Patents

Literature

2245 results about "L&D process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

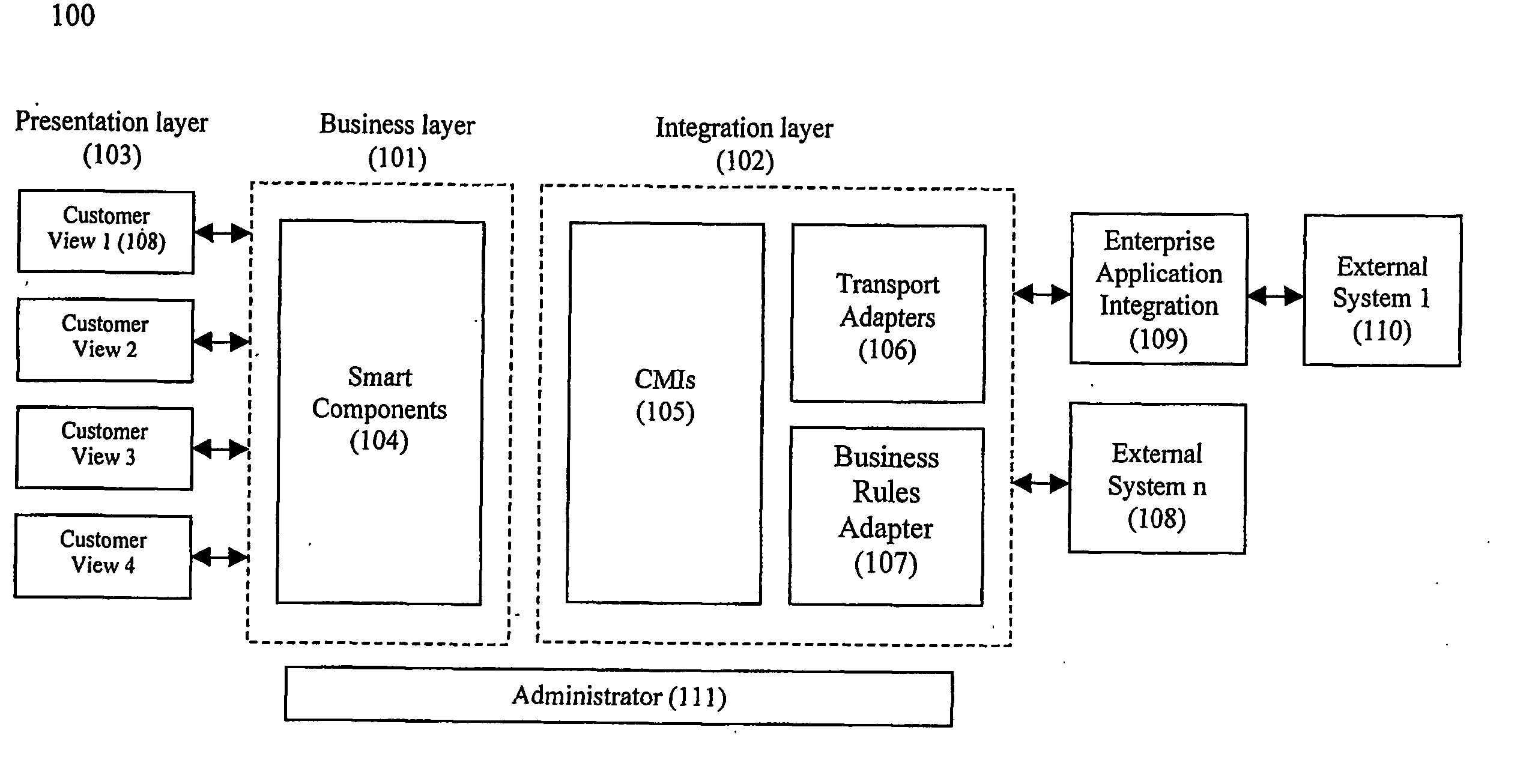

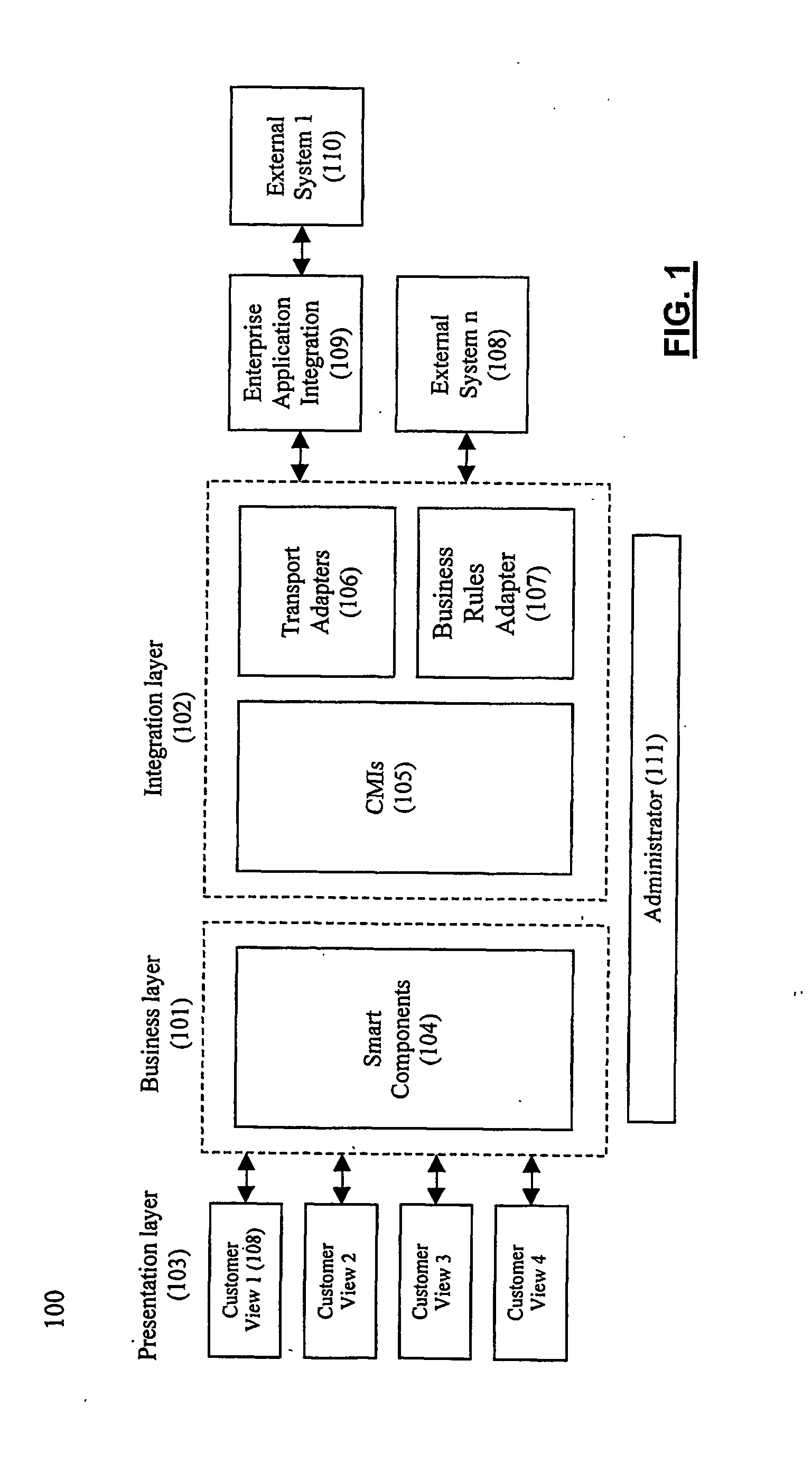

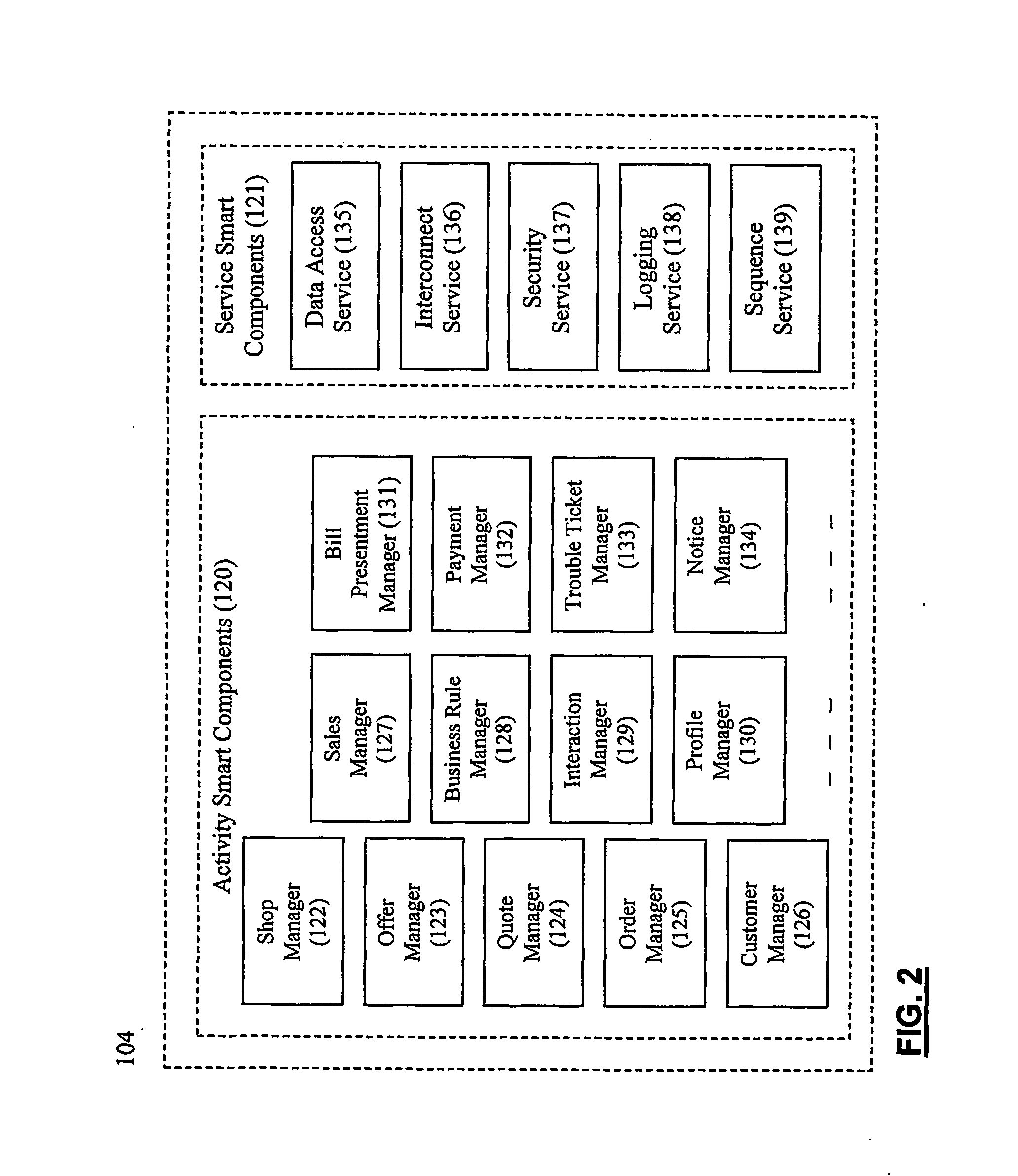

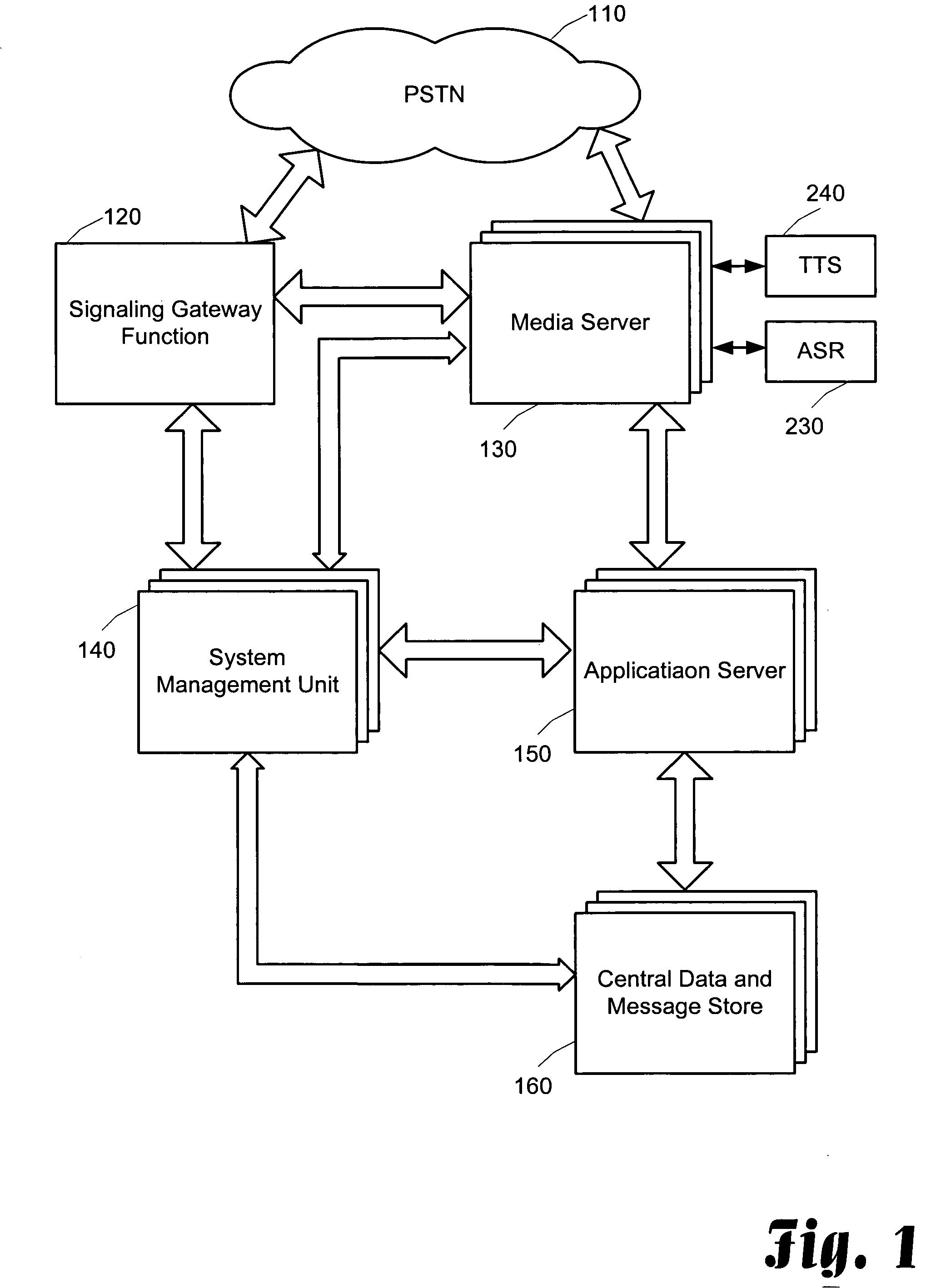

System and method for establishing eletronic business systems for supporting communications servuces commerce

ActiveUS20060059107A1Easy to addEasy to liftPayment protocolsBilling/invoicingEnterprise application integrationSupporting system

Owner:NETCRACKER TECH SOLUTIONS

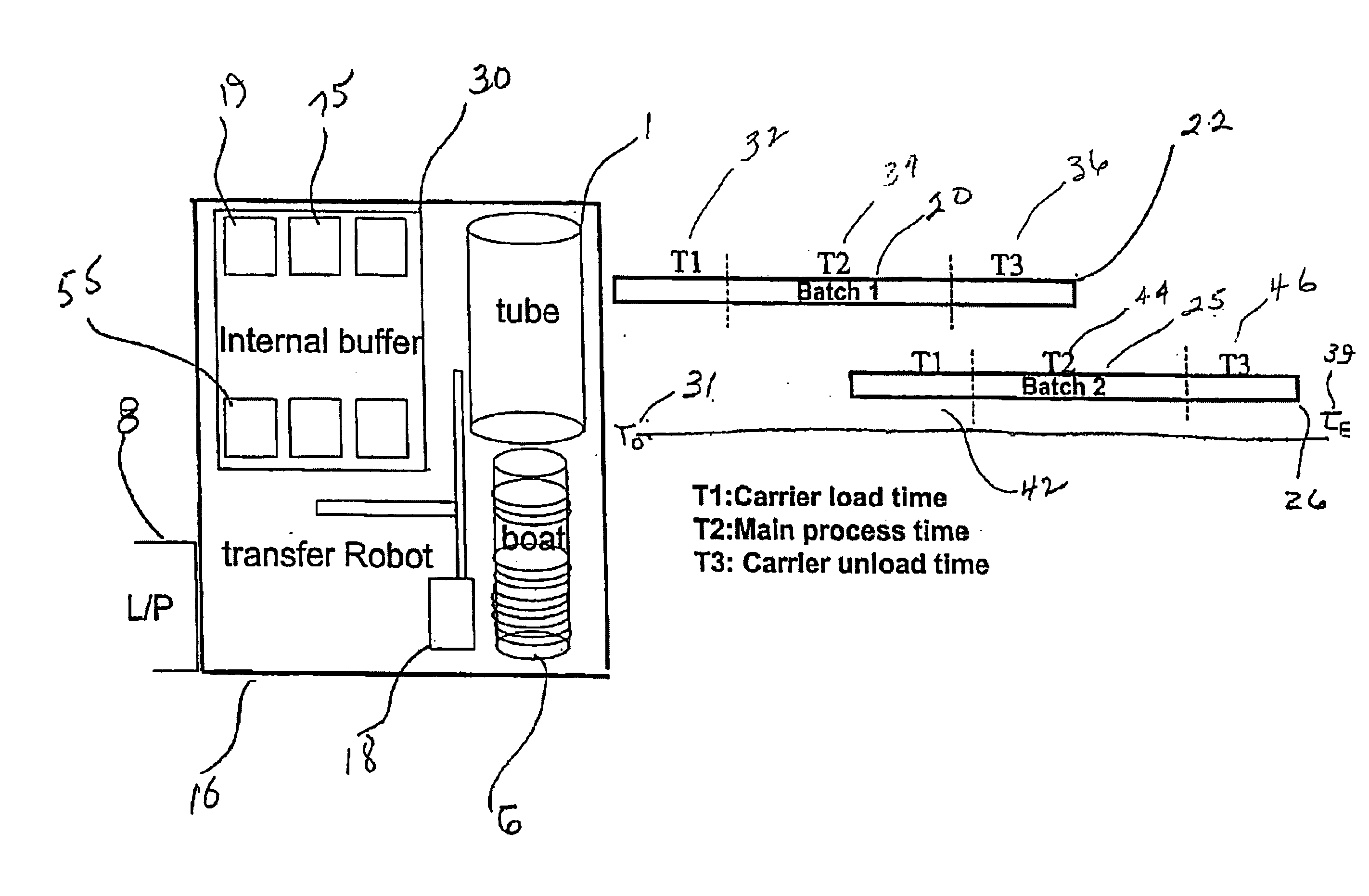

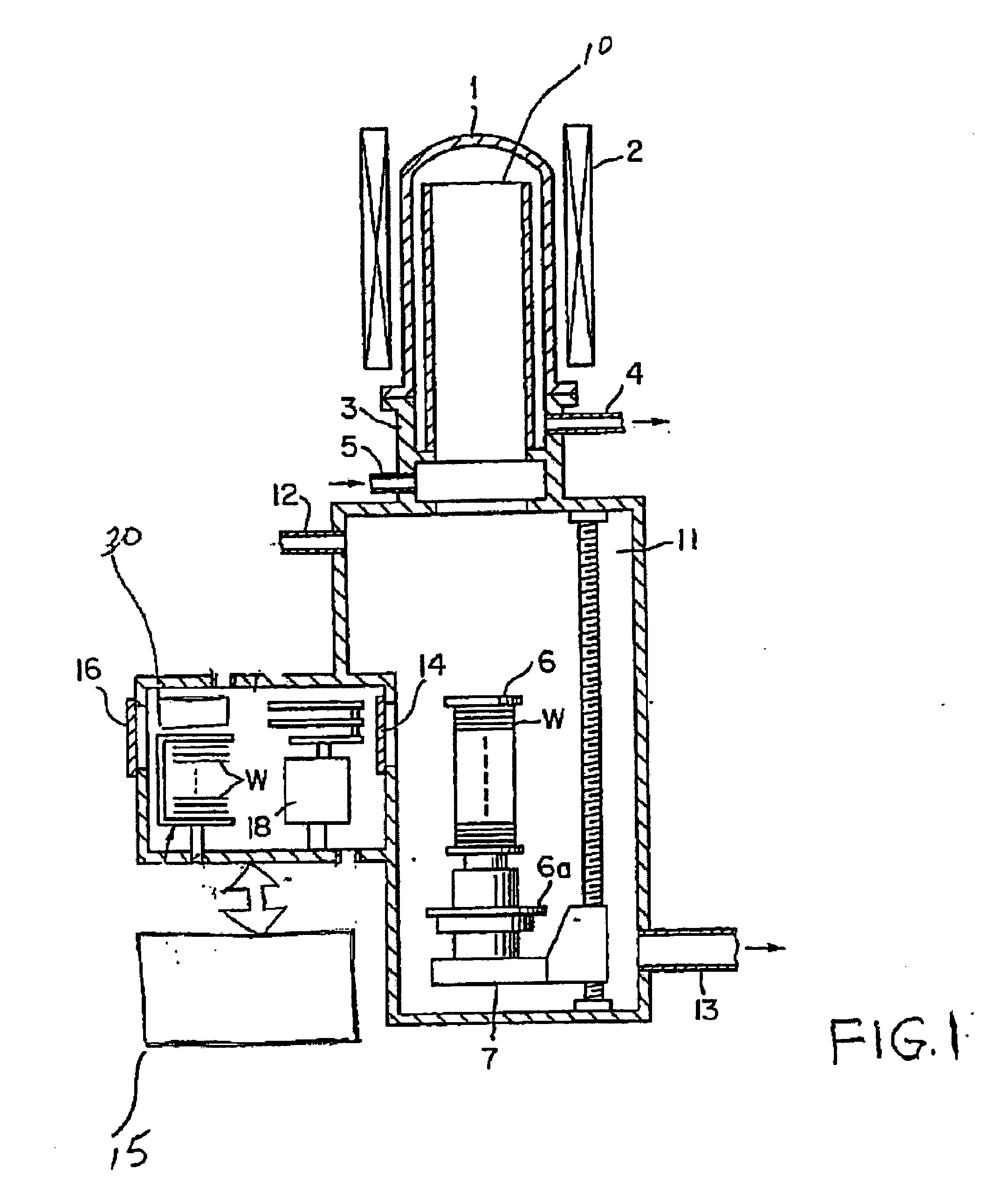

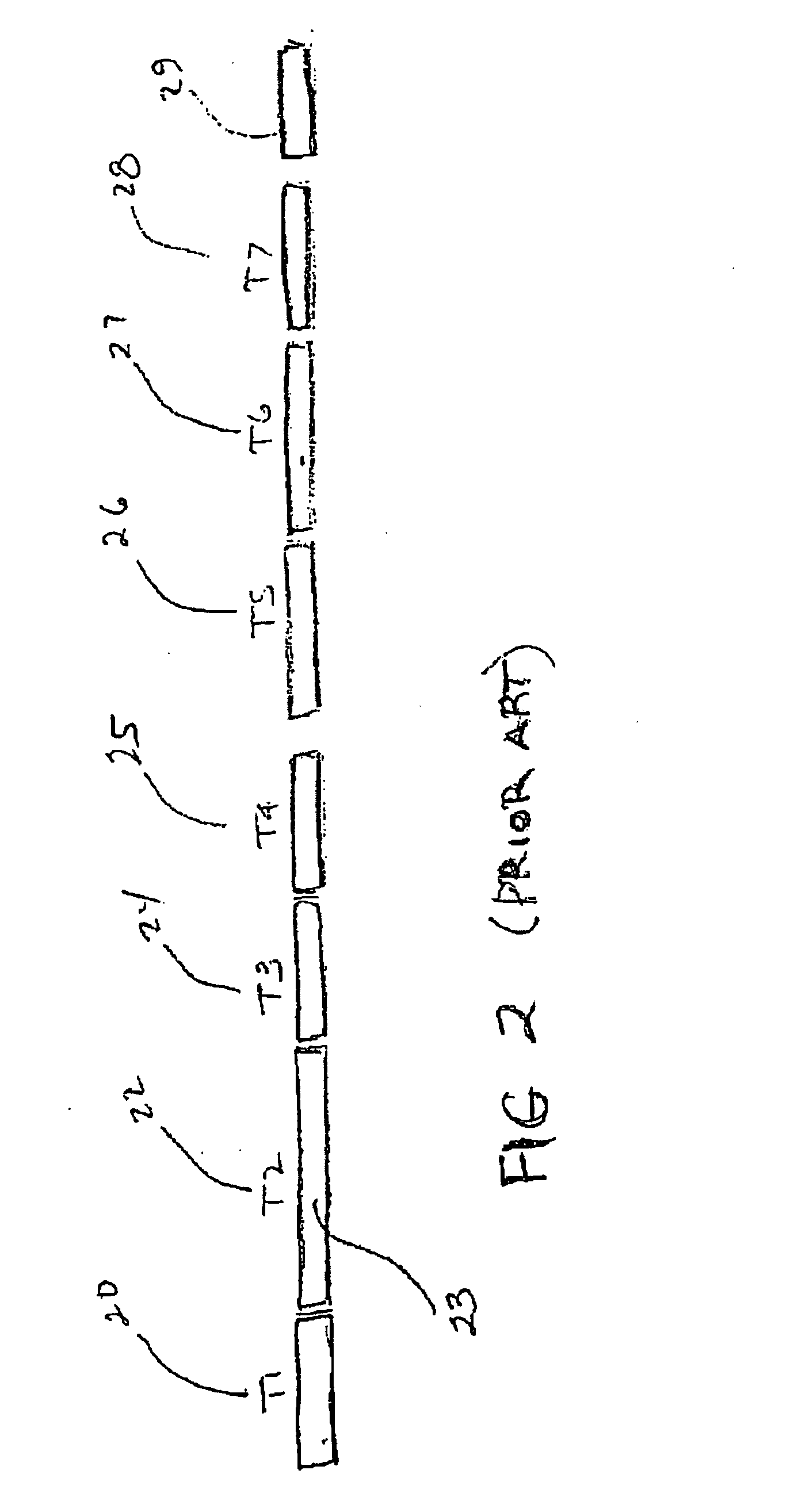

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

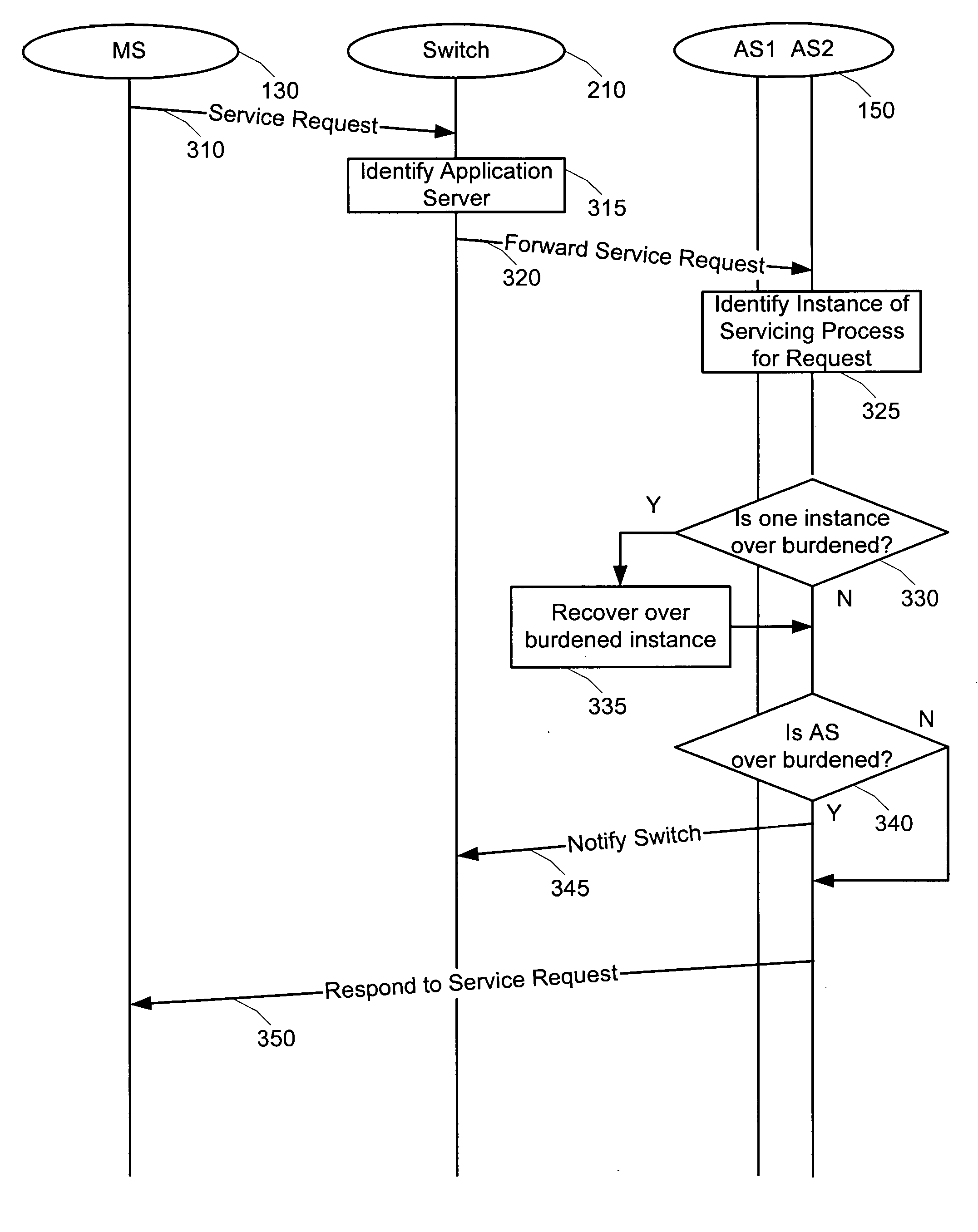

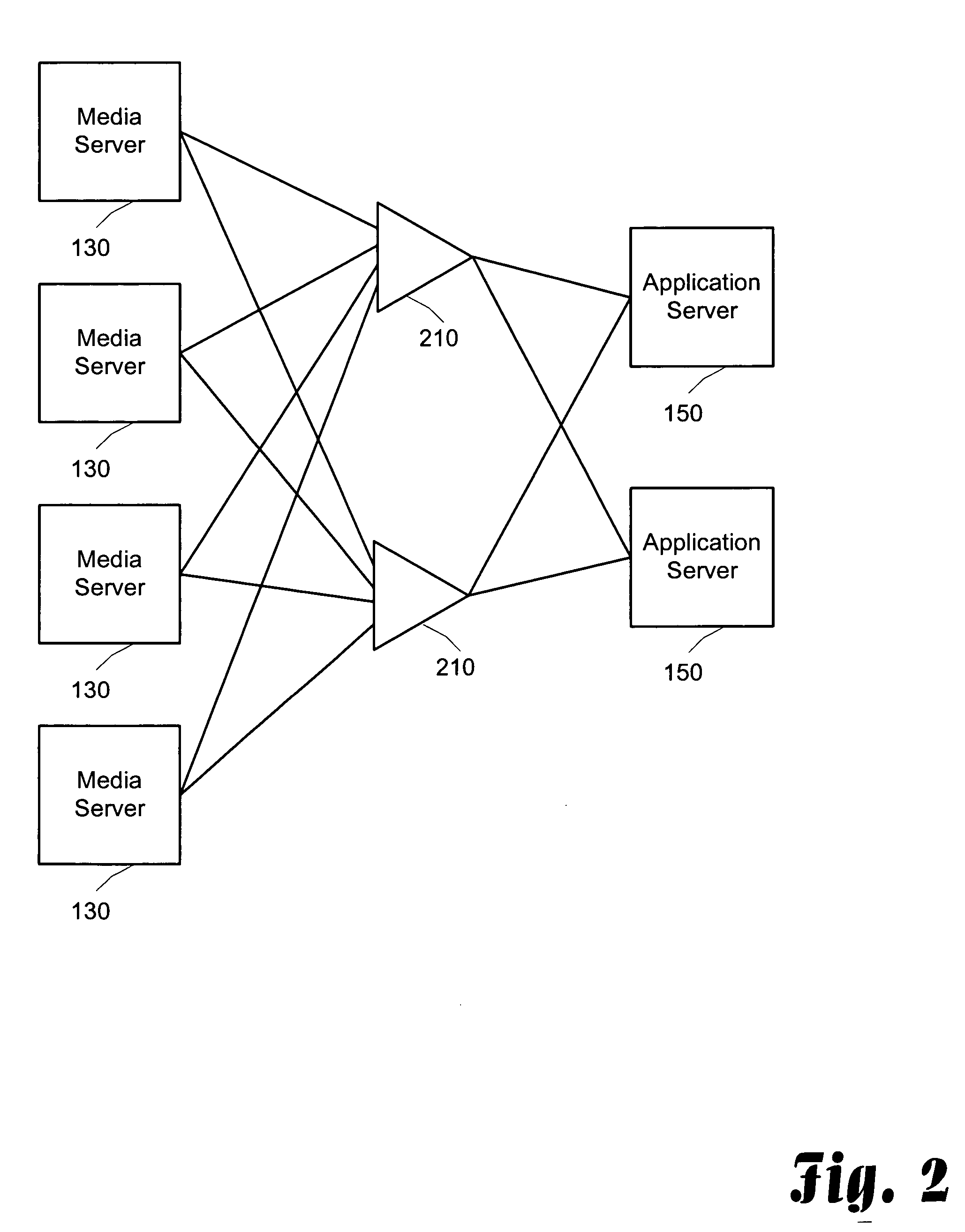

Load balancing in a distributed telecommunications platform

InactiveUS20060209695A1Balance processing loadError preventionResource allocationVirtual switchDistributed computing

Processing is allocated within a distributed telecommunications at two levels—the component level and the process level. At the component level, a virtual switch is employed to route service requests to one of a group of components that are configured to process the service request. The decision can be made autonomously by the virtual switch or entirely based on information provided by the component or even by a combination of both. At the process level, each component establishes multiple instances of the serving process and then selects one instance to process the service requests. The component monitors the processing burden of the instance of the process and if a degradation in performance is anticipated, the component selects an alternative instance of the serving process to handle subsequent requests.

Owner:GLENAYRE ELECTRONICS INC

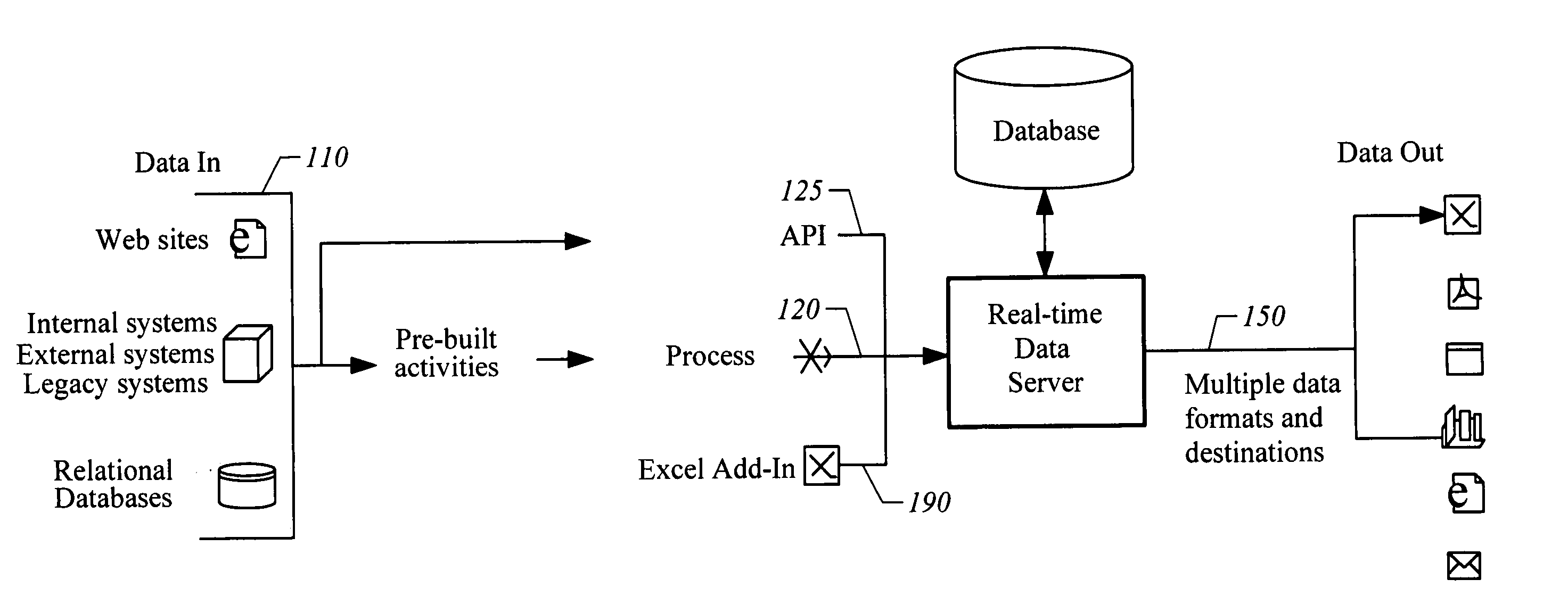

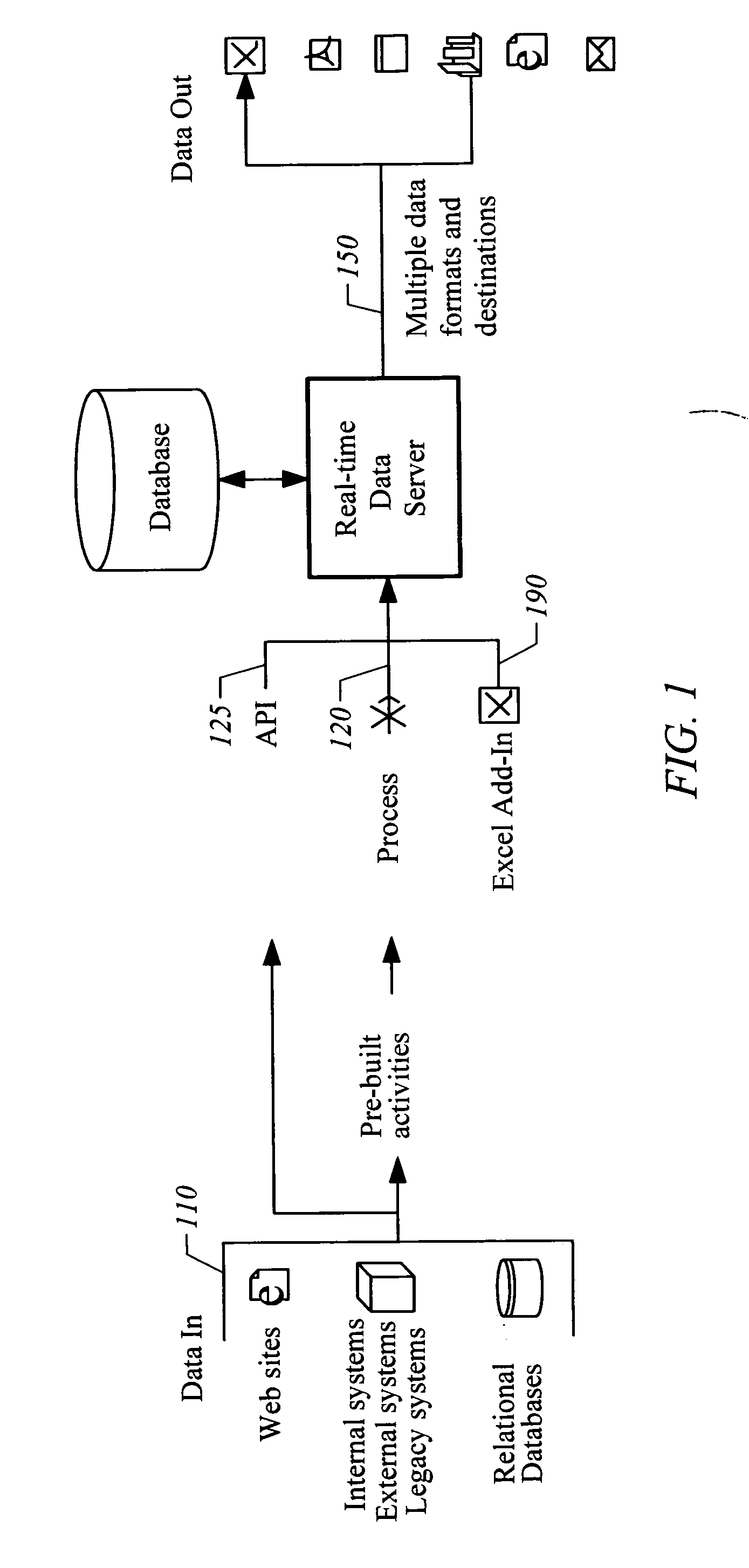

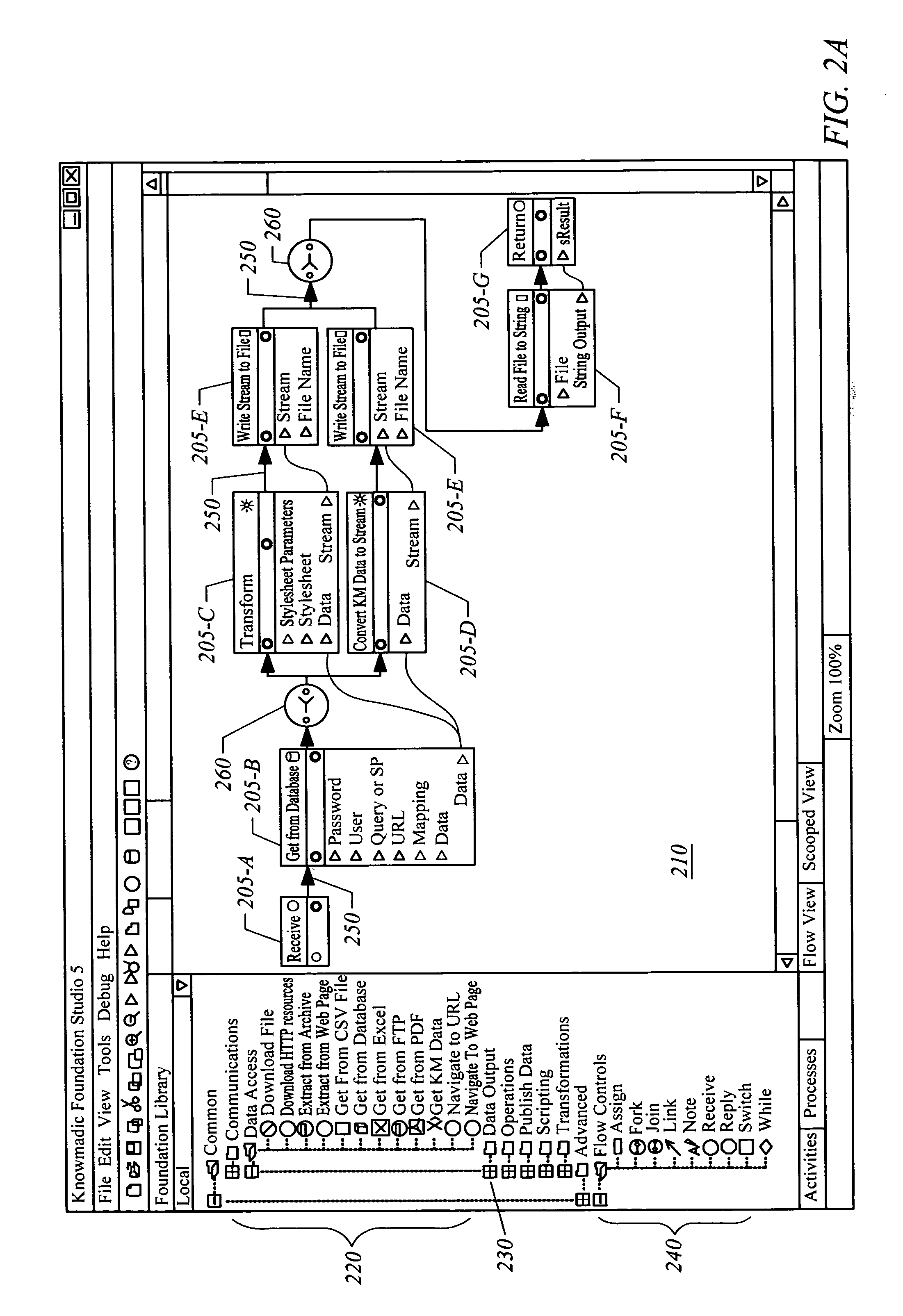

System and method for integrating disparate data and application sources using a web services orchestration platform with business process execution language (BPEL)

InactiveUS20050251527A1Special service provision for substationDigital data processing detailsOrchestrationSystems approaches

An apparatus, system, method, and computer readable medium is disclosed for integrating disparate data and application sources using a web services orchestration platform, with business process execution language (BPEL).

Owner:FWO NEWCORP

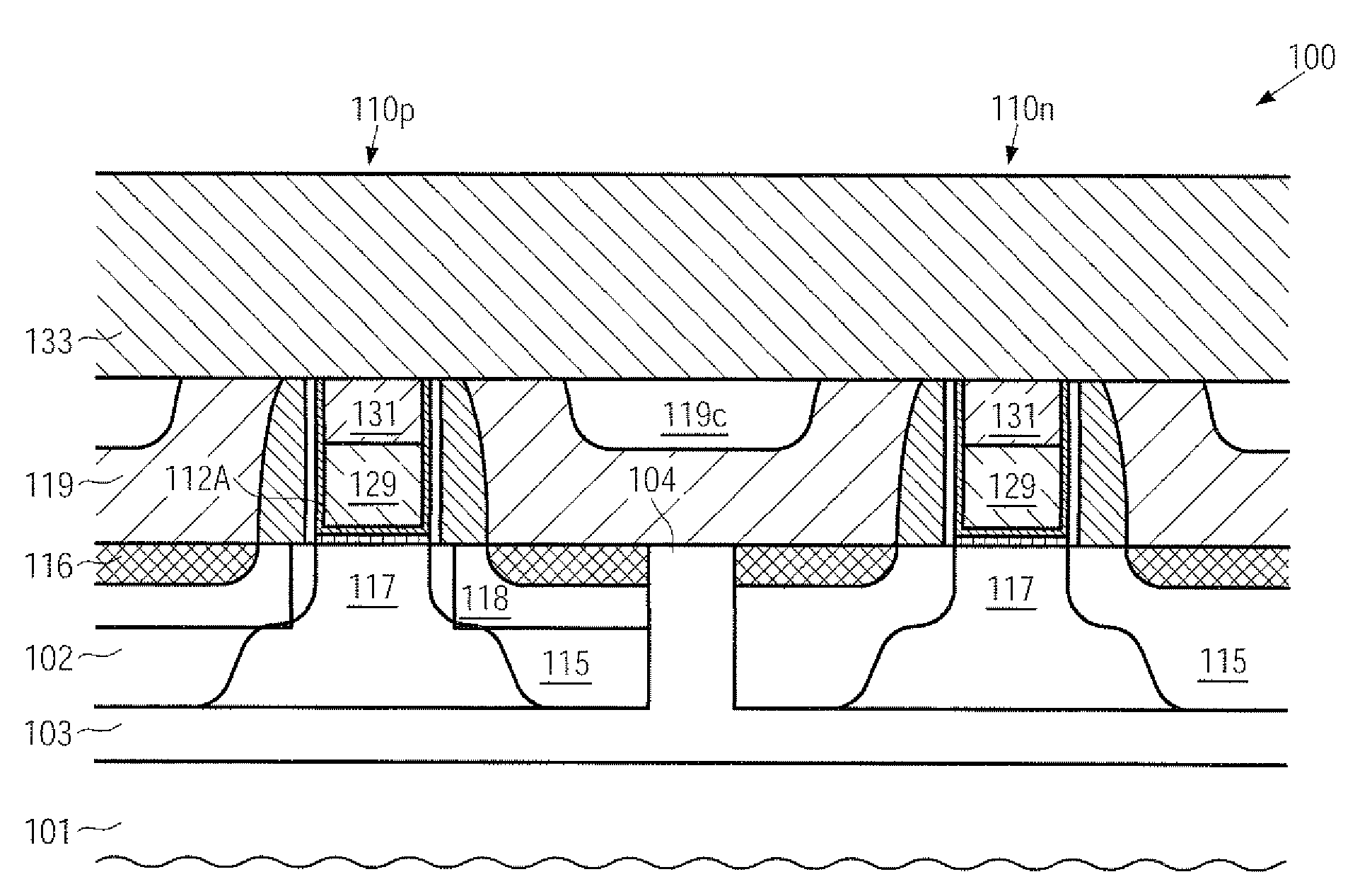

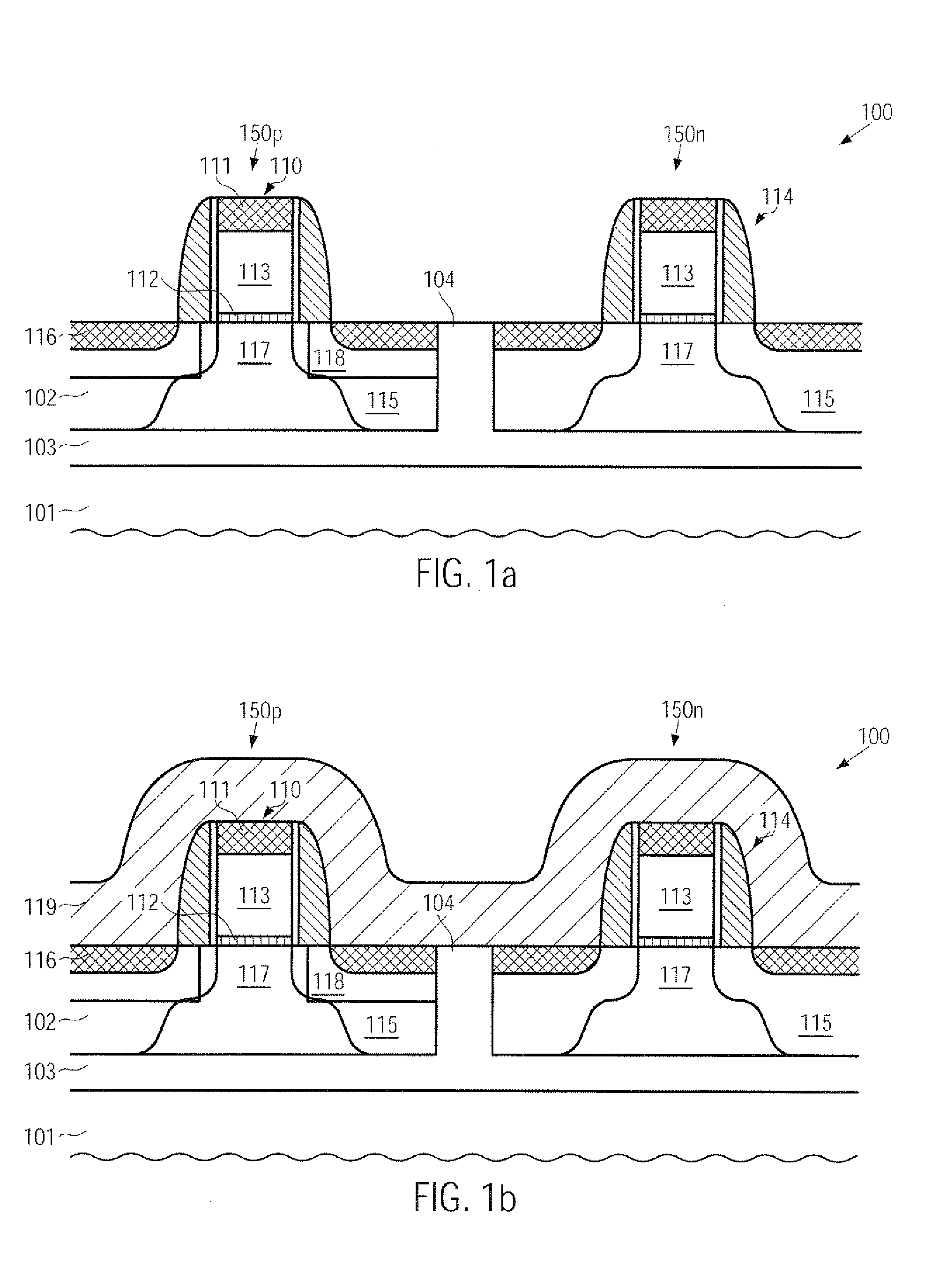

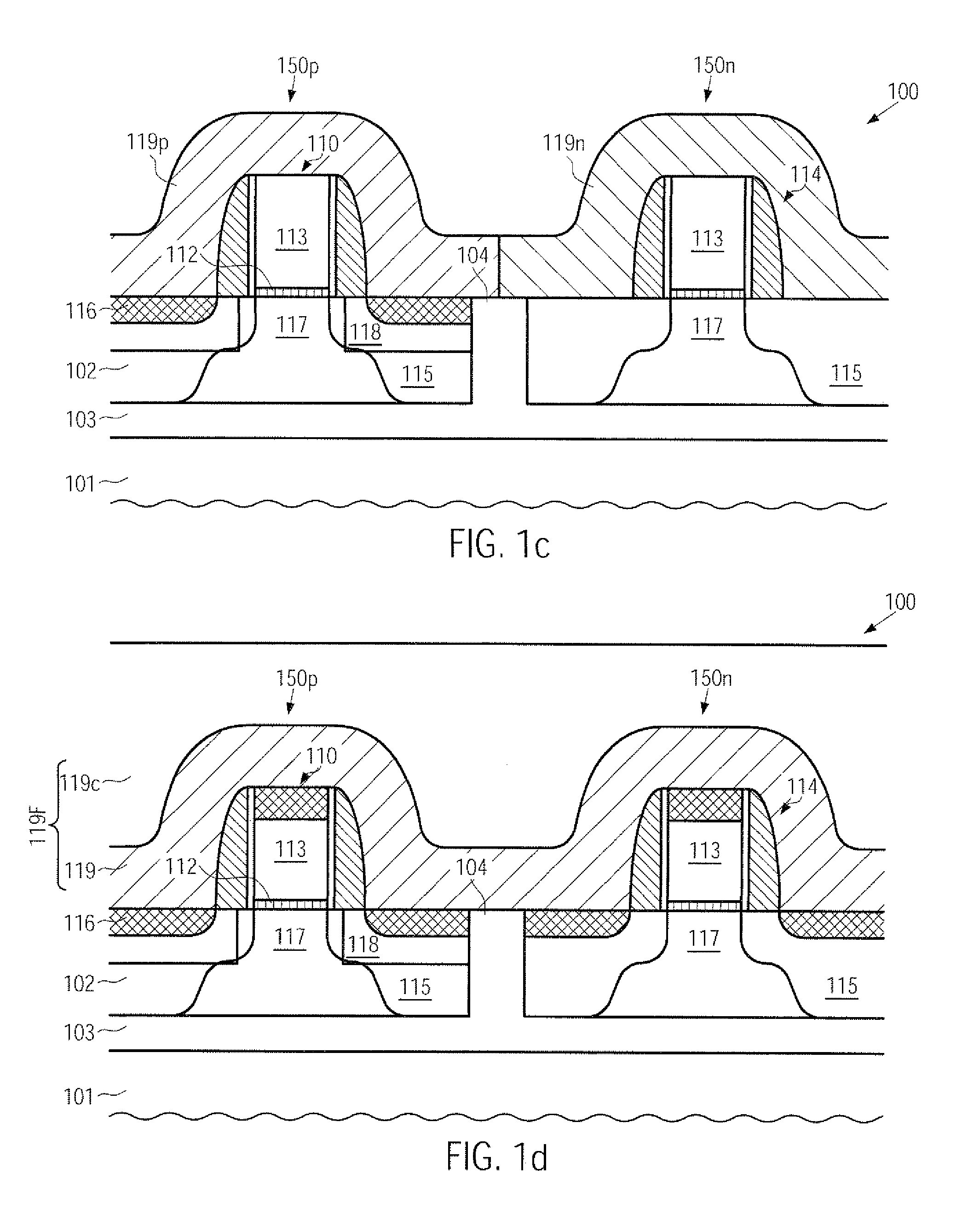

Method of forming high-k gate electrode structures after transistor fabrication

InactiveUS20090087974A1High degreeDeleterious effectSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSDielectric

A sophisticated high-k metal gate electrode structure may be formed after the deposition of a first part of an interlayer dielectric material, thereby providing a high degree of process compatibility with conventional CMOS techniques. Thus, sophisticated strain-inducing mechanisms may be readily implemented in the overall process flow, while nevertheless avoiding any high temperature processes during the formation of the sophisticated high-k dielectric gate stack.

Owner:ADVANCED MICRO DEVICES INC

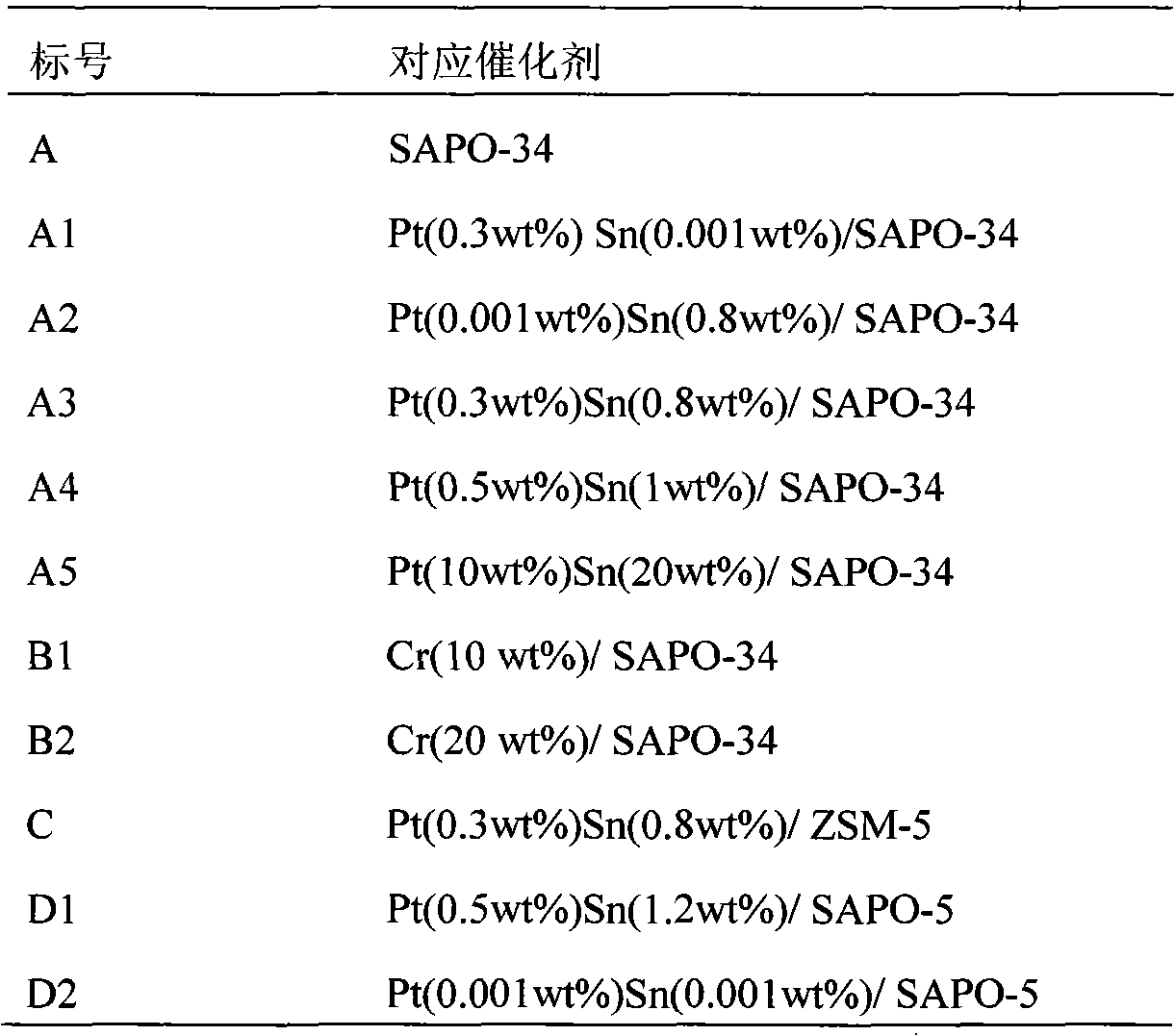

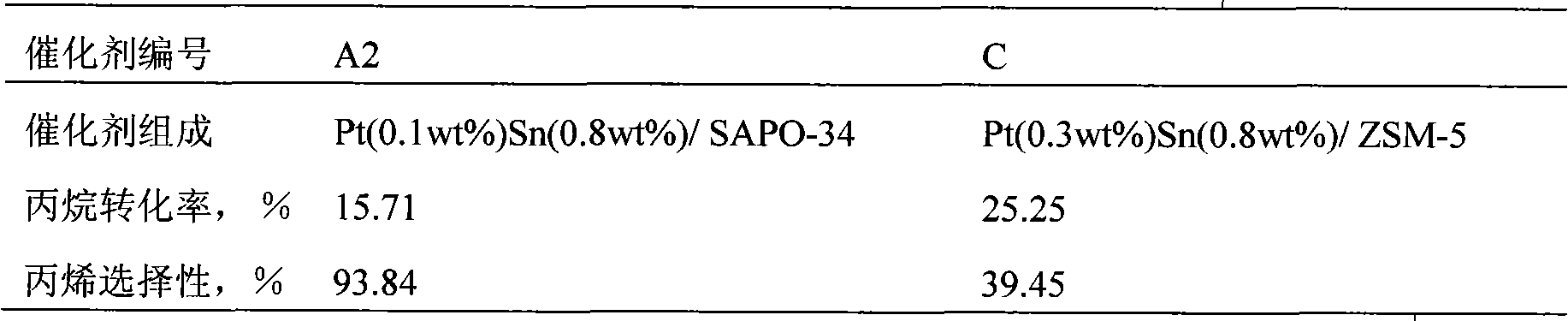

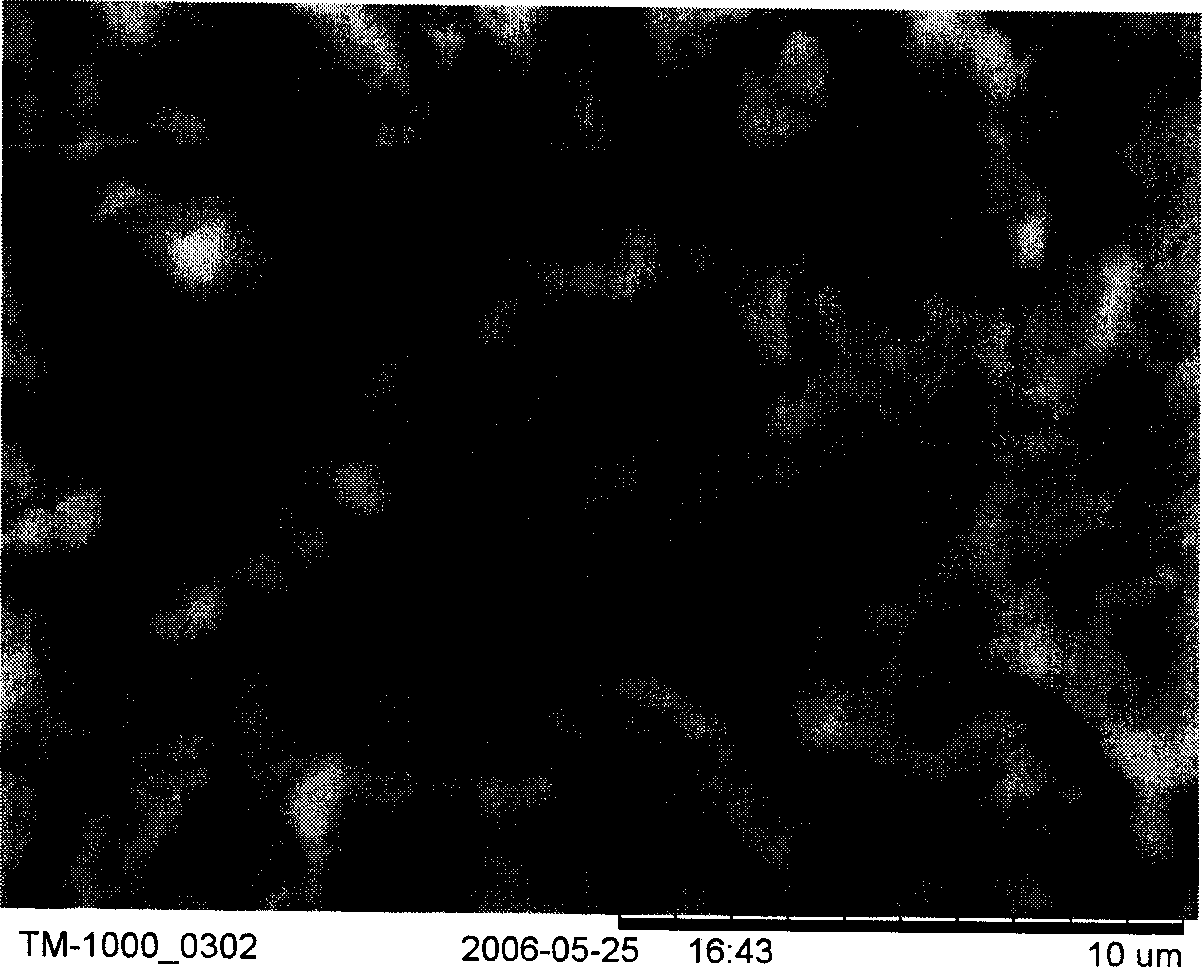

Catalyst for preparing olefin by dehydrogenating low-carbon alkane, and preparation method and application thereof

InactiveCN101623633AHigh selectivitySuitable for acidityCatalyst activation/preparationHydrocarbonsAlkaneMolecular sieve

The invention relates to a catalyst for preparing olefin by dehydrogenating low-carbon alkane, and a preparation method and an application thereof, which belong to the technical field of the preparation of basic organic chemical raw materials. The catalyst is prepared by a dipping method of using an aluminium silicophosphate molecular sieve as a carrier, VIII group or VIB group elements as active constituents and IVA group elements as an auxiliary agent. In the process for preparing olefin by dehydrogenating low-carbon alkane, the catalyst is firstly reduced by hydrogen gas, then participates in a reaction, and is finally regenerated. Compared with the existing catalyst for preparing olefin by dehydrogenating low-carbon alkane, the catalyst has a pore shape selecting function and moderate acidity, thereby the selectivity of the low-carbon alkane can reach more than 90 percent in the process for preparing olefin by dehydrogenating low-carbon alkane. The preparation method of the catalyst is simple; the regeneration process flow of the reaction has a large choice, a fixed bed, a fluidized bed or a moving bed can be used as a reactor, and the catalyst can be regenerated in the reactor or outside the reactor.

Owner:TSINGHUA UNIV

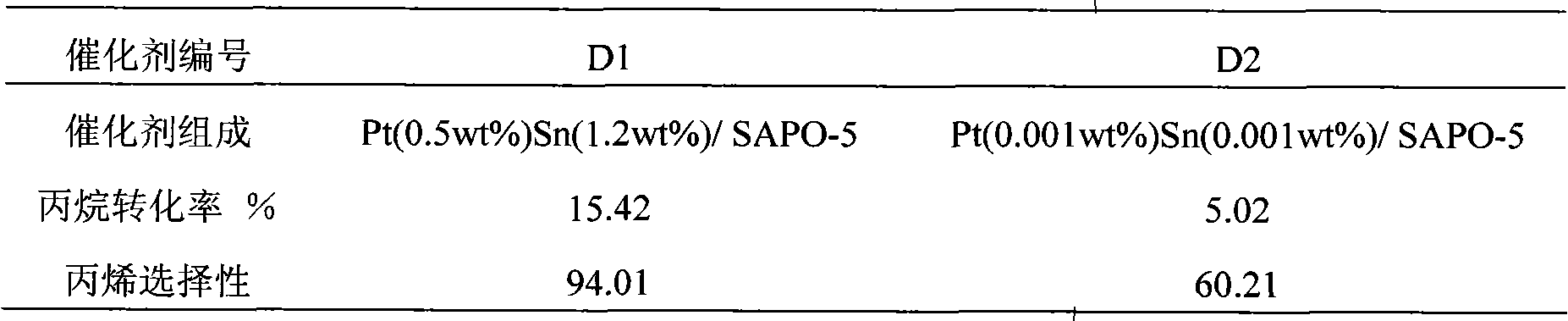

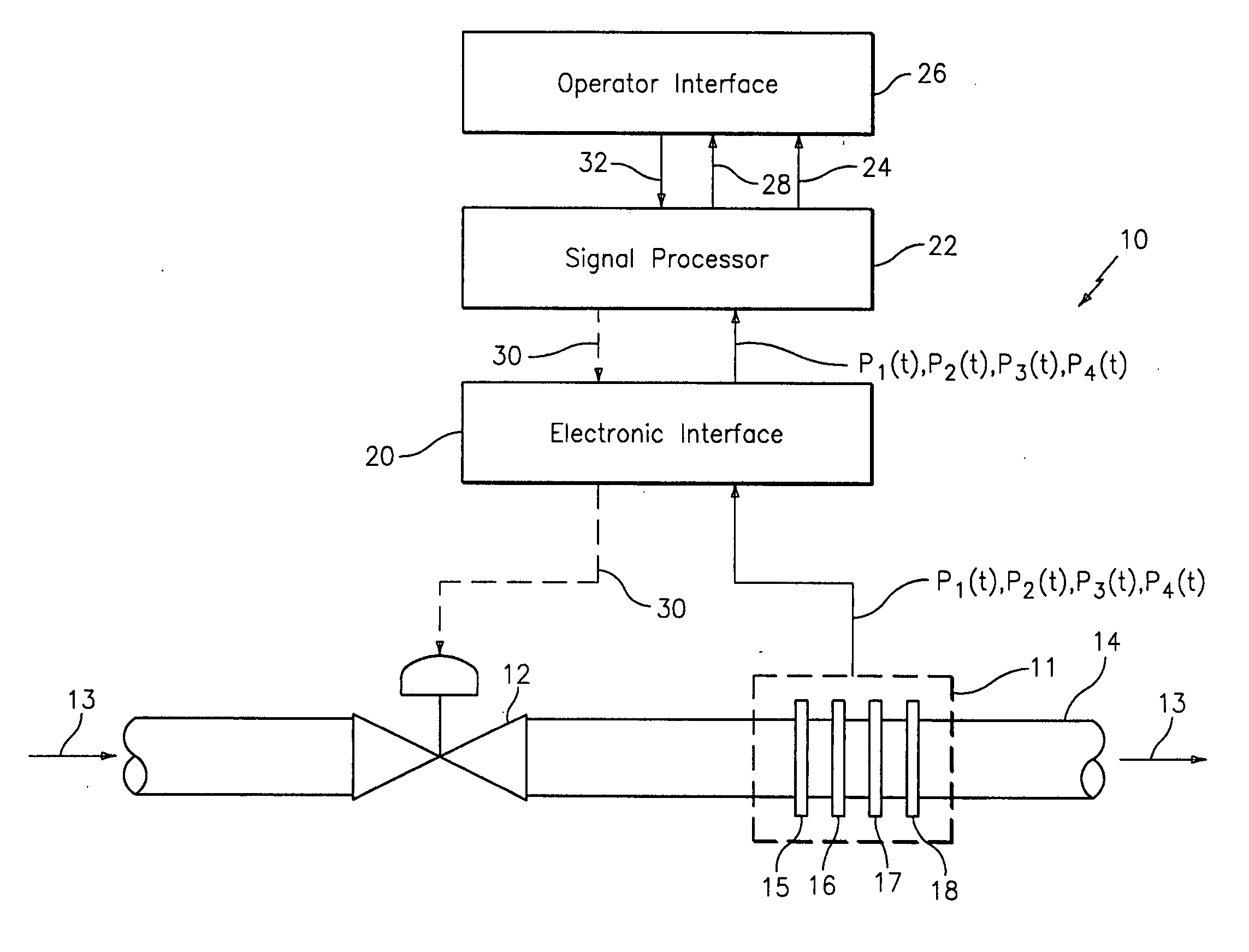

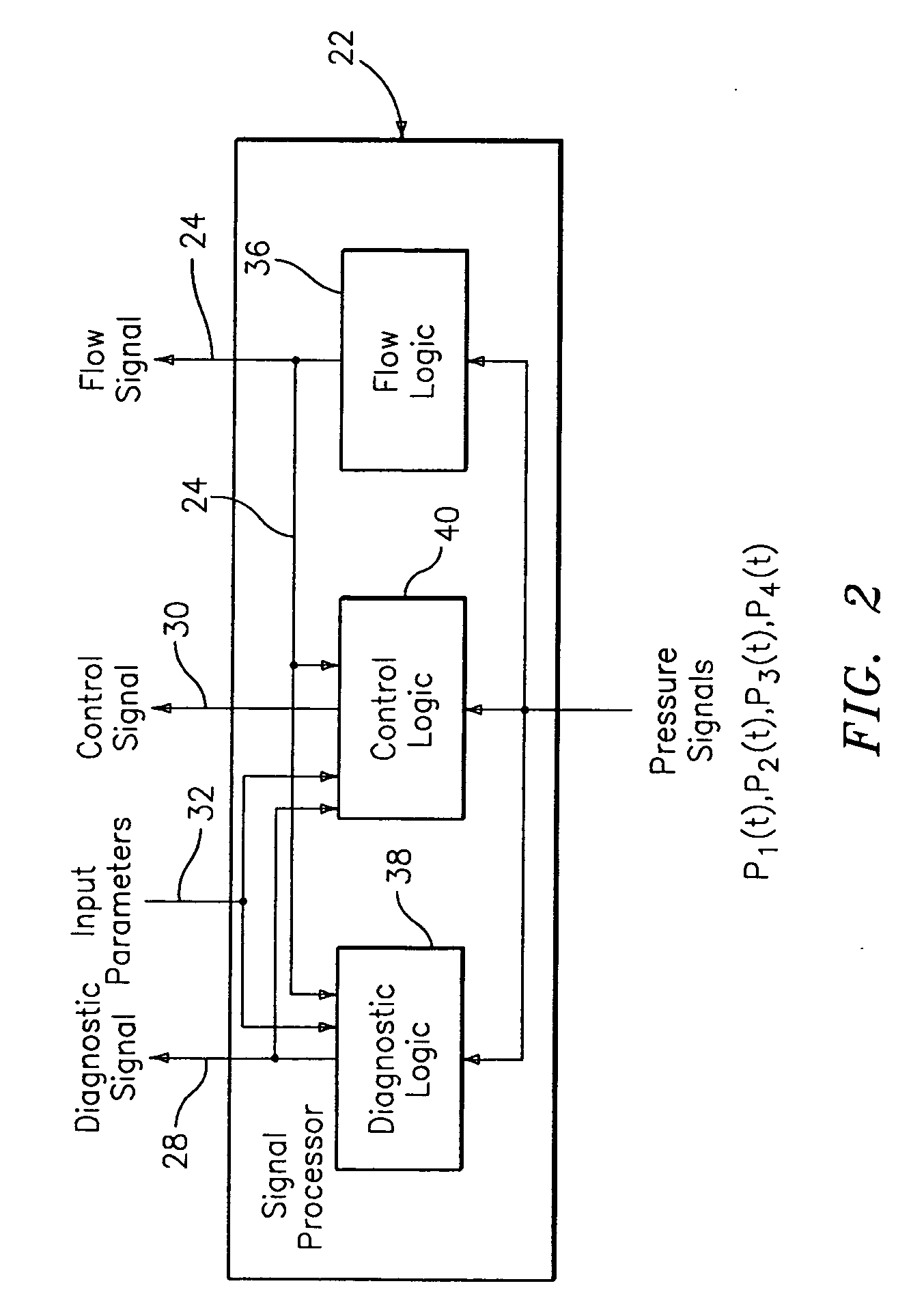

System and method for operating a flow process

ActiveUS20050005711A1Effective regulationTelemetry/telecontrol selection arrangementsTesting/calibration apparatusControl signalDistributed control system

A system for monitoring, diagnosing, and / or controlling a flow process uses one or more flow meters based on an array of pressure sensors. A signal processor outputs at least one of a flow signal, a diagnostic signal, and a control signal in response to the pressure signals from the pressure sensors. The flow signal indicates the at least one parameter of the fluid, the diagnostic signal indicates a diagnostic condition of a device in the flow process, and the control signal is effective in adjusting an operating parameter of at least one device in the flow process. The system may be arranged as a distributed control system (DCS) architecture for monitoring a plurality of flow meters based on array-processing installed at various locations throughout a flow process.

Owner:EXPRO METERS

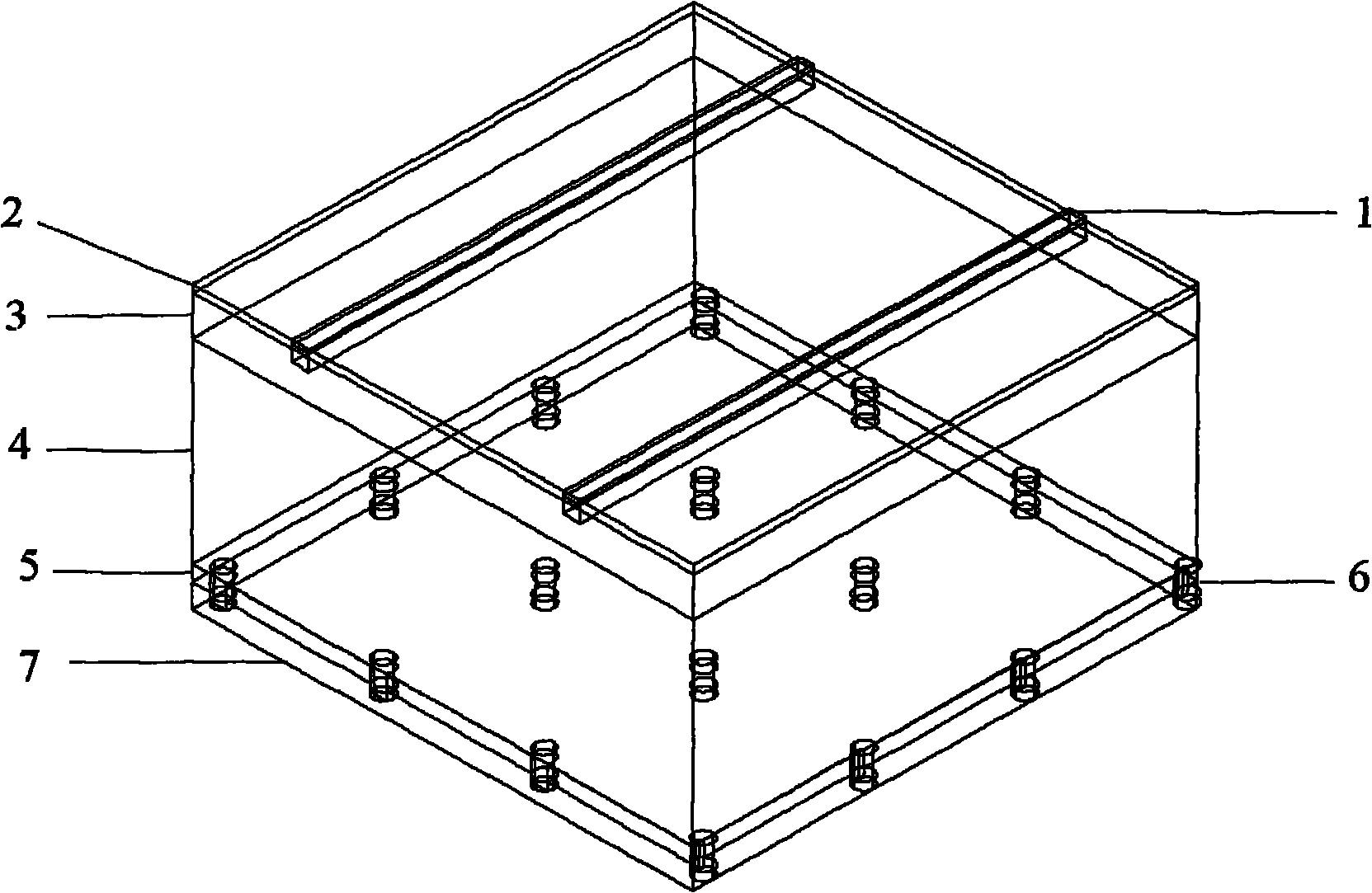

Method for preparing N-type crystalline silicon solar cell with aluminum-based local emitters on back side

InactiveCN101853897AAvoid damageAvoid Edge Leakage SituationsFinal product manufactureSemiconductor devicesP–n junctionMaterials science

The invention provides a method for preparing an N-type crystalline silicon solar cell with aluminum-based local emitters on the back side. The method comprises the following steps: firstly, selecting N-type silicon wafers to carry out the surface-textured etching process; further forming a front surface field through phosphorous diffusion; depositing a passivating film on the front surface after the phosphorosilicate glass is formed during the removal of diffused phosphorous; carrying out the back-side chemical polishing process on the silicon wafers to remove the N+ layer formed on the back side during the phosphorous diffusion; then, sequentially printing an aluminum layer or a silver-aluminum layer through the passivating film deposited on the back side, local holes or grooves on the back side and screens on the back side; then, printing silver paste on the front surface; and finally, carrying out the one-step sintering process to form a local P+ layer on the back side and allowing the P+ layer to coming into ohmic contact with the electrodes on the front and back surfaces. By using the N-type substrate, forming local aluminum-based P-N junctions on the back side and further using the back-side chemical polishing process to remove the edge junctions, the invention can substitute for the conventional stacking-type plasma etching process, simplify the technological procedures and further bring a series of performance improvement to cells.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

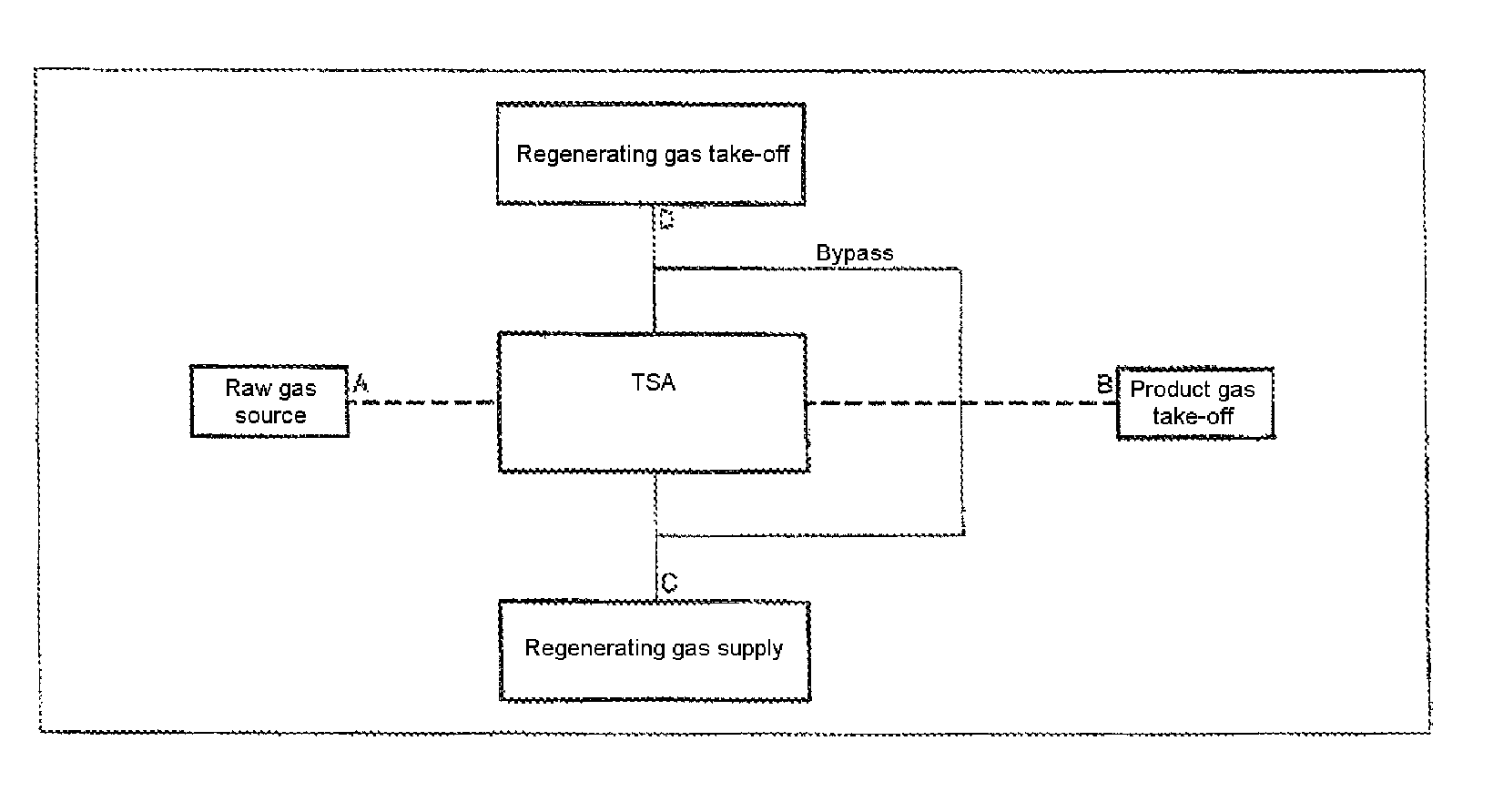

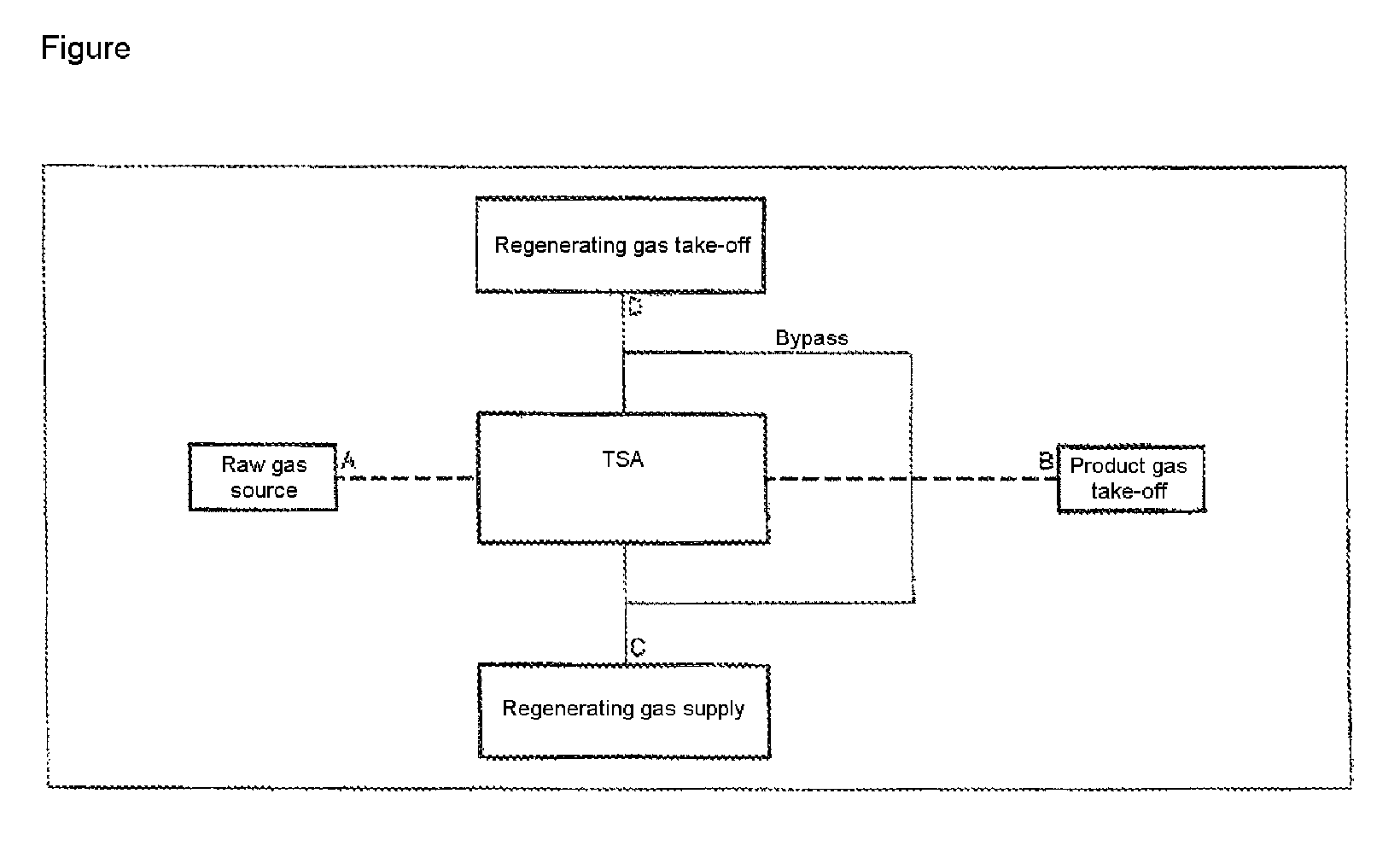

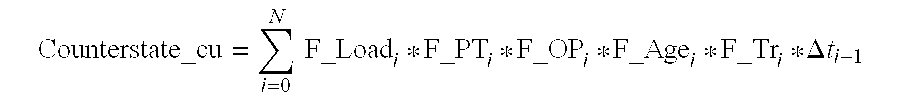

TSA process

In a TSA process of an at least two-component raw gas, to adjust for fluctuation in load, the cycle time of at least one method step is extended in the event of falling below the design load value.

Owner:LINDE AG

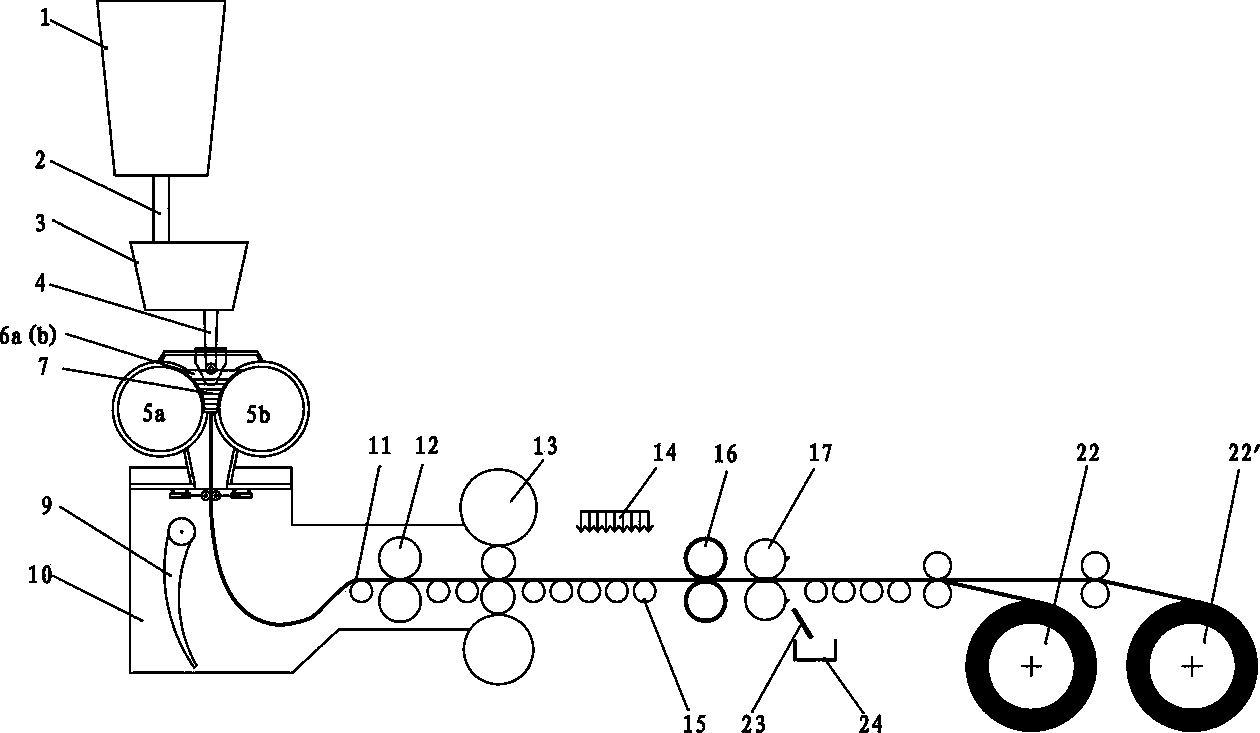

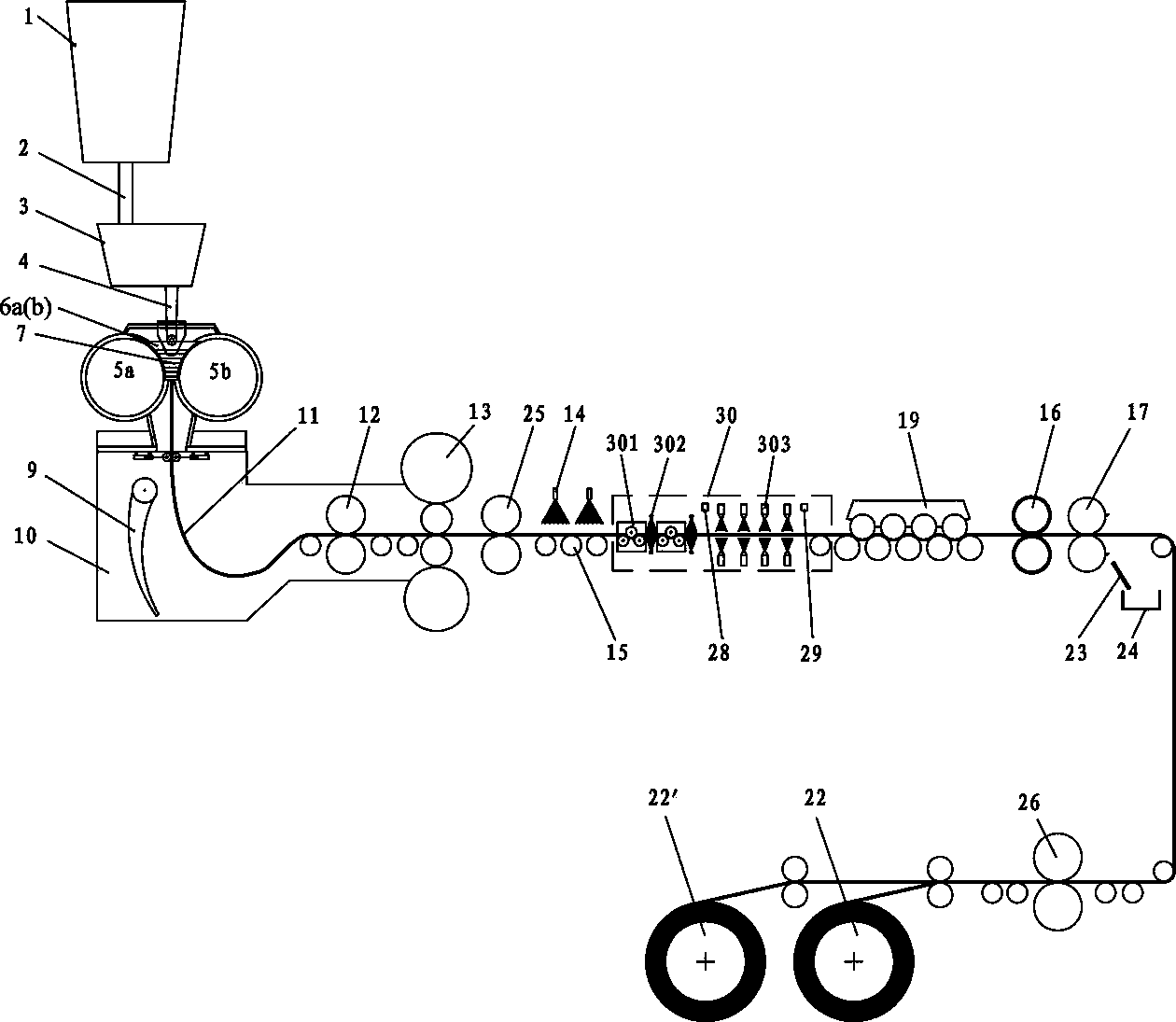

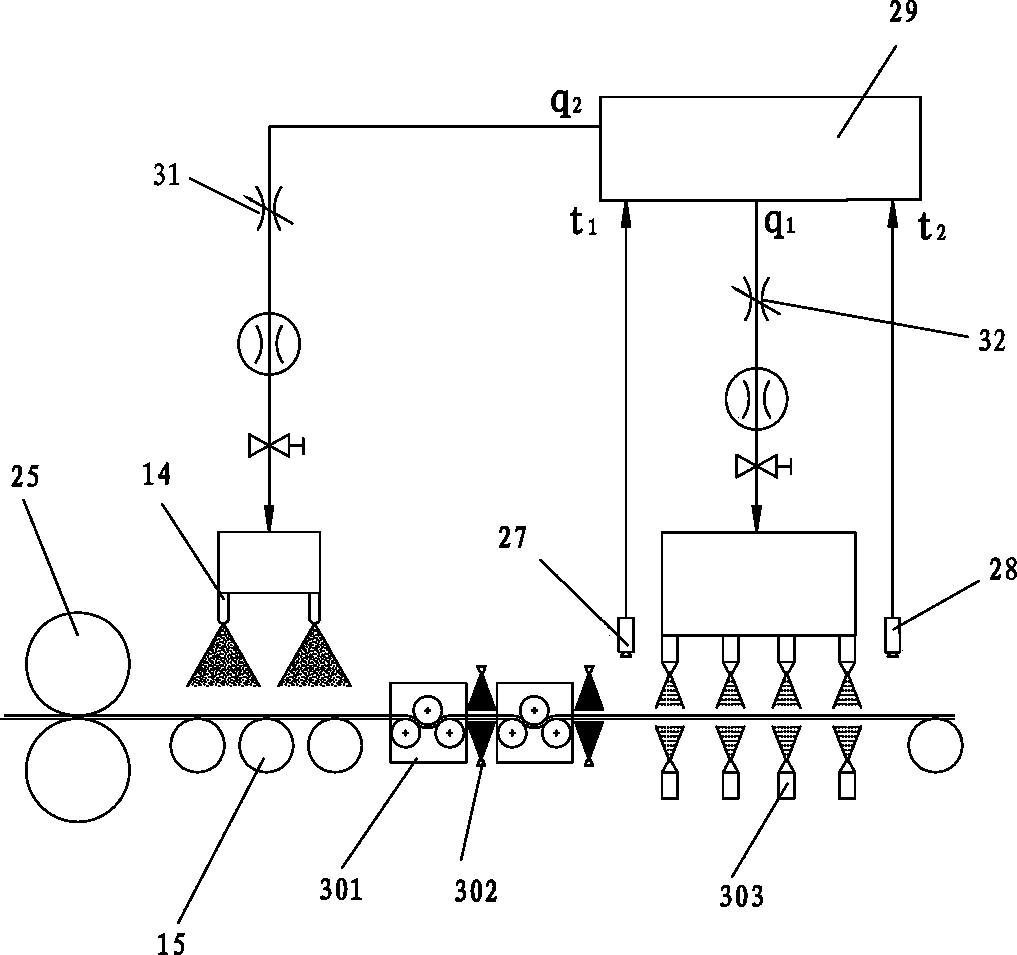

Method for producing high-strength thin strip steel in short process

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

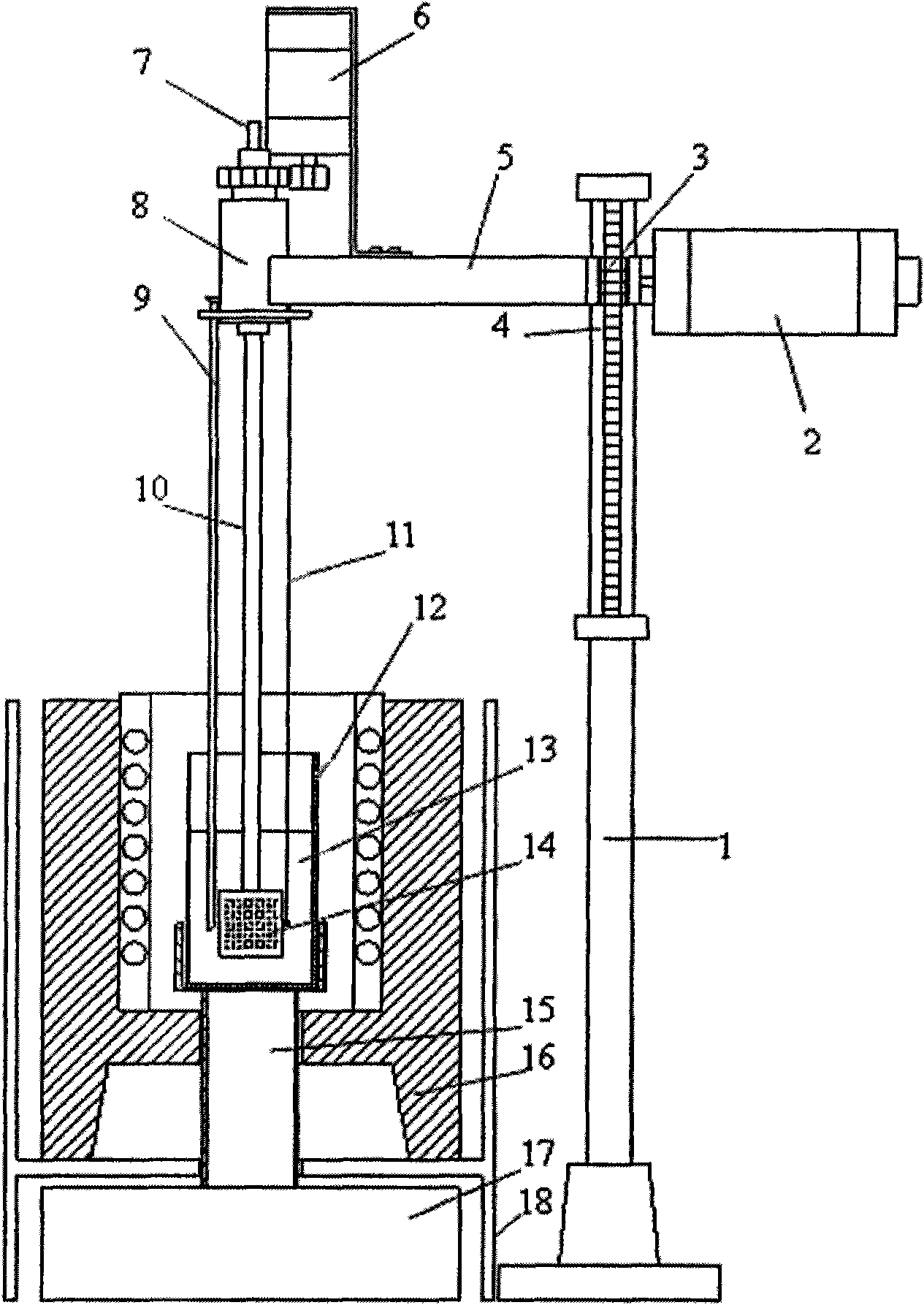

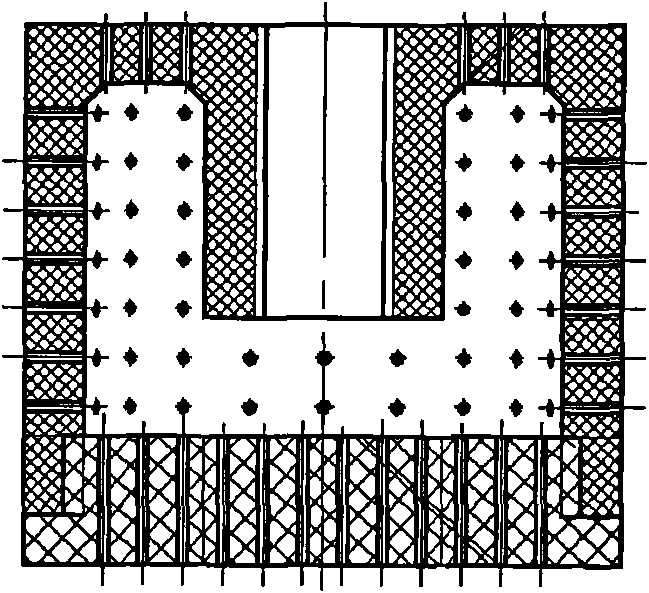

Preparation method and device of semi-solid slurry

The invention discloses a preparation method and a device of semi-solid slurry. Three processes of air current stirring, electromagnetic vibration and addition of heterogeneous nucleating agents are comprehensively utilized by the method. A graphite head with holes is connected with a hollow stirring rod, and a rotating motor drives the stirring rod to rotate through gear transmission and drives the graphite head to rotate; gas passes through a sleeve barrel and reaches the graphite head through the hollow stirring rod, and then, the gas overflows out of small holes, thereby realizing the purposes of blowing and stirring the molten metal in a rotating way; an electromagnetic vibration table can realize electromagnetic vibration on the molten metal in a crucible; the heterogeneous nucleating agents are added into the molten metal to promote further spheroidization and refinement of slurry tissues; after the molten metal is smelted, the graphite head is inserted into the molten metal for blowing and stirring the molten metal in a rotating way; and simultaneously, the molten metal is vibrated, and the heterogeneous nucleating agents are added through a powder feeding pipe, thereby preparing the semi-solid slurry with round and smooth primary grains. The prepared semi-solid slurry has the advantages of purity, no pollution, simple used equipment, easy control of process parameters, short pulping processes, small energy consumption and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

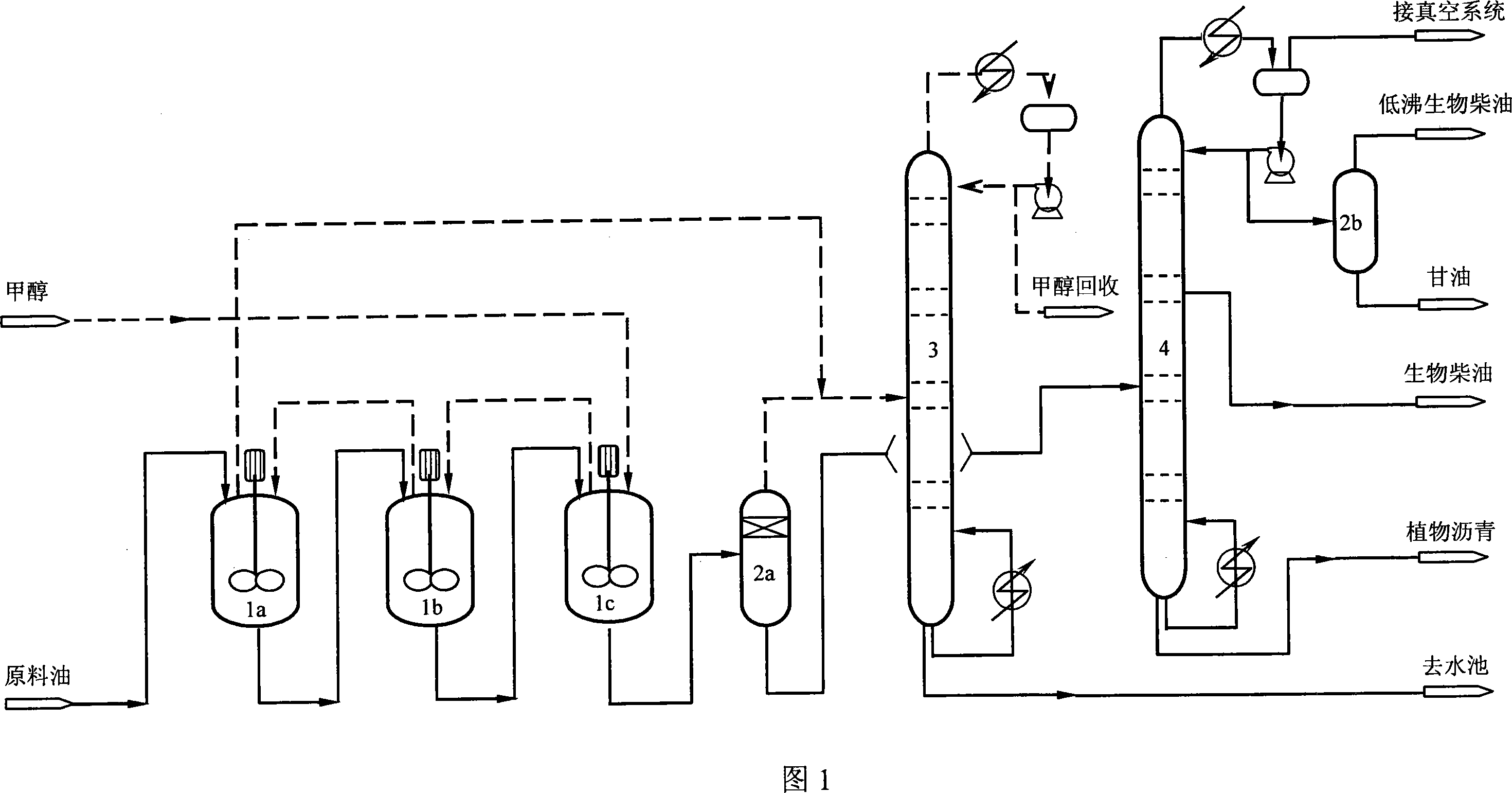

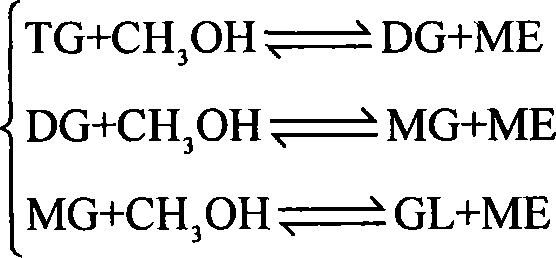

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

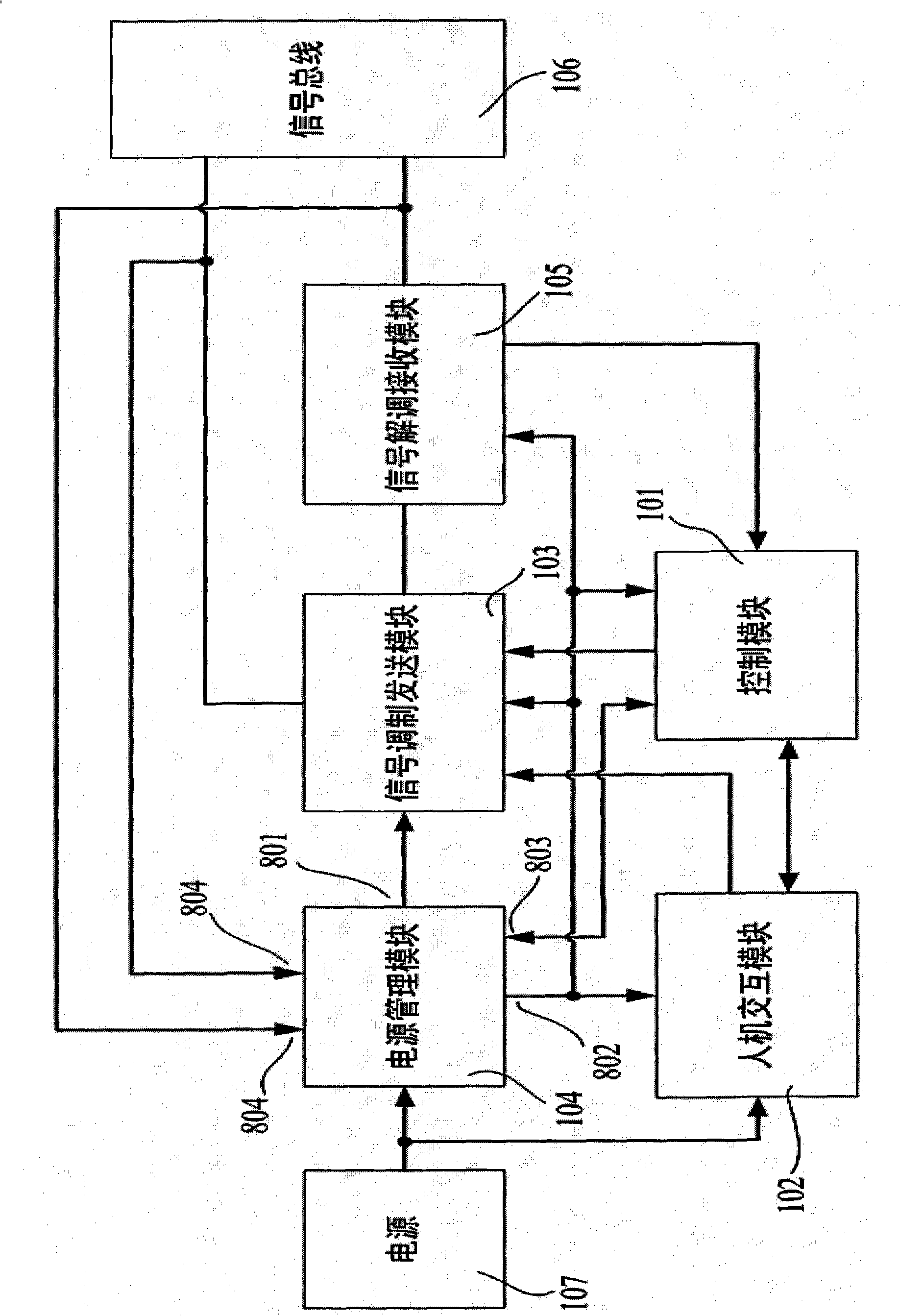

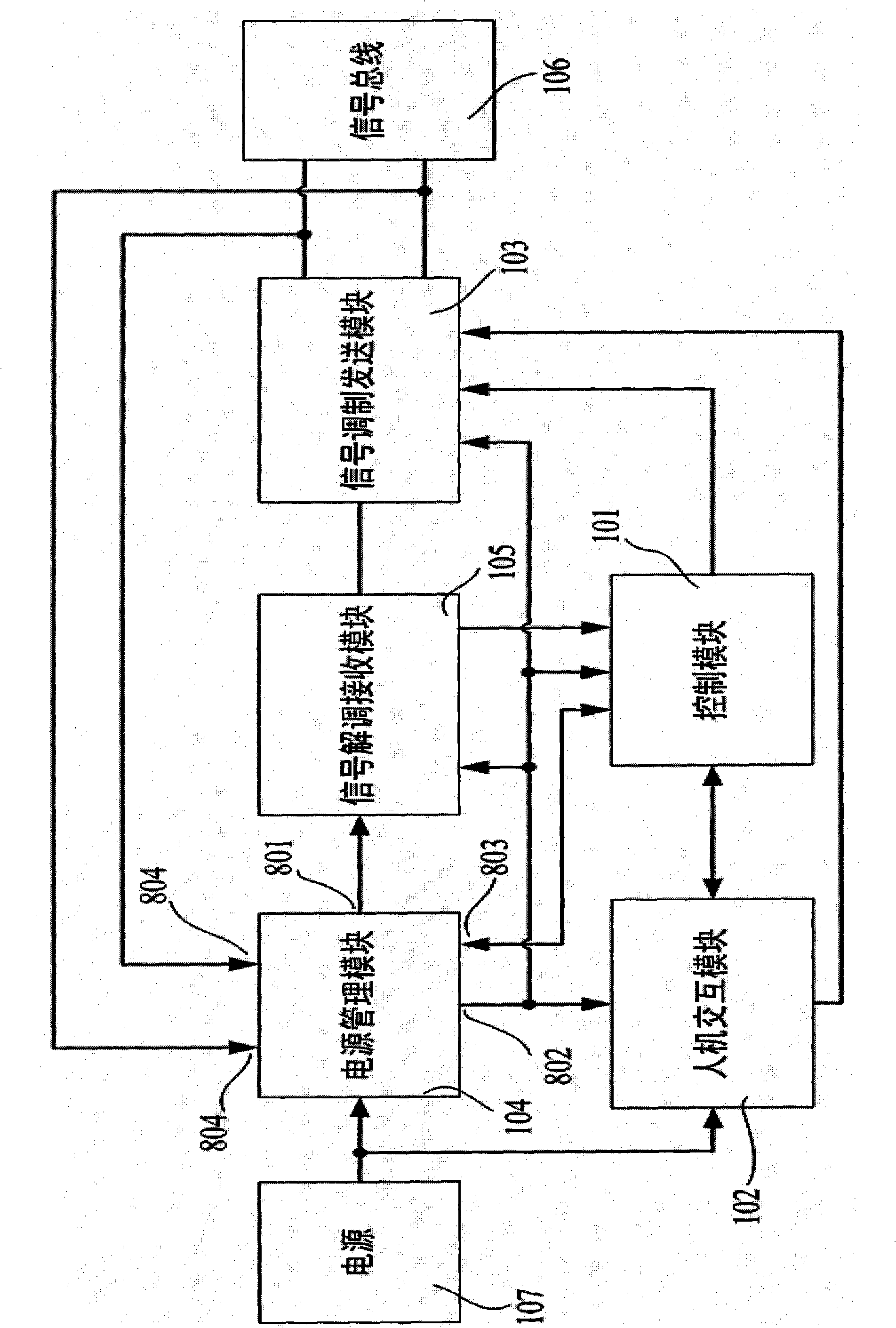

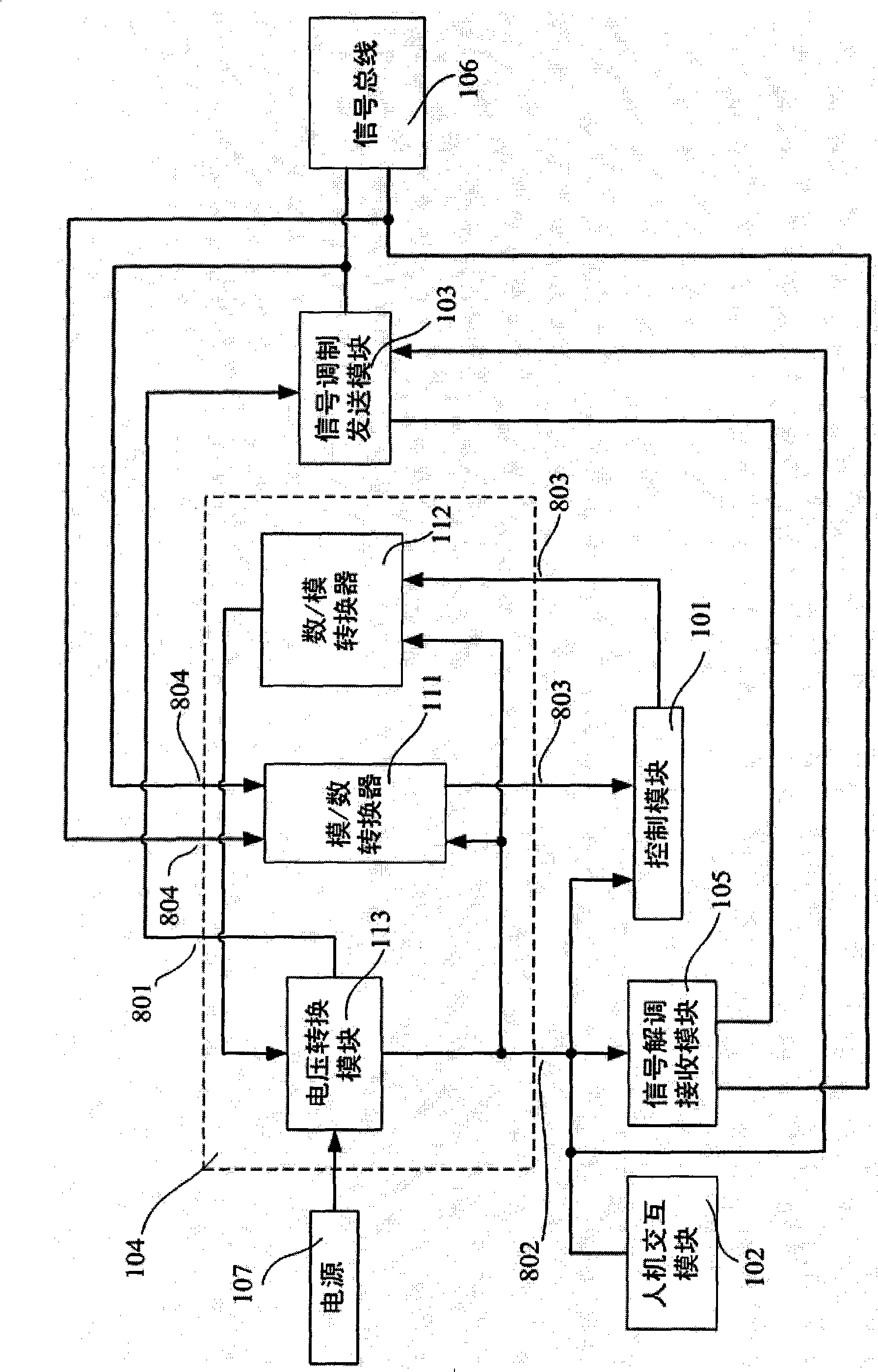

Detonating device and main control process flow thereof

The invention provides an electronic detonator initiation device, which comprises a control module, a man-machine interactive module, a power supply management module, a single modulation and transmission module, a signal demodulation and receiving module, a signal bus and a power supply, wherein the power supply management module can include an analog / digital converter, a digital / analog converter and a voltage conversion module; the signal modulation and transmission module can include a signal modulation module and a boost module; the signal demodulation and receiving module can include a signal sampling module and a signal conditioning circuit; and the man-machine interactive module can include a set and display device, and an authorization device, a locking device or an anti-misoperation switch. The invention also provides a main control process of the initiation device, and explains the flow processes of the communication voltage management process, the signal transmission process, the signal receiving process, the charging process and the initiation process in detail. According to the technical scheme, the initiation device matched with an electronic detonator can achieve the basic functions such as two-way communication with the electronic detonator and initiation of the electronic detonator.

Owner:颜景龙 +1

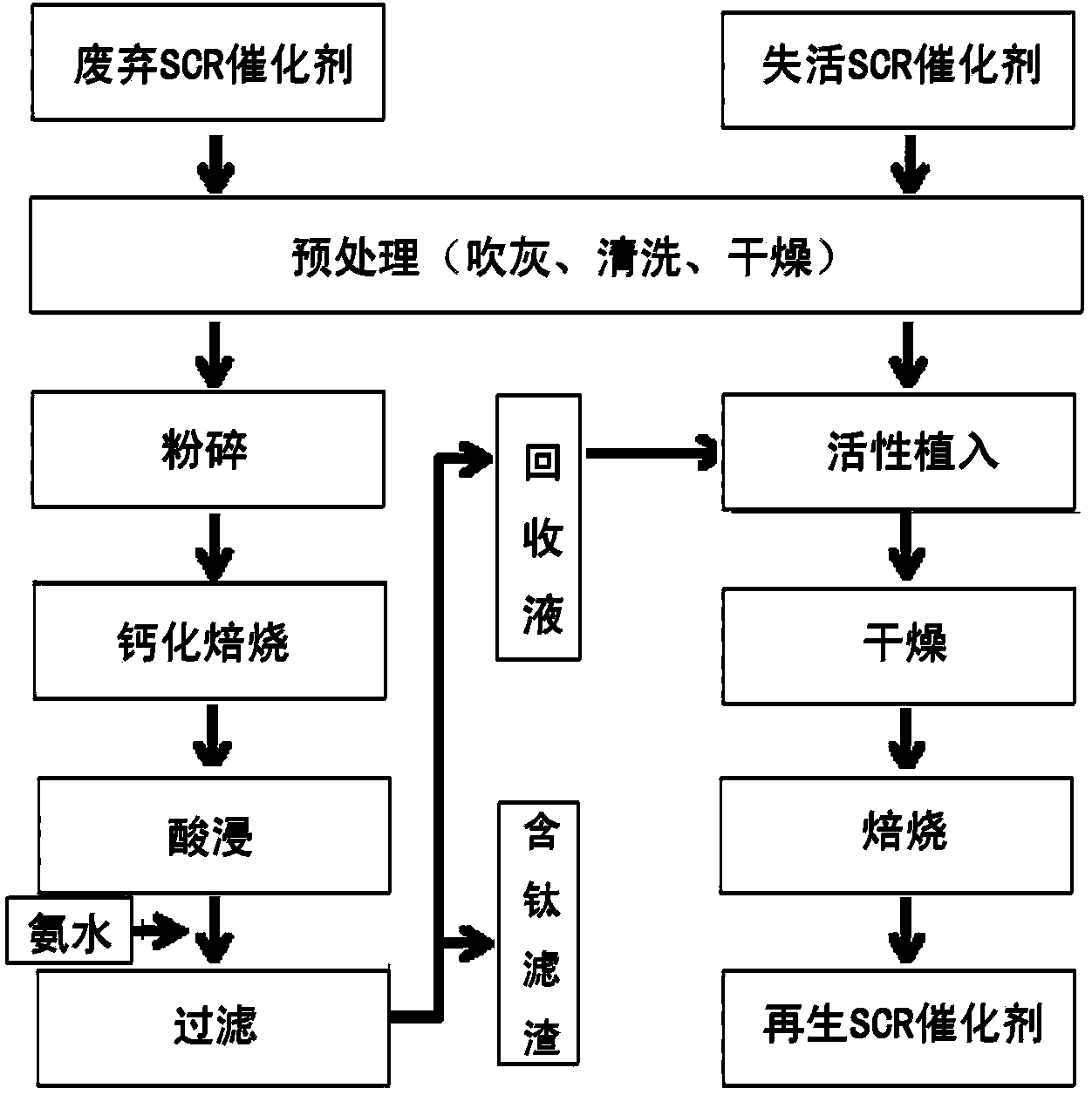

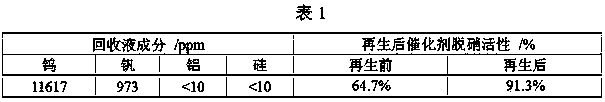

Method for regenerating denitration catalyst by utilizing waste SCR (Selective Catalytic Reduction) catalyst recovery liquid

ActiveCN103846112AShort processing cycleIncrease productivityCatalyst regeneration/reactivationCatalyst activation/preparationAmmonium hydroxideTitanium

The invention discloses a method for regenerating a denitration catalyst by utilizing a waste SCR (Selective Catalytic Reduction) catalyst recovery liquid. The method comprises the following steps: after soot blowing, cleaning and drying pretreatment on a waste SCR catalyst, smashing the waste SCR catalyst into powder; evenly mixing the powder with calcium carbonate to obtain a mixture; roasting the mixture to obtain a roasted material; re-smashing the roasted material to obtain a re-smashed material and adding the re-smashed material into a dilute sulphuric acid solution; adjusting the value of pH to 8-11 by ammonium hydroxide; filtering for separating out titanium-containing residues and thus obtaining a recovery liquid; after soot blowing, cleaning and drying pretreatment on an inactivated SCR catalyst block body, soaking the block body in the recovery liquid; drying the block body; roasting the block body in a muffle furnace with the temperature of 400-600 DEG C, thereby obtaining the regenerated SCR catalyst with denitration activity being recovered. The method organically integrates catalyst recovery and regeneration technologies. The precious metal components of the waste SCR catalyst are fully utilized, the problem of vanadium, tungsten or molybdenum separation-purification is avoided, the recovery and regeneration technology process is shortened, and the treatment expenditure of the waste SCR denitration catalyst is lowered.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

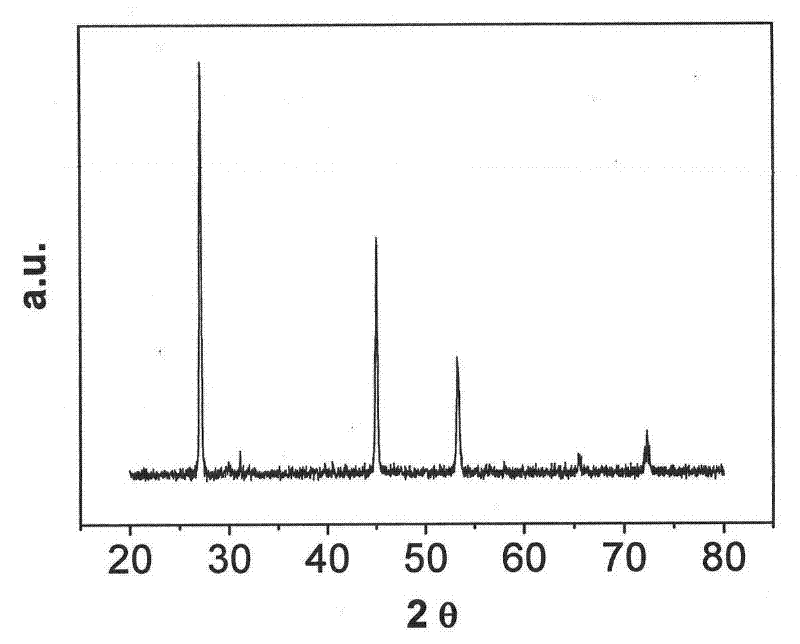

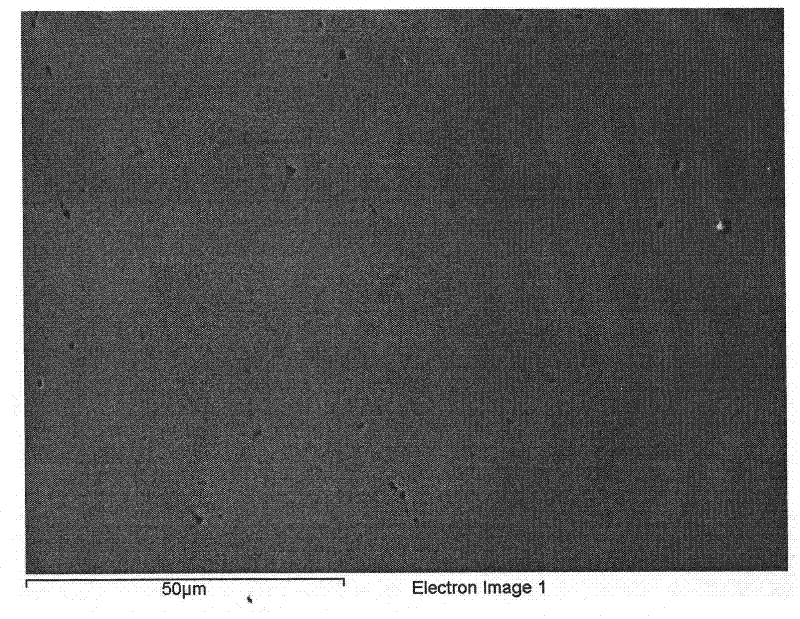

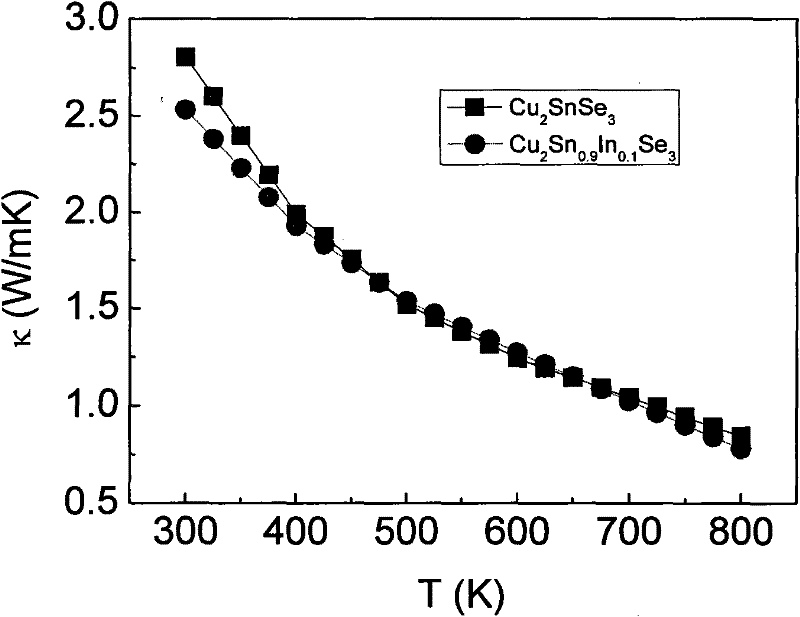

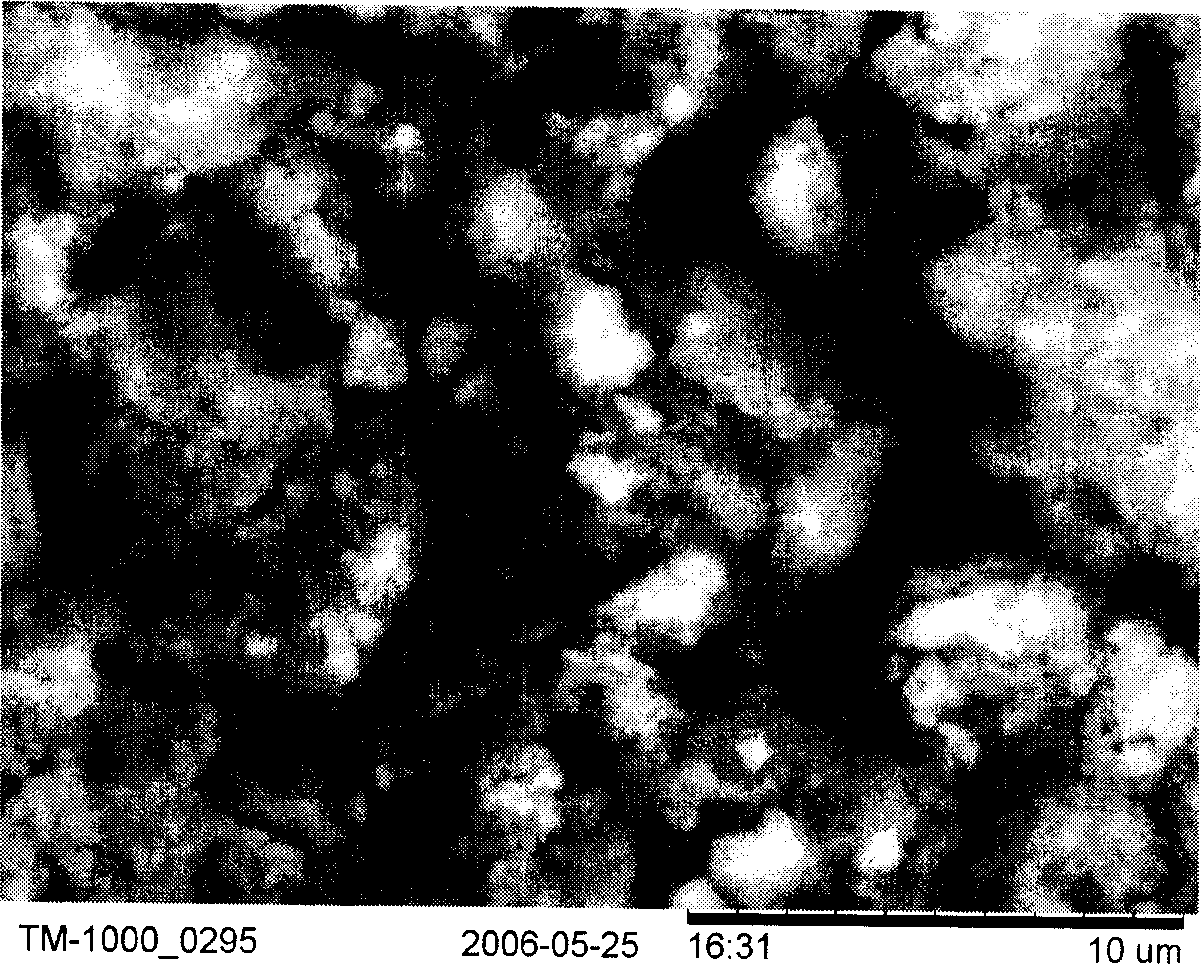

Method for preparing thermoelectric material of ternary diamond structure

ActiveCN102194989AExcellent thermoelectric performanceShort processing timeThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsAdamite

The invention relates to a method for preparing a thermoelectric material of a ternary diamond structure. The method comprises the steps of: raw material preparation, heat-preservation reaction, annealing treatment, spark plasma sintering and the like. In the invention, by applying a fusion-process preparation technology, rapid spark plasma sintering and other methods and controlling technological parameters, the method for preparing the thermoelectric material of the ternary diamond structure is realized and has the advantages of simple and convenient technology, short flow time, high feasibility and good thermoelectric performance, and the thermoelectric material of the ternary diamond structure, prepared with the method provided by the invention, has favorable thermoelectric performance and can be used as a p-type thermoelectric material. The method has the characteristics of simplicity, strong operability, low cost, good industrial prospect and the like.

Owner:中科西卡思(苏州)科技发展有限公司

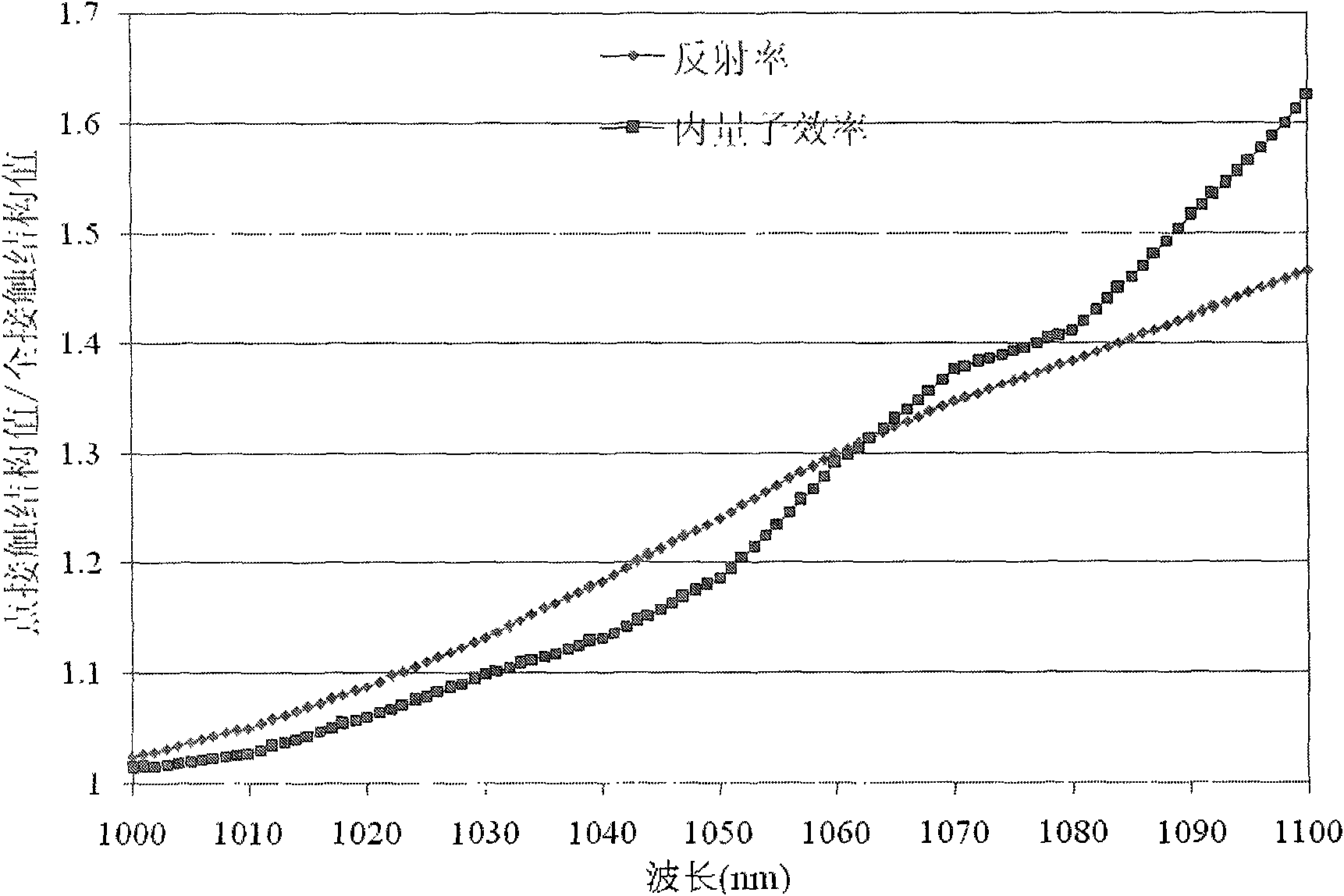

Solar battery slice technology for efficient and low-cost film crystal silicon

InactiveCN101241952AExcellent electrical performanceAppearance of high qualityFinal product manufactureSemiconductor devicesSilicon solar cellSlurry

The present invention is a technique for manufacturing a crystalline silicon solar cell piece, especially a technique for manufacturing a high-efficiency, low cost and thin-sheet solar cell piece, and the invention belongs to the solar energy application field. The technique aims at the thin-sheet crystal silicon chip with thickness less than 200 mu m, by adopting innovated technique and developing the original technique, combines the domestic cell whole equipment which is independently developed, settles the contradiction between the thin sheet and the fraction ratio, finished product rate and the electrical property, and satisfies the request of the cell piece product line to the high efficiency and low cost. The technique for manufacturing crystal silicon solar cell piece is subdivided to seven steps according to the process flow: eliminating the injury and coarsen the surface, diffusing to make a knot, plasma etching for eliminating the edge, PSG eliminating, PECVD depositing Si3N4 film, printing positive back electrode slurry and back field slurry on the silk screen, and co-baking to form an ohm contact. When the technique is adopted for the size 125*125mm<2>, the efficiency of the single crystalline silicon solar cell piece is up to 16.5, and the efficiency of the polycrystalline silicon solar cell is up to 15.0%.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Production method of whole wheat flour

The invention relates to a production method of whole wheat flour, solving the problems that wheat bran is difficult to crash, deficient in nutrient component utilization and shorter in shelf life. The production method of the whole wheat flour comprises the following steps: clearing wheat material, removing impurities in the wheat material, then rinsing to obtain wheat grains, carrying out heat treatment for sterilizing, killing enzyme and drying, and then crashing the wheat grains, wherein various known treating methods, such as a microwave heating method or a hot-air drying method can be adopted in the heat treatment method. As the optimal schemes, the water content of the rinsed wheat grains is 15-20 percent, and the water content of the wheat grains subject to heat treatment is below 14 percent. The invention has the advantages that: (1) the process flows are shortened; (2) the quality of the wheat bran is ensured by the rapid heat-moisture treatment, the shelf life is prolonged, and the problem that the wheat bran is difficult to crash is also solved; (3) the nutritional components in the whole wheat flour are stabilized, and the nutritional value of the product is improved.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Method for producing nano-scale white carbon black with rice hull ash

The invention relates to a method for preparing nanometer level white carbon black by rice husk ash. The method is characterized in that the process method comprises the following steps: the rice husk ash is treated by an alkaline method to prepare soluble glass; and a soluble glass solution is subjected to condensation, heat insulation, acidic reaction, aging, rinsing, filtering, preparing, homogenizing, spraying and drying, and airflow pulverization. The method has the technical effects that the method reduces cost, improves corrosion resistance, high hardness and high toughness of the material, and has simple preparation process flow, low production cost and good stability.

Owner:NANCHANG UNIV

Composite catalyst used for reforming hydrogen prodn. using methane and water vapor as raw material, preparing process and use

ActiveCN1903431AFacilitated releasePromote absorptionHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

A composite catalyst for preparing hydrogen by reforming the CO2 adsorbed and intensified methane vapor is proportionally prepared from CaO, NiO and Al2O3 as carrier. It features that the heat generated by reaction between calcium oxide and CO2 is used to promote said reforming reaction. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process of preparing alumina carrier

ActiveCN101088605ALarge apertureEasy to makePhysical/chemical process catalystsRefining to eliminate hetero atomsAluminateResidual oil

The present invention relates to process of preparing alumina carrier. The process includes the steps of: neutralizing acid aluminum salt and basic aluminate, ageing, filtering, washing, forming, drying and roasting to obtain the alumina carrier. The ageing is completed in the conditions of temperature higher than the neutralizing temperature and pH value higher than the neutralizing pH value. The process is simple, and the prepared alumina carrier has great pore size and great pore volume, and may be used in heavy oil and residual oil hydrogenating catalyst, especially residual oil hydrodemetalizing catalyst and residual oil desulfurizing catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

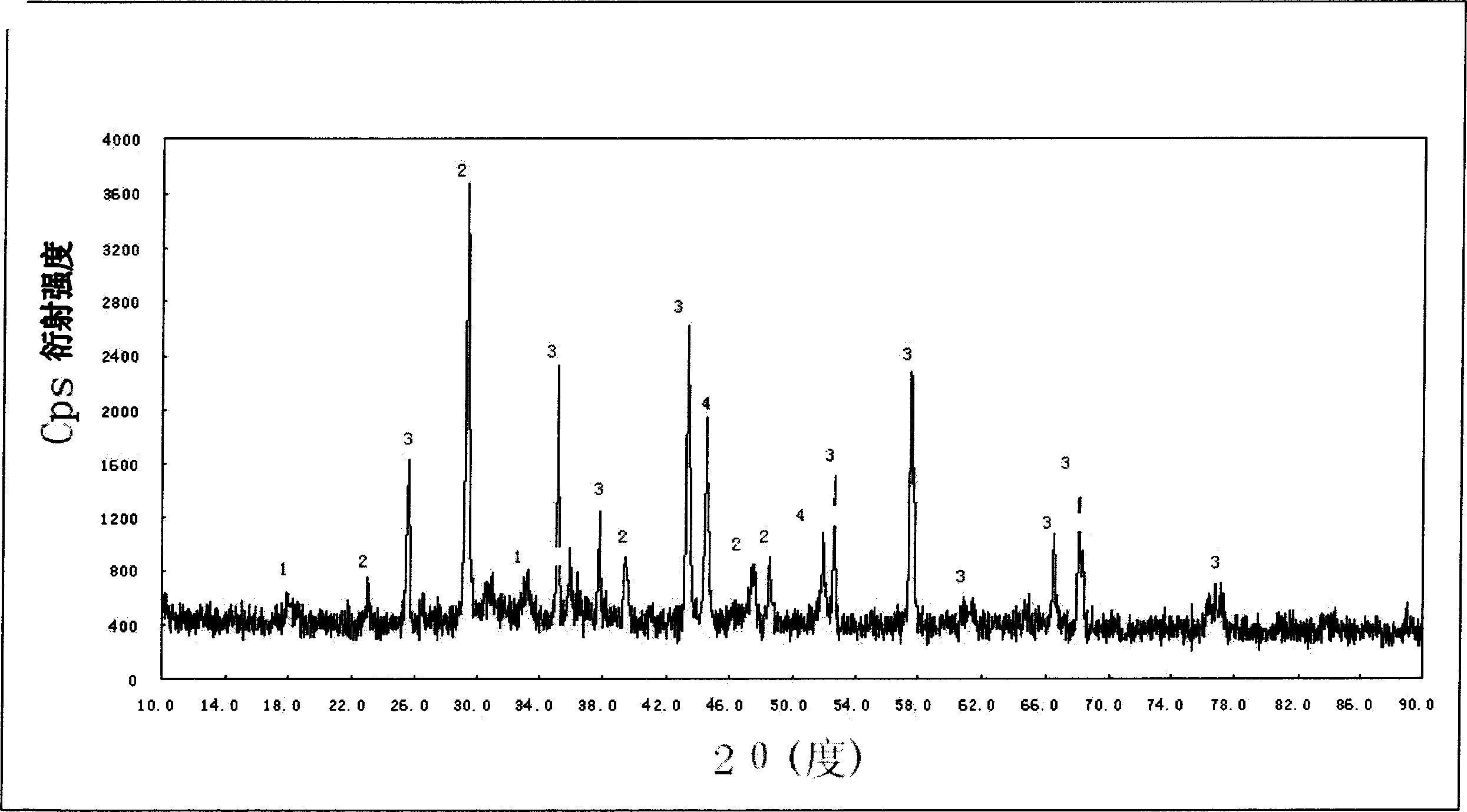

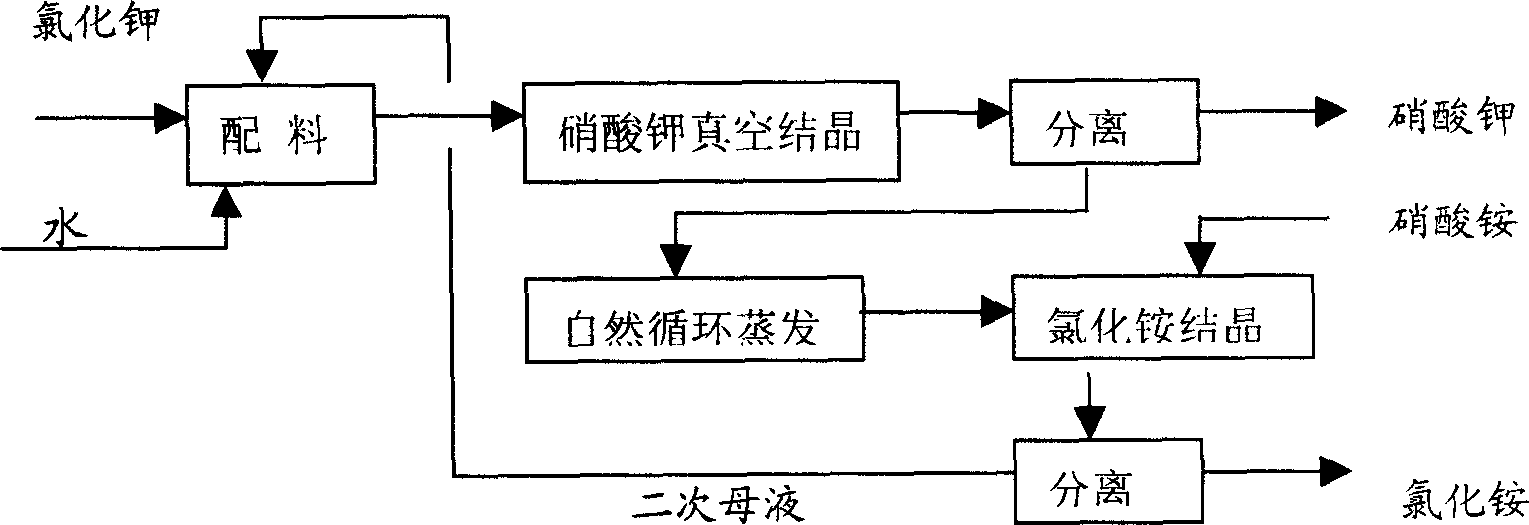

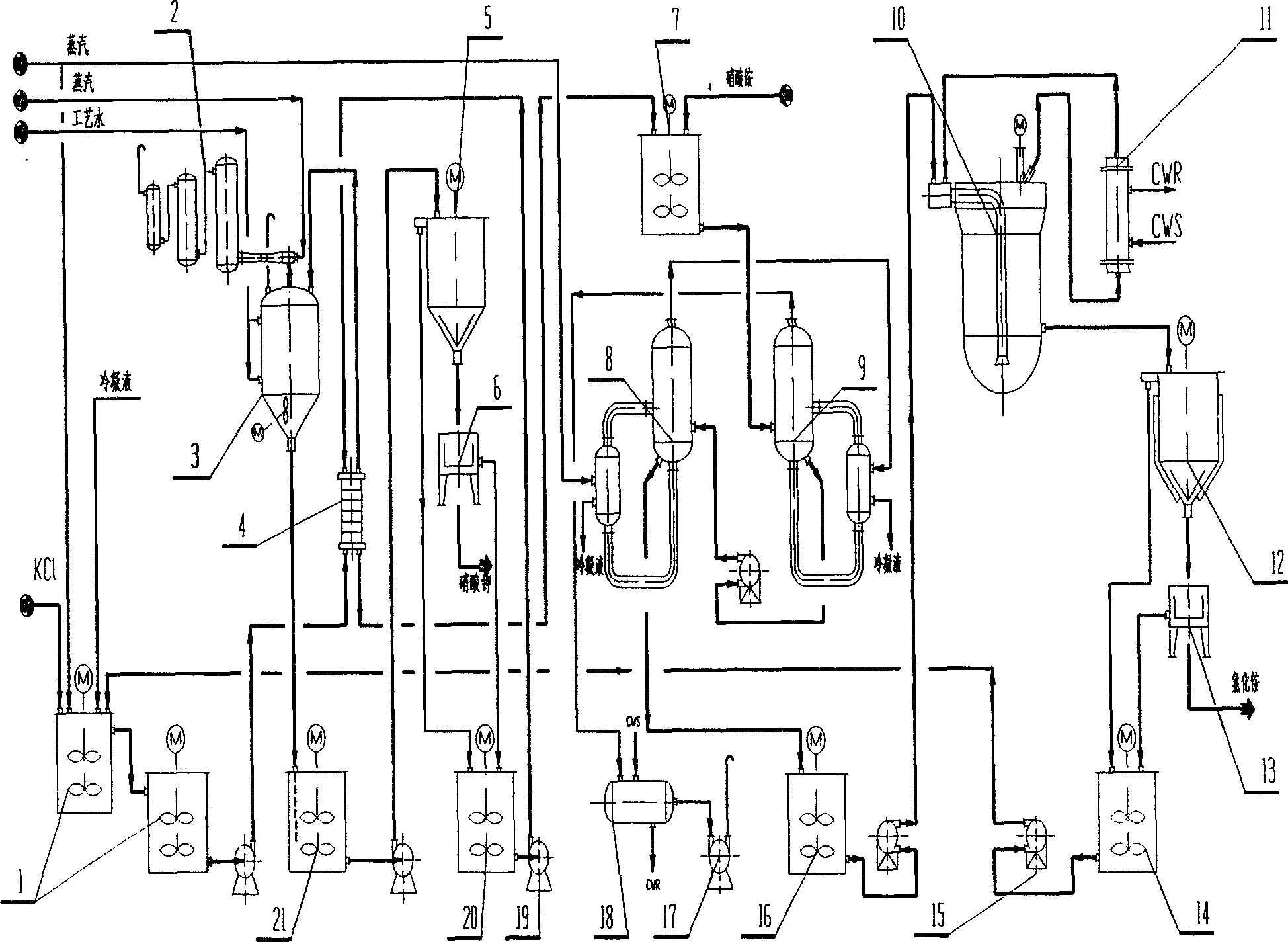

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

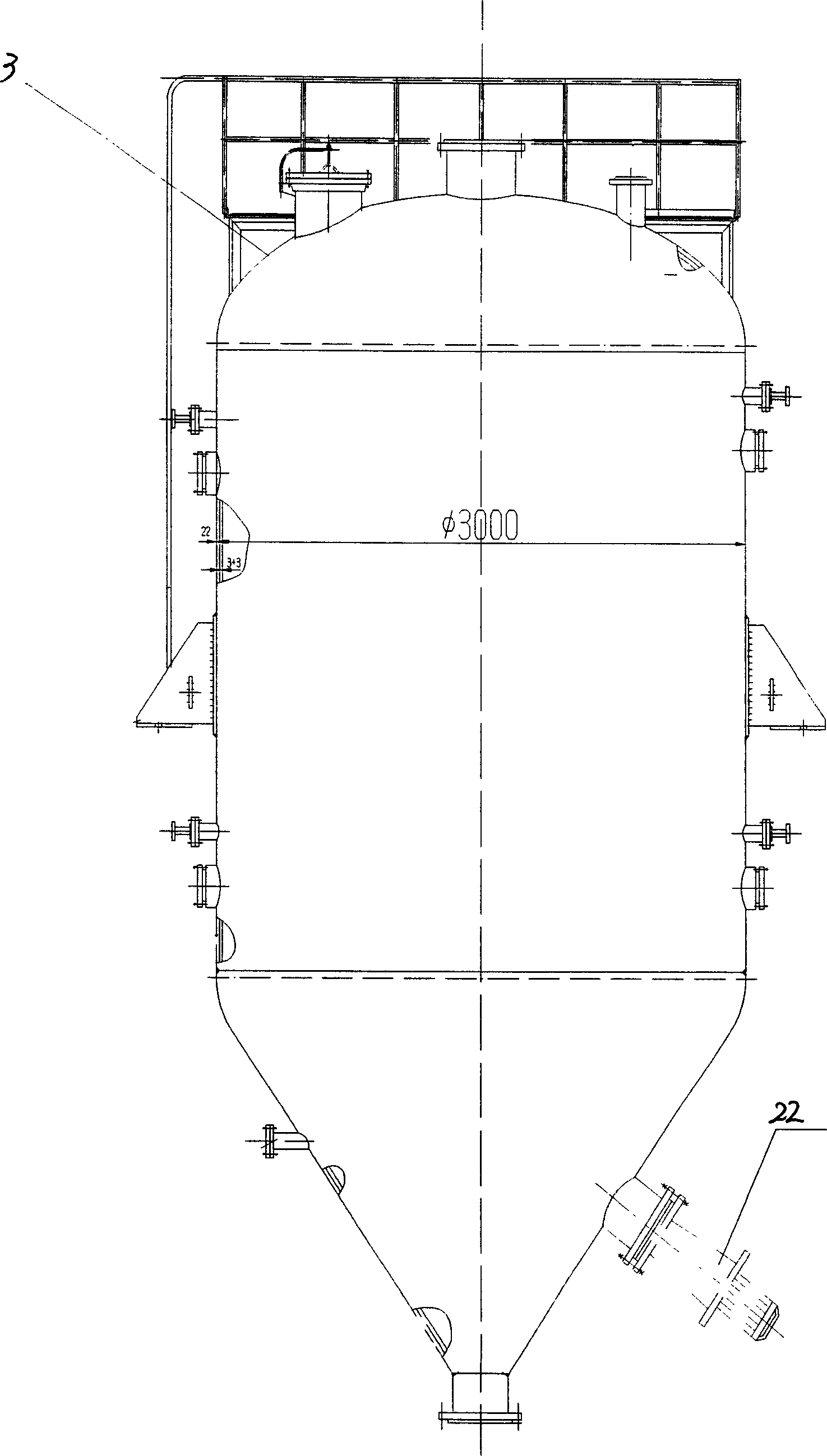

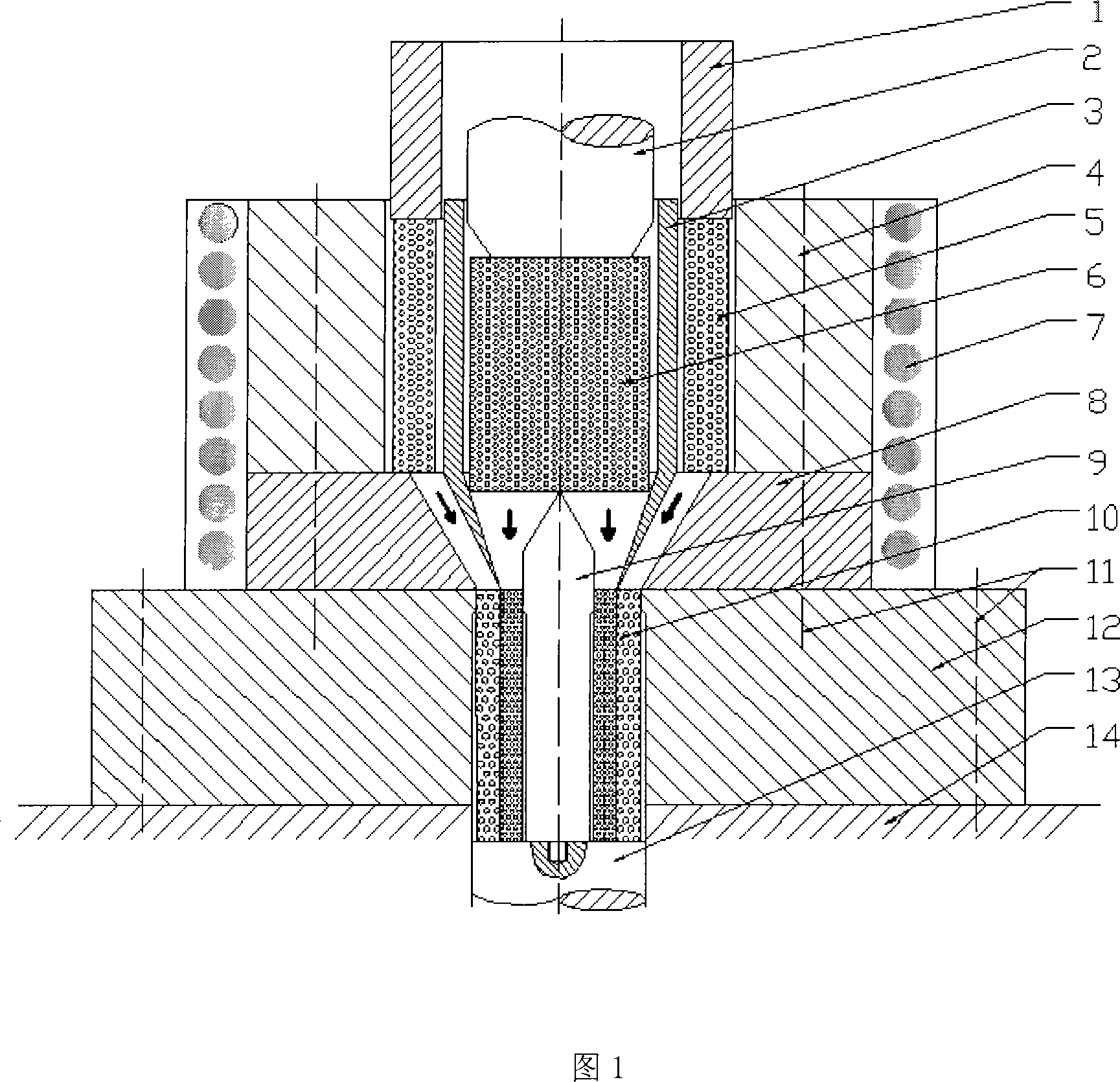

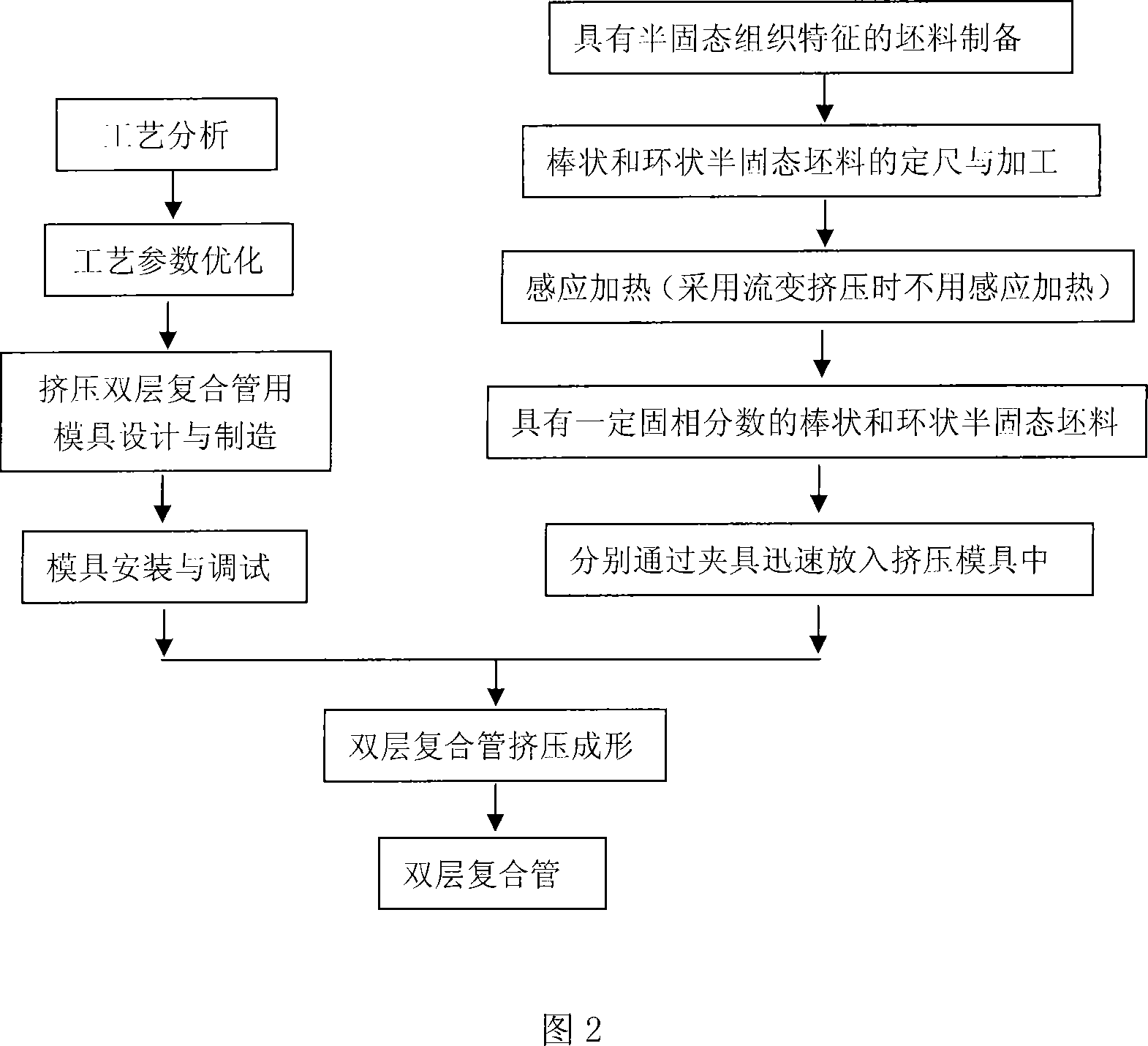

Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

InactiveCN101020201AReduce consumptionImprove product qualityExtrusion diesExtrusion control devicesTemperature controlControl system

The present invention relates to semi-solid forming technology, and is especially semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe. The technological process includes the following steps: pre-heating the mold to 200-300 deg.c and establishing temperature control system, setting the induction heated blank into the extruding mold, and extruding at regulated speed and stroke to obtain the required composite pipe. The new extruding process for making composite pipe has short procedure, low power consumption and high product quality.

Owner:TSINGHUA UNIV

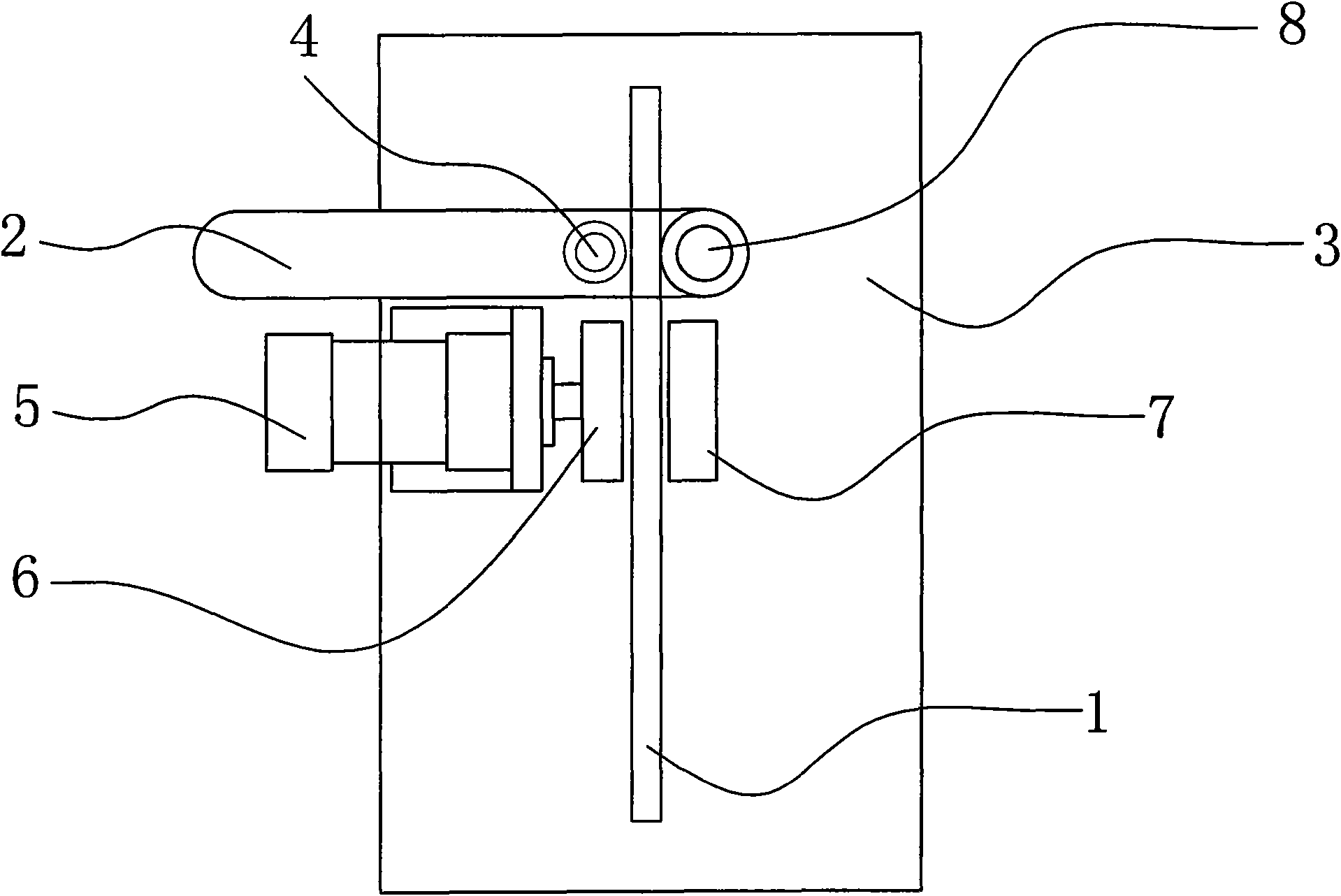

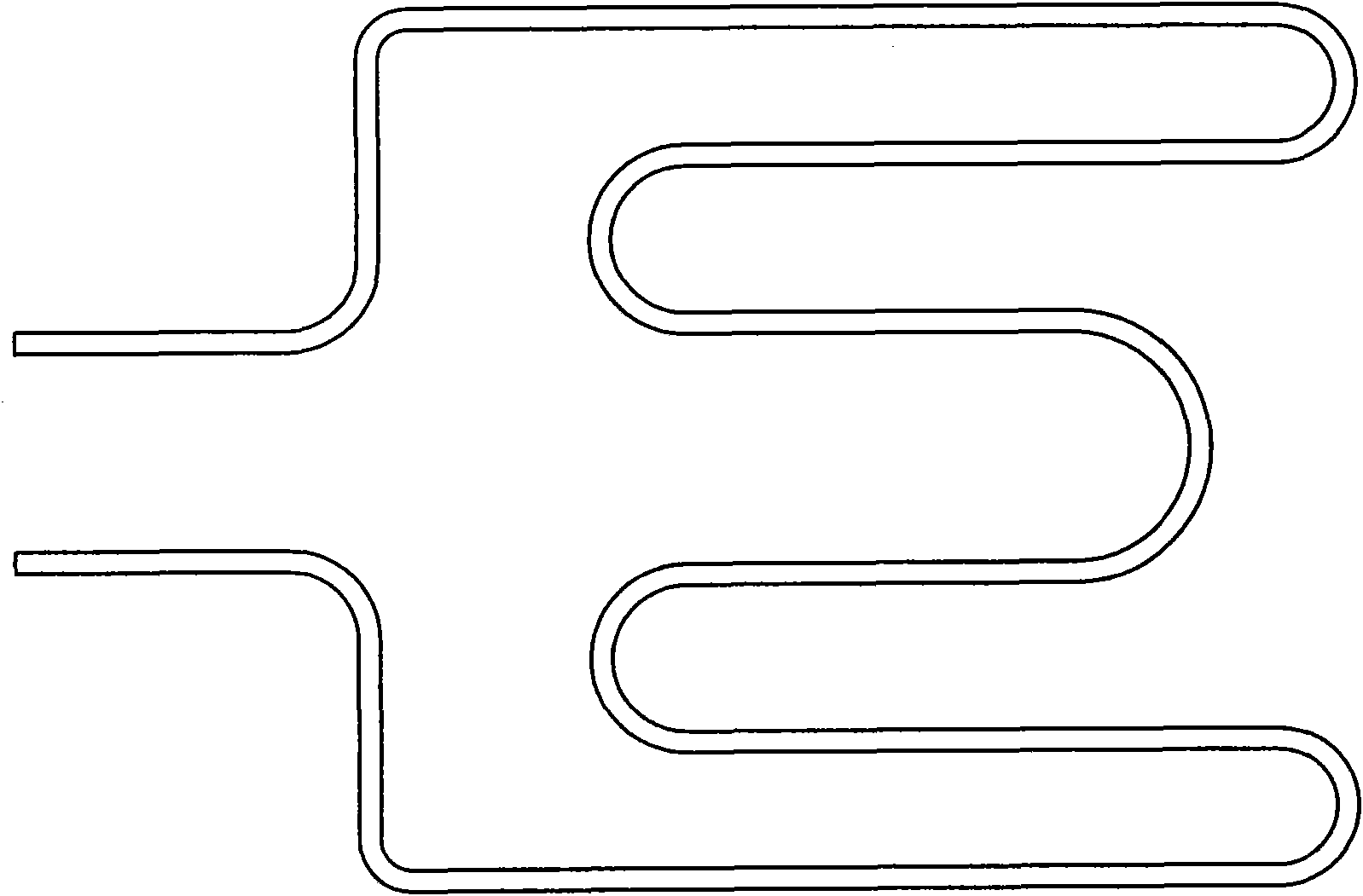

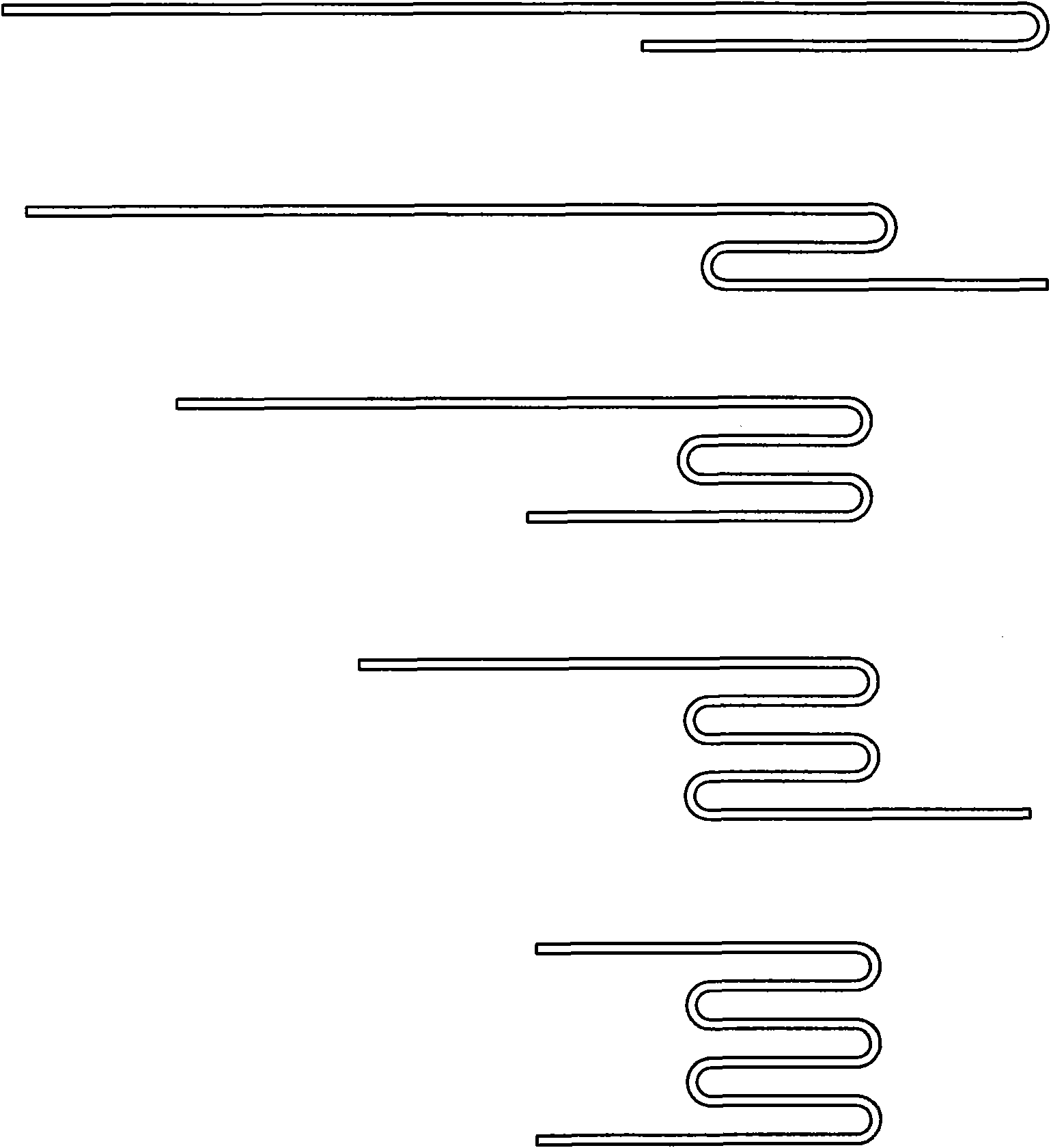

Electrical heating tube plane numerical controlled tube bending method and numerical controlled bending device using same

The invention relates an electrical heating tube plane numerical controlled tube bending method which comprises the technological processes of setting parameters, tube placing, tube fetching, and bending and forming, wherein the three processes of tube placing, tube fetching and bending and forming are repeated, and the parameters in a numerical controlled system are set so as to finish the wholeaction process. As the tube placing process, tube fetching process and the bending and forming process are adopted, the whole process needs no human intervention, and avoids the influence of human factors on the size, radius and angle of the bent product, thereby achieving the purposes of reducing the product fraction defective and production cost. Compared with the processing mode in the prior art, the method has the advantage of improving production efficiency; and compared with the existing processing equipment, a numerical controlled bending device adopted by the method has the advantagesof convenient operation and simple structure.

Owner:张明放

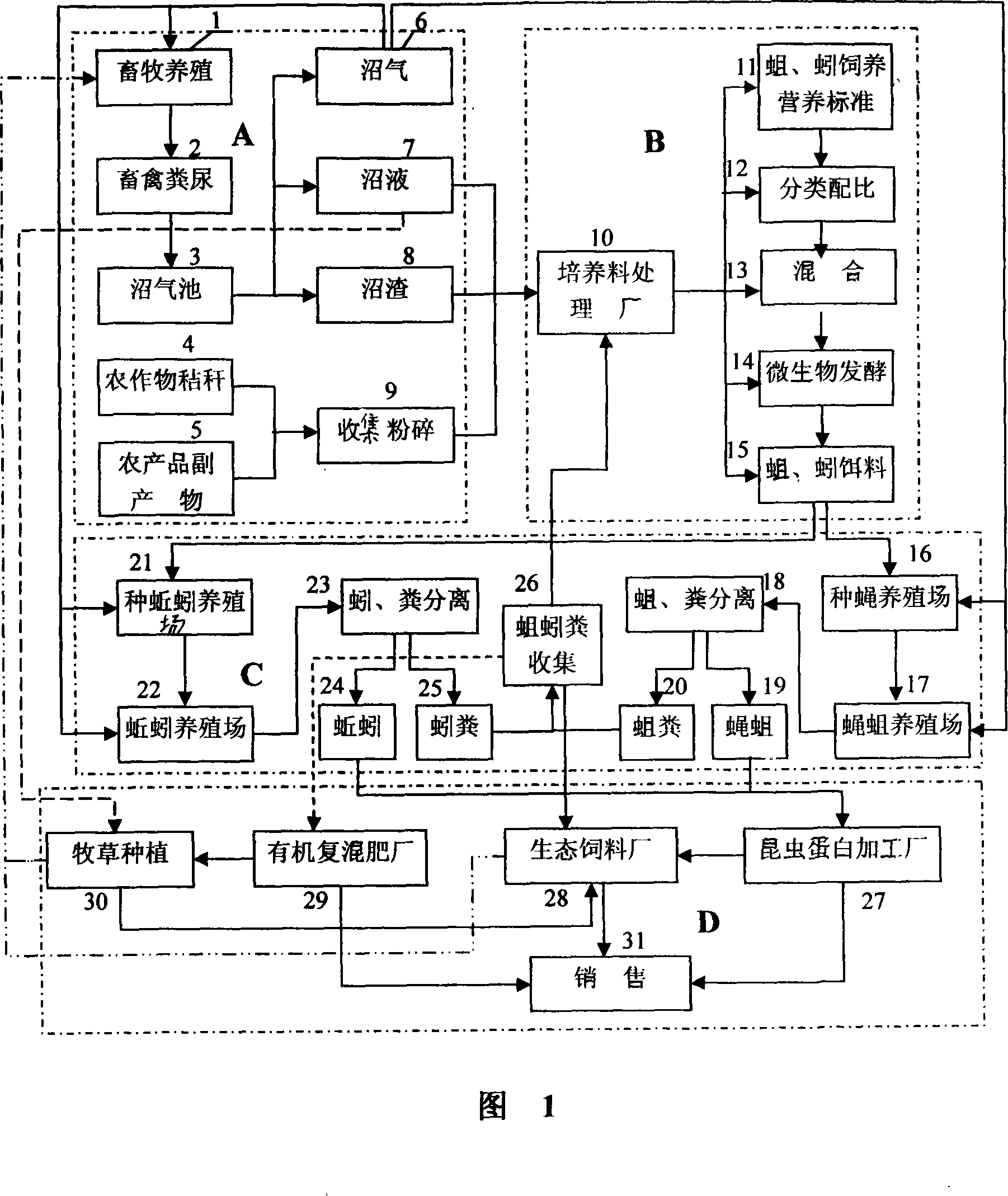

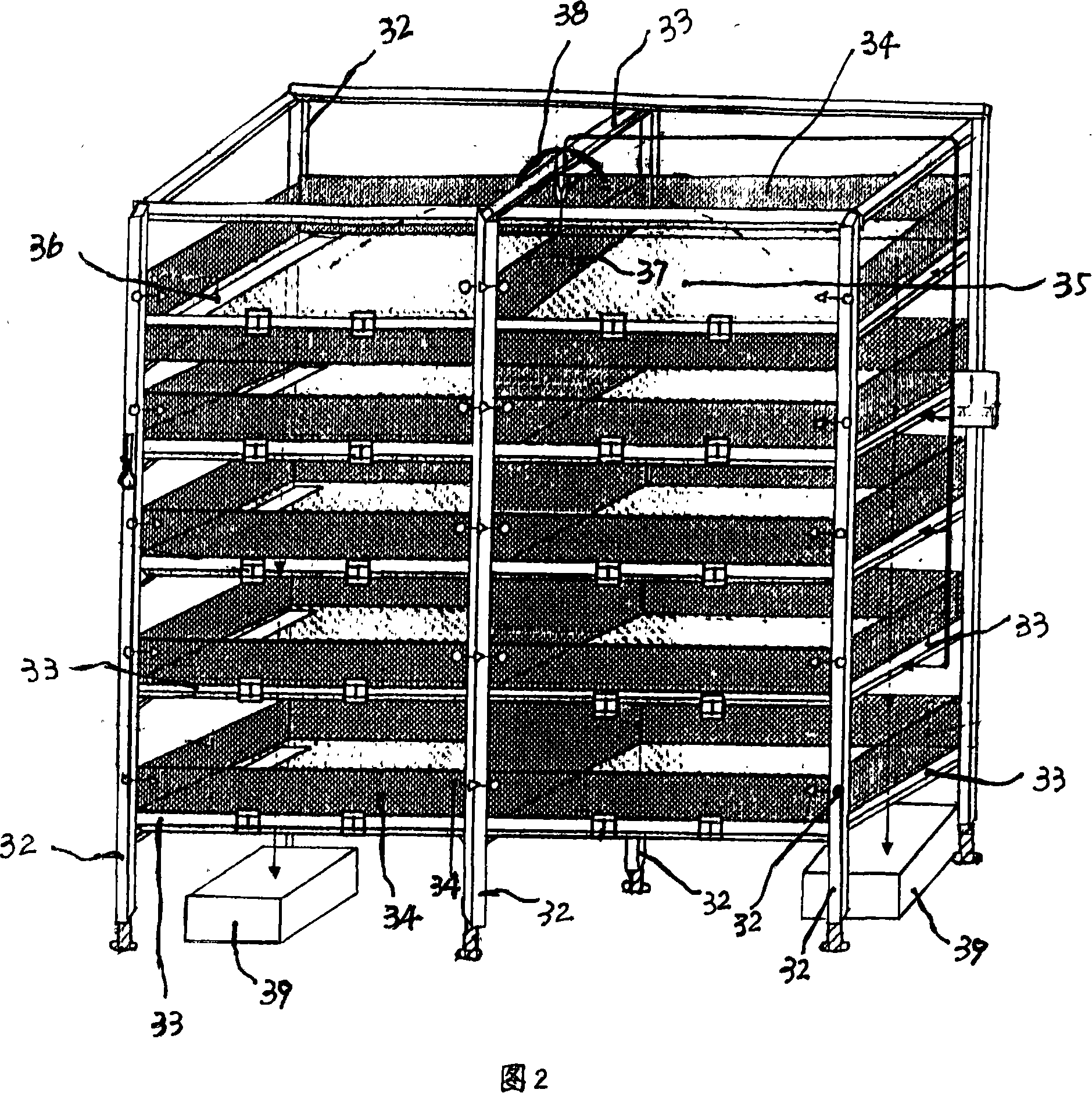

Fly maggot, earthworm ecological efficient circulation culturing method and culturing apparatus therefor

The present invention relates to a maggot and earthworm ecological high-effective circulating cultivation method and cultivation equipment by using said method, belonging to the field of maggot and earthworm cultivation technology. Said cultivation process includes the following several processes: raw material supply process, bait processing process, circulating cultivation process and pasture planting and product processing process. Besides, said invention also provides the concrete steps of above-mentioned every process, and concrete operation method of said cultivation equipment.

Owner:李金穗 +1

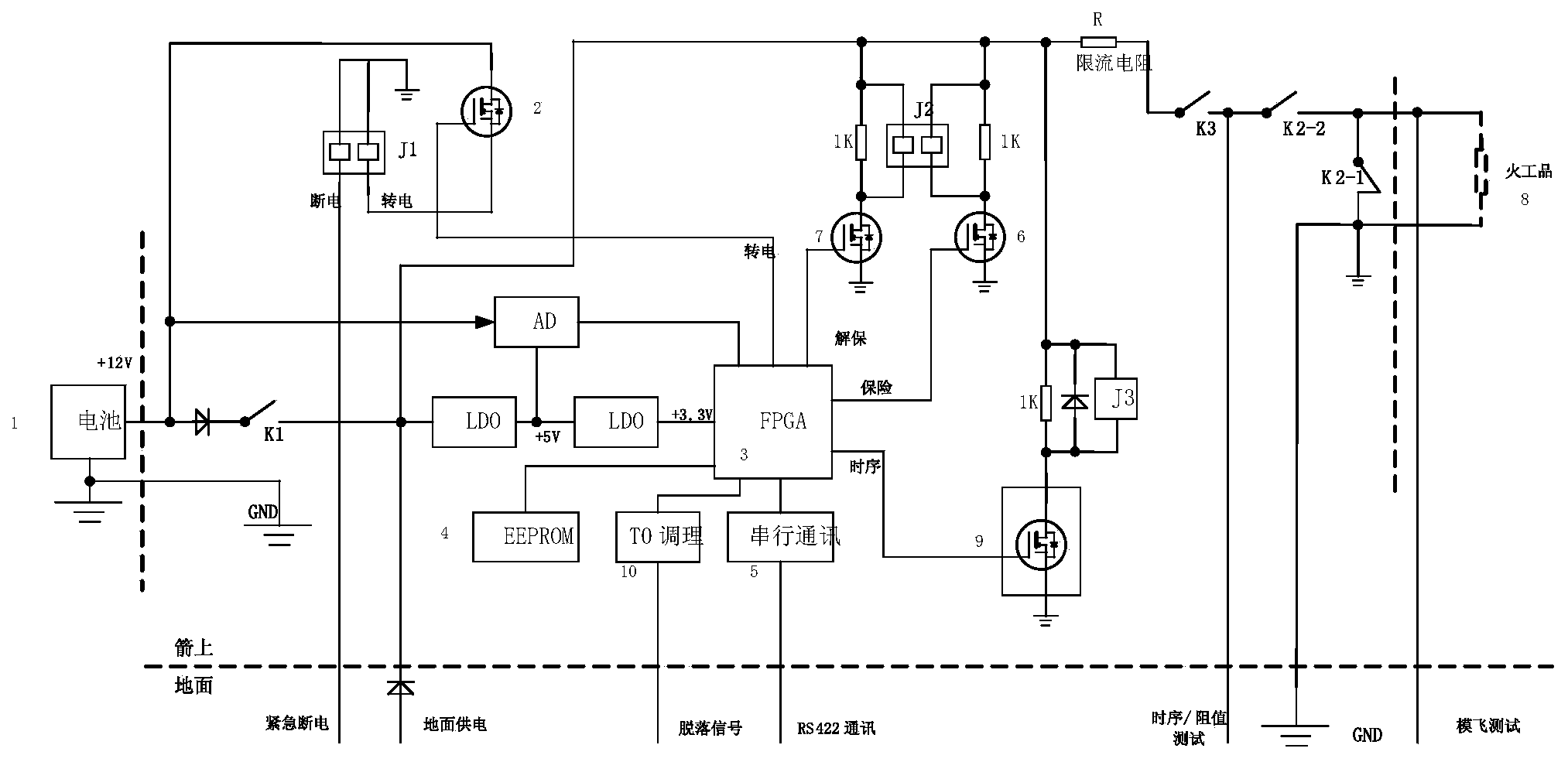

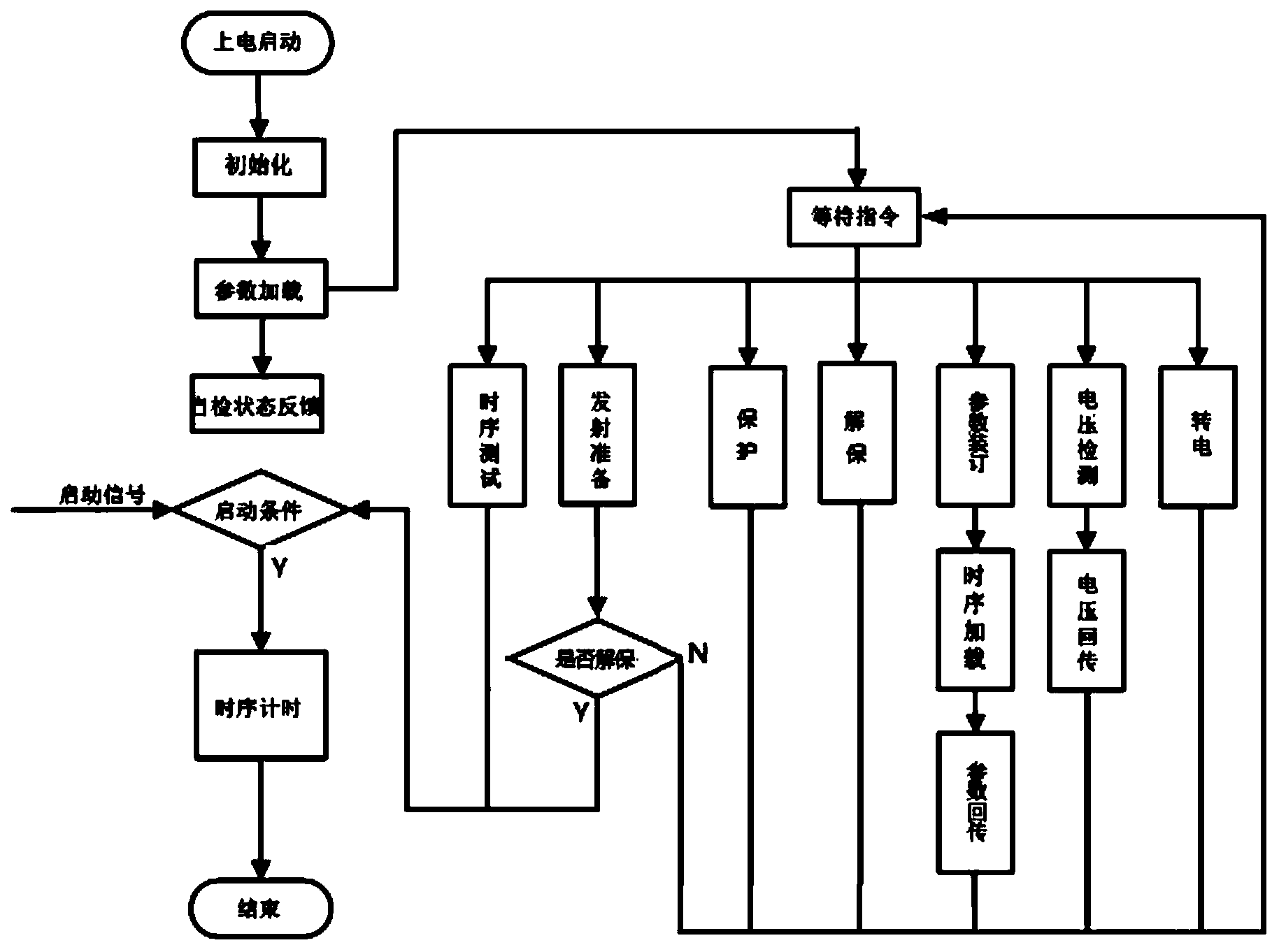

Rocket time sequence controller and control method

The invention relates to a rocket control technology, in particular to time sequence control of a rocket. A rocket time sequence controller is characterized by comprising a power supply / distribution circuit, a time sequence control circuit and an ignition circuit; the controller adopts multiple safety protection measures; on hardware, the controller mainly depends on an initiating explosive device protection circuit to guarantee the safety of initiating explosive devices in the rocket storage, transportation and test process; the reliability of time sequence control output is improved by parallel connection of dual backups; on software, an even triggering mechanism is adopted, that is, when the time sequence controller receives a corresponding control instruction, the hardware can perform a corresponding action; after the performed action is correct, a state signal of finishing the action is returned; when a FPGA controls a flow, a corresponding state feedback signal is detected; and after the action is performed, a next action is performed. The rocket time sequence controller satisfies the resistance value testing and time sequence testing requirements of the initiating explosive devices before the rocket is launched, and guarantees the safety of the initiating explosive devices in the testing process.

Owner:中国航天科技集团公司第四研究院第四十一研究所

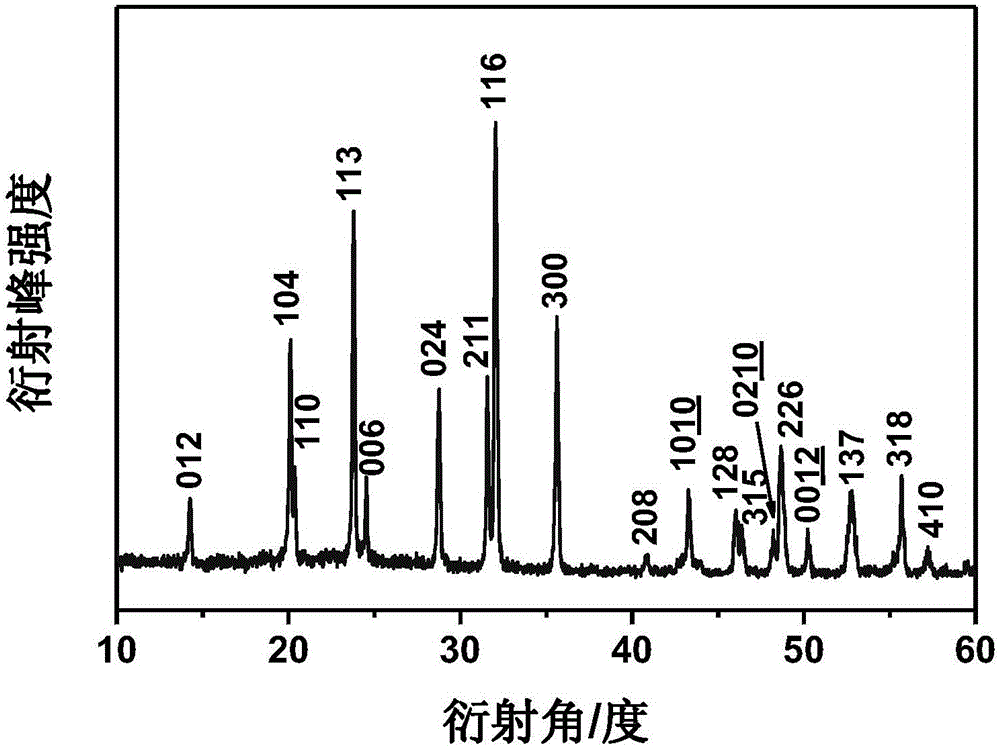

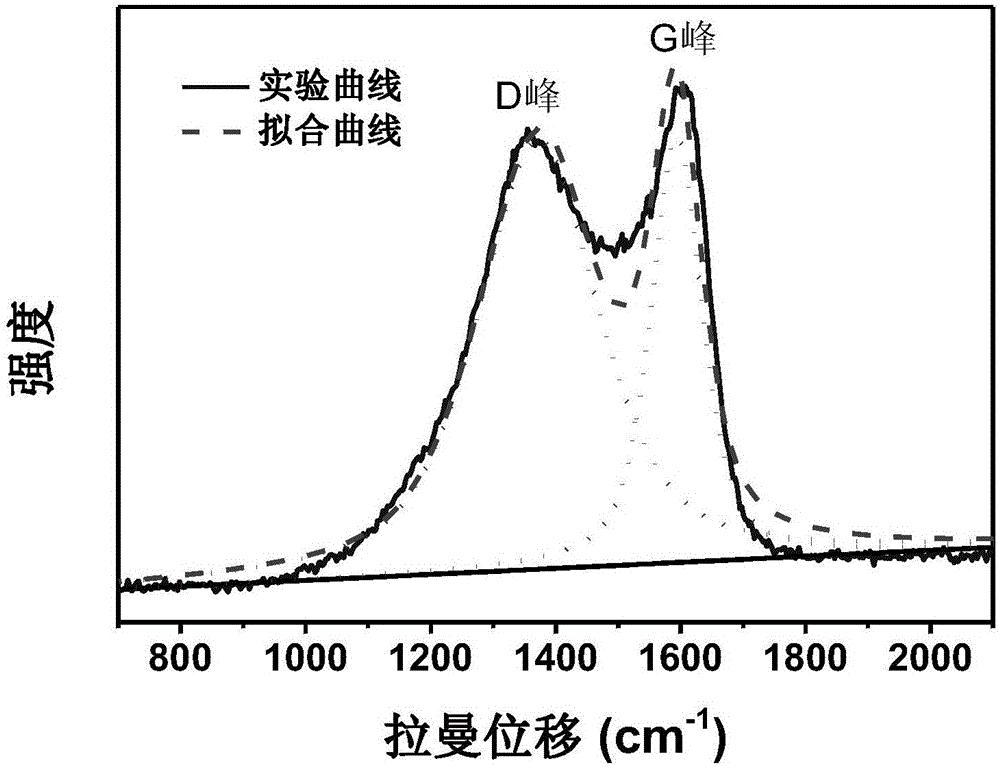

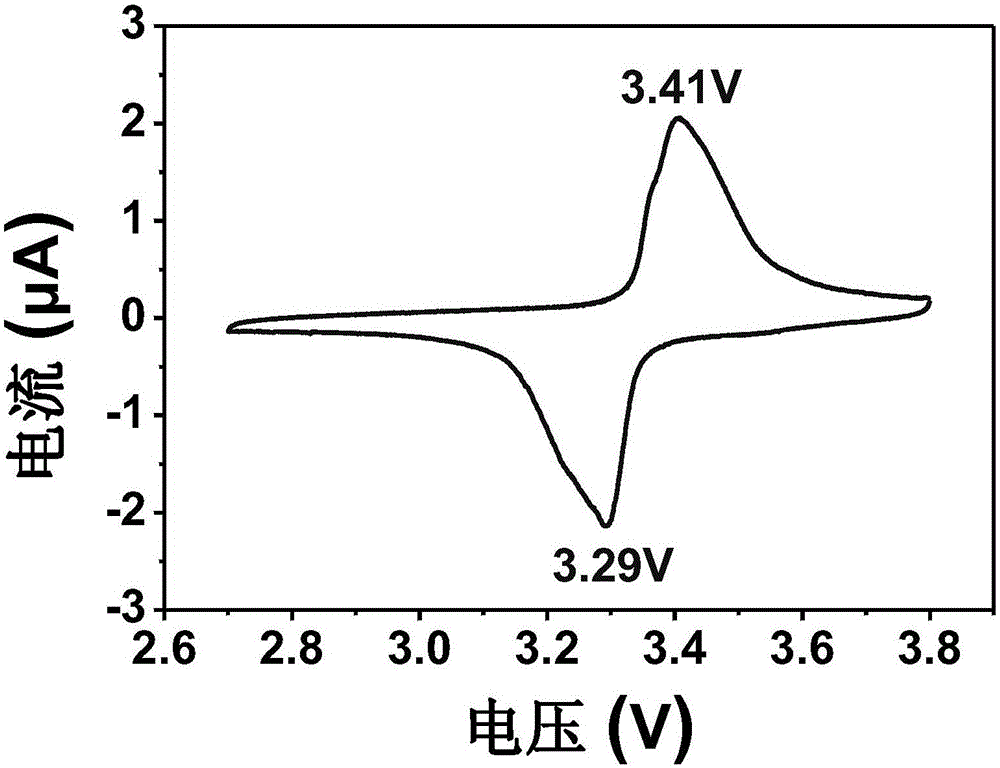

Preparation method for cathode material Na3V2(PO4)3/C of sodium ion battery

InactiveCN105140468ARestore fully and evenlyMix well and evenlyCell electrodesSecondary cellsSodium-ion batteryReducing atmosphere

The invention discloses a preparation method for a cathode material Na3V2(PO4)3 / C of a sodium ion battery. The preparation method comprises the following steps of: (1) taking a high-valent vanadium source compound, a sodium source compound, a phosphorus source compound and a reducing agent as raw materials, weighing the reaction raw materials according to the molar ratio of a sodium element, a vanadium element and a phosphorus element of being 3:2:3 and the molar ratio of the reducing agent and the high-valent vanadium source compound of being 3:1 to 15:1, carrying out mechanical ball grinding for 2 to 20 hours, and reducing high-valent vanadium into low-valent vanadium at a normal temperature; and (2) forwarding a precursor obtained through ball grinding in the step (1) into an inert atmosphere or a reducing atmosphere, and carrying out heat preservation for 4 to 20 hours at 600-900 DEG C to obtain the Na3V2(PO4)3 / C. The method has the advantages of short flow and low cost, and is easy to control, the prepared Na3V2(PO4)3 / C is high in purity and crystallinity, and the production of the cathode material Na3V2(PO4)3 / C of the sodium ion battery at a large scale is easy to realize.

Owner:WUHAN UNIV

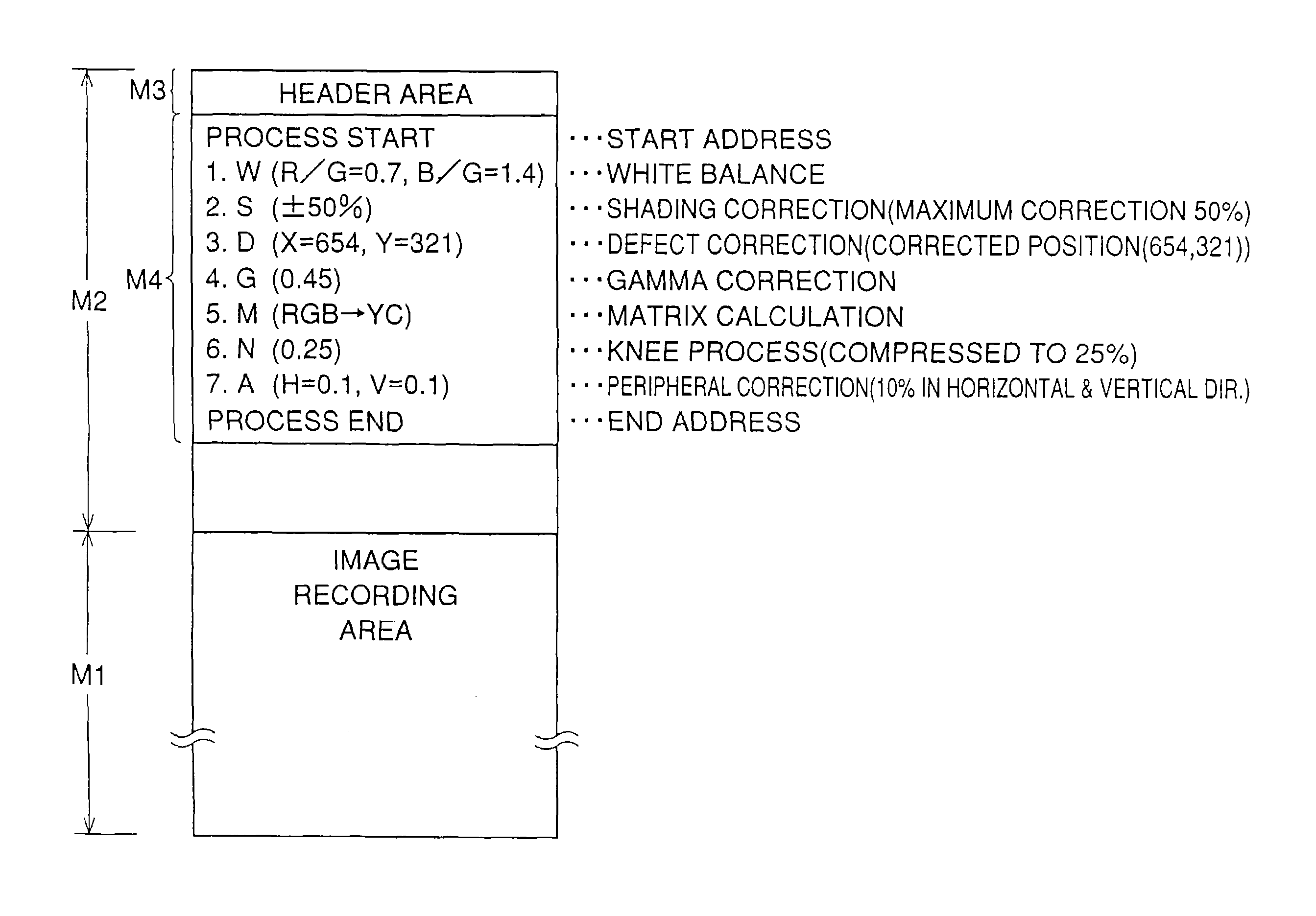

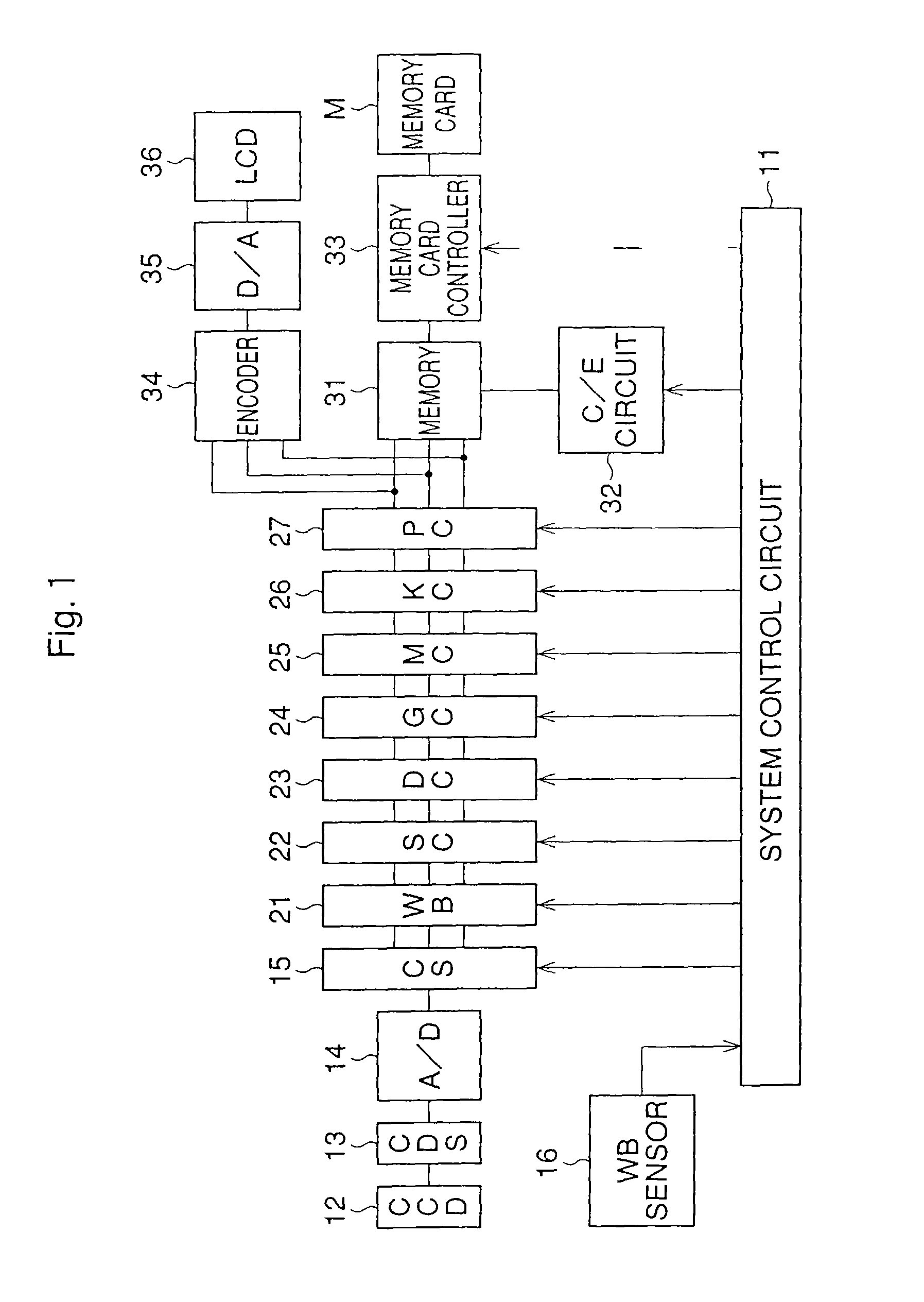

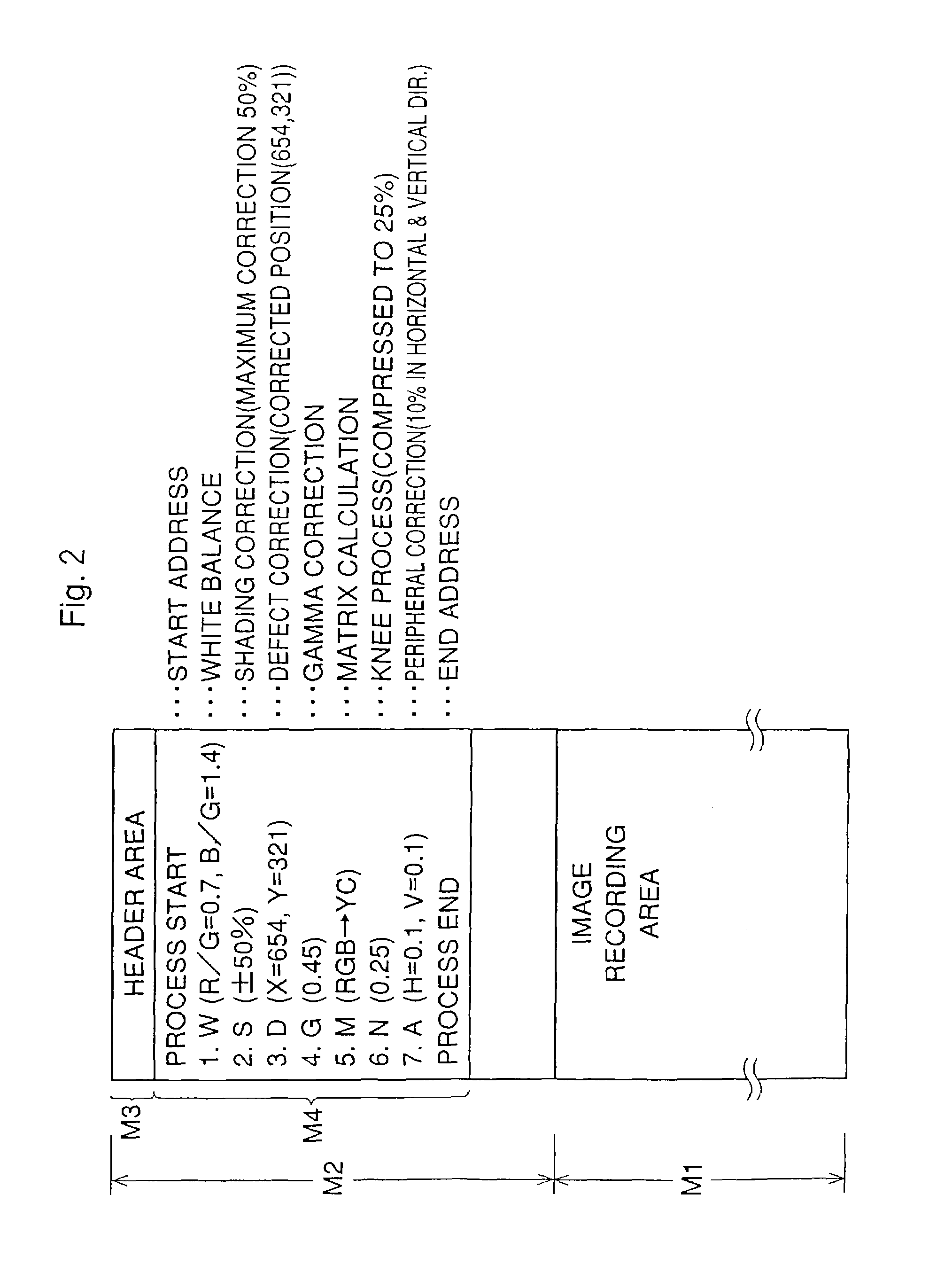

Image correction processing device

InactiveUS7474338B2Television system detailsColor signal processing circuitsComputer hardwareImage recording

An image recording medium includes an image recording area in which an image signal can be recorded. The image signal is subjected to multiple image correction processes in a process order. The image recording medium also includes an information recording area in which data is recorded. The data indicates the process order in which the image correction processes were performed. An image signal process order system performs the image correction processes in a process order. The image signal process order system records the process order in the recording medium. An image signal process order device perform restoration process order in a restoration order. The restoring order is the reverse of the process order.

Owner:PENTAX RICOH IMAGING CO LTD

Rapid crystallization polylactic acid composite material and preparation method thereof

InactiveCN101544813AIncrease the rate of crystallizationImprove mechanical propertiesNatural mineralMechanical property

The invention relates to a rapid crystallization polylactic acid composite material and a preparation technique thereof. The composite material comprises the following components in portion by weight: 59 to 98 portions of hypocrystalline poly-L-lactic acid, 1 to 40 portions of organic modified natural mineral, 1 to 20 portions of organic crystallization promoter, 0.1 to 1.0 portion of heat stabilizer, and 0.05 to 1.0 portion of lubricant. The sum of the mass percentage of the components is 100 percent. The preparation method for the material comprises the following steps: firstly preparing the modified natural mineral; then mixing the components according to the components of the composite material; agitating and mixing the raw materials evenly through a high-speed agitator; and adding the co-mixture into a twin screw extruder for extrusion and granulation. The method improves the crystallization rate of a polylactic acid matrix through the synergistic action of organized mineral and the crystallization promoter. Due to the addition of the organic crystallization promoter, the method strengthens the mechanical properties of the polylactic acid composite material, while simultaneously quickening the crystallization rate of polylactic acid, thereby avoiding the defect of greatly reducing the mechanical properties of the polylactic acid composite material caused by the addition of a single inorganic mineral nucleating agent. The price of adopted fillers is low; and the whole preparation method has a simple technological process and less consuming time of the technological process, and can realize the large-scale industrialized production.

Owner:SHANGHAI UNIV

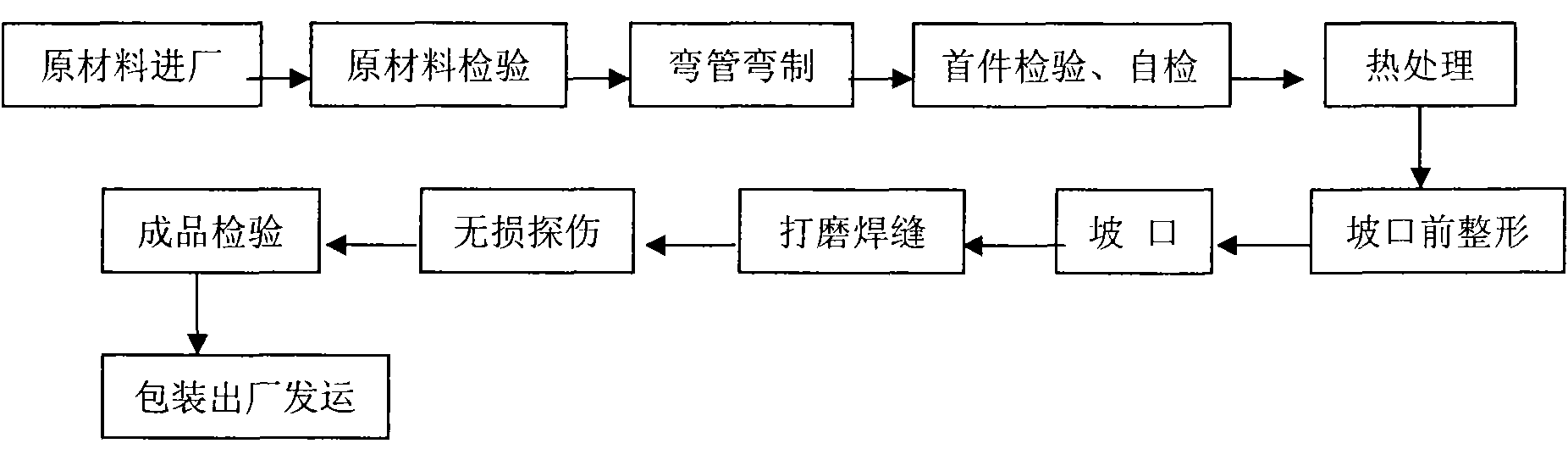

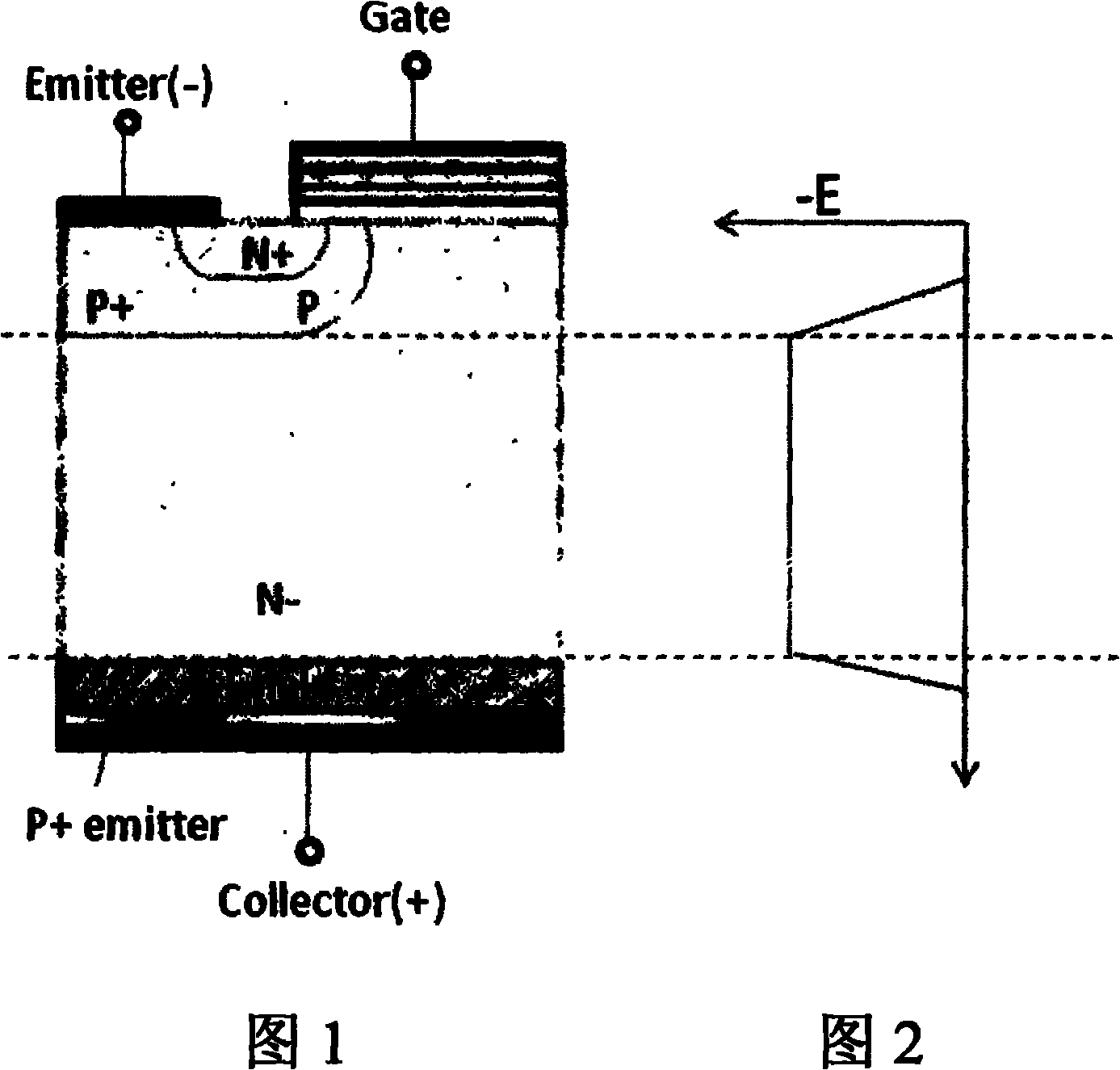

Method for producing hot-bending elbow

The invention discloses a method for producing a hot-bending elbow, and relates to the technical field of treatment of metal pipes and piping systems. The method comprises the following steps: purchasing raw materials, and storing; inspecting the raw materials; bending to obtain the elbow; carrying out first sample inspection and self-inspection; heat-treating; shaping before beveling; beveling; grinding welding seams; carrying out nondestructive inspection; carrying out product inspection; and packing, and sending the finished products out of the factory. From purchasing the raw materials to sending the finished products out of the factory, the invention specifies a complete and strict technological process. Thus, the invention has the advantages of safe production process, high speed, controllability and stable quality, and is a refined method for producing hot-bending elbows.

Owner:CHINA PETROLEUM PIPELINE BUREAU +1

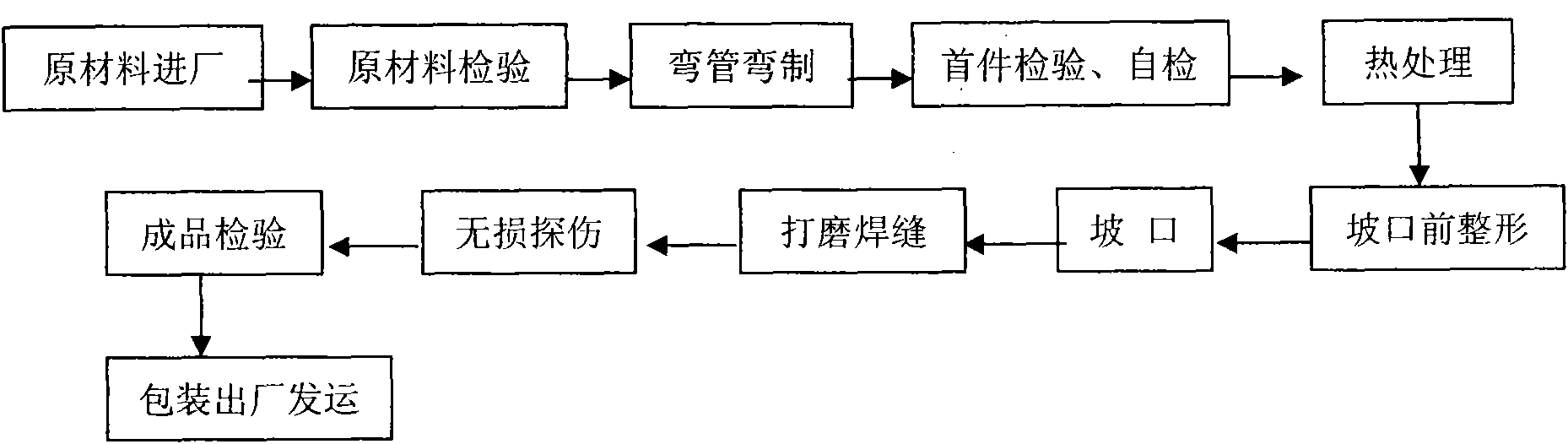

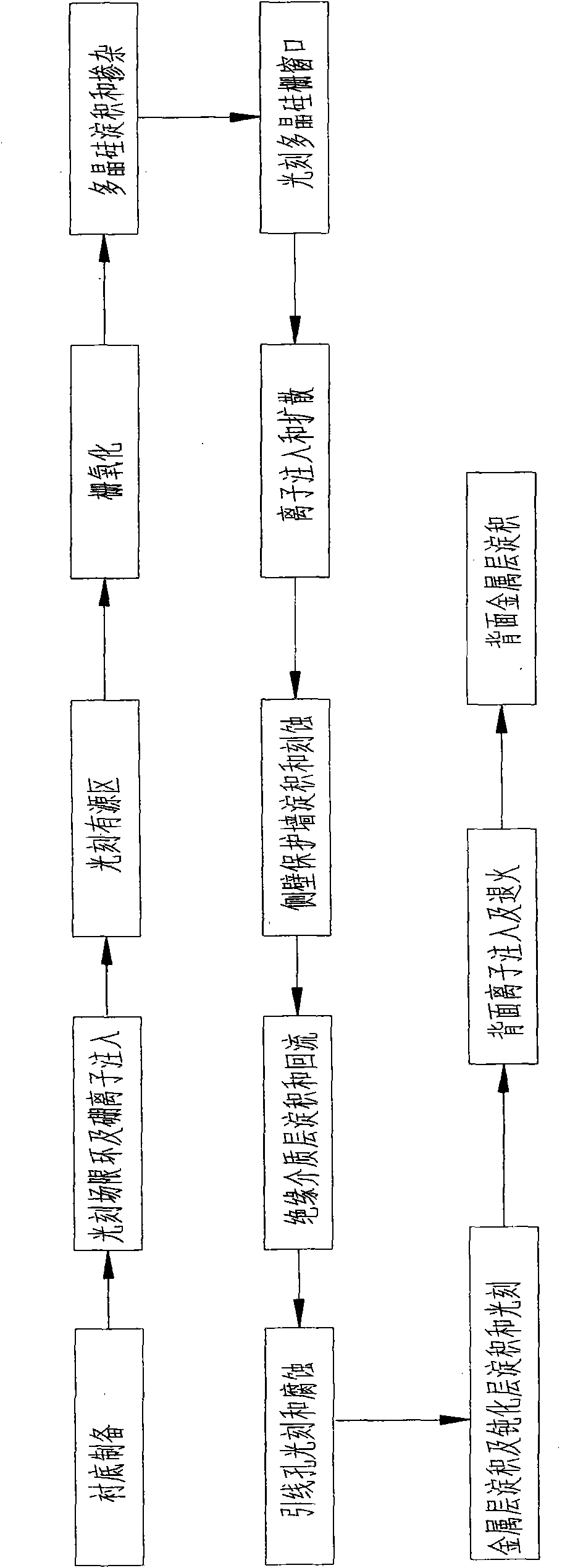

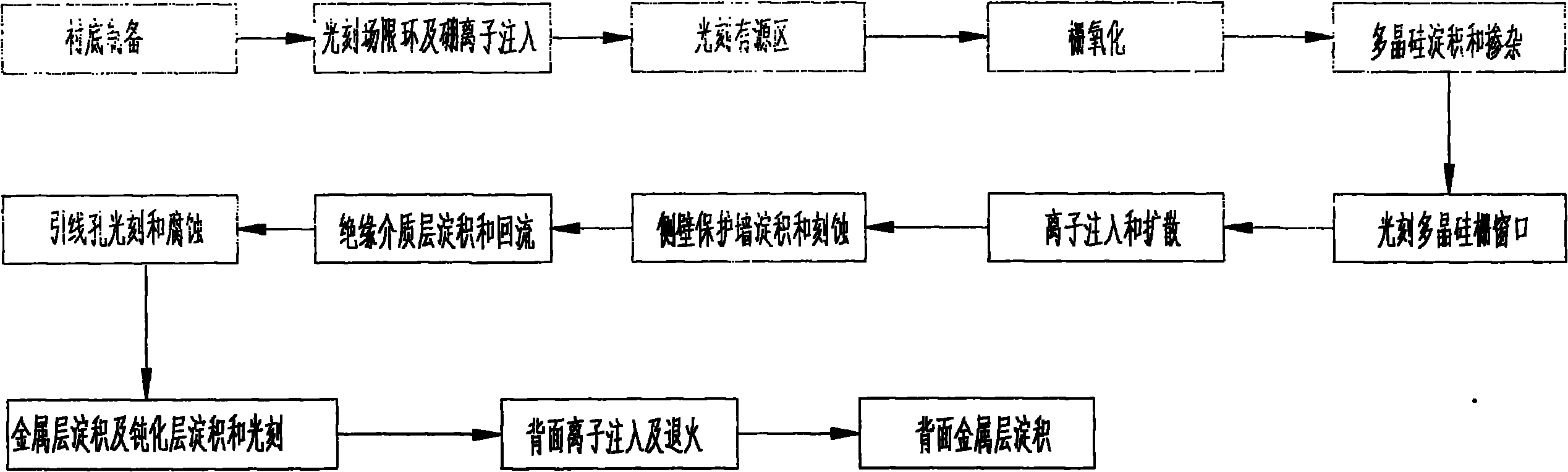

Preparation method of field blocking type bipolar transistor of insulated gate

ActiveCN102142372ASimple processReduce Fragmentation RateSemiconductor/solid-state device manufacturingSemiconductor devicesBoronPolysilicon gate

The invention relates to a preparation method of a field blocking type bipolar transistor of an insulated gate, which comprises the following steps of: pre-diffusing N+ type semiconductor impurities on a positive surface and a negative surface of an N-type single wafer after the N-type single wafer is cleaned; forming N+ impurity regions through main diffusion and knotting; removing one N+ impurity region as a front surface of a silicon wafer through grinding; polishing the front surface of the silicon wafer to obtain a substrate material; photoetching a field-limiting ring to form a P+ window of the field-limiting ring; performing boron ion injection; forming a window of a source region through photoetching; performing polysilicon deposition and doping after a silicon wafer gate is oxidized; injecting ions in the window of the silicon wafer gate, and forming a P impurity region and an N+ impurity region through diffusion; depositing and refluxing an insulated dielectric layer, photoetching a lead hole and depositing a metal layer to form an emitting electrode and a grid electrode; thinning the N+ impurity region at the back of the silicon wafer through grinding; annealing the N+ impurity region to form a P+ impurity region after the boron ions are injected in the N+ impurity region; and depositing a metal layer to form a collecting electrode. The method has the characteristics of having simplified process flow, achieving low production cost, and being beneficial for realizing the soft turn-off of an IGBT (Insulated Gate Bipolar Translator).

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com