Antimony-free reinforced flame-retardant polybutylece terephthalate (PBT) environmental-friendly material and preparation method thereof

An environmentally friendly material, PBT resin technology, applied in the field of flame retardant PBT environmental protection materials and its preparation, can solve the problems of slow crystallinity, poor molding processability of alloy materials, and low CTI of products, and achieve good flame retardancy and durability High tracking index and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

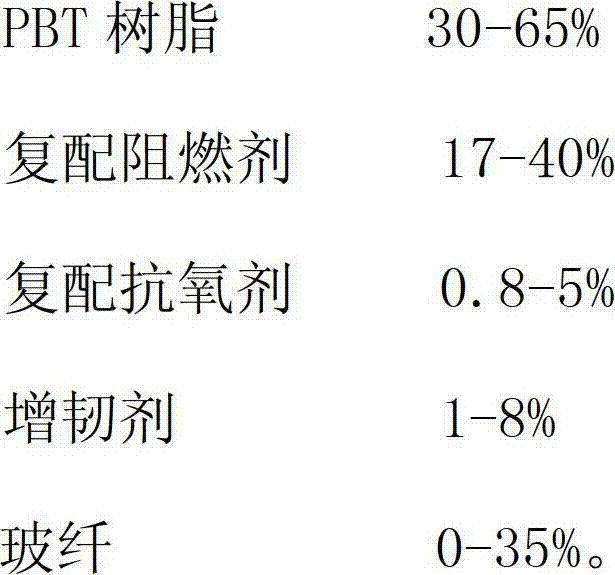

Method used

Image

Examples

Embodiment Construction

[0053] (1) First bake polybutylene terephthalate PBT at 120-150°C for 2-5 hours, and control the moisture content of the resin below 0.05%;

[0054] (2) Put the polybutylene terephthalate PBT treated in step (1) directly into the mixer through the resin delivery pipeline and mix it with compound flame retardant, toughener, compound antioxidant and black masterbatch Machine mixing for 2-30 minutes;

[0055] Or the polybutylene terephthalate PBT treated in step (1) is fed through the resin, composite flame retardant, toughening agent, composite antioxidant, and black masterbatch separately from the loss-in-weight metering feeder Twin-screw extruder, plasticizing and melting;

[0056] (3) Add alkali-free glass fiber and mix evenly to obtain the product.

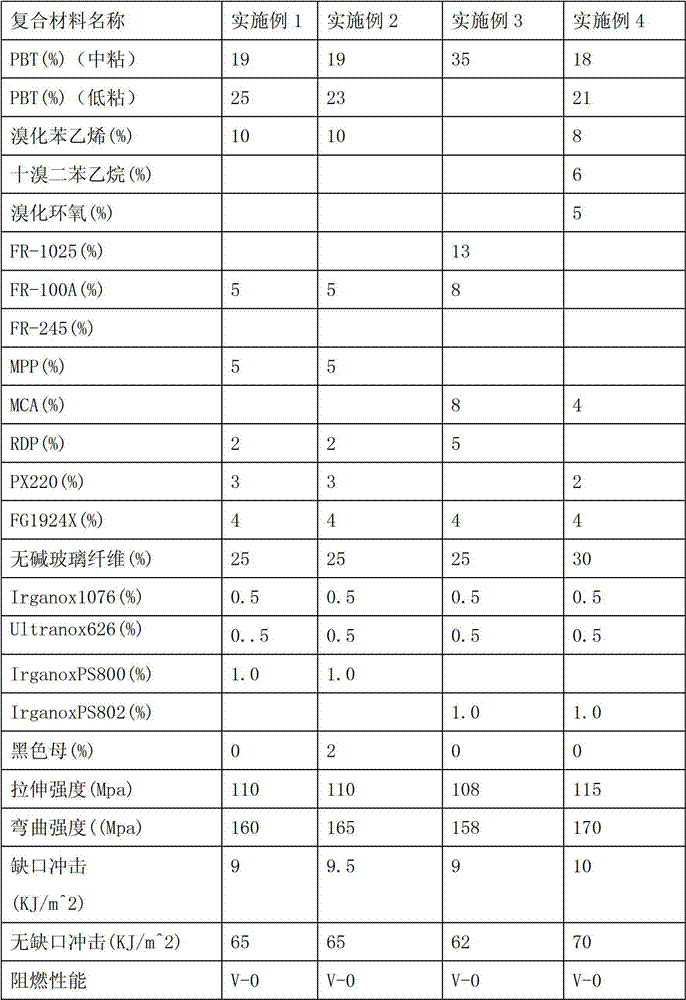

[0057] The name and consumption of each component are shown in Table 1:

[0058]

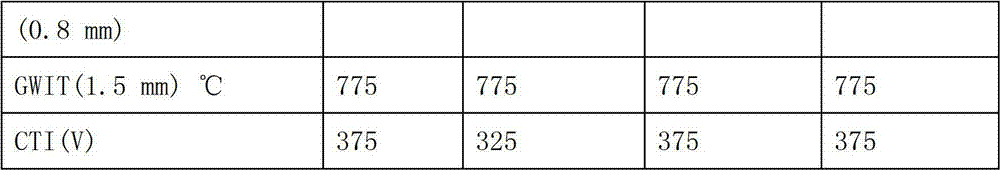

[0059]

[0060] The mechanical performance testing standards in the above tables are all carried out in accordance with the relevant AST...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com