Patents

Literature

62results about "Red lead" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for recovering lead oxides from exhausted batteries

ActiveUS7507496B1Speed up the processObtained inexpensivelySolvent extractionPrimary cell maintainance/servicingLead dioxideLead oxide

A process for recovering lead oxides from the spent paste of exhausted lead acid batteries. The process provides heating the spent paste with an alkali hydroxide solution at elevated temperatures prior to calcinations. Calcination is at various temperatures so that either lead mono-oxide, lead dioxide or red lead is obtained as the principal product. There is also provided the use of the lead oxide to prepare the paste for positive and negative electrodes or other lead compounds.

Owner:RETRIEV TECH +1

Recovery of high purity lead oxide from lead acid battery paste

There is provided a process for recovering high purity litharge PbO from spent lead acid battery paste at low temperatures and the further preparation of highly pure lead oxides and Pb(OH)2.

Owner:RETRIEV TECH

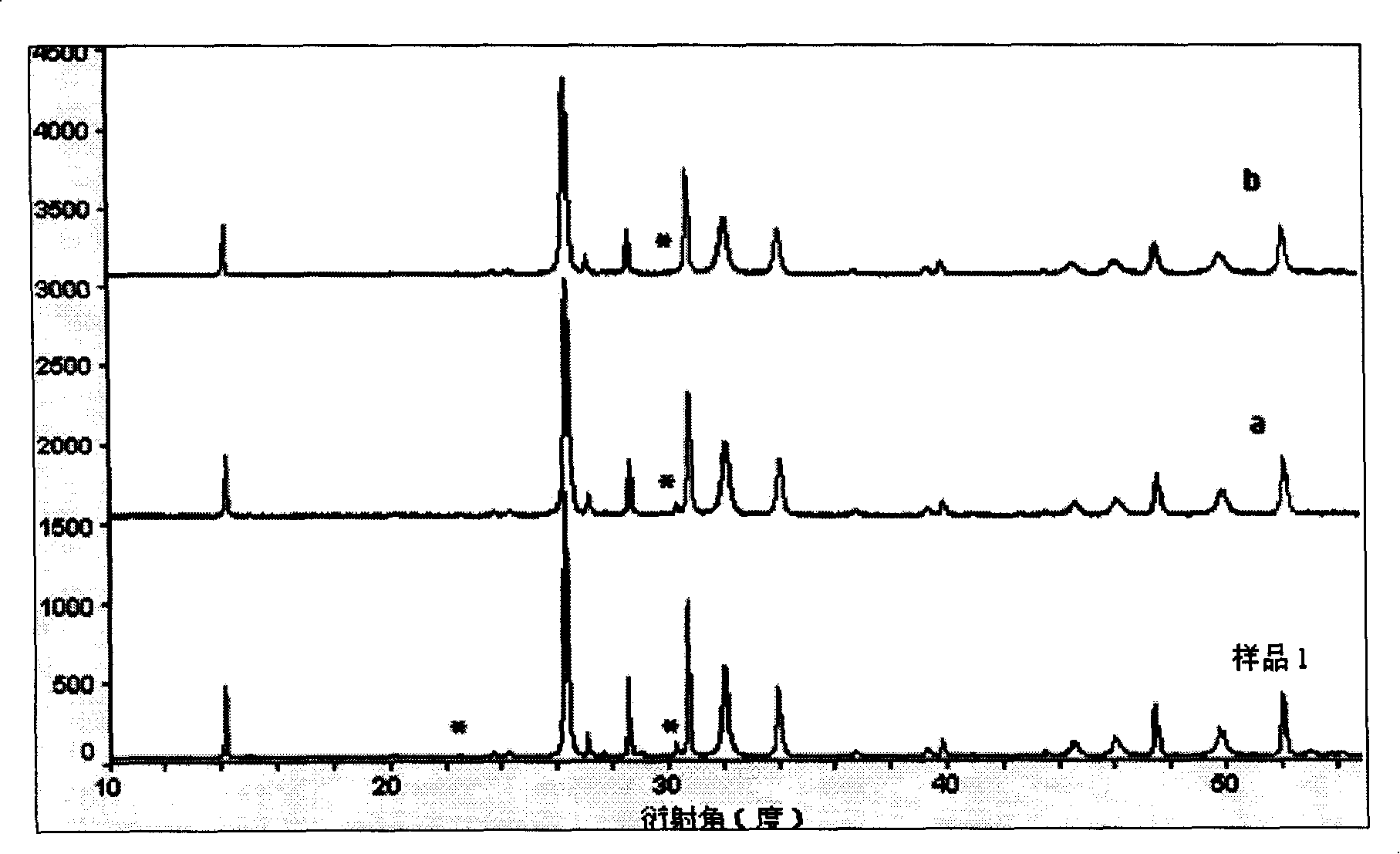

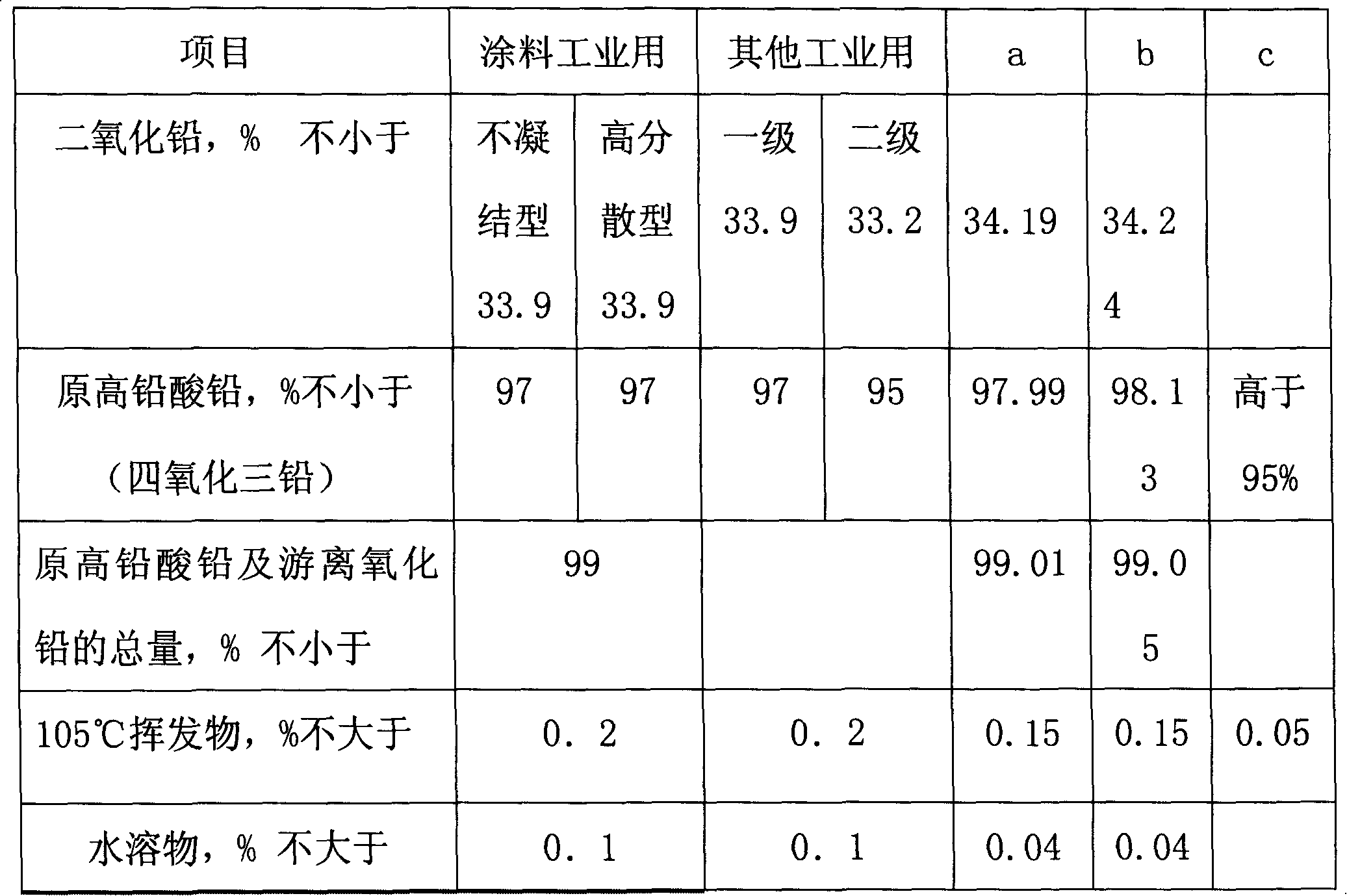

Method for preparing high-quality red lead by lead slime of lead-acid batteries

InactiveCN101205080ASave resourcesReduce dosageLead dioxideSolid waste disposalTube furnaceGranularity

The invention relates to a method for preparing high-quality red lead from lead slime of a waste lead-acid battery. The invention includes the following steps: the lead slime in the waste lead-acid battery is taken out and mixed with no regard of cathode and anticathode; then the lead slime is repeatedly washed to neutral and is dried and triturated to lead slime powder with granularity above 200 meshes; the lead slime powder is mixed with water solution containing dispersant and desulfurizer by a certain proportion; the mixture is adequately stirred and decarbolized under 25 to 90 DEG C for 1 to 24 hours; the liquid part is removed and the lead containing solids is washed to neutral; the material is tiled in a box style muffle furnace or a tube furnace to have a thickness of 1 to 20 cm and is roasted under temperature of 400 to 500 DEG C for 2 to12 hours; then the red lead is prepared. The invention method has the advantages of low preparation cost, high lead recycling ratio, high quality, lower energy consumption and lower environment pollution.

Owner:HUNAN UNIV

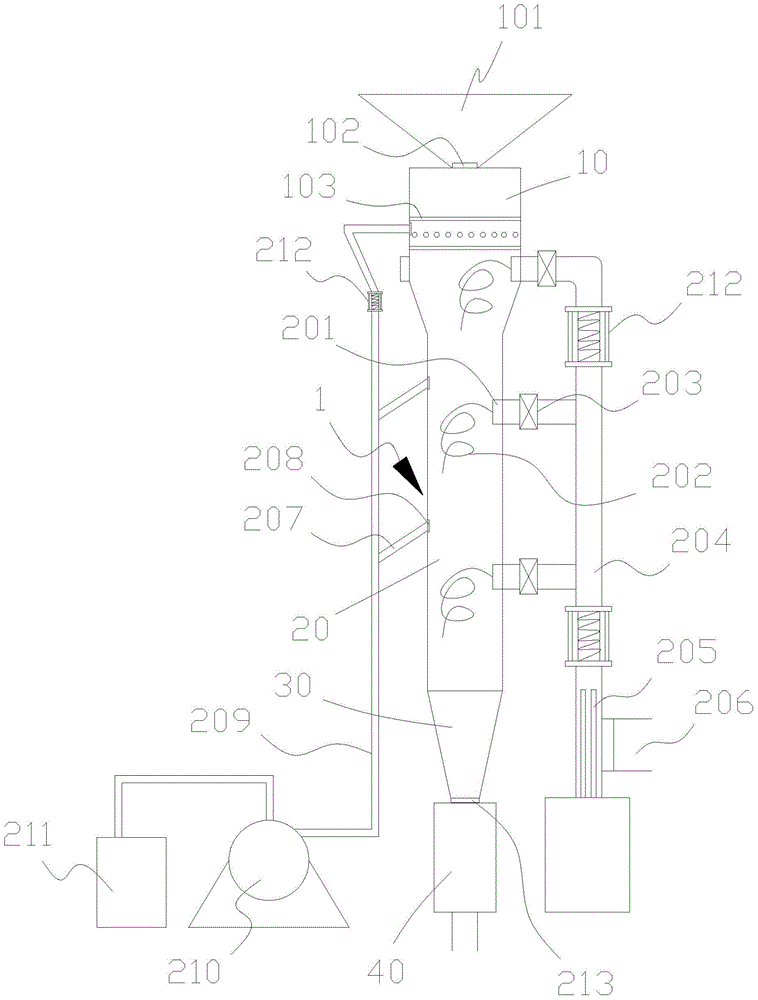

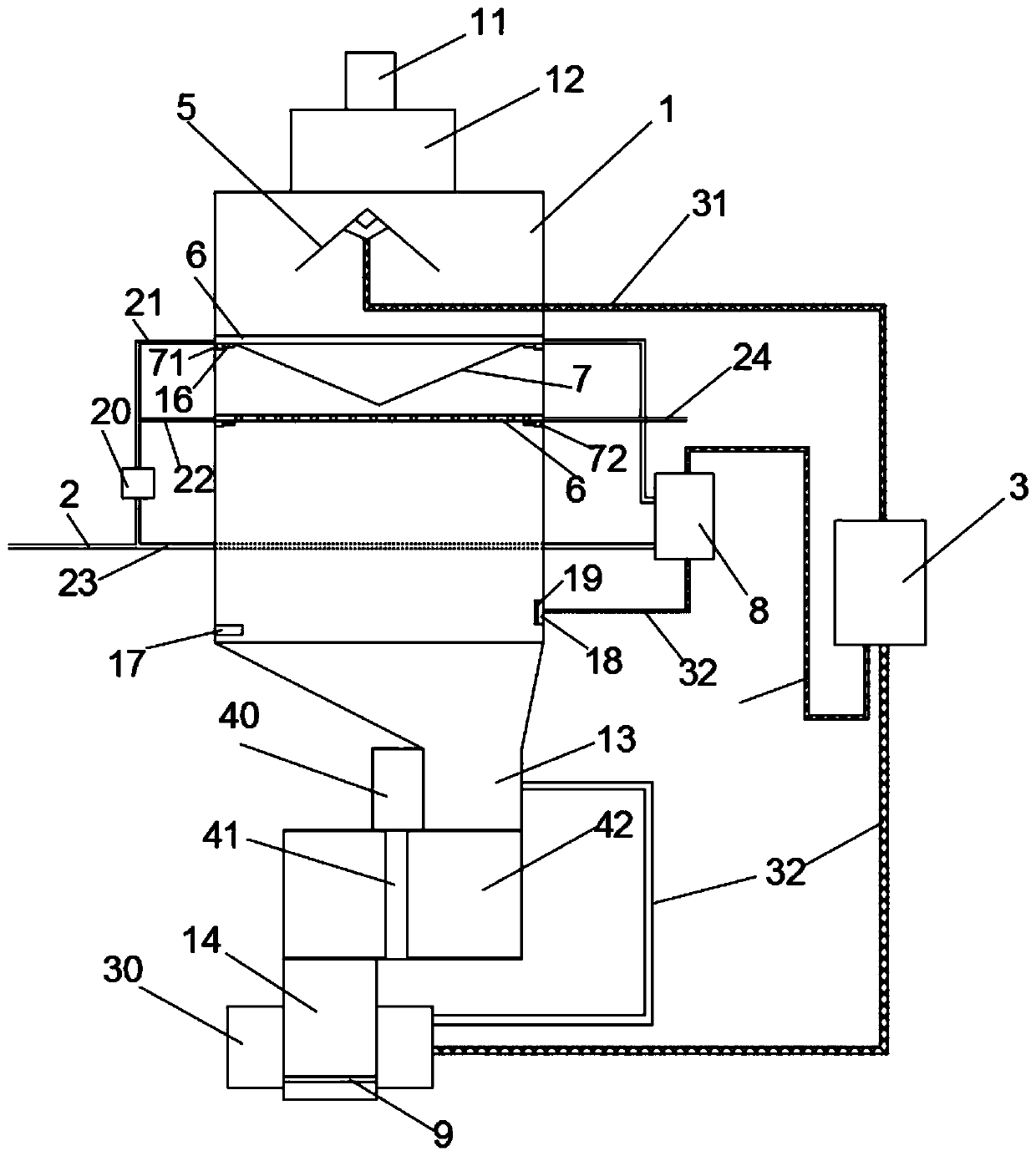

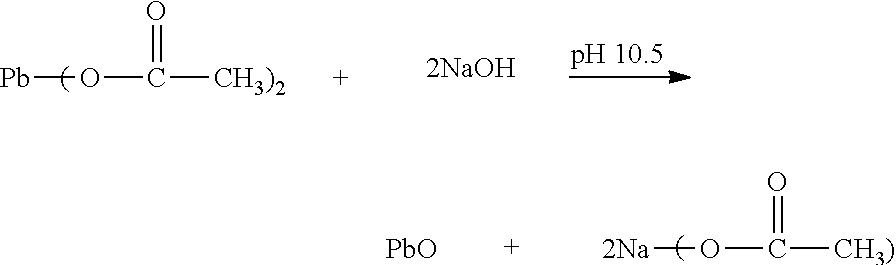

Method for rapidly preparing red lead by means of air flow

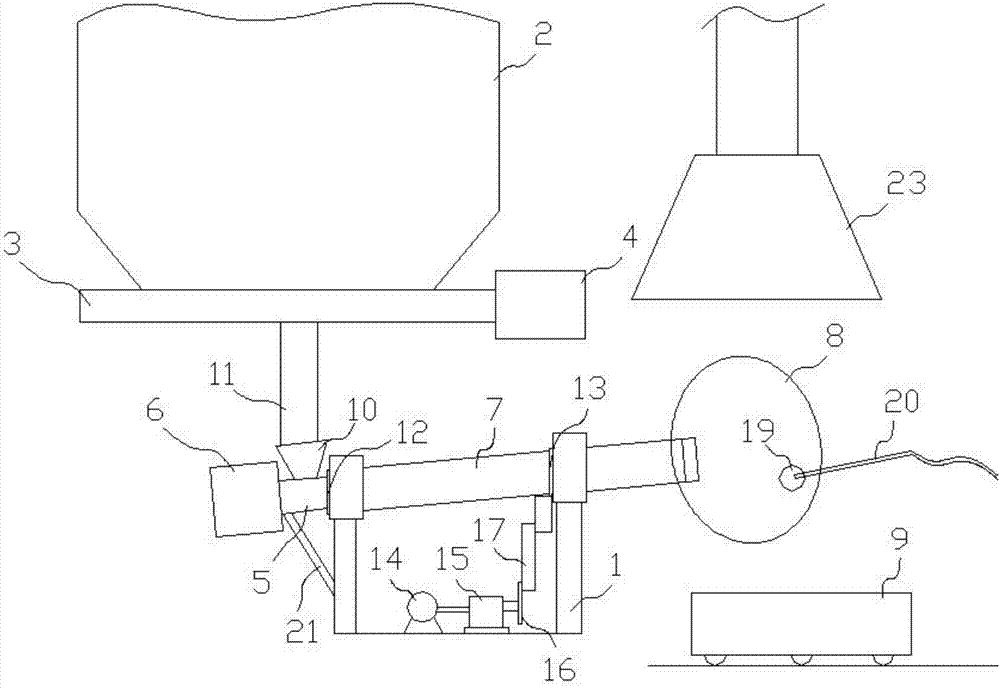

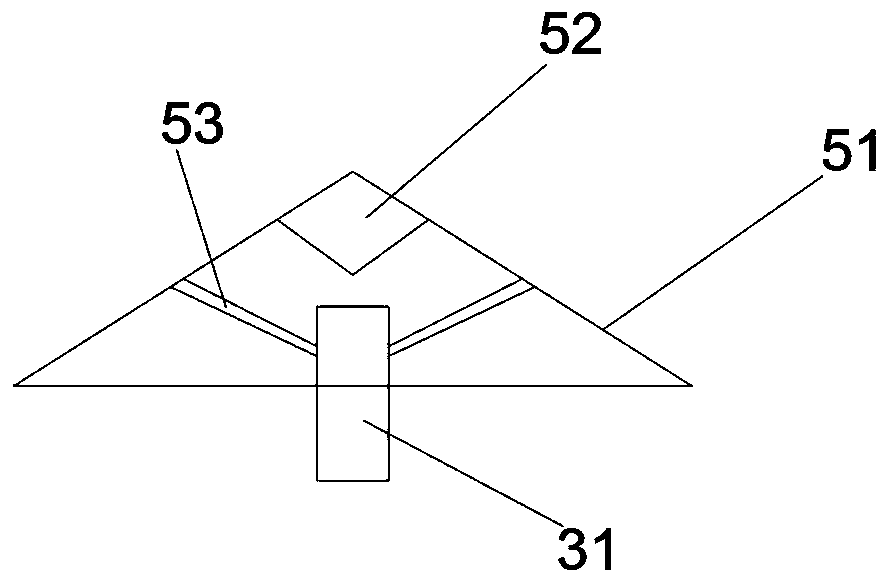

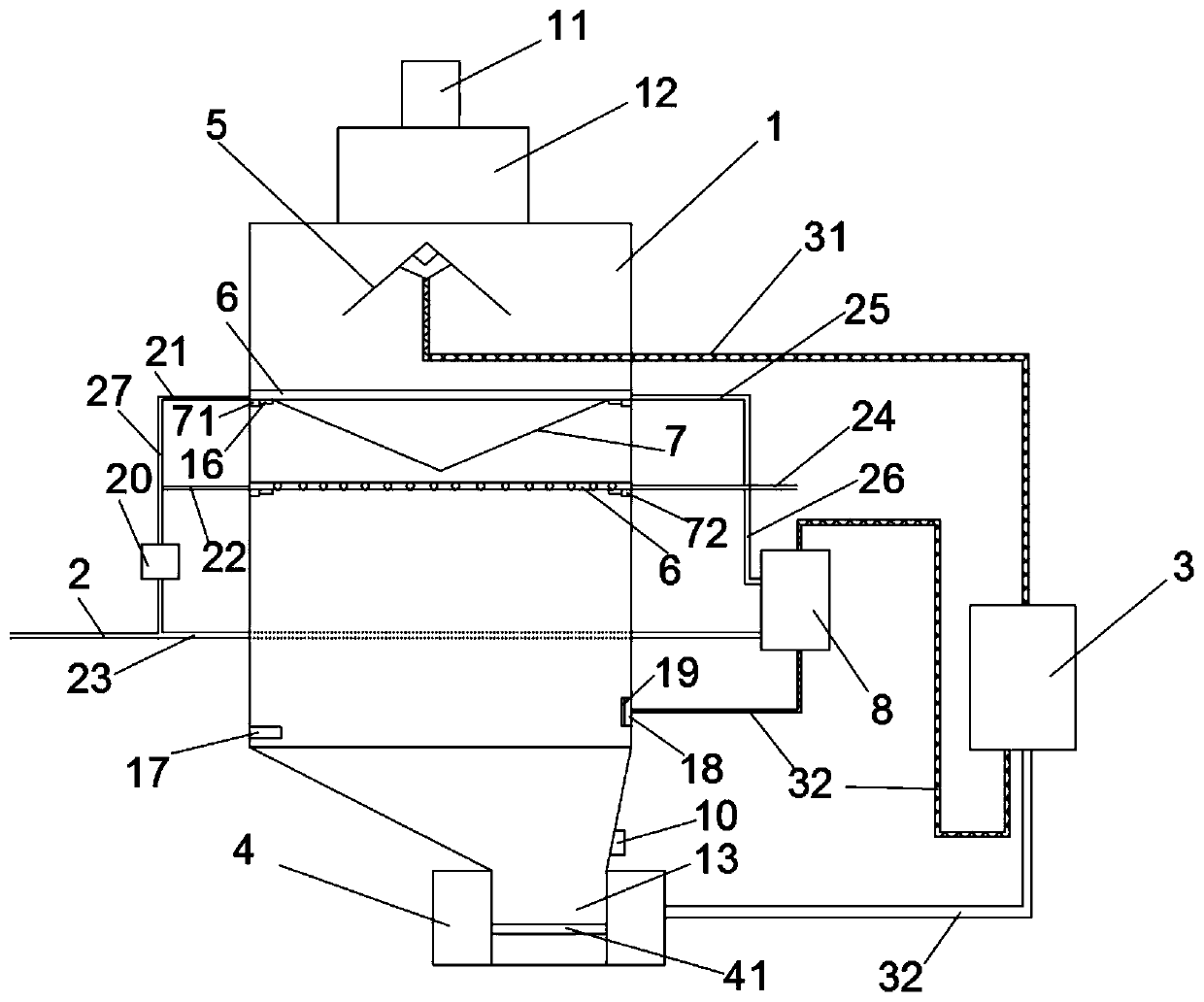

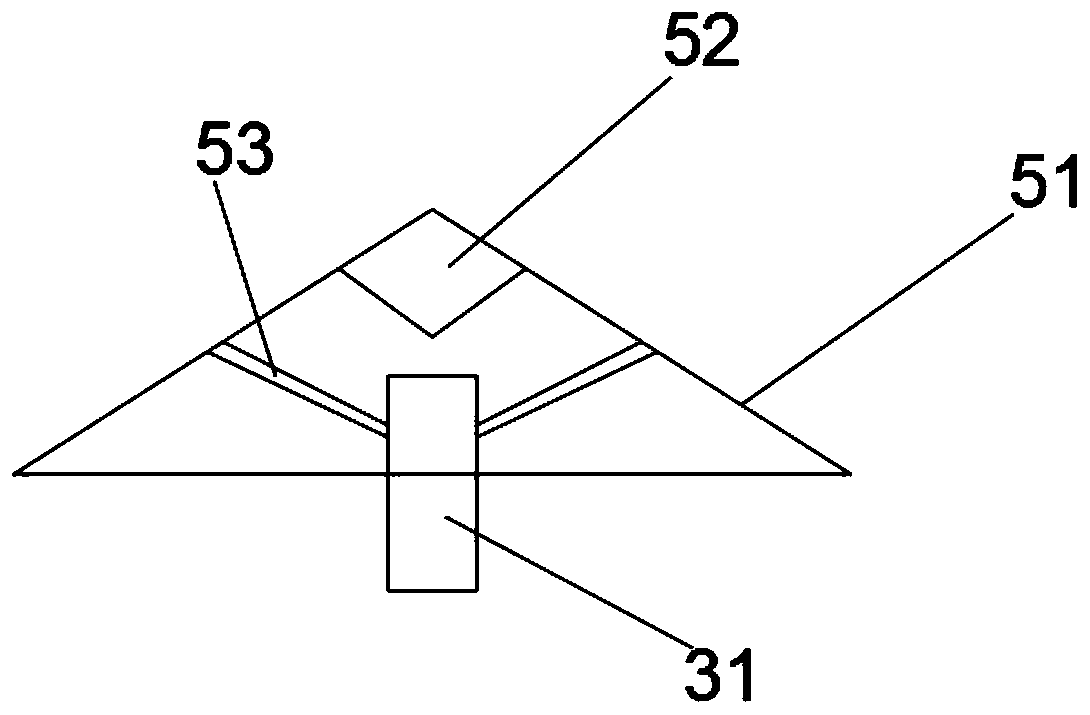

ActiveCN105197986AFast preparationAvoid pollutionEnergy inputRed leadProcess engineeringPressure difference

The invention discloses a method for rapidly preparing red lead by means of air flow. The method is achieved by combining a ground-to-air missile type red lead energy-saving oxidation furnace, that is to say, the flow velocity of air in the oxidation furnace is increased through air supply, and the air pressure in the oxidation furnace is increased by means of in-and-out air pressure difference, so that the purpose of increasing oxygen in the oxidation furnace is achieved, and the purpose of rapidly preparing the red lead is achieved. According to the method for rapidly preparing the red lead by means of the air flow, solar thermal energy and inexhaustible natural wind are effectively utilized, a red lead produce is rapidly prepared, the production cost is reduced, the production efficiency is improved, environmental pollution is avoided, and energy resources are greatly saved; more importantly, the production process is cleaner and safer, and fatal potential safety hazards are eliminated.

Owner:JIESHOU CITY JUNMA IND & TRADE

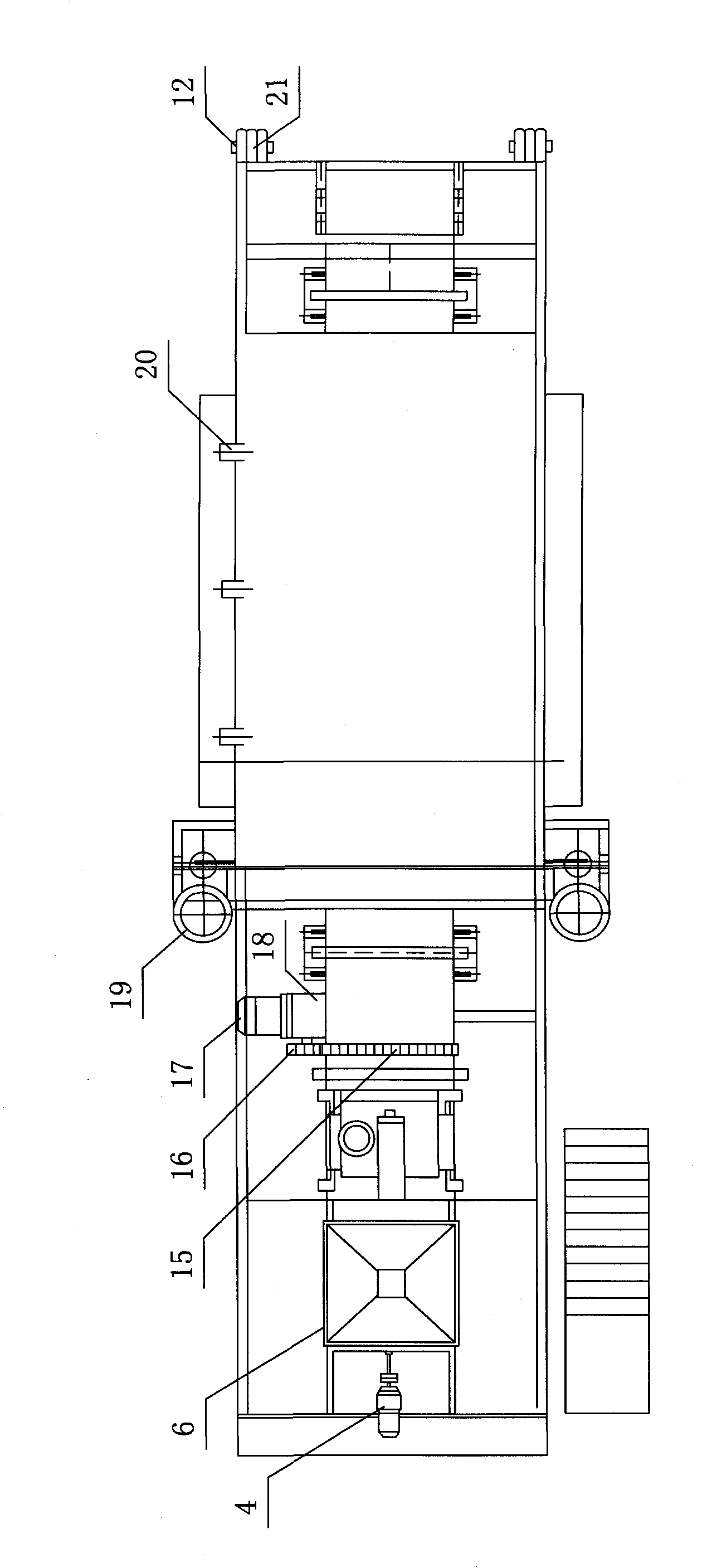

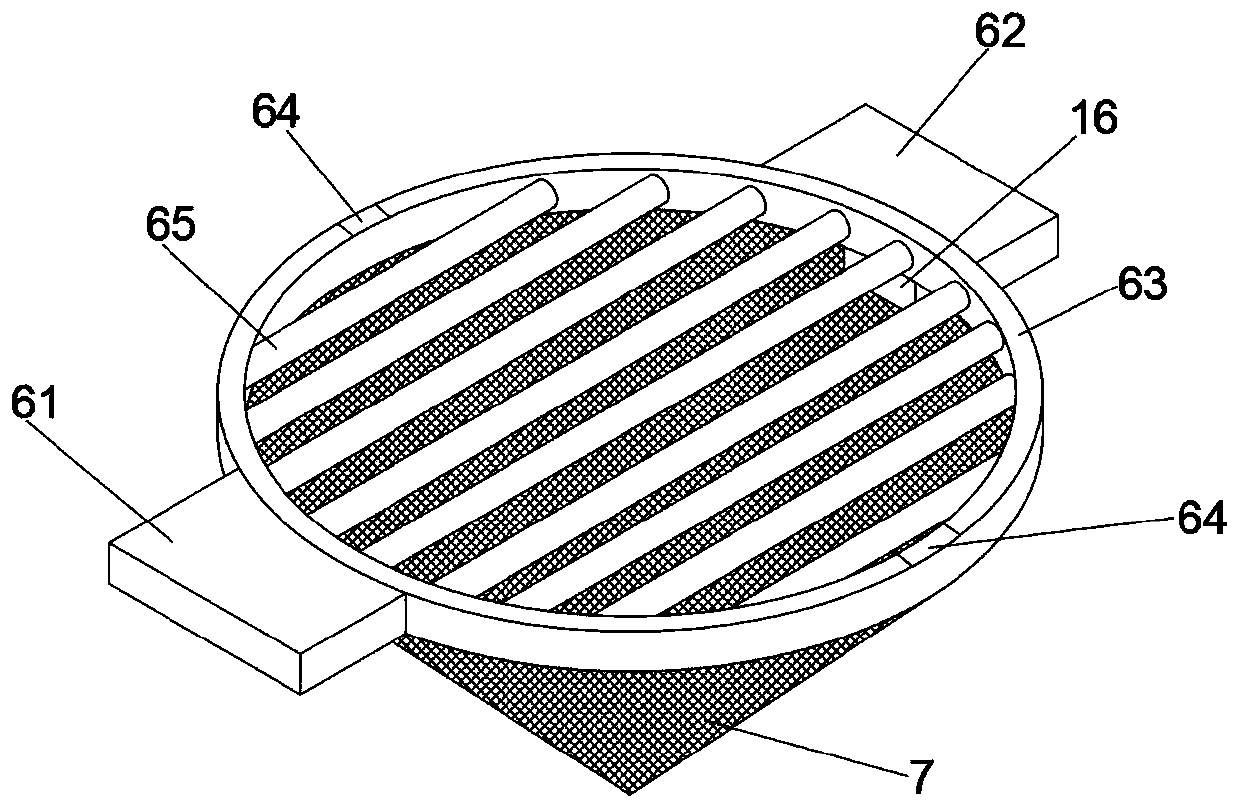

Vertical read-lead mobile oxidation furnace

The invention discloses a vertical read-lead mobile oxidation furnace. The upper end of a furnace body is provided with an upper oxidation chamber, while the middle part is provided with a middle oxidation chamber, and the lower end is provided with a lower oxidation chamber; the bottom of the upper oxidation chamber is provided with an upper group of heat collecting tubes, the bottom of the middle oxidation chamber is provided with a middle group of heat collecting tubes, the bottom end of the lower oxidation chamber is provided with a lower group of heat collecting tubes, and heat dissipation holes are formed on the circumferences of branches of the upper, middle and lower groups of heat collecting tubes; the left side of the furnace body is provided with a combustion chamber, the left end of the combustion chamber is provided with an oil nozzle and an electronic igniter, and the right side of the combustion chamber is provided with a main heat supply pipe; the right side of the main heat supply pipe is provided with upper, middle and lower shunt pipes in turn, and the three shunt pipes are connected and arranged at inlets of the three groups of heat collecting tubes respectively; the upper end of the upper oxidation chamber is provided with a waste heat collecting chamber, and the upper end of the waste heat collecting chamber is provided with a feed hopper; and the lower side of the lower oxidation chamber is provided with a baiting hopper, the bottom end of the baiting hopper is provided with a cooling barrel, the lower end of the cooling barrel is provided with a blanking box, a distribution sieve is arranged in the blanking box, and the lower end of the distribution sieve is provided with a discharge hopper and a distribution hopper.

Owner:张保兴

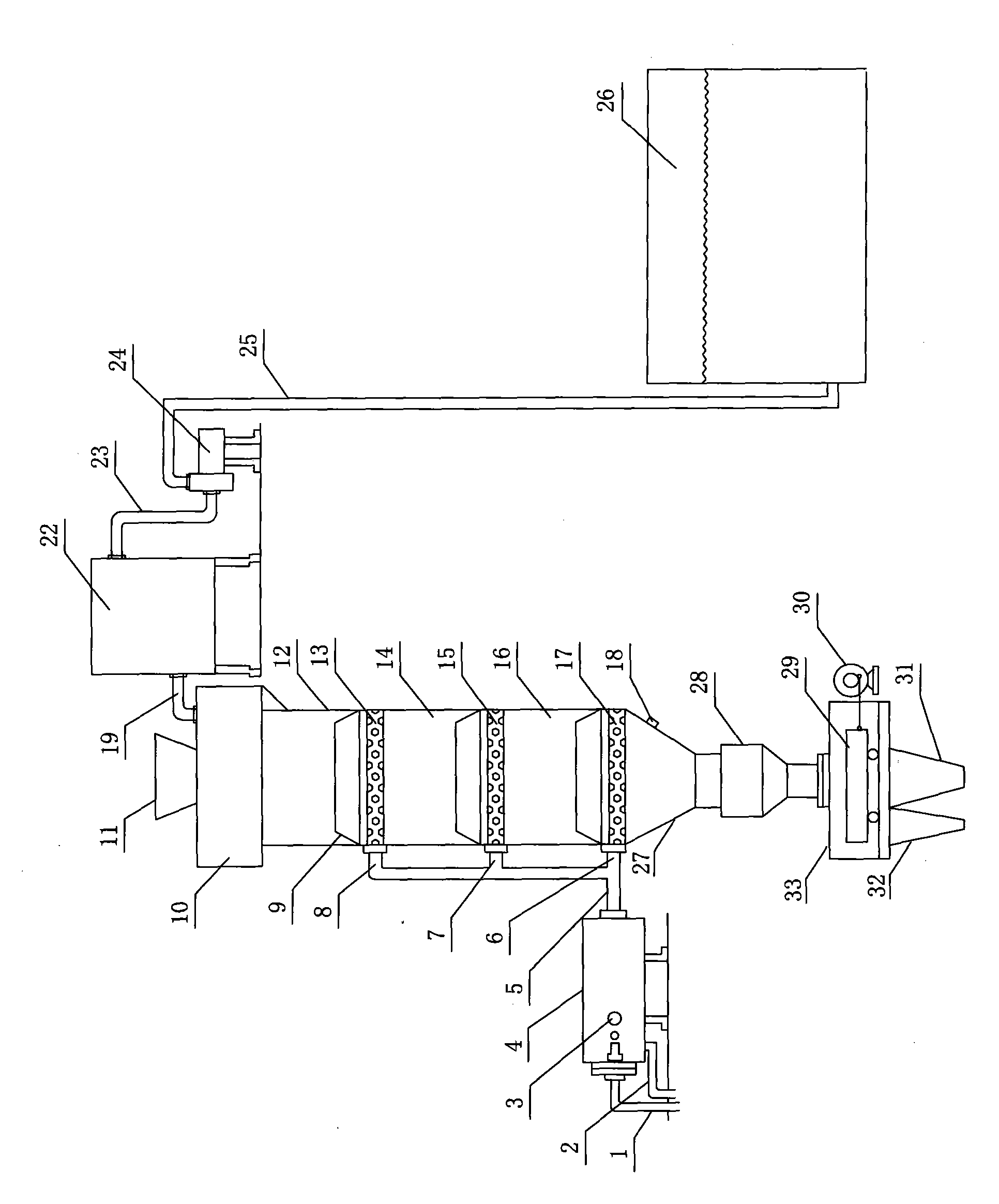

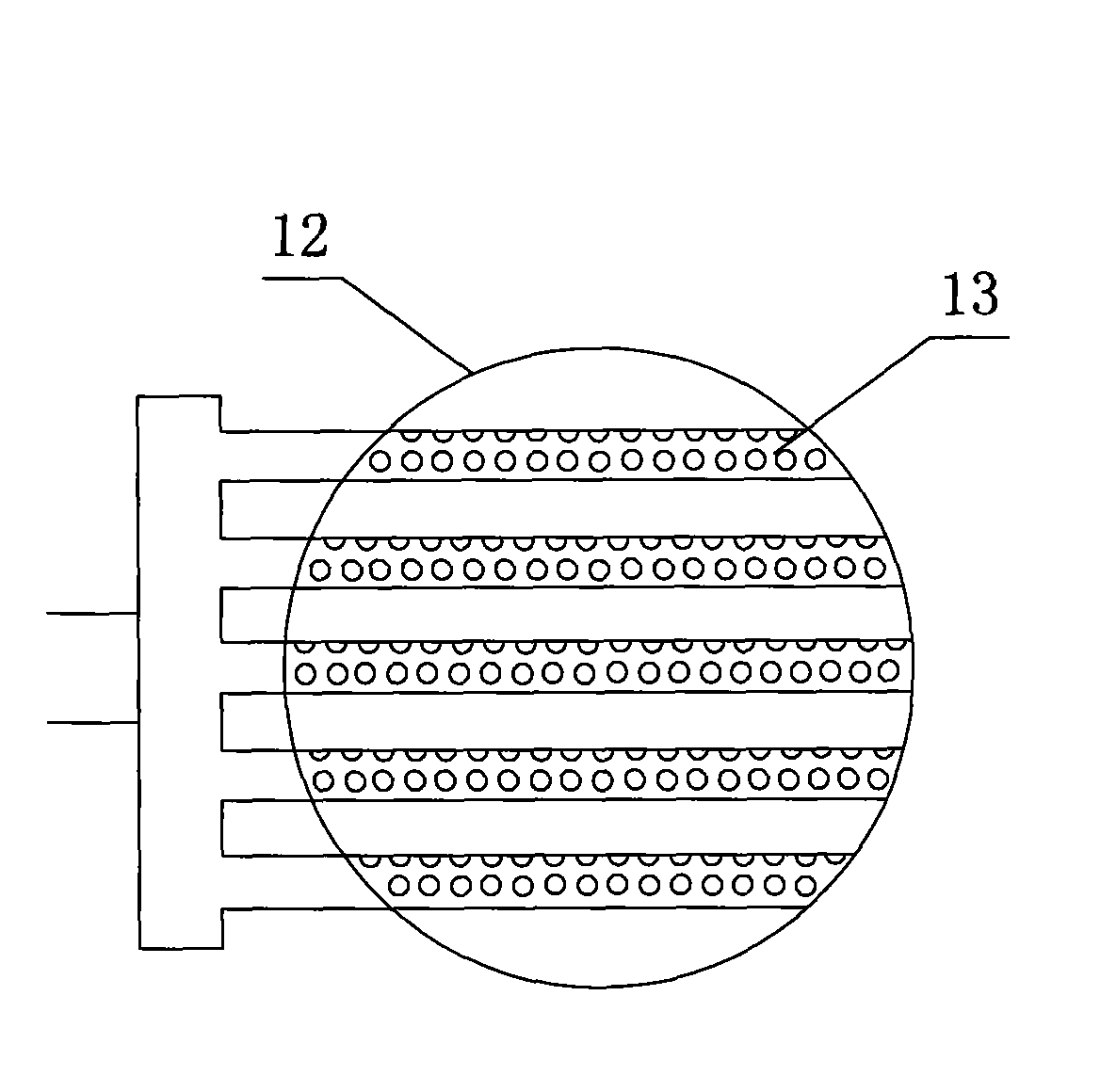

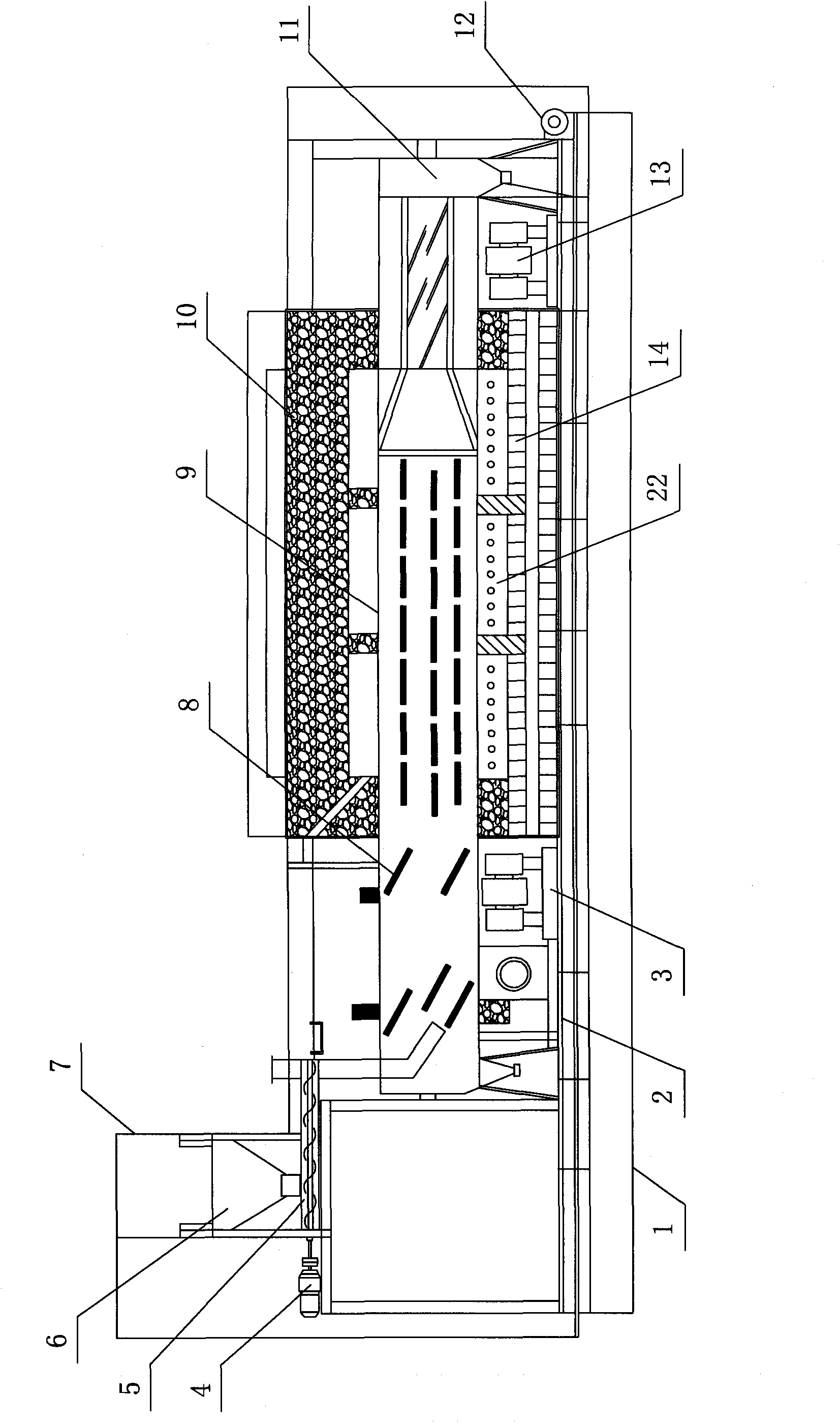

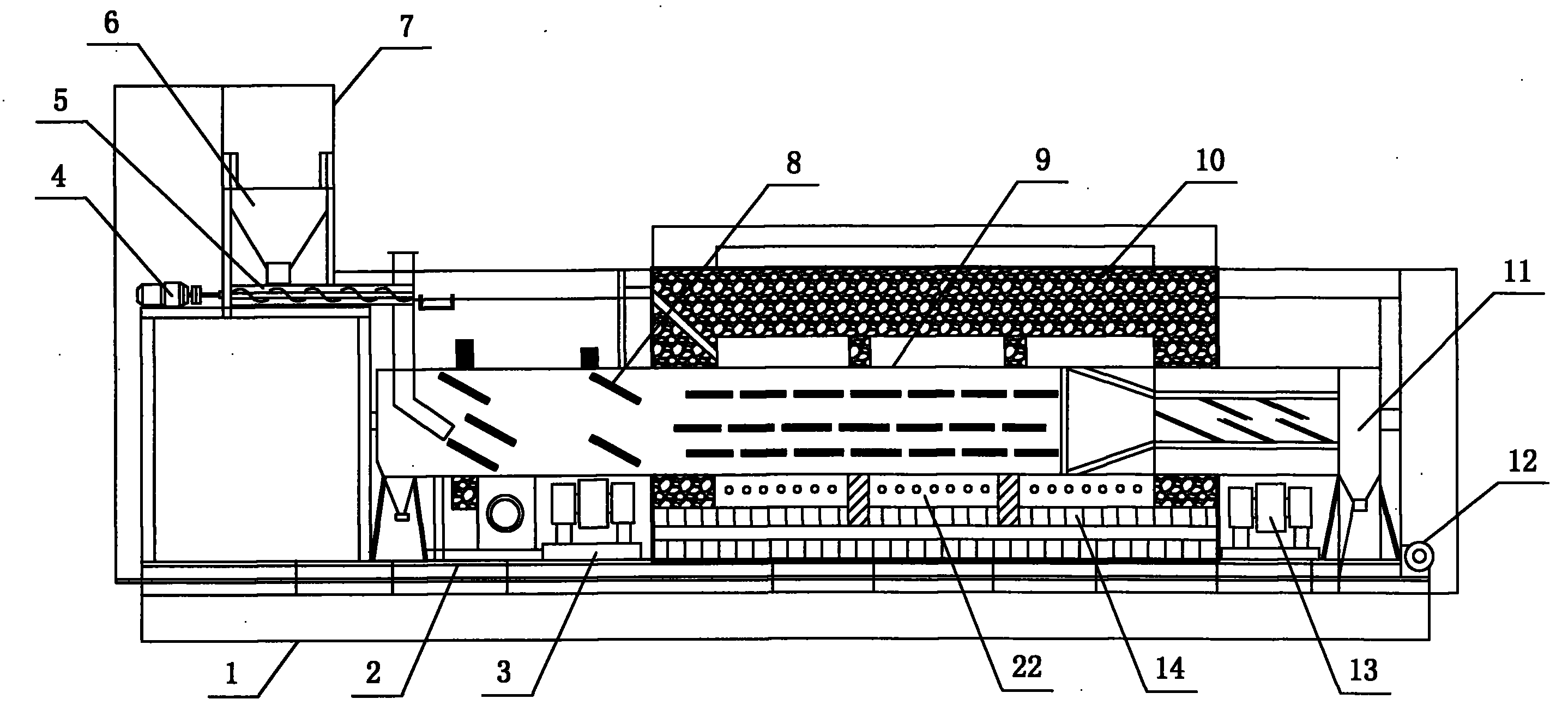

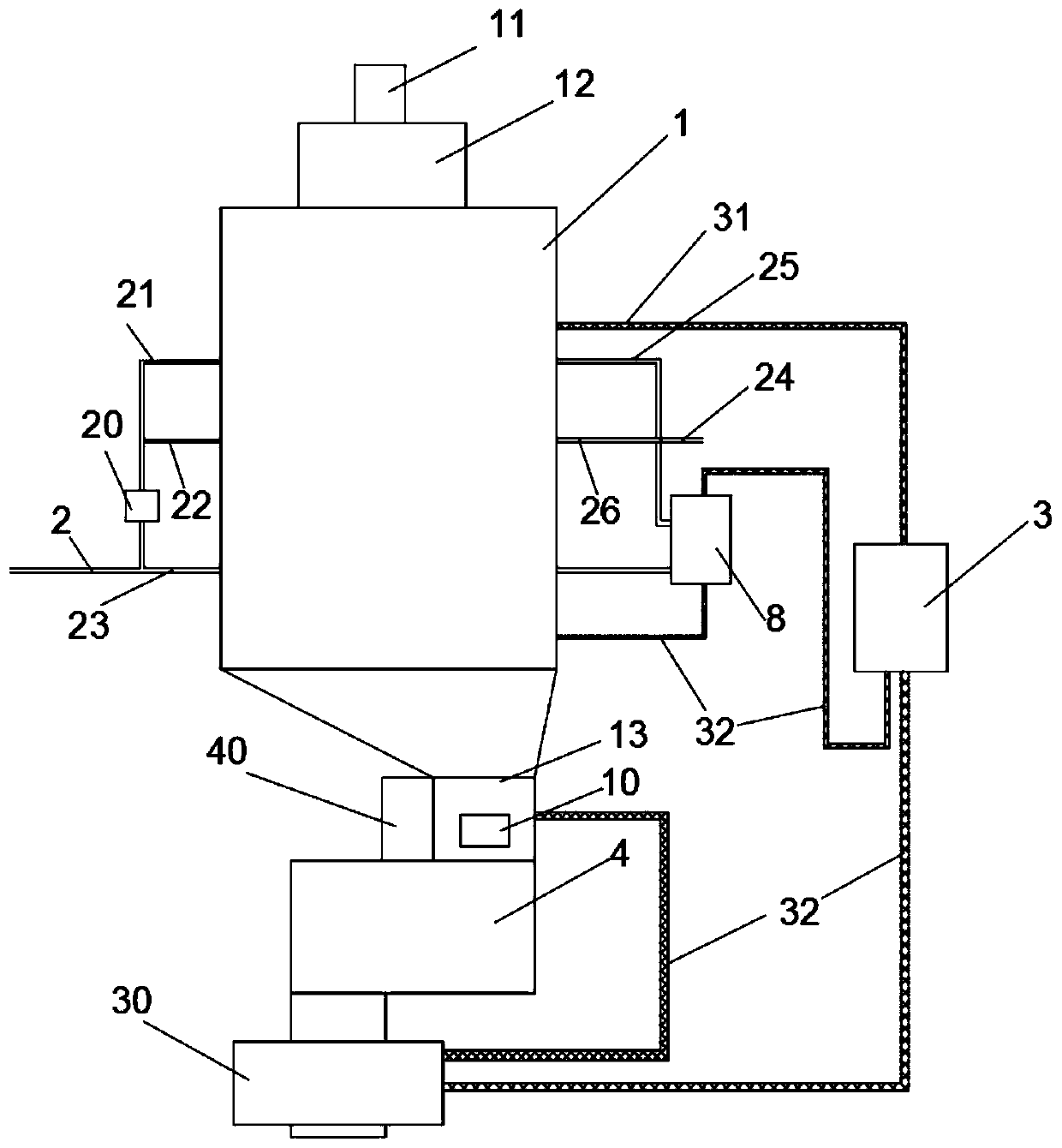

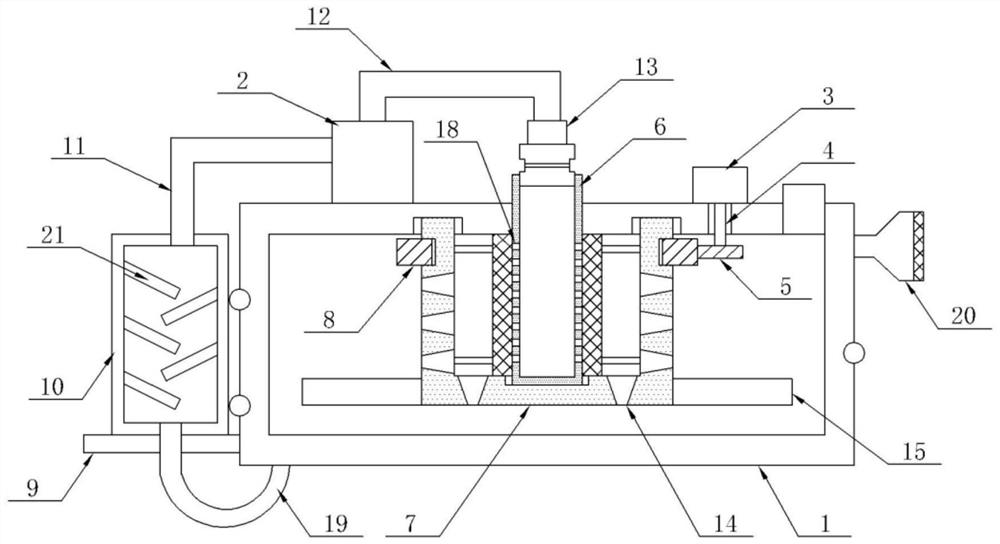

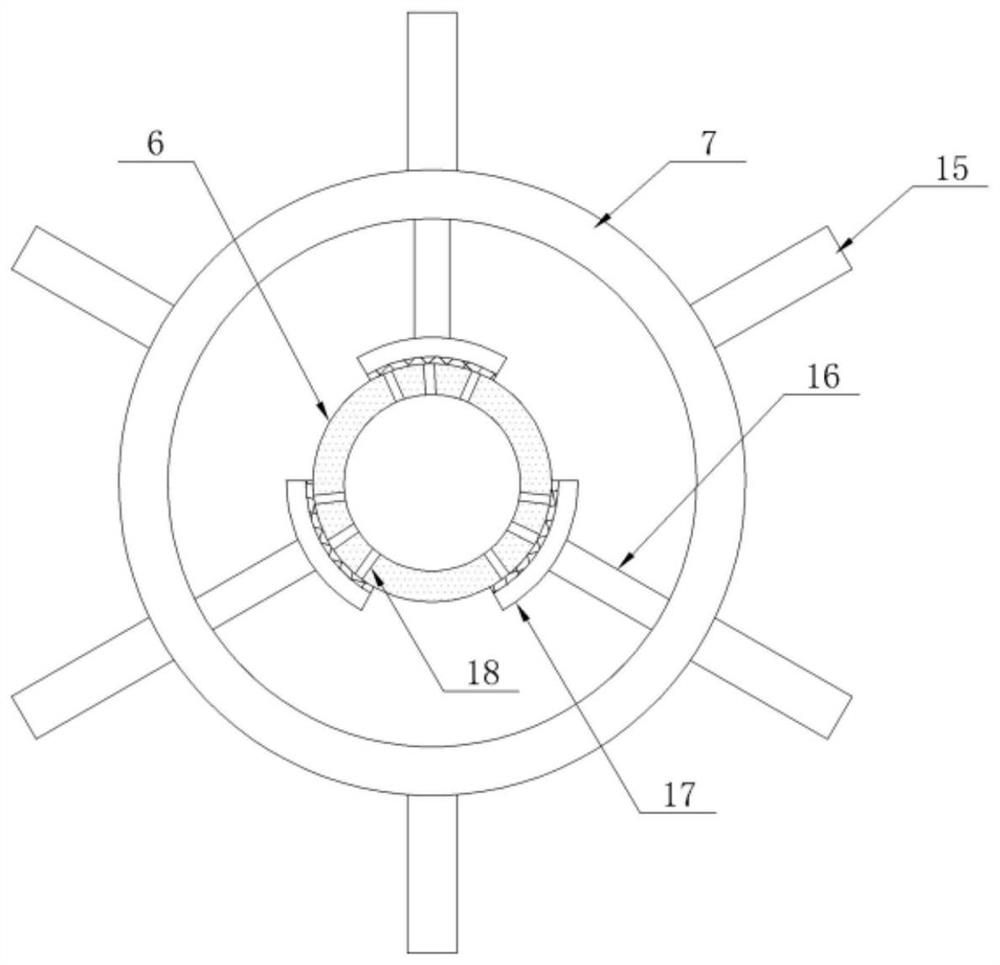

Surface-to-air-missile-type red lead energy-saving oxidizing furnace

The invention discloses a surface-to-air-missile-type red lead energy-saving oxidizing furnace which comprises an oxidizing furnace body, wherein the oxidizing furnace body 1 is a cylinder structure, and is divided into an upper furnace body, a middle furnace body and a lower furnace body from top to bottom; and aluminum silicate fiber felt is wrapped around the outside of the oxidizing furnace body to achieve the effects of thermal insulation and sound insulation, and is fixed by a four-foot bracket. Heat generated by electric heating is blown by a Root's blower and directly sent into the oxidizing furnace via a heat transfer tube, thereby supplying heat to the raw material. The surface-to-air-missile-type red lead energy-saving oxidizing furnace can implement clean production to avoid environmental pollution, can implement quick preparation of red lead, enhances the production efficiency, maximally utilizes the energy, implements the microcomputer control on the oxidizing process, avoids the occupational hazards, and ensures good health of the staff.

Owner:JIESHOU CITY JUNMA IND & TRADE

Method for preparing highly oxidized lead powder from waste battery lead plaster

ActiveCN103436702AHarm reductionReduce manufacturing costRed leadWaste accumulators reclaimingLead carbonateCooking & baking

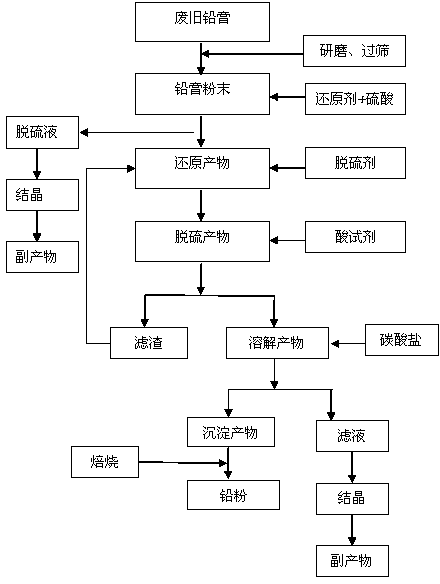

The invention discloses a method for preparing highly oxidized lead powder from a waste battery lead plaster, which comprises the following steps: (1) grinding a waste lead plaster into powder; (2) adding a sulfuric acid solution and reducer into the lead plaster powder, sufficiently reacting, separating to remove the liquid, washing the solid material to neutral with water, and baking; (3) adding desulfurizer into the solid material obtained in the step (2), sufficiently reacting, separating to remove the liquid, washing the solid material to neutral with water, and baking; (4) adding an acid solution into the solid material obtained in the step (3), sufficiently reacting, removing the insoluble impurities to obtain a lead-containing solution, adding carbonate into the solution, sufficiently reacting, removing the liquid, washing the solid with water, and baking to obtain a pure lead carbonate solid; and (5) calcining the lead carbonate solid obtained in the step (4) in a muffle furnace to obtain the highly oxidized lead powder. The method has the advantages of low preparation cost, simple technical process and high lead recovery rate and quality, and can obviously lower energy consumption and reduce environmental pollution.

Owner:YANGZHOU APOLLO BATTERY

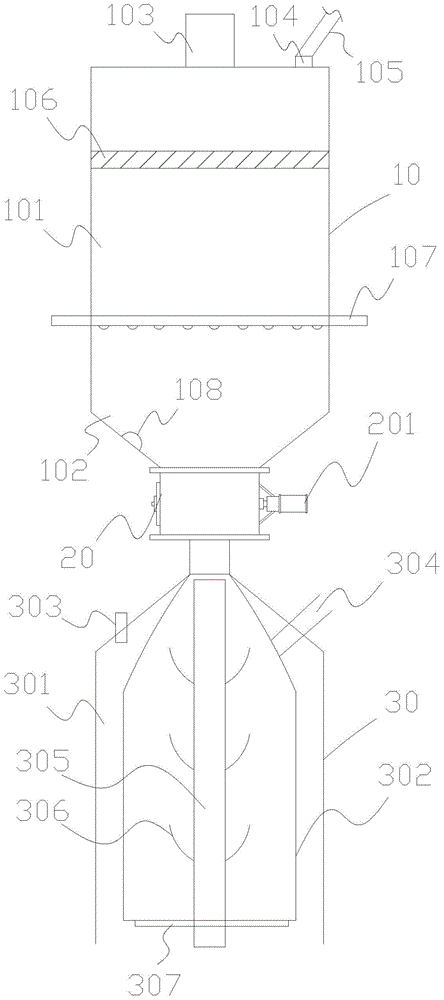

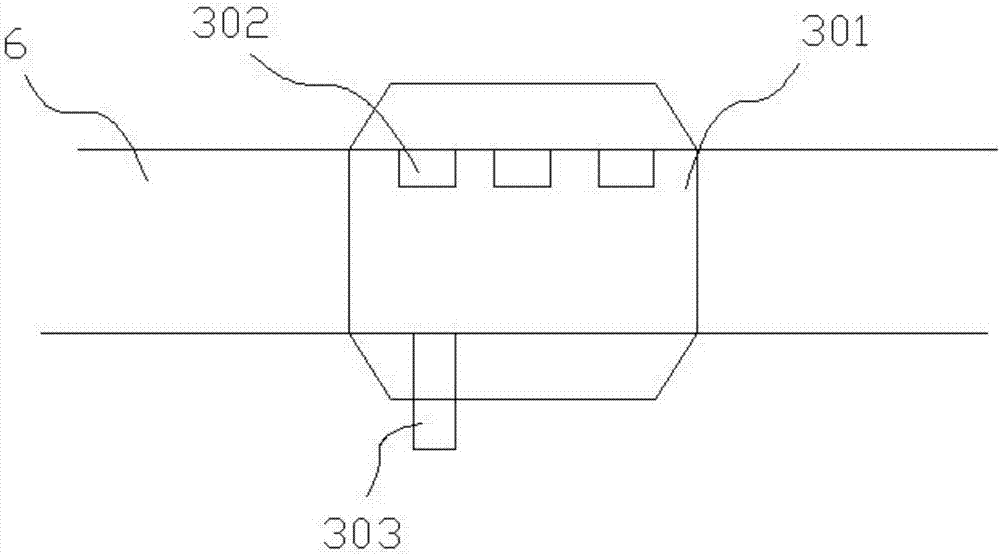

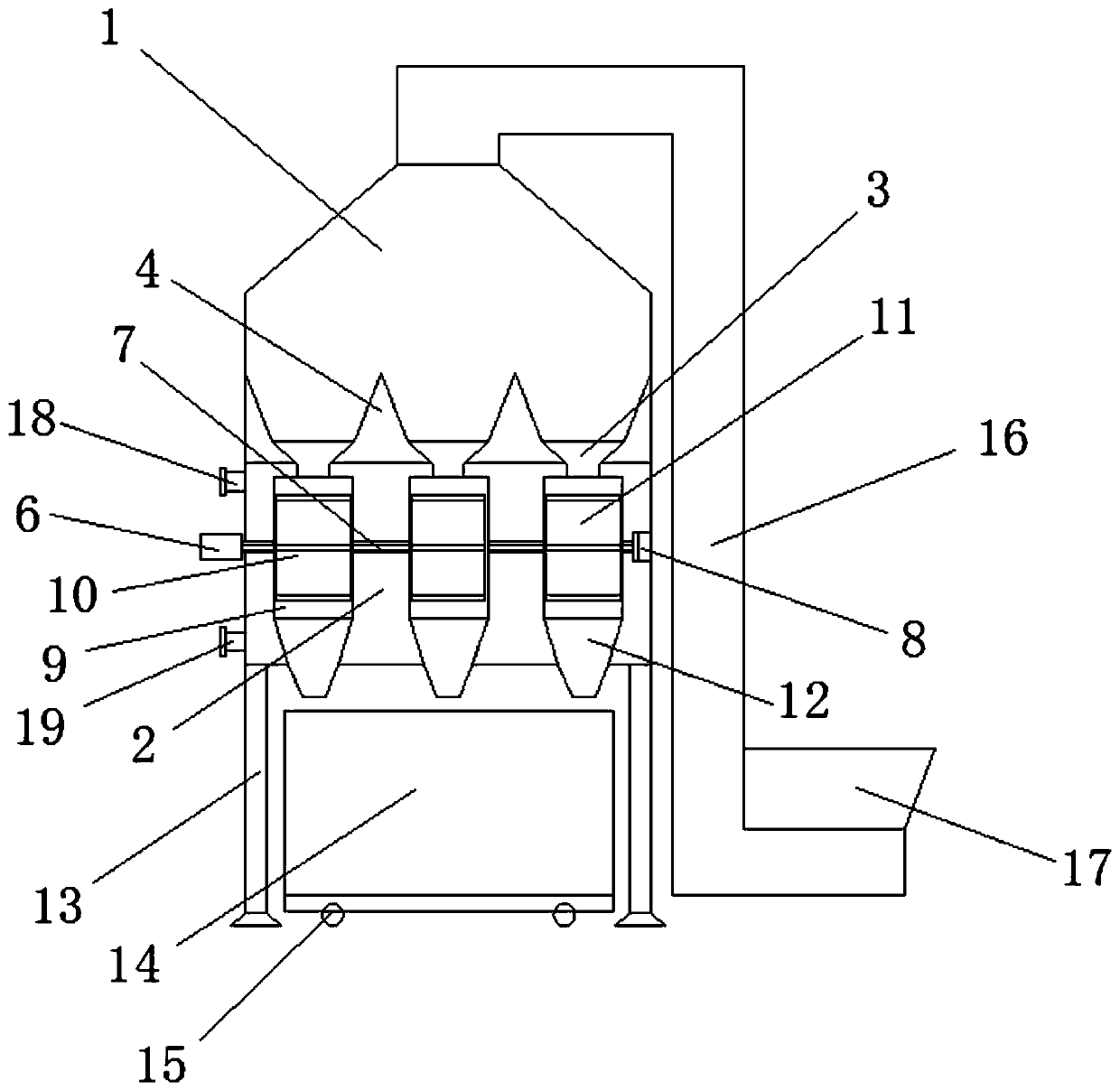

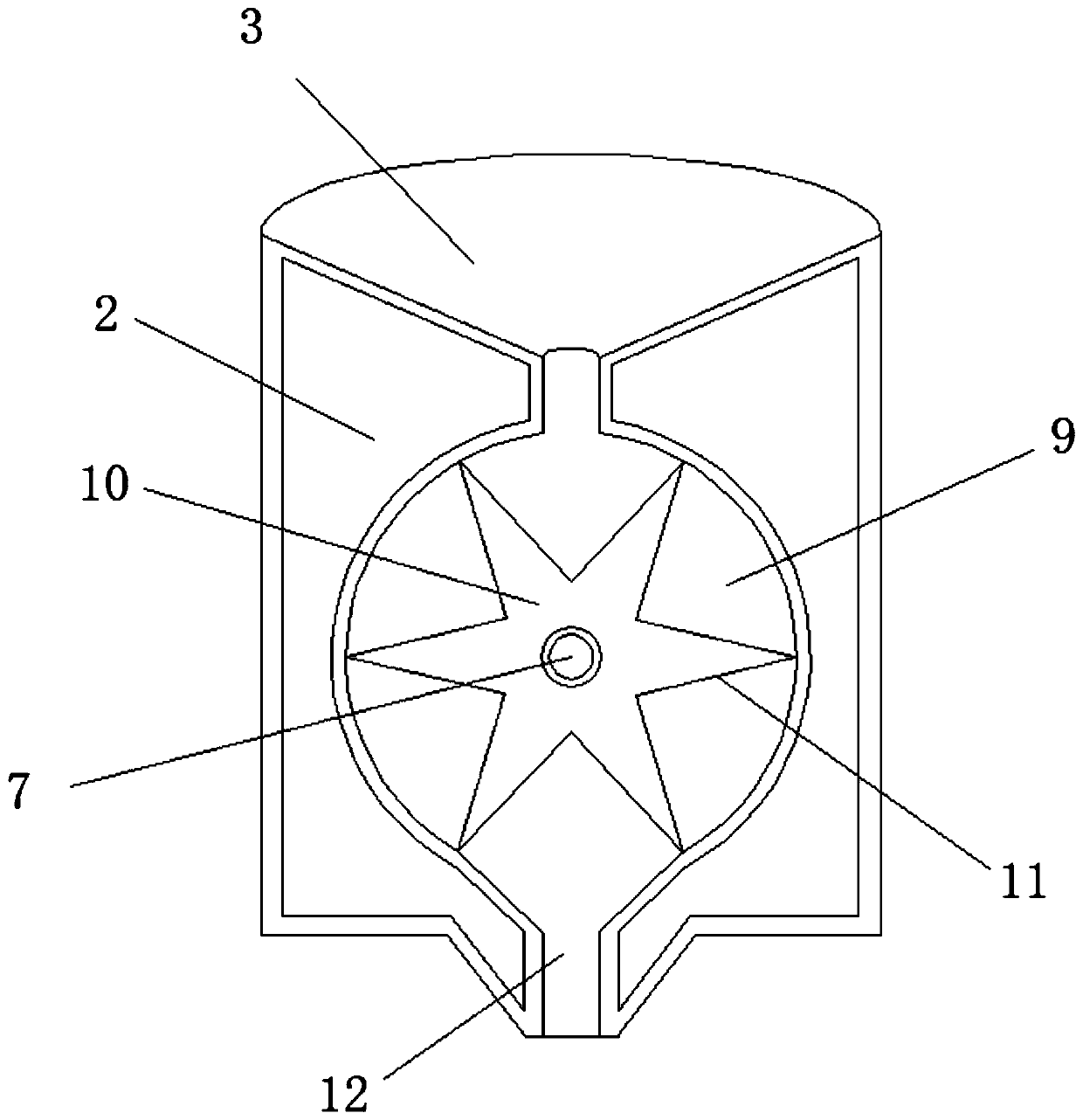

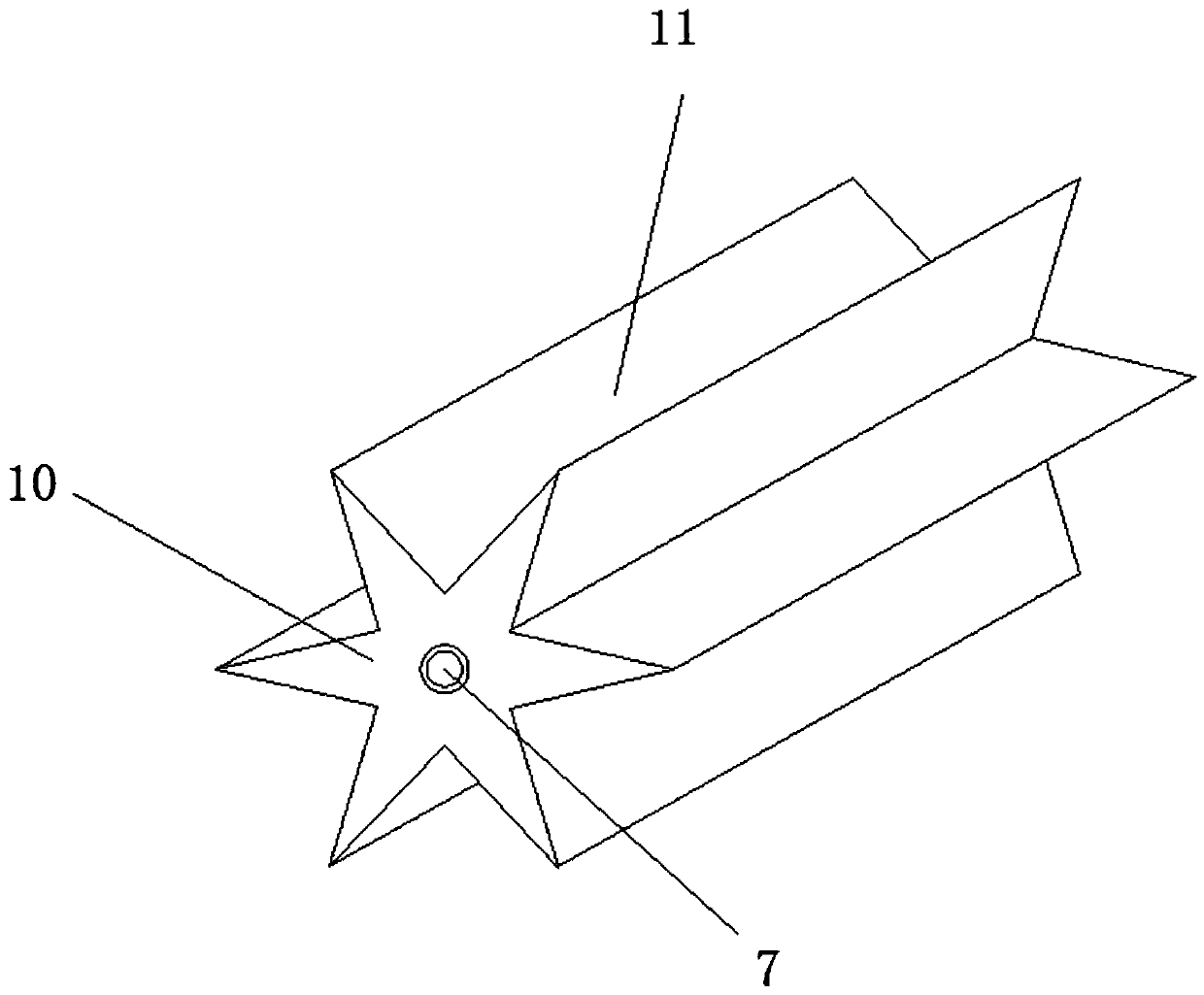

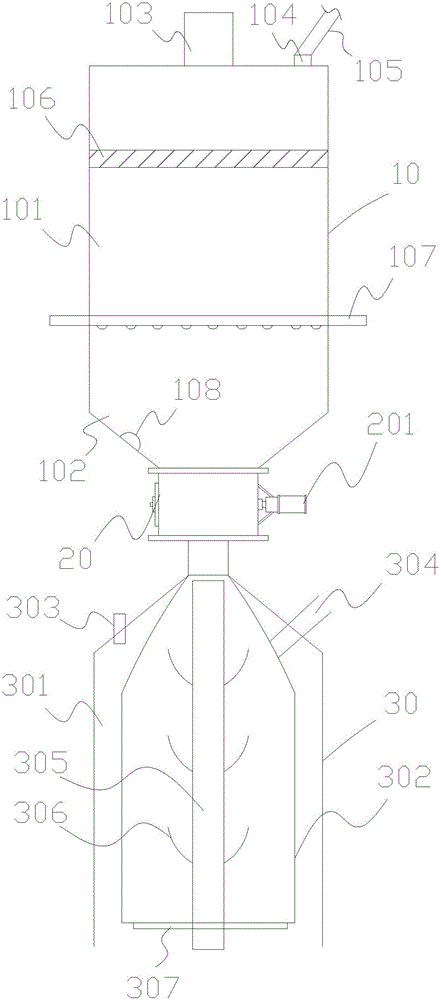

Discharge cooling device of red lead oxidizing furnace

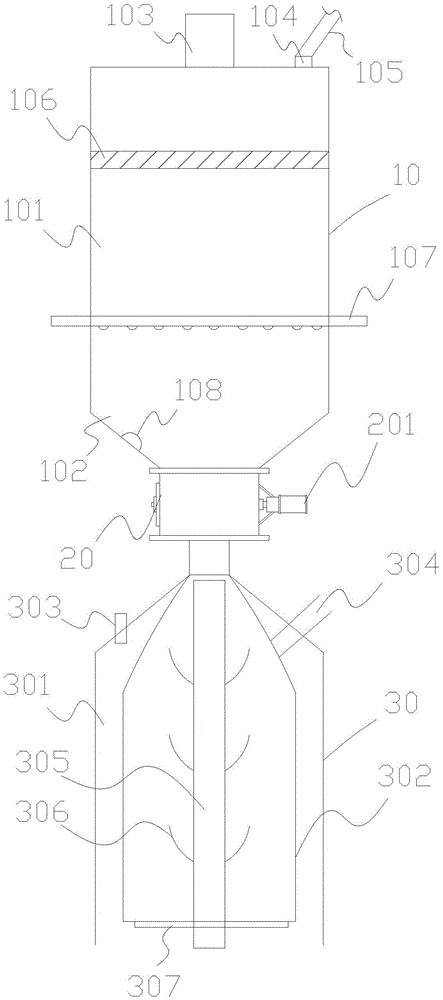

ActiveCN105645467ASimple structural designReasonable structural designRed leadHandling discharged materialEngineeringGate valve

The invention discloses a discharge cooling device of a red lead oxidizing furnace. The device comprises a storage bin on the upper portion, an off fan in the middle and a discharge barrel on the lower portion. The off fan is driven by a motor and connected with the storage bin and the discharge barrel, and the discharge barrel, the off fan and the storage bin are vertically communicated into a whole. The top of the storage bin is provided with a feed inlet. The 1 / 3 position below the top of the storage bin is provided with an upper layer and a lower layer of criss-cross blocking rollers. The 2 / 3 position below the top of the storage bin is provided with an air inlet pipe. The portion, stretching into the bin, of the air inlet pipe is provided with a plurality of air outlets in the downward direction. The portion, outside the bin, of the air inlet pipe is connected with a main air inlet pipe. The discharge barrel is composed of a shell and an inner container. The caliber of the upper portion of the shell and the inner container are integrally connected to the off fan. One side of the top of the shell is provided with an air inlet hole, and the other side of the top of the shell is provided with an air outlet hole. The air outlet hole is led to a dust remover through a corrugated pipe. A strong magnetism iron bar is installed between the upper caliber and the lower caliber inside the inner container. Three hoppers are installed around the strong magnetism iron bar from top to bottom. A discharge outlet in the bottom of the inner container is provided with a brake valve.

Owner:JIESHOU CITY JUNMA IND & TRADE

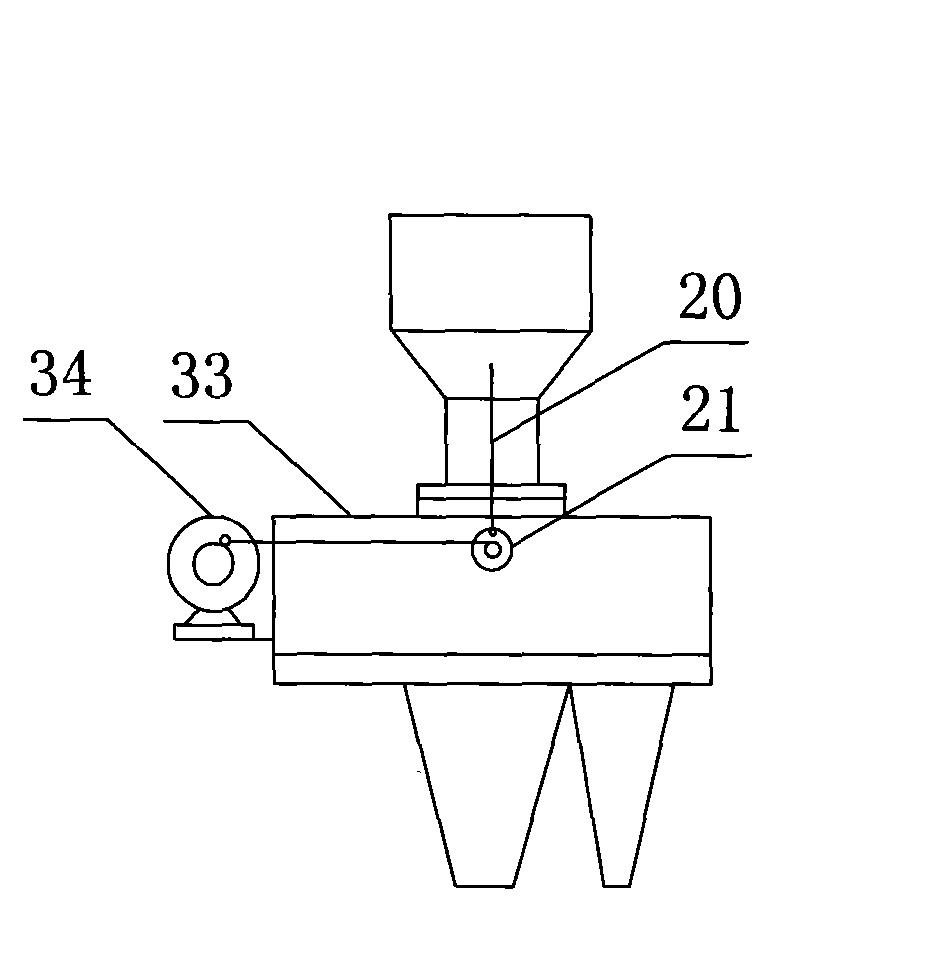

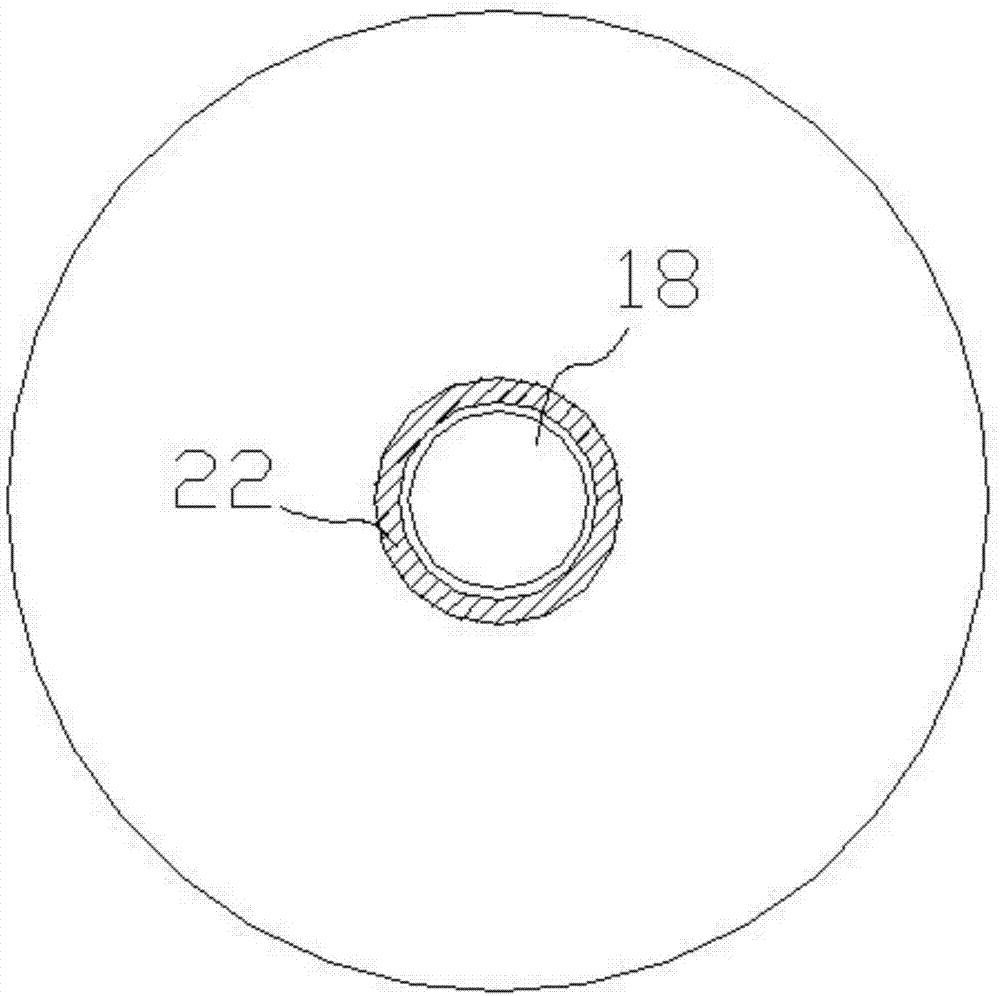

Water process energy-saving granulation technology for red lead production

A water process energy-saving granulation technology for red lead production comprises the following steps: (1) dedusting cooling (pretreatment); (2) screw conveying; (3) re-conveying; (4) deironing; (5) granulator starting; (6) water process granulation; and (7) exhausting dedusting. The technology has the advantages of simple process, easiness in operation, realization of automatic streamline working of the production flow of red lead, increase of the production efficiency, energy saving, consumption reduction, and avoiding of occupational hazards; and iron in lead powder is removed to provide guaranteeing for the production of the high-quality red lead product.

Owner:安徽徽能化工科技有限公司

Method of quickly preparing red lead by utilizing intelligent oxygen supply device

ActiveCN103950971AShort oxidation timeIncrease production capacityRed leadLEAD TETROXIDELead(II,IV) oxide

The invention discloses a method of quickly preparing red lead by utilizing an intelligent oxygen supply device. The method comprises the following the steps: preparing red lead (lead tetroxide) by the intelligent oxygen supply device; compressing and storing pure oxygen gas prepared by oxygen preparation equipment in the intelligent oxygen supply device; adding air for diluting; controlling oxygen content to 35%-40% at a normal temperature under normal pressure by intelligent oxygen measuring equipment, wherein the intelligent oxygen measuring equipment intelligently switches on or switches off an air adding switch when the oxygen content is lower than or higher than 35%-40%; storing the diluted oxygen gas in a gas storage tank; heating the gas storage tank by a solar heating device or an electric heating device; controlling a temperature to 200 DEG C; and injecting the oxygen gas to a roasting bin and an oxidizing bin at a speed of 10L / m by an air feeder and an air guide tube. The device and the method disclosed by the invention can shorten oxidizing time, increase yield, save energy resource, lower consumption, save production cost and improve production efficiency.

Owner:JIESHOU CITY JUNMA IND & TRADE

Method for preparing red lead from positive electrode waste lead paste of lead-acid storage battery

ActiveCN107732350AReasonable ratioHigh purityLead-acid accumulatorsCell electrodesEnvironmental resistanceBiochemical engineering

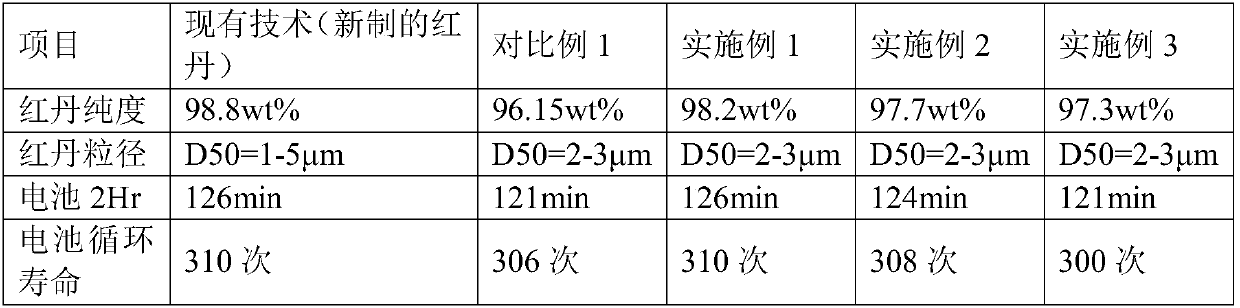

The invention relates to the battery recycling field, and discloses a method for preparing red lead from positive electrode waste lead paste of a lead-acid storage battery. According to the method, the positive electrode waste lead paste generated in the production process of the lead-acid storage battery, and the positive electrode lead paste recycled from the waste lead-acid storage battery areused as the raw materials to prepare red lead; the raw materials are reasonable in proportion and the process requirement is simple, so that red lead with relatively high purity can be prepared and relatively low energy consumption is achieved; compared with a new battery, the performance of the battery prepared from the red lead obtained by the method is not basically lowered; in preparation of red lead, the secondary product also can be used for preparing a battery additive 4BS(4PbO.PbSO<4>); and therefore, by virtue of the method, the cost is lowered, the problem of the waste material generated in the production and recycling processes of the lead-acid storage battery is solved, and green and environment protection is achieved, so that the method is very suitable for industrial production.

Owner:CHAOWEI POWER CO LTD

Energy-saving device for preparing nano-scale lead tetraoxide (red lead)

InactiveCN101780977AIngenious ideaReasonable structureNanostructure manufactureChemical industryLead(II,IV) oxideEngineering

The invention discloses an energy-saving device for preparing nano-scale lead tetraoxide (red lead). A bracket is arranged at the upper end of a pedestal; the bracket is provided with a front riding wheel and a rear riding wheel; a rotary kiln cylinder body is arranged on each riding wheel; a hinge sleeve is arranged at the rear end of the bracket; the rotary kiln cylinder body is connected to the bracket through a hinge pin; a material-pushing rib is arranged on the inside cylinder wall of the rotary kiln; an insulating furnace body is arranged on the outside of the rotary kiln; an insulating layer is arranged in the insulating furnace body; a heating furnace body is arranged at the upper end of the bracket; a gear ring is arranged on the circumference at the front end of the rotary kiln cylinder body; a motor is arranged on the right bracket of the gear ring; a reduction box is arranged in the motor; a hydraulic lift pump is arranged on the right bracket of the motor; a feed box is arrange at the left front end of the rotary kiln cylinder body; a discharging box is arranged at the rear end of the rotary kiln cylinder body; a feed hopper is arranged on the lower side of the feed box; a feed motor is arranged at the front end of the feed hopper; and a spiral stock pusher is arranged on the right side of the feed motor.

Owner:JIESHOU CITY JUNMA IND & TRADE

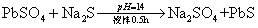

Method for converting lead sulfate into lead tetraoxide

The invention discloses a method for converting lead sulfate in a waste lead-acid storage battery into lead tetraoxide, comprising the following steps of: firstly, reacting the lead sulfate, excessive soluble sulfide salt and a small amount of ammonia water, and converting the lead sulfate into lead sulfide; then filtering out the lead sulfide, adding the lead sulfide into hot dilute nitric acid, and fully reacting; then steaming solution, continuously heating to be certain temperature, after reactants are decomposed completely, putting residues into a stirring ball mill for grinding, simultaneously, introducing oxygen-nitrogen mixed gas with certain oxygen content, and obtaining a final product, namely the lead tetraoxide. The method is simple and practical, high temperature is not needed, the energy consumption is low, the pollution is less, the prepared lead tetraoxide can be used as an active substance which is reused in a lead-acid storage battery.

Owner:双登天鹏冶金江苏有限公司

Method for preparing lead oxide by using lead-acid storage battery positive electrode plate coating waste lead paste

InactiveCN104961155AEasy to separateWill not bring pollution problemsRed leadBiochemical engineeringLead oxide

The present invention discloses a method for preparing lead oxide by using lead-acid storage battery positive electrode plate coating waste lead paste. The method comprises: 1) drying waste lead paste, and detecting the mass content of lead sulfate in the waste lead paste; 2) weighing a certain amount of waste lead paste, adding a prepared desulfurization solution, and reacting with the lead sulfate in the waste lead paste so as to finally remove the lead sulfate in the waste lead paste; 3) carrying out solid-liquid separation on the reaction product obtained in the step 2), and washing the obtained filter cake with deionized water until no desulfurization solution exists; 4) drying the filter cake prepared in the step 3), and crushing the dried filter cake to prepare powder; and 5) calcining the powder prepared in the step 4) in a high temperature furnace to obtain the lead oxide. According to the present invention, the positive electrode additive lead oxide capable of being recycled by the lead-acid storage battery is prepared through the simple and easy-performing method, the raw materials are easy to obtain, the components of the positive electrode waste lead paste of most of the lead-acid storage battery manufacturing companies are substantially the same, the substance stability is good, and the method is suitable for large-scale promotion.

Owner:CHAOWEI POWER CO LTD

Production technique for red lead containing rare earth

The invention discloses a production technique for red lead containing rare earth, relating to the technical field of red lead production. The production technique is characterized by comprising the following steps: (1) melting lead at the temperature of 670DEG C and fast pouring into cold water to obtain lead foam; (2) oxidizing the foam lead to obtain lead hydroxide in the presence of an oxidization accelerator; (3) enabling the lead hydroxide to react with 4%-5% acetic acid to obtain lead acetate; (4) adding rare earth elements into lead carbonate; (5) introducing carbon dioxide in the lead carbonate and the rare earth elements at atmospheric temperature to obtain lead carbonate precipitate; and (6) filtering the lead carbonate precipitate and firing at the temperature of 470DEG C to obtain the red lead. The production technique is simple in formula, convenient to control, good in stability, high in formation efficiency, and capable of greatly increasing the early-stage capacity and prolonging the cycle life of a storage battery.

Owner:JIESHOU CITY JUNMA IND & TRADE

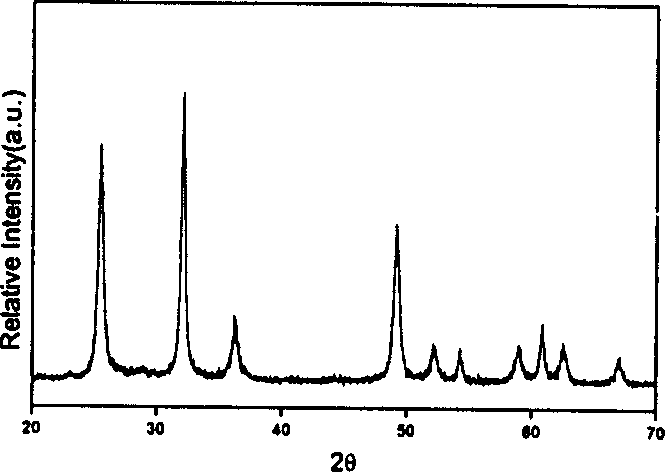

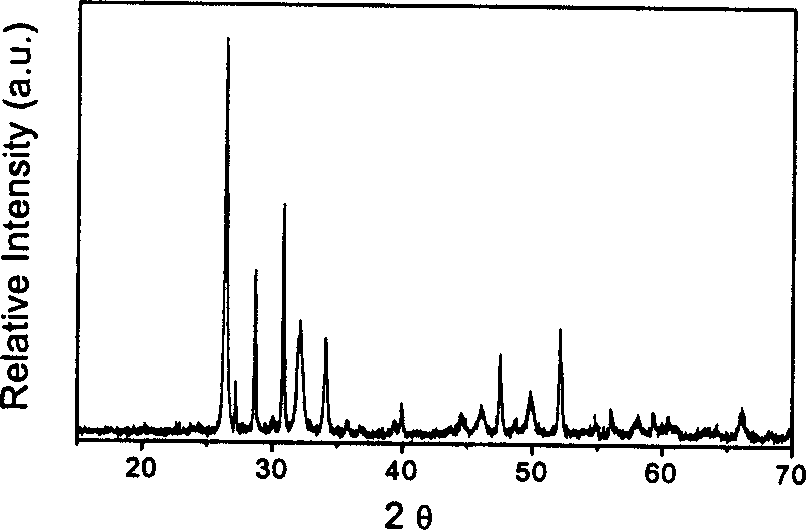

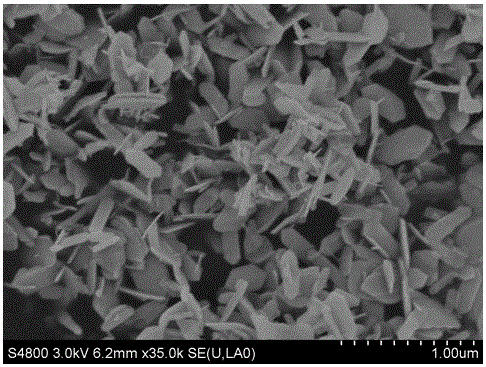

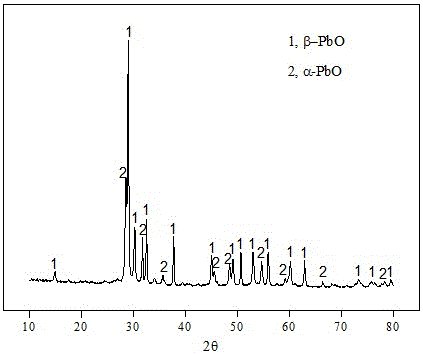

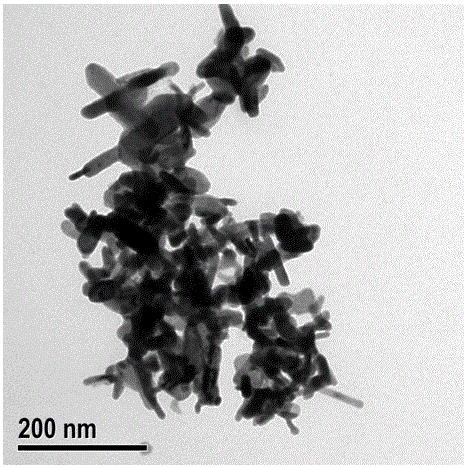

Process for synthesizing alpha, beta type lead dioxide and leadleaden oxide naon crystal

InactiveCN1171797CNo pollution in the processImprove pollutionLead dioxideRed leadCrystallographyLead dioxide

The method for synthesizing alpha and beta type lead dioxide nano crystal and lead tetraoxide nano crystal includes the following steps: adding lead salt or lead oxide into water to prepare solution, adding sodium hydroxide, regulating pH value of solutino to 9-14, making said solution produce liquid-phase reaction with oxidants of chlorine gas, etc., under the condition of 30-60 deg.C can obtain alpha type lead dioxide nano crystal, under the condition of 60-200 deg.C can obtain beta type lead dioxide nano crystal, then pyrolyzing the obtained lead dioxide nano crystal at 410-430 deg.C and can obtain lead tetraoxide nano crystal.

Owner:TSINGHUA UNIV

Method for preparing lead oxide by using lead-acid storage battery positive electrode acid leaching waste lead mud

The present invention discloses a method for preparing lead oxide by using lead-acid storage battery positive electrode acid leaching waste lead mud. The method comprises: 1) drying waste lead mud, and detecting the mass content of lead sulfate in the waste lead mud; 2) weighing a certain amount of waste lead mud, adding a prepared desulfurization solution, and reacting with the lead sulfate in the waste lead mud so as to finally remove the lead sulfate in the waste lead mud; 3) carrying out solid-liquid separation on the reaction product obtained in the step 2), and washing the obtained filter cake with deionized water until no desulfurization solution exists; 4) drying the filter cake prepared in the step 3), and crushing the dried filter cake to prepare powder; and 5) calcining the powder prepared in the step 4) in a high temperature furnace to obtain the lead oxide. According to the present invention, the acid leaching waste lead mud generated during the lead-acid storage battery positive electrode plate production process is adopted as the raw material, such that the raw materials are easy to obtain; and the components of the positive electrode acid leaching waste lead mud of most of the lead-acid storage battery manufacturing companies are substantially the same, such that the substance stability is good, and the method is suitable for large-scale promotion.

Owner:CHAOWEI POWER CO LTD

Discharging cooling device of red lead oxidation furnace

ActiveCN111023843ACause occupational diseaseRealize comprehensive utilizationRed leadEnergy inputCold airCooling tower

The invention discloses a discharging cooling device of a red lead oxidation furnace. The discharging cooling device comprises a rotary valve, a water inlet pipeline, a water outlet pipeline, a heat exchanger, an induced draft fan and a cooling tower. The cooling tower is provided with a feed port, a discharge port and an air outlet. The rotary valve is installed on the feed port of the cooling tower. The cooling tower is internally provided with a cooling headgear, a cooling plate and a thermometer. The cooling headgear is connected with the induced draft fan, and the cooling plate is connected with the water inlet pipeline and the water outlet pipeline. The air outlet is connected with the heat exchanger through a gas pipeline, and the heat exchanger is connected with the induced draft fan through a gas pipeline. The discharge port is further provided with a control panel, the control panel is correspondingly and electrically connected with the rotary valve, the induced draft fan andthe thermometer. The temperature measured by the thermometer can be displayed on the control panel. According to the discharging cooling device, the shortcomings of the prior art are overcome, cooling is carried out by blowing cold air, and then through the cooling of the two-layer cooling plate, the utilization of waste heat is realized, occupational diseases to staffs due to dust generated in the production process are avoided, and quantitative discharging at a charging port can be carried out, and packaging is convenient.

Owner:JIESHOU CITY JUNMA IND & TRADE

Method for preparing rare earth red lead by using red lead production process

InactiveCN108550797AReduce manufacturing costNo pollution in the processChemical industryRed leadProduct inspectionEnvironmental resistance

A method for preparing rare earth red lead by using a red lead production process is characterized in that the method comprises the following steps: S1, lead ingot melting and powdering; S2, additionof a rare earth element into a Baji powdering furnace; S3, cooling and dust removal; S4, water process granulation; S5, screen separation; S6, calcination oxidation; S7, finished product inspection; and S8, finished product packaging. The method has the advantages of no environmental pollution or occupational hazards, energy saving and reduction of the production cost of enterprises, so the marketcompetitiveness of enterprise products is enhanced, and the technology makes the enterprises have great environmentally-friendly, ecological and economic benefits.

Owner:JIESHOU CITY JUNMA IND & TRADE

Waste heat utilization method of oxidized red lead powder

ActiveCN111043864AEliminate hazardsAchieve recyclingRed leadEnergy inputCold airEnvironmental engineering

The invention discloses a waste heat utilization method of oxidized red lead powder. The waste heat utilization method includes the following steps of quantitative feeding, cold air blowing, first-time waste heat recycling, oscillation cooling, second-time waste heat recycling, third-time waste heat recycling and flying dust recycling. The waste heat utilization method overcomes the defects in theprior art; according to the waste heat utilization method, the oxidized red lead powder with the temperature being about 500 DEG C is cooled through normal-temperature air and is subjected to two times of cooling plate cooling, and therefore the temperature at which the oxidized red lead powder flows out from a discharge port can be lower than 60 DEG C, and workers can directly package the red lead powder; and by means of the effect of a dust removal cover and an induced draft fan at the position of the discharge port, recycling of oxidized red lead powder flying dust is achieved, and harm caused by the oxidized red lead powder flying dust to the workers is eliminated.

Owner:JIESHOU CITY JUNMA IND & TRADE

Method for preparing nano lead oxide powder by using waste lead-containing soldering tins

The invention discloses a method for preparing nano lead oxide powder by using waste lead-containing soldering tins. According to the method, the waste lead-containing soldering tins separated from waste circuit boards are put into a vacuum furnace, and air is introduced into the vacuum furnace to oxidize the waste soldering tins into lead oxide and tin dioxide by adopting a vacuum oxygen control method. Meanwhile, the vacuum furnace is heated to evaporate out the lead oxide according to different boiling points of the lead oxide and the tin dioxide, and then the lead oxide is carried into a condensation chamber by unreacted nitrogen and is condensed into nano powder. By controlling a system pressure, heating and condensing temperatures, and a condensation distance, two forms of nano lead oxide powder are prepared. Meanwhile, the residues in a crucible are tin dioxide powder. The nano lead oxide product prepared by the method disclosed by the invention has a broad application prospect in the fields of lead glass manufacturing, ceramic materials, pigment, light-emitting diodes, and lead acid storage batteries; and the prepared byproduct namely tin dioxide is a transparent conductive material is widely applied in the fields of electrode preparation, sensors, batteries, liquid crystal display and the like.

Owner:EAST CHINA NORMAL UNIV

Preparation method of lead oxide

PendingCN112551573ASimple processImprove efficiencyLead-acid accumulatorsFinal product manufactureLead carbonateExhaust fumes

The invention relates to a preparation method of lead oxide, and the method is characterized by comprising the following steps of: 1. desulfurizing waste lead plaster, and carrying out solid-liquid separation to obtain a lead carbonate-containing cured product; and 2, carrying out high-temperature smelting on the lead carbonate-containing cured product to obtain lead oxide and waste gas, inputtingthe waste gas into an ammonia water device to produce a sulfur removal agent containing ammonium carbonate, and using the sulfur removal agent containing ammonium carbonate to desulfurize the waste lead plaster in the step 1. The preparation method of lead oxide is simple in process, high in efficiency and low in cost.

Owner:HANGZHOU QIANLIZHIXING TECH CO LTD

Discharge cooling method for lead tetroxide oxidizing furnace

ActiveCN105692693ASimple structural designReasonable structural designRed leadEngineeringCooling methods

The invention discloses a discharge cooling method for a lead tetroxide oxidizing furnace. The discharge cooling method comprises the following steps of firstly, initial discharging: finished product materials oxidized in the lead tetroxide oxidizing furnace directly fall into a storage bin from an outlet of the oxidizing furnace, firstly fall on material blocking rollers in the bin and then fall on air inlet pipes; secondly, cooling air supplying: a blower supplies air to the storage bin through a main air inlet channel at the speed of 150m<3> / h; thirdly, heat transfer: a heat outlet hole is formed in the top end of the storage bin; on one hand, the heat generated by falling of initial discharged materials and the falling process is directly inputted to the lead tetroxide oxidizing furnace through a corrugated pipe; fourthly, discharging: a discharger is driven by a motor to downwards discharge products in the storage bin at the speed of 4kg / min; fifthly, secondary discharging: the discharger feeds the finished product materials into a discharging cylinder, the finished product materials firstly fall into a first-stage funnel; when the finished product materials in the first-stage funnel are enough and exceed the elastic limit of a shrapnel below the first-stage funnel, the finished product materials in the first-stage funnel fall into a second-stage funnel; according to the mode, the descending speed of the finished product materials is retarded, so that the aims of dissipating heat and cooling are achieved.

Owner:JIESHOU CITY JUNMA IND & TRADE

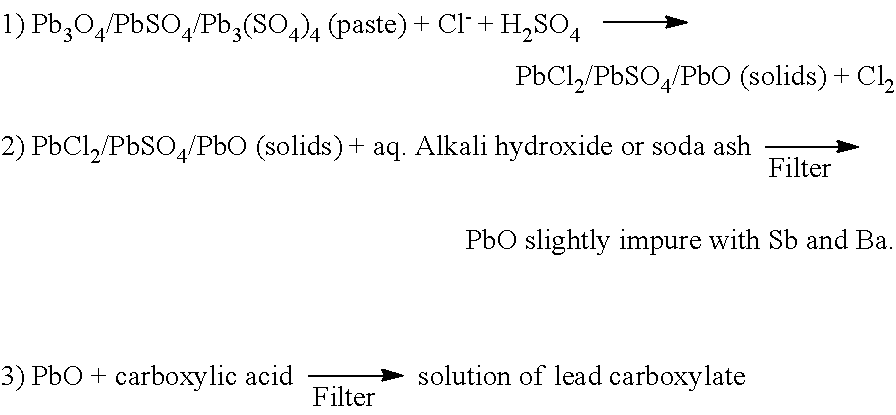

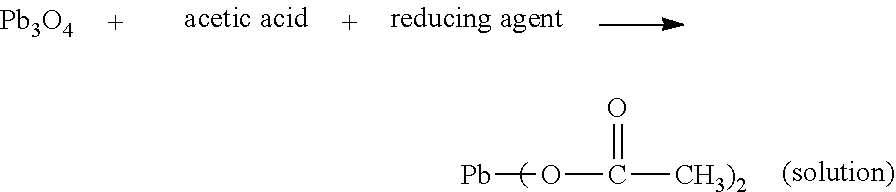

Recovery of high purity lead oxide from lead acid battery paste

The invention relates to the low temperature recovery of lead oxide (PbO) from lead acid battery paste through the preparation of lead carboxylate from the battery paste and the conversion of the lead carboxylate to PbO.

Owner:RETRIEV TECH

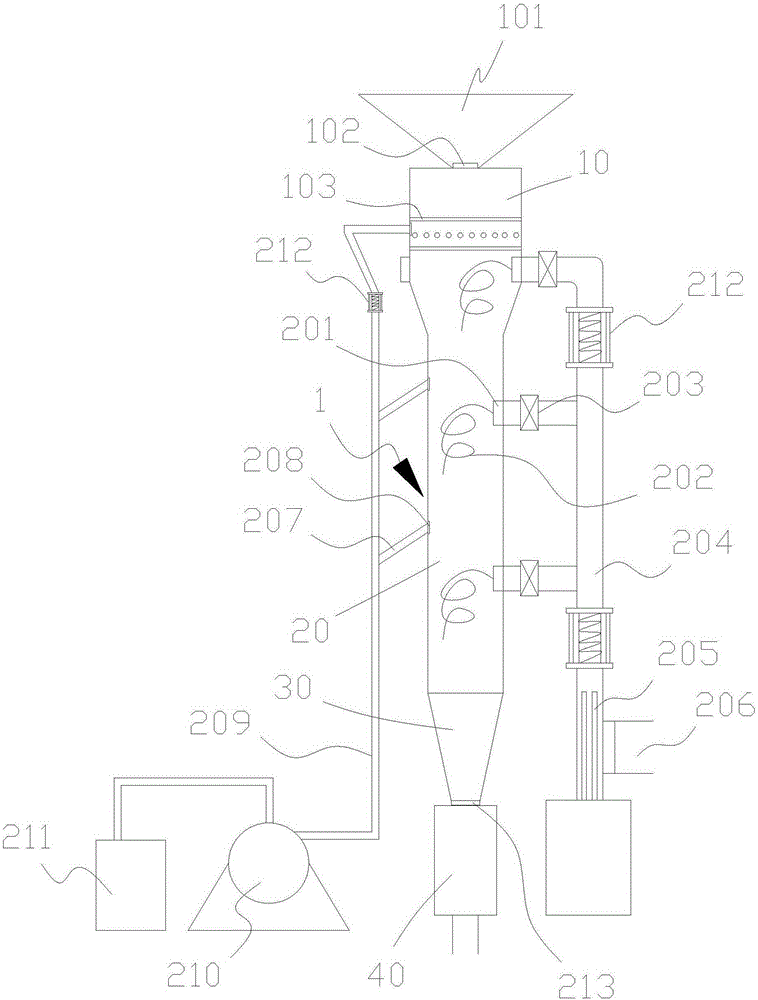

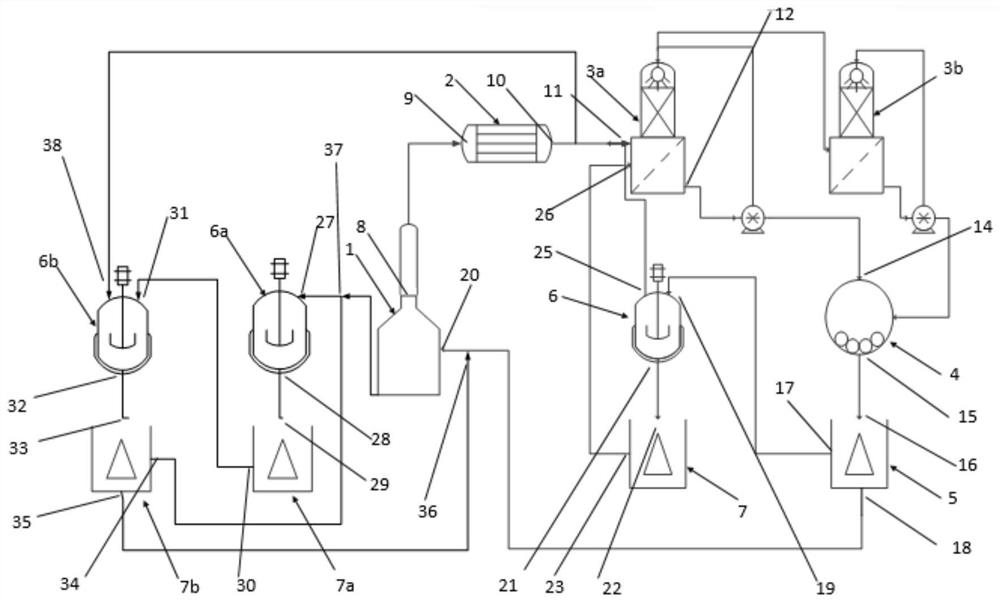

Lead tetraoxide oxidation technology

ActiveCN106517317AFully oxidizedSolve the problem of adding an appropriate amount of ammonium nitrate as a catalystRed leadEnergy inputLead(II,IV) oxideEngineering

The invention relates to a lead tetraoxide oxidation technology which comprises the following steps: 1) preheating air; 2) blowing the preheated air into an oxidizing furnace; 3) performing three-section temperature control on the oxidizing furnace, wherein the temperature of the oxidizing furnace from top to bottom is divided into the first section of temperature controlled at 450-510 DEG C, the second section of temperature controlled at 420-460 DEG C and the third section of temperature controlled at 380-420 DEG C; 4) putting the material into the oxidizing furnace from top to bottom and performing oxidizing reaction; 5) storing the oxidized material after fully reacting in a hearth of the oxidizing furnace into a storage silo and cooling; 6) reducing the temperature of the oxidized material in the storage silo to 60 DEG C or below and then taking out from the storage silo. According to the invention, the purpose of quickly preparing red lead can be achieved, the yield is increased, the resource is saved, the cost is saved and the production efficiency is increased.

Owner:湖南省水口山共建新材料有限公司

Method for recycling red lead process gas

ActiveCN106861334AProtect your healthReduce consumptionCombination devicesRed leadFiltrationProcess engineering

The invention discloses a method for recycling red lead process gas. In a red lead production calcining process, inlet air needs to be heated by an air heater, so in order to protect the air heater and prolong the life of the air heater, the red lead process gas must be subjected to dust removal and filtration; the content of oxygen in the red lead process gas is much lower than the concentration of oxygen in air, so if the purified and filtered process gas is directly heated together with the inlet air and input into an oxidizing furnace, the aim of accelerating oxidization of lead powder cannot be achieved, but the oxidization speed is reduced. Therefore, the input amount of the oxygen needs to be increased at the air inlet end to make the oxygen enter the air heater together with the process gas and the air, so the process gas can be recycled without discharge, and quick oxidization can be achieved to improve the production efficiency.

Owner:安徽徽能化工科技有限公司

Discharge cooling device of red lead oxidation furnace

ActiveCN110715556AThe function of uniform feedingIncrease contact areaRed leadHandling discharged materialThermodynamicsEngineering

The invention discloses a discharge cooling device of a red lead oxidation furnace. The device comprises an unloading bin, a water cavity, a storage box and a lifter; the unloading bin is positioned at the upper part of the water cavity; four sets of support feet are fixedly mounted at the bottom of the water cavity; the storage box is positioned at the bottom of the water cavity; the top of the lifter communicates with the top of the unloading bin; three sets of hoppers are fixedly mounted at the bottom of the unloading bin; guide plates are fixedly connected to the two sides of the hoppers;three sets of circular cavities are arranged in an inner cavity of the water cavity; the bottoms of the hoppers communicate with the tops of the circular cavities; and unloading ports are formed in the bottoms of the circular cavities, and are positioned at the top of the storage box. The device relates to the field of red lead processing equipment, is simple in structure, convenient and practical, achieves an uniform unloading function, separates red leads into small parts for heat dissipation in batches, and increases the contact area with the red leads through a water cooling mode to greatly improve the cooling effect.

Owner:池州市芯村里新材料科技有限公司

Energy-saving and environment-friendly oxygen supply device for red lead production equipment

InactiveCN112441612AReduce inflowIncrease profitChemical industryRed leadOxygen utilization rateGear drive

The invention discloses an energy-saving and environment-friendly oxygen supply device for red lead production equipment. The device comprises a reaction furnace, an air pump and a motor are arrangedon the left side and the right side of the outer wall of the top of the reaction furnace correspondingly, a feeding pipe is arranged on the portion, located on the right side of the motor, of the outer wall of the top of the reaction furnace, and the bottom output end of the motor is provided with a rotating rod through a coupling. During use, the motor drives the rotating rod and the gear to rotate, the gear drives the outer gear ring and the movable sleeve to rotate, the movable sleeve rotates to drive a connecting rod and a separation blade to rotate, the separation blade rotates to enableair in an inner cavity of an air storage pipe to flow into an inner cavity of the movable sleeve through an exposed through hole, and then the air in the inner cavity of the movable sleeve is sprayedout through an air outlet hole, so that the rotating speed of the separation blade determines the amount of the air entering the movable sleeve through the through hole. Therefore, the rotating speedof the motor is controlled to control the amount of the air flowing into the reaction furnace through the air outlet hole, the air fully reacts with red lead, and the oxygen utilization rate is improved.

Owner:扬州佐仕科技有限公司

A red lead oxidation furnace discharge cooling device

ActiveCN105645467BSimple structural designReasonable structural designRed leadHandling discharged materialLead oxideEngineering

The invention discloses a discharge cooling device of a red lead oxidizing furnace. The device comprises a storage bin on the upper portion, an off fan in the middle and a discharge barrel on the lower portion. The off fan is driven by a motor and connected with the storage bin and the discharge barrel, and the discharge barrel, the off fan and the storage bin are vertically communicated into a whole. The top of the storage bin is provided with a feed inlet. The 1 / 3 position below the top of the storage bin is provided with an upper layer and a lower layer of criss-cross blocking rollers. The 2 / 3 position below the top of the storage bin is provided with an air inlet pipe. The portion, stretching into the bin, of the air inlet pipe is provided with a plurality of air outlets in the downward direction. The portion, outside the bin, of the air inlet pipe is connected with a main air inlet pipe. The discharge barrel is composed of a shell and an inner container. The caliber of the upper portion of the shell and the inner container are integrally connected to the off fan. One side of the top of the shell is provided with an air inlet hole, and the other side of the top of the shell is provided with an air outlet hole. The air outlet hole is led to a dust remover through a corrugated pipe. A strong magnetism iron bar is installed between the upper caliber and the lower caliber inside the inner container. Three hoppers are installed around the strong magnetism iron bar from top to bottom. A discharge outlet in the bottom of the inner container is provided with a brake valve.

Owner:JIESHOU CITY JUNMA IND & TRADE

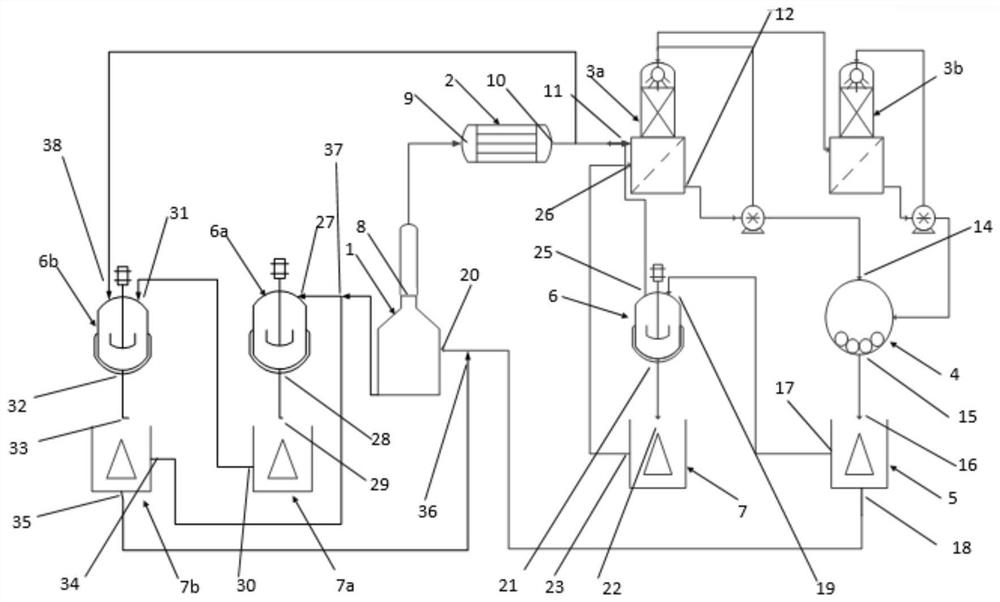

Preparation method and device of lead-acid storage battery positive electrode material

ActiveCN112582606ASimple processImprove efficiencyLead-acid accumulatorsLead monoxideLead carbonateLead oxide

The invention relates to a preparation method of a positive electrode material of a lead-acid storage battery, which is characterized by comprising the following steps: 1, carrying out ammonia desulfurization on waste lead plaster, and carrying out solid-liquid separation to obtain a lead carbonate-containing condensate; 2, carrying out high-temperature smelting on the cured product containing lead carbonate to obtain alpha lead oxide, beta lead oxide, lead tetroxide and waste gas, and inputting the waste gas into an ammonia water device to produce a sulfur removal agent containing ammonium carbonate, wherein the sulfur removal agent containing ammonium carbonate is used for desulfurizing the waste lead plaster in the step 1; and 3, the alpha lead oxide, the beta lead oxide and the lead tetroxide are mixed into paste through sulfuric acid. The preparation method of the positive electrode material of the lead-acid storage battery is simple in process and high in efficiency.

Owner:HANGZHOU QIANLIZHIXING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com