An ultra-high temperature two-way detonator tube for oil and gas wells

An ultra-high temperature, detonation tube technology, applied in wellbore/well components, production fluids, earthwork drilling, etc., to achieve high detonation reliability, high detonation sensitivity, and ensure the effect of bidirectional detonation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

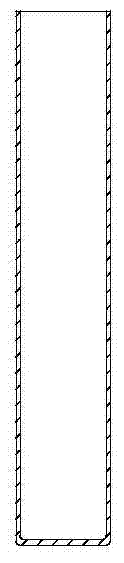

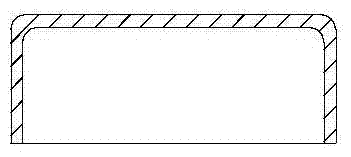

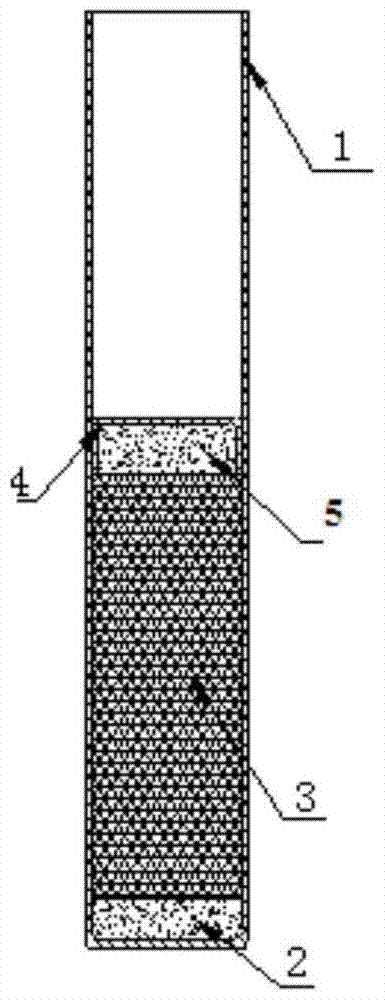

[0022] 1. see figure 1 — image 3 , a kind of ultra-high temperature two-way detonator tube for oil and gas wells provided by the invention, it is made up of four parts such as a metal tube 1 with one end open and one end closed, two types of high explosives and a metal cap 4. Two kinds of high explosives A and B are installed in the metal tube 1, and their distribution in the metal tube 1 is as follows: starting from the closed end of the metal tube 1, the first high explosive A, the high explosive B and the second high explosive A are arranged in sequence. . The first secondary explosive A and the second secondary explosive A are equally distributed on both ends of the secondary explosive B. The first high explosive A and the second high explosive A are high temperature resistant high explosives with high shock wave sensitivity, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com