Corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device

A supercritical water oxidation and reactant technology, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. Corrosion and failure of structural materials, etc., to reduce the harshness of the service environment, reduce the overall maintenance cost, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

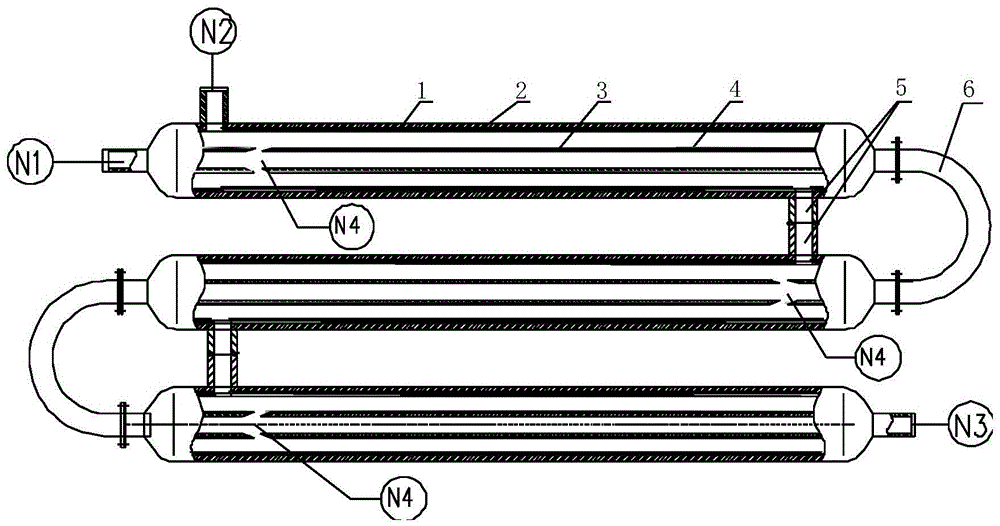

[0026] see figure 1 , the present invention is formed by connecting multiple reactant mixing-preoxidizers in series: the core tube 3 outlet of the first reactant mixing-preoxidizer and the core tube 3 inlet of the second reactant mixing-preoxidizer pass through The connection of the core tube 6 is realized, and the outlet of the core tube 3 of the second reactant mixing-preoxidizer is connected by the core tube 6 to the inlet of the core tube 3 of the third reactant mixing-preoxidizer, and so on, thus forming Supercritical water oxidation reactant mixing-core tube channel of pre-oxidizer. The outlet of the outer pipe branch pipe 5 of the first section supercritical water oxidation reactant mixing-preoxidizer is connected to the second section reactant mixing-outer pipe branch pipe 5 inlet of the preoxidizer, and the second section supercritical water oxidation reactan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com