High-CTI (Comparative Tracking Index) anti-flaming PA (Polyamide) for photovoltaic material and preparation method thereof

A technology of flame retardant polyamide and photovoltaic materials, applied in the polymer field, can solve the problems of less research on PA/LLDPE alloys, and achieve the effects of saving strategic resources, good electrical properties, and improving fluidity and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Treatment of raw materials: PA resin is baked at 110°C for 4 hours, and the moisture content is controlled to be less than 0.1%; PA resin, PE resin and all additives except glass fiber are placed in a high-mixer in proportion, Stir at high speed for 3 to 5 minutes to fully mix the components;

[0045] (2) Melt extrusion: Put the mixed materials into the twin-screw extruder, and at the same time melt and extrude, introduce the alkali-free glass fiber into the glass fiber port. During the melt extrusion, the screw temperature is: 230℃ in the first zone , Zone two 250℃, zone three 245℃, zone four 240℃, zone five 235℃, zone six 240℃, zone seven 245℃, zone eight 250℃, die head 260℃, screw speed is 340 rpm;

[0046] (3) Granulation and post-processing: the extruded materials are cooled, air-dried, pelletized, and magnetized to obtain finished products.

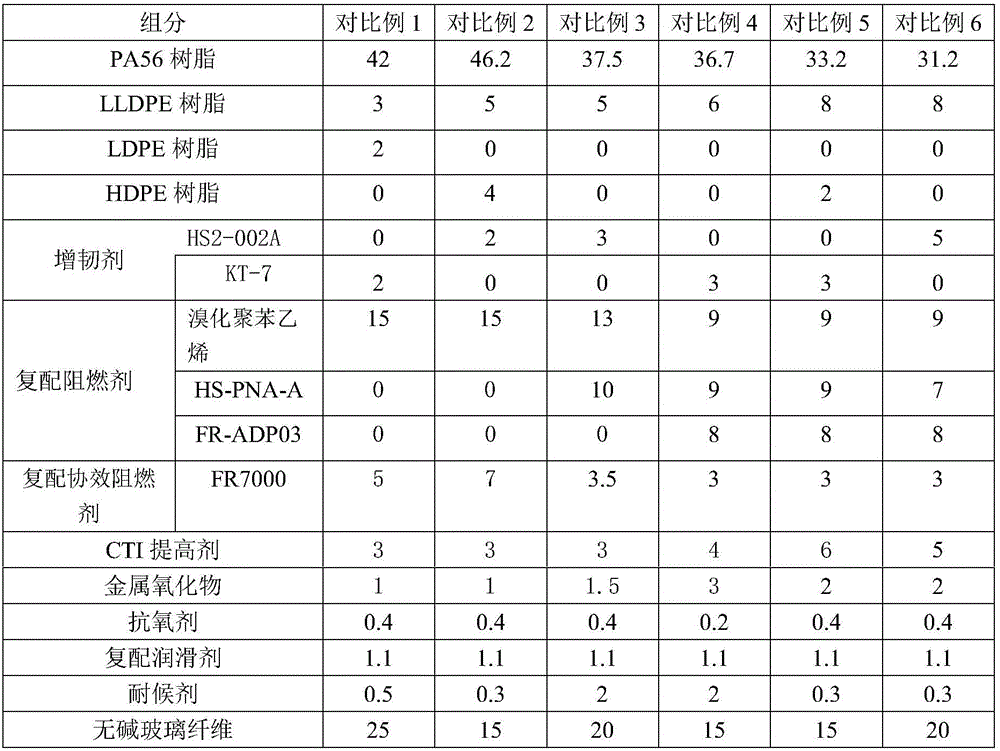

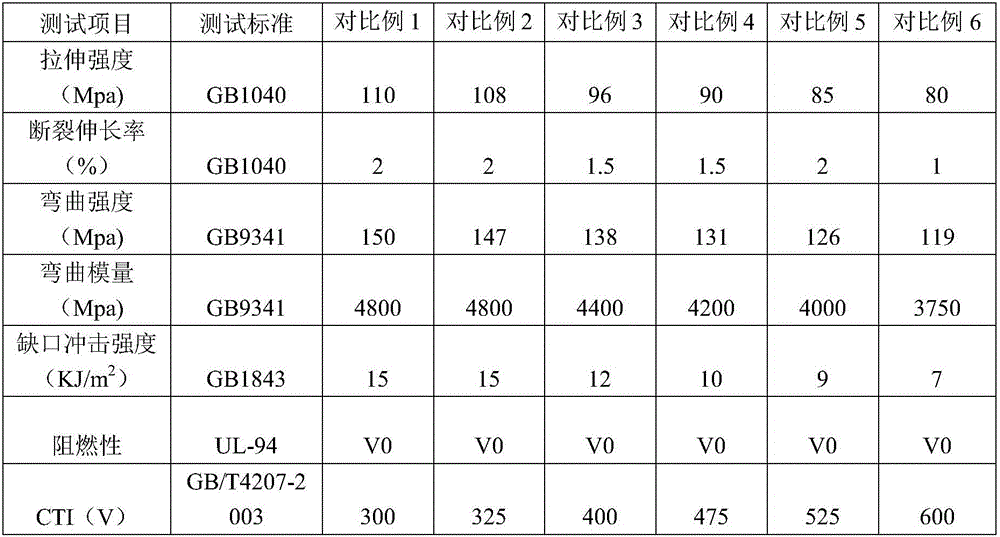

[0047] Table 1 shows the weight percentage of each component in Examples 1-6:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com