Patents

Literature

212 results about "Comparative Tracking Index" patented technology

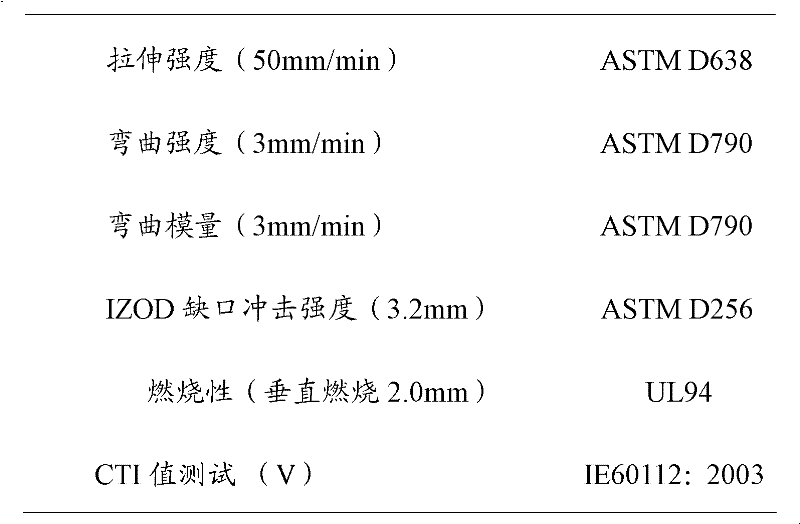

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Comparative Tracking Index or CTI is used to measure the electrical breakdown (tracking) properties of an insulating material. Tracking is an electrical breakdown on the surface of an insulating material wherein an initial exposure to heat chars the material, and the char is more conductive than the original insulator, producing more current flow, more heat, and eventually complete failure.

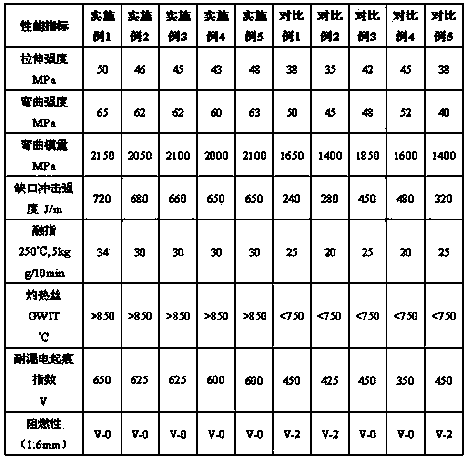

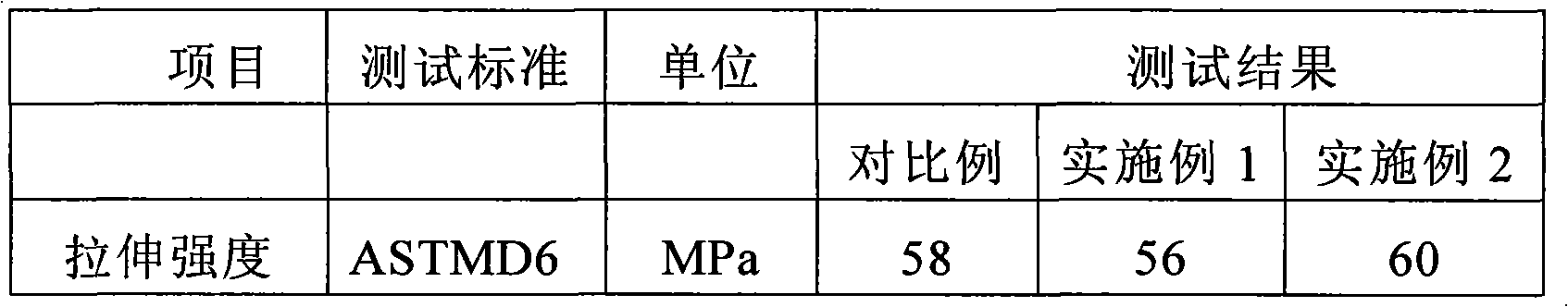

Polyamide composition with flame retardance and thermoplasticity

The invention discloses a polyamide composition with flame retardance and thermoplasticity. The polyamide composition with flame retardance and thermoplasticity comprises the following components in percentage by weight: 30-90% of thermoplastic polyamide resin, 5-40% of a brominated flame retardant, 0.5-15% of a flame-retardant synergist and 0-50% of a reinforcing material. According to the polyamide composition, the brominated flame retardant, the high-efficiency flame-retardant synergist (namely zinc borate) and organic silicon are added in polyamide resin, on the one hand, the polyamide composition can replace antimony trioxide which is a rare material and is limited to be exploited by the nation at present, limited strategic resources of the nation can be saved, and the cost is lowered; and on the other hand, the flame retardance, a CTI (comparative tracking index) value and GWIT (glow wire ignition temperature) of the polyamide composition can be improved greatly, and the safety guarantee is provided for the use of the flame-retardant polyamide product on electronic appliances with high requirements.

Owner:KINGFA SCI & TECH CO LTD +1

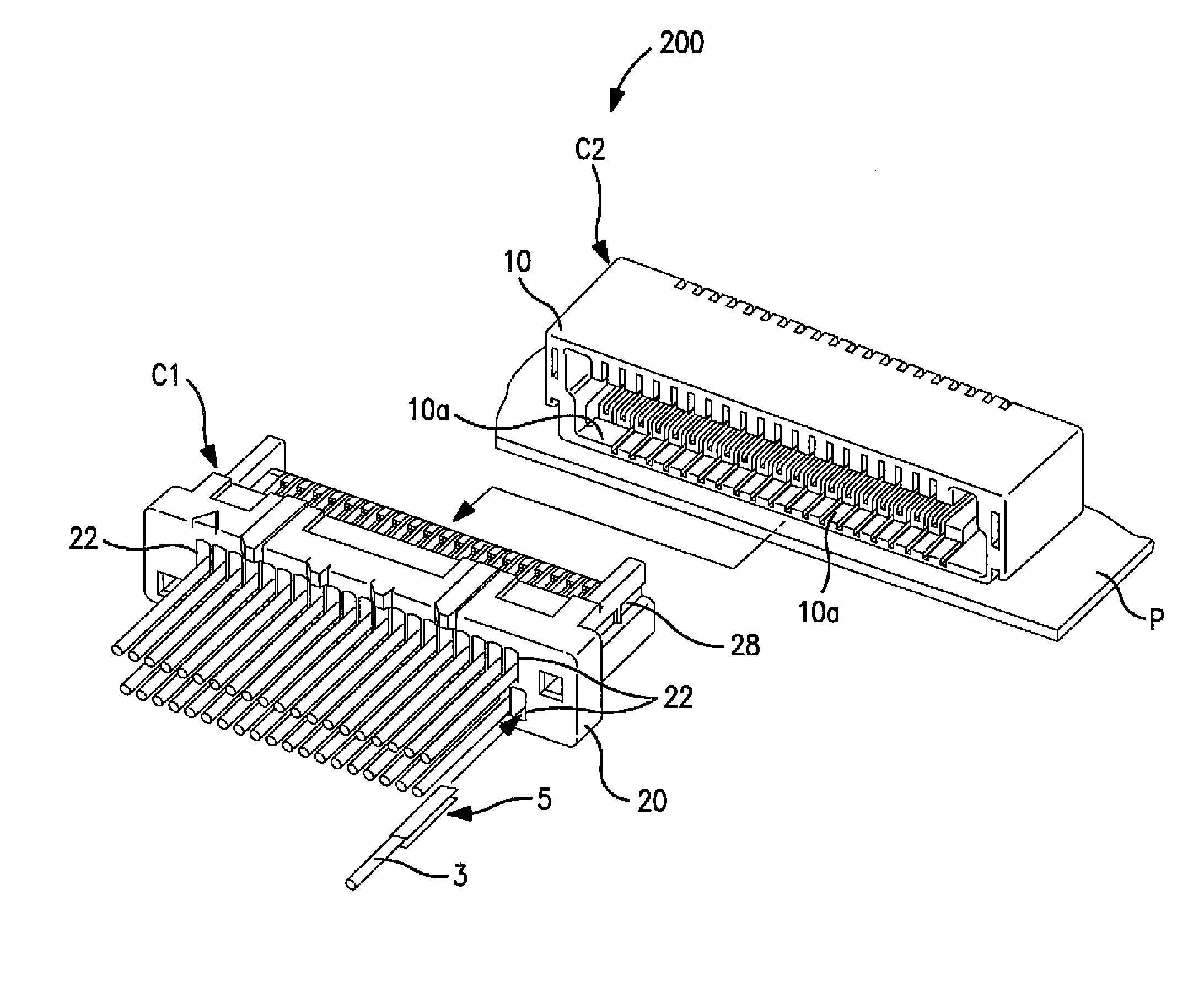

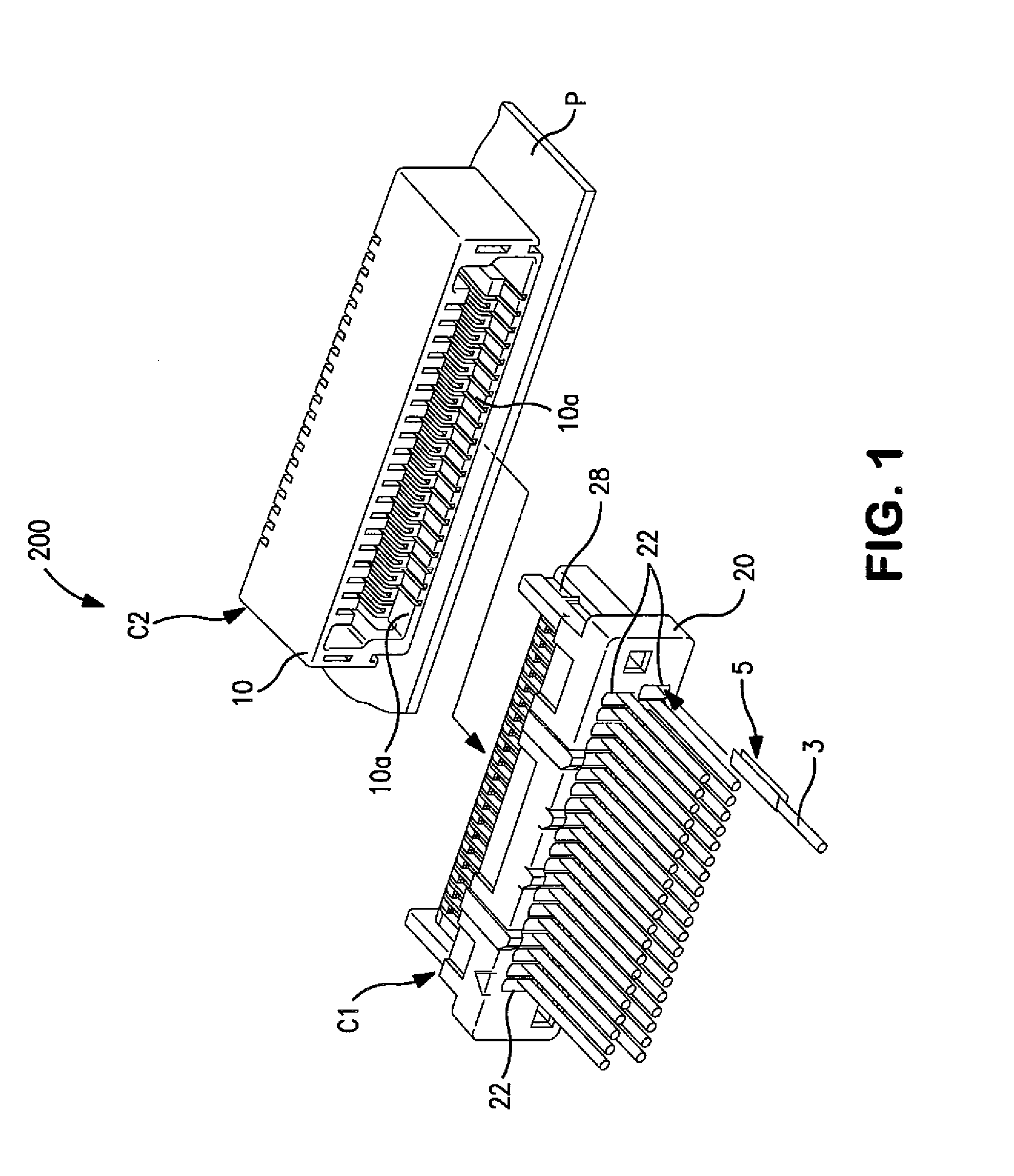

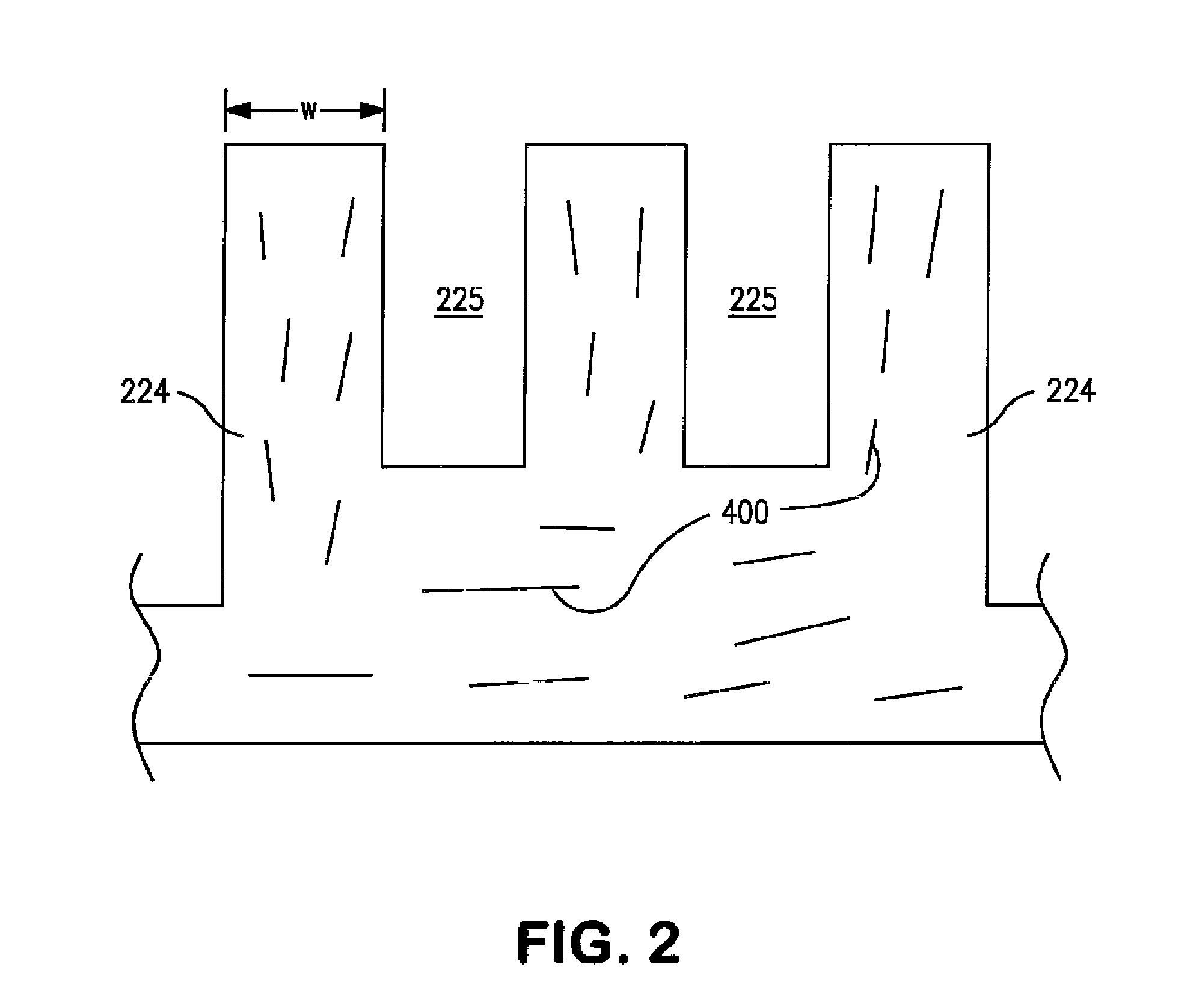

Liquid Crystalline Polymer Composition for High Voltage Electronic Components

InactiveUS20130123420A1Liquid crystal compositionsPlastic/resin/waxes insulatorsLiquid crystallinePolymeric surface

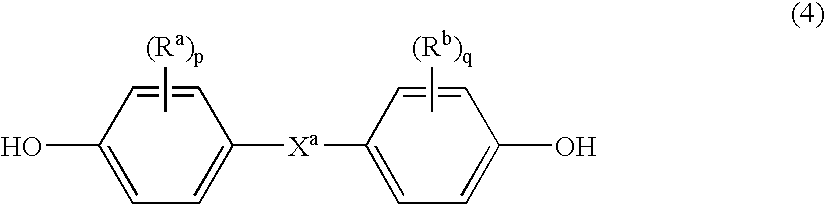

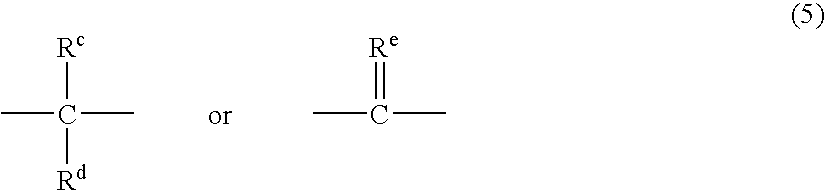

A liquid crystalline polymer composition having a relatively high comparative tracking index (“CTI”) is provided. The present inventors have discovered that high CTI values can be achieved through the use of inorganic particles in combination with a functional aromatic compound. While not fully understood, it is believed that the functional compound can react with the liquid crystalline polymer and create smaller degraded polymer chains. In combination with the inorganic particles, these smaller chains can potentially form insulated regions at the surface of the polymer that hinder the formation of conductive carbonaceous deposits during the tracking process, which could otherwise lead to failure during testing.

Owner:TICONA LLC

High-heat-resistance and high-CTI (Comparative Tracking Index) inflaming retarding polyamide composite material and production process thereof

The invention provides a high-heat-resistance and high-CTI (Comparative Tracking Index) inflaming retarding polyamide composite material, comprising the following components of a composite flame retardant, an inflaming retarding synergist, a compatilizer, an inorganic filler, an antioxidant, a lubricating agent and glass fibers. The high-heat-resistance and high-CTI inflaming retarding polyamide composite material disclosed by the invention can stably pass through a CTI value of 500 V, and has a higher heat-resistance temperature and better physical performances.

Owner:横店集团得邦工程塑料有限公司

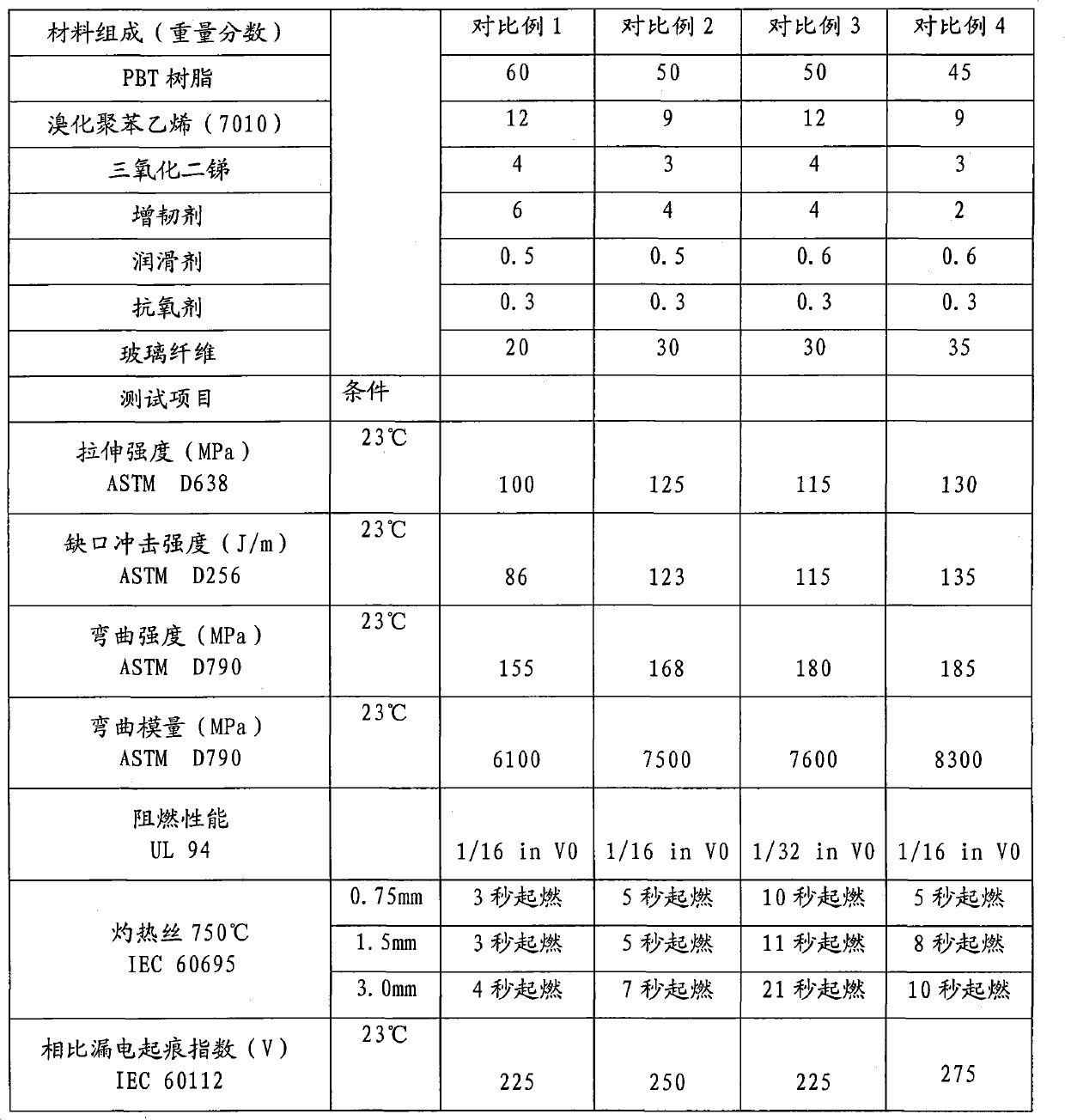

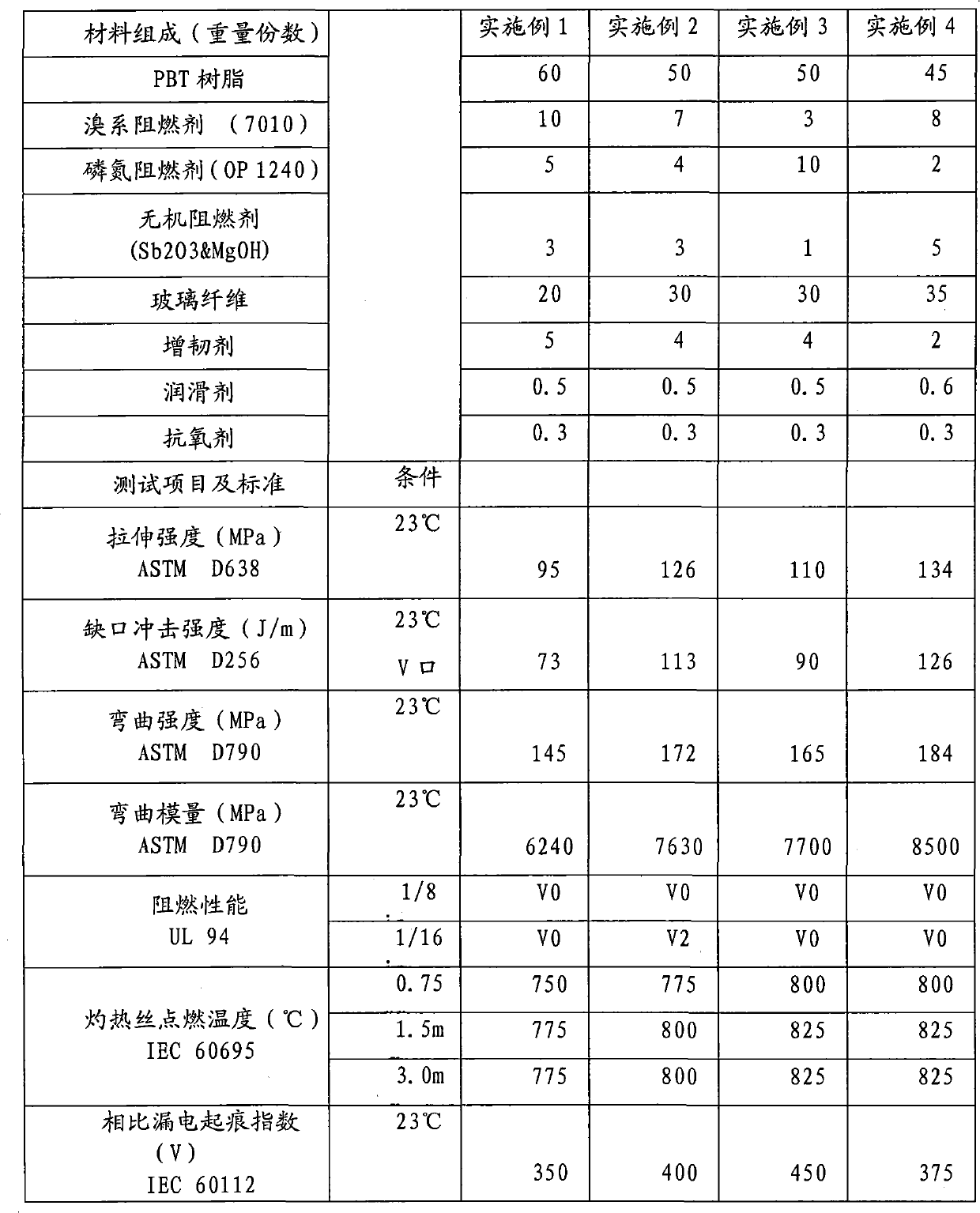

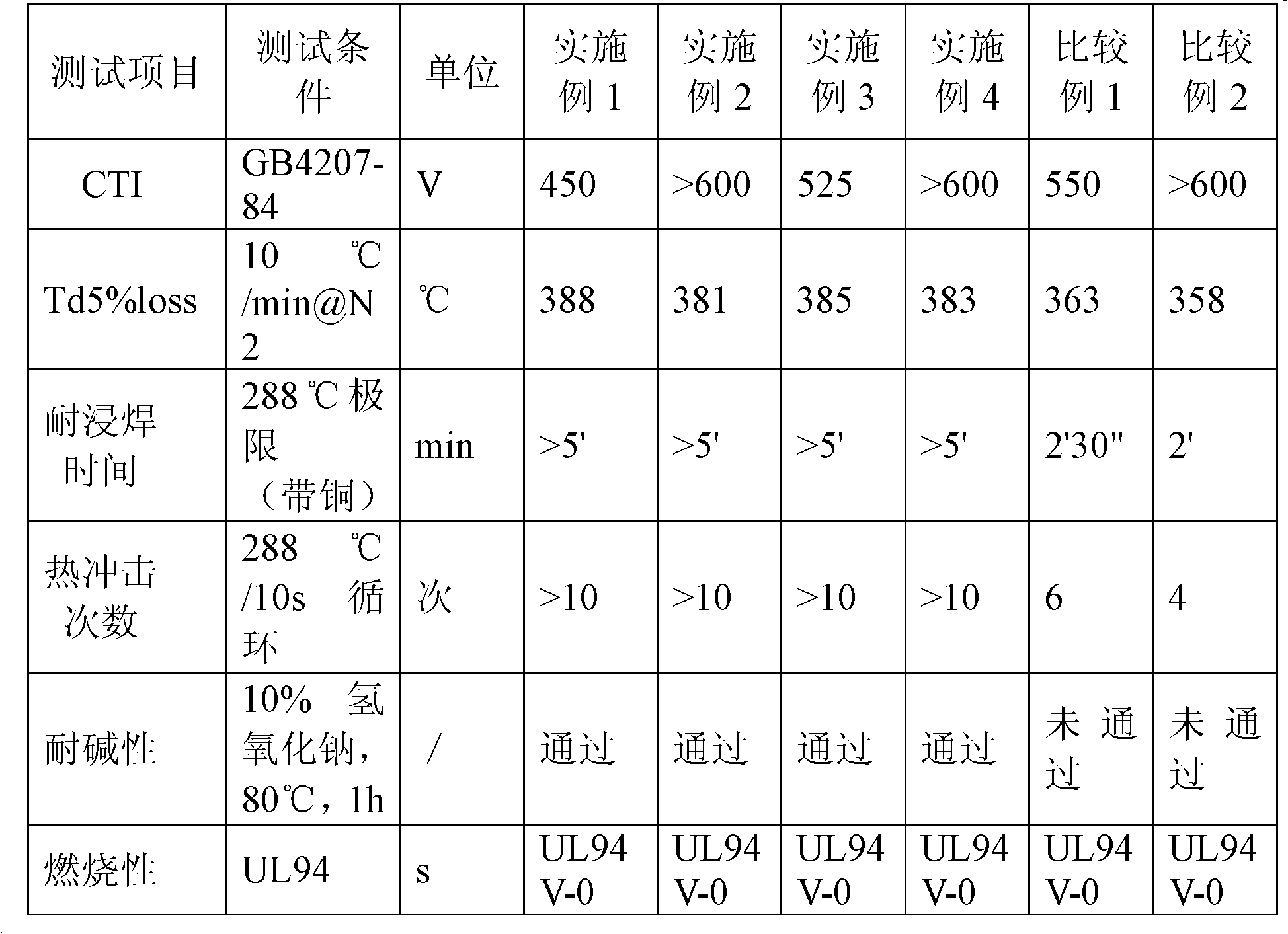

Flame-retardant enhanced PBT material and preparation method thereof

InactiveCN101817972ARaise the ignition temperatureHigh tracking indexComparative Tracking IndexAntioxidant

The invention discloses a flame-retardant enhanced PBT material and a preparation method thereof. The flame-retardant enhanced PBT material comprises the following components in percentage by weight: 45 to 60 percent of PBT resin, 3 to 10 percent of brominated flame retardant, 1 to 10 percent of phosphorus-nitrogen flame retardant, 1 to 5 percent of inorganic flame retardant, 2 to 5 percent of toughening agent, 20 to 35 percent of glass fiber, 0.3 to 1 percent of lubricating agent, and 0.1 to 0.6 percent of antioxidant. The flame-retardant enhanced PBT material has high ignition temperature of glowing filament, high comparative tracking index, and better mechanical property, and can be widely applied to the field of unattended electronic and electric products.

Owner:SHENZHEN KEJU NEW MATERIAL

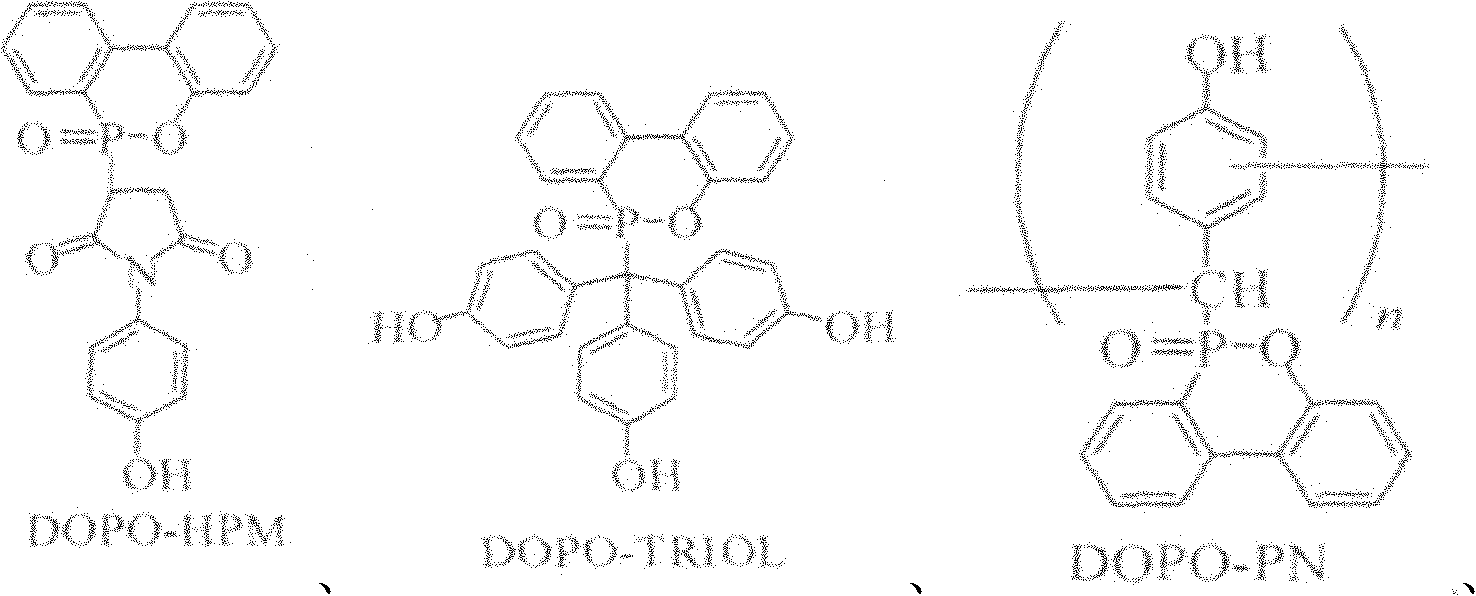

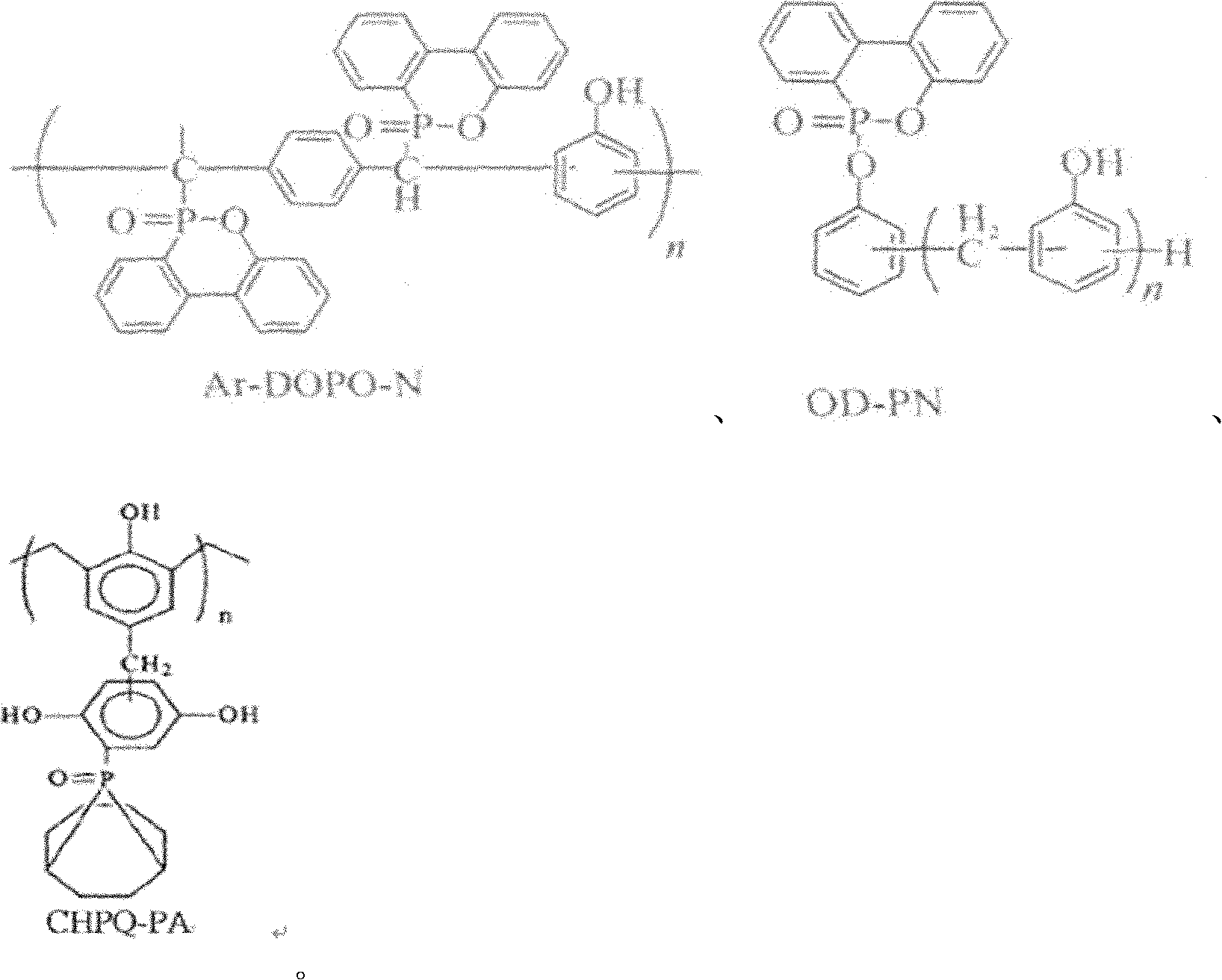

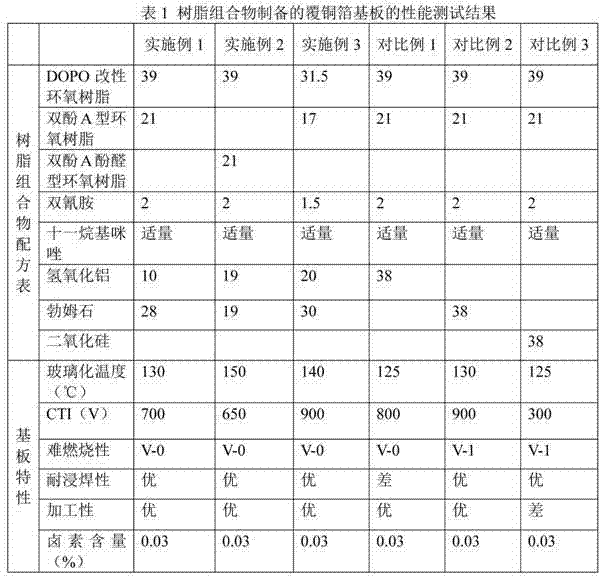

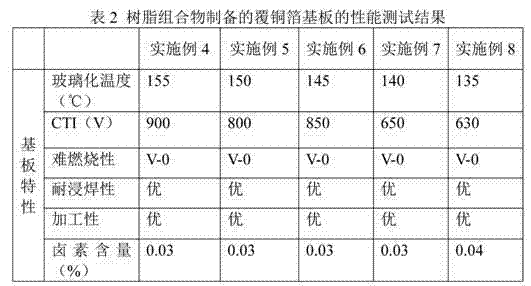

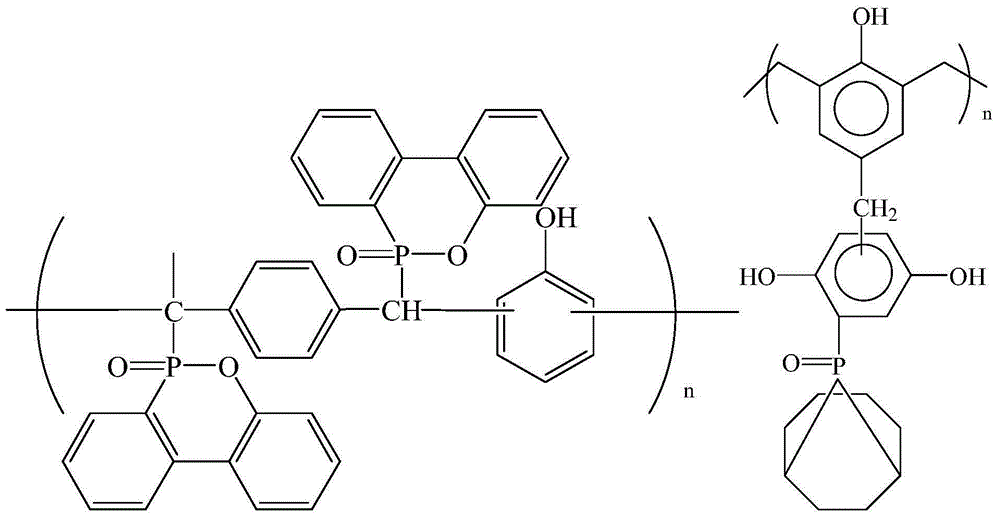

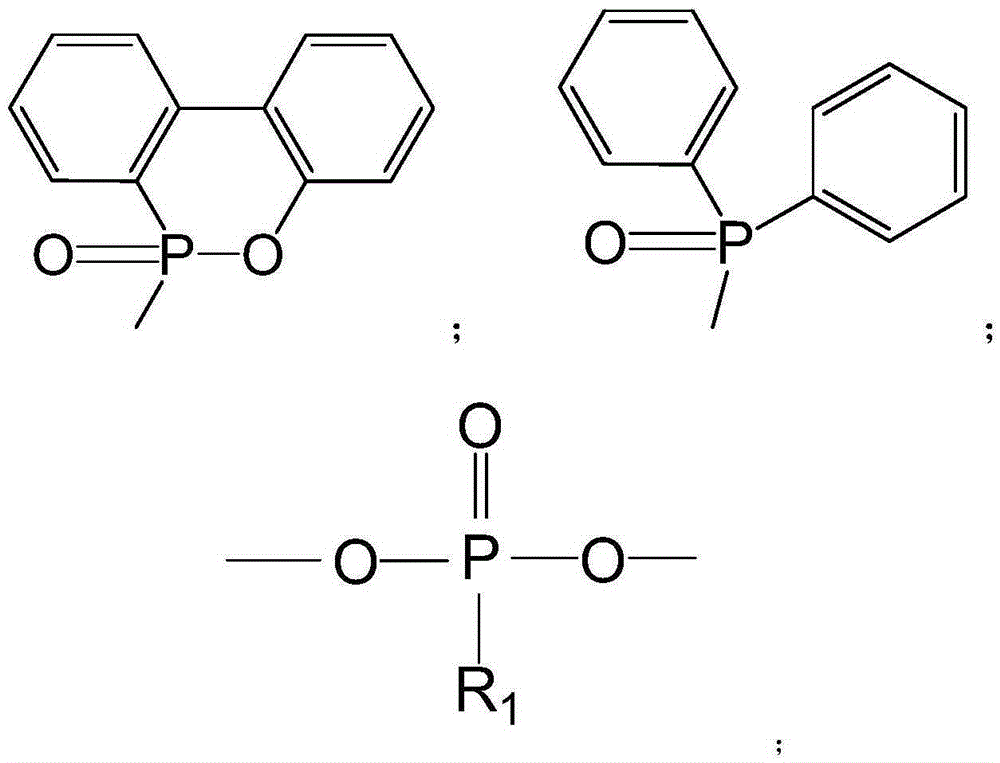

Halogen-free flame retardant epoxy resin composition and copper clad plate prepared from same

ActiveCN102093670AHigh tracking characteristicsHigh CTICircuit susbtrate materialsMetal layered productsOrganic solventComparative Tracking Index

The invention relates to a halogen-free flame retardant epoxy resin composition and a copper clad plate prepared from the same. The halogen-free flame retardant epoxy resin composition comprises bisphenol A epoxy resin, carboxyl-terminated butadiene acrylonitrile, phosphorous resin, nitrogen fire retardant, amine curing agent, curing accelerator, filler and organic solvent. The copper clad plate prepared from the halogen-free flame retardant epoxy resin composition comprises a halogen-free flame retardant epoxy resin composition layer arranged on one or both surfaces of the laminated plate, and a copper foil pressed on the halogen-free flame retardant epoxy resin composition layer, wherein the laminated plate comprises a plurality of bonded sheets, and the halogen-free flame retardant epoxy resin composition layer is formed by coating the halogen-free flame retardant epoxy resin composition. The halogen-free flame retardant epoxy resin composition provided by the invention has high tracking property. The copper clad plate prepared from the halogen-free flame retardant epoxy resin composition has high CTI (comparative tracking index), good fire resistance and other good overall properties, has good processing characteristics, avoids dried flower dry flowers, cloth mark exposure and defects, and is suitable for fabricating single-sided or double-sided printed circuit boards withmanufacturing requirement on CTI larger than or equal to 400 V.

Owner:GUANGDONG SHENGYI SCI TECH

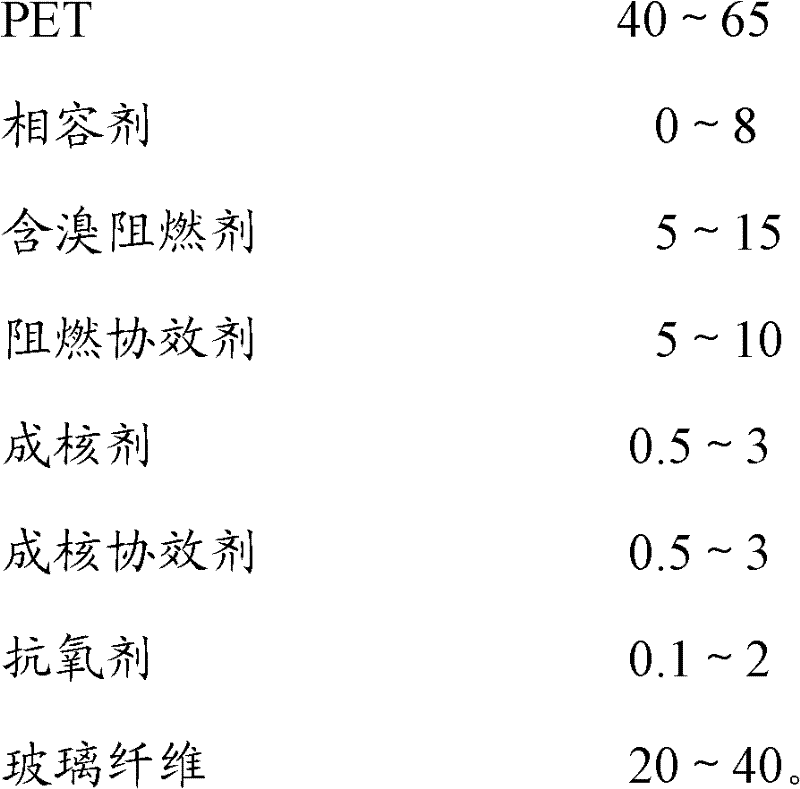

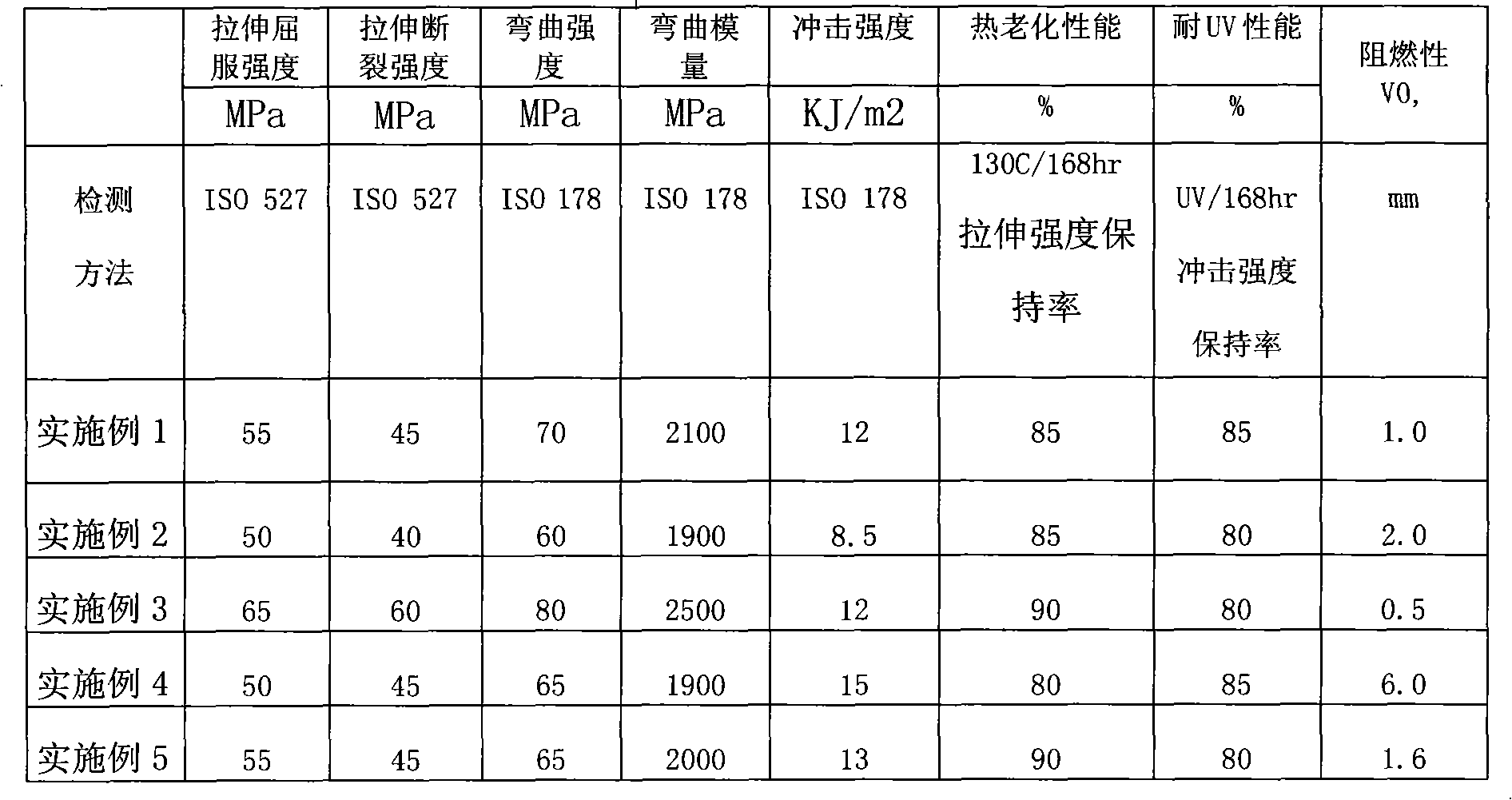

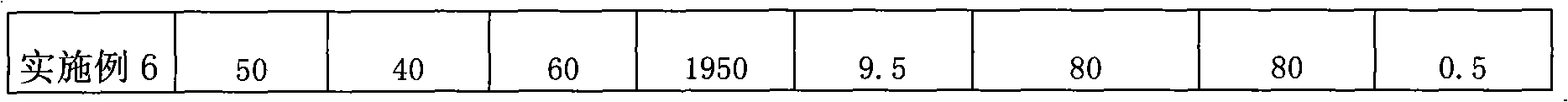

PET (polyethylene terephthalate) engineering plastic and preparation method and application thereof

InactiveCN102504500AEasy to stretchEasy to bendPolyethylene terephthalate glycolPolyethylene terephthalate

Owner:惠州市沃特新材料有限公司

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

High-CTI (comparative tracking index) halogen-free flame retardant resin composition for copper-clad laminate

The invention discloses a high-CTI (comparative tracking index) halogen-free flame retardant resin composition for a copper-clad laminate. The composition comprises the following components in parts by weight: 30-70 parts of polyepoxy resin, 1-5 part of curing agent, 0.01-1 parts of curing promoter, and 20-60 parts of filler. The resin composition disclosed by the invention remains high heat resistance while being endued with a high CTI value. The resin composition disclosed by the invention not only contains phosphorus epoxy resin, but also is added with some tough epoxy resins, so that the processing characteristics are greatly improved. The copper-clad laminate fabricated with the resin composition disclosed by the invention has the characteristics of high heat resistance, high CTI value, no halogen, good processing characteristics and the like.

Owner:无锡宏仁电子材料科技有限公司

Flame-retardant non-reinforced nylon with high glow wire and high CTI (comparative tracking index) value, and preparation method thereof

InactiveCN103319885AEasy to processGood technical applicabilityComparative Tracking IndexMechanical property

The invention relates to the technical field of a high polymer material, and discloses a flame-retardant non-reinforced nylon with a high glow wire and a high CTI (comparative tracking index) value. The flame-retardant non-reinforced nylon comprises the following components in parts by weight: 30-50 parts of PA6, 25-35 parts of PA66, 18-28 parts of fire retardant, 3-6 parts of flame retardant synergist, 5-10 parts of halogen-free flame retardant, 2-4 parts of flexibilizer, 0.1-0.3 part of oxidant, and 0.3-0.6 part of lubricating agent. The invention also discloses a preparation method of the nylon. By adopting the flame-retardant non-reinforced nylon with the high glow wire and the high CTI value disclosed by the invention, on the one hand, the flame retardant property of the nylon is enhanced; and meanwhile, the glow wire initiation temperature (GWIT) and the comparative tracking index (CTI) are improved; and on the other hand, the mechanical property and the processability of the nylon are not damaged or reduced.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

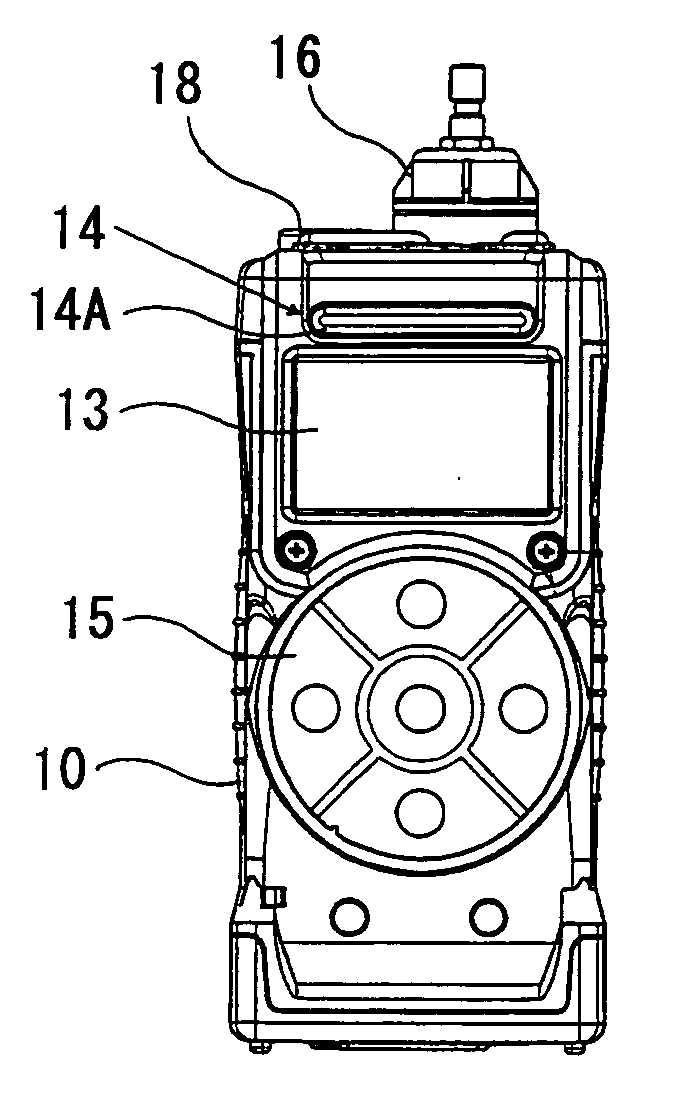

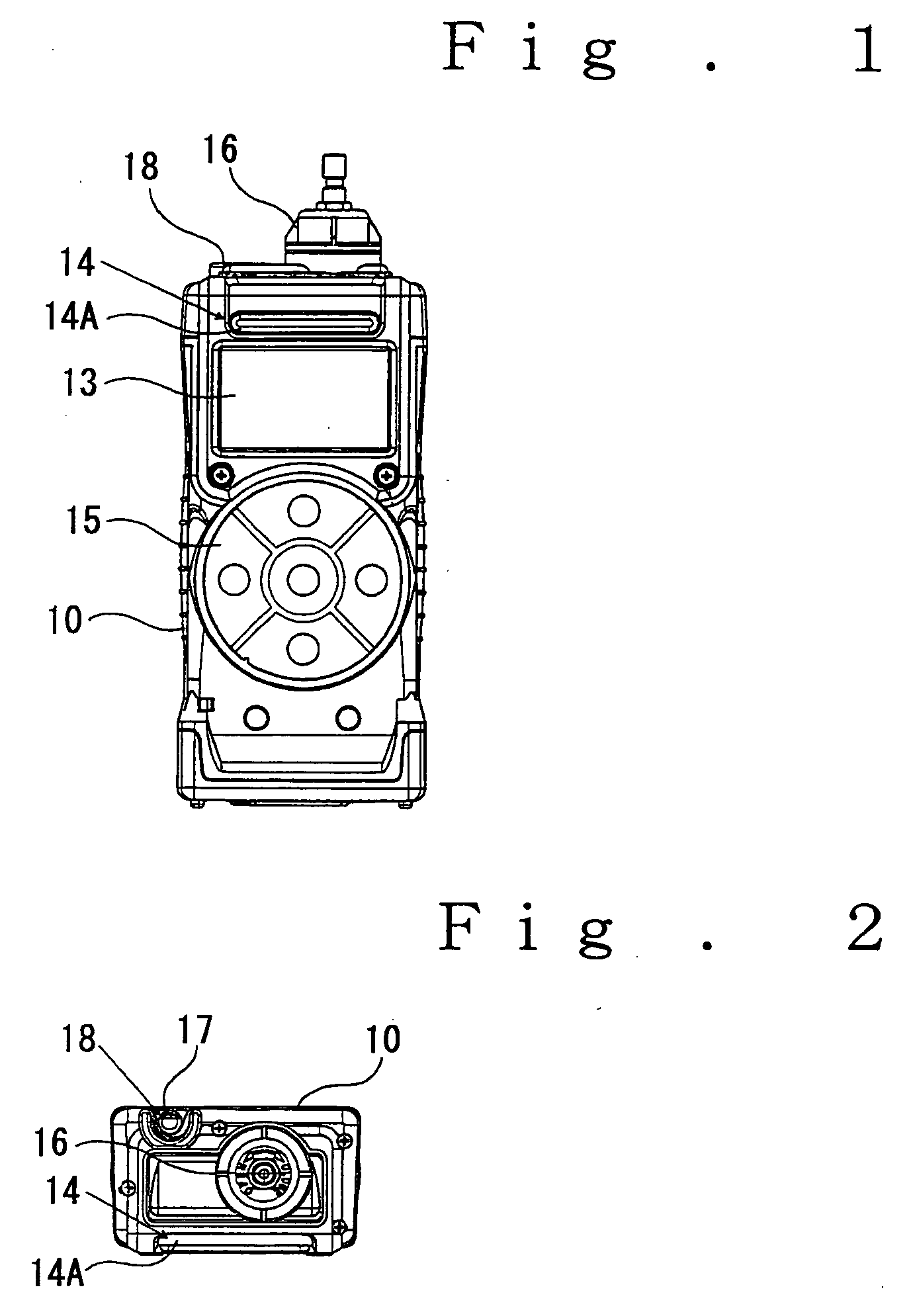

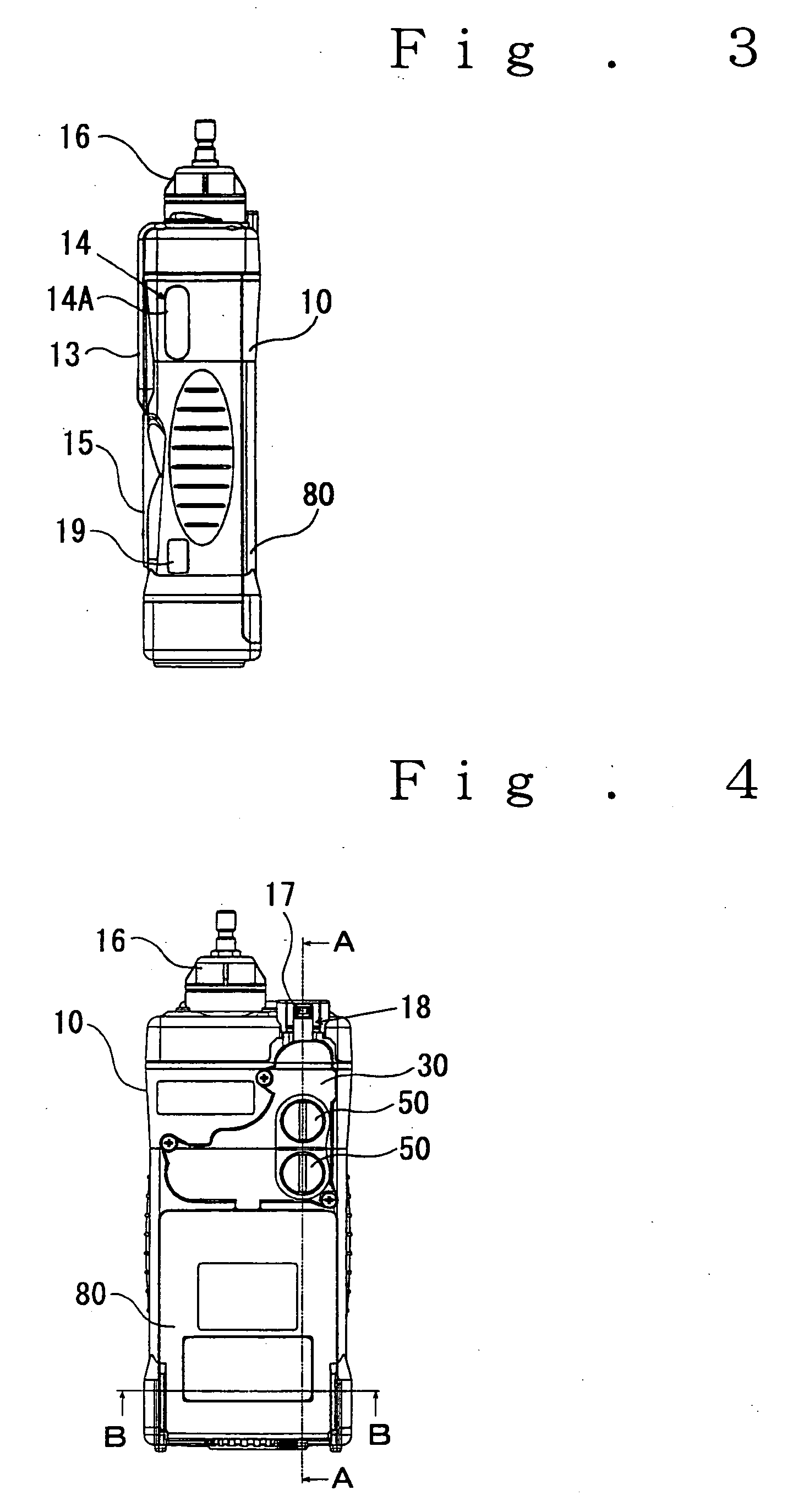

Explosion-proof portable gas detector

ActiveUS20060010974A1Easy to makeEasy to useFluid pressure measurementUsing mechanical meansElectrical resistance and conductanceCountermeasure

The invention provides an explosion-proof portable gas detector that is easy to be fabricated as a small-sized one handy to carry and high in convenience for use, and has explosion-proofness sufficient in a countermeasure against static electricity and high in reliability. The explosion-proof portable gas detector has at least gas sensors, a signal processing circuit, a display mechanism and a power source part within a housing in the form of a slim and flat box holdable by grasping with a hand. The whole or a part of the housing is formed of a static charge-controlling resin material having an insulating resistance value of at most 1 GΩ and a comparative tracking index of at least 90 V.

Owner:RIKEN KEIKI KK

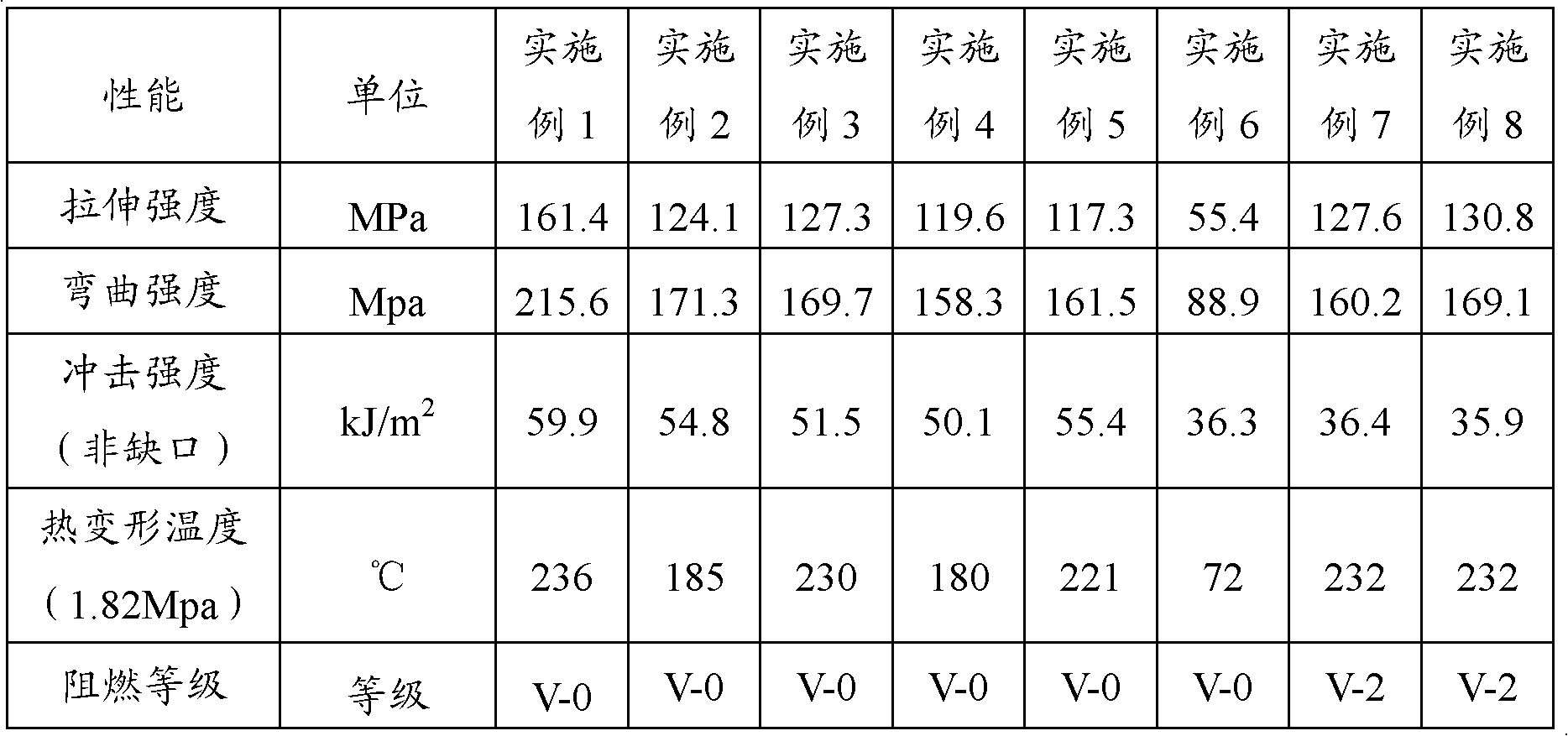

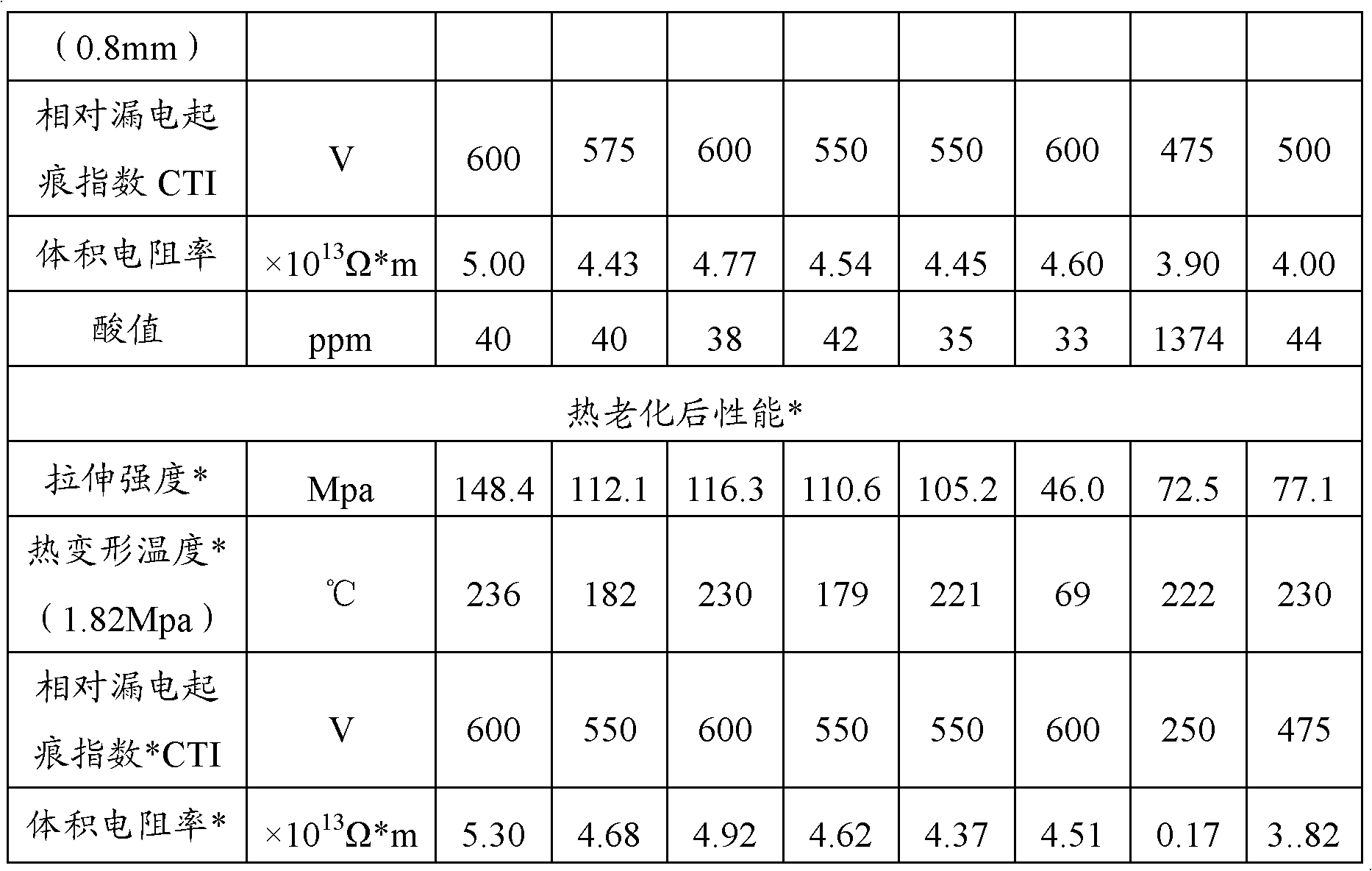

Low-acid-separation red phosphorus inflaming retarding reinforced polyamide material as well as preparation method and application thereof

The invention discloses a low-acid-separation red phosphorus inflaming retarding reinforced polyamide material which is prepared from the following raw materials by weight: 40%-65% of polyamide, 5%-25% of red phosphorus fire retardant, 1%-2% of anti-separation auxiliary agent, 0.5%-5.0% of heat stabilizer, 0.5%-2% of lubricating agent and 15%-40% reinforcing component. According to the invention, acid separation caused by the presence of red phosphorus can be greatly reduced; the low-acid-separation red phosphorus inflaming retarding reinforced polyamide material has good thermal properties such as heat resistance, ageing resistance and the like, good mechanical properties such as high strength and the like, and good electrical properties such as high CTI (Comparative Tracking Index), and is particularly suitable for preparation of electronic and electric appliances, especially for electronic products which are used under the high-temperature high-humidity rigorous conductions. The invention also discloses a preparation method of the low-acid-separation red phosphorus inflaming retarding reinforced polyamide material. The preparation method is simple, has good controllability and is easy to industrially produce; and by using the preparation method, the separation of acid in the preparation process can be reduced.

Owner:CGN JUNER NEW MATERIALS +1

Halogen-free and flame-retardant nylon master batch with high CTI (Comparative Tracking Index) value and preparation method thereof

The invention relates to halogen-free and flame-retardant nylon master batch with a high CTI (Comparative Tracking Index) value and a preparation method thereof. The performance of nylon is influenced by the conventional nylon flame retardant. The master batch is a mixture. Every 100 parts by weight of master batch contain 40-75 parts by weight of main a flame retardant, 1-20 parts by weight of a flame-retardant synergist, 20-40 parts by weight of carrier resin, 0.4-2 parts by weight of an antioxidant, 1-5 parts by weight of a CTI improver, 0.5-3 parts by weight of a coupling agent and 0.5-5 parts of a dispersing agent. The method comprises the following steps of: uniformly stirring and mixing the raw materials proportionally, lifting, and drying at the temperature of 60-100 DEG C in vacuum to obtain a crude material; and melting, extruding and granulating the crude material through a dual-screw extruder to obtain a finished master batch. The master batch provided by the invention can be directly added into a nylon substrate proportionally, so that the flame retardance of the nylon material is improved efficiently, harmful gas is not emitted during burning, and a CTI value of over 500V is obtained; and the preparation method has the advantages of easiness for operating, low energy consumption and easiness for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Halogen-free enhanced flame-retardant high-CTI value PA6 material for circuit breaker and preparation method thereof

The invention discloses a halogen-free enhanced flame-retardant high-comparative tracking index (CTI) value polyamide6 (PA6) material for a circuit breaker and a preparation method thereof, and relates to a thermoplastic polymer fiber enhanced flame-retardant material and a preparation method thereof. The material solves the problem that the conventional halogen-free enhanced flame-retardant PA6 has low compatibility, low comparative tracking index (CTI value), poor mechanical property, low heat resistance and unqualified 960-degree glowing filament. The material is prepared from the following components: PA6 resin, glass fibers, a silane coupling agent, a complex halogen-free flame retardant, an antioxidant, a weather-resistant agent and a processing agent. The method for preparing the material comprises the following steps of: performing combinatorial optimization on an extruder screw, uniformly mixing the PA6 resin, the complex halogen-free flame retardant, the antioxidant and the processing agent and putting into a double-screw extruder; quantitatively adding the glass fibers, fully melting, compounding, extruding through a machine head, bracing wires, cooling, granulating and drying in the double-screw extruder; and finally, packaging. The product has the advantages of high CTI value, good flame retardant property, excellent mechanical property, high heat resistance and good performance of the glowing filament, and the preparation method is simple in process.

Owner:福建奥峰科技有限公司

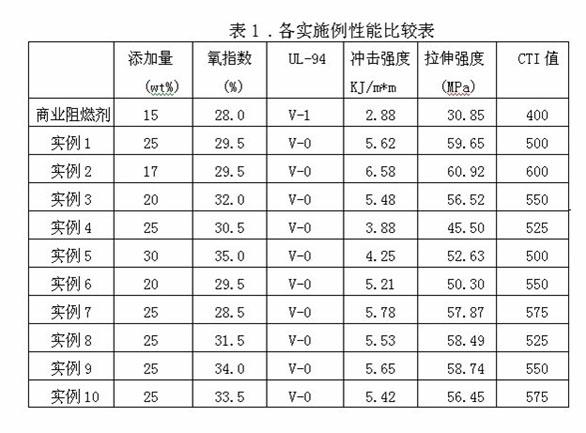

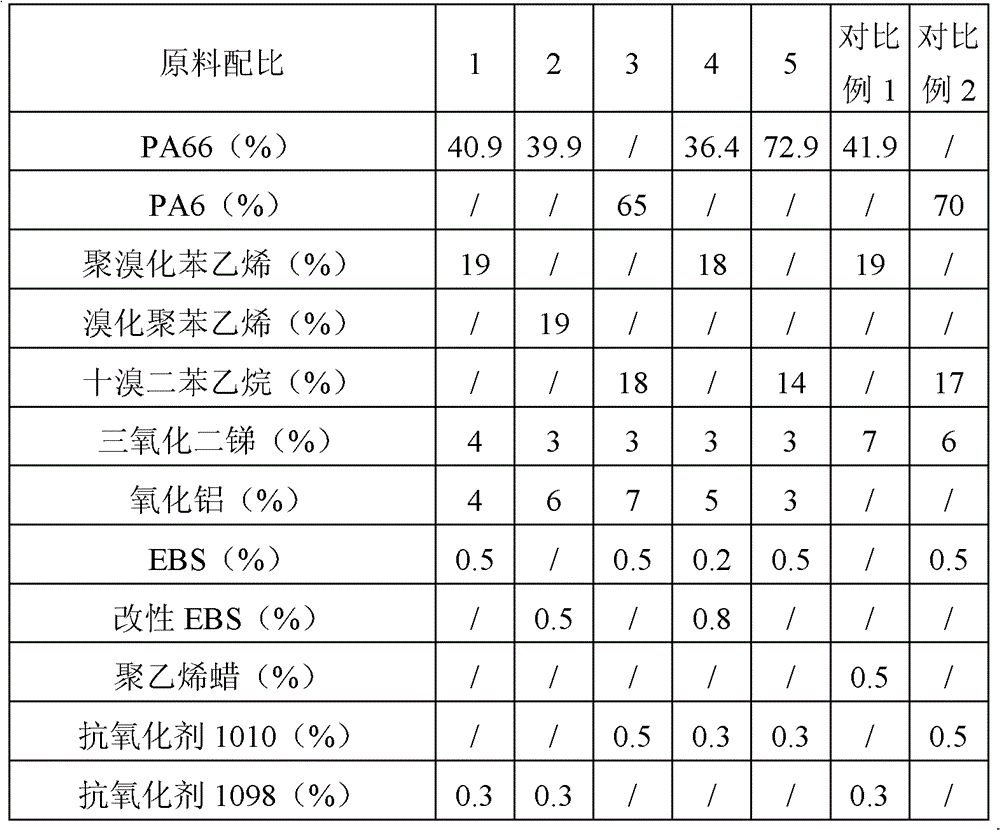

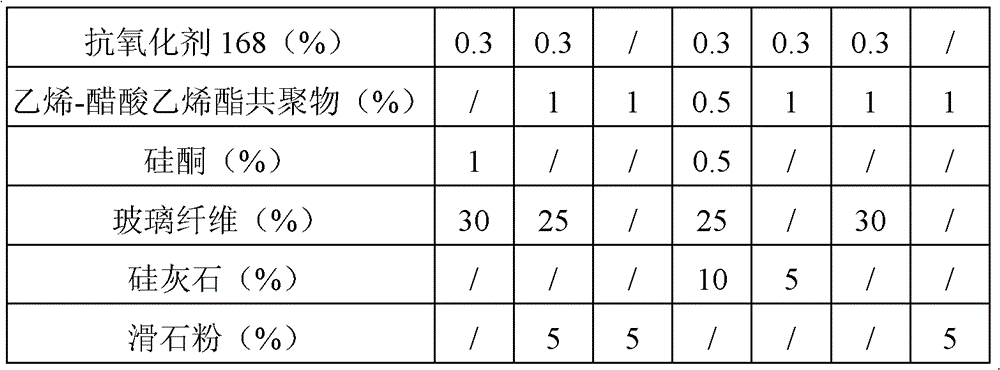

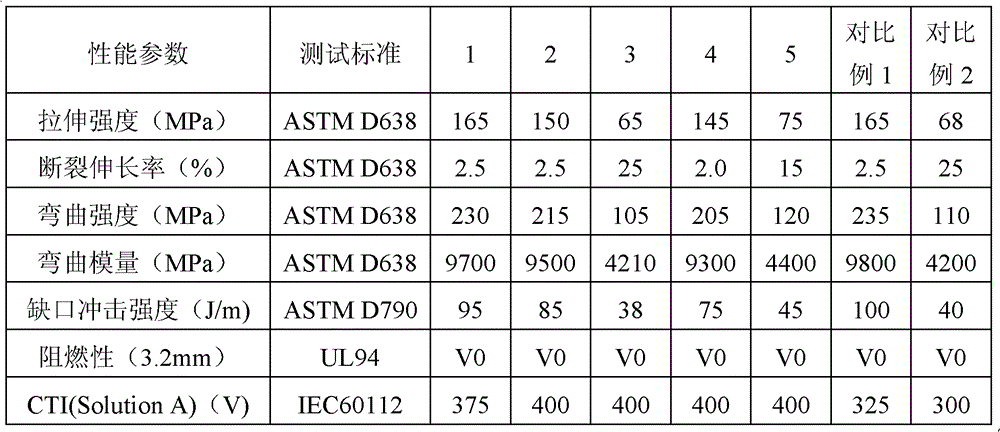

Flame-retardant nylon composite and preparation method and application thereof

The invention discloses a flame-retardant nylon composite, which comprises the following components in percentage by weight: 35 to 75 percent of polyamide, 5 to 25 percent of halogen flame retardant, 2 to 10 percent of flame-retardant synergist, 0.1 to 3 percent of lubricant, 0.1 to 1 percent of antioxidant, 0.3 to 3 percent of surface modifying agent and 5 to 35 percent of enhancement modifying agent, wherein the flame-retardant synergist consists of antimonous oxide and aluminum oxide in a weight ratio of (3:7)-(1:1). The invention also discloses a preparation method for the flame-retardant nylon composite and application of the flame-retardant nylon composite. According to the preparation method, the using amount of the antimony sesquioxide is reduced effectively, and a comparative tracking index (CTI) value of the prepared flame-retardant nylon composite can be improved by 50 to 100 V. The flame-retardant nylon composite can be prepared by the conventional equipment and the conventional method, manufacturing equipment is not needed to be transformed, and industrial production is easy to realize.

Owner:上海耐特复合材料制品有限公司

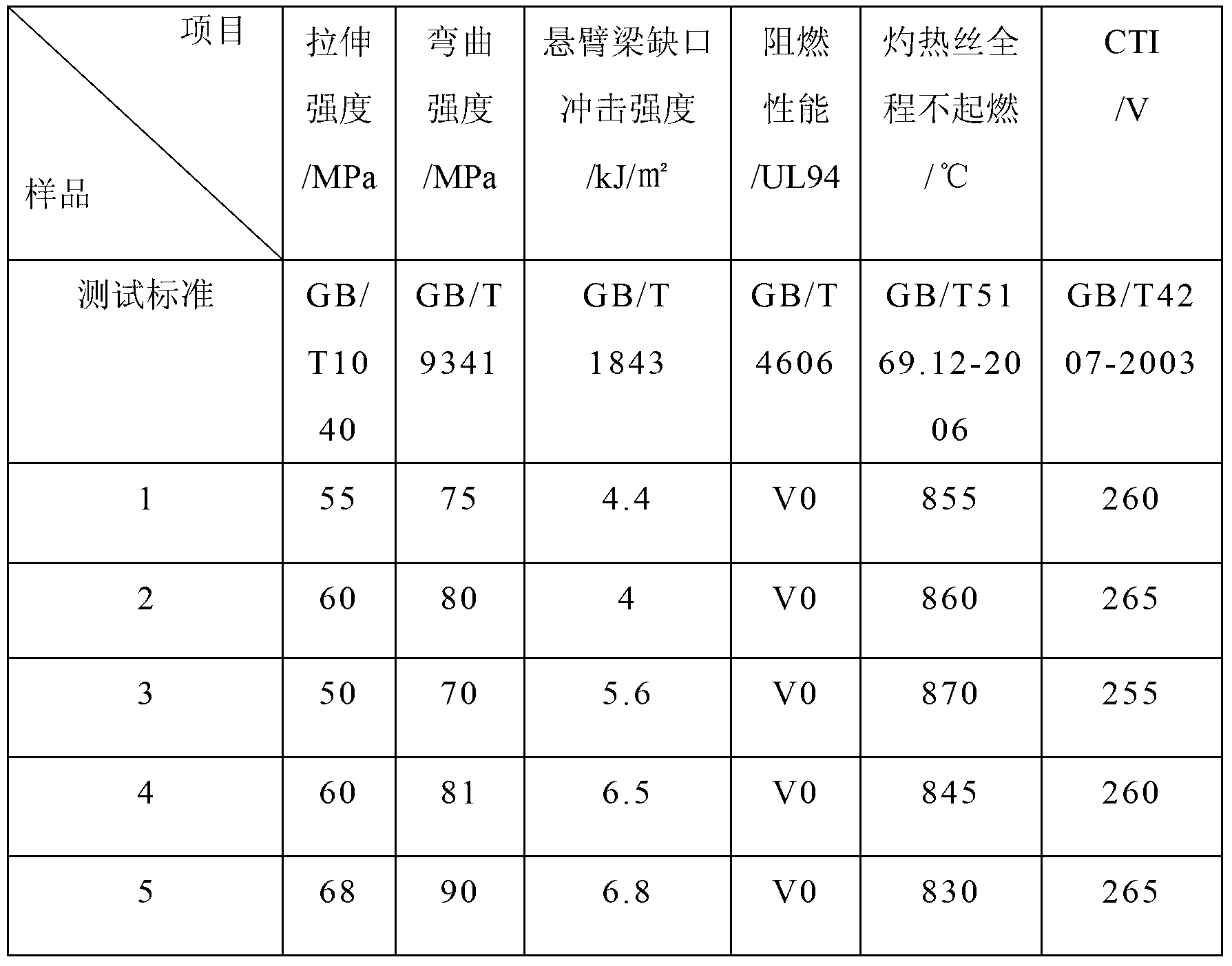

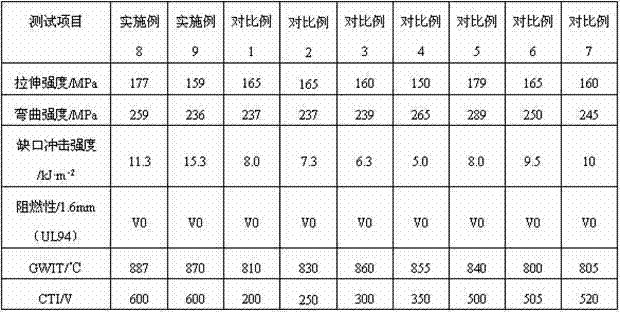

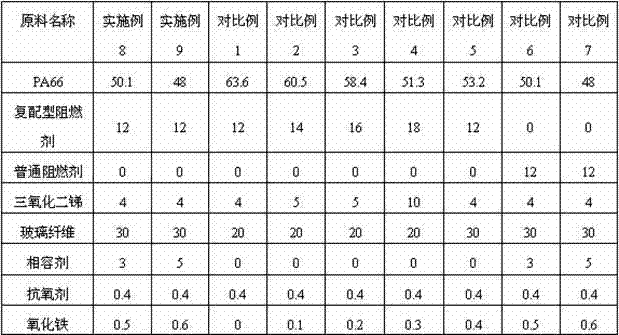

Halogen-free flame retardant continuous long glass fiber reinforced polyamide 66 composite material and preparation method thereof

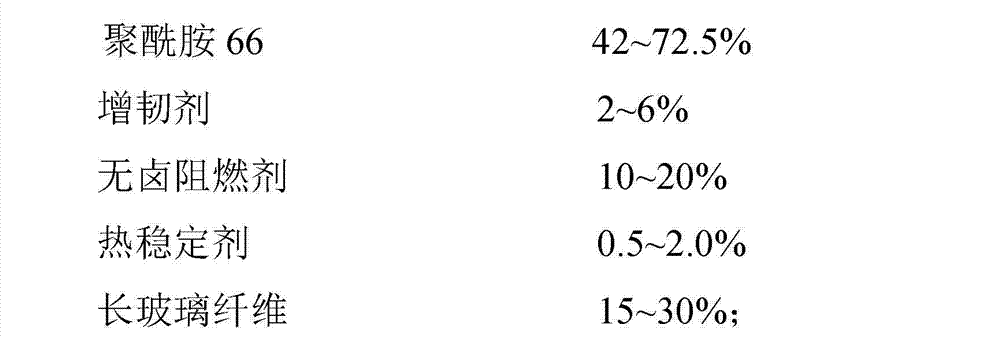

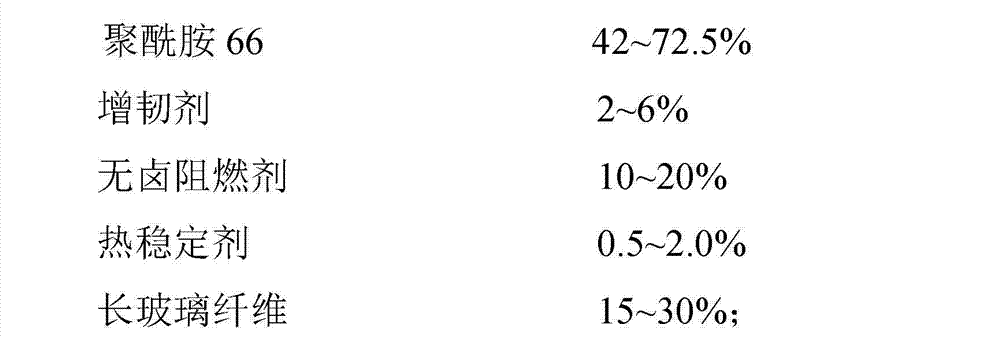

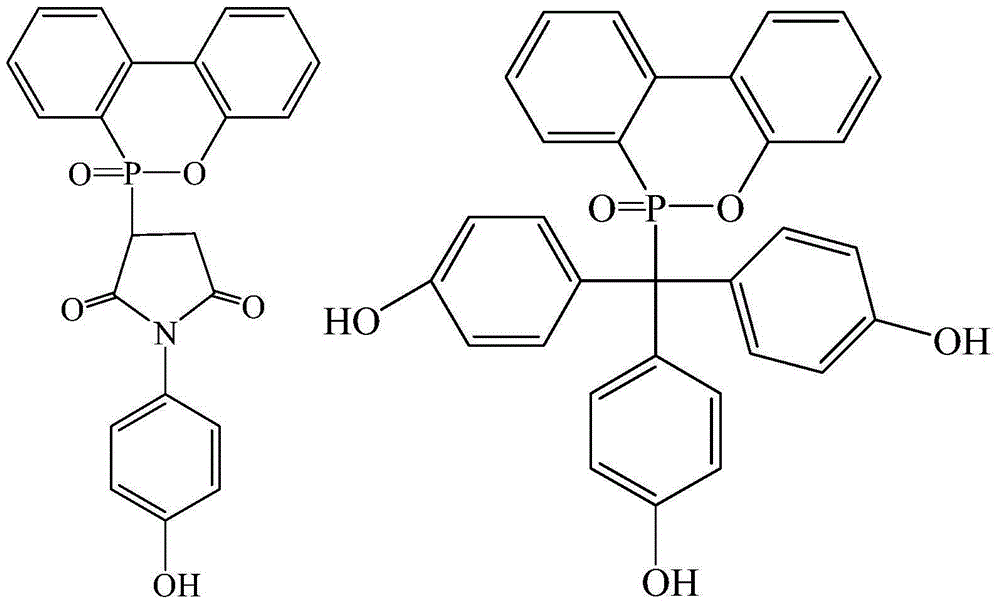

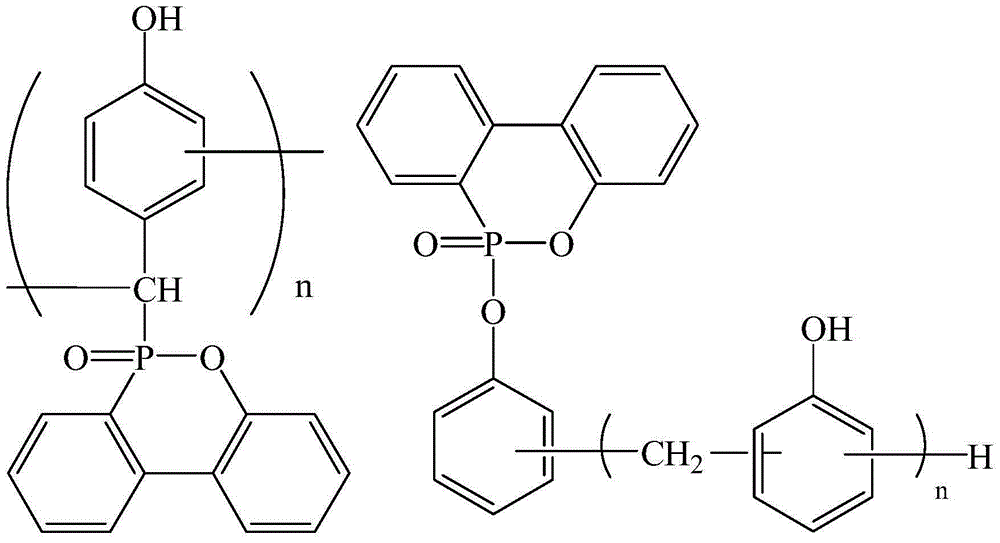

The invention discloses a halogen-free flame retardant continuous long glass fiber reinforced polyamide 66 composite material which comprises the following ingredients by weight percent: 42-72.5% of polyamide 66, 2-6% of flexibilizer, 10-20% of halogen-free flame retardant, 0.5-2.0% of heat stabilizer and 15-30% of long glass fiber, wherein the relative viscosity of the polyamide 66 is 2.0-3.0; and the long glass fiber is an LFT (Long Fiber Thermoplastic) alkali-free continuous long glass fiber specially used for polyamide 66. The prepared material has high fluidity, excellent heat resistance, high rigidity, high impact, high size stability, excellent flame retardant property and high CTI (comparative tracking index) value; through detection, the tensile strength of the material is not less than 150MPa, the flexural modulus is not less than 7000MPa, the notch impact strength is not less than 15KJ / m<2>, the heat distortion temperature (1.80MPa) is not less than 250 DEG C, the flame retardant grade is UL94 1.6mmV-0, and the CTI value is not less than 500V; and moreover, the defect in halogen-free flame retardant high temperature decomposition is solved by using a technique of high-low-temperature double-melting body infiltration tank serial connection.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

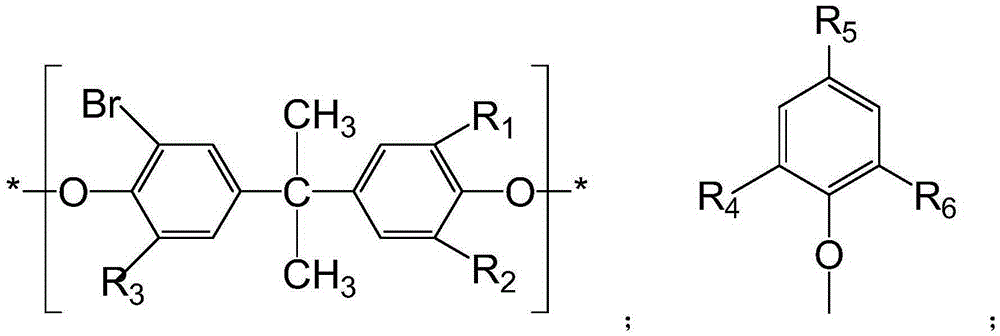

Epoxy resin composition for copper-clad plate and application thereof

ActiveCN105175995AImproved tracking indexEffective cost controlSynthetic resin layered productsPrinted circuit aspectsPolymer scienceHalogen

The present invention relates to an epoxy resin composition for copper-clad plate and application thereof. The epoxy resin composition can be used for preparing a prepreg and a copper clad laminate. The composition uses brominated bisphenol A and phenolic aldehyde containig phosphorus as a bromine source and a phosphorus source respectively; and the ratio of the two in the epoxy resin is adjusted to control the bromine content at 5-12%, phosphorus content at 0.2-1.5%; and the flame resistance reaches up to grade UL94 V-0. The prepreg and laminate produced by the epoxy resin composition not only has reduced halogen content and improved heat resistance, but also gains improved pressure resistance of substrate, low moisture absorption, good adhesion, reactivity and workability, realizes comparative tracking index higher than 600V, and greatly reduces the cost of production.

Owner:GUANGDONG SHENGYI SCI TECH

High-glowing-filament high-CTI (comparative tracking index) super-tough flame-retardant PBT/PC (polybutylene terephthalate/polycarbonate) alloy material and preparation method thereof

The invention relates to a high-glowing-filament high-CTI (comparative tracking index) super-tough flame-retardant PBT / PC (polybutylene terephthalate / polycarbonate) alloy material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 15-70 parts of PBT, 10-25 parts of PC, 10-25 parts of compound toughener, 5-20 parts of bromine flame retardant, 3-10 parts of phosphorus-nitrogen flame retardant, 2-5 parts of inorganic flame-retardant synergistic agent, 0.1-0.5 part of ester exchange inhibitor, 0.1-0.5 part of anti-dripping agent PTFE (polytetrafluoroethylene), 0.1-0.5 part of lubricant and 0.1-0.5 part of antioxidant. The PBT / PC alloy material has excellent comprehensive properties; and the ASTM (American Society for Testing and Materials) notch impact strength is greater than 600 J / m, the flame retardancy reaches UL94V-0, the glowing filament temperature GWIT is greater than 850 DEG C, and the CTI is greater than 600V, thereby greatly widening the application range of the PBT / PC alloy material.

Owner:上海日之升科技有限公司

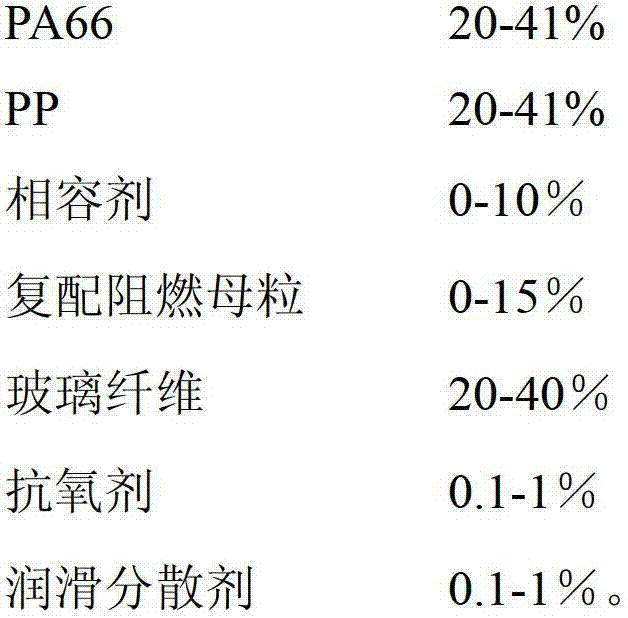

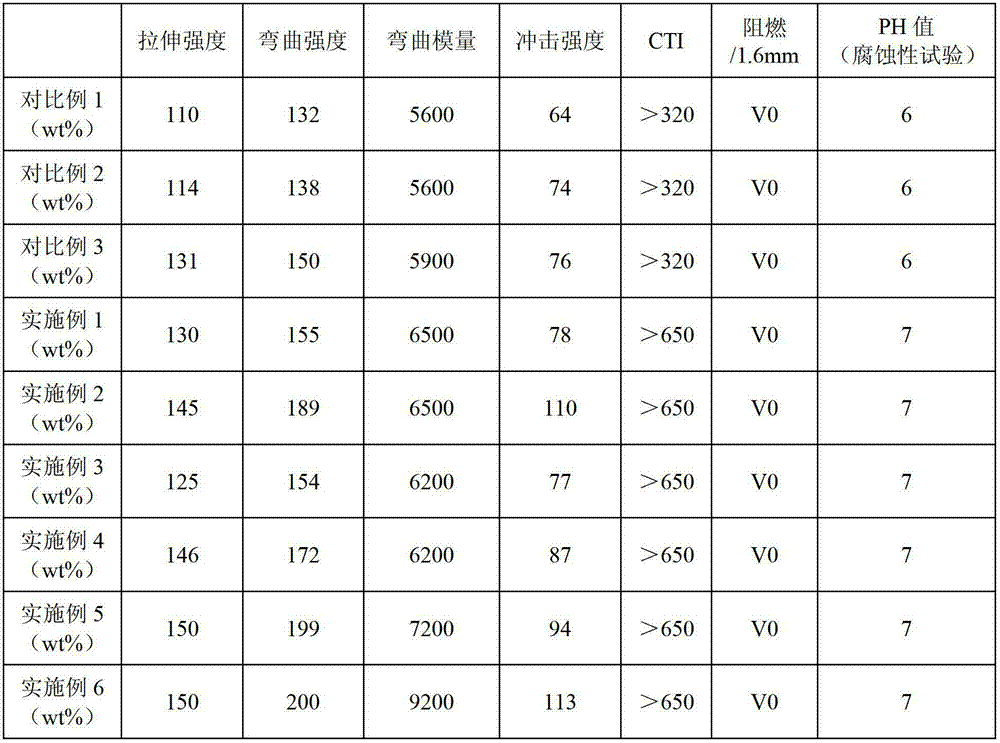

Flame-retardant glass fiber reinforced PA (polyamide) 66/PP (propene polymer) alloy composition and preparation method thereof

The invention relates to a flame-retardant glass fiber reinforced PA (polyamide) 66 / PP (propene polymer) alloy composition and a preparation method thereof. Components of the alloy composition includes, by weight, 20-41% of PA66, 20-41% of PP, 0-10% of compatilizer, 0-15% of compounded flame-retardant masterbatches, 20-40% of glass fibers, 0.1-1% of antioxidant and 0.1-1% of lubricating dispersant. The preparation method of the flame-retardant glass fiber reinforced PA66 / PP alloy composition includes the following steps of weighing the components according to the proportion to place into a high-mixing machine for mixing for 2-5 minutes, discharging for extruding and pelleting by a double-screw extruder, wherein the processing temperature ranges from 225 DEG C to 245 DEG C, and revolution of screws ranges from 30Hz to 40Hz. Compared with the prior art, the flame-retardant glass fiber reinforced PA66 / PP alloy composition has the advantages of high CTI (comparative tracking index) value, low precipitation of flame retardant, no halogen, environment-friendliness and balanced comprehensive performance, and can be widely applied to the fields of electronic appliances, including contactors, leakage protector, shells of breakers and the like.

Owner:SHANGHAI SUNNY

Polyester, polycarbonate and polyamide blends and articles having enhanced balance of glow wire ignition temperature, comparative tracking index, and flame retardant properties

The invention relates to a molding composition containing: (a) a polycarbonate component; (b) a polyester component; (c) a polyamide component; (c) a halogenated flame retarding component; and (d) a carboxy reactive component. The composition exhibits excellent properties that are highly useful in applications such as electronic components. The composition may also contain other components, such as impact modifiers. The invention also relates to articles made from the composition as well as methods of making and using the composition.

Owner:SABIC INNOVATIVE PLASTICS IP BV

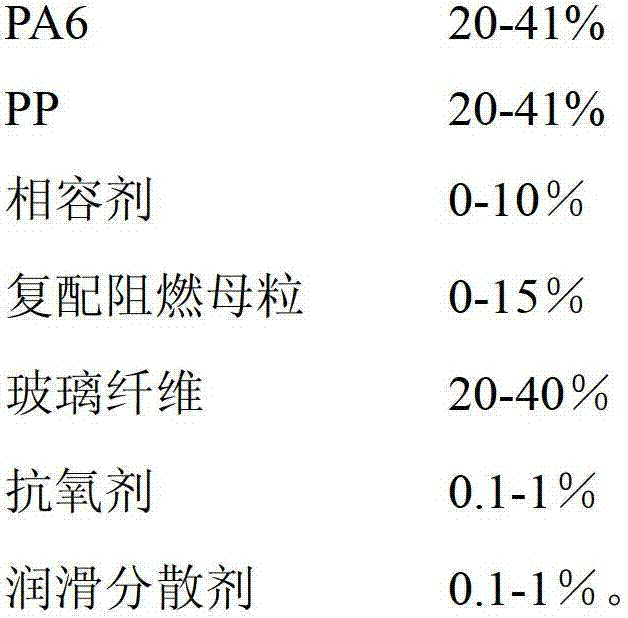

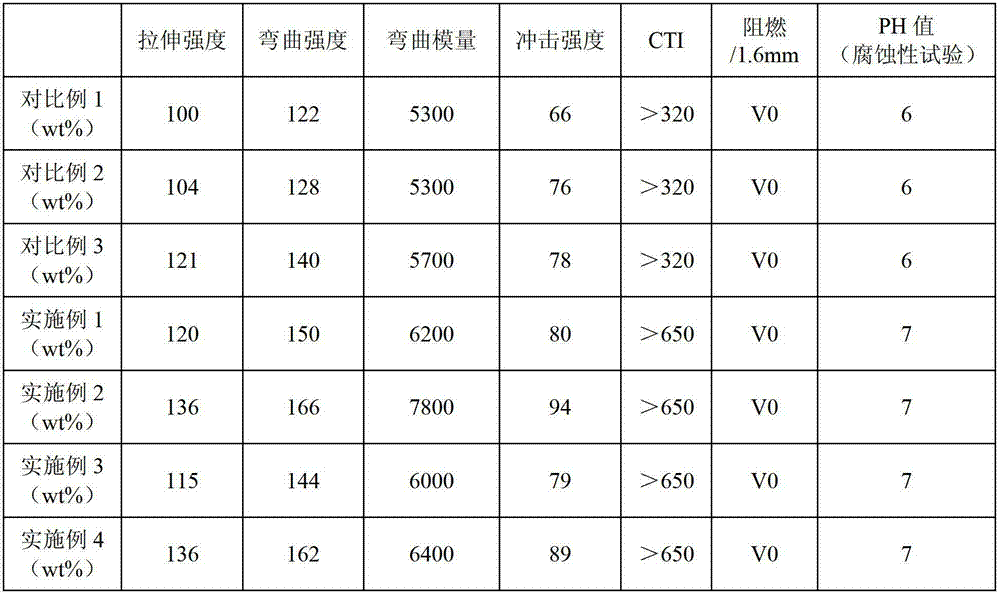

Flame-retardant glass fiber reinforced polyamide 6/polypropylene (PA6/PP) alloy composite and preparation method thereof

InactiveCN102775771AImprove mechanical propertiesCTI improvementMasterbatchComparative Tracking Index

The invention relates to a flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite and a preparation method of the flame-retardant glass fiber reinforced polyamide 6 / polypropylene (PA6 / PP) alloy composite. The composite comprises the following components in percentage by weight: 20-40 percent of polyamide 6 (PA6), 20-41 percent of polypropylene (PP), 0-10 percent of a compatilizer, 0-15 percent of compound flame-retardant masterbatch, 20-40 percent of glass fiber, 0.1-1 percent of an antioxygen and 0.1-1 percent of a lubricant dispersing agent. The preparation method of the composite comprises the following steps of: weighing each component according to the weight proportions; putting the components into a high mixing machine to mix for 2-5 minutes; discharging; and extruding and pelleting by a twin-screw extruder to process at the temperature of 200-225 DEG C under the condition of screw revolution of 30-40HZ. Compared with the prior art, the composite has the advantages of high comparative tracking index (CTI) value, low flame-retardant precipitation property, halogen-free environment friendliness, comprehensive performance equalization and the like, and can be widely applied to products of contacts, leakage protectors, circuit breaker shells and the like in the electronics field.

Owner:SHANGHAI SUNNY

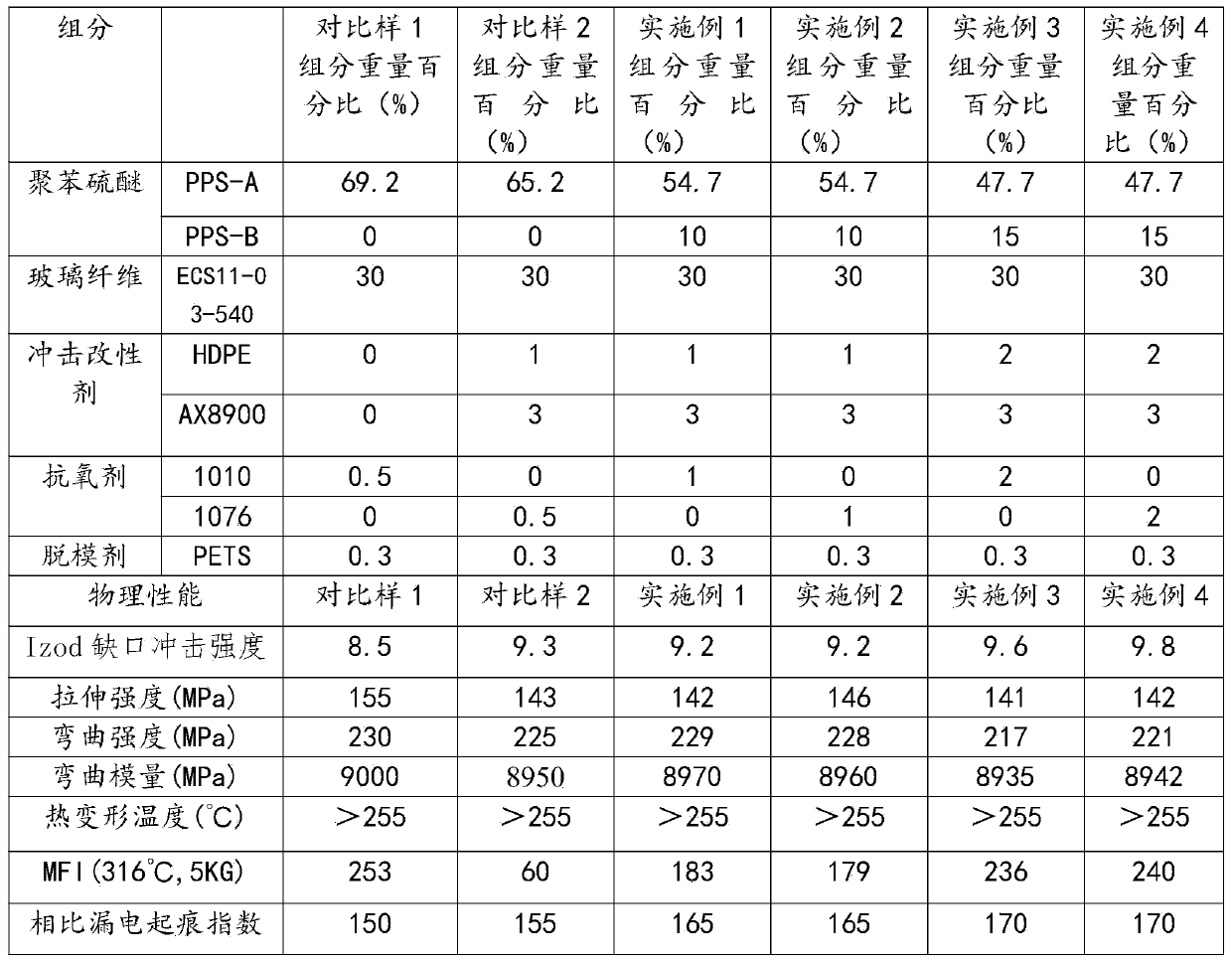

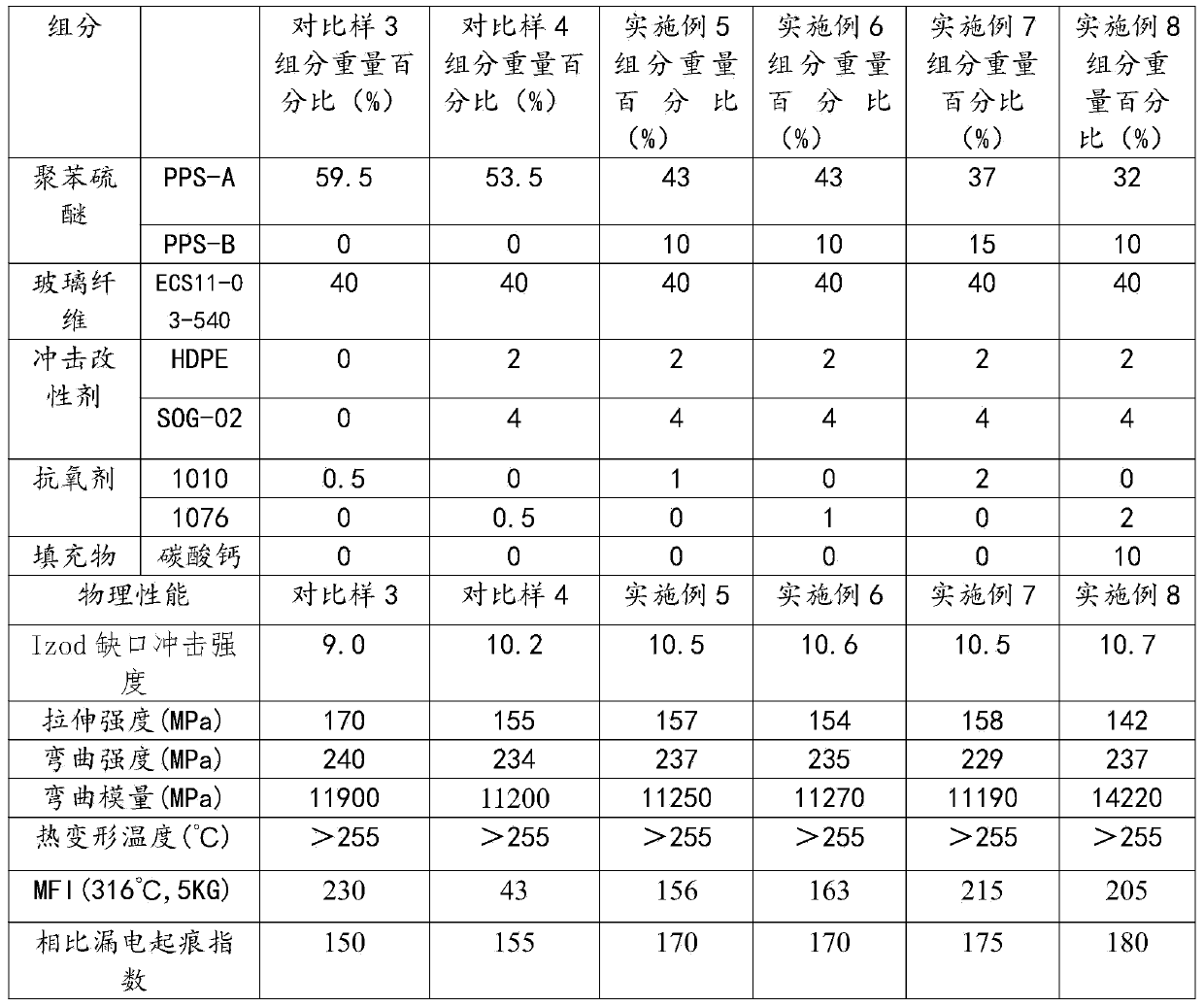

Composite polyphenyl thioether material

The invention provides a composite polyphenyl thioether material. The composite material consists of the following components by weight percent: 40-80% of polyphenyl thioether, 20-50% of glass fiber, 3-10% of an impact modifier, and 1-2% of an antioxidant. The composite polyphenyl thioether material has favorable impact property, heat resistance and higher comparative tracking index, at the same time, the composite polyphenyl thioether material has higher flowability, and the composite polyphenyl thioether material is suitable for manufacturing electrical and electronic products, mechanical products, automobile parts and other heat-resistant and corrosion-resistant products.

Owner:南京真宸科技有限公司

Environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952379AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly flame retardant glass fiber reinforced polybutylece terephthalate (PBT) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PBT, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of toughening agent, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PBT material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in composite material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

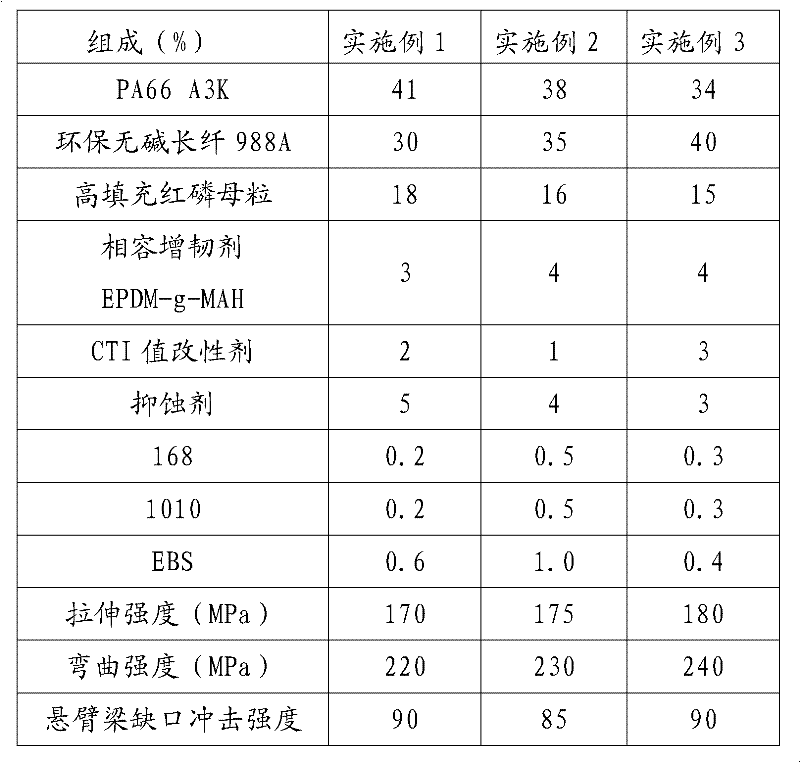

Halogen-free flame retarding strengthened PA66 material and preparation method thereof

The invention discloses a halogen-free flame retarding strengthened PA66 material and a preparation method thereof. The PA66 material comprises the following components by weight percent: 34% to 41% of PA66 resin, 30% to 40% of alkali-free long glass fiber, 15% to 18% of high filling red phosphorus masterbatch, 1% to 3% of CIT (comparative tracking index) improving agent, 3% to 5% of anti-corrosion inhibiting corrosion agent, 3% to 5% of compatible flexibilizer, 0.4% to 1% of antioxygen and 0.4% to 1% of lubricant. The sum of the weight percent of the components is 100%. In the halogen-free flame retarding strengthened PA66 material, the red phosphorus masterbatch is selected as a flame retardant, the flame retarding strengthened PA66 is applied to a shell of a breaker so that the CTI value of the flame retarding strengthened PA66 is greatly improved and the corrosivity to metal is reduced. The material has high cost performance, low additive amount, efficient flame retarding and high CTI value are realized, and the corrosivity of the material to metal is reduced by adding the inhibiting corrosion agent, therefore, the application field of the material is expanded, the service life of a product is prolonged, and the new requirement on the application field of electric products is met.

Owner:SHENZHEN KEJU NEW MATERIAL

Environment-friendly flame retardant glass fiber reinforced polyamide 66 (PA66) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value and preparation method thereof

InactiveCN102952399AHigh GWIT valueImprove impact performanceMagnesium phosphateComparative Tracking Index

The invention discloses an environment-friendly flame retardant glass fiber reinforced polyamide 66 (PA66) material with high comparative tracking index (CTI) value and high glow wire ignition temperature (GWIT) value, which comprises the raw material components by weight percent: 45-68% of PA66, 6-20% of compound fire retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of compatilizer, 0.1-1% of antioxidant and 0.1-1% of oxide, wherein the compound fire retardant comprises brominated polystyrene, magnesium hypophosphite and talcum powder. The invention also discloses a preparation method of the environment-friendly flame retardant glass fiber reinforced PA66 material with high CTI value and high GWIT value. The composite material is higher in GWIT value and CTI value, better in flame retardant effect, environment-friendly in material and balanced in combination properties, thus being widely applied to products in the field of electronic electric appliances such as a low-voltage electronic capacitor shell, a load break switch, a carbon brush bracket, a moulded case circuit breaker and the like.

Owner:SHANGHAI SUNNY

Halogen-free flame-retardant polycarbonate/styrene base resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant polycarbonate / styrene base resin composition and a preparation method thereof, and the composition comprises the following components in parts by weight: 650-900 parts of polycarbonate, 0.1-250 parts of styrene base resin, 20-100 parts of toughening compatibilizer, 10-100 parts of metal inorganic compound, 5-50 parts of organic silicon, 70-150 parts of complex flame retardant, 1-10 parts of antioxidant A, 1-15 parts of antioxidant B and 0-20 parts of other auxiliary materials. The preparation method comprises the following steps: mixing raw materials in a high-speed mixing machine, then introducing into a twin-screw extruder, adding the complex flame retardant in the lateral line feeding way, performing extrusion and granulation and finally getting the product. Compared with the prior art, the halogen-free flame-retardant polycarbonate / styrene base resin composition has the advantages of high comparative tracking index (CTI), high glow-wire ignition temperature (GWIT), halogen-free flame retardance, environment friendliness and the like.

Owner:HEFEI GENIUS NEW MATERIALS

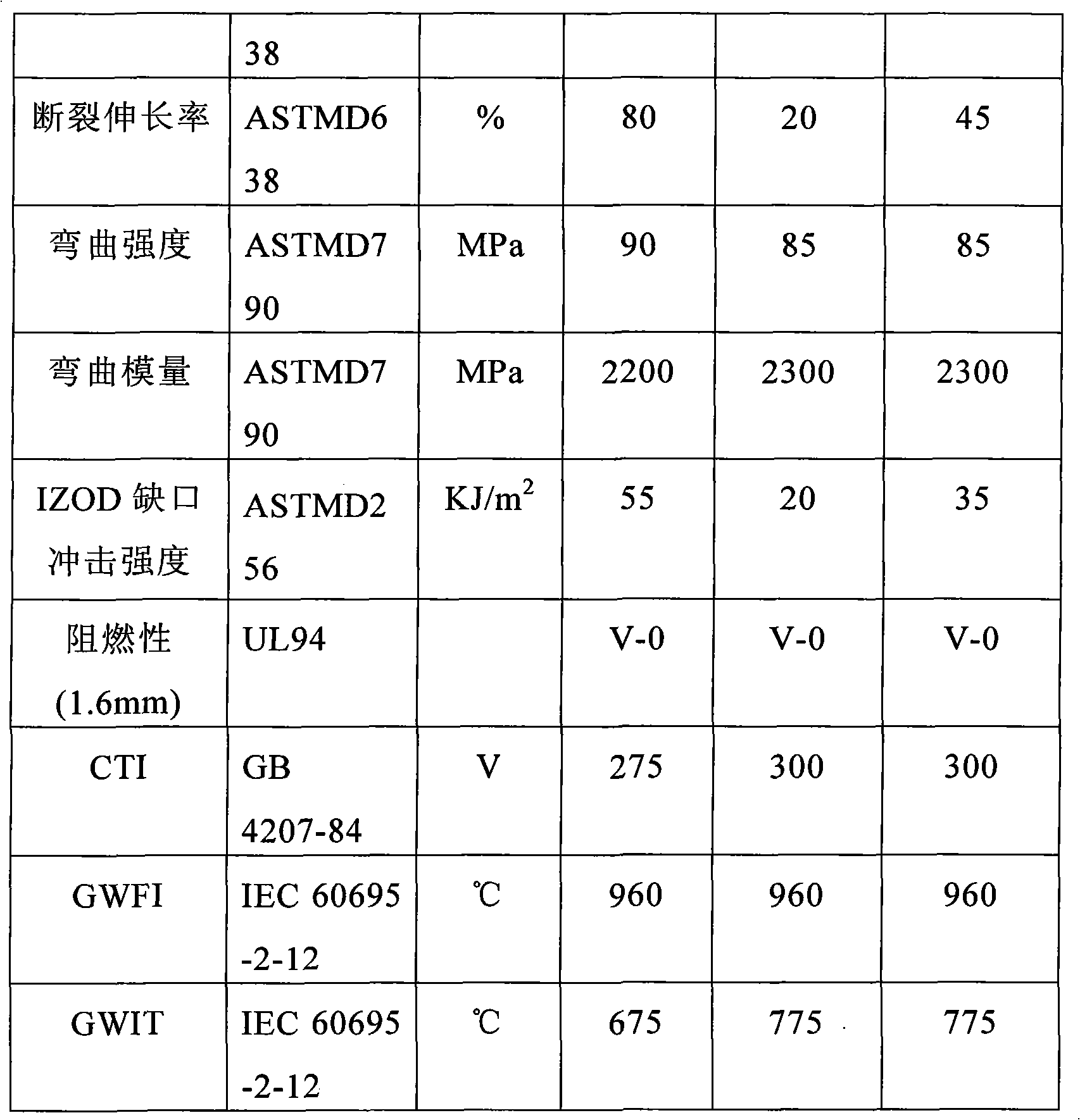

Halogen-free resin composition and resin-coated copper foil and copper-clad plate prepared from same

ActiveCN102051023AExcellent tracking resistanceImprove heat resistanceMetal layered productsHeat resistanceComparative Tracking Index

The invention relates to a halogen-free resin composition and a resin-coated copper foil and copper-clad plate prepared from the same. The halogen-free resin composition comprises the following components in parts by weight: 20-30 parts of phosphorous epoxy resin, 5-15 parts of bisphenol A epoxy resin, 10-20 parts of novolac epoxy resin, 10-20 parts of phenoxy resin, 35-50 parts of barium sulphate filler and 0.5-1.5 parts of dicyandiamide; the resin-coated copper foil prepared from the resin composition comprises a copper foil and the halogen-free resin composition coated on the copper foil; and the copper-clad plate prepared from the halogen-free resin composition comprises a plurality of superimposed bonding sheets and the resin-coated copper foil compounded at one side or the two sides of the bonding sheets. The halogen-free resin composition provided by the invention has excellent tracking resistance, heat resistance and alkali resistance; the resin-coated copper foil and copper-clad plate prepared from the halogen-free resin composition have high comparative tracking index, thus meeting the requirement of high comparative tracking index; and meanwhile, the heat resistance and alkali resistance are excellent, thus meeting the halogen-free flame retarding requirement.

Owner:GUANGDONG SHENGYI SCI TECH

Epoxy resin composition and application thereof

ActiveCN105273362AAdd a small proportionFlame retardant easySynthetic resin layered productsCircuit susbtrate materialsEpoxyComparative Tracking Index

The invention relates to an epoxy resin composition and application thereof. The epoxy resin composition is prepared from epoxy resin containing phosphorus and bromine, and can be used for preparing preimpregnation materials and copper-foil-covered laminated plates. The epoxy resin containing phosphorus and bromine is adopted, phosphorus and bromine in the epoxy resin are set at the specific content and proportions to obtain the epoxy resin composition, and thus the fire resistance of the epoxy resin composition can reach UL94 V-0 grades; the preimpregnation materials and the laminated plates prepared through the epoxy resin composition have low moisture absorption, good heat resistance, cohesiveness, reactivity and processability, and compared with traditional high CTI plates filled with a large amount of aluminum hydroxide, it can be achieved that the comparative tracking index (CTI) is larger than or equal to 600 V with a small amount of aluminum hydroxide or without aluminum hydroxide.

Owner:GUANGDONG SHENGYI SCI TECH

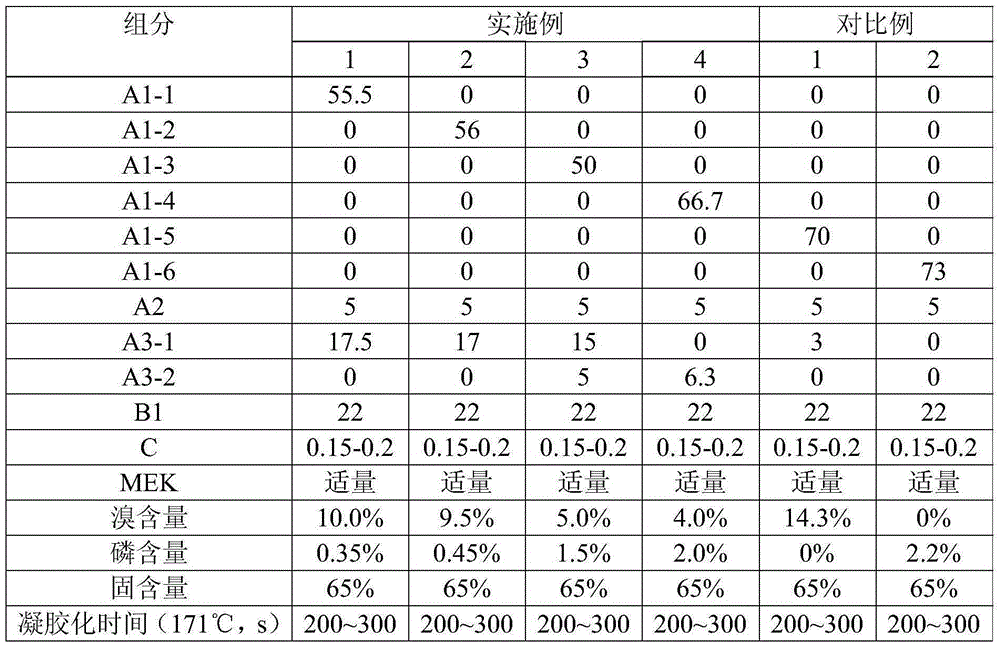

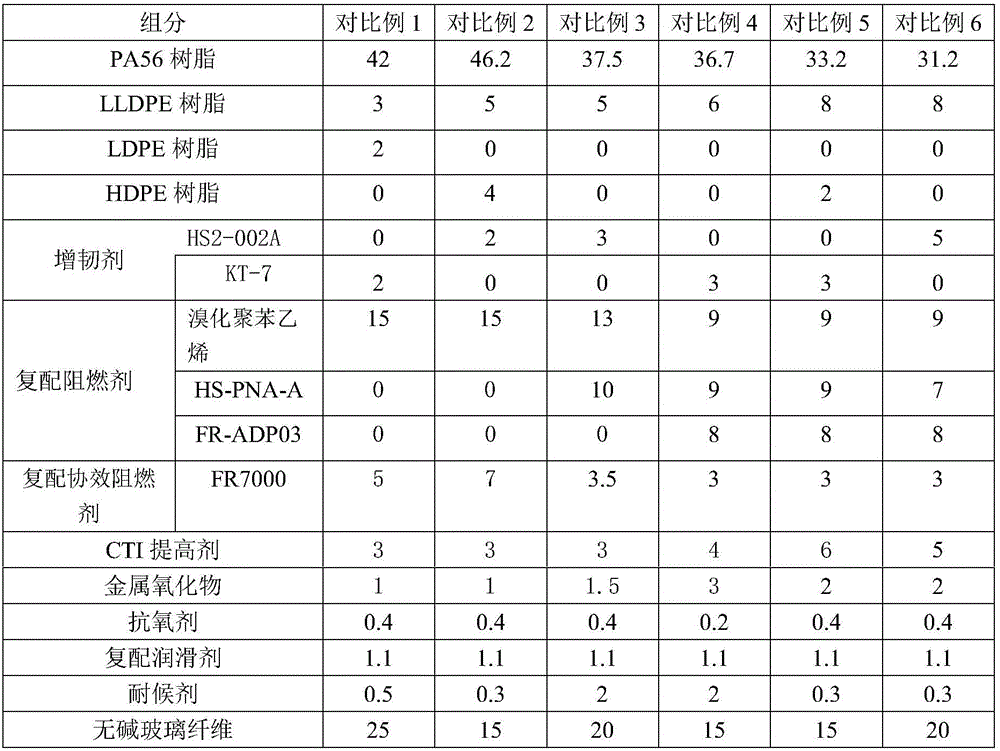

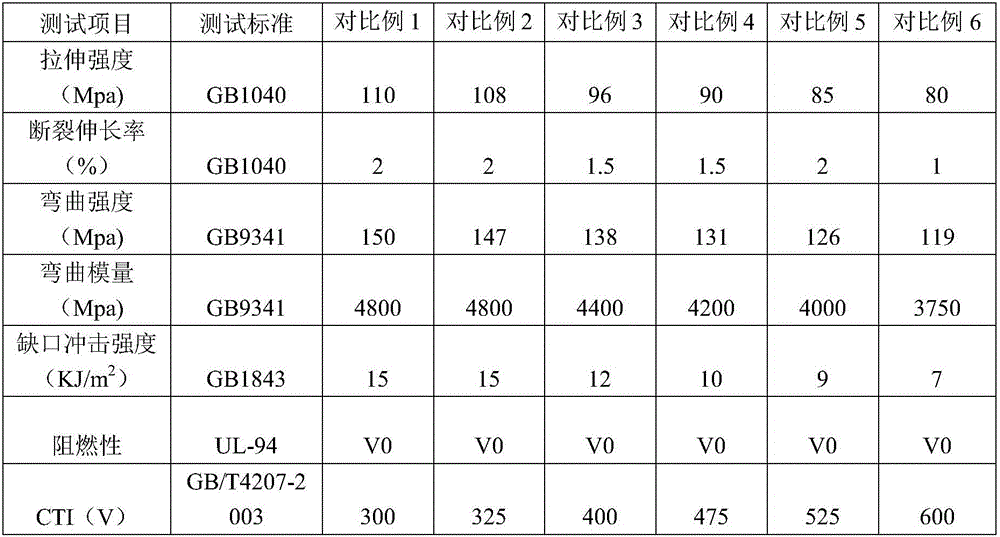

High-CTI (Comparative Tracking Index) anti-flaming PA (Polyamide) for photovoltaic material and preparation method thereof

The invention discloses high-CTI (Comparative Tracking Index) anti-flaming PA (Polyamide) for a photovoltaic material and a preparation method thereof. The high-CTI anti-flaming PA for the photovoltaic material is characterized in that the high-CTI anti-flaming PA is prepared from the following raw materials in percentage by weight: 31.2 to 42.2 percent of PA resin, 5 to 10 percent of PE (Poly Ethylene) resin, 2 to 5 percent of toughening agent, 15 to 26 percent of composite flame retardant, 3 to 7 percent of composite synergetic flame retardant, 3 to 6 parts of CTI increasing agent, 1 to 3 percent of metal oxide, 0.2 to 0.4 percent of antioxidant, 1 percent of composite lubricating agent, 0.3 to 2 percent of weather-resisting agent and 15 to 25 percent of alkali-free glass fiber. The high-CTI anti-flaming PA for the photovoltaic material, provided by the invention, has the advantages of very high notch impact strength, very good flame retardance, lower production cost and good processing fluidity.

Owner:GUANGDONG WAYLAM ENG PLASTICS

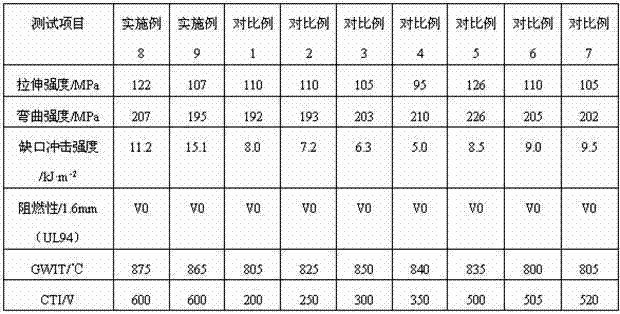

Flame retardant polyamide composition, and preparation method and application thereof

ActiveCN107603210AImprove flame retardant performanceImprove high temperature processing performanceManufacturing cost reductionPolymer science

The invention belongs to the technical field of high polymer materials, particularly relates to a brominated flame retardant polyamide composition, and specifically relates to the brominated flame retardant polyamide composition which has high-efficiency flame retardance, high CTI (Comparative Tracking Index) value, high GWIT (Glow Wire Initiation Temperature) value, high heat resistance, precipitation resistance and colour change resistance, and a preparation method and application thereof. The flame retardant polyamide composition provided by the invention comprises the following componentsin percentage by weight: 30 to 80 percent of polyamide resin, 5 to 30 percent of a brominated flame retardant, 1 to 15 percent of a flame retardant synergist and 0 to 50 percent of a reinforcing material; the flame retardant synergist is a composition of stannate and kaolin which are in the weight ratio of 5:1 to 1:5. According to the flame retardant polyamide composition provided by the invention, the manufacturing cost is reduced, and meanwhile, an excellent flame retarding effect of the polyamide material is ensured (the flame retardant grade is grade UL-94 V0, and the GWIT is greater thanor equal to 875 DEG C), and the high temperature resistant processability of the material is improved; when the injection moulding processing temperature is up to 280 DEG C, even 325 DEG C, the surface of an injection moulding piece does not have precipitate basically and colour change; moreover, the injection moulding piece has excellent mechanical properties, and the precipitate resistance in ahumid environment is also good.

Owner:本松新材料技术(芜湖)有限公司

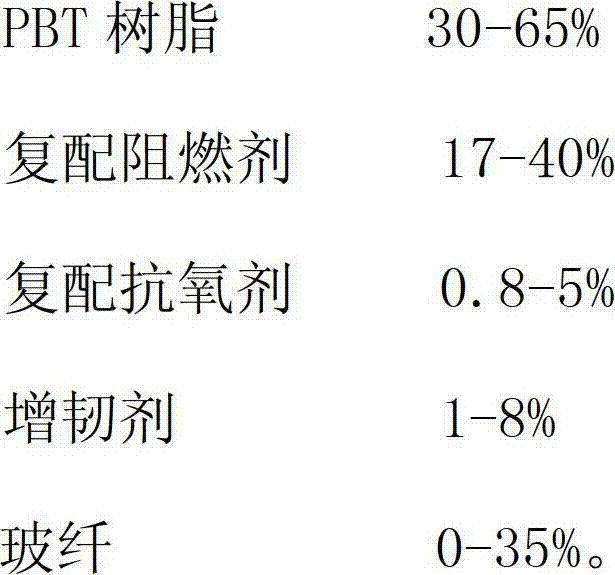

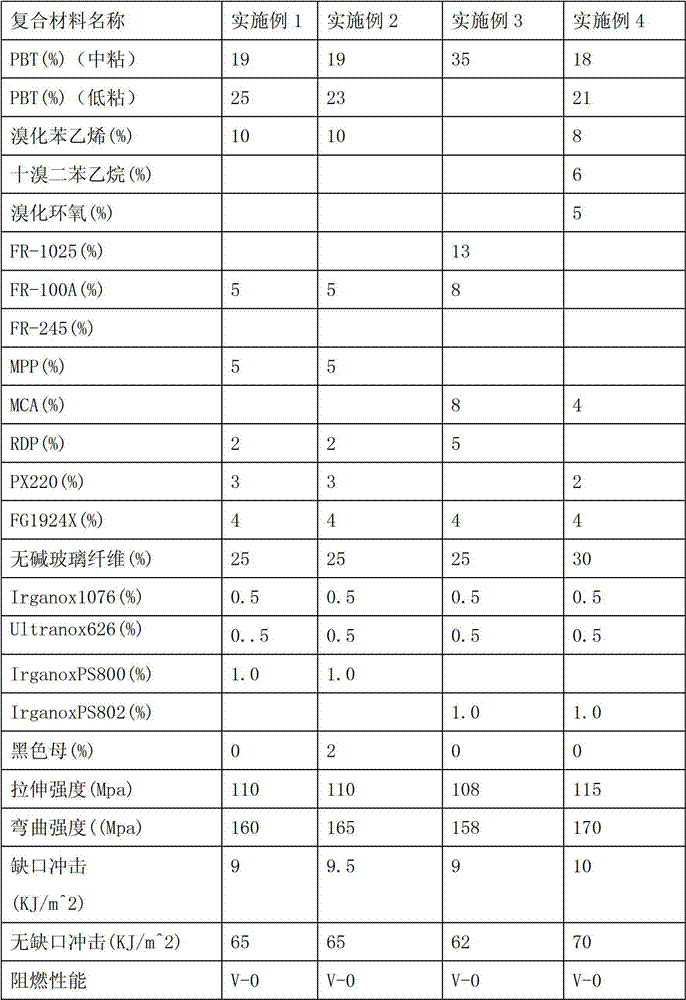

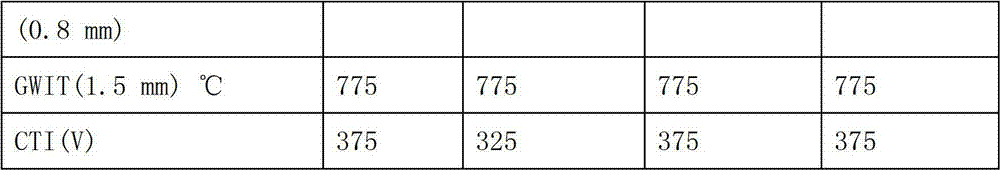

Antimony-free reinforced flame-retardant polybutylece terephthalate (PBT) environmental-friendly material and preparation method thereof

InactiveCN102775747AImprove securityProcess environmental protectionPolymer scienceComparative Tracking Index

The invention discloses an antimony-free reinforced flame-retardant PBT environmental-friendly material and a preparation method thereof. The material is mainly composed of PBT resin, a compounding flame retardant, a compounded antioxidant, a flexibilizer and glass fibers; and has the advantages of being antimony-free and high in glow wire ignition temperature (GWIT), comparative tracking index (CTI) and relative temperature index (RTI).

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com