Patents

Literature

90results about "Lead monoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for recovering lead oxides from exhausted batteries

ActiveUS7507496B1Speed up the processObtained inexpensivelySolvent extractionPrimary cell maintainance/servicingLead dioxideLead oxide

A process for recovering lead oxides from the spent paste of exhausted lead acid batteries. The process provides heating the spent paste with an alkali hydroxide solution at elevated temperatures prior to calcinations. Calcination is at various temperatures so that either lead mono-oxide, lead dioxide or red lead is obtained as the principal product. There is also provided the use of the lead oxide to prepare the paste for positive and negative electrodes or other lead compounds.

Owner:RETRIEV TECH +1

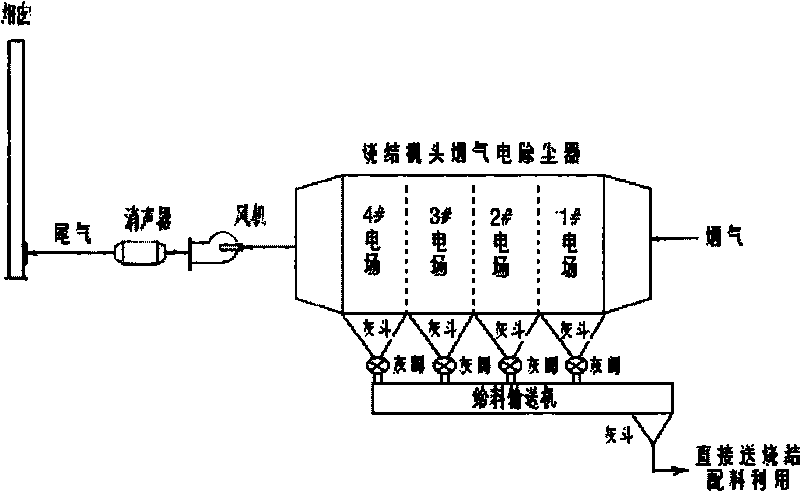

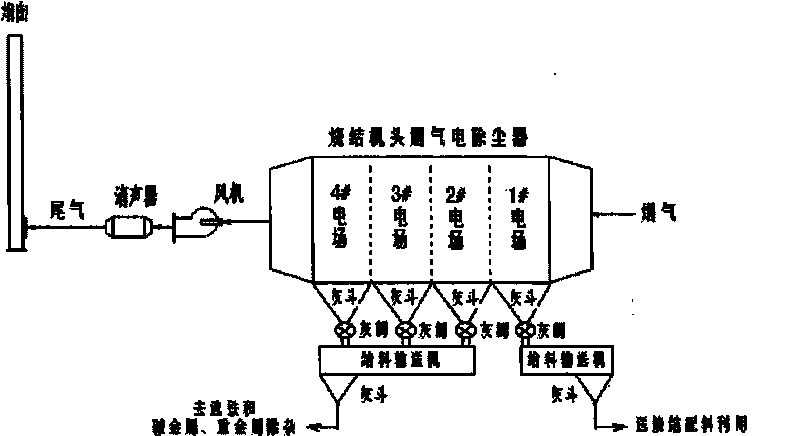

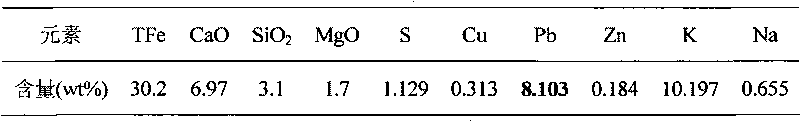

Overall treatment method of steel works sintering dust

ActiveCN101723713ASolve efficiency problemsSolve the problem that the flue gas often exceeds the standardCalcium/strontium/barium carbonatesIron oxides/hydroxidesPotassiumSlurry

The invention relates to an overall treatment method of steel works sintering dust, which is characterized by comprising the following steps: carrying out stage treatment on electrically precipitated dust in a sintering head, conveying the electrically precipitated dust produced in a primary electric field directly to a sintering field (a stock yard or a material distribution room) for material application in case of sintering; mixing the electrically precipitated dust produced in a subsequent electric field and then carrying out stirring pulping, gradient magnetic separation, carbon selection by flotation and solid-liquid separation; when the solid-liquid separation is finished, using the obtained potassium solution for producing potassic fertilizer and extracting lead product from the obtained tailing slurry.The method of the invention has the advantages that different process routes are adopted to effectively recover and comprehensively utilize contained multiple valuable resources such as ferrum, carbon, potassium, lead and the like according to different contents of alkali metal such as potassium and sodium and heavy metal compounds such as lead, zinc and copper in different electric field precipitated dust in a sintering head electric precipitator.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

Recovery of high purity lead oxide from lead acid battery paste

There is provided a process for recovering high purity litharge PbO from spent lead acid battery paste at low temperatures and the further preparation of highly pure lead oxides and Pb(OH)2.

Owner:RETRIEV TECH

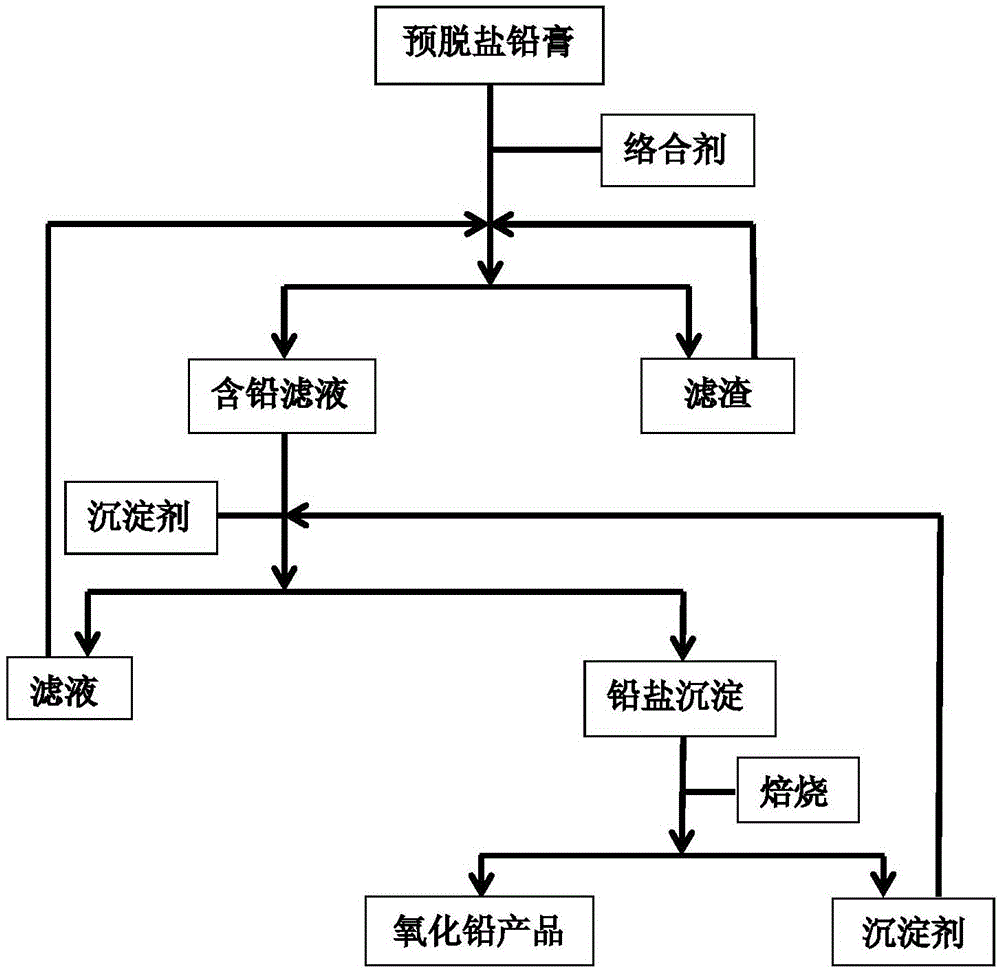

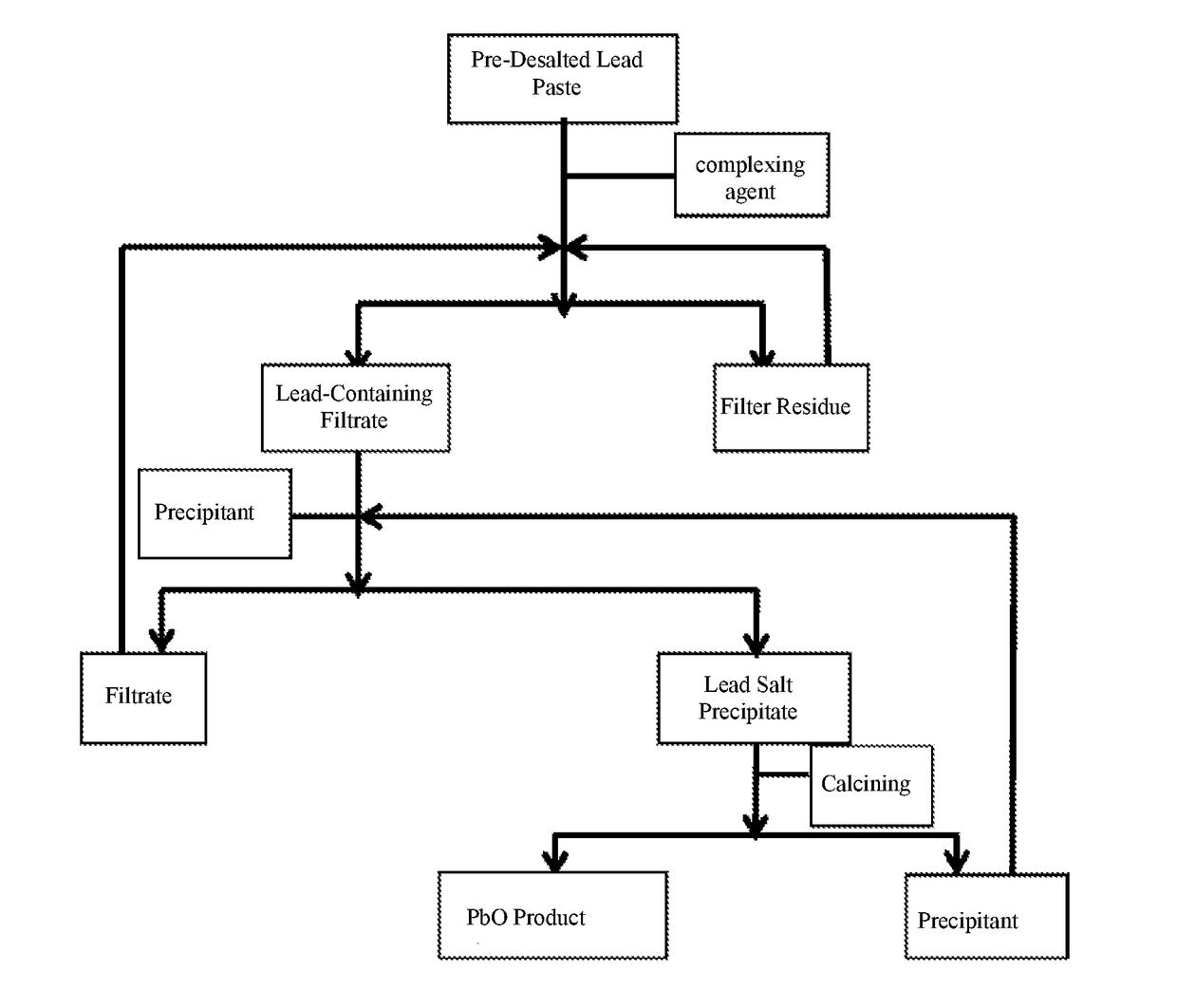

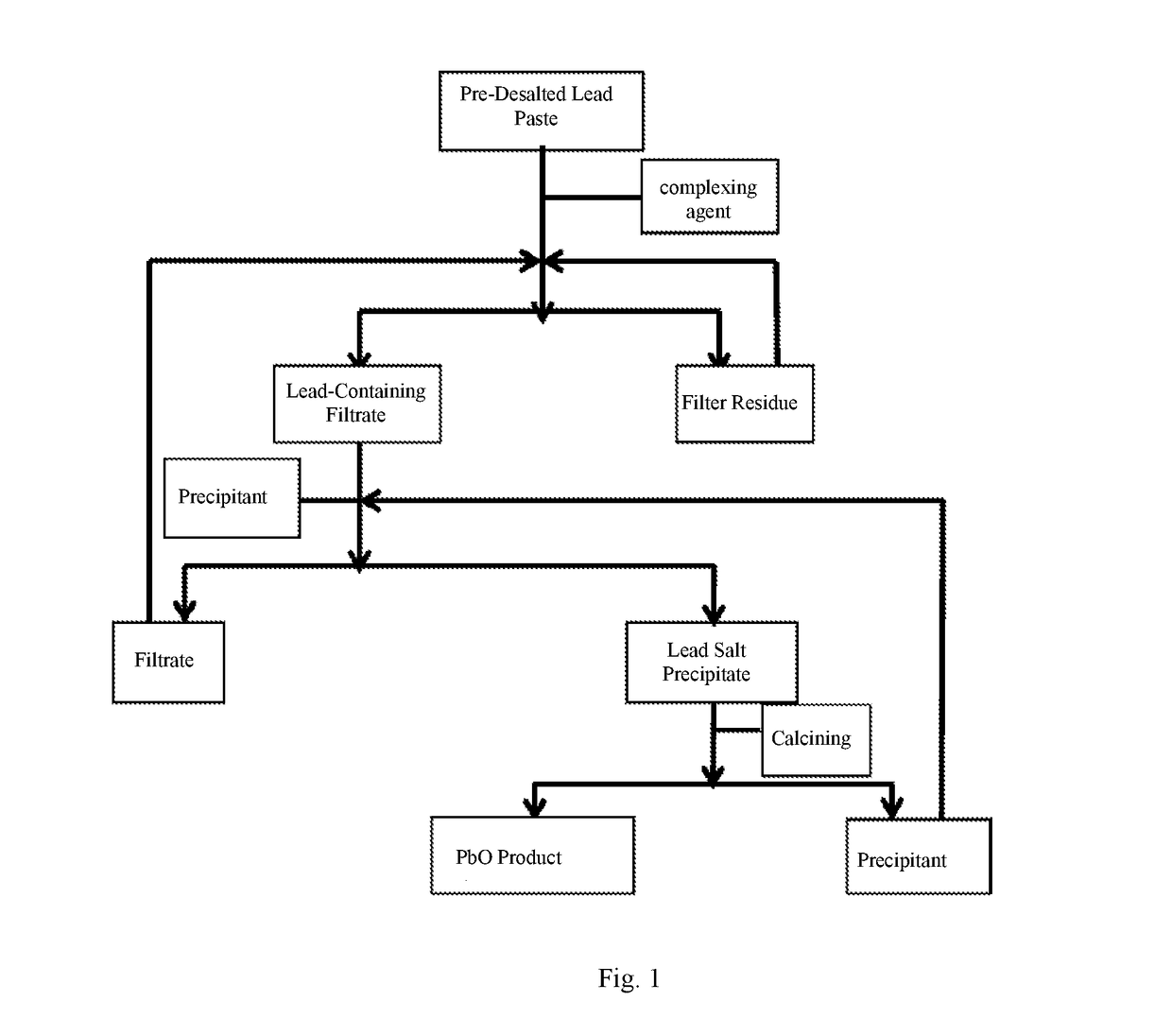

Method for recovering lead oxide from waste lead plaster

ActiveCN104141045AAtom economy is highIn line with the principles of atom economyLead-acid accumulatorsLead monoxideLead saltLead oxide

The invention provides a method for recovering lead oxide from waste lead plaster. The method comprises the following steps: a, dissolving pre-desalted lead plaster by using a complexing agent solution, and reacting all PbOs with a complexing agent to generate complexing ions so as to obtain a lead-containing solution and filter residues; b, adding a precipitating agent into the lead-containing solution, reacting the precipitating agent with the lead complexing ions to generate lead salt precipitation and the regenerated complexing agent; and c, roasting the lead salt precipitation to obtain lead oxide, and regenerating the precipitating agent. The method can be widely suitable for lead plaster formed by mixing various sources, the process conditions are relatively mild, a process is relatively environment-friendly, and the final recovery rate of lead oxide can reach more than 99%, so that the method has very high application values in the industry of recovery treatment of waste lead-acid batteries.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing superfine lead oxide by using electrode active materials of wasted lead acid batteries

ActiveCN102747227ALong-lasting useReduce the risk of contaminationLead monoxideWaste accumulators reclaimingEconomic benefitsLead oxide

The invention discloses a method for preparing superfine lead oxide by using electrode active materials of wasted lead acid batteries. According to the invention, the superfine powder disclosed herein can be directly used for producing new lead acid batteries by the prior art, lead acid batteries can be recycled, and the method is a production technology which accords with circular economy principles. The method can eliminate the pollution generated by the waste lead acid batteries at the source, has the characteristics of low production cost and high economic benefit, and is suitable for existing lead acid battery production enterprises to let practical and affordable lead acid batteries be used with persistence and reassurance.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV +1

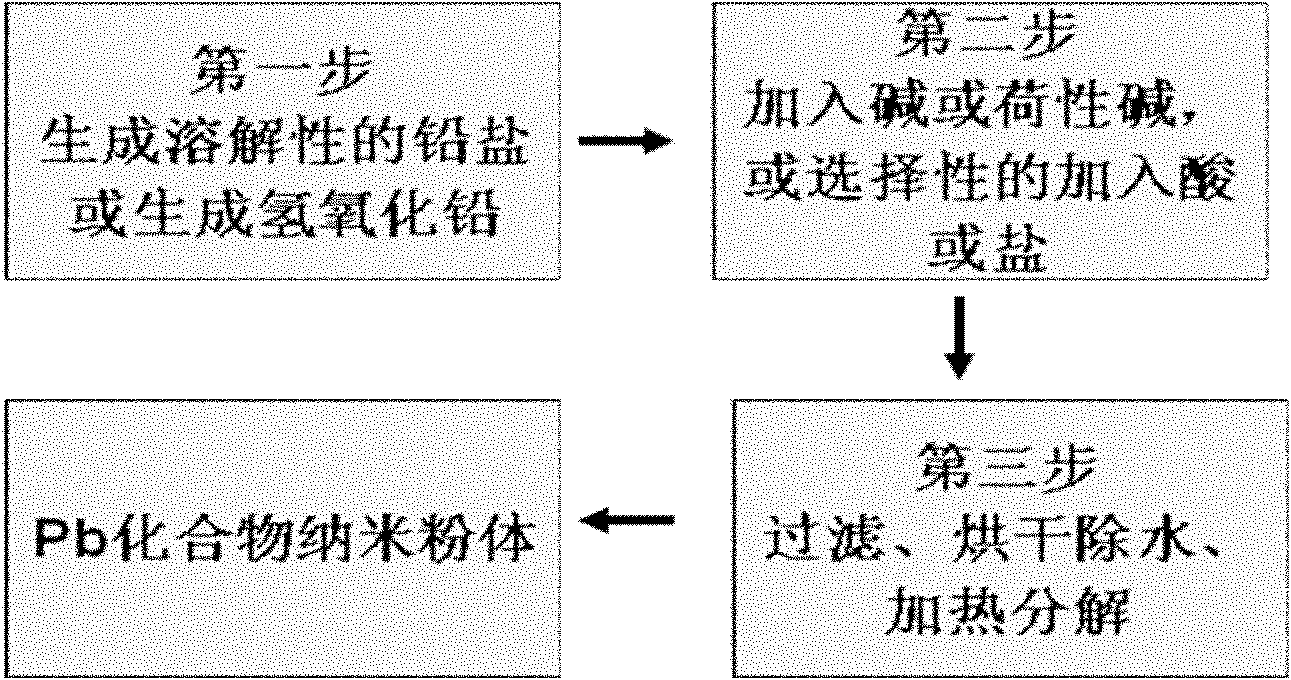

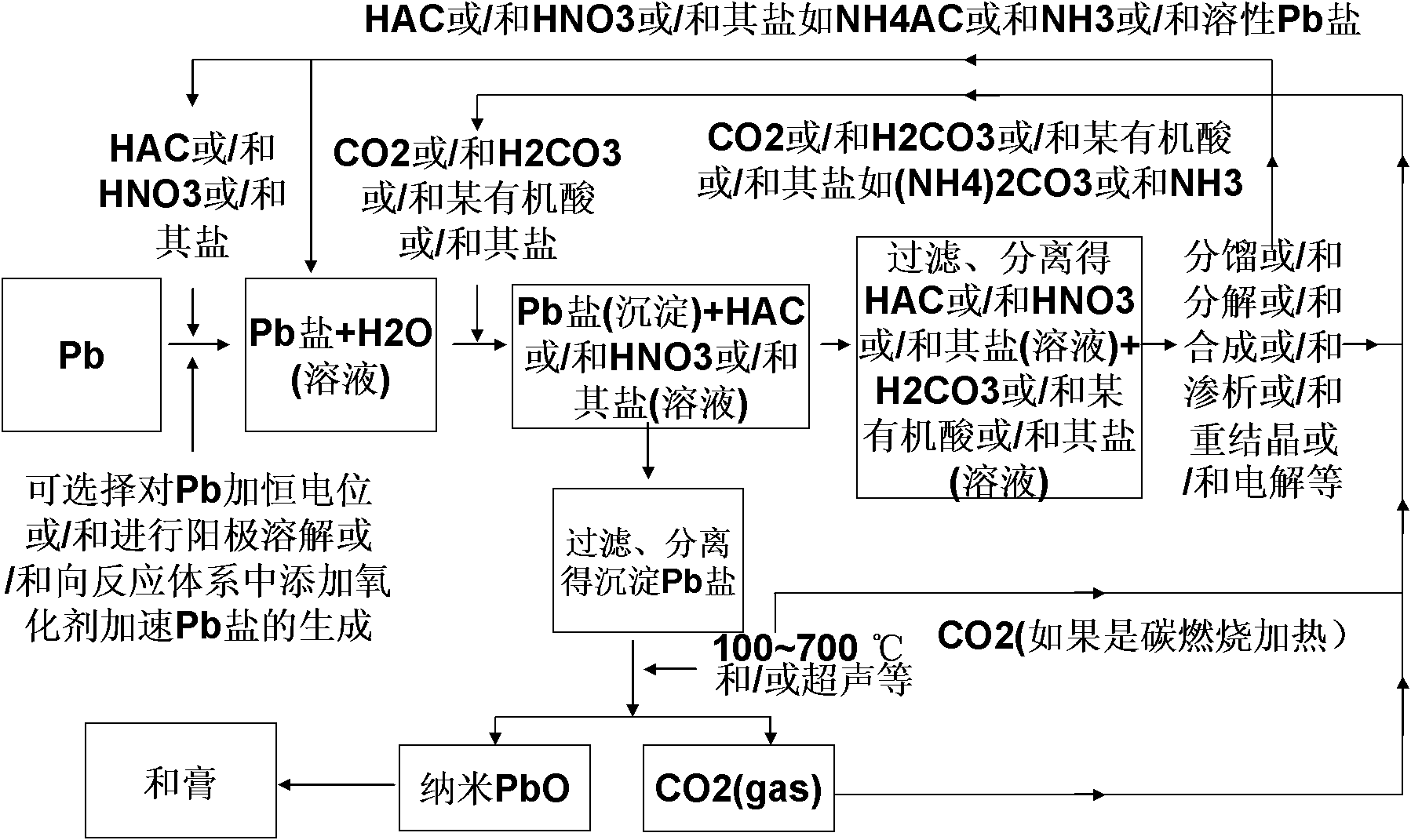

Lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery

ActiveCN102689922AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologySolubilityLead salt

The invention discloses a lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery. The lead compound nano-powder preparation method comprises the following steps that 1, lead, a lead salt or waste lead-acid battery lead paste reacts with one or more organic or inorganic compounds to produce a soluble lead salt solution or a lead hydroxide solution; 2, one or more alkalis or caustic alkalis are added into the soluble lead salt solution, or a part or excess amount of H2CO3 or CO2, sulfuric acid, one or more organic acids or their salts are added into the lead hydroxide solution, and 3, lead oxide or lead hydroxide precipitates obtained by the step 2 are filtered and are subjected to drying and pyrolysis to form the lead compound nano-powder. The lead compound nano-powder preparation method realizes environmentally friendly recovery and production, has low energy consumption, greatly reduces a production cost, and shortens a production period. The lead compound nano-powder obtained by the lead compound nano-powder preparation method is conducive to improvement of technical product performances.

Owner:杨春晓

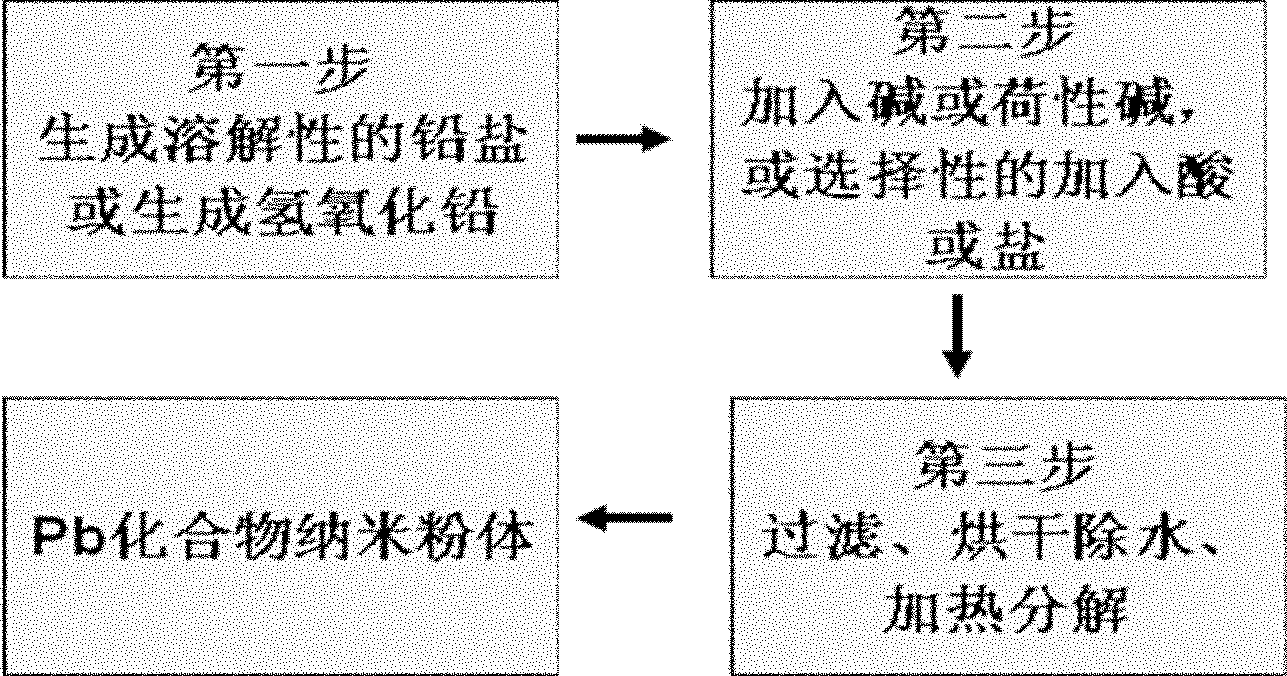

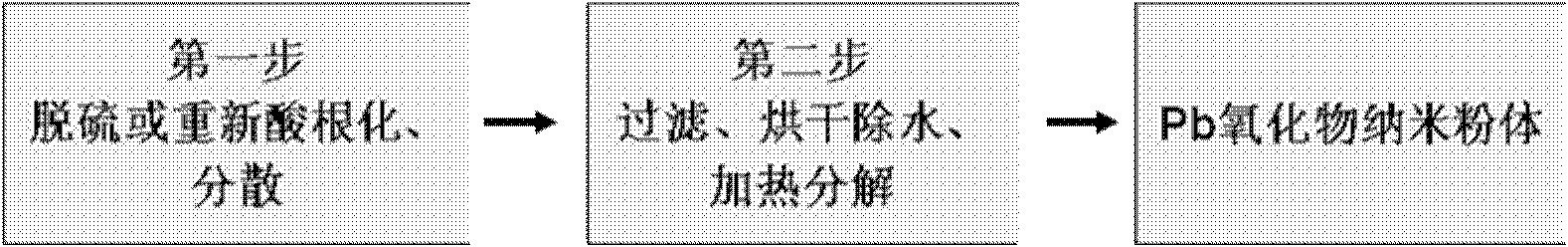

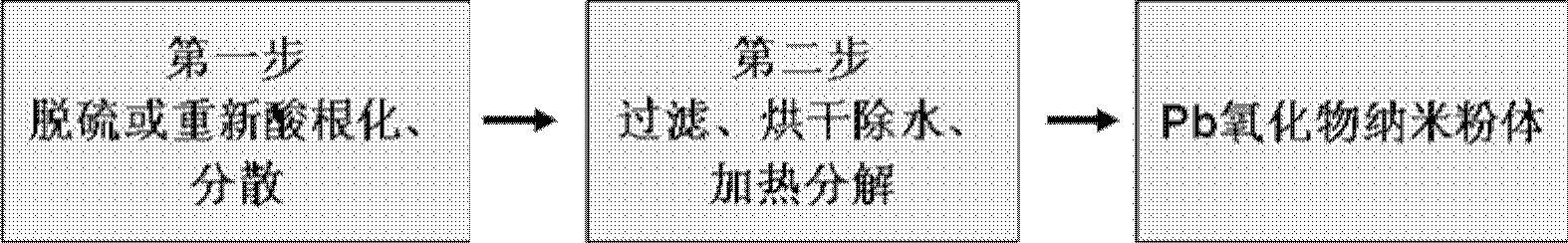

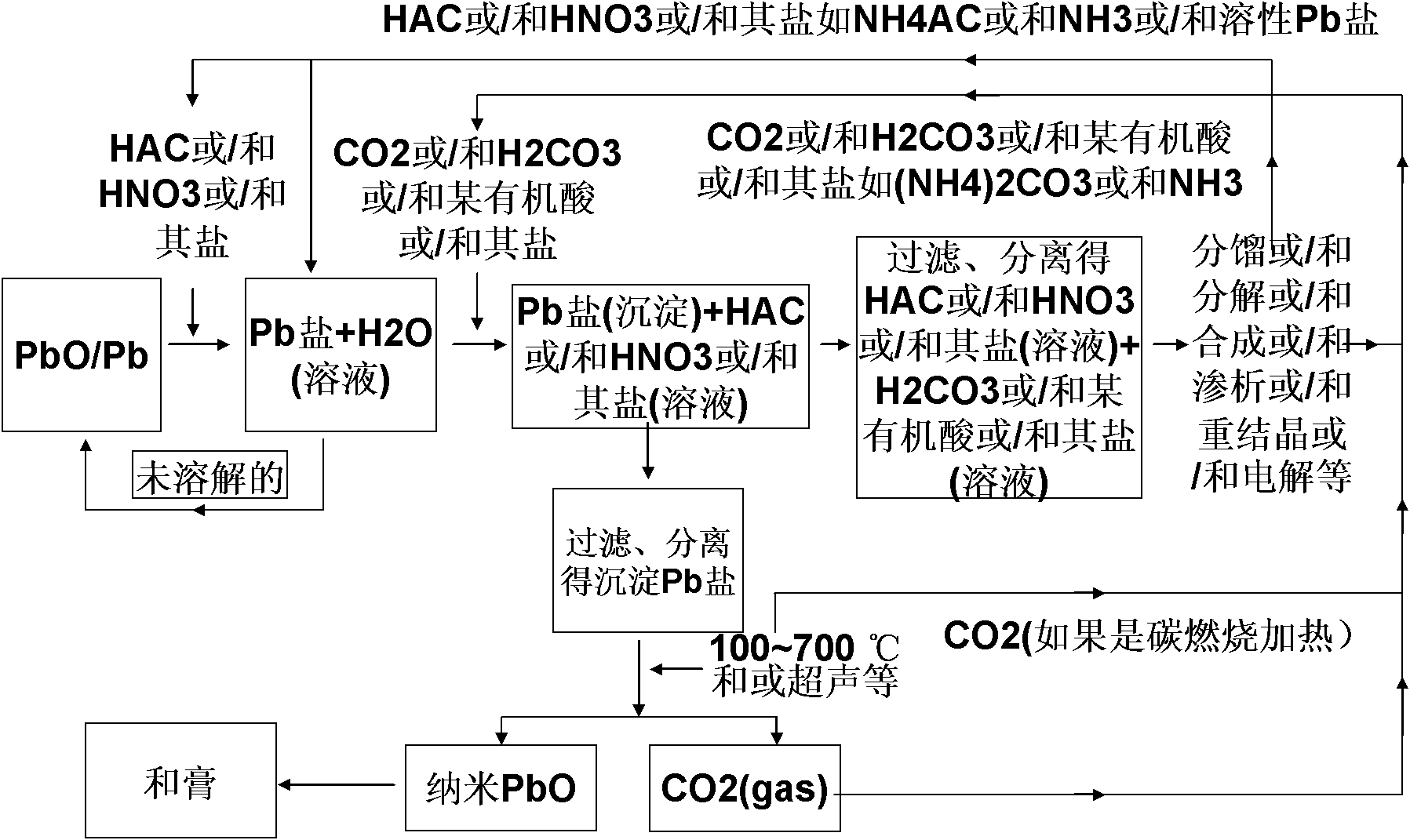

Preparation method of Pb oxide nano powder for recovery and manufacture of lead acid battery

ActiveCN102689921AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologyDecompositionLead salt

The invention discloses a preparation method of a Pb oxide nano powder for recovery and manufacture of a lead acid battery. The method comprises the steps of: (1) reacting lead salt or waste lead acid battery lead paste with an organic or inorganic compound capable of complexing with Pb atom / ion, so as to realize desulphurization or reloading of acid radical; and (2) carrying out treatment processes of filtering, drying for removing water and heating for decomposition, so as to obtain the Pb oxide nano powder. The method of the invention realizes an environment-friendly and energy-efficient recovery and production process with substantially reduced production cost; meanwhile, the prepared Pb oxide powder is beneficial for enhancement of product performance.

Owner:杨春晓

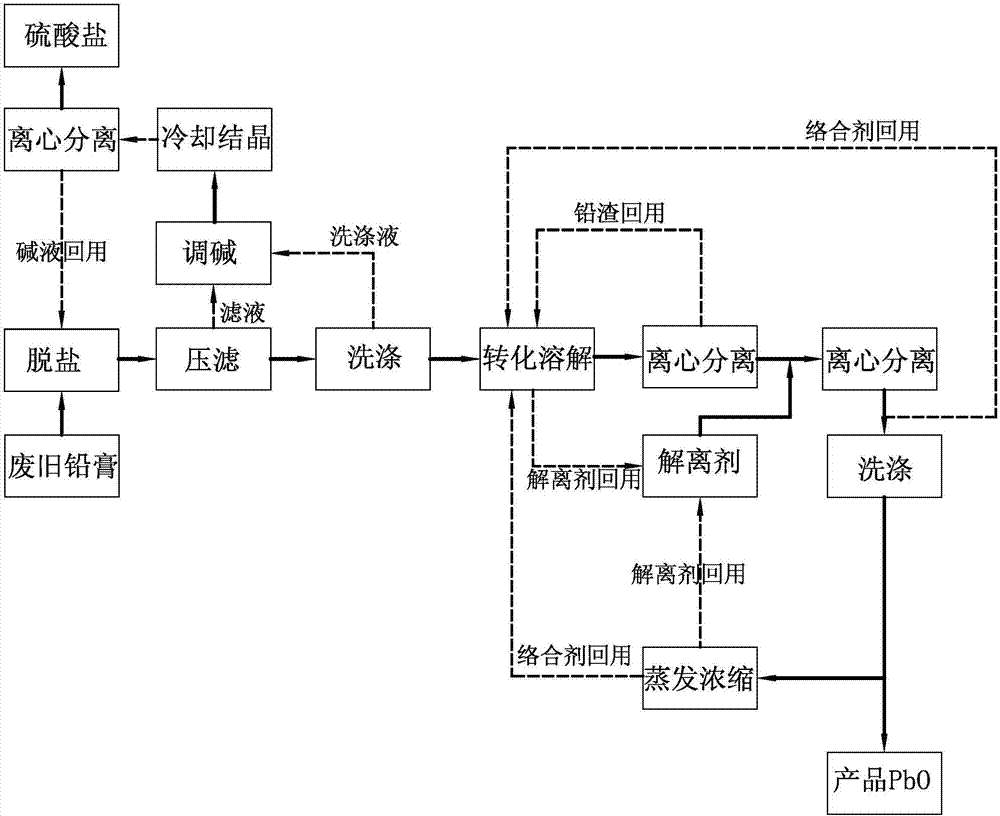

Method for recycling lead oxide from lead plaster of waste lead-acid storage battery

ActiveCN107460339AImprove economyAchieve a reversible cycleLead monoxideWaste accumulators reclaimingEnvironmental resistanceLead dioxide

The invention relates to the technical field of clean recycling of waste batteries and discloses a method for recycling lead oxide from lead plaster of a waste lead-acid storage battery. The method comprises the following steps that (1) pre-desalination is conducted, specifically, the lead plaster of the waste lead-acid storage battery is added with alkali liquor to be subjected to pre-desalination, so that lead acid, lead acetate, lead nitrate, lead perchlorate or lead carbonate in the lead plaster is removed; (2) dissolution is conducted, specifically, a complexing agent solution is added into the lead plaster subjected to pre-desalination, all PbO in the lead plaster reacts with a complexing agent to generate lead complex ions, and a lead-bearing solution and filter residues are obtained; (3) dissociation is conducted, specifically, the pH value of the lead-bearing solution is adjusted by adding a dissociation agent solution, so that the lead complex ions are dissociated, and the PbO and a mixed solution containing the complexing agent and a dissociation agent are obtained; and (4) separating is conducted, specifically, a lead oxide product is obtained after solid-liquid separation and washing. According to the method, the technological condition is mild, the technological process is environmentally friendly, the technological procedure is simple, energy consumption is small, the cost is low, the lead oxide recycling rate is high, the purity is high, and the method has very high industrial application value.

Owner:CHAOWEI POWER CO LTD

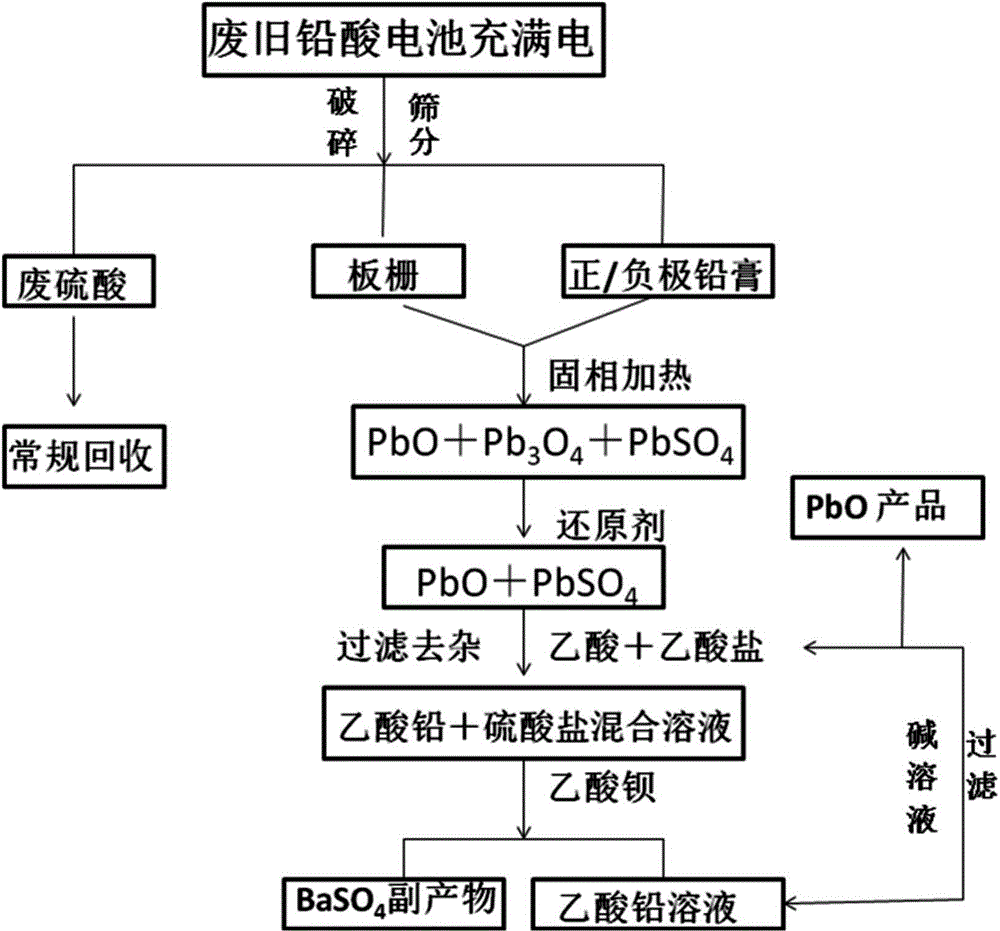

Method for preparing PbO from waste lead-acid battery by using direct wet method

ActiveCN104393364AGuaranteed purityOvercome the problem that desulfurization is not easy to controlLead monoxideWaste accumulators reclaimingAcetic acidLead oxide

The invention provides a method for recovering waste lead-acid batteries to directly produce high-purity lead oxide, wherein the utilized chemical raw materials can be recycled. The preparation method of a high-purity PbO powder comprises the steps of fully charging a waste battery, performing solid-phase mixing on positive / negative lead plaster and waste grid lead powder, and completely converting lead in the lead plaster to lead raw materials consisting of lead oxide PbO and PbSO4 by heating and reduction reaction; leaching by using a mixed liquid of acetic acid and acetate, desulfuring by using byproduct barium sulfate of barium acetate, depositing lead in an alkali liquid to directly obtain the high-purity PbO products, wherein the acetate mother liquid can be used for the next circulation; therefore, the defects that steps of the current lead oxide synthesis process are complex, the purity is low, and a large amount of chemical raw materials is consumed are overcome; the cost is reduced; the technical value-added is high; the energy conservation and environment friendliness are provided; and the method is suitable for large-scale industrial production.

Owner:中国人民解放军军事科学院防化研究院

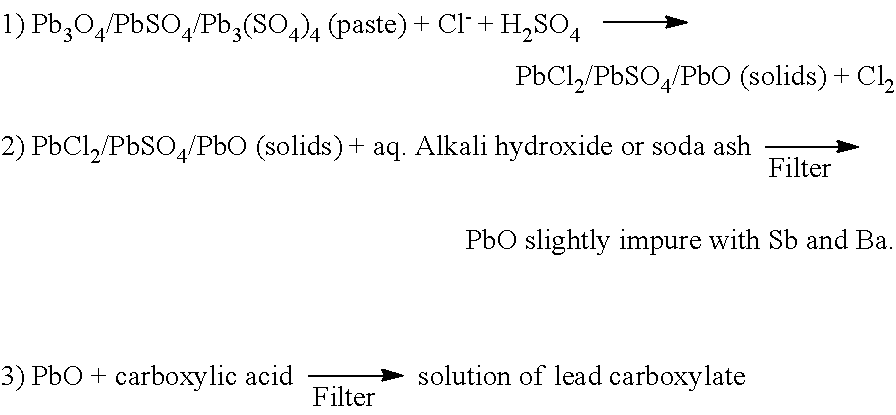

Recovery of high purity PbO

ActiveUS7785561B1High purityTin compoundsPrimary cell maintainance/servicingLead oxideMetal particle

A process for producing high purity lead oxide from impure lead compounds particularly from waste lead battery paste which includes an oxidation-reduction step. The process results in a reduction of impure lead compounds to the +2 valence state and metal particle contaminants are oxidized to the +2 state.

Owner:RETRIEV TECH +1

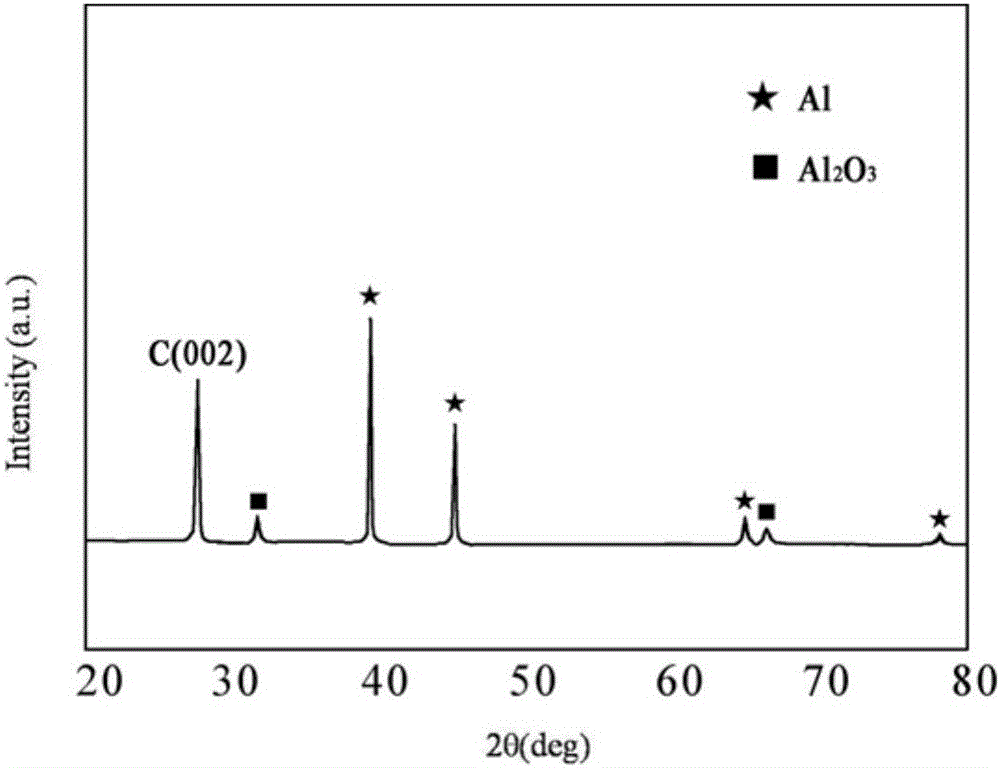

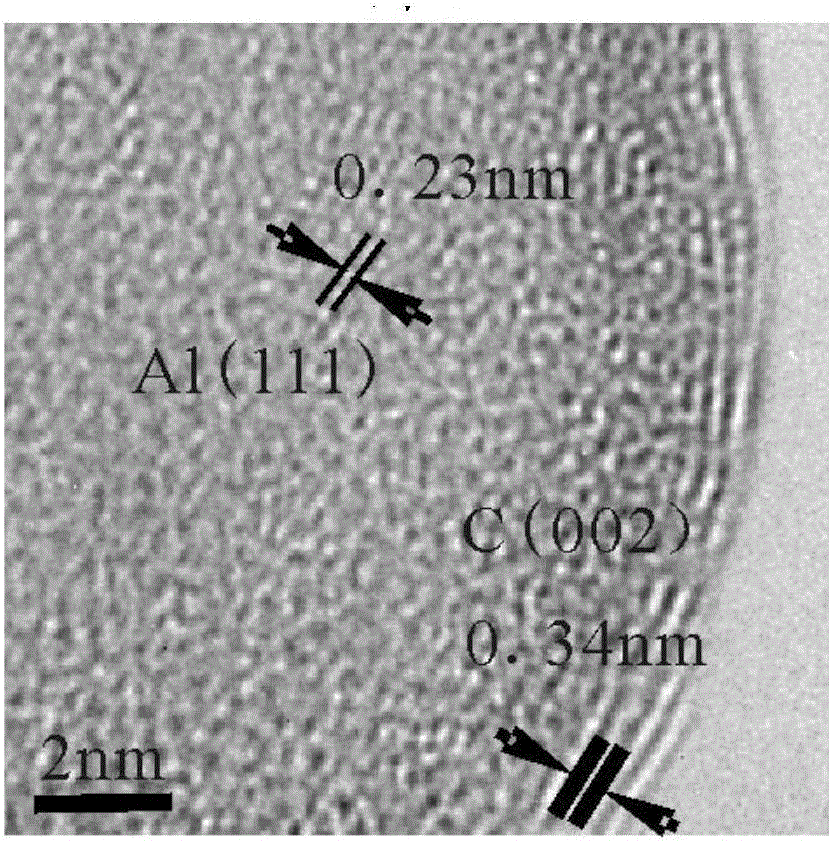

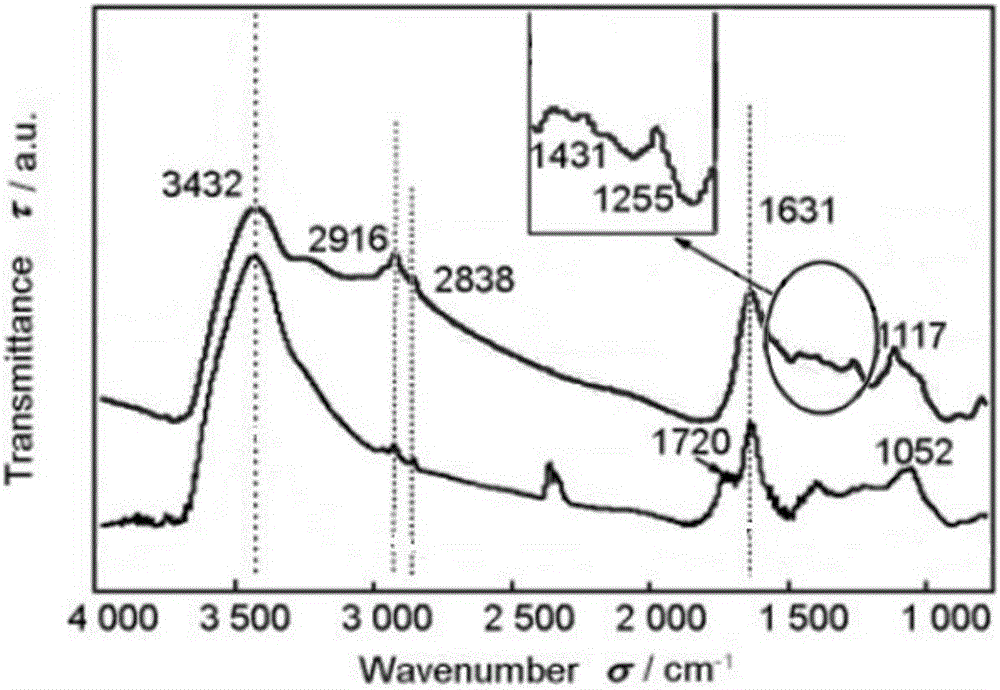

Graphene-metal or semimetal shell-core structure composite material and preparation method thereof

ActiveCN106045794AImprove performanceSolve application barriersAlkali/alkaline-earth/beryllium/magnesium hydridesCarbon compoundsSemimetalOrganic solvent

The invention relates to a graphene-metal or semimetal shell-core structure composite material and a preparation method thereof. The method comprises the steps that obtained modified graphene oxide is taken as a base to be concentrated and dried by evaporation, and then organic solvent displacement is conducted to obtain an organic solution of the modified graphene oxide; the surface of metal or semimetal is coated with the modified graphene oxide through a liquid-phase self-assembly method to form a graphene-metal or semimetal coating solution; after filtering and drying are conducted, the graphene-metal or semimetal shell-core composite material is obtained. According to the method, a conventional organic matter and inorganic matter coating process is improved, the influences of the water solvent and high temperature on the activity of some metals and semimetals with the high reaction activity are reduced, process realization of a coating method is expanded, and application barriers of the graphene and the active metal or semimetal in an energy-containing material are solved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

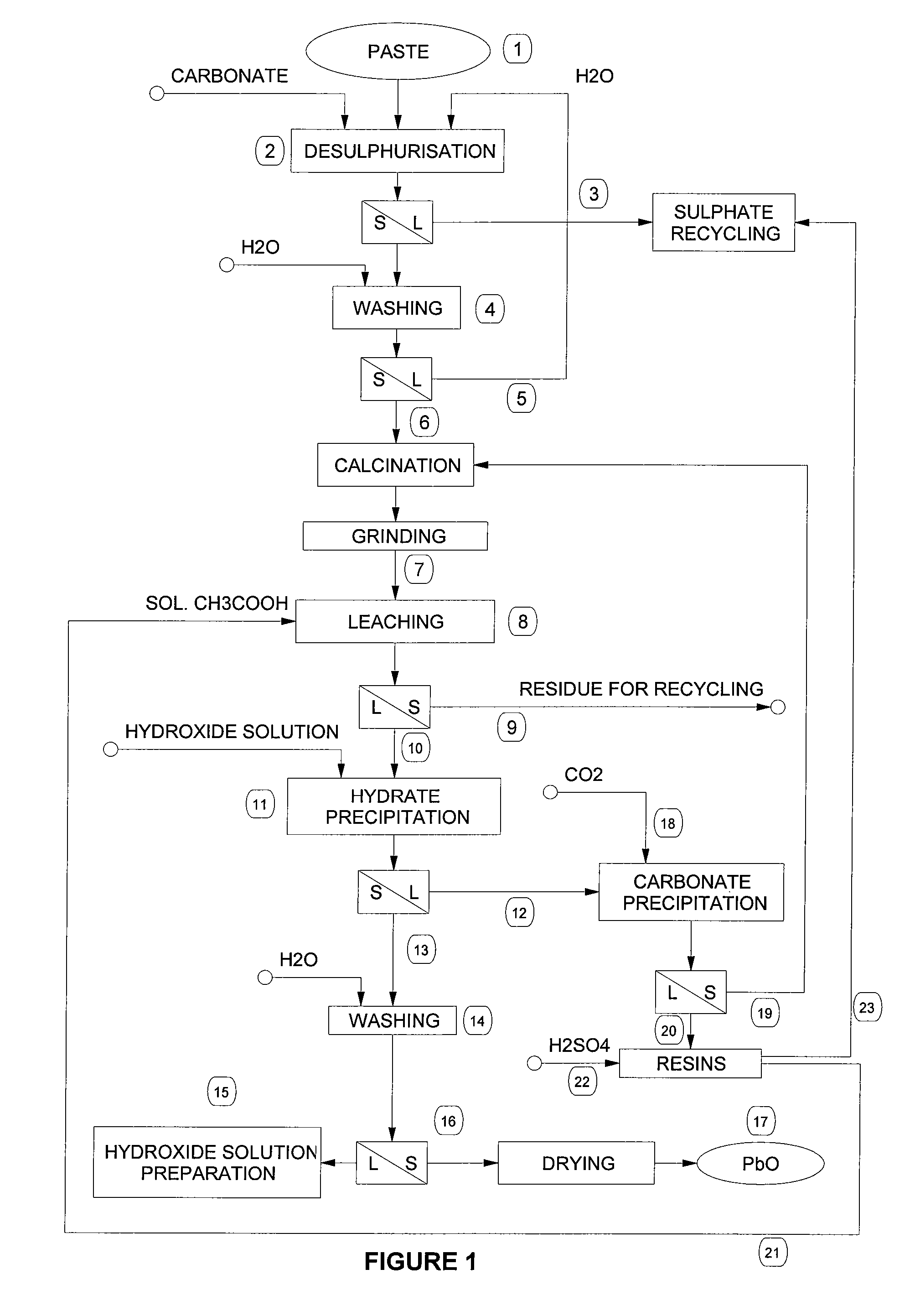

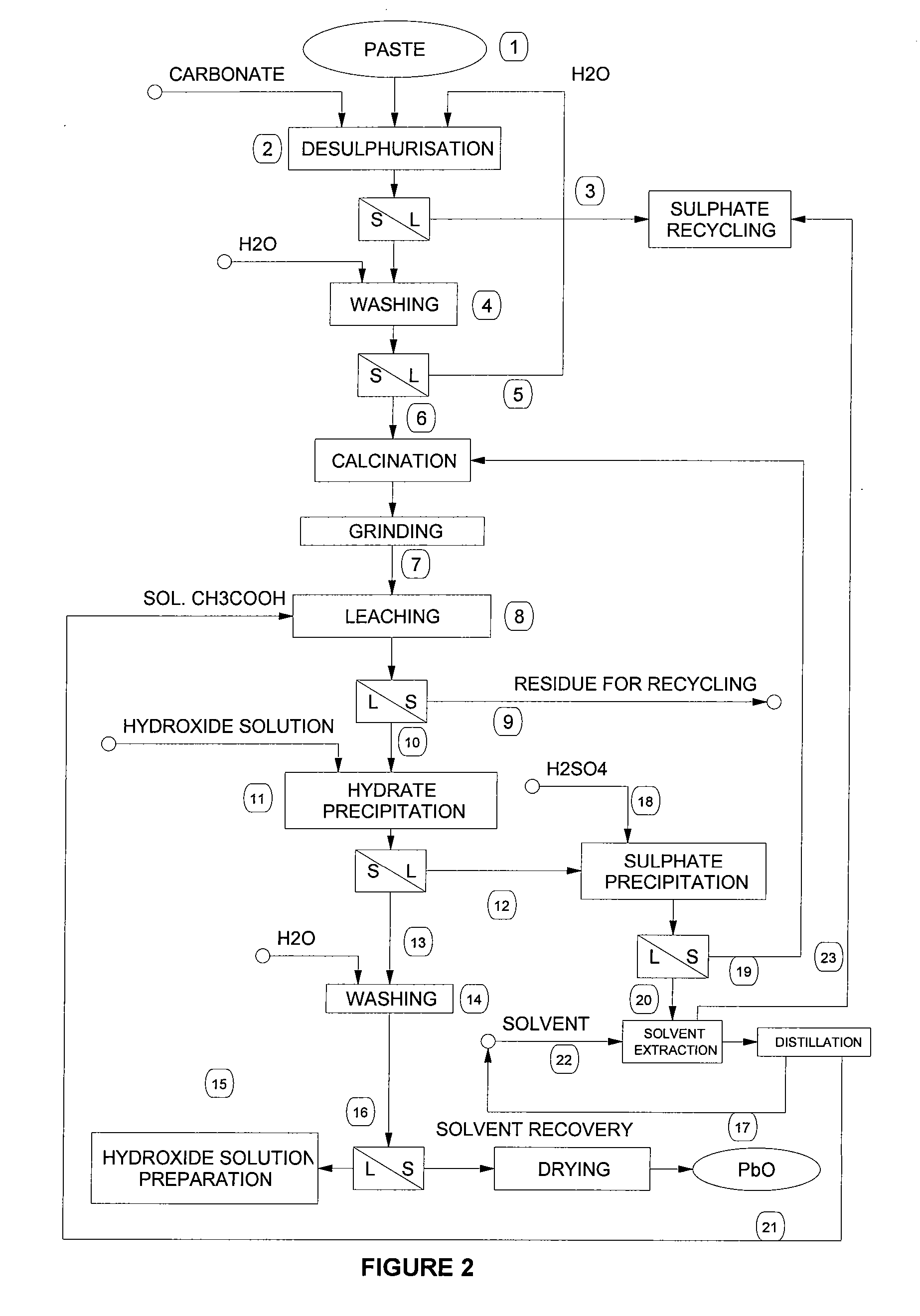

Process for the production of lead hydrate or monoxide of high purity, from materials and/or residues containing lead in the form of sulphates, monoxides and/or other compounds

InactiveUS20060239903A1High purityLead-acid accumulatorsLead monoxideAlkaline earth metalLead(II) acetate

Process for the production of lead hydrate or monoxide of high purity, from materials and / or residues containing lead in the form of sulphates, monoxides and / or other compounds, such as the paste coming from exhaust acid batteries, comprising the following steps of desulphurisation of the material and / or residue containing lead sulphate in an aqueous suspension with a suitable carbonate or hydrate in order to get conversion of the lead sulphate into a carbonate or hydrate, calcination of this desulphurised material and / or residue in order to get impure lead monoxide, followed by cooling and grinding, leaching of the impure lead monoxide by an aqueous solution of acetic acid followed by filtering to separate a solid residue, consisting mainly of non converted lead sulphate, from a lead acetate solution, precipitation of the lead acetate in solution by means of an alkaline hydroxide or alkaline-earth hydroxide, able to obtain soluble acetates, in order to get a precipitate, depending on the precipitation temperature, in the form of either lead hydrate or lead monoxide, followed by filtering of the obtained precipitate, separating a solution, at least one washing cycle and subsequent separation of the washing liquid, drying and optional calcination of the filtered and washed precipitate to get high purity lead hydrate or monoxide depending on the drying temperature.

Owner:STC SRL

Preparation method of lead-acid battery PbO nano-powder

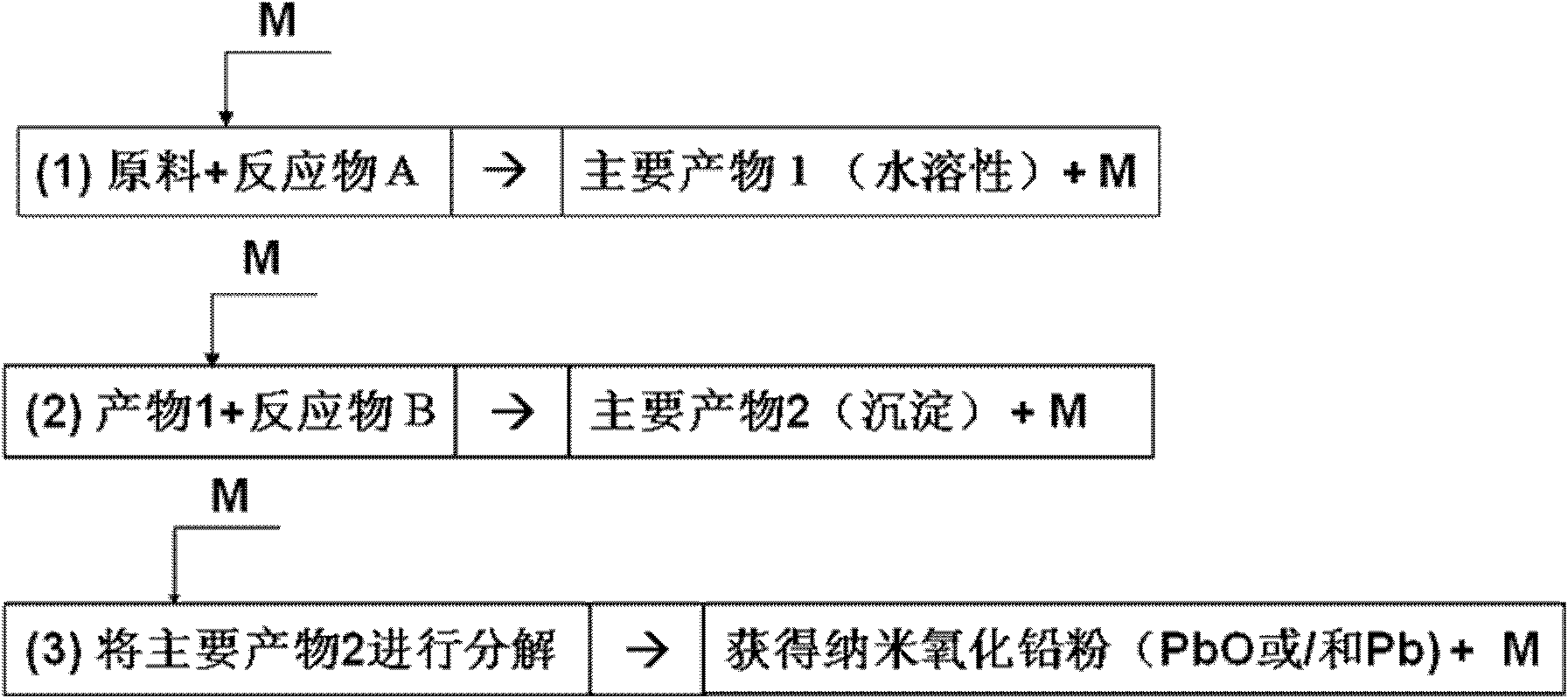

ActiveCN102689923AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologyWater solubleReagent

The invention discloses a preparation method of lead-acid battery PbO nano-powder. The preparation method comprises the following steps that 1), lead-containing raw materials and one or more reactants A undergo a reaction to produce a water-soluble main product 1; 2), the water-soluble main product 1 and reactants B undergo a reaction to produce main product precipitates 2; and 3) the main product precipitates 2 are decomposed so that the lead-acid battery PbO nano-powder is obtained. The preparation method has the advantages that recovery and production processes are environmentally friendly and consume less energy; a production period is shortened; the lead-acid battery PbO nano-powder obtained by the preparation method is conducive to improvement of technical product performances; and the one or more reactants A or / and the reactants B can be recycled fully or partly so that a production cost is greatly reduced.

Owner:杨春晓

Process for obtaining pure litharge from lead acid battery paste

The present invention relates to the recovery of high purity litharge from spent lead acid battery paste at a low temperature which does not produce sulfur dioxide. In the process lead acetate is produced which is converted to pure litharge.

Owner:RETRIEV TECH

Lead recycling

ActiveUS8323376B2Simple methodOrganic chemistryPrimary cell maintainance/servicingLead oxideAqueous solution

The present invention describes a method of recycling lead from lead containing waste, the method comprising the steps of mixing the battery paste with aqueous citric acid solution so as to generate lead citrate; isolating lead citrate from the aqueous solution; and converting the lead citrate to lead and / or lead oxide.

Owner:CAMBRIDGE ENTERPRISE LTD

Method for recycling lead oxide used for cathode of lead-acid cell directly from waste lead plaster

ActiveCN104520240AAvoid consumptionReach the effect of recyclingLead monoxideWaste accumulators reclaimingLead oxideEngineering

The present invention relates to a method for recycling lead oxide used for a cathode of a lead-acid cell directly from waste lead plaster. The method comprises the steps that in presence of desulfurization conditions, the waste lead plaster contact with a baric desulfurizing agent and solid-liquid separation is preformed on the mixture after the contact, so as to obtain a filtered liquid and filtered residue; and conversion reaction is performed on the filtered residue under the temperature of 350-750 DEG C, enabling lead-containing ingredients of the filtered residue to be converted to lead oxide. According to the method, a barium sulfate additive can be supplemented in a quantitative manner in a desulfurizing process, thereby realizing recycling a lead oxide raw material applicable to the cathode of the lead-acid cell directly from the waste lead plaster, greatly reducing recycling cost and energy consumption, and raising the rate of multipurpose utilization of the waste lead plaster.

Owner:CHAOWEI POWER CO LTD +1

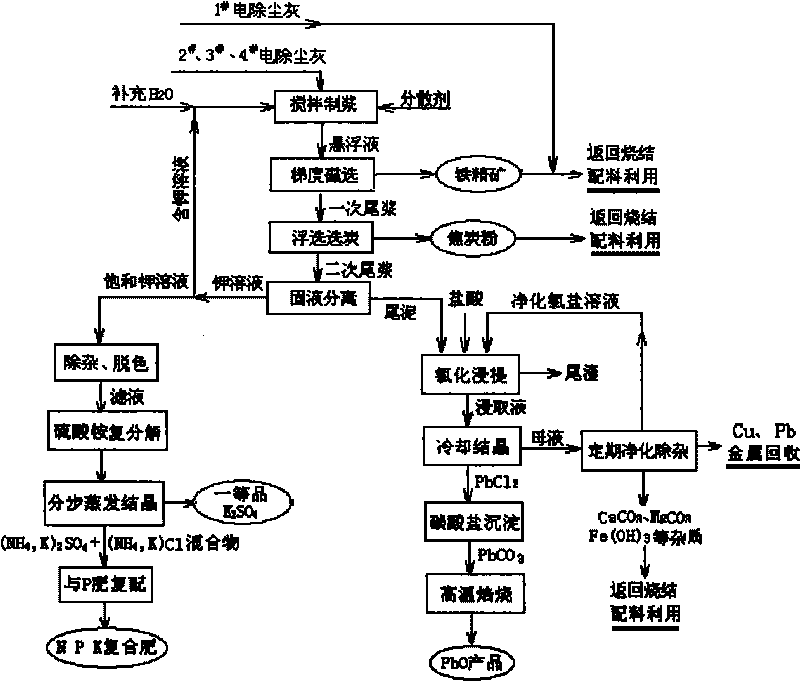

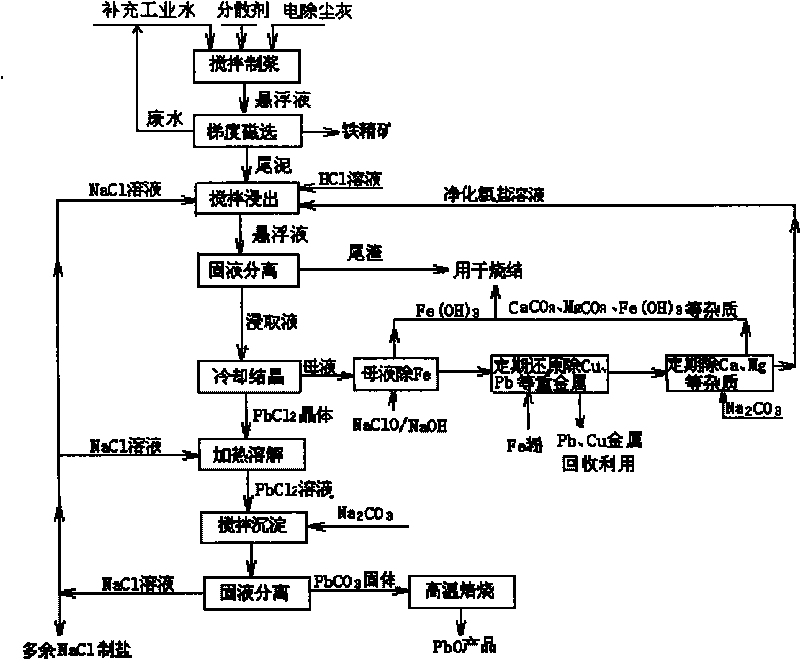

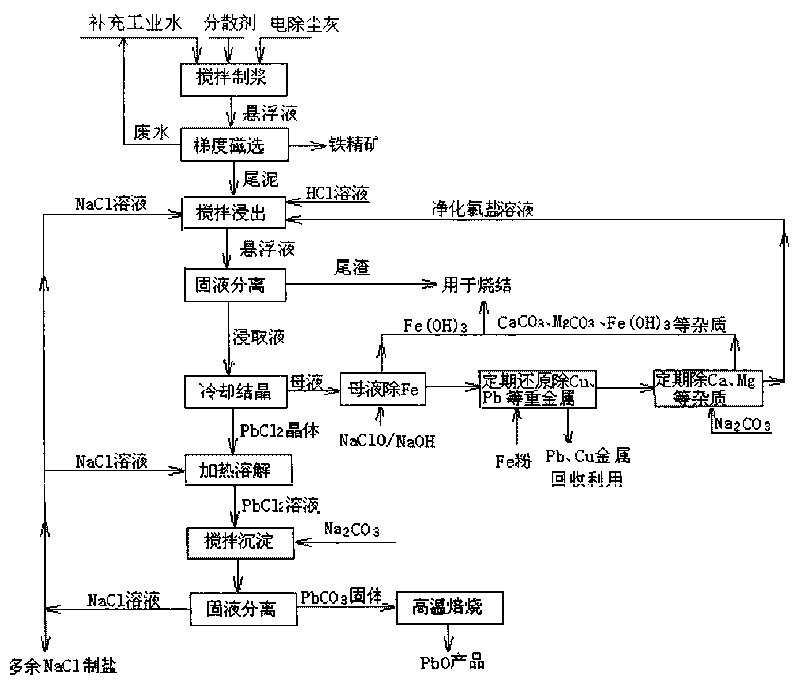

Method for recovering lead chloride from sintered ashes and preparing lead monoxide

ActiveCN101723439AExtended service lifeReduce the shutdown rateLead monoxideLead halidesLead chlorideSlurry

The invention discloses a method for recovering lead chloride from sintered ashes and preparing lead monoxide, which mainly comprises the following steps of: (A) adding the sintered ashes into industrial water while stirring to prepare into suspension slurry, and carrying out two-stage gradient magnetic concentration consisting of a weak magnetic concentration and strong magnetic concentration on the suspension slurry of the sintered ashes; (B) adding tail mud obtained from the magnetic concentration in to a NaCl solution, and recovering lead in the tail mud by adopting a chlorination extraction mode of hydrochloric acid and NaCl; and (C) dissolving PbCl2 crystal in a NaCl water solution, adding Na2CO3 into the solution for complete precipitation reaction, centrifugally filtering and washing the suspension solution, and drying and roasting the obtained solid to obtain a lead monoxide produce. The invention can not only completely remove corrosion and damages of elements of lead, copper and the like on a blast furnace when the sintered ashes are directly recycled during iron and steel melting, but also recover and comprehensively utilize the valuable elements.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD +1

Method for recovering lead oxide from waste lead paste

ActiveUS20170271725A1Reduce decreaseReduction procedureLead-acid accumulatorsLead monoxideLead oxideLead salt

A method for recovering lead oxide from a pre-desalted lead paste, comprising the following steps: a. dissolving the pre-desalted lead plaster by using a complexing agent solution, and making all of PbO therein react with the complexing agent to generate lead complexing ions, obtaining a lead-containing solution and a filter residue; b. adding a precipitant to the lead-containing solution, and then the precipitant reacting with the lead complexing ions to generate a lead salt precipitate and the regenerated complexing agent; c. calcining the lead salt precipitate to obtain lead oxide and regenerate the precipitant. The final recovery rate of lead oxide of the method can reach 99% or more.

Owner:BEIJING UNIV OF CHEM TECH

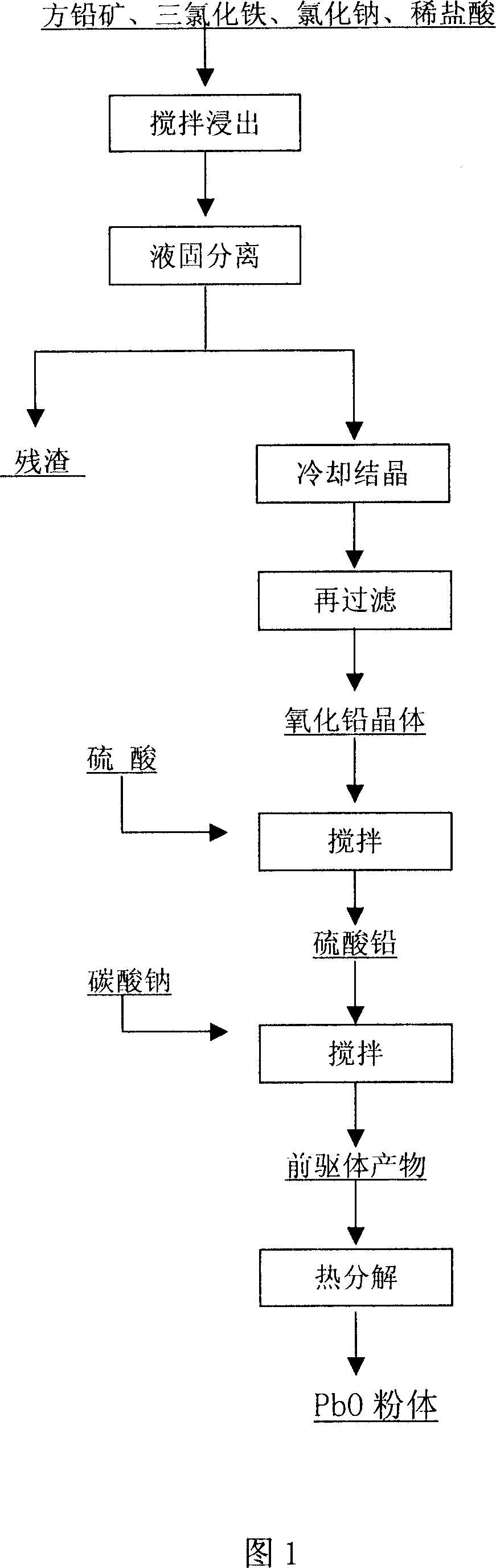

Method of directly producing ultra-fine lead oxide powder from galena concentrate

InactiveCN1920065AExpand sourceReduce contentLead monoxideProcess efficiency improvementLead carbonateLead oxide

The invention relates the method for producing super fine lead oxide powder from blue lead finished ore. The method comprises the following steps: using blue lead finished ore as raw material, leaching, crystallizing, getting PbCl2 crystal, adding sulfuric acid into PbCl2 crystal to get PbSO4 powder, carrying out chemical precipitation method for PbSO4 powder, getting the mixture of PbCO3 and 2PbCO3.Pb(OH)2, carrying out thermal decomposition, and getting the ultra-fine and high-purity beta-PbO. The method has the advantages of reducing the cost, extending the origin of raw materials, and reducing the impurity. The product has high activity, and the particle mean size of the products is 4.0-5.0 mum.

Owner:CENT SOUTH UNIV

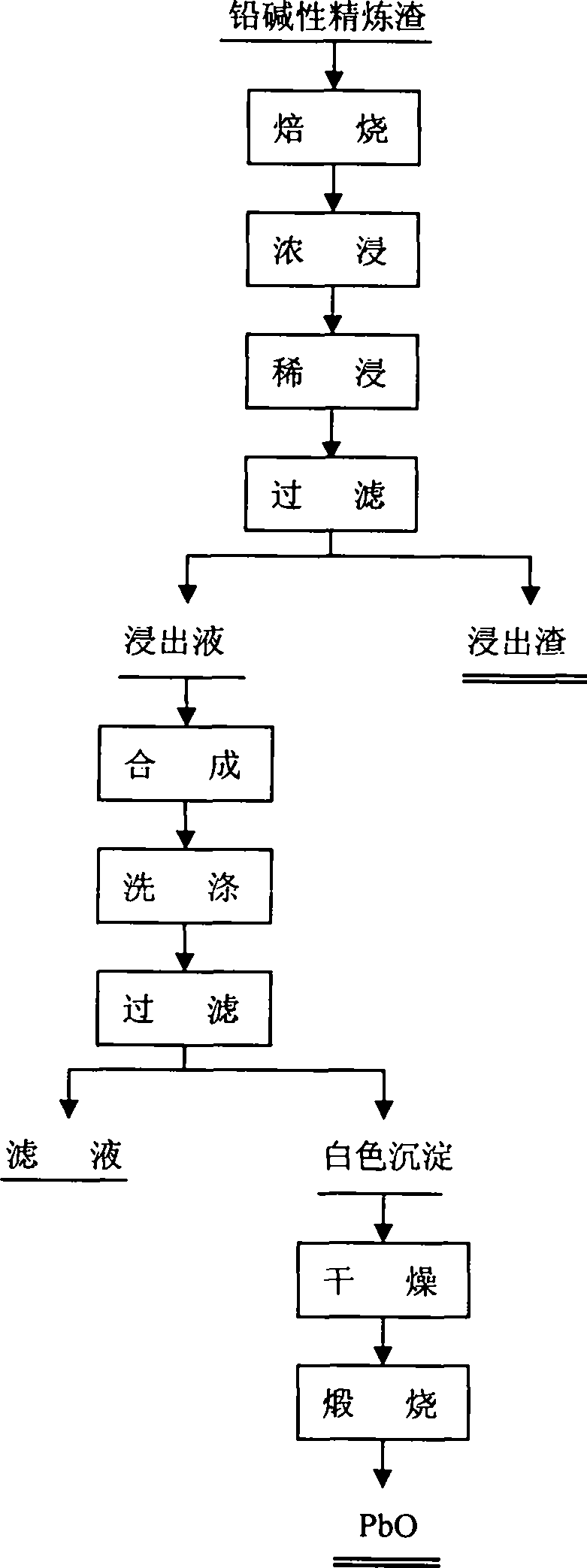

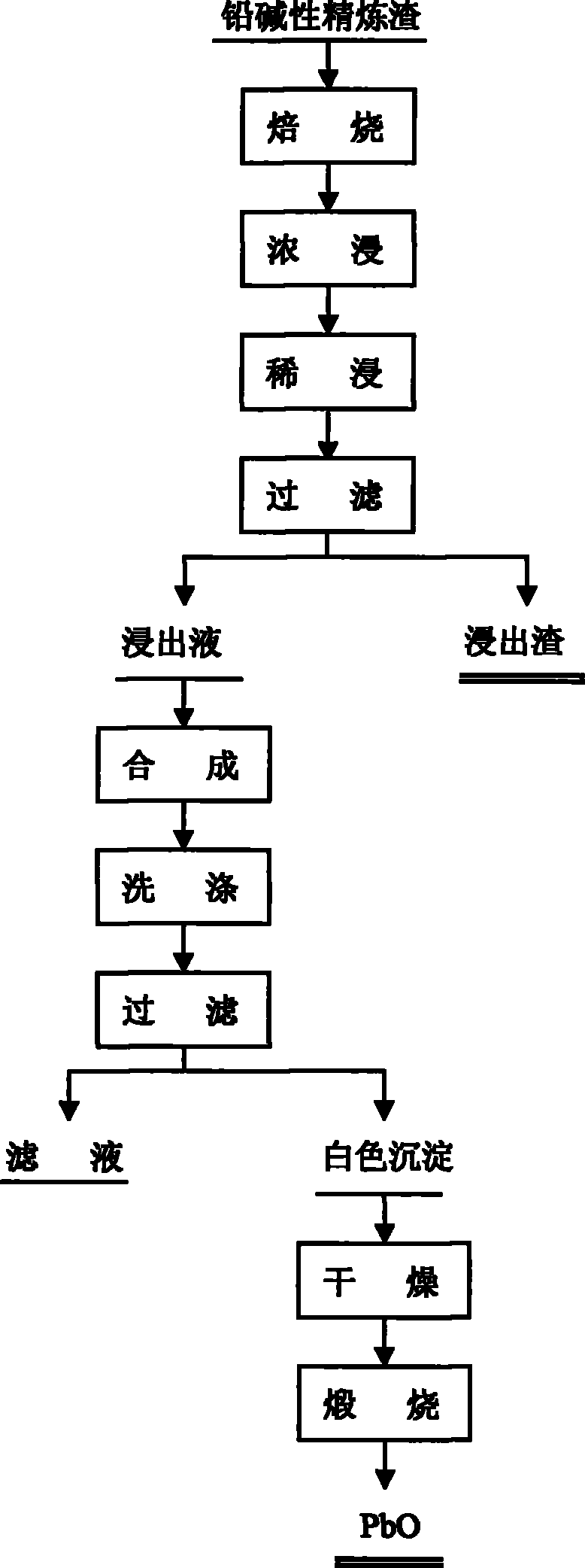

Method for comprehensive recovery of lead and tin from alkaline refining slag of lead

ActiveCN101768668AReduce the difficulty of refining tin removalAchieve separationLead monoxideProcess efficiency improvementLead nitrateSlag

The invention relates to a method for comprehensive recovery of lead and tin from alkaline refining slag of lead, comprising the following steps: 1. oxidizing roasting: oxidizing roasting is carried out on the alkaline refining slag of lead for 2-6h at 300-500 DEG C;2. leaching: nitric acid leaching is carried out on roasted slag, the roasted slag is filtered and separated to obtain lead nitrate solution and zinc slag;3. synthesis: lead nitrate solution is precipitated by sodium hydroxide solution, pH value is controlled while the solution is continuously stirred, thus generating white lead hydroxide sediment which is filtered, washed and dried to obtain white lead hydroxide powder;4. calcination: the white lead hydroxide powder is calcinated to obtain yellow powder yellow lead, namely PbO powder. With the method, lead and tin in the alkaline refining slag of lead are effectively recovered and tin can be ploughed in the lead system; in addition, the method has the advantages of reliable technology and high comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

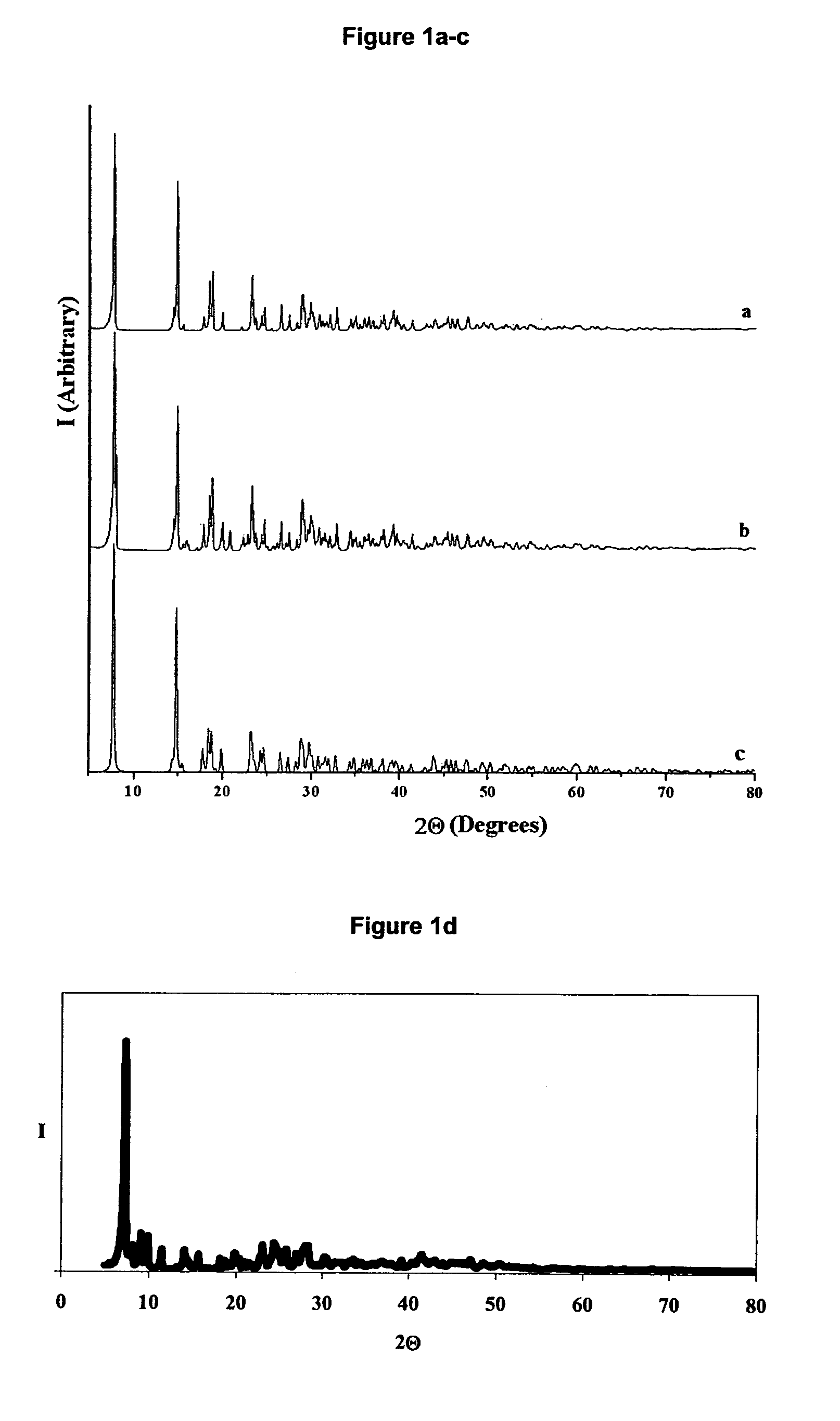

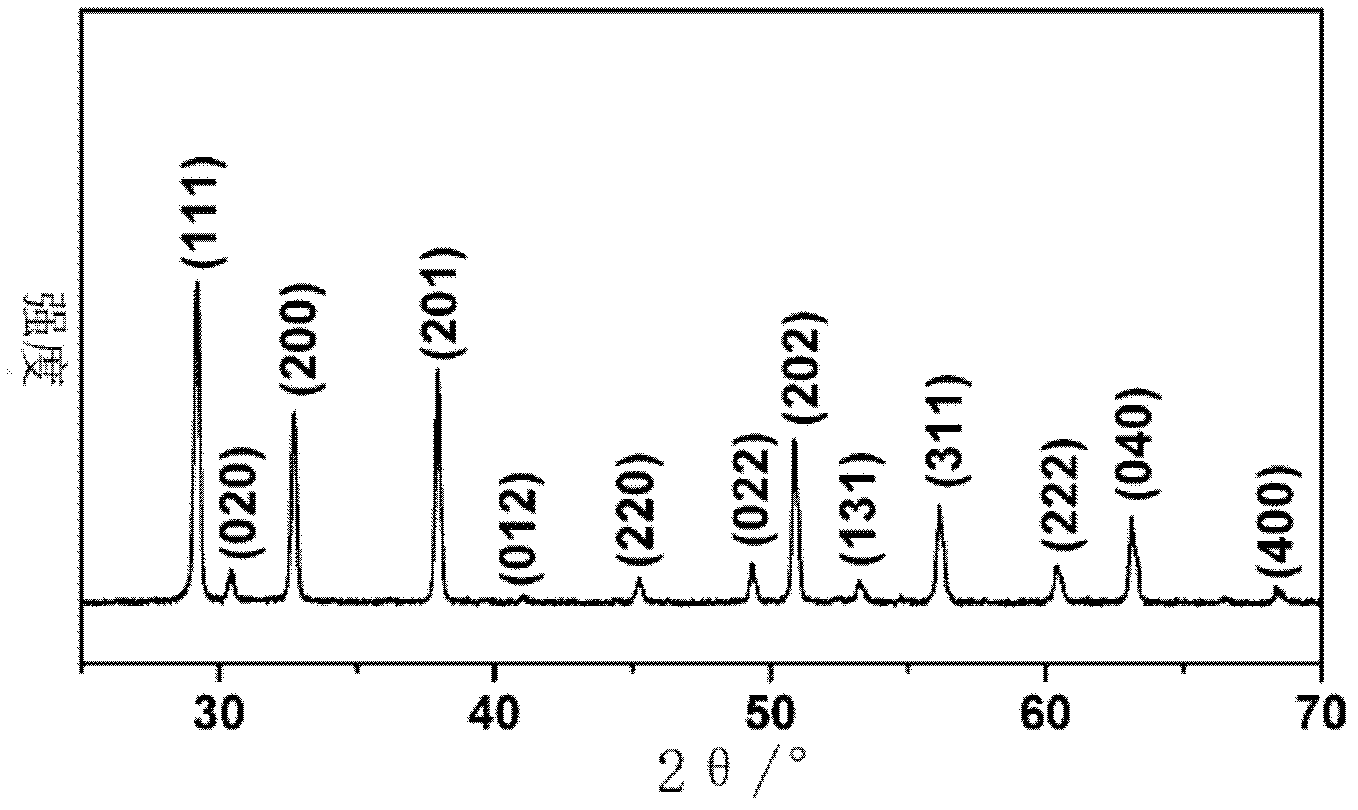

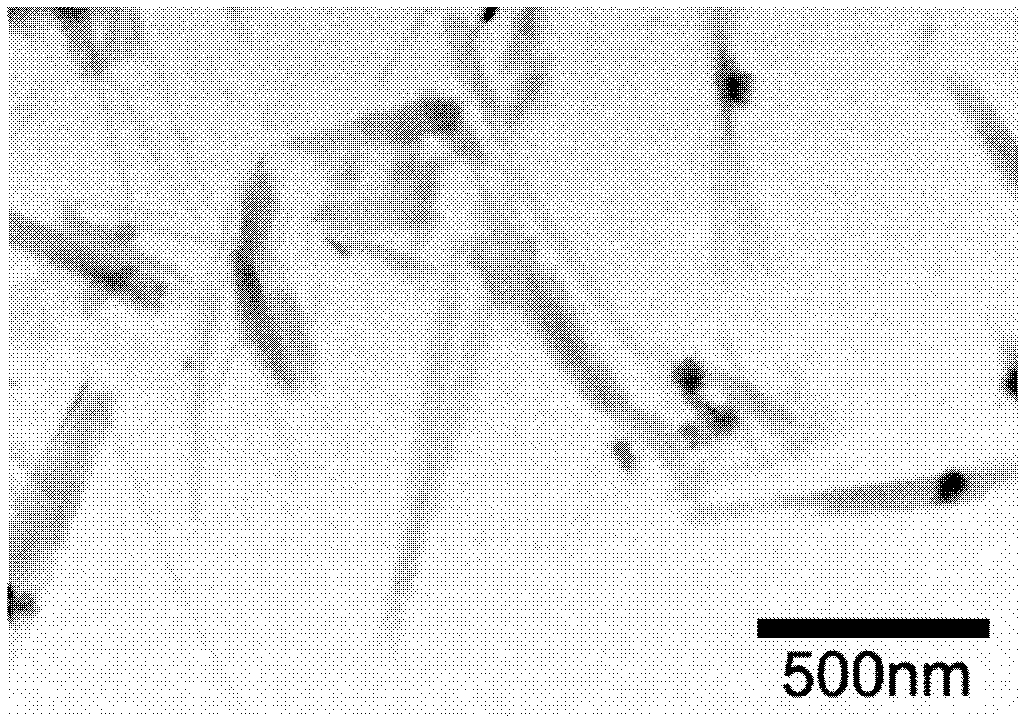

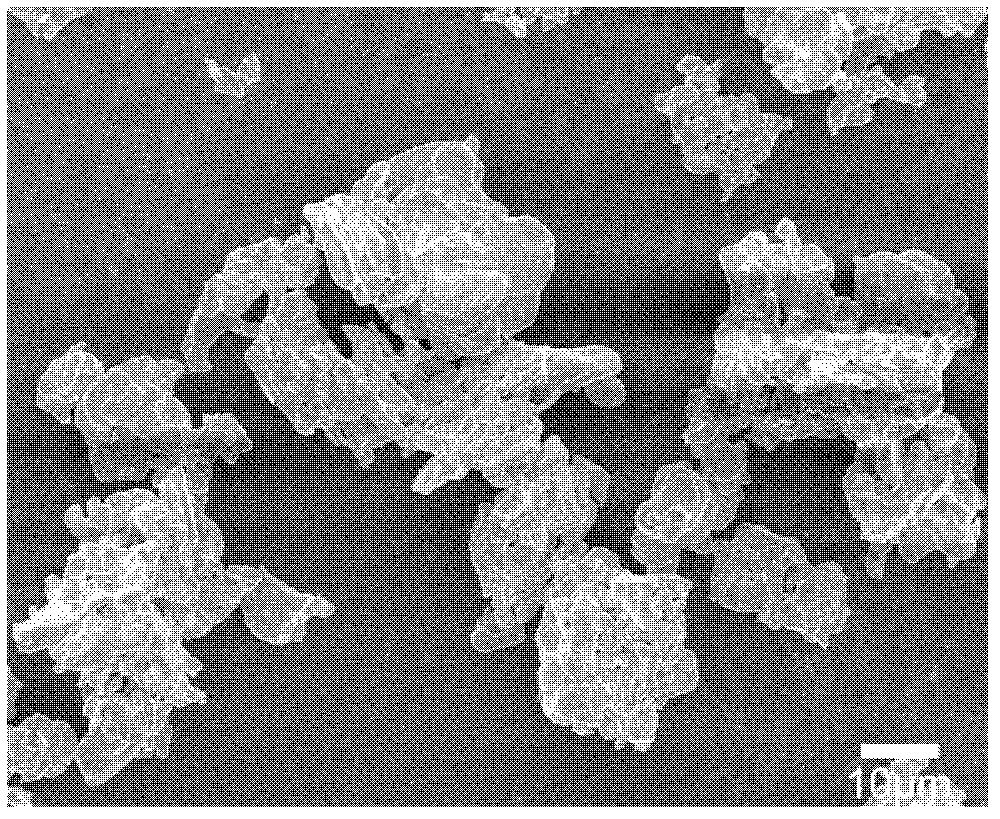

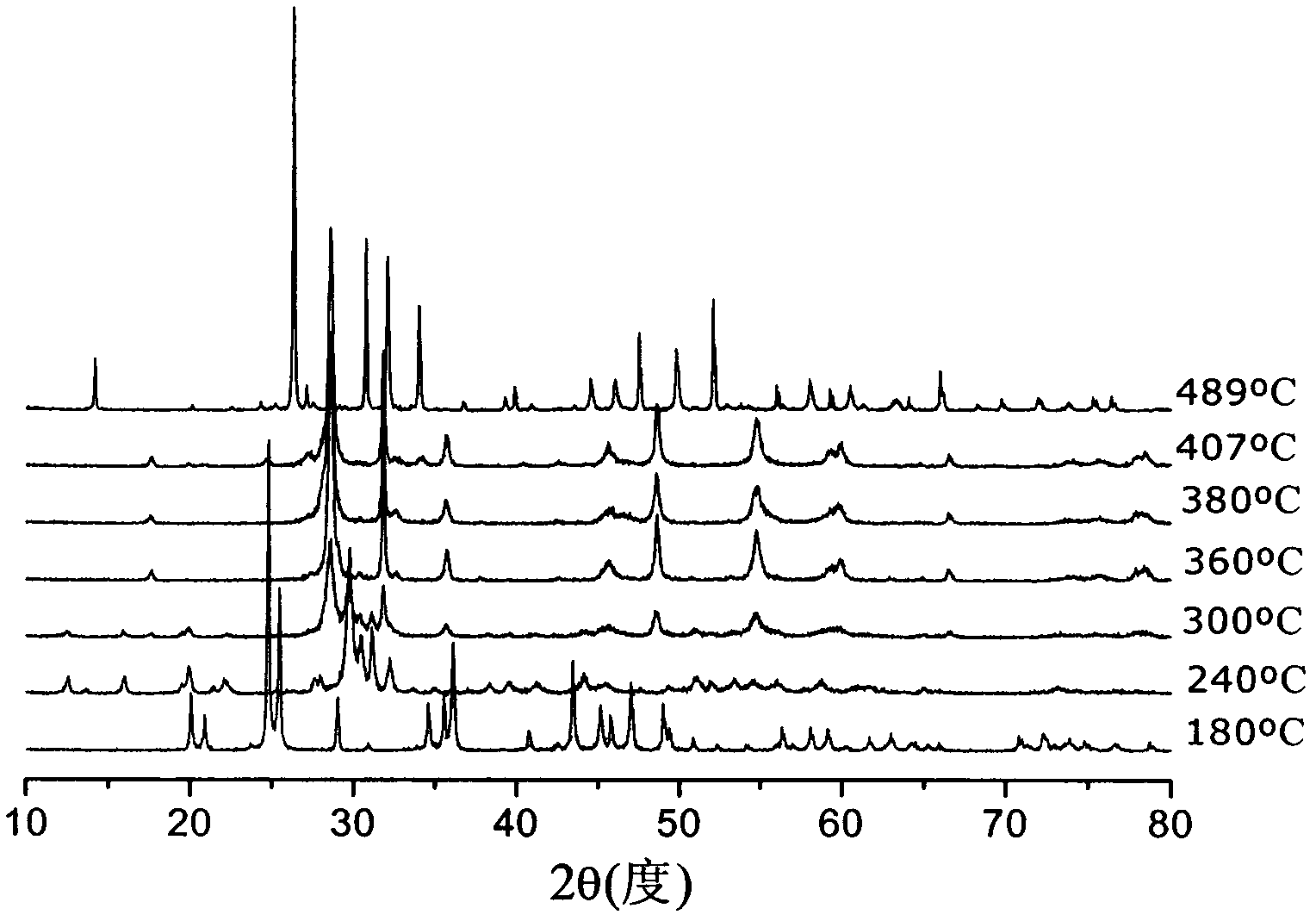

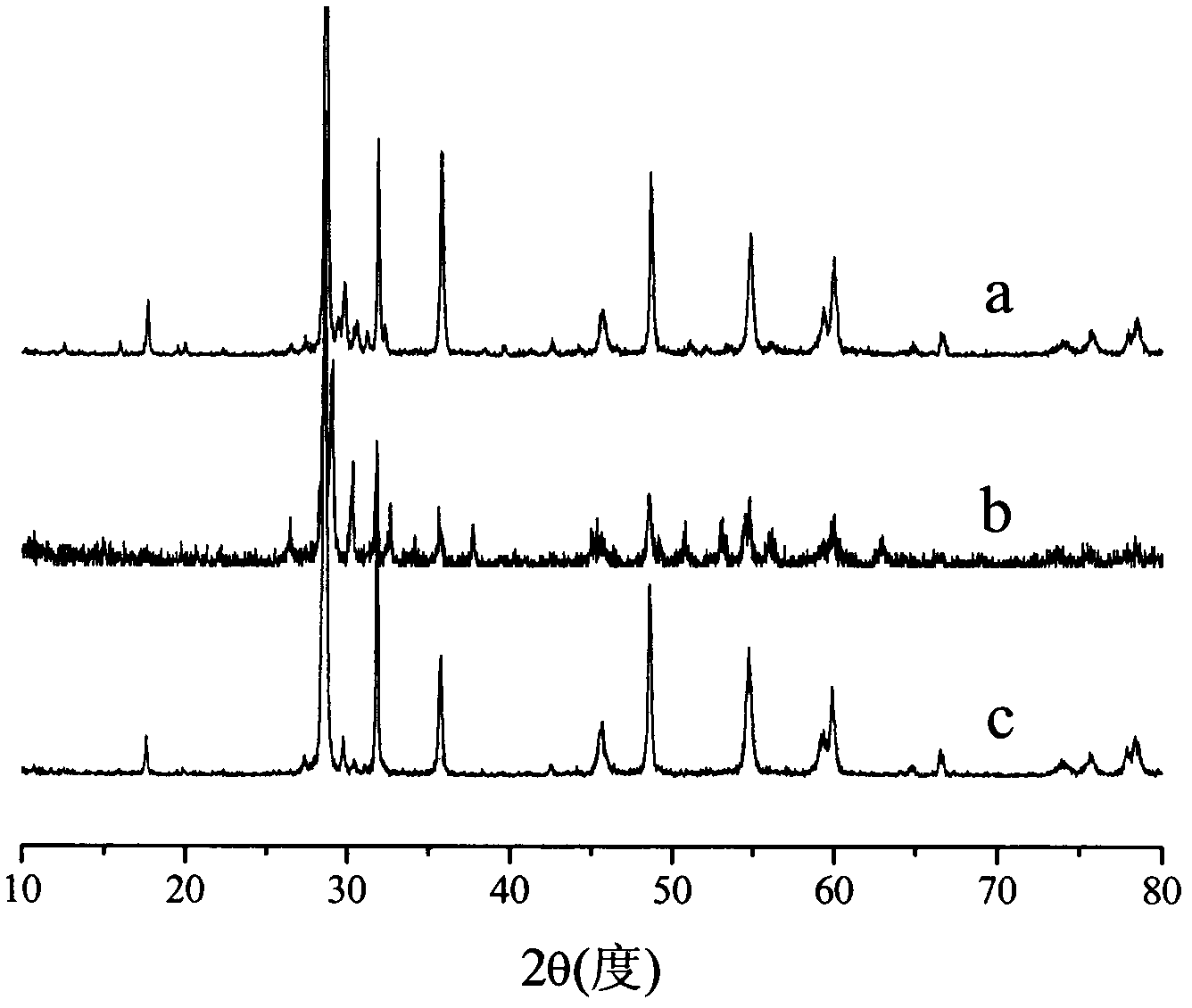

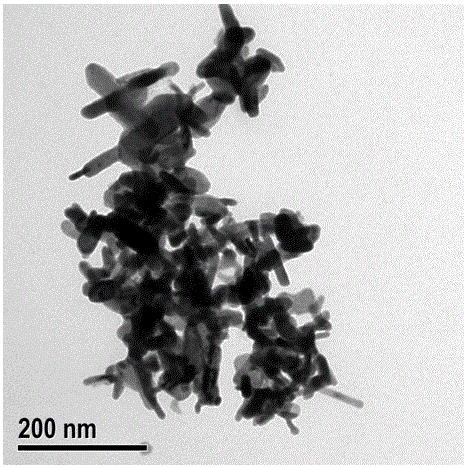

Preparation method for orthorhombic nanometer lead oxide and tetragonal-phase nanometer lead oxide

InactiveCN102616833AHigh purityGood monodispersityLead monoxideNanotechnologyReaction temperatureLead oxide

The invention relates to a preparation method for an orthorhombic nanometer lead oxide and a tetragonal-phase nanometer oxide, which belongs to the technical field of preparation of nanometer materials. The preparation method includes using an orthorhombic bulk lead oxide as a raw materials and oleic acid and oleylamine as auxiliary materials; obtaining transparent Pb solution by means of heating and stirring; obtaining the orthorhombic nanometer lead oxide when the clear Pb solution becomes muddy at the temperature of 270 DEG C; obtaining pure tetragonal-phase lead oxide nanometer crystals when the Pb solution becomes muddy at the temperature of 220 DEG C; and obtaining mixture of the orthorhombic nanometer lead oxide and tetragonal-phase nanometer lead oxide when the reaction temperature ranging from 230 DEG C to 250 DEG C. The orthorhombic nanometer lead oxide and the tetragonal-phase nanometer oxide which are high in purity, uniform in shape and fine in monodispersity can be obtained. The raw material is simple and easy to obtain, is synthesized at one step and is low in cost. Besides, the preparation method has the advantages of short production period, high repeatability, fine sample crystallinity and the like, and has a potential of producing nanometer lead oxide on a large scale.

Owner:JILIN UNIV

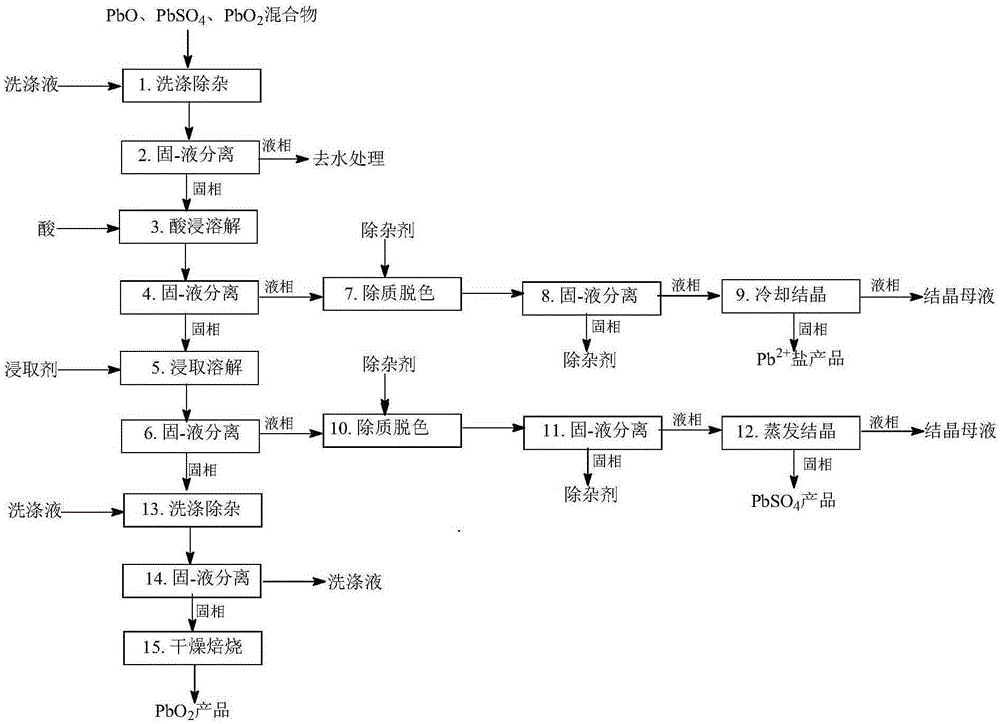

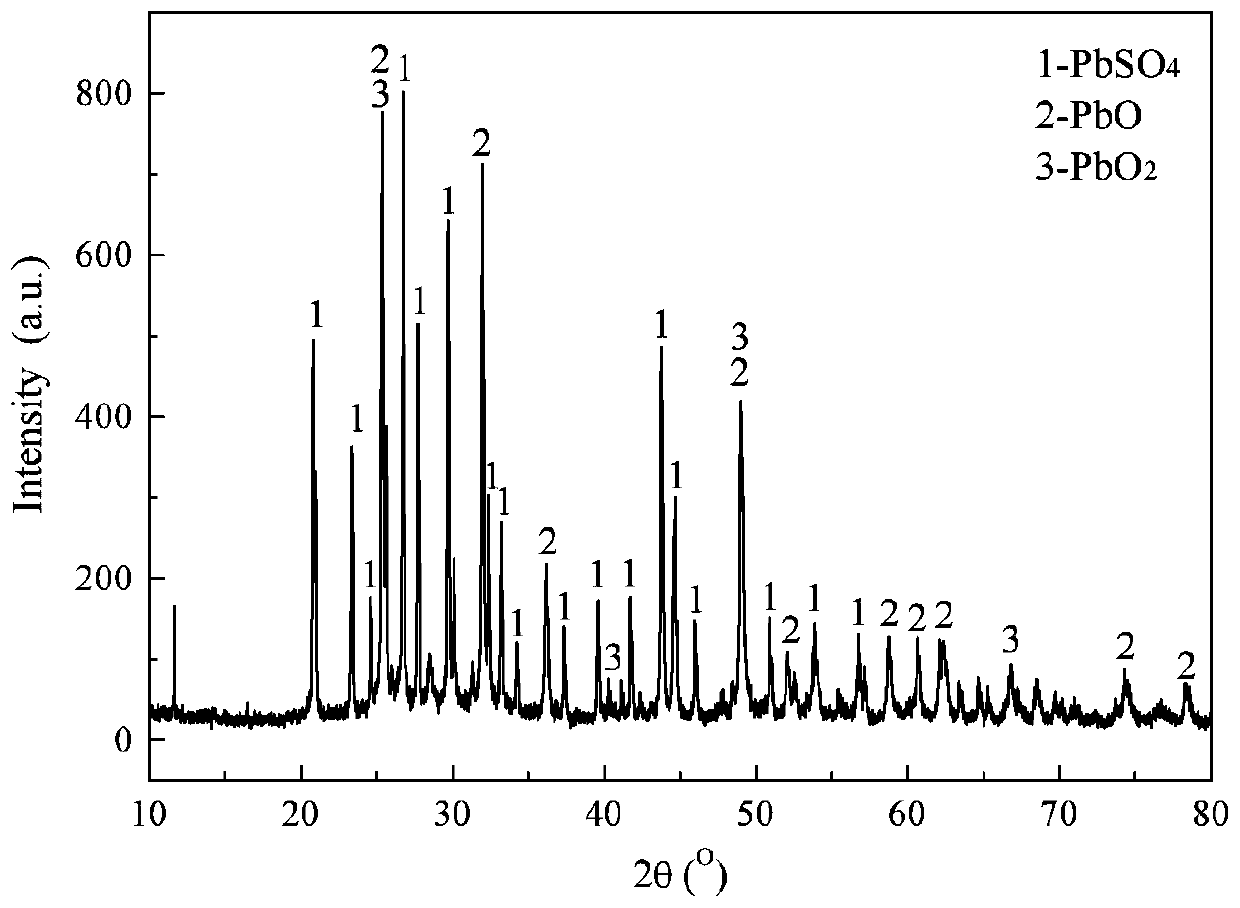

Separation method of PbO, PbSO4 and PbO2 mixture

ActiveCN105197987ADirect useSimple processLead compounds preparationLead dioxideCouplingInorganic compound

The invention relates to a separation method of a PbO, PbSO4 and PbO2 mixture, in particular to a process and a technology of resource comprehensive utilization of a lead containing material of a waste lead storage battery, and belongs to the technical field of comprehensive utilization of three wastes of the waste lead storage battery or separation and refining of inorganic compounds. The separation method comprises steps as follows: PbO, PbSO4 and PbO2 mixture containing lead plaster obtained from the lead containing material, treated with a physical separation method, of the waste lead storage battery is taken as a raw material, the raw material is treated with technologies including acid pickling dissolving, leaching dissolving, separation, refining and solid-liquid separation coupling, and separation of the PbO, PbSO4 and PbO2 mixture is realized. The process is reasonable, the preparation method is simple, the purity and the yield of products are high, by-products in the process are greatly reduced, the comprehensive utilization cost of the lead plaster resource is reduced, the process is safe and reliable, and large-scale industrialization is facilitated.

Owner:YANGZHOU UNIV

Positive paste prepared from 100% alpha-PbO lead powder

InactiveCN105470501AImprove consistencyExtend your lifeLead-acid accumulatorsLead monoxideFiberGraphite

The invention discloses positive paste prepared from 100% alpha-PbO lead powder, and relates to the field of lead storage battery manufacturing. The positive paste disclosed by the invention comprises the following components in parts by weight: 10000 parts of alpha-PbO lead powder, 1100-2000 parts of deionized water, 300-500 parts of sulfuric acid, 10-100 parts of graphite and 5-15 parts of short fiber. According to the positive paste, the consistency of the battery positive paste can be effectively improved, and the improvement of pole plate consistency can effectively improve the consistency of the battery; and after a storage battery is manufactured, the problem of pole plate softening after the battery is used can be overcome, and the service life of the battery can be effectively prolonged.

Owner:CHAOWEI POWER CO LTD

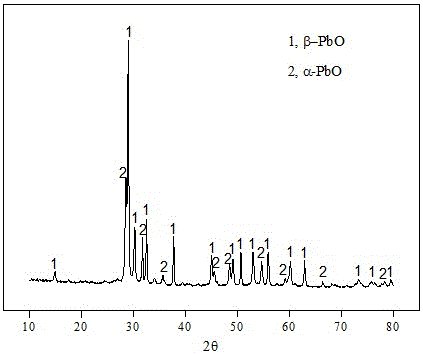

Synthesis method of alpha-PbO

The invention belongs to the technical field of artificial synthesis of natural minerals and particularly relates to an artificial synthesis method of alpha-PbO. According to the technical scheme, the synthesis method of alpha-PbO comprises the following steps that: 10g-25g of lead nitrate, 10g-30g of urea and 0-5g of surfactant are mixed and then are put into a container, 200g-500g of distilled water is added into the container, and the raw materials in the container react continually for 4-7 hours in oil bath at a temperature of 80-100 DEG C to obtain a precursor, wherein the raw materials are continually stirred in the reaction process and are metered in mass; and the obtained precursor is cured for 2-5 hours at a temperature of 300-410 DEG C. The alpha-PbO prepared by the synthesis method is high in purity and does not contain other impurities; and according to the synthesis method, the reaction conditions are mild, and feature equipment is not needed, thereby facilitating mass production.

Owner:UNIV OF JINAN

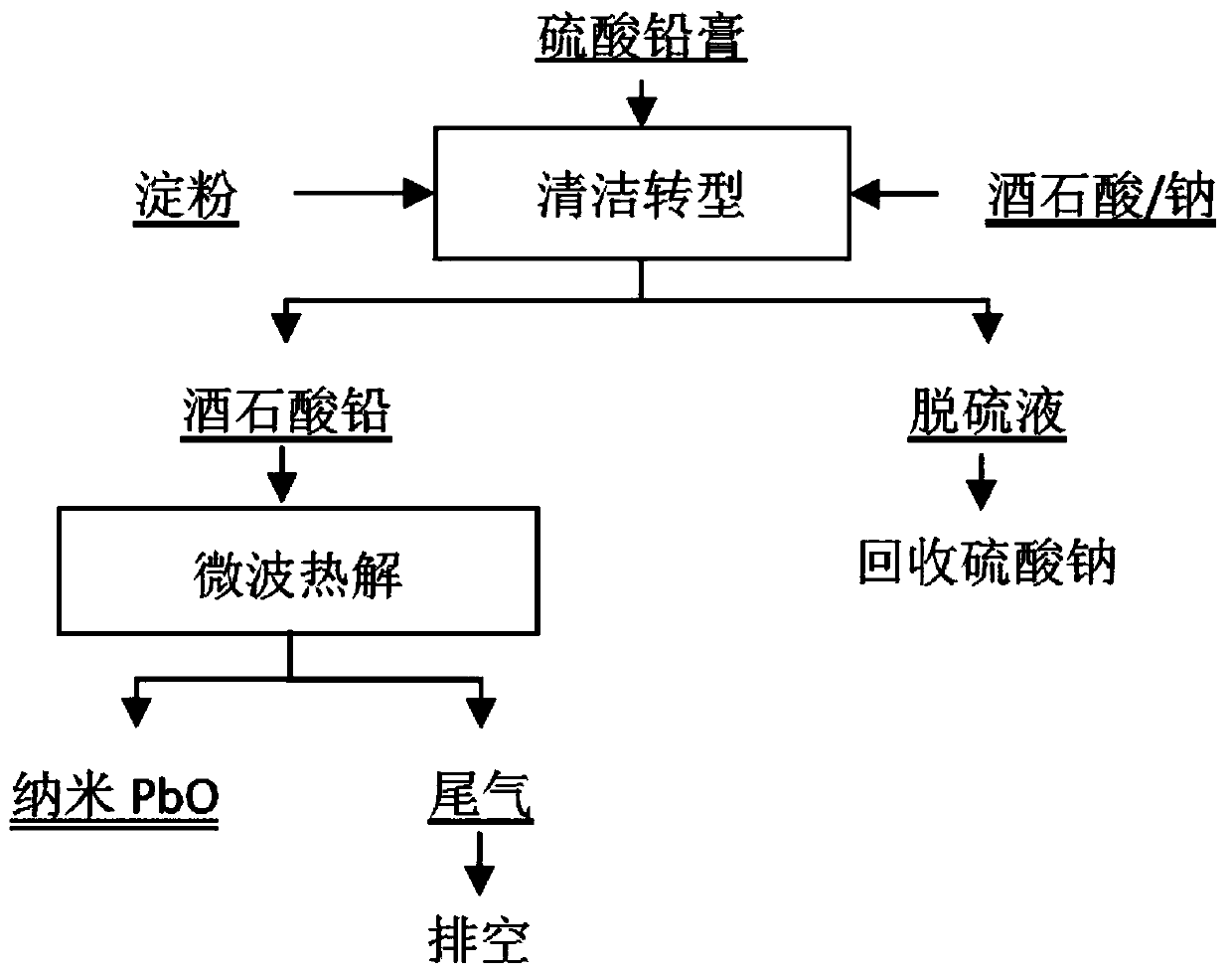

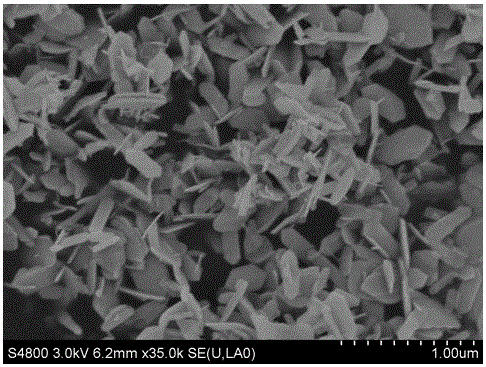

Method for producing nanometer lead oxide through clean transformation-microwave pyrolysis of lead sulfate paste

InactiveCN110745862ANot corrosiveGood atom economyLead monoxideNanotechnologyMicrowave pyrolysisResource recovery

The invention belongs to the technical field of resource circulation and material metallurgy, and particularly discloses a method for producing nanometer lead oxide through clean transformation-microwave pyrolysis of lead sulfate paste. A purpose of the invention is to solve the problem of difficult recovery of lead sulfate paste disassembled from the waste lead storage battery. According to the invention, clean and non-toxic tartaric acid / sodium and starch are respectively used as a transformation agent and a reducing agent; a high-activity lead tartrate precursor is obtained after solution reaction desulfurization; and thermal decomposition is performed under the penetration effect of microwaves to produce nanometer lead oxide, the nanometer lead oxide can be recycled as a high-performance lead storage battery production raw material, and tail gas is decomposed into oxycarbide and water vapor so as to be directly discharged. According to the invention, the method has characteristicsof clean and environment-friendly process and waste recycling, realizes the efficient resource recovery of waste lead sulfate paste, and is easy to carry out industrial production.

Owner:HUNAN UNIV OF TECH

Method for preparing nano lead oxide powder by using waste lead-containing soldering tins

The invention discloses a method for preparing nano lead oxide powder by using waste lead-containing soldering tins. According to the method, the waste lead-containing soldering tins separated from waste circuit boards are put into a vacuum furnace, and air is introduced into the vacuum furnace to oxidize the waste soldering tins into lead oxide and tin dioxide by adopting a vacuum oxygen control method. Meanwhile, the vacuum furnace is heated to evaporate out the lead oxide according to different boiling points of the lead oxide and the tin dioxide, and then the lead oxide is carried into a condensation chamber by unreacted nitrogen and is condensed into nano powder. By controlling a system pressure, heating and condensing temperatures, and a condensation distance, two forms of nano lead oxide powder are prepared. Meanwhile, the residues in a crucible are tin dioxide powder. The nano lead oxide product prepared by the method disclosed by the invention has a broad application prospect in the fields of lead glass manufacturing, ceramic materials, pigment, light-emitting diodes, and lead acid storage batteries; and the prepared byproduct namely tin dioxide is a transparent conductive material is widely applied in the fields of electrode preparation, sensors, batteries, liquid crystal display and the like.

Owner:EAST CHINA NORMAL UNIV

Method for synthesizing high-activity superfine lead oxide powder by waste lead paste

InactiveCN107134602ALow priceReduce corrosionLead monoxideCell electrodesLead oxideSurface-active agents

The invention discloses a method for synthesizing high-activity superfine lead oxide powder by waste lead paste. The method has the advantages that used desulfurizing agents are low in cost and easy to obtain and can be recycled, the method breaks a traditional desulfurizing-calcining process, a reduction leaching process is added in order to acquire high-activity superfine PbO (lead oxide powder), used reduction leaching agents are low in cost, corrosion of the reduction leaching agents for a kettle is smaller than that of commonly-used nitric acid, requirements for devices are not strict, and polyvinylpyrrolidone serving as surface active agents is added to synthesize high-activity superfine PbO, so that novel high-performance lead-acid battery products are prepared.

Owner:HUBEI GREENHOME MATERIALS TECH INC

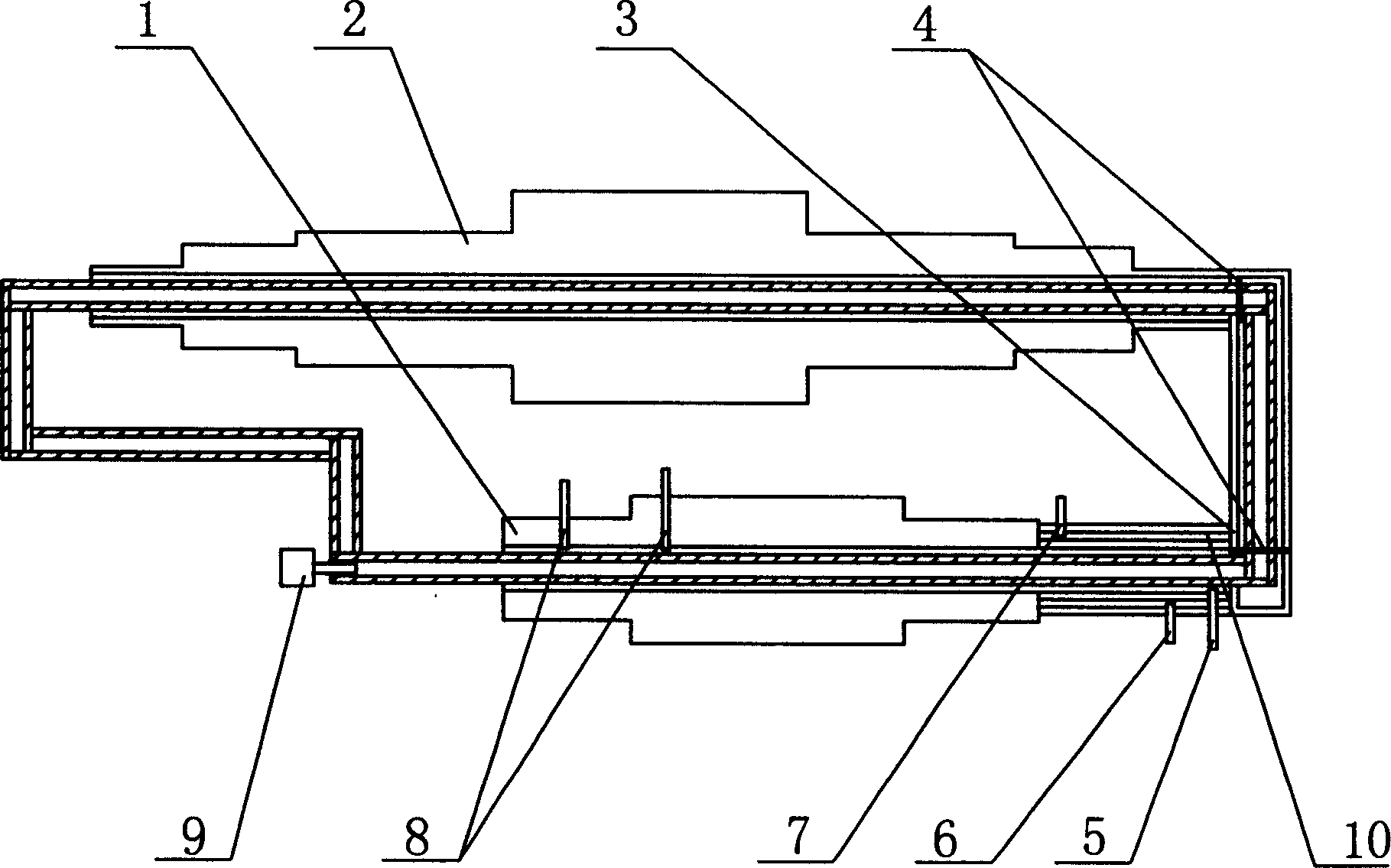

Drying method of raw material blank in continuous production of vanadium nitride and its device

ActiveCN1657419ASolve moisture absorptionExtended service lifeLead monoxideVanadium compoundsHigh volume manufacturingVanadium nitride

A process and apparatus for drying the raw material blanks in the continuous production of vanadium nitride is disclosed. The raw material blanks are fed in a sealed electric furnace communicated via a sealed channel and a valve to a sintering furnace while protective gas is filled in it. After they are dried at 400-700 deg.C for 4-7 hr, they are transferred via said sealed channel into sintering furnace.

Owner:PANZHIHUA IRON AND STEEL

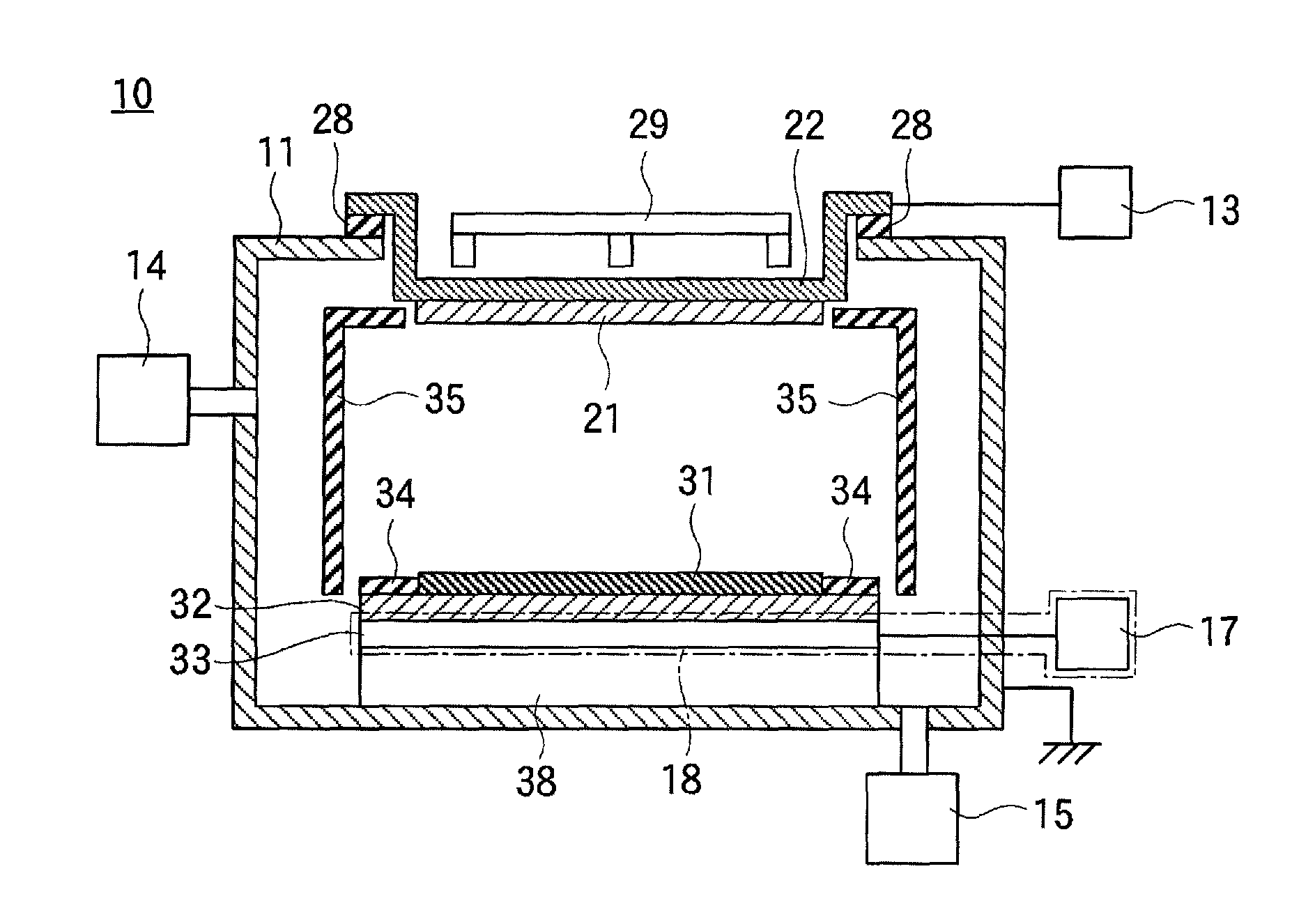

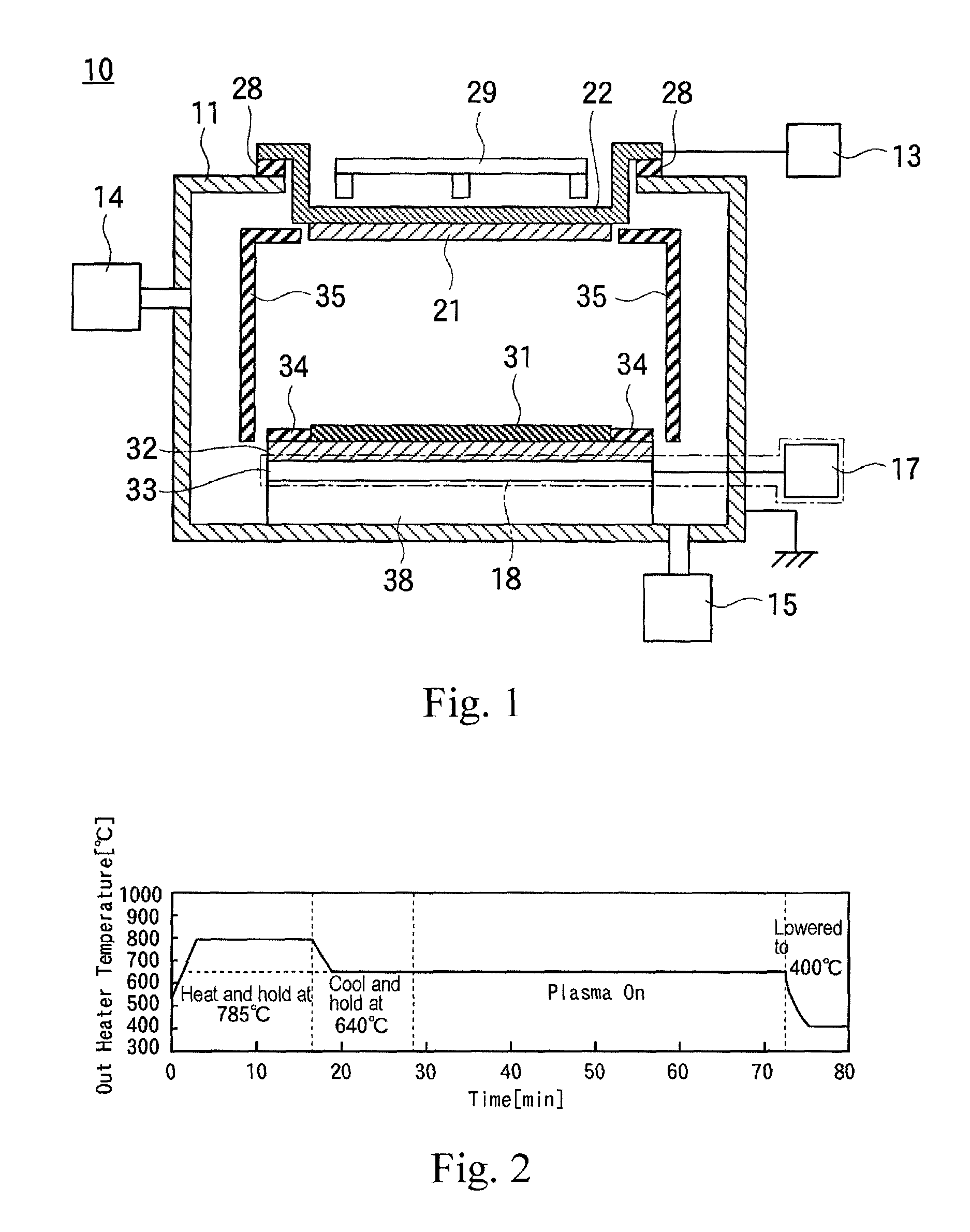

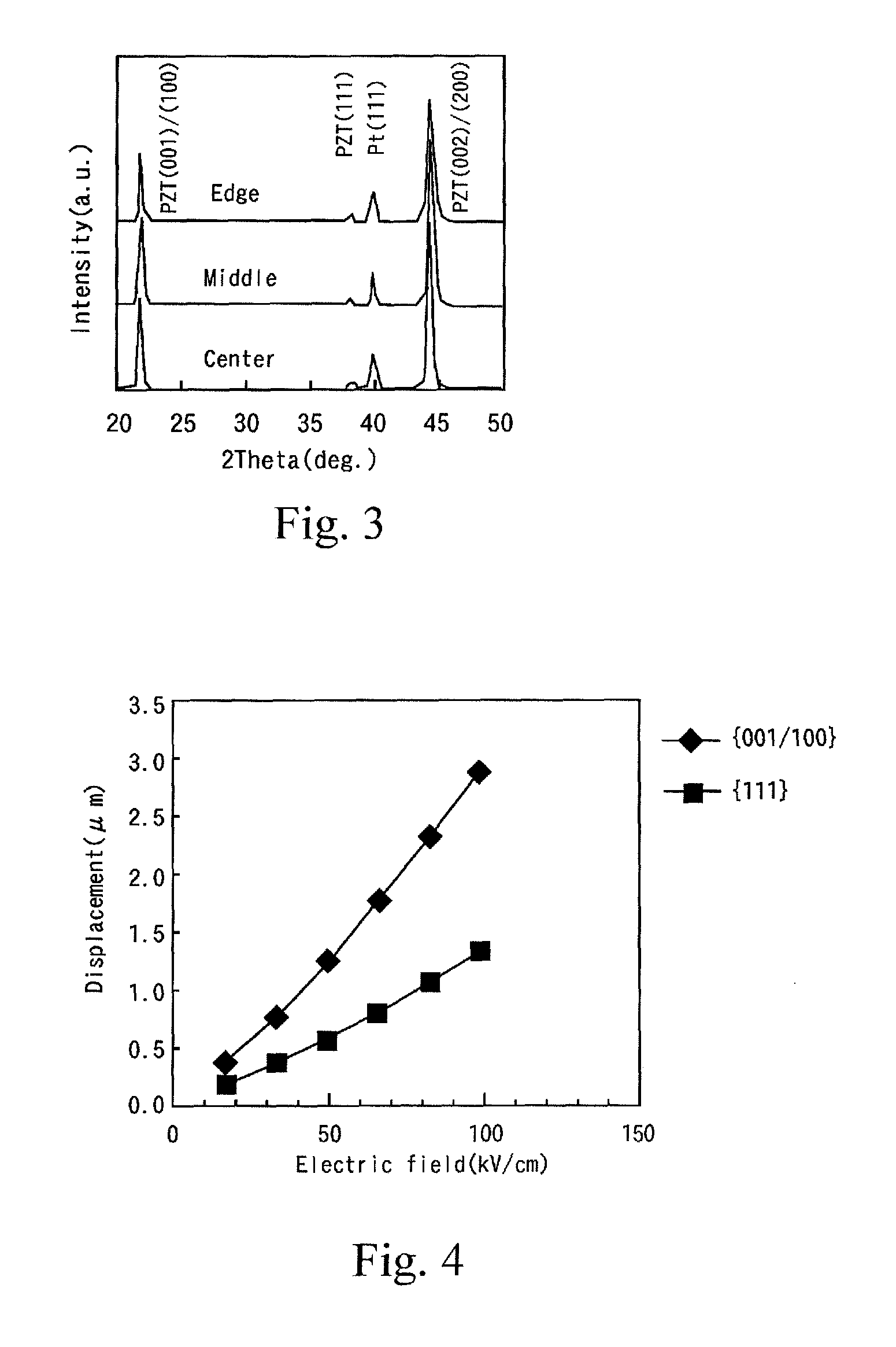

Method for forming dielectric thin film

A method for forming a dielectric thin film that forms a PZT thin film having a (100) / (001) orientation. After a seed layer is formed by adhering PbO gas to a surface of a substrate, a voltage is applied to a target of lead zirconate titanate (PZT) and perform sputtering, while the substrate is heated inside of an evacuated vacuum chamber. Then, a PZT thin film is formed on the surface of the substrate. Because Pb and O are supplied from the seed layer, a PZT film having a (001) / (100) orientation can be formed without lack of Pb.

Owner:ULVAC INC

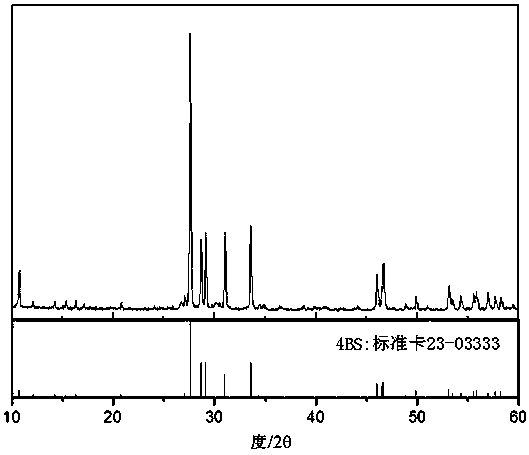

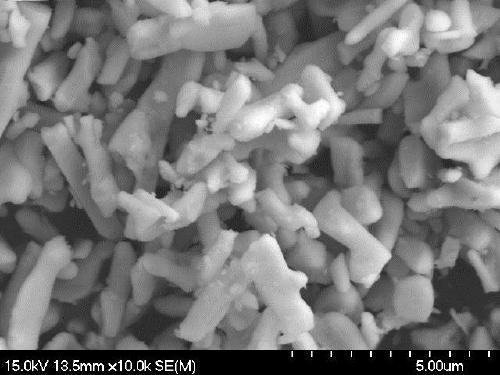

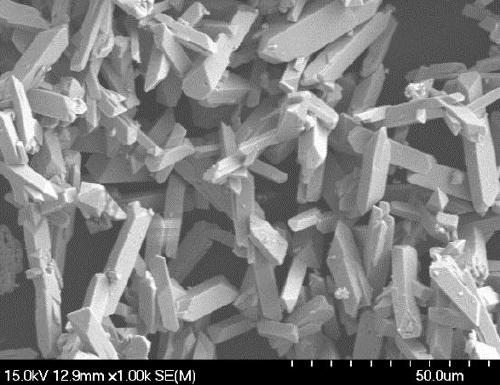

High-performance battery small-crystal-size 4BS additive preparation method

ActiveCN109133160AHigh purityImprove electrochemical performanceLead-acid accumulatorsLead monoxideAlcoholSulfate radicals

The invention discloses a high-performance battery small-crystal-size 4BS additive preparation method which includes the steps: adding lead-bearing reaction raw materials into water, adding raw materials containing sulfate radicals at a first stage and a second stage and performing reaction under ultrasonic conditions to obtain turbid liquid; centrifugally separating the turbid liquid to obtain solid precipitates; calcining the solid precipitates, cooling products to room temperature and grinding and sieving the products to obtain solid powder; dispersing the solid powder into mixed solvents of ethyl alcohol and the water, performing ultrasonic treatment for a period of time, performing suction filtration on the turbid liquid, drying filter cakes and then grinding and sieving the filter cakes to obtain small-crystal-size 4BS. The method is simple in operation and low in cost, the prepared 4BS is high in purity and small in crystal-size, can serve as a lead-acid battery electrode plateadditive and has high product application values, and the service life of an electrode plate can be prolonged.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com