Immobilization method for improving activity of microorganisms in well cementation cement paste

A technology for cementing cement slurry and microbial activity, which is applied to chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting microorganisms, microbial death, adverse effects on the mechanical strength of cementing cement, etc., and prolongs service life. , the effect of improving the density and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

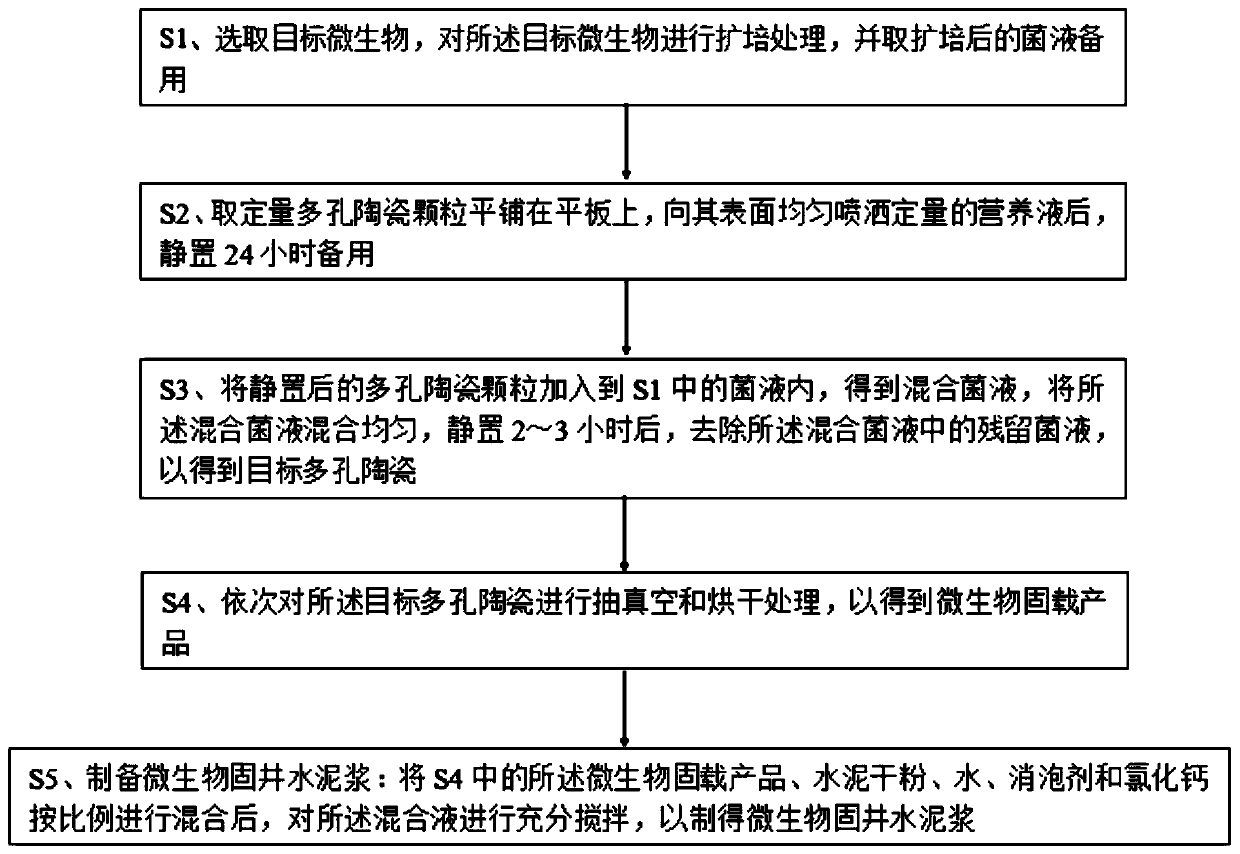

[0034] S1. Selecting target microorganisms, carrying out expansion treatment on the target microorganisms, and taking the expanded bacterial solution for later use;

[0035] S2. Spread 200g of porous ceramic particles on a flat plate, evenly spray 200ml of nutrient solution on the surface, and let it stand for 24 hours for later use;

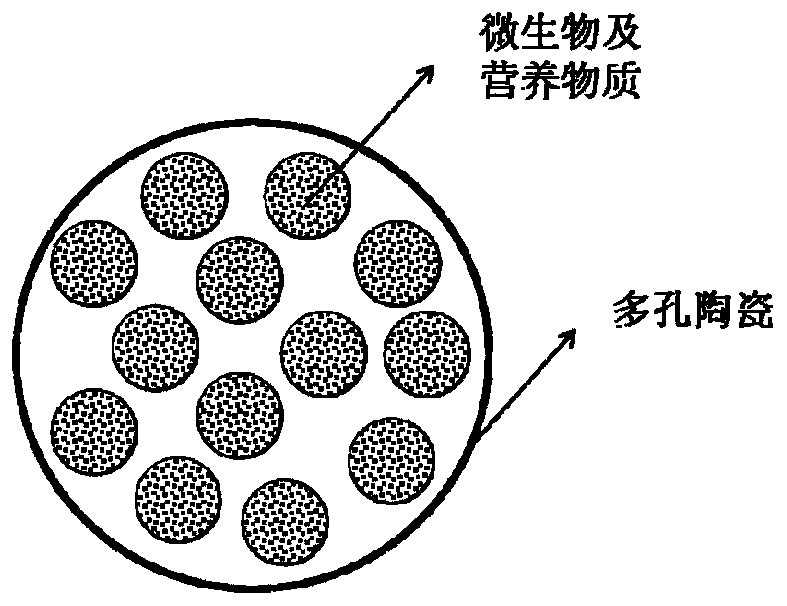

[0036] S3. Add the porous ceramic particles after standing to the bacterial liquid in S1 to obtain a mixed bacterial liquid, use a magnetic stirrer to mix the mixed bacterial liquid evenly, and after standing for 2.5 hours, remove the mixed bacterial liquid The residual bacterial liquid in order to obtain the target porous ceramics;

[0037] S4, placing the target porous ceramic in a container connected with a vacuum pump, vacuumizing it, and drying it at a drying temperature of 34° C. for 24 hours to obtain a microorganism-immobilized product;

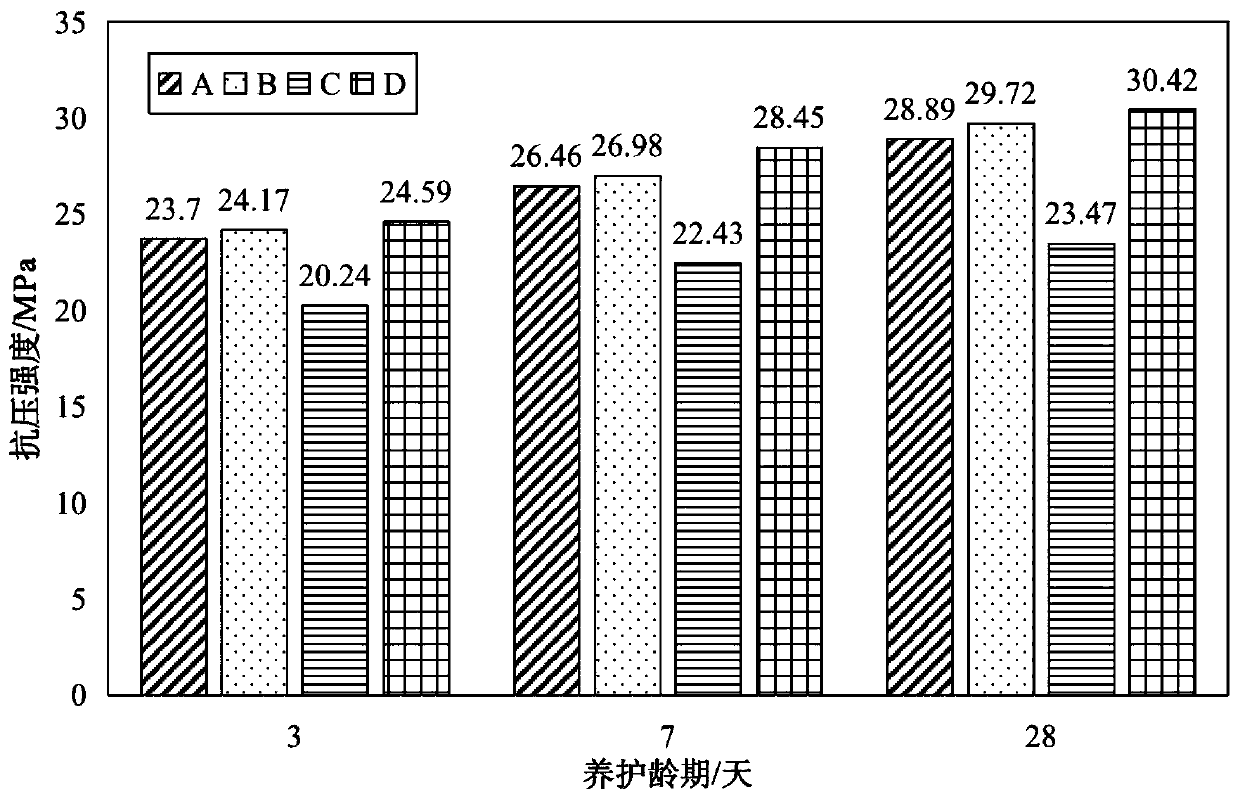

[0038] S5. Preparation of microbial cementing cement slurry: Weigh 300g of the microorganism-immobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com