Overall treatment method of steel works sintering dust

A technology for comprehensive treatment and sintering of ash, applied in fertilizer mixtures, iron oxide/iron hydroxide, applications, etc., can solve the problems of increased operating energy consumption of dust removal devices, difficulty in blast furnace ignition, hidden dangers of blast furnace equipment safety accidents, etc. The effect of equipment investment and raw material consumption, optimization of recycling routes, and minimization of recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

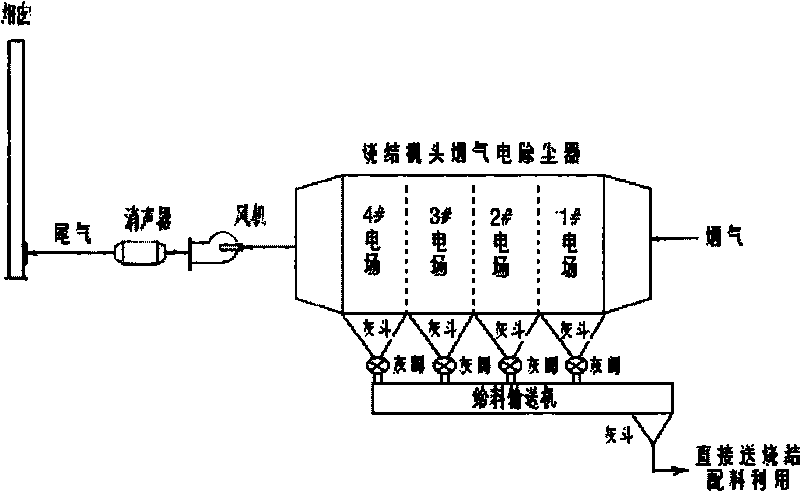

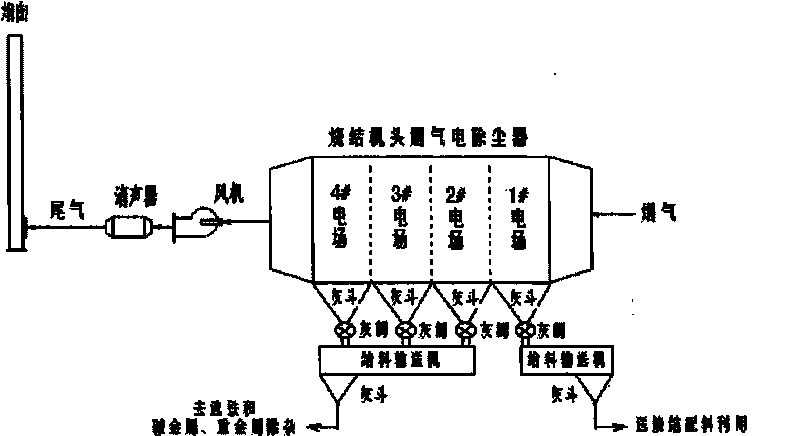

Method used

Image

Examples

Embodiment 1

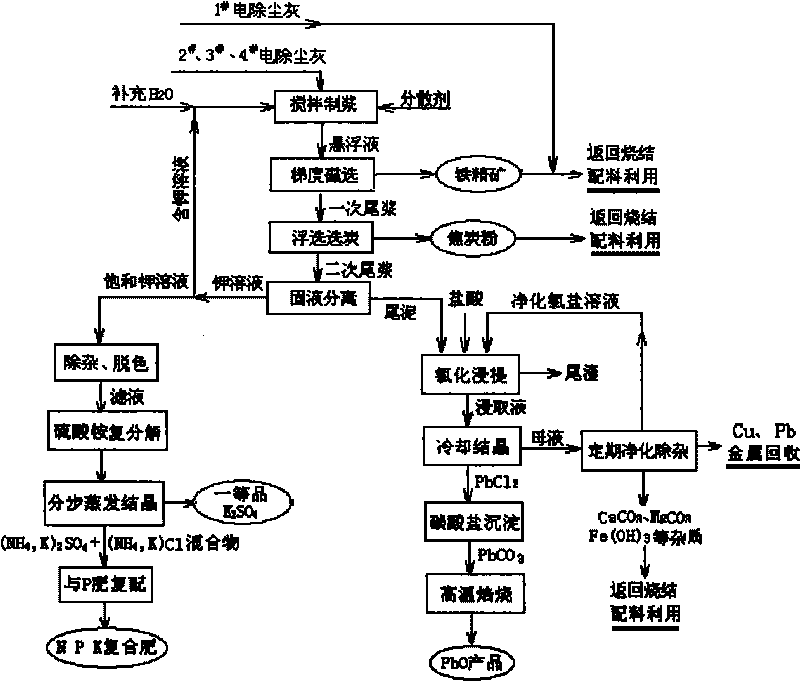

[0031] Take the sintering head electrostatic precipitator 2 # ~4 # Electric field dust removal mixed ash 200Kg, its chemical composition analysis is shown in Table 2:

[0032] Table 2 Example 1 in 2 # ~4 # Chemical composition of electric field dust removal mixed ash

[0033]

[0034] Add 2000L of industrial water at a solid-to-liquid ratio of 1:10, add 1.0kg of industrial sulfuric acid and 0.5kg of sodium dodecylbenzenesulfonate as a dispersant, and stir for a certain period of time to obtain a sintered ash suspension. The obtained suspension slurry is combined with magnetic separation (weak magnetic strength 800T, strong magnetic strength 1600T) through "weak magnetic → strong magnetic" to obtain iron concentrate and primary tailing slurry. Coke powder and secondary tailings are obtained from the primary tailings through "flotation charcoal separation", and the iron concentrate and coke powder are reused as sintering ingredients. After the secondary tailings are cent...

Embodiment 2

[0042] take 2 # ~4 # The electric field sintering head ESP mixed ash is 400Kg, and its chemical composition analysis is shown in Table 5.

[0043] Table 5 Example 2 in 2 # ~4 # Chemical Composition of ESP Mixed Ash in Electric Field Sintering Machine Head

[0044]

[0045] Add 4000L of industrial water at a solid / liquid ratio of 1:10, add 5.0kg of industrial sulfuric acid and 0.80kg of dodecyltrimethylammonium bromide (chloride) as a dispersant, and stir for a certain period of time to obtain a sintered ash suspension , the resulting suspension slurry is subjected to "weak magnetic → strong magnetic" combined magnetic separation (weak magnetic strength 800T, strong magnetic strength 1600T) to obtain iron concentrate and primary tailings, and the primary tailings are subjected to "flotation carbon separation" to obtain coke powder and The secondary tailings, iron ore concentrate and coke powder are reused in the sintering batching process. After the secondary tailings s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com