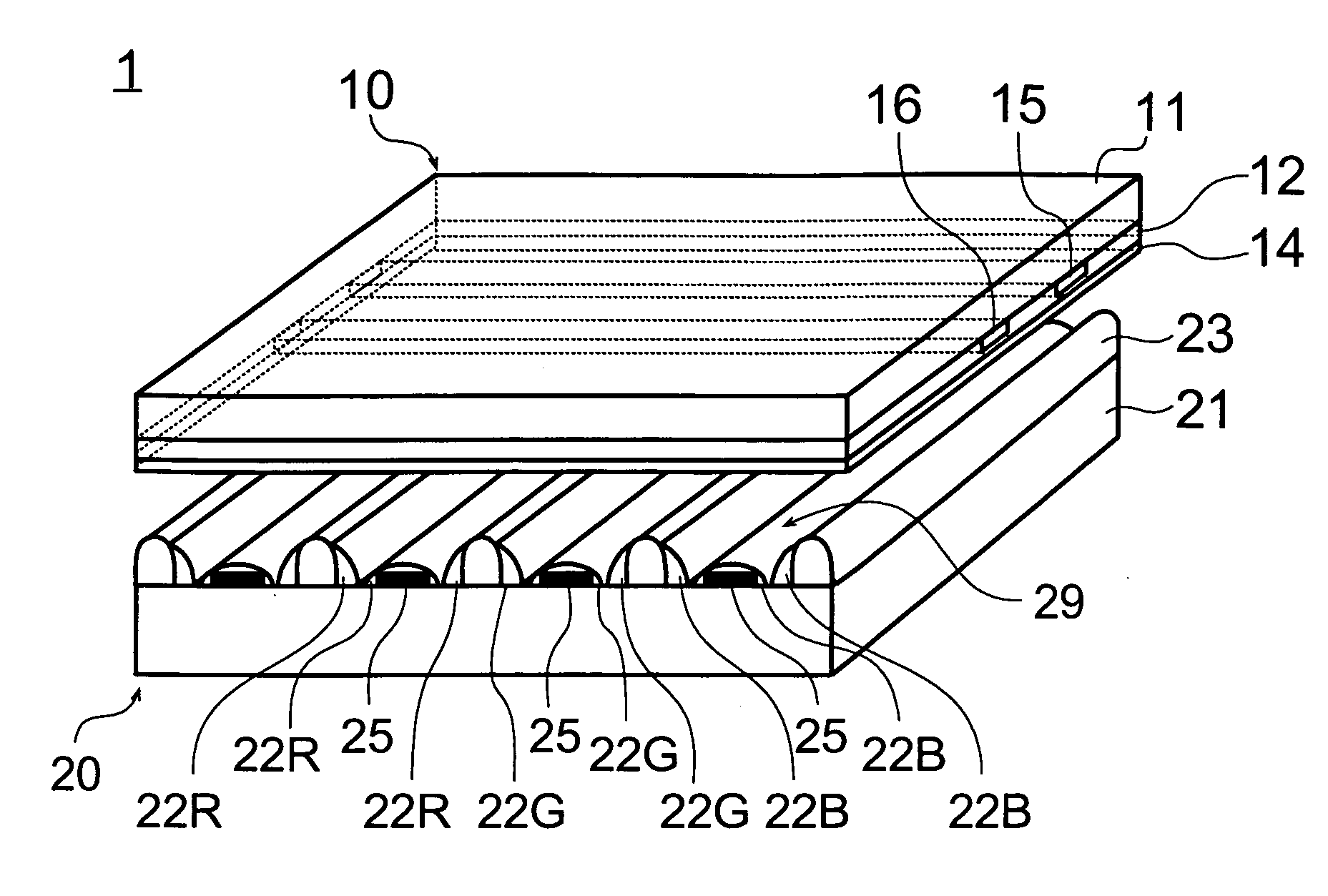

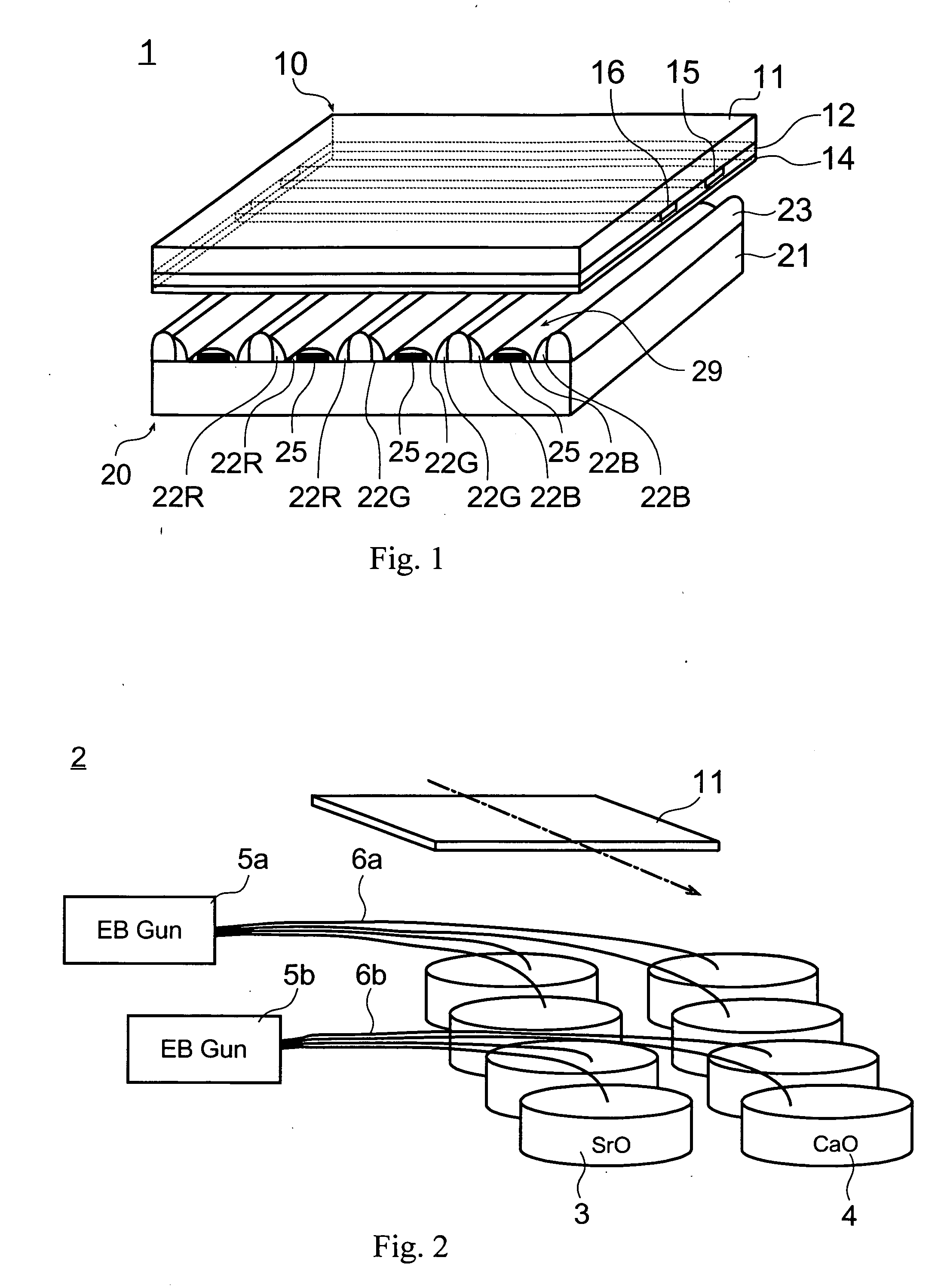

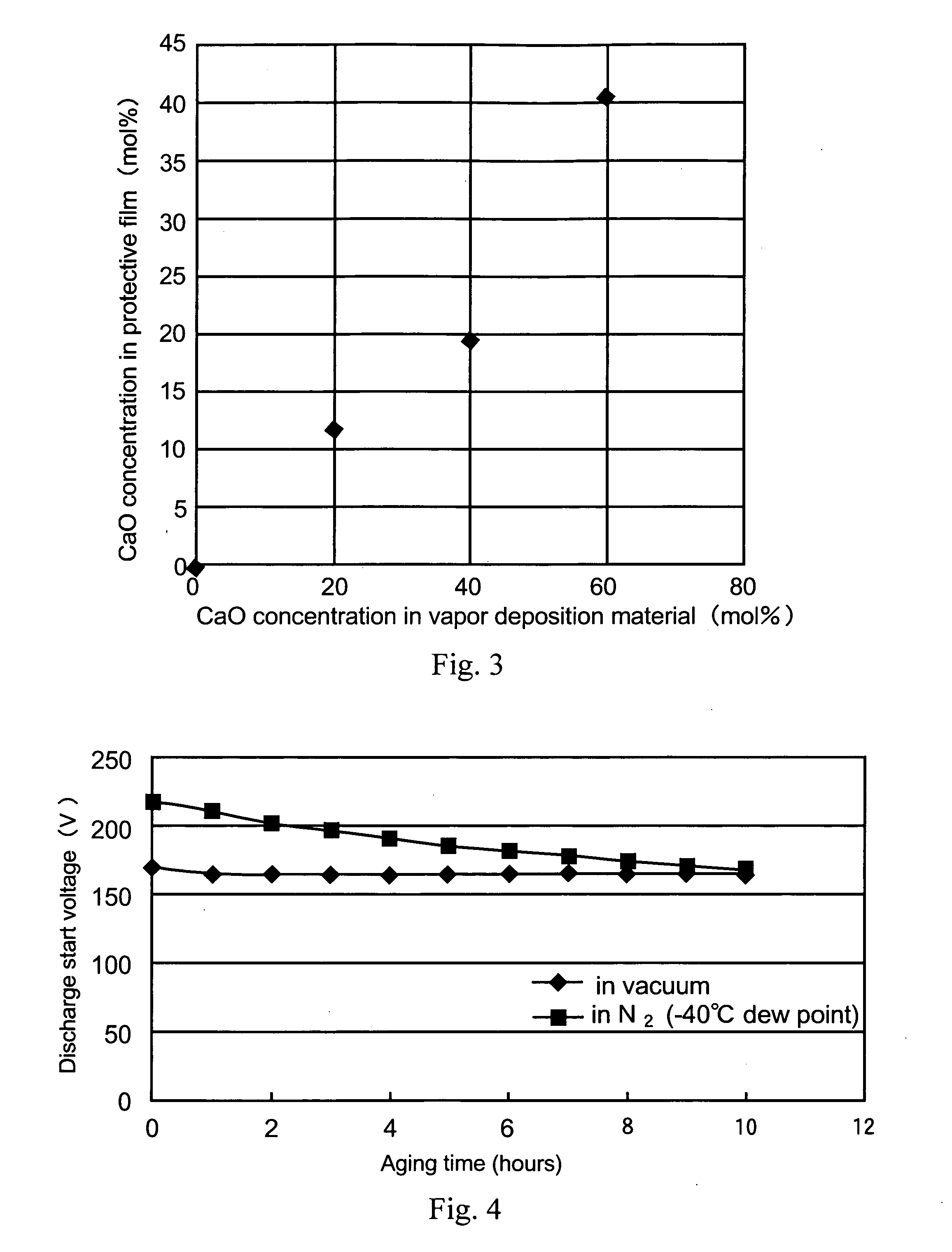

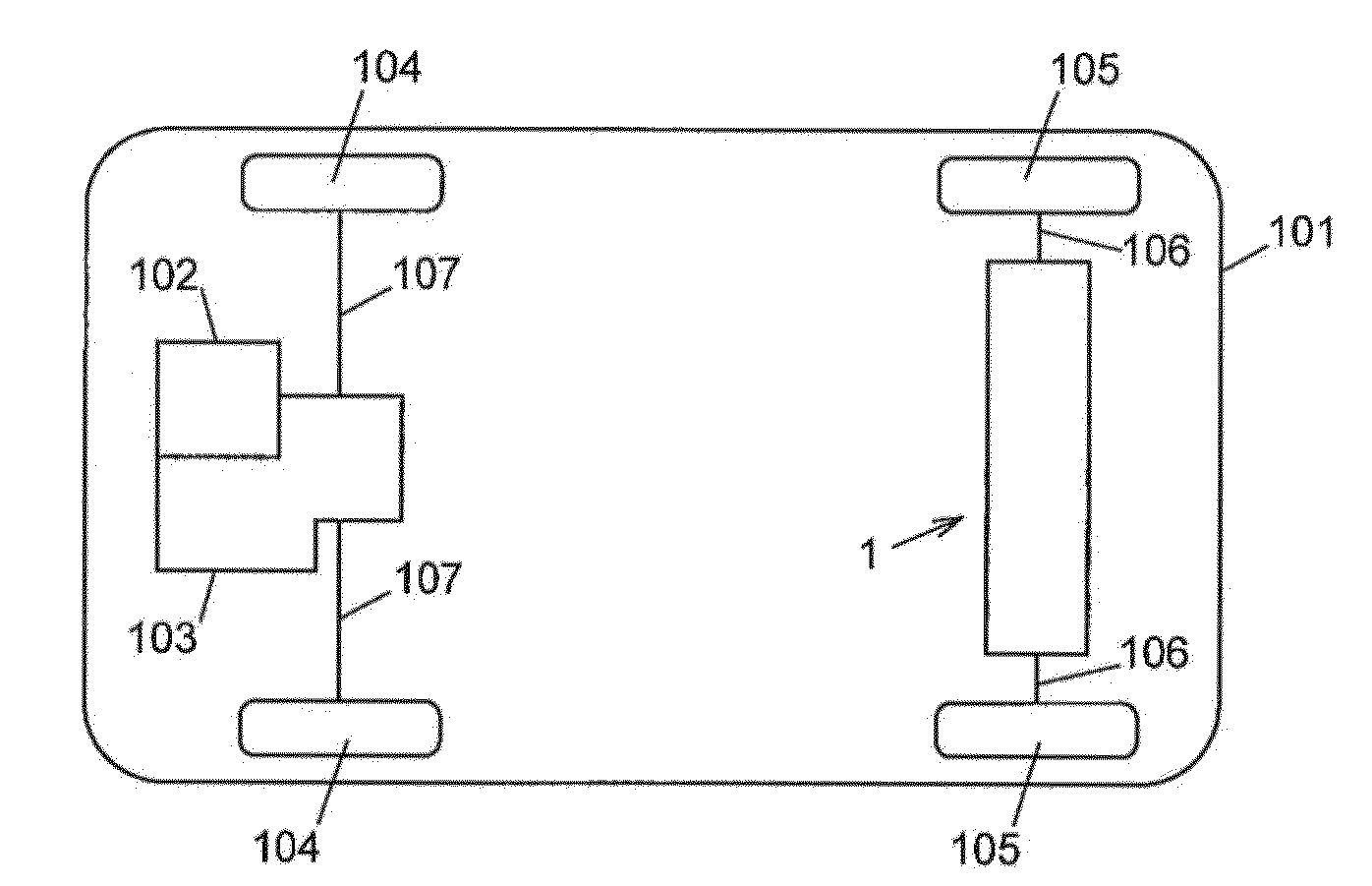

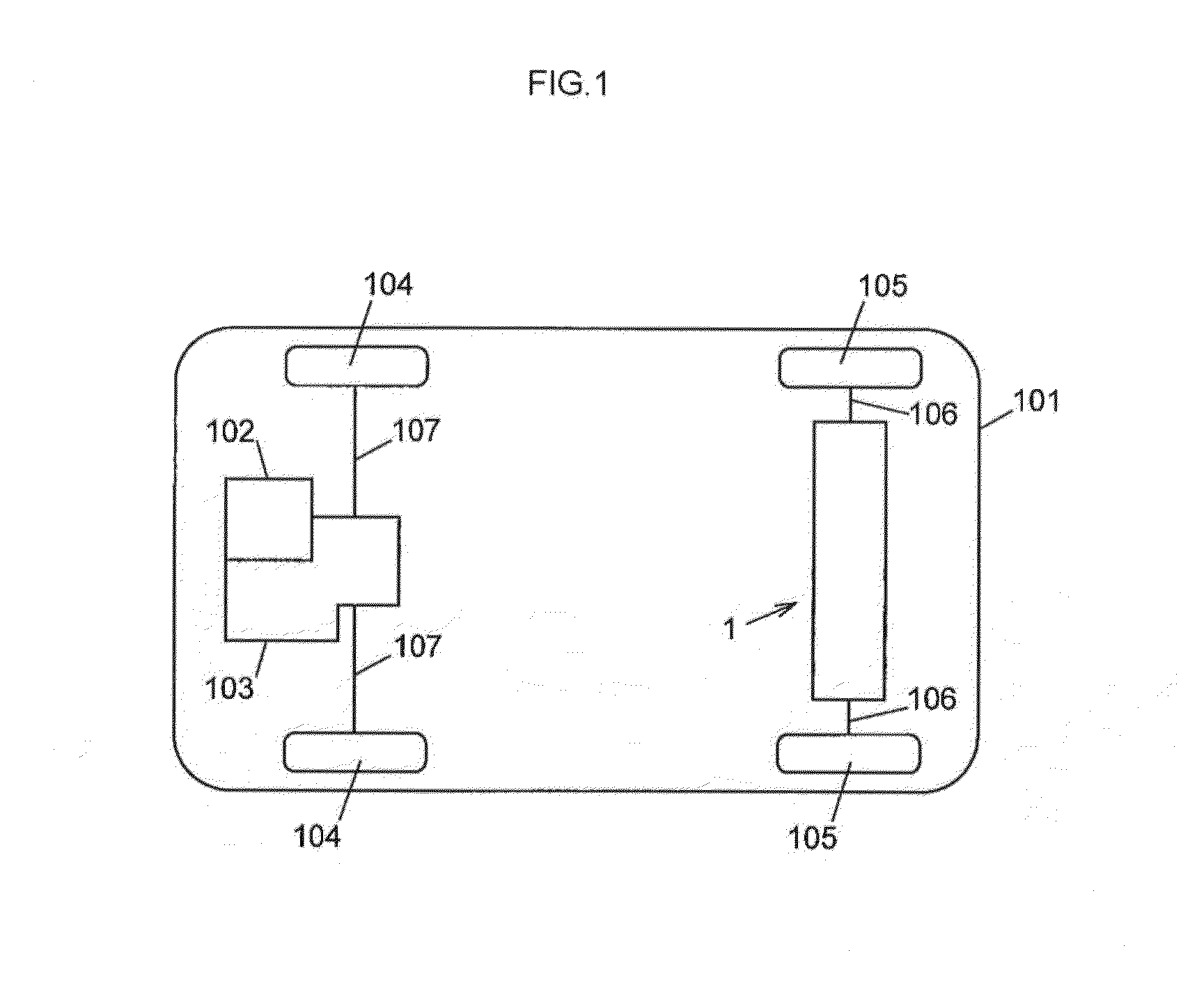

Protective film for plasma display panel and method for manufacturing this protective film, and plasma display panel and method for manufacturing thereof

InactiveUS20070108905A1Low discharge voltageExtend service lifeTube/lamp screens manufactureSustain/scan electrodesWork functionEngineering

A plasma display panel 1 of the present invention has a protective film 14 over a sustaining electrode 15 and a scanning electrode 16, with the main components of the protective film being CaO and SrO, and the concentration of the CaO in the protective film 14 is 20 mol % or more and 90 mol % or less. This protective film 14 has a smaller work function than a conventional MgO film so light can be emitted at a lower discharge voltage than in the past. If the discharge voltage is lower, the protective film 14 will be sputtered more slowly so that the service life of the plasma display panel 1 will be longer. Also, since the plasma-gas contains xenon gas, the plasma display panel of the present invention has higher brightness.

Owner:ULVAC INC

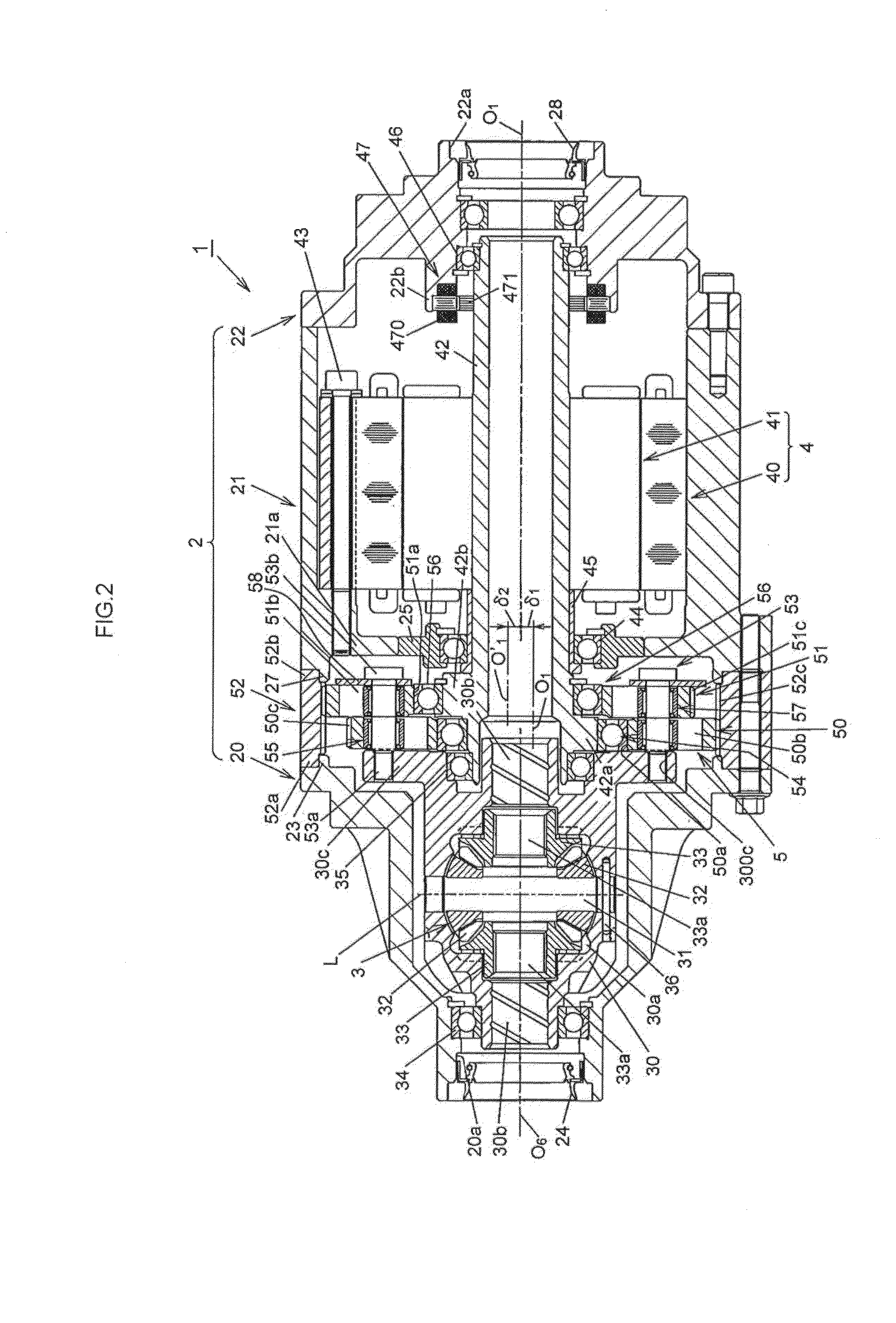

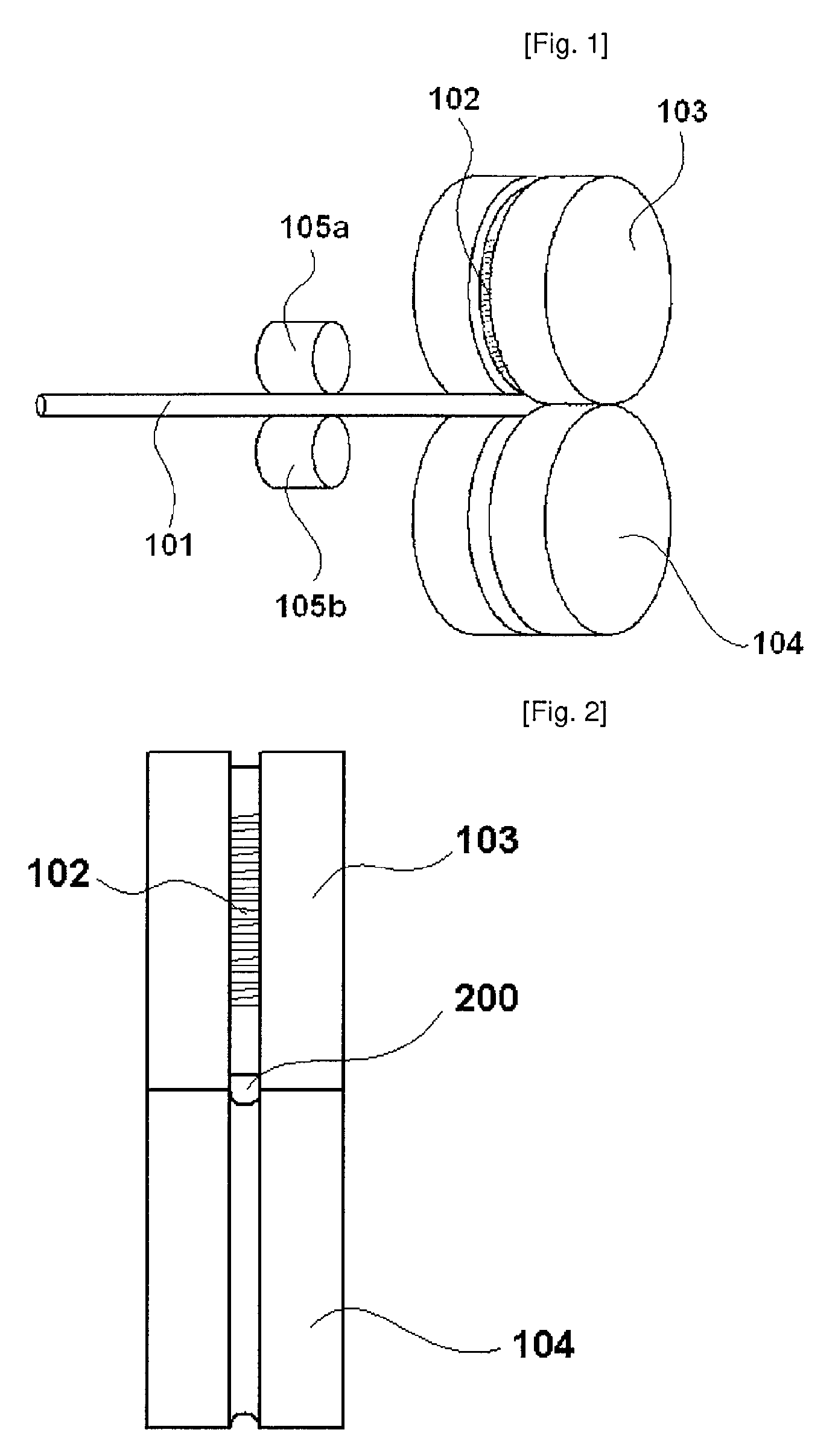

Speed reduction mechanism, and motor torque transmission device including the same

InactiveUS20130143707A1Cost reductionExtend service lifeElectric propulsion mountingToothed gearingsNeedle roller bearingEngineering

In a reduction-transmission mechanism, a plurality of output members are arranged at such positions that a size that is the sum of a fitting clearance formed between an outer periphery of each output member and a corresponding one of needle roller bearings, a fitting clearance formed between the needle roller bearing and an inner periphery of an input member, which defines a corresponding one of a plurality of pin insertion holes, and a radial internal clearance in the needle roller bearing is smaller than a size that is the sum of a fitting clearance formed between a ball bearing and an outer periphery of an eccentric portion, a fitting clearance formed between the ball bearing and an inner periphery of the input member, which defines a center hole, and a radial internal clearance in the ball bearing.

Owner:JTEKT CORP

Corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device

ActiveCN105621588AReduce the harshness of the service environmentExtend service lifeSpecific water treatment objectivesWater/sewage treatment apparatusCorrosionHigh concentration

The invention discloses a corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device. The device is composed of a plurality of reactant mixing-pre-oxidizing device core tubes and outer tubes in a series connection mode along the way, and a core tube channel and an outer tube channel are formed. The core tube channel is sequentially provided with a plurality of reactant A injection ports along the way, the reactant A injection ports are used for injecting reactants A into the outer tube channel in a grading mode, and the outer tube channel is used for stage-by-stage mixing of the reactants A and reactants B and supercritical water oxidation reaction. The mixing and oxidizing process of organic waste and an oxidizing agent is effectively controlled, ultra-high-temperature damage caused by local concentrated heat release is avoided, and intensified corrosion of the high-concentration oxidization agent on equipment materials is relieved. The corrosion inhibition type supercritical water oxidation reactant mixing-pre-oxidizing device is arranged on an entrance of a supercritical water oxidation reactor, the service environment harshness of the supercritical water oxidation reactor is remarkably reduced, the service life of the reactor is prolonged easily, overall maintenance cost in the later stage of the supercritical water oxidation reactor is reduced, and the corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device can be widely applied to performing supercritical water oxidation reactant on various heavy-pollution industrial wastewater and sludge.

Owner:XI AN JIAOTONG UNIV

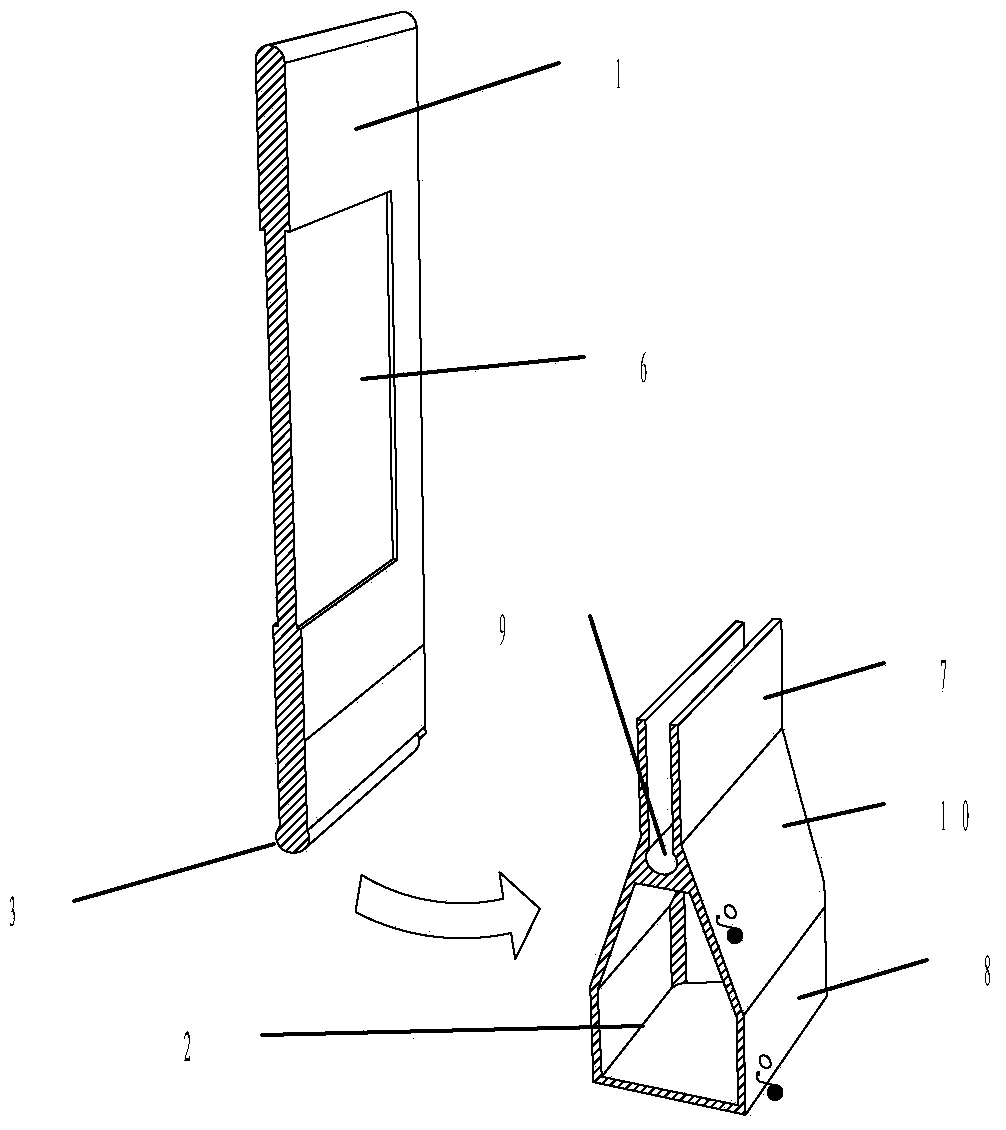

Combined type surrounding baffle

ActiveCN103758397AExtend service lifeExpand the scope of useFencingTraffic signalsEngineeringHead joints

The invention discloses a combined type surrounding baffle which comprises vertical boards and bases. Each vertical board is detachably connected with the corresponding base in a circular head joint mode. Every two adjacent vertical boards are mutually and detachably connected in a dovetail joint mode and every two adjacent bases are mutually and detachably connected in a dovetail joint mode; the bases are made of an abrasion-resistant polyurethane material. The bases of the surrounding baffle are made of the anti-collision abrasion-resistant material and can solve the problems that the bases are crashed and abraded by a vehicle and then damaged, the service life of the construction surrounding baffle is prolonged, and all components can be reused due to the up-and-down assembled structure. Meanwhile, the bases can be separated from the upper vertical boards to be used independently, the phenomenon that the bases are damaged and the upper vertical boards are abandoned along with the bases is avoided, resources are saved, the advantages of the bases are developed to the greater extent, and due to the fact that the up-and-down assembled structure is conveniently detached, the transportation space is saved.

Owner:安徽德合衡建筑工程有限公司

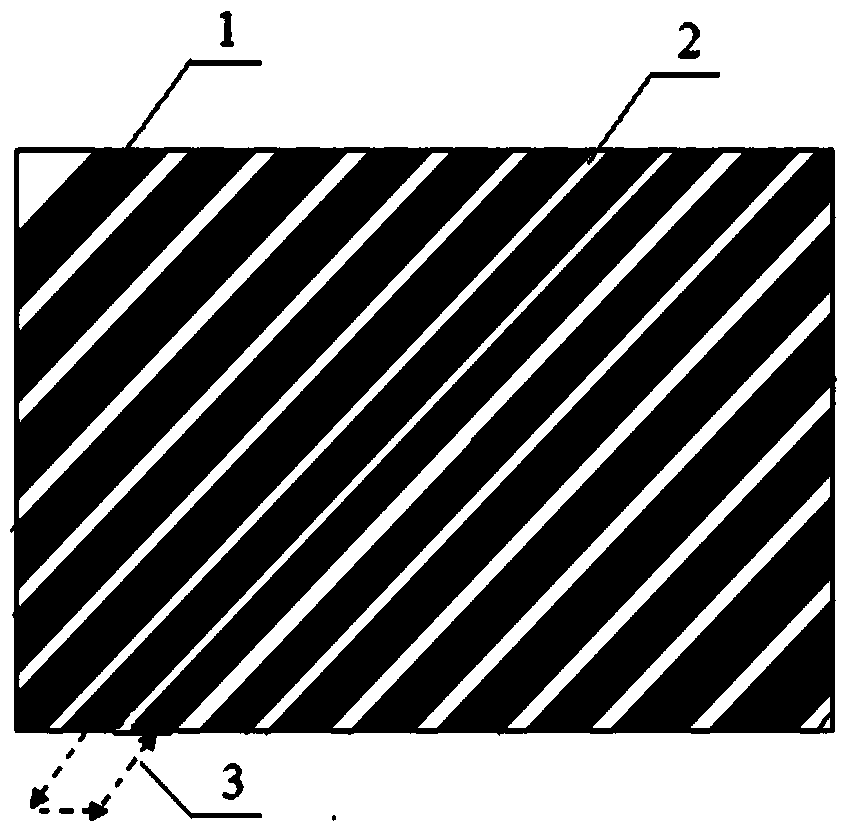

Method for online laser broadband quenching on surface of steel rail

InactiveCN104212965AGood toughnessExtend service lifeFurnace typesHeat treatment furnacesBroadbandHardness

The invention discloses a method for online laser broadband quenching on a surface of a steel rail, which can synchronously improve the hardness and the toughness of the steel rail, and can realize online laser quench hardening. The method comprises the following steps: an induction spray gun and a laser emitting head of an optical fiber laser are fixed on a mechanical arm; firstly, the induction spray gun is used for spraying one layer of light absorbing paint (graphite particles+SiO2 particles with the mass percentage of 5-20%, particle size of the particles within 50 nm-1 um) on the surface of the steel rail; and then, the wheel-rail contact surface of the steel rail is quickly scanned by using the optical fiber laser to obtain a laser quench hardened layer with the structure as the martensite, bainite and retained austenite mixed structure. The method uses the afterheat of the online steel rail to reduce the space, the energy and the resource; the optical fiber laser is smaller than a CO2 laser in volume, so that the movement is convenient; and quenching bands are adopted for laser quenching, and have certain distances, so that the crack phenomenon is reduced.

Owner:UNIV OF SCI & TECH LIAONING

Balancer shaft arrangement for engine

ActiveUS20060037576A1Extend service lifeLessens uneven loadingShaftsMachines/enginesBalance shaftBending moment

An engine includes a balancer shaft that is supported at its both ends through bearings disposed within an engine crankcase. The balancer shaft lies generally parallel with a crankshaft and includes balancer weights, which are provided generally at the ends of the balancer shaft. At least one of the balancer weights is made up of first and second weight portions. The first and second weight portions are disposed on opposite sides of the corresponding bearing. In this manner, the bending moment on the shaft is reduced and, consequently, the balancer shaft can have a smaller diameter to reduce the size of the crankcase.

Owner:YAMAHA MOTOR CO LTD

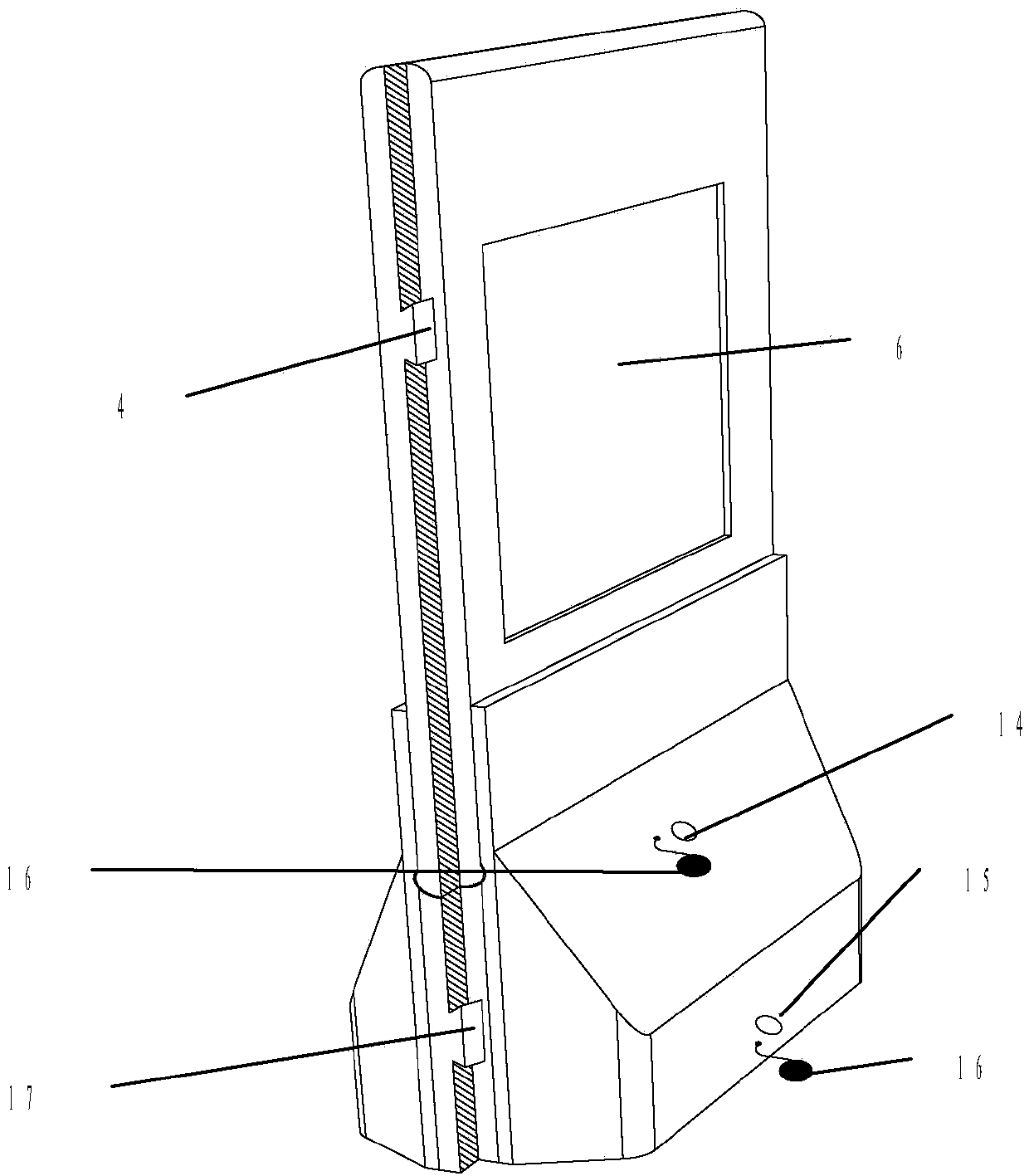

Intelligent curtain

InactiveCN108514315AExtend service lifeRealize automatic sunshade functionCurtain suspension devicesLight protection screensGlass windowEngineering

The invention discloses an intelligent curtain. The intelligent curtain comprises a window installation slot. The inner end is provided with an automatic folding curtain retracting device, a roller blind retracting device and a glass window body, respectively, in the direction from the inside to the outside of the house. The automatic folding curtain retracting device is composed of a vertical hollow box body I, an elongated hollow mounting box body I, a screw rod, a rotating motor, an elongated rail, a fixing seat, an arc-shaped guide rail, a curved guide groove, and a slider, a main-shaped sliding member, a sub-shaped sliding member, a main curtain rod, a secondary curtain rod, a movable rod, a hook and a curtain body. The roller blind retracting device is composed of a vertical hollow box body II, an elongated hollow mounting box body II, a reel, a roller blind body, a disc-shaped turret, a frequency modulation motor, a rotating disc, a vertical rail, and a vertical guide. a groove,a guide rod, a fixed block and a connecting rod. A light intensity sensor and a temperature and humidity sensor may be disposed on one side of the outer end of the vertical hollow box. The intelligent curtain has the advantages of simple structure and strong practicability.

Owner:方秀琴

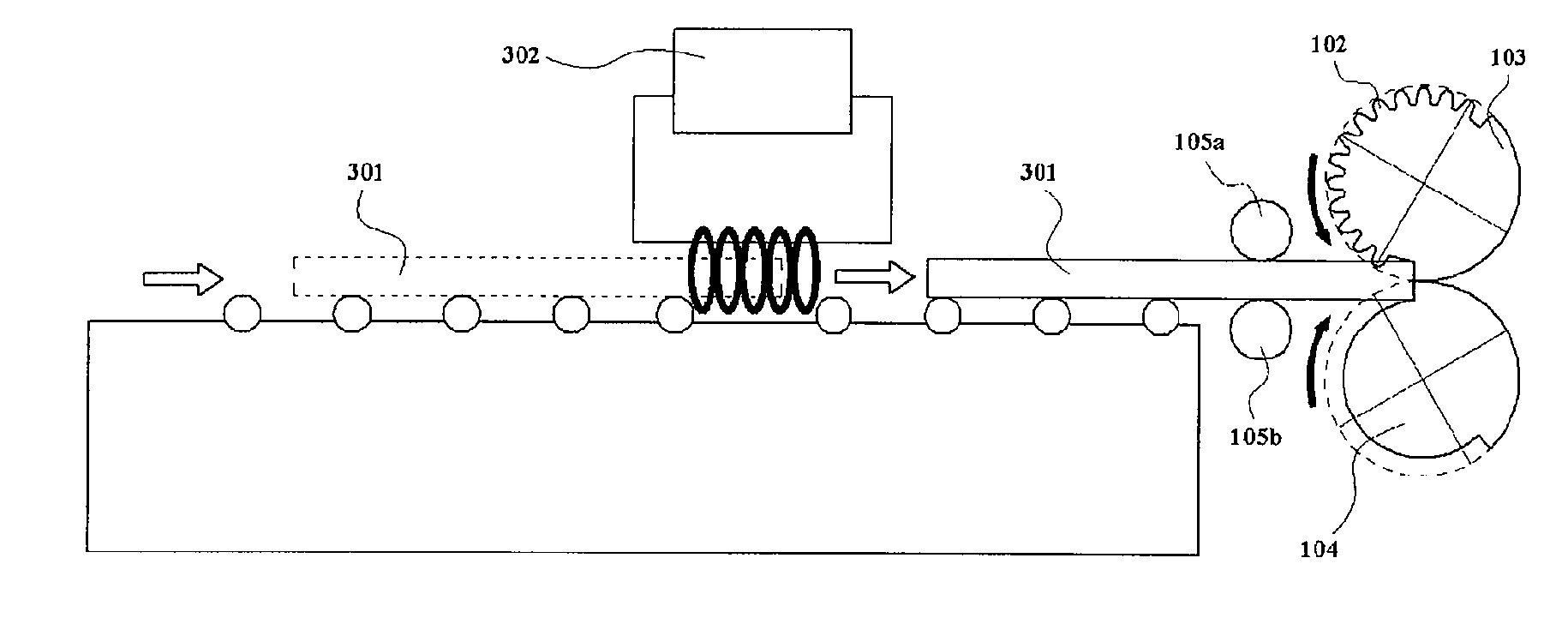

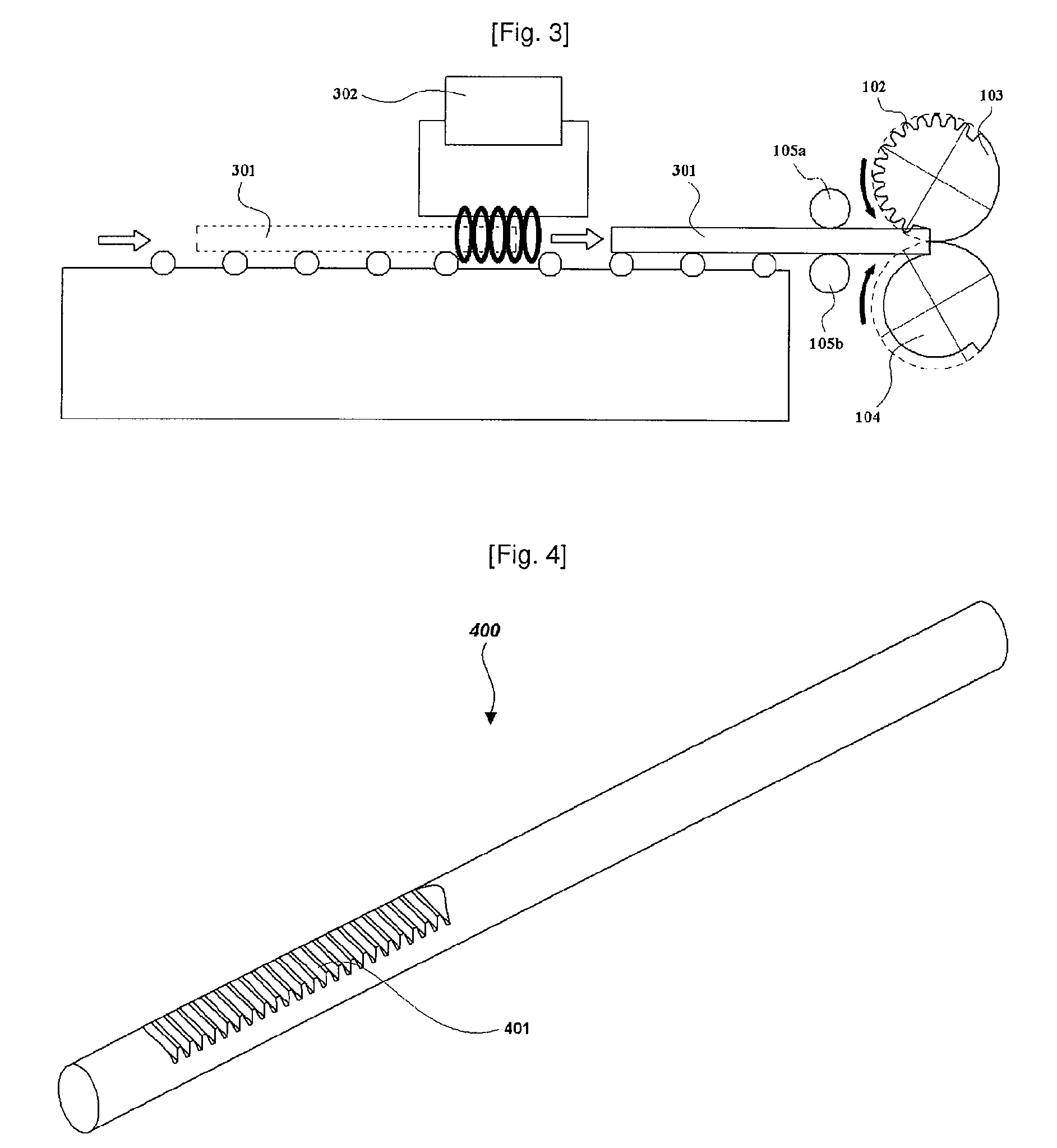

System for manufacturing linear gear and the method thereof

InactiveUS20090158804A1Extend service lifeLow loadShaping toolsMetal-working feeding devicesGear toothHigh load

The present invention relates to a system for and a method of manufacturing a linear gear (rack gear), in which a forming roll and a guide roll are used to form gear teeth in a sequential manner so as not to require a high load, thereby enabling to easily manufacture the rack gear. A system for manufacturing a rack gear according to the invention includes a forming roll having a convexo-concave portion formed on a part of the surface contacting with a linear bar, a guide roll adapted to roll while facing the forming roll, and at least one support member for supporting the linear bar so as to allow the linear bar to linearly move. A method of manufacturing a rack gear according to the invention includes a first step of passing a linear bar through between a pair of rollers provided in front of a forming roll and a guide roll, a second step of charging the linear bar into a charging hole between the forming roll and the guide roll, a third step of rolling the forming roll and the guide roll to partly form teeth on the outer circumferential surface of the linear bar, and a fourth step of rolling the forming roll and the guide roll forward or backward to discharge the linear bar.

Owner:ILJIN LIGHT METAL CO LTD

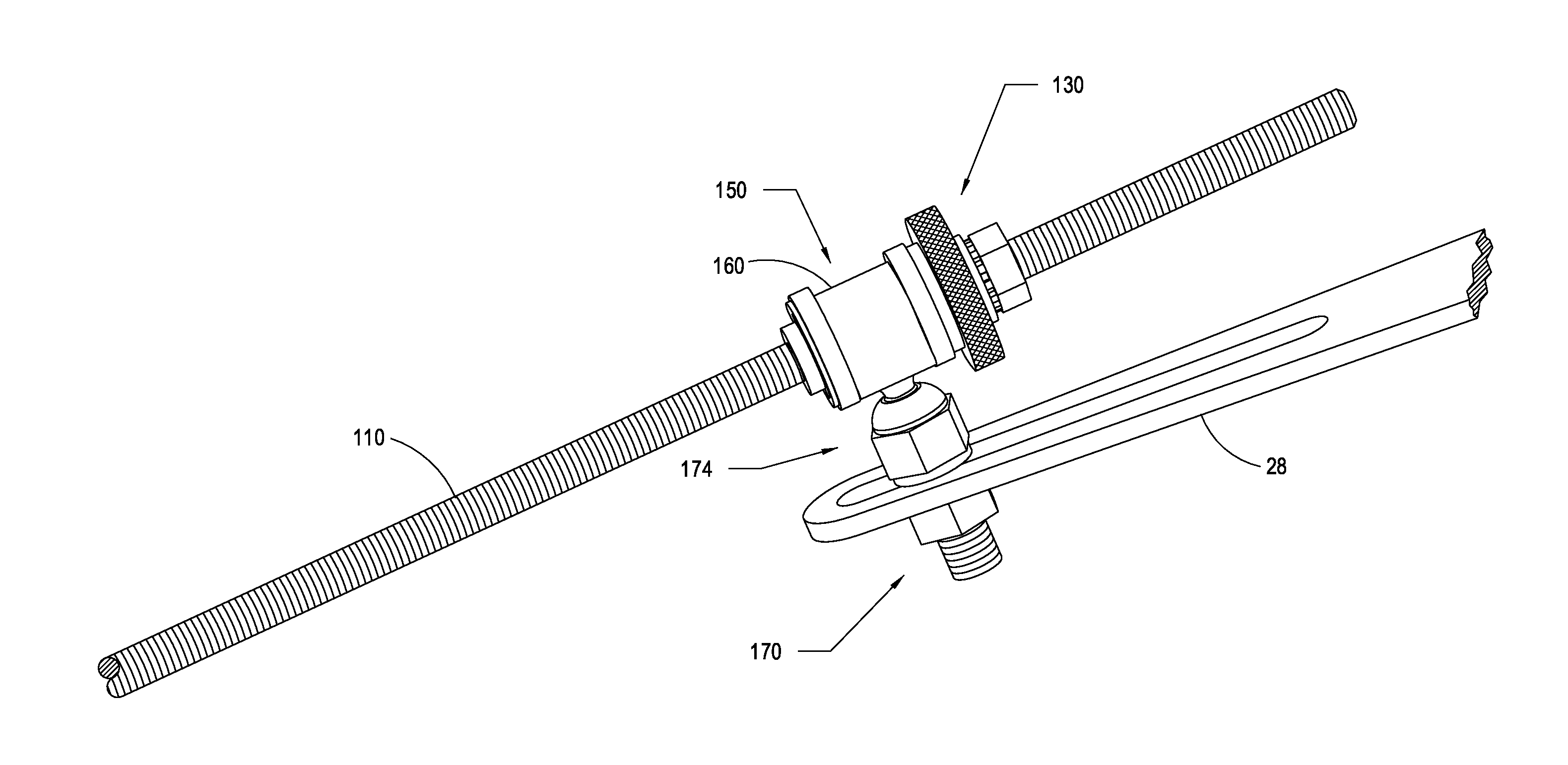

Linkage coupling apparatus

InactiveUS20120107039A1Extend service lifeReduction in air contaminantYielding couplingToothed gearingsEngineeringLinkage concept

An apparatus for adjustably coupling a threaded linkage rod to an arm of a fuel valve, air valve, air damper, damper blade assembly, or actuator that can include a sleeve, a collar, and a lock restraining axial movement of the collar with respect to the sleeve. The sleeve may include an inside threaded wall defining a sleeve bore axially receiving the linkage rod. The collar may include (i) a collar body having a collar bore axially receiving the sleeve and (ii) an about radial extension for engagement with the arm of the fuel valve, air damper, or actuator. Rotation of the sleeve causes axial movement of the sleeve, and thus the collar locked thereto, along the linkage rod. Fine position adjustments can be made to the position of the radial extension, and thus the arm of the fuel valve, air damper, or actuator engaged thereto, with respect to the linkage rod.

Owner:MCCLELLAND KENNETH RAE

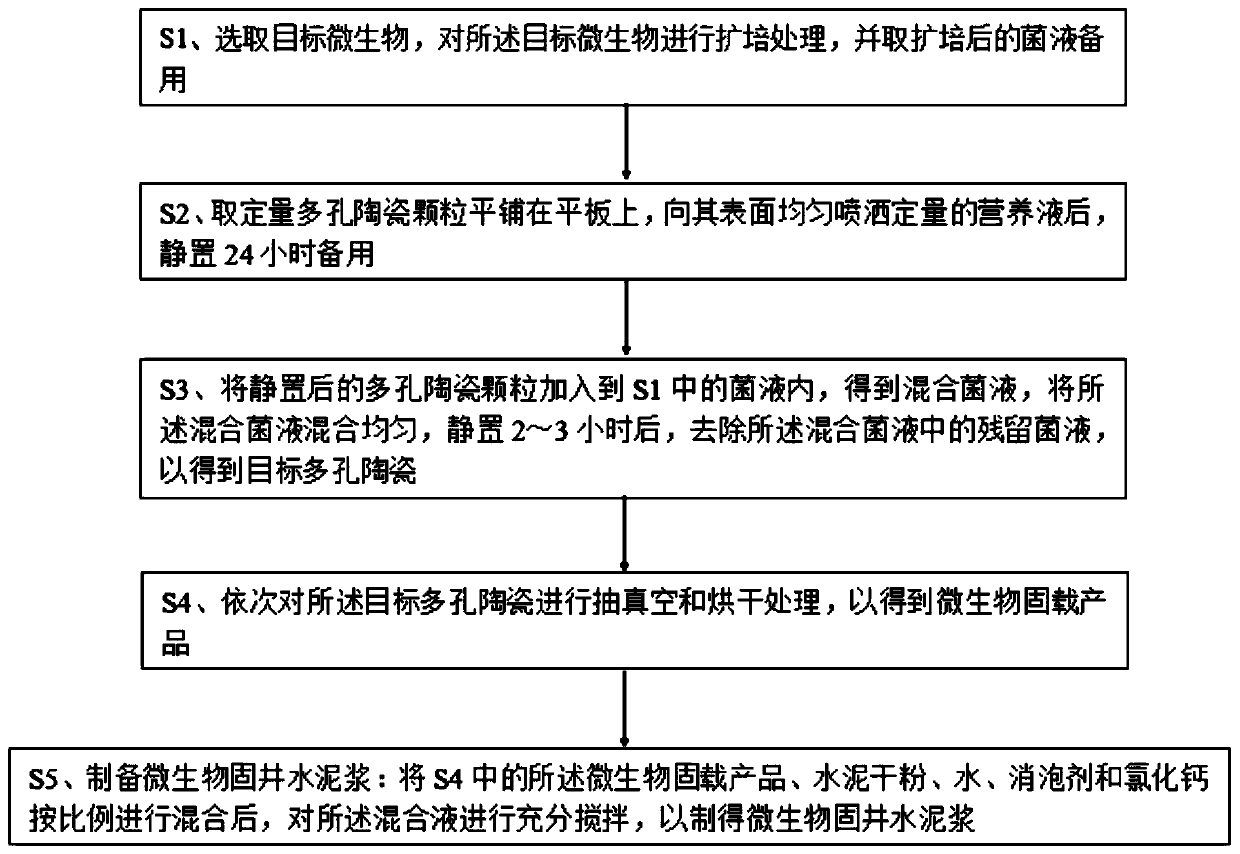

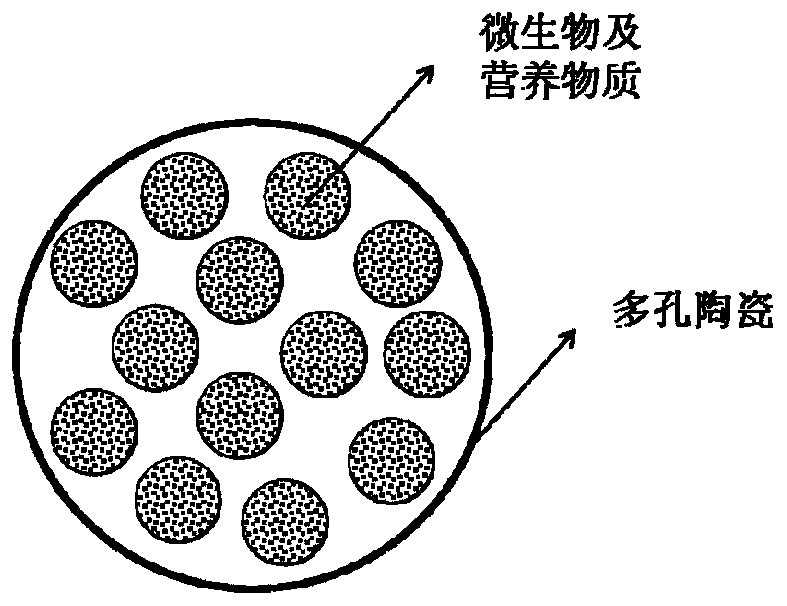

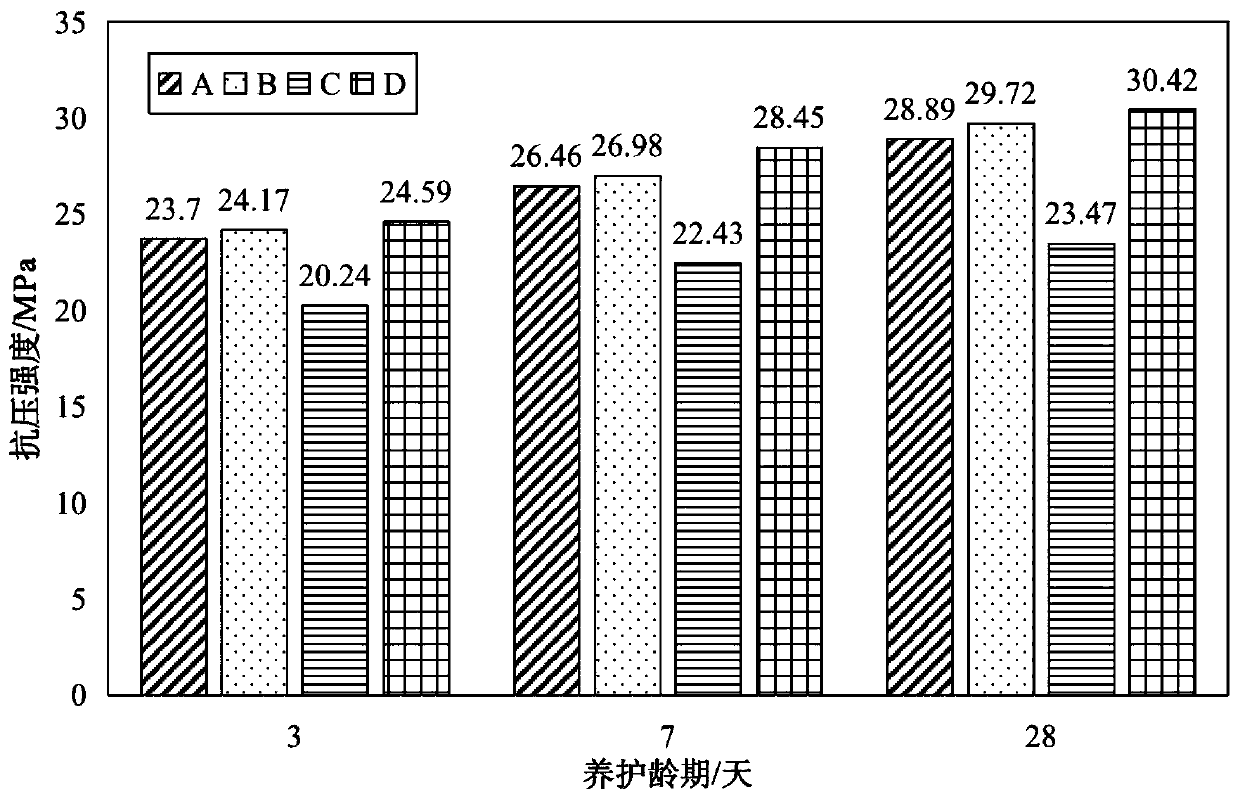

Immobilization method for improving activity of microorganisms in well cementation cement paste

InactiveCN111393088AImproved compactness and impermeabilityExtend service lifeDrilling compositionWell cementingMineralogy

The invention belongs to the technical field of bioengineering and oil and gas exploitation engineering, and particularly relates to an immobilization method for improving activity of microorganisms in well cementation cement paste, which mainly comprises the following steps: S1, selecting target microorganisms for expanding culture treatment, and taking bacterial liquid after expanding culture for later use; S2, taking a certain amount of porous ceramic particles, flatly laying the porous ceramic particles on a flat plate, uniformly spraying a certain amount of nutrient solution to the surfaces of the porous ceramic particles, and performing standing for 24 hours for later use; S3, preparing target porous ceramic; S4, preparing a microorganism immobilized product; and S5, preparing the microbial well cementation cement paste. The invention discloses the immobilization method for improving the activity of microorganisms in the well cementation cement paste. The microorganisms are immobilized in a porous material in this way, and then the microorganism well cementation cement paste is prepared. The activity of microorganisms in cement paste can be prolonged, porous ceramic particlesand the well cementation cement paste can be solidified into a cementation body with certain impermeability and mechanical properties through the mineralization effect of the microorganisms, and theservice life of the well cementation cement paste can be greatly prolonged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com