Fuel combustion supporting system capable of improving fuel combustion efficiency

A technology of combustion efficiency and combustion-supporting system, applied in the direction of adding non-fuel substances to fuel, charging system, combustion method, etc., can solve problems such as insufficient combustion, and achieve the effect of protecting the environment and increasing the combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

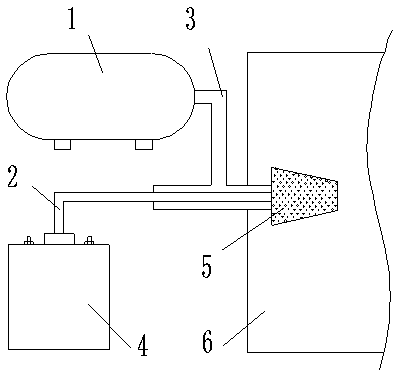

[0039] Example 1: In figure 1 Among them, the combustion system includes: fuel container 1, HHO gas delivery pipe 2, fuel delivery pipe 3, HHO generator 4, combustion-supporting reactor 5 and combustion device 6; the outlet of HHO generator 4 is connected with HHO gas delivery pipe 2, and the fuel The outlet of the container 1 is connected with a fuel delivery pipe 3, and the front ends of the HHO gas delivery pipe 2 and the fuel delivery pipe 3 have a combustion-supporting reactor 5, and the combustion-supporting reactor 5 is placed in a combustion device 6.

[0040] Said fuel includes: natural gas, coal, heavy oil, diesel, gasoline, kerosene, shale gas, biomass fuel, etc.

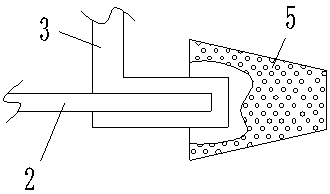

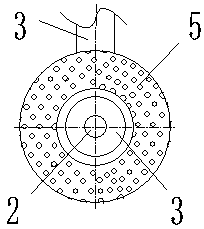

[0041] exist figure 2 , image 3 In the HHO gas delivery pipe 2 and the fuel delivery pipe 3, the HHO gas delivery pipe 2 penetrates into the fuel delivery pipe 3, and at the contact part where the HHO gas delivery pipe 2 and the fuel delivery pipe 3 penetrate, the fuel delivery pipe 3 and the outer w...

Embodiment 2

[0048] Example 2: In Figure 4 , Figure 5 Among them, the HHO gas delivery pipe 2 and the fuel delivery pipe 3 are connected in parallel. Others are the same as in Example 1.

Embodiment 3

[0049] Example 3: In Figure 9 Among them, the burner is a fuel engine 7. Fuel engine 7 includes: air filter 7-1, fuel tank 7-2, engine air supply pipe 7-3, engine exhaust pipe 7-4 and engine fuel supply pipe 7-5; Air intake port, exhaust port and fuel intake port, air filter 7-1 is connected with air intake port by engine air supply pipe 7-3, and the fuel oil in the fuel tank 7-2 passes engine fuel supply pipe 7- 5. It is connected to the fuel inlet, and the engine exhaust pipe 7-4 is discharged through the exhaust pipe of the fuel engine; the engine air supply pipe 7-3 is connected to the HHO gas delivery pipe 2, and the other end of the HHO gas delivery pipe 2 is connected to the HHO The HHO generator gas outlet 4-6 of the generator 4 is connected; the HHO gas generated by the HHO generator and the gas of the air filter 7-1 are delivered to the gas engine 7 at the same time.

[0050] The cylinder inner wall metal body of the fuel engine 7 is a combustion-supporting reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com