Material distribution method and device for production of ceramic tile

A technology of ceramic tiles and fabrics, applied in the direction of supply devices, forming conveyors, manufacturing tools, etc., can solve the problems that it is difficult to reflect the fine and smooth texture of natural stone, limited fineness of stone texture, coarse ore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

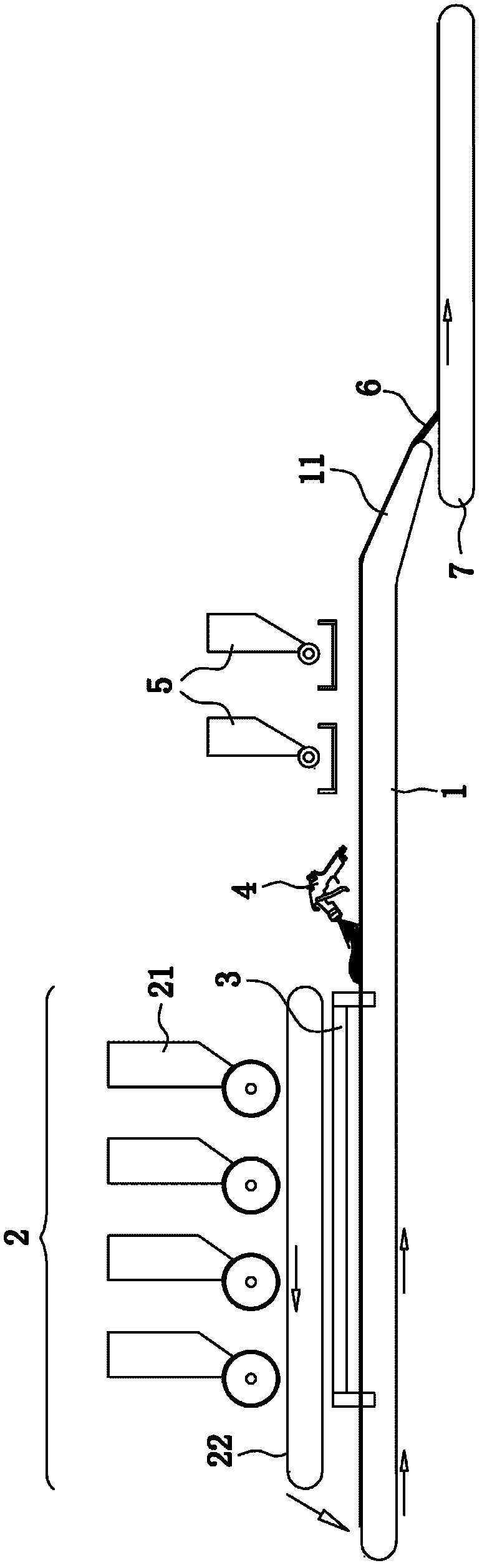

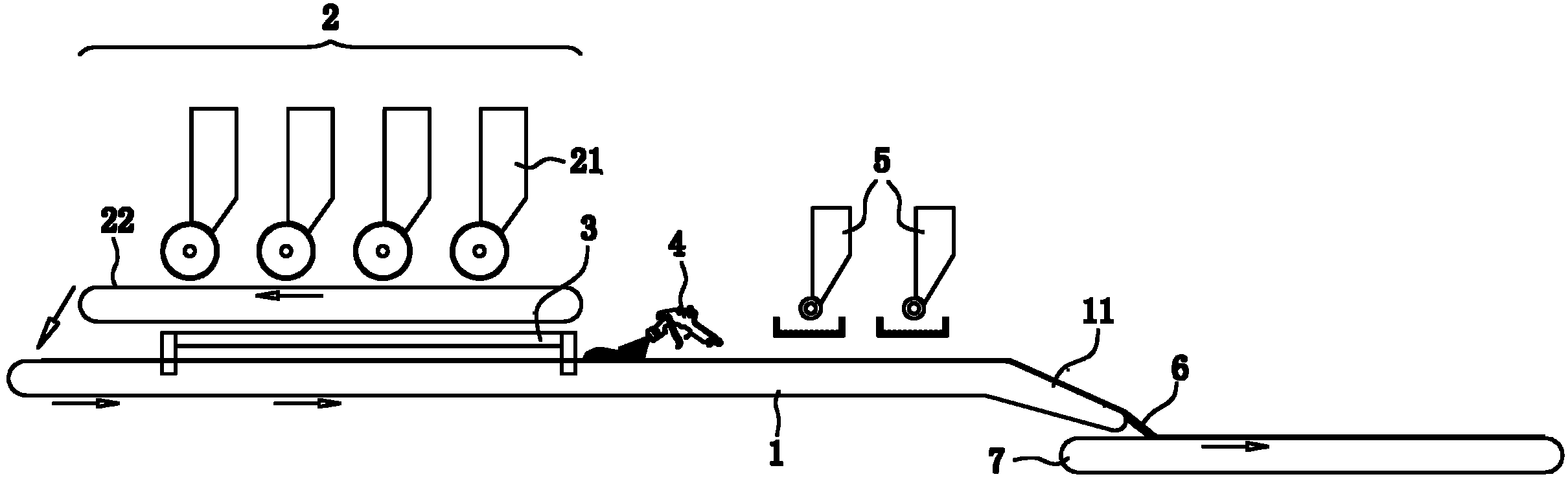

[0010] Now set forth the present invention in detail in conjunction with accompanying drawing:

[0011] The method for distributing ceramic tiles of the present embodiment, its production steps are as follows:

[0012] ① Lay the fabric on the first feeding belt, ② The fabric is shaped by the shaper, ③ Spray a layer of colored liquid layer on the surface of the fabric to form an irregular texture pattern. The generated texture pattern is sprayed on the surface of the fabric, and the coloring liquid used for spraying can be ink or glaze. ④ Distribute the thread material randomly on the surface of the liquid layer. The arrangement of the thread material is random, so the thread material does not form on the surface of the liquid pattern layer. Regular accumulation, ⑤ Transfer the above-mentioned distributed ceramic materials to the second feeding platform, requiring the speed of the first feeding belt to be faster than the speed of the second feeding belt, where the ceramic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com