Preparation method for orthorhombic nanometer lead oxide and tetragonal-phase nanometer lead oxide

A technology of lead oxide and orthorhombic phase, which is applied in the field of preparation of nanomaterials to achieve the effects of short production cycle, high repeatability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

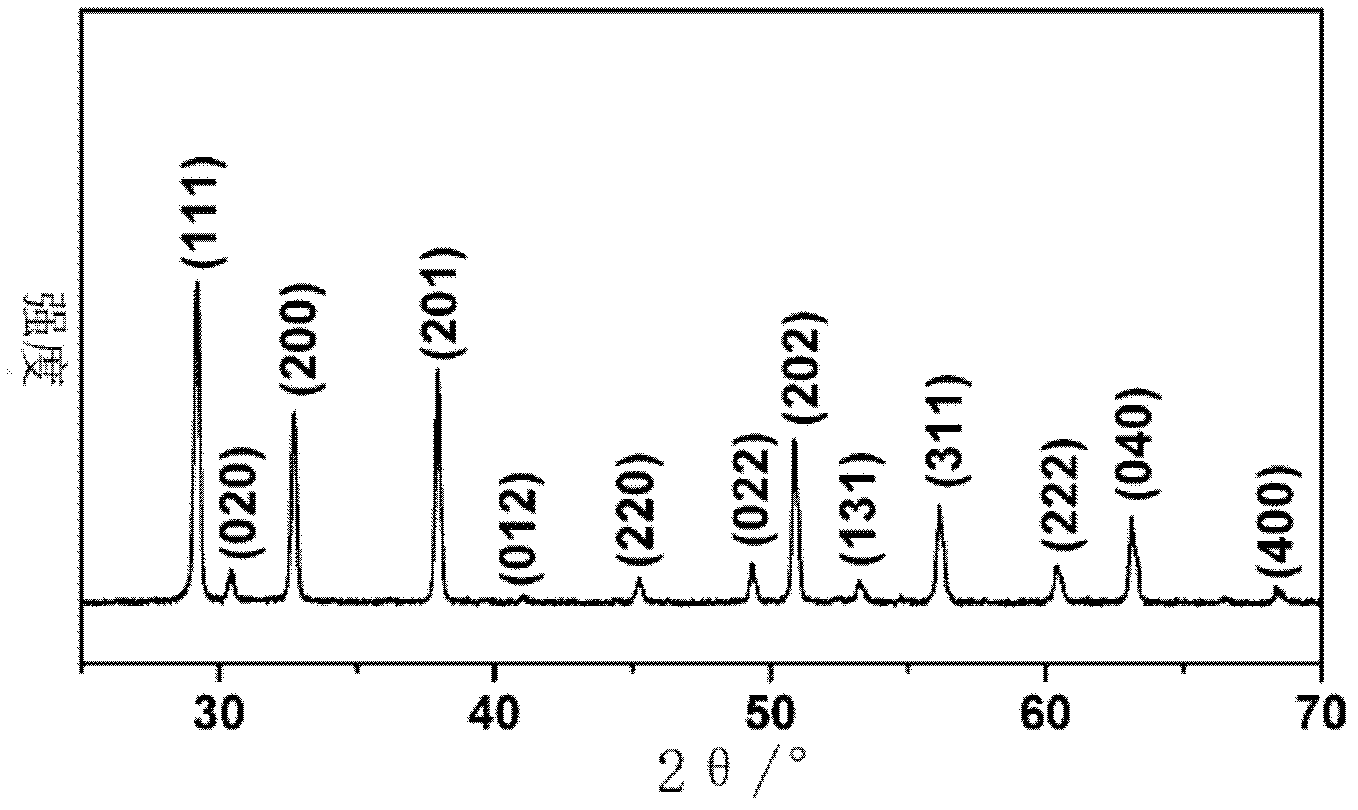

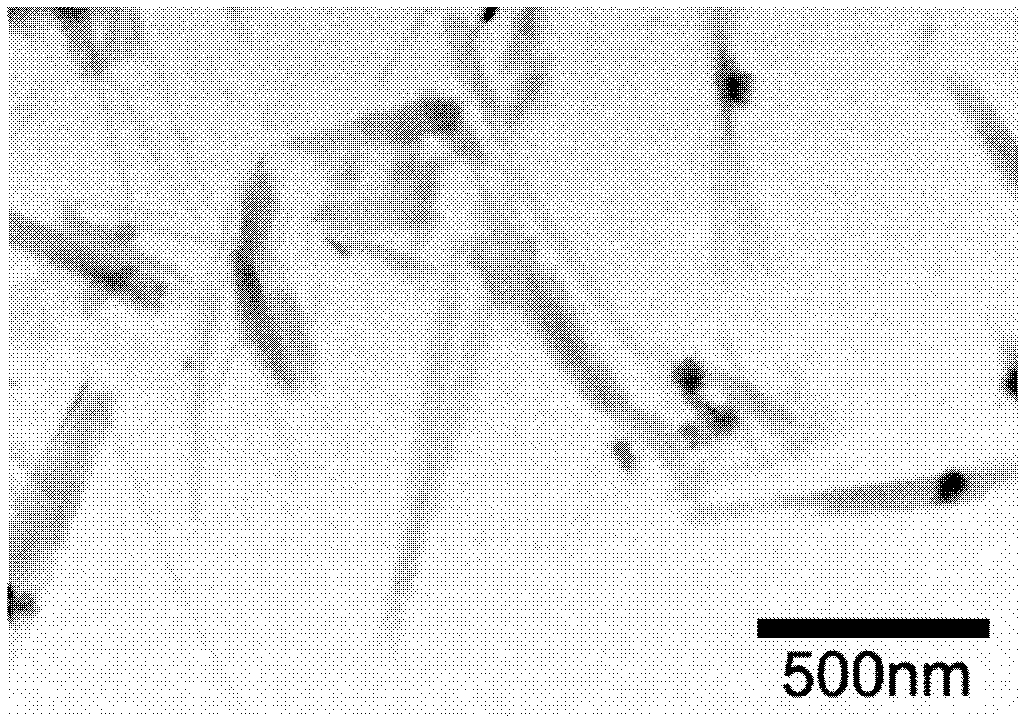

[0019] Embodiment 1 The process of synthesizing orthorhombic nano-lead oxide

[0020] Put 0.223g of orthorhombic bulk lead oxide powder, 1ml of oleic acid and 5ml of oleylamine into a 50mL three-necked bottle, then plug the two sides of the three-necked bottle with rubber stoppers, and connect the middle port to the Schlenk system , Insert a thermocouple from the side port of the three-necked bottle under the liquid surface, heat and stir, the heating rate is controlled at 25°C / min and when heated to 160°C, the lead oxide is completely dissolved to form a Pb-ligand complex solution. When the temperature continued to rise to 270°C, the color of the solution gradually turned yellow-green and turbid, and what was produced at this time was pure orthorhombic nano-lead oxide. After 10 minutes of reaction, a nano-lead oxide sample is obtained through nucleation and growth, and the sample is washed three times with a mixed solution of methanol and acetone at a volume ratio of 1:1 to o...

Embodiment 2

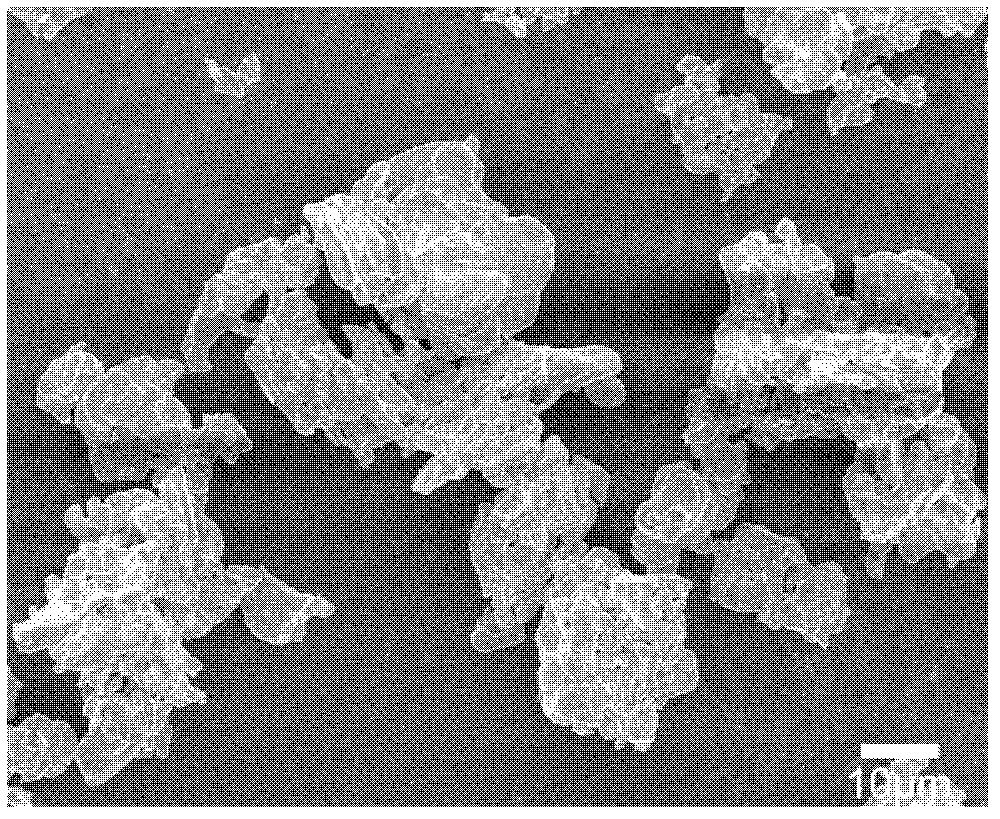

[0022] Embodiment 2 The process of synthesizing tetragonal phase nano lead oxide

[0023] Put 0.223g of orthorhombic bulk lead oxide powder, 1ml of oleic acid and 5ml of oleylamine into a 50mL three-necked bottle, then plug the two sides of the three-necked bottle with rubber stoppers, and connect the middle port to the Schlenk system , Insert a thermocouple from the side port of the three-necked bottle under the liquid surface, heat and stir, the heating rate is controlled at 18°C / min, when the lead oxide is heated to 140°C, the lead oxide is completely dissolved to form a Pb-ligand complex solution. When the temperature continued to rise to 220°C, the color of the solution gradually turned yellow and turbid, and what was produced at this time was pure tetragonal phase nano-lead oxide. After 10 minutes of reaction, a nano-lead oxide sample is obtained through nucleation and growth, and the sample is washed three times with a mixed solution of methanol and acetone with a volum...

Embodiment 3

[0025] Embodiment 3 The process of synthesizing orthorhombic phase and tetragonal phase nano lead oxide mixture

[0026] The process of synthesizing orthorhombic phase and tetragonal phase nano-lead oxide mixture is basically the same as the process of synthesizing orthorhombic phase nano-lead oxide in Example 1, except that the heating rate is controlled at 20°C / min, and the transparent Pb-ligand complex solution will be in At 230°C, it starts to turn yellow and turbid, and at this time, a mixture of orthorhombic and tetragonal nano-lead oxides is formed. React at 230-250°C for 10 minutes to obtain nano-lead oxide samples through nucleation and growth. Wash the samples three times with a mixed solution of methanol and acetone with a volume ratio of 1:1 to obtain orthorhombic and tetragonal phase nano-lead oxides. mixture.

[0027] Figure 6 It is the X-ray diffraction pattern of the mixture of orthorhombic and tetragonal nano-lead oxides, which completely corresponds to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com