Patents

Literature

277results about How to "Improve intrinsic safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

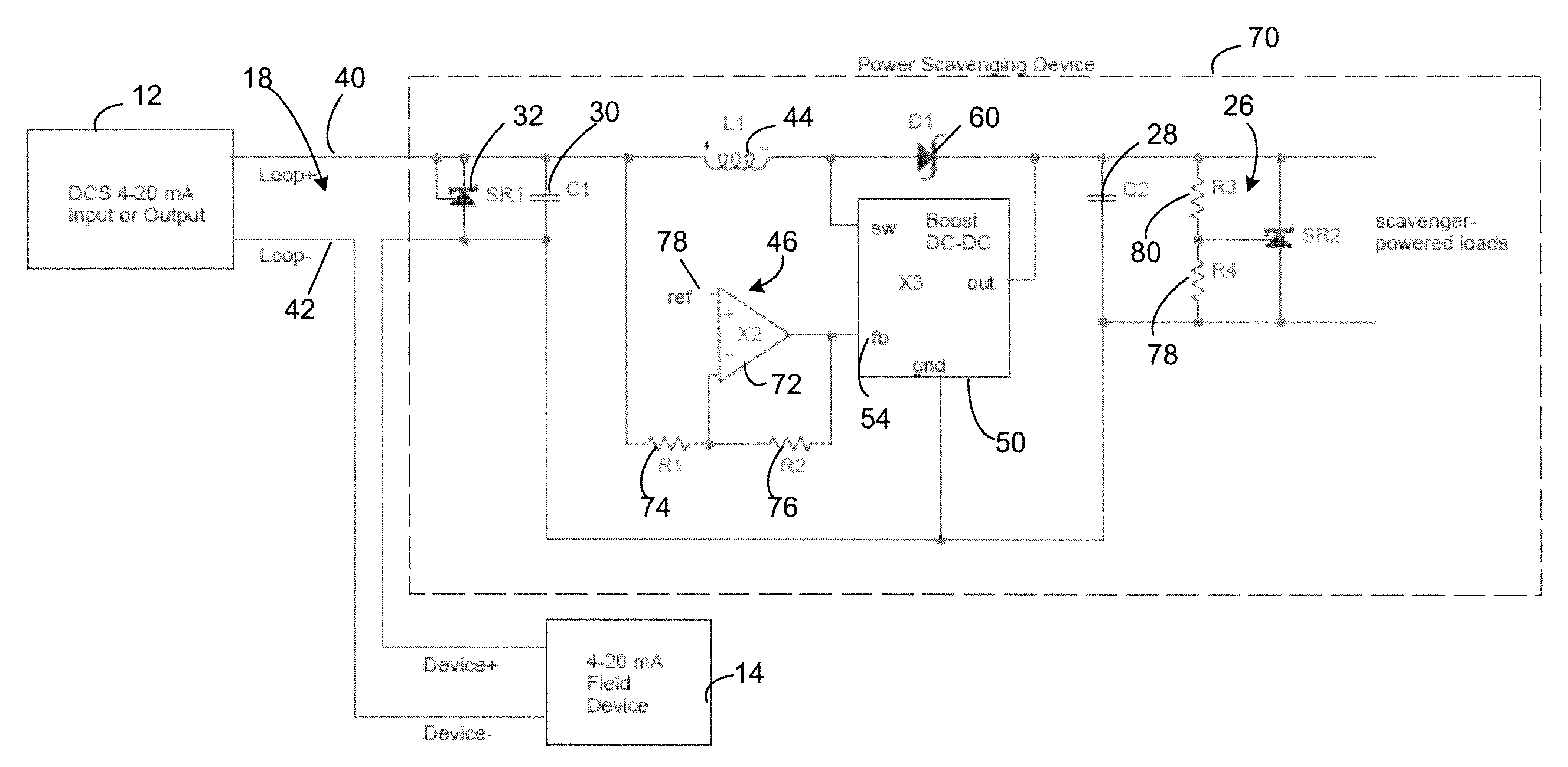

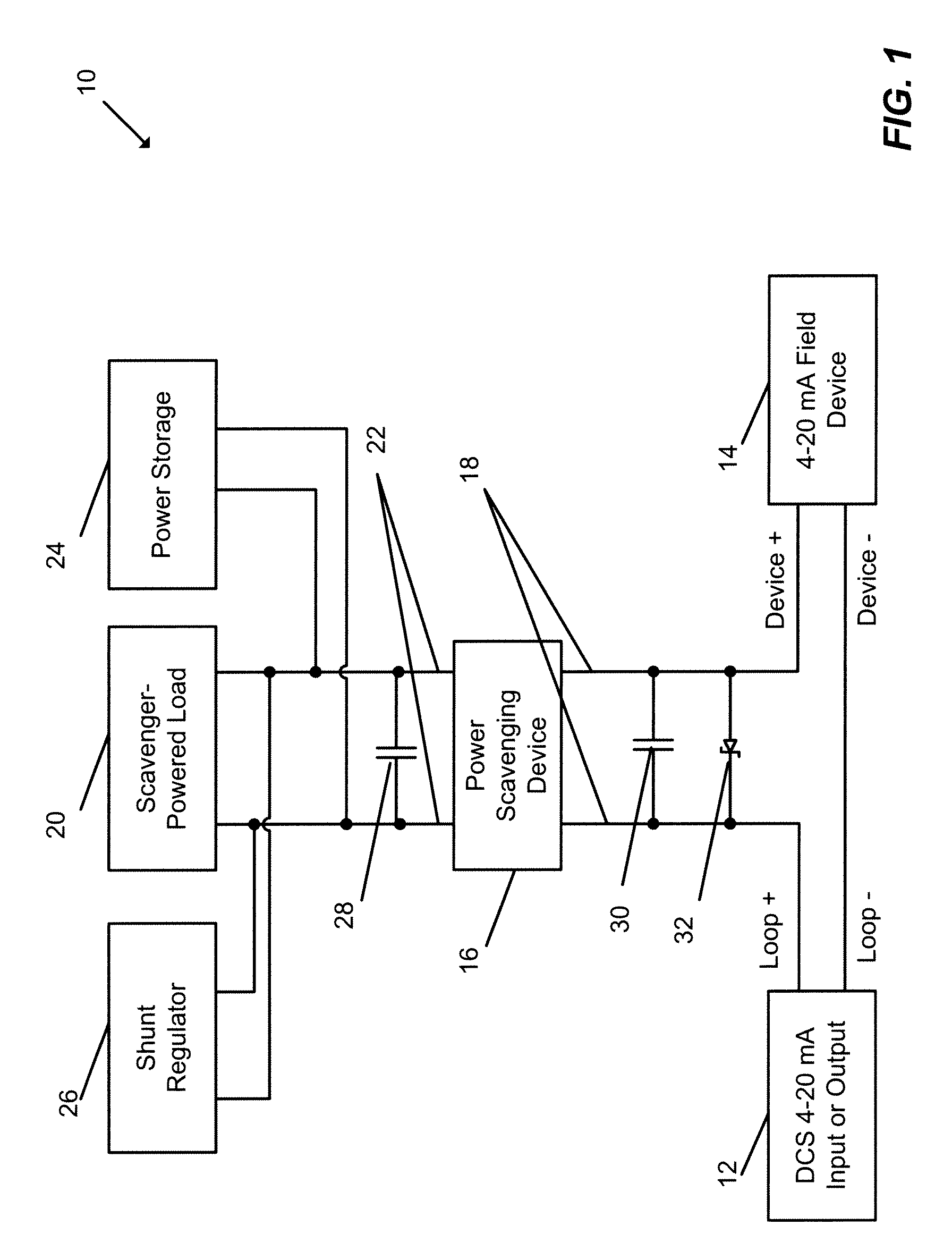

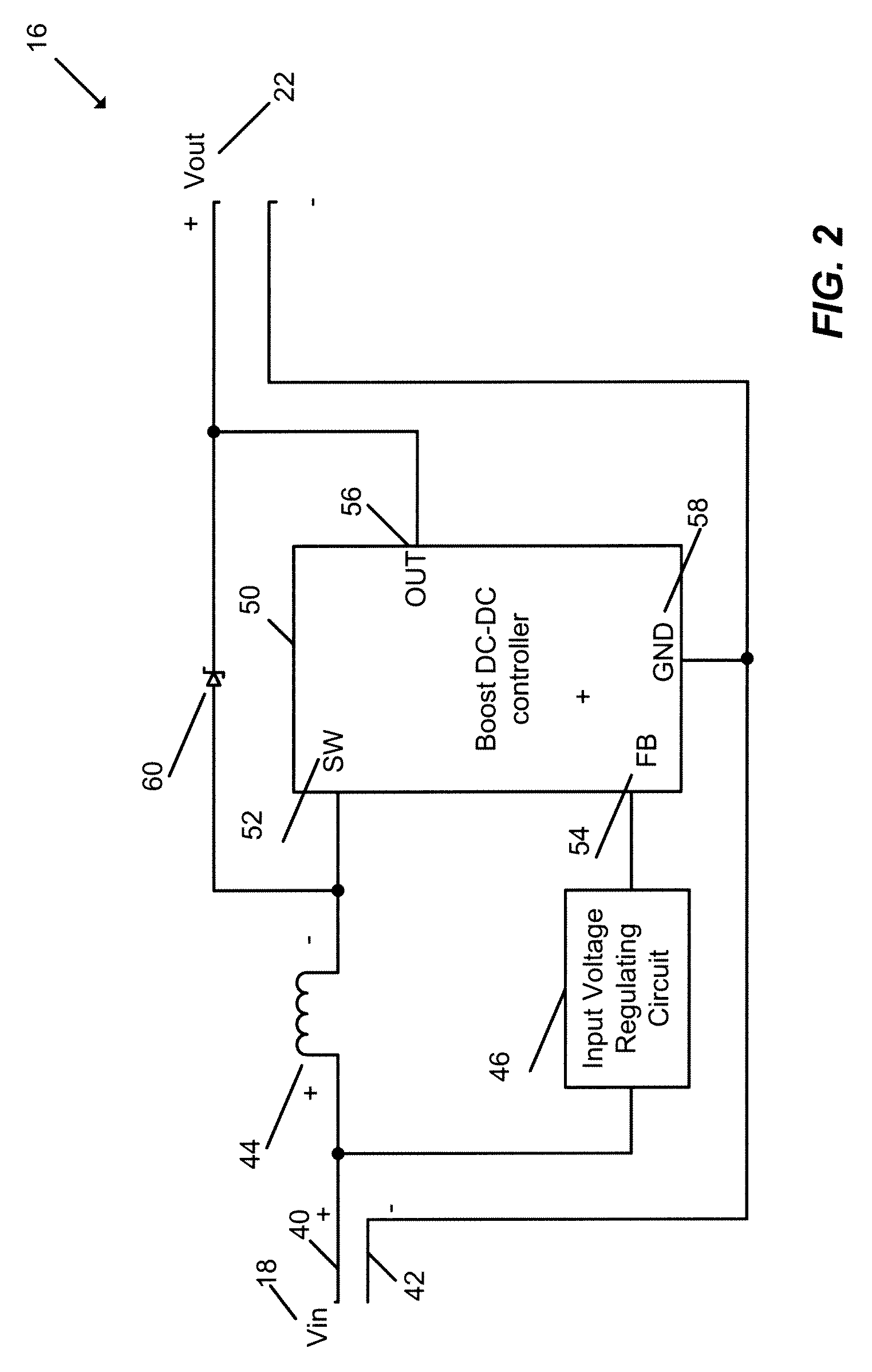

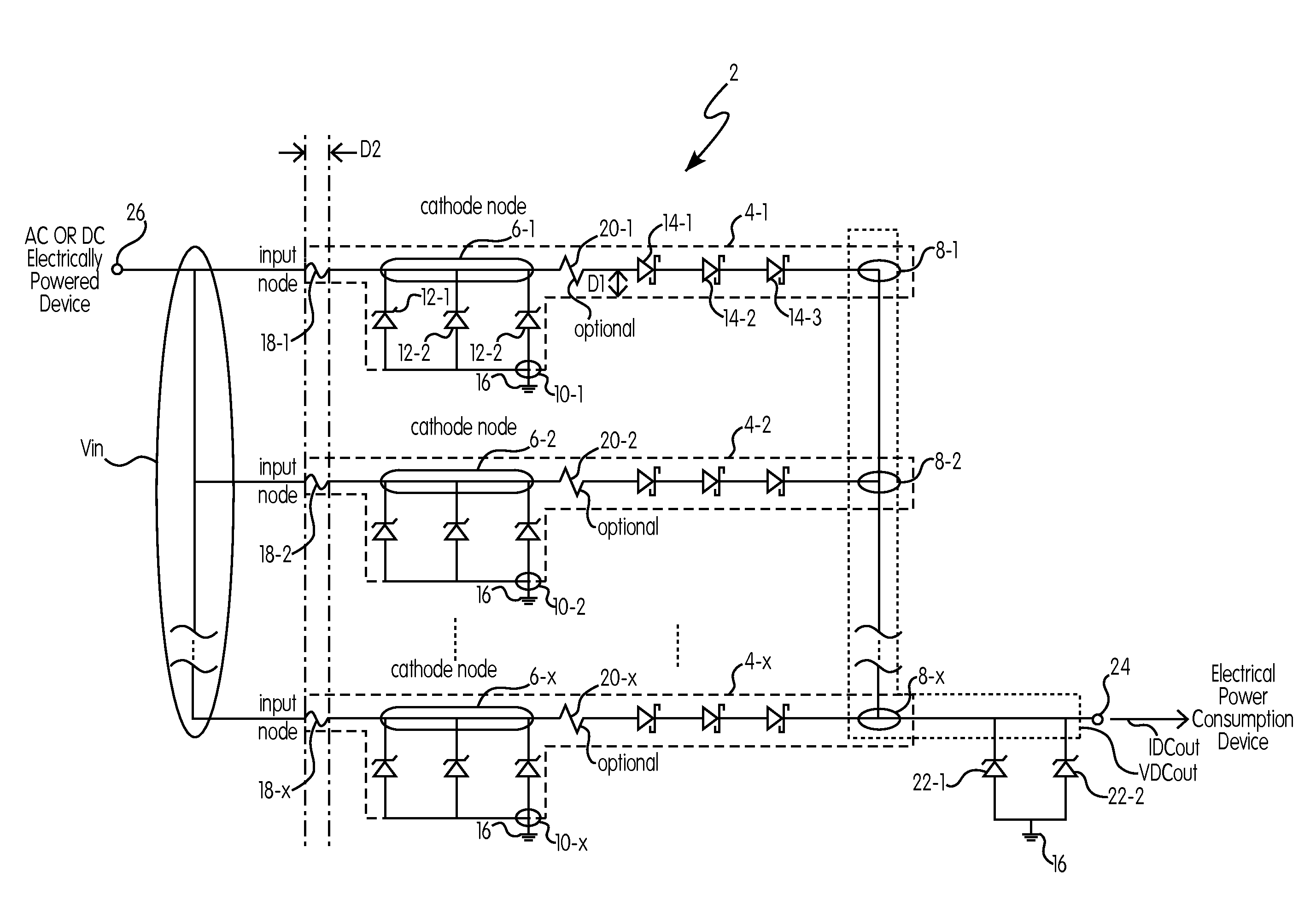

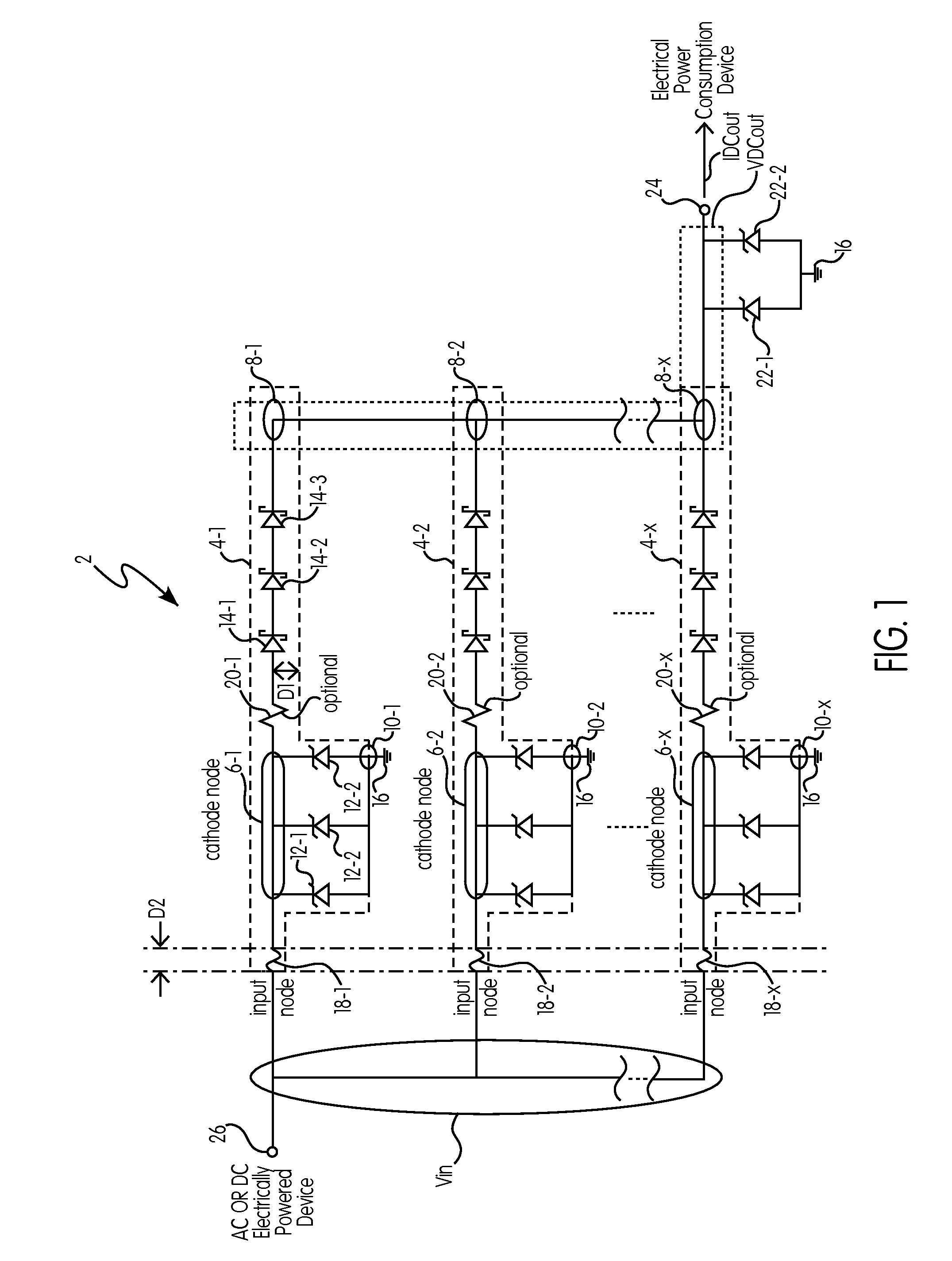

Input regulated DC to DC converter for power scavenging

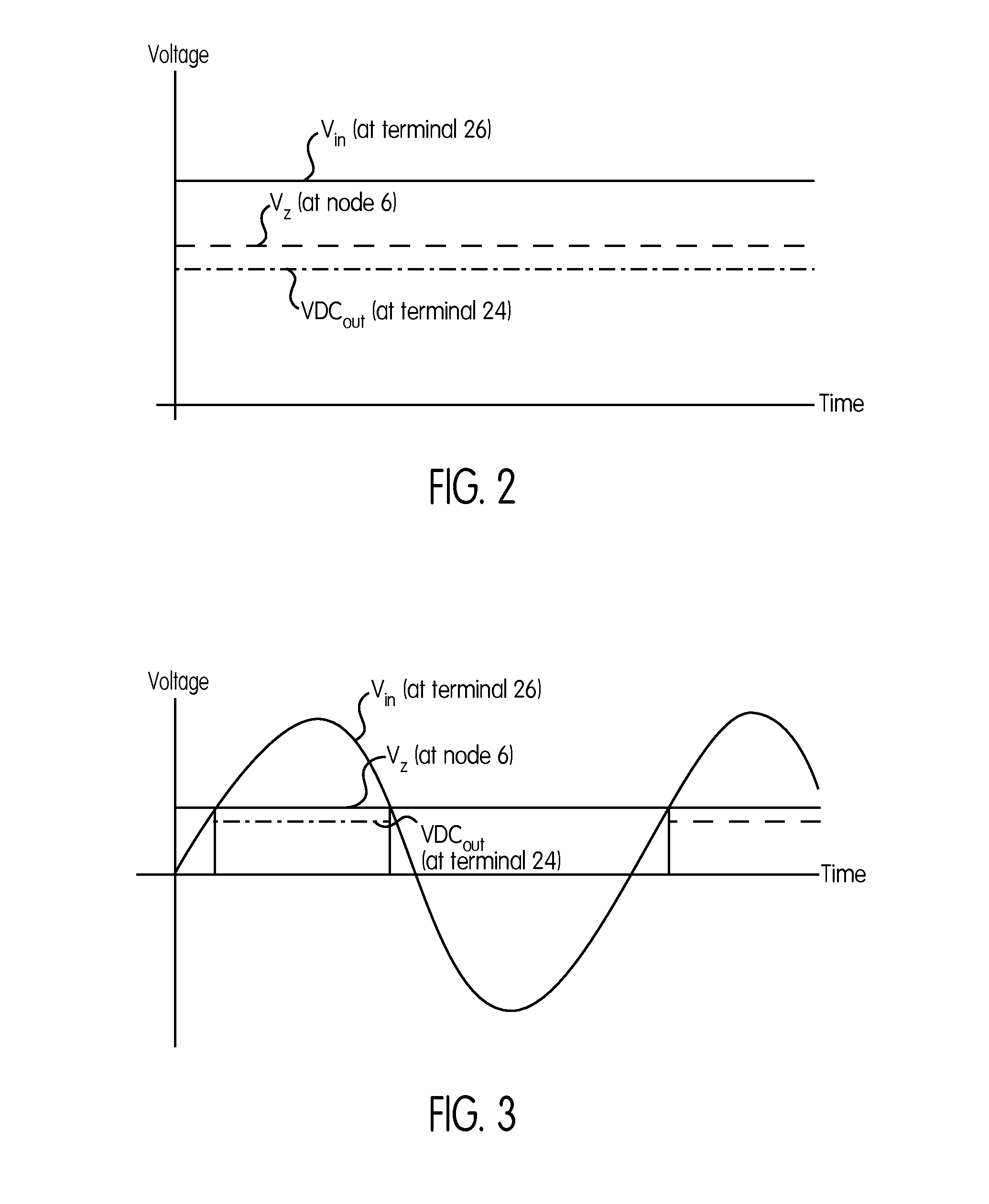

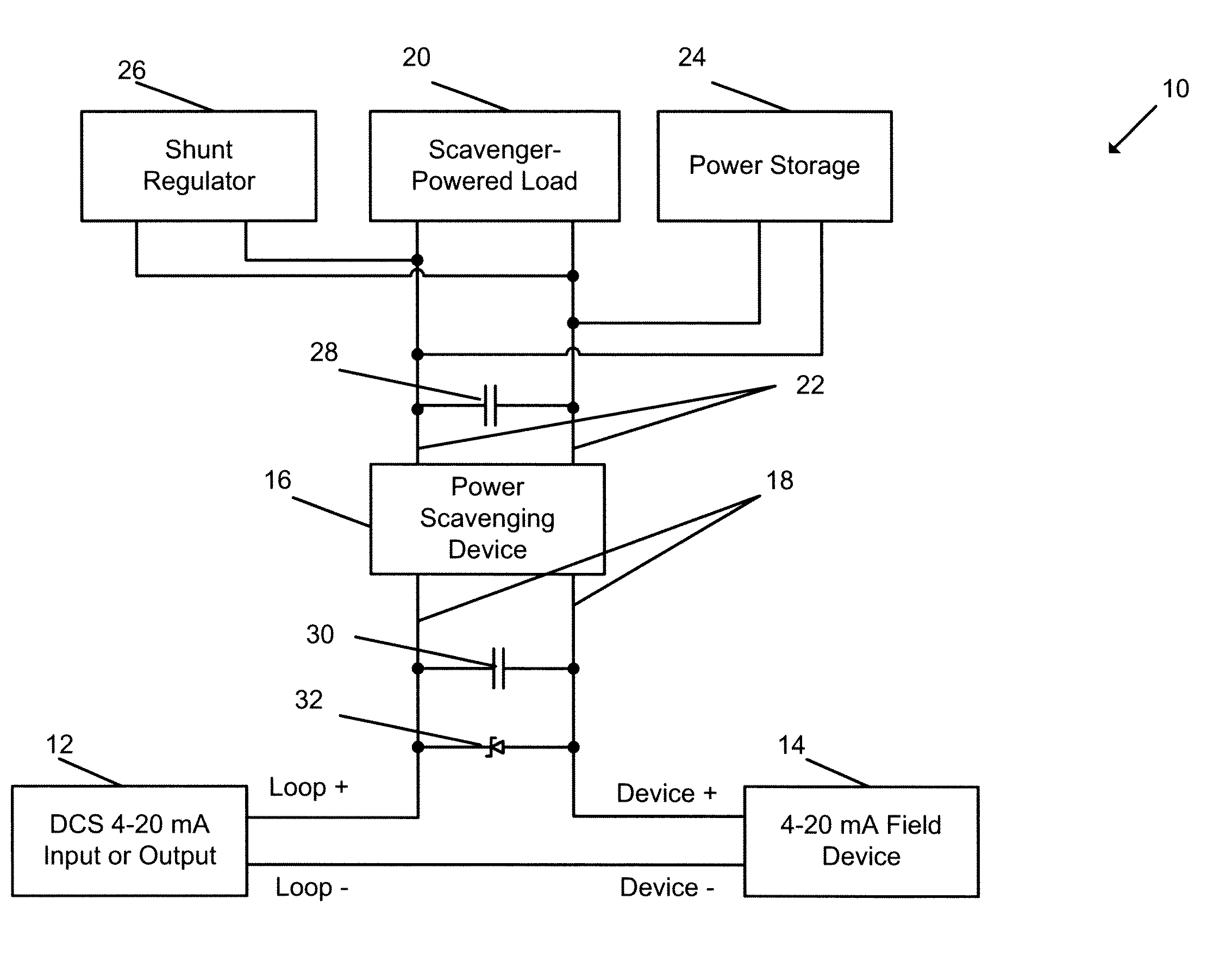

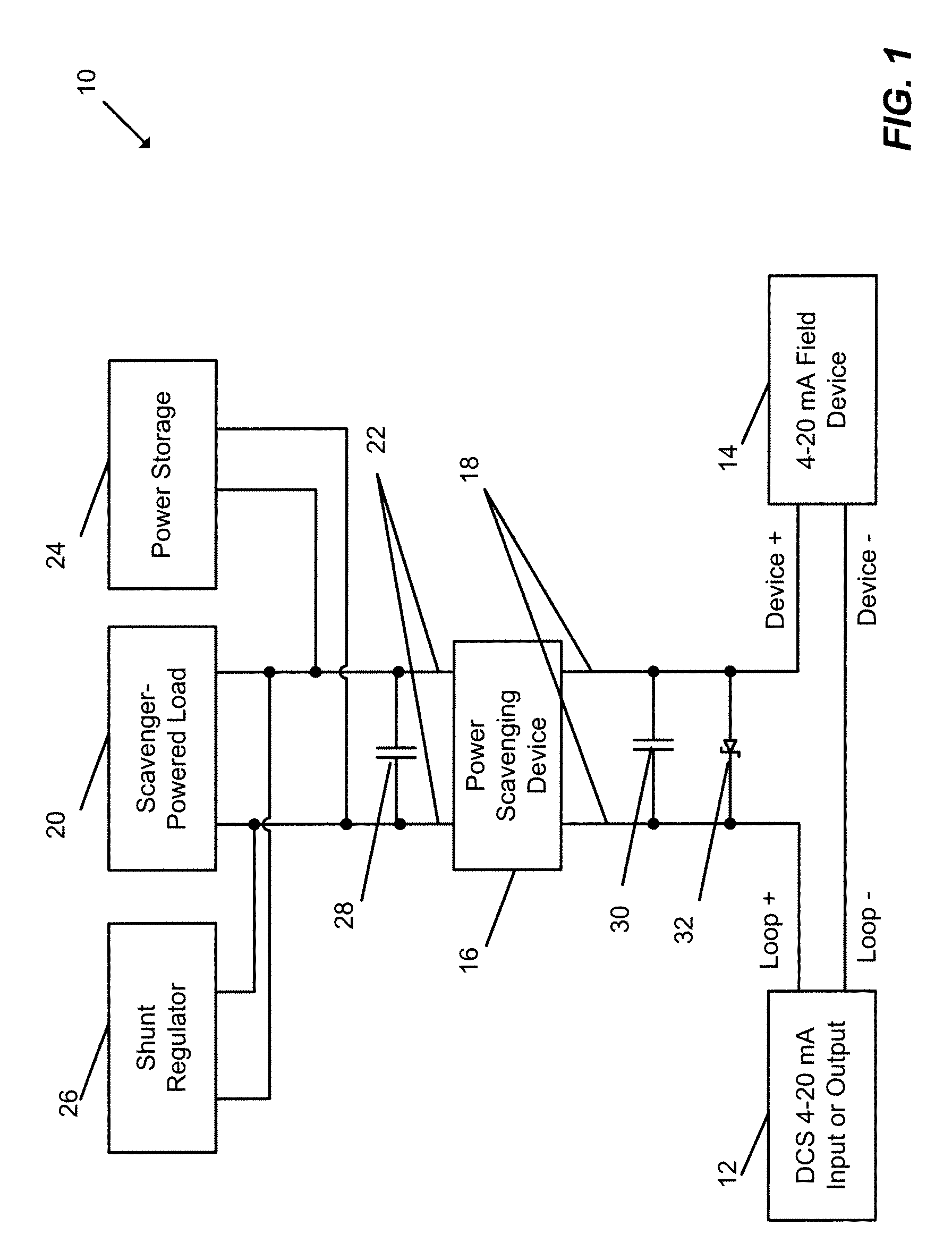

ActiveUS20090015216A1Improve intrinsic safetyImproving impedanceDc network circuit arrangementsBatteries circuit arrangementsVoltage dropEngineering

A method of scavenging power in a circuit having a power source generating electric current includes connecting a power scavenging device having an input terminal pair and an output terminal pair to the circuit via the input terminal pair, dynamically regulating a voltage drop across the input terminal pair of the power scavenging device, harvesting electrical energy available at the regulated voltage drop from the electric current flowing through the first input terminal pair of the power scavenging device, and providing the harvested electrical energy at the output terminal pair of the power scavenging device.

Owner:FISHER CONTROLS INT LLC

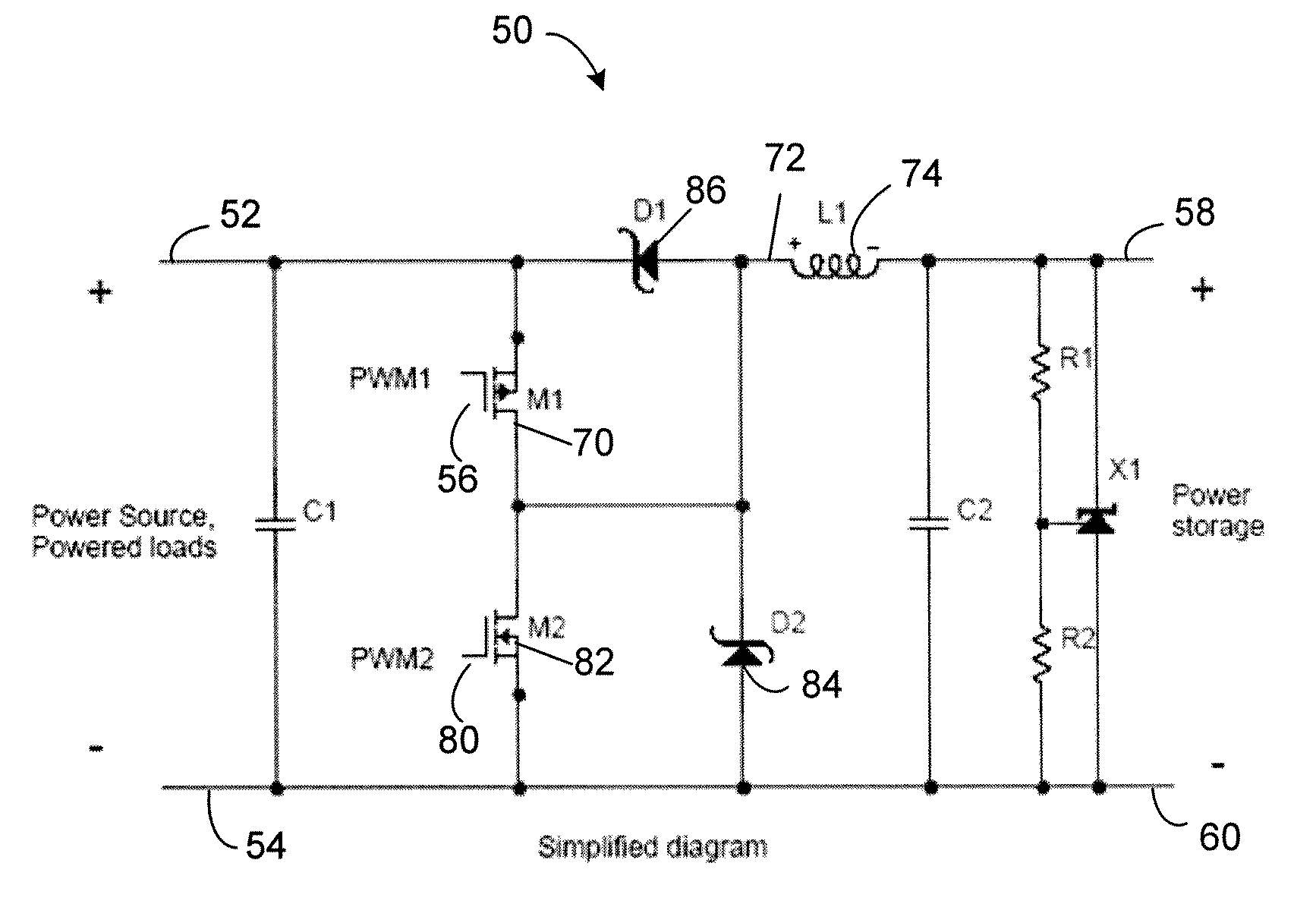

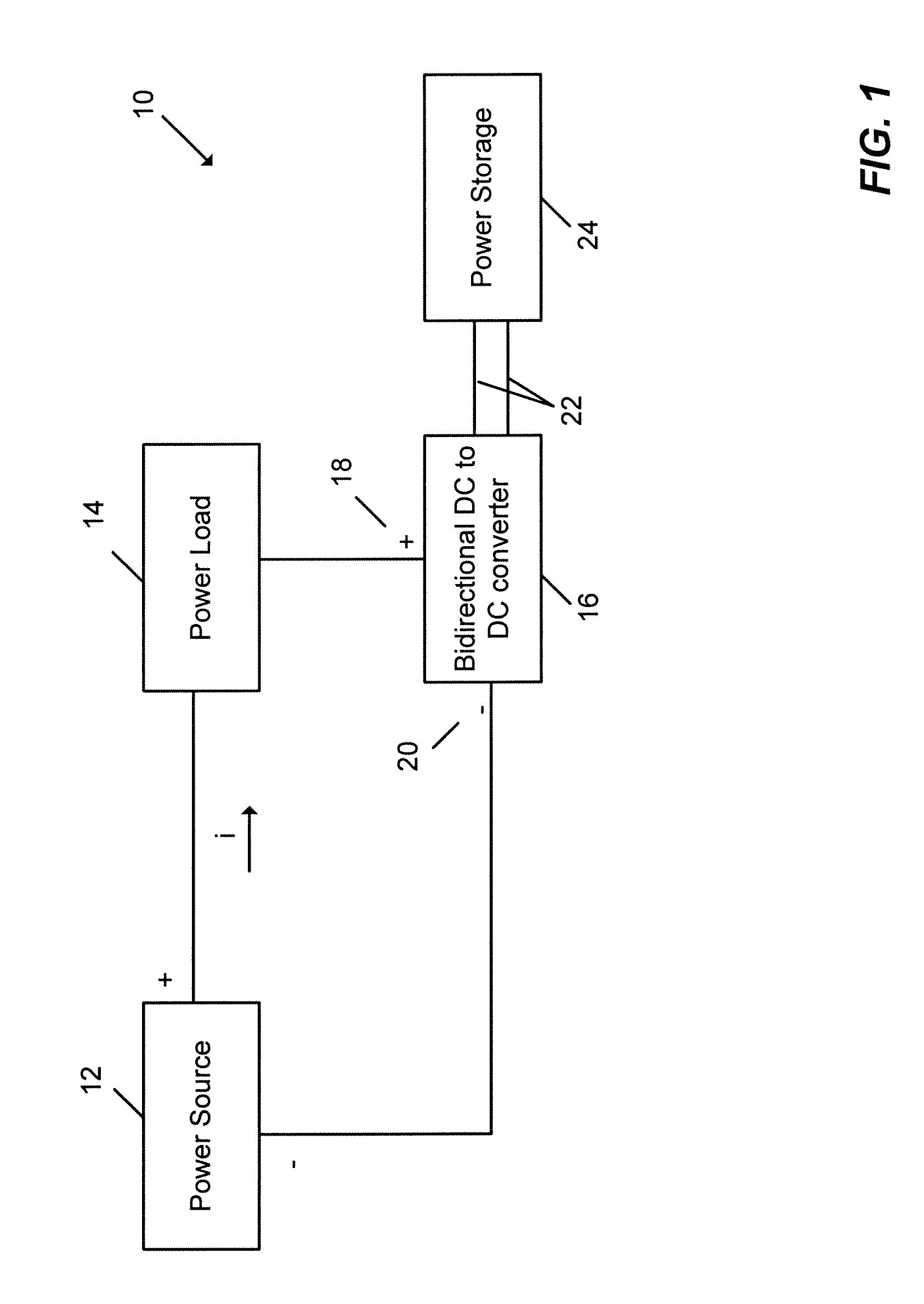

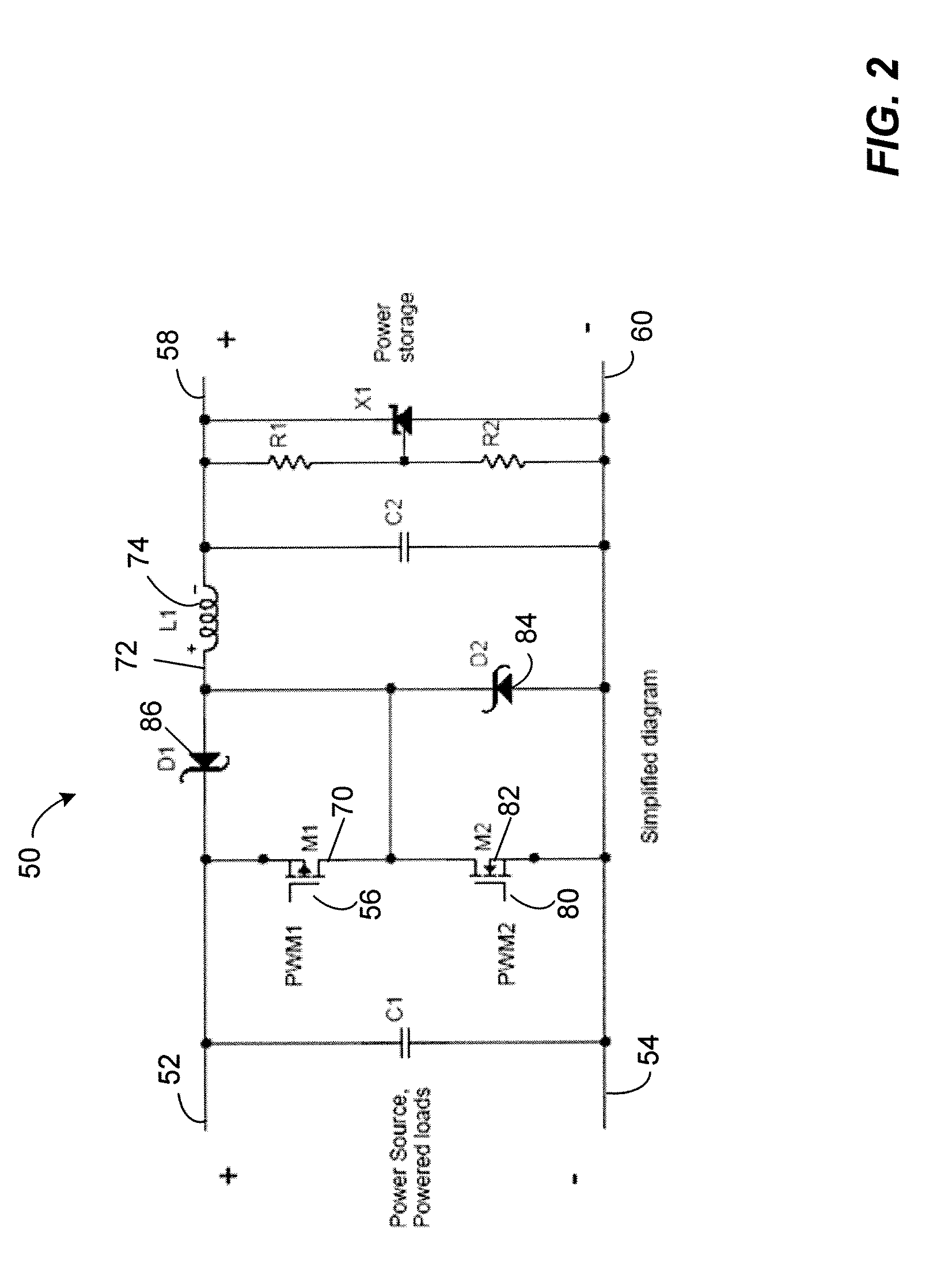

Bidirectional DC to DC Converter for Power Storage Control in a Power Scavenging Application

ActiveUS20080310195A1Improve circuit efficiencyMaximize useDc-dc conversionElectric variable regulationOperation modeElectric power

A bidirectional DC to DC converter having a first operational mode and a second operational mode includes a first terminal pair that has a positive terminal and a negative terminal and that connects the converter to a first electric circuit, a second terminal pair that has a positive terminal and a negative terminal and that connects the converter to a second electric circuit, an accumulation element for temporary accumulation of electric energy; and a switching circuit connected to the first terminal pair, the second terminal pair, and the accumulation element. Electric energy is transferred from the first electric circuit to the second electric circuit via the accumulation element in the first operational mode of the bidirectional DC to DC converter and, from the second electric circuit to the first electric circuit via the accumulation element in the second operational mode of the DC to DC converter.

Owner:FISHER CONTROLS INT LLC

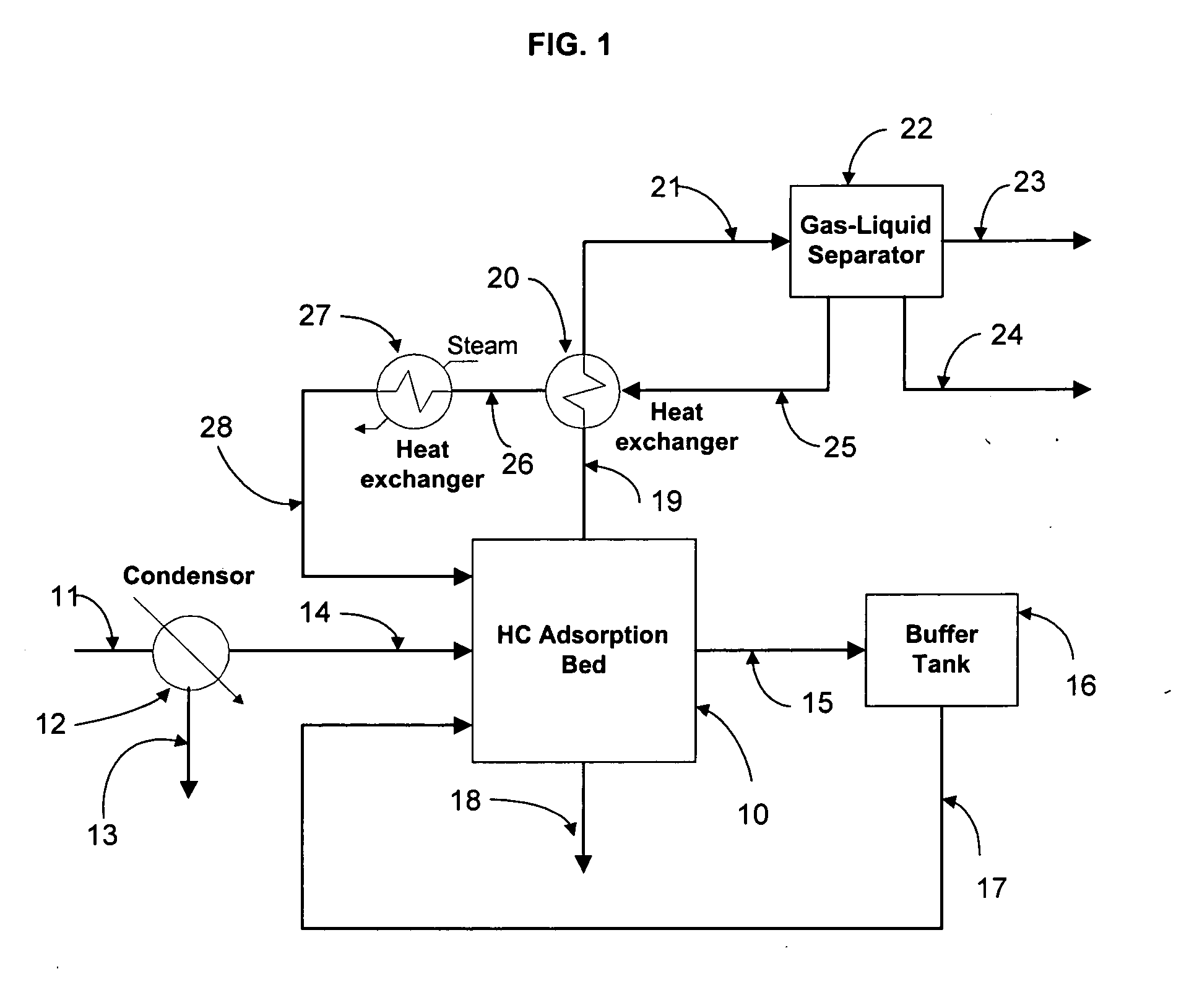

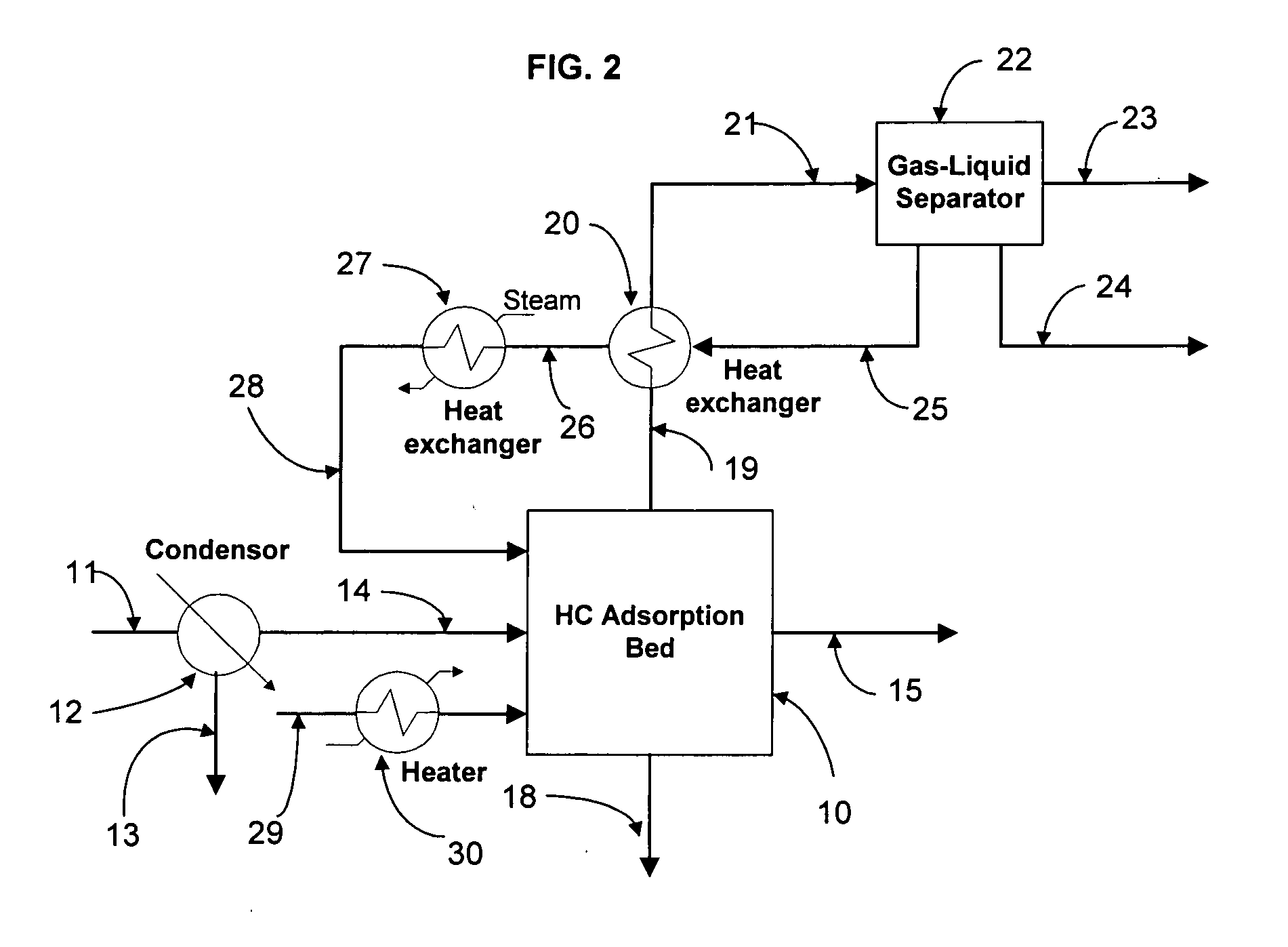

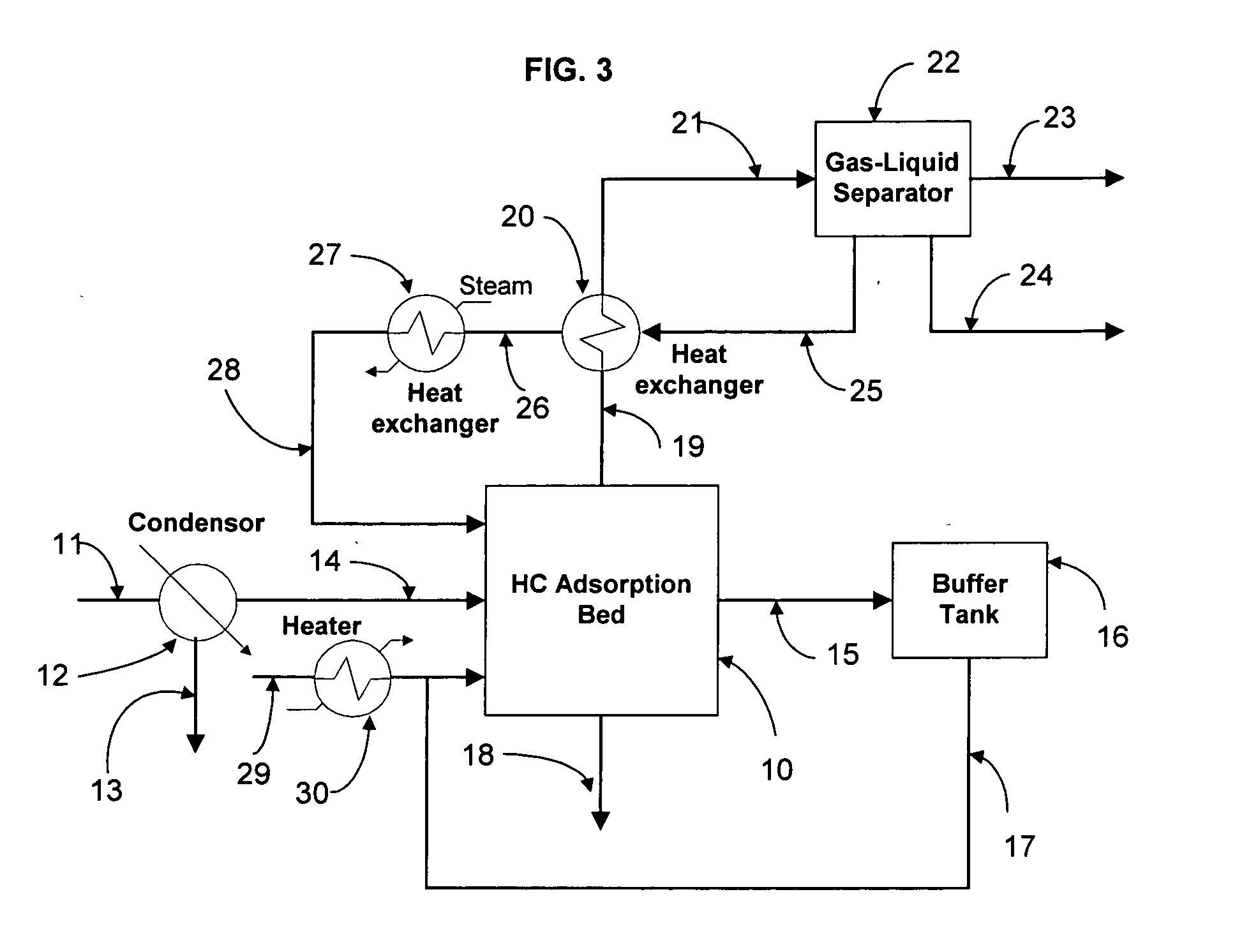

Hydrocarbon separation process

InactiveUS20050203327A1Lowering capitalReduce operating expensesMemory architecture accessing/allocationGas treatmentAlkaneSorbent

The present invention provides for a process of separating hydrocarbons such as short chain paraffins and olefins from non-hydrocarbon gases using short-cycle time concentration swing adsorption processes. The hydrocarbons are adsorbed from the gaseous stream on highly siliceous nanoporous materials, e.g., such as of aluminum-deficient faujasite-type zeolites, by way of a pressure, vacuum or temperature swing adsorption, then desorbed from the adsorbent in the presence of steam. Optionally, the steam is desorbed from the adsorbent through the use of air or inert gas or a recycle of the waste gas effluent. The invention also provides for a new method of preparing novel shapes such as beads and monolithic structures of the highly sileceous nanoporous materials.

Owner:BOC GRP INC

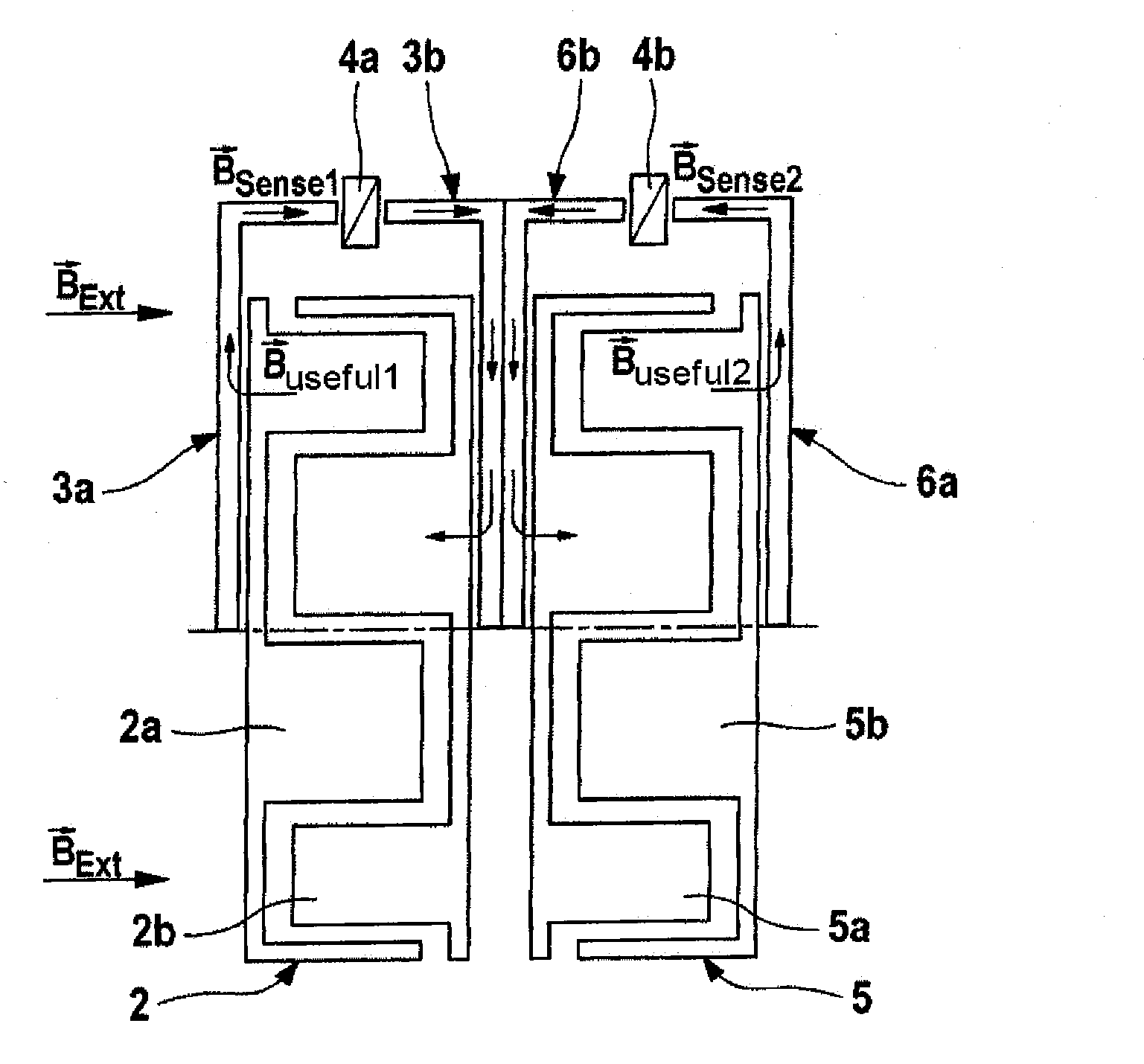

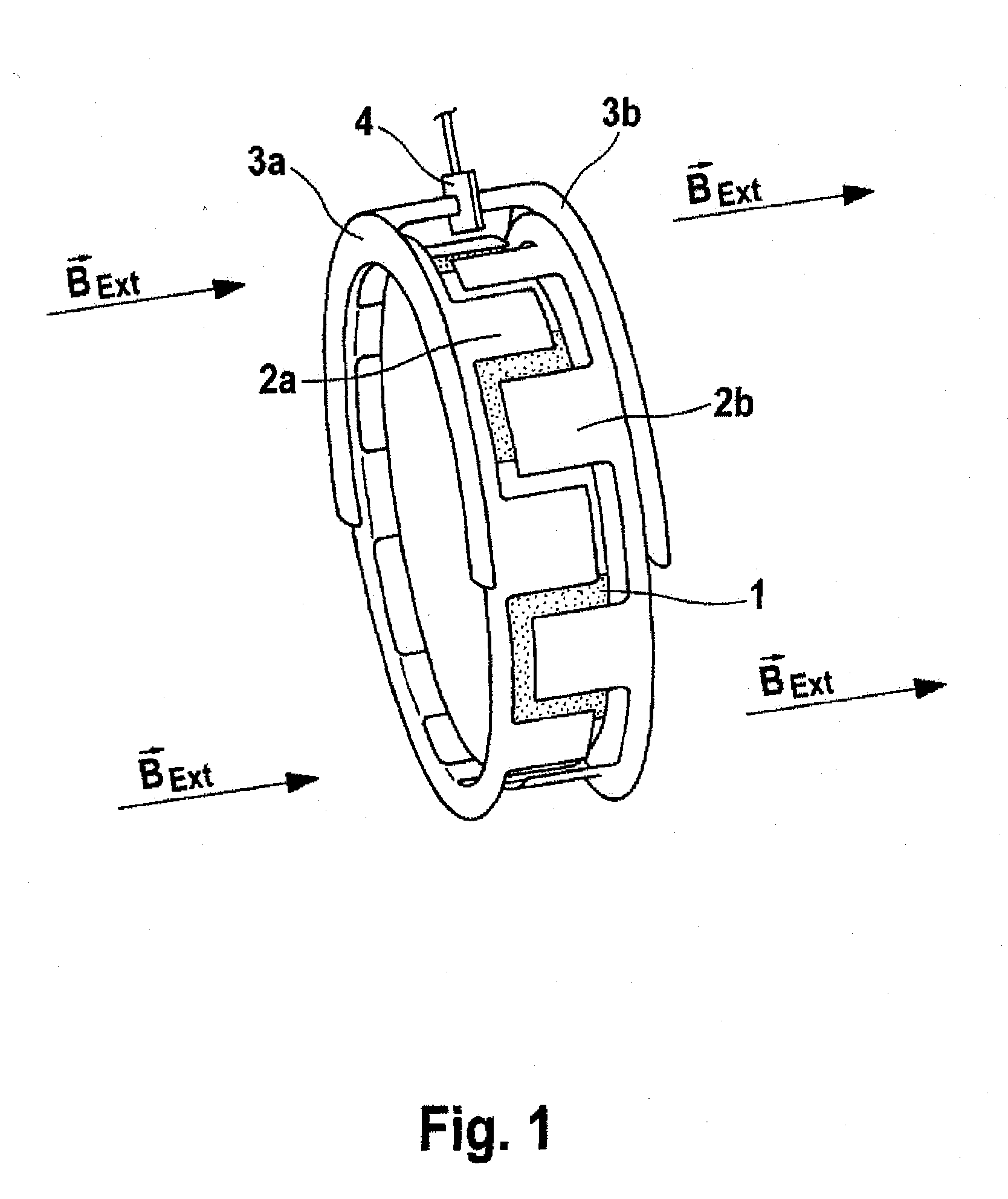

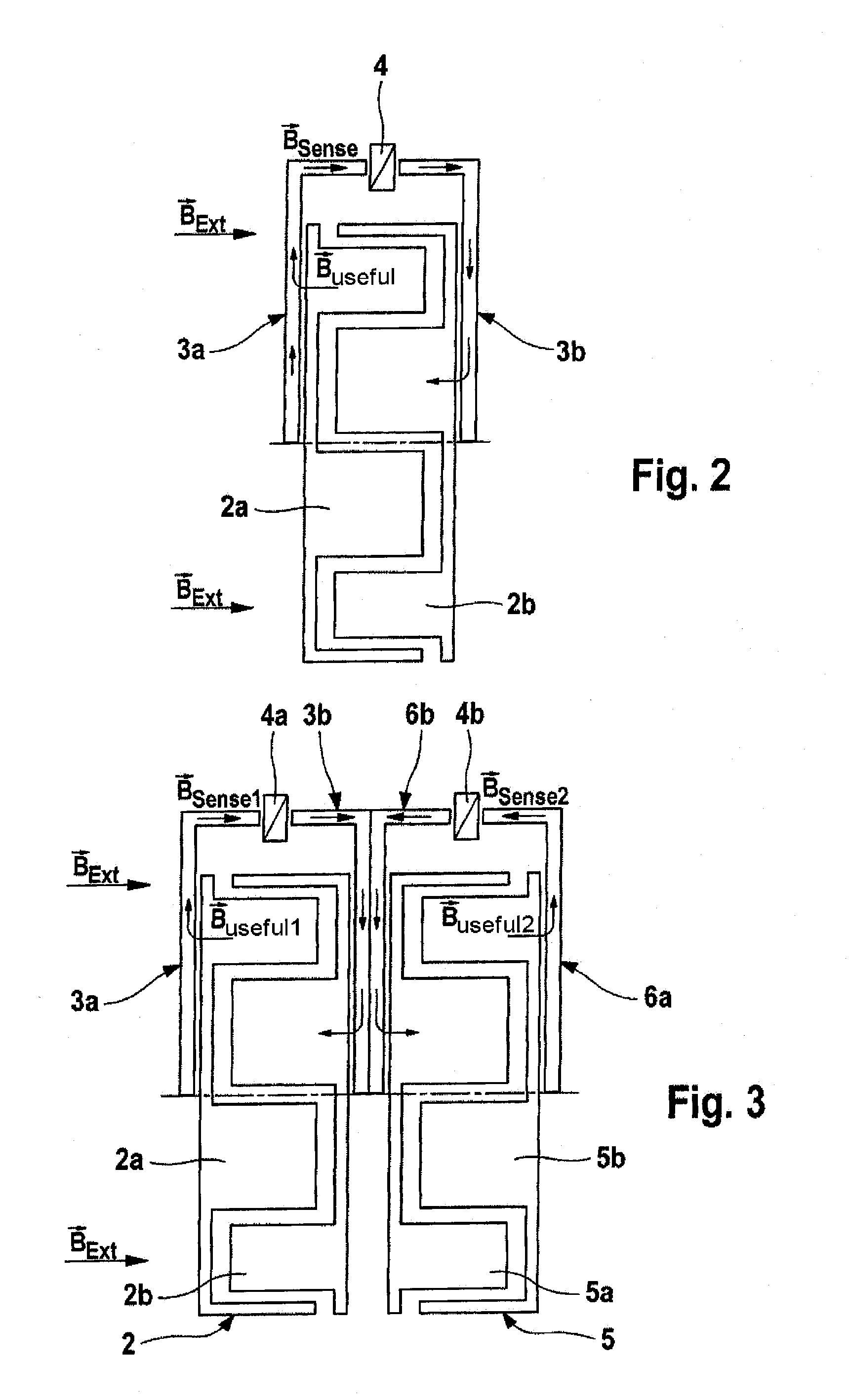

Torque sensor with reduced susceptibility to failure

InactiveUS20100005909A1Less susceptibleImprove reliabilityWork measurementTorque measurementEngineeringReduced susceptibility

A sensor arrangement with relatively low disturbance susceptibility for measurement of a torque acting on a shaft, wherein the shaft has a first shaft section and a second shaft section and these two shaft sections can rotate with respect to one another, having at least one magnetic encoder which is arranged on the first shaft section, and having a stator which is arranged on the second shaft section, wherein the stator has two stator elements which each have projecting fingers, wherein at least one additional, second stator, likewise having two stator elements which each have projecting fingers, is arranged on the second shaft section, and these stators are associated with the magnetic encoder.

Owner:CONTINENTAL TEVES AG & CO OHG

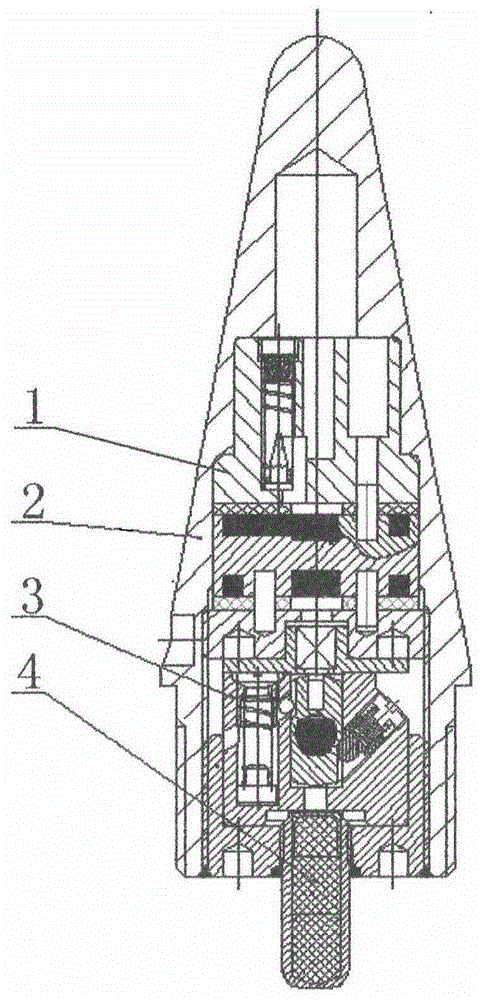

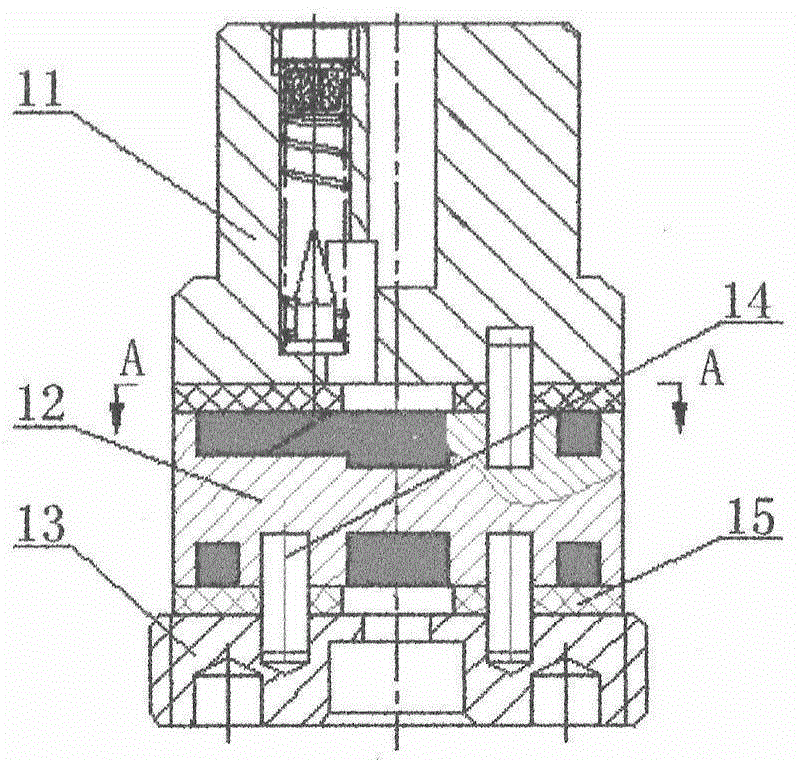

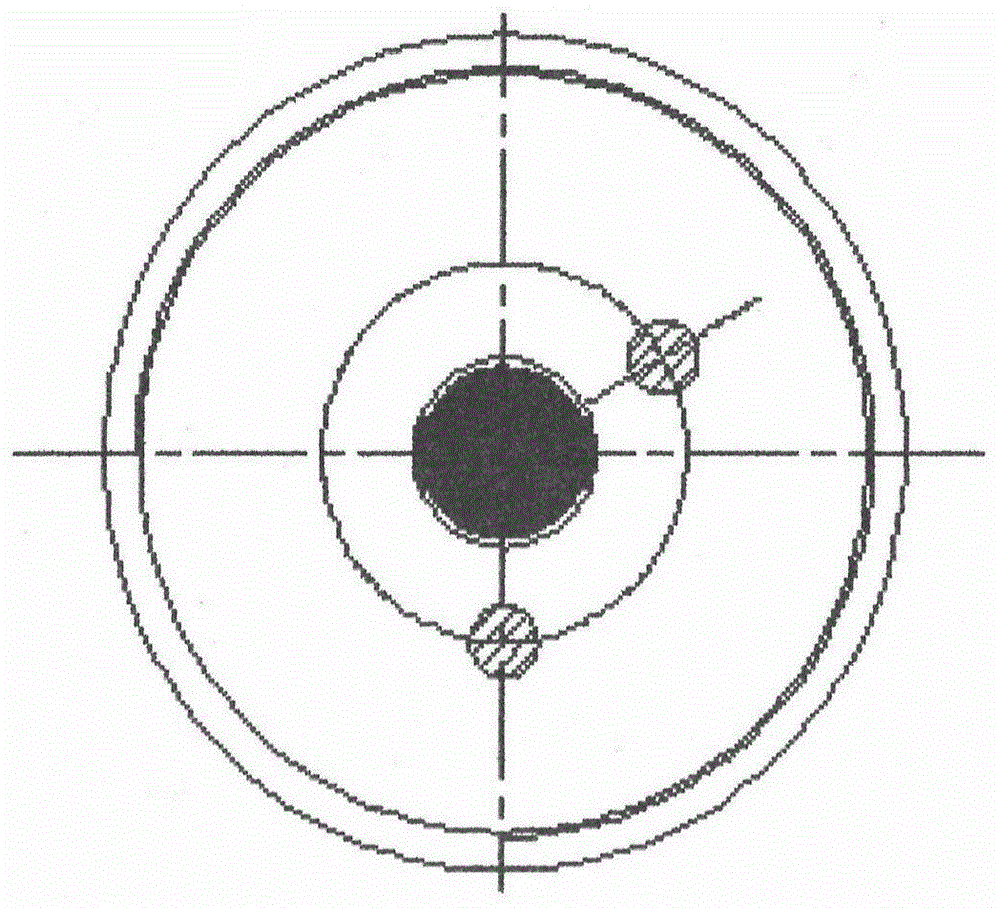

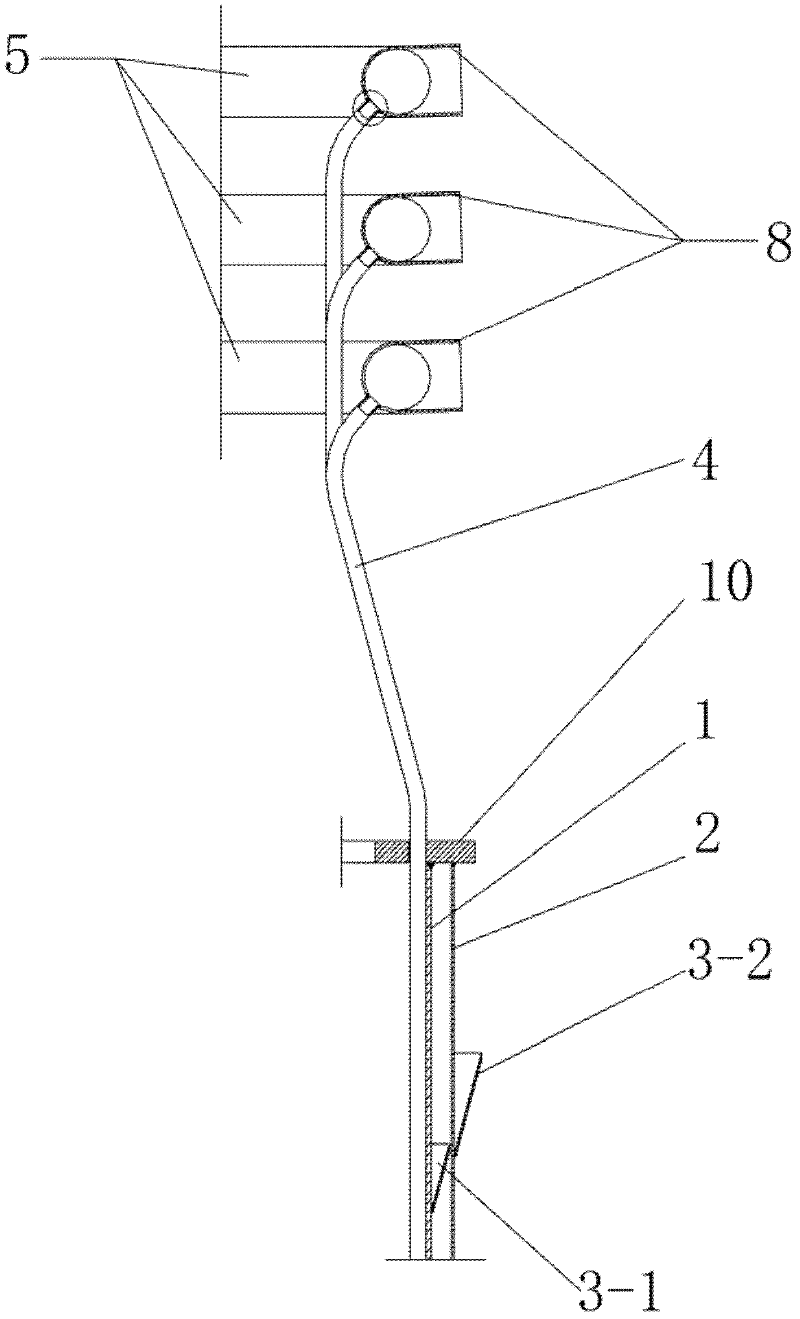

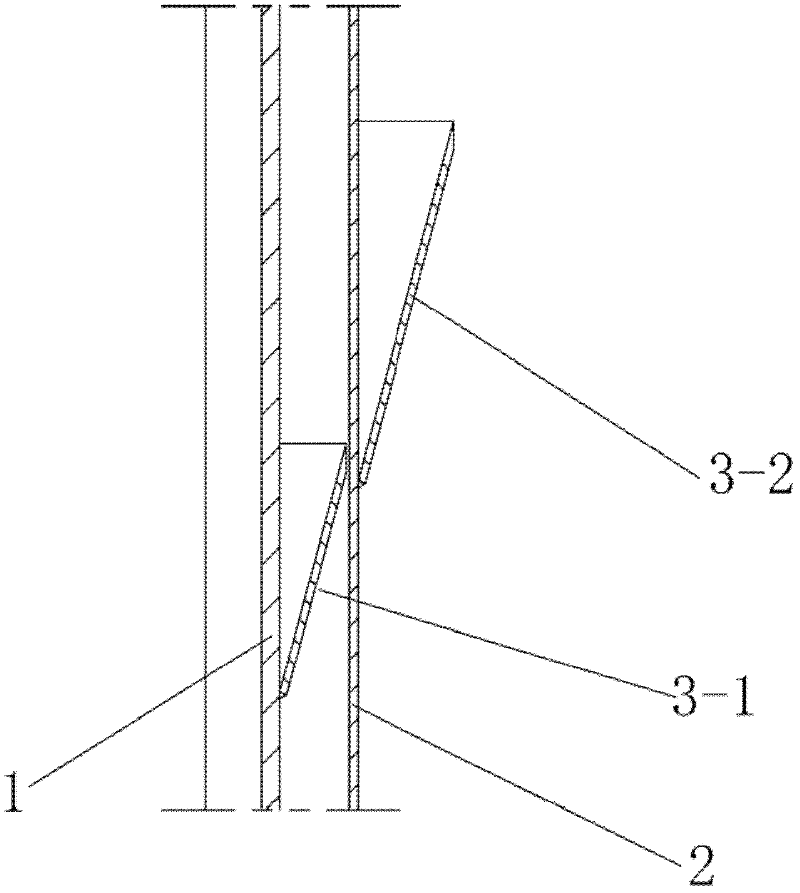

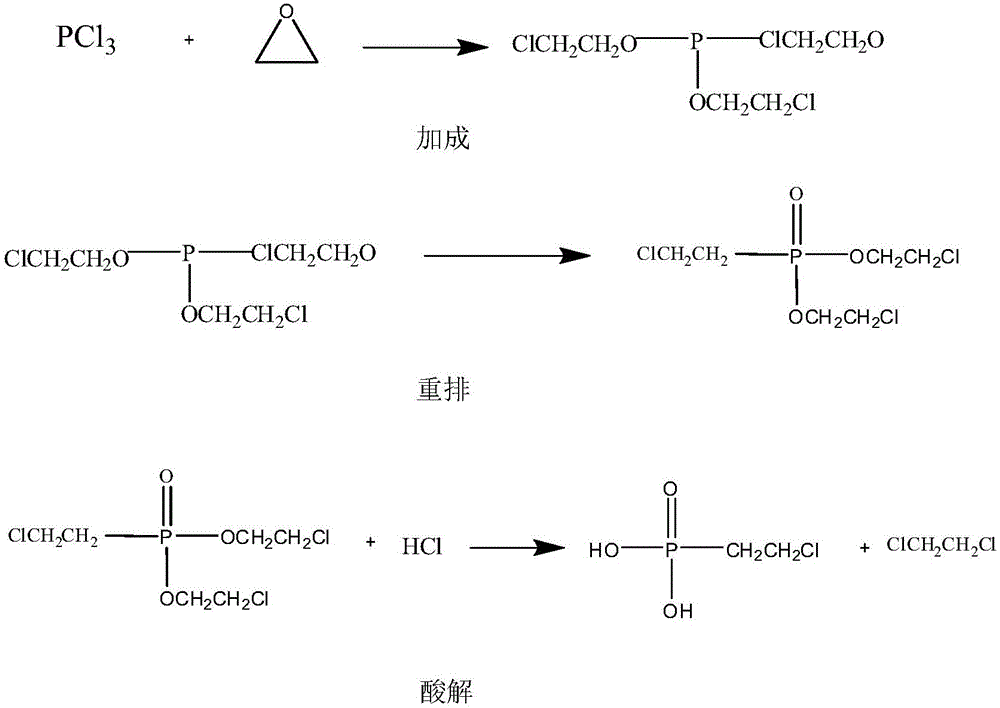

Fuze device for artificial precipitation projectile

InactiveCN105890473AImprove the reliability of fire transmissionImprove intrinsic safetyAmmunition fuzesDetonatorEngineering

The invention discloses a fuze device for an artificial precipitation projectile. The fuze device comprises a fuze body, an ignition self-destructive mechanism, a safety mechanism and a detonator, wherein the middle of the fuze body is a cavity structure; and in the cavity structure, the ignition self-destructive mechanism is arranged at the upper part of the cavity structure, the safety mechanism is arranged at the lower part of the ignition self-destructive mechanism, and the detonator is inserted into the lower part of the safety mechanism. The ignition self-destructive mechanism produces flames after being ignited, the flames are transmitted into the detonator under the control of the safety mechanism, a gunpowder charging projectile body of the artificial precipitation projectile is arranged at the lower part of the detonator, the flames enter the gunpowder charging projectile body via the detonator, and gunpowder in the gunpowder charging projectile body is detonated so as to produce thrust to launch the artificial precipitation projectile. The fuze device eliminates the potential safety risk that the chamber of the existing artificial hail preventing and precipitation increasing projectile explodes, solves the potential safety problems of the existing artificial precipitation increasing and hail preventing projectile, such as dud, half explosion and large explosion remnant fragments, and has high safety and high reliability.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

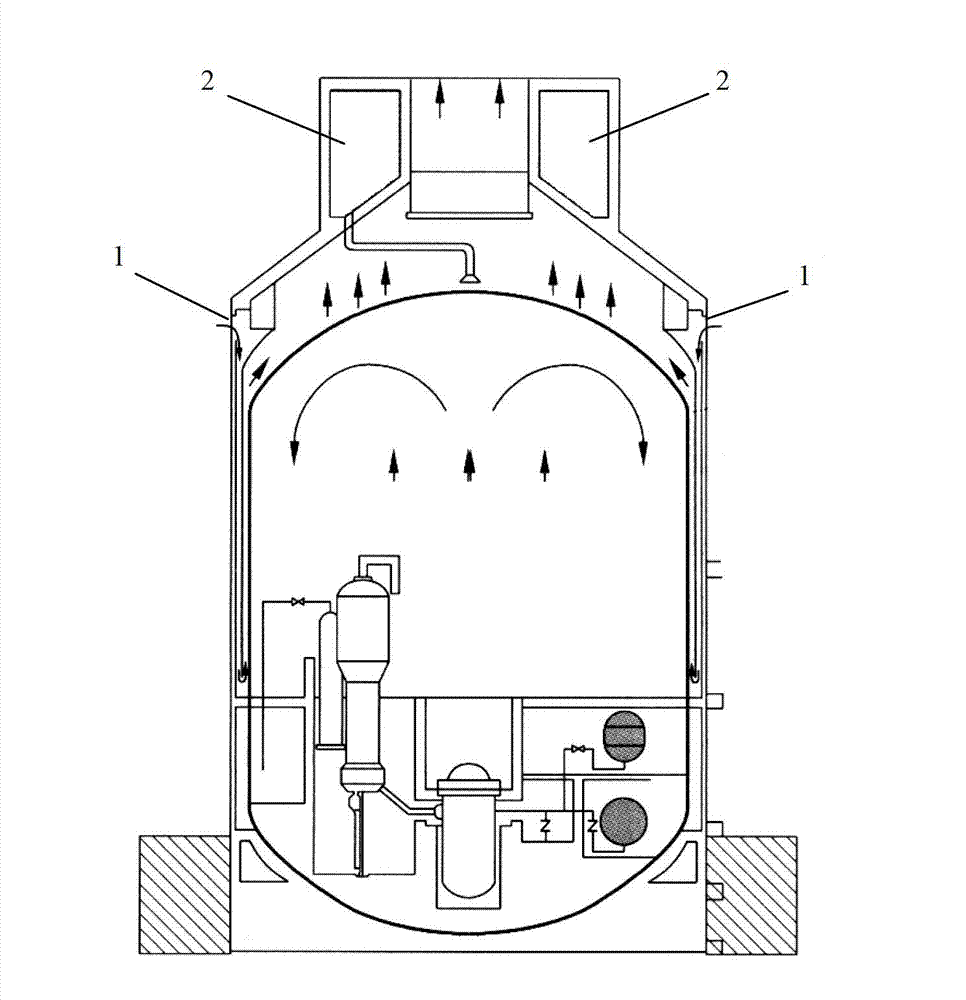

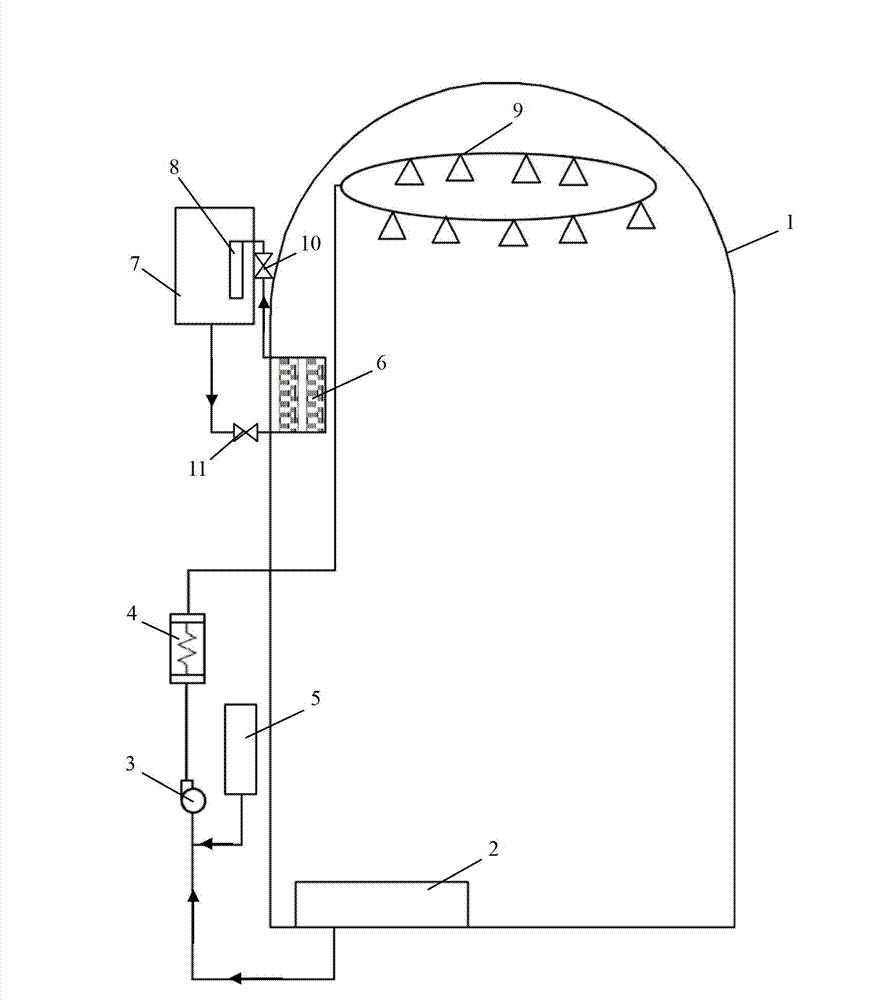

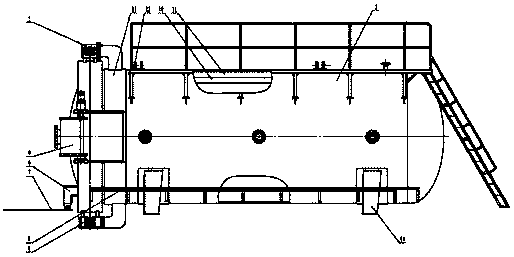

Active and passive combined heat removal device for containment

InactiveCN102881342AIntegrity guaranteedImprove securityNuclear energy generationCooling arrangementIntrinsic safetyReactor design

The invention belongs to the reactor design technology, and particularly relates to an active and passive combined heat removal device for containment. The active and passive combined heat removal device structurally comprises a containment spraying system and a passive containment heat leading-out system; one end of a pipeline of the containment spraying system is connected with a refueling water tank, and the other end of the pipeline of the containment spraying system is connected to a spraying header on the top of the containment by a spraying pump and a heat exchanger; and the passive containment heat leading-out system comprises a heat exchanger or heat exchanger set, the heat exchanger or heat exchanger set is arranged in the containment and is connected with a heat exchange water tank by a riser pipeline or a downcomer pipeline, and the heat exchange water tank is arranged on the outer portion of the containment, and is higher than the heat exchanger or heat exchanger set. The active and passive combined heat removal device has the advantages that dependence of the traditional nuclear power plant with an active safety system on a safety power source is changed, and intrinsic safety of a heat removal system of the containment of a nuclear power plant is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

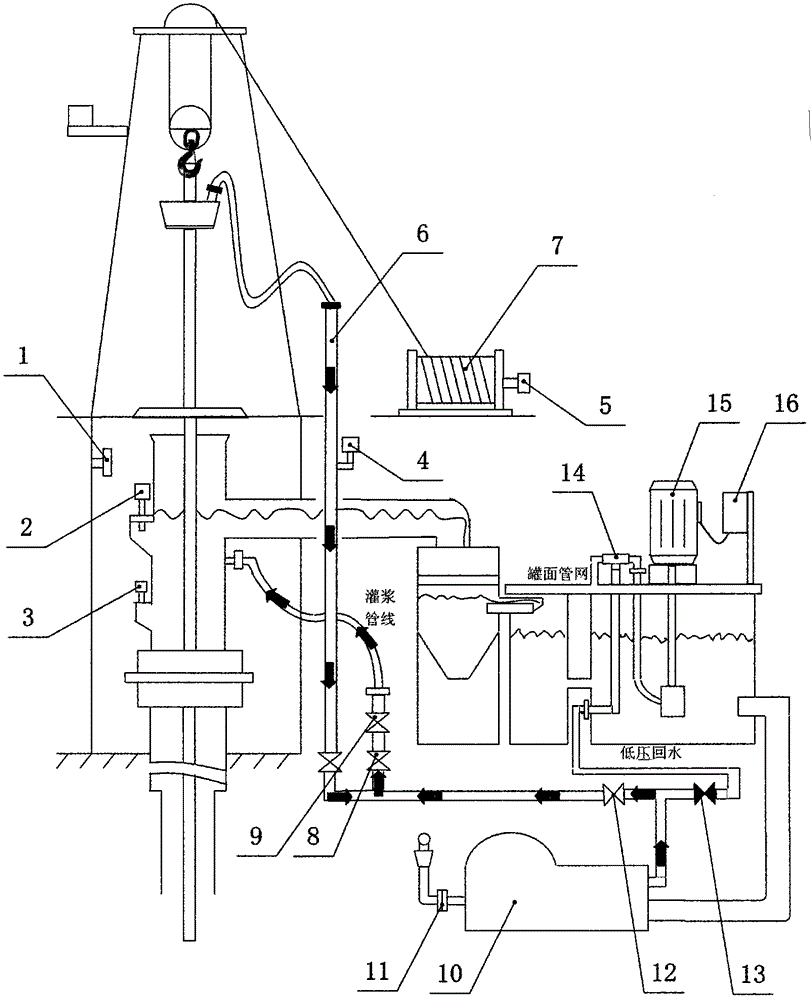

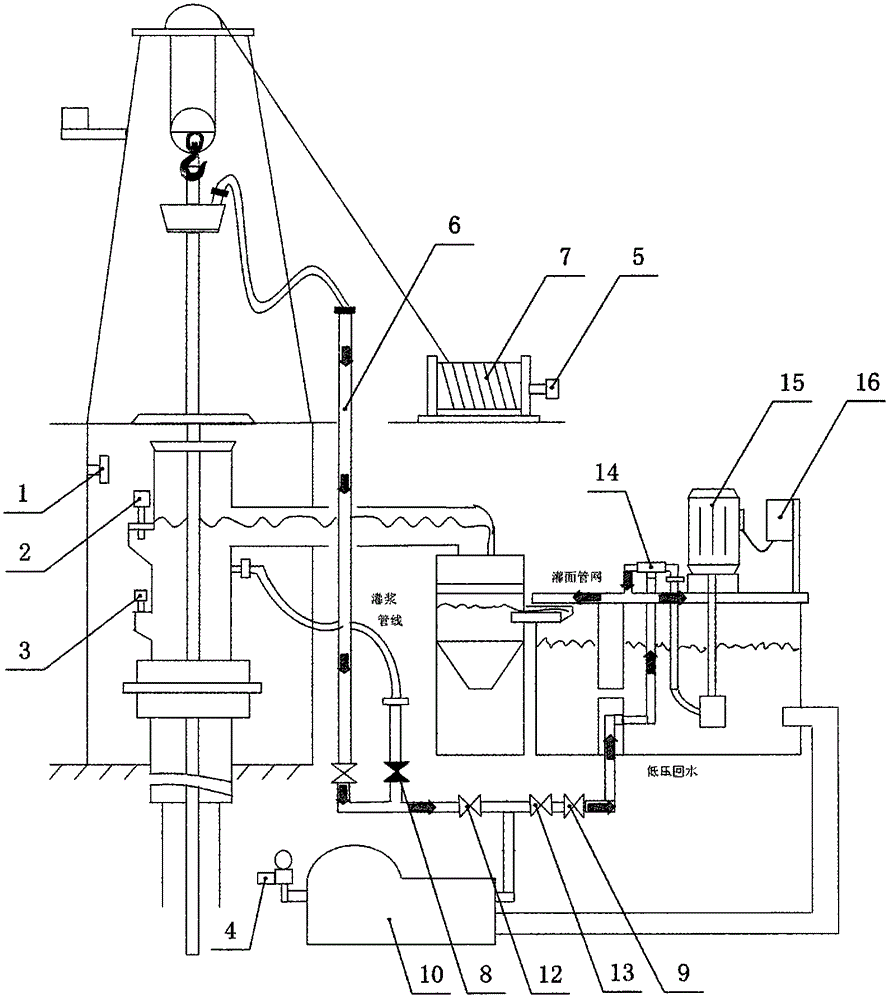

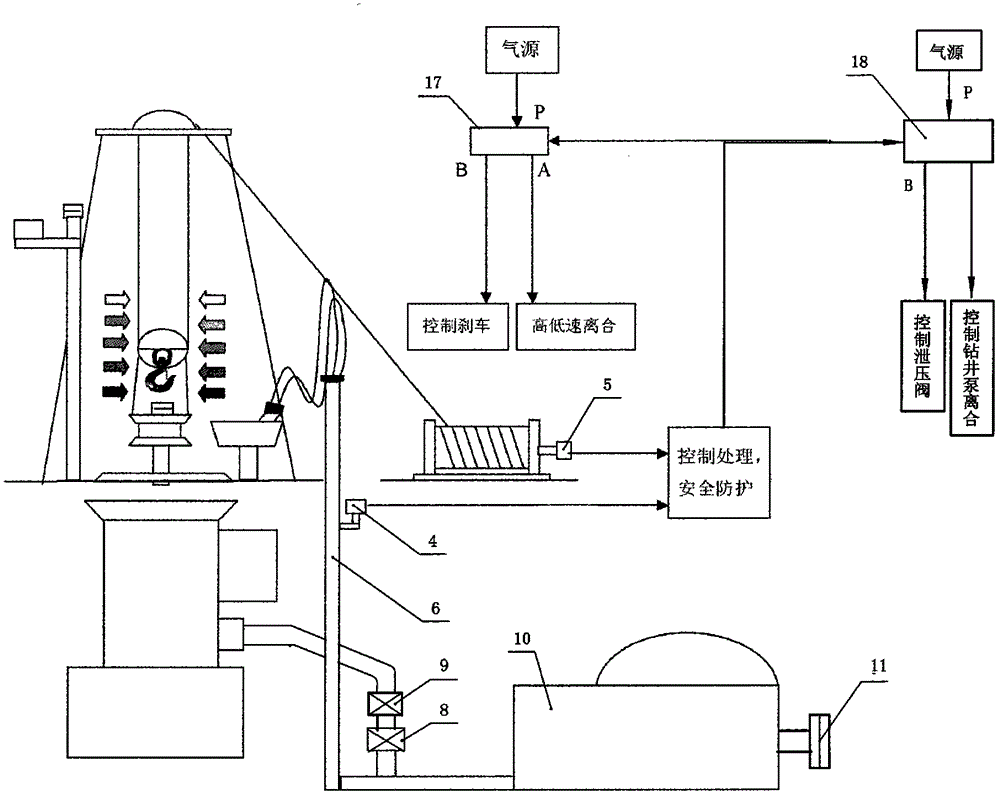

Safe monitoring and protection device for drilling and intelligent protection system of safe monitoring and protection device

ActiveCN104879114AMeet the needs of exploration and developmentAchieve integrationAutomatic control for drillingData transmissionData acquisition unit

The invention relates to the technical field of petroleum drilling safety, in particular to a safe monitoring and protection device for drilling and an intelligent protection system of the safe monitoring and protection device. The safe monitoring and protection device for drilling comprises a data acquisition unit, a control processing unit and a safe protection execution unit; the control processing unit comprises an PLC (programmable logic controller) and an industrial personal computer, the PLC is connected with the industrial personal computer through a serial port; various kinds of sensors of the data acquisition unit acquire on-site operation data and transmit the data to the PLC and the industrial personal computer in real time; the safe protection execution unit comprises a pumping pressure protection mechanism and a runner wagon protection mechanism; a pressure sensor mounted on a vertical pipe or a slurry pump, a winch sensor mounted on a winch barrel and a weight transducer mounted on a deadline anchor output signals to be connected with the PLC; the PLC is in control connection with the pumping pressure protection mechanism and the runner wagon protection mechanism. According to the safe monitoring and intelligent protection device for drilling, the safe protection execution unit comprises a pumping pressure protection sub-system which mainly adopts an active response type safe protection method, and when pumping pressure reaches a set protection value, the pump stops firstly and then pressure relief is performed.

Owner:PUYANG BAIFU REIDE PETROLEUM SCI & TECH CO LTD

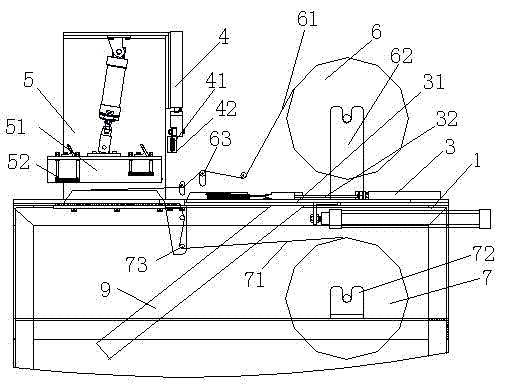

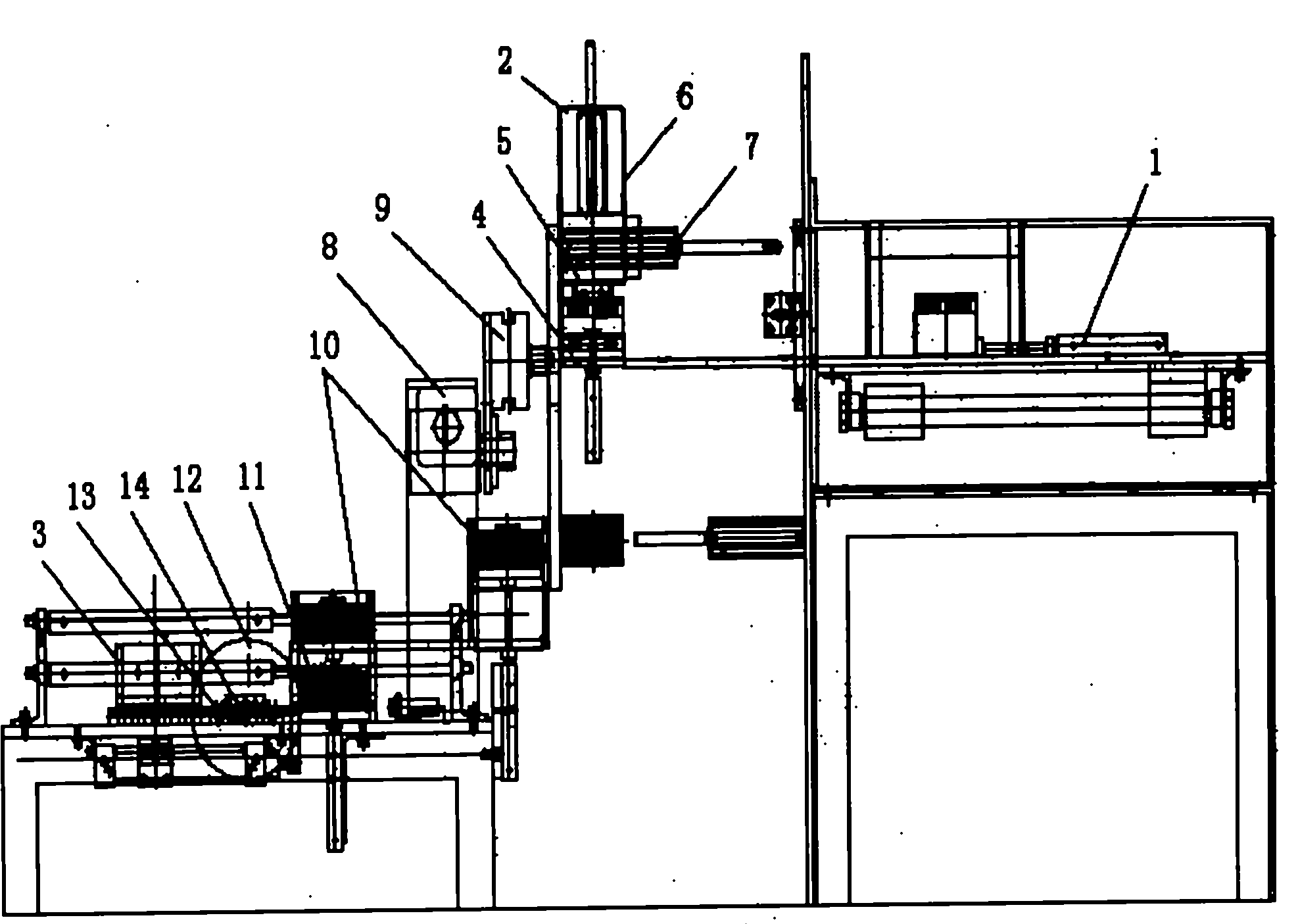

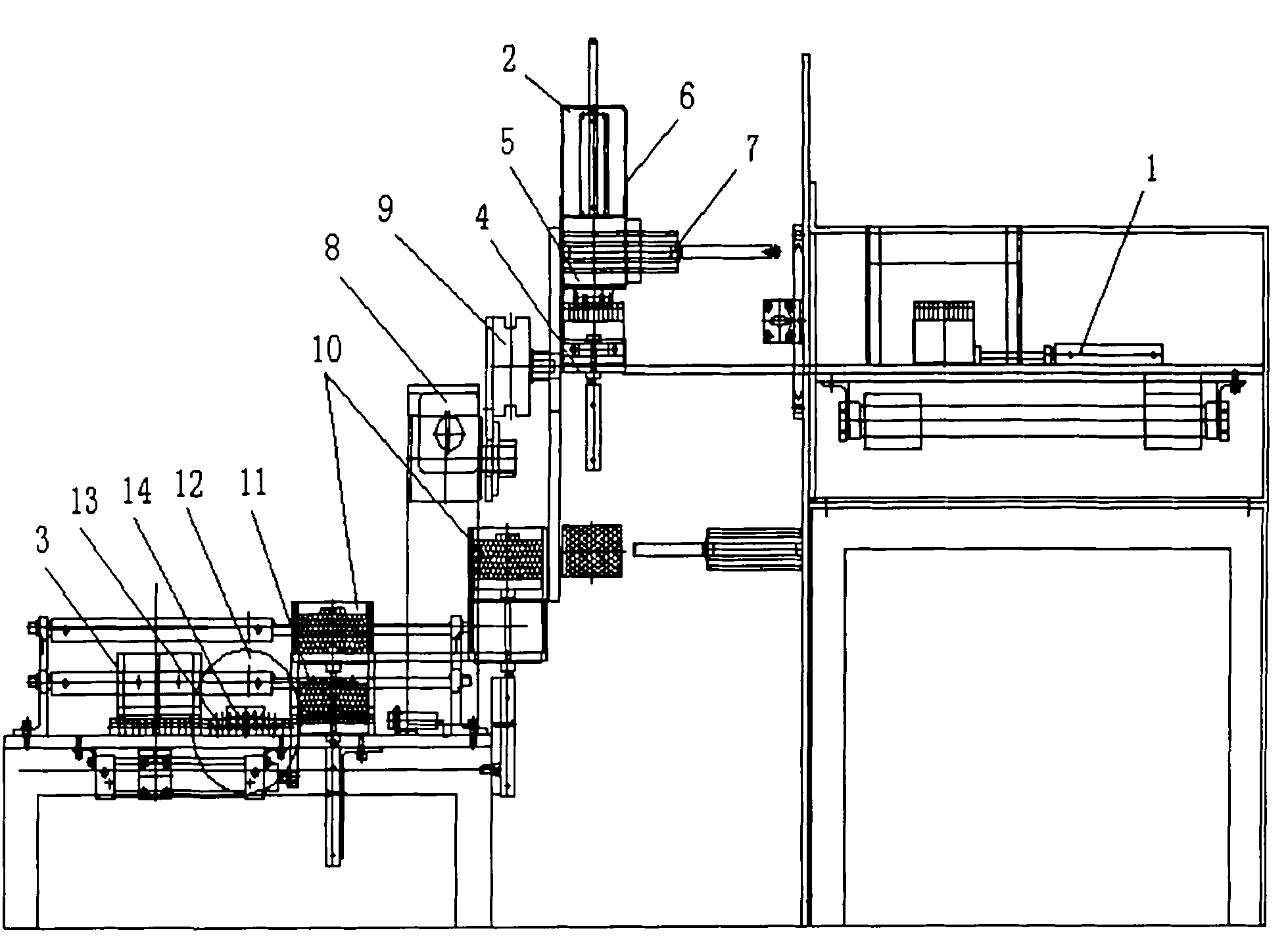

Automatic electric detonator packaging machine

ActiveCN102897334APrecise and reliable controlImprove intrinsic safetyPackaging by pressurising/gasifyingWrappingProgrammable logic controllerElectricity

The invention relates to an automatic electric detonator packaging machine which relates to an automatic packaging machine capable of automatically taking electric detonators out, reshaping the electric detonators and packing the electric detonators with a thermal sealing mode in the electric detonator production process. The automatic electric detonator packaging machine aims to solve the problems that in the prior art, the full-manual operation is low in efficiency and the safety can not be ensured. The technical scheme of the automatic electric detonator packaging machine is as follows: the operation of the automatic electric detonator packaging machine is entirely controlled by a PLC (programmable logic controller) control system, and comprises a mould conveying device, a pipe bagging device, a device for cutting two sealed ends, a side sealing device, a upper film feeding device and a lower film feeding device, wherein the mould conveying device, the pipe bagging device, the device for cutting two sealed ends and the side sealing device are positioned on a workbench according to the order of stations, the upper film feeding device is positioned above the workbench, and the lower film feeding device is positioned under the workbench. The automatic electric detonator packaging machine can prevent operators from directly contacting the dangerous electric detonators, enhances the internal safety, meets the automatic and isolate production requirements on the functions of the stations, and enhances the production efficiency. The automatic electric detonator packaging machine is mainly applied to the automatic packaging of the electric detonator and other objects of the similar structures.

Owner:YAHUA GROUP MIANYANG INDAL

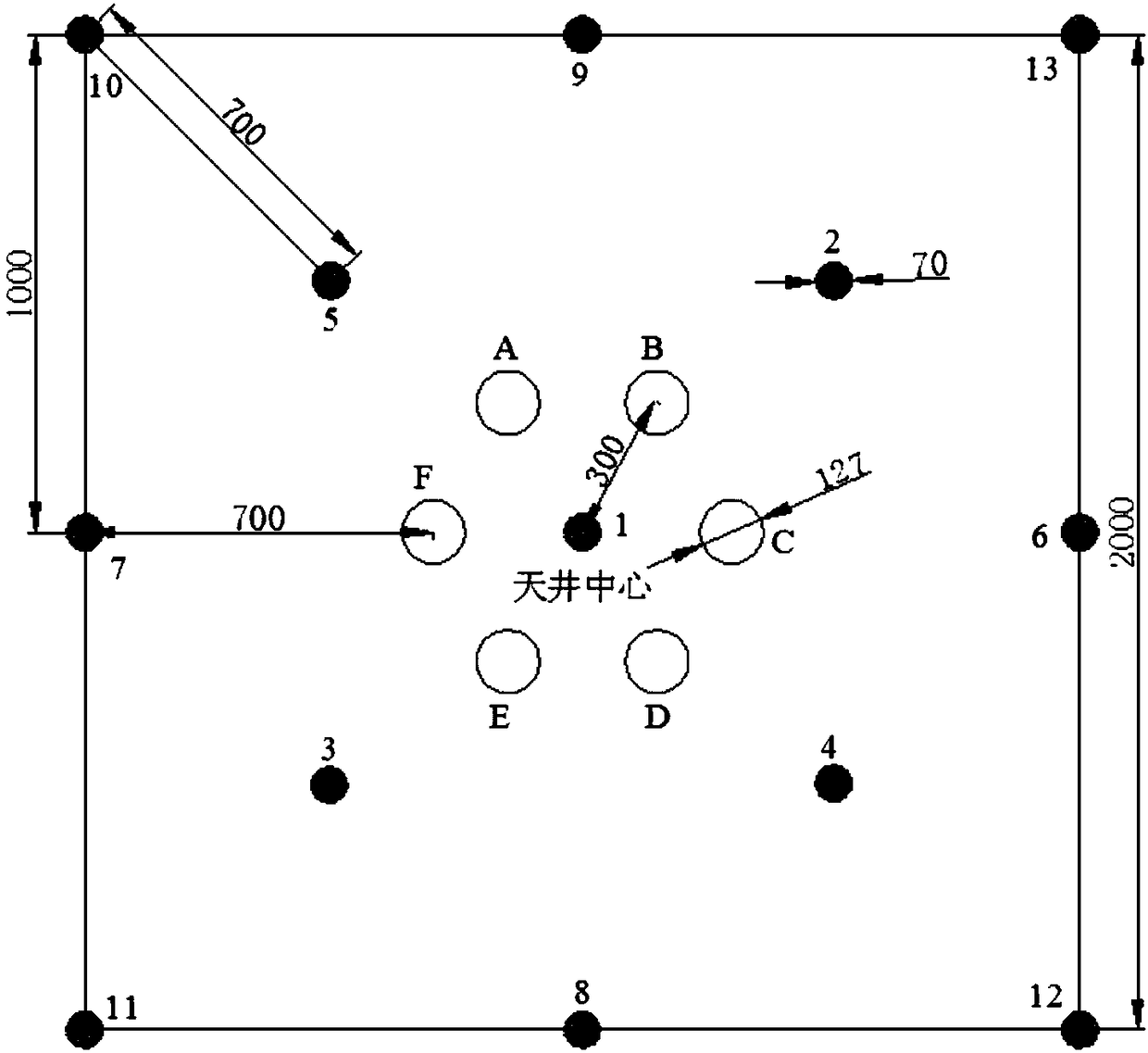

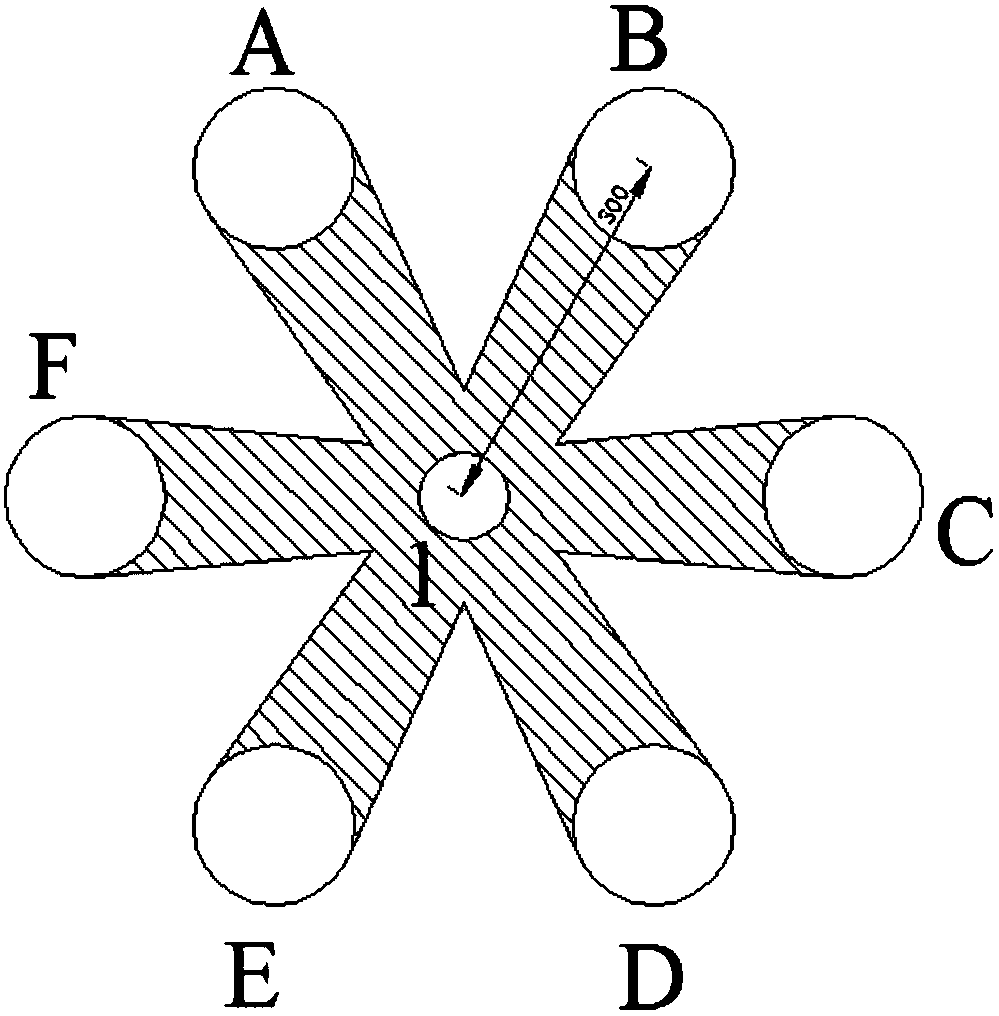

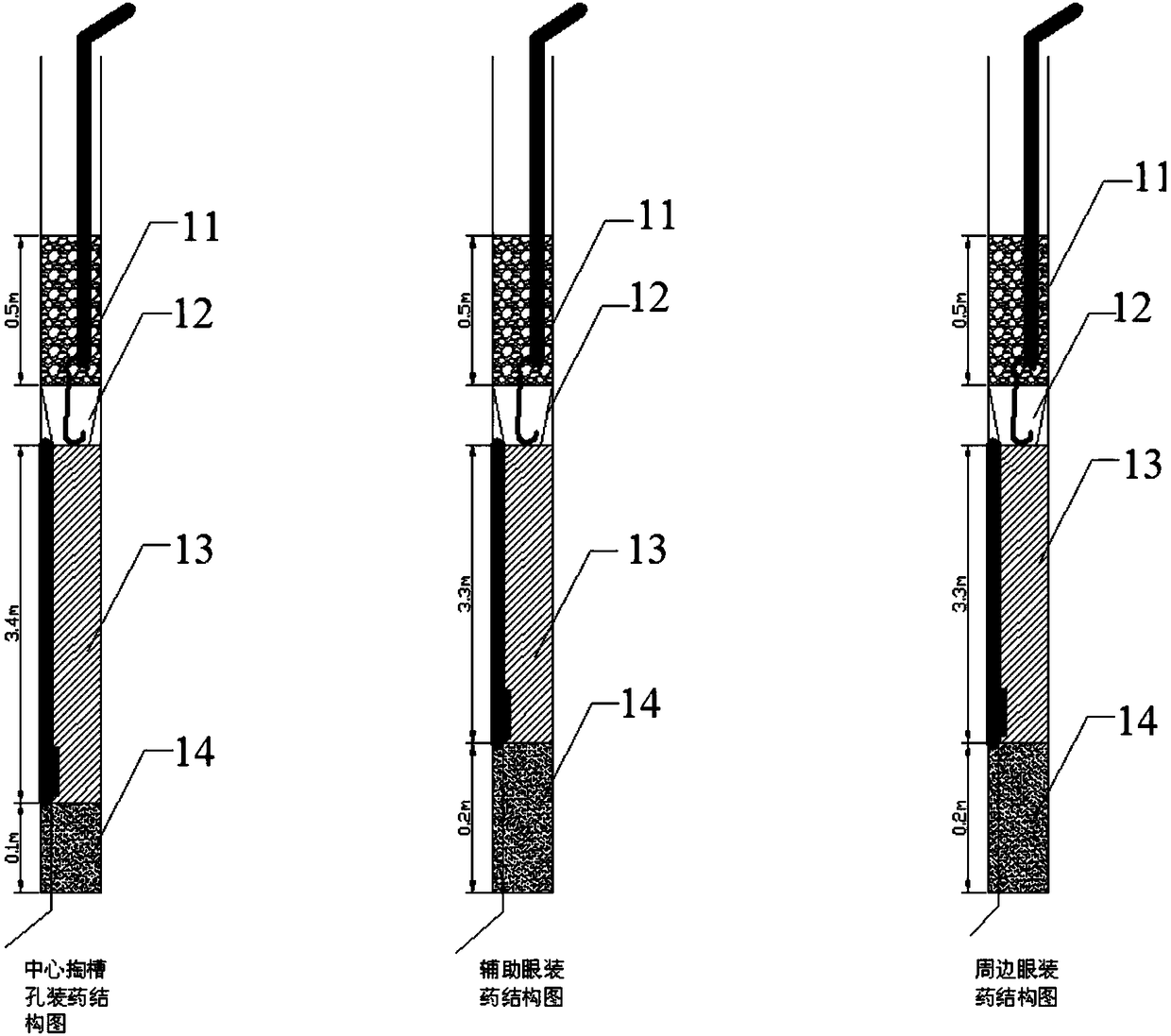

Simultaneous shaft sinking method for segmented raise

InactiveCN108613599AImprove working environmentImprove intrinsic safetyDisloding machinesBlastingIntrinsic safetyStructure of the Earth

The embodiment of the invention discloses a simultaneous shaft sinking method for a segmented raise. The simultaneous shaft sinking method comprises the steps that a cutting mode is selected, specifically, a barrel-shaped cutting mode is selected; the hole diameter of a central cutting hole and the hole diameter of cutting empty holes are determined, specifically, the hole diameter of the centralcutting hole is phi 70 mm, and the hole diameter of the cutting empty holes is phi 127 mm; blast holes are arranged, specifically, four auxiliary holes and eight peripheral holes are selected to be arranged; the blasting segment height is determined, specifically, the central cutting hole, the auxiliary holes and the peripheral holes are all 10 m long, blasting is conducted three times, the firstlayer is 3.5 m, the second layer is 3.0 m, the third layer is 3.5 m, and the blasting sequence from bottom to top is adopted; the elementary error time is determined, specifically, a half-second delaydetonator is selected, a segment exists between every two adjacent segments, and the delay time is 1 s; and the charging structure and parameters are determined. According to the simultaneous shaft sinking method for the segmented raise, the raise operation environment is improved, the operation efficiency is improved, the medium-short raise construction safety risk is reduced, and the raise raising intrinsic safety is improved.

Owner:湖北三鑫金铜股份有限公司

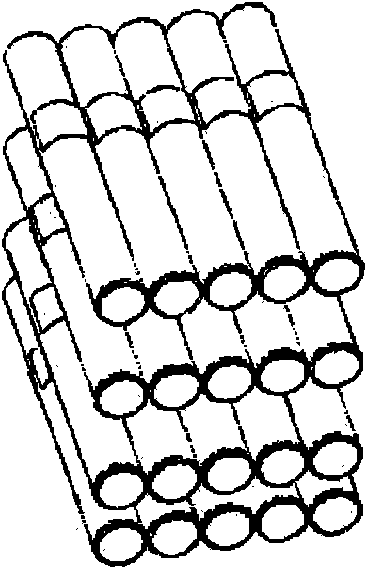

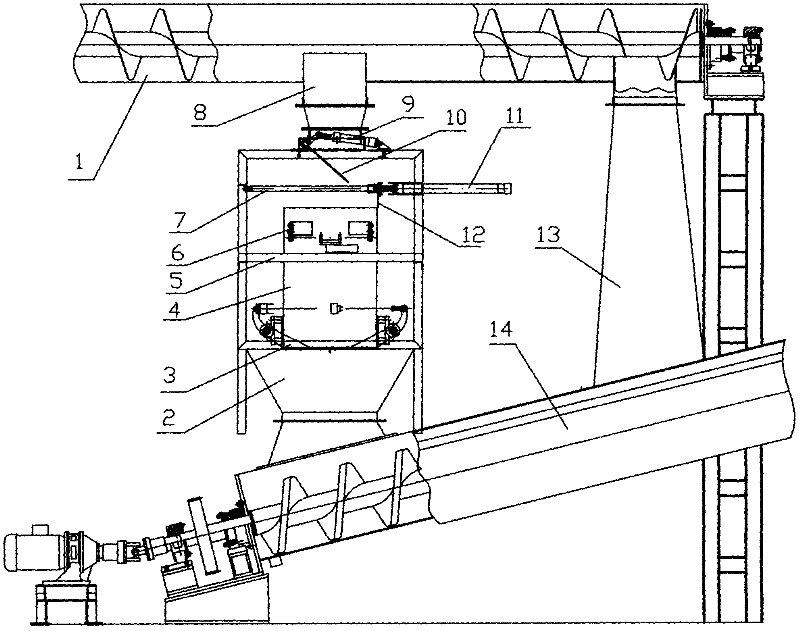

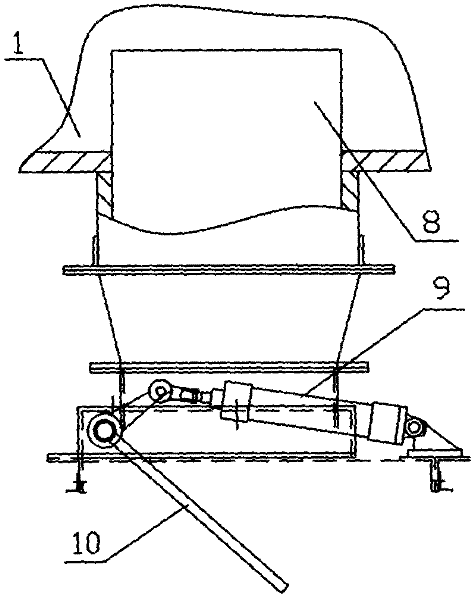

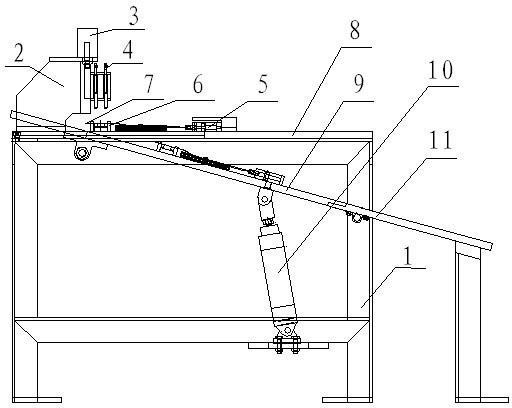

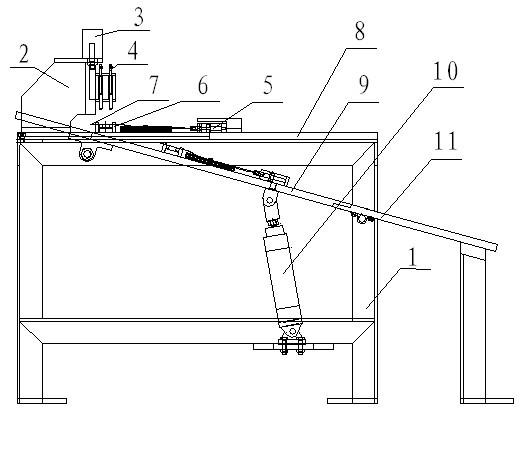

Process for charging and packing industrial powder explosive cartridge and vibratory charging machine

The invention relates to the technical field of explosives, in particular to a process for charging and packing an industrial powder explosive cartridge and a vibratory charging machine. The process for charging and packing the industrial powder explosive cartridge is characterized by comprising a cartridge finishing and fixed connecting process, a cartridge charging process and a cartridge sealing process. The vibratory charging machine is characterized by comprising a stander; the stander is provided with a frame conveying mechanism, a charging station and a sealing station; the charging station is provided with a charging ramming mechanism and a compaction mechanism; and the sealing station is provided with a sealing mechanism. The process has the advantages of short flow, high safety performance, high working efficiency, good charging quality, and the like; and the vibratory charging machine has the advantages of high essential safety level, high product quality qualification rate, high automation degree, large capacity, compact and reasonable structure, little occupied area, few operation personnel at a dangerous area, and the like.

Owner:蒙宝林

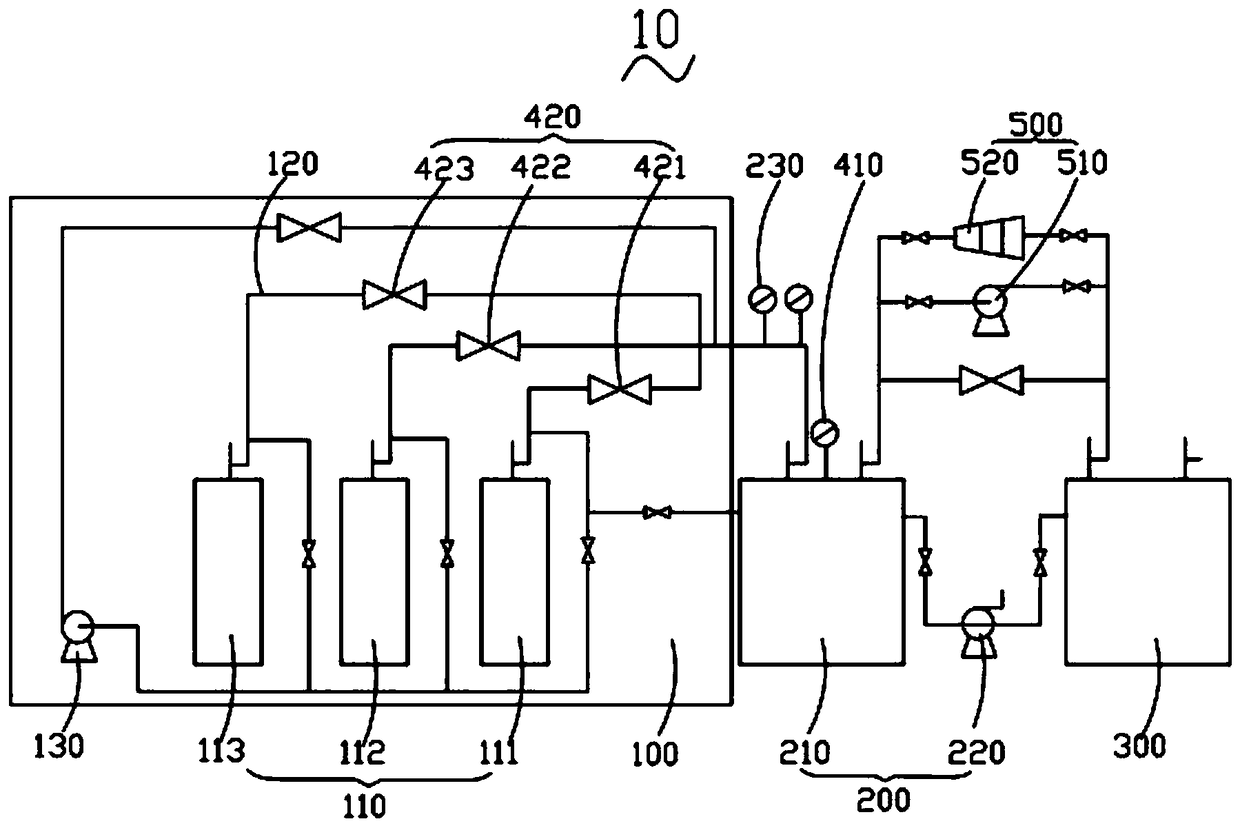

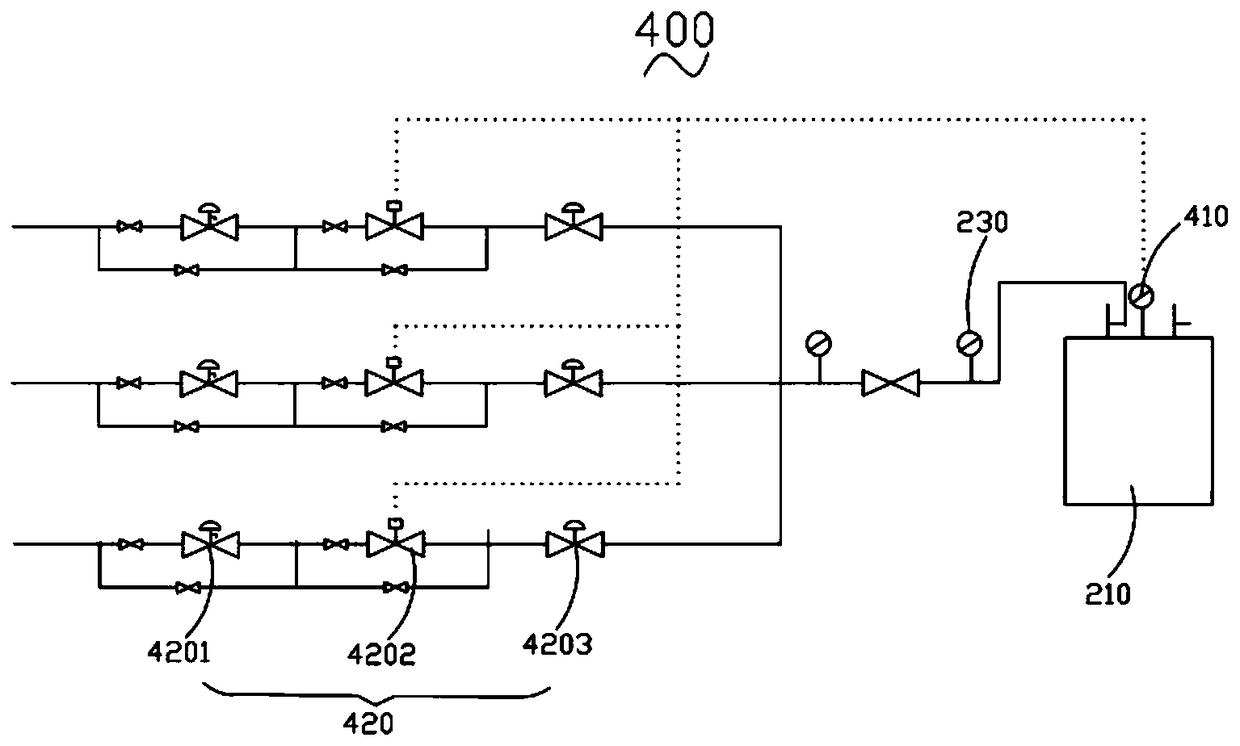

Gas mixing and compounding method and gas mixing and compounding system

InactiveCN109316987AImprove stabilityImprove applicabilityTransportation and packagingMixer accessoriesGas cylinderProcess engineering

The invention provides a gas mixing and compounding method and a gas mixing and compounding system. The system comprises a gas inlet device, a gas mixing device and a gas regulating box. The gas mixing device comprises a gas mixing tank and a vacuum pump. The gas mixing tank is connected to one end, away from a gas supply bottle, of a gas conveying pipeline. The inlet of the vacuum pump is respectively connected to the gas mixing tank and the gas regulating box. The outlet of the gas mixing tank is connected to the inlet of the gas regulating box. The gas mixing tank is provided with a pressure controller, and the pressure controller is used for detecting gas pressure in the gas mixing tank. The method is capable of, according to a Dalton's law of partial pressure, changing a more difficultly measured volume variable into a more easily measured pressure variable, and according to a partial pressure of each gas in the gas mixing tank, determining a volume ratio of each gas component inan obtained mixed gas, thereby overcoming an error, of a traditional flowmeter or a double-linkage proportion regulating value, caused by the effects of gas density, a turbulence degree and the like,and improving stability of the whole gas mixing system.

Owner:NINGXIA UNIVERSITY

Temperature and humidity adjusting device for safety test chamber system

InactiveCN104111677AEliminate pollutionStrong fatigue resistanceSimultaneous control of multiple variablesInherent safetyIntrinsic safety

The invention provides a temperature and humidity adjusting device for a chemical fire explosion safety test chamber system. The device provided by the invention comprises a temperature adjusting device and a humidity adjusting device. According to the chemical fire explosion safety test chamber system with the temperature and humidity adjusting device, harms of a runaway reaction, combustion explosion, decomposable explosion and the like which are generated during the process of large-scale chemical risk assessment test are eliminated, and simultaneously, effluents, exhaust gas and waste residues that are generated during collection test process undergo centralized processing. Inherent safety of the fire explosion risk test process is raised, and the effect of reducing environmental pollution is also achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic composite solid propellant and preparation method thereof

ActiveCN107867962AAchieve moldingImprove securityNon-explosive fillers/gelling/thickening agentsAmmonium perchlorate explosive compositionsInherent safetyPlasticizer

The invention provides a thermoplastic composite solid propellant applicable to a solid booster. The thermoplastic composite solid propellant is prepared from components in percentage by mass as follows: 55%-70% of an oxidant, 10%-20% of a thermoplastic resin adhesive, 10%-20% of a plasticizer, 5%-20% of metal fuel and 3%-8% of auxiliaries. According to the prepared thermoplastic composite solid propellant, relative independence of mixing and pouring, integrated formation of the propellant and secondary formation of engine charge can be realized according to temperature adjustment, and melt mixing and formation of the thermoplastic propellant can be realized at relatively low temperature lower than 90 DEG C, so that inherent safety of preparation of the thermoplastic propellant is greatlyimproved; compared with a traditional thermosetting propellant, crosslinking curing process is omitted, technological process is shortened, recovery and repeated processing of waste products can be realized, and production cost is reduced. The thermoplastic propellant is prepared with a hot melt mixing-cooling formation technology, and application of components absorbing moisture easily in the propellant is realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

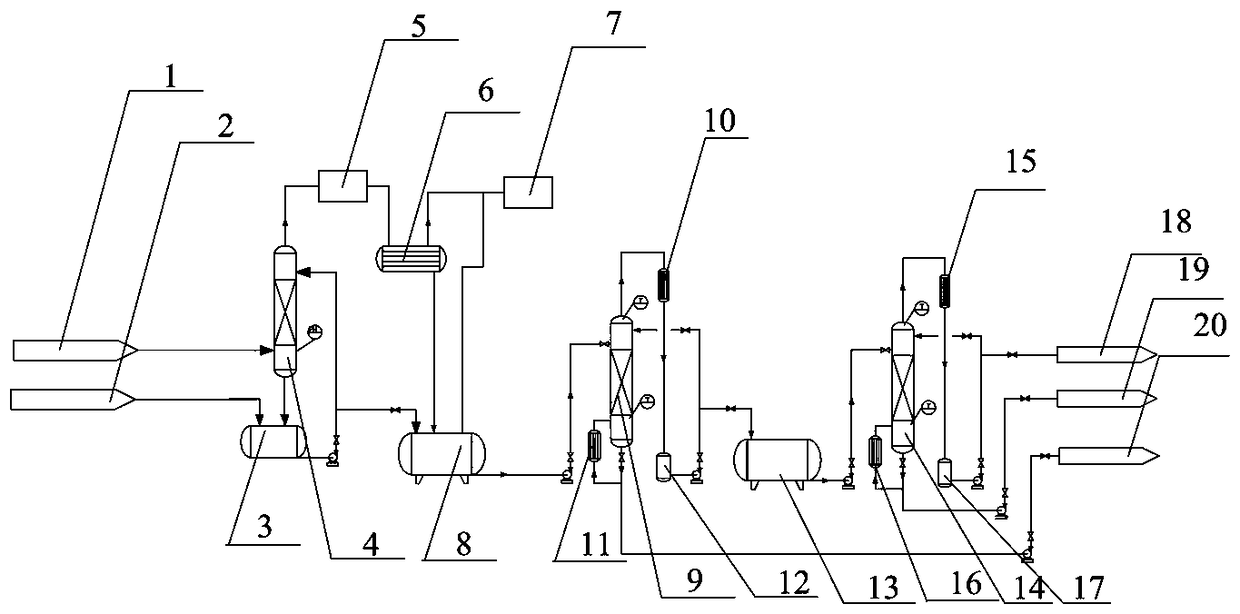

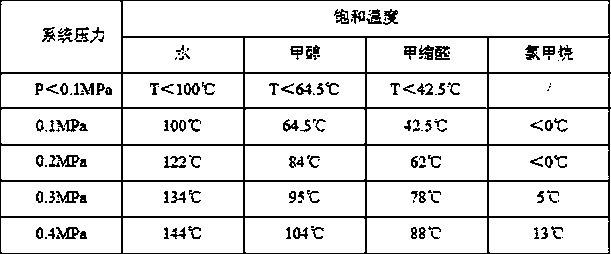

Alkyl ester method glyphosate solvent recovery system and process

PendingCN108380029AImprove intrinsic safetyReduce system pressureGas treatmentOrganic compound preparationSolventChemistry

The invention provides an alkyl ester method produced glyphosate solvent recovery method. A diluted methanol solution collection tank is connected with the upper part of a primary rectifying tower through a pipeline, and the primary rectifying tower is connected with a return tank I through a condenser I; the return tank I is connected with a methyl alcohol methylal solution intermediate tank; themethyl alcohol methylal solution intermediate tank is connected with a secondary rectifying tank, a return tank II is connected to a methyl alcohol methylal finished product tank, and the secondary rectifying tank is connected to a methyl alcohol finished product tank. The recovery process comprises the following steps: enabling diluted methanol inside the diluted methanol solution collection tank to enter into the primary rectifying tower, enabling gas inside the primary rectifying tower to condense through the condenser to return back to the return tank, and feeding to the methyl alcohol methylal solution intermediate tank; feeding to the methyl alcohol finished product tank from a secondary rectifying tower extraction pump, condensing liquid at the bottom of the tower through the condenser and then feeding to the methyl alcohol finished product tank. According to the equipment and process provided by the invention, the defect that a traditional liquid-phase recovery process highlydepends on a graphite condenser and the problem that a traditional gas-phase recovery process is unstable in operation are solved, the process has the characteristics of energy saving and economical efficiency, and the steam consumption of glyphosate is 1.2t.

Owner:HUBEI TAISHENG CHEM

Low-melting-point thermoplastic solid propellant and preparation method thereof

ActiveCN108147934ARealize complementary advantagesImprove mechanical propertiesNon-explosive/non-thermic compositionsPressure gas generationElastomerPlasticizer

The invention relates to a low-melting-point thermoplastic solid propellant and a preparation method thereof, and belongs to the technical field of composite solid propellants. The propellant is prepared from the following components by mass percent: 55%-70% of oxidant, 10%-20% of thermoplastic elastomer binder, 10%-20% of plasticizer, 5%-20% of metal fuels and 3%-8% of auxiliaries. The prepared low-melting-point thermoplastic solid propellant has the advantages that melting mixing and forming of the thermoplastic propellant at a relatively low temperature lower than 95 DEG C can be realized,process safety of thermoplastic propellant preparation is greatly improved, a curing and cross-linking process in comparison with a thermoplastic propellant is cut out, process flow is shortened, production efficiency is improved, production cost is reduced and repeated processing of waste products can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Gel type emulsion explosive and preparation thereof

InactiveCN101328099AImprove intrinsic safetyImprove securityExplosive working-up apparatusLow speedEmulsion explosive

The invention discloses a gel-type emulsion explosive and a method for preparing the same. The explosive is prepared by 75%-86% of ammonium nitrate, 4%-7% of emulsifier-compound grease, 0.5%-4% of crystal modifier and water balance, different models of coal permissible products are prepared by adding 3%-7% of flame reducer into the explosive. When preparation, the ammonium nitrate, crystal modifier, water and flame reducer are mixed, heated and dissolved to form an oxidant water solution as an aqueous phase solution, the emulsifier-compound grease is heated to form a combustible agent solution as an oil phase solution, the aqueous phase solution and oil phase solution are pumped into an open type emulsifier for emulsification after accurate measurement and are sensitized to finished products in a low speed mixing device by means of a belt device. The explosive energy of the product can be released to a maximum extent, the density can reach 1.4g / cm<3>, the explosion strength can reach 360ml and the detonation velocity can reach 6500m / s.

Owner:耿一平

Method and device for automatically detecting powder material accumulation density

ActiveCN102175566ADetectiveFunctionalSpecific gravity measurementControl systemProgrammable logic controller

The invention relates to a method and a device for automatically detecting powder material accumulation density, relating to a device for detecting powder (granular) material accumulation density. The method comprises the following steps of: (1) connecting a material dividing hopper with an original spiral conveyer pipe; (2) opening a material dividing valve at the lower part of the material dividing hopper so that materials fall to a material weighing hopper supported by a weighing sensor; (3) scraping stacks at the top of the material weighing hopper through a material pushing scraping plate driven by a material pushing cylinder; (4) transmitting weight information of the material weighing hopper to a PLC (programmable logic controller) control system for calculating, comparing and displaying by the weighing sensor; (5) opening a material discharging valve at the lower part of the material weighing hopper so that the materials fall to a material receiving hopper and enter to a secondary spiral conveyer; and (6) pushing the materials falling from the material receiving hopper to be combined with the materials falling from an original spiral conveyer material discharging tube and sending to next procedure together by the secondary spiral conveyer. The device disclosed by the invention has the advantages of automatic identifying function, high accuracy, fast speed and high efficiency; and the device is capable of realizing full check, and effectively controlling the product quality.

Owner:青海海西东诺化工有限公司

Spherical filler modifying material formula

The invention relates to a spherical filler modifying material formula. The material comprises a base material and a modifying agent. The base material is any one selected from nylon 6, polyphenylene sulfide, polyether ether ketone, and nylon 11. The modifying agent is any one selected from carbon fiber, carbon nano-tubes, carbon black, or thermal-conductive electric-conductive plastic. According to different market application and demands, the spherical filler modifying material is derived into a series of products with different structures and components, wherein different base material and modifying agent ratios are adopted. When the spherical filler modifying material provided by the invention is used for producing spherical hollow fillers, compared with explosion-proof materials with polyurethane foamed materials and metal foil grid structures, the production of residues such as scraps is prevented, pollution phenomena such as oil oxidation is prevented, subsequent influence is prevented, and service life is long. The filler is easy to fill, to disassemble, and to wash. Installation and maintenance costs are low. The filler is especially suitable for vessels with complicated internal space or small local space, and vessels which are hard to fill by using the polyurethane foamed material and metal foil grid structured explosion suppression materials.

Owner:BEIJING ANTAIQUAN TECH

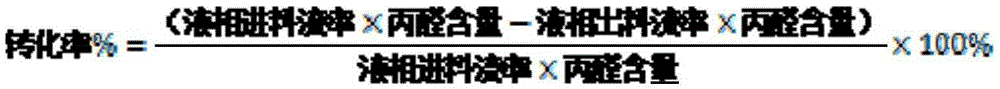

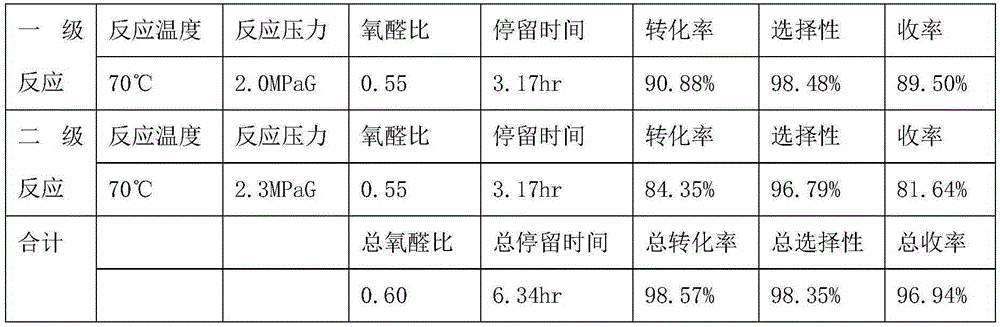

Continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde

InactiveCN105254484AReduce pollutionSimple processOrganic compound preparationCarboxylic compound preparationPropanoic acidGas phase

The invention relates to a continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde. The method comprises the steps that propionaldehyde enters a reactor through a liquid phase inlet in the bottom of a first-order oxidation reactor and makes contact with and is mixed with some compressed air, a majority of propionaldehyde in the raw material is converted into propionic acid through an oxidation reactor, a first-order oxidation product containing a small amount of propionaldehyde continuously enters a second-order or multi-order oxidation reactor and is continuously subjected to the oxidation reaction with the compressed air, and finally the propionic acid with the high-purity is generated. The device comprises two or more oxidation reactors connected in series, a condenser is arranged on the top of each oxidation reactor, and gas phase pipelines and backflow pipelines are arranged between the oxidation reactors for connection. A tail gas processing device is arranged behind each oxidation reactor. A gas phase pipeline is arranged between each condenser and the corresponding tail gas processing device for connection. The reaction conditions are mild, the product yield is high, the product quality is good, the propionaldehyde conversion rate is larger than 98.5%, the selectivity of the propionic acid is larger than 97.5%, and the product purity is larger than 99.5%.

Owner:TIANJIN UNIV

Method for refining hydroxyethylcellulose

InactiveCN102492044AFacilitate continuous passageGreat operating flexibilityProduction lineInorganic acids

The invention belongs to the technical field of production methods for hydroxyethylcellulose and particularly relates to a method for refining the hydroxyethylcellulose. The invention aims to solve the technical problem that a method for refining the hydroxyethylcellulose is required to be provided, the method is simple and convenient in technologies, and an obtained product has high quality. The method for refining the hydroxyethylcellulose comprises the following steps of: neutralizing, crosslinking, washing, filtering, drying and crushing, wherein a neutralizer used in the neutralizing step is inorganic acid. By changing the variety of the neutralizer, the continuous production can be performed by the method for refining the hydroxyethylcellulose, the whiteness and free-running property of the product obtained through processing are high, and the stability of the product is higher. In addition, a production line is continuous, so that the production efficiency of the production line is greatly improved, the operating labor intensity of workers is reduced, the essential safety of the production line is improved, and the consumption of energy sources and raw materials is reduced.

Owner:LUZHOU NORTH CHEM IND

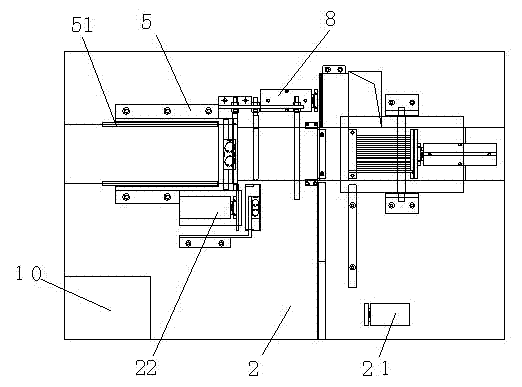

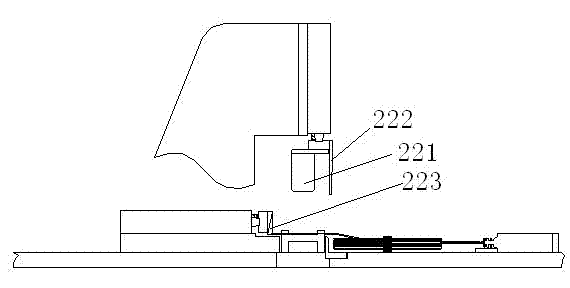

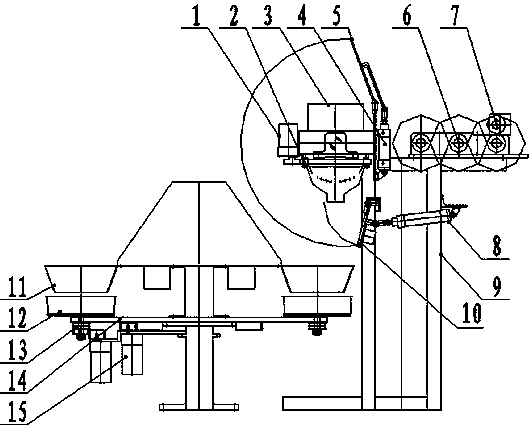

Machine for automatically assembling detonator into die

The invention provides a machine for automatically assembling a detonator into a die, and relates to equipment for automatically assembling a detonator into a die, which aims to solve the problems of low manual operating efficiency and failure in security guarantee in the prior art. The machine can reliably realize operation of automatically assembling the packaged semi-finished detonator into the production die in an automatic production line of the detonator. In order to achieve the purpose, the technical scheme adopted in the invention is as follows: the machine comprises a case delivery cylinder and a detonator-fetching rotating device, wherein, the case delivery cylinder is used for pushing the detonator to be assembled to a rear-end station, the detonator-fetching rotating device is used for receiving the detonator to be delivered from the case delivery cylinder, overturning and then conveying the detonator to be assembled to the rear-end station, and the rear end of the detonator-fetching rotating device is connected with the device for assembling the detonator to be assembled into the designated die. The machine of the invention is mainly applied to automatically assemble the detonator in the civil explosion field.

Owner:YAHUA GROUP MIANYANG INDAL

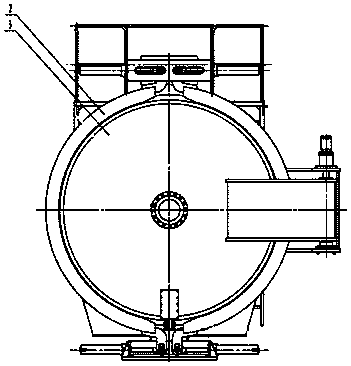

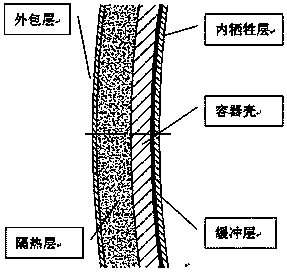

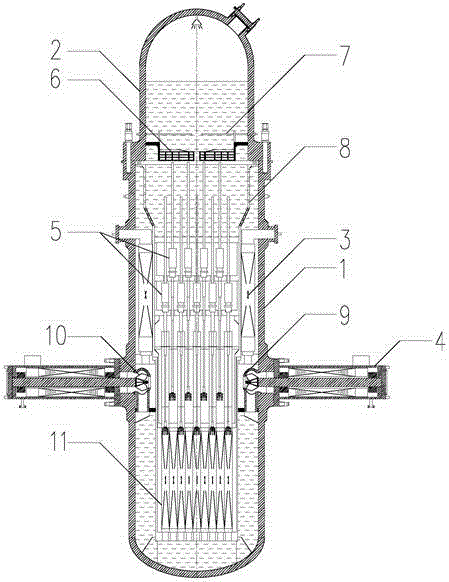

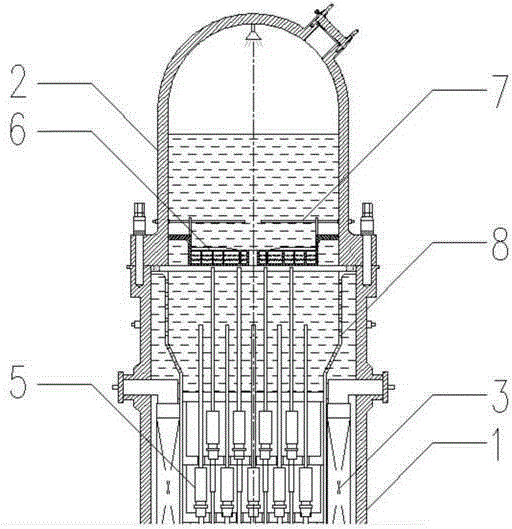

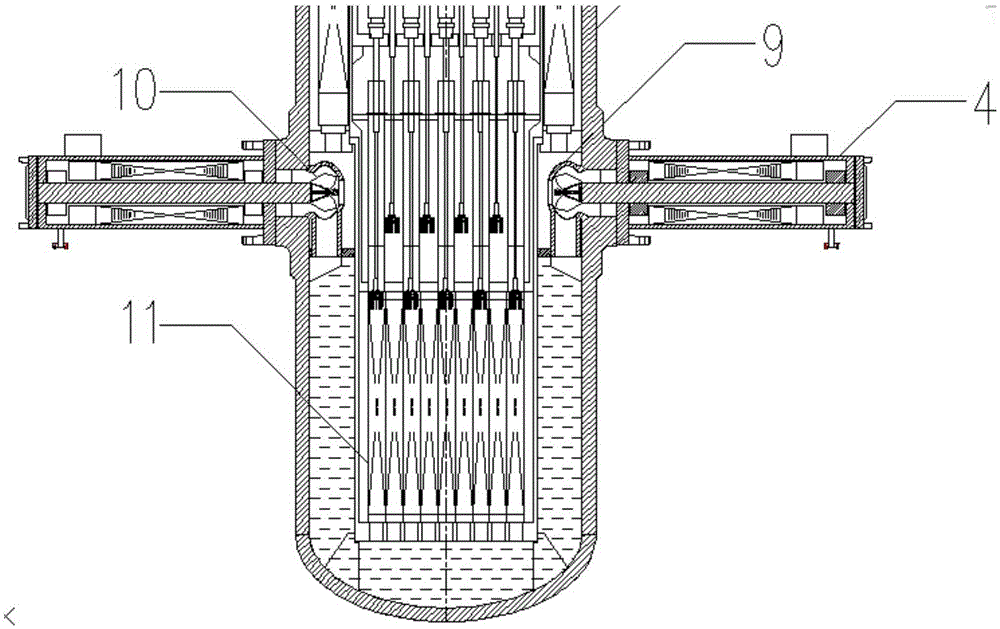

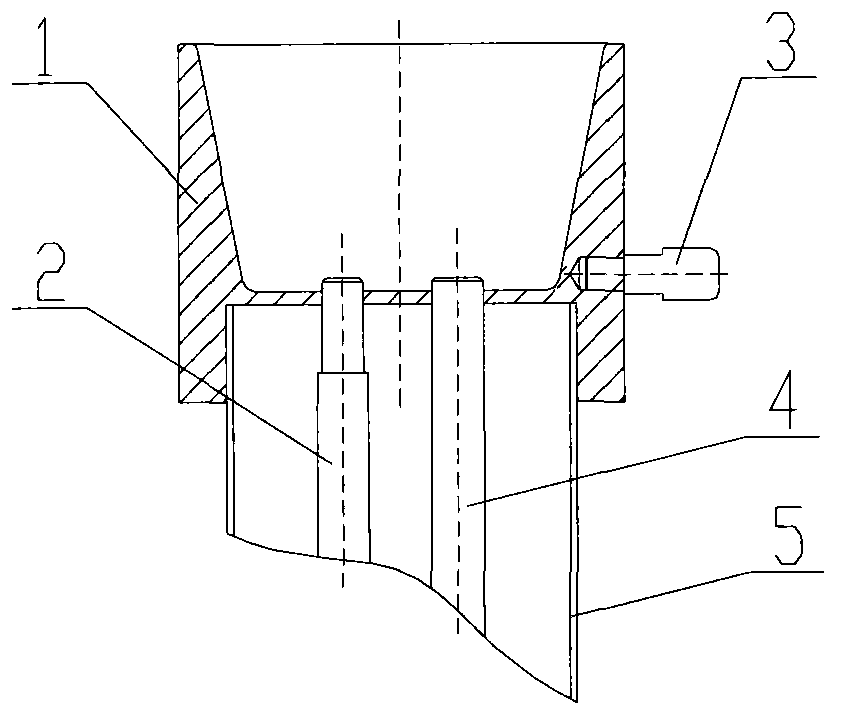

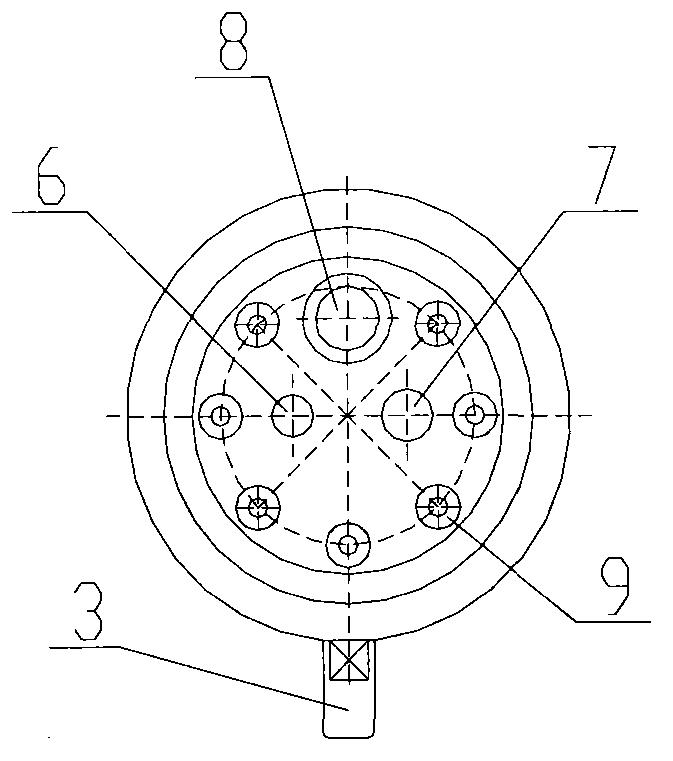

Integrated modular pressurized water reactor with 69 reactor core

InactiveCN106887261AAddressing economies of scaleImprove securityNuclear energy generationFuel element assembliesElectricityReactor pressure vessel

The invention belongs to field of integrated modular pressurized water reactor technology, and concretely relates to an integrated modular pressurized water reactor with a 69 reactor core. A voltage-stablizer, multiple modular steam generators, multiple wet winding main pumps, and multiple groups of control rod drive mechanisms are totally and internally arranged in a reactor pressure vessel in order to integrate into an integrated pressurized water reactor module; The voltage-stablizer is also used as a top cover of the reactor pressure vessel, an inverted cap shaped double-layer stainless steel thermal insulation board with a composite structure and air interlayers is internally arranged in the voltage-stablizer, electric heating elements are circumferentially and uniformly and horizontally arranged in the voltage-stablizer, and the electric heating elements are arranged on the thermal insulation board; multiple groups of built-in control rod drive mechanisms are arranged below the thermal insulation board and above the reactor core by using a modular double layer assembling arrangement. The product better solves contradiction of safety and economical efficiency of small reactors with good engineering realizability.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Explosive filling riser of primer

The invention belongs to the technical field of primer production of civil explosive industry, and particularly relates to an explosive filling riser of a primer. The riser comprises a riser body, a push rod, a first core rod, a second core rod and a primer shell, wherein the first core rod and the second core rod are vertically placed in the primer shell side by side; the first core rod and the second core rod are arranged opposite to the center of the primer shell; the upper end of the primer shell is provided with an opening; the first core rod and the second core rod protrude out of the upper end of the primer shell for 5-8 mm; the bottom end of the riser body is provided with a first core rod positioning hole, a second core rod positioning hole, a pouring hole and an exhaust hole respectively; the riser body is placed on the primer shell and is assembled with the first core rod and the second core rod; and the push rod is arranged on the riser body at a position which is 20 mm away from the bottom end. The product provided by the invention has a simple structure and is safe and reliable. Field personnel and the labor intensity of workers are reduced, and the production efficiency and the intrinsic safety of production are improved.

Owner:CHINA WUZHOU ENG GRP +1

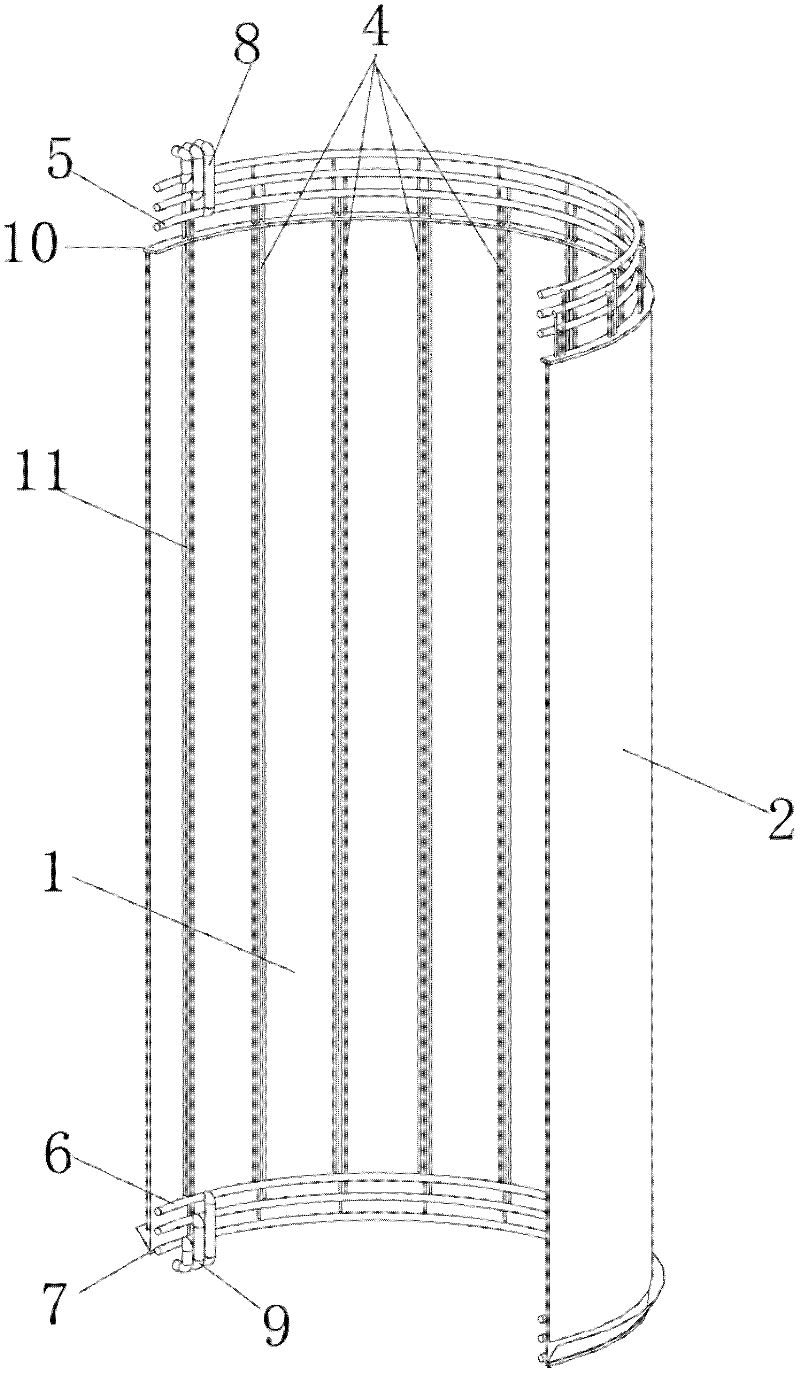

Water-cooling wall

ActiveCN102332314ASimple systemLess equipmentNuclear energy generationCooling arrangementSystem safetyMature technology

The invention discloses a water-cooling wall, which relates to the technical field of nuclear safety. The water-cooling wall comprises a barrel-shaped side wall and a water-cooling tube arranged on the barrel-shaped side wall, wherein the upper end of the barrel-shaped side wall is communicated with an outlet header; the lower end of the water-cooling tube is communicated with an inlet header; the outlet header and an outlet main tube are communicated; and the inlet header and an inlet main tube are communicated. based on a non-dynamic safe concept, the water-cooling wall performs heat exchange only in natural circulation modes, such as thermal radiation, heat conduction, heat convection and the like, and the effect of an active part, such as a water pump and the like, is not required. A simplified system, less equipment and the mature technology are adopted so as to reduce influence of uncertain factors on system safety as much as possible and increase the inherent safety of a high temperature gas cooled reactor.

Owner:CHINERGY CO LTD

Intrinsic Safety Barrier

ActiveUS20160248241A1Improved intrinsic safety barrier arrangementImprove intrinsic safetyEmergency protective arrangement detailsEmergency protective arrangements for limiting excess voltage/currentIntrinsic safetyEngineering

An improved intrinsic safety barrier arrangement for an electrical device or component. A method of intrinsic safety barrier operation for an electrical device or component is also disclosed.

Owner:MSA TECH

Input regulated DC to DC converter for power scavenging

ActiveUS7911189B2Improve intrinsic safetyImproving impedanceDc network circuit arrangementsBatteries circuit arrangementsVoltage dropEngineering

Owner:FISHER CONTROLS INT LLC

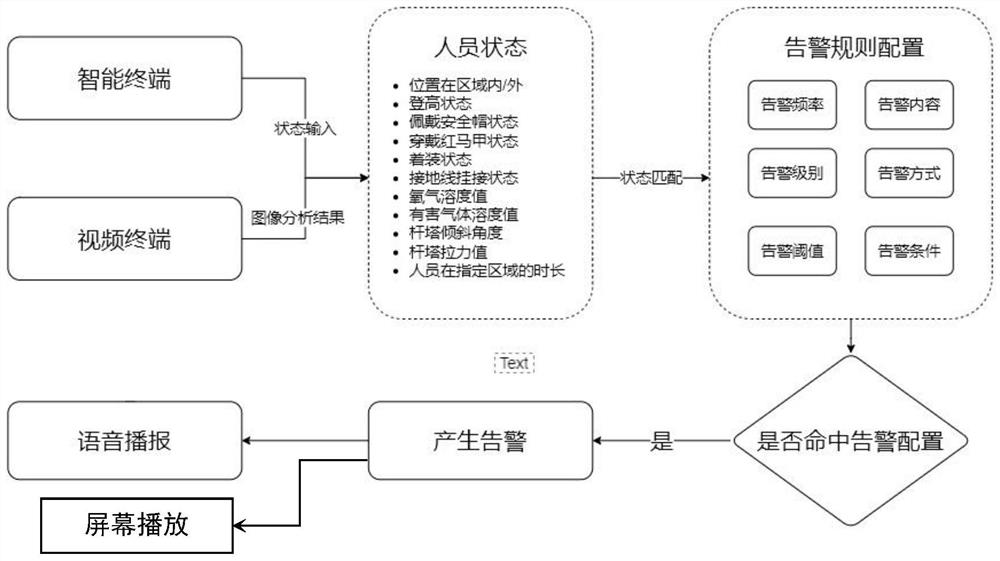

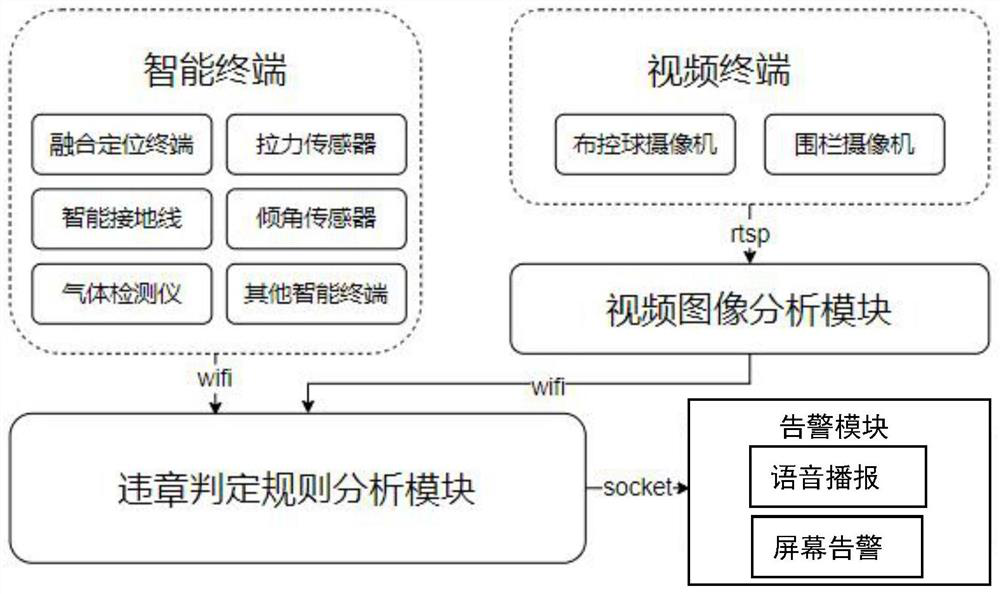

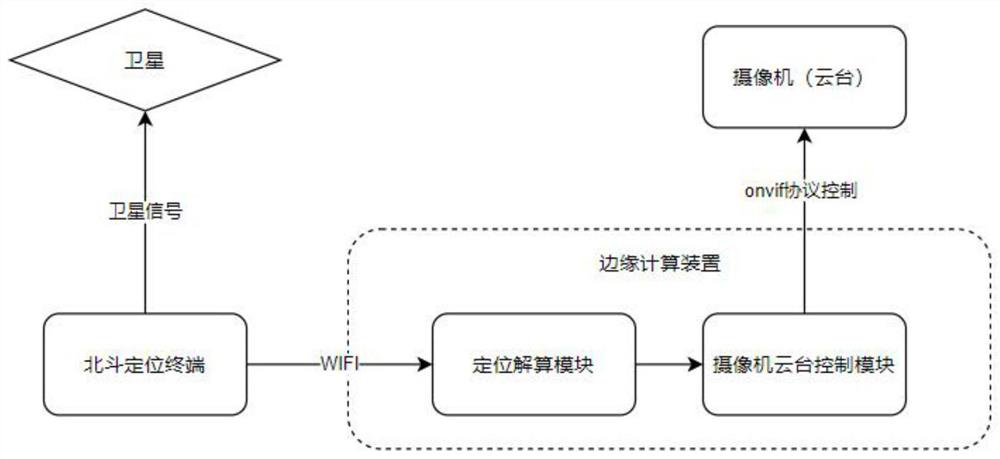

Method and system for judging violation behaviors of electric power operation site

PendingCN114821406AImprove intrinsic safetyEliminate hidden dangersData processing applicationsCharacter and pattern recognitionReal time analysisTerminal equipment

The invention provides a method and a system for judging violation behaviors of an electric power operation site. The method comprises the following steps: acquiring a site video image through a video terminal, and analyzing the dressing and action states of field personnel in the image in real time; personnel positioning data are obtained through intelligent terminals carried by field personnel, and sensor detection values are obtained in real time through intelligent terminals distributed on a working site; a violation judgment rule analysis module performs comprehensive analysis according to a video analysis result in combination with personnel positioning data and sensor detection values transmitted by various intelligent terminals, and judges whether field personnel have violation behaviors and whether a working environment has risks in real time, if yes, a video terminal is linked to perform field snapshot and evidence obtaining, and if not, the video terminal is linked to perform field evidence obtaining. And the alarm description of the corresponding violation behavior or the operation environment risk is sent to the alarm module to give an alarm. According to the invention, the violation behaviors of the personnel are comprehensively judged based on the linkage cooperation of multiple types of intelligent terminal equipment, so that the safety supervision of operators is improved, and blind areas are eliminated.

Owner:FUJIAN YIRONG INFORMATION TECH +1

Device for automatically detecting electric detonators and rejecting waste electric detonators

ActiveCN102059223AExquisite structureIt can be seen from the structural characteristics that its advantages are: the appearance of the whole machine is beautifulSortingDetonatorElectricity

The invention discloses a device for automatically detecting electric detonators and rejecting waste electric detonators, relating to a device for waste treatment. The invention aims to provide a device for automatically detecting whether electric detonator products are qualified or not and automatically rejecting the unqualified products. The device greatly improves the production efficiency, realizes man-machine isolation operation and has favorable safety. For achieving the aims, the invention adopts the technical scheme: the device for automatically detecting electric detonators and rejecting waste electric detonators is entirely installed on a bracket, the top of the bracket is a detecting table board, one side of the detecting table board is supported by a supporting frame and provided with a detection control device below which a detecting column is arranged, and a lead detecting part is just arranged below the detecting column when a detecting mould for fixing the lead detecting part in a limit fire tube mould is arranged on the detecting table board. The invention can be used for detecting electric detonators and products with similar structures and rejecting waste products.

Owner:YAHUA GROUP MIANYANG INDAL

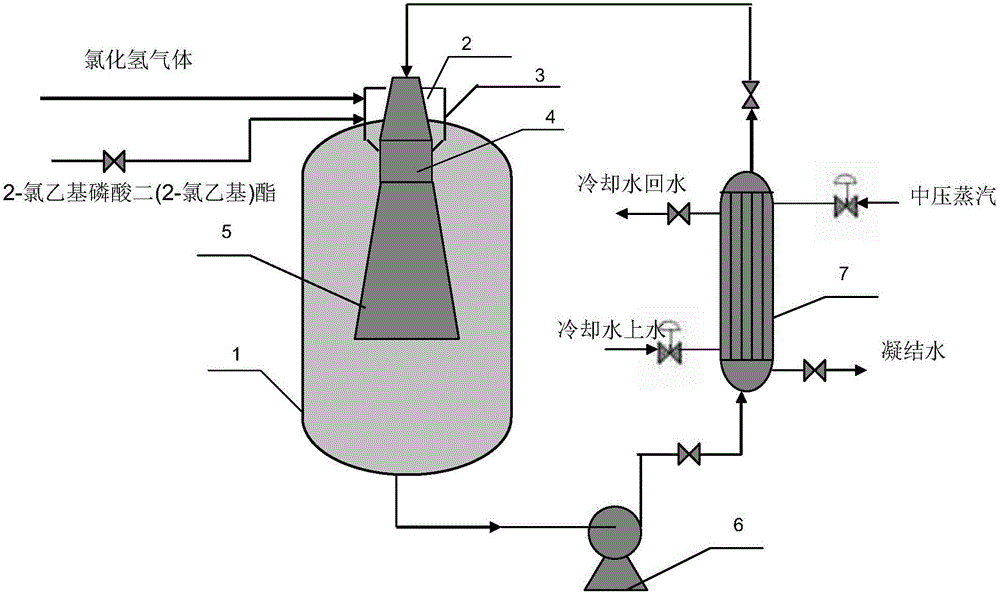

Venturi circulation loop reactor for continuous production of ethephon and method

InactiveCN105749849ACompact structureLower operating temperatureGroup 5/15 element organic compoundsChemical industryProcess engineeringEthephon

The invention discloses a venturi circulation loop reactor for continuous production of ethephon.The reactor comprises a reactor body, a venturi mixer located at the upper end of the reactor body and a circulating heat exchanger.The venturi mixer comprises a venturi nozzle, a mixing chamber and a diffusion chamber which are sequentially connected from top to bottom.An induction chamber is arranged on the outer side of the venturi nozzle which extends out of the top of the reactor body.One end of the circulating heat exchanger is connected with the bottom end of the reactor body, and the other end of the circulating heat exchanger is connected with the venturi nozzle.The outer side of the induction chamber is connected with an air inlet.The outer side of the nozzle is connected with a raw material port.Compared with the prior art, energy consumption and equipment investment expenses can be greatly reduced, the occupied area can be reduced, and investment of capital construction is saved.The technical route is simple, equipment is compact, product quality is good, energy is saved, consumption is reduced, and the requirement for sustainable development is met.

Owner:JIANGSU ANPON ELECTROCHEM

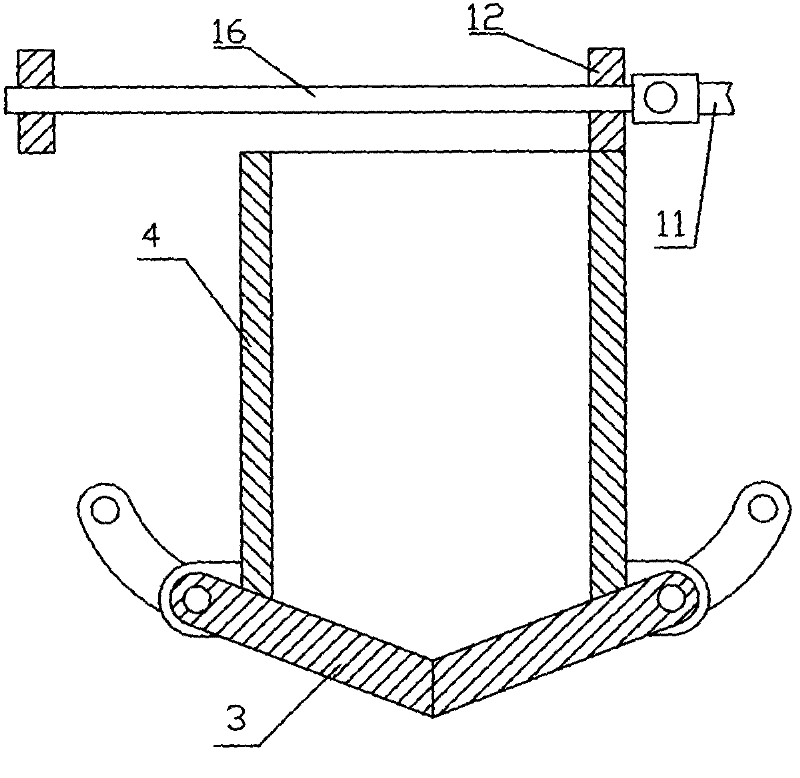

Automatic suction filtration and tray distributing machine

ActiveCN103463848AImprove intrinsic safetyIncrease productivityLiquid materialGravity filtersFiltrationControl engineering

The invention discloses an automatic filtrating and tray distributing machine, relates to a medicament suction filtration and equipartition device, and aims to solve the problems that the manual operation efficiency is low and the safety can not be guaranteed in the prior art. The automatic suction filtration and tray distributing machine comprises a suction filtration barrel, a medicament receiving platform, and medicament trays arranged on the medicament receiving platform; the suction filtration barrel is arranged on a suction filtration barrel bracket; an overturn drive device and an autorotation drive device respectively drive the suction filtration barrel to incline, overturn and autorotate; the medicament trays are arranged below the suction filtration barrel, rotate along with the medicament receiving platform and are driven to autorotate by synchronizing wheels; a suction filtration device is arranged below the suction filtration barrel, and is used for performing suction filtration in the suction filtration barrel; liquid subjected to suction filtration is placed in a receiving pipe seat arranged below the suction filtration device. By using the automatic filtrating and tray distributing machine, the solid-liquid separation is realized by taking vacuum negative pressure as power; a medicament is distributed uniformly, so that operating personnel does not need to be contacted with hazardous articles directly; and therefore, the intrinsic safety of processes is improved. The structure is simple; the production efficiency is effectively improved; the production cost is reduced.

Owner:YAHUA GROUP MIANYANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com