Patents

Literature

5639 results about "Material distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

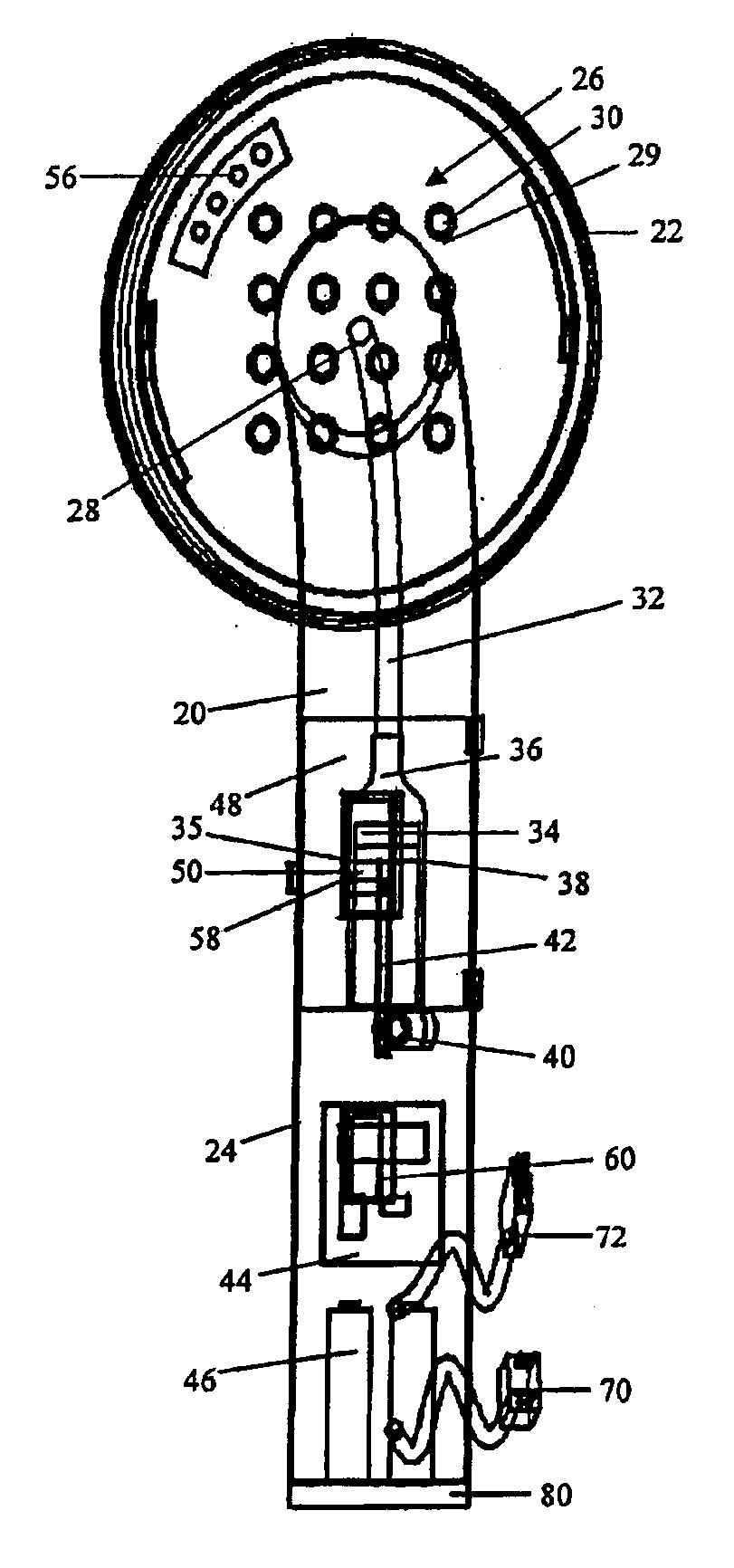

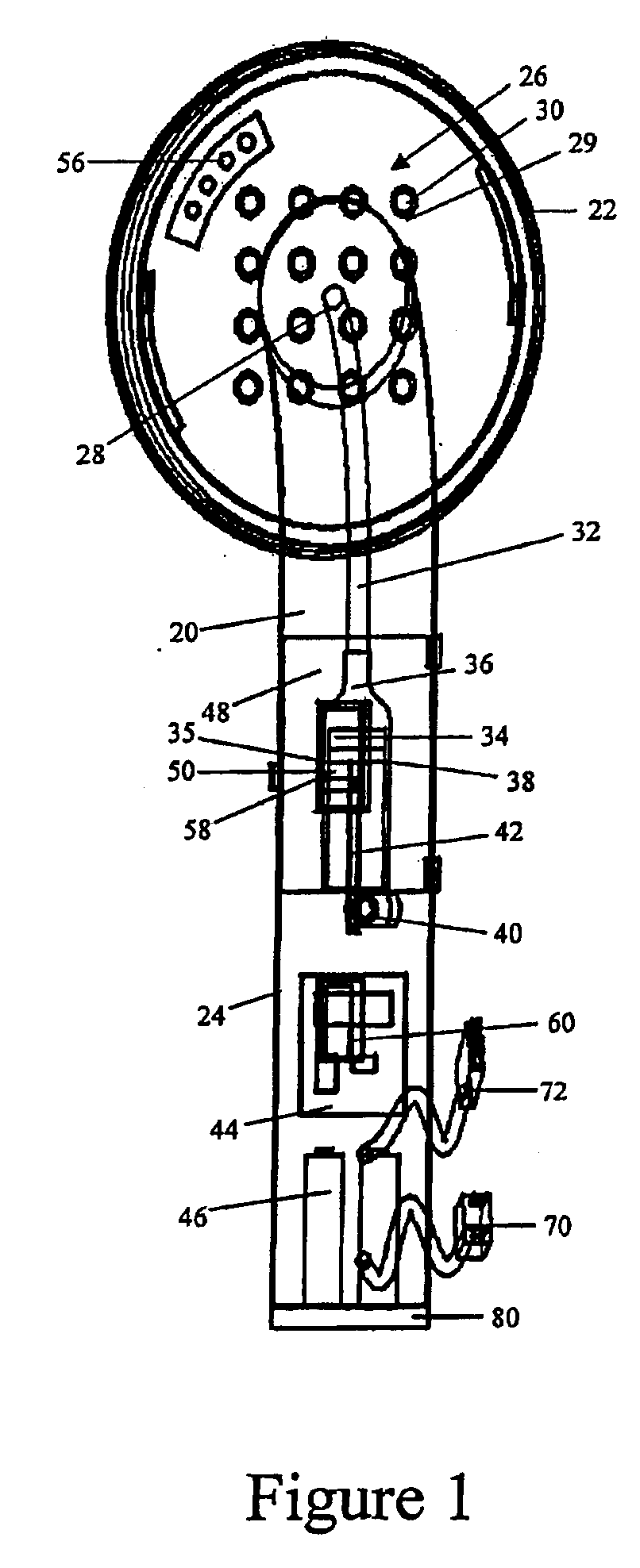

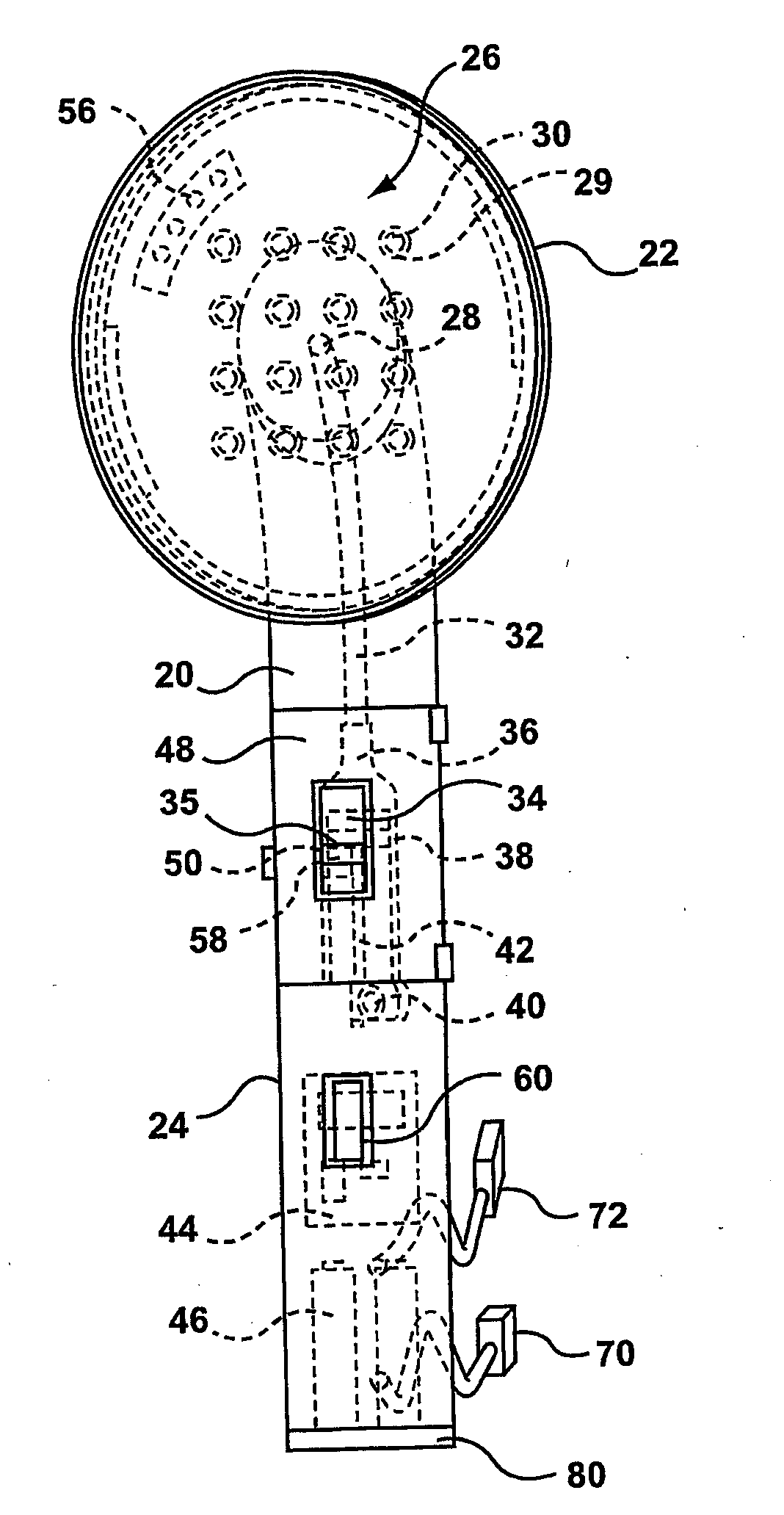

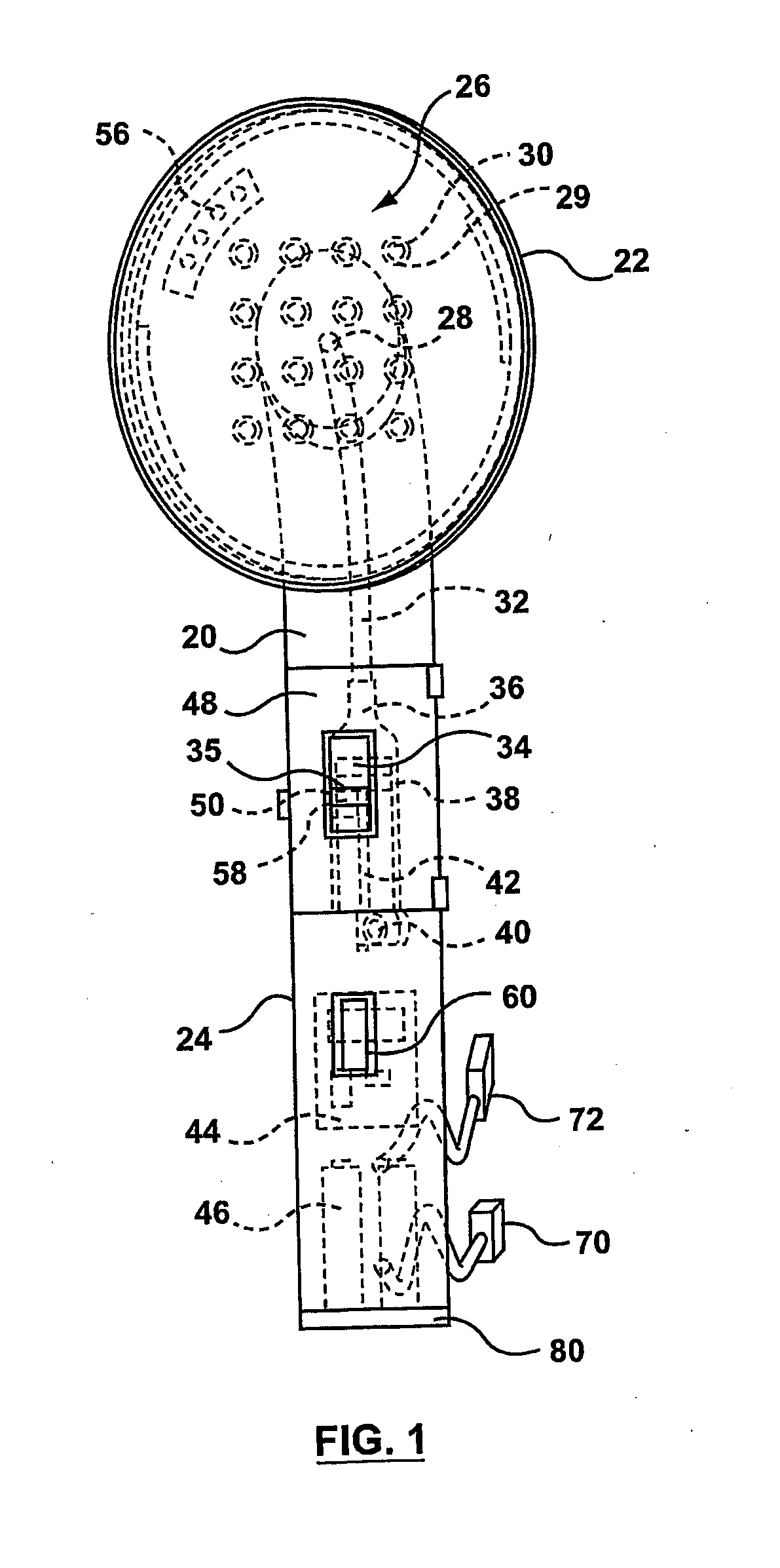

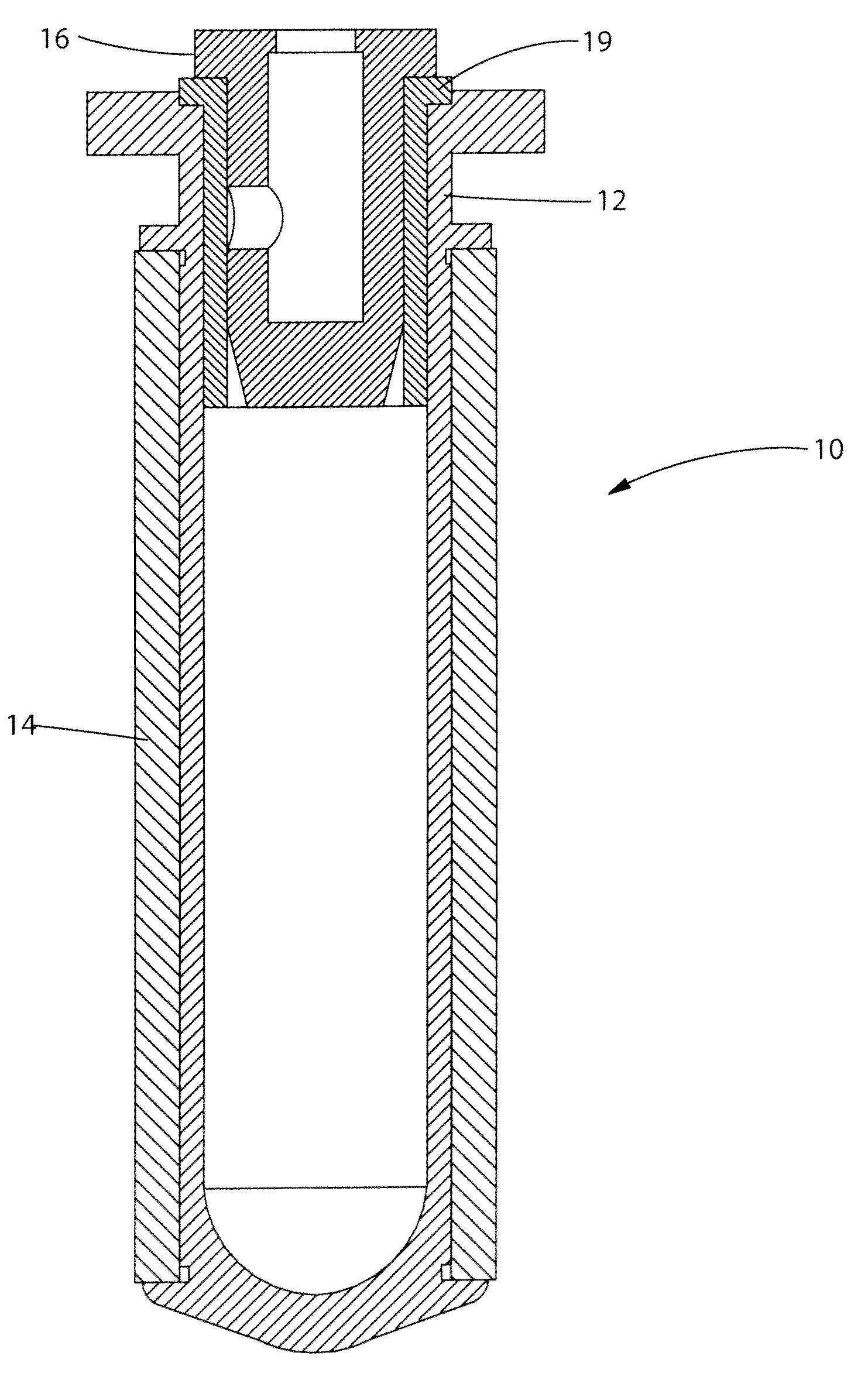

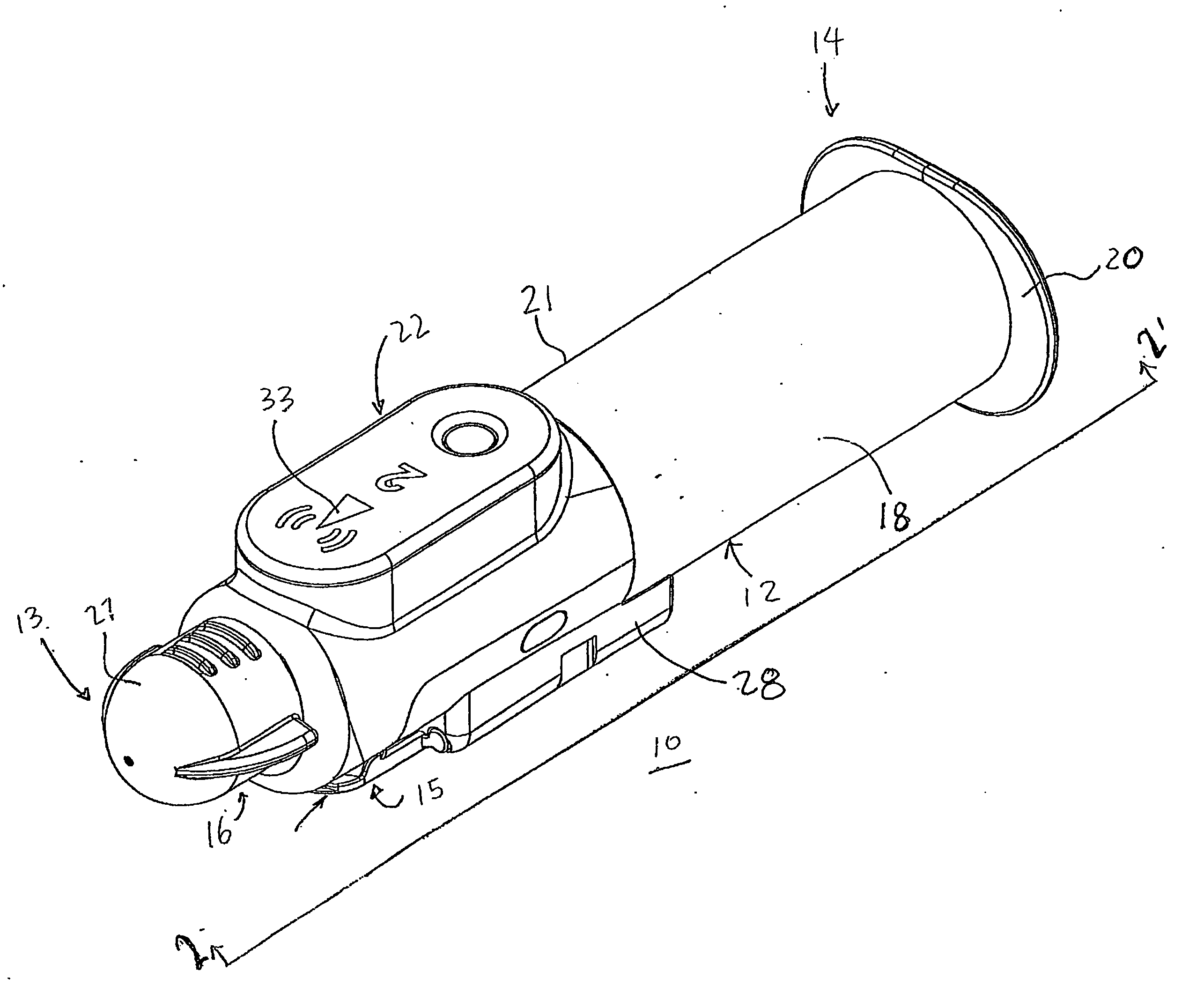

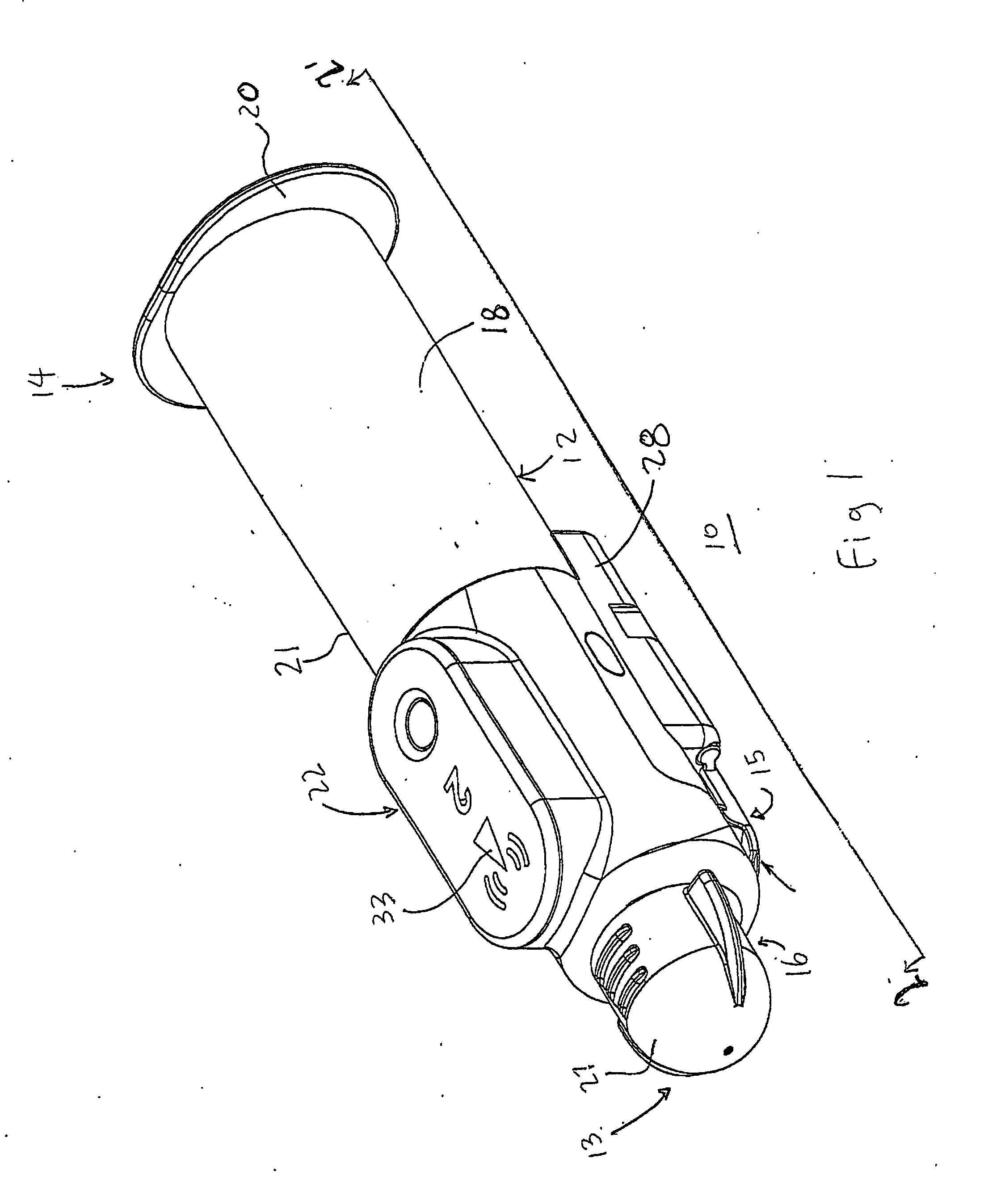

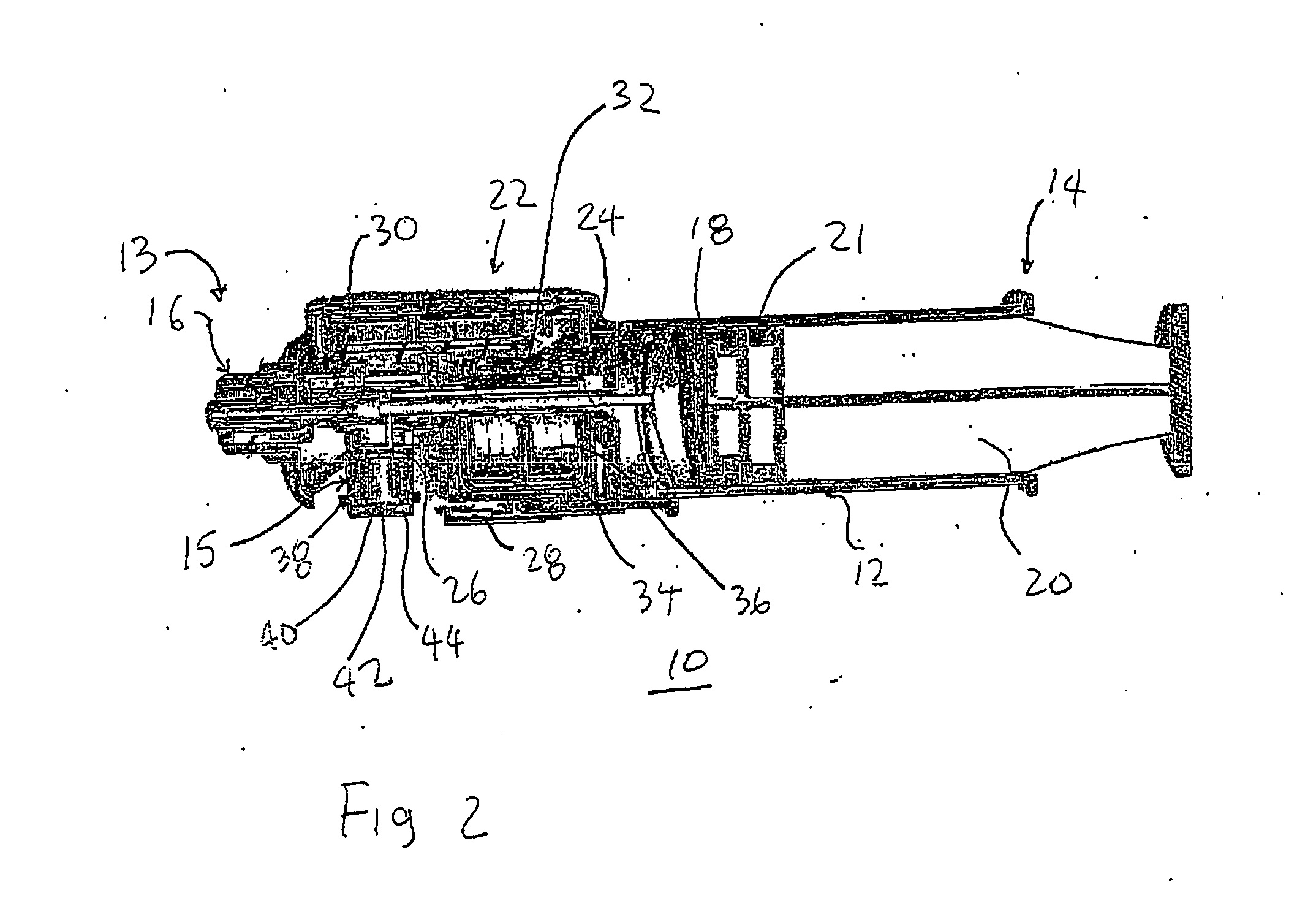

Therapy device and system and method for reducing harmful exposure to electromagnetic radiation

The invention is directed to a therapy device, including a body, an energy source disposed on the body for emitting a desired wavelength of electromagnetic radiation, and a proximity sensor for sensing proximity of the device to a desired surface. Also disclosed are a material dispensing system disposed on the body for dispensing a desired material for use with the device and accessories and compositions used with the therapy device, including interchangeable energy source-containing heads and interchangeable material containers. Methods for using the therapy device are also disclosed.

Owner:SYNERON BEAUTY

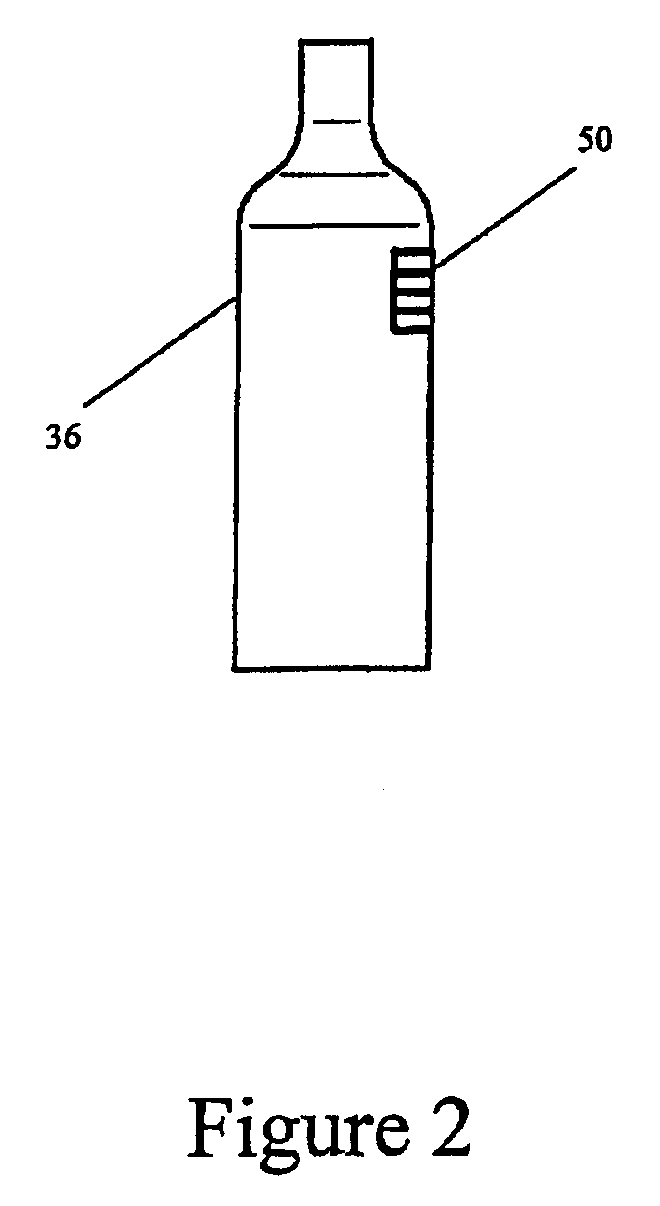

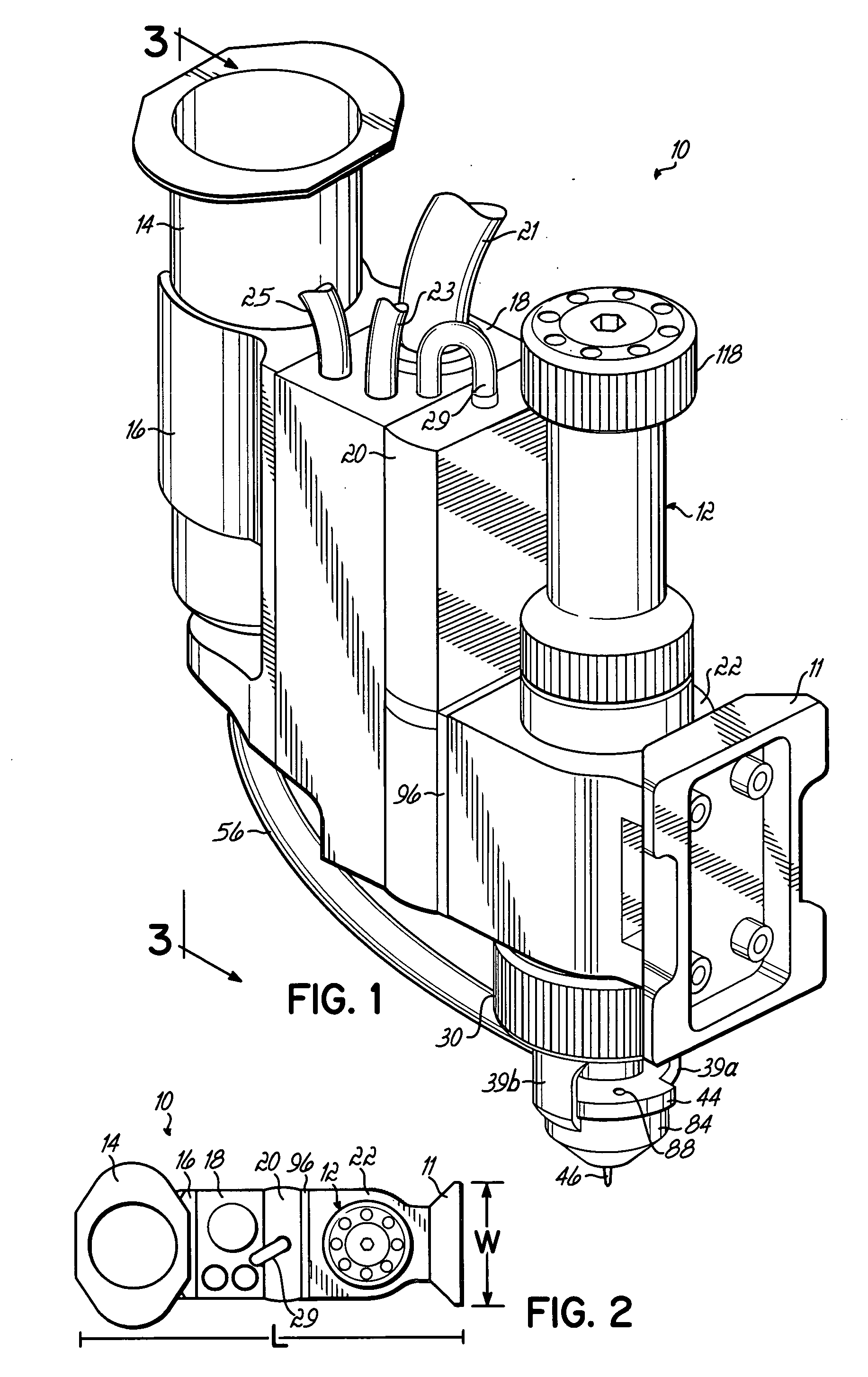

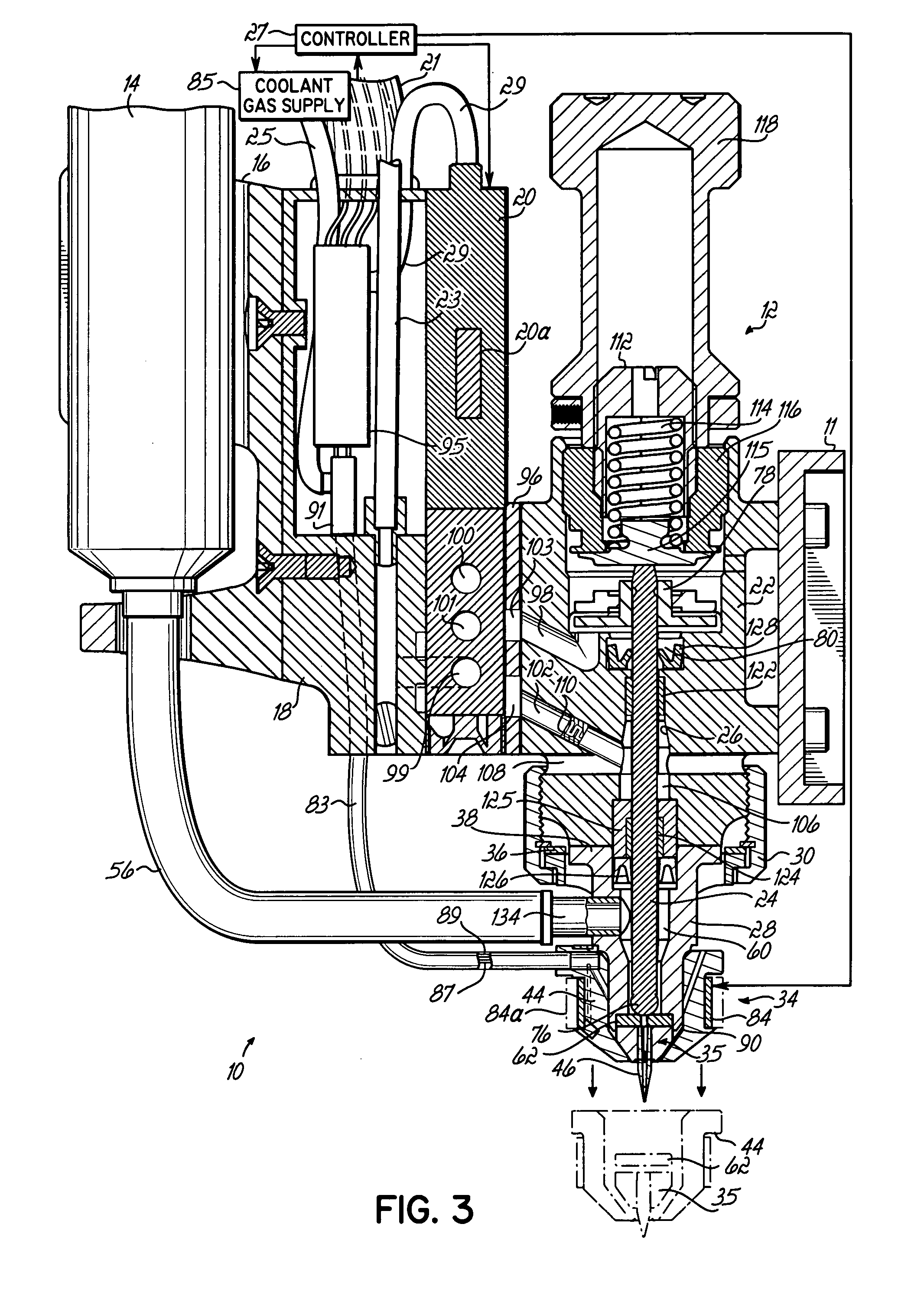

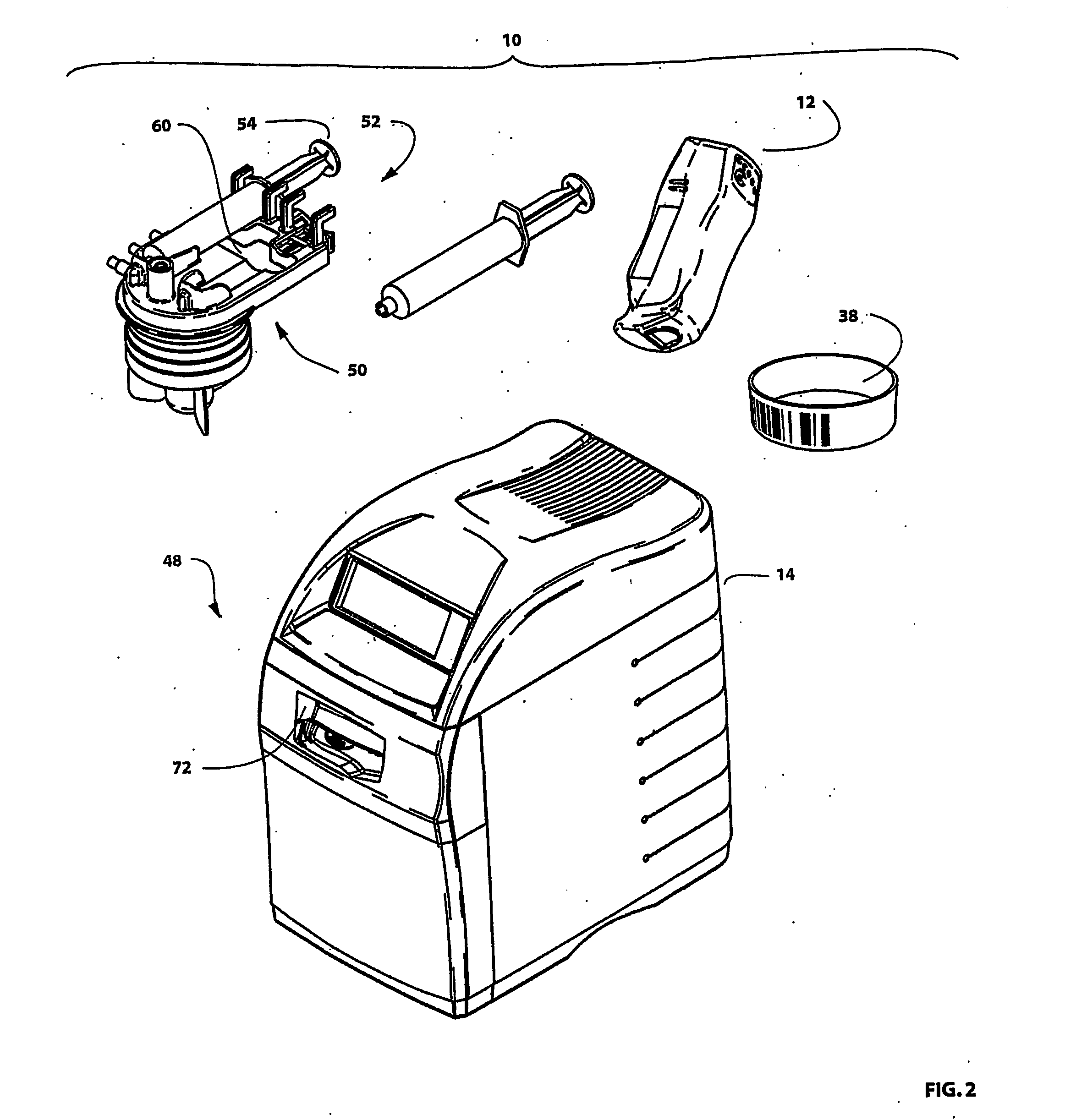

Apparatus and method for dispensing discrete amounts of viscous material

InactiveUS20060157517A1Liquid surface applicatorsDomestic cooling apparatusEngineeringMaterial distribution

Apparatus and methods for dispensing small amounts of a viscous material onto a workpiece. The narrow-profile dispensing apparatus includes a fluid chamber, a nozzle, and a valve seat disk representing individual components that are removable from a main body of the dispensing apparatus for cleaning and / or replacement. The nozzle is coupled with the fluid chamber by a heat transfer body that may be cooled by, for example, a cooling fluid routed through an air pathway defined in the heat transfer body. The main body of the dispensing apparatus may be cooled by air exhausted from an air cavity of a pneumatic actuator regulating the movement of a needle to control the flow of viscous material in the dispensing apparatus.

Owner:NORDSON CORP

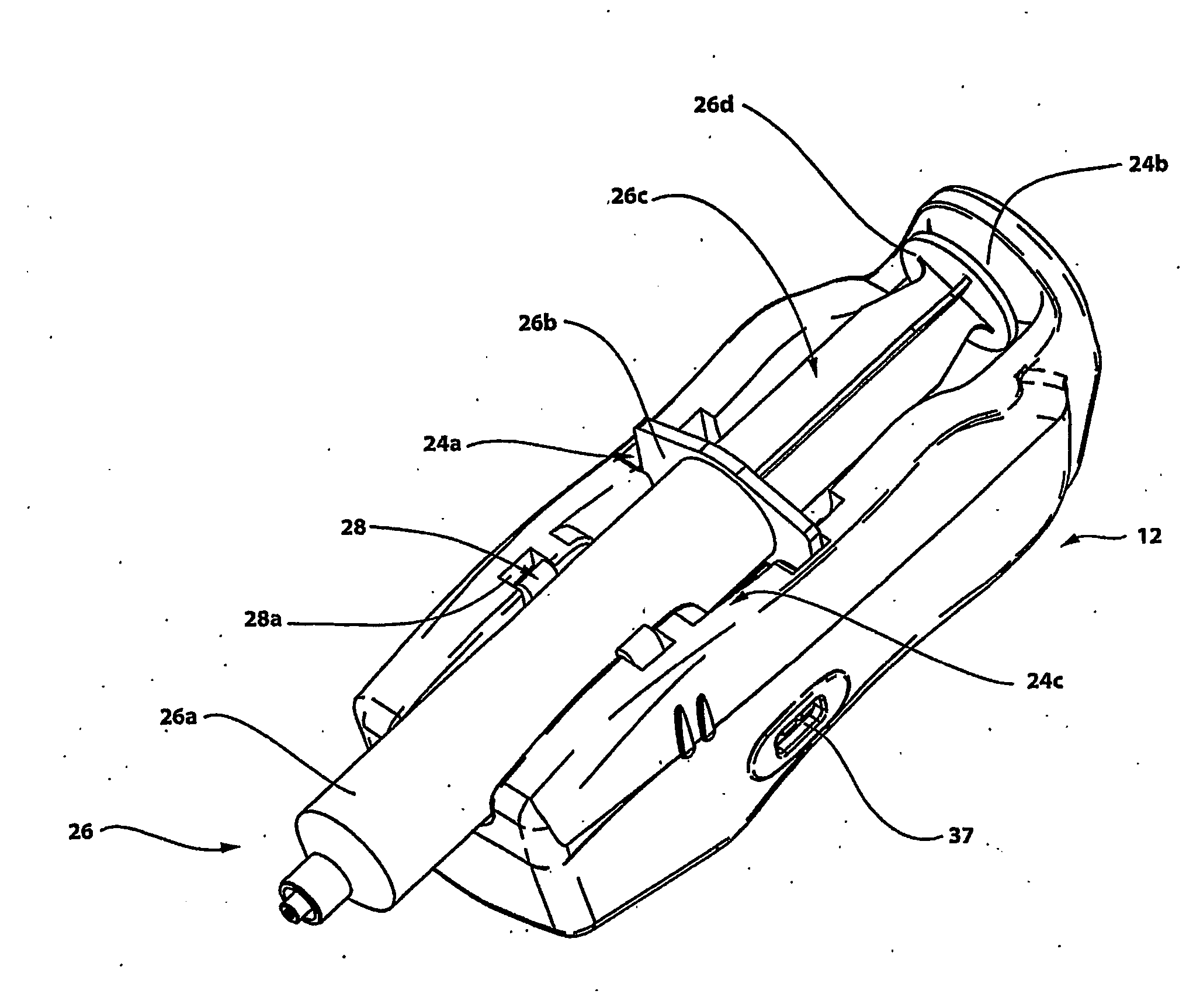

Medical treatment control system

A device for controlling the collection and delivery of materials to a patient, the device has a dispenser-engaging portion, the dispenser-engaging portion being operable in a release position to receive a materials dispenser when the dispenser is in a materials-containing configuration, the dispenser-engaging portion being operable in a lock condition for locking the dispenser therewith, and access control means for controlling the release and lock positions according to a material transaction condition.

Owner:VASOGEN IRELAND LTD

Therapy device and system and method for reducing harmful exposure to electromagnetic radiation

The invention is directed to a therapy device, including a body, an energy source disposed on the body for emitting a desired wavelength of electromagnetic radiation, and a proximity sensor for sensing proximity of the device to a desired surface. Also disclosed are a material dispensing system disposed on the body for dispensing a desired material for use with the device and accessories and compositions used with the therapy device, including interchangeable energy source-containing heads and interchangeable material containers. Methods for using the therapy device are also disclosed.

Owner:SYNERON BEAUTY

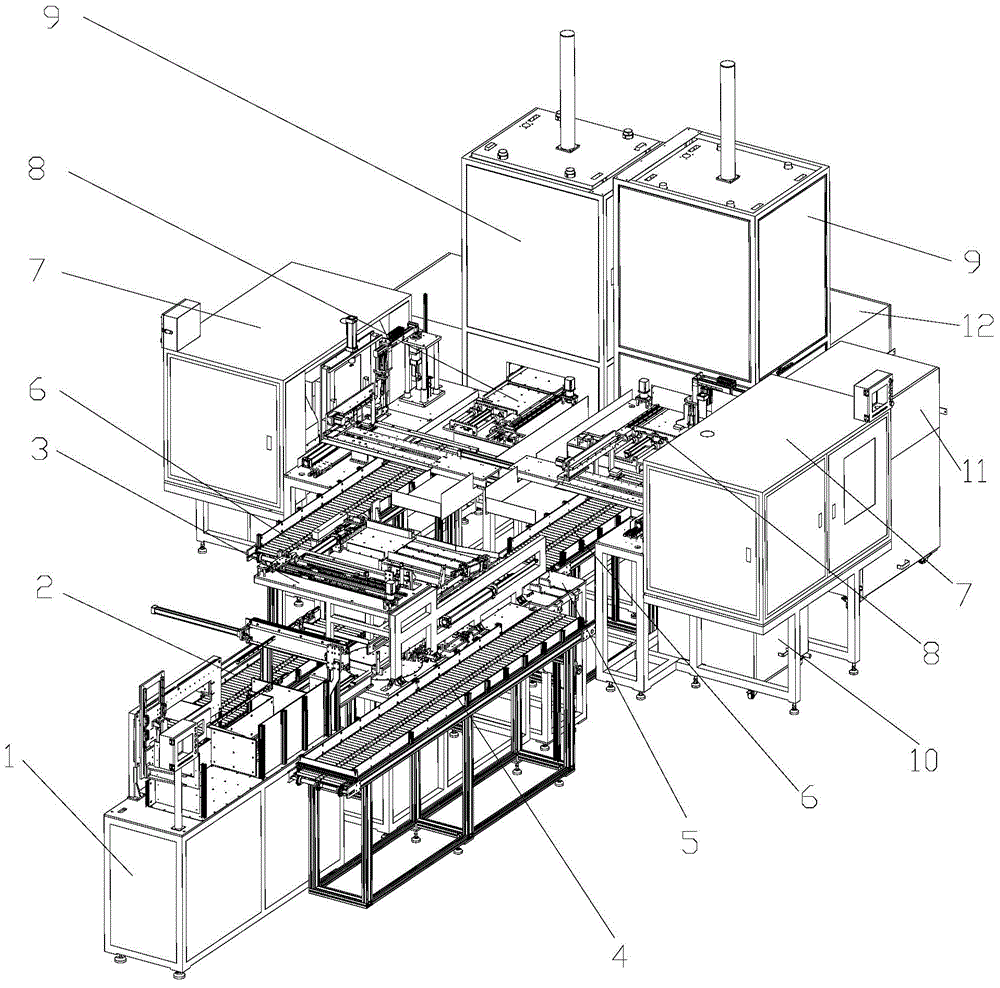

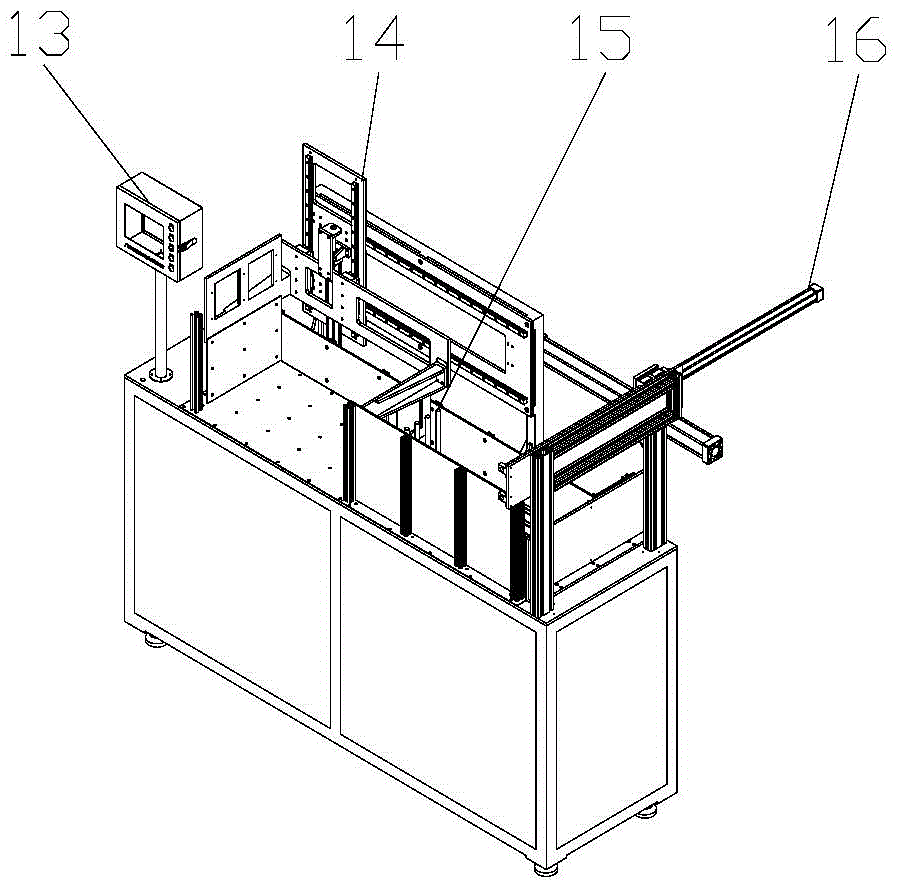

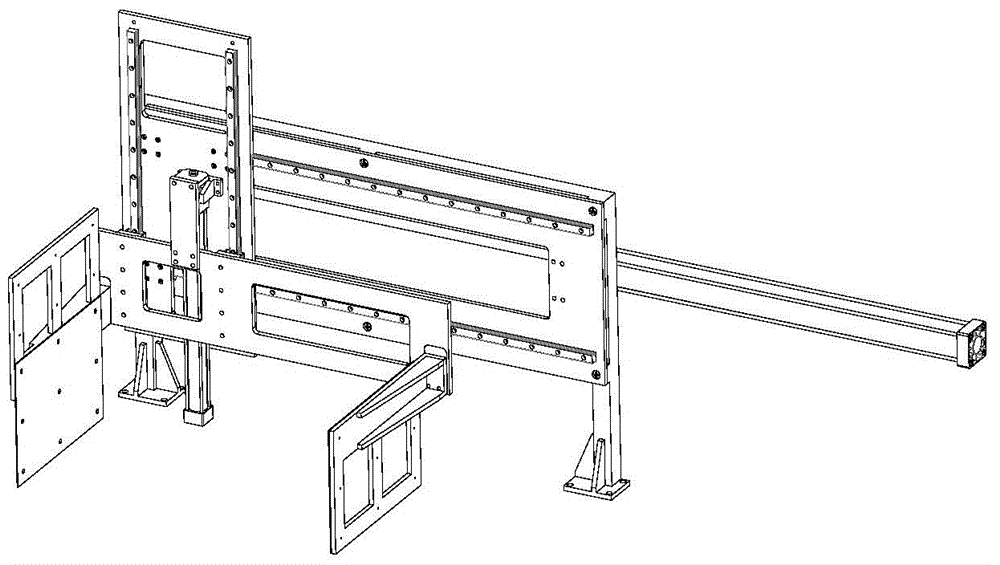

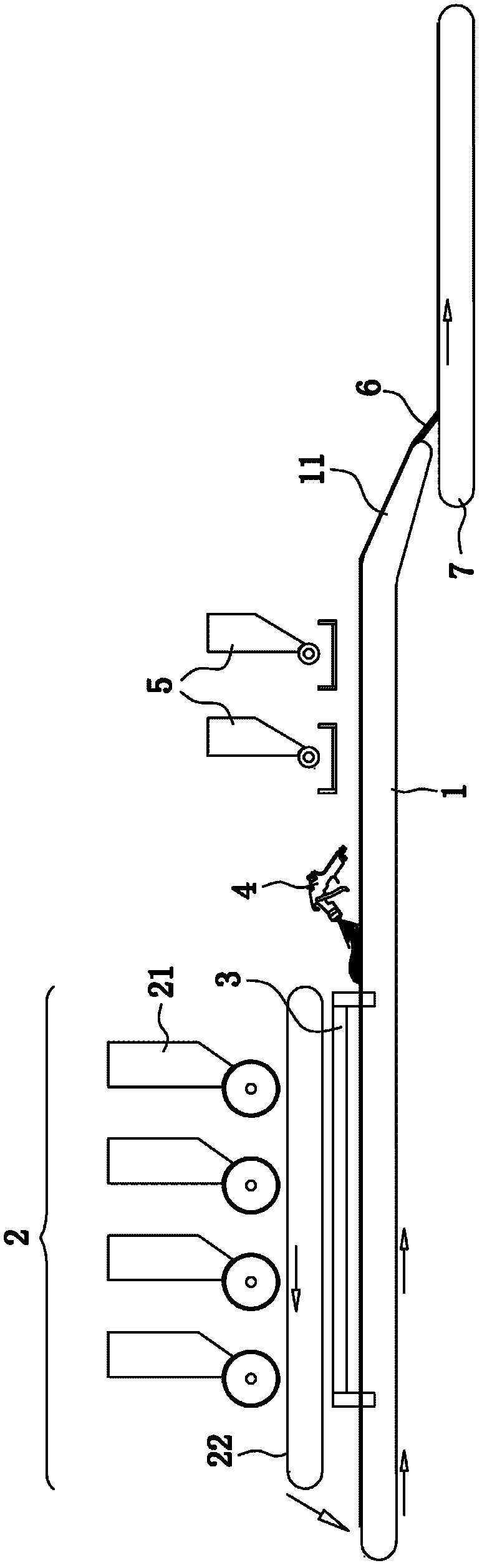

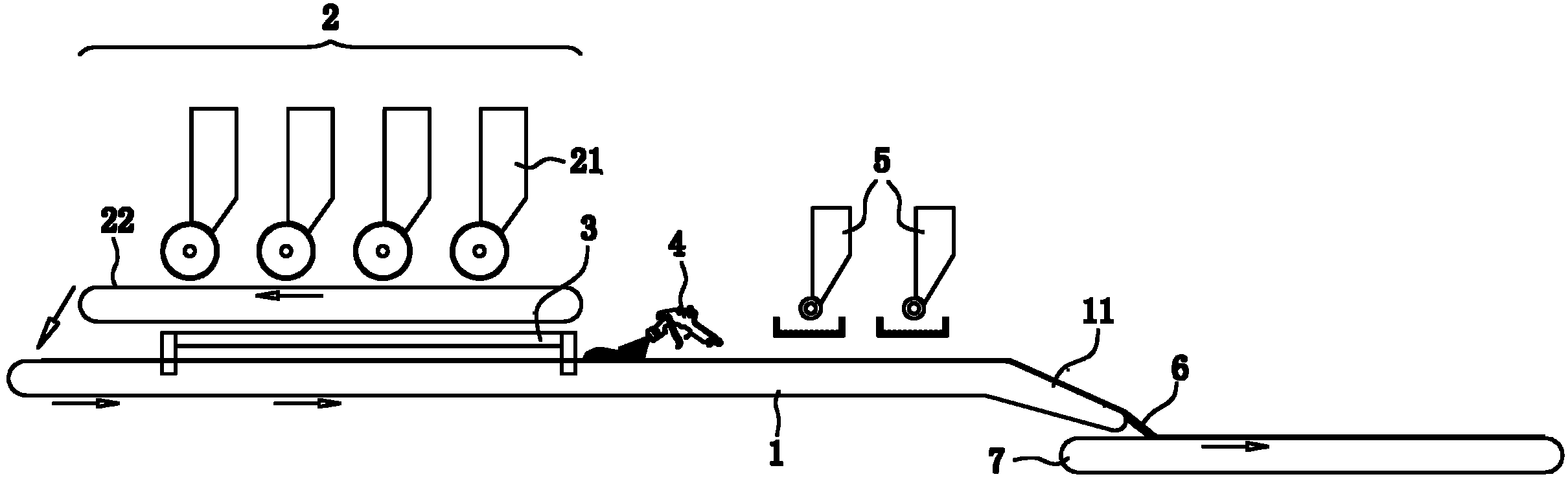

Novel waste power battery full-automatic dismantling device and method

ActiveCN104157927AReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryMaterial distribution

The invention relates to a novel waste power battery full-automatic dismantling device including: 1, a loading mechanism, 2, a loading conveyer, 3, a four-station material poking mechanism, 4, material distribution conveyers, 5, cutting devices, 6, separation feeding mechanisms, 7, separators, 8, outer shell storage boxes, and 9, electric core storage boxes. Along the power battery heading direction, the loading mechanism, the loading conveyer, the four-station material poking mechanism, the material distribution conveyers, the cutting devices, the separation feeding mechanisms and the separators are successively arranged; the outer shell storage boxes and the electric core storage boxes are respectively connected with the separators. The invention also relates to a novel waste power battery full-automatic dismantling method. The device has the advantages of simple structure and high dismantling efficiency, adopts a battery mechanical dismantling way integrating electrode head end one-time cutting and electric core clipping-out, and belongs to the power battery recycling processing field.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

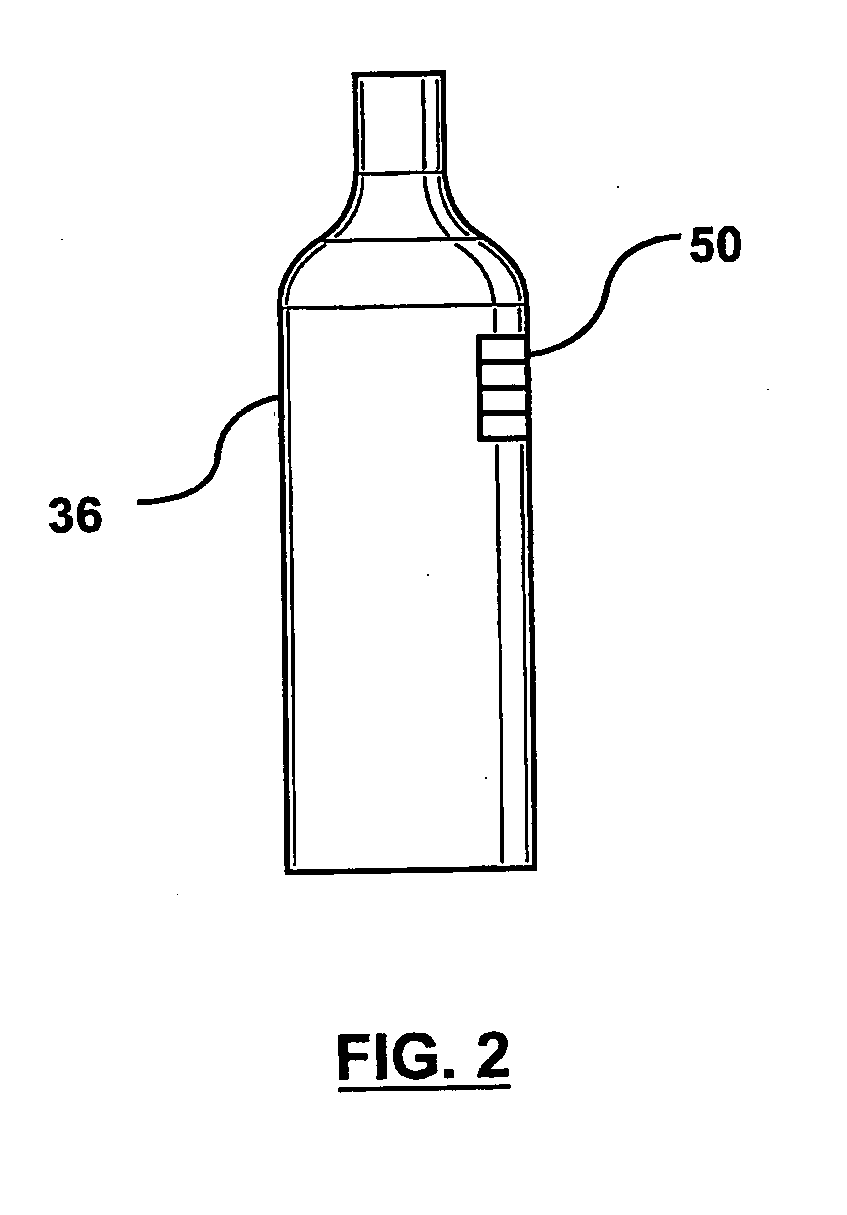

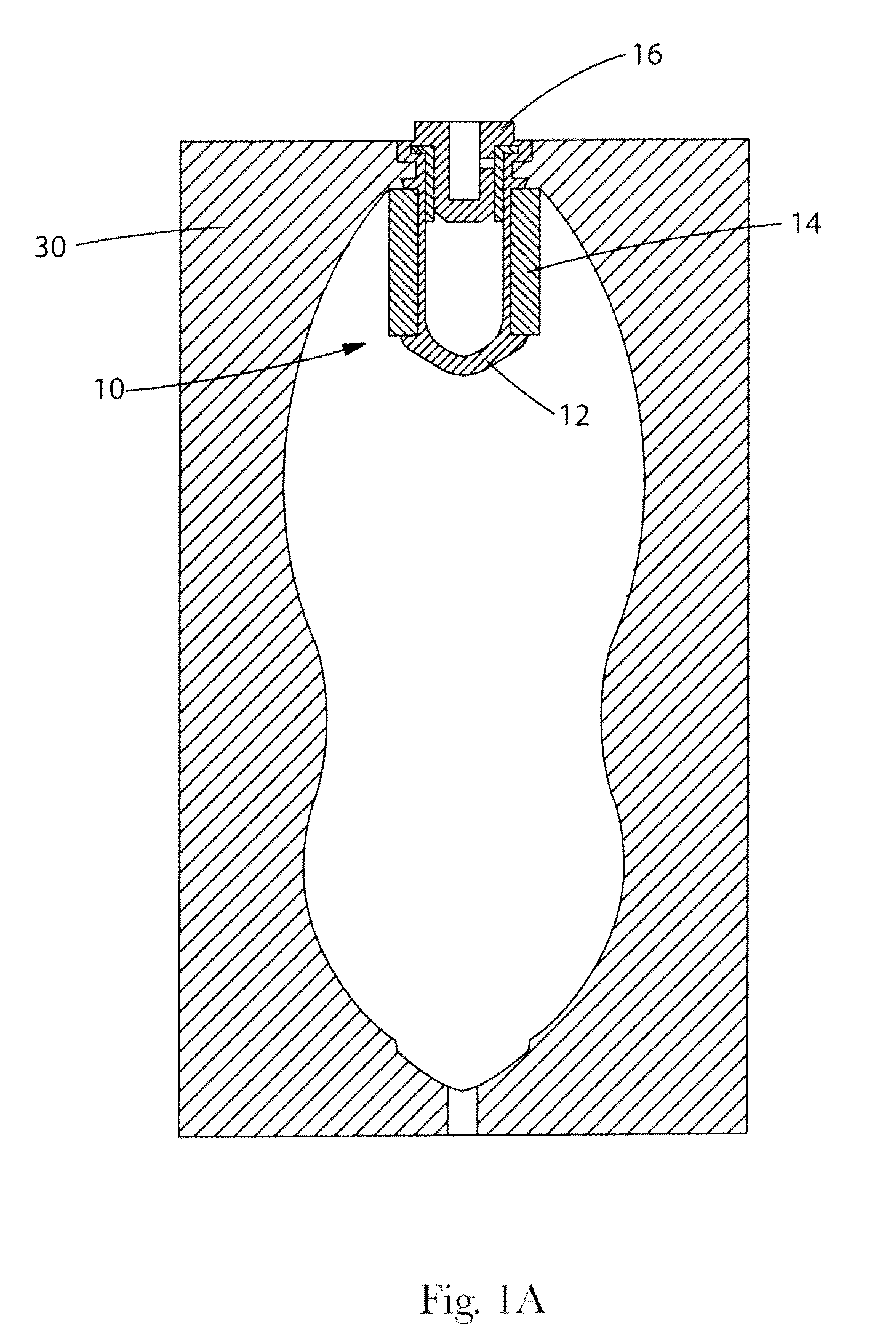

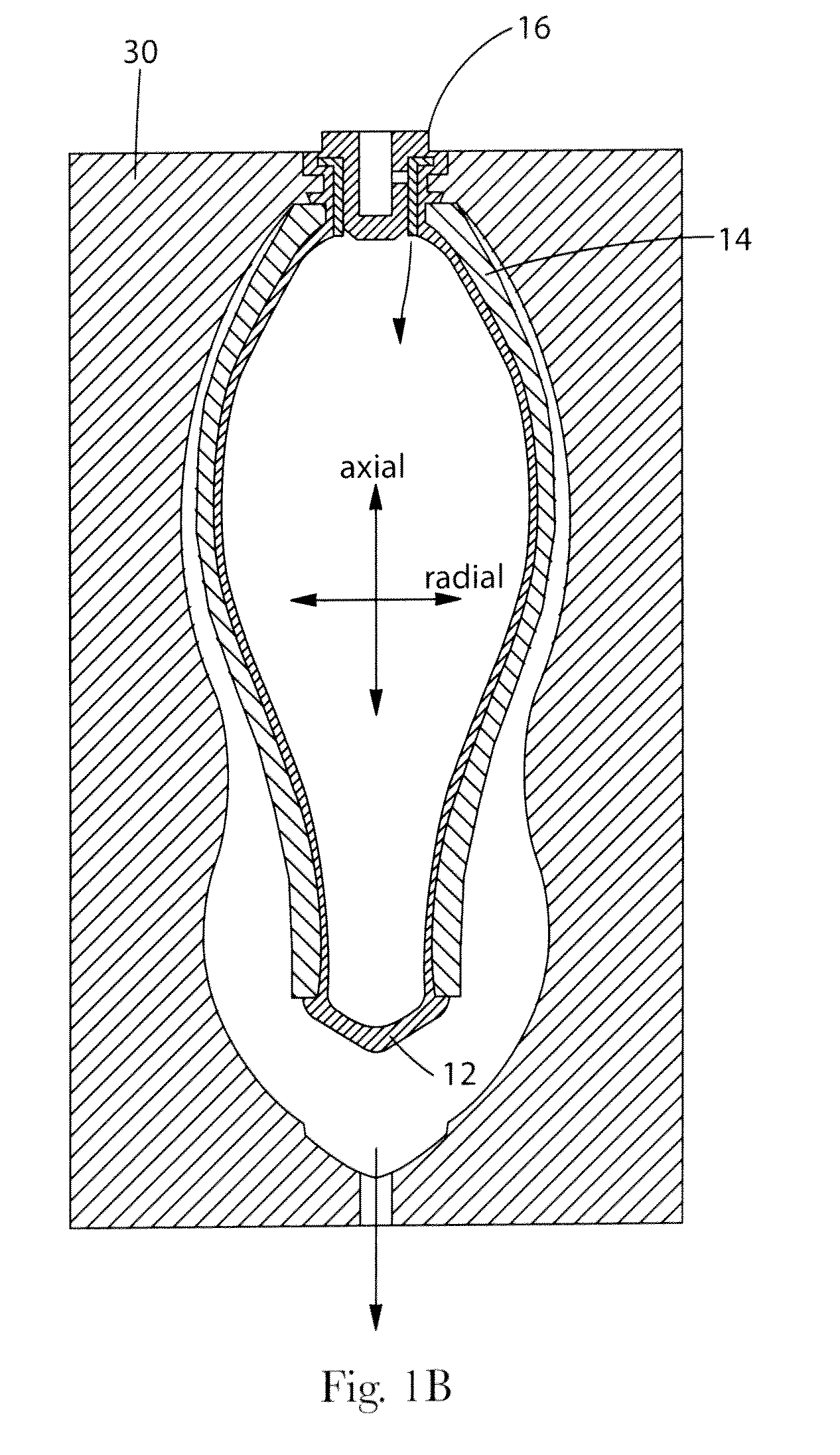

Material dispensing system and method for making same

ActiveUS20100133295A1Sufficient elongationLiquid transferring devicesDomestic articlesEngineeringMechanical engineering

Material dispensing systems and methods for make such systems are described. The material dispensing systems employ a collapsible container that is at least partially surrounded by an elastically deformable band. The band stretches as the container is filled with a flowable composition, thereby creating potential energy which can then be used to dispense the composition in lieu of a propellant and / or pressurized container.

Owner:THE PROCTER & GAMBLE COMPANY

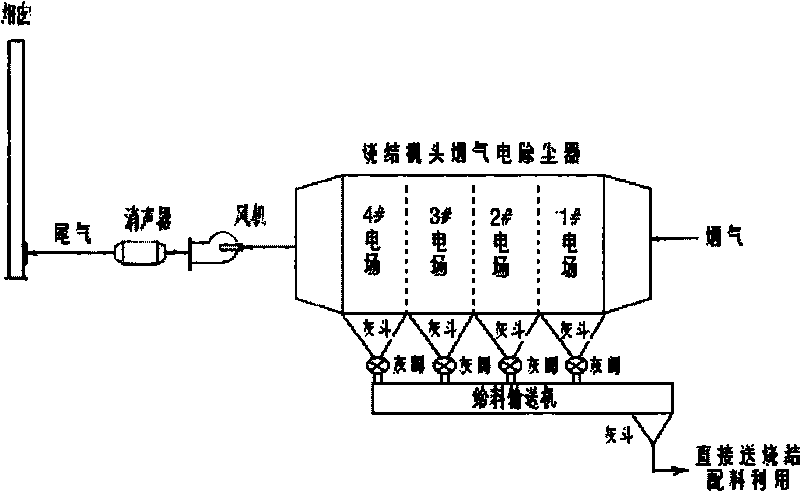

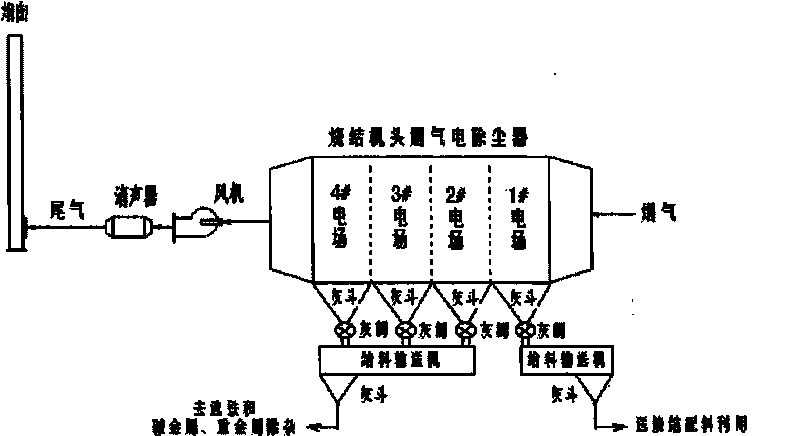

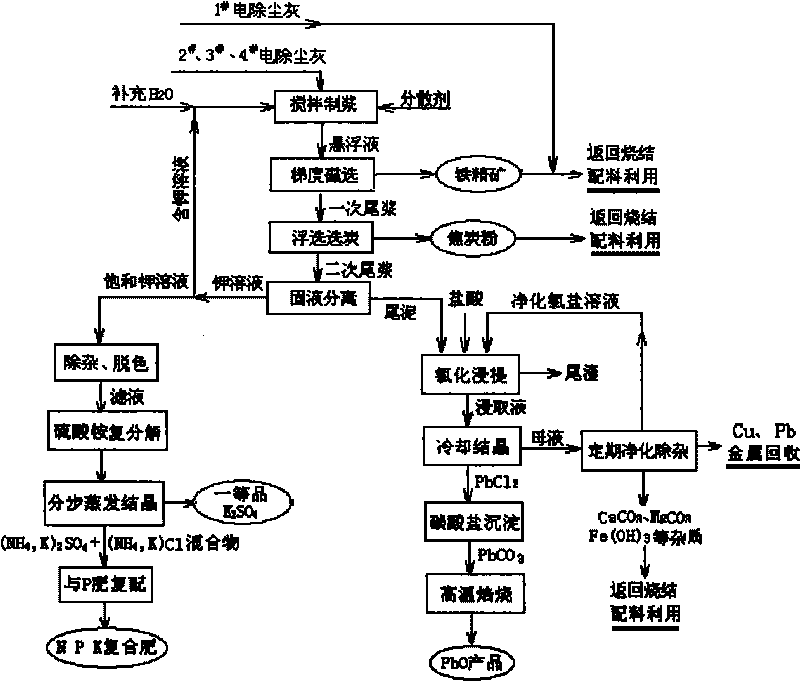

Overall treatment method of steel works sintering dust

ActiveCN101723713ASolve efficiency problemsSolve the problem that the flue gas often exceeds the standardCalcium/strontium/barium carbonatesIron oxides/hydroxidesPotassiumSlurry

The invention relates to an overall treatment method of steel works sintering dust, which is characterized by comprising the following steps: carrying out stage treatment on electrically precipitated dust in a sintering head, conveying the electrically precipitated dust produced in a primary electric field directly to a sintering field (a stock yard or a material distribution room) for material application in case of sintering; mixing the electrically precipitated dust produced in a subsequent electric field and then carrying out stirring pulping, gradient magnetic separation, carbon selection by flotation and solid-liquid separation; when the solid-liquid separation is finished, using the obtained potassium solution for producing potassic fertilizer and extracting lead product from the obtained tailing slurry.The method of the invention has the advantages that different process routes are adopted to effectively recover and comprehensively utilize contained multiple valuable resources such as ferrum, carbon, potassium, lead and the like according to different contents of alkali metal such as potassium and sodium and heavy metal compounds such as lead, zinc and copper in different electric field precipitated dust in a sintering head electric precipitator.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

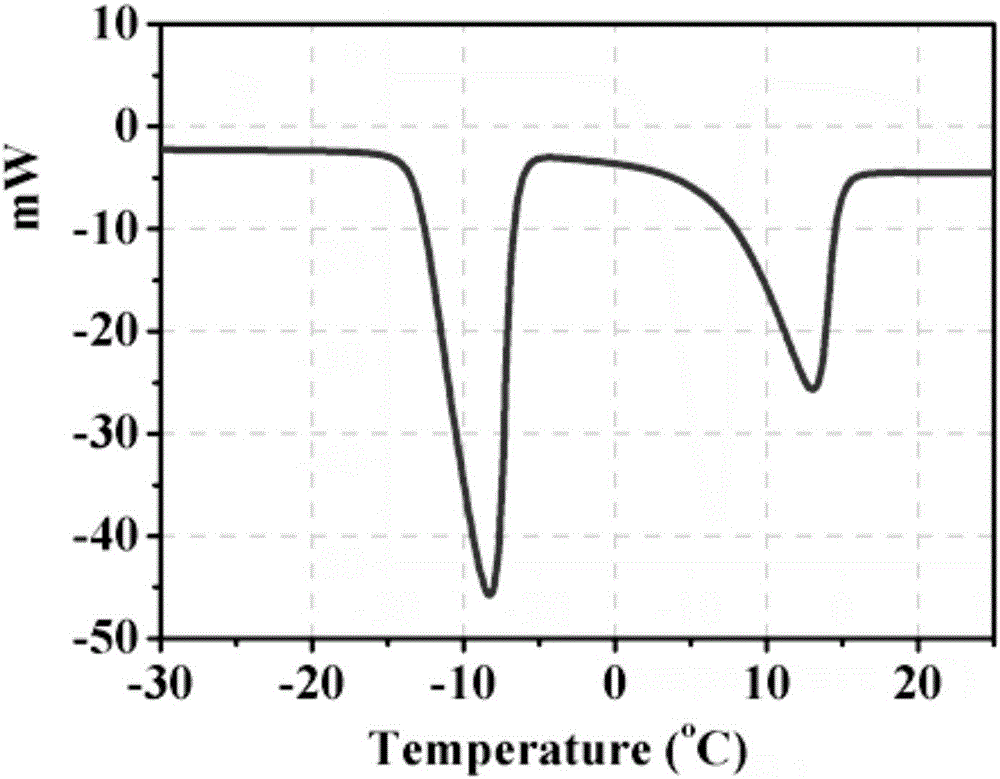

Phase change cold storage material with double phase change points and preparation method thereof

InactiveCN106675525AHigh latent enthalpy of phase changeThe role of proper thawingHeat-exchange elementsDouble phaseCold storage

The invention discloses a phase change cold storage material with double phase change points and a preparation method thereof. The phase change cold storage material with double phase change points is prepared from the following raw materials in percentage by weight: 0 to 60 percent of inorganic salts, 5 to 60 percent of organic phase change materials, 20 to 95 percent of de-ionized water, 0.1 to 2 percent of surfactants, 1 to 5 percent of thickening agents and 1 to 5 percent of nucleating agents. The phase change cold storage material provided by the invention has double phase change points; the temperature can be controlled between the double phase change point temperatures in the material distribution process; the freezing and cold storage effect is achieved; the proper unfreezing effect can also be achieved; in addition, the material has high phrase change latent heat enthalpy value (greater than 220kJ / kg); the more efficient and faster temperature reduction effect is achieved; in addition, the temperature can be permanently maintained in a specific temperature range.

Owner:贺迈新能源科技(上海)有限公司

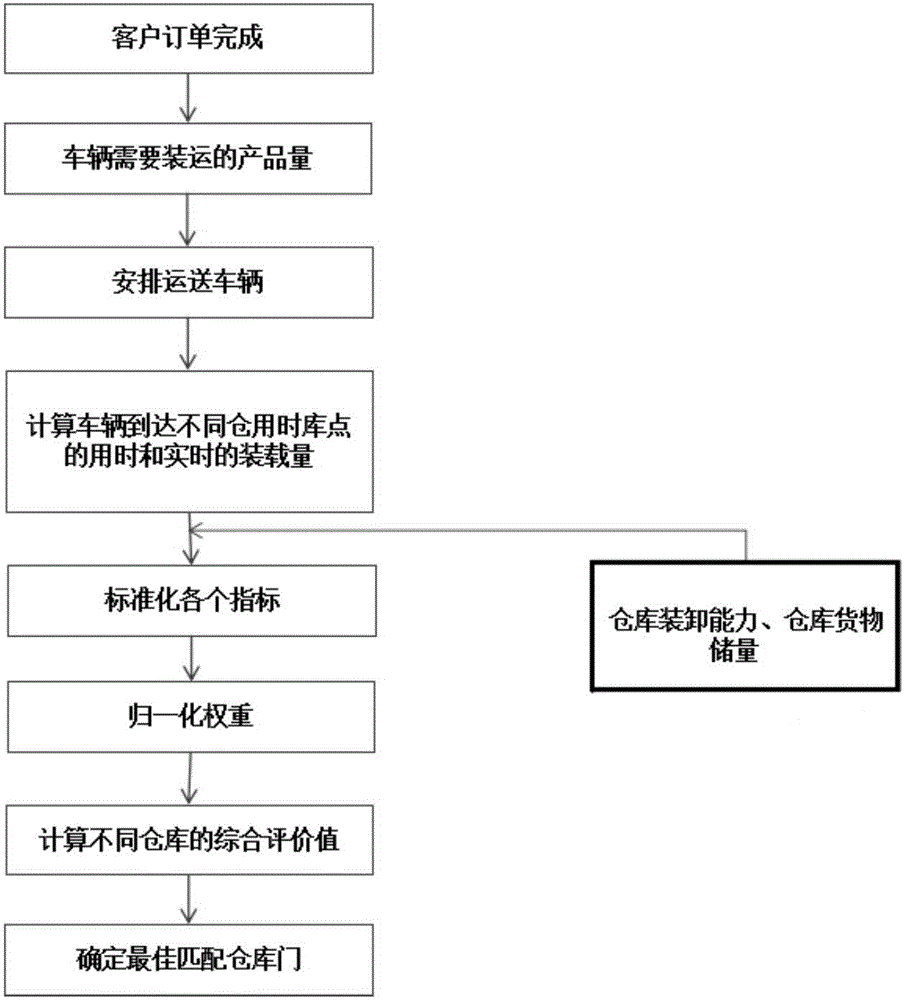

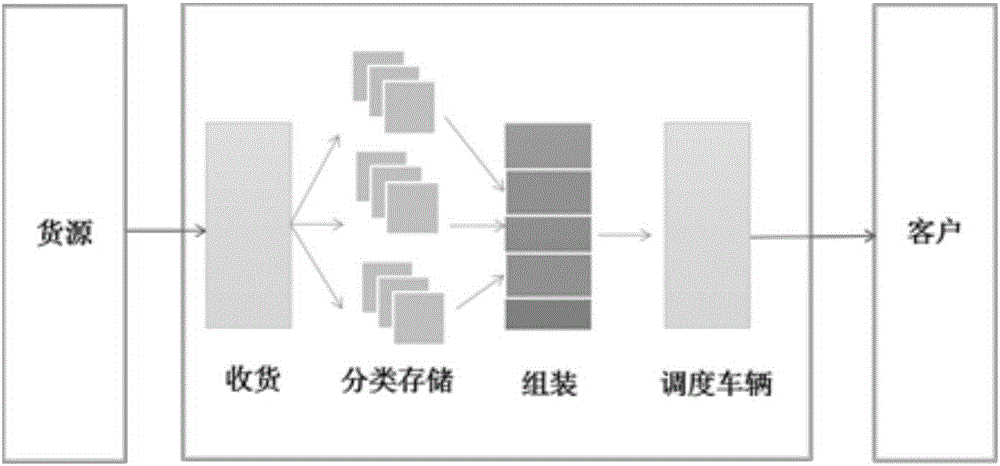

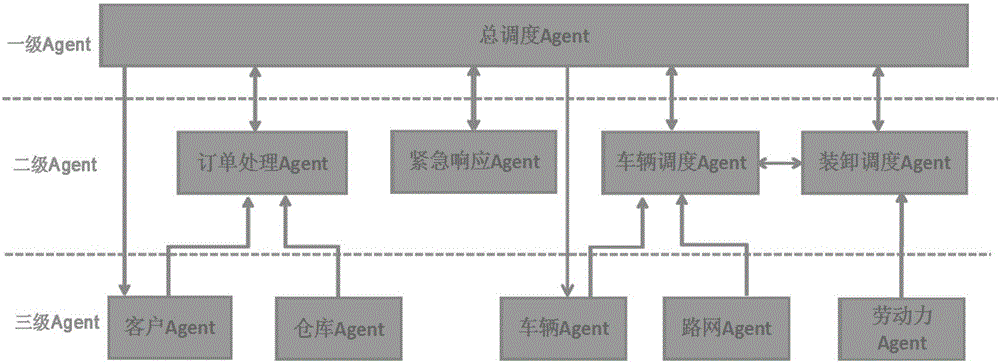

Multi-agent-based platform scheduling intelligent sorting model structure

ActiveCN105976030AGive full play to the advantagesTimely updateGenetic modelsForecastingLogistics managementDecision taking

The invention discloses a multi-agent-based platform scheduling intelligent sorting model structure. Steel material logistics distribution belongs to heavy-duty transportation in transportation and needs special handling equipment and large-scale transportation vehicles. In a distribution and loading process, the loading efficiency and sequence (platform scheduling) of vehicles are directly related to distribution aging. Platform scheduling is a multi-constraint combination optimization complex system. Reasonable ordering and optimization are essential. According to the invention, a multi-agent technology is used to research real-time vehicle scheduling decisions; a combination optimization complex system using a platform-based scheduling ordering system and multi-agent algorithm design as multiple constraints is constructed; a multi-agent technology provides a new solution for the research of real-time vehicle scheduling decisions to improve the efficiency of freight operations; the optimal solution is acquired; an auxiliary vehicle identification technology is used to carry out whole-process monitoring on distribution vehicles; efficient vehicle scheduling and precise handling are realized; and precise steel material distribution is realized.

Owner:WUHAN BAOSTEEL CENT CHINA TRADE

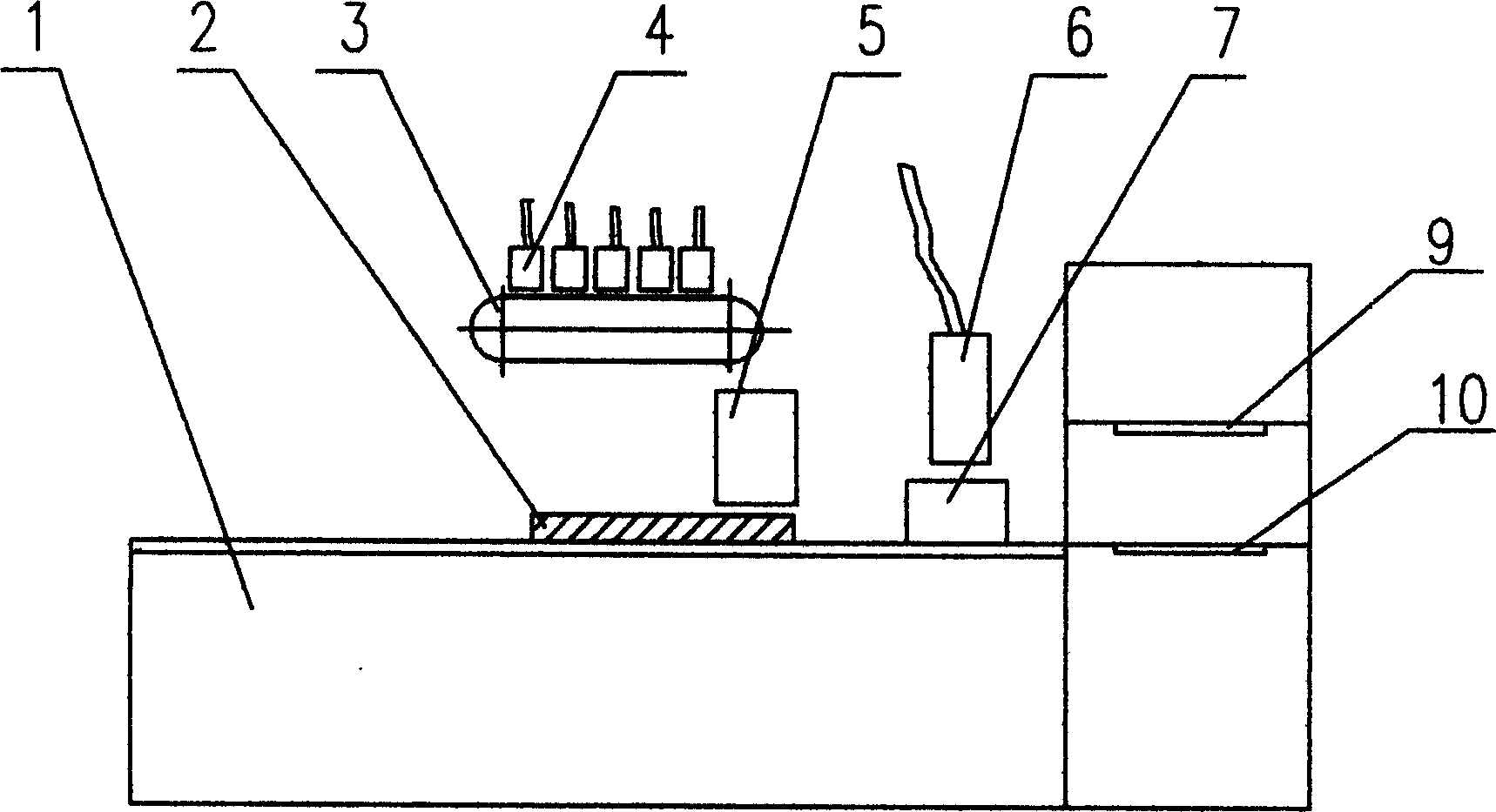

Distributing method for ceramic tile

InactiveCN1586851ADelicate and rich colorsThe pattern is natural and smoothFeeding arrangmentsSurface patternBrick

The material distributing method for ceramic tile is one back side forming process including first distributing powder material and then distributing base material. Fine powder, granular material and their mixture are loaded one layer by one layer onto the conveying belt, added into specially designed lattice via bin to complete the first material distribution; and the base material then falls from the movable bin to fill the mold cavity to complete the second material distribution. During the twice material distribution, the lattice is filled with the fine powder or the mixture of fine powder and the granular material. The present invention has the features of multiple tube material distribution and lattice material distribution, and can form natural and fluent patterns and grains similar to that of natural stone material. The present invention has raised material distribution speed and the back side formation process has no influence on the surface pattern of the returned lattice.

Owner:TEDI CERAMIC FOSHAN CITY

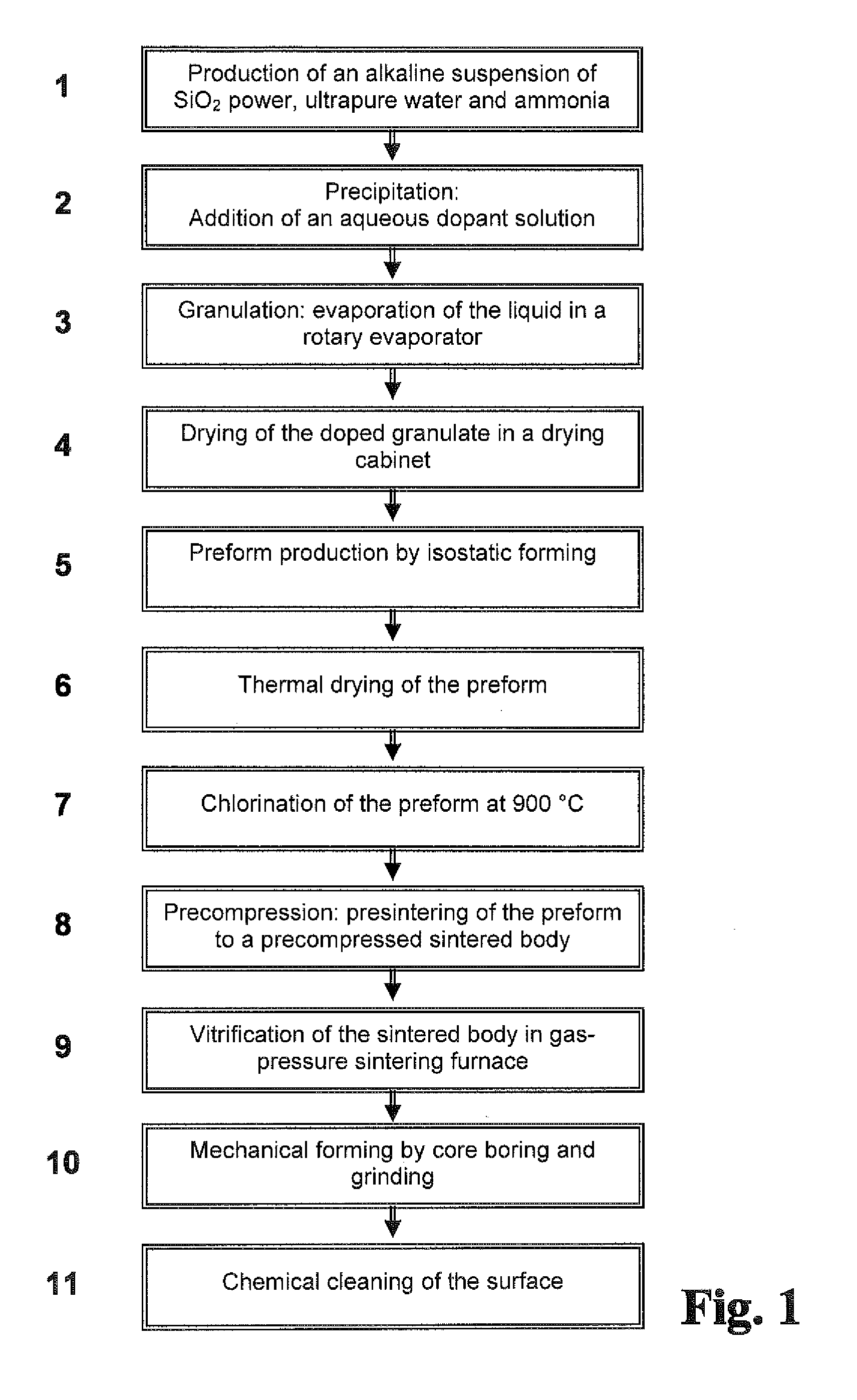

Method for producing doped quartz glass

ActiveUS20100251771A1Improve homogeneityGlass shaping apparatusCeramic shaping apparatusMaterial distributionQuartz

The invention relates to a method allowing cost-effective production of doped quartz glass, particularly laser-active quartz glass, that is improved with regard to the homogeneity of the doping material distribution, in that a suspension is provided comprising SiO2 particles and an initial compound for at least one doping material in an aqueous fluid, the fluid being removed under formation of a doped intermediate product comprising particles of the doping material or particles of the precursor substance or the doping material, and the doped quartz glass is formed by sintering the doped intermediate product, wherein at least part of the particles of the doping material or the particles of the precursor substance of the same is generated in the suspension as a precipitate of a pH-value-controlled precipitation reaction of the initial compound.

Owner:HERAEUS QUARZGLAS +1

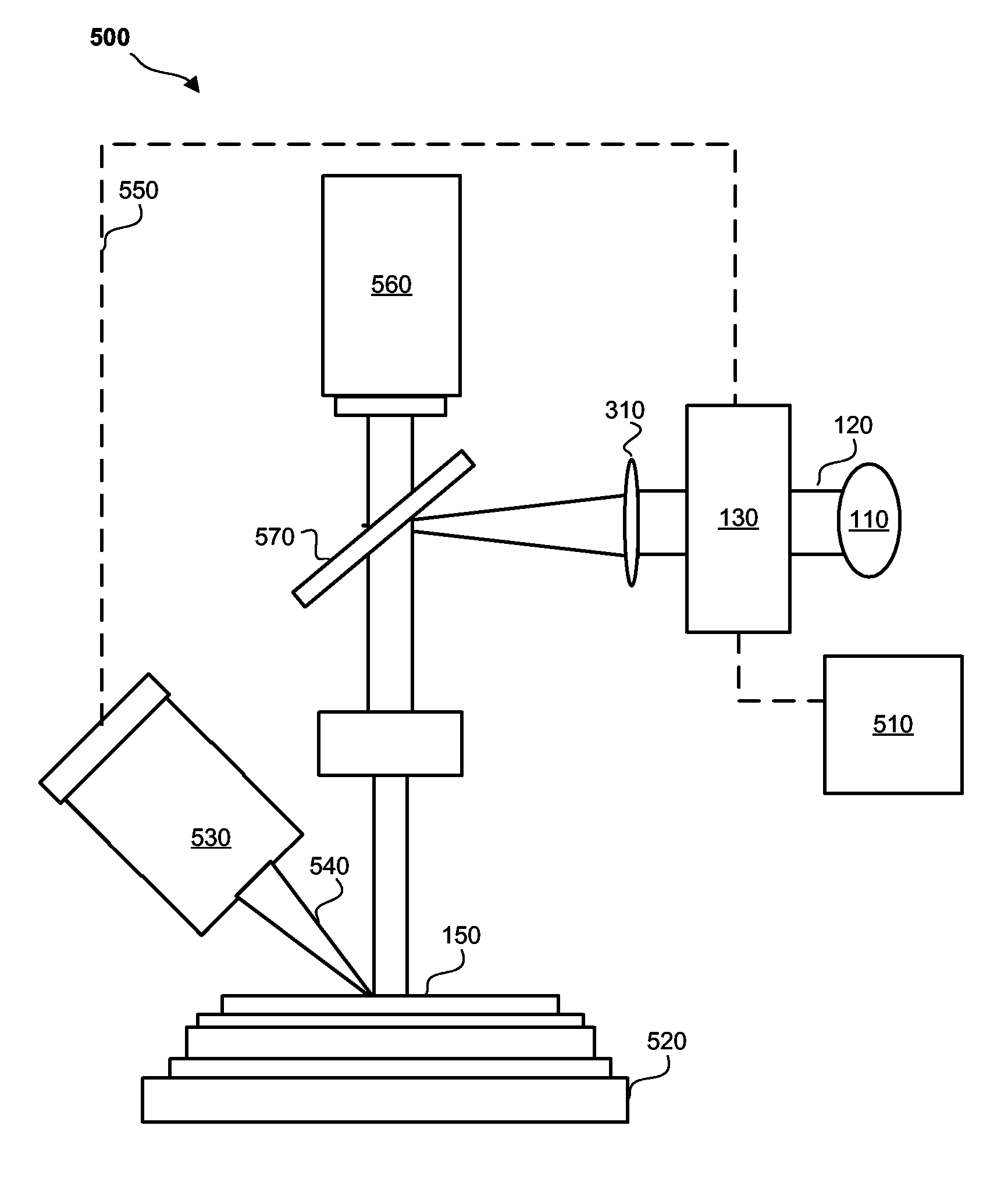

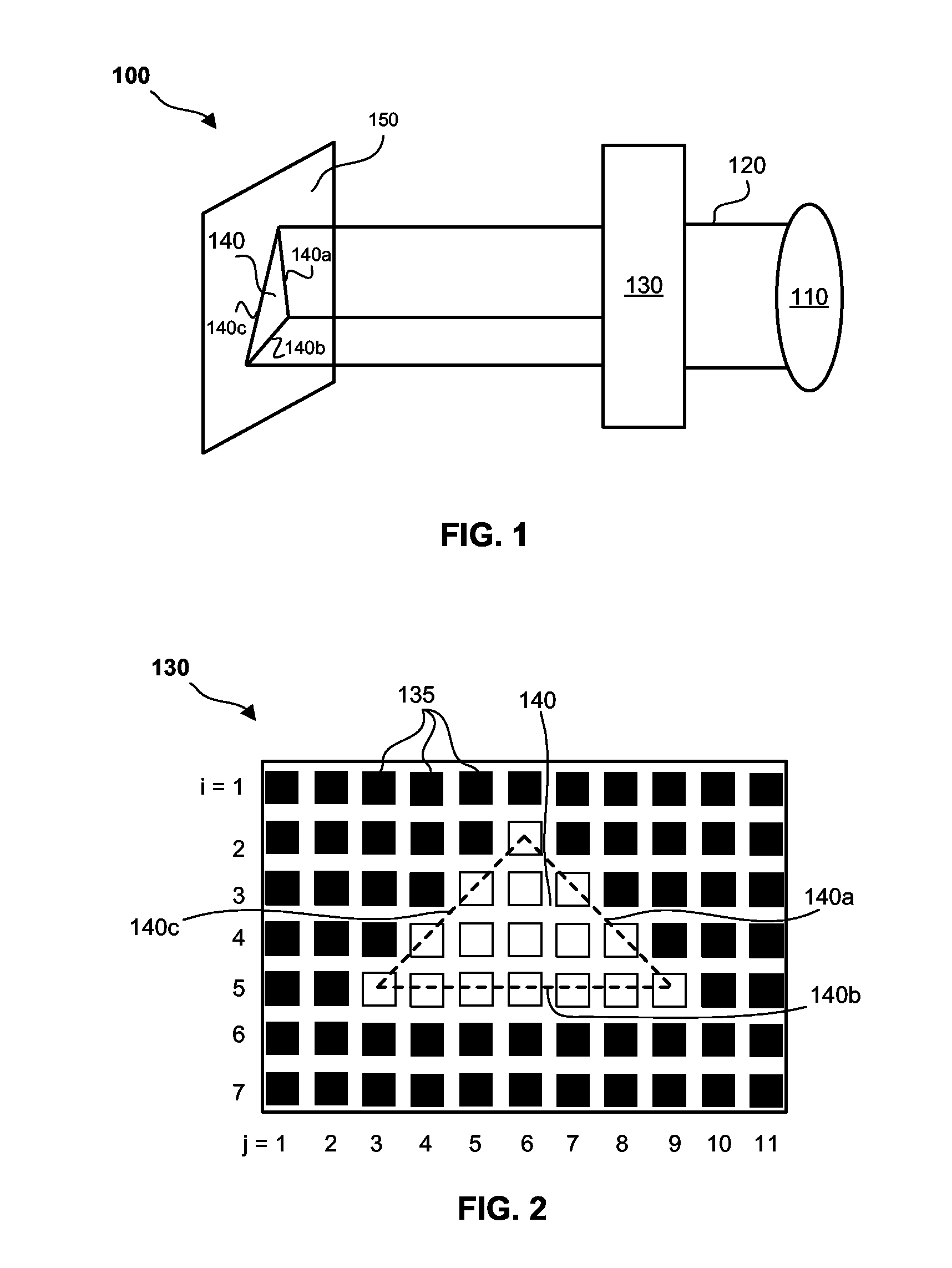

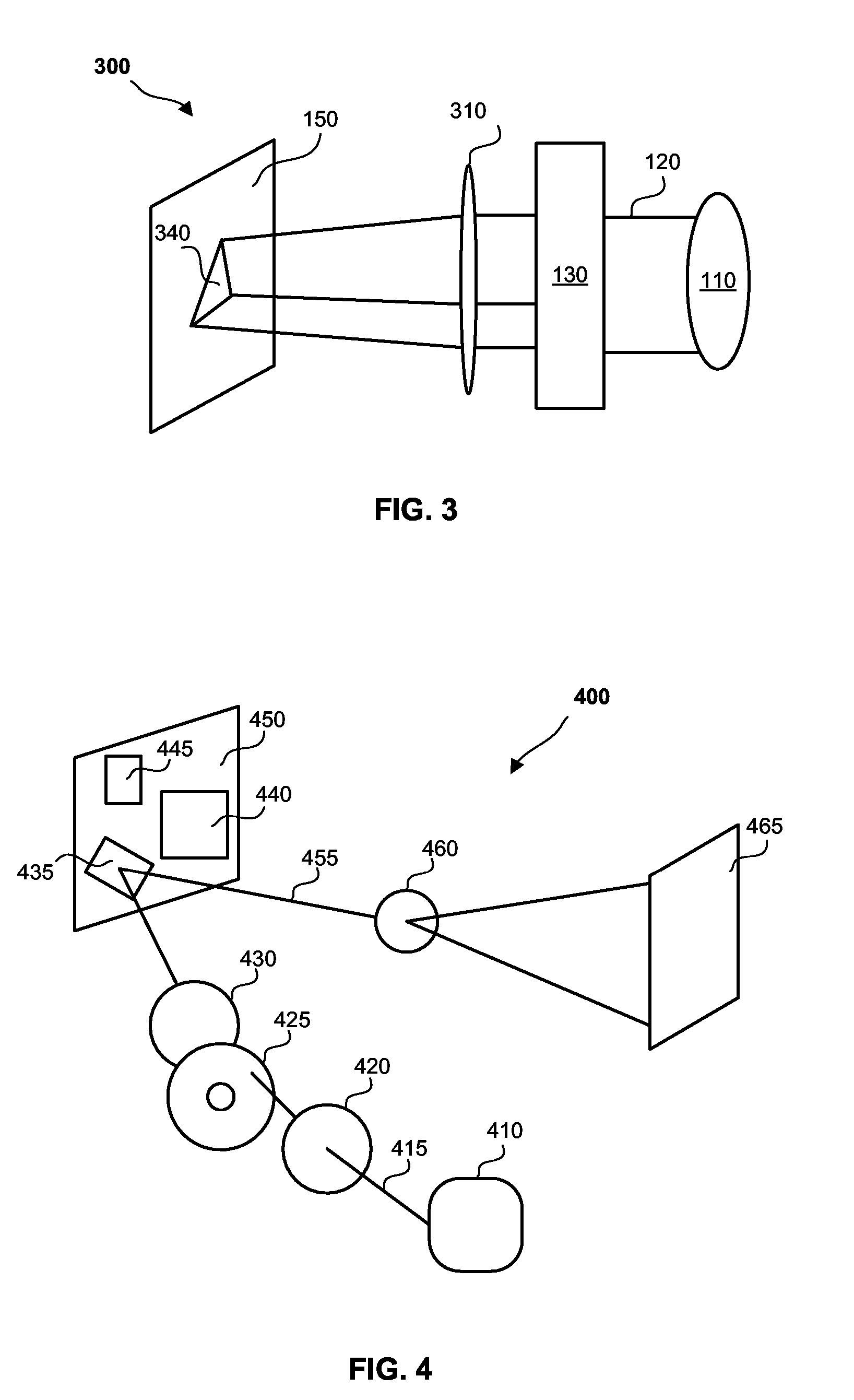

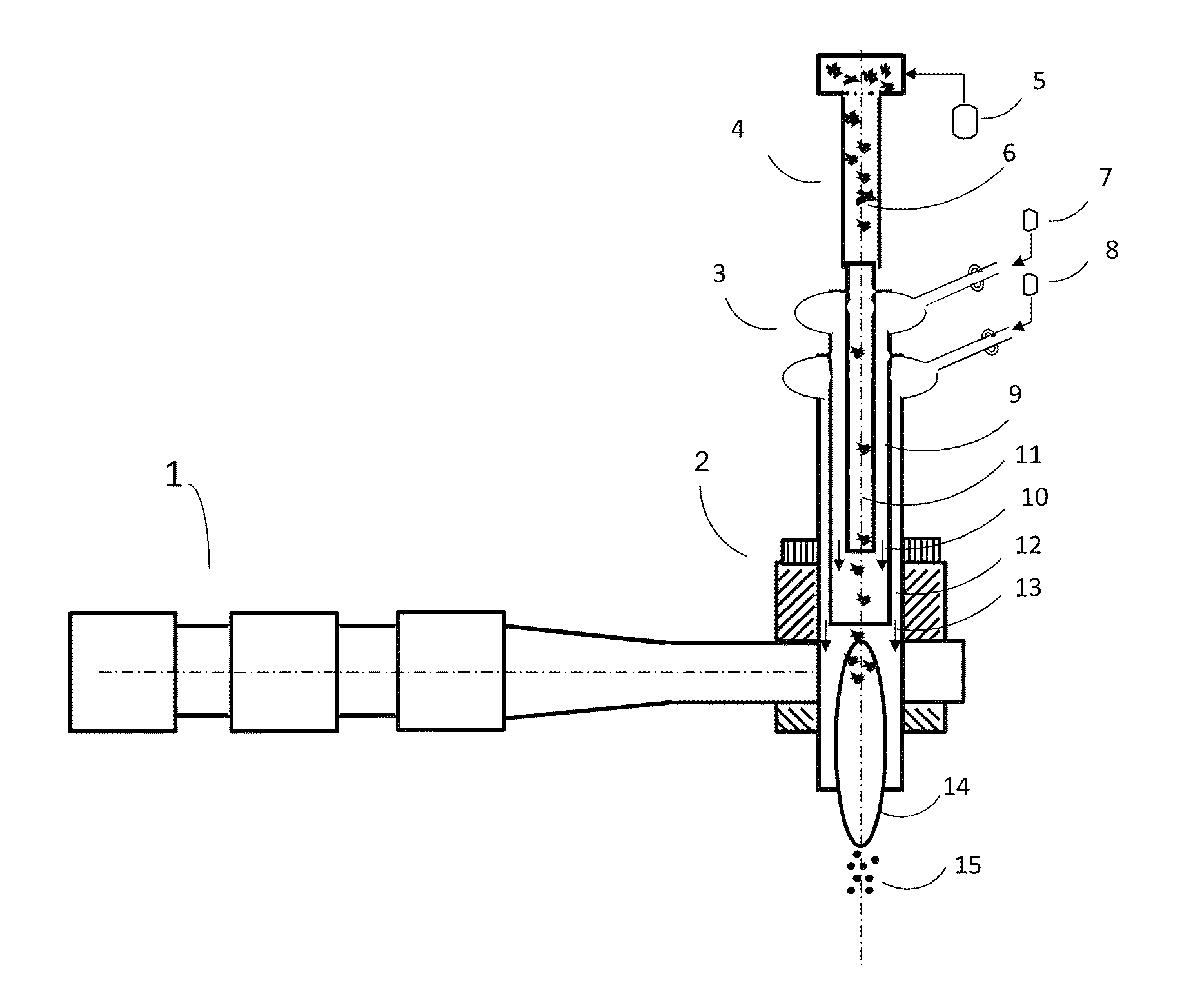

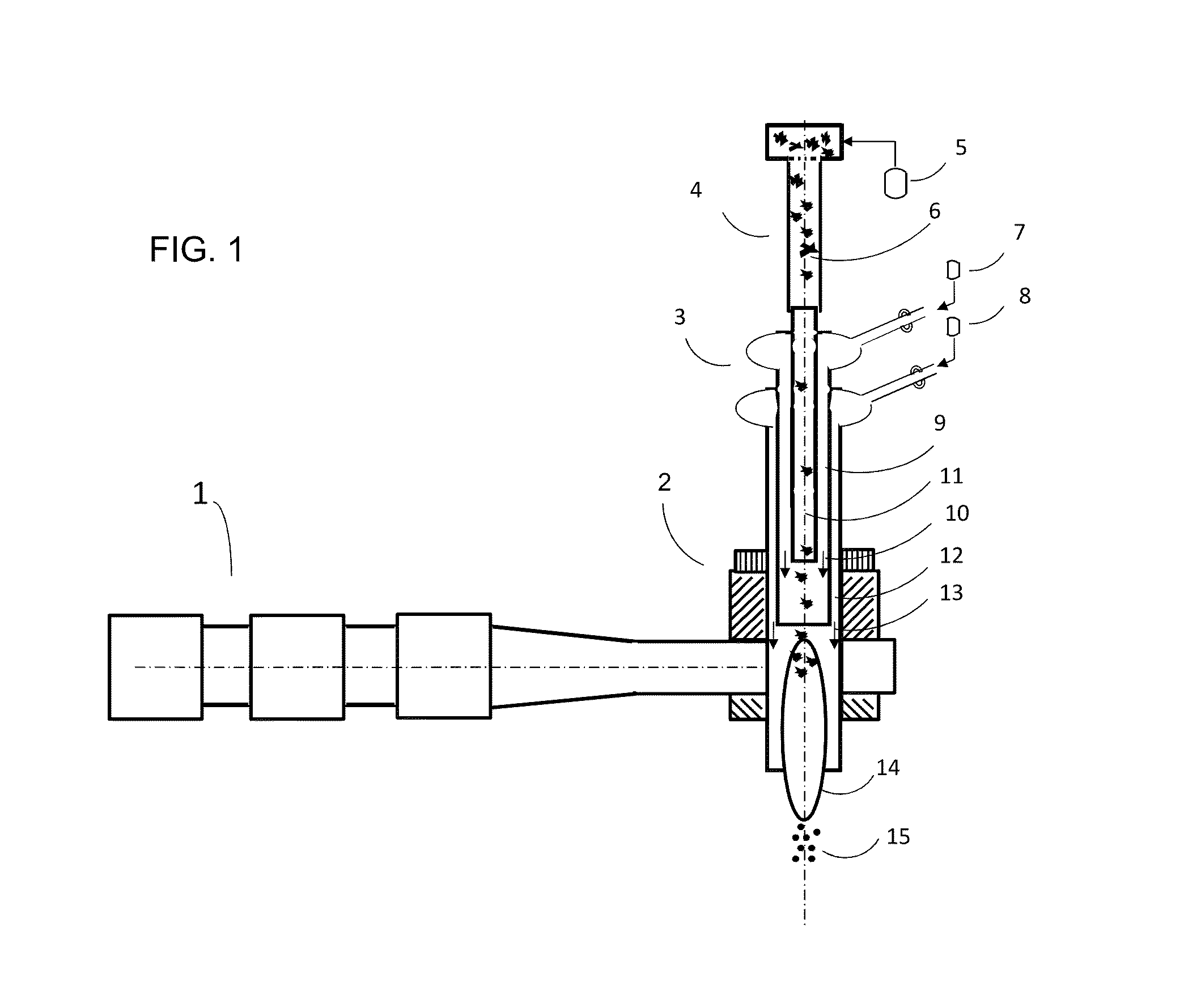

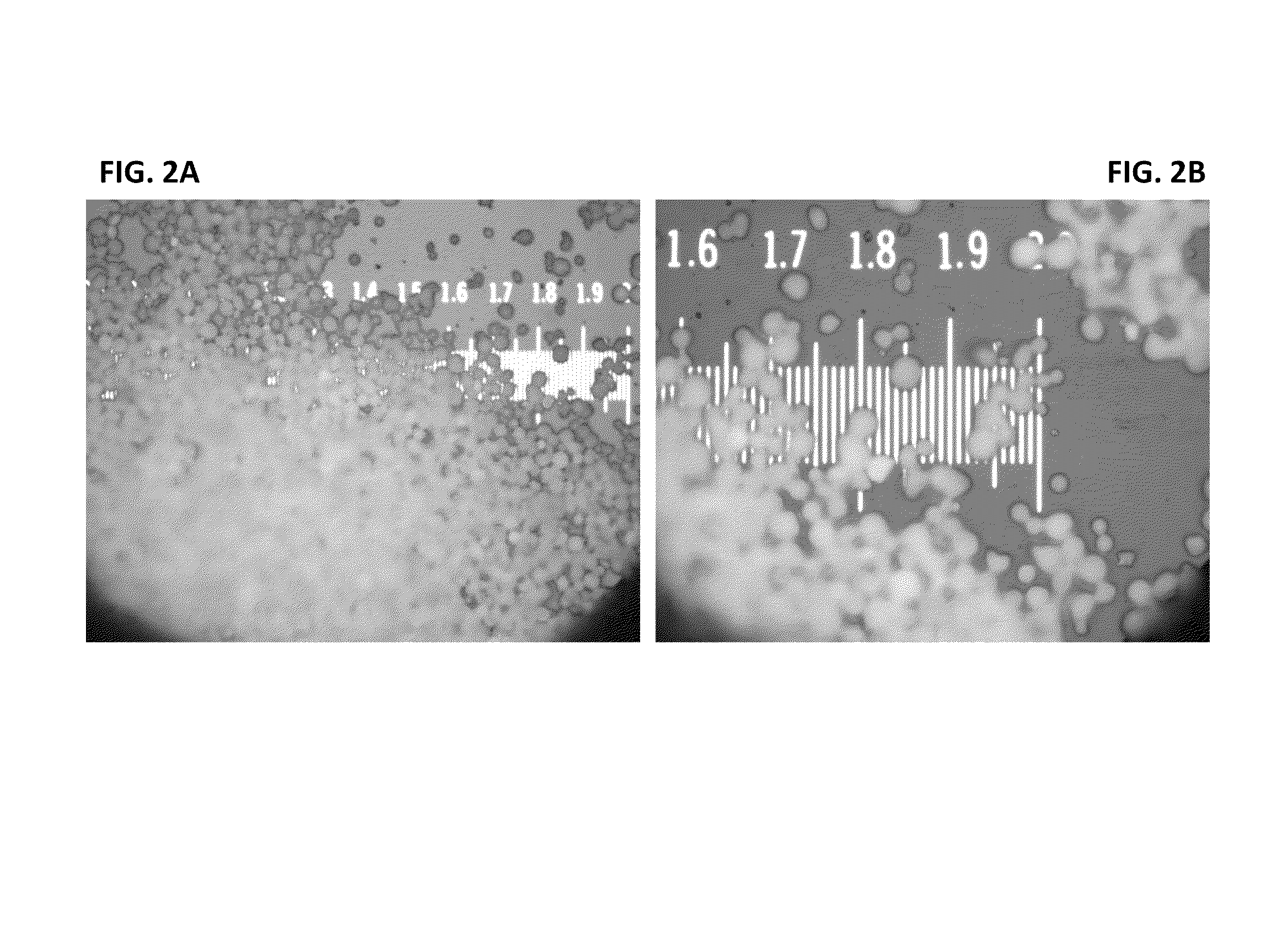

Systems and methods for laser material manipulation

InactiveUS20060119743A1Television system detailsColor television detailsLiquid-crystal displayLaser imaging

A laser material manipulation system is provided for material manipulations such as laser ablation, laser deposition and laser machining. The system includes a laser for emitting laser pulses and a laser imaging device having an array of controllable imaging elements. The laser imaging device receives the laser pulses emitted from the laser, forms a laser image through the controllable imaging elements, and projects the laser image onto a target material which needs to be manipulated. The projected laser image manipulates the material according to a desired manipulation pattern. The laser can be a femtosecond laser. The laser imaging device can be a liquid crystal display (LCD) or a digital micromirror device (DMD). An SEM can be used for monitoring the material distribution and dynamically adjust the laser image according to the monitor result.

Owner:CHOSEN TECH

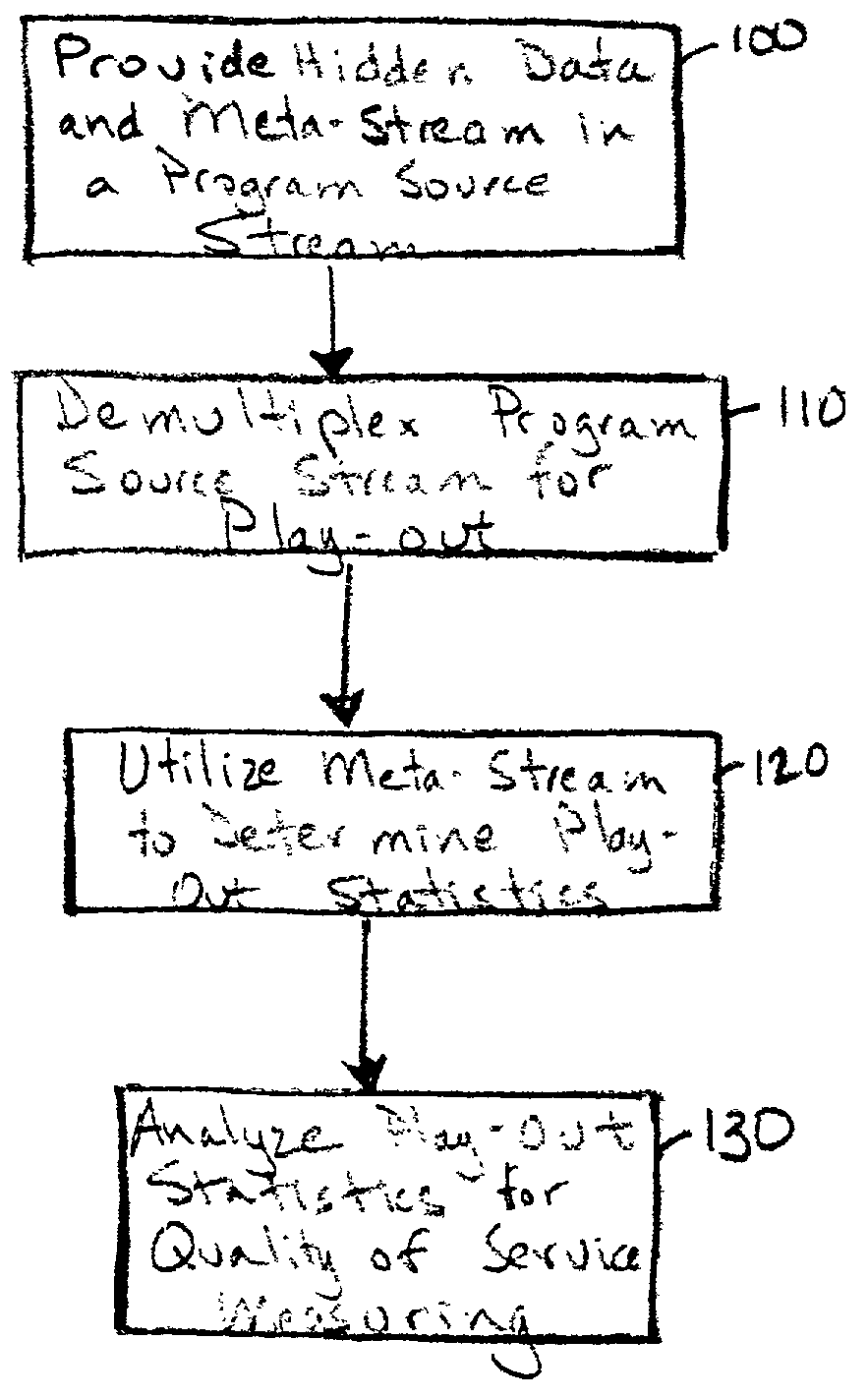

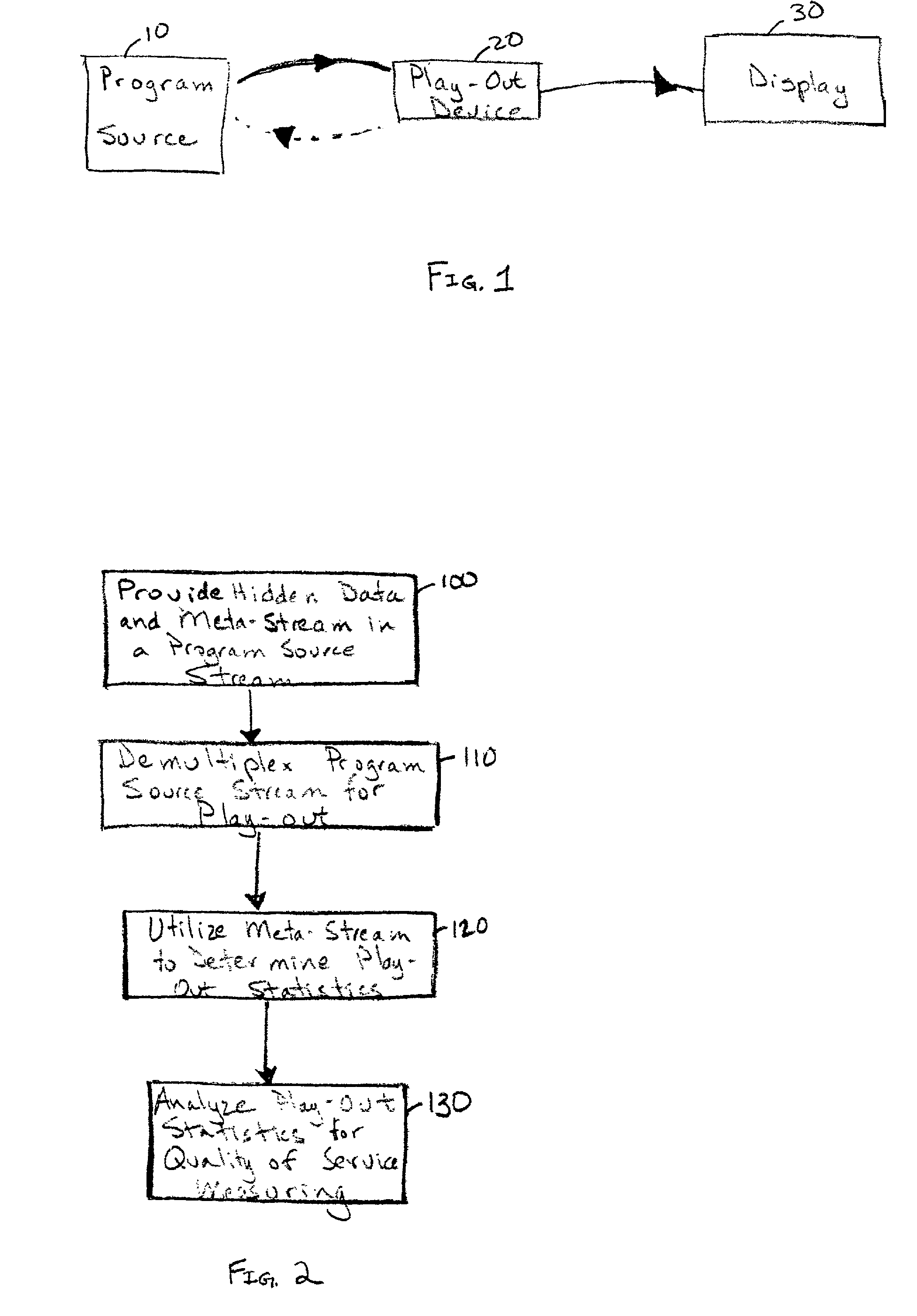

Method and system for automated monitoring of quality of service of digital video material distribution and play-out

ActiveUS7617509B1Ability to efficientlyError preventionFrequency-division multiplex detailsDigital videoQuality of service

Method and system aspects provide for automated monitoring of quality of service of digital video material being distributed and played. The aspects include embedding a signature in each frame of the digital video material by a program source device control. Computation of play-out statistics for the digital video material based on the signature by a program play-out device control is also included.

Owner:IBM CORP

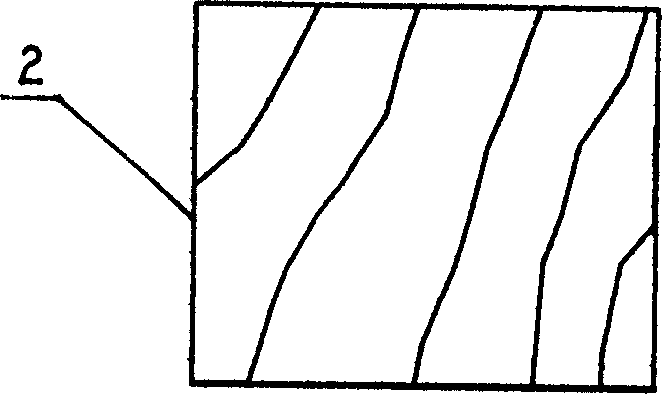

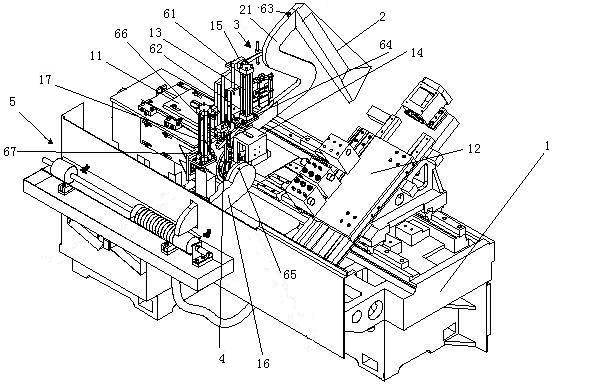

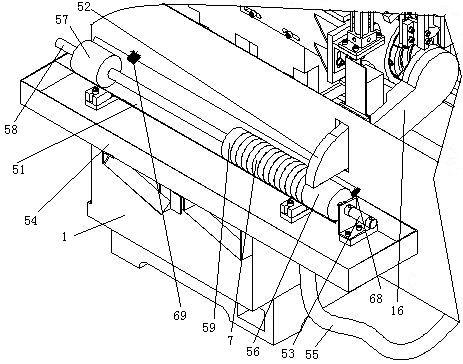

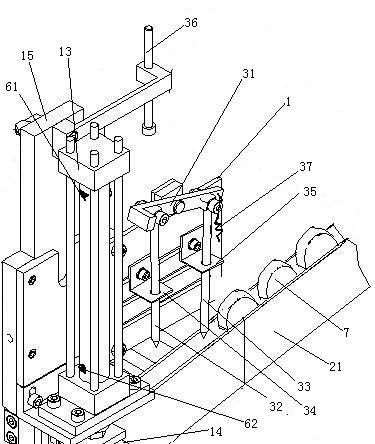

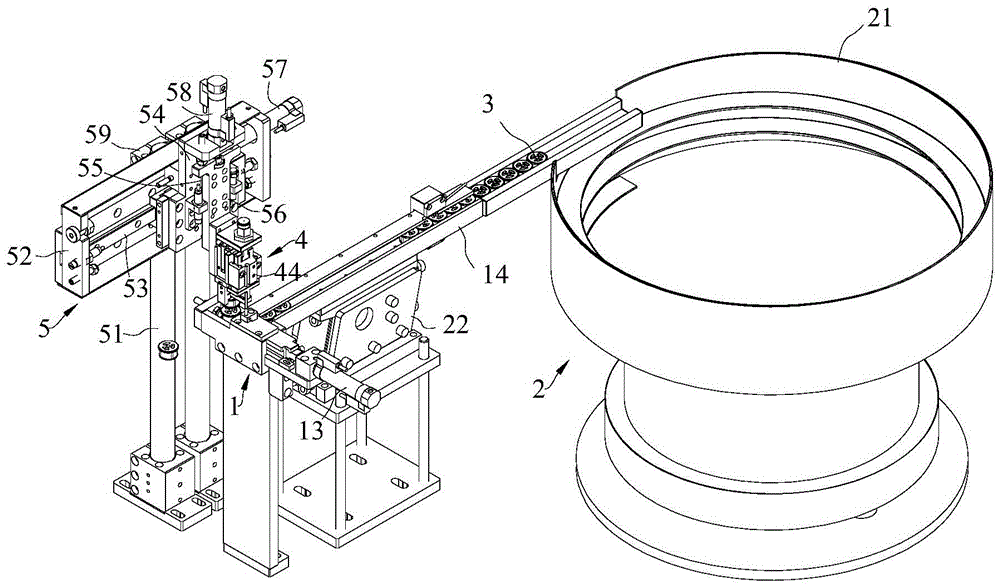

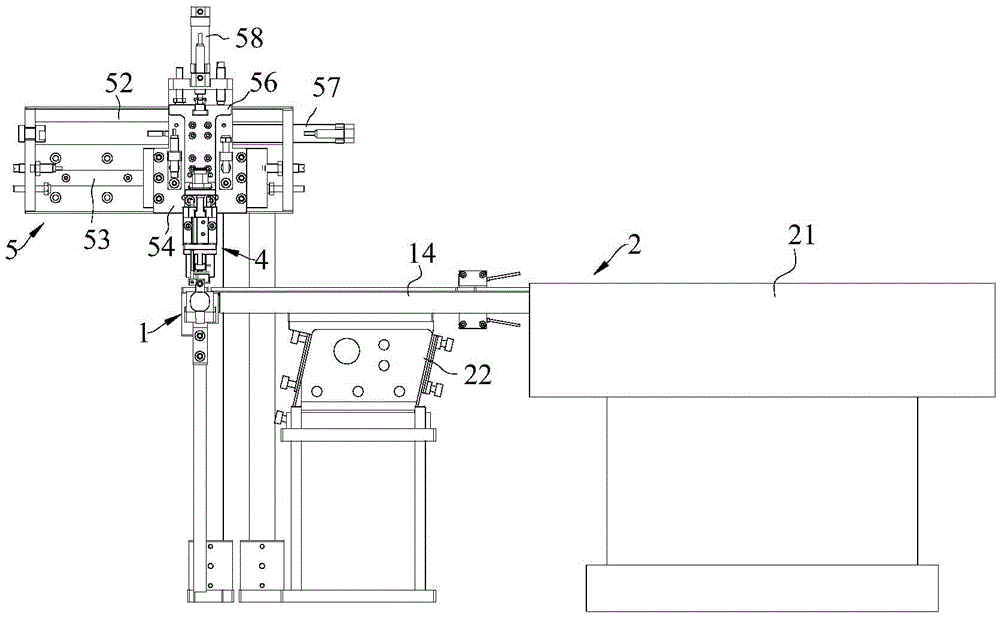

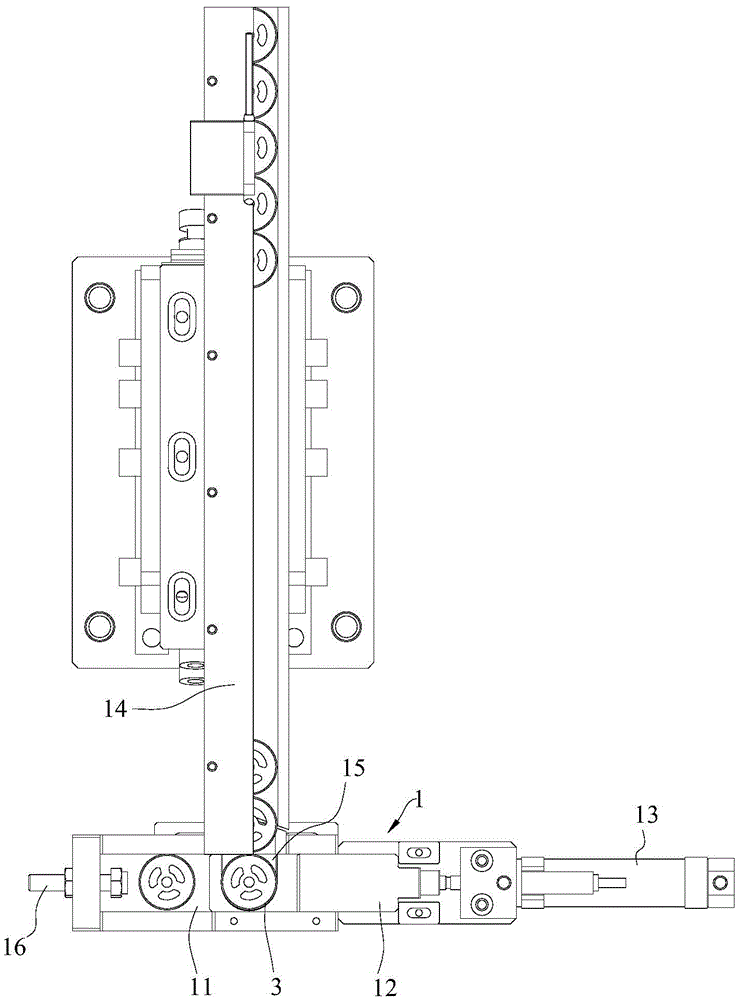

Machine for automatically processing bearing outer ring

InactiveCN102205425AReduce impactGood overall cutting performanceAutomatic/semiautomatic turning machinesMaterial distributionAutomation

The invention relates to a machine for automatically processing a bearing outer ring. The machine for automatically processing a bearing outer ring comprises a machine frame, an automatic elevator, a main shaft, a main motor for driving the main shaft, a chuck mechanism, a cutter block, a control device, a material feeding seat, a material ejection air cylinder for driving the material feeding seat, a material conveying oil cylinder for driving the material feeding seat and the material ejection air cylinder, a material loading channel, a stacking mechanism, a movable material unloading channel, and a material receiving air cylinder which drives the material unloading channel; a material distribution mechanism is arranged at the joint of the material loading channel and the material feeding seat; one end of the material loading channel which is butted with the material feeding seat is lower that the other end of the material loading channel; and one end of the material unloading channel which is butted with the chuck mechanism is higher than the other end of the material unloading channel. The invention provides the machine for automatically processing the bearing outer ring; in the machine, the processes from material loading to product stacking are all automated, and the machine has high processing efficiency; and the problems of low automation degree and processing efficiency during processing of the conventional bearing outer ring are solved.

Owner:ZHEJIANG KAIDA MACHINE TOOL

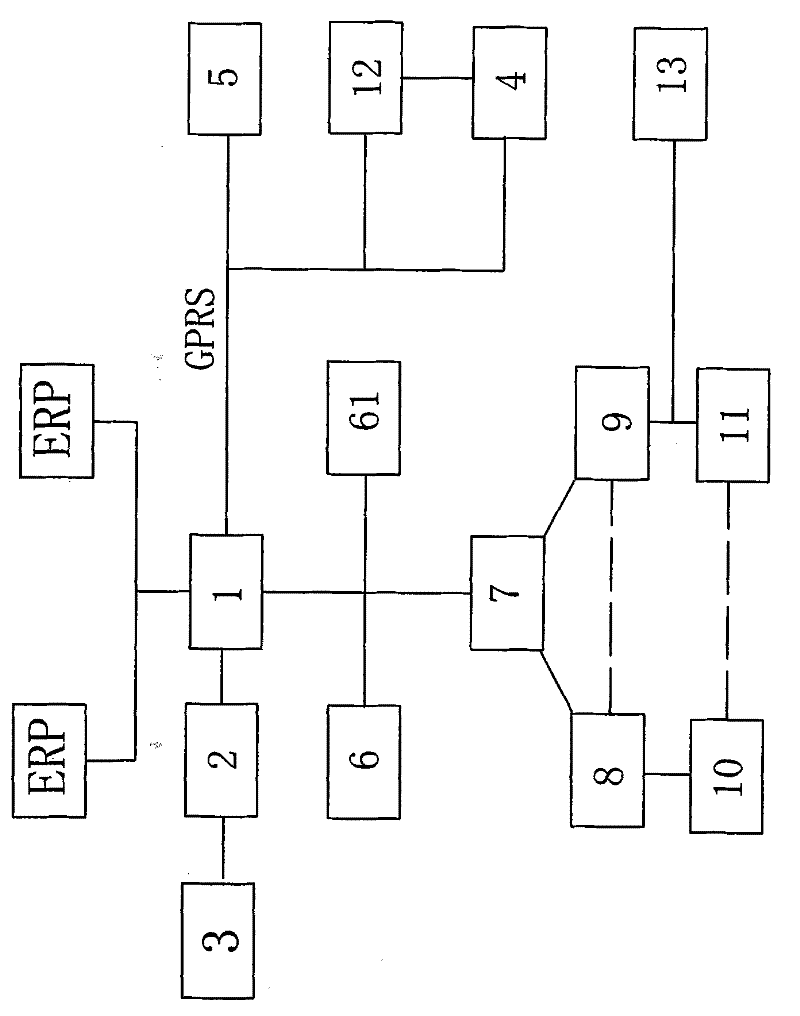

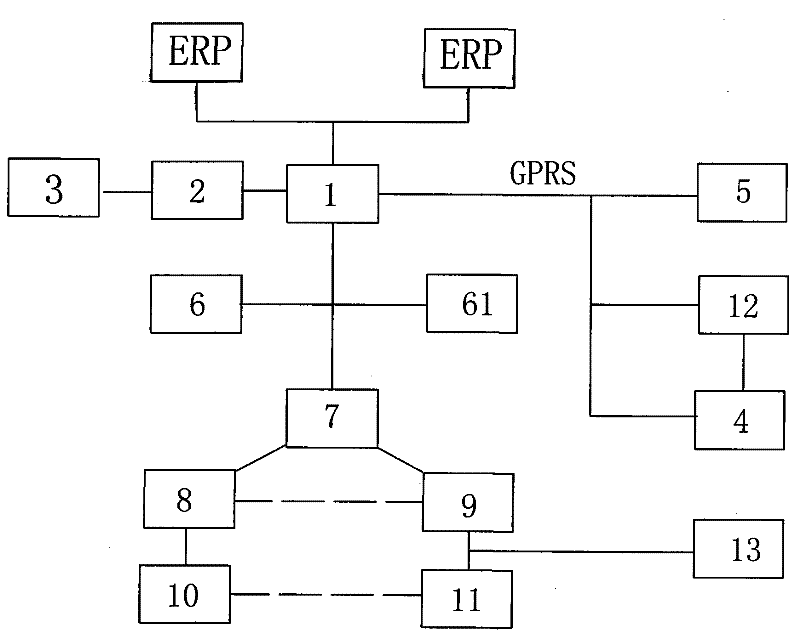

aps/mes lean manufacturing management system

InactiveCN102262757AImprove reaction speedImprove reaction efficiencyInstrumentsSoftware systemHand held

APS / MES lean manufacturing management system, including system hardware and system software, the software in the hardware is integrated in the main system software, and is seamlessly connected with the main system; the system hardware includes: industrial touch all-in-one machine connected to the host server and LED electronic kanban and The RFID card reader used to read the RFID card, the wireless receiving and transmitting device is connected with the host server, the handheld terminal and the terminal touch screen through the sensor, and the host server is also connected with the host of the logistics distribution center and the host of the delivery center; the system software includes: Supply chain management, sales management, procurement management, warehouse management, subcontract processing, production order, process route, workshop scheduling plan, handheld terminal module, terminal touch screen, material distribution, LED electronic kanban control system software module; system software The management module is divided into: basic data module, supply chain management module, equipment management module, production management module, and handheld terminal module; each module is composed of its corresponding sub-modules.

Owner:王圣亮

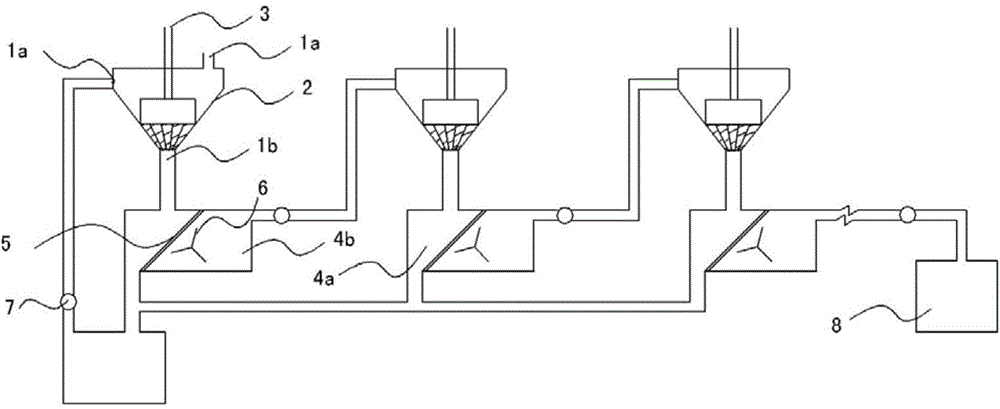

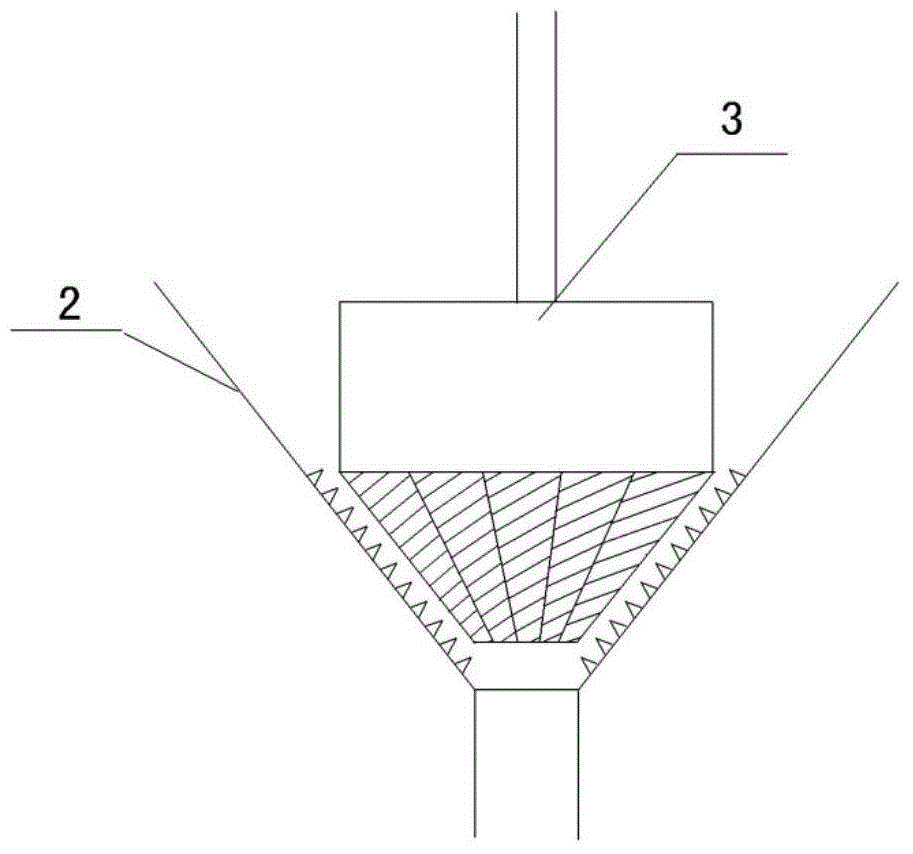

Machine-like stripping device for ton-scale production of graphene and production method of machine-like stripping device

The invention discloses a machine-like stripping device for ton-scale production of graphene and a production method of the machine-like stripping device. The machine-like stripping device is characterized by comprising one or more stages of stripping devices which are connected in series, wherein each stripping device comprises a material bin, a rotor, a material distribution bin and the like, the lower part of the rotor is matched with that of the material bin, and when the rotor rotates, relative friction is formed at the matching position between the outer surface of the rotor and the inner surface of the material bin. During use, graphite raw material receives the shearing action of a friction force at the matching position, and Van der Waals forces among graphite layers of the graphite collapse so that the graphite is stripped and thinned into graphene which is fed into the material distribution bin. The machine-like stripping device for ton-scale production of graphene is simple to operate and can realize batch production of graphene, and the obtained graphene has a perfect crystal structure, a large specific surface area and good conductivity.

Owner:合肥微晶材料科技有限公司

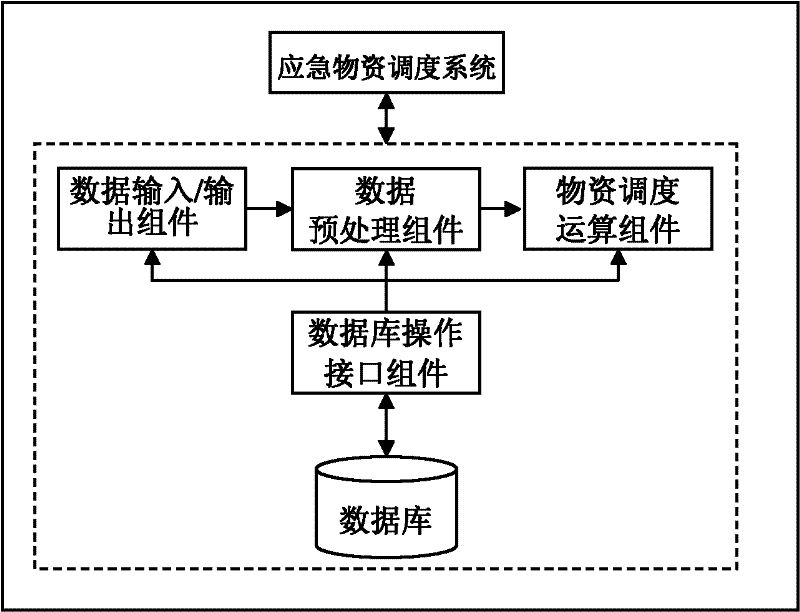

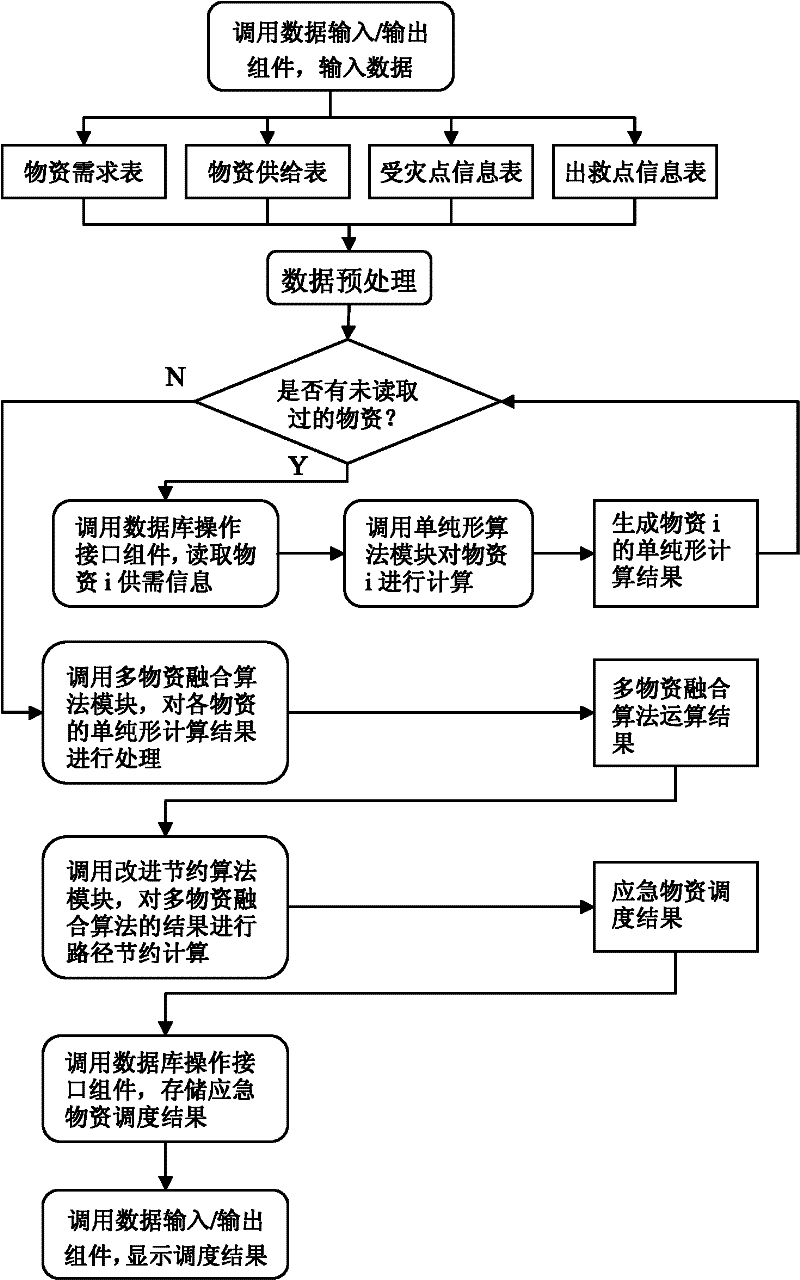

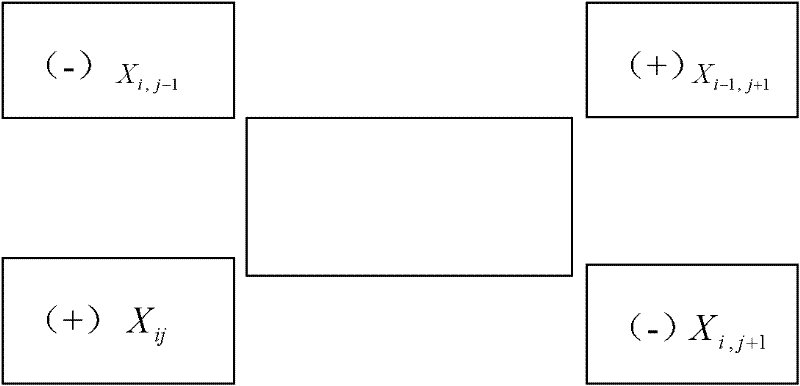

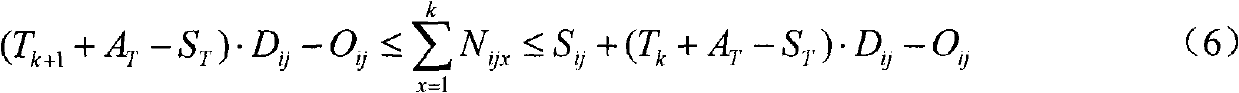

Emergency material dispatching system and calculating method

The invention provides an emergency material dispatching method and system. The system comprises the following structures of: a data input / output module, a data preprocessing module, a material dispatching and operating module, a database operation interface module and a system interface. Aiming at multi rescue point-multi disaster point-multi material dispatching problem, the emergency material dispatching system is used for solving the problem that the vehicle is not full-loaded through comprehensively using multiple algorithms and optimizing multi-material distribution and distribution path so that the model calculating result is more excellent and much faster; and by using the system provided by the invention, locations of the emergency event disaster point and the material distribution point, distance between the emergency event disaster point and the material distribution point, road network as well as other spatial information are provided to the emergency material dispatching; and the emergency material dispatching result can be visually displayed. The emergency material dispatching system provided by the invention has the advantages of stronger practicability and capability of being widely used; and the problems in the prior art are overcome.

Owner:BEIJING NORMAL UNIVERSITY

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

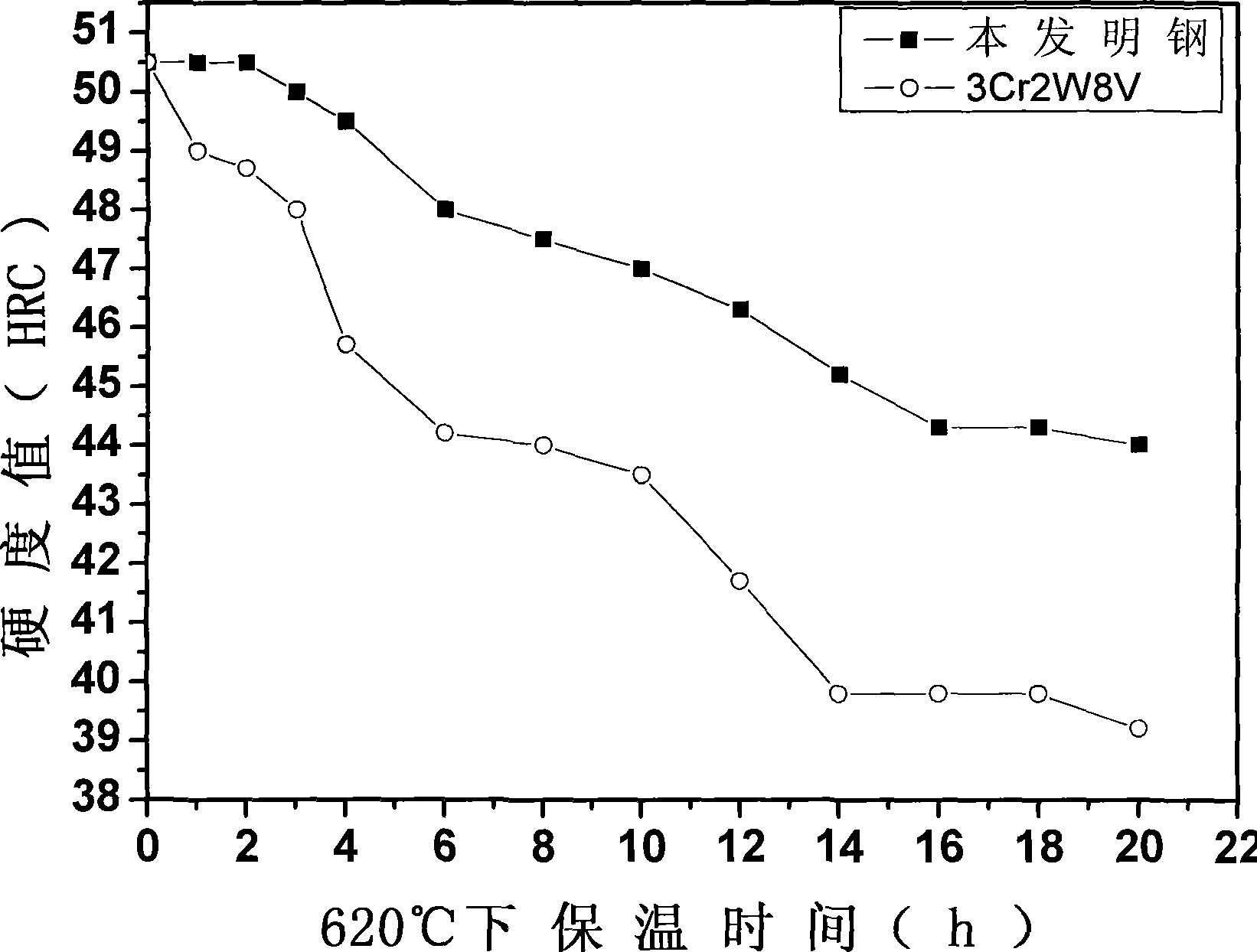

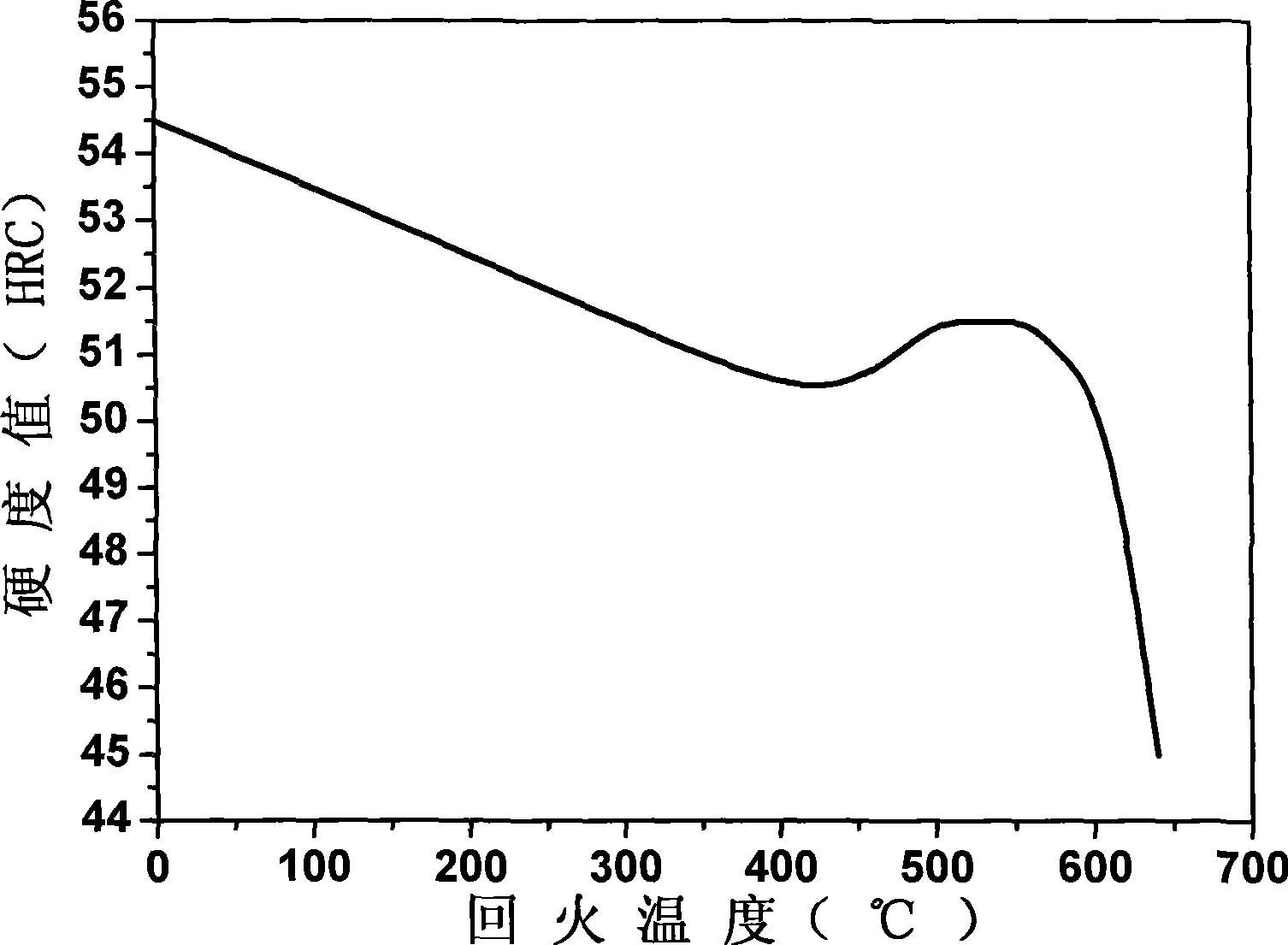

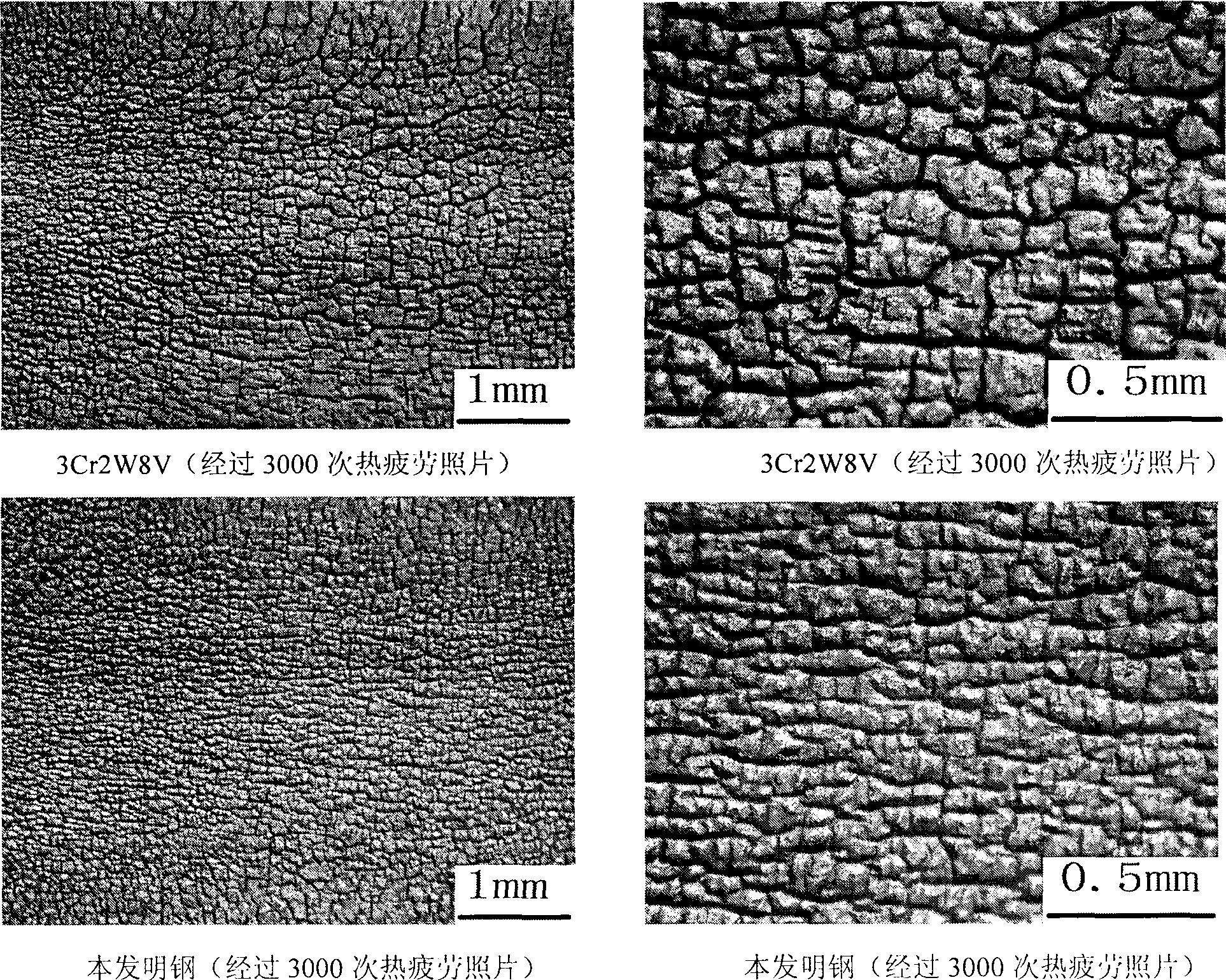

High manganese and low chromium type high strength and toughness hot-work die steel and preparation method thereof

The invention relates to a high-manganese and low chromium type high-obdurability hot-work die steel, pertaining to the technical field of alloy steel manufacturing process. The constituents of the steel and the weight percent are as follows: C: 0.3 percent to 0.6 percent, Si: 0.1 percent to 0.5 percent, Mn: 0.5 percent to 1.5 percent, Cr: 1.5 percent to 4.0 percent, Mo: 1.0 percent to 3.0 percent, V: 0.4 percent to 1.3 percent, W: 0.5 percent to 2.0 percent, P: less than 0.02 percent, S: less than 0.02 percent and Fe as the rest. The preparation process of the hot-work die steel is as follows: material distribution, induction smelting and molding, followed by electroslag remelting; at the temperature of 1,200 DEG C to 1,280 DEG C, homogenization treatment is carried out for 8h to 10h, then forging and annealing are carried out, the materials are heated to the temperature of 1,000 DEG C to 1,100 DEG C for austenization, and two times of tempering are carried out at the temperature of 580 DEG C to 640 DEG C after oil quenching or high-pressure air quenching. The hot-work die steel has high thermal stability, high heat resistance and good thermal fatigue property.

Owner:SHANGHAI UNIV

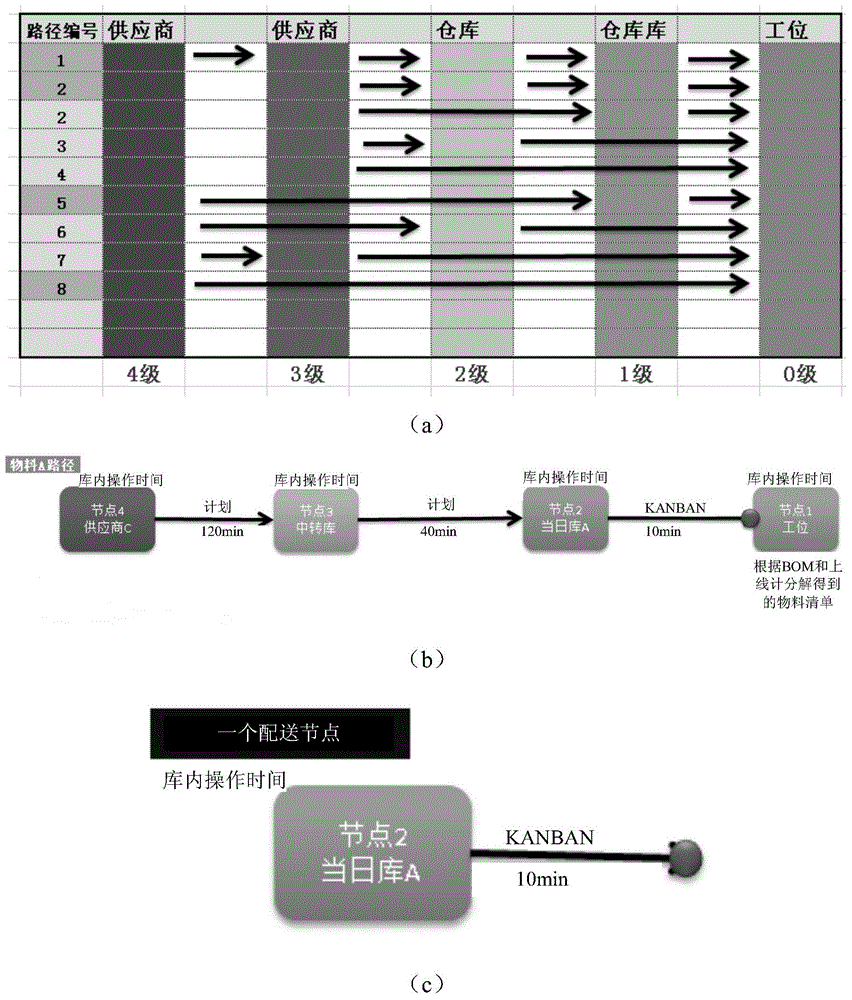

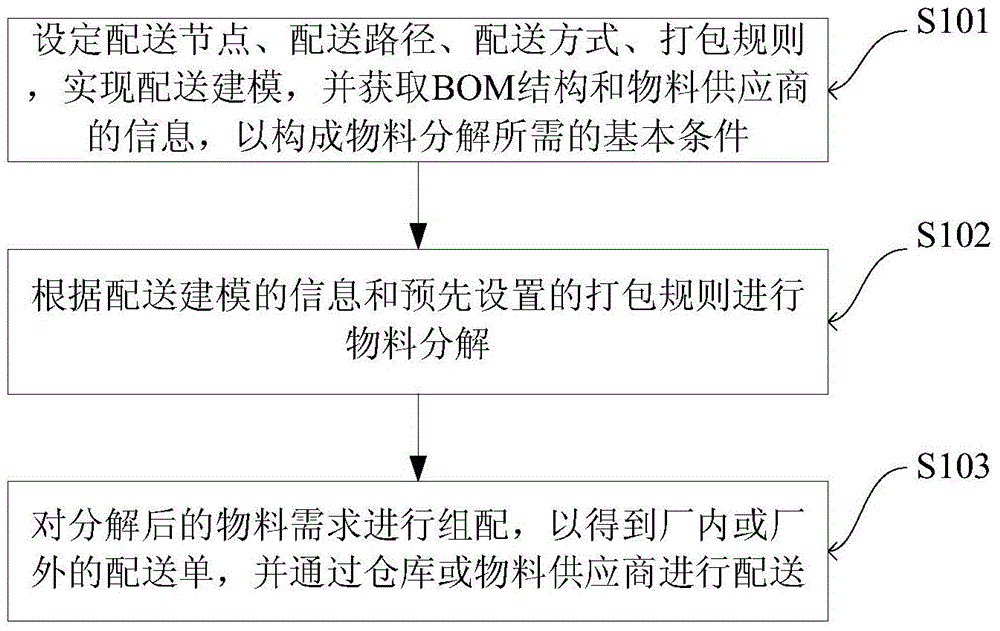

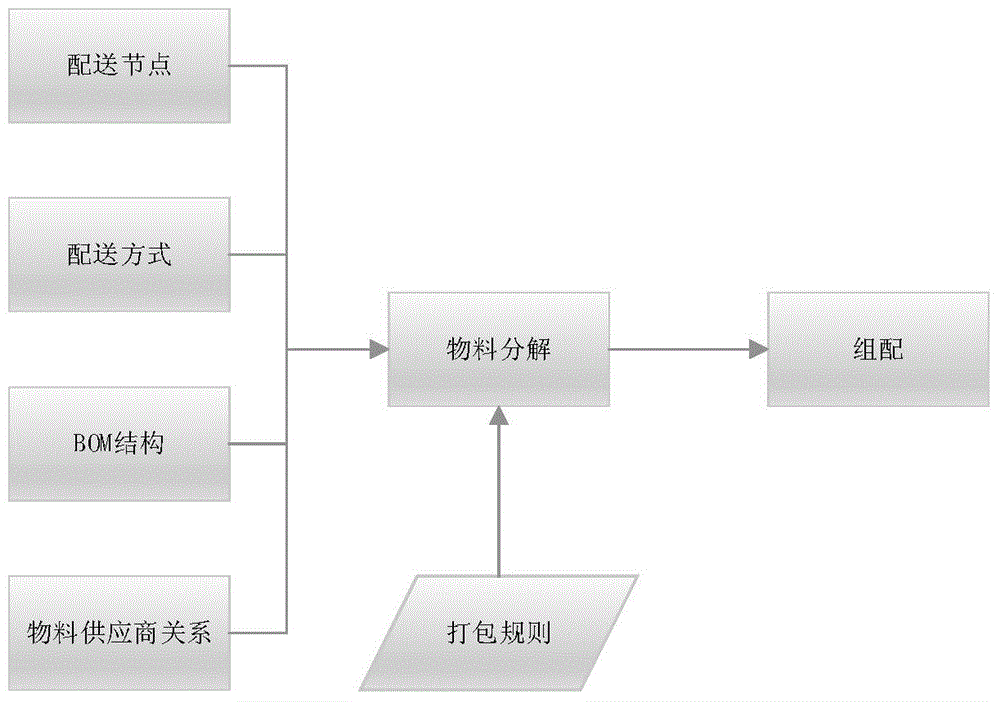

Material distribution method

ActiveCN104463521ARealize real-time decomposition and real-time distributionMeet the needs of pull distributionLogisticsDecompositionDistribution system

The invention discloses a material distribution method. The material distribution method includes the following steps that distribution nodes, distribution paths, distribution modes and a packaging rule are set for achieving distribution modeling; information of a BOM structure and a material supplier is acquired, and then basic conditions required for material decomposition are formed; material decomposition is conducted according to distribution modeling information and the preset packaging rule; decomposed material requirements are assembled, in-plant or out-plant distribution bills are acquired, and the materials are distributed through a warehouse or the material supplier. By the adoption of the method, the complexity of an existing distribution system is lowered, the stability and the timeliness of the system are improved, real-time decomposition and real-time distribution (JIT) of the materials are achieved, and the requirements for material pull type distribution in multi-variety, small-batch and mixed flow production in modern discrete manufacturing are met.

Owner:EPIC HUST TECH WUHAN

Material distribution method and device for production of ceramic tile

InactiveCN102303357AHigh degree of simulationHigh degree of clusteringFeeding arrangmentsShaping conveyorsLiquid layerBrick

The invention discloses a material distribution method and device for the production of a ceramic tile, wherein the method comprises the steps of: 1, distributing a surface material on a first feeding belt; 2, shaping the surface material by a shaping machine; 3, coating a coloring liquid layer, which forms irregular textured patterns, on the surface of the surface material; 4, randomly distributing a ceramic material on the surface of the liquid layer; and 5, transferring the distributed ceramic material to a second feeding platform and piling up the ceramic material on the second feeding platform to complete material distribution, wherein the first feeding belt has the speed higher than that of a second feeding belt. By adopting the technical proposal, a pattern which is both delicate and raw and which is extremely close to natural texture can be formed, thus the simulation for surface texture of the finished ceramic tile product is improved.

Owner:佛山市新海舟科技有限公司

Real-time material distribution method in mechanical product assembling process

InactiveCN101950387AEasy to manage on siteNo stack pressureLogisticsMaterial consumptionMaterial distribution

The invention discloses a real-time material distribution method in a mechanical product assembling process, which is characterized in that: according to the production plan on the same day, calculating to obtain all required parts; by considering the storage capability, the existing amount, the material lead time and the product cycle time of each part on each station, calculating a material distribution scheme; distributing the parts in time on small batches according to the obtained distribution scheme; simultaneously, tracking the on-site production situation by an MES system in real time; recording manufacturing product situation and the material consumption situation of each station; and timely feeding back production plan information and station inventory information. The method of the invention can realize on-time material distribution, feeds back and adjusts the distribution scheme in time according to real-time working condition, can improve production efficiency and lowers product cost.

Owner:HEFEI UNIV OF TECH

Selectable eccentric remodeling and/or ablation of atherosclerotic material

ActiveCN1867299AAvoid dischargeDischarge not requiredDiagnosticsCatheterMedicineMaterial distribution

This present invention provided a catheter and catheter system for eccentric remodeling and / or removal of atherosclerotic material of a blood vessel of a patient include an elongate flexible catheter body with a radially expandable structure. A plurality of electrodes or other electrosurgical energy delivery surfaces can radially engage atherosclerotic material when the structure expands. An atherosclerotic material detector near the distal end of the catheter body may measure circumferential atherosclerotic material distribution, and a power source selectively energizes the electrodes to eccentrically remodel the measured atherosclerotic material.

Owner:MINNOW MEDICAL

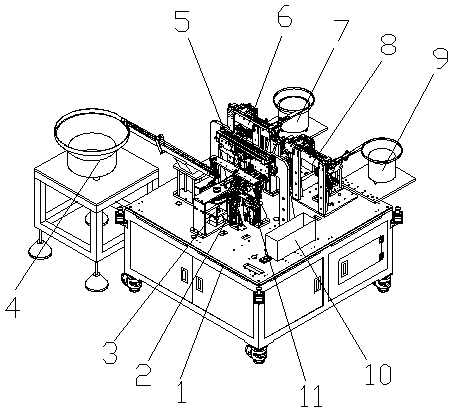

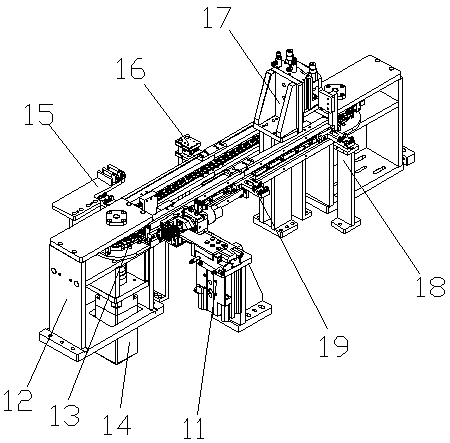

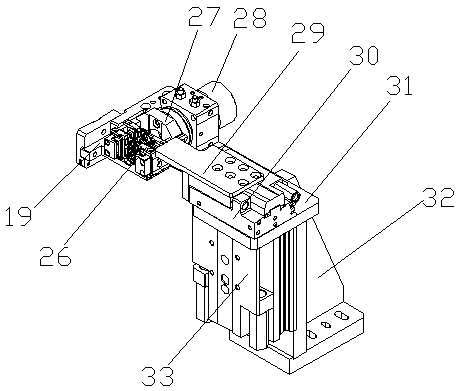

Automatic safety valve filter screen installation device

ActiveCN105479134AImprove job stabilityLower assembly costsMetal working apparatusEngineeringMaterial distribution

The invention discloses an automatic safety valve filter screen installation device which comprises a filter screen material distribution mechanism. The filter screen material distribution mechanism comprises a material distribution guide groove, a material distribution block and a material distribution power piece. A material supply guide groove is formed in the right side of the material distribution guide groove. A clamping groove is formed in the side, right opposite to the material supply guide groove, of the material distribution block. The automatic safety valve filter screen installation device further comprises a filter screen clamping mechanism capable of clamping a filter screen in the material distribution guide groove and installing the filter screen in a safety valve. The filter screen clamping mechanism comprises a clamping jaw mechanism and a mechanical hand. In work, the material distribution power piece drives the material distribution block to be located at the rear end of the material distribution guide groove, the clamping groove of the material distribution block is right opposite to the material supply guide groove, the filter screen enters the clamping groove of the material distribution block through the material supply guide groove, the material distribution power piece drives the material distribution block to move forwards along the material distribution guide groove, the material distribution block pushes the filter screen to the front end of the material distribution guide groove through the clamping groove, the filter screen in the material distribution guide groove is clamped and installed in the safety valve through the filter screen clamping mechanism, and the whole filter screen installation work is finished. The automatic safety valve filter screen installation device can be used for replacing manual operation, work stability is good, the assembling cost is low, and work efficiency is improved.

Owner:SHENZHEN WILLIAM AUTOMATION EQUIP

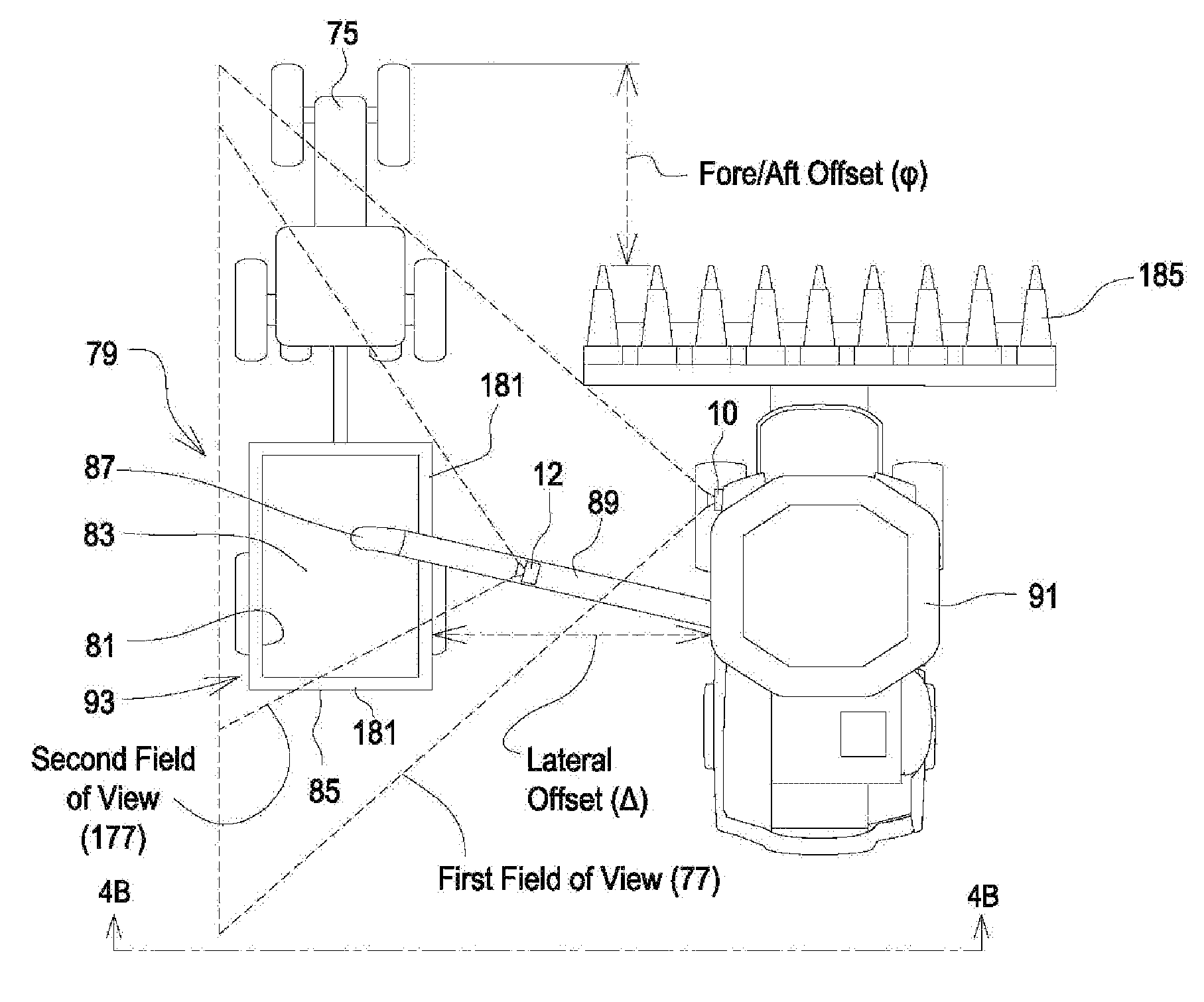

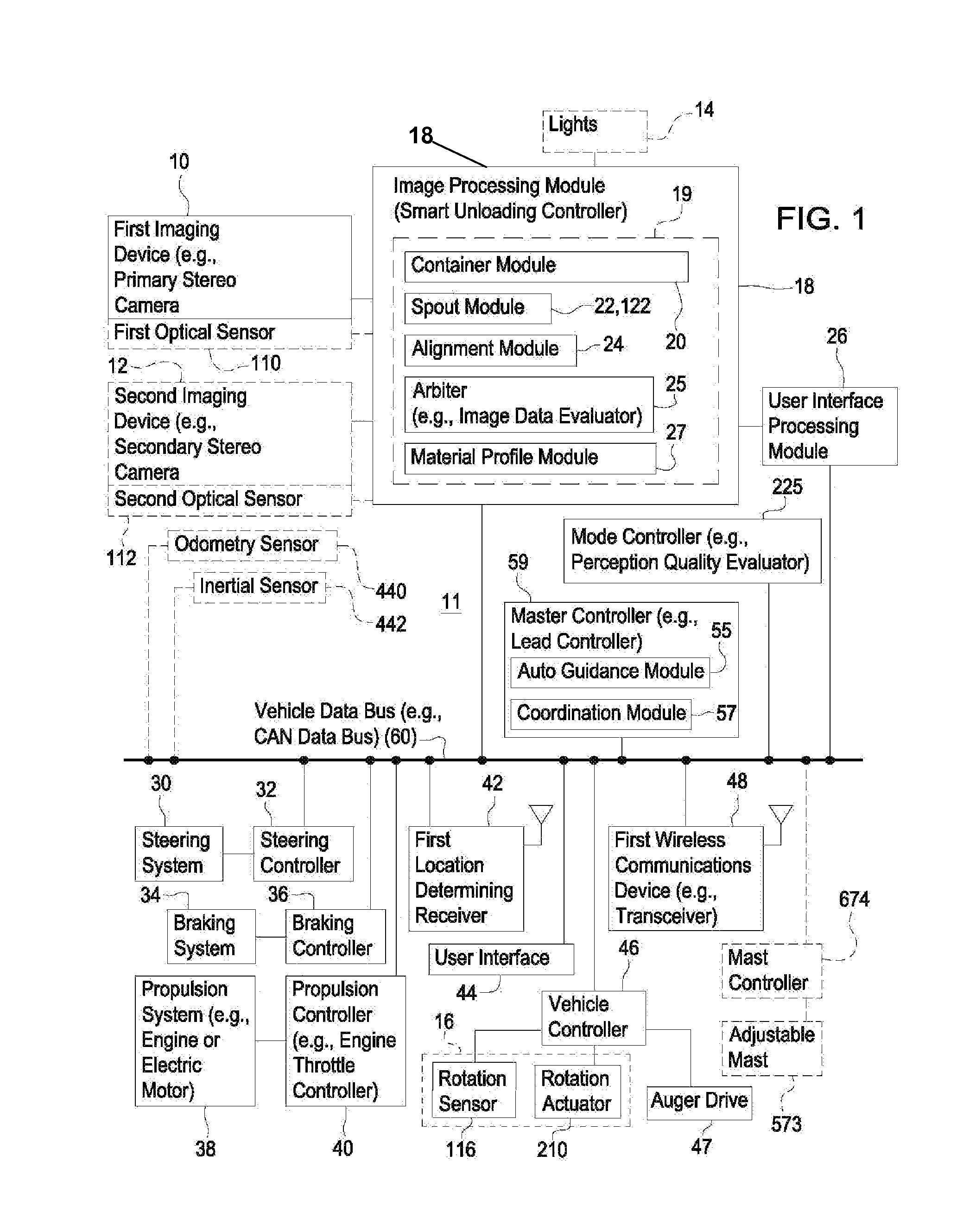

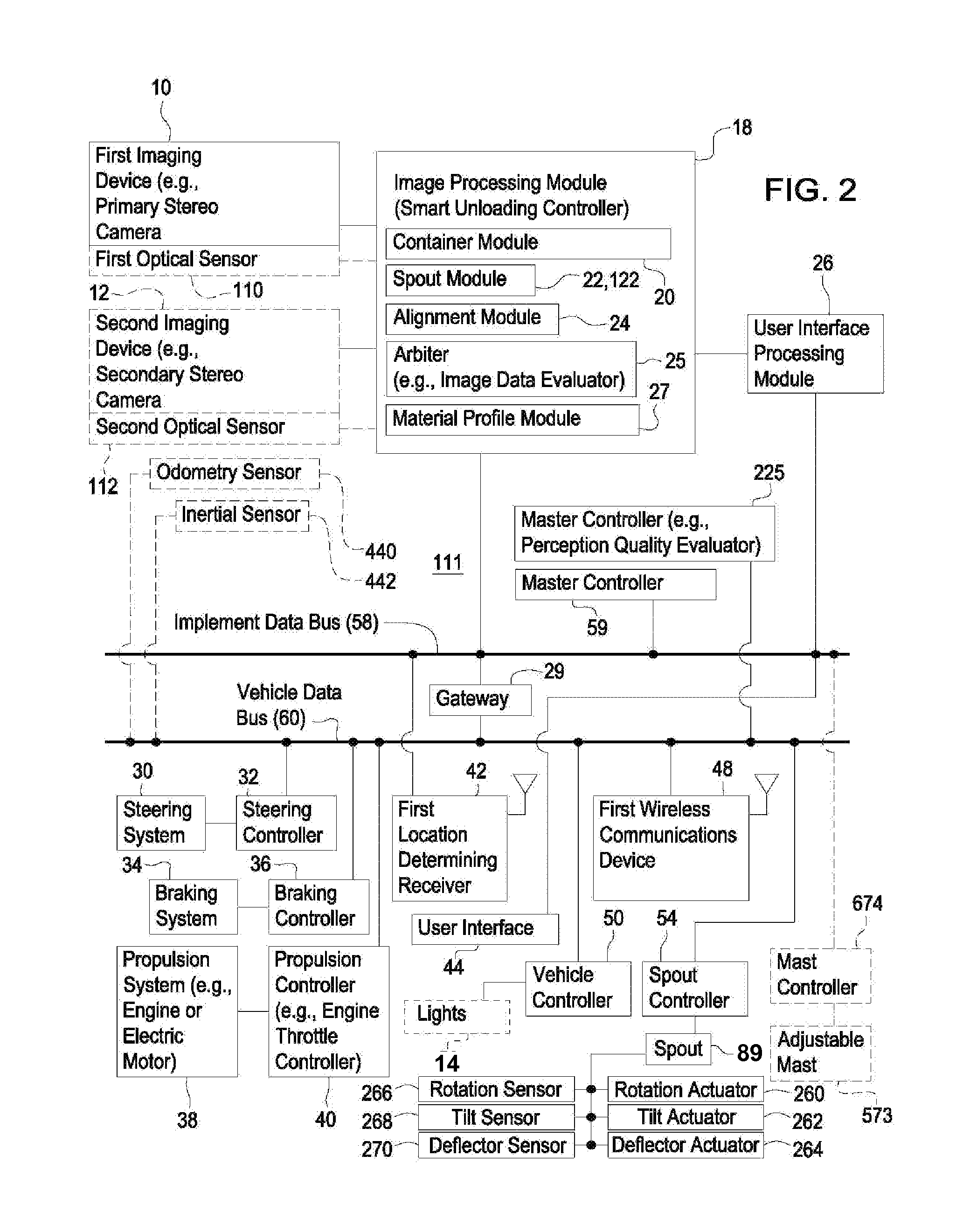

System And Method Of Material Handling Using One Imaging Device On The Receiving Vehicle To Control The Material Distribution Into The Storage Portion Of The Receiving Vehicle

ActiveUS20140350801A1Easy transferImage enhancementImage analysisMaterial distributionComputer science

A single imaging device collects image data of a storage portion. A container module identifies a container perimeter of the storage portion in at least one of the collected image data. A spout module is adapted to identify a spout of the transferring vehicle in the collected image data. An arbiter determines whether to use the image data based on an evaluation of the intensity of pixel data or ambient light conditions. An alignment module is adapted to determine the relative position of the spout and the container perimeter and to generate command data to the propelled portion to steer the storage portion in cooperative alignment such that the spout is aligned within a central or target zone of the container perimeter.

Owner:DEERE & CO

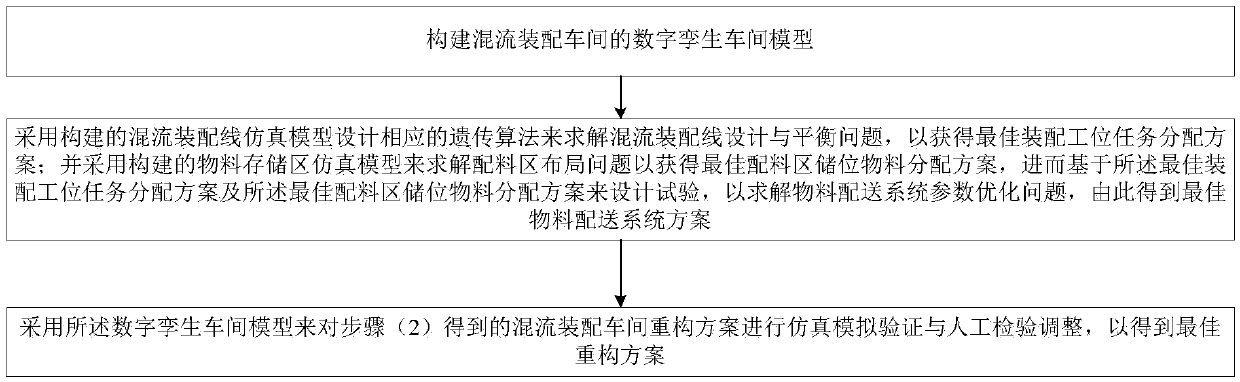

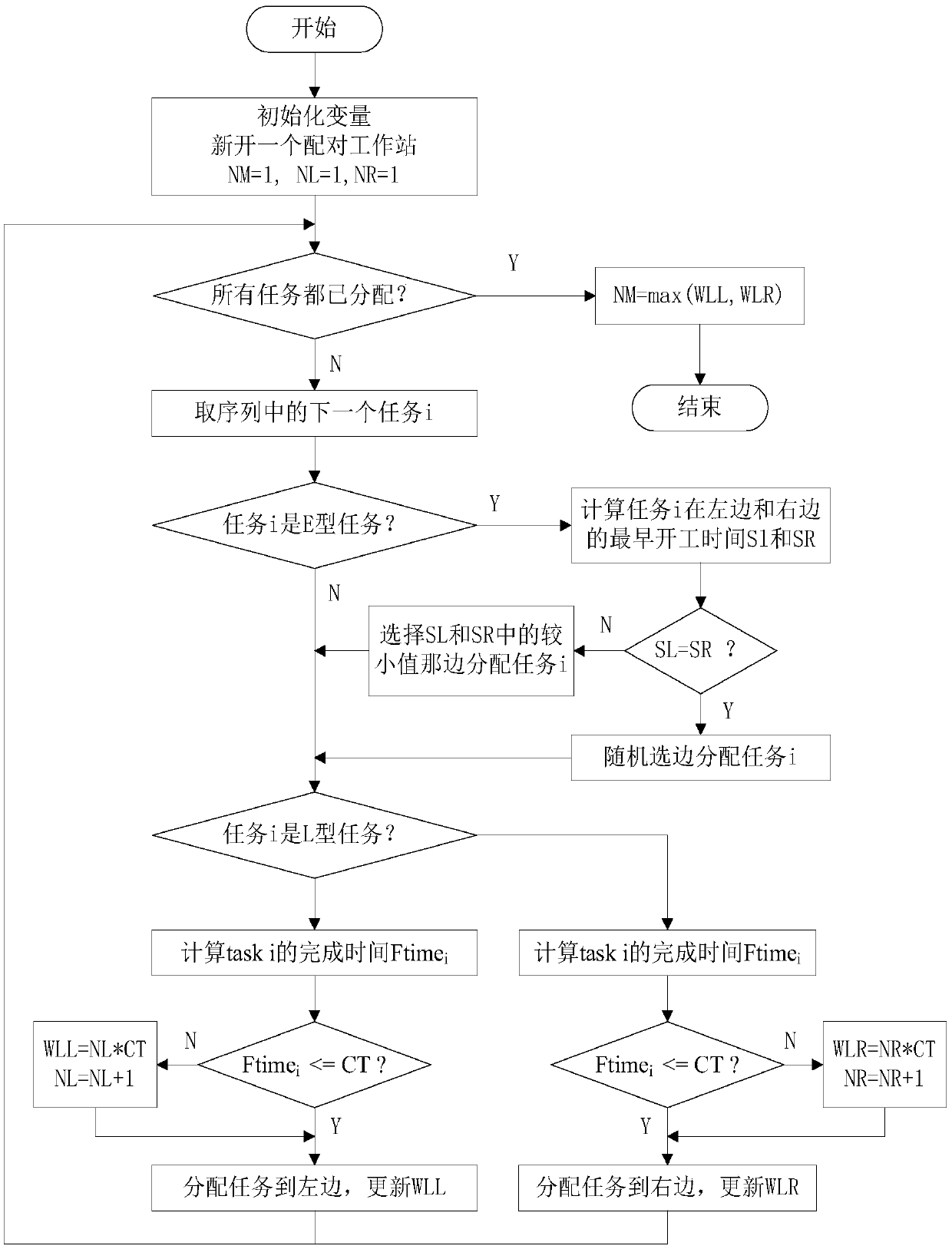

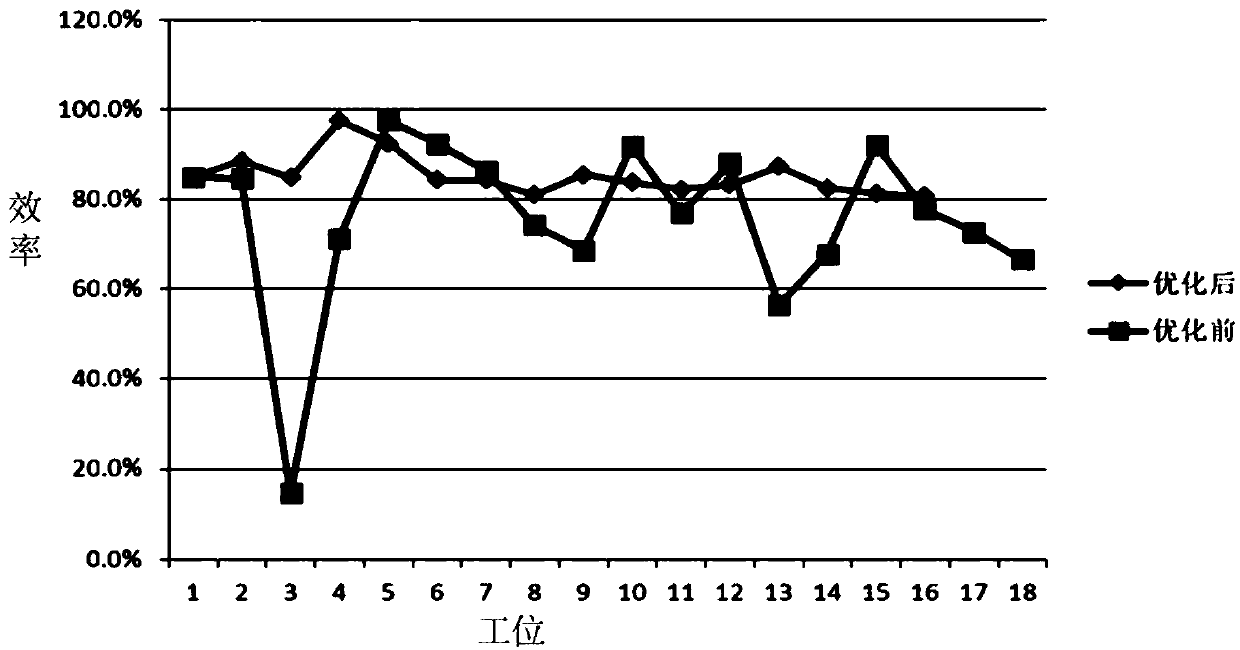

Mixed flow assembly workshop rapid reconstruction method and system based on digital twin

ActiveCN109657354ASolve balance problemsFix layout issuesDesign optimisation/simulationLogisticsSimulationReconstruction method

The invention belongs to the related technical field of factory virtual simulation, and discloses a mixed flow assembly workshop rapid reconstruction method and system based on digital twinning, and the method comprises the following steps: (1) building a digital twinning workshop model of a mixed flow assembly workshop; (2) solving the design and balance problems of the mixed flow assembly line by adopting the constructed mixed flow assembly line simulation model so as to obtain an optimal assembly station task allocation scheme; A built material storage area simulation model is adopted to solve and obtain an optimal batching area storage position material distribution scheme, and then a test is designed on the basis of the optimal assembly station task distribution scheme and the optimalbatching area storage position material distribution scheme so as to obtain an optimal material distribution system scheme through solving; And (3) carrying out simulation verification and manual inspection adjustment on the mixed flow assembly workshop reconstruction scheme obtained in the step (2) by adopting the digital twin workshop model to obtain an optimal reconstruction scheme. The methodis high in efficiency, use and flexibility, and reconstruction efficiency is improved.

Owner:无锡雪浪数制科技有限公司

Fully automatic assembling machine for spring fasteners

InactiveCN108390236AQuick and automatic assemblyHigh efficiency of one-time assemblyContact member assembly/disassemblyAssembly machinesDistribution controlMaterial distribution

The invention relates to a fully automatic assembling machine for spring fasteners. The fully automatic assembling machine comprises a rack and a power distribution control box. The rack is provided with a circulation conveying device, a rubber shell feeding device, a fastener feeding device and a spring feeding device, wherein the rubber shell feeding device, the fastener feeding device and the spring feeding device are sequentially arranged on the periphery of the circulation conveying device. The rubber shell feeding device comprises a rubber shell feeding vibration disc disposed on the left front side of the circulation conveying device, and the rubber shell feeding vibration disc is communicated with a rubber shell material distribution block through a rubber shell conveying track; arubber shell conveying manipulator matched with the rubber shell material distribution block is disposed above the circulation conveying device, a rubber shell clamping device is arranged on the portion, below the rubber shell conveying manipulator, of the right front side of the circulation conveying device, and a fastener pushing-in device matched with the circulation conveying device is arranged under the rubber shell clamping device. The circulation conveying device is adopted for feeding and conveying materials, and the fasteners are pushed into insertion holes in a rubber shell from bottom to up through the fastener pushing-in device. The one-time assembling efficiency is high, the operation is convenient, fast and automatic assembly of the spring fasteners is achieved, and the production efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

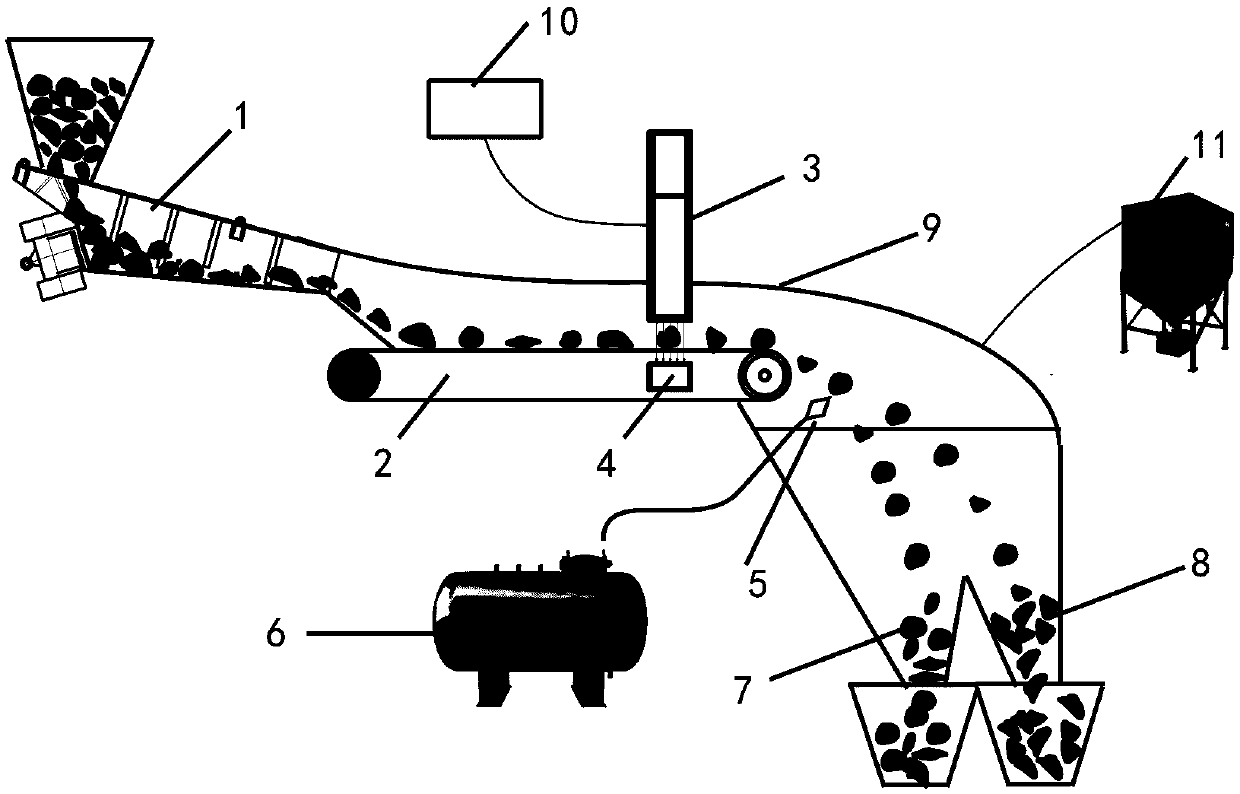

Telligent dry separator (TDS)

InactiveCN105499154AReduce in quantityLess-associative articulation pointSortingDust controlElectric control

The invention discloses a telligent dry separator (TDS). The telligent dry separator is characterized in that an intelligent identification method is adopted for establishing corresponding analysis models according to different characteristics of coal quality, through big data analysis, digitalized identification is conducted on coal and gangue, and finally the gangue is discharged through an intelligent execution system. The telligent dry separator (TDS) comprises four major systems, namely a feeding system, a material distribution system, an identification device and an execution mechanism, and three auxiliary systems, namely an air supplying system, a dedusting system and an electric control system. By means of the telligent dry separator (TDS), separation precision can be improved, the lower separation limit can be further lowered, and a condition is created for achieving the effect that all block raw materials ranging from 3mm to 300 mm adopt the intelligent dry separation process. Compared with traditional cleaning equipment, the telligent dry separator (TDS) has the advantages that on the aspect of construction investment, a system can be simplified, investment can be reduced, and the construction period can be shortened; on the aspect of separation effects, precision can be guaranteed, the heat value can be raised, and no coal slime is generated; on the aspect of production cost, consumption can be lowered, maintenance can be reduced, and manual work can be decreased.

Owner:TIANJIN MEITENG TECH CO LTD

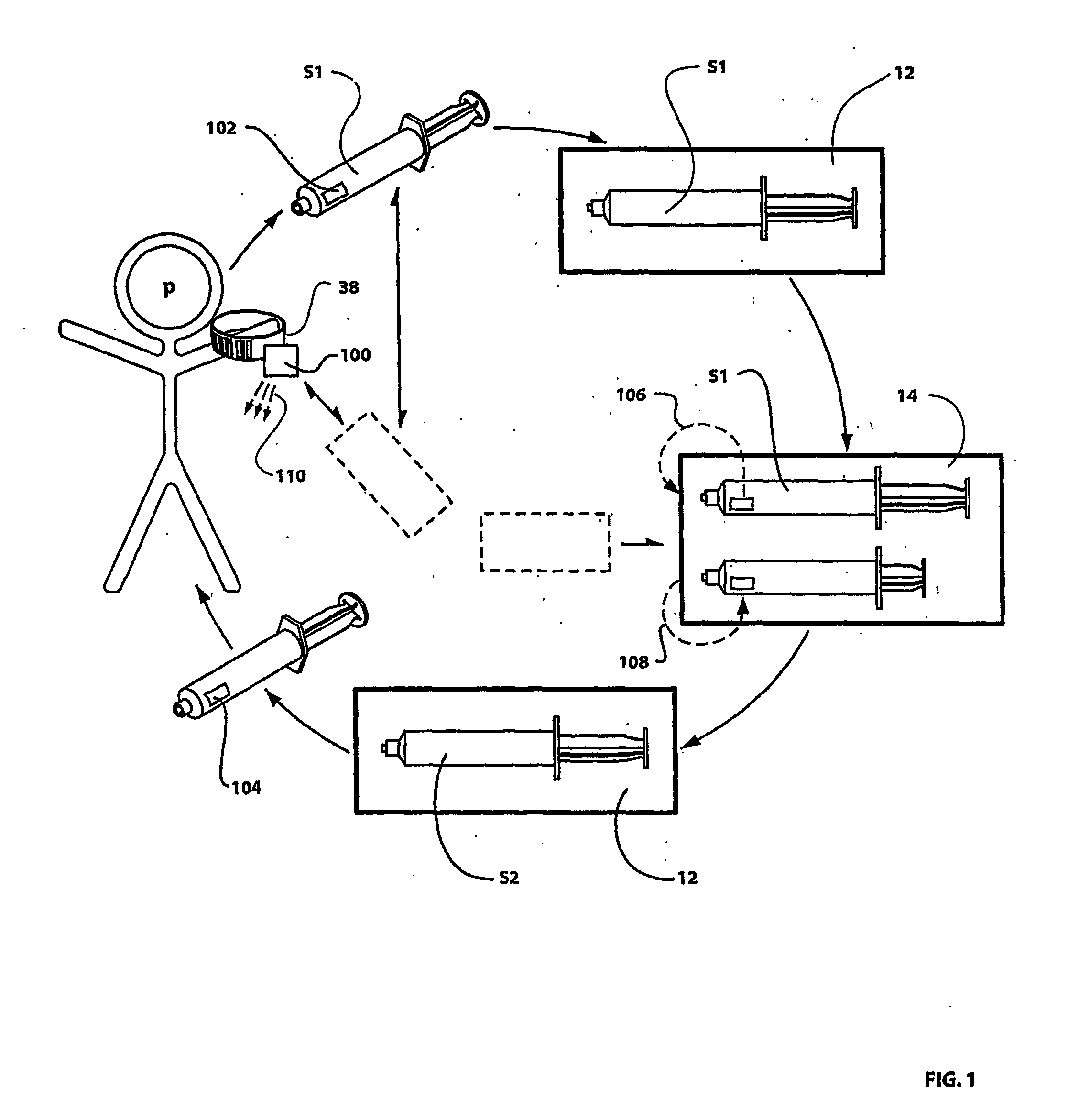

Permission-based material dispenser

InactiveUS20060270997A1Eliminate the risk of contaminationAutomatic syringesMedical devicesMaterial distributionBiomedical engineering

A syringe includes a releasable lock means for allowing discharge of a treated biological fluid sample to the patient in response to a release signal to the releasable lock means. The release signal is issued following a positive outcome from a verification process dependent upon temporal data from certain events in the collection, treatment and delivery of the biological fluid sample, and identity data of the patient and the syringe with the treated biological fluid.

Owner:VASOGEN IRELAND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com