Water process energy-saving granulation technology for red lead production

A technology of granulation and water method, which is applied in the field of water-based energy-saving granulation equipment for red lead production, can solve the problems of affecting product quality, low production capacity, and high production cost, so as to avoid occupational hazards, improve production efficiency, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A water-based energy-saving granulation process for red lead production, the method steps are as follows:

[0038] (1) Dust removal and cooling (pretreatment)

[0039] The lead powder obtained by melting the lead ingot is transported to the bag filter through the pipeline under the action of the induced draft fan, and the dust is removed and the temperature is lowered to about 100°C. The initial temperature of the lead powder is about 380°C;

[0040] (2) Screw conveying

[0041] The first auger (screw conveyor) is installed in parallel at the bottom of the bag filter, and the first auger runs counterclockwise at a speed of 30 rpm. Under the action of the action, it is continuously transported to the discharge port of the first auger (direction is downward), and then from the discharge port to the auger in the granulation equipment;

[0042] (3) Re-delivery

[0043] A second auger is also installed under the first auger. The speed and direction of the second auger are...

Embodiment 2

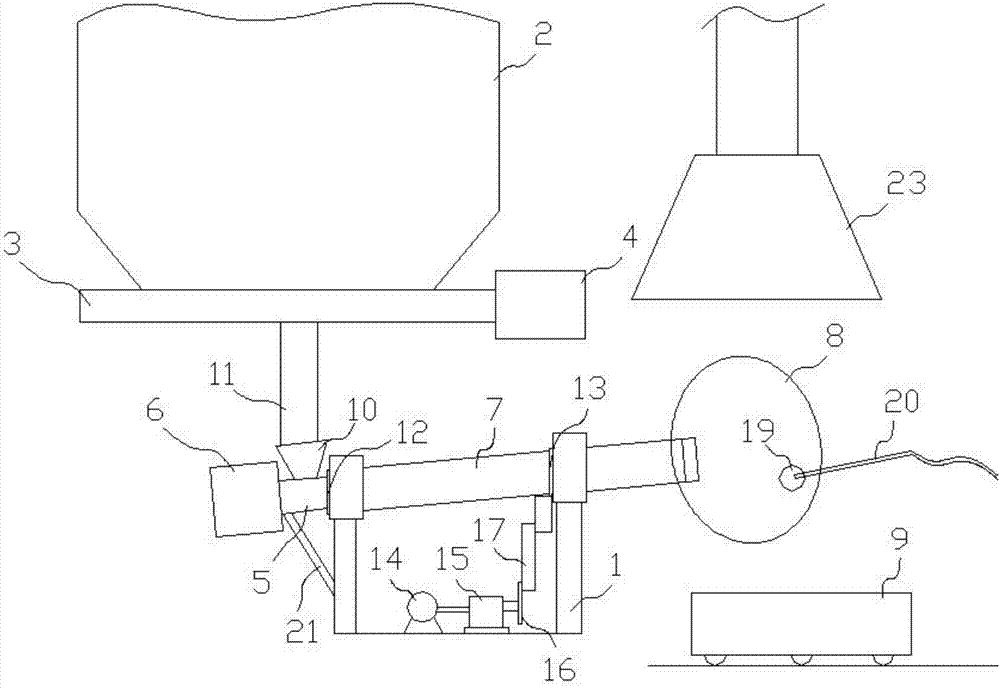

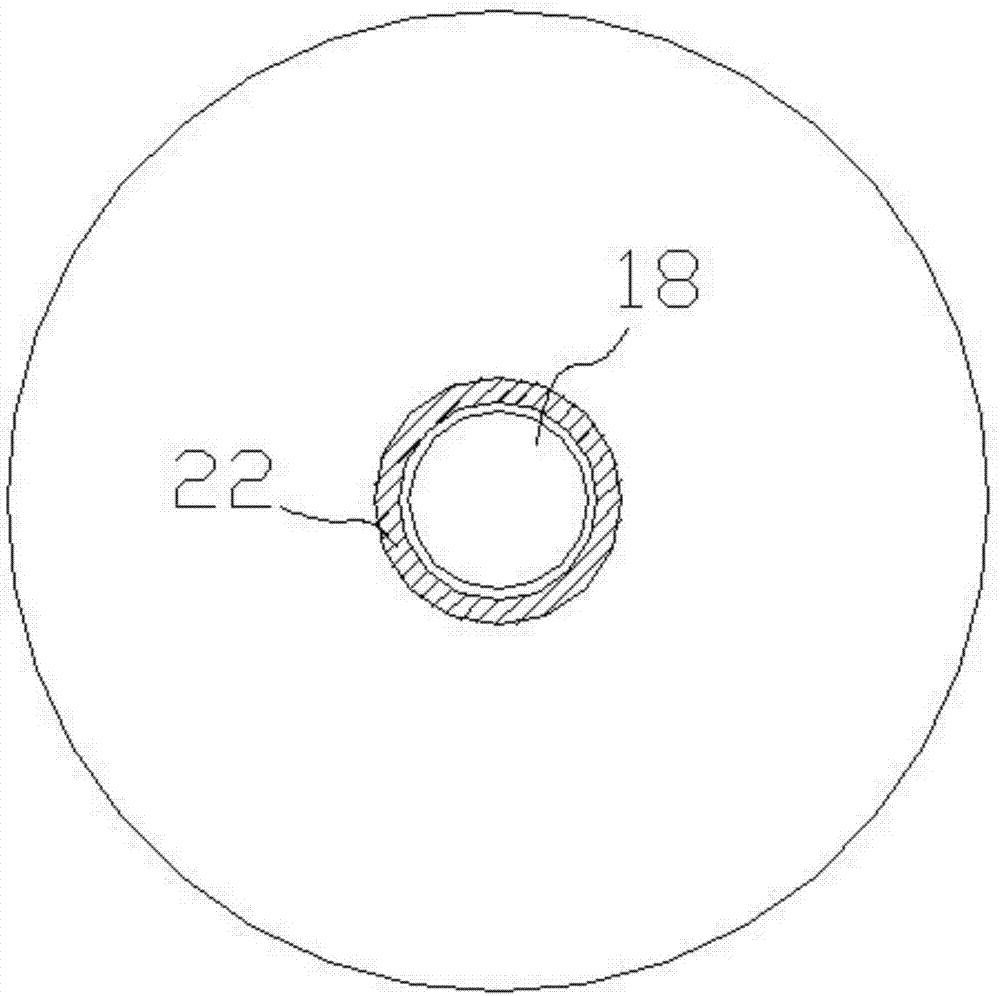

[0053] see figure 1 , figure 2 :

[0054] A water-based energy-saving granulation device for red lead production, comprising: support 1, bag filter 2, discharge auger 3, discharge motor 4, feed auger 5, feed motor 6, tube barrel 7, granulation Barrel 8 and material storage box 9, the granulation tube 8 is installed on the bracket 1, the feeding auger 5 is installed in the tube tube 7, and one end extends to the granulation tube 8, but it is not connected with the granulation tube 8 and can work alone , the other end stretches out about 80 centimeters from the pipe 7, and there is a red lead feed port 10 at the upper end of the stretched part, and the tail is connected with the feed motor 6, and the feed motor 6 is responsible for the work of the feed auger 5 alone, and the feed auger 5 The blades in the center rotate counterclockwise and are responsible for transporting the raw materials entering the feed auger 5 to the granulation barrel 8 at a speed of 30 revolutions per ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com