Method for preparing nano lead oxide powder by using waste lead-containing soldering tins

A lead oxide and nanotechnology, applied in the field of solid waste recycling, can solve the problems of environmental pollution, insufficient technology, low added value of recycled products, etc., and achieve the effects of simple process, low cost and remarkable treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of method utilizing waste and old leaded solder to prepare nano lead oxide powder, comprises the following steps:

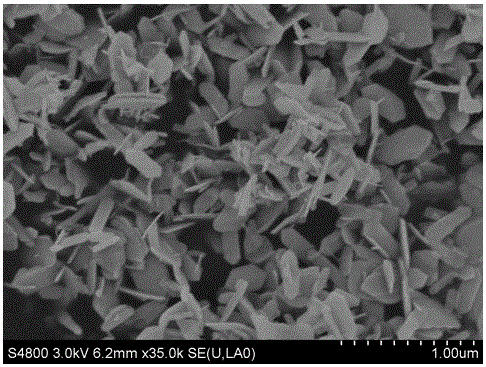

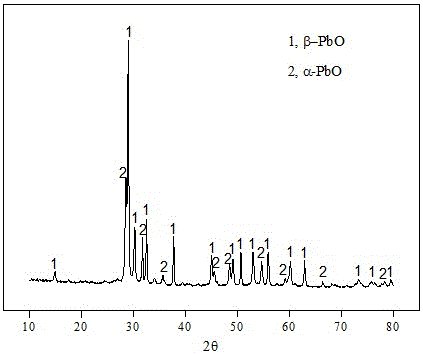

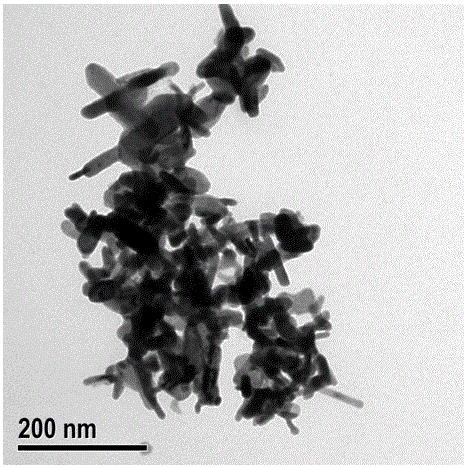

[0030] Weigh 20 g of waste lead-containing solder separated from waste circuit boards into a corundum crucible, and then put the crucible into the heating chamber of a tube-type vacuum furnace. A quartz plate is placed in the condensation chamber at a distance of 60cm from the heating chamber as the condensation base; the heating chamber and the condensation chamber are separated by an insulating pipe plug, and there is a hole in the middle of the pipe plug so that the air can carry the lead oxide vapor through; the closed system is powered by a mechanical pump Evacuate the system pressure to 1Pa, and then adjust the inlet valve to let air in so that the dynamic pressure in the vacuum furnace is maintained at 1000Pa. Heat the evaporation chamber to 1000°C at a heating rate of 10°C / min and maintain it for 60 minutes; adjust the temperature of the con...

Embodiment 2

[0032] A kind of method utilizing waste and old leaded solder to prepare nano lead oxide powder, comprises the following steps:

[0033]Weigh 20 g of waste lead-containing solder separated from waste circuit boards into a corundum crucible, and then put the crucible into the heating chamber of a tube-type vacuum furnace. Place a quartz plate at 60 cm in the condensation chamber as the condensation base. The middle of the heating chamber and the condensing chamber is separated by an insulating pipe plug, and there is a hole in the middle of the pipe plug so that the air carrying lead oxide vapor can pass through. After sealing the system, the mechanical pump pumps the system pressure to 1Pa, and then adjusts the inlet valve to let air in so that the dynamic pressure of 1000Pa is maintained in the vacuum furnace. Heat the evaporation chamber to 1000°C at a heating rate of 10°C / min and keep it for 100min. Adjust the temperature of the condensation chamber to 100°C and maintain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com