Method for recovering lead chloride from sintered ashes and preparing lead monoxide

A lead monoxide and sintered ash technology, applied in the directions of lead monoxide, lead oxide, lead halide, etc., can solve the problems of nodulation in the furnace, reducing the strength of the blast furnace charge, cracking of the furnace wall, etc. Longevity and the effect of reducing the wind break rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

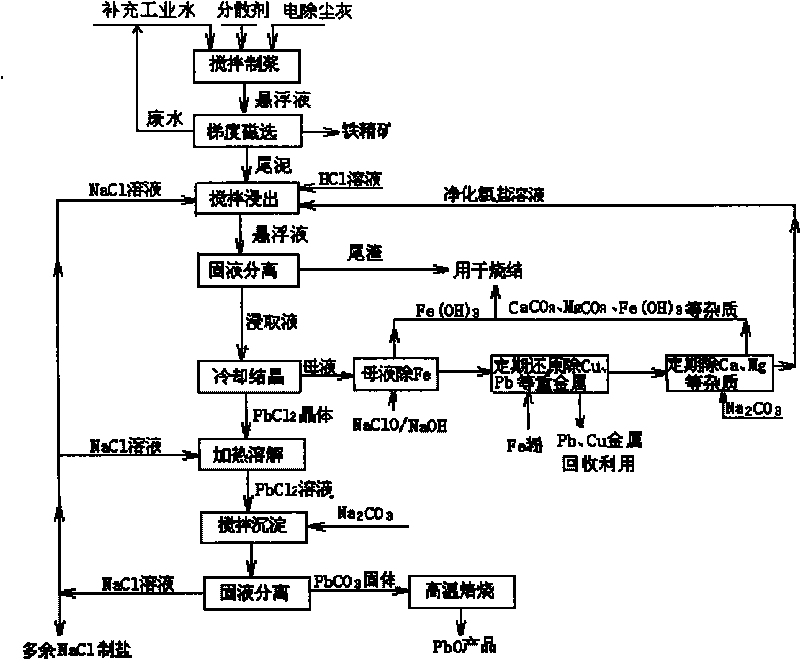

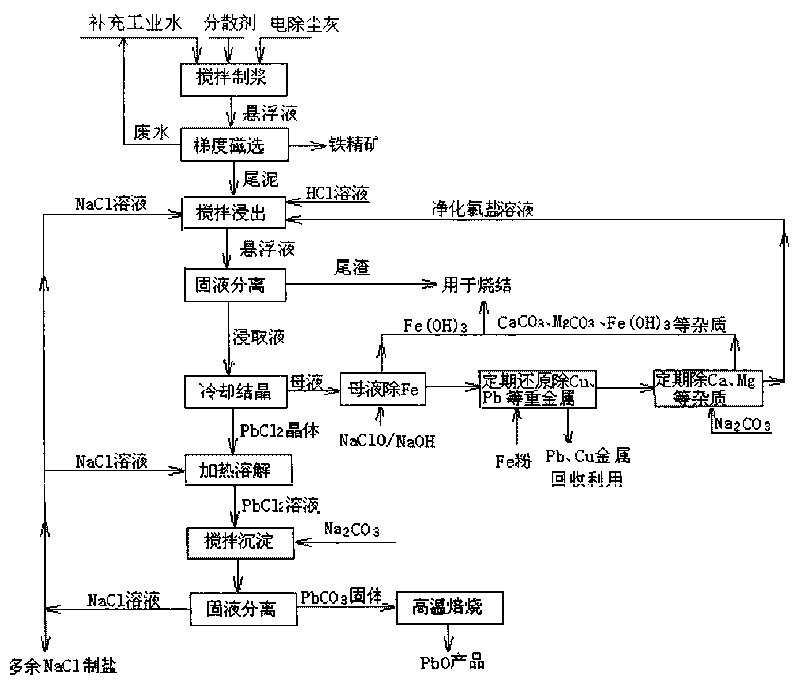

Method used

Image

Examples

Embodiment 1

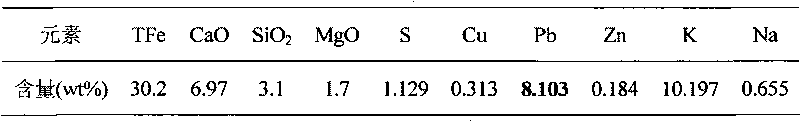

[0020] Weigh 600g of sintered head electrostatic dust, and its chemical composition analysis is shown in Table 1, Table 4.

[0021] Table 1 Example 1 Sample Chemical Composition

[0022]

[0023] The sintered ash was added to the 6L aqueous solution to which 2g of dispersant had been added and stirred to obtain a sintered ash suspension. The suspension was subjected to two-stage gradient magnetic separation of "weak magnetic → strong magnetic", and the tail slurry was filtered and dried to obtain 294 g of iron with a content of 294 g. 57.7% iron concentrate with 0.92% lead and 244.5g of tailings with 18.46% lead.

[0024] The tail sludge after the above magnetic separation is divided into three leaching times. First, 1 / 3 of the tail sludge was added to 163 mL of NaCl solution with a concentration of 300 g / L. Under the conditions of a stirring speed of 100 r / min and a temperature of 85 °C, 10 mL of concentrated hydrochloric acid was added until the pH of the suspension syst...

Embodiment 2

[0026] Weigh 1000g of sintered head electrostatic dust, and its chemical composition analysis is shown in Table 2.

[0027] Table 2 Example 2 sample chemical composition

[0028]

[0029] The sintered ash was added to 10 L of aqueous solution to which 10 g of dispersant had been added and stirred to obtain a sintered ash suspension. The suspension was subjected to two-stage gradient magnetic separation of "weak magnetic → strong magnetic", and the tailings were filtered and dried to obtain 532 g of iron with an iron content of 532 g. 56.8% iron ore concentrate with 0.63% lead and 368.6g of tailings with 17.03% lead.

[0030] The tail sludge after the above magnetic separation is divided into 4 times of leaching. First, 1 / 4 of the tail sludge was added to 185 mL of NaCl solution with a concentration of 300 g / L. Under the condition that the stirring speed was 100 r / min and the temperature was 85 °C, 12 mL of concentrated hydrochloric acid was added until the pH of the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com