Machine for automatically assembling detonator into die

An automatic and detonator technology, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of low manual operation efficiency and unguaranteed safety, and achieve the effects of improving intrinsic safety, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0016] preferred embodiment

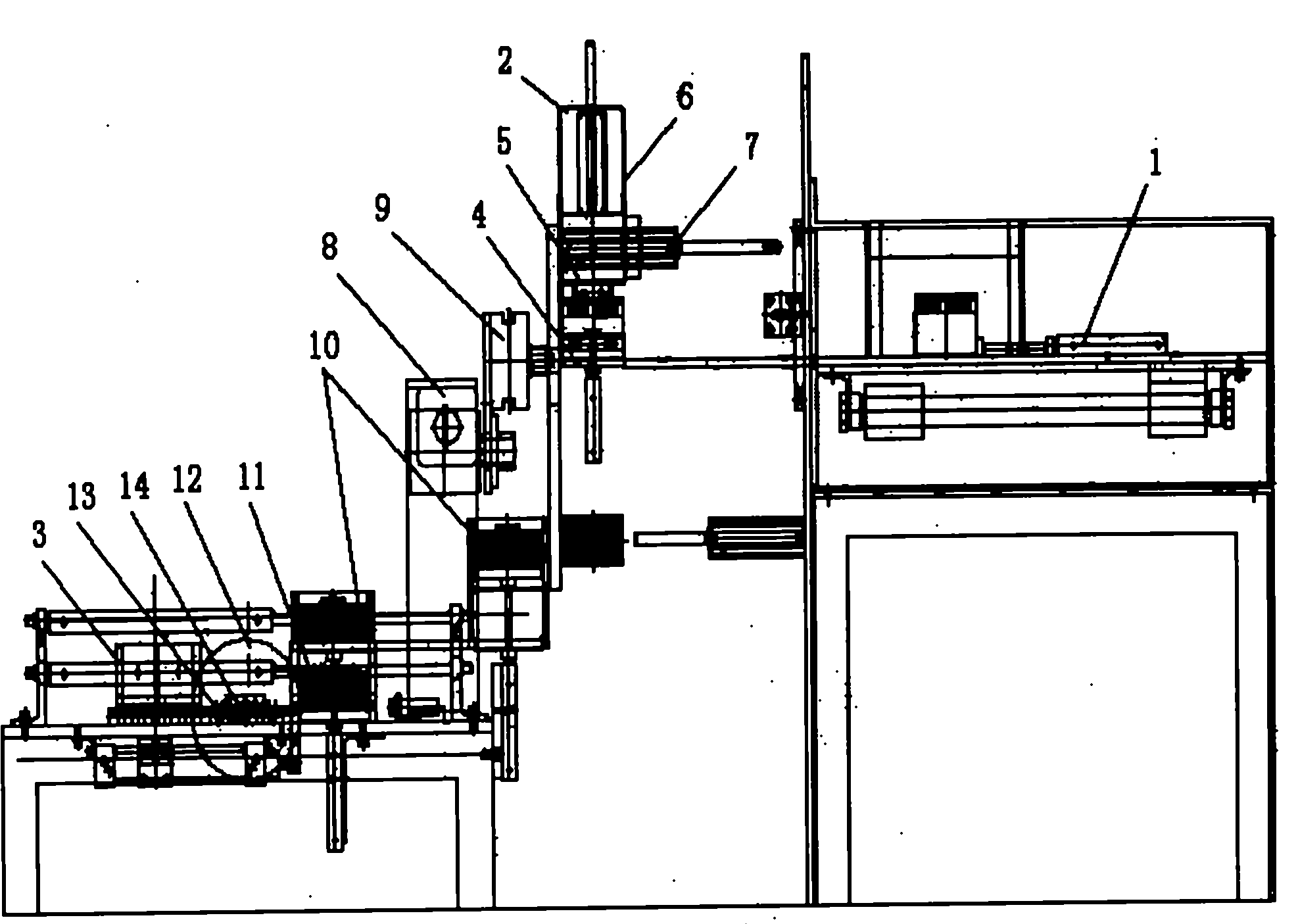

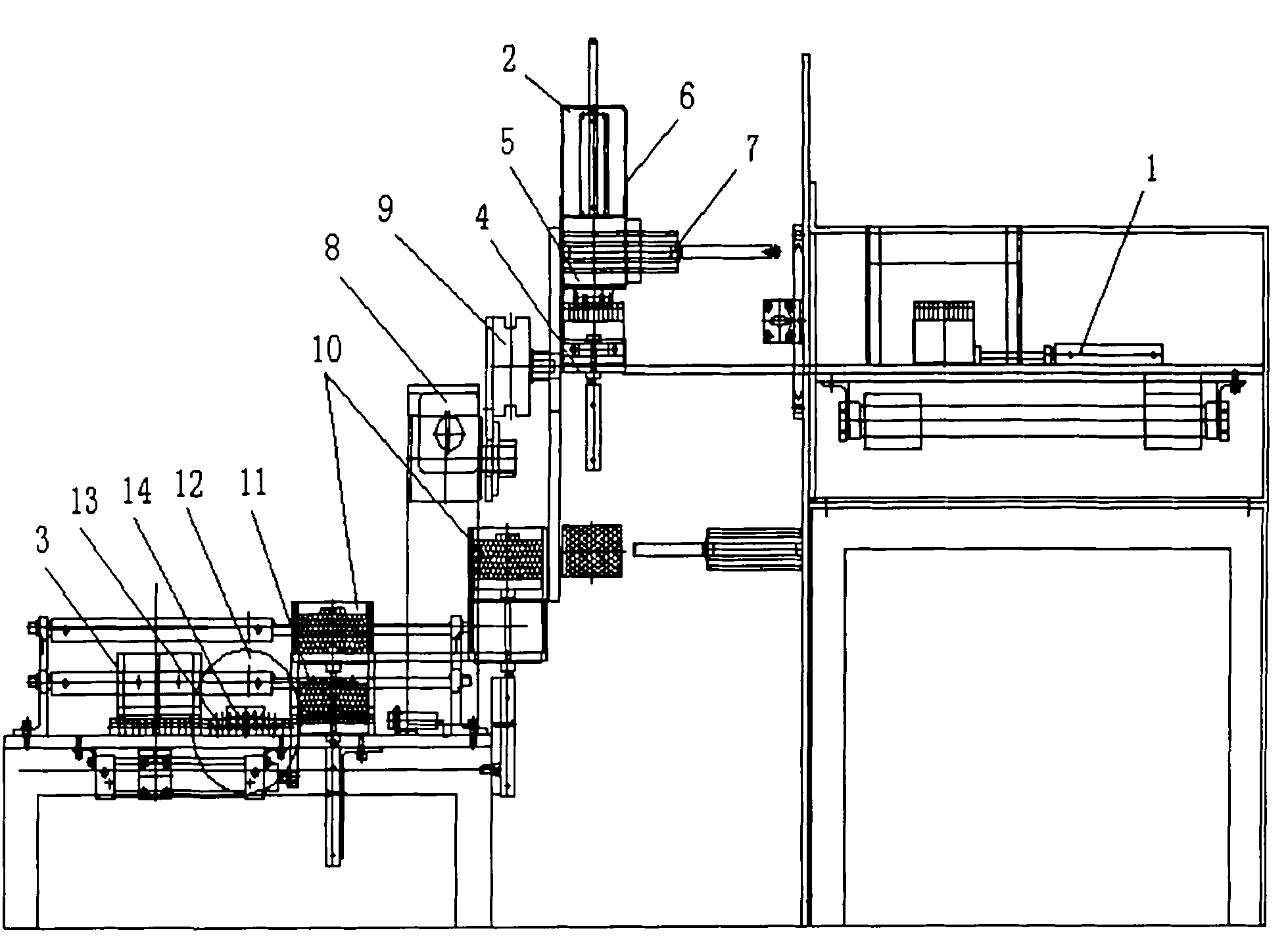

[0017] Such as figure 1 In the shown detonator automatic molding machine, the operator puts the boxed semi-finished detonator (detonator to be installed) on the workbench outside the safety protection plate, and the detonator detonator box to be installed is sent into the box by the box feeding cylinder 1. Take the tube rotating device 2 and put it on the box plate 4. The 180-degree turning cylinder 8 turns over, and the detonator breaks away from the bottom of the box and enters the turning tube frame 5. The 90-degree turning cylinder 9 rotates, so that the detonator enters a horizontally placed state. The pipe outlet wicket 6 is opened, and the pipe outlet cylinder 7 pushes the detonator into the tube delivery box 10, and the tube delivery box 10 moves to the top of the slide tube box 11, so that the detonator enters the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com