Patents

Literature

57results about How to "Improve detonation sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-safety emulsion explosive for coal mine

ActiveCN102424643AImprove detonation sensitivityEnhanced ability to resist deflagrationExplosivesChemistryEmulsion explosive

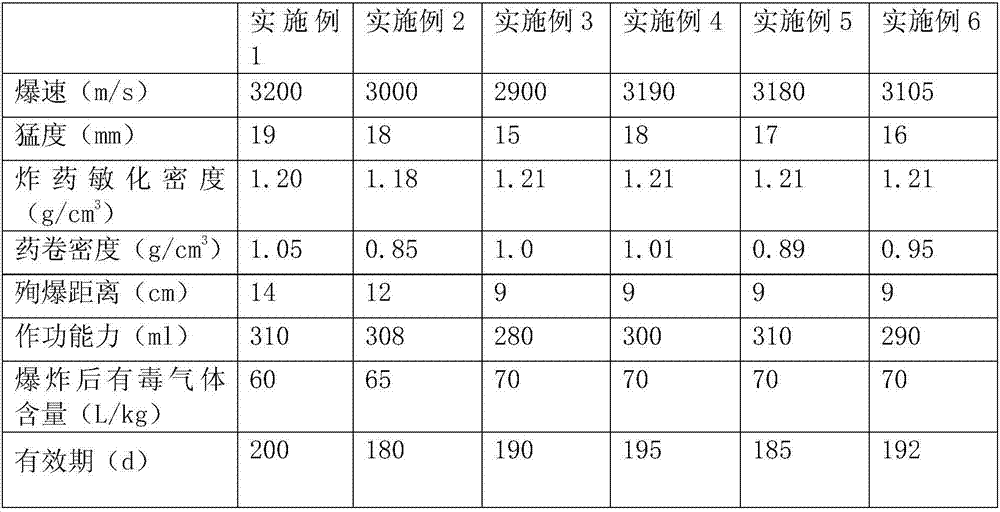

The invention relates to high-safety emulsion explosive for a coal mine. The explosive comprises the following raw materials: ammonium nitrate, sodium nitrate, calcium nitrate, sensitizing agent, urea, compound flame inhibitor, water, compound emulsifier, a compound oil phase, foaming agent, foaming accelerating agent and expanded perlite; and the preparation steps of the high-safety emulsion explosive are as follows: preparing a water phase, preparing the oil phase, emulsifying, cooling, sensitizing and charging and packaging.The explosive performance accords with the GB18095-2000 standard, a mine-gas-safety test shows that the test reading is 250g, 0 / 5 when any flammable item is suspended, the mine gas does not ignite gas, and the safety level of the explosive is one grade higher than that of the explosive for three-grade coal mines with the highest grade in China; and on the premise of ensuring the safety of combustible gas, a new formula with the compound flame inhibitor, the compound foaming agent and ethanolamine nitrate or potassium nitrate added as the sensitizing agent is adopted, thus, the initiation sensitivity of the explosive is improved, the anti-deflagrability capability of the explosive is enhanced, and the safe production of the coal mine is better ensured.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

MY type colloid emulsified civil explosive and production process thereof

ActiveCN103626615AImprove detonation sensitivityEnhanced ability to resist deflagrationExplosive working-up apparatusNon-explosive/non-thermic compositionsPotassium nitrateExplosive Agents

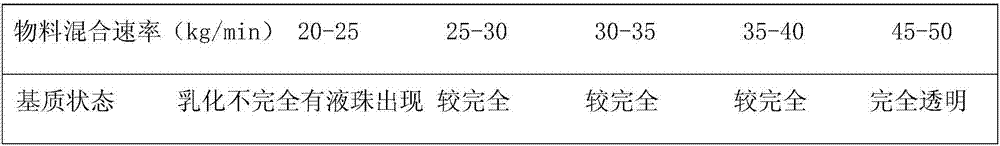

The invention discloses an MY type colloid emulsified civil explosive which comprises the following raw materials in percentage by weight: 35%-45% of ammonium nitrate, 6.5%-7.5% of sodium nitrate, 6%-10% of potassium nitrate, 15%-16% of flame inhibitors, 1.5% of urea, 3.5%-4% of emulsifying agents, 10% of water, 6%-6.3% of oil phases, 1.6%-1.8% of foaming agents, 0.15% of foaming promoters, 4.2%-4.4% of expanded perlite, 0.5% of mixed rare earth and 2.5%-6.5% of titanium hydride. The preparation process of the emulsified explosive comprises the steps of water phase preparation, oil phase preparation, emulsification, sensitization and charging. The MY type colloid emulsified civil explosive disclosed by the invention ensures the safety of the emulsified explosive, enhances the explosiveness and detonation sensitivity of the emulsified explosive and has high storage stability.

Owner:宜兴市阳生化工有限公司

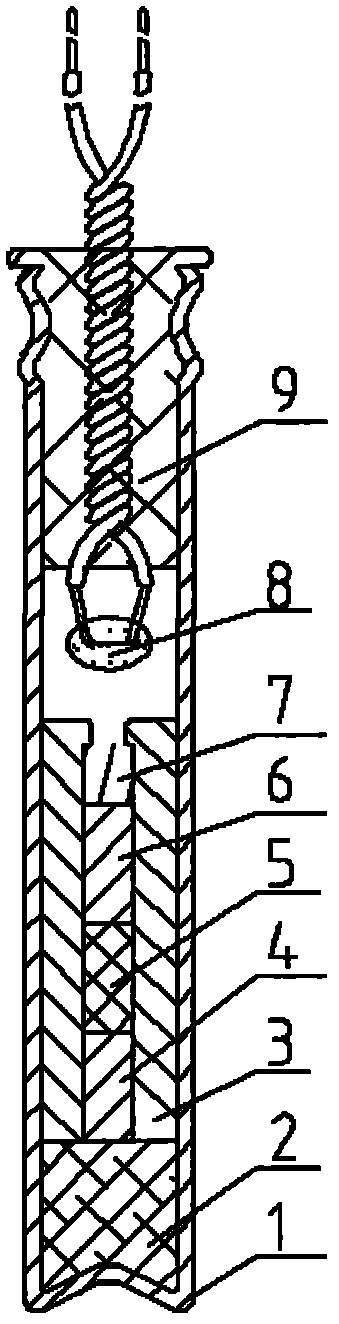

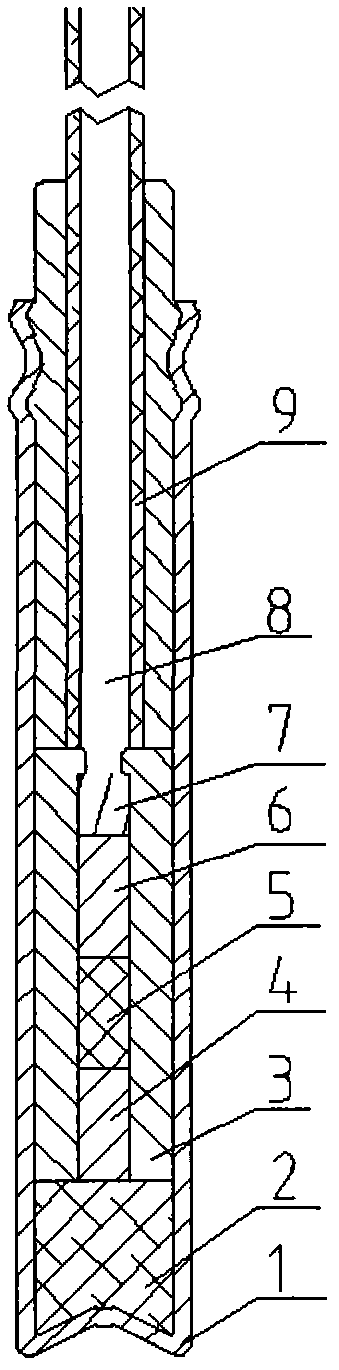

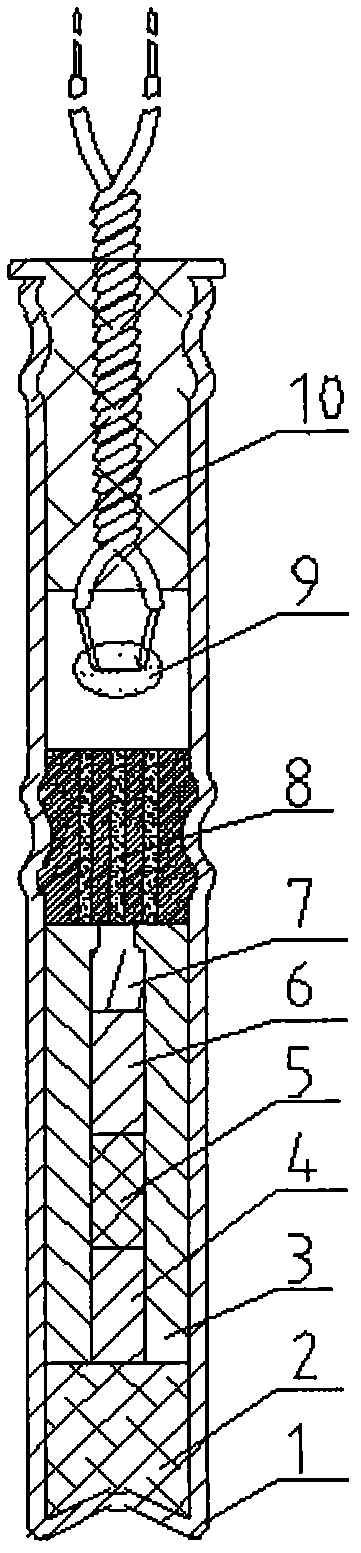

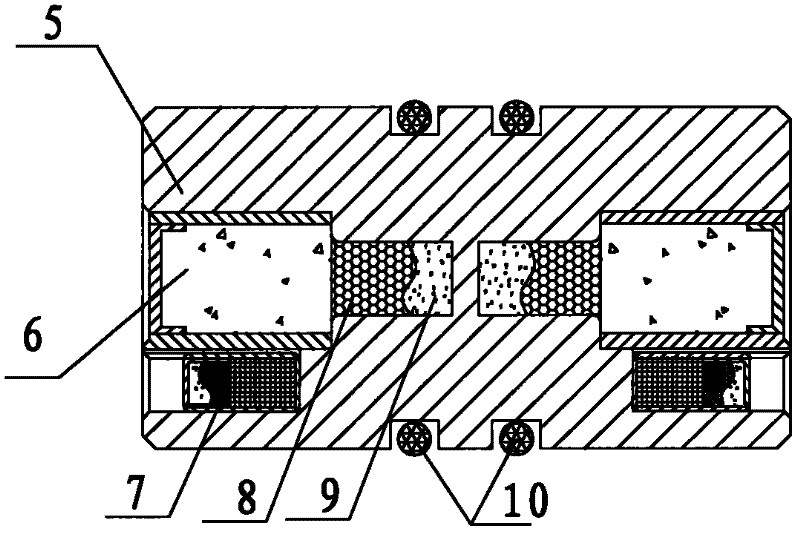

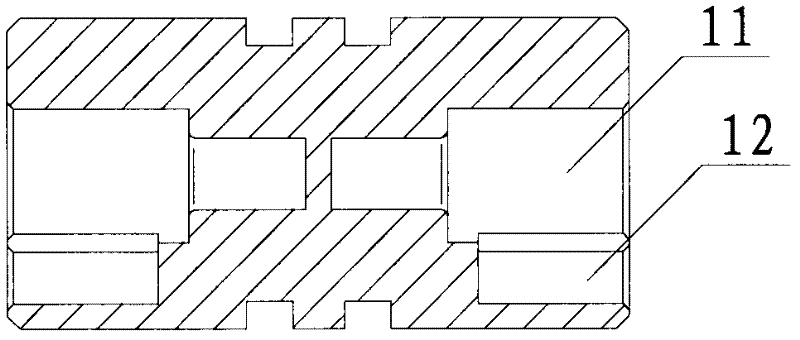

A non-priming charge detonator

The invention relates to the structure, charge and production process of a non-priming charge detonator. The invented non-priming charge detonator includes two types of instant detonators, electric igniter tip and non-electric plastic nonel, and a millisecond delay detonator with a lead core delay body. It stimulates the combustion of gunpowder in the steel pipe to generate high-pressure gas, which acts on the high explosive to make it burn in the steel pipe and develop into a high-speed detonation at the bottom of the steel pipe, thereby making a non-priming detonator. The design is optimized for reliable operation and simple fabrication.

Owner:ANHUI UNIV OF SCI & TECH

Novel sensitization bubble carrier colloidal emulsion explosive and preparation method thereof

The invention discloses novel sensitization bubble carrier colloidal emulsion explosive. The colloidal emulsion explosive comprises the following components: inorganic oxidizer salt, water, a compound oil phase, an emulgator, a compound flame inhibitor, a sensitizer, a foaming agent and a foaming accelerant, wherein the inorganic oxidizer salt is a mixture of ammonium nitrate, sodium nitrate and urea. The invention also designs a preparation method of the novel sensitization bubble carrier colloidal emulsion explosive. The preparation method comprises the following steps: firstly preparing a water phase, adding an oil phase to the water phase for mixing, then sequentially emulsifying and sensitizing, and finally filling to obtain a finished product. The novel sensitization bubble carrier colloidal emulsion explosive is good in water resistance, excellent in explosive performance, proper in sensitivity, suitable for blasting of various environments, simple and convenient in production process, low in affect on environment and low in cost.

Owner:宜兴市阳生化工有限公司

Low-temperature-resistant high-power coalmine-permitted water-gel explosive and manufacturing method thereof

InactiveCN103319290ALow crystallization pointCrystal form controlExplosivesMethylamine nitrateFormamide

The invention relates to a low-temperature-resistant high-power coalmine-permitted water-gel explosive and a manufacturing method thereof. The explosive is composed of a methylamine nitrate solution, water, ammonium nitrate, sodium nitrate, formamide, urea, sodium dodecylbenzenesulfonate, sesbania powder, fine atomized aluminum powder, a composite alkali metal halide flame inhibitor, expanded perlite powder, a foam stabilizer and a crosslinking agent. According to the invention, sodium nitrate and sesbania powder are first well mixed; ammonium nitrate is dissolved in water, such that an ammonium nitrate solution is prepared; formamide is dissolved in the methylamine nitrate solution; the three are mixed in an agent mixing tank; the composite alkali metal halide flame inhibitor, the fine atomized aluminum powder, the expanded perlite powder, the foam stabilizer and the crosslinking agent are sequentially added; and the mixture is well mixed and is packaged into sticks. The explosive has high explosion power, and can be normally initiated and detonated under an experimental temperature of 0 DEG C to -20 DEG C. The explosive does not contain toxic component, and does not pollute the environment. The process is simple, and continuous production can be realized.

Owner:安徽理工大学爆破工程与器材研究所

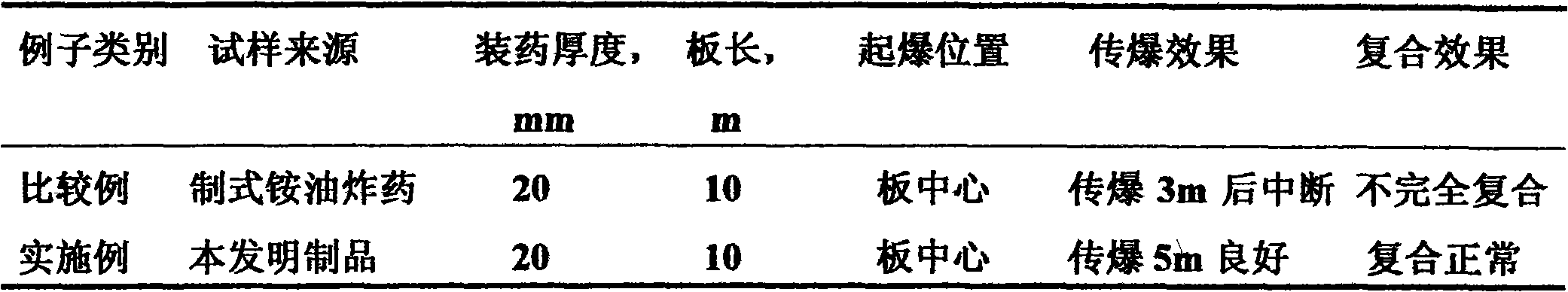

High-looseness high-sensitivity ammonium nitrate fuel oil explosive for explosion welding and preparation method thereof

InactiveCN101948363AChange the old concept that cannot be mixedGood crystal shapeExplosivesDetonationSorbent

The invention provides a high-looseness high-sensitivity ammonium nitrate fuel oil explosive for explosion welding and a preparation method thereof. The high-looseness high-sensitivity ammonium nitrate fuel oil explosive is characterized by comprising a powdery compound modifying agent and aiming at solving the unsolved problems of easily serious agglomeration under severe environments of rainy reason, foggy days and the like, low detonation sensitivity during winter charge, poor explosion propagation property when a large board explodes and compounds during the practical use of the traditional porous ammonium nitrate fuel oil explosive. The added powdery compound modifying agent comprises a crystal pattern transition agent, a dispersing agent, a lubricating agent, an absorbing agent and a centralite. The preparation method comprises the steps of: adding the compound modifying agent and the porous granulated ammonium nitrate together into an edge runner mill, raising the temperature to ensure that the porous ammonium nitrate is sensitized through crystal transition, and then adding fuel oil after the temperature is reduced, and evenly stirring and mixing at low temperature to obtain the modified porous ammonium oil explosive with good looseness, high detonation sensitivity and explosion propagation distance of exceeding 5m. The invention is especially suitable for the large-board compound explosive welding engineering.

Owner:殷海权

Compounded oil phase for powder nitramon

InactiveCN101172915AImprove detonation sensitivityImprove combustion effectExplosivesDetonationLiquid fuel

The invention discloses a composite oil phase with nitromethane, in particular to the composite oil phase for powder type ammon explosives. The invention comprises the raw materials by weight proportions: 72 to 92 proportions of solid fuel oil, 5.0 to 20 proportions of liquid fuel oil, 2.0 to 5.0 proportions of nitromethane, and 1.0 to 3.0 proportions of condensation compounds of aromatic sulphonate and aldimine. The invention also discloses a preparation method thereof. The method comprises the steps as follow: the solid fuel oil is firstly melted, and liquid fuel oil, condensation compound of organic acid salt aldehydes and nitromethane are added in turn for being mixed fully, and then the mixture is cooled and packed. The invention is characterized in that the burning thermal value is high; the viscosity is small; and the dispersion on the surface of powder type ammonium nitrate grain to form a moisture proof anti-blocking water resistance oil membrane is easy, thus the detonation Sensitivity and the detonation energy of the powder type ammon explosives are improved. The utility model used for the powder type ammon explosives has the advantages that the oil phase with the nitromethane is simple and reliable, has low cost and facilitates the industrialization production and utilization.

Owner:ANHUI UNIV OF SCI & TECH +1

Modified expanded ammonium nitrate explosive

In the prior art, the expanded ammonium nitrate explosive has disadvantages of low density, small volume power and easy agglomeration. For solving the disadvantages in the prior art, the present invention provides a modified expanded ammonium nitrate explosive with advantages of stable quality, simple production and low cost. The modified expanded ammonium nitrate explosive provided by the present invention has characteristics of good detonation sensitivity, stable detonation velocity, easy charging, no agglomeration, high charge density and large volume power. The technical scheme of the modified expanded ammonium nitrate explosive is that: the modified expanded ammonium nitrate explosive is prepared through mixing the following raw materials, wherein the raw materials comprise, by weight, 80-90% of expanded ammonium nitrate, 3-5% of hull, 2-3% of diesel fuel, 1-2% of % composite wax, 0.10-0.12% of qctadecyl amine, 0.2-0.5% of calcium fluoride and 2-12% of porous granular ammonium nitrate.

Owner:HUBEI TIANSHEN INDAL

Powdery emulsion explosive for on-site mixed loading and preparation method of powdery emulsion explosive

ActiveCN106008122AReduce production and transportation costsImprove intrinsic safetyExplosive working-up apparatusNon-explosive/non-thermic compositionsCelluloseExplosive Agents

The invention discloses a powdery emulsion explosive for on-site mixed loading. The powdery emulsion explosive comprises powdery latex substrate and a sensitizer. The mass ratio of the powdery latex substrate to the sensitizer is 30: (1-1.5). The powdery latex substrate comprises sodium nitrate, crystal modifiers, flame inhibitors, water, compound additives, oil-phase materials, compound emulsifiers and emulsification assistants. The sensitizer comprises expanded perlite, carboxymethyl cellulose, polyvinyl alcohol, ammonium bicarbonate, phosphoric acid, water, urea and ammonium nitrate. The invention further discloses a preparation method of the powdery emulsion explosive for on-site mixed loading. The emulsion explosive has high detonation velocity, brisance and coupling degree and few fumes; cost is low, the state of the explosive is hard, and work capacity is high; less poisonous gas is generated during preparation, safety of operators can be improved, and environment protection can be realized; the preparation process is simple and easy to operate.

Owner:宜兴市阳生化工有限公司

High-stability emulsion explosive for smooth blasting and preparation method of emulsion explosive

InactiveCN107353174AGuaranteed Detonation CapabilityGuaranteed explosive effectNon-explosive/non-thermic compositionsEmulsion explosiveMethylamine nitrate

The invention discloses an emulsion explosive for high-stability smooth surface blasting. The emulsion explosive comprises the following components in parts by mass: solid ammonium nitrate: 30-40 parts, sodium nitrate: 7-9 parts, methylamine nitrate: 10‑13 parts, aluminum powder: 8‑10 parts, water: 7‑11 parts, density regulator: 7‑9 parts, stearic acid: 5‑7 parts, crosslinking agent: 4‑6 parts, foaming paste : 1-3 parts, composite emulsifier: 2-4 parts, sensitizer: 5-7 parts, pentaerythritol tetranitrate: 0.5-1 part; the present invention also designs a kind of emulsified explosive with high stability smooth blasting The preparation method is simple and easy, the preparation cost is low, and the prepared emulsion explosive has good detonation sensitivity and explosive performance, good stability and uniform quality.

Owner:宜兴市阳生化工有限公司

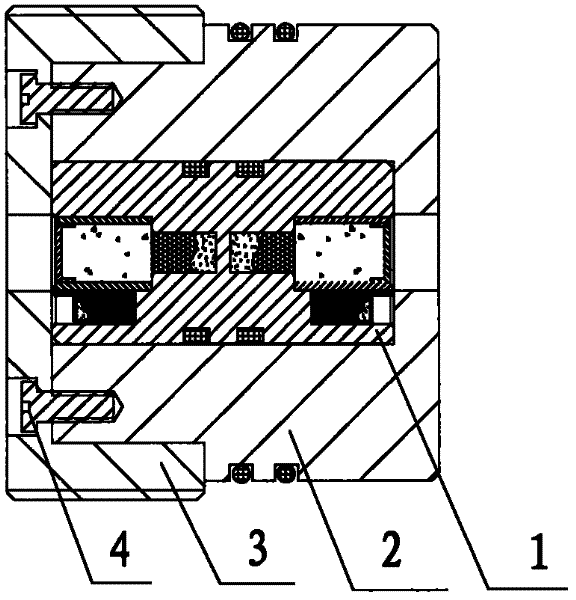

Bidirectional energization explosion-propagating device

ActiveCN102410005AMeet the construction process requirementsImprove detonation sensitivityFluid removalDetonatorDual effect

The invention discloses a bidirectional energization explosion-propagating device, belonging to the field of blasting supplies for oil and gas wells. The explosion-propagating device includes a clapboard with a symmetrical explosive loading structure, a clapboard coat with an explosion-expanding hole and a clapboard fixing member with an explosion-expanding hole, wherein explosion-expanding tubes and detonators in parallel with each other are installed at two ends of the clapboard, high explosive is filled in the explosion-expanding tubes in a pressing manner, initiating explosive filled in the clapboard is transmitted to the explosion-expanding tubes through the high explosive, the clapboard is positioned between the clapboard coat and the clapboard fixing member, and the two explosion-expanding tubes are respectively aligned to the two explosion-expanding holes. According to the bidirectional energization explosion-propagating device, any one of the two ends can integrate the dual effects of high initiating sense degree and strong initiating ability, and the problem of bidirectional energization explosion-propagating in traditional oil and gas well perforations is solved; not only the success rate of first-time downhole perforating is improved, but also the construction cost is saved; and simultaneously the bidirectional energization explosion-propagating device has the advantage of more convenience and more safety for use.

Owner:WUHUA ENERGY TECH CO LTD

Water-gel explosive

ActiveCN106495973AIncrease detonation hotspotImprove detonation sensitivityExplosivesCross-linkDetonation

The invention discloses a water-gel explosive which comprises a sensitizer, a density regulator, explosion enhancing metal powder, an oxidant, a reduction agent and a cross-linking agent. When explosives are subjected to explosion propagation roll by roll and the water-gel explosive bears the strong action of compression waves, a hot spot is provided by the existing density regulator, so that the explosive is detonated under pressure; by combining sensitization achieved through a sensitizer, sensitization achieved by absorbing micro bubbles through the explosion enhancing metal powder and sensitization achieved with the density regulator as a bubble carrier, the detonation sensitivity and explosion performance of the water-gel explosive in the environment with the water depth being 50 m or above are guaranteed. The detonation hot spot of the water-gel explosive is greatly increased by means of combined sensitization and material selection, the detonation sensitivity and explosion performance of the water-gel explosive are guaranteed when the explosive bears water static pressure at the water depth of 50 m or above, influences of deep water static pressure and permeation are effectively reduced, meanwhile the detonation sensitivity and explosion performance are guaranteed when the explosive bears strong compression waves in water, and an existing problem of deep water explosion is solved.

Owner:ANHUI LEIMING CHEM CO LTD

Method for preparing anti-caking puffed ammonium nitrate explosive

ActiveCN110803970AGood detonation sensitivityStable detonation velocityExplosivesPressure gas generationAmmonium hydroxideEngineering

The invention discloses a method for preparing an anti-caking puffed ammonium nitrate explosive and relates to the technical field of puffed ammonium nitrate explosives. The method comprises the following steps: S1, adding 20-30% ammonium hydroxide into a 90-91% ammonium nitrate solution, adjusting the pH value of the ammonium nitrate solution, and keeping the pH value to 7.5-8.5; S2, adding 0.10-0.15 part by weight of a puffing agent into 100 parts by weight of the ammonium nitrate solution, and heating and puffing the ammonium nitrate solution into powdery ammonium nitrate; S3, adding the powdery ammonium nitrate into a mixing machine, and adding 4 parts by weight of dried wood meal, 4 parts by weight of an oil phase material and 0.1 part by weight of quicklime powder; and S4, performingcooling and dehumidification on the mixture, and performing uniform mixing, so as to obtain the puffed ammonium nitrate explosive.

Owner:湖北东神天神实业有限公司

Environment-friendly and low-cost plastic film packaging colloidal emulsion explosive and preparation method thereof

InactiveCN107556147ALow costEasy to operateExplosive working-up apparatusAcetic acidExplosive Agents

The invention discloses an environment-friendly and low-cost plastic film packaging colloidal emulsion explosive. The emulsion explosive is prepared from components in parts by mass as follows: 30-40parts of ammonium nitrate, 10-15 parts of sodium nitrate, 15-20 parts of paraffin, 20-25 parts of water, 7-9 parts of an emulsifier, 3-5 parts of an emulsification aid, 8-10 parts of a sensitizing agent, 3-5 parts of a sensitization accelerant, 7-9 parts of a foaming agent, 1-3 parts of acetic acid, 3-5 parts of a flame inhibitor and 2-4 parts of an adhesive. The invention also designs a preparation method of the environment-friendly and low-cost plastic film packaging colloidal emulsion explosive. The preparation method is simple and easy to implement, the preparation cost is low, and the prepared emulsion explosive has higher compression-resistant and anti-deformation capacity and has good explosion performance and safety performance.

Owner:宜兴市阳生化工有限公司

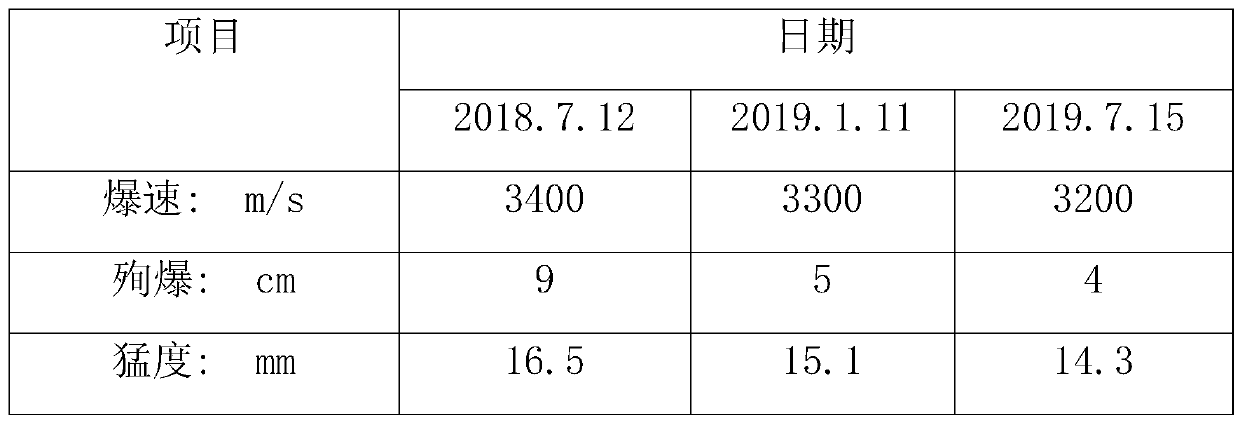

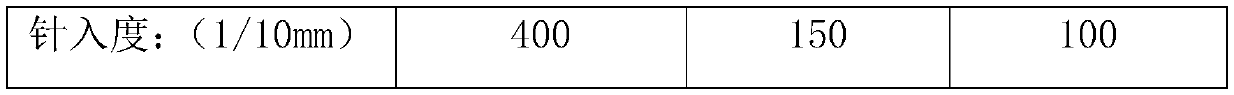

Special water-gel explosive for extremely-cold environment and preparation method thereof

The invention discloses a special water-gel explosive for an extremely-cold environment. In allusion to the reason for loss of detonator sensitivity during the use of the water-gel explosive in the extremely-cold environment, through a reasonable formula and a reasonable technology, the frost resistance and the detonator sensitivity of the water-gel explosive in the extremely-cold environment are improved, still good detonator sensitivity and explosive performance of the water-gel explosive in the extremely-cold environment of -25 DEG C are achieved, and using requirements are met. The special water-gel explosive for the extremely-cold environment overcomes the technical difficulties that a detonator of an ordinary water-gel explosive cannot be detonated smoothly in an extremely-cold environment of 25 DEG C below zero and the like, and meets the requirements when a user uses the water-gel explosive for blasting in the extremely-cold environment.

Owner:淮北矿业控股股份有限公司

High-performance mixed-loaded emulsion explosive and preparation method thereof

InactiveCN110655433AReduce production and transportation costsRealize fillingNon-explosive/non-thermic compositionsExplosive ingredient compoundingExplosive AgentsMicrocrystalline wax

The invention discloses a high-performance mixed-loaded emulsion explosive. The explosive is composed of the following components in parts by mass: 60 to 70 parts of an oxidizing agent, 5 to 7 parts of an oil phase, 10 to 15 parts of water, 5 to 7 parts of aluminum powder, 1 to 3 parts of an emulsifier, 0.5 to 1.2 parts of a sensitizer, 0.02 to 0.05 part of a sensitization accelerator and 1 to 2 parts of a flame inhibitor. The oxidizing agent is composed of the following components by the weight percentage: 35 to 45% of ferric nitrate, 15 to 18% of sodium nitrate, 5 to 7% of zinc nitrate, 7 to9% of calcium nitrate and the balance being ammonium nitrate, wherein the sum of the weight percentages of the components is 100%. The oil phase is composed of the components in parts by mass: 3 to 5parts of engine oil, 1 to 3 parts of diesel oil, 0.5 to 1 part of petroleum calcium sulfonate, 1 to 3 parts of microcrystalline wax, 0.7 to 1.0 part of vegetable pitch and 1 to 2 parts of base oil. The invention further provides a preparation method of the high-performance mixed-loaded emulsion explosive; the preparation method is simple and easy to implement, and the prepared emulsion explosiveis good in stability and low in cost.

Owner:宜兴市阳生化工有限公司

Heat-resistant porous granular ammonium nitrate fuel oil explosive and preparation method thereof

The invention discloses a heat-resistant porous granular ammonium nitrate fuel oil explosive. The heat-resistant porous granular ammonium nitrate fuel oil explosive is characterized by comprising, by weight, 92-98% of porous granular ammonium nitrate and 2-8% of oil-phase material, and the oil-phase material is base oil or is a mixture of the base oil and antioxidant. The invention further discloses a preparation method of the heat-resistant porous granular ammonium nitrate fuel oil explosive. The heat-resistant porous granular ammonium nitrate fuel oil explosive and the preparation method thereof have the advantages that by means of cooperation between the base oil and the porous granular ammonium nitrate, the base oil is adsorbed easily by the porous granular ammonium nitrate, and mixing is more uniform, so that detonation sensitivity of the explosive is improved; the prepared explosive can be used at the temperature above 120 DEG C, so that the problem of poor heat resistance of a porous granular ammonium nitrate fuel oil explosive at high temperature is solved.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Extrusion-resistant colloidal explosive for underwater explosion and preparation process of extrusion-resistant colloidal explosive

InactiveCN108586168AImprove detonation sensitivityImprove explosive powerExplosive working-up apparatusCross-linkMicrocrystalline wax

The invention discloses an extrusion-resistant colloidal explosive for underwater explosion. The extrusion-resistant colloidal explosive comprises the following components: microcrystalline wax, a methylamine nitrate solution, methylamine nitrate, ammonium nitrate, sodium nitrate, perlite, a foaming agent, a foaming accelerant, sesbania powder, a stabilizer, a cross-linking agent, a surfactant, water, an oxidant, a sensitizer, an emulsification foaming adhesive and an emulsifier. The invention further designs a preparation process of the extrusion-resistant colloidal explosive for underwater explosion. The preparation process is simple and feasible, and the prepared explosive is high in extrusion resistance, high in bubble immobilization capability, long in preservation life and stable inquality, and bubbles are not liable to aggregate or overflow after being extruded.

Owner:宜兴市阳生化工有限公司

Method for performing heat treatment on sensitized explosive

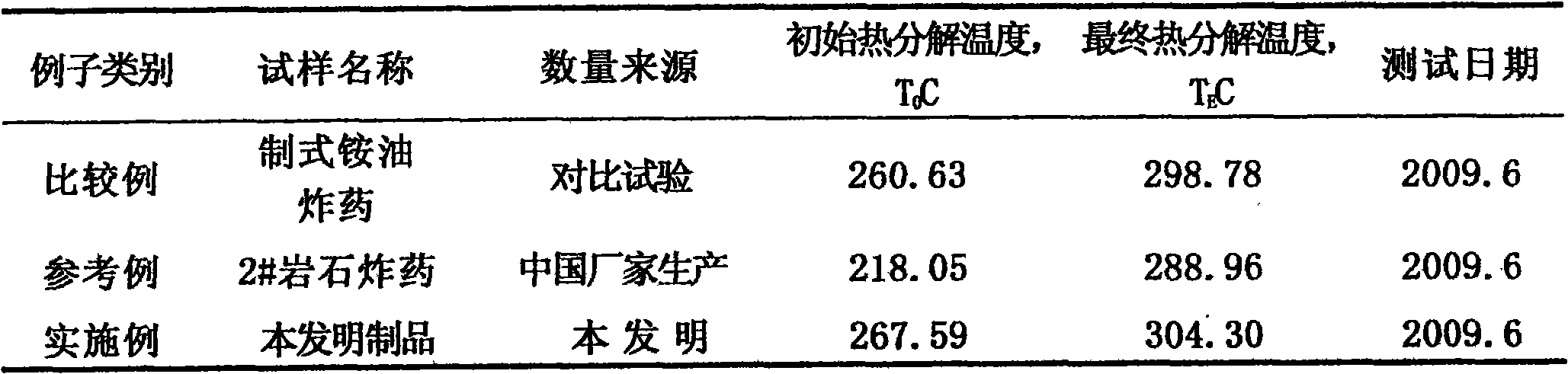

ActiveCN103708984AImprove detonation sensitivitySelf-sensitizing effectExplosive working-up apparatusDecompositionRoom temperature

The invention discloses a method for performing heat treatment on a sensitized explosive, which comprises the following steps: performing heat treatment on an explosive, keeping the temperature for a certain time, and cooling to room temperature, thus obtaining the porous sensitized explosive, wherein the heat treatment temperature is the initial decomposition temperature of the explosive + / - 10 DEG C. According to the invention, the explosive is subjected to heat treatment at the initial decomposition temperature, so that part of the explosive is decomposed and solvent is volatilized; and in the method, no sensitizer needs to be added, and micro / nano pores are increased in explosive crystals, so that the sensitivity to initiation of the explosive is enhanced, thus achieving self sensitization effect.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

Formula technology of low-detonation-velocity seismic explosive columns

The invention relates to a formula technology of low-detonation-velocity seismic explosive columns. The technology adopts a low-detonation-velocity puffed ammonium nitrate explosive as a main charge to prepare the low-detonation-velocity seismic explosive columns. The formula of the low-detonation-velocity seismic explosive columns comprises 83.0-87.0% of puffed ammonium nitrate, 3.0-4.0% of wood powder, 2.0-3.0% of composite oil, 4.0-5.0% of a high-energy additive and 6-8% of a diluent.

Owner:肖兰

Compounded oil phase for powder nitramon

InactiveCN100548937CImprove detonation sensitivityImprove combustion effectExplosivesDetonationOil phase

The invention discloses a composite oil phase containing nitromethane, especially a composite oil phase for powdery ammonium nitrate explosives, comprising the following raw materials in parts by weight: solid fuel oil 72-92, liquid fuel oil 5.0-20, Nitromethane 2.0-5.0, beta naphthalene sulfonic acid sodium salt and formaldehyde condensate 1.0-3.0, the invention also discloses its production method. The method is as follows: after melting the solid fuel oil, adding liquid fuel oil, organic acid salt aldehyde condensate and nitromethane respectively in sequence, stirring and mixing, and packing after cooling. The invention has the advantages of high combustion calorific value, low viscosity, easy dispersion on the surface of powdered ammonium nitrate particles, and the formation of a moisture-proof, caking-proof and water-resistant oil film. Increased the detonation sensitivity and explosion energy of powdered ammonium nitrate explosives. The compound oil phase process for the powdery ammonium nitrate explosive of the present invention is simple, reliable and low in cost, and is convenient for industrialized production and application.

Owner:ANHUI UNIV OF SCI & TECH +1

Seismic charge with low detonation velocity

InactiveCN102442869AImprove detonation sensitivityImprove stabilityExplosivesImage resolutionHigh energy

The invention relates to a seismic charge with low detonation velocity. The process takes an expanded ammonium nitrate explosive with the low detonation velocity as a main charge to produce the seismic charge with the low detonation velocity. The invention provides an environmentally friendly formulation process for the seismic charge with the low detonation velocity, which can effectively improve the resolution of the obtained map data. The seismic charge with the low detonation velocity comprises the following components: 83.0% to 87.0% of expanded ammonium nitrate, 3.0% to 4.0% of wood flour, 2.0% to 3.0% of compound oil phase, 4.0% to 5.0% of high-energy additive and 6% to 8% of diluent.

Owner:张作超

Production process of powdery emulsion explosive without single-compound explosive

InactiveCN108623420AImprove explosive powerAvoid damageExplosive working-up apparatusNon-explosive/non-thermic compositionsParticulatesAdhesive

The invention discloses a production process of powdery emulsion explosive without single-compound explosive. The production process comprises the following steps: (1) preparing an aqueous phase: dissolving ammonium nitrate and sodium nitrate into water, adding a dispersing agent and mixing uniformly; (2) preparing an oil phase: after melting a solid composite oil phase, pouring into a liquid composite oil phase and mixing uniformly; (3) preparing expanded oil ammonium nitrate: gathering and mixing the aqueous phase and the oil phase into a dynamic mixer according to the mass ratio of 1:1, discharging, feeding the materials mixed in the dynamic mixer into a tank, and performing negative pressure vacuum treatment to form the expanded oil ammonium nitrate; (4) preparing an adhesive: dissolving polyacrylamide into water; (5) preparing a finished product: adding porous particulate ammonium nitrate and light diesel oil into a mixing machine to obtain the finished product. The production process provided by the invention is simple and practical; the produced explosive has certain free-flowing property and cohesive property, excellent explosion property, high applicability, low pollutionand low cost.

Owner:宜兴市阳生化工有限公司

Explosive recrystallization preparation method and device for explosive crystallization

InactiveCN106699488AImprove quality consistencySolve efficiency problemsExplosive working-up apparatusShock sensitivityEngineering

The invention discloses an explosive recrystallization preparation method and a device for explosive crystallization. An explosive stock solution is poured into a grille crystallizing pan, and then the grille crystallizing pan is placed in a precise constant-temperature heating water tank, heated to 59-61 DEG C and kept at the constant temperature; a top-end air suction system is started, and the air suction speed is stabilized at 0.73-0.77 m / s, so that all explosives are crystallized. The device for explosive crystallization comprises the precise constant-temperature heating water tank, the grille crystallizing pan and the top-end air suction system, wherein the grille crystallizing pan is placed in constant-temperature water in the precise constant-temperature heating water tank, so that the periphery and the bottom of the grille crystallizing pan can be heated by the constant-temperature water, the top-end air suction system is arranged right above the grille crystallizing pan, and a grille of the grille crystallizing pan is arranged on the inner bottom surface of the grille crystallizing pan. The method and the device have a function of precisely controlling the temperature and the volatilization speed of the recrystallized stock solution, the initiation sensitivity of prepared explosives is obviously improved, the shock sensitivity is greatly reduced, and the production efficiency is substantially improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

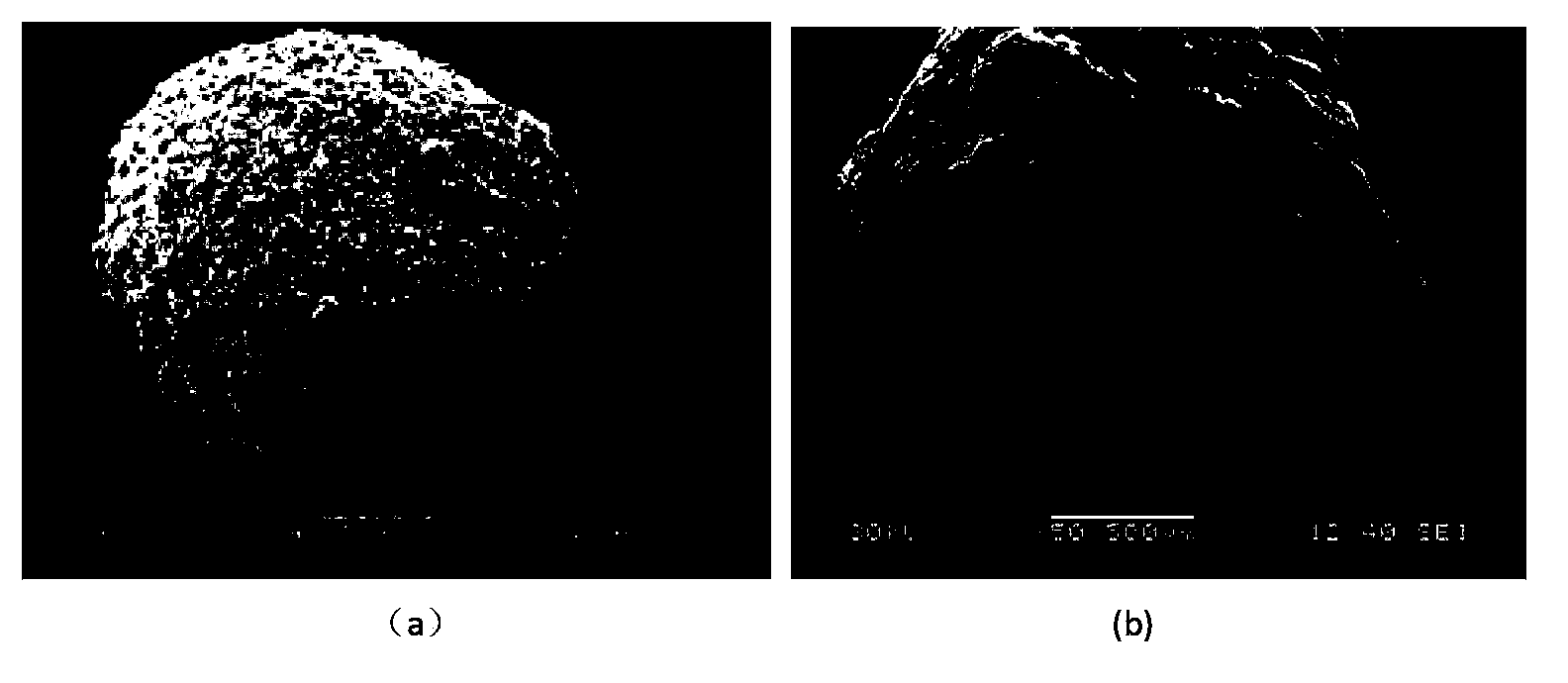

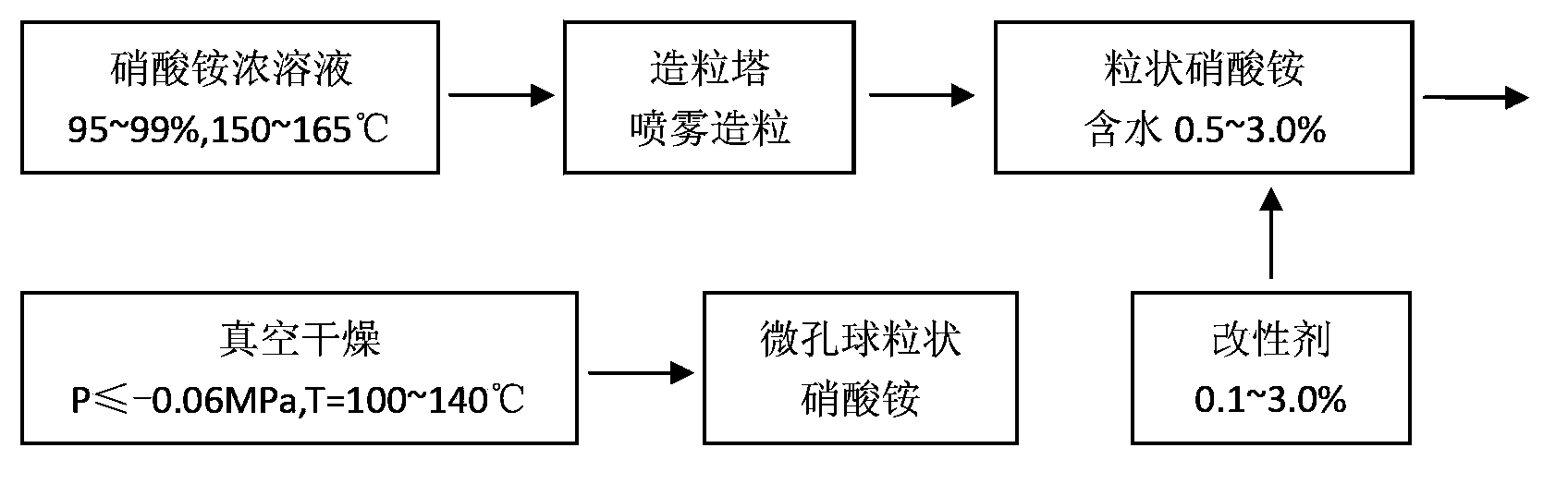

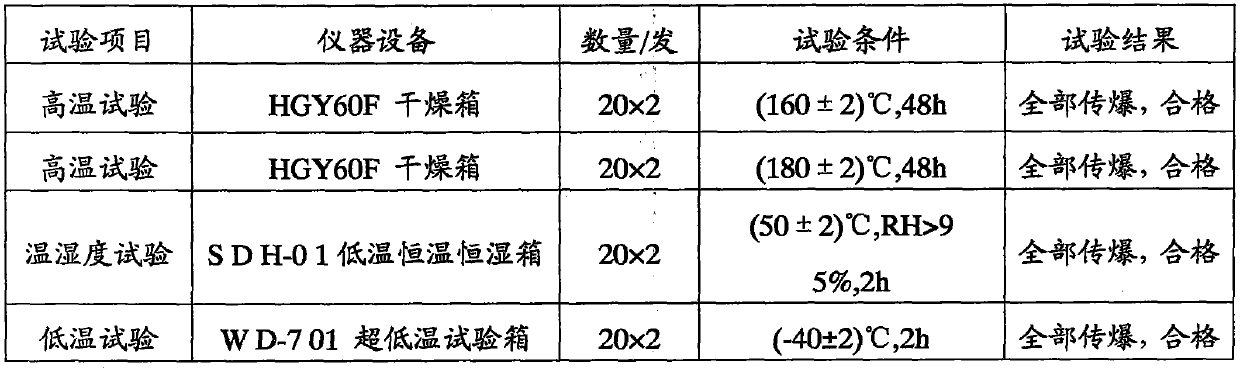

Microporous pelletal ammonium nitrate and preparation method thereof

InactiveCN103896695AIncrease the number ofReduce in quantityExplosive working-up apparatusDetonatorPrill

The invention discloses microporous pelletal ammonium nitrate and a preparation method thereof. The method comprises the following steps: adding pelletal or ellipsoidal ammonium nitrate containing proper moisture; quickly gasifying and emitting moisture in particles under the constraint conditions at certain temperature and negative pressure; leaving a lot of extremely small 'channels' inside the particles, so as to form solid ammonium nitrate-microporous pelletal ammonium nitrate particles in which a lot of tiny pores are evenly distributed. The tiny pores can be subjected to adiabatic compression to form high-temperature and high-pressure 'hot spots' when being in initiation energy instantaneous shock, so as to stimulate explosion of the overall explosive. The prepared microporous pelletal ammonium nitrate not only has all advantages of porous pelletal ammonium nitrate, but also is higher in oil absorption rate and large in superficial area, and the prepared microporous granular ammonium nitrate explosive (MANFO) has the characteristics of small detonator initiation sensitivity, small critical diameter and the like, and is safer to explode. Therefore, the microporous pelletal ammonium nitrate is more convenient to use, wider in application range, and more excellent in use effect.

Owner:NANJING UNIV OF SCI & TECH

Temperature-resistant explosive for assembly of detonating primer in oil exploitation and preparation method thereof

ActiveCN105503486AGood explosion reliabilityImprove pressure performanceExplosive working-up apparatusNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsShock waveDetonation

The invention provides a temperature-resistant explosive for assembly of a detonating primer in oil exploitation and a preparation method thereof. The temperature-resistant explosive for assembly of the detonating primer in oil exploitation is prepared from 98.5-99.5 wt% of cyclotetramethylene tetramine (HMX) and 0.5-1.5 wt% of binding agent soft acrylic resin 2#. The temperature-resistant explosive has the advantages of being good in reliability of detonation transmission, high in explosive initiation sensitivity and shock wave sensitivity, great in power, resistant to high temperature and good in explosive pressing property. The preparation method is easy and convenient to operate and suitable for industrial production.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

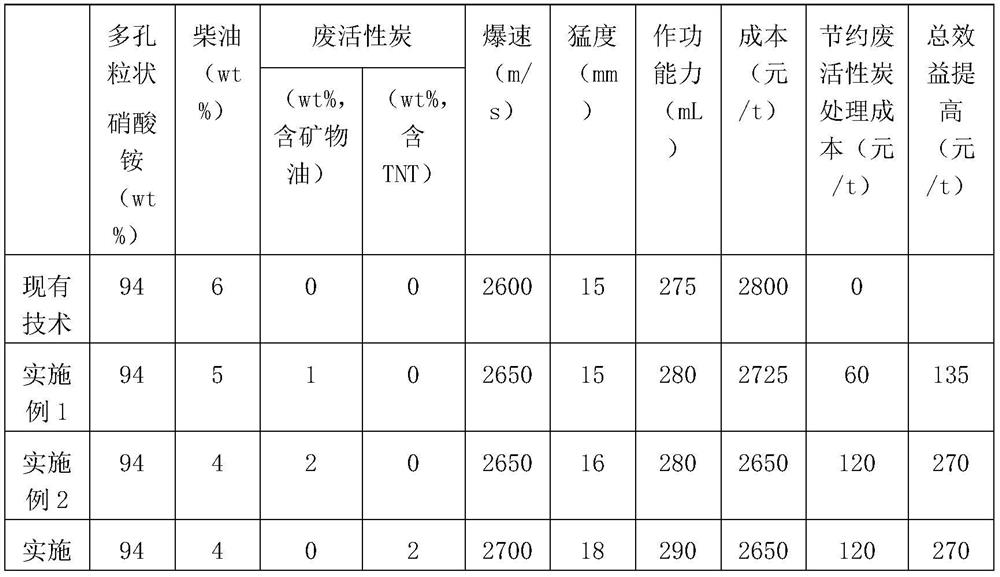

Porous granular ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN114230426AReduce usagePlay the effect of saving energy and reducing consumptionExplosive ingredient compoundingActivated carbonExplosive Agents

The invention discloses a porous granular ammonium nitrate fuel oil explosive, and also discloses a preparation method of the porous granular ammonium nitrate fuel oil explosive. The method has the advantages that 1, by adding the waste activated carbon adsorbed with mineral oil steam and TNT, the activated carbon and substances adsorbed by the activated carbon can be used as a reducing agent in the porous granular ammonium nitrate fuel oil explosive and can replace a part of diesel oil, the use amount of the diesel oil is reduced, and the effect of saving energy is achieved; 2, the waste activated carbon is used as a preparation raw material of the porous granular ammonium nitrate fuel oil explosive, so that the treatment problem of the waste activated carbon can be solved, the treatment cost of the waste activated carbon is reduced, and harm generated in the treatment process of the waste activated carbon is avoided; according to the invention, waste can be turned into wealth, and the production concept of long-term sustainable development is met; 3, the waste activated carbon is granular, so that the free-running property of the porous granular ammonium nitrate fuel oil explosive is not influenced after the waste activated carbon is added as a raw material, and on-site mixed loading is facilitated; and 4, the detonation velocity, brisance, work capability and other properties of the porous granular ammonium nitrate fuel oil explosive can be effectively improved.

Owner:内蒙古生力民爆股份有限公司

A kind of preparation method of anti-caking expanded ammonium nitrate explosive

The invention discloses a method for preparing an anti-caking puffed ammonium nitrate explosive and relates to the technical field of puffed ammonium nitrate explosives. The method comprises the following steps: S1, adding 20-30% ammonium hydroxide into a 90-91% ammonium nitrate solution, adjusting the pH value of the ammonium nitrate solution, and keeping the pH value to 7.5-8.5; S2, adding 0.10-0.15 part by weight of a puffing agent into 100 parts by weight of the ammonium nitrate solution, and heating and puffing the ammonium nitrate solution into powdery ammonium nitrate; S3, adding the powdery ammonium nitrate into a mixing machine, and adding 4 parts by weight of dried wood meal, 4 parts by weight of an oil phase material and 0.1 part by weight of quicklime powder; and S4, performingcooling and dehumidification on the mixture, and performing uniform mixing, so as to obtain the puffed ammonium nitrate explosive.

Owner:湖北东神天神实业有限公司

An ultra-high temperature two-way detonator tube for oil and gas wells

The invention relates to an ultra-high temperature two-way detonation tube for oil and gas wells, which comprises a metal tube with one end open, two types of ultra-high temperature resistant explosives are installed in the metal tube, and the explosives at the opening end of the tube are sealed with a moisture-proof metal cap. The invention realizes the dual functions of the ultra-high temperature two-way detonation tube with high detonation sensitivity and strong output capability, solves the problem of bidirectional, safe and reliable detonation transmission in the existing ultra-high temperature oil and gas well perforation; The success rate is high, saving construction cost and construction risk; at the same time, the present invention is convenient and safe in terms of production, transportation, storage and use.

Owner:WUHUA ENERGY TECH CO LTD

A rock powder civil emulsion explosive and its production process

ActiveCN103724143BIncrease energy densityReduce pollutionExplosive working-up apparatusNon-explosive/non-thermic compositionsToxic gasExplosive Agents

The invention discloses a rock powder emulsion explosive for civilian use, which is made of the following raw materials in parts by weight: ammonium nitrate: 74-83%, calcium nitrate: 3.5-4%, oil phase: 3.2-3.5%, and composite emulsifier: 3-3.5%, urea: 2%, composite flame suppressant: 5-8%, porous granular ammonium nitrate: 0.5-3%, titanium hydride: 1-2%, mixed rare earth: 0.3%; the production process of the emulsion explosive In order to prepare water phase, oil phase, emulsification, add components to the emulsification matrix, negative pressure drying to make powder, add components to the powder and mix, and then make rock powder emulsion explosive. The composition and production process of the emulsion explosive of the invention can improve the detonation performance of the emulsion explosive, reduce the content of toxic gas, and produce a high-performance, safe rock powder emulsion explosive with little pollution.

Owner:宜兴市阳生化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com