Patents

Literature

39results about How to "Prevent overheating damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

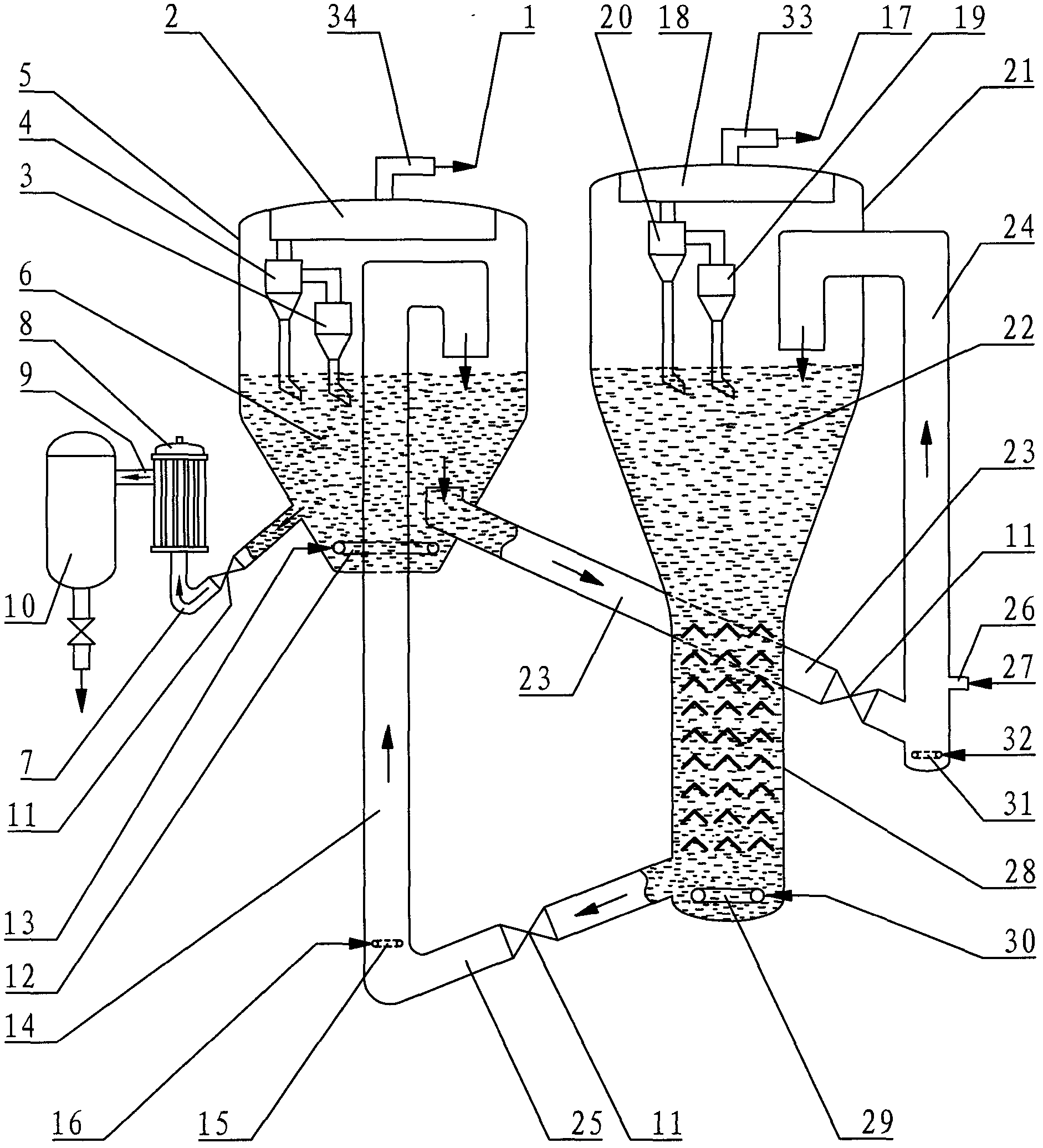

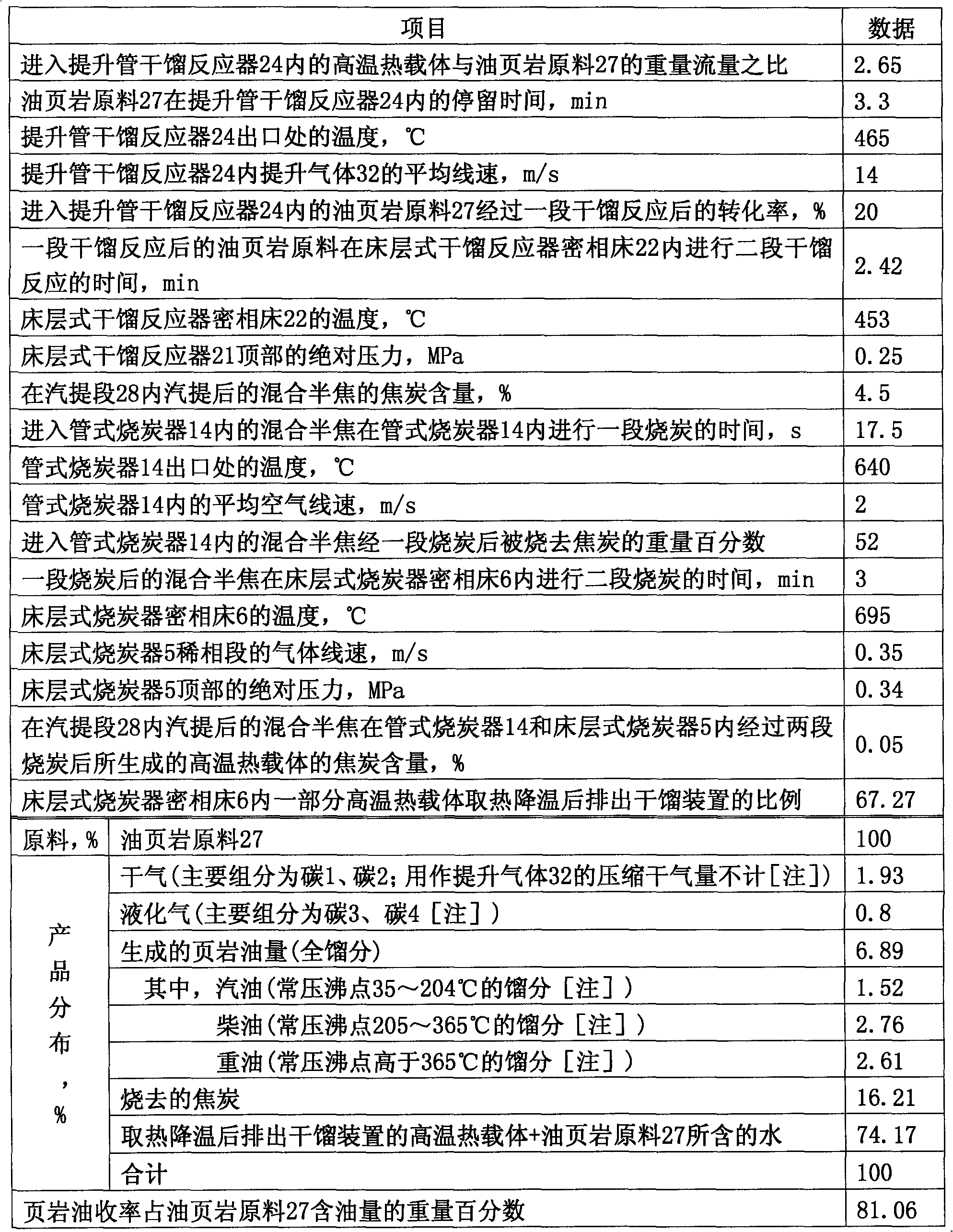

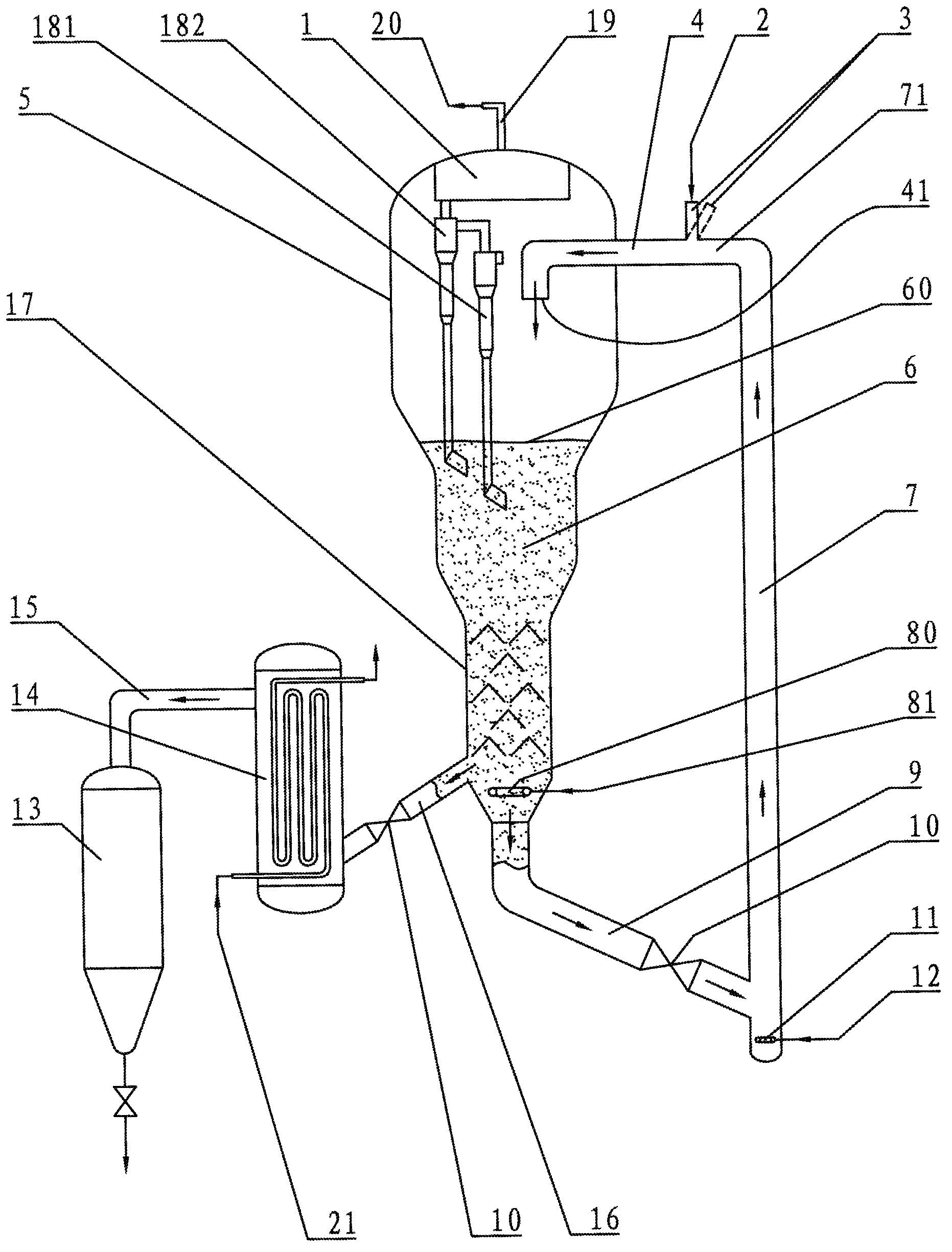

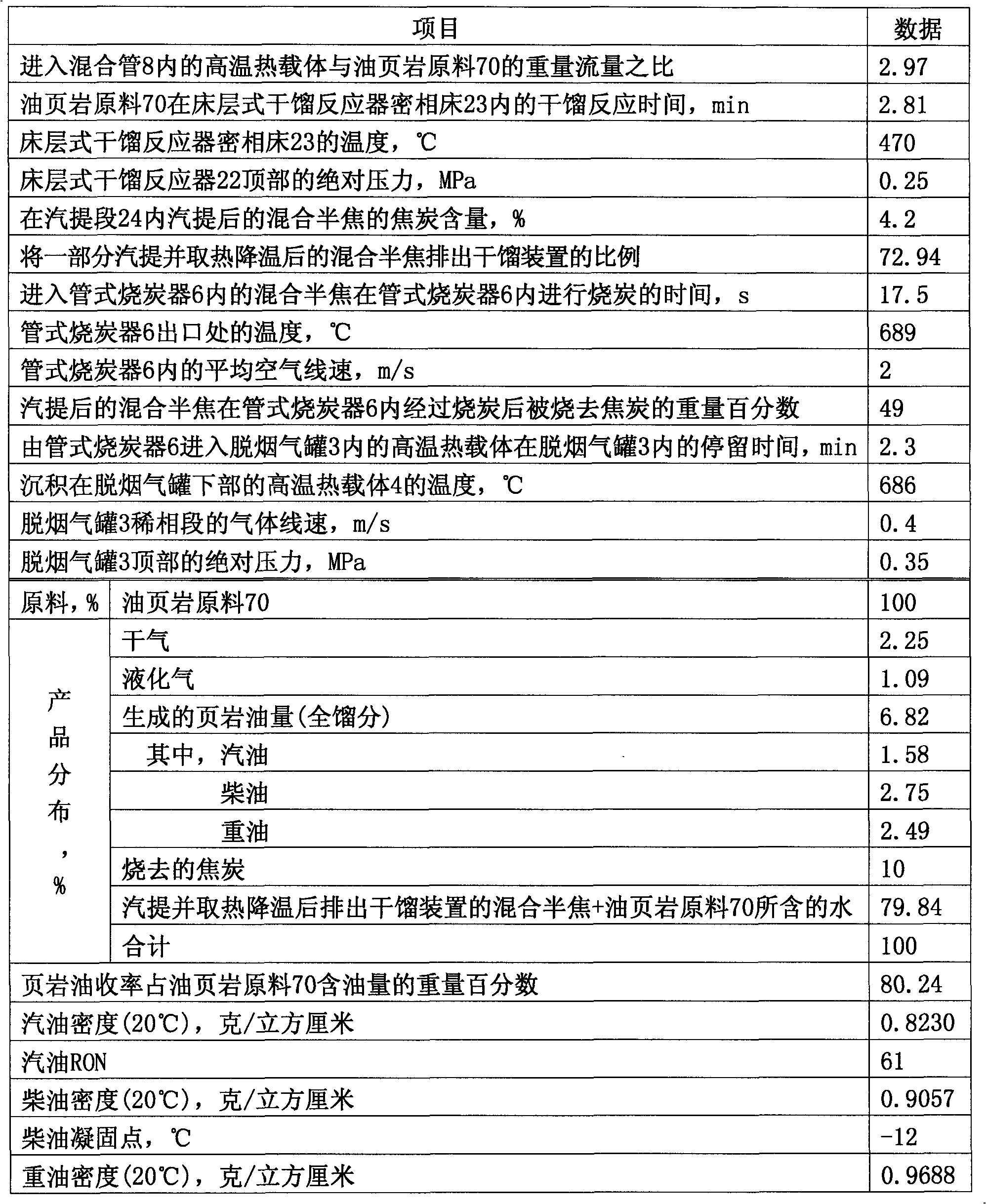

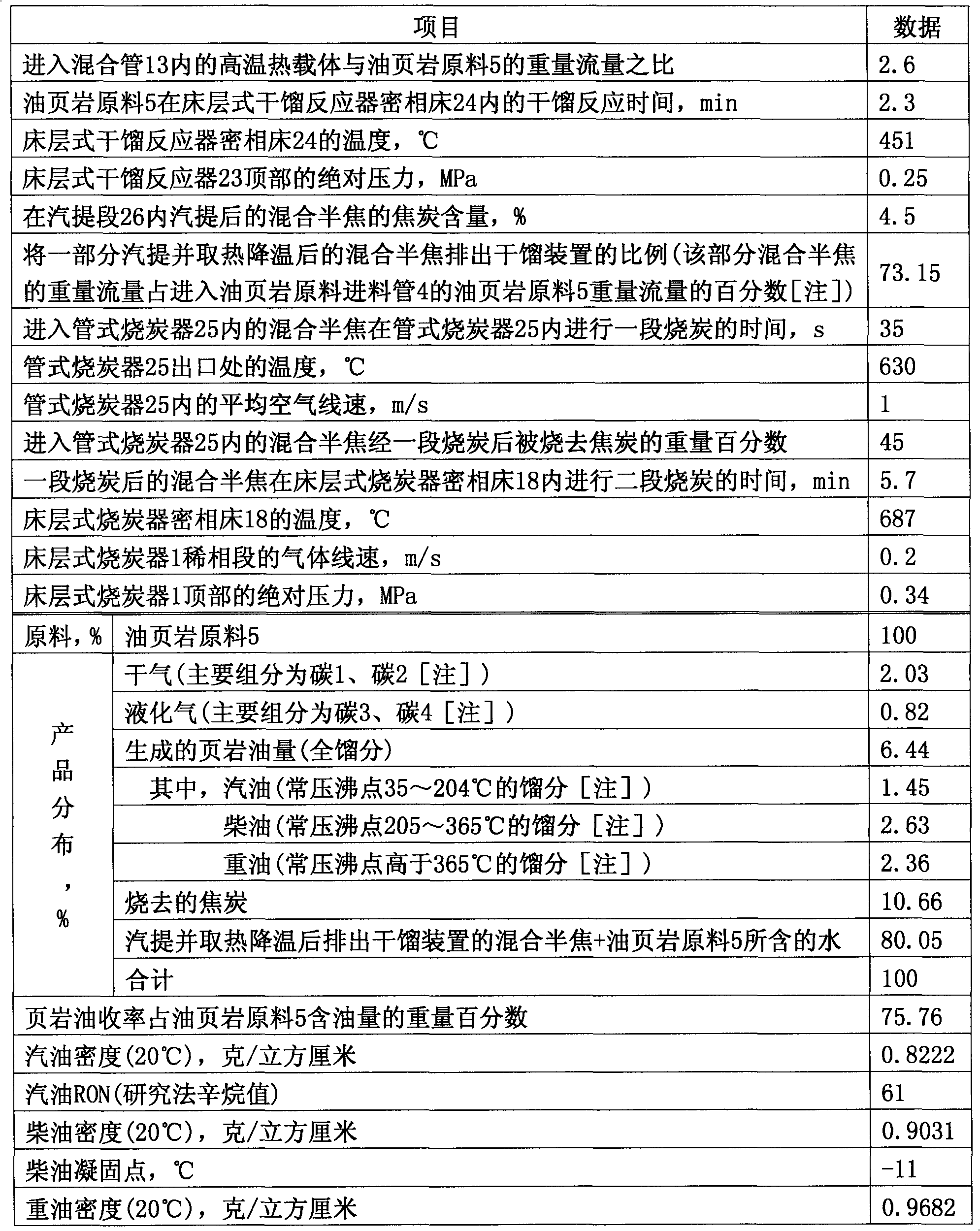

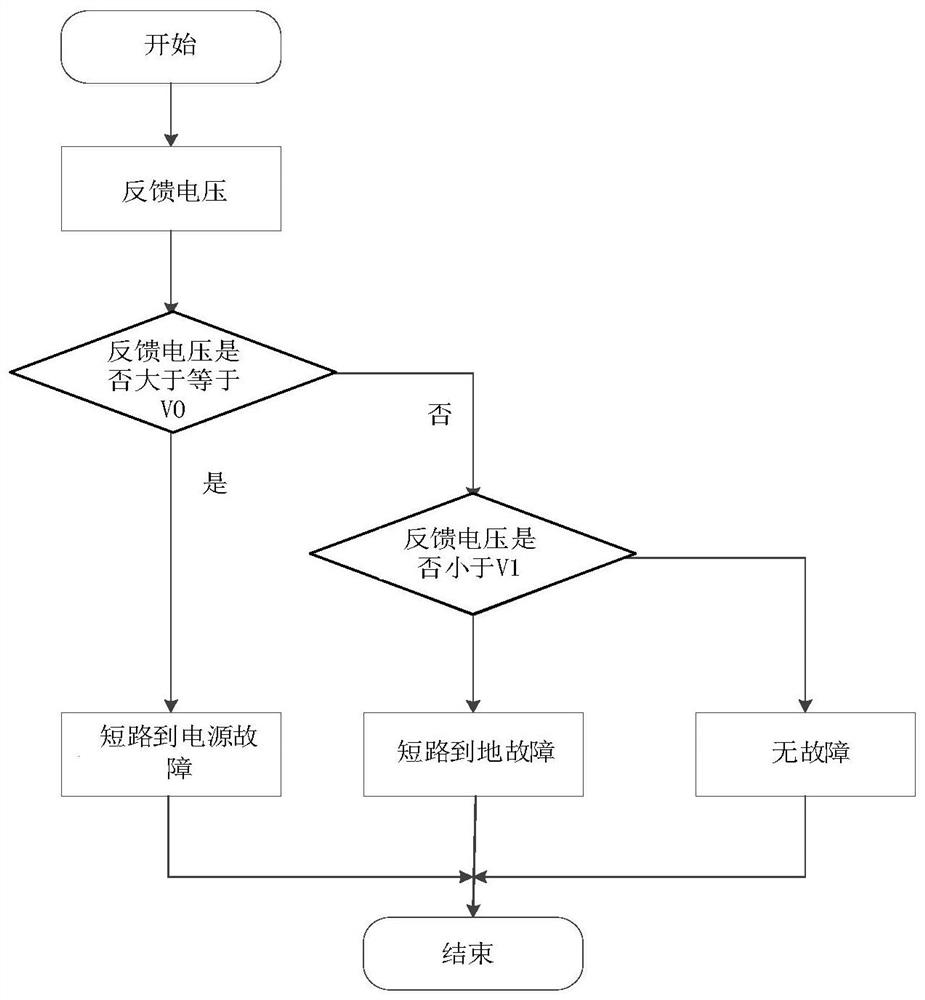

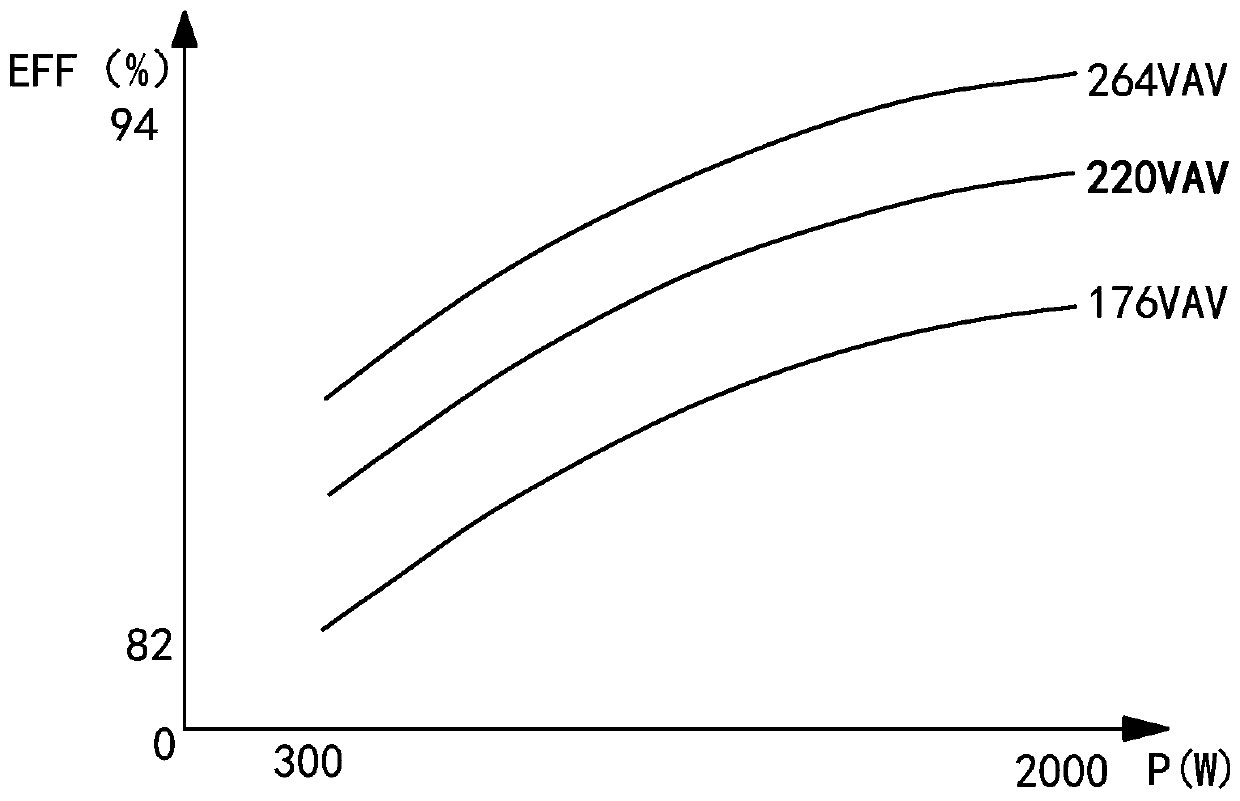

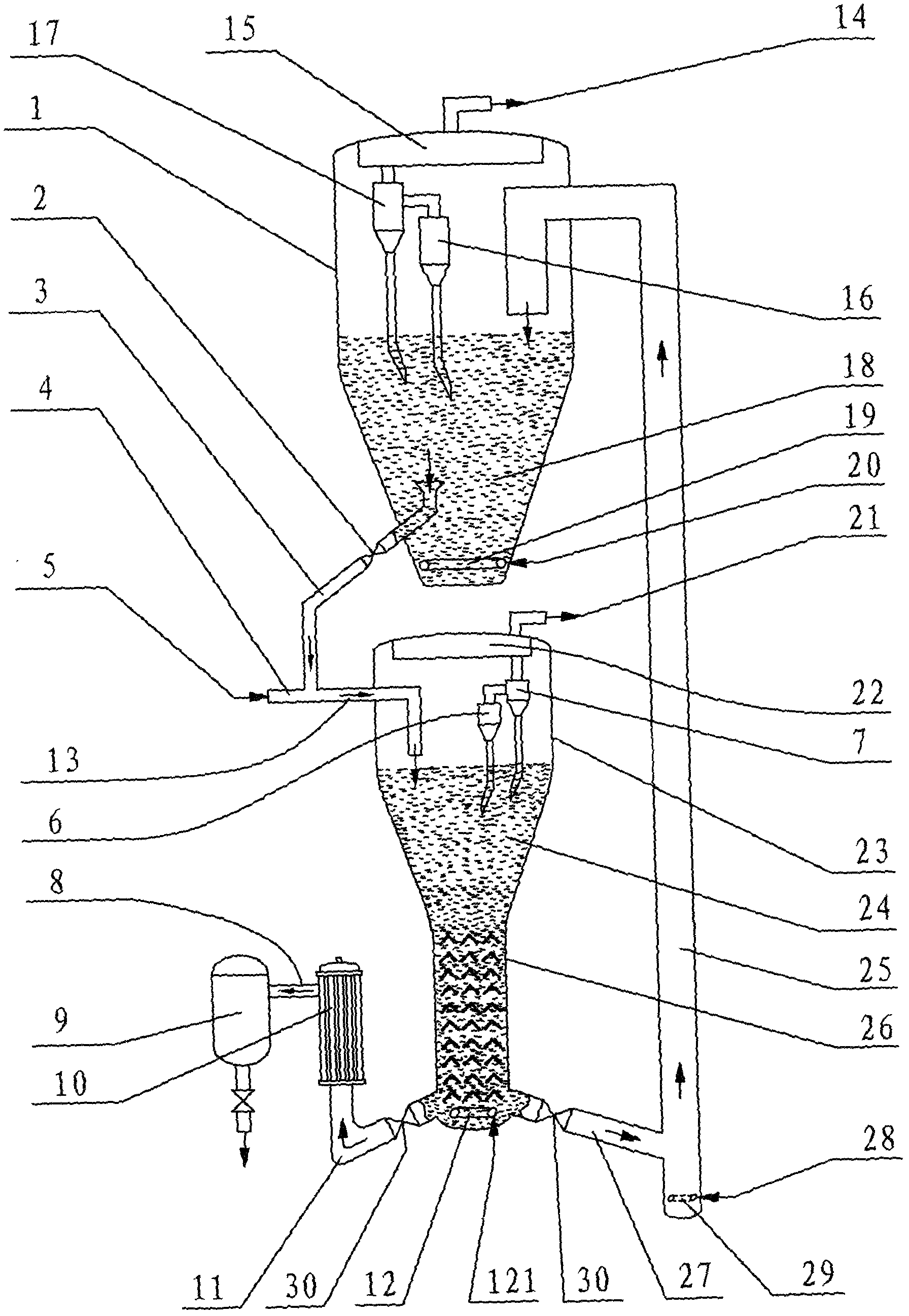

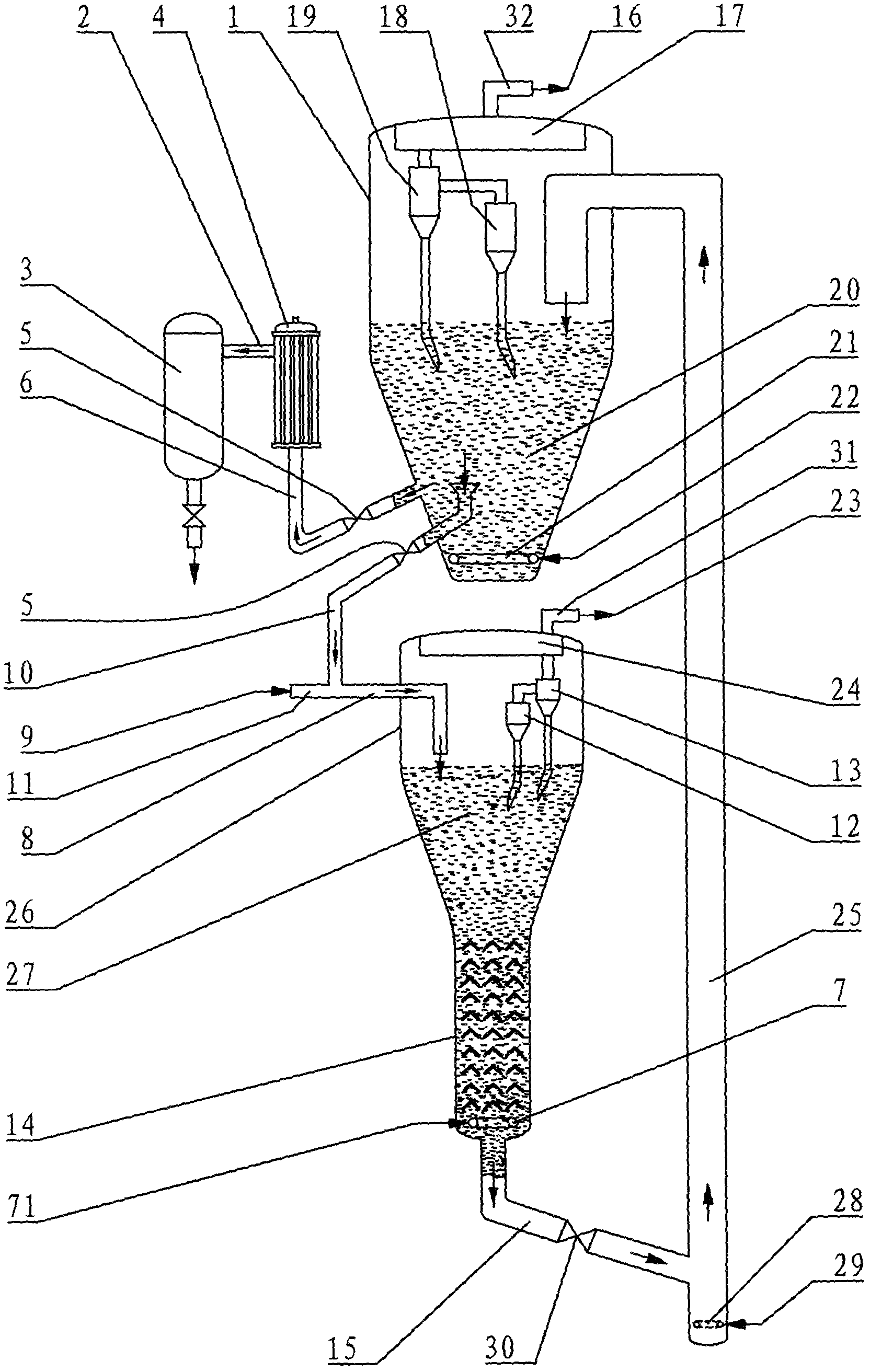

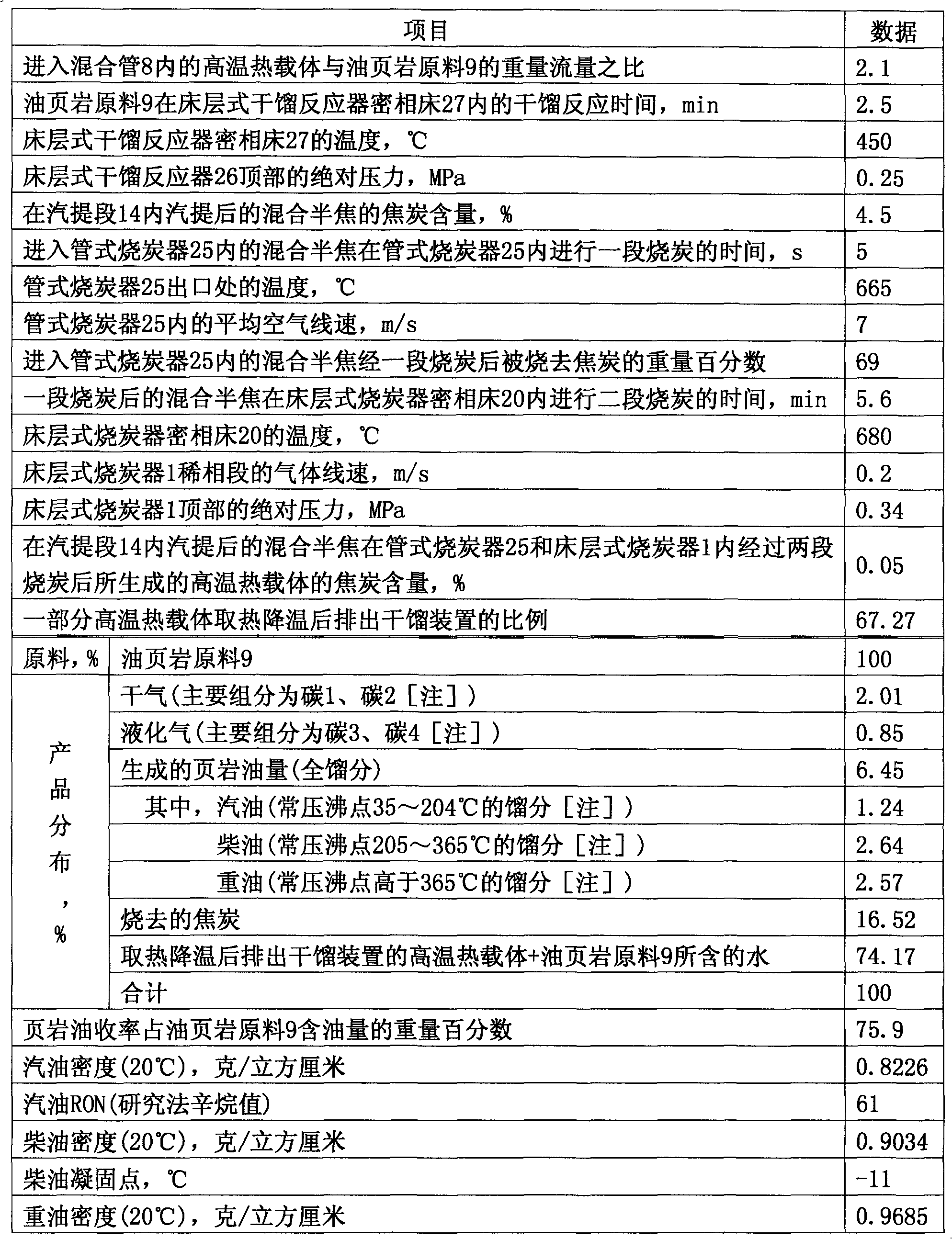

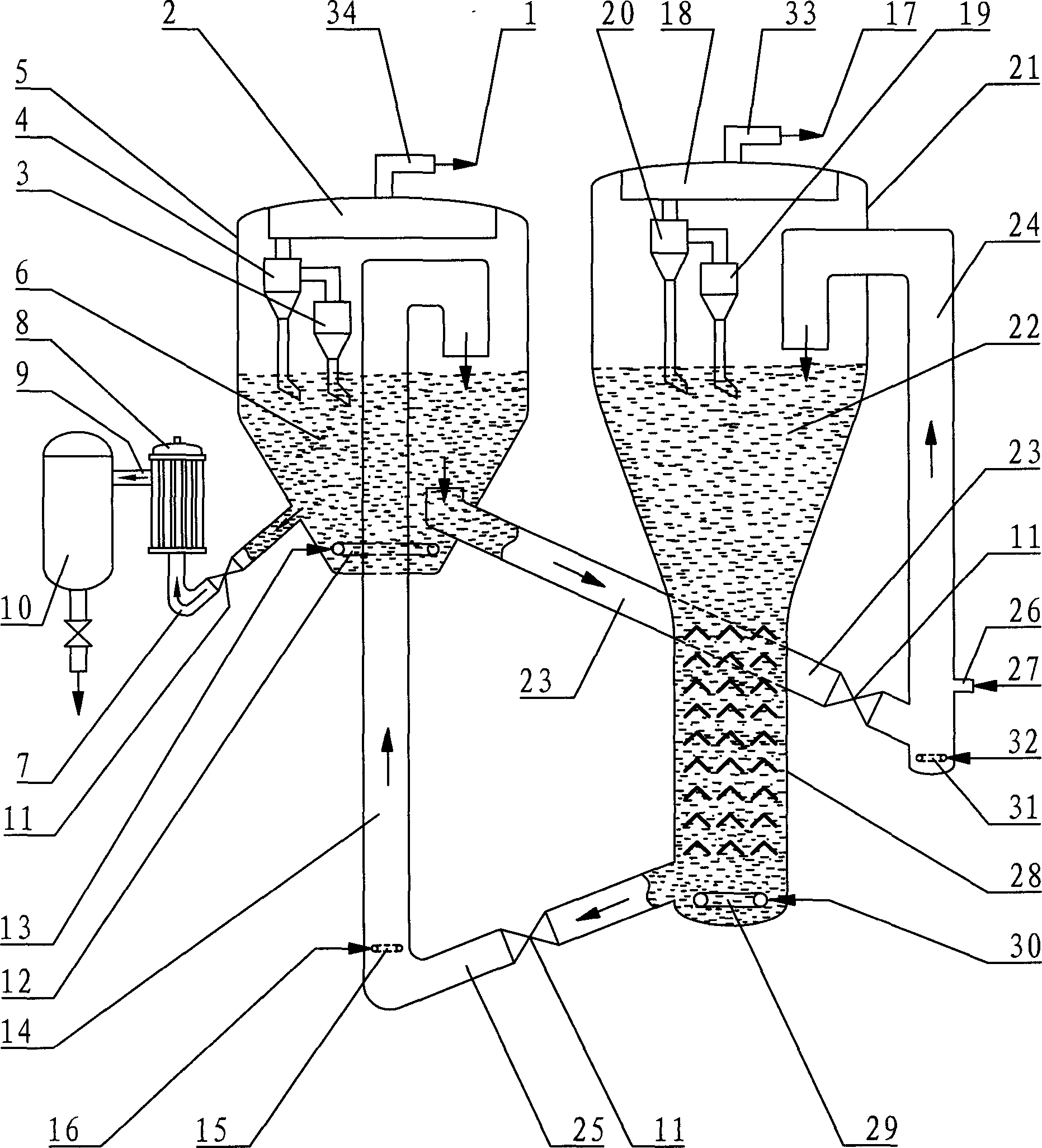

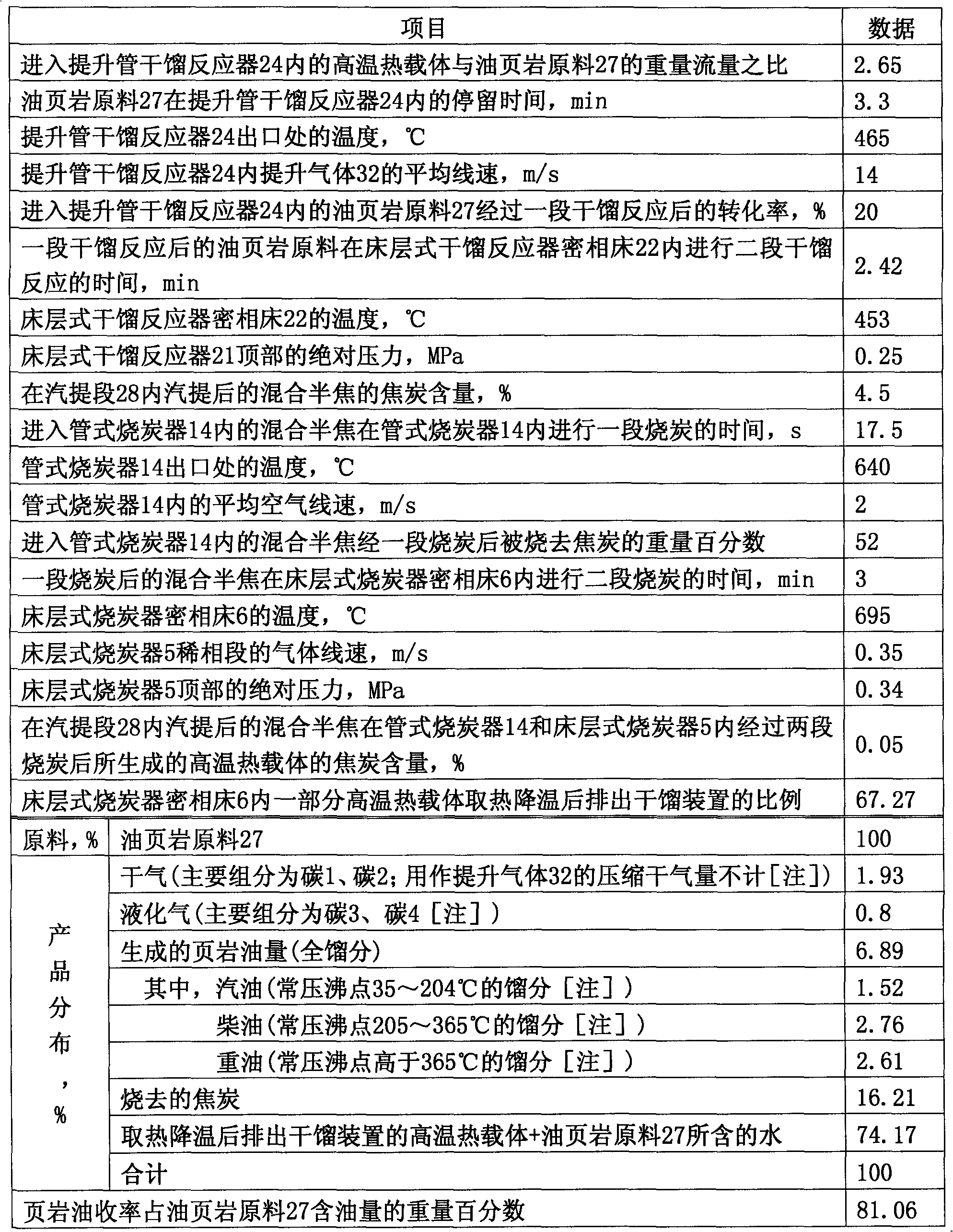

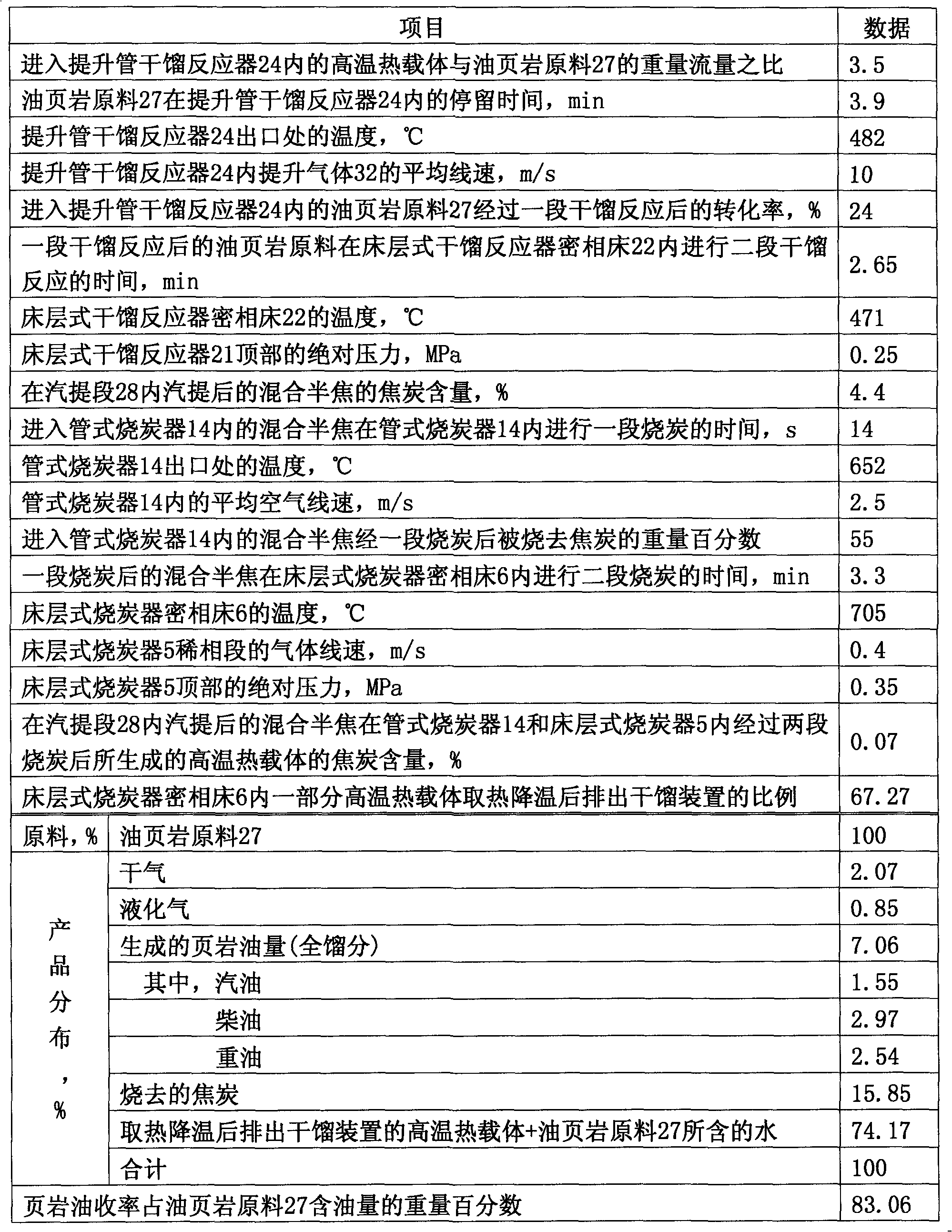

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131448AEasy to controlPrevent overheating damageSpecial form destructive distillationHeat carrierChemistry

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems caused by high coal burning load borne by a coal burning device in an existing destructive distillation technique and also solve the problem of low extraction rate of shale oil. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that a section of destructive distillation reaction is carried out on oil shale raw materials (27) and high-temperature heat carriers after the oil shale raw materials (27) and the high-temperature heat carriers are mixed in a lifting pipe destructive distillation reactor (24); the oil shale raw materials enter a bed type destructive distillation reactor (21) for a second section of destructive distillation reaction after the first section destructive distillation reaction is carried out on the oil shale raw materials, and then mixed carbocoal is formed and enters a pipe type coal burning device (14) after oil gas contained in the mixed carbocoal is extracted in a steaming mode; and a section of coal burning is carried out on the mixed carbocoal which enters the pipe type coal burning device; and the mixed carbocoal enters a bed type coal burning device (5) for a second section of coal burning after the first section coal burning is carried out on the mixed carbocoal. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

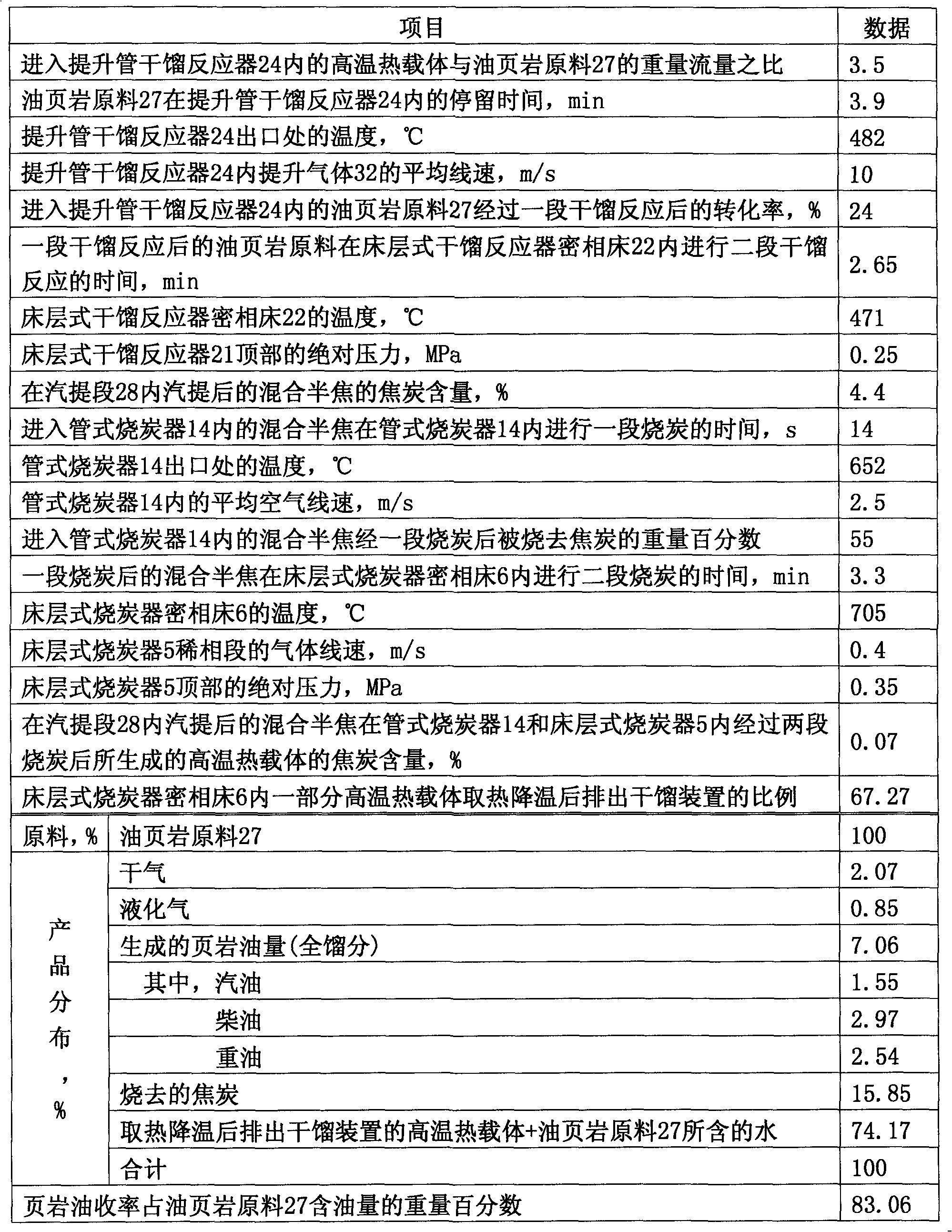

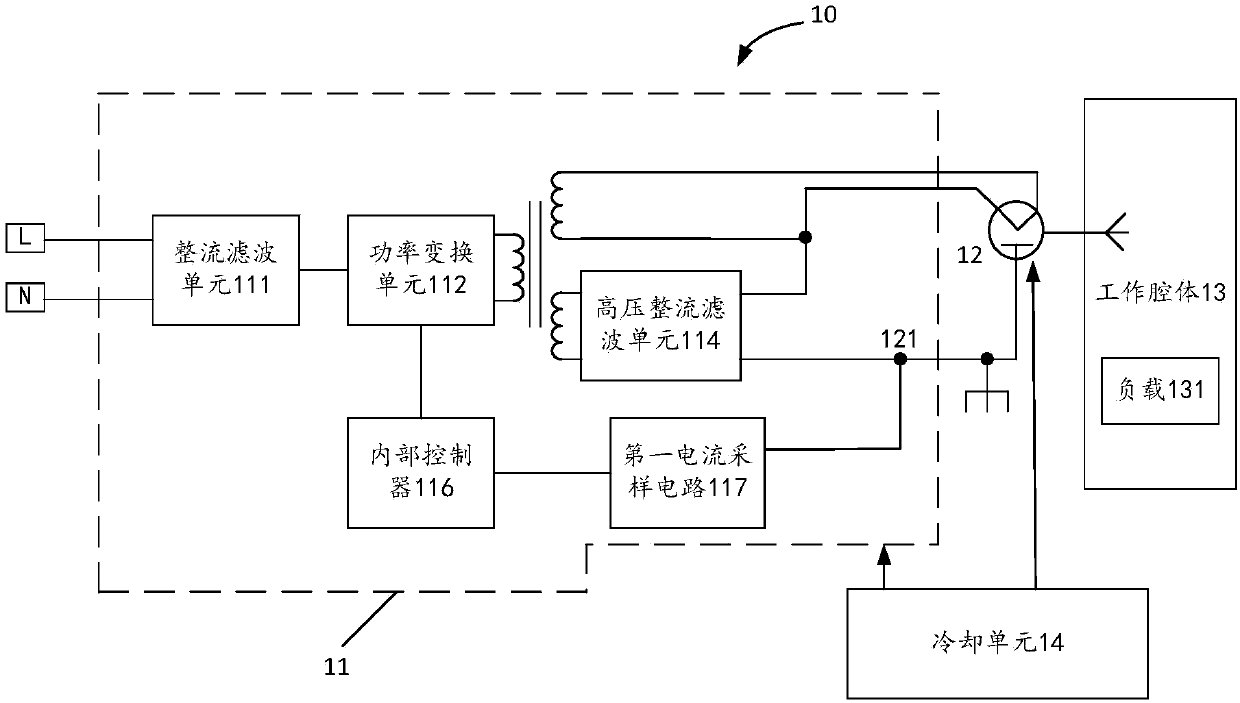

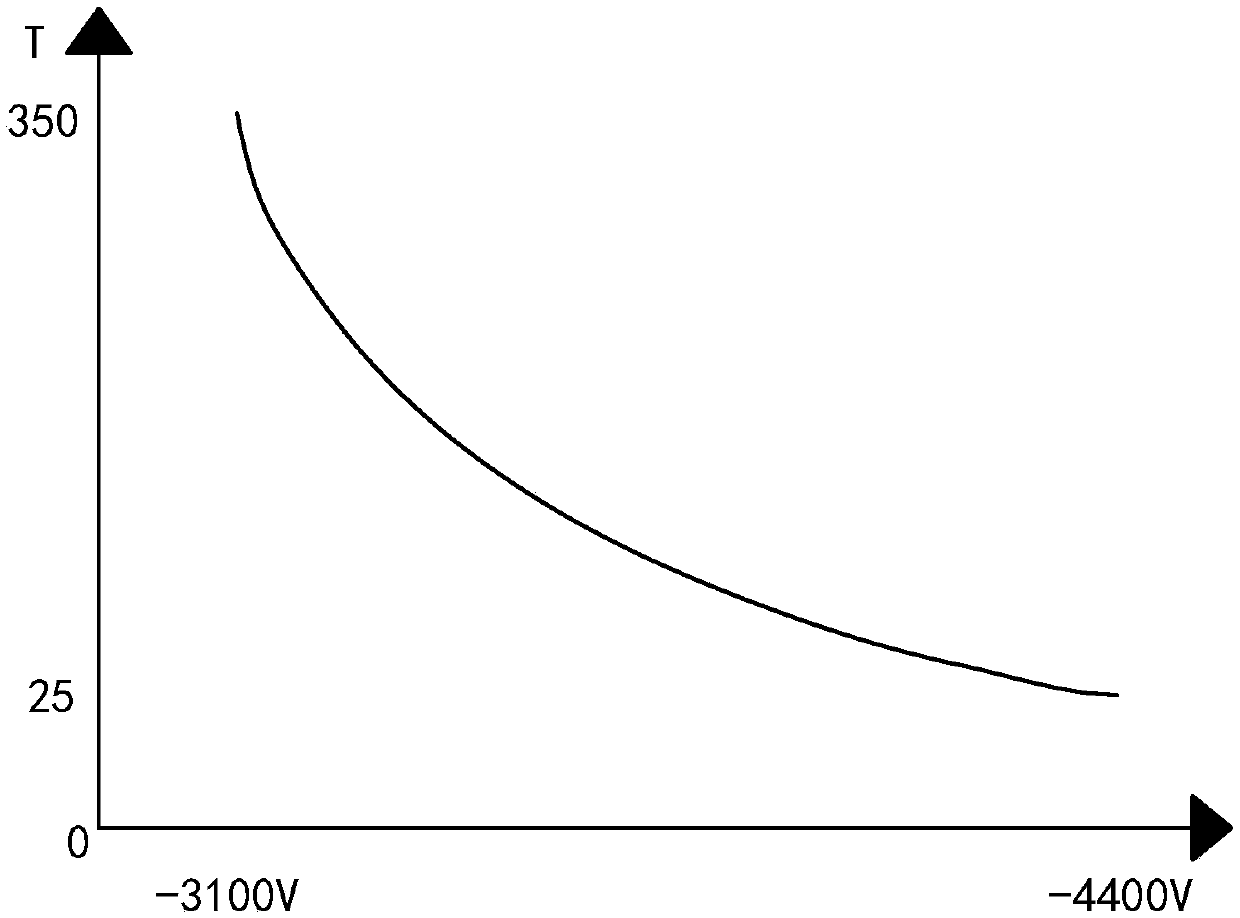

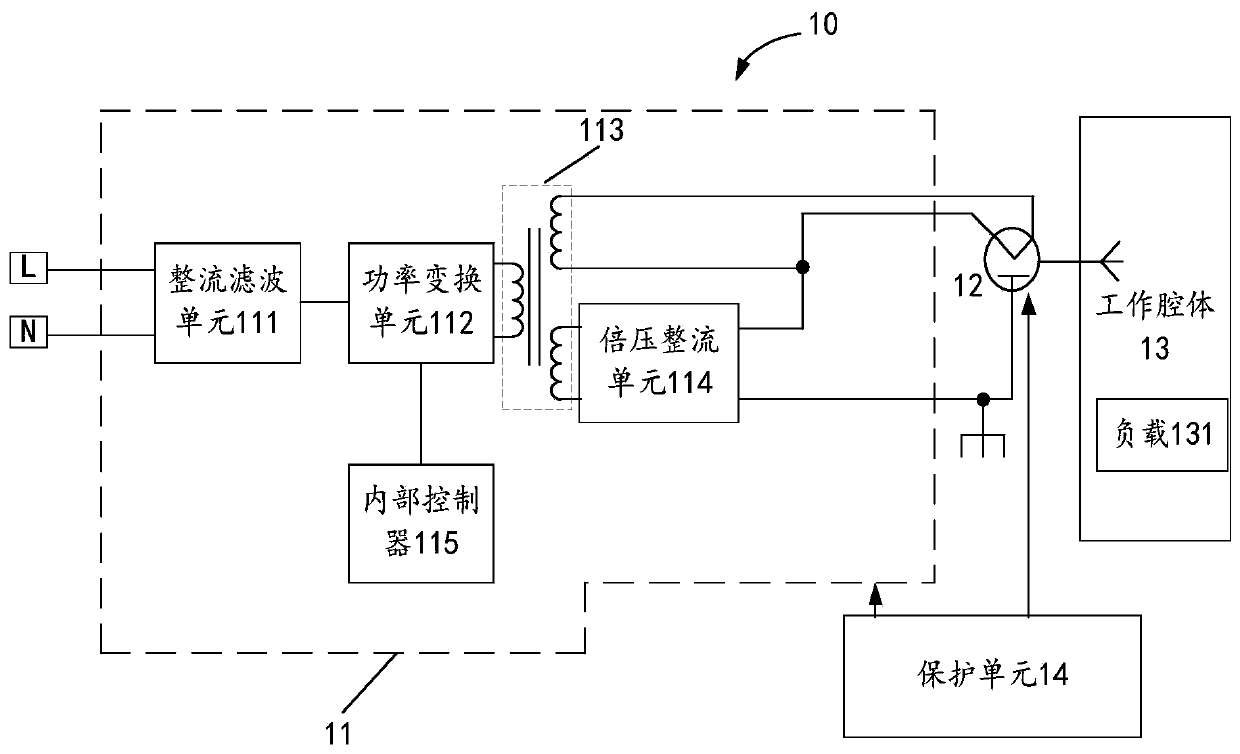

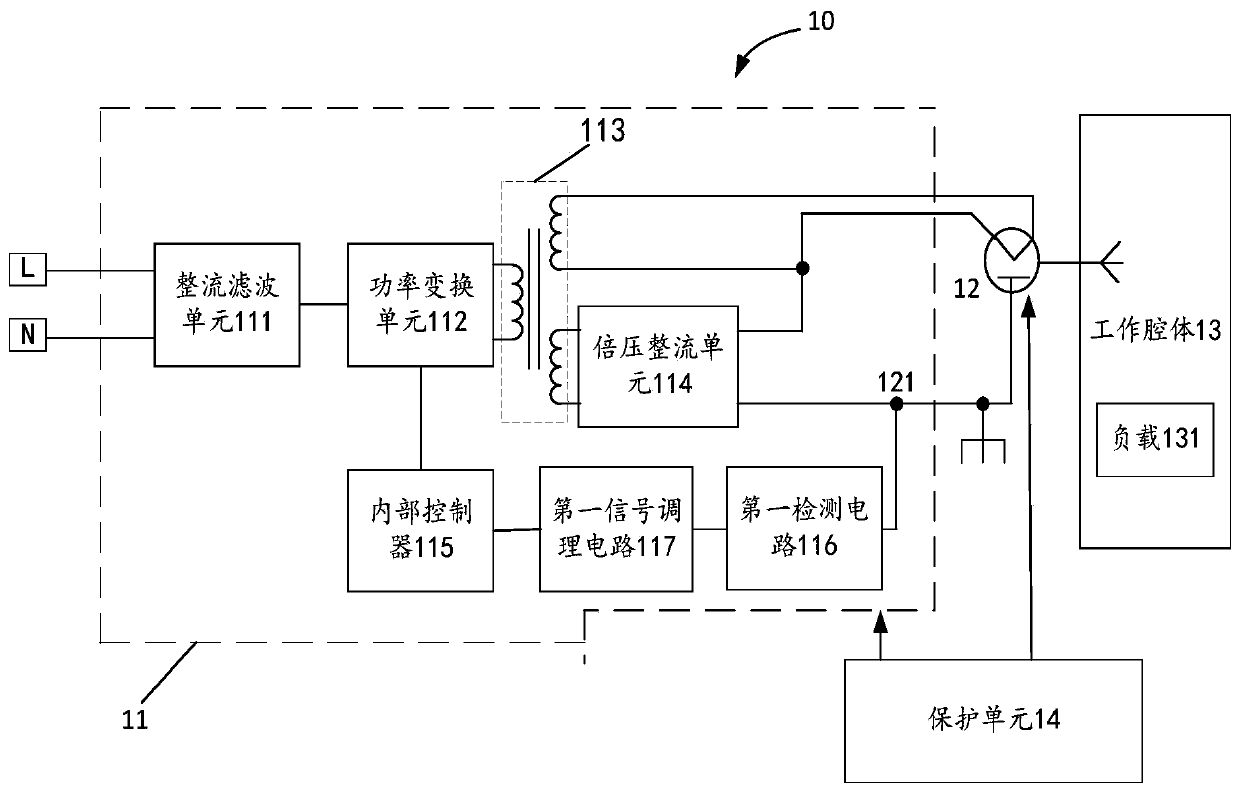

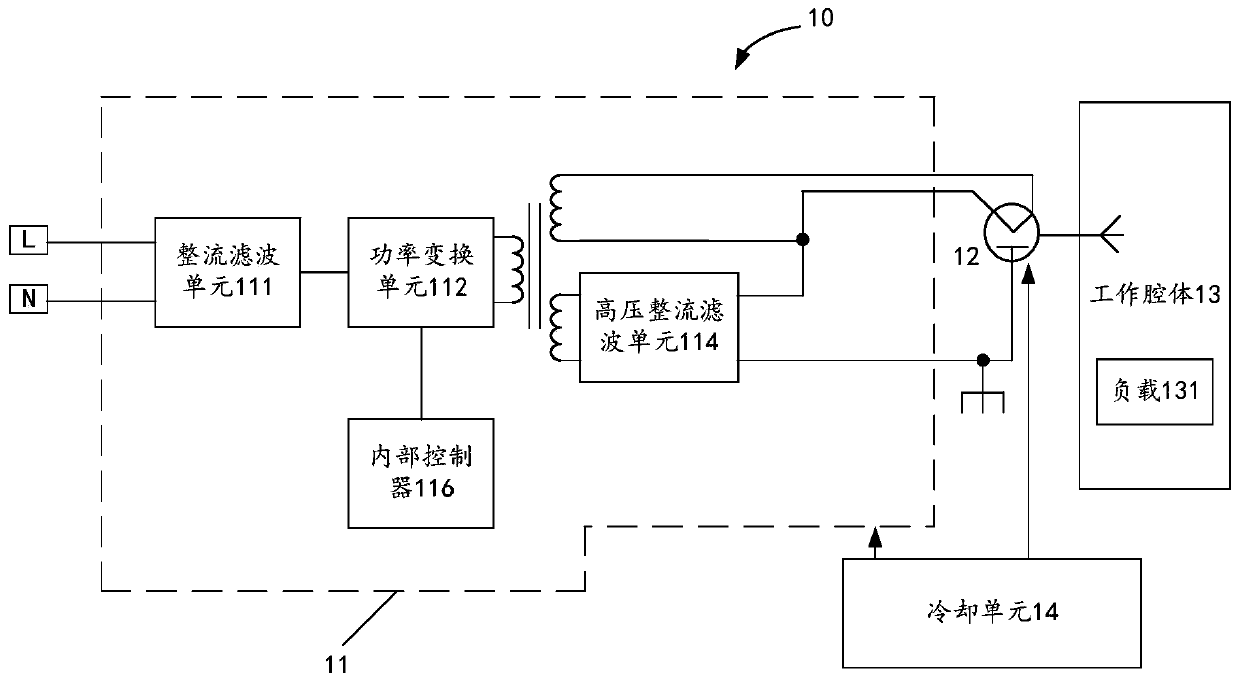

Temperature regulating method, apparatus, and system of magnetron, variable-frequency power supply, and microwave apparatus

ActiveCN107592694AReflect the anode temperaturePrevent overheating damageApparatus with intermediate ac conversionOhmic-resistance heatingMicrowaveAnode voltage

The invention relates to the field of microwave apparatuses, in particular, to a temperature regulating method and apparatus of a magnetron, a controller, a variable-frequency power supply, a temperature regulating system of a magnetron, and a microwave apparatus. The temperature regulating method comprises: determining an anode current flowing through a magnetron and an output power of the variable-frequency power supply for driving the magnetron to work; calculating an anode voltage of the magnetron according to the anode current of the magnetron and the output power of the variable-frequency power supply; and adjusting the output power of the variable-frequency power supply based on the anode voltage of the magnetron. Therefore, the anode current of the magnetron is obtained directly toreflect the anode temperature of the magnetron accurately; and the anode temperature of the magnetron is adjusted by adjusting the output power of the variable-frequency power supply, so that over-temperature damages of the magnetron are avoided.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

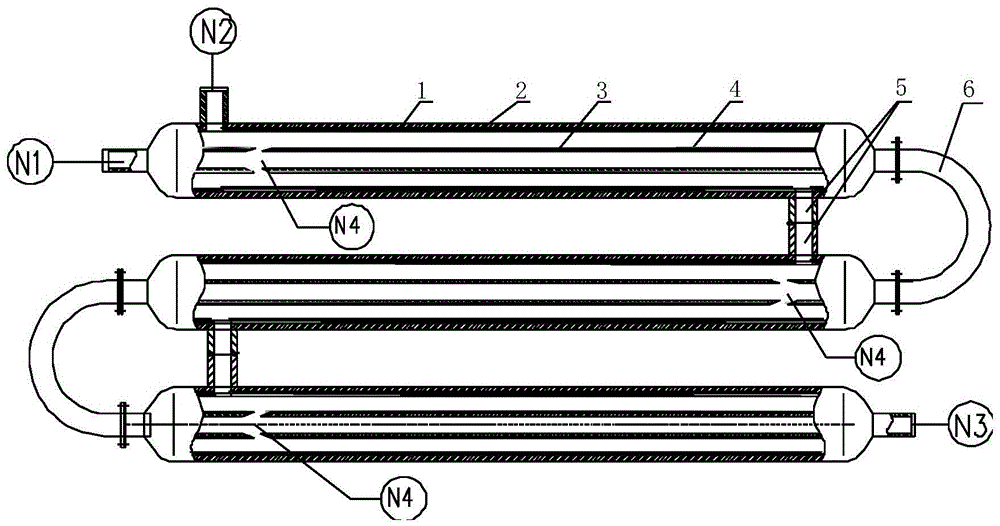

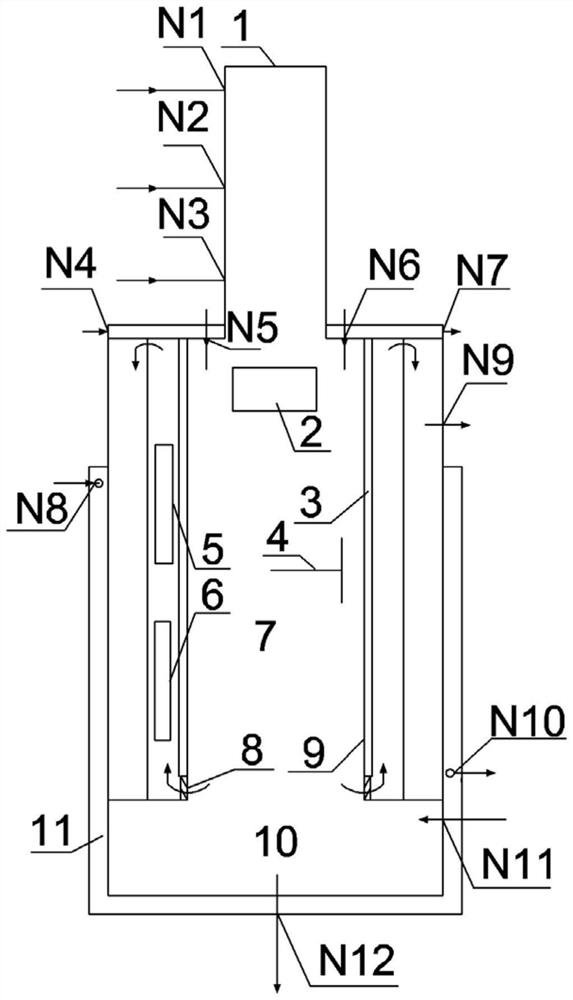

Corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device

ActiveCN105621588AReduce the harshness of the service environmentExtend service lifeSpecific water treatment objectivesWater/sewage treatment apparatusCorrosionHigh concentration

The invention discloses a corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device. The device is composed of a plurality of reactant mixing-pre-oxidizing device core tubes and outer tubes in a series connection mode along the way, and a core tube channel and an outer tube channel are formed. The core tube channel is sequentially provided with a plurality of reactant A injection ports along the way, the reactant A injection ports are used for injecting reactants A into the outer tube channel in a grading mode, and the outer tube channel is used for stage-by-stage mixing of the reactants A and reactants B and supercritical water oxidation reaction. The mixing and oxidizing process of organic waste and an oxidizing agent is effectively controlled, ultra-high-temperature damage caused by local concentrated heat release is avoided, and intensified corrosion of the high-concentration oxidization agent on equipment materials is relieved. The corrosion inhibition type supercritical water oxidation reactant mixing-pre-oxidizing device is arranged on an entrance of a supercritical water oxidation reactor, the service environment harshness of the supercritical water oxidation reactor is remarkably reduced, the service life of the reactor is prolonged easily, overall maintenance cost in the later stage of the supercritical water oxidation reactor is reduced, and the corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device can be widely applied to performing supercritical water oxidation reactant on various heavy-pollution industrial wastewater and sludge.

Owner:XI AN JIAOTONG UNIV

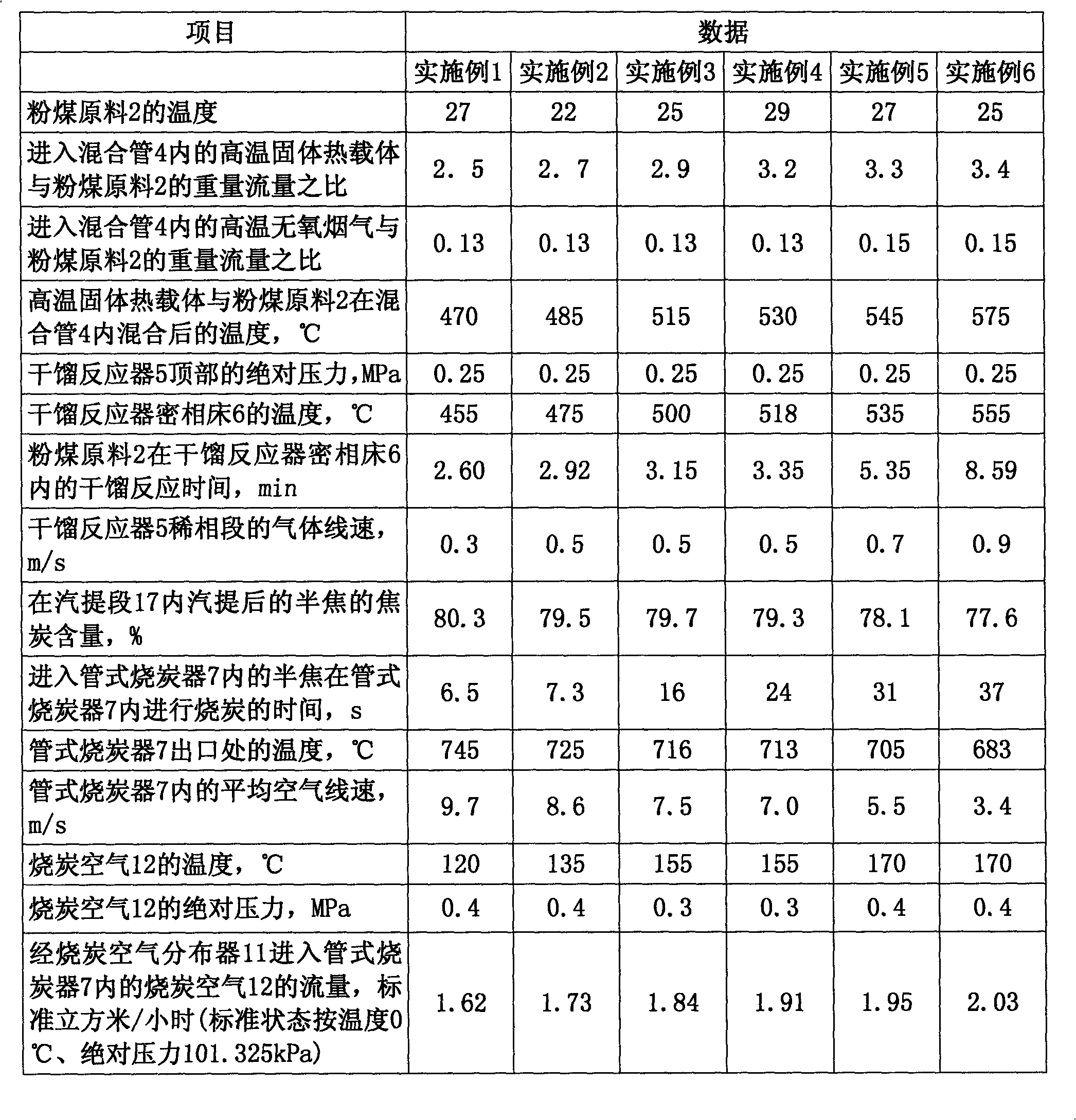

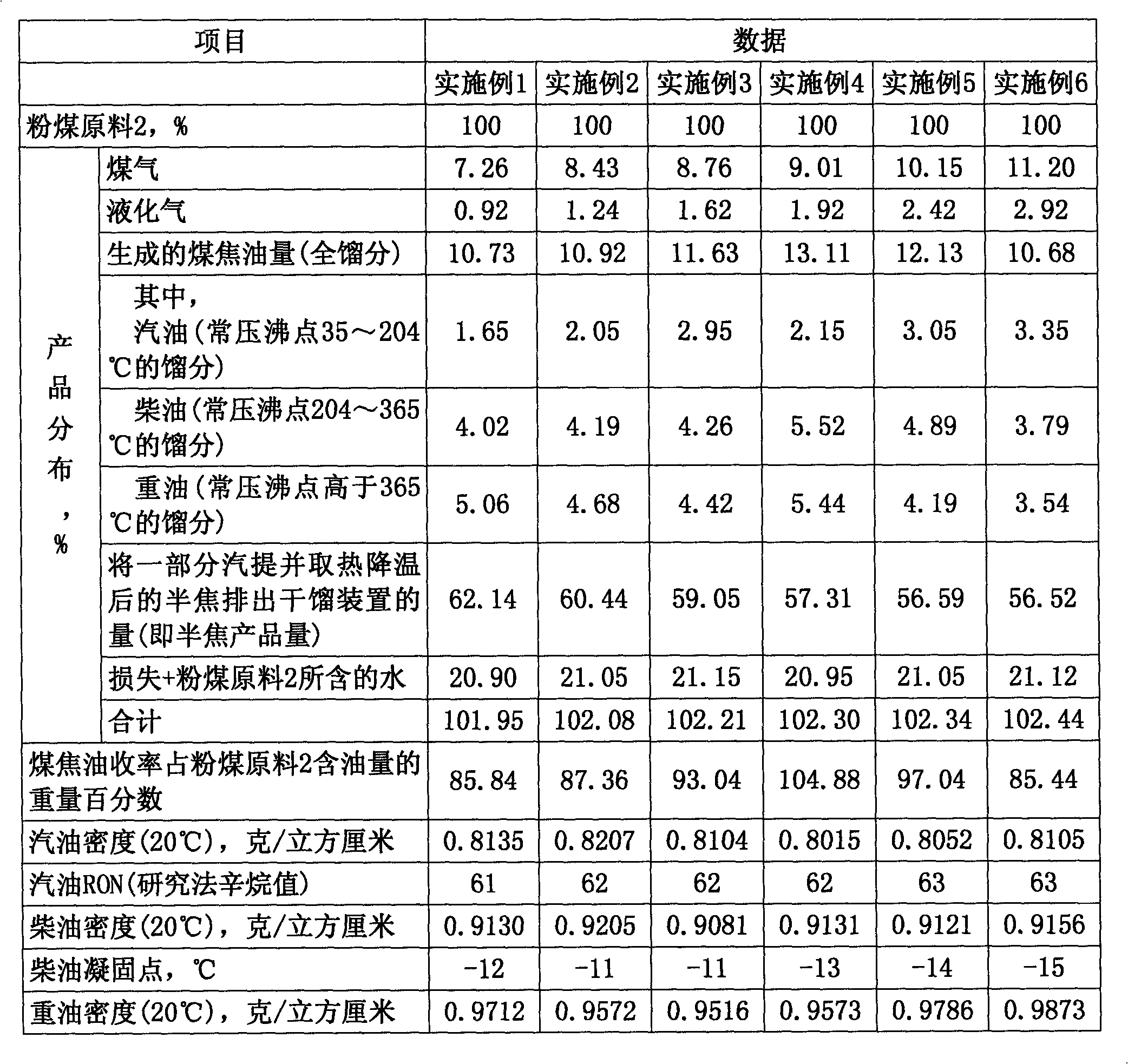

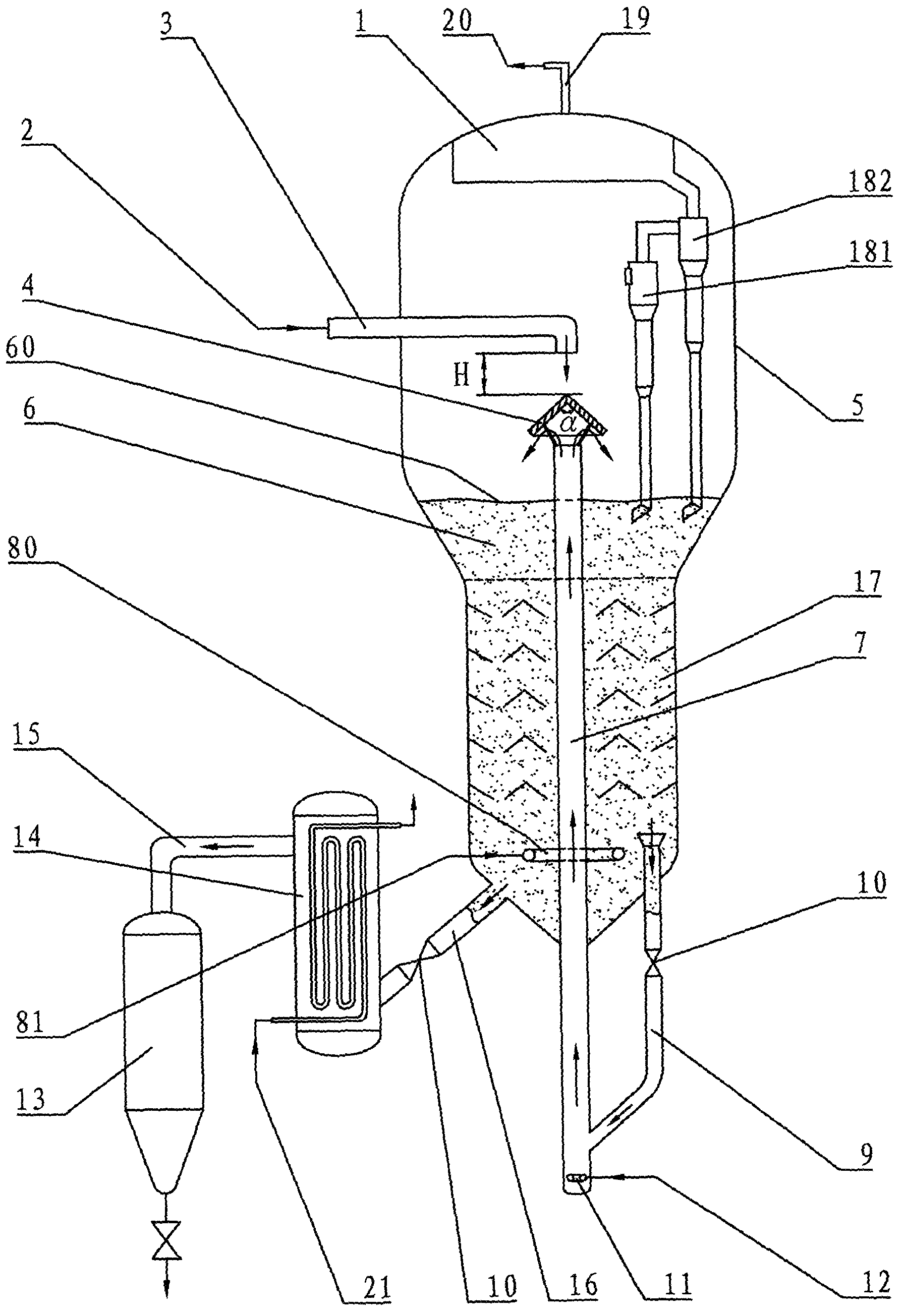

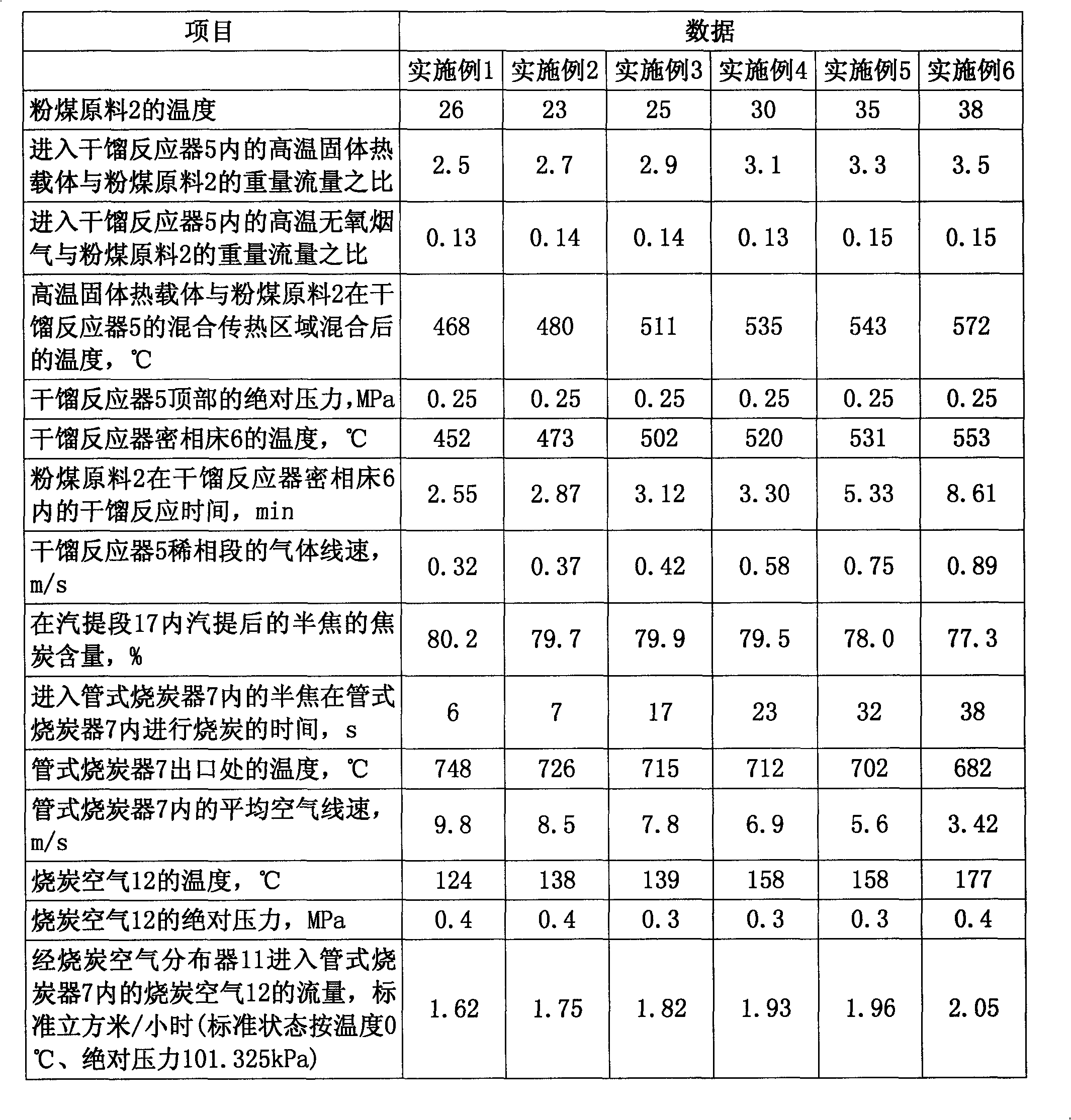

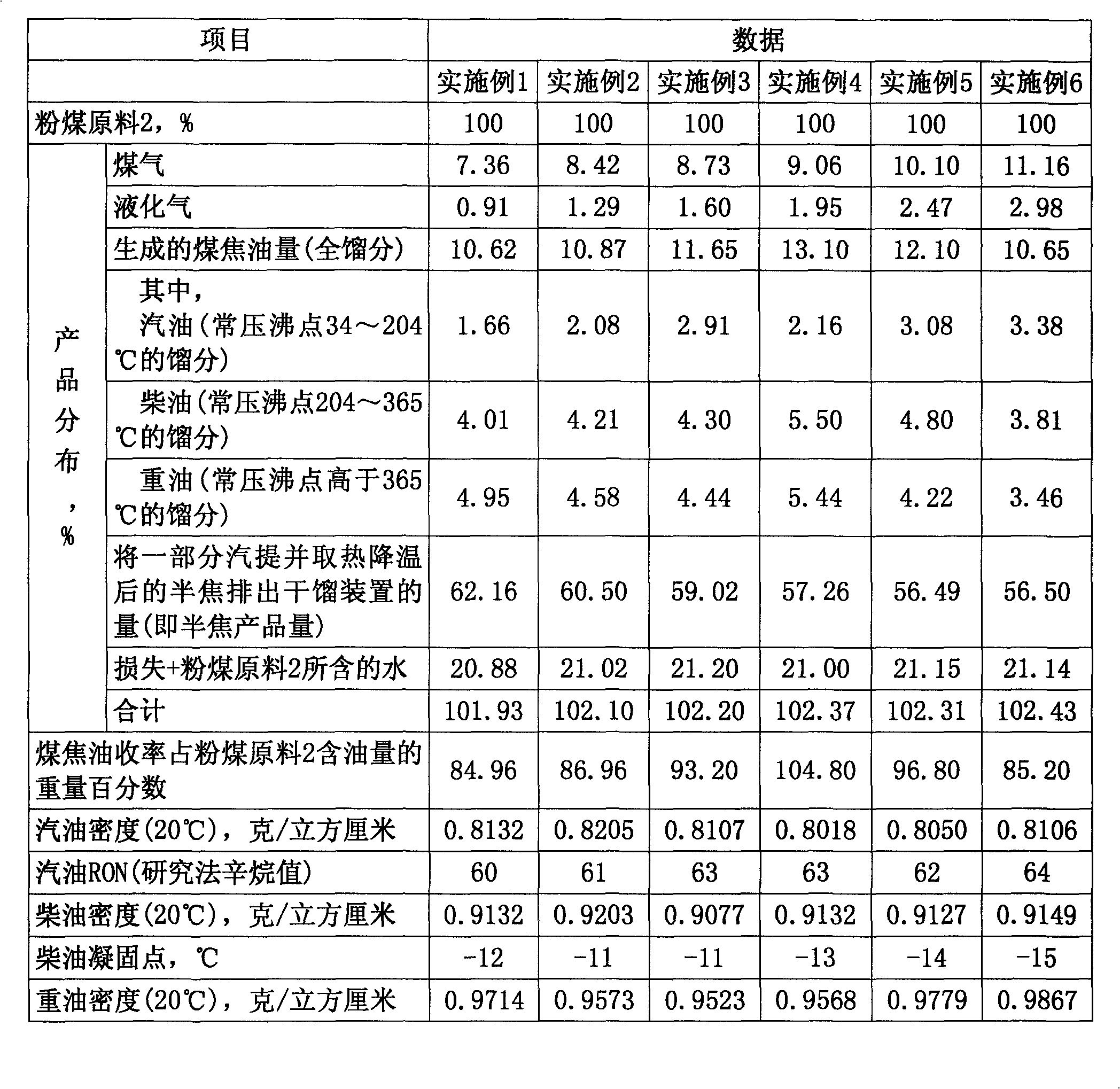

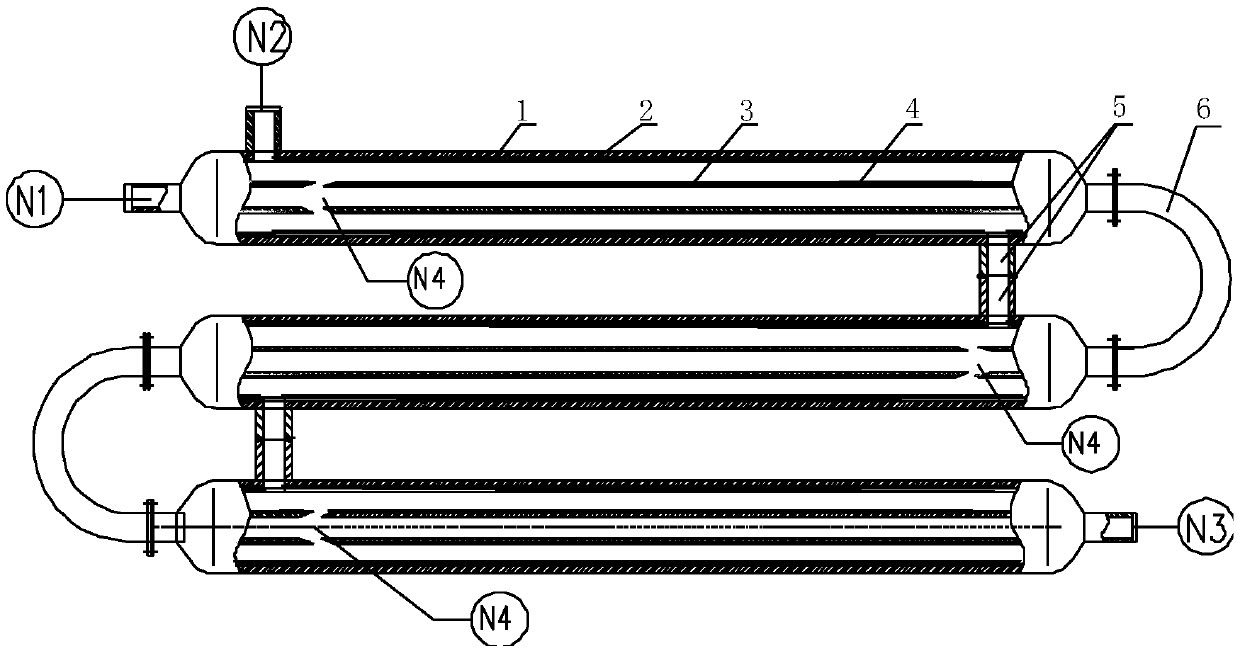

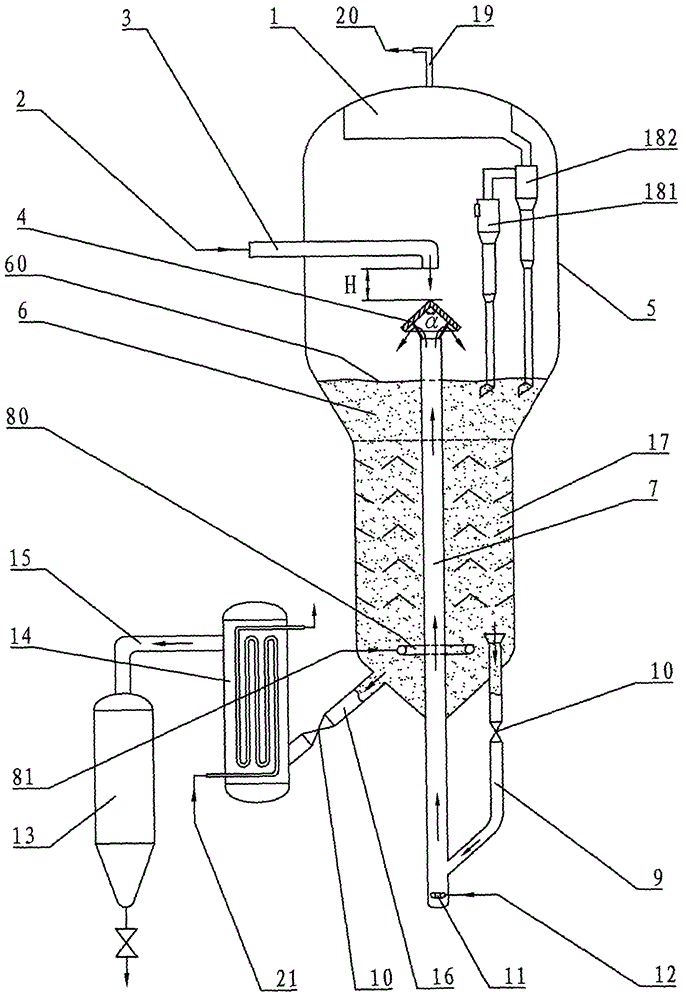

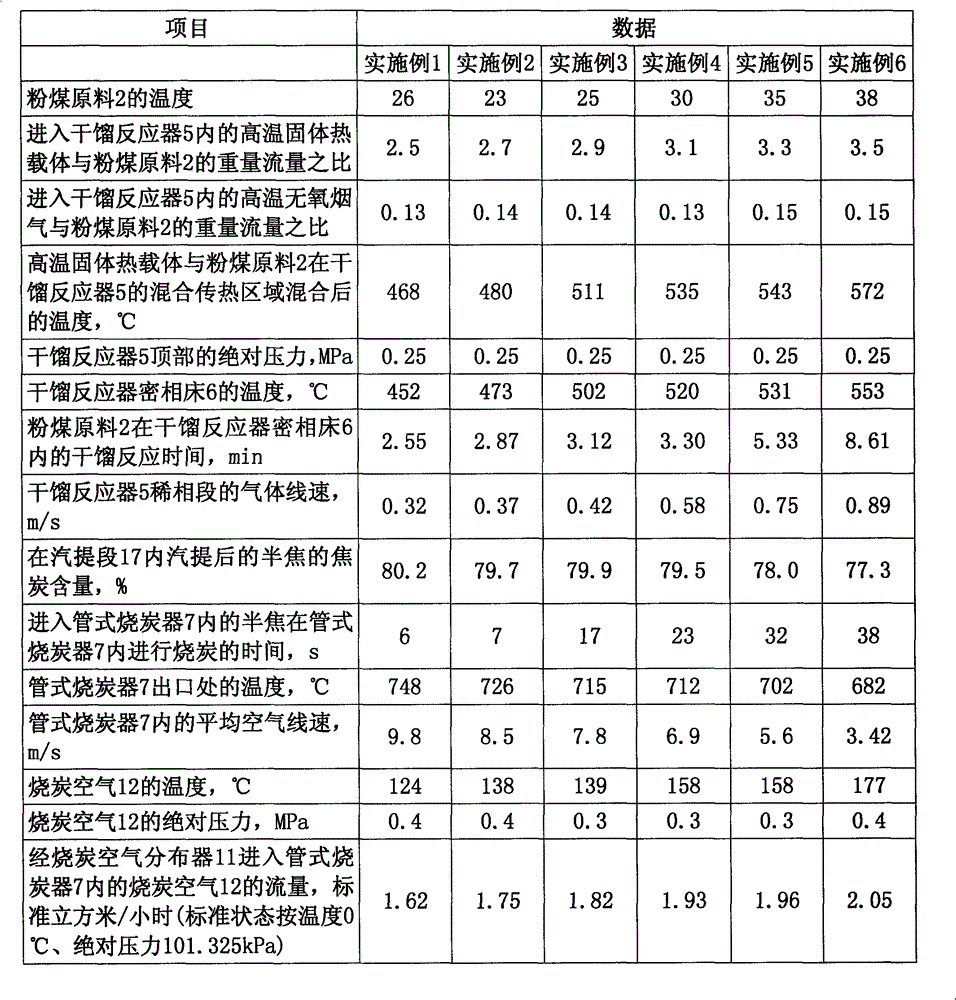

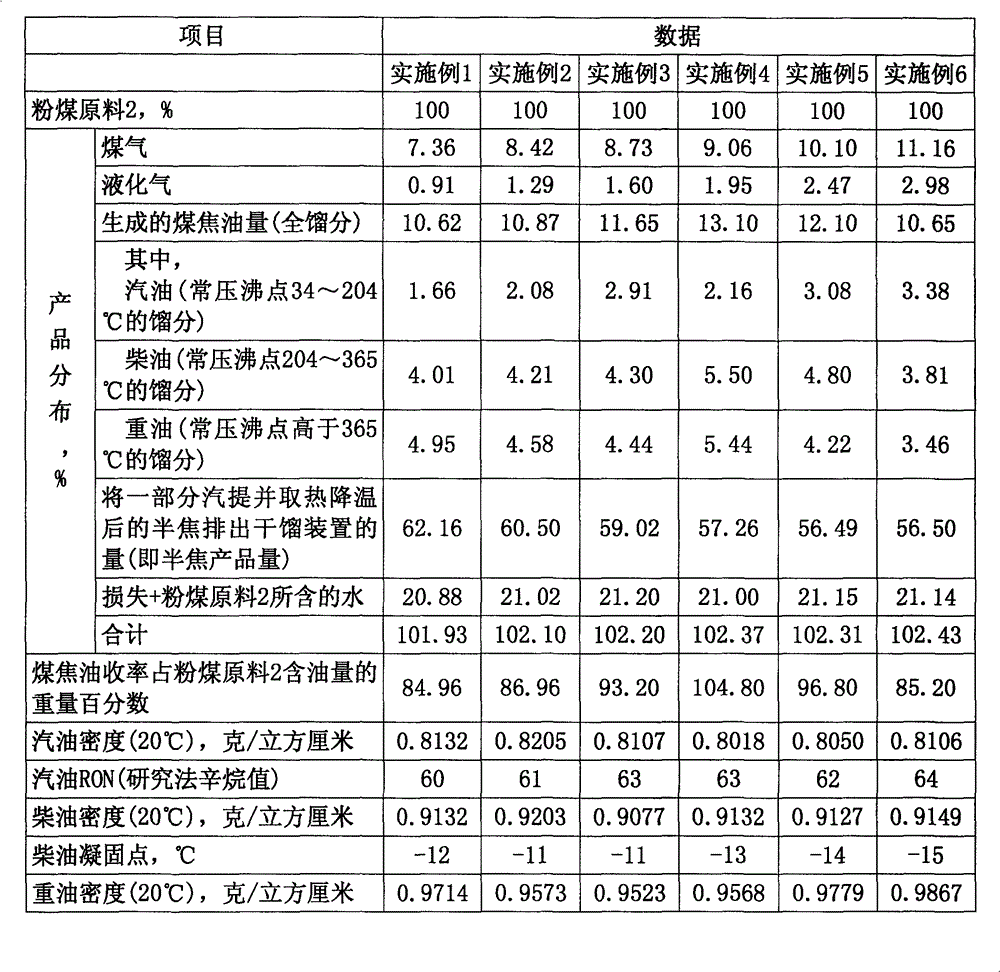

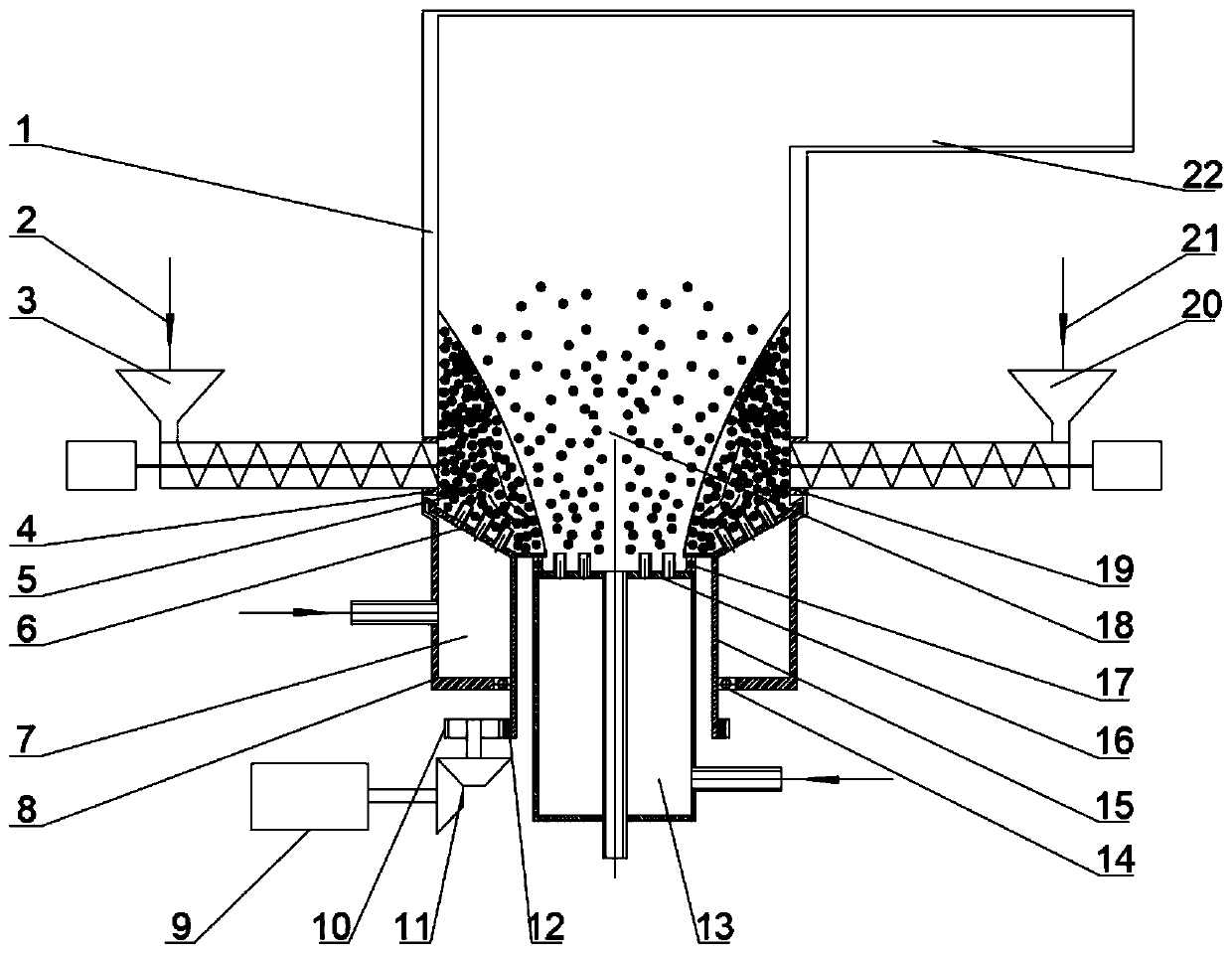

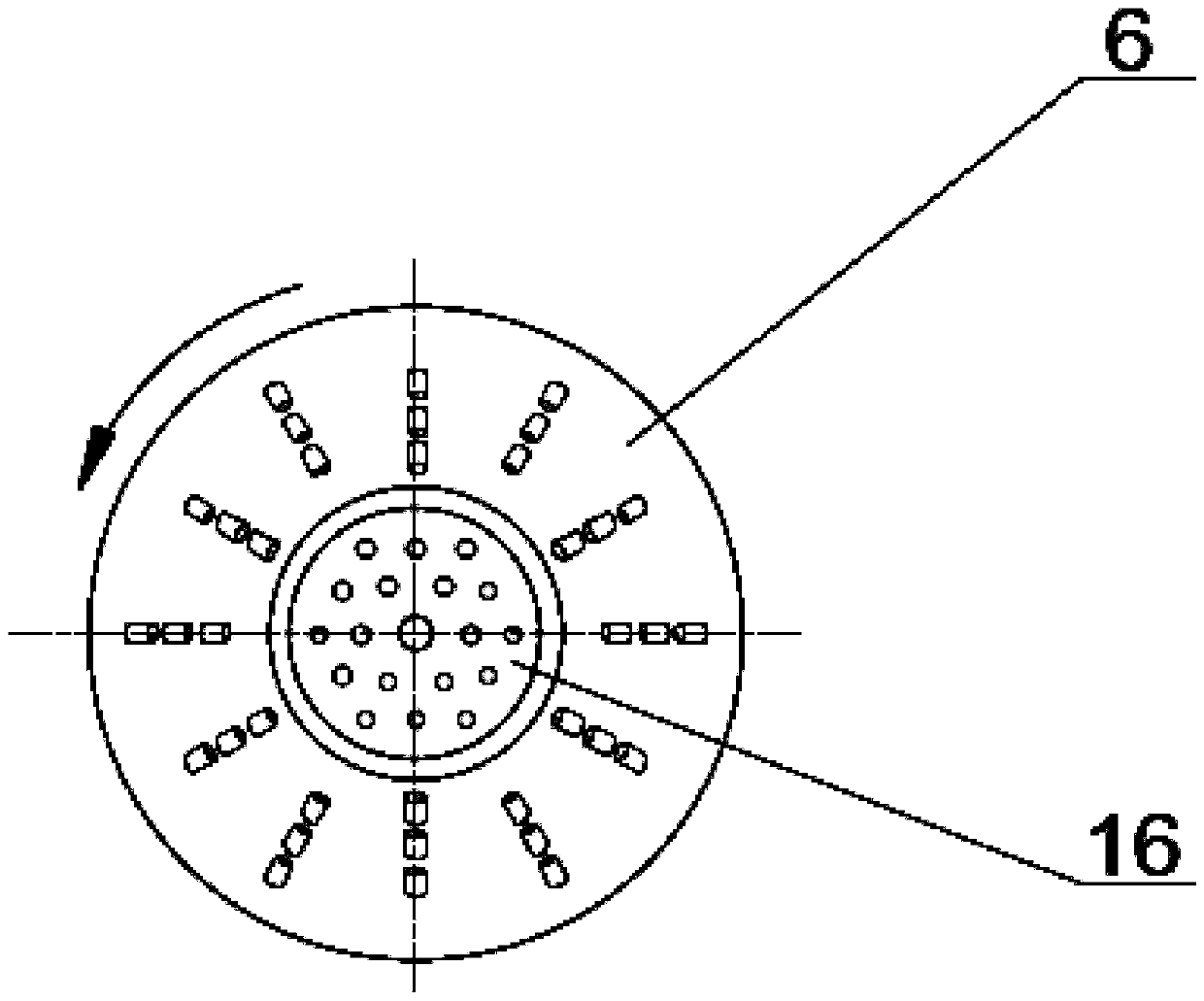

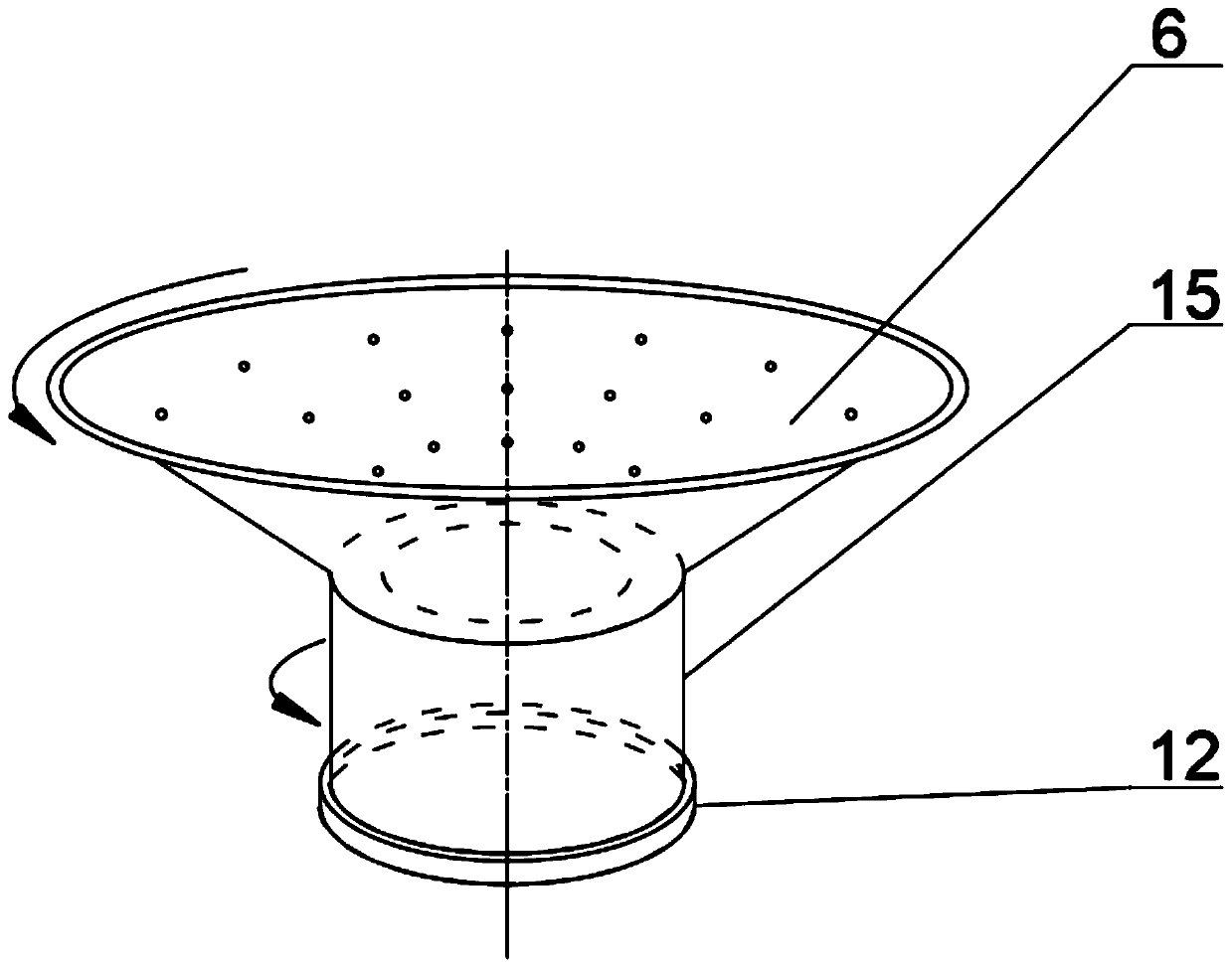

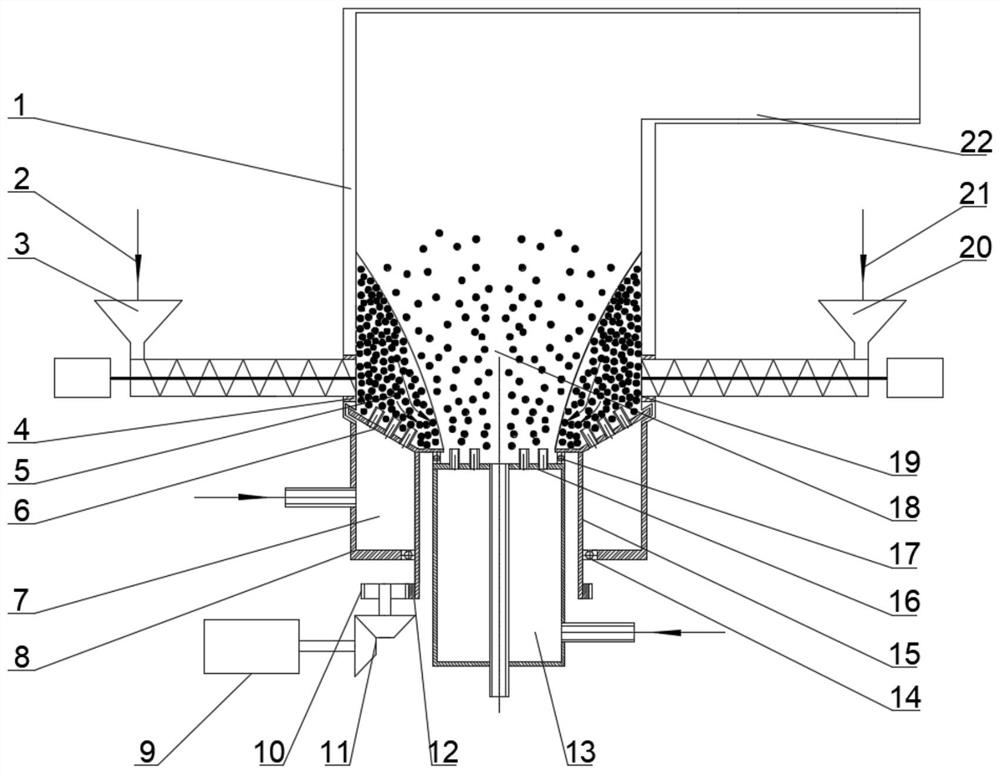

Powder coal dry distillation method and device

ActiveCN103571510AReduce dosageReduce circulationDirect heating destructive distillationSpecial form destructive distillationHeat carrierGas compressor

The invention discloses a powder coal dry distillation method and device, and aims to solve the problems that the technical process is, the circulation amount of the solid heat carrier is high, the gas heat carrier needs to be delivered by a gas compressor and the like in the existing powder coal dry distillation technique. The dry distillation method comprises the following steps: A. a powder coal raw material (2), and a high-temperature solid heat carrier and a high-temperature oxygen-free flue gas from a tubular charcoal burner (7) are mixed in a mixing tube (4) and enters a dry distillation reactor (5) to perform dry distillation reaction; B. after entrained oil gas is stripped out from semicoke formed in the step A in a stripping section (17), part of the semicoke is cooled and discharged out of the dry distillation device, and the other part enters the tubular charcoal burner; and C. the semicoke entering the tubular charcoal burner contacts charcoal burning air (12) to perform charcoal burning, thereby generating the high-temperature solid heat carrier and high-temperature oxygen-free flue gas. The invention also discloses a powder coal dry distillation device for implementing the dry distillation method. The method and device can be used for dry distillation processing of various types of powder coal.

Owner:CHINA PETROCHEMICAL CORP +1

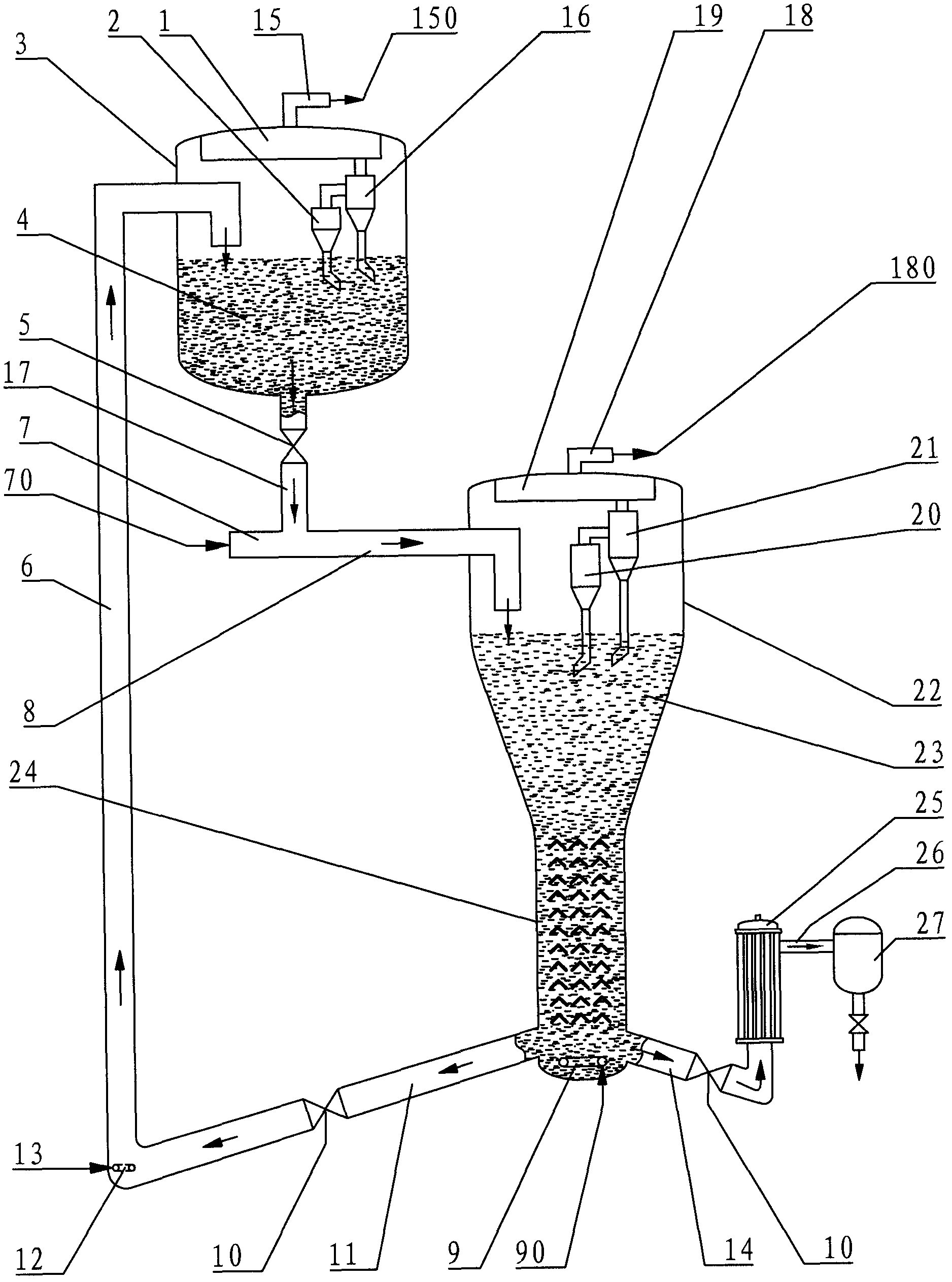

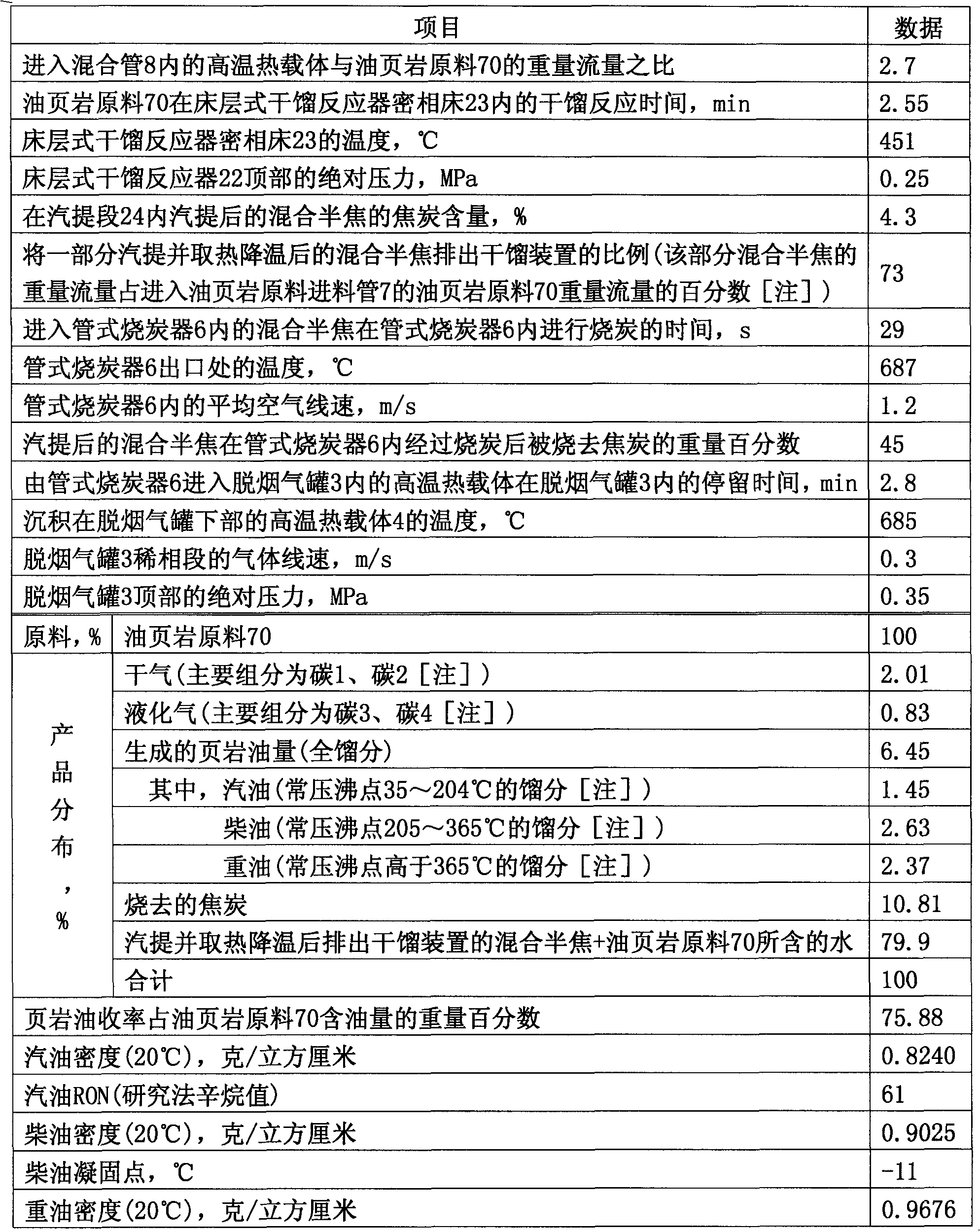

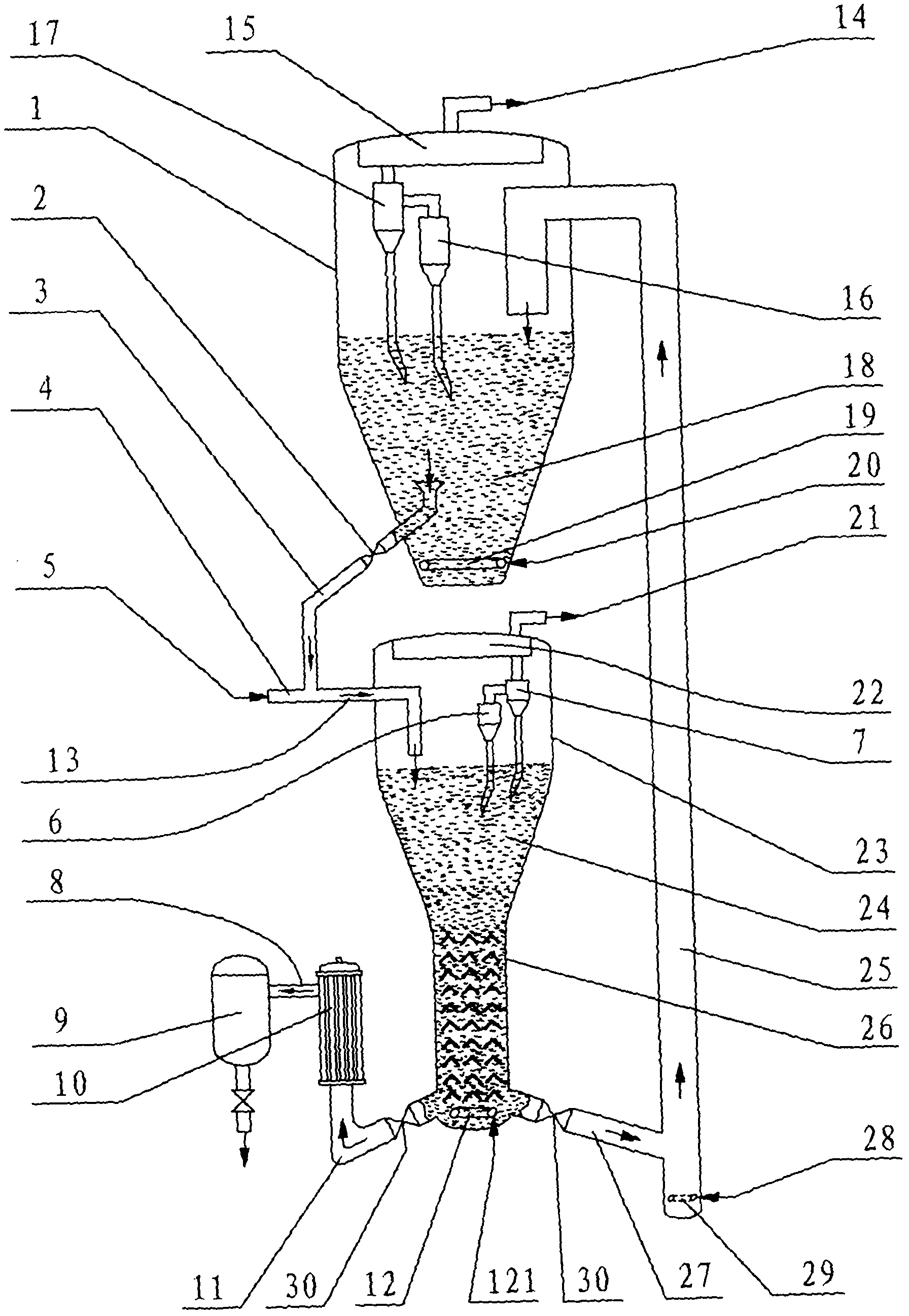

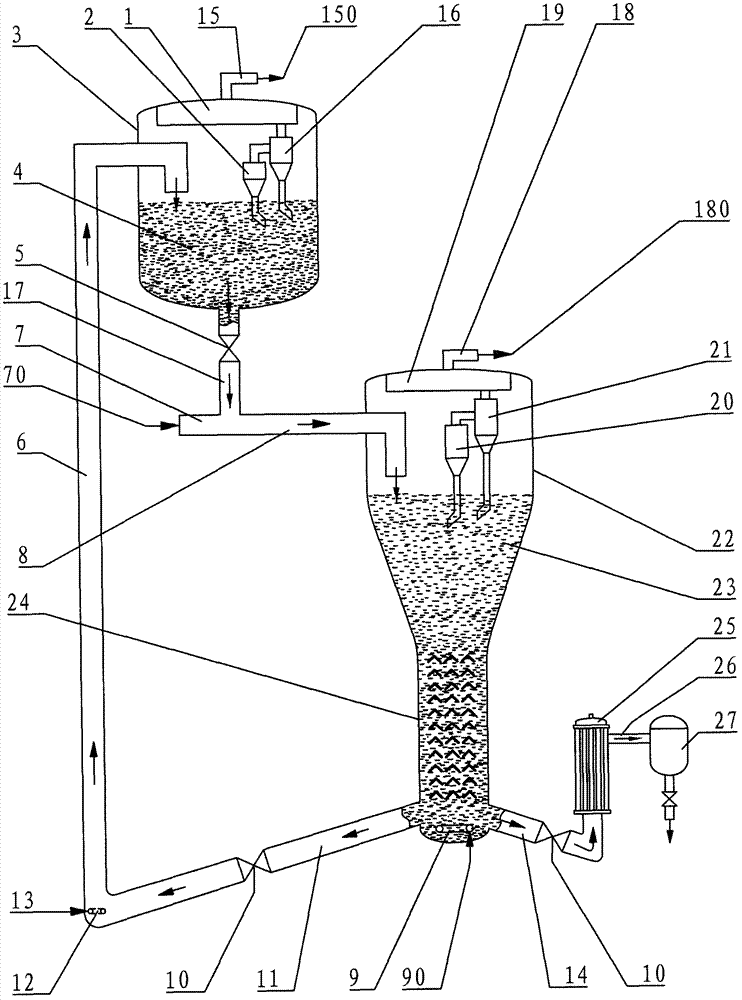

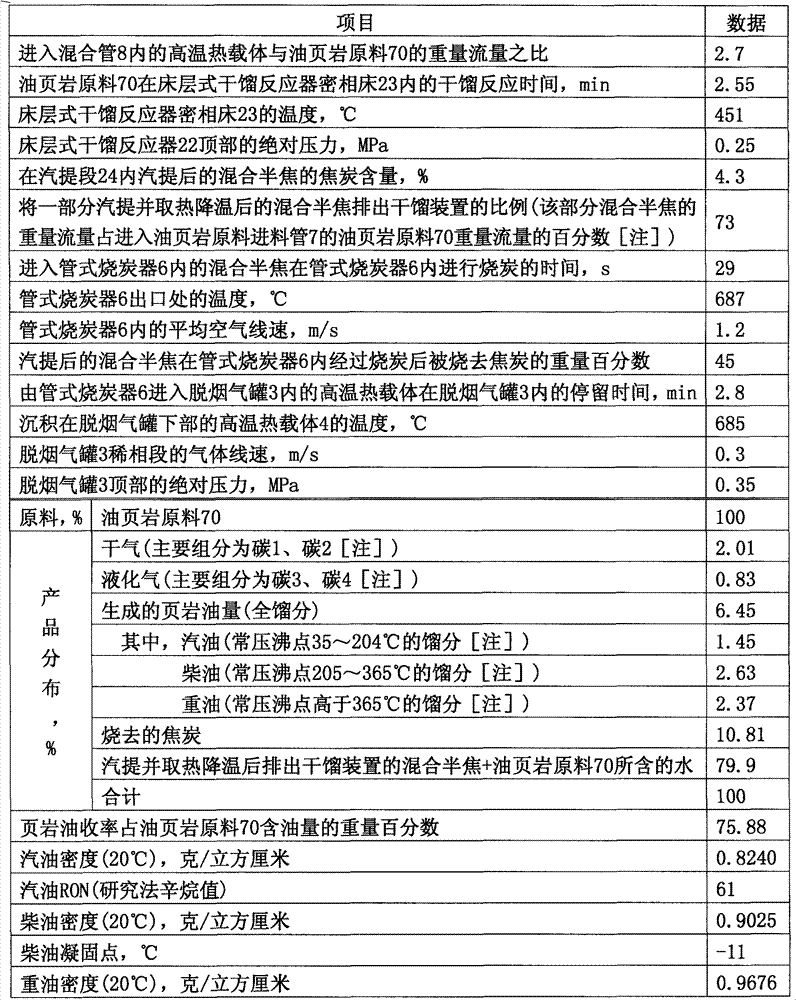

Method and device for fluid-bed destructive distillation of oil shale

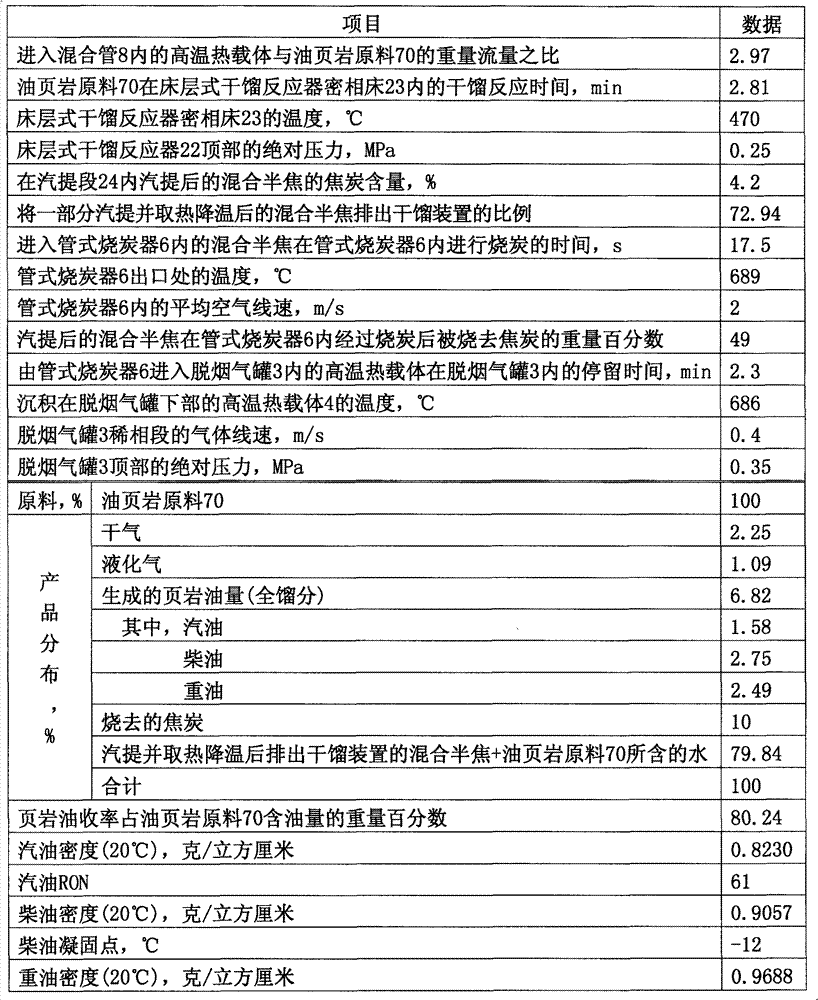

ActiveCN103131444APrevent overheating damageGuaranteed long-term operationDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems of high coal burning load due to the fact that all mixed carbocoal enters a coal burning device for coal burning and the like in the prior art. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that that destructive distillation reaction is carried out on oil shale raw materials and high-temperature heat carriers from a smoke removing tank (3) after the oil shale raw materials and the high-temperature heat carriers are mixed in a mixing pipe (8), and oil gas contained in the formed mixed carbocoal is extracted from a steam extracting section (24) in a steaming mode; part of the mixed carbocoal is discharged out of the destructive distillation device after the oil gas is extracted from the mixed carbocoal and the mixed carbocoal is cooled, and the other part of the mixed carbocoal enters a pipe type coal burning device (6); and coal burning is carried out on the mixed carbocoal entering a pipe type coal burning device, the high-temperature heat carriers and the smoke which are produced after the coal burning enter the smoke removing tank for separation. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

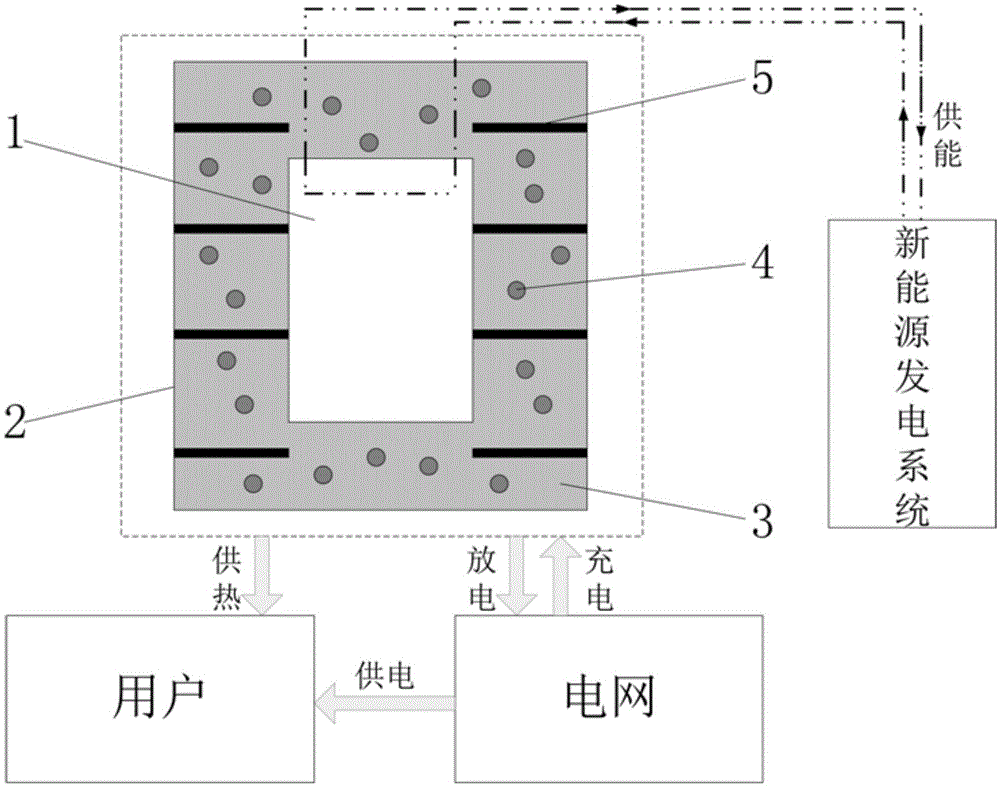

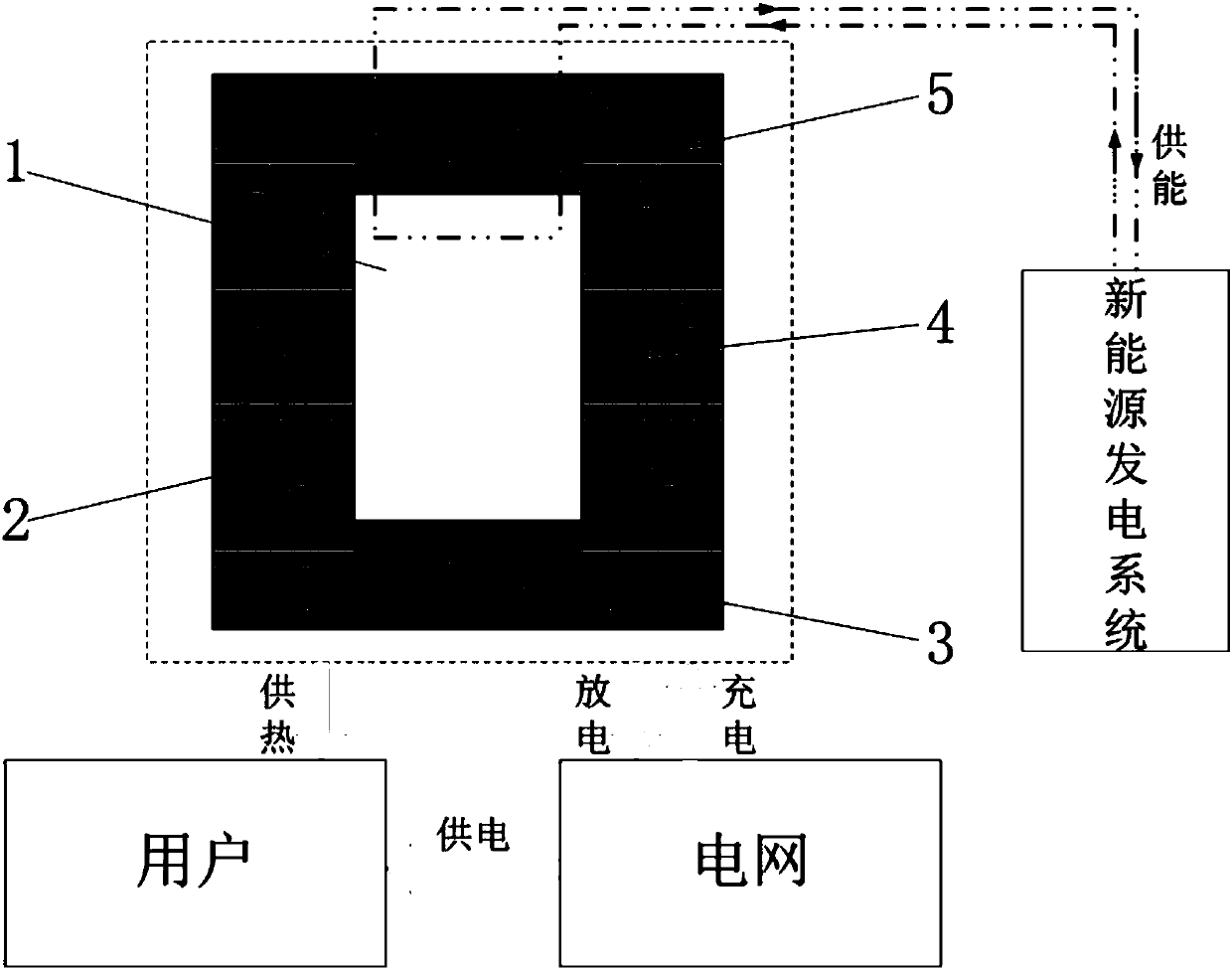

Energy storage type new energy battery protection system used for intelligent energy net and method of energy storage type new energy battery protection system

ActiveCN105655666AAvoid overheating damageImprove cooling effectSecondary cellsBatteriesFiberNew energy

The invention discloses an energy storage type new energy battery protection system used for an intelligent energy net and a method of the energy storage type new energy battery protection system. The system consists of a battery pack, a shell, a polyhydric alcohol phase change material, a fatty acid phase change material capsule and a fiber material fin. The solid-phase polyhydric alcohol phase change material is used to absorb heat and melt, so as to restrain the sharp temperature increment of the battery pack within a short time, the solidification of a liquid phase fatty acid phase change material in the fatty acid phase change material capsule is used to preserve heat of the battery pack, and the characteristic that a heat conductivity coefficient of the fiber material fin is increased along with temperature increment is used to further realize functions of improving heat dissipation under high temperature and enhancing freeze prevention under low temperature for the battery pack; the polyhydric alcohol phase change material absorbs heat, stores energy and supplies the heat to users, and is energy-saving, economical and environmentally friendly; the system is high in adaptation, and can be used in an extreme environment with great temperature difference change; the phase change materials are good in repeatability, and the service life is long.

Owner:ZHEJIANG UNIV

Supercritical water oxidation reactor and method suitable for radioactive waste treatment

PendingCN114842996APrevent wall damage from overheatingEfficient separationRadioactive decontaminationBulk chemical productionEngineeringEnvironmental geology

The invention discloses a supercritical water oxidation reactor and method suitable for radioactive waste treatment, the supercritical water oxidation reactor comprises an end cover area, a reaction area and a salt storage area, and a core area of the reaction area is provided with a scraping brush, a stirrer and other mechanical devices. A nuclide salt storage area is arranged at the bottom and is provided with a mechanical stirring device and a tertiary oxidant inlet. According to the invention, supercritical water oxidation treatment of radioactive wastes can be realized, nuclides are removed by using the characteristic that the solubility of nuclides in supercritical water is small, and meanwhile, the nuclides are mechanically removed by using a scraping brush, and meanwhile, due to the existence of the cooling film type wall, not only can the heat of a reaction area be absorbed to prevent the wall surface from being overheated, but also the waste heat of the wall surface can be utilized. And meanwhile, a sacrificial thin lining is arranged at a key part of the reactor, so that radioactive wastes generated after the device is decommissioned are minimized. The reactor has important application value in the field of supercritical water oxidation treatment of radioactive wastes.

Owner:XI AN JIAOTONG UNIV

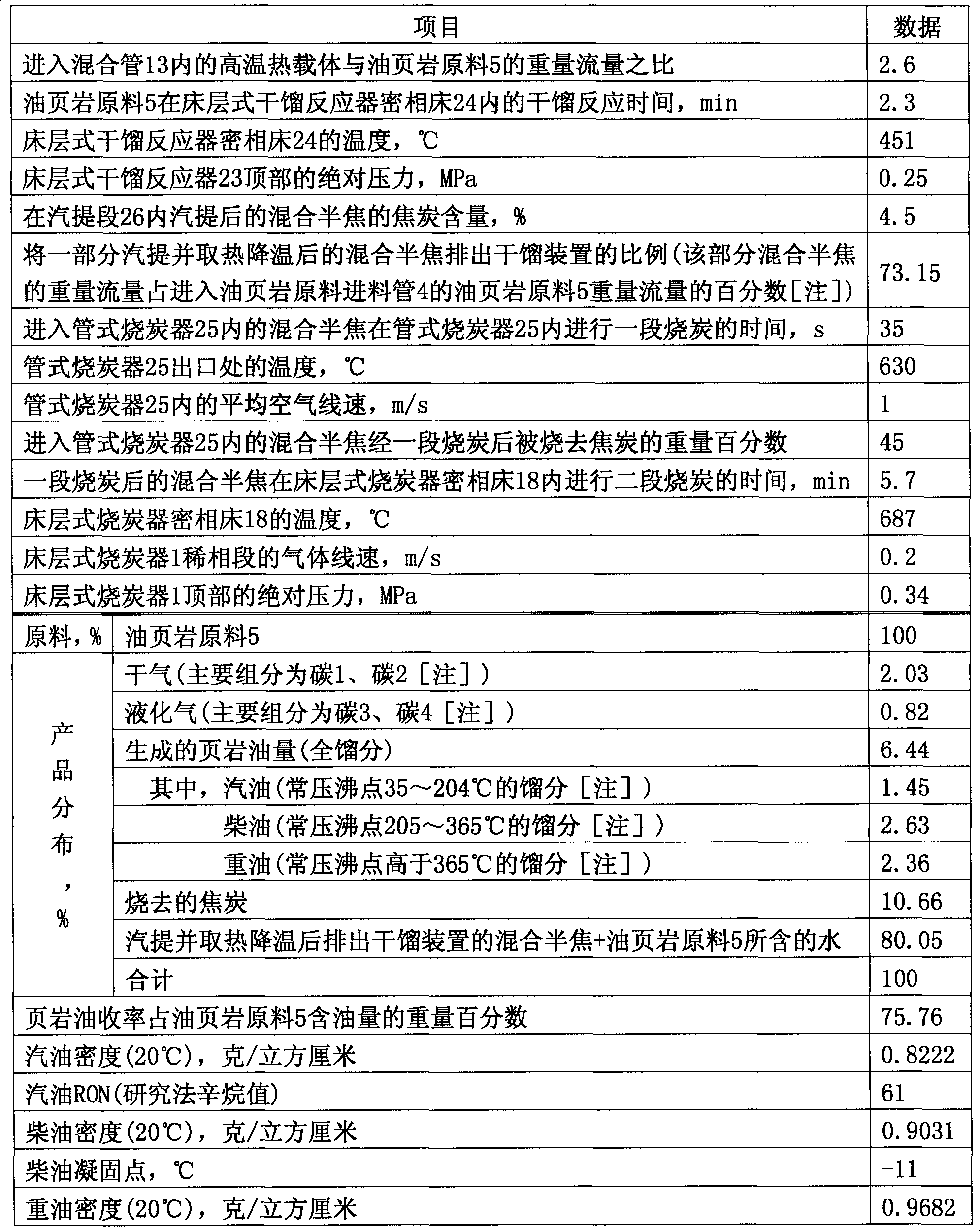

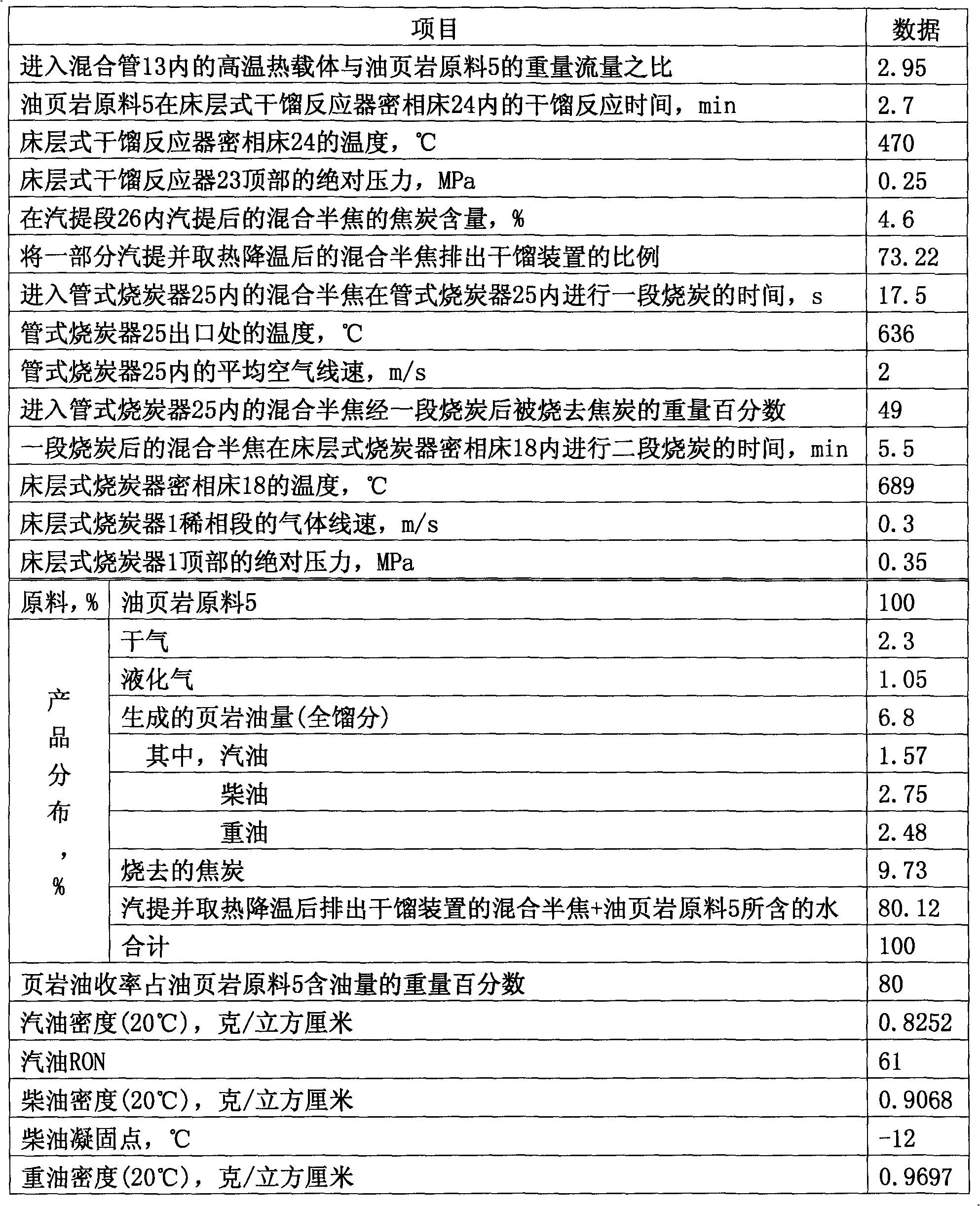

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131446APrevent overheating damageGuaranteed long-term operationSpecial form destructive distillationHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems of high coal burning load due to the fact that all mixed carbocoal enters a coal burning device for coal burning and the like in the prior art. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that destructive distillation reaction is carried out on oil shale raw materials (5) and high-temperature heat carriers from a bed type coal burning device (1) after the oil shale raw materials (5) and the high-temperature heat carriers are mixed in a bed type destructive distillation reactor (23), and oil gas contained in the formed mixed carbocoal is extracted from a steam extracting section (26) in a steaming mode; part of the mixed carbocoal is discharged out of the destructive distillation device after the oil gas is extracted from the mixed carbocoal and the mixed carbocoal is cooled, and the other part of the mixed carbocoal enters a pipe type coal burning device (25); and a first coal burning is firstly carried out on the mixed carbocoal entering the pipe type coal burning device, and then the mixed carbocoal enters a bed type coal burning device for a second coal burning. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

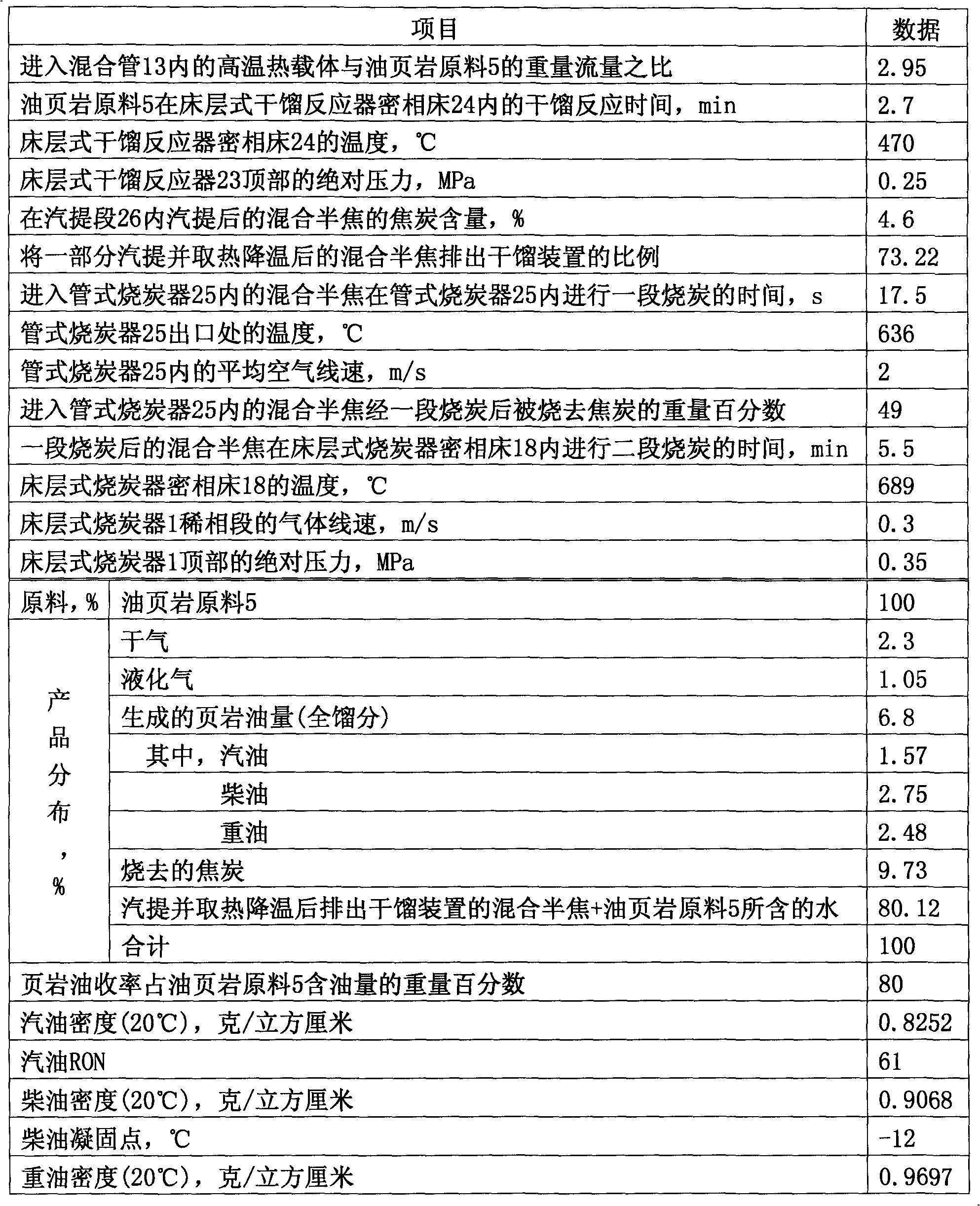

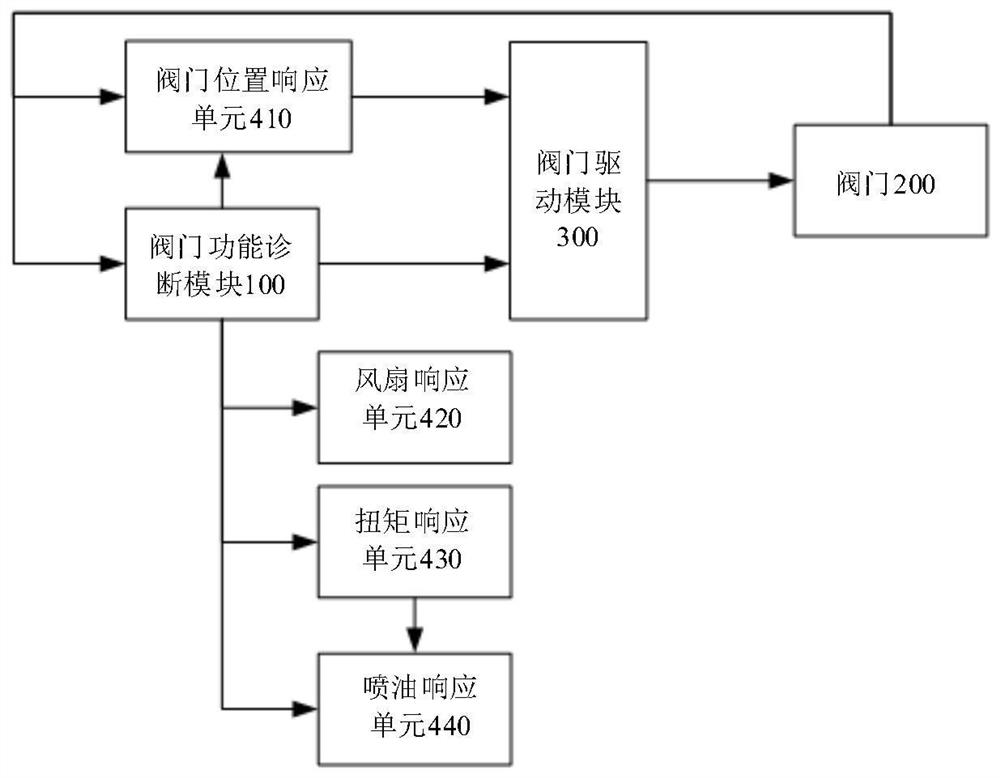

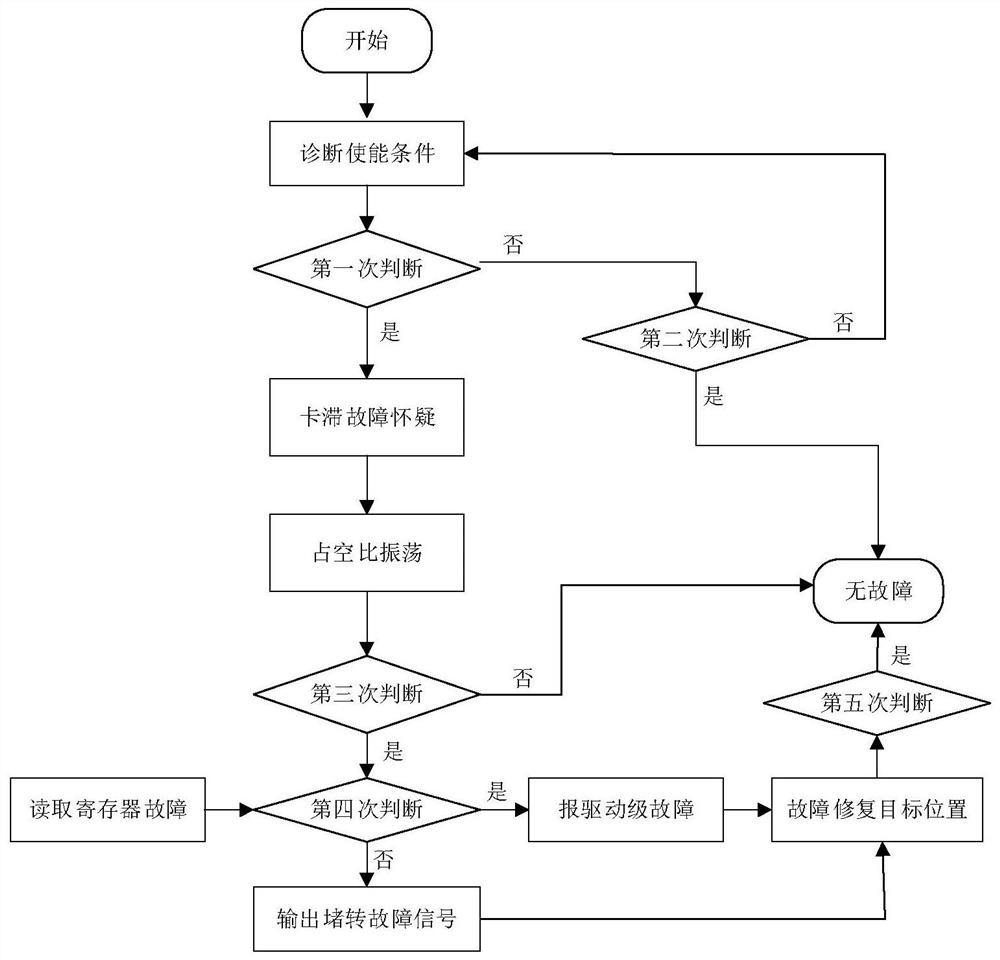

Diagnostic system and diagnostic method for valve type thermostat and vehicle

ActiveCN113309604AAvoid damageImprove work efficiencyCoolant flow controlMachines/enginesThermostatControl theory

The invention provides a diagnostic system and diagnostic method for a valve type thermostat and a vehicle. By means of the diagnosis system and the diagnosis method, whether a valve of the valve type thermostat breaks down or not can be diagnosed, the fault is reported or not according to the diagnosis result, if it is diagnosed that a suspected locked-rotor fault exists, repair is tried before the locked-rotor fault is reported, if repair succeeds, the locked-rotor fault is not reported, and false alarm is avoided. In addition, response can be made according to reported faults, so that an engine is maintained in a safe temperature range, and the engine is prevented from being damaged due to over-temperature. The vehicle comprises the engine provided with the valve type thermostat and the diagnostic system of the valve type thermostat.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

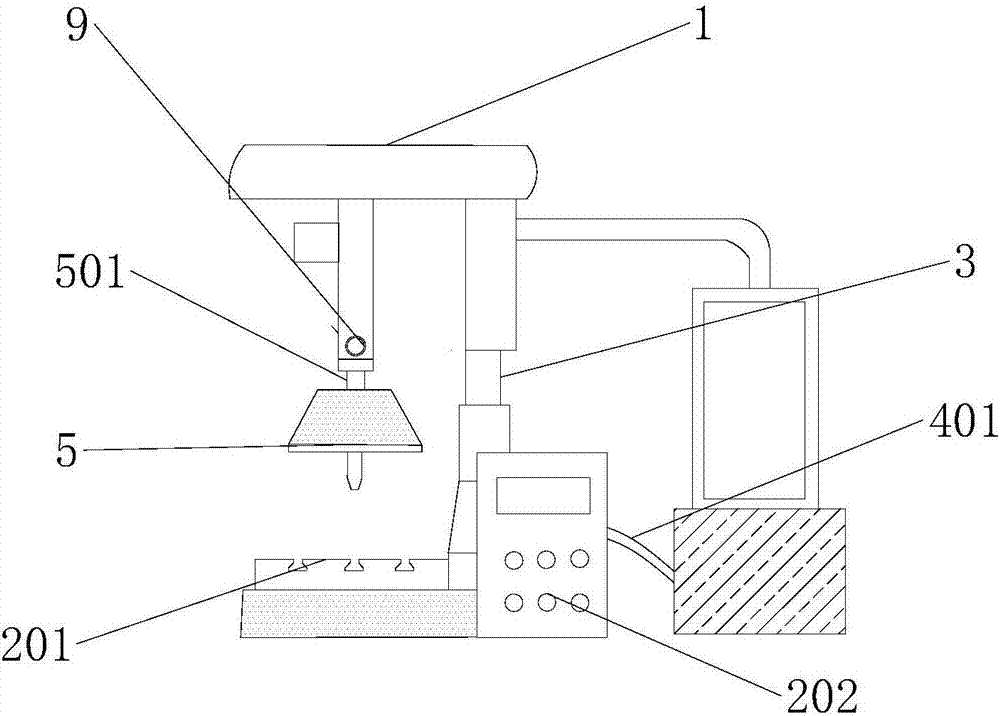

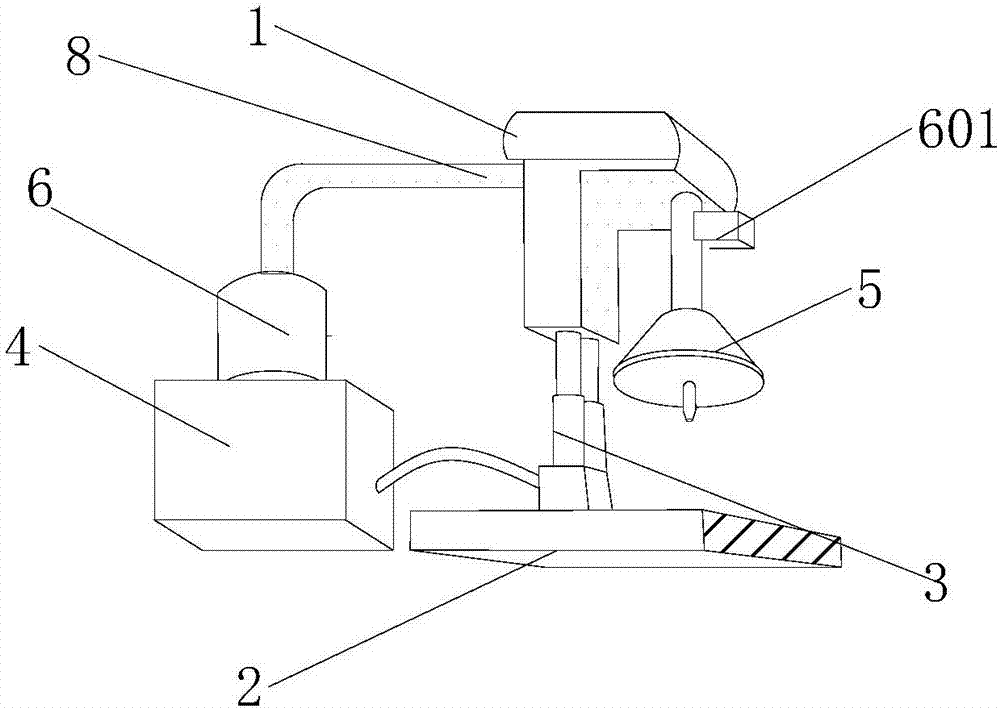

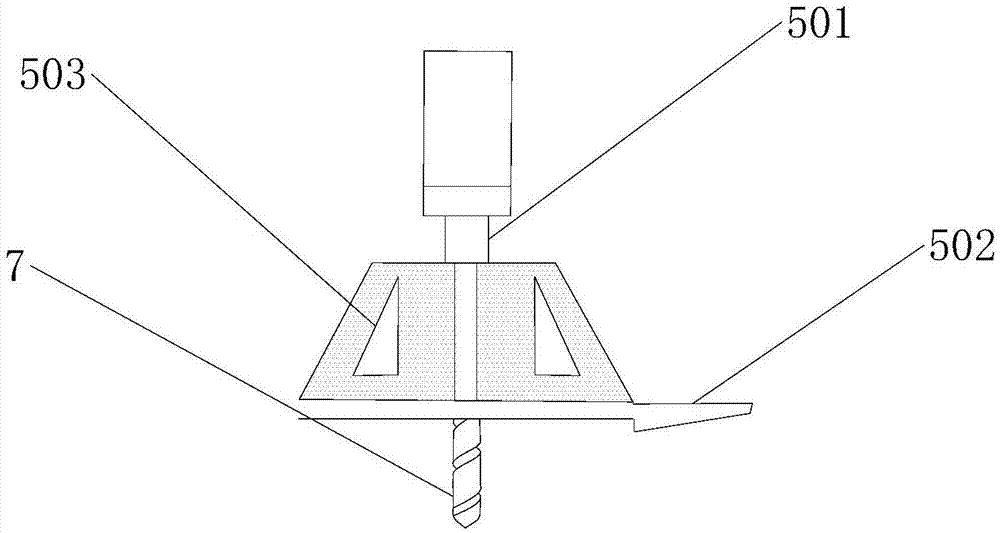

Punching device for hardware fittings

InactiveCN107877009AIncrease in sizeExpand the scope of activitiesLaser beam welding apparatusHigh energyHydraulic pump

The invention discloses a punching device for hardware fittings, which comprises a device body and a device base, the device base is provided under the device body, the device base is connected to the device body by transmission, a hydraulic pump is provided on the left side of the device body, the hydraulic pump It is fixedly connected to the device body, a pressure-resistant tube is provided on the right side of the hydraulic pump, and one end of the pressure-resistant tube is fixedly connected to the hydraulic pump. A laser generator is installed under the device body, and the laser generator is fixedly connected to the device body. There is a laser drill above the drilling device for hardware accessories. The laser drill uses the laser beam to heat the material to cut. Compared with the motor drill, the laser spot is small, the energy density is high, and the cutting surface is smooth and beautiful. The surface roughness of the hole is very small, and there is no contact with the workpiece, so there is no wear of the tool, and it can cut a variety of materials.

Owner:WUXI WEI KELAI TECH CO LTD

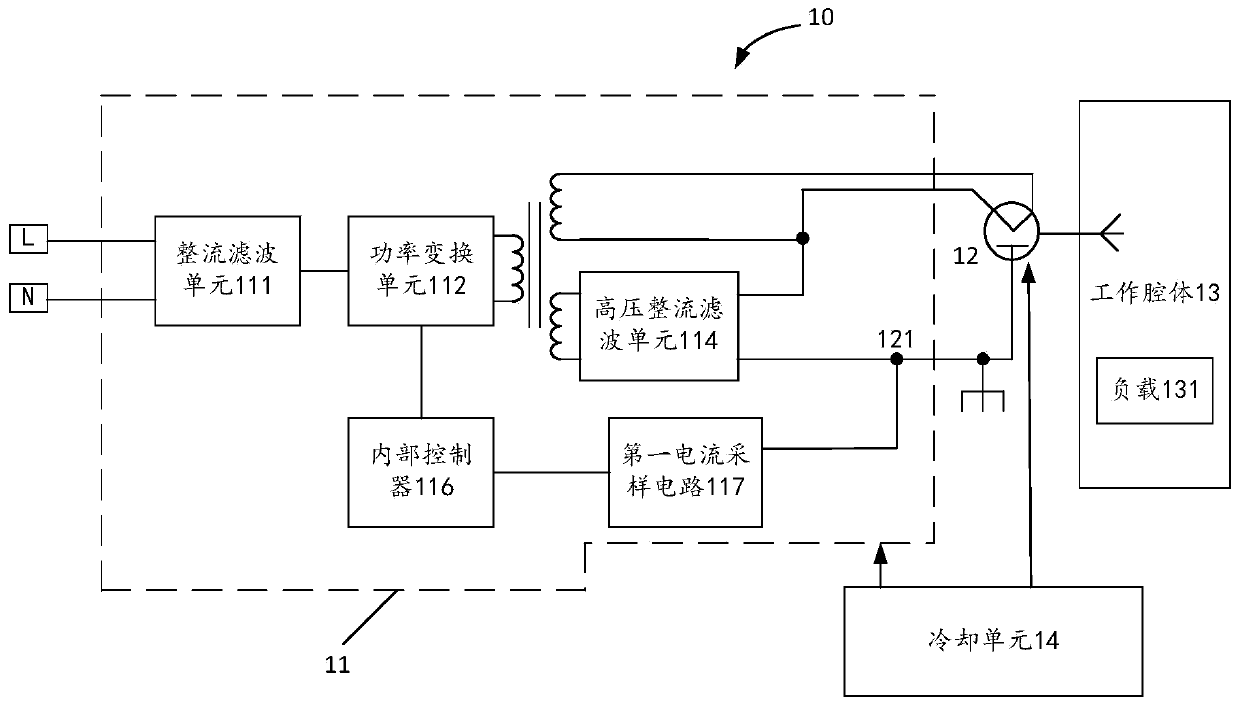

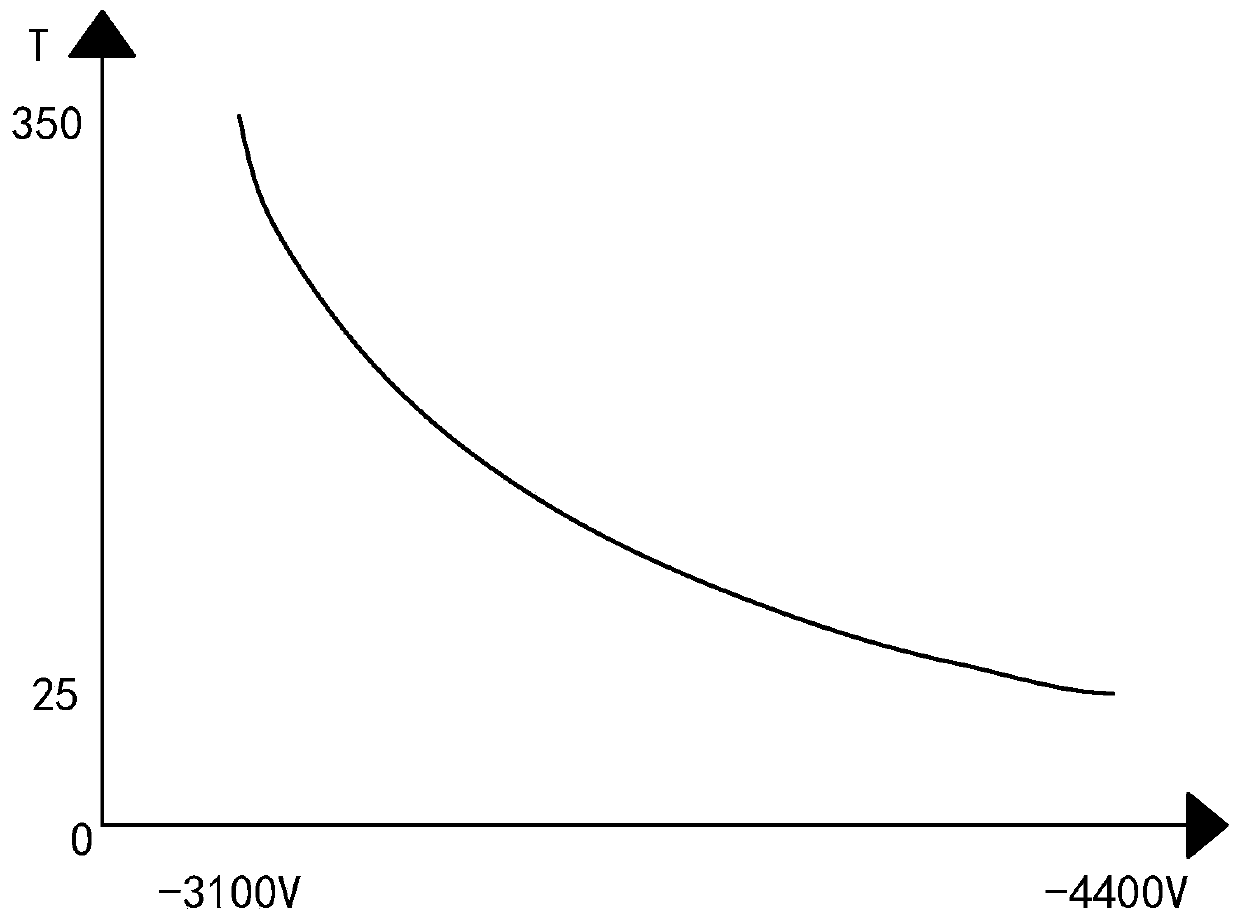

Magnetron state detection method and device, controller and magnetron state detection circuit and system

ActiveCN110530553APrevent overheating damageAccurate settingThermometer detailsElectrical testingMicrowaveElectric power

The invention relates to the field of microwave equipment and discloses a magnetron state detection method and device, a controller and a magnetron state detection circuit and system. The magnetron state detection method comprises the steps of firstly obtaining anode temperature of a magnetron and a temperature compensation value; secondly, calculating a preset temperature threshold according to the temperature compensation value; and finally determining the state of the magnetron according to the anode temperature of the magnetron and the preset temperature threshold. Therefore, the preset temperature threshold in the method can be changed along with the temperature compensation value, and the preset temperature thresholds in different environments are different, so that setting of the preset temperature threshold is more accurate, thereby accurately identifying the state of the magnetron; and when the magnetron is in a no-load condition, output power of a variable-frequency power supply is reduced and stop measures are further taken, thereby avoiding an overtemperature damage to the magnetron, avoiding the condition that the other devices cannot normally work due to overtemperature and avoiding power waste at the same time.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

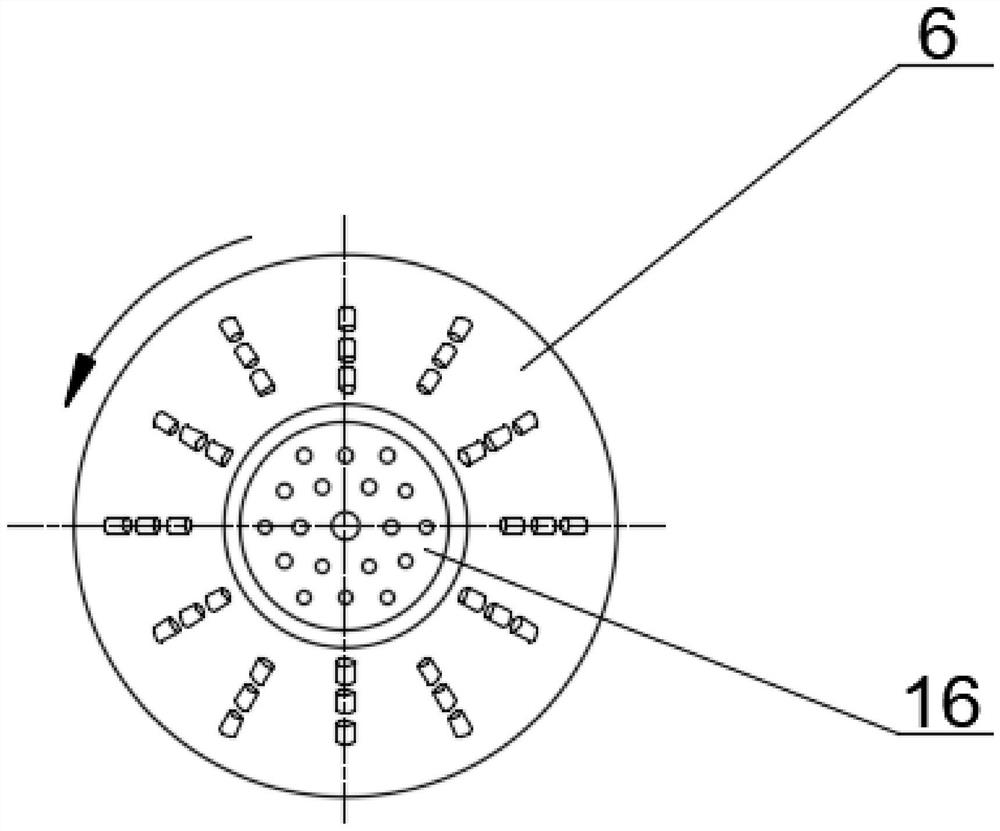

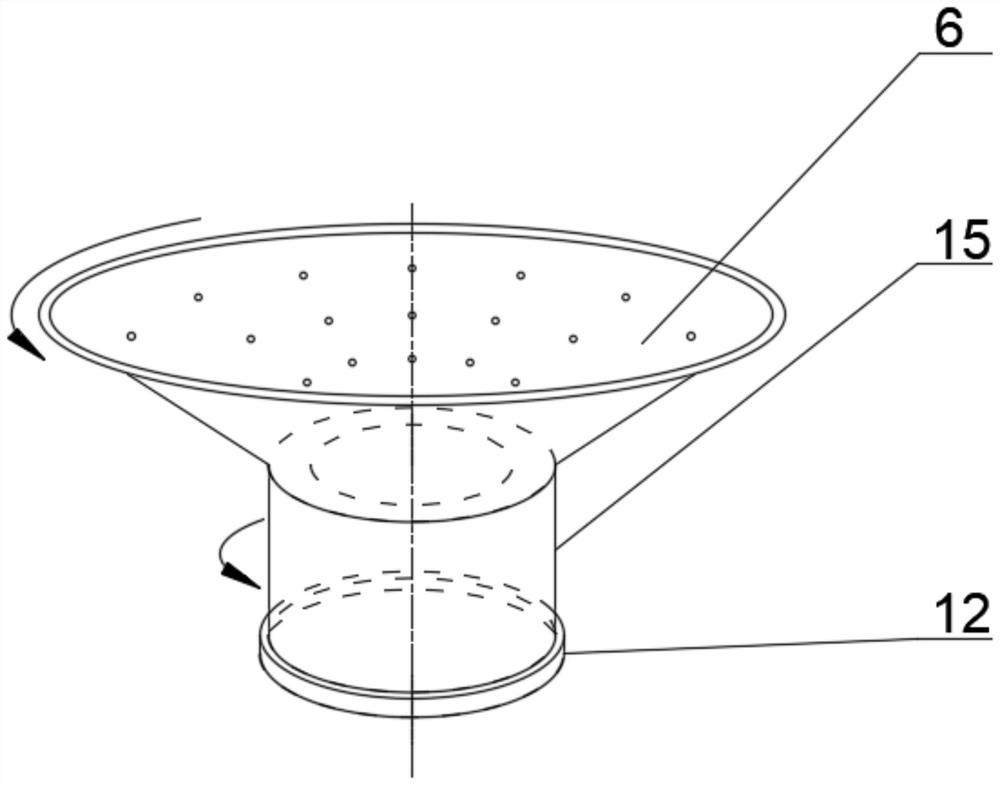

Fluidized bed destructive distillation method and device of pulverized coal

ActiveCN104178184ASmall sizeReduce storageDirect heating destructive distillationSpecial form destructive distillationFluidized bedPulverized fuel ash

The invention discloses a fluidized bed destructive distillation method and device of pulverized coal, and solves the problems of large coke burning load and unideal charking effect in the prior art. The destructive distillation provided by the invention includes the steps of: A, mixing pulverized coal raw material (1) with high temperature coal ash, conducting a destructive distillation reaction on the mixture in a destructive distillation dense phase section bed layer of a bed-type destructive distillation reactor (50) to generate oil gas and pulverized coal semicoke; and subjecting the mixture of pulverized coal semicoke and coke ash to stripping in a stripper (10) in steam; B, charking the mixture of pulverized coal semicoke and coke ash subjected to stripping in a charking canister (15) to generate regenerated semicoke; C. charking the regenerated semicoke in a riser reactor (18) to generate coal ash containing coke; and D, charking coal ash containing coke in a charking dense phase section bed layer of a bed type charking device (60) to generate high temperature coal ash. The invention discloses a fluidized bed destructive distillation device of pulverized coal for realizing the above method. The invention can be used for destructive distillation processing of a variety of pulverized coals.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Powder coal dry distillation method and device

ActiveCN103571511AReduce dosageReduce circulationDirect heating destructive distillationSpecial form destructive distillationHeat carrierGas compressor

The invention discloses a powder coal dry distillation method and device, and aims to solve the problems that the technical process is, the circulation amount of the solid heat carrier is high, the gas heat carrier needs to be delivered by a gas compressor and the like in the existing powder coal dry distillation technique. The dry distillation method comprises the following steps: A. a powder coal raw material (2), and a high-temperature solid heat carrier and a high-temperature oxygen-free flue gas from a tubular charcoal burner (7) are mixed in a mixing heat transfer region to perform contact heat transfer, and are subject to dry distillation reaction; B. after entrained oil gas is stripped out from semicoke formed in the step A in a stripping section (17), part of the semicoke is cooled and discharged out of the dry distillation device, and the other part enters the tubular charcoal burner; and C. the semicoke entering the tubular charcoal burner contacts charcoal burning air to perform charcoal burning, thereby generating the high-temperature solid heat carrier and high-temperature oxygen-free flue gas. The invention also discloses a powder coal dry distillation device for implementing the dry distillation method. The method and device can be used for dry distillation processing of various types of powder coal.

Owner:CHINA PETROCHEMICAL CORP +1

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131446BPrevent overheating damageGuaranteed long-term operationSpecial form destructive distillationHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems of high coal burning load due to the fact that all mixed carbocoal enters a coal burning device for coal burning and the like in the prior art. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that destructive distillation reaction is carried out on oil shale raw materials (5) and high-temperature heat carriers from a bed type coal burning device (1) after the oil shale raw materials (5) and the high-temperature heat carriers are mixed in a bed type destructive distillation reactor (23), and oil gas contained in the formed mixed carbocoal is extracted from a steam extracting section (26) in a steaming mode; part of the mixed carbocoal is discharged out of the destructive distillation device after the oil gas is extracted from the mixed carbocoal and the mixed carbocoal is cooled, and the other part of the mixed carbocoal enters a pipe type coal burning device (25); and a first coal burning is firstly carried out on the mixed carbocoal entering the pipe type coal burning device, and then the mixed carbocoal enters a bed type coal burning device for a second coal burning. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131444BPrevent overheating damageGuaranteed long-term operationDirect heating destructive distillationLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems of high coal burning load due to the fact that all mixed carbocoal enters a coal burning device for coal burning and the like in the prior art. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that that destructive distillation reaction is carried out on oil shale raw materials and high-temperature heat carriers from a smoke removing tank (3) after the oil shale raw materials and the high-temperature heat carriers are mixed in a mixing pipe (8), and oil gas contained in the formed mixed carbocoal is extracted from a steam extracting section (24) in a steaming mode; part of the mixed carbocoal is discharged out of the destructive distillation device after the oil gas is extracted from the mixed carbocoal and the mixed carbocoal is cooled, and the other part of the mixed carbocoal enters a pipe type coal burning device (6); and coal burning is carried out on the mixed carbocoal entering a pipe type coal burning device, the high-temperature heat carriers and the smoke which are produced after the coal burning enter the smoke removing tank for separation. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

A corrosion-inhibiting supercritical water oxidation reactant mixing-preoxidation device

ActiveCN105621588BReduce the harshness of the service environmentExtended service lifeSpecific water treatment objectivesWater/sewage treatment apparatusHigh concentrationInjection port

The invention discloses a corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device. The device is composed of a plurality of reactant mixing-pre-oxidizing device core tubes and outer tubes in a series connection mode along the way, and a core tube channel and an outer tube channel are formed. The core tube channel is sequentially provided with a plurality of reactant A injection ports along the way, the reactant A injection ports are used for injecting reactants A into the outer tube channel in a grading mode, and the outer tube channel is used for stage-by-stage mixing of the reactants A and reactants B and supercritical water oxidation reaction. The mixing and oxidizing process of organic waste and an oxidizing agent is effectively controlled, ultra-high-temperature damage caused by local concentrated heat release is avoided, and intensified corrosion of the high-concentration oxidization agent on equipment materials is relieved. The corrosion inhibition type supercritical water oxidation reactant mixing-pre-oxidizing device is arranged on an entrance of a supercritical water oxidation reactor, the service environment harshness of the supercritical water oxidation reactor is remarkably reduced, the service life of the reactor is prolonged easily, overall maintenance cost in the later stage of the supercritical water oxidation reactor is reduced, and the corrosion inhibition type supercritical water oxidation reactant mixing and pre-oxidizing device can be widely applied to performing supercritical water oxidation reactant on various heavy-pollution industrial wastewater and sludge.

Owner:XI AN JIAOTONG UNIV

Powder coal dry distillation method and device

ActiveCN103571511BReduce dosageReduce circulationDirect heating destructive distillationSpecial form destructive distillationHeat carrierGas compressor

Owner:CHINA PETROCHEMICAL CORP +1

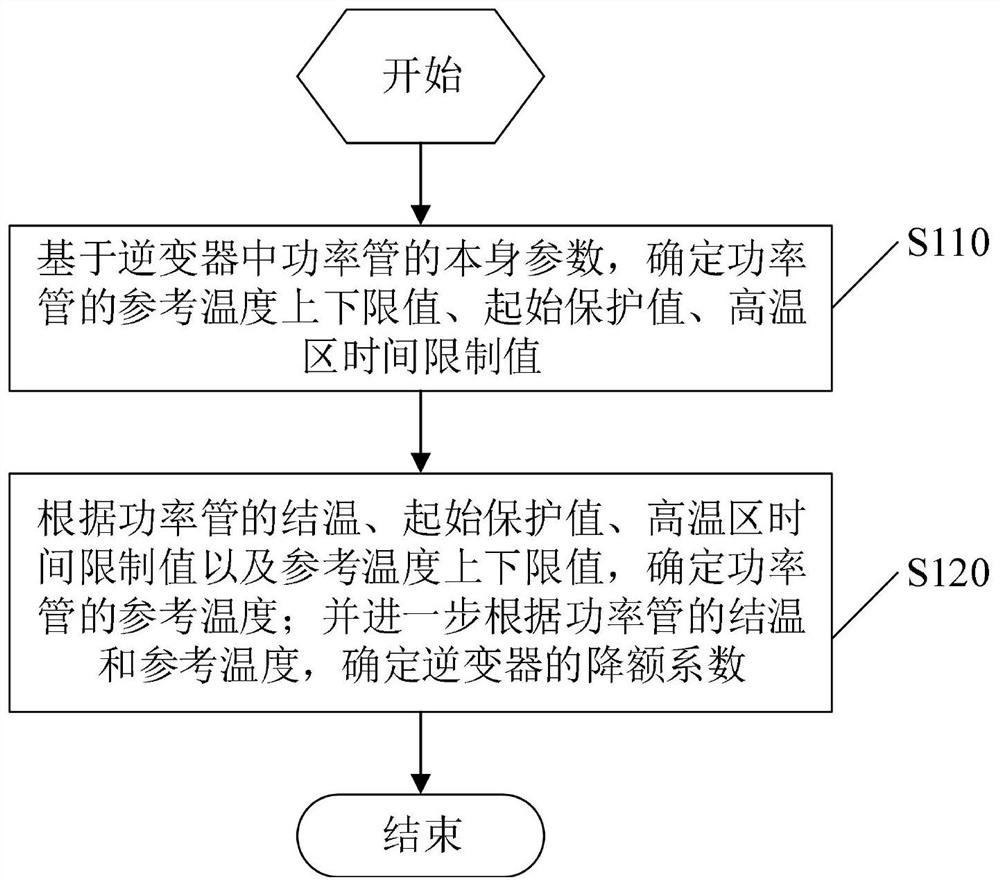

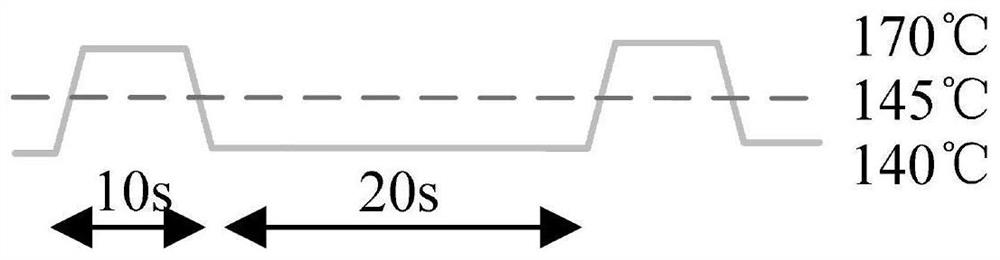

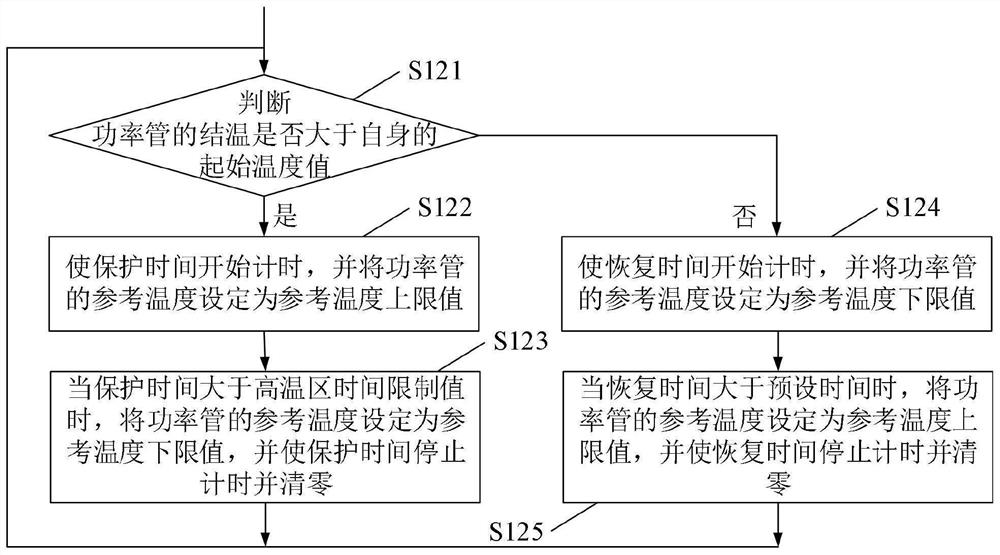

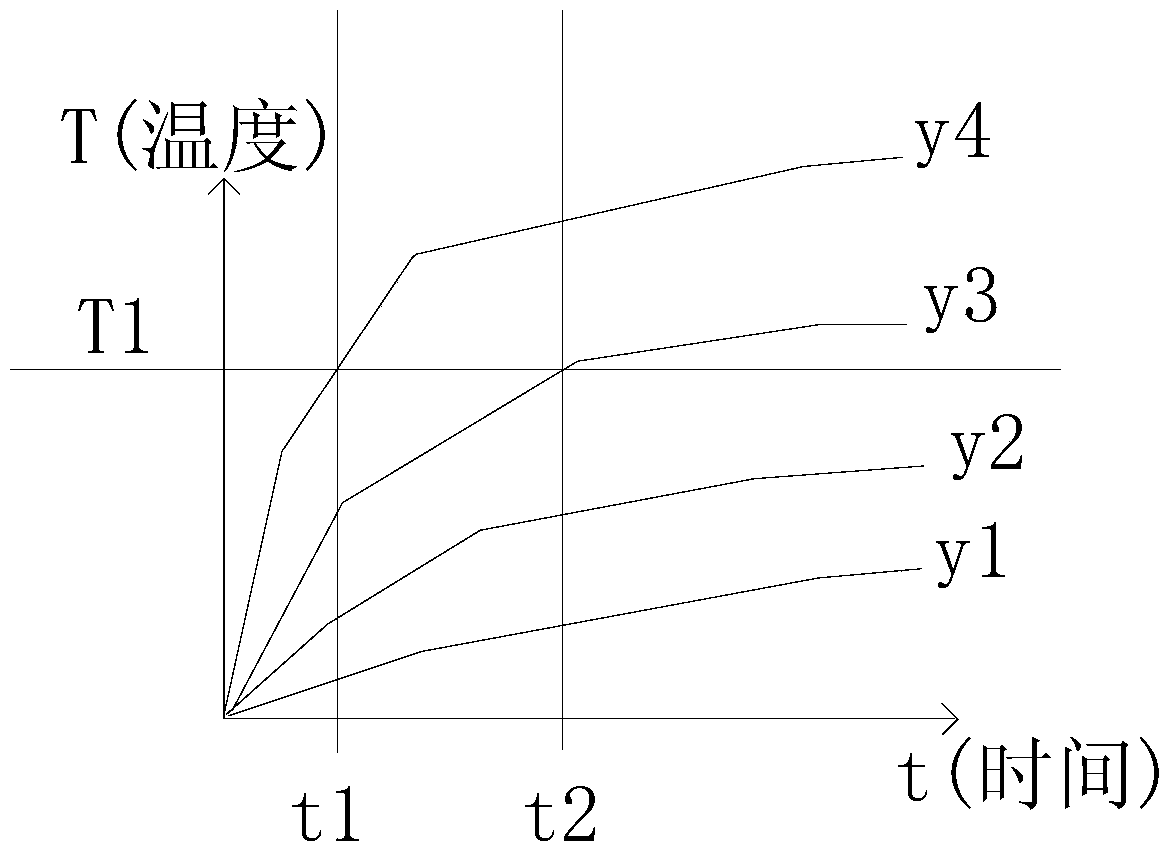

Inverter derating protection method and controller

ActiveCN112104215BImprove output performancePrevent overheating damageAC motor controlEmergency protective arrangements for automatic disconnectionControl engineeringJunction temperature

The present application relates to an inverter derating protection method and controller, which determines the derating coefficient of the inverter, and can wait for the time in the high temperature zone when the junction temperature of its own power tube rises above the initial protection value After the time limit of the limit value, the inverter is derated to run, that is, the power tube can still operate normally within the time limit value of the high temperature zone, thereby improving the output capacity of the inverter; and in the high temperature zone time limit value After a certain period of time, the inverter will be derated, and the inverter will resume normal operation after the junction temperature of its own power tube drops to less than or equal to the initial protection value and wait for a preset period of time, so as to avoid over-temperature damage to the power tube. , and then the derating protection method of the inverter realizes the over-temperature protection of the inverter; in summary, the derating protection method of the inverter provided by the present application takes both the output capability and the over-temperature protection of the inverter into consideration.

Owner:合肥阳光电动力科技有限公司

Destructive distillation method and device for fluidized bed of oil shale

ActiveCN103131447BPrevent overheating damageGuaranteed long-term operationDirect heating destructive distillationLiquid hydrocarbon mixture productionFluidized bedCoke

The invention discloses a destructive distillation method and a device for a fluidized bed of oil shale to solve the problems that charking loading born by a charking appliance is enabled to be high, charking temperature is hard to control, and the charking appliance is prone to be damaged by over temperature due to the fact that one charking appliance is utilized to conduct charking in the prior art. The destructive distillation method includes the following steps: A. mixing a oil shale raw materials (90) with a high-temperature carrier in a bed type charking appliance (1), enabling the mixed oil shale materials and the high-temperature carrier to enter a bed type destructive distillation reactor (26) to conduct a destructive distillation reaction, stripping carried oil gas in the formed mixed semi-coke through stream, and enabling the mixed semi-choke to enter into a pipe type charking appliance (25); B. conducting one-stage charking on the mixed semi-choke which enters the pipe type charking appliance along the pipe type charking appliance; C. enabling the mixed semi-choke which is conducted the one-stage charking to enter the bed type charking appliance (1) to conduct two-stage charking. The invention discloses the destructive distillation device used for achieving the destructive distillation method for the fluidized bed of the oil shale. The destructive distillation method and the device for the fluidized bed of the oil shale are mainly used for destructive distillation processing of various granularity oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

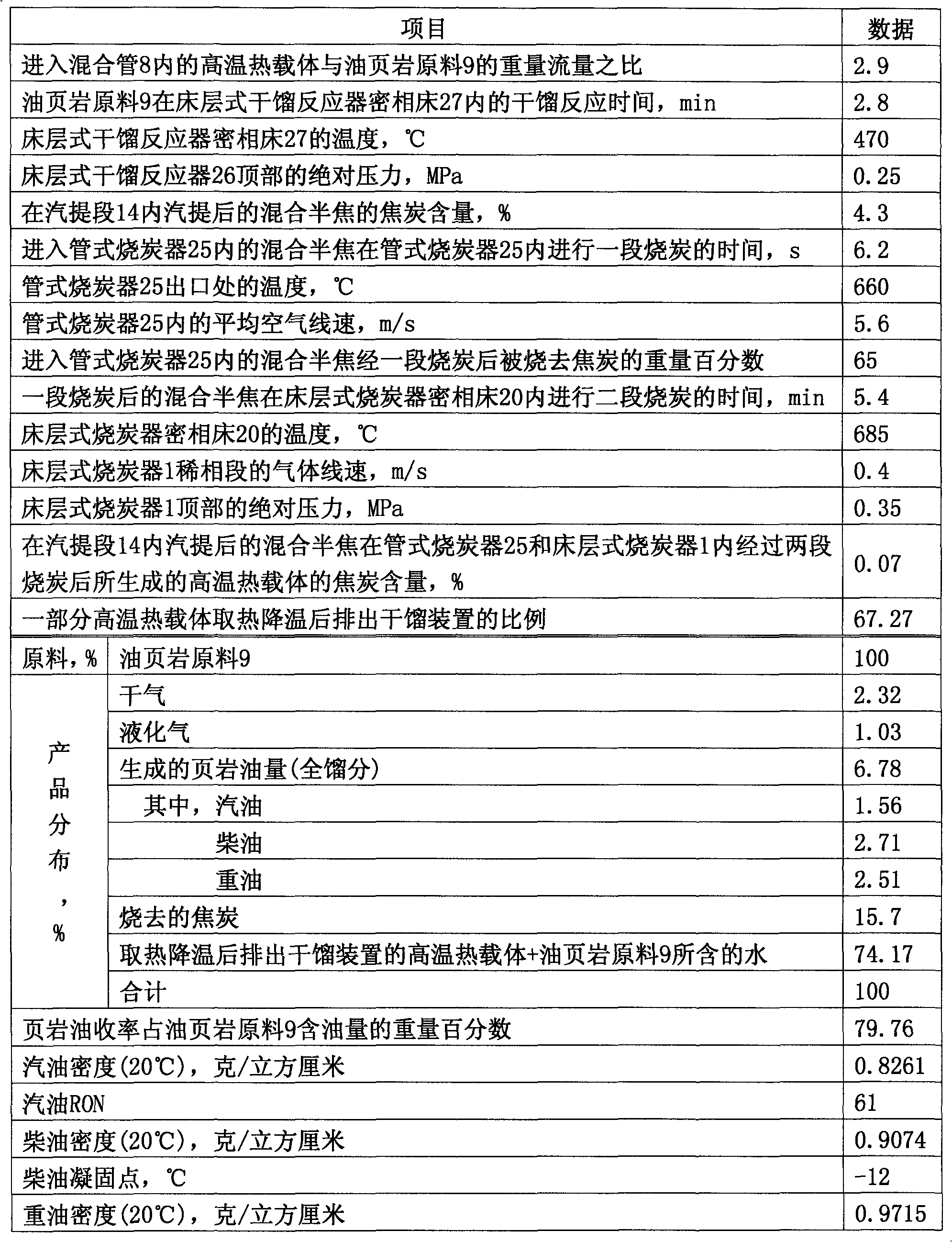

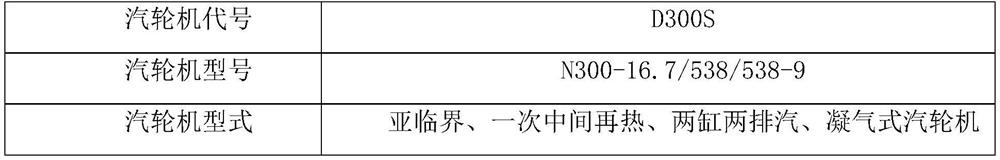

Control method of combined heat and power generation unit for cooperative steam extraction of cold section and hot section of reheater

ActiveCN112502788AAvoid risk of damagePrevent overheating damageSteam useSpace heating and ventilation detailsTemperature controlMeasurement device

An embodiment of the invention discloses a control method of a combined heat and power generation unit for cooperative steam extraction of a cold section and a hot section of a reheater. The combinedheat and power generation unit comprises a first heat supply steam header, a second heat supply steam header, the boiler reheater, a high-pressure cylinder, an intermediate-pressure cylinder, a data acquisition and control device, a thrust pad lubricating oil system, a pipeline, a measuring device and a valve. The data acquisition and control device (57) is observed to enable the steam extractionflow of the cold section of the boiler reheater to be basically close to the steam extraction flow of the hot section of the boiler reheater, and meanwhile whether parameters such as axial displacement, first shaft vibration, second shaft vibration, first bearing bush cover vibration, second bearing bush cover vibration, thrust pad temperature and reheater pipe wall metal temperature are within asafety range value or not is observed. According to the control method, online monitoring and adjusting of unit operation parameters are achieved, the effects of temperature control and vibration reduction are achieved, the service life of equipment is prolonged, the steam extraction and heat supply flexibility of the unit is improved, and full utilization of energy is achieved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

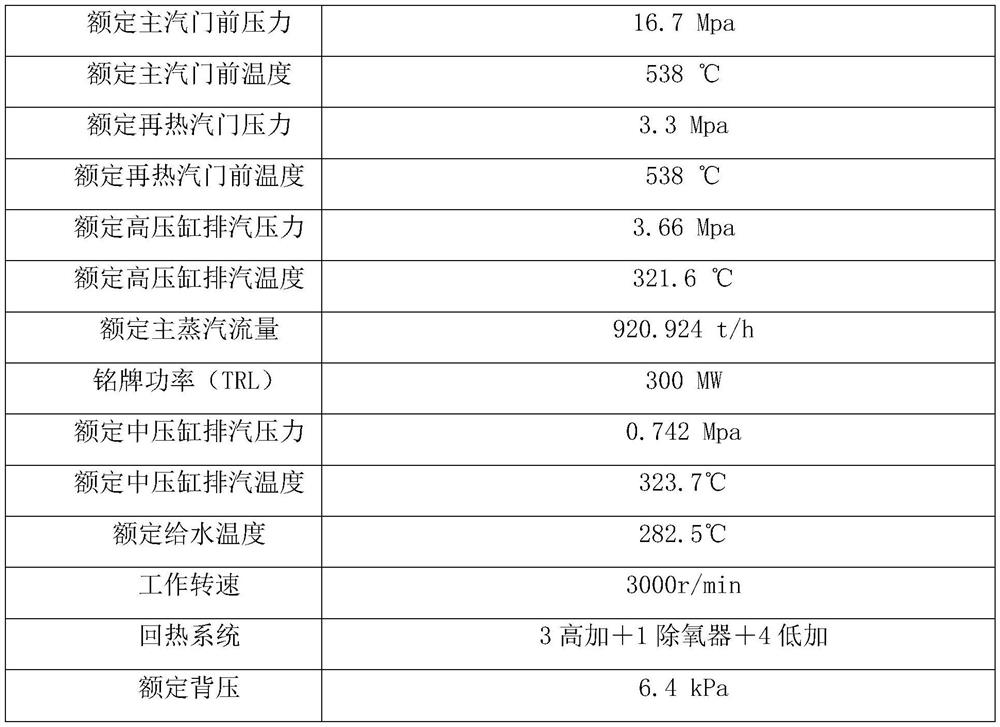

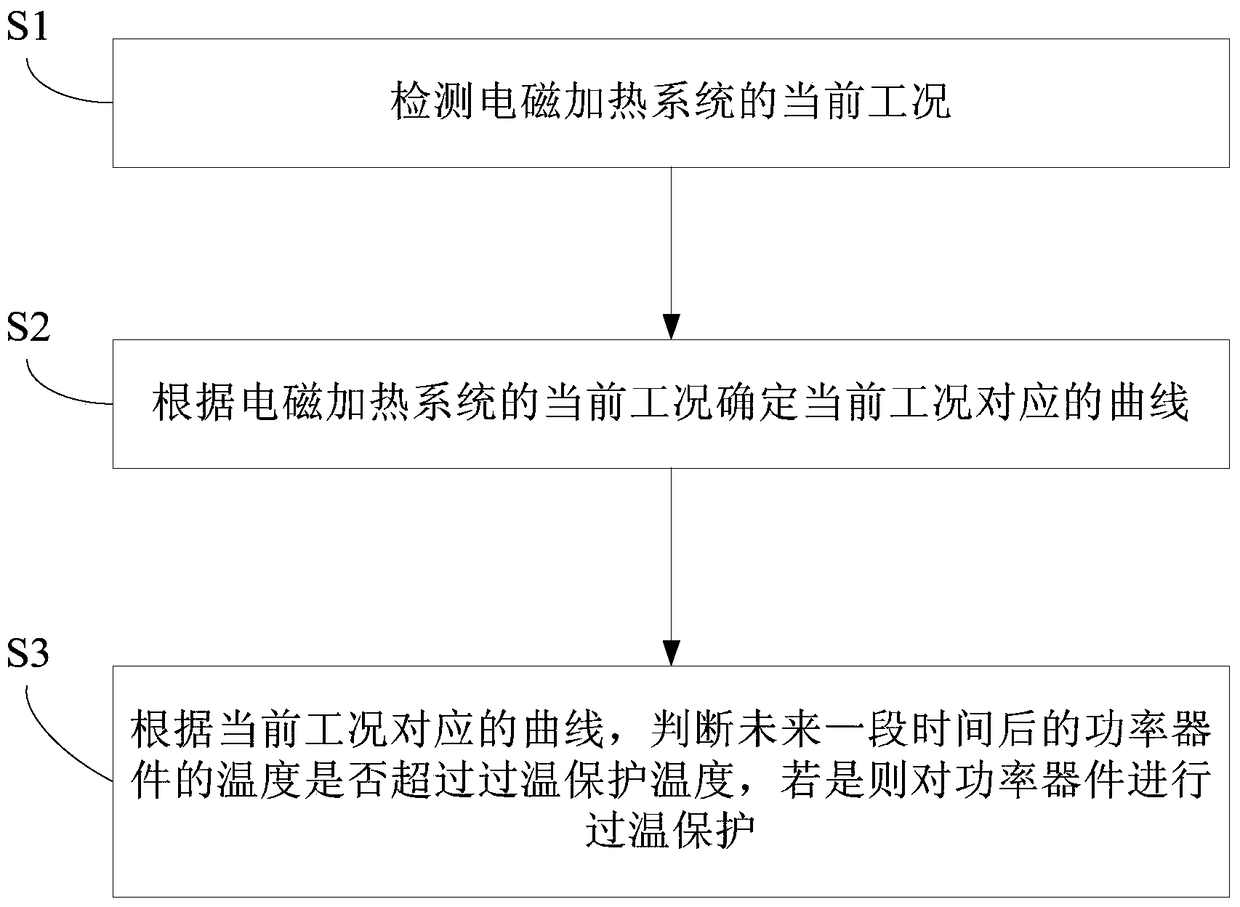

Over-temperature protection method and device for electromagnetic heating system and power device thereof

ActiveCN105490253BImprove reliabilityPrevent overheating damageEmergency protective circuit arrangementsElectric/magnetic/electromagnetic heatingOvervoltageEngineering

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Method and device for fluid-bed destructive distillation of oil shale

ActiveCN103131448BHigh yieldPrevent overheating damageSpecial form destructive distillationHeat carrierFluidized bed

The invention discloses a method and a device for fluid-bed destructive distillation of oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale solve the problems caused by high coal burning load borne by a coal burning device in an existing destructive distillation technique and also solve the problem of low extraction rate of shale oil. The method for the fluid-bed destructive distillation of the oil shale comprises the steps that a section of destructive distillation reaction is carried out on oil shale raw materials (27) and high-temperature heat carriers after the oil shale raw materials (27) and the high-temperature heat carriers are mixed in a lifting pipe destructive distillation reactor (24); the oil shale raw materials enter a bed type destructive distillation reactor (21) for a second section of destructive distillation reaction after the first section destructive distillation reaction is carried out on the oil shale raw materials, and then mixed carbocoal is formed and enters a pipe type coal burning device (14) after oil gas contained in the mixed carbocoal is extracted in a steaming mode; and a section of coal burning is carried out on the mixed carbocoal which enters the pipe type coal burning device; and the mixed carbocoal enters a bed type coal burning device (5) for a second section of coal burning after the first section coal burning is carried out on the mixed carbocoal. The invention discloses the device for the fluid-bed destructive distillation of the oil shale, wherein the device for the fluid-bed destructive distillation of the oil shale is used for realizing the method for the fluid-bed destructive distillation of the oil shale. The method and the device for the fluid-bed destructive distillation of the oil shale are mainly used for destructive distillation processing of various kinds of powder oil shale raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +2

Magnetron temperature adjustment method, device and system, frequency conversion power supply and microwave equipment

ActiveCN107592694BReflect the anode temperaturePrevent overheating damageApparatus with intermediate ac conversionOhmic-resistance heatingThermodynamicsMicrowave

The invention relates to the field of microwave equipment, in particular to a magnetron temperature adjustment method and its device, a controller, a frequency conversion power supply, a magnetron temperature adjustment system and microwave equipment. Wherein, the magnetron temperature adjustment method includes: determining the anode current flowing through the magnetron and the output power of the variable frequency power supply, the output power is used to drive the magnetron to work; according to the anode current of the magnetron and the output power of the variable frequency power supply Power, calculate the anode voltage of the magnetron; adjust the output power of the variable frequency power supply according to the anode voltage of the magnetron. Therefore, it can directly obtain the anode current of the magnetron so as to accurately reflect the anode temperature of the magnetron, and adjust the anode temperature of the magnetron accurately and reliably by adjusting the output power of the variable frequency power supply to avoid overheating of the magnetron damage.

Owner:SHENZHEN MEGMEET ELECTRICAL CO LTD

Excess temperature protector for driving motor of electric automobile

InactiveCN100353633CPrevent overheating damageImprove reliabilityEmergency protective circuit arrangementsCurrent rangeDrive motor

The invention is an electric auto driving motor cooling fun protector, according to the working current range, determining if the cooling fan works normally: if it is abnormal, send trouble information to an motor controller, which can stop the driving motor working or reduce output power of the driving motor, thus preventing overtemperature damage, even destruction to the driving motor caused by the abnormal working of the cooling fan, and the invention can be used not only in protecting electric auto driving motor but also in protecting other driving motors in need of cooling fans.

Owner:北京京工大洋电机科技有限公司

Fluidized bed combustion furnace and combustion method

ActiveCN111288438ASolve the problem of incomplete combustionReduce volumeFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringFluidized bed combustion

The invention discloses a fluidized bed combustion furnace and a combustion method. The fluidized bed combustion furnace comprise a fluidized combustion area and a rotary drying and layer combustion area; a material inlet of a fluidized bed is arranged on the rotary drying and layer combustion area, and the rotary drying and layer combustion area communicates with the fluidized combustion area; the rotary drying and layer combustion area is used for realizing rotary drying and layer combustion of materials; and the fluidized combustion area is used for carrying out fluidized combustion on thematerials which have passed through the rotary drying and layer combustion area. The materials enter the combustion furnace through the material inlet of the fluidized bed, and are firstly stacked inthe rotary drying and layer combustion area for rotation, drying and partial layer combustion, and continuously input materials extrude the materials subjected to drying and layer combustion out of the rotary drying and layer combustion area and enter the fluidized combustion area for fluidized combustion. By means of the technical scheme in the invention, the problems that in an existing fluidized bed combustion technology, the requirement on the particle size of materials is high, crushing treatment is needed firstly, the energy consumption is large, and the residence time of fuel in a furnace is too short, so that large-particle materials and high-humidity materials cannot be fully combusted are solved.

Owner:JIANGSU UNIV +1

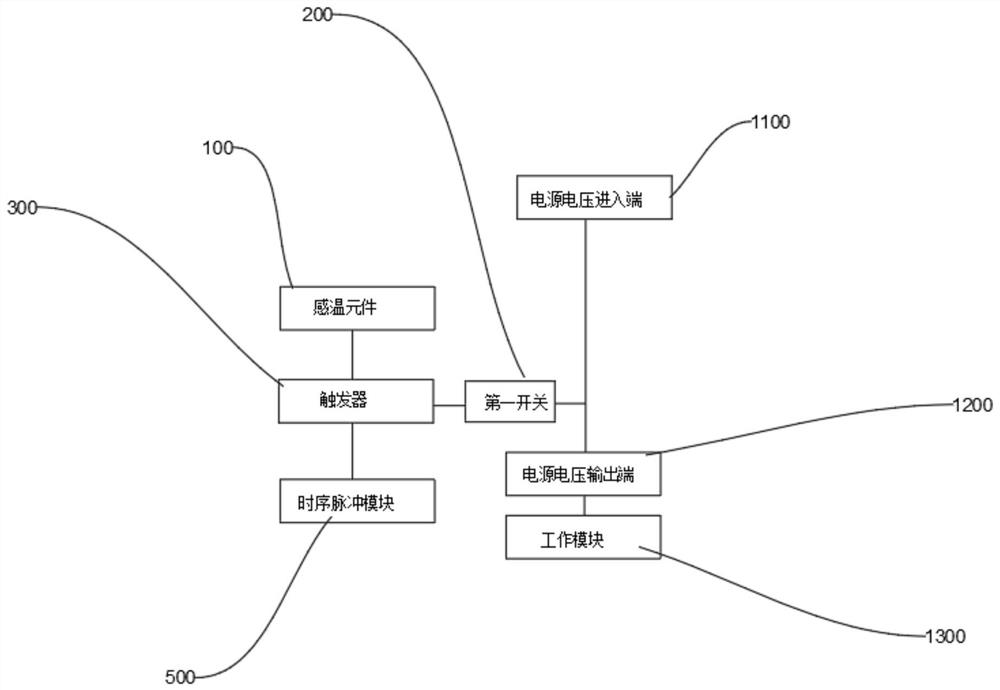

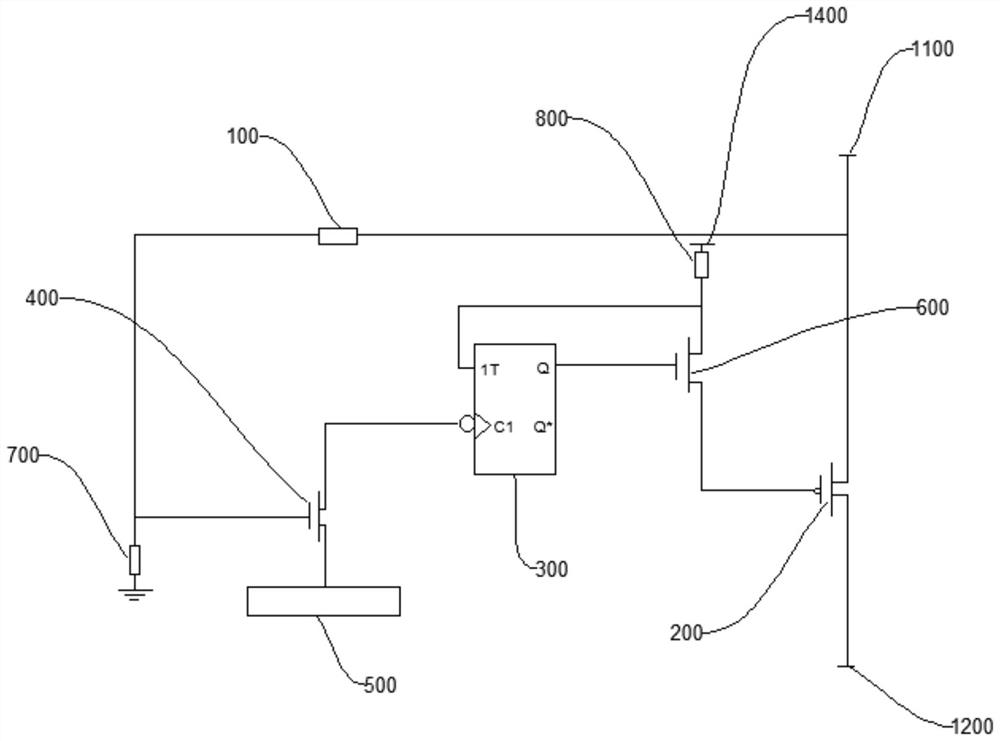

Driving chip protection circuit, circuit board and display device

PendingCN114326186APrevent overheating damageAvoid damageStatic indicating devicesEngineeringHemt circuits

The invention relates to a driving chip protection circuit, a circuit board and a display device. The driving chip protection circuit comprises a power supply voltage input end and a power supply voltage output end, wherein the power supply voltage output end is configured to be connected with a working module of a driving chip; the circuit further comprises a temperature sensing element used for obtaining temperature information of the driving chip; the first switch is connected between the power supply voltage input end and the power supply voltage output end; the input end of the trigger protection module is connected with the temperature sensing element, the output end of the trigger protection module is connected with the first switch, and the trigger protection module is used for controlling the first switch to be switched on or switched off according to the temperature information obtained by the temperature sensing element. According to the scheme, temperature protection can be carried out on the driving chip, and over-temperature damage of the driving chip is prevented.

Owner:MIANYANG HKC OPTOELECTRONICS TECH CO LTD +1

An energy storage type new energy battery protection system and method for smart energy network

ActiveCN105655666BPrevent overheating damageAvoid destructionSecondary cellsBatteriesFiberNew energy

Owner:ZHEJIANG UNIV

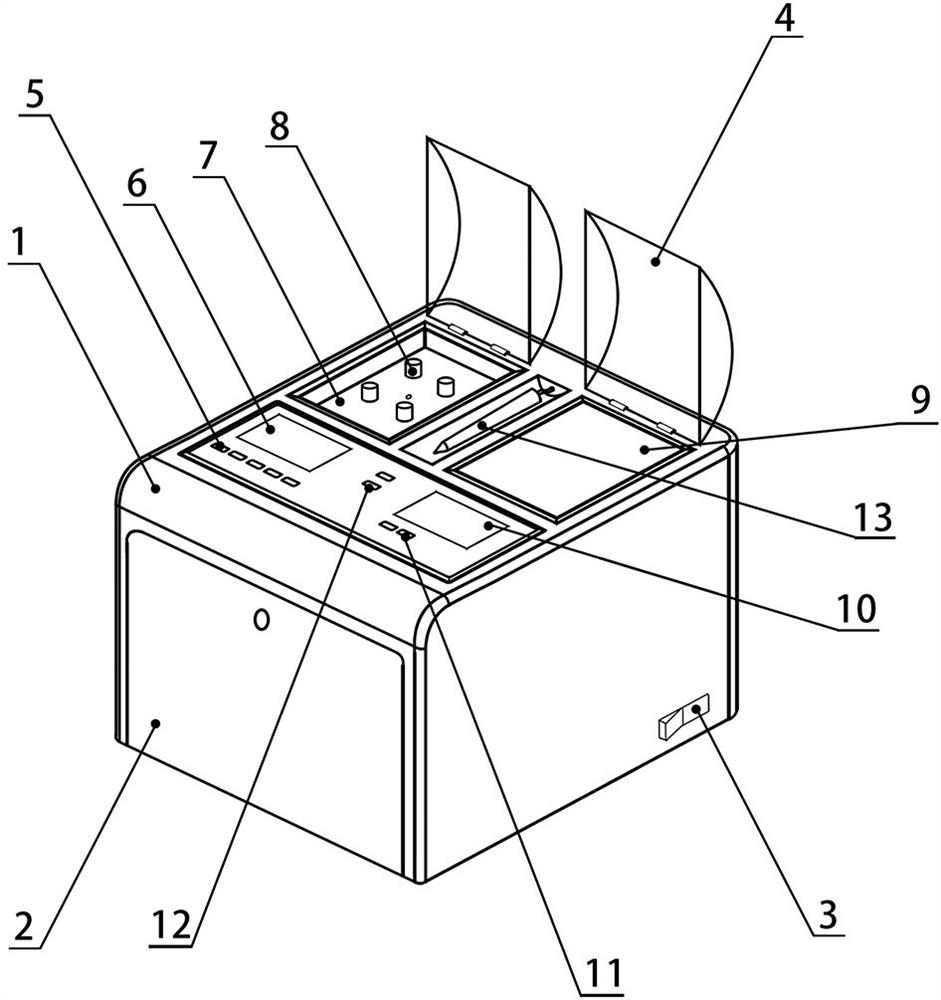

Spreading and baking all-in-one machine for frozen slices

InactiveCN112284840AReasonable designAchieve fine tuningPreparing sample for investigationElectric machineryMachine

The invention discloses a spreading and baking all-in-one machine for frozen slices, which solves the problems that the existing equipment is troublesome to operate, the slices are difficult to form in the preparation process of tissue slices, and experimenters need to do a large number of spreading and baking exercises, and belongs to the technical field of medical machinery. The invention provides an instrument for flaking by using liquid surface tension and integrating spreading and baking. The instrument comprises a machine body, a spreading area, a baking area, a trace liquid suction penarea, a liquid collection area, a motor area and a control area. According to the invention, convenient slice spreading, fine liquid pumping and slice fishing, slice baking and liquid refilling can berealized to make preparations for slice fishing next time, and the slice fishing success rate and the slice beauty degree are significantly improved.

Owner:杜可晨

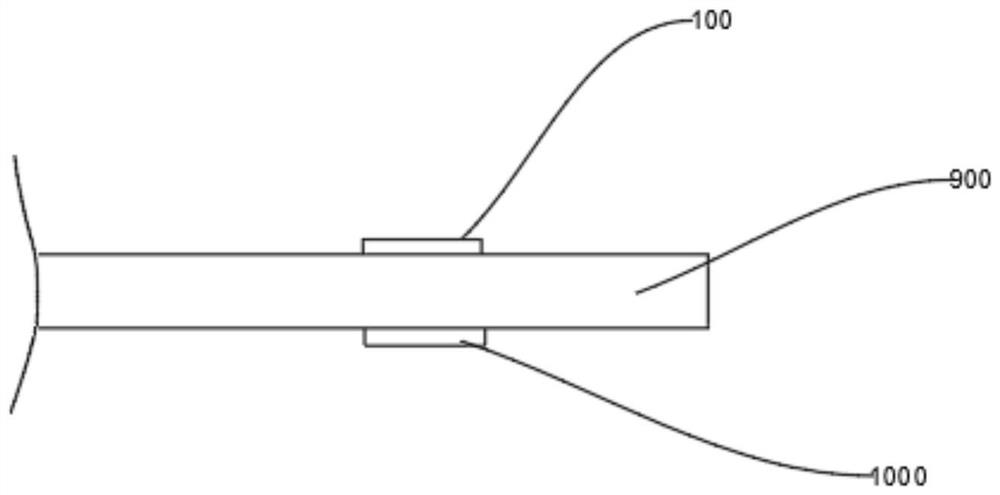

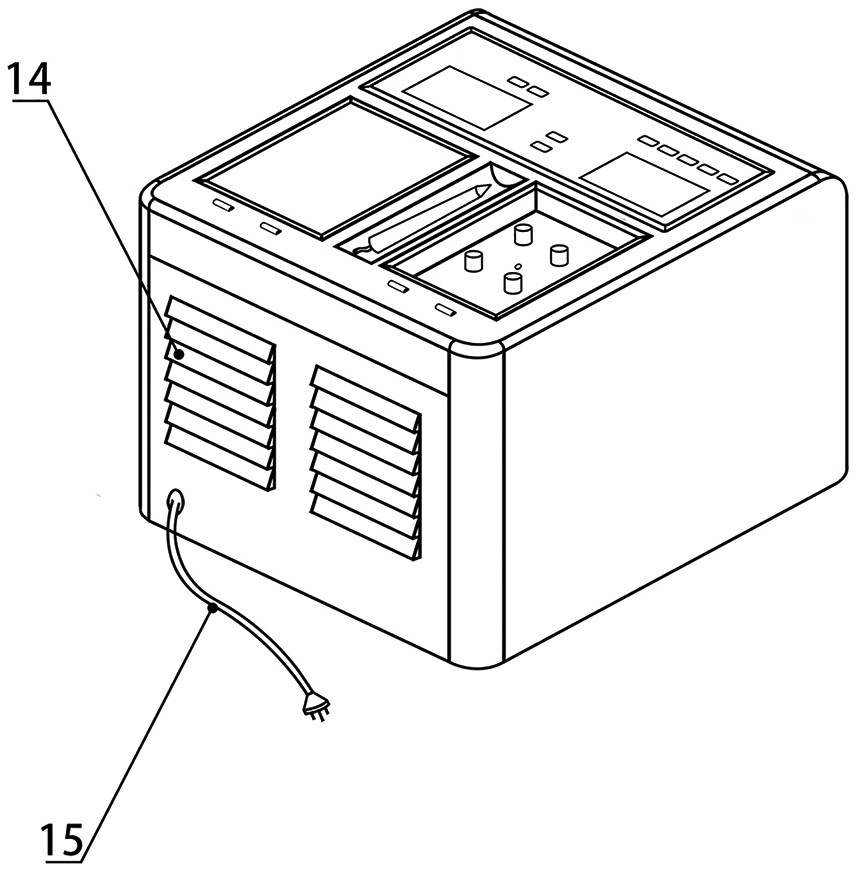

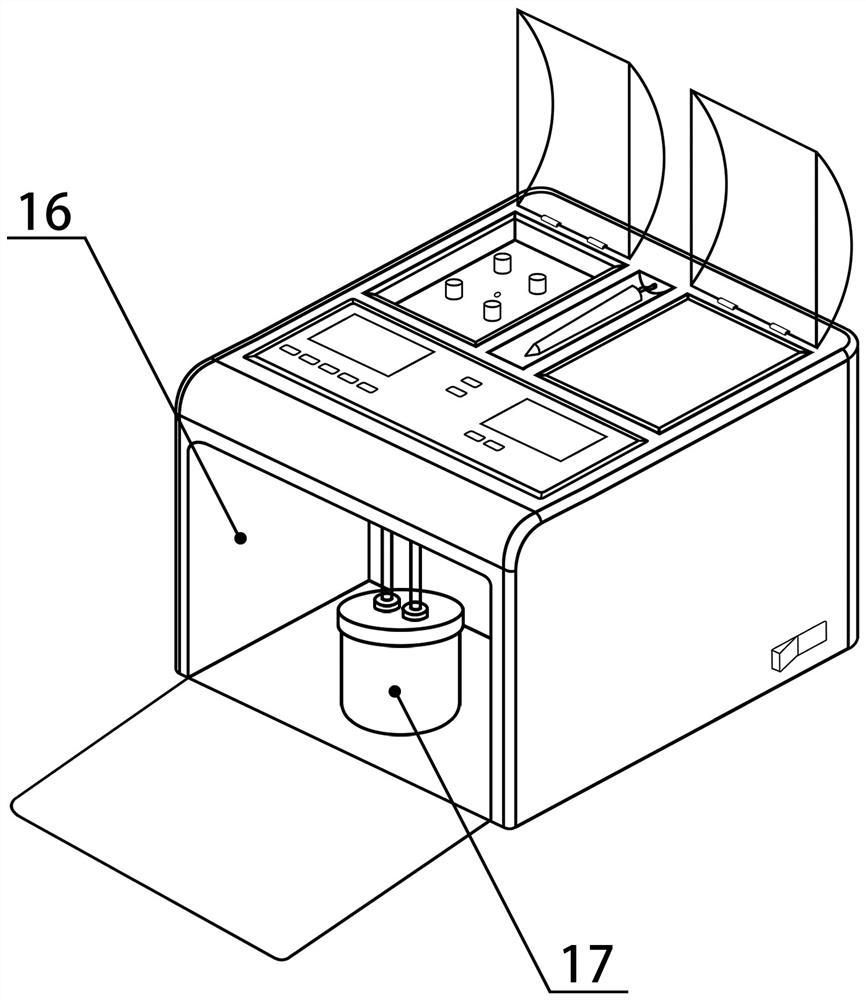

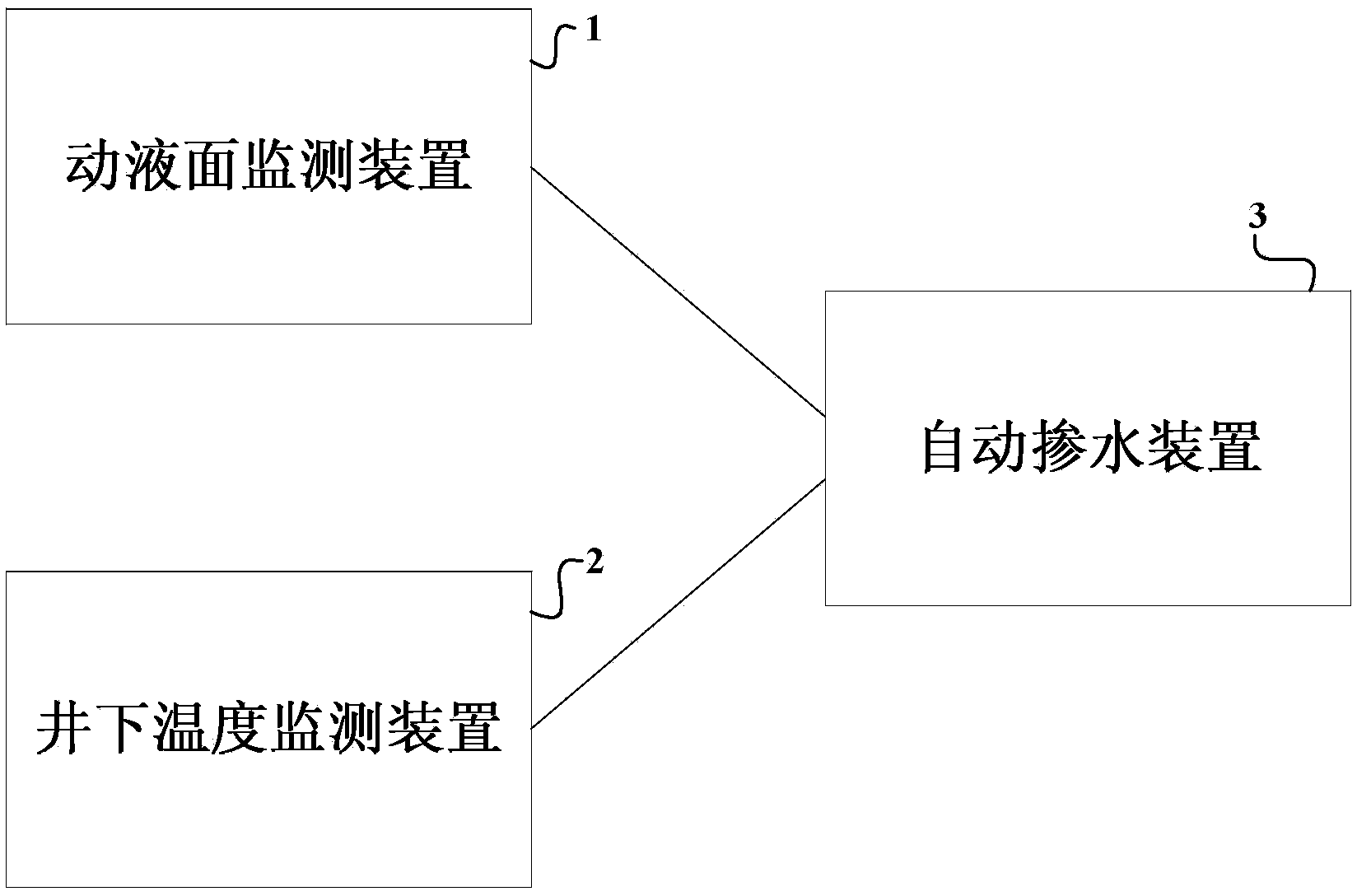

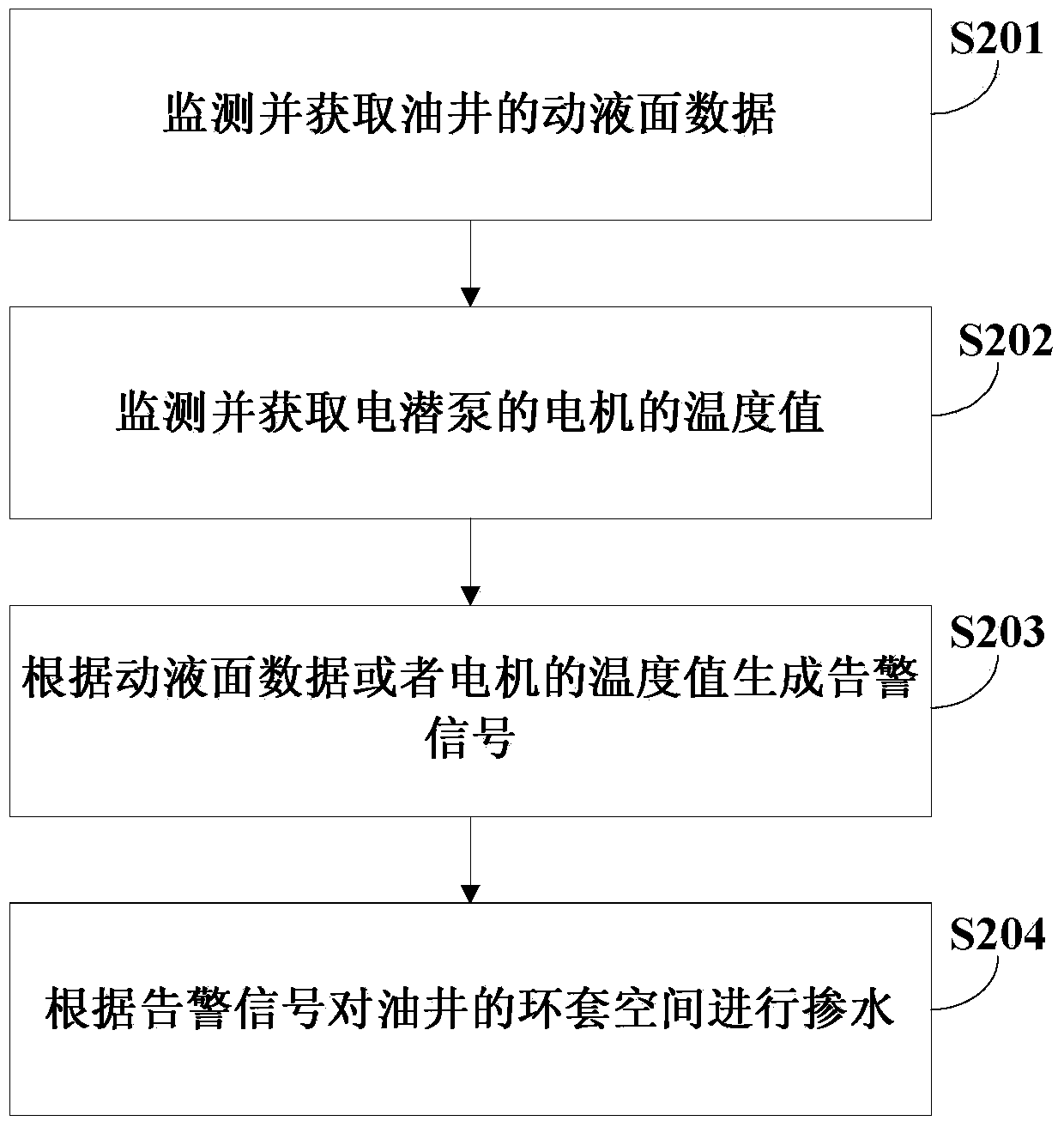

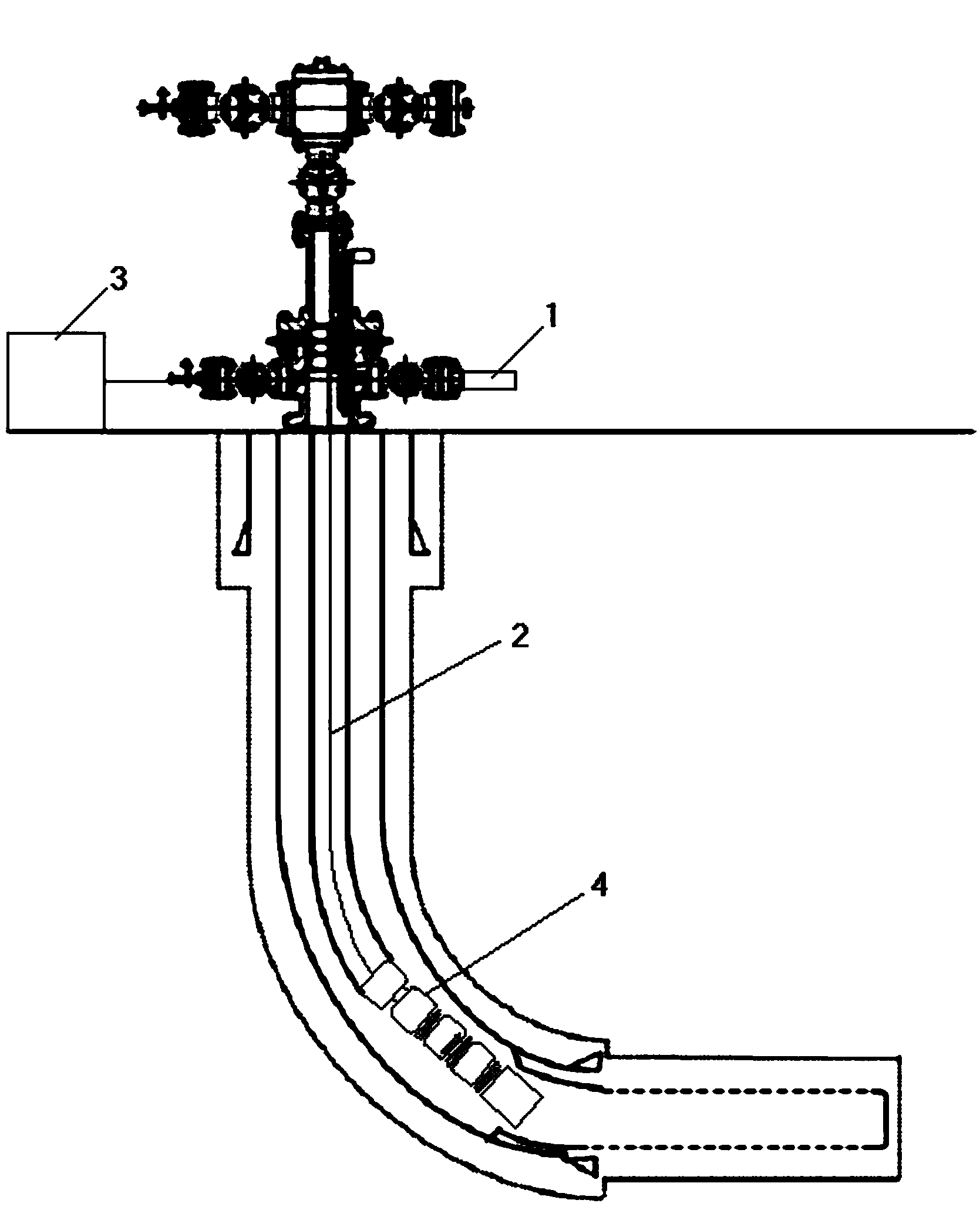

Well control protection device and method for electric submersible pump

ActiveCN103850921ALower working temperaturePrevent overheating damagePump controlPositive-displacement liquid enginesElectricityWorking fluid

The invention discloses a well control protection device and method for an electric submersible pump. The electric submersible pump is arranged in an oil well. The well control protection device comprises a working fluid level monitoring device, an underground temperature monitoring device and an automatic watering device, wherein the working fluid level monitoring device is arranged at the wellhead of the oil well, and is used for monitoring and acquiring the working fluid level data of the oil well and transmitting to the automatic watering device; the underground temperature monitoring device is arranged on a pump head of the electric submersible pump, is used for monitoring and acquiring the temperature value of an electric submersible pump motor and transmitting to the automatic watering device; the automatic watering device is connected with the working fluid level monitoring device and the underground temperature monitoring device, and is used for generating a warning signal according to the working fluid level data or the temperature value of the motor and watering the loop space of the oil well according to the warning signal.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com