Patents

Literature

250results about How to "Excellent electrical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar battery slice technology for efficient and low-cost film crystal silicon

InactiveCN101241952AExcellent electrical performanceAppearance of high qualityFinal product manufactureSemiconductor devicesSilicon solar cellSlurry

The present invention is a technique for manufacturing a crystalline silicon solar cell piece, especially a technique for manufacturing a high-efficiency, low cost and thin-sheet solar cell piece, and the invention belongs to the solar energy application field. The technique aims at the thin-sheet crystal silicon chip with thickness less than 200 mu m, by adopting innovated technique and developing the original technique, combines the domestic cell whole equipment which is independently developed, settles the contradiction between the thin sheet and the fraction ratio, finished product rate and the electrical property, and satisfies the request of the cell piece product line to the high efficiency and low cost. The technique for manufacturing crystal silicon solar cell piece is subdivided to seven steps according to the process flow: eliminating the injury and coarsen the surface, diffusing to make a knot, plasma etching for eliminating the edge, PSG eliminating, PECVD depositing Si3N4 film, printing positive back electrode slurry and back field slurry on the silk screen, and co-baking to form an ohm contact. When the technique is adopted for the size 125*125mm<2>, the efficiency of the single crystalline silicon solar cell piece is up to 16.5, and the efficiency of the polycrystalline silicon solar cell is up to 15.0%.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

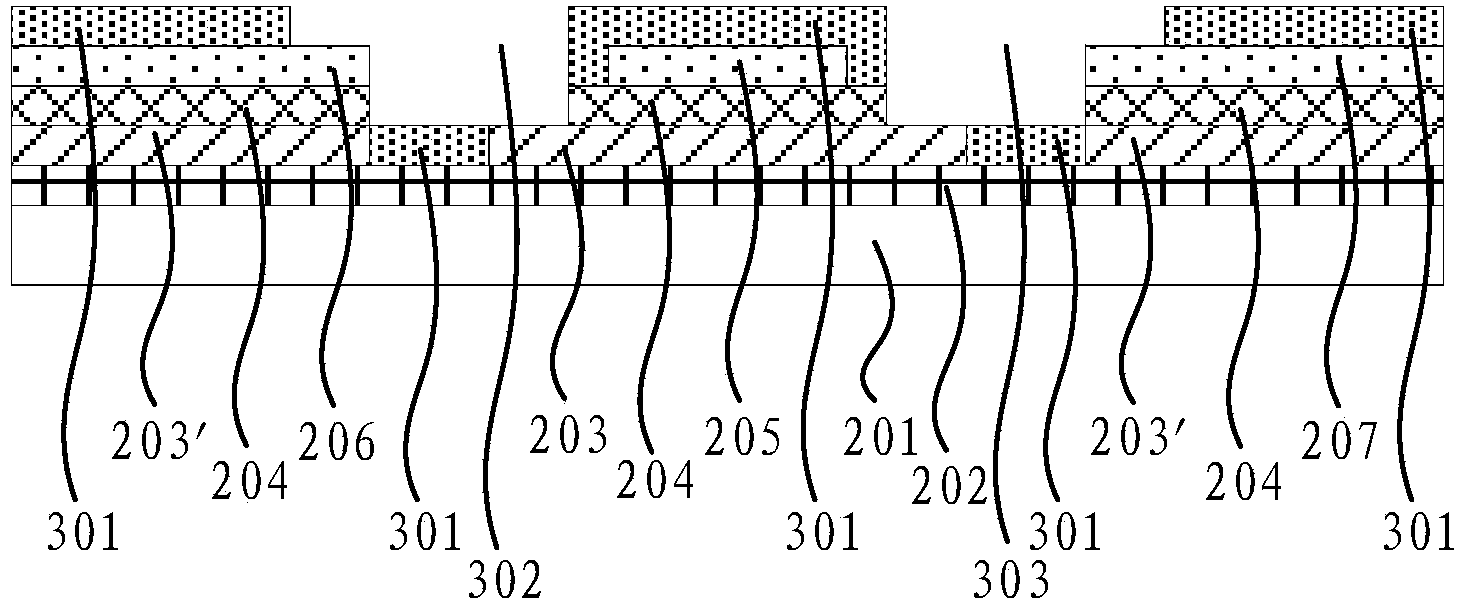

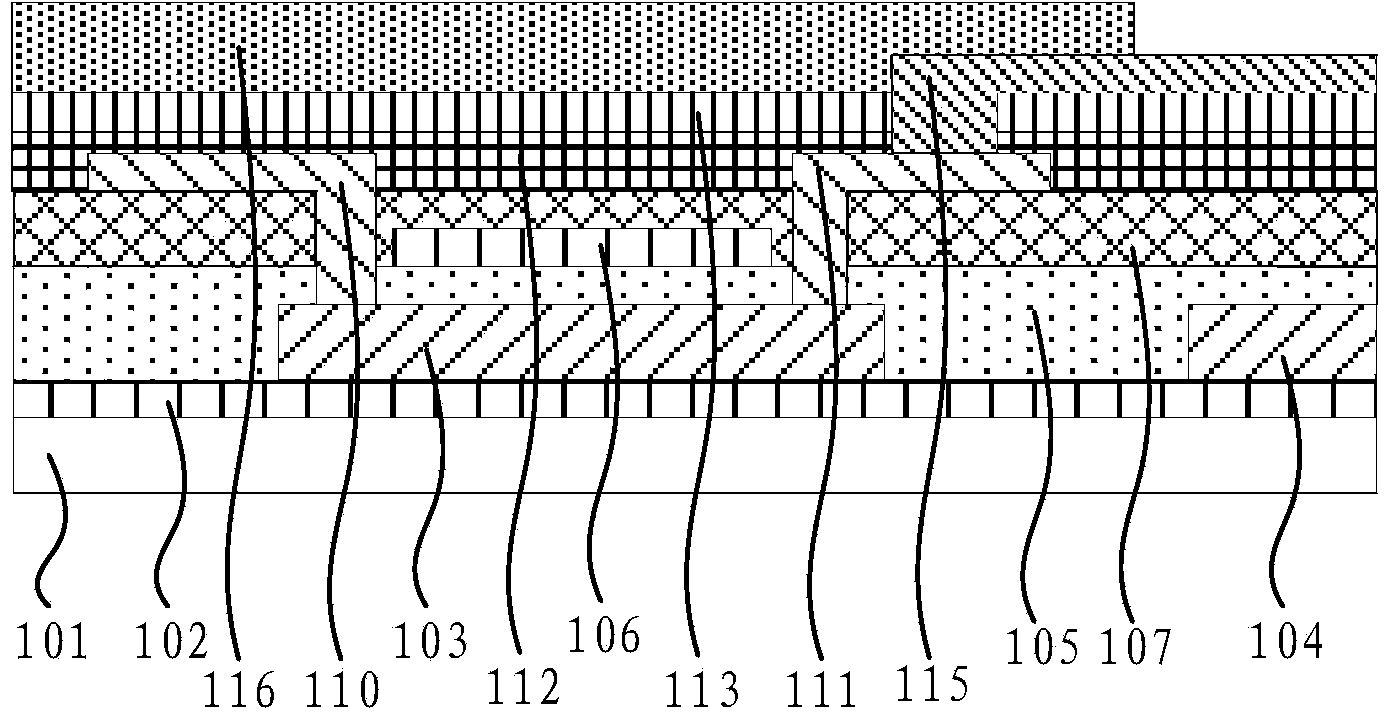

Array substrate, preparing method thereof and display device

ActiveCN104022076AImprove yieldReduce the number of patterning processesSolid-state devicesSemiconductor/solid-state device manufacturingComposition processDisplay device

The invention provides an array substrate, a preparing method thereof and a display device, wherein the preparing method comprises the steps of: forming an active material layer, a gate electrode insulating layer and a metal film on a substrate, forming a pattern which comprises an active layer and a pattern that comprises a gate electrode, a source electrode, a drain electrode, a gate line and a data line through a primary composition process; forming a passivation layer on the substrate, forming a source electrode contact hole, a drain electrode contact hole and an over-bridge structure contact hole through a secondary composition process; and forming a transparent conductive film on the substrate, eliminating partial transparent conductive film through a film peeling process for forming a source electrode contact part, a drain electrode contact hole, a pixel electrode and an over-bridge structure. According to the preparing method, number of times in using the composition process is reduced. The array substrate has advantages of simple preparing process, high production efficiency and high yield rate.

Owner:BOE TECH GRP CO LTD

Array substrate, preparing method thereof and display device

ActiveCN104022077AReduce parasitic capacitanceExcellent electrical performanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrically conductiveData lines

The invention provides an array substrate, a preparing method thereof and a display device, wherein the preparing method comprises the steps of: forming a pattern and a gate electrode insulating layer on a substrate, wherein the pattern comprises an active layer; forming a metal film on the gate electrode insulating layer, patterning the metal film through a primary composition process for forming the pattern which comprises a gate electrode, a source electrode, a drain electrode, a gate line and a data line; forming a passivation layer on the substrate; patterning the passivation layer through the primary composition process for forming a source electrode contact hole, a drain electrode contact hole and an over-bridge structure contact hole; and forming a transparent conductive film on the substrate, eliminating partial transparent conductive film through a film peeling process for forming a source electrode contact part, a drain electrode contact hole, a pixel electrode and an over-bridge structure. According to the preparing method, number of times in using the composition process is reduced. The array substrate has advantages of simple preparing process, high production efficiency and high yield rate.

Owner:BOE TECH GRP CO LTD

Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

InactiveCN1888103ASolve the problem of fragmentationExcellent electrical performanceChemical vapor deposition coatingGas phaseCarbon nanotube

The present invention is preparation process of carbon nanotube reinforced copper-base composite material with high strength and high conductivity, and belongs to the field of copper-base composite material preparing technology. The preparation process includes the following steps: adding nickel nitrate hexahydrate, yttrium nitrate hexahydrate and ethanol soaked copper powder in certain weight proportion into distilled water to obtain nickel nitrate solution; dropping sodium hydroxide solution to the nickel nitrate solution to produce neutralizing reaction obtaining ternary Ni(OH)2 / Y(OH)3 / Cu colloid; washing, filtering, drying, grinding and calcining to obtain Ni / Y / Cu catalyst precursor; setting the precursor into reaction furnace, introducing H2 to reduce, and introducing N2 and reaction gas for catalytic cracking reaction to obtain composite carbon nanotube / Cu powder; initially pressing the composite powder, sintering and re-pressing to obtain carbon nanotube in-situ reinforced copper-base composite material.

Owner:TIANJIN UNIV

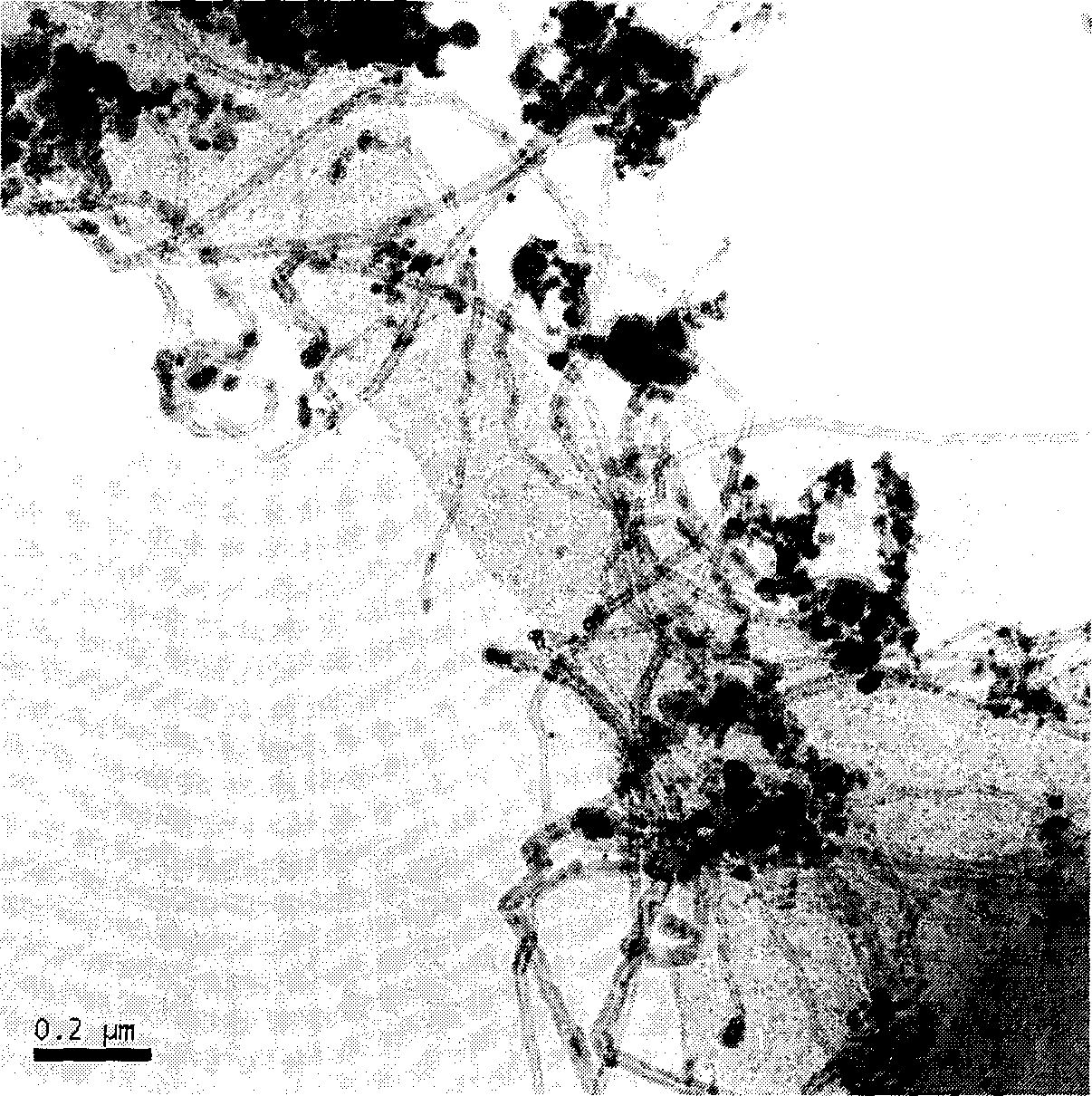

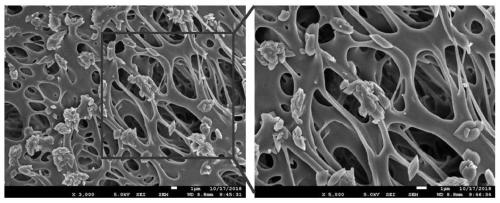

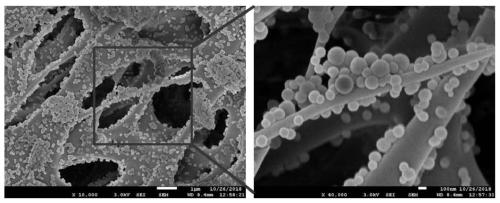

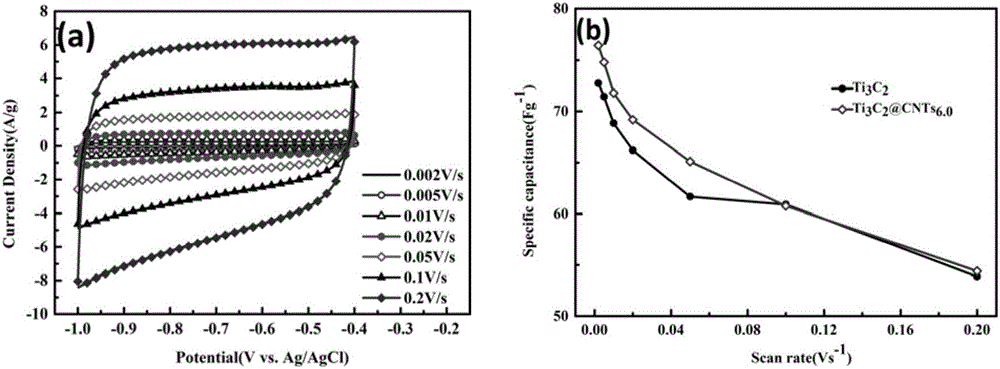

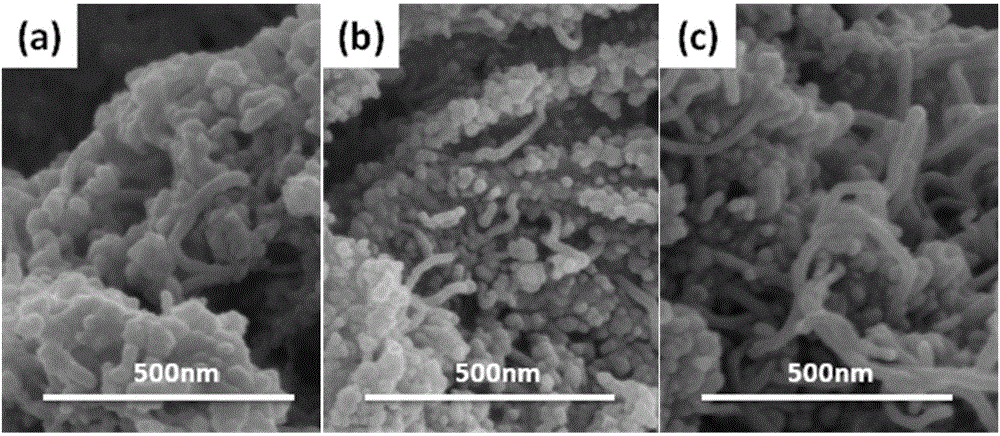

A method for prepare a nitrogen doped carbon nanotube three-dimensional composite material by in-situ growth of a small lay of titanium carbide

InactiveCN109167066AImprove conductivityAchieve controlled growthCell electrodesTetramethylammonium hydroxideFreeze-drying

The invention belongs to the technical field of preparation of nano-functional materials, in particular to a method for preparing a nitrogen doped carbon nanotube three-dimensional composite materialby in-situ growth of a few layers of titanium carbide, immersing ternary layered Ti3AlC2 ceramic powder in hydrofluoric acid solution, heating and stirring, centrifugally cleaning with ultrapure waterand absolute ethanol, drying to obtain two-dimensional layered titanium carbide nano-powder, adding it into tetramethylammonium hydroxide solution, heating and stirring, centrifuging with deionized water to obtain a few layers of titanium carbide nano-sheet dispersion; Adding cobalt salt into a dispersion of a few layers of titanium carbide nano-sheets for reaction, adding dicyandiamide, heatingand stirring until dicyandiamide is completely dissolved, freezing, and freeze-drying to obtain precursor powder; Nitrogen-doped carbon nanotubes (CNTs) three-dimensional composites were prepared by in-situ growth of a few layers of titanium carbide after grinding the precursor powder and heat treatment. A three-dimensional composite material is prepared by a simple pyrolysis method using a few layers of titanium carbide as a carrier, cobalt as a catalyst, dicyandiamide as a carbon and nitrogen source, and the electrochemical performance of the few layers of titanium carbide can be improved.

Owner:UNIV OF JINAN

Method for manufacturnig silicon high-speed semiconductor switch device

InactiveCN1471146AExcellent electrical performanceDensity Spatial Distribution OptimizationSemiconductor/solid-state device manufacturingGate turn-off thyristorPlatinum

The method is applicable to manufacture silicon semiconductor binistor with at least one PN junction such as GTO, IGBT etc. General manufacturing steps is carried out till the step of making metalized electrode. Platinum-silicon alloy is made on surface of silicon. Using proton or particle injection forms local high density defect area. Heating and annealing makes the defect area absorb platinum to convert to platinum impurity range. Then, General manufacturing steps is carried out till manufacturing completion. The performances of the invention are better than present life control technique. The parts made by the invention possesses higher switching speed and backward recovery speed, but the forward voltage drop and reverse leakage are not increased visibly.

Owner:BEIJING UNIV OF TECH

Silicon rubber self-adhesive tape

InactiveCN101921550AExcellent electrical performanceGood chemical stabilityFilm/foil adhesivesVulcanizationManufacturing technology

The invention provides a silicon rubber self-adhesive tape which belongs to the technical field of chemical product manufacturing. The silicon rubber self-adhesive tape is made from methyl vinyl silicon rubber, fume silica, tackifier, vinyl silicon oil and iron red; the production technology comprises the steps of mixing the raw materials and placing the mixture in a gamma ray irradiation field of 60Co for radiation vulcanization. The product not only satisfies the manufacturing need of a special engine, but also can serve as an insulation protection product under high temperature and high pressure for electric insulation protection of a large-scale motor, an electromotor, special machines, and the like, and can satisfy the strong insulation sealing requirement on the industries such as shipbuilding, mining, petroleum production, chemical engineering, steel making and the like under severe environments of specially high temperature and high pressure.

Owner:长春中科应化特种材料股份有限公司

A silicone composition, a preparing method thereof and uses of the composition

ActiveCN106398227ALong active periodEasy to use in constructionSemiconductor/solid-state device detailsSolid-state devicesCapacitanceCeramic capacitor

A silicone composition is disclosed. The composition includes 20-80 parts by weight of organic silicone, 2-60 parts by weight of MQ resin, 1-20 parts by weight of hydrogen-containing silicone and an effective amount of a hydrosilylation catalyst and a hydrosilylation inhibitor. The invention also discloses a preparing method of the silicone composition, a method of using the silicone composition for encapsulating electronic elements such as pressure-sensitive resistors, ceramic capacitors and thermistors, and a method of using the silicone composition for embedding electronic elements such as capacitors. The composition has a long active period, and can be stably stored for long term at 100 DEG C or below. The composition after encapsulating and embedding the electronic elements has excellent flexibility and resistance to cold and hot alternation, and has good moisture resistance and resistance to large-current impact.

Owner:天津凯华绝缘材料股份有限公司

High-temperature-resistant moisture-proof mould-proof environment-friendly cable material and preparation method thereof

InactiveCN102911441AEasy to prepareExcellent electrical performanceOrganic insulatorsMaleic anhydridePOLYETHYLENE WAX

The invention discloses a high-temperature-resistant moisture-proof mould-proof environment-friendly cable material and a preparation method thereof. The cable material is composed of a mixture A and a mixture B, wherein the mixture A comprises, by weight, 30-40 parts of high-density vinyl resin, 20-30 parts of polyacrylate, 25-35 parts of maleic anhydride grafted poly ethylene, 20-30 parts of methyl vinyl silicon rubber, 1-3 parts of semi-reinforcing carbon black, 40-60 parts of light calcium carbonate, 1-3 parts of N, N'-m-phenylenedimaleimide, 1.5-2.5 parts of aniline-methyl-triethoxysilane, 1-3 parts of calcium stearate, 3-4 parts of antioxidant DSTP and 10-20 parts of mica powder; the mixture B comprises, by weight, 50-70 parts of chlorinated polyethylene, 30-40 parts of poly(styrene-butadiene-styrene), 20-30 parts of ethylene-ethyl acetate copolymer, 0.3-0.5 part of poly(4-methyl-1-pentene), 1-3 parts of antiager TPPD, 2-4 parts of polyethylene wax, 5-10 parts of polycaprolactone, 2-3 parts of sodium dibutyl naphthalene sulfonate, 1-3 parts of superfine polyvinyl alcohol, 2-4 parts of isooctyl thioglycolate dimethyl tin and 10-15 parts of zinc borate. The preparation method is simple, and the cable material has excellent electric performance, good physical mechanical performance and meets requirements of temperature change of different environments.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

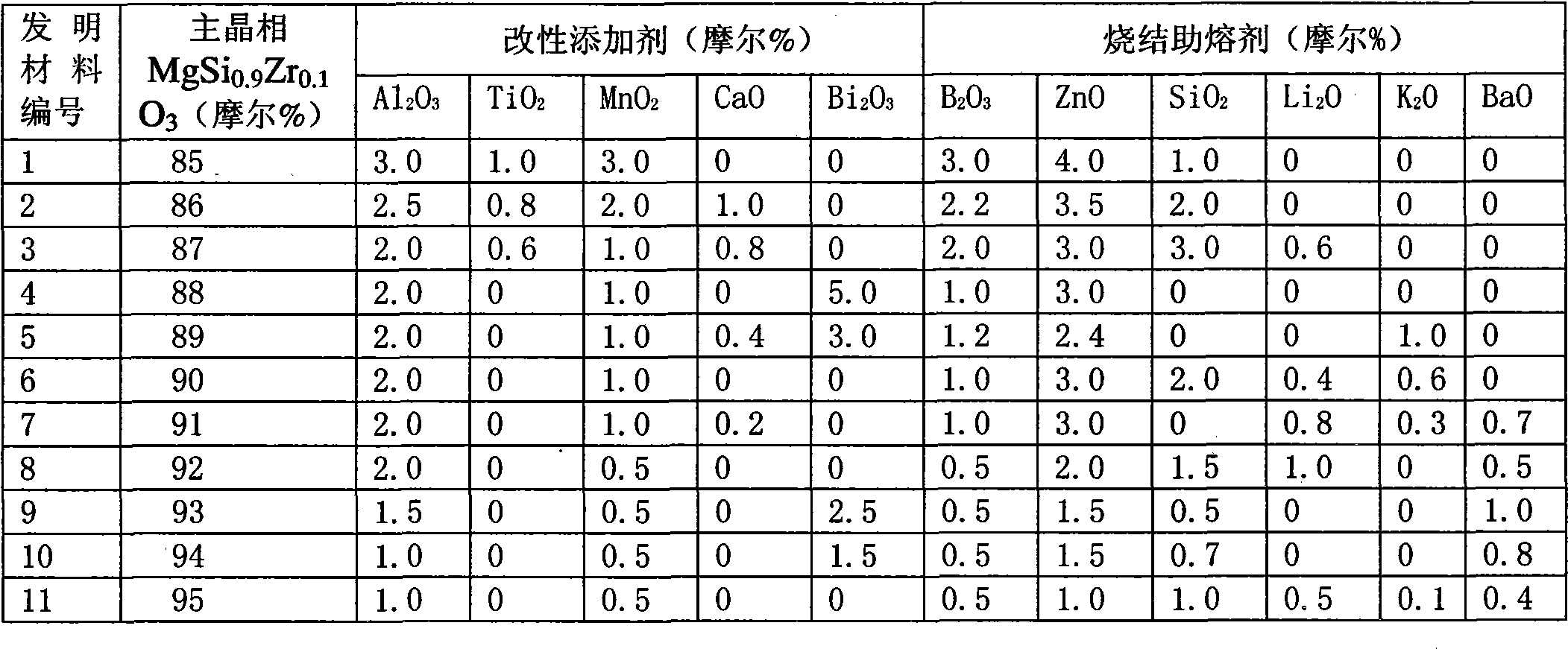

Ceramic dielectric material matched with nickel inner electrode and production method of capacitor produced by ceramic dielectric material

ActiveCN101786864ASolve the problem of co-firingResistantFixed capacitor dielectricStacked capacitorsCeramic capacitorReducing atmosphere

The invention discloses a ceramic dielectric material matched with a nickel inner electrode and a production method of a capacitor produced by the ceramic dielectric material. The ceramic dielectric material consists of a main crystal phase, a property-modifying additive and a sintered fluxing agent, wherein the main crystal phase is MgZrxSi(1-x)O3, and x is more than or equal to 0.05 and less than or equal to 0.15; the property-modifying additive is one or more of MnO2, Al2O3, CaO, Bi2O3 and TiO2; and the sintered fluxing agent is one or more of B2O3, SiO2, ZnO, Li2O, K2O and BaO. The ceramic dielectric material can meet the COG characteristic in the EIA standard, has good uniformity, uniform particle size distribution, high dispersibility, good molding technique and excellent dielectricproperty and meets the environmental requirement. When the material is used for making a multi-layer chip ceramic capacitor (MLCC), the material and the nickel electrode can be matched and sintered under the reducing atmosphere, the crystal particles of a ceramic body after sintering can grow uniformly and densely, the dielectric layer can be well matched with the inner electrode, and the productperformance is stable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

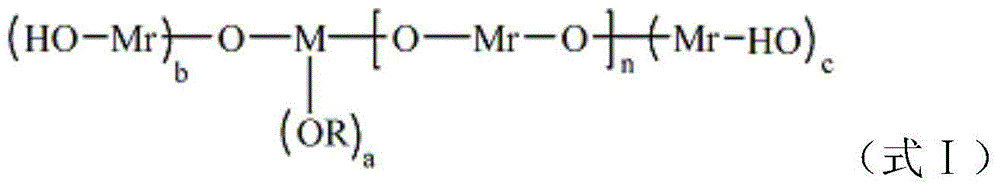

Flame retardant compound, flame retardant epoxy resin and flame retardant composition

InactiveCN104530131AImprove heat resistanceImprove water resistanceGroup 5/15 element organic compoundsEpoxyHeat resistance

The invention discloses a flame retardant compound, flame retardant epoxy resin and a flame retardant composition. In a molecular structure, the flame retardant compound contains a phosphonitrilic group, the phosphonitrilic group is prepared from the following components in percentage by weight: at least 50 wt% of 3-ring phosphonitrilic group, at most 30 wt% of chain-like phosphonitrilic group and at most 45 wt% of more than 4-ring phosphonitrilic group. According to the flame retardant compound disclosed by the invention, the 3-ring phosphonitrilic group contains a phosphorus nitrogen ring formed by three phosphorus nitrogen atoms, the chain-like phosphonitrilic group contains a phosphorus nitrogen chain formed by at most two phosphorus nitrogen atoms, and the more than 4-ring phosphonitrilic group contains a phosphorus nitrogen ring formed by at least four phosphorus nitrogen atoms, so that the flame retardant compound is good in flame retardancy, a cured material of the flame retardant compound is good in heat resistance, water resistance, adhesiveness, mechanical property and electric property, and the flame retardant compound is an environment-friendly fire retardancy material with large economy.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

Preparation method of N-type crystalline silicon double-sided back contact solar cell

InactiveCN102683493AExcellent electrical performanceSimple preparation processFinal product manufactureSemiconductor devicesElectricityPhosphorus doped

The invention discloses a preparation method of an N-type crystalline silicon double-sided back contact solar cell, which comprises the following steps of: (1) cleaning and velvet-making; (2) carrying out local phosphorus doping on the back surface of a silicon chip; (3) carrying out boron diffusion on the front surface of the silicon chip; (4) etching a peripheral junction; (5) passivating the front surface and the back surface of the silicon chip or the front surface of the silicon chip; (6) arranging antireflective films on the front surface and the back surface of the silicon chip; (7) forming a hole on the silicon chip; (8) arranging a hole metal electrode in the hole; and printing metal electrodes on the double sides and sintering to obtain the N-type crystalline silicon double-sided back contact solar cell. The preparation method has the advantages that the local phosphorus doping is carried out on the back surface of the silicon chip, a non-phosphorus doping area on the back surface of the silicon chip is a peripheral area of a hole to be formed on the silicon chip, and the problems of short circuit and electricity leakage at the diffused junction are avoided in the solar cell obtained by the preparation method, so that the remarkable effect is obtained.

Owner:CSI CELLS CO LTD +1

Chip separation method for 3D stacked chip encapsulator

ActiveCN104465315AConvenient electrical measurement and analysisExcellent electrical performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingElectricityWax

The invention discloses a chip separation method for a 3D stacked chip encapsulator. The method comprises the steps that acoustic scanning micro-detection is conducted on the internal structure of a 3D stacked chip encapsulated ULSI sample to determine a region to be ground and the area of the region to be ground; the 3D stacked chip encapsulated ULSI sample is fixed to a grinding table through hot molten wax; grinding is conducted, wherein a grinding drill bit, the grinding intensity and the grinding direction are selected according to the area of the ground region, an encapsulating material and chips are removed, and the region is ground to a protective layer covering the surface of a target chip; a chemical etching method is adopted to remove the protective layer. According to the chip separation method, grinding is used as a main mode, and chemical etching is used as an auxiliary mode; a specific local region is removed through grinding, and the internal structure of the lower chips and bonding wires of the lower chips are not damaged; the protective layer covering the surface of the target chip or chip binder is removed through the chemical etching method, and then the target chip is exposed; the internal structure of the obtained target chip and the bonding wire on the target chip are complete and not damaged, and therefore subsequent electrical logging analysis is facilitated.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

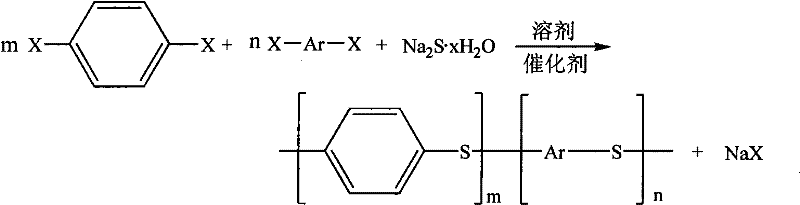

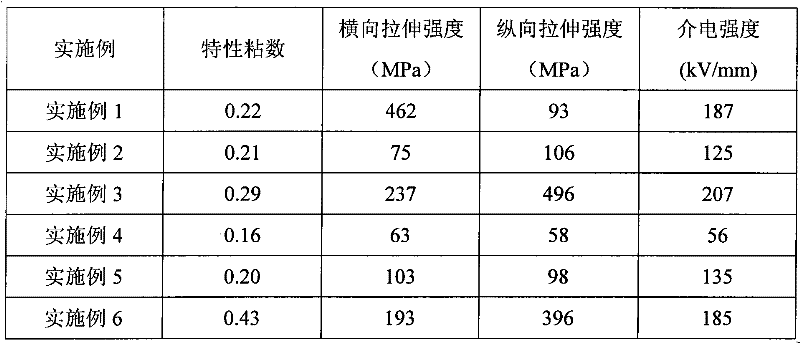

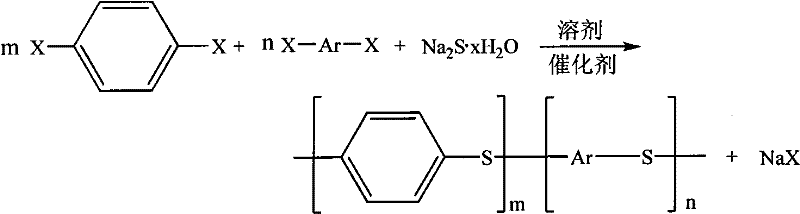

Preparation method of polyarylene sulfide film

The invention discloses a preparation method of polyarylene sulfide film, characterized by comprising the following steps of: adding 5-100 parts of auxiliaries, 20-80 parts of catalyst, 1-100 parts of alkali and 200-600 parts of organic solvent to a reaction kettle with a nitrogen inlet / outlet pipe, a water separator, a stirrer and a thermometer; adding 130 parts of 60% sodium sulfide, under nitrogen protection, performing dehydration reaction at the temperature of 160-200 DEG C for 0.5-3 hours; cooling to 80-150 DEG C, adding 147-352 parts of aromatic compound polyhalide, reacting at the temperature of 110-250 DEG C for 1-8 hours; keeping at the temperature of 160-320 DEG C for 1-8 hours; filtering the reactant liquor, separating, washing the polymer, drying, purifying with deionized water and acetone, and drying at the temperature of 120 DEG C and the vacuum degree of 0.09MPa for 24 hours to obtain the high molecular weight polyarylene sulfide film-grade resin; preparing the high molecular weight polyarylene sulfide film-grade resin into polyarylene sulfide resin particles by twin screw extrusion granulation; drying the polyarylene sulfide resin particles at the temperature of 100-120 DEG C for 4-10 hours and extruding to form film of 1-3mm in a casting machine; and laterally stretching the film for 2-10 times and then longitudinally stretching the film for 2-10 times in a two-way film stretching machine to prepare the film with even thickness.

Owner:SICHUAN UNIV

Low temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and preparation thereof

InactiveCN101475371ALow costExcellent electrical performanceCeramicsDielectric antennasCeramic capacitor

The invention discloses a low-temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and a preparation method thereof. The formula of raw materials of the ceramic material comprises the following compositions: 30 to 45 percent of zinc oxide, 2 to 14 percent of magnesium oxide, 50 to 60 percent of titania and an auxiliary sintering agent. The preparation method comprises: taking the zinc oxide, basic magnesium carbonate and the titania as raw materials, mixing the raw materials, adding a grinding aid for ball milling, drying, sieving and presintering, and obtaining clinker; and mixing the obtained clinker with the titania, the auxiliary sintering agent and an additive, performing drying, granulation and press forming after secondary ball milling, finally sintering the mixture for 2 to 8 hours at a temperature of between 900 DEG C and 1,000 DEG C, and obtaining the ceramic material. The ceramic material prepared by the method has the advantages of superior microwave dielectric property, low sintering temperature, low cost and the like, and is suitable for microwave devices such as multi-layer ceramic capacitors, filters, resonators and dielectric antennas.

Owner:SOUTH CHINA UNIV OF TECH

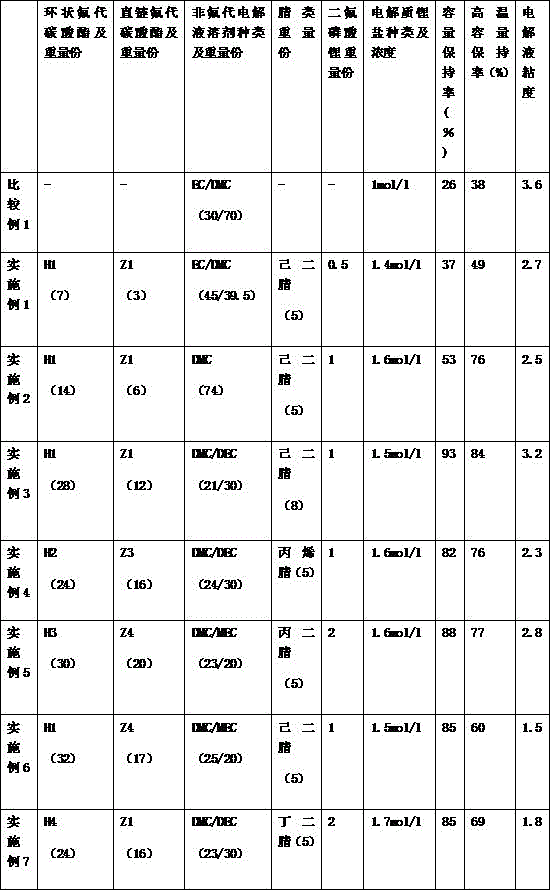

High-voltage electrolyte for lithium ion battery

InactiveCN106159328ALow viscosityImprove wettabilitySecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageDifluorophosphate

The invention provides high-voltage electrolyte for a lithium ion battery. The high-voltage electrolyte is composed of an electrolyte lithium salt, fluorocarbonate, nitriles, a solvent and an additive, wherein the electrolyte lithium salt is LiPF6 with the concentration of 1.2mol / L-1.6mol / L; a fluorocarbonate solvent accounts for 10%-60% of the total mass of the solvent; the nitriles account for 5%-15% of the total mass of the solvent; a non-aqueous organic solvent accounts for 23%-84.5% of the total mass of the solvent; the additive is lithium difluorophosphate and accounts for 0.5%-2% of the total mass of the solvent. By compounding and combining cyclic fluorocarbonate, straight-chain fluorocarbonate, the nitriles, the additive and the like, the high-voltage heat stability of the electrolyte is prone to improve and the problems that the high-temperature circulating stability of conventional electrolyte is poor and the high-temperature storage is not ideal are improved. Meanwhile, the electrolyte has small viscosity when the materials are matched; the wetting property of an electrode material is facilitated, the liquid injection time of the lithium ion battery is shortened and the rate performance of the battery is improved.

Owner:湖北诺邦科技股份有限公司

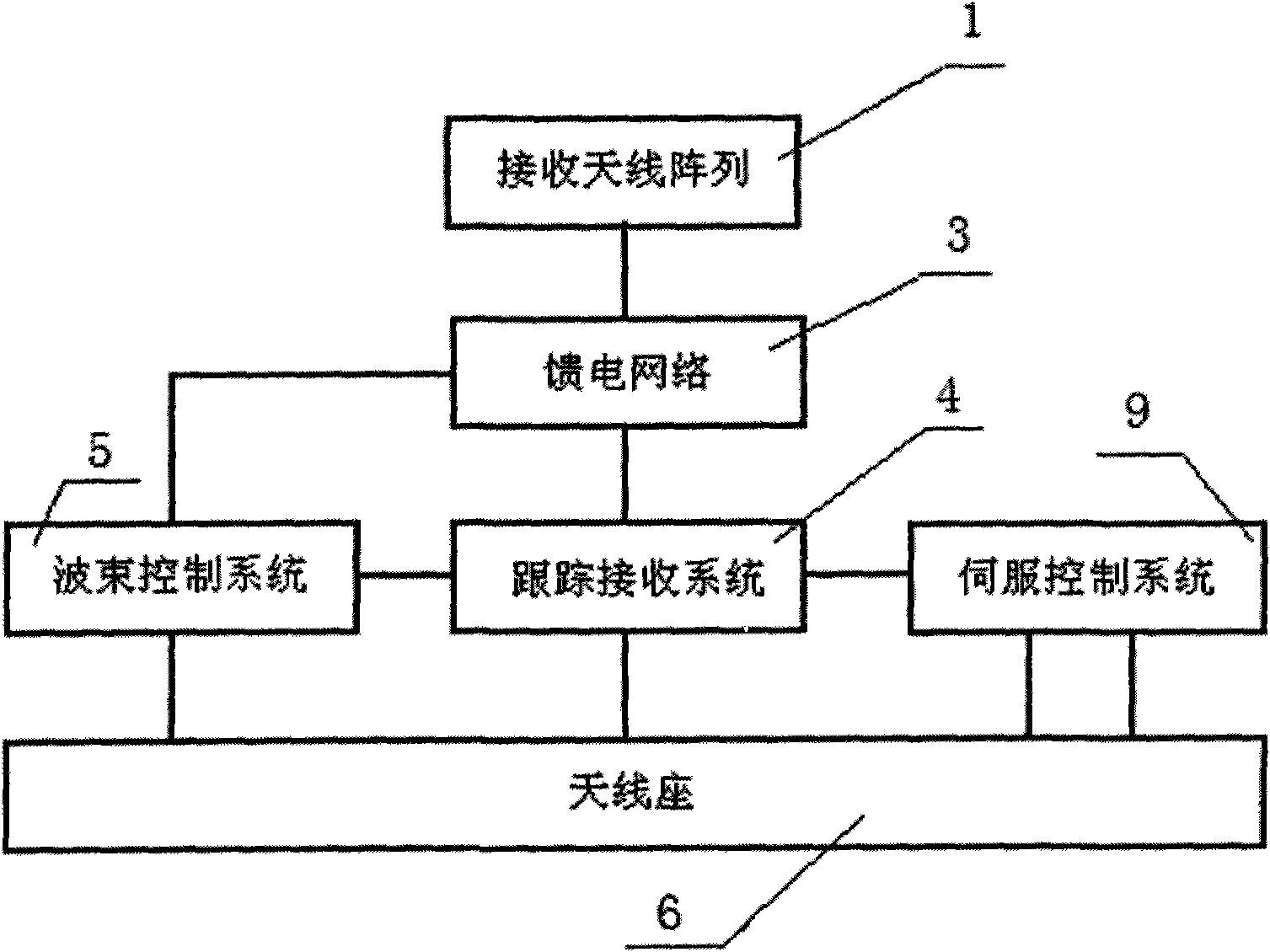

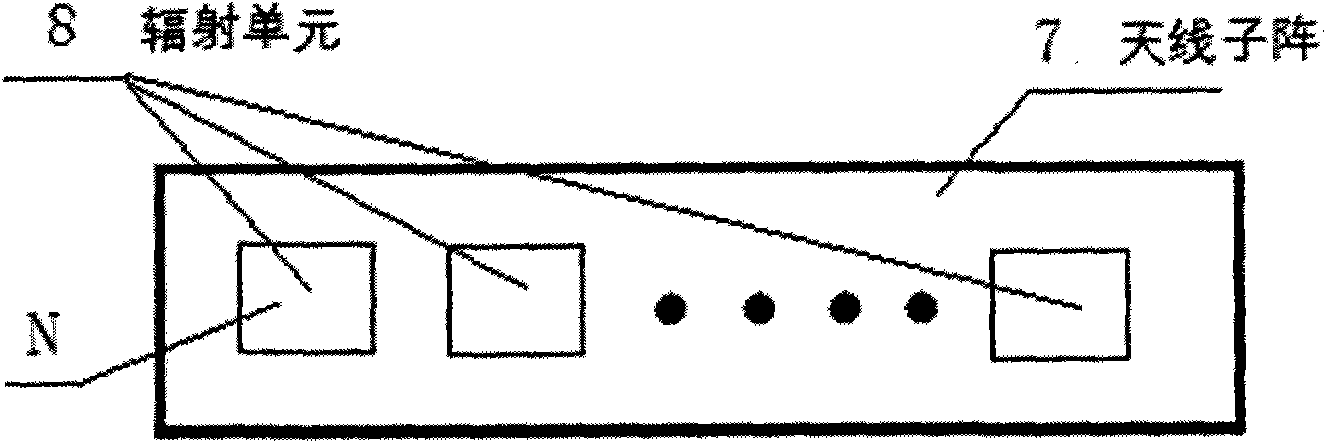

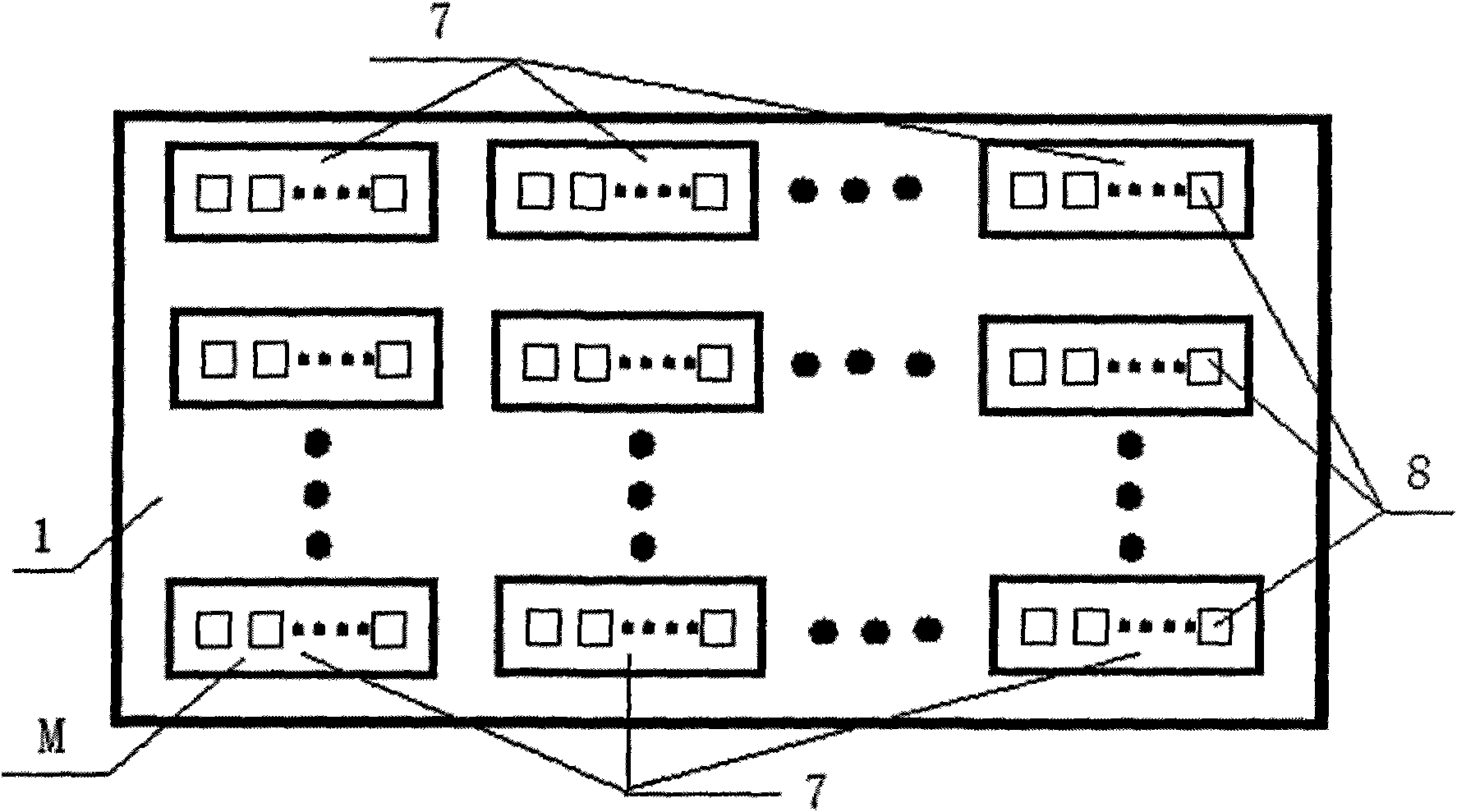

Phased array mobile satellite receiving antenna

ActiveCN101615721AExcellent electrical performanceEasy to installAntennasControl systemSignal tracking

The invention discloses a phased array mobile satellite receiving antenna with plane structure, relating to a high-efficiency communication signal receiving device in a mobile satellite communication system. The antenna comprises a receiving antenna array, a feed network, a tracking and receiving system, a servocontrol system, a wave beam control system and an antenna pedestal. The invention adopts the tracking mode of combining two-dimensional phased array electric scanning and tracking with two-dimensional mechanical tracking to realize quick satellite searching and unremitting satellite signal tracking and receiving. The invention has the characteristics of high efficiency, low outline, high searching speed, high tracking precision, unremitting satellite signal receiving and the like, and is especially favourable for designing and manufacturing the ground mobile receiving antenna of high-performance satellite communication in the mobile satellite communication system.

Owner:BEIJING HUADA ZHIBAO ELECTRONICS SYST

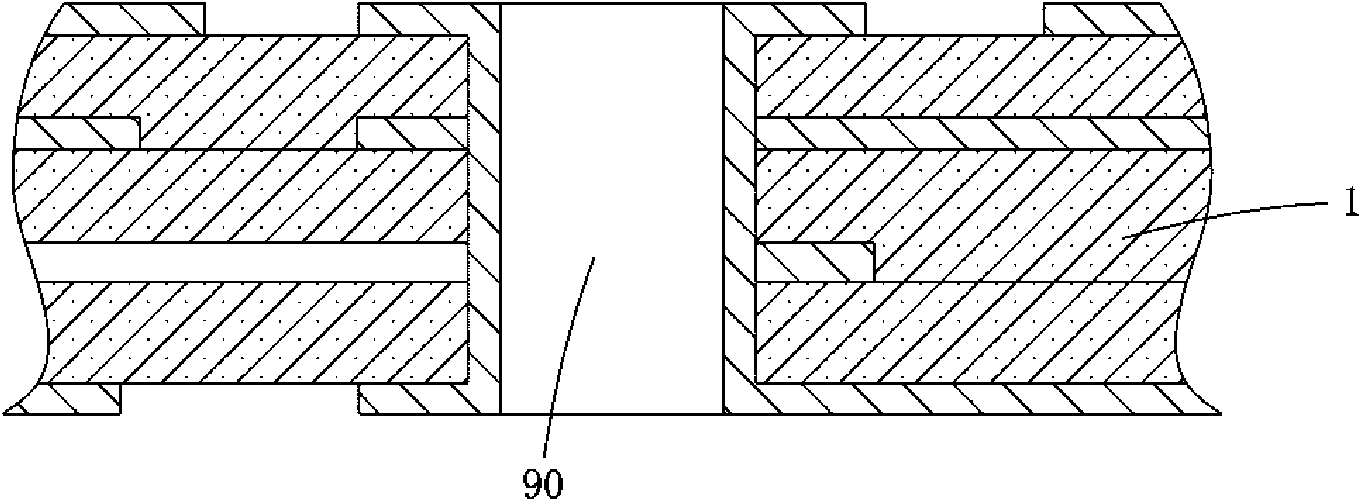

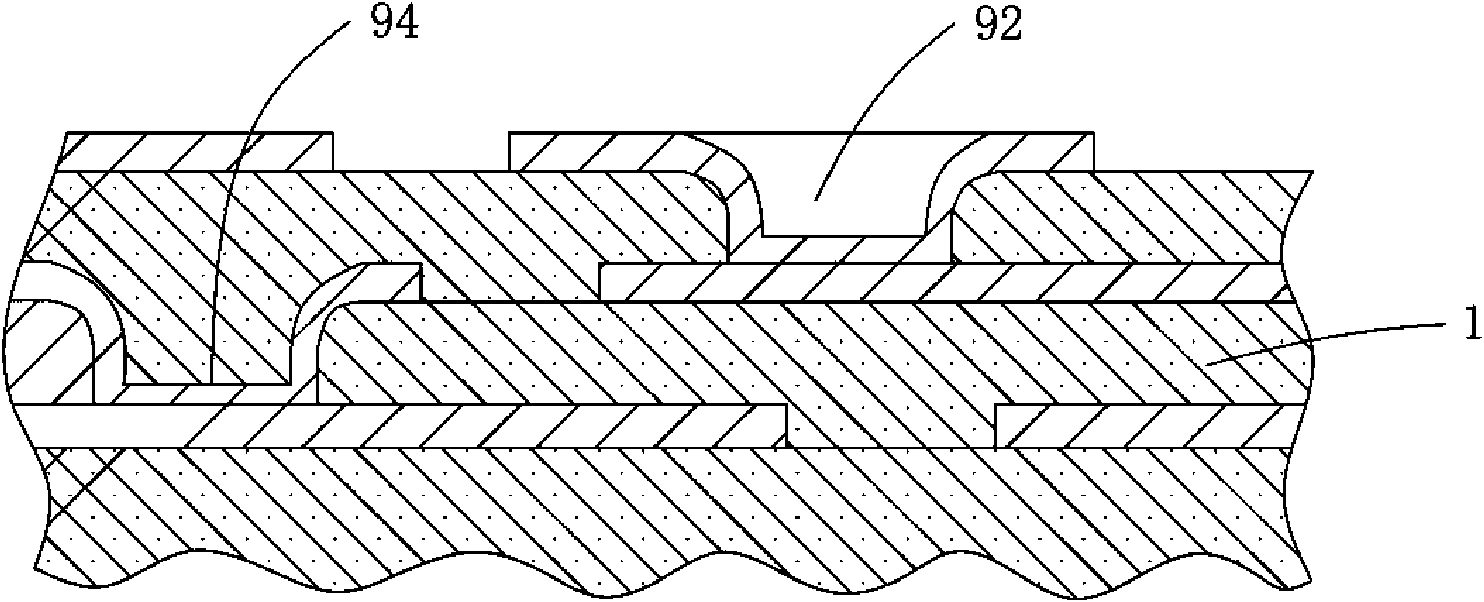

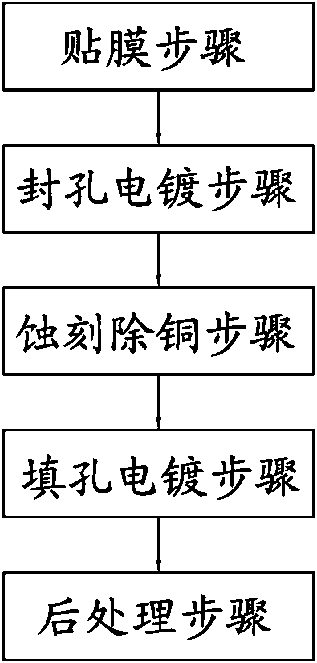

Method for molding via hole of printed circuit board

ActiveCN101605434AReduce area occupationExcellent electrical performancePrinted element electric connection formationCopper highEngineering

The invention relates to a method for molding a via hole of a printed circuit board, which comprises the steps of: film attachment, in which the surfaces of upper and lower surface copper layers of an insulating dielectric layer drilled with the via hole are attached with photosensitive films, and the positions, which correspond to the via hole, on the photosensitive films are provided with film openings; hole-sealing electroplating, in which an orifice end, which is near a first surface, of the via hole is closed through a copper electroplating process on the first surface of the insulating dielectric layer; hole-filling electroplating, in which the via hole is completely filled with copper, and the filled copper is connected with the surface copper layer of a second surface of the insulating dielectric layer, namely the connection of solid via holes between upper and lower adjacent line layer patterns is realized; and the post-treatment, in which the two surfaces of the insulating dielectric layer are subjected to subsequent treatment respectively, and a level conducting surface which is convenient for implementing subsequent pattern line production working procedures is obtained by removing the photosensitive films, removing the filled copper higher than the surface copper layers, and leveling the board surface. The method has the advantages of simple, convenient and feasible process, low cost, and small area occupation, and upper and lower corresponding line rackets of the hole are integrally preserved, are not damaged by the via hole and have good electrical properties.

Owner:美龙翔微电子科技(深圳)有限公司

Polyvinyl chloride/graphene nanocomposite and preparation method thereof

InactiveCN104710709ASolve the problem of difficult dispersionImprove mechanical propertiesGraphene nanocompositesPlasticizer

The invention discloses a conductive polyvinyl chloride / graphene nanocomposite with good mechanical property and thermal stability and a preparation method thereof. The conductive polyvinyl chloride / graphene nanocomposite comprises the following raw materials in parts by weight: 100 parts of a polyvinyl chloride resin, 10-50 parts of a plasticizer, 1-10 parts of a thermal stabilizer, 0.1-5 parts of a lubricant and 0-8 parts of graphene. The conductive polyvinyl chloride / graphene nanocomposite solves the problem that the conductivity of the PVC is poor, and remarkably improves the mechanical property and thermal stability of the PVC; the conductivity is up to 1.06*10<-6> S / cm; and the tensile strength is increased by 40.66%.

Owner:LIAOCHENG UNIV

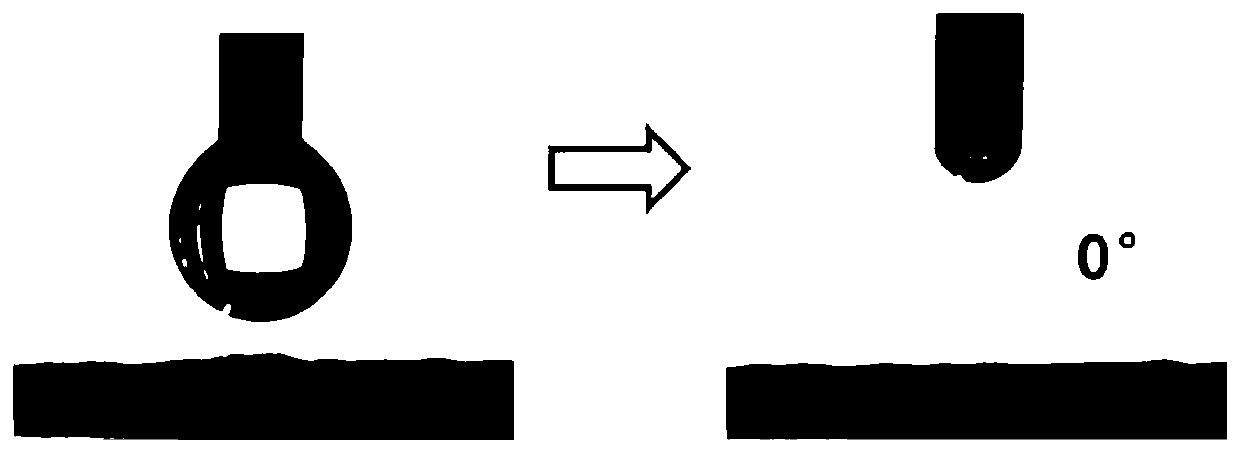

Method for preparing superamphiphobic polysulfone membrane for membrane distillation

ActiveCN110433662AProcess stabilityGood bondingSeawater treatmentWater/sewage treatment bu osmosis/dialysisSilica nanoparticlesSilane compounds

The invention discloses a simple efficient method for preparing a superamphiphobic polysulfone membrane, and relates to the field of membrane separation. Firstly, a polysulfone membrane having an interpenetrating network pore structure is prepared by a conventional solvent-induced phase inversion manner, and interpenetrating network pores form a 'concave angle structure' on the surface of the membrane; then a stepwise sol-gel process is used to generate, in an in-situ manner, uniformly distributed silica nanoparticles on walls of the interpenetrating network pores to provide a certain nano-scale roughened structure for the polysulfone membrane; and finally, the roughened polysulfone membrane surface is coated with a fluorosilane compound film having low surface energy to obtain the superamphiphobic polysulfone membrane. Dual infiltration resistant functions for water droplets and organic liquid droplets are achieved, the contact angle of a water droplet can be 150 degrees or above, andthe contact angle of n-hexane can reach 65 degrees or above. The prepared superamphiphobic polysulfone membrane when applied in a membrane distillation process has a salt interception rate of 99.5% or above and has high anti-wetting stability.

Owner:QINGDAO UNIV OF SCI & TECH

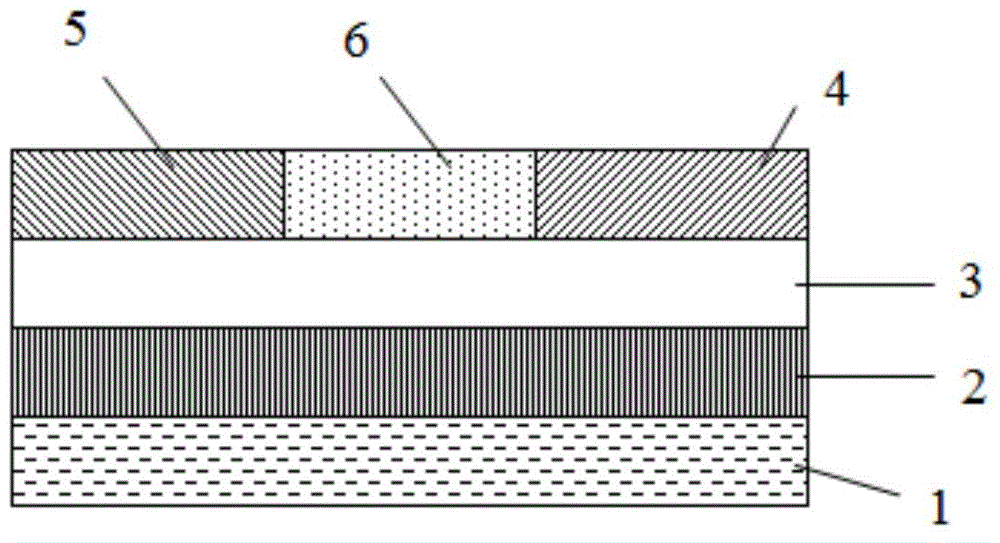

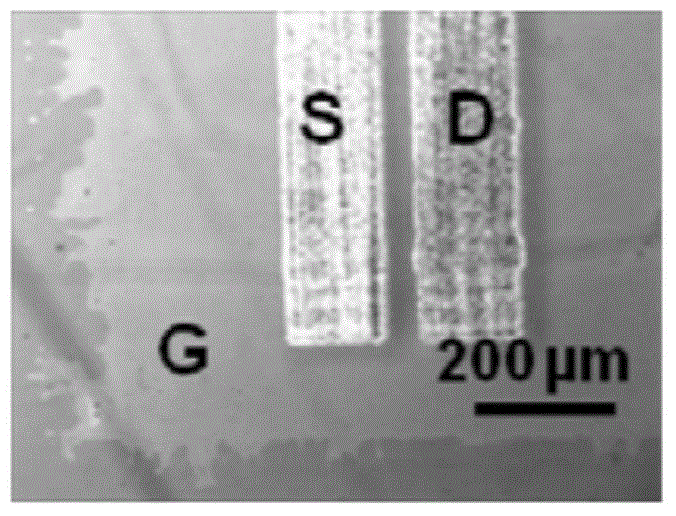

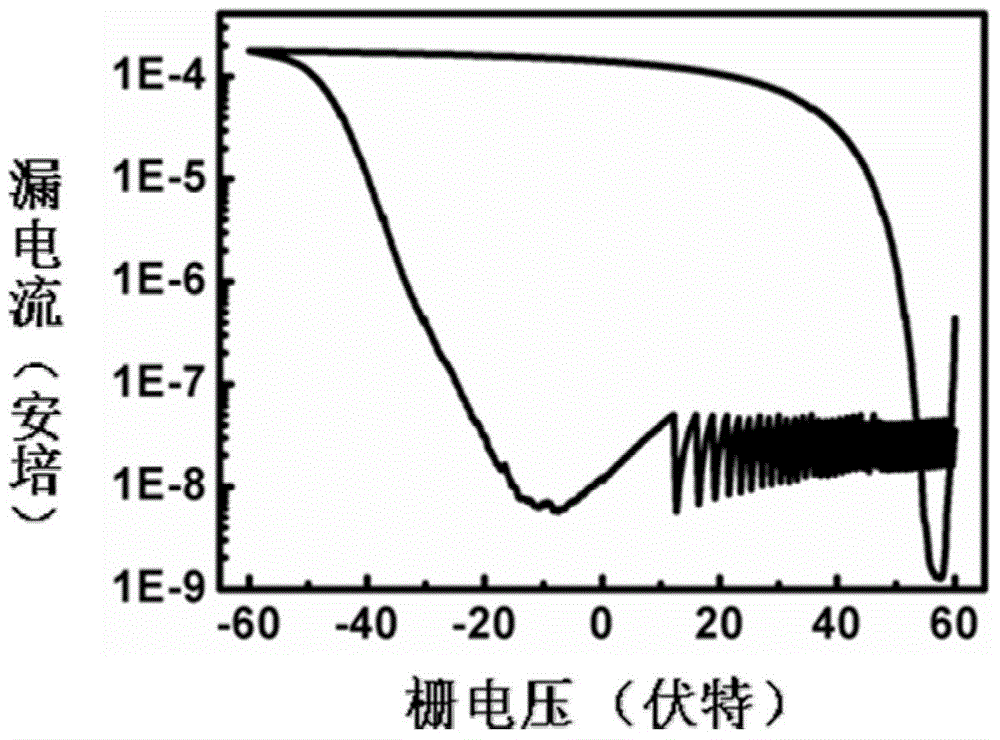

Preparation method for printing independent carbon nano tube thin film transistor in large area

ActiveCN104576394AExcellent electrical performanceSimple processNanoinformaticsSemiconductor/solid-state device manufacturingCarbon nanotubeElectrode array

The invention discloses a preparation method for printing an independent carbon nano tube thin film transistor in a large area. The preparation method comprises the following steps: (a) providing a substrate; (b) preparing a gate electrode array on the substrate by a printing technology; (c) preparing a dielectric layer on the gate electrode array by an atomic deposition technology, a spin coating technology or the printing technology; (d1) firstly preparing a source electrode and a drain electrode on the dielectric layer by the printing technology, wherein a trench which is 10-200 microns in width is formed between the source electrode and the drain electrode; then preparing a carbon nano tube active layer in the trench by the printing technology; or (d2) preparing the carbon nano tube active layer which is 10-200 microns in width on the dielectric layer by the printing technology, and then respectively preparing the source electrode and the drain electrode on the two sides of the active layer. The preparation method provided by the invention is simple in technology, environmental-friendly, convenient to operate and low in cost.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Preparation method of silver nanowire modified flexible fiber sensor electrode

ActiveCN107525832AHigh tensile strengthExcellent electrical performanceElectroconductive/antistatic filament manufactureFibre typesConductive materialsGraphene

The invention relates to the field of sensors, and discloses a preparation method of a silver nanowire modified flexible fiber sensor electrode. A flexible conductive fiber is prepared with a solution mixing method, wherein SBS (styrene-butadiene-styrene) is taken a as flexible substrate, poly 3,4-ethylenedioxythiophene-polystyrene sulfonate-graphene is taken as a conductive material, the electrode is modified with a silver nanowire, and the silver nanowire modified flexible fiber sensor electrode containing SBS / graphene / poly 3,4-ethylenedioxythiophene-polystyrene sulfonate is obtained. The sensor electrode can be applied in the fields of medical biological monitoring, environment and hygiene monitoring and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing modified calcined superfine kaoline filler

InactiveCN1528829ASimple processEasy to manufactureInorganic pigment treatmentElectricityMaterials science

The invention is a manufacturing method of modified calcuination superfine kaolinsol filler, which beongs to the manufacturing technique field of inorganic material, it uses superfine slice kaolinsol or superfine kalolinsol as the material, through low temperature calcuination and organic modified process, the filler can be produced. It has the advantage of simple process, convenient in manufacturing, the temperature is low, and the electricity performance of the product is good. The product applies to PVC wire and cable; it has excellent electricity insulation. It can decrease the cost of the PVC wire and cable.

Owner:EAST CHINA NORMAL UNIV

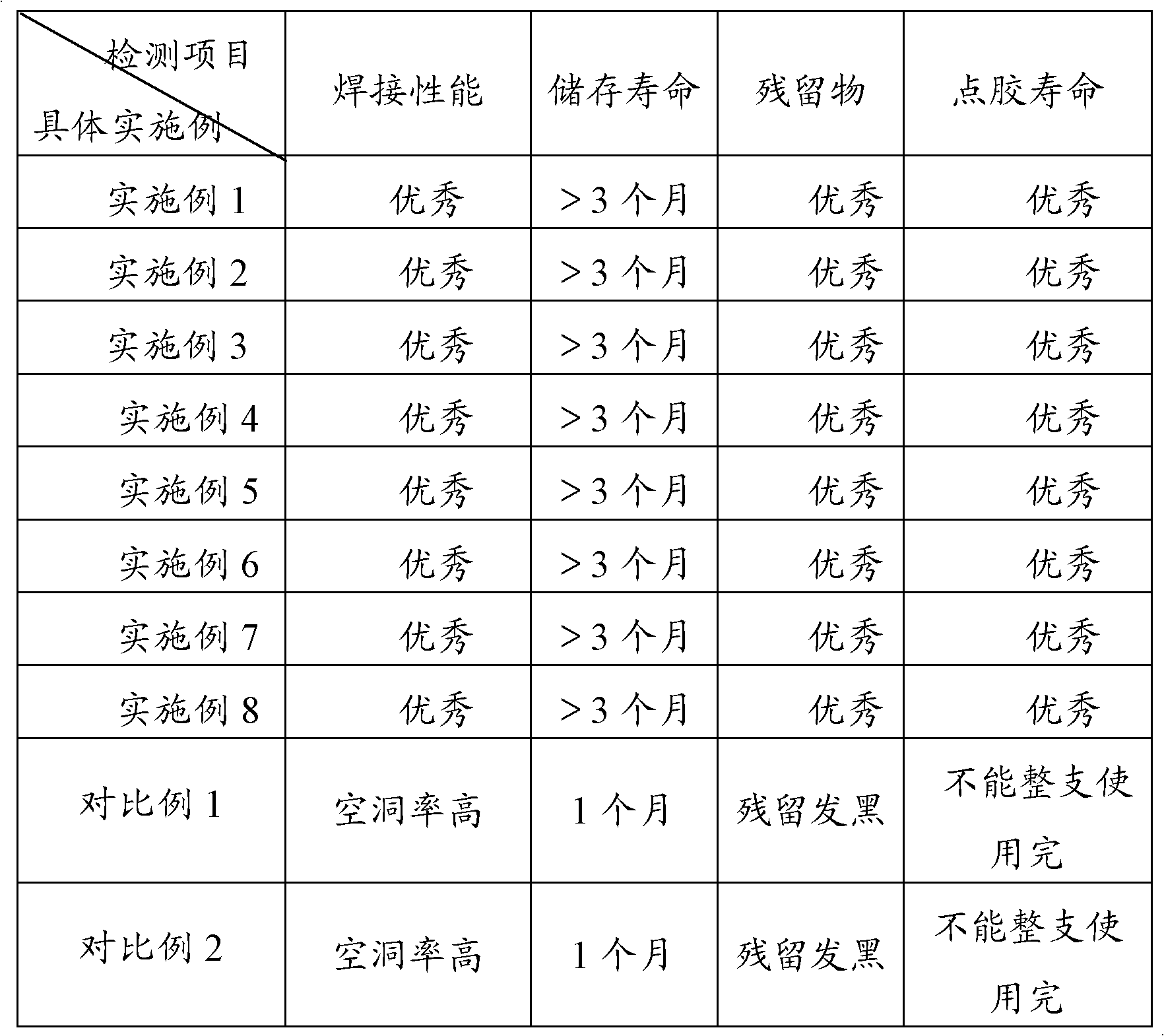

Spot coating type high-temperature soldering paste and preparation method thereof

InactiveCN102049631ATin evenlyNo size pointConductive pattern formationWelding/cutting media/materialsActive agentAlloy

The invention belongs to the technical field of soldering paste, and particularly relates to high-temperature soldering paste used for spot coating type operation and a preparation method of the high-temperature soldering paste. The high-temperature soldering paste comprises soldering flux and Sn / Pb / Ag tin-based alloy powders distributed in the soldering flux; the soldering flux includes the following components by weight percentage: 30 to 40 percent of polymerized rosin, 8 to 15 percent of hydrogenated rosin, 2 to 4 percent of modified hydrogenated castor oil, 2 to 4 percent of hydrogenated castor oil wax, 5 to 6 percent of active agent, 1 to 2 percent of hydroquinone, 1 to 2 percent of ethylene bis stearamide, and solvent; and the soldering paste adopts a syringe type package and is prepared through vacuumizing defoaming process and other process. The soldering paste has the advantages of stable performance, uniform spot coating, no phenomena of hardening and layering during the storage, no phenomenon of surface crusting on the surface in contact with air, long storage life and service life, good expansion rate and good insulation resistance; and particularly, residues after reflow soldering at the high temperature above 340 DEG C is unsintered and is easy to clean.

Owner:东莞市特尔佳电子有限公司

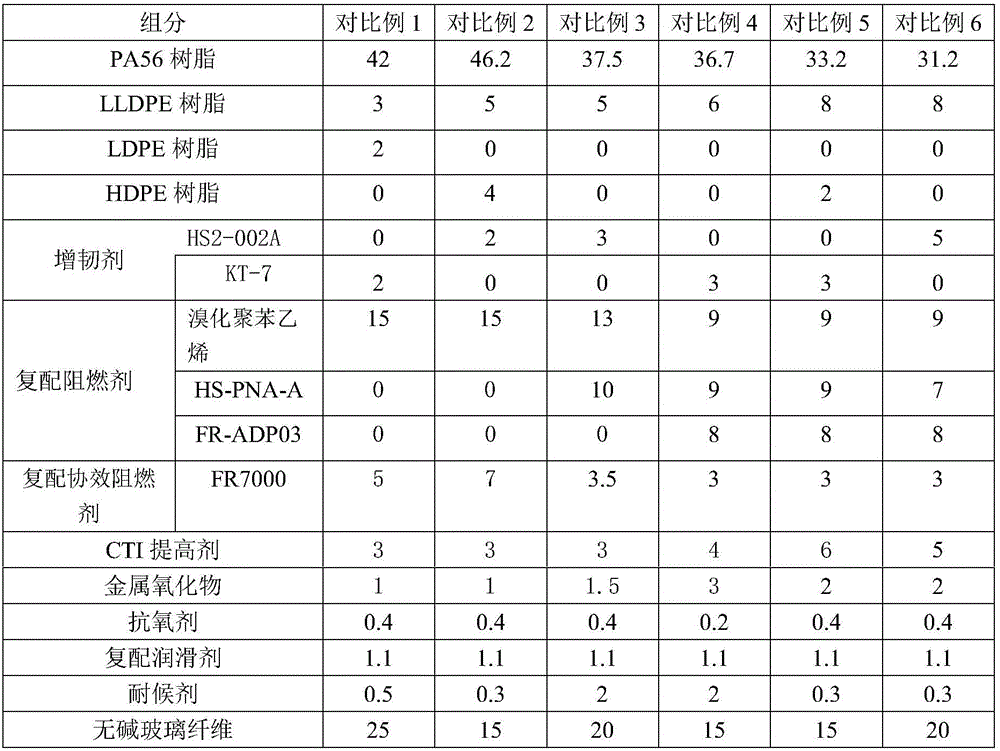

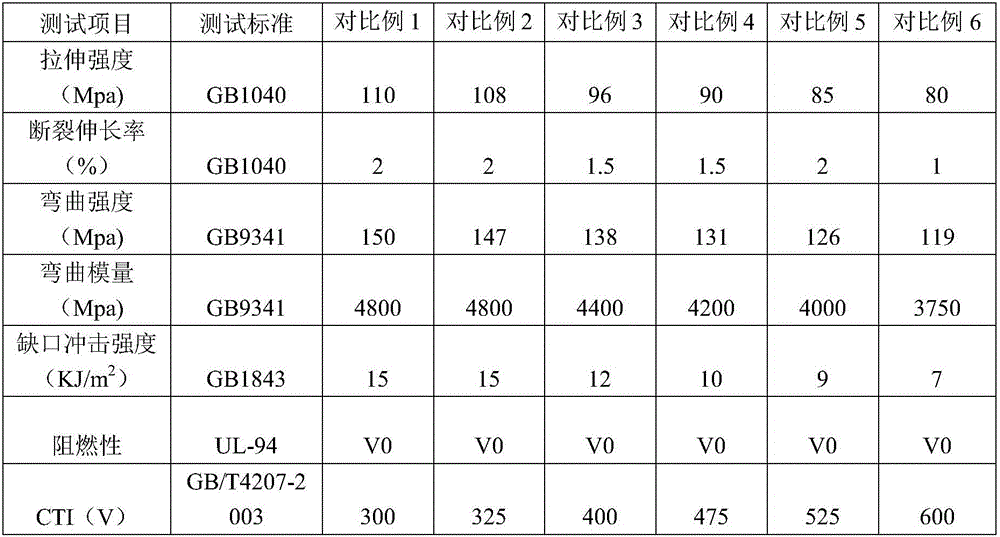

High-CTI (Comparative Tracking Index) anti-flaming PA (Polyamide) for photovoltaic material and preparation method thereof

The invention discloses high-CTI (Comparative Tracking Index) anti-flaming PA (Polyamide) for a photovoltaic material and a preparation method thereof. The high-CTI anti-flaming PA for the photovoltaic material is characterized in that the high-CTI anti-flaming PA is prepared from the following raw materials in percentage by weight: 31.2 to 42.2 percent of PA resin, 5 to 10 percent of PE (Poly Ethylene) resin, 2 to 5 percent of toughening agent, 15 to 26 percent of composite flame retardant, 3 to 7 percent of composite synergetic flame retardant, 3 to 6 parts of CTI increasing agent, 1 to 3 percent of metal oxide, 0.2 to 0.4 percent of antioxidant, 1 percent of composite lubricating agent, 0.3 to 2 percent of weather-resisting agent and 15 to 25 percent of alkali-free glass fiber. The high-CTI anti-flaming PA for the photovoltaic material, provided by the invention, has the advantages of very high notch impact strength, very good flame retardance, lower production cost and good processing fluidity.

Owner:GUANGDONG WAYLAM ENG PLASTICS

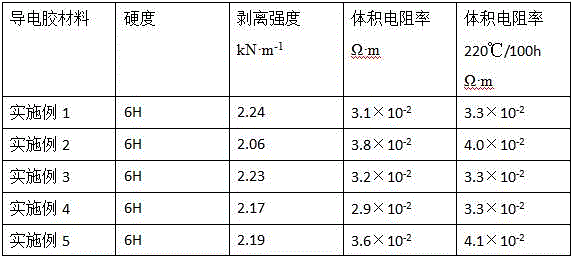

Photo-curing and thermal curing heat-resistant conductive adhesive material and preparation method thereof

InactiveCN105907357AExcellent electrical performanceFast heat curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesConductive materialsThermal stability

The invention discloses a photo-curing and thermal curing heat-resistant conductive adhesive material, which is prepared from the following raw materials in parts by weight: 10 to 30 parts of basic adhesive materials, 50 to 90 parts of conductive fillers, 3 to 10 parts of active monomer additives, 2 to 6 parts of thermal initiators, 0.5 to 1.5 parts of thermal initiators, 1 to 2 parts of photoinitiators, 3 to 8 parts of active diluting crosslinking agents, 8 to 15 parts of plasticizing modifiers and 3 to 6 parts of inorganic fillers. The invention also discloses a preparation process of the photo-curing and thermal curing heat-resistant conductive adhesive material. The conductive material provided by the invention has excellent electric performance; the thermal curing and the curing are combined; the simultaneous effect taking is achieved; the fast curing of the conductive glue is realized. The conductive adhesive simultaneously has excellent thermal stability; when the environment temperature rises to 220 DEG C, the conductive adhesive can still have good conduction reliability.

Owner:JIN BAOLI TECH SUZHOU

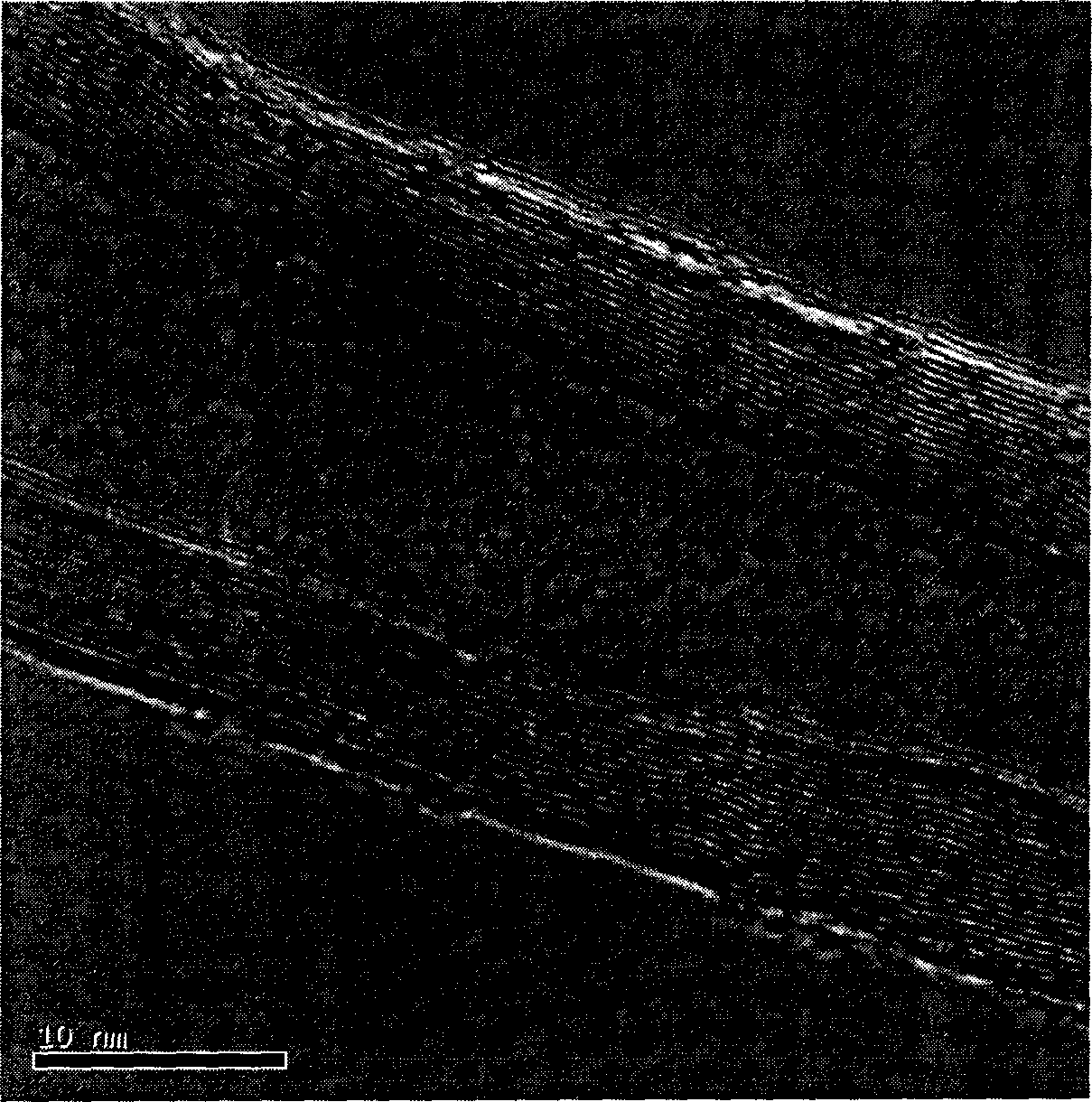

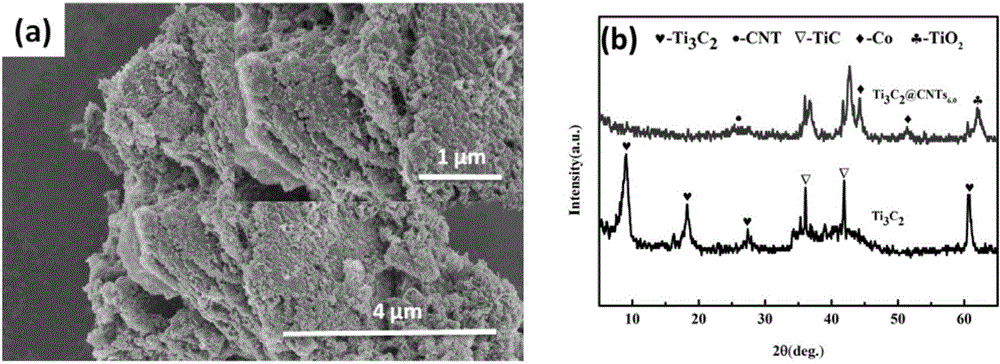

3D composite having CNTs (carbon nanotubes) growing on Ti3C2 in situ and preparation method of 3D composite

ActiveCN106783230ALow costIncrease the lengthMaterial nanotechnologyHybrid capacitor electrodesMass ratioCarbon nanotube

The invention belongs to the technical field of preparation of nano functional materials and particularly relates to a 3D composite having CNTs (carbon nanotubes) growing on Ti3C2 in situ and a preparation method of the 3D composite. Firstly, Ti3C2 nano powder is added to ultrapure water to be dispersed uniformly, then Co(NO3)2.6H2O is added, and a liquid phase reaction is conducted; after the liquid phase reaction ends, urea is added to a reaction liquid, the mixture is continuously stirred at the constant temperature to evaporate moisture, and precursor powder is obtained, wherein the mass ratio of Ti3C2 nano powder to Co(NO3)2.6H2O to urea is (0.2-1.0): (0.1-0.4): (3.0-30.0); the precursor powder is ground fine and subjected to heat treatment, and the 3D composite having the CNTs growing on Ti3C2 in situ is obtained. Ti3C2 serves as a carrier, cobalt serves as a catalyst, urea serves as a carbon source, the 3D composite is prepared with a simple pyrolysis method, and the electrochemical performance of the Ti3C2 can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

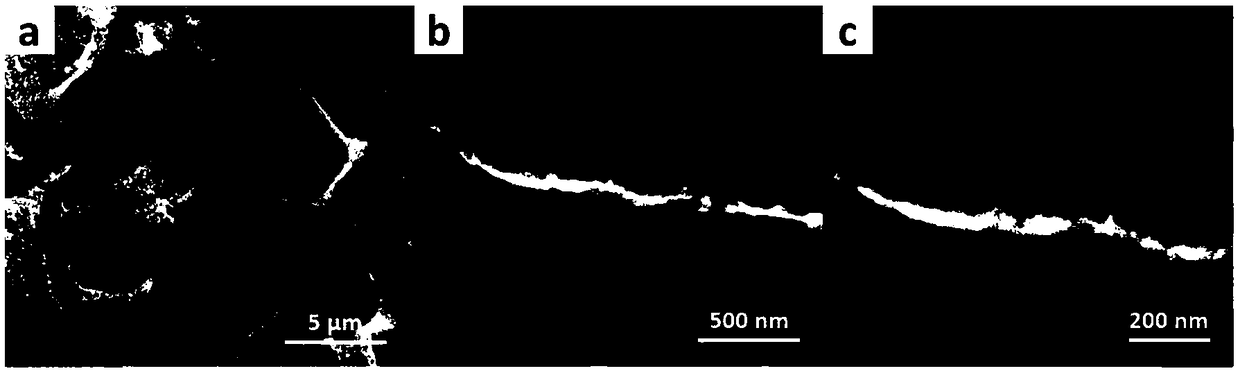

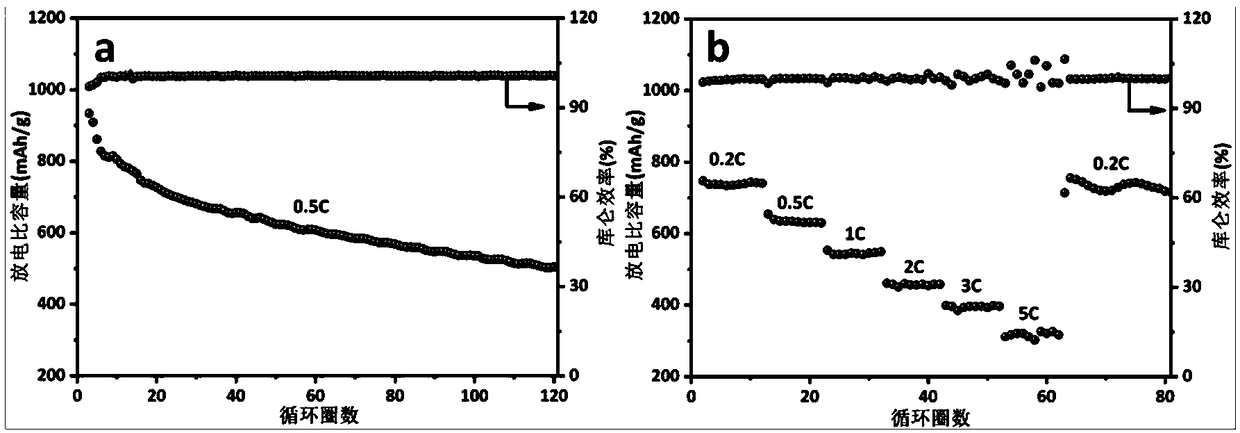

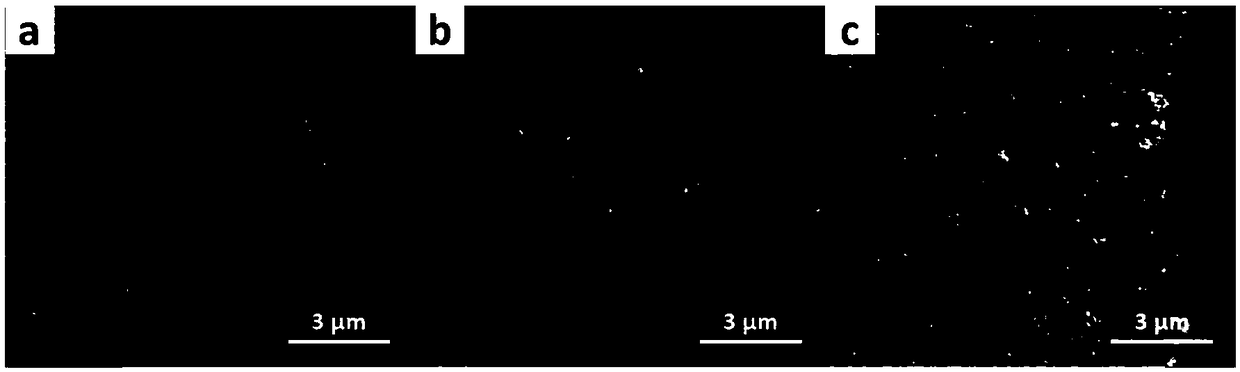

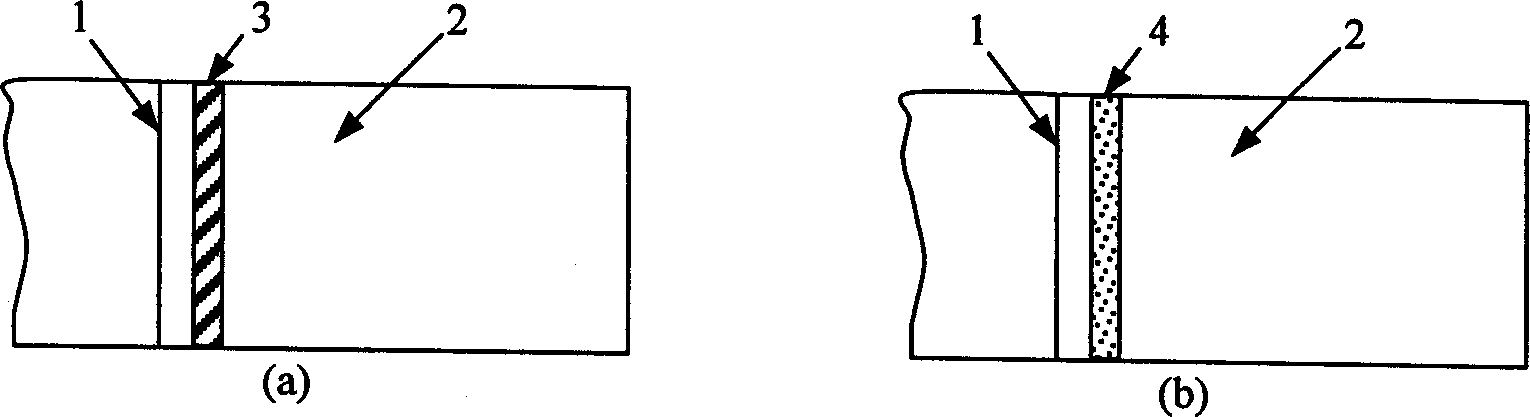

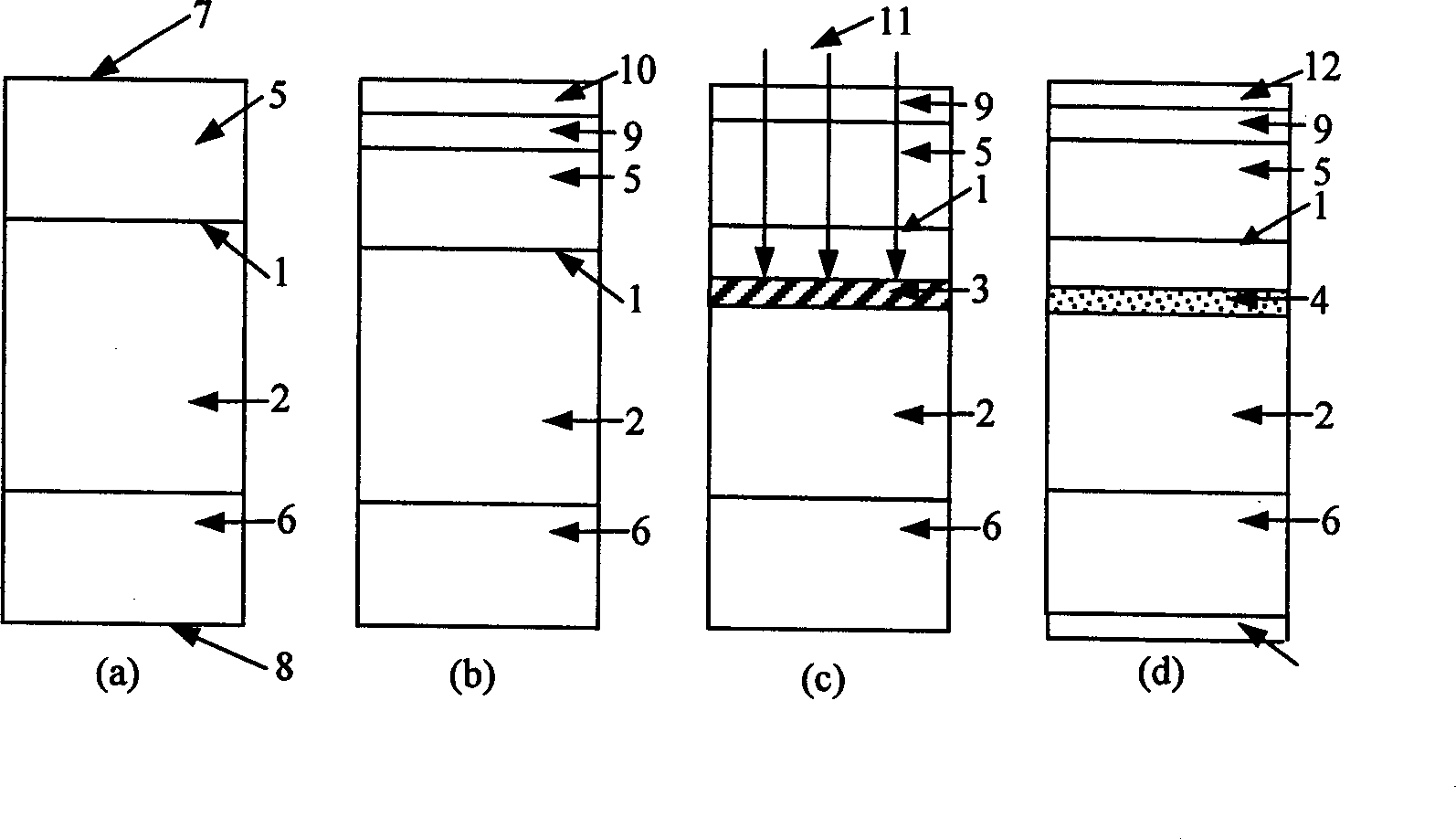

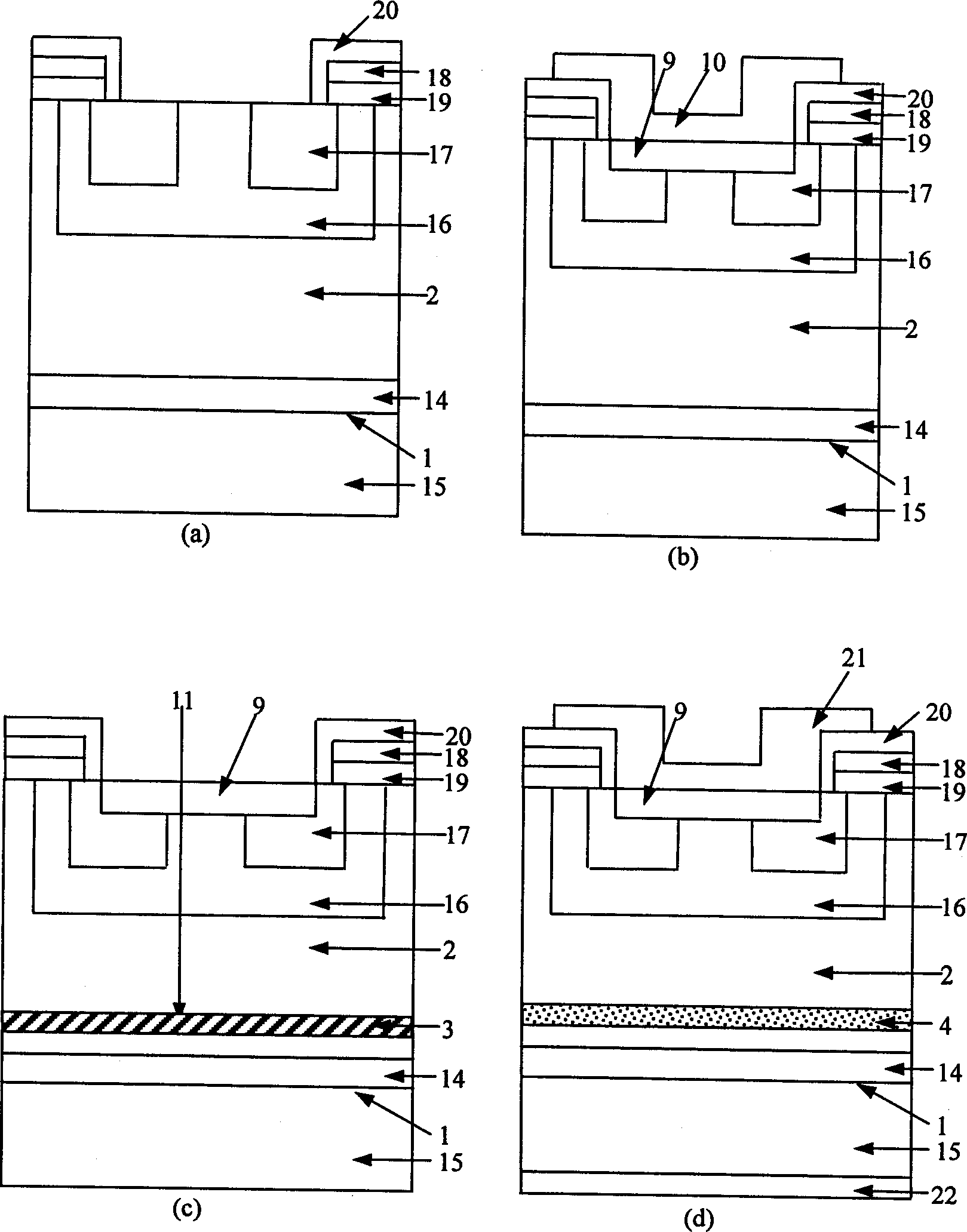

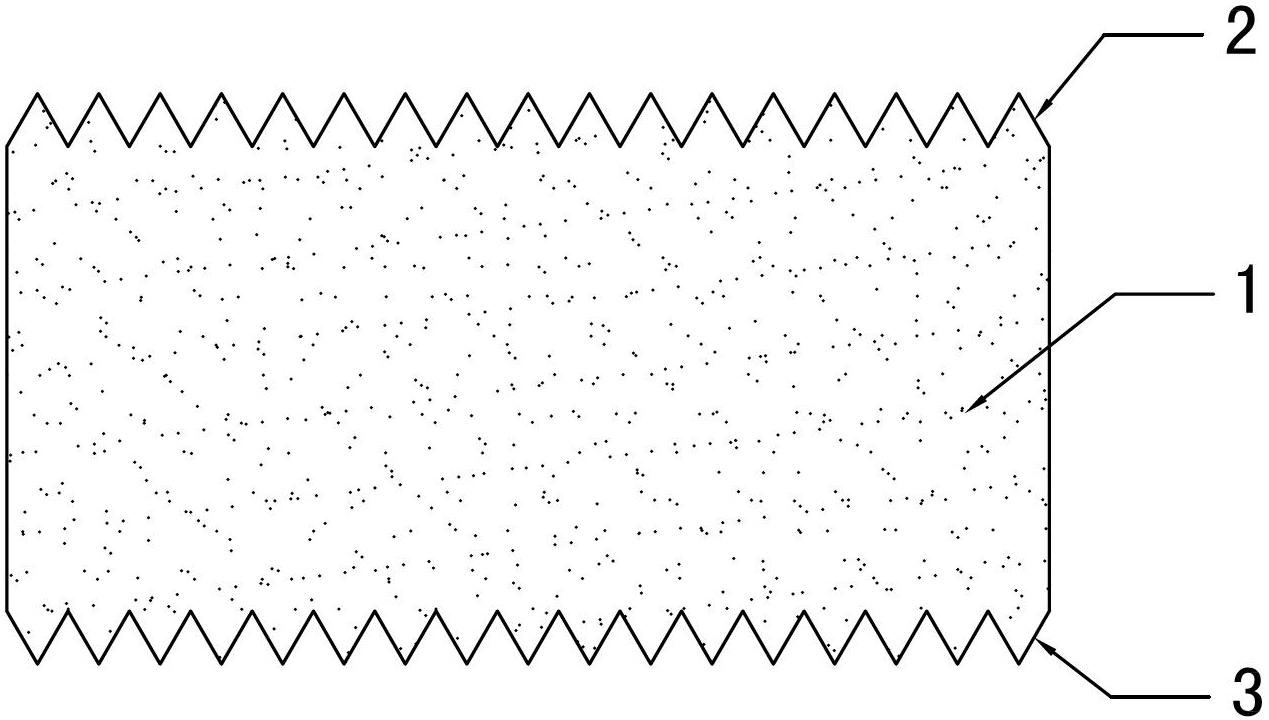

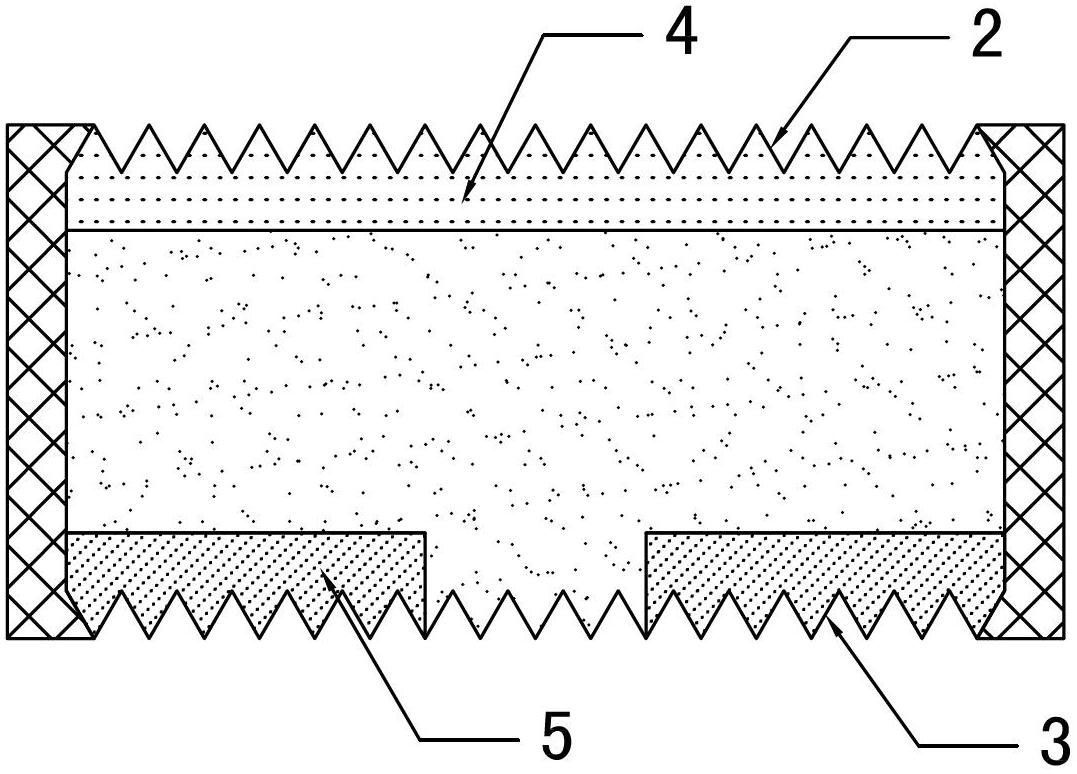

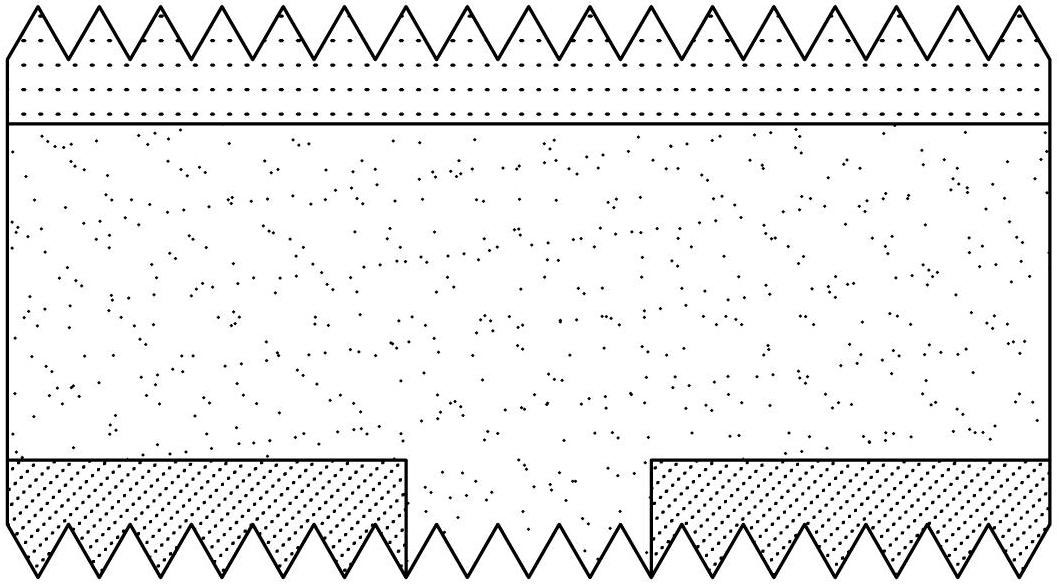

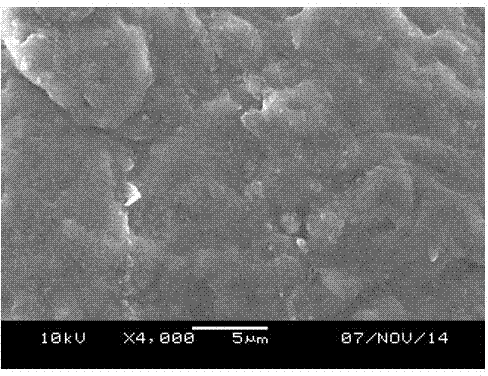

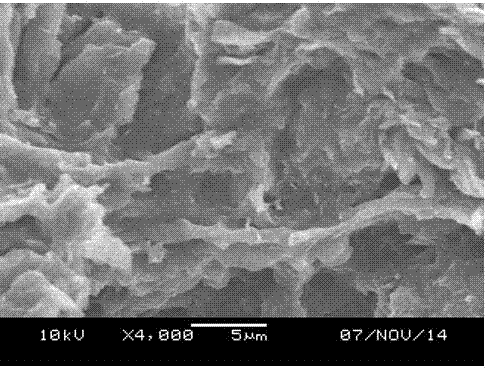

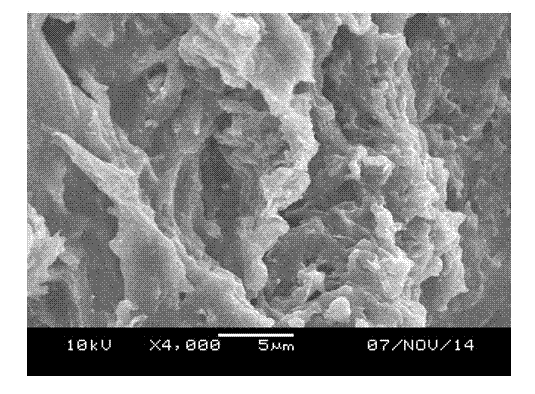

Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method

The present invention discloses a solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method. According to the method, a nickel compound, a cobalt compound and a manganese compound are matched according to a stoichiometric ratio to prepare a solution having uniform components, the solution is subjected to atomization through an ultrasonic atomizer to form droplets, and the whole atomization thermal decomposition process is rapidly completed, such that component segregation of the droplets does not occur timely so as to ensure component distribution uniformity of the Li[Ni0.8Co0.1Mn0.1]O2 precursor; and regular spherical particles are formed after the droplets are dried, agglomeration is less, and the subsequent washing and grinding is not required, such that high purity of the product is ensured so as to obtain the Li[Ni0.8Co0.1Mn0.1]O2 precursor with good sphericity. The method has the following advantages that: the preparation process is simplified, the stoichiometric ratio of the components can be precisely controlled, the prepared powder has high purity, and the Li[Ni0.8Co0.1Mn0.1]O2 material with an excellent electrical performance is easily prepared after sintering.

Owner:NANJING UNIV

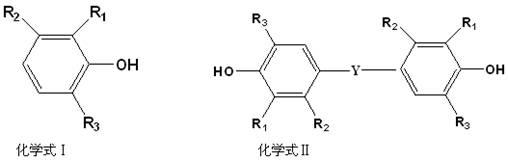

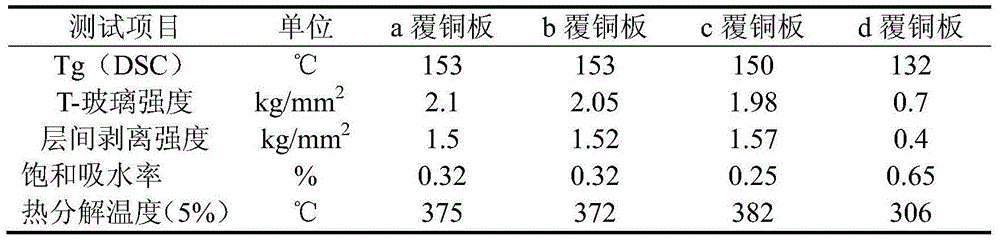

Preparation method for amination polyphenyl ether

ActiveCN102516532AImprove electrical performanceIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsEpoxyPolymer science

The invention discloses a preparation method for amination polyphenyl ether, which is characterized by including the following steps that low-molecular-weight polyphenyl ether with double hydroxyl is generated through oxidation, coupling and copolymerization of two kinds of phenol, and low-molecular-weight polyphenyl ether resin with double amino is obtained through a process such as nitration. Compared with conventional polyphenyl ether resin, the polyphenyl ether resin with the double amino is more in active groups cross-linked with epoxy, larger in cross-linking degree with epoxy resin, can remarkably improve poly-p-phenylene oxide / epoxy (PPO / EP) compatibility, can increase proportion of the polyphenyl ether resin in a PPO / EP system, and accordingly remarkably improves condensate electrical property of a resin system.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

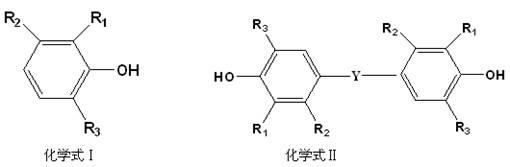

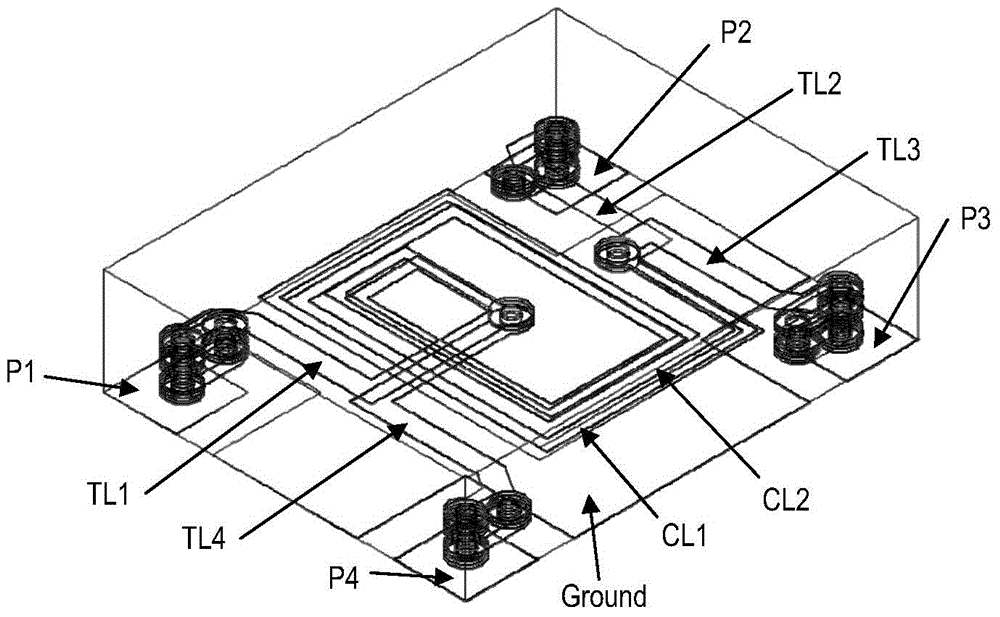

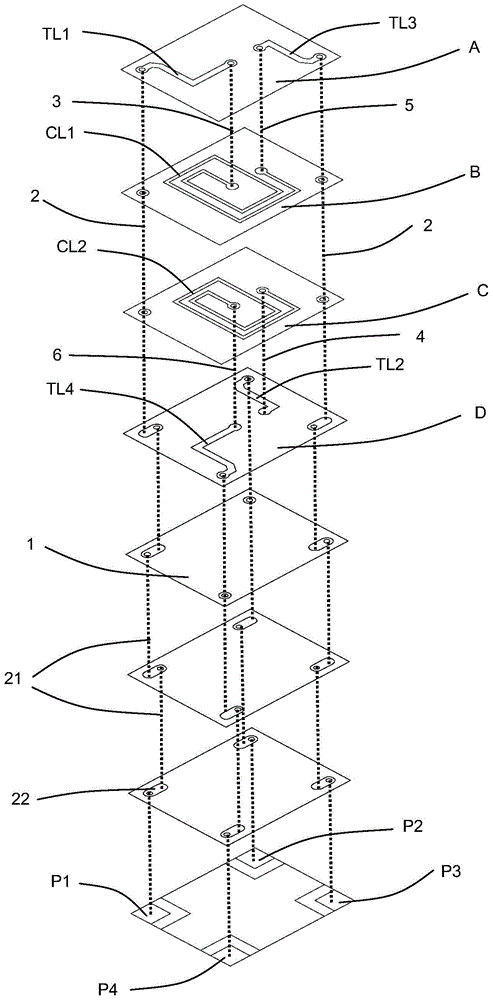

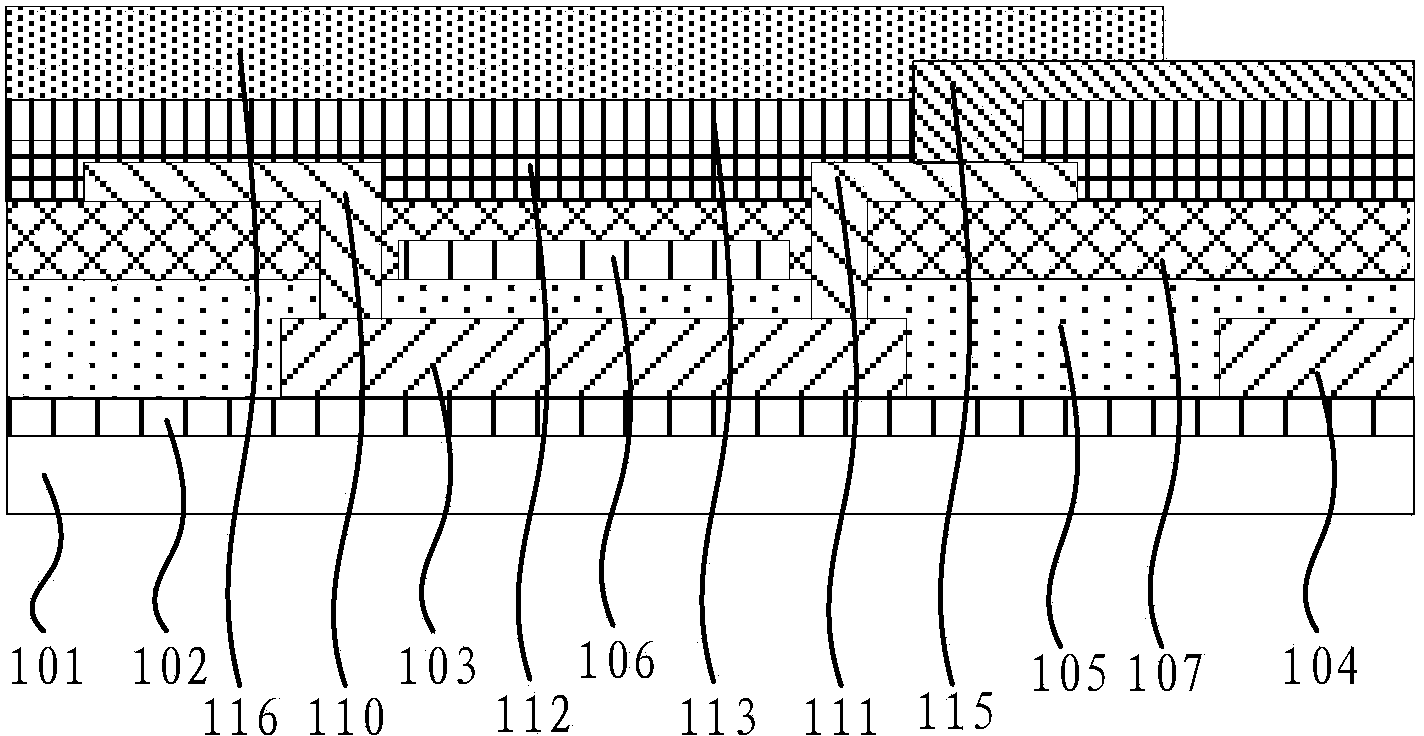

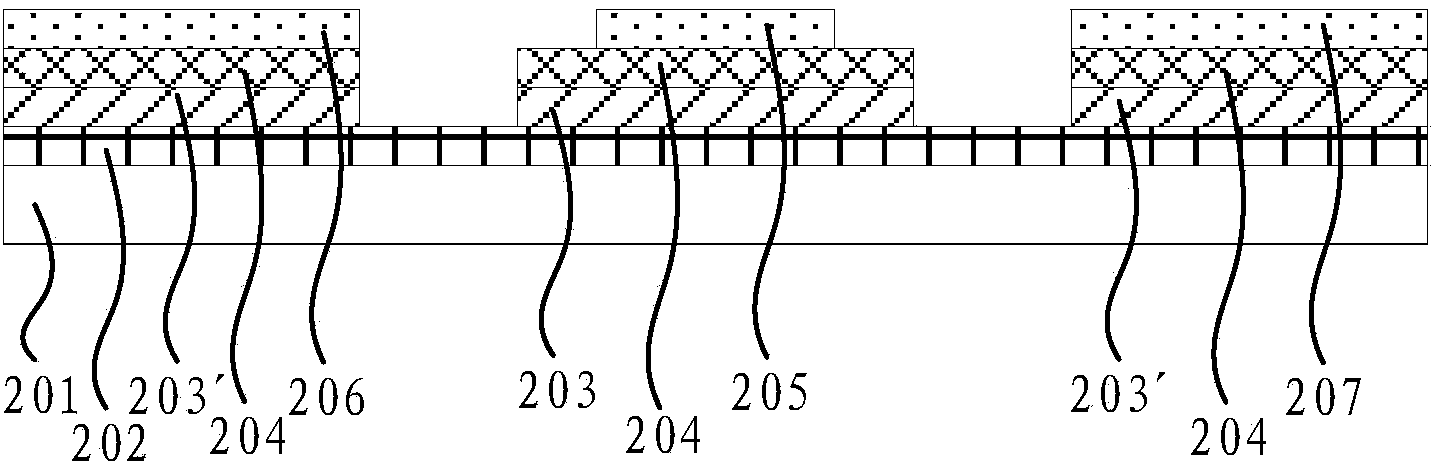

Sheet type LTCC miniaturized 3dB directional coupler

ActiveCN103825076AExcellent electrical performanceStable temperature performanceCoupling devicesFrequency bandOhm

The invention discloses a sheet type LTCC miniaturized 3dB directional coupler which is wide in frequency band, small in size, stable in temperature performance, small in insertion loss, balanced in amplitude and good in phase balance characteristics. The sheet type LTCC miniaturized 3dB directional coupler comprises four ports which are printed at the four corners on the bottom surface of a first bottom substrate and are provided with impedance input of 50 ohms, i.e., an input port, a straight-through port, a coupling port and an isolation port. The input port and the straight-through port are connected with a first coupling band-shaped wire on a second substrate through a first asymmetric band-shaped wire and a third asymmetric band-shaped wire which are arranged on the same substrate. The coupling port and the isolation port are connected with a second coupling band-shaped wire on a third substrate through a second asymmetric band-shaped wire and a fourth asymmetric band-shaped wire which are arranged on the other same substrate. The first coupling band-shaped wire and the second band-shaped wire represent rotary-shaped patterns and are coupled in a band-shaped mode at upper wide edges and lower wide edges. According to the invention, the coupling wires represent the rotary-shaped patterns so that quite large coupling wire length can be obtained on a limited substrate area, thus a quite wide frequency scope is obtained. The sheet type LTCC miniaturized 3dB directional coupler has the advantages of simple structure, high yield, good batch consistency and low cost.

Owner:SHENZHEN SUNLORD ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method](https://images-eureka.patsnap.com/patent_img/2227c3bc-5b81-47d5-8a09-7ecbbbc97922/HDA00002569672600011.PNG)

![Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method](https://images-eureka.patsnap.com/patent_img/2227c3bc-5b81-47d5-8a09-7ecbbbc97922/HDA00002569672600012.PNG)

![Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method Solid spherical Li[Ni0.8Co0.1Mn0.1]O2 positive electrode material precursor preparation method](https://images-eureka.patsnap.com/patent_img/2227c3bc-5b81-47d5-8a09-7ecbbbc97922/HDA00002569672600021.PNG)