Patents

Literature

4847results about "Feeding arrangments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

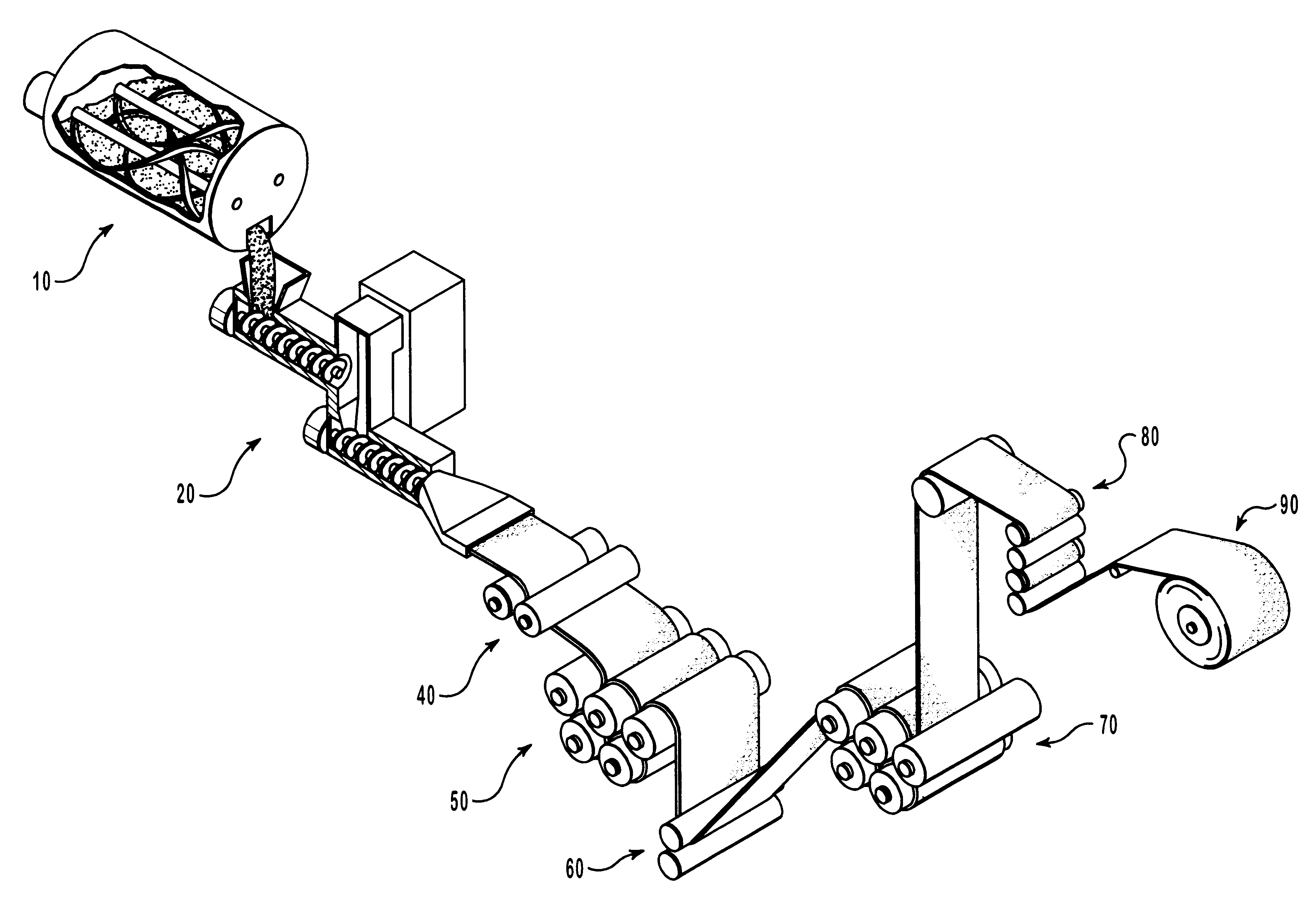

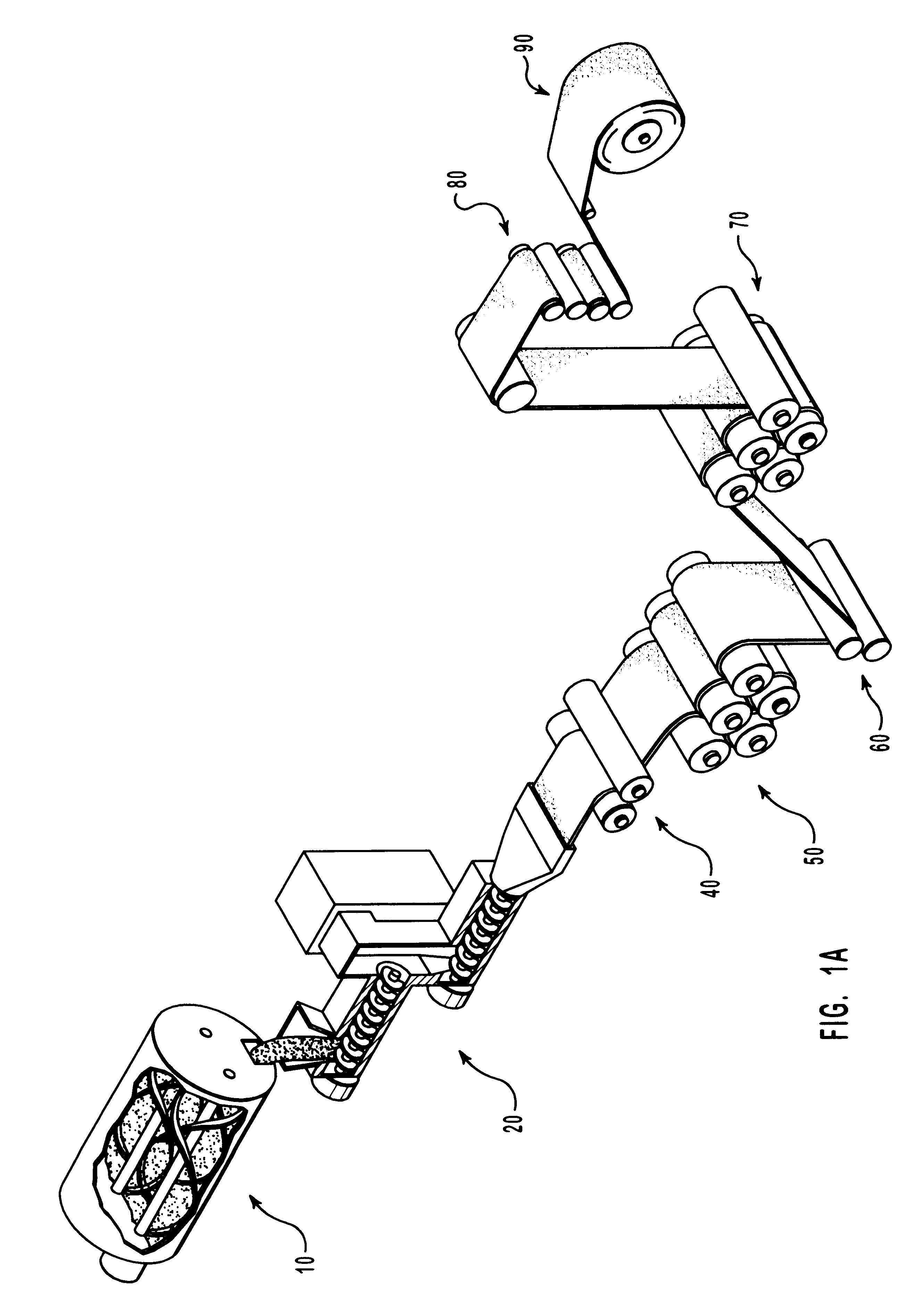

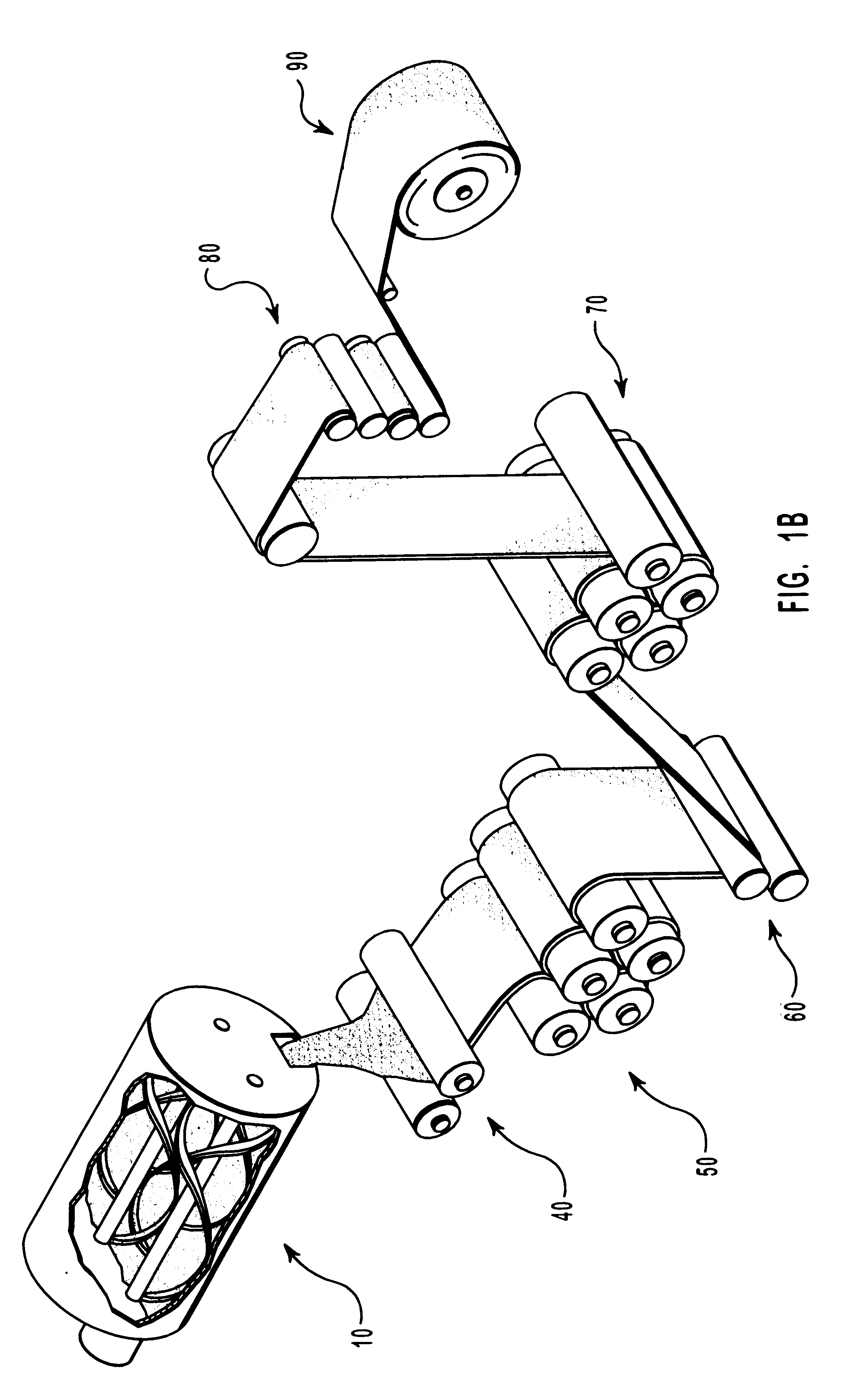

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

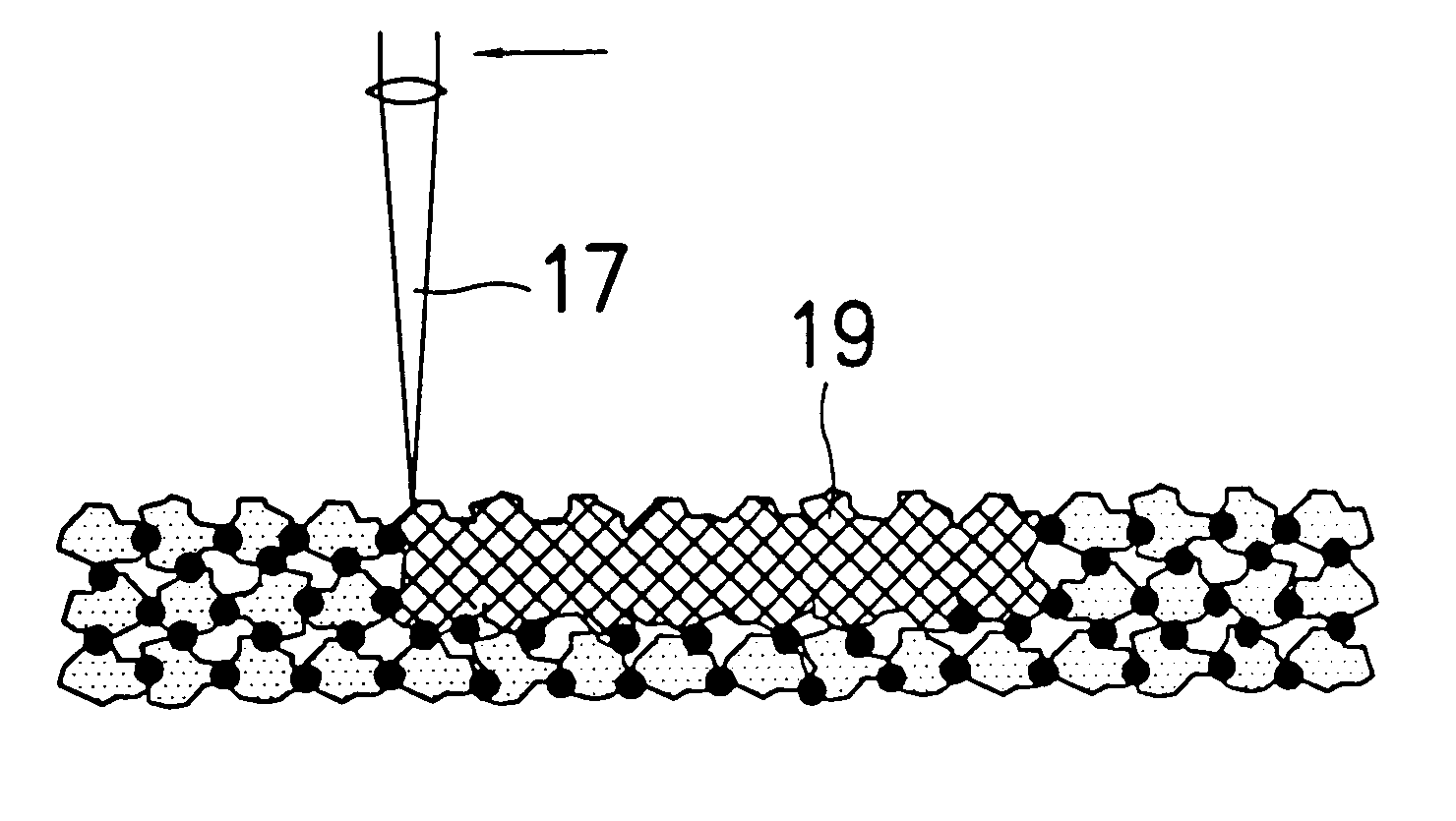

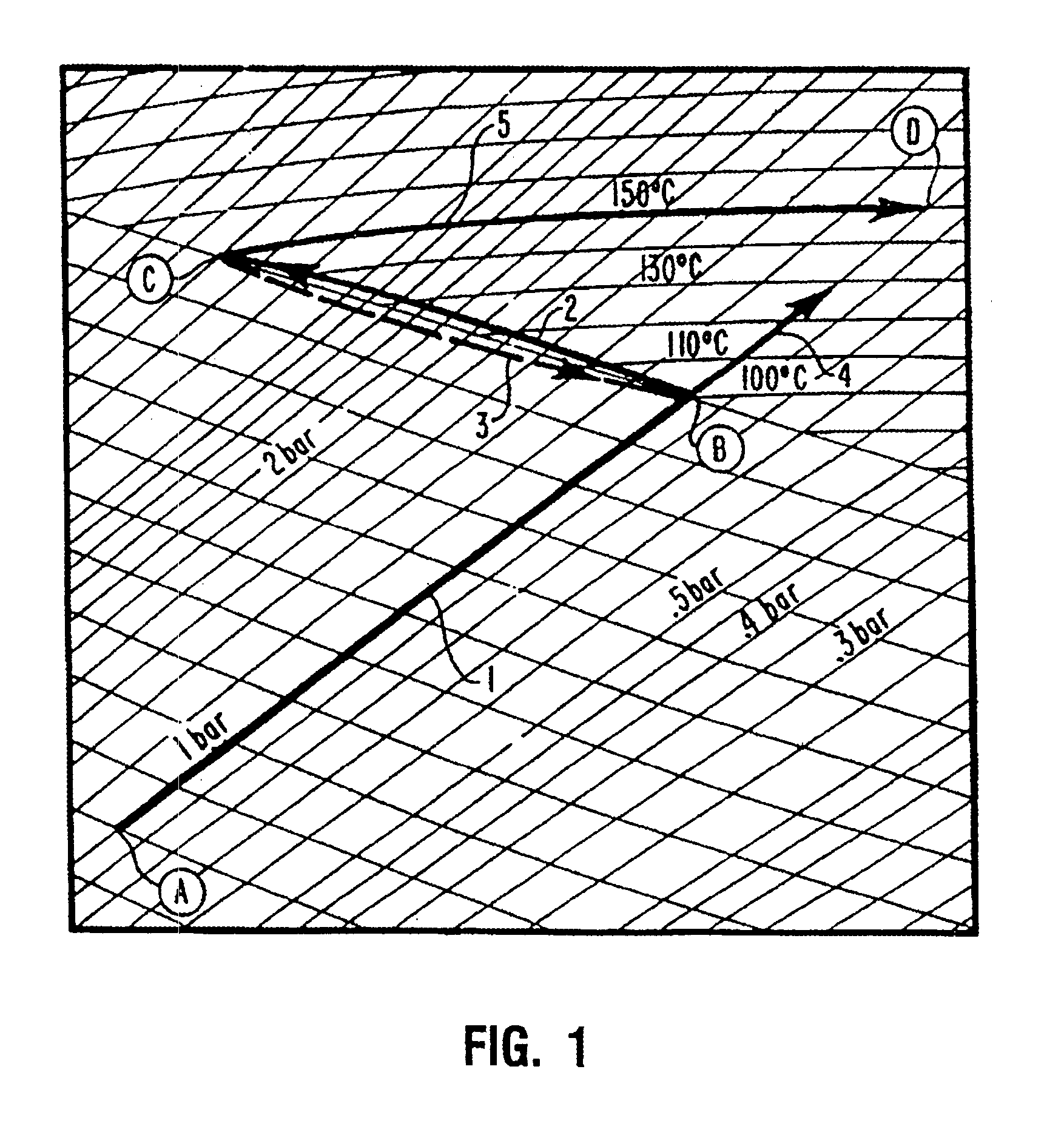

Method for rapid forming of a ceramic work piece

InactiveUS6217816B1Rapid productionPrevent dislocationAdditive manufacturing apparatusFeeding arrangmentsHeat fusionLaser beams

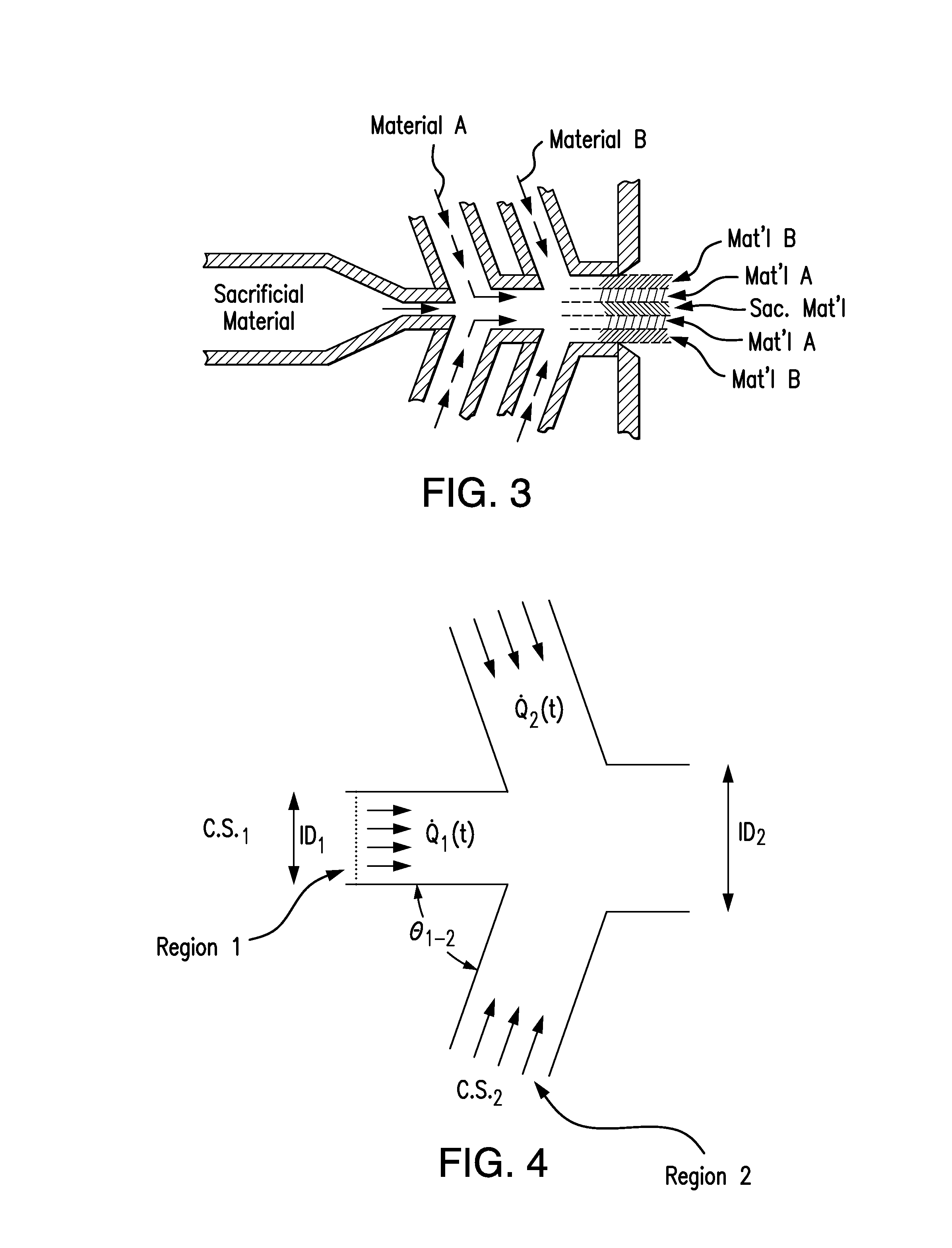

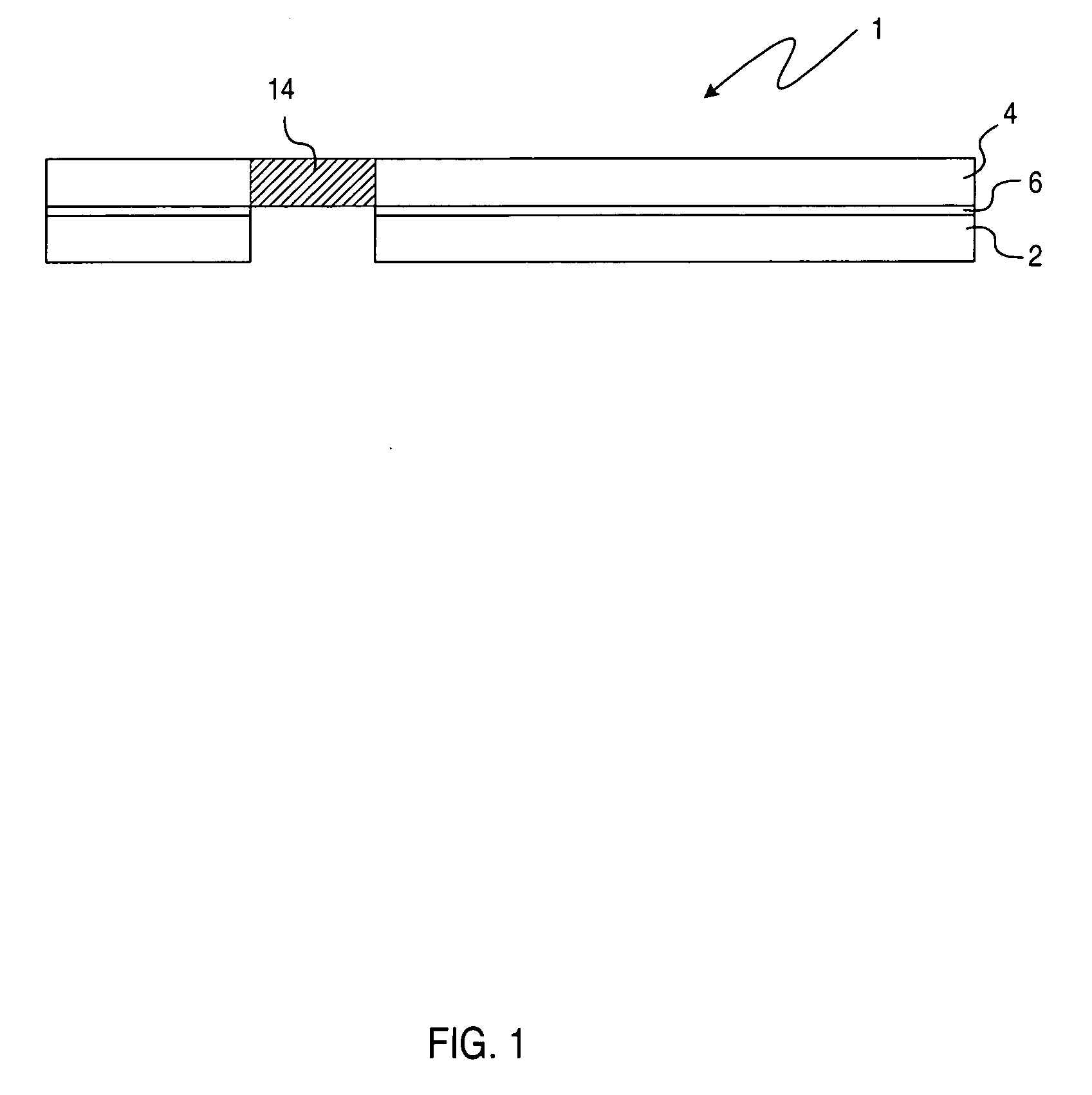

An inorganic binder and a dissolving agent are put into ceramic powder. They are mixed to form a plastic green mixture. Then the said mixture is formed into a thin green layer. Preferably, this thin green layer will be preheated and dried such that the thin green layer will be hardened due to the bonding effect of the inorganic binder. A portion of the thin green layer exposed under a directed high-energy beam is sintered, preferably by a laser beam, to cause ceramic molecules to bond together locally due to heat fusion. By controlling the scanning path of the high-energy beam, a two-dimensional thin cross section of the ceramic part in arbitrary form can be produced. A second thin ceramic layer can be built onto the first thin ceramic layer and bonded to it by the same method. After multiple repetitions of this procedure a three dimensional ceramic part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, will be removed with suitable method. A ceramic part can be rapidly produced in this way.

Owner:NAT SCI COUNCIL

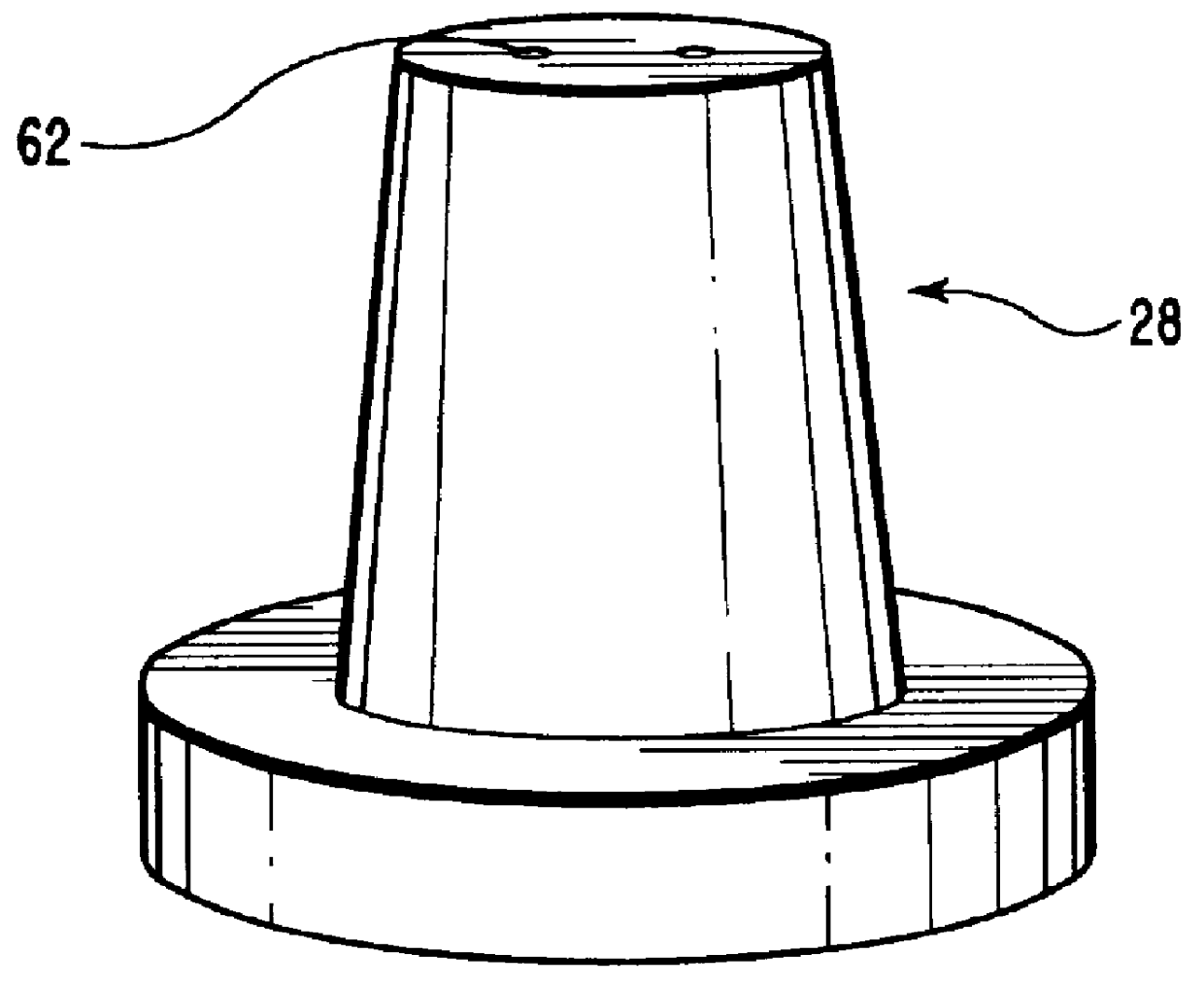

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

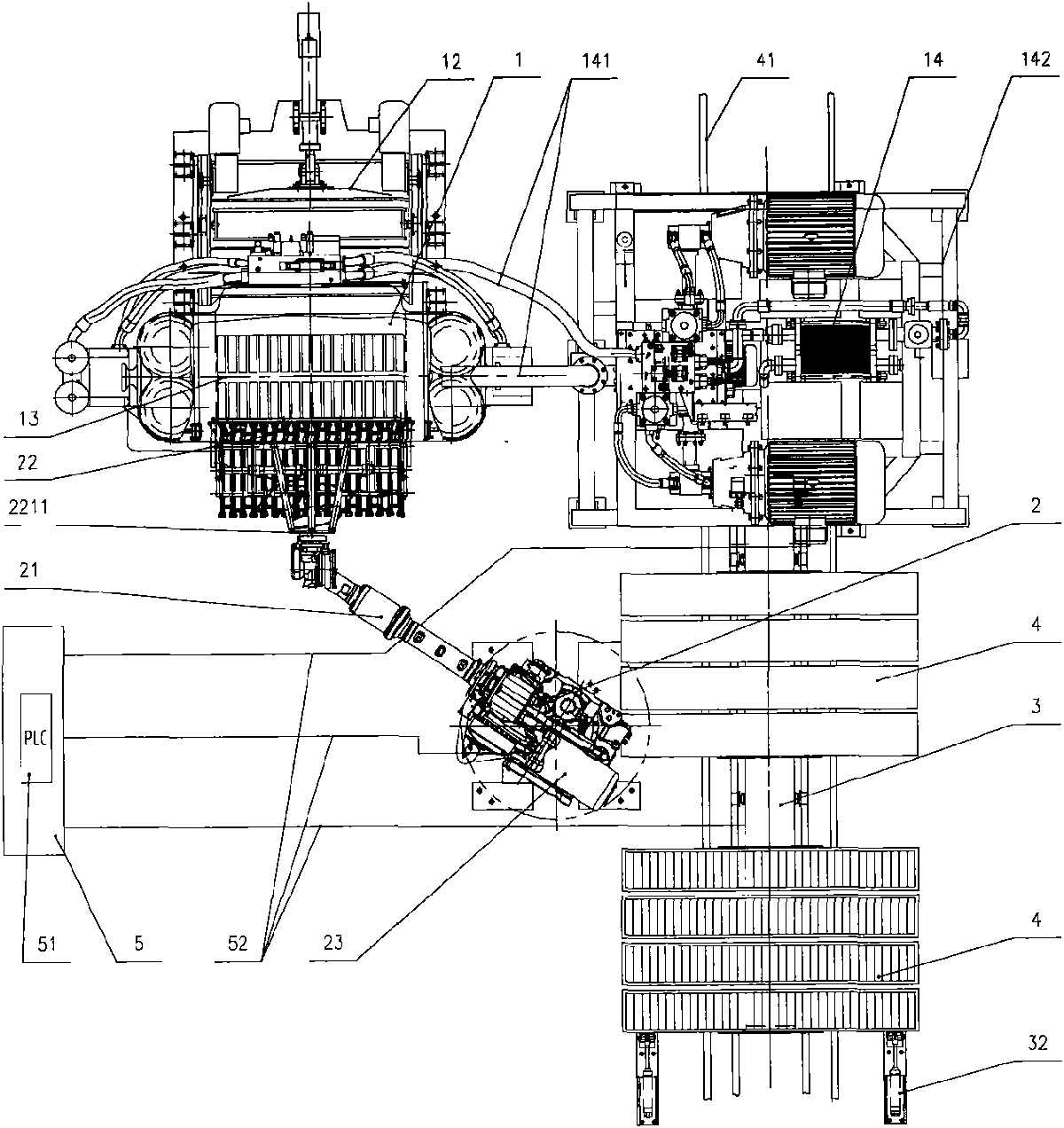

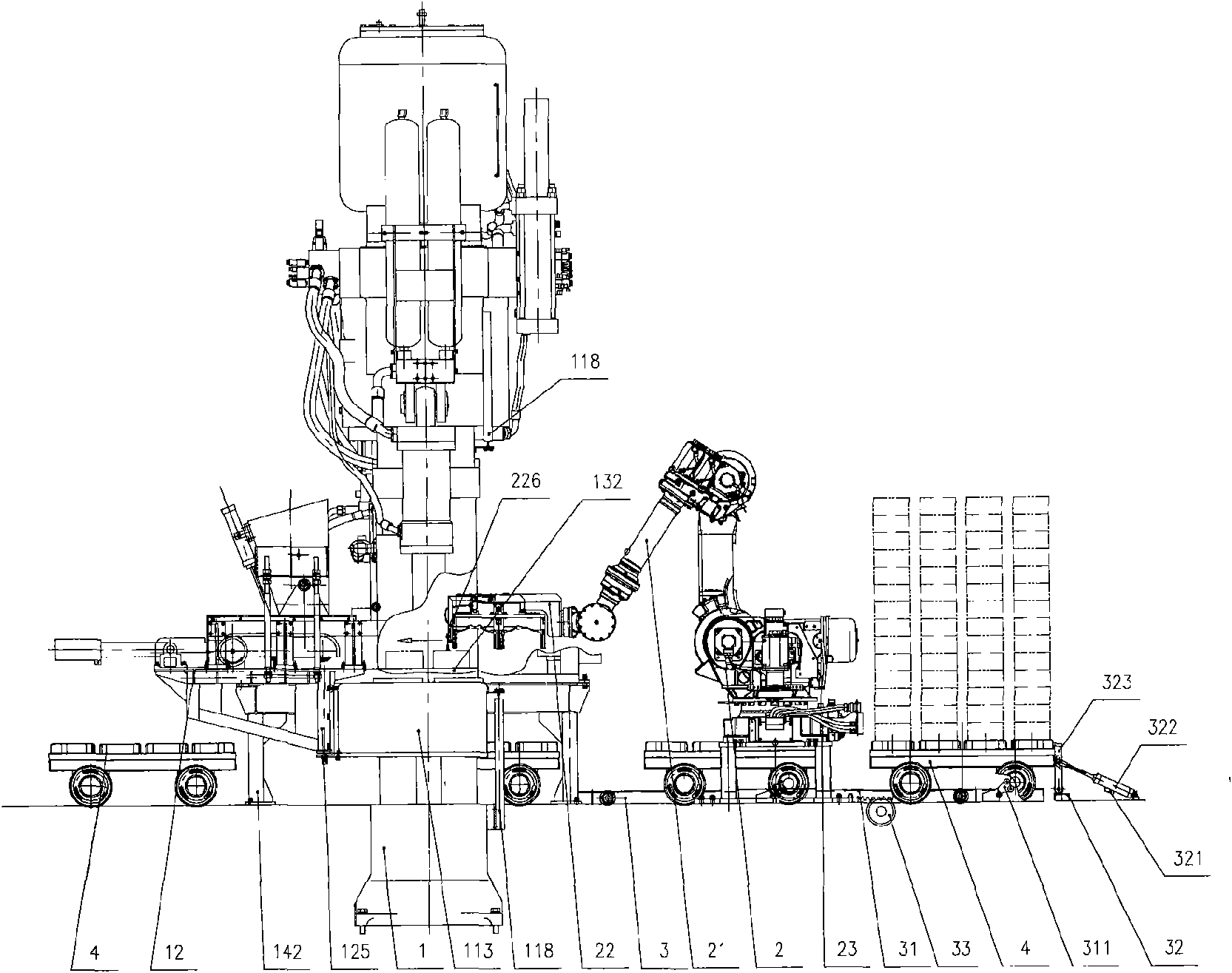

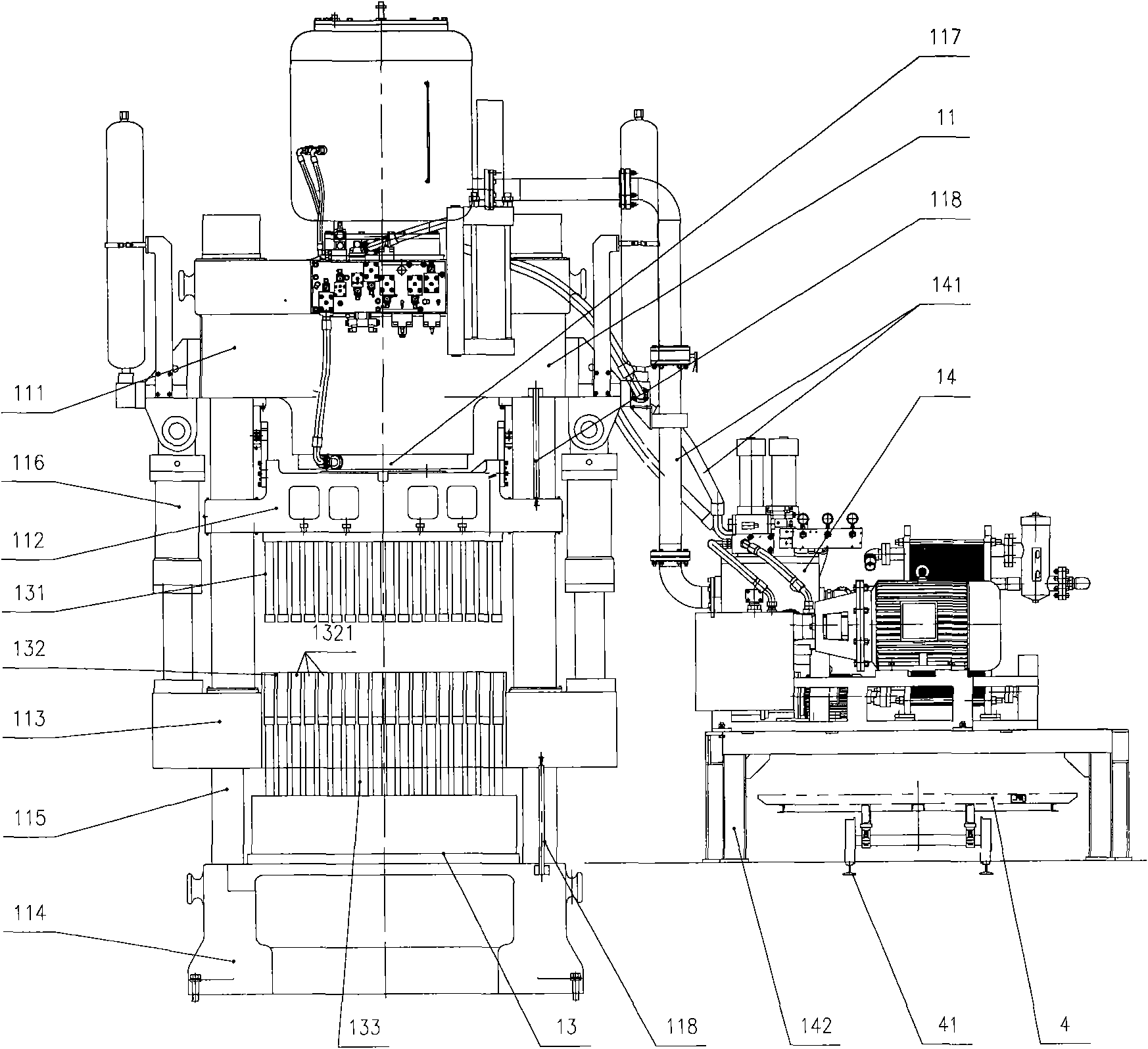

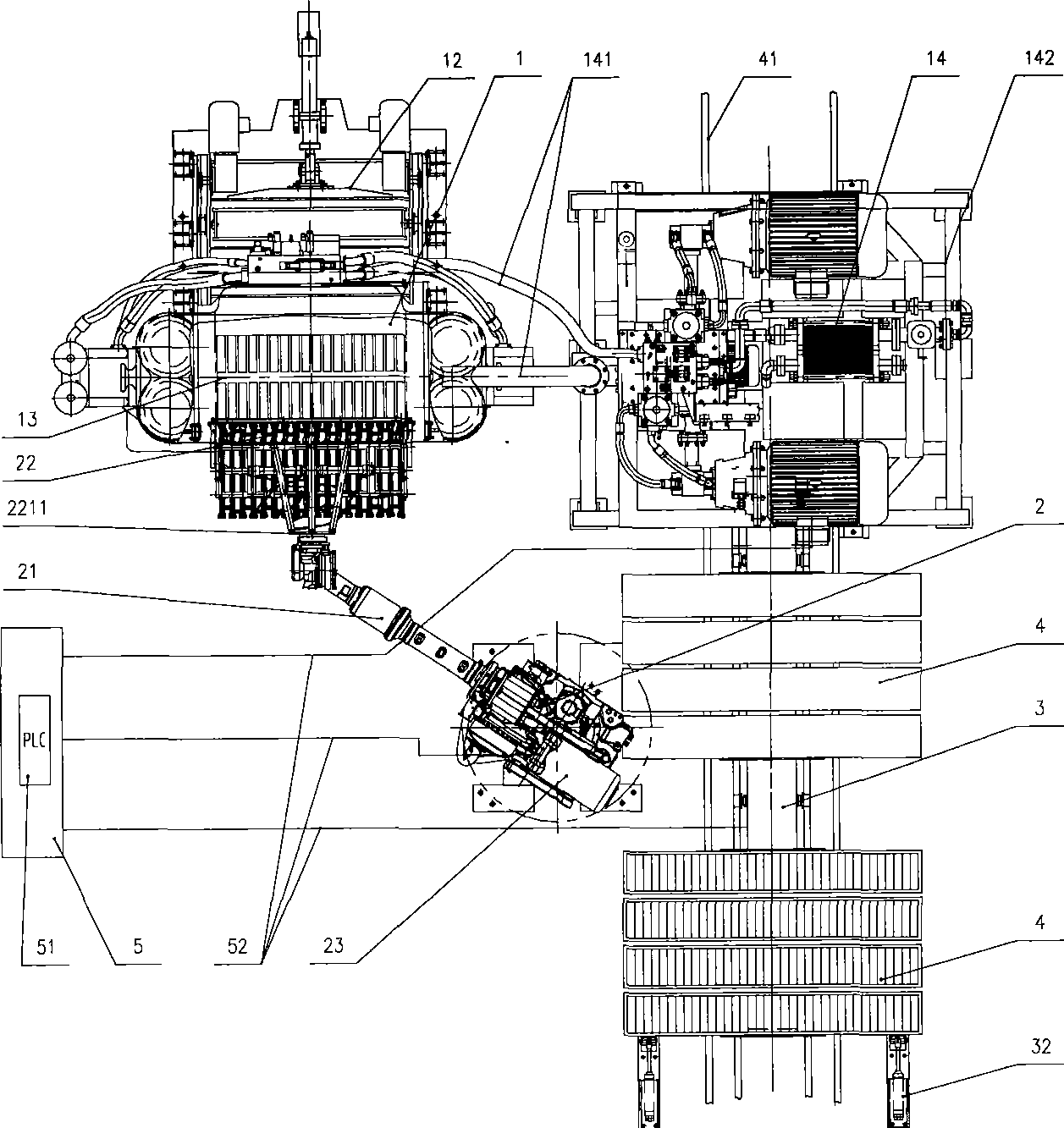

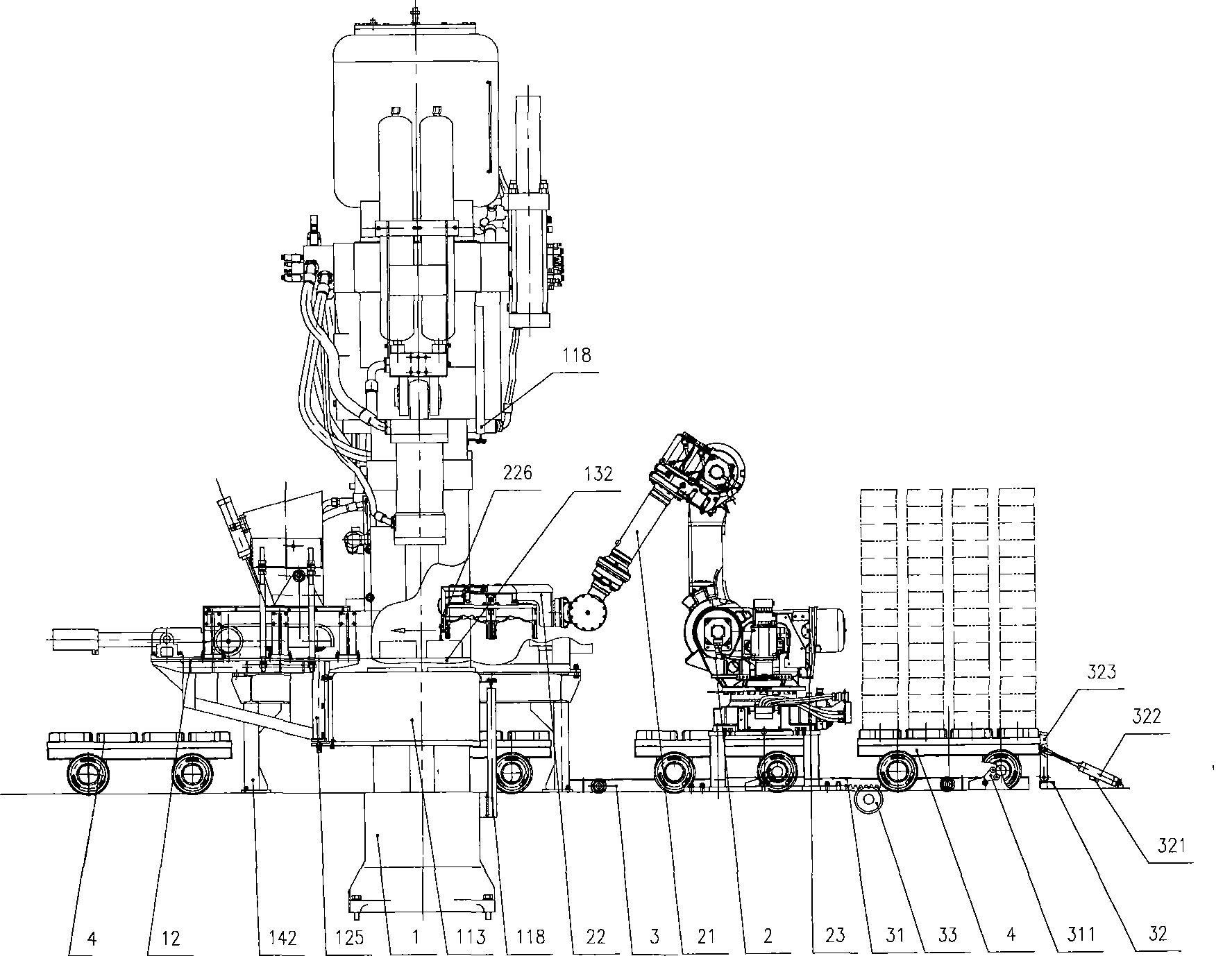

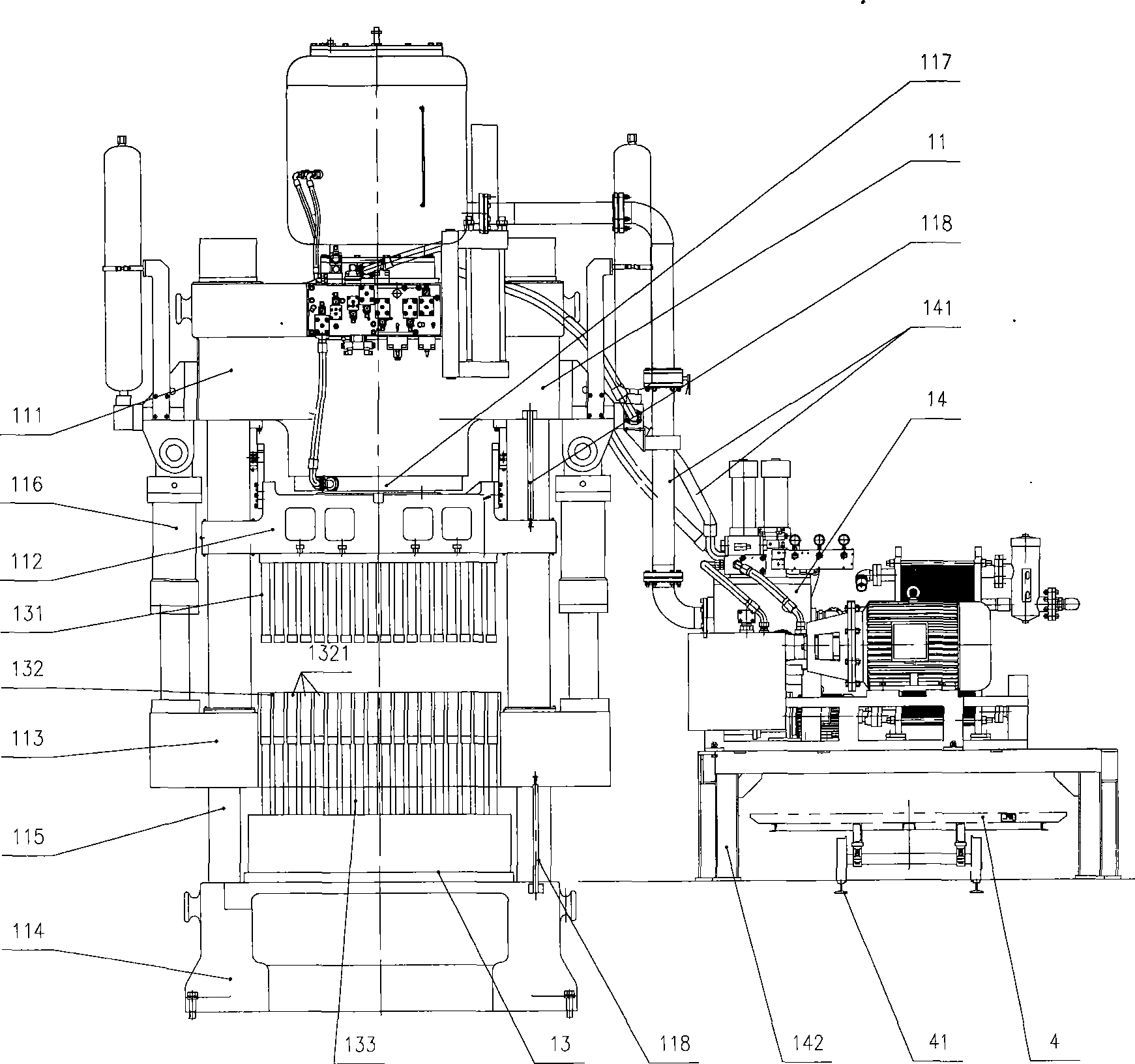

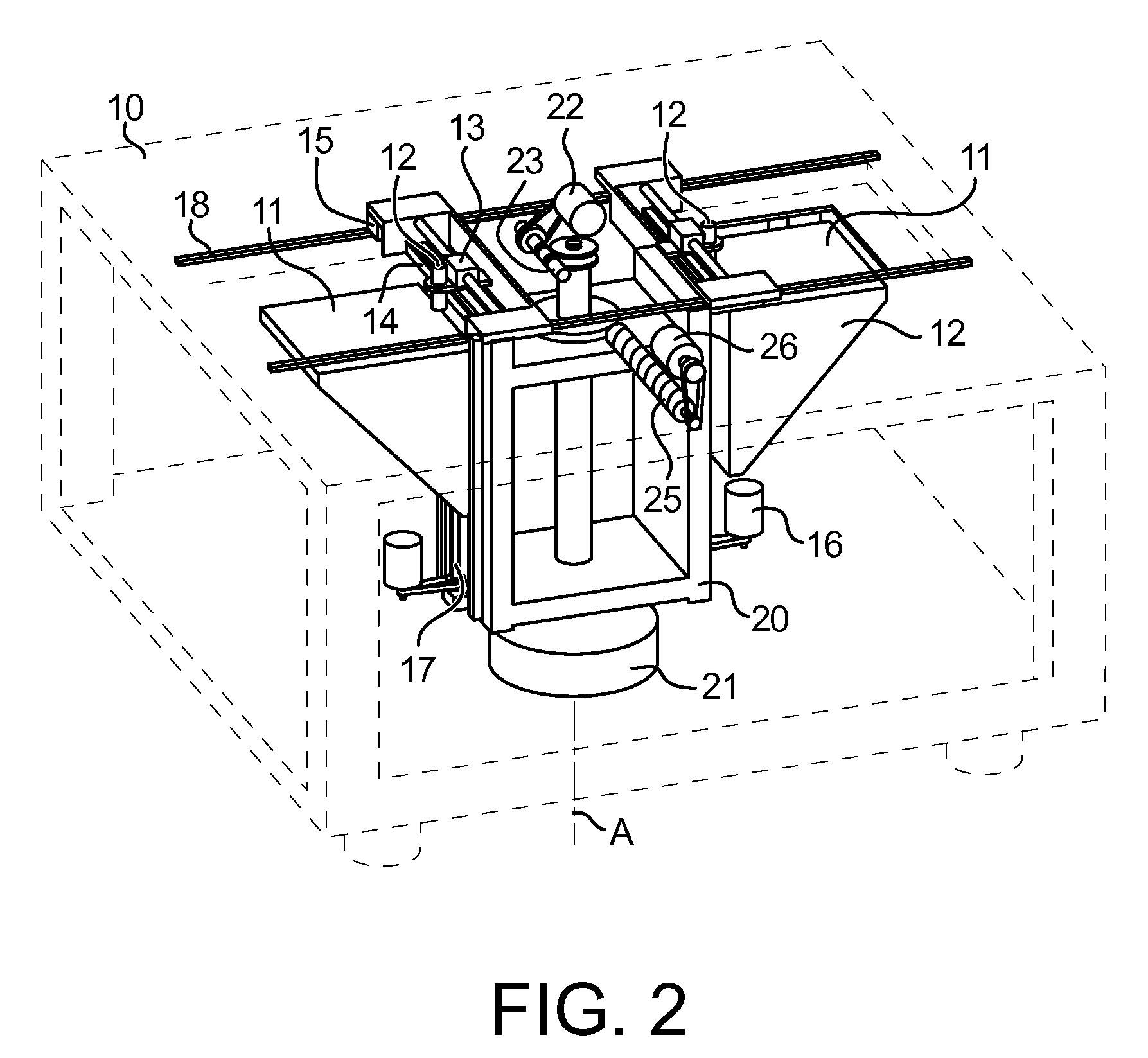

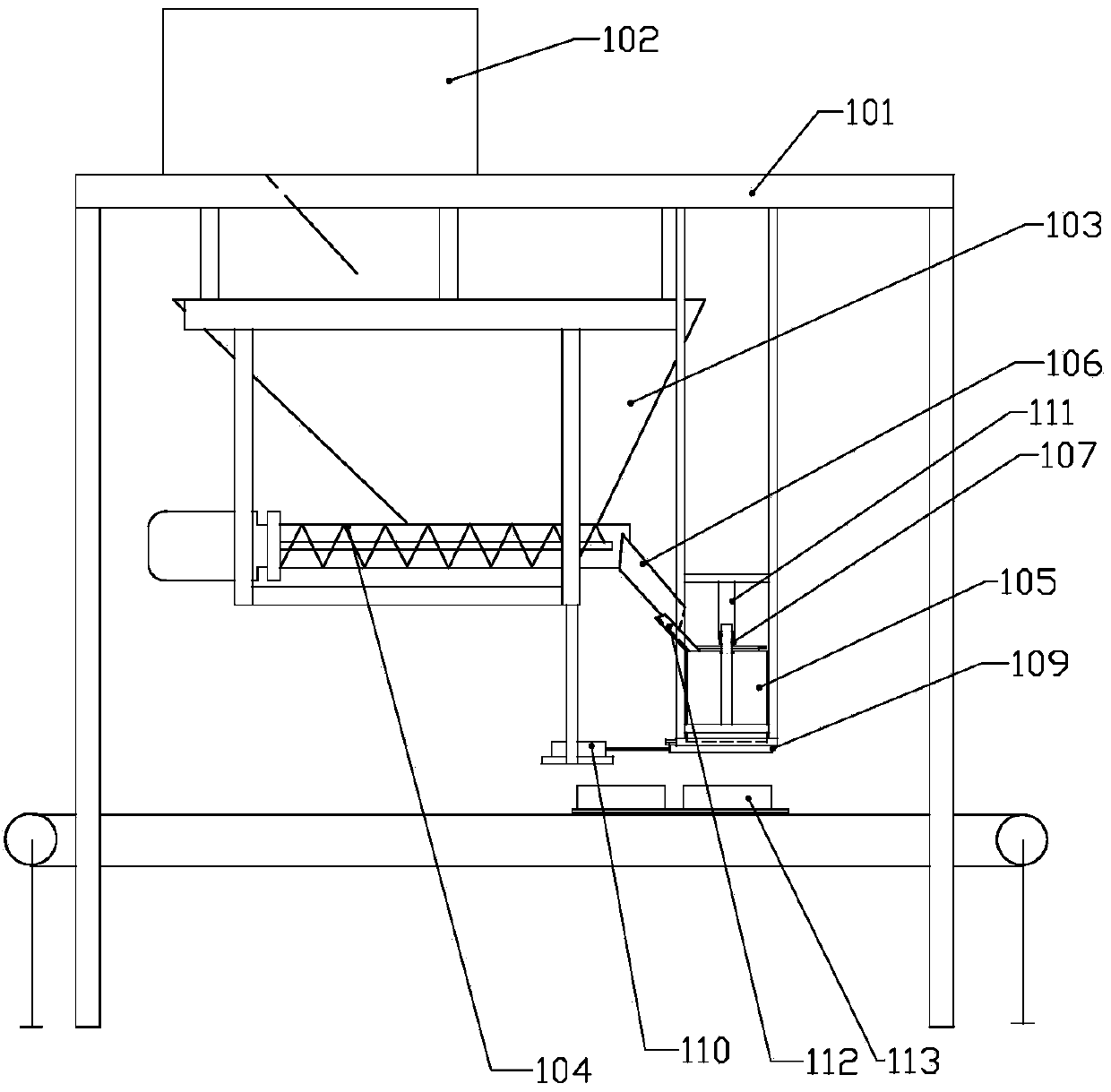

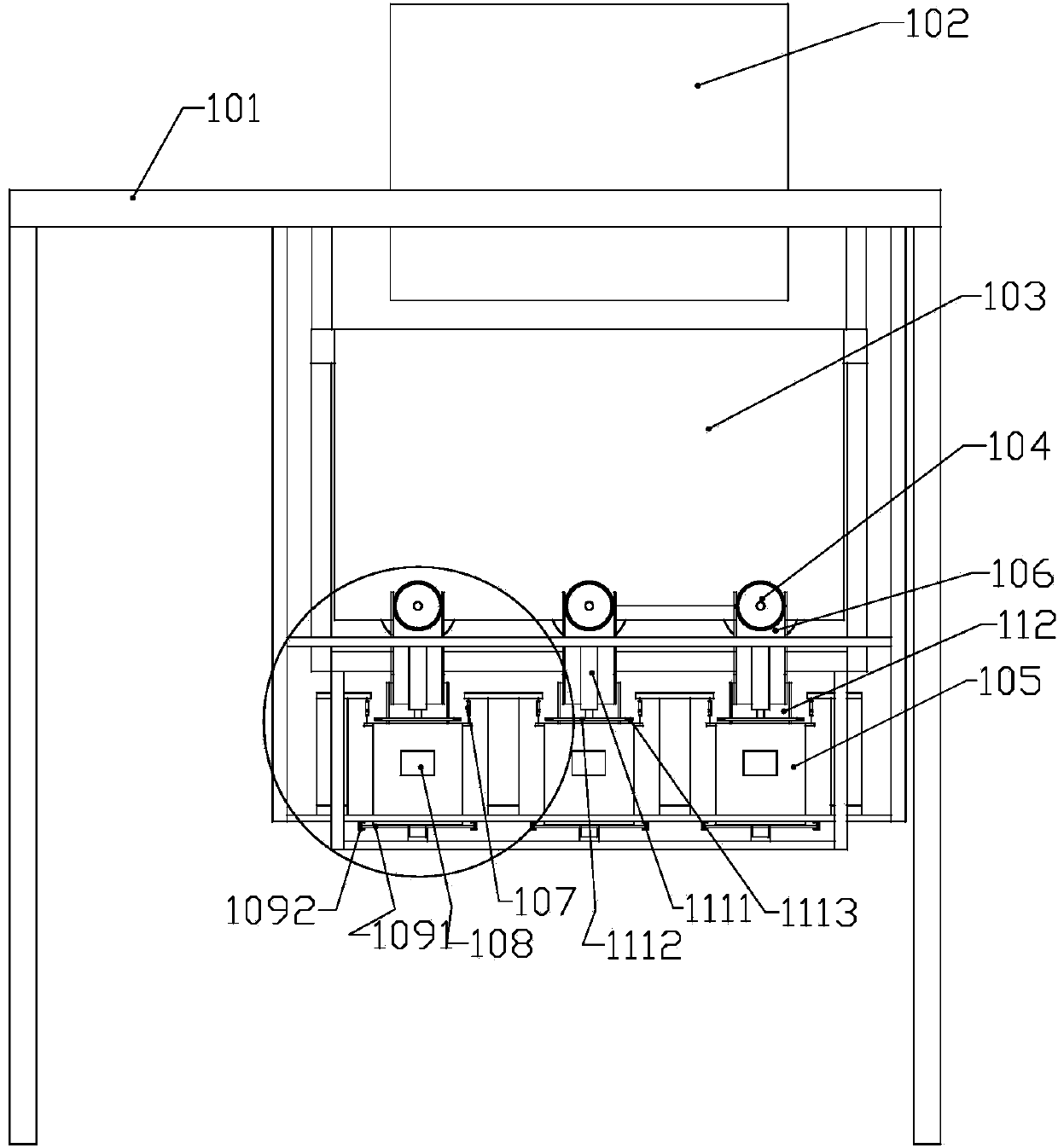

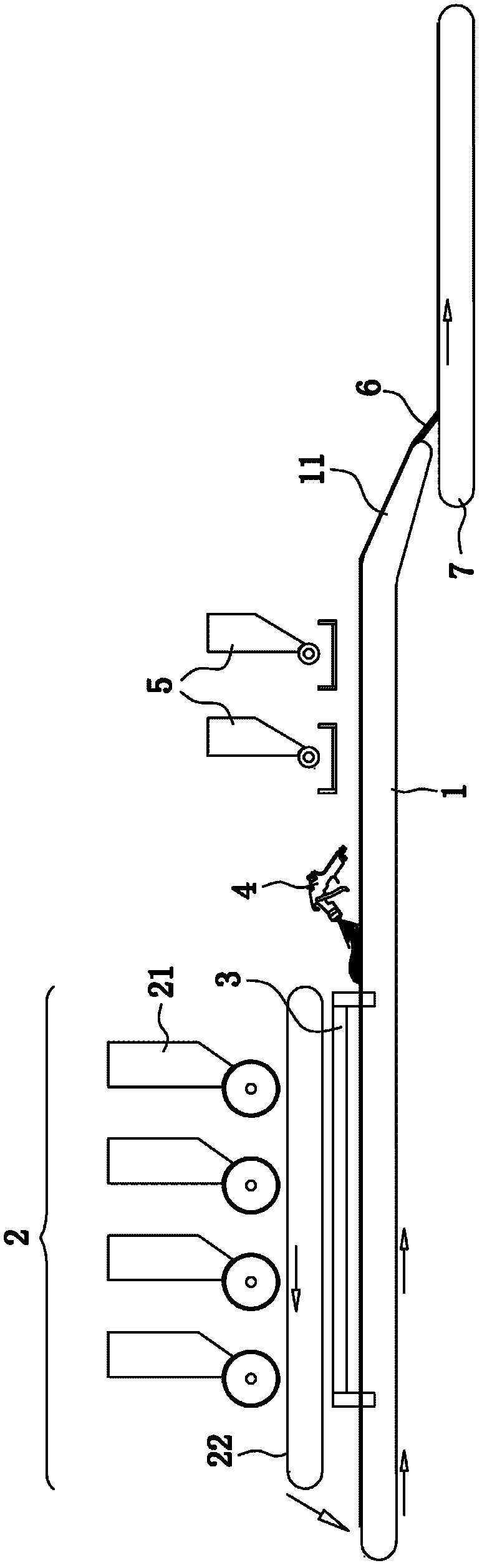

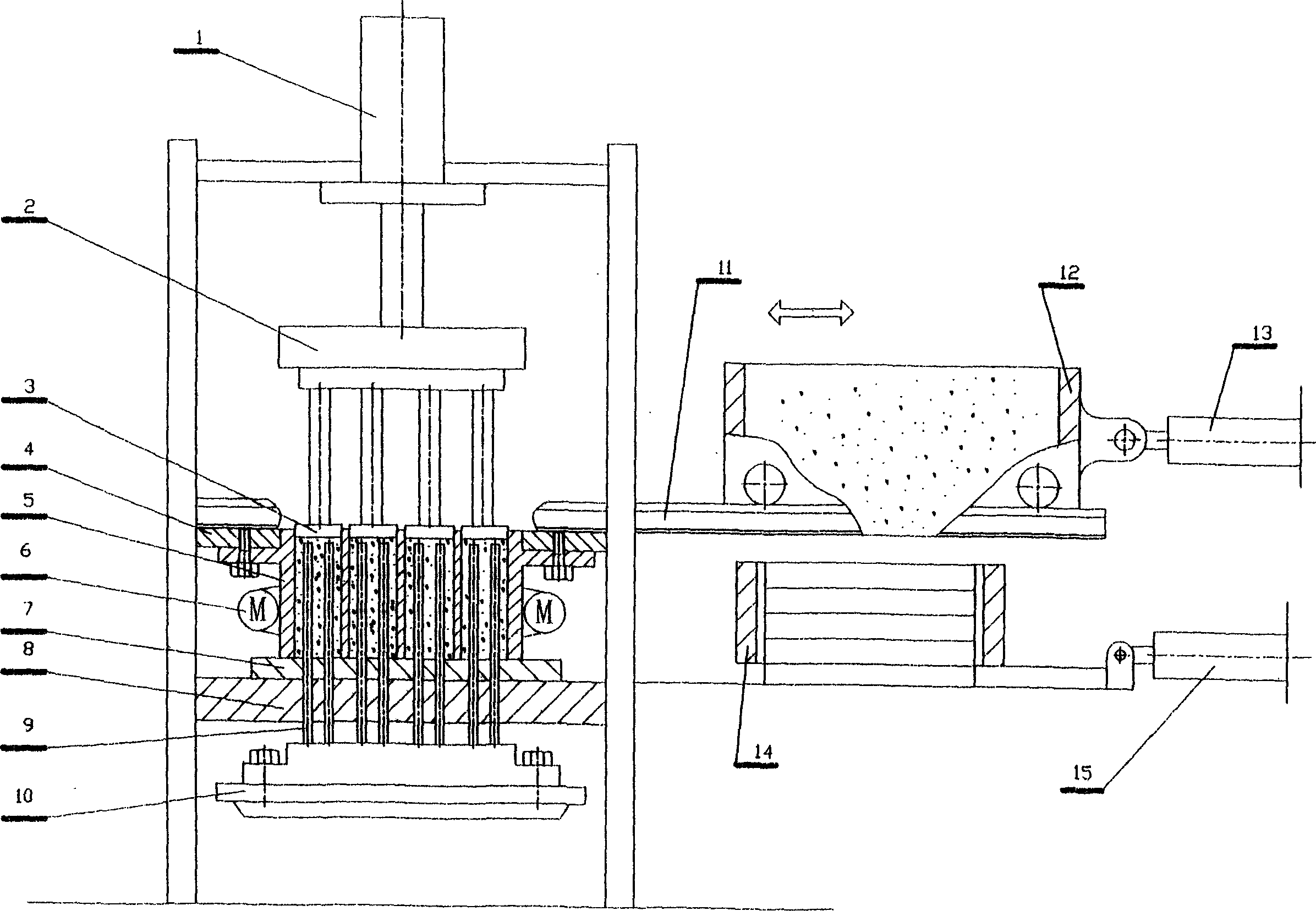

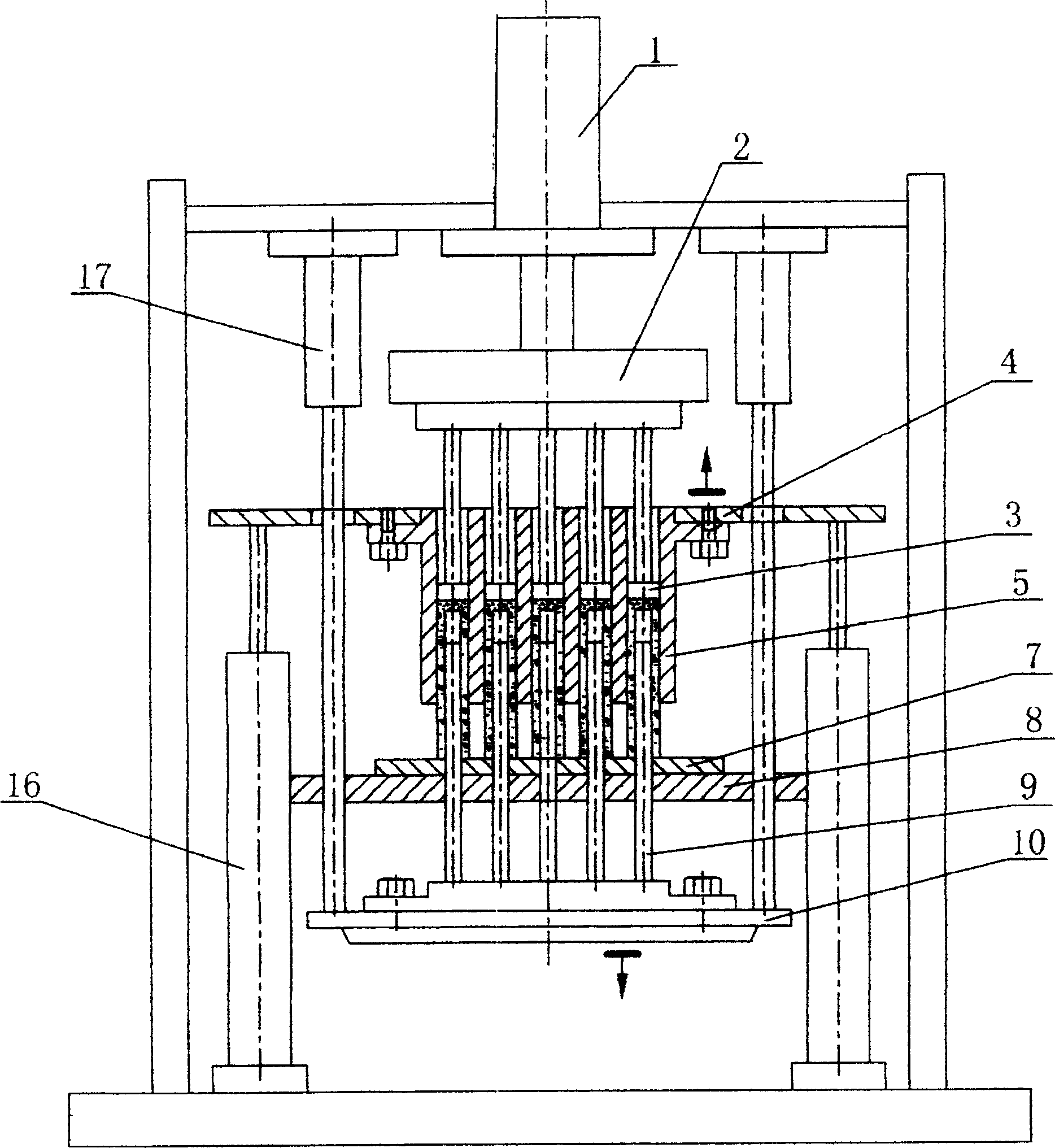

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

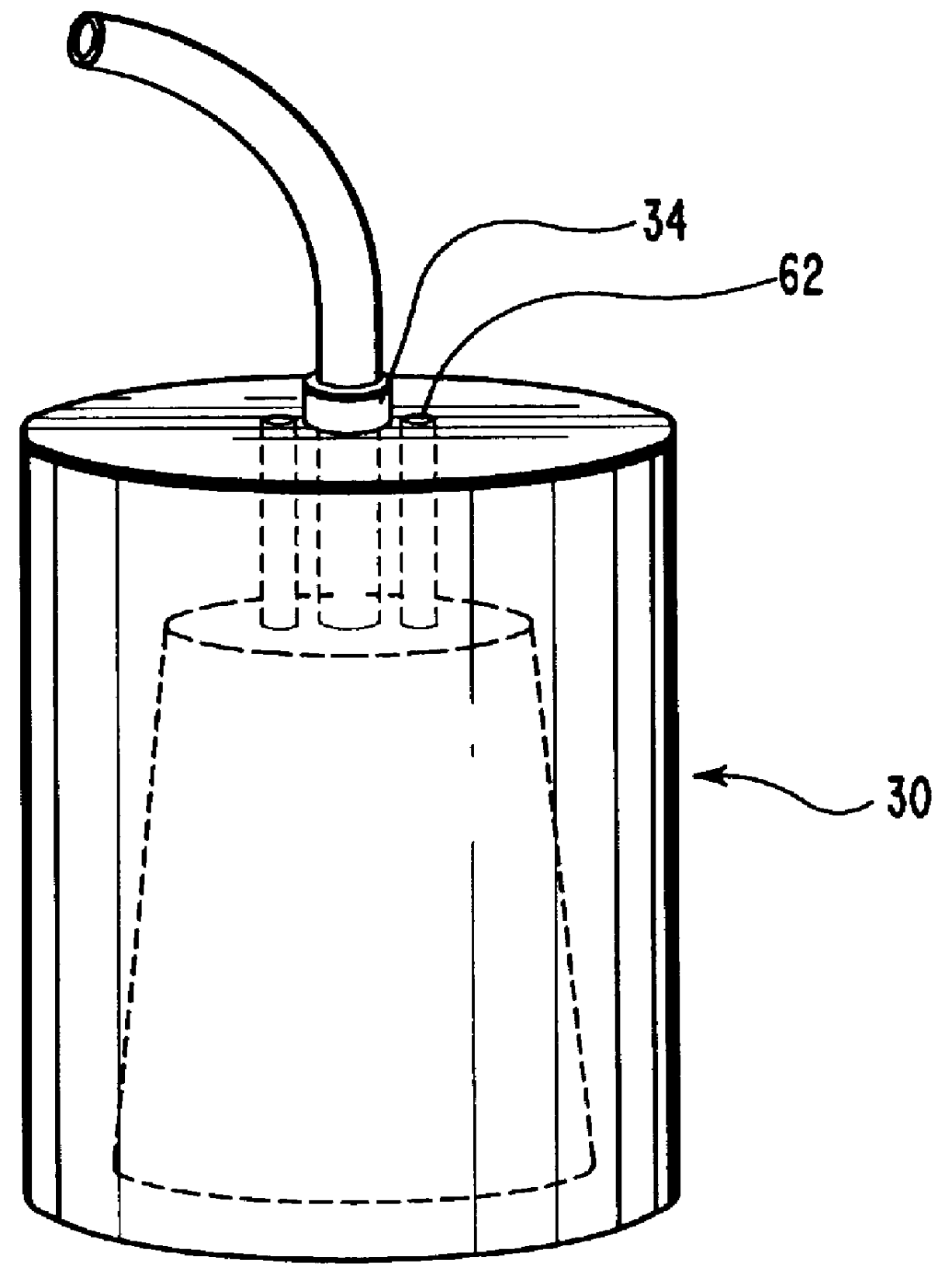

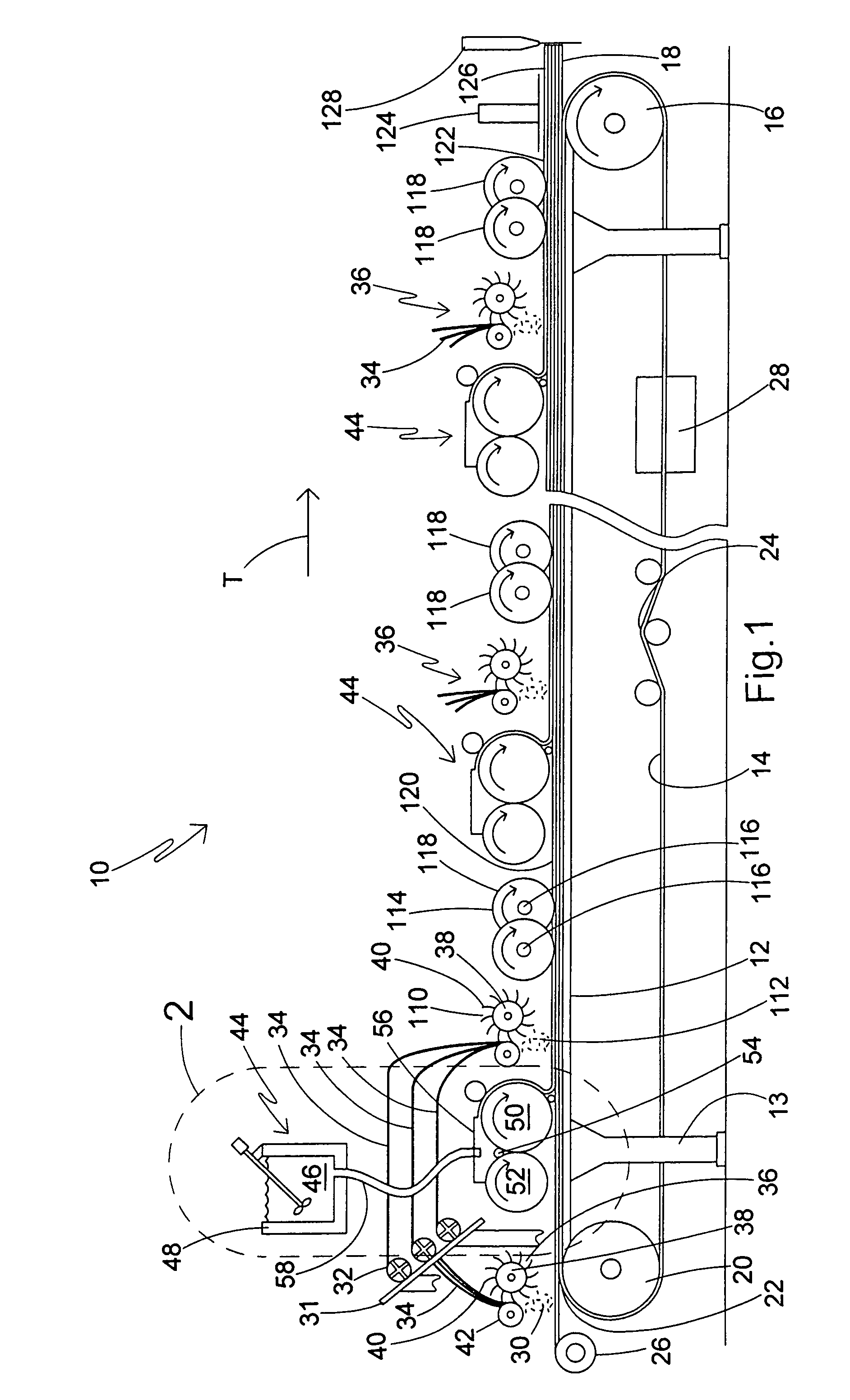

Slurry feed apparatus for fiber-reinforced structural cementitious panel production

Owner:UNITED STATES GYPSUM CO

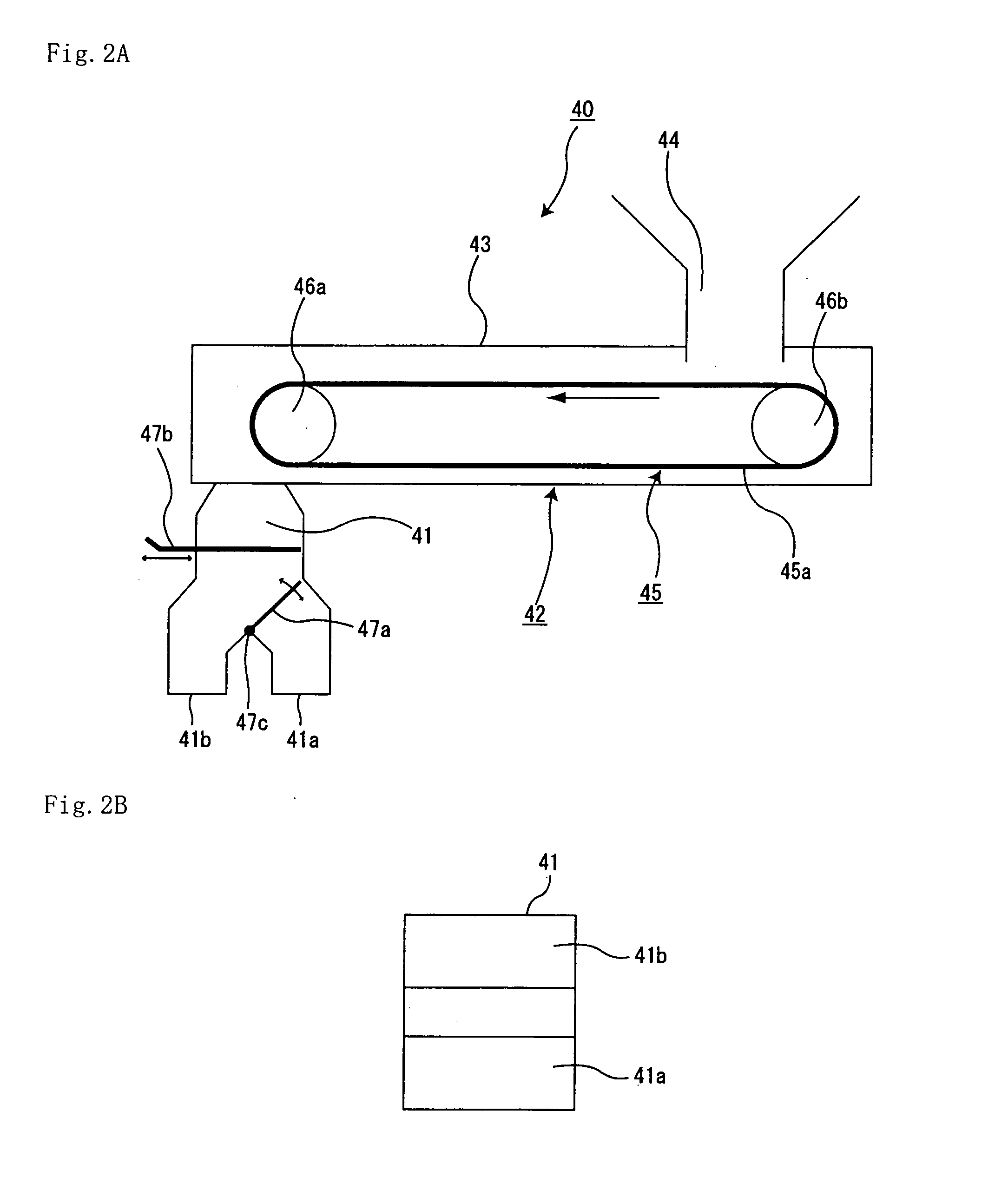

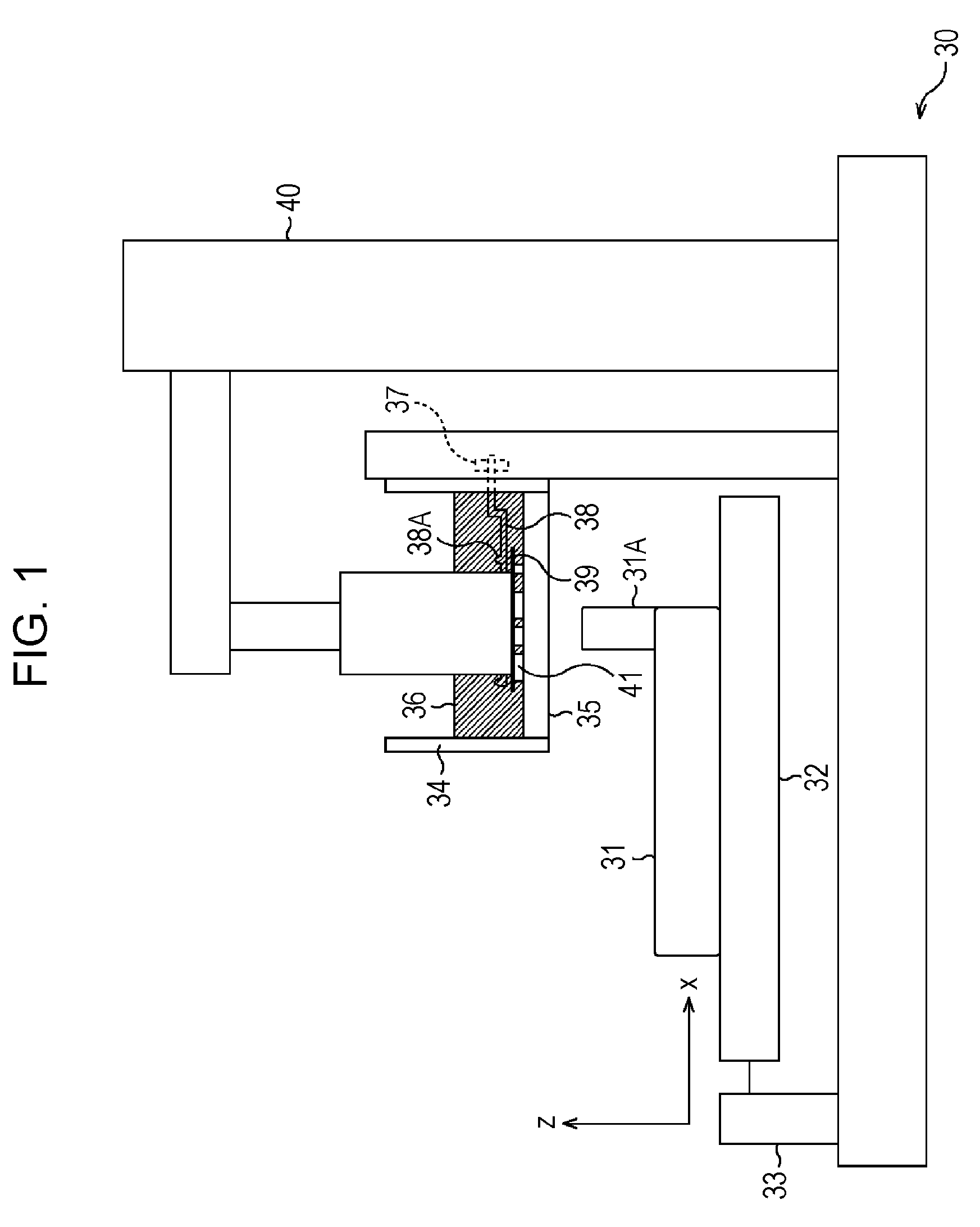

Transporting apparatus and method for manufacturing honeycomb structured body

InactiveUS20070152382A1Inhibit deteriorationReliable transportationFeeding arrangmentsLoading/unloadingEngineeringMechanical engineering

Owner:IBIDEN CO LTD

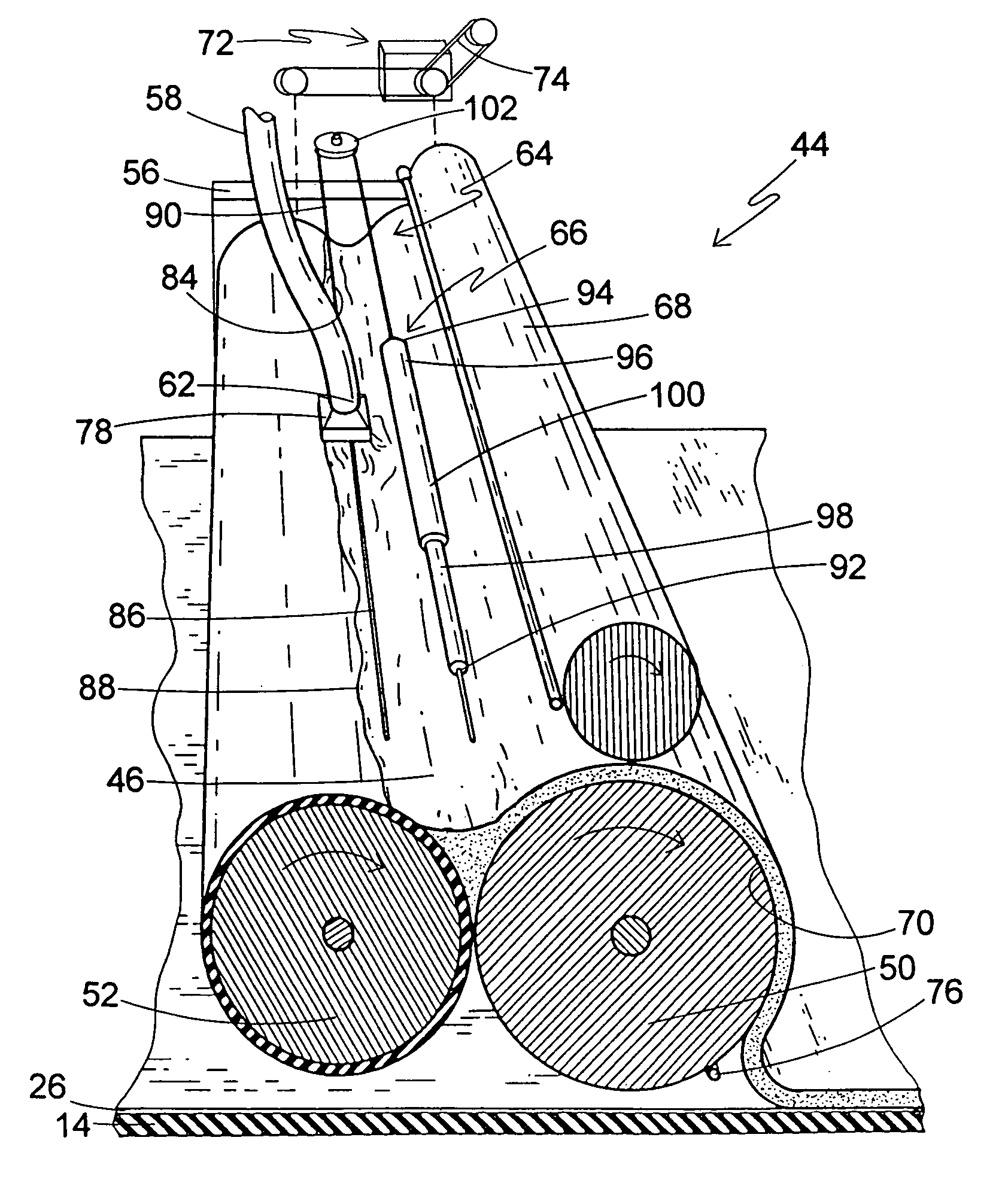

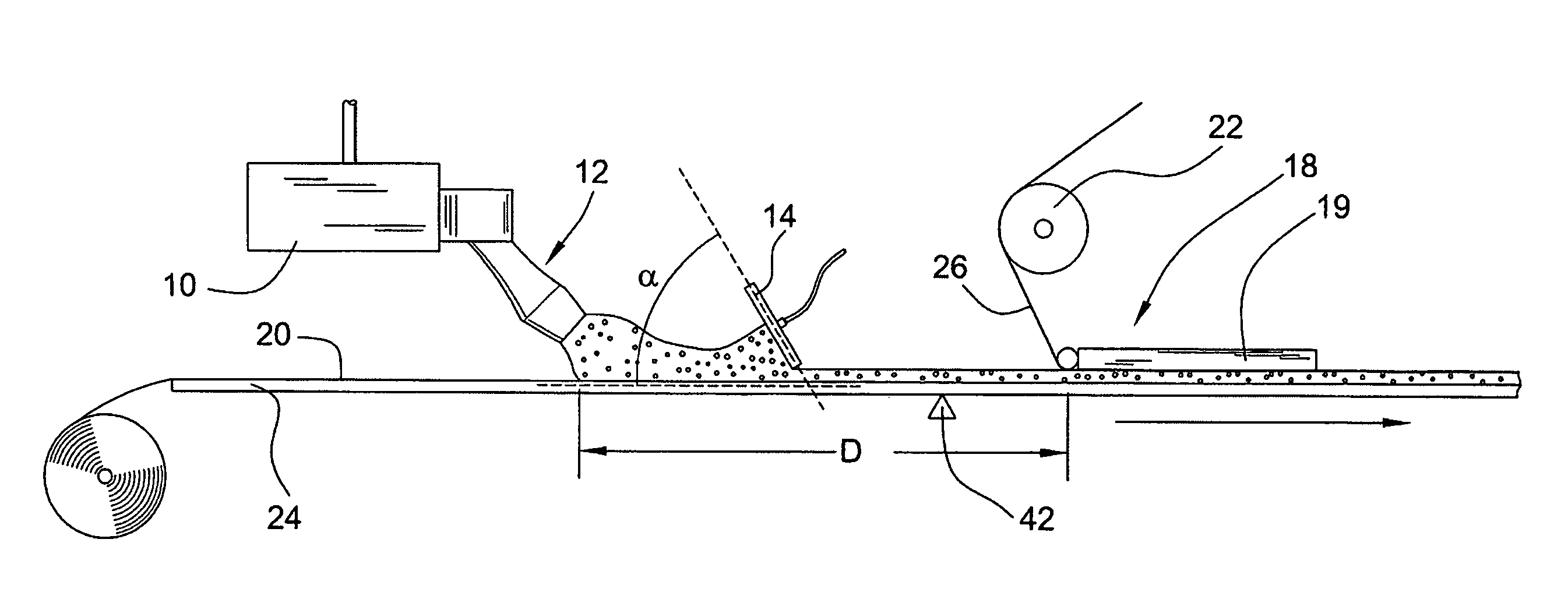

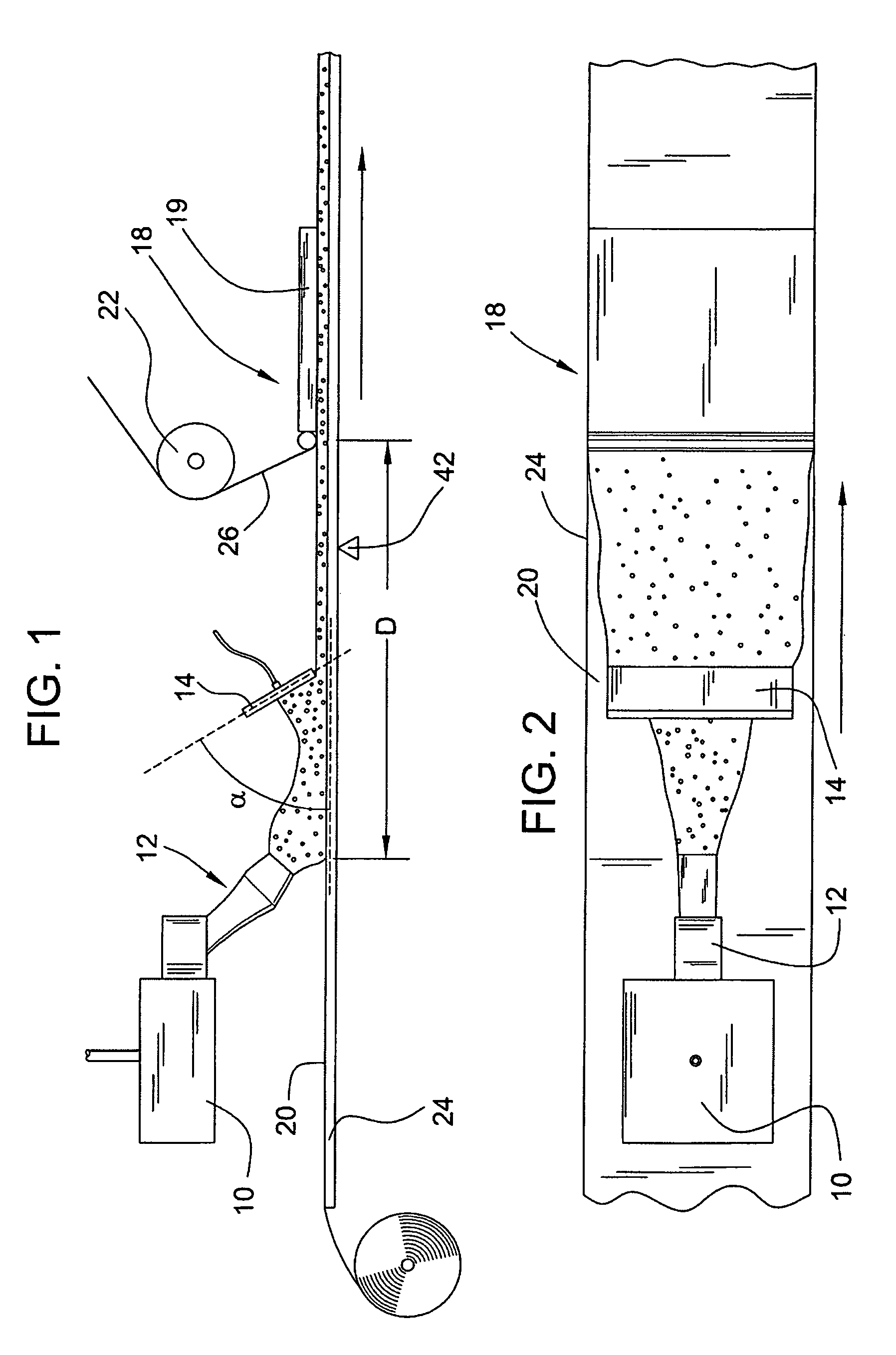

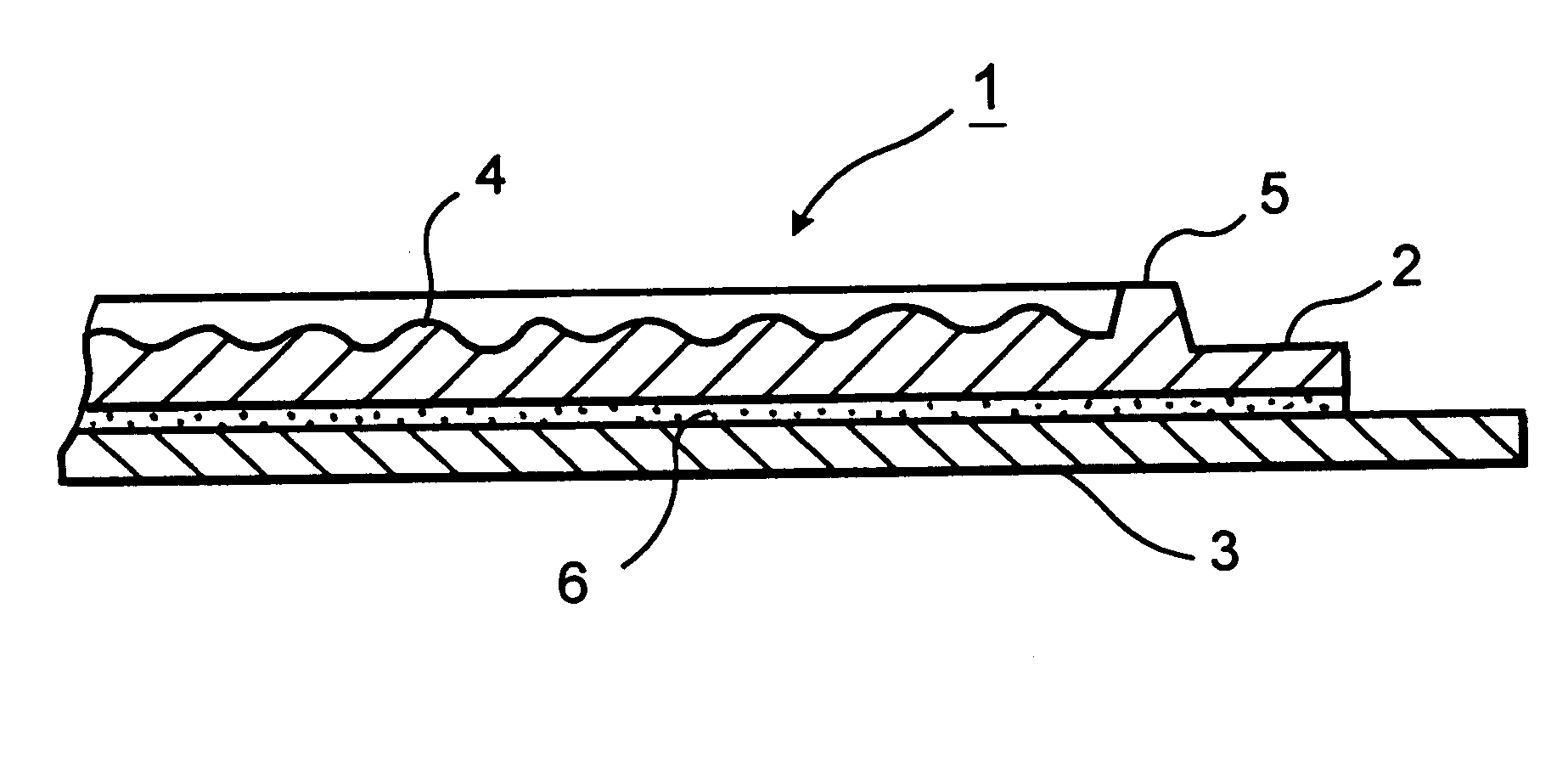

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

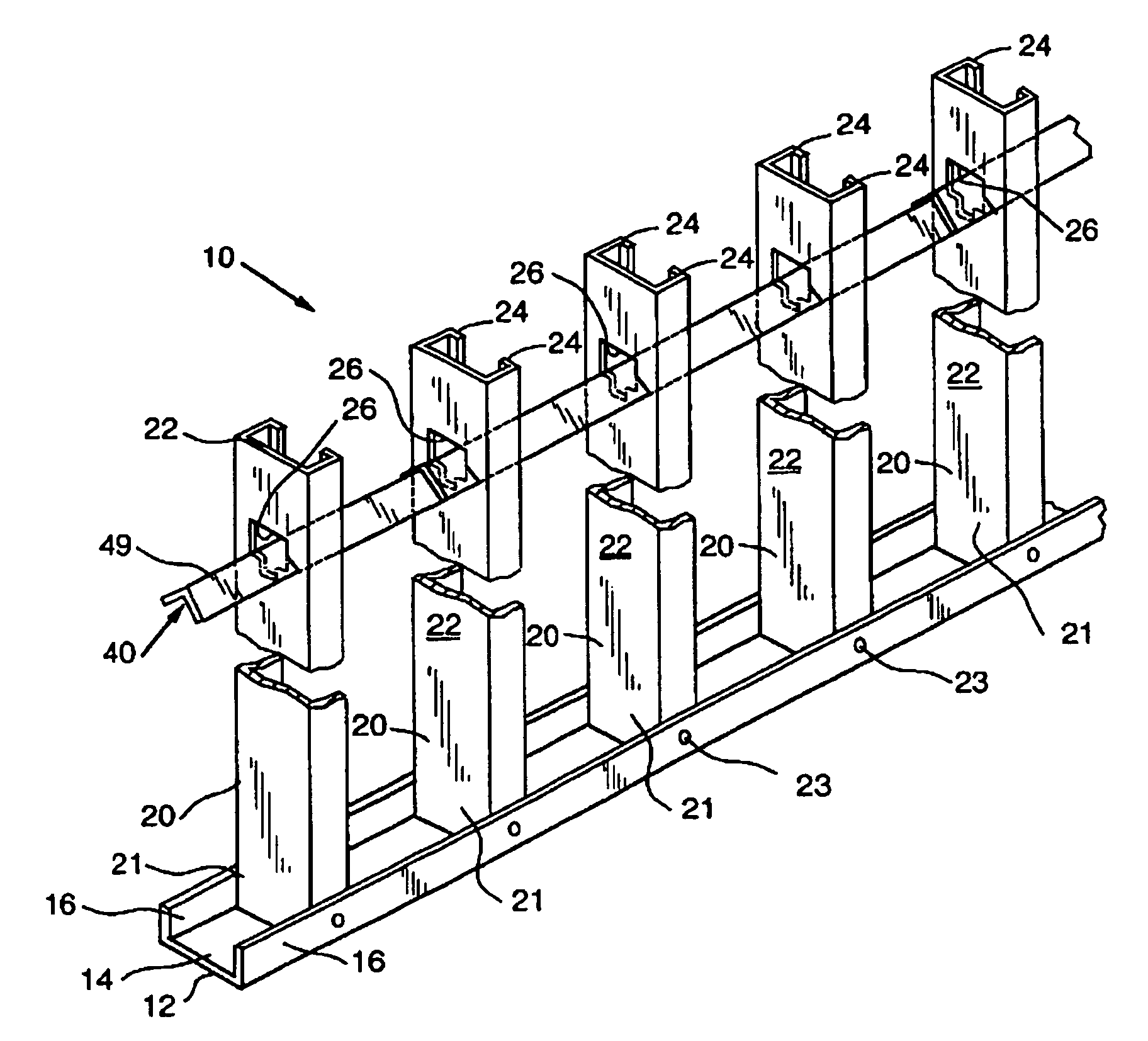

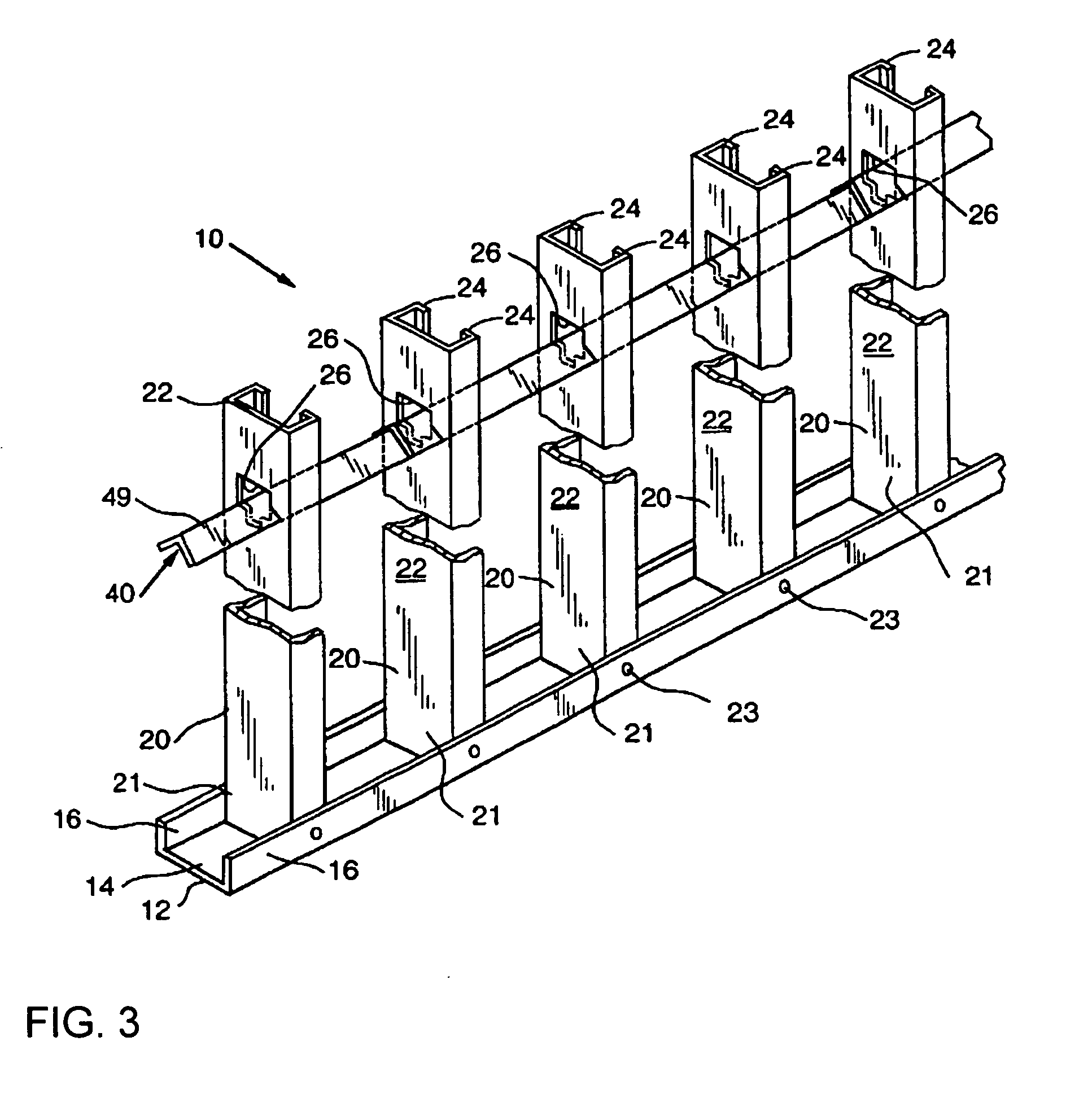

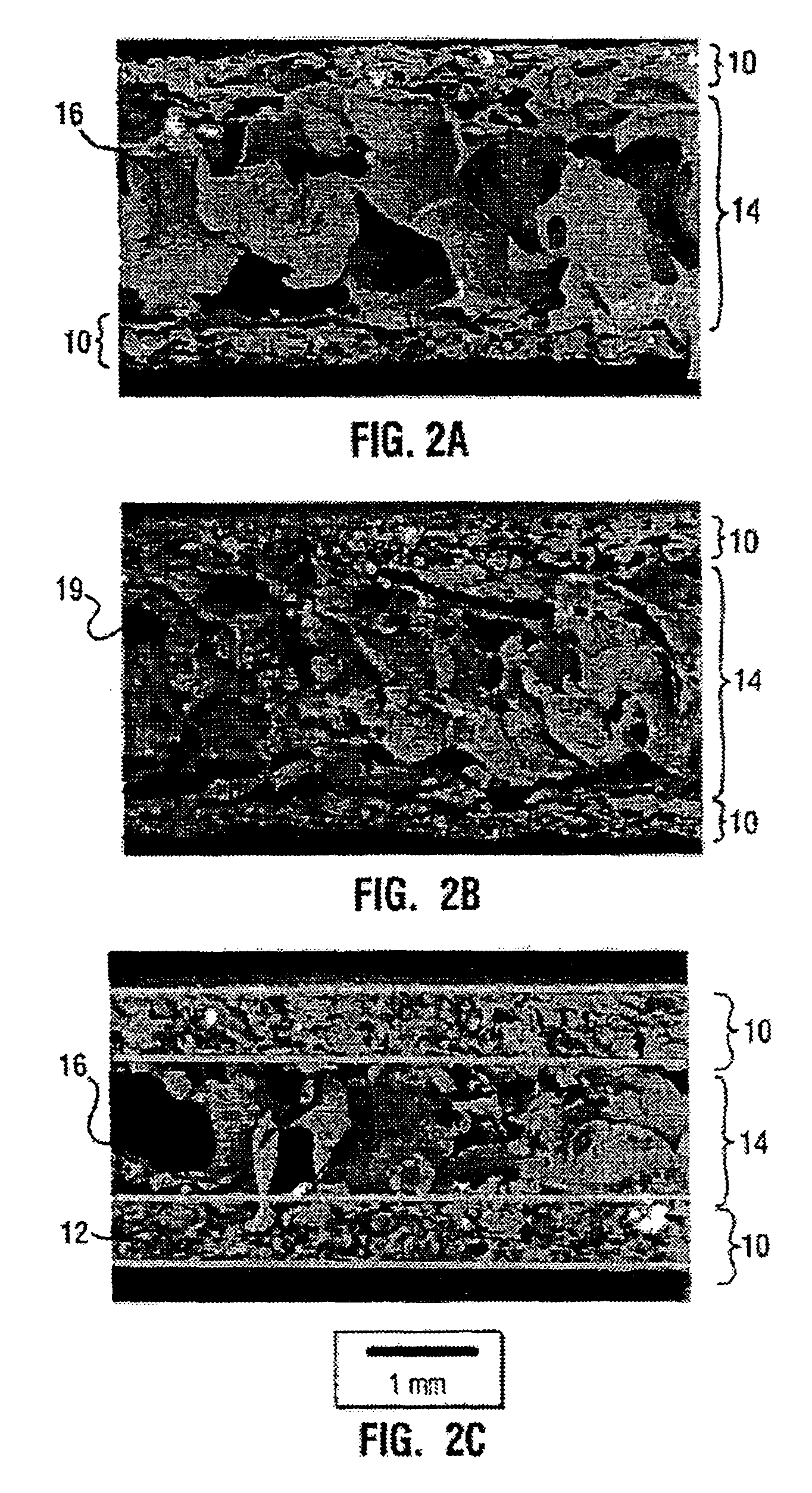

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

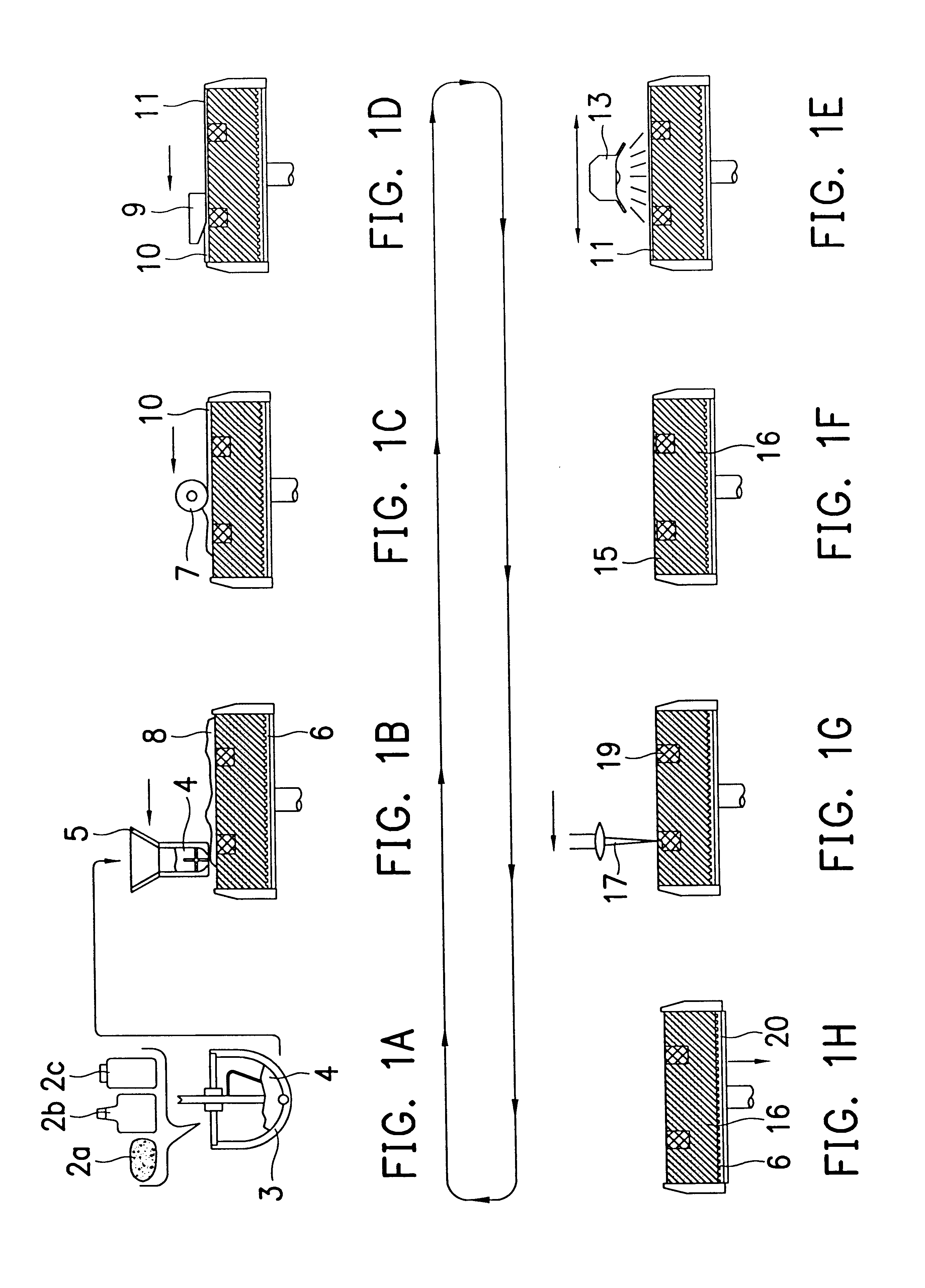

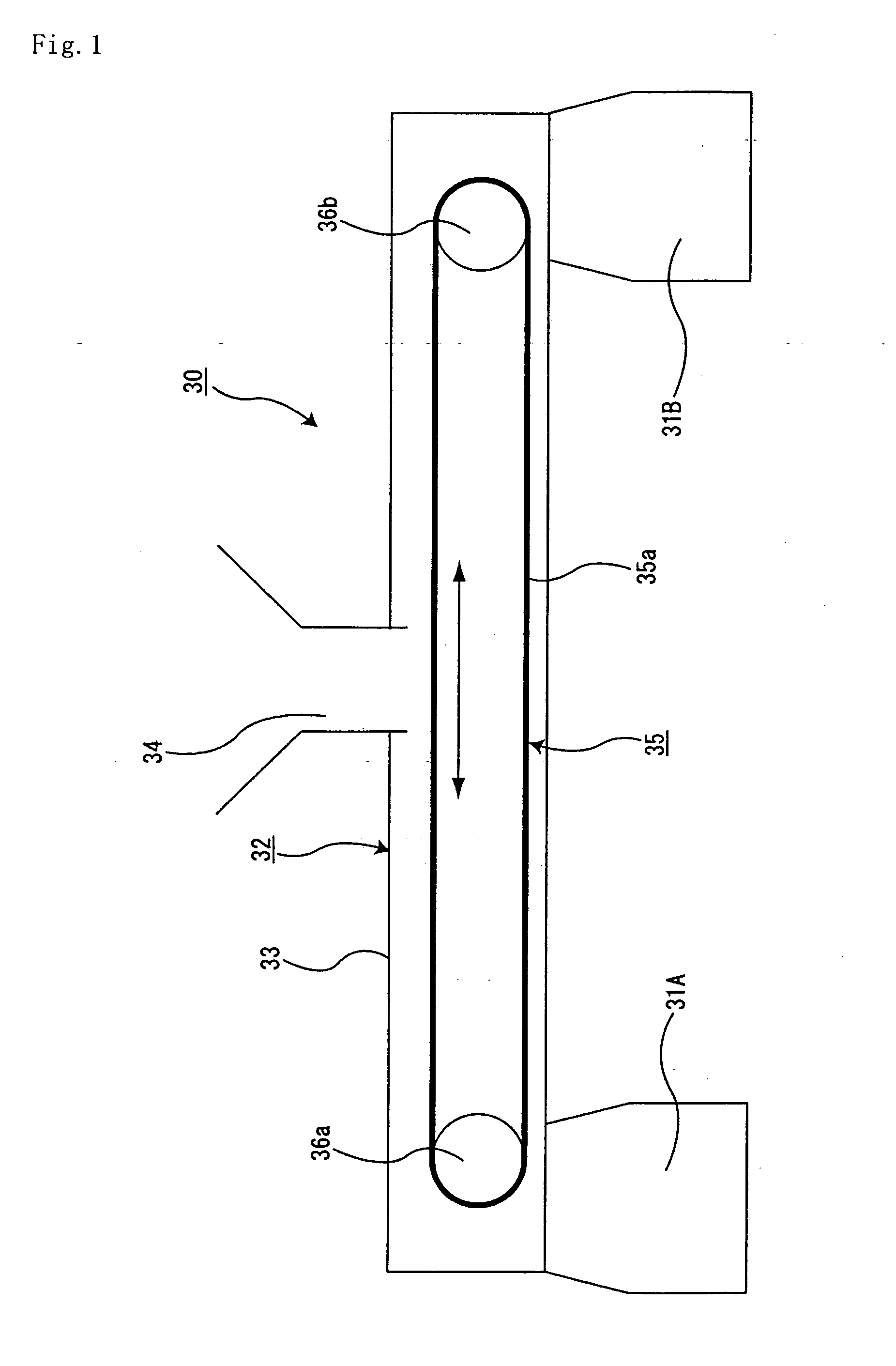

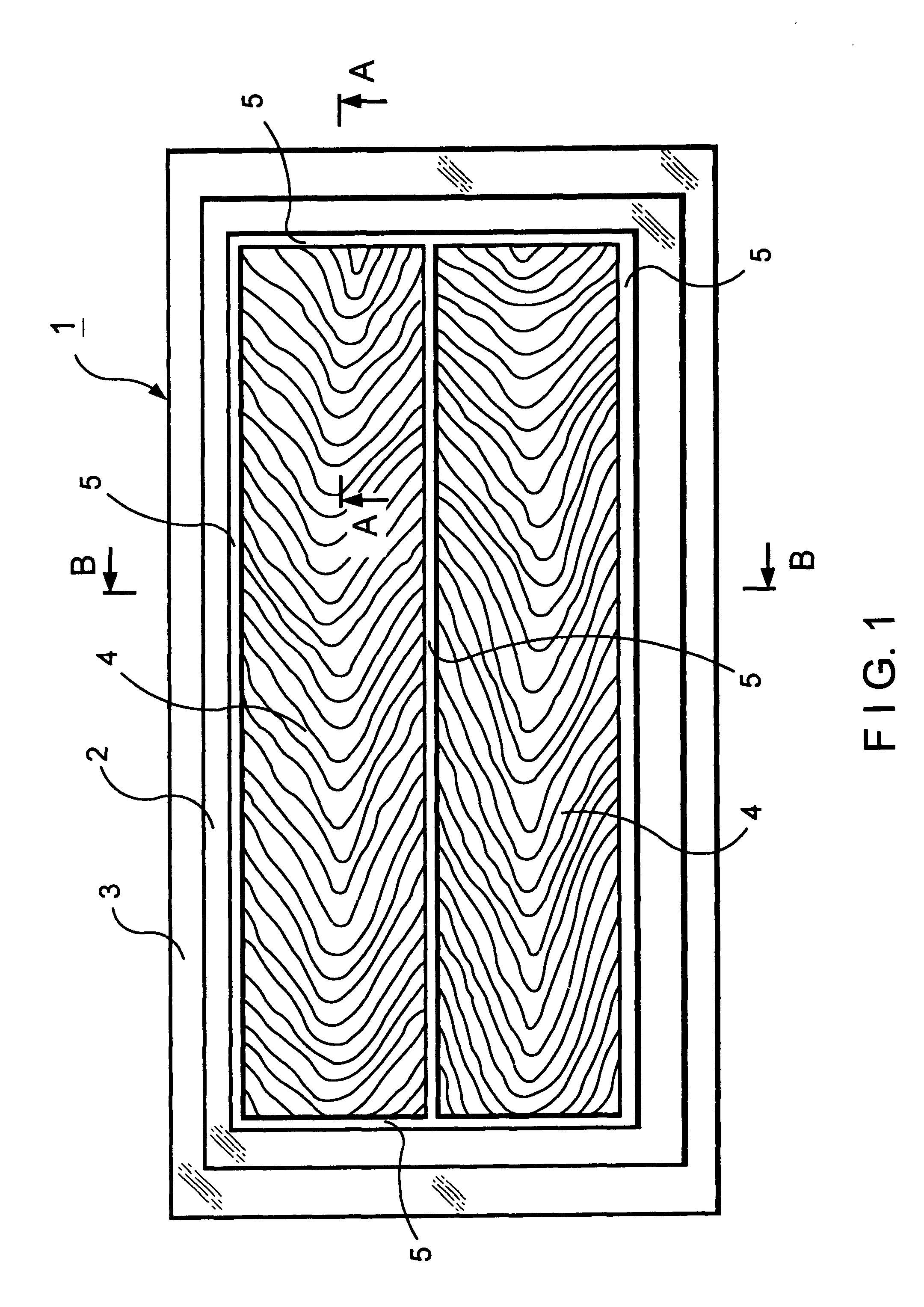

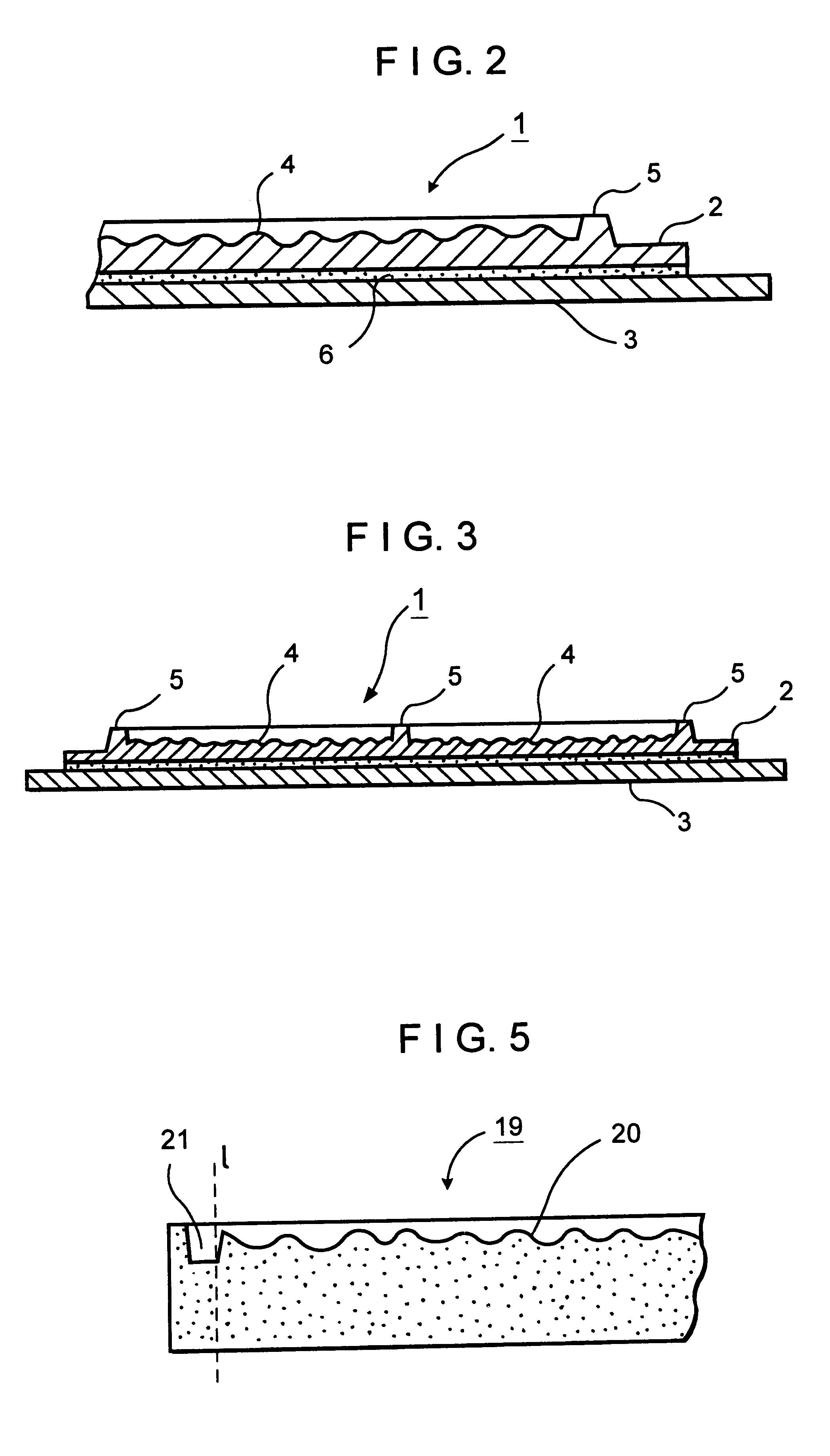

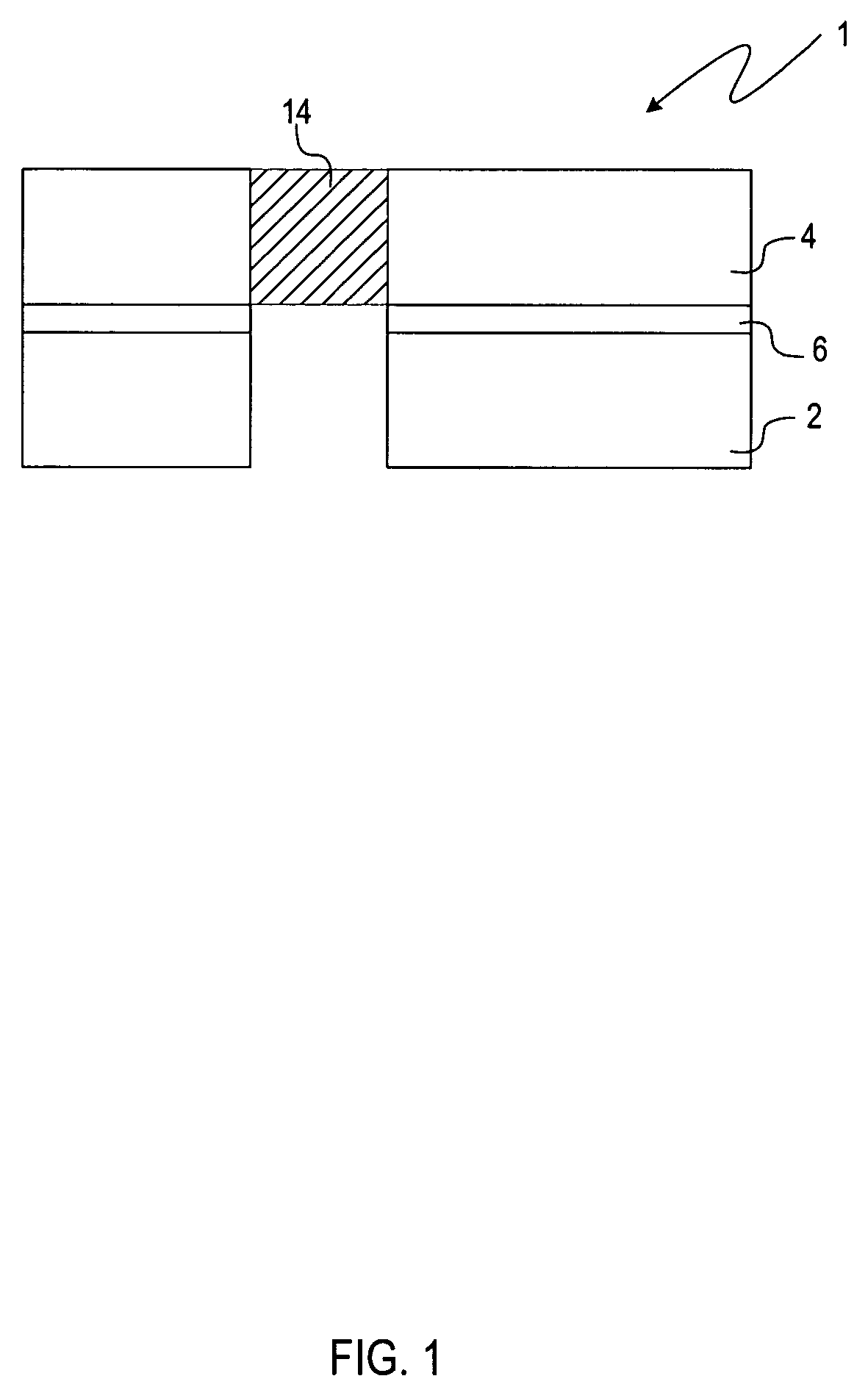

Method of manufacturing an inorganic board

A mold used for manufacturing an inorganic board and a method of manufacturing an inorganic board by employing said mold are provided in the present invention. Said mold consists of a mold part made of a fiber reinforced plastic and a metal part attached to the back of said mold part, and because of said metal part, the difference in the coefficient of thermal expansion between said mold and an inorganic board manufactured on said mold is small.

Owner:NICHIHA CORP

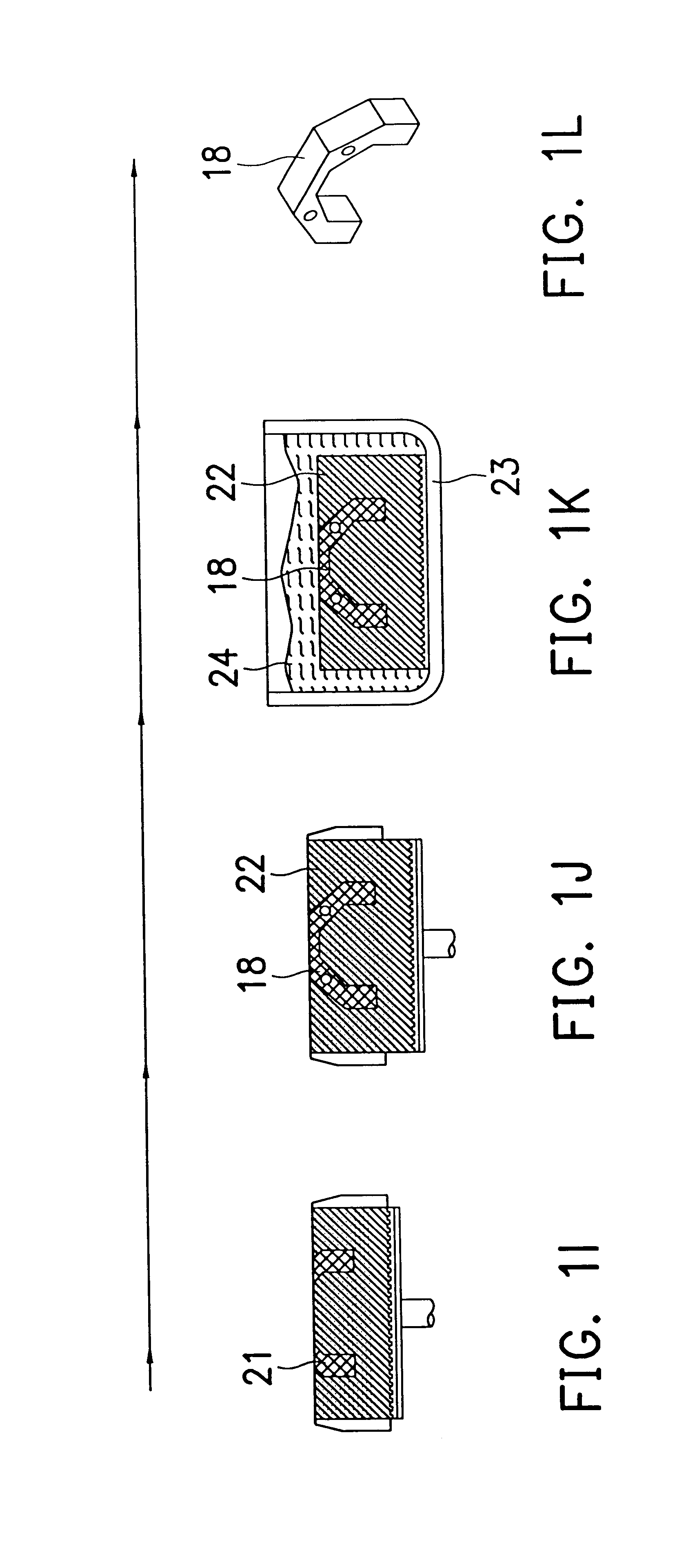

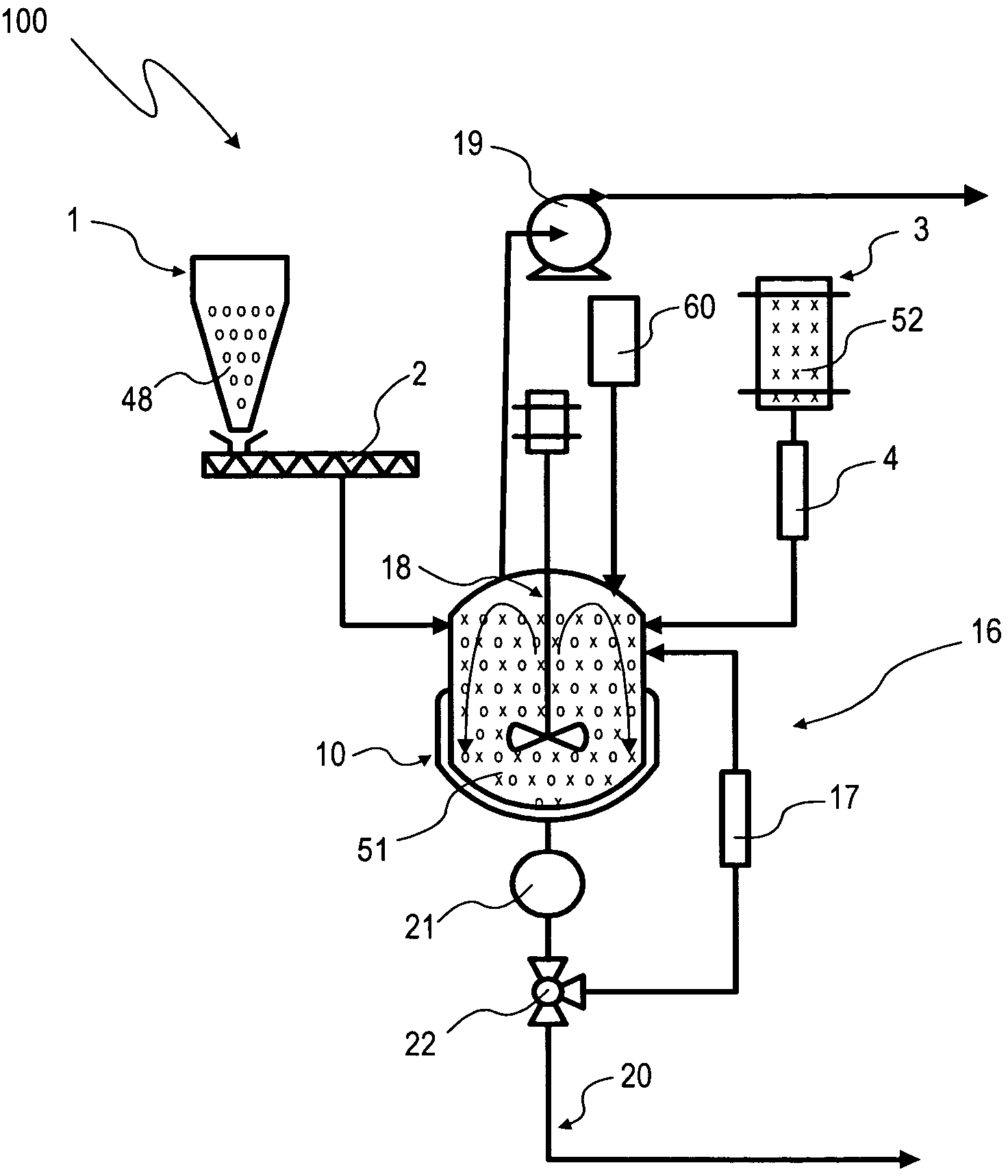

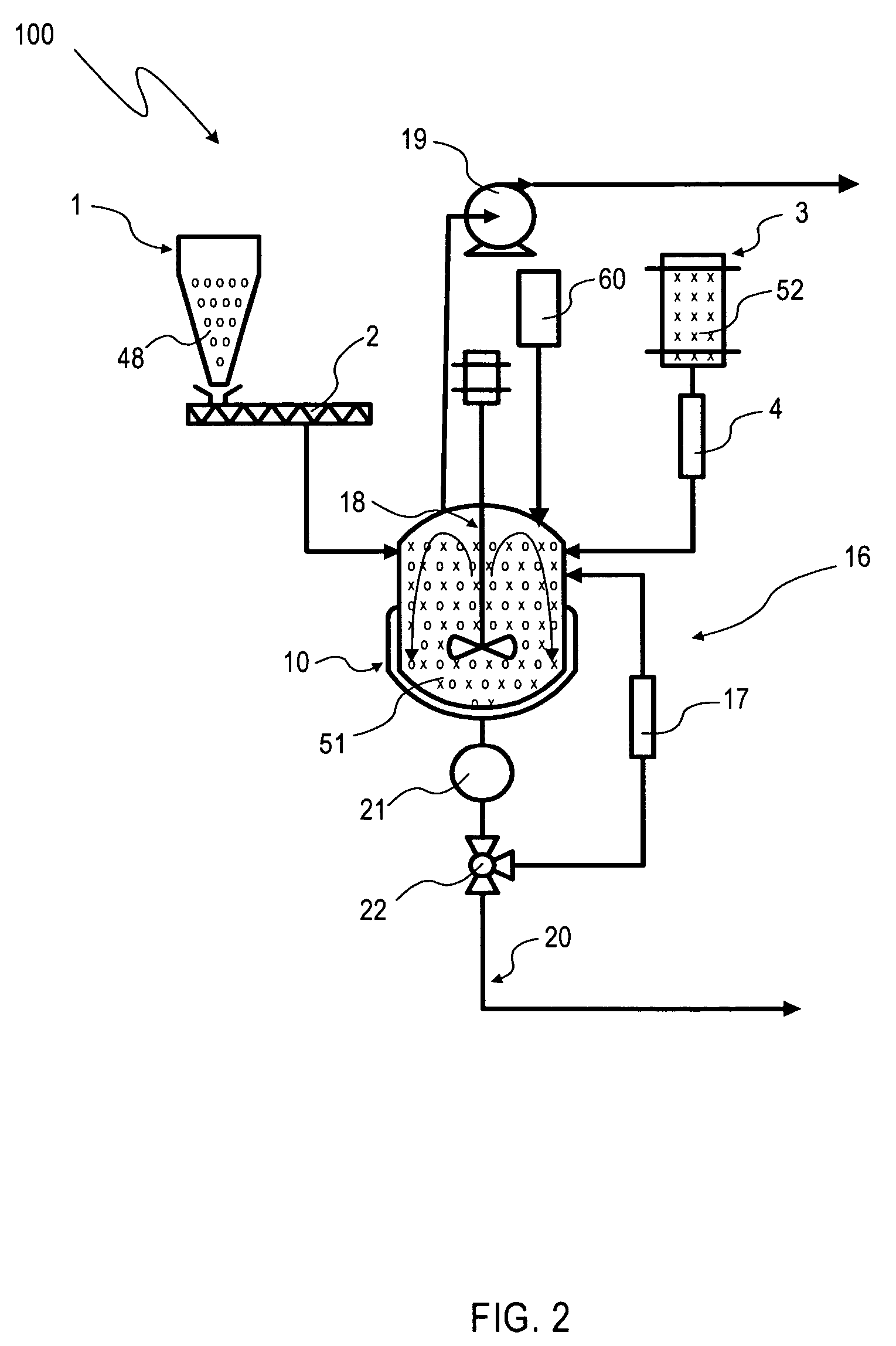

Method and machine for producing three-dimensional objects by means of successive layer deposition

Inventive machine allowing the simultaneous fabrication of several objects by a method of “rapid prototyping” type, by depositing a succession of layers of heat-fusible fluid.It chiefly comprises a crossbar (20) carrying two platforms (11) on each of which an object is fabricated by deposition. Two fixed work stations are arranged diametrically opposite each other so that the jet (12) of each of these fixed stations can perform a depositing operation at the same time as the other jet (12). After each deposit, the crossbar is rotated 180° to alternate the depositing operations of the two different materials.Particular application to prototyping jewellery models.

Owner:MARSAC NICOLAS

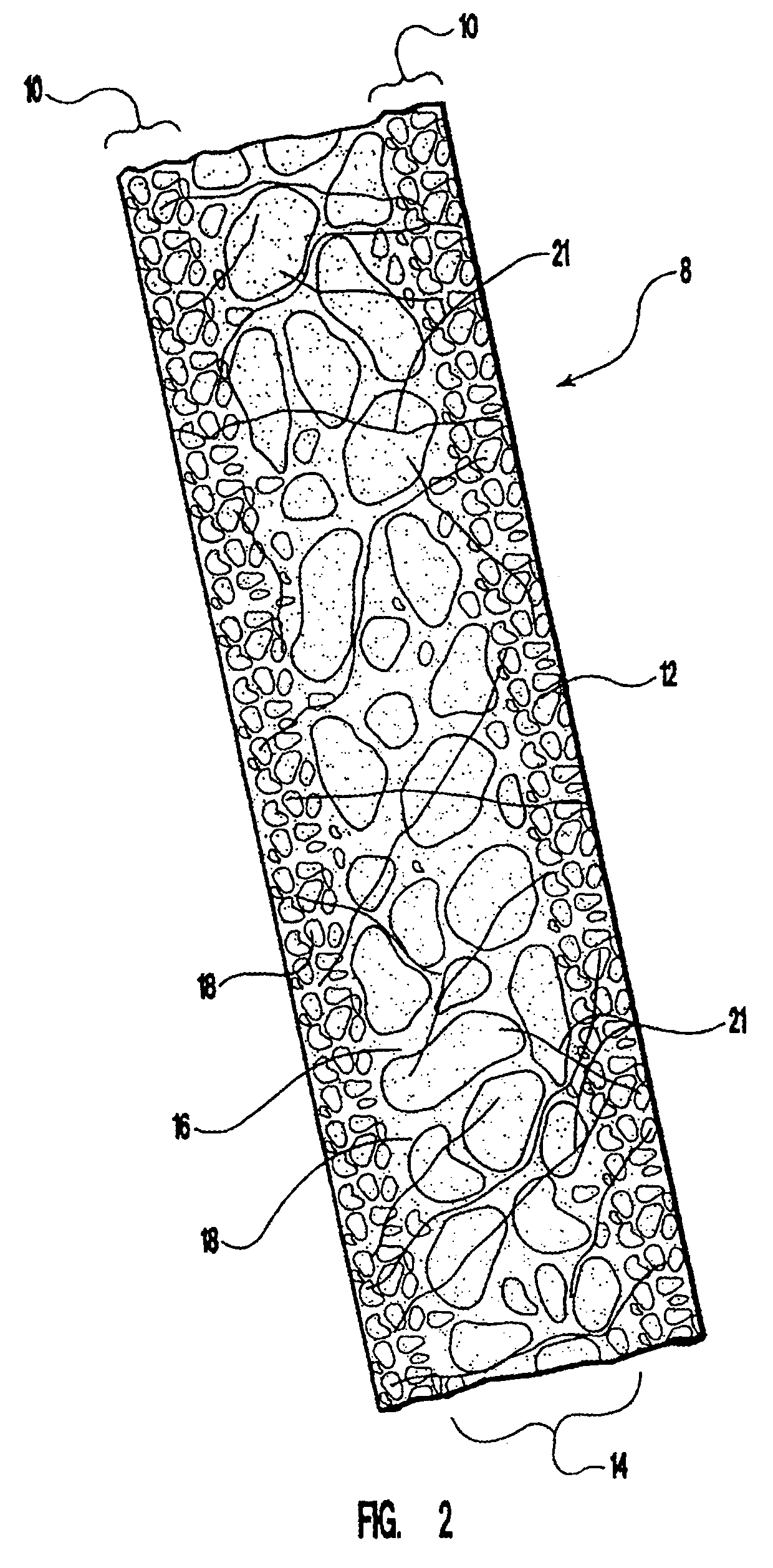

Compositions for manufacturing fiber-reinforced, starch-bound articles having a foamed cellular matrix

InactiveUSRE39339E1Avoid lack of toughnessHigh strengthClosure lidsSolid waste managementPolymer sciencePaperboard

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a fiber-reinforced, starch-bound cellular matrix. Suitable mixtures used to form the articles are prepared by first preparing a viscous preblended mixture comprising water, a gelatinized starch-based binder, and fibers having an average length greater than about 2 mm. The highly viscous preblended mixture effectively transfers the shearing forces of the mixer to the fibers. The final moldable mixture is then prepared by mixing into the preblended mixture the remaining starch-based binder, water, and other desired admixtures, e.g., mold-releasing agents, inorganic filler rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The moldable mixtures are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled foamed structural matrix. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic-based materials and have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

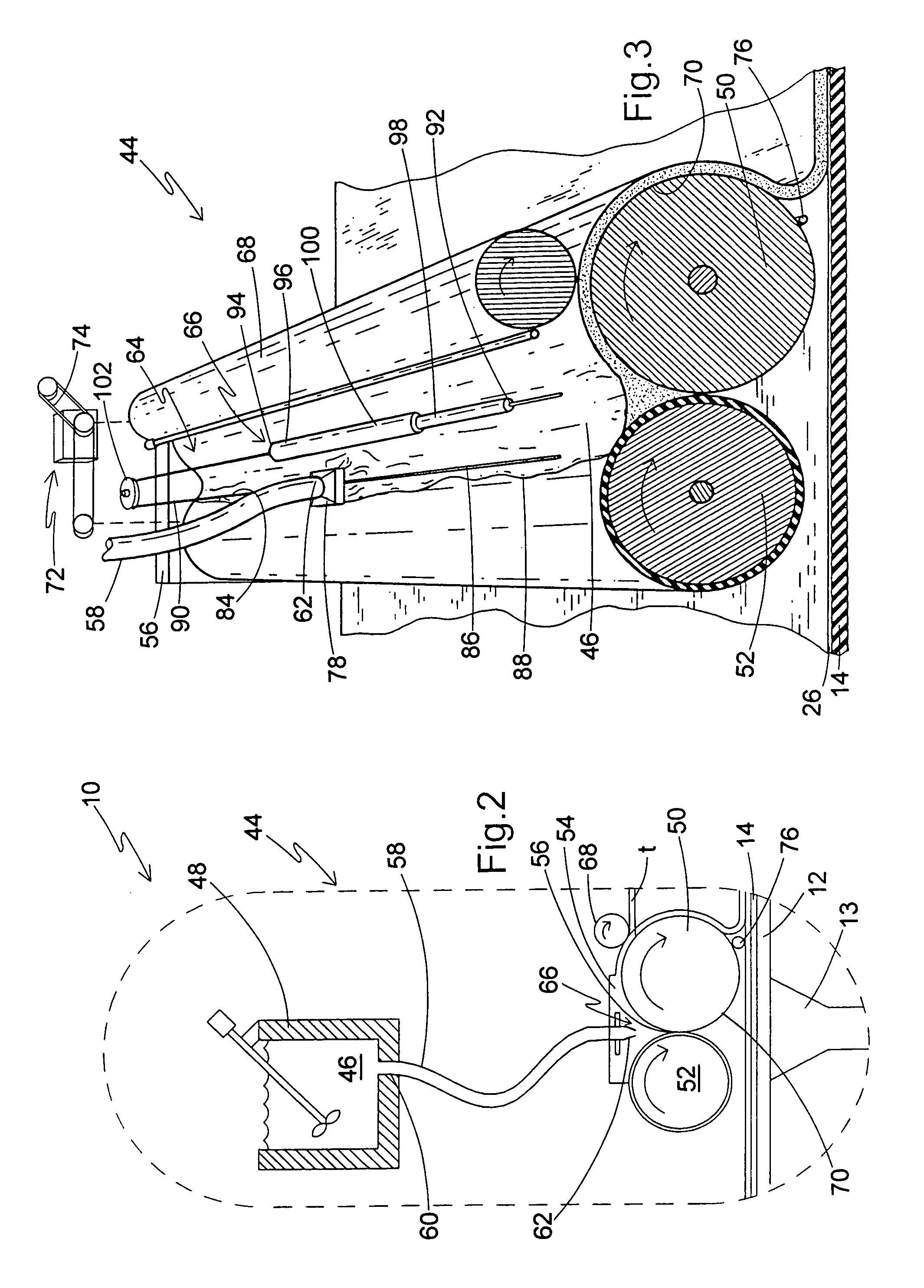

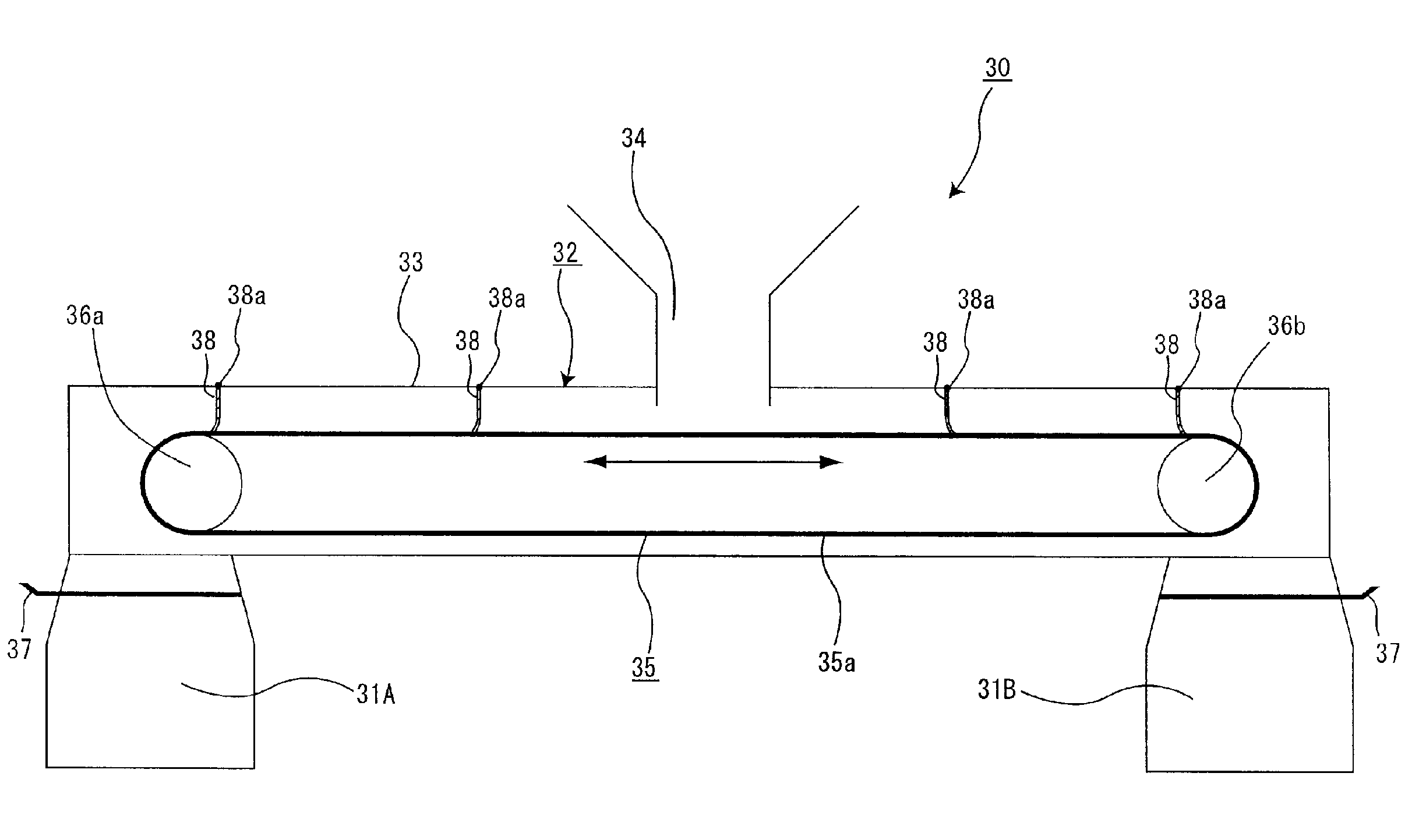

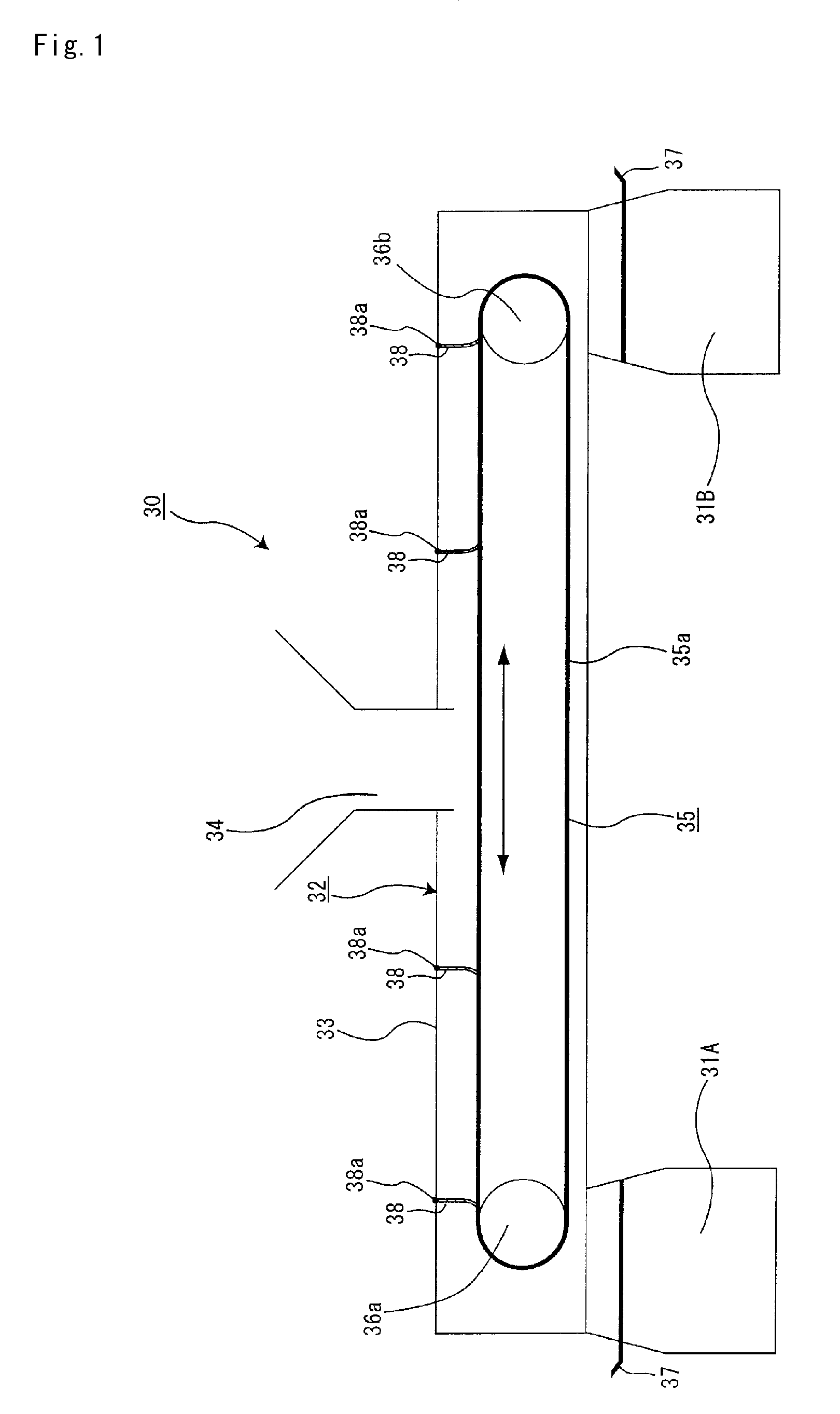

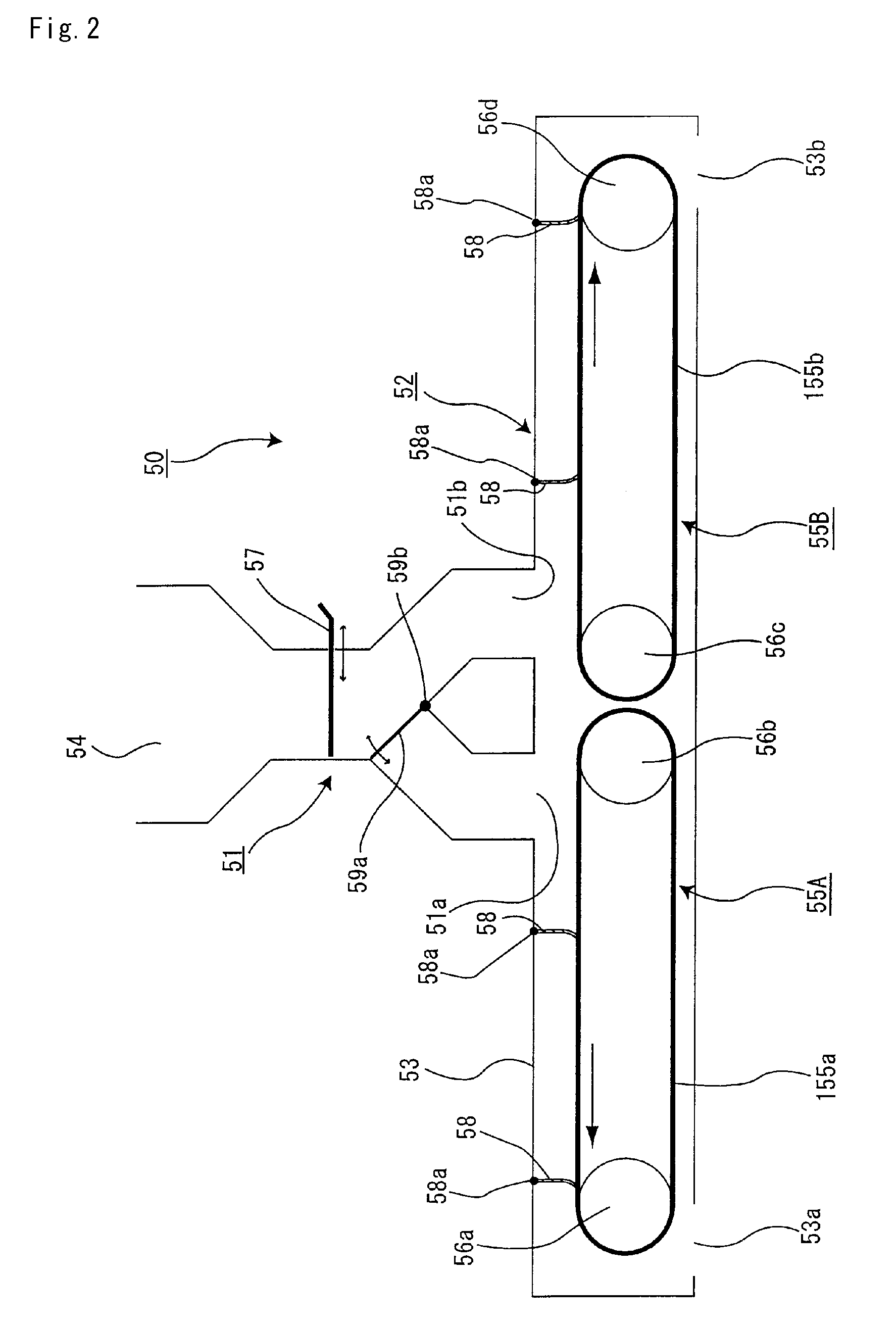

Conveyer apparatus and method for manufacturing honeycomb structure

InactiveUS20080211127A1Semi-permeable membranesPhysical/chemical process catalystsEngineeringMoisture

A conveyer apparatus including a conveyer portion having disposed therein a conveyer configured to convey a wet mixture. The conveyer is configured to convey the wet mixture such that a percentage of change in moisture content of the wet mixture from before conveyance of the wet mixture to after conveyance is about 3% or less.

Owner:IBIDEN CO LTD

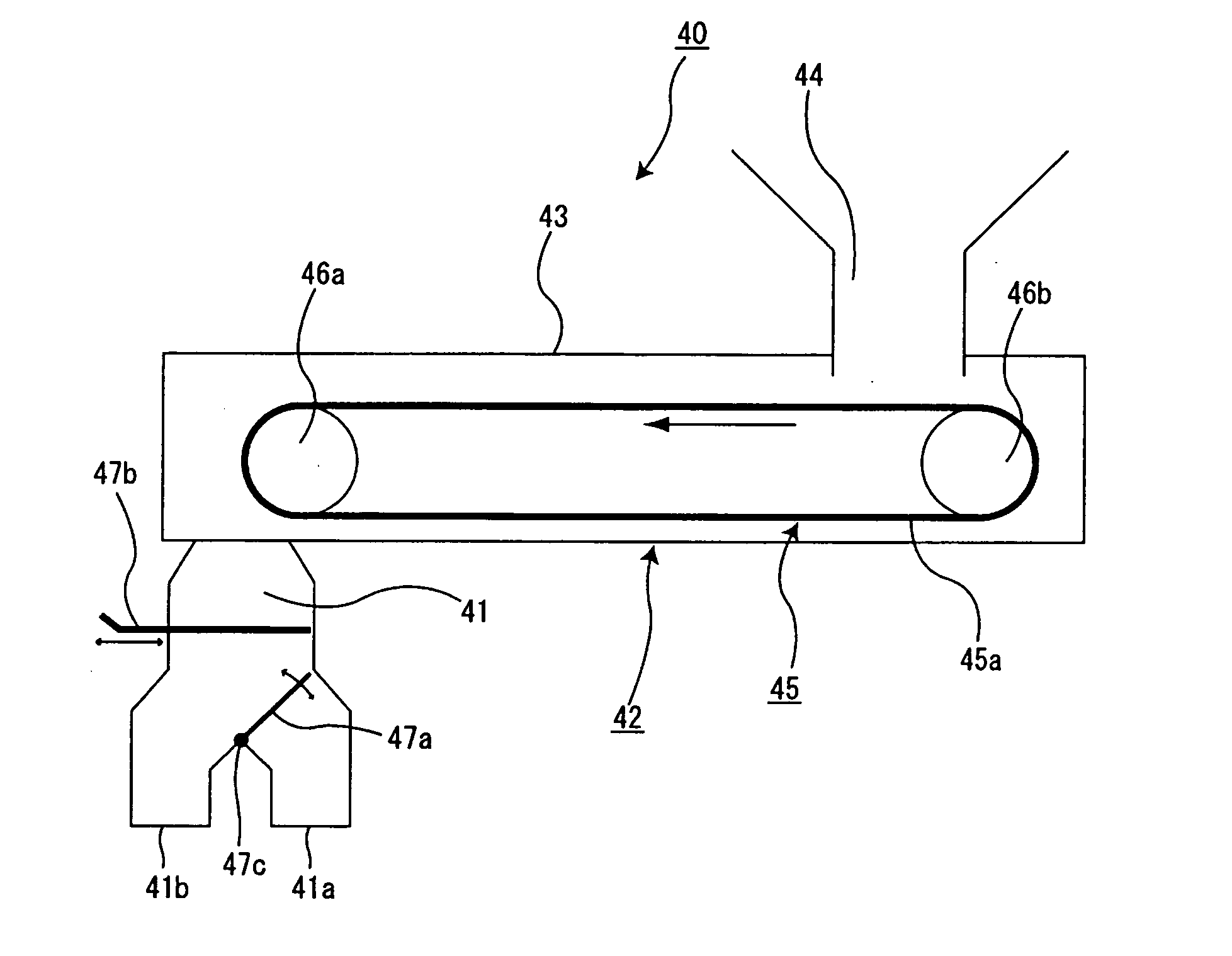

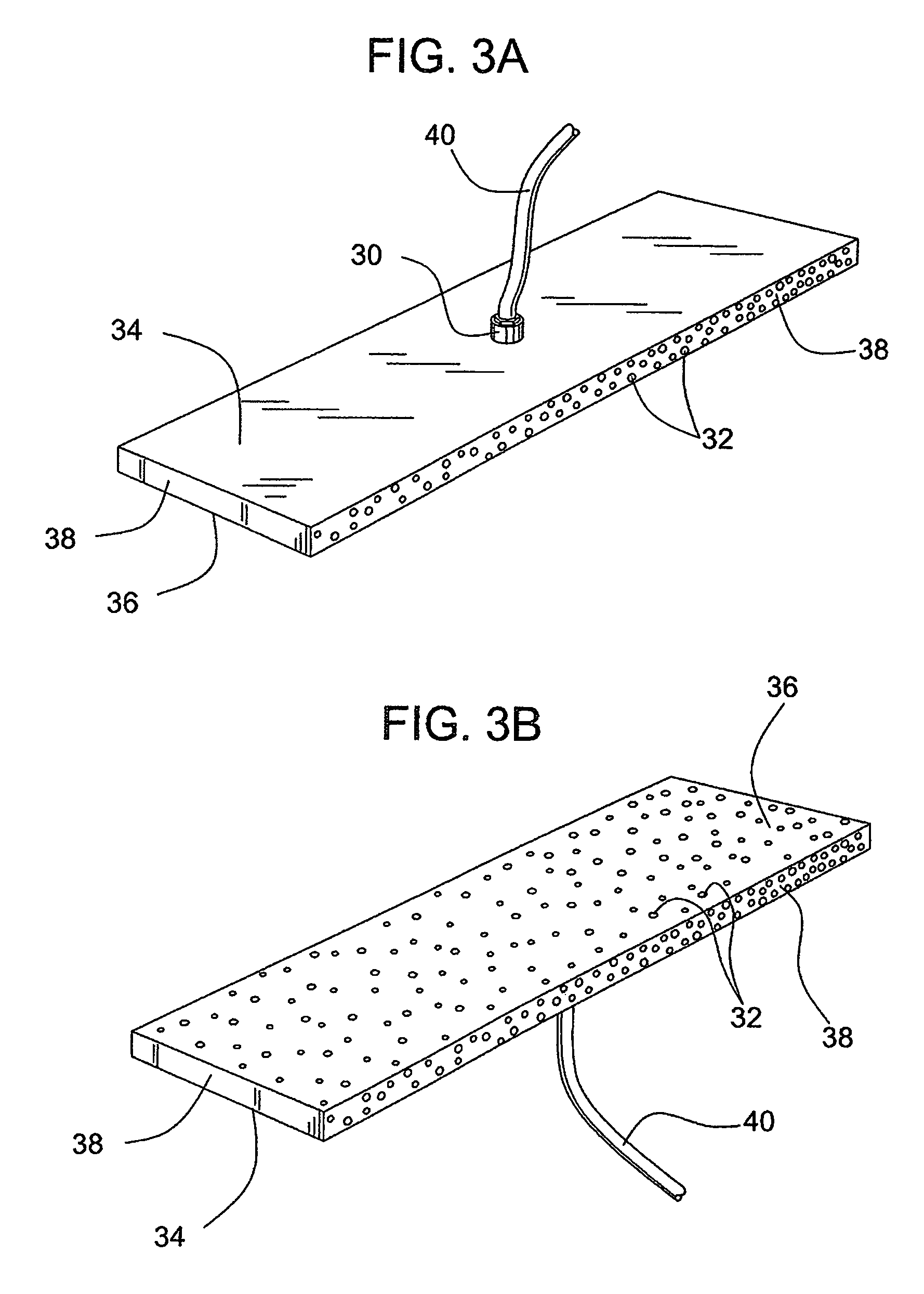

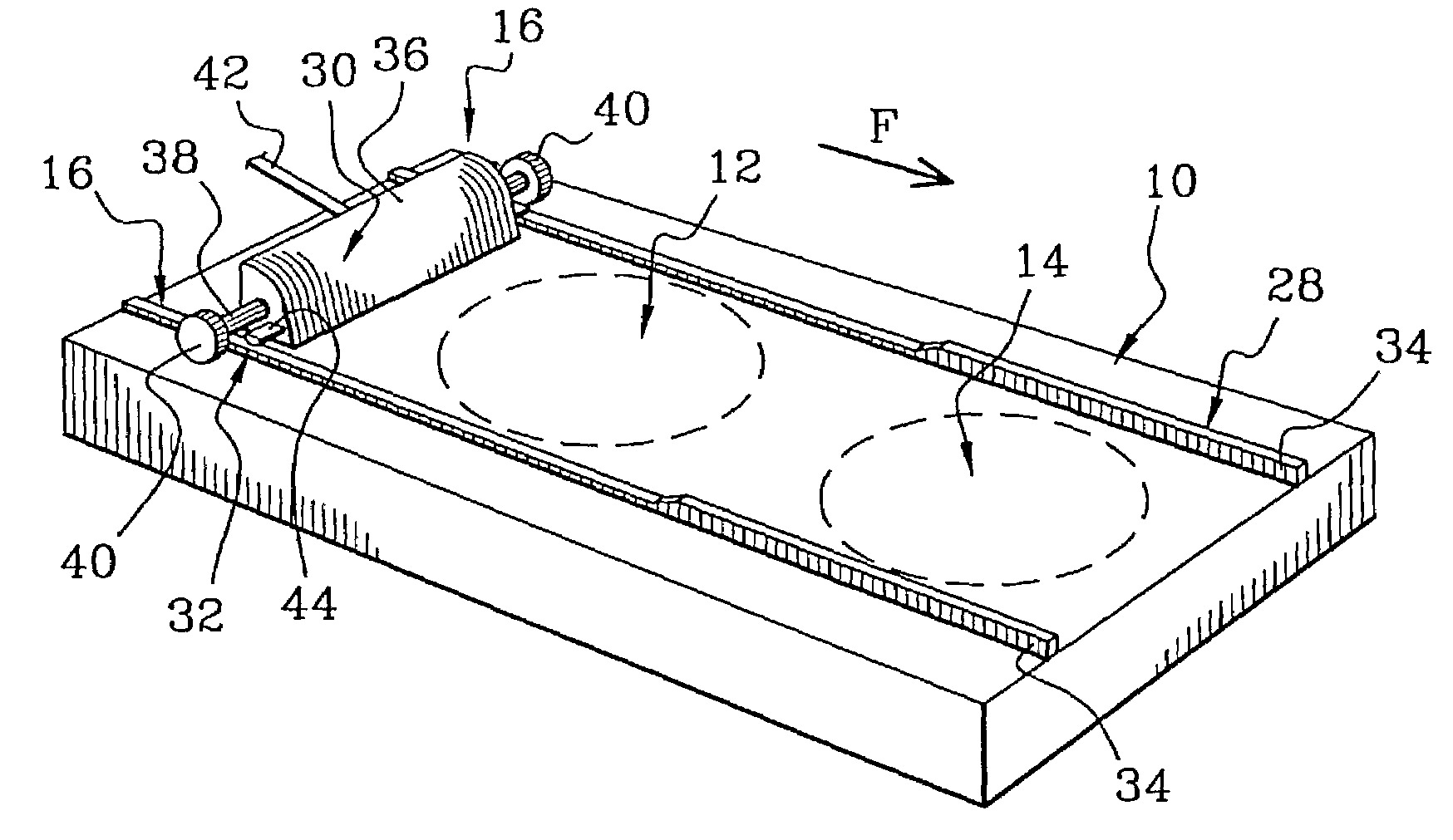

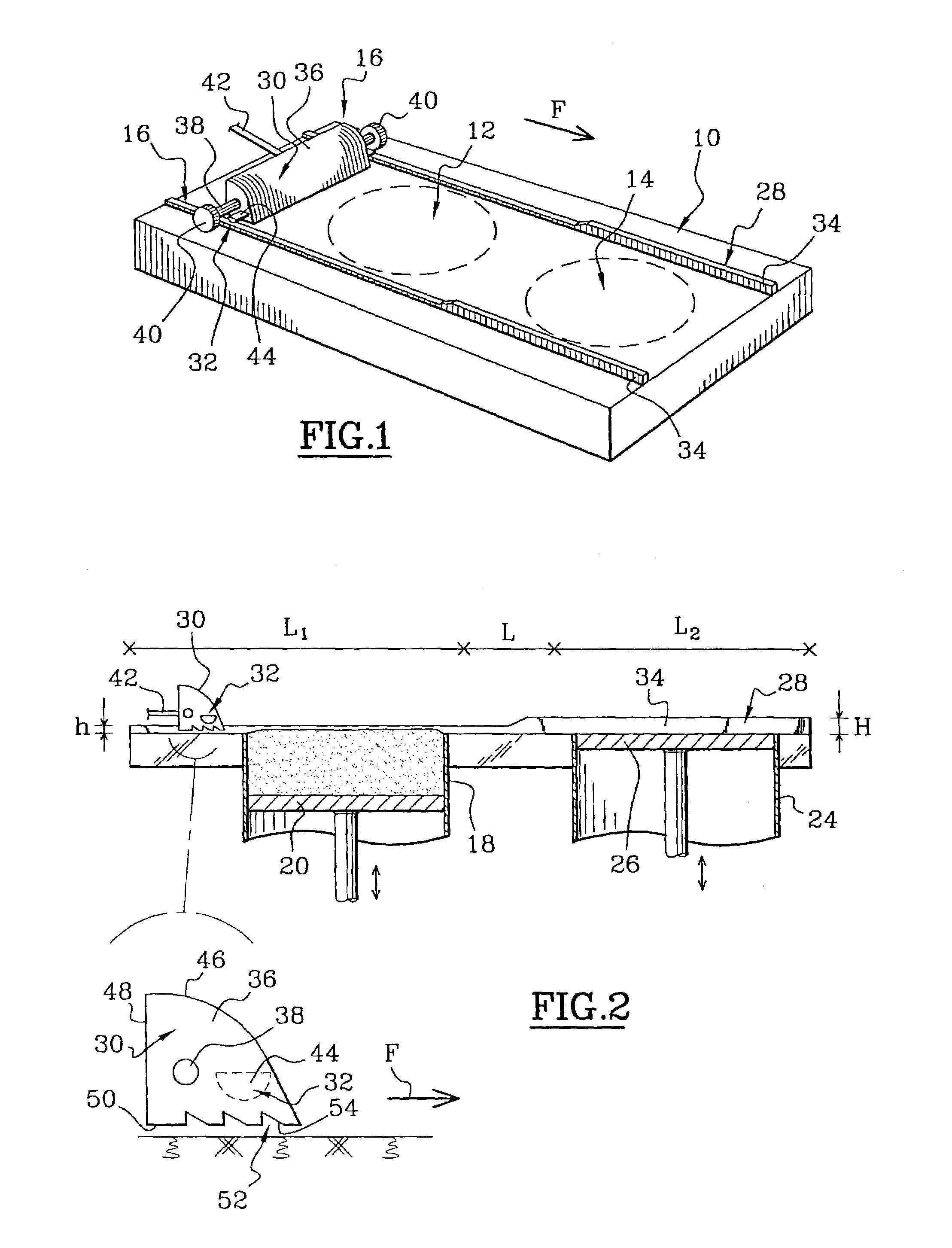

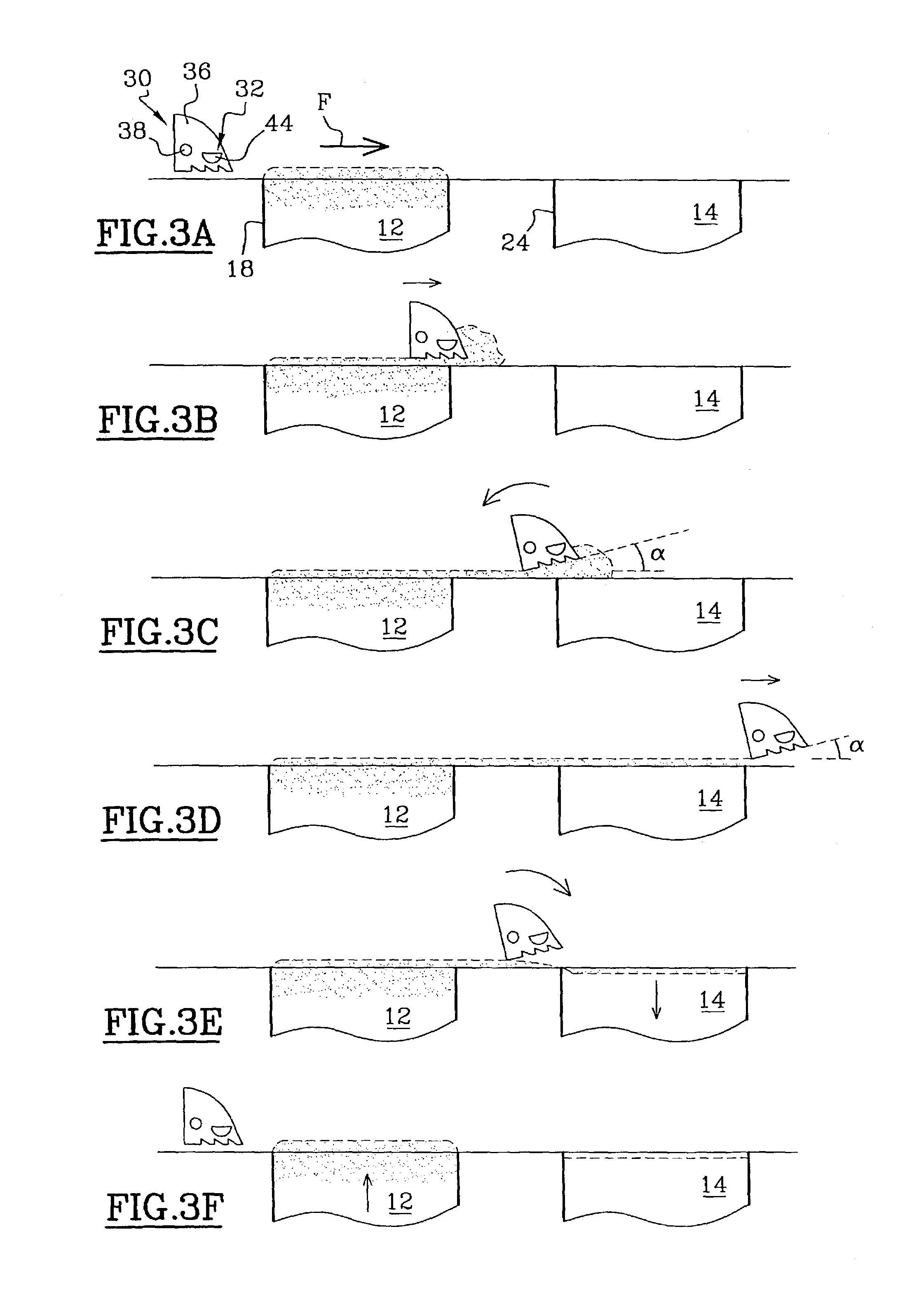

Device for applying thin layers of a powder or pulverulent material and corresponding method

A device for applying a thin layer of a powder on a support means (14) includes a device (12) for storing the powder, a screed (30) that includes a shoe (36) with a working surface, as well as a device (28) for guiding in translation in a direction of movement F. The shoe (36) is rotatable and includes a device (32, 34) for inclining the to take at least two positions, the first in which the working surface is parallel to the support (14) for the layers to take up a predetermined volume of powder and a second in which this working surface is inclined at an angle α relative to the support.

Owner:PHENIX SYST

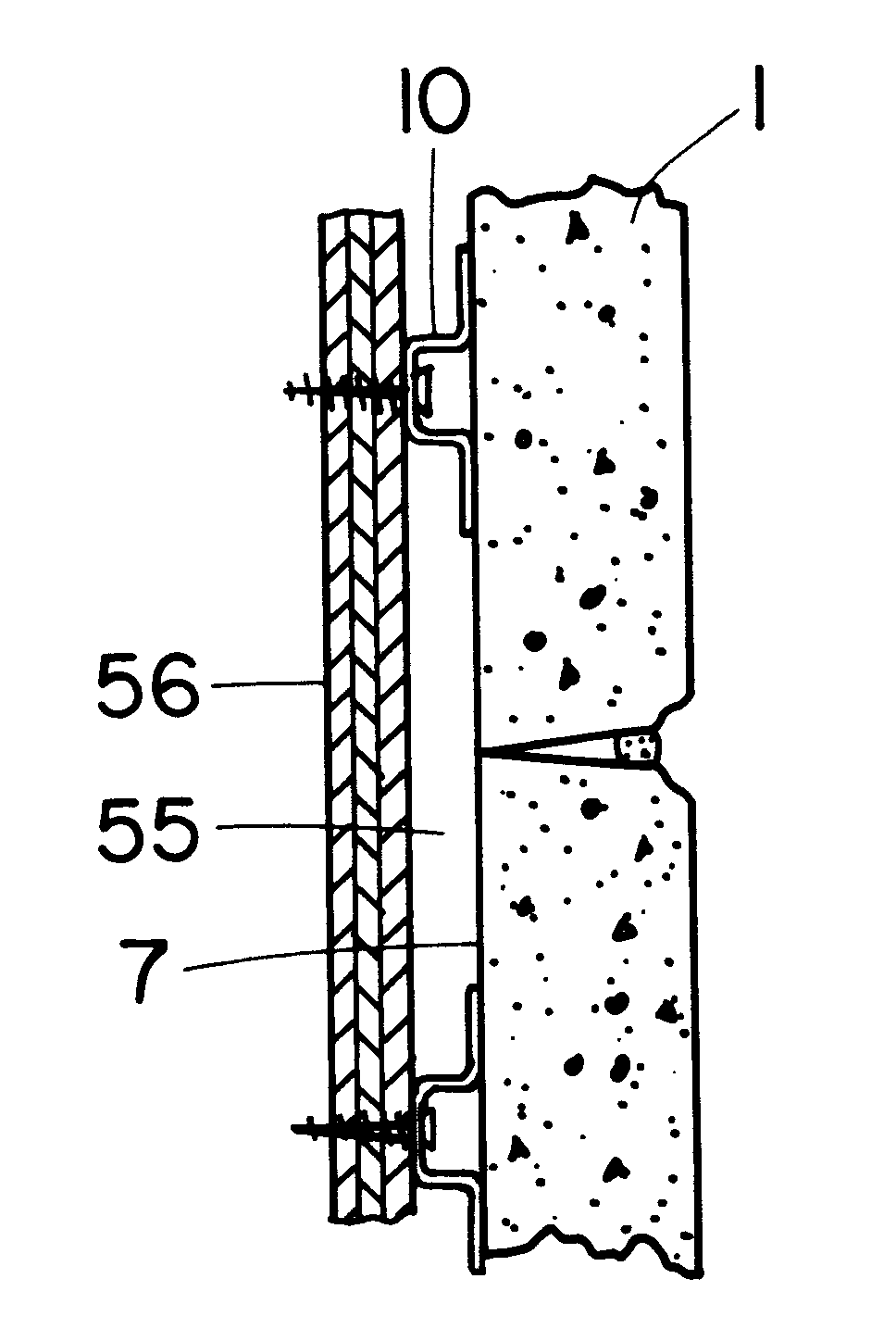

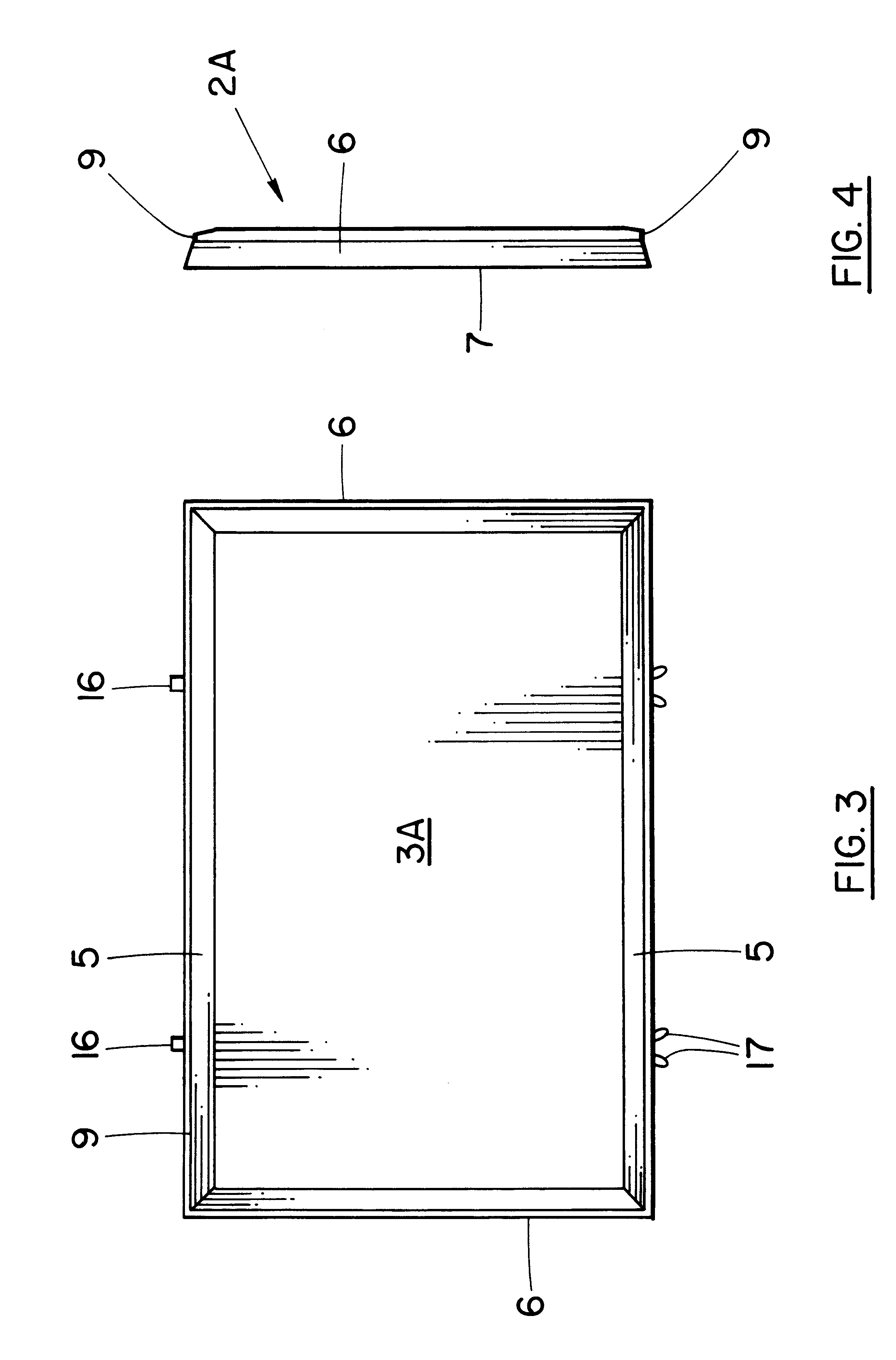

Concrete panel construction

A concrete panel system comprising a plurality of concrete panels arranged in side-by-side fashion on a substantially vertical supporting wall, each of the panels comprising a rectangular body having a front surface and a rear surface and beveled side edges, the side edges each forming an angle of between eighty-five and ninety degrees with the rear surface, and a concave caulking groove lying between and connecting each of the beveled side edges with the front face, the side edges of adjacent panels forming a V-joint between the adjacent panels, a flexible sealant material in a portion of the caulking grooves of adjacent panels and a portion of the V-joint for providing a seal between adjacent panels, and a hanger element embedded in the rear of the panels for securing the panels to the supporting wall.

Owner:STONETILE CANADA

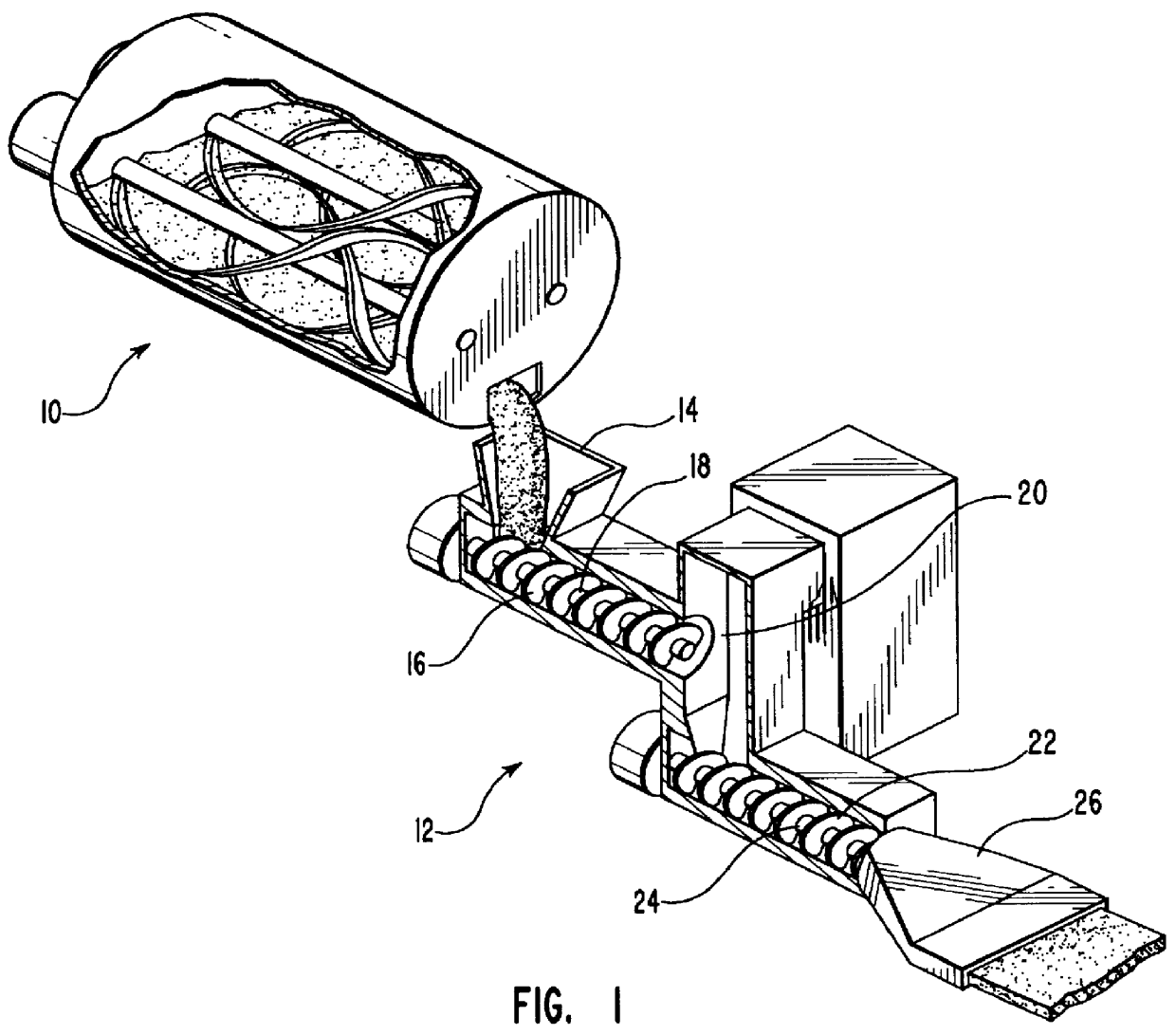

Extrusion Process For Proppant Production

Owner:HALLIBURTON ENERGY SERVICES INC

Cement concrete permeable brick, permeable road and production methods thereof

InactiveCN101671987AComply with quality deviationMitigate the heat island effectSingle unit pavingsClimate change adaptationPondingBrick

The invention relates to a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. At present, most of urban construction adopting the rigid hardened ground has the problems of dust blowing at a fine day, water accumulation and impermeable ground at a rainy day, no groundwater level supplement, no relief of urban heat island effect, and the like. The invention aims to develop a cement concrete permeable brick, a cement concrete permeable road and production methods thereof. The cement concrete permeable brick is formed by pressing and molding a base material layer and a surface material layer, and both the base material layer and the surface material layer contain cement, sand, stone, water adsorbing resin, asphalt powder, diffusant and a water reducing agent. The production method of the permeable brick is realized by molding the permeable brick by a computer full-automatic building block forming machine; and the production method of the cement concrete permeable road is realized by directly pressing the cement concrete permeable road through a road roller. The invention can achieve the aims of water adsorption, water retention, permeability and practicability, can be widely used for a highway, an airport runway, a roadway, a footway, a square, garden construction, and the like and solve the problem of road icing.

Owner:SHAANXI SUNSHINE RAIN ECOLOGICAL TECH

Spinning apparatus, and apparatus and process for manufacturing nonwoven fabric

Owner:JAPAN VILENE CO LTD

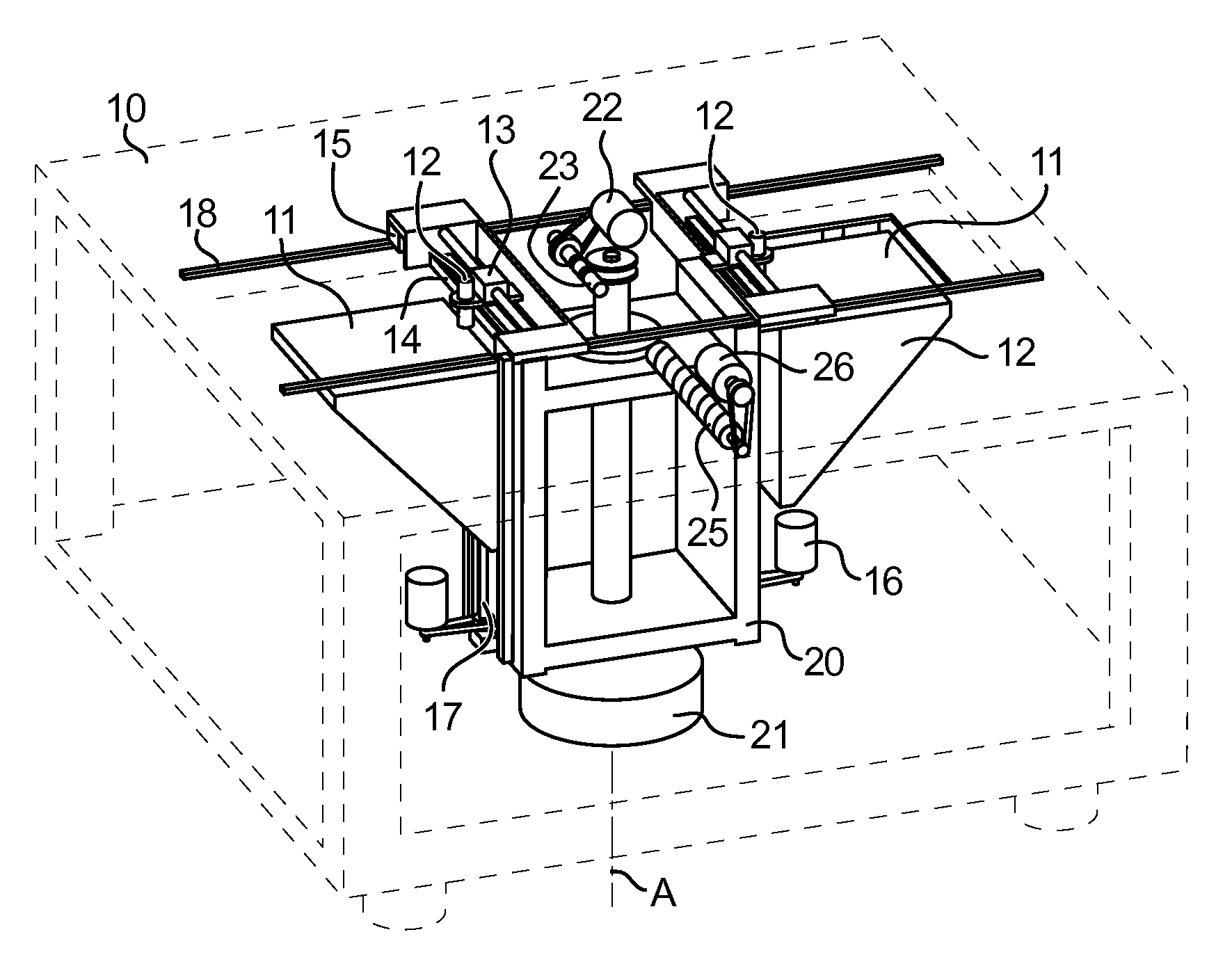

Optical molding apparatus and optcial molding method

An optical molding apparatus molds a three-dimensional model by stacking cured layers. Each cured layer is formed by emitting light according to cross-sectional-shape data of the three-dimensional model onto a surface of photo-curable resin. The optical molding apparatus includes a container that contains the photo-curable resin, a movable stage that is movable in a direction orthogonal to the surface of the photo-curable resin, an optical system that emits the light onto the surface of the photo-curable resin contained in the container so as to form each cured layer on the movable stage, and a discharging mechanism that performs a discharging operation for discharging new photo-curable resin onto a surface of each cured layer formed on the movable stage before stacking a subsequent cured layer.

Owner:SONY CORP

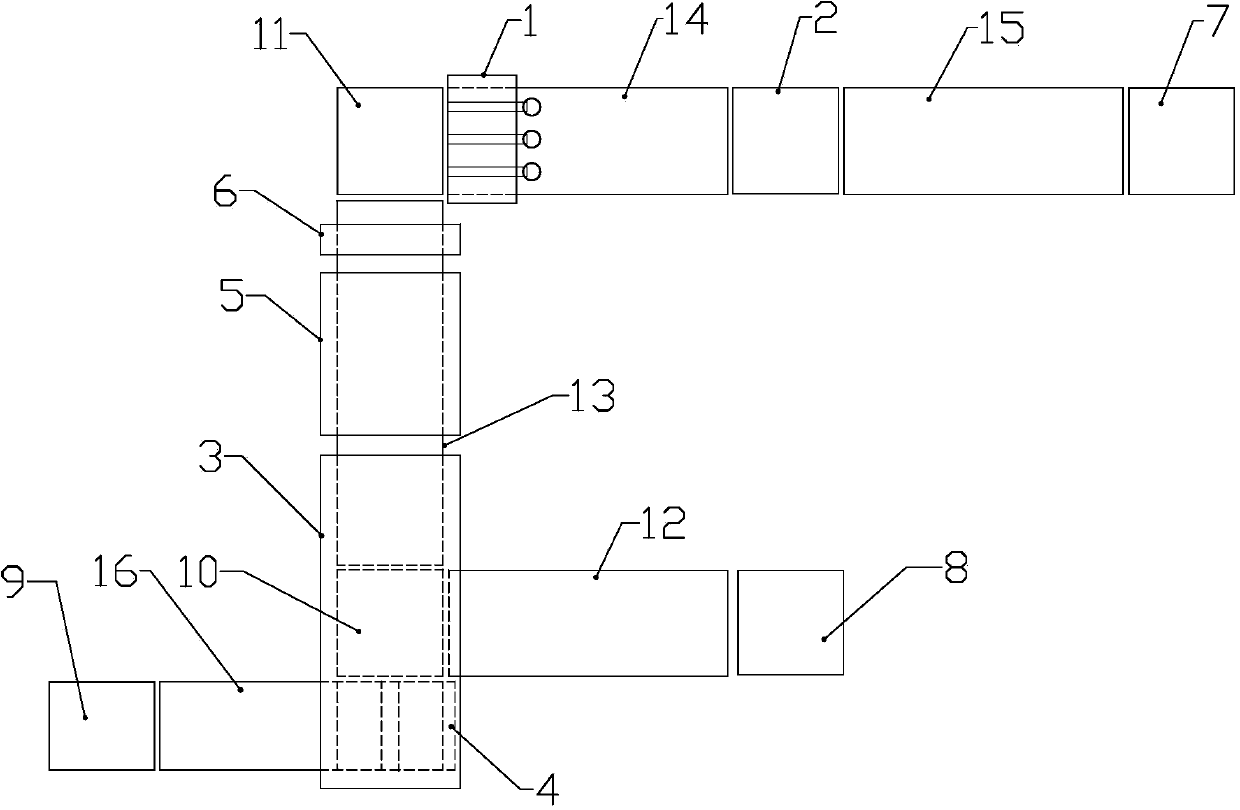

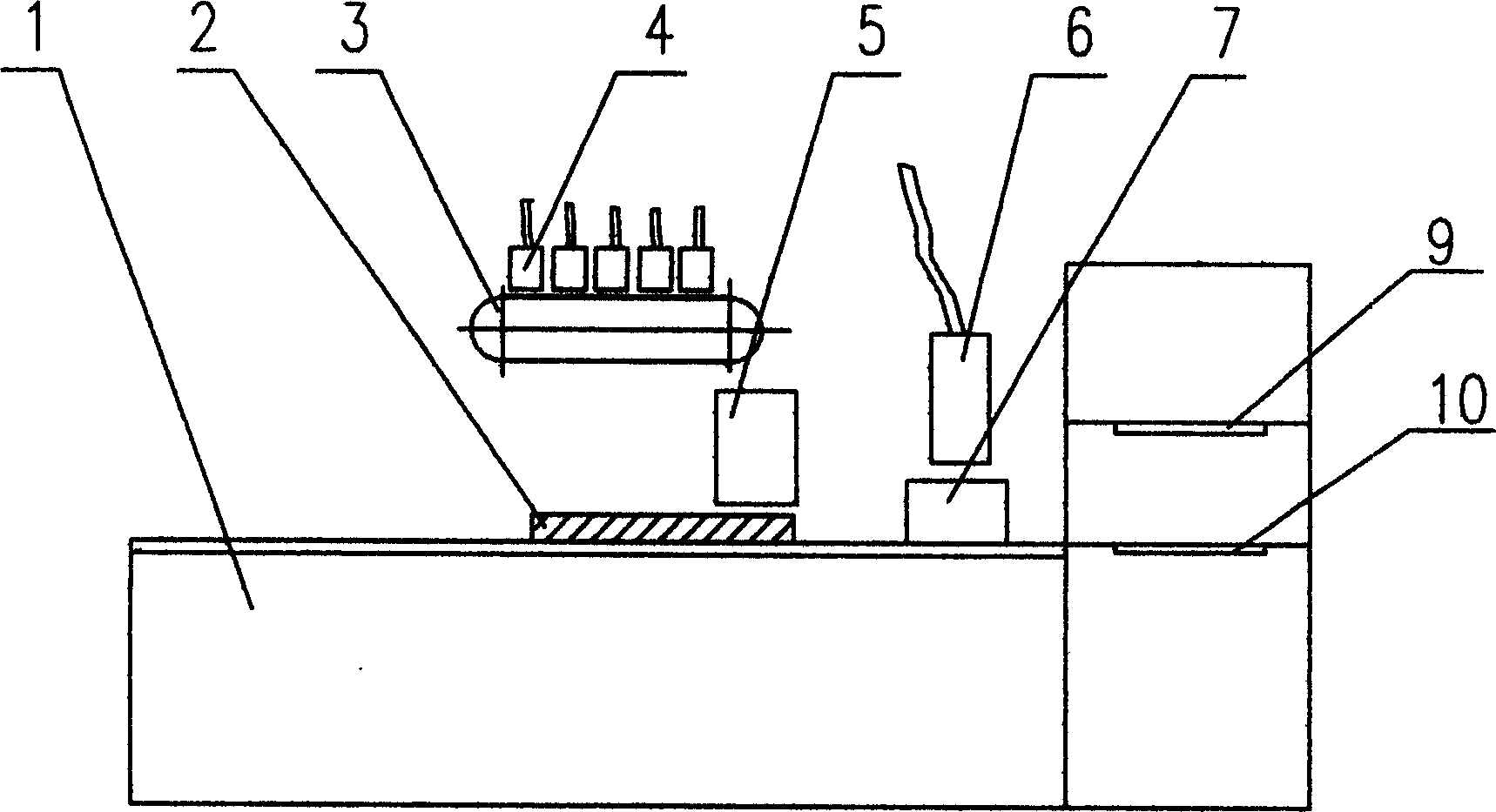

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

Method for manufacturing direct shear test structural plane model

ActiveCN101718644ALong sampling costLow efficiencyPreparing sample for investigationFeeding arrangmentsSize determinationOperability

The invention relates to a method for manufacturing a direct shear test structural plane model. The method comprises the following steps of: (1) the selection and the processing of a virgin rock structural plane: selecting a virgin rock structural plane to be used as a sample, and leveling an original structural plane of the rock mass; then coating a mould release agent at a selected position determined according to the specific size of a structural plane model, and spreading an isolating membrane; (2) putting a lower mould on the selected position of the original structural plane, and pouring a uniformly stirred mixed material into the lower mould; after carrying out water retention maintenance on the sample, turning over a lower disk structural plane sample together with the lower mould, and removing the used isolating membrane on the lower disk structural plane; (3) coating the mould release agent on the prepared lower disk structural plane, and spreading the isolating membrane; centering and putting an upper mould on a lower mould, and then pouring a uniformly stirred mixed material of weighed raw materials into the upper mould again; and (4) demoulding. The method has specific principle, strong maneuverability, low cost and good use effect.

Owner:GUANGZHOU FULI CONSTR & INSTALLATION ENG

Apparatus for forming a striation reduced chemical mechanical polishing pad

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

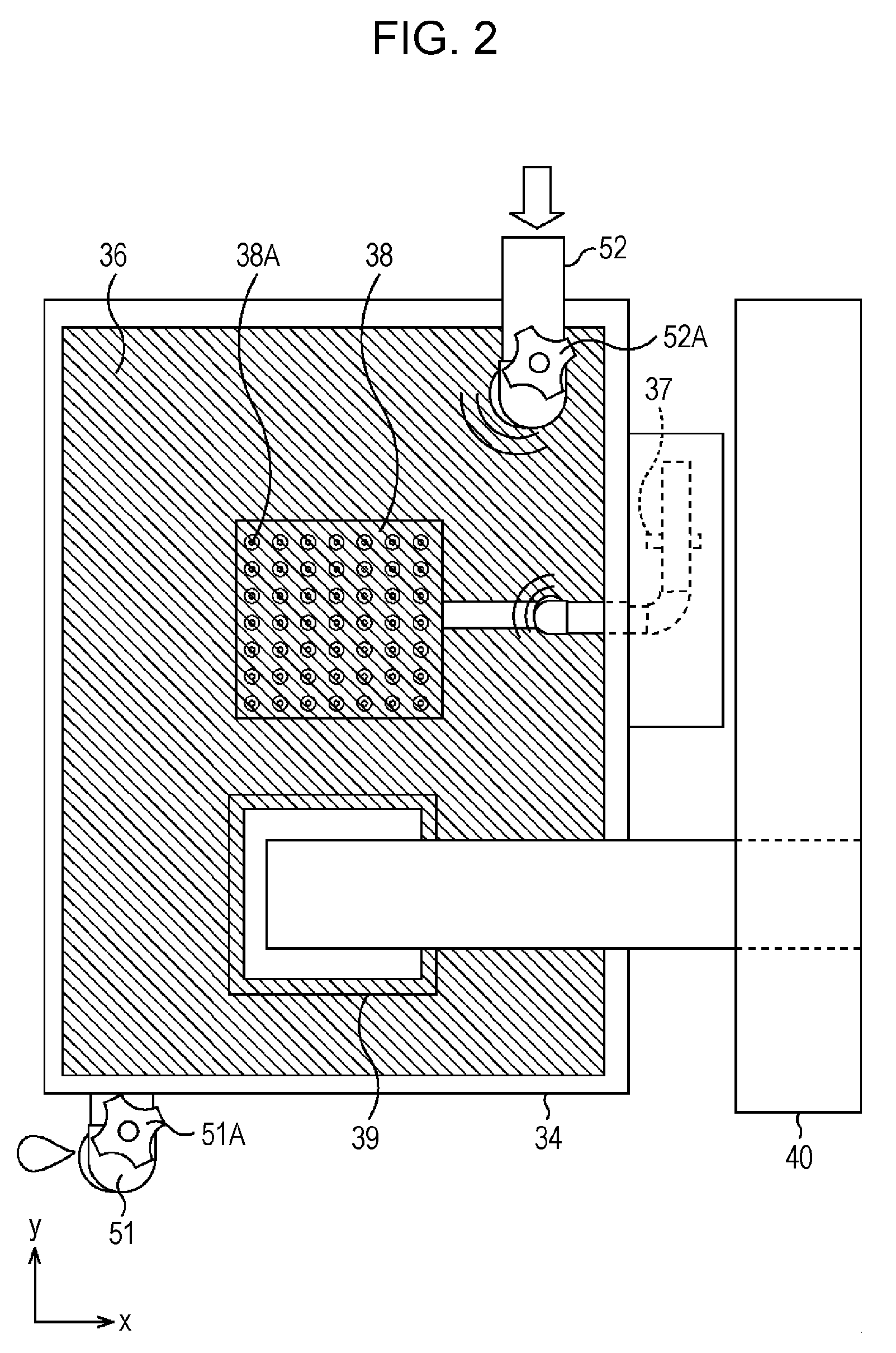

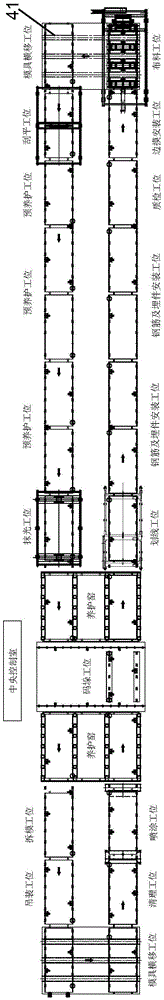

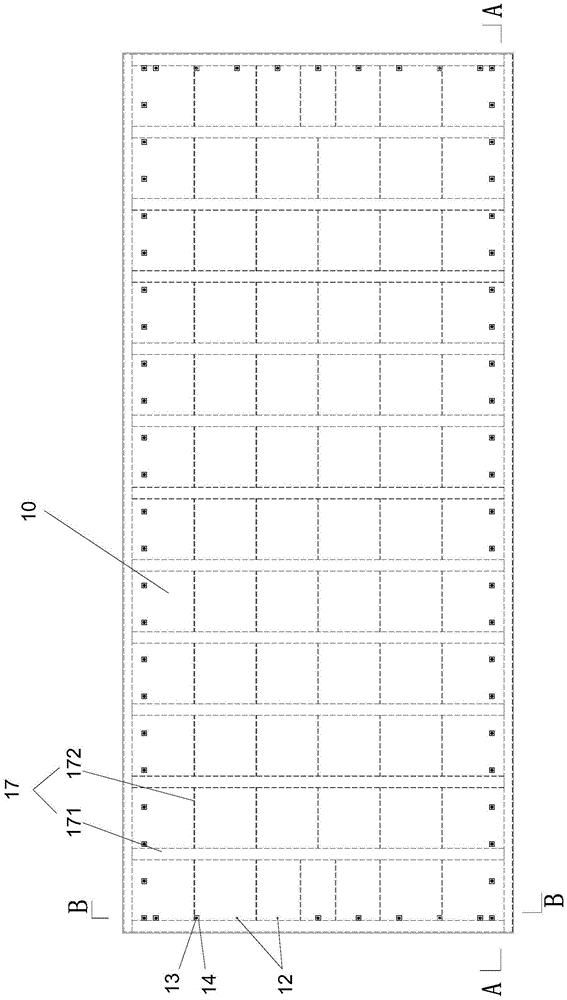

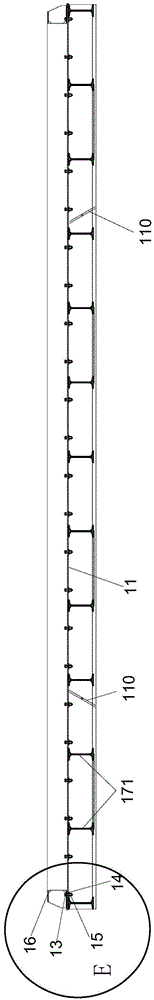

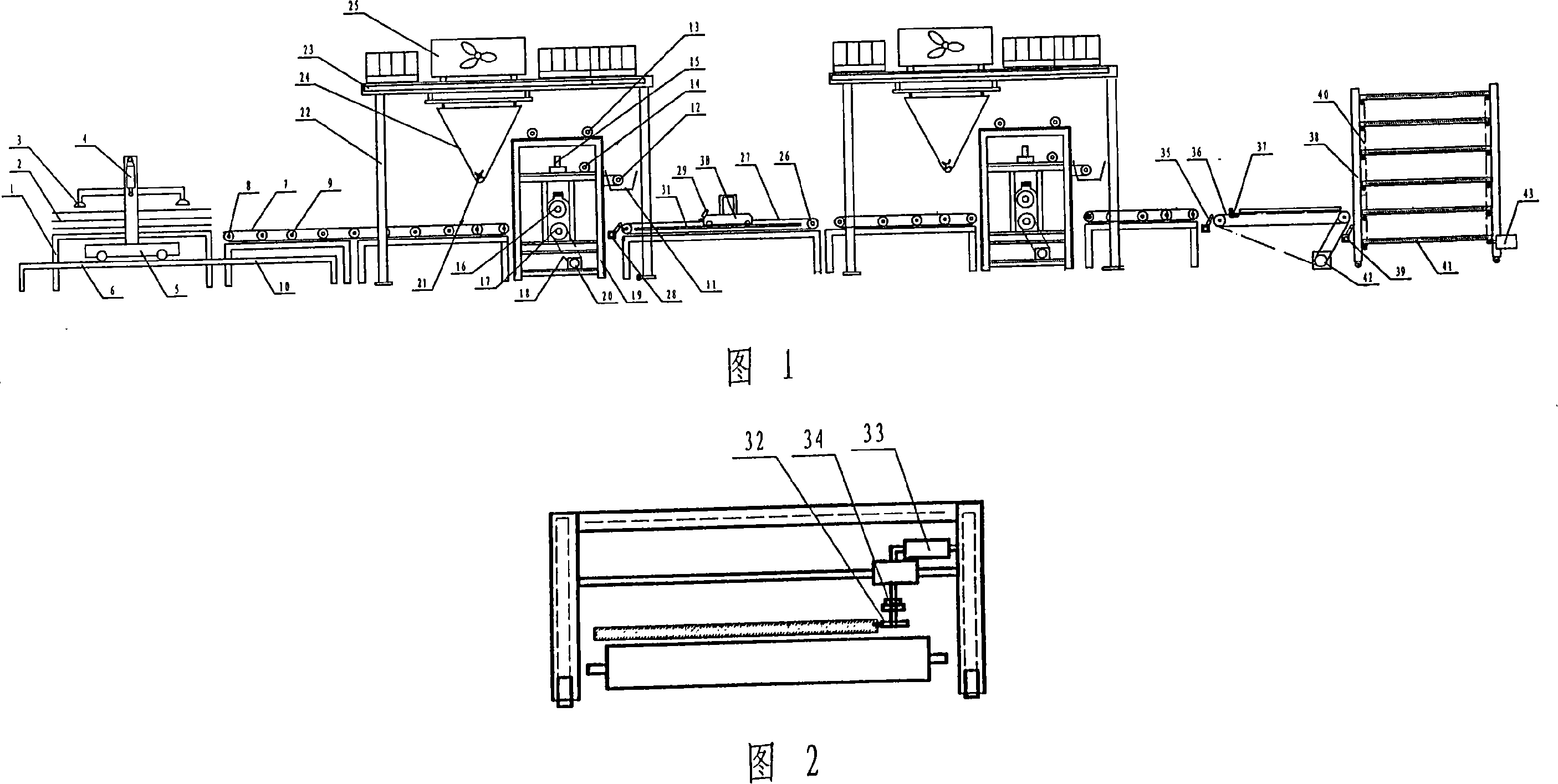

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

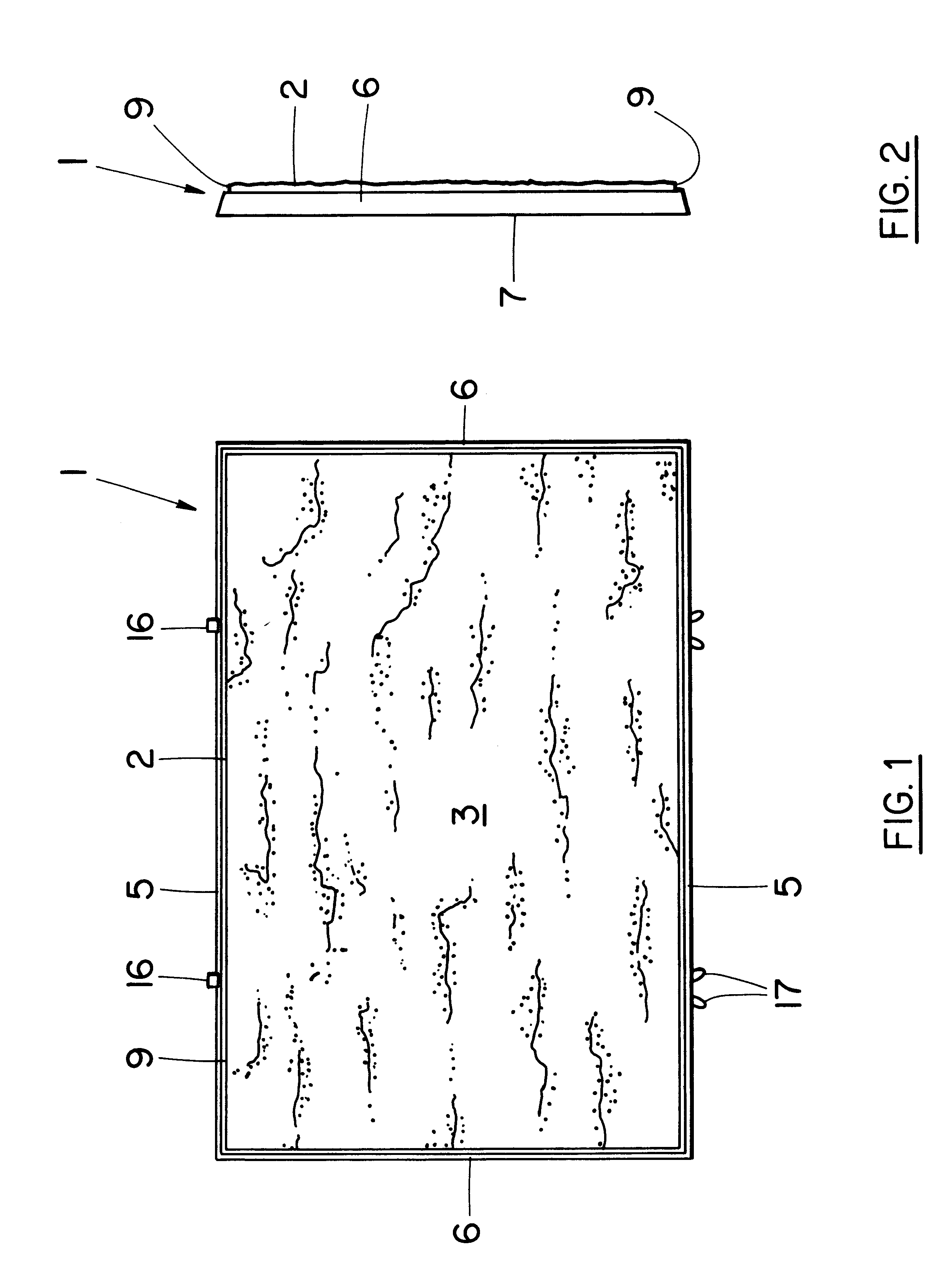

Distributing method for ceramic tile

InactiveCN1586851ADelicate and rich colorsThe pattern is natural and smoothFeeding arrangmentsSurface patternBrick

The material distributing method for ceramic tile is one back side forming process including first distributing powder material and then distributing base material. Fine powder, granular material and their mixture are loaded one layer by one layer onto the conveying belt, added into specially designed lattice via bin to complete the first material distribution; and the base material then falls from the movable bin to fill the mold cavity to complete the second material distribution. During the twice material distribution, the lattice is filled with the fine powder or the mixture of fine powder and the granular material. The present invention has the features of multiple tube material distribution and lattice material distribution, and can form natural and fluent patterns and grains similar to that of natural stone material. The present invention has raised material distribution speed and the back side formation process has no influence on the surface pattern of the returned lattice.

Owner:TEDI CERAMIC FOSHAN CITY

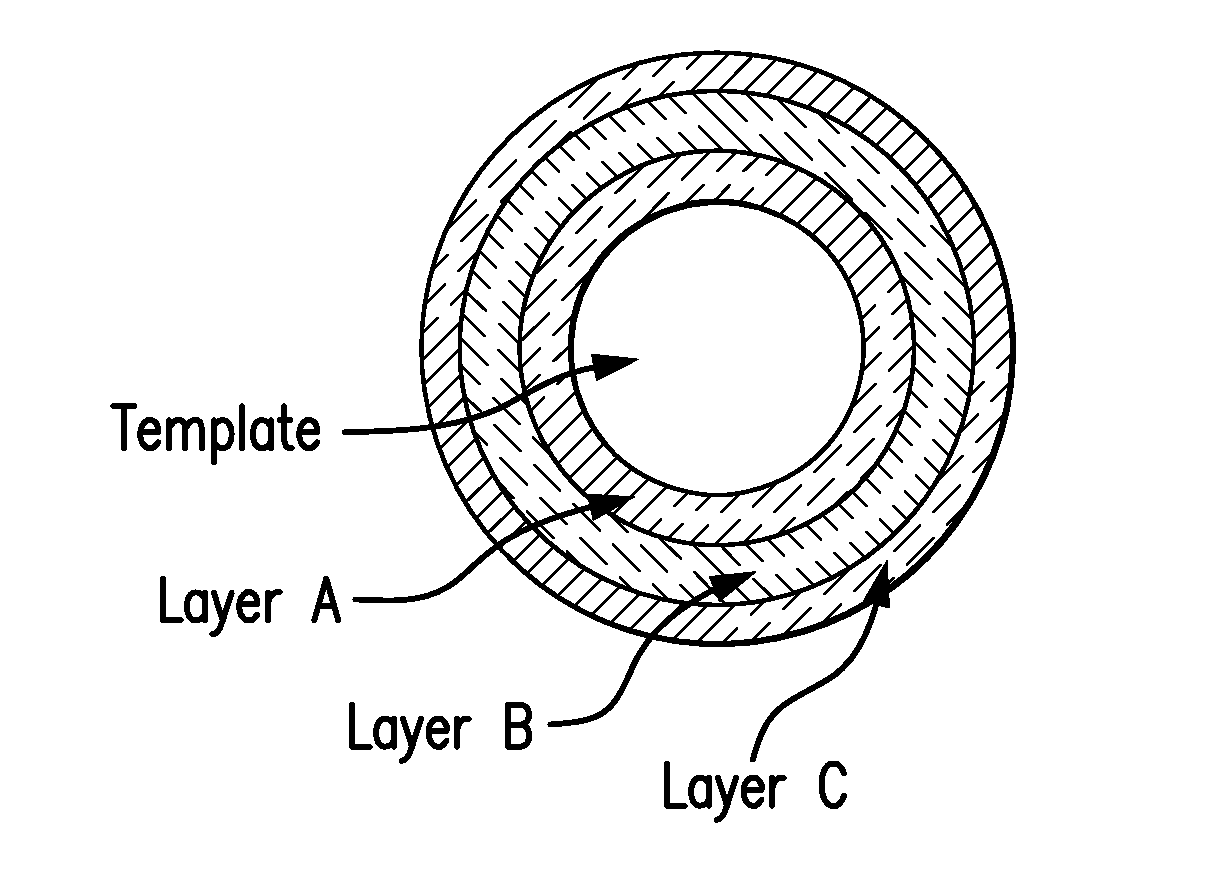

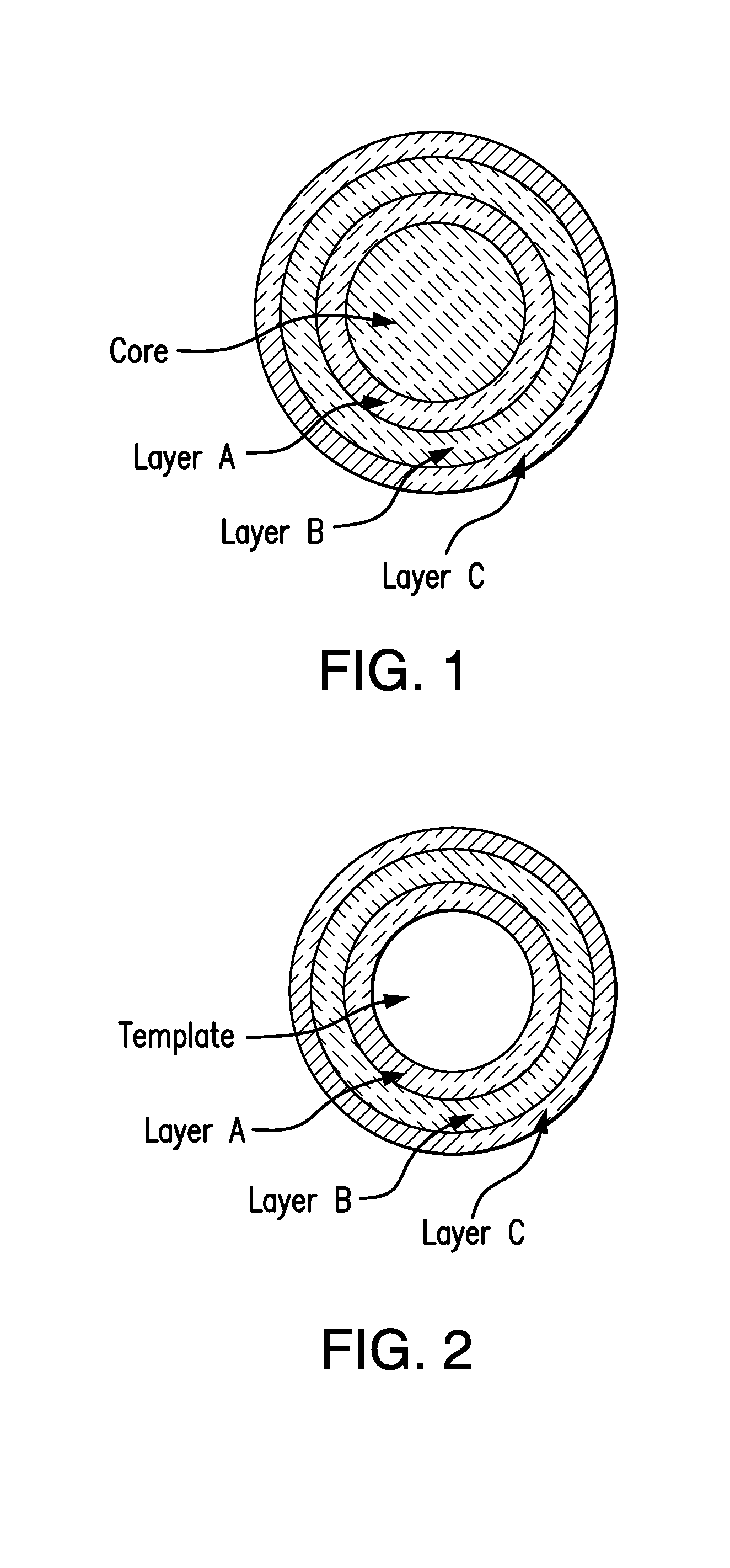

Paving block and molding process therefor

InactiveUS20070216058A1Produce multipleHigh strengthConfectionerySweetmeatsEngineeringUltimate tensile strength

A paving block that closely resembles a used mined cobblestone. The blocks are manufactured by a bi-layer concept that is subjected to processes that cause the layers to structurally integrate. The process and composition permit the mass production of blocks having independent top topographies that emulate the surfaces of original cobblestones and with a comparable strength.

Owner:ECOLOGICA CARMELO

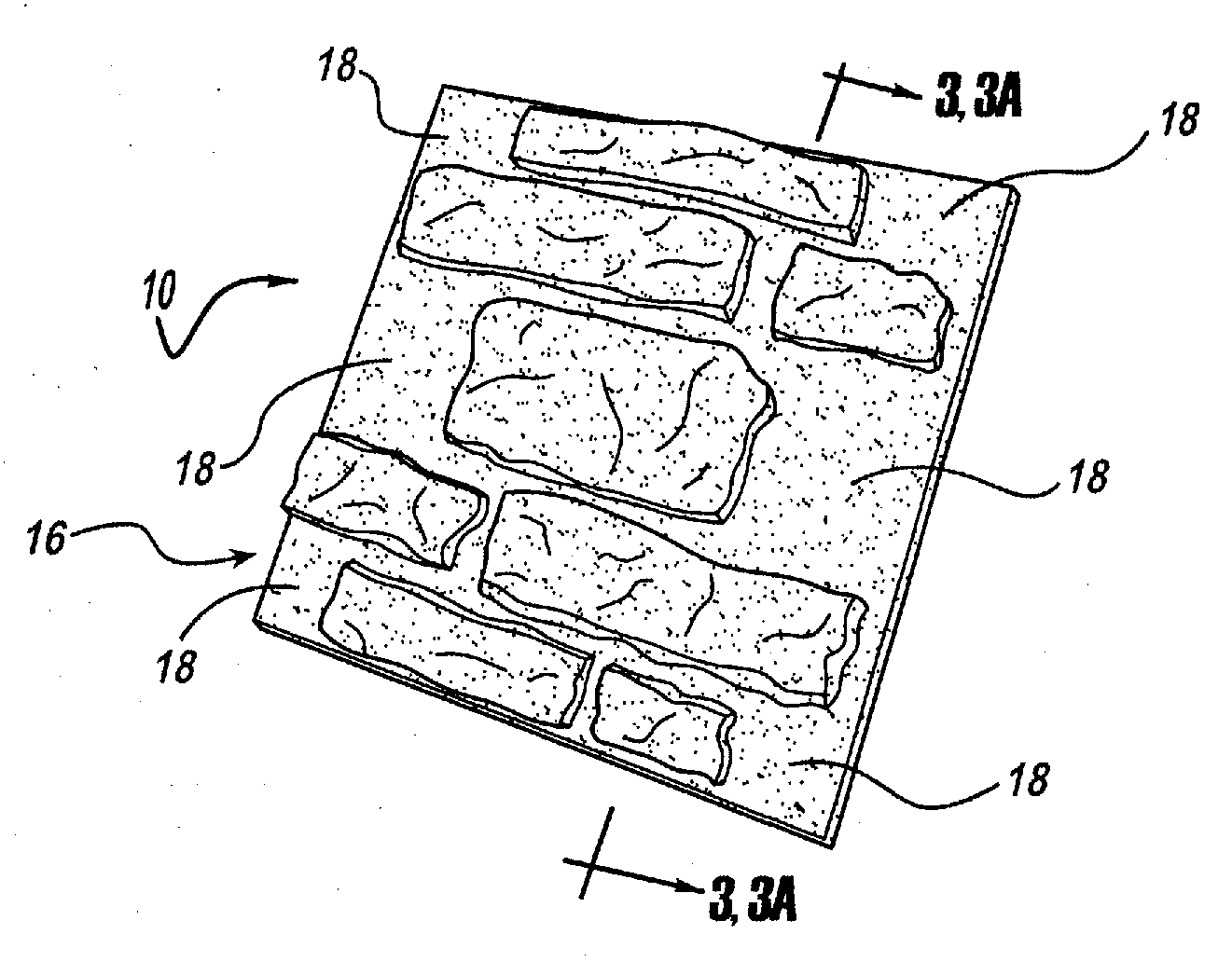

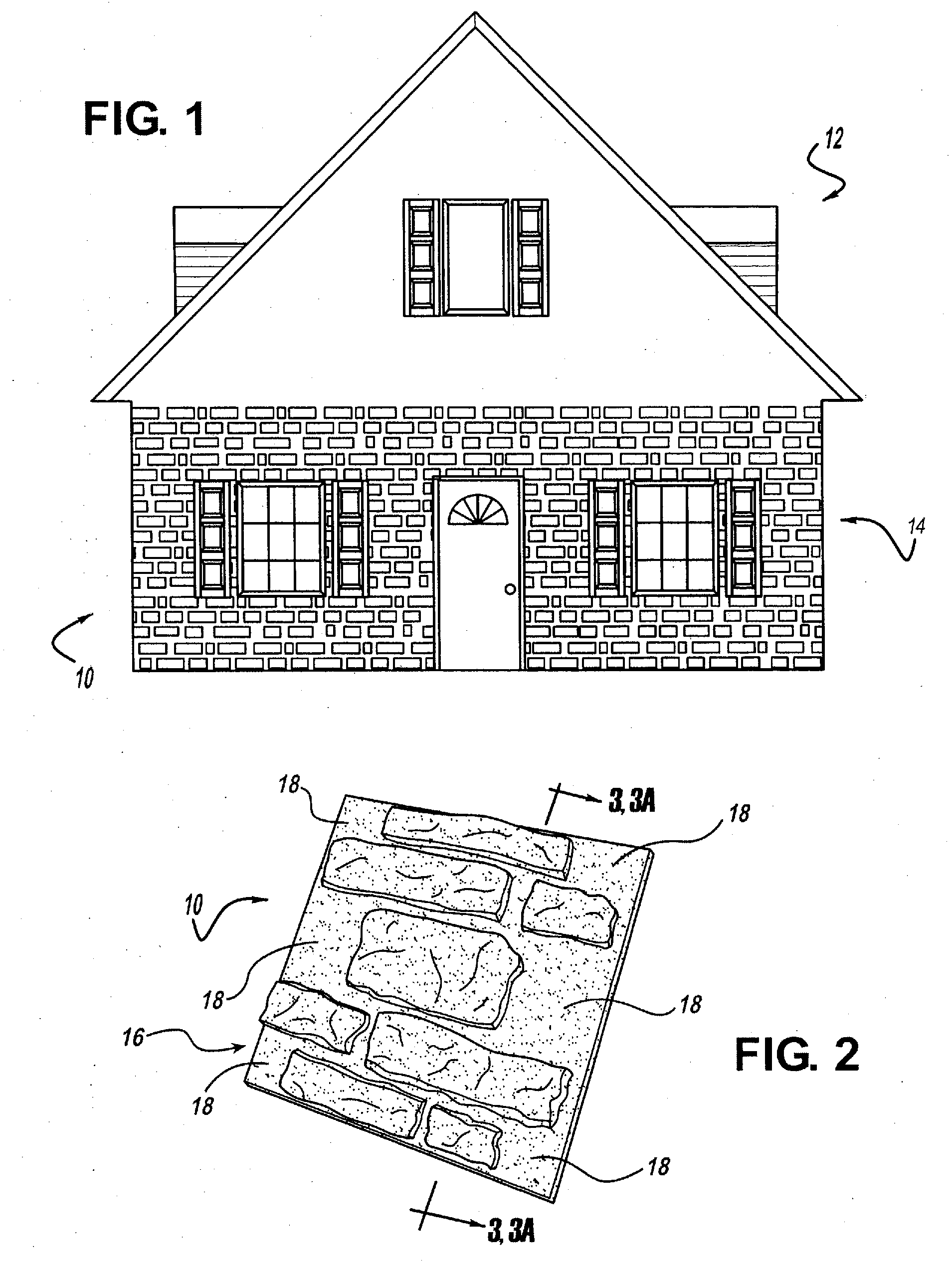

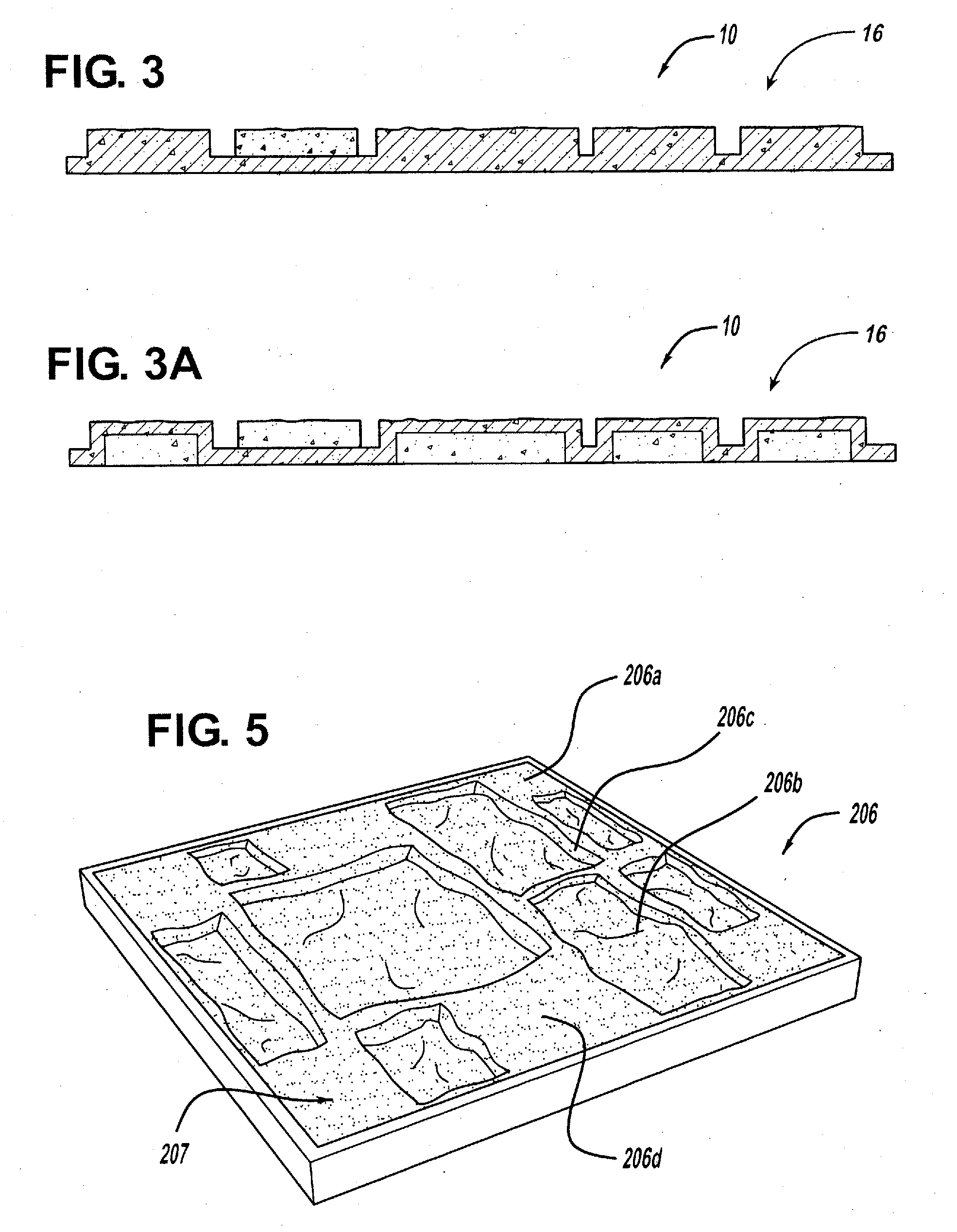

Stone work simulation system

InactiveUS20090235600A1Eliminate needOverall shapeConstruction materialCovering/liningsAdhesiveSlurry

A stone work simulation system including panels formed from a cementitious material. The panels of the system can be cast or injection molded from cementitious slurry, including hydraulic cement, or gypsum cement and an optional latex / water mixture. A desired amount of the slurry is added to the mold, the surface of which includes several spaced apart depressions formed therein to closely resemble a pattern of stones at least partially disposed in a mortar matrix. Optionally, the mold can include a number of flat spaces formed between the depressions. Optionally, a reinforcing mesh is also provided in the mold. A colorant can be disposed on the bottom mold surface prior to the introduction of the mesh and the slurry to impart a color pattern to the system. After sufficient curing, the panel is removed from the mold and is ready for immediate use and / or further processing, such as additional surface coloring. In use, the system can be mounted to a building surface, such as a wall, e.g., with a mechanical fastener, adhesive, mortar, cement, and / or the like. To provide distinctiveness to the system, a plurality of individual simulated stones (e.g., that have been formed separately or as a separable unit, e.g., according to the process above) that are sized, shaped, and colored similarly to or differently from the system, can be incorporated onto the flat spaces formed on the system to form a unique finished product and avoid the appearance of the installed system being an arrangement of individual panel units.

Owner:TAPCO INTERNATIONAL CORPORATON

Material distribution method and device for production of ceramic tile

InactiveCN102303357AHigh degree of simulationHigh degree of clusteringFeeding arrangmentsShaping conveyorsLiquid layerBrick

The invention discloses a material distribution method and device for the production of a ceramic tile, wherein the method comprises the steps of: 1, distributing a surface material on a first feeding belt; 2, shaping the surface material by a shaping machine; 3, coating a coloring liquid layer, which forms irregular textured patterns, on the surface of the surface material; 4, randomly distributing a ceramic material on the surface of the liquid layer; and 5, transferring the distributed ceramic material to a second feeding platform and piling up the ceramic material on the second feeding platform to complete material distribution, wherein the first feeding belt has the speed higher than that of a second feeding belt. By adopting the technical proposal, a pattern which is both delicate and raw and which is extremely close to natural texture can be formed, thus the simulation for surface texture of the finished ceramic tile product is improved.

Owner:佛山市新海舟科技有限公司

Automatic shaping method and equipment for load-bearing hollow brick

InactiveCN1657251ALiberate labor intensitySpeed up the flowDischarging arrangementMouldsBrickEngineering

A method for automatically shaping the load-bearing hollow brick includes such steps as preparing concrete, stirring, filling in mould, inserting core mould while vibrating, hydraulic pressing, and demoulding. Its apparatus is composed of electric power control box, control mechanism, motor, concrete preparing system, shaping system, feeding unit, and discharging unit.

Owner:广西金瓯建材机械有限公司

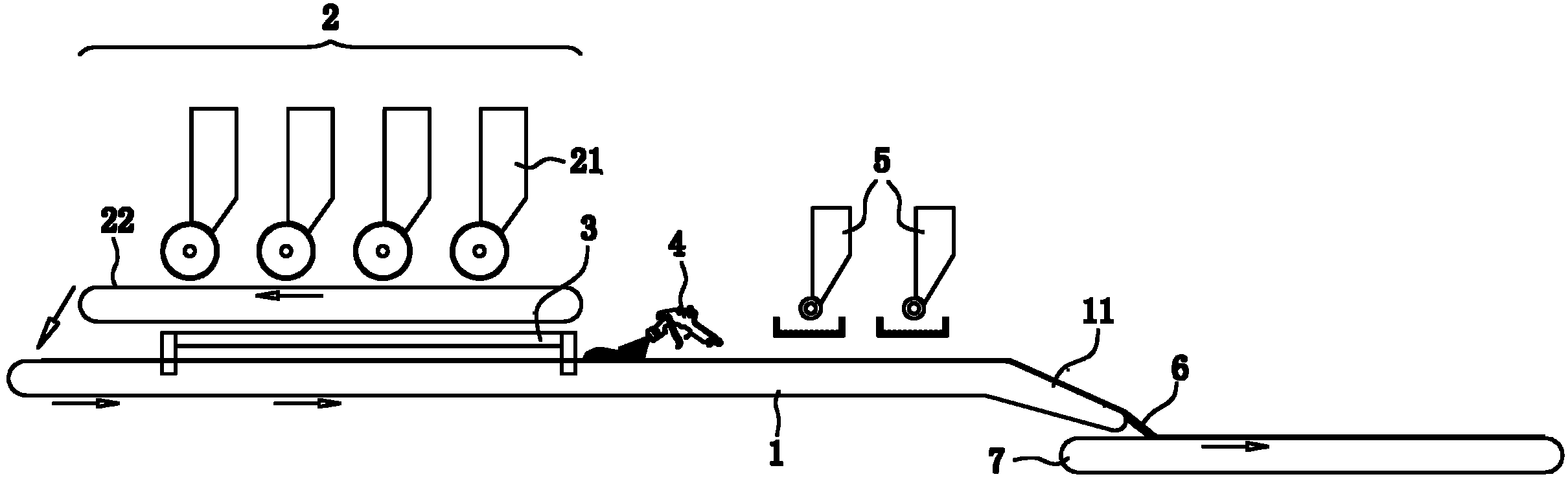

Compound thermal insulation wall plate and external wall heat-insulation board producing line

InactiveCN101138866AIncrease productivityEasy to operateDischarging arrangementCeramic shaping plantsProduction lineThermal insulation

The present invention discloses a production line of a composite heat proof wall plate and an external heat proof plate of an external wall. The production line includes an automatic mounting moulding board mechanism, cloth-net roll mechanisms, a reseau cloth automatic cutting mechanism and an automatic plate-sending, shelf-installing and shelf-sending mechanism which are orderly linked by a belt feeding production chain. Mixing and material-dropping mechanisms are arranged above a section of belt feeding production chain between the automatic mounting moulding board mechanism and a first group of cloth-net roll mechanism and between a forward group of cloth-net roll mechanism and a next group of cloth-net roll mechanism. At least two groups of matched mixing and material-dropping mechanisms and the cloth-net roll mechanisms are arranged. The production line can produce the composite heat proof wall plate and at the same time can also produce the external heat proof plate of an external wall and has the characteristics of high production efficiency, simple and convenient operation and high quality of processing.

Owner:泰安鲍文特科技有限公司

Apparatus for forming a porous reaction injection molded chemical mechanical polishing pad

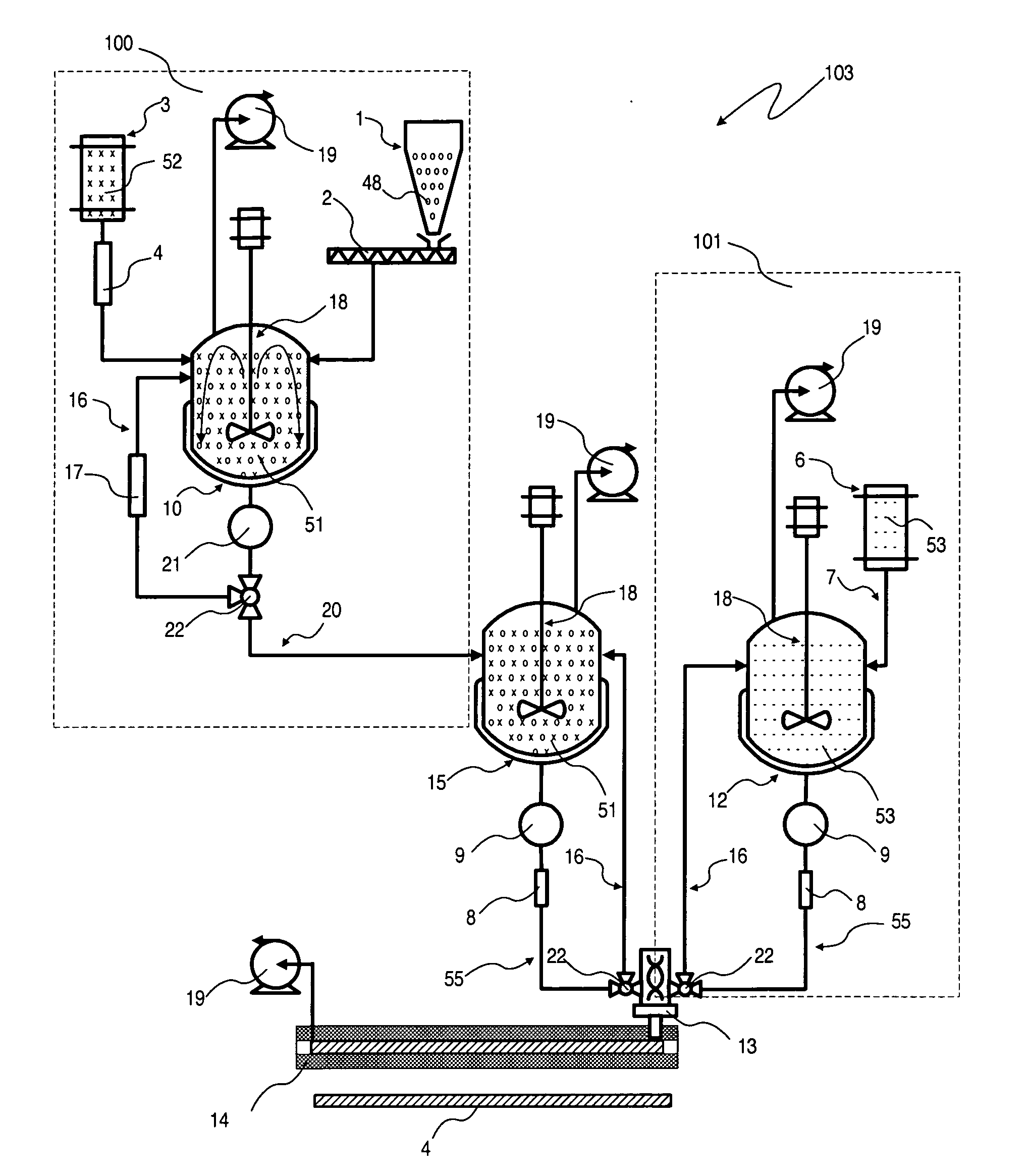

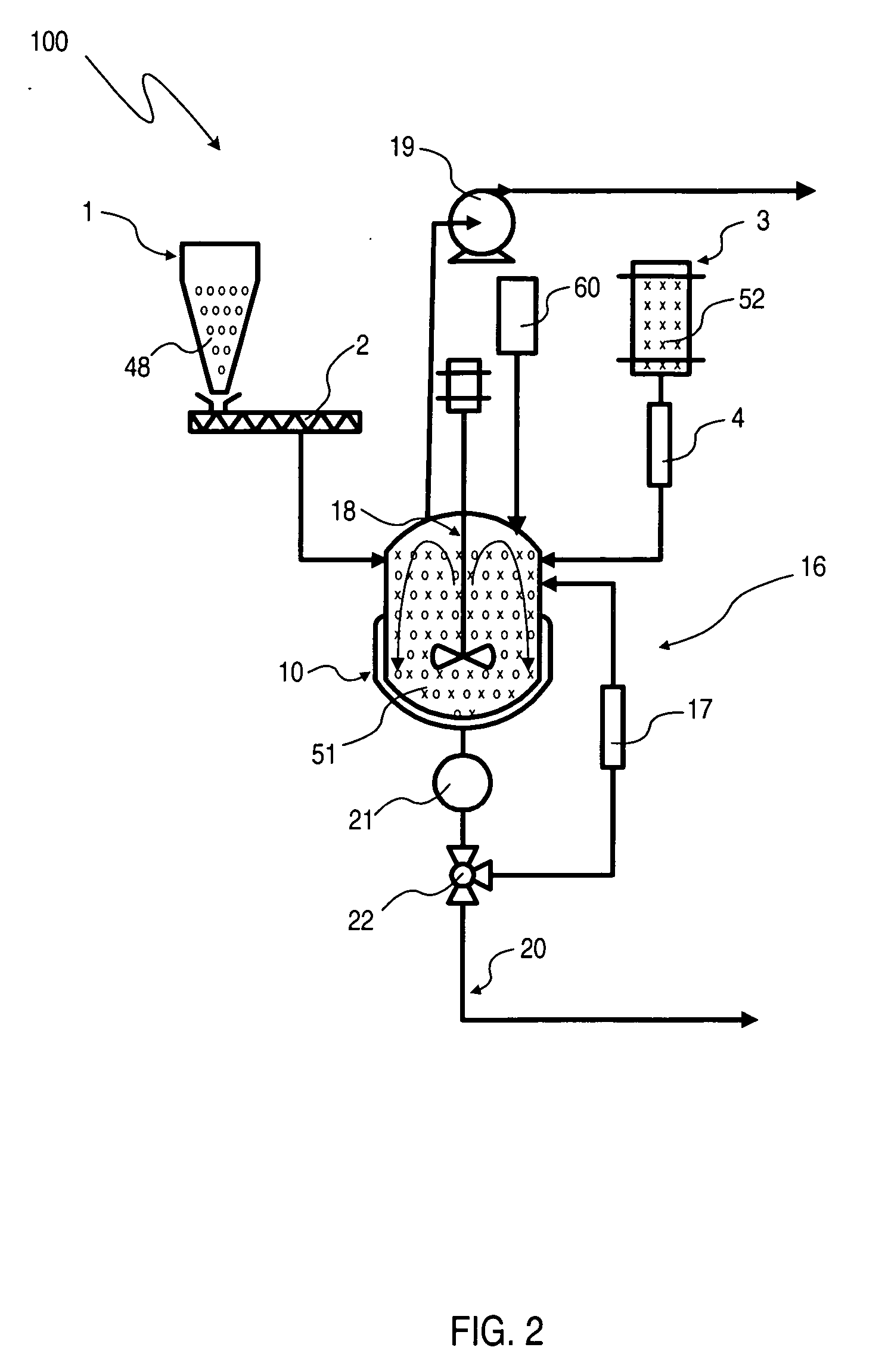

The present invention provides an apparatus for forming a chemical mechanical polishing pad, comprising a tank with polymeric materials, a storage silo with microspheres, a isocyanate storage tank with isocyanates and a premix prep tank for forming a pre-mixture of the polymeric materials and the microspheres. The invention further provides a premix run tank for storing the pre-mixture, a mixer for forming a mixture of the pre-mixture and the isocyanates, a closed mold for reaction-injection molding the mixture and a vacuum for degassing at least one of the tank, isocyanate storage tank or the mold.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com