Fluidized bed combustion furnace and combustion method

A fluidized combustion and fluidized bed technology, which is applied in the field of energy and environmental protection, can solve the problems of high particle size requirements, inability to fully burn materials with larger particle sizes, and short residence time, so as to reduce pollution and save energy. The effect of reducing consumption and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

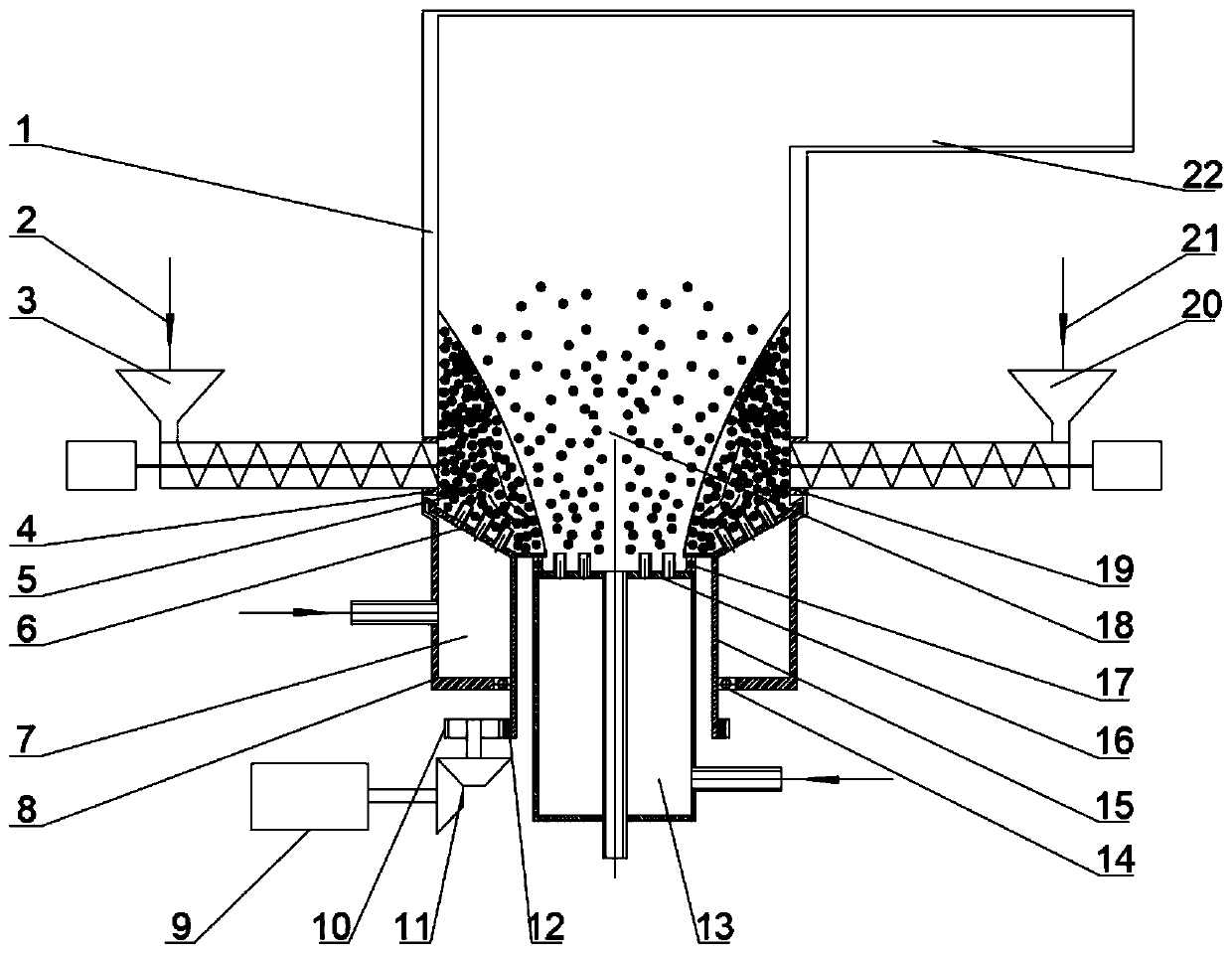

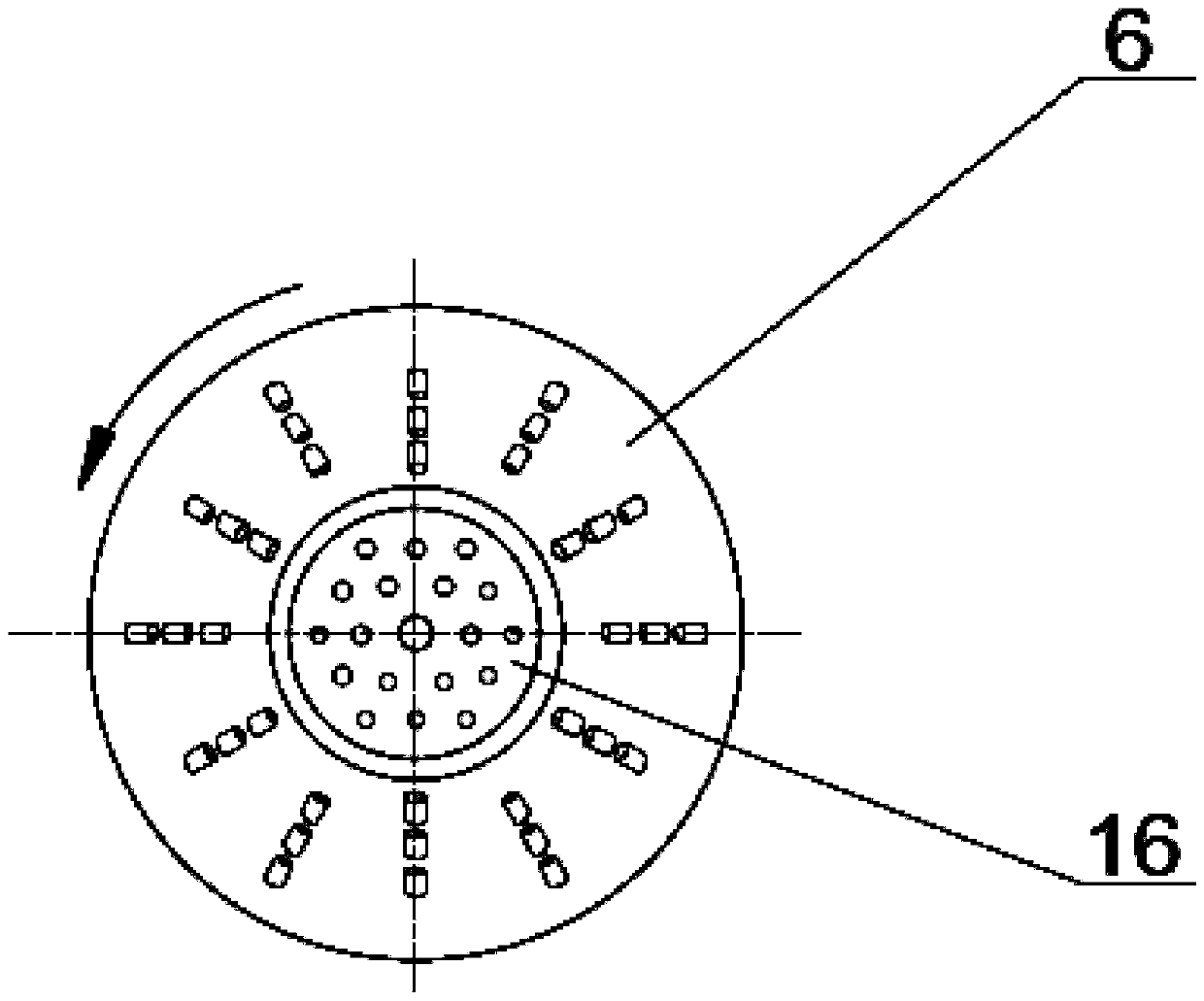

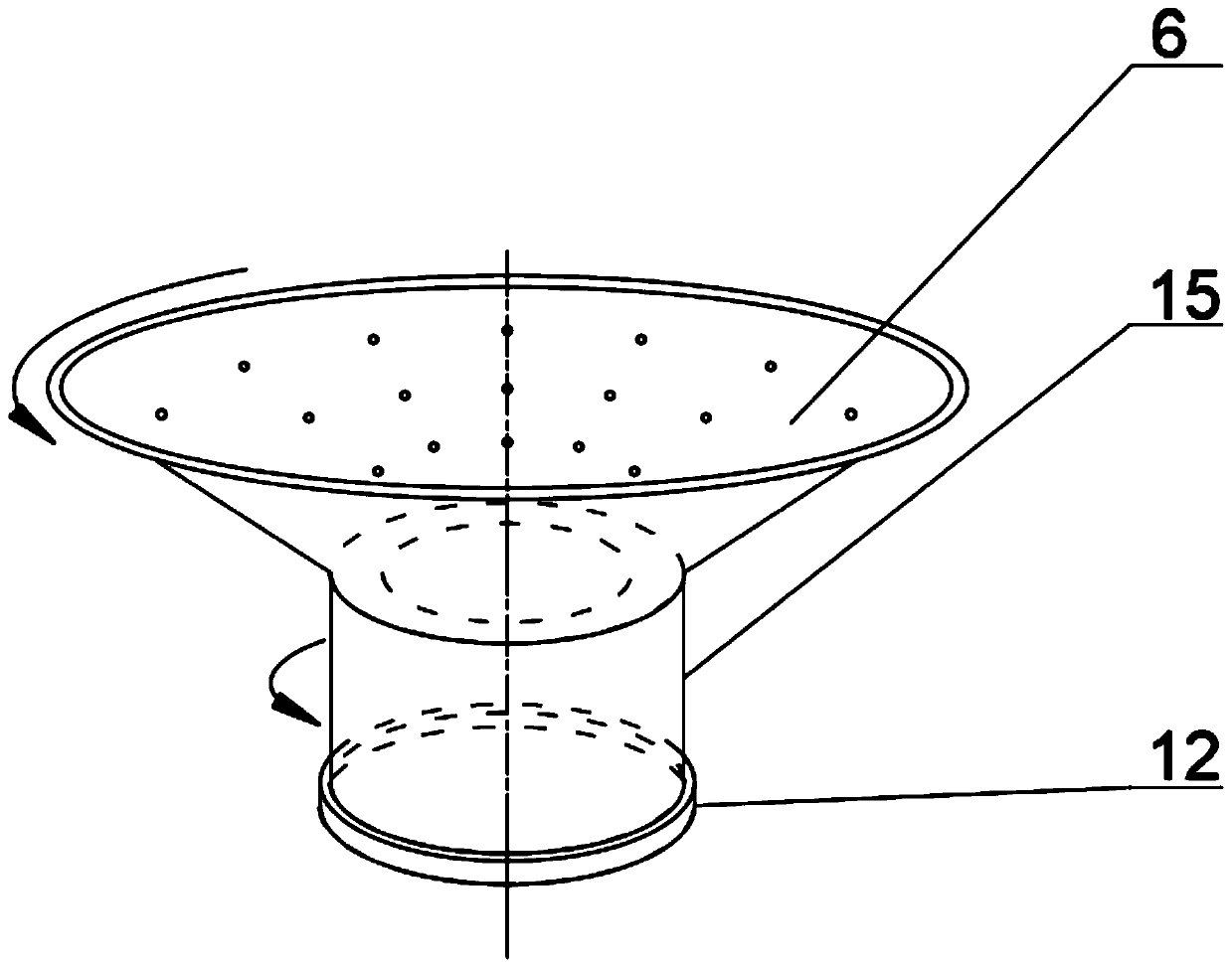

[0044] In order to solve the problems in the prior art that materials need to be crushed before combustion, resulting in high energy consumption and large particle size materials cannot be fully burned, and the material burnout rate is low, the embodiment of the present application provides a fluidized bed combustion Furnace and combustion method, by setting a rotatable dry layer combustion area outside the fluidized combustion area in the combustion furnace, the materials entering the furnace are first rotated on the rotating dry layer combustion area for drying and layer combustion, so that the material shrinks through drying The volume may become easily broken and easy to burn. When the dry material goes around the feed port with the drying layer combustion zone, it will be squeezed and pushed into the fluidized combustion zone by the incoming new material. Under the action of high-speed fluidized wind, The dry materials collide with each other and break into small particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com